Method for preparing electrode material, electrode material, electrode and battery

An electrode material and electrode technology, applied in the field of nanomaterials and chemical power sources, can solve the problems of low capacity, serious and complex preparation process of iron oxide composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 4.5g of ferric chloride hexahydrate, 12g of sodium acetate and 3.3g of polyethylene glycol into 160ml of ethylene glycol, and ultrasonically oscillate for 30 minutes to obtain a uniform mixed solution; The reaction was carried out for 12 hours. The hydrothermal product was successively cleaned by centrifugation with deionized water and absolute ethanol, and after vacuum freeze-drying at a temperature of -60°C and a pressure of 0 kPa for 6 hours, the product was obtained; ℃ for 8 hours, and cooled to room temperature to obtain a hollow spherical ferrous oxide and iron composite electrode material.

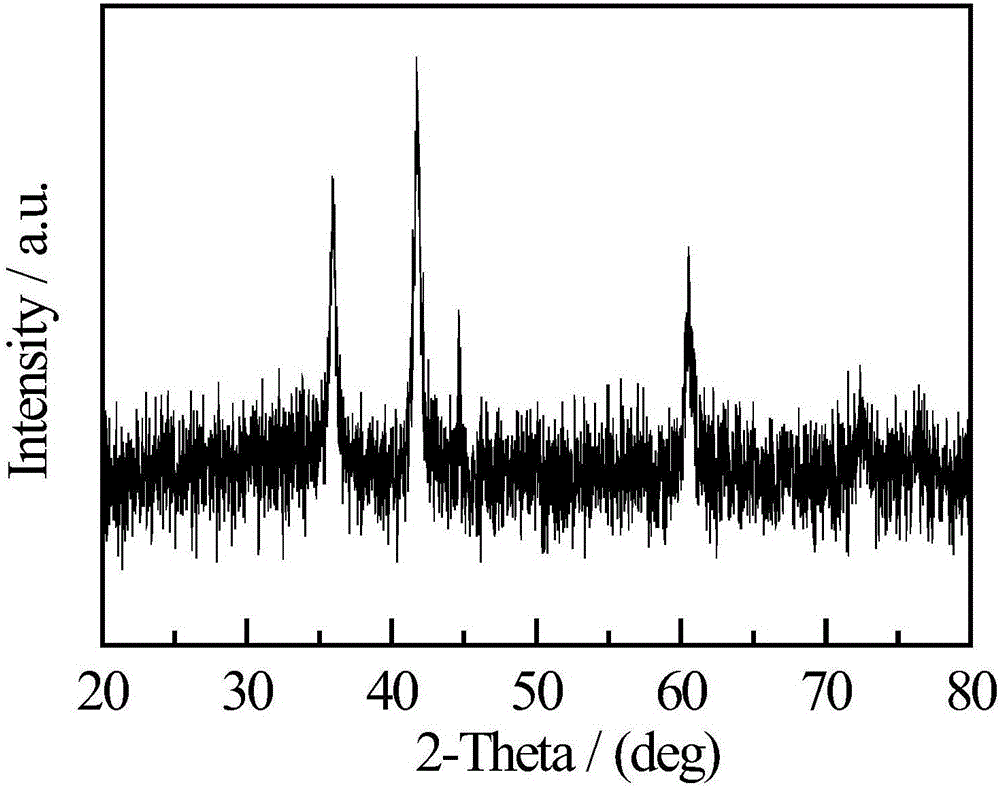

[0026] figure 1 is the XRD pattern of the obtained ferrous oxide and iron composite electrode material, by figure 1 The diffraction peaks of FeO and Fe can be seen in the material.

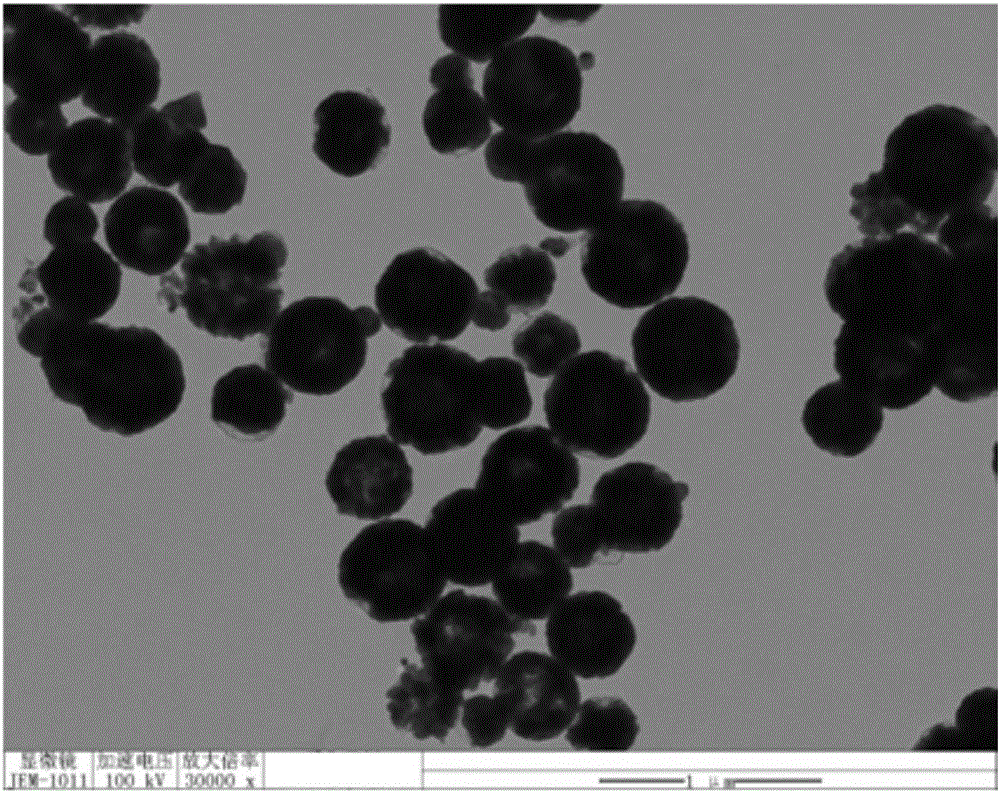

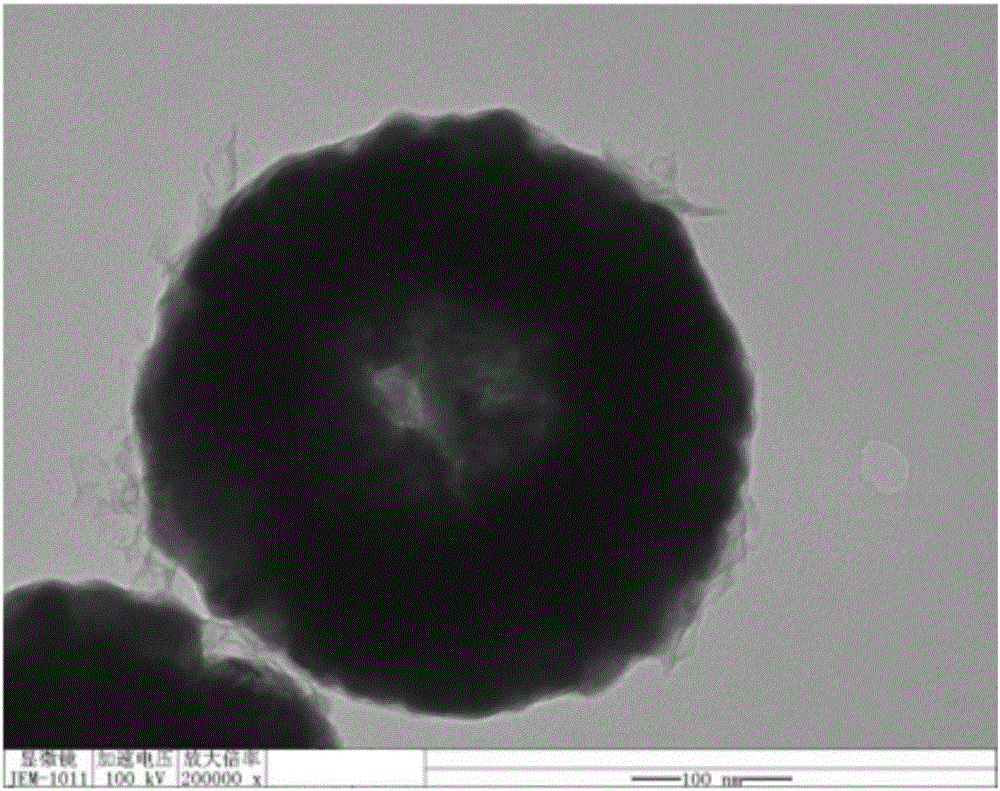

[0027] figure 2 and image 3 It is the morphology of the ferrous oxide and iron composite electrode material prepared in Example 1 observed under a scanning electron microscope. It can ...

Embodiment 2

[0032] Add 1g of ferric chloride hexahydrate, 6g of sodium acetate and 0.9g of polyethylene glycol into 80ml of ethylene glycol, and ultrasonically oscillate for 200 minutes to obtain a uniform mixed solution; React for 24 hours. The hydrothermal product was successively washed with deionized water and absolute ethanol, and vacuum freeze-dried at a temperature of 0°C and a pressure of 101kPa for 30 hours to obtain the product; Calcined for 5 hours and cooled to room temperature to obtain a hollow spherical ferrous oxide and iron composite electrode material.

[0033] The composite electrode material prepared in Example 2 and the polyvinylidene fluoride binder are prepared into an electrode in a mass ratio of 4:1, and the electrolyte solute is LiPF 6 , the solvent is mixed by ethylene carbonate, diethyl carbonate and dimethyl carbonate in a volume ratio of 1:1:1, LiPF 6 The concentration is 1mol / L, and the electrode and electrolyte are assembled to form a button battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com