Porous adsorption supported light-catalyzed reaction film and preparation method and application thereof

A photocatalytic reaction and porous adsorption technology, applied in the field of photocatalysis, can solve the problems of long photocatalytic reaction film preparation cycle, poor adsorption and degradation performance, and low photocatalytic efficiency, and achieve good reusability, good adhesion, The effect of enhancing light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

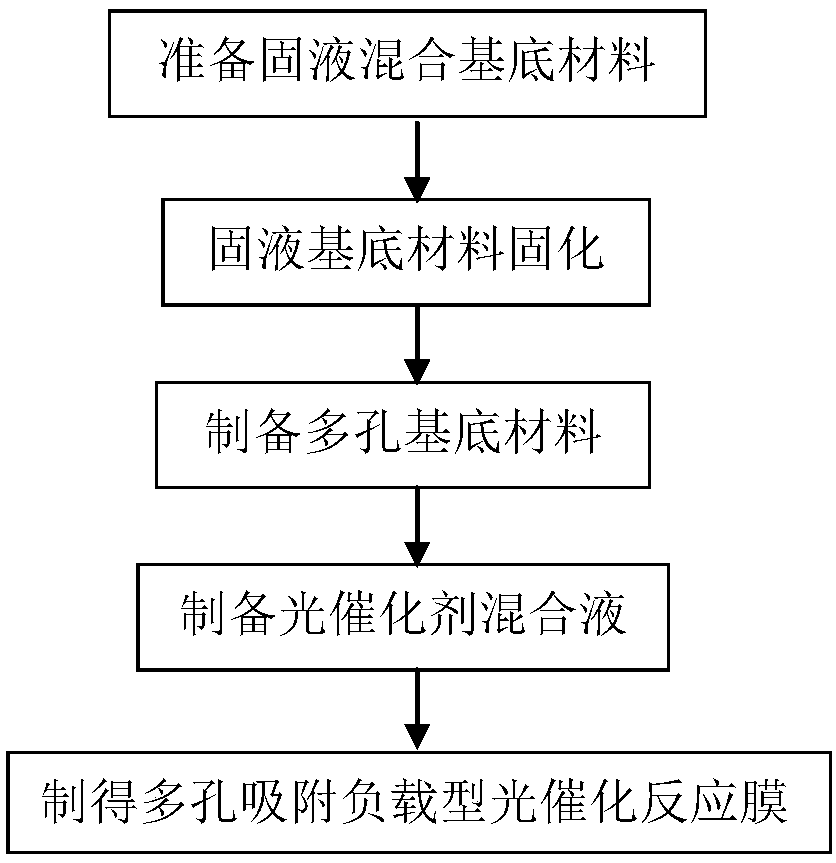

[0035] The invention provides a method for preparing a porous adsorption-loaded photocatalytic reaction film, figure 1 It is a flowchart of a preparation method of a porous adsorption-loaded photocatalytic reaction membrane, comprising the following steps:

[0036] (1) Prepare 1.5g of PDMS mixed solution with PDMS solution and curing agent according to the ratio of 10:1, and mix evenly to obtain the mixed solution; weigh 4.5g of citric acid and 1.5g of the above mixed solution and pour it into a 5mm high vessel , stir and mix evenly to obtain a solid-liquid mixed material;

[0037] (2) Place the solid-liquid mixed material obtained above horizontally in a vacuum hood and evacuate for 1 hour. The vacuum condition is greater than -0.1Mpa to remove small closed-cell bubbles. Manually flatten the surface and put it in an oven at 70°C. Bake for 1-1.5h;

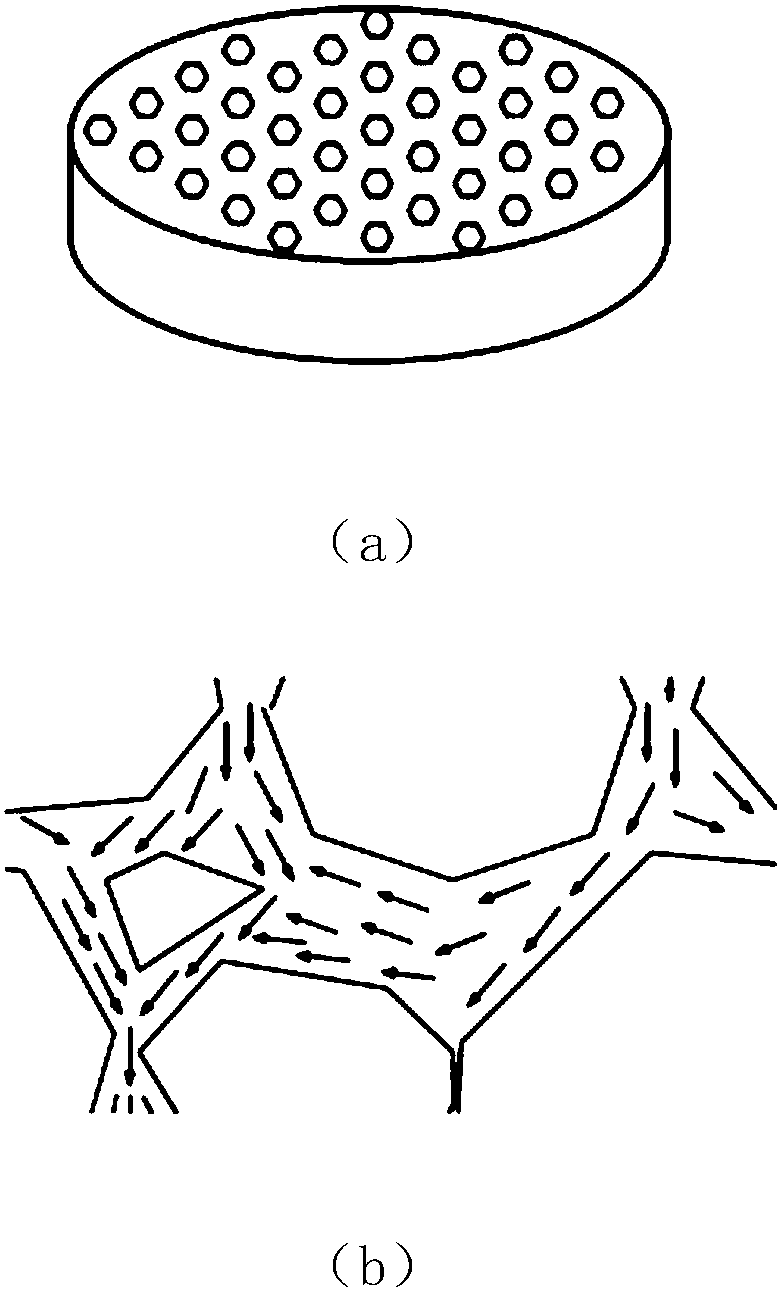

[0038] (3) After taking out the dried solid mixture, put it in water, squeeze it for about 5 minutes, and after the citric acid...

Embodiment 2

[0042] The invention provides a method for preparing a porous adsorption-loaded photocatalytic reaction membrane, comprising the following steps:

[0043] (1) Prepare 1.5g of PDMS mixed solution with PDMS solution and curing agent according to the ratio of 10:1, and mix evenly to obtain the mixed solution; weigh 3g of citric acid and 1.5g of the above mixed solution and pour it into a 5mm high vessel , stirring and mixing evenly to obtain a solid-liquid mixed material;

[0044] (2) Place the solid-liquid mixture material obtained above horizontally in a vacuum hood to evacuate for 1 hour, remove the small closed-cell bubbles, manually flatten the surface, and bake in an oven at 70°C for 1-1.5 hours;

[0045] (3) Take out the dried solid mixture, put it in water, squeeze it by hand for about 5 minutes, and after the citric acid is completely dissolved, put it in an oven at 110°C and bake it repeatedly for 1-2 hours until it is dried to obtain porous PDMS base material;

[004...

Embodiment 3

[0049] The invention provides a method for preparing a porous adsorption-loaded photocatalytic reaction membrane, comprising the following steps:

[0050] (1) Prepare 1.5g of PDMS mixed solution with PDMS solution and curing agent according to the ratio of 10:1, and mix evenly to obtain the mixed solution; weigh 4.5g of citric acid and 1.5g of the above mixed solution and pour it into a 5mm high vessel , stir and mix evenly to obtain a solid-liquid mixed material;

[0051] (2) Place the solid-liquid mixture material obtained above horizontally in a vacuum hood to evacuate for 1 hour, remove the small closed-cell bubbles, manually flatten the surface, and bake in an oven at 70°C for 1-1.5 hours;

[0052] (3) Take out the dried solid mixture, put it in water, squeeze it by hand for about 5 minutes, and after the citric acid is completely dissolved, put it in an oven at 110°C and bake it repeatedly for 1-2 hours until it is dried to obtain porous PDMS base material;

[0053] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com