Preparation method of spinel lithium titanate nano tube/wire for lithium battery and capacitor

A technology of titanate nanotubes and lithium halite titanate, which is applied in the field of nanomaterial preparation technology and energy, can solve the problems of complex process and no obvious improvement in the electrochemical performance of nano lithium titanate, and achieve simple equipment and easy large-scale industrialization Production, fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation technique of the present invention mainly comprises following two aspects:

[0027] 1. Preparation of titanate nanotubes / nanowires from industrially produced titanium dioxide

[0028] This method of preparing titanate nanotubes / nanowires fully utilizes the pulverization effect of ultrasonic waves to fully pulverize large particle materials into fine particles, increases the contact area between materials, and reduces the mass transfer resistance of the reaction; The instantaneous local ultra-high temperature and ultra-high pressure generated by the chemical reaction accelerates the reaction, and then crystallizes by low-temperature hydrothermal to obtain titanate nanotubes / nanowires. After post-treatment, titanate nanotubes / nanowires are formed.

[0029] Process steps: Mix 1-5 grams of industrially produced titanium dioxide with 40 ml of 5-25 mol / liter NaOH solution, place in an ultrasonic generator, and perform ultrasonic chemical reaction at a temperature...

Embodiment 1

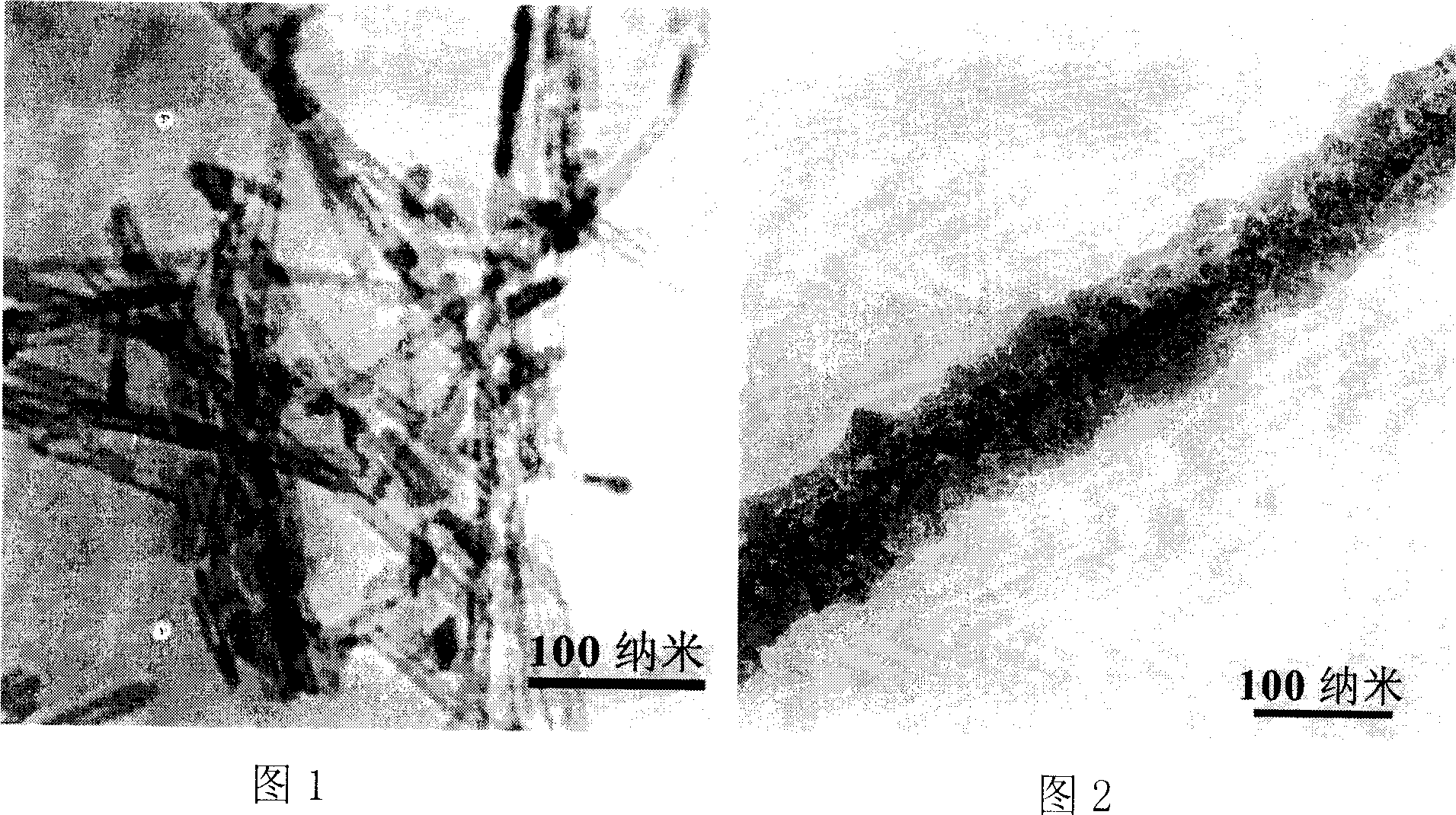

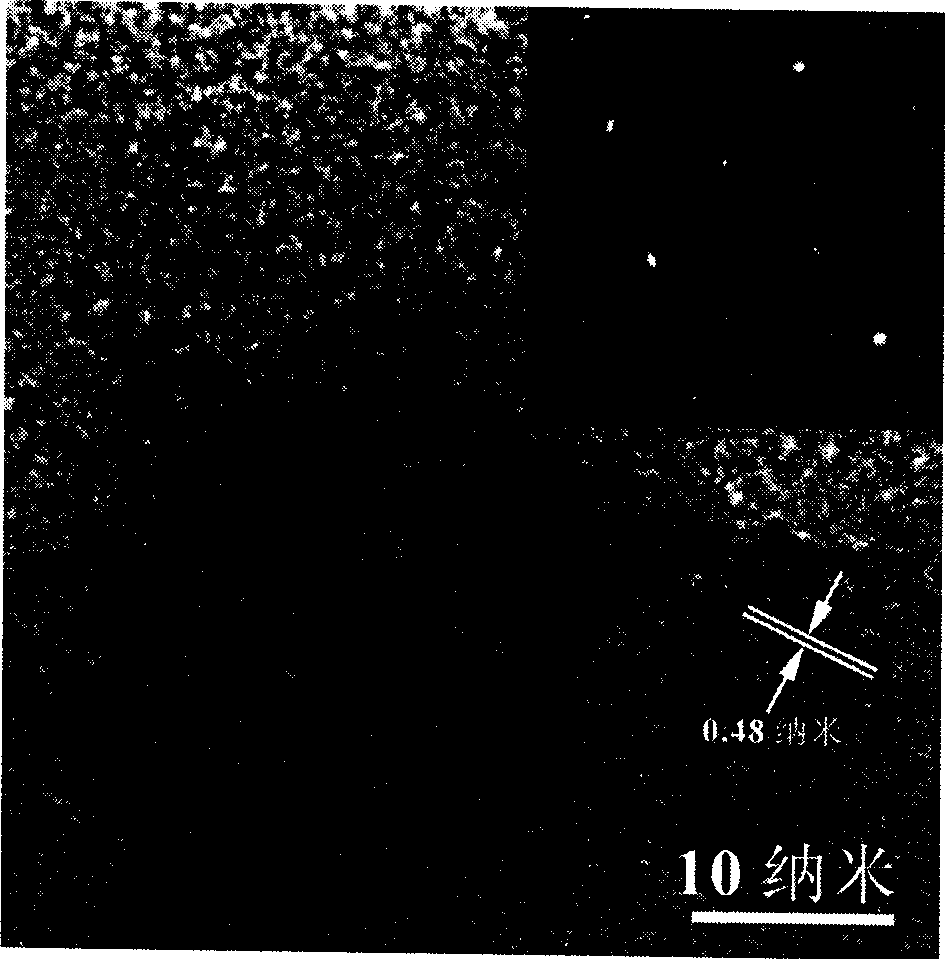

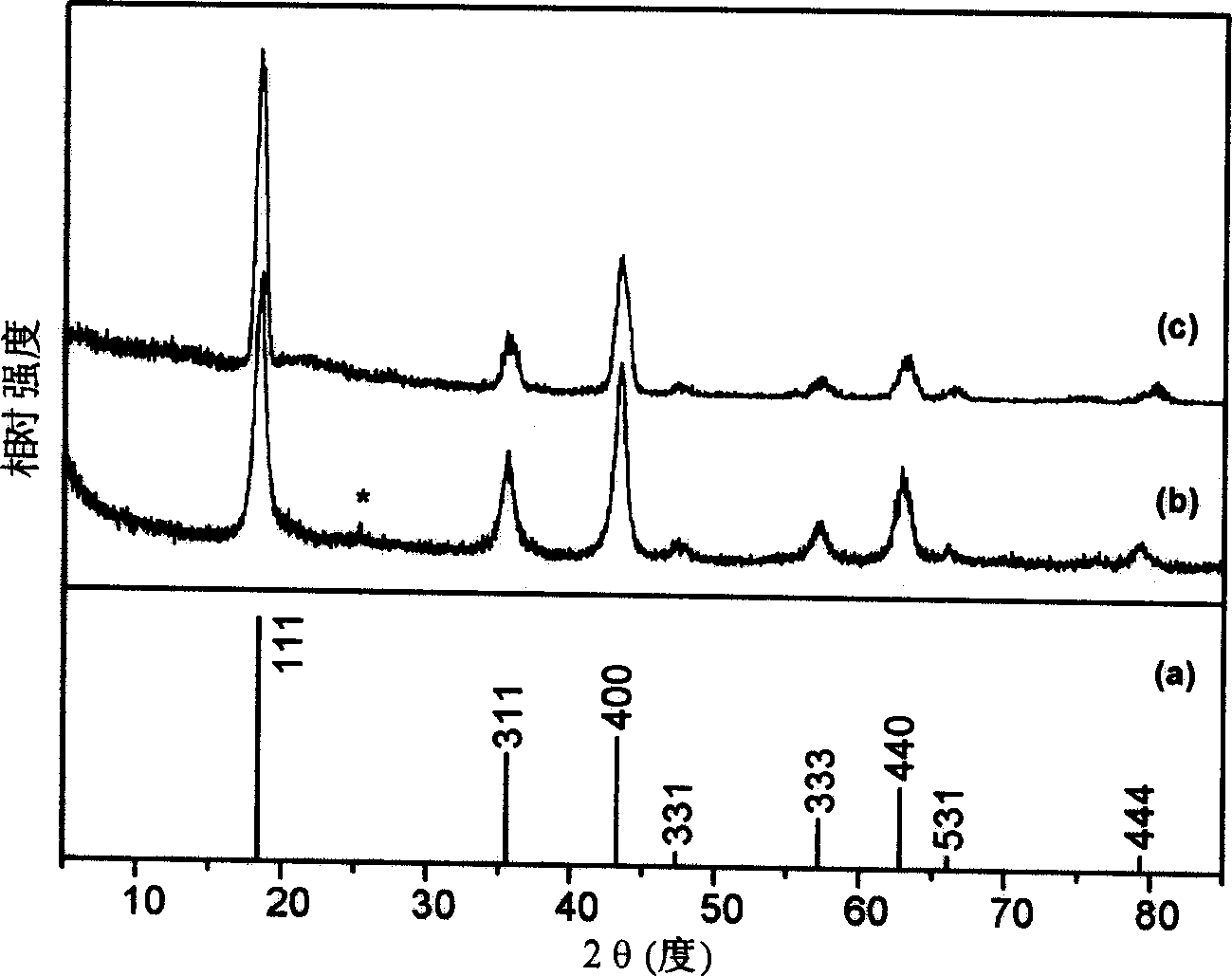

[0034] Embodiment 1: Preparation of titanate nanotubes

[0035] Weigh 1 g, 1.5 g, and 2.5 g of industrially produced anatase or rutile crystal form titanium dioxide powder, put them into a Erlenmeyer flask, add 40 ml of NaOH solution with a concentration of 5 or 10 mol / liter, and put them into an ultrasonic Generator, at 0.5W / cm 2 Ultrasonic with high power for 2 hours at a temperature of 30-80°C. Then move it into a 40ml polytetrafluoroethylene-lined autoclave, conduct a hydrothermal reaction at 110-120°C for 20 hours, centrifuge the white product from excess alkali, and use 0.1 mol / liter of HNO 3 Neutralize until the pH value is 3-7, age for 8 hours, rinse with deionized water, exchange with absolute ethanol three times, and dry to obtain titanate nanotubes. Its molecular formula is H 2 Ti 3 o 7 .

[0036] Repeat the above steps to 100W / cm 2 Ultrasound at a high power for 0.2 hours at a temperature of 60-80° C. to obtain titanate nanotubes.

[0037] The above operati...

Embodiment 2

[0040] Embodiment 2: Preparation of titanic acid nanowires

[0041] Weigh 3 grams, 4 grams or 5 grams of industrially produced titanium dioxide powder of anatase or rutile crystal form, put it into a Erlenmeyer flask, add 40 milliliters of NaOH solution with a concentration of 20 or 25 mol / liter, and put it into Ultrasonic generator, at 0.5W / cm 2 Ultrasonic with high power for 2 hours at a temperature of 30-80°C. Then move it into a 40ml polytetrafluoroethylene-lined autoclave, conduct a hydrothermal reaction at 170-180°C for 48 hours, centrifuge the white product from excess alkali, and use 0.1 mol / liter of HNO 3 Neutralize until the pH value is 5-7, age for 8 hours, then rinse with deionized water, exchange with absolute ethanol three times, and dry to obtain titanate nanowires; its molecular formula is H 2 Ti 3 o 7 .

[0042] Repeat the above steps to 100W / cm 2 Ultrasonic with high power for 0.5 hours at a temperature of 60-80° C. to obtain titanic acid nanowires.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com