Patents

Literature

4667results about How to "Short preparation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

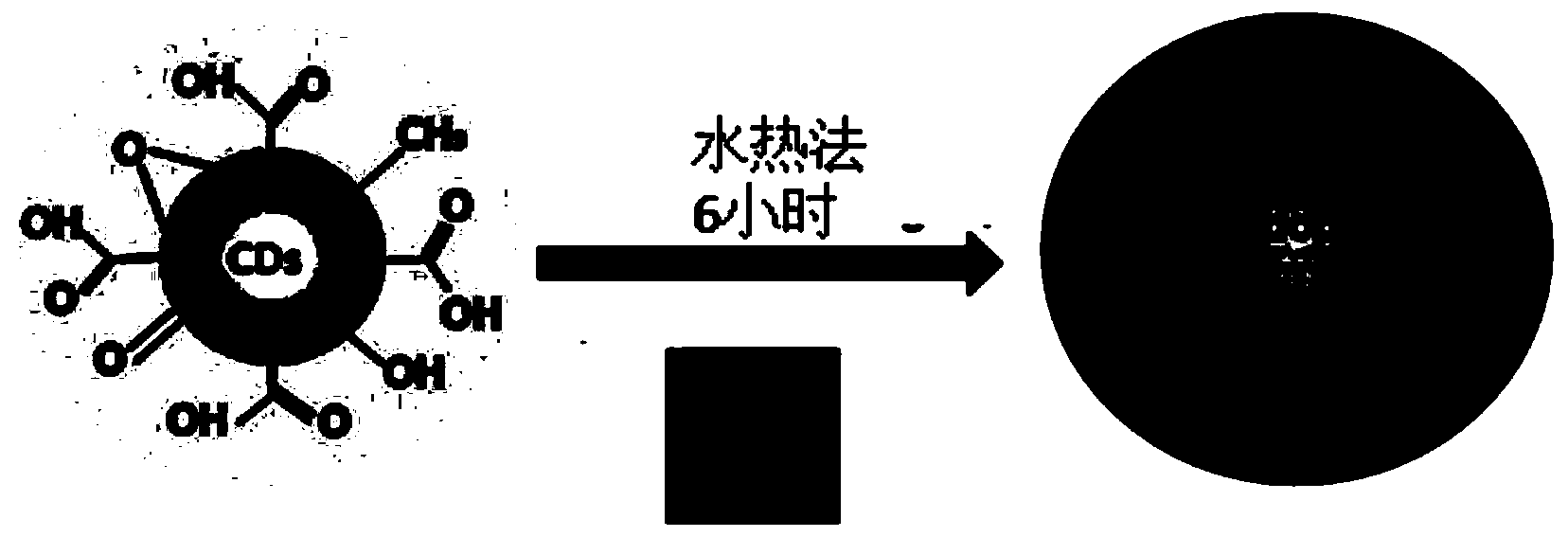

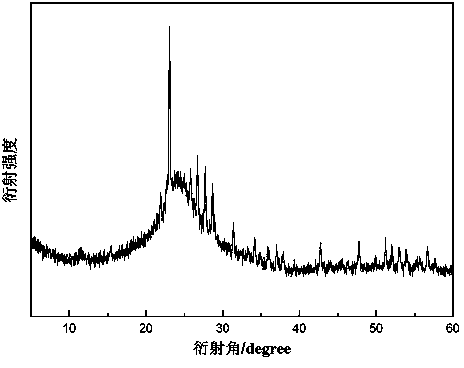

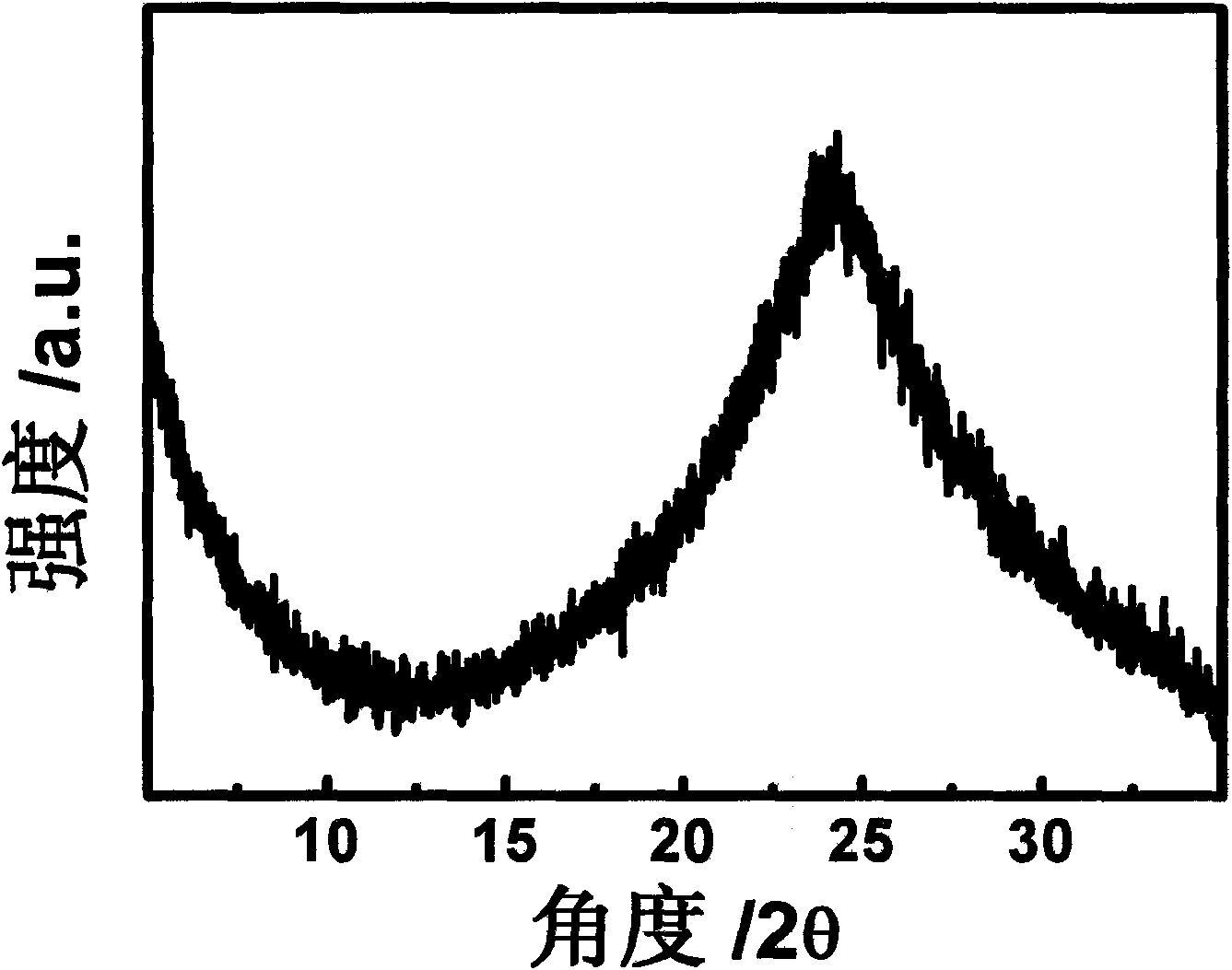

Nitrogen-doped high-luminescent carbon quantum dot and preparation method thereof

ActiveCN103923647ASimple processShort preparation cycleMaterial nanotechnologyLuminescent compositionsUltimate tensile strengthRepeatability

The invention provides a nitrogen-doped high-luminescent carbon quantum dot and a preparation method thereof. The preparation method comprises the following steps: reacting by using a sodium citrate solution as a carbon source and ethanediamine as a source of N under a sealing condition, cooling an obtained product, then separating, and drying a solution obtained after separation so as to obtain the nitrogen-doped high-luminescent carbon quantum dot. The preparation method is simple in process, short in preparation period, low in manufacturing cost and good in repeatability; obtained raw materials are simple and easily available. The nitrogen-doped high-luminescent carbon quantum dot prepared by using the method is uniform in size distribution and high in luminescent density; the luminescent density of the nitrogen-doped high-luminescent carbon quantum dot is about 20 times of that of a general quantum dot, so that the application of the nitrogen-doped high-luminescent carbon quantum dot in the field of cell marking can be expanded. As the improvement of the luminescent density is caused by nitrogen doping, the nitrogen-doped high-luminescent carbon quantum dot prepared by the method has unique application when being used for detecting whether N exists in environments.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

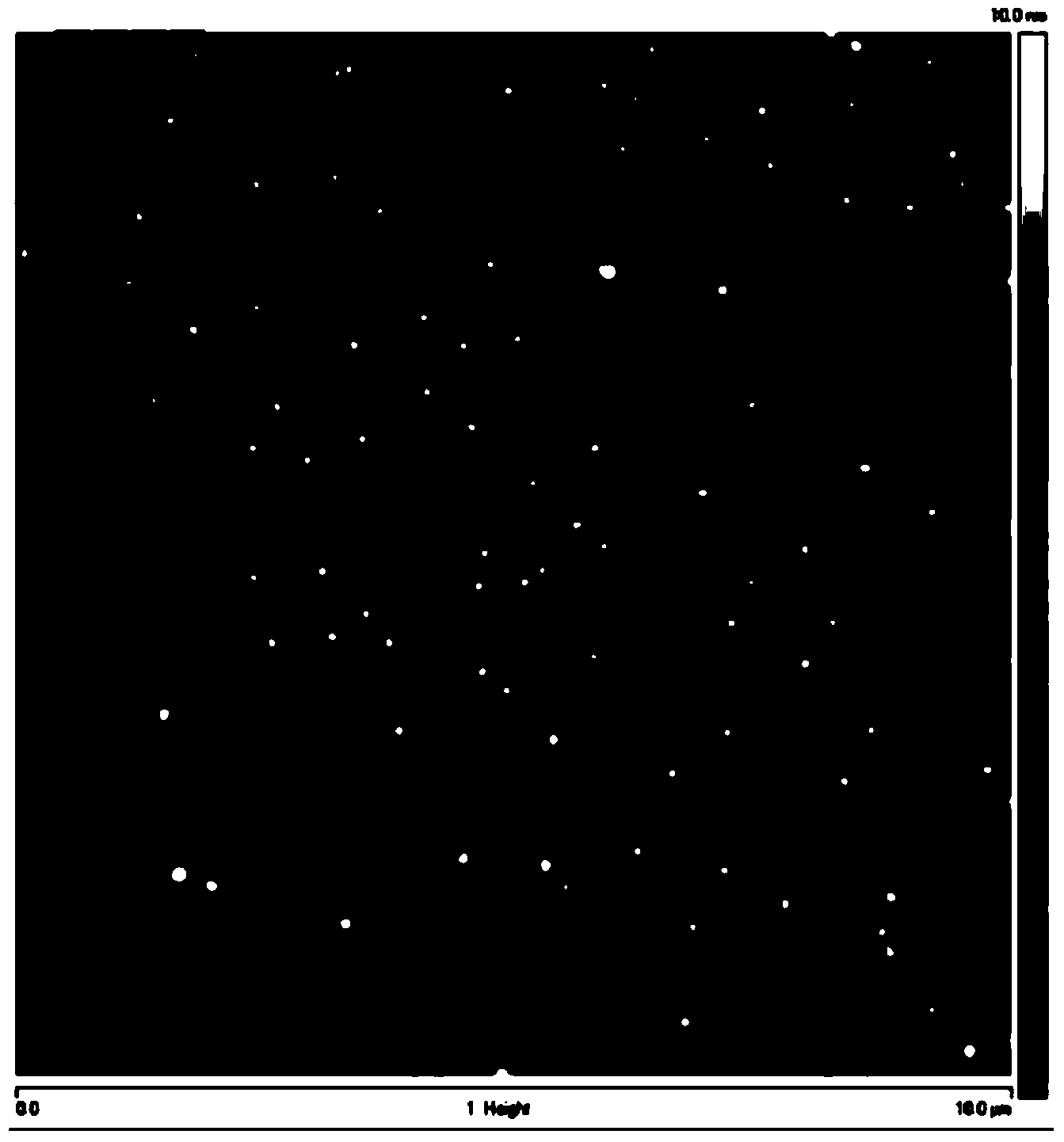

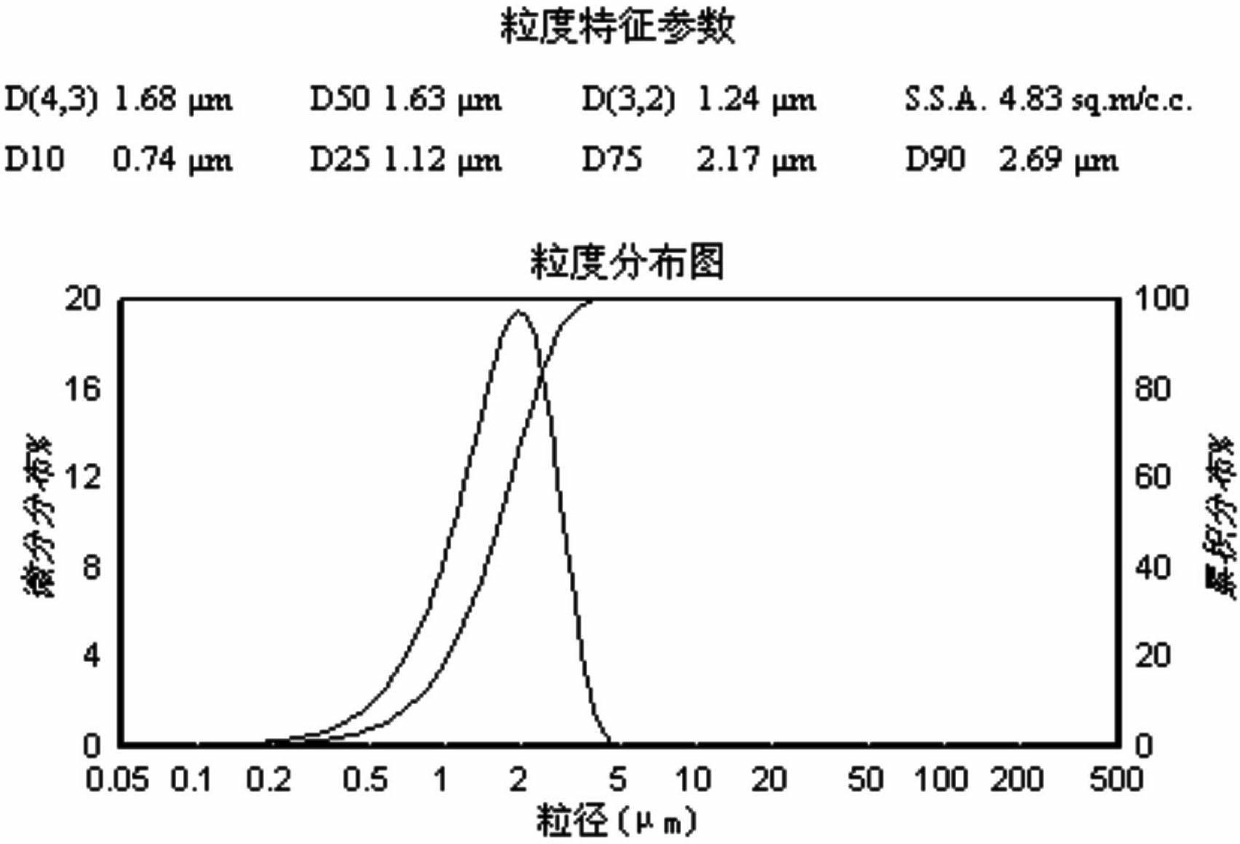

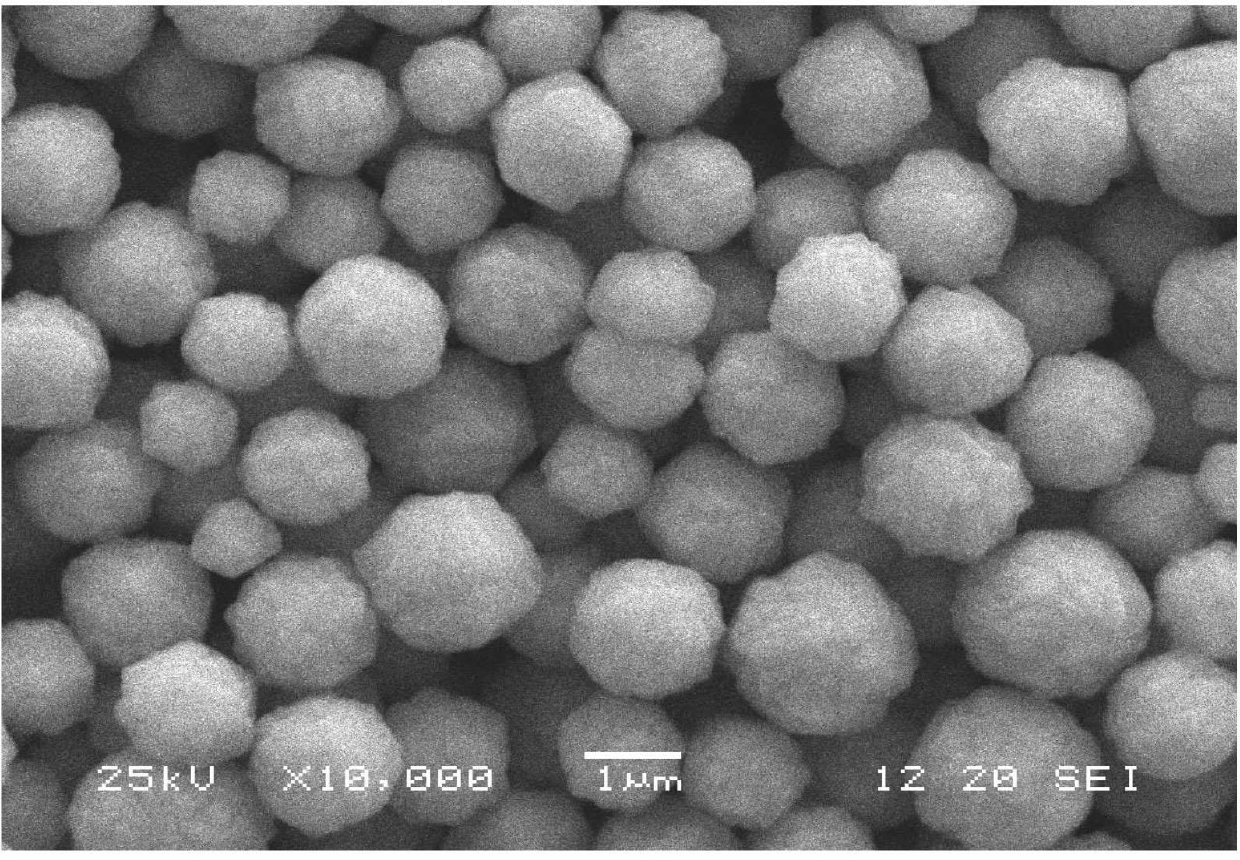

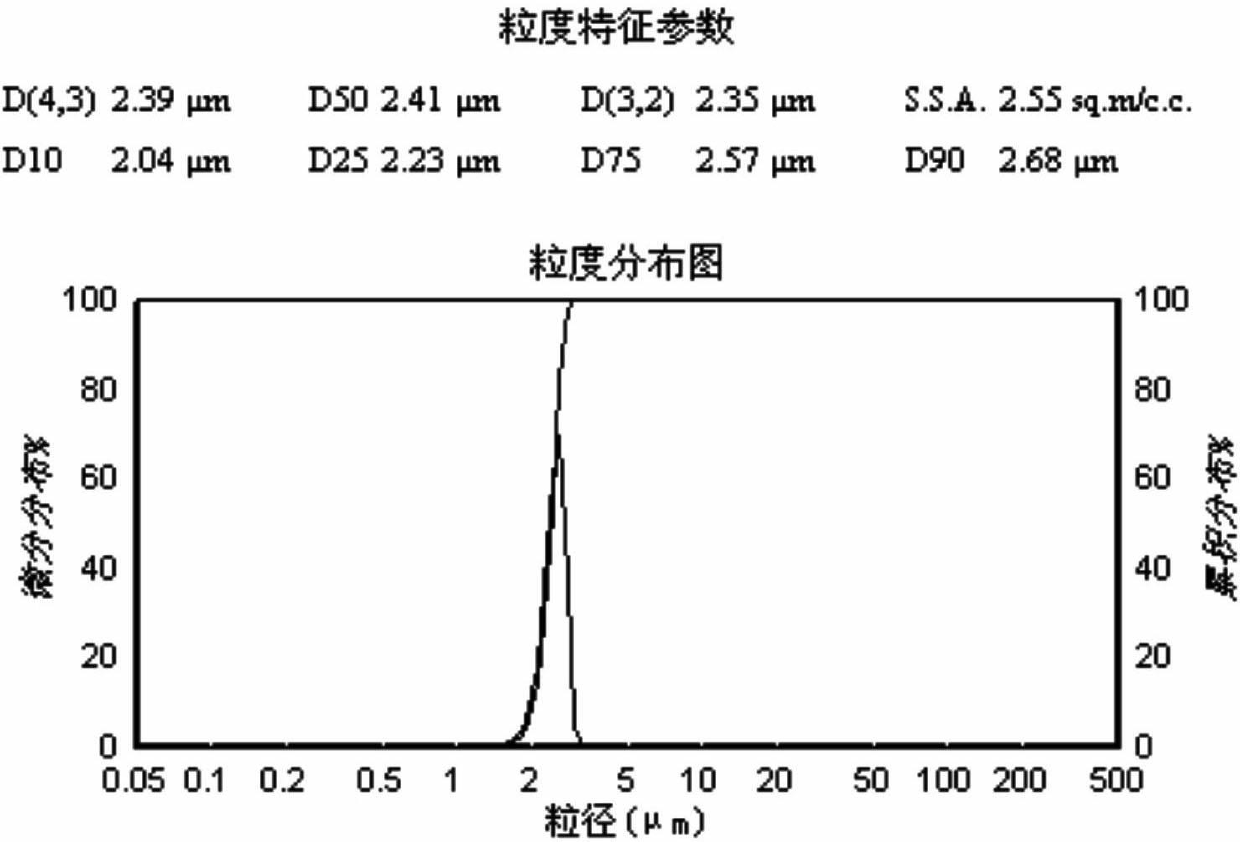

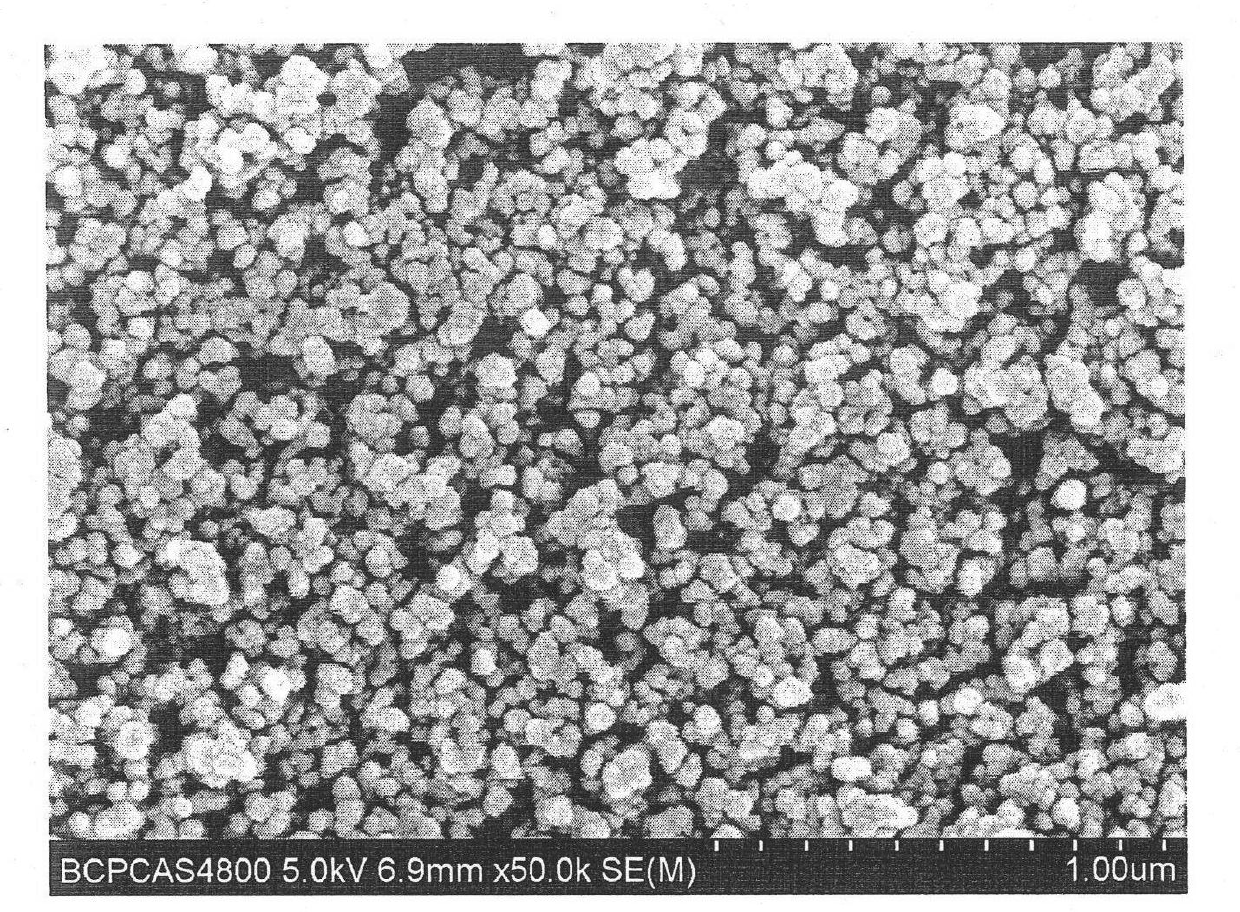

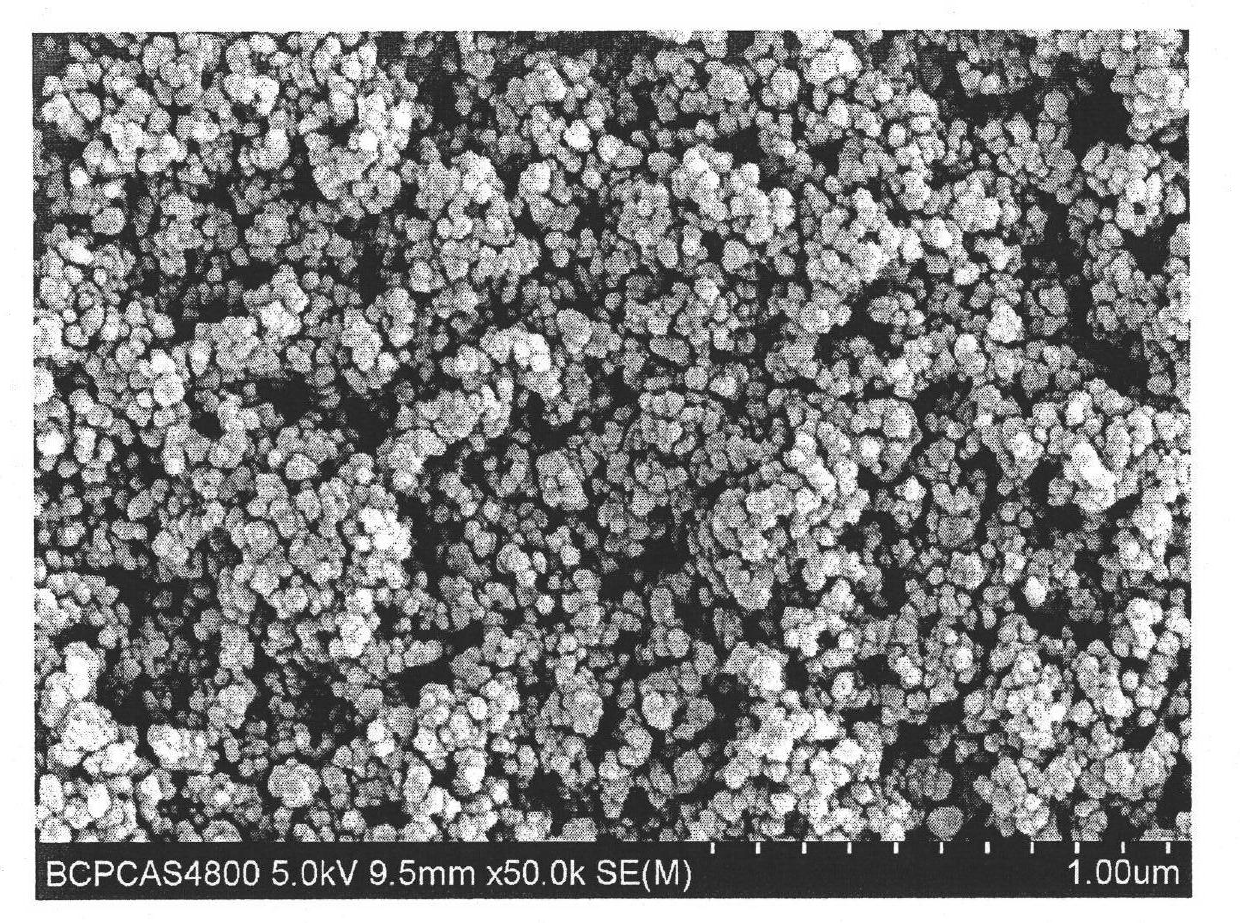

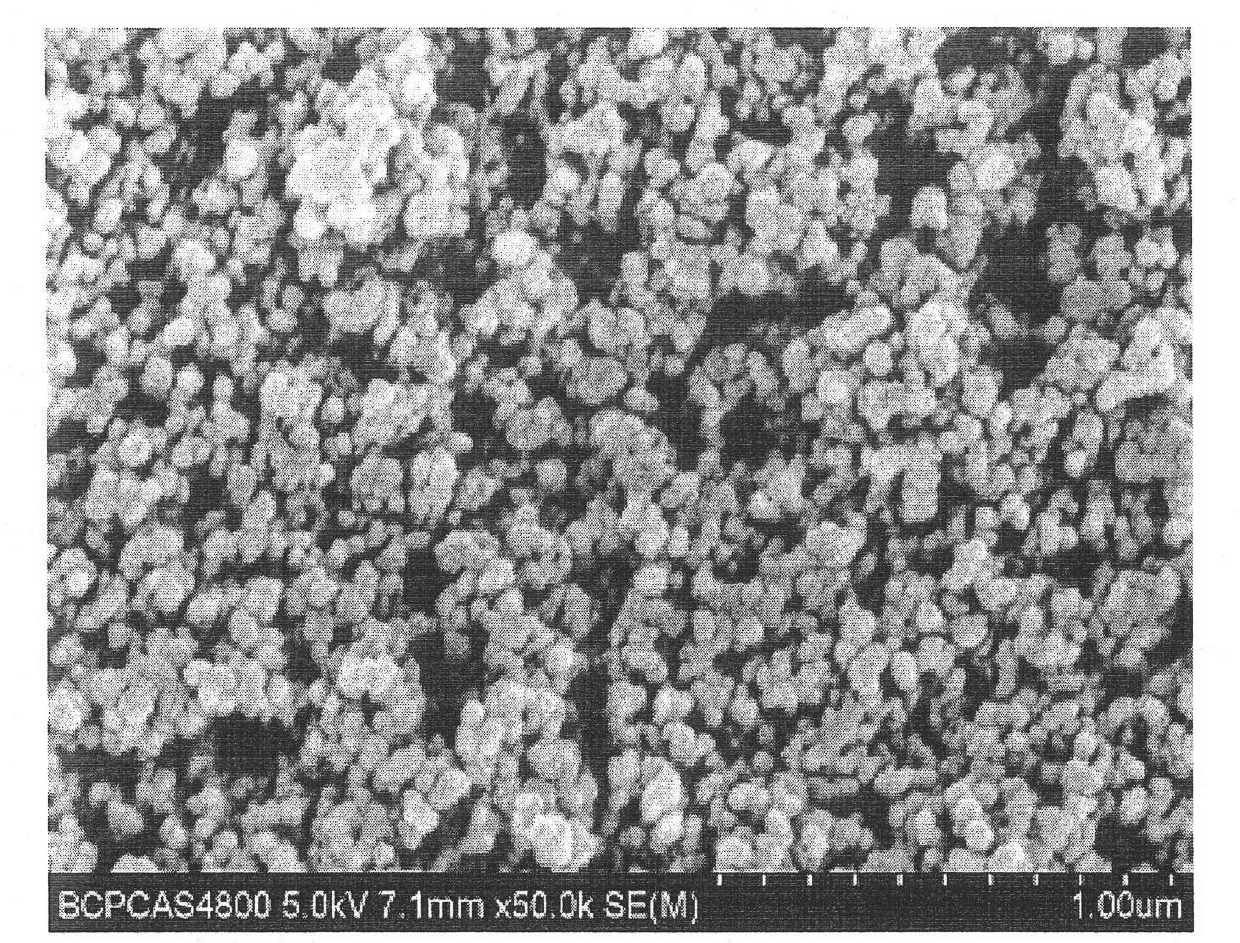

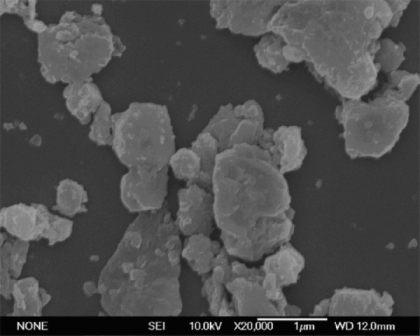

Spherical silver powder and preparation method thereof

ActiveCN102632248ANarrow particle size distributionSimple preparation processPyrrolidinonesDisplay device

The invention discloses a spherical silver powder, wherein the particle size distribution range of the spherical silver powder is 0.1-5 mum, and the D50 particle size is 1.0-3.5 mum; the tap density of the spherical silver powder is greater than 3.6 g / cm<3>; and the specific surface area of the spherical silver powder is less than 1.0 m<2> / g. The preparation method for the spherical silver powder comprises the following step of: with L-ascorbic acid as a reductive agent and polyvinylpyrrolidone as a protective agent, reducing silver out of a reaction material, namely silver nitrate solution, by a chemical reduction method, wherein the pH value of the reaction system is controlled to be constant between 3 to 6 during the whole reaction process of the chemical reduction method, so as to keep the speed of the reduction reaction for silver nitrate stable. The spherical silver powder disclosed by the invention is narrow in particle size distribution range, excellent in dispersity, high in tap density, small in specific surface area, and especially suitable for preparing a silver paste for the electrode of a solar cell and the electrode of a plasma displayer.

Owner:NAT UNIV OF DEFENSE TECH +1

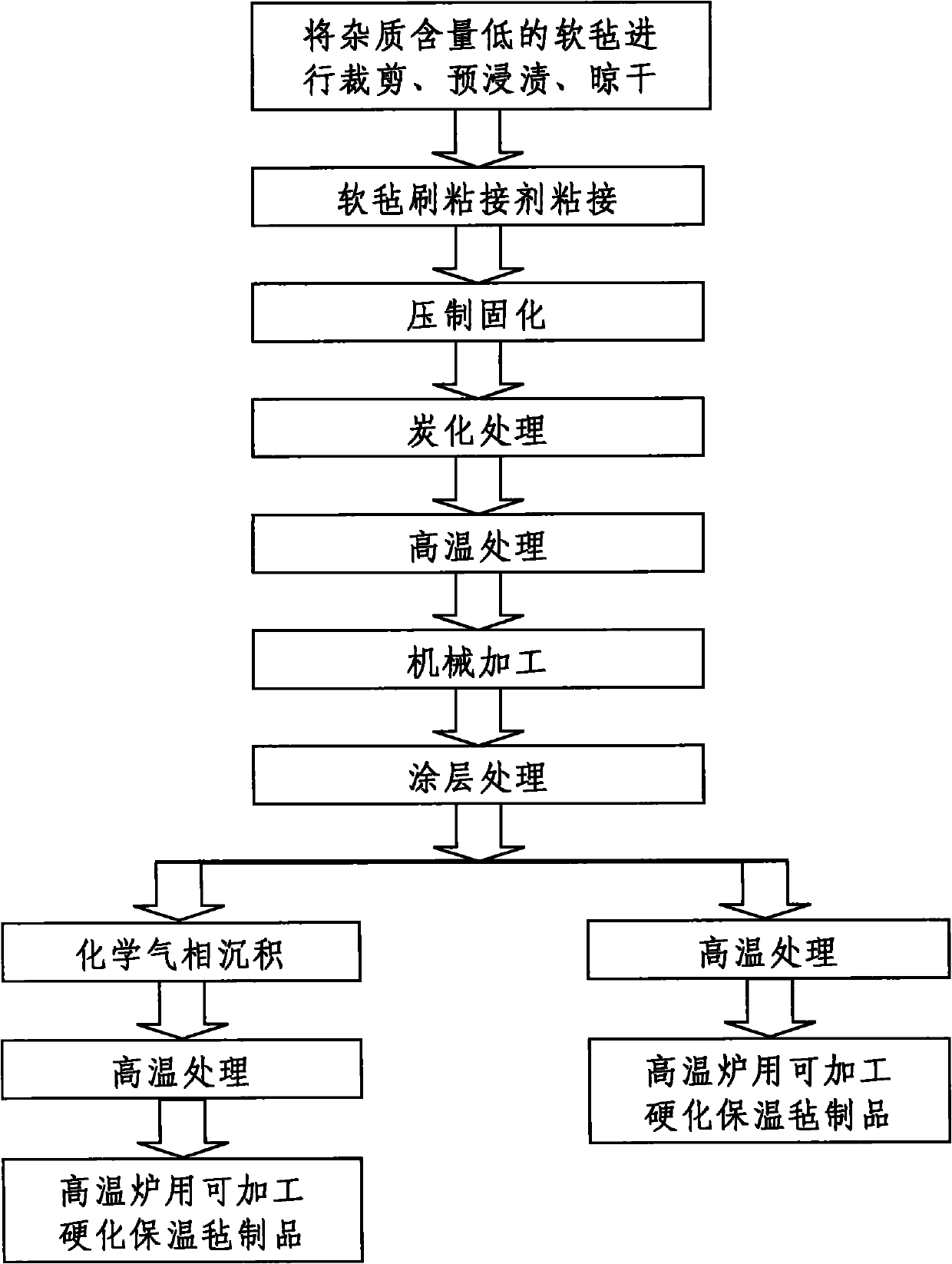

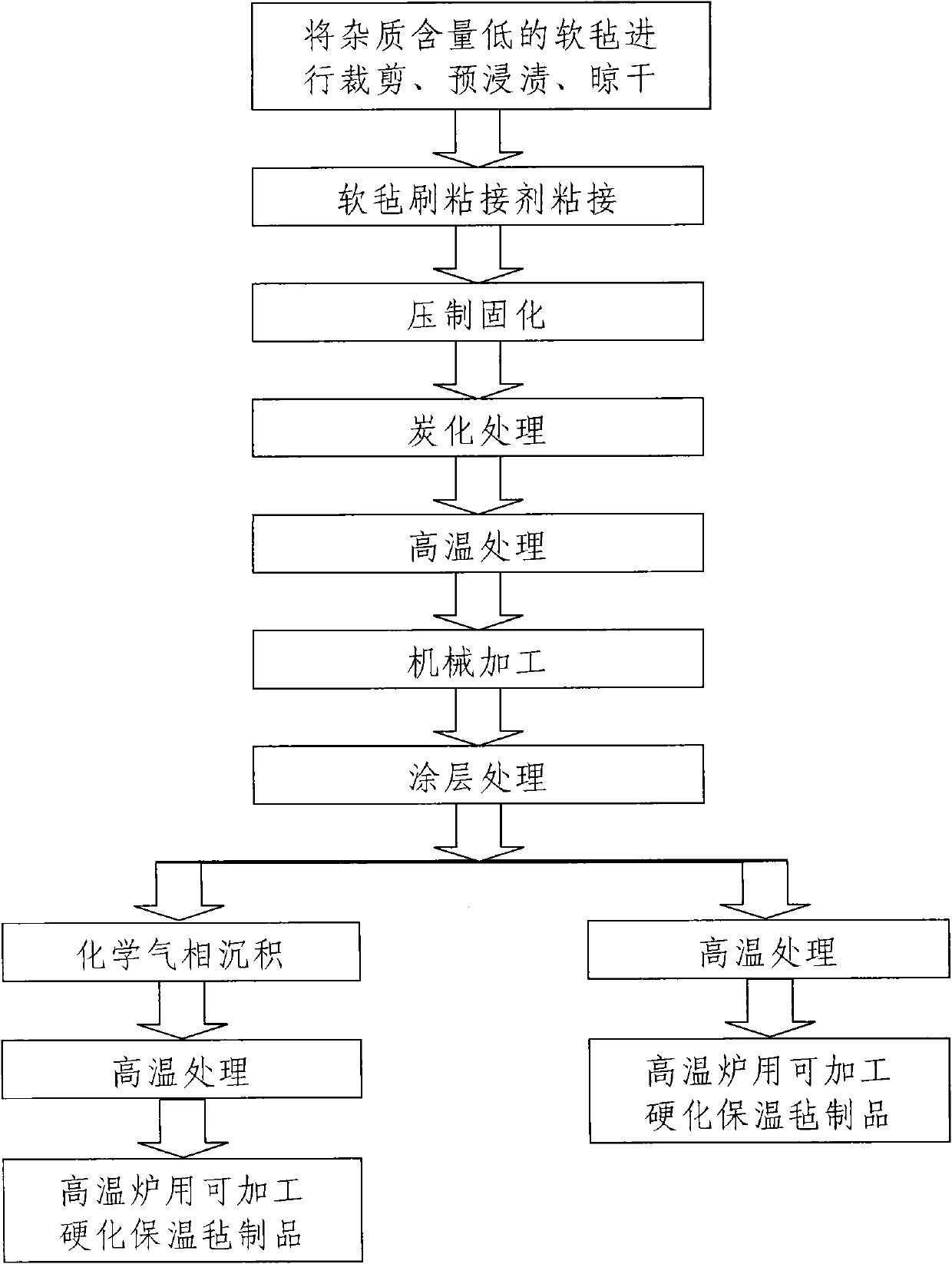

Method for preparing work hardening insulation quilt for high temperature furnace

The invention relates to a method for preparing a work hardening insulation quilt for a high temperature furnace, which comprises the following steps of: 1, cutting, pre-impregnating and airing a soft quilt; 2, adhering the soft quilt by using an adhesive; 3, pressing and curing for forming; 4, performing carbonization treatment; 5, performing high temperature treatment; 6, machining; 7, performing coating treatment; and 8, performing chemical vapor deposition treatment and high temperature treatment, or directly performing high temperature treatment to obtain the work hardening insulation quilt for the high temperature furnace. The method has the advantages of simple technological process and suitability for mass production; and the prepared work hardening insulation quilt has the heat conductivity of less than or equal to 0.5W / m.K, the ash content of less than or equal to 2,000ppm, high mechanical properties and high-temperature dimensional stability and excellent processability, does not generate volatile matters when used in the high temperature furnace, cannot pollute the product, and has important significance for prolonging the service life of the insulation quilt in the high temperature furnace.

Owner:XIAN CHAOMA SCI TECH

Method for preparing titanium dioxide films for dye-sensitized solar battery

ActiveCN101770869AFacilitate conductionImprove continuityLight-sensitive devicesSolid-state devicesSlurrySolar battery

The invention relates to a method for preparing titanium dioxide films for a dye-sensitized solar battery, comprising the following steps: (a) titanium dioxide sol with 1-10 wt percent of titanium dioxide, 5-10nm of grain size and 10-100mg / mL of concentration and titanium dioxide powder with 5-15 wt percent of titanium dioxide and 20-40nm of grain size are uniformly ground, 80-90 wt percent of pore-forming agent is added, and the obtained 100wt percent of mixture are grounded for 0.5-2 hours; (b) titanium dioxide slurry is coated on conductive glass and is dried for 5-15 minutes at 100-130 DEG C; and (c) the conductive glass coated with the titanium dioxide slurry is sintered for 0.5-2 hours at 450-500 DEG C; by adopting the method in the invention, the process is simple, the operation is easy, the preparation period is short, thereby being beneficial to industrialization; in addition, the photoelectricity conversion efficiency of the dye-sensitized solar battery assembled by the titanium dioxide films is high by adopting the method.

Owner:ENN SCI & TECH DEV

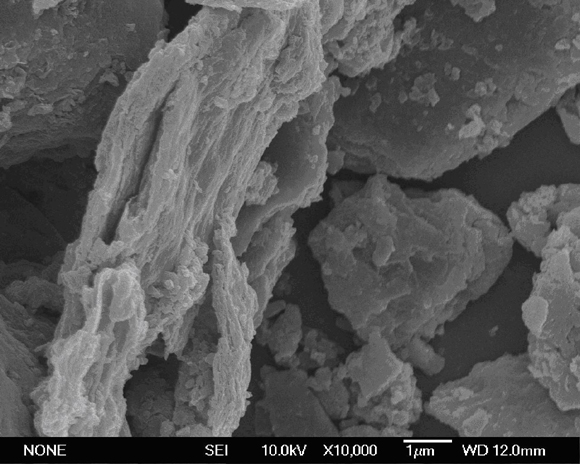

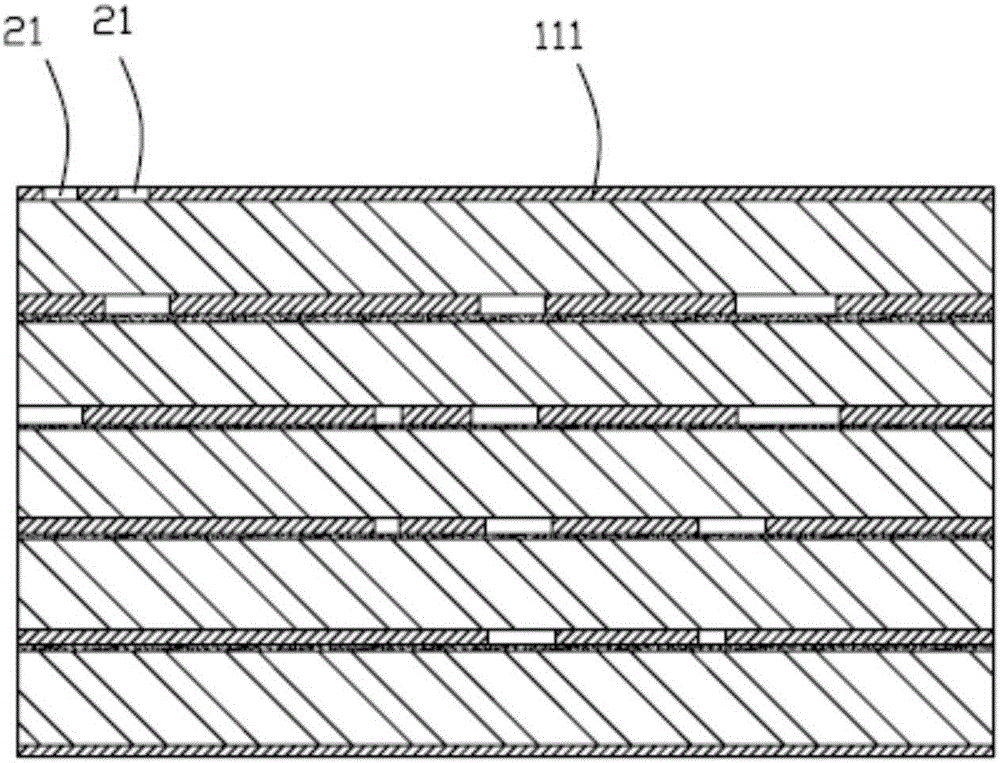

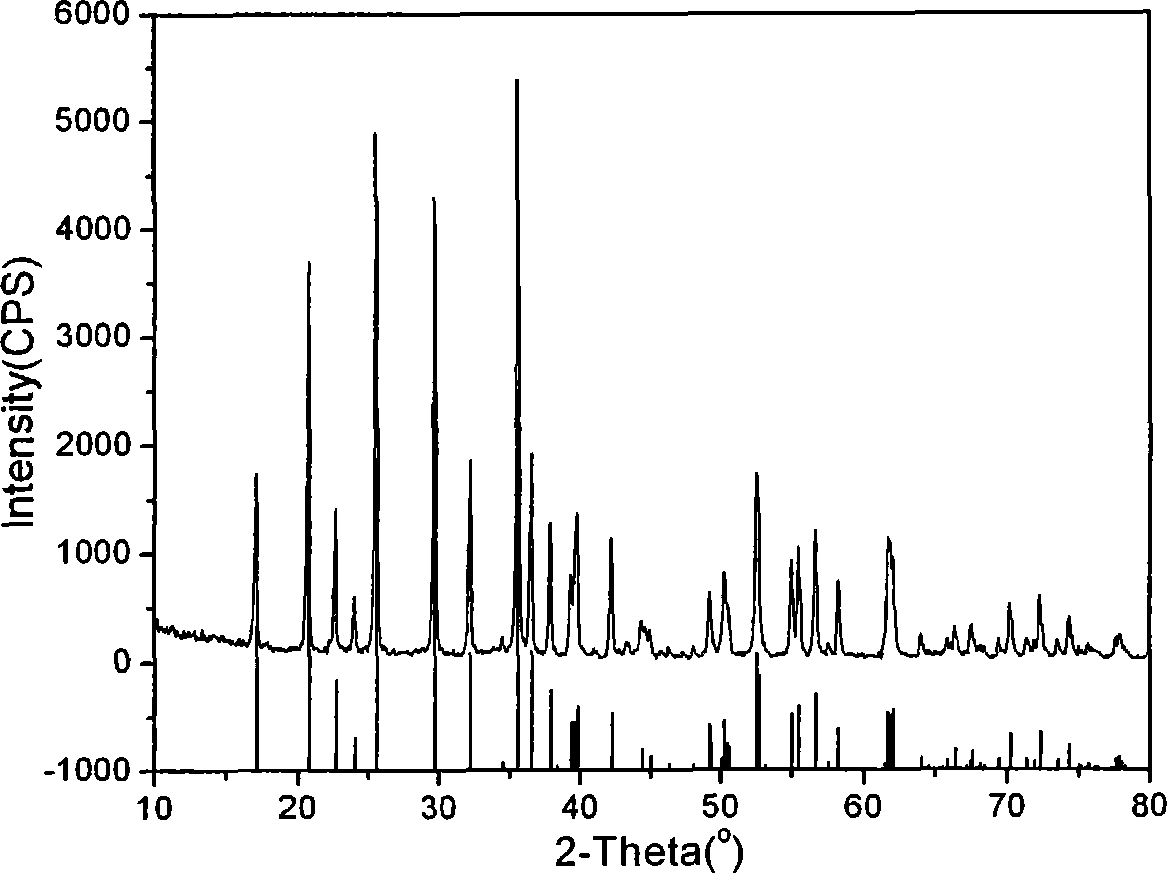

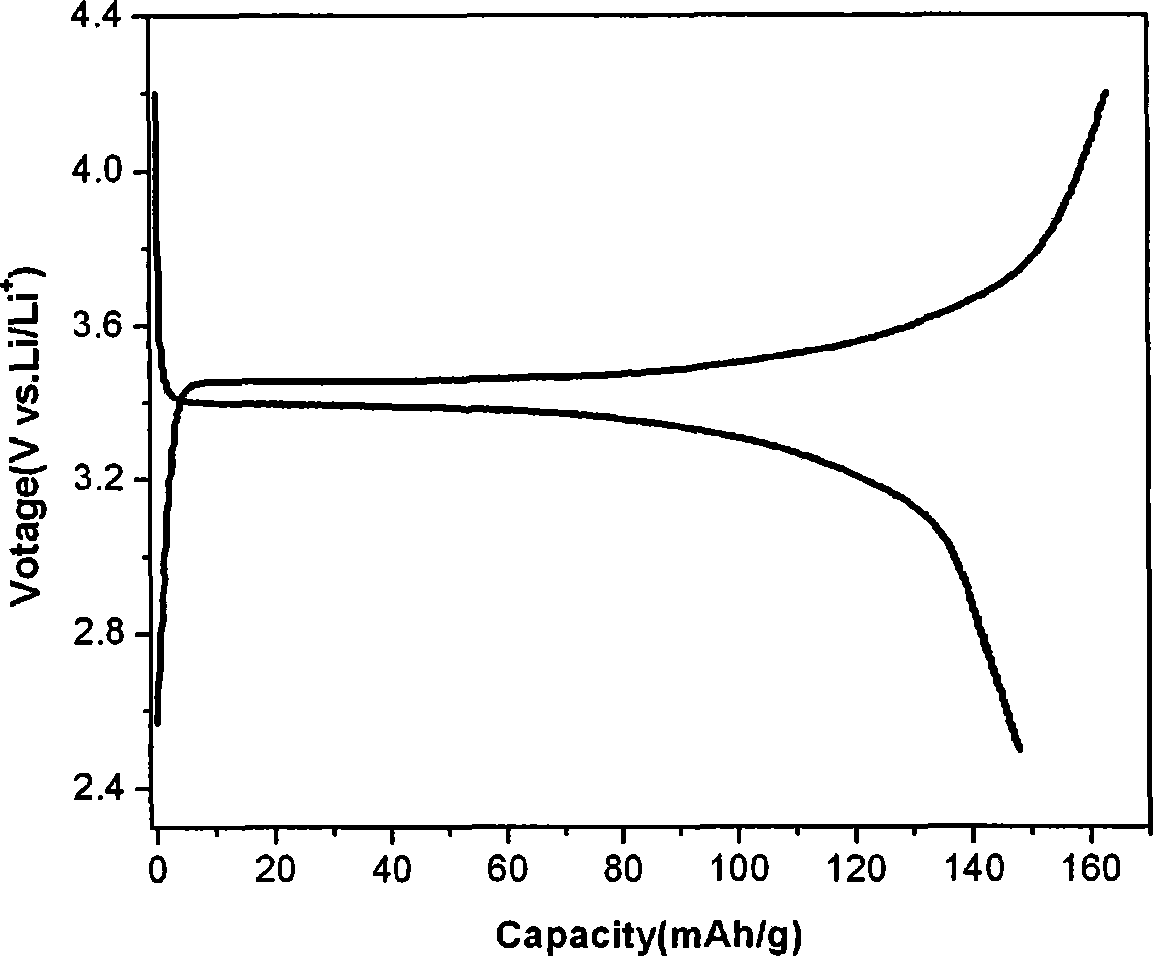

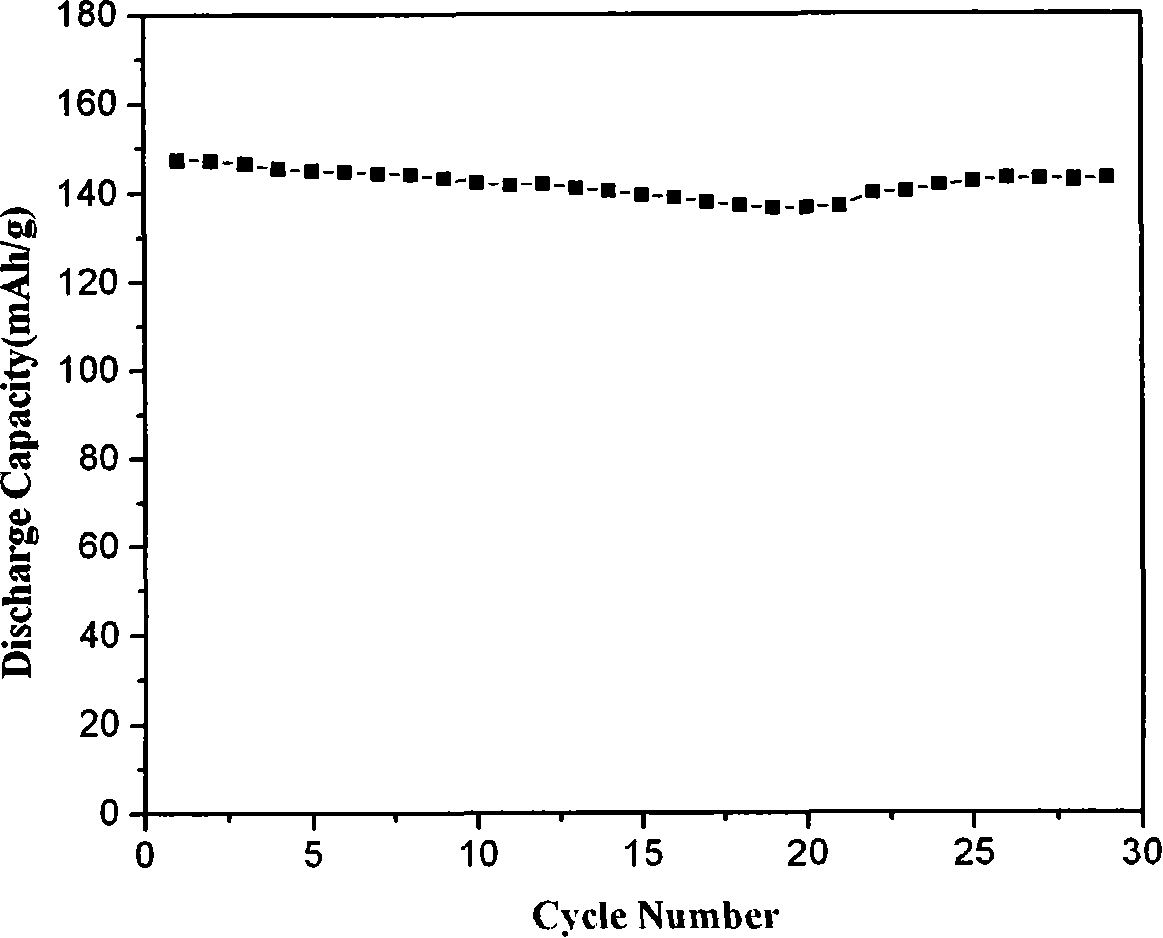

Graphene/phosphoric acid iron-lithium composite material with sandwich structure and preparation method thereof

InactiveCN102148371ASimple preparation processShort preparation cycleNon-aqueous electrolyte accumulator electrodesO-Phosphoric AcidLithium-ion battery

The invention relates to a graphene / phosphoric acid iron-lithium composite material with a 'sandwich' structure and a preparation method thereof. The structure characteristics of the graphene / phosphoric acid iron-lithium composite material are that: blocky particles are formed by a grapheme laminated sheet which is completely coated by a phosphoric acid iron-lithium shell; and the insides of the particles present a similar 'sandwich' structure overlapped by a plurality of layers of phosphoric acid iron-lithium and graphene one by one. The preparation method thereof adopts a 'two-step' method. The characteristic steps are as follows: a graphene / phosphoric acid iron precursor with a 'sandwich' structure is compounded by a liquid phase method during the first step; then lithium is embedded in the second step; lithium iodide liquid phase low temperature reaction is adopted for embedding the lithium; then the graphene / phosphoric acid iron-lithium composite material is obtained through high temperature calcination under reducing (inertia) atmospheres; moreover, the graphene / phosphoric acid iron-lithium composite material can also be formed by the embedding of the lithium through high temperature solid phase reaction. The graphene / phosphoric acid iron-lithium composite material prepared by the method has high capacity and good charging-discharging circulating performances, and is suitable to be used as an anode material of a lithium ion battery.

Owner:SHANGHAI UNIV

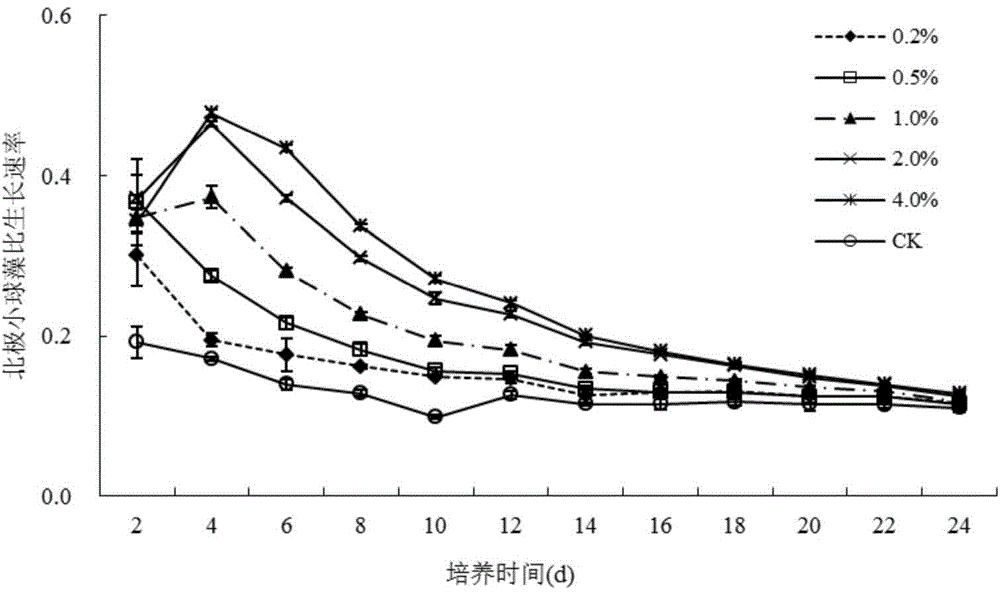

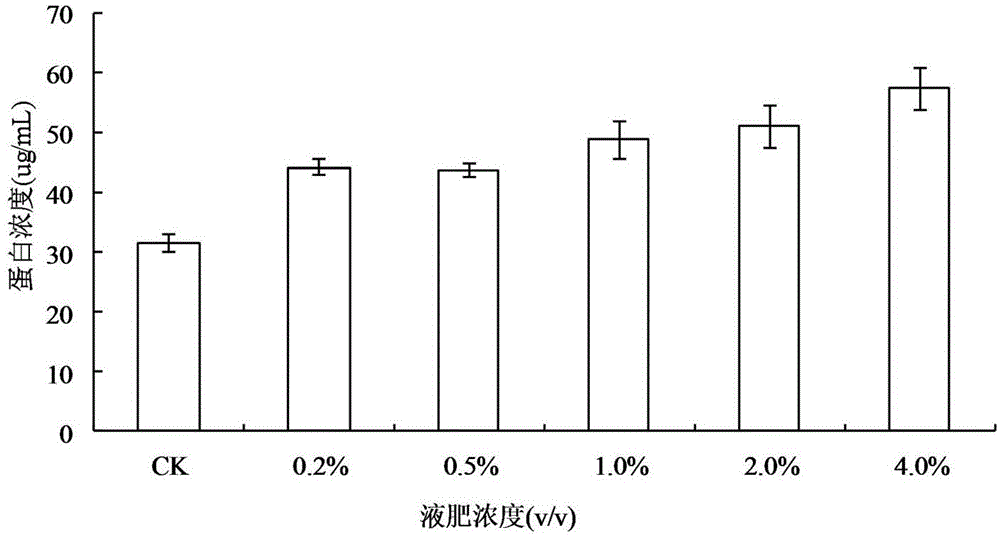

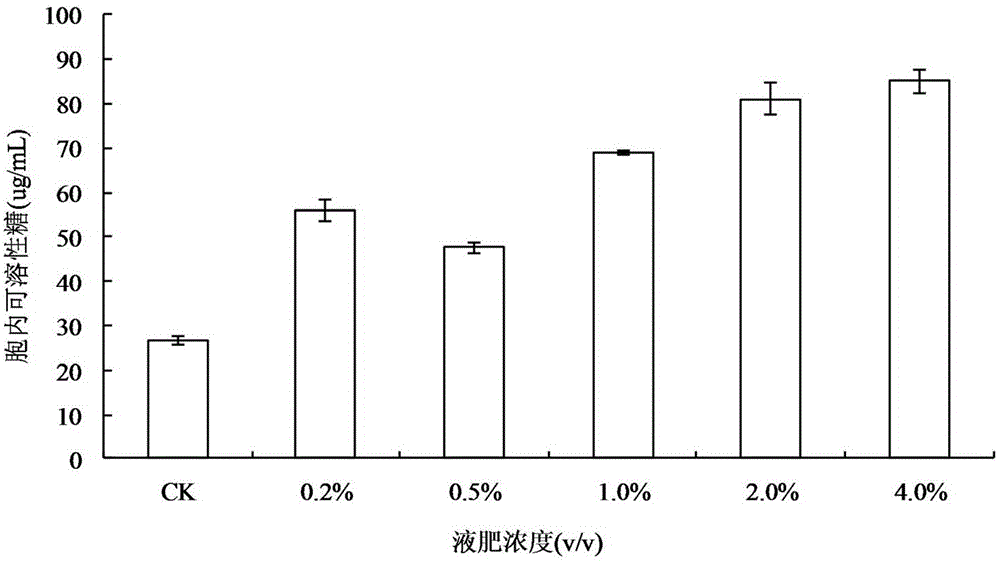

Method for producing organic seaweed fertilizer employing algae processing waste and prepared fertilizer

ActiveCN104387171ASimple and fast operationShort preparation cycleOrganic fertilisersAmmonium salt fertilisersHydrolysateAgricultural residue

The invention belongs to the fields of forestry and agricultural residue recycling and organic fertilizer production, and provides a method for producing an organic seaweed fertilizer employing an algae processing waste, and an organic seaweed fertilizer and an organic seaweed compound fertilizer prepared by the method. The method mainly comprises the following steps: crushing and evenly mixing the algae waste; decomposing an algae cell wall, polysaccharide and protein in an enzymolysis manner; carrying out solid-liquid separation on enzymatic hydrolysate, leaching enzymolysis algal residues to prepare extractum by adopting ethanol; mixing the enzymatic hydrolysate with the extractum to form an organic seaweed liquid fertilizer; mixing with a certain ratio of algae residue to form an organic seaweed granular fertilizer; and preparing the organic seaweed compound fertilizer after a proper amount of chemical fertilizer is added. The organic seaweed fertilizer is prepared by the wastes generated in macro-algae processing and micro-algae processing processes as the raw material, so that the operation is simple and convenient; the preparation cycle is short; a new idea for processing the wastes is provided for macro-algae or micro-algae processing enterprises; the environmental friendliness of enterprise production and processing is improved; and economic benefits of the enterprises are improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

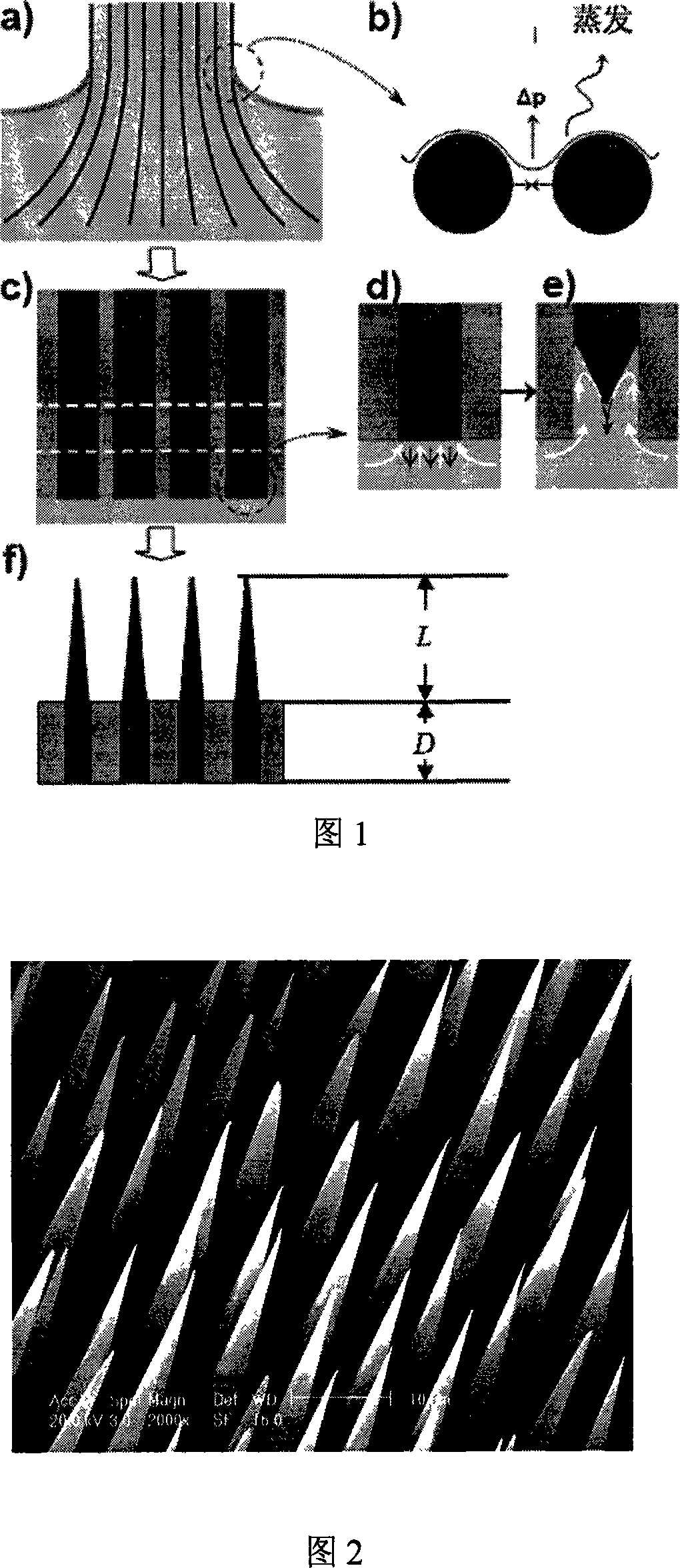

Method for preparing micrometer and submicron probe arrays

InactiveCN101143705AOrderly rowsReduce manufacturing costSemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesFiberMicrometer

The invention discloses a method of preparing a micrometer and sub-micrometer needle array. The method adopts the self-assembly technology and integrates the filling, cutting and controllable corrosion technologies. First, the self-assembly technology is adopted to technically assemble the micrometer / sub-micrometer fiber; and then the polymeric compound is filled, finally the micrometer and sub-micrometer needle array is prepared by the cutting and the controllable corrosion technologies. The invention has the advantages of low cost, no need of complicate equipments and technologies, capability of quick batch production, large area of needle array, smooth needle surface, adjustable diameter, length and taper, etc., and is widely applicable in the detecting, sensing, optical, biology and medicine fields, etc.

Owner:NANJING UNIV

Lactobacillus plantarum fermented fruit and vegetable juice blends and preparation method thereof

ActiveCN103284243AShort manufacturing cycleShort preparation cycleFood scienceOrganic acidAntioxidant

The invention discloses lactobacillus plantarum fermented fruit and vegetable juice blends and a preparation method thereof. The lactobacillus plantarum fermented fruit and vegetable juice blends comprises the following raw material components: 10-90 parts of fruit and vegetable original juice, 8 parts of white sugar, 0.1-0.5 part of thickening stabilizing agent and 0.01-0.03 part of compound antioxidant. The invention also provides a preparation method of the lactobacillus plantarum fermented fruit and vegetable juice blends. The lactobacillus plantarum fermented fruit and vegetable juice blends provided by the invention is reasonable in nutrient matching; through screening and fermenting optimal lactobacillus plantarum strains, the content of amino acid in the fruit and vegetable juice is increased, novel vitamins and organic acids are synthesized, aroma constituents are generated, the original bitter and astringent taste of vegetables is improved, nutrients of different fruits and vegetables can be included in one final product so that different nutrient demands of consumers are met; meanwhile, the problem of sediment of the product within a guarantee period is solved through the addition of the thickening stabilizing agent, and the problem of color uniformity of the product within the guarantee period is solved through the addition of the compound antioxidant.

Owner:HEBEI BROS ILONG FOOD TECH LLC

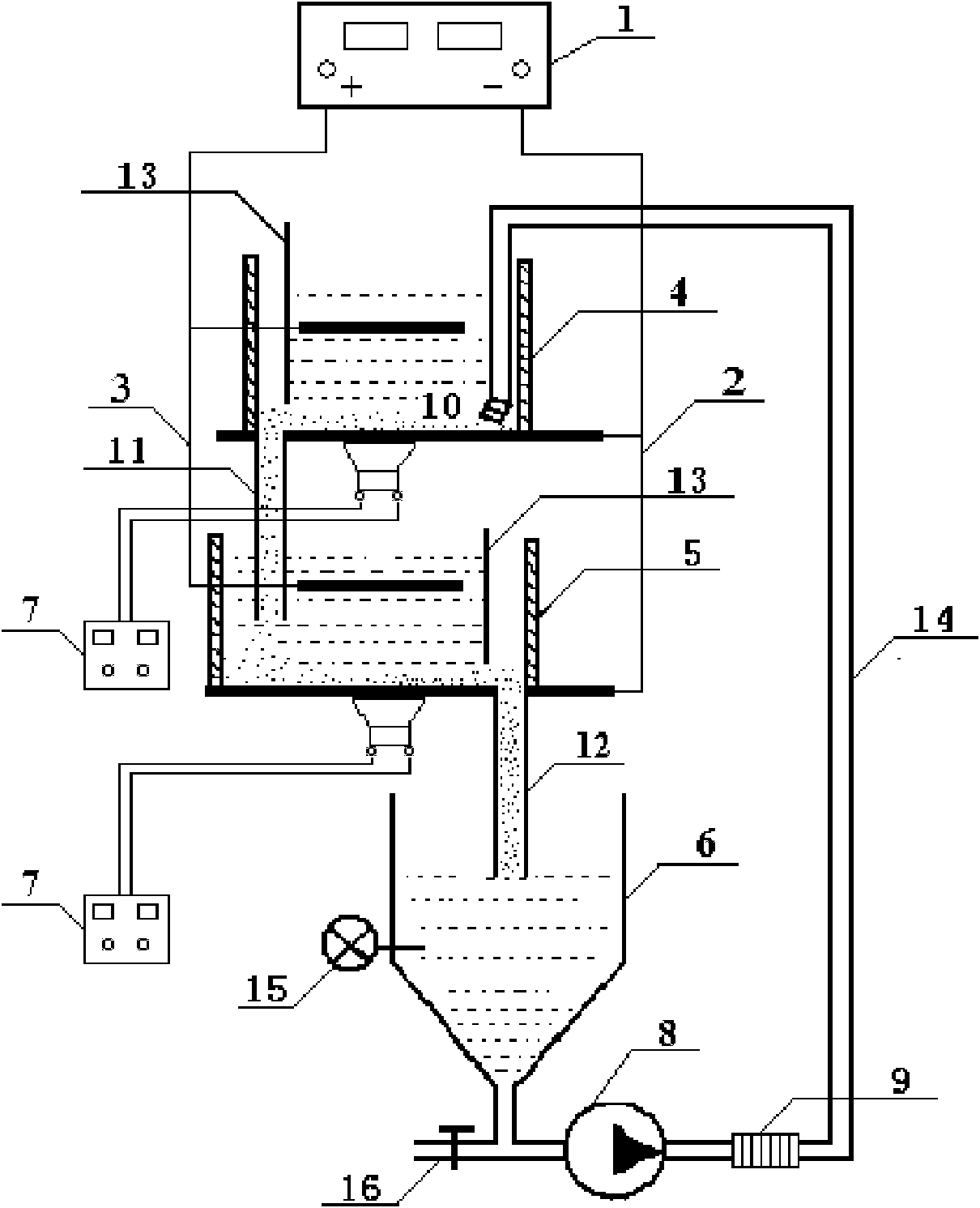

Electroplating device of copper plating of graphite powder and technique

InactiveCN101665965AShort preparation cycleIncrease productivityElectrolysis componentsSteel platesSurface-active agents

The invention discloses an electroplating device of copper plating of graphite powder and a technique. The reaction device comprises a special electroplating bath with the bottom part of being a cathode stainless steel plate, and carries out multi-group overlapping of 1 to 3 plating baths according to production needs, thus improving deposition efficiency and shortening deposition time. The bottompart of the cathode stainless steel plate is provided with an ultrasonic vibrating device, and leads metallic copper to be deposited on graphite particles so as to form a copper-coated graphite powder compound material. The electrolyte adopted by the flowing copper-coating technique is as follows: 8 to 12g.dm<-3> of CuSO4, 0 to 20g.dm<-3> of NaH2PO2.H2O, and little amount of surface active agent.The applied current density is 20 to 40A.dm<-2>, the reaction temperature is 60 DEG C, the loading amount of the graphite powder is 5 to 15g.dm<-3>, the flow speed of the plating solution is controlled into 8 to 12dm<-3>.min<-1>, and the electroplating time is 20 to 40min. The device for preparing the graphite powder material shortens the production period, the prepared copper-plated layer of thecopper-coated graphite powder is even and continuous and has the same thickness, the production efficiency is improved and the production cost is reduced. The device has simple structure, reasonabletechnique design and convenient operation.

Owner:GCI SCI & TECH +1

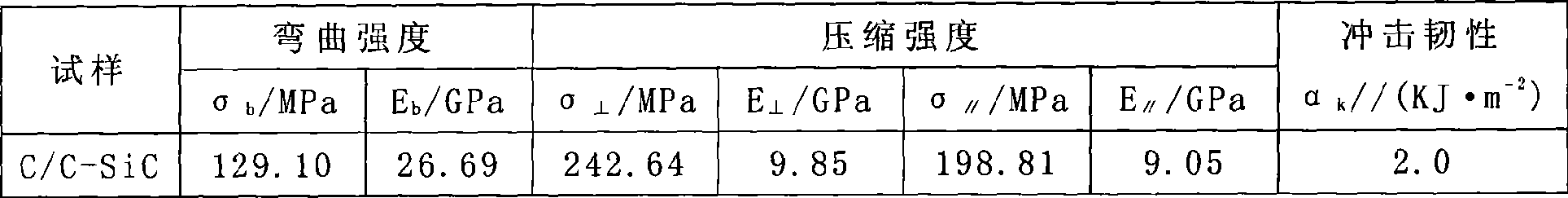

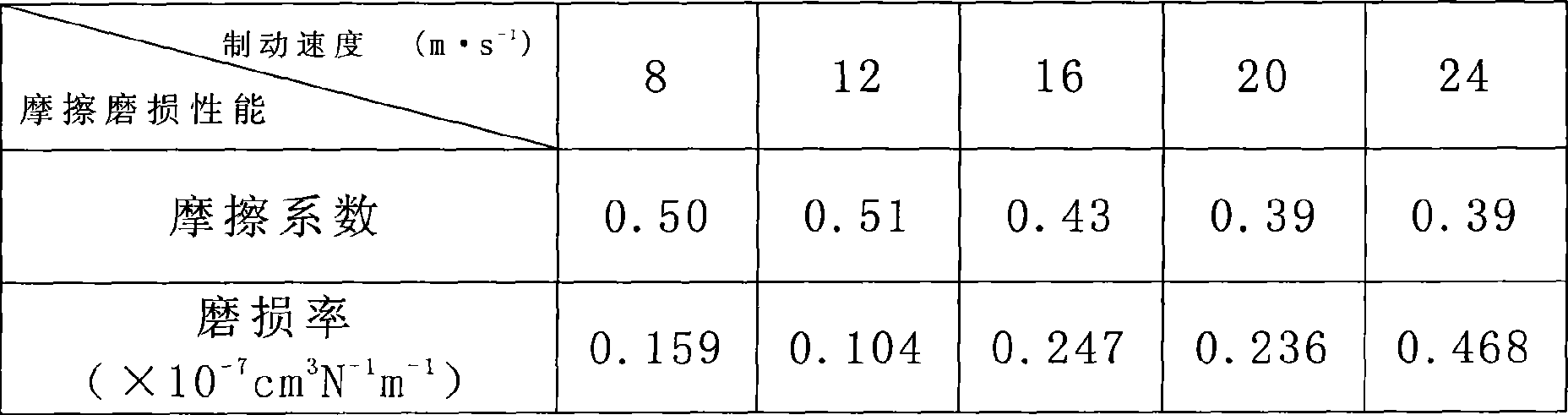

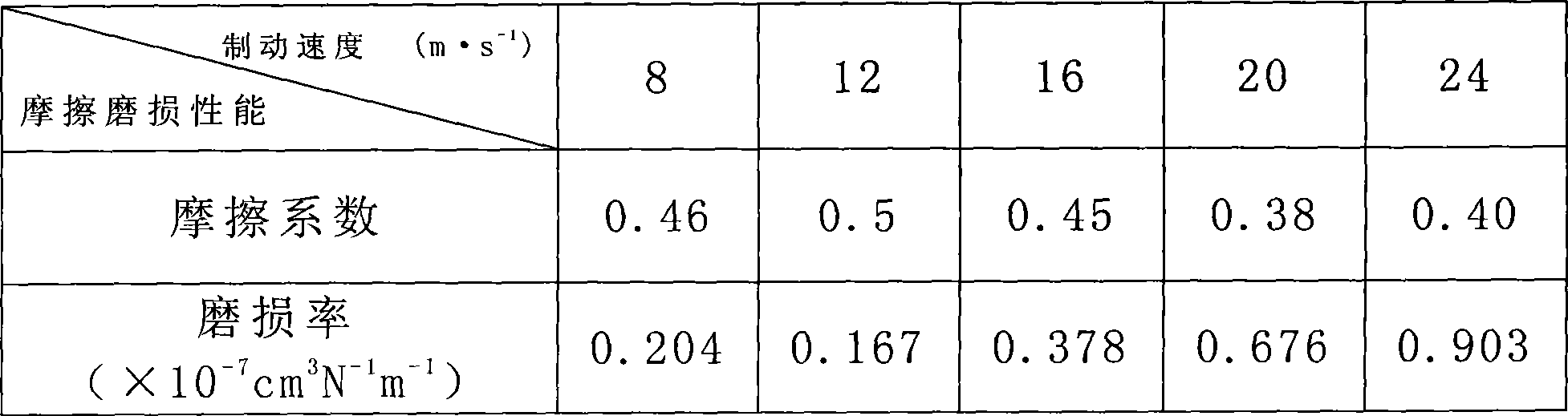

Preparation of carbon fiber reinforced carbon-silicon carbide double matrix friction material

The invention discloses a preparation method for a carbon fiber enhanced carbon-carborundum double-matrix abrasive material. Short chopped carbon fiber, graphite powder, industrial silicon powder and caking agent are employed to be pressed into the block material of carbon fiber enhanced graphite powder and silicon powder (C / C-Si) in a cooling way; then mechanical cracking and pelleting are carried out to the prepared C / C-Si block material; next, the grains are thermally pressed into a C / C-Si biscuit; and then the C / C-Si biscuit is carbonized to prepare a C / C-Si porous body; and finally non-dipping directional fused silica impregnating is carried out to the C / C-Si porous body to prepare the carbon fiber enhanced carbon-carborundum double-matrix (C / C-SiC) abrasive material. The invention relates to a preparation method for a carbon fiber enhanced carbon-carborundum double-matrix abrasive material having higher mechanical property and excellent abrasion resistance and wear performances,with the advantages of short preparation cycle, low cost, and being capable of engineering.

Owner:CENT SOUTH UNIV

Method for rapidly manufacturing injection-mould insert with follow-cooling passageway

InactiveCN1850396AImprove cooling effectQuality improvementIncreasing energy efficiencySelective laser sinteringThree-dimensional graph

The present invention discloses a quick manufacture method of injection mould insert with form-following cooling flow passage. Said method includes the following steps: firstly, according to the injection mould cavity surface profile utilizing three-dimensional CAS software (for example Pro / Engineer or Unigraphics) to set form-following cooling flow passage, then making the mould three-dimensional graph be derived according to STL format file and inputted into the computer of selective laser sintering system; according to user's requirements adopting mixed powder of metal with different properties and high-molecule as forming raw material powder, making said mixed powder undergo the process of the above-mentioned laser sintering system to obtain the mould insert blank, making the mould insert blank undergo the processes of degreasing, secondary sintering and metal melt-infiltration so as to obtain the compact insert.

Owner:HUAZHONG UNIV OF SCI & TECH

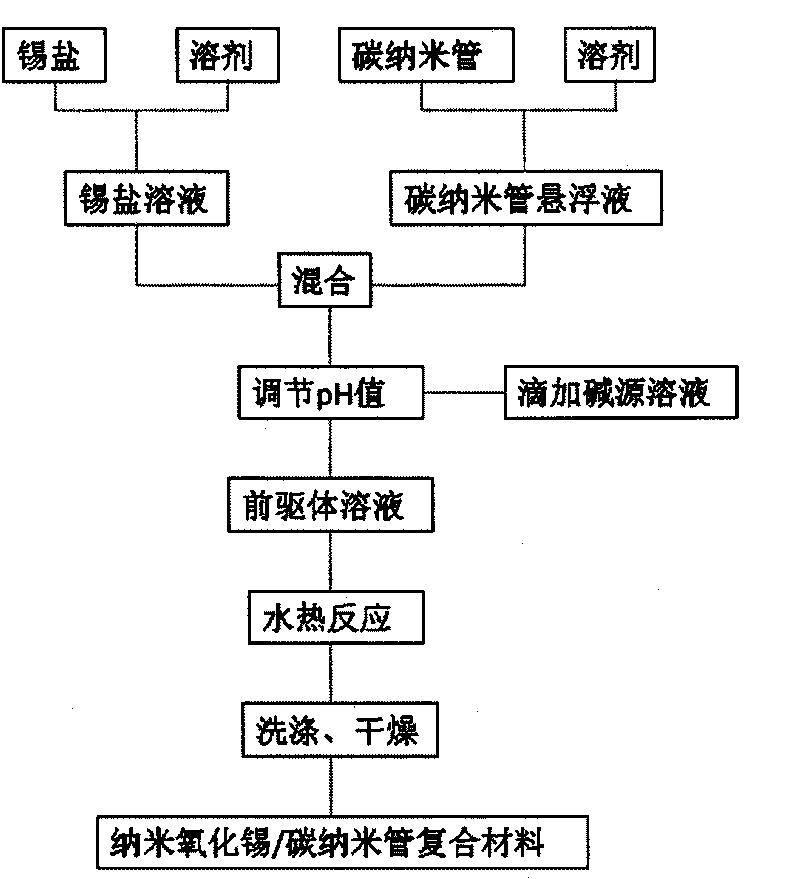

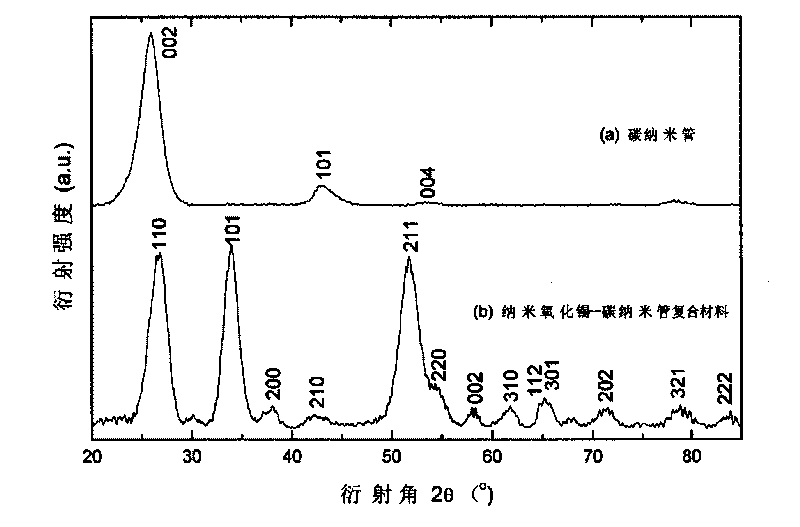

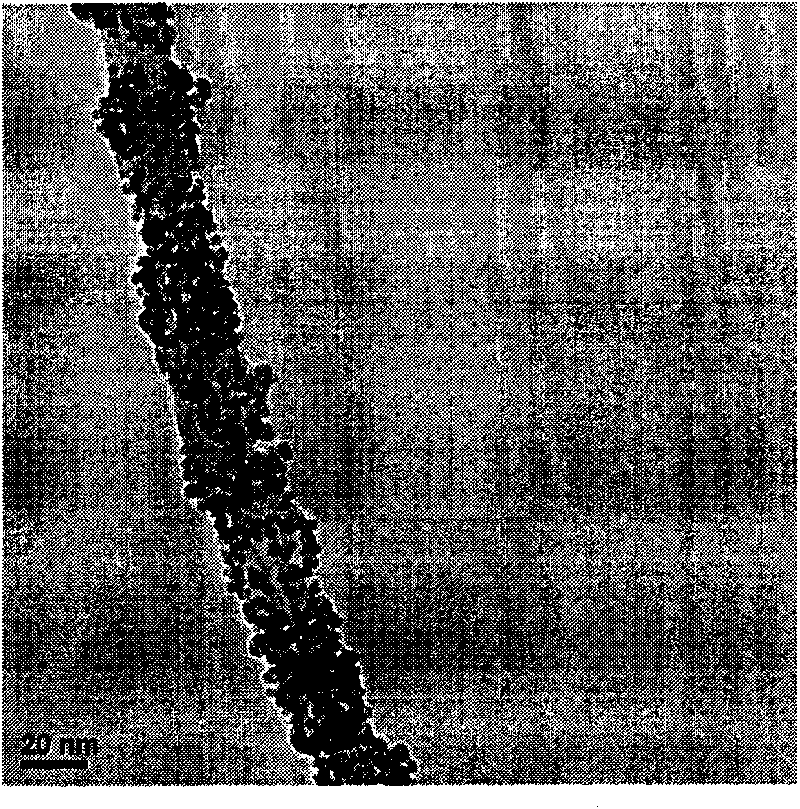

In-situ synthesis method for nano tin dioxide/carbon nano tube composite material

InactiveCN101704504AControllable particle sizeShape is easy to controlNanostructure manufactureTin dioxideSynthesis methods

The invention discloses an in-situ synthesis method for a nano tin dioxide / carbon nano tube composite material, which mainly uses an inorganic tin salt, a carbon nano tube and an alkali source as raw materials. The experimental process mainly comprises the steps of precursor preparation, hydrothermal reaction, precipitate washing and drying and the like. The in-situ synthesis method for the nano tin dioxide / carbon nano tube composite material has the advantages that: a hydrothermal method is adopted to realize the in-situ deposition and the growth of the nano tin dioxide on the surface of the carbon nano tube; the obtained SnO2 nano particles have small and uniform particle size (less than 10nm), are well-crystallized, are uniformly coated on the surface of the carbon nano tube, and are tightly combined with the carbon nano tube; the composite material has potential application prospect in the aspects of a gas sensor material, an anode material of a lithium ion battery and the like. The method has no addition of any surface active agent, has simple and easily-obtained materials, simple process without pollution, short preparation period, mild reaction condition and low cost, and is suitable for large-scale production, so the method is an environment-friendly synthesis method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

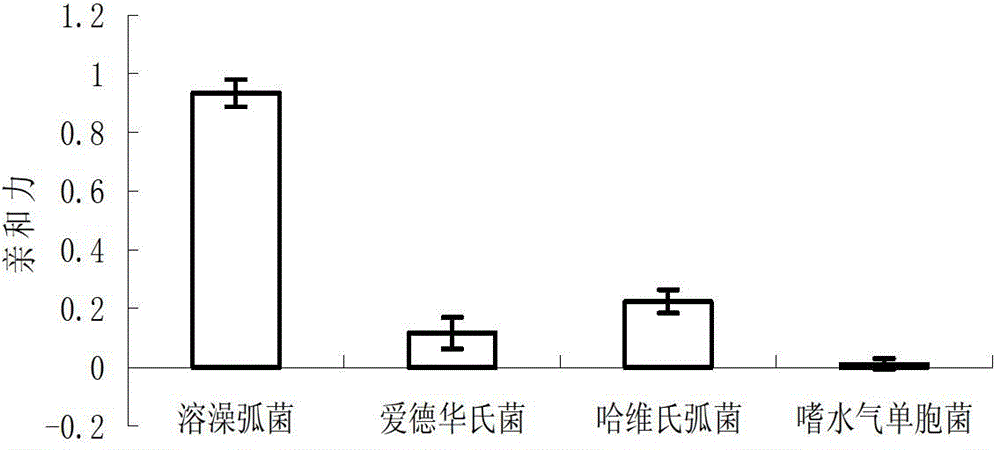

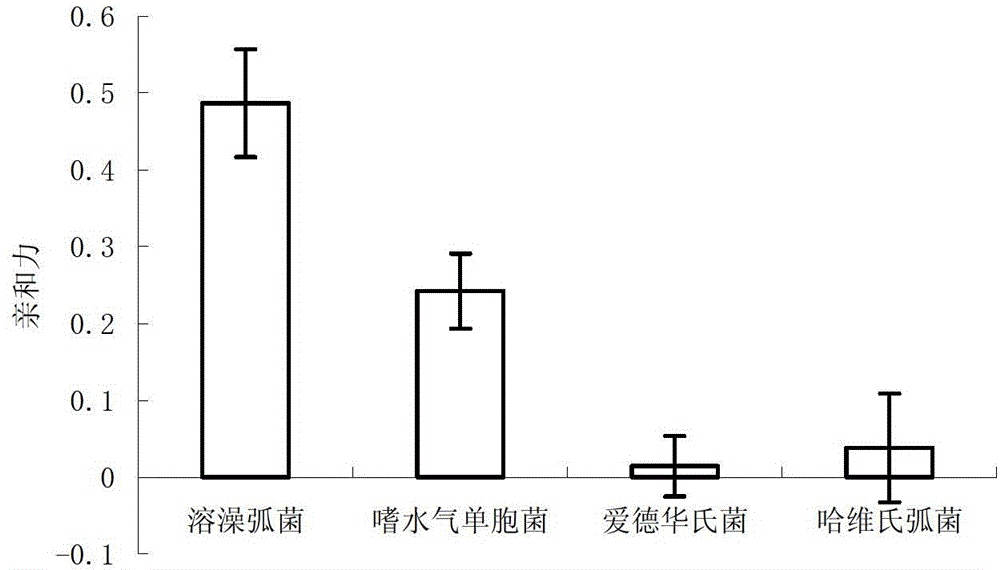

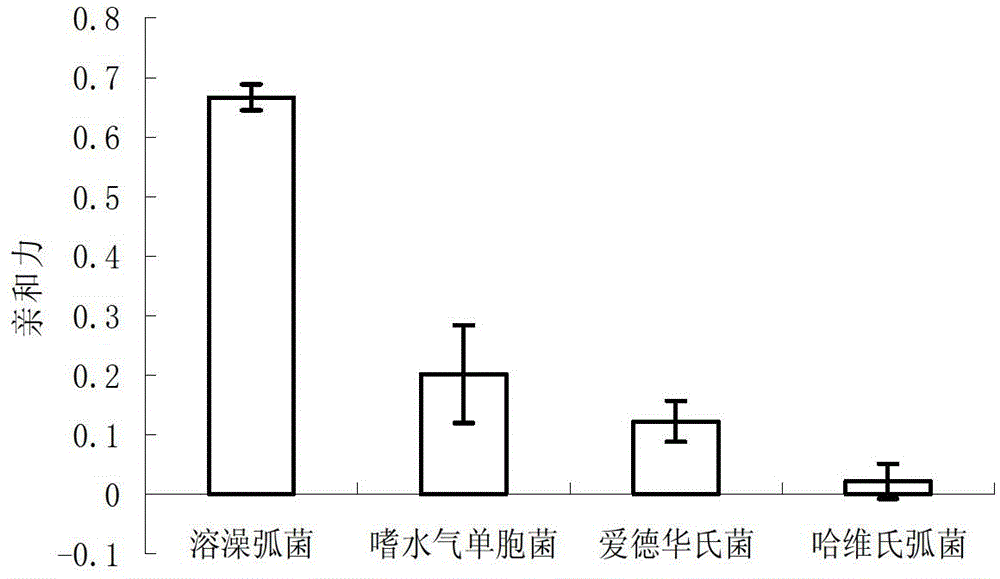

Six oligonucleotide sequences and application thereof

InactiveCN103060326AImprove stabilityQuick checkMicrobiological testing/measurementDNA preparationOligonucleotideAntibody

The invention relates to six oligonucleotide sequences and an application thereof, relating to the recognition detection of vibrio alginolyticus. The invention provides six oligonucleotide sequences capable of inactivating the recognition detection of vibrio alginolyticus, a preparation method and an application thereof. The oligonucleotide sequence has the characteristics of being quick in detection, simple in operation, superior to that of antibody and the like in stability, and the preparation method is easy and relatively short in preparation period. The six oligonucleotide sequences comprise oligonucleotide sequences of SEQ ID No.1-6, and the recognition detection of vibrio alginolyticus can be inactivated by adopting one of the oligonucleotide sequences. The preparation method comprises the following steps: synthesizing an ssDNA oligonucleotide library used for filtering; carrying out SELEX filtering after the oligonucleotide library is mixed with inactivated vibrio alginolyticus till the affinity is not raised obviously; then cloning and sequencing; and selecting a highly copied ssDNA thereof to carry out verification of affinity specificity and determination of affinity constants so as to obtain corresponding an aptamer. The six oligonucleotide sequences can be used for recognition detection of inactivated vibrio alginolyticus.

Owner:JIMEI UNIV

New-type of inorganic bone grafting material and its prepn and use

InactiveCN101020085AGood biocompatibilityPromote degradationProsthesisSulfateBiocompatibility Testing

The present invention is one kind of new inorganic bone grafting material and belongs to the field of medical material. The inorganic bone grafting material consists of beta-tricalcium phosphate grain in 20-80 wt% and alpha-calcium sulfate semihydrate powder in 20-80 wt%, and the alpha-calcium sulfate semihydrate powder form layered structure in the surface and / or pores of beta-tricalcium phosphate grain. Both beta-tricalcium phosphate and alpha-calcium sulfate semihydrate have excellent biocompatibility and excellent in vivo degrading performance, and the composite artificial bone grain may be used in repairing bone defect of different shapes. The composite artificial bone grain has wide material source, convenient use, excellent performance, simple preparation process, low cost and other advantages.

Owner:GENERAL HOSPITAL OF PLA

Low-temperature preparation method of C/SiC ceramic matrix composite material

InactiveCN101224988AImprove performanceImprove mechanical propertiesProcess equipmentCeramic composite

The invention discloses a low-temperature preparation method for a C / SiC ceramic composite, which is characterized in that: with ceramic properties of the precursor of the organic polymer under low temperature, carbon fibers are adopted as reinforcing materials and infiltration pyrolysis is adopted for the precursor; processing steps, such as the carbon fibers pre-treatment, vacuum infuse, high-temperature pyrolysis, and densification, are applied to prepare C / SiC ceramic composites with excellent mechanical properties under low temperature. Compared with the traditional preparation method for ceramic composites, the low-temperature preparation method has the advantages of reducing preparation temperature, simplifying processing facilities, reducing cost, and shortening preparation cycle.

Owner:NAT UNIV OF DEFENSE TECH

Microbial straw rotting agent and preparation method thereof

The invention provides a microbial straw rotting agent, which adopts the strains having mutual synergistic action without generating antagonistic action as production strains: cellulase preparation, Fomes annosus, Bacillus subtilis, Thermobifida fusca, Bacillus pumilus and Saccharomyces cerevisiae. The microbial straw rotting agent has high decomposition effect on the main components of the straws, has biological control function, and can inhibit growth of crop sheath blight, rice blast, wheat root rot, strawberry gray mold and other pathogens. The product has the advantages of short manufacturing period, high production efficiency and low cost, and is safe and convenient to use.

Owner:安徽莱姆佳生物肥业有限公司

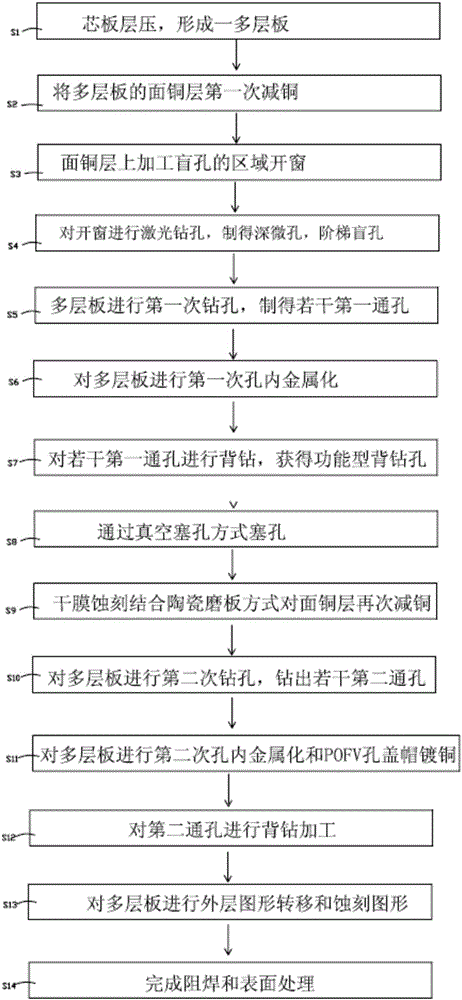

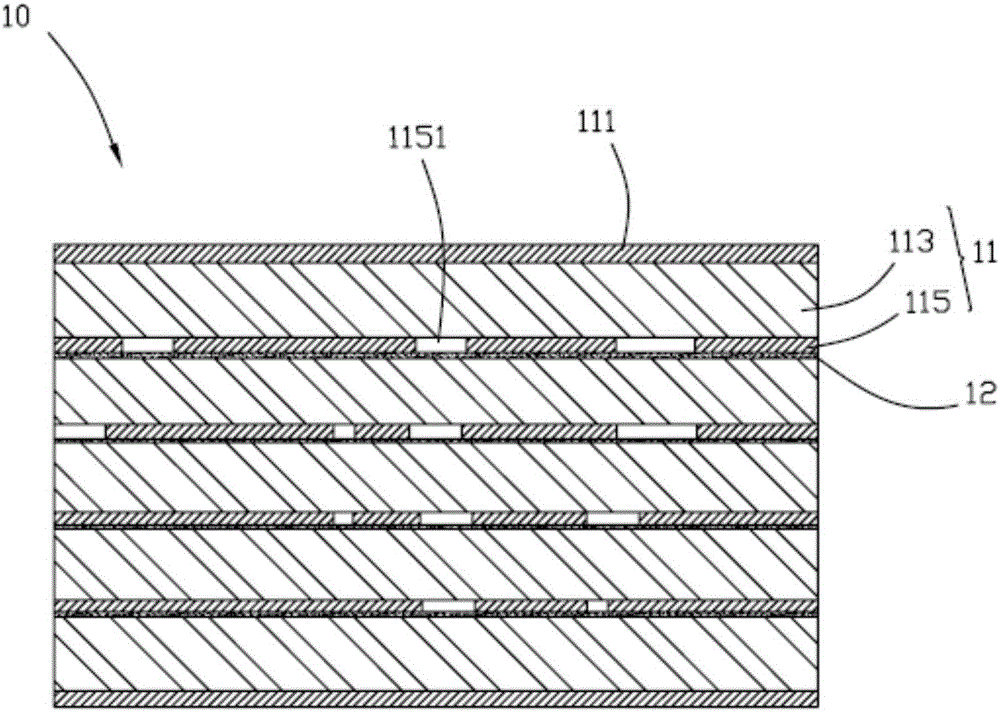

Manufacturing method of high-speed PCB and PCB

ActiveCN106793577AShort preparation cycleLow costPrinted circuit aspectsMultilayer circuit manufactureFine lineConnection type

The invention provides a manufacturing method of a high-speed PCB and the PCB. The manufacturing method includes the following steps that 1, lamination is carried out after a normal inner layer graph is manufactured; 2, copper reduction is carried out to achieve the size of 6 micrometers to 8 micrometers after lamination is completed; 3, +4.5 mil copper etching windowing is carried out on a deep micropore region and a first-order blind hole region overall; 4, laser drilling is carried out to complete deep micropore and first-order blind hole machining; 5, through holes needing resin hole plugging are mechanically drilled for the first time; 6, the interiors of the holes are metalized for the first time; 7, the through holes are back-drilled for the first time; 8, vacuum hole plugging is carried out; 9, the holes are covered with dry films, single side +5 mil dry film covering is carried out on deep micropores, first-order blind holes and the first through holes; 10, chemical copper reduction and ceramic grinding plate copper reduction are carried out to achieve the size of 20 micrometers to 25 micrometers; 11, second through holes are mechanically drilled; 12, the interiors of the holes are metalized for the second time, and POFV blocking is carried out; 13, the second through holes are back-drilled, and connection type functional holes are machined; 14, an outer layer graph is transferred, and a fine line graph is etched; 15, solder resisting and surface treatment are completed. The high-complexity high-speed PCB can be manufactured, the manufacturing period is short, and the cost is low.

Owner:DONGGUAN SHENGYI ELECTRONICS

Process for preparing glass fiber composite type silicon dioxide aerogel insulation quilt

The invention discloses a process for preparing a glass fiber composite type silicon dioxide aerogel insulation quilt. The process mainly comprises the following steps: absorbing a silicon dioxide aerogel liquid till being saturated by using a glass fiber quilt, gelling under specific conditions, and drying supercutical fluid CO2 to form a reinforced aerogel material. The glass fiber composite type silicon dioxide aerogel insulation quilt prepared by using the process is excellent in heat preservation property, mechanical property and fireproof and waterproof property, and is convenient to construct. By adopting the process, a solvent replacement step is avoided, the operation is simple and easy, the operation process is controllable, and continuous production can be achieved.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

A preparation method of a sulfur-supported graphene aerogel composite material

InactiveCN103996830ASimple processShort preparation cycleCell electrodesSecondary cellsLithium-ion batteryPolymer

The invention relates to a preparation method of a sulfur-supported graphene aerogel composite material, and belongs to the technical field of lithium ion battery cathode materials. The preparation method mainly includes steps of: subjecting a graphene oxide dispersion liquid, ethanol and sulfur / carbon disulfide which are main raw materials to a hydrothermal reaction at 100-200 DEG C for 6-48 h to obtain sulfur-supported graphene aerogel, and obtaining the sulfur-supported graphene aerogel composite material covered by a polymer through a chemical oxidation method. According to a sulfur-supported graphene aerogel cathode prepared by the preparation method, graphene is staggered and connected to form a three-dimensional conductive network, the supramaximal surface area can absorb more sulfur, and covering by the polymer can overcome a problem of volume expansion of sulphur and a problem of material smashing in charge-discharge processes. In addition, the composite material prepared by the preparation method can be directly used as a pole piece, thus omitting tedious processes, such as pulping and coating in traditional electrode preparation. The preparation method is prone to industrial production.

Owner:SHANGHAI UNIV

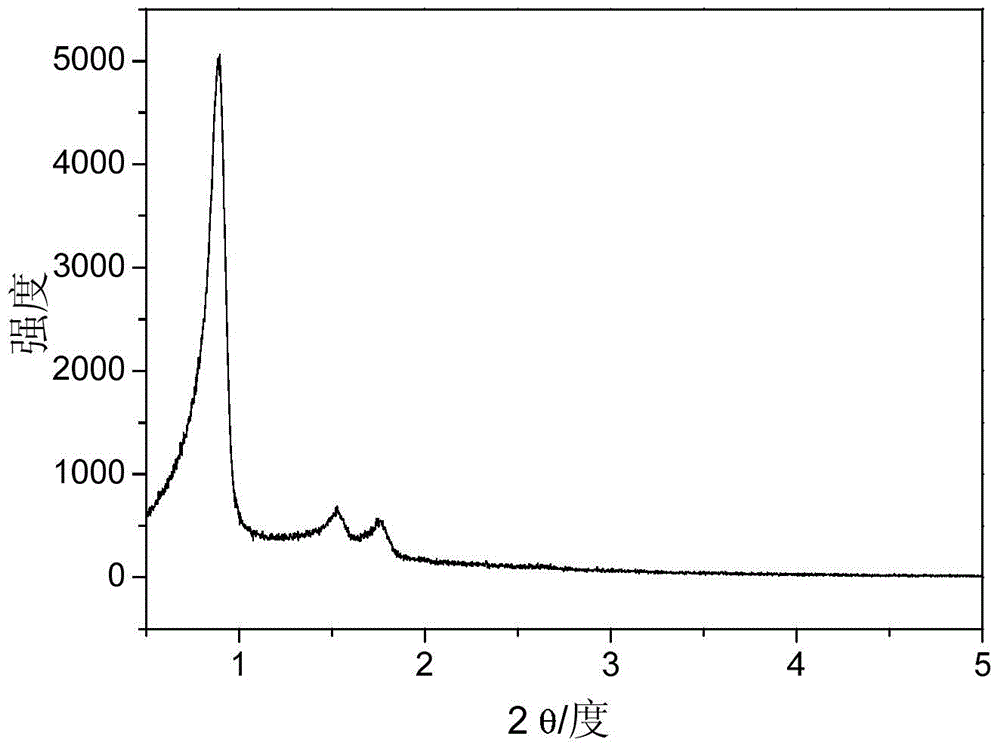

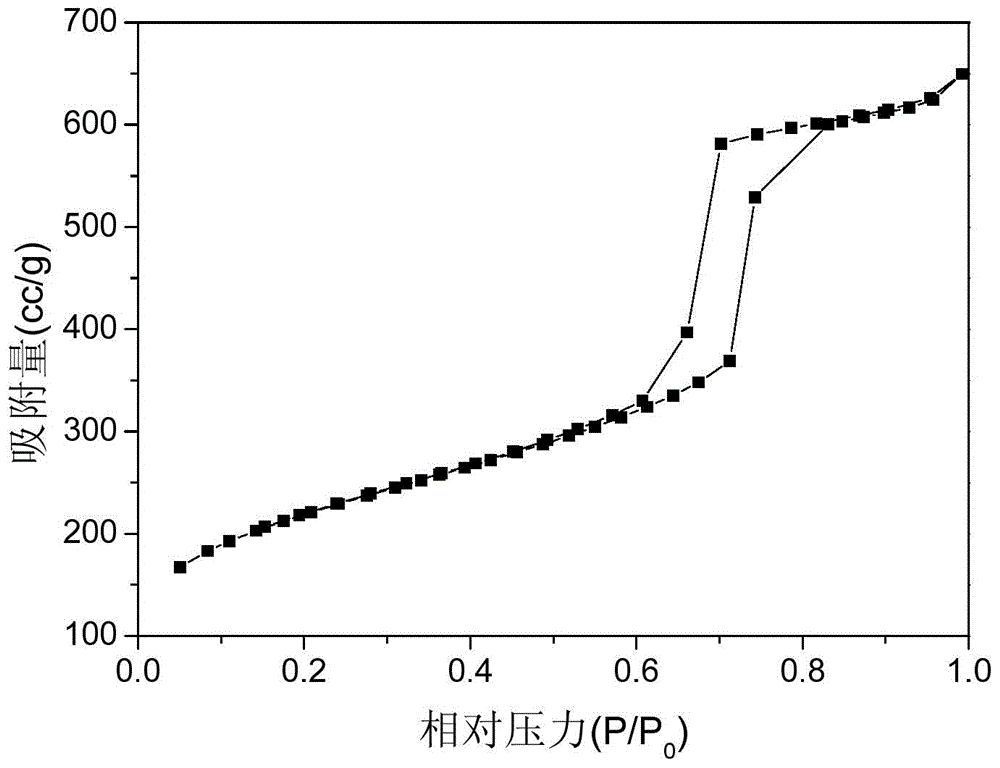

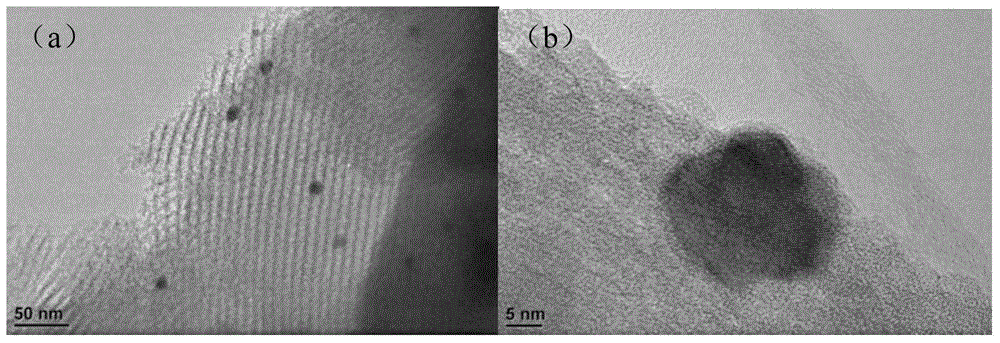

Dehydrogenation catalyzing material as well as preparation method and application thereof

ActiveCN103816933AImprove stabilitySuppressor enrichmentMolecular sieve catalystsHydrocarbonsPlatinumPtru catalyst

The invention provides a dehydrogenation catalyzing material as well as a preparation method and application thereof. The dehydrogenation catalyzing material comprises the following components by weight: 0.5-5% of platinum element, 1-10% of IVA metal, 0.1-1% of Al and the balance of mesoporous silicon material, wherein the mesoporous silicon material serves as a carrier, the platinum element serves as a catalyst, the IVA metal serves as a first auxiliary and the Al serves as a second auxiliary. Compared with a multiple dipping method, the preparation method has the advantages that the active components and auxiliary elements are dipped and carried on the mesoporous silicon carrier in one step, so that the preparation method is simple in operation and short in preparation cycle; molecules of the active components and auxiliaries of the catalytic material obtained through one-step dipping are in fuller contact, which is beneficial to inhibit the enrichment of carbon on the active components, so that the deactivation rate is reduced and the stability of the catalytic material is increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Cellulose nanocrystal/graphene composite colored film and fast preparation method thereof

The invention relates to a cellulose nanocrystal / graphene composite colored film and a fast preparation method thereof. The cellulose nanocrystal / graphene composite colored film can be prepared under the existence of a flow field by adopting a vacuum filtration method, the composite film has a cholesteric liquid crystal phase structure, and the color of the composite film can be regulated by controlling the ultrasonic time during preparation process. The prepared colored film can absorb water, and the color can be changed along with the change of humidity. The cellulose nanocrystal / graphene composite colored film has application values in the photoelectric field and the preparation of anti-counterfeit labels, anti-counterfeit paper and high-grade discoloring anti-counterfeit ink.

Owner:QINGDAO UNIV OF SCI & TECH

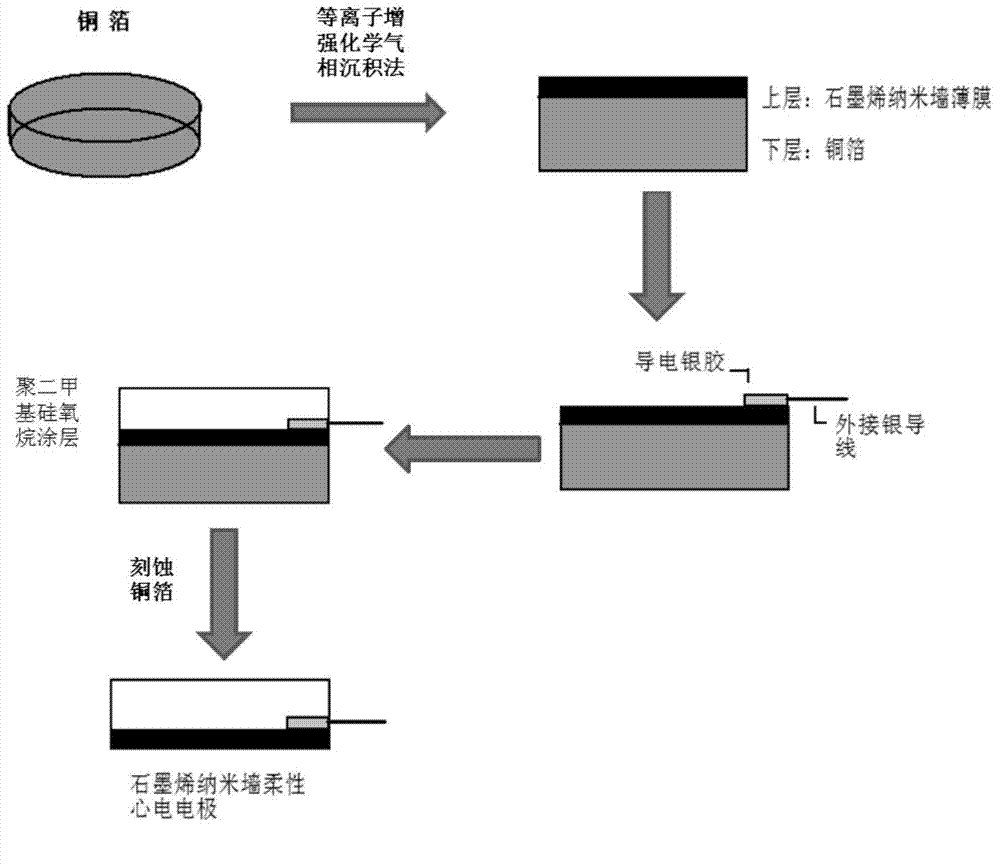

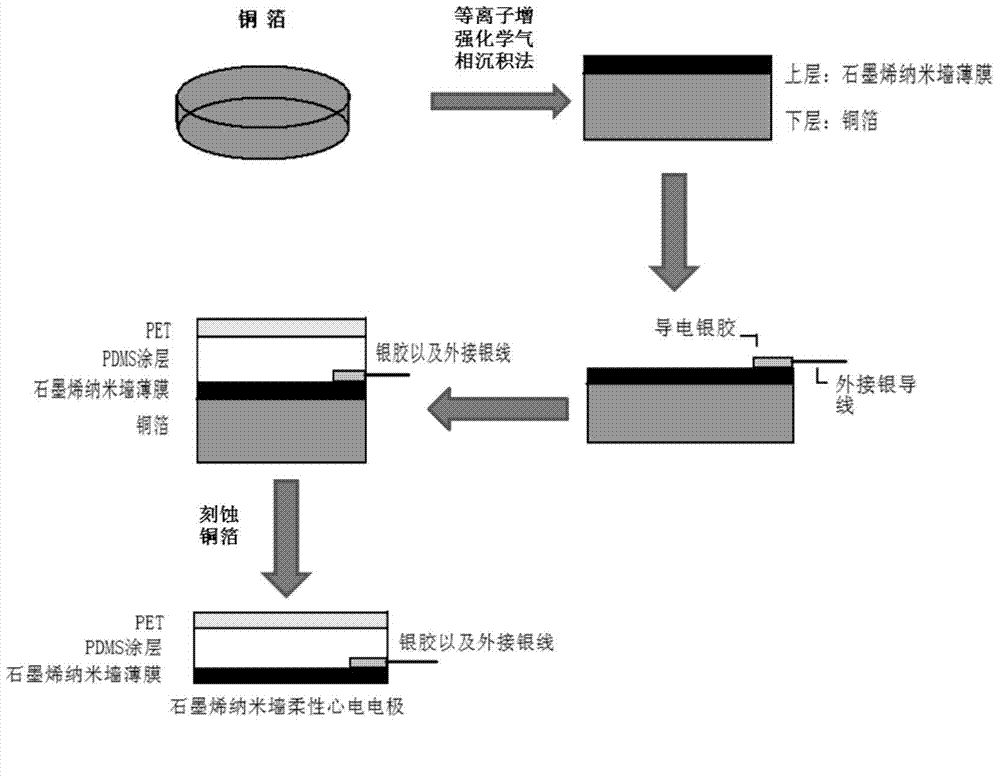

Graphene nanowall flexible electrocardio-electrode and preparation method thereof

ActiveCN104739403AImprove conductivityIncrease contact areaDiagnostic recording/measuringSensorsAdhesivePotential difference

The invention discloses a graphene nanowall flexible electrocardio-electrode and a preparation method thereof. The flexible electrocardio-electrode comprises a flexible substrate layer and a graphene nanowall layer, wherein a layer of conductive silver adhesives coats the side edge of the graphene nanowall layer and connected with a metal conductor. The graphene nanowall flexible electrocardio-electrode is high in flexibility, and can be closely clung to a body surface; the acquired potential difference is accurate; in addition, the electrode is small in impedance, outstanding in conductive performance, difficult to be polarized, resistant to interference and resistant to noise; in addition, the service life of the electrode can be greatly prolonged due to the corrosion resistance of graphene. The graphene nanowall flexible electrocardio-electrode is simple and convenient to operate, short in manufacturing cycle and easily produced by mass.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

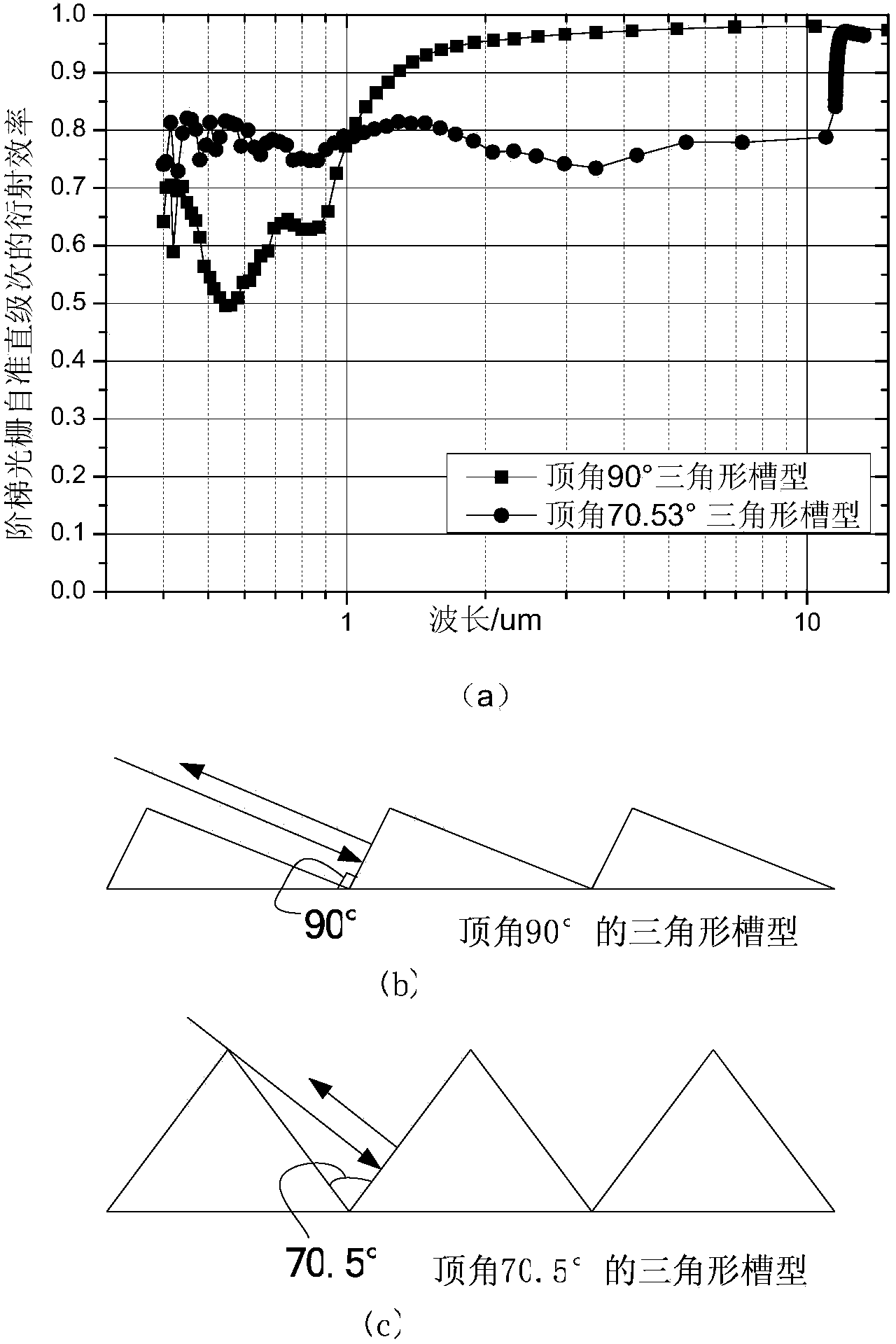

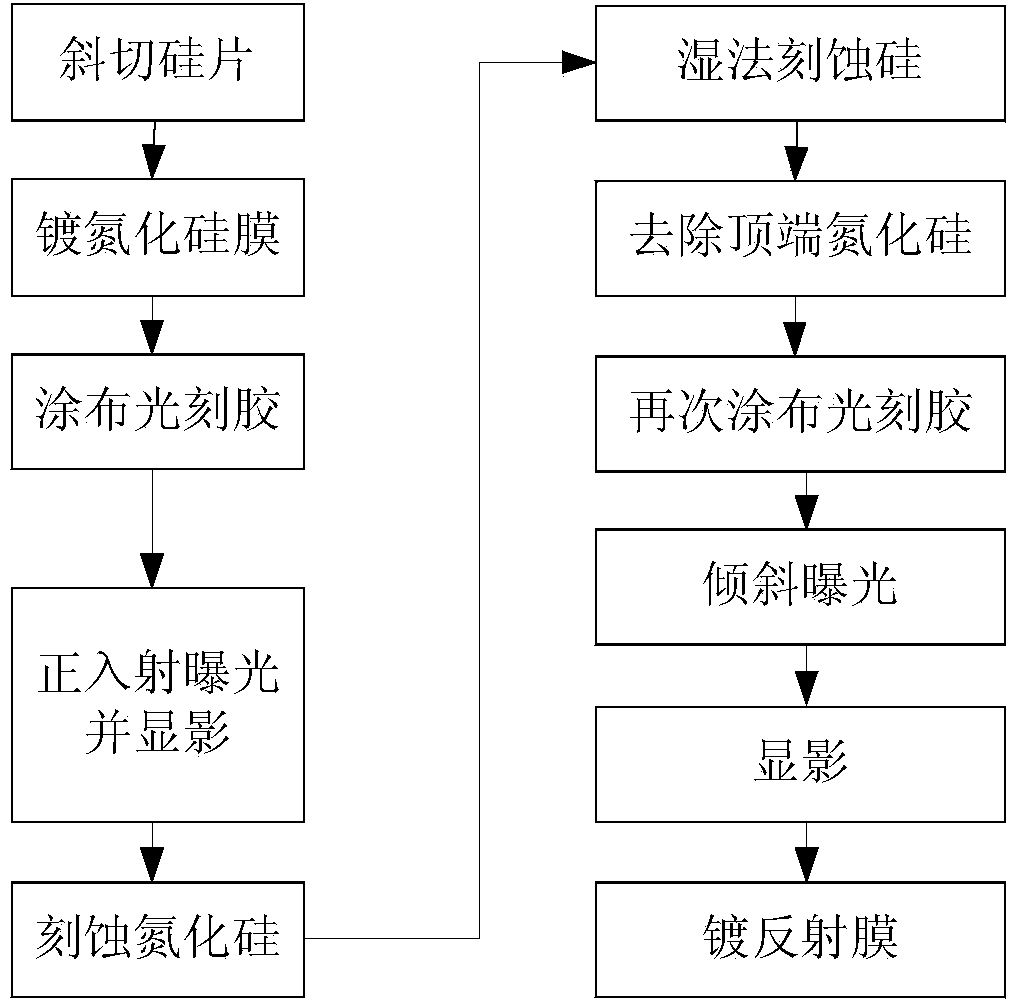

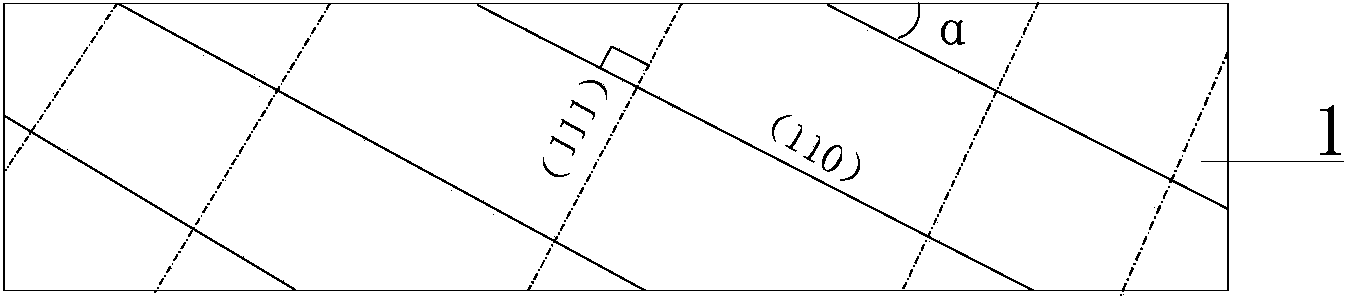

Method for manufacturing triangular groove echelon gratings with 90-degree vertex angles

ActiveCN103901520AMake anyMeet the conditions for perfect sparkleDiffraction gratingsPhotomechanical exposure apparatusBroadbandWave band

The invention provides a method for manufacturing triangular groove echelon gratings with 90-degree vertex angles. Each triangular groove echelon grating is composed of a silicon grating structure (1), photoresist (3) and a metal film (4). A manufactured grating groove is a triangle with the vertex angle being 90 degrees, so that the diffraction efficiency higher than that of an echelon grating with the vertex angle being not 90 degrees can be achieved. Each grating structure is produced in an obliquely-cut monocrystalline wafer, the shining angles of the gratings are determined by an obliquely-cut angle for cutting each silicon wafer, and gratings with any blazing angles can be manufactured; according to the 90-degree vertex angles, grooves of silicon gratings with the vertex angles being not 90 degrees are filled with photoresist, then photoetching is conducted again, and the original silicon gratings with the vertex angles being not 90 degrees are converted into the triangular groove gratings with the vertex angles being 90 degrees. According to the manufactured grating structure, the shining face of each grating is a smooth monocrystal silicon <111> grate plane, scattering can be effectively lowered, and the diffraction efficiency of each grating is improved. The purpose that all the gratings have high diffraction efficiency on a broadband is achieved according to the fact that using wave bands can choose to be coated with various different reflecting film layers on the surfaces of the gratings.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing graphite alkenyl nanometer materials by electron beam irradiation method

InactiveCN101559941AHigh reversible lithium storage capacityImprove performanceNanostructure manufactureSolution stateCvd graphene

The invention relates to a method for preparing graphite alkenyl nanometer materials by an electron beam irradiation method. The method comprises the following steps: firstly, oxidizing natural graphite to obtain oxidized graphite; secondly, realizing the stripping between layers of the oxidized graphite by ultrasonic sound at the state of solution; and finally reducing the oxidized graphite through certain dosage of electron beam irradiation, and obtaining the graphite alkenyl nanometer materials. The method has simple preparation process, short preparation period and high yield, can be operated at normal temperature, does not add any catalyst and chemical initiator, and can be applied on a large scale.

Owner:SHANGHAI UNIV

Preparation method of high superficial area porous carbon material

InactiveCN1830769AShort preparation cycleSimple processElectrolytic capacitorsCell electrodesPorous carbonPotassium hydroxide

A porous carbon with high specific surface area used as the electrode of super capacitor and lithium battery is prepared through proportionally dissolving resorcin, formaldehyde, and potassium (or sodium) hydroxide as catalyst in water, laying aside at 80-95 deg.C for 1-3 days to obtaining water-phase gel, drying, carbonifying at 650-900 deg.C for 30-180 min, water washing and drying.

Owner:DALIAN UNIV OF TECH

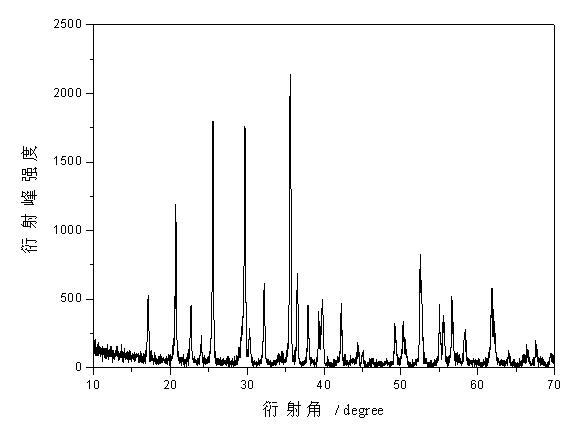

LiFePO4/C nano composite positive pole material and preparation method thereof

InactiveCN101159328AAchieve hybridControl chemical compositionElectrode manufacturing processesChemical industryPhosphateLithium-ion battery

The invention discloses a nano-composite positive material LiFePO4 / C and a fabrication method, relating to a fabrication method of positive material of a lithium-ion battery. The invention uses the method of liquid-phase coprecipitation, the certain amount of lithium resource, iron resource and phosphate resource is weighted as the quality mol ratio of Li:Fe:P = (3.0-3.3):(1.0-1.1):(1.0-1.1), and the appropriate amount of carbon-doped material and organic surfactant is added in the reaction vessel; by controlling the reaction conditions like concentration, temperature etc. of the reaction solution, precursor gels are fabricated, and the precursor gels are separated, cleaned, filtered and dried to obtain precursor powder; the precursor powder is tableted and put into the crucible with microwave absorbent, and then the crucible is placed in the microwave oven, with the microwave power controlled between 100 to 600W and heated for 30 min, to obtain nano-sized composite positive material LiFePO4 / C. The technique method in the invention has the advantages of short periods, saved energy consumption, ease to control the process, suitability for industrialization and so on. The composite positive material LiFePO4 / C fabricated in the invention is characterized by high purity, small particle size lower than 100 nm, and good electrochemical properties.

Owner:上海微纳科技有限公司

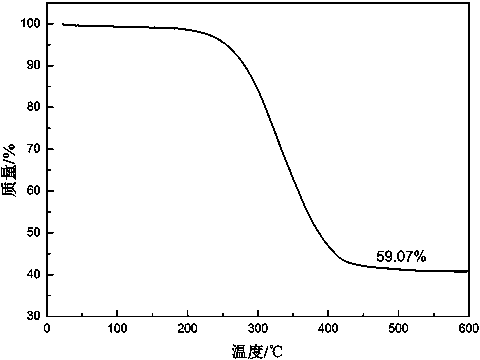

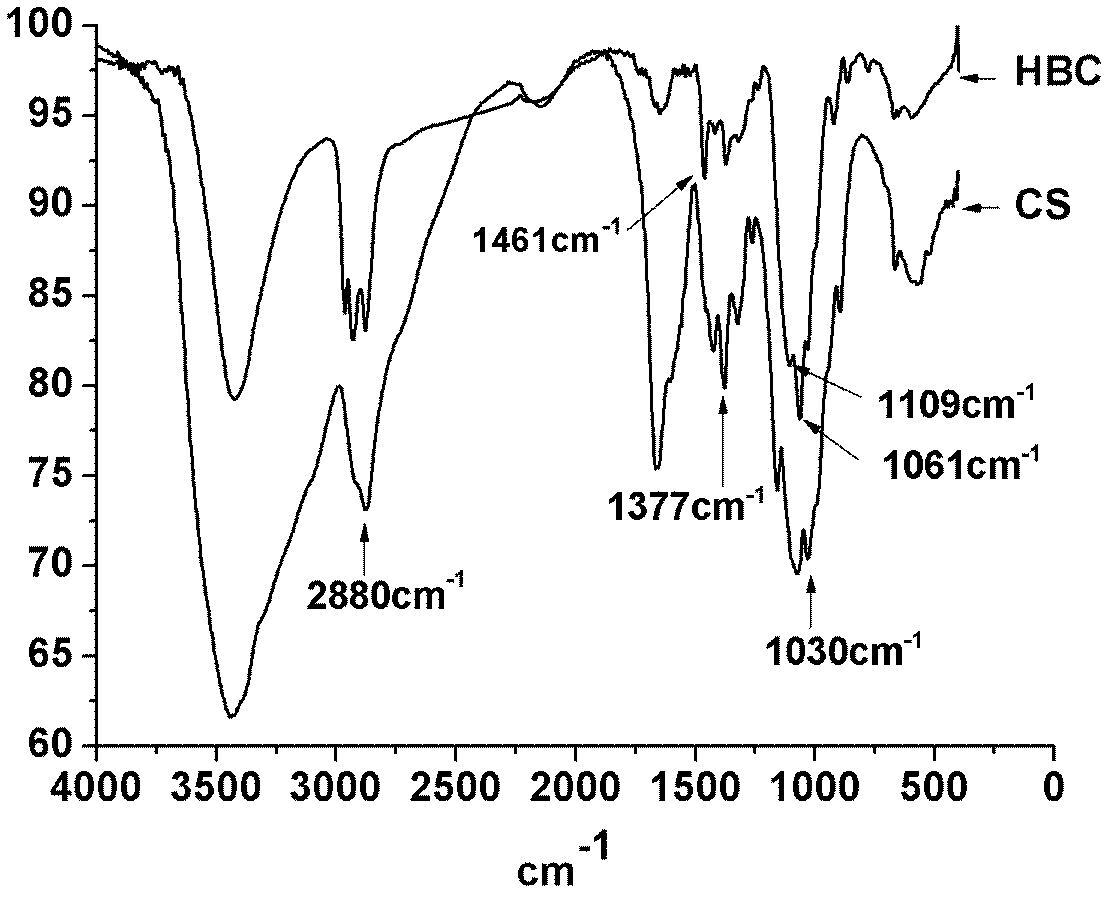

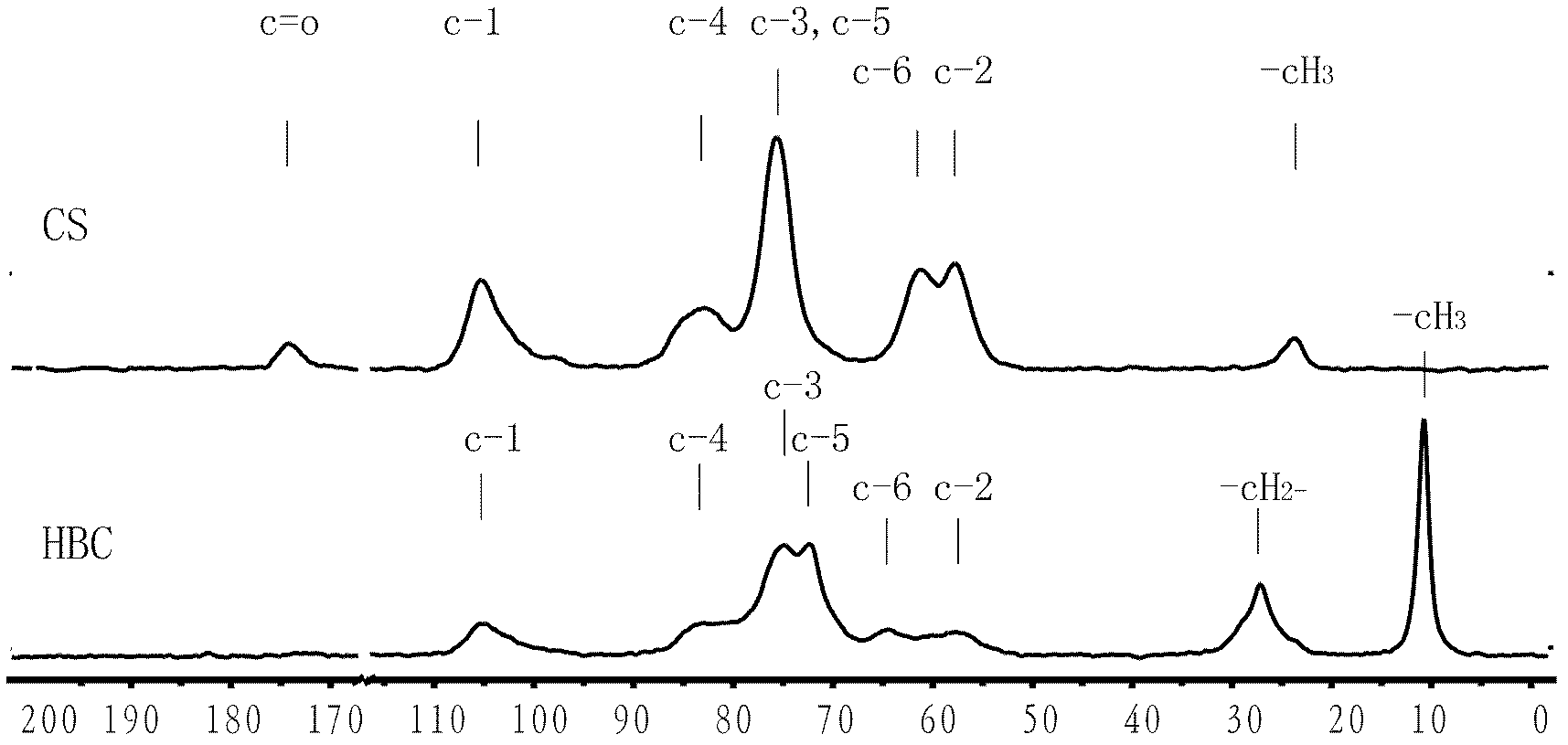

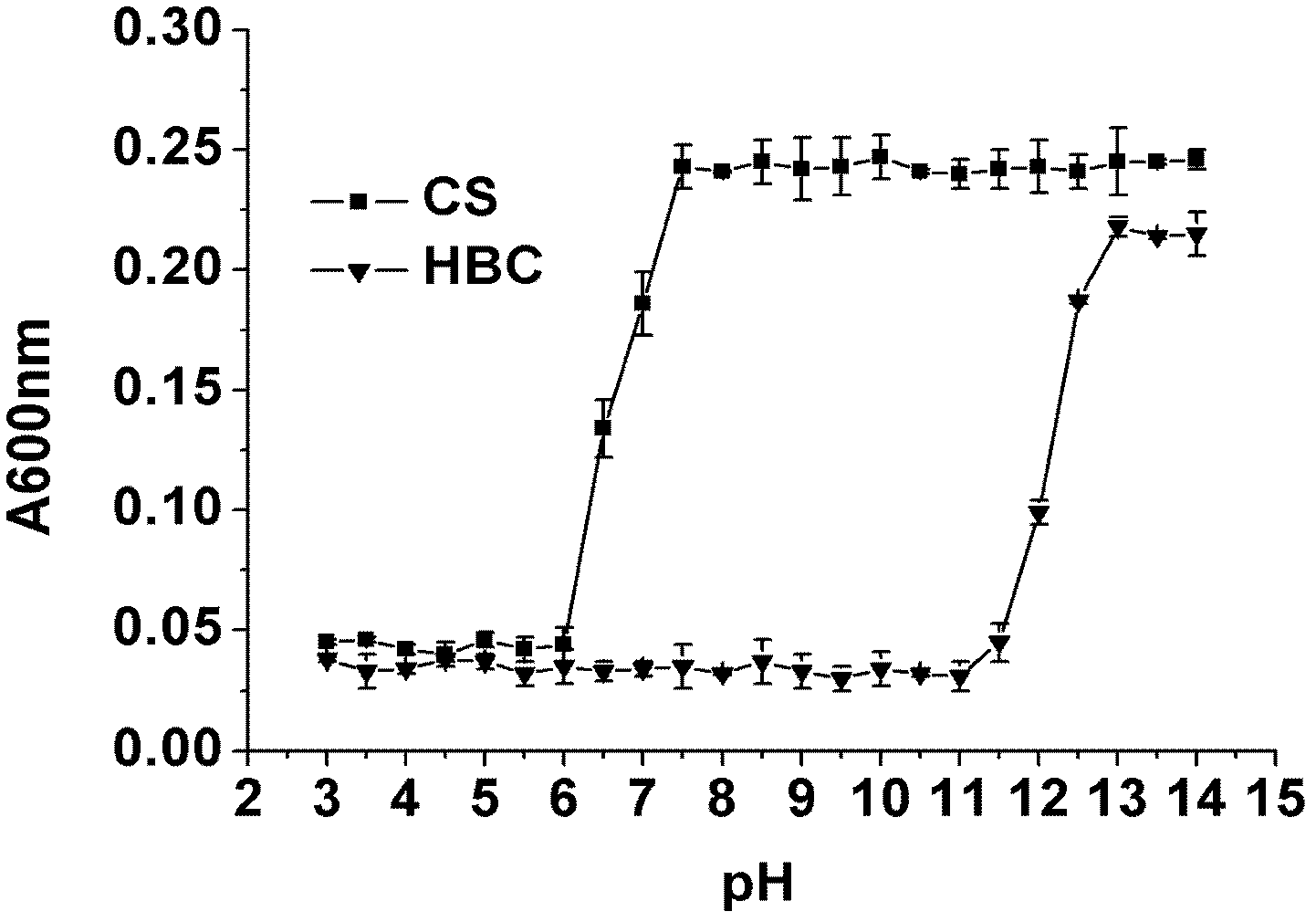

A kind of preparation method of chitosan hydroxybutyl derivative

ActiveCN102276756AShort preparation cycleImprove preparation efficiencyMicrowave - actionChitosan derivative

The invention relates to a preparation method of a chitosan hydroxybutyl derivative. Chitosan is used as a raw material; 1,2-epoxybutane is used as an etherifying agent; the hydroxybutyl modification of the chitosan is performed in an isopropanol aqueous solution dispersion system under microwave action with controlled reaction temperature and time; a chitosan derivative, hydroxybutyl chitosan, is successfully prepared; the preparation period is greatly shortened, and the preparation efficiency is increased. During the reaction, the hydroxybutyl modification of the chitosan is performed orderly under the microwave action and with controlled reaction temperature and time, which shortens the preparation period. The product has a wider pH dissolution range, and has a soluble property in weakacid, neutral, and weak alkaline aqueous solutions, that is to say, the limitation that chitosan is only soluble in acids or acid solutions is improved; the aqueous solution of the product has temperature sensitivity, can be transformed between an aqueous solution and hydrogel by adjusting the temperature; and the product is widely applicable to fields of biomedicine, tissue engineering, pharmaceutical carriers, chemical engineering, food, cosmetics, etc.

Owner:惠众国际医疗器械(北京)有限公司

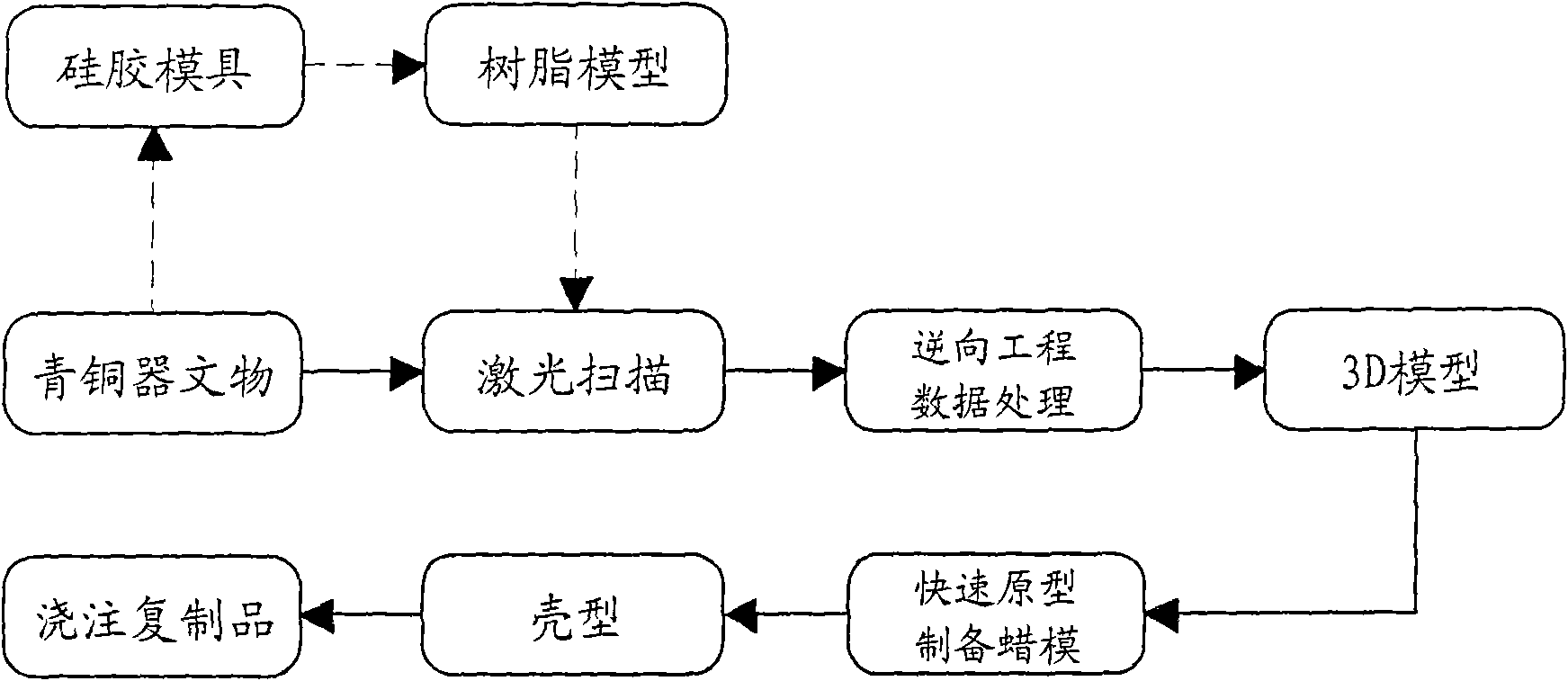

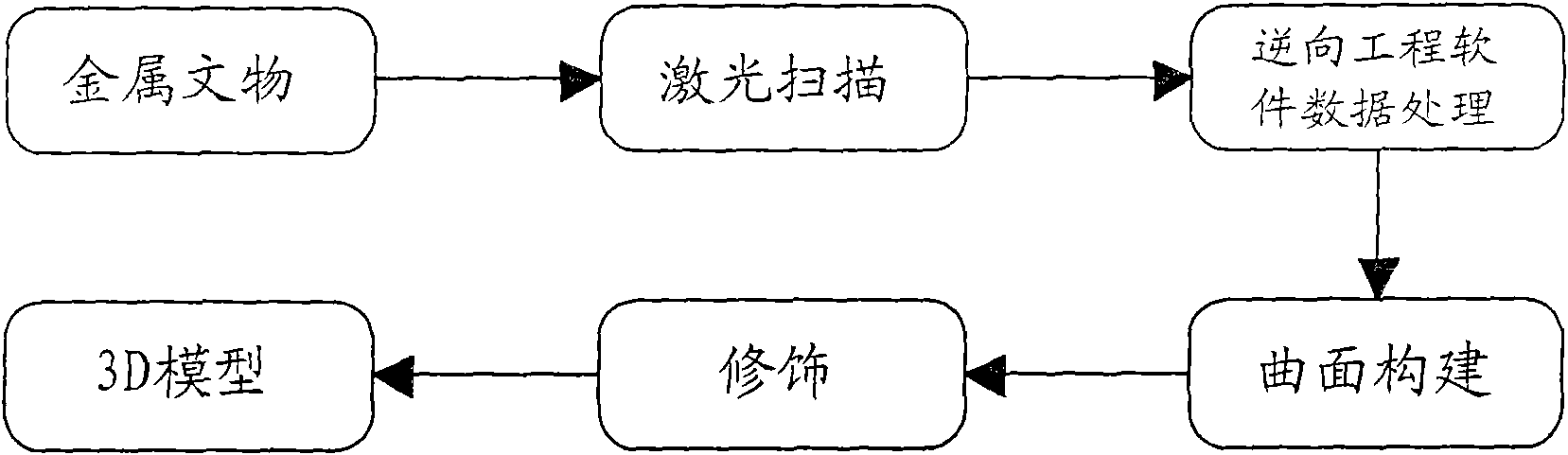

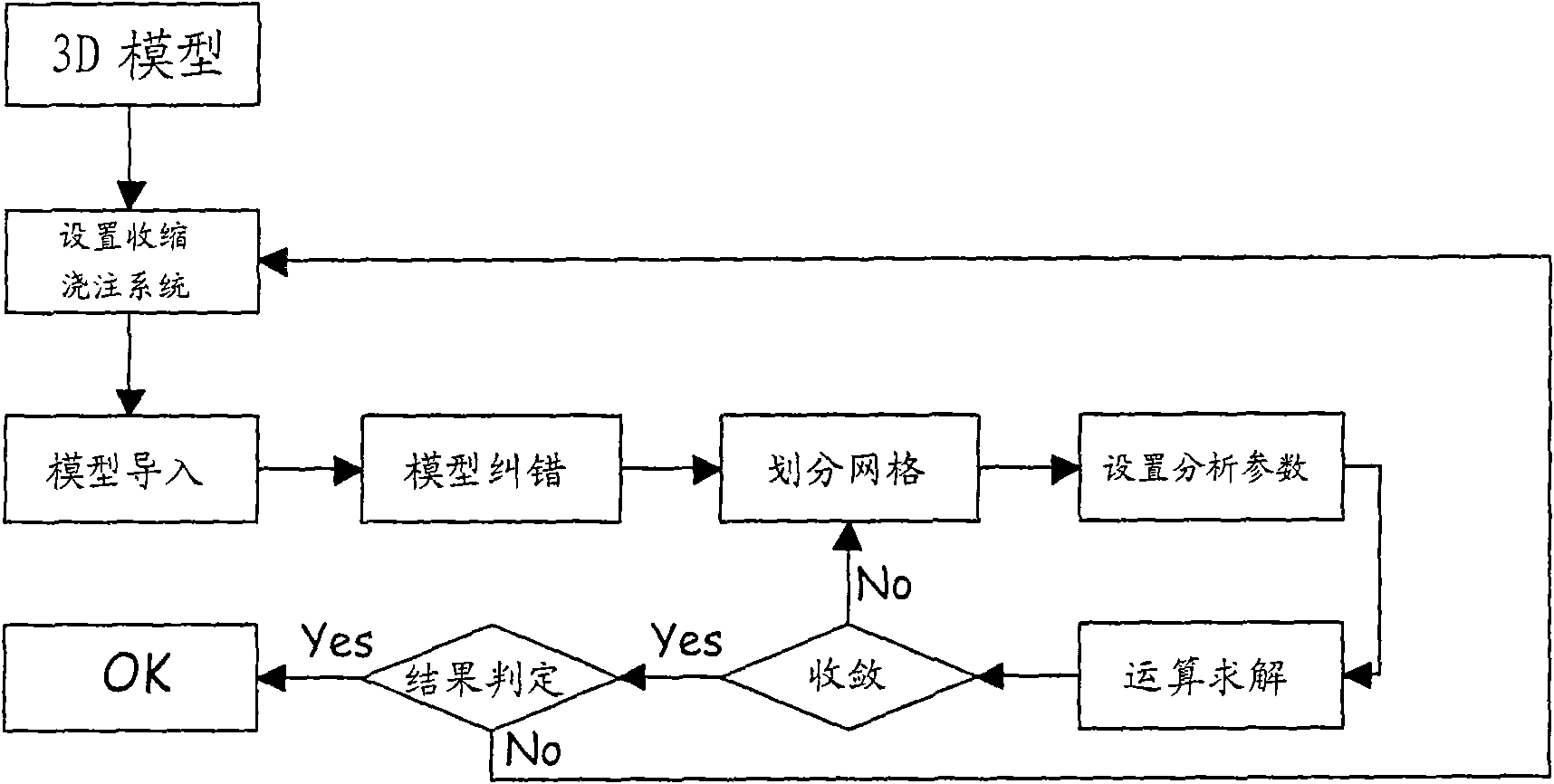

Method for replicating metal relic with high fidelity

InactiveCN101554647AAdvanced technologyPrecision workmanshipFoundry mouldsFoundry coresWaxLaser scanning

The invention discloses a method for replicating a metal relic with high fidelity, and the method comprises the following steps: (1) an original metal relic is scanned directly by utilizing a laser scanner and a three-dimensional (3D) model of the original metal relic is acquired by reverse engineering; (2) the real process of real investment shell casting is simulated by adopting a finite element method, and the 3D model is modified according to the simulation result (such as contraction); (3) according to the modified 3D model, an accurate wax model is produced by adopting a quick prototyping method; and (4) a shell is produced by utilizing the wax model and liquid metal is poured according to the best simulation technological parameters, thus obtaining the replication with high fidelity. In the method, the accurate wax model can be produced without touching the original relic, and therefore, the relic cannot be damaged; and the method also introduces reverse engineering, quick prototyping and casting process simulation technology into the replication of the metal relic, and compared with the traditional method, the produced metal relic replication has high fidelity and can achieve the effect of representing the relic verve.

Owner:XIAMEN UNIV OF TECH

Preparation method of in-situ grown graphene reinforced metal-based composite material

The invention relates to a preparation method of an in-situ grown graphene reinforced metal-based composite material. Carbon-containing organic matter and metal or metal alloy powder are dissolved and mixed in a solvent, mechanically stirred, heated at the temperature of 50-150 DEG C and mixed, the solvent is evaporated, and prefabricated powder is obtained through vacuum drying at the temperature of 50-100 DEG C and grinding; and through the powder metallurgy technique of a hot-press forming method or a cold-press-sintering method or an SPS sintering method, the prefabricated powder is pressed and formed, the carbon-containing organic matter is transformed into graphene, and the three-dimensional graphene / metal-based composite material is obtained. The preparation method is simple, easy to implement and short in preparation cycle, and industrialized batch production is easy; and in addition, the graphene directly grows on a metal matrix in the preparation process, the crystallisation degree of the graphene in the obtained graphene reinforced metal-based composite material is high, the number of defects is small, and the dispersity is good. The preparation method has potential application prospects in the composite material field, the functional material field and the like.

Owner:TIANJIN UNIV

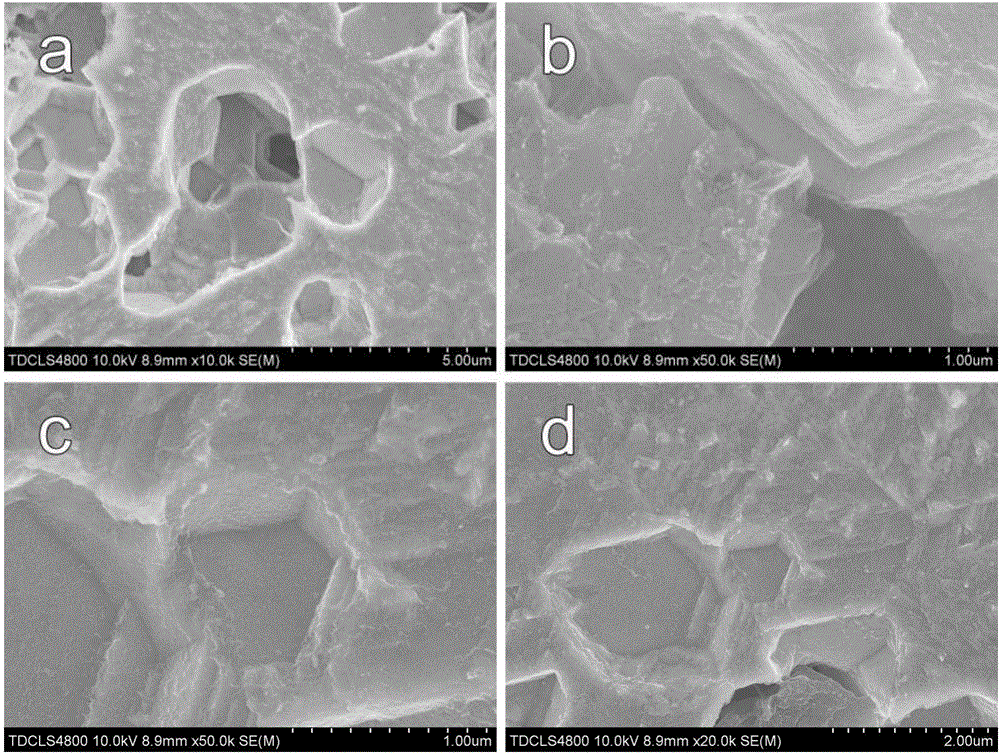

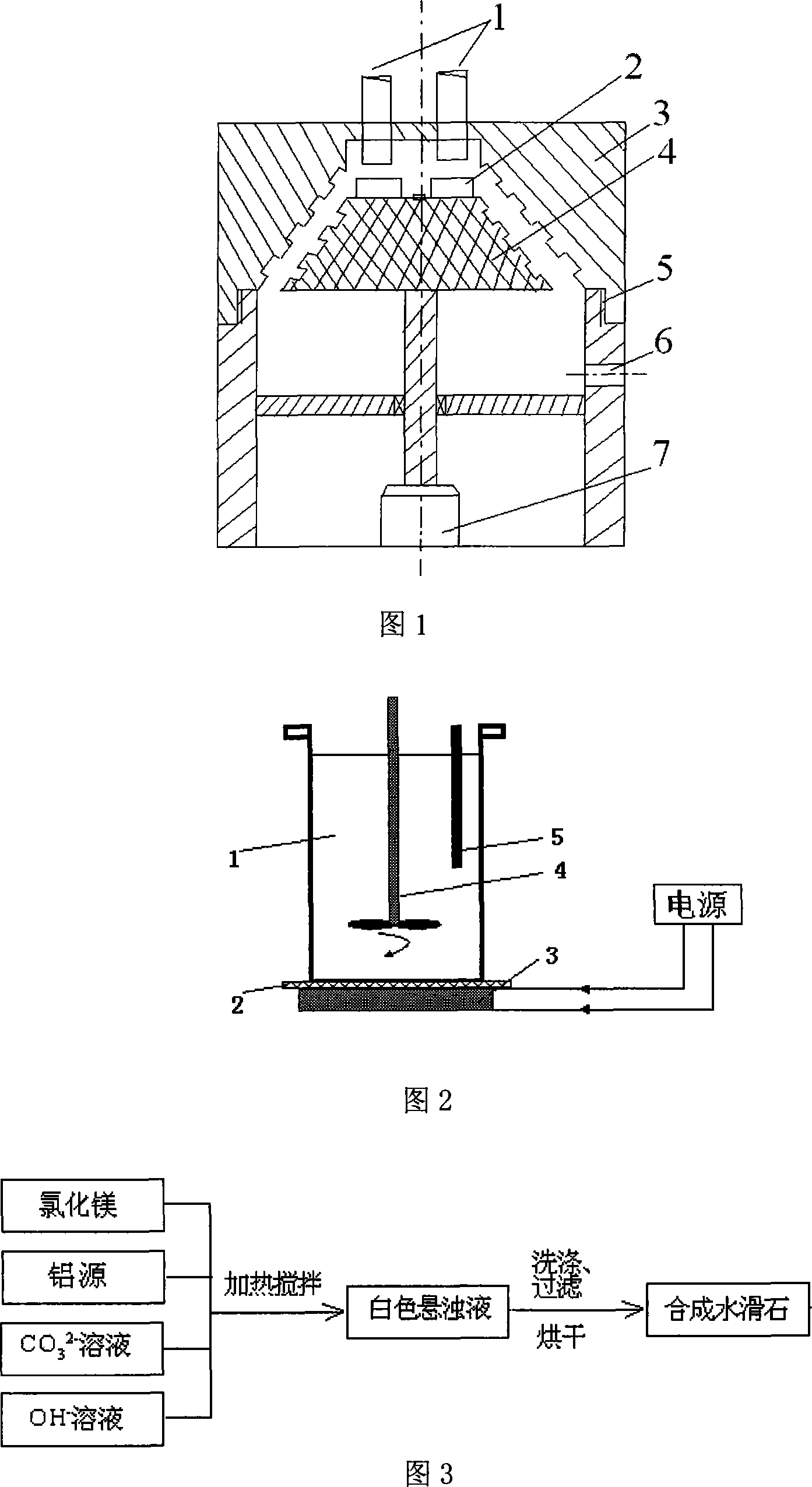

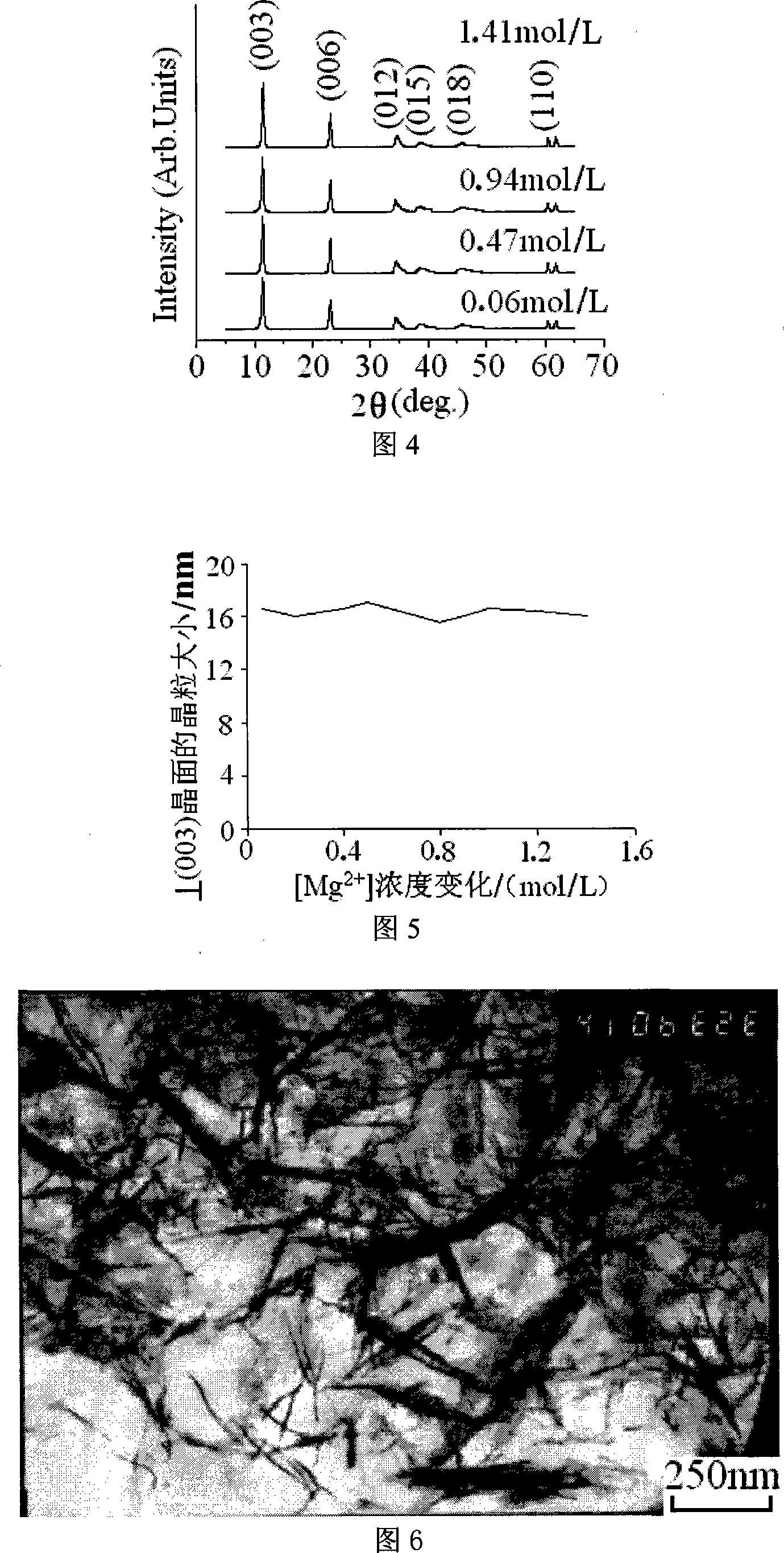

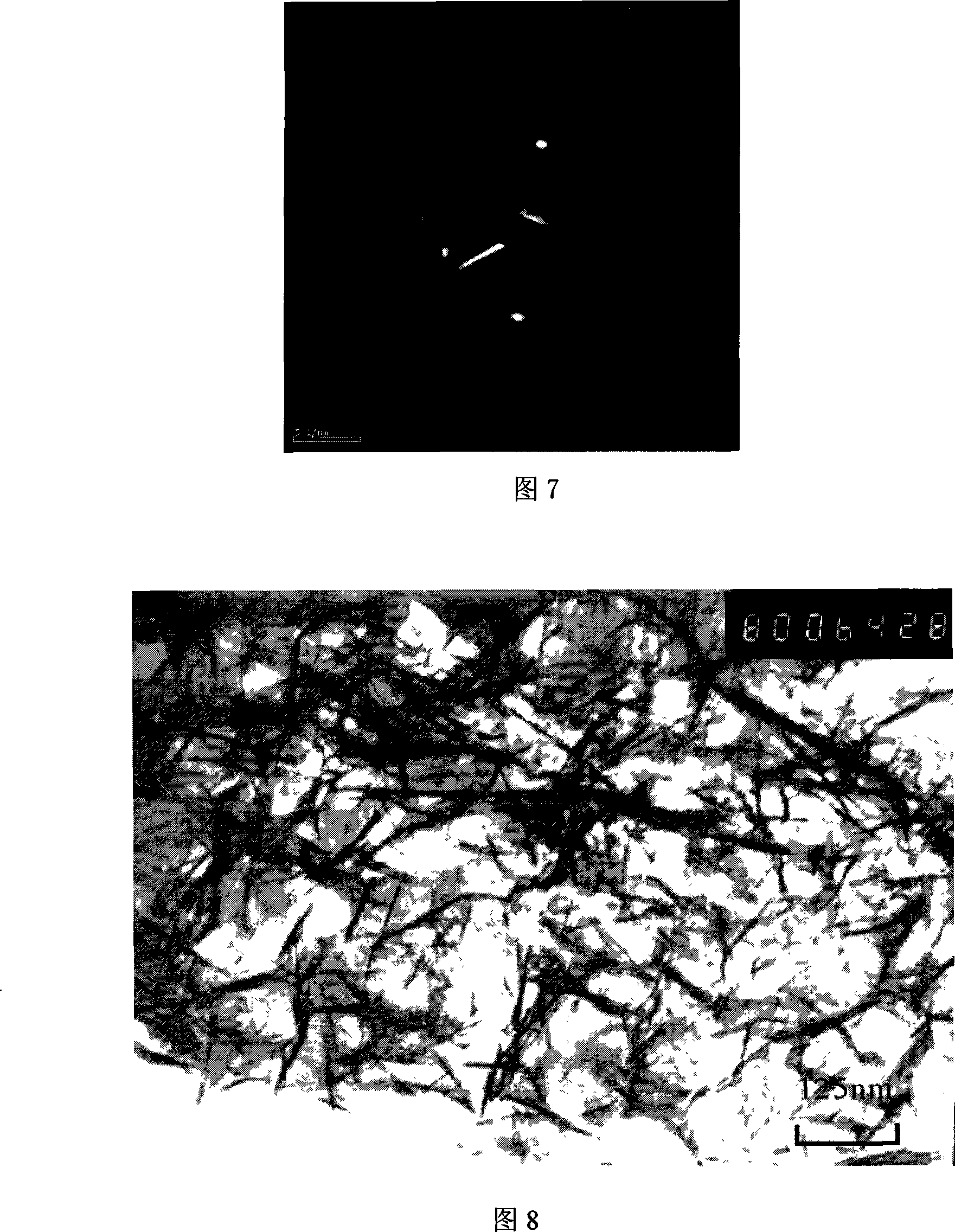

Needle, flake-shaped nano single crystal mg-al hydrotalcite Mg8Al2(OH)16CO3 4H2O preparation method

ActiveCN101187060AGood dispersionUniform sizePolycrystalline material growthSingle crystal growth detailsSingle crystalFire retardant

The invention discloses a process for preparing acicular, flake nano single crystal magnesia-alumina hydrotalcite Mg6Al2(OH)16C.4H2O, and the prepared Mg6Al2(OH)16CO3.4H2O is used as a flame retardant of power electronic devices. Acicular components comprise 0.06-1.41 mol / L crystal magnesium chloride, 0.02-0.47 mol / L aluminum salt, 0.3-4.5 mol / L sodium hydroxide and 0.094-1.368 mol / L sodium carbonate, and flake components are added with modifier basing on the above components. The invention has the process steps that the crystal magnesium chloride and the sodium hydroxide are firstly dissolved in deionized water and heated and stirred, and then the aluminum salt and sodium carbonate are added into the solution, the deionized water and the sodium hydroxide are added every 20 minutes during reaction, the time of reaction is 0.5-2 hours, and the solution is cooled until room temperature and is washed, filtered and dried. The crystal morphology of the prepared acicular nano single crystal magnesia-alumina hydrotalcite is that the diameter is 10-20 nanometer, the length is 60-130 nanometer, the diameter is 25-80 nanometer, and the length is 200-500 nanometer. The crystal morphology of the flake nano single crystal magnesia-alumina hydrotalcite is that the thickness is 10-20 nanometer, the diameter is 50-100 nanometer, the thickness is 20-30 nanometer, and the diameter is 60-200 nanometer. The process for preparation of the invention has short period and simple process, is prepared at atmospheric pressure, and is suitable for industrial production.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com