Patents

Literature

73 results about "Metallic nanotubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanotube articles with adjustable electrical conductivity and methods of making the same

InactiveUS20060276056A1Improve the immunityElectrical resistance increaseMaterial nanotechnologyFixed capacitor dielectricElectrical resistance and conductanceElectrical conductor

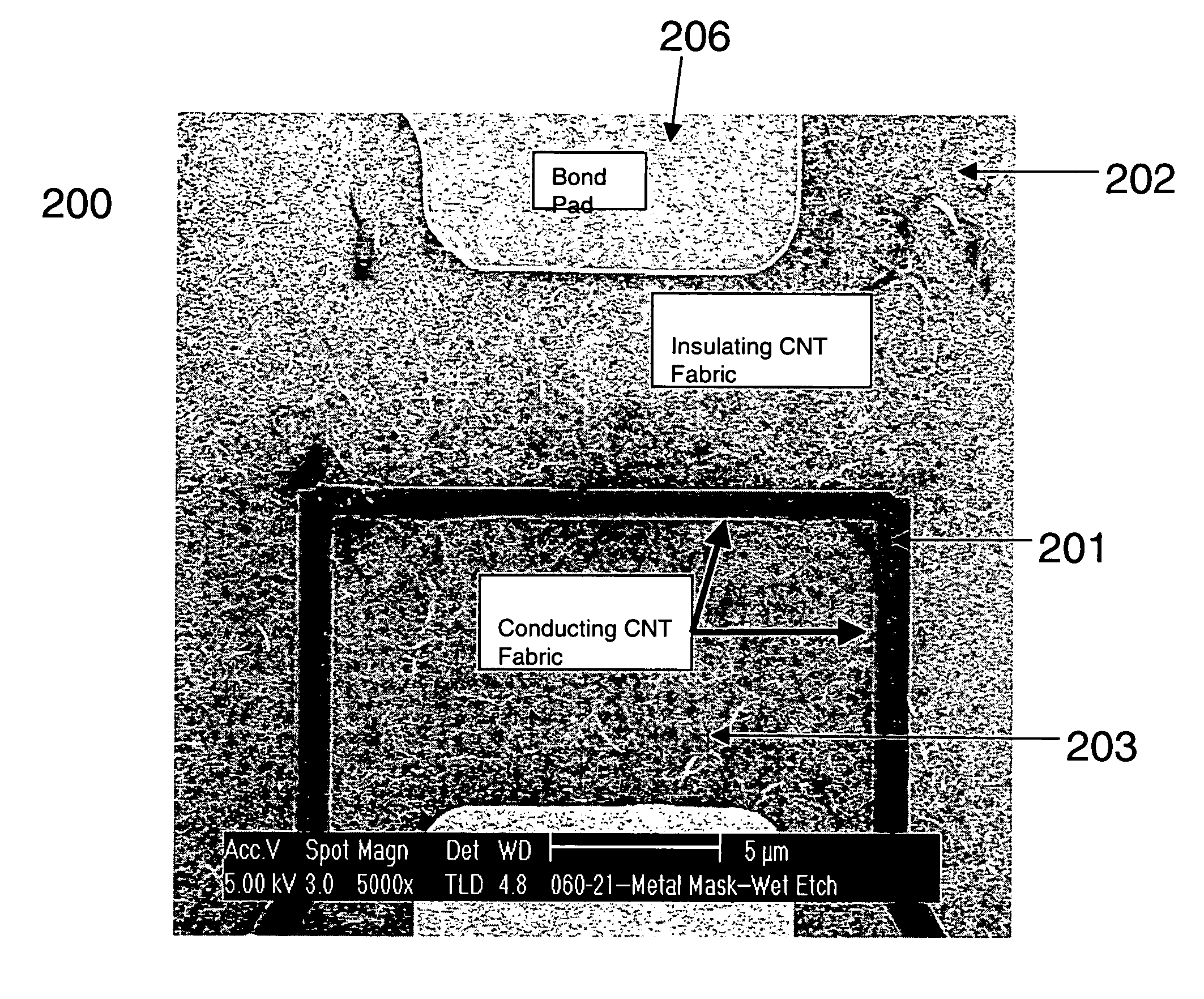

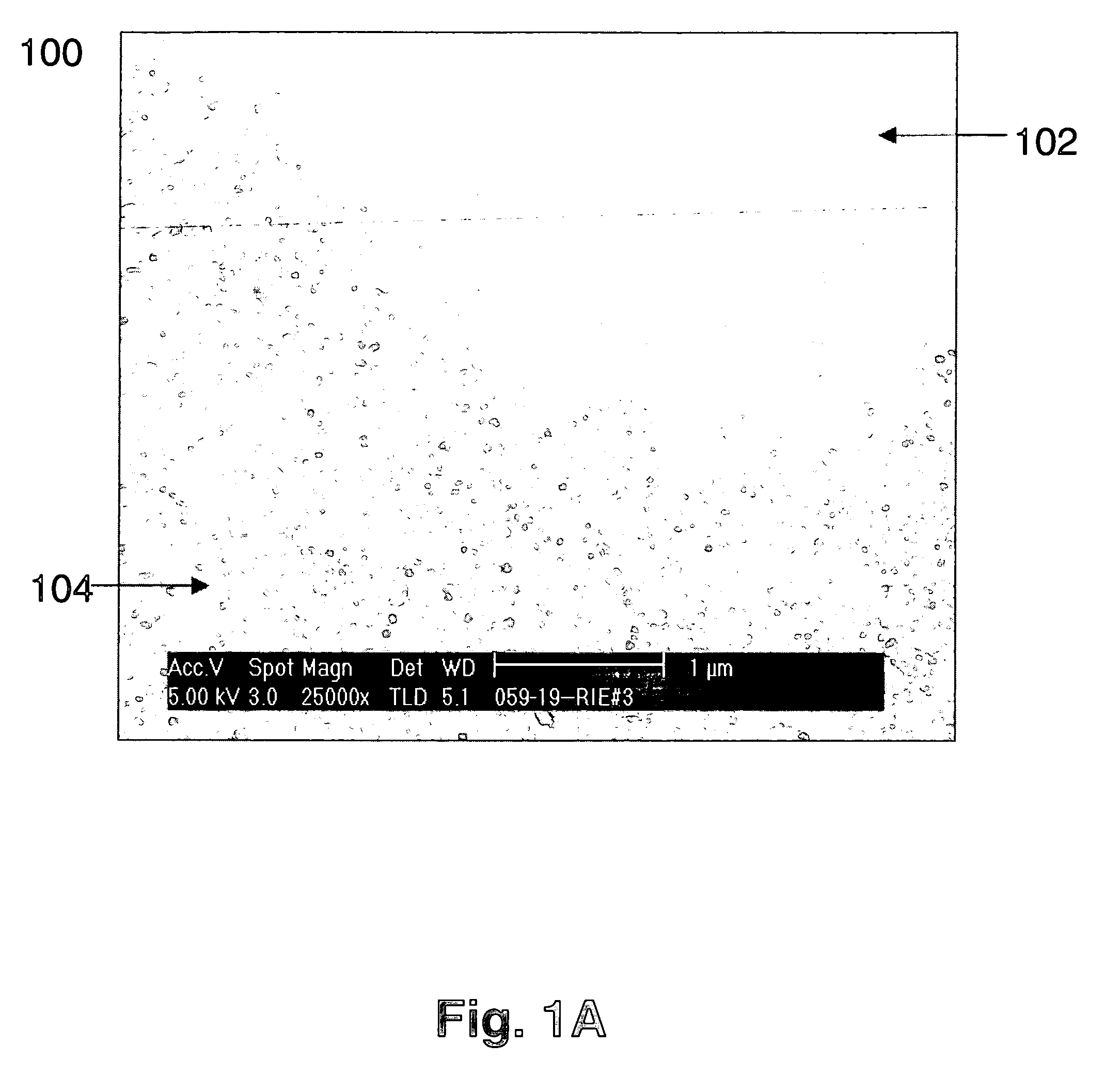

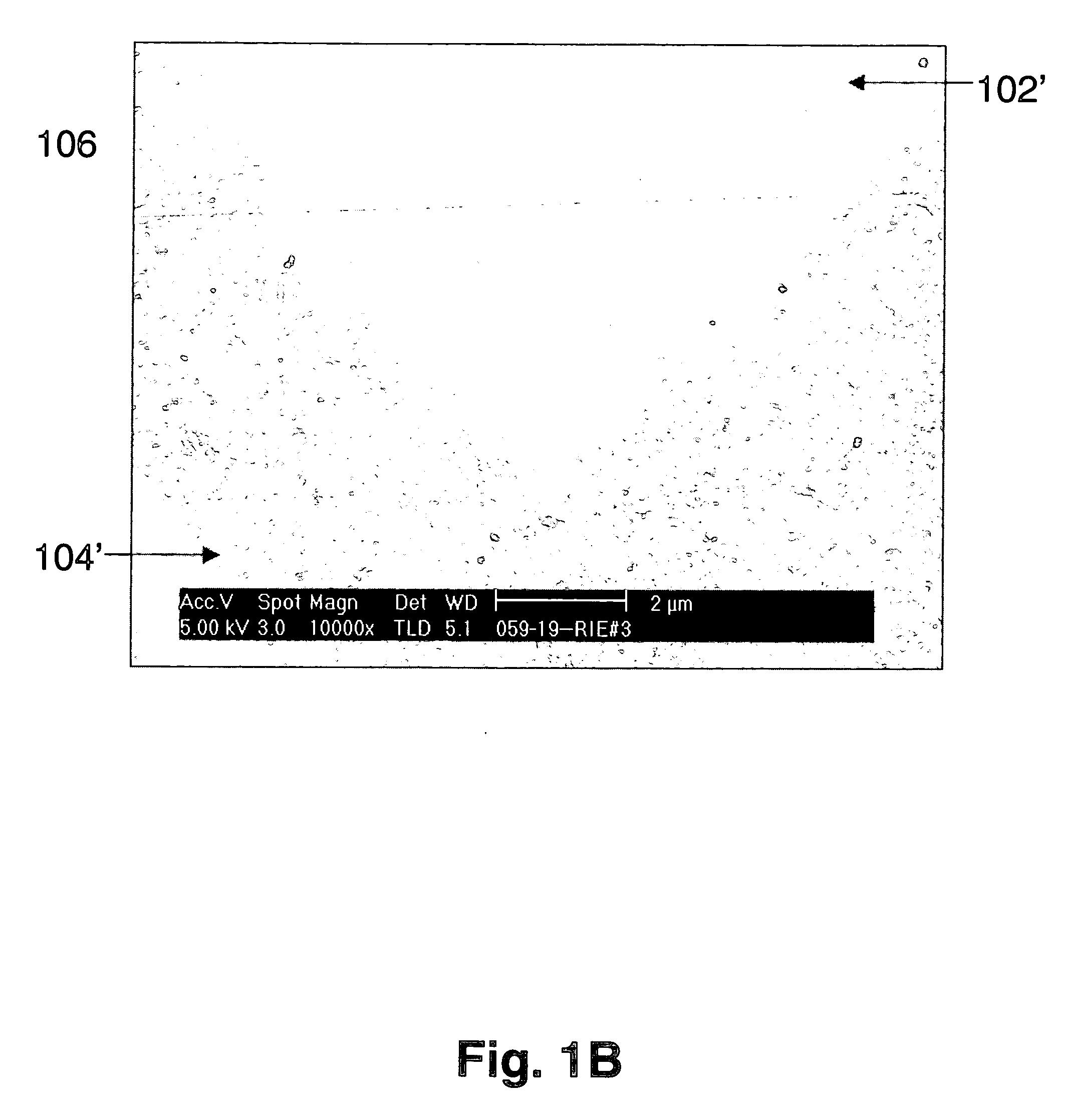

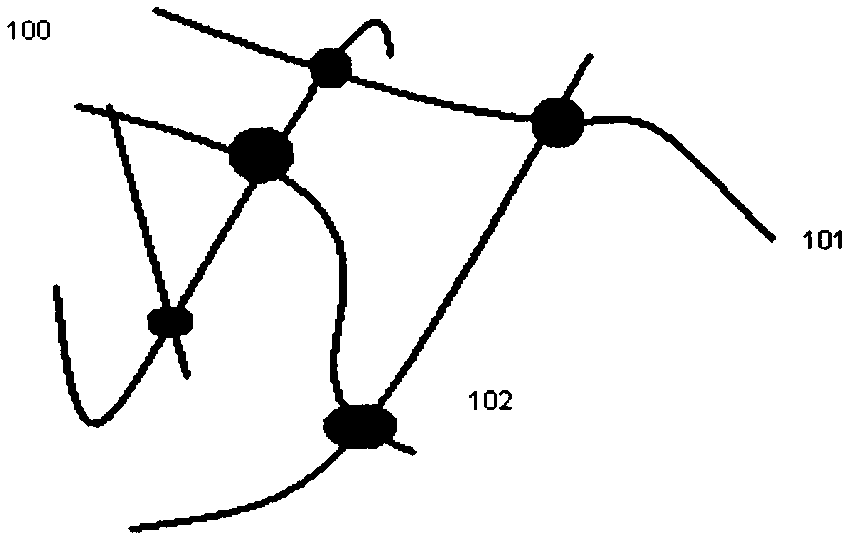

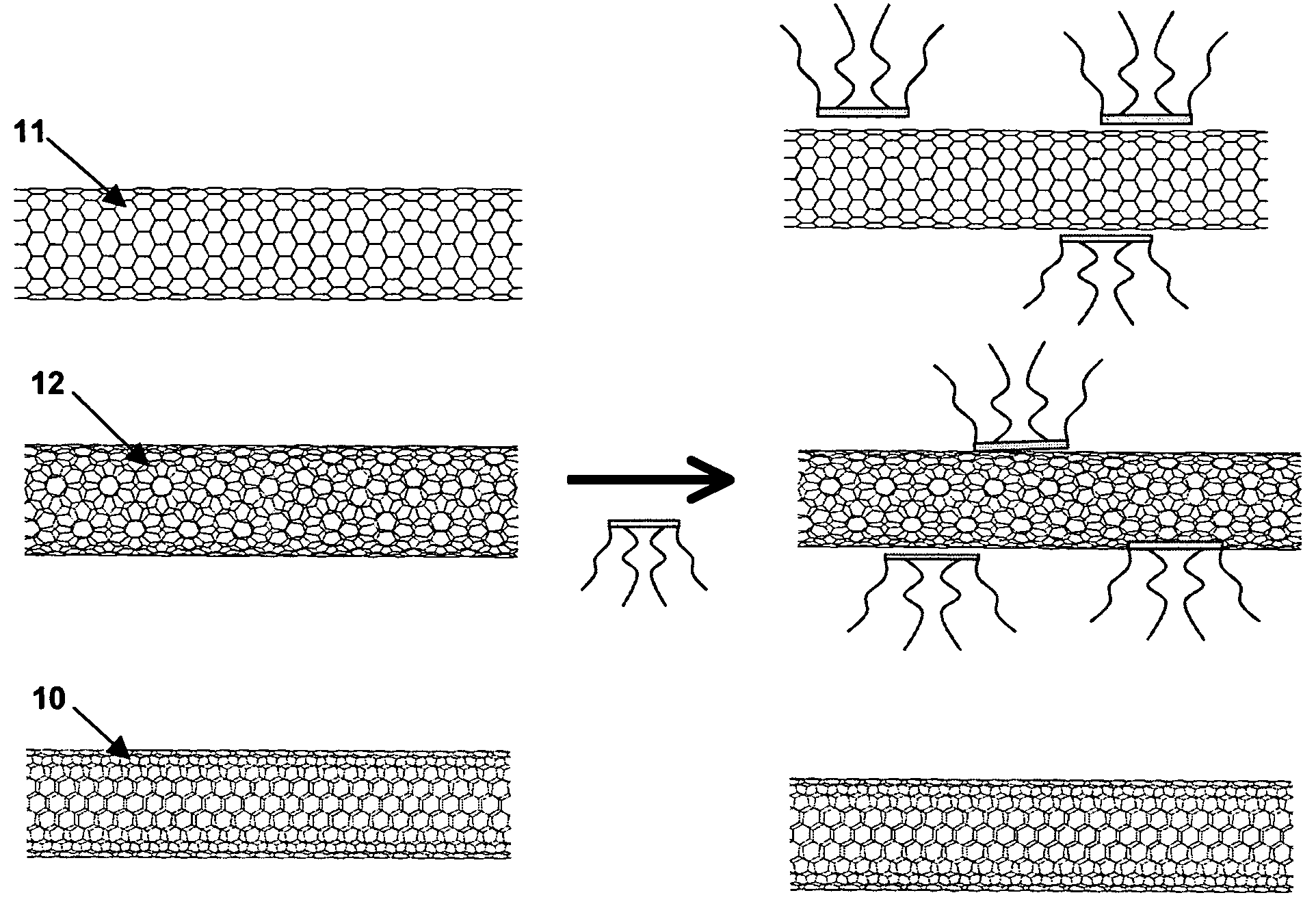

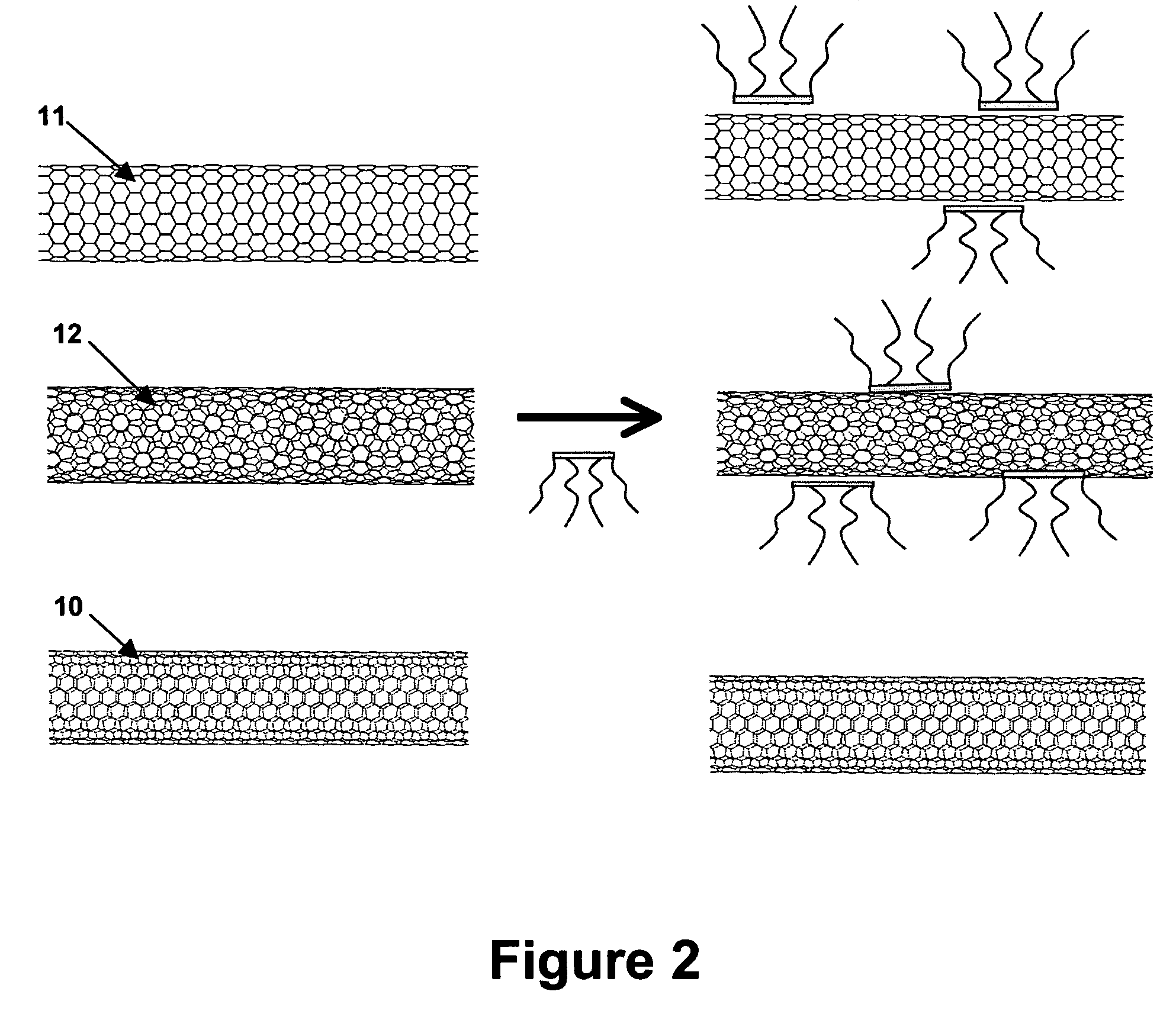

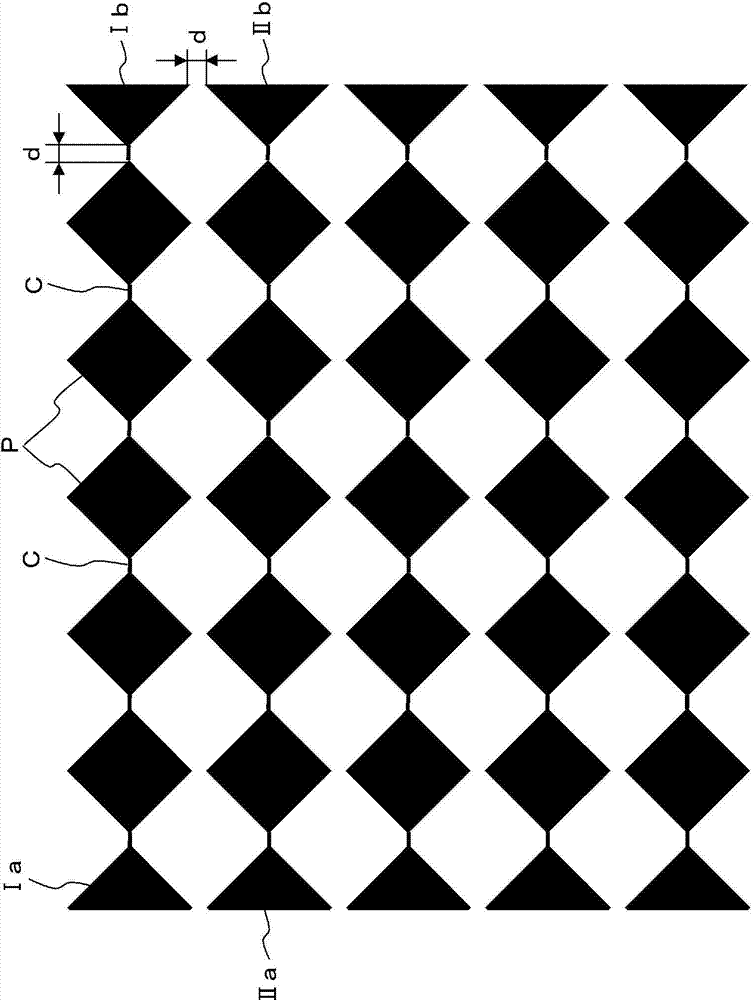

Nanotube articles having adjustable electrical conductivity, and methods of making the same. A patterned article includes conducting nanotubes that define a plurality of conductive pathways along the article, and also includes nanotubes of modified electrical conductivity. The modified nanotubes may electrically isolate the conducting nanotubes from other conductors. The nanotube segments may originally be semiconducting nanotubes, metallic nanotubes, nanotubes, single walled carbon nanotubes, multi-walled carbon nanotubes, or nanotubes entangled with nanotubes. The various segments may have different lengths and may include segments having a length shorter than the length of the article. A strapping material may be positioned to contact a portion of the plurality of nanotube segments. Such a strapping layer may also be used for making electrical contact to the nanotube fabric especially for electrical stitching to lower the overall resistance of the fabric.

Owner:NANTERO

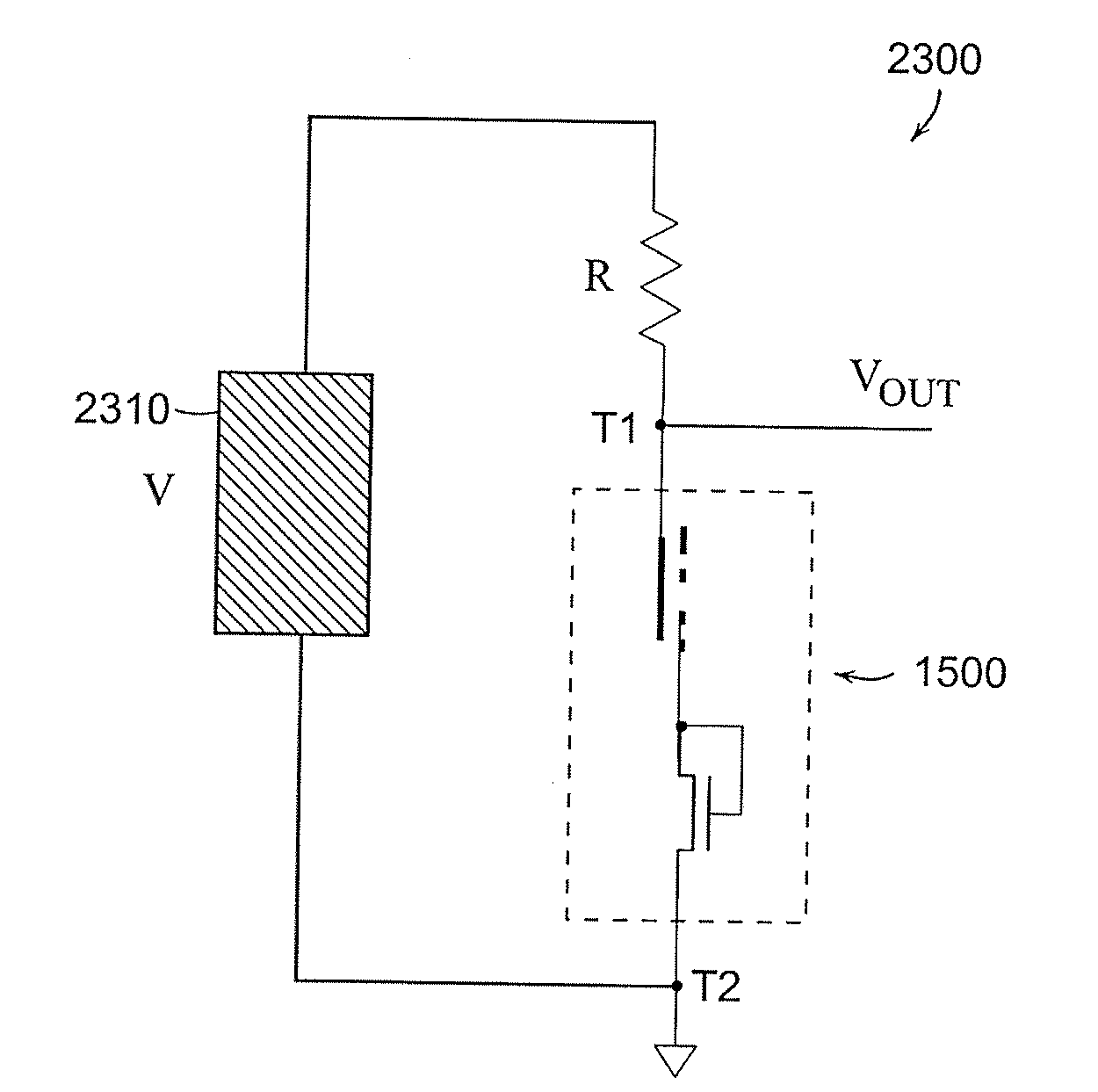

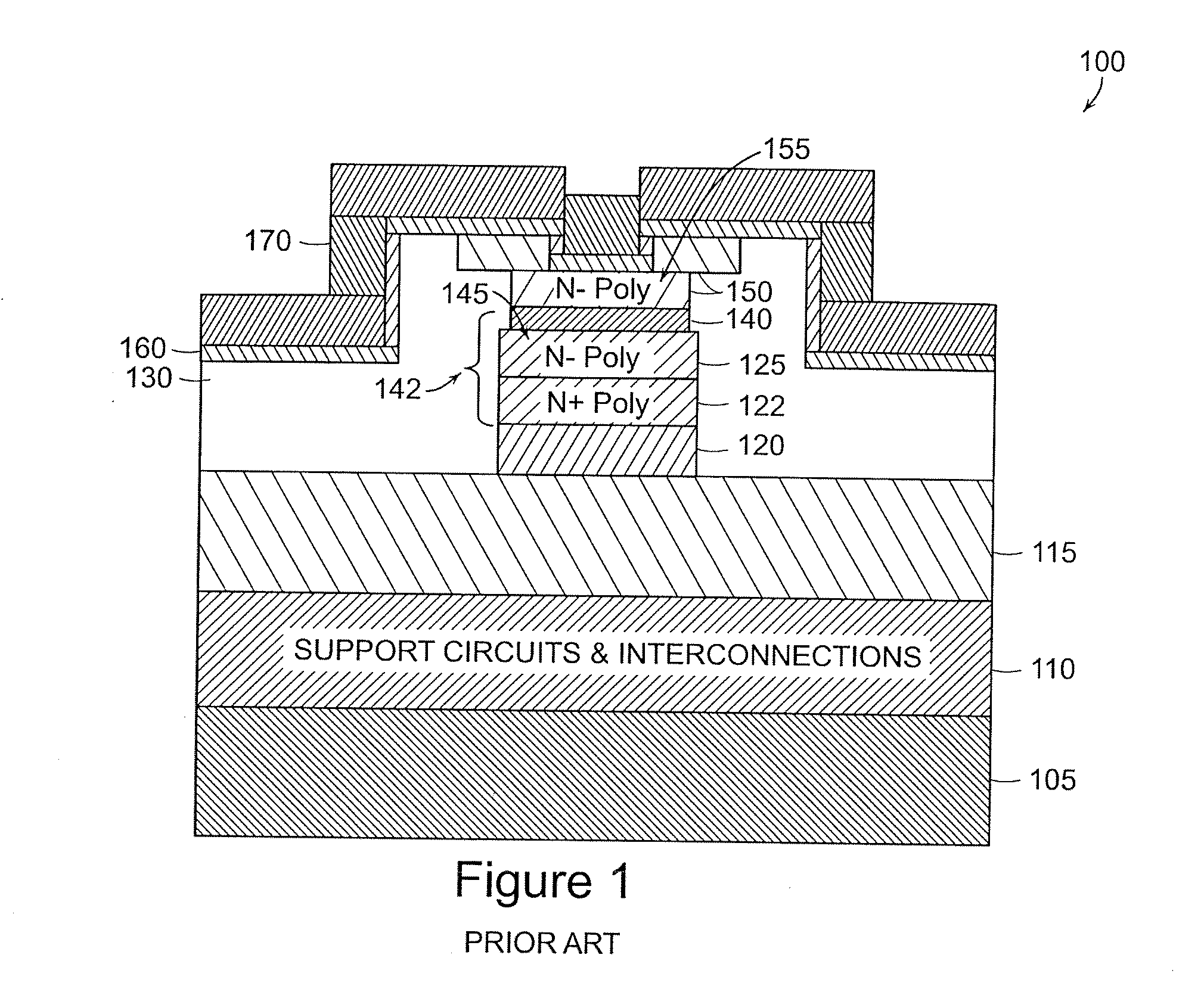

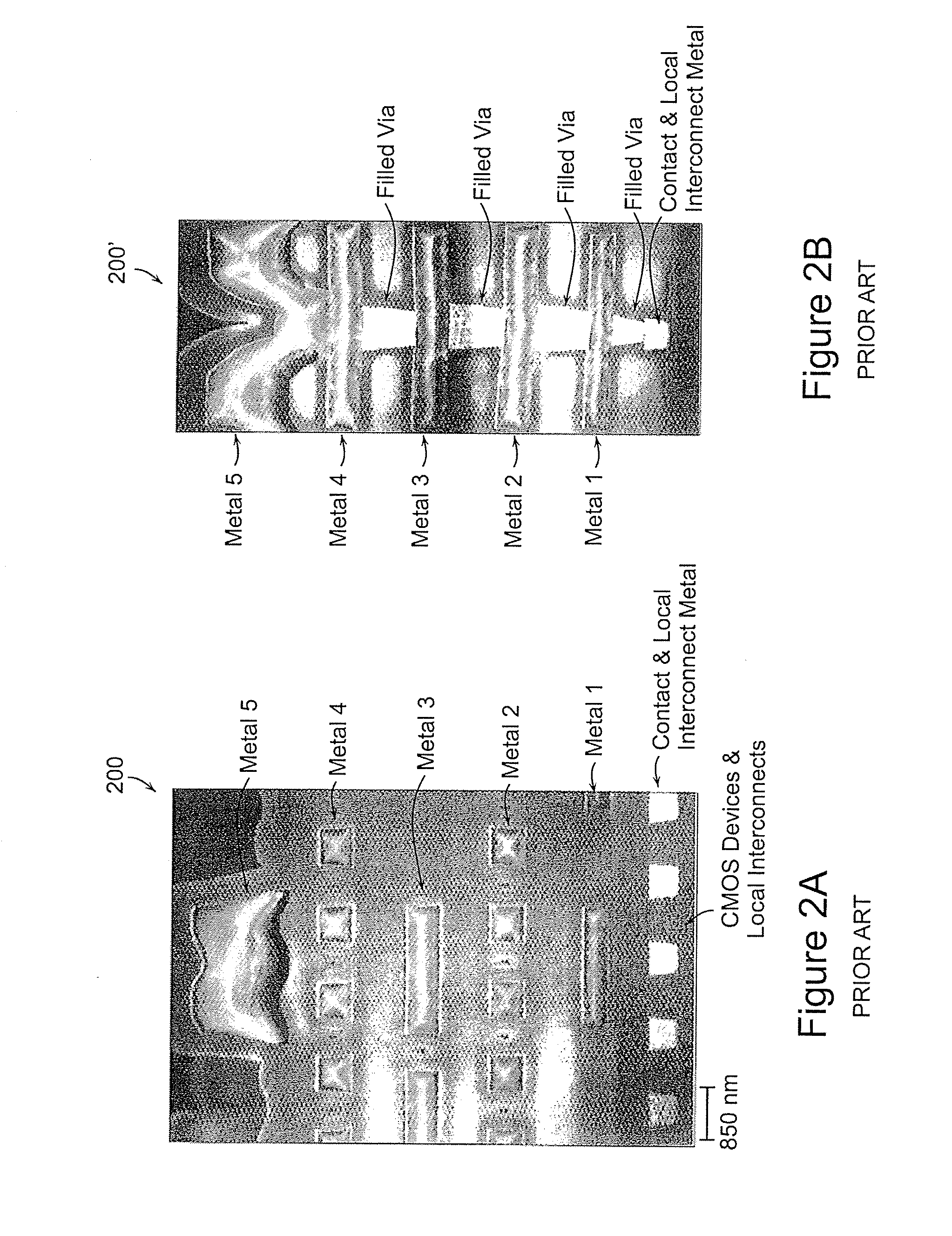

Nonvolatile nanotube diodes and nonvolatile nanotube blocks and systems using same and methods of making same

ActiveUS20080157257A1High resistance stateLow resistance stateSemiconductor/solid-state device detailsNanoinformaticsSchottky barrierSemiconductor materials

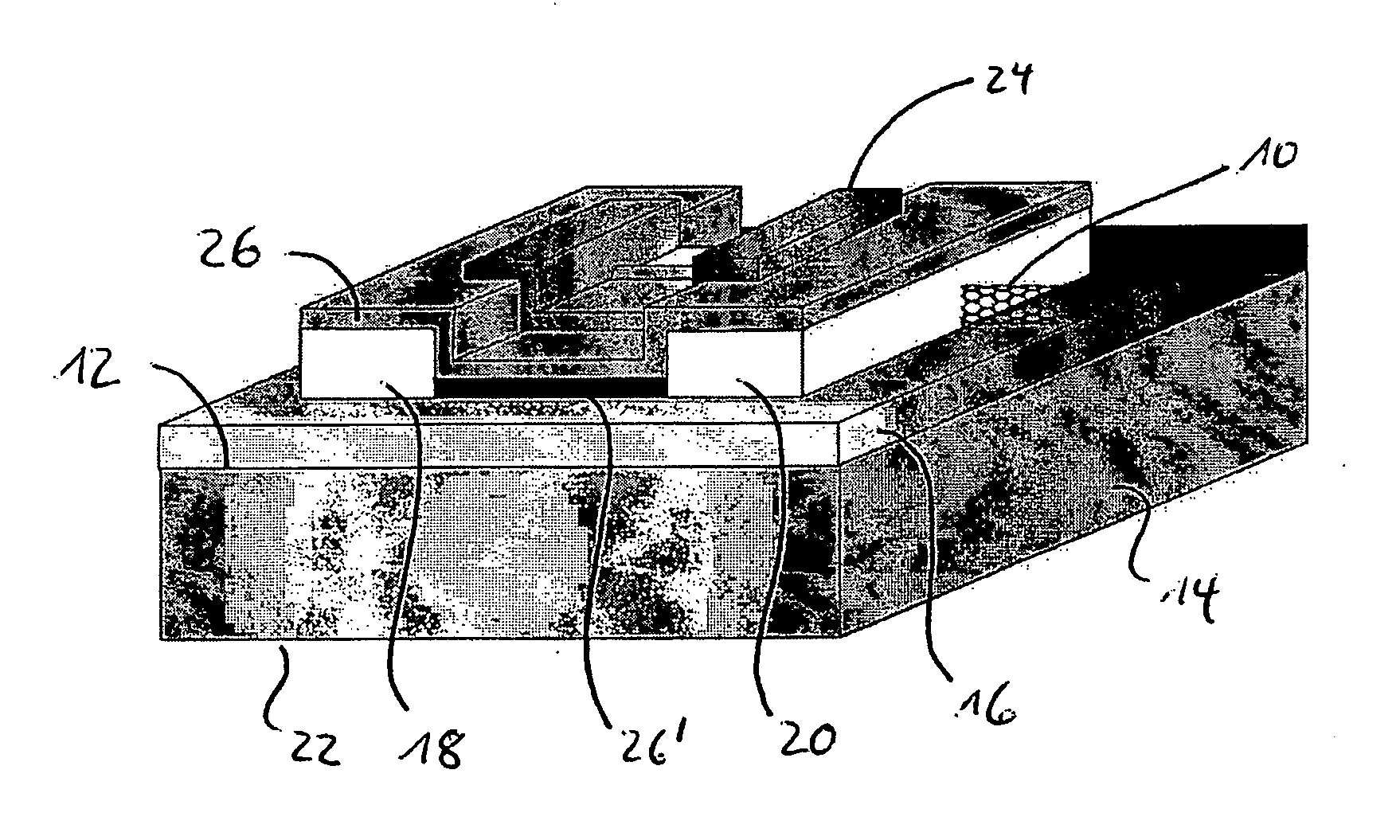

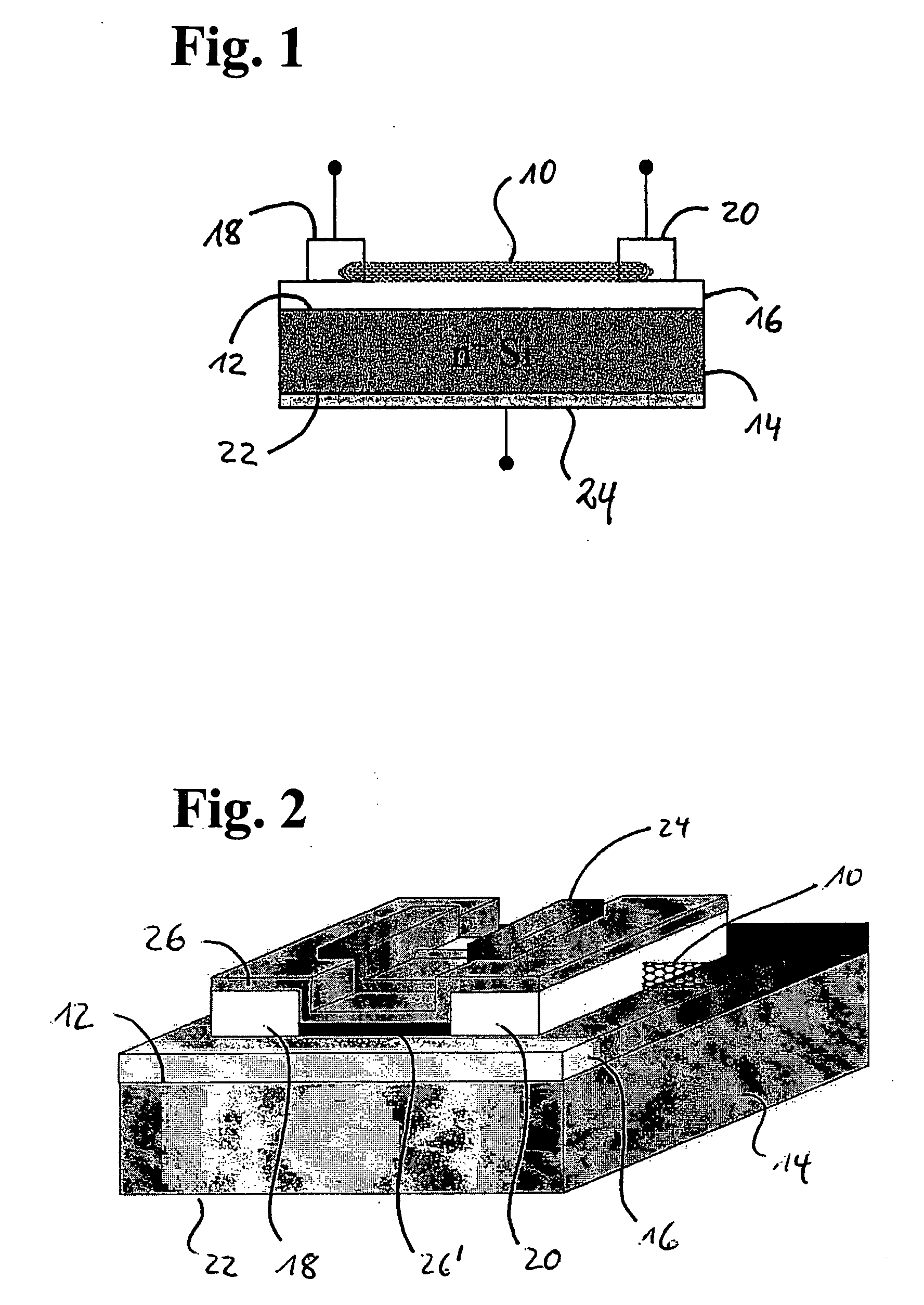

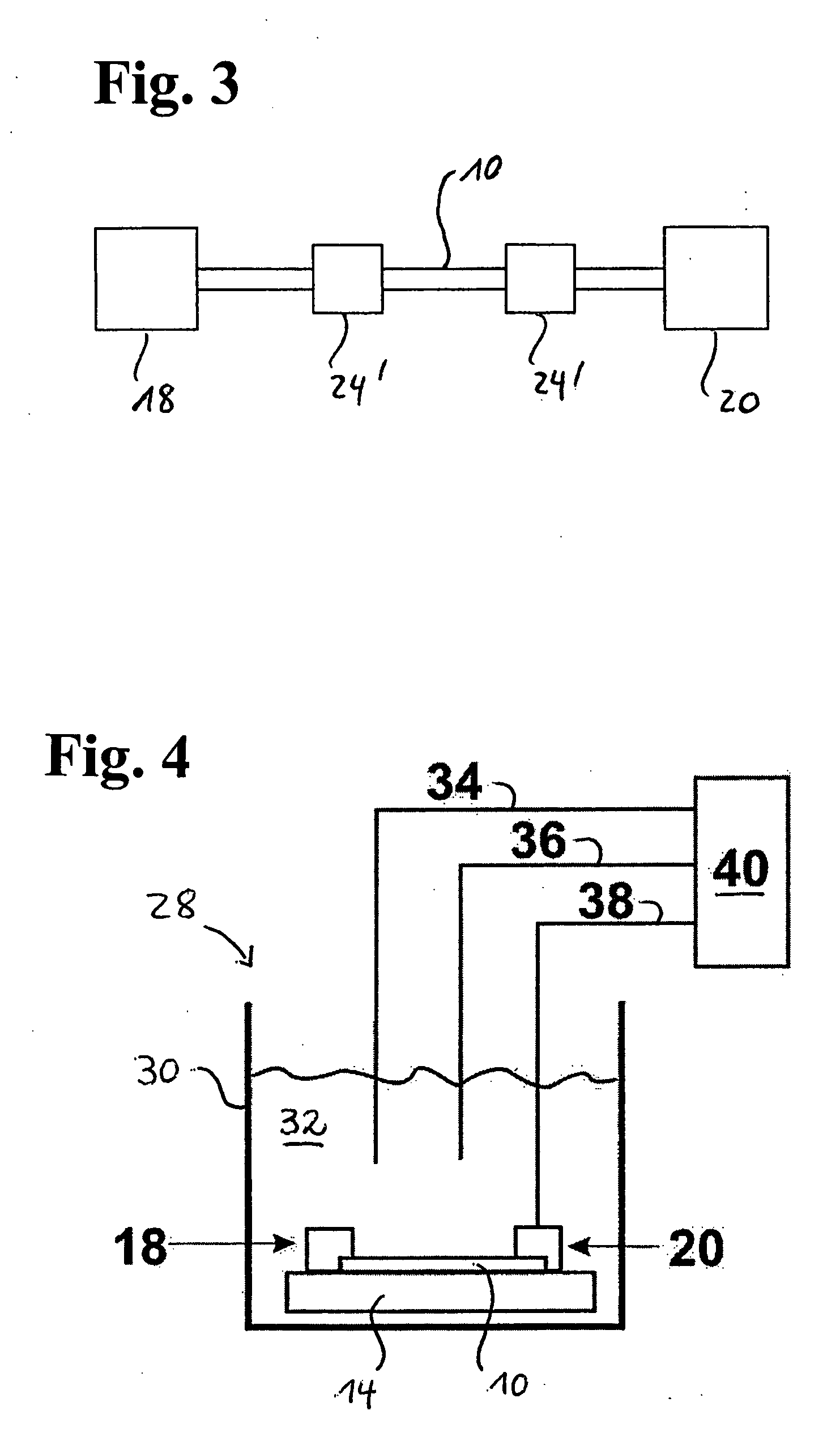

Under one aspect, a nanotube diode includes: a cathode formed of a semiconductor material; and an anode formed of nanotubes. The cathode and anode are in fixed and direct physical contact, and are constructed and arranged such that sufficient electrical stimulus applied to the cathode and the anode creates a conductive pathway between the cathode and the anode. In some embodiments, the anode includes a non-woven nanotube fabric having a plurality of unaligned nanotubes. The non-woven nanotube fabric may have a thickness, e.g., of 0.5 to 20 nm. Or, the non-woven nanotube fabric may include a block of nanotubes. The nanotubes may include metallic nanotubes and semiconducting nanotubes, and the cathode may include an n-type semiconductor material. A Schottky barrier can form between the n-type semiconductor material and the metallic nanotubes and / or a PN junction can form between the n-type semiconductor material and the semiconducting nanotubes.

Owner:NANTERO

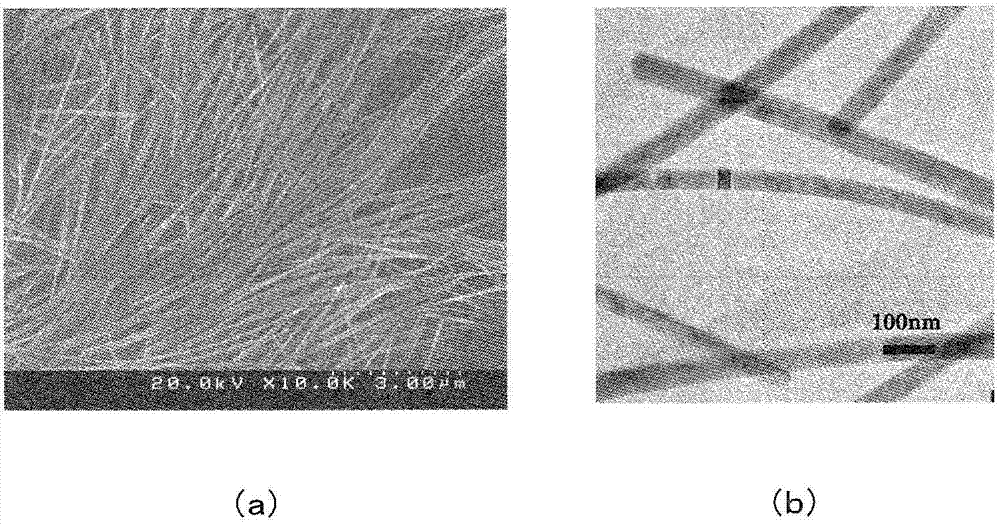

Carbon nano material/metal nano material composite nano ink

InactiveCN102993820AReduce manufacturing costLow costConductive layers on insulating-supportsInksCyclohexanoneKetone

The invention provides a carbon nano material / metal nano material composite nano ink which comprises solvent, an additive, a carbon nano material and a metal nano material. The carbon nano material / metal nano material composite nano ink is characterized in that the solvent can comprise water, alcohol organic solvent (ethanol(alcohol), isopropanol, n-butanol and the like), ester organic solvent (ethyl acetate, butyl acetate, ethylene-propylene acetate and the like), benzene organic solvent (methylbenzene, dimethylbenzene and the like) and ketone organic solvent (cyclohexanone, acetone, methylethylketone, butanone and the like); the additive comprises surfactant, pH value stabilizer, defoaming agent, diluter, reinforcer and the like; the carbon nano material comprises a single-layer carbon nanotube, a double-layer carbon nanotube, a multi-layer carbon nanotube and graphene; the metal (copper, silver, gold, platinum, nickel and the like, also including an alloy nano material, an ITO metal composite nano material and the like) nano material further comprises a metal nanoparticle, a metal nanowire or a metal nanotube; the components of the nano ink must include one carbon nano component and one metal nano component, such as a single-layer carbon nanotube and copper nanowire composite ink, a double-layer carbon nanotube and silver nanowire composite ink, a single-layer carbon nanotube and silver nanoparticle composite ink or any other possible combination; the components can be regulated according to specific applications; and a composite nano conductive film can be formed on different bases through different electronic printing processes. The ink can be used in the printing of a flexible base material and can be conveniently prepared into a flexible conductive film.

Owner:杨阳

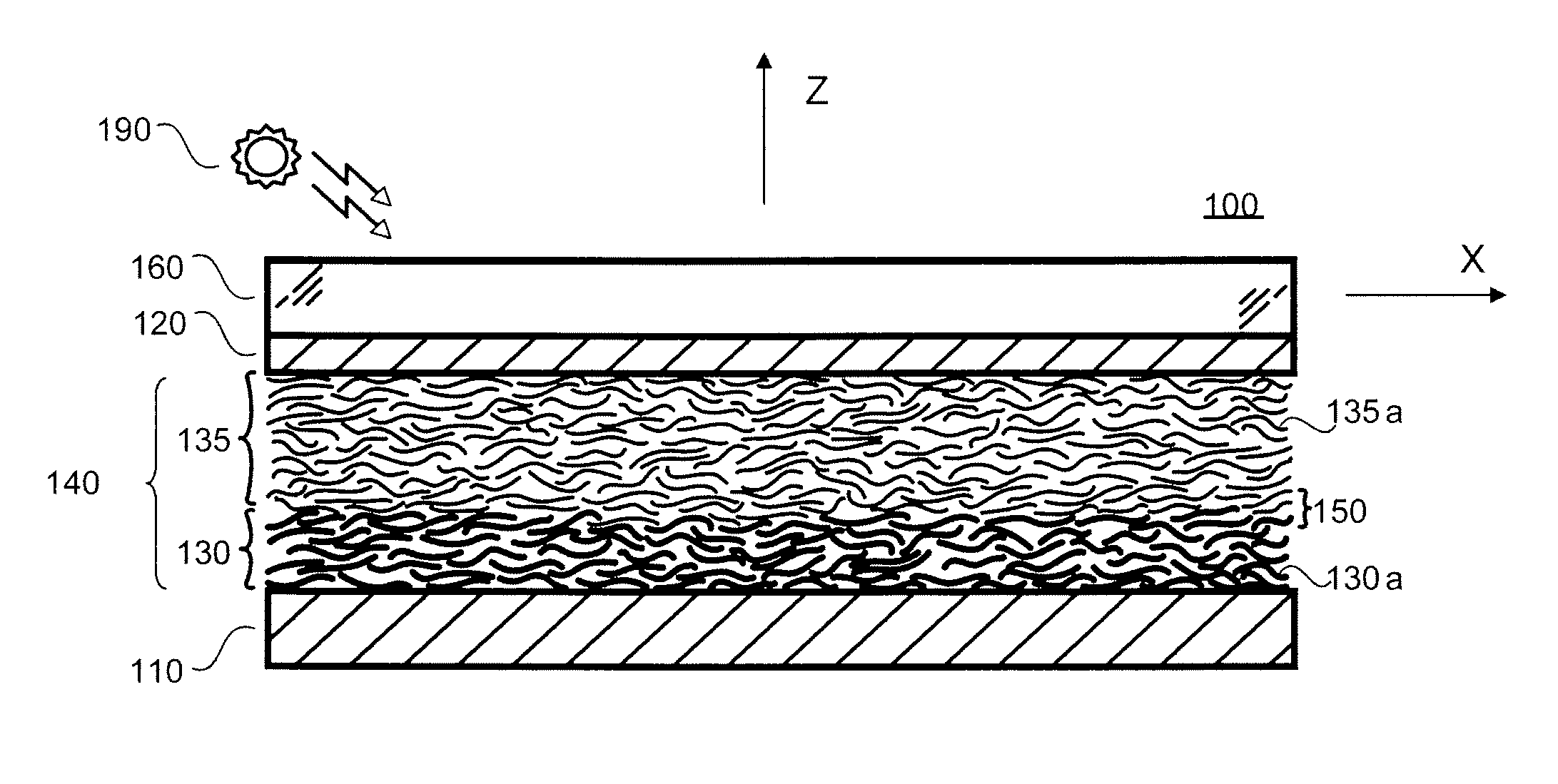

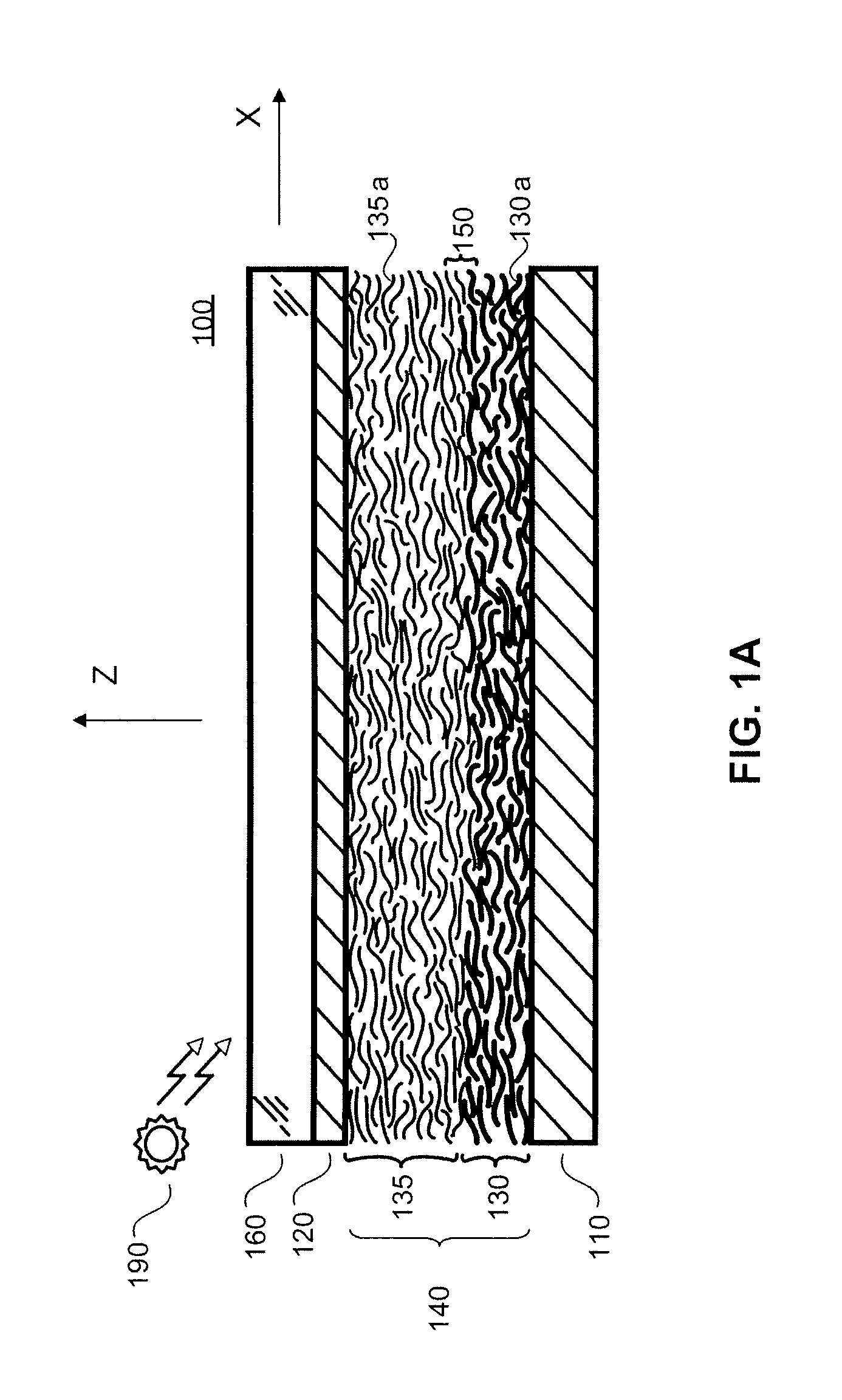

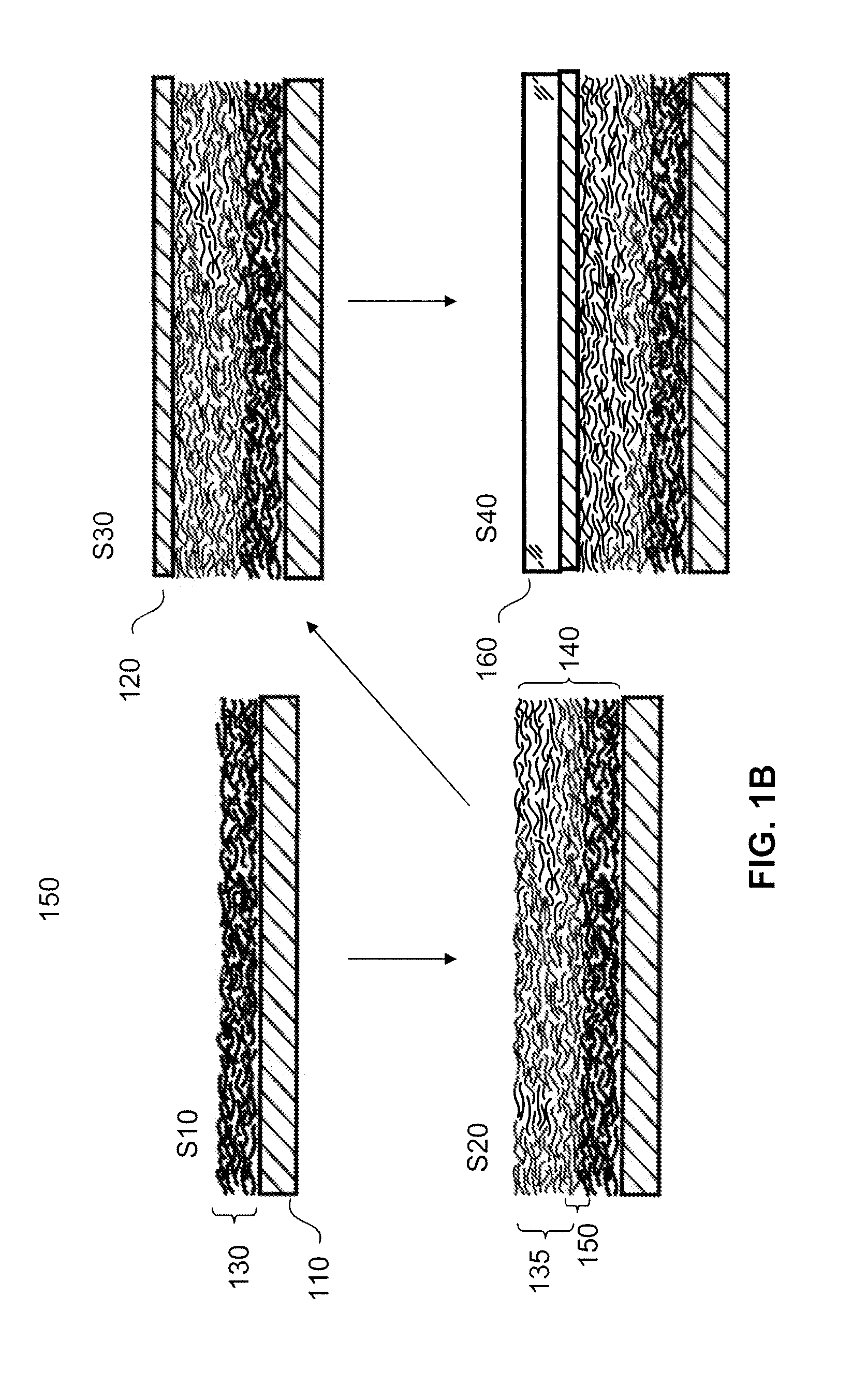

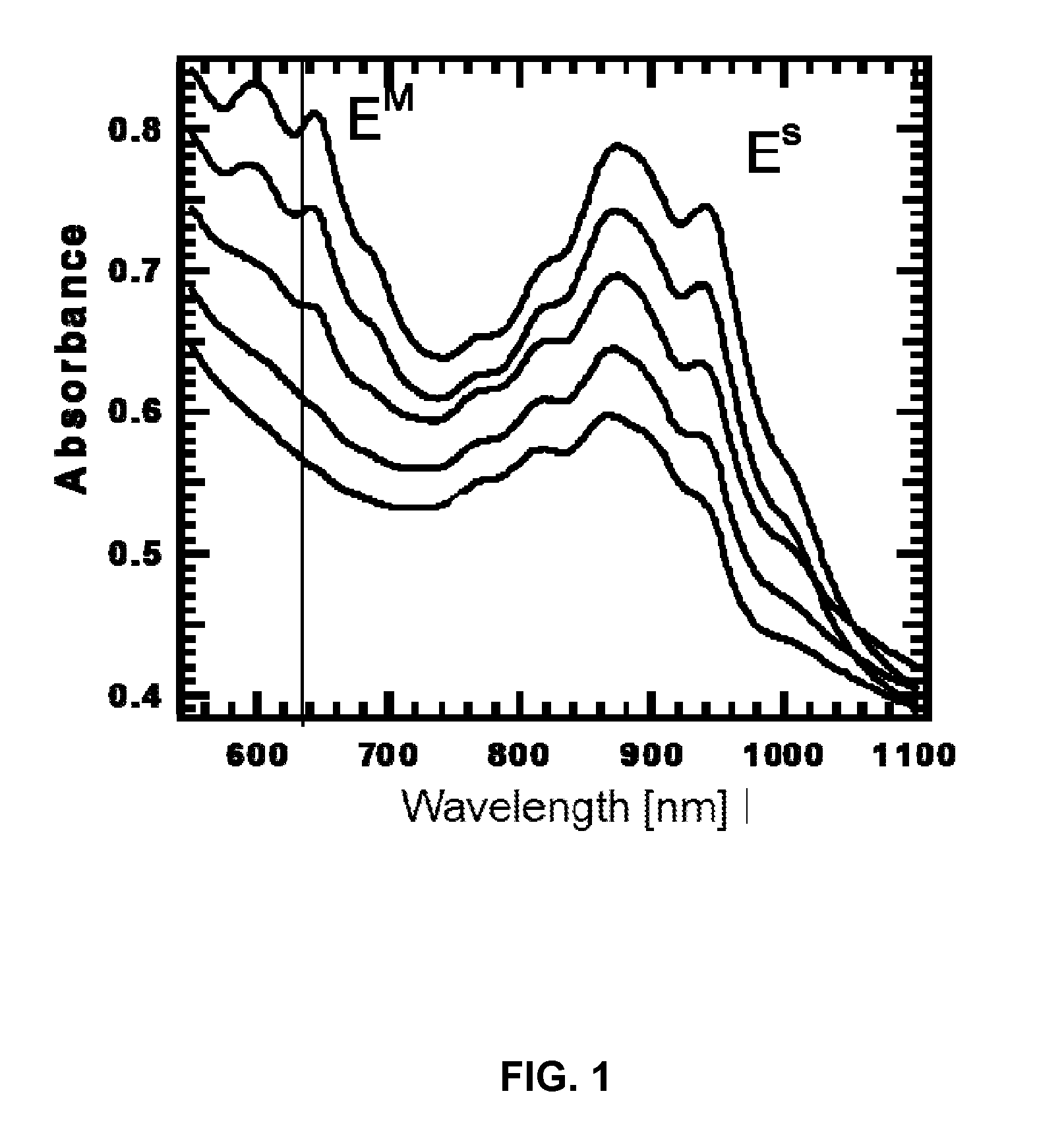

Photovoltaic devices using semiconducting nanotube layers

InactiveUS20110203632A1Improve light absorptionPV power plantsNanoinformaticsSchottky barrierMetal insulator

Photovoltaic (PV) devices employing layers of semiconducting carbon nanotubes as light absorption elements are disclosed. In one aspect a layer of p-type carbon nanotubes and a layer of n-type carbon nanotubes are used to form a p-n junction PV device. In another aspect a mixed layer of p-type and n-type carbon nanotubes are used to form a bulk hetero-junction PV device. In another aspect a metal such as a low work function metal electrode is formed adjacent to a layer of semiconducting nanotubes to form a Schottky barrier PV device. In another aspect various material deposition techniques well suited to working with nanotube layers are employed to realize a practical metal-insulator-semiconductor (MIS) PV device. In another aspect layers of metallic nanotubes are used to provide flexible electrode elements for PV devices. In another aspect layers of metallic nanotubes are used to provide transparent electrode elements for PV devices.

Owner:NANTERO

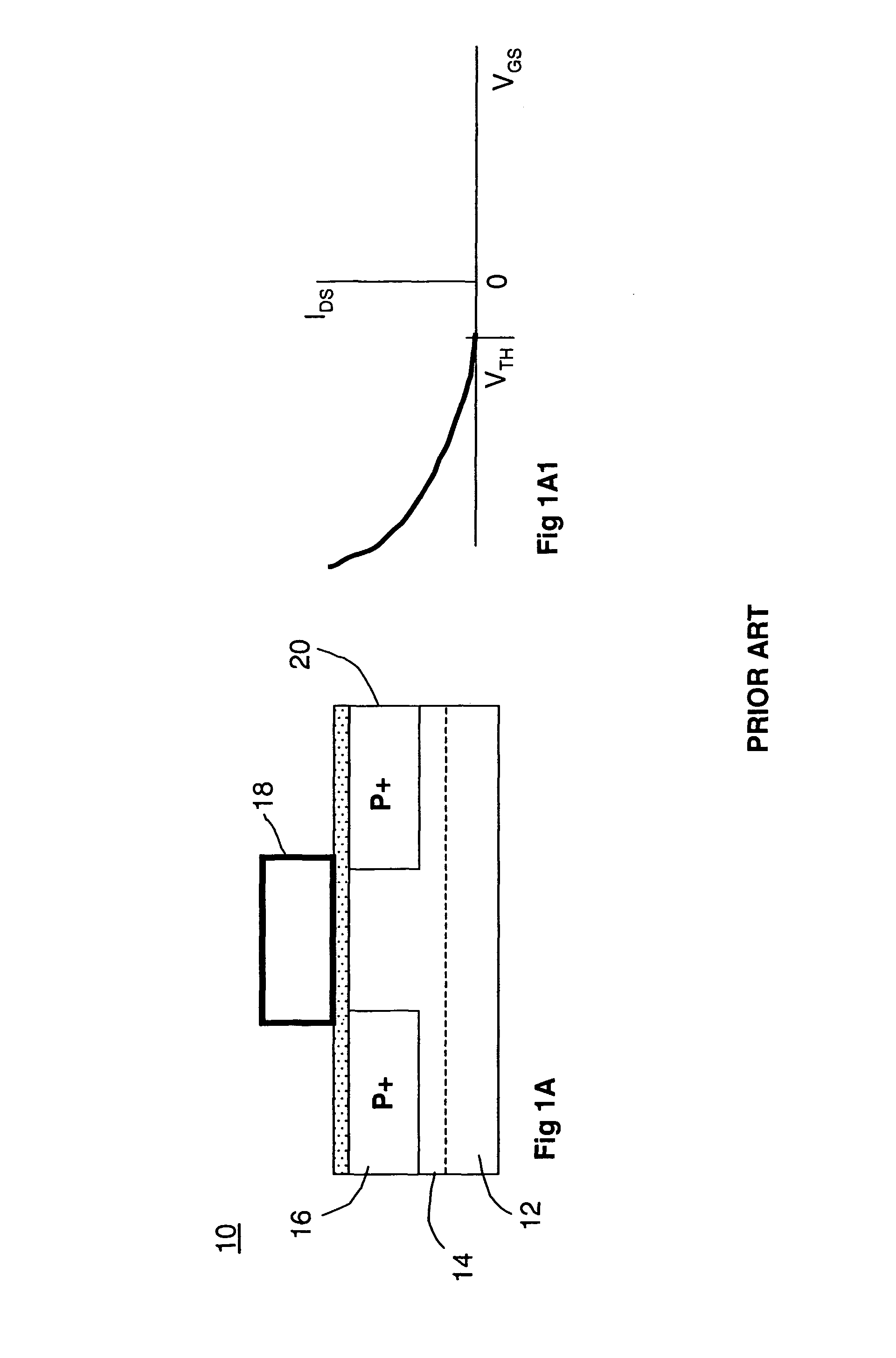

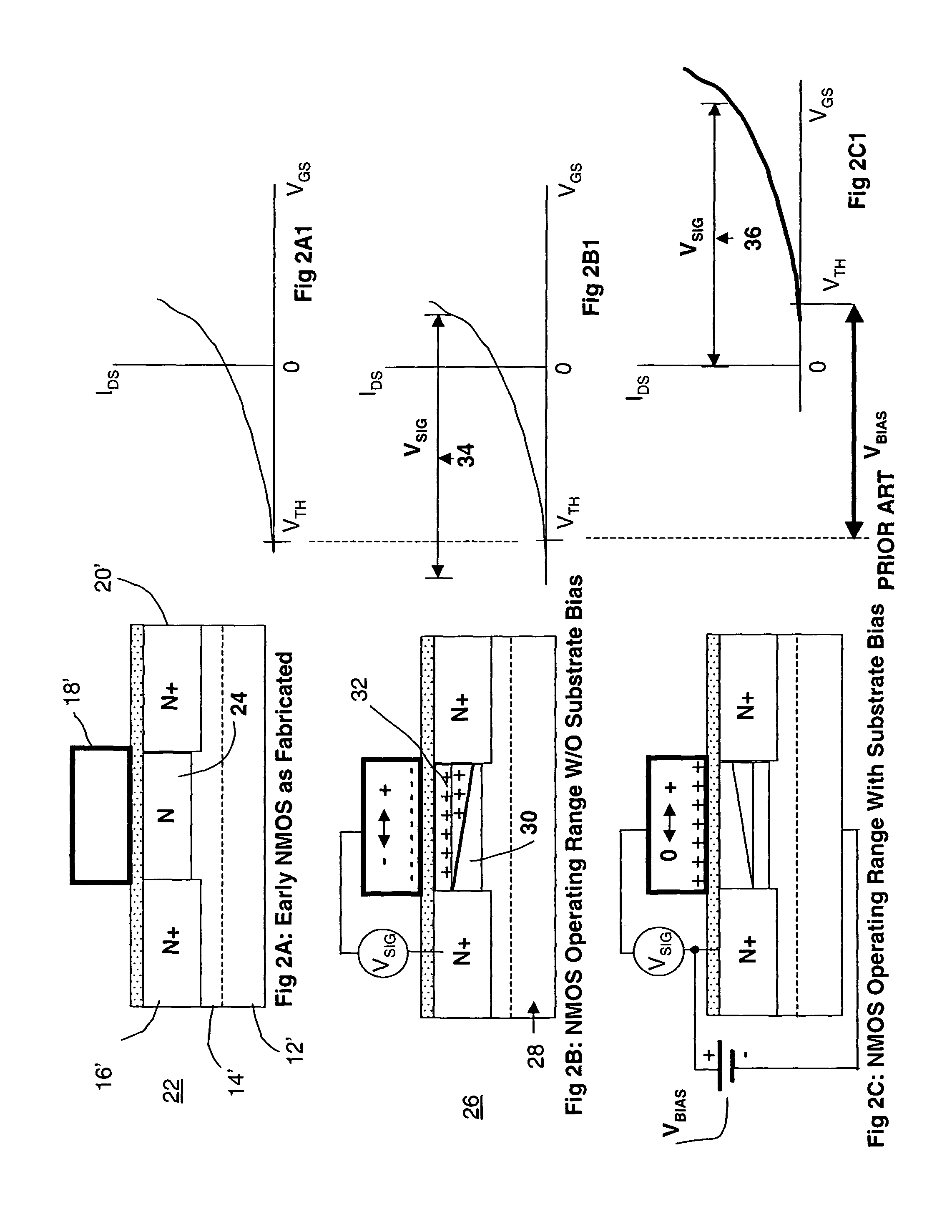

Method of fabricating carbon nanotube field-effect transistors through controlled electrochemical modification

InactiveUS7091096B2Poses problemImprove the immunityNanoinformaticsSolid-state devicesCompound (substance)Carbon nanotube field-effect transistor

The invention relates to a method of fabricating a structure with field-effect transistors each comprising a source electrode, a drain electrode, a channel extending between the source and drain electrodes and at least one gate electrode associated with the channel for controlling the conductance of the channel, wherein the channel comprises one or more semiconducting single-wall carbon nanotubes. The method includes the steps ofa) depositing a plurality of single-wall carbon nanotubes on a substrate, the carbon nanotubes including a mixture of metallic carbon nanotubes and semiconducting carbon nanotubes,b) providing before or after step a) source and drain electrodes on the substrate so that one or more carbon nanotubes extend between the source and drain electrodes,c) applying a variable gate voltage to switch off the semiconducting tubes extending between the source and drain electrodes,d) wetting the surface of the structure including the transistors with a chemical to achieve a chemical bond between a radical supplied by the chemical and some carbon atoms of the metallic nanotubes, whereby these metallic nanotubes become non-conductive.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

Method for preparing nano tube of some metalloid oxides and metals with size and shape being controllable

InactiveCN1462720AHigh yieldUniform diameterMaterial nanotechnologyPolycrystalline material growthAmphiphilePolyethylene glycol

A process for preparing the size and shape controllable ampholytic metal oxides and their metallic nanotubes features that based on the principle that under existance of excessive alkali the ampholytic metal hydroxide can become coordinate anions, under the action of surfactant as "soft template", the ampholytic metal oxide and its metallic nanotubes can be prepared by direct hydrothermal reaction or redox reaction (for example, ZnO, CuO, Al2O3, PbO2, SnO2 and relative metals). Its advantages are simple process, controllable sizes of nanotube, uniform wall thickness, and high output.

Owner:NORTHEAST NORMAL UNIVERSITY

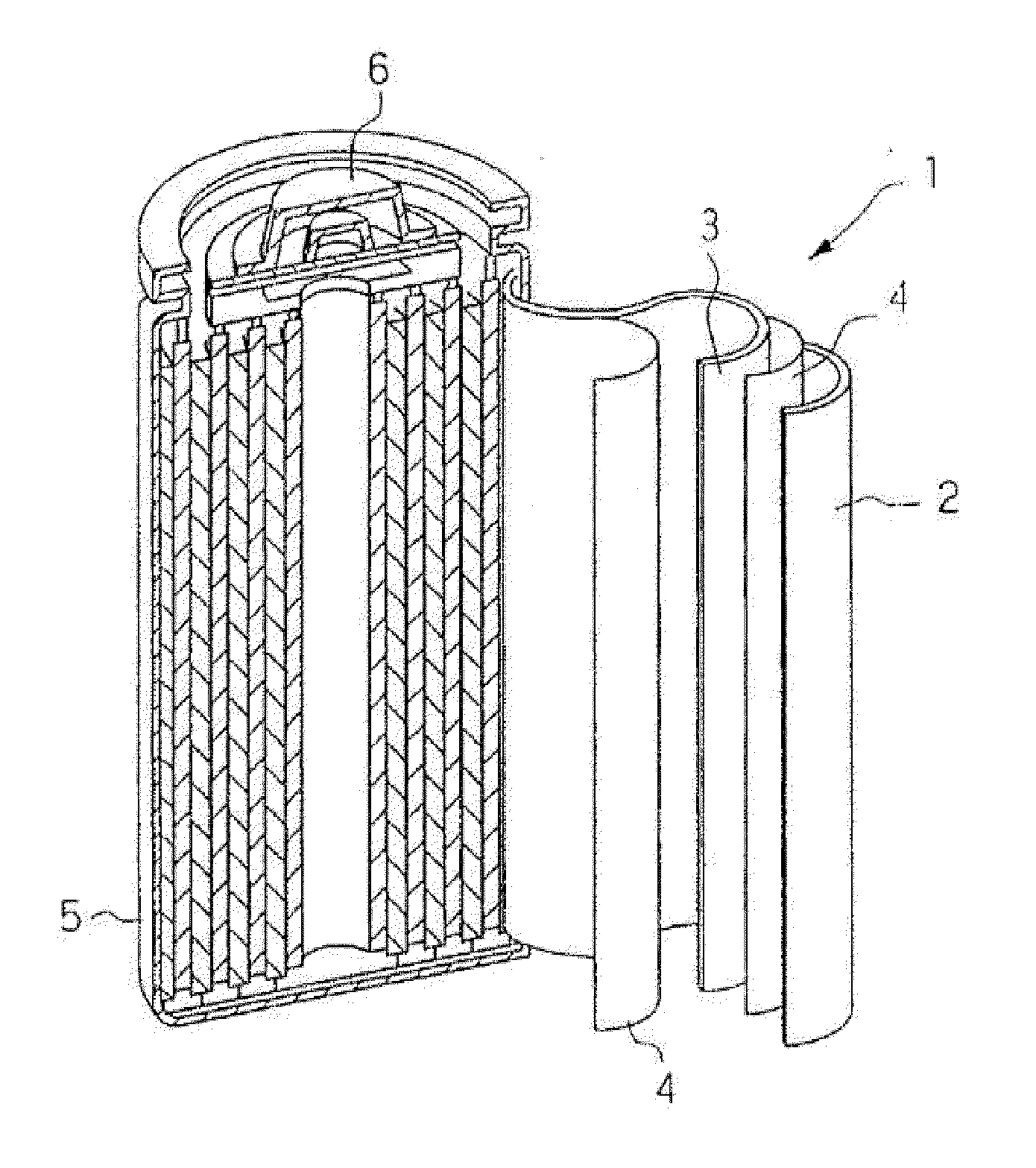

Negative electrode including metal/metalloid nanotubes, lithium battery including the negative electrode, and method of manufacturing the negative electrode

Owner:SAMSUNG ELECTRONICS CO LTD +1

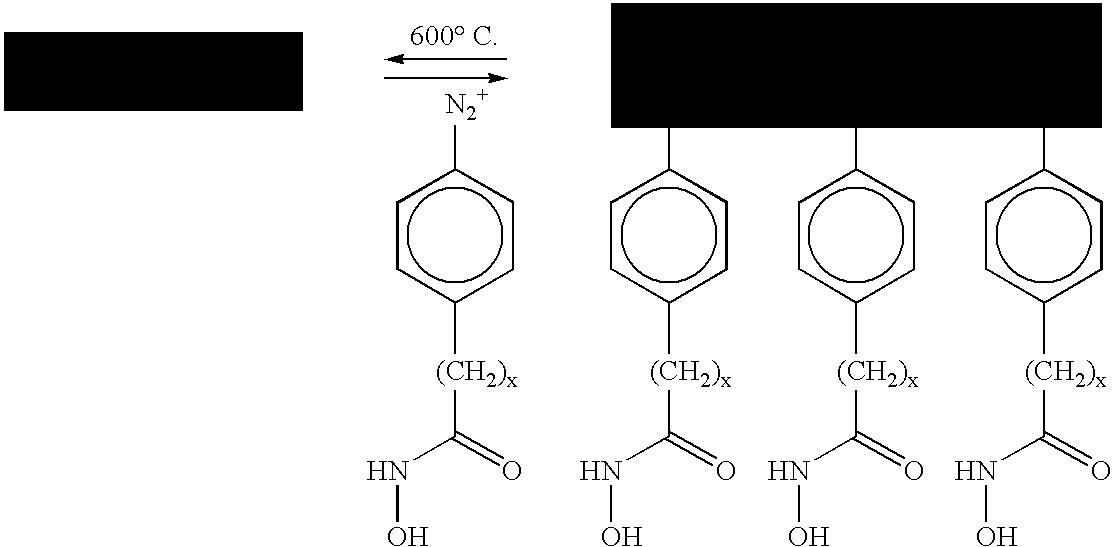

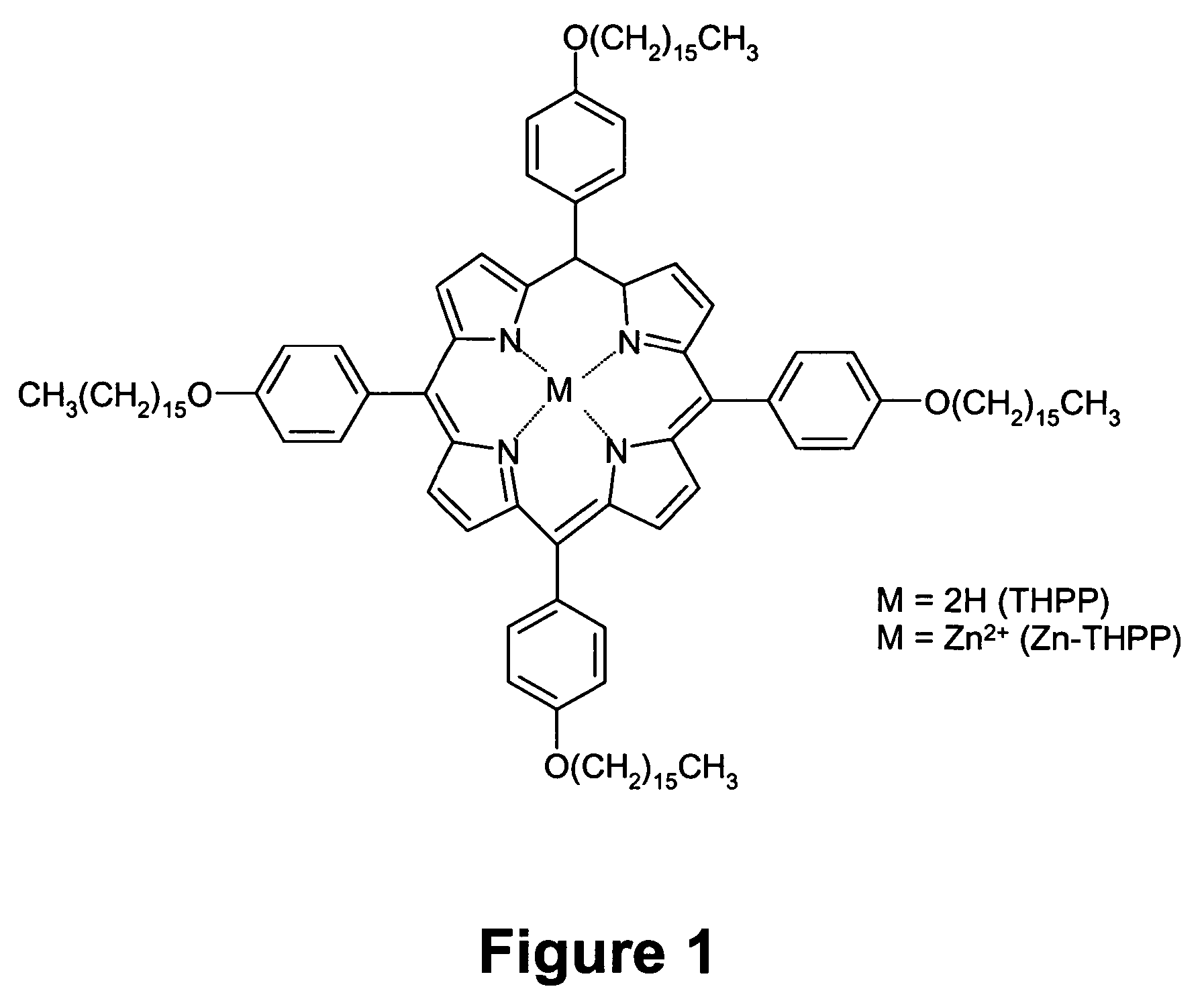

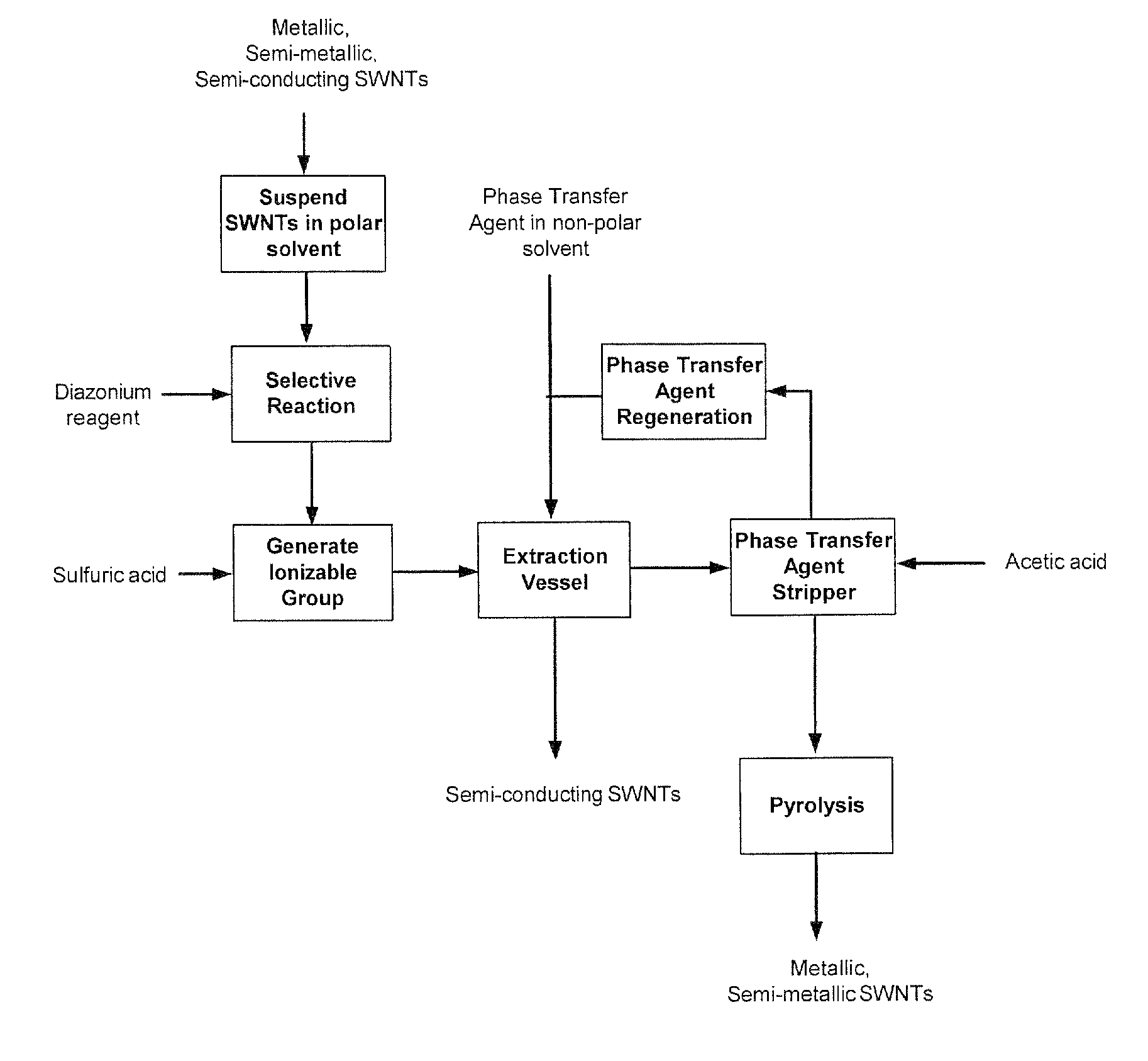

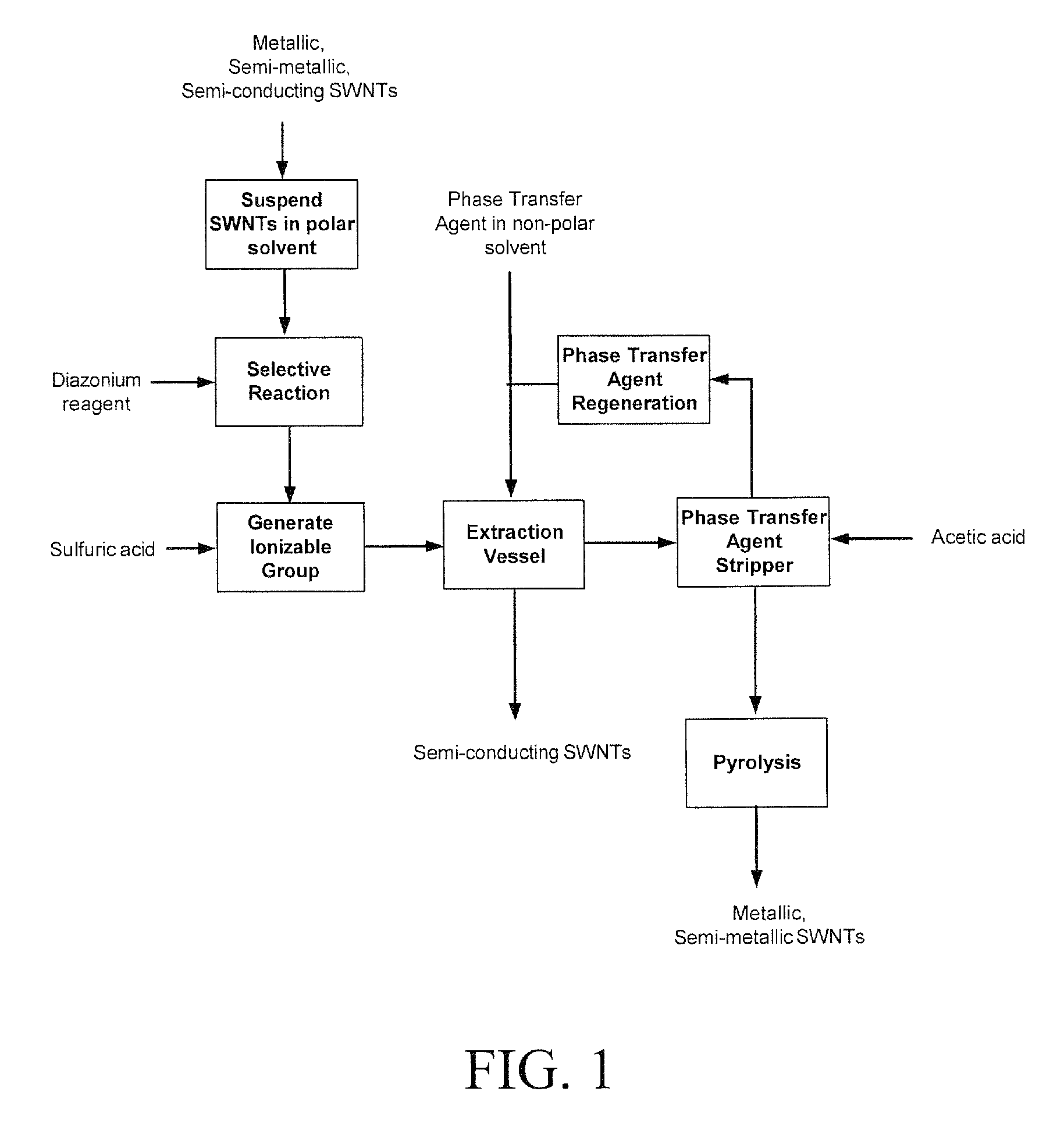

Method of separating metallic and semiconducting carbon nanotubes from a mixture of same

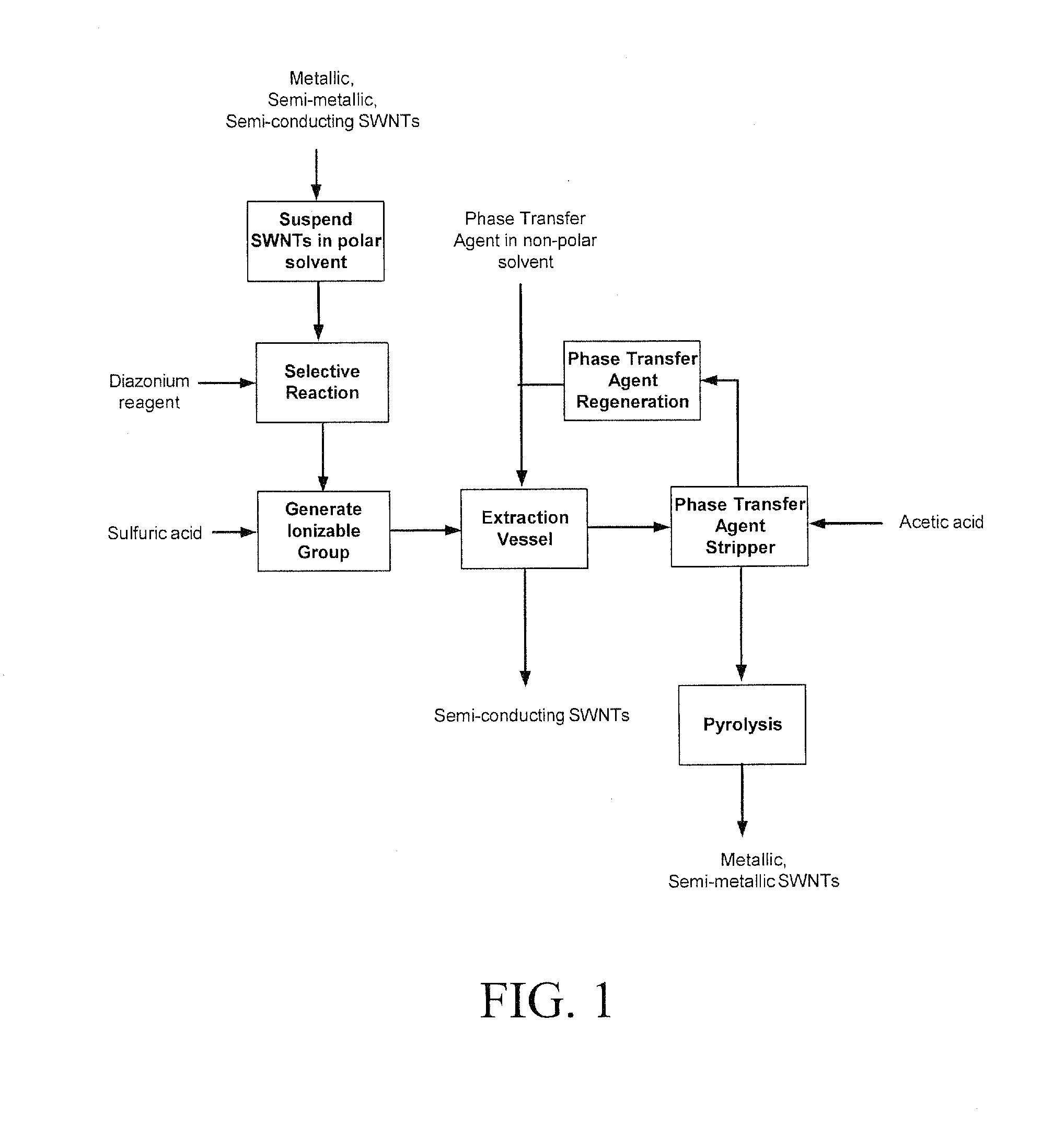

InactiveUS20090232724A1Permit separationMaterial nanotechnologyGroup 5/15 element organic compoundsSolubilityMetallic nanotubes

A method which permits large-scale separation of a semiconducting carbon nanotube from a mixture of metallic and semiconducting carbon nanotubes based on differences in solubility resulting from preferentially reacting the metallic carbon nanotubes with an acid functional aryldiazonium salt to form a substantially fully functionalized metallic nanotubes which can be easily separated from the unfunctionalized semiconducting carbon nanotubes.

Owner:IBM CORP

Coating forming composition used for forming transparent conductive film

InactiveUS20130251983A1Good dispersionImprove conductivityConductive layers on insulating-supportsPrinted circuit detailsMetal nanowiresHardness

To provide a material capable of obtaining a transparent conductive film having an excellent conductivity, Optical transmission, Environmental reliability, suitability for process, adhesion and hardness in a single application process, and to provide a transparent conductive film using the same and a device element using the same. A coating forming composition containing at least one kind selected from the group of metal nanowires and metal nanotubes as a first component, a polymer compound having a hydroxyl group as a second component, a compound having a group 13 element or a transition metal element as a third component, and further a solvent is prepared to obtain a transparent conductive film by the coating.

Owner:JNC CORP

Process for separating metallic from semiconducting single-walled carbon nanotubes

Owner:CLEMSON UNVERSITY RES FOUND

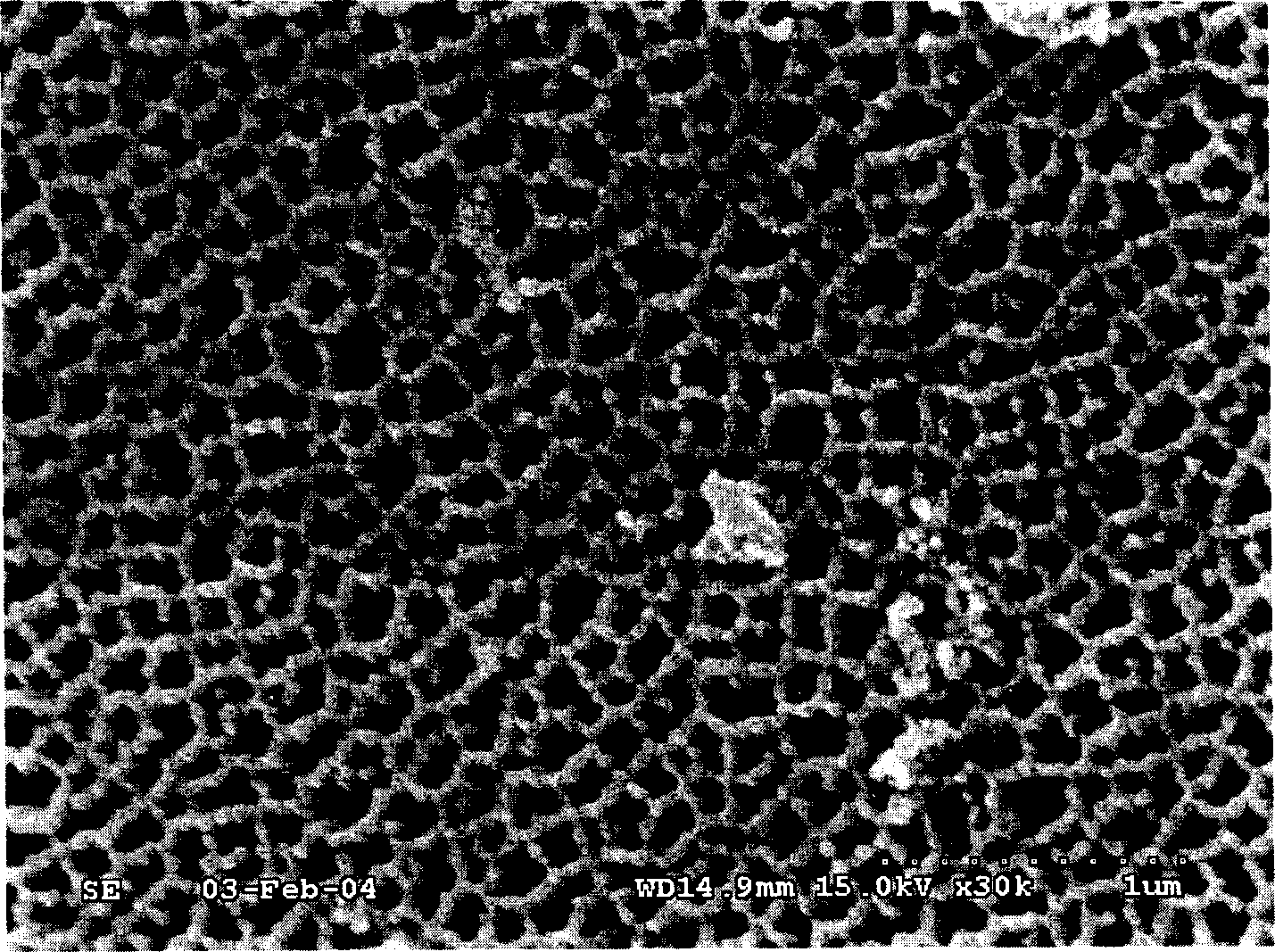

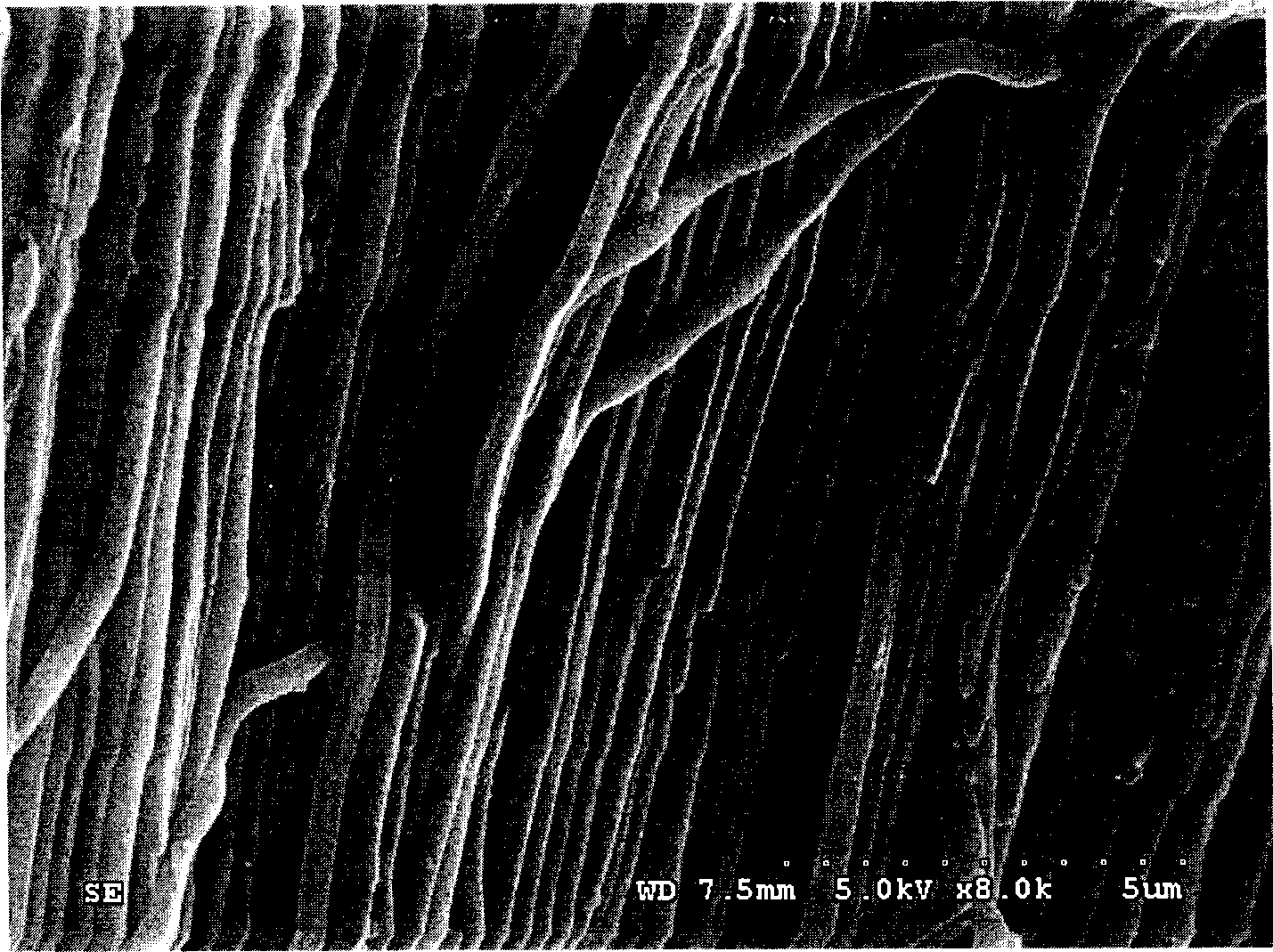

Noble metal nanotube and method for preparation thereof

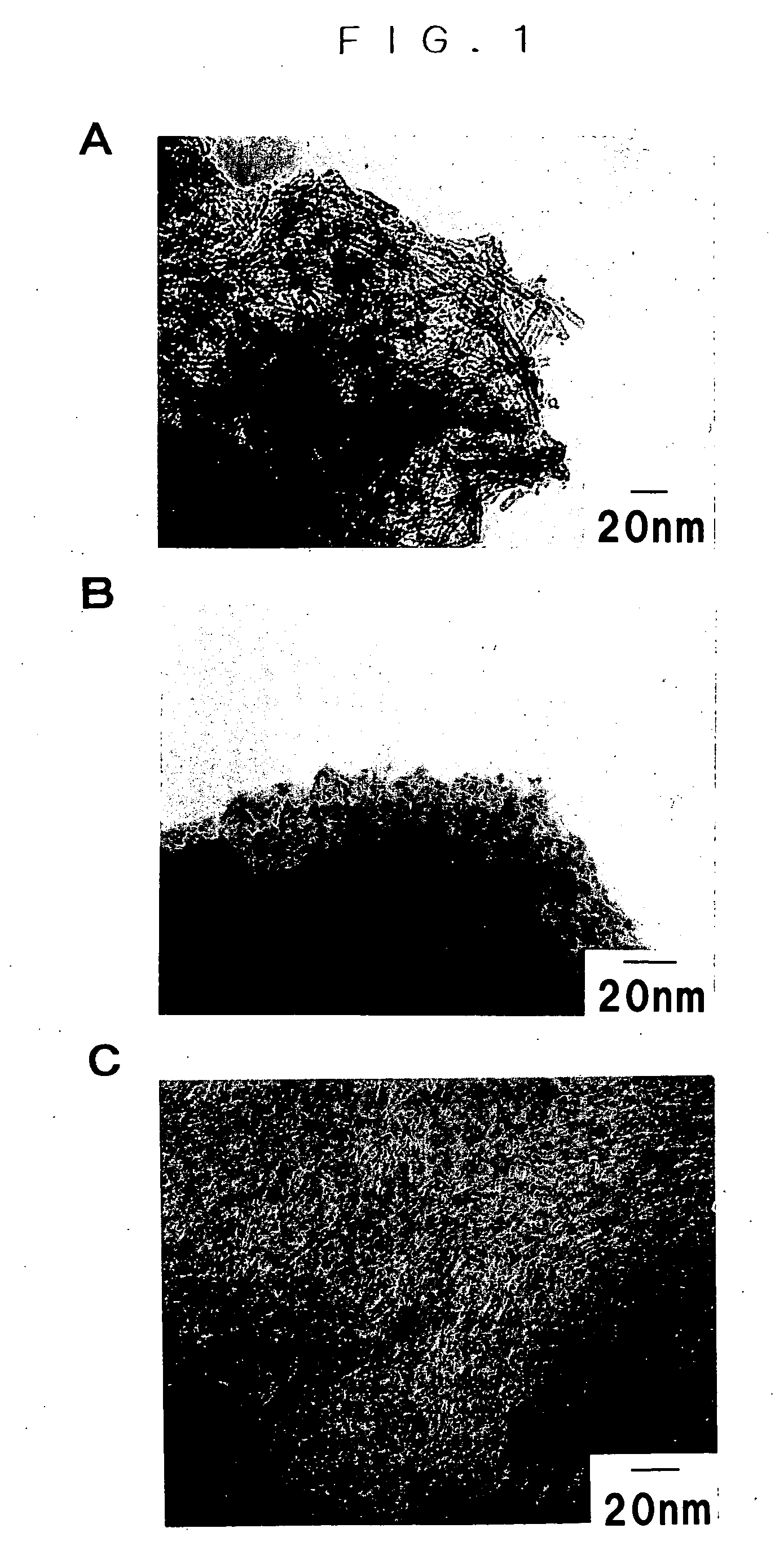

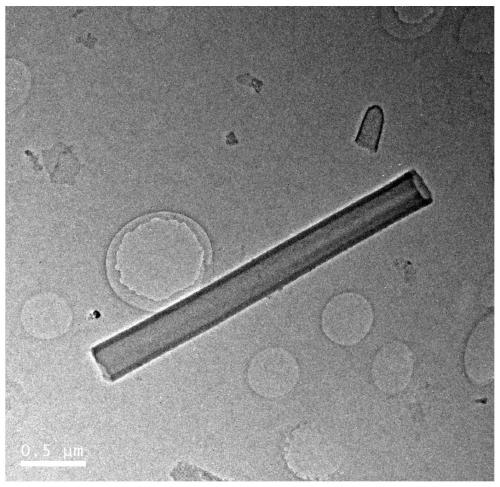

InactiveUS20050229744A1Parts are smallMaterial nanotechnologyCell electrodesIridiumMetallic nanotubes

A nanotube of which basic skeleton is made of a noble metal element is provided. The skeleton of the nanotube is made of (1) a single noble metal element of gold (Au), silver (Ag), platinum (Pt), palladium (Pd), rhodium (Rh), or iridium (Ir) as noble metal elements, of (2) a mixture in which (Ru) is added to the above (1) in any proportion, or of (3) a mixture in which a base metal element is added to the above (1) or (2) in any proportion, and the noble metal nanotube has a tubular form of about 5-7 nm in outer diameter, about 2-4 nm in inner diameter, about 1-2 nm in thickness, and 10 nm or more in length.

Owner:JAPAN SCI & TECH CORP

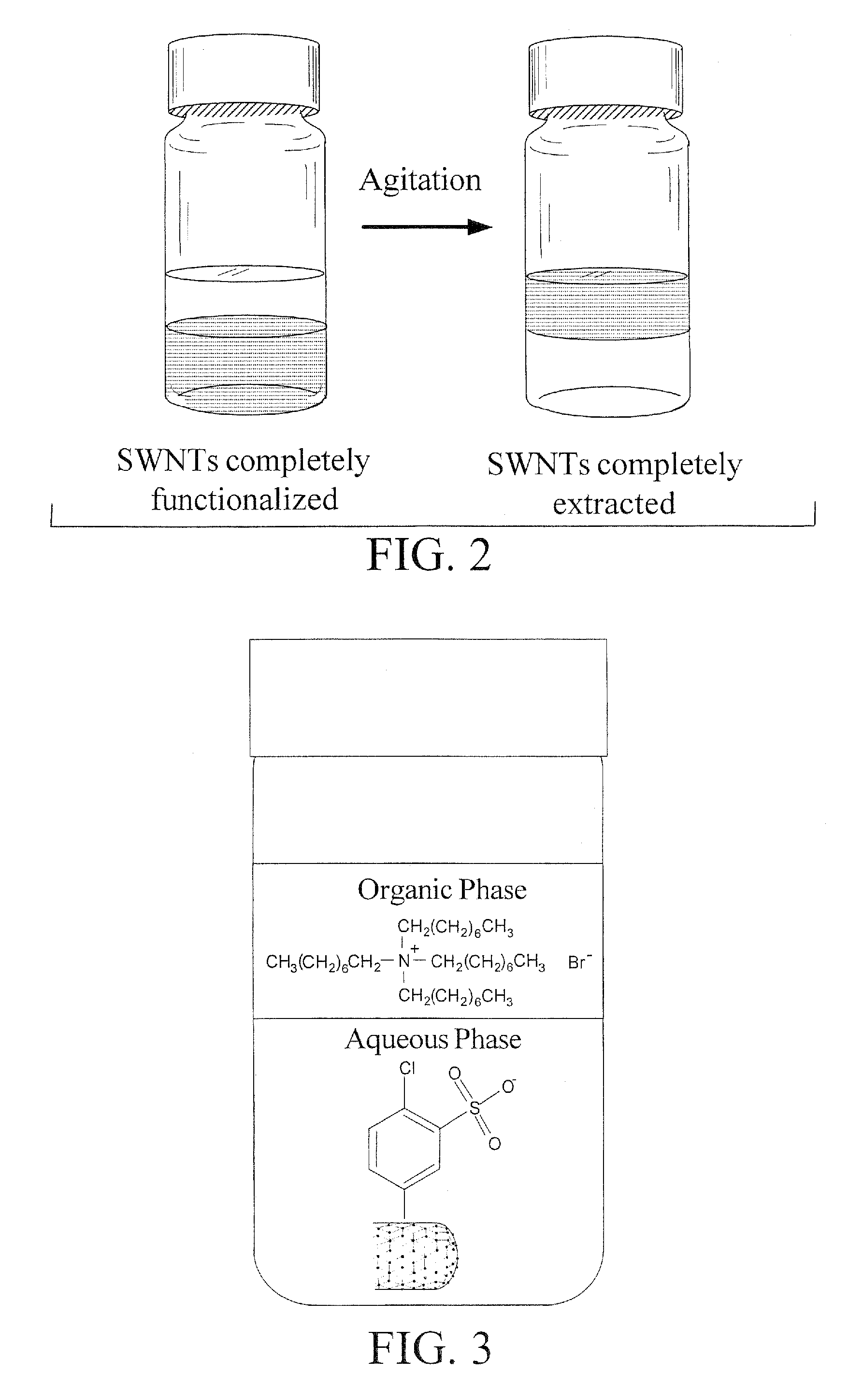

Type Separation of Single-Walled Carbon Nanotubes via Two-Phase Liquid Extraction

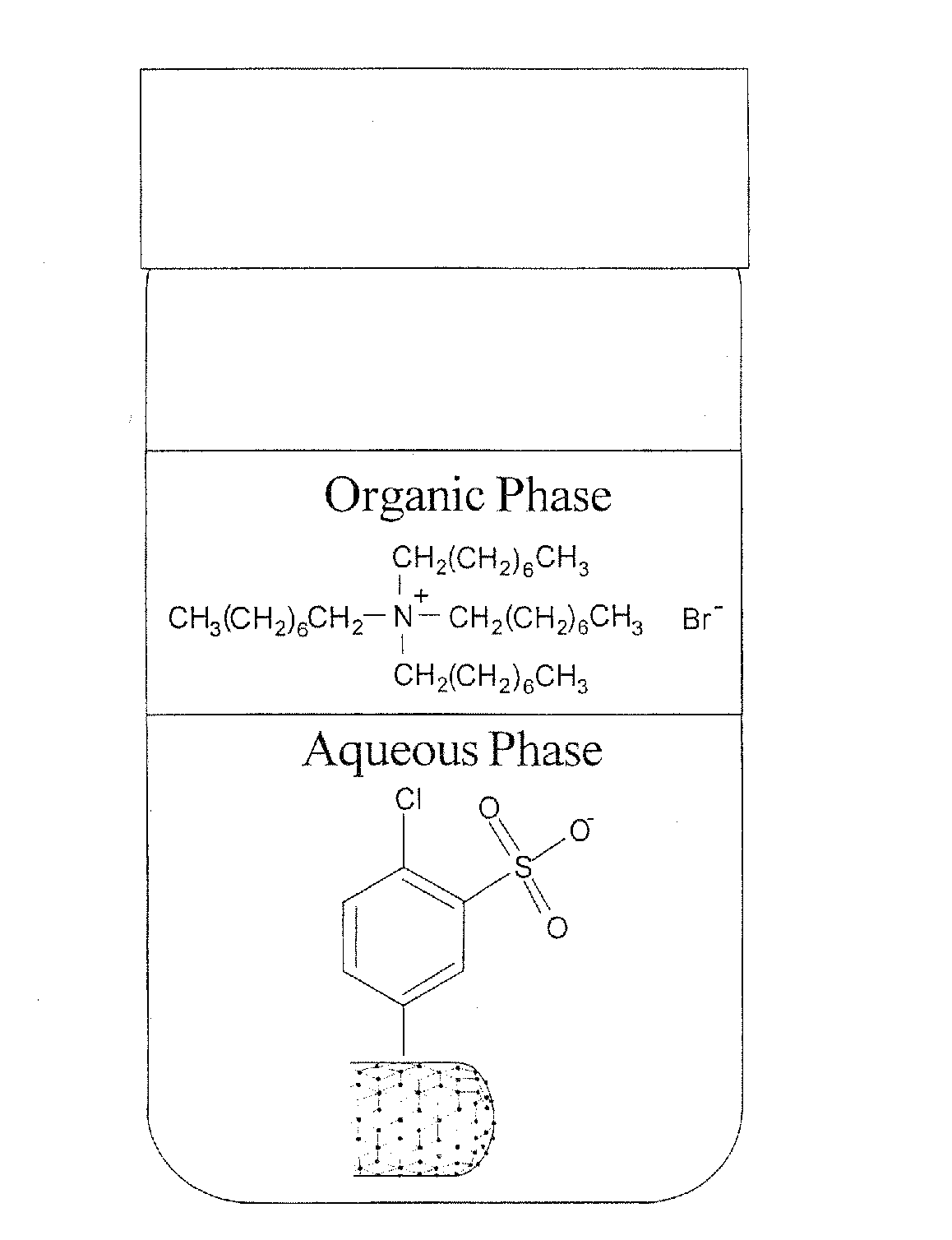

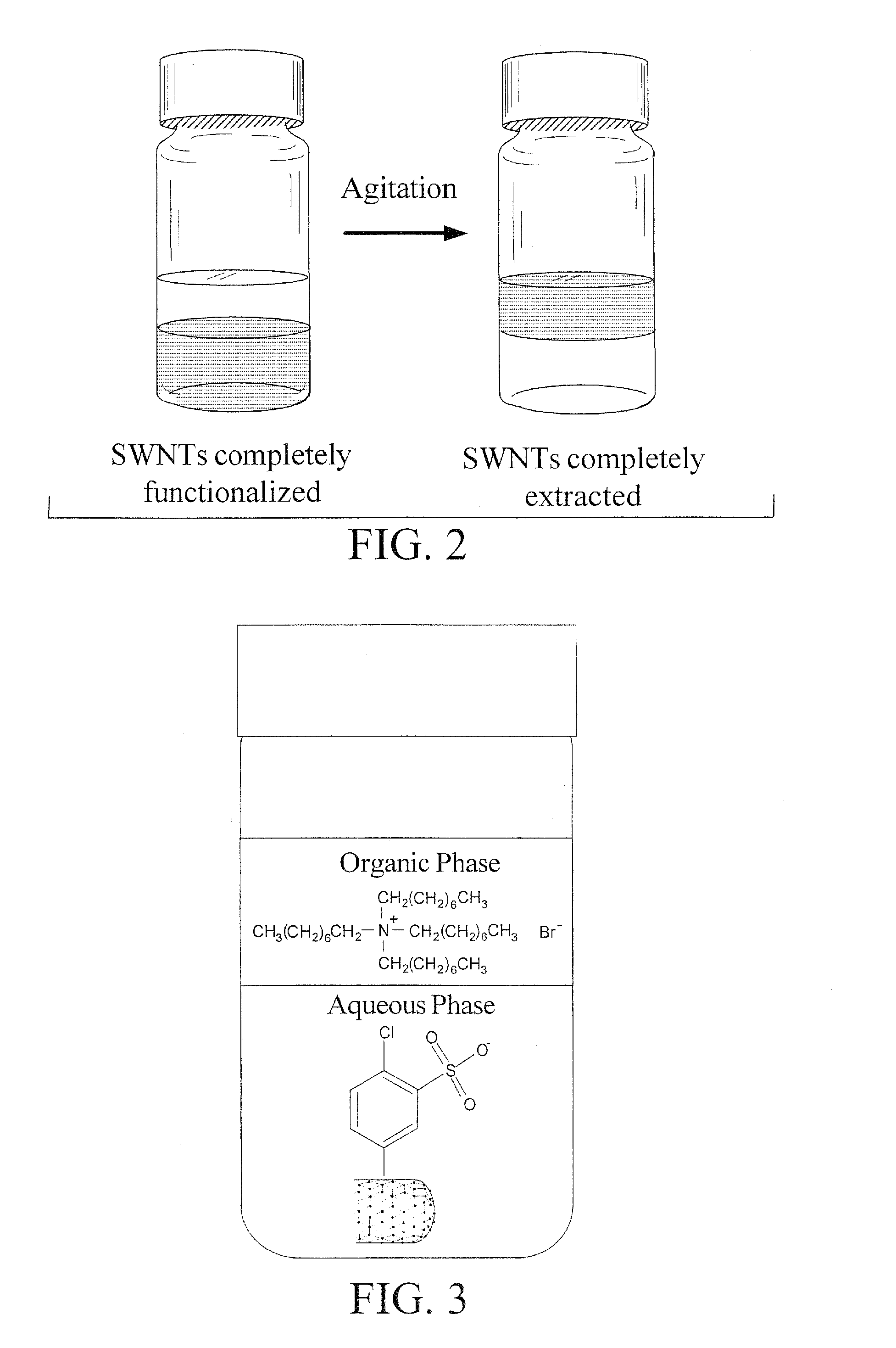

InactiveUS20100166637A1Improve scalabilityEasy to collectMaterial nanotechnologyMaterial analysis by observing effect on chemical indicatorCell separationMetallic nanotubes

The subject invention provides a two-phase liquid-liquid extraction process that enables sorting and separation of single-walled carbon nanotubes based on (n, m) type and / or diameter. The two-phase liquid extraction method of the invention is based upon the selective reaction of certain types of nanotubes with electron withdrawing functional groups as well as the interaction between a phase transfer agent and ionic moieties on the functionalized nanotubes when combined in a two-phase liquid solution. Preferably, the subject invention enables efficient, bulk separation of metallic / semi-metallic nanotubes from semi-conducting nanotubes. More preferably, the subject invention enables efficient, bulk separation of specific (n, m) types of nanotubes.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

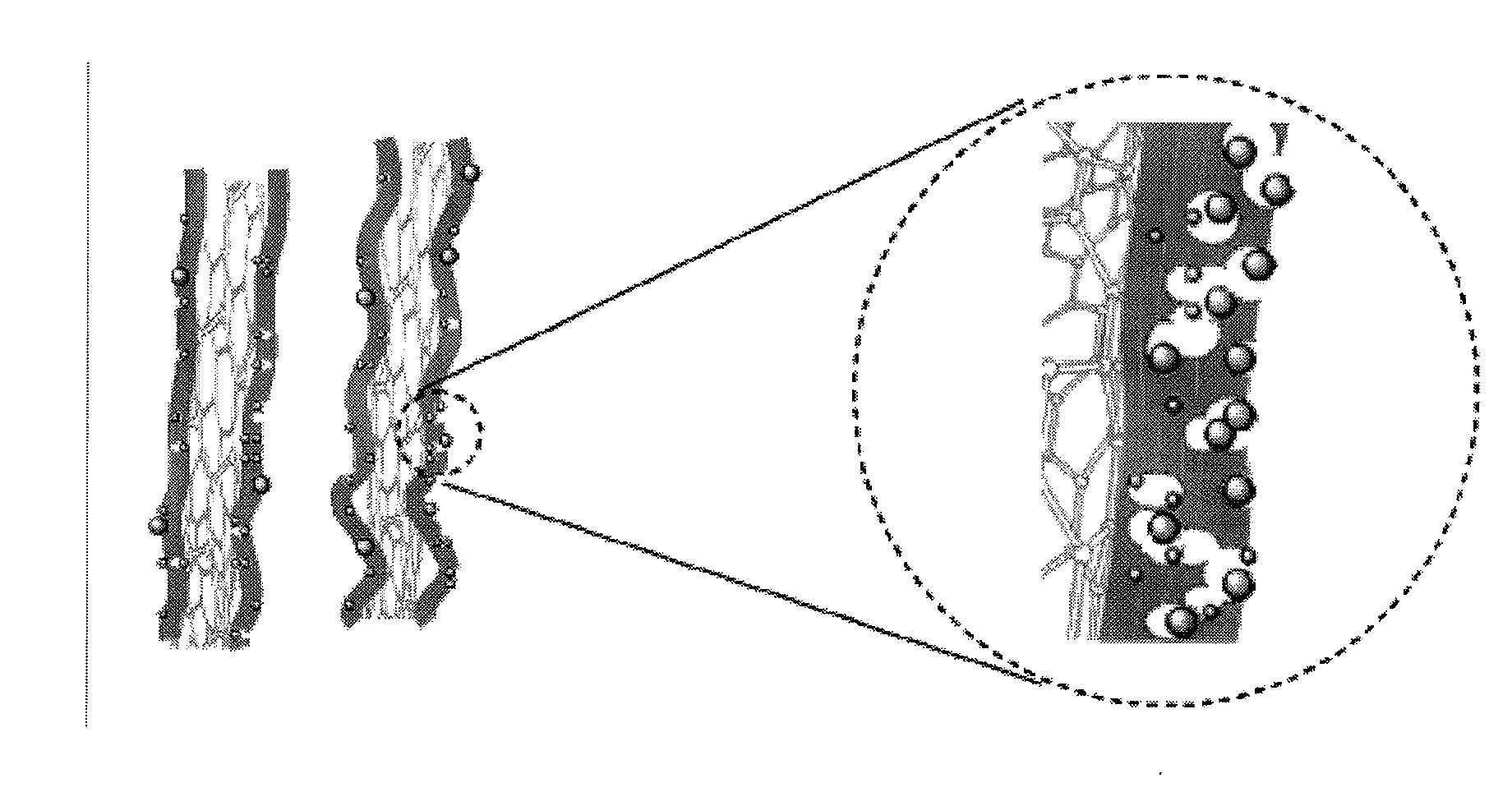

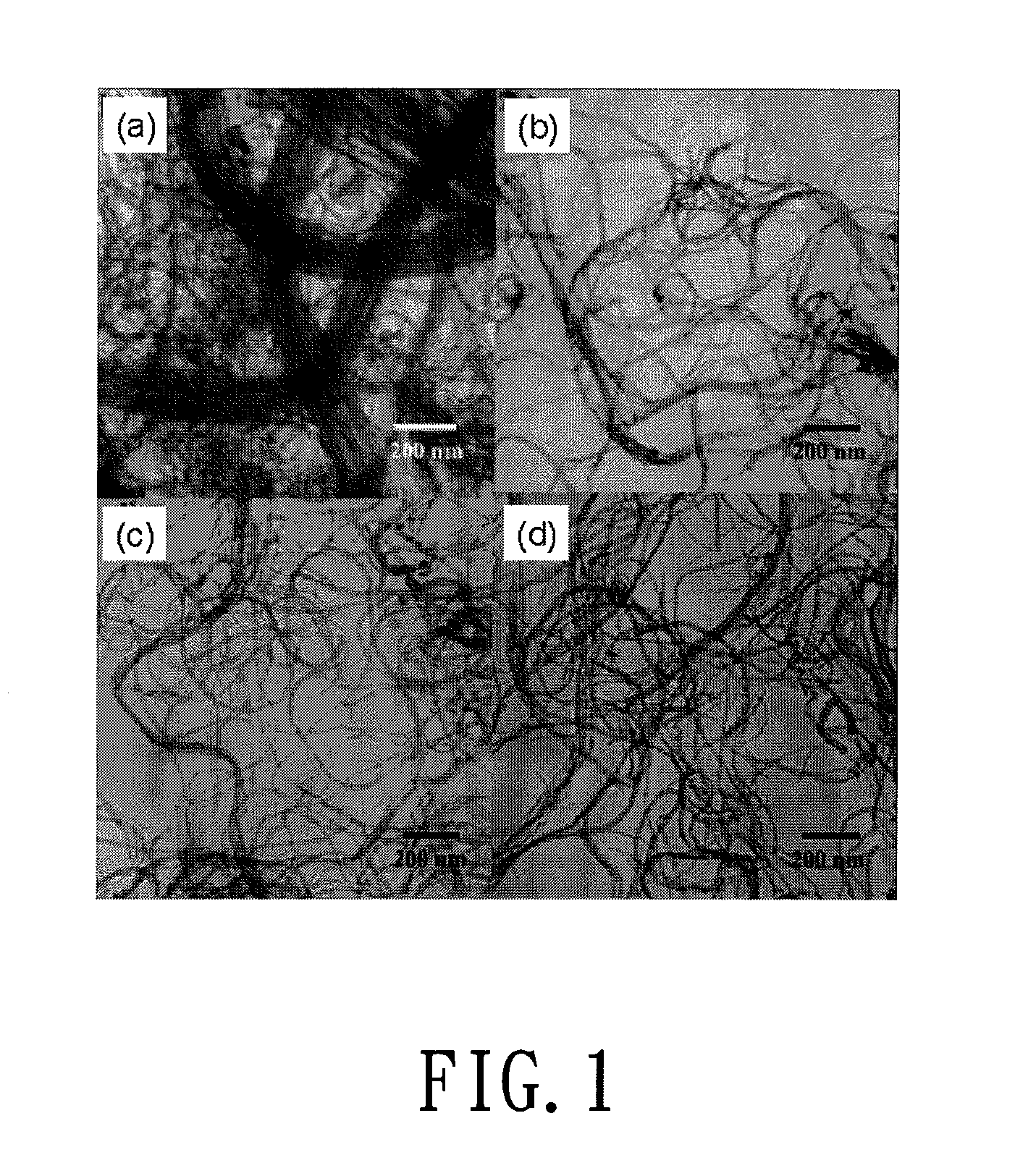

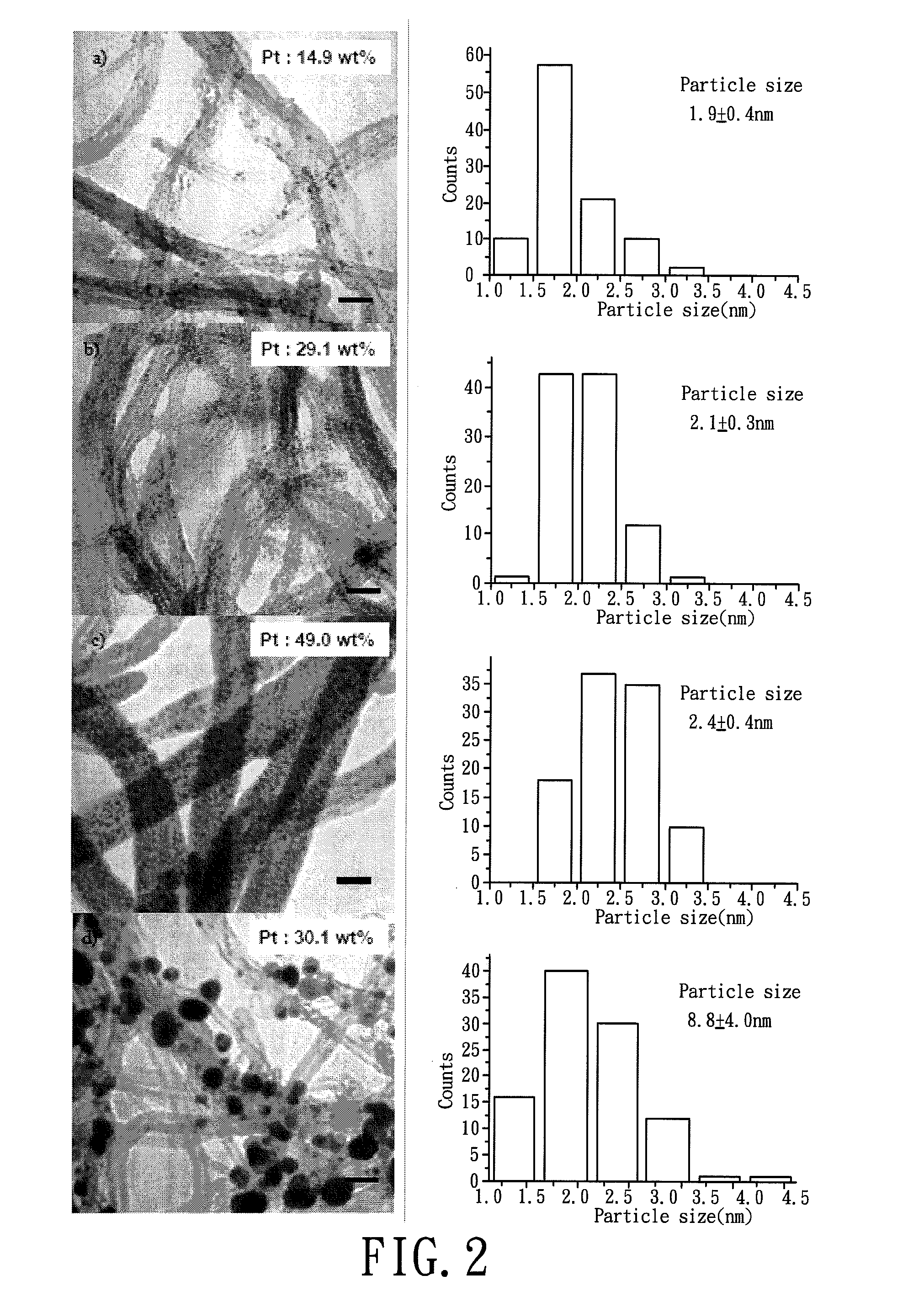

Methods of preparing carbinized nanotube composite and metal-nanotube composite catalyst

A method for preparing a metal-nanotube composite catalyst for an electro-chemical oxygen reduction reaction includes: debundling carbon nanotubes (CNTs); loading a carbon-containing polymeric material onto the surfaces of the nanotubes that have been debundled; carbonizing in situ the carbon-containing polymeric material on the carbon nanotubes to form carbon char layers surrounding the surfaces of the carbon nanotubes; and loading metal catalyst particles on the carbon nanotubes. The carbon char layers contain high amount of nitrogen and may be formed into a porous structure.

Owner:NAT CHENG KUNG UNIV

Coating forming composition used for forming transparent conductive film

InactiveUS20130153829A1Lower surface resistance valueHigh light transmittanceMaterial nanotechnologyConductive layers on insulating-supportsTransparent conducting filmSolvent

A subject is to provide a material capable of obtaining a transparent conductive film that is excellent in conductivity, optical transmission, environmental reliability, suitability for process and adhesion in a single application process, and to provide the transparent conductive film and a device element using the same; a solution is to prepare a coating forming composition containing at least one kind selected from the group of metal nanowires and metal nanotubes as a first component, polysaccharides and a derivative thereof as a second component, an active methylene compound as a third component, an electrophilic compound as a fourth component and a solvent as a fifth component to obtain the transparent conductive film by using the coating.

Owner:JNC CORP

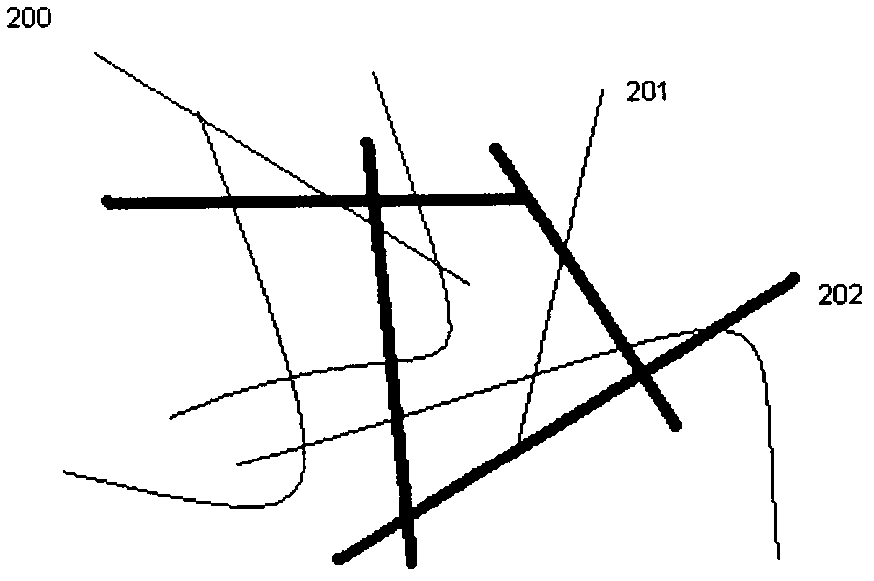

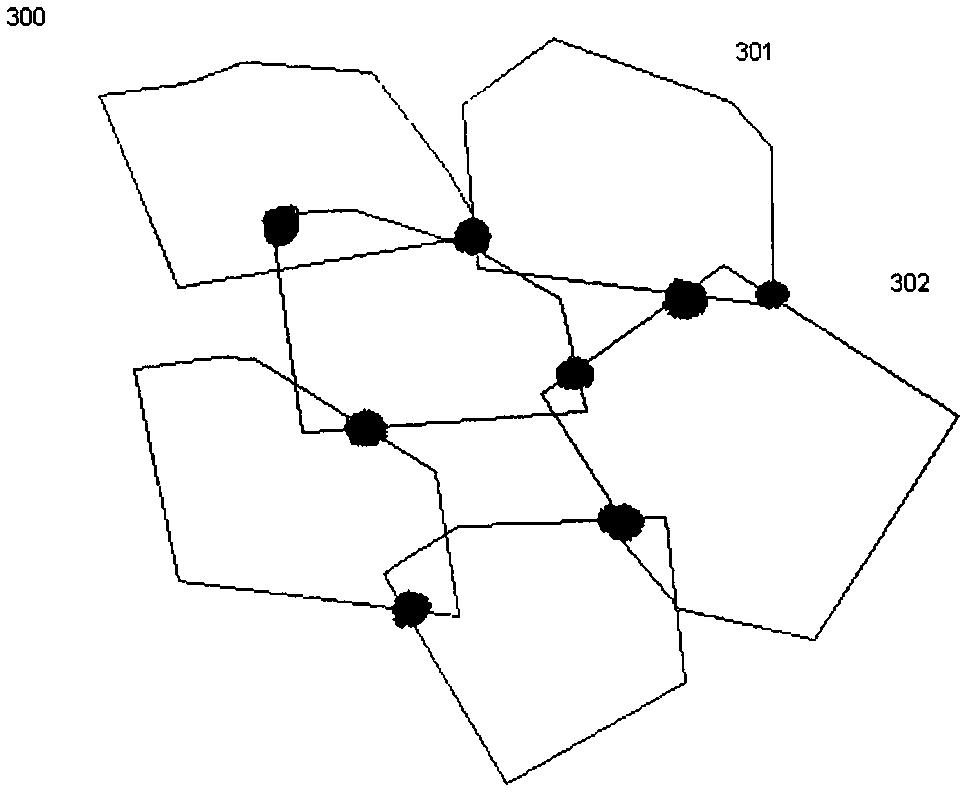

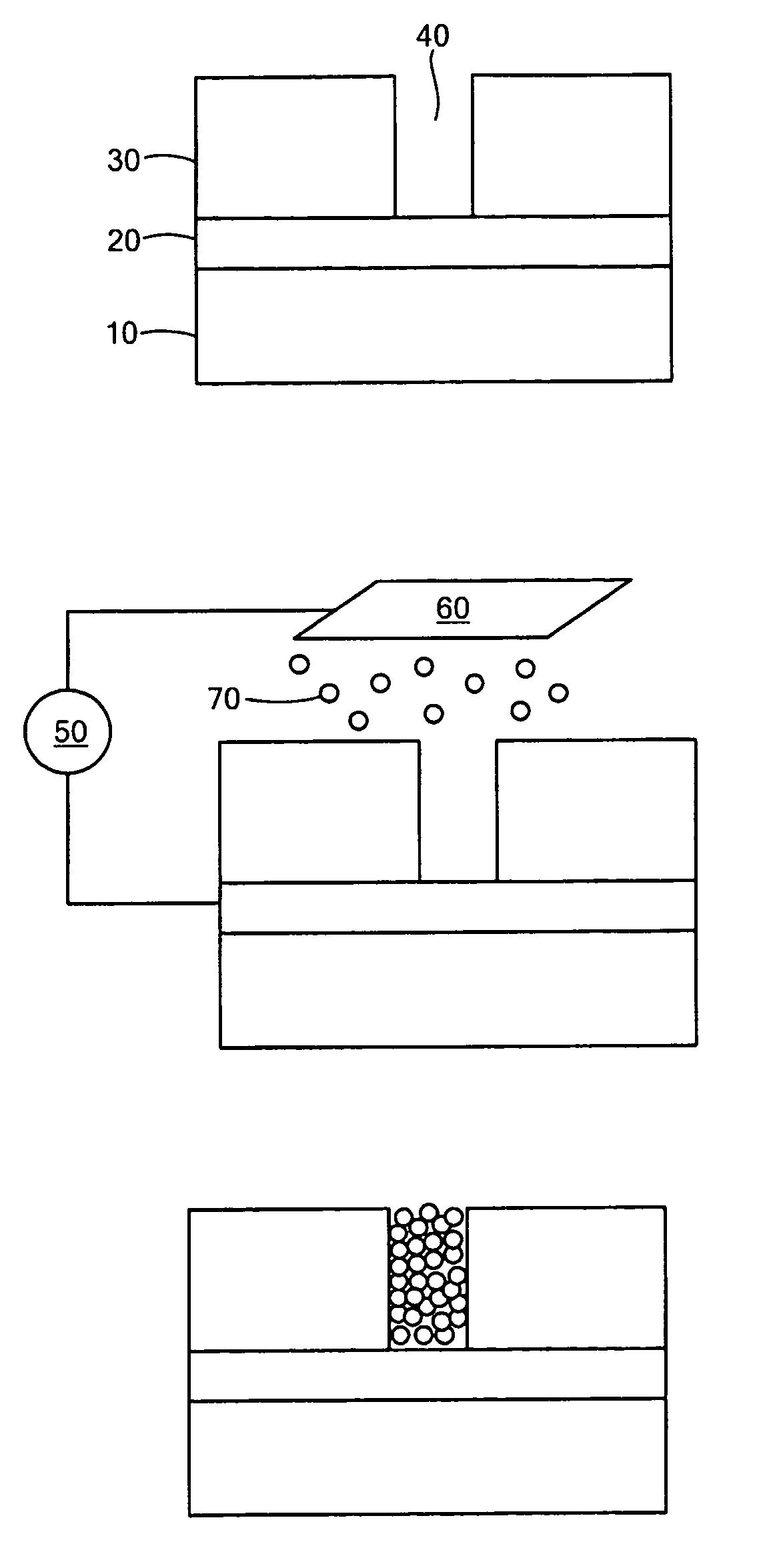

Nanoscale interconnects fabricated by electrical field directed assembly of nanoelements

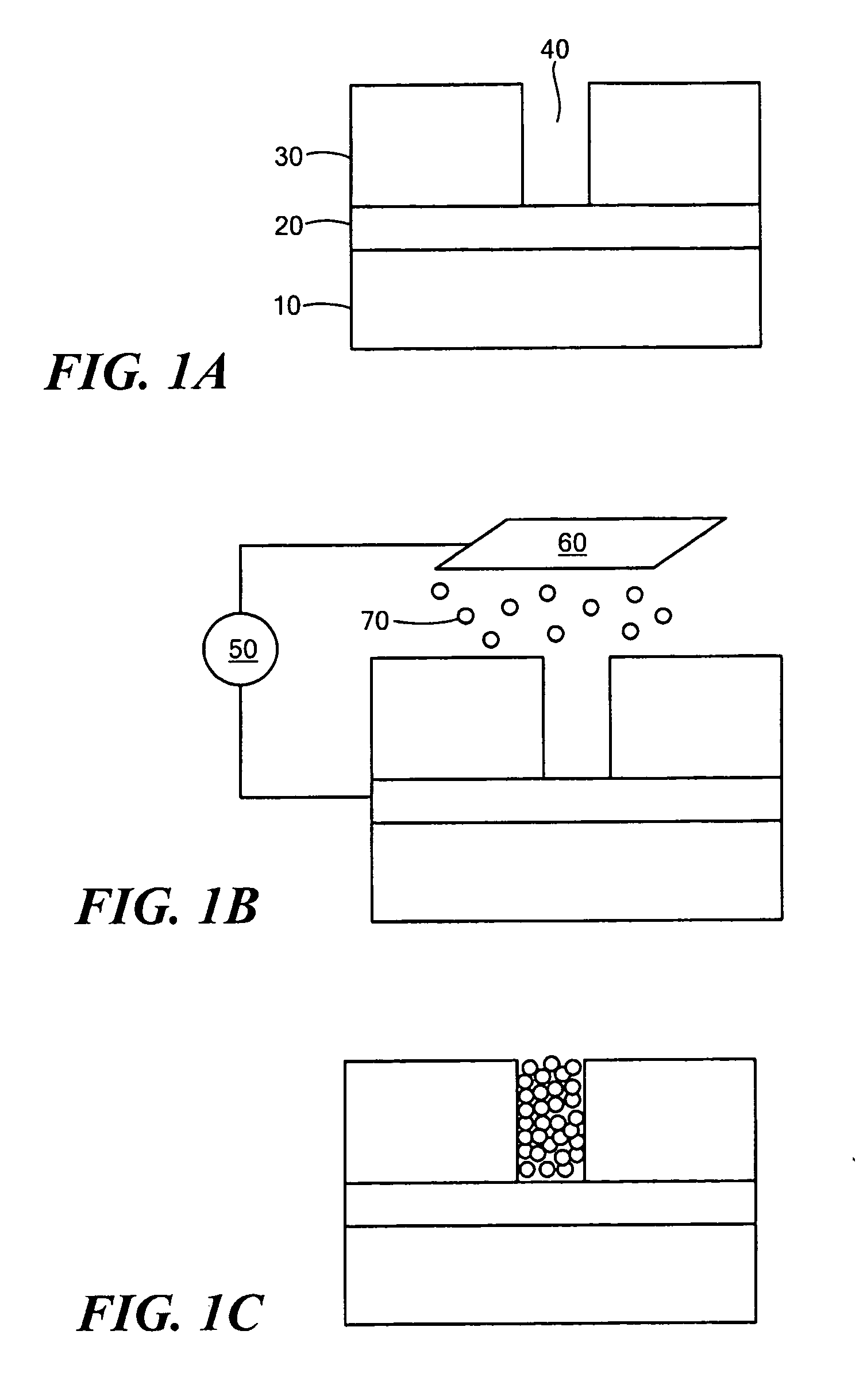

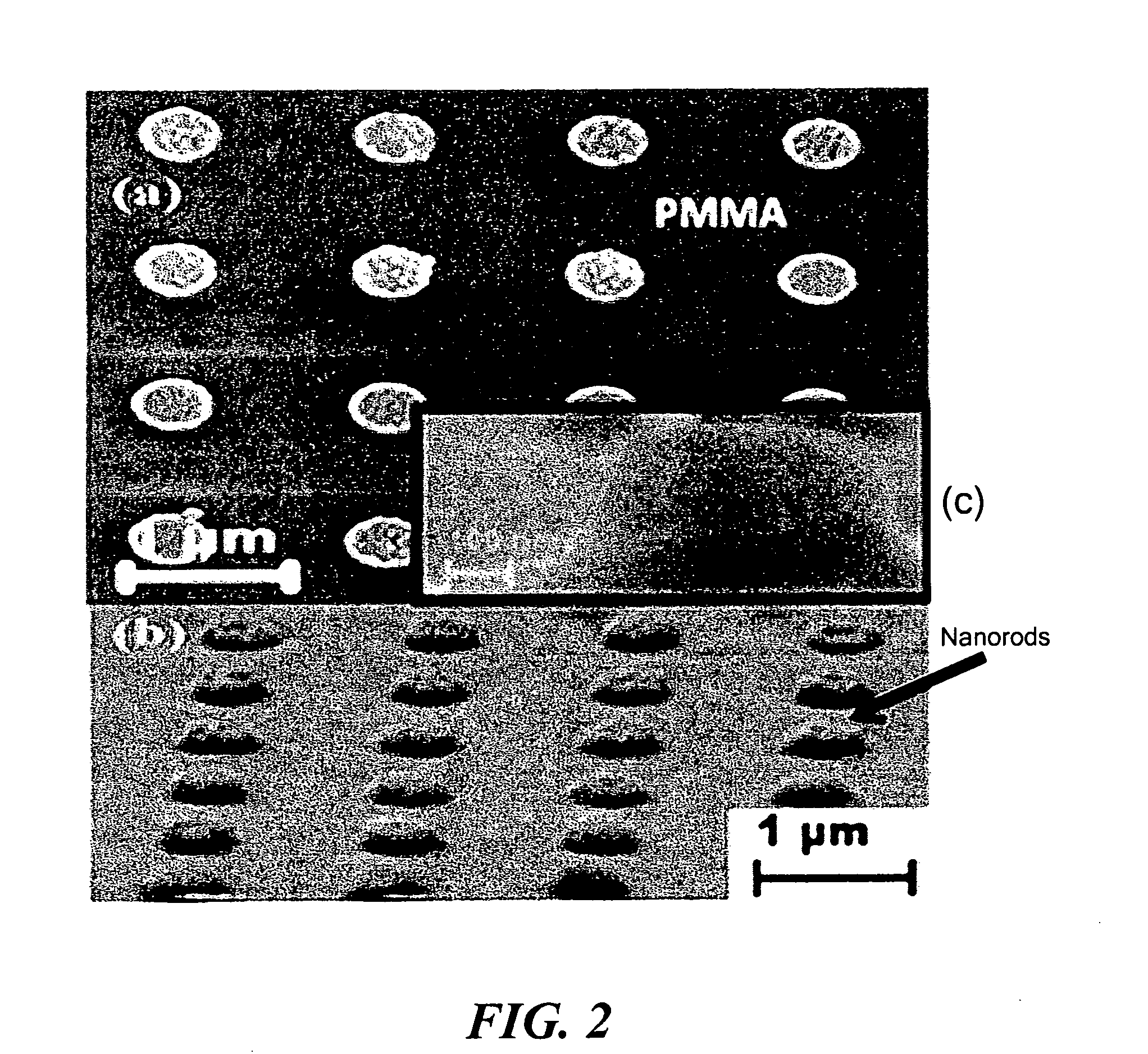

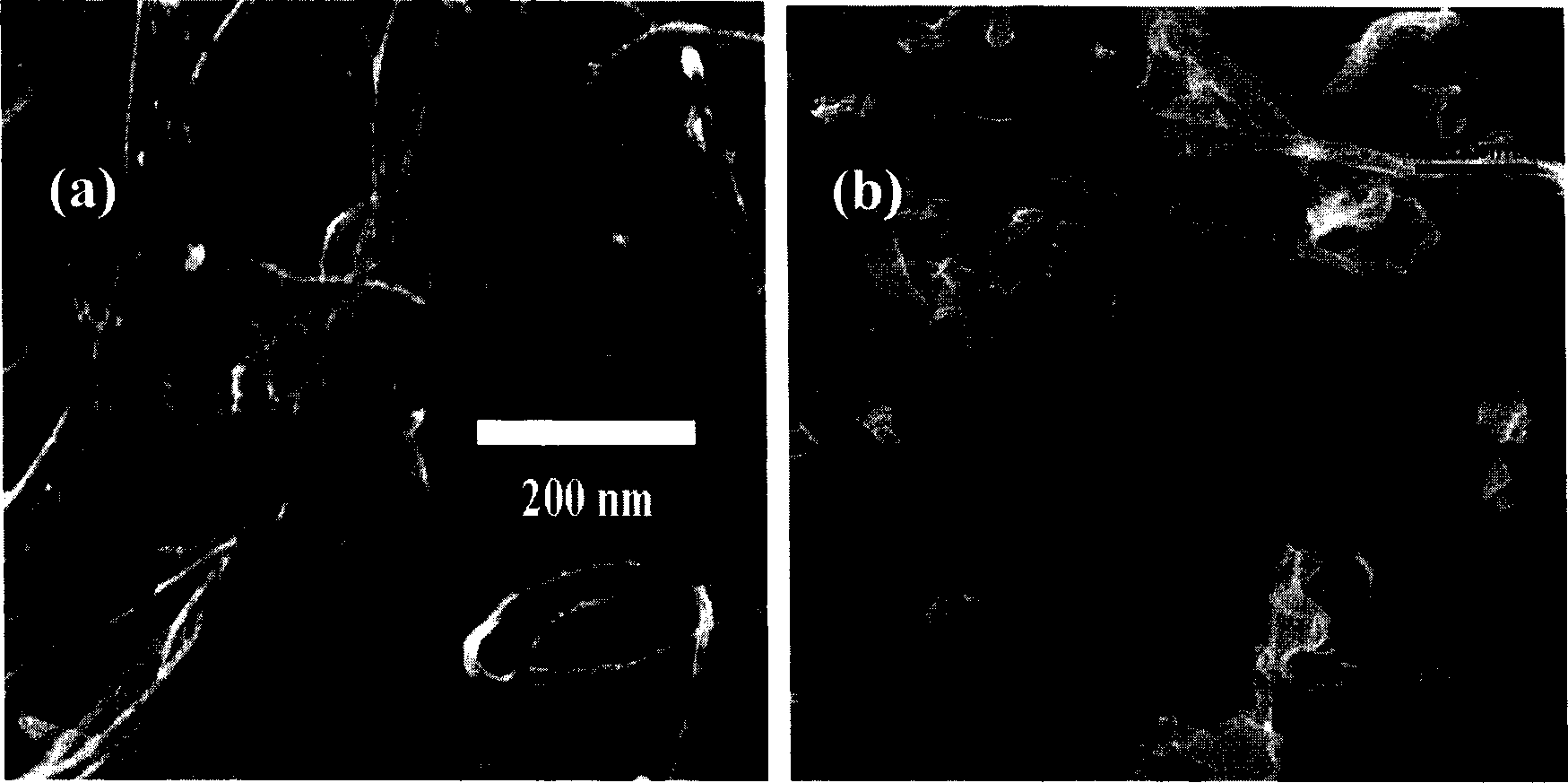

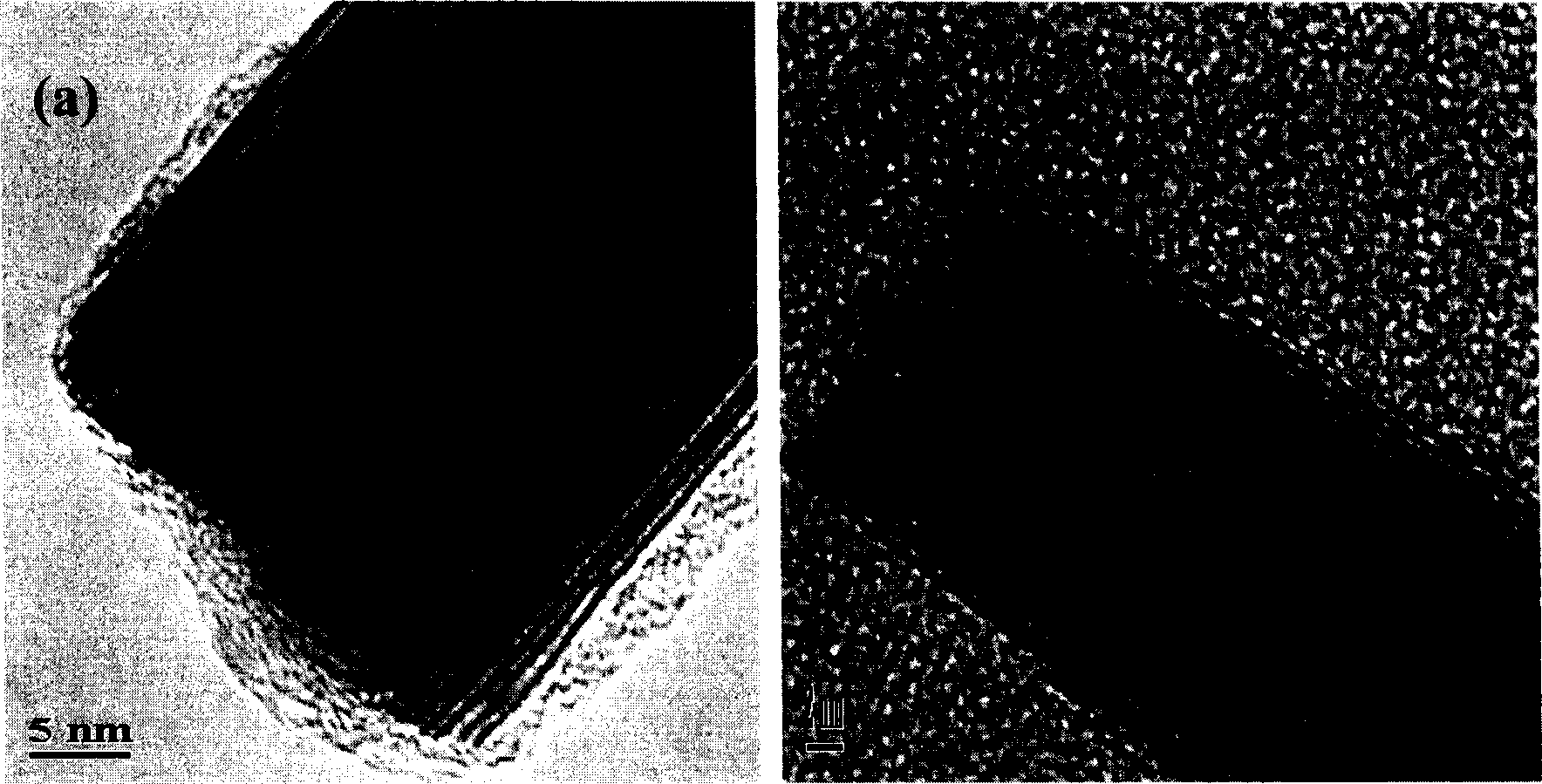

ActiveUS20120326310A1Process controlReduce concentrationMaterial nanotechnologySemiconductor/solid-state device detailsMetallic nanotubesNanotube

The invention provides a fast, scalable, room temperature process for fabricating metallic nanorods from nanoparticles or fabricating metallic or semiconducting nanorods from carbon nanotubes suspended in an aqueous solution. The assembled nanorods are suitable for use as nanoscale interconnects in CMOS-based devices and sensors. Metallic nanoparticles or carbon nanotubes are assembled into lithographically patterned vias by applying an external electric field. Since the dimensions of nanorods are controlled by the dimensions of vias, the nanorod dimensions can be scaled down to the low nanometer range. The aqueous assembly process is environmentally friendly and can be used to make nanorods using different types of metallic particles as well as semiconducting and metallic nanaotubes.

Owner:NORTHEASTERN UNIV

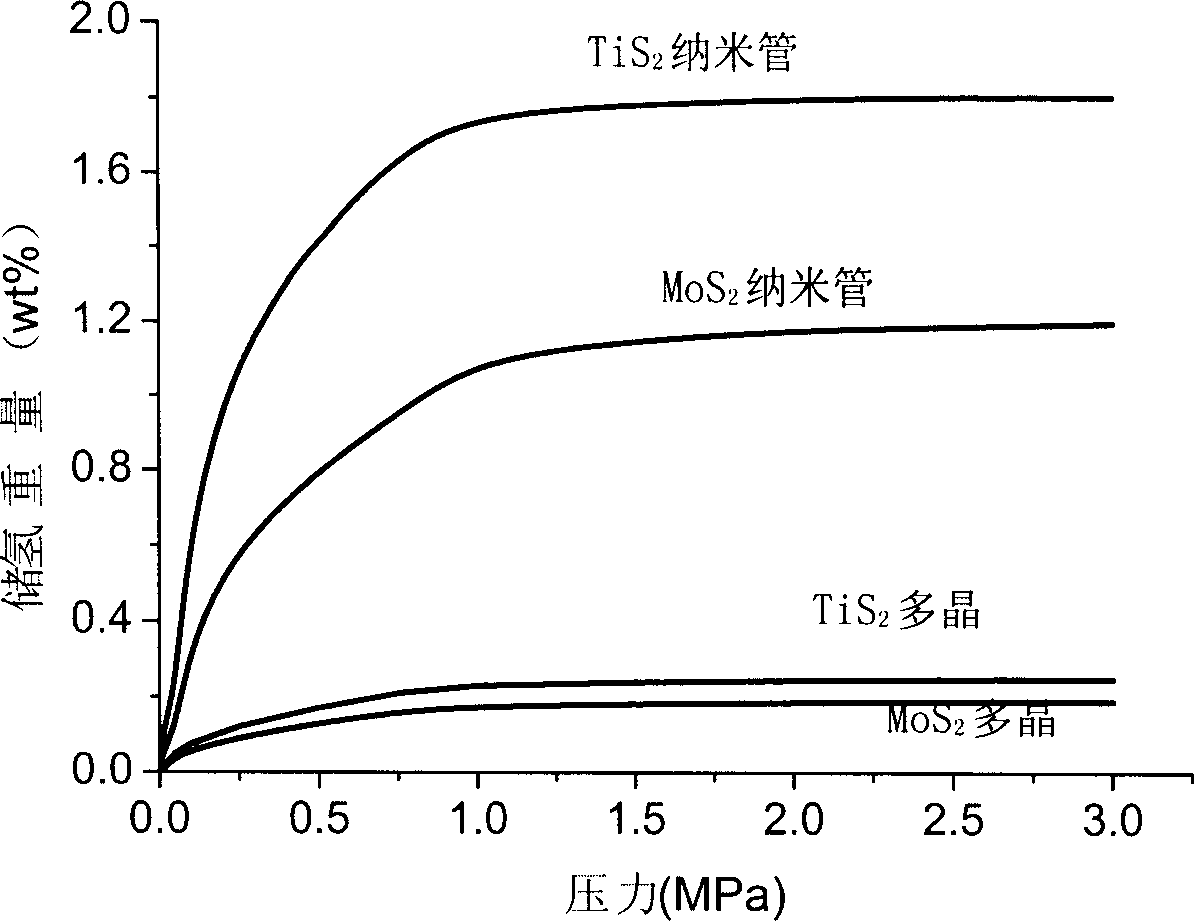

Transition metal sulfied nano-pipe and preparation process and its application

InactiveCN1413910AAvoid internal short circuitExtend working lifeZirconium compoundsTitanium compoundsHydrogenSingle-Walled Nanotube

A nanotube of transition metal sulfide (MSx, where M is Ti, Sr, Nb, Mo, W, etc and X=1 or 2) is prepared by low-temp gas-solid catalytic reaction. The said nanotube has unique laminated tubular structure and large specific surface area, and can be used as the hydrogen bearing or lithium bearing electrode of battery as it has high change-discharge speed and excellent cycle life.

Owner:NANKAI UNIV

Type separation of single-walled carbon nanotubes via two-phase liquid extraction

InactiveUS8703092B2Improve scalabilityEasy to collectMaterial nanotechnologyPigmenting treatmentMetallic nanotubesElectron

The subject invention provides a two-phase liquid-liquid extraction process that enables sorting and separation of single-walled carbon nanotubes based on (n, m) type and / or diameter. The two-phase liquid extraction method of the invention is based upon the selective reaction of certain types of nanotubes with electron withdrawing functional groups as well as the interaction between a phase transfer agent and ionic moieties on the functionalized nanotubes when combined in a two-phase liquid solution. Preferably, the subject invention enables efficient, bulk separation of metallic / semi-metallic nanotubes from semi-conducting nanotubes. More preferably, the subject invention enables efficient, bulk separation of specific (n, m) types of nanotubes.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

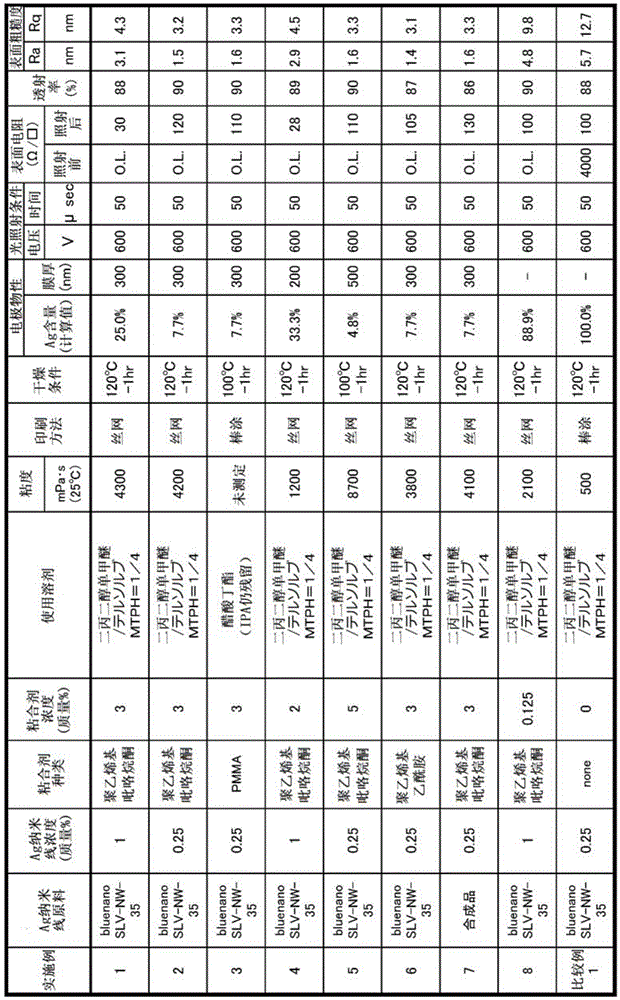

Transparent electrode and method for producing same

ActiveCN105493203AIncrease production capacityCompatible with surface smoothnessConductive layers on insulating-supportsSynthetic resin layered productsElectrical resistance and conductanceSurface resistivity

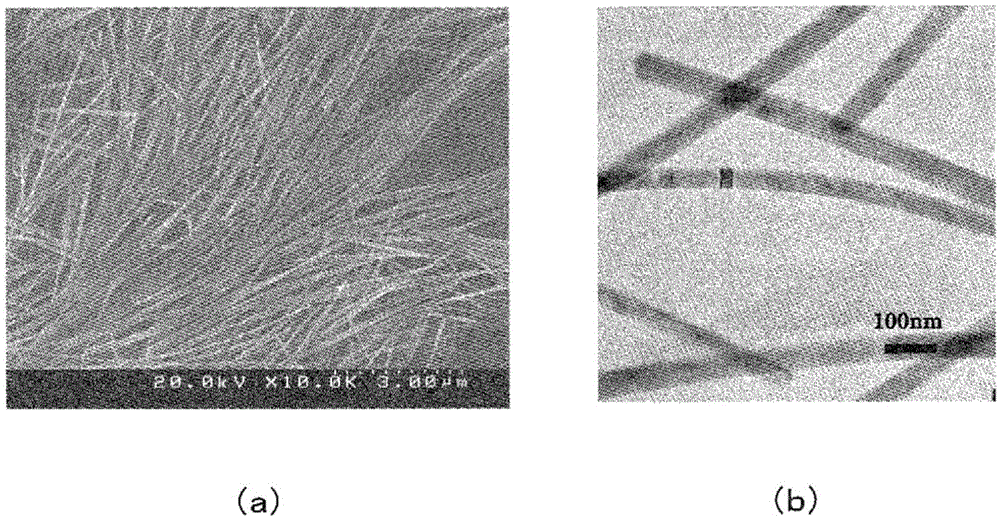

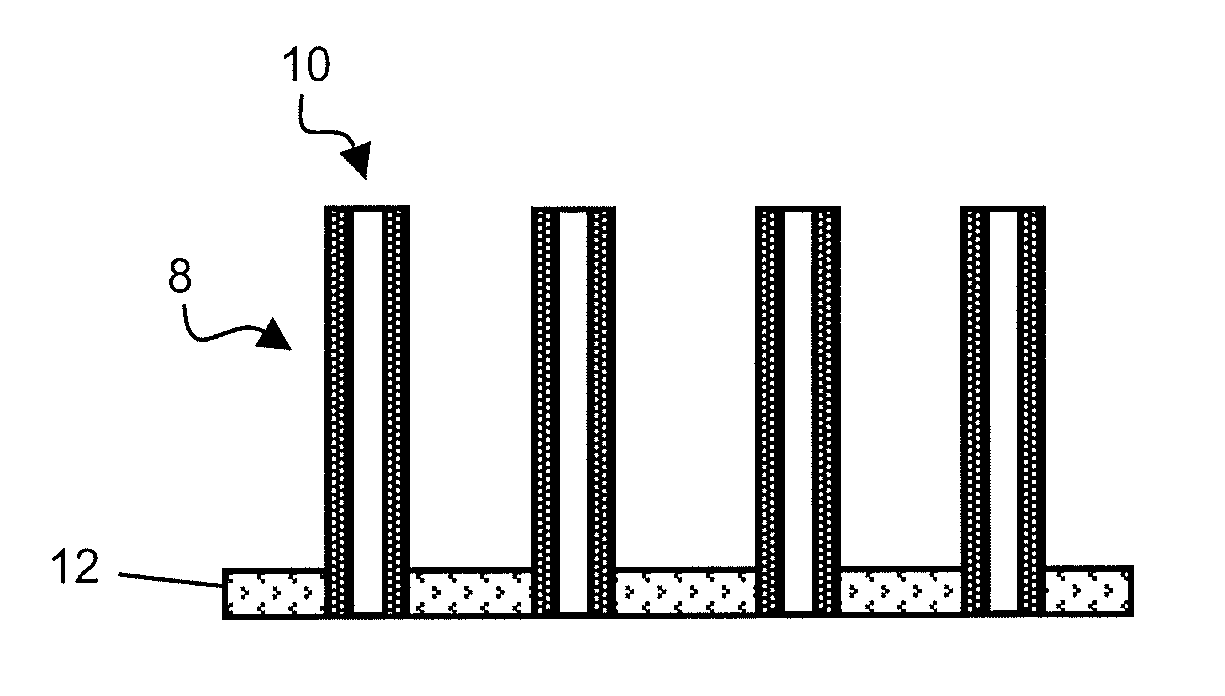

To provide: a transparent electrode which uses metal nanowires and / or metal nanotubes as a conductive component and has surface smoothness, conductivity and light transmittance at the same time, while exhibiting high productivity; and a method for producing this transparent electrode. A transparent electrode which has a surface resistivity of 0.1-500 [Omega] / - and a surface arithmetic average roughness (Ra) satisfying Ra <= 5 nm is obtained by: printing an electrode pattern of a desired form on a substrate with use of a transparent conductive ink that is obtained by dispersing metal nanowires and / or metal nanotubes in a solution, which is obtained by dissolving, in a solvent, a thermosetting or thermoplastic binder resin that does not exhibit fluidity in the temperature range of 5-40 DEG C, said transparent conductive ink containing 100-2,500 parts by mass of the binder resin per 100 parts by mass of the metal nanowires and / or the metal nanotubes; and then irradiating the printed electrode pattern with pulsed light.

Owner:株式会社力森诺科

Preparation method for electro-conductive magnetic nanotube

InactiveCN103708416AUniform depositionIncrease the lengthMaterial nanotechnologyLiquid/solution decomposition chemical coatingChemical platingFiber bundle

The invention relates to a preparation method for an electro-conductive magnetic nanotube, and belongs to the field of functional nanometer materials. The chemical plating method is adopted in synthesis of the electro-conductive metal nanotube. The method comprises the following steps that a, a nano-fiber bundle is prepared through the melt-extrusion phase separation method; b, chemical plating is carried out on the nano-fiber bundle in the step a to obtain an electro-conductive nano-fiber bundle; c, a solvent is used for dissolving the nano-fiber bundle, wrapped by metal, in the step b. The chemical plating method is adopted for preparing the metal nanotube, and therefore the chemical stability is good, the preparation process is simple, the synthesis cost is low, and the application field is wide.

Owner:WUHAN TEXTILE UNIV

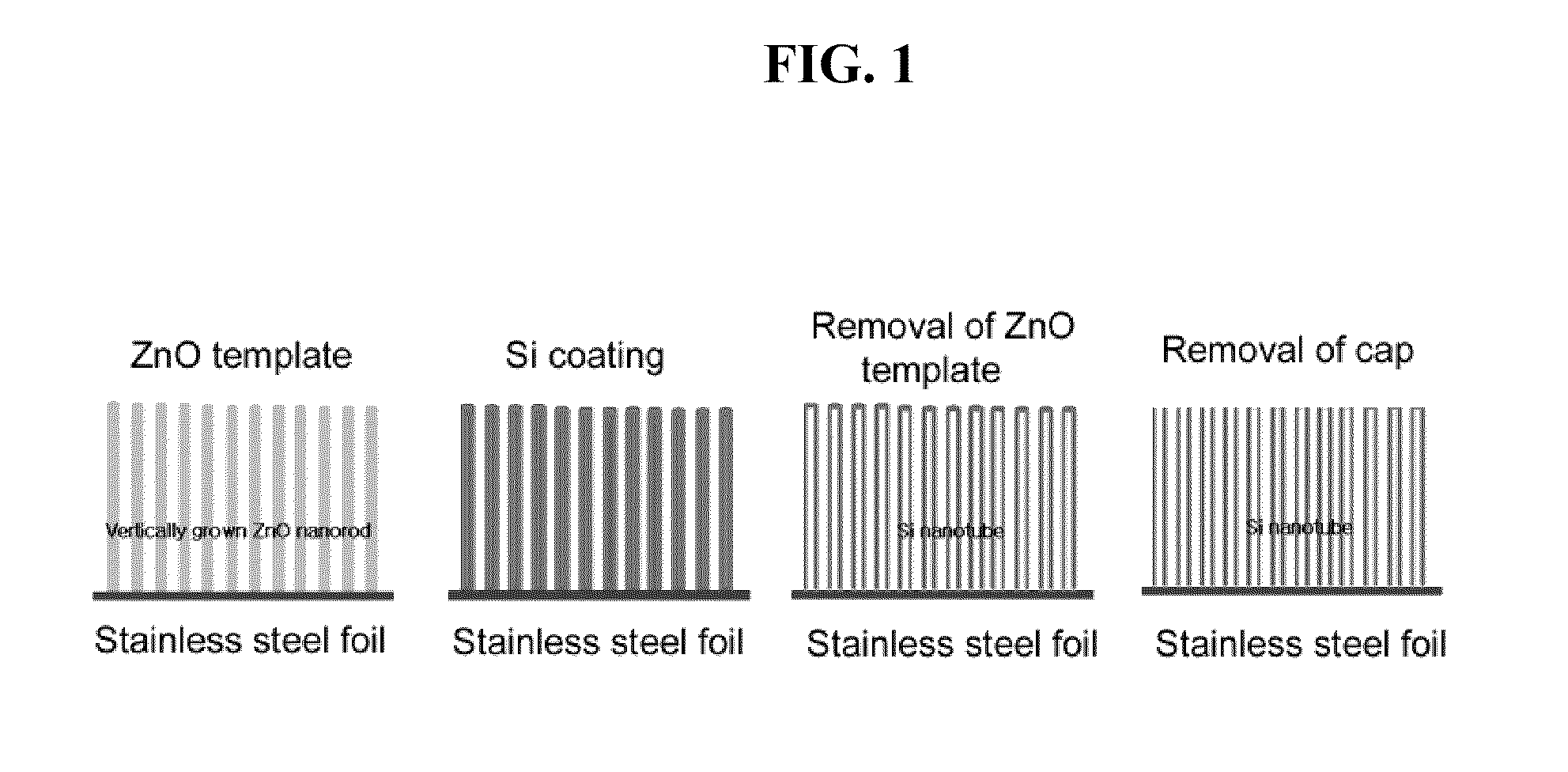

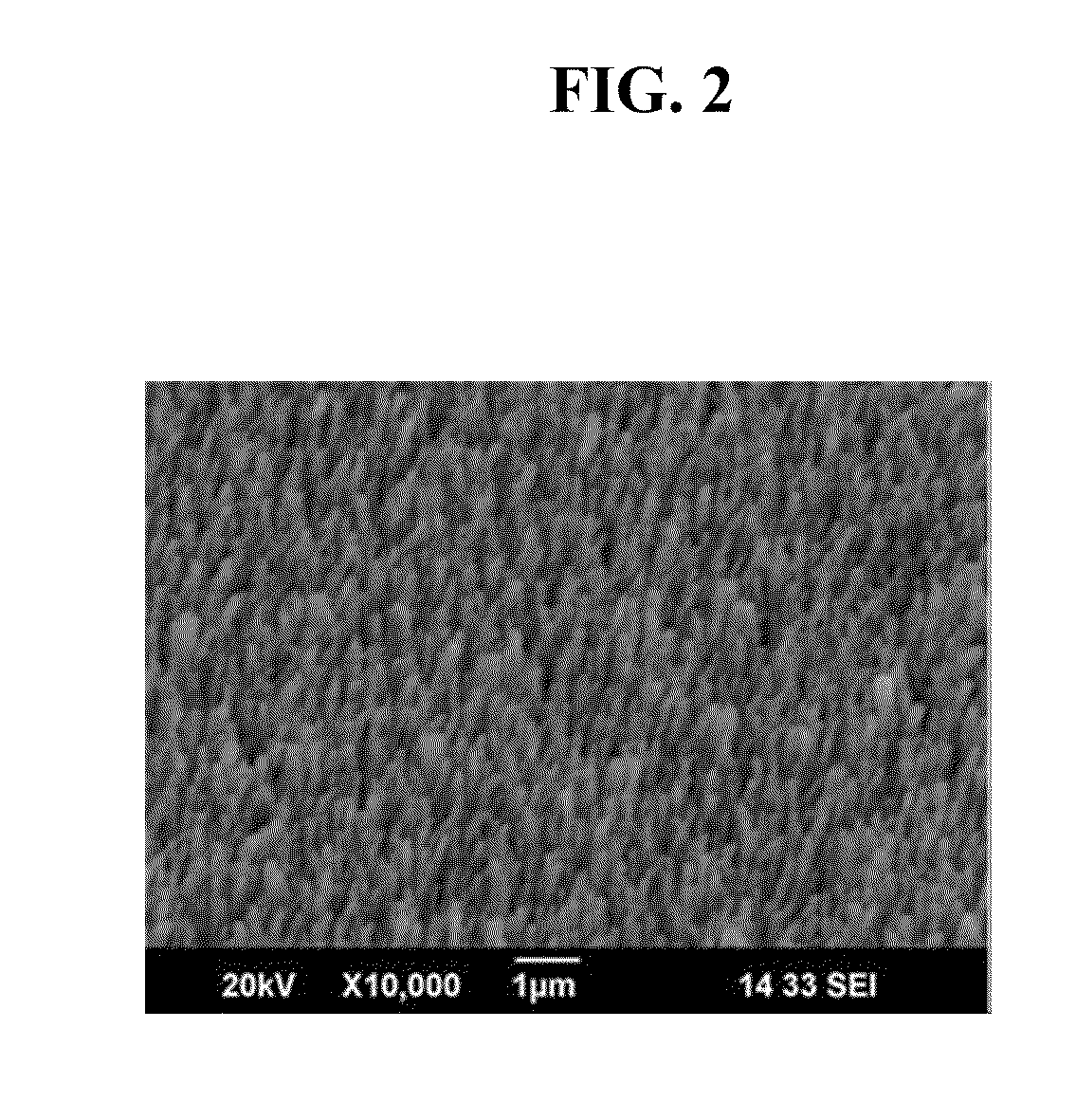

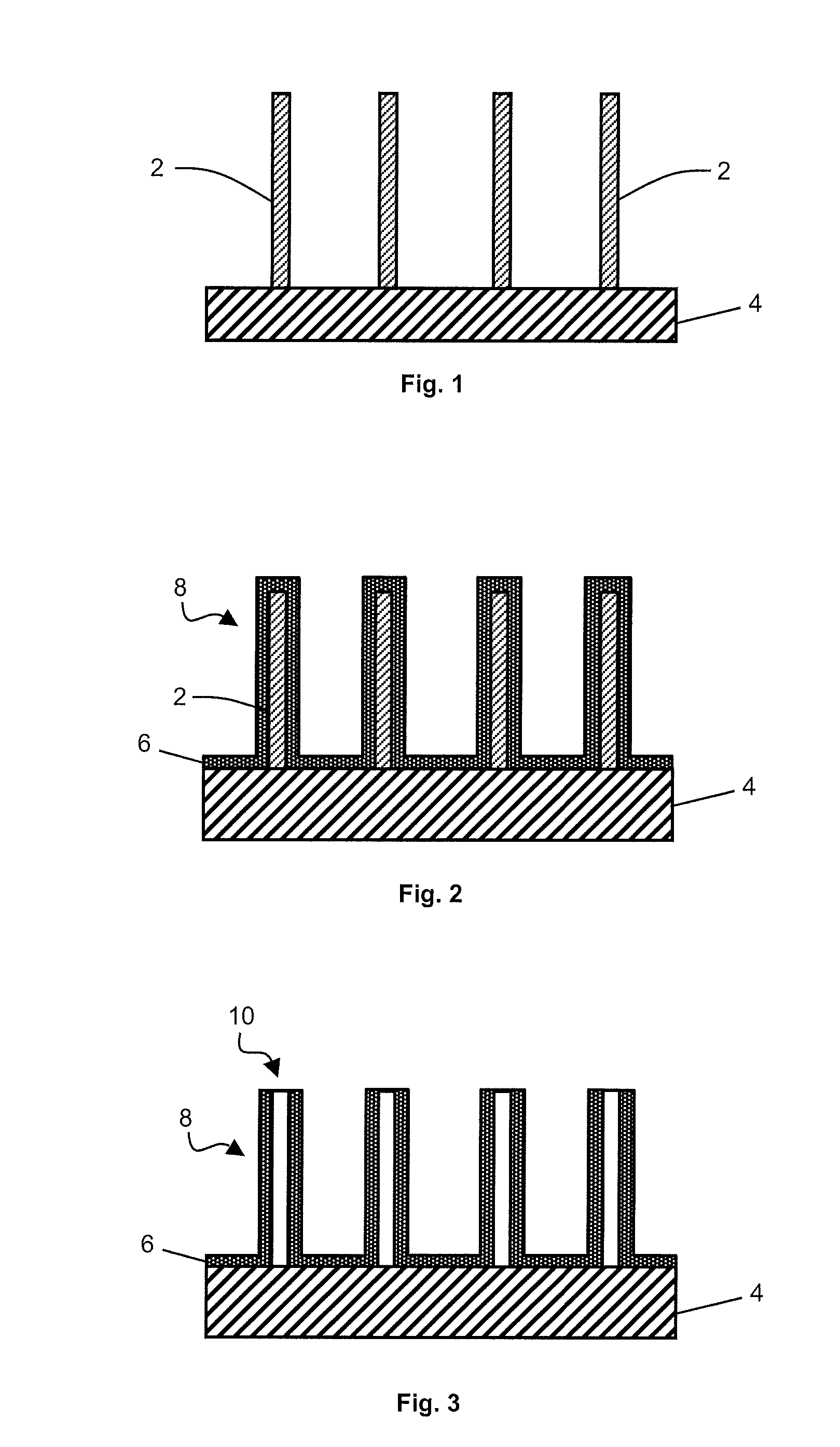

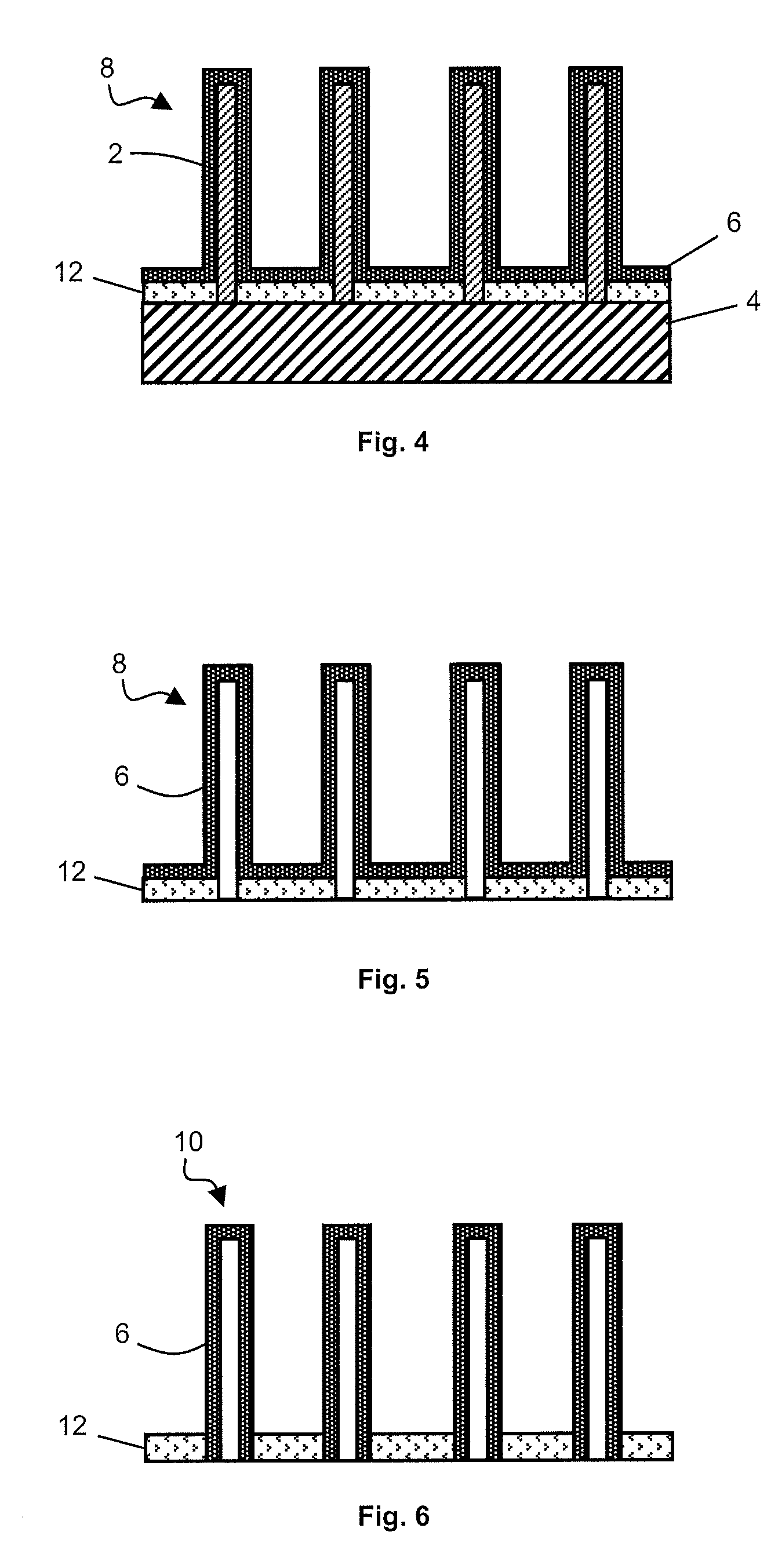

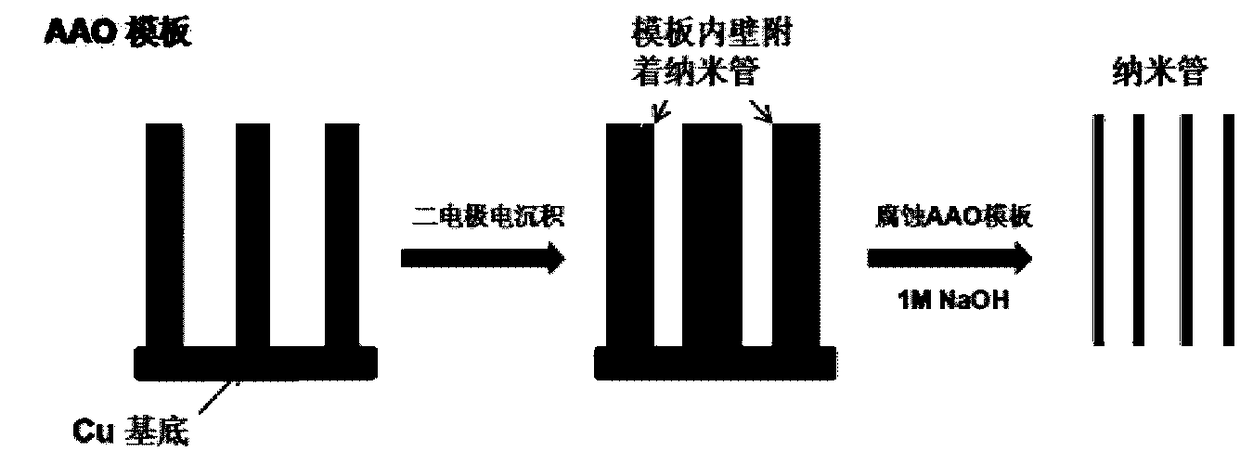

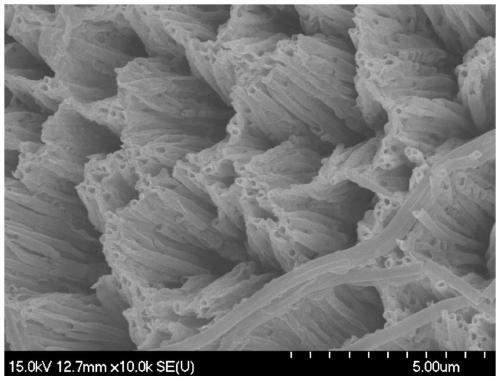

Array of metallic nanotubes

InactiveUS20140015159A1Easy to implementDimensional constraints on the nanotubes to be relaxedMaterial nanotechnologyPolycrystalline material growthNanowireMetallic nanotubes

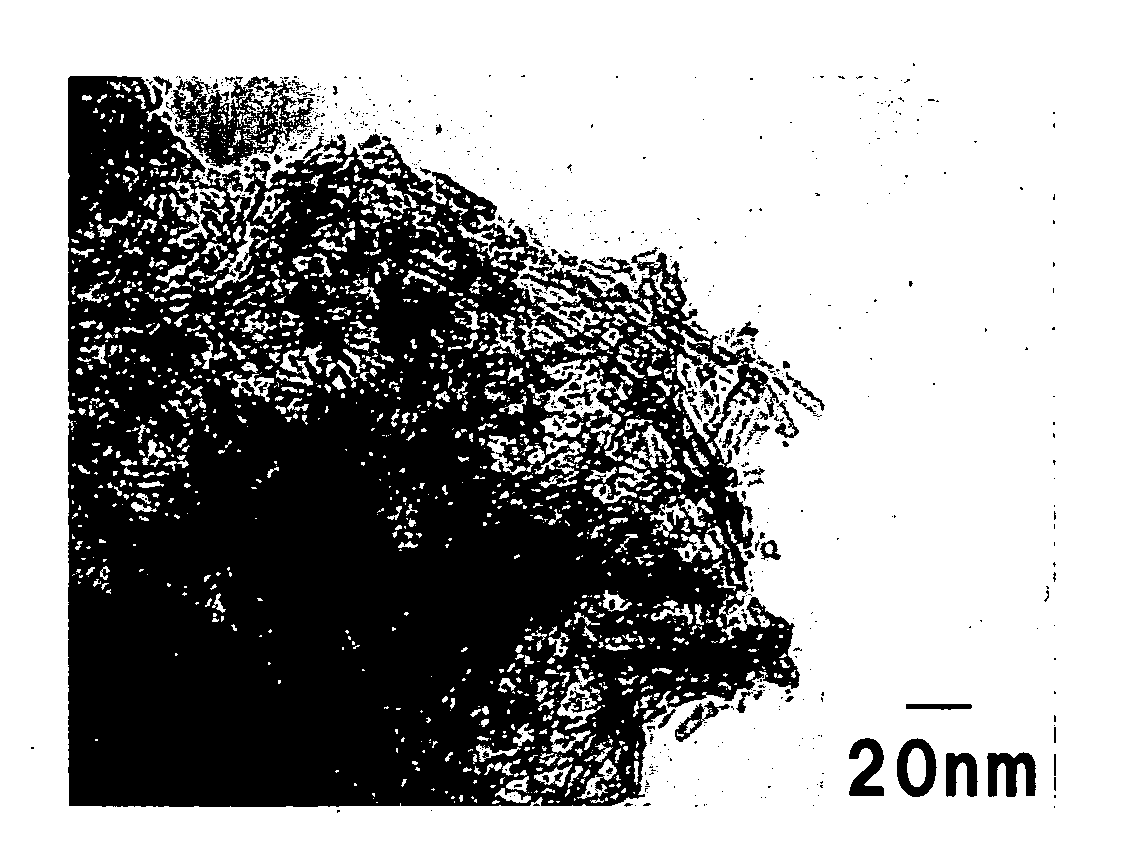

A method for producing an array or bed of metallic nanotubes includes formation of nanowires made from sacrificial material on a growth support, deposition of a metal layer on the nanowires so as to form metallic nanotubes concentric with the nanowires, deposition of a polymer binding layer between the nanowires, elimination of the support, the binding layer supporting the metallic nanotubes, and etching of the sacrificial material.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Transparent conductive ink, and method for producing transparent conductive pattern

ActiveCN104303238ASuppress manufacturing costInhibiting environmentApparatus for heat treatmentInksSimple Organic CompoundsMetallic nanotubes

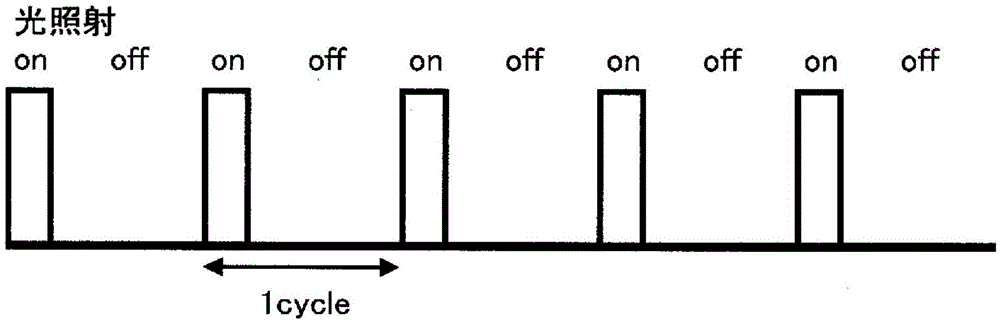

[Problem] To provide: a transparent conductive ink which uses, as a conductive component, metal nanowire and / or metal nanotubes, and which can form a coating film that is both conductive and optically transparent; and a method for producing a transparent conductive pattern wherein the transparent conductive ink is used to create a transparent conductive pattern by means of easy manufacturing steps, the method having reduced manufacturing costs and environmental impact. [Solution] A transparent conductive ink in which metal nanowire and / or metal nanotubes are dispersed in a dispersion medium which comprises shape retaining material having a viscosity of 1.0 x 103-2.0x106 mPa.s at 25°C and comprising an organic compound having a molecular weight range of 150-500, and a method, for forming a transparent conductive pattern, using the transparent conductive ink to print an arbitrarily shaped pattern on a substrate, heat treating and drying same, and then irradiating pulsed light on the dried pattern.

Owner:OSAKA UNIV +1

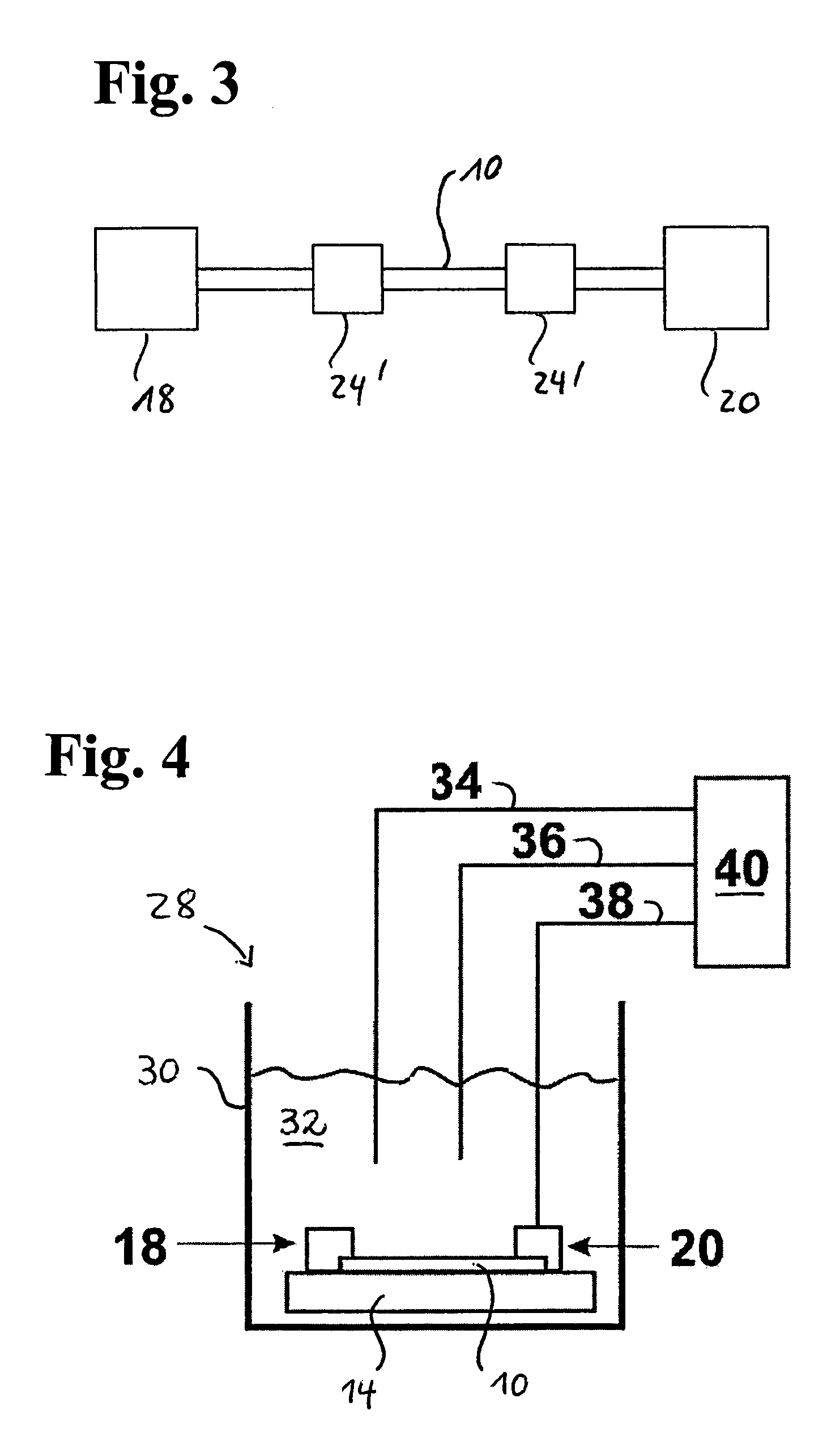

Method of fabricating carbon nanotube field-effect transistors through controlled electrochemical modification

InactiveUS20060024871A1Poses problemImprove the immunityNanoinformaticsSolid-state devicesCompound (substance)Carbon nanotube field-effect transistor

The invention relates to a method of fabricating a structure with field effect transistors, said transistors each comprising a source electrode, a drain electrode, a channel extending between the source and drain electrodes and at least one gate electrode associated with the channel for controlling the conductance of the channel, wherein the channel comprises one or more semiconducting single-wall carbon nanotubes. The method includes the steps of a) depositing a plurality of single-wall carbon nanotubes on a substrate, said carbon nanotubes comprising a mixture of metallic carbon nanotubes and semiconducting carbon nanotubes, b) providing before or after step a) source and drain electrodes on the substrate so that one or more carbon nanotubes extend between the source and drain electrodes, c) applying a variable gate voltage to switch off the semiconducting tubes extending between the source and drain electrodes, d) wetting the surface of the structure including the transistors with a chemical to achieve a chemical bond between a radical supplied by said chemical and some carbon atoms of the metallic nanotubes, whereby these metallic nanotubes become non-conductive.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

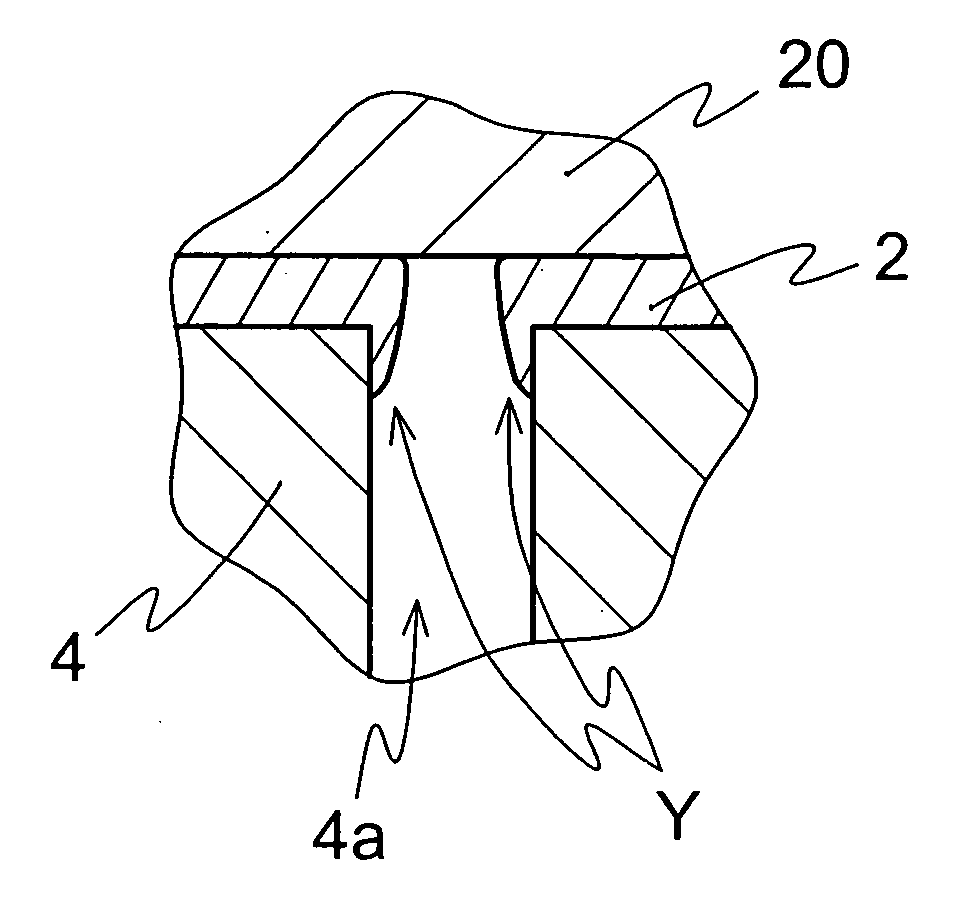

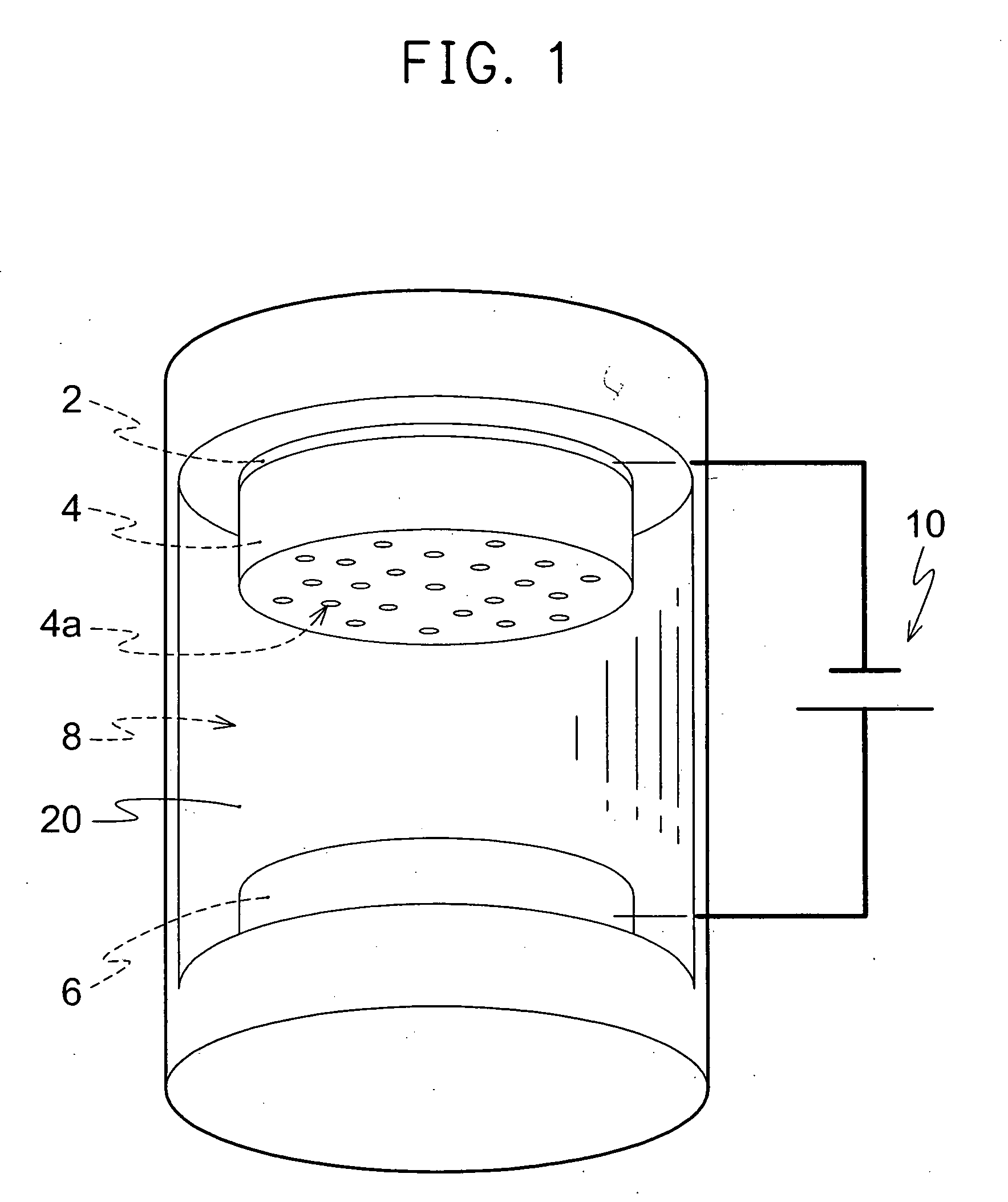

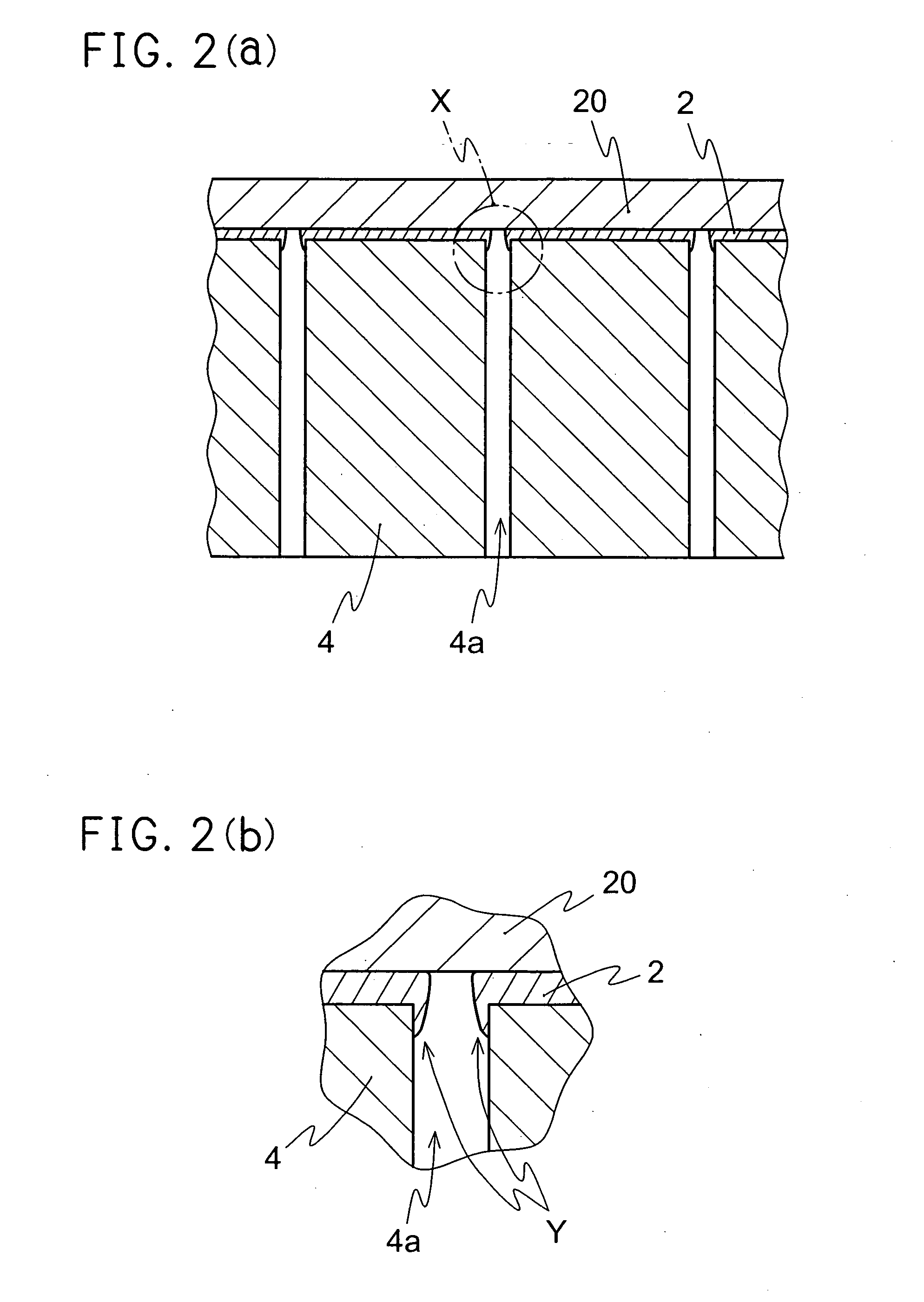

Apparatus for Manufacturing Metal Nanotube and Process for manufacturing Metal Nanotube

Disclosed is a low-cost, high quality metal nanotube comprising Ni, Fe, Co or the like. A metal thin film having a thickness of 10 to 80 nm is formed as a cathode on one surface of a film having penetrated holes, and an electrolyte solution is filled between an anode and the cathode to which a voltage is applied. Metal ions in the electrolyte solution are electrochemically deposited on the walls of the penetrated holes, thereby forming metal nanotubes. A thermoplastic resin porous film such as a polycarbonate film, an alumina porous film or aluminum anodic oxide film may be used as the film, and the diameters of the penetrated holes are preferably 15 to 500 nm. The metal thin film can be formed by sputtering, and preferably comprises a platinum-palladium alloy. The electrochemical processing of nanostructured tailored materials is a unique technique.

Owner:FUKUNAKA YASUHIRO

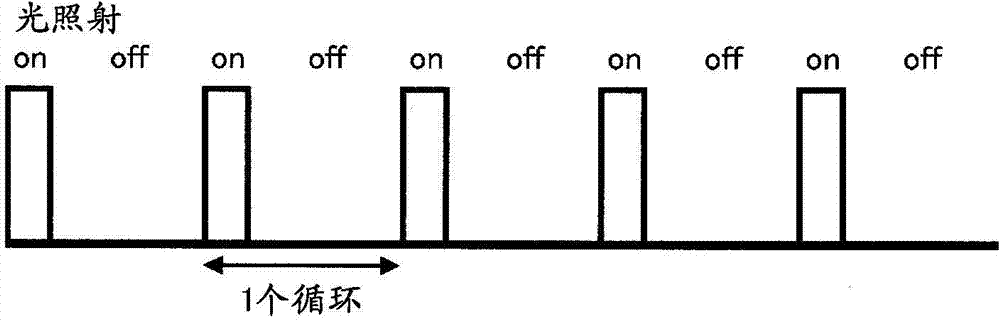

Method for preparing magnetic metal nanotubes through pulse electrodeposition

ActiveCN108277462AIncreased activation polarizationReduce concentration variationAnodisationVacuum evaporation coatingMetallic nanotubesNanotube

The invention relates to a method for preparing magnetic metal nanotubes through pulse electrodeposition, wherein the method has huge potential application prospects on the aspect of magnetic recording materials. The method has the beneficial effects of being simple, convenient to implement and extremely high in maneuverability. The lengths and the diameters of the prepared magnetic metal nanotubes can be effectively controlled; and according to the method, the cost is relatively low, the requirement for instrument precision is not strict, applicability is extremely high, the method can be used for preparing the various magnetic metal nanotubes and is not limited to preparing the singular magnetic metal nanotube, obvious changing cannot occur in the process steps, and mass production preparation is facilitated.

Owner:NINGBO ZHETIE JIANGNING CHEM +1

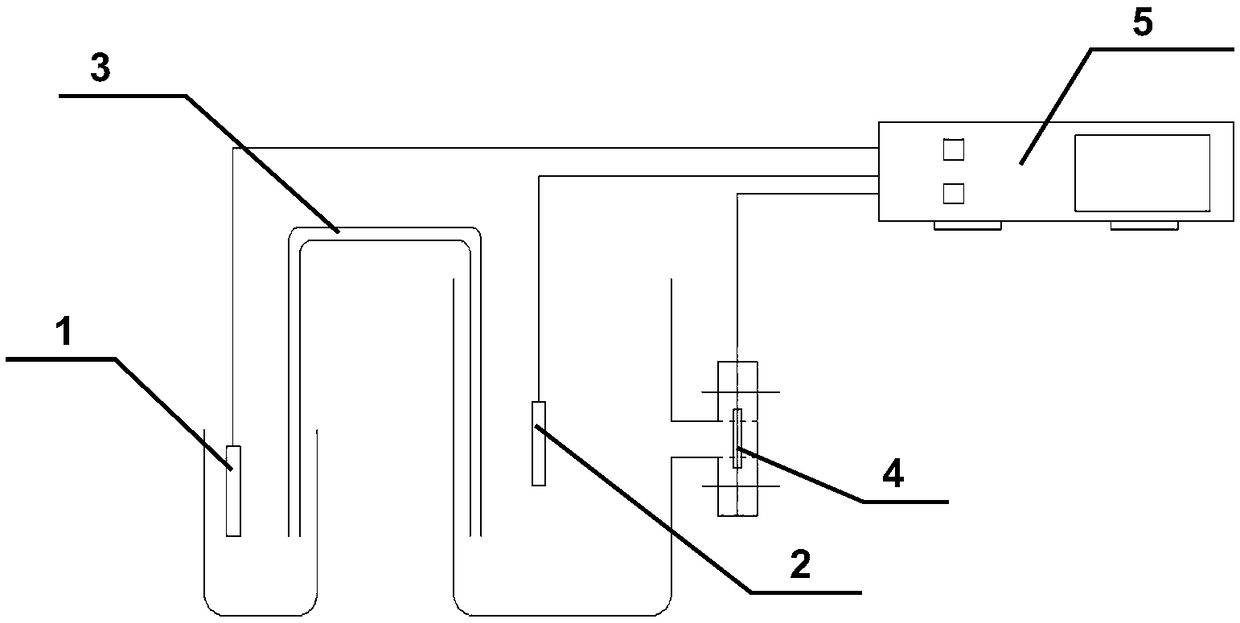

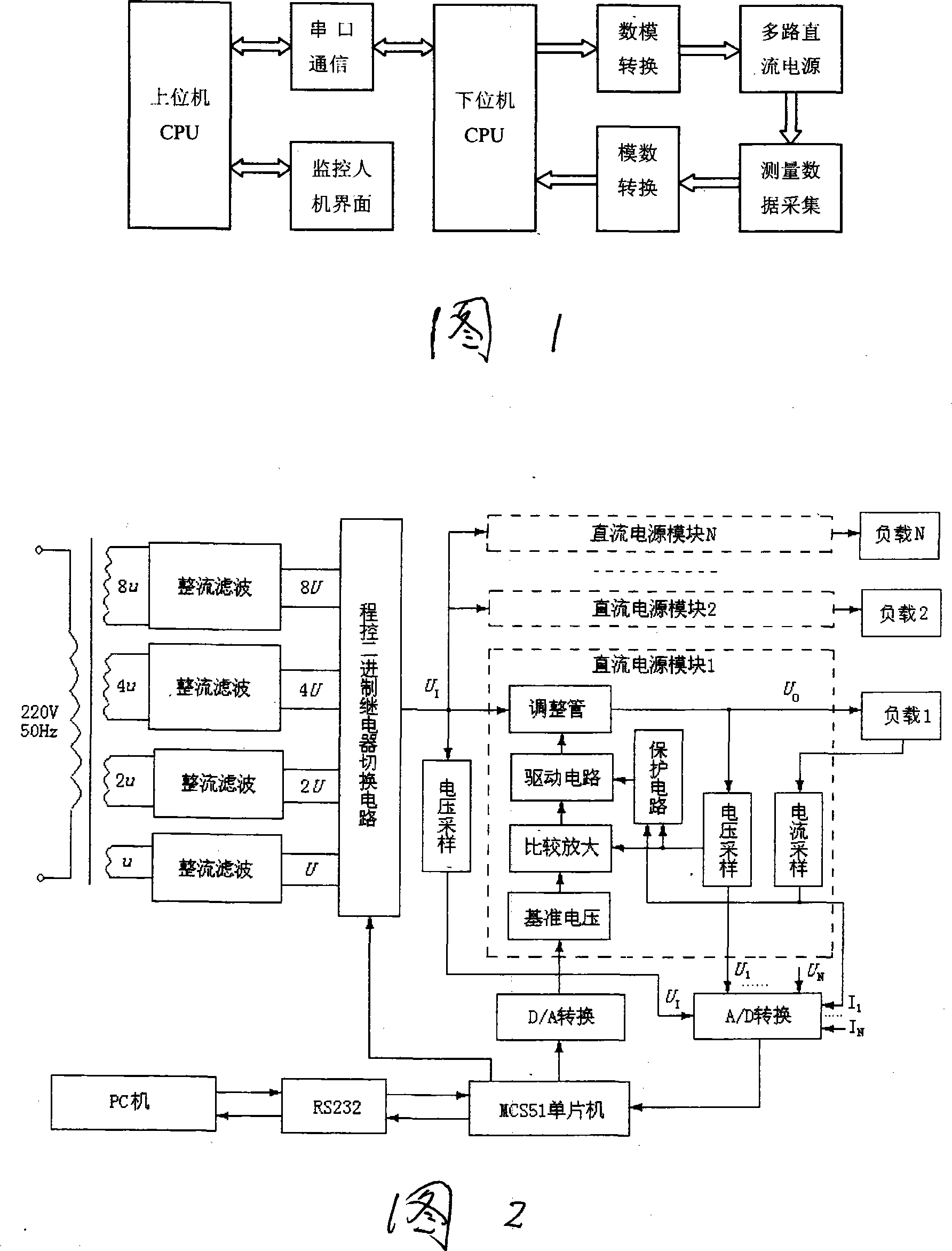

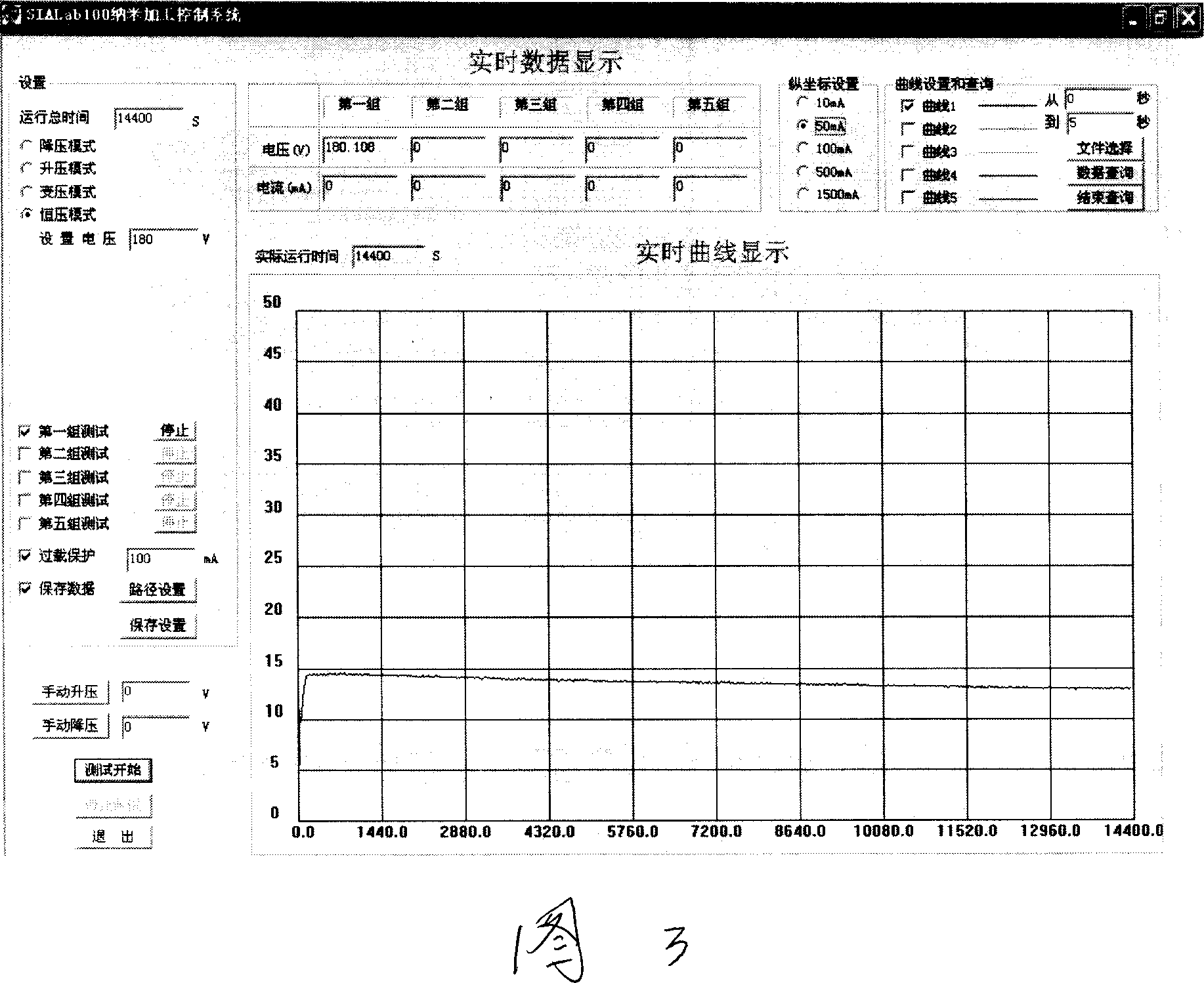

Programmable power supply system dedicated for nano processing

InactiveCN101145050AGood reproducibilityIncrease powerTotal factory controlProgramme total factory controlMicrocontrollerData acquisition

The present invention relates to a program-controlled power system specially used in nanometer-processing, and belongs to the field of electronic technology. The present invention adopts dual-CPU program-controlled power structure, and mainly consists of an upper personal computer, a lower single chip computer, a multi-way DC power controlled by the single chip computer, a detector for output voltage and current as well as a serial communication circuit arranged between the upper and lower computers and the dual-CPU; under the support of the program-controlled software specially used in nano-processing, the present invention has the advantages that with high power, high precision of the voltage control and data collection, good stability as well as a plurality of modes of voltage control, the present invention can control the voltage output of the multi-way DC by a program, and can real-time show the testing curve, save the data and curve and check the data; the program-controlled power system is applicable to the processing of materials such as the nanometer tube array of anodic aluminum oxide or can be a template to prepare other metals and non-metallic nanometer tubes; the present invention also can be applicable to other nanometer-research and the preparation of oxide nanometer material as well as biochemical analysis.

Owner:YANGZHOU UNIV

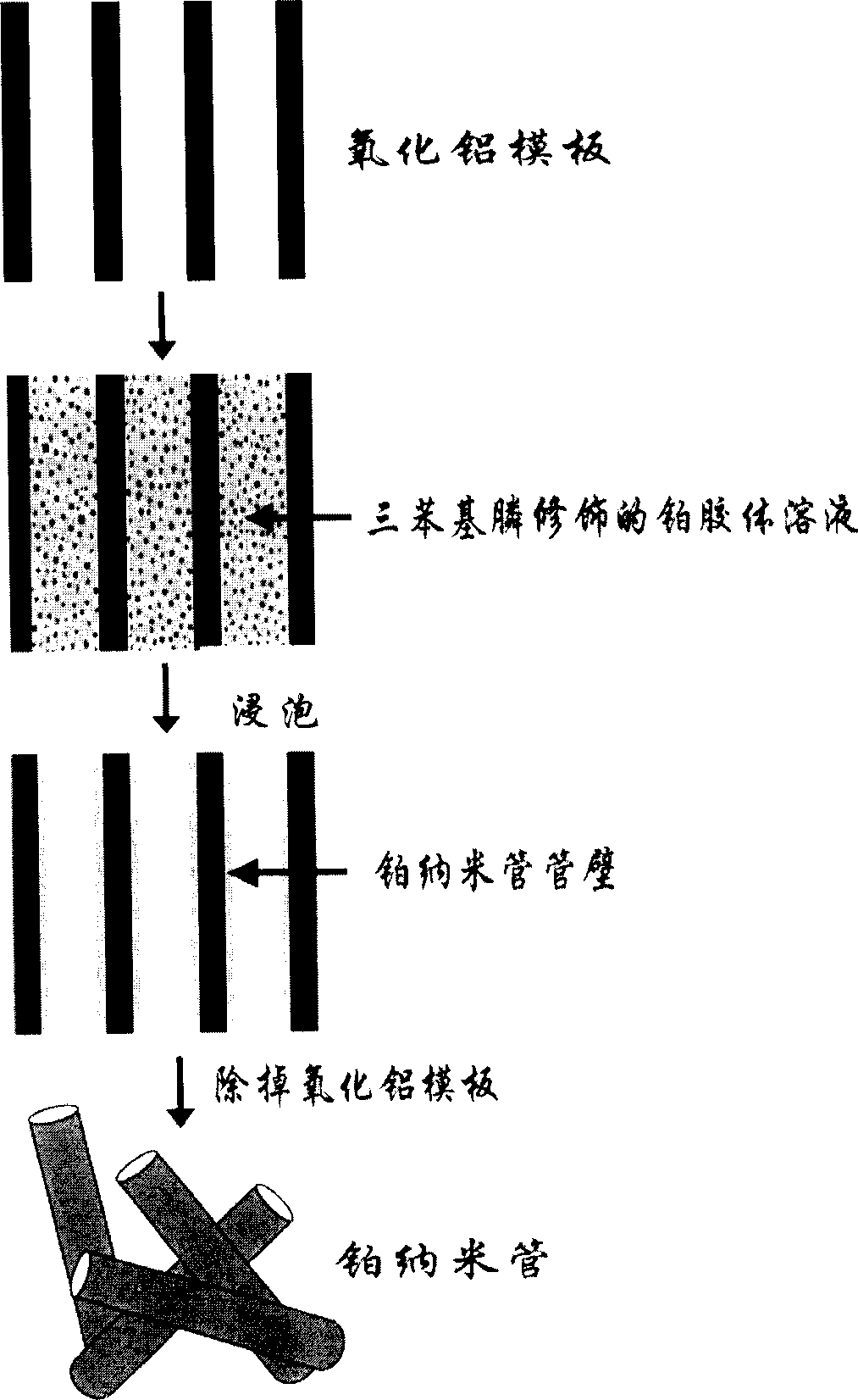

Metal nanometertube preparation method

InactiveCN1769519AEasy to operateLarge adjustment rangeNanostructure manufactureLiquid/solution decomposition chemical coatingSolubilityOrganic solvent

This invention relates to the metal nanometer tube making method, which includes the following steps: fistly making the metal colloid water-solubility solution, then extracting the metal from the water-solubility solution by the organic substance that has the coordination action with the metal, and distributing it in the organic solvent to get the metal colloid solution. The metal will deposit on the substrate when various substrates dips in this solution. If the substrate is the moulding board with the nanometer opening, then the metal will deposit on the inwall of the opening to form the matel nanometer tube. Controlling the dipping time and dipping number can get the nanometer tubes with different thickness. Using the moulding boards with different internal diameter nanometer opening can get the namometer tubes with different diametics. And using this invention can not only obtain the metal namometer tube whose structure and dimension can be controlled, and can obtain the metal nanometer tube array whose height is ordered.

Owner:INST OF CHEM CHINESE ACAD OF SCI

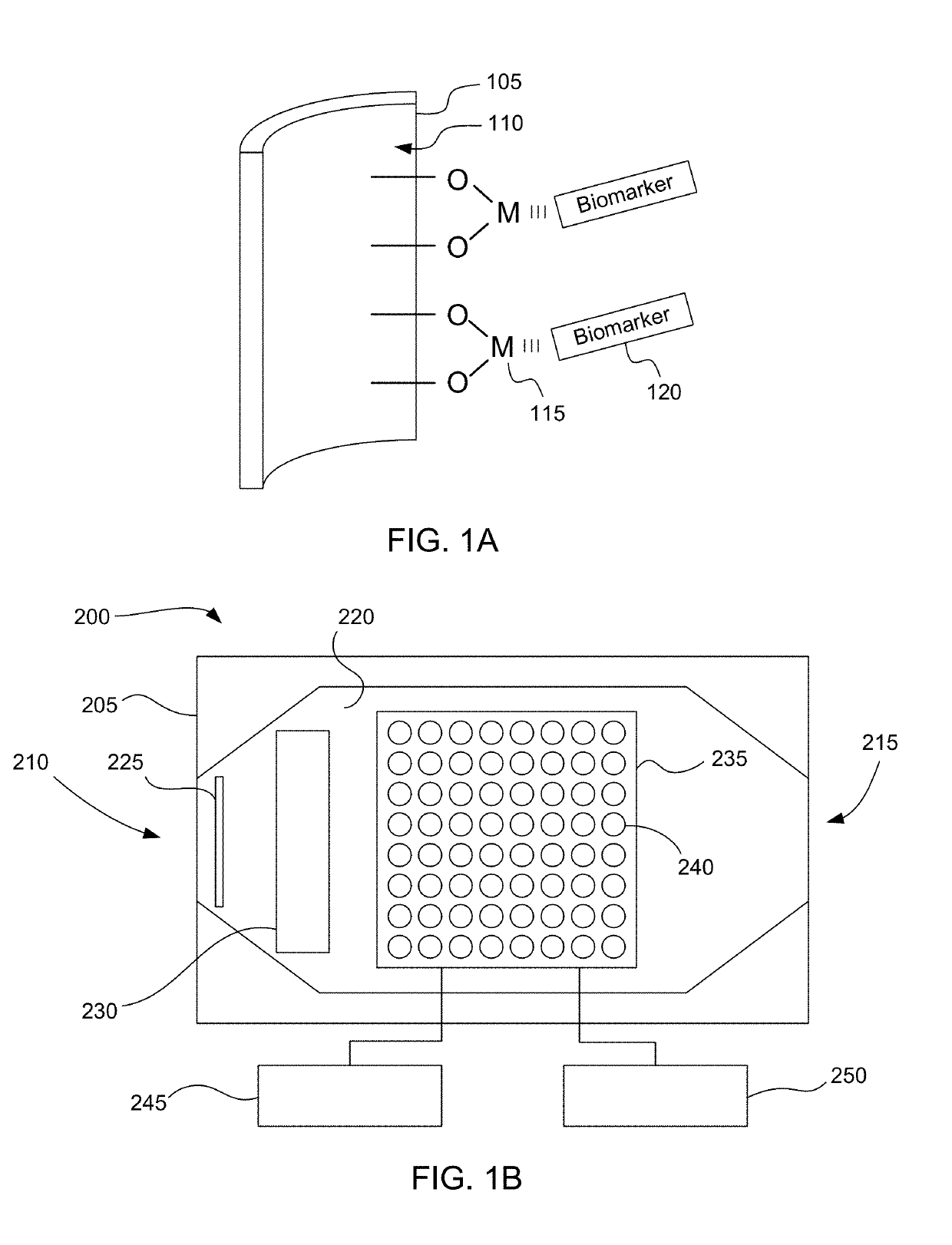

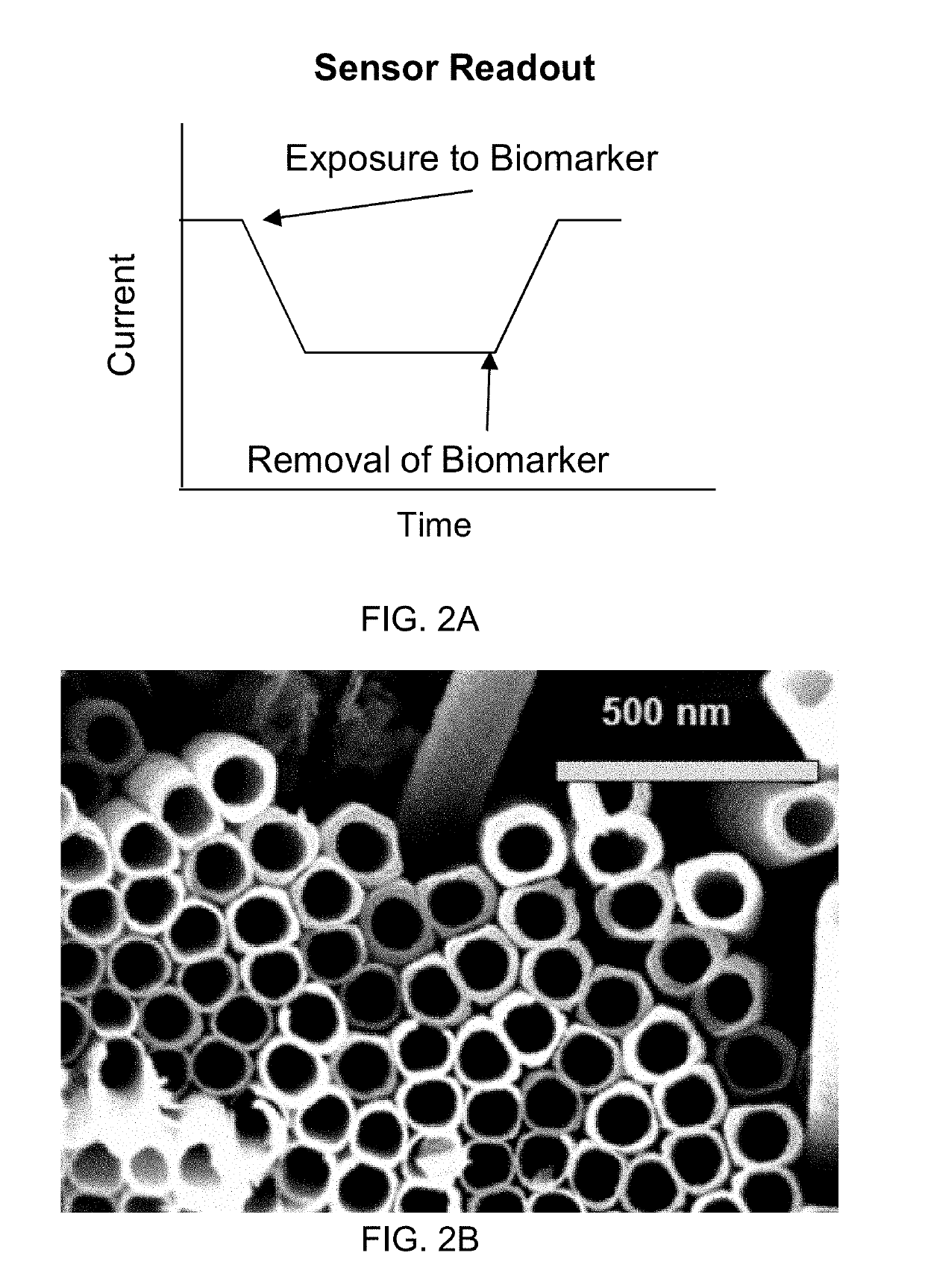

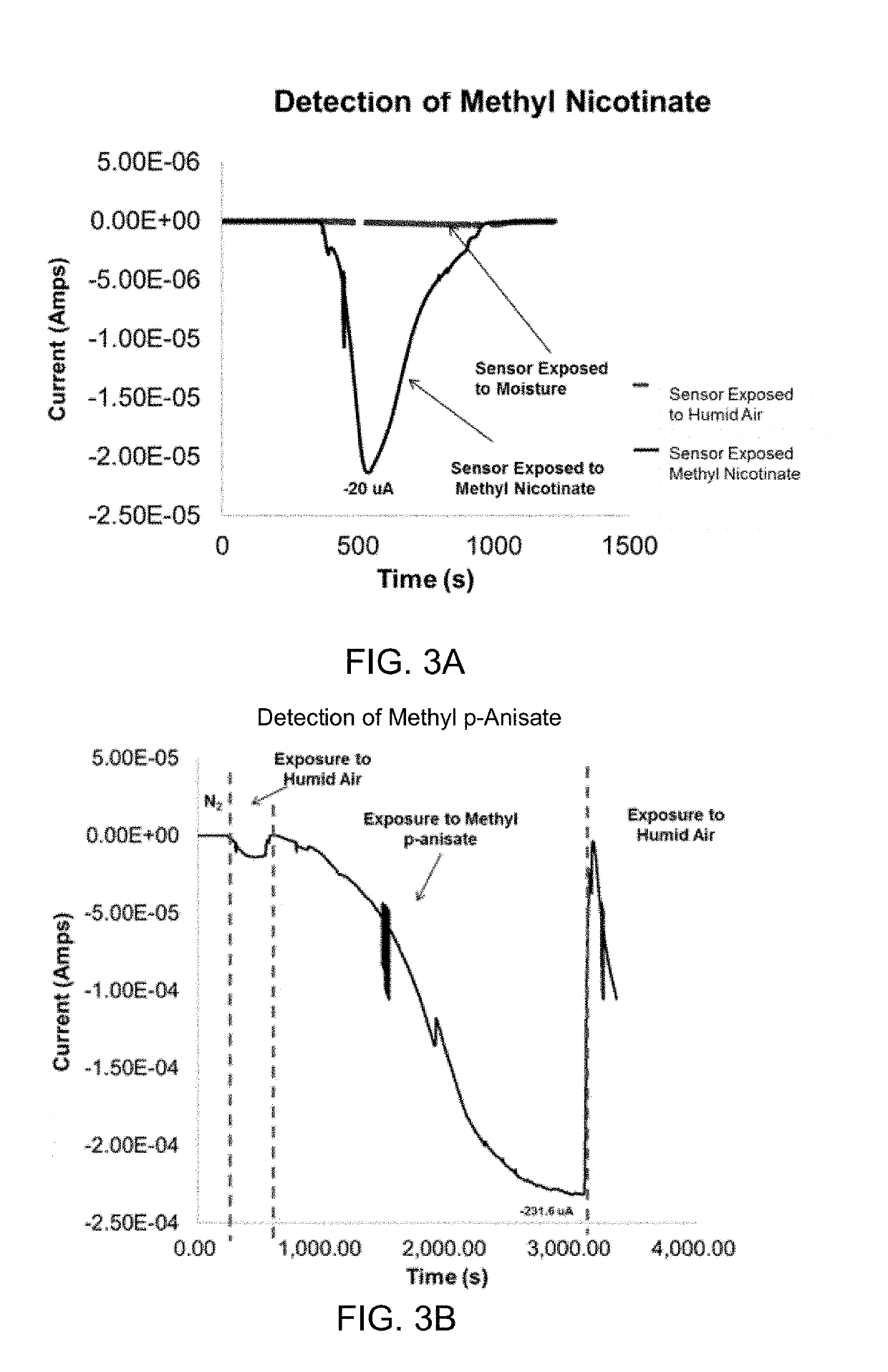

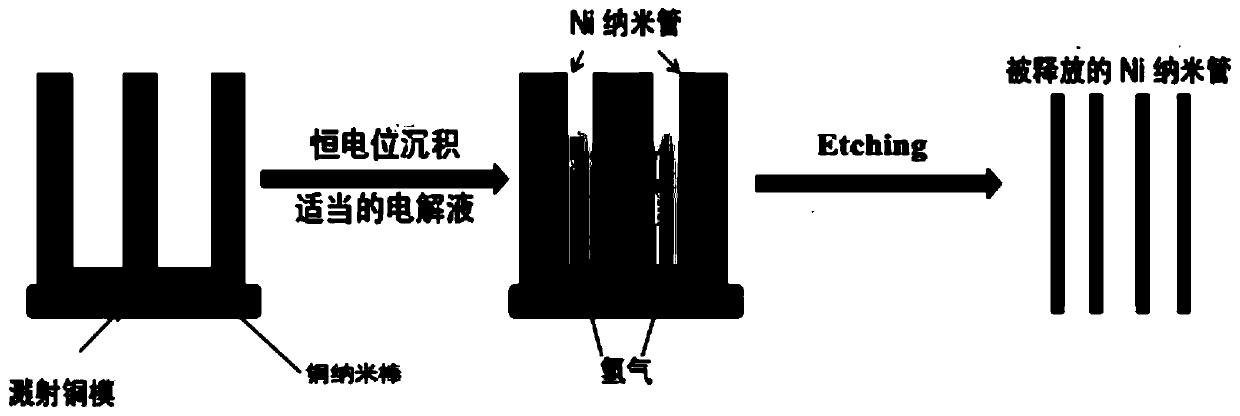

Functionalized nanotube sensors and related methods

ActiveUS20190219540A1Biological material analysisMaterial electrochemical variablesPower flowCurrent sensor

Functionalized nanotube arrays, sensors, and related methods of detecting target compounds are presented. A functionalized nanotube array can include a plurality of metal oxide nanotubes. The metal oxide nanotubes can be formed of a metal oxide and can have an interior or exterior surface that is optionally functionalized with at least one metal ion. These metal nanotubes can be used in a sensor for detecting target compounds such as volatile organic compounds, and biomarkers in a fluid environment. The sensor can further include a power source configured to apply a voltage to the nanotube array and a current sensor configured to monitor and detect changes in a response current which varies upon binding with the target compounds.

Owner:UNIV OF UTAH RES FOUND

Method for preparing magnetic metal nanotubes by controlling electrodeposition conditions

ActiveCN109778250AEasy to makeEconomical and fast to prepareMaterial nanotechnologySurface reaction electrolytic coatingSalt bridgeAuxiliary electrode

The invention relates to the field of nano materials and discloses a method for preparing magnetic metal nanotubes by controlling electrodeposition conditions. The method comprises the following stepsof (a) preparing a template; (b) performing constant-potential deposition of the nanotubes, wherein (b-1) a salt bridge is prepared; (b-2) a conductive layer is applied in a spattering mode, namely,a layer of copper film is sputtered on an anodic aluminum oxide template; and (b-3) constant-potential electrodeposition is carried out, wherein an anodic aluminum oxide template sputtered with the copper film, a platinum sheet and a saturated calomel electrode are used as a working electrode, a counter electrode and a saturated calomel electrode in a three-electrode system correspondingly, an auxiliary electrode is soaked in a saturated KCl solution, and a saturated KCl solution is connected with electrolyte through the salt bridge, wherein deposition conditions are as follows: the pH value is 2-3, the deposition potential is-1-3V, and the deposition time is 300-600s; and (c) releasing the magnetic metal nanotubes, wherein the anodic aluminum oxide template obtained in the step (b) is soaked in a post-treatment solution to remove the aluminum oxide template and the copper film.

Owner:NINGBO ZHETIE JIANGNING CHEM

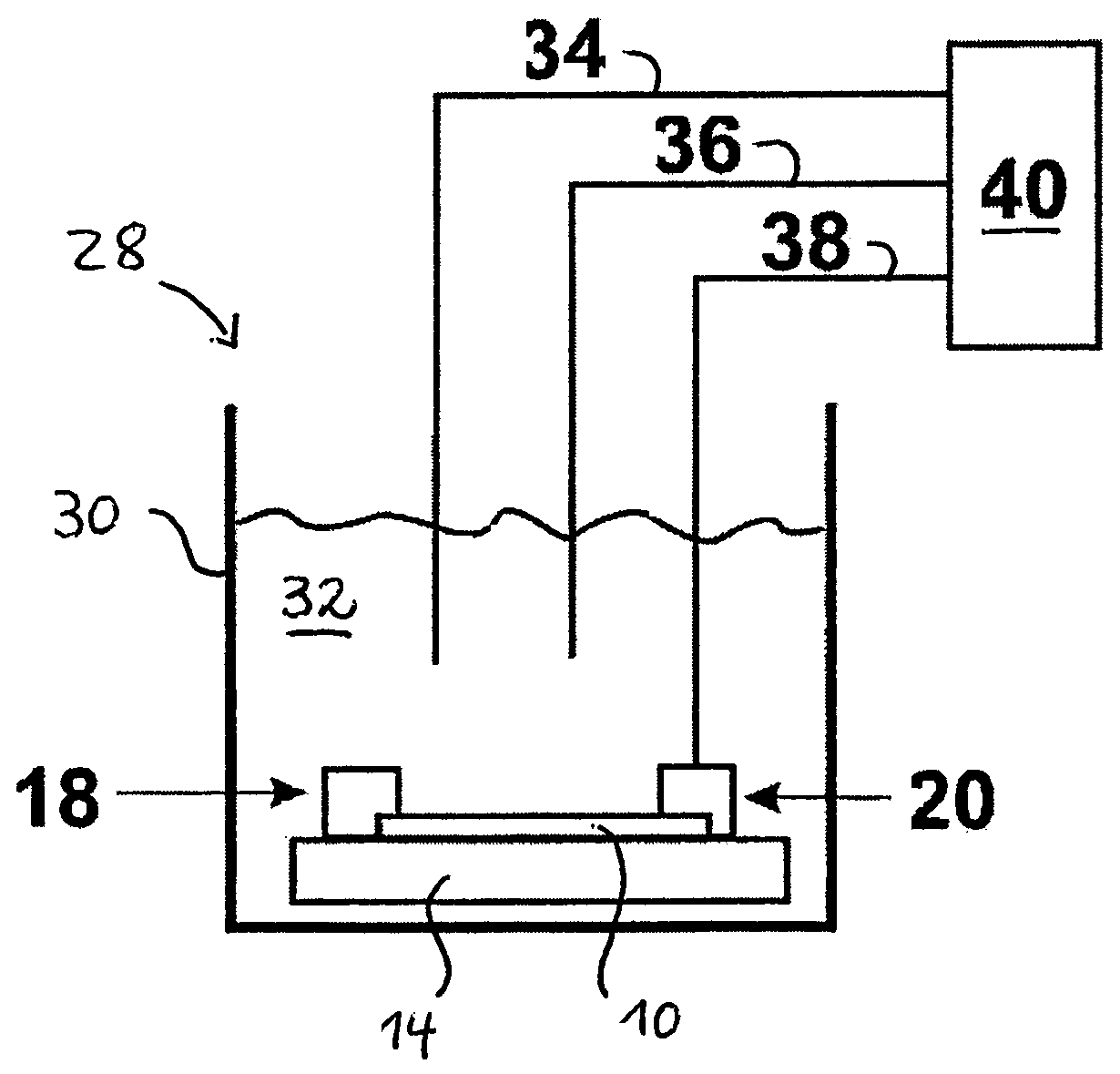

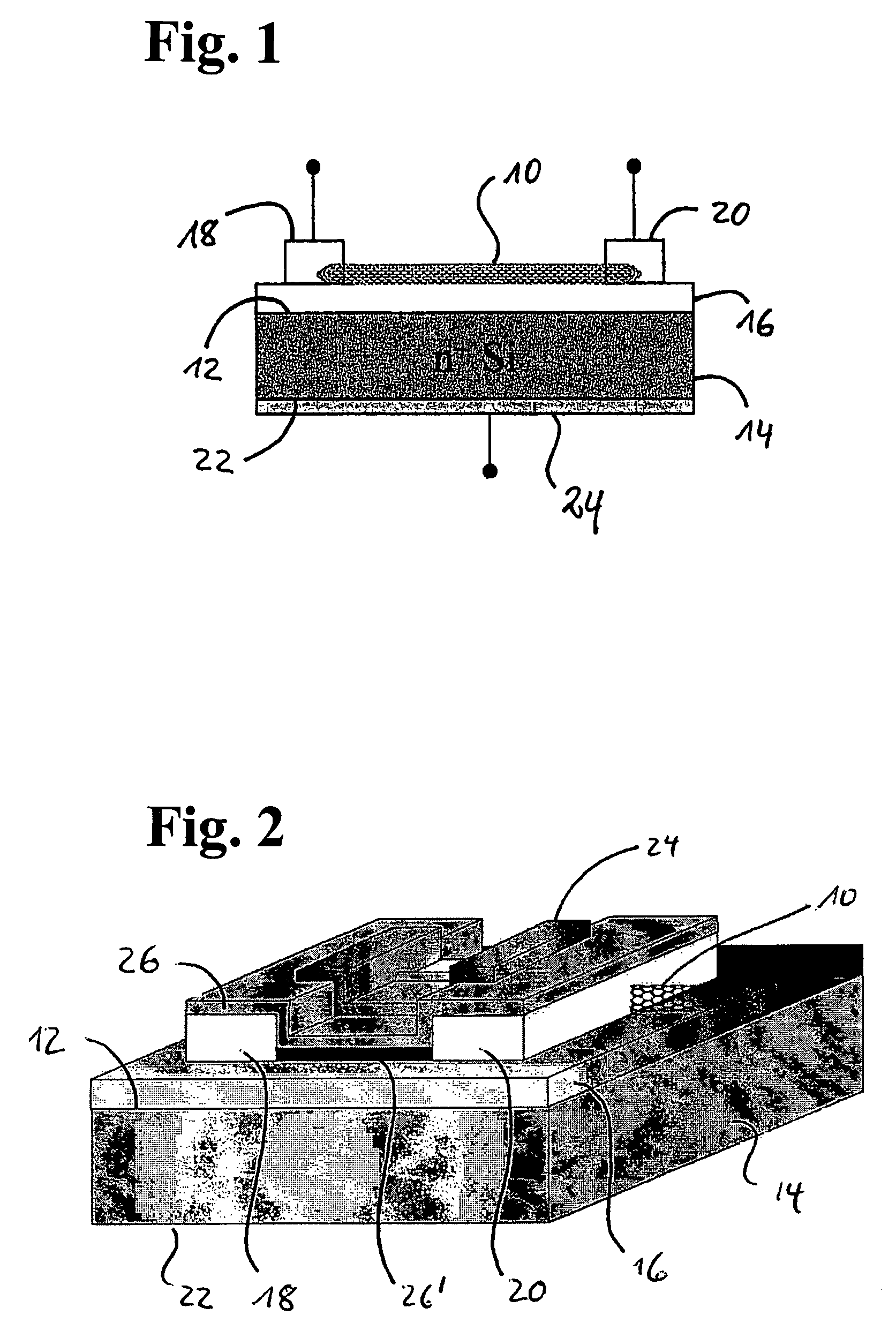

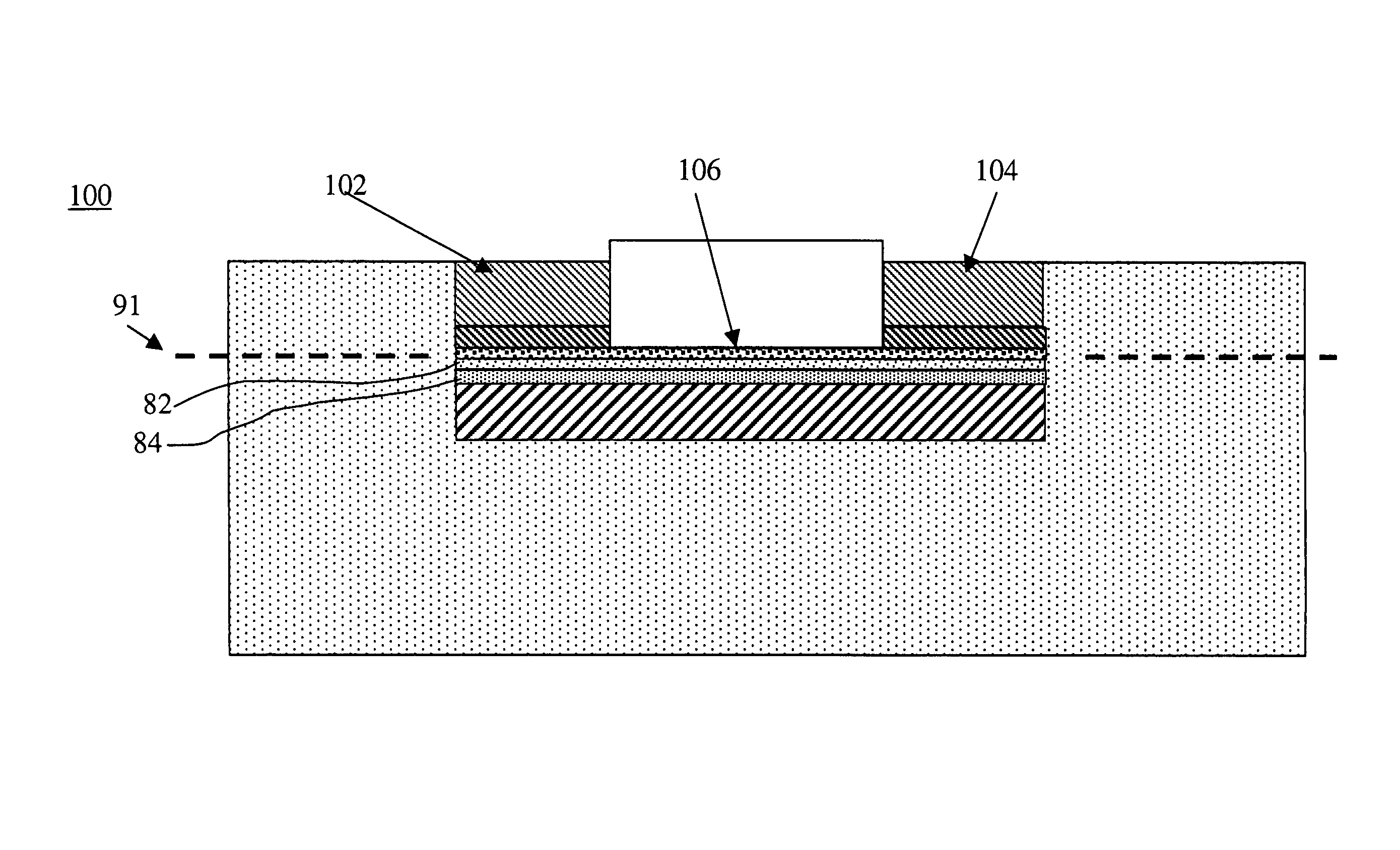

Field effect device having a channel of nanofabric and methods of making same

Field effect devices having channels of nanofabric and methods of making same. A nanotube field effect transistor is made to have a substrate, and a drain region and a source region in spaced relation relative to each other. A channel region is formed from a fabric of nanotubes, in which the nanotubes of the channel region are substantially all of the same semiconducting type of nanotubes. At least one gate is formed in proximity to the channel region so that the gate may be used to modulate the conductivity of the channel region so that a conductive path may be formed between the drain and source region. Forming a channel region includes forming a fabric of nanotubes in which the fabric has both semiconducting and metallic nanotubes and the fabric is processed to remove substantially all of the metallic nanotubes.

Owner:NANTERO

Material for removing contaminants from water

ActiveUS20180214851A1Fast adsorptionImprove adsorption capacityAlkali metal oxides/hydroxidesNon-contaminated water treatmentMetallic nanotubesNanotube

A composite comprises a carbonaceous and a metallic nanotube conjugated with a carbonaceous support. The composite may be used to remove contaminants from water.

Owner:AUBURN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com