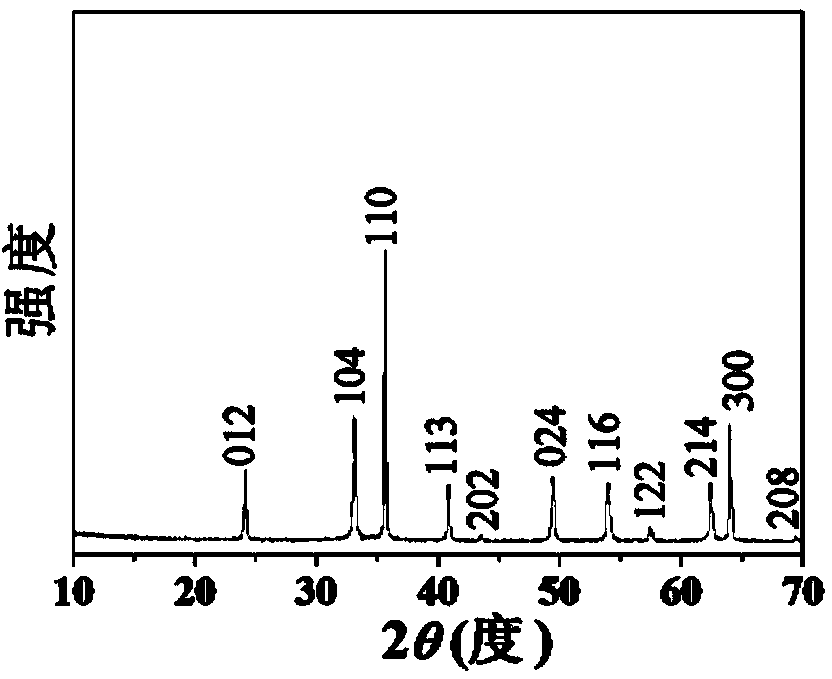

Micro and nano alpha-Fe2O3 material and preparation method thereof

A micro-, nano-technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as complex processes, and achieve the effects of controllable size, uniform morphology and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of micronano α-Fe 2 o 3 Materials with a cylindrical one-dimensional superstructure, cylindrical micro-nano α-Fe 2 o 3 The column is 1.5-2.5 microns high and 350-450 nanometers in diameter.

[0026] A kind of micronano α-Fe 2 o 3 The preparation method of material, the step comprises:

[0027] A. Dissolve ferric chloride in water to obtain an iron salt solution, add an appropriate amount of glycerin, stir vigorously on a magnetic stirrer at room temperature for 30 minutes until the solution is evenly mixed, and then pour the mixture into the polytetrafluoroethylene in a stainless steel autoclave in the lining;

[0028] B. Raise the temperature, react at 140°C for 50 hours, cool to room temperature, wash the product with deionized water and ethanol, and dry it in vacuum at 60°C for 6 hours to constant weight to obtain the final micronano α-Fe 2 o 3 Material;

[0029] The concentration of the iron salt solution in the step A is 0.05 mol / L; the volume ratio...

Embodiment 2

[0031] A kind of micronano α-Fe 2 o 3 Materials with a cylindrical one-dimensional superstructure, cylindrical micro-nano α-Fe 2 o 3 The columns are 1.5-2 microns high and 230-400 nanometers in diameter.

[0032] A kind of micronano α-Fe 2 o 3 The preparation method of material, the step comprises:

[0033] A. Dissolve ferric nitrate in water to obtain an iron salt solution, add appropriate amount of ethylene glycol, stir vigorously on a magnetic stirrer at room temperature for 30 minutes until the solution is evenly mixed, and then pour the mixture into a polytetrafluoroethylene (PTFE) in a stainless steel autoclave Vinyl lined;

[0034]B. Raise the temperature, react at 160°C for 2 hours, cool to room temperature, wash the product with deionized water and ethanol, and dry it in vacuum at 60°C for 6h to constant weight to obtain the final micronano α-Fe 2 o 3 Material;

[0035] The concentration of the iron salt solution in the step A is 0.002 mol / L; the volume ratio...

Embodiment 3

[0037] A kind of micronano α-Fe 2 o 3 Materials with a cylindrical one-dimensional superstructure, cylindrical micro-nano α-Fe 2 o 3 The columns are 2.2-3 microns high and 300-350 nanometers in diameter.

[0038] A kind of micronano α-Fe 2 o 3 The preparation method of material, the step comprises:

[0039] A. Dissolve ferric ammonium sulfate in water to prepare iron salt solution, add appropriate amount of 1, 3-propanediol and polyvinylpyrrolidone, stir vigorously on a magnetic stirrer at room temperature for 30 minutes until the solution is evenly mixed, then pour the mixture into In the polytetrafluoroethylene lining of stainless steel autoclave;

[0040] B. Raise the temperature, react at 120°C for 30 hours, cool to room temperature, wash the product with deionized water and ethanol, and dry it in vacuum at 50°C for 8 hours to constant weight to obtain the final micronano α-Fe 2 o 3 Material;

[0041] The concentration of the iron salt solution in the step A is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com