Patents

Literature

210 results about "Dissolved iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

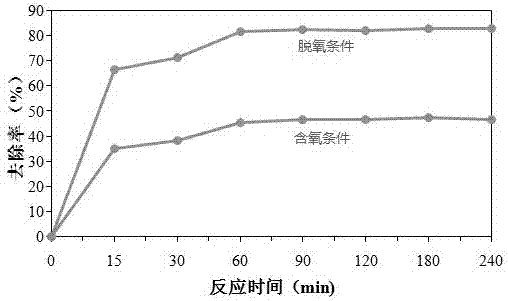

Dissolved iron is mainly present as Fe(OH)2+ (aq) under acidic and neutral, oxygen-rich conditions. Under oxygen-poor conditions it mainly occurs as binary iron. Iron is part of many organic and inorganic chelation complexes that are generally water soluble.

Method of treating digested sludge

InactiveUS20050000908A1Improve filtering effectKeep drySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeWastewater

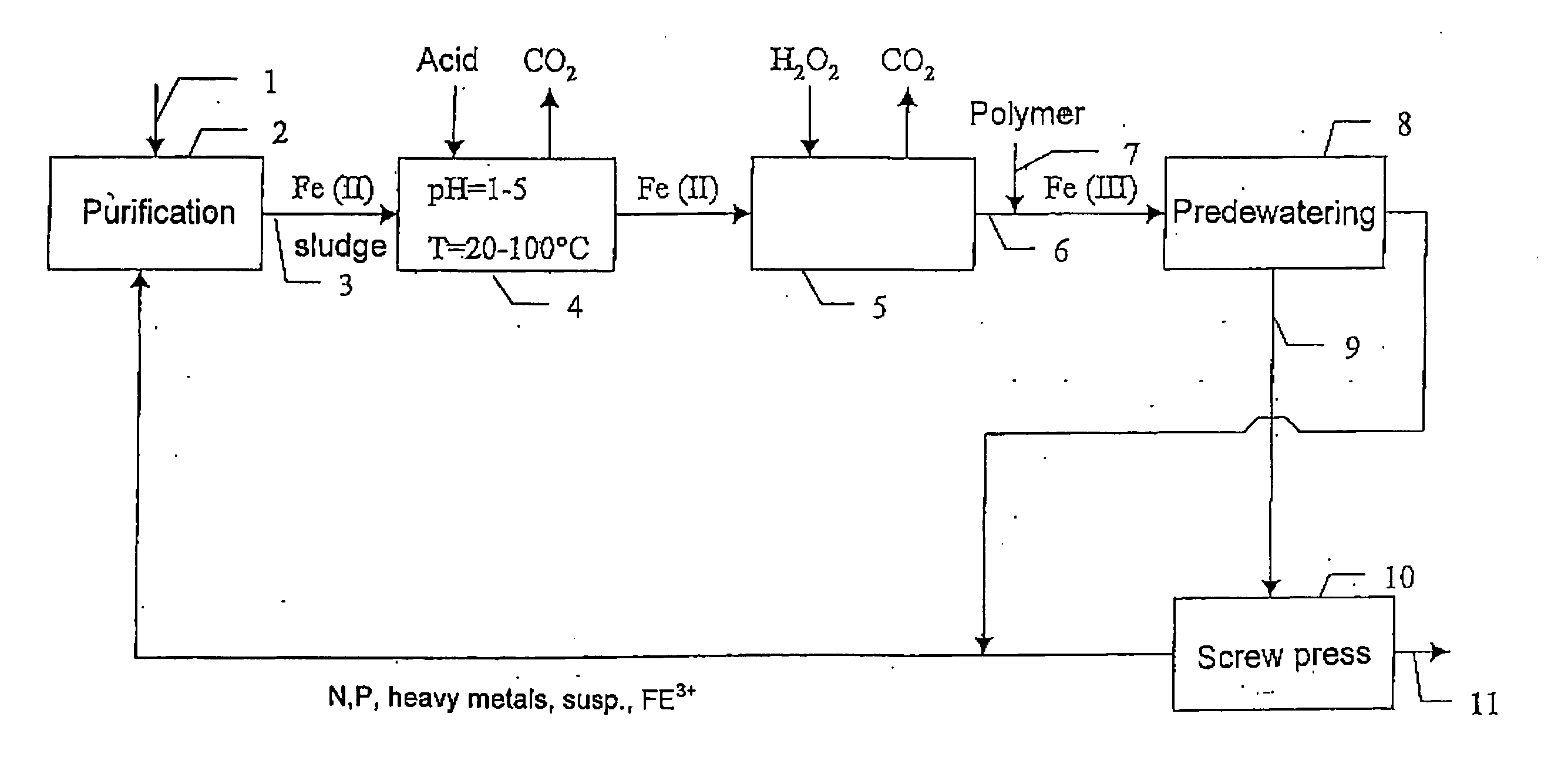

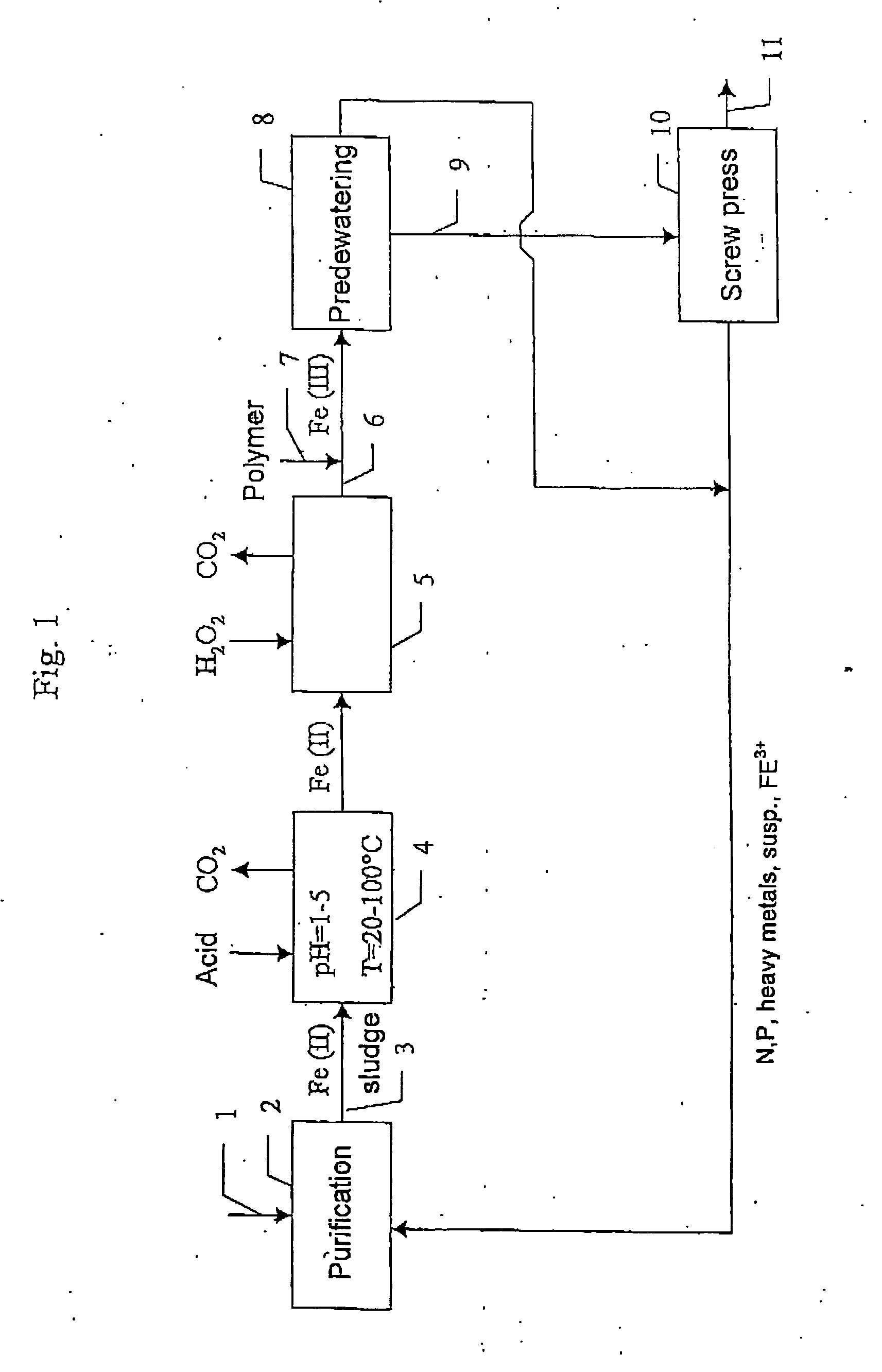

A method of treating, in wastewater purification, sludge containing organic matter, divalent iron and phosphorus, in which the sludge that is treated is made to contain dissolved iron and phosphorus at a molar ratio Fe:P of above 1:1, the sludge is treated at 0-100° C. with an acid at a pH of 1-5 for dissolution of divalent iron and phosphorus from the sludge, the sludge is supplied with an oxidiser selected from hydrogen peroxide and percompounds, wherein divalent iron is oxidised by Fenton's reaction to trivalent iron, and (i) trivalent iron is precipitated as trivalent iron phosphate (ii) free radicals with a deodorisation and sanitation effect are formed by Fenton's reaction, the sludge is then dewatered at a pH of at most 7, and the aqueous solution obtained in dewatering is recirculated to the wastewater purification.

Owner:KEMIRA KEMI AB

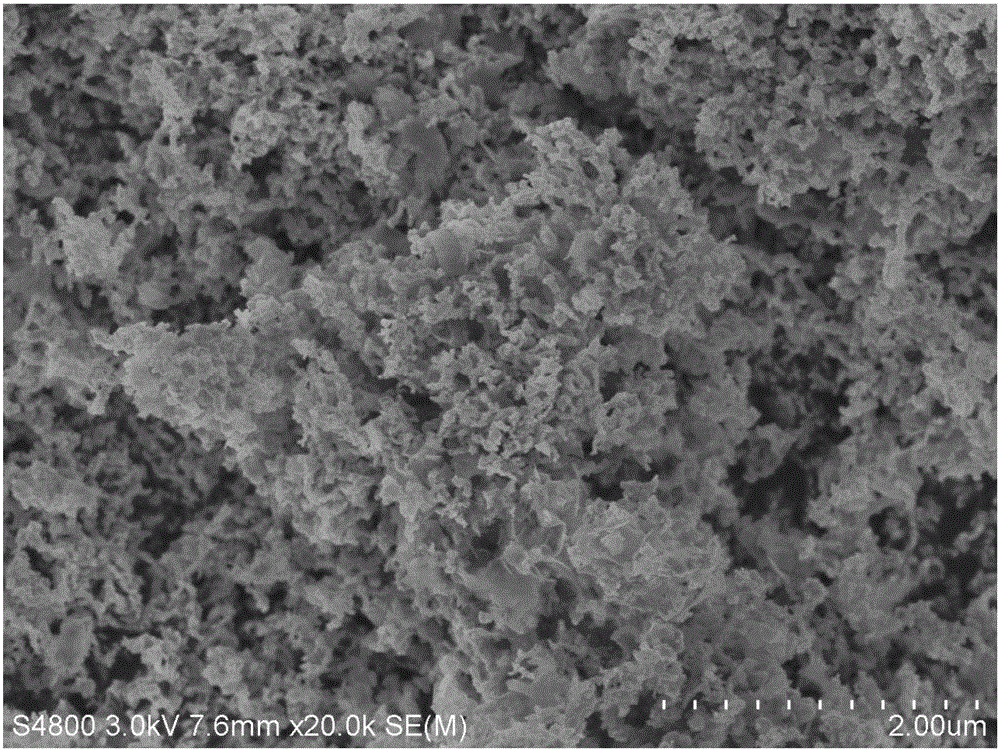

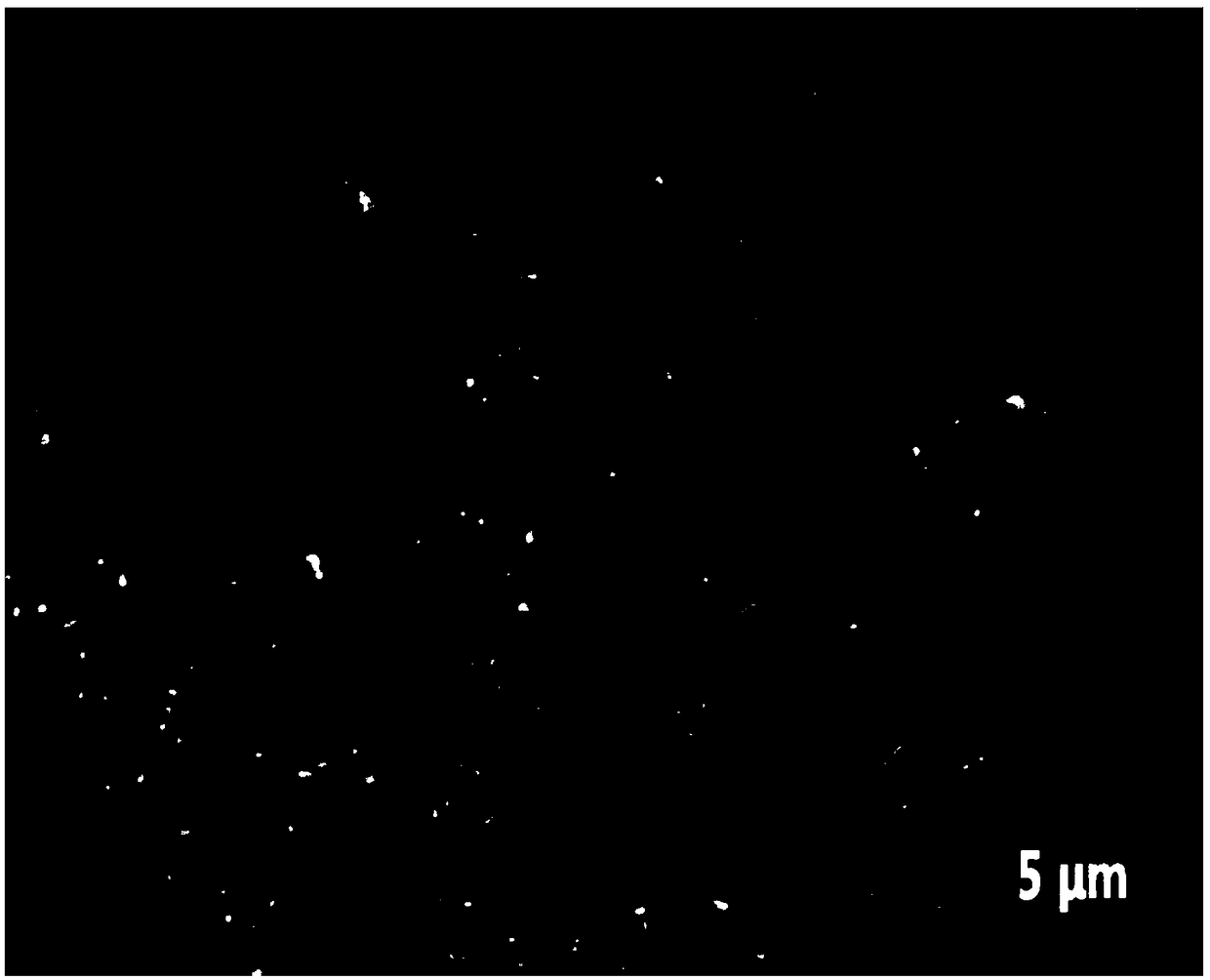

Magnetic carrier iron ordered mesoporous carbon, preparation method and application thereof

InactiveCN103301809AEfficient removalLow toxicityOther chemical processesWater contaminantsSource materialMagnetite Nanoparticles

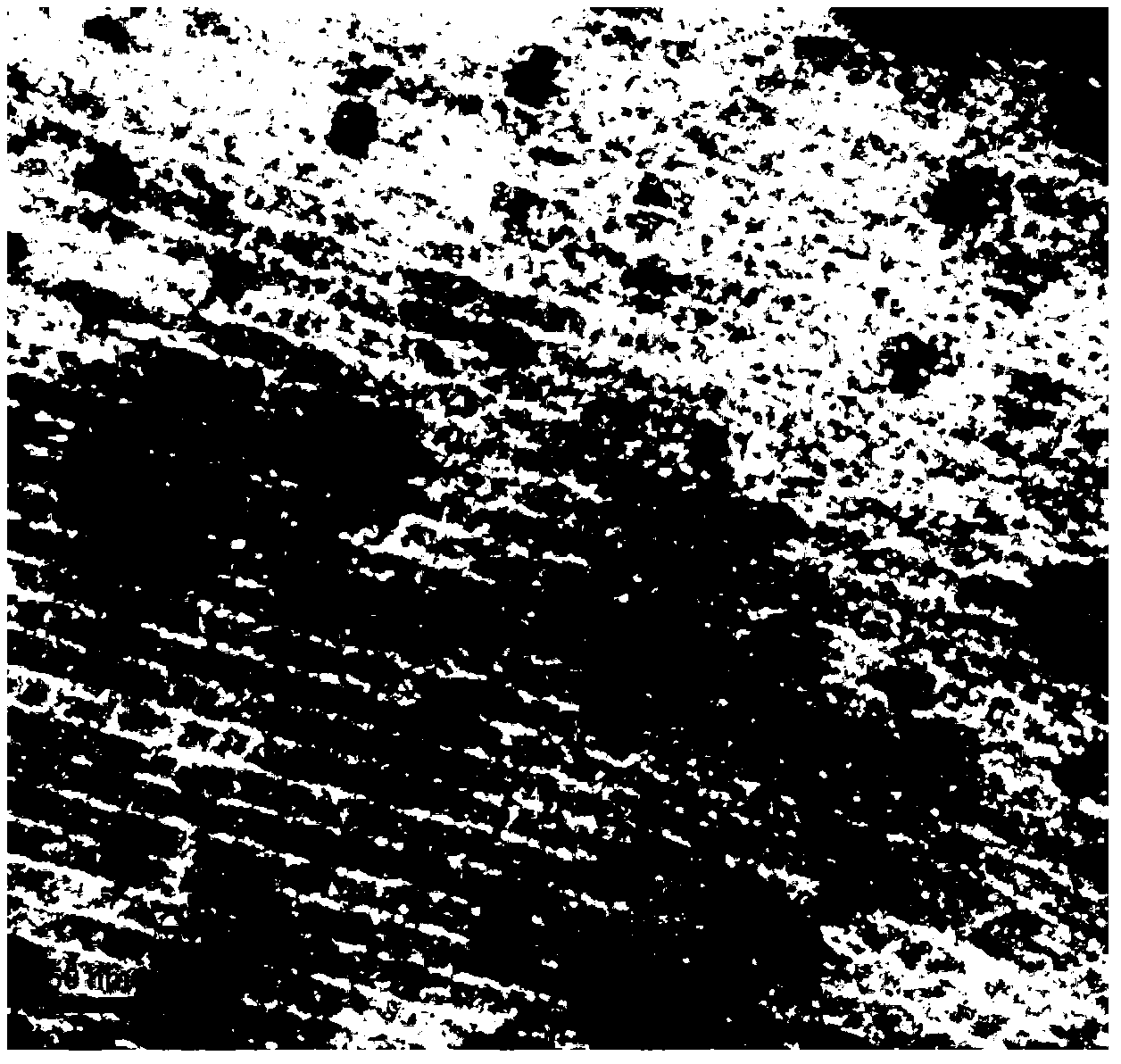

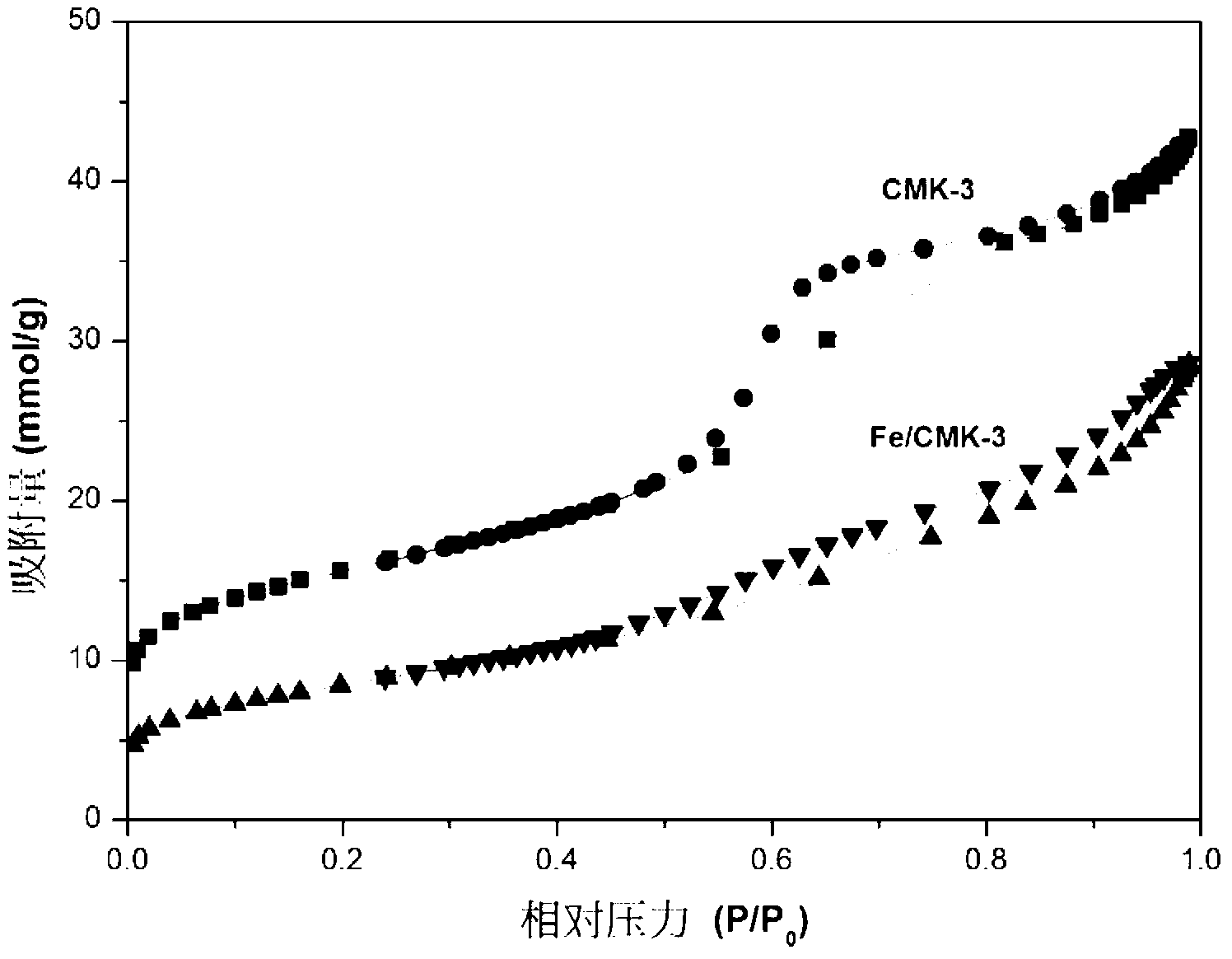

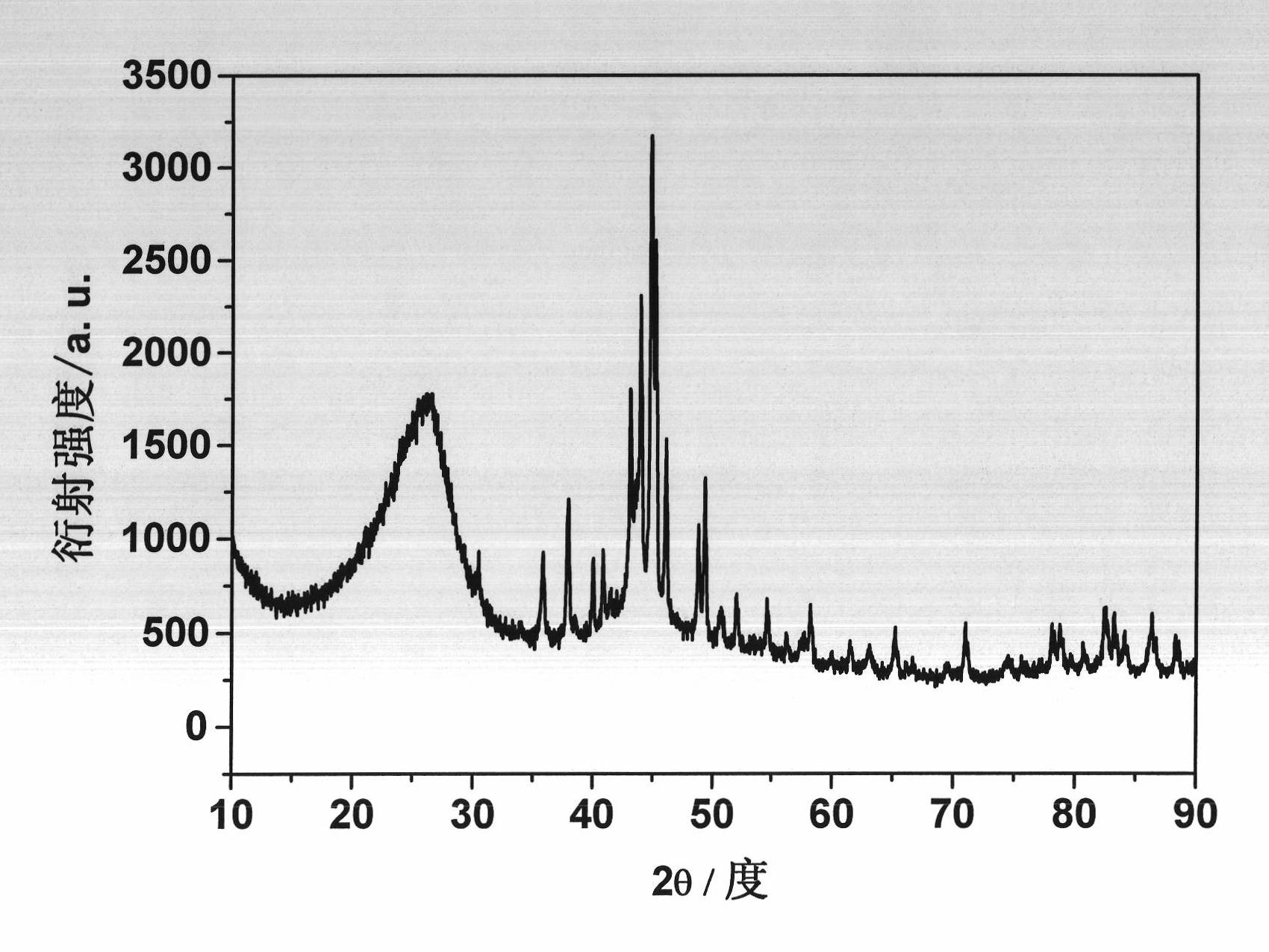

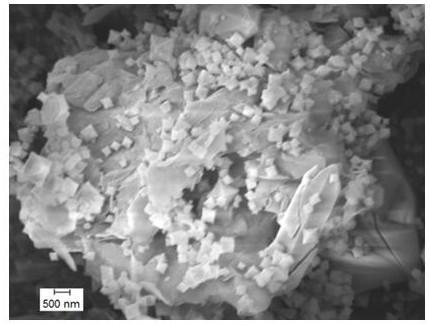

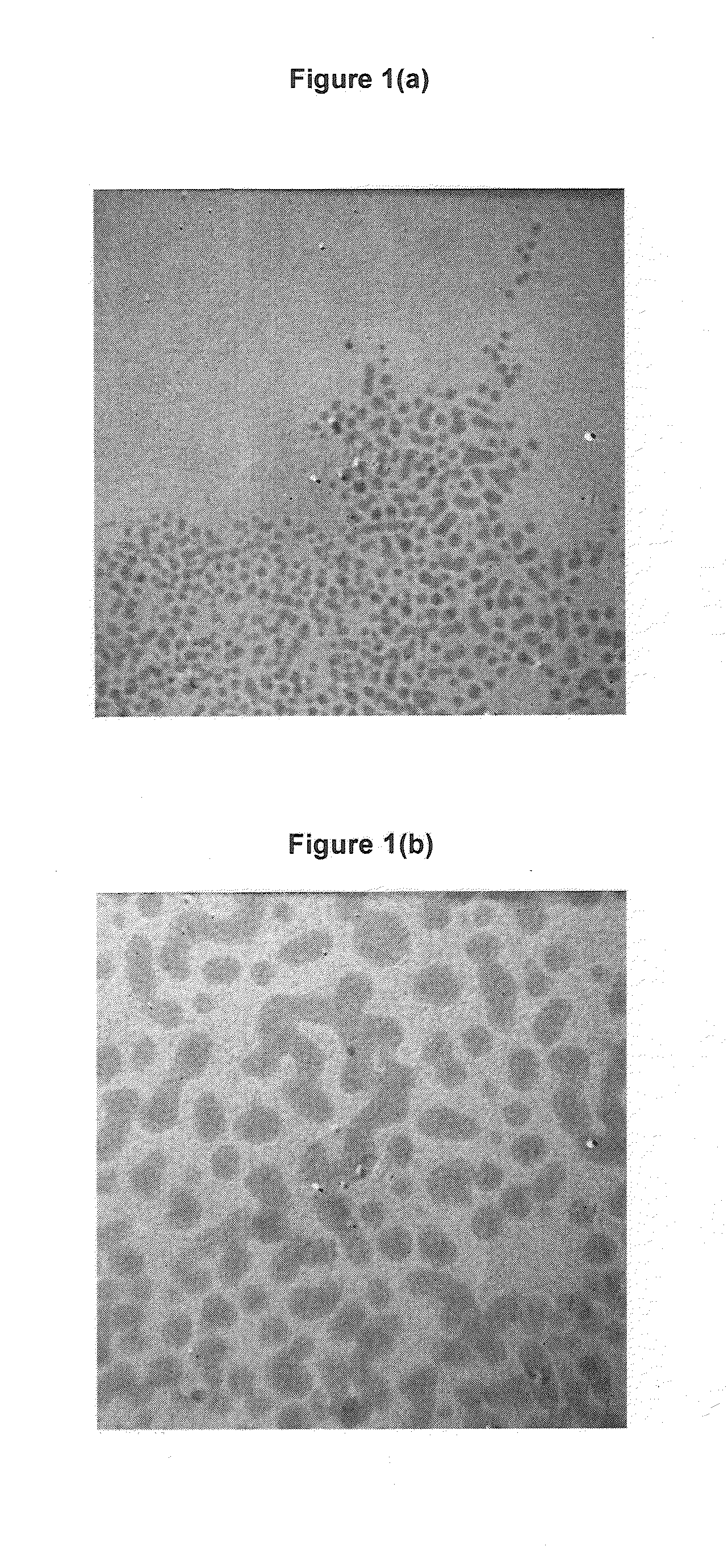

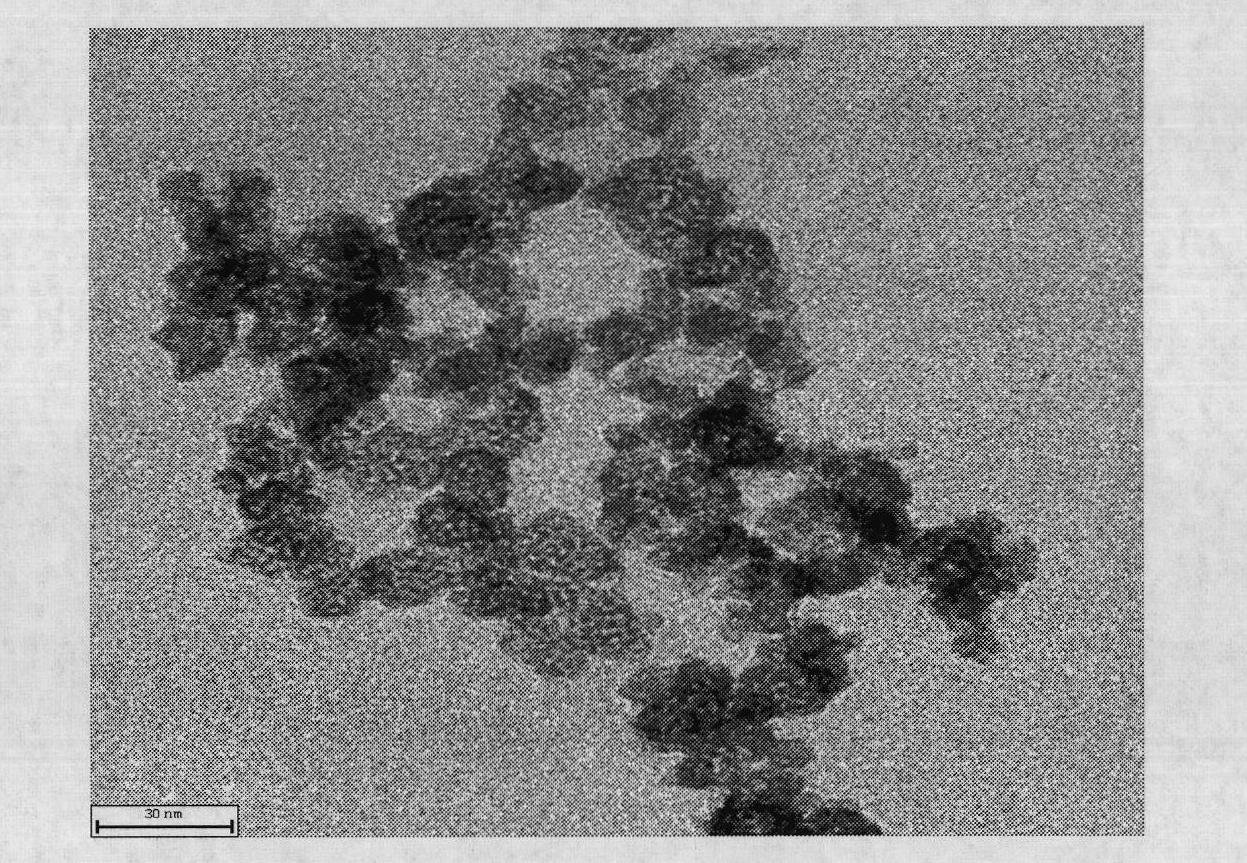

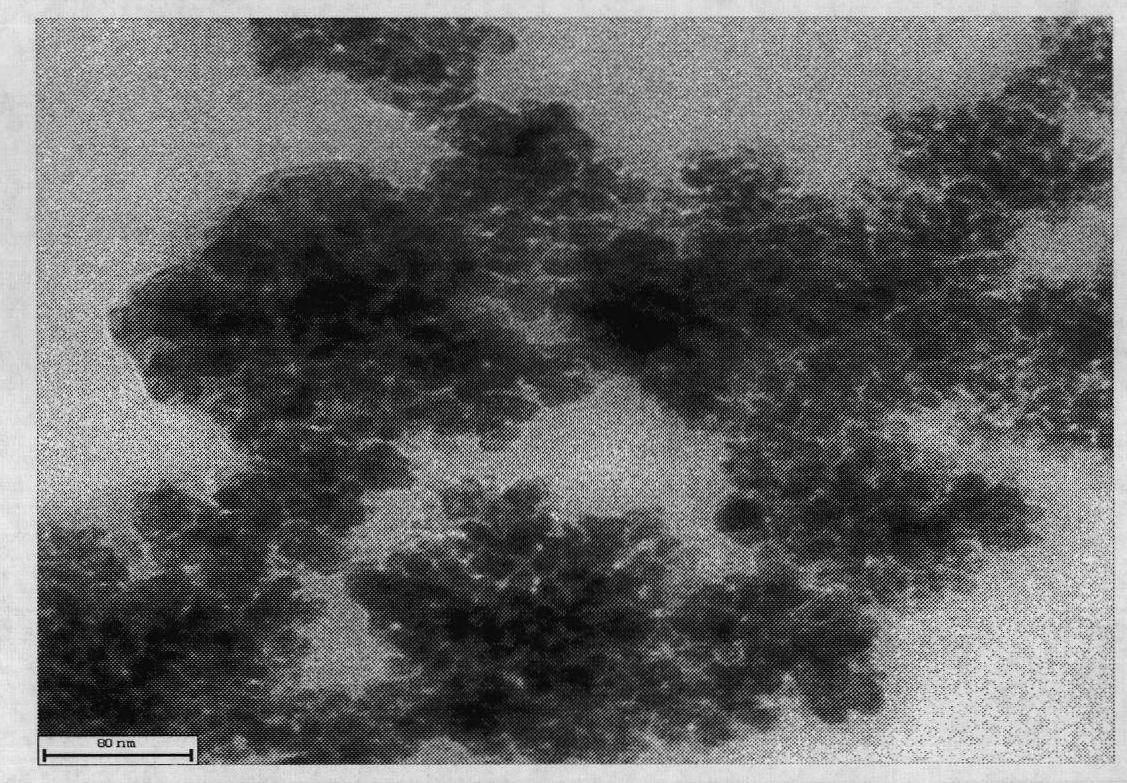

The invention discloses a magnetic carrier iron ordered mesoporous carbon. The ordered mesoporous carbon is taken as a carrier, the carrier is prepared by a hard template method, and magnetic nanoparticles are loaded onto the carrier by a nano-joint casting method; the magnetic nanoparticles mainly consist of zero-valent iron and oxide of iron, wherein the proportion of the iron element is taken as 1-1.5m mol of each gram of a mesoporous silicon template, and the pore diameter distribution of the mesoporous carbon is mainly concentrated nearby 5nm and 3.8nm. A perpetration method of the magnetic carrier iron ordered mesoporous carbon provided by the invention comprises the following steps of: dissolving iron source materials and cane sugar in sulfuric acid, dipping the mesoporous silicon template, and adopting two-section type heat treatment; secondly, dipping by cane sugar-containing sulfuric acid solution, and adopting two-section type heat treatment; and finally carrying out constant-temperature high-temperature carbonization so as to obtain the silicon template in a demoulding way by hot NaOH solution, and drying to obtain the magnetic carrier iron ordered mesoporous carbon. The magnetic carrier iron ordered mesoporous carbon disclosed by the invention has the characteristics of being large in specific surface area and pore volume, wide in application range, stable in physicochemical property and the like, and the heavy metal hexavalent chromium ions in water body can be removed.

Owner:HUNAN UNIV

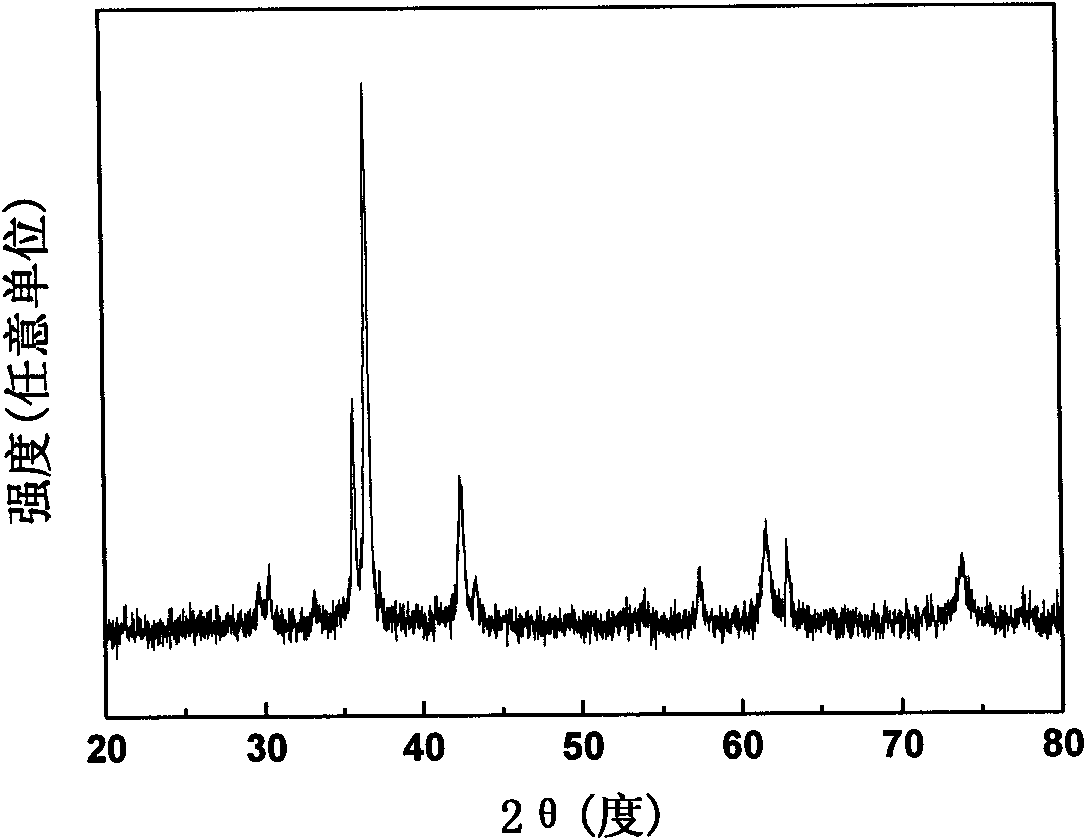

Method and application of environment-friendly synthesis nanometer zero-valent iron-nickel bimetal materials

The invention relates to a method of environment-friendly synthesis nanometer zero-valent iron-nickel bimetal materials. The method includes the following steps of weighing 20 g-60 g of green tea to be added into 1 liter of distilled water, heating the mixture for 40 min-60 min at the temperature of 60 DEG C-80 DEG C, cooling the mixture to the room temperature, and obtaining a green tea extracting solution by filtering the mixture; dissolving iron salt and nickel salt in the distilled water to prepare an iron-nickel mixed solution; adding the iron-nickel mixed solution into a three-opening flask, heating the solution in water bath at the temperature of 25 DEG C to 70 DEG C, stirring the solution for 10 min-60 min at the rate of 350 r / min, dropwise adding the green tea extracting solution in the stirring process, continuing to stir for 20 min, and obtaining environment-friendly synthesis nanometer zero-valent iron-nickel suspension liquid; and separating the suspension liquid through a suction filtration method, and drying obtained precipitates in a vacuum drying box for 12 h-48 h at the temperature of 40 DEG C-70 DEG C so that the environment-friendly synthesis nanometer zero-valent iron-nickel bimetal materials can be obtained. The preparation process is simple, the reaction condition is moderate, the cost is greatly reduced, and the method has the huge application and popularization potential in the field of chromium-contaminated soil and groundwater remediation.

Owner:TAIYUAN UNIV OF TECH

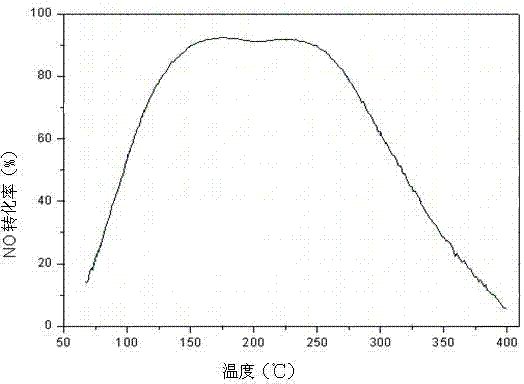

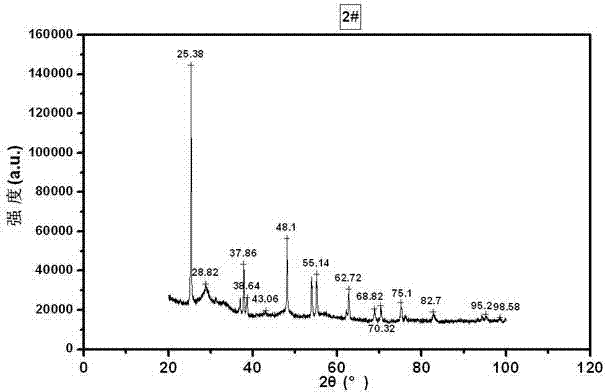

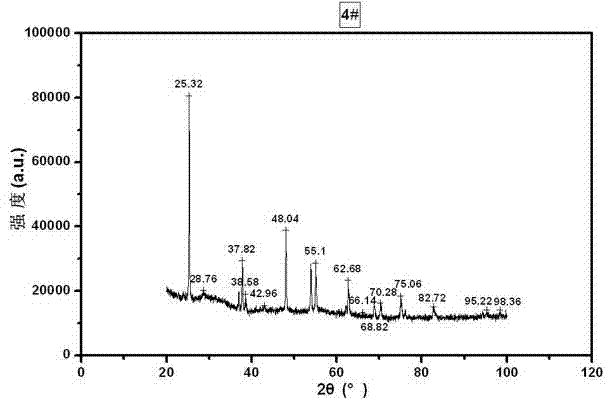

Iron-based low-temperature SCR denitration catalyst and preparation method thereof

InactiveCN104722307AObvious cost advantageLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereCerium nitrate

The invention provides an iron-based low-temperature SCR denitration catalyst and a preparation method thereof. Iron and cerium compounds are taken as active components, or iron, manganese and cerium compounds are taken as active components, titanium oxide is taken as a carrier, the molar ratio of iron, manganese and cerium is 1:(0.5-4):(0.5-1.5), and the molar ratio of iron and titanium oxide is 0.15-0.25. The preparation method comprises the steps of dissolving iron nitrate, manganese nitrate and cerium nitrate in deionized water, adding the titanium oxide, stirring intensely so as to mix the above compounds thoroughly, then performing ultrasonic mixing, putting the mixture into an oven for drying, calcining in an air atmosphere, and then grinding the mixture into powder. The iron-based low-temperature SCR denitration catalyst provided by the invention has an obvious advantage in cost, and meanwhile, the iron-based low-temperature SCR denitration catalyst has higher denitration efficiency under a medium and low temperature.

Owner:STATE GRID CORP OF CHINA +2

Nano-iron powder prepn. method

InactiveCN1751829AImprove reducibilityImprove magnetic propertiesCoatingsIron saltsHydrazine compound

A process for preparing iron nanoparticles includes such steps as proportionally dissolving iron salt in alcohol, water, or their mixture, proportionally adding NaOH solution and hydrazine hydrate solution, stirring, and heating at 80-120 deg.C while refluxing until the mother liquid becomes colorless and transparent. Its advantages are high purity, adjustable granularity and high output rate (more than 99%).

Owner:UNIV OF SCI & TECH OF CHINA

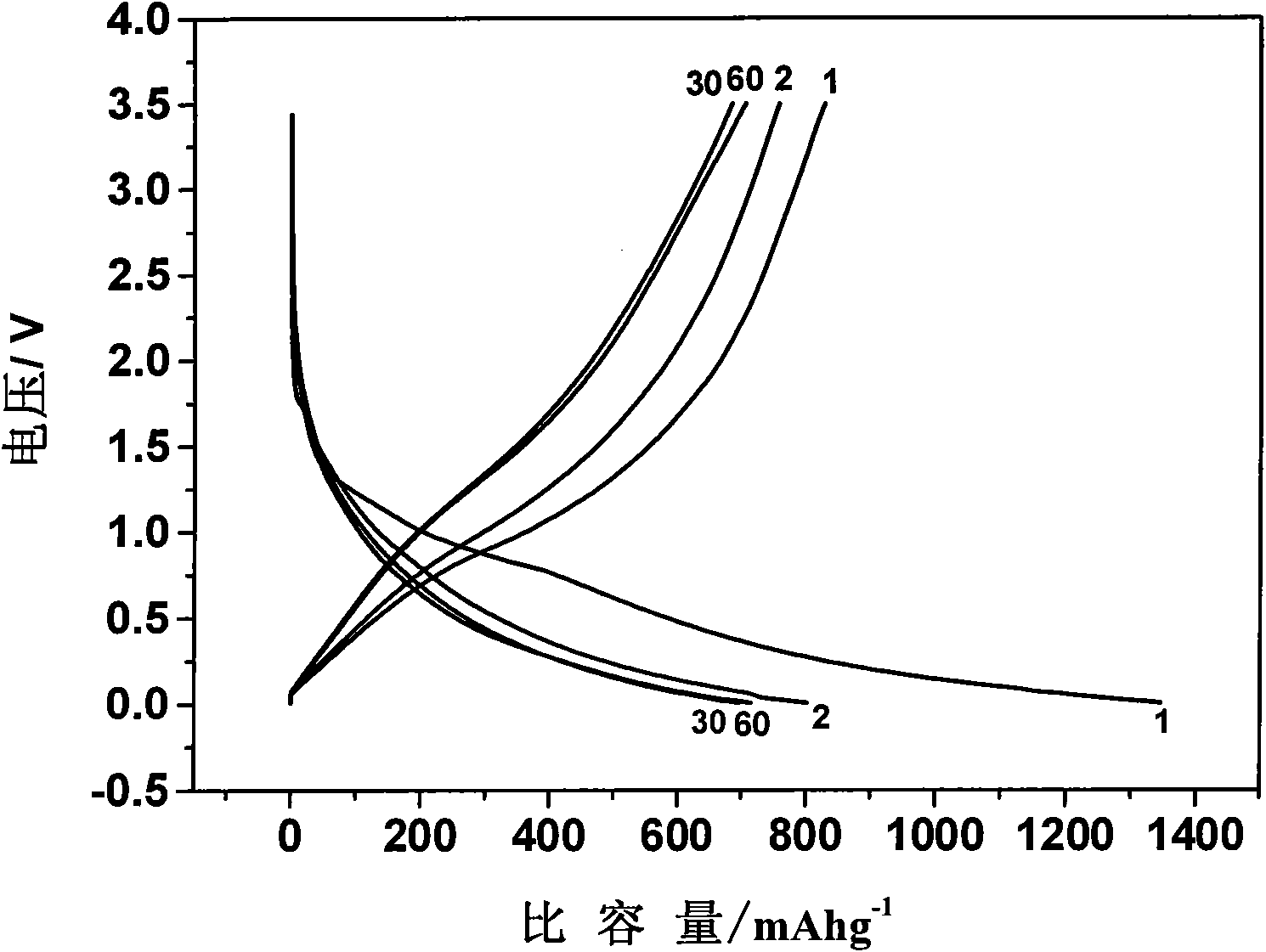

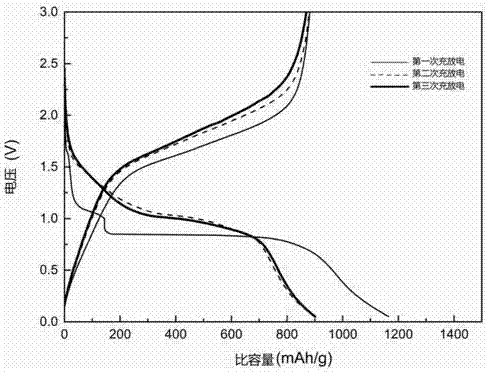

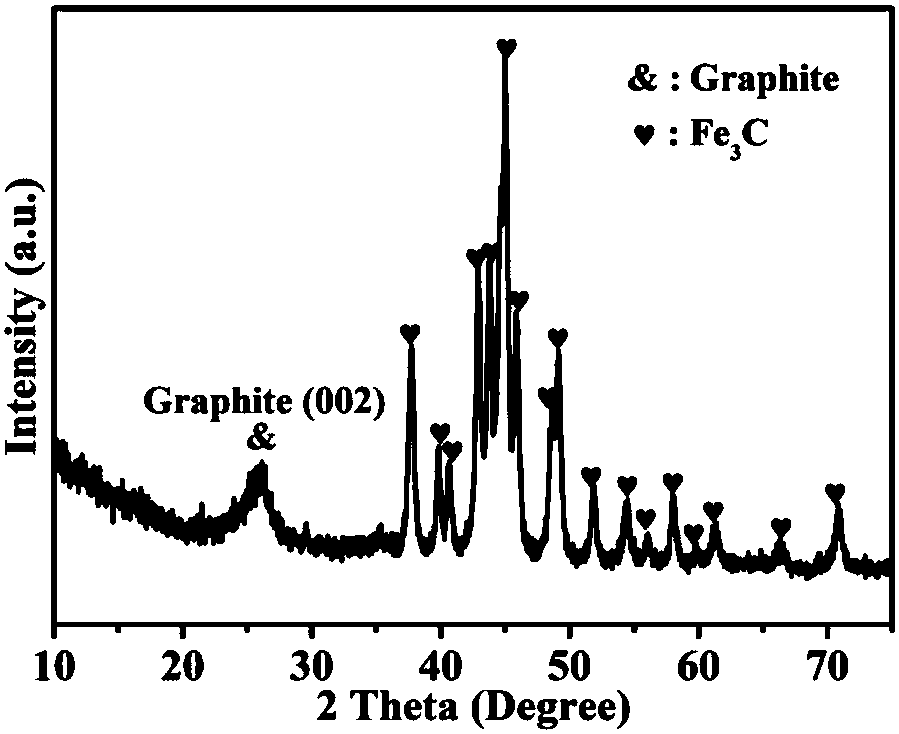

C/Fe3C lithium ion battery negative material and preparation method thereof

InactiveCN102024938AThe preparation process takes a short timeEasy to operateCell electrodesArgon atmospherePyrazine

The invention relates to a C / Fe3C lithium ion battery negative material and a preparation method thereof, which belong to the field of the lithium ion battery negative material and electrochemistry. The lithium ion battery negative material consists of amorphous carbon and Fe3C. The preparation method of the material comprises the following steps of: dissolving iron phthalocyanine, pyrazine and asurfactant in an organic solvent for thermal polymerization; and performing heat treatment on a polymerization product in argon atmosphere or performing heat treatment on Prussian blue at a certain temperature under the protection of the argon atmosphere, wherein a discharge voltage platform of the negative material is at 0.75V in average; the reversible specific capacity of the material can be kept at 700mAh / g within a voltage range of between 0.005 and 3.5V at the charge and discharge rate of 100mA / g after 60 cycles and does not obviously attenuate; in addition, the material has high chargeand discharge rate performance and broad application prospect.

Owner:BEIJING UNIV OF TECH

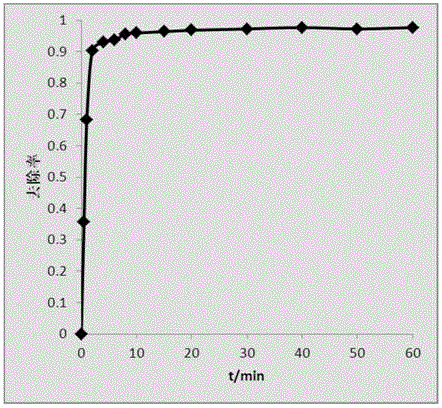

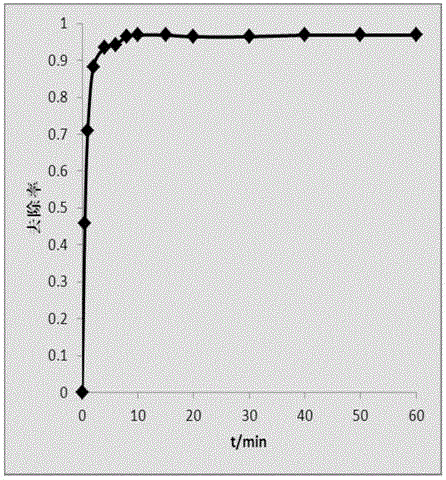

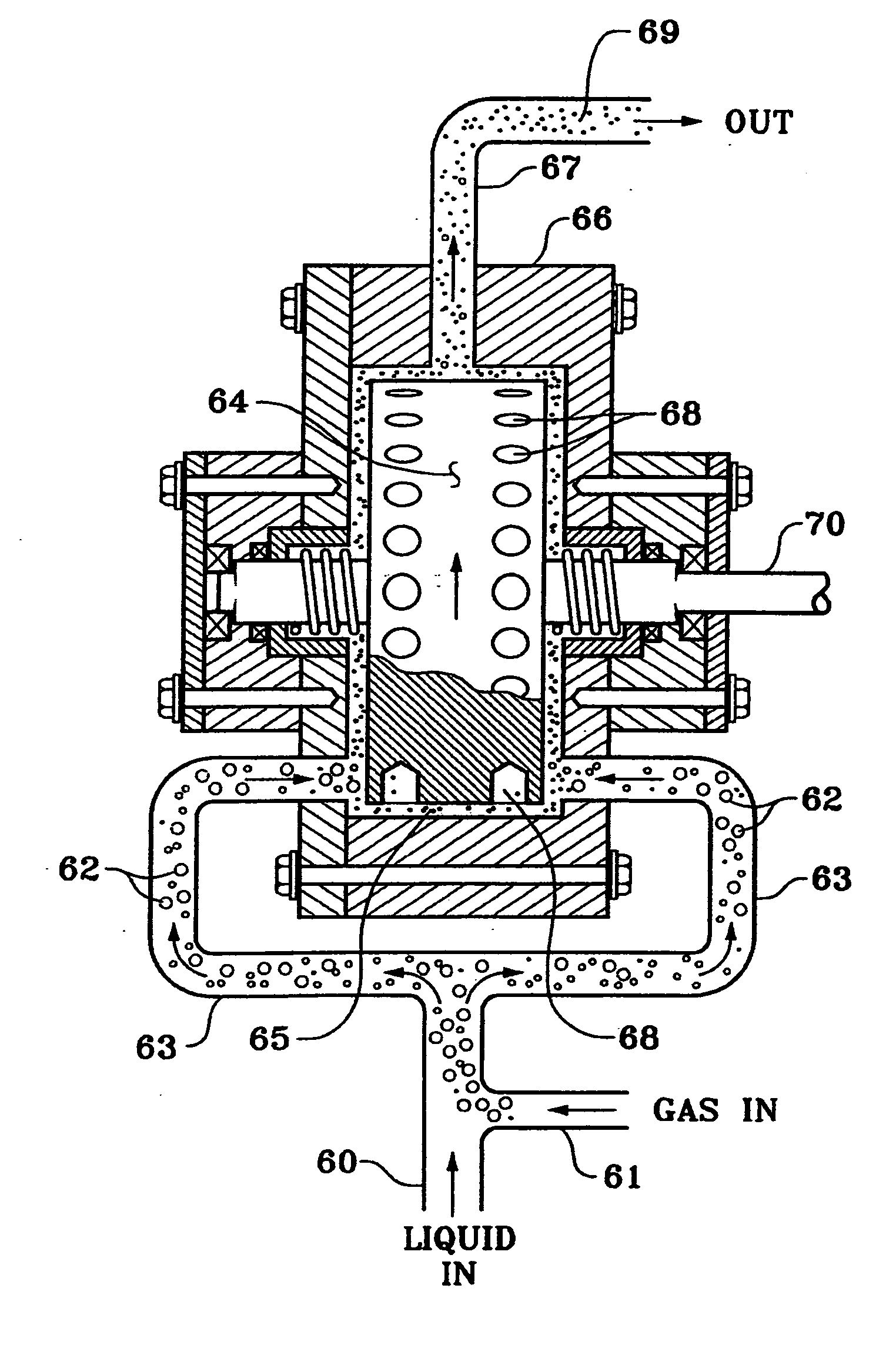

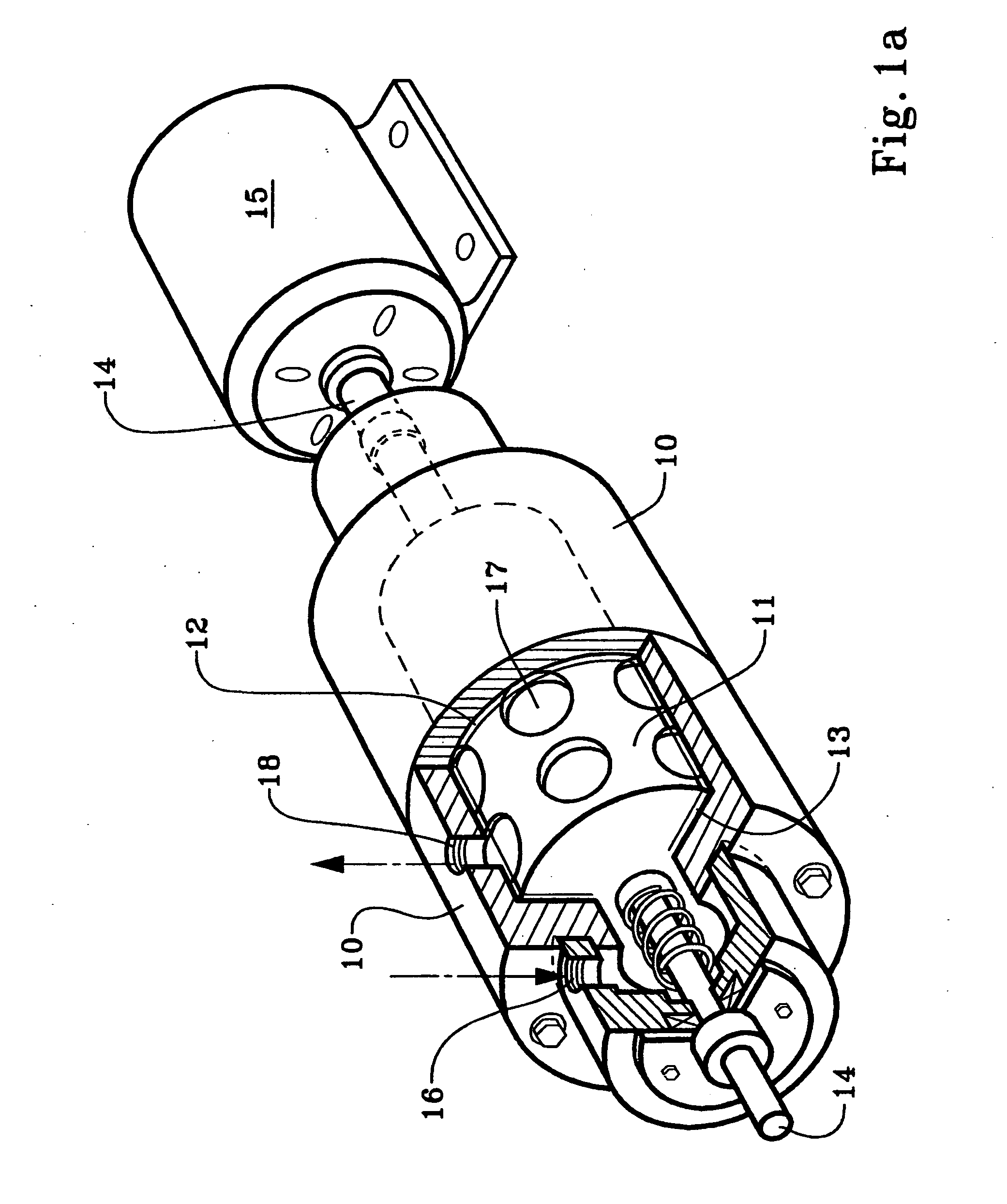

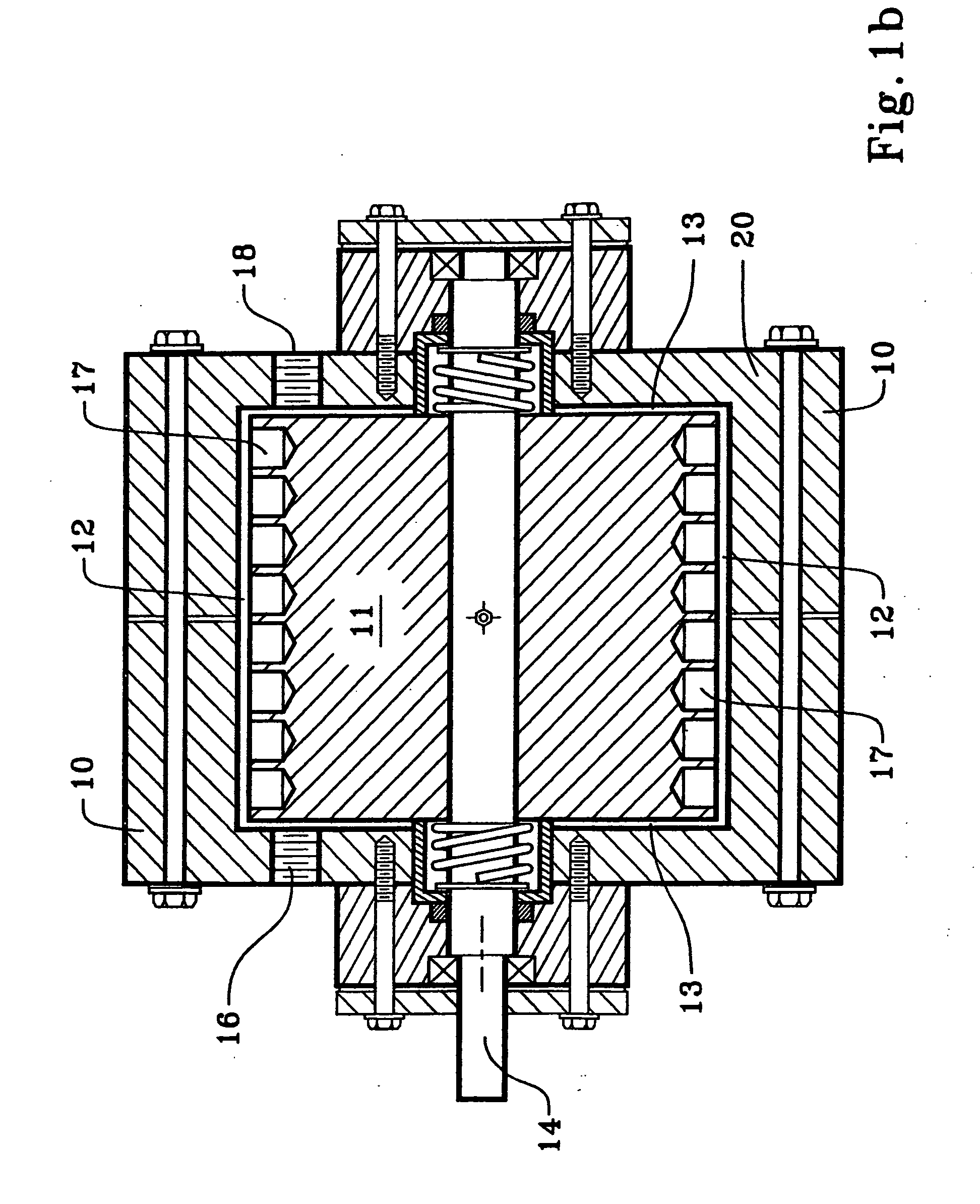

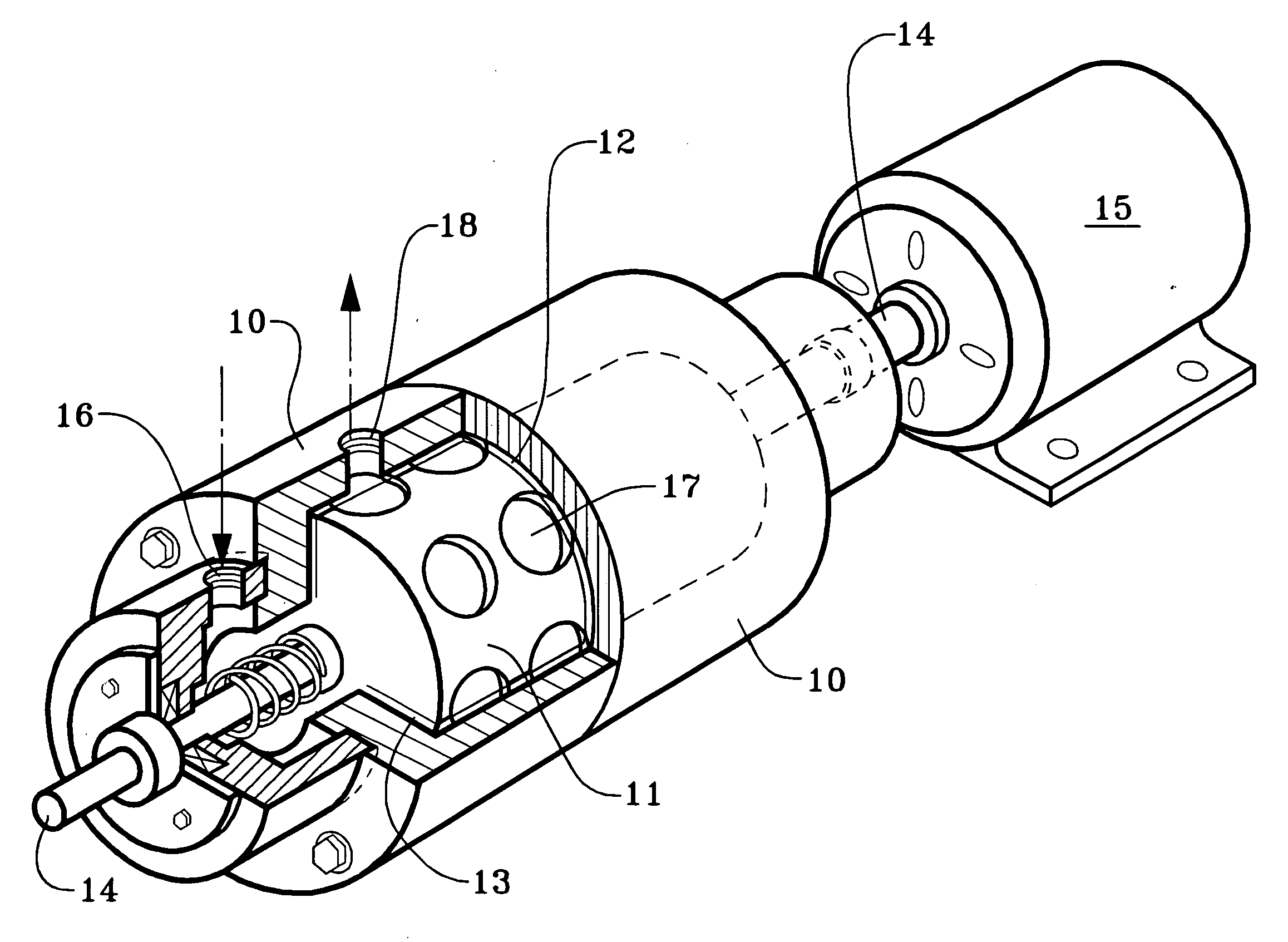

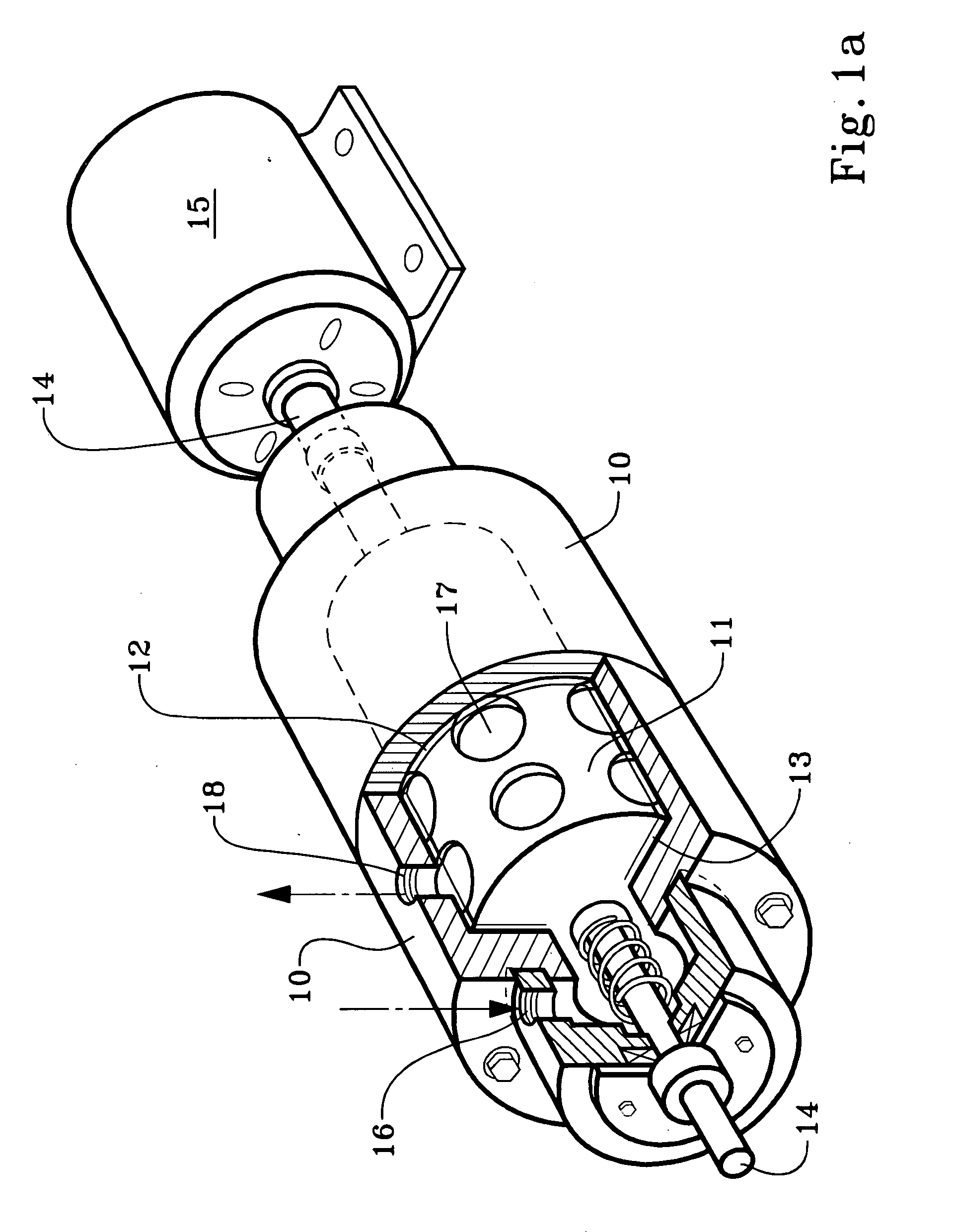

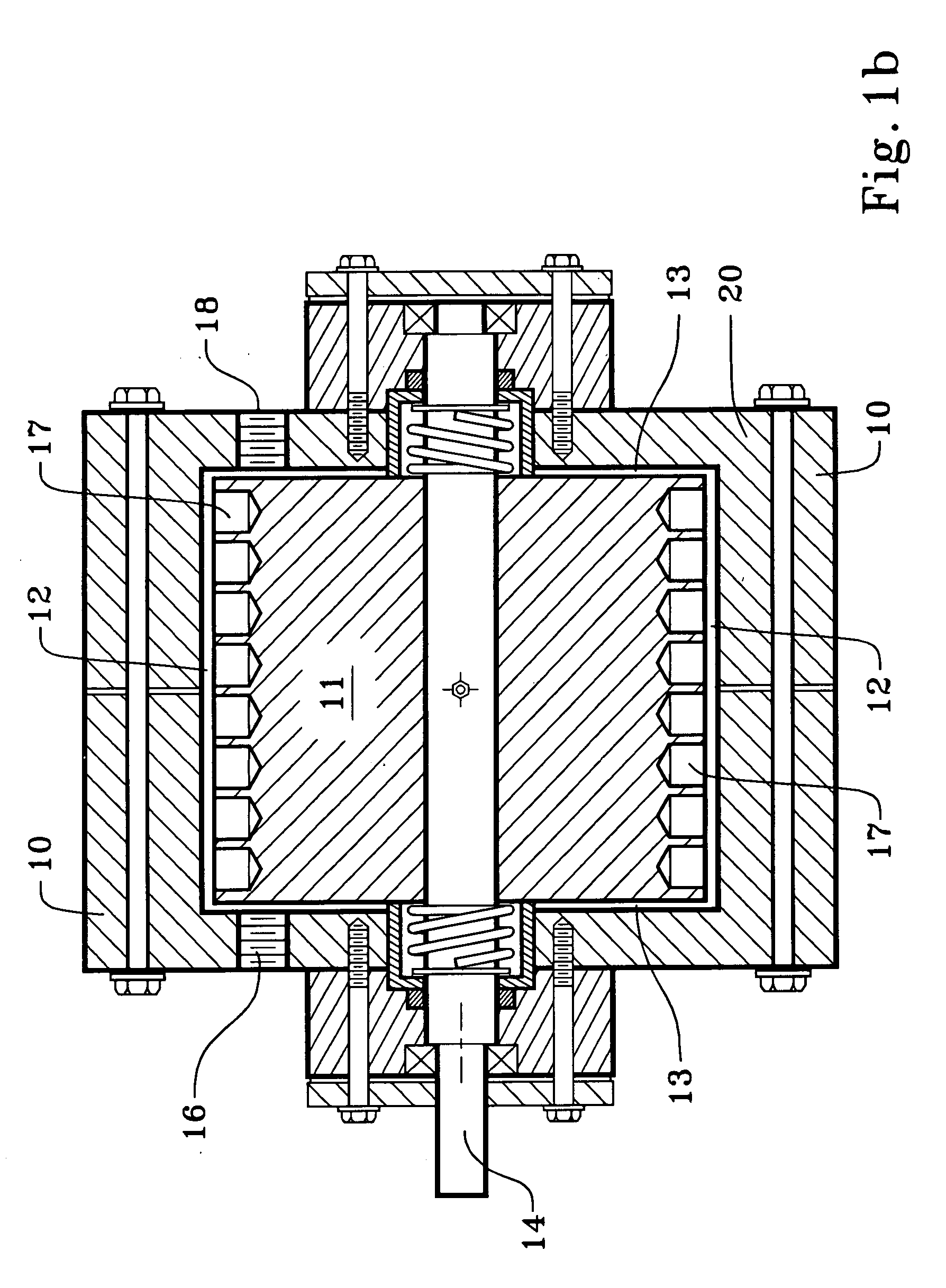

Method of removing dissolved iron in aqueous systems

InactiveUS20090184056A1Rapidly decompose peroxideIncrease oxidation rateTransportation and packagingRotary stirring mixersActivated carbonCavitation

Oilfield completion, drilling, produced, flowback, and workover fluids containing iron are treated to remove the iron by passing them through a cavitation device together with an oxidizing agent and with the addition of lime. The cavitation device intimately mixes the oxidizing agent with the fluid while increasing the temperature of the fluid, thus promoting the oxidation reaction. Lime contributes to an increase in pH while promoting the formation of floc. Ferric hydrate and other solids or colloidal iron are removed in a filter capable of removing particles as small as 0.5 micron. The system may be enhanced by the addition of a bed of activated carbon capable of catalyzing the oxidation reaction.

Owner:TOTAL SEPARATION SOLUTIONS

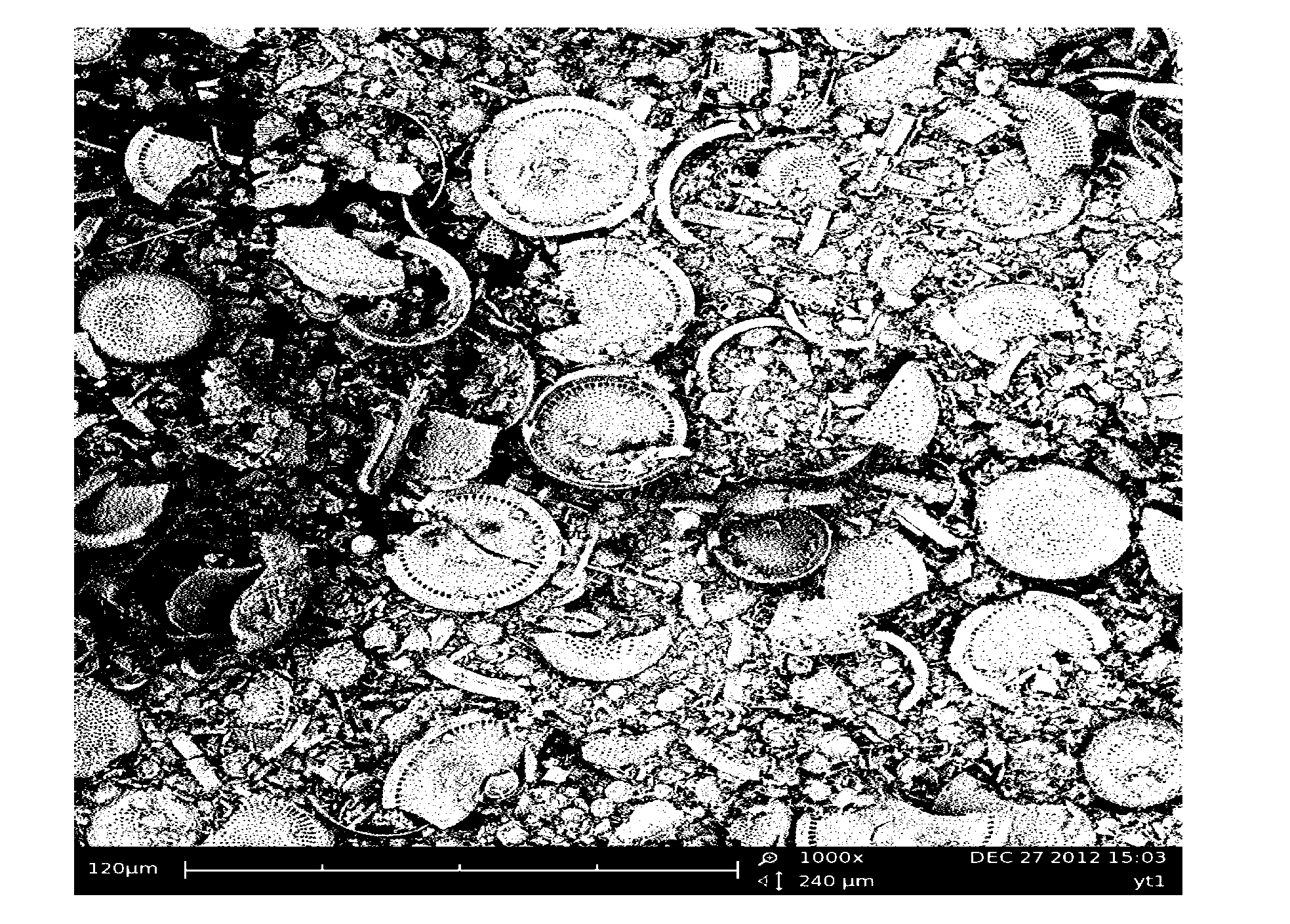

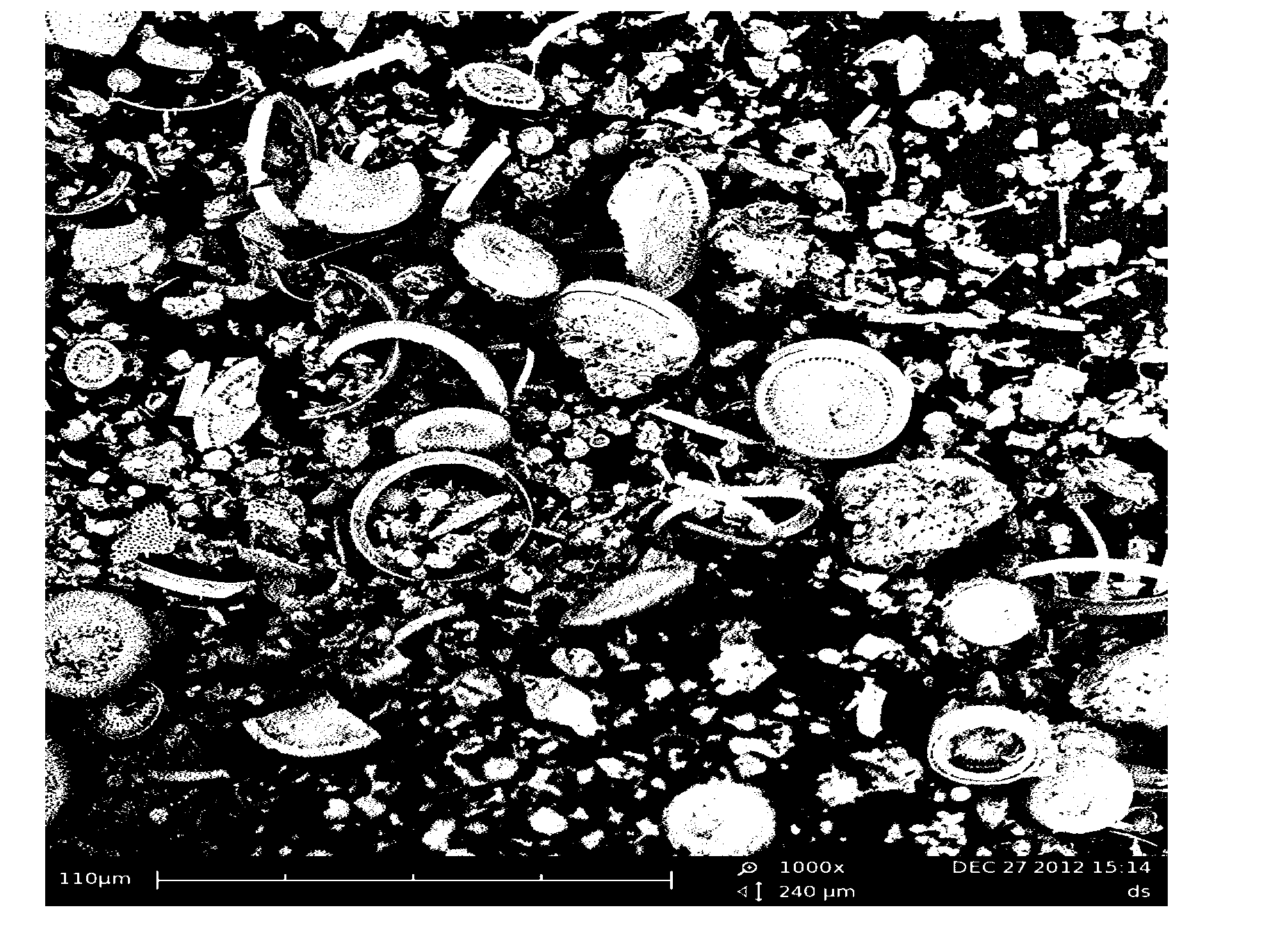

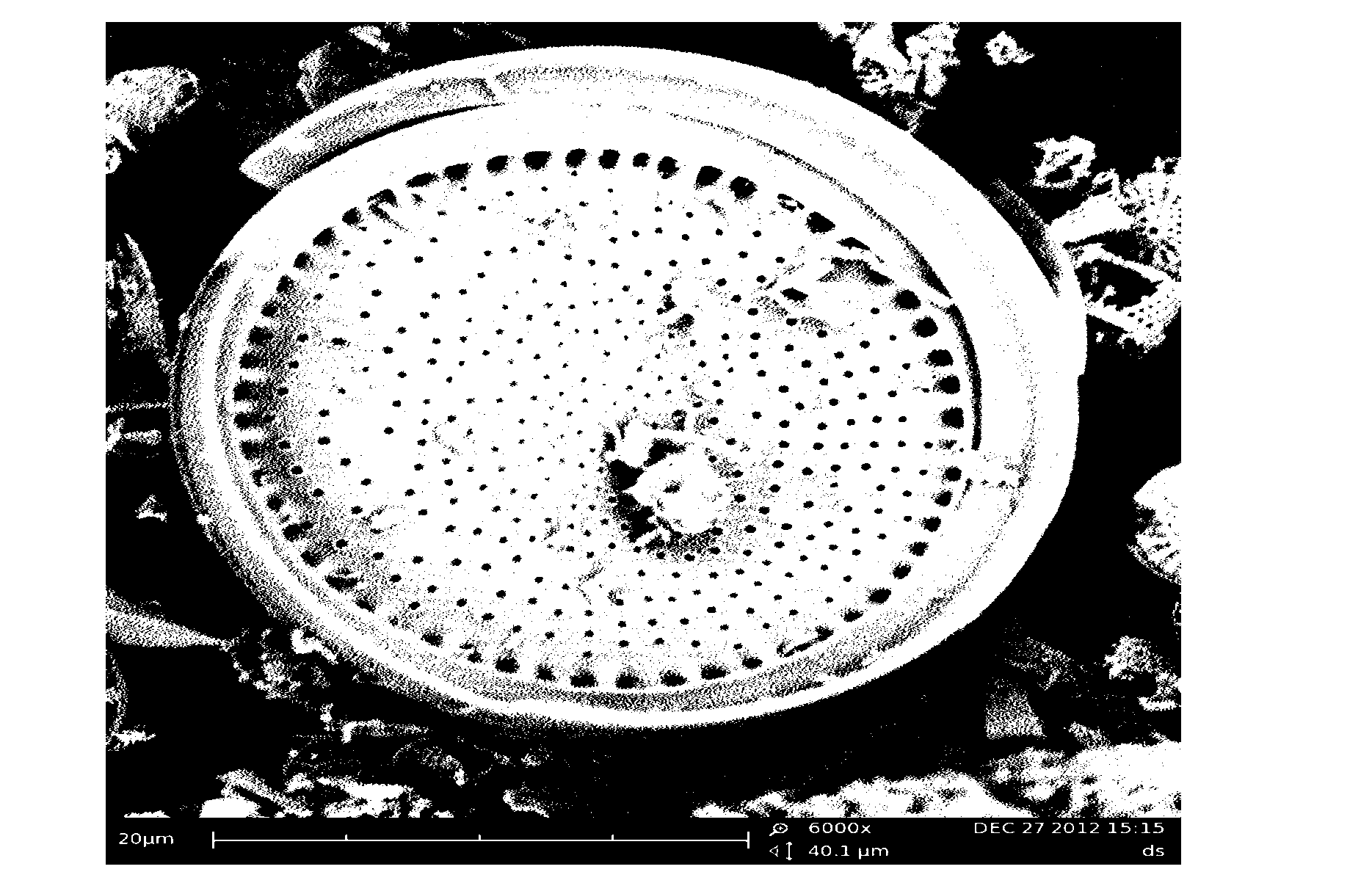

Preparation method of kieselguhr load type compound photocatalyst with iron ions doped titanium dioxide

InactiveCN101628236ASignificant purification and decolorizationAbundant resourcesWater/sewage treatment by irradiationOther chemical processesWater bathsIron salts

The invention discloses a preparation method of a kieselguhr load type compound photocatalyst with iron ions doped with titanium dioxide, comprising the following steps: (1) mixing titanic acid esters or titanium salt with an alcoholic solvent, and then adding kieselguhr into the alcoholic solvent and stirring so as to form slurry; (2) dissolving iron salt into water to form an iron salt solution, and in a water bath with the temperature of 10-95 DEG C, dropping the iron salt solution into the slurry and stirring so that the titanic acid esters or the titanium salt inside the slurry is hydrolyzed to obtain colloidal sols; (3) aging the colloidal sols under room temperature to obtain dried gel; and (4) baking the dried gel for 0.5-5 hours under the temperature of 200-800 DEG C to obtain the kieselguhr load type compound photocatalyst with the iron ions doped with the titanium dioxide. The compound photocatalyst prepared by the method can effectively process waste water.

Owner:ZHEJIANG SCI-TECH UNIV

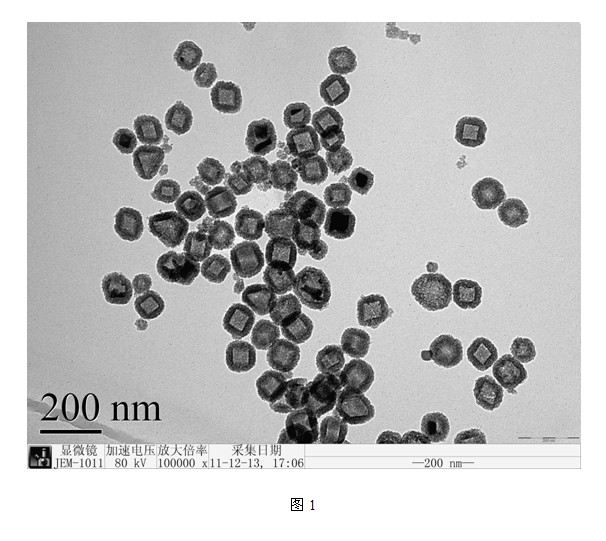

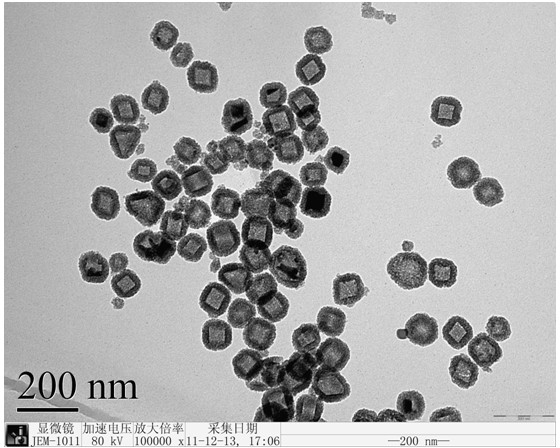

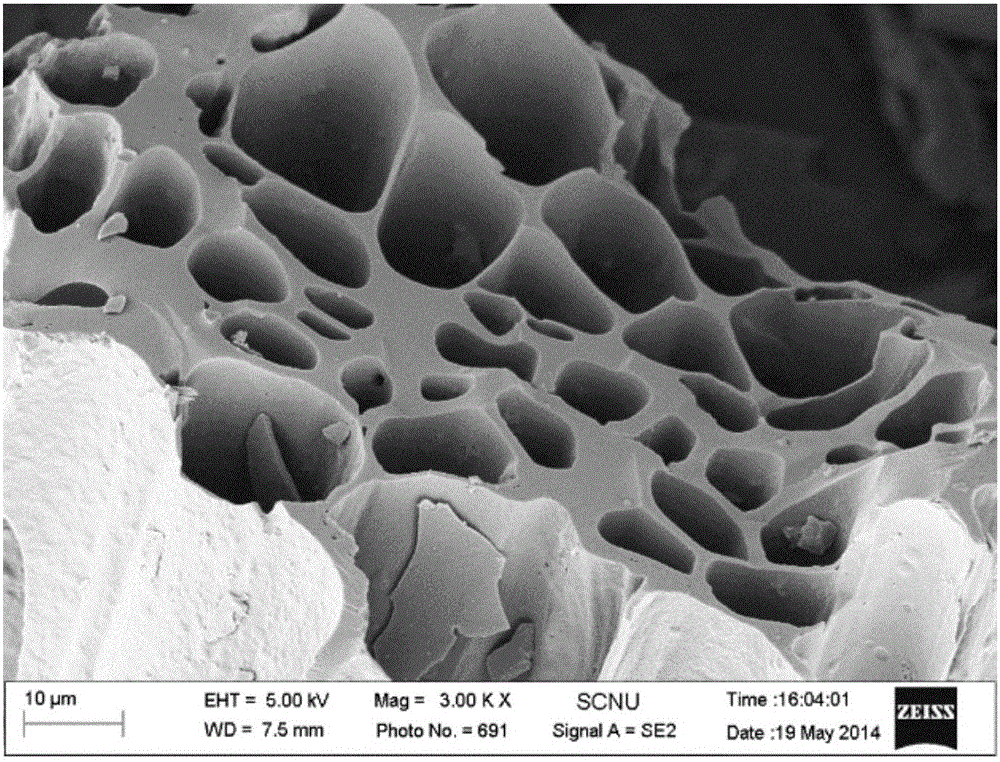

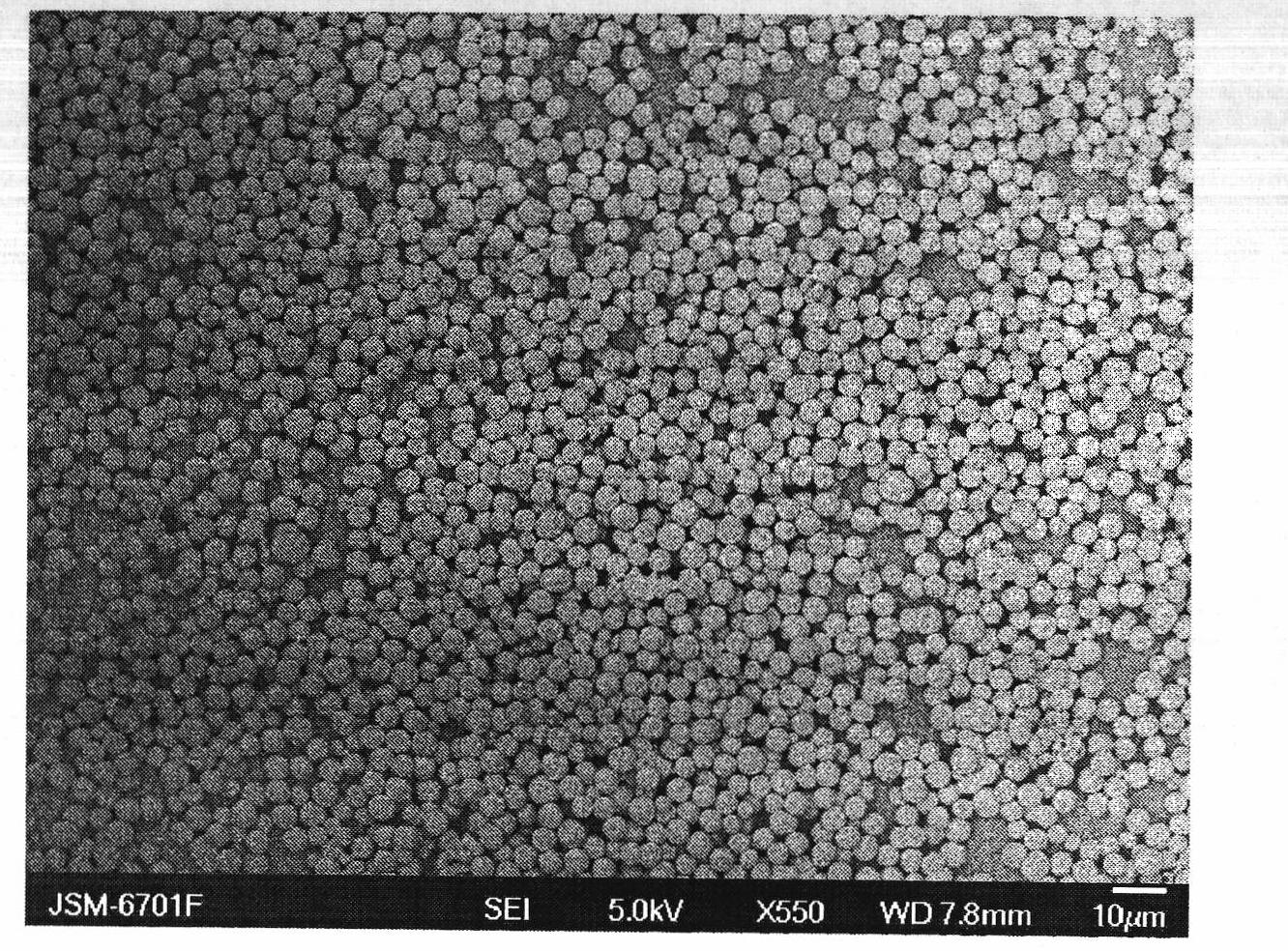

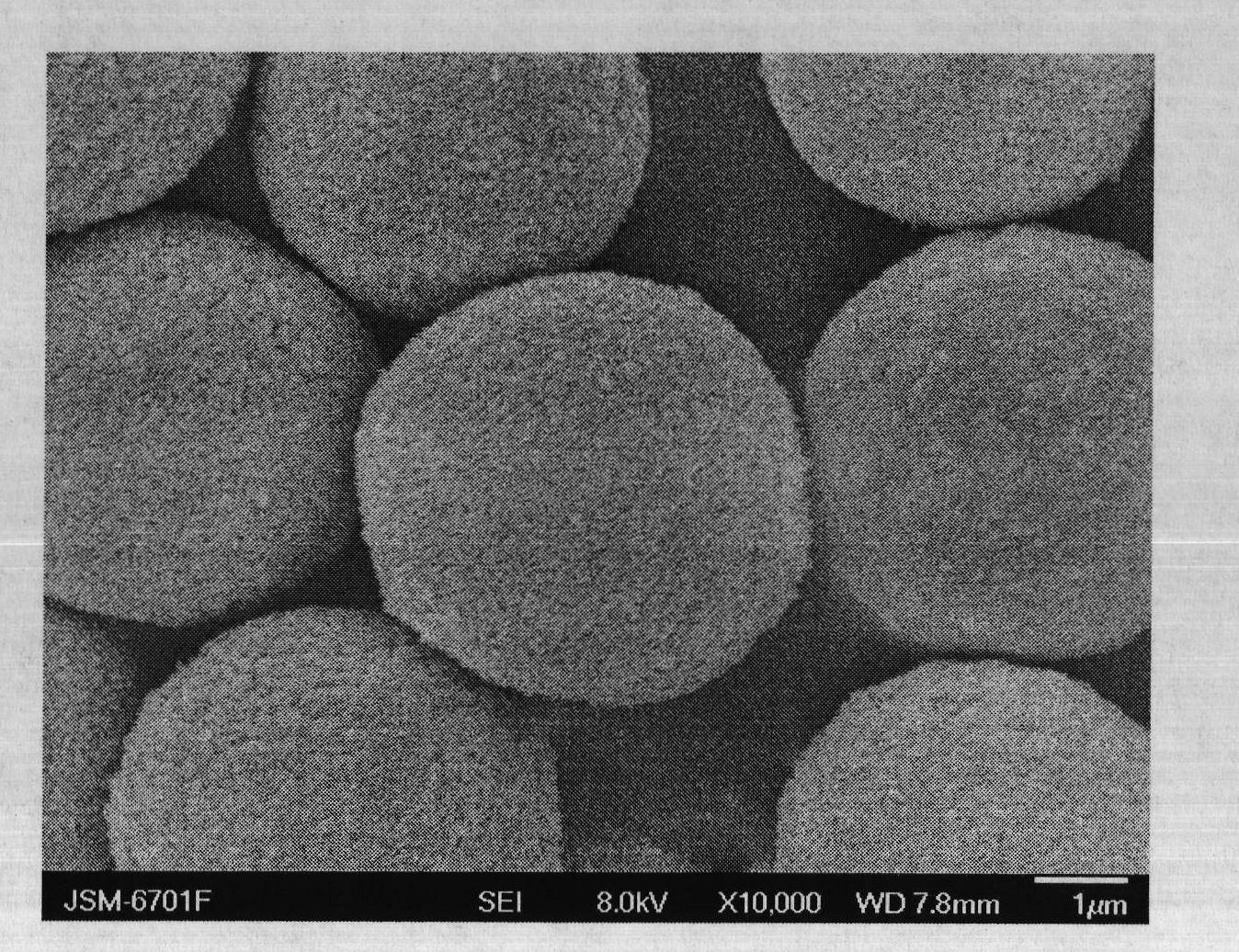

Preparation method for controllable hollow mesoporous silicon dioxide nanospheres

The invention provides a preparation method for controllable hollow mesoporous silicon dioxide nanospheres. The method comprises the following steps of: dissolving iron salt, acetic acid and polyvinylpyrrolidone in ethanol, and uniformly stirring and mixing, then transferring the solution into a polytetrafluoroethylene reaction kettle, and reacting while heating to obtain an iron oxide nanoparticle suspension; adding ethanol, deionized water and cetyl trimethyl ammonium bromide into the iron oxide nanoparticle suspension, adding alkali to adjust the pH value to be 7-12, slowly adding tetraethoxysilane in a stirring condition so as to for 12-72 hours, filtering, drying, and roasting at 400-600 DEG C, thus obtaining a mesoporous silicon dioxide-coated iron oxide nanomaterial with a core-shell structure; and completely soaking the obtained mesoporous silicon dioxide-coated iron oxide nanomaterial with the core-shell structure in a prepared acidic etching solution, dissolving an iron oxide used as a hard template, and washing with the deionized water and the ethanol, filtering and drying, thus obtaining the hollow mesoporous silicon dioxide nanospheres. The preparation method for the controllable hollow mesoporous silicon dioxide nanospheres disclosed by the invention has the advantages of being simple in synthesis process, moderate in operation condition, cheap in raw material and easy in acquisition of raw materials, and easy in enlargement and synthesis.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

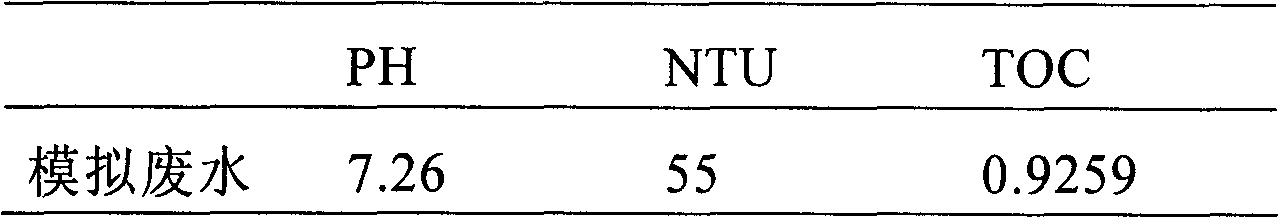

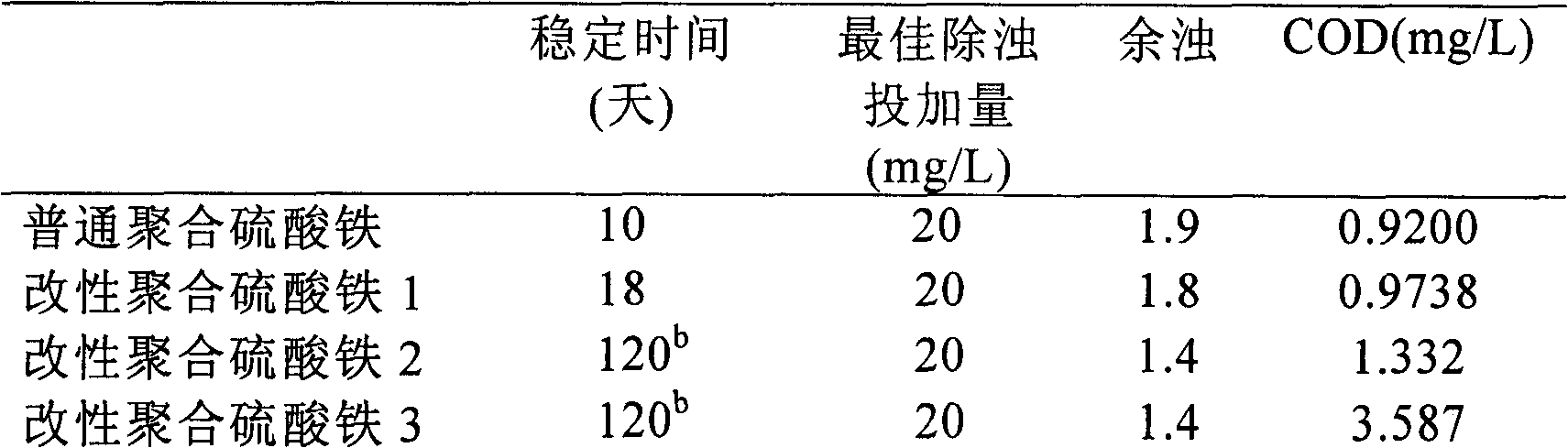

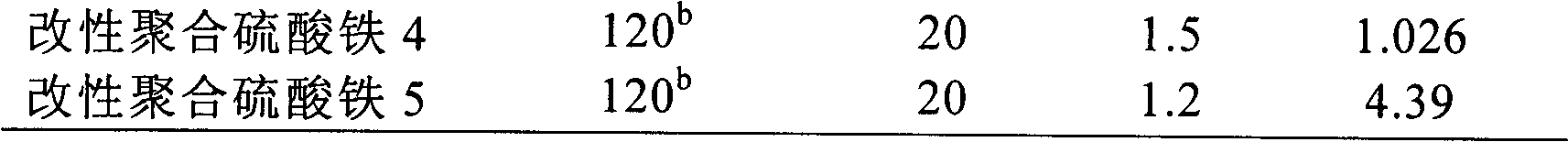

Preparation method of polymerized iron flocculant

InactiveCN102807273AImprove stabilityEnhanced adhesive bridging abilityWater/sewage treatment by flocculation/precipitationFlocculationFerrous salts

The invention relates to a preparation method of a polymerized iron flocculant, which comprises the steps of: mixing a certain amount of ferrous salt (or ferric salt), inorganic acid and water under stirring condition to completely dissolve iron salt; adding a certain amount of oxidant and sufficiently stirring to completely oxidize ferrous ion into ferric ion; and adding a certain amount of inorganic base and polymerization inhibitor to partially hydrolyze and polymerize ferric ion, and then aging at normal temperature for some time to obtain modified polymerized iron flocculant. Compared with the prior art, the prepared modified polymerized iron flocculant has the advantages that the stability is improved, the bonding bridging capability is enhanced, alum flower is rapid in forming and large, the coagulation effect is improved and the like; and when the modified poly iron flocculant is used under certain conditions, the water outflow quality is not significantly influenced under the condition that the flocculation effect is significantly improved.

Owner:TONGJI UNIV

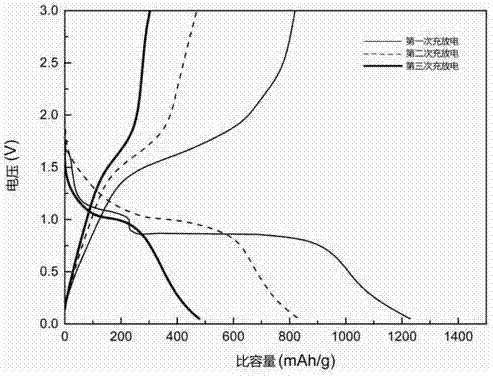

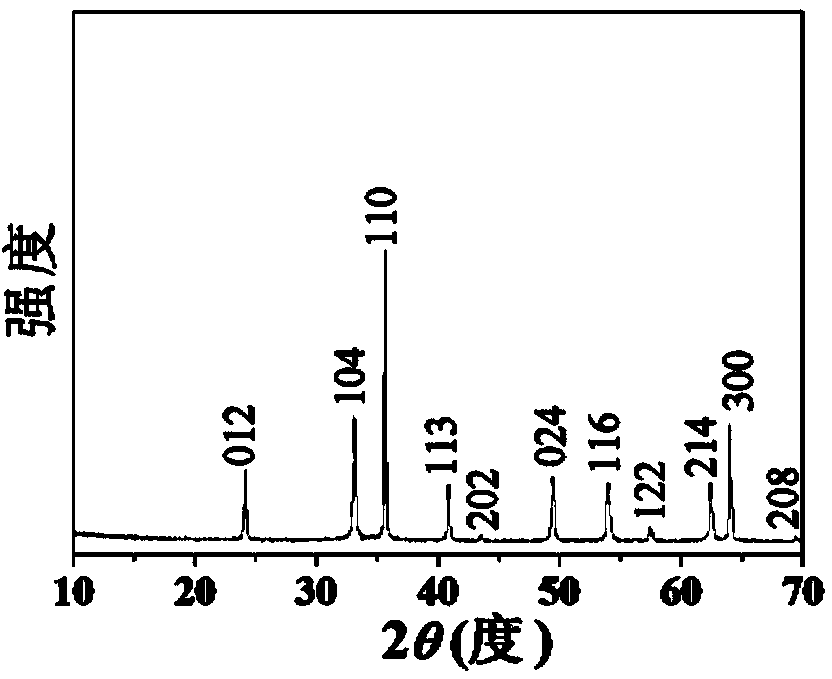

Preparation method of monodisperse Alpha-iron oxide nanosheet

InactiveCN106992295ANo pollution in the processSimple processMaterial nanotechnologyCell electrodesNitrateReaction temperature

The invention relates to a preparation method of a monodisperse Alpha-iron oxide nanosheet, comprising the steps of 1) dissolving P123 in ethylene glycol, stirring, and continuing to dissolve iron nitrate in the ethylene glycol to obtain clarified solution, wherein the molar concentration of the iron nitrate in the clarified solution is 0.5-2 mol / L; 2) adding KOH solution into the clarified solution of step 1) to obtain reddish brown precursor solution; 3) hydrothermally reacting the precursor solution of step 2) at the temperature of 180-200 DEG C for 24-30 h to obtain the monodisperse Alpha-iron oxide nanosheet. The preparation method has a simple technical process, is easy to control, free of environmental pollution and low in cost and facilitates large-scale production; the obtained monodisperse Alpha-iron oxide nanosheet has excellent cycle performance as a lithium-ion battery anode material.

Owner:ZHEJIANG UNIV

Catalyst for ternary copolymerization of norbornenes, tetrafluoroethylene and pentenes and ternary copolymerization method

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Kieselguhr loading solid superacid type Fenton catalyst preparation method

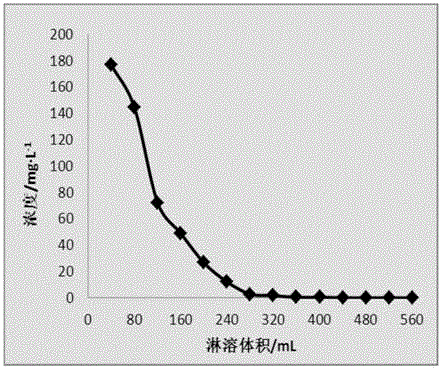

InactiveCN103285887AImprove catalytic abilityFacilitate catalytic degradationPhysical/chemical process catalystsWater/sewage treatment by oxidationWastewaterDissolved iron

The invention relates to a kieselguhr loading solid superacid type Fenton catalyst preparation method, belongs to water treatment, and in particular relates to the kieselguhr loading solid superacid type Fenton catalyst preparation method which is mainly used for solving a problem of poor catalytic efficiency of a catalyst prepared by utilizing conventional kieselguhr as a carrier. The preparation method comprises steps of: 1, soaking original kieselguhr into an inorganic acid solution, and drying, screening and putting the soaked original kieselguhr in a muffle furnace to activate; 2, dissolving iron salt into deionized water, then adding the activated kieselguhr, dropwise adding alkali liquor to regulate the pH, ageing, drying and then adding the kieselguhr into steeping liquor, filtering and drying so as to obtain a precursor; and 3, putting the precursor into the muffle furnace to calcinate at a high temperature so as to obtain a kieselguhr loading solid superacid type Fenton catalyst. The prepared loading catalyst has high catalytic efficiency and low pH requirements and can be widely applied to organic wastewater treatment.

Owner:JILIN YINDA WATER AFFAIR TECH

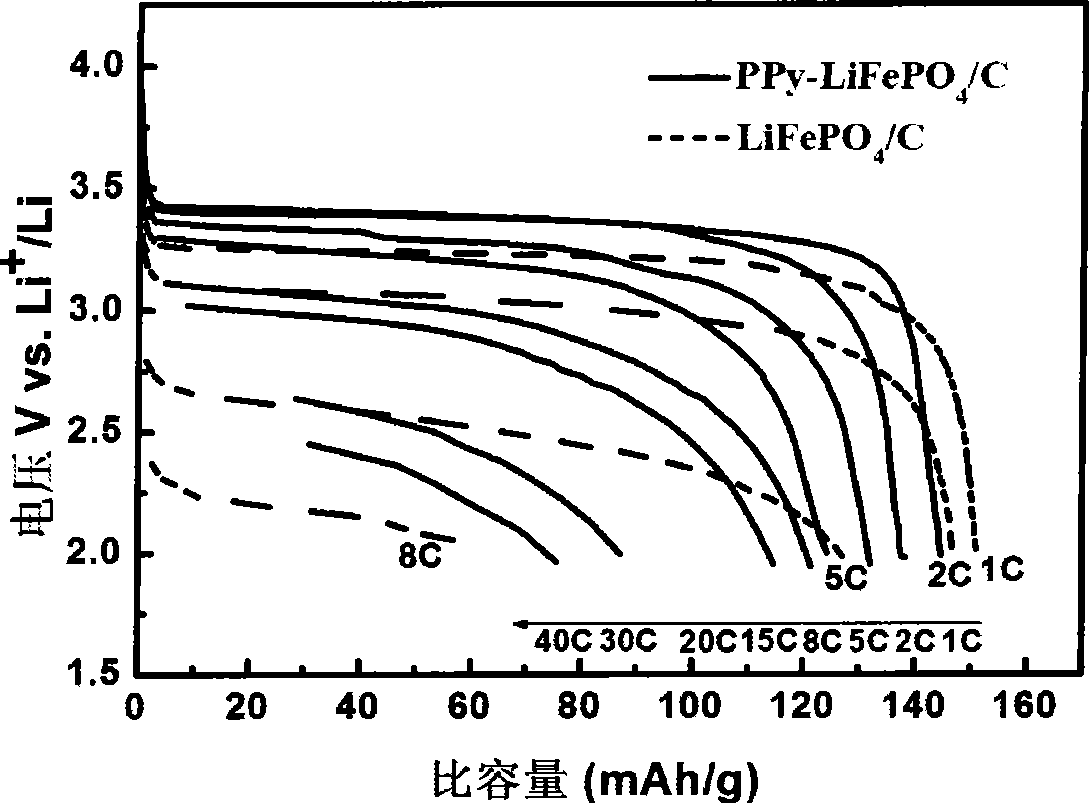

Preparation for polypyrole coated lithium iron phosphate

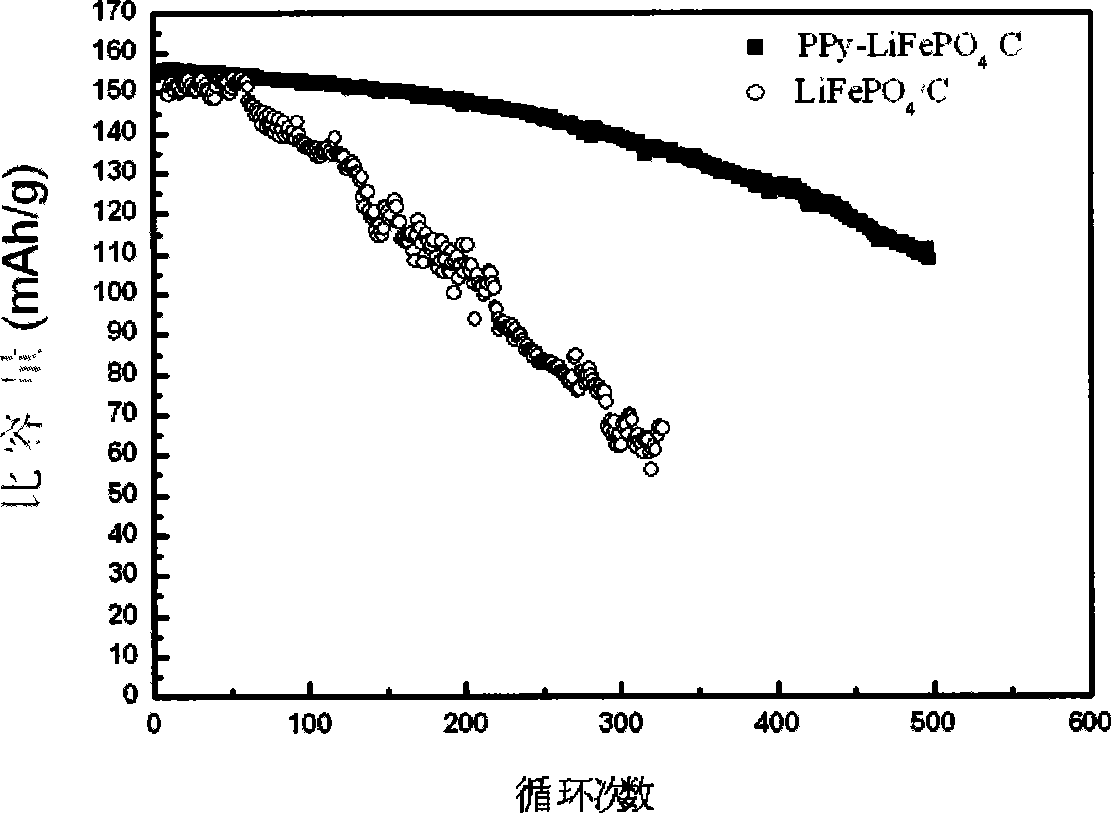

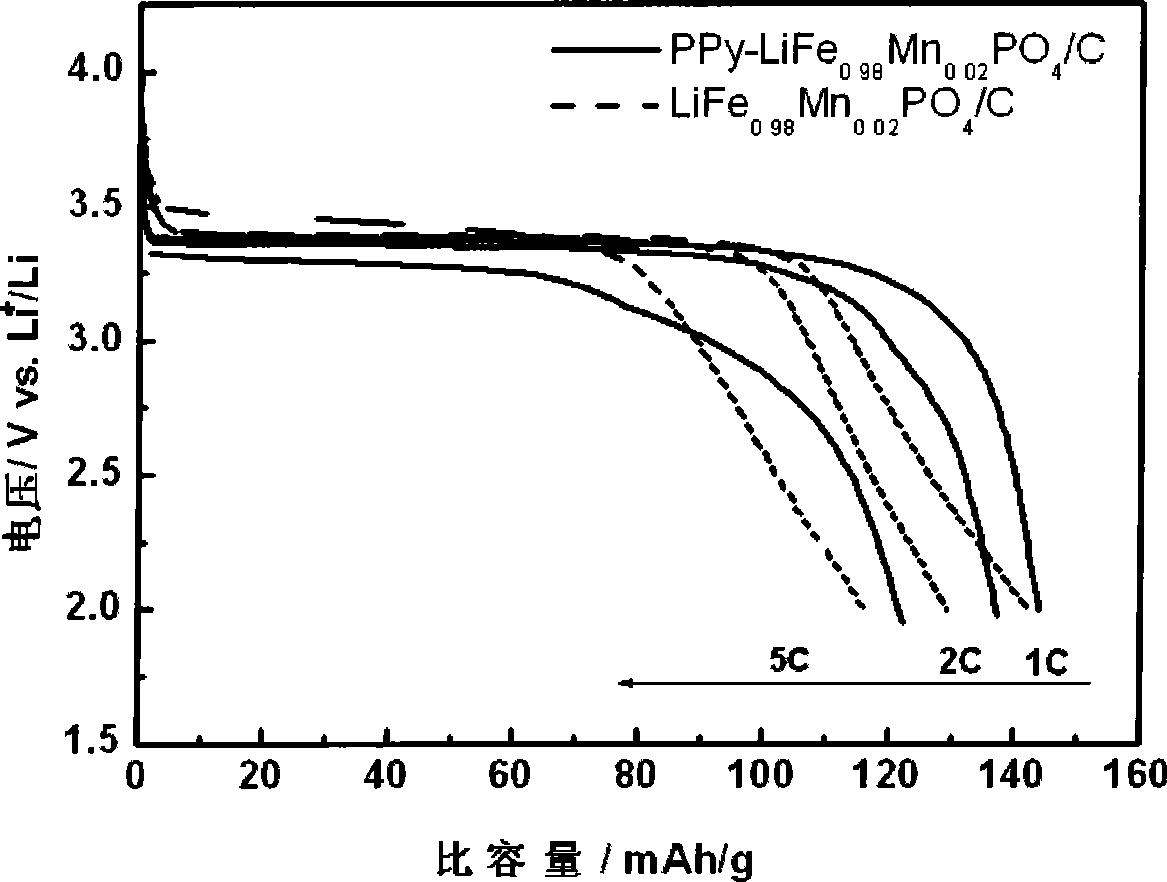

ActiveCN101478039AImprove stabilityImprove conductivityElectrode manufacturing processesElectrode carriers/collectorsTest batteryHigh rate

The invention discloses a preparation method of polypyrrole-coated lithium iron phosphate. The preparation method comprises the following steps: dissolving iron(III) p-toluenesulfonate hexahydrate in alcohol; ultrasonically dispersing lithium iron phosphate powder in the alcohol; placing into a sealed container; adding pyrrole monomers under low-temperature stirring condition; stirring for a period of time, so that the pyrrole monomers generate polymerization reaction on the surface of lithium iron phosphate; filtering; washing; drying; grinding; and sieving to obtain polypyrrole-coated lithium iron phosphate. The polypyrrole-coated lithium iron phosphate prepared by the method can be assembled with lithium tabs to form a test battery, which has an reversible capacity of 115 mAh / g during charge / discharge at 20C rate and an initial specific capacity of 155 mAh / g during charge / discharge cycle at 55 DEG C and 5C rate and can keep the specific capacity at 90% the initial value after 300 cycles. Accordingly, the test battery exhibits excellent high-rate charge / discharge capability and good high-temperature cycle stability. The method is simple and feasible, and suits large-scale industrial production.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

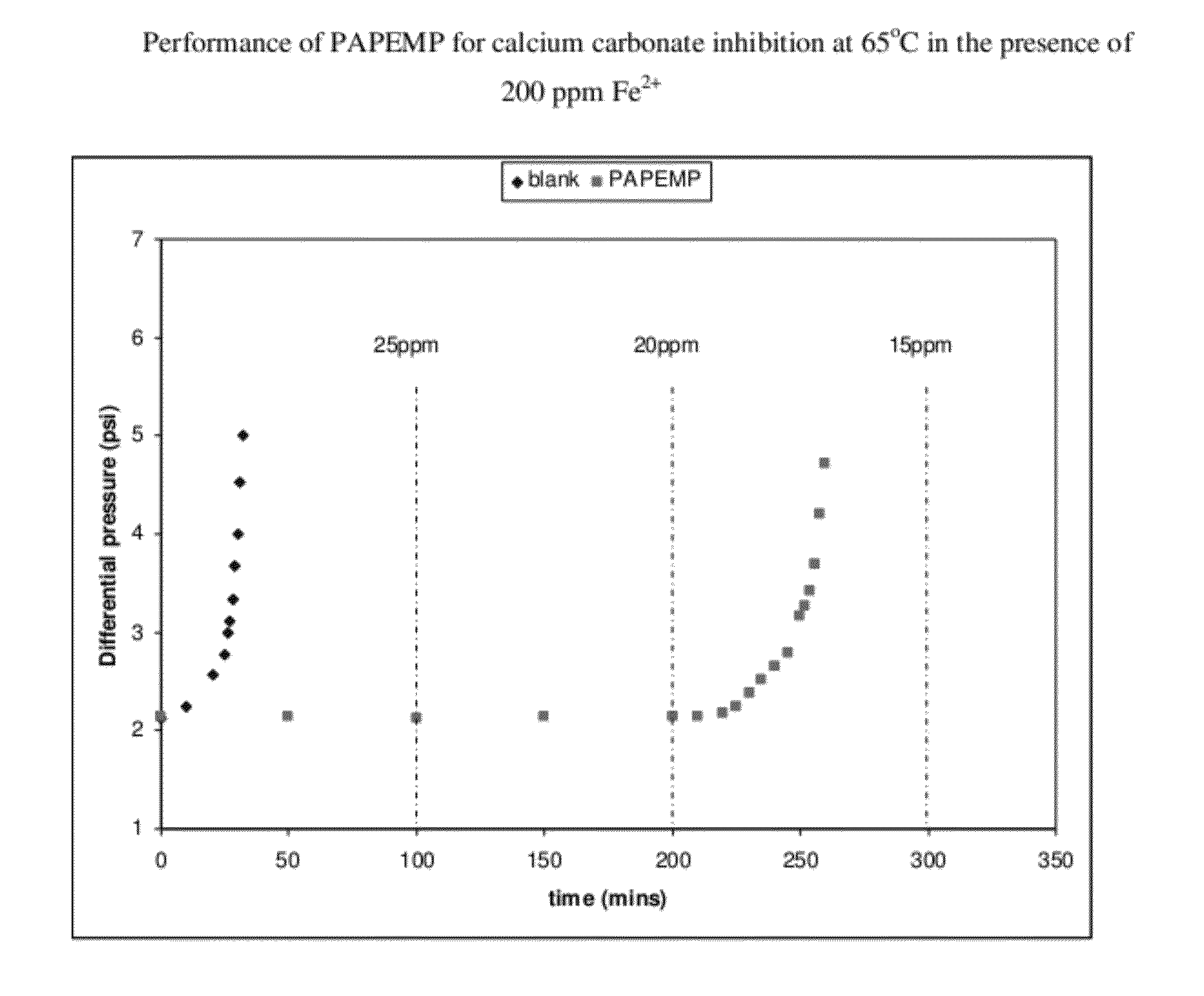

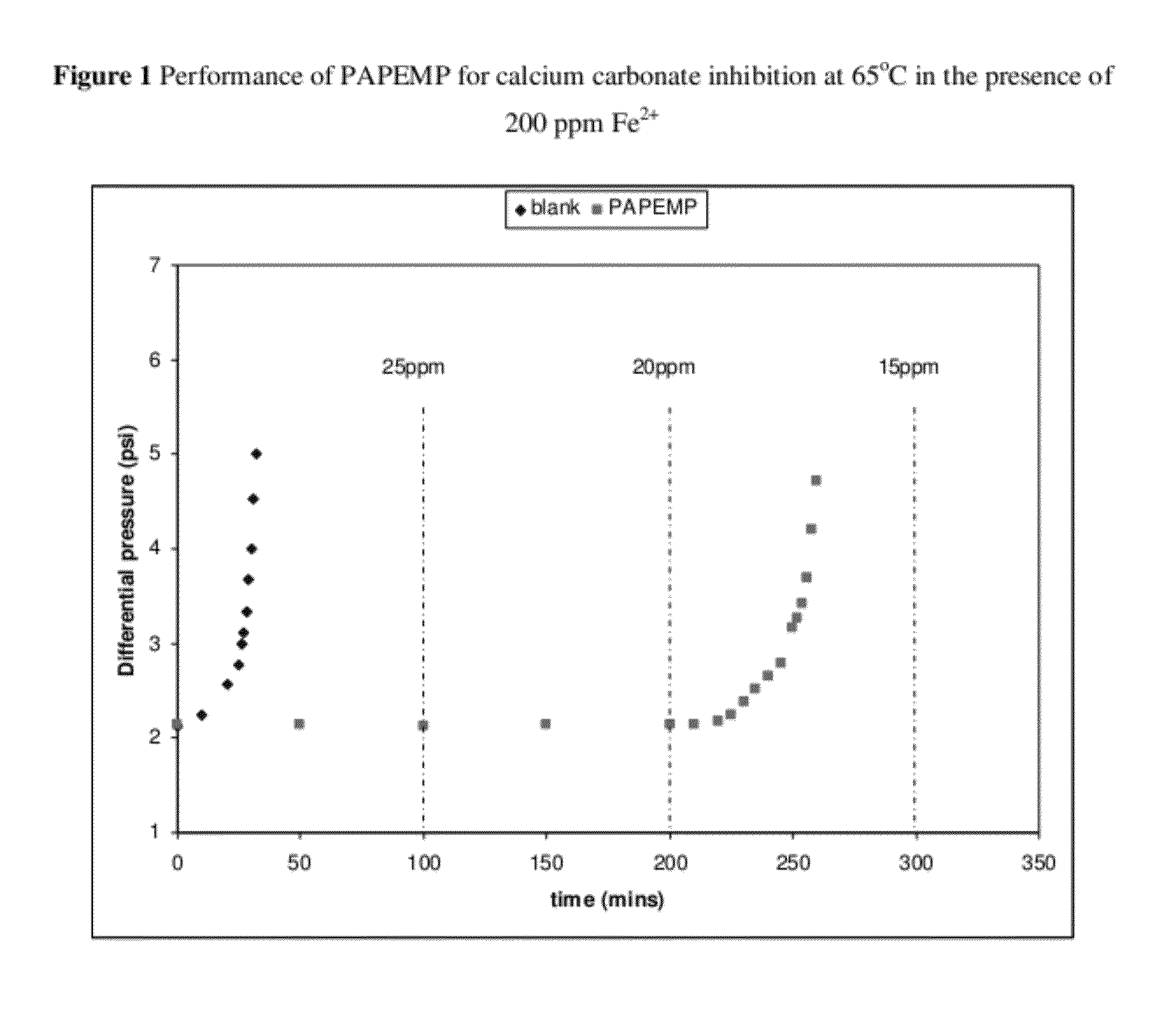

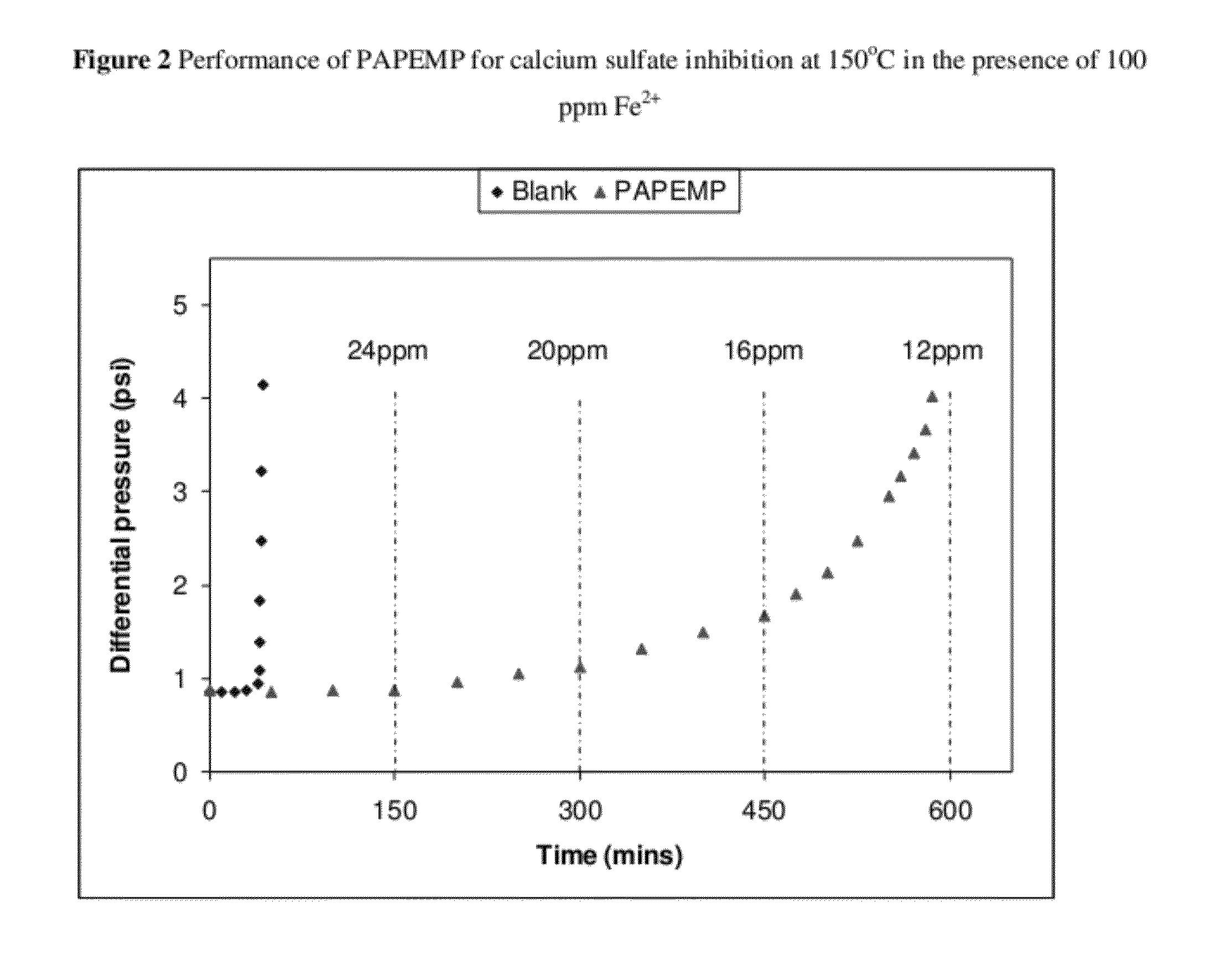

Method for preventing scale formation in the presence of dissolved iron

The present invention relates to a method of using threshold scale inhibitors of the formula:wherein n is 2 or 3 and M is hydrogen or an alkali metal cation, for preventing calcium carbonate, iron carbonate, and calcium sulfate scale formation in oilwell brines containing dissolved iron.

Owner:BAKER HUGHES INC

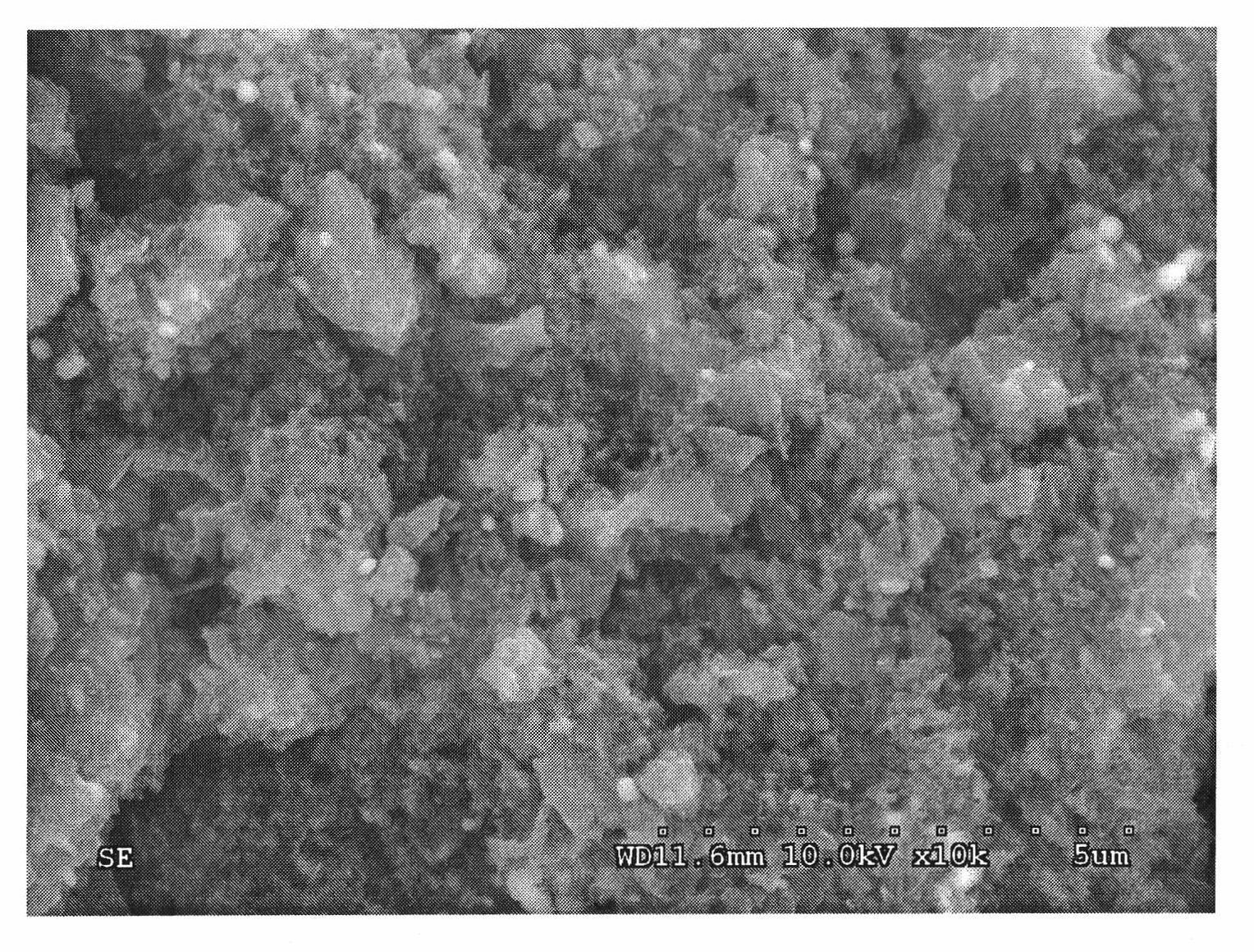

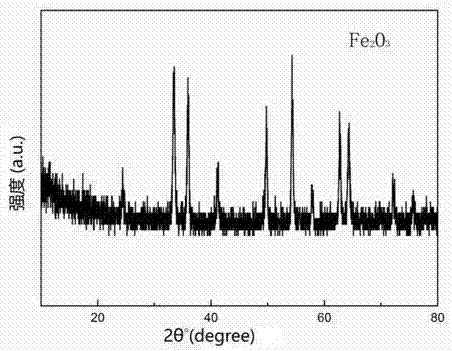

Micro and nano alpha-Fe2O3 material and preparation method thereof

The invention relates to a micro and nano alpha-Fe2O3 material and a preparation method thereof. The micro and nano alpha-Fe2O3 material has a cylindrical one-dimensional superstructure. The preparation method comprises the steps of dissolving iron salt, mixing the dissolved iron salt with polyol, putting a mixture in a reaction kettle, reacting for 2-60 hours at the temperature of 120-180 DEG C, cooling to room temperature, cleanly washing a product by using water and ethanol, and carrying out vacuum drying on the product until the weight is constant, thereby obtaining the final micro and nano alpha-Fe2O3 material. According to the micro and nano alpha-Fe2O3 material and the preparation method thereof, the morphology of the micro and nano alpha-Fe2O3 material is controlled through the volume ratio of the soluble iron salt, water and the polyol, so that the cylindrical self-assembled one-dimensional superstructure of uniform size is obtained, and a gas sensitive element can be made from the micro and nano alpha-Fe2O3 material and is used for detecting toxic gases; the preparation method has the characteristic of mild reaction conditions, and the prepared micro and nano alpha-Fe2O3 material with the one-dimensional superstructure has the characteristics of uniform morphology and controllable size.

Owner:ANHUI NORMAL UNIV

Multi-microelement injecta and its preparation method and application

InactiveCN1517085AImprove stabilityImprove solubilityMetabolism disorderHeterocyclic compound active ingredientsSodium molybdateCopper chloride

An injecta for supplying multiple microelement to human body contains Cr, Cu, Fe, Mn, Mo, Se, Zn, I, F, sorbitol, hydrochloric acid and the water for injection. It is prepared through dissolving sorbitol in said water, adding hydrochloric acid to said water and dissolving iron chloride in it, respectively dissolving zinc chloride, manganese chloride, copper chloride, sodium selenite, sodium molybdate and potassium iodide in said water and adding them to said sorbitol solution, mixing with the solution of hydrochloric acid, respectively dissolving chromium chloride and sodium fluoride in said water and slowly adding them to resultant mixture, and regulating.

Owner:费森尤斯卡比华瑞制药有限公司

Method for producing high-purity quartz sand

The invention discloses a method for producing high-purity quartz sand. The method comprises the following steps: magnetic separation, floatation separation, staged de-sliming, acid-leaching washing, drying and finished product obtaining. Through magnetic separation, garnet, hematite, limonite, ilmenite and coenobium particles thereof are removed. Mica and Fe2 in the quartz are removed through floatation separation. Through adding a dispersant for scrubbing, electric repulsion on the surfaces of impurity minerals and quartz particles is increased, and the effect of separating the impurity minerals from the quartz particles is enhanced. In particular, through double acid leaching and double washing, film iron on the surfaces of silica sand particles and iron minerals or iron-containing minerals accompanying in the quartz sand are separated through the function of acid in dissolving iron and other harmful elements. The high-purity quartz sand is produced through the strict technical steps.

Owner:临沂晟泉矿业有限公司

Method of removing dissolved iron in aqueous systems

InactiveUS20090183922A1Rapidly decompose peroxideIncrease oxidation rateWaste water treatment from quariesWater/sewage treatment with mechanical oscillationsActivated carbonCavitation

Oilfield completion, drilling and workover fluids containing iron are treated to remove the iron by passing them through a cavitation device together with an oxidizing agent. The cavitation device intimately mixes the oxidizing agent with the fluid while increasing the temperature of the fluid, thus promoting the oxidation reaction. Ferric hydrate and other solids or colloidal iron are removed in a filter capable of removing particles as small as 0.5 micron. The system may be enhanced by the addition of a bed of activated carbon capable of catalyzing the oxidation reaction.

Owner:TOTAL SEPARATION SOLUTIONS

Montmorillonite-loaded iron salt MOFs adsorbent and preparation method thereof

The invention discloses a preparation method of a montmorillonite-loaded iron salt MOFs adsorbent. The method includes: dissolving iron salt and organic ligand into polar solvent, adding acidized montmorillonite, stirring and uniformly dispersing; transferring mixed dispersion liquid to a reactor, heating to 100-180 DEG C, and performing reaction for 8-24h; cooling after reaction is finished, andcentrifuging to collect a product; washing the product to remove unreacted iron salt and the organic ligand, and drying to obtain faint yellow powder namely the montmorillonite-loaded iron salt MOFs adsorbent. By a special structure and properties of montmorillonite, in-situ loading of biocompatible iron salt MOFs on the surface of lamellar montmorillonite is realized according to a hydrothermal method; by control of a microscopic size and structure of the iron salt MOFs, the obtained adsorbent is higher in stability and adsorption effectiveness than the iron salt MOFs. In addition, the adsorbent is great in dye waste liquid adsorption performance and has a promising application prospect in the field of adsorption removal of dye wastewater.

Owner:NORTHWEST NORMAL UNIVERSITY

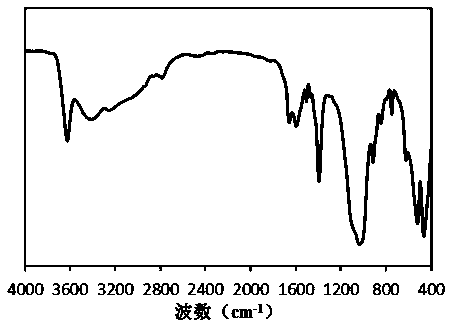

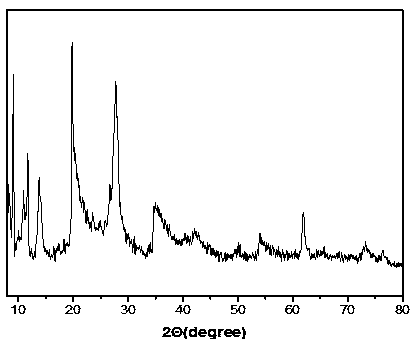

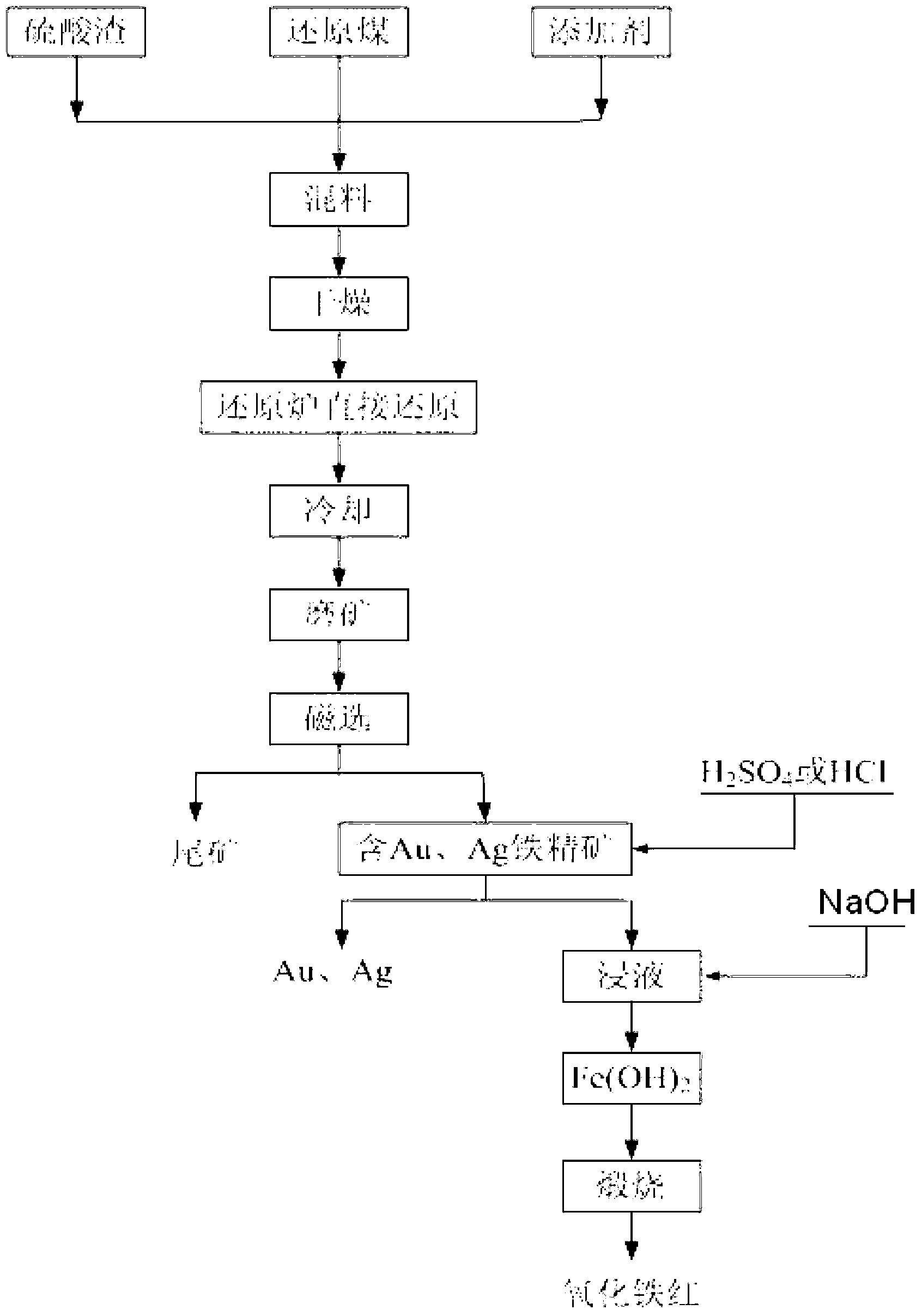

Comprehensive recovery method of sulfuric-acid residue containing gold and silver

ActiveCN103305701ASolve the problem that cannot be used reasonably and efficientlyHigh recovery rateFerric oxidesProcess efficiency improvementRecovery methodSodium Bentonite

The invention discloses a comprehensive recovery method of sulfuric-acid residue containing gold and silver. The method comprises the steps of: firstly, mixing gold and silver sulfuric-acid residue, reductive pulverized coal and bentonite and pelletizing; then carrying out direct reduction on dry pellets for 10-40 minutes inside a reduction furnace at the reduction temperature of 1100-1300 DEG C; carrying out water quenching and cooling on the reduced metal pellets and then carrying out grinding and magnetic separation, wherein tailings obtained after magnetic separation can be used as cement packing and the iron ore concentrate obtained after magnetic separation contains gold and silver; dissolving iron ore concentrate by adopting dilute sulphuric acid or diluted hydrochloric acid, wherein gold and silver cannot be dissolved and serve as sediments to be enriched in the residues; and directly conveying the gathered the residues to a smelting procedure. By adopting the technique, comprehensive recovery and utilization of gold, silver and iron in the sulfuric-acid residue containing gold and silver can be achieved; the yields of gold, silver and iron are high; the recovery rate of gold is 100%; the recovery rate of silver is over 95%; the recovery rate of iron is over 85%; the valuable elements, such as gold, silver and iron in the sulfuric-acid residue can be extracted to the maximal extent; and good economic benefit and social benefit are achieved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

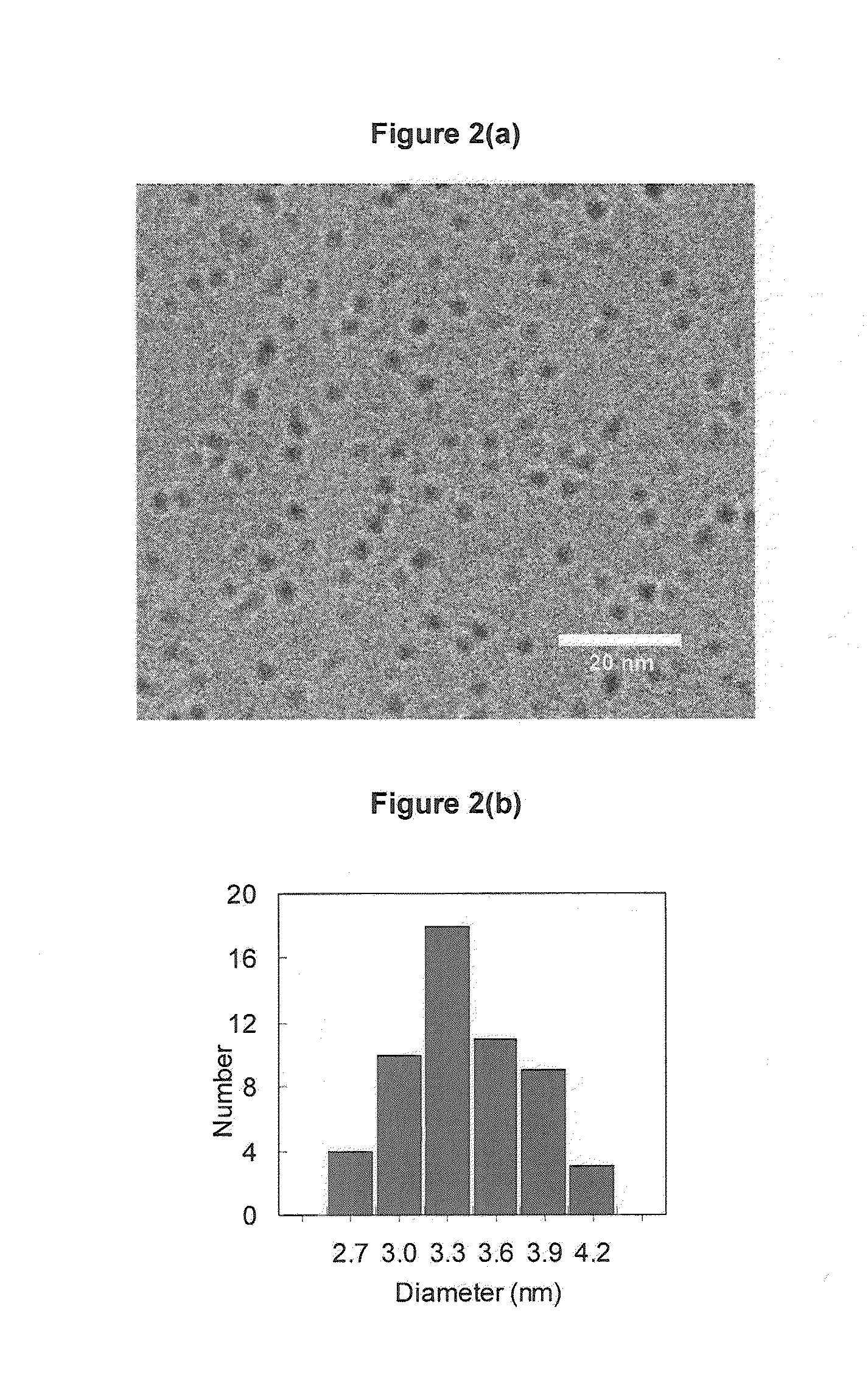

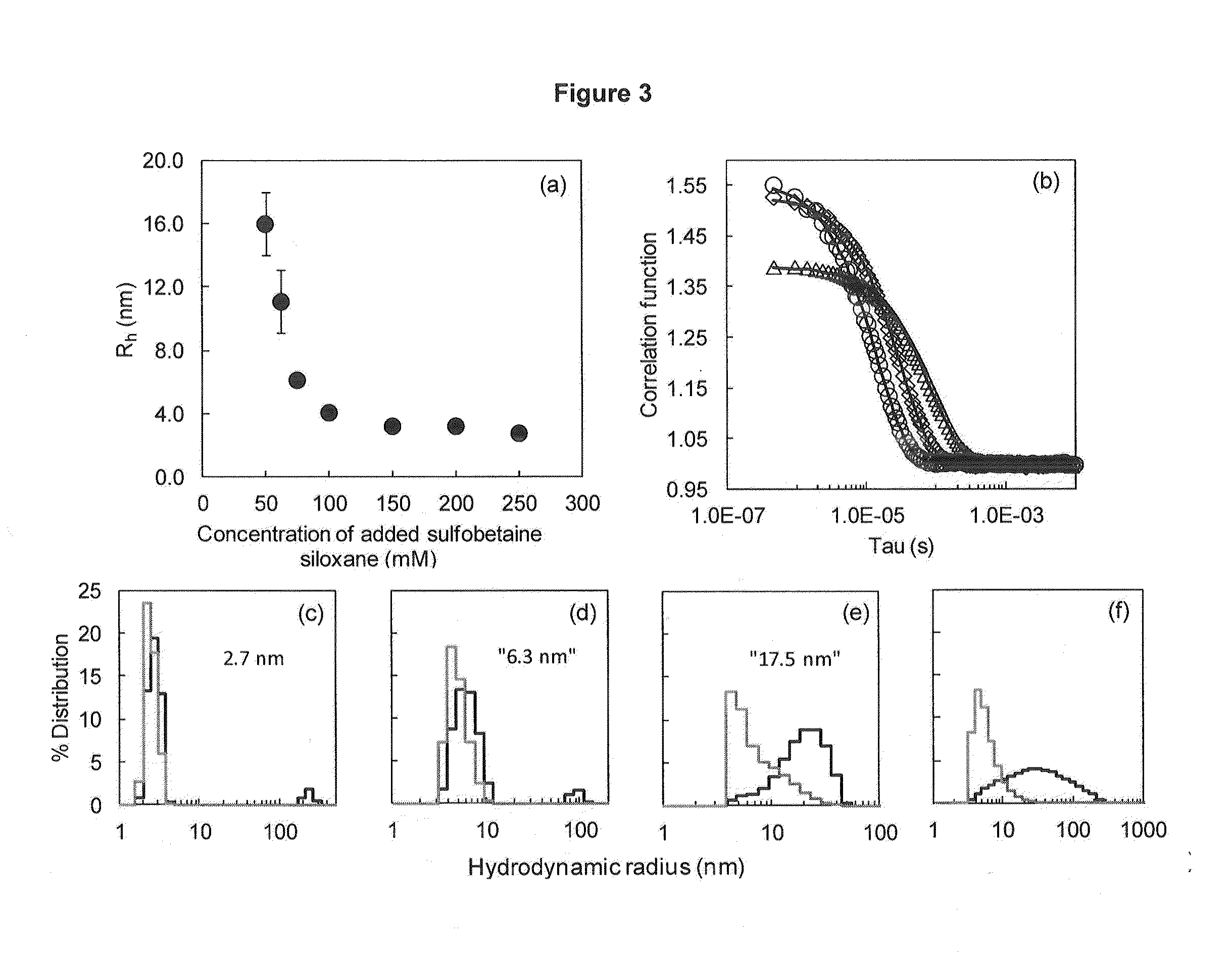

Stable Iron Oxide Nanoparticles and Method of Production

ActiveUS20130256583A1NanomagnetismOrganic/organic-metallic materials magnetismSilanesIron oxide nanoparticles

A method of preparing a dispersion of stabilized iron oxide nanoparticles that comprise cores and coatings on the cores, which comprise zwitterionic functional groups chemically bound to the cores, using a single solution that comprises dissolved iron ions and a zwitterion silane and / or a hydrolyzed product of the zwitterion silane.

Owner:FLORIDA STATE UNIV RES FOUND INC

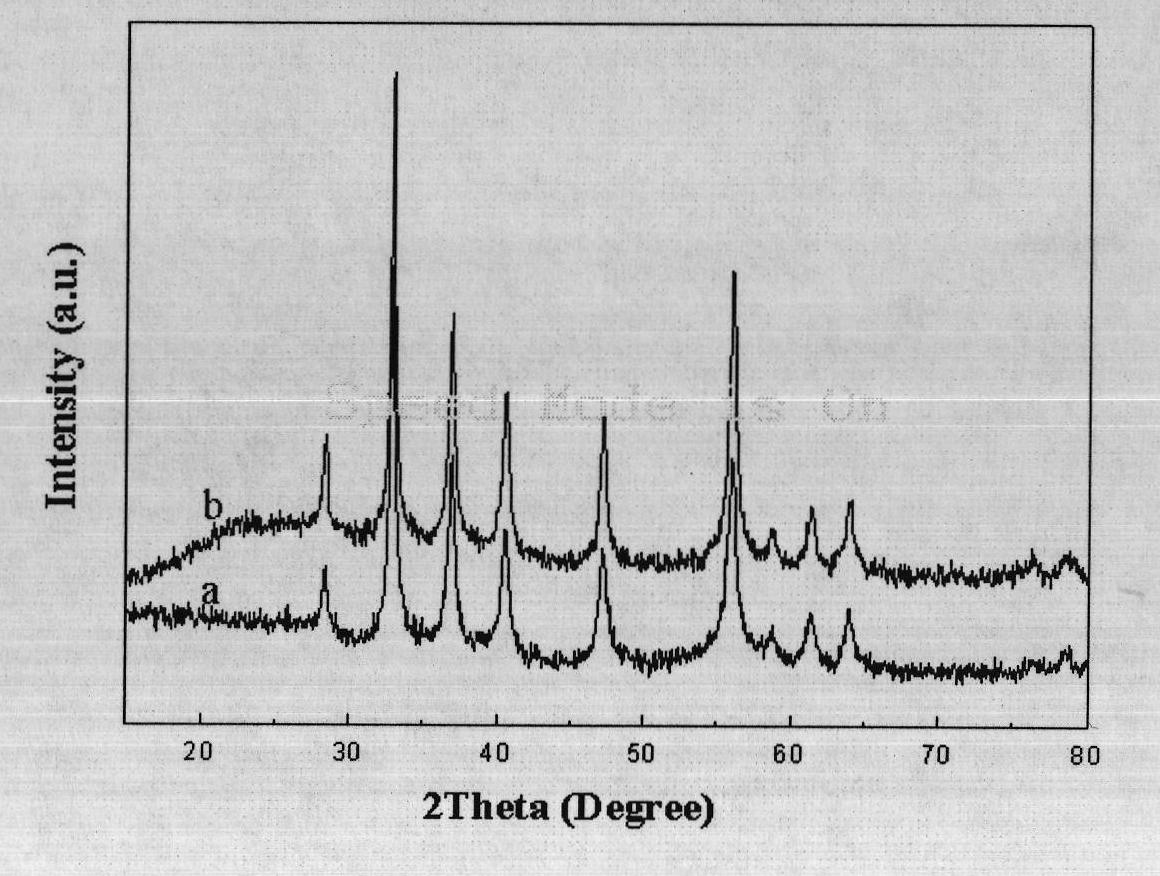

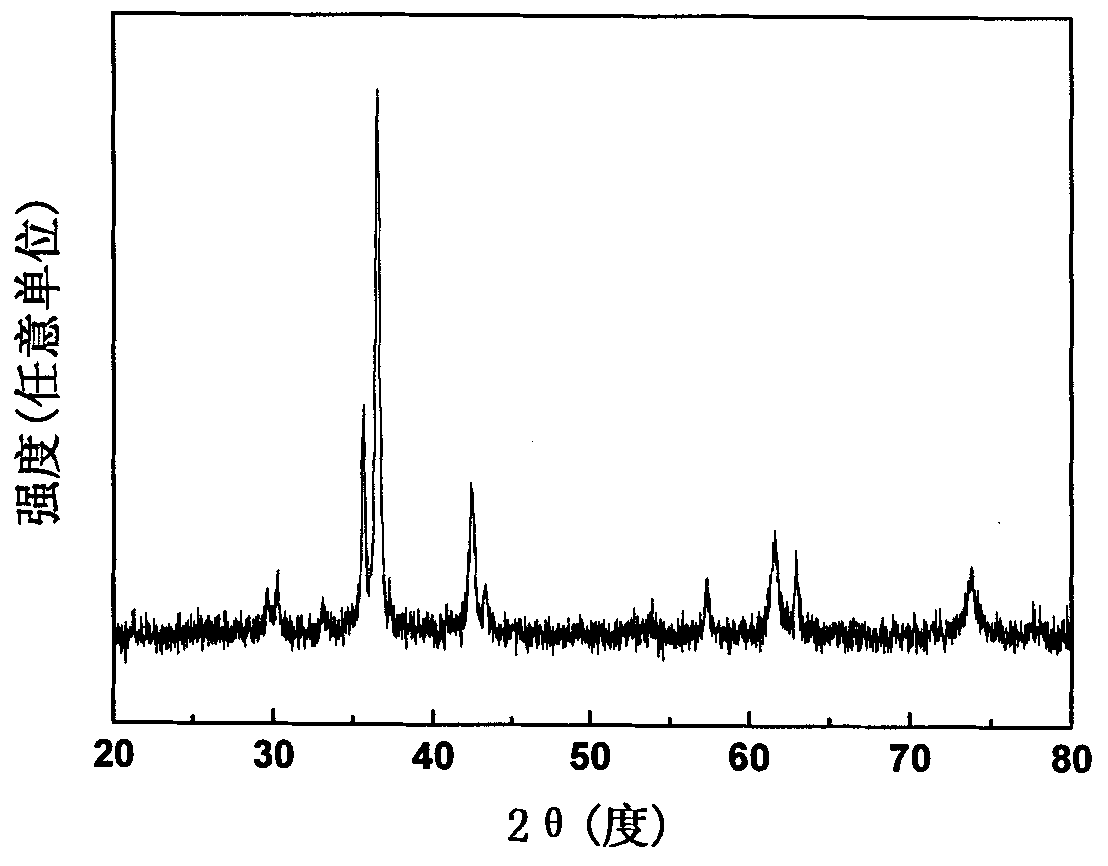

Preparation method of nano Ni/Fe-biochar composite material and application of nano Ni/Fe-biochar composite material in in-situ restoration of polybrominated diphenyl ether polluted soil

ActiveCN105670635AImprove liquidityImprove stabilityAgriculture tools and machinesContaminated soil reclamationDispersityHigh concentration

The invention discloses a preparation method of a nano Ni / Fe-biochar composite material and application of the nano Ni / Fe-biochar composite material in in-situ restoration of polybrominated diphenyl ether polluted soil. The preparation method comprises the following steps: dissolving iron salt or ferrous salt and polyvinylpyrrolidone in an ethanol water solution, uniformly mixing, adding biochar particles, and uniformly mixing to obtain a solution A; adding a reducer-containing ethanol water solution into the solution A, stirring to react completely, separating out the reaction product, washing, and adding into an ethanol water solution to obtain a solution B; and dropwisely adding a nickel-salt-containing ethanol water solution into the solution B, stirring to react completely, separating out the product material, washing, and drying to obtain the nano Ni / Fe-biochar composite material. The nano Ni / Fe bimetal particles are carried on the biochar, thereby further enhancing the flowability of the nanoparticles. The nano Ni / Fe-biochar composite material is beneficial to soil in-situ restoration due to the stability and dispersity. The nano Ni / Fe-biochar composite material can be used for restoring high-concentration PBDEs polluted soil, and has high restoration efficiency.

Owner:师大清远环境修复科技有限公司

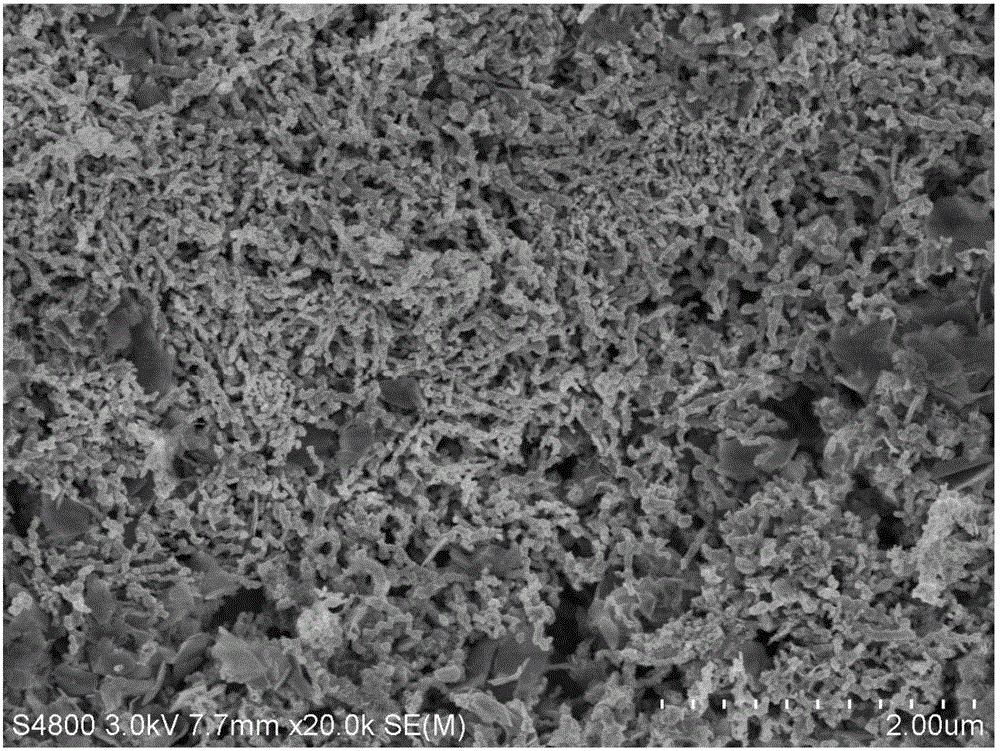

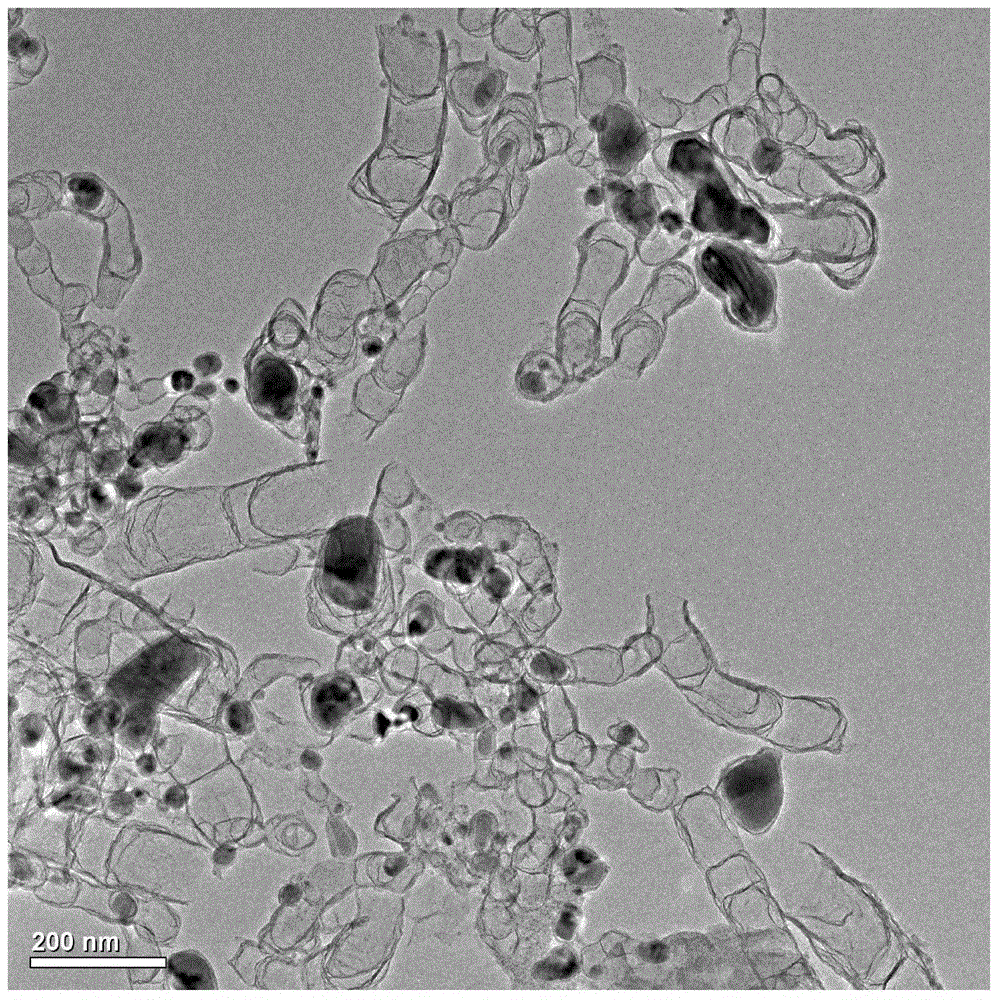

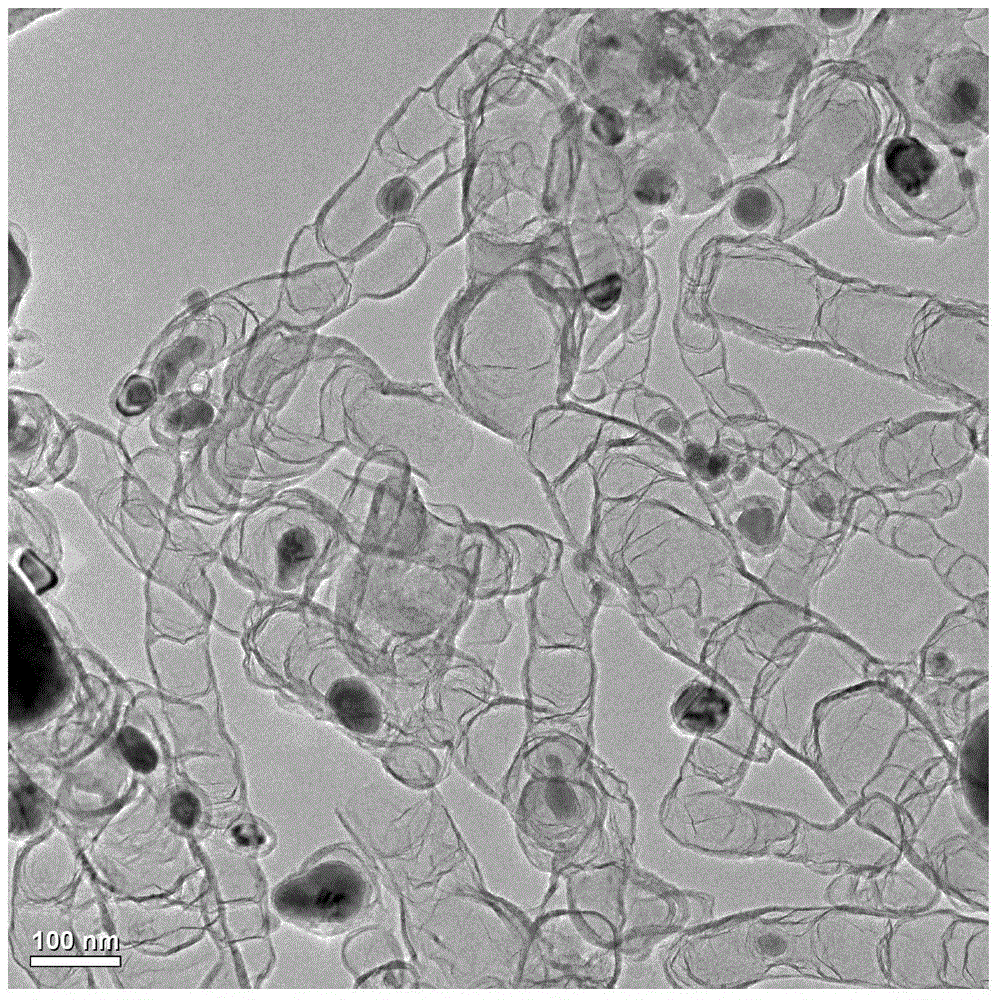

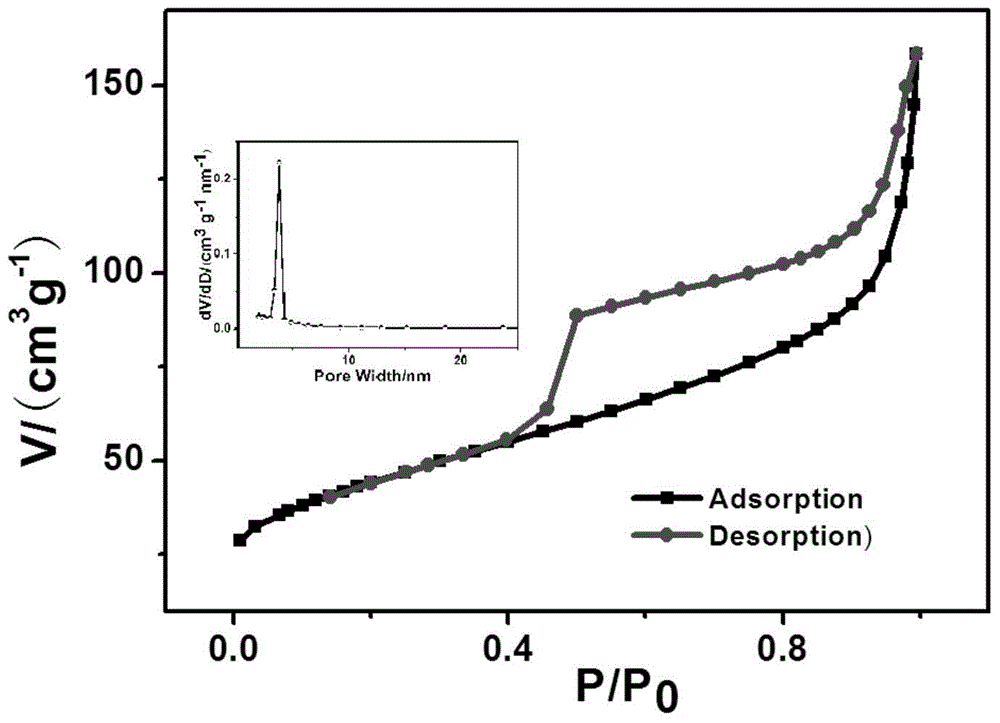

Bamboo joint-like carbon nano-tube preparation method

InactiveCN104528683AThe method is simple and fastLow costMaterial nanotechnologySolubilityEnvironmental resistance

The present invention relates to a bamboo joint-like carbon nano-tube preparation method, wherein technical problems of high cost, poor environmental protection, not high carbon nano-tube content in the product, and inconvenient mass production of the existing bamboo joint-like carbon nano-tube preparation method are solved with the method of the present invention. The method of the present invention comprises: dissolving 0.50-1.00 g of melamine in ultrapure water, sequentially adding 5.0-10.0 mL of a 0.10 g / ml surfactant and 5.0-10.0 mL of a 1.0 wt% dissolved iron salt, uniformly stirring, carrying out an ultrasonic treatment for 4-6 h, placing the residue obtained from the solution being subjected to drying at a temperature of 80 DEG C into a quartz boat, heating to a temperature of 750-900 DEG C under nitrogen gas protection, and carrying out a heat treatment for 1-3 h to obtain the bamboo joint-like carbon nano-tubes. According to the present invention, the method has characteristics of simplicity, convenience, low cost, green environmental protection, and easy mass production, and the prepared bamboo joint-like carbon nano-tube has wide application prospects in fields of fuel cells, biological sensing, and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

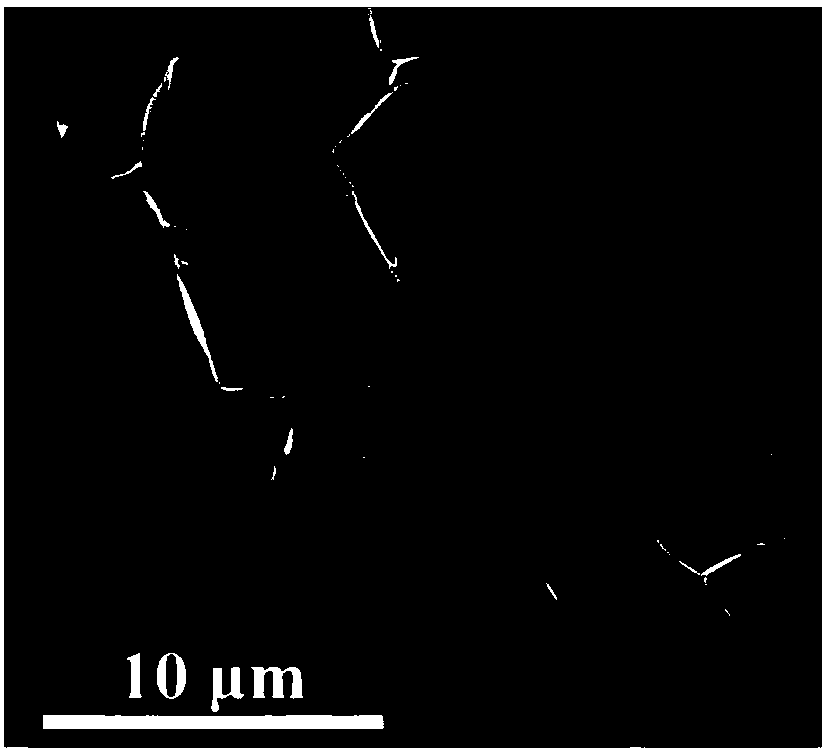

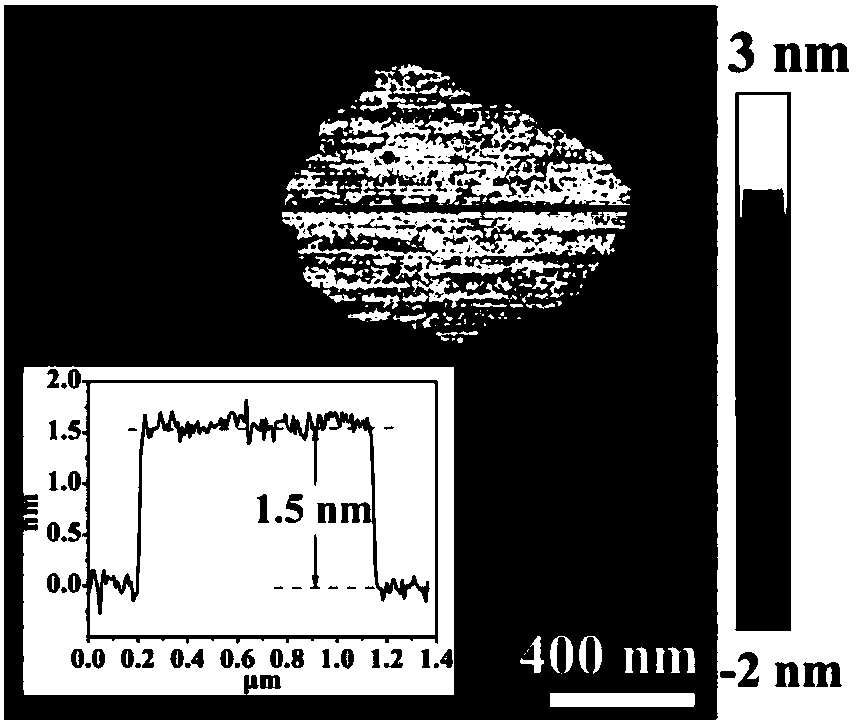

Three-dimensional porous nitrogen-doped graphene composite material and preparation method of nitrogen-doped graphene

ActiveCN108264037AGood lookingSimple methodMaterial nanotechnologyGrapheneWater bathsPorous graphene

The invention relates to a three-dimensional porous nitrogen-doped graphene composite material and a preparation method of nitrogen-doped graphene, which belong to the field of a functional nano material. The method comprises the following steps: respectively dissolving iron nitrate nonahydrate and polyvinylpyrrolidone in deionized water to prepare a mixed solution, performing ultrasonic mixing, placing the mixed solution in an air-blast drying box for complete drying, and grinding the material to powder; transferring the ground powder to a crucible and placing the powder in a tubular furnace,and heating and insulating the material under inertia protection atmosphere to obtain the three-dimensional porous nitrogen-doped graphene composite material; placing the iron carbide nano particles-modified three-dimensional porous graphene composite material in strong acid for water-bath heating, and after the solution is reduced to room temperature, performing steps of filtering, cleaning, centrifugation, and freeze drying to obtain the three-dimensional porous nitrogen-doped graphene. The graphene has the advantages of short production period, low cost, strong repeatability and large-scale preparation, has important reference effect for preparation of the graphene composite material, and has the wide application prospect in the fields of energy storage and catalysis.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of iron disulfide microspheres

The invention discloses a preparation method of iron disulfide microspheres. Specifically, the method comprises the steps of: dissolving iron chloride, or iron chloride and urea in a mixed solution consisting of ethylene glycol and N,N-dimethylformamide, thus obtaining a clear homogeneous solution containing iron ions; adding sulfur powder; subjecting the mixed solution to a reaction for 10-20h at a temperature of 150-170DEG C, conducting separation with a conventional method, thus obtaining black powder, i.e. pyrite-type monodispersed iron disulfide microspheres. Products obtained with the method of the invention have uniform particle size and appearance, good technological repeatability and stable quality. Thus, the method provided in the invention is expected to be applied in the fields of solar energy conversion, heavy metal ion fixation, etc.

Owner:LANZHOU LANSHI ZHONGKE NANOTECHNOLOGY CO LTD

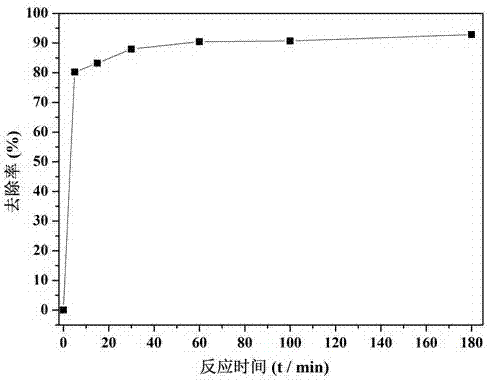

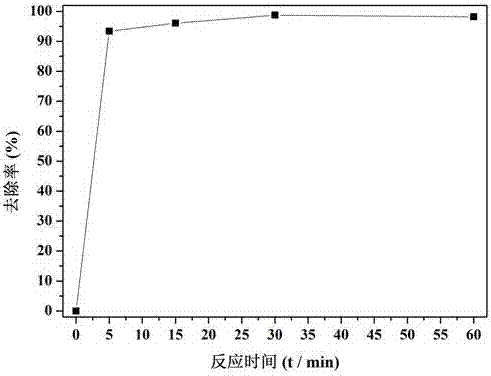

Method of removing chromium (VI) and dye pollutants by using plant polyphenol substances for in-situ synthesizing iron-based material

InactiveCN106915813ANot easily oxidizedImprove stabilityWater treatment parameter controlWater contaminantsIron saltsDissolved iron

The invention discloses a method of removing chromium (VI) and dye pollutants by using plant polyphenol substances for in-situ synthesizing an iron-based material. The method comprises the steps of: 1) performing water-extraction to plant tissue to obtain plant tissue extract liquid, and dissolving iron salt in deionized water to produce an iron salt solution; 2) adding the iron salt solution to the wastewater comprising the Cr (VI) and dyes with uniform mixing, and allowing the liquid to stand for 5-30 min; 3) adding the plant tissue extract liquid with uniform mixing and allowing the liquid to stand for a reaction for 2-48 h. In the method, the iron salt, which is abundant in environment, is used as a precursor; and plant extract liquid (such as green tea) is used as a chelating agent and a reducing agent for iron ions. By adding the raw materials to a polluted field or a pollutant treatment reactor system, the iron-based material, which has stable reducing property, is produced in situ, so that the target pollutants are high-effectively degraded. The method achieves recovery in situ, is green and pollution-free, has high activity and good cyclic property, is high in effect and is economical, is easy to control and has wide available range. The method also can be used in recovery of chromium.

Owner:SUN YAT SEN UNIV

Method for preparing magnetic iron oxide nano particles

ActiveCN102153147AUniform particle sizeContinuous productionFerroso-ferric oxidesNanotechnologyTetramethylammonium hydroxidePolyethylene glycol

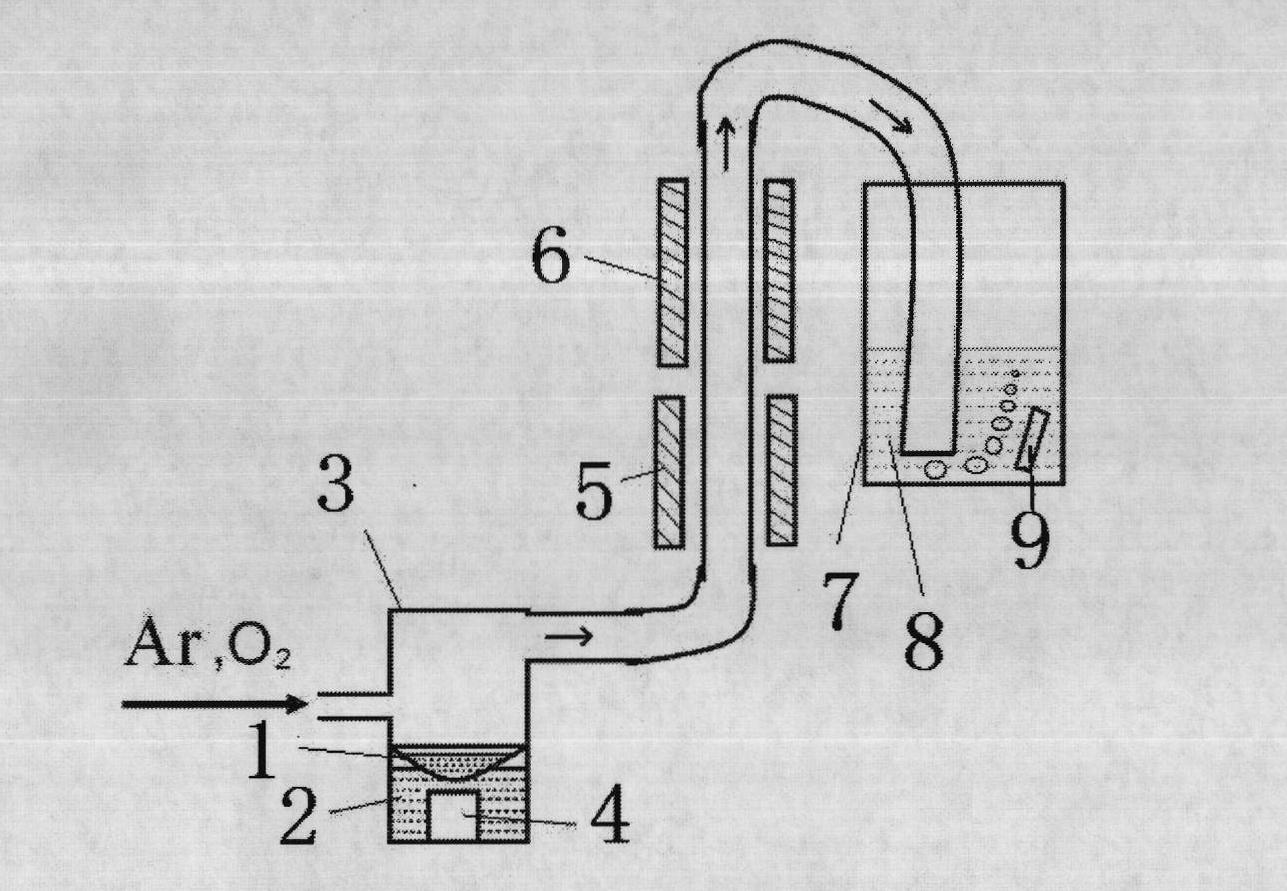

The invention discloses a method for preparing magnetic iron oxide nano particles. The method comprises the following steps of: dissolving iron pentacarbonyl and a modifier into a solvent, atomizing by virtue of an ultrasonic atomizer, loading a solution into a heater by virtue of a carrier gas, carrying out gasification, decomposition and oxidation, introducing products into collected fluid, mixing, stirring, and carry outing surface reaction to obtain modified magnetic iron oxide nano particles. The modifier used in atomized liquid and the collection fluid is selected from oleic acid or oleic amine, triethylene glycol, polyethylene glycol PEG and derivates thereof, glucosan, citric acid, tetramethylammonium hydroxide, carboxylic acid polyethylene glycol and derivates thereof, polyvinylpyrrolidone (PVP) and dimercapto succinic acid or a mixture of the substances; the carrier gas is a mixed gas of oxygen gas and argon gas, and the heating process is carried out in two stages. By applying the method disclosed by the invention, the magnetic iron oxide nano particles with uniform particle sizes can be prepared while the advantages of speediness, high efficiency, continuous production and low pollution are achieved; and the prepared iron oxide nano particles can be used in the fields such as biology, medicine, catalysis and mechanical lubrication.

Owner:江苏龙力泵阀制造有限公司

Preparation method of Cu2O/NiFe2O4 magnetic composite

The invention relates to a preparation method of a Cu2O / NiFe2O4 magnetic composite, belonging to the technical field of preparation of magnetic composite material. The method of the invention is characterized by comprising the following steps: dissolving iron salt and nickel salt in distilled water according to a certain ratio, then adding surfactant polyvinylpyrrolidone, adjusting the pH value of the solution to 9-11 with sodium hydroxide, then pouring the reaction solution in a high-pressure reaction tank and placing in a muffle furnace to keep temperature for 8-10 hours at 200-250 DEG C for fully reacting; washing the product, performing suction filtration and vacuum drying to obtain magnetic nickel ferrite power for standby; then dissolving copper salt and glucose in distilled water with a certain volume, adding the prepared nickel ferrite power in the obtained solution; stirring evenly, adding defined amounts of NaOH solution and hydrazine hydrate solution, continuously stirring to fully react; and then washing, performing suction filtration and vacuum drying, and finally obtaining the Cu2O / NiFe2O4 magnetic composite power.

Owner:SHANGHAI UNIV

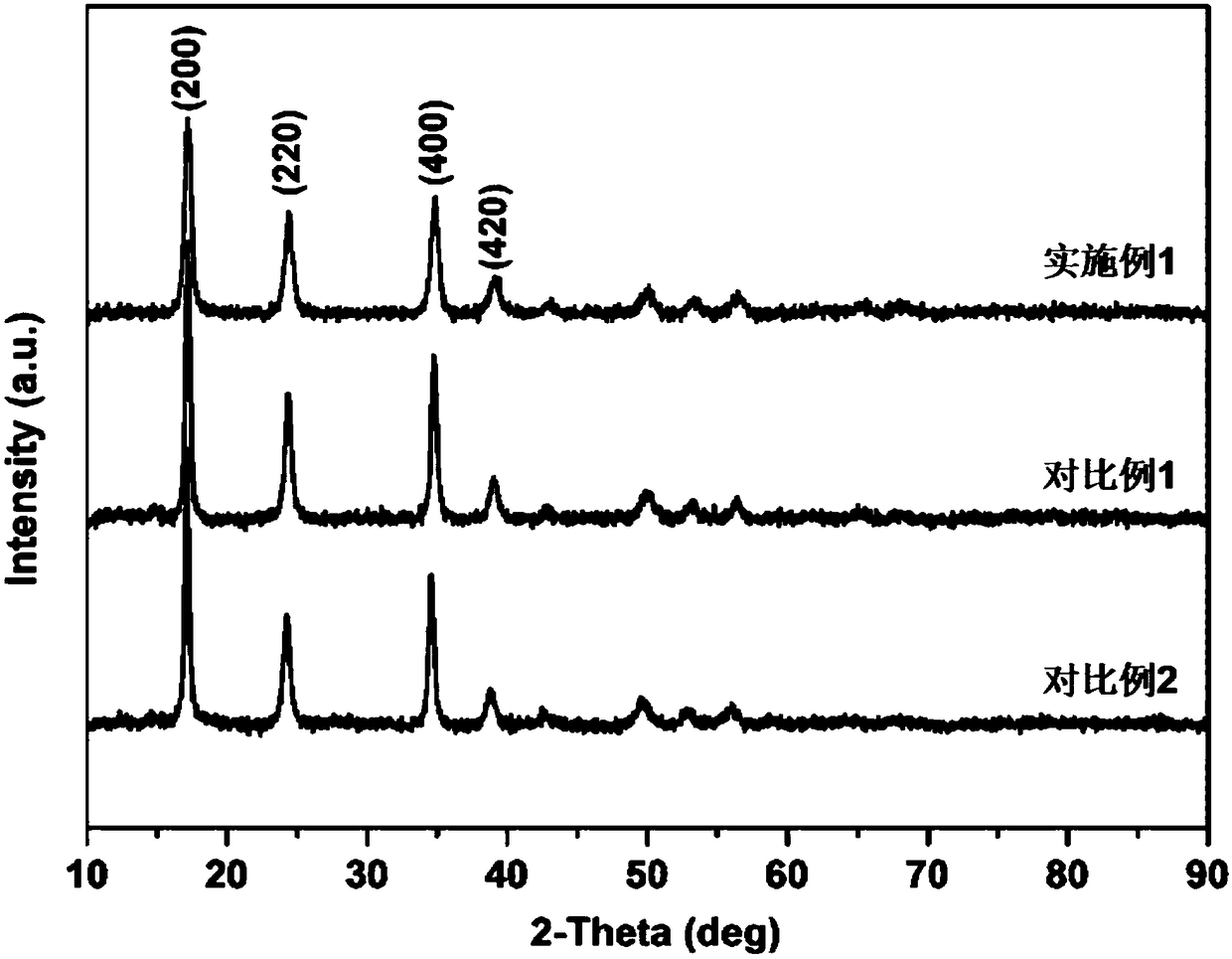

A cathode material for sodium ion battery and a preparation method thereof

ActiveCN109273682AIncrease sodium storage capacityImprove cycle stabilityCell electrodesSecondary cellsDissolved ironSodium-ion battery

The invention discloses a positive electrode material of a sodium ion battery and a preparation method thereof. cathode material of the sodium ion battery, The preparation method comprises the following steps of: dissolving iron salt in a fluorinated ionic liquid, stirring the obtained mixed solution with a carbon source, a Prussian blue sodium ion cathode material, and carrying out solvothermal reaction to obtain an iron-based fluoride and carbon in-situ coating modified Prussian blue composite sodium ion battery cathode material. The invention can effectively improve the sodium storage capacity and cycle stability of the sodium ion battery composite material, and can also increase the conductivity of the sodium ion battery composite material through a simple in-situ coating process of the iron-based fluoride and the carbon source.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com