Patents

Literature

147results about How to "Economic treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

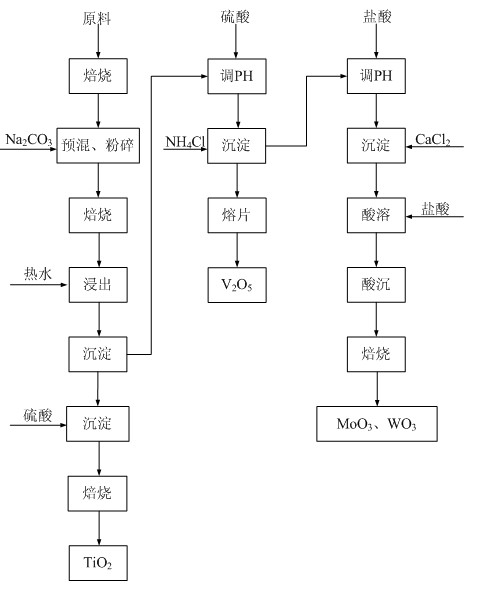

Method for recycling metal oxide from waste flue gas denitration catalyst

The invention discloses a method for recycling a metal oxide from a waste flue gas denitration catalyst, comprising the following steps of: crushing the waste flue gas denitration catalyst to carry out pre-roasting pretreatment at high temperature; adding Na2CO3 into the waste flue gas denitration catalyst according to the proportion, mixing, pulverizing and roasting at high temperature to obtain a sintering block; crushing the sintering block and putting the crushed sintering block into hot water, and stirring and lixiviating to obtain titanate; adding sulphuric acid into the titanate, filtering, water-washing and roasting to obtain TiO2; adding the sulphuric acid into the lixiviated filtering liquid to regulate a pH value to 8.0-9.0; adding excessive NH4Cl for vanadium precipitation; decomposing NH4VO3 obtained from filtering at high temperature to prepare a V2O5 product; adding hydrochloric acid into the filtering liquid subjected to the vanadium precipitation to regulate a pH value to 4.5-5.0; adding CaCl2 for molybdenum and tungsten precipitation; treating the CaM0O4 and CaWO4, obtained from filtering, with the hydrochloric acid and roasting to obtain MoO3 and WO3. The method of the invention has the advantages of simple process and apparatus, high recycling efficiency, good product technical data, large treatment capacity and the like.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

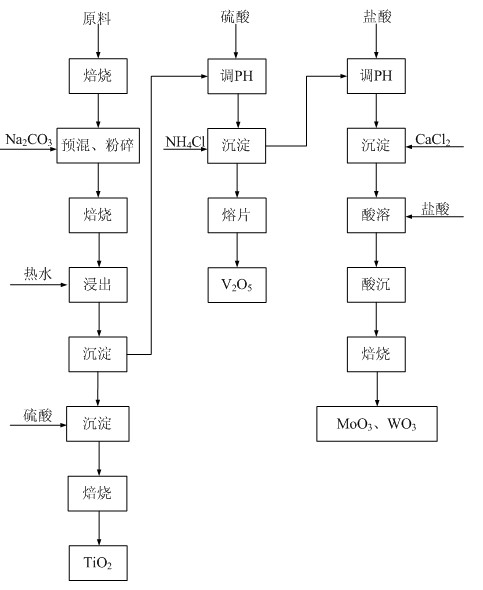

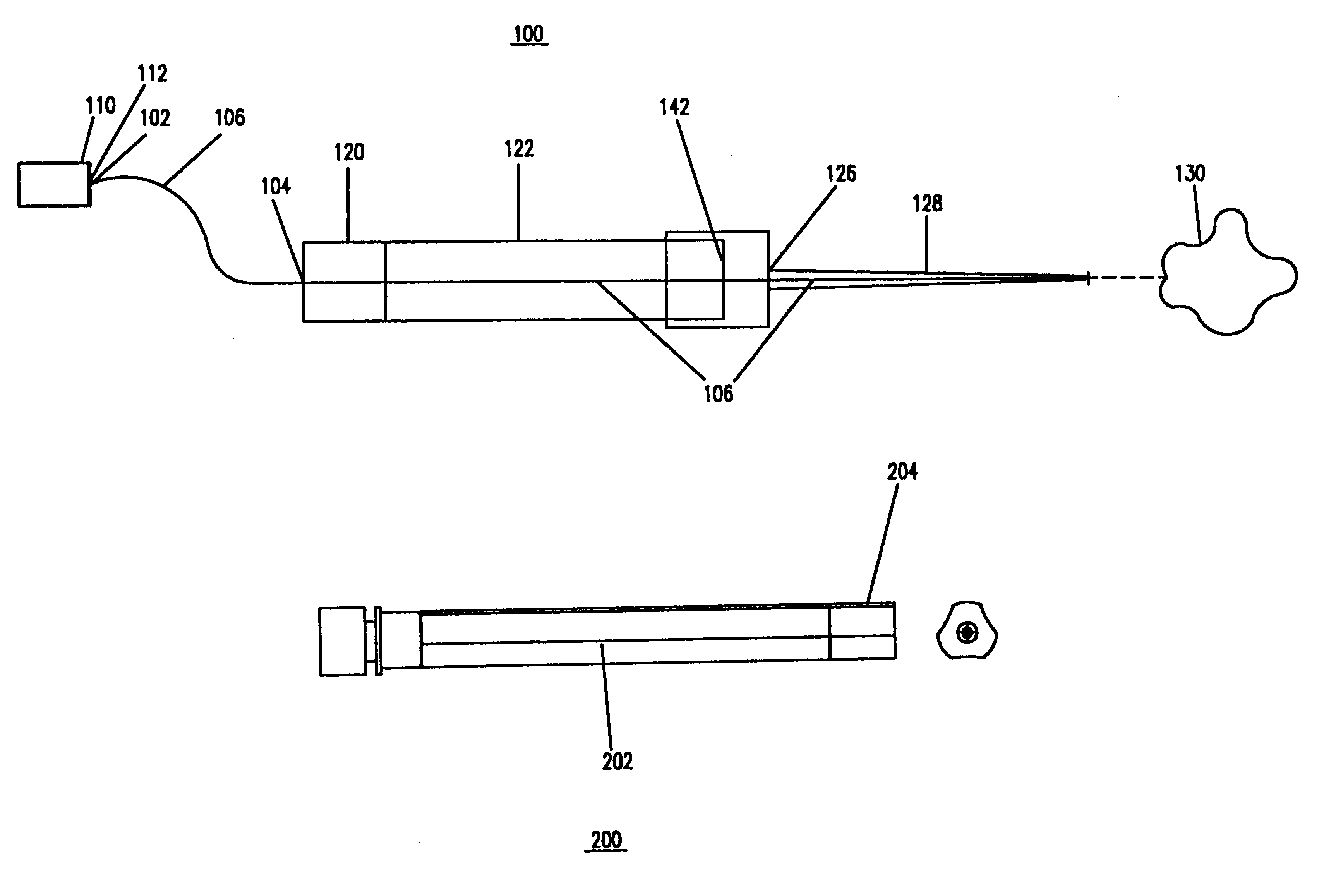

Method for recycling nickel, cobalt and manganese synchronously from waste residues containing nickel, cobalt and manganese

ActiveCN106319228AReduce separation costsSimple processProcess efficiency improvementManganeseCobalt

The invention discloses a method for recycling nickel, cobalt and manganese synchronously from a sulfuric acid leaching solution containing waste residues of nickel, cobalt and manganese. The method comprises the steps of firstly, removing iron and aluminum from the leaching solution through an oxidation and precipitation method; then, removing the element copper through extraction; then, extracting zinc; and finally, extracting nickel, cobalt and manganese synchronously with tributyl phosphate and saponified neodecanoic acid. By means of the method, nickel, cobalt and manganese in the leaching solution containing the waste residues of nickel, cobalt and manganese can be extracted and recycled synchronously; calcium and magnesium in a raw solution cannot exert an influence on the extraction process; separation cost for recycling the elements nickel, cobalt and manganese separately is lowered; and raw material cost for preparing a nickel-cobalt-manganese-salt ternary battery material is lowered.

Owner:JINGMEN GEM NEW MATERIAL

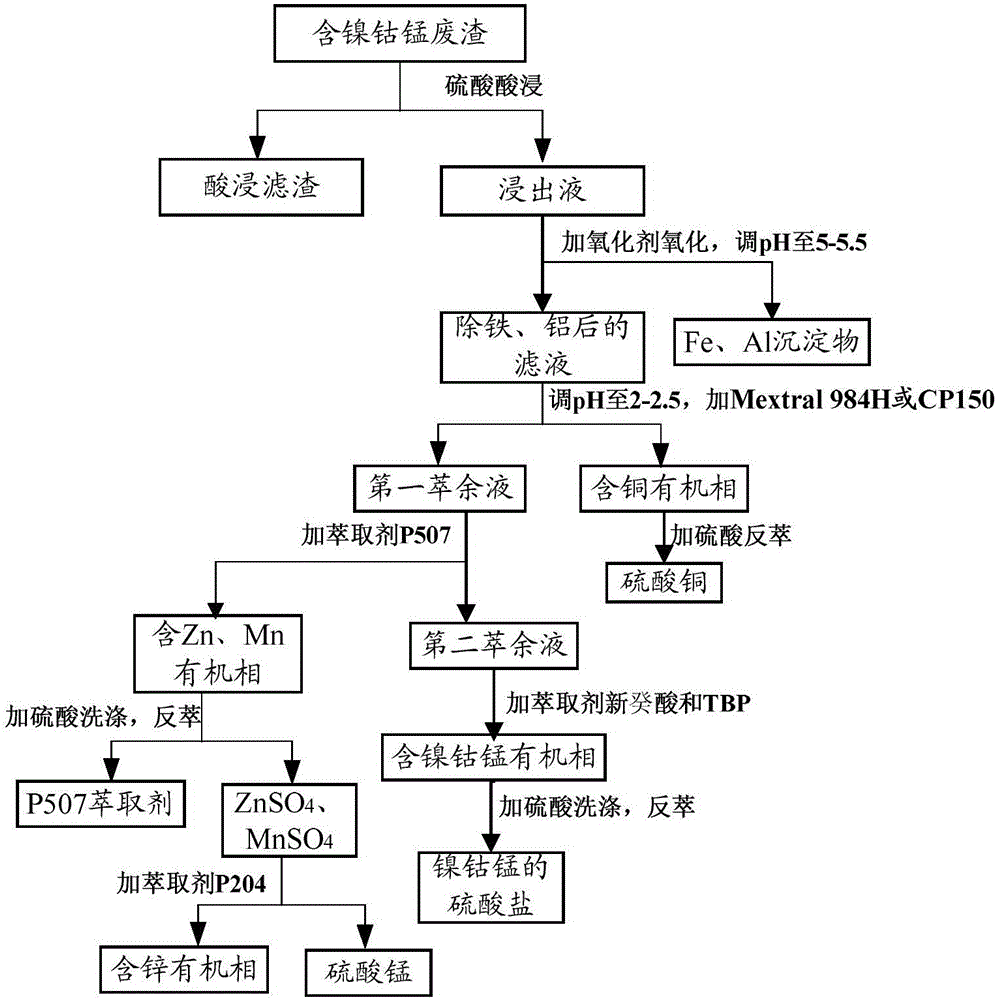

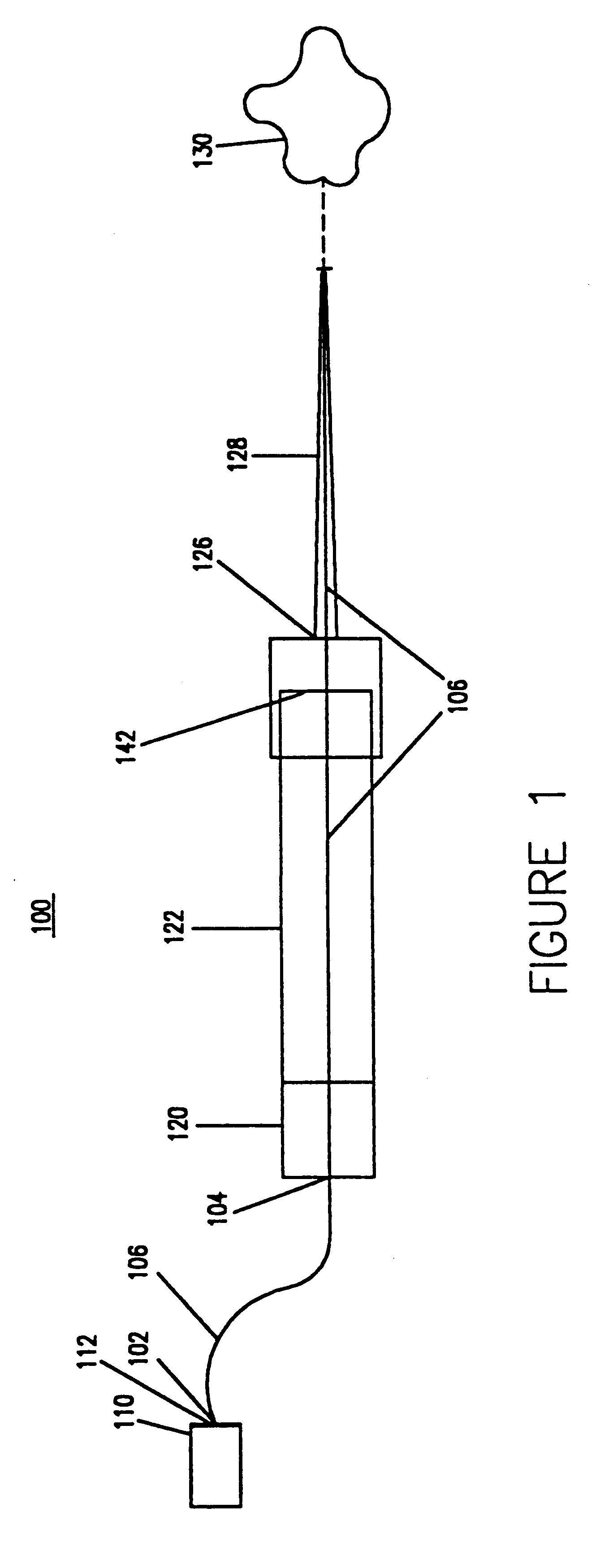

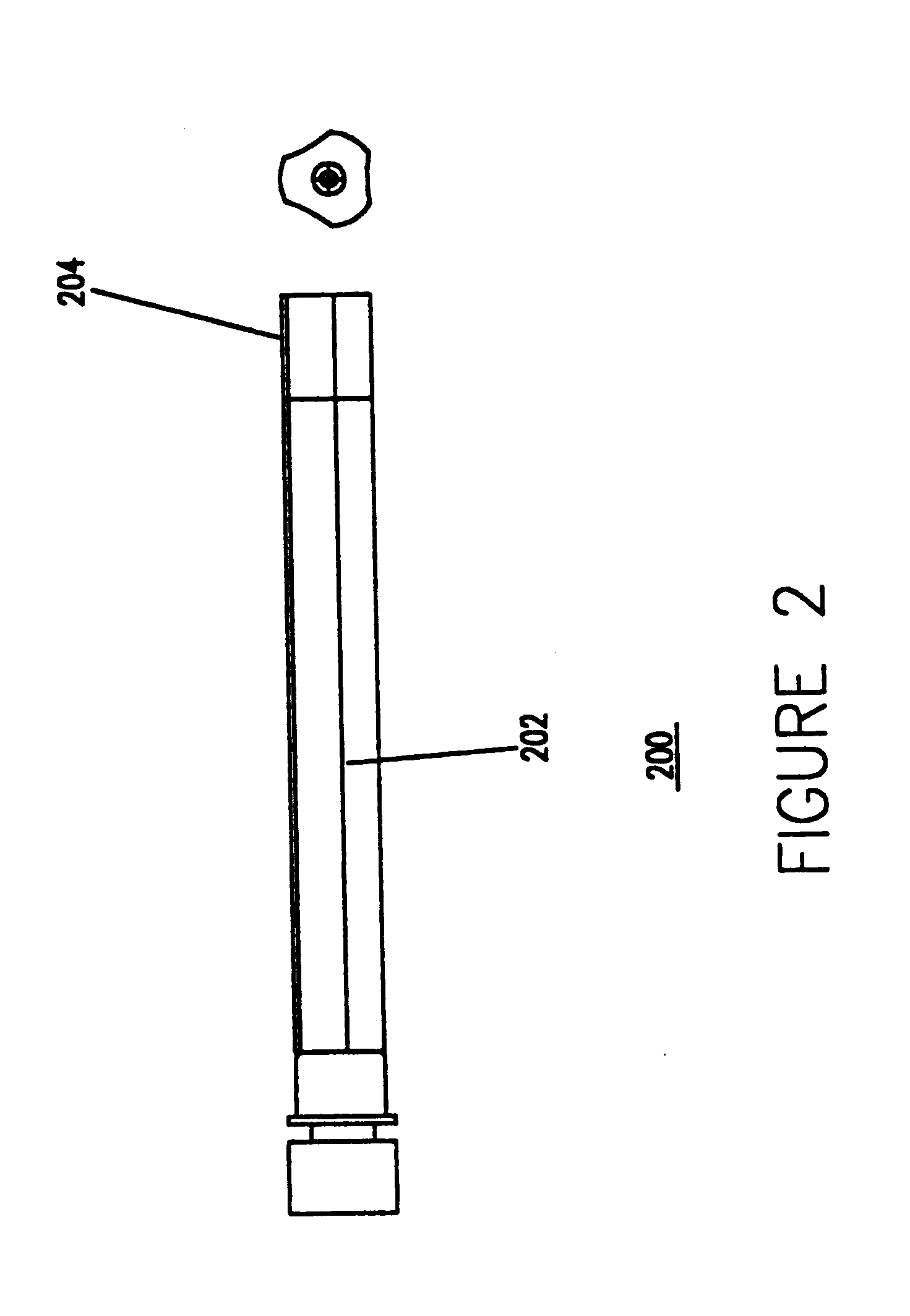

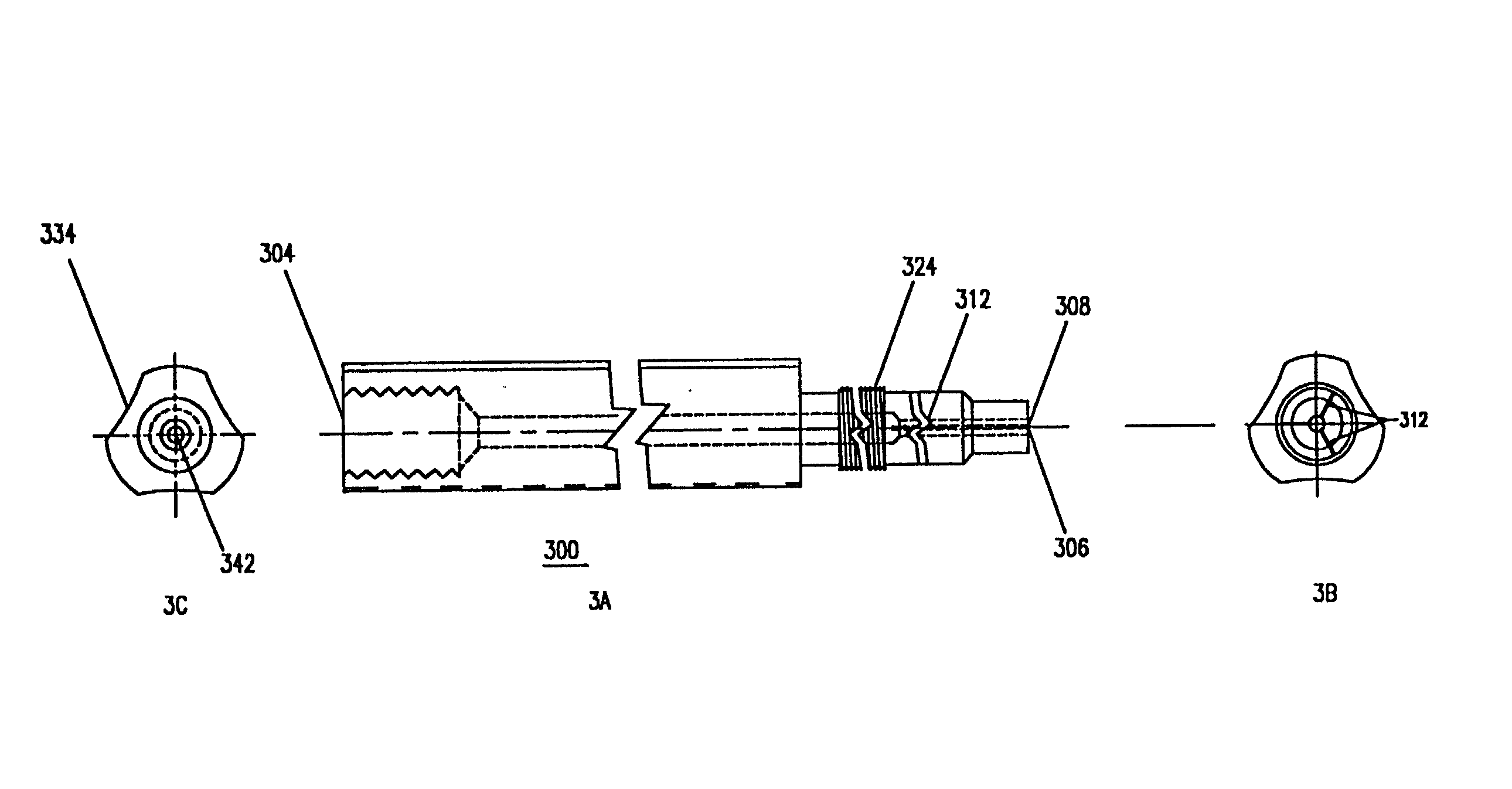

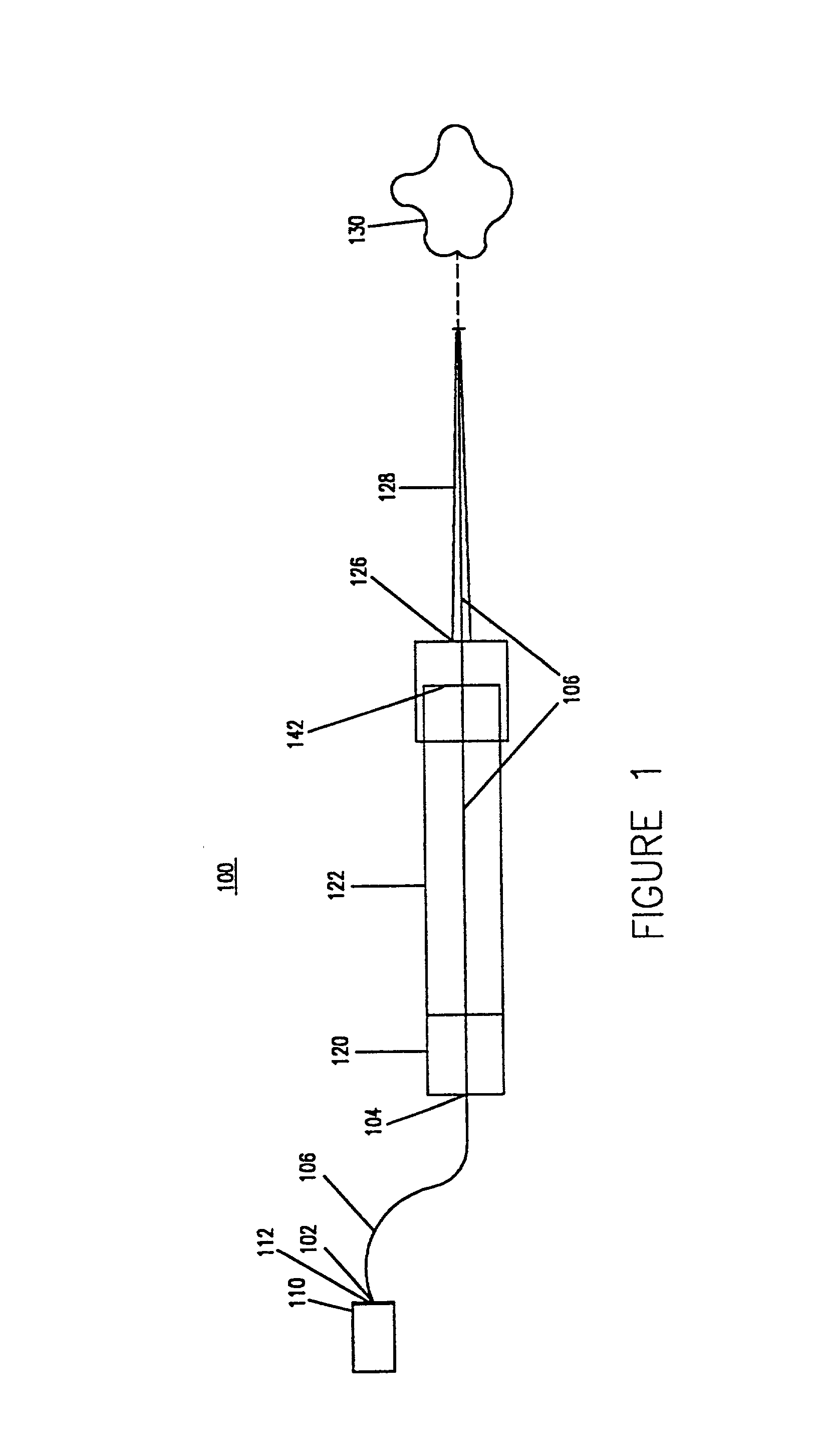

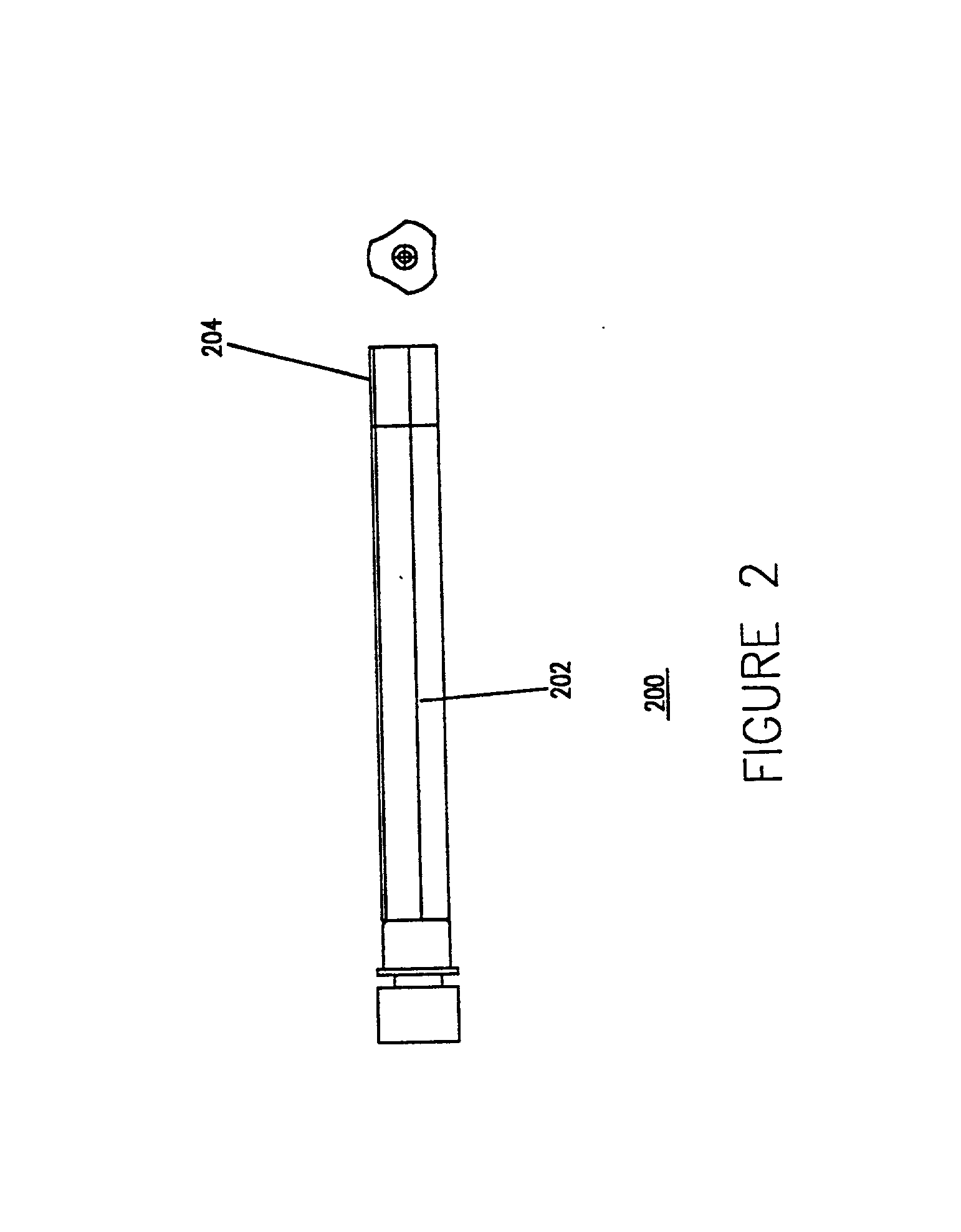

Optical fiber-handpiece combination for medical laser treatments

InactiveUS6574401B2Safe and practical and economical for medical laser treatmentAvoid vertical movementDiagnosticsSurgical instrument detailsFiberAdhesive

Owner:BIOLITEC PHARMA MARKETING

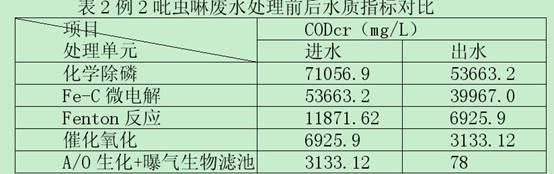

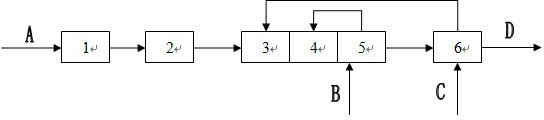

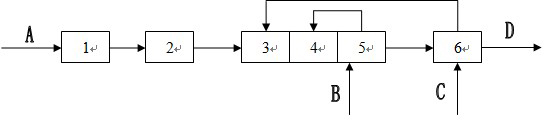

Imidacloprid pesticide wastewater treatment method

ActiveCN102040318AImprove biodegradabilityImprove the overall physical and chemical treatment effectMultistage water/sewage treatmentChemical treatmentPretreatment method

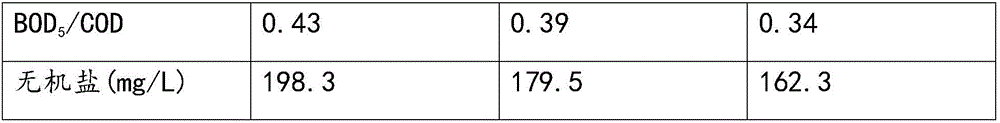

The invention relates to improvement on an imidacloprid pesticide wastewater treatment method. The imidacloprid pesticide wastewater treatment method is characterized by comprising the following steps of: performing physical and chemical pretreatment, namely performing chemical phosphorus removal and ferrum-carbon (Fe-C) micro-electrolysis sequentially and then performing Fenton oxidation and catalytic oxidation respectively; and performing biochemical treatment, namely performing aerobic biochemical treatment in the presence of salt-tolerant aerobic bacteria. By the imidacloprid pesticide wastewater treatment method, the total physical and chemical treatment effect is greatly improved; physical and chemical pretreatment can be performed at normal temperature and normal pressure; organic matters difficult to biochemically degrade is degraded and the biochemical property of the wastewater is improved under the condition of low cost; the dilution factor of the wastewater is greatly reduced; and the using amount of diluting water is reduced by 50 to 80 percent, so that the treatment is more economic. The imidacloprid pesticide wastewater treatment method is simple in pretreatment method, mild and stable in process reaction condition, simple in operation (for example, the catalytic oxidation can be performed at normal temperature and normal pressure and a catalyst can be recycled), low in operating cost, good in treatment effect, low in the using amount of the diluting water during the subsequent biochemical treatment and low in total treatment cost, and the water from the biochemical treatment can reach a national level 1 of discharge standard.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

Optical fiber-handpiece combination for medical laser treatments

InactiveUS20020064328A1Safe and practical and economical for medical laser treatmentAvoid vertical movementDiagnosticsSurgical instrument detailsFiberAdhesive

The present invention describes a multi-component handpiece that is both economical and practical for surgical laser treatment. A disposable optical fiber is inserted into a reusable handpiece. The distal end of the optical fiber is protected by a micro-walled protective tube to prevent the disposable fiber from chipping before and during insertion into the handpiece. Once the optical fiber is protected, it is inserted into the handpiece by threading the optical fiber through the cap, body, and cannula of the handpiece until the fiber extends slightly beyond the distal end of the needle. The micro-walled protective tube is removed from the end of the optical fiber, the optical fiber is positioned, and the cap is tightened. The cap and body of the handpiece cooperate to produce a tight friction fit that prevents longitudinal movement of the optical fiber during laser therapy. The tight friction fit holds the optical fiber in place without the use of adhesives, which allows for facilitated removal of the disposable fiber after use. Furthermore, a disposable fiber allows for convenient resterilization of the handpiece to eliminate the transmission of disease from one patient to the next without having to dispose

Owner:BIOLITEC PHARMA MARKETING

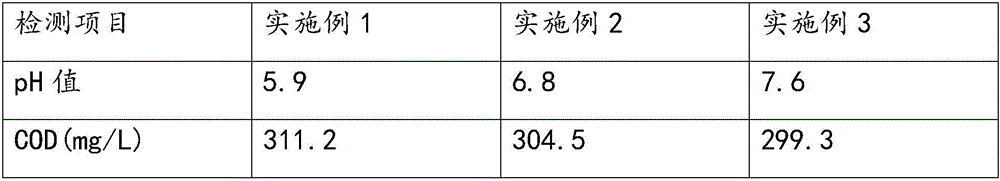

Effective printing and dyeing sewage treatment method

InactiveCN102659280AEconomic treatmentEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeWater quality

The invention discloses an effective printing and dyeing sewage treatment method, belongs to the field of industrial sewage treatment and is suitable for treating sewage difficult to degrade. The effective printing and dyeing sewage treatment method comprises the steps of automatically flowing printing and dyeing sewage into a primary settling tank to remove settleable substances and floaters in the sewage; pumping water out of the primary settling tank into a hydrolysis and acidification tank for hydrolysis and acidification; carrying out biological treatment on water out of the hydrolysis and acidification tank in an A2O reaction tank in which powdered activated carbon is fed; and carrying out coagulative precipitation on sewage subjected to biological treatment in a coagulative precipitation tank and discharging. After the printing and dyeing sewage is treated by the method, various effluent water indexes can basically reach the discharge standards of Major Water Pollutant Emission Limit of Urban Sewage Treatment Plants and Key Industries in Taihu (DB32 / T1072-2007). Through the method, the problems of bad treatment effect, unstable effluent water quality, large floor area, large sludge yield and high treatment cost of a traditional process are solved, and the economic and efficient treatment of the printing and dyeing sewage is realized.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

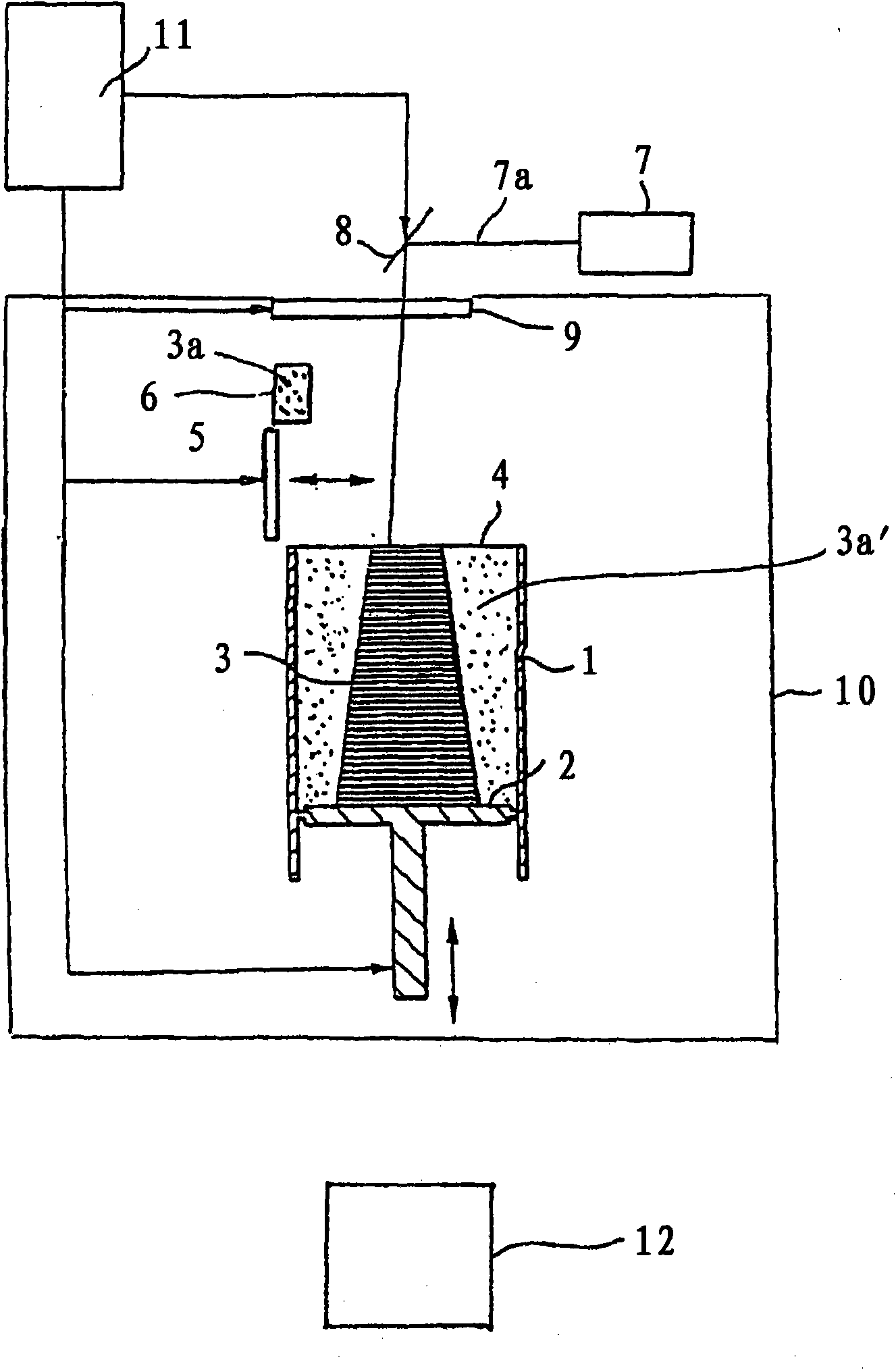

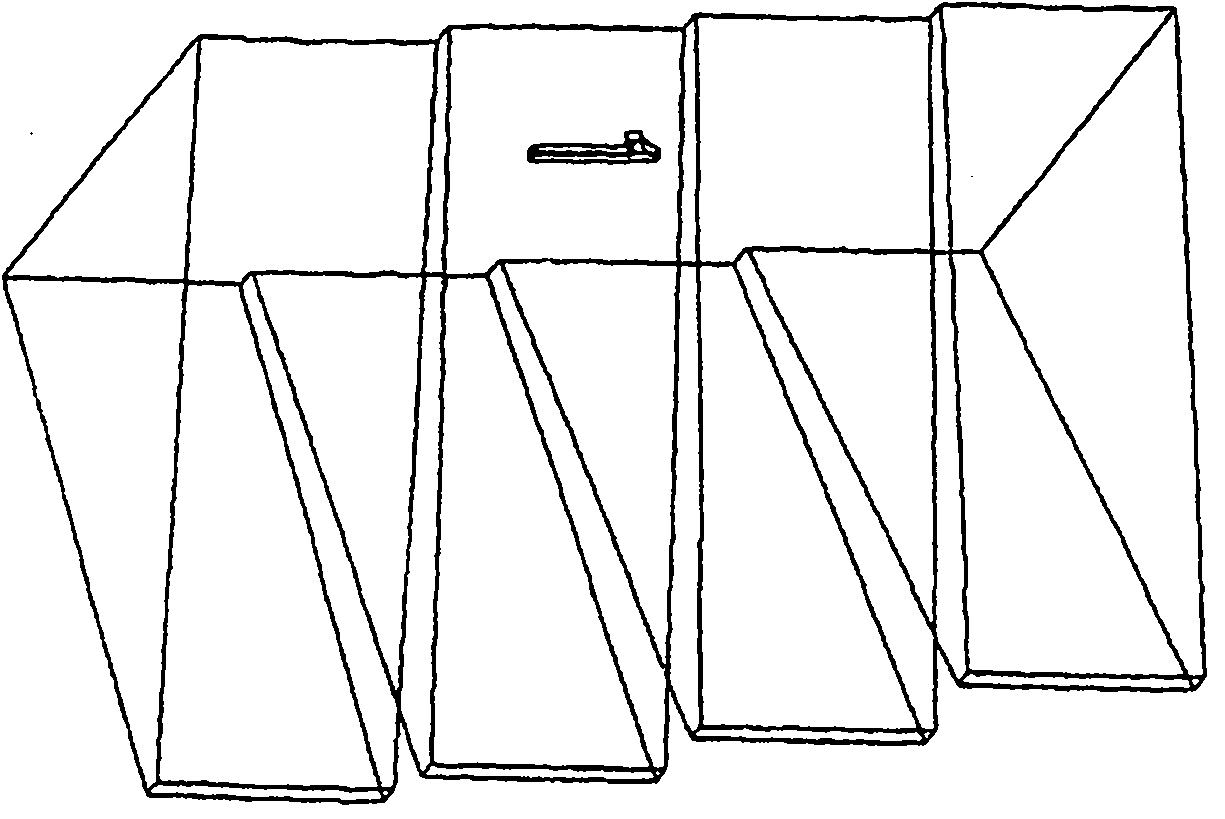

Method and device for the layered production of a three-dimensional object from a powdery material

ActiveCN101842222AGood environmental compatibilityEconomic treatmentAdditive manufacturing apparatusPlastic recyclingElectromagnetic radiationMaterials science

The invention relates to a method for producing a three-dimensional object by selectively compacting layers of a powdery material (3a) in the areas corresponding to the cross-section of the object (3) in the respective layer, by applying electromagnetic radiation (7a). The powder used is a plastic powder, preferably polyamide. After the production of the object, the non-compacted powder (3a') is subjected to a water or vapour treatment at a higher temperature, is subsequently dried and then is used again to produce a new object.

Owner:EOS ELECTRO OPTICAL SYST

Method for fully recovering silicon dioxide in waste SCR (Selective Catalyst Reduction) catalyst

The invention relates to the field of smoke denitration, in particular to a method for fully recovering silicon dioxide in a waste SCR (Selective Catalyst Reduction) catalyst. The method comprises the following steps: soaking the pulverized waste SCR catalyst with three to four times of water to remove impurities, leaching powder from which the impurities are removed with excessive thick alkaline solution with the concentration of 60-80wt%, filtering to obtain a Na2TiO3 solid, adding sulfuric acid into filtrate, regulating pH to 11.5-12.5 at a temperature of 70-90 DEG C, leaving the mixture to stand for 0.5-1h, filtering, and discarding filter cakes; adding sulfuric acid into the filtrate until the pH is regulated to 9-10 to obtain the silicate filter cakes, heating and stirring the silicate filter cakes in mixed acid of dilute sulfuric acid and oxalic acid at a temperature of 40-60 DEG C for 1-2h, filtering, washing the filter cakes with deionized water, washing off acid radical ions in the solid, and obtaining high-purity silicon dioxide through heating and decomposition. Therefore, the recovery of the silicon dioxide in the waste SCR catalyst can be realized without a roasting process.

Owner:沈阳远大固废处理有限公司

Treatment method for water containing vanadium, chromium and iron and smelting process for high chromium vanadium titanium magnetite concentrate

ActiveCN103952517AEconomic treatmentEasy to handleProcess efficiency improvementSmelting processMagnetite

The invention provides a treatment method for water containing vanadium, chromium and iron and a smelting process for high chromium vanadium titanium magnetite concentrate. The treatment method for the water containing vanadium, chromium and iron comprises the following steps: filling the water containing vanadium, chromium and iron; controlling temperature of the water containing vanadium, chromium and iron to be higher than a theoretical liquidus temperature of 65-120 DEG C, carrying out bottom blowing, and adding a desilicification agent into a steel ladle in batches; removing slag in the steel ladle or dumping and discharging the slag; blowing oxygen into the water containing vanadium, chromium and iron under the condition that gas is introduced into the steel ladle in a bottom blowing way, wherein oxygen blowing amount is controlled to be 23-32Nm<3> per ton iron, and controlling temperature of the water containing vanadium, chromium and iron in an oxygen blowing process to be higher than the theoretical liquidus temperature of 25-80 DEG C by adding a cooling agent into the vanadium, chromium and iron-containing water; removing slag or replacing the steel ladle, so that vanadium chromium slag and molten iron are obtained. The treatment method for the water containing vanadium, chromium and ironhas the advantages that the requirement that a technology for comprehensively utilizing a high chromium vanadium titanium magnetite concentrate resource by a non blast furnace process is smoothly carried out can be met, a vanadium chromium resource is effectively recycled, and the molten iron with the carbon content according to the follow-up electric furnace steel making requirement can be obtained.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

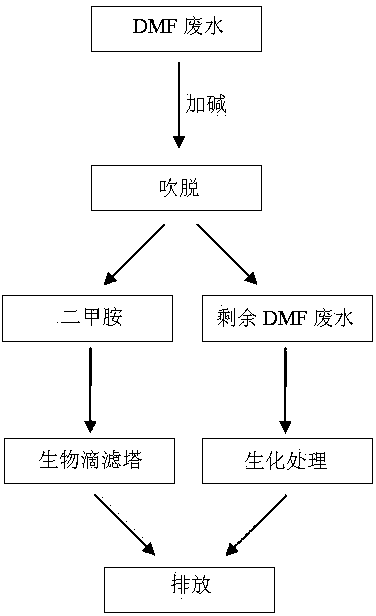

Combined treatment method of N, N-dimethylformamide (DMF) wastewater

InactiveCN103449662AAvoid secondary pollutionImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentN dimethylformamideExisting Treatment

The invention discloses a combined treatment method of N, N-dimethylformamide (DMF) wastewater, relates to the field of environment protection and water pollution treatment, and in particular relates to a combined treatment method for treating the N, N-DMF wastewater. The method specifically comprises the following steps: firstly decomposing the DMF wastewater into dimethylamine and formate under an alkali condition, then carrying out air stripping, introducing the dimethylamine waste gas generated in the air stripping into a bio-trickling tower for treatment, and directly carrying out biochemical treatment on the air-stripped wastewater. According to the combined treatment method disclosed by the invention, a physic-chemical method and a biological method are combined, a feasible process for treating the DMF wastewater is provided, the toxicity of the DMF wastewater is reduced by means of the physical-chemical method, the biodegradability of the DMF wastewater is improved, and the generated dimethylamine organic waste gas and wastewater are subjected to advanced treatment by means of the bio-chemical method. By adopting the combined treatment method disclosed by the invention, the effective and economical treatment of the DMF wastewater is achieved, and the problems of secondary pollution, difficult regeneration, low efficiency and the like easily caused by the existing treatment methods of adsorption, extraction, chemical oxidization and the like are solved.

Owner:NANJING TECH UNIV

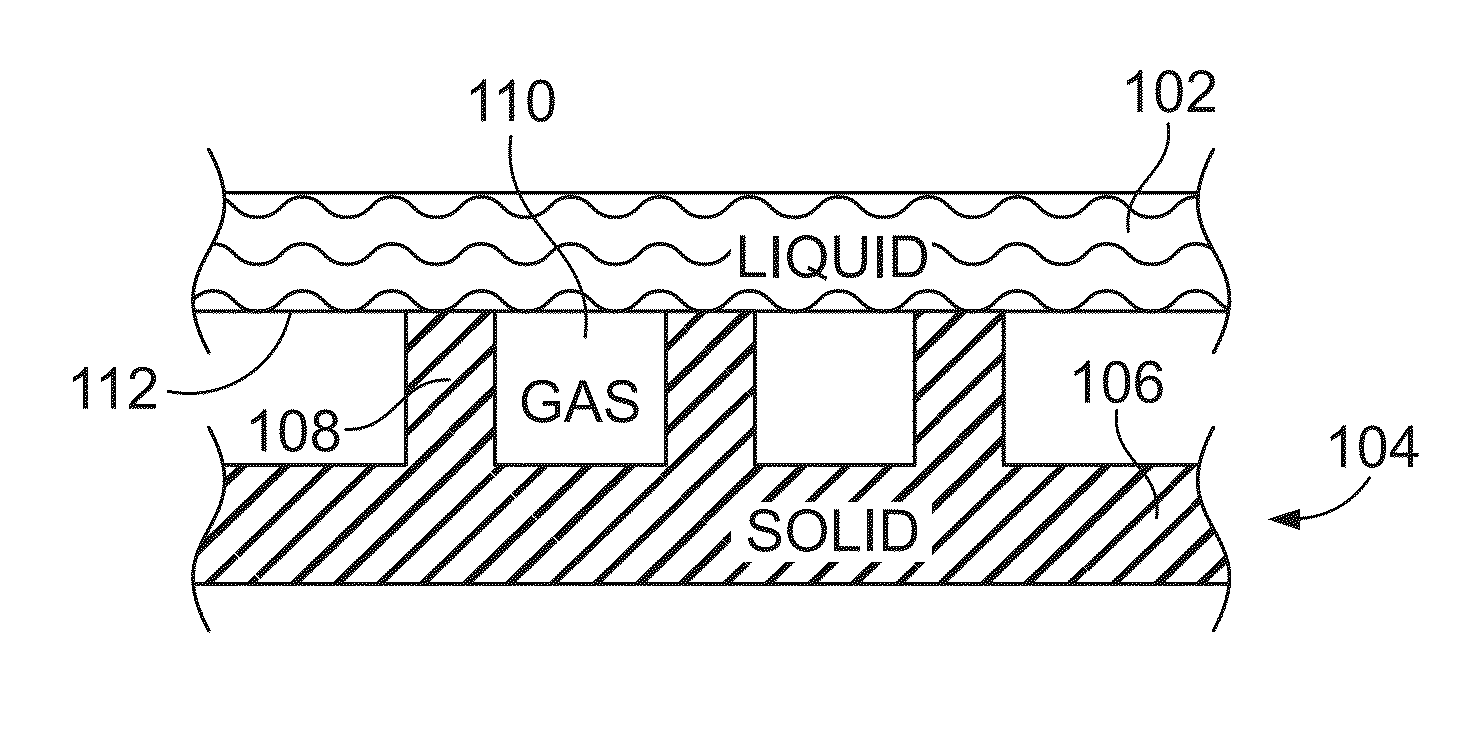

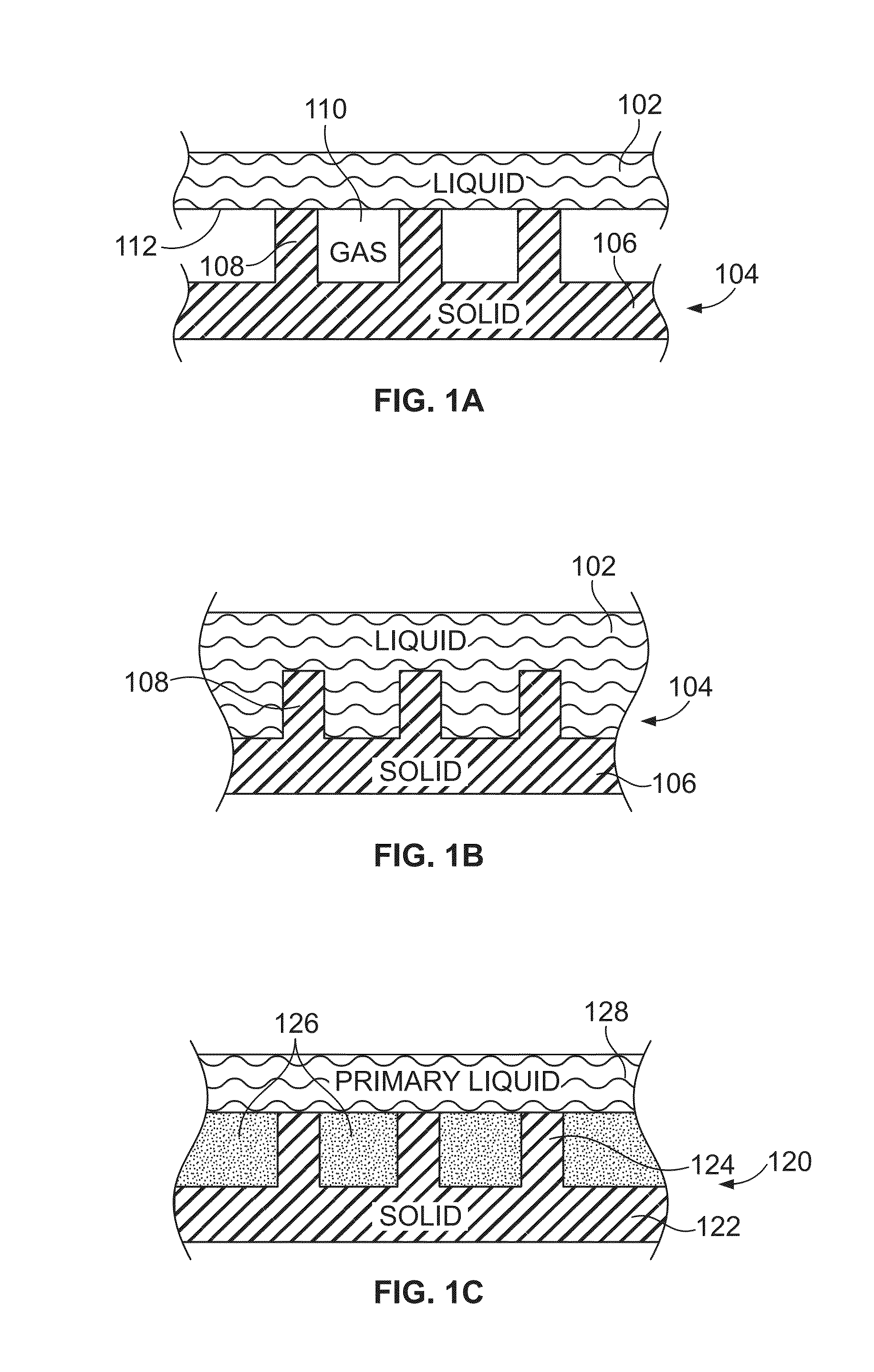

Articles and methods providing liquid-impregnated scale-phobic surfaces

InactiveUS20140290699A1Promote growthReduce nucleationHollow article cleaningCorrosion preventionVolumetric Mass DensityCharacteristic matrix

This invention relates generally to articles, devices, and methods for inhibiting or preventing the formation of scale during various industrial processes. In certain embodiments, a vessel is provided for use in an industrial process, the vessel having a textured, liquid-impregnated surface in contact with a mineral solution, wherein the liquid-impregnated surface comprises a matrix of features spaced sufficiently close to stably contain an impregnating liquid lubricant therebetween or therewithin, wherein the impregnating lubricant has a low surface energy density, and wherein the spreading coefficient Sos(w) of the impregnating lubricant (subscript ‘o’) on the substrate (subscript ‘s’) in the presence of the salt solution (subscript ‘w’) is greater than zero, such that the impregnating lubricant fully submerges the textured substrate.

Owner:MASSACHUSETTS INST OF TECH

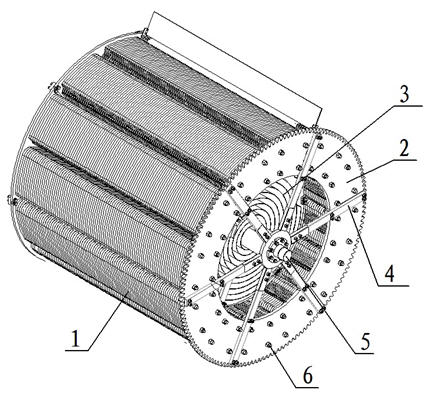

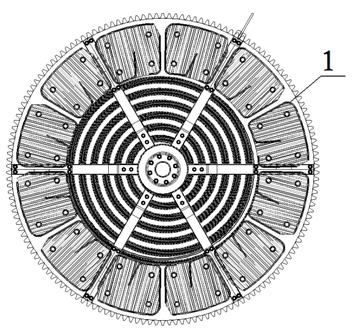

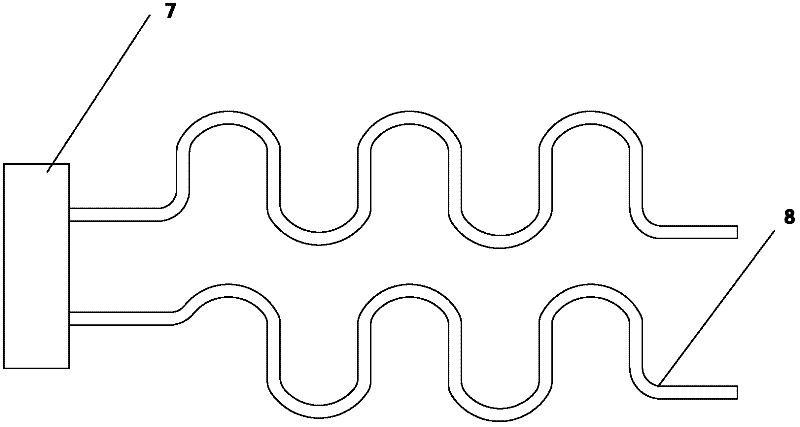

Self-aerated biofilm reactor and sewage treatment system applying same

InactiveCN102502954AEconomic treatmentSave resourcesMultistage water/sewage treatmentSustainable biological treatmentTreatment effectBiofilm

The invention discloses a self-aerated biofilm reactor and a sewage treatment system applying the same. The self-aerated biofilm reactor comprises circular ring-shaped disk sheets; a plurality of disk sheets are laminated and fixed together through fixing rods; cylinder structures are hermetically formed by blind plates at two ends of each disk sheet; support frames are fixed on the blind plates at two ends of the disk sheet, and are connected through a central rotating shaft; and an adsorption material is filled and fixed in the hollow portion of each cylinder. The self-aerated biofilm reactor can be mutually combined with a plurality of sewage treatment devices to improve the sewage treatment efficiency. The invention provides the self-aerated biofilm reactor and the sewage treatment system adopting the self-aerated biofilm reactor, is more economical in sewage treatment, saves the resources, and is high in treatment effect.

Owner:北京安力斯环境科技股份有限公司

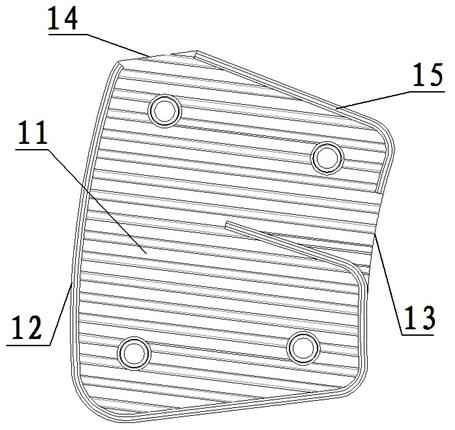

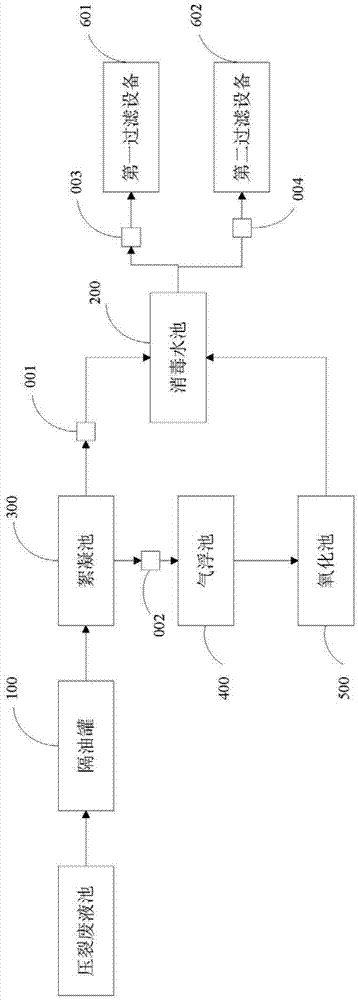

Oilfield fracturing wastewater treatment equipment

InactiveCN103588333AEasy to moveSmall footprintFatty/oily/floating substances removal devicesMultistage water/sewage treatmentOil separationSmall footprint

The invention provides oilfield fracturing wastewater treatment equipment which comprises an oil separation tank, an overall reaction tank, a disinfection tank and a composite filtration system, which are connected in order. The oilfield fracturing wastewater treatment equipment is integrated mobile equipment. As the oilfield fracturing wastewater treatment equipment is integrated mobile equipment, the equipment is convenient to move and occupies little space; processes such as construction, installation and the like of traditional water treatment equipment are saved; and the equipment is convenient to use. In addition, the oilfield fracturing wastewater treatment equipment can be adopted to process wastewater by different processes according to different destinations of wastewater. The equipment has advantages of strong applicability, wide application range, economical treatment process and simple operation.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

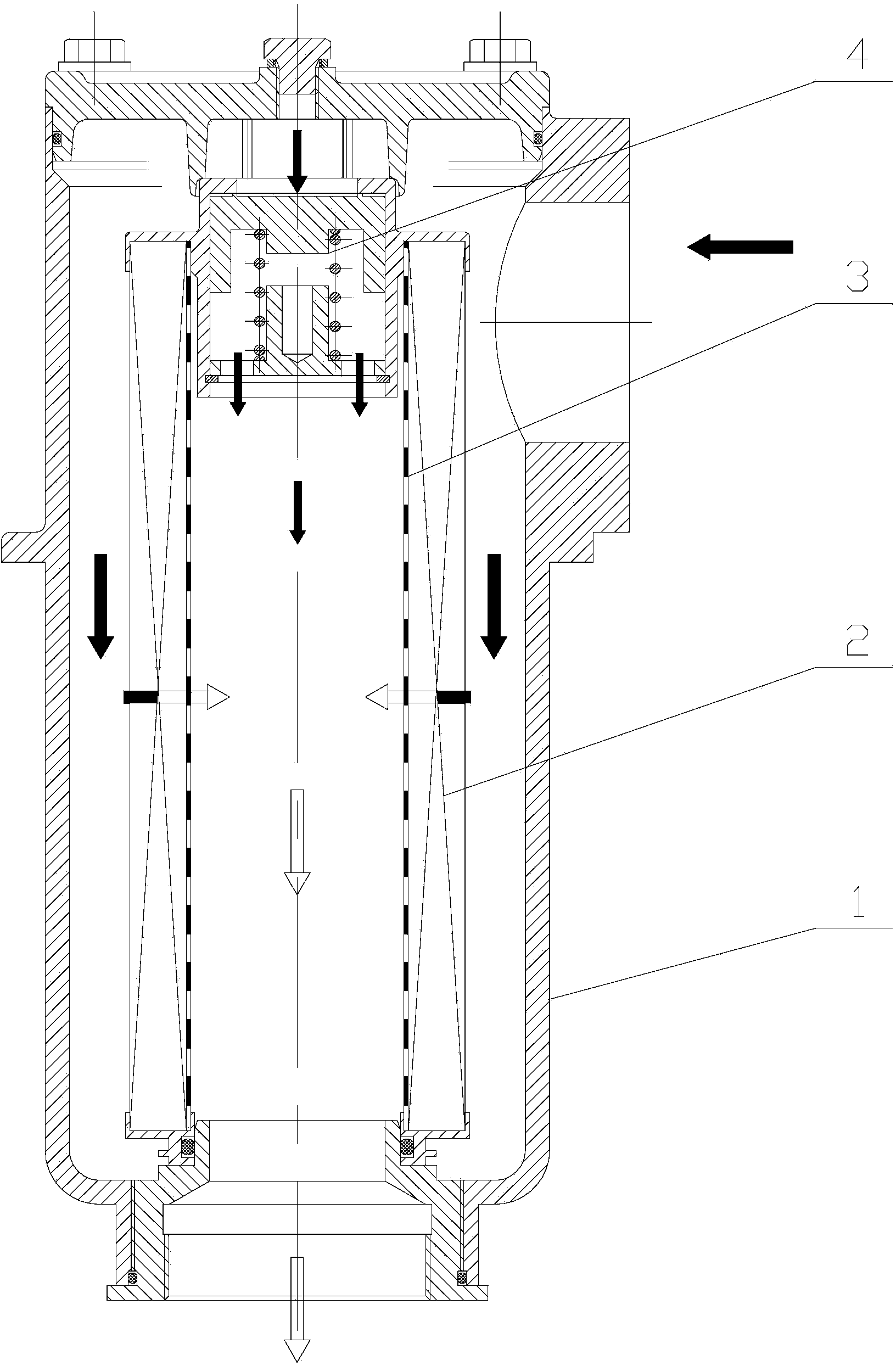

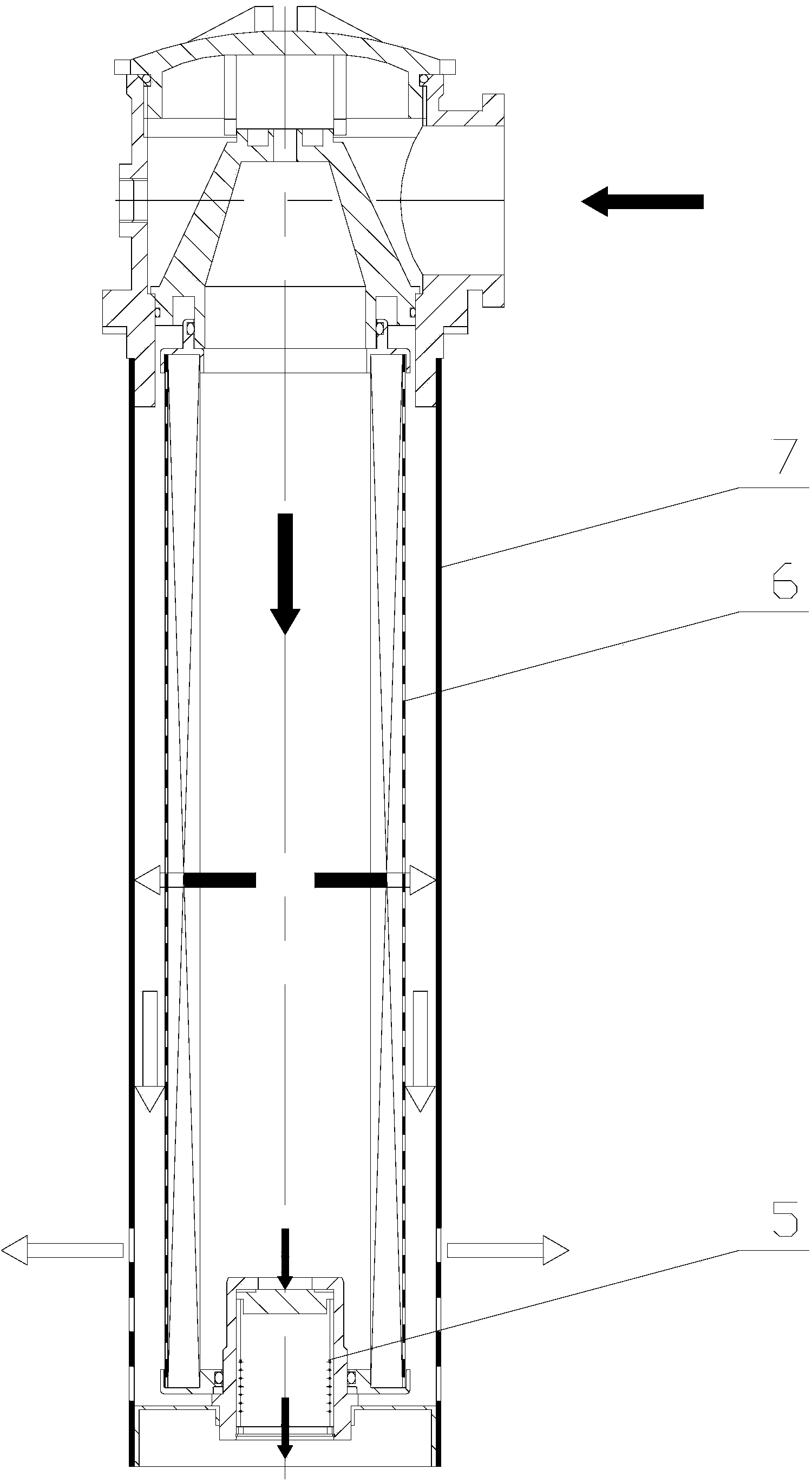

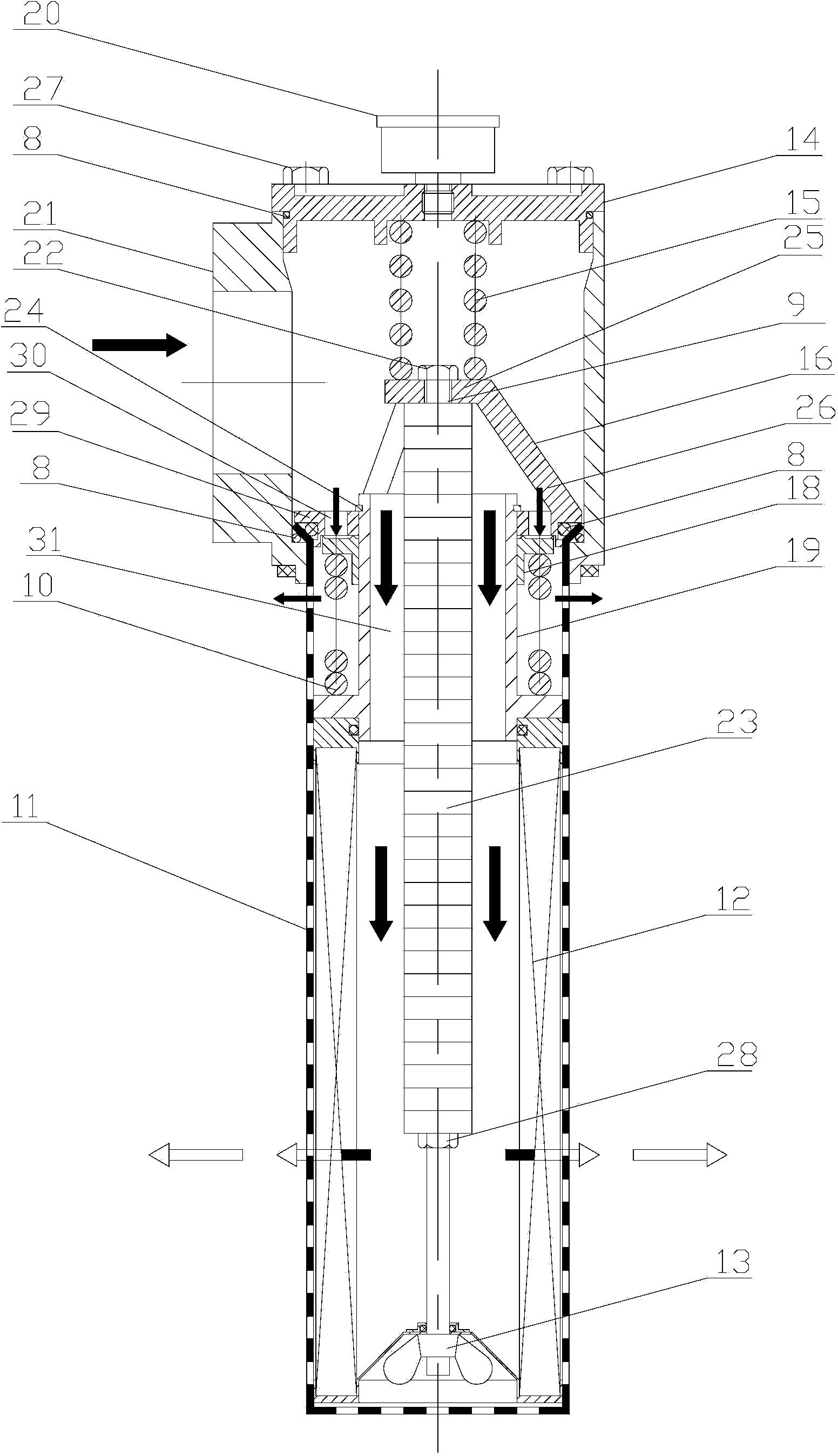

Return filter and method of filtering fluid by using return filter

ActiveCN103867537AIngenious designSave materialFluid-pressure actuator componentsMetal particleWaste management

The invention discloses a return filter and a method of filtering fluid by using the return filter. The return filter comprises a filter cover, a filter head and a filter cartridge, wherein the filter head is arranged between the filter cover and the filter cartridge; an unframed filter element is arranged below the inner wall of the filter cartridge; a bypass valve is arranged at the upper end of the unframed filter element; a magnetic bar is arranged in the centers of the bypass valve and the unframed filter element. When the return filter is used, the fluid enters the filter head from an opening of the filter head, and enters an inner cavity of the unframed filter element by downwards flowing along an inner hole of the bypass valve; most metal particles in the fluid are absorbed by the magnetic bar, and a first level of purification of the fluid is completed; the fluid is filtered by the unframed filter element, and finally passes through holes in the filter cartridge to enter a container. The return filter and the method of filtering the fluid by using the return filter have the beneficial effects that the structural design is ingenious, the economic efficiency is improved, and the environment protection is reinforced; when the filter element is replaced and the fluid passes by the bypass valve, contaminants which are intercepted in the filter element cannot reflow to the container, and the service life of equipment is prolonged.

Owner:SHANGHAI LANGJING FLUID TECH

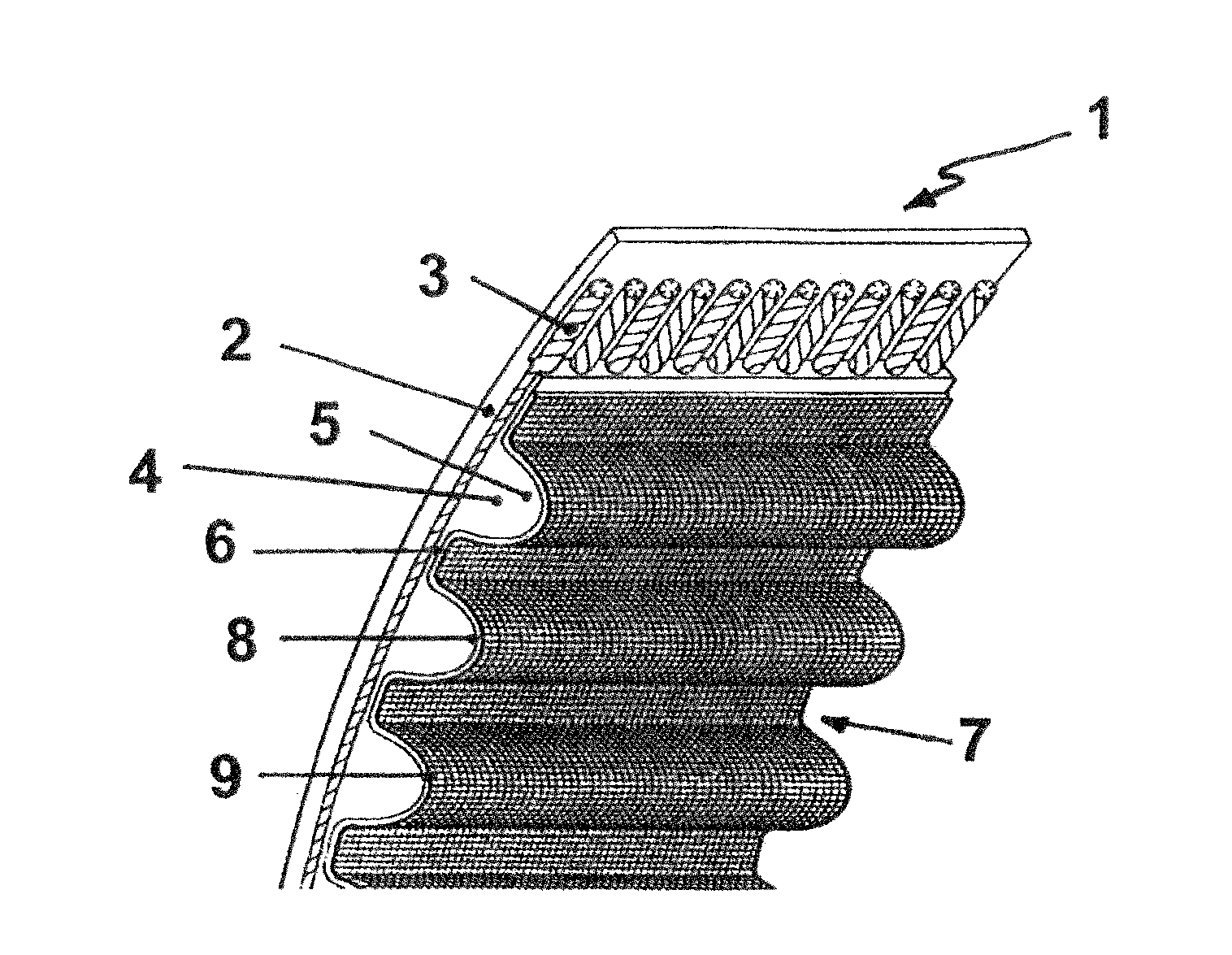

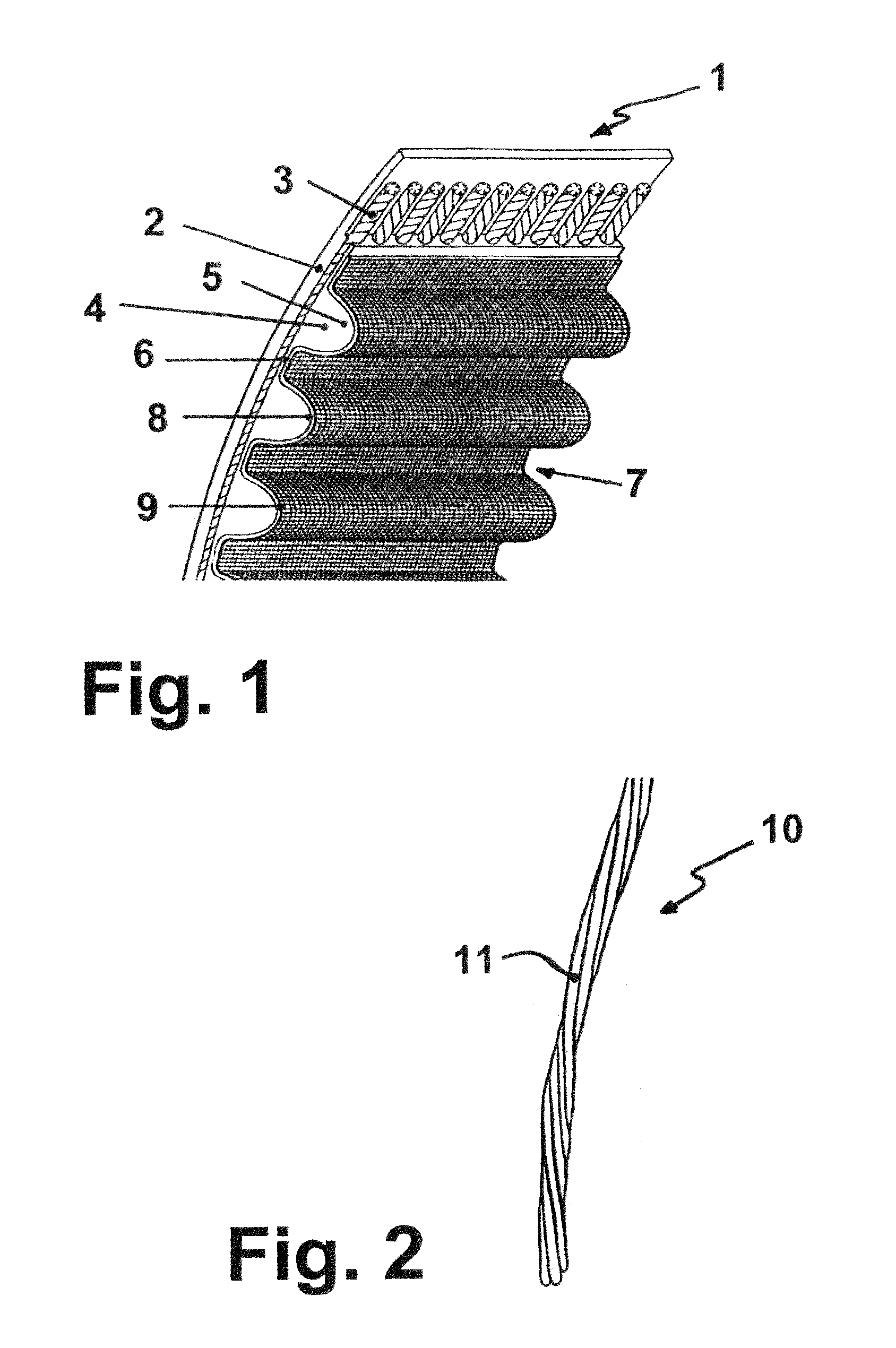

Belt having a tension member, in particular a carbon tension member, which is prepared with a cross-linked polyurethane, and preparation method

ActiveUS20140243134A1Economic treatmentFulfil requirementsV-beltsRopes and cables for vehicles/pulleyCross-linkHardness

A belt comprises at least a belt body made of a polymer material having elastic properties, the belt including a cover layer as a belt backing, a substructure having a force-transmission zone, and a tension member in a ribbed design embedded in the belt body. The tension member is prepared with a cross-linked polyurethane in such a way that the polyurethane fills at least part of the tension member cavities. The polyurethane filling material enters into a mechanical connection to the tension member on the one hand and an adhesive connection to the belt body on the other hand. The polyurethane filling material has a Shore A hardness that is 0.5 to 10 times harder than the Shore A hardness of the belt body. The belt body is preferably likewise made of cross-linked polyurethane, in particular using a carbon tension member.

Owner:CONTITECH ANTRIEBSSYST

Method for preparing bioethanol by utilizing kelp processing waste

InactiveCN101880693APromote the development of quality and energyEconomic treatmentBiofuelsMicroorganism based processesLiquid solidSaccharomyces cerevisiae

The invention relates to a method for preparing bioethanol by utilizing kelp processing waste. The method comprises the following steps: firstly cleaning the kelp processing waste, homogenizing, sterilizing and preparing p pretreatment liquid; further carrying out hydrolysis saccharification on the pretreatment liquid: adding activated trichoderma viride fermentation liquid according to the volume ratio of 5-20% or / and adding cellulase according to the weight-volume ratio of 0.5-1g / L for carrying out the hydrolysis saccharification on the pretreatment liquid, wherein the temperature for the hydrolysis saccharification is 45-55 DEG C, the pH is 5-7 and the time is 36-48h; further adding well activated saccharomyces cerevisiae zymocyte into liquid after the hydrolysis saccharification according to the volume ratio of 10-20% for fermentation, and preparing ethanol, wherein the fermentation temperature is 25-35 DEG C, the pH is 4-6 and the fermentation time is 50-60h; and carrying out liquid-solid separation on the fermentation liquid after the fermentation is finished, and evaporating out the ethanol from supernatant fluid in the reduced pressure distillation method. The method has simple process and low cost, and can not only solve the environmental pollution problem of the kelp processing waste, but also provide a new material source for large-scale production of the ethanol and promote the development of marine biomass energy.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

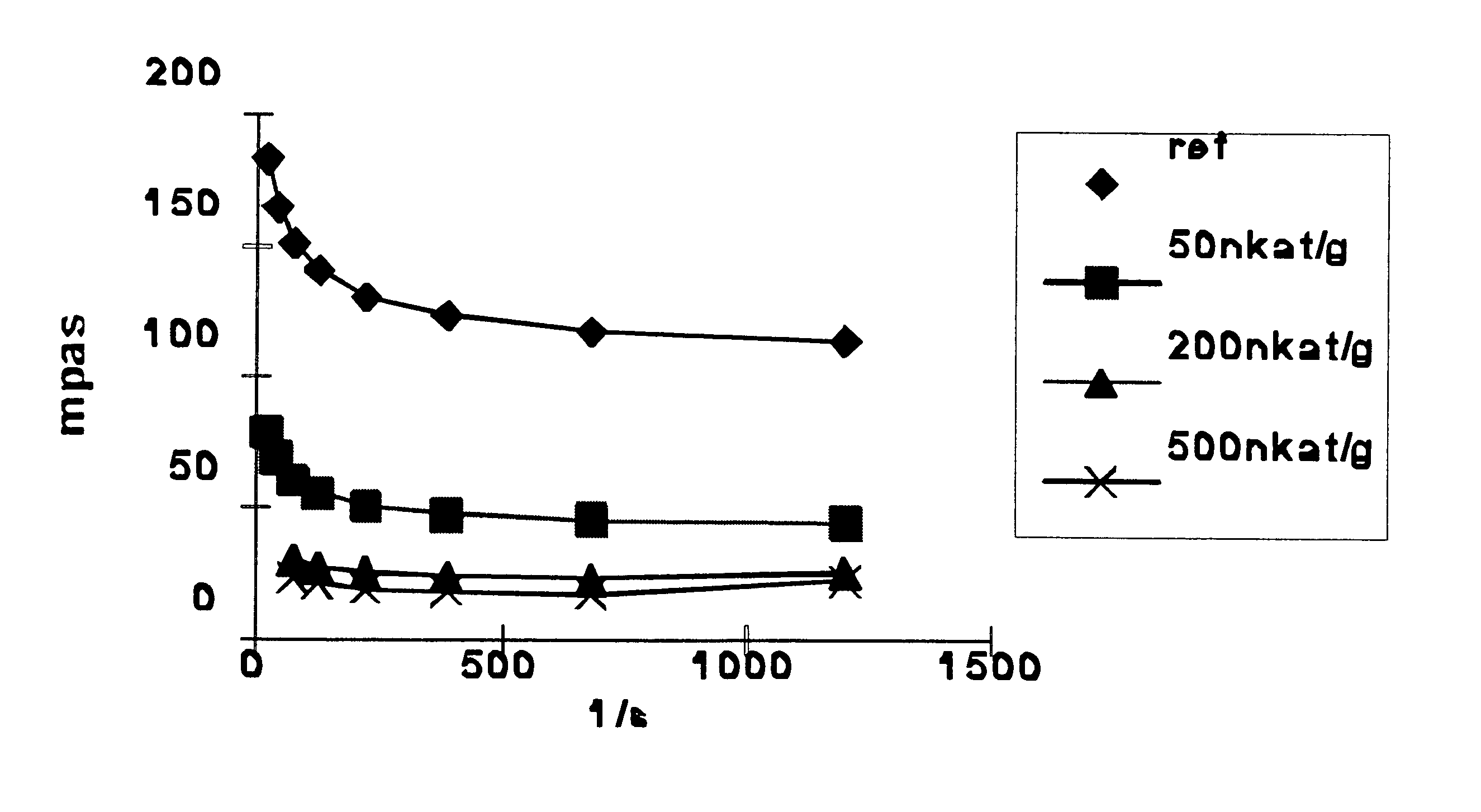

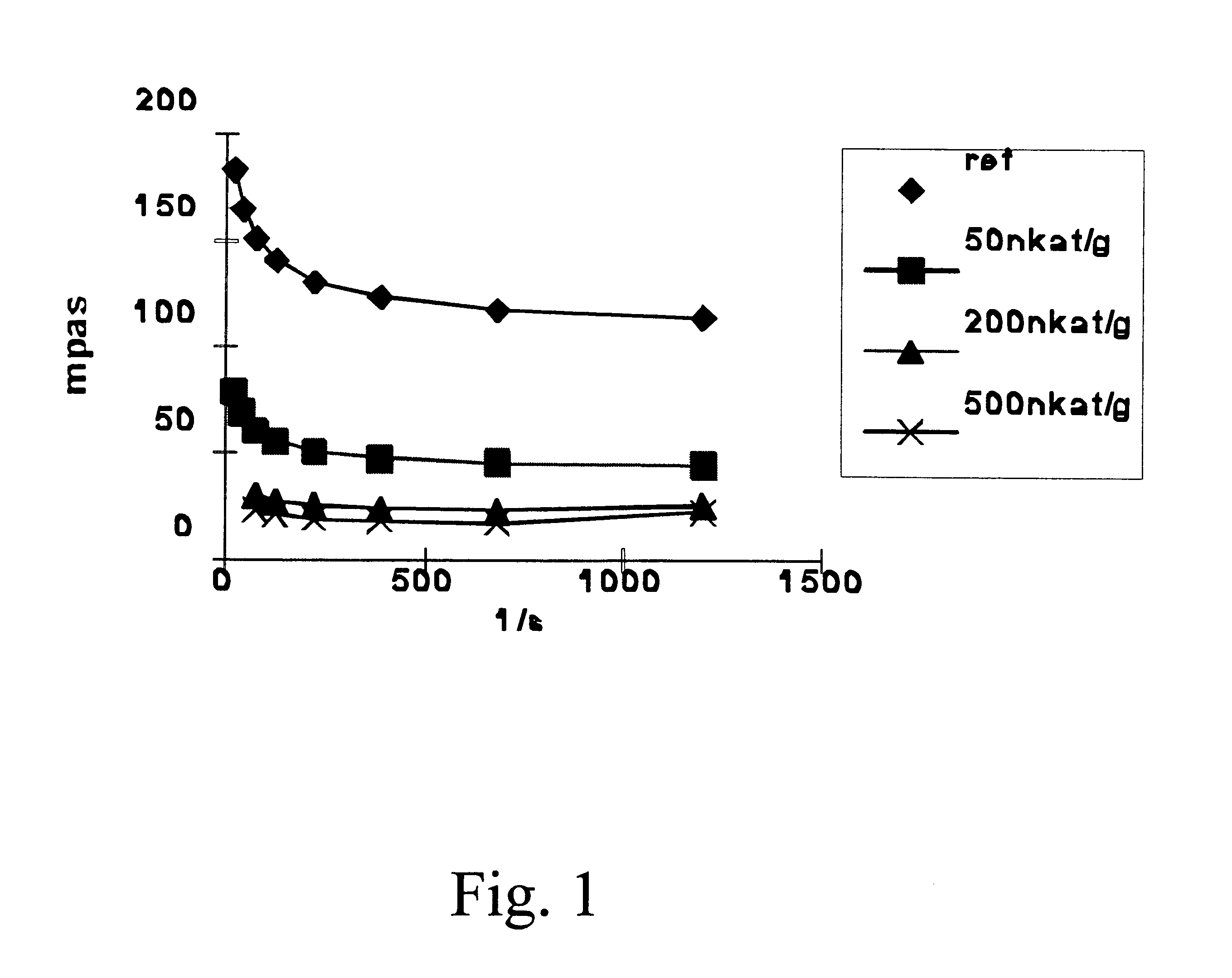

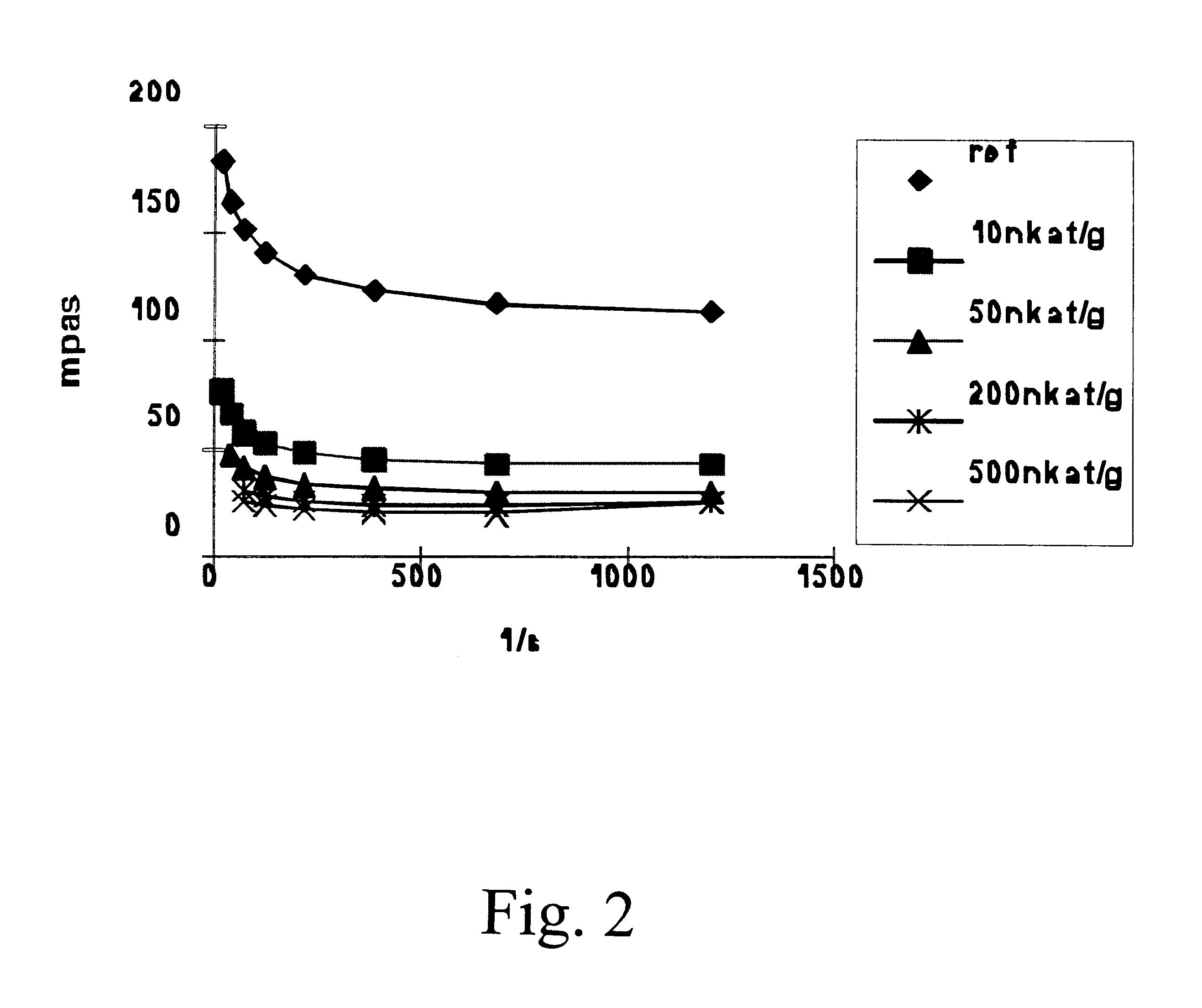

Process for concentrating soluble and colloidal substances in process waters

InactiveUS6425975B1High viscosityEconomic treatmentSludge treatment by de-watering/drying/thickeningPulp liquor regenerationFiberAfter treatment

The invention relates to a process for enhancing the concentration of the fiber derived dissolved and colloidal substances in process water that comes from mechanical pulping. According to the invention, process water is treated with enzyme preparations that have an effect on carbohydrates and that contain mannanase and / or endoglucanase, in particular, which break down the soluble carbohydrate polymers contained by the process water into low molecular weight oligosaccharides. The treatment prevents an increase in viscosity so that process water can be concentrated into a high dry content, or the treatment can be used to lower the viscosity of previously concentrated process water to facilitate after-treatment.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

Method for treating waste water from food industry

InactiveCN106348523AEconomic treatmentEasy to handleWater/sewage treatment by irradiationSpecific water treatment objectivesActivated carbon filtrationUltrafiltration

The invention relates to a method for treating waste water from the food industry, which includes the steps of: A. Waste water flows through aplurality of grilles and is flocculated and added with air via blowing, and then is settled; B. First waste water is sterilized with ultraviolet, whose pH is adjusted to 5.5-7.5 with base; C. Waste water flows into an anaerobic aeration tank and an aerobic tank, and next is treated by the oxygen film bioreactor, and then is filtered by an activated carbon filter and by a ultrafiltration membrane filter, finally is settled; D. Waste water is filtered firstly by a cartridge filter, and then by a microfiltration membrane filtration process, filtering by a ultrafiltration membrane filter, and finally by a reverse osmosis membrane filter, to obtain the discharge water in accordance with the environmental standard. Compared with the prior art, the method for treating waste water from the food industry is a simple, convenient and fast method for neutralizing waste water from the food industry, as well as a method for removing suspended solids, metal oxides, colloids, organic matters, nitrogen source materials and bacteria, etc., which not only can be used for economically, efficiently treating a large amount of waste water, with simple operation procedures, low operating costs, and smaller covering area, but also have remarkable treatment effects.

Owner:潘纪鸿

Method for treating the surface of a metallic substrate

ActiveUS20150337171A1High and adjustable pot lifeEasy to handleSynthetic resin layered productsLaminationSilanesAcyl group

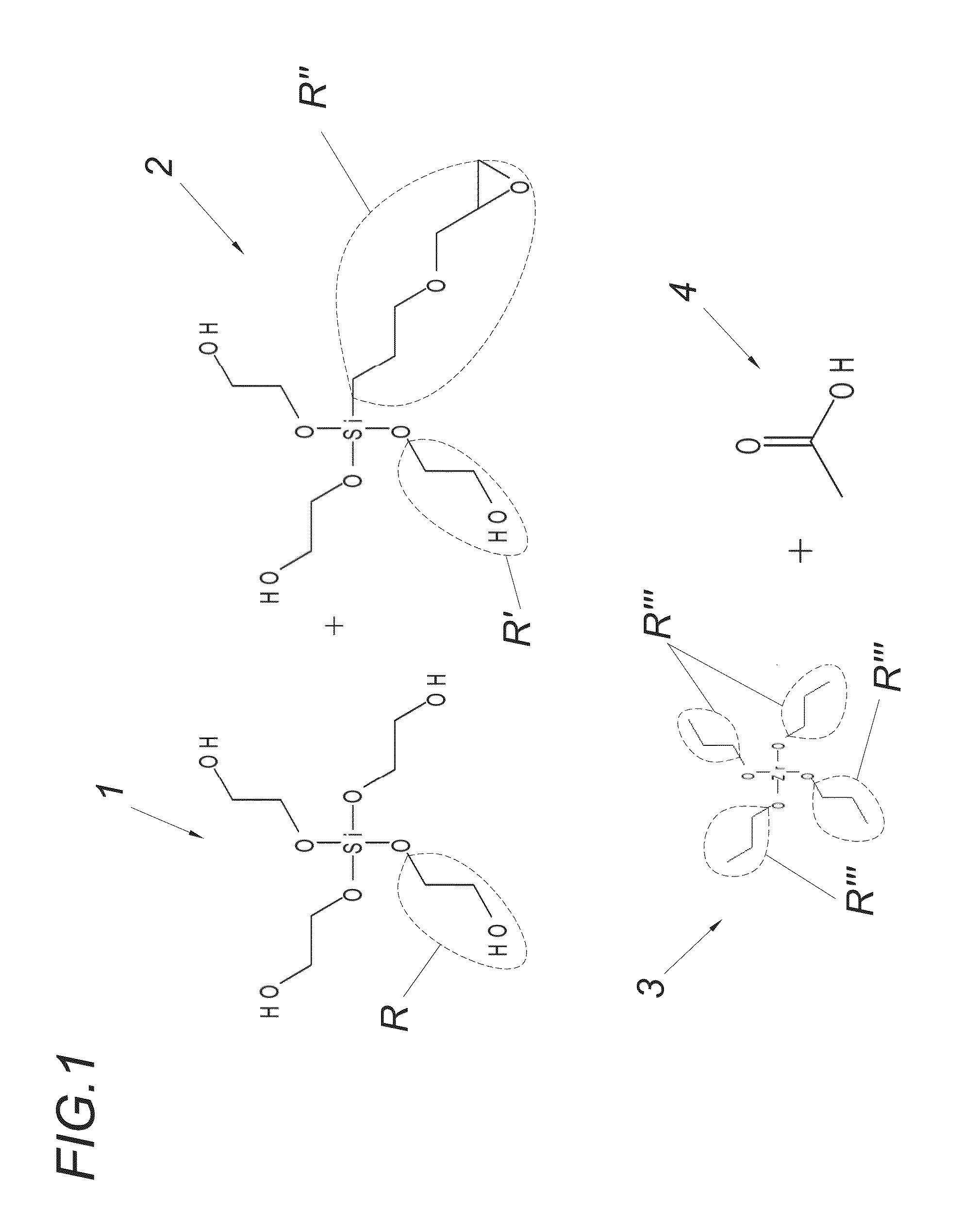

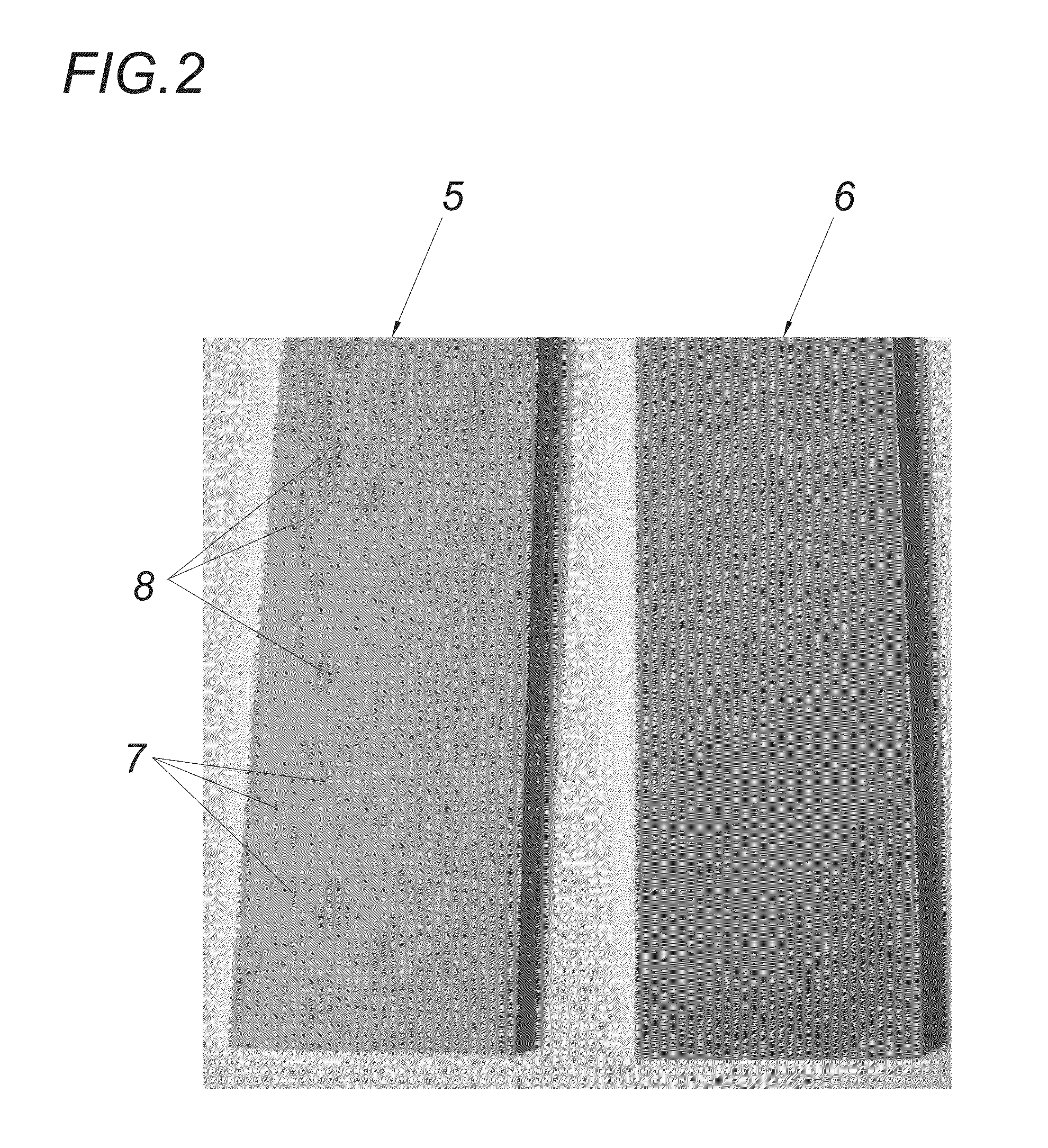

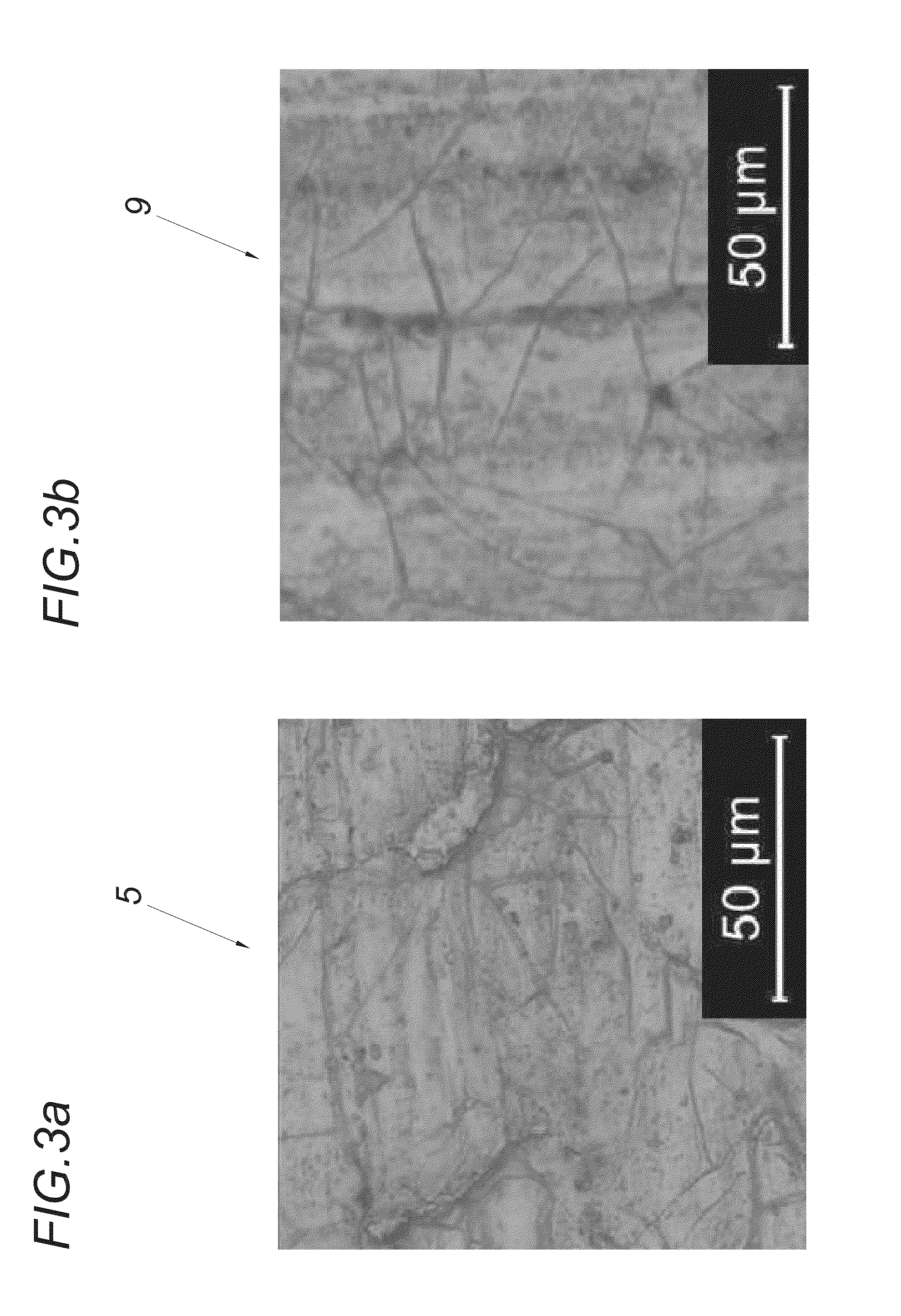

An advantageous method for treating the surface of a metallic substrate made of aluminum or an aluminum alloy, comprising the following steps: providing a water-based mixture with a sol, comprising alkoxy silanes of general chemical formula Si(OR)4 and organoalkoxy silanes of general chemical formula R″Si(OR′)3, in which R and R′ are linear or branched, short-chained hydrocarbon groups with at least one hydroxyl group and R″ is an organic group with a glycidoxy-, merkapto-, amino-, methacryl-, allyl- and / or vinyl-group, applying the mixture to the surface of the metallic substrate and at least in sections, hardening the mixture with a formation of a sol-gel coating connected to the metallic substate.

Owner:AMAG ROLLING

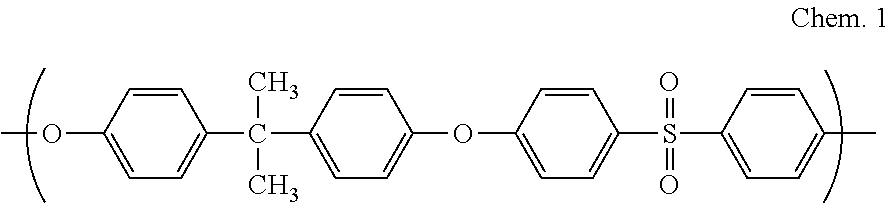

Composite semipermeable membrane and manufacturing method therefor

InactiveUS8960449B2Economic burdenEconomic treatmentSemi-permeable membranesMembranesOrganic solventAqueous solution

In manufacturing a composite semipermeable membrane useful for separating a liquid mixture selectively, it is rendered possible to provide a composite semipermeable membrane that exhibits reduced deterioration of water permeability and solute removing property as a result of drying and that demonstrates reduced economic burden and load for waste liquid treatment without impairing the water permeability or solute removal ratio of the composite semipermeable membrane through change of the membrane manufacturing method, by making a saccharide exist in an aqueous polyfunctional amine solution in performing interfacial polycondensation by bringing the aqueous solution of the polyfunctional amine into contact with an organic solvent solution containing a polyfunctional acid halide on a microporous support membrane.

Owner:TORAY IND INC

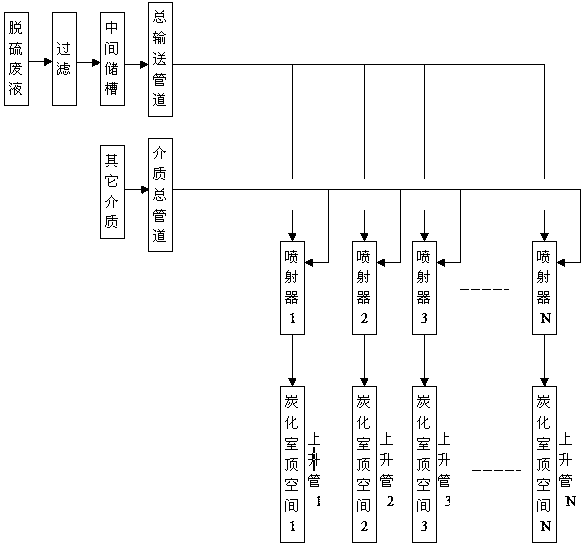

Technology for treating coking desulfurization waste liquid by raw gas residual heat

ActiveCN103588339ARealize resource utilizationAvoid consumptionMultistage water/sewage treatmentDistillation gas withdrawalHigh energyLiquid storage tank

A technology for treating a coking desulfuration waste liquid by raw gas residual heat comprises the steps as follows: the pre-treated coking desulfuration waste liquid is sent to a coking desulfuration waste liquid storage tank and then is sent to a total coking desulfuration waste liquid conveying pipeline after pressurized; and during the coking process of a carbonizing chamber, the coking desulfuration waste liquid in the total conveying pipeline is sent to an ejector through a branch pipeline and ejected to a high-temperature raw gas area, so that the coking desulfuration waste liquid is vaporized and has a pyrolysis conversion reaction. With the adoption of the technology, the problems of high energy consumption, large investment, complicated operation, secondary pollution, poor product quality and the like generated when the desulfuration waste liquid is treated by adopting a conventional method are effectively solved; and compared with a conventional processing technique, the energy is saved by higher than 95%, and the conversion rate of substances such as sulforhodanide and the like in the desulfuration waste liquid is up to 99%.

Owner:TAIYUAN UNIV OF TECH

Method for treating restaurant wastewater and garbage

PendingCN107721064AProcessing scienceEconomic treatmentSolid waste disposalTransportation and packagingPre treatmentEnergy consumption

The invention designs a method for treating restaurant wastewater and garbage. The method comprises the following treatment processes: pretreating the restaurant wastewater and garbage, crushing the restaurant garbage, dehydrating the restaurant garbage, treating the wastewater obtained after the restaurant garbage is dehydrated, and treating the substances obtained after the restaurant garbage isdehydrated. According to the method, the restaurant wastewater and the restaurant garbage can be scientifically and economically treated, so that the problem of environmental pollution is solved; furthermore, the energy consumption is low, and the cost is low; and meanwhile, useful components in the restaurant wastewater and the restaurant garbage can be utilized.

Owner:惠州市良化新材料有限公司

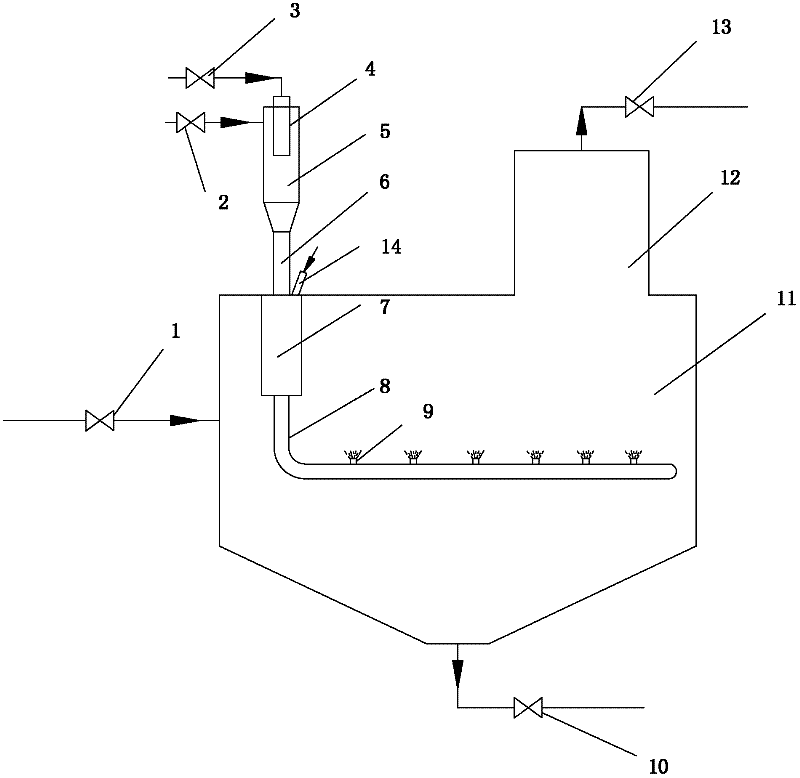

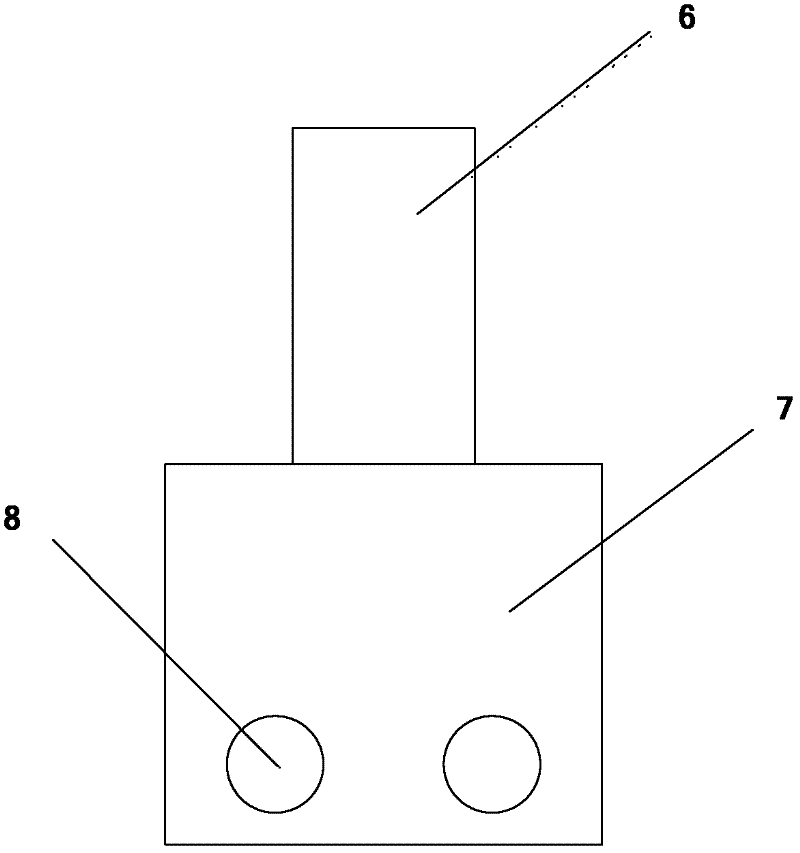

Equipment and method for treating severe sewage by using high pressure burning and evaporation in water

InactiveCN102351260AEasy to handleSave spaceWater/sewage treatment by heatingCombustion chamberEvaporation

The invention discloses equipment and a method for treating severe sewage by using high pressure burning and evaporation in water, belonging to the field of sewage treatment technology which has the advantages of energy saving and emission reduction and is favorable for environmental protection. To effectively overcome the problem of treatment of severe sewage in the fields of petroleum, chemicals, the nuclear industry, smelting and the like and to realize comprehensive control of high viscosity, high brine and high organics wastewater, the invention provides an evaporator for condensing sewage by using high pressure burning and evaporation in water. According the method in the invention, a gas or liquid fuel is used as a source of energy, spray combustion of the fuel and air is formed ina combustion chamber, flames are directly jetted into sewage by using the combustion cabin technology; therefore, high efficiency heat exchange and evaporation of sewage are realized, an obtained concentrate is discharged in the form of slurry, and zero discharge of sewage is basically achieved; high temperature high pressure steam and exhaust gas can be reused. Evaporation equipment provided in the invention has high heat exchange efficiency and a high heat utilization rate; investment for the equipment is small; it is convenient to operate and maintain the equipment; and the complete equipment can realize high efficiency treatment of severe sewage.

Owner:DALIAN UNIV OF TECH

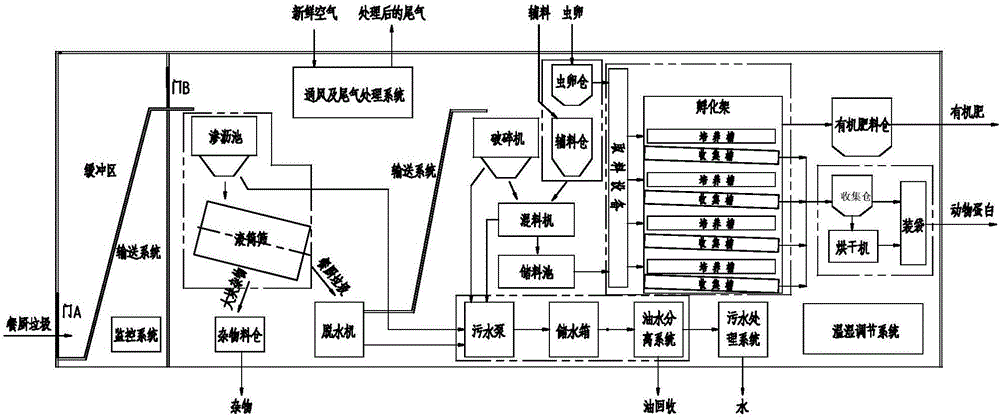

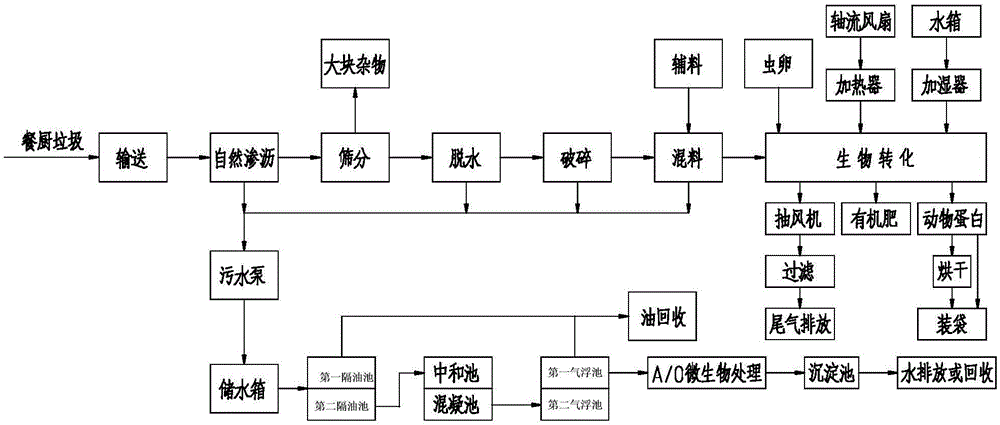

Kitchen waste treatment system based on biotransformation

ActiveCN106391656ANo secondary pollutionMeet emission standardsTransportation and packagingSolid waste disposalMaggotEconomic benefits

The invention discloses a kitchen waste treatment system based on biotransformation. The kitchen waste treatment system based on biotransformation comprises a pretreatment device, an incubation device and a waste water treatment device. The pretreatment device is connected with the incubation device. Sewage produced by the pretreatment device and the incubation device enters the waste water treatment device. The pretreatment device is used for screening, dewatering and smashing kitchen waste and mixing the smashed kitchen waste with auxiliary materials. The incubation device is used for incubating eggs of insects into larvae, and the pretreated kitchen waste is used for feeding the larvae to enable the larvae to grow. The incubation device is internally provided with an incubation frame and a collection bin. The incubation frame is provided with cultivation frames and collection grooves. The cultivation frames are used for containing pretreated kitchen waste. The collection grooves are used for collecting the larvae. The collection grooves are connected with the collection bin. According to the kitchen waste treatment system based on biotransformation, the kitchen waste is pretreated and then fed into the incubation frame for feeding the insects so that maggots and organic fertilizer can be acquired, harmless treatment is performed on the kitchen waste, and economic benefits are obtained.

Owner:宁波市博尔环保科技有限公司

Sewage treatment device and method for synchronously recycling water and electric energy

ActiveCN110272171ATake advantage ofResolve enrichmentWater/sewage treatmentMultistage water/sewage treatmentPeristaltic pumpSaline water

The invention discloses a sewage treatment device and method for synchronously recycling water and electric energy, and belongs to the field of sewage treatment. The method comprises the following steps that with urban sewage as inflow water, a mud-water mixed liquid is taken as a feed solution and enters a feed solution passage of a membrane assembly through a peristaltic pump, and brine is taken as a draw solution and enters a draw solution passage of the membrane assembly through a high-pressure pump. By utilizing the osmotic pressure difference of the two sides of an FO membrane, water flows from the feed solution side to the draw solution side, the mixed draw solution has high pressure and pushes a turbine to rotate in the outflowing process, and therefore the electric energy is generated. The diluted draw solution passes through a draw solution recycling system to obtain recycled water, and meanwhile, the concentrated draw solution continues to be used for the FO membrane. The sewage treatment device and method for synchronously recycling the water and electric energy are scientific and reasonable in technical design and have important significance for expanding the application of the forward osmosis membrane in sewage treatment.

Owner:JIANGNAN UNIV

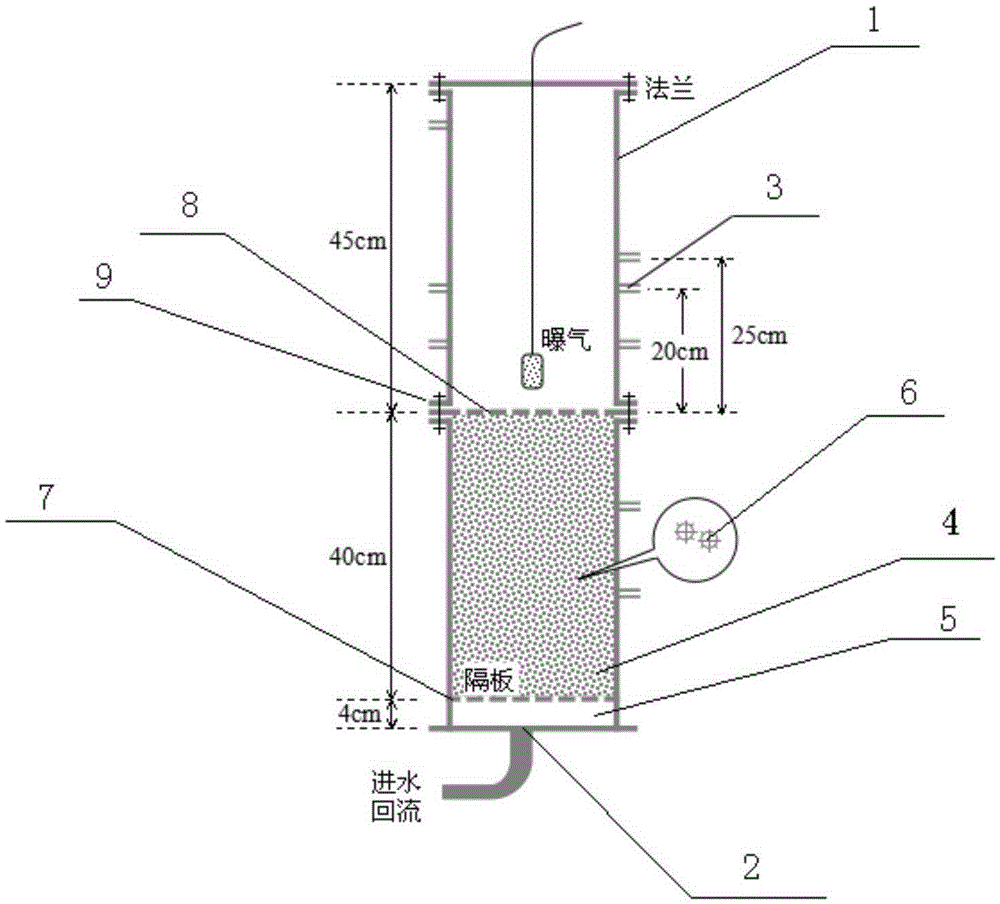

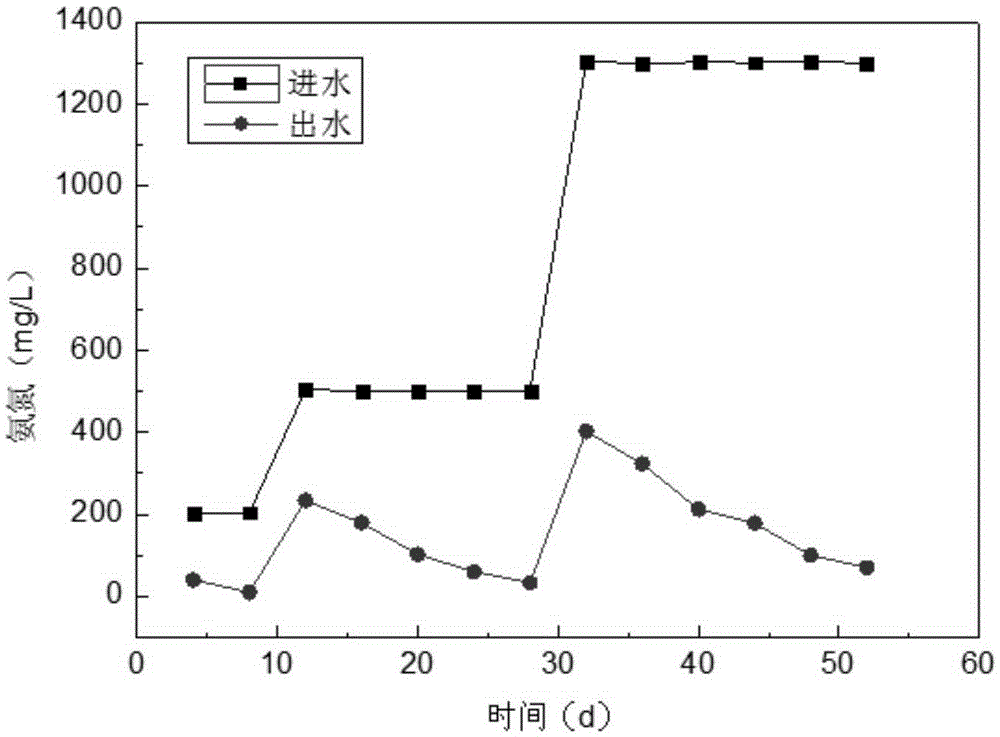

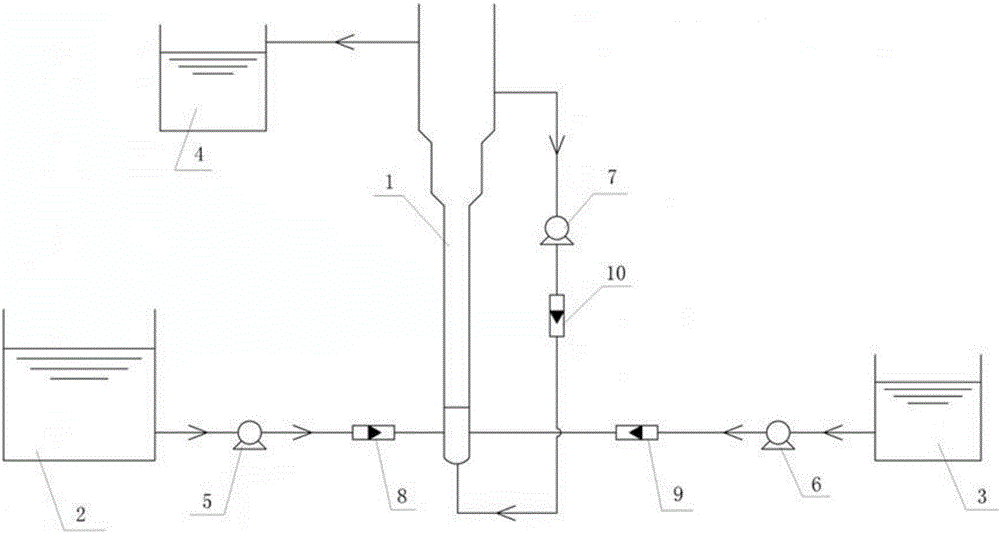

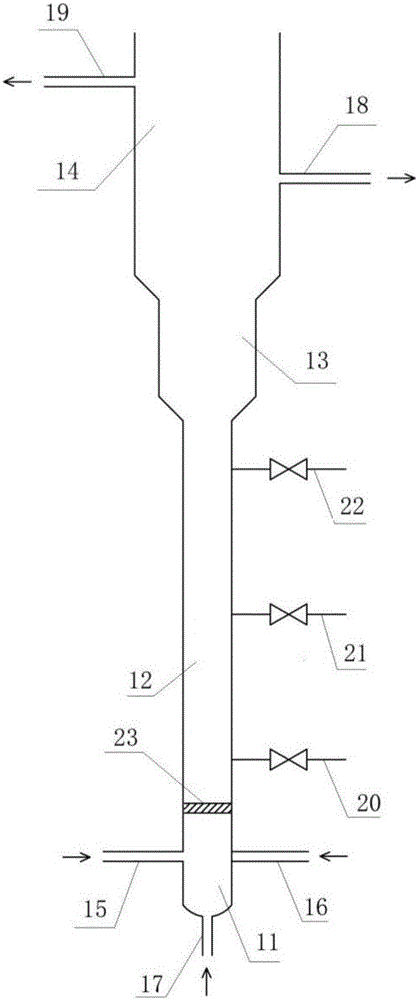

Reactor capable of quickly starting anaerobic ammonia oxidation coupling nitrosation reaction and quick-start method

ActiveCN105254011AFully attachedAvoid churnTreatment with aerobic and anaerobic processesPorosityStart time

The invention relates to a reactor capable of quickly starting an anaerobic ammonia oxidation coupling nitrosation reaction and a quick-start method. A gravel layer is laid at the bottom inside the reactor, a lower partition board provided with holes is arranged on the gravel layer, a filler layer is arranged on the lower partition board, gaps are formed inside the filler layer, the porosity of the filler layer ranges from 0.6 to 0.8, the thickness of the filler layer accounts for 2 / 5-1 / 2 the height of the reactor, and an upper partition board provided with holes is arranged at the top of the filler layer. By means of the reactor, an aerobic zone and an anaerobic zone can be separated, synchronous nitrification and anaerobic ammonia oxidation reactions are started quickly, and nitrogen-containing waste water can be efficiently treated. By means of the reactor, sludge can be attached to filler and fixed to the lower layer of the reactor, sludge loss can be prevented, partition of an aerobic layer and an anaerobic layer is effectively achieved, starting time of an anaerobic ammonia oxidation coupling nitrosation process can be effectively shortened, the process flow is simplified, and the operation is simple.

Owner:山东美泉环保科技有限公司

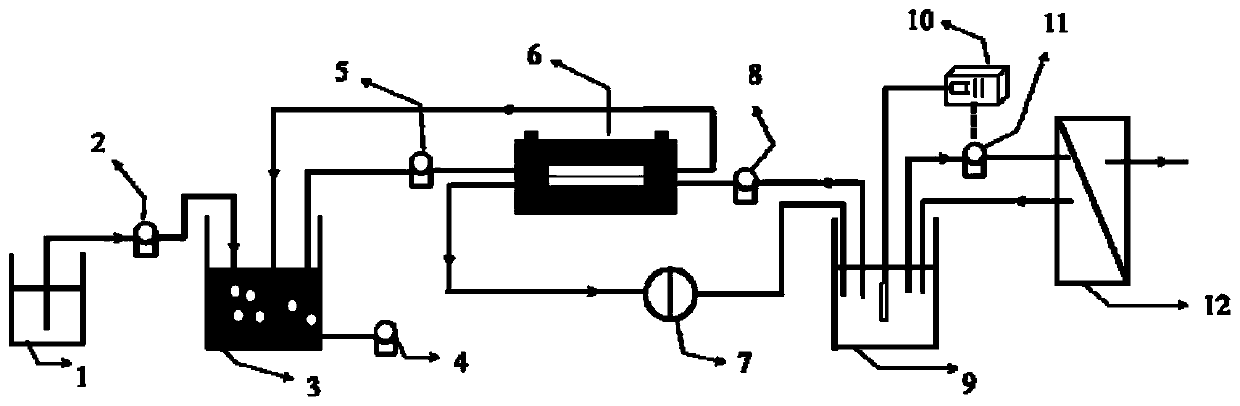

Method and device for preparing sandy cryolite from fluoride waste water

PendingCN106830034AAvoid environmental pollutionWide range of applicationsAluminium fluoridesFluidized bedWater tanks

The invention discloses a device for preparing sandy cryolite from fluoride waste water. The device comprises a fluidized bed reactor, a waste water tank, a chemical box and a water collecting box, wherein a water inlet of the fluidized bed reactor is connected with the waste water groove through a water inlet pump; a chemical inlet of the fluidized bed reactor is connected with the chemical box through a chemical feeding pump; a water outlet of the fluidized bed reactor is connected with the water collecting groove; a backflow outlet of the fluidized bed reactor is connected with a backflow inlet of the fluidized bed reactor through a backflow pump; cryolite crystal seeds are arranged in the fluidized bed reactor; a sampling opening is formed in the fluidized bed reactor. The invention also provides a method for preparing the sandy cryolite from the fluoride waste water. The fluorine can be recovered from the waste water for preparing the sandy cryolite.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for treating high-concentration organic sewage difficult to degrade

InactiveCN101265003AEasy to handleEconomic treatmentTreatment with anaerobic digestion processesWater/sewage treatment bu osmosis/dialysisLiquid wasteHigh concentration

The invention relates to a method for treating difficultly degraded high concentration organic wastewater, comprising the steps of (1) adding organic wastewater to be treated into a regulating tank, pumping into a hydrolysis and acidification reactor via a feeding pump, and continuously stirring for 8 hours; (2) adding the treated wastewater from step (1) into an internal circulation anaerobic reactor with feeding speed of 8-10 mL / h, adjusting the ratio of volatile fatty acid and base in the internal circulation anaerobic reactor to 0.3-0.4, and continuously stirring for 12 hours; (3) adding the treated wastewater from step (2) into a membrane treatment system with membrane pore size of 0.2 mum, membrane flux of 80L(m3*d), cross flow speed of 3.5 m / s, circulation ratio of 20:1 and operating pressure of 0.1 Mpa; and (4) collecting the purified water after treatment in step (3), and recycling the concentrated waste liquid to the regulating tank in step (1).

Owner:北京水气蓝德科技有限公司

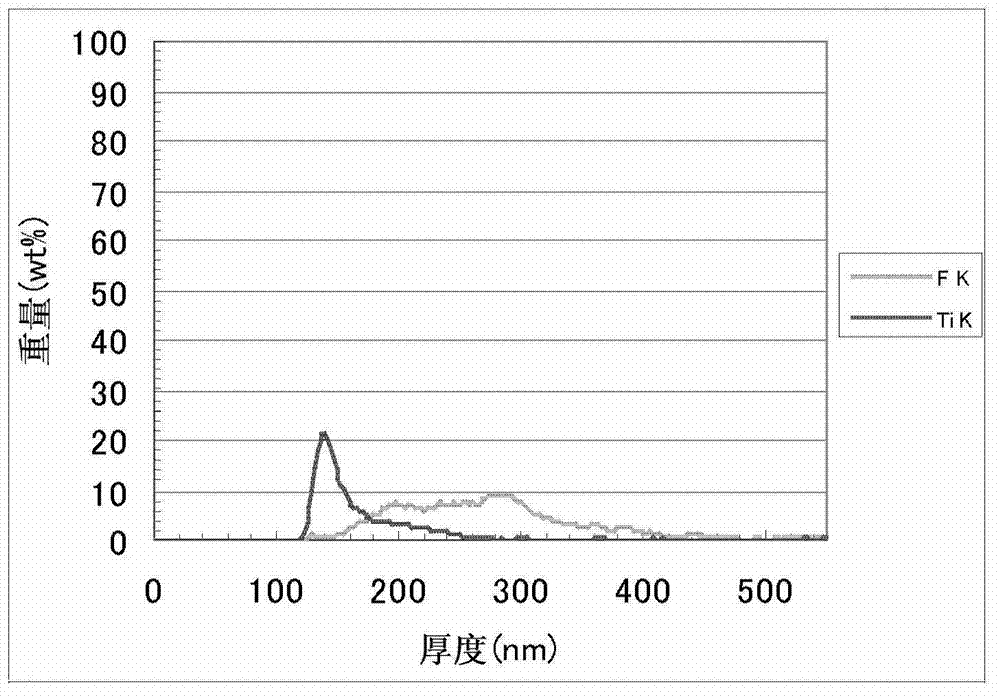

Surface-treated fluorescent bodies and process for production of surface-treated fluorescent bodies

InactiveCN102822313AImprove moisture resistanceEffective surface treatmentSolid-state devicesLuminescent compositionsElement analysisPhosphor

The present invention aims to provide a surface-treated phosphor having high dispersibility and capable of significantly enhancing moisture resistance without deteriorating the fluorescence properties, and a method for producing the surface-treated phosphor. The surface-treated phosphor includes: a phosphor body; and a surface treatment layer containing at least one specific element selected from elements of the third to sixth groups of the periodic table, and fluorine, the phosphor body having the surface treatment layer on the surface thereof, wherein, when a cross section of the surface treatment layer is subjected to a thickness-wise elemental distribution analysis by a combination of an electron microscopic analysis and an energy-dispersive X-ray element analysis, a peak indicating the maximum content of the specific element appears nearer to the surface than a peak indicating the maximum fluorine content.

Owner:SEKISUI CHEM CO LTD

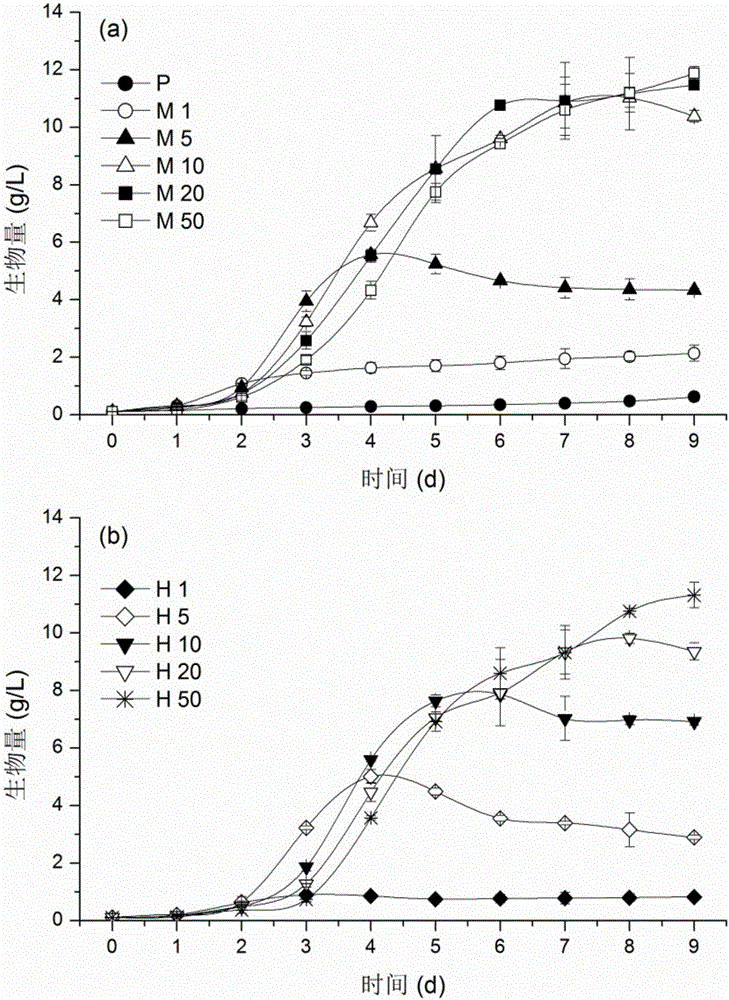

Method for nitrogen abundance transformation treatment of wastewater with high ammonia nitrogen

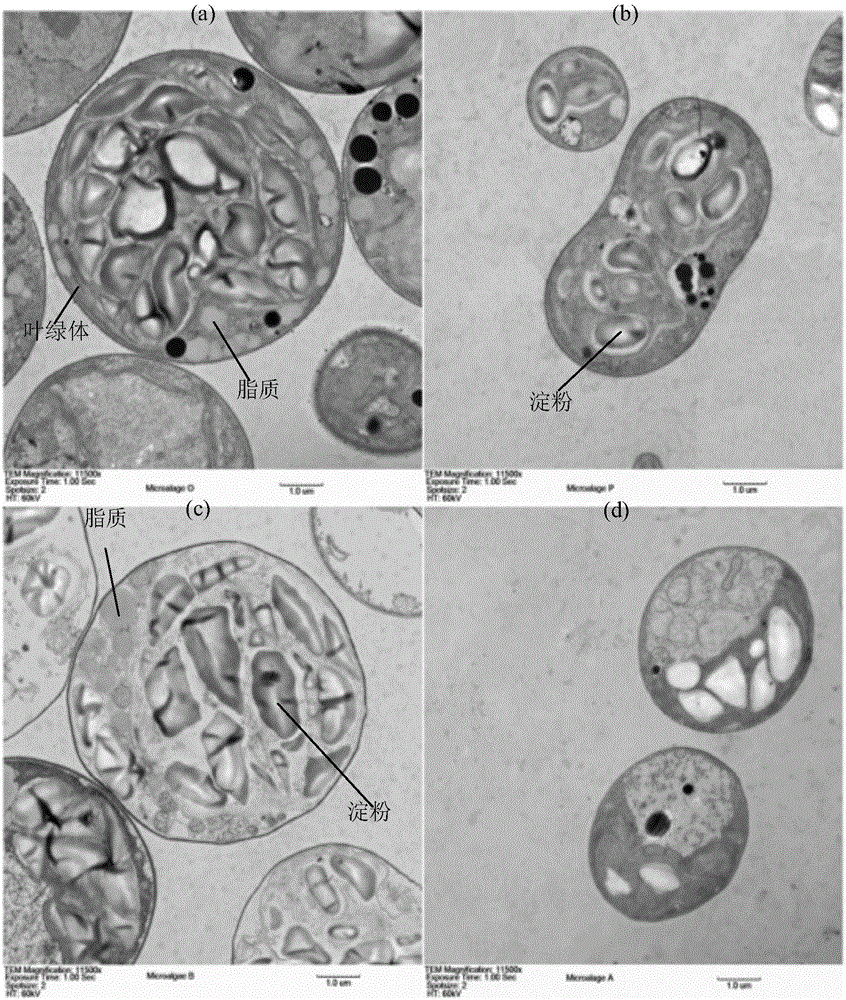

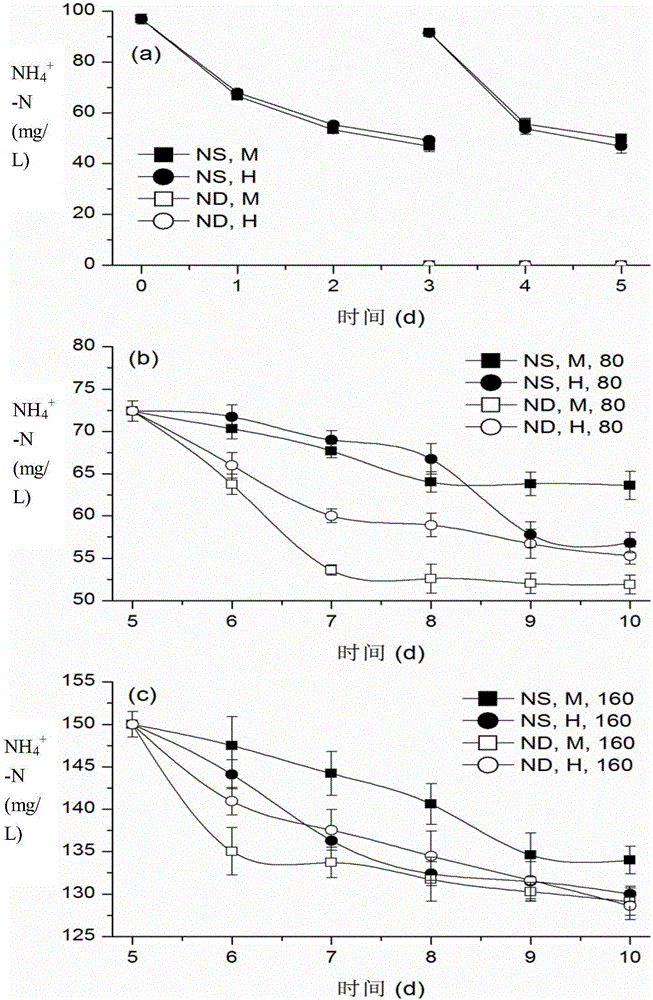

InactiveCN105858894AEfficient removalTo achieve the purpose of purifying wastewaterBacteriaUnicellular algaeHigh concentrationChloroplast

The invention discloses a method for nitrogen abundance transformation treatment of wastewater with high ammonia nitrogen by utilizing mixotrophic microorganisms; with use of microbial cells, such as microalgae, photobacteria and other chemical energy bacteria, obtained from pre-culture or harvested from a culture system, mixotrophic microbial cells are subjected to rapid culture accumulation in an abundant nitrogen culture medium, and followed by mixotrophic microorganisms are harvested and are transferred to a nitrogen limited culture medium, are subjected to nitrogen limited culture for 2-4 days, finally are transferred into the wastewater with high ammonia nitrogen and are subjected to autotrophic growth under illumination conditions; because the mixotrophic microorganisms need to synthesize liposome for saving energy in the nitrogen limited process, and simultaneously degrade chloroplast and other organelles, in the abundant nitrogen transformation process under the illumination conditions, a large number of ammonia nitrogen nutrient sources are needed for synthesizing chlorophylls and other assemblies needed for photosynthesis, and thus the high-concentration ammonia nitrogen in the wastewater can be effectively removed, and the purpose of purifying the wastewater is achieved.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com