Transport system and transport method

A technology of conveying device and conveying path, which is applied in the direction of transmission device, packaging, material inspection products, etc., which can solve the problems of device structure and maintenance operation complexity, etc., and achieve the effect of lightened inspection work, less number of parts and excellent maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

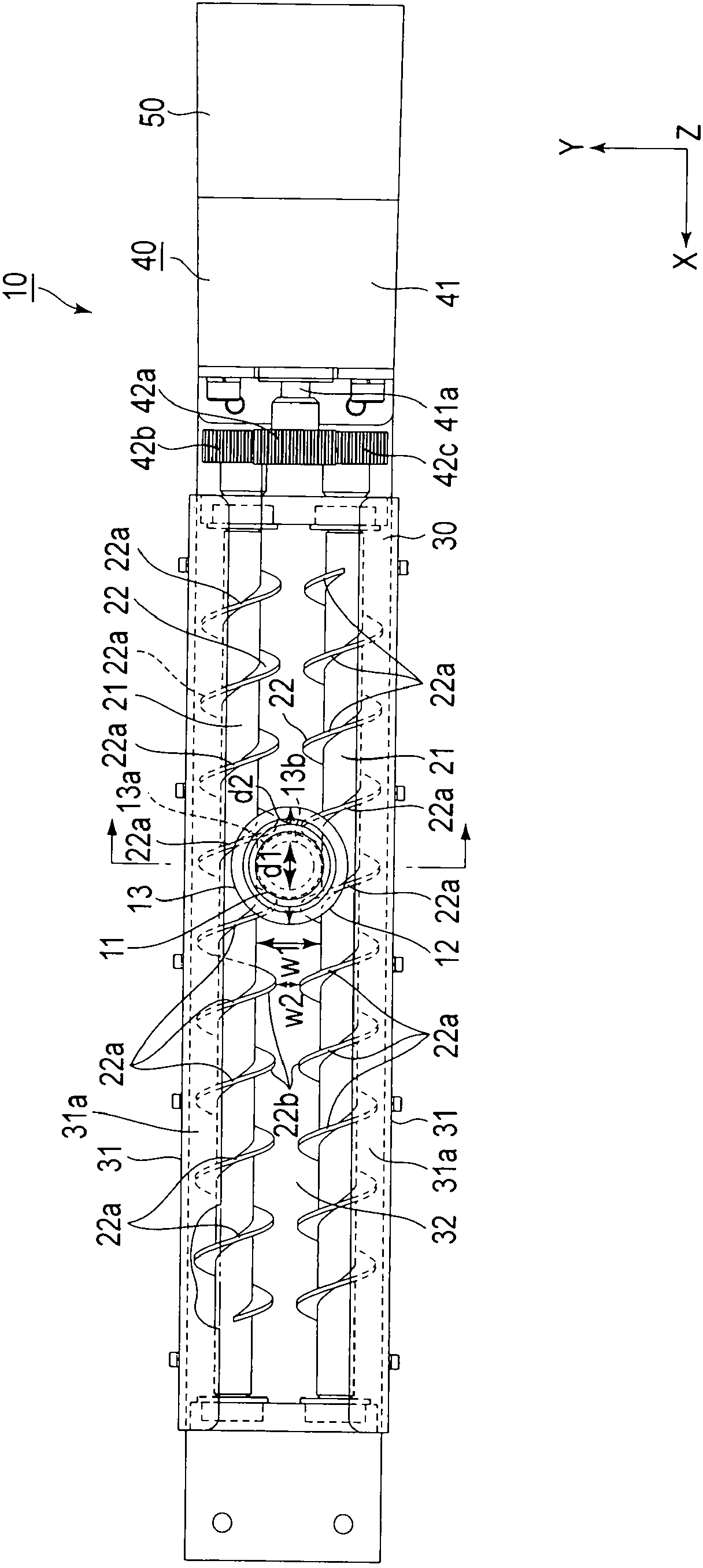

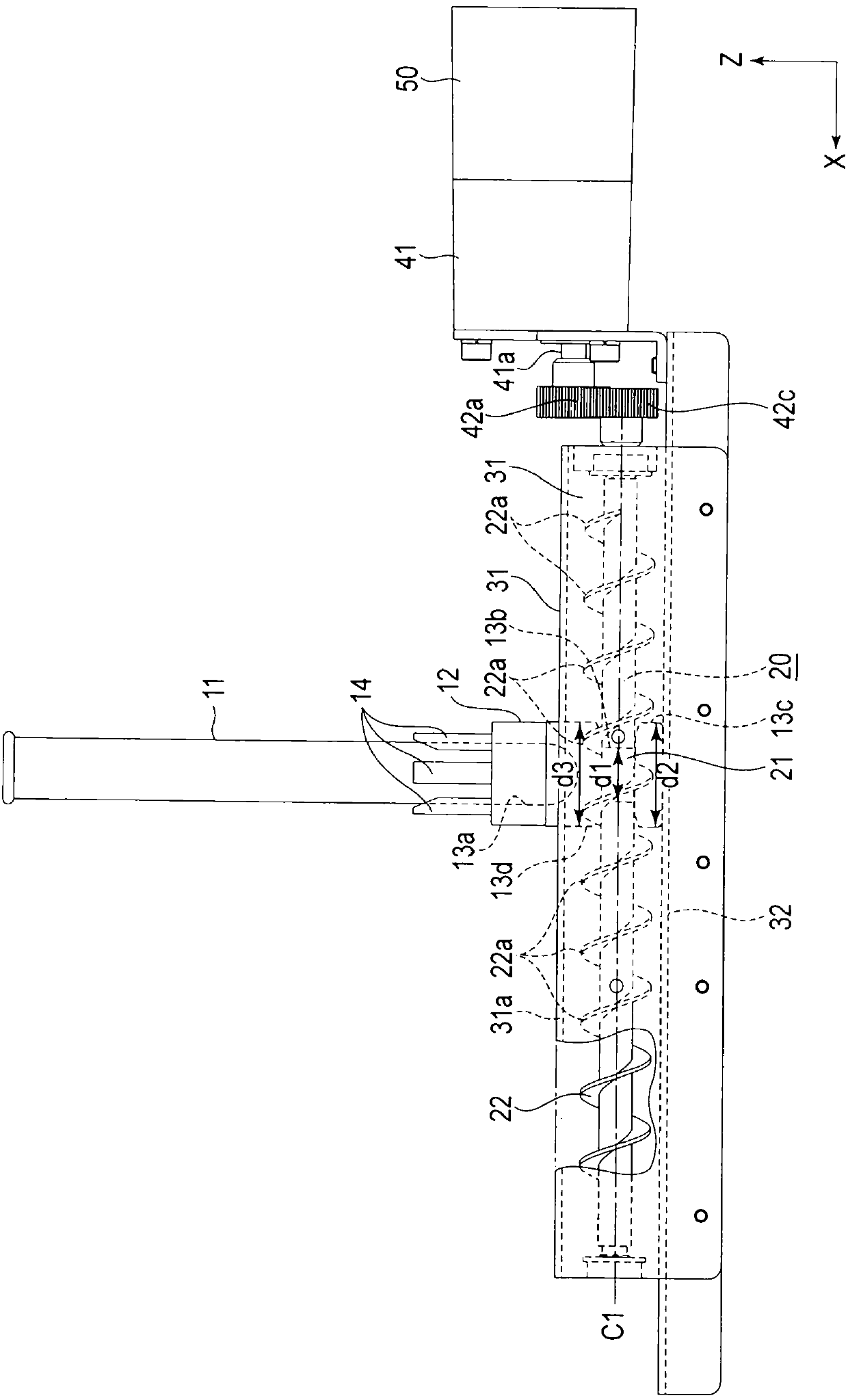

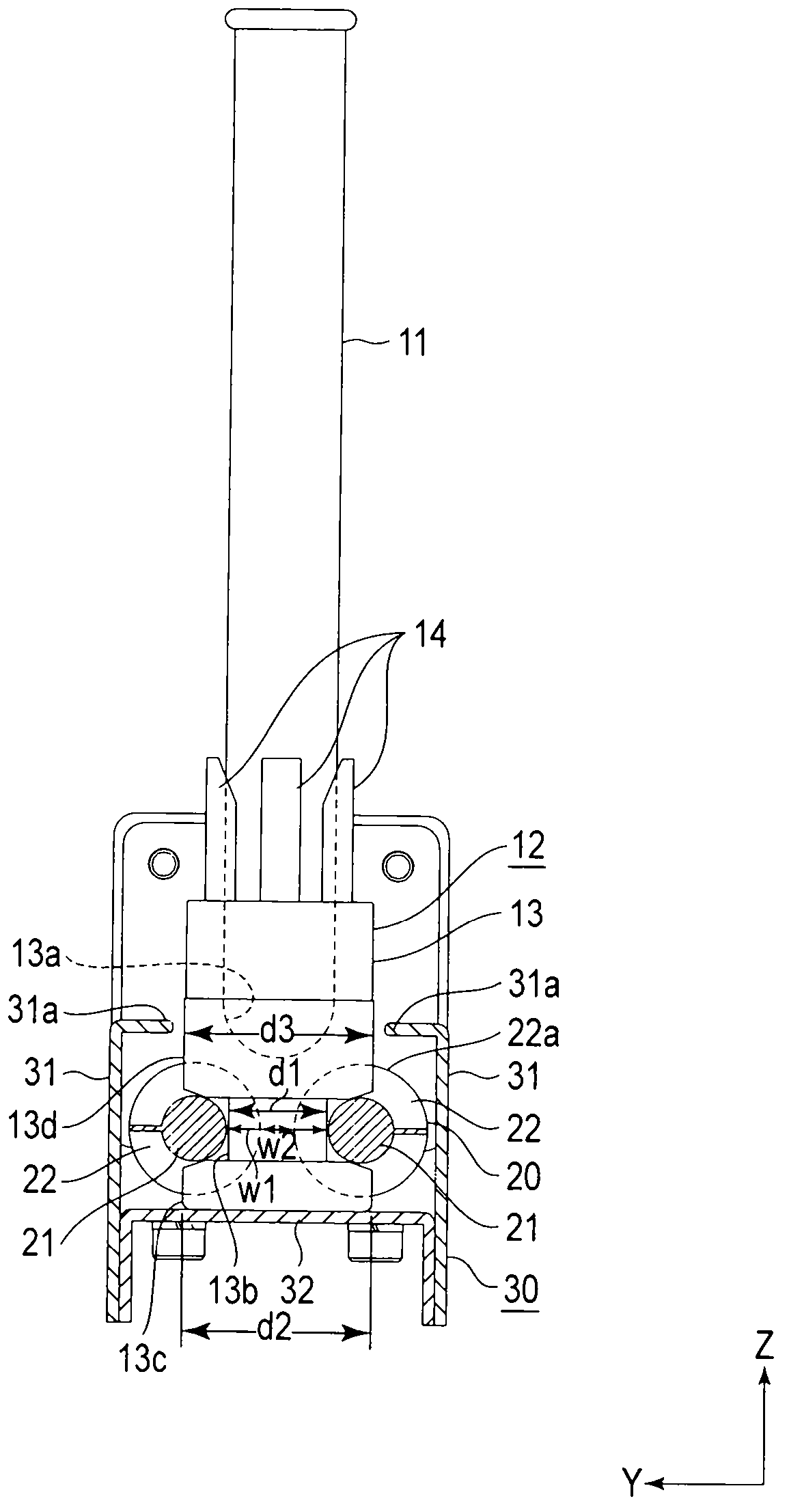

[0017] Next, the transport device 10 according to the first embodiment of the present invention will be described. figure 1 is a plan view of the transport device 10 of the present embodiment, figure 2 is a side view of the delivery device 10, image 3 is a cross-sectional view of the conveying device 10 . In addition, in each figure, the structure is enlarged, reduced, and abbreviated and shown appropriately for description. Arrows X, Y, and Z in the figure indicate three directions perpendicular to each other.

[0018] The transport device 10 has a function of transporting a holding member 12 holding a test tube 11 as a sample container containing a sample such as blood from one end side to the other end side in the transport direction along the arrow X.

[0019] The conveying device 10 includes: a lead screw 20 arranged along a predetermined conveying path; a frame 30 having a pair of guide rails 31 arranged on both sides of the lead screw 20 with a certain width; a dri...

no. 2 Embodiment approach

[0039] Next, a transport device 100 according to a second embodiment of the present invention will be described. Figure 4 is a plan view of the transport device 100 of the present embodiment, Figure 5 is a side view of the delivery device 100, Figure 6 is a cross-sectional view of the conveying device 100 . In addition, in each figure, the structure is enlarged, reduced, and abbreviated and shown appropriately for description. Arrows X, Y, and Z in the figure indicate three directions perpendicular to each other.

[0040] The conveying device 100 of the present embodiment includes: a lead screw 20 arranged so as to extend over a predetermined conveying path; a frame 30 having a pair of guide rails 31 set to a certain width supporting both sides of the lead screw 20 ; and a driving part. 40 , which drives the lead screw 20 to rotate; the control unit 50 , which controls the operation of the driving unit 40 .

[0041] In addition, in this embodiment, the point of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com