Effective printing and dyeing sewage treatment method

A printing and dyeing sewage and treatment method technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, textile industry wastewater treatment, etc. It can solve the problem of unstable effluent quality, large floor area, and poor treatment effect, etc. problems, to achieve good nitrogen and phosphorus removal effect, small footprint, and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

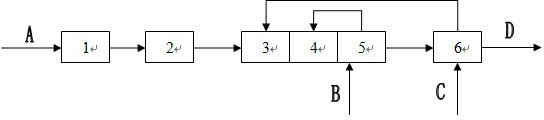

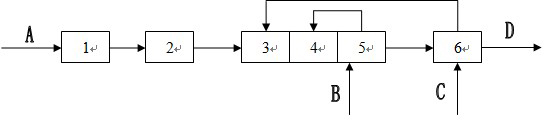

Image

Examples

Embodiment 1

[0034] A printing and dyeing enterprise in Yixing, Jiangsu discharged sewage, COD was 445.4mg / L, NH 3 -N is 37.45mg / L, TN is 42.3mg / L, TP is 13.1mg / L, and the chromaticity is 230 times. The hydrolysis tank adopts an upflow hydrolysis tank, and the sewage enters from the bottom of the hydrolysis tank, and the water is dispersed and distributed through the water distribution system for hydrolysis and acidification, and the residence time is 30h. After the sewage is hydrolyzed and acidified, the effluent overflows into A through the upper overflow weir of the upflow hydrolysis tank. 2 The O(PACT) reaction tank flows through the anaerobic tank, the anoxic tank and the aerobic tank, and internal reflux (reflux ratio 50%) and sludge reflux (reflux ratio 250%) are set at the end of the aerobic tank.

[0035]Powdered activated carbon is added to the aerobic pool, the dosage is 100mg / L, and the residence time is 20h. After biological treatment, the effluent enters the coagulation sed...

Embodiment 2

[0039] Wastewater discharged from a printing and dyeing enterprise in Xuchang, Henan, COD is 755.4mg / L, NH 3 -N is 67.45mg / L, TN is 72.3mg / L, TP is 15.1mg / L, and the chromaticity is 330 times. Other operating conditions are the same as in Example 1, but internal return (reflux ratio 25%) and sludge return (return ratio is 300%) are set at the end of the aerobic tank. After treatment, the effluent quality COD is 55.2mg / L, NH 3 -N is 1.77mg / L, TN is 14.6mg / L, TP is 0.36mg / L, and the chromaticity is 20 times. The effluent water quality indicators of each section of the whole process are shown in Table 2.

[0040] Table 2 Outlet water quality indicators of each section (unit: mg / L)

[0041]

Embodiment 3

[0043] A printing and dyeing enterprise in Zhejiang, sewage discharge: COD is 456.4mg / L, NH 3 -N is 57.45mg / L, TN is 63.3mg / L, TP is 12.5mg / L, and the chromaticity is 290 times. Other operating conditions are the same as in Example 1. The hydrolytic acidification tank adopts a push-flow type, and the hydrolytic acidification residence time is 24 hours. After the treatment, the effluent water quality COD is 50.2mg / L, and the NH 3 -N is 1.37mg / L, TN is 12.6mg / L, TP is 0.41mg / L, and the chromaticity is 18 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com