Return filter and method of filtering fluid by using return filter

A technology for filtering fluids and filters, which is applied to fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc. It can solve the problems of backflow filters not being economical and environmentally friendly, oil pollution, etc., and achieve material and energy saving The effect of fewer materials and filter element parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

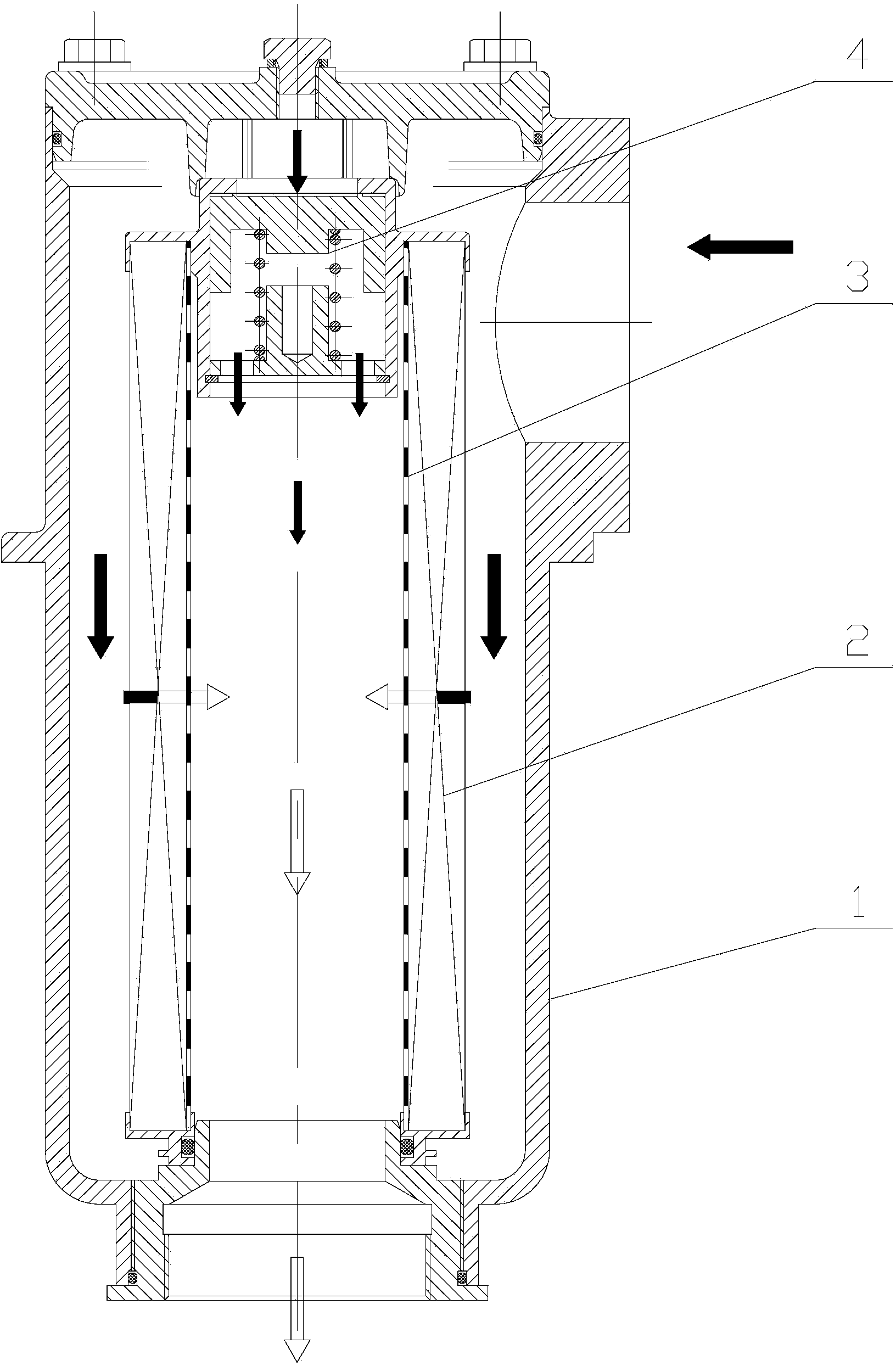

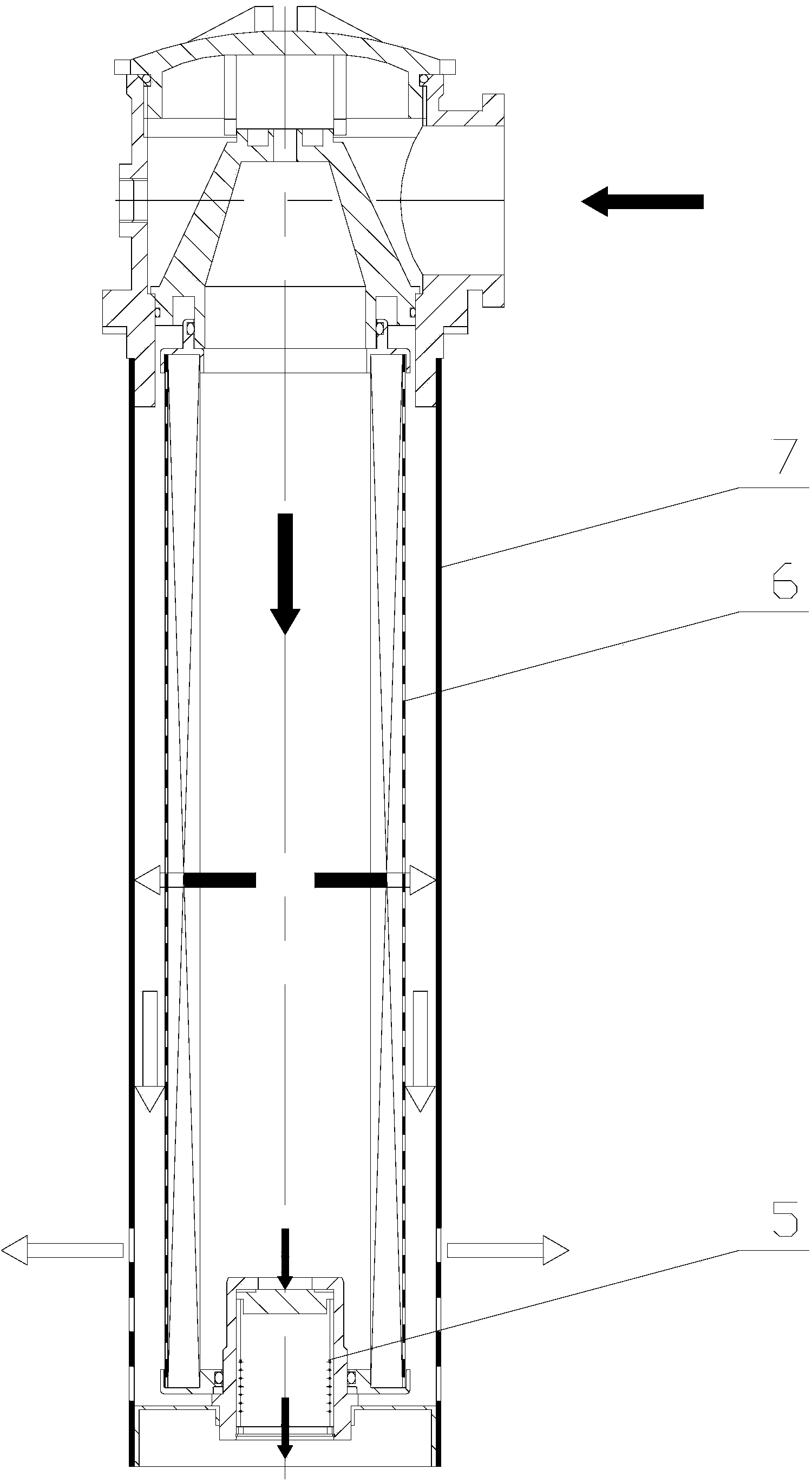

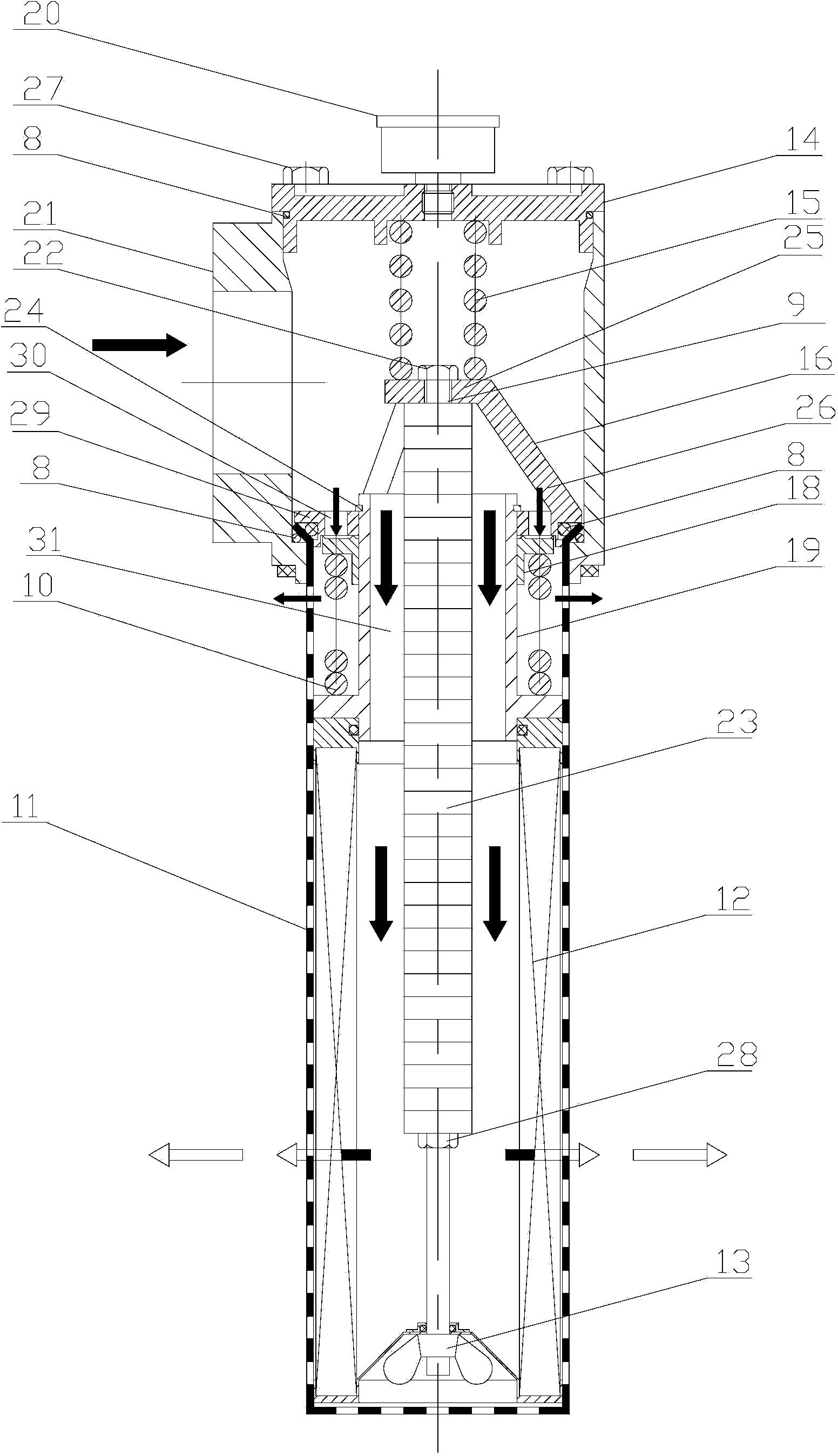

[0031] The backflow filter of the present invention will be described in further detail below in conjunction with specific drawings.

[0032] Such as image 3 Shown is the backflow filter of the present invention, including a filter cover 14, a filter head 21 and a filter cartridge 11, wherein the filter head 21 is located between the filter cover 14 and the filter cartridge 11, and the filter cartridge 11 A frameless filter core 12 is arranged below the inner wall, a bypass valve is provided at the upper end of the frameless filter core 12, and a magnetic rod 23 is arranged at the center of the bypass valve and the frameless filter core 12, and the bottom of the magnetic rod 23 extends to The middle and lower part of the frameless filter element 12.

[0033] The bypass valve includes a support frame 16, a retaining ring 24, a bypass valve body 19, a bypass valve cover 18 and a bypass valve spring 10, the support frame 16 is located in the filter head 21, the bypass valve Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com