Transparent conductive ink, and method for producing transparent conductive pattern

A technology of transparent conductivity and material retention, applied in the direction of conductive pattern formation, transparent dielectrics, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of silver nanowire insulation difficulties, high manufacturing costs, waste of developer Eliminate problems such as liquids, and achieve the effect of suppressing manufacturing costs and environmental loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112]

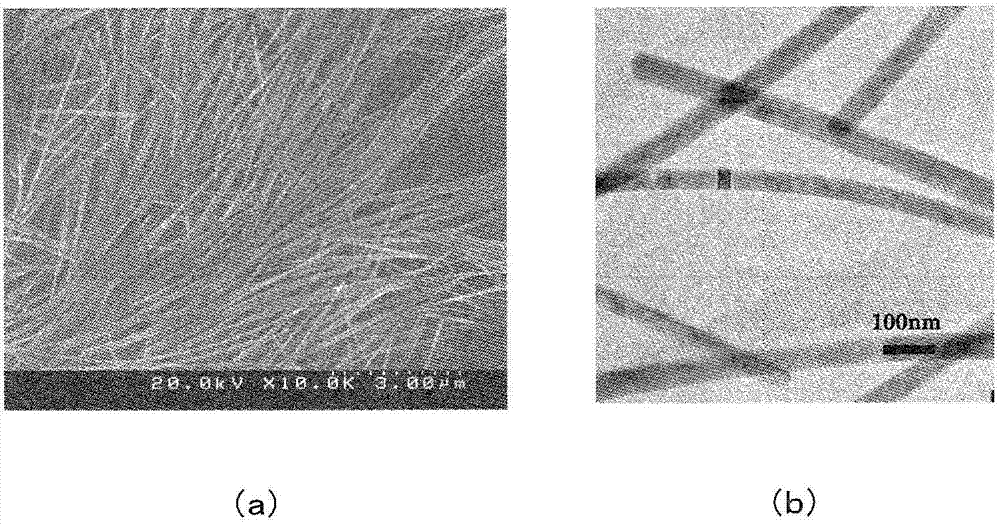

[0113] Polyvinylpyrrolidone K-90 (manufactured by Nippon Shokubai Co., Ltd.) (0.049 g), AgNO 3 (0.052g) and FeCl 3 (0.04 mg) was dissolved in ethylene glycol (12.5 ml), and the reaction was heated at 150°C for 1 hour. The obtained precipitate was isolated by centrifugation, and the precipitate was dried to obtain the target silver nanowire. exist figure 2 (a) and (b) show SEM images of the obtained silver nanowires. The SEM used was FE-SEM S-5200 manufactured by Hitachi High-Tech Corporation.

[0114] Depend on figure 2 (a) and (b), it can be seen that the silver nanowires are rod-shaped, and the diameter of the rod-shaped wires is about 70 nm, and the length is 10-20 μm, and the rod-shaped wires account for more than about 95% of the total. Furthermore, the remainder is granular.

[0115] The above ethylene glycol, AgNO 3 , FeCl 3 It is manufactured by Wako Pure Chemical Industry Co., Ltd.

[0116] In addition, the length and diameter of the silver nanow...

Embodiment 2、3

[0123] Except for changing the types and amounts of dibutyl ether, tersolub MTPH, and viscosity adjusting solvents in Example 1 to the amounts shown in Table 1, it was prepared in the same manner as in Example 1 so that the concentrations listed in Table 1 were obtained. transparent conductive ink.

Embodiment 4~7、9~13

[0125] As silver nanowires, instead of using the above-mentioned synthetic products, commercially available product SLV-NW-35 (isopropanol dispersion made by bluenano company, concentration is 10mg / ml, the diameter of silver nanowires is 35nm, and the length is about 15 μm ( catalog value)), a small amount of terpineol (manufactured by Nippon Terpen Chemical Co., Ltd.) was added to the silver nanowire dispersion to make it well dispersed, and then the isopropanol was distilled off and the solvent was replaced. Then, Tersolbu MTPH (manufactured by Nippon Terpen Chemical Co., Ltd., isobornylcyclohexanol) and terpineol were added so that the concentration of the final dispersion medium became the compounding ratio (mass ratio) described in Tables 1 to 3, and used ( Co., Ltd. ARV-310 manufactured by Shinky Co., Ltd. was well dispersed to obtain a dispersion liquid. In addition, the quantity of the small amount of terpineol which was added initially was calculated in advance and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com