Imidacloprid pesticide wastewater treatment method

A pesticide wastewater and treatment method technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex process operation and high treatment cost, and achieve low consumption, The effect of low operating cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The comprehensive wastewater produced by imidacloprid pesticide in a pesticide factory is treated by the method of the present invention: chemical phosphorus removal, Fe-C micro-electrolysis, Fenton, catalytic oxidation and A / O+biological aerated filter method. The specific steps are as follows.

[0021] 1) Chemical phosphorus removal: Add milk of lime to the comprehensive wastewater of imidacloprid pesticide production to adjust the pH to 10.0 for chemical phosphorus removal, and at the same time add PAM coagulant for precipitation and separation.

[0022] 2) Fe-C micro-electrolysis: After chemical phosphorus removal, the wastewater is added acid to adjust the pH to 2.0. After entering the Fe-C micro-electrolysis cell for 6 hours of reaction, add alkali to neutralize and add flocculant to coagulate and precipitate.

[0023] 3) Fenton reaction: Fe-C micro-electrolytic coagulation and precipitation effluent, dilute with water according to 1:2, adjust pH=3.0, ad...

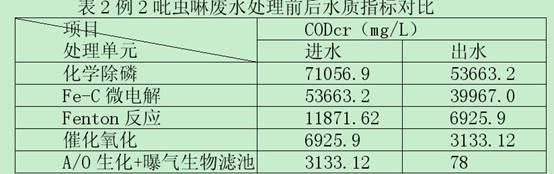

Embodiment 2

[0028] Example 2: A pesticide factory imidacloprid pesticide production comprehensive wastewater, using the method of the present invention: chemical phosphorus removal, Fe-C micro-electrolysis, Fenton, catalytic oxidation and A / O + biological contact oxidation biochemical treatment, the specific steps are as follows.

[0029] 1) Chemical phosphorus removal: In the comprehensive wastewater produced by imidacloprid pesticides, milk of lime is added to adjust the pH to 11.0 for chemical phosphorus removal, and PAM coagulant is added at the same time for precipitation and separation.

[0030] 2) Fe-C micro-electrolysis: After chemical phosphorus removal, the wastewater is adjusted to pH 3.0, and enters the Fe-C micro-electrolysis cell. After 8 hours of reaction, it is neutralized and coagulated to precipitate.

[0031] 3) Fenton reaction: Fe-C micro-electrolytic coagulation and precipitation effluent, dilute with water according to 1:3, adjust pH=3.0, add H concentration of 30wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com