Method for preparing graphite alkenyl nanometer materials by electron beam irradiation method

An electron beam irradiation, nanomaterial technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of low process efficiency, environmental protection, long time pyrolysis reduction, and highly toxic hydrazine hydrate, and achieve superior performance. , The effect of short preparation period and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

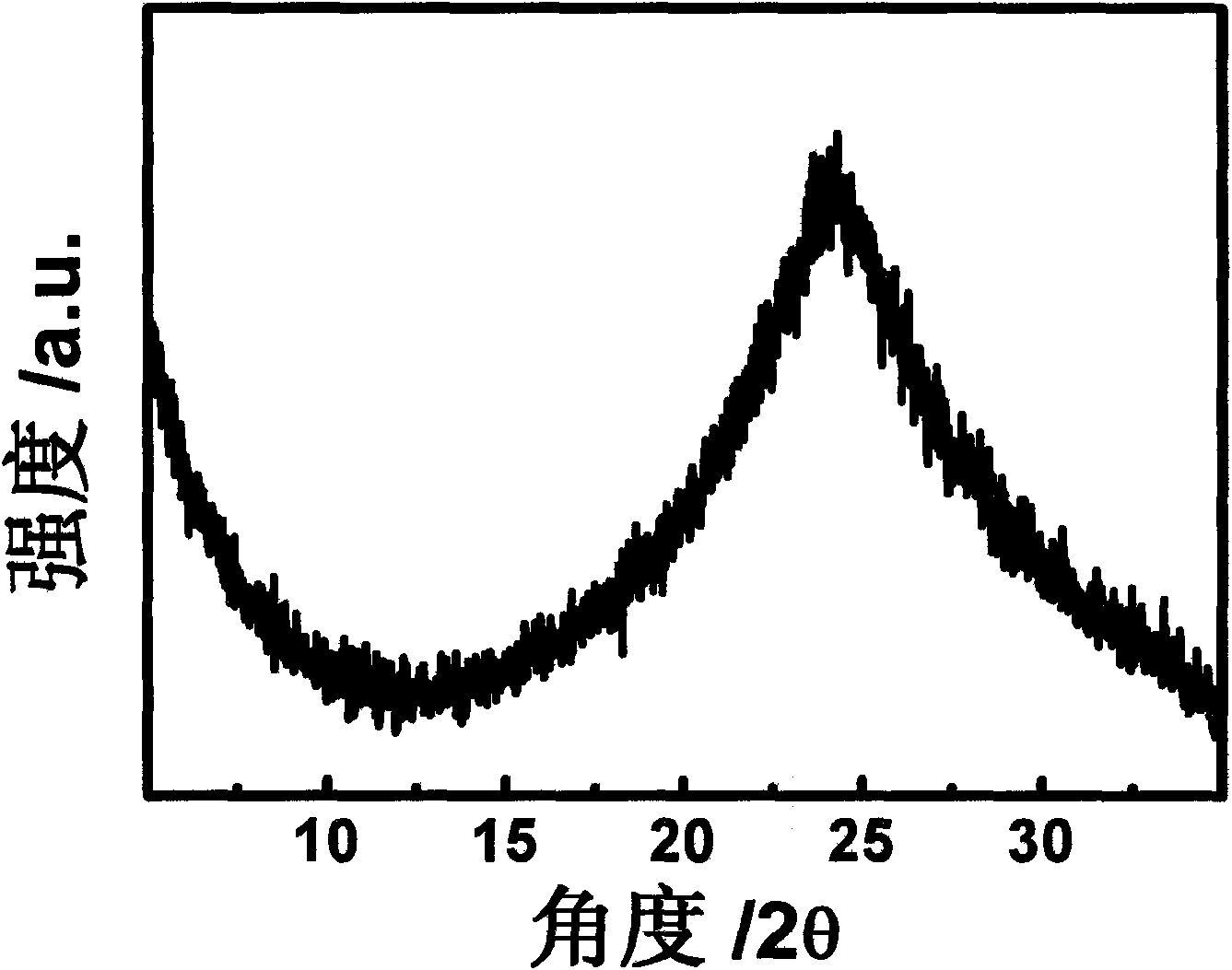

[0021] Embodiment one: at first, potassium persulfate (K 2 S 2 o 8 ) 2.5g, phosphorus pentoxide (P 2 o 5 ) 2.5g, dissolved in 12ml of concentrated sulfuric acid, heated to 80°C; then 3g of natural graphite as the above solution, kept at 80°C for 4.5 hours; cooled to room temperature, diluted with 500ml of deionized water, and left to stand overnight; filtered, with Float with 0.2mm filter to remove residual acid; dry in a vacuum oven at 60°C; dissolve the above product in 120ml of concentrated sulfuric acid, slowly add 15g of potassium permanganate into the solution in an ice bath; stir at a constant temperature of 35°C for 2 hours, then Slowly dilute with 250nl water, let it stand for 2 hours; add 700ml water to dilute, 20mlH 2 o 2 (30%) was added to the above solution; filtered and then washed with 1 L of 1:10 HCl solution; dissolved in a small amount of water or ethanol, ultrasonicated for 20-30 minutes, washed, filtered, and separated to obtain a precipitate for use; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com