Patents

Literature

1261results about How to "Improve oxidation capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

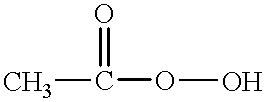

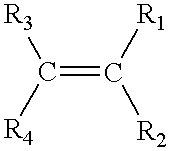

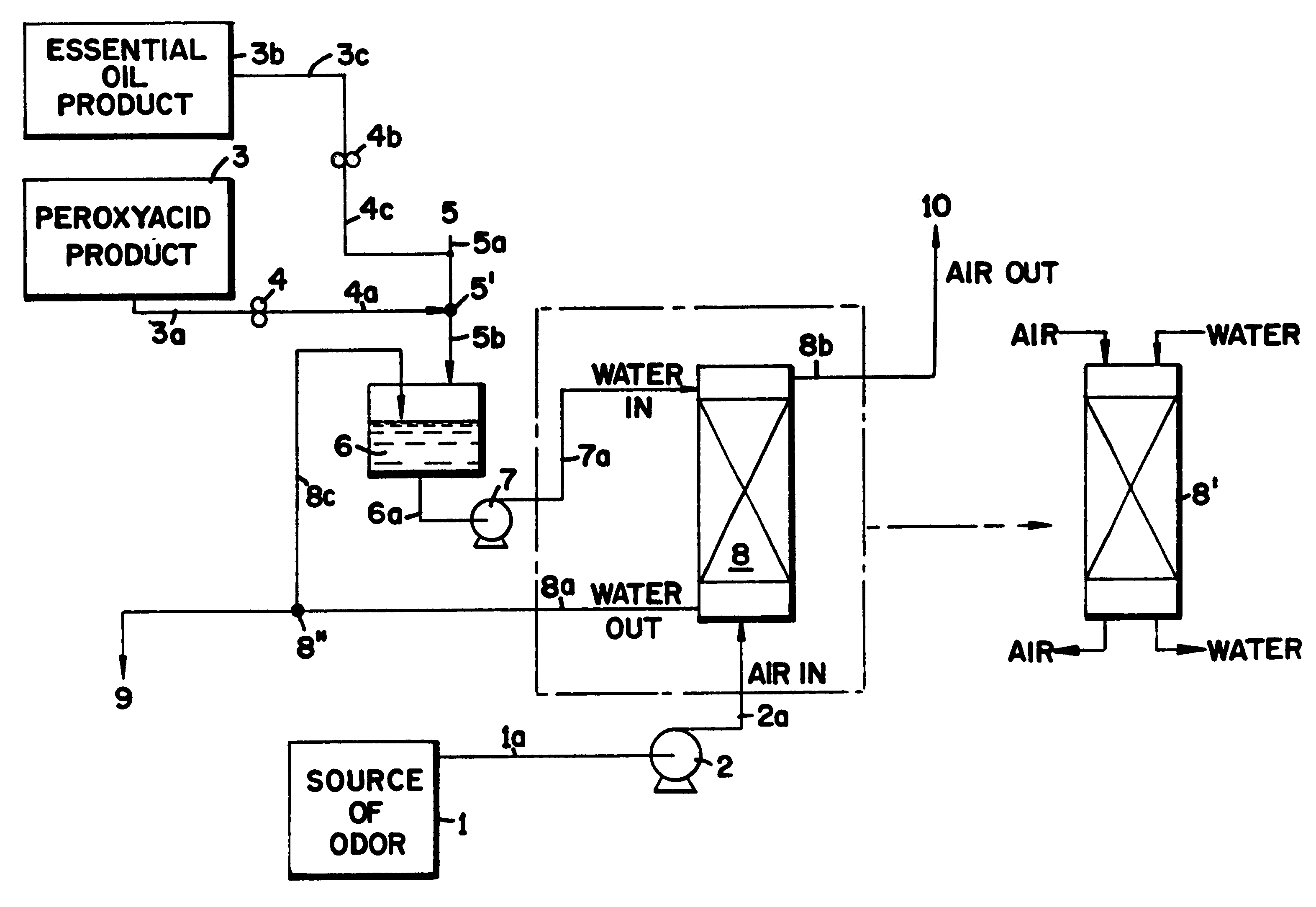

Simultaneous use of peroxygen and olefin compound in odor reduction

InactiveUS6277344B1Improved malodor removalEnhanced mass transferCyanogen compoundsOrganic chemistryGas phasePeroxy acid

Disclosed is a process for the treatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent in either a counterflow or cocurrent flow process. In the process, the effluent is contacted with an aqueous solution comprising a peroxyacid compound and one or more essential oils. When contacted with the peroxyacid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. In this way, odor removal from the gas is preferred and odor compounds are efficiently transferred into the aqueous treatment solution. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

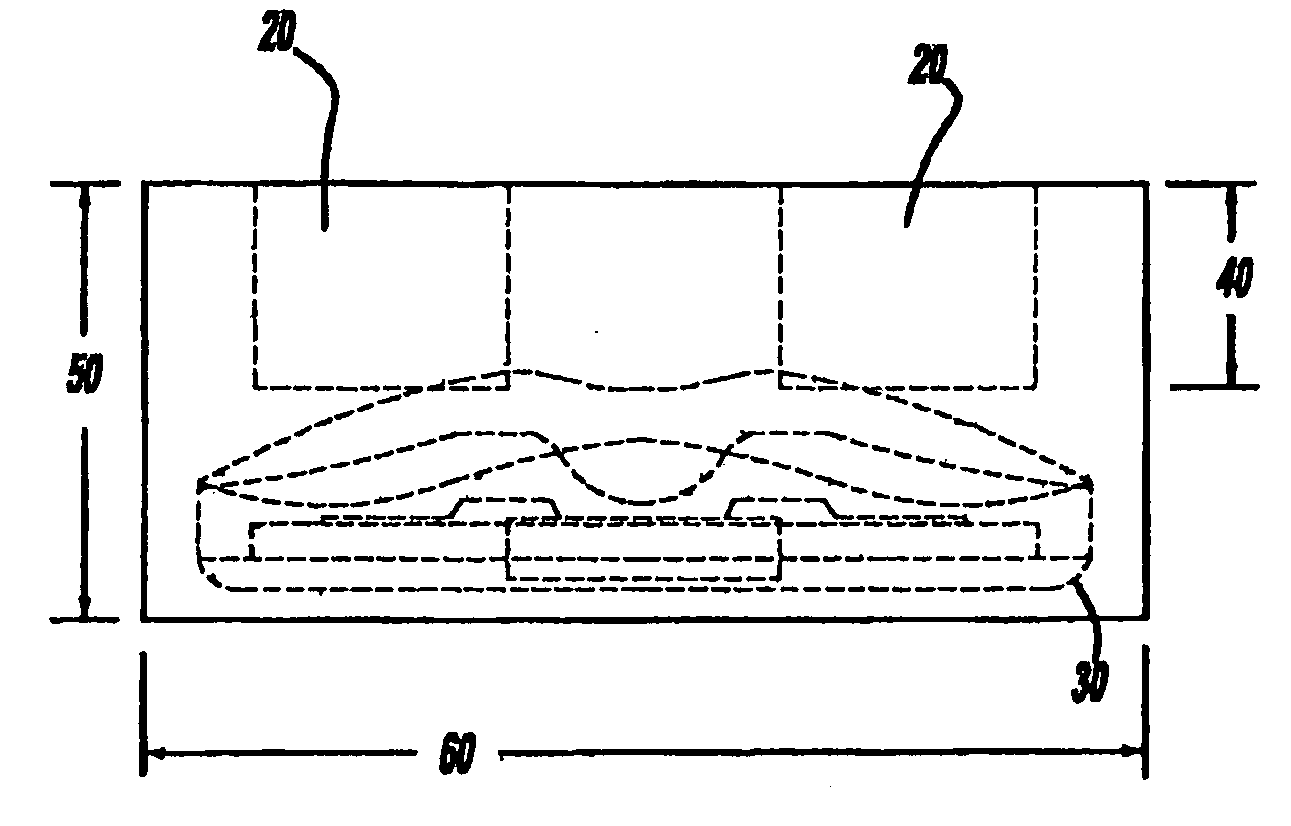

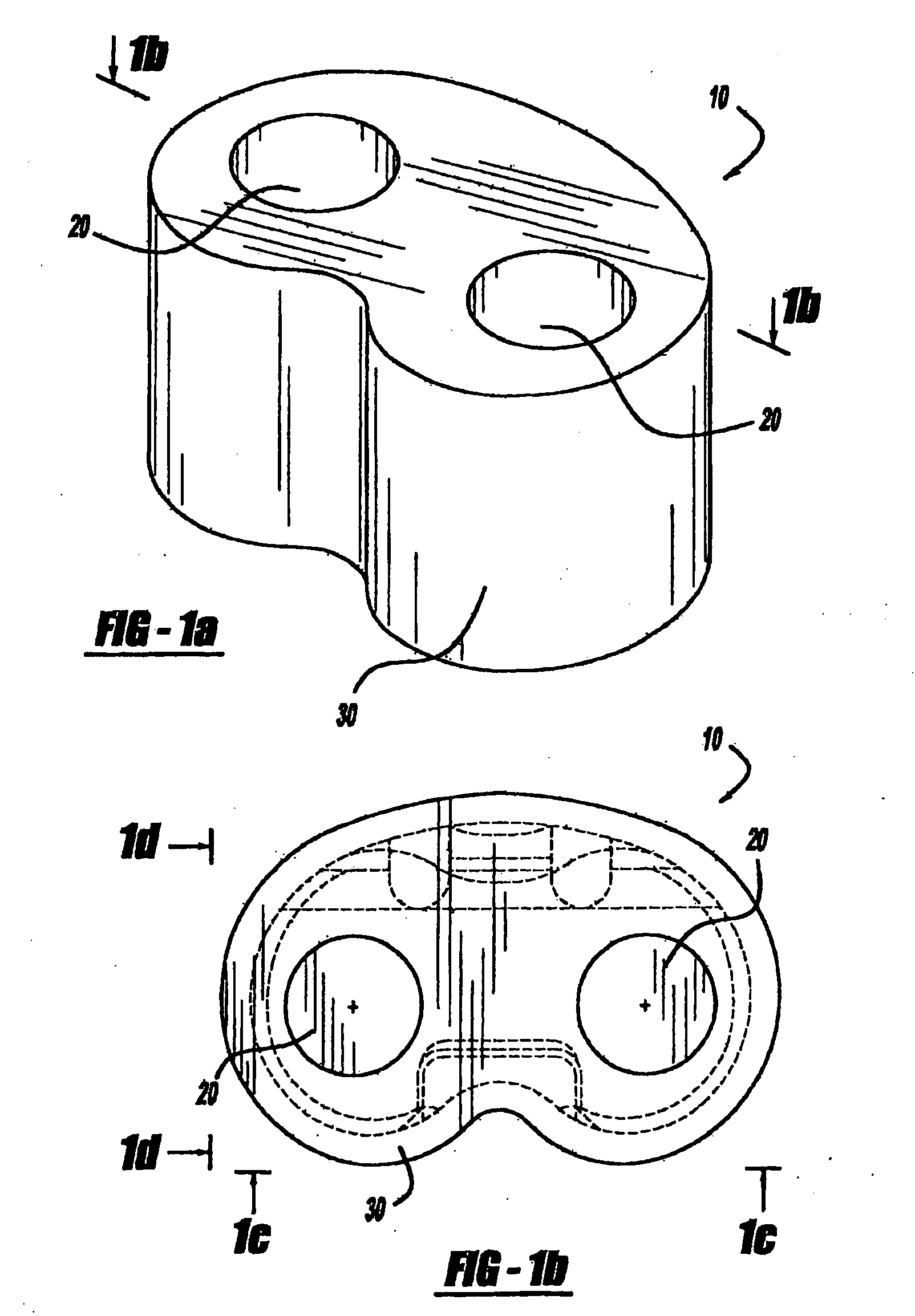

Antioxidant doping of crosslinked polymers to form non-eluting bearing components

InactiveUS20090030524A1Improve wear resistanceGood biocompatibilityBone implantJoint implantsAntioxidantCrosslinked polymers

Methods provide a non-eluting antioxidant doped UHMWPE in the form of an implant bearing component. The process includes the steps of: (a) providing a preform; (b) irradiating the preform with γ-irradiation to crosslink the UHMWPE; (c) doping the crosslinked preform by exposing it to an antioxidant composition at a temperature below the melting point of the UHMWPE; (d) removing the doped material from contact with the antioxidant composition; and then (e) annealing by heating the doped material at a temperature above 30° C. and below the melting point of the UHMWPE; followed by (f) making an implant bearing component from the doped material, wherein at least 1 mm but no more than about 15 mm of material are removed to make the component.

Owner:BIOMET MFG CORP

Method for purifying exhaust gases

InactiveUS6153159AImprove oxidation capacityReduce concentrationOrganic chemistryNitrogen compoundsDiesel engineLow emission

Thermal catalysts, particularly catalysts coated with precious metals, are used to reduce the concentration of CO, HC and NOx in exhaust gases from internal-combustion engines. While catalysts coated with precious metals exhibit catalytic activity from about 140 DEG C., to ensure very low emission levels thermal catalysts need to be heated during cold starting so that the pollutants produced during the cold start react. The specification discloses a catalyst with a photocatalytic semiconductor illuminated with UV light for this purpose. Suitable for use as the photocatalytic material is e.g. titanium dioxide. This enables pollutant levels to be reduced immediately after the engine has been started and even at relatively low ambient temperatures. The invention is suitable for use with diesel engines and lean-mixture spark-ignition engines.

Owner:VOLKSWAGEN AG

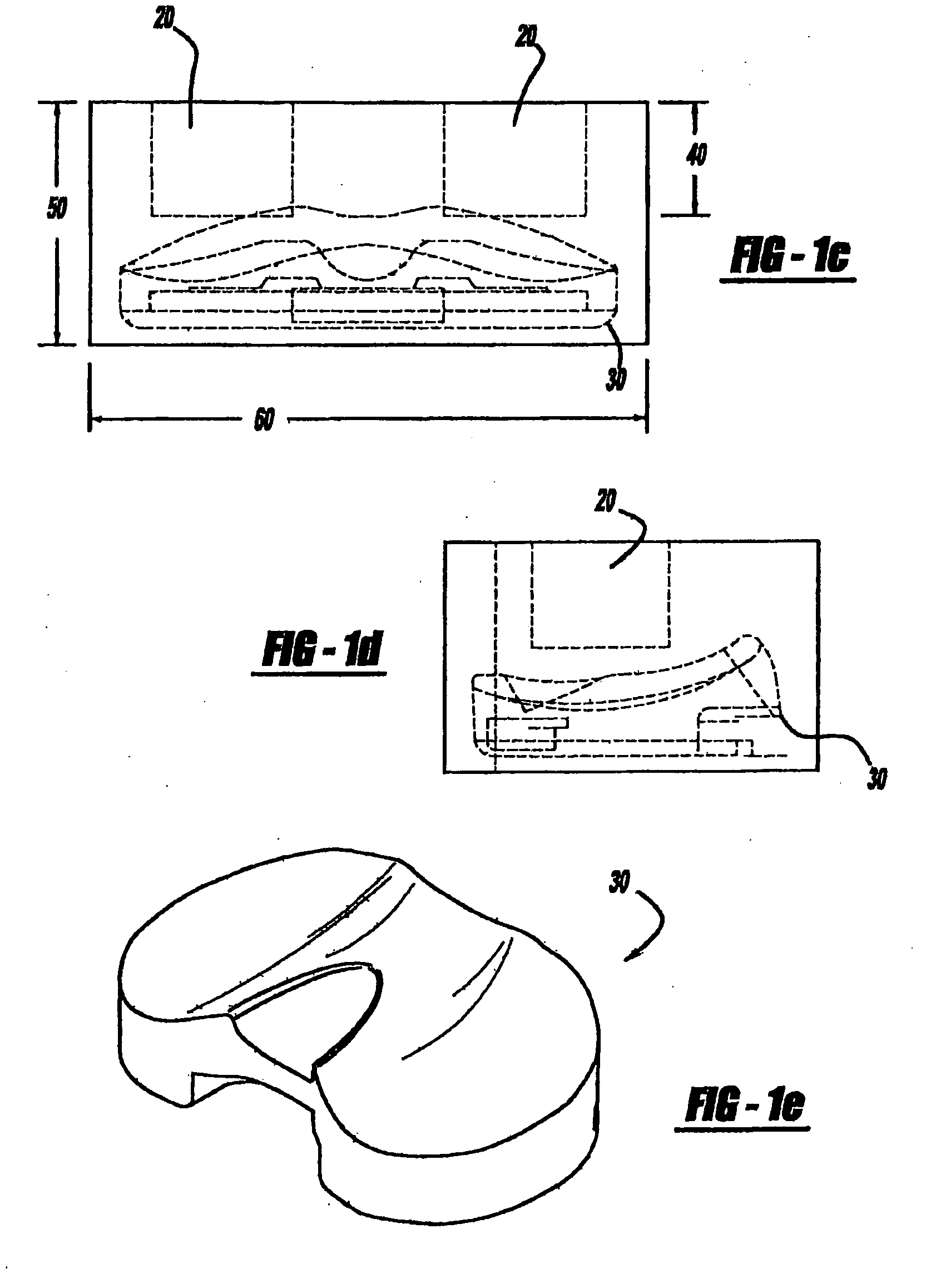

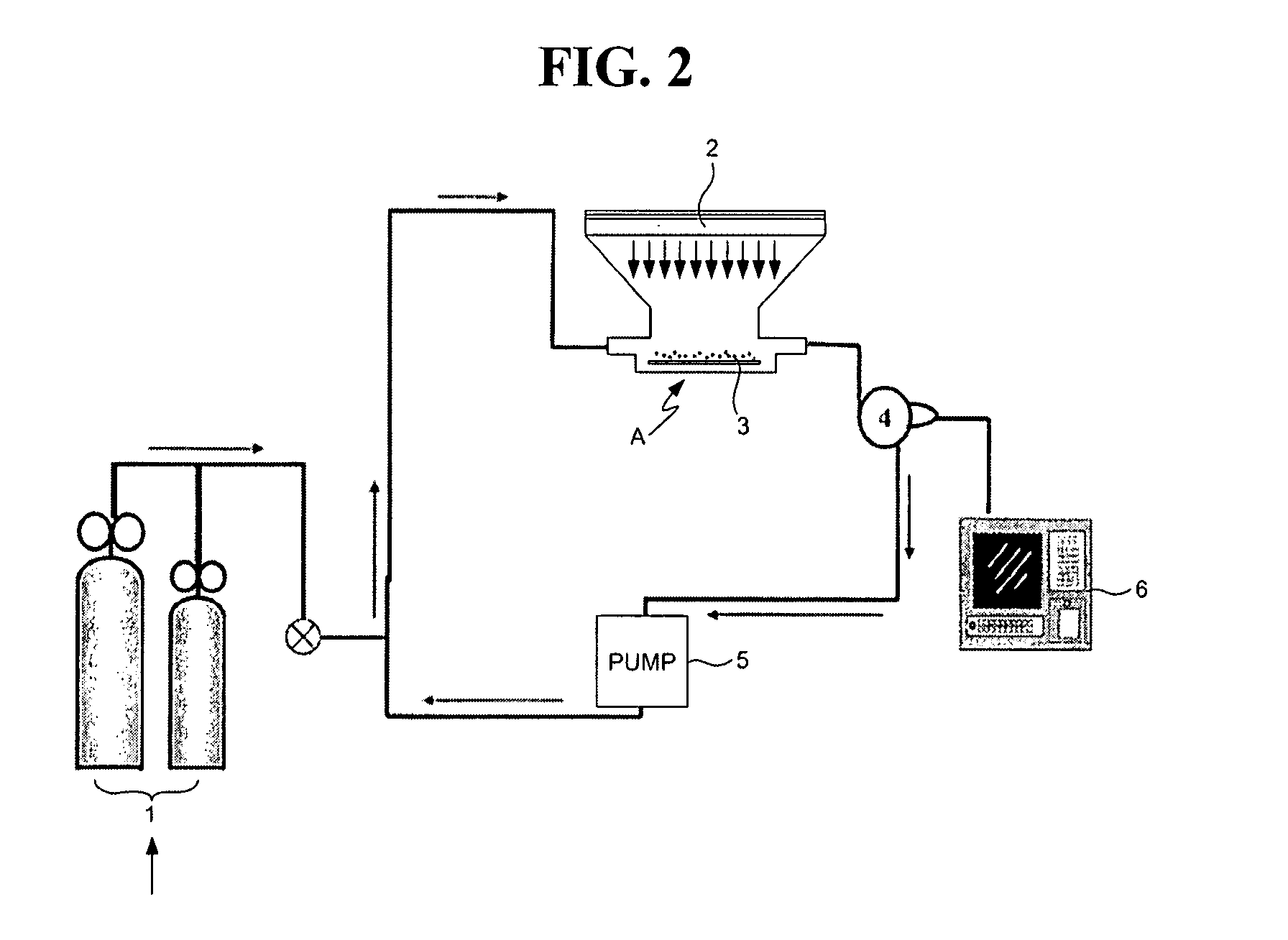

Method and Apparatus for an Improved Aerosol Generator and Associated Uses and Equipment

ActiveUS20110114744A1Reduce probabilityLow temperature of insideMovable spraying apparatusSpray nozzlesChemical reactionTransducer

The invention is an apparatus and methods for optimizing the performance and protecting one or more aerosol generating transducers from deterioration while operating in a chemically reactive aqueous solution by utilizing one or more protective barrier techniques to eliminate chemical interaction between the aqueous solution and the transducers, among other features of the generator including these transducers. The method of the present invention produces an aerosol producing transducer with the transducer housing and assembly to be constructed in such a way as to assure its efficient and effective long-term and problem free operation in an aqueous solution that is chemically reactive.

Owner:ALTAPURE

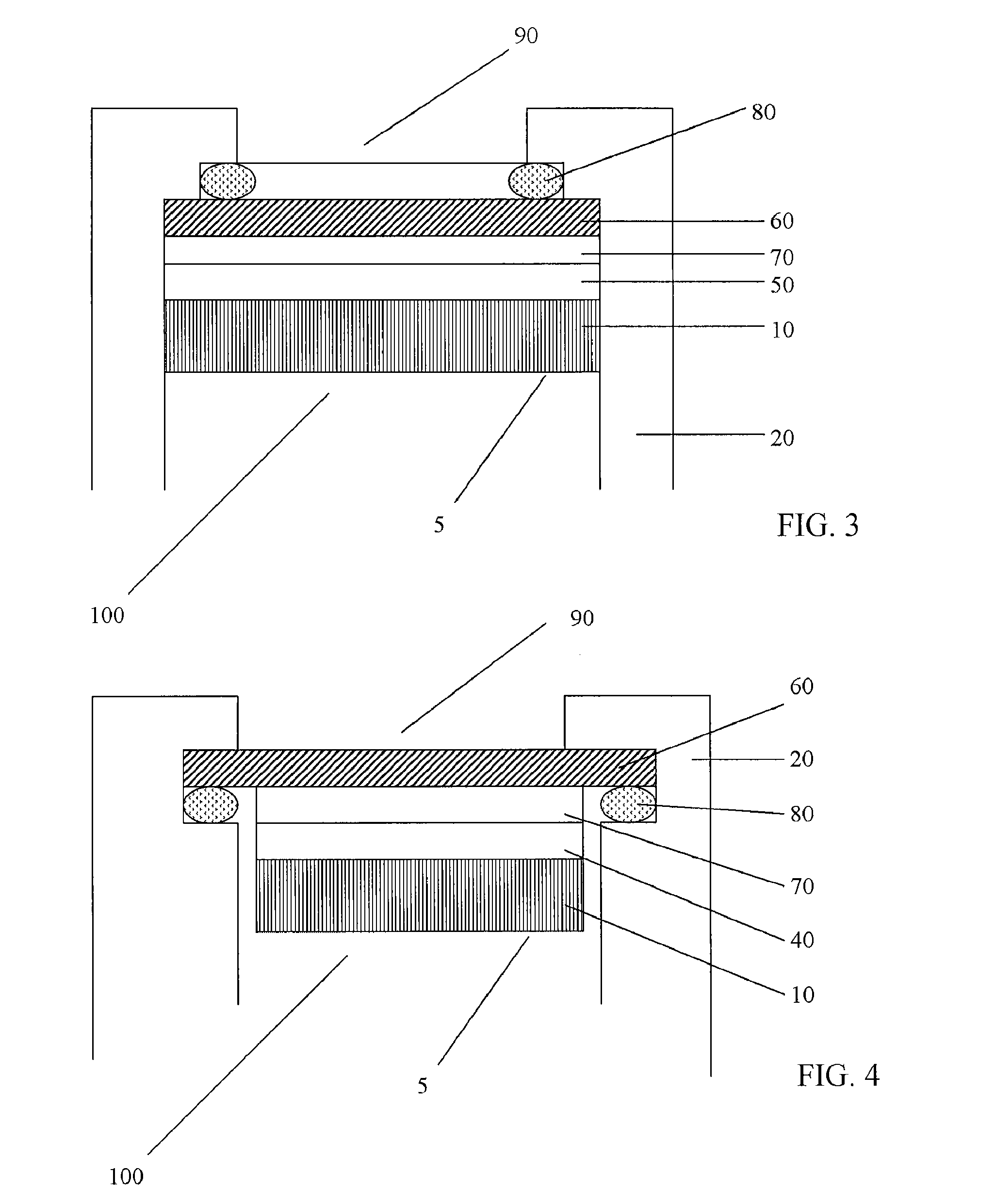

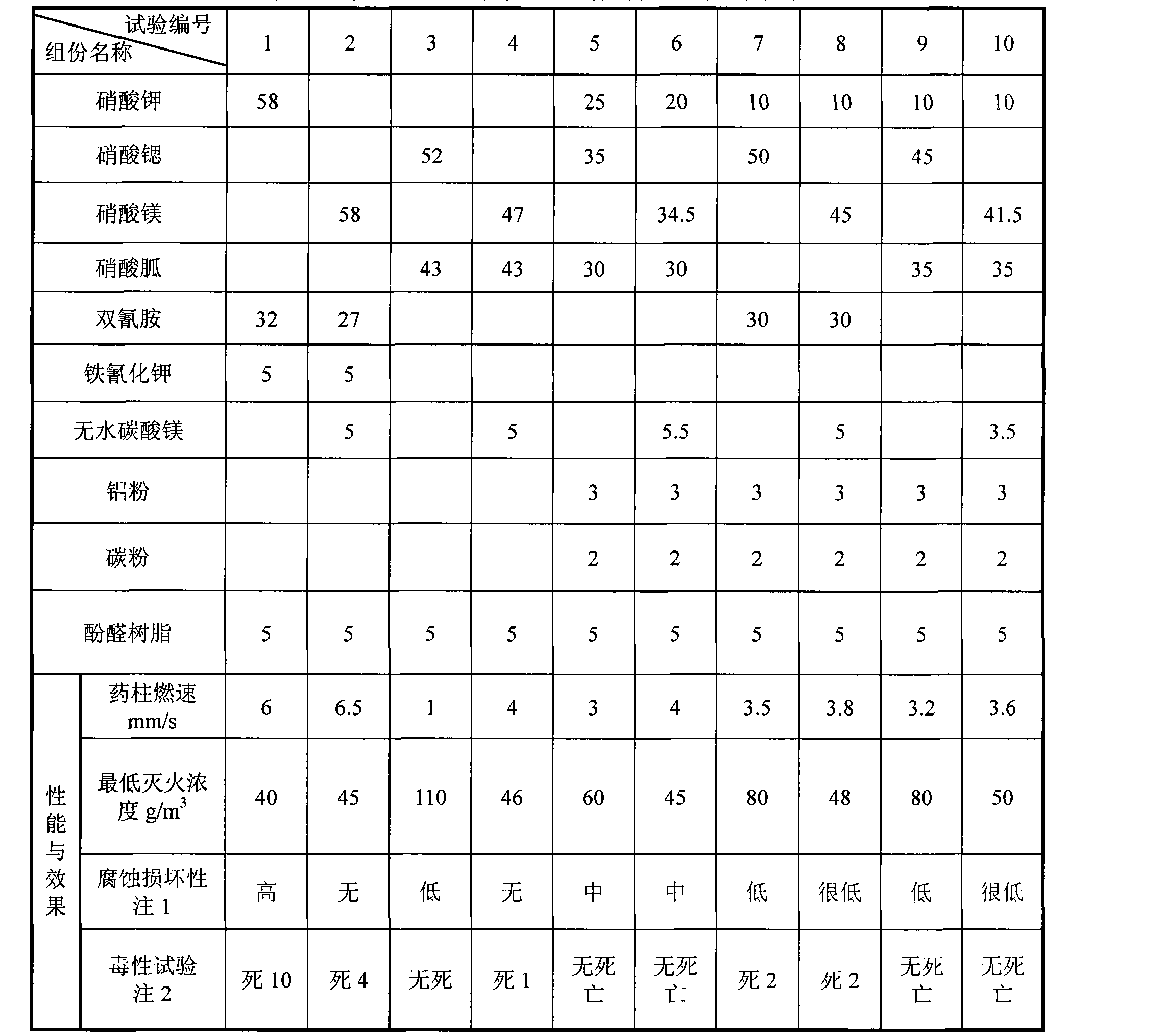

Extinguishment combination with hot gas sol

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

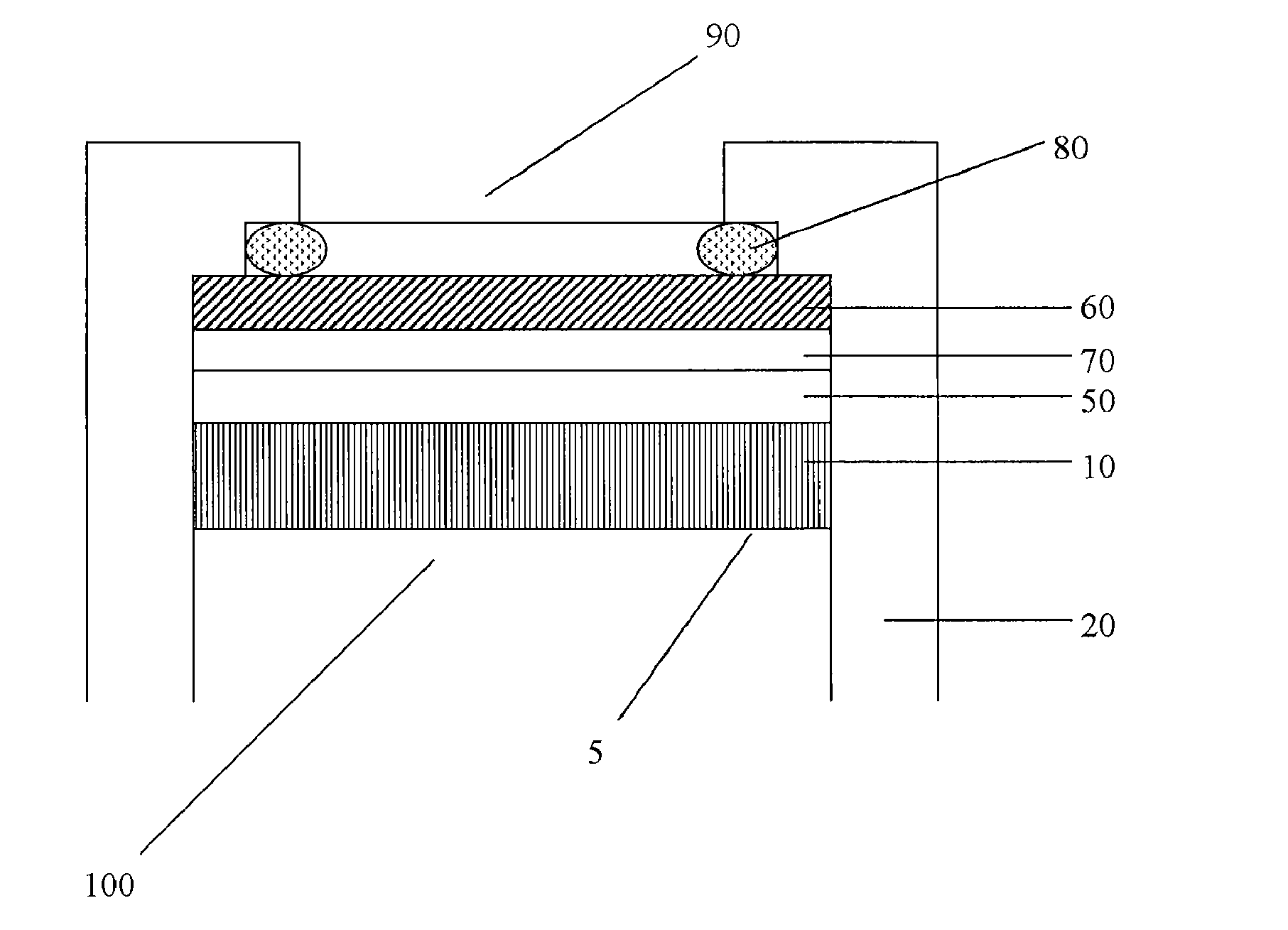

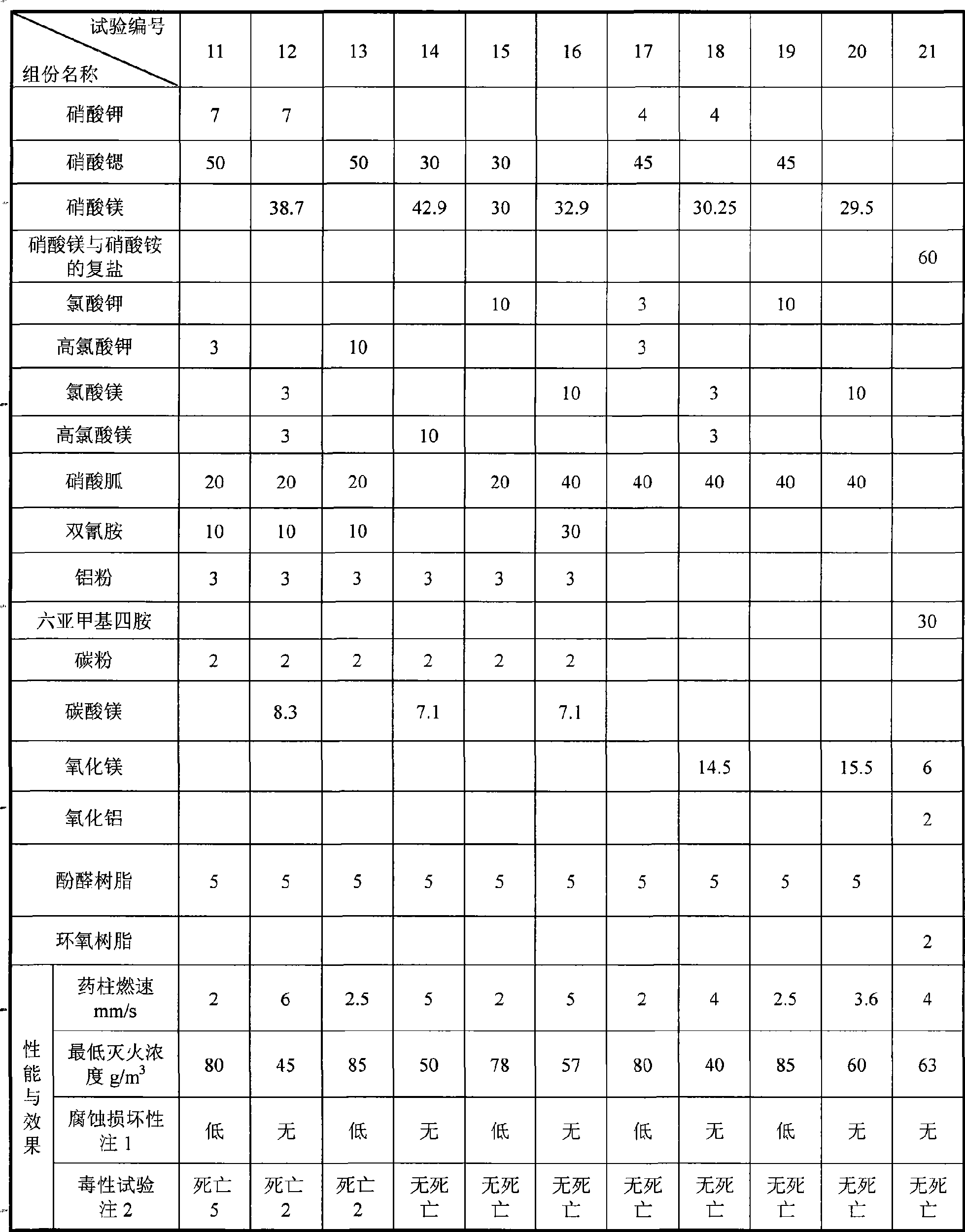

Ammonia desulfurization technology and device utilizing high potential energy

ActiveCN101579600ASolve the problem of large investmentReduce power consumptionDispersed particle separationFlue gasEngineering

The invention belongs to the field of environmental protection equipment, which relates to an ammonia desulfurization technology and a device utilizing high potential energy. The device comprises a desulfurizing tower, a concentrated crystallizing pool, an oxidation communication device, a low-level circulation pump, a high-level circulation pump, a crystal pulp pump and a centrifugal drying system which are positioned outside the tower; the desulfurizing tower is divided into an upper layer section and a lower layer section, and a gas cap through which only flue gas can pass is arranged between the upper layer section and the lower layer section; the lower layer section of the desulfurizing tower and the oxidation communication device are both provided with an oxidation gas distributor and an oxidation gas deflector; and spray heads are 2 to 4 layers. Under the precondition that normal desulfurization efficiency is ensured, the invention not only saves the investment but also reduces the running cost.

Owner:江苏世纪江南投资有限公司

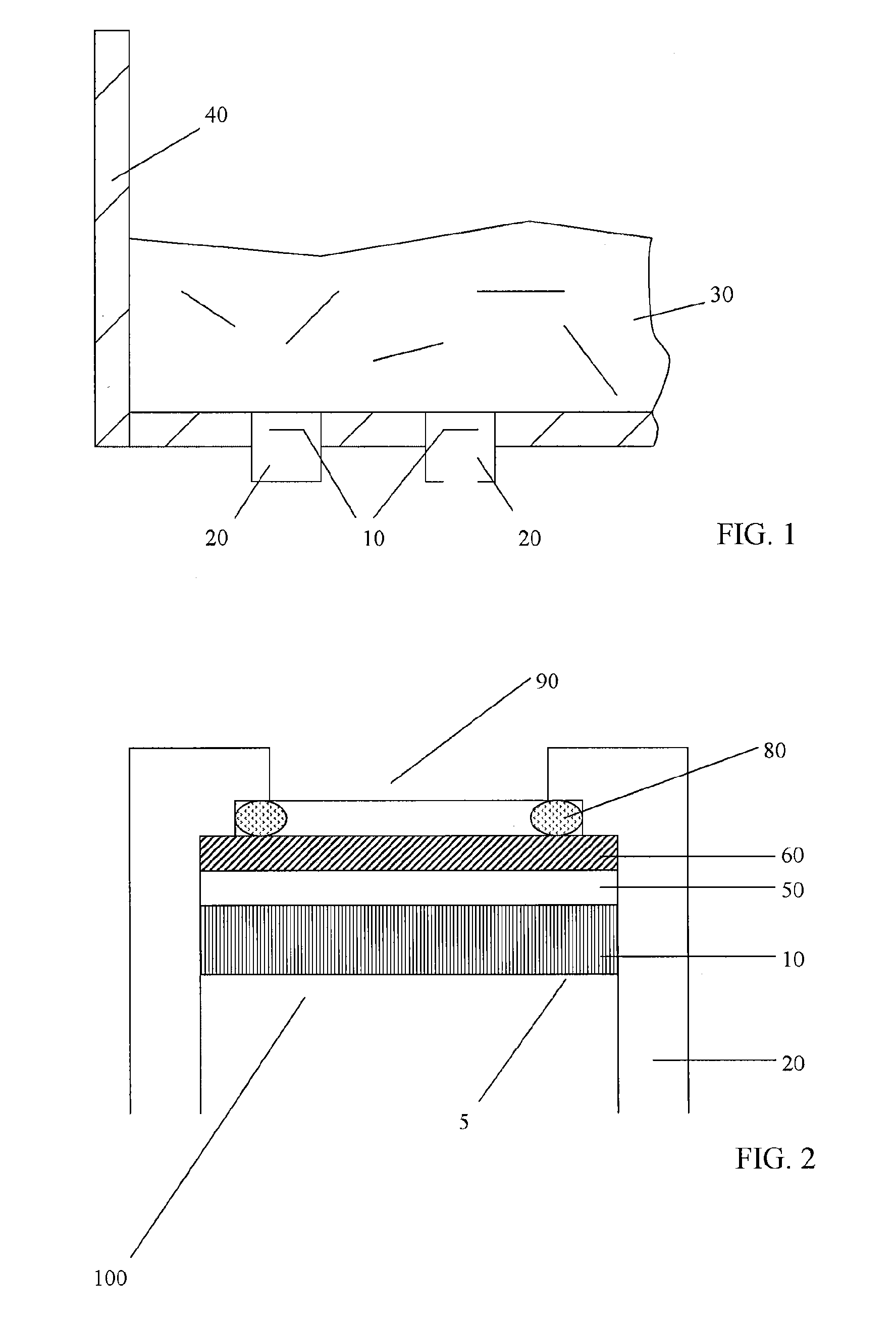

Polyolefin microporous membrane

InactiveUS20100129720A1Improve cycle performancePromote oxidationSemi-permeable membranesSolid electrolytesPolymer sciencePolyolefin

Provided are a polyolefin microporous membrane having a thickness of from 1 to 100 μm, a pore diameter of from 0.01 to 1 μm, and protrusions having a height of from 0.5 to 30 μm formed by embossing on at least one of the surfaces of the membrane; a production method of the membrane; and a separator for battery made of the membrane.

Owner:ASAHI KASEI CHEM CORP

Flux-cored wire for austenitic stainless steel welding

ActiveCN102451961AReduce carbon contentImprove oxidation capacityArc welding apparatusWelding/cutting media/materialsManganeseRutile

The invention discloses a flux-cored wire for austenitic stainless steel welding. The flux-cored wire consists of a flux core and an external steel belt; the external steel belt is an austenitic stainless steel belt of which the carbon content is less than 0.025 percent; the carbon content of the flux core is not greater than 0.04 percent and carbon accounts for 18.0 to 24.0 percent based on the total weight of the flux-cored wire; the flux core comprises the following components in percentage by weight: 18.5 to 25.0 percent of metal chromium powder, 8.0 to 10.0 percent of metal nickel powder, 2.0 to 5.0 percent of electrolytic manganese metal, 1.0 to 3.0 percent of aluminum magnesium alloy, 28.0 to 35.0 percent of rutile, 3.0 to 5.0 percent of quartz, 2.0 to 5.0 percent of zircon sand, 2.0 to 5.0 percent of feldspar, 1.0 to 2.0 percent of cryolite, 2.0 to 5.0 percent of arc stabilizer and the balance of iron powder; and the arc stabilizer consists of K2O, Na2O and TiO2 in a weight ratio of (6.0-8.0):(8.0-10.0):(68.0-70.0), and the water content is not greater than 400 ppm.

Owner:CHINA JINGYE ENG TECH CO LTD +1

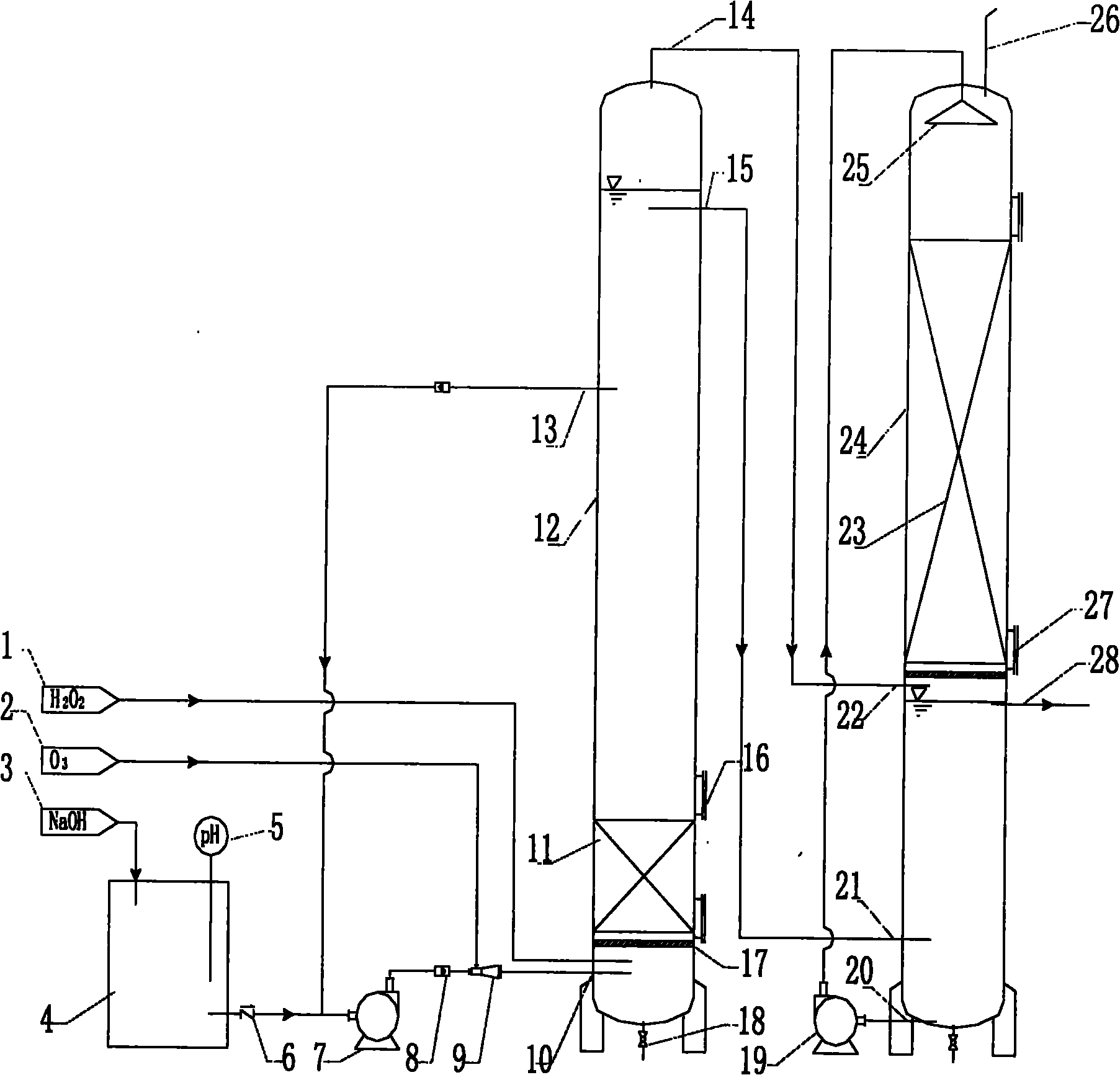

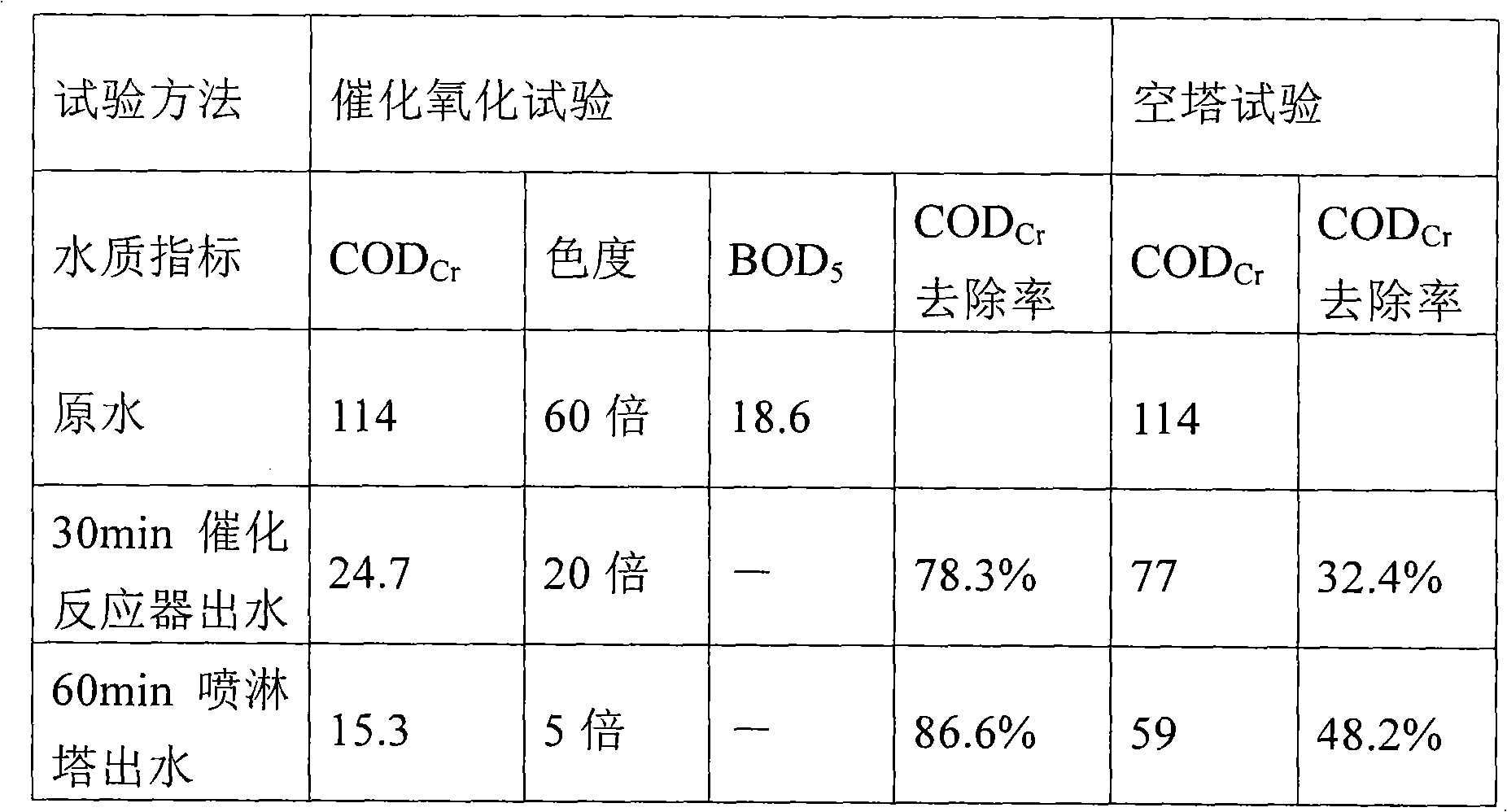

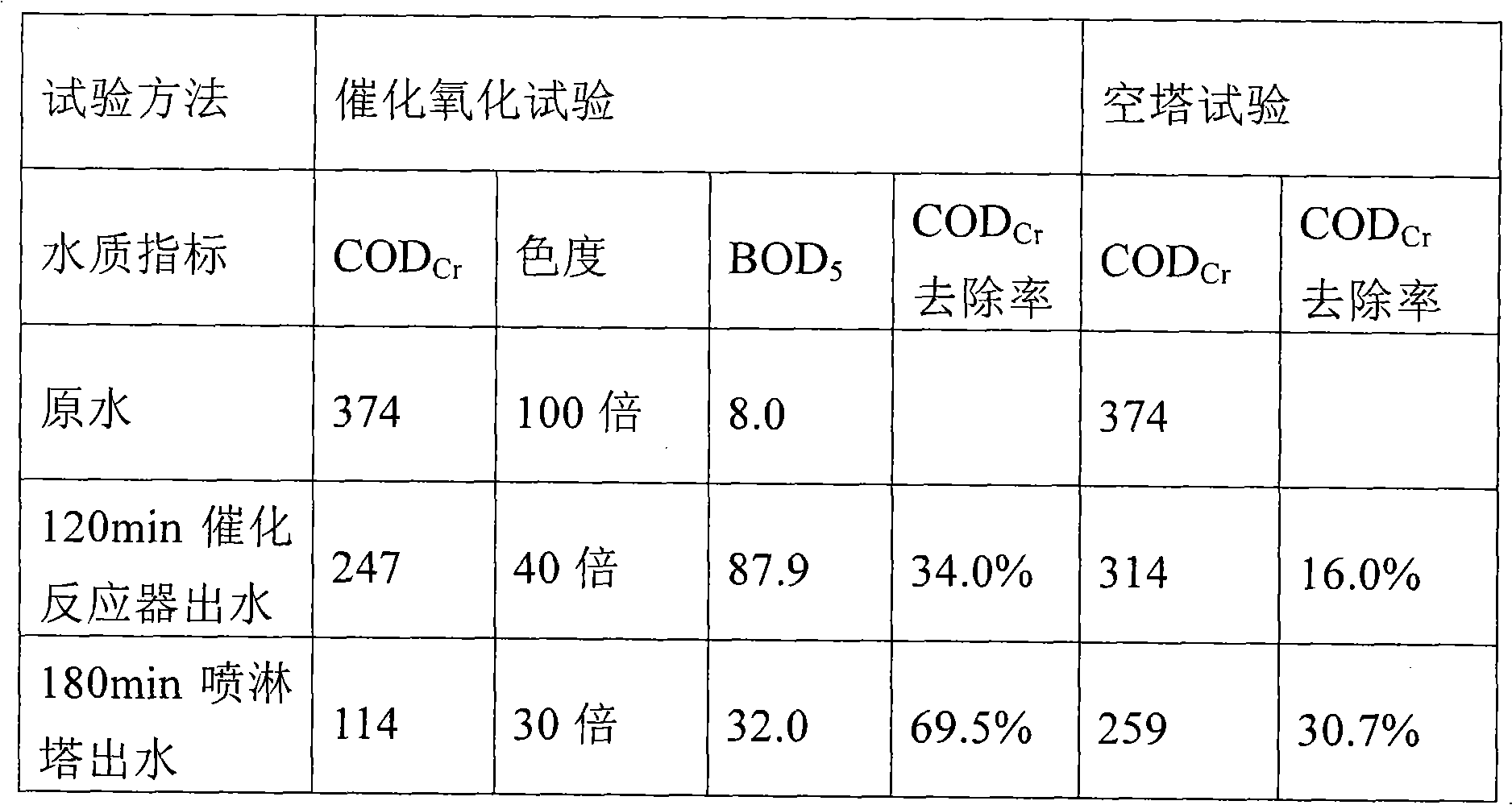

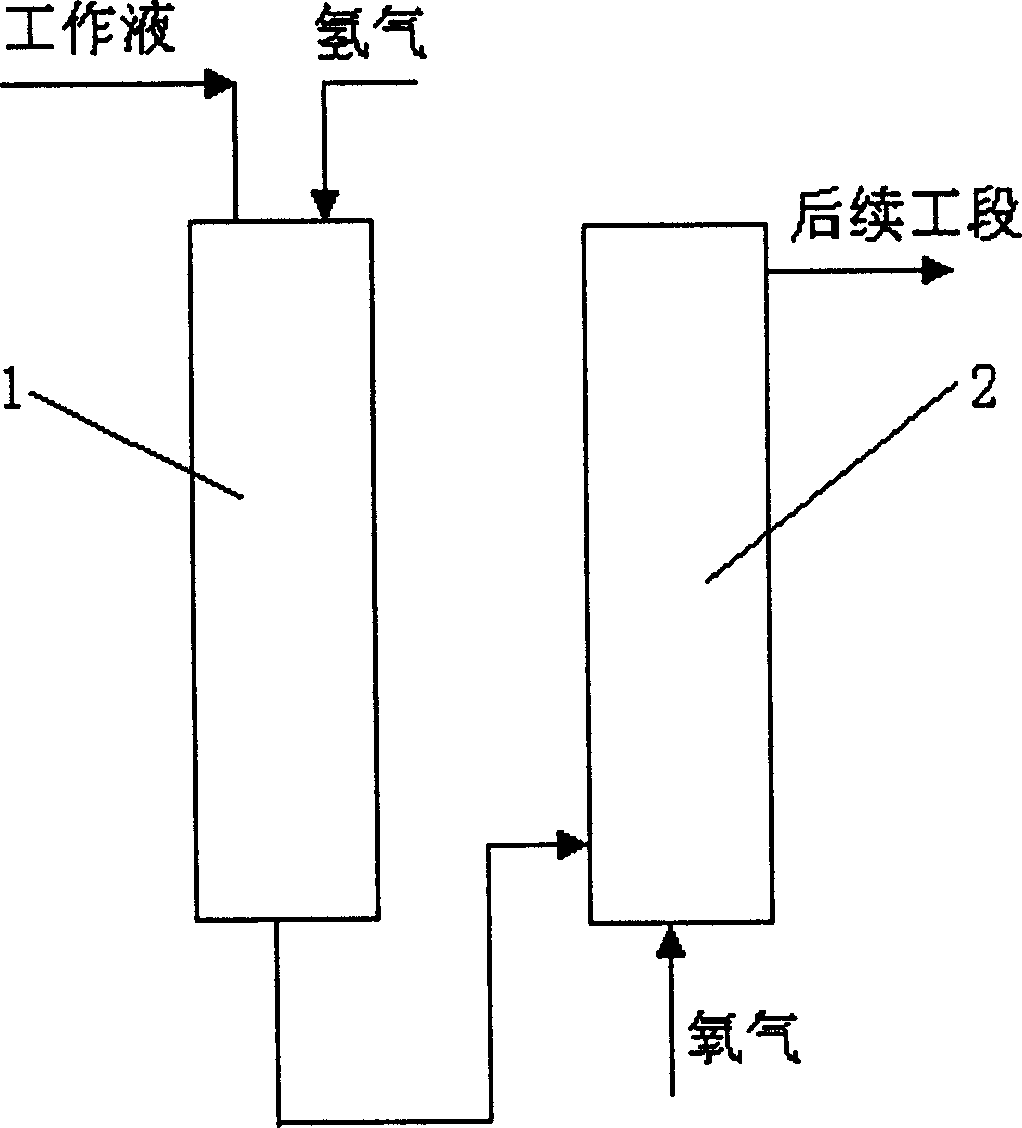

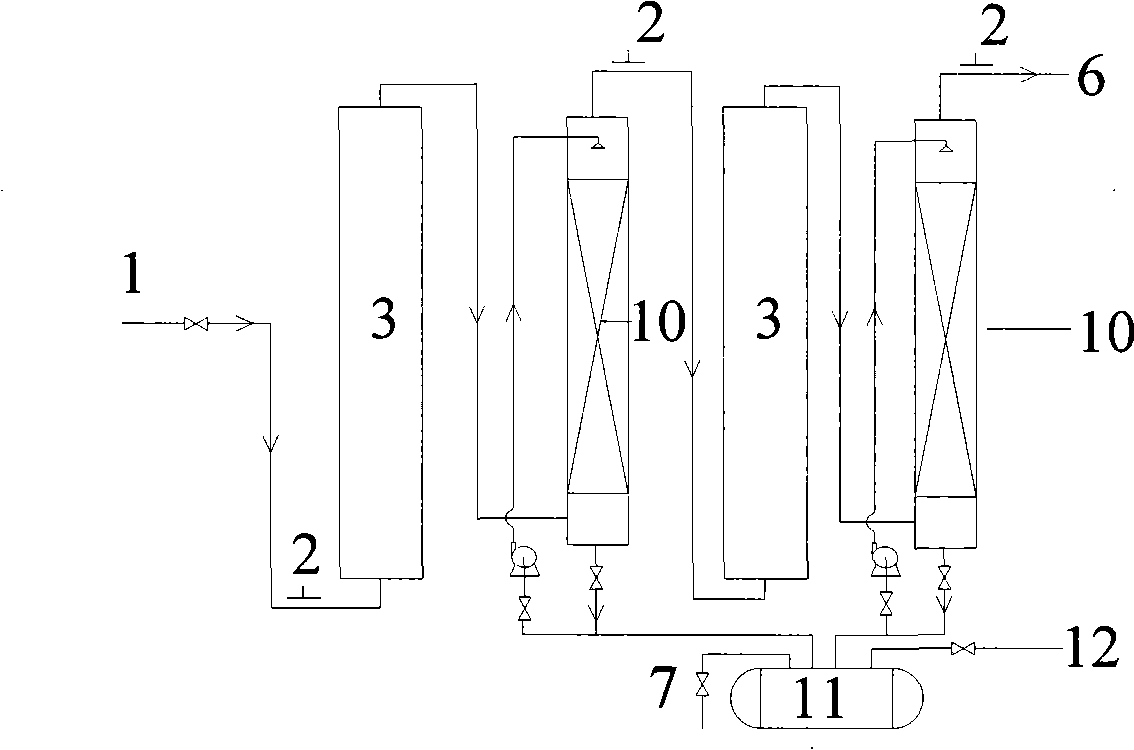

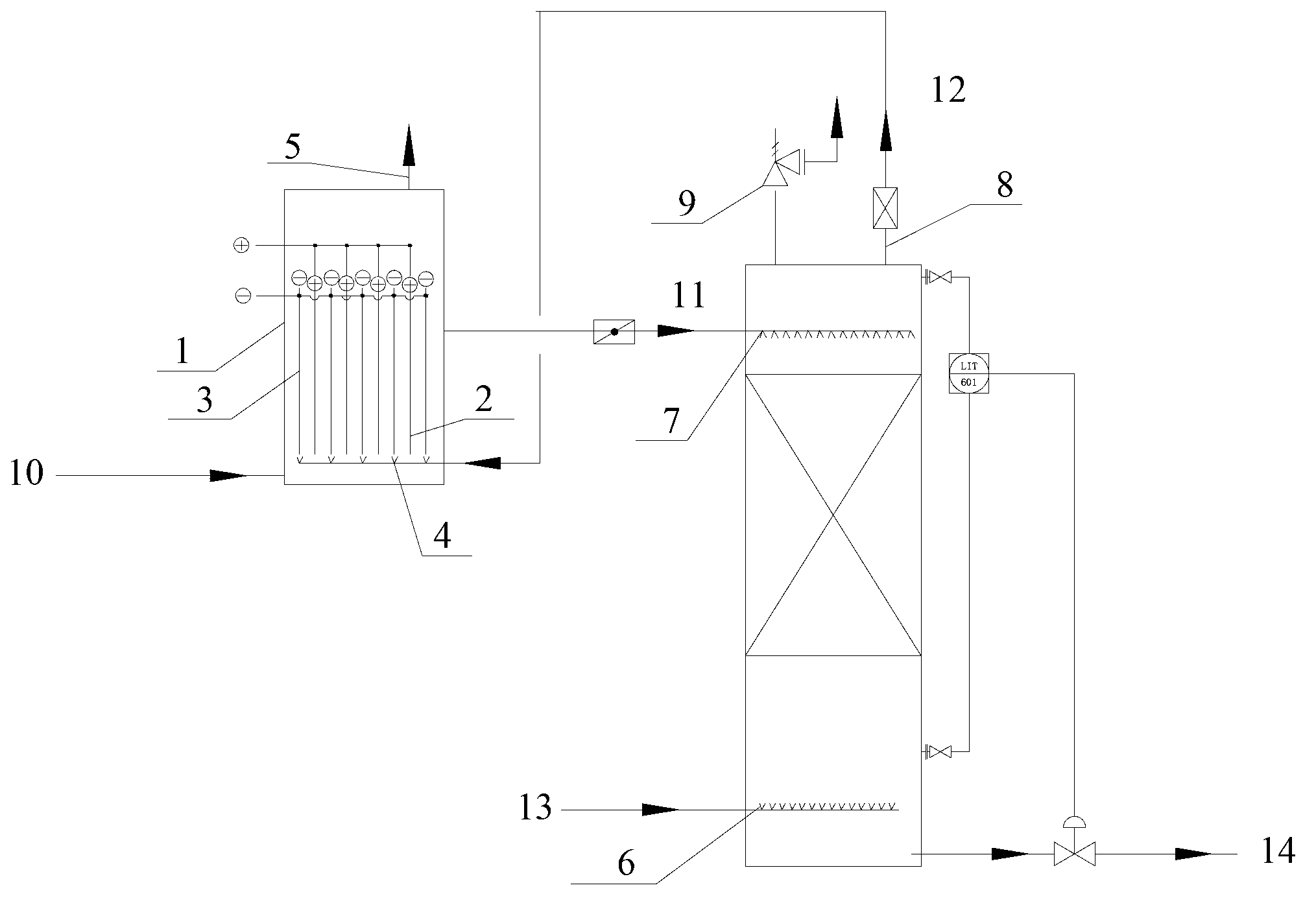

Equipment and method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone

ActiveCN101781036AIncrease contact areaImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentWastewaterPh regulation

The invention provides equipment and a method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone. The equipment comprises a feeding system, an ozone catalytic reaction tower and a spray absorbing tower; the feeding system comprises a wastewater pH regulation device, a wastewater feeding pipeline, a hydrogen peroxide aqueous solution feeding pipeline, an ozone feeding pipeline and a pH regulator feeding pipeline; the wastewater pH regulation device is communicated with the wastewater feeding pipeline and the pH regulator feeding pipeline respectively; the ozone feeding pipeline is communicated with the wastewater feeding pipeline; the ozone catalytic reaction tower is communicated with the wastewater feeding pipeline and the hydrogen peroxide aqueous solution feeding pipeline respectively so that wastewater undergoes once catalytic reaction in the presence of a first catalyst to generate a liquid flow and an ozone tail gas flow which are subjected to initial treatment; and the spray absorbing tower is communicated with a catalytic reaction system, is used for spraying at least one part of the liquid flow which is subjected to the initial treatment, and is contacted with the ozone tail gas flow in the presence of a second catalyst to undergo second catalytic reaction.

Owner:ENN ENVIROTECH CO LTD

Organic flux system in hydrogen peroxide producing process

ActiveCN1552618AImprove solubilityImprove hydrogen efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolventSolubility

An organic solvent system for preparing H2O2 is prepared from C9-C10 arylhydrocarbon (100 wt portions), trioctyl phosphate (0.5-50), and 2-methylcyclohexyl acetate (0.5-90). Its advantages are high solubility of anthraquinone and hydrogenated anthraquinone in it, low by-effect and high productivity of H2O2.

Owner:YICHANG SUPENG TECH CO LTD

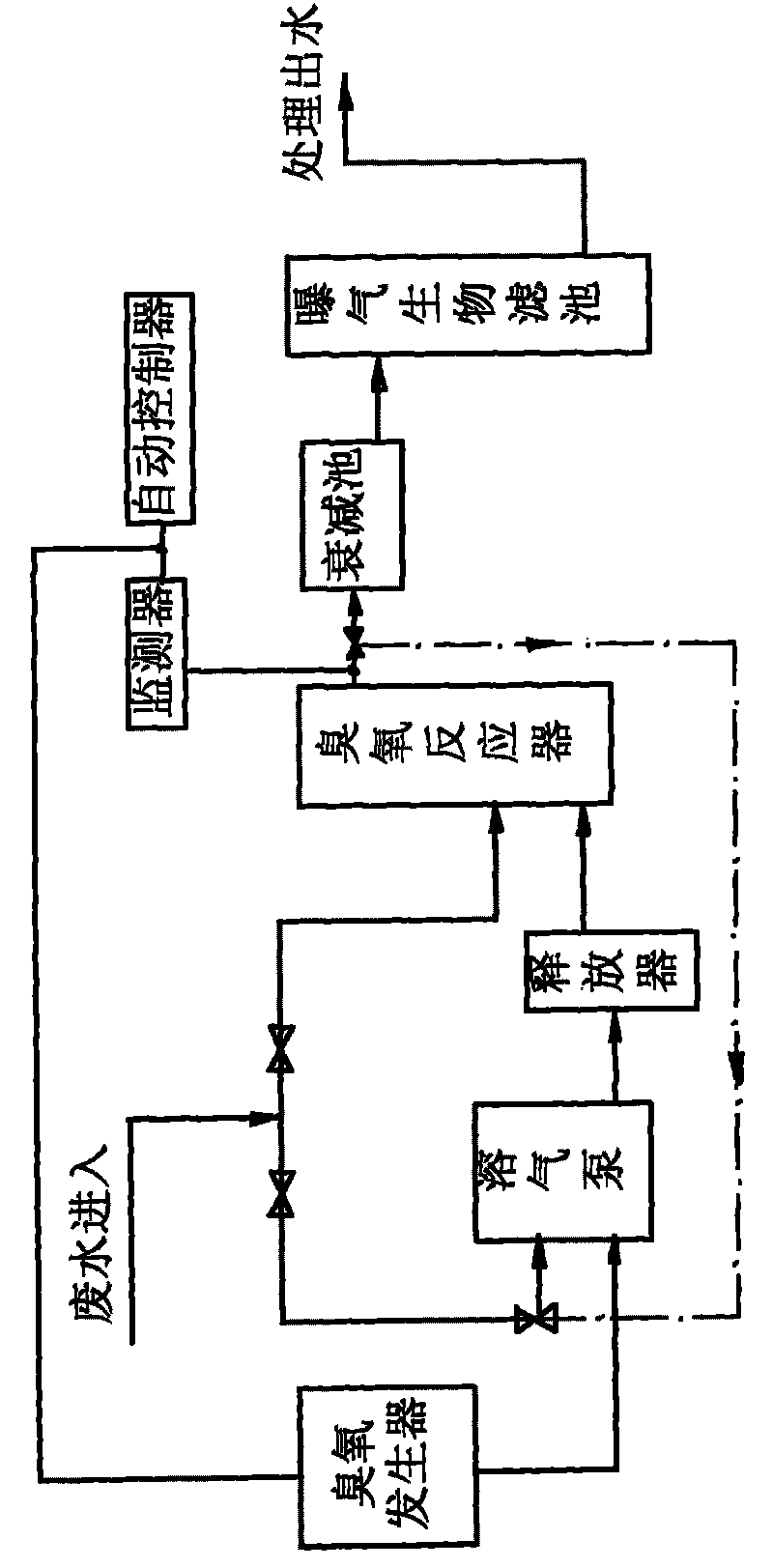

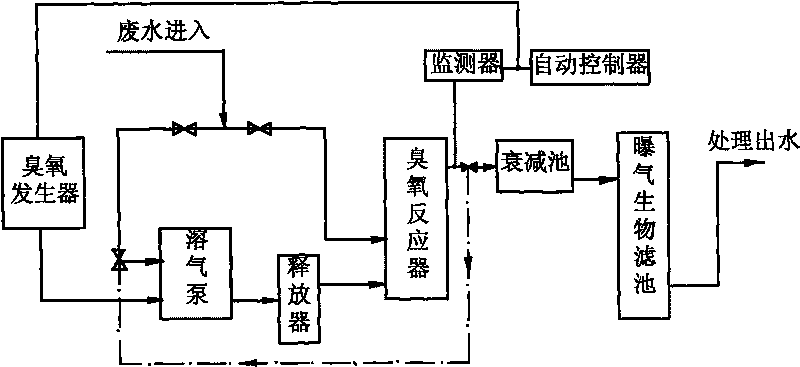

Method for increasing utilization rate of ozone jointly processing waste water with biological aerated filter

InactiveCN101700944AReal-time monitoring of residual concentrationAutomatic adjustment of ozone outputMultistage water/sewage treatmentSustainable biological treatmentUltrasound attenuationComing out

The invention discloses a method for increasing utilization rate of ozone jointly processing waste water with a biological aerated filter, which comprises the following steps: a dissolvent air pump communicated with water is inhaled with ozone; under the pressurization of the dissolvent air pump, the ozone is dissolved in water; an air-release device decompresses and releases water dissolved with ozone to an ozone reactor so that the ozone forms micro-bubbles which fully contact with waste water entering into the ozone reactor, thus oxidizing and processing organic matter in waste water; the waste water enters into an attenuation pool after being oxidized and processed by the ozone reactor; the water coming out of the attenuation pool reenters the biological aerated filter for biology treatment and then is discharged; an automatic monitoring and controlling device is used for monitoring ozone remnant concentration in yielding water oxidized and processed by the ozone reactor in real time and automatically adjusts the ozone output quantity of the ozone reactor. The ozone addition quantity is adopted for automatically regulation control in real time, thus avoiding that the ozone quantity generated in the ozone reactor is less than the ozone quantity required by water treatment and the occurrence of waste as the ozone quality is larger than the required ozone amount; therefore, the utilization rate of the ozone is increased by 20-45%.

Owner:汤苏云

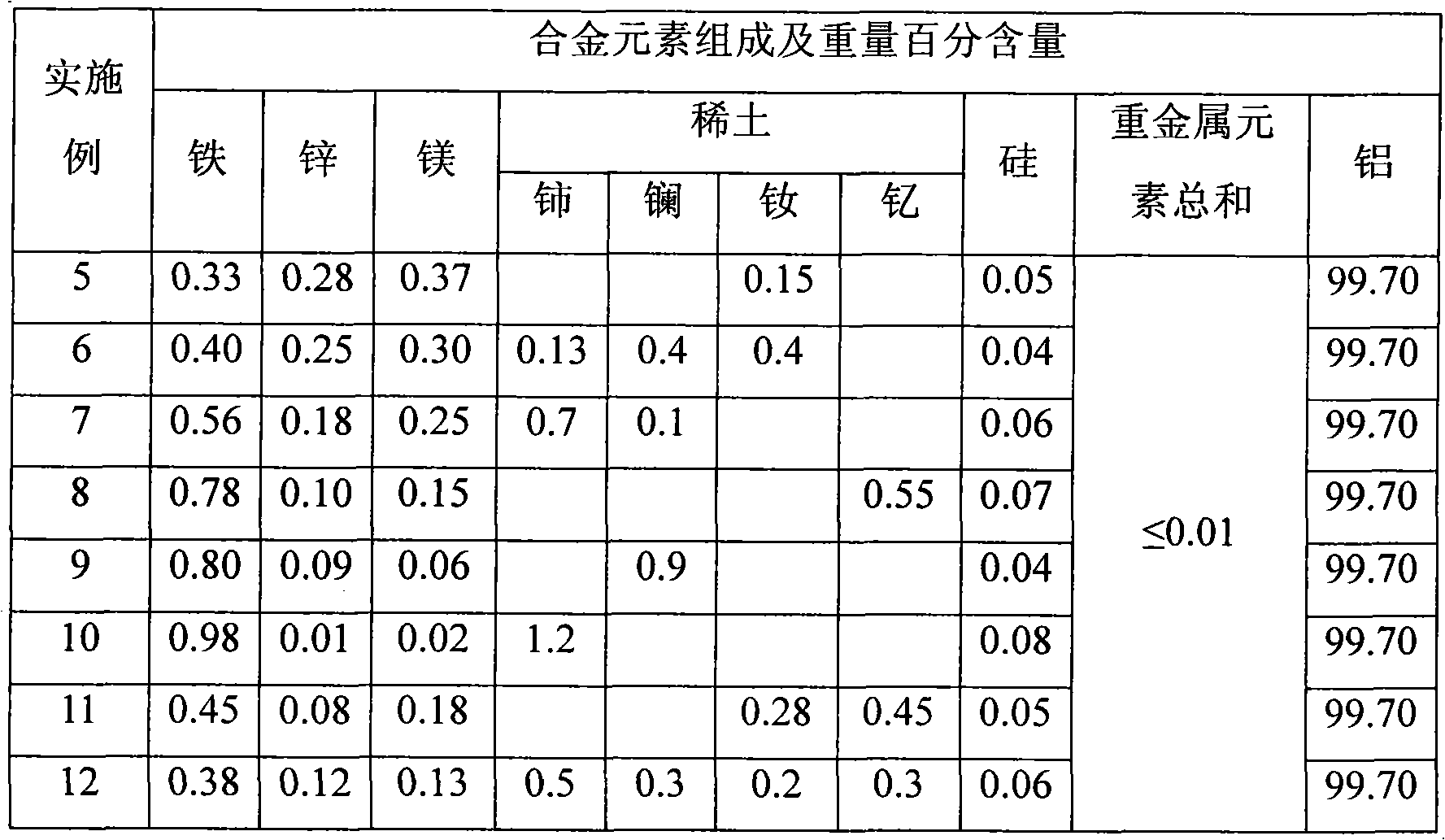

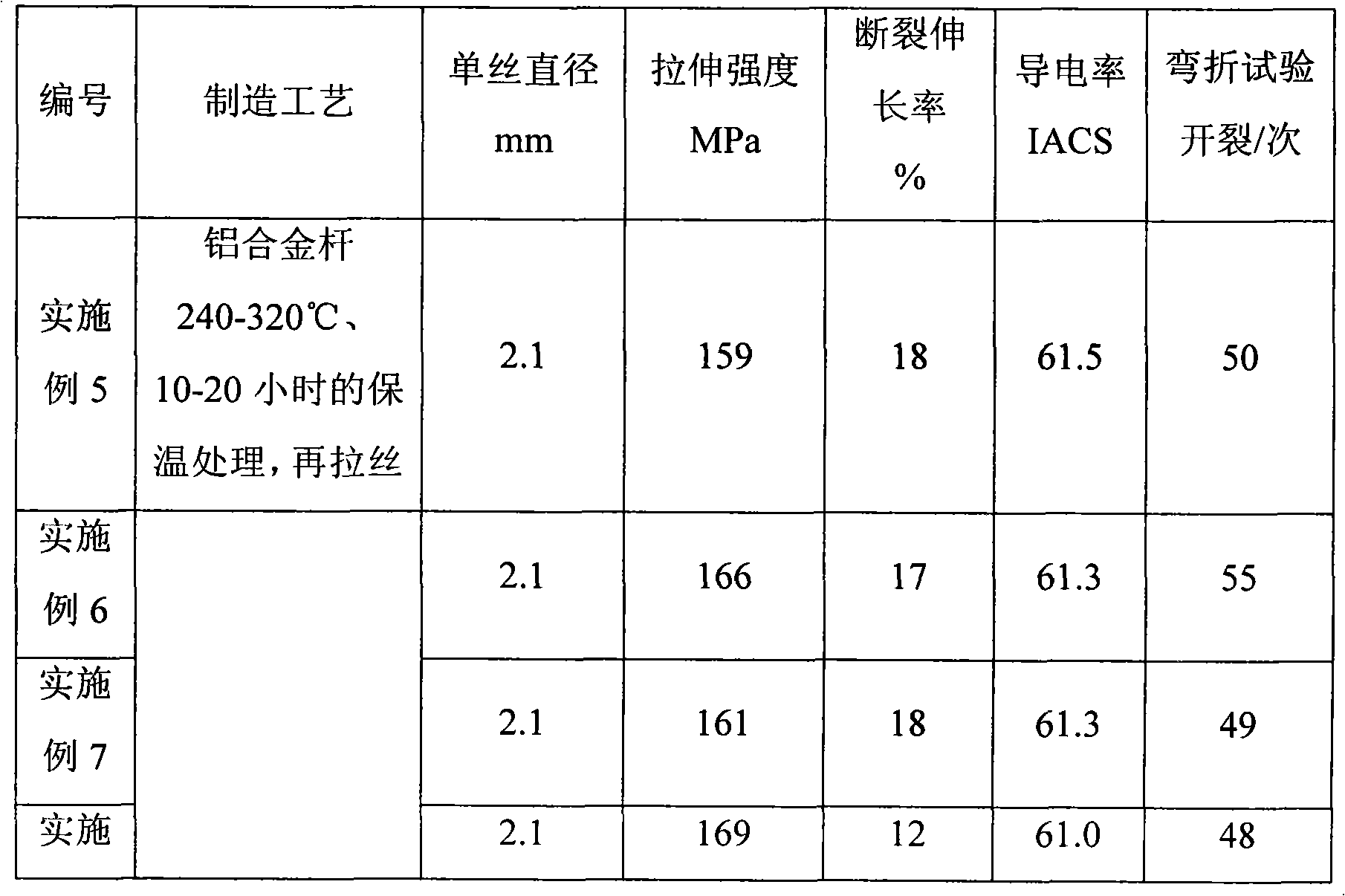

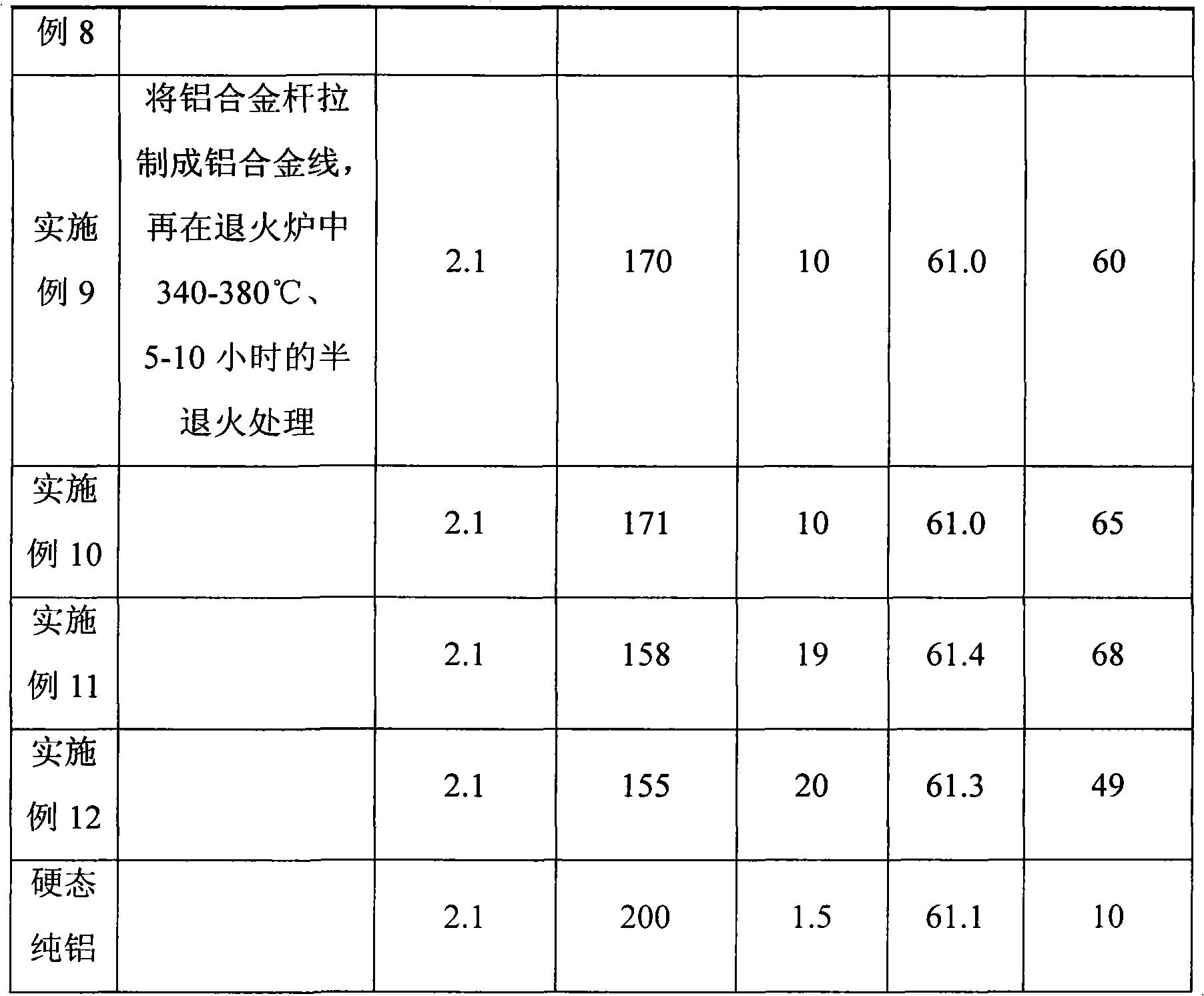

Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

InactiveCN101880799AReduce defect densityGood match of strength and toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy elementRare-earth element

The invention discloses an Al-Fe-Zn-Mg rare earth alloy wire and a preparation method thereof. The aluminum alloy comprises the following elements: 0.3-1.2wt% of Fe, 0.01-0.3wt% of Zn, 0.01-0.4wt% of Mg, 0.1-1.5wt% of rare earth element and the balance of Al and inevitable impurities, wherein the rare earth element is composed of one or more of cerium, lanthanum, neodymium and yttrium. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy rod through smelting, casting and rolling, performing insulation treatment in a heat holding cover at 240-320 DEG C for 10-20 hours, wiredrawing and extruding insulating material on the wire; or preparing an aluminum alloy rod through smelting, casting and rolling, drawing the aluminum alloy rod to prepare the aluminum alloy wire, performing semi-annealing treatment in an annealing furnace at 340-380 DEG C for 5-10 hours, and finally extruding insulating material on the wire. The aluminum alloy wire prepared by the method of the invention has excellent electrical property, mechanical property and corrosion resistance and can be used in the wire and cable conductors.

Owner:ANHUI JOY SENSE CABLE

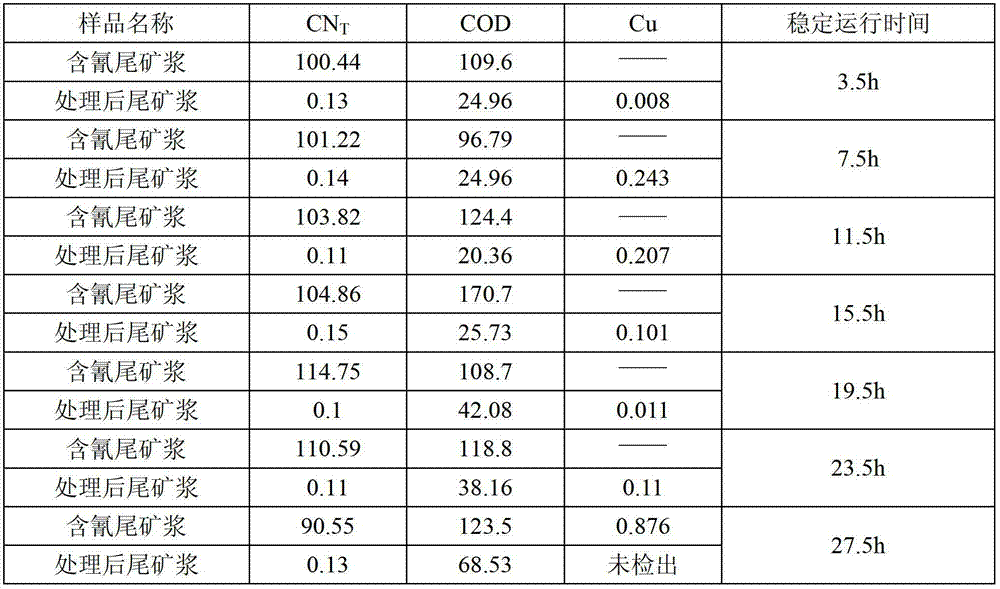

Harmless comprehensive treatment method for cyanide-containing tailing pulp

ActiveCN103086548AReduce loadEasy to handleWaste water treatment from quariesWater contaminantsActivated carbonSlag

The invention discloses a harmless comprehensive treatment method for cyanide-containing tailing pulp. The method is composed of three steps including pulp concentration, cyanide-degradation pretreatment and oxidation, wherein the step of pulp concentration is implemented as follows: the concentration of pulp is increased to be 50% by using a thickener, and applyin liquid supernatant subjected to thickening is applied to a factory selection process, wherein a thickening principle is implemented as follows: solid-liquid separation is conducted by using gravity settling; the step of cyanide-degradation pretreatment is implemented as follows: a cyanide-degradation drug is put into the pulp subjected to concentration; and the step of oxidation is implemented as follows: oxidation is implemented by using a commonly used oxidation method, and meanwhile, activated carbon is put in the stage of oxidation. Useful cyanides are concentrated and recycled, so that the load of follow-up processing is reduced; through the step of cyanide-degradation pretreatment, the cyanide load of an oxidated part is reduced, cyanides such as ferric-cyanide which are difficult to oxidize are fixed, and an oxidant is saved; pulp can easily reach the standard in the process of oxidation treatment, and is stable; and tailing slag which reaches the standard through processing are common solid wastes.

Owner:SHAANXI TAIBAI GOLD MINING IND CO LTD

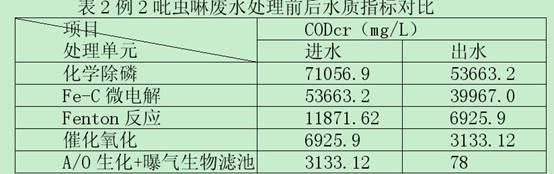

Imidacloprid pesticide wastewater treatment method

ActiveCN102040318AImprove biodegradabilityImprove the overall physical and chemical treatment effectMultistage water/sewage treatmentChemical treatmentPretreatment method

The invention relates to improvement on an imidacloprid pesticide wastewater treatment method. The imidacloprid pesticide wastewater treatment method is characterized by comprising the following steps of: performing physical and chemical pretreatment, namely performing chemical phosphorus removal and ferrum-carbon (Fe-C) micro-electrolysis sequentially and then performing Fenton oxidation and catalytic oxidation respectively; and performing biochemical treatment, namely performing aerobic biochemical treatment in the presence of salt-tolerant aerobic bacteria. By the imidacloprid pesticide wastewater treatment method, the total physical and chemical treatment effect is greatly improved; physical and chemical pretreatment can be performed at normal temperature and normal pressure; organic matters difficult to biochemically degrade is degraded and the biochemical property of the wastewater is improved under the condition of low cost; the dilution factor of the wastewater is greatly reduced; and the using amount of diluting water is reduced by 50 to 80 percent, so that the treatment is more economic. The imidacloprid pesticide wastewater treatment method is simple in pretreatment method, mild and stable in process reaction condition, simple in operation (for example, the catalytic oxidation can be performed at normal temperature and normal pressure and a catalyst can be recycled), low in operating cost, good in treatment effect, low in the using amount of the diluting water during the subsequent biochemical treatment and low in total treatment cost, and the water from the biochemical treatment can reach a national level 1 of discharge standard.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

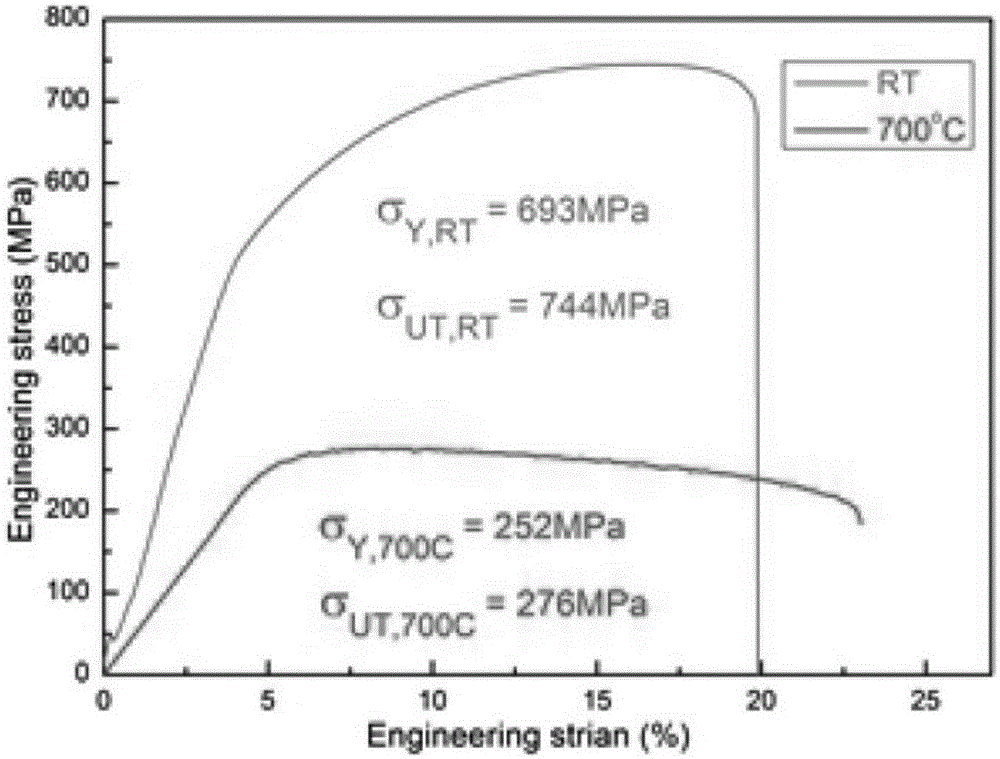

Oxide-dispersion-strengthening ferrite/martensitic steel and preparing method

The invention relates to oxide-dispersion-strengthening ferrite / martensitic steel with the excellent high-temperature strength and the good oxidation resistance and a preparing method of the oxide-dispersion-strengthening ferrite / martensitic steel. The oxide-dispersion-strengthening ferrite / martensitic steel comprises 8% to 10% of Cr, 0.5% to 2% of W, 1.5% to 5.5% of Al, 0.1% to 0.4% of V, 0.1% to 0.5% of Mn, 0% to 1.0% of Zr, 0% to 1.0% of Hf and 0.25% to 0.5% of Y2O3. The content of C and the content of N are controlled to be lower than 0.1%, and at least one kind of the Hf and the Zr is contained; the oxygen content of atomized powder is controlled to be lower than 0.05 wt.%, the atomized powder with the particle size ranging from 50 meshes to 200 meshes is selected to be mechanically alloyed with Al powder, Zr powder, Hf powder and Y2O3 powder, and the size of obtained powder ranges from 90 micrometers to 200 micrometers; silicate glass is used for wrapping, compressing and molding, the pressure is started to be boosted to 120 MPa to 180 MPa at the temperature of 850 DEG C, a two-stage sintering manner in which the temperature ranging from 850 DEG C to 950 DEG C is kept for 1 hour and the temperature ranging from 1050 DEG C to 1150 DEG C is kept for 1 hour is adopted, the tensile strength of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 250 MPa to 320 MPa, and the ductility of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 18% to 32%; and the oxidation performance of the dispersion-strengthening steel is also greatly improved on the premise that the high-temperature strength and the high-temperature plasticity are guaranteed, and after 100-h oxidation is carried out at the temperature of 850 DEG C, the oxidation weight increase only ranges from 0.0327 mg / cm<3> to 0.098 mg / cm<3>.

Owner:UNIV OF SCI & TECH BEIJING

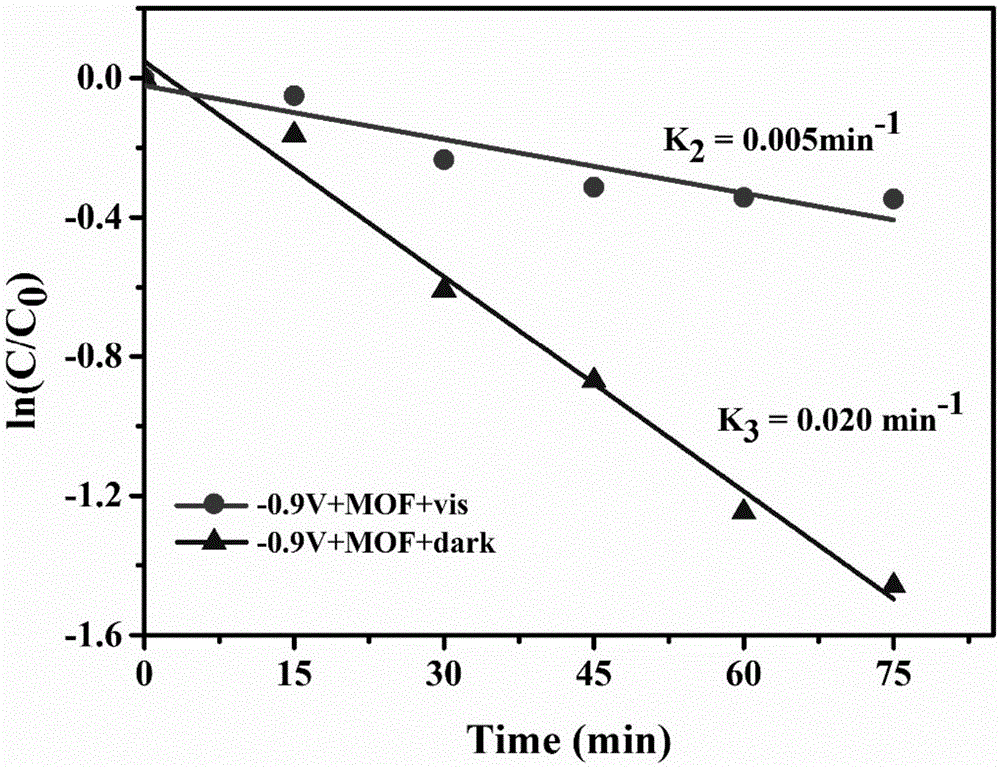

Carbon-aerogel-carried bimetal organic framework electro-Fenton cathode and preparation method thereof

ActiveCN105110423AEfficient degradationReduce energy consumptionWater/sewage treatment by irradiationWater contaminantsMetal-organic frameworkCombined technique

The invention relates to a carbon-aerogel-carried bimetal organic framework electro-Fenton cathode and a preparation method thereof. The preparation method comprises the following steps: by using a block carbon aerogel as a substrate electrode, carrying out hydrothermal reaction to load a bimetal organic framework onto the substrate electrode, filtering, washing, and carrying out vacuum drying to obtain the carbon-aerogel-carried bimetal organic framework electro-Fenton cathode, wherein the bimetal organic framework is a Fe / Co bimetal organic framework. Compared with the prior art, by combining the photocatalytic technique and electro-Fenton, the carbon-aerogel-carried bimetal organic framework electro-Fenton cathode can degrade organic pollutants by using the higher-efficiency low-energy-consumption advanced oxidation technique, thereby providing a new way for using the electro-Fenton cathode in the photocatalytic / electro-Fenton combined technique for treating nondegradable organic pollutants. The carbon-aerogel-carried bimetal organic framework electro-Fenton cathode has the advantages of simple technical operation, energy saving and high efficiency, and has very wide application range in the field of actual water treatment.

Owner:TONGJI UNIV

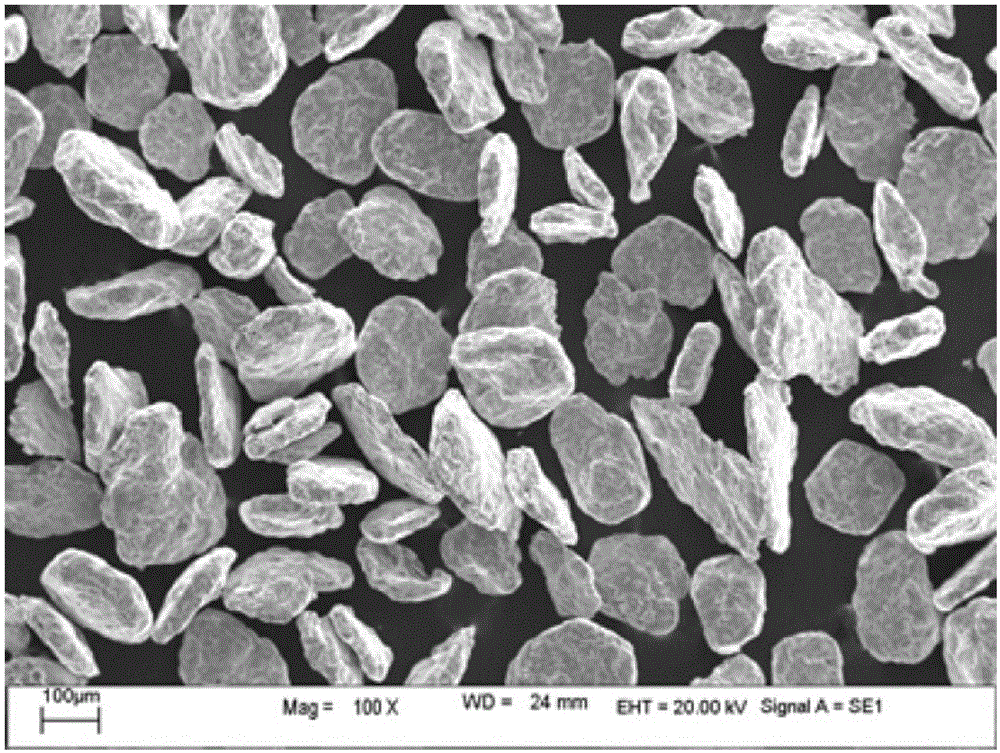

Process for preparing coal-based agglomerated activated carbon

The invention discloses a process for preparing coal-based agglomerated activated carbon. The process has the following beneficial effects: the non-caking coal produced in the wide ditches is taken as a main raw material; the special caking coal type, namely gas-fat coal, is blended in the coal blending procedure; furthermore, the oxidation procedure is added in the process; the process parameters such as pulverized coal particle distribution, forming pressure, coal activation temperature and time and the like in the general production process are adjusted; at the same time, the slow carbonization technology is used instead of the traditional rapid carbonization procedure; and oxygen-enriched air is fed into activation equipment. The coal-based activated carbon prepared by the process can ensure the product strength and bulk density on the basis of satisfying the iodine adsorption of the activated carbon and is better in industrial application value.

Owner:SHENHUA XINJIANG ENERGY

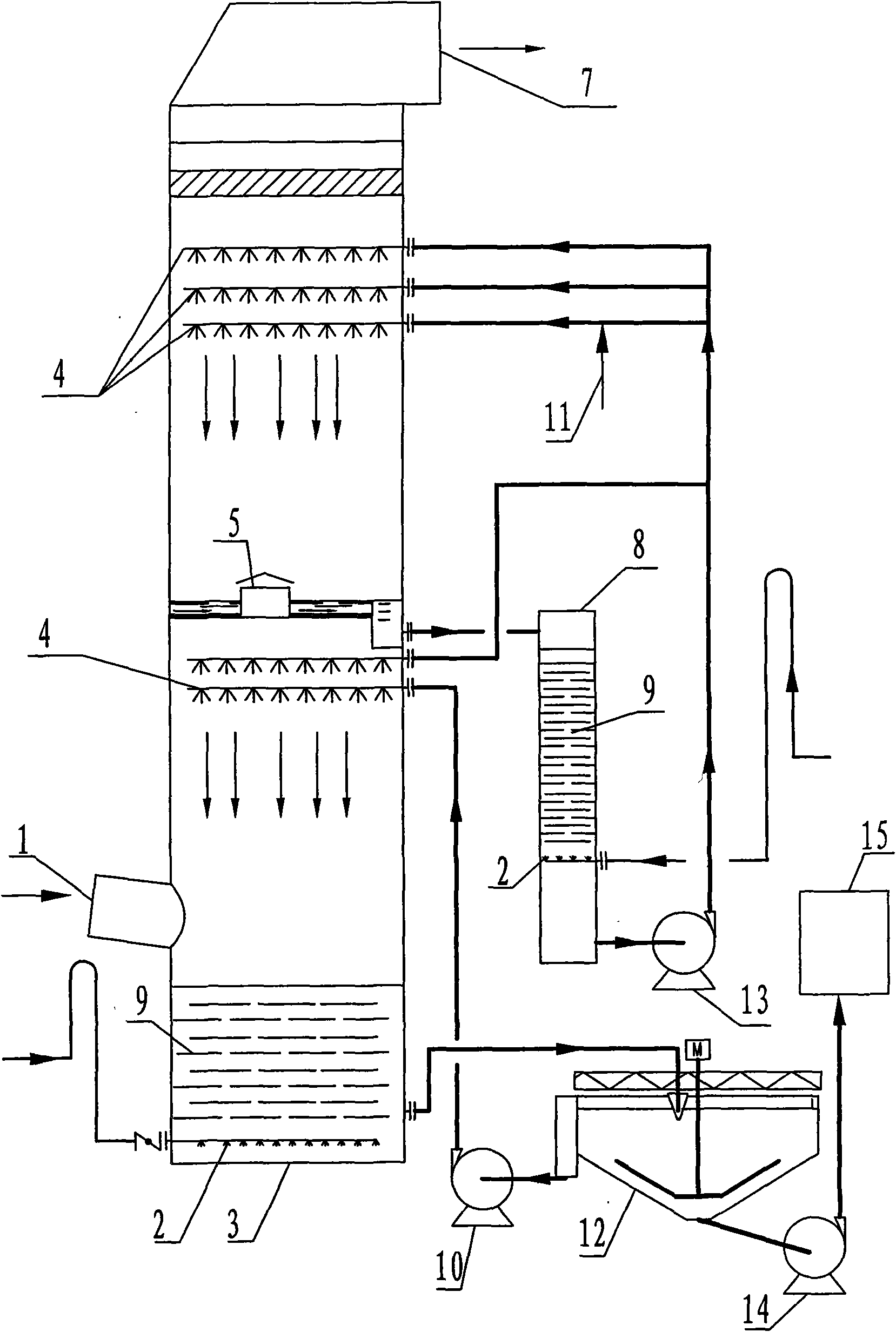

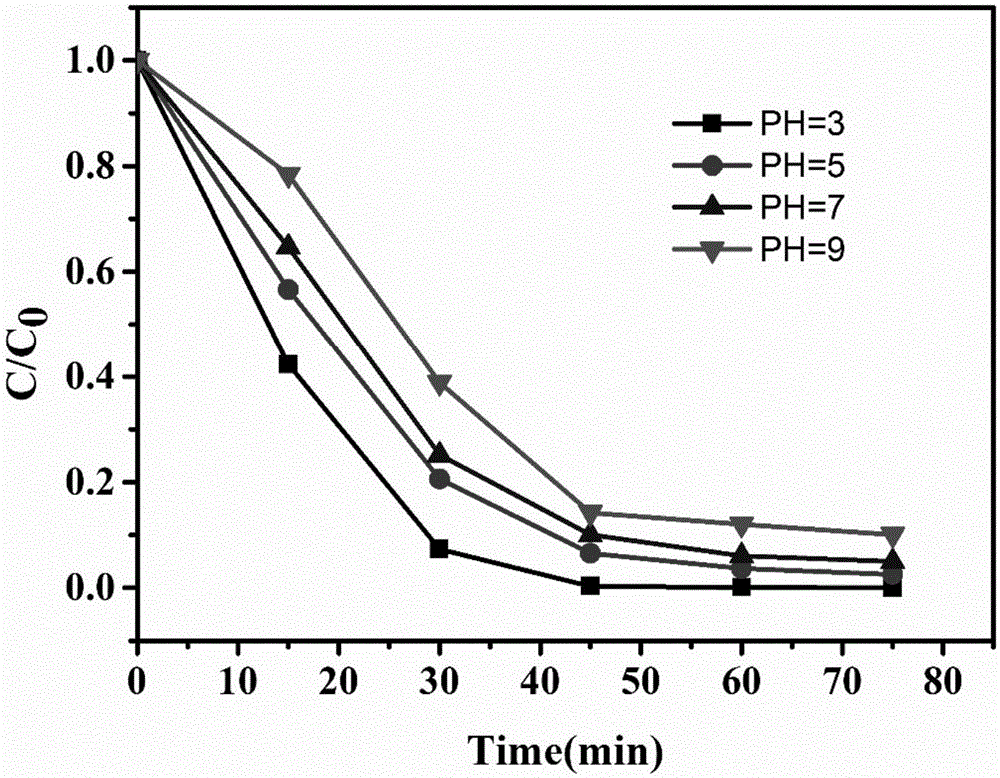

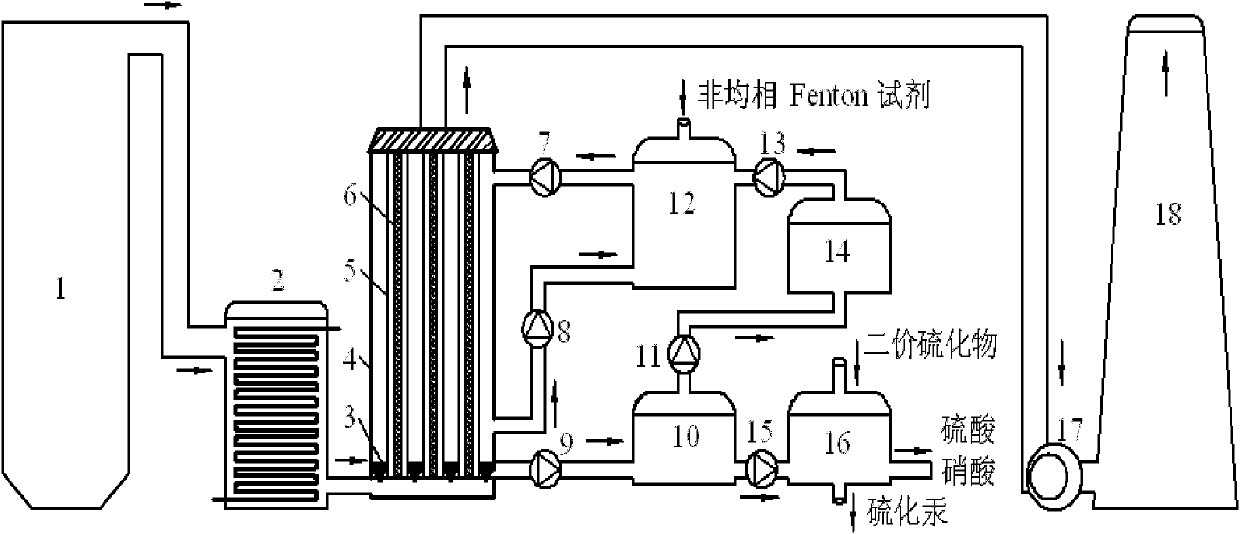

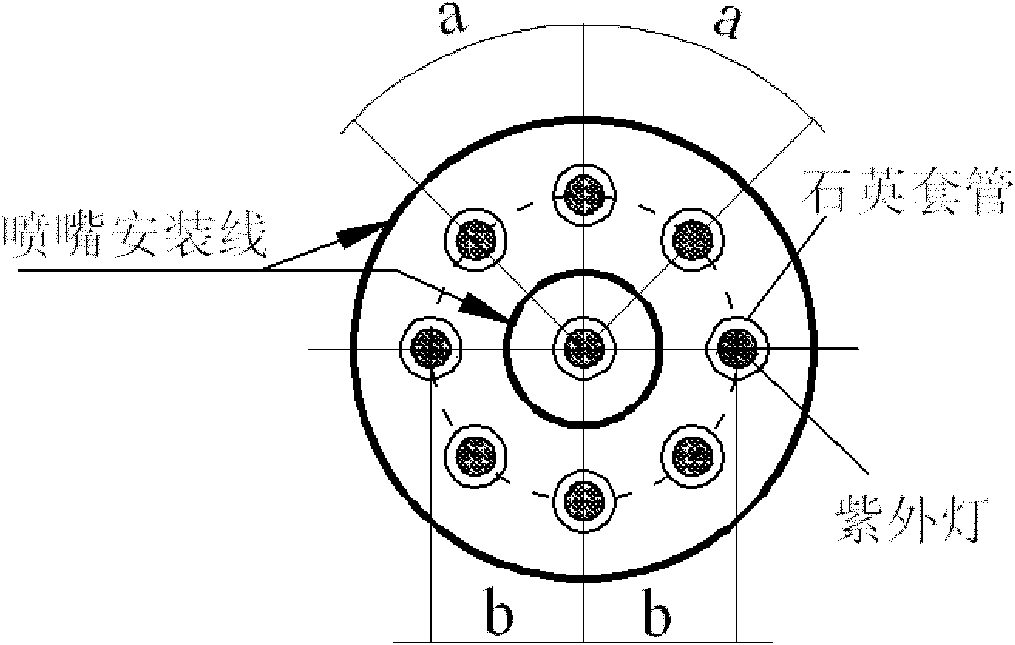

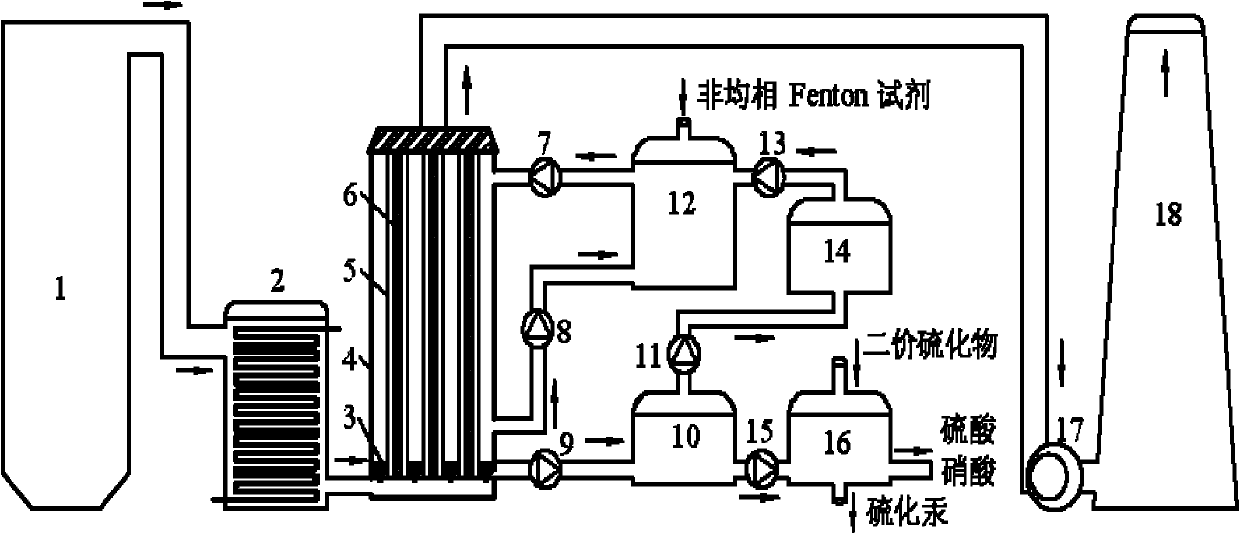

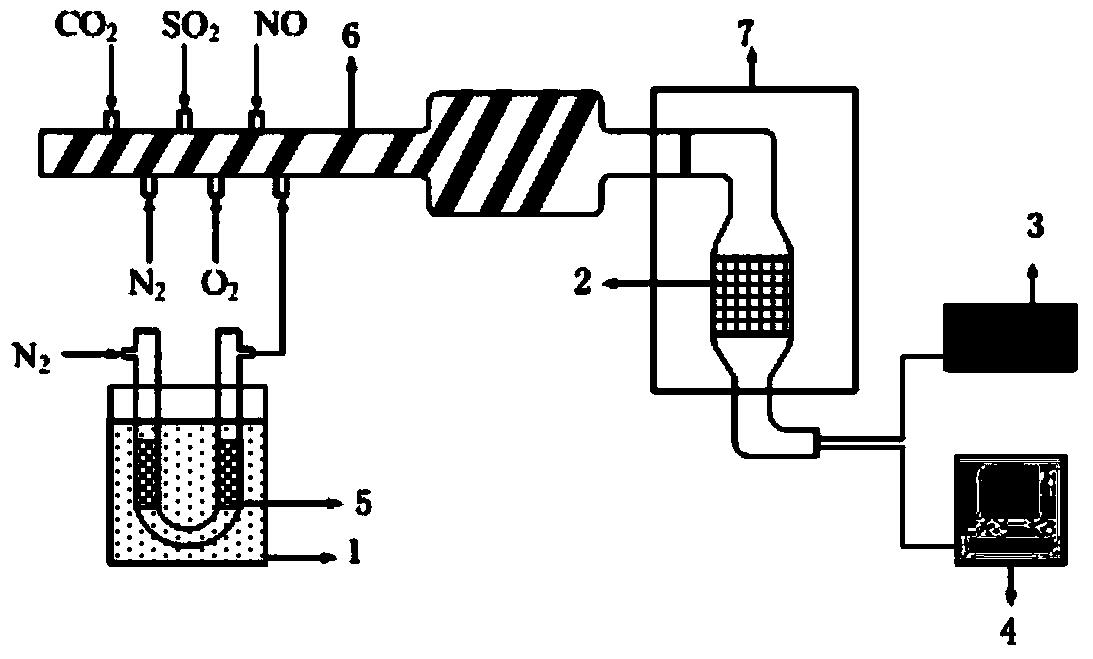

Heterogeneous-Photo-Fenton-based integrated smoke gas purification system

InactiveCN102166471ANo secondary pollutionImprove oxidation capacityDispersed particle separationAir quality improvementHydroxyl radicalPollution

The invention discloses a heterogeneous-Photo-Fenton-based integrated smoke gas purification system. The smoke gas purification system generates a hydroxyl radical (.OH) with strong oxidizability by using heterogeneous Photo-Fenton to oxidize SO2, NO and Hg0 in the smoke gas into H2SO4, HNO3 and Hg2<+> respectively, wherein the H2SO4, the HNO3 and the Hg2<+> are fixed in solution; after reaction,a solid catalyst in mixed solution can be recycled through simple primary precipitation separation; a small amount of Hg2<+> in the solution can be generated into insoluble HgS by adding the same mole ratio of S2<->, and then the HgS is recycled through secondary precipitation separation; and the remaining sulfuric acid and nitric acid solution can be used as an industrial raw material to be further recycled. The whole integrated desulfuration, denitration and demercuration processes generate no secondary pollution, so the heterogeneous-Photo-Fenton-based integrated smoke gas purification system has a very good application prospect.

Owner:SOUTHEAST UNIV

Method for extracting xylan from woody fiber material

A process for extracting xylan from wooden fibre material features that under the catalysis of microwave, the alkali solution containing hydrogen peroxide in directly sued to treat raw material for performing extraction of xylane and bleaching it at same time. Its advantages are high speed, less consumption of alkali, and high extracting rate. The resultant xylan solution can be deposited in organic solvent or superfilted and dried to obtain light-color xylan product.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

Gas phase oxidation-liquid phase reduction method for absorbing and removing nitrous oxides in exhaust air

InactiveCN101279185AAchieve emission standardsSimple processDispersed particle separationGas phaseEmission standard

The invention provides a gas-phase oxidation / liquid-phase reduction method for absorbing and removing NOx. The method utilizes O2 in waste gases as an oxidizer; after be processed by non-catalyst oxidization or catalyzed oxidation by modified active carbon materials, NOx waste gas with low oxidization degree reacts with an alkaline reducing solution fully to remove NOx. After going through multi-grade oxidization, reduction and absorption, the NOx in waste gases can fully meet the emission standard. The method of the invention has the advantages of being able to realize up-to-standard emission of NOx waste gas with low oxidization degree, simple technique, small cost and high removing efficiency.

Owner:ZHEJIANG UNIV OF TECH

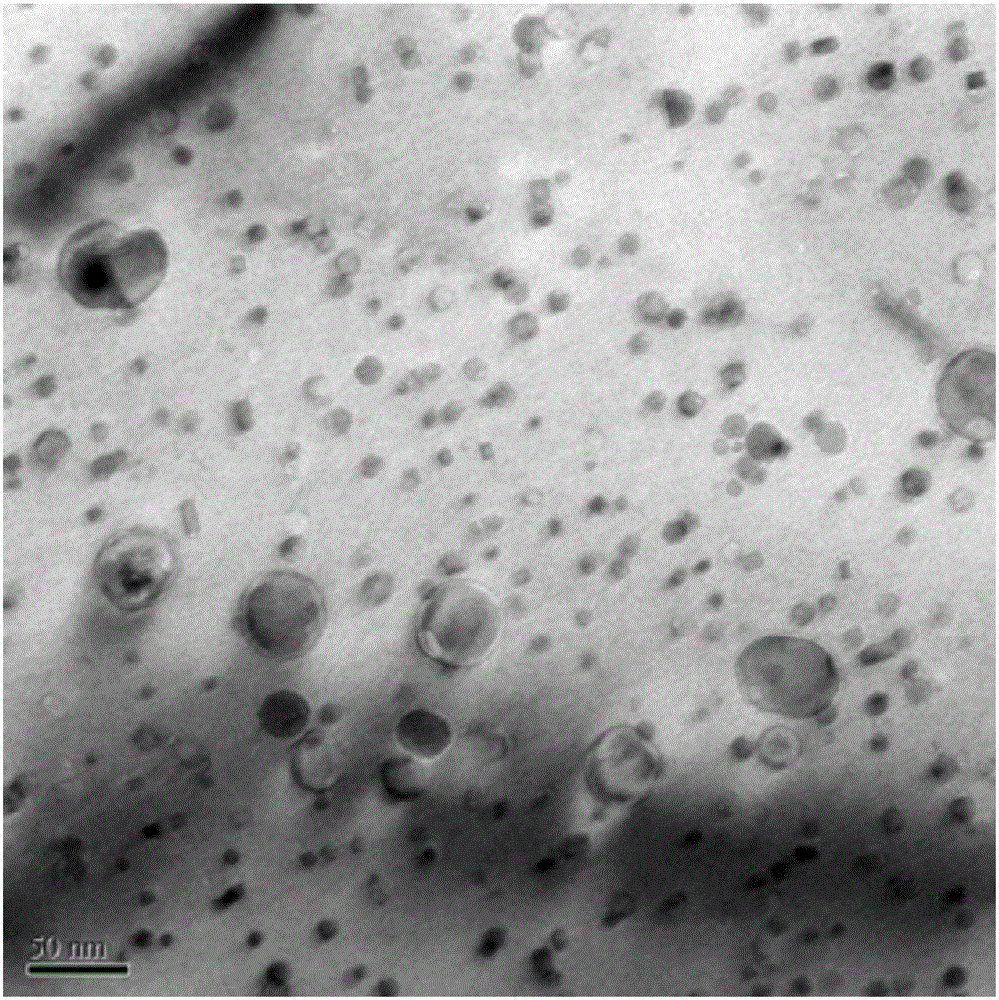

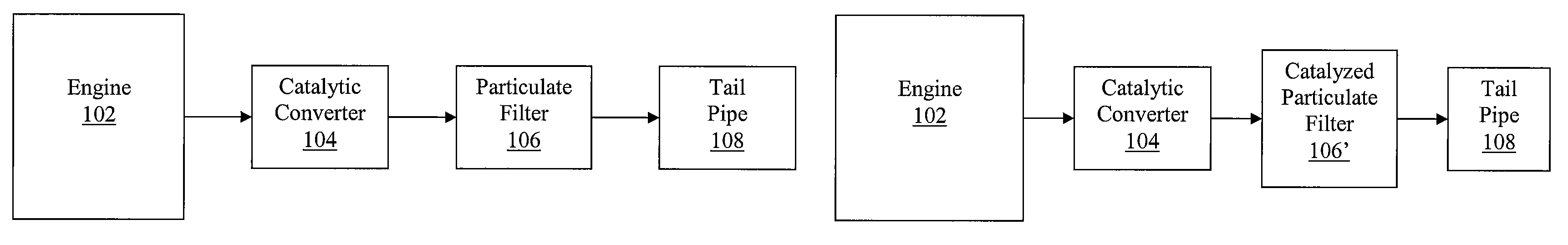

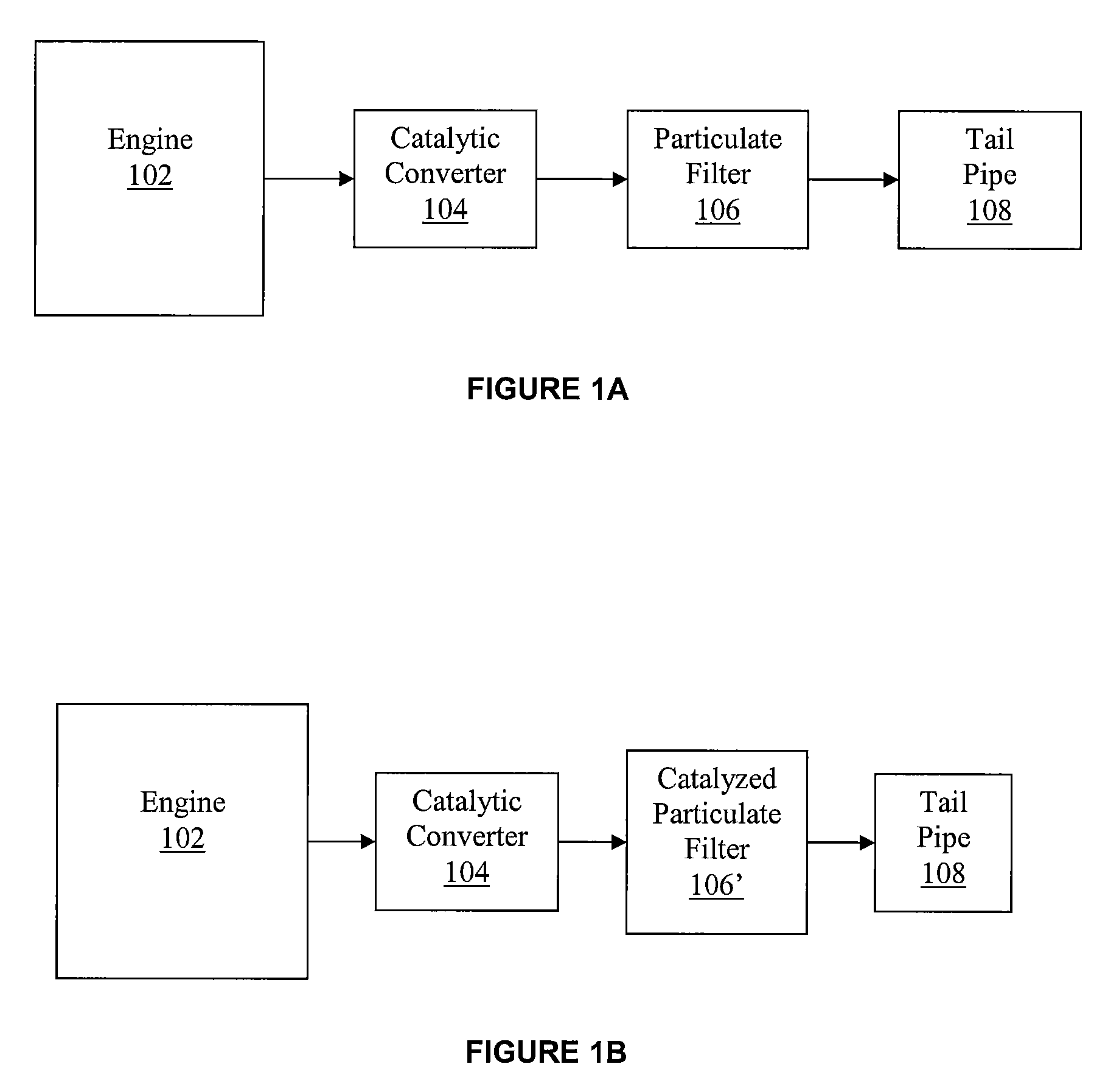

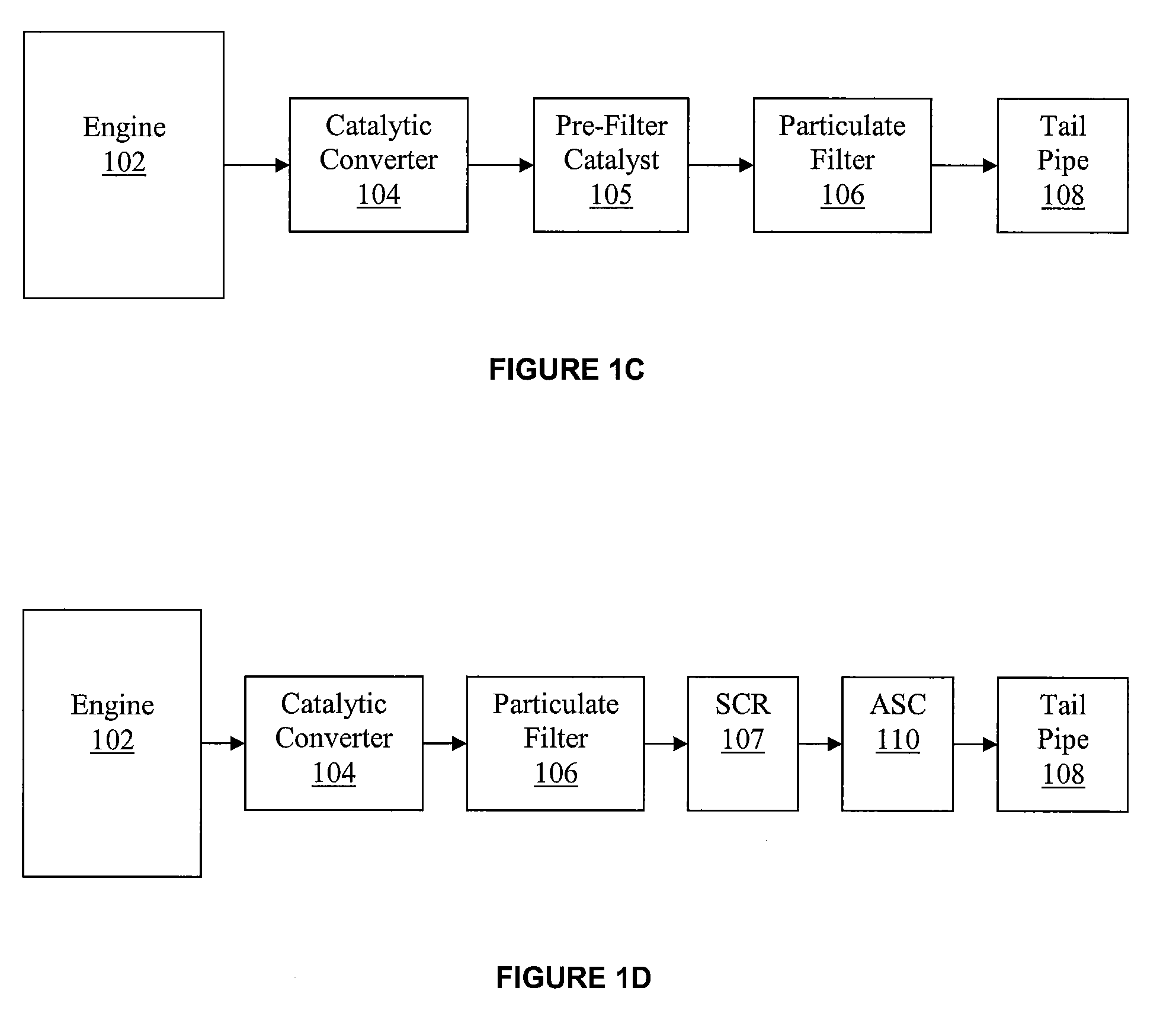

Platinum-bismuth catalysts for treating engine exhaust

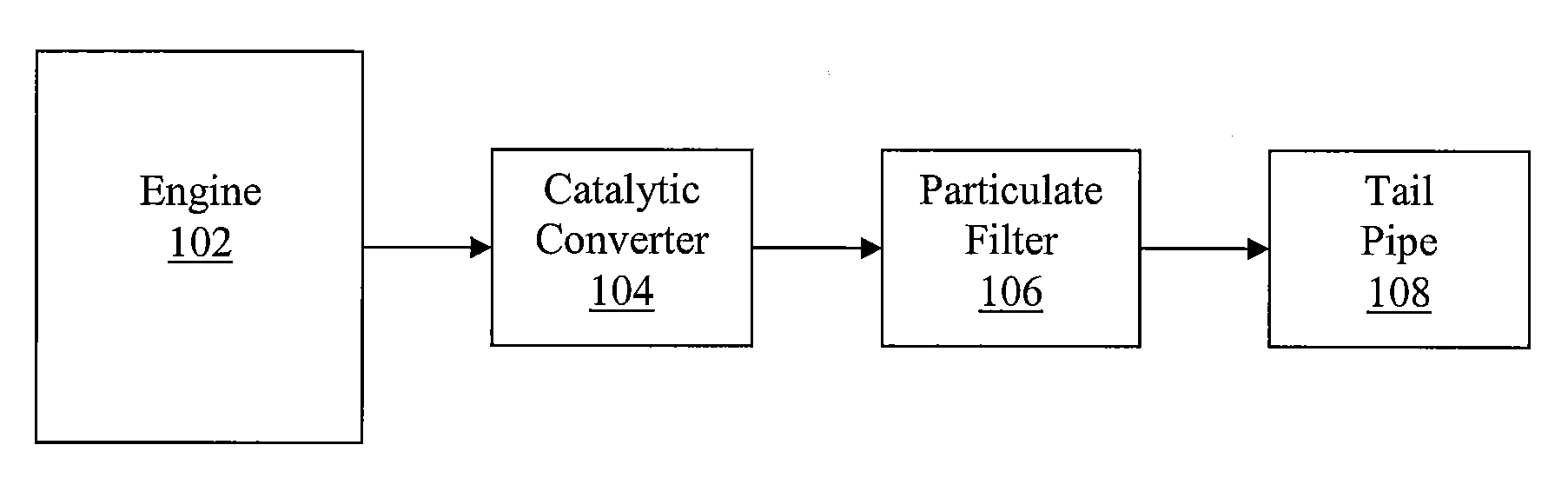

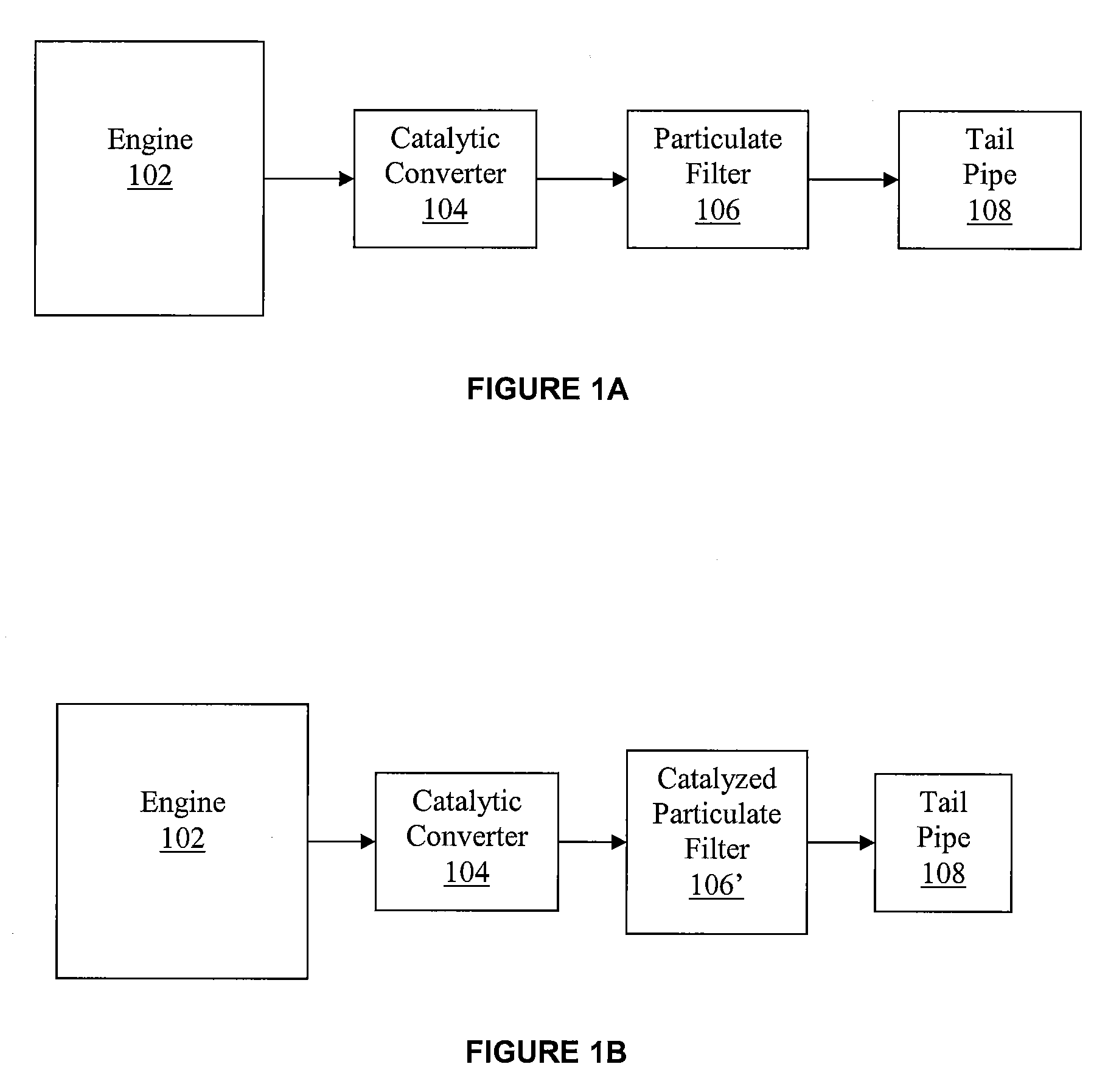

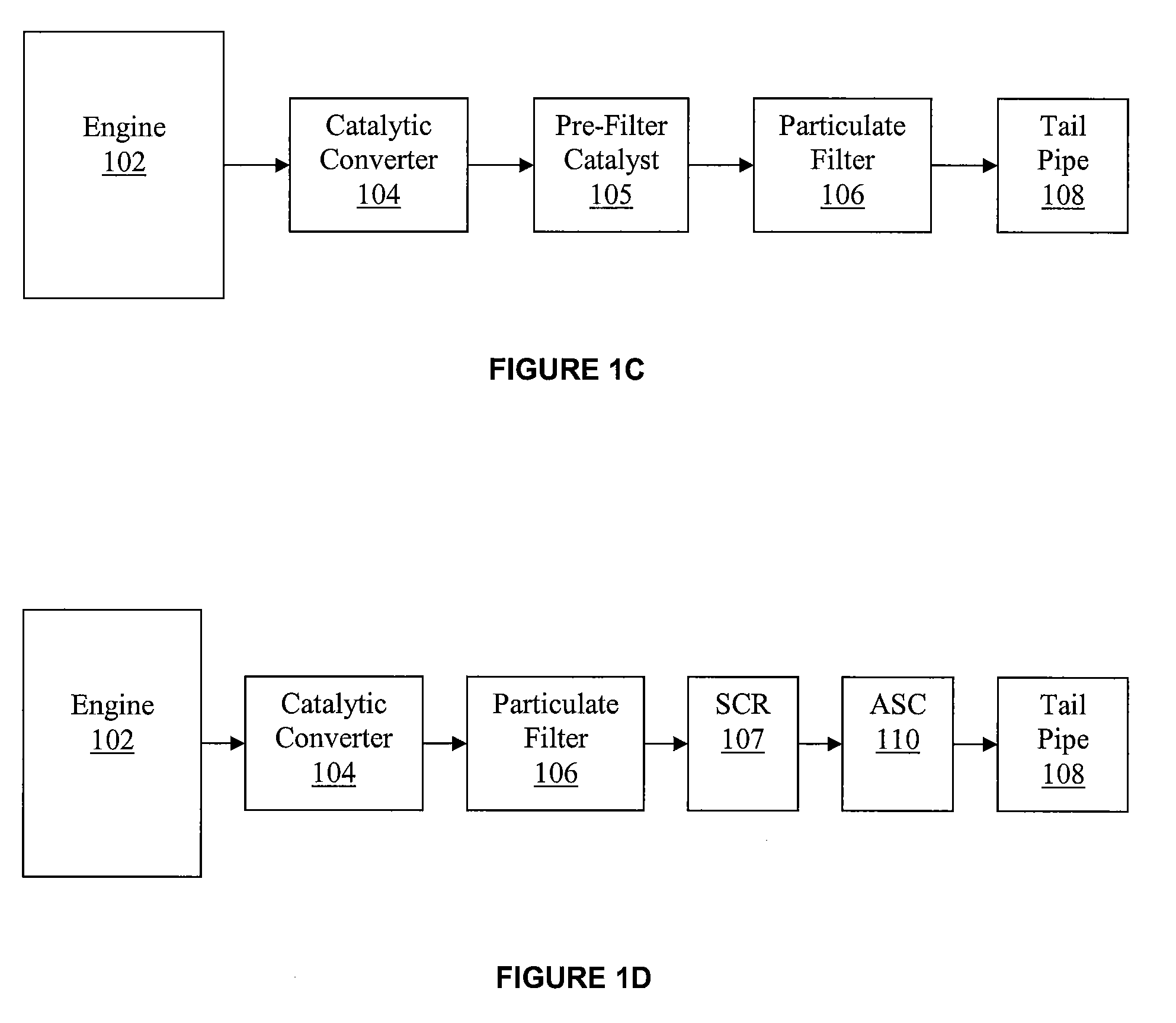

InactiveUS7611680B2Improve oxidation capacityQuantity minimizationCombination devicesNitrogen compoundsParticulatesPlatinum

An engine exhaust catalyst containing precious metal nanoparticles is promoted with bismuth. The bismuth promotion improves the catalyst's CO oxidation performance. Also, by varying the amount of bismuth that is added, the NO conversion rate that can be realized with the catalyst can be controlled. The control over the NO conversion rate is important because the passive regenerative performance of a particulate filter used in engine exhaust systems is based on the amount NO2 that is present in the exhaust stream that reaches the particulate filter. The amount of NO2 being produced needs to be optimized (not necessarily maximized) so that adequate particulate filter regeneration performance can be maintained while avoiding unused, toxic NO2 from being exhausted into the atmosphere.

Owner:SHUBIN

Nutrient regulation and control agent for reducing lead and cadmium content of leaf vegetables and using method thereof

ActiveCN101921144ARaise the pHIncrease productionFertilising methodsFertilizer mixturesCadmium CationBiology

The invention discloses a nutrient regulation and control agent for reducing the lead and cadmium content of leaf vegetables, which comprises the following substances in percentage by weight: 18%-24% of sodium silicate, 16%-20% of calcium carbonate, 9%-12% of magnesium sulfate, 22%-30% of urea, 9%-11% of diammonium phosphate and 16%-21% of potassium sulfate. The using method of the nutrient regulation and control agent comprises the following steps: before planting the vegetable, uniformly mixing the sodium silicate, calcium carbonate, magnesium sulfate, urea, diammonium phosphate and potassium sulfate to obtain a mixture; base-applying all of the mixture, 20-60 kg per mu; turning over and harrowing uniformly so that the regulation and control agent and the polluted soil are uniformly mixed and seeding or transplanting can be performed; or base-applying half of the mixture, and uniformly dispersing the other half of the mixture into the soil after final singling of seedlings; and loosening the soil and sprinkling water. The regulation and control agent of the embodiment of the invention reduces the bioactivity of heavy metals in the soil, reduces absorption of the heavy metals of the leaf vegetable and improves the soil fertility.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

Method and device for enhanced ozone oxidation wastewater treatment of ozone tail gas

ActiveCN103304018AImprove processing effectEasy to handleWater/sewage treatment by oxidationExhaust gasChemistry

The invention relates to a method and a device for enhanced ozone oxidation wastewater treatment of ozone tail gas. According to the method, ozone and oxygen in ozone oxidation reaction tail gas are subjected to electrocatalytic reduction to obtain hydrogen peroxide; the hydrogen peroxide catalyzes the ozone to generate hydroxyl radicals; and organic matters in wastewater are mineralized and decomposed. The device comprises a pre-electrolysis unit and an ozone oxidation unit, wherein a tail gas outlet of the ozone oxidation unit is connected to the pre-electrolysis unit. According to the method and the device, oxygen and ozone resources in the tail gas are fully utilized; destroying treatment is not needed; and an ozone oxidation treatment effect is enhanced.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

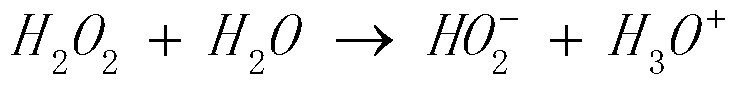

Catalyst for oxidation of metal mercury

ActiveUS7842644B2Efficiently oxidizedImprove performanceDispersed particle filtrationElectrostatic separationHoneycomb likeMercury oxidation

A catalyst is provided having higher mercury oxidation performance than a conventional catalyst without increasing catalyst quantity or enhancing SO2 oxidation performance and constitutes an oxidation catalyst for metal mercury, which contains a molybdenum and vanadium complex oxide, for example, MoV2O8, as a main component having a catalytic activity and is formed by placing the molybdenum and vanadium complex oxide in layers only on the surface of a plate-like or honeycomb-like porous carrier. The porous carrier contains Ti and W and has a function of an NOx removal catalyst as a whole.

Owner:MITSUBISHI POWER LTD

Platinum-Bismuth Catalysts For Treating Engine Exhaust

InactiveUS20080003155A1Improve oxidation capacityQuantity minimizationCombination devicesNitrogen compoundsPlatinumParticulates

An engine exhaust catalyst containing precious metal nanoparticles is promoted with bismuth. The bismuth promotion improves the catalyst's CO oxidation performance. Also, by varying the amount of bismuth that is added, the NO conversion rate that can be realized with the catalyst can be controlled. The control over the NO conversion rate is important because the passive regenerative performance of a particulate filter used in engine exhaust systems is based on the amount NO2 that is present in the exhaust stream that reaches the particulate filter. The amount of NO2 being produced needs to be optimized (not necessarily maximized) so that adequate particulate filter regeneration performance can be maintained while avoiding unused, toxic NO2 from being exhausted into the atmosphere.

Owner:SHUBIN

Aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and preparation method thereof

InactiveCN103725825AMeet general requirementsReduce phosphorus contentManufacturing convertersSteelmakingRed mud

The invention discloses an aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and a preparation method thereof, belonging to the field of converter steelmaking. The dephosphorizing agent is mainly prepared from the following raw materials by mass percent: 50-70% of dried red mud, 5-15% of lime, 15-30% of iron ore concentrate or iron sheet ball, 2-10% of light roasting dolomite, and 0.5% of binding agent. The dephosphorizing agent is prepared by the following steps of crushing the raw materials, mixing uniformly, pressing into chunks, roasting for 2-4 hours at 300-500 DEG C, cooling down, and then crushing into the dephosphorizing agent with grain size of 15-30mm. The dephosphorizing agent is added in dephosphorizing step in steelmaking by the converter, can be used for processing molten iron with middle or low content of phosphorus, and can remove more than 90% of phosphorus. By utilizing large amount of CaO and Fe2O3 in the red mud, the dephosphorizing agent not only has good dephosphorizing effect, but also solves the problem of red mud pollution, thus recycling the red mud and lowering the cost for steelmaking.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

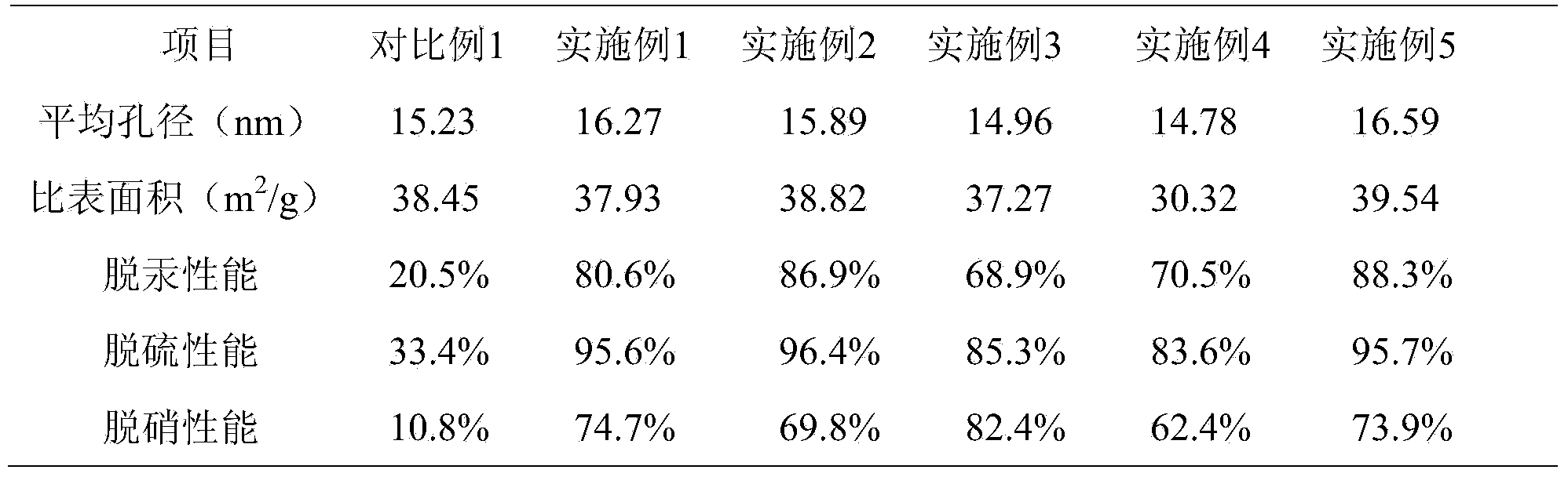

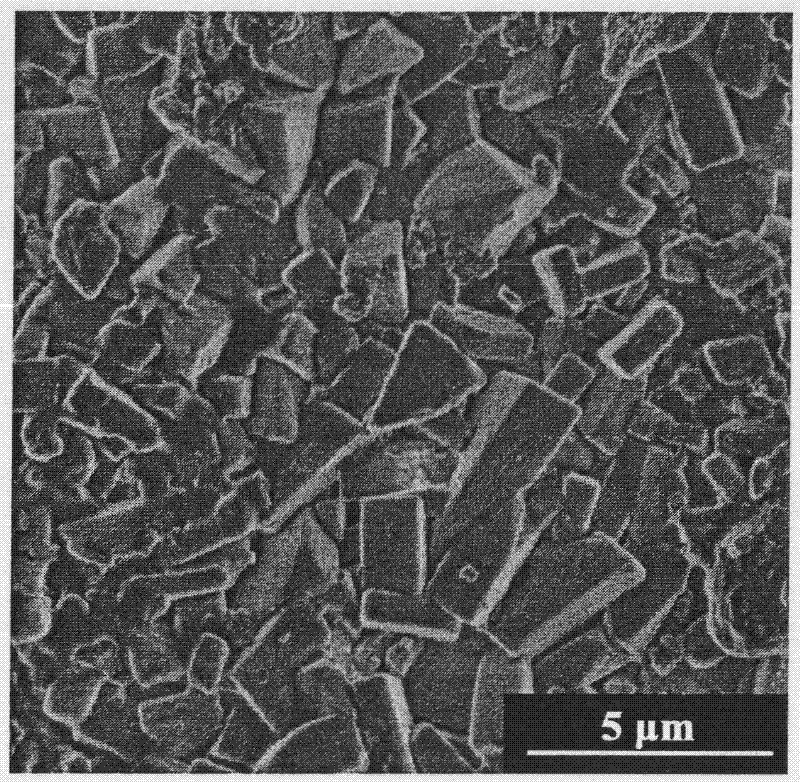

Flue gas demercuration, desulfurization and denitration adsorbent and preparation method thereof

InactiveCN103521164ALow priceEfficient removalOther chemical processesDispersed particle separationRed mudFlue gas

The invention discloses a flue gas demercuration, desulfurization and denitration adsorbent and a preparation method thereof. The adsorbent is red mud modified by combination of MnO2 and V2O5, wherein the mass of MnO2 and V2O5 accounts for 5-15 percent of the total mass of the adsorbent, and the molar ratio of Mn / V in the MnO2 and V2O5 is 0.5-2.0. The preparation method comprises the following steps: heating and immersing activated red mud in the Mn(NO3)2 and NH4VO3 mixed solution for 8-12 hours; drying, roasting, crushing and screening. The flue gas demercuration, desulfurization and denitration adsorbent prepared by the method is simple in preparation method, low in raw material cost, remarkable in demercuration, desulfurization and denitration effect and the like.

Owner:SOUTHEAST UNIV

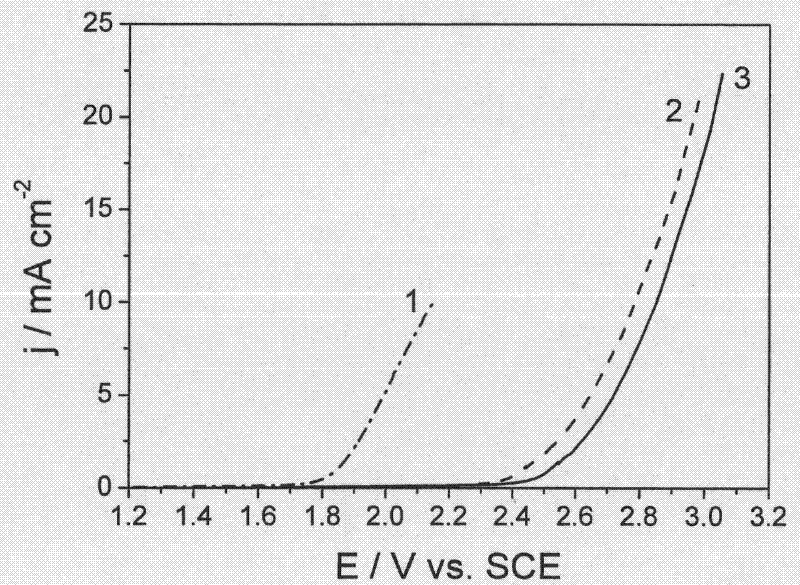

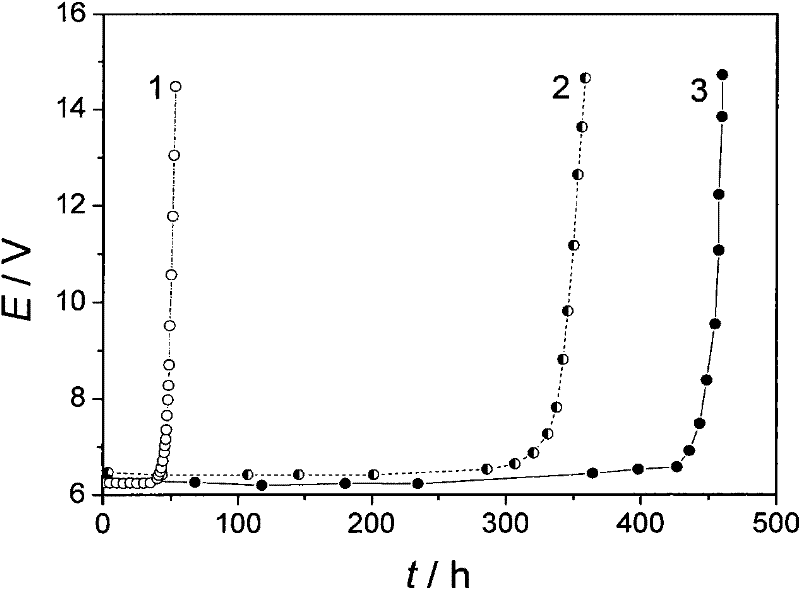

Electrode Ce doped PbO2 used for treating waste water and its preparation method

InactiveCN102190351AImprove stabilityImprove oxidation capacityWater/sewage treatment by electrochemical methodsElectricitySocial benefits

The invention relates to an electrode Ce doped PbO2 used for treating waste water and its preparation method. The electrode is a F-PbO2-CeO2 / TiO2-NTs / Ti electrode. The method for producing the electrode comprises that: obtaining a titania nano-tubes array (TiO2-NTs / Ti) matrix prepared by an anodization processing, doping rare earth Ce, preparing a doped-type F-PbO2-CeO2 / TiO2-NTs / Ti electrode by using an electrodeposition method. Compared with the prior art, the PbO2 electrode by the present invention has the advantages of high oxygen evolution potential, strong catalytic activity, stable electrode electrochemical performance and long service life. Compared with the traditional PbO2 electrode, the oxygen evolution potential of the electrode is higher than 2.4 V, and accelerated and strengthen life is more than 400 hours, the service life can reach about 40 years. The electrode has the advantages of simple preparation technology and low manufacturing cost, and can be effectively used for an electrochemical oxidation treatment of organic waste water which has high density and is difficult to degrade, the electrode also has a wide economic and social benefit.

Owner:TONGJI UNIV

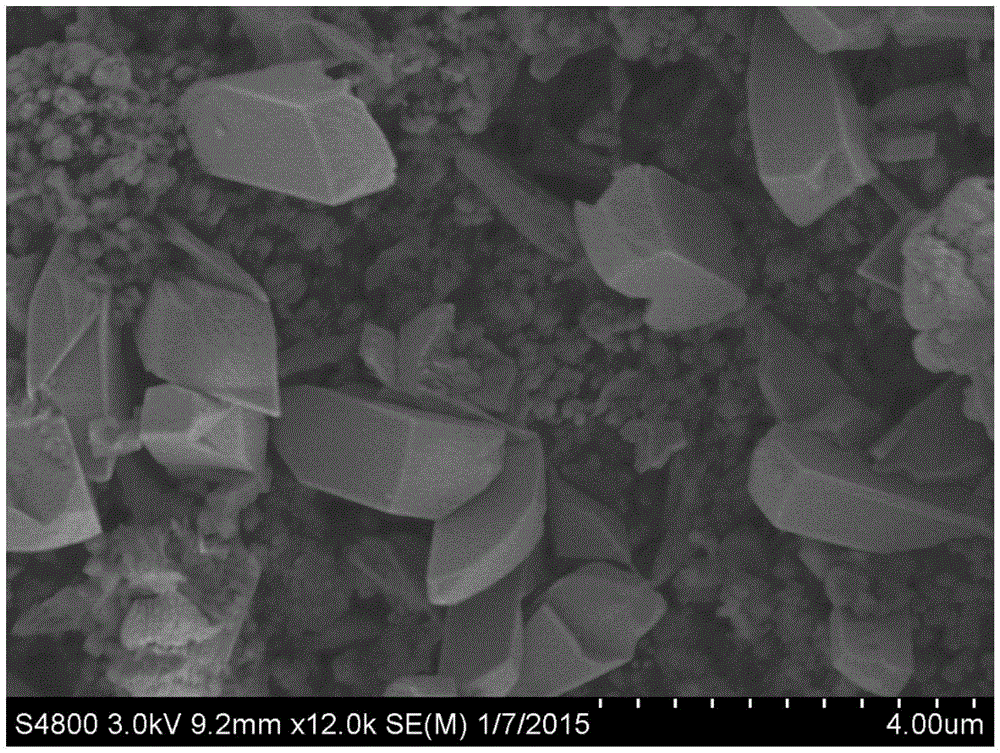

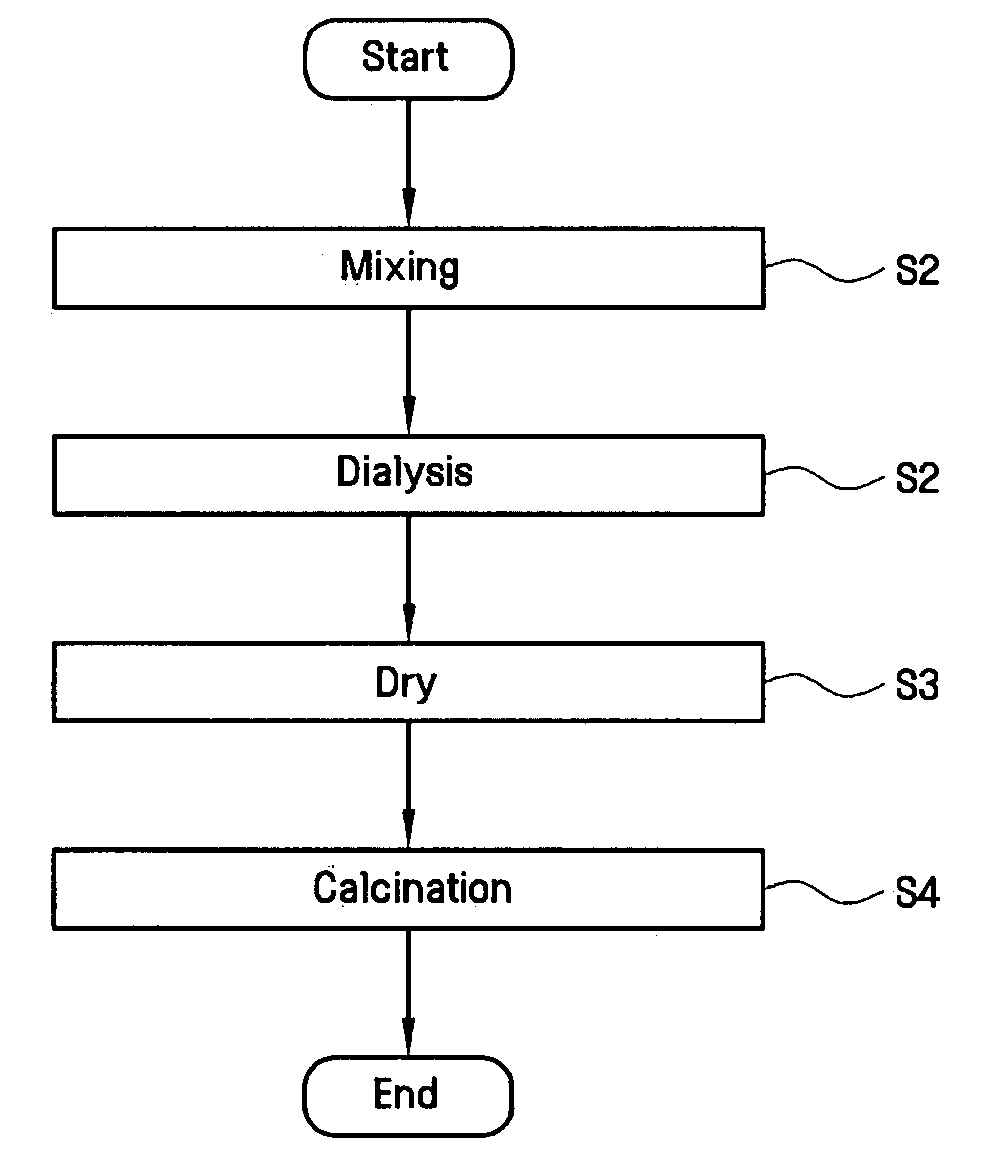

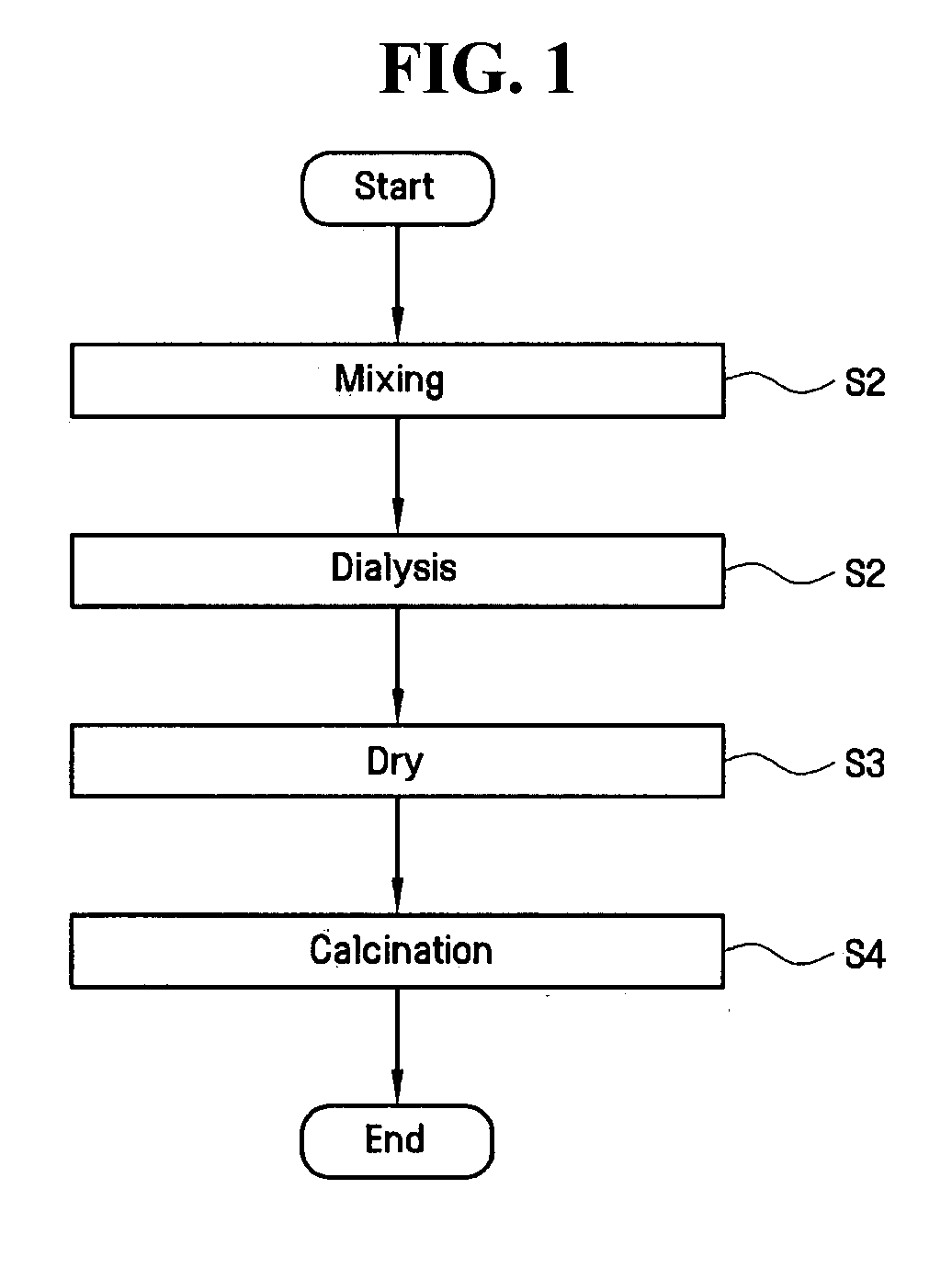

Photocatalyst materials having semiconductor characteristics and methods for manufacturing and using the same

InactiveUS20070193875A1Strong oxidation abilityRapidly and effectively oxidizingSemiconductor/solid-state device manufacturingDialysisPhysical chemistryAir treatment

New types of photocatalyst materials are disclosed together with methods for preparing and using these materials, as well as air treatment systems incorporating such materials. The photocatalyst materials of this invention consist essentially of very small particles of a first-metal oxide, the first-metal being a metal that exhibits photo-induced semiconductor properties, having ions of a second-metal dispersed throughout its lattice structure, the second-metal being selected from the group of dopant metals. Such photocatalyst materials are prepared by the steps of mixing first-metal and second-metal precursors, removing nonessential ions from the mixture, drying the resulting product, and calcinating the dried product to produce the completed photocatalyst material.

Owner:SAMSUNG ELECTRONICS CO LTD

Monolithic Pd catalyst for purifying industrial organic waste gas and preparation method thereof

InactiveCN103240083AImprove oxidation capacityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumHeat stability

The invention relates to a monolithic Pd catalyst for catalytic purification of industrial organic waste gas and a preparation method thereof. The catalyst comprises a cerium-zirconium solid solution, La2O3, Nb2O5, Al2O3, noble metal Pd and a cordierite-honeycomb ceramic supporter. The preparation method comprises the following step: coating the cerium-zirconium solid solution, La2O3, Nb2O5, a pseudo-boehmite binding agent and the noble metal Pd on the surface of the cordierite-honeycomb ceramic supporter in twice, wherein the total mass of the cerium-zirconium solid solution, La2O3, Nb2O5 and Al2O3 coated for each liter of catalyst is 40g; and the loading amount of Pd contained in each liter of catalyst is 0.3g. The catalyst can prevent surface carbon deposition, and has satisfactory burning resistance and heat stability.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com