Patents

Literature

126results about How to "Fully attached" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

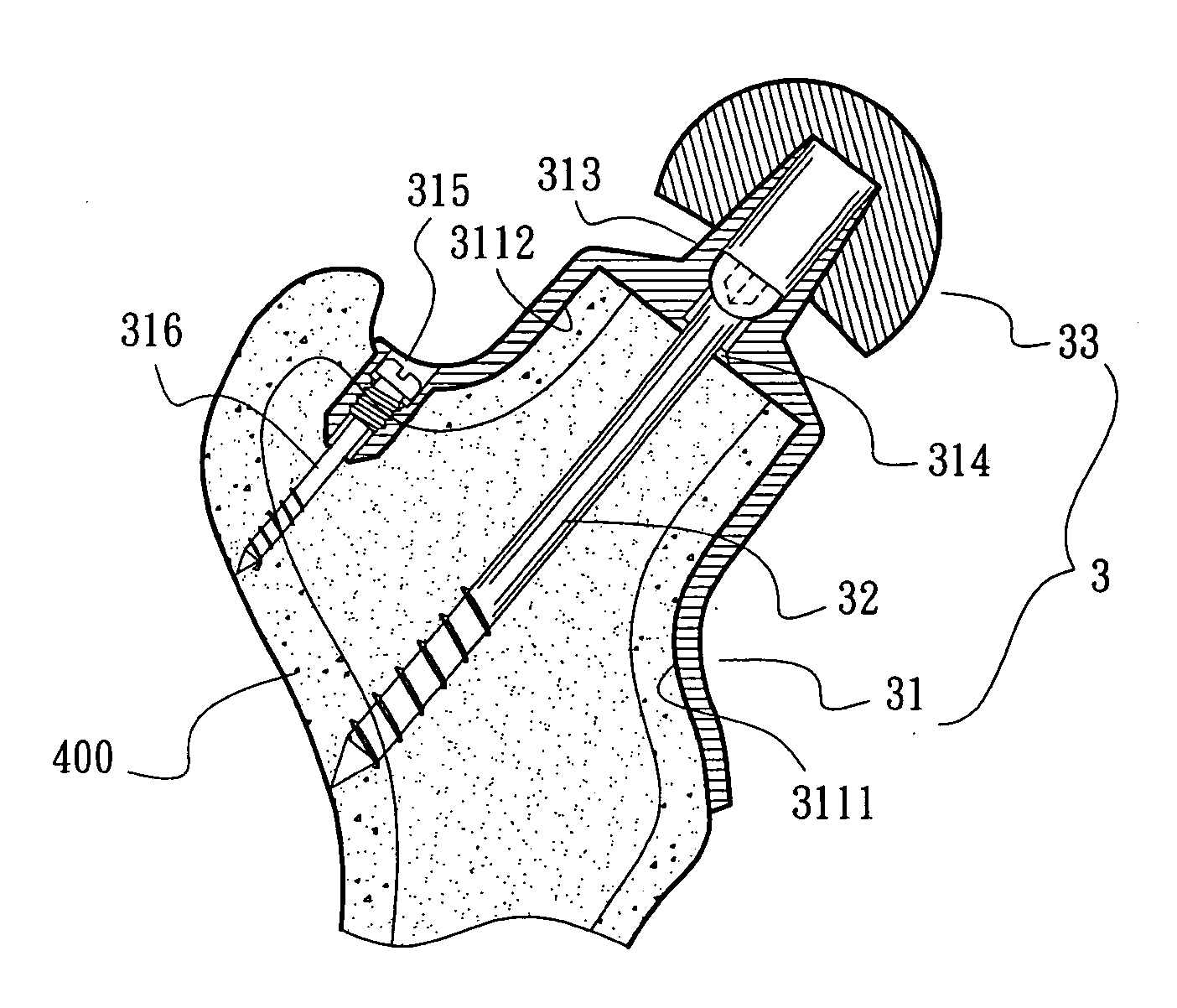

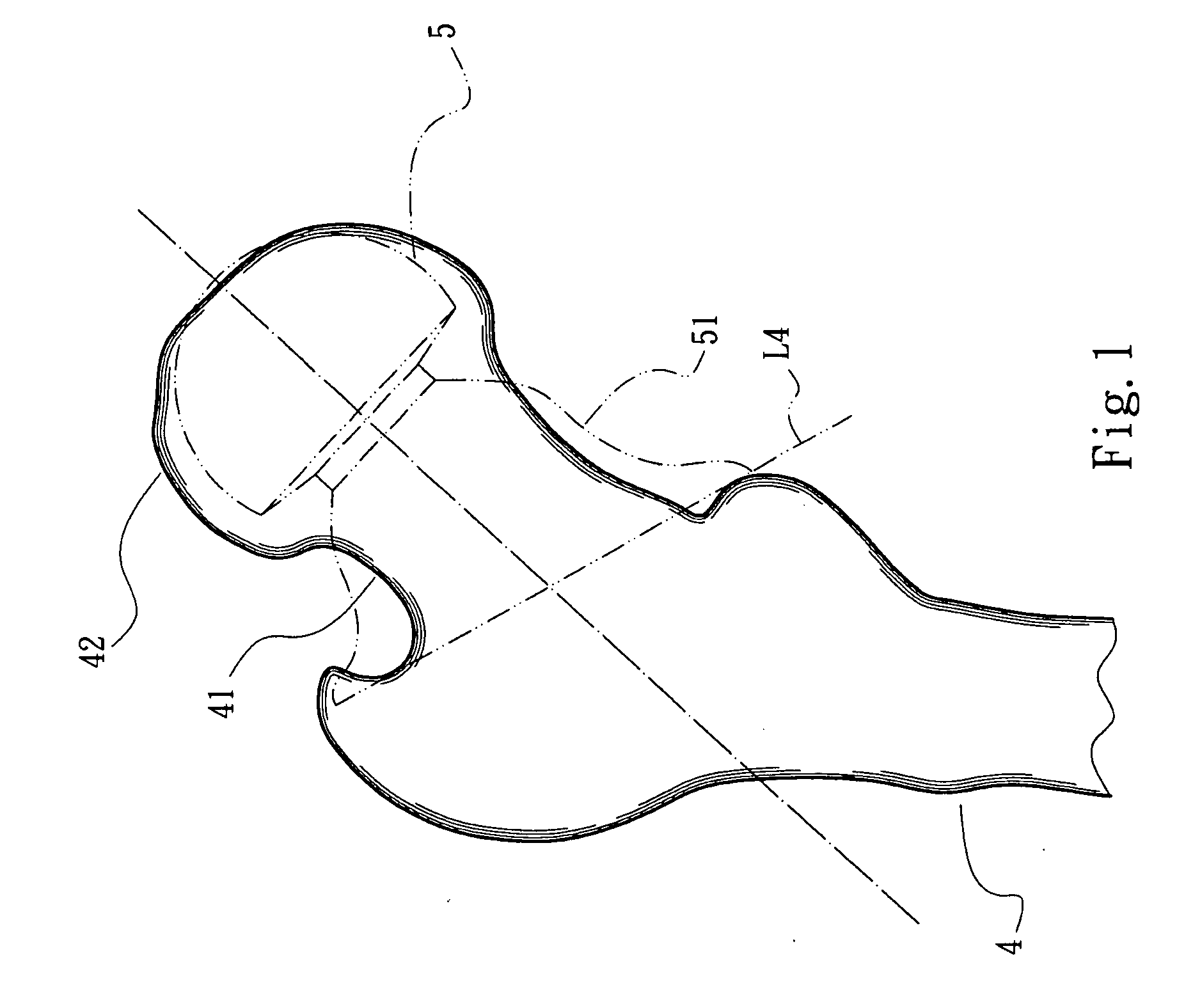

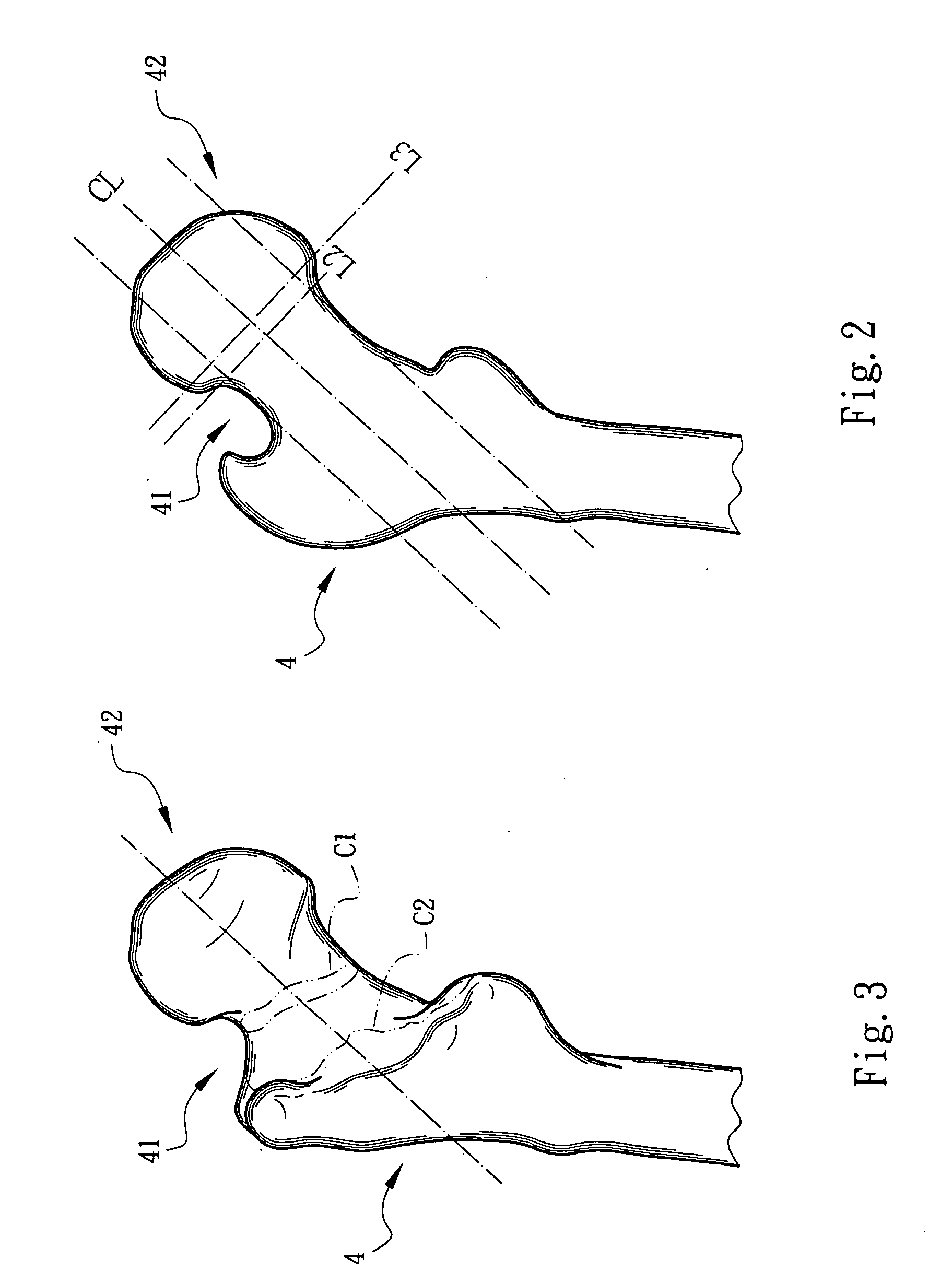

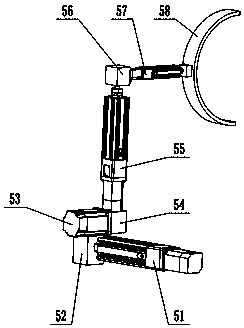

Femoral head prosthesis assembly and operation instruments thereof

InactiveUS20100168866A1Improve fitImprove the quality of operationSurgeryJoint implantsRight femoral headFemoral head prosthesis

A femoral head prosthesis assembly and operation instruments thereof. The operation instruments include a hollow femoral neck holder with a configuration adapted to the surface configuration of the femoral neck and a shaper blade for cutting a replacement end of the femur into a predetermined configuration. A guide tube is disposed on a top face of the femoral neck holder. A transverse slot is formed on the femoral neck holder for indicating a femoral head cutting line. The femoral head prosthesis assembly includes a cap body and an artificial femoral head. A root section of the cap body has an inner surface in conformity to the surface of the femoral neck. A top section of the cap body has a cross section adapted to that of the replacement end. The cap body can be precisely securely bonded with the replacement end of the femur.

Owner:SHIH GRANT LU SUN

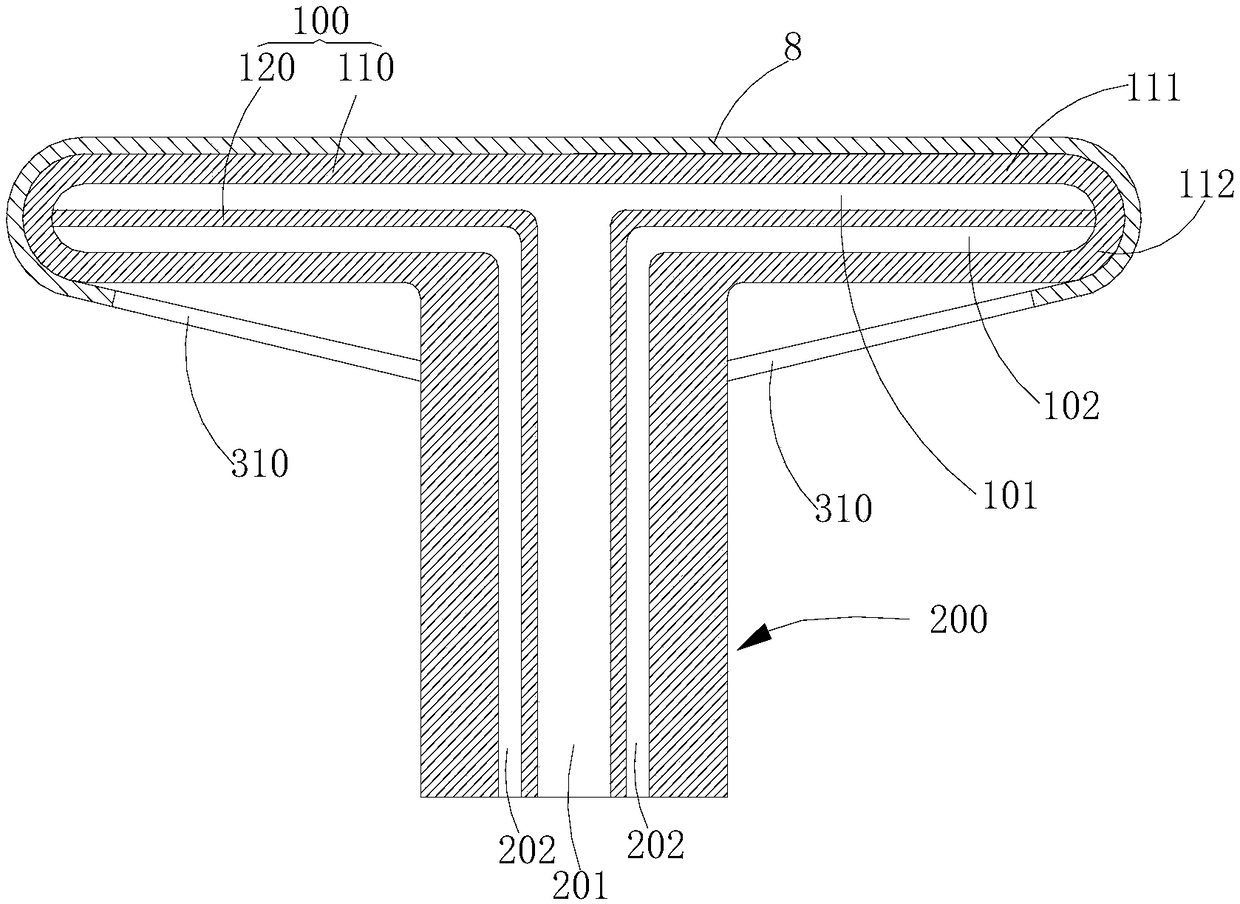

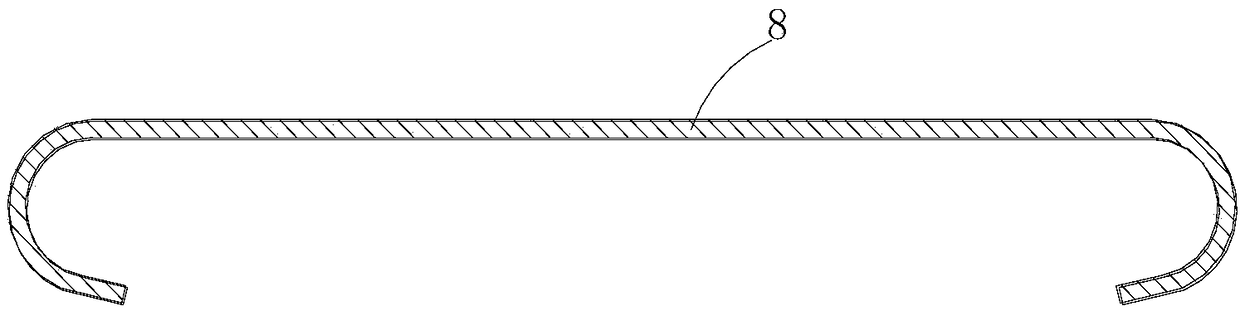

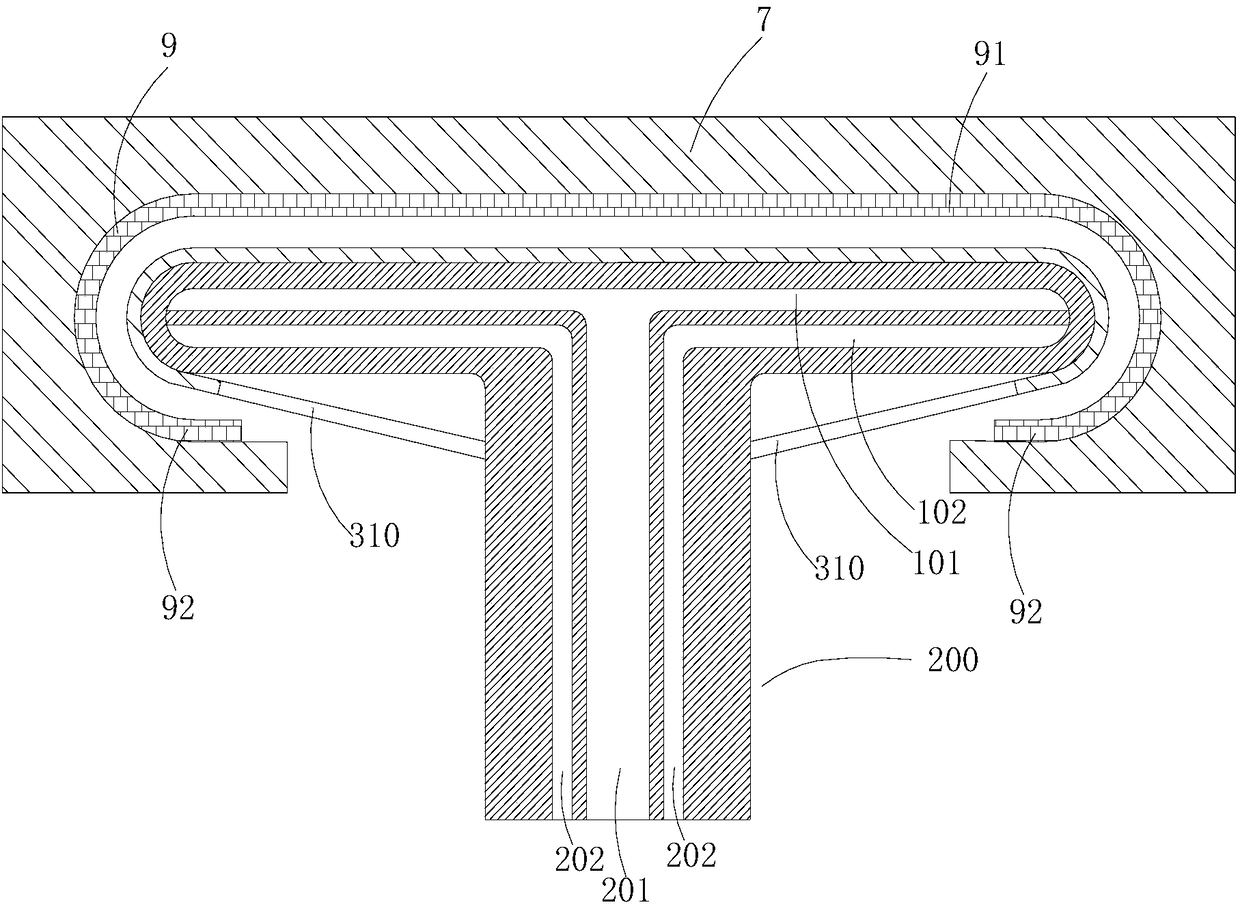

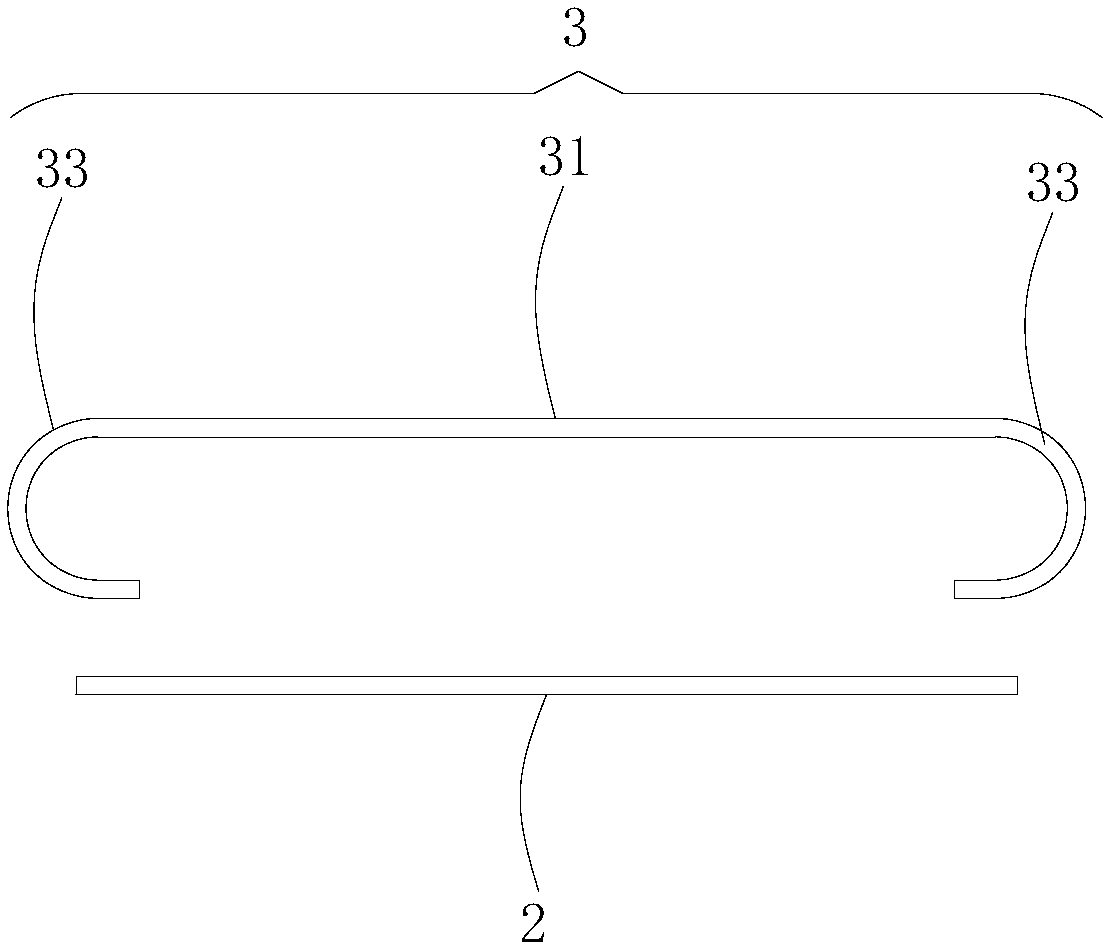

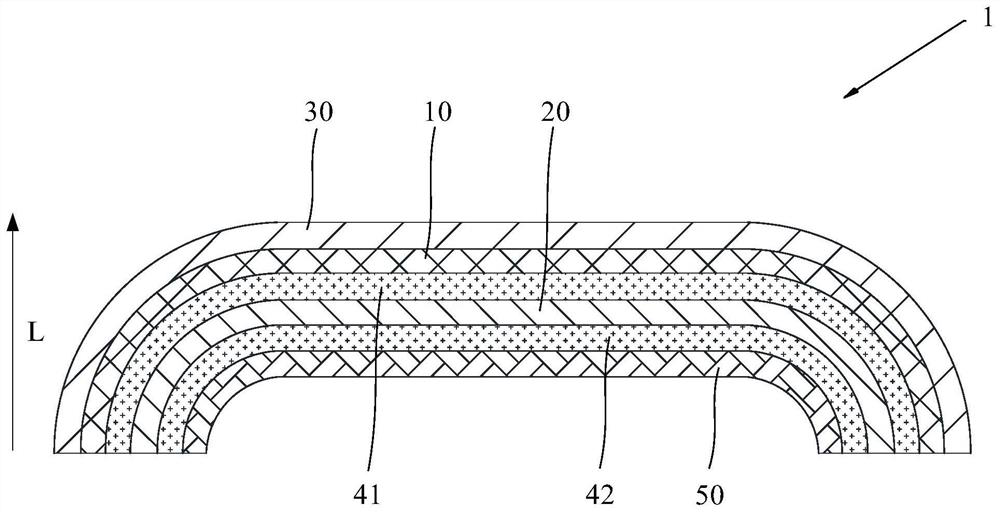

Fitting device and method for special-shaped curved surface cover plate and flexible screen

The invention relates to a fitting device for a special-shaped curved-surface cover plate and a flexible screen. The fitting device comprises a fitting body for pressing a flexible screen, a support body and a tensioning mechanism for elastically connecting the two ends of the flexible screen to the bottom of the support body or the joint body; the fitting body is provided with an air bag shell and an elastic partition wall which is positioned on the inner side; the air bag shell is provided with a flat wall and a curved wall which are used for at least pressing a flat area or an end of an archook area of the special-shaped curved surface cover plate; the flat wall and the curved wall form a flat air cavity and a bending air cavity respectively with the elastic partition wall. The fittingdevice is provided with a flat air cavity and a bending air cavity, and the air cavity can be controlled respectively, on the one hand, the fitting device can effectively control the strength of thewhole fitting body in the non-inflatable state, maintain a good shape, and effectively control the deformation of the fitting body in the inflatable state, which is more conducive to the control of the fitting strength, so as to be more favorable for controlling the bonding force; on the other hand, the different areas of the flexible screen can be attached by step, so that the bonding effect is further improved. The invention also provides a fitting method.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

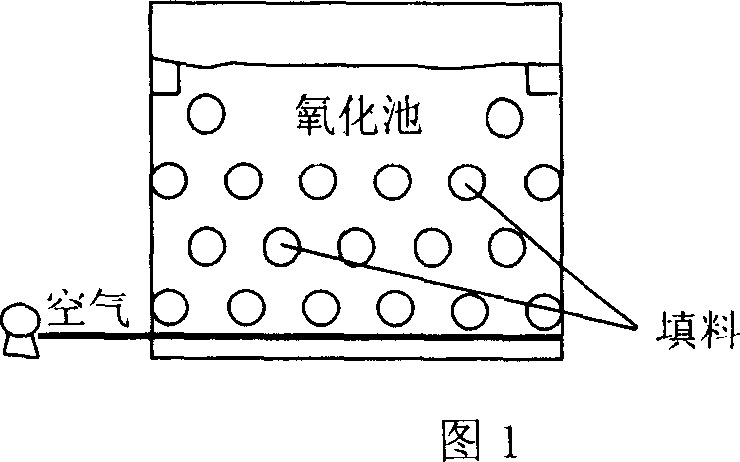

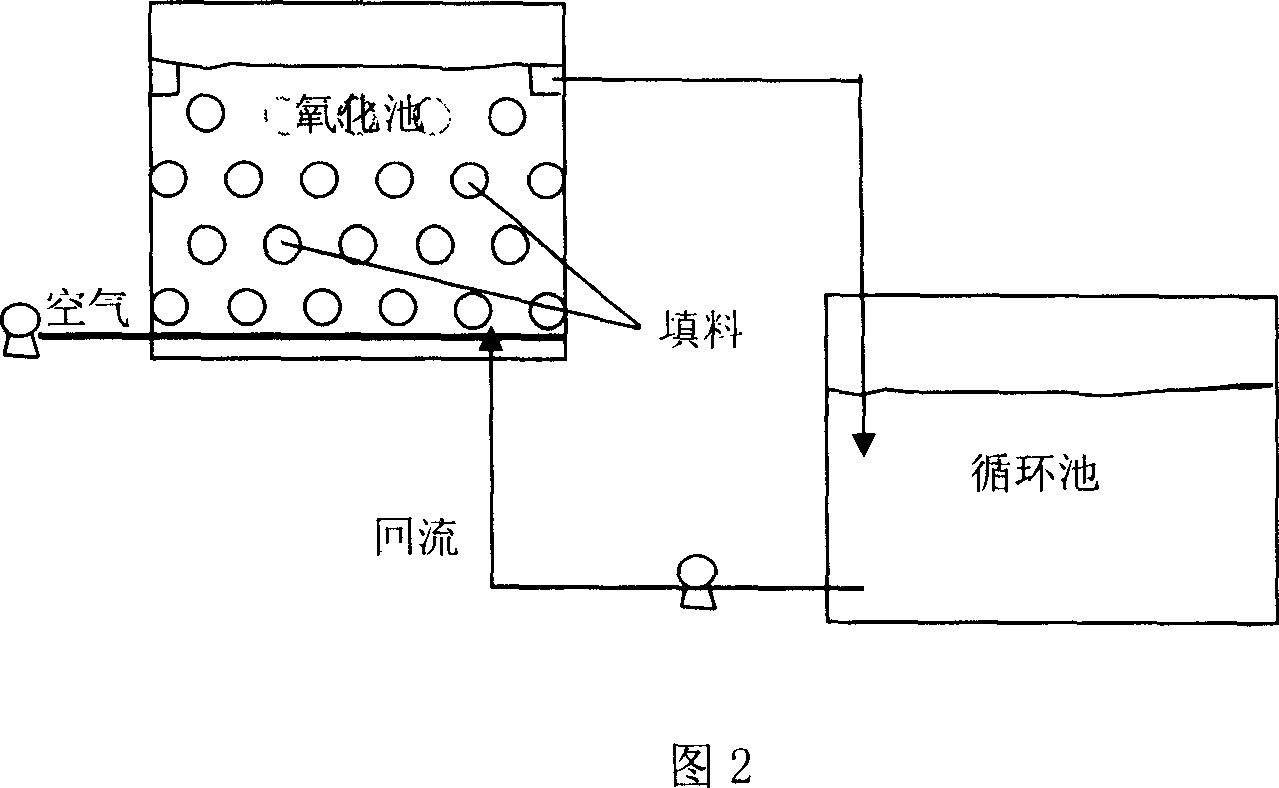

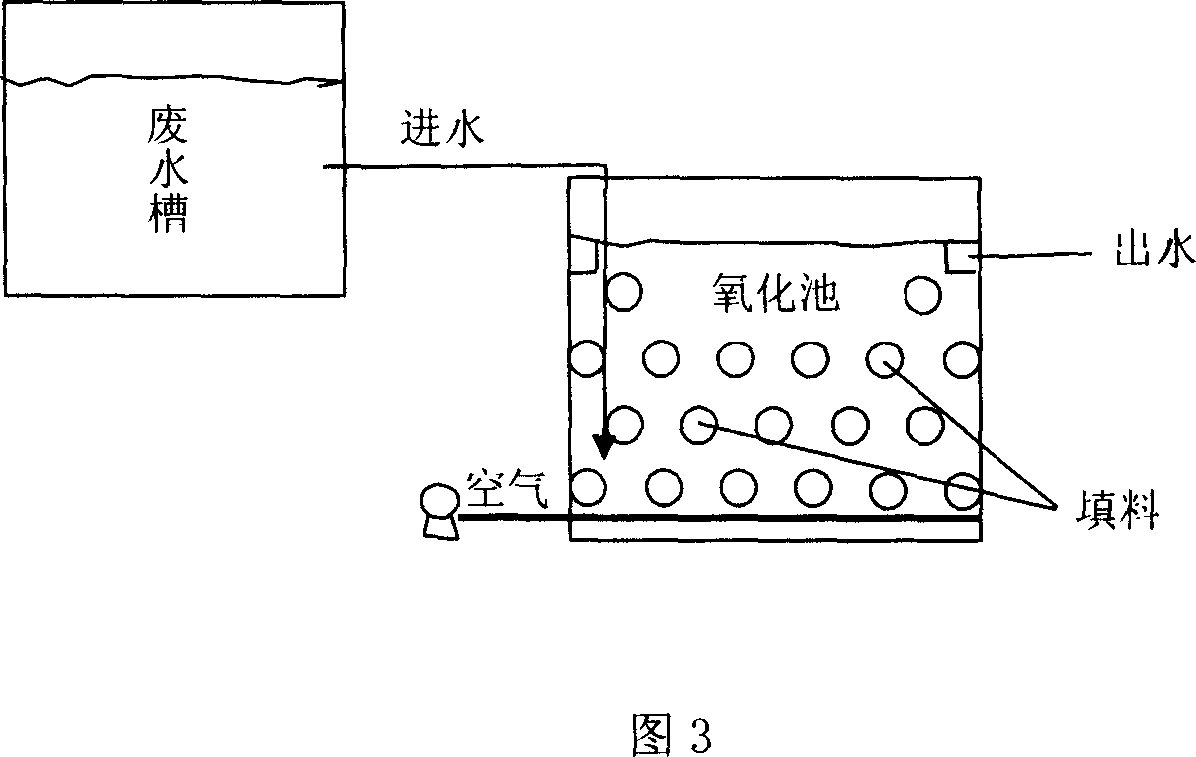

Film coating method of filling material in biological contact oxidation pond

ActiveCN101041507AIncrease microbial biomassFully attachedSustainable biological treatmentBiological water/sewage treatmentActivated sludgeHigh density

The invention discloses a suspending film method of filler in biological contact oxidation pond, which comprises the following steps: fistedly domesticating activated sludge; adding nutrient solution into domestic activated sludge and armed waste water miscible liquids; mixing evenly; injecting into oxidation pond; aerating; cycle culturing; making microbe adhere on carrier; stewing and settling span; discharging all of sludge water miscible liquids; proceeding waste water culture from low density to high density continually till forming stable shockproof biological film.

Owner:山西科腾环保新材料股份有限公司

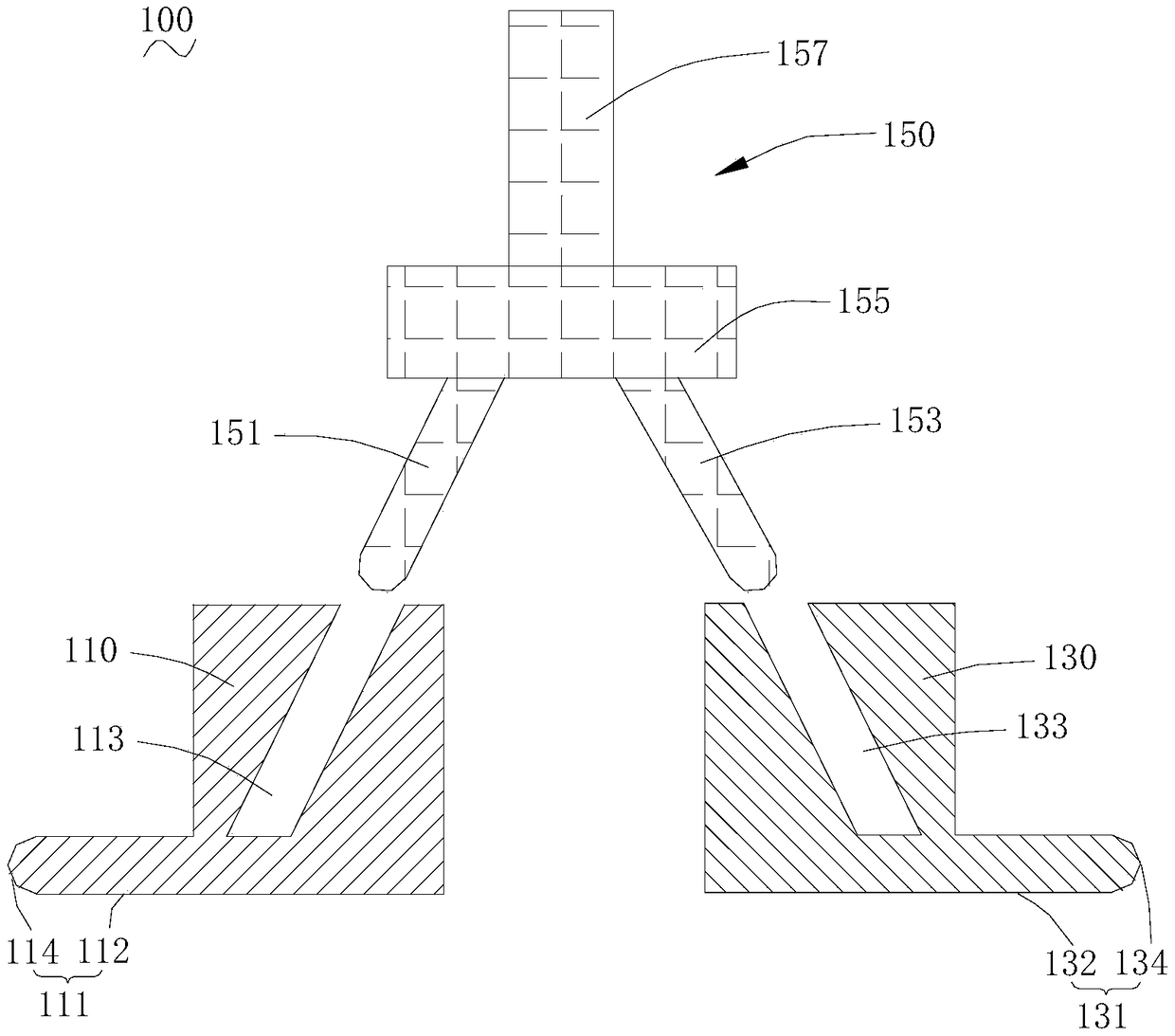

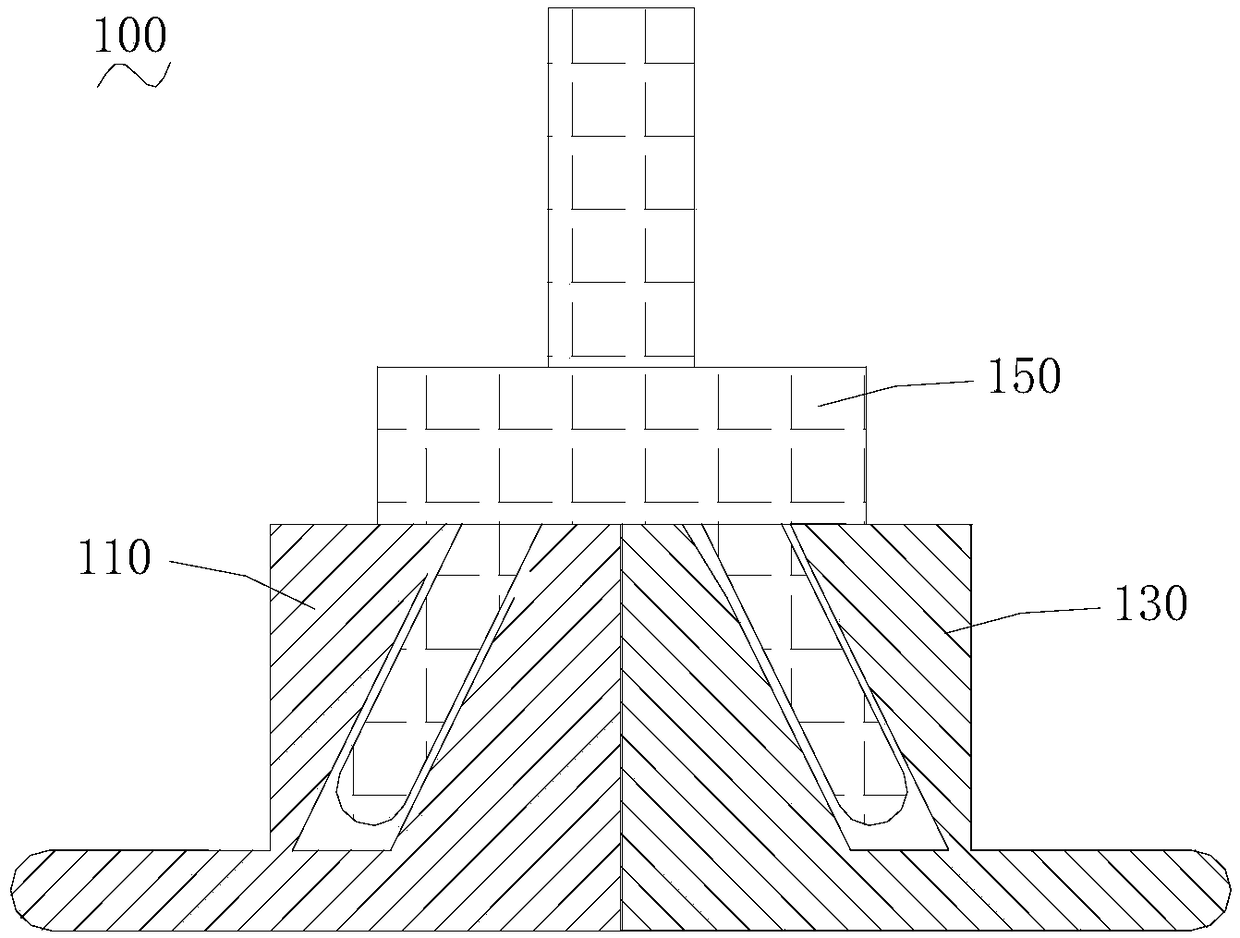

Fitting device and method for special-shaped curved surface cover plate and flexible screen

ActiveCN108615468AFully attachedImprove fitLamination ancillary operationsControlling laminationEngineeringSurface cover

The invention relates to a fitting device for a special-shaped curved surface cover plate and a flexible screen. The fitting device comprises a first fitting half for pressing one side of the flexiblescreen and a second fitting half for pressing the other side of the flexible screen, a movement driving component used to drive the first fitting half and the second fitting half to move in the leftand right direction. The periphery of the first fitting half has a first pressing wall, the first pressing wall includes a first bending wall and a first flat wall; the periphery of the second fittinghalf comprises a second pressing wall, the second pressing wall comprises a second bending wall and a second flat wall. The above-mentioned fitting device attaches different regions of the flexible screen step by step to fully attach the arc hook region of the irregular curved cover to further improve the fitting effect. The invention also provides a fitting method.

Owner:YUNGU GUAN TECH CO LTD

Inflatable protective home barrier

InactiveUS7866101B2Rapid deploymentFirmly attachedRoof covering using tiles/slatesTents/canopiesFire protectionEase of Access

A fire protection system for homes and other structures including a pliable multi-layered shroud of fire-resistant material having an inflatable support structure embedded therein. The inflatable support structure includes a web of inflatable channels for rapid deployment from a folded configuration to an inflated configuration in which the fire-resistant material partially envelops a structure. The shroud is packed in an enclosure having a bi-fold top panel for ease of access. The enclosure also has one or more air hose couplings to which the inflatable support structure is connected for rapid inflation and deployment out of the enclosure. A plurality of tethers are also provided as tie-downs, which anchor the heat resistant shroud. The system affords ample rapid deployment protection from neighboring fires and heat exposure therefrom.

Owner:BOGGS JR PATRICK H

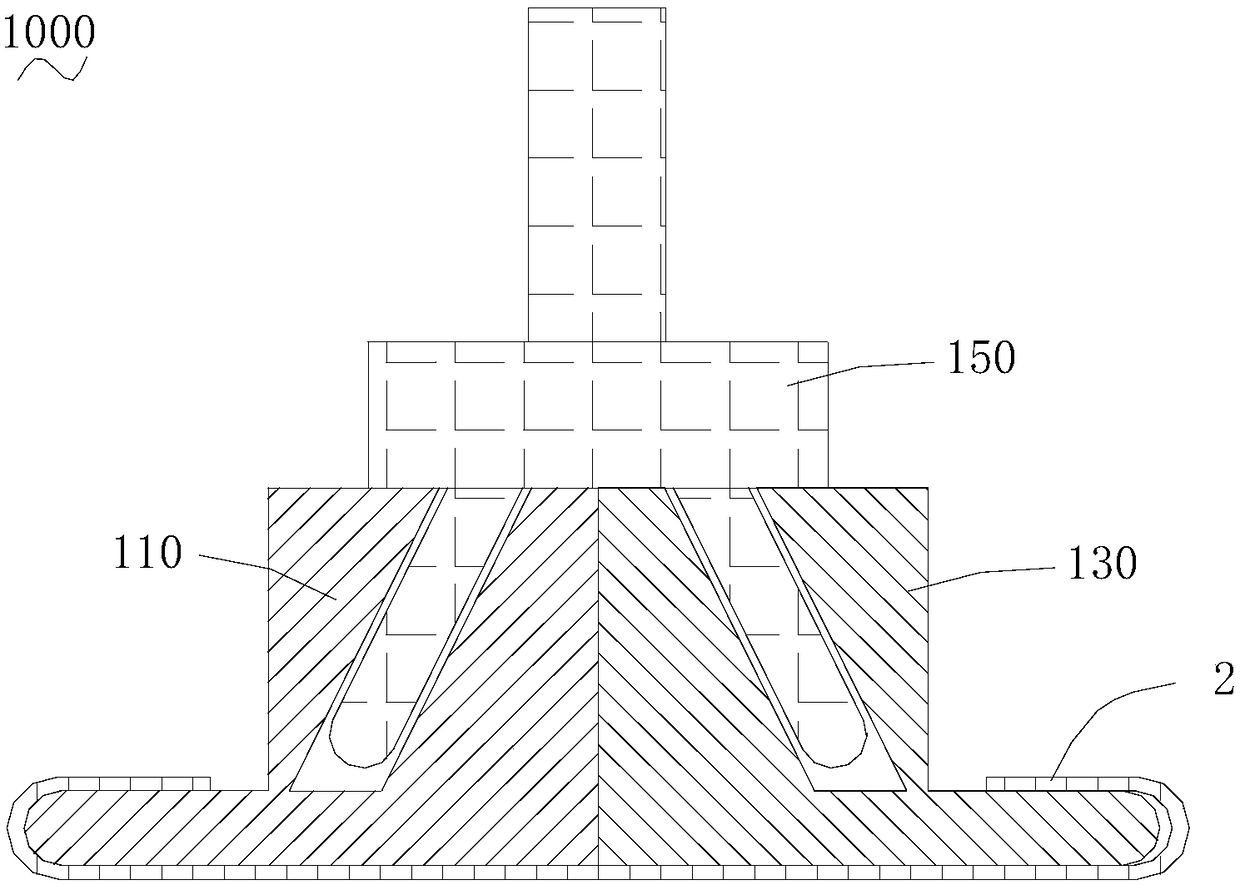

Fitting device and method for special-shaped curved surface cover plate and flexible screen

ActiveCN108615465AFully attachedAvoid interferenceLaminationLamination apparatusEngineeringSurface cover

The invention relates to a fitting device and a fitting method of a special-shaped curved surface cover plate and a flexible screen. The fitting device comprises a fitting body for pressing the flexible screen; the fitting body comprises an adsorption unit for adsorbing the flexible screen, wherein the adsorption unit comprises a plurality of sub-adsorption units arranged at intervals; a variablesize expansion unit, the variable size expansion unit includes a plurality of sub-expansion units arranged at intervals; wherein the adsorption unit and the expansion unit are jointly formed with a pressing surface which is matched with the shape of the inner surface of the special-shaped curved-surface cover plate; the expansion unit includes a conventional state in which the pressure surface size is smaller than the size of the special-shaped curved-surface cover plate, and an expansion state in which the pressure surface size is matched with the size of the special-shaped curved-surface cover plate. The above-mentioned fitting device for the special-shaped curved surface cover plate and the flexible screen is provided with a plurality of sub-adsorption units which are arranged at intervals used for adsorbing the flexible screen; and when the expansion unit is in the expanded state, the pressing surface is pressed to the flexible screen so as to be fully attached, and the fitting effect is further improved.

Owner:YUNGU GUAN TECH CO LTD

Stereoscopic surface woodgrained ceramic tile, stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and decoration technology

InactiveCN109291723AGood printing performance and firing performanceEasy to operateSpecial ornamental structuresCalciteCeramic glaze

The invention relates to a stereoscopic surface woodgrained ceramic tile, a stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and a decoration technology. The ceramic tile is composed of a green body layer, a cover glaze layer, an emboss effect glaze layer, a pattern decoration layer and a surface protective glaze layer which are sequentially compounded. The stereoscopic surface woodgrained ceramic tile emboss effect glaze layer comprises the following materials including, by weight, 2.5-3 parts of zinc oxide, 20-30 parts of feldspar, 15-20 parts of frit, 10-12 parts of washed kaolin, 8-10 parts of calcite, 8-10 parts of burning talc and 20-30 parts of home-made quartz. The decoration technology comprises the steps that (1) long-strip-shaped green bodies are obtainedby pressing woodgrained brick powder, the surfaces of the green bodies are coated with cover glaze, and formulated emboss effect glaze materials are printed on the surfaces of the green bodies, coatedwith the cover glaze, in a rubber covered roller engraving mode; (2) decoration is performed by means of ink jet patterns, and the ink jet patterns cover the glaze surface and the printed emboss effect glaze on the whole; and (3) the green bodies are coated with clear protective glaze, and then kiln firing is performed.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

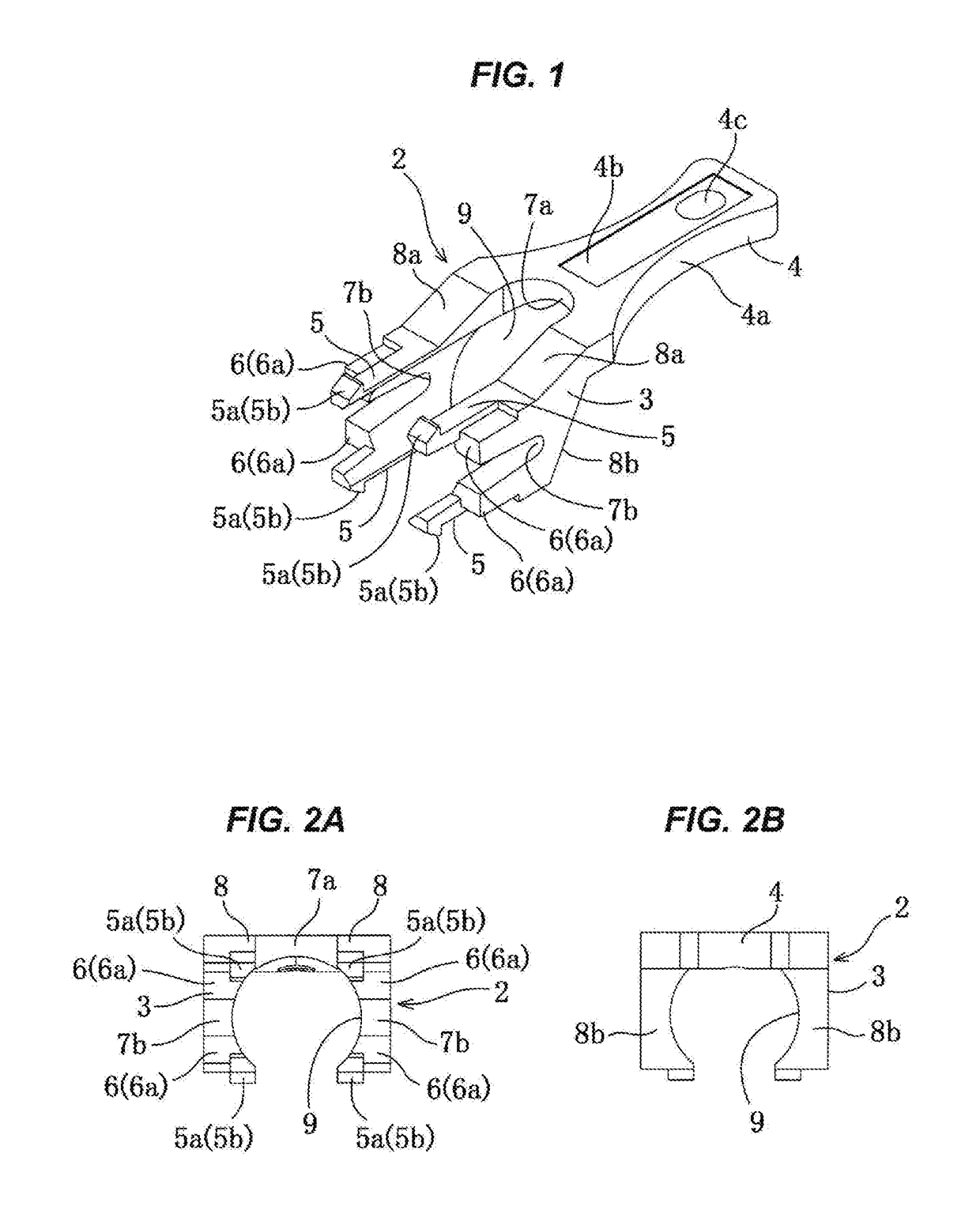

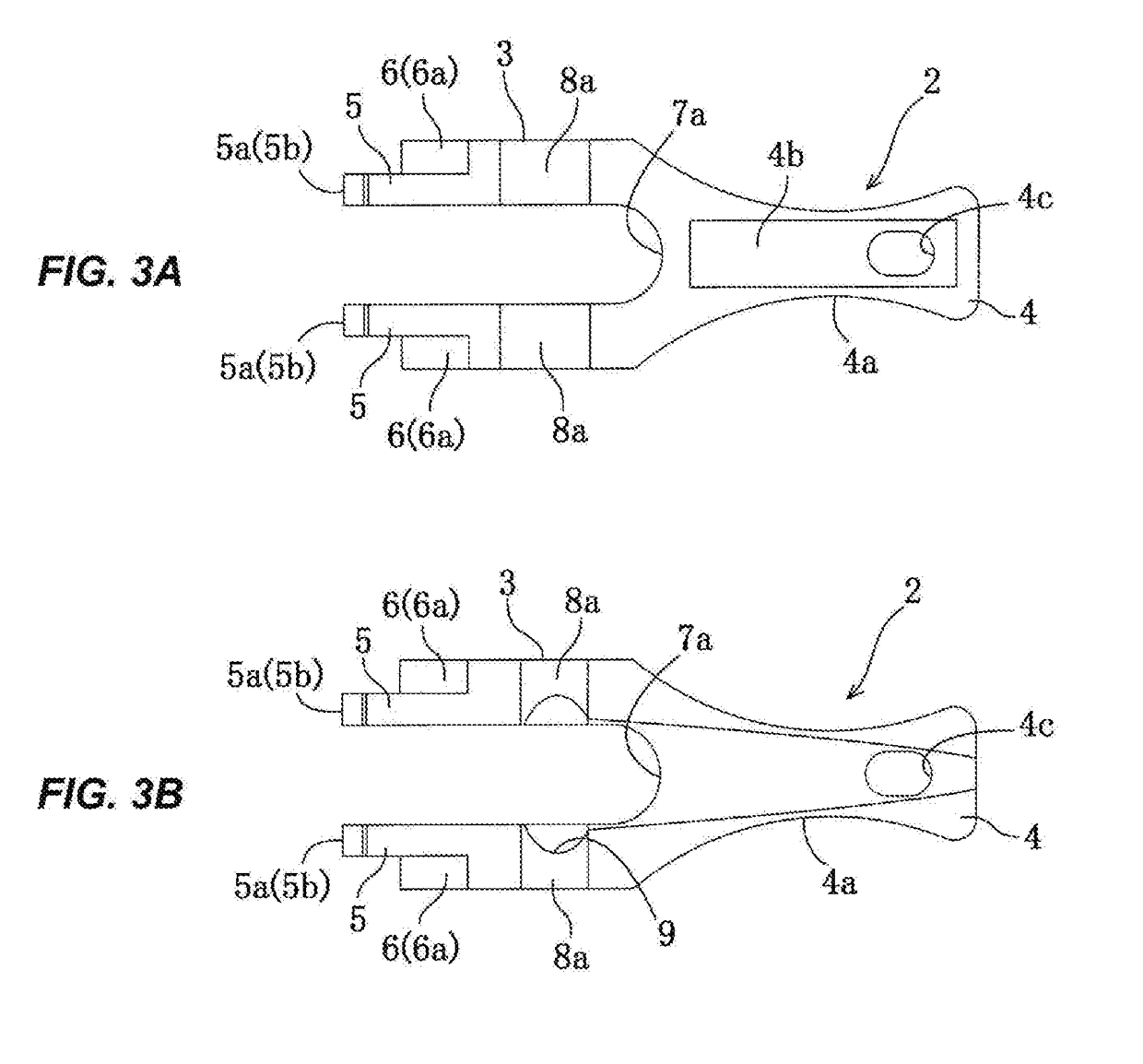

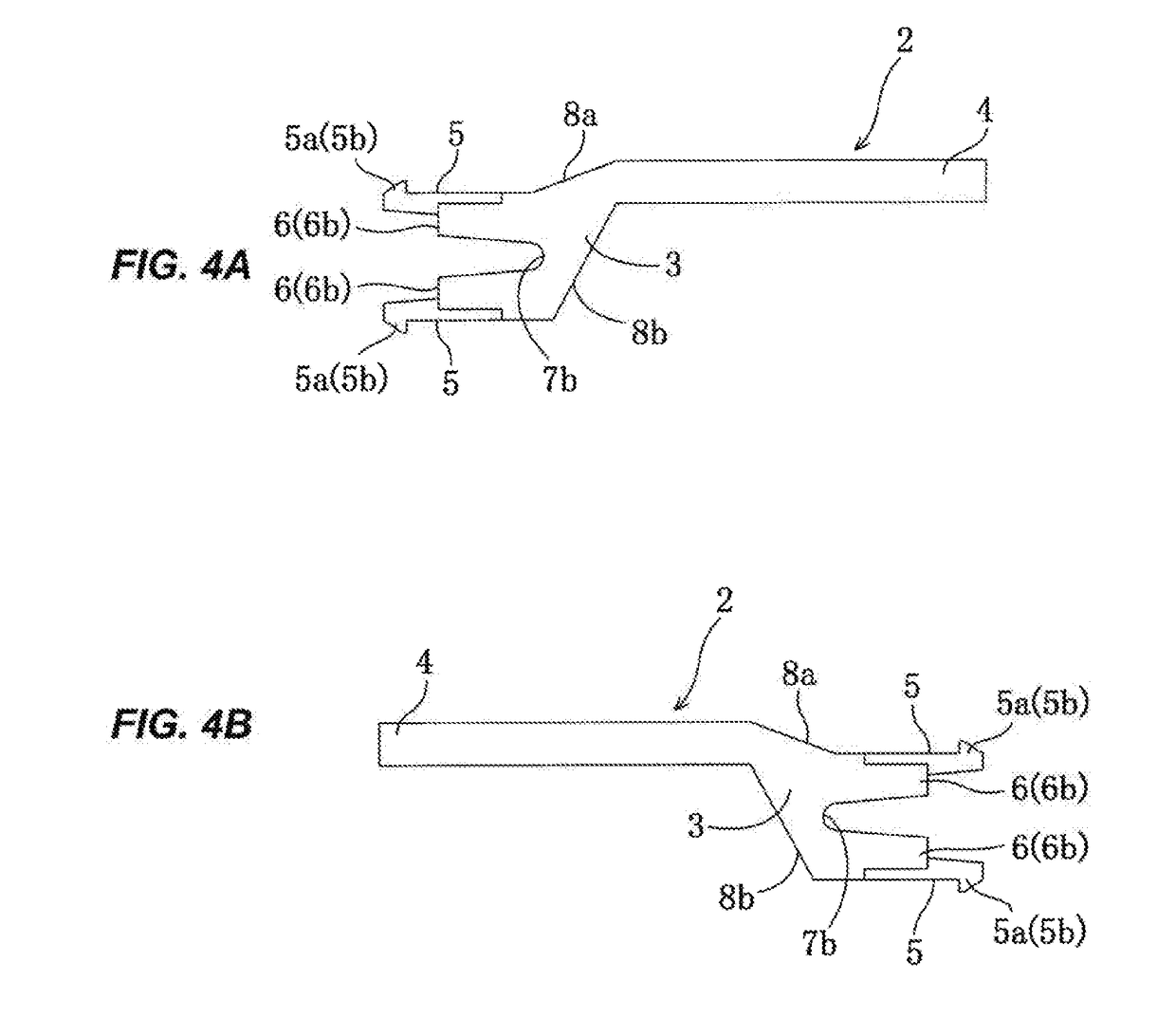

Tab for optical connector

Provided is a tab (2) including operating member (3) which is provided with an engaging part (5a) at a tip of a plurality of arms (5) so as to detachably attach and hold in each of a plurality of engaging holes (13a) formed at the rear end of a coupling (13), and gripping member (4) which is extendingly provided from the back of the operating member (3), wherein the coupling (13) advances and retreats 3 with respect to a housing (18) by an operation of the operating member (3) in association with the advance and retreat of the gripping member (4), and forward pressing or backward pressing of the plug body (1) is released.

Owner:SANWA DENKI KOGYO KK

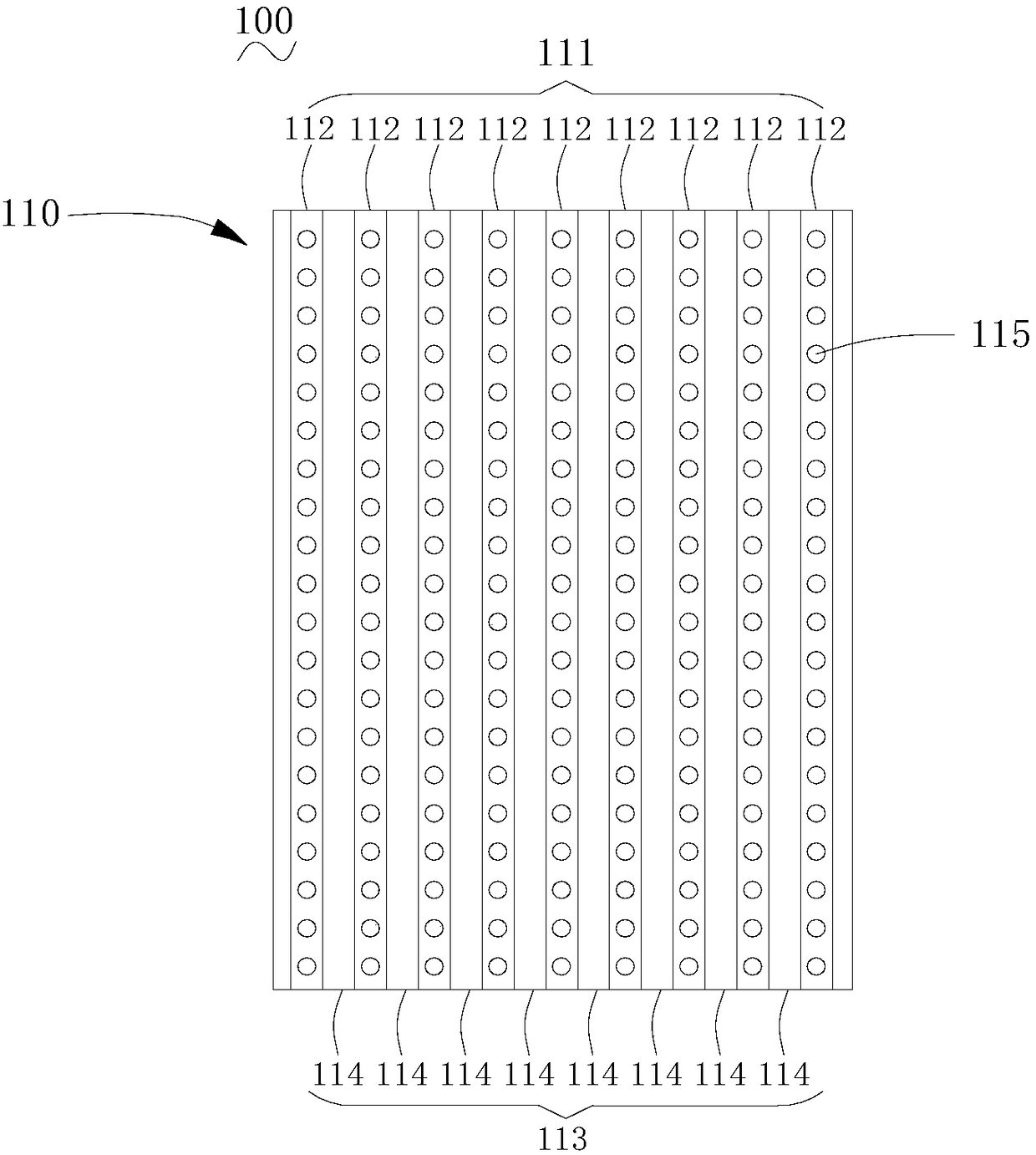

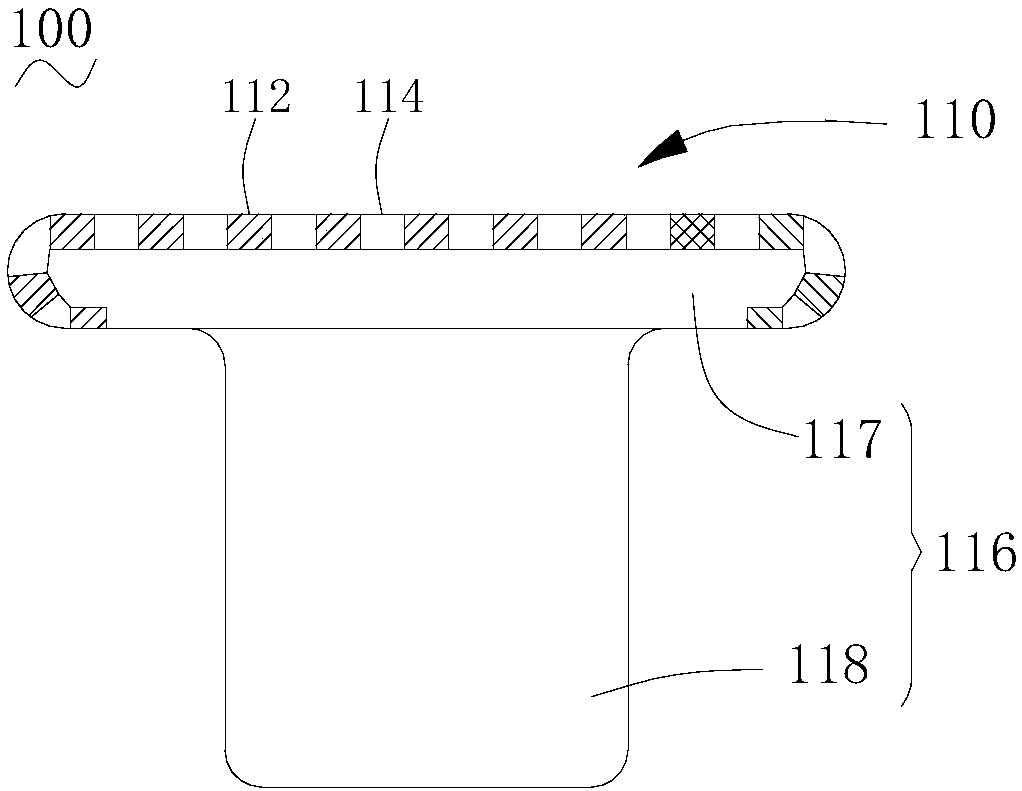

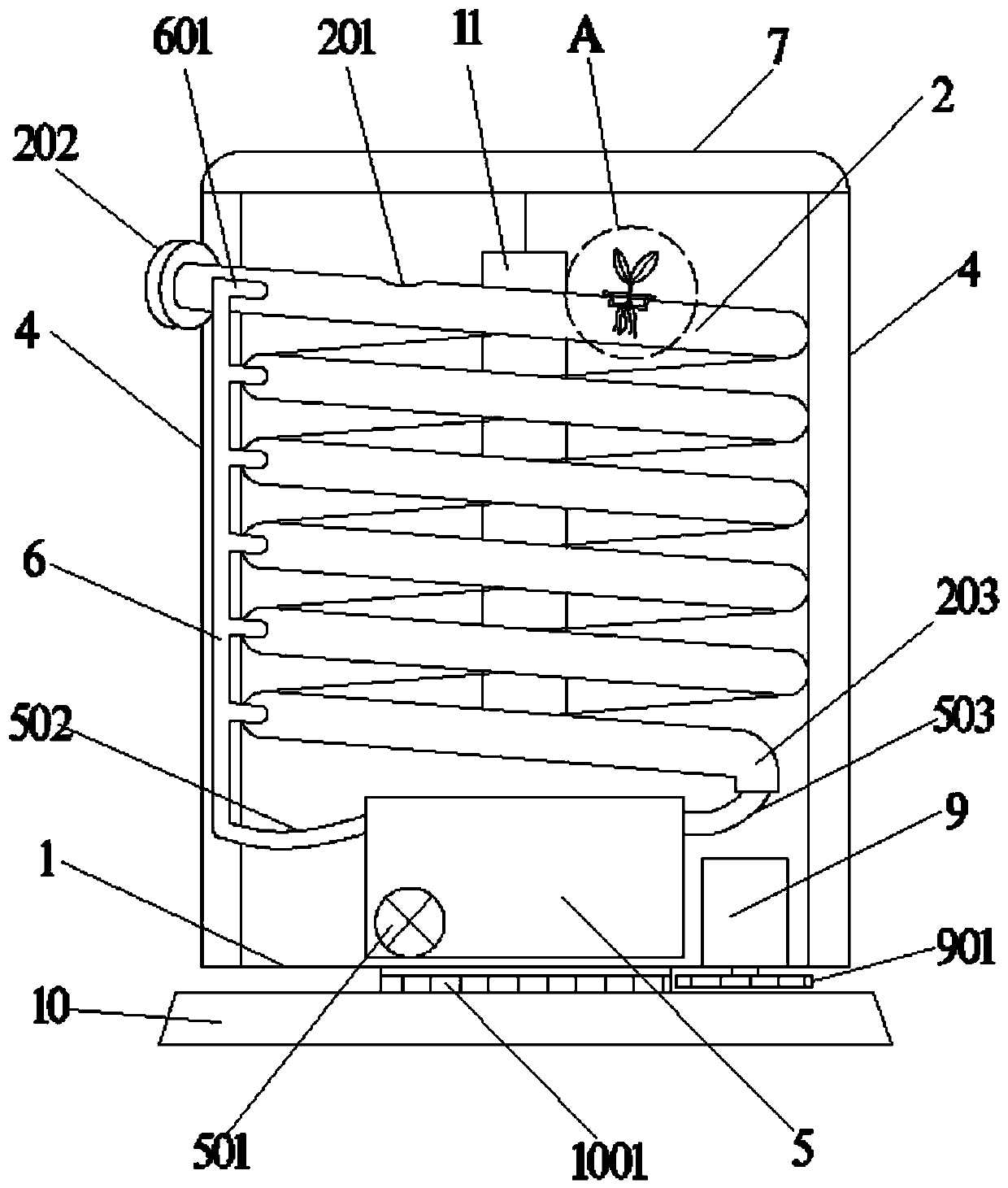

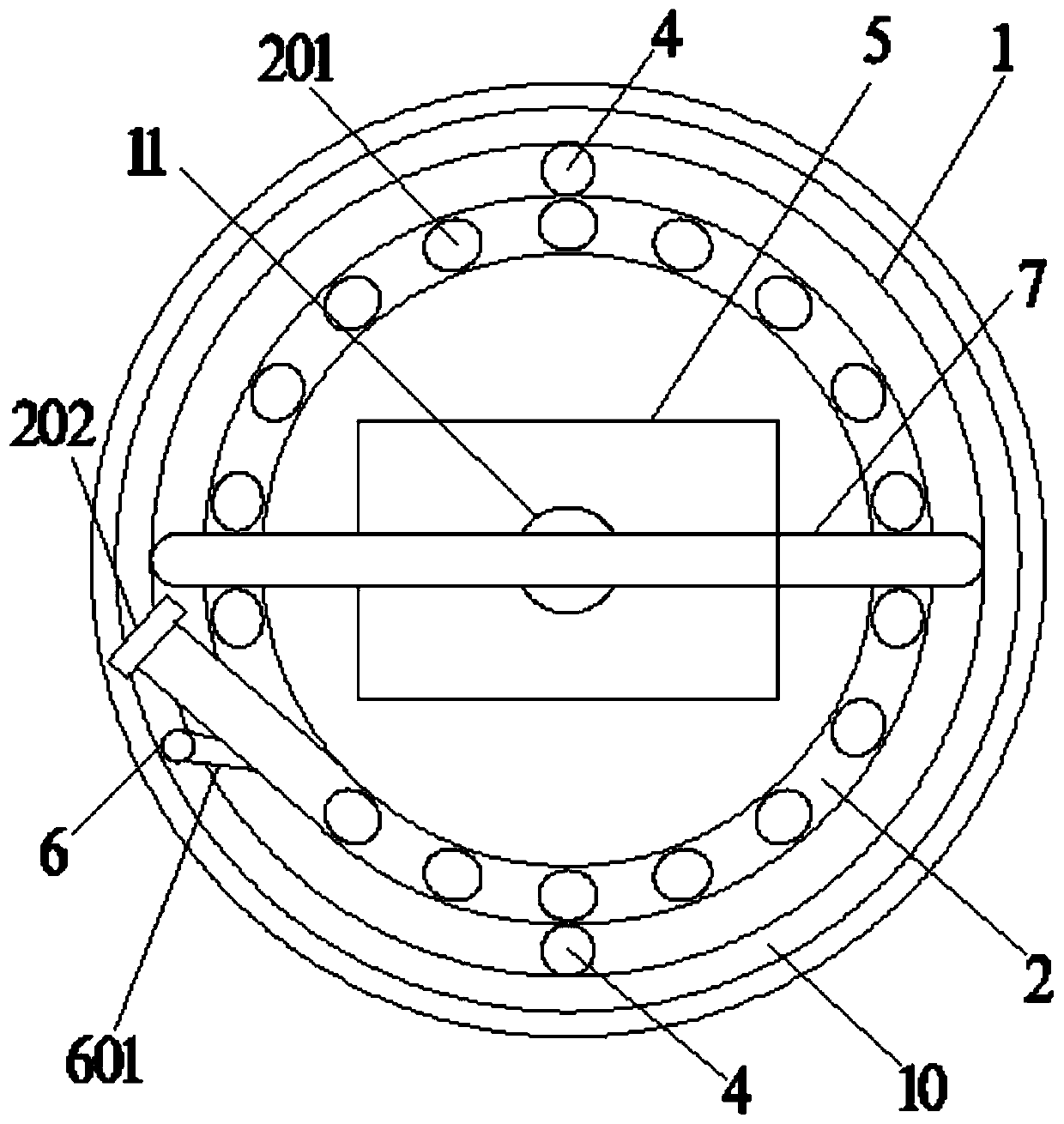

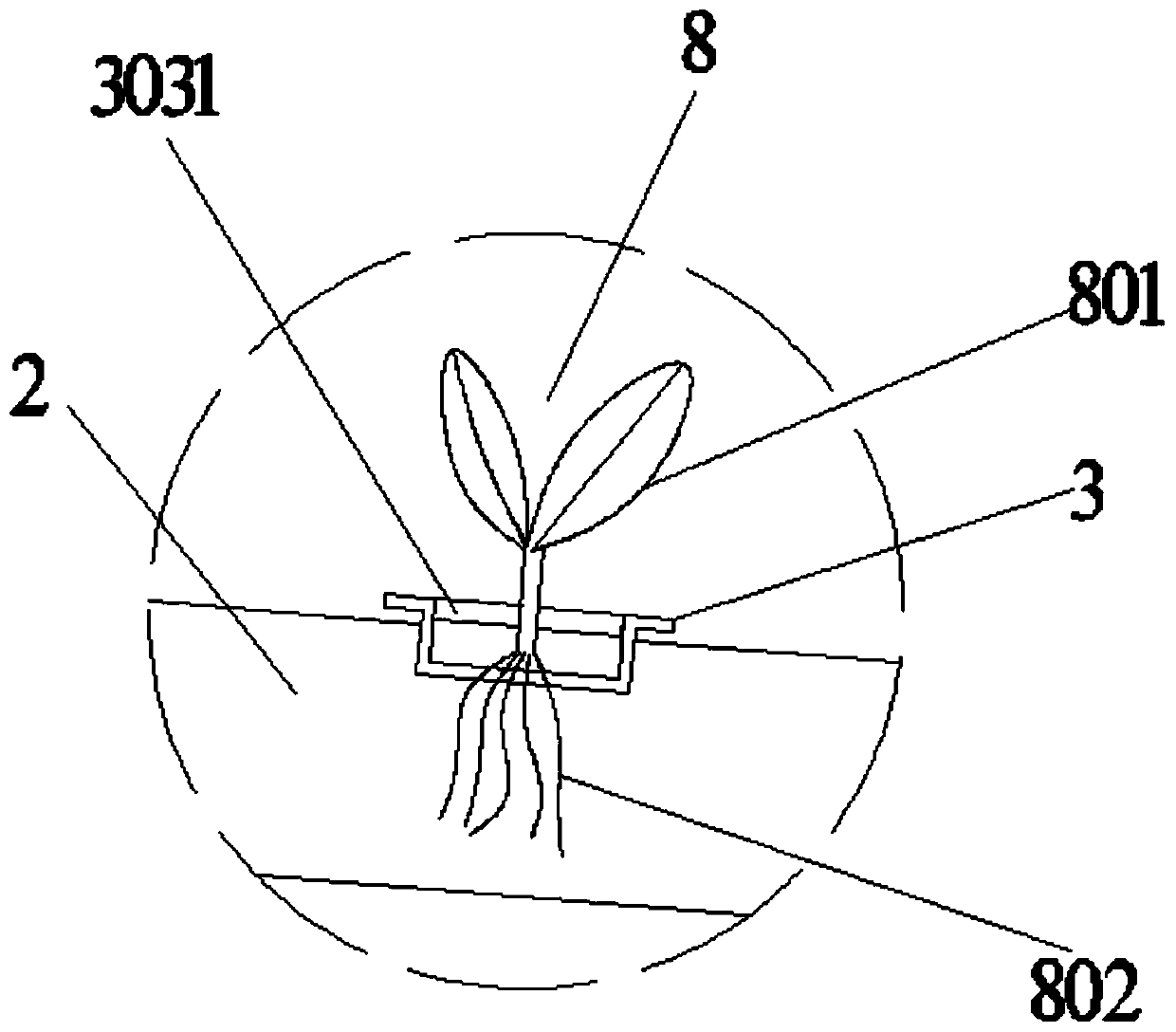

Aerosol cultivation device

InactiveCN110226509AIncrease profitFully attachedAgriculture gas emission reductionCultivating equipmentsPlant rootsNebulizer

The invention discloses an aerosol cultivation device, and belongs to the technical field of waterless cultivation equipment. The aerosol cultivation device in the technical scheme is characterized inthat multiple cultivation openings distributed at the same distance are formed in a spiral cultivation pipeline and used for placing field planting cups, cultivated plants can be placed in the corresponding field planting cups, multiple plants can be cultivated maximally in a certain floor area, a nutrient solution is atomized by an ultrasonic atomizer in the device and then input into the spiralcultivation pipeline through air distribution branch pipes, nutrient solution aerosol is enabled to be attached to the plant roots and wet the plant roots when flowing in the spiral cultivation pipeline, and the roots of each plant can be sufficiently wetted by the flowing-in nutrient solution through the narrower pipeline; besides, a rotating base tray is arranged below the device and can rotateto allow each plant to be illuminated when the sunlight is sufficient, and a light supplementing lamp is arranged in the middle of the spiral cultivation pipeline and supplements light to the plantswhen the natural illumination is insufficient; compared with a relatively traditional mode, the device has the advantages that the plant lighting effect is improved, the nutrient solution is sprayed to the plant roots more comprehensively, and the utilization rate of the nutrient solution is higher.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

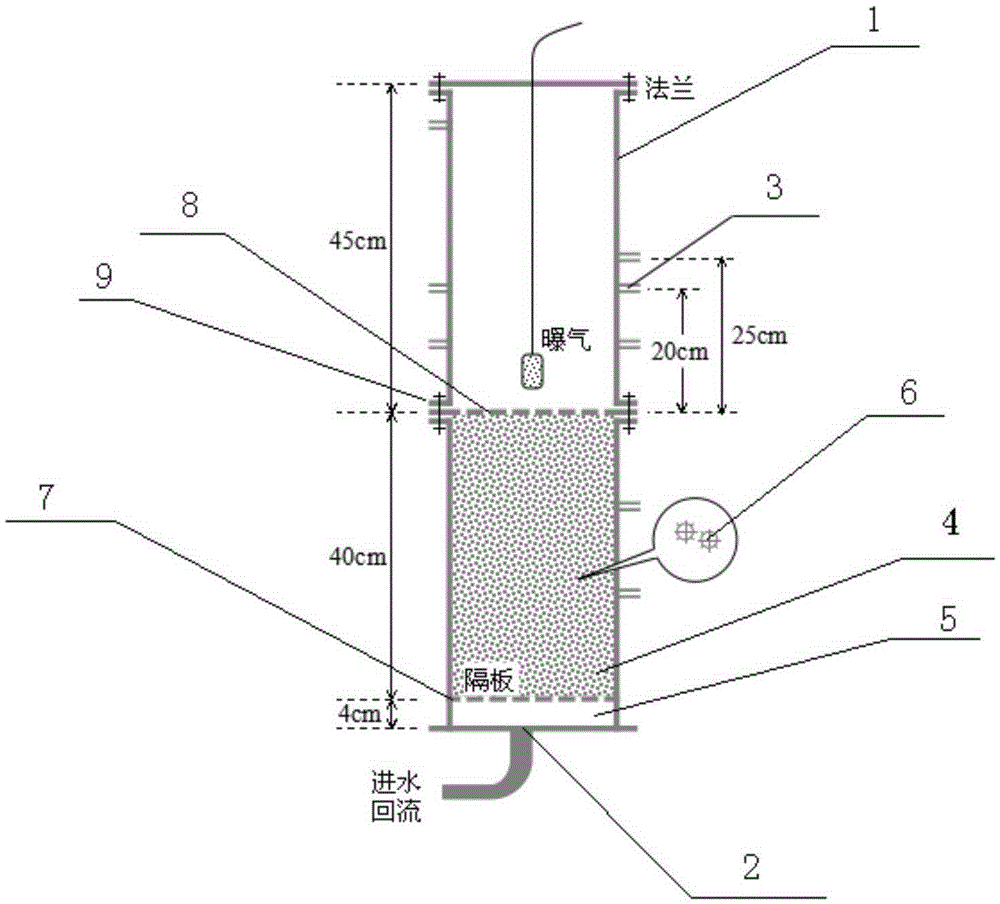

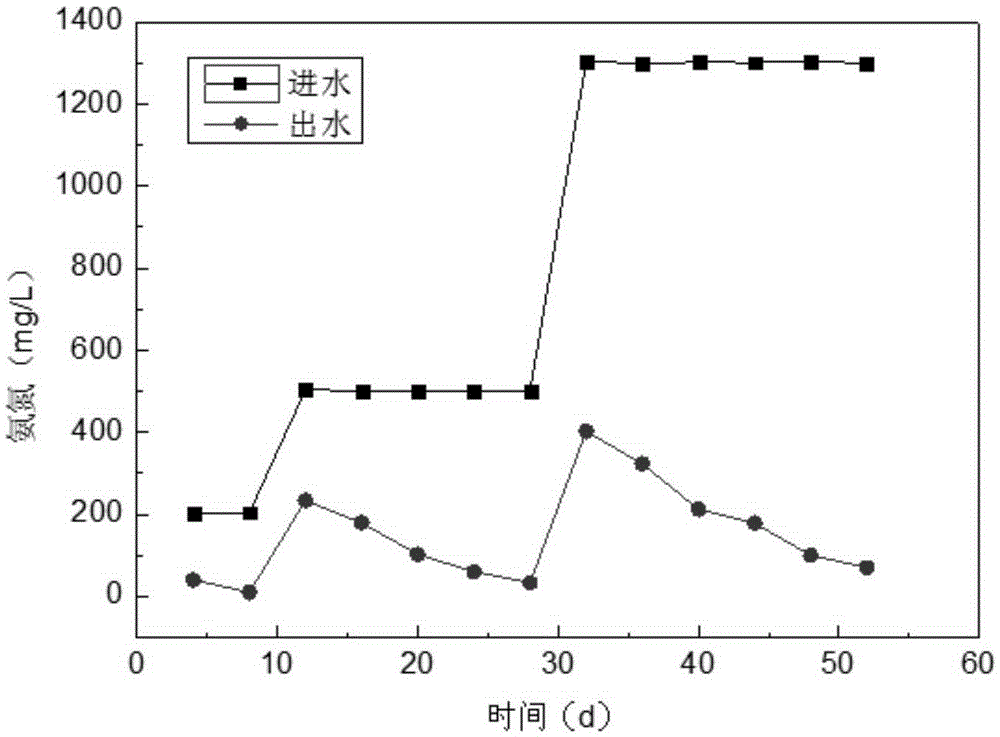

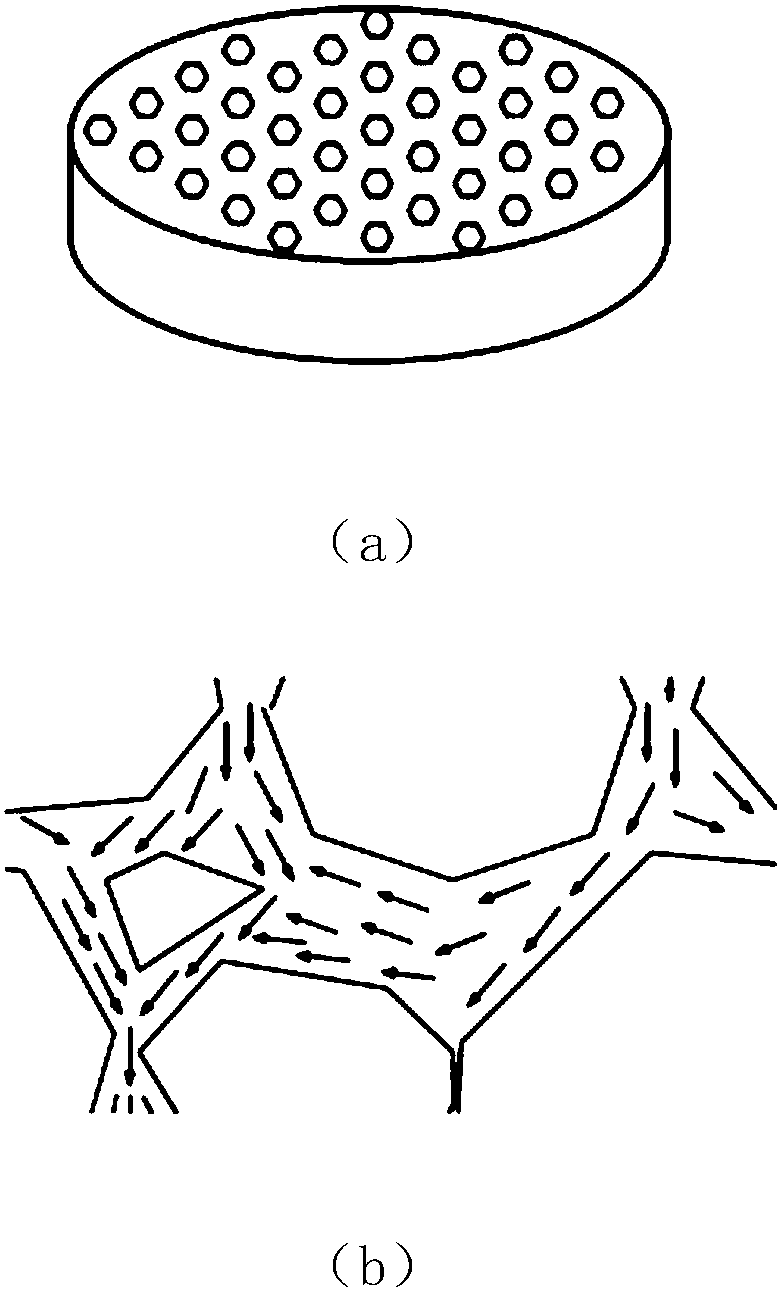

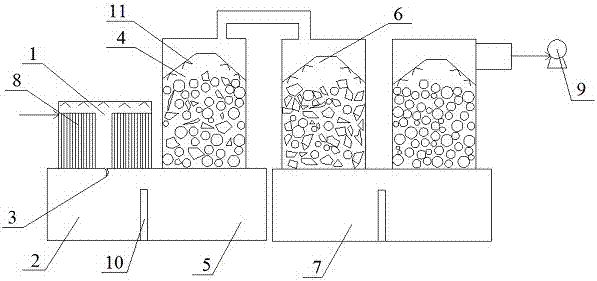

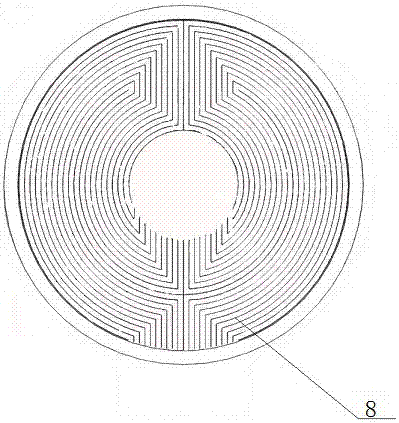

Reactor capable of quickly starting anaerobic ammonia oxidation coupling nitrosation reaction and quick-start method

ActiveCN105254011AFully attachedAvoid churnTreatment with aerobic and anaerobic processesPorosityStart time

The invention relates to a reactor capable of quickly starting an anaerobic ammonia oxidation coupling nitrosation reaction and a quick-start method. A gravel layer is laid at the bottom inside the reactor, a lower partition board provided with holes is arranged on the gravel layer, a filler layer is arranged on the lower partition board, gaps are formed inside the filler layer, the porosity of the filler layer ranges from 0.6 to 0.8, the thickness of the filler layer accounts for 2 / 5-1 / 2 the height of the reactor, and an upper partition board provided with holes is arranged at the top of the filler layer. By means of the reactor, an aerobic zone and an anaerobic zone can be separated, synchronous nitrification and anaerobic ammonia oxidation reactions are started quickly, and nitrogen-containing waste water can be efficiently treated. By means of the reactor, sludge can be attached to filler and fixed to the lower layer of the reactor, sludge loss can be prevented, partition of an aerobic layer and an anaerobic layer is effectively achieved, starting time of an anaerobic ammonia oxidation coupling nitrosation process can be effectively shortened, the process flow is simplified, and the operation is simple.

Owner:山东美泉环保科技有限公司

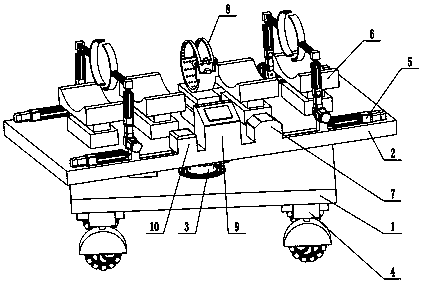

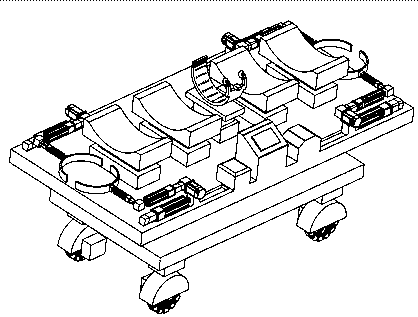

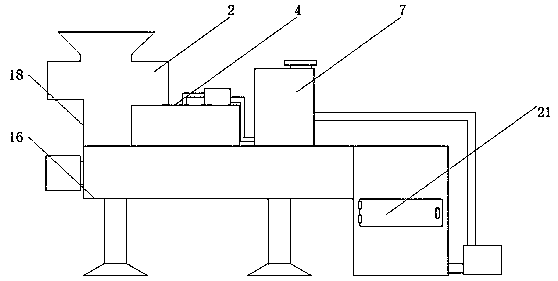

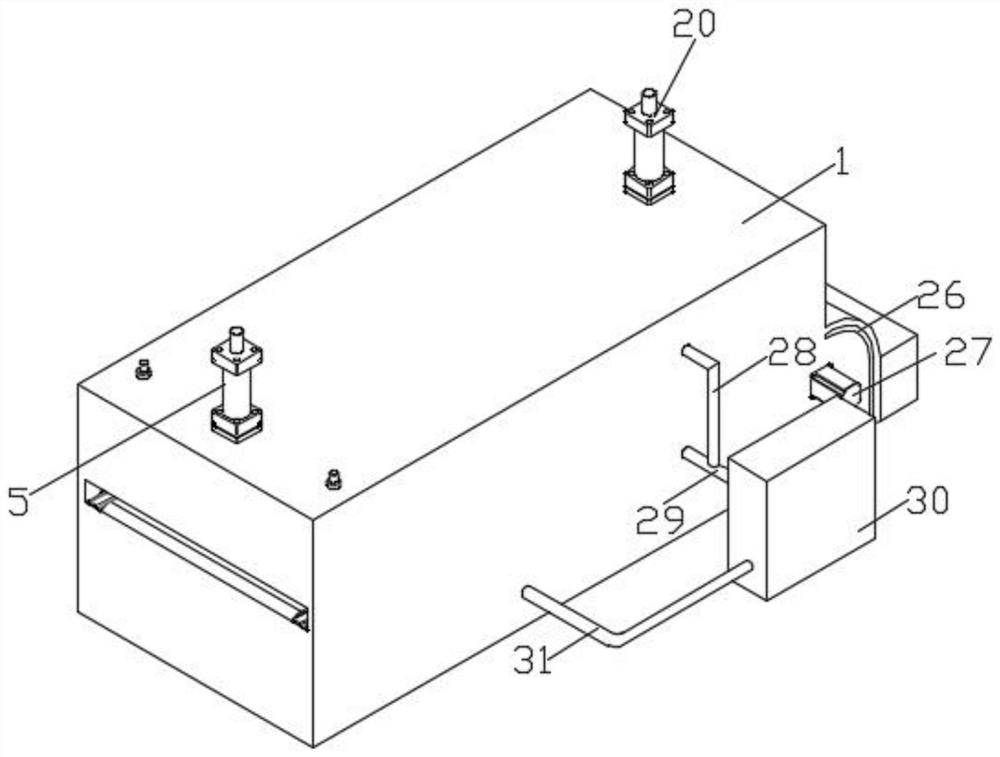

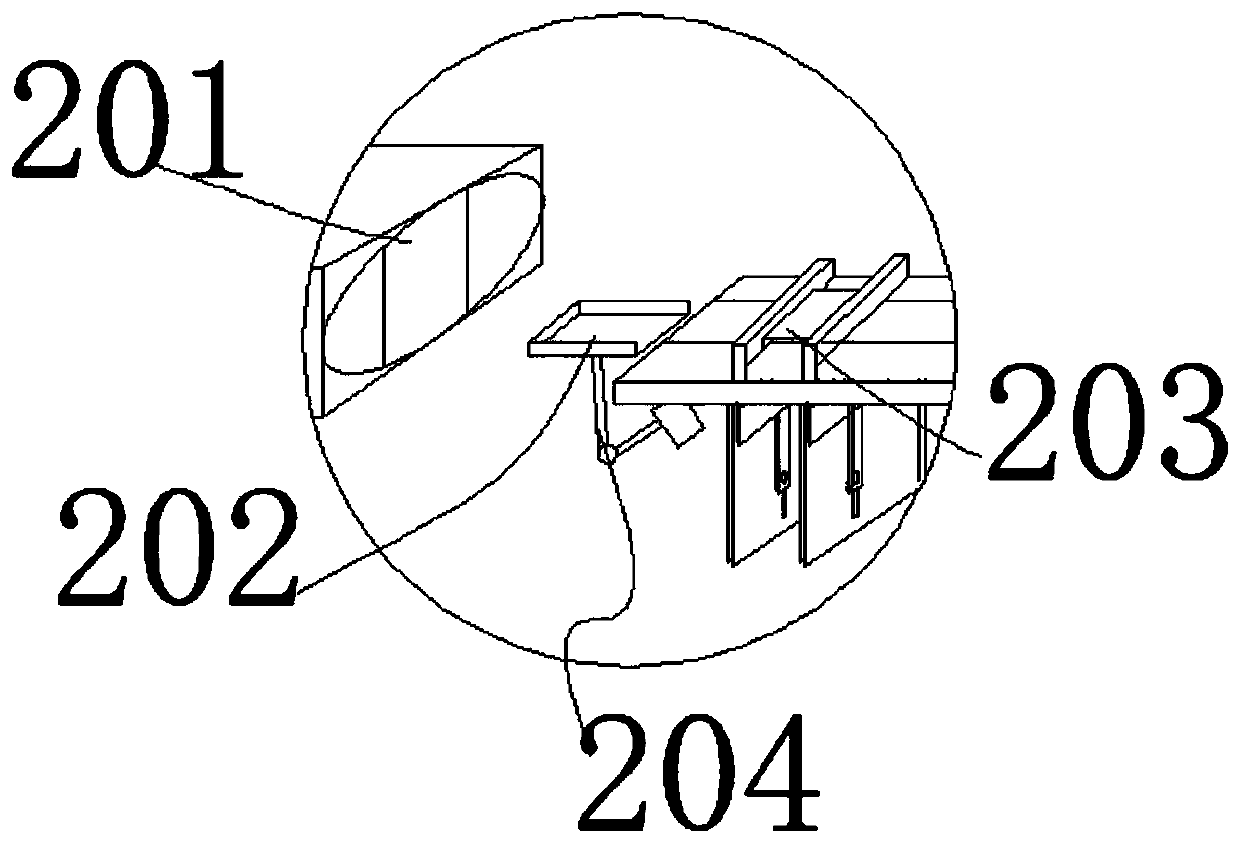

Automatic hot melting welding machine and welding method

ActiveCN110315763AHigh degree of visualizationEasy to operatePipe connection arrangementsComputer moduleEngineering

The invention provides an automatic hot melting welding machine. The automatic hot melting welding machine comprises an upper bottom plate, a clamping unit, a supporting unit and a fixing devic, wherein the clamping unit is arranged on the upper bottom plate, the supporting unit is arranged on the upper bottom plate, the fixing device is arranged on the upper bottom plate and is positioned in themiddle of the supporting unit, a hot melting welding machine body and a console are arranged on the upper bottom plate, a controller is arranged in the console, a hot melting sleeve is attached to a pipeline to be welded through the fixing device, the hot melting welding machine is controlled to heat the hot melting sleeve through the console, the controller comprises an SSR, an SCR, a PLC and anAD acquisition module, and voltage and current signals are correspondingly collected, converted, displayed and heated and controlled through the SSR, the SCR, the PLC and the AD acquisition module. According to the automatic hot melting welding machine, a motor which is internally arranged in an upper arc plate is used for driving a gear C to rotate so as to drive the upper arc plate to slide in asliding groove A of a lower arc plate, and then the hot melting sleeve is driven to carry out complete sleeving on the pipeline to be welded.

Owner:TIANJIN JINENG PIPE

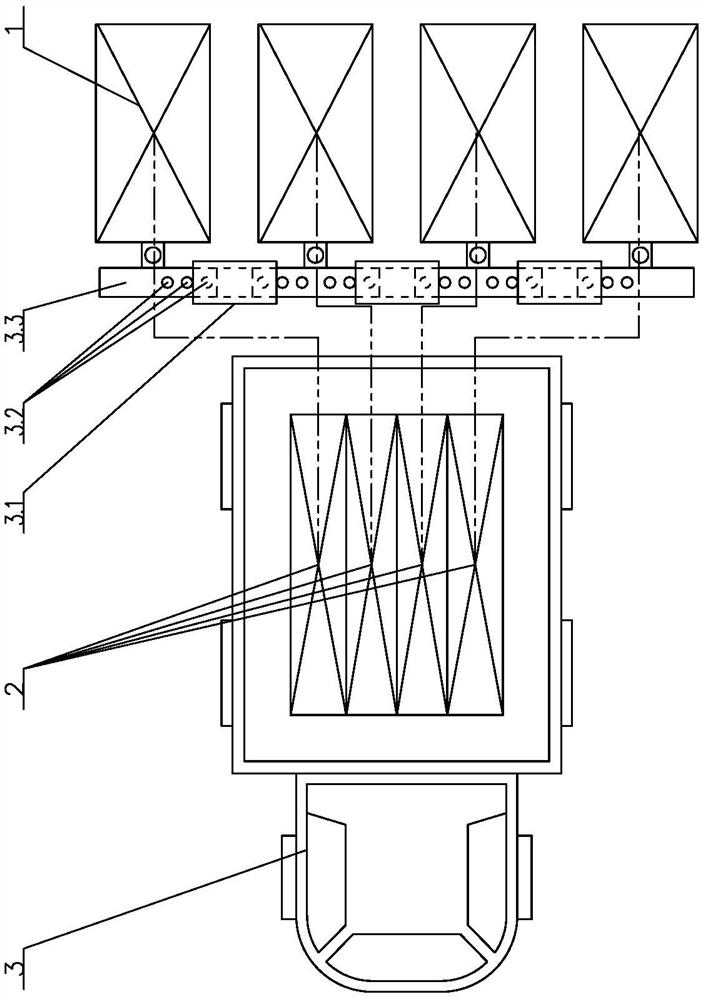

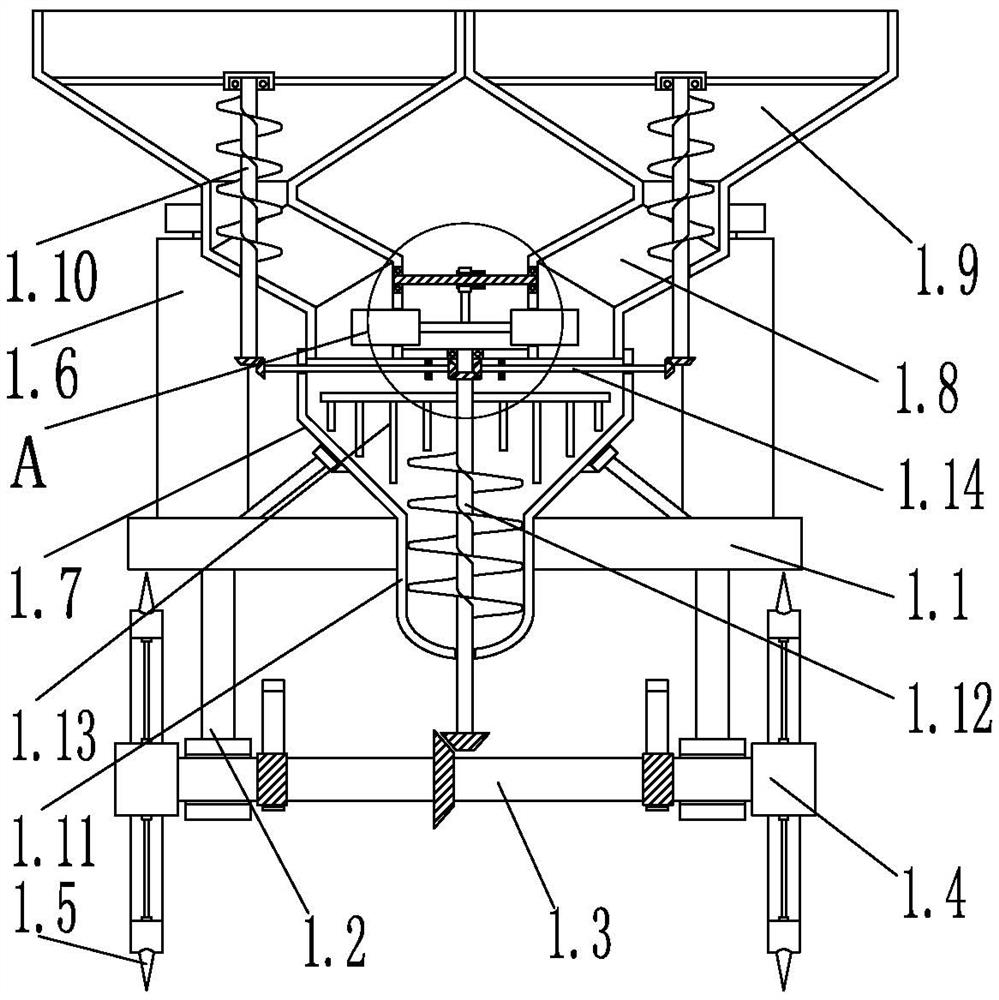

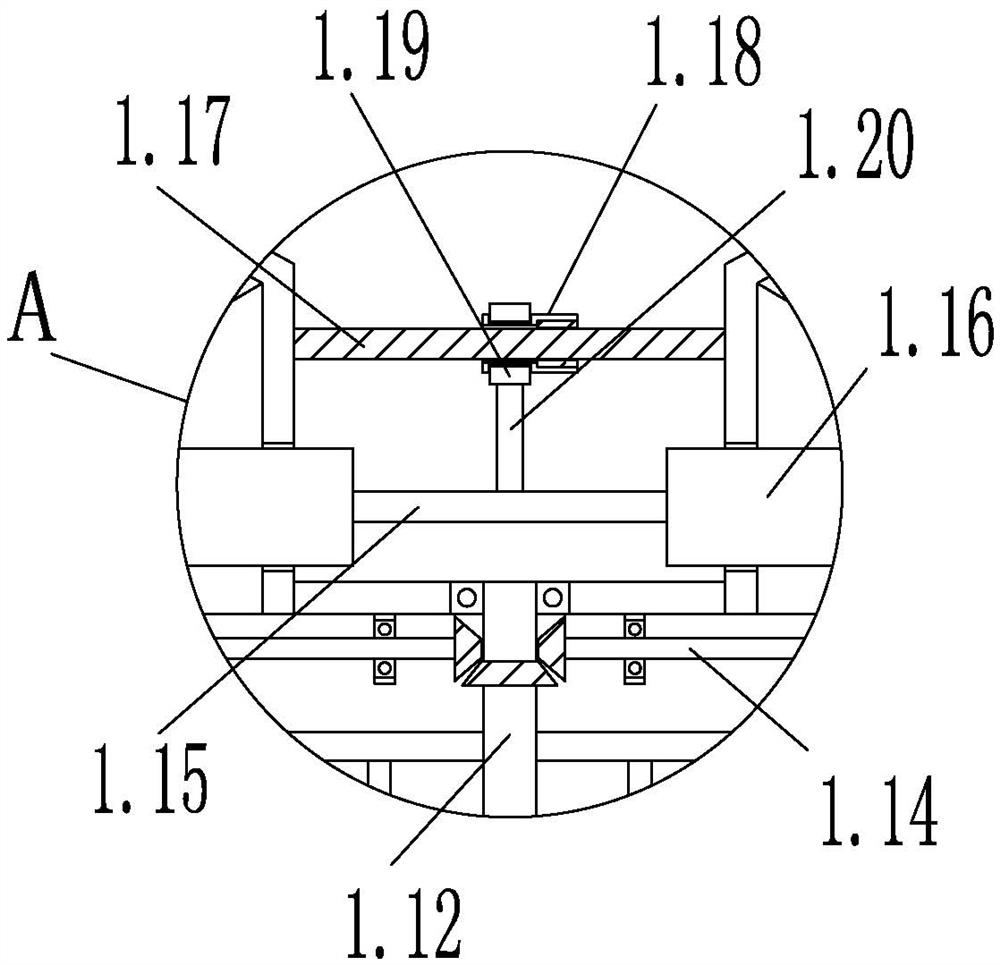

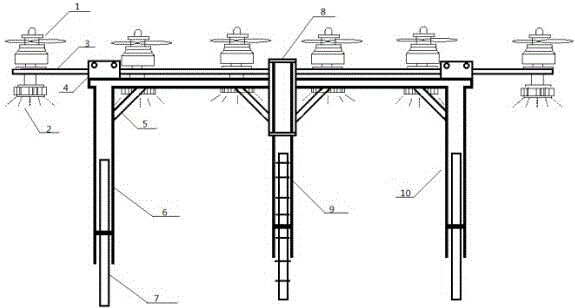

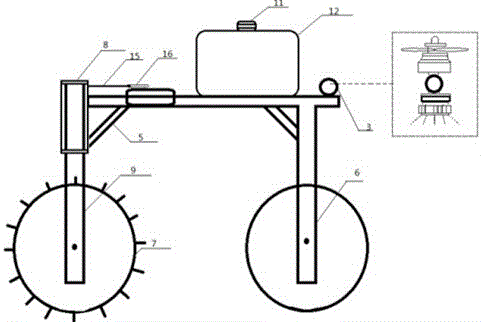

Mixed planting integrated sowing equipment of ensiled Zea mays L. and Glycine max (Linn.) Merr., and mixed planting method

ActiveCN112913376ASow evenlyGood energy saving effectRegular seed deposition machinesGrain treatmentsSeederAgricultural engineering

The invention discloses mixed planting integrated sowing equipment of ensiled Zea mays L. and Glycine max (Linn.) Merr., and a mixed planting method, and belongs to the technical field of ensiled Zea mays L. and Glycine max (Linn.) Merr. planting. The mixed planting integrated sowing equipment is characterized by comprising fertilizer smashing, vibrating and sieving equipment, a sower installation traverse frame and at least two groups of sower bodies, wherein the sower installation traverse frame is horizontally fixed on the rear part of an agricultural vehicle, each group of sower bodies is horizontally hinged and fixed to the sower installation traverse frame in parallel, and the fertilizer smashing, vibrating and sieving equipment is installed and fixed on the hopper of the agricultural vehicle. The mixed planting integrated sowing equipment is provided with a seed and fertilizer pre-mixing mechanism and an automatic material-mixing type sower, so that while sowing operation efficiency is effectively improved, the texture and the fertility of the soil can be improved, a yield is further improved, and labor intensity is lowered.

Owner:MAIZE RES INST SHANDONG ACAD OF AGRI SCI

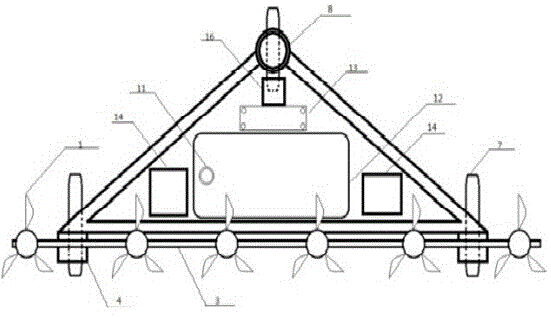

Paddy field plant protection robot

InactiveCN105353756AReduce harmReduce weightPosition/course control in two dimensionsControl systemAgricultural engineering

The invention discloses a paddy field plant protection robot, and relates to the technical field of agriculture plant protection machinery. The paddy field plant protection robot comprises a mist spray module, a control system, a driving device and a machine rack, wherein the machine rack comprises a triangular support, three wheels, a rotating shaft and three support columns; a driving system is connected with the wheels and the control system, and the control system and the mist spray module are arranged on the triangular support. The beneficial effects of the paddy field plant protection robot are that the paddy field plant protection robot is reasonable in design, extensive in applicability, excellent in applied technology, good in trafficability and stable in structure; the paddy field plant protection robot can effectively walk in plants, the cost is saved, agricultural plant output is improved, and benefits are increased.

Owner:HEFEI DUOJIA AGRI SCI & TECH

Biological agent synergized inorganic fertilizer and preparation method thereof

PendingCN109503274AEffective survivalAvoid high temperatureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersGrowth plantMicrobial agent

The invention discloses biological agent synergized inorganic fertilizer and a preparation method thereof, and belongs to the technical field of agricultural fertilizer. The method comprises the following steps: firstly, preparing a microbial agent, an organic protective carrier and process water into a flowable bacterial solution; secondly, sequentially coating the surface of granular inorganic fertilizer with the bacterial solution in the first step, anti-caking powder and an anti-caking oil agent in a fertilizer anti-caking packaging barrel to form the biological agent synergized inorganicfertilizer. The preparation method of the biological agent synergized inorganic fertilizer disclosed by the invention has the advantages that the biological agent synergized inorganic fertilizer withuniform coating and no risk of bacterial powder falling is obtained without any disturbance to the production process of fertilizer; in addition, the organic protection carrier in the bacterial solution coating can play dual roles of a microbial agent, protector and a plant growth stimulant.

Owner:中国-阿拉伯化肥有限公司

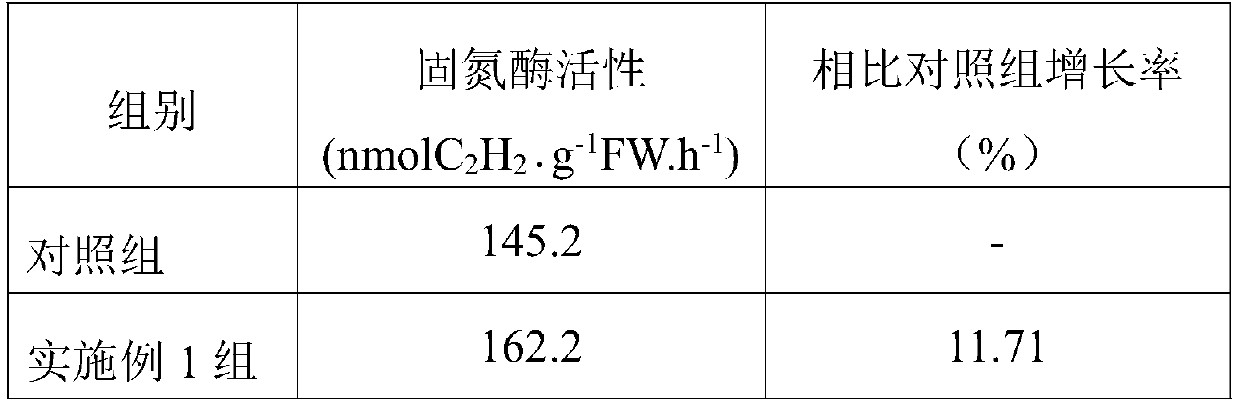

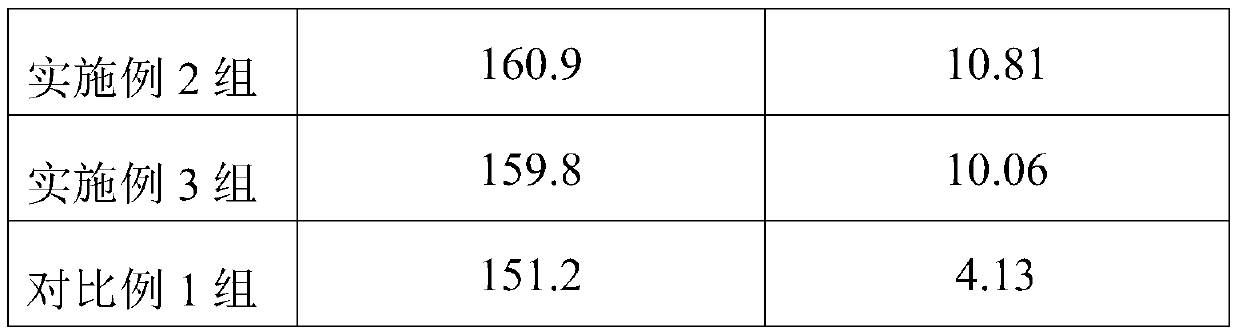

Planting method for promoting nitrogen fixation of sugarcane

ActiveCN111567350AImprove nitrogen fixation capacityIncrease productionBio-organic fraction processingSugarcane cultivationBiotechnologyNutrition

The invention relates to the technical field of sugarcane planting, and particularly discloses a planting method for promoting nitrogen fixation of sugarcane. The method comprises the following stepsof detoxifying single-bud seed stems of the sugarcane; carrying out sand culture on the single-bud seed stems of the sugarcane, and carrying out nitrogen fixation bacterium inoculation treatment on sugarcane seedlings when each sugarcane seedling grows out 3-4 leaves; scientifically and cooperatively applying nitrogen-phosphorus-potassium base fertilizer, nitrogen fixation microbial fertilizer andorganic fertilizer in a soil preparation trench for providing nutrition required by sugarcane growth, and planting the sugarcane seedlings subjected to inoculation treatment; and after the sugarcaneseedlings grow for 2-3 months, spraying a nitrogen fixation synergist solution to the leaf surfaces of the sugarcane. According to the planting method, the nitrogen fixation capacity of the sugarcaneis improved, the application frequency and the application amount of nitrogen fertilizer are reduced, the yield and quality of the sugarcane are improved, and the economic benefits of the sugarcane are improved.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

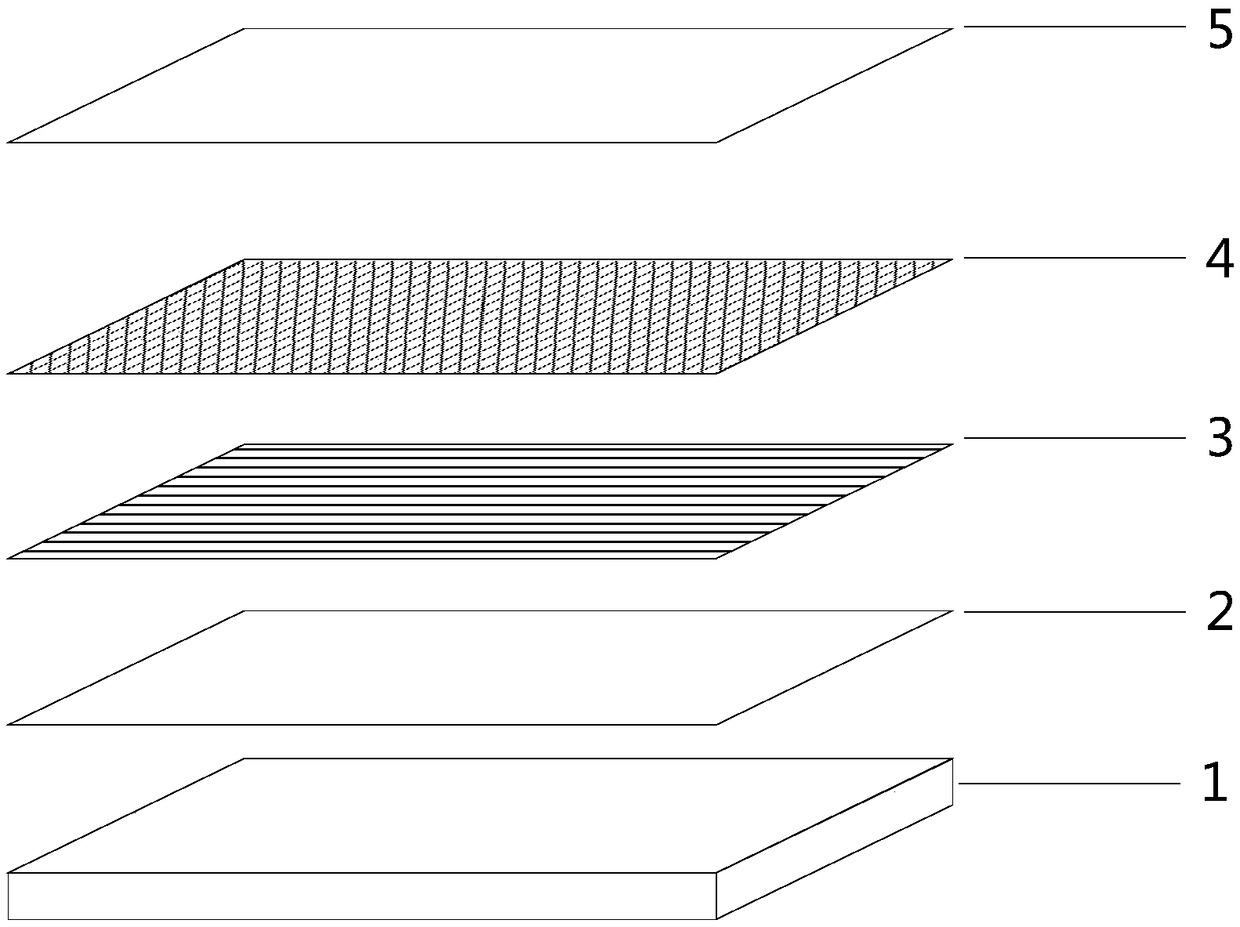

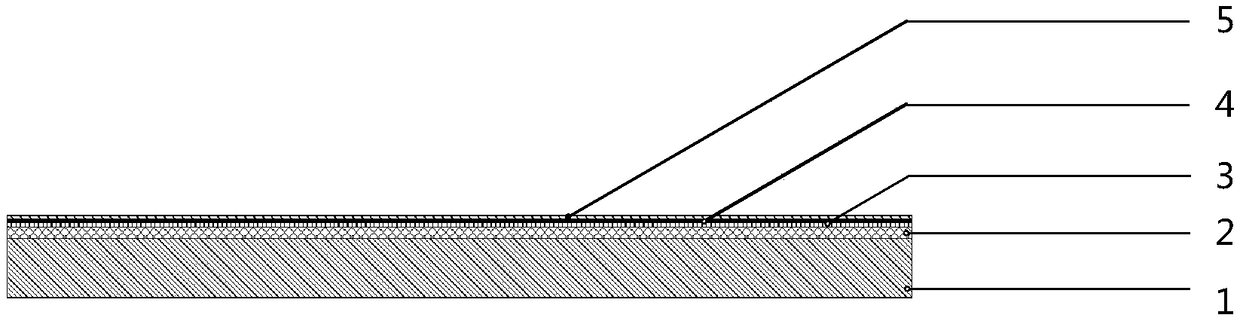

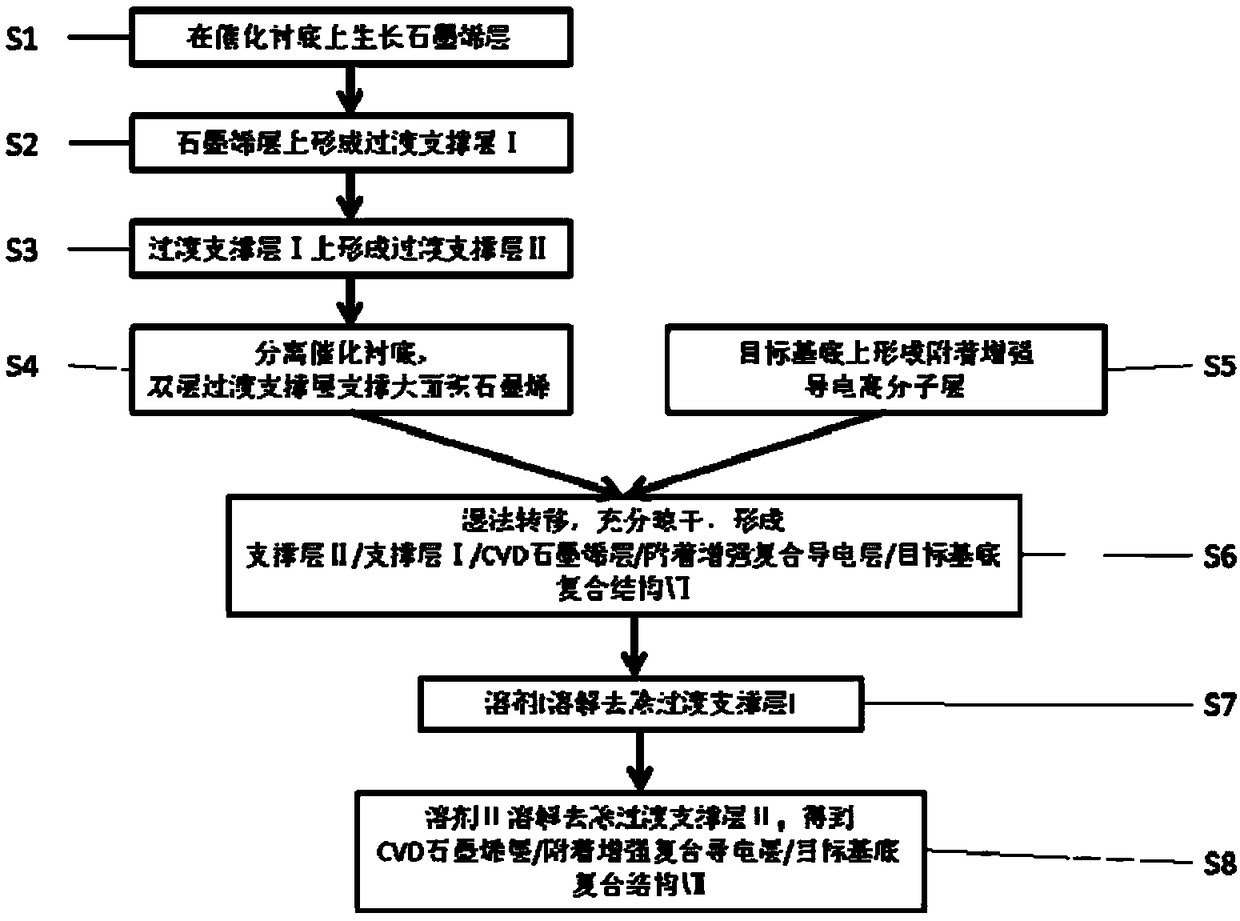

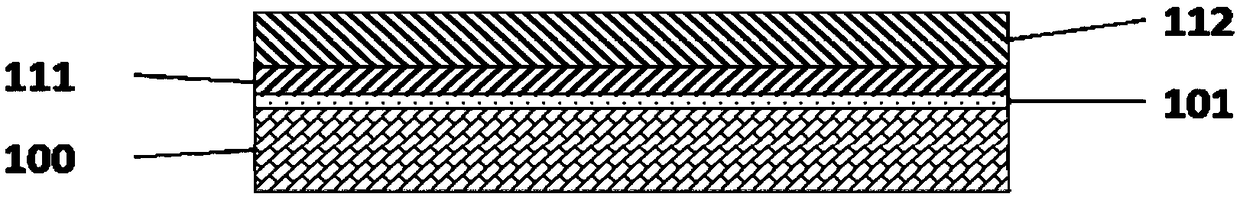

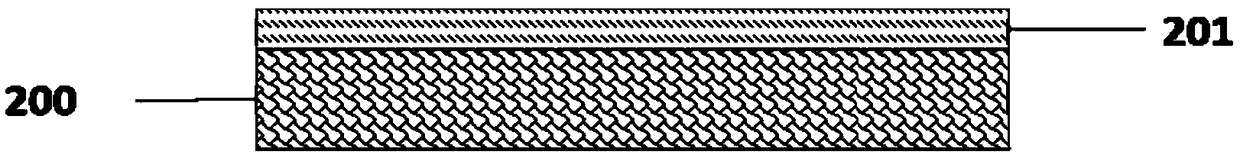

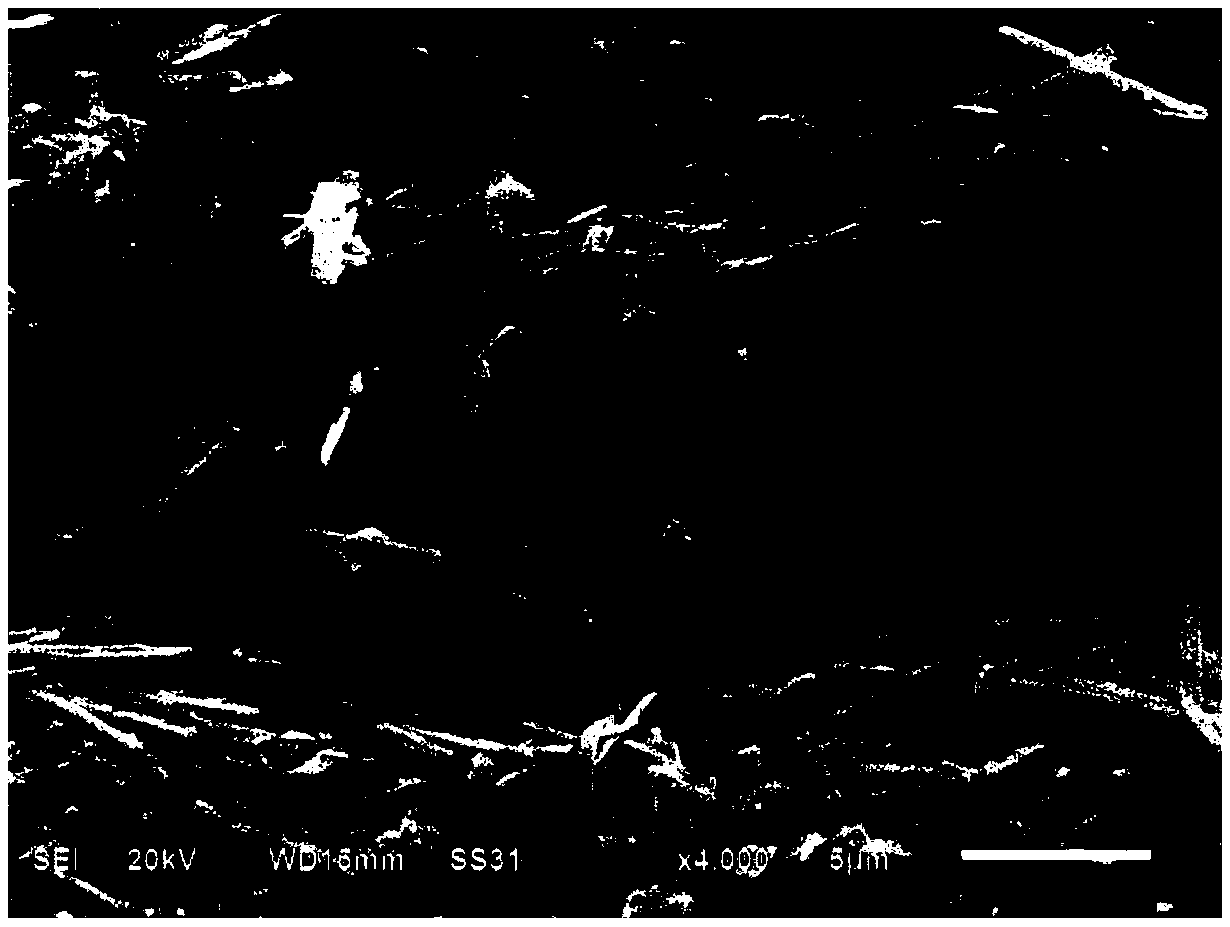

Graphene adhesion-enhanced composite conductive structure and preparation method thereof

ActiveCN108648853ARealize large area clean and non-destructive transferGood adhesionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersConductive polymerNanotechnology

The invention discloses a graphene adhesion-enhanced composite conductive structure capable of realizing the enhanced adhesion of graphene to a target substrate, and a preparation method thereof. Thegraphene adhesion-enhanced composite conductive structure comprises a CVD graphene layer, a conductive polymer layer, and a target substrate arranged from top down. The preparation method comprises the steps of: S1, generating a graphene layer on the catalytic substrate; S2, coating a thermoplastic resin I on the surface of the grapheme to form a transition support layer I; S3, continuing to coata thermoplastic resin II on the surface to form a transition support layer II; S4, separating the catalytic substrate to obtain a structure IV; S5, coating the conducting polymer on the target substrate to obtain a structure V; S6, dragging a structure IV from the structure IV from water by the wet process; S7, removing the transition support layer II; and S8, removing the transition support layerI, thereby obtaining the composite structure VII. The graphene adhesion-enhanced composite conductive structure and the preparation method thereof are used to keep the graphene intact and not damaged, and the complete transfer preparation of the large-area graphene may be realized.

Owner:CHONGQING GRAPHENE TECH

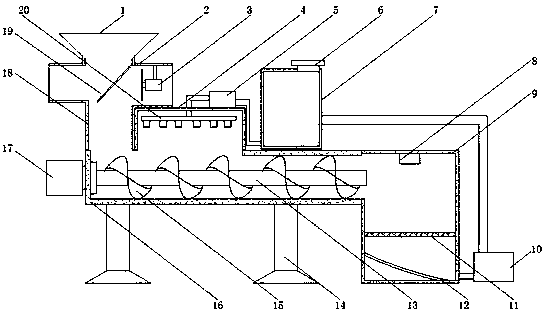

Coating device for watermelon seeds

PendingCN108925174AQuality improvementImprove germination rateSeed coating/dressingEngineeringChemical preparation

The invention discloses a coating device for watermelon seeds. The coating device for watermelon seeds comprises an air duct, a liquid spraying tank, a material collecting box and a spiral conveyor, wherein a material inlet tube is fixedly installed at one side of the top of the spiral conveyor, a material inlet hopper is fixedly installed at the top of the material inlet tube, and the material inlet tube communicates with the spiral conveyor; the air duct which is fixedly mounted on the material inlet tube is parallel to the spiral conveyor, an air inlet is formed in one end of the air duct,and an air outlet is formed in the other end of the air duct; a fan is fixedly installed on the inner wall of one end of the air duct through a bracket, the other end of the air duct communicates withthe outside, and a filter plate is fixedly mounted in the material inlet tube. The coating device has a simple structure and convenient operation, and hollow shells, residues and dust in the seeds are blown off through the fan, so that the germination rate of the seeds is improved, and unnecessary waste of chemicals is reduced; since excess chemical liquid can be pumped into a chemical preparation box through a second delivery pump, the chemical liquid can be reused, so that unnecessary waste of the chemical liquid is reduced, and the processing cost is saved.

Owner:朱迁

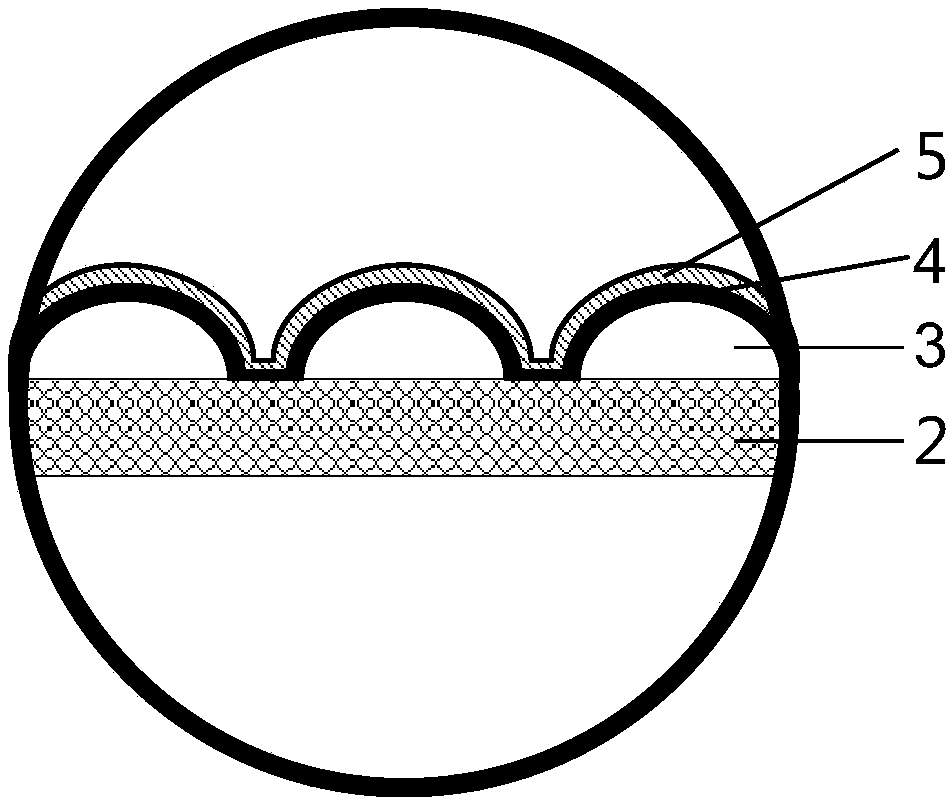

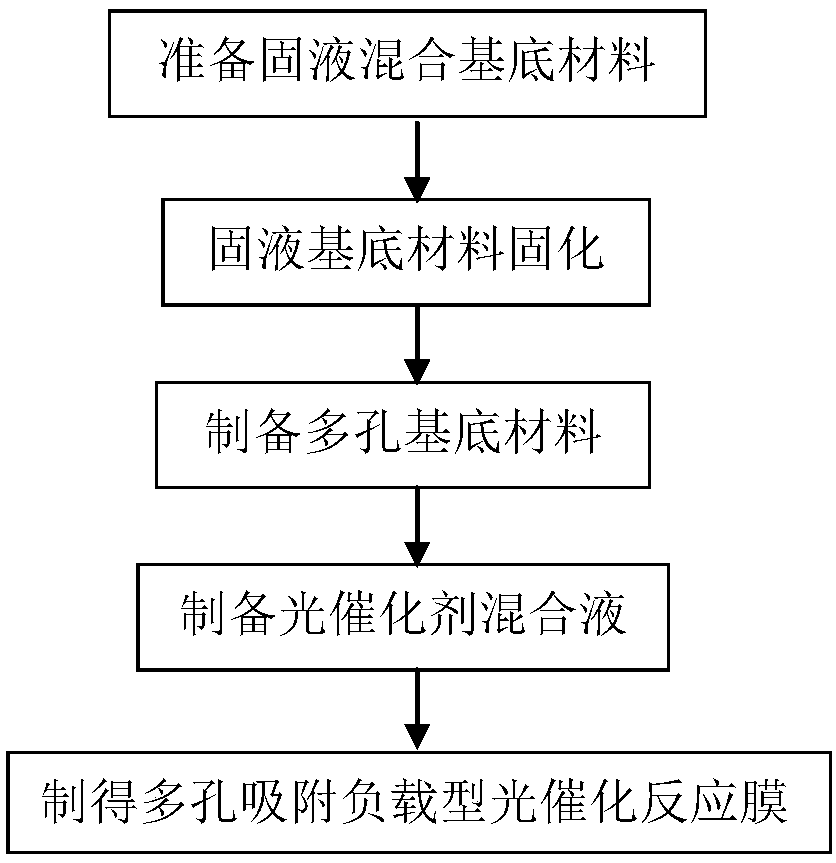

Porous adsorption supported light-catalyzed reaction film and preparation method and application thereof

InactiveCN108579821AEfficient killingImprove adsorption capacityBiocideWater/sewage treatment by irradiationPhotocatalytic reactionInorganic ions

The invention discloses a porous adsorption supported light-catalyzed reaction film and a preparation method and application thereof. The preparation method comprises the following steps: after mixinga polydimethylsiloxane prepolymer with a curing agent, adding pore-forming particles for curing, and then removing the pore-forming particles to obtain a porous polydimethylsiloxane substrate material; after uniformly mixing a binder and nanometer titanium dioxide to obtain a photocatalyst mixed solution; pouring the photocatalyst mixed solution onto the porous polydimethylsiloxane substrate material, and heating to remove a solvent for dissolving the binder, thereby obtaining the porous adsorption supported light-catalyzed reaction film. The light-catalyzed reaction film prepared in the invention has the effects of large specific surface area, good adsorption performance, high catalytic efficiency, stable performance, easy recycling and the like. When the light-catalyzed reaction film isapplied to degrading organic matters, killing bacteria and adsorbing inorganic ions, the bacteria can be killed efficiently, and the organic matters or inorganic ions can be adsorbed and degraded.

Owner:HUAZHONG UNIV OF SCI & TECH

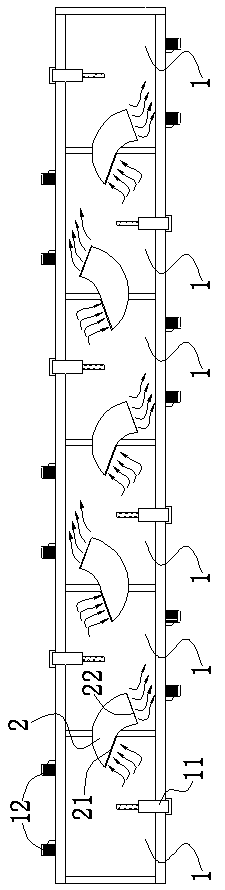

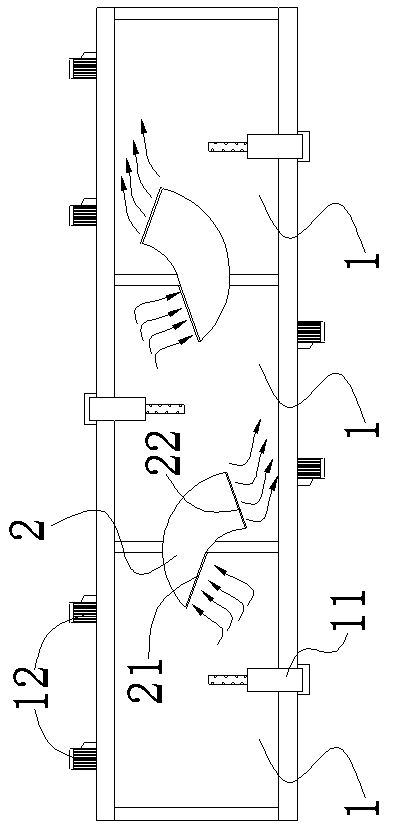

Setting machine thermal-cycling and waste-removing system

InactiveCN103741421ARealize inner loopReduce energy consumptionHeating/cooling textile fabricsDrying solid materialsToxic materialEngineering

The invention discloses a setting machine thermal-cycling and waste-removing system which comprises a cloth feeding device, and a plurality of drying rooms which are connected with the cloth feeding device and are connected with each other in an end-to-end manner; one side of each drying room is provided with a heating device, and the other side is provided with a pair of blower fans; an upper air channel and a lower air channel which are communicated with the pair of blower fans are disposed in each drying room; connecting pipes are disposed between at least two or more than two drying rooms; an air inlet is disposed at one end of each connecting pipe, and an air outlet is disposed at the other end of each connecting pipe; the air inlet is disposed near the heating device of the drying room, and the air outlet is disposed near the pair of blower fans of the drying room. The advantages of the system of the invention are that being different from current heat recovery systems with a single drying room, the system realizes internal circulation of hot air between drying rooms; with the disposed waste-removing device, the system can not only recover residual heat energy, but also remove waste gas, oil smoke and toxic substances generated during setting process, and realizes the effects of discharge reduction and environment protection.

Owner:张子军

Antistatic and antibacterial textile fabric and preparation method thereof

InactiveCN112647304AImprove antibacterial propertiesImprove antistatic performanceElectroconductive/antistatic filament manufactureBiochemical fibre treatmentPolymer scienceAnti bacterial

The invention discloses antistatic and antibacterial textile fabric and a preparation method thereof. The antistatic and antibacterial textile fabric has good antistatic and antibacterial effects through spinning of double-layer fabric, inner-layer fabric is antistatic fabric, and zinc oxide whiskers are added into the antistatic fabric, so that the antistatic effect of the prepared antistatic and antibacterial textile fabric is effectively improved; meanwhile, through dip dyeing and coating of composite hydrosol, the antibacterial effect of the antistatic and antibacterial textile fabric is effectively improved; and according to FZ / T01042-1996 measurement, the induction voltage of the antistatic and antibacterial textile fabric is 2388-2597 V. Meanwhile, the invention further discloses dip dyeing equipment. The dip dyeing equipment flattens the surface of basic fabric before the basic fabric is subjected to dip dyeing, wrinkles are prevented, and the composite hydrosol can be fully attached to the basic fabric through double processing of dip dyeing and coating.

Owner:陈快安

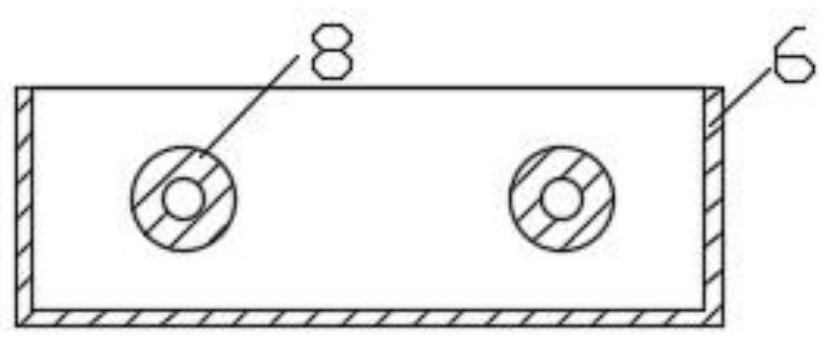

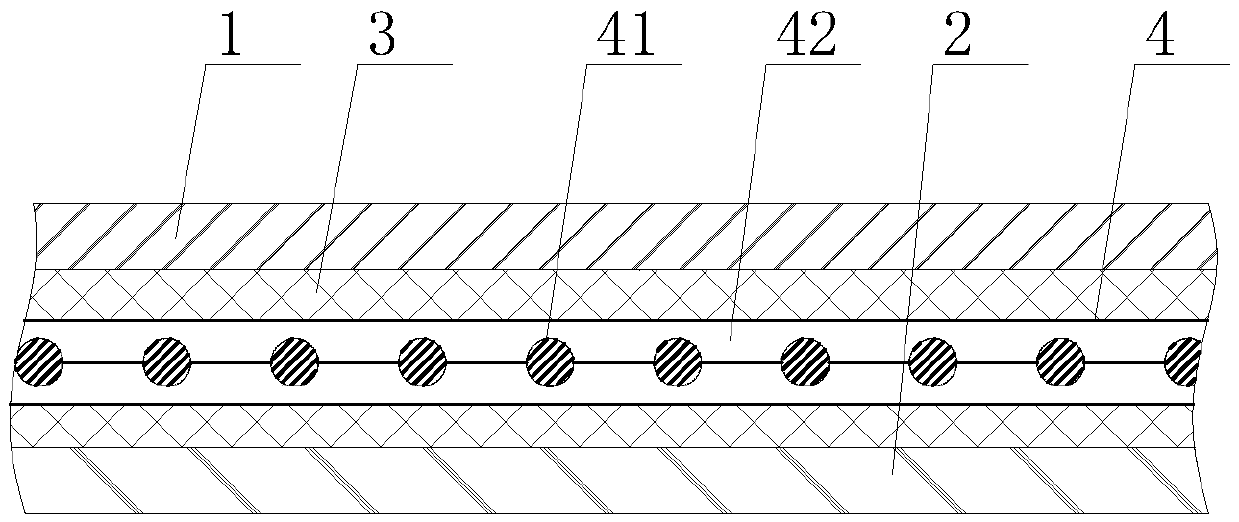

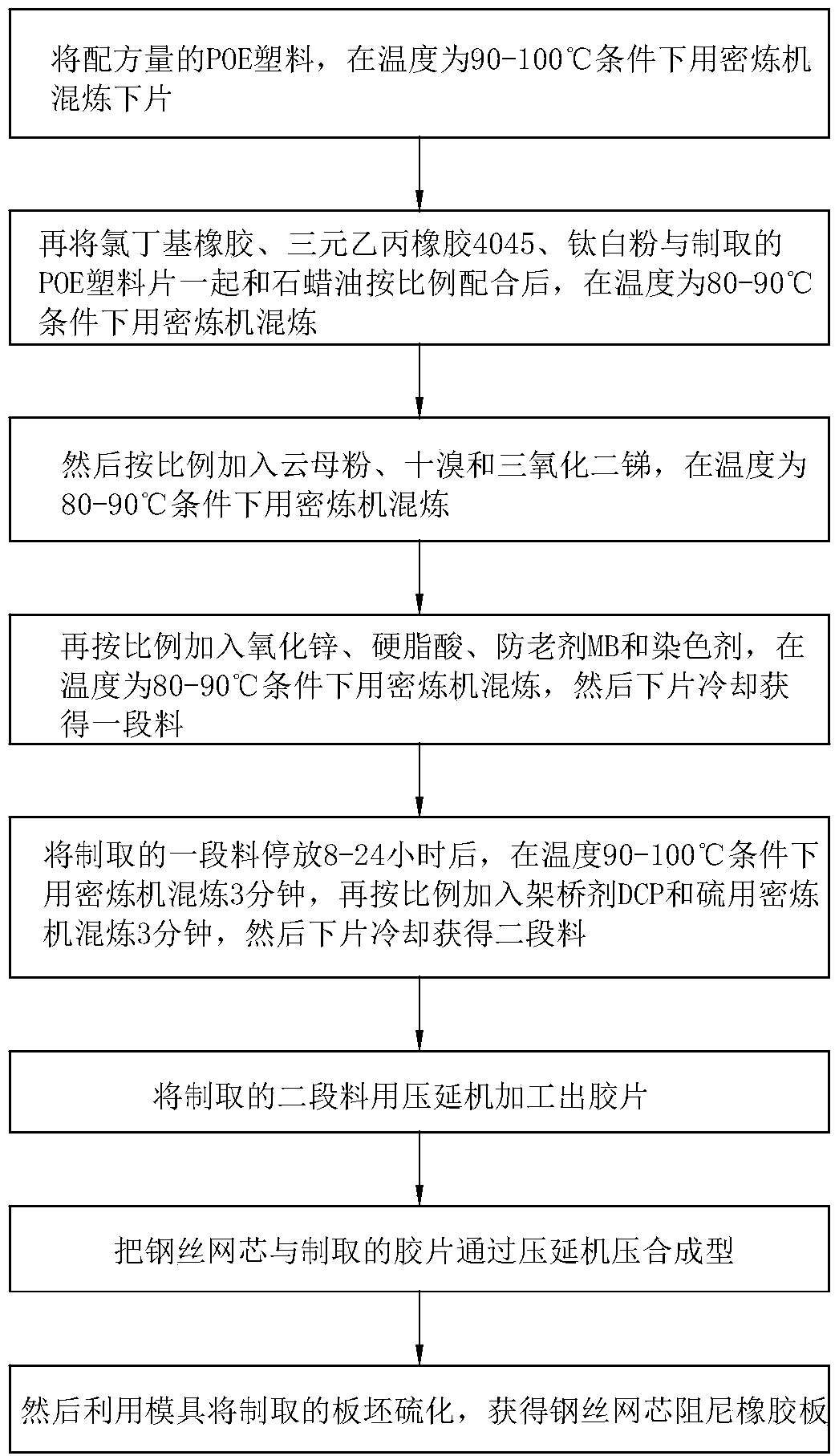

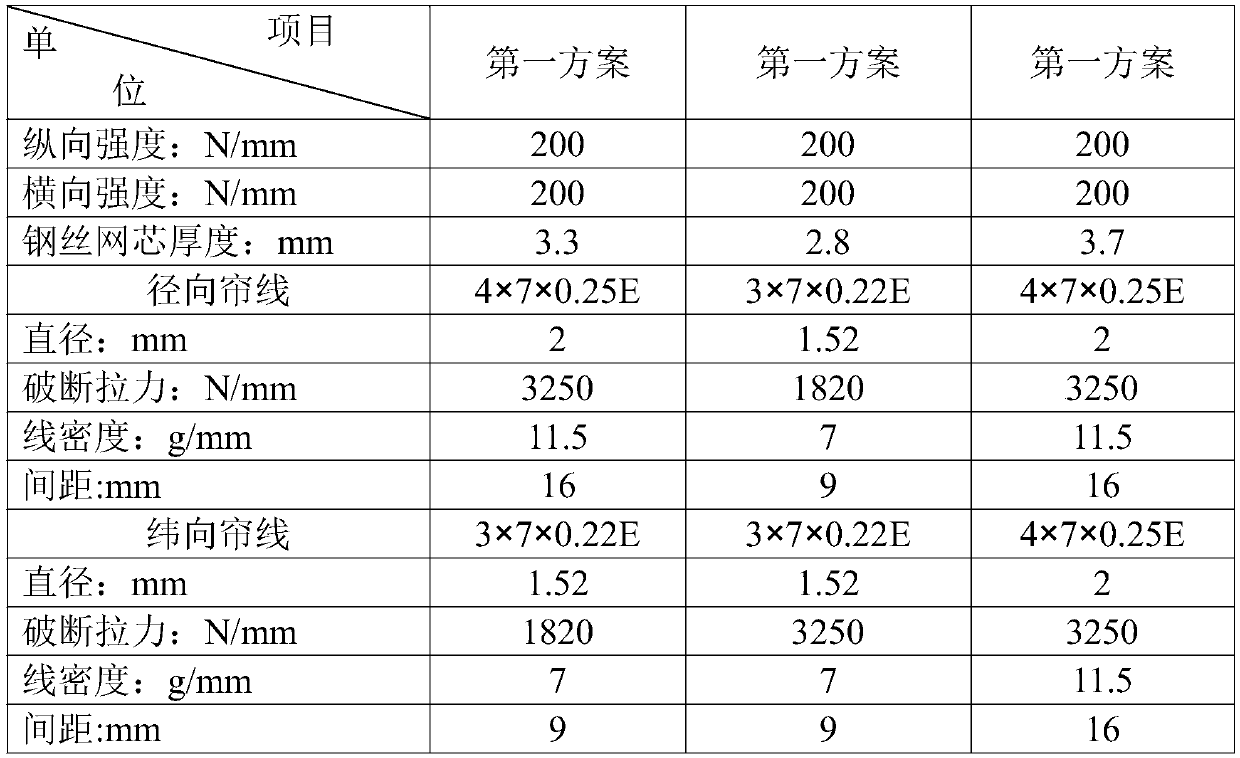

Marine steel mesh core damping rubber plate and preparation method thereof

PendingCN109679177AHigh breaking forceImprove fatigue resistanceLaminationLamination apparatusElastomerPolymer science

The invention relates to a marine steel mesh core damping rubber plate and a preparation method of the marine steel mesh core damping rubber plate. The damping rubber plate comprises an upper coveringrubber layer, a framework layer and a lower covering rubber layer, wherein the framework layer is internally provided with a steel mesh core; the upper covering rubber layer and the lower covering rubber layer are made of damping rubber; and the damping rubber comprises the following raw materials in parts by weight: 60 parts of chlorobutyl rubber 1086, 30 parts of ethylene-propylene-diene monomer 4045, 10 parts of POE (polyolefin elastomer) plastic, 5 parts of zinc oxide, 1 part of stearic acid, 2 parts of antiager MB, 5 parts of a colorant, 40 parts of a mica powder, 30 parts of decamethonium, 10 parts of antimonous oxide, 10 parts of titanium dioxide, 10 parts of paraffin oil, 8 parts of a bridging agent DCP (dicumyl peroxide) and 0.8 parts of sulfur. The damping rubber plate has the advantages of high damping, shock absorption, flame retardance, tear resistance, ozone resistance, acid-base resistance, aging resistance and the like, and excellent comprehensive performance and is applicable to high load and harsh conditions.

Owner:青岛富耐特矿业科技有限公司

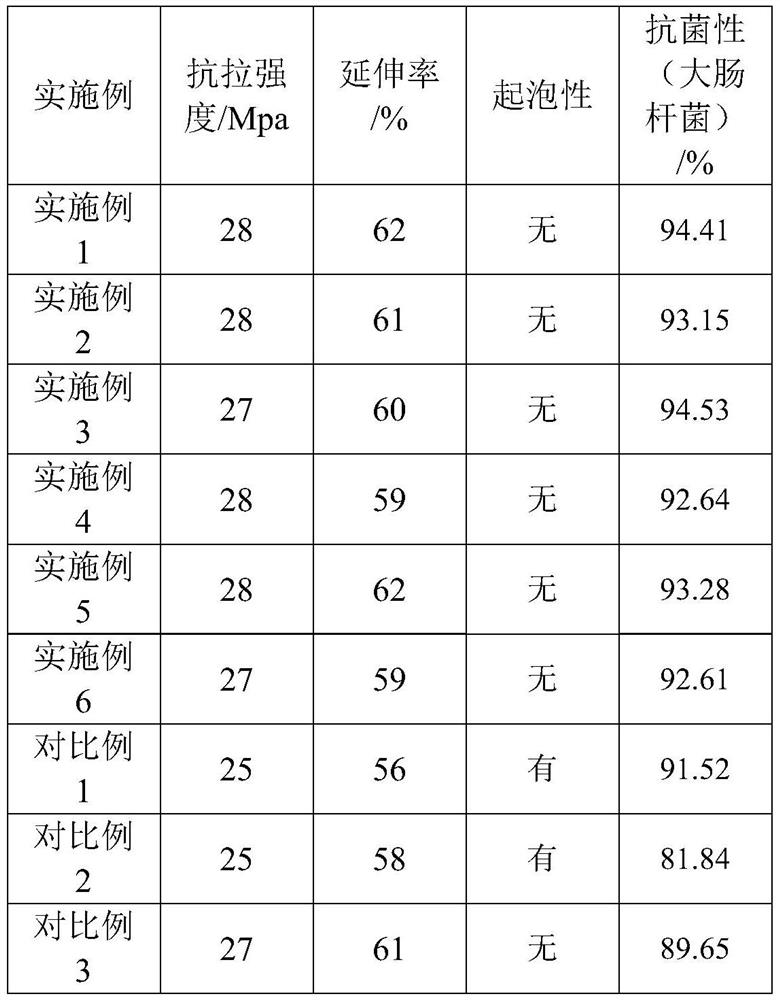

Difficult-to-foam sealant and preparation method thereof

ActiveCN112266754AImprove bindingWill not affect construction efficiencyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAntibacterial agent

The invention provides a difficult-to-foam sealant and a preparation method thereof. The sealant comprises a component A and a component B; the component A comprises the following components, by weight: 80-90 parts of polyaspartic acid ester, 1-3 parts of a leveling agent, 1-3 parts of an antifoaming agent, 5-10 parts of nano titanium dioxide and 1-3 parts of oxazolidine; and the component B comprises the following components, by weight: 75-90 parts of a curing agent, 1-3 parts of an antibacterial agent and 5-10 parts of a thickening agent. The component A and the component B are mixed to forma polyurea product, and the sealant has excellent tensile strength and elongation, is not easy to foam in a humid and hot environment, and also has very good antibacterial property and ultraviolet resistance.

Owner:安徽牛元新材料有限公司

Antibacterial outer shell used for automotive electronic igniter

The invention discloses an antibacterial outer shell used for an automotive electronic igniter. The outer shell comprises the following raw materials in parts by weight: 125-135 parts of a main material, 1-2 parts of isopropyl tri(dioctylpyrophosphate) titanate, 0.5-1.2 parts of maleic anhydride, 1-5 parts of a composite antibacterial agent, 5-10 parts of precipitated barium sulfate, 2-6 parts ofheavy calcium carbonate, 1-6 parts of calcined kaolin, 2-4 parts of graphene, 1-2 parts of trimethylethoxysilane, 2-4 parts of a dispersant, 1-2 parts of an anti-aging agent, and 1-2 parts of a defoaming agent, wherein the composite antibacterial agent is prepared by the following processes: performing uniform mixing on houttuynin and toluene, adding a hydrogen peroxide aqueous solution dropwise,raising the temperature, performing stirring, performing extraction by adopting dichloromethane, collecting an organic phase, performing evaporation to dryness, adding nano zinc oxide, nano silver oxide, sepiolite powder and water, performing mixing, raising the temperature, performing stirring, raising the temperature, continuing stirring, performing cooling, performing filtering, performing washing, and performing drying to obtain the composite antibacterial agent.

Owner:蚌埠泰欣电子科技有限公司

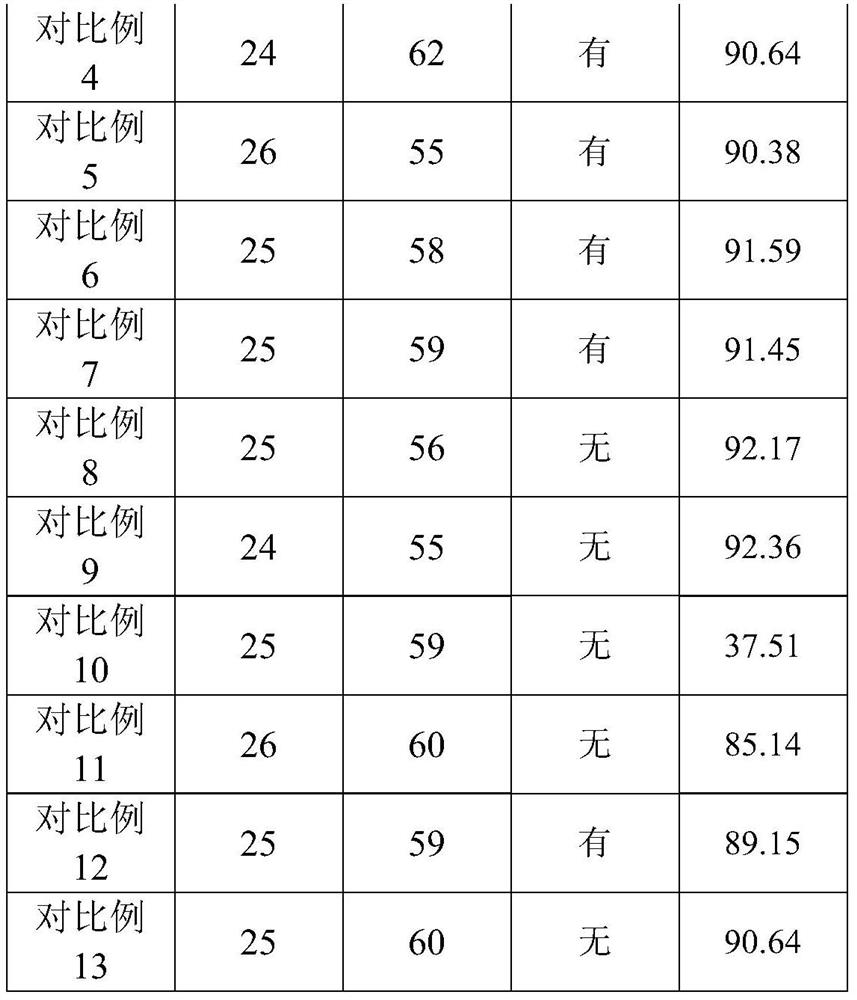

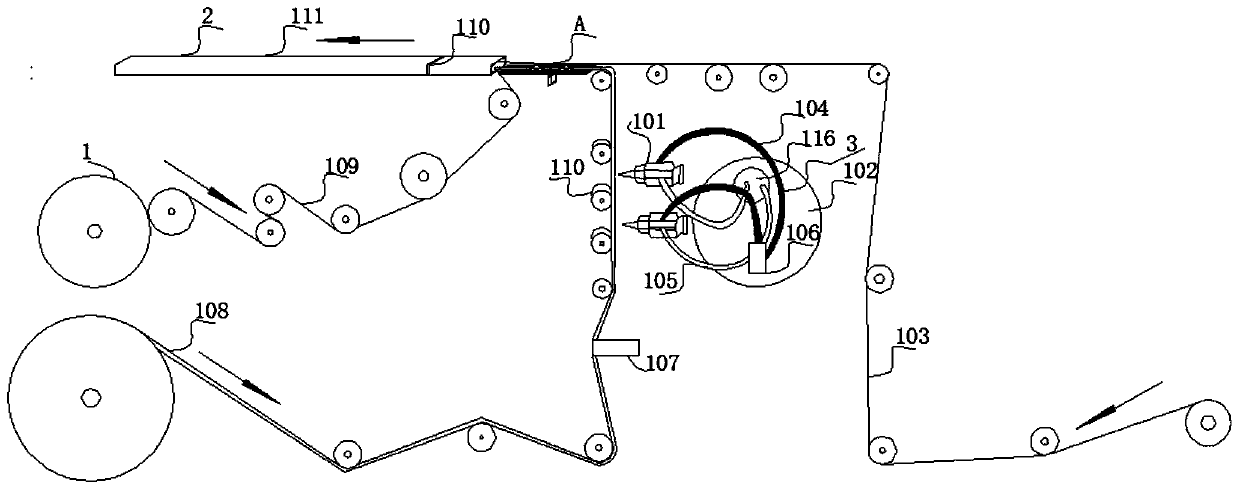

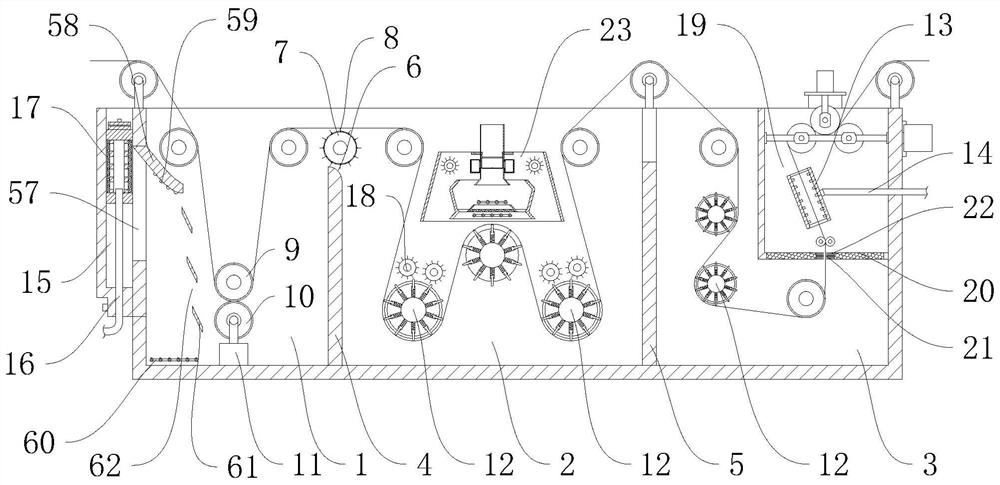

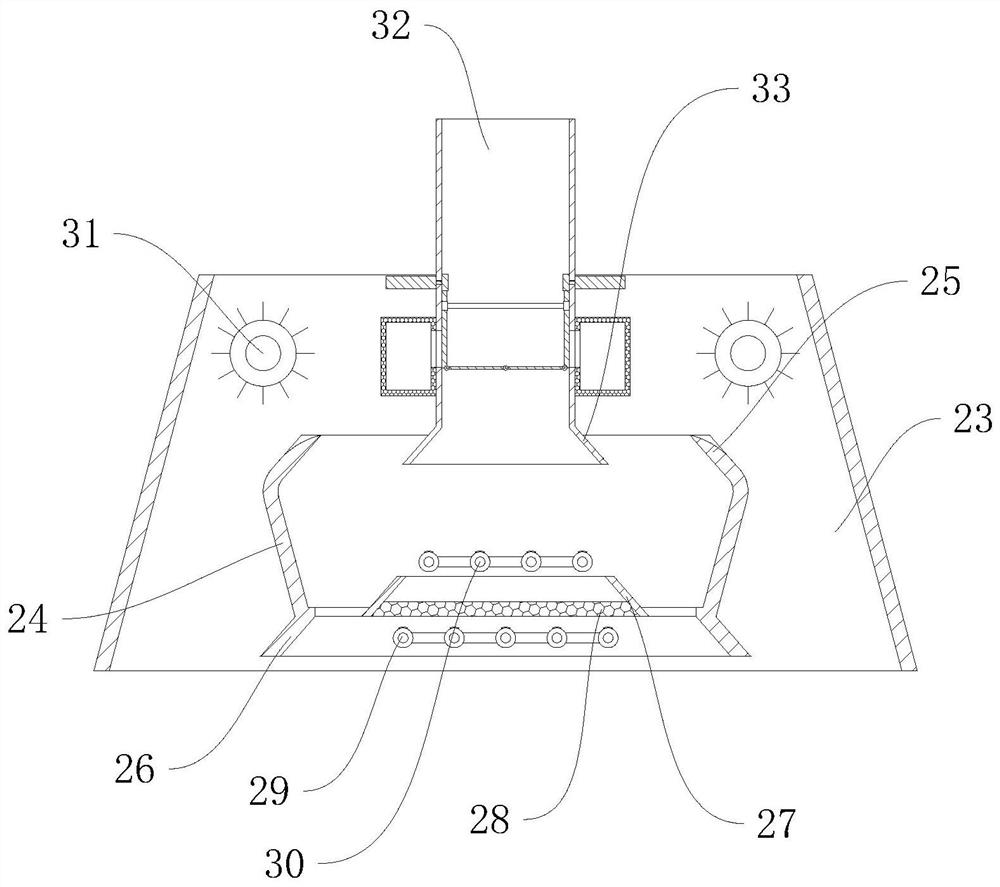

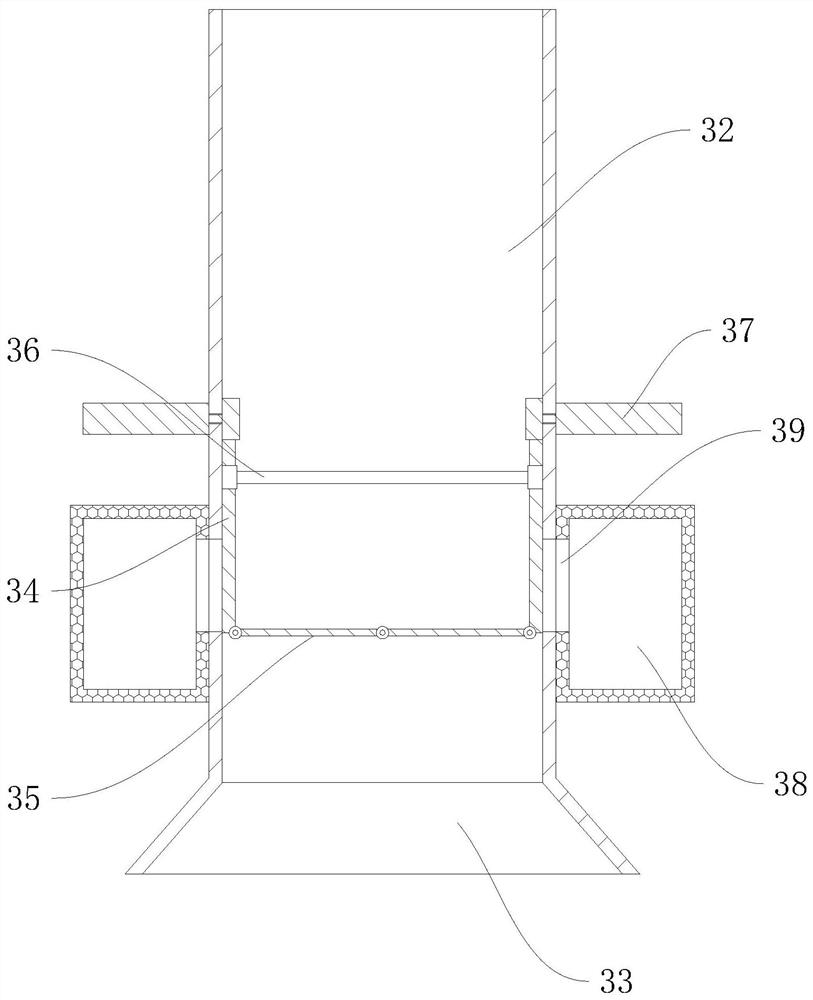

Cigarette filter online flavoring molding equipment

The invention discloses cigarette filter online flavoring molding equipment, and specifically relates to the technical field of cigarette processing. The cigarette filter online flavoring molding equipment is characterized in that a flavor spraying device, an adjusting assembly, a cloth cutting assembly and a tobacco shred coiling device are designed, the amount of flavor liquid adsorbed by non-woven cloth can be adjusted conveniently through control of a liquid spraying tube, and liquid sprayed from a liquid spraying head is in the form of mist, so that the flavor can be fully attached to thenon-woven cloth, and fragrance sheets are more fragrant. During implementation, the non-woven cloth is conveyed into a slicing device through an adjusting wheel and a steering wheel, the non-woven cloth with flavor can be cut to a required length more conveniently through control of the slicing frequency of a slicing tool and the speed of a crawler belt, and filter tobacco shreds, the non-woven cloth and filter sticks are conveyed into the tobacco shred coiling device coiling device through the adjusting assembly to be molded integrally by coiling, so that the flavoring effect can be kept constant and even improved without the need of controlling the speed of the non-woven cloth and filter stick adjusting assembly; the operation is convenient; meanwhile the cigarette filter processing project becomes easier.

Owner:杨成云 +1

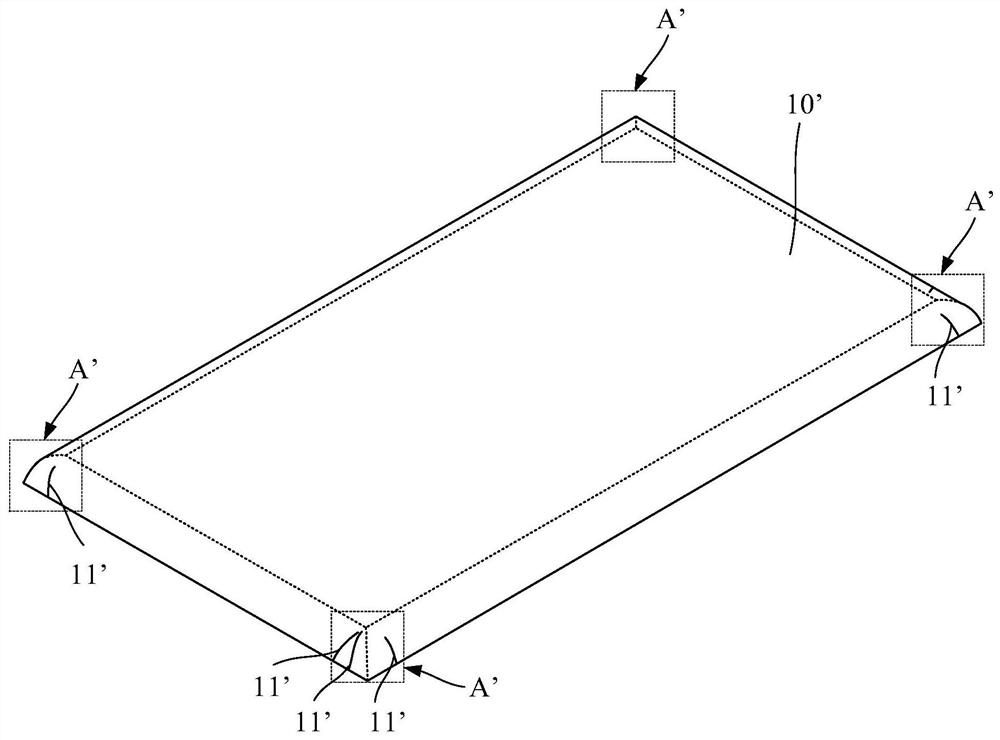

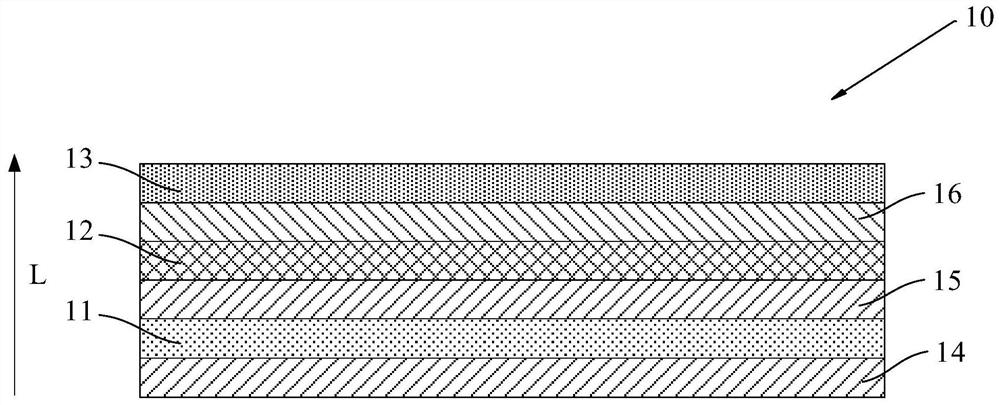

Polaroid, display module and processing method of polaroid

PendingCN112241039AFully attachedNo light leakSolid-state devicesPolarising elementsEngineeringFlexible display

According to a polaroid, a display module and a processing method of the polaroid, the polaroid can be better attached to the curved surface cover plate, and the beneficial technical effects of beingfree of wrinkles and color fading and smooth in appearance are achieved. The polaroid is made of a telescopic material, is shaped into a curved surface shape through a hot-pressing process, and comprises a polarizing functional layer, the polarizing functional layer is used for converting light passing through the polarizing functional layer into linearly polarized light from natural light, and protecting a protective layer of the polarizing functional layer, wherein the polarizing functional layer and the protective layer are both made of telescopic materials. The display module comprises a flexible display screen, the polaroid and a curved surface cover plate which are sequentially stacked in the light emitting direction. The polaroid processing method comprises the steps of placing a polaroid to be machined on a curved surface profiling base table; and enabling the polaroid to have a curved surface shape corresponding to the shape of the curved surface profiling base station througha hot pressing process.

Owner:BOE TECH GRP CO LTD

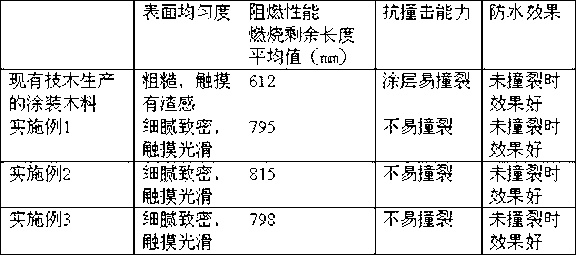

Painting timber taking Chinese red pine timber as raw material

InactiveCN103302712AEasy to melt intoGood adhesionWood treatment detailsPretreated surfacesCalcium bicarbonateEngineering

The invention discloses a painting timber taking Chinese red pine timber as a raw material, belonging to the technical field of wood sheet material production. The painting timber comprises a degreasing procedure, a drying procedure, a burdening procedure, a sanding procedure, a repairing procedure, a painting procedure, a sanding procedure and a paint spraying. The painting timber provided by the invention has the beneficial effects that superfine micro Chinese red pine wood flour is utilized as a main raw material to repair timber, the painting material and the Chinese red pine timber are sufficiently fused into a whole, meanwhile, the proper amount of calcium bicarbonate, white emulsion, wheat flour and a solidified agent for the painting material are utilized for manufacturing the painting material, the painting material is fine, smooth and wet, and the adhesive force is strong; the painting material can be easily attached on the top through the rigid degreasing and drying, the eroded foundation is avoided, and the painting material does not contain contamination such as formaldehyde; the coating structure of a product provided by the invention is delicate and compact, the flame retardant property is strong, the painting is uniform, the impact resisting capacity is strong, a water-proof effect is good, the property of the Chinese red pine timber is improved, and the application range is also greatly increased; the economical value is fully displayed, and the wildness timber create conditions are protected.

Owner:重庆家和琴森木业有限公司

Ecological transfer printing fabric production system

ActiveCN113071200AFully attachedImprove integrityTransfer printingPrinting press partsTextile printerEnvironmental engineering

The invention discloses an ecological transfer printing fabric production system, and relates to the technical field of textile printing and dyeing. The technical scheme is as follows: the ecological transfer printing fabric production system comprises a transfer printing film printing system, a fabric pretreatment system and a fabric transfer printing system, wherein the fabric pretreatment system comprises a treatment tank; the interior of the treatment tank is divided into a treatment tank I, a treatment tank II and a treatment tank III through a partition plate I and a partition plate II; the upper end of the partition plate II is higher than the upper edge of the partition plate I; a communicated liquid outlet tank is arranged on one side, far away from the treatment tank II, of the treatment tank I; the liquid outlet tank is communicated with the treatment tank I through a liquid outlet; the inner side of the upper end of the liquid outlet is connected with a drainage plate; the drainage plate extends downwards and inclines towards the treatment tank I; and a bubbling pipe III is arranged at the position, corresponding to the lower part of the drainage plate, of the bottom of the treatment tank I. According to the the ecological transfer printing fabric production system provided by the invention, the surface of the fabric can be subjected to fine wetting treatment, and the fitting completeness of the fabric and a transfer pattern is improved, so that the fabric transfer printing effect and quality are improved.

Owner:绍兴柯桥正莹绣品有限公司

Chroming mist recycling method

ActiveCN107376592AAchieve emission goalsDoes not require manual maintenanceGas treatmentUsing liquid separation agentFilling materialsWastewater

The invention discloses a chroming mist recycling method. A pure physical method is adopted for absorbing chroming mist generated in an electroplating production process into serially connected recycling treating units through a notch fan cover and then performing the processes of diffusing, colliding, coring, agglomerating and settling, so that the chroming mist is stopped and absorbed to the surfaces of a baffle plate and a filling material, and meanwhile, the chroming mist is intermittently and circularly flushed back to the present collecting tank, so that the chroming mist is intercepted, captured and recycled. No wastewater is discharged in the whole process, so that the purpose of environment-friendly emission of the chroming mist is achieved.

Owner:石家庄印钞有限公司

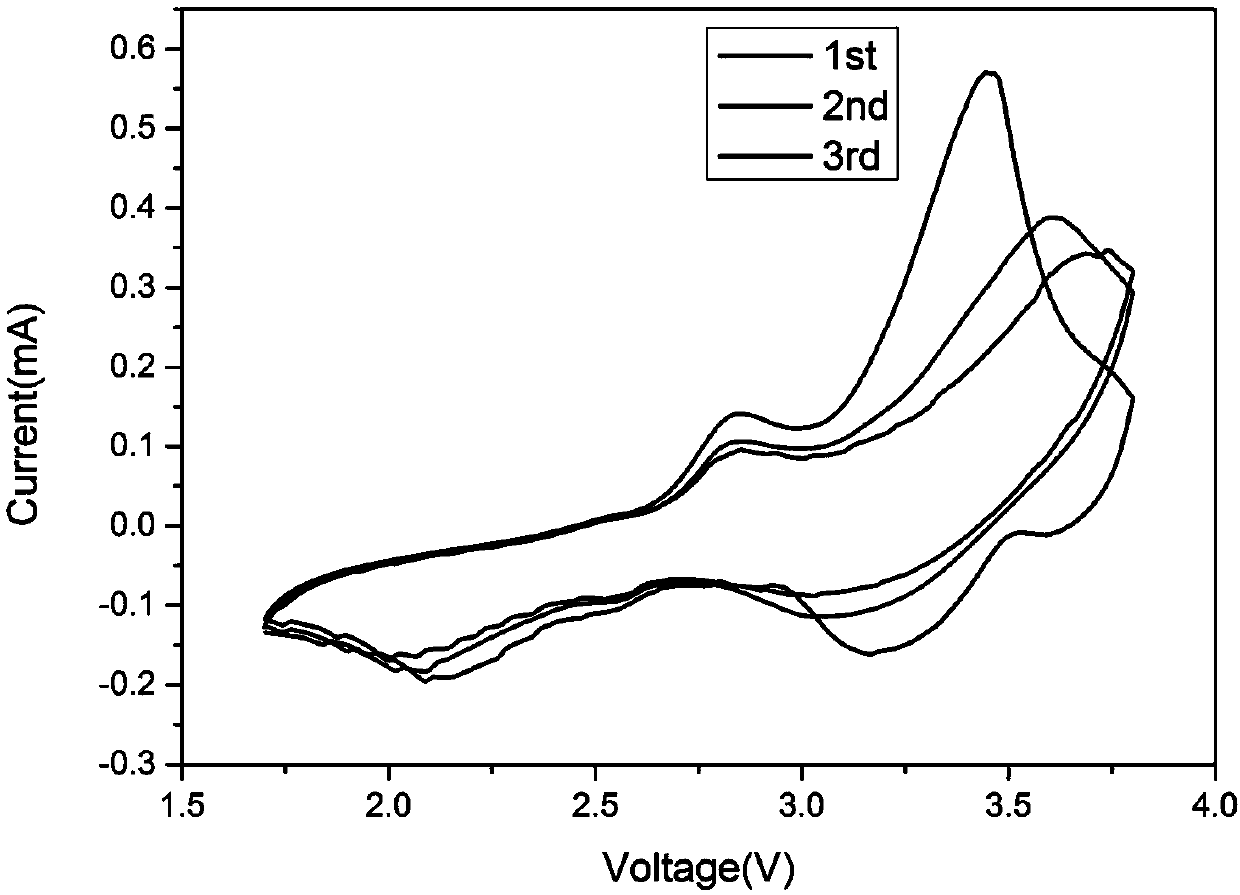

Preparation method of vanadium oxide nanoribbon-foam nickel composite self-supporting electrode material

ActiveCN109616616AReduce slurry coatingGood contactMaterial nanotechnologyElectrode thermal treatmentSurface-active agentsPentoxide

The invention relates to a preparation method of a vanadium oxide nanoribbon-foam nickel composite self-supporting electrode material. Due to the fact that vanadium pentoxide is directly attached to foam nickel by adopting a hydrothermal reaction and post-sintering treatment, not only are the processes of size mixing, coating and the like in the battery assembly process omitted, but also the vanadium pentoxide nanoribbons make contact with foam nickel very well, electron transport can be enhanced, intercalation and deintercalation of lithium ions in the material are promoted, the ubiquitous problem that the sample morphology is destroyed in charging and discharging is significantly reduced, and the cycling stability is enhanced; in addition, by means of selection of a surface active agent,more nano vanadium pentoxide can be attached to foam nickel, therefore, vanadium pentoxide can generate more nanoribbons, the diffusion distance of the lithium ions is shortened, the dynamic performance of vanadium oxide as a cathode material is improved, and the quick charging and discharging requirement can be met; and meanwhile, the nano vanadium pentoxide material has the large surface activearea and can well and fully make contact with an electrolyte solution to improve the capacity of the electrode material.

Owner:XIANGTAN UNIV

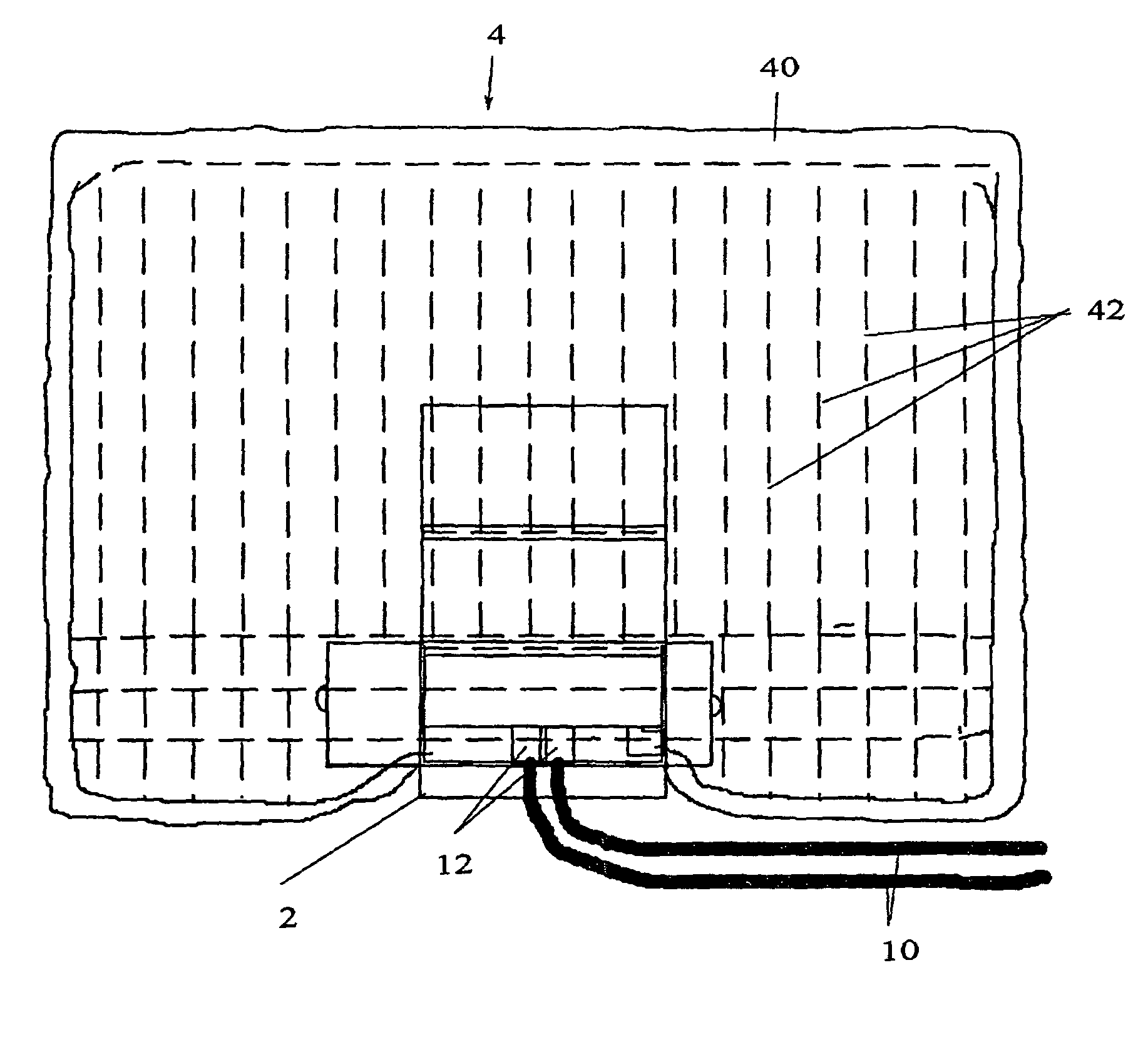

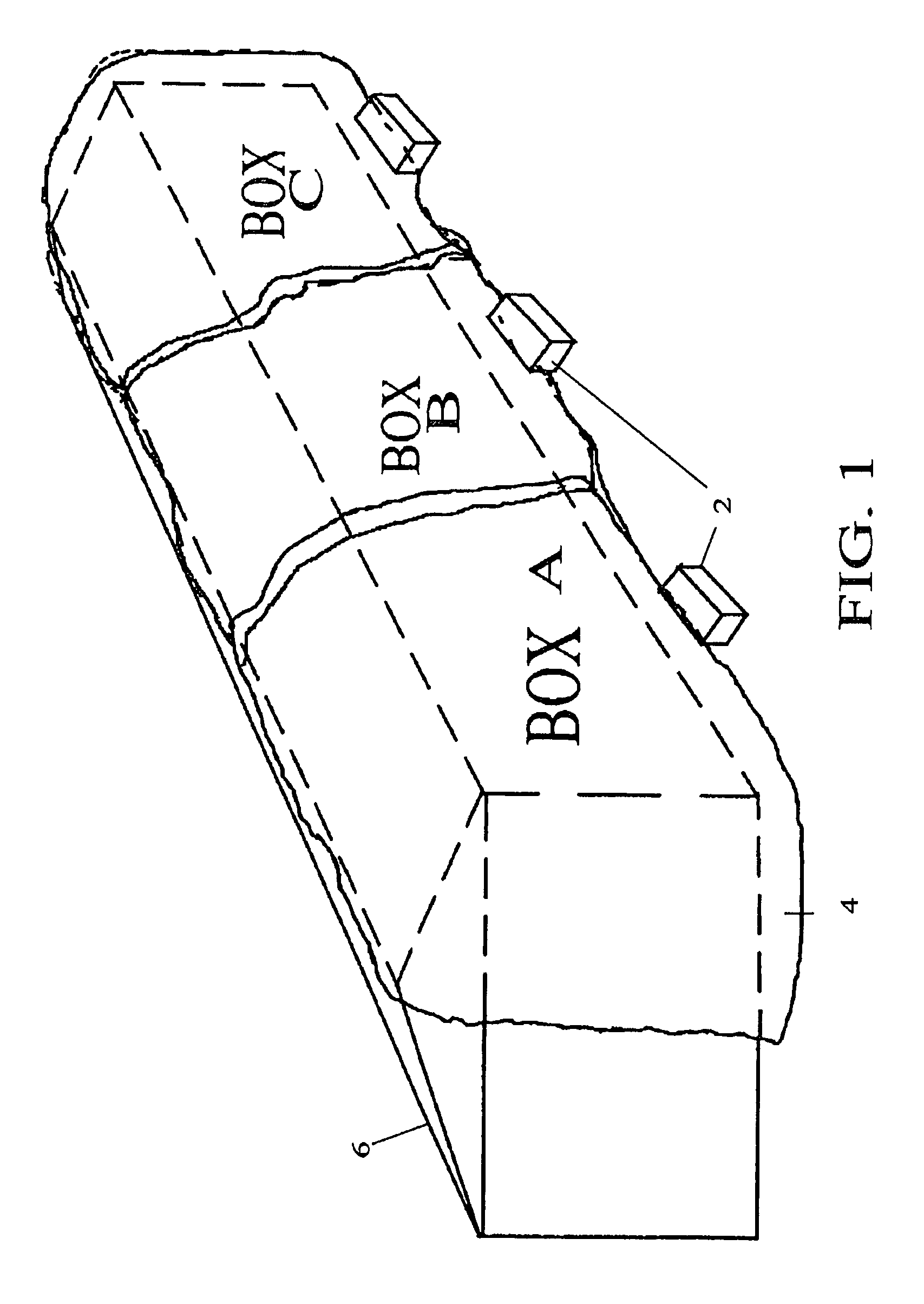

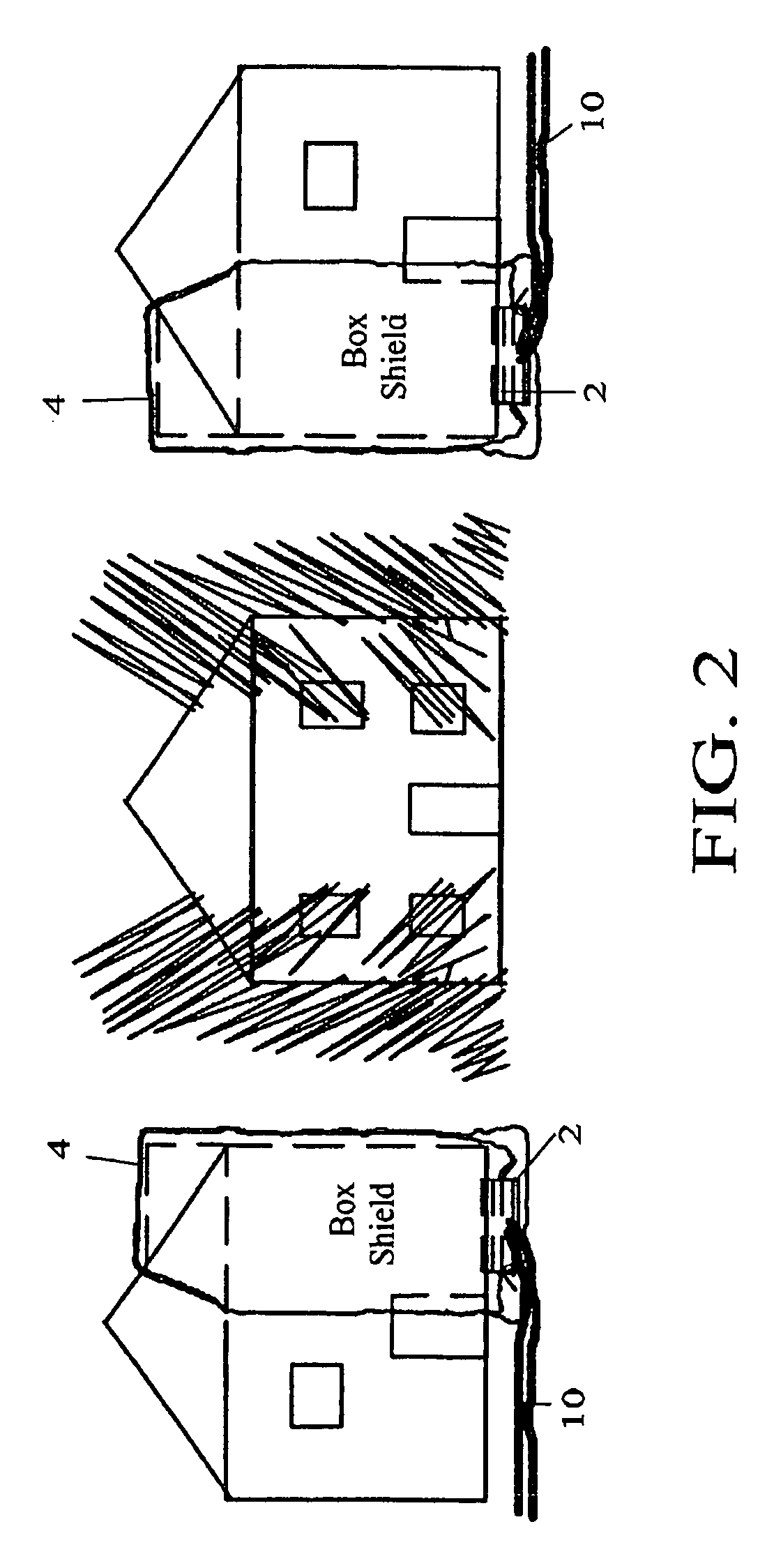

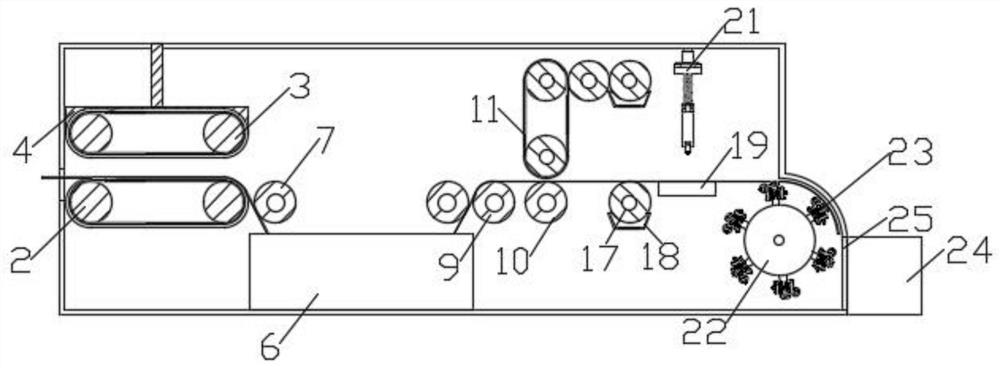

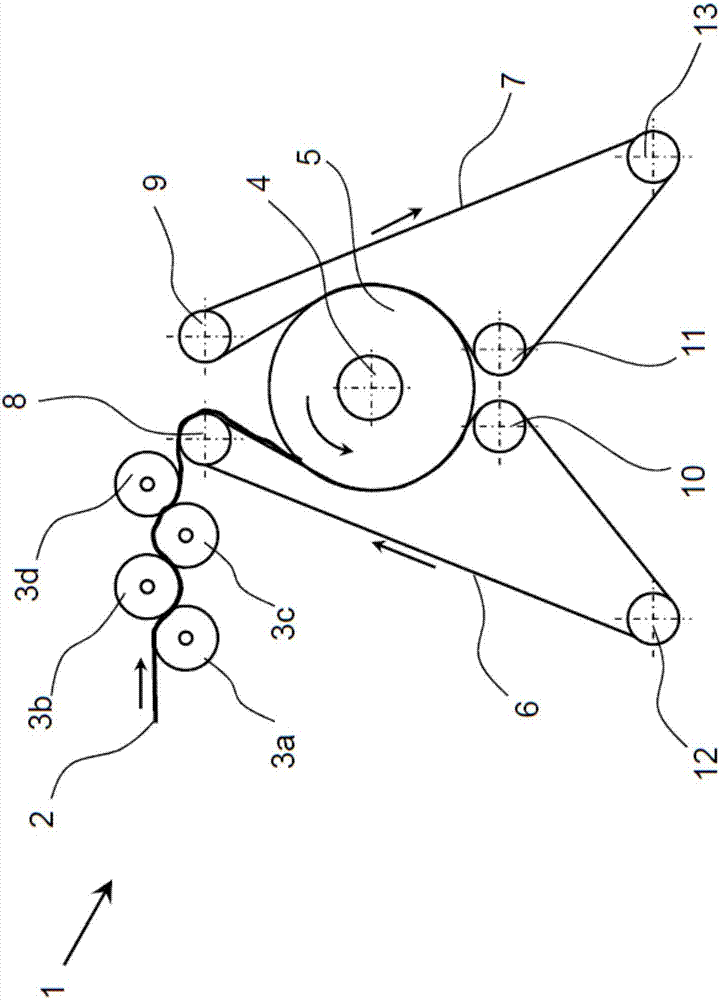

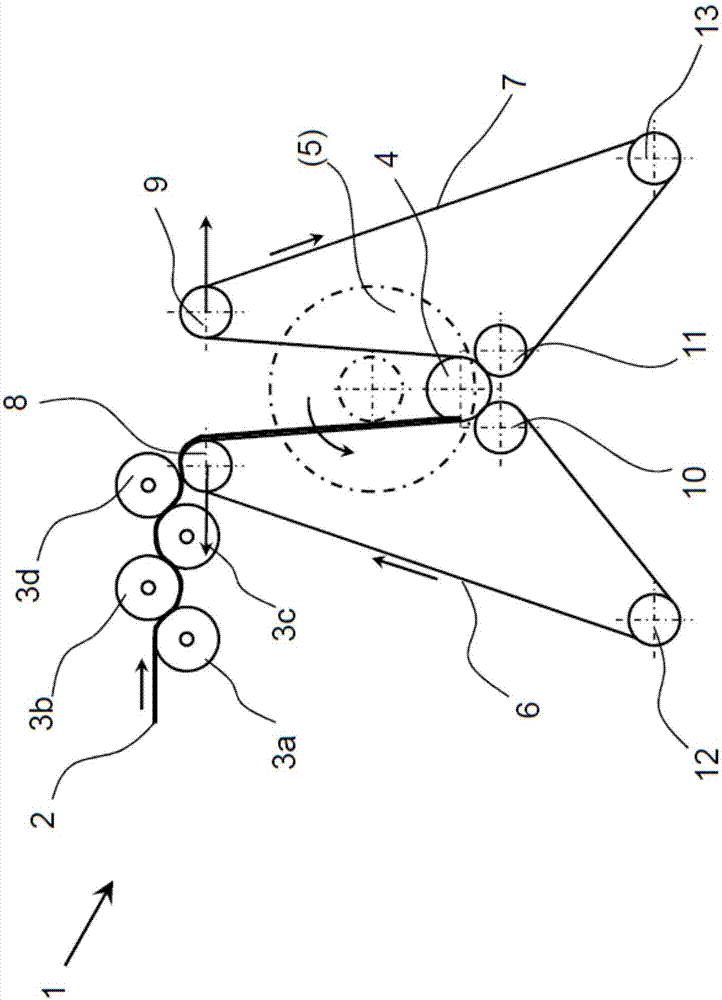

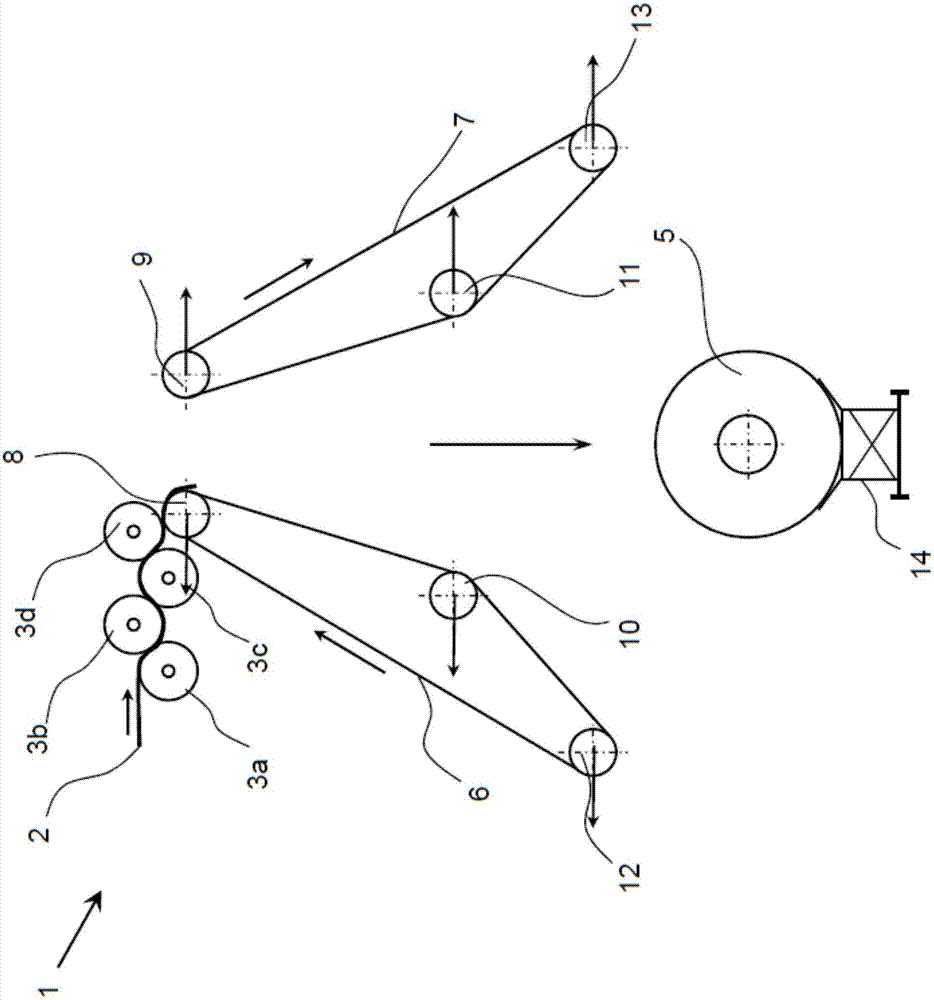

Coiling machine for coiling cotton strips into cotton coils

The invention relates to a coiling machine and method for coiling fiber strips prepared from cotton fibers (2) to bobbins (4). The cotton fibers are led to the bobbins (4) through a continuously rounding first belt (6). The coiling machine and the method are characterized in that a continuously rounding second belt (7) leads the cotton fibers (2) along the bobbins (4).

Owner:TRUETZSCHLER GRP SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com