Patents

Literature

793results about How to "Uniform diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

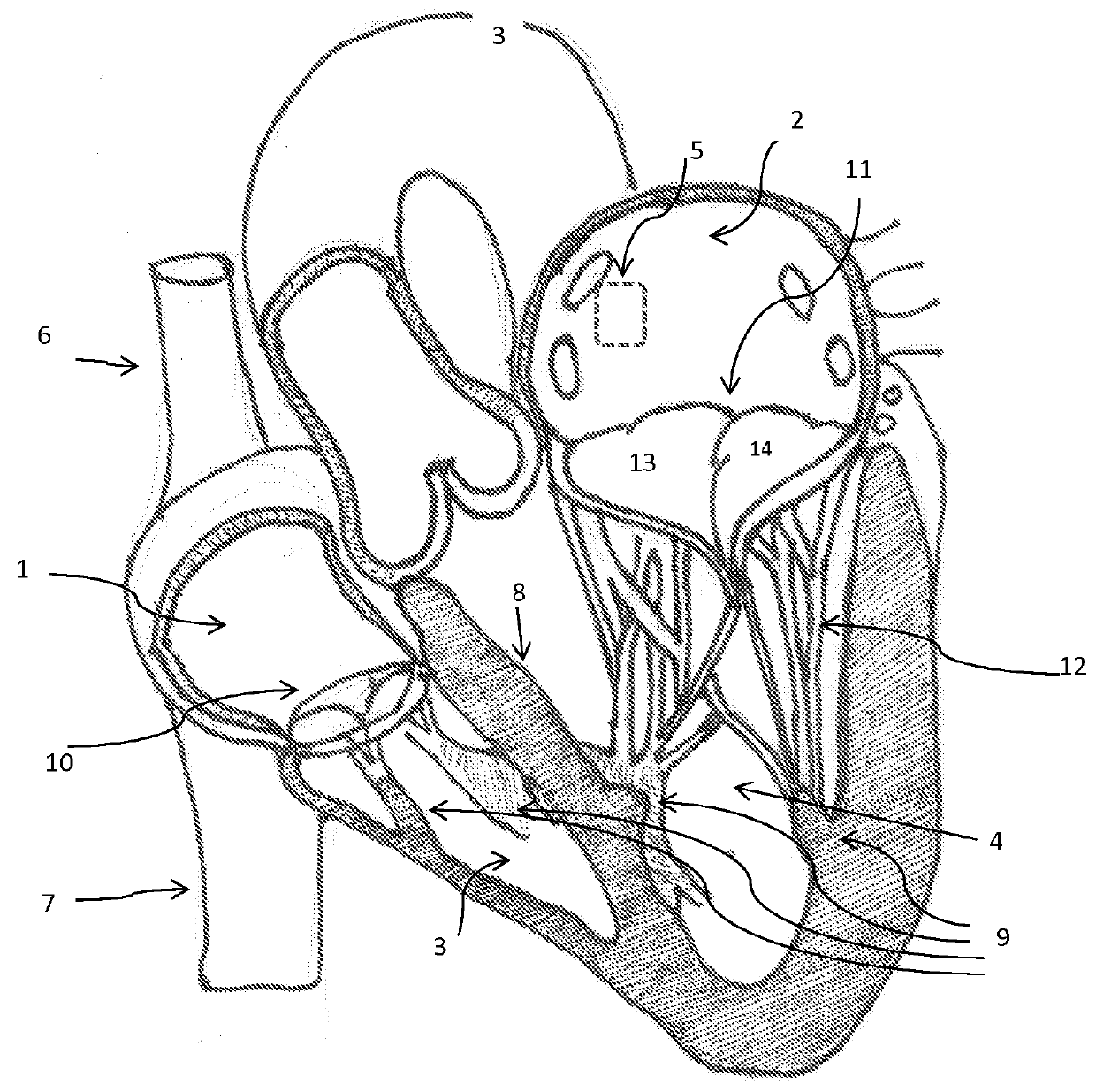

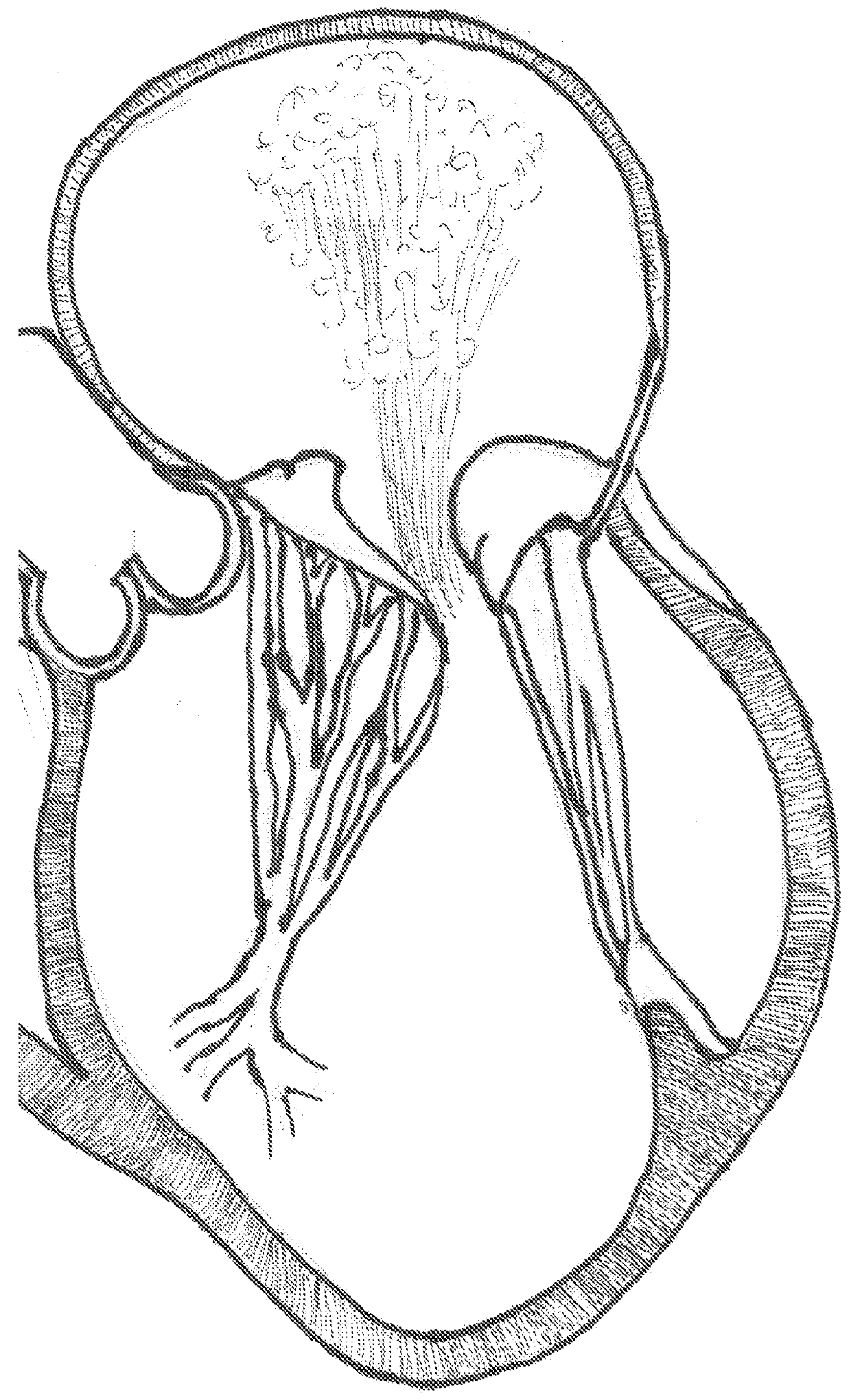

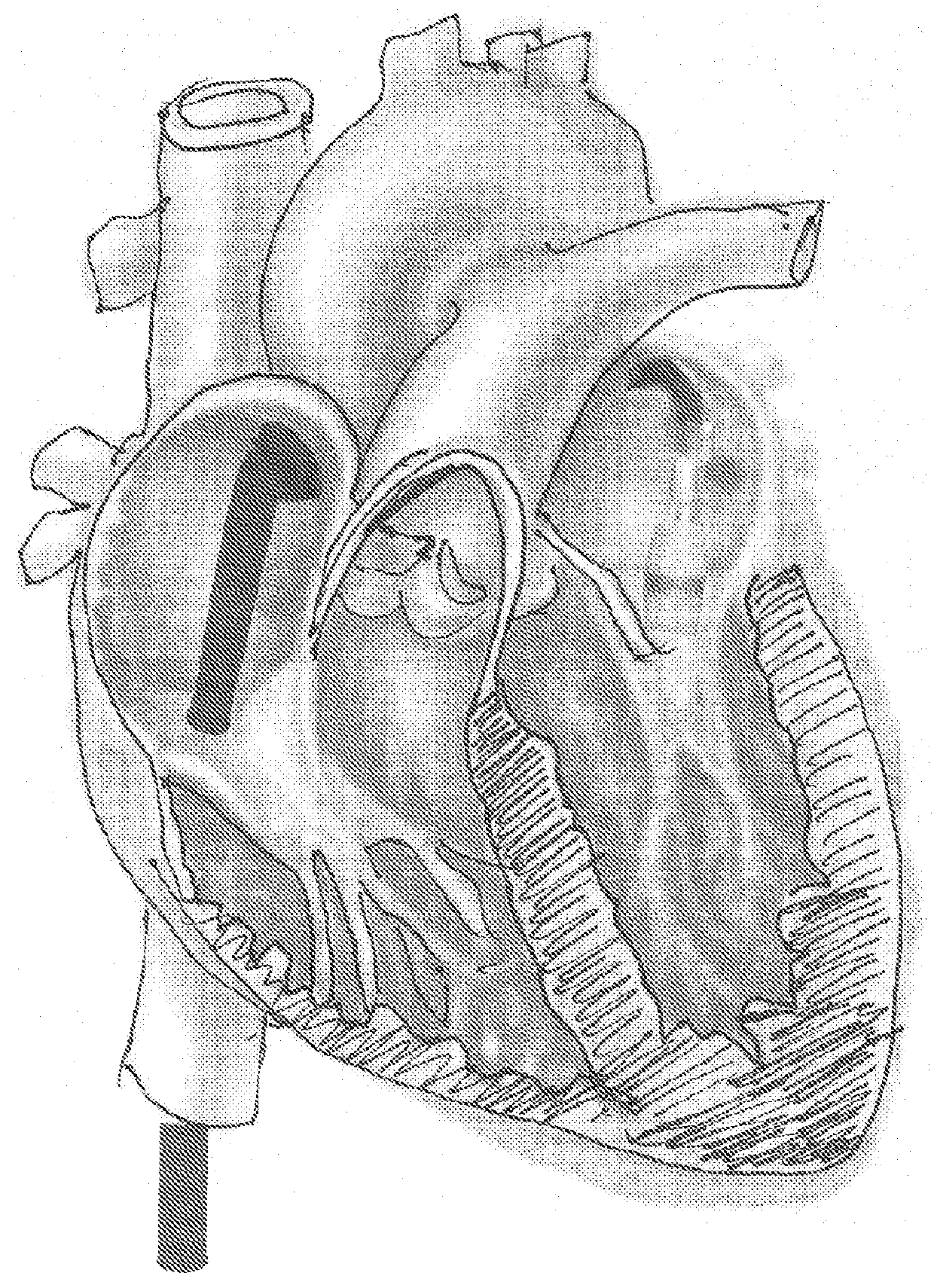

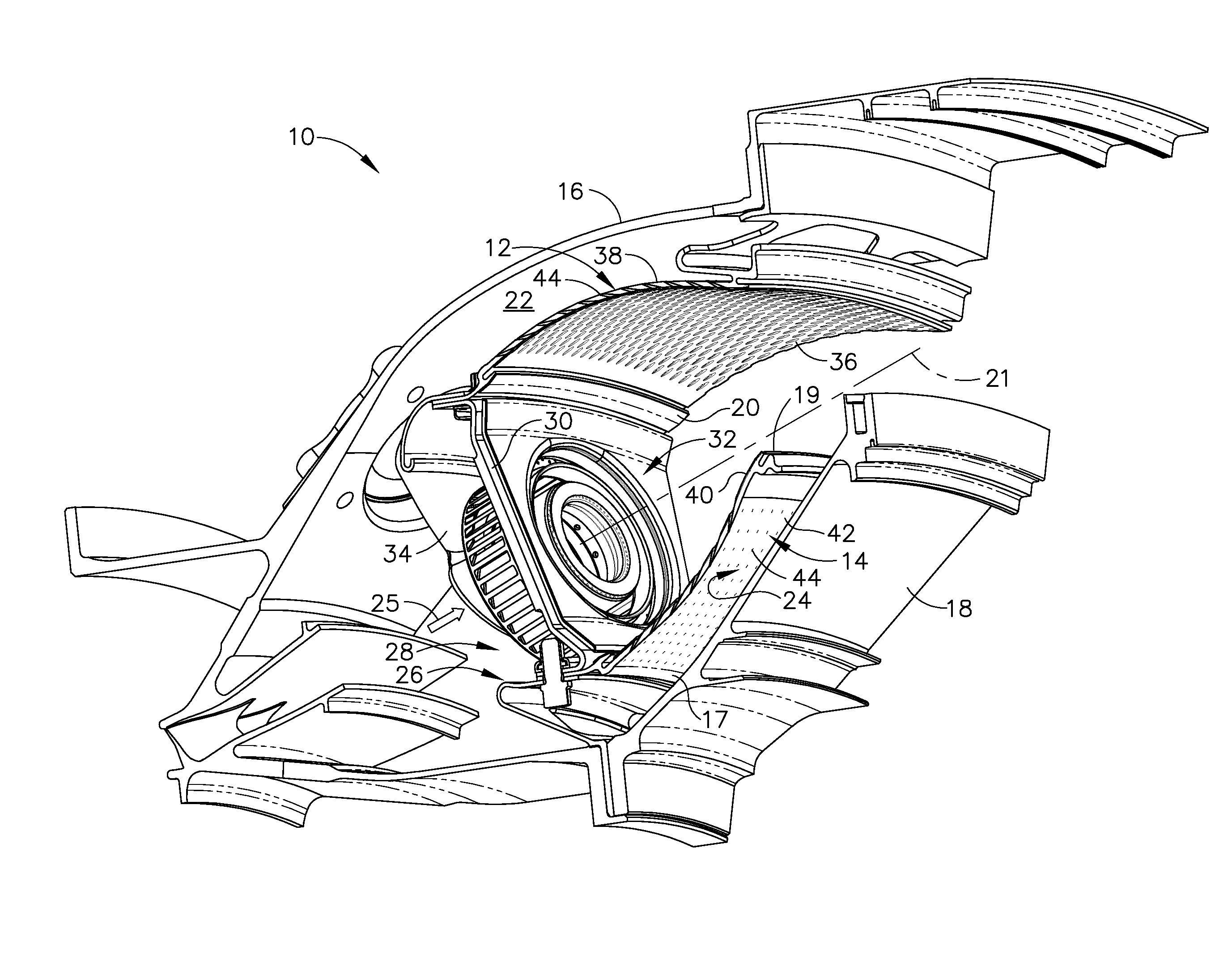

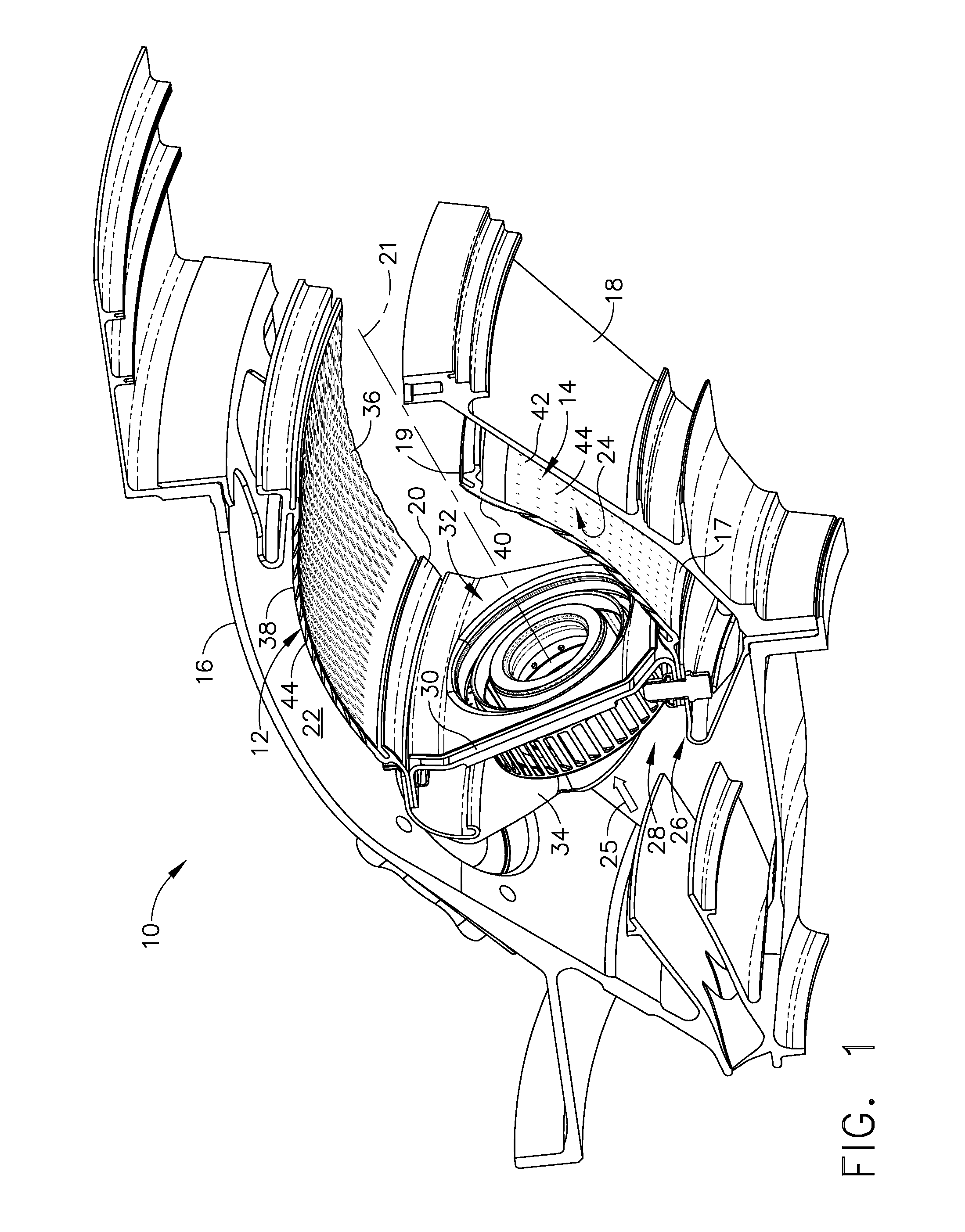

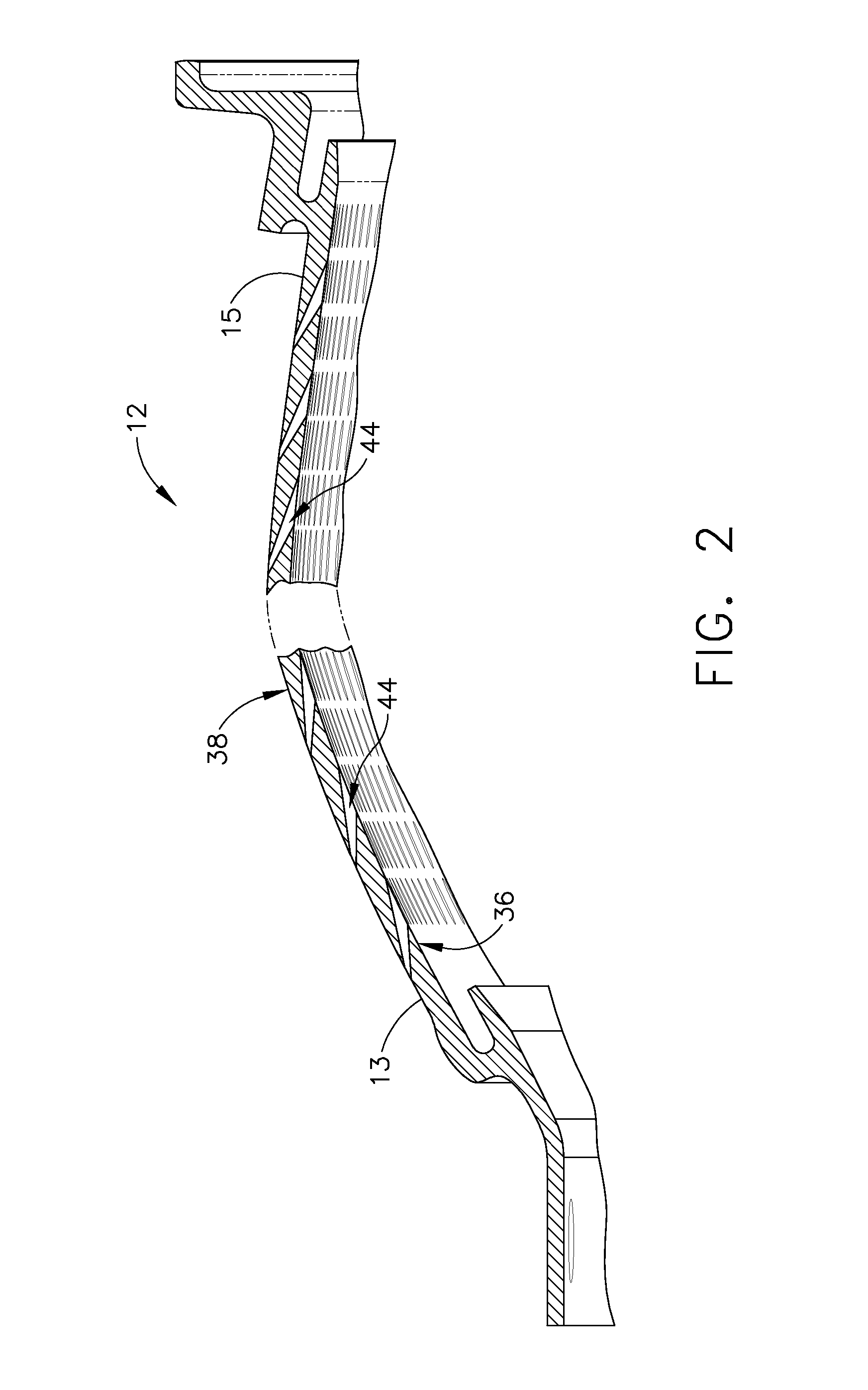

Catheter-guided replacement valves apparatus and methods

ActiveUS20160030171A1Reduced overall height dimensionMinimize intrusionStentsHeart valvesStructure and functionCatheter

The present invention is a replacement mitral valve suitable for catheter-based deployment. The replacement mitral valve has structure and dimensions that are uniquely suited to engage the annulus surrounding the native mitral valve and to restore normal function to a diseased valve. The invention describes the structures and functions of a replacement mitral valve and methods that are adapted for minimally invasive, catheter-based deployment of the valve.

Owner:NAVIGATE CARDIAC STRUCTURES

Seed coatings, coating compositions and methods for use

InactiveUS20120220454A1Promote seedling establishmentEasy to keepBiocideDead plant preservationCoatingFood science

Coating compositions and methods of use, allowing for improved water and / or nutrient usage by seeds, plants, shrubs, and vegetation, among others, are disclosed.

Owner:RHODIA OPERATIONS SAS

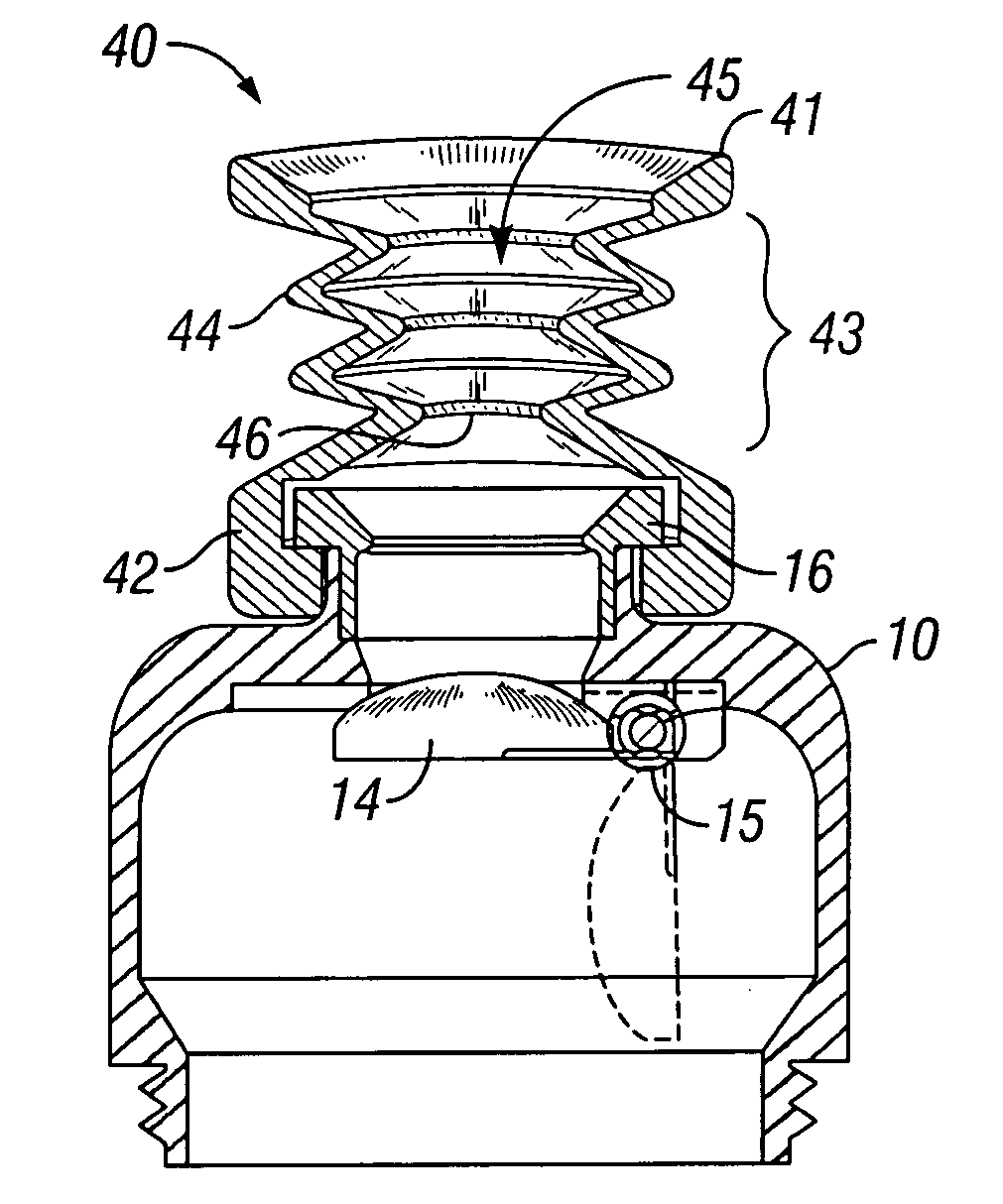

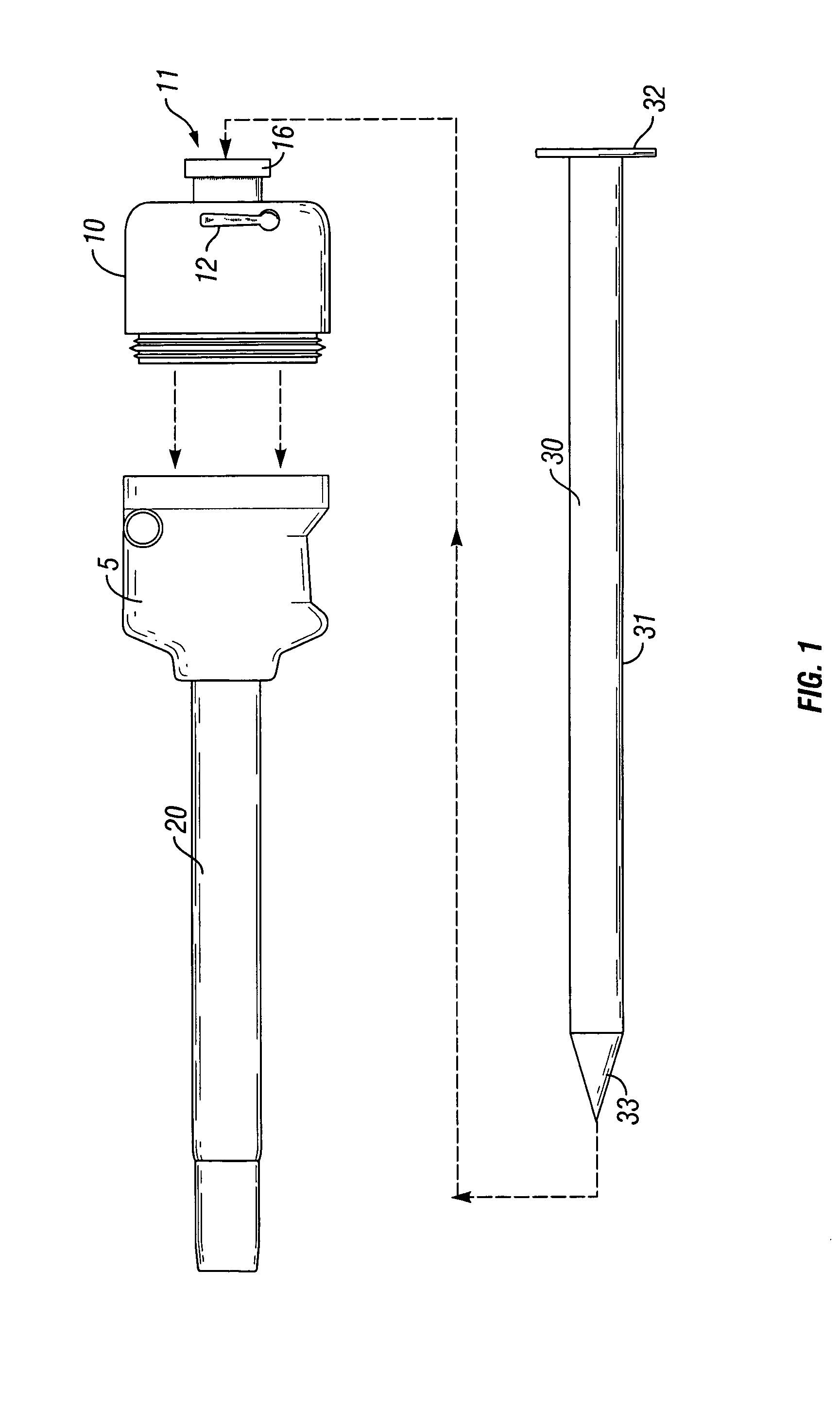

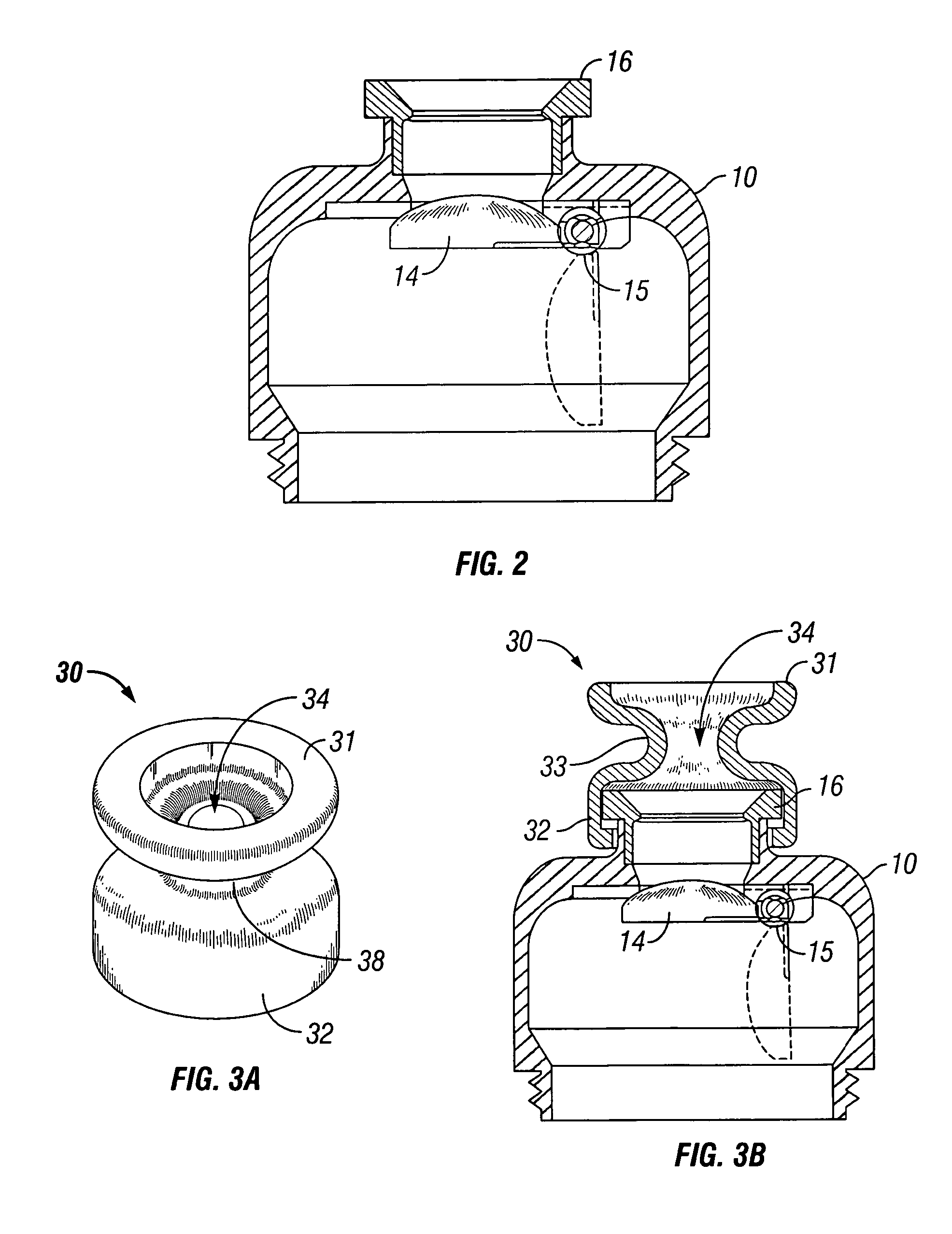

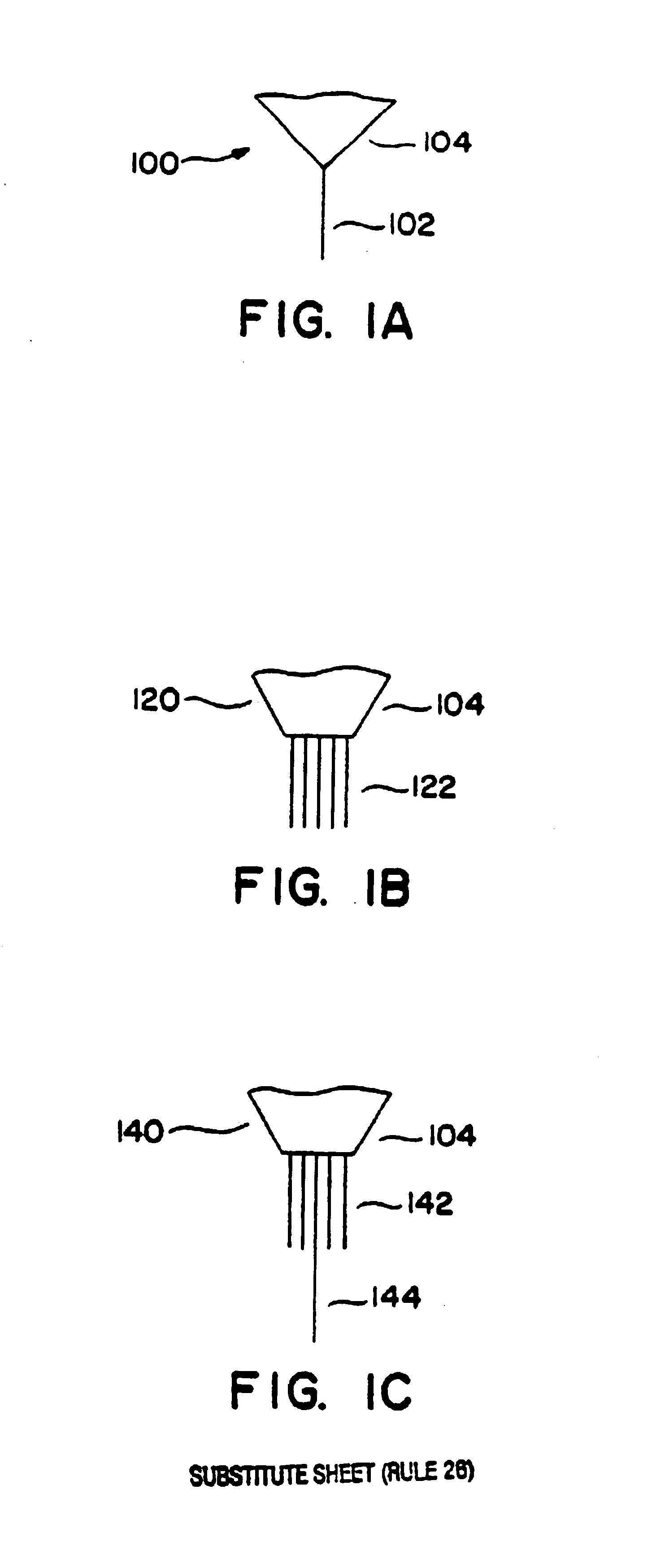

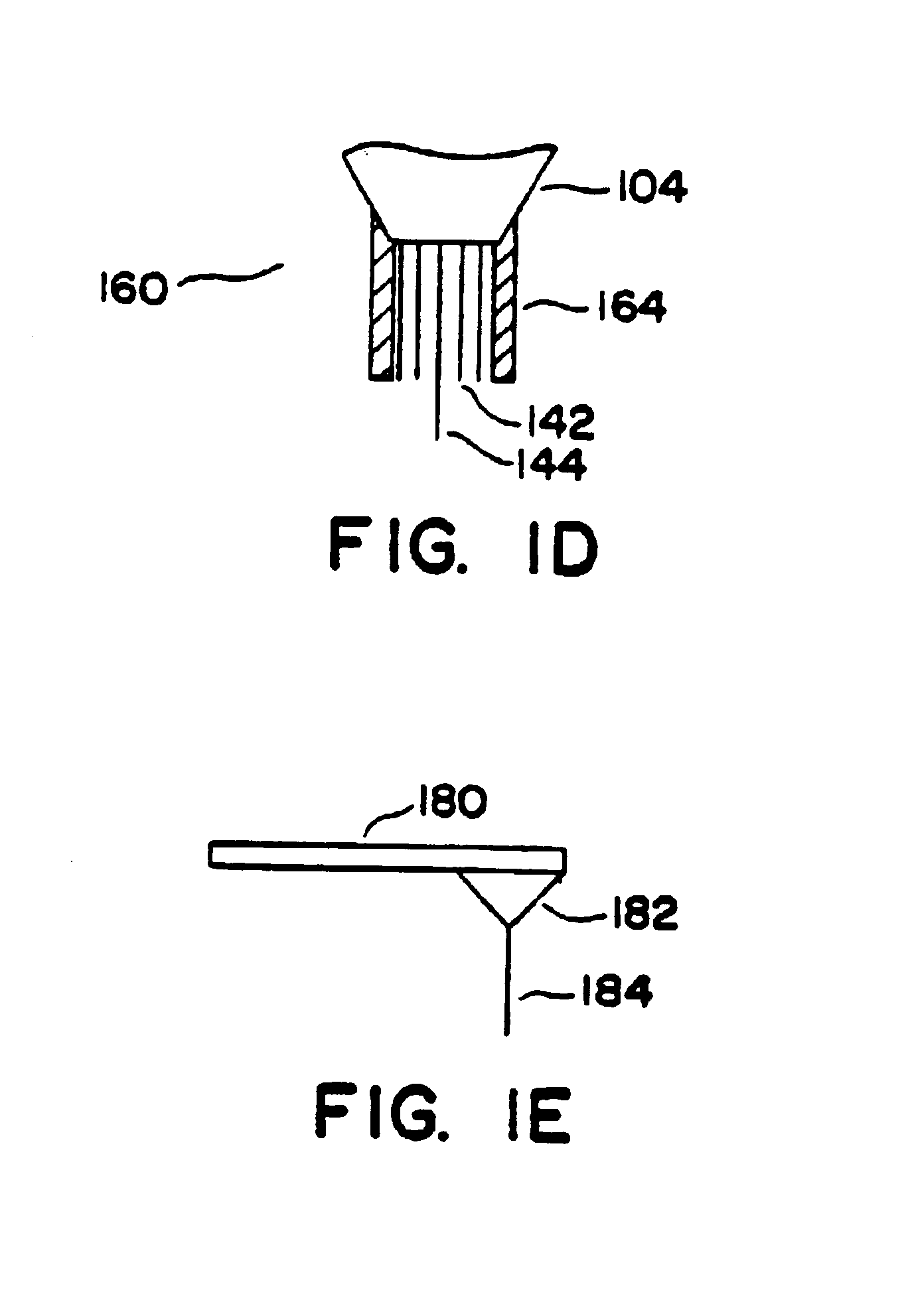

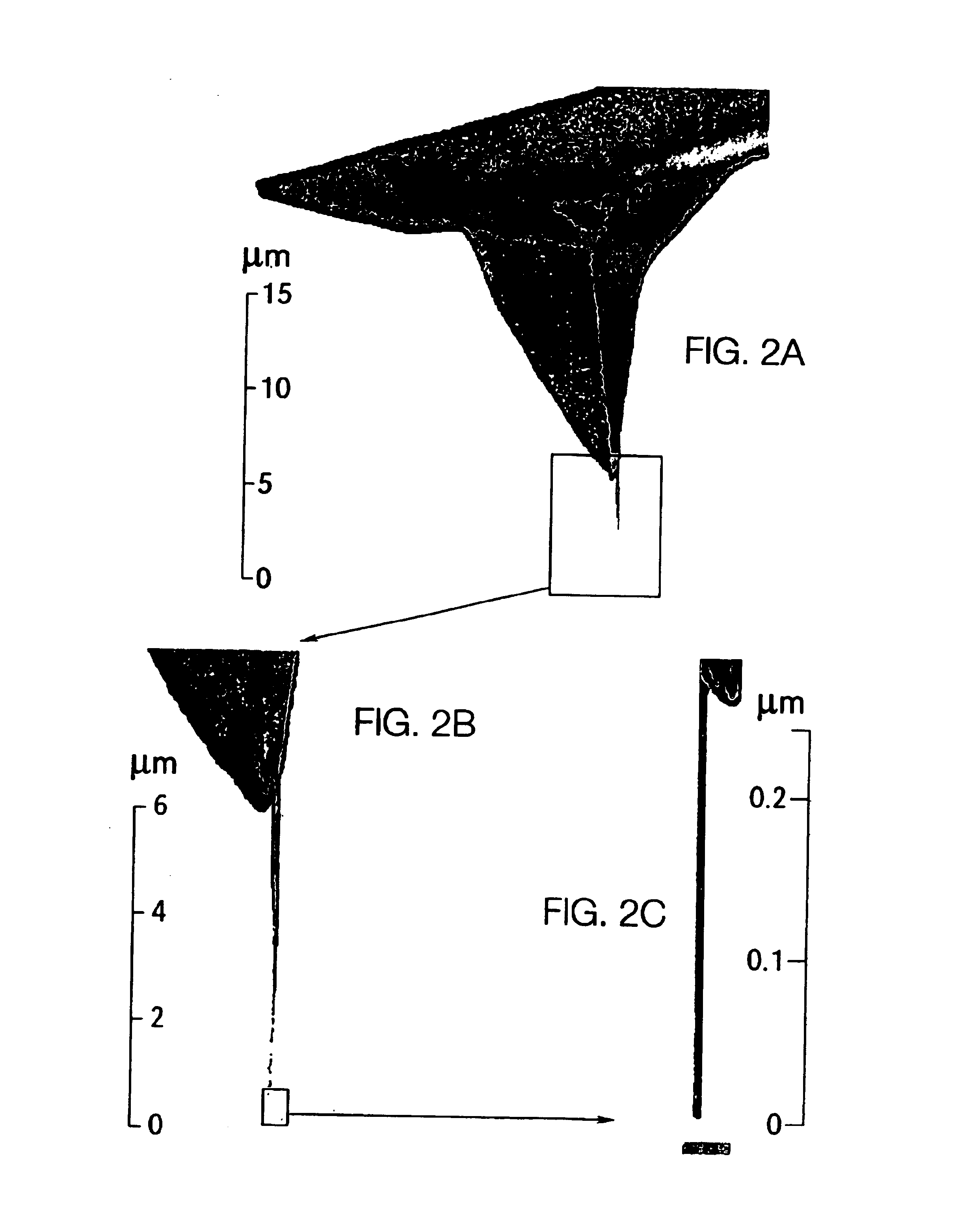

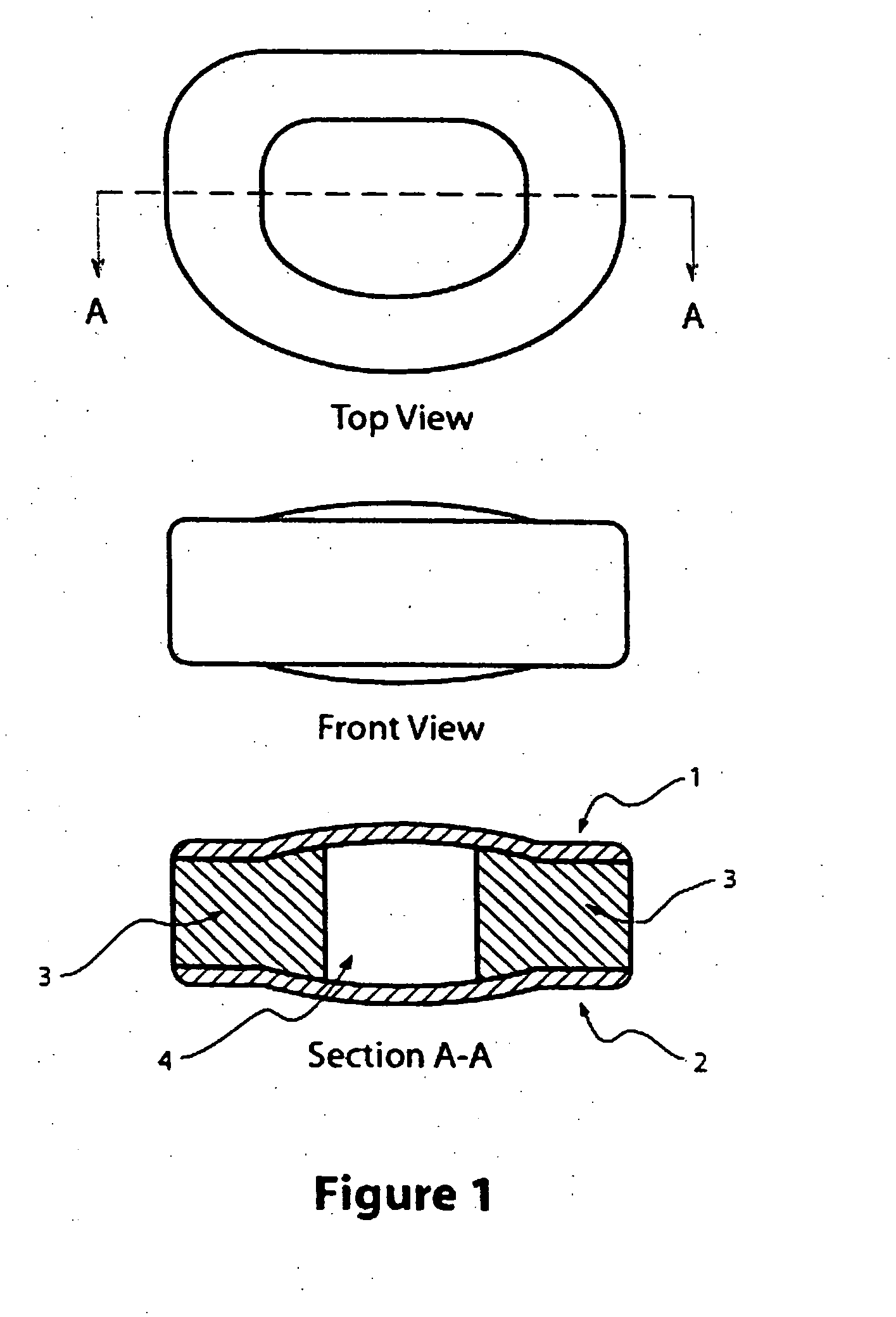

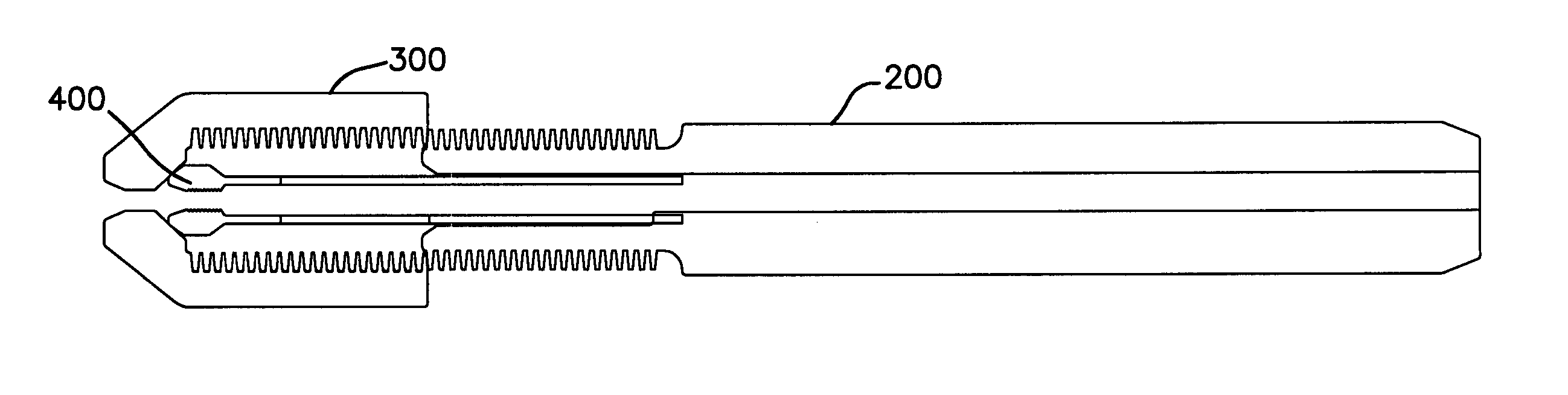

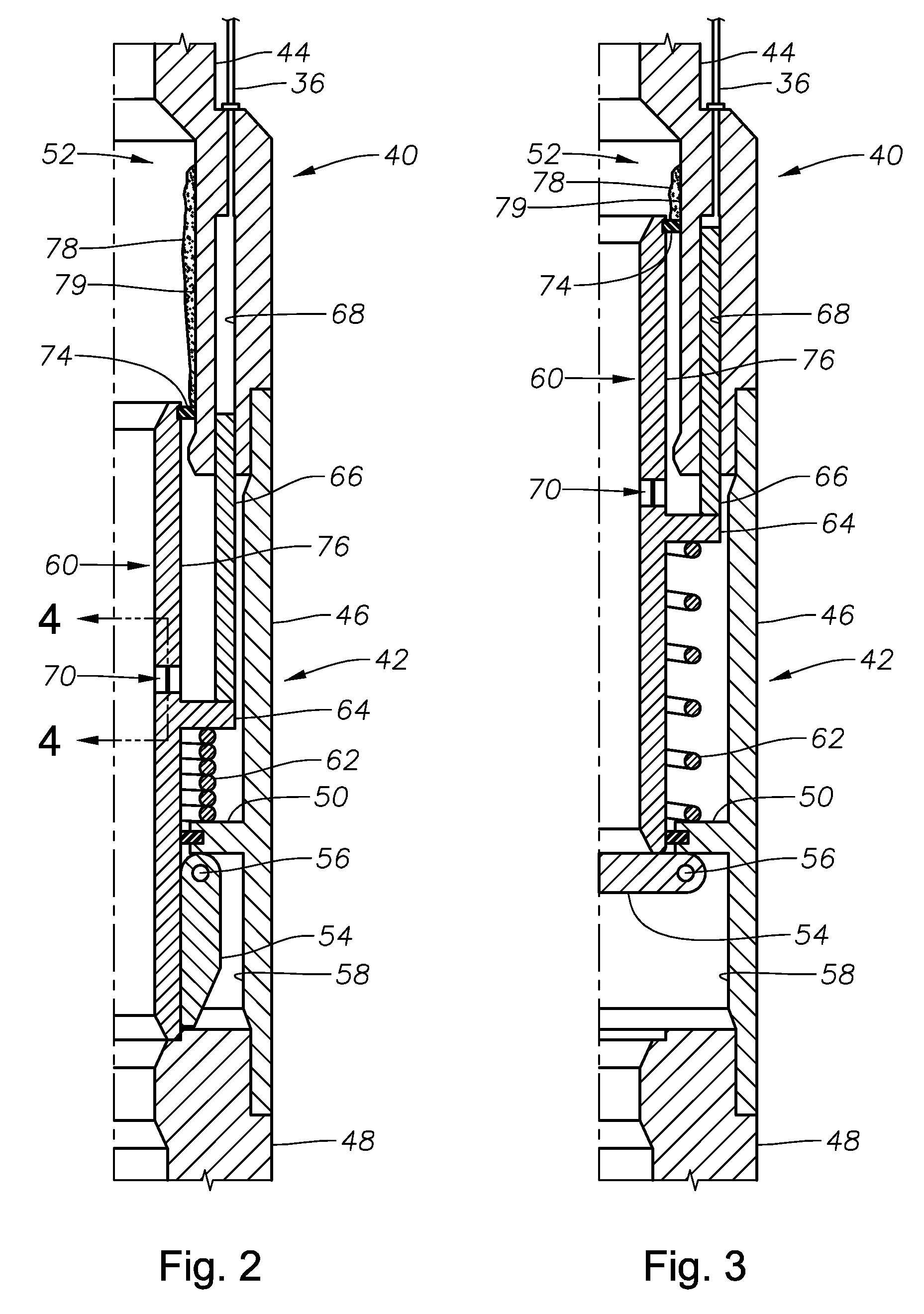

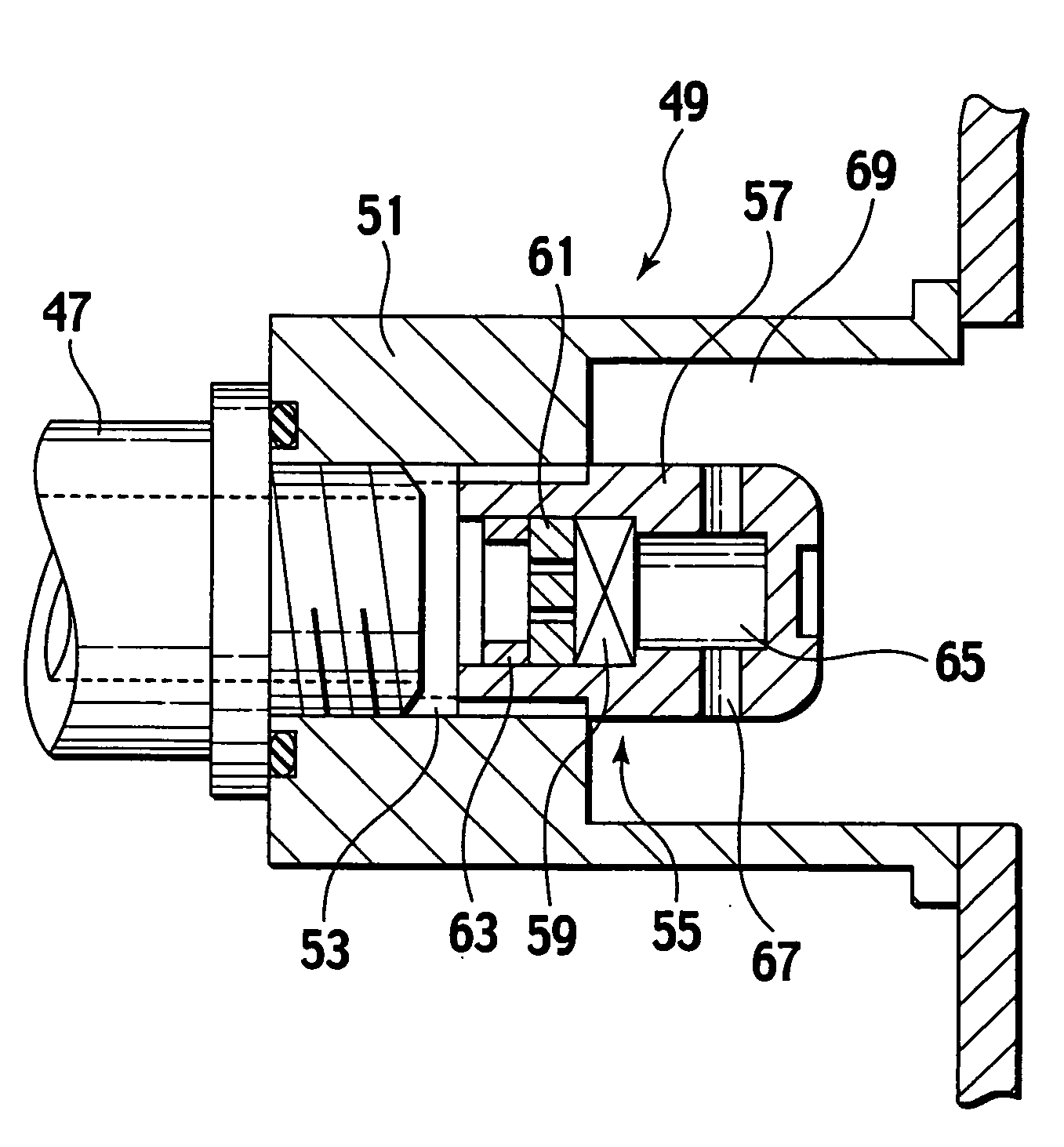

Trocar seal

InactiveUS20050209608A1Increase the diameterUniform diameterEar treatmentCannulasSurgical deviceGeneral surgery

A seal is disclosed for installation on the proximal end of a trocar to seal on surgical instruments having varying diameters. The seal has a general hourglass shape with an upper portion, a bottom portion and a sealing portion interposed between the upper and bottom portions. The bottom portion is formed for mating engagement with the access port at the proximal end of the trocar. A passage exists between the upper and bottom portions, and the diameter is expandable from 2 mm to about 13 mm. Various configurations of such a seal are disclosed.

Owner:COOPERSURGICAL INC

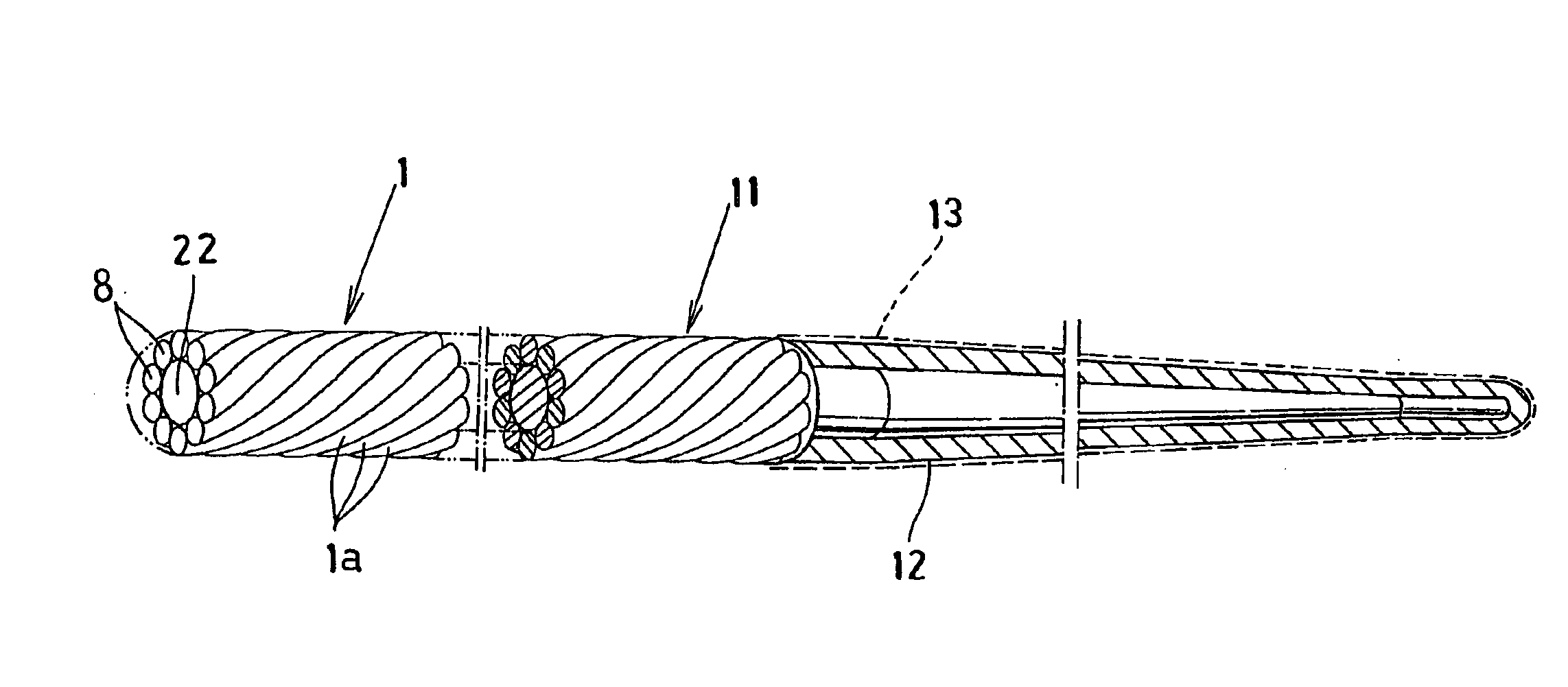

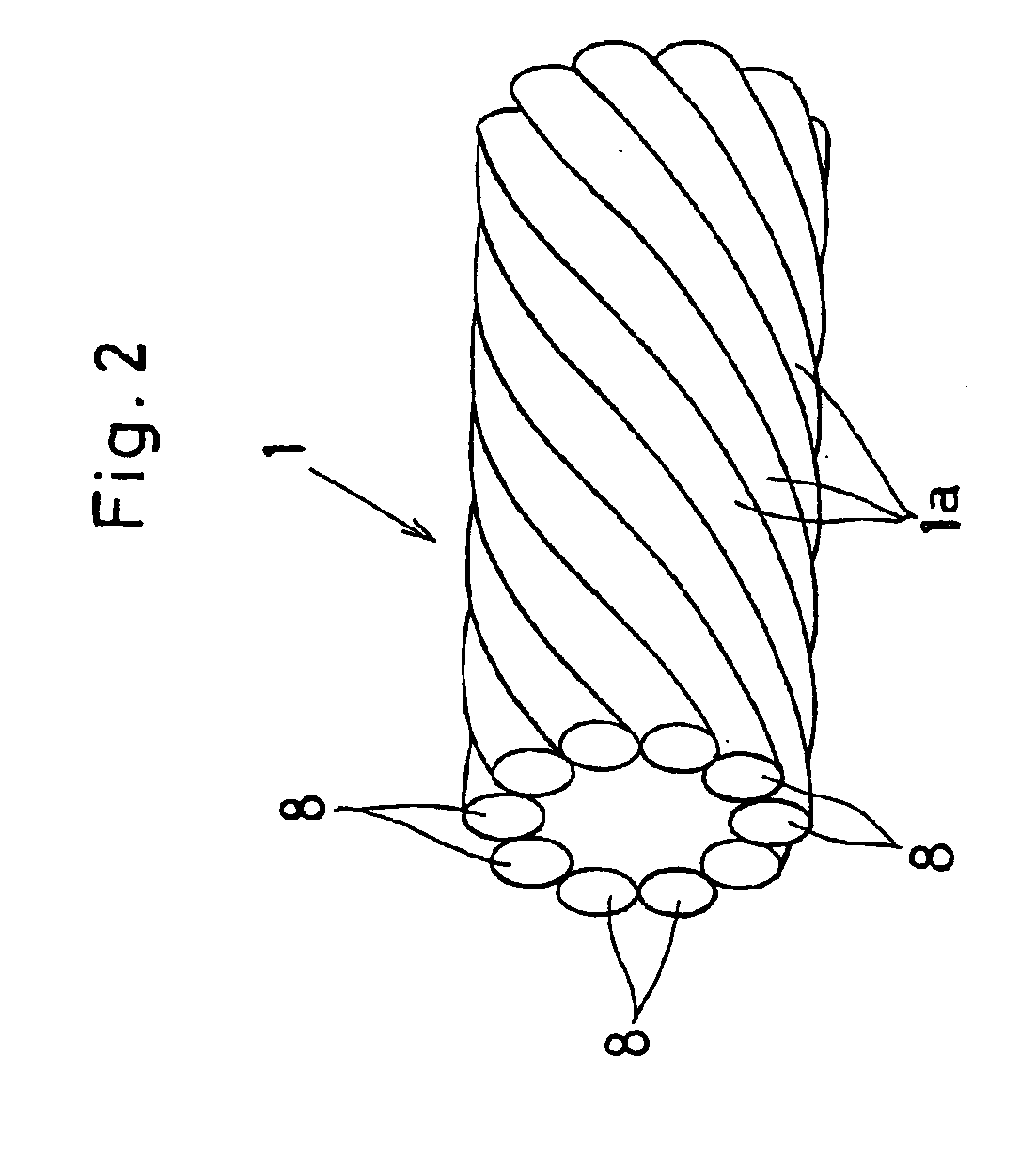

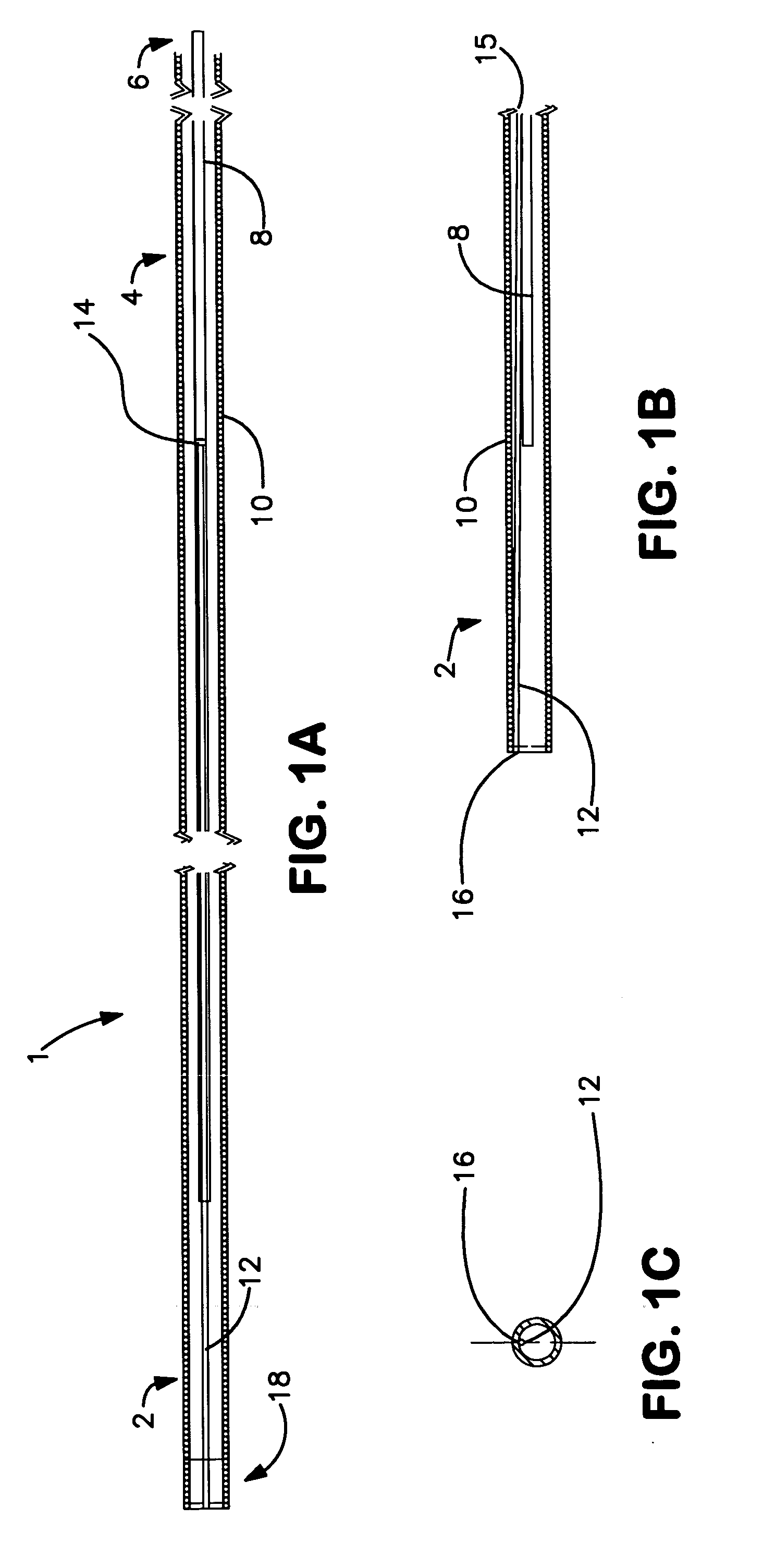

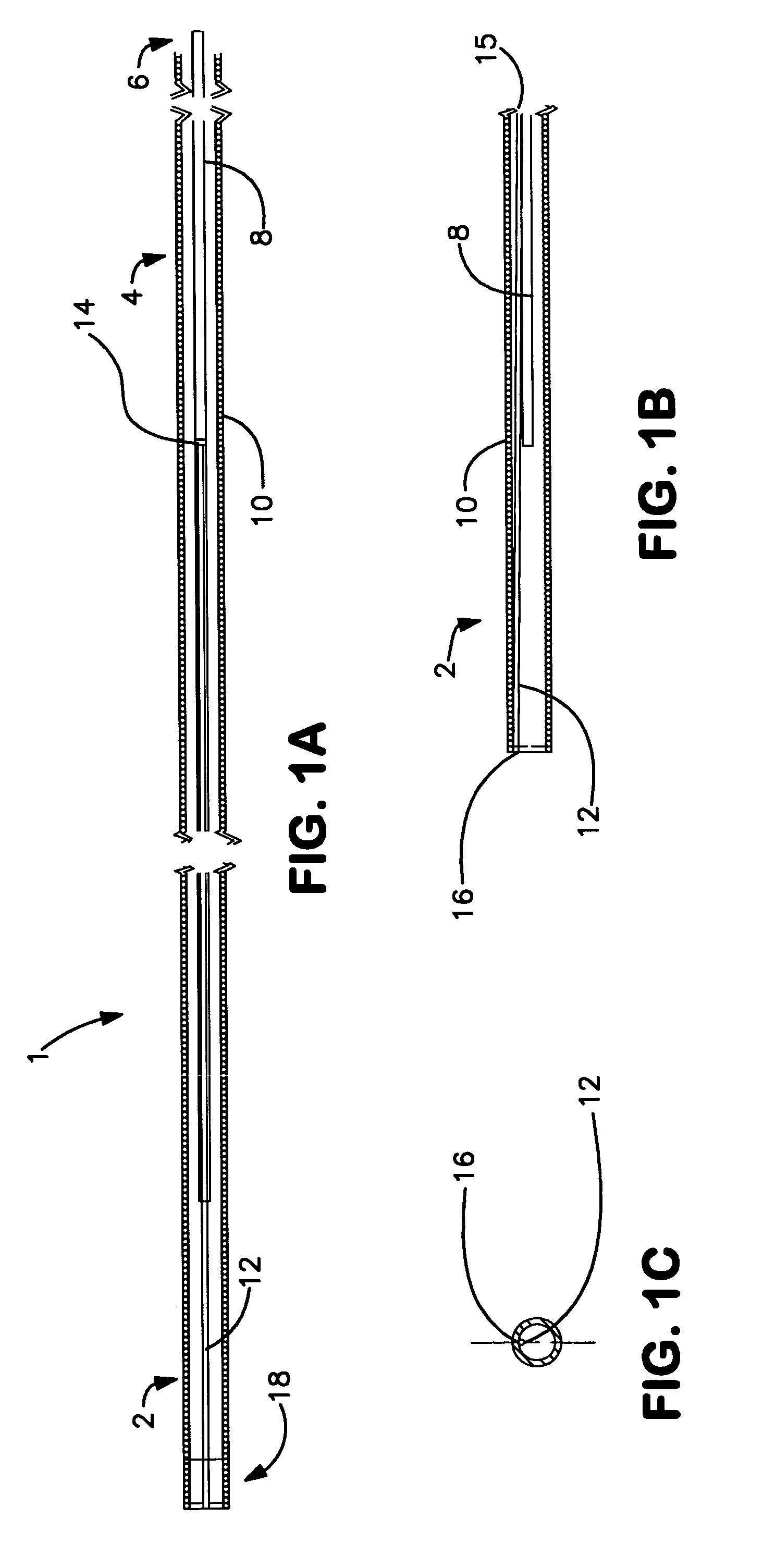

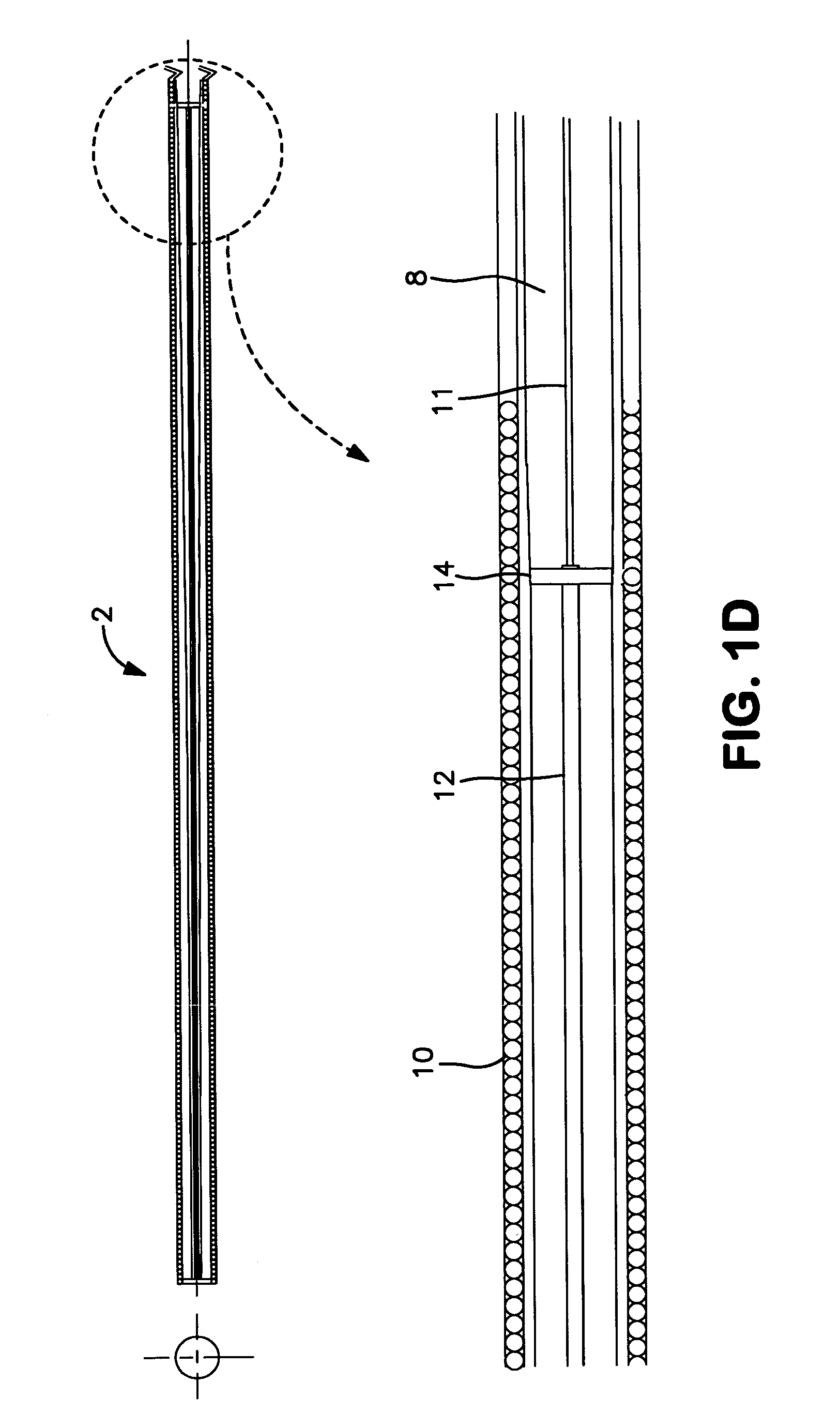

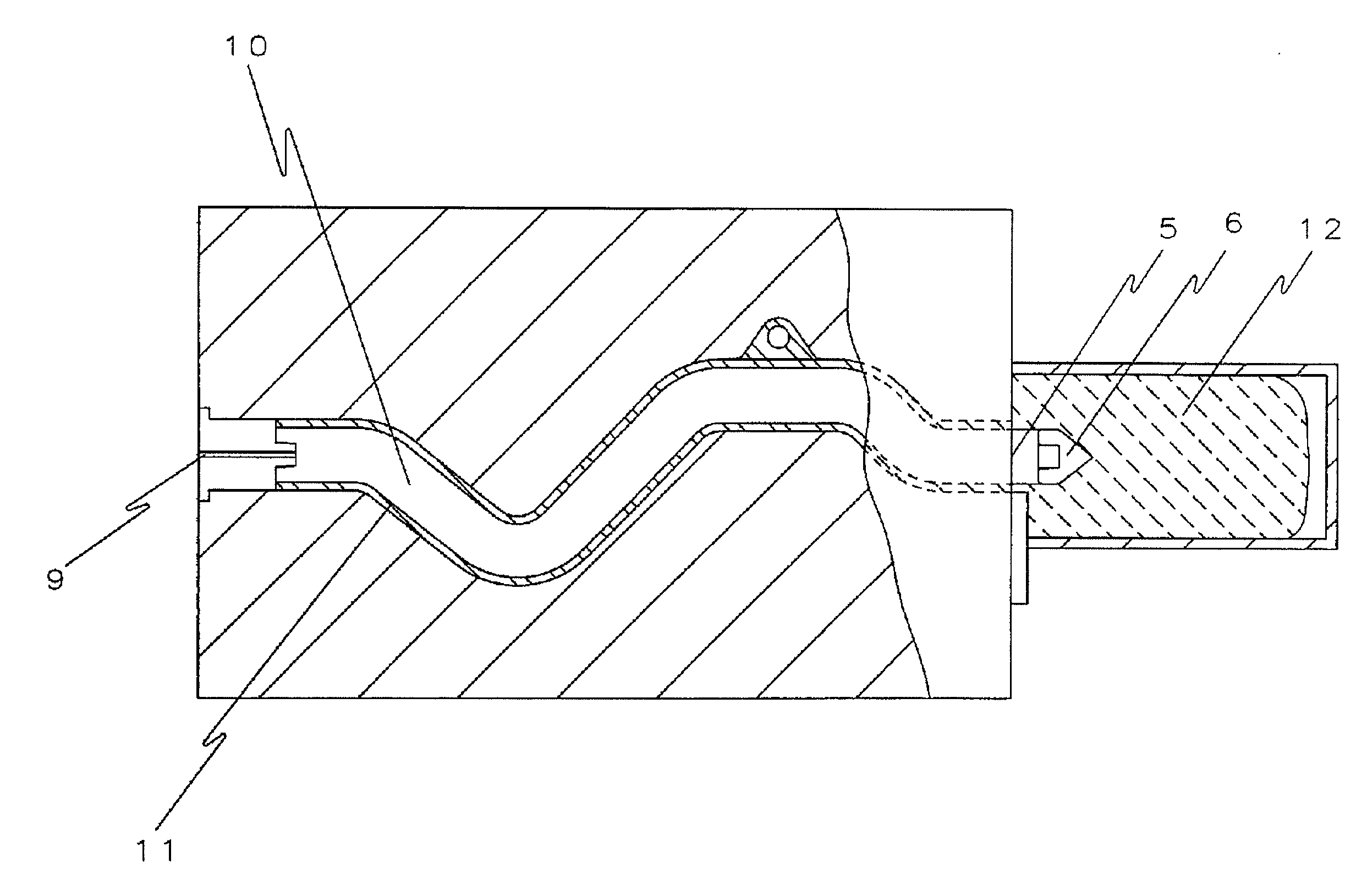

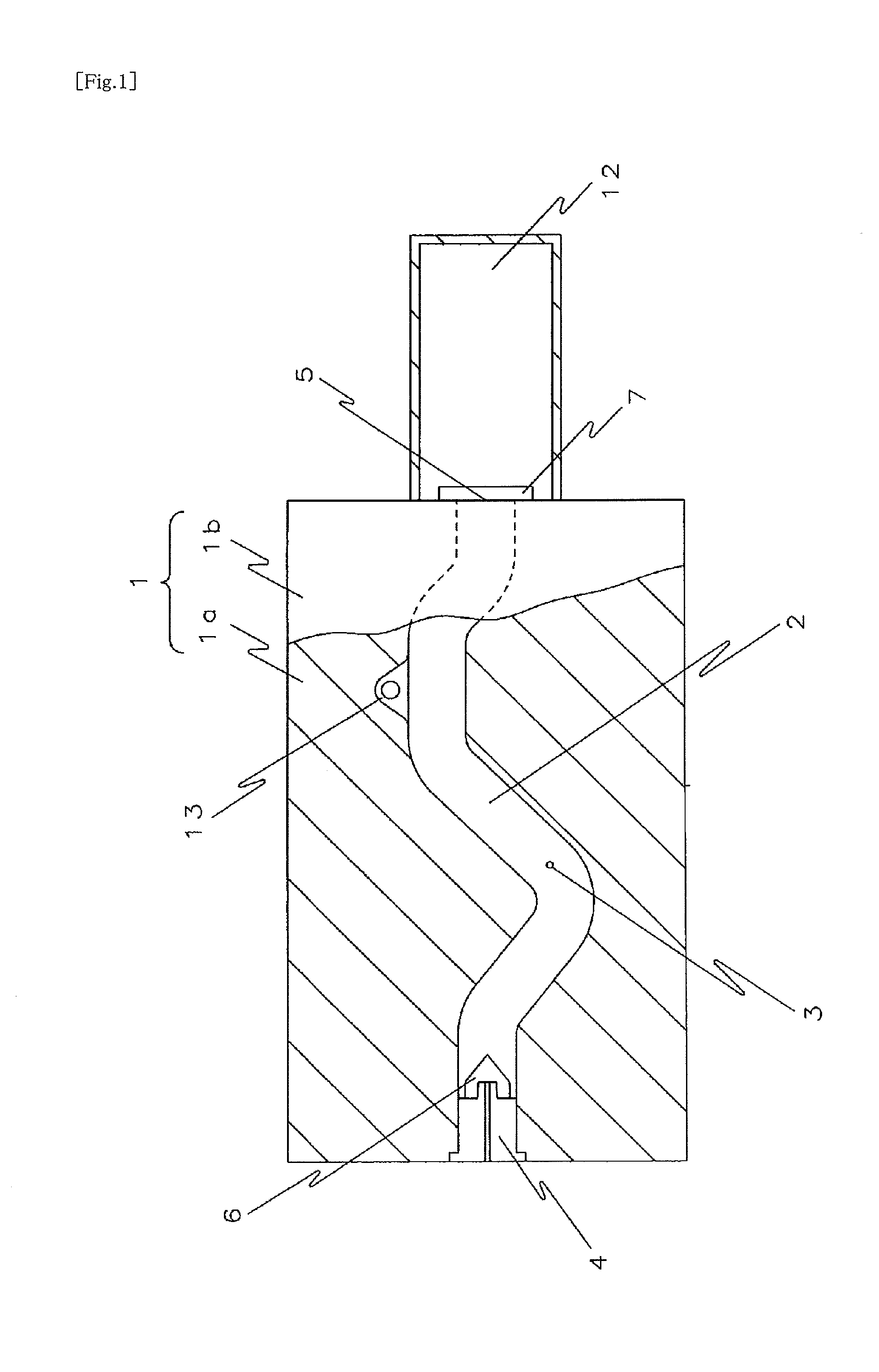

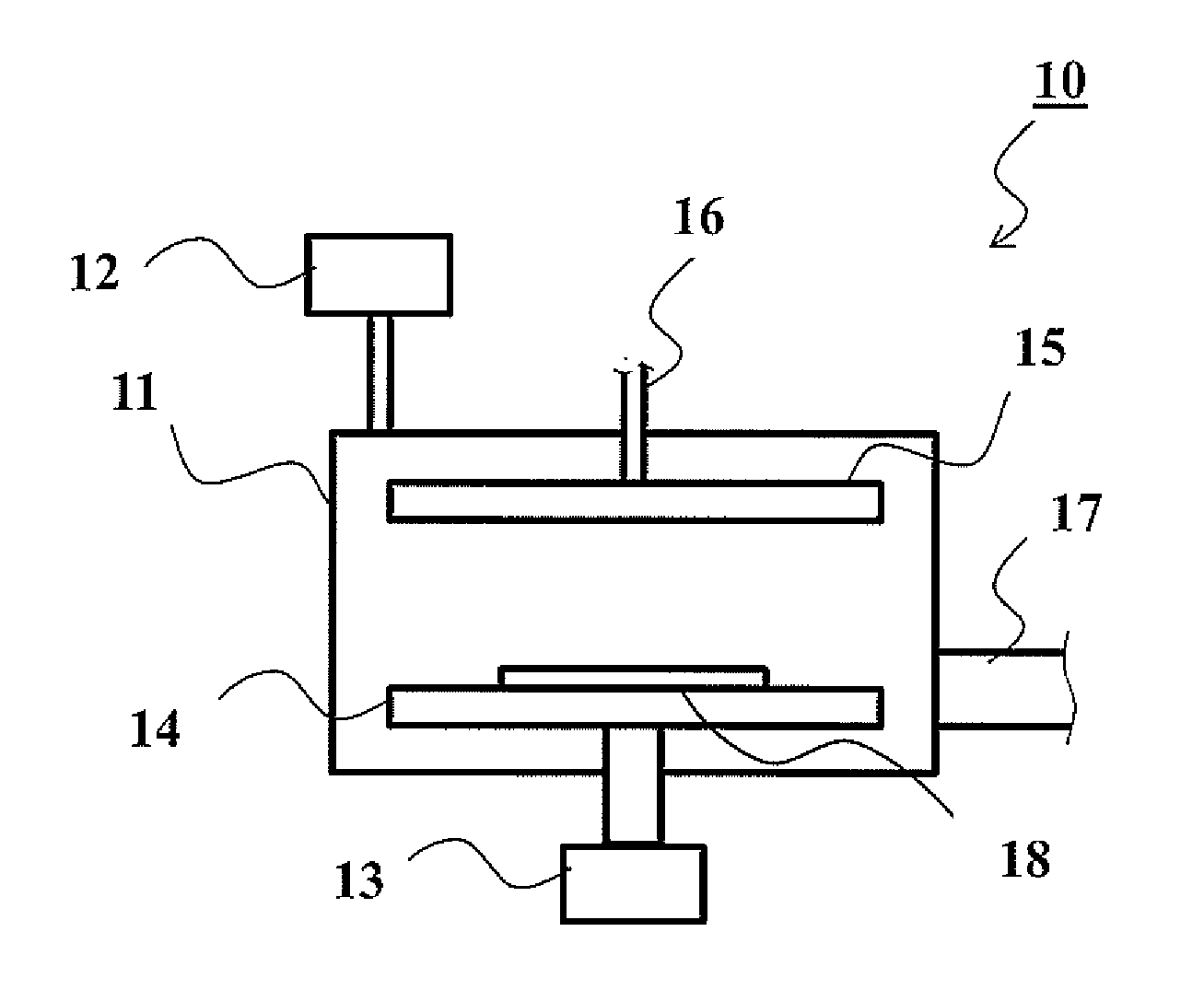

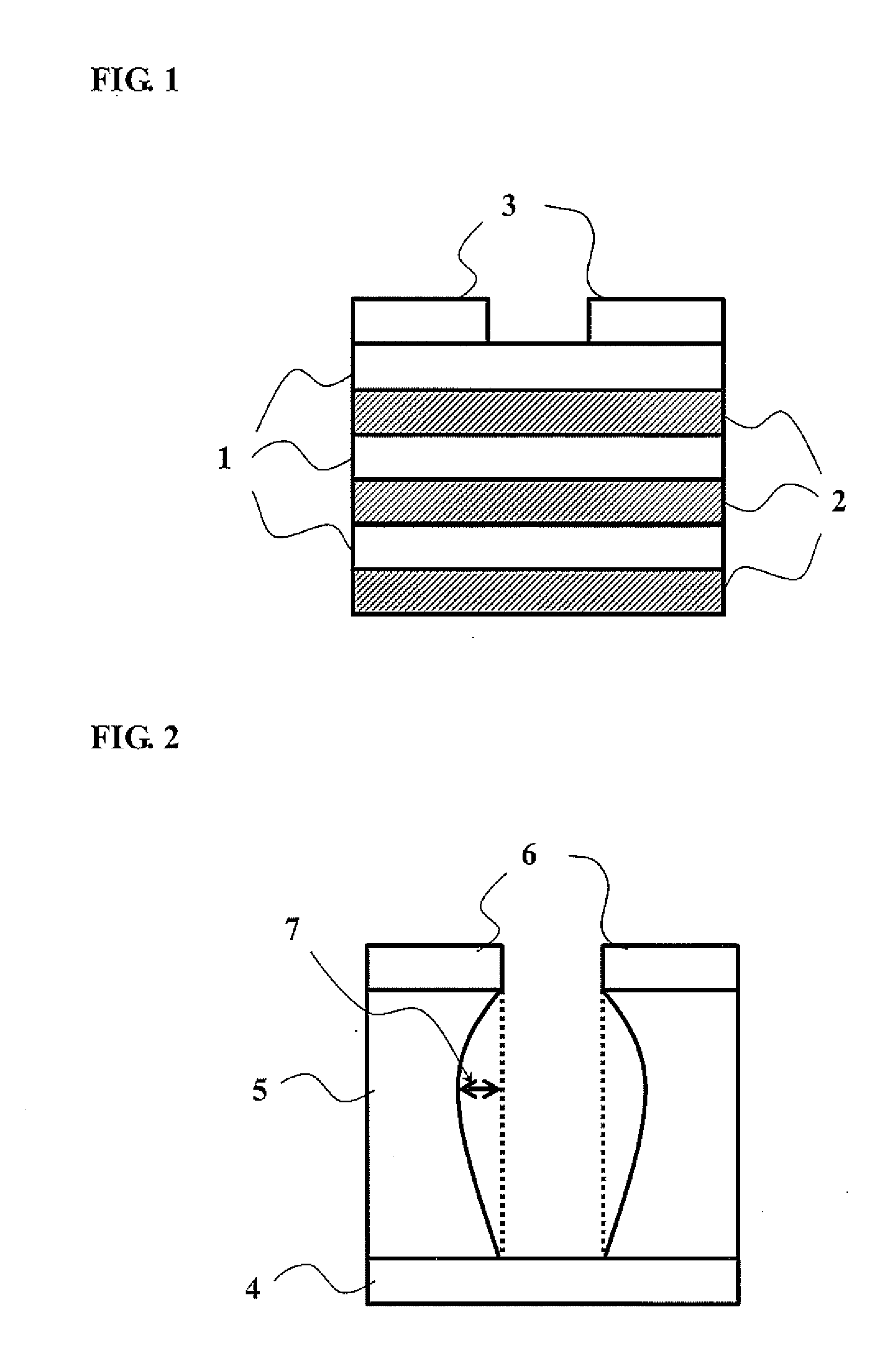

Wire-stranded medical hollow tube, and a medical guide wire

InactiveUS6881194B2Good flexibilitySmoothly introducedGuide wiresMedical devicesContact pressureEngineering

In a wire-stranded hollow tube (1), a plurality of metallic wires (8) preformed with a predetermined forming rate are twisted along a circular line into a careless hollow configuration. When twisting the metallic wires (8), the neighboring metallic elements (1a, 1a) are subjected to compression with no gap between the neighboring metallic elements (1a, 1a). This increases a contact pressure between the neighboring metallic elements (1a, 1a) to attain a good tightness with a good circularity and diametrical uniformity secured therebetween, thus preventing the wire-stranded hollow tube (1) from inadvertently collapsing. A tightness is strengthened between the neighboring metallic elements (1a, 1a) when the metallic elements (1a, 1a) of different helical pitch are used. By applying the wire-stranded hollow tube (1) to a medical guide wire, a quick torque response and a good torque transmissibility are ensured which lead to a good manipulatability with a favorable follow-on capability.

Owner:ASAHI INTECC CO LTD

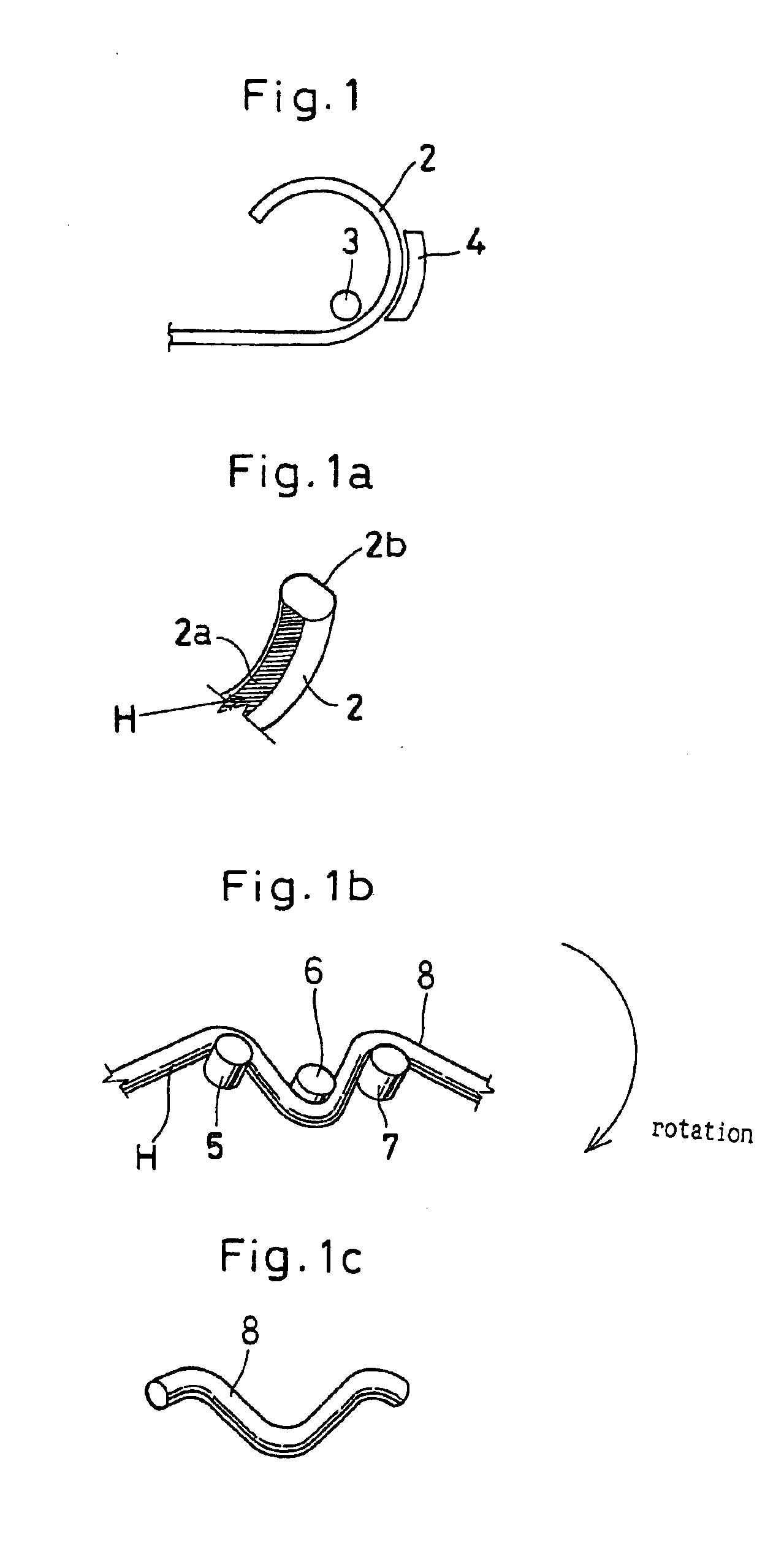

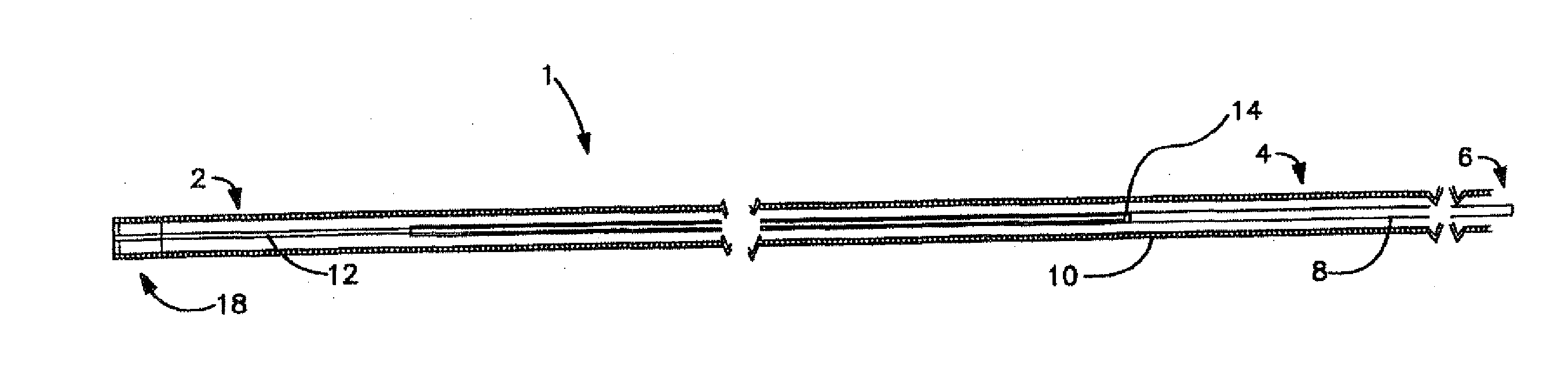

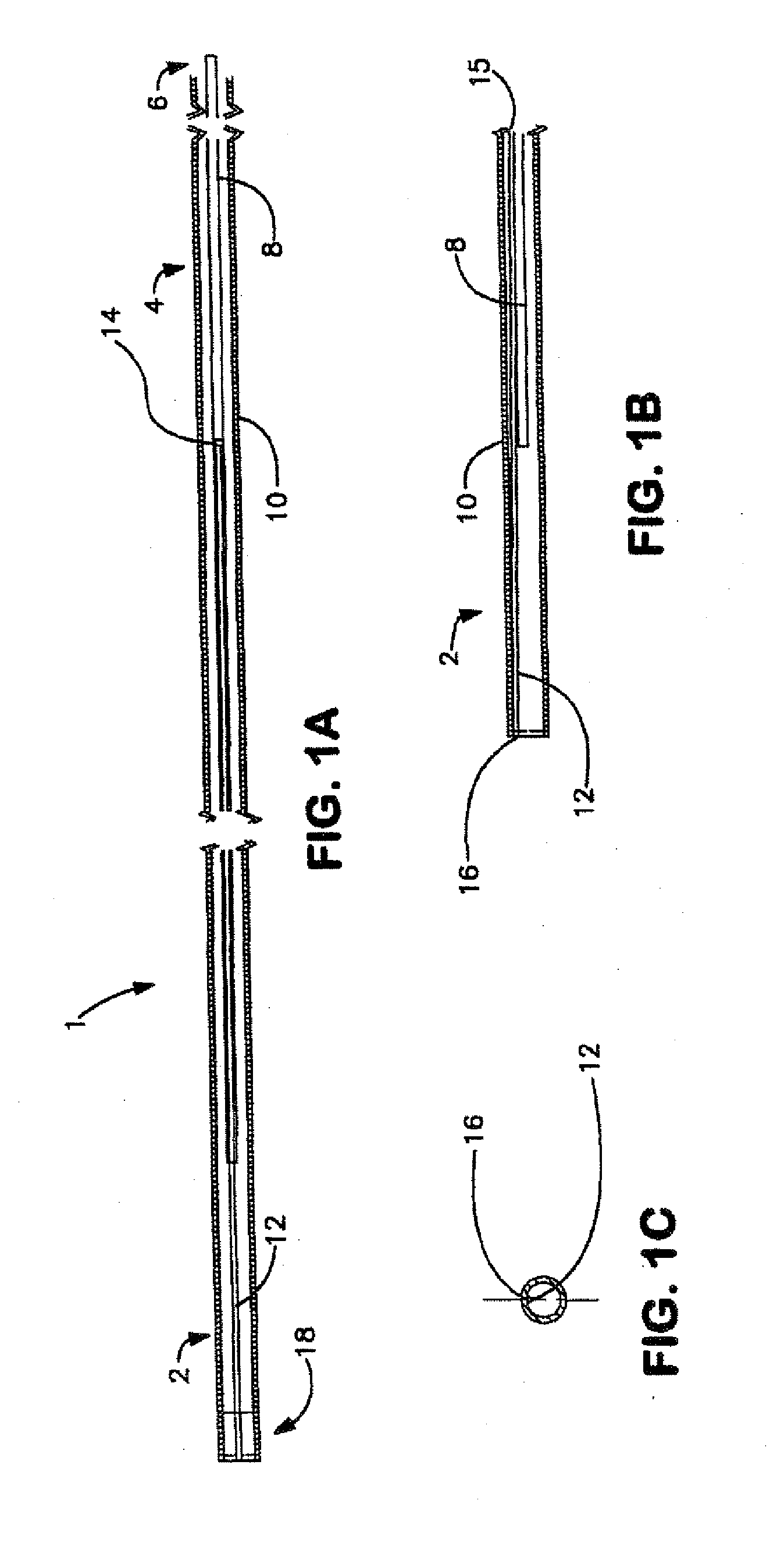

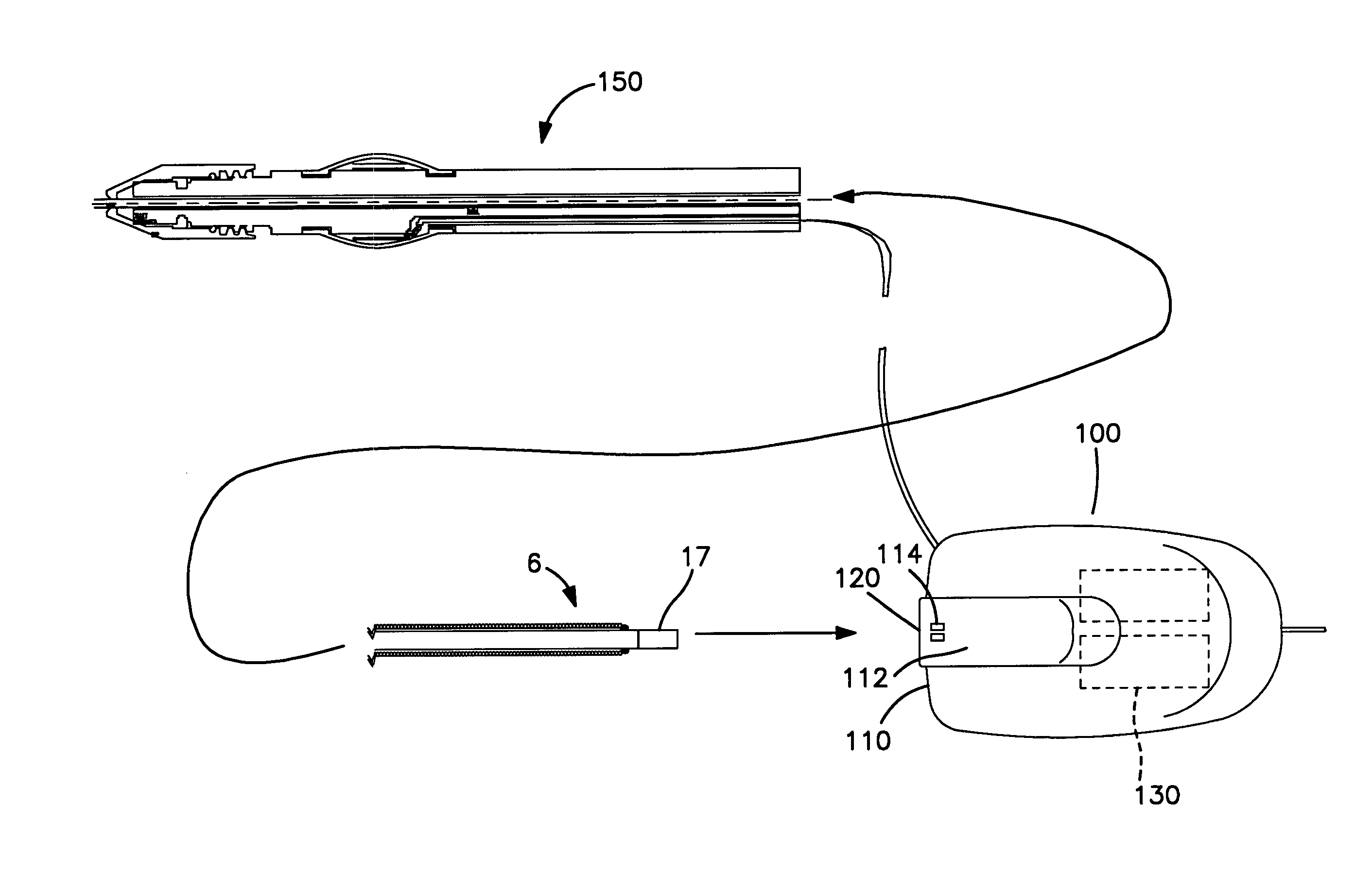

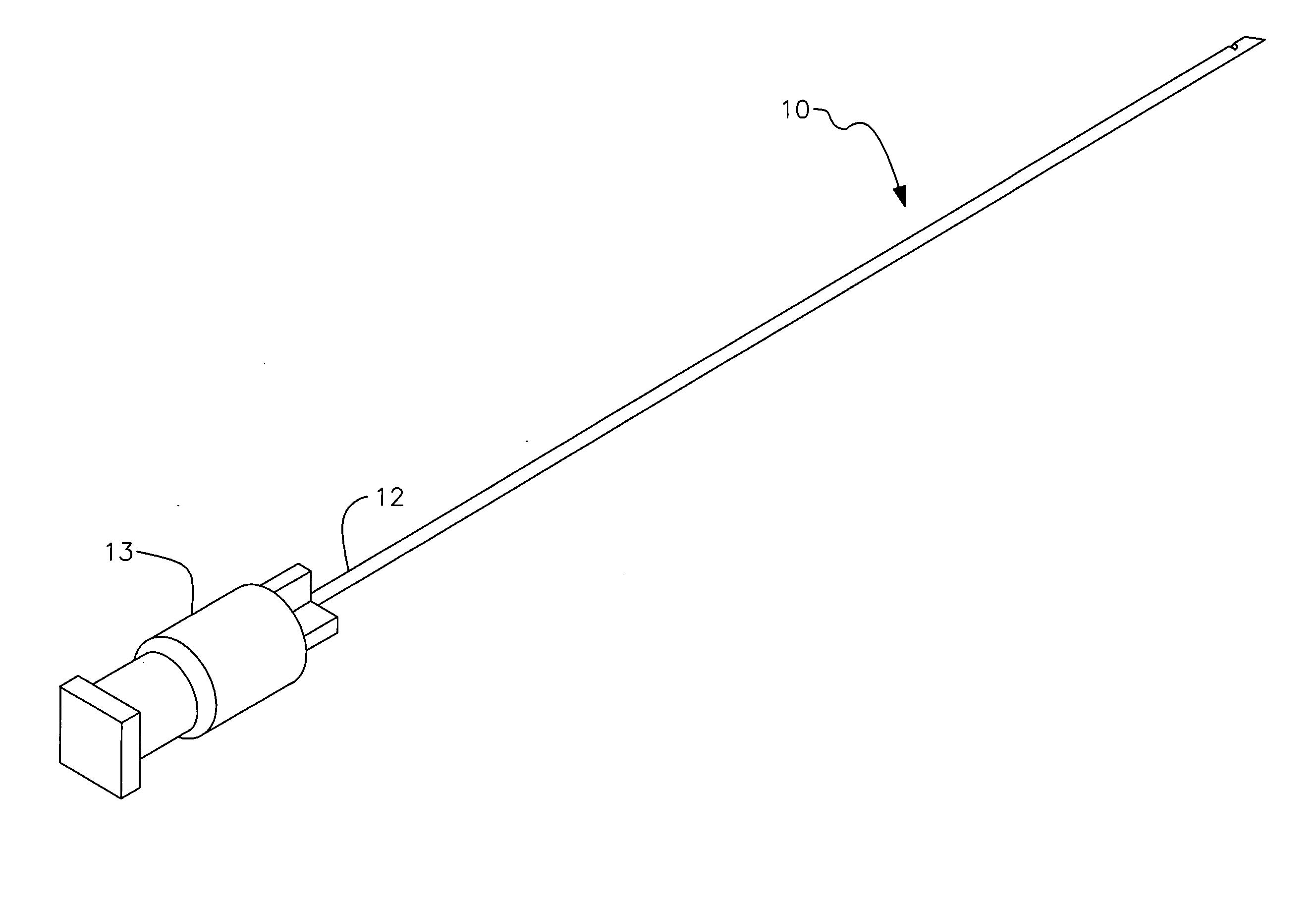

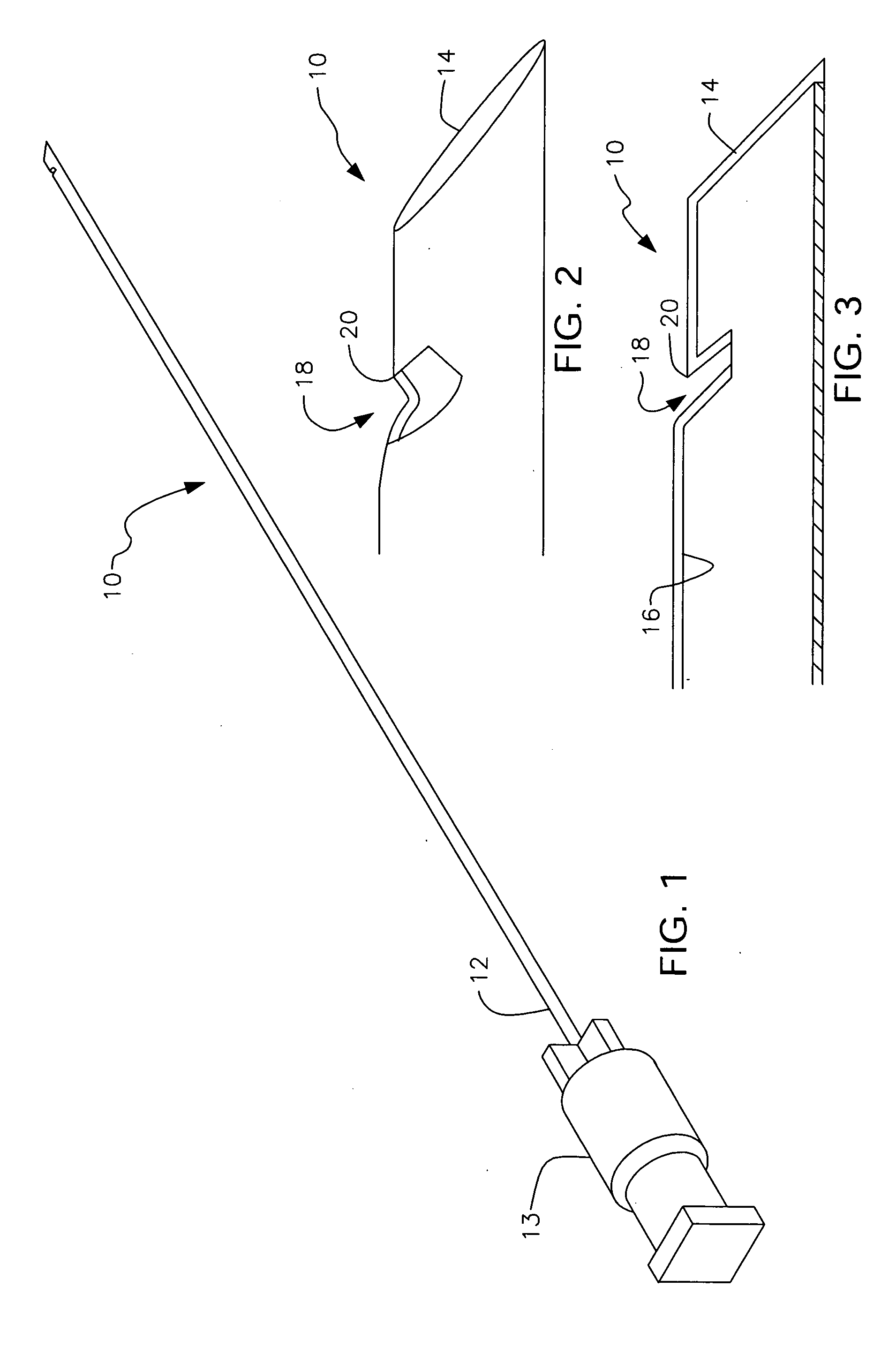

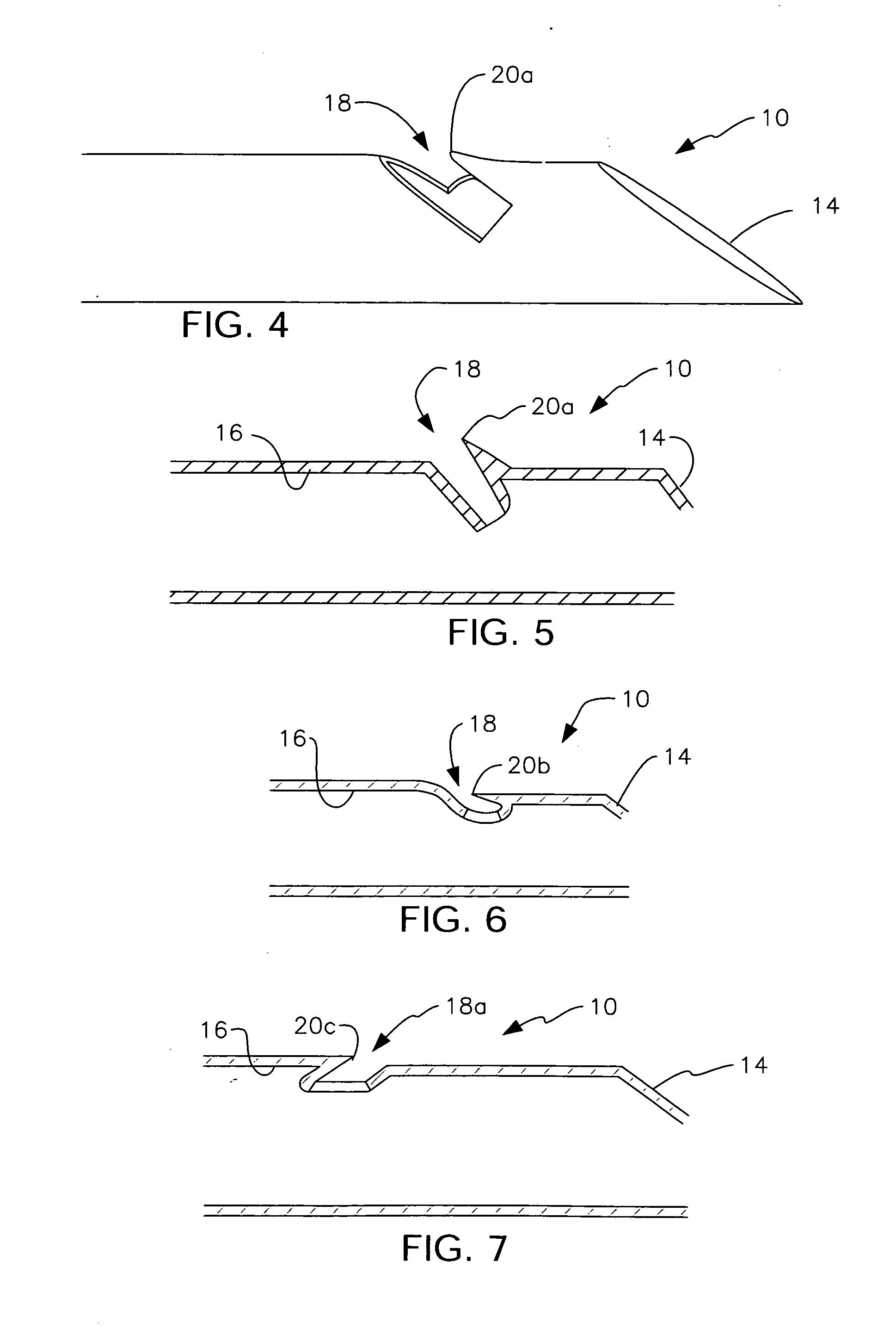

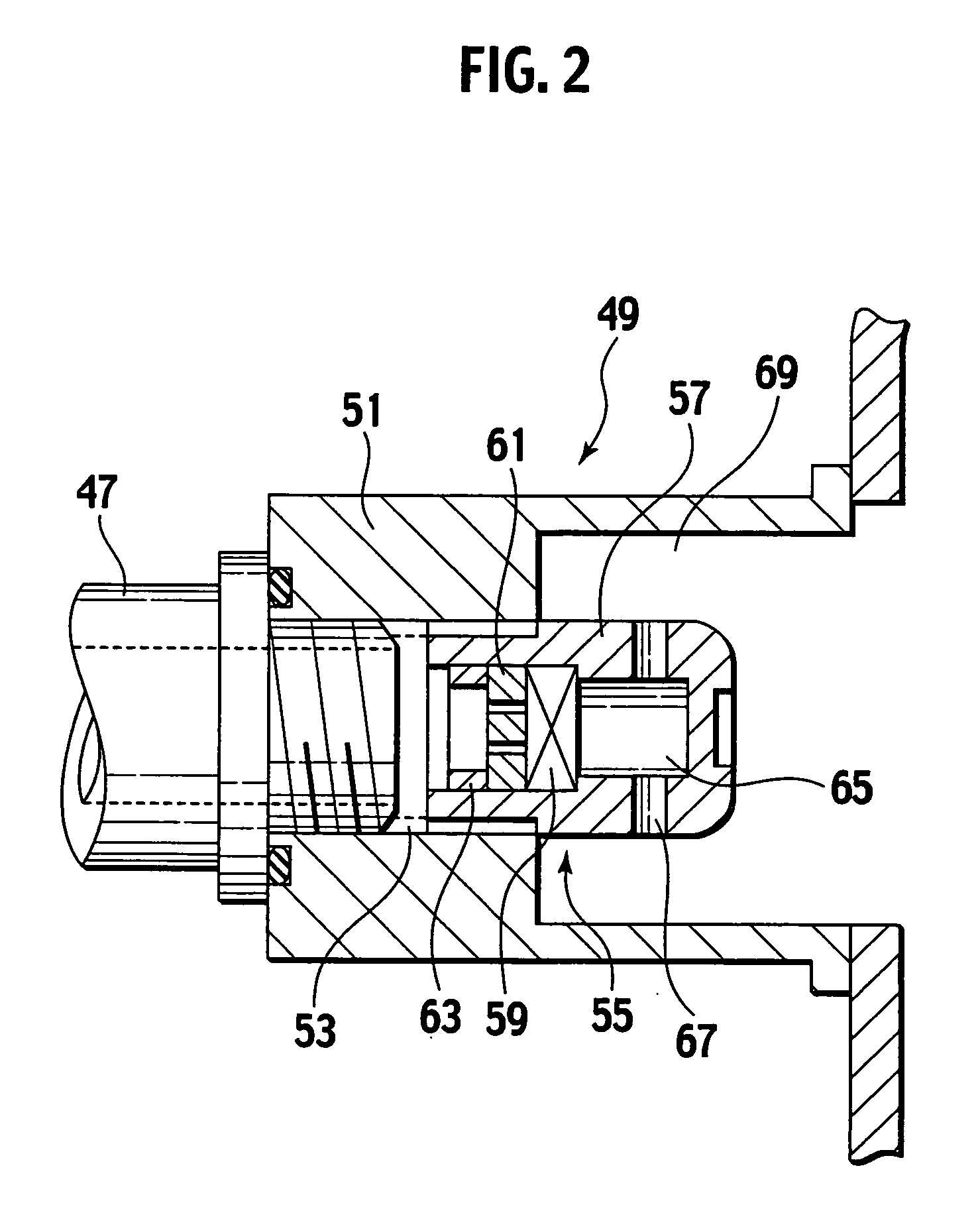

Vascular guidewire control apparatus

ActiveUS20120271198A1Shorten the timeSaving of other resourceGuide wiresDiagnostic recording/measuringEngineeringControl theory

A controller for use with a guidewire, such as a vascular guidewire, provides a mechanism for gripping and applying a torque to the guidewire without the need to thread the guidewire axially through the controller and at a location close to a point of access of the guidewire. In one embodiment, the controller includes a side-access, multi-part assembly including a collet or other gripping element that applies a uniform radially inward force on the guidewire. In another embodiment, for use with guidewires having active electrically controllable elements, the controller integrally or removably incorporates a switch or other mechanism to initiate an energized state. The controller thereby permits ergonomic, single-handed control of an electronically steerable guidewire, including axially displacing, torquing and steering the guidewire.

Owner:THE CLEVELAND CLINIC FOUND

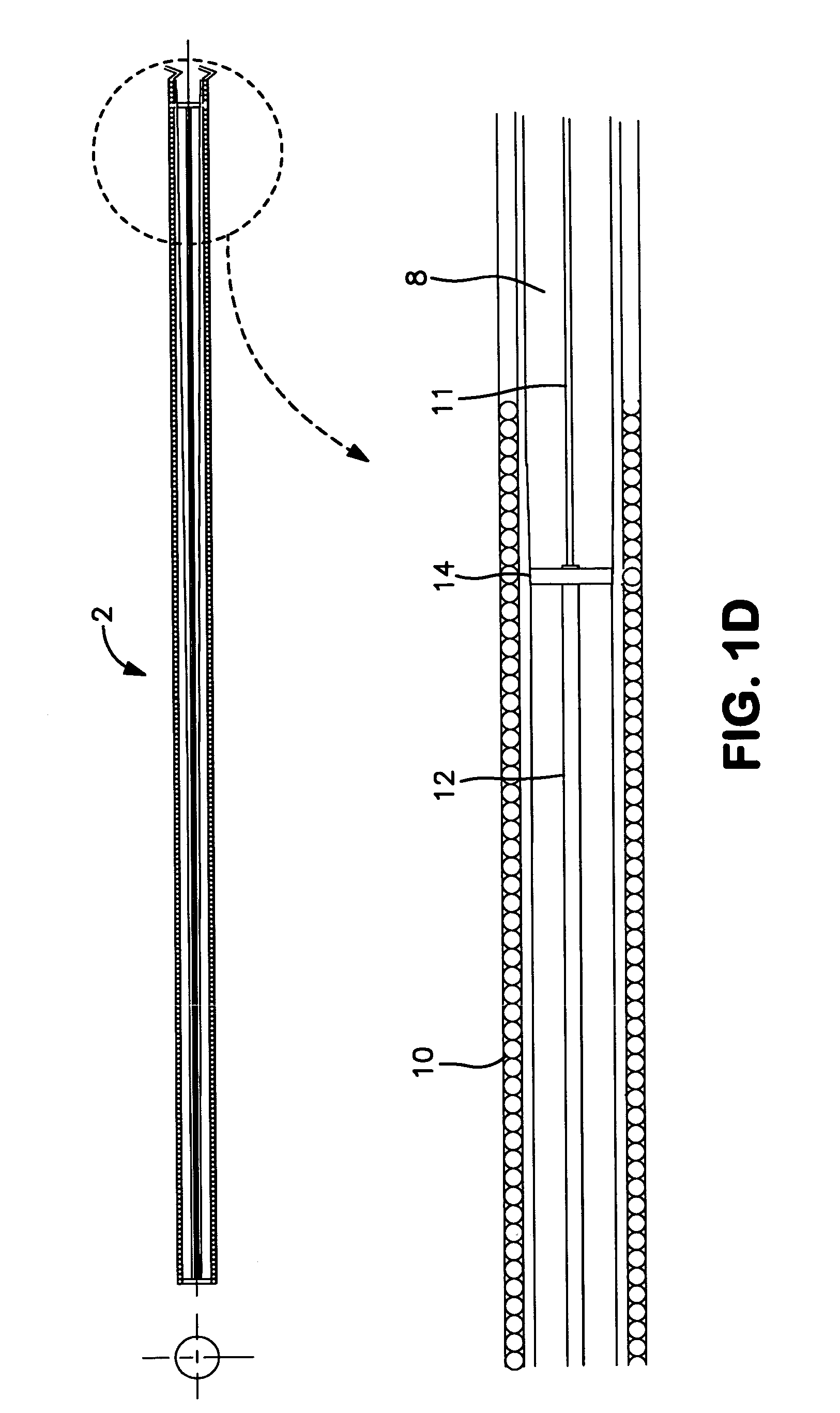

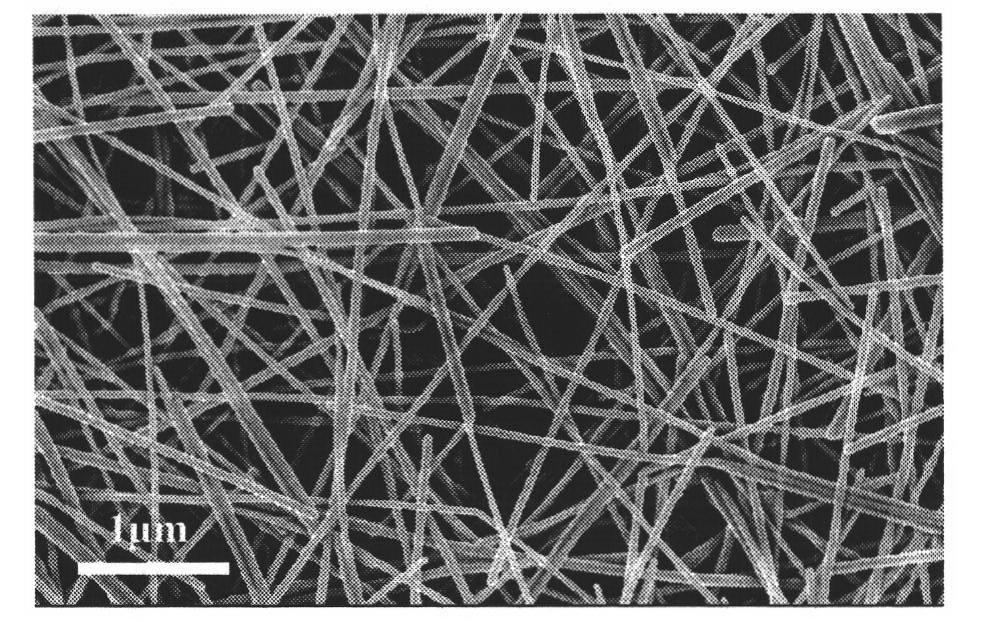

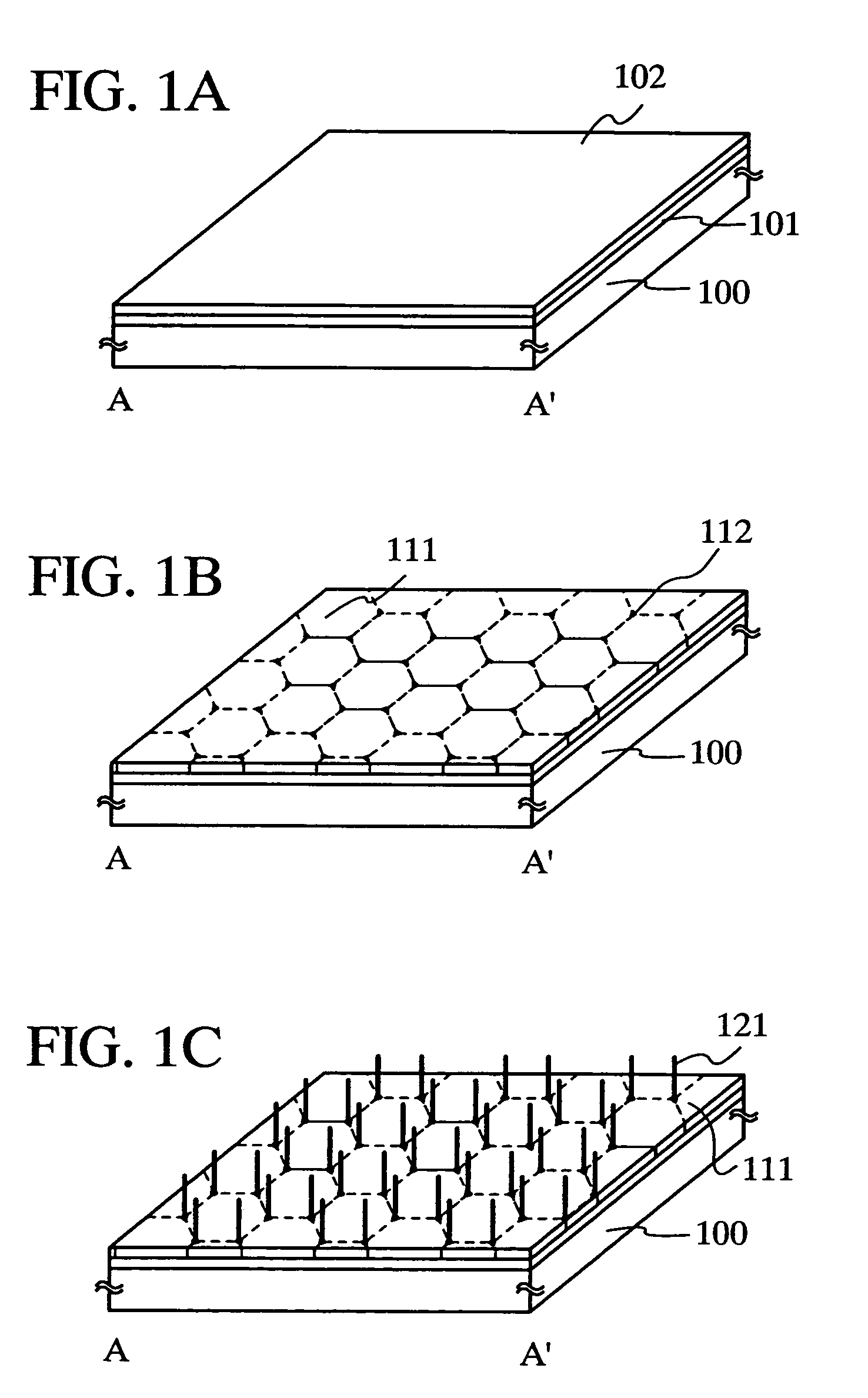

Method of forming composite arrays of single-wall carbon nanotubes and compositions thereof

InactiveUS6939525B2Hard to damageUniform diameterMaterial nanotechnologyCarbon compoundsMolecular arrayCarbon nanotube

This invention relates generally to forming arrays of single-wall carbon nanotubes (SWNT) and compositions thereof. In one embodiment, the present invention involves forming an array from more than one separately prepared molecular arrays or templates to prepare a composite structure. The multiple arrays can be the same or different with respect to the SWNT type or geometric arrangement in the array.

Owner:RICE UNIV

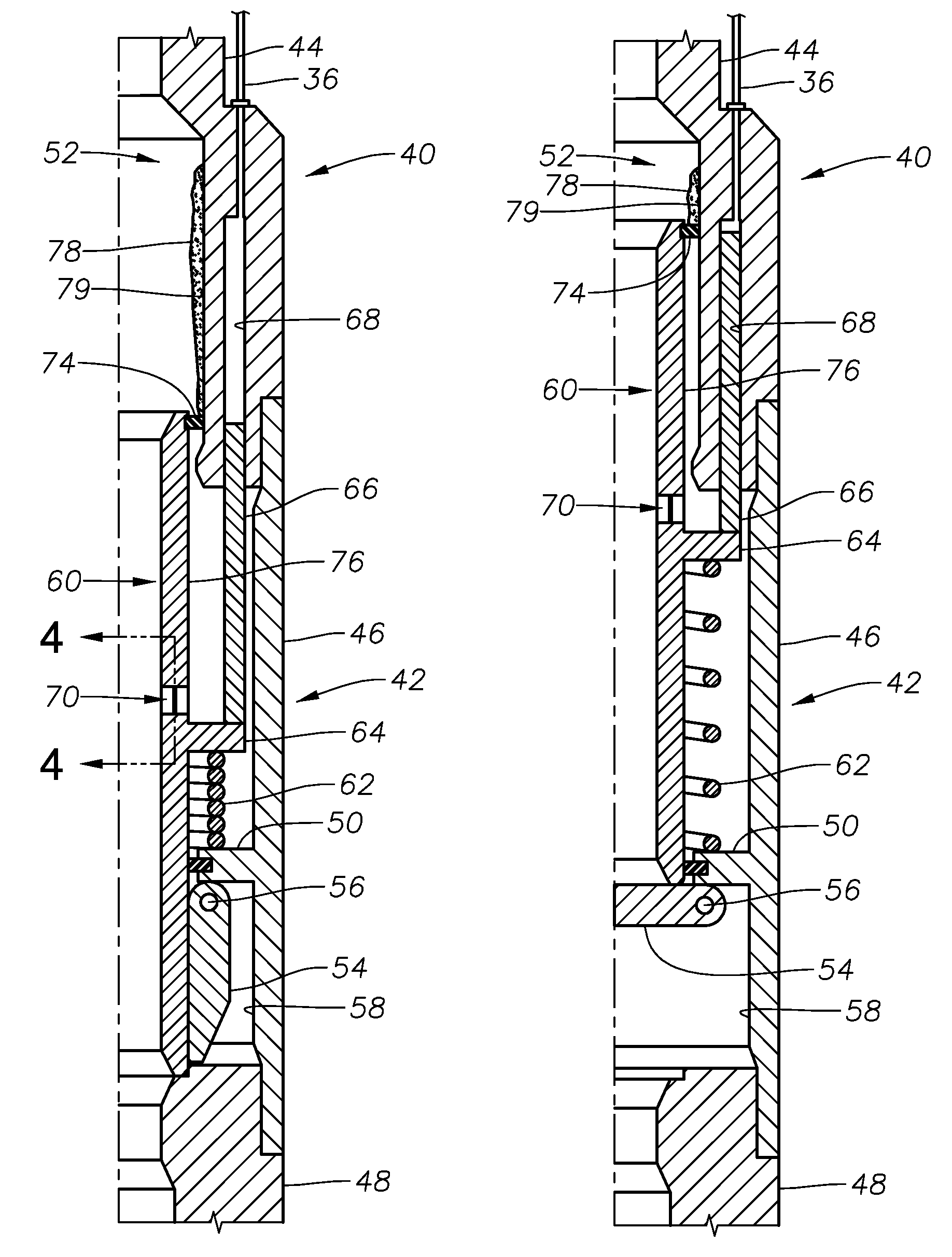

Vascular guidewire control apparatus

InactiveUS20050277851A1Shorten the timeSaving of other resourceGuide wiresInfusion syringesAxial displacementElectric control

A controller for use with a guidewire, such as a vascular guidewire, provides a mechanism for gripping and applying a torque to the guidewire without the need to thread the guidewire axially through the controller and at a location close to a point of access of the guidewire. In one embodiment, the controller includes a side-access, multi-part assembly including a collett or other gripping element that applies a uniform radially inward force on the guidewire. In another embodiment, for use with guidewires having active electrically controllable elements, the controller integrally or removably incorporates a switch or other mechanism to initiate an energized state. The controller thereby permits, among other advantages, ergonomic, single-handed control of an electronically steerable guidewire, including axially displacing, torquing and steering the guidewire.

Owner:WINDCREST

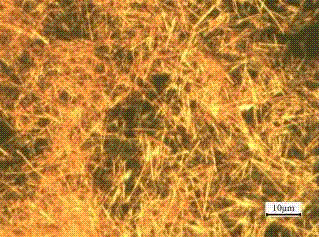

High-concentration fast preparation method for silver nanowires

InactiveCN101934378AShort reaction timeImprove reaction efficiency and equipment utilizationCopper chlorideMother liquor

The invention discloses a high-concentration fast preparation method for silver nanowires. The method comprises the following steps of: under the protection of inert gas, adding high-concentration silver nitrate glycol solution and polymer glycol solution into pre-heated glycol solution, and adding copper chloride serving as control agent at the same time so as to obtain mother liquor of the silver nanowires; and performing centrifugal separation and purification on the mother liquor so as to obtain pure silver nanowires diffused in ethanol solution. The high-concentration fast preparation method for silver nanowires has the advantages of high efficiency, low cost, simple process, high repeatability, high stability, fast reaction, high yield and adjustable and controllable shape and size of the silver nanowires, and makes the large-scale fast preparation and the application and research of the silver nanowires possible.

Owner:ZHEJIANG UNIV

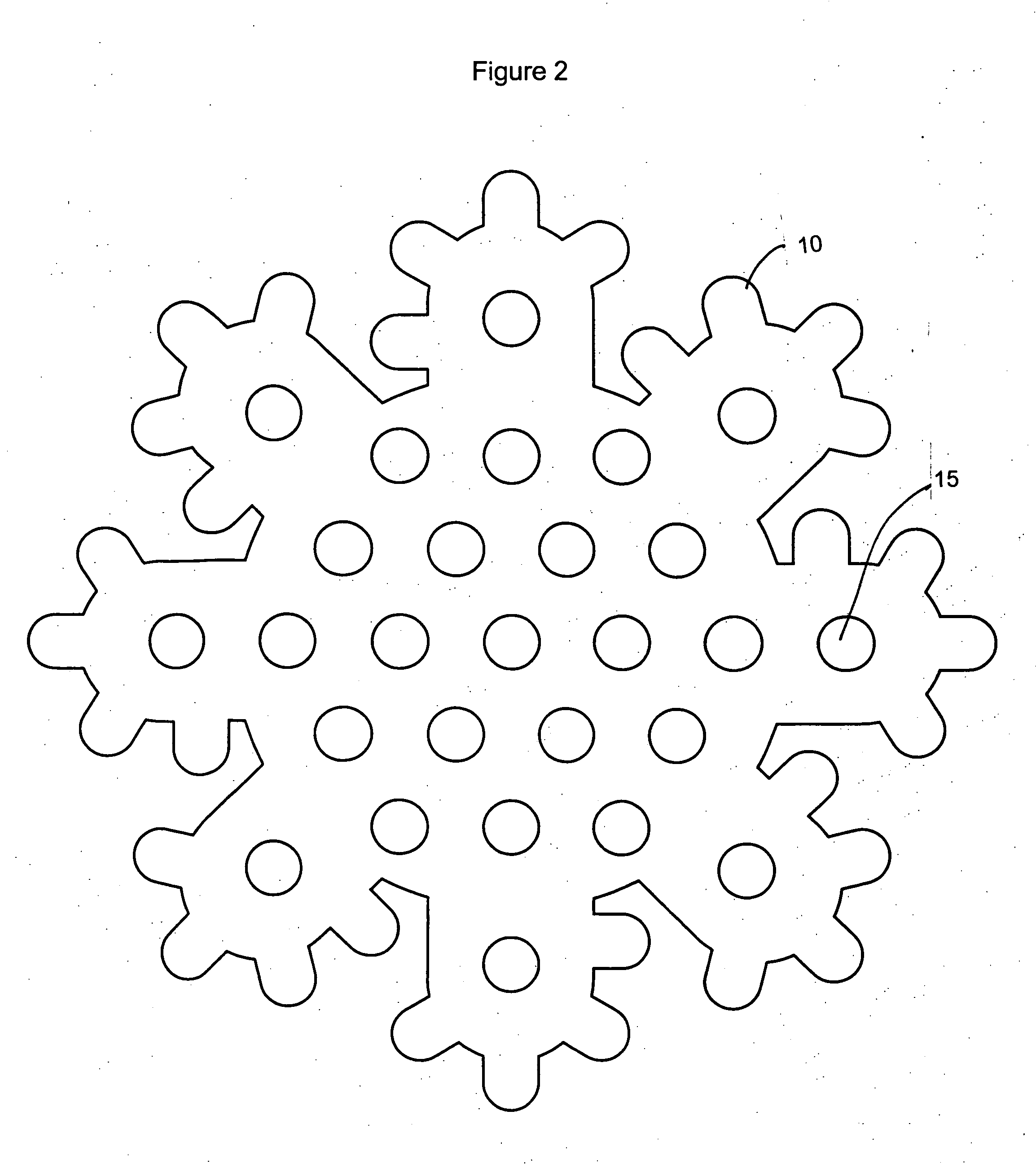

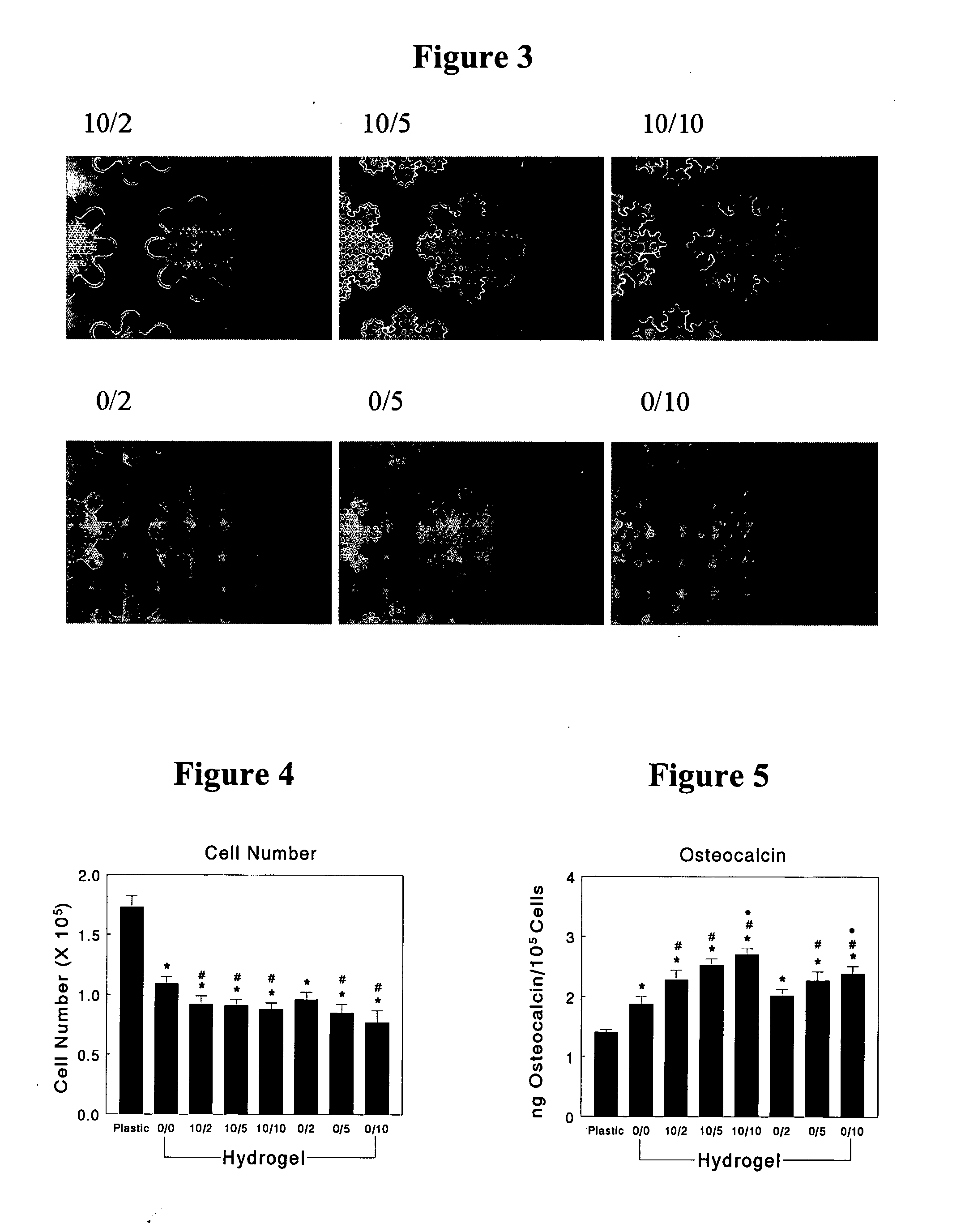

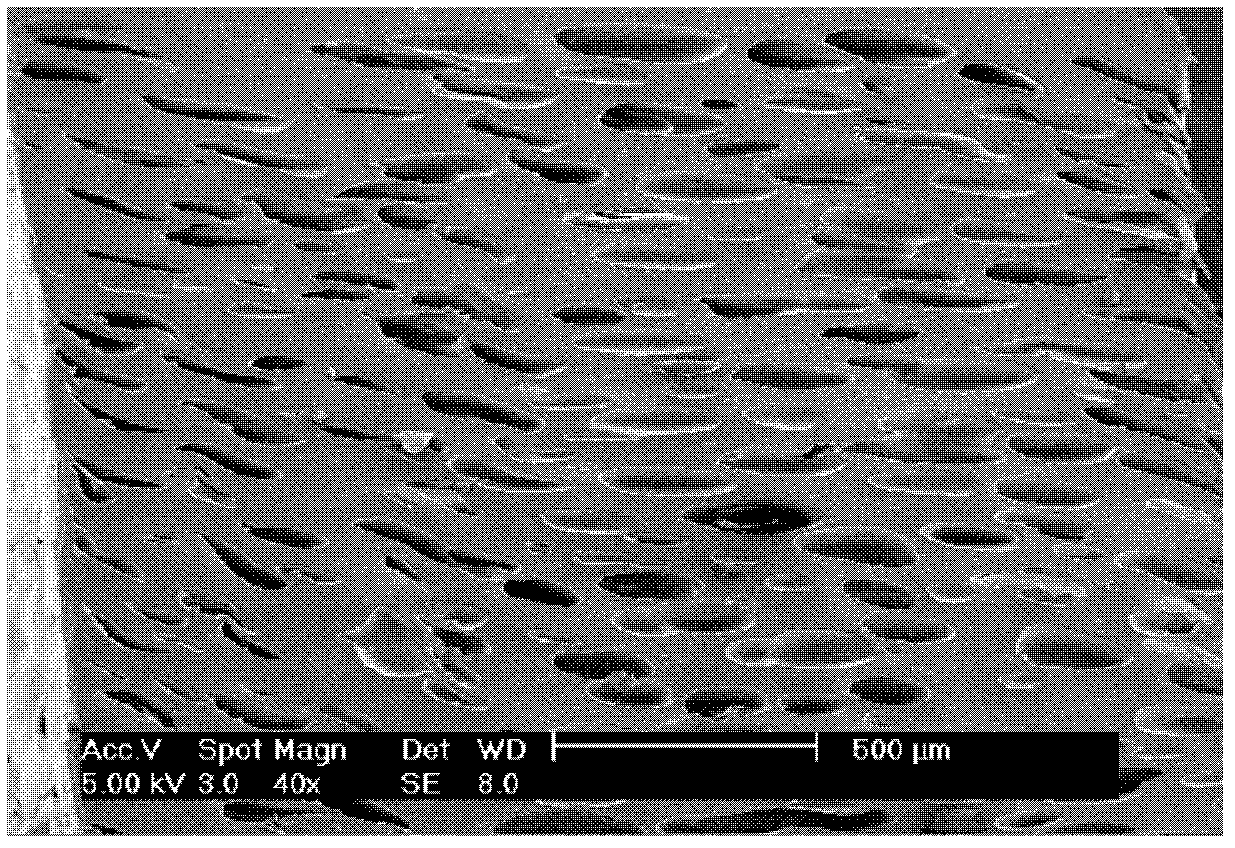

Surface directed cellular attachment

ActiveUS20050196452A1Uniform diameterPowder deliveryBiocideBiomedical engineeringBiological materials

Implantable biomaterials, particularly hydrogel substrates with porous surfaces, and methods for enhancing the compatibility of biomaterials with living tissue, and for causing physical attachment between biomaterials and living tissues are provided. Also provided are implants suitable for load-bearing surfaces in hard tissue repair, replacement, or augmentation, and to methods of their use. One embodiment of the invention relates to an implantable spinal disc prosthesis.

Owner:GEORGIA TECH RES CORP

Dual Action Aspiration Biopsy Needle

InactiveUS20050090765A1Reduce intrusionExpensive to performCannulasSurgical needlesAxis of symmetryAspiration biopsy

Owner:MEDICAL DEVICE TECH

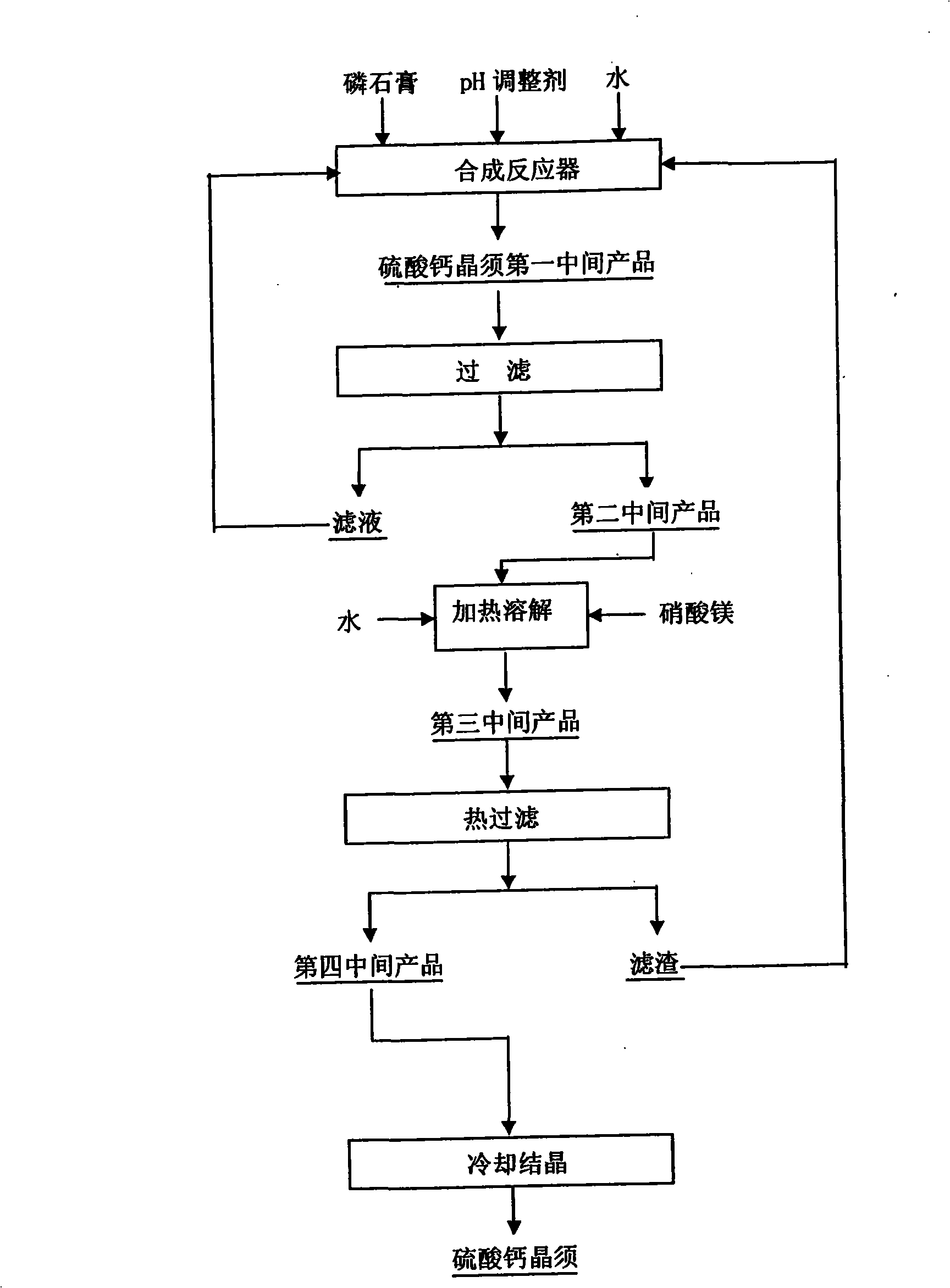

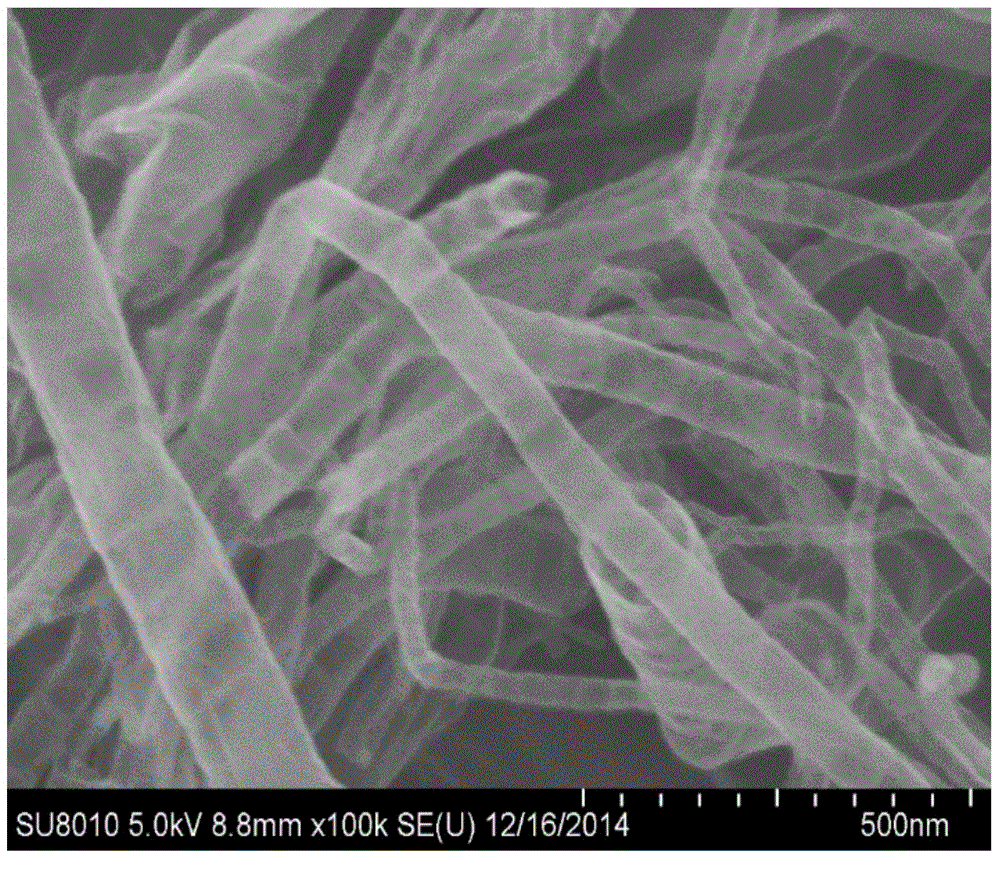

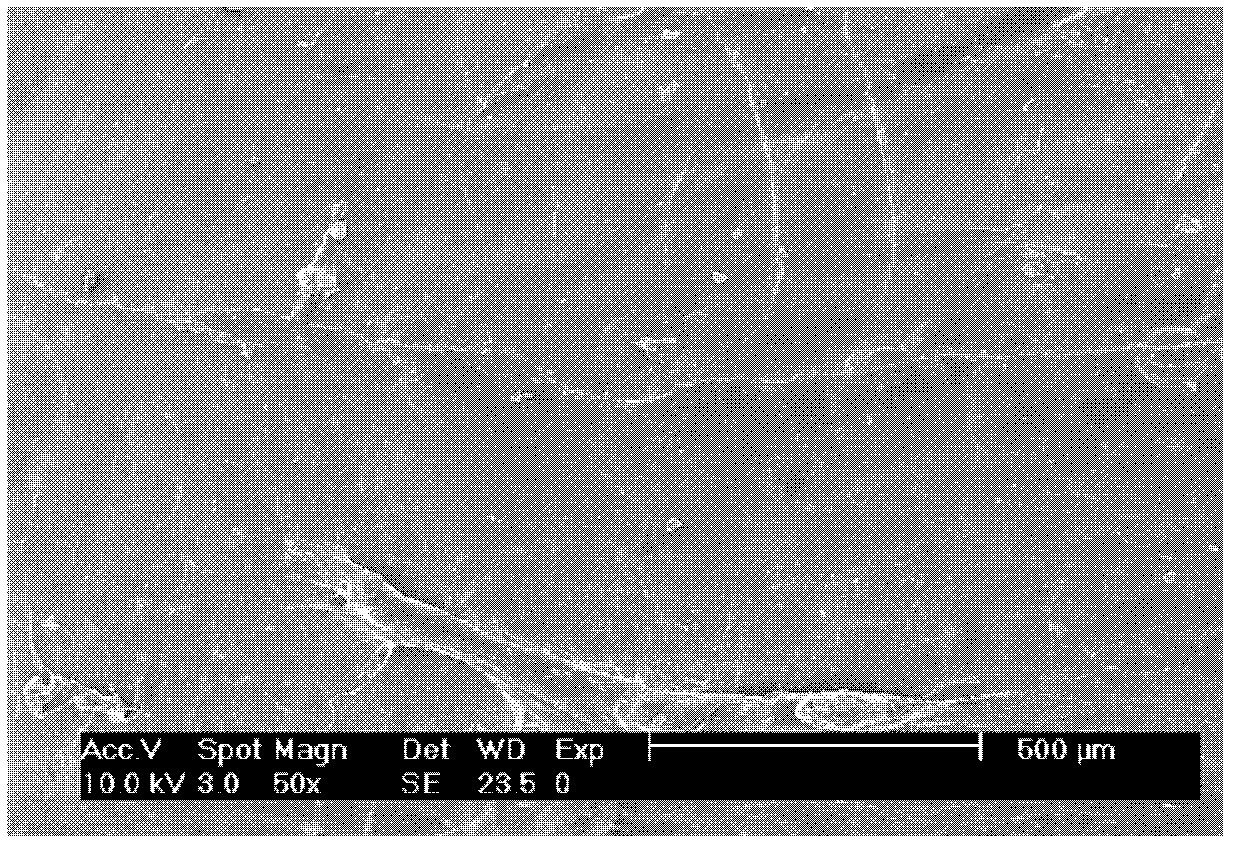

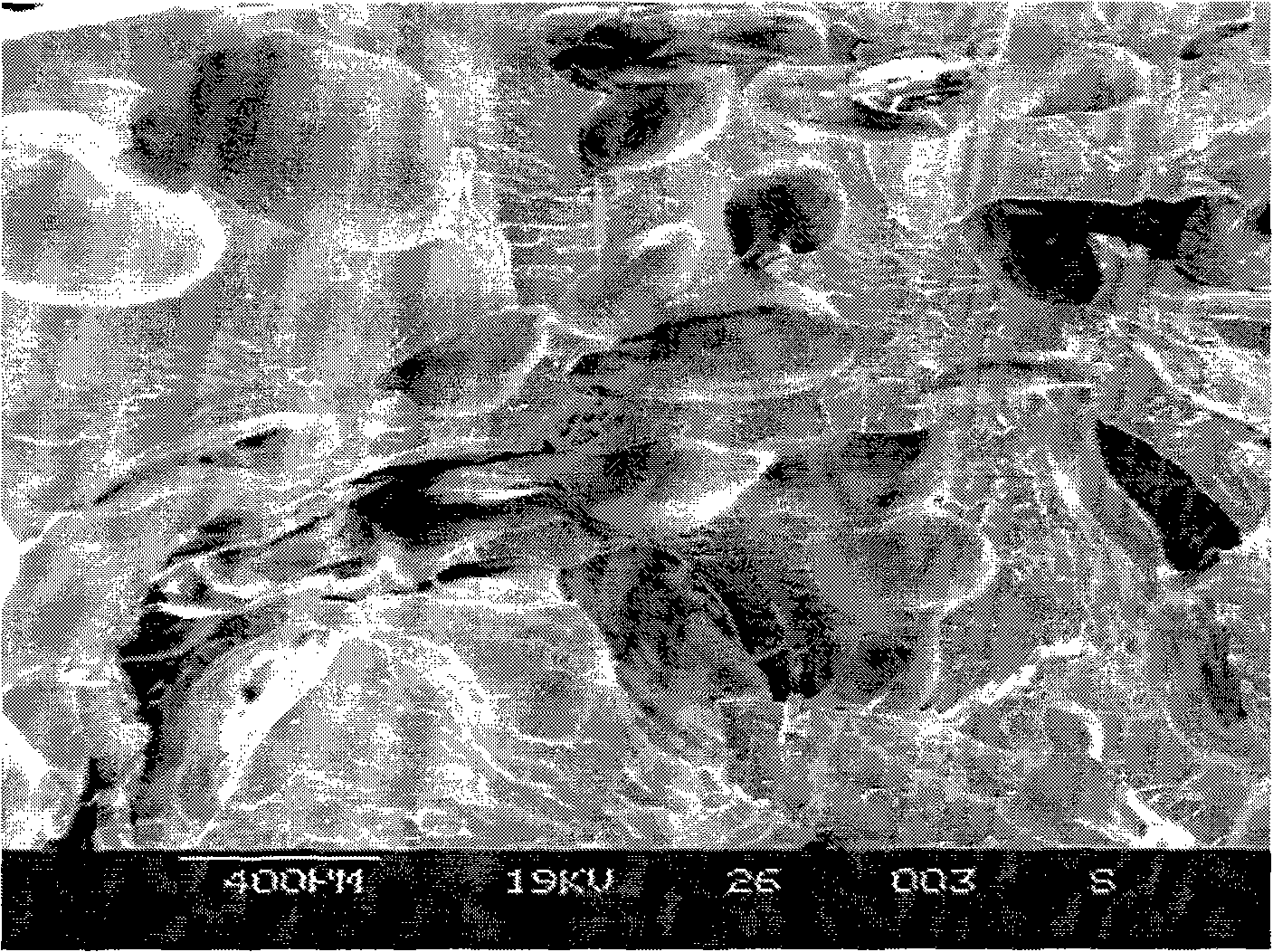

Process for preparing calcium sulphate whiskers from ardealite

InactiveCN101311355AUniform lengthImprove qualityPolycrystalline material growthFrom normal temperature solutionsSulphate IonChemical preparation

The invention relates to a method for preparing calcium sulphate crystal whisker by using phosphogypsum, which belongs to the technical field of phosphorous chemical preparation. Solid drogs phosphogypsum is used as raw material; after a synthetic reaction, filtering, heating and dissolving, thermal filtering and cooling crystallization for the raw material, the calcium sulphate crystal whisker product with the controllable diameter and length is prepared, the diameter of the crystal whisker is 1-4mum and the length of the crystal whisker is 50-200mum. The adoption of the solid drogs phosphogypsum for preparing the calcium sulphate crystal whisker reduces the production volume of natural plaster, saves resources, turns the waste into benefit, lowers the production cost of the calcium sulphate crystal whisker and improves added value of the product in the process of utilizing the phosphogypsum. The obtained calcium sulphate crystal whisker has excellent property, low cost and wide application.

Owner:YUNNAN MINZU UNIV

Cooling Holes For Gas Turbine Combustor Having A Non-Uniform Diameter Therethrough

InactiveUS20080271457A1Non-uniform diameterUniform diameterPropellersRotary propellersGas turbinesEngineering

A gas turbine combustor liner, including a shell having a first end adjacent to an upstream end of the combustor and a second end adjacent to a downstream end of the combustor, where the shell also has a hot side, a cold side, and a centerline axis therethrough. A plurality of small, closely-spaced film cooling holes are formed in the shell through which air flows for providing a cooling film along the hot side of the shell. Each cooling hole has a non-uniform diameter as it extends through the shell. In particular, each cooling hole includes a first opening located at the cold side of the shell having a first diameter and a second opening located at the hot side of the shell having a second diameter, wherein the second diameter of the second opening is larger than the first diameter of the first opening. It is preferred that the shape of each cooling hole be substantially frusto-conical.

Owner:GENERAL ELECTRIC CO

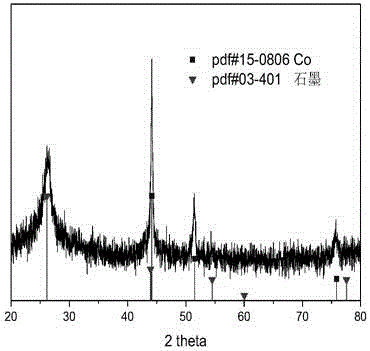

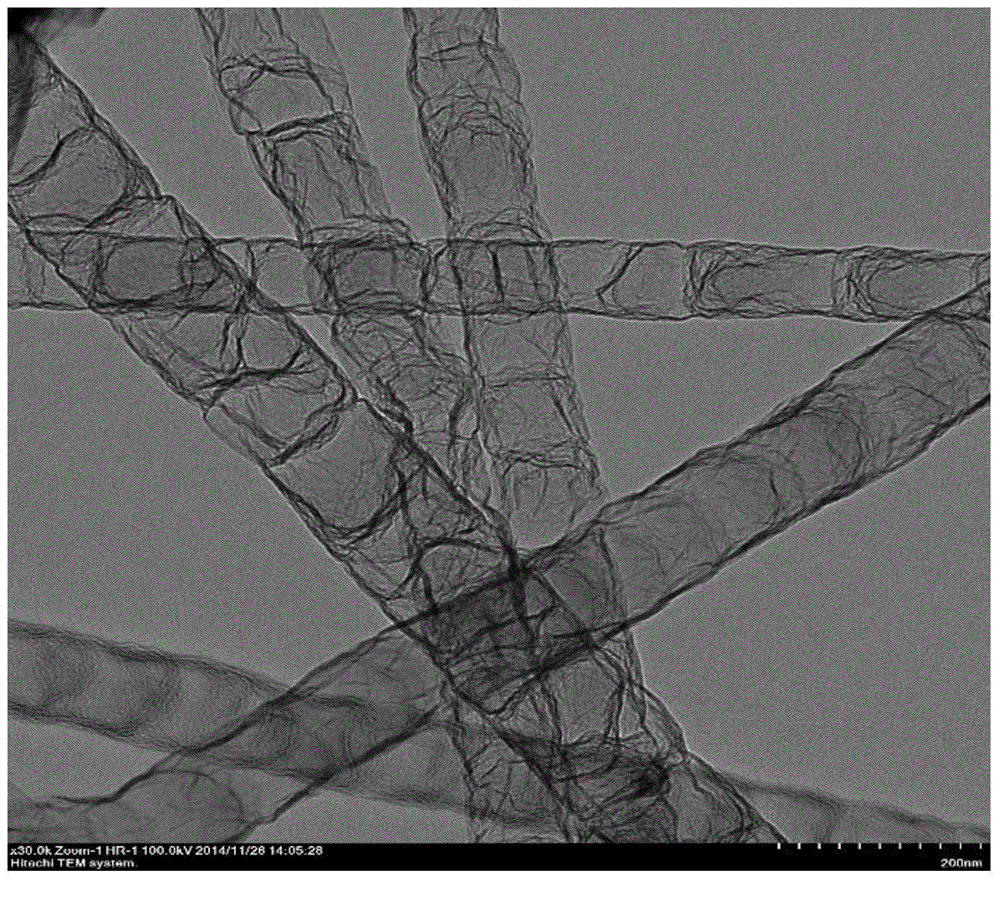

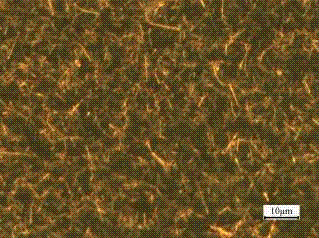

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

The invention discloses a method for synthesis of a cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The method includes: dissolving a soluble cobalt salt and an amine polymer in a hydrophilic reagent according to a mole ratio of 1:(2-200), performing evaporation at 60DEG C, conducting grinding after cooling, performing calcination at 400-1400DEG C under nitrogen atmosphere, then treating the sample with acid, and carrying out washing, centrifugation and drying so as to obtain the cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The obtained cobalt nanoparticles have small particle size and are employed to coat the head of a carbon nanotube evenly so as to combine tightly with the carbon nanotube. The composite material has application prospects in fuel cell anode materials, lithium ion battery cathode materials and the like. The method designed by the invention has the advantages of easily available raw materials, simple process and no pollution, short preparation period, mild reaction conditions, low cost, and mass synthesis capability, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

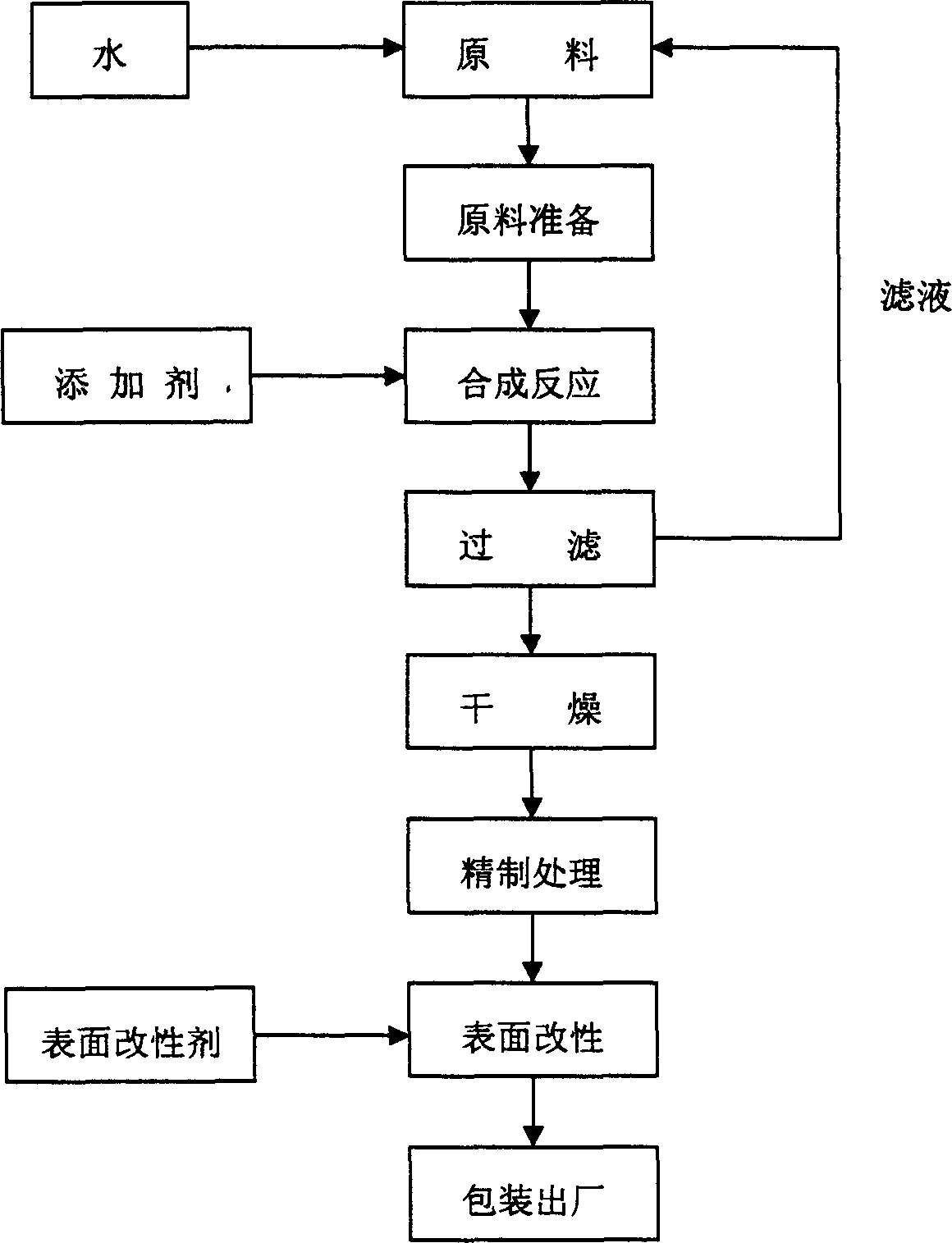

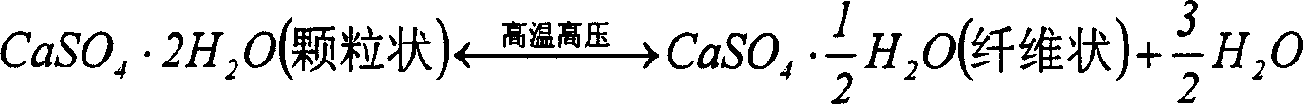

Process for preparing calcium sulfate whisker

InactiveCN1598083AControl lengthIncrease production capacityPolycrystalline material growthCalcium/strontium/barium sulfatesChemical reactionSulfate

This invention is a preparation method of calcium sulfate crystal whisker. The material is plaster stone (CaSO4.2H2O) and water in the entire production. After raw material preparation, building up reactions, dehydrate, refine and edulcoration. Its characteristic is that the active content of plaster stone up to above 95%, the whiteness is above 90%. Mixed with water and turn into plaster stone slime, then put them into reactor to make them have chemical reaction, then on the other procedures. The calcium sulfate crystal whisker made by this method has good performance, low cost, and can be used in all kinds of industries.

Owner:NORTHEASTERN UNIV

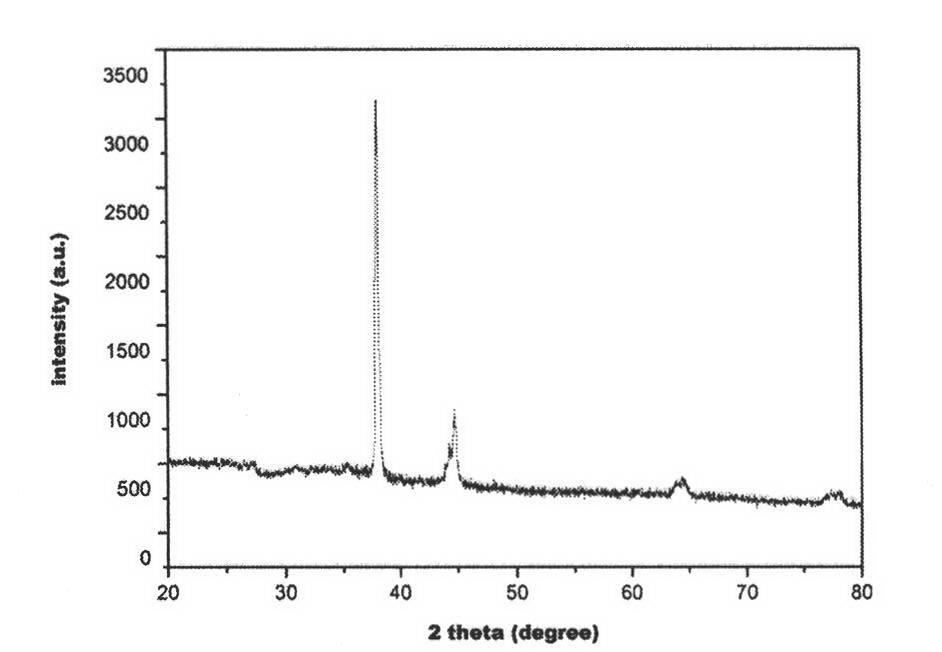

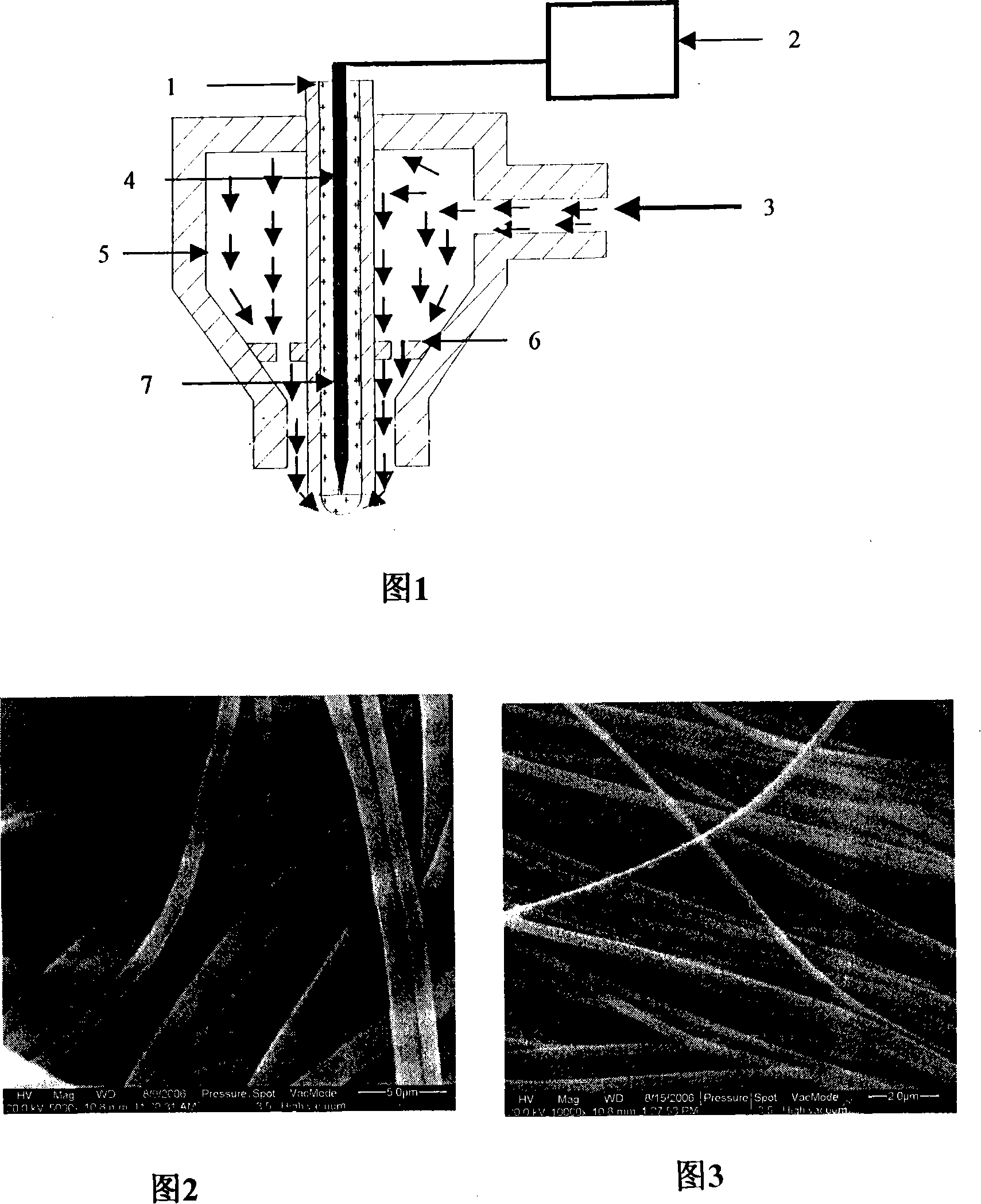

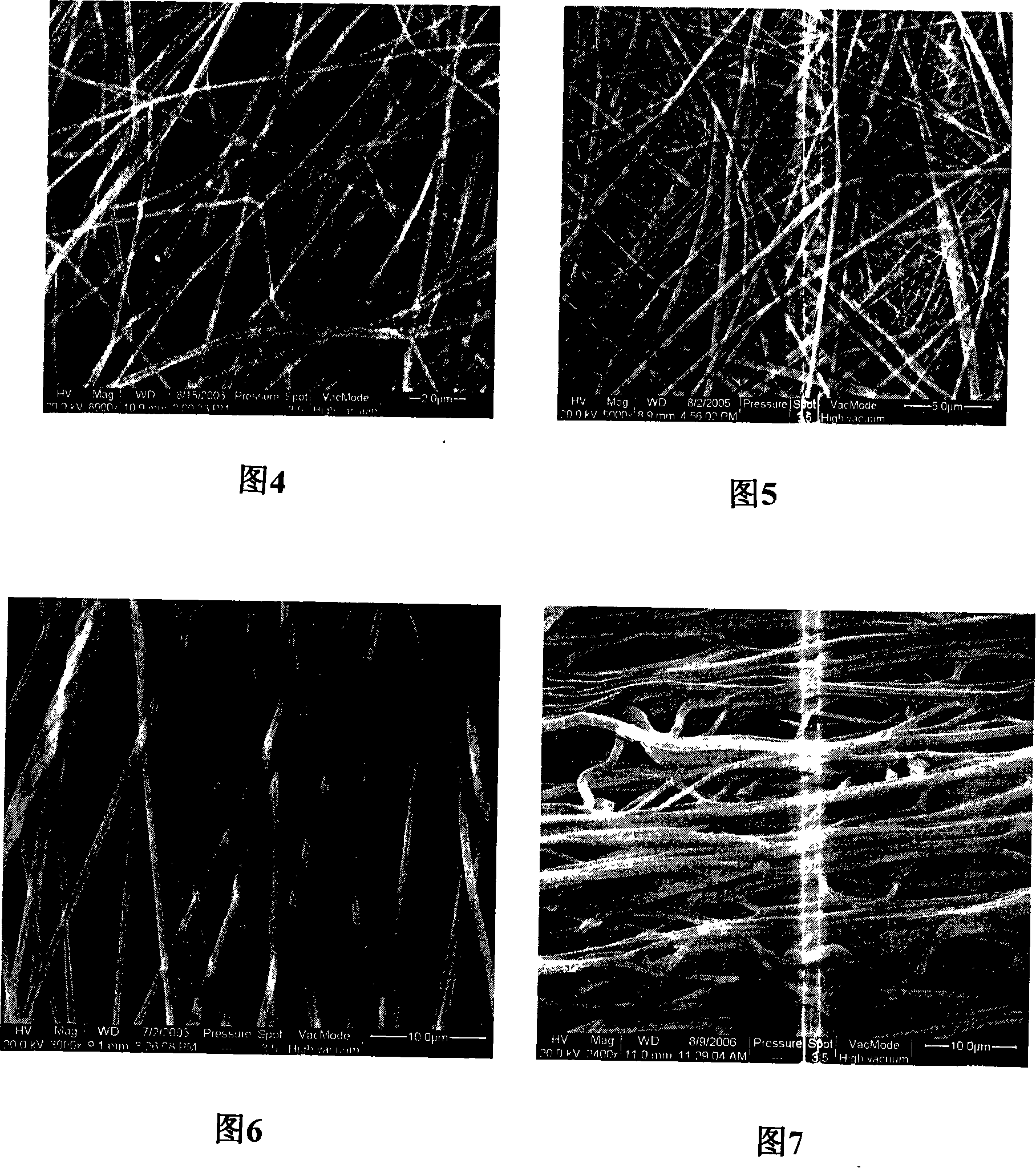

High-speed air-blowing static spinning composite preparation method and device for ultra-fine polymer fibre

The invention relates to a compound preparing method and device for the super thin polymer fiber high speed airflow static filature. The invention is to enhance the static filature speed through the high speed airflow. The invention separates the airflow passage form the solution passage through the sleeve pipe; the central capillary is the passage for the polymer solution and the outer pipe is the airflow passage. The polymer solution will shoot up from the liquid drop. The high speed airflow from the outer sleeve pipe produces the siphon effect to the polymer solution in the central capillary to overcome the surface tension of the liquid drop and speed the shooting out of the solution shooting flow in one hand; in the other hand the high speed airflow speeds up the volatilization of the solvent and the moving speed shooting to the other polar. The speed of the filature of the invention is ten times higher than the single static filature, moreover the formed nanometer fiber has a smooth surface and the diameter size and distribution is similar to the diameter of the single static filature.

Owner:JIANGXI NORMAL UNIV

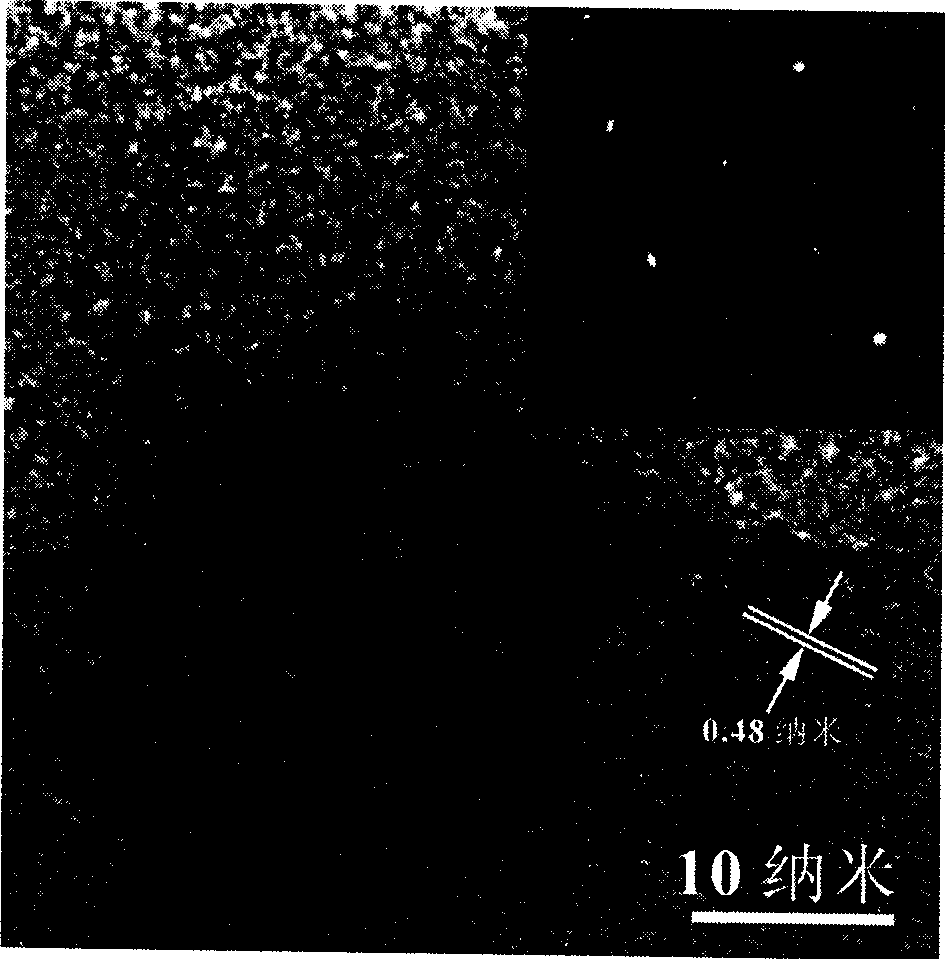

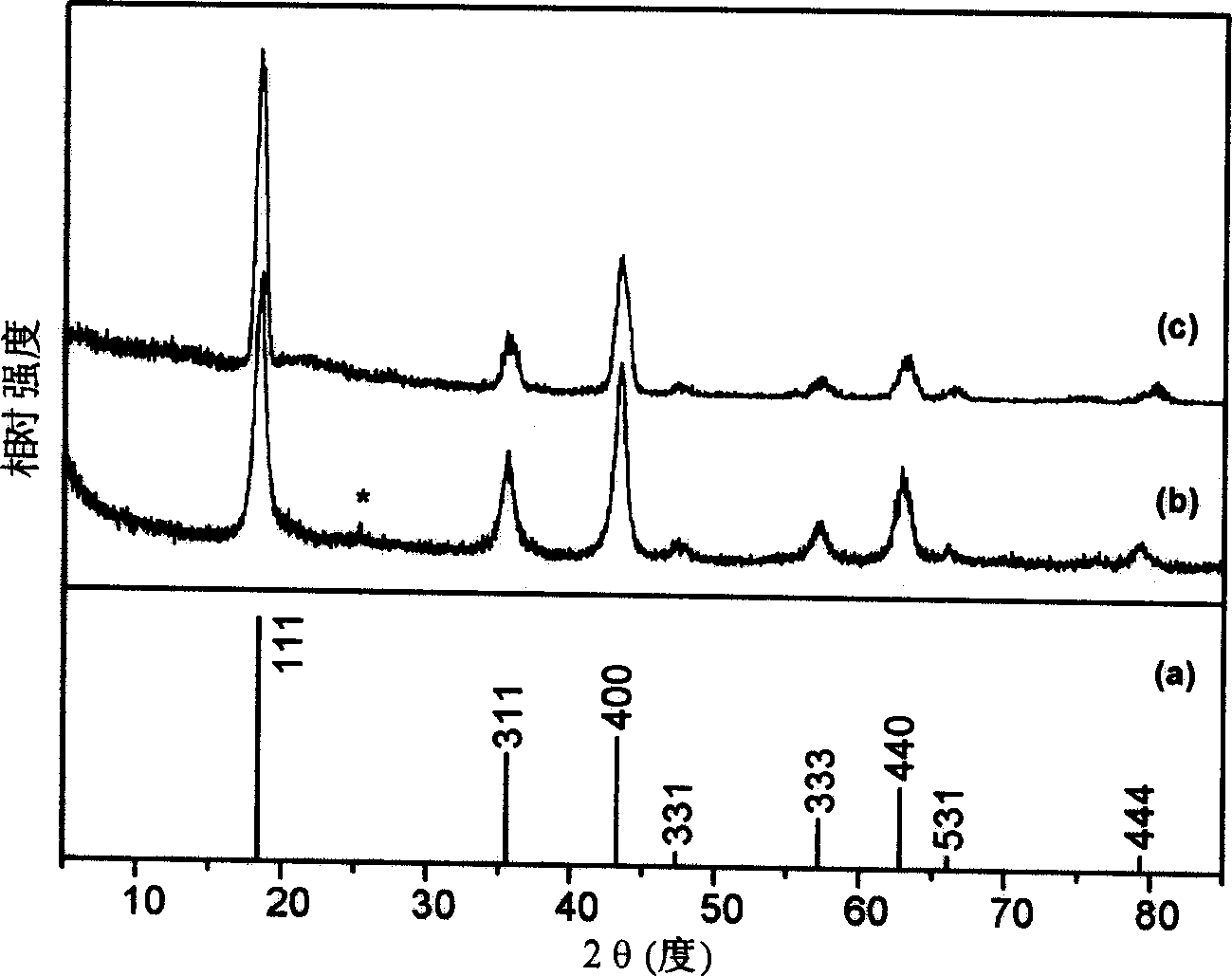

Preparation method of spinel lithium titanate nano tube/wire for lithium battery and capacitor

InactiveCN1725530AReduce energy consumptionUniform shapeNanostructure manufactureElectrode manufacturing processesNanowireIon exchange

This invention discloses a preparation method for spinel lithium titanate nm pipes / nm lines used in Li batteries and capacitors, which applies cheap industrial TiO2 as the raw material and supersonic chemical method to prepare said nm pipes / lines then takes them as the raw materials to be mixed with a certain quantity of soluble Li salt solution to be baked in air and by low-temperature hydrothermal ion exchange method to manufacture spinel lithium titanate nm pipes / lines with uniform shape, uniform diameter and even larger major diameter ratio and big ratio surface area.

Owner:TSINGHUA UNIV

Vascular guidewire control apparatus

Owner:WINDCREST

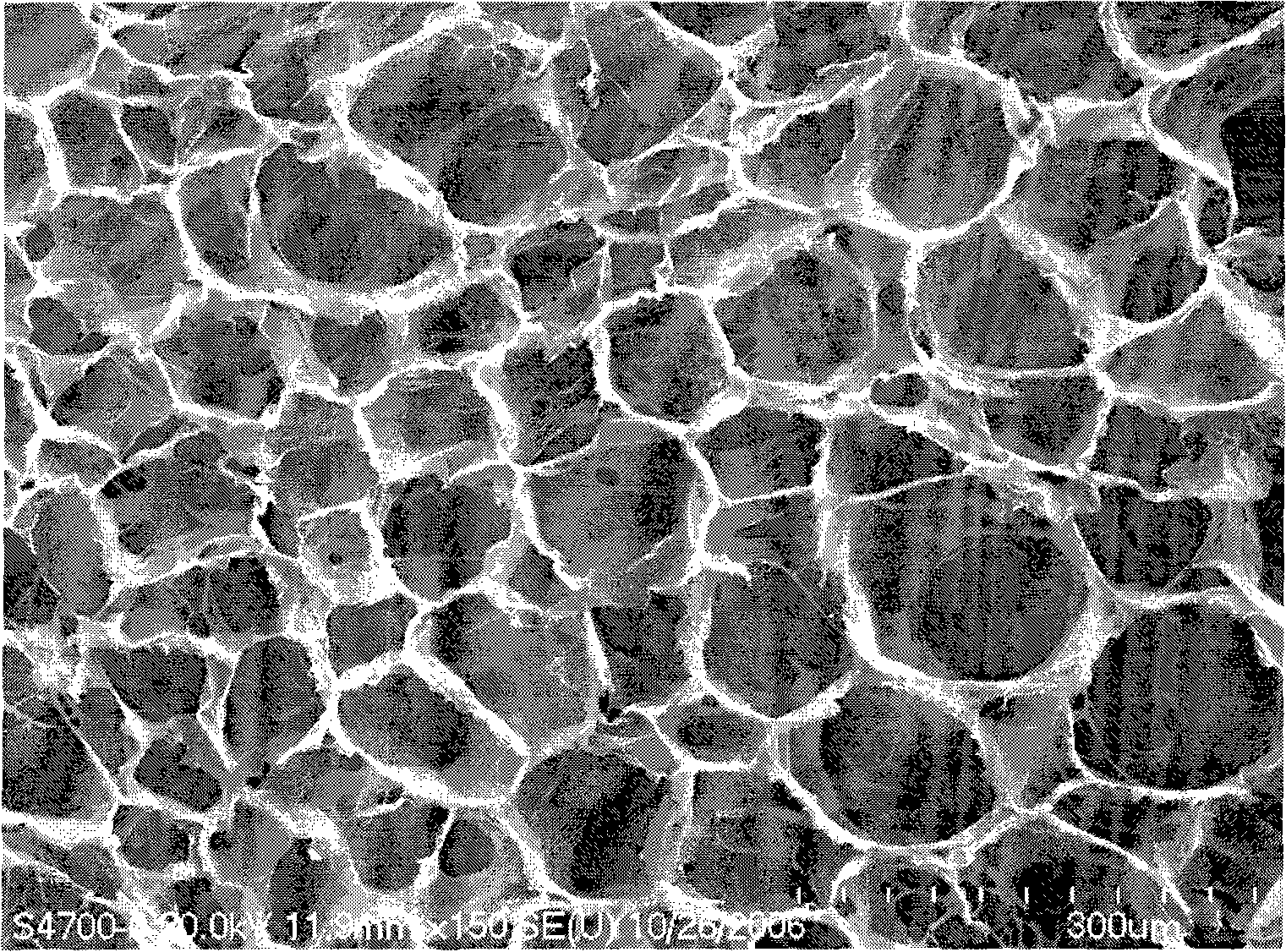

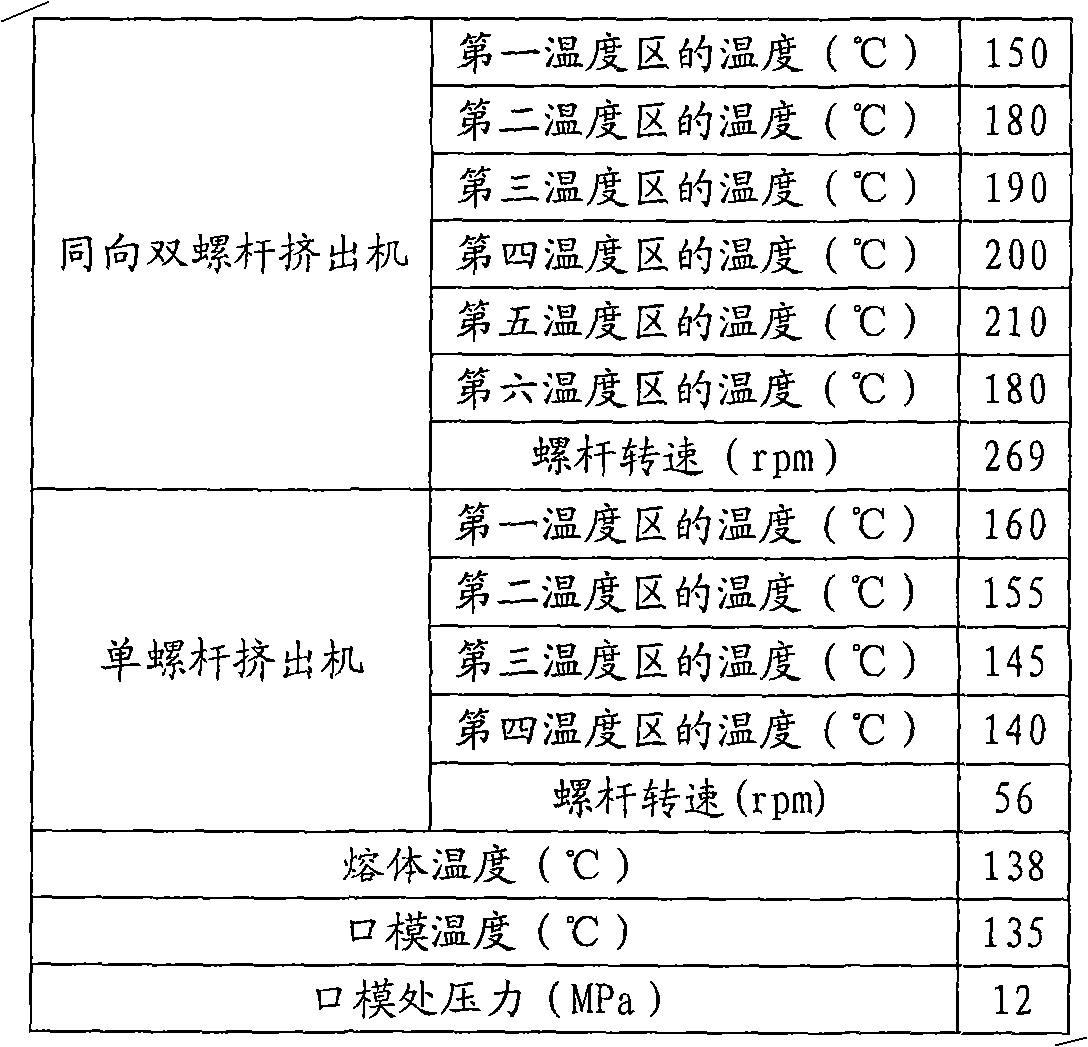

High-melt strength polypropylene foam material and preparation method thereof

The invention discloses a high-melt strength polypropylene foam material and a preparation method thereof. The matrix resin of the foam material is high-melt strength polypropylene. The high-melt strength polypropylene foam material has the following characteristics: (1) the melt index (190 DEGC / 2.16kg) is 1.0-10g / min; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the molecules with molecular weight over 5 million is greater than or equal to 0.8% by weight; and (4) (Mz+1) / Mn is greater than or equal to 70. The foam material is prepared by premix melting, blending and foaming of the following components in parts by weight: 100 parts of high-melt strength polypropylene and 1-15 parts of foaming agent. The obtained foam material meets the environmental protection requirements of degradability, uniform cell, high physical heat resistance, low production cost and smooth surface, and is suitable for continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

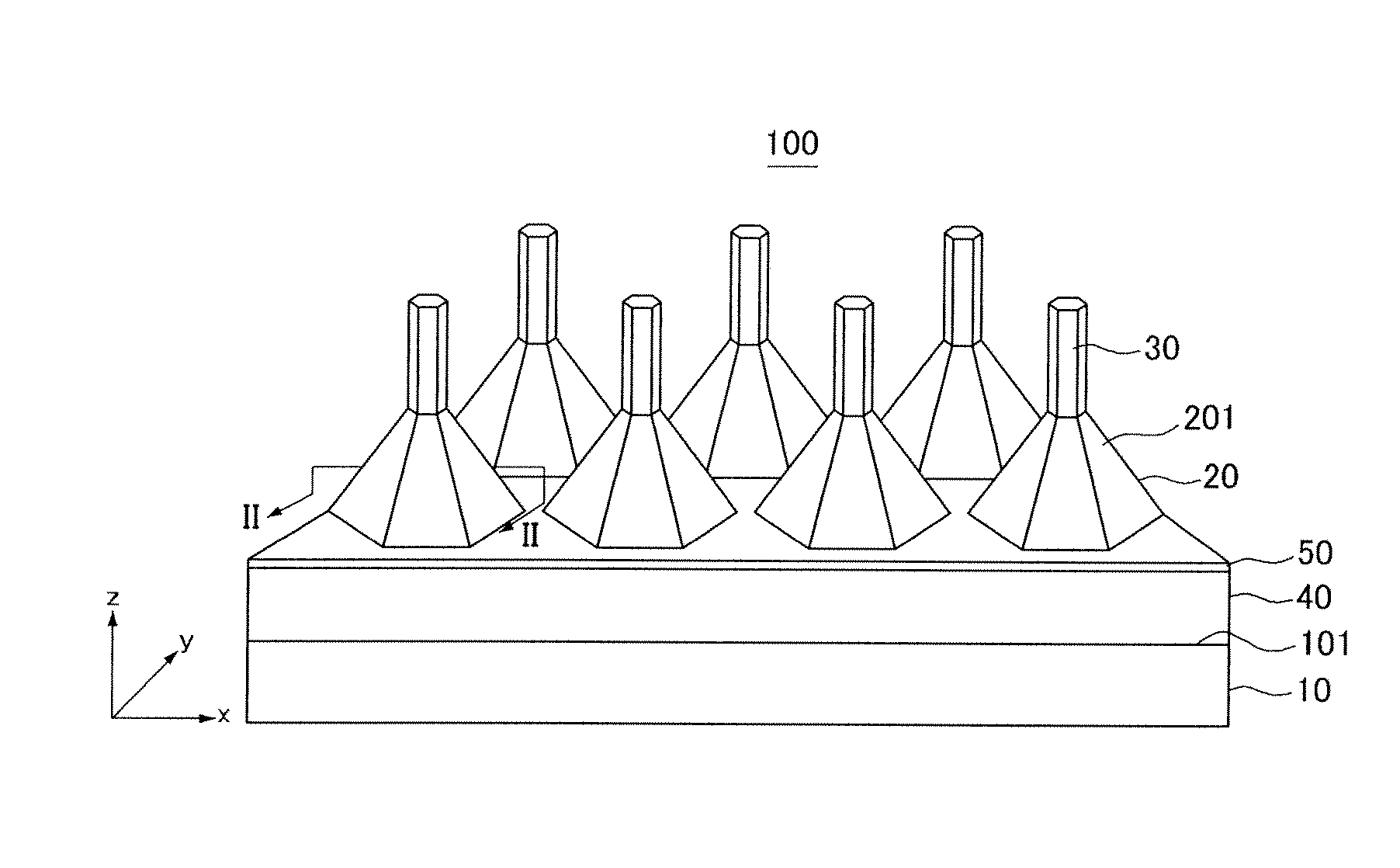

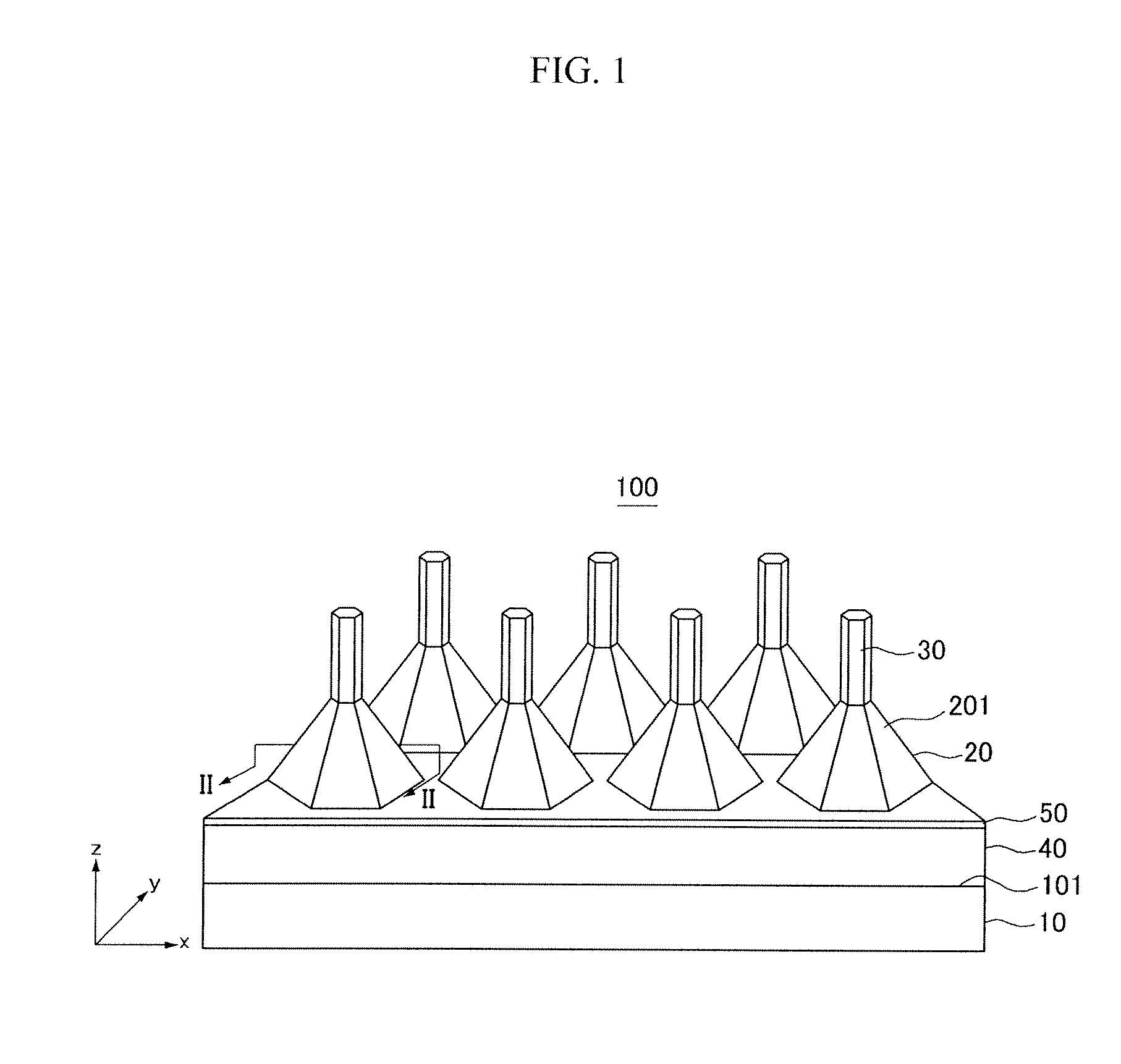

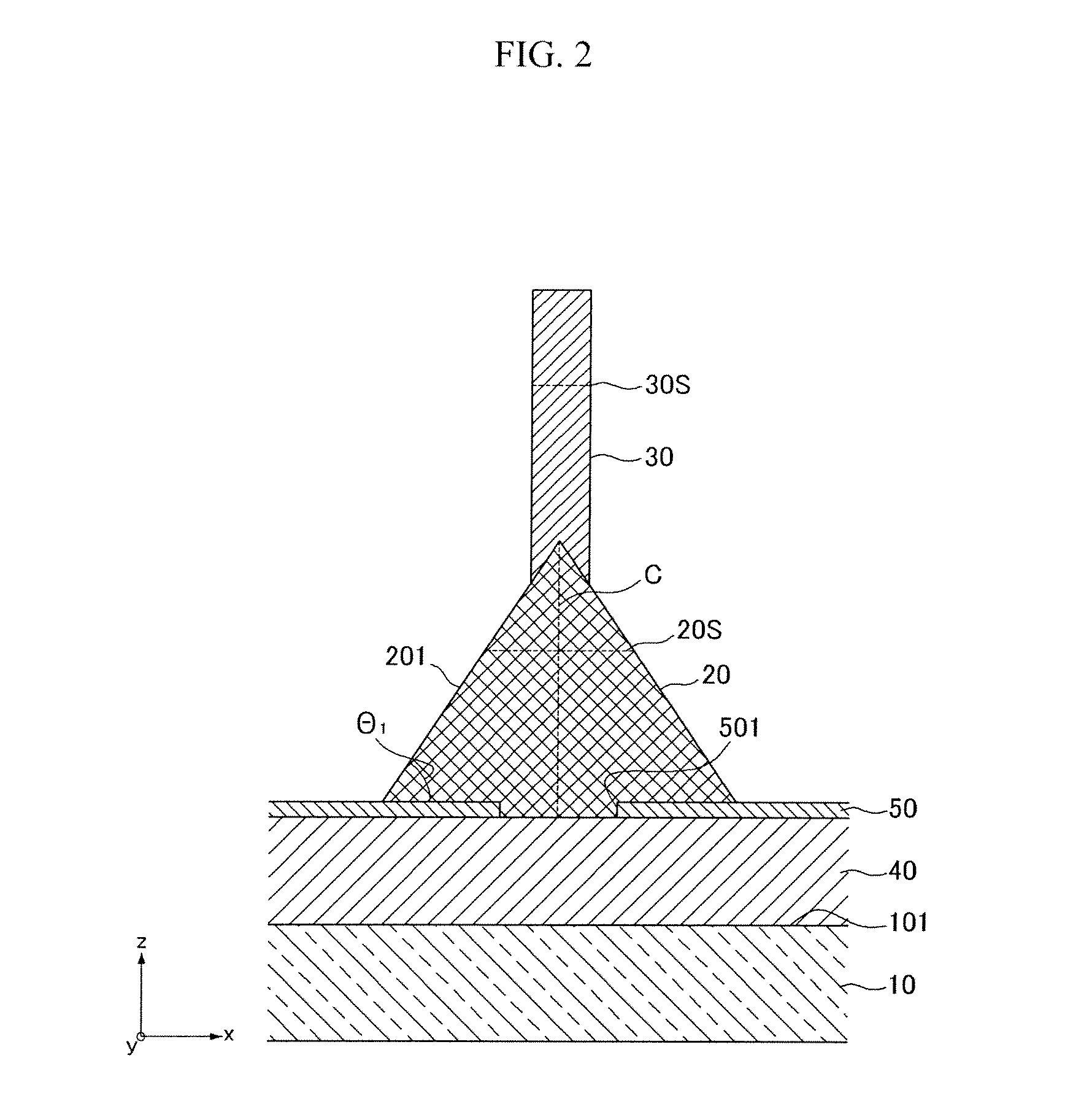

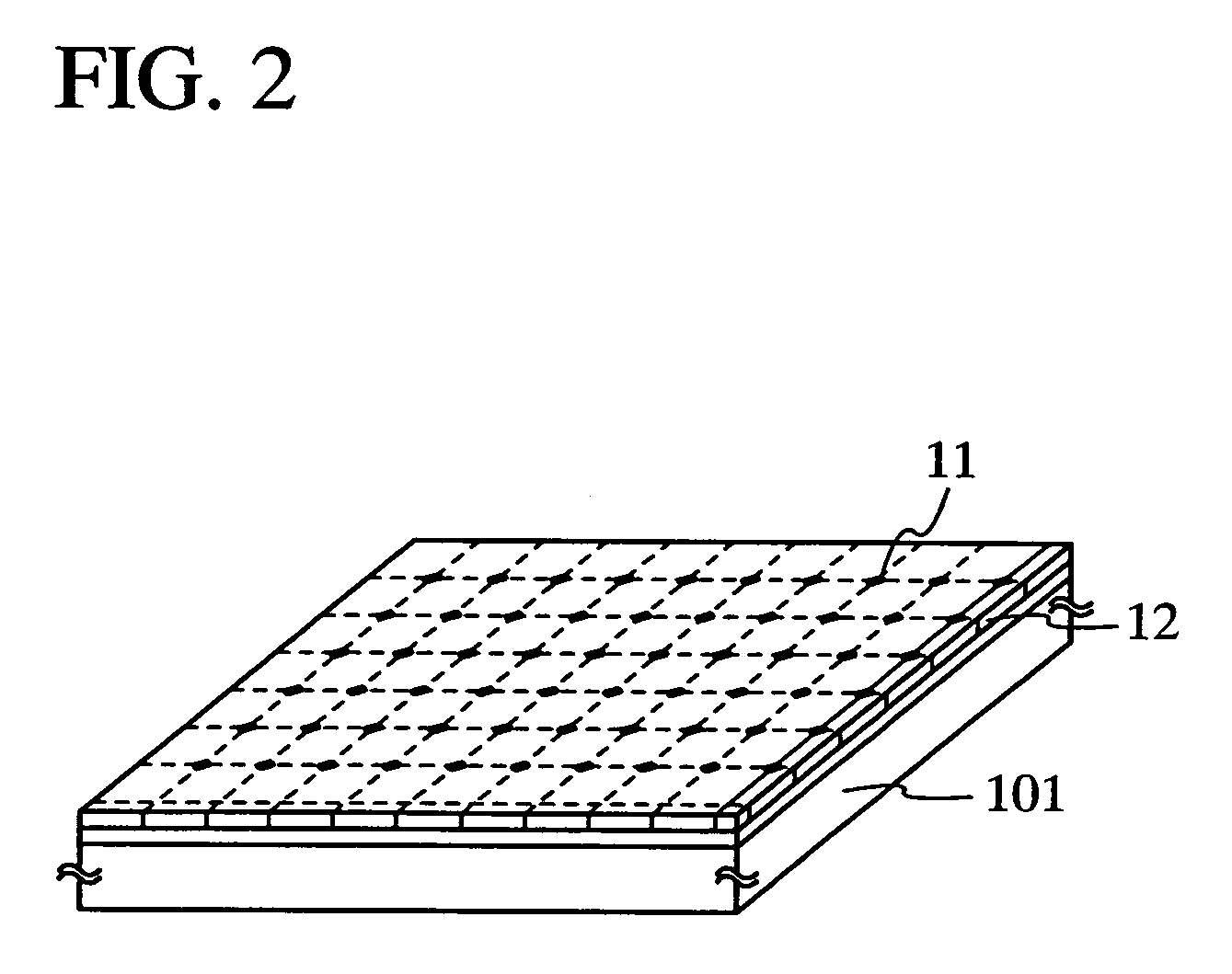

Nanodevice Comprising a Nanorod and Method for Manufacturing the Same

ActiveUS20090068411A1High purityHighly integratedPolycrystalline material growthLayered productsOptoelectronicsNanodevice

A nanodevice including a nanorod and a method for manufacturing the same is provided. The nanodevice according to an embodiment of the present invention includes i) a substrate; ii) at least one crystal that is located on the substrate and includes a plurality of side surfaces forming an angle with each other; and iii) at least one nanorod that is located on the crystal and extends along a direction that is substantially perpendicular to a surface of the substrate

Owner:LG DISPLAY CO LTD

Method for manufacturing ultrafine carbon fiber and field emission element

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing nanometer carbon fiber/foam coal through taking coal liquefaction residues as raw materials

The method for preparing nanometer carbon fiber / foam coal through taking coal liquefaction residues as raw materials belongs to the scientific and technological field of coal materials of the scientific and technological branch of inorganic non-metallic materials. The method takes the coal liquefaction residues as the coal source of the foam coal, and compounds metallic / foam coal compound materials through the supercritical foaming method or the formwork method, and prepares the nanometer carbon fiber / foam coal compound materials through the chemical vapor deposition of organic matter. The method fully utilizes the characteristics of metallic accelerating agent containing abundant coal organic matter, iron-contained compound and the like in the coal liquefaction residues, and prepares metallic / foam coal compound materials, and the nanometer carbon fiber completely covers on the surface of the foam coal after the chemical vapor deposition. The novel nanometer carbon fiber / foam compound materials have the structural characteristics of solid foam and hollow nanometer carbon fiber. And the method is expected to be used in the fields of catalyzer and a catalyzer carrier, a fuel battery electrode material, high-effective sorbent of a fixed bed reactor and the like.

Owner:DALIAN UNIV OF TECH

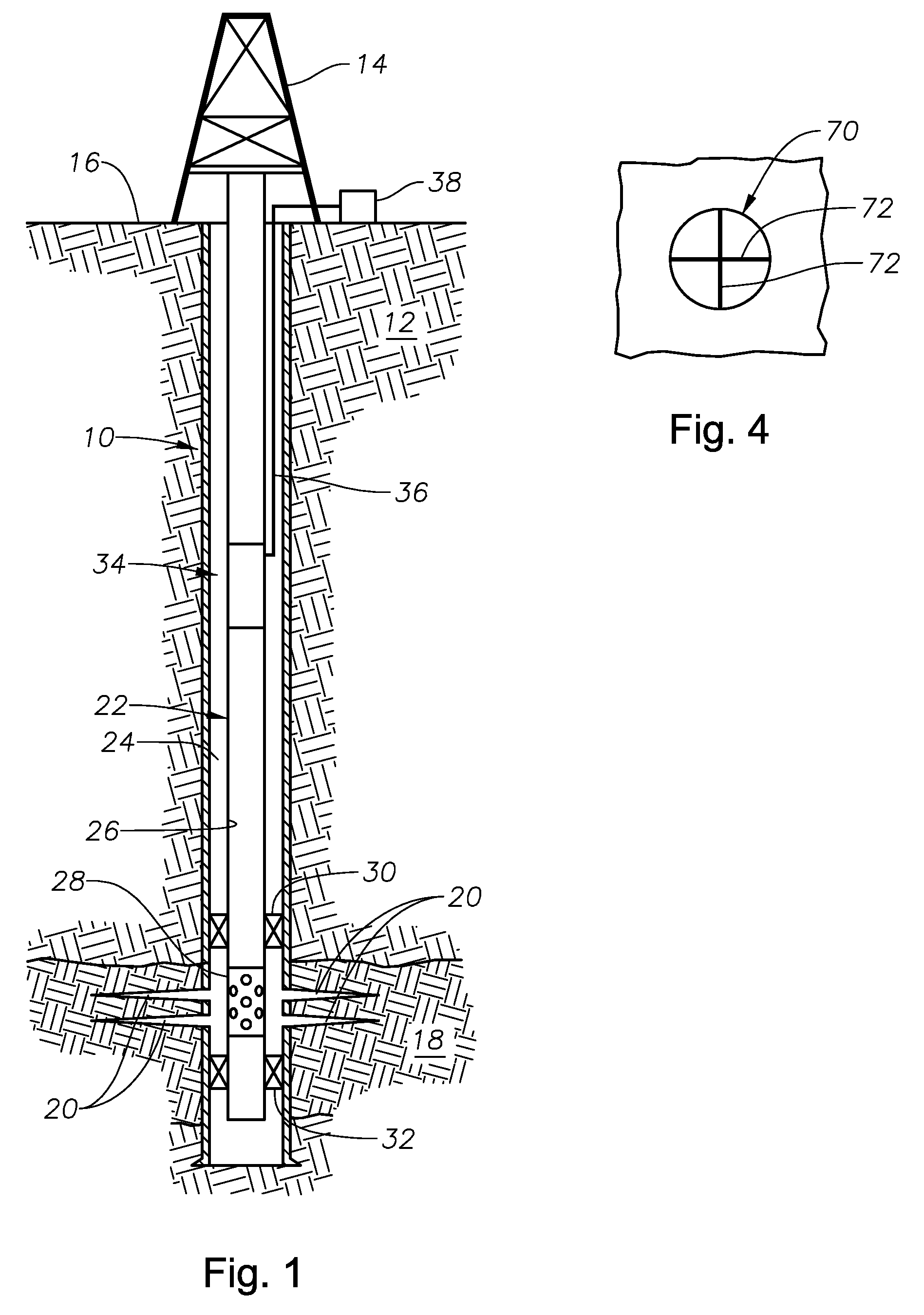

Methods and apparatus for negating mineral scale buildup in flapper valves

ActiveUS7896082B2Prevent scalingEliminate buildupConstructionsCleaning apparatusSleeve valveEngineering

Methods and devices for negating scale buildups on interior surfaces of a sliding sleeve valve housing above the flow tube. In some aspects, a wiper member provides additional clearance between the flow tube and housing to compensate for scale buildup. In other aspects, the interior surface of the valve housing is provided with a sleeve that is disposed between the interior surface of the valve housing and the general flowbore passing through the valve housing to protect the interior surface against scale buildup.

Owner:BAKER HUGHES INC

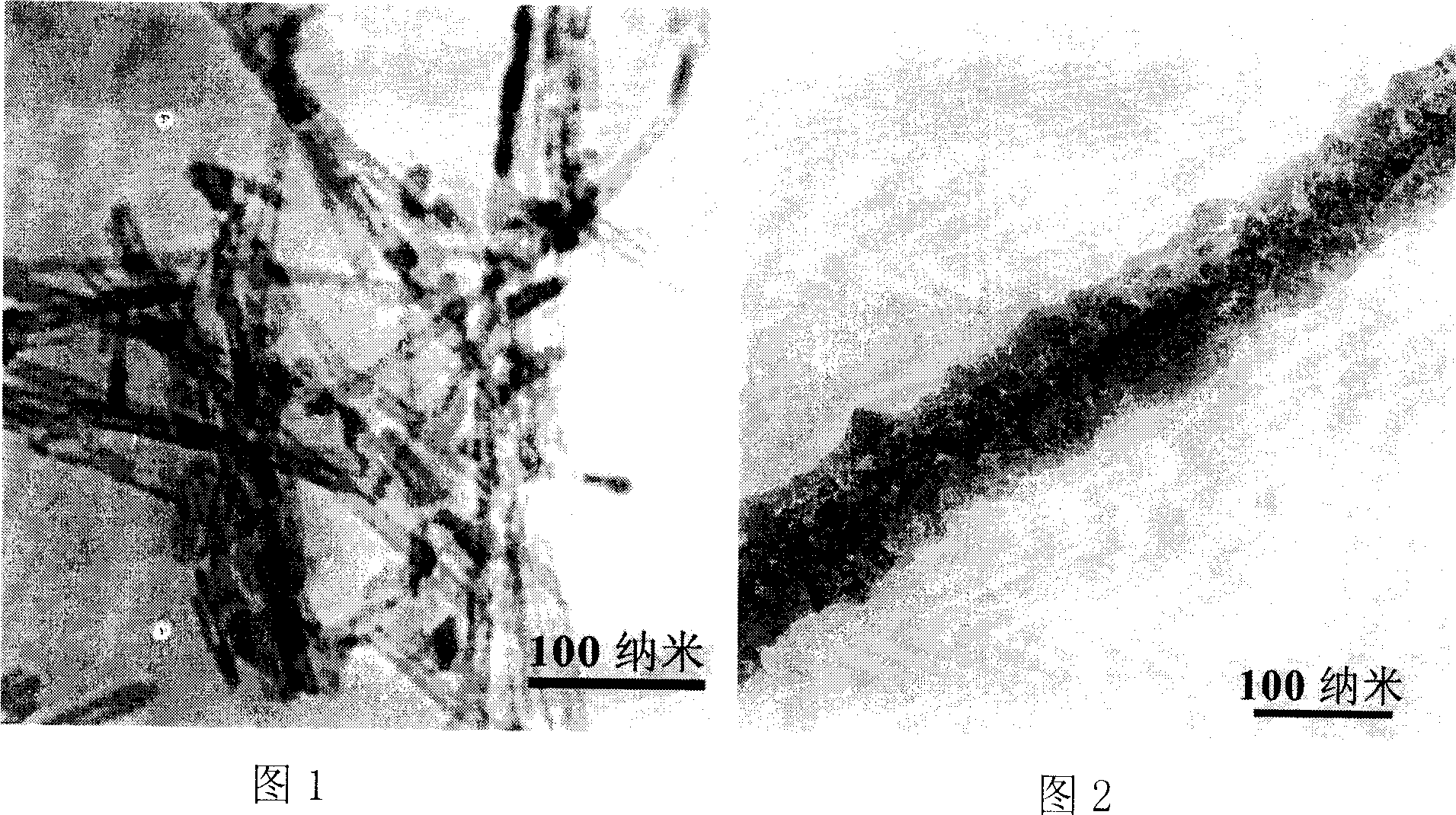

Method for preparing nano tube of some metalloid oxides and metals with size and shape being controllable

InactiveCN1462720AHigh yieldUniform diameterMaterial nanotechnologyPolycrystalline material growthAmphiphilePolyethylene glycol

A process for preparing the size and shape controllable ampholytic metal oxides and their metallic nanotubes features that based on the principle that under existance of excessive alkali the ampholytic metal hydroxide can become coordinate anions, under the action of surfactant as "soft template", the ampholytic metal oxide and its metallic nanotubes can be prepared by direct hydrothermal reaction or redox reaction (for example, ZnO, CuO, Al2O3, PbO2, SnO2 and relative metals). Its advantages are simple process, controllable sizes of nanotube, uniform wall thickness, and high output.

Owner:NORTHEAST NORMAL UNIVERSITY

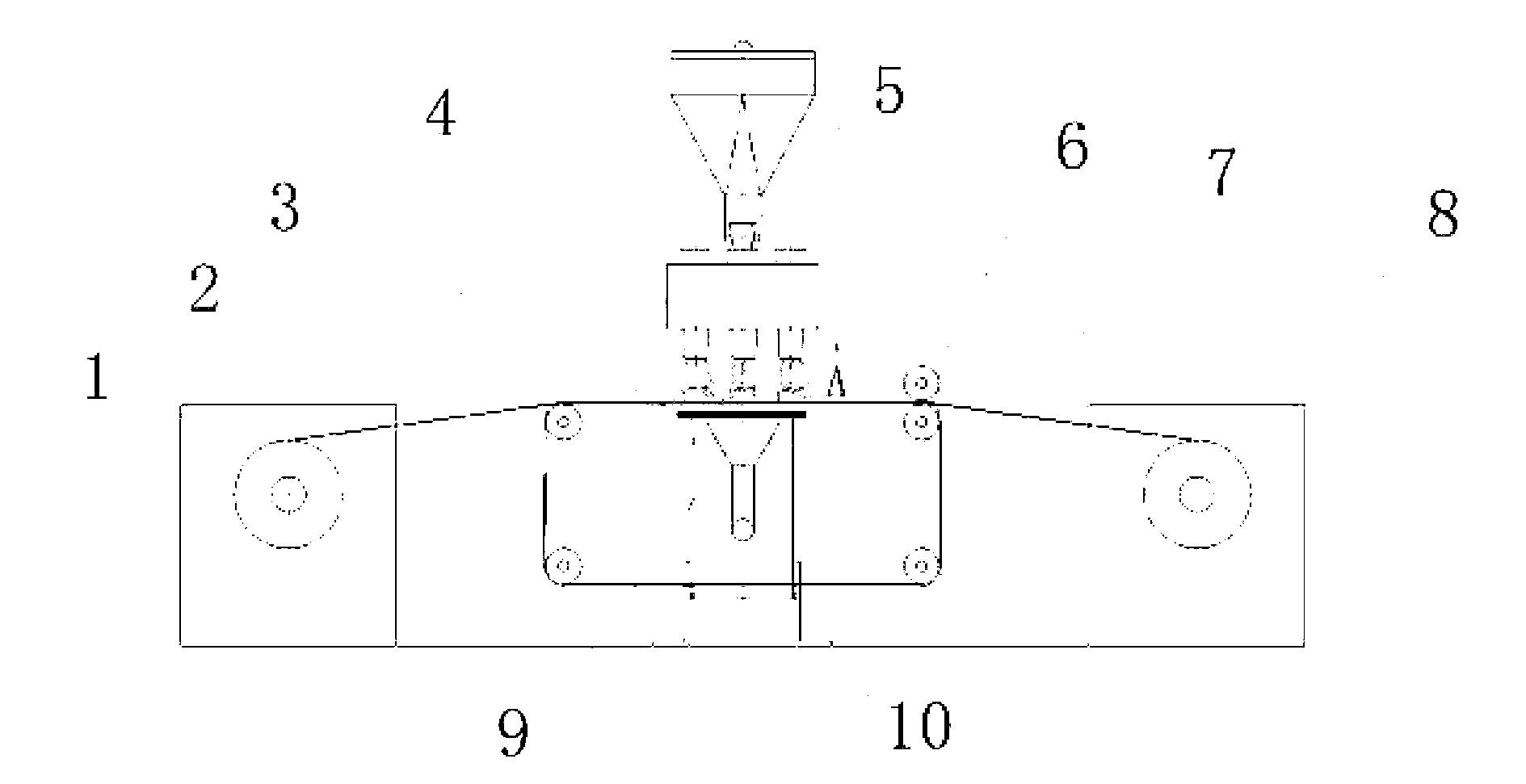

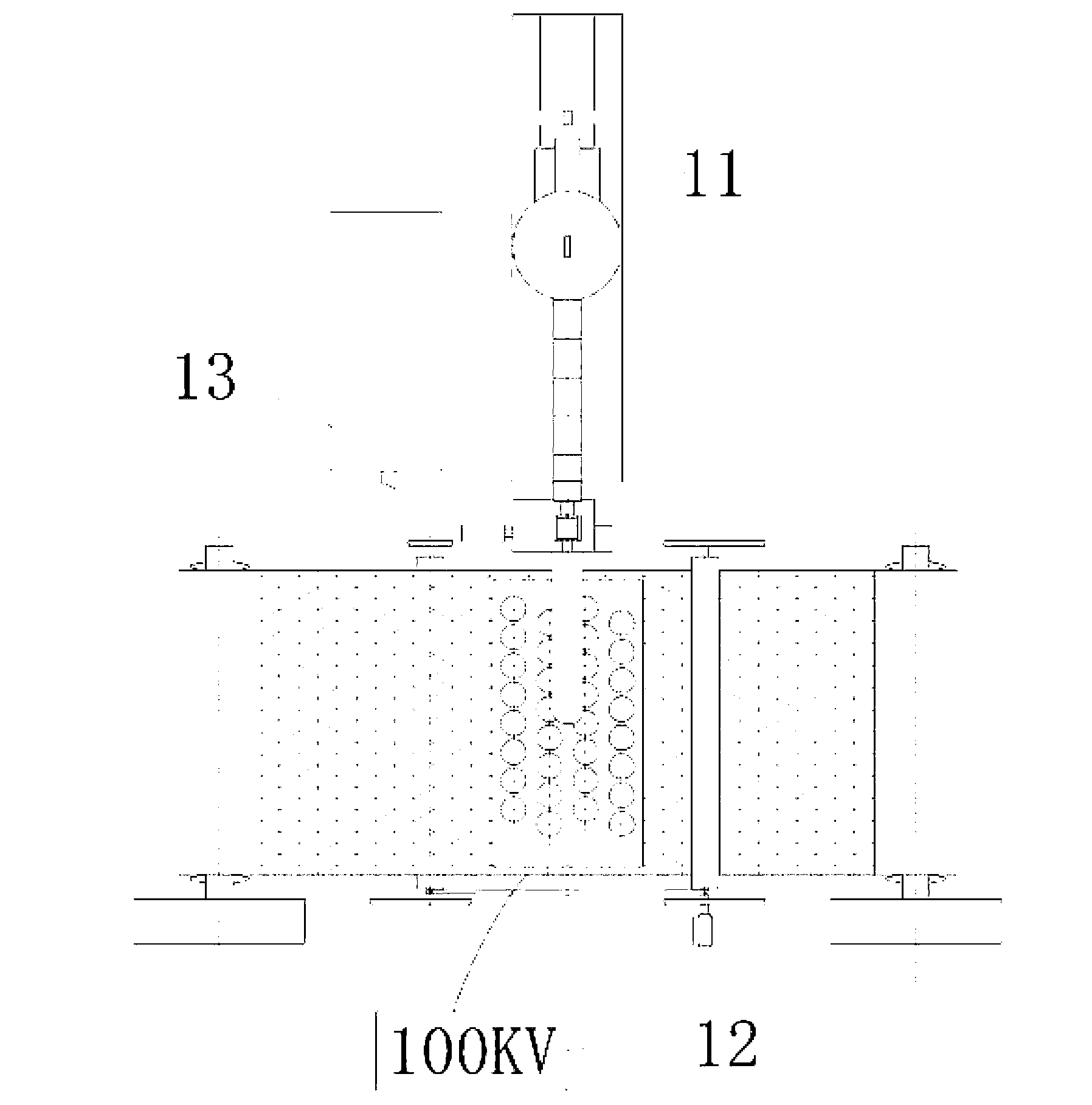

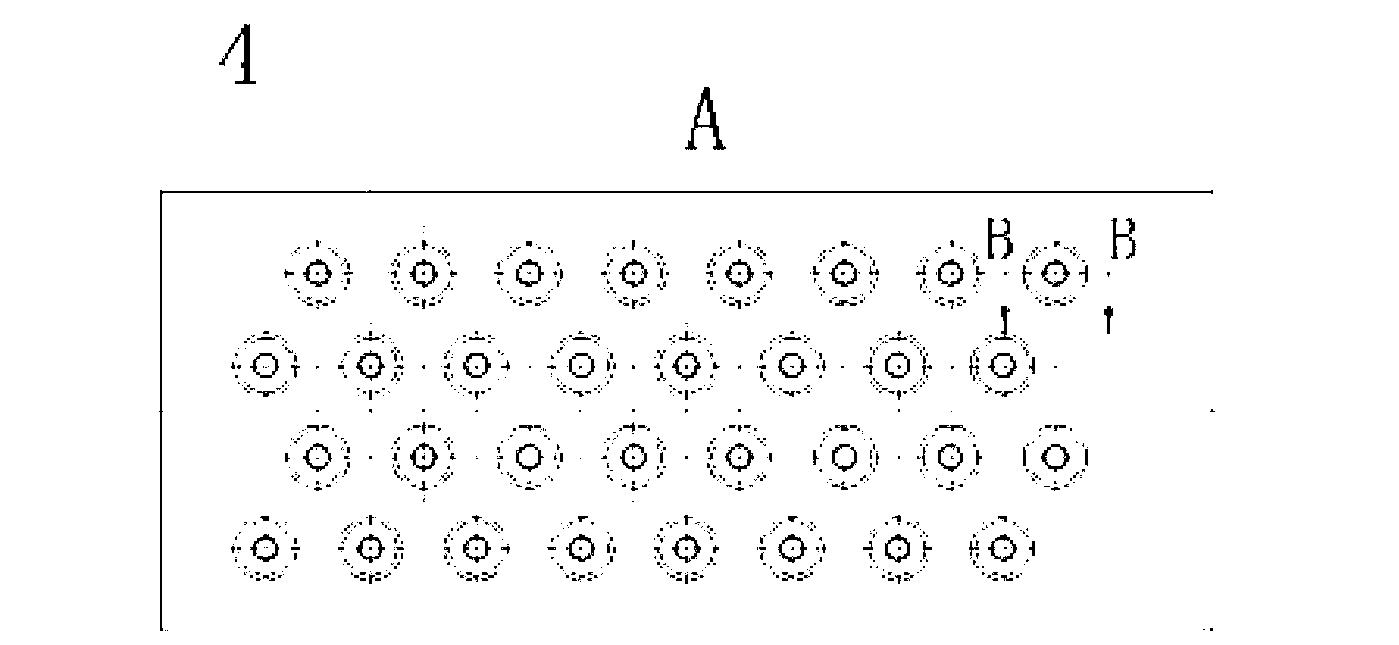

Device and process for mass production of nanometer fiber by melt electro-spinning method

ActiveCN102839431AMelt thinningFlexible arrangementSpinnerette packsFilament/thread formingMelt blowingNanofiber

The invention relates to a device and a process for mass production of nanometer fiber by a melt electro-spinning method, belonging to the field of electro-spinning. The device mainly comprises a base fabric unwinding device, a conveyor belt device, a high-voltage electrode net, a spinning die head assembly, a melt body metering pump, a static removal roller, base fabric, a base fabric winding device, a hot wind return path, an electrode net insulation support, a melt body transmission device, a high-voltage static generator and an air heating system, wherein by the application of a primary division runner in the spinning die head assembly, primary division and accurate partition temperature control of a melt body can be realized; with the creation of a nozzle on an airflow-assisted inner conical face and the assistance of high-speed hot air, secondary division thinning of a melt body layer is realized; by the whole device and the corresponding process, the problems of thick fiber and low yield of the traditional melt body spinning device and process are solved, the device and the process can substitute a melt blowing method to be the main production device and process for production of non-woven materials, and a new path is provided for the production of hundred-nanometer fiber products.

Owner:BEIJING UNIV OF CHEM TECH

Polypropylene open-cell foaming material and preparing process thereof

The invention relates to a polypropylene foaming material for opening aperture and a preparation method thereof, which pertains to the polymeric material field and aims at solving the disadvantages of the existing foaming material for opening aperture of high technological cost, difficulty in recovery, environmental pollution and complicated operation. The foaming material of the invention consists essentially of polypropylene resin composition, and the composition consists of polypropylene A with a melt flow velocity of 0.01 to 10g / 10min, polyethylene B with an Mw of 600,000 to 5,000,000, a compatilizer C and a normal additive; the additive accounts for no more than 10 weight percent, and B accounts for 1 to 40 weight percent while C accounts for 0 to 5 weight percent in the mixture of A, B and C. The composition is heated over the molten temperature thereof in the invention, a physical foaming agent with 1 to 20 percent of the melt in weight is injected under the pressure larger than the pressure of the melt, then the mixture is exposed under the environment with a pressure lower than the pressure of the composition melt, thus the polypropylene foaming material for opening aperture is prepared. The invention has the advantages of low cost, simple operation, no pollution, uniform and unblocked foam pores, and the opening percentage of at least 50 percent.

Owner:BEIJING UNIV OF CHEM TECH +1

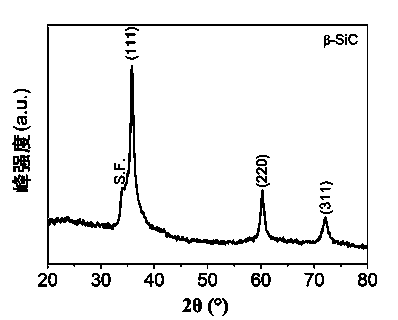

Preparation method of porous silicon carbide nanofiber

ActiveCN103966701AUniform diameterLarge specific surface areaArtificial filament chemical after-treatmentFiltrationElectrospinning

The invention discloses a preparation method of a porous silicon carbide nanofiber. The preparation method comprises the following steps of: (1) preparing a carbon nanofiber precursor polymer spinning solution; (2) performing electrostatic spinning to prepare a polymer nanofiber; (3) carrying out pre-oxidization crosslinking on the polymer nanofiber; (4) carrying out high-temperature firing on the pre-oxidized polymer nanofiber to prepare a carbon nanofiber; and (5) carrying out carbon thermal reduction on the carbon nanofiber and silicon powder to obtain the porous silicon carbide nanofiber. According to the preparation method, the morphology, the diameter and the ordering of the obtained silicon carbide nanofiber can be effectively regulated and controlled through simple means; the production cycle is relatively short so that expanded production can be conveniently realized and the preparation process is simple so that the industrial production can be conveniently realized; the porous silicon carbide nanofiber has wide application prospect in the fields of high-temperature filtration, high-temperature catalysis, catalyst carriers, heat insulation and sound insulation, gas separation, chemical sensors and the like.

Owner:NAT UNIV OF DEFENSE TECH

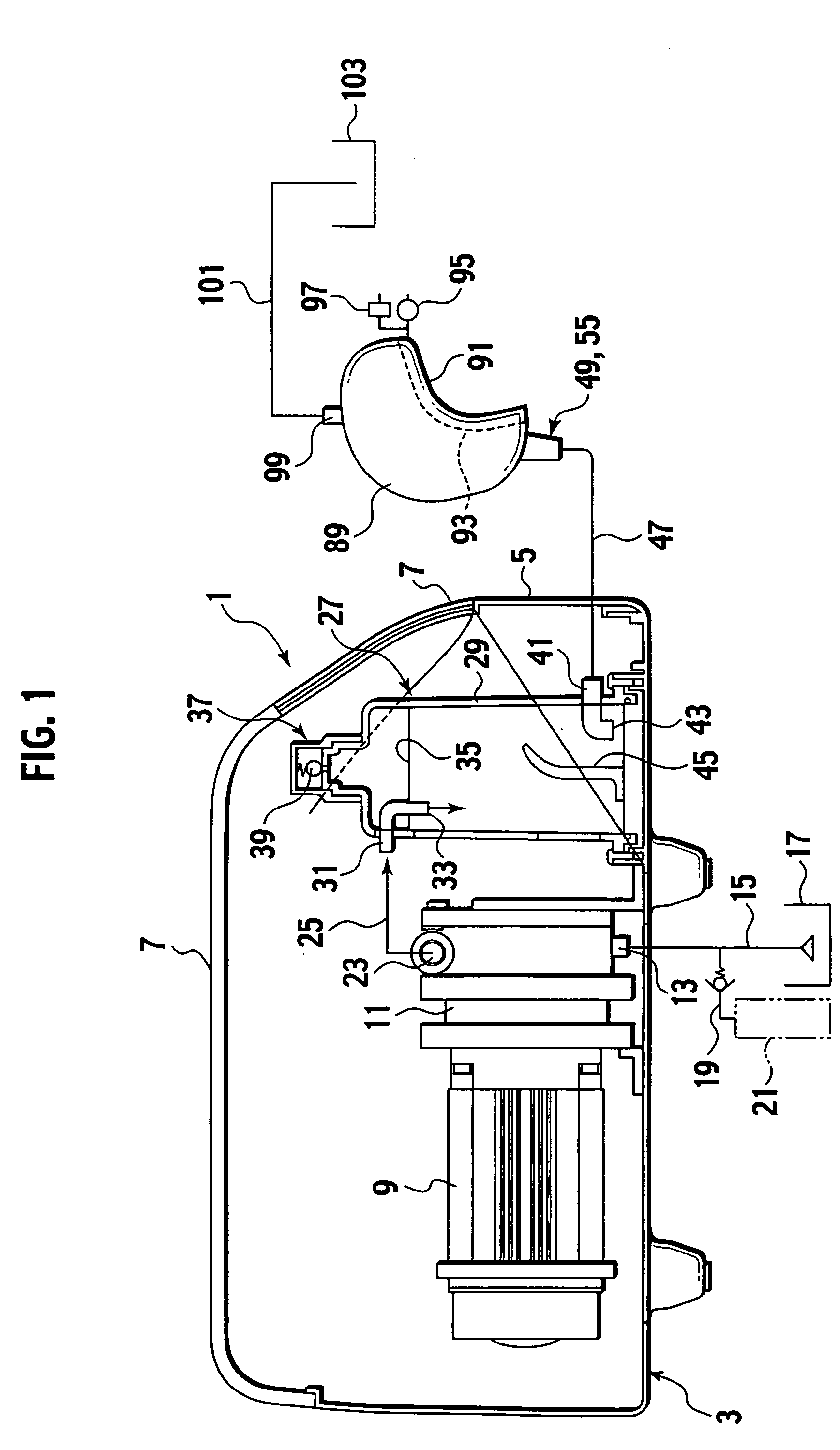

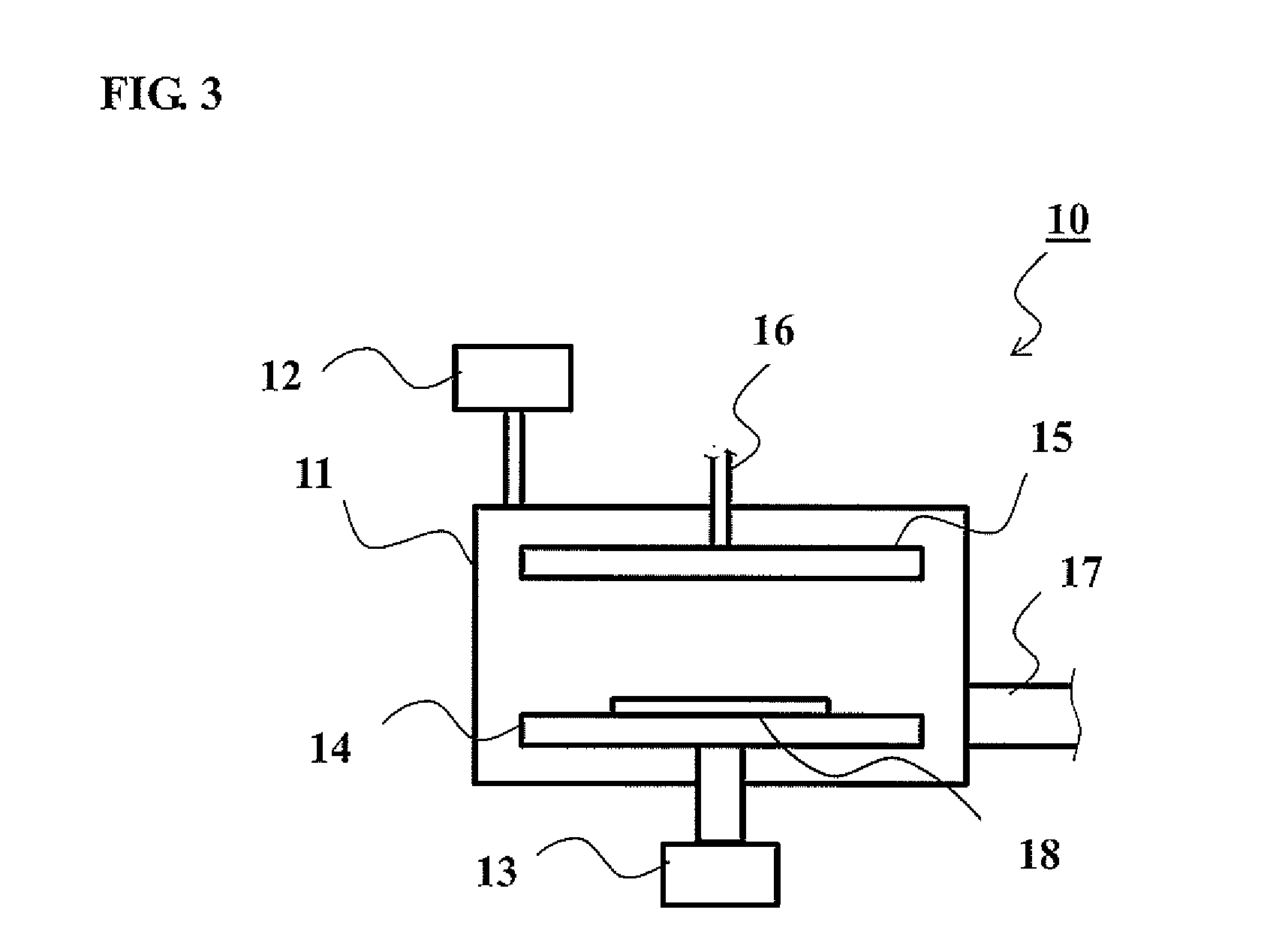

Microbubble generating device and hair washing device utilizing the same

InactiveUS20070108640A1Uniform bubble diameterUniform diameterFlow mixersMixing methodsExhaust valveMicrobubbles

A dissolving water making unit and a bubble generating unit are provided. The dissolving water making unit includes a gas dissolving device for dissolving gas in water. The bubble generating unit includes a bubble generating nozzle and a bubble generating cartridge. The dissolving water making unit sucks water from a water source, and sucks gas to make dissolving water from a mixed solution in which the water and the gas are mixed together. The dissolving water is obtained by dissolving the gas in the water. The bubble generating unit generates microbubbles from the dissolving water supplied from the dissolving water making unit. The gas dissolving device includes a closed vessel; an inflow port which is provided in the closed vessel, and which is provided for causing the mixed liquid sucked from the source to flow into the closed vessel; an exhaust valve which is provided in an upper portion of the closed vessel, and which is provided for exhausting excess gas from the mixed liquid; and an outflow port which is provided near a bottom portion of the closed vessel, and which is provided for causing the dissolving water to flow out from the closed vessel to the bubble generating unit. Between the inflow port and the outflow port, the closed vessel has a retention region in which the dissolving water flows slowly, in which air is dissolved in the dissolving water to substantial saturation, and in which the dissolving water hardly contains fine bubbles. A hair washing device includes a hair washing bowl having an opening portion in which a head region can be accepted. The bubble generating unit is attached to a lower portion of the hair washing bowl. In an upper portion of the hair washing bowl, an exhaust port for exhausting water from the hair washing bowl is provided.

Owner:SHIGEN KAIHATSU

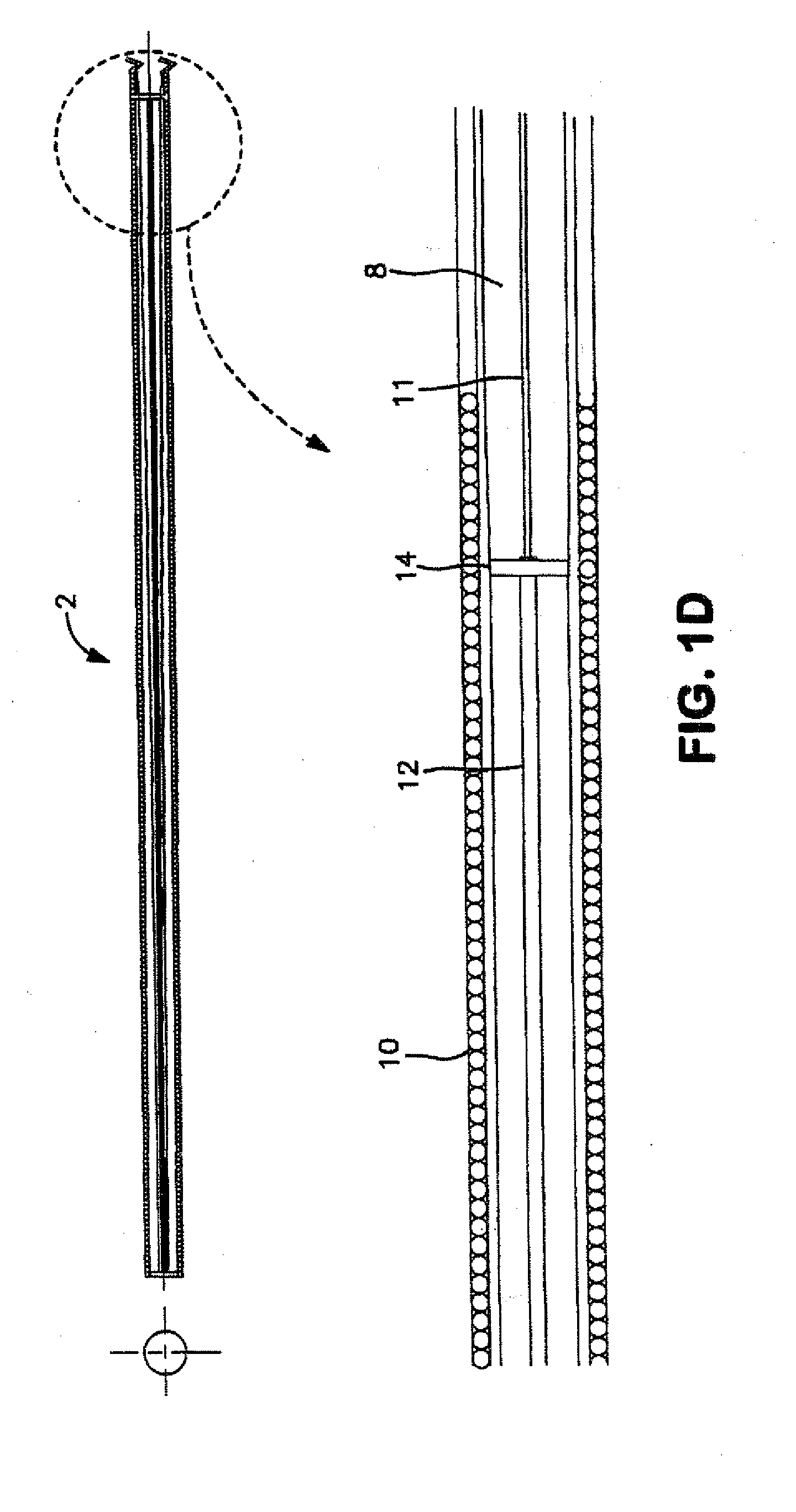

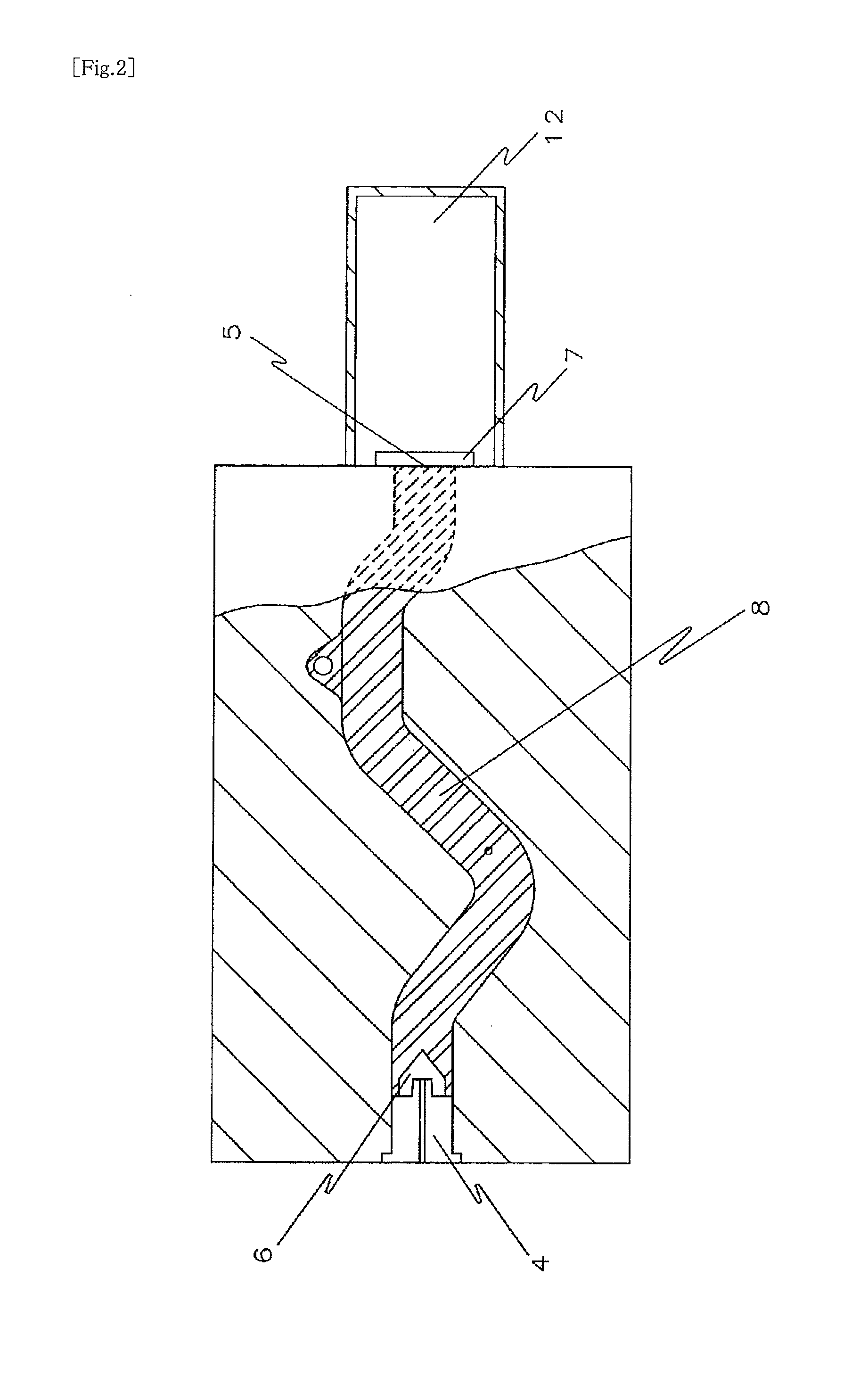

Method of manufacturing hollow body

ActiveUS20120068388A1Uniform inner diameterUniform thicknessTubular articlesHollow articlesMaterials scienceSurface smoothness

A hollow body formed of a thermoplastic resin and having uniform inner diameter and thickness and an excellent inner surface smoothness, and, in particular, a pipe-shaped hollow body having a bent portion is manufactured by injection molding.A method of manufacturing a hollow body includes injecting a molten resin 8 into a mold cavity 2 of a mold 1, the mold cavity 2 having on its one end a pressure port 4 provided with a floating core 6 and on its other end an outlet 5, pressure-injecting a pressurized fluid through the pressure port 4 after the injection of the molten resin 8, and moving the floating core 6 toward the outlet 5, and, at the same time, extruding the molten resin 8 from the outlet 5. In the method, the floating core 6 is constituted of a columnar portion and a top portion, which is continuously connected to one surface of the columnar portion and has a shape that a cross-sectional area perpendicular to a central axis of the columnar portion gradually decreases from one surface side of the columnar portion. When a diameter of the columnar portion is represented by A, the height of the columnar portion is 0.1 A to 1 A, and the height of the top portion is 0.3 A to 1.6 A.

Owner:RP TOPLA

Dry Etching Method

ActiveUS20160218015A1Reduce bumpsReduce depressionSemiconductor/solid-state device manufacturingSilicon oxidePlasma Gases

Disclosed is a dry etching method for a laminated film in which at least one silicon layer and at least one silicon oxide layer are laminated together. The dry etching method includes generating a plasma gas from a dry etching agent and etching the laminated film with the plasma gas under the application of a bias voltage. The dry etching agent contains an unsaturated hydrofluorocarbon represented by the following formula: C3HxFy where x is an integer of 1 to 5; y is an integer of 1 to 5; and x and y satisfy a relationship of x+y=4 or 6, and iodine heptafluoride. The volume of the iodine heptafluoride in the dry etching agent is 0.1 to 1.0 times the volume of the unsaturated hydrofluorocarbon in the dry etching agent.

Owner:CENT GLASS CO LTD

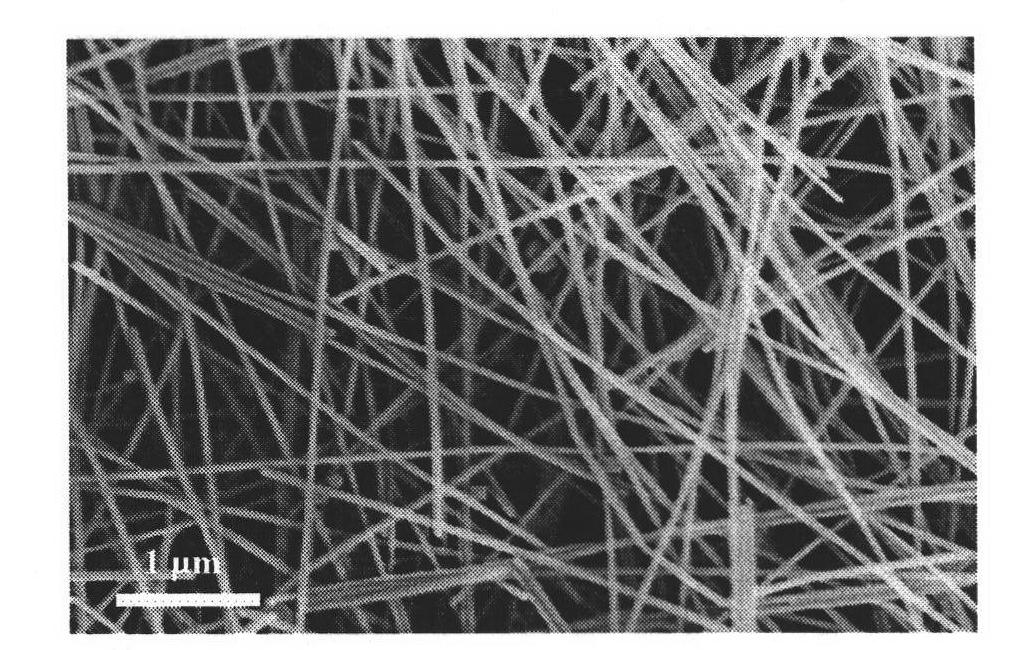

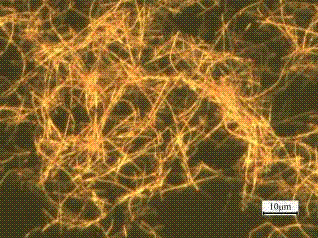

Controllable preparation method of monocrystal copper nanowires

InactiveCN102251278AFlat surfaceUniform radial thicknessPolycrystalline material growthFrom normal temperature solutionsDivalent metalIon

The invention relates to a preparation method of copper nanowires and in particular relates to a controllable preparation method of high-yield monocrystal copper nanowires in a liquid-phase reduction manner. The controllable preparation method comprises the steps: firstly, mixing a divalent metal copper salt solution and ethylenediamine, and heating in a water bath to form a single and stable copper ion chelate compound; mixing a strong base solution with hydrazine hydrate, and preparing a reducing agent in the water bath at the same temperature; then transferring the two mixture solutions into a reaction vessel, fully stirring to reach a uniform state, covering well, and placing in the water bath at the same temperature for heating reaction to prepare the copper nanowires; and fishing out flaky copper nanowires floating on the upper layer of the solution, washing the flaky copper nanowires with deionized water and absolute ethyl alcohol in sequence three times, and drying at room temperature under an Ar gas protection condition to prepare the copper nanowires. The controllable preparation method provided by the invention has the advantages of simple process, low cost and high yield, and the prepared copper nanowires are of monocrystal structures, and have relatively smooth surfaces, uniform radial thickness, and controllable and more uniform length and diameter.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com