Patents

Literature

371results about "Micrometers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Measuring instrument

ActiveUS7043852B2High measurement accuracyMicrometersMechanical measuring arrangementsMeasuring instrumentEngineering

A measuring instrument that includes a tube 21 having a female thread 211 and a spindle 3 having a lead screw 31 screwing with the female thread 211 and capable of being advanced and retracted in an axial direction along with rotation around the axial center, and measures dimensions etc. of a workpiece according to displacement in an axial direction of the spindle 3 based on a rotation amount of the spindle 3. According to this measuring instrument, a pitch P of the lead screw 31 is twice as large or more than the difference between an external diameter R and a core diameter r thereof, and the difference between the external diameter R and the core diameter r is one-fifth or less of the external diameter R. Because of the lead screw 31 with the large pitch, the spindle 3 can be moved at high speed, thus enhancing operational performance of the measuring instrument.

Owner:MITUTOYO CORP

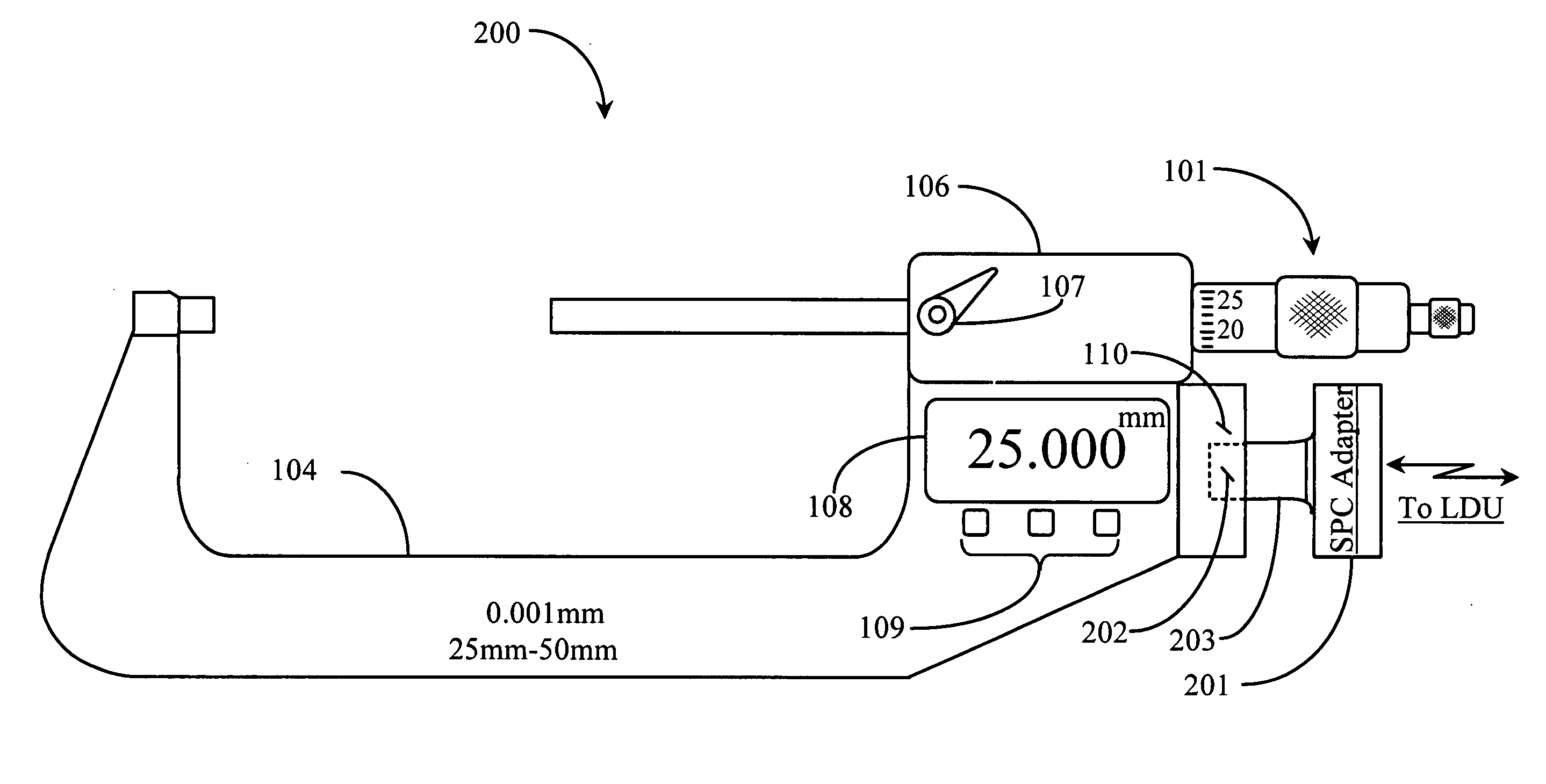

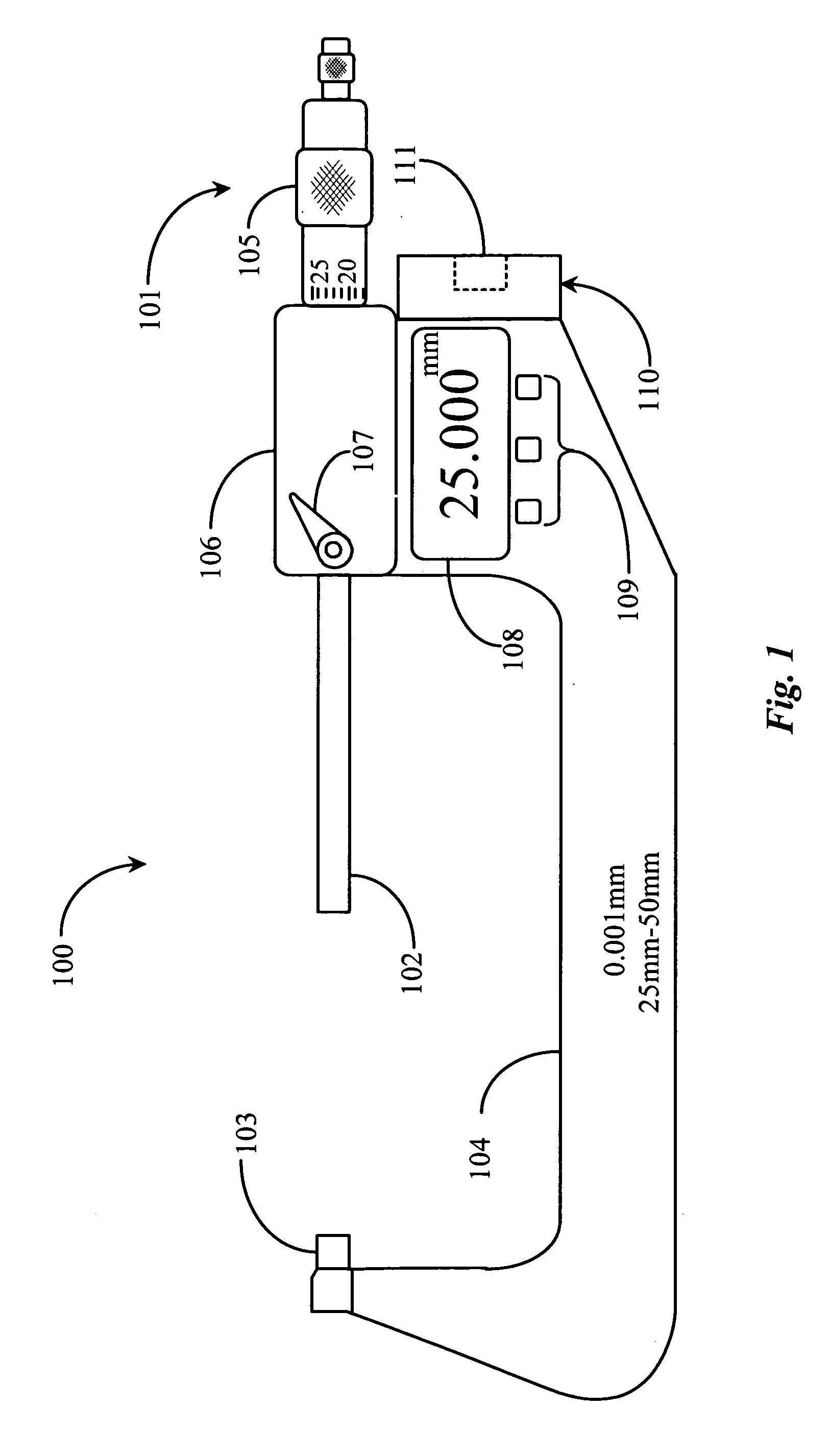

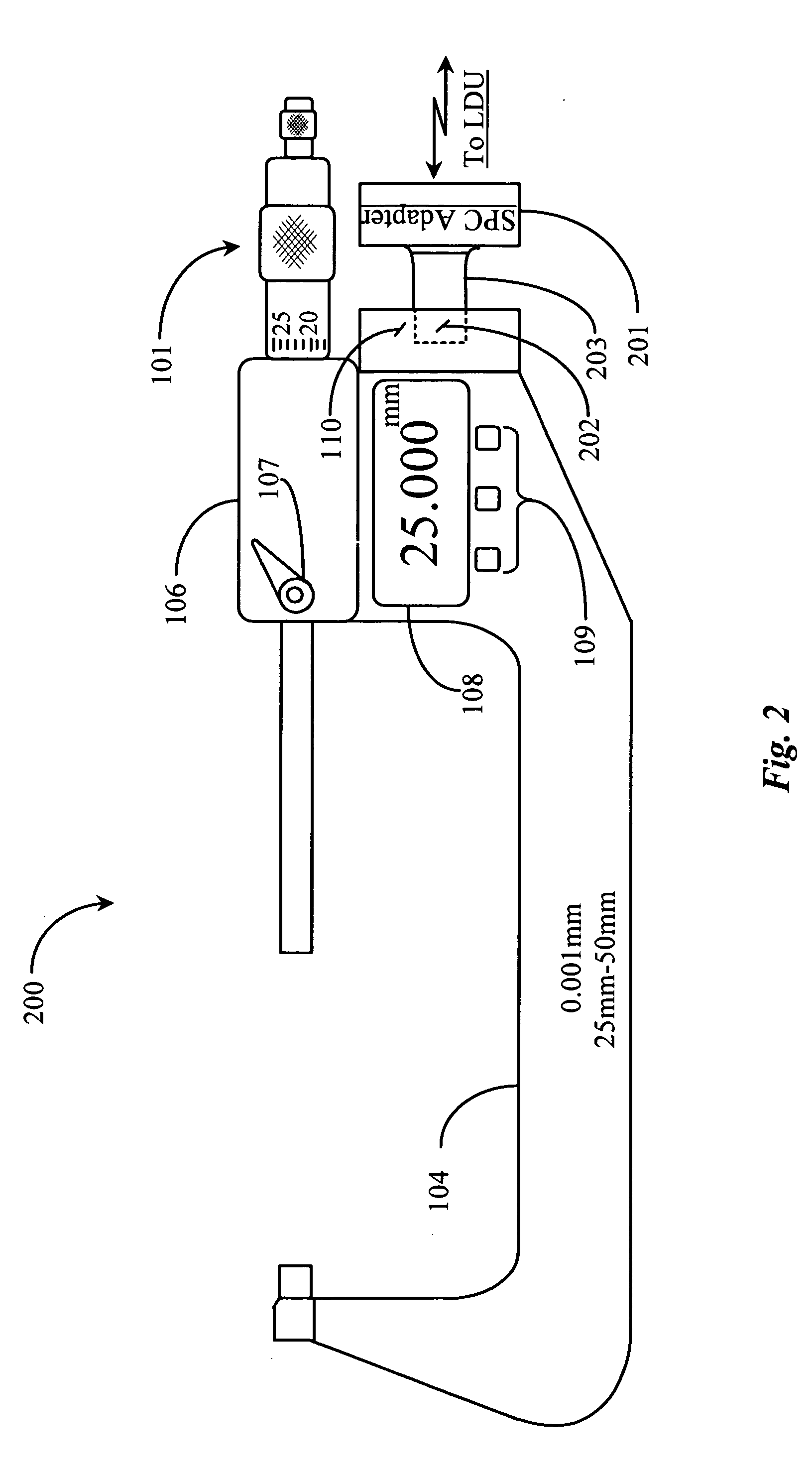

System for wireless local display of measurement data from electronic measuring tools and gauges

InactiveUS20060162178A1Telemetry/telecontrol selection arrangementsMicrometersWireless dataWireless data transmission

A system for acquiring and displaying data in a measurement process includes a local display unit enabled for wireless data reception, and a measuring tool for acquiring measurement data, the tool being enabled for wireless data transmission. The system is characterized in that the acquired data is transmitted from the measuring tool to the local display unit and displayed thereon.

Owner:FREIDIN PHILIP MANUEL

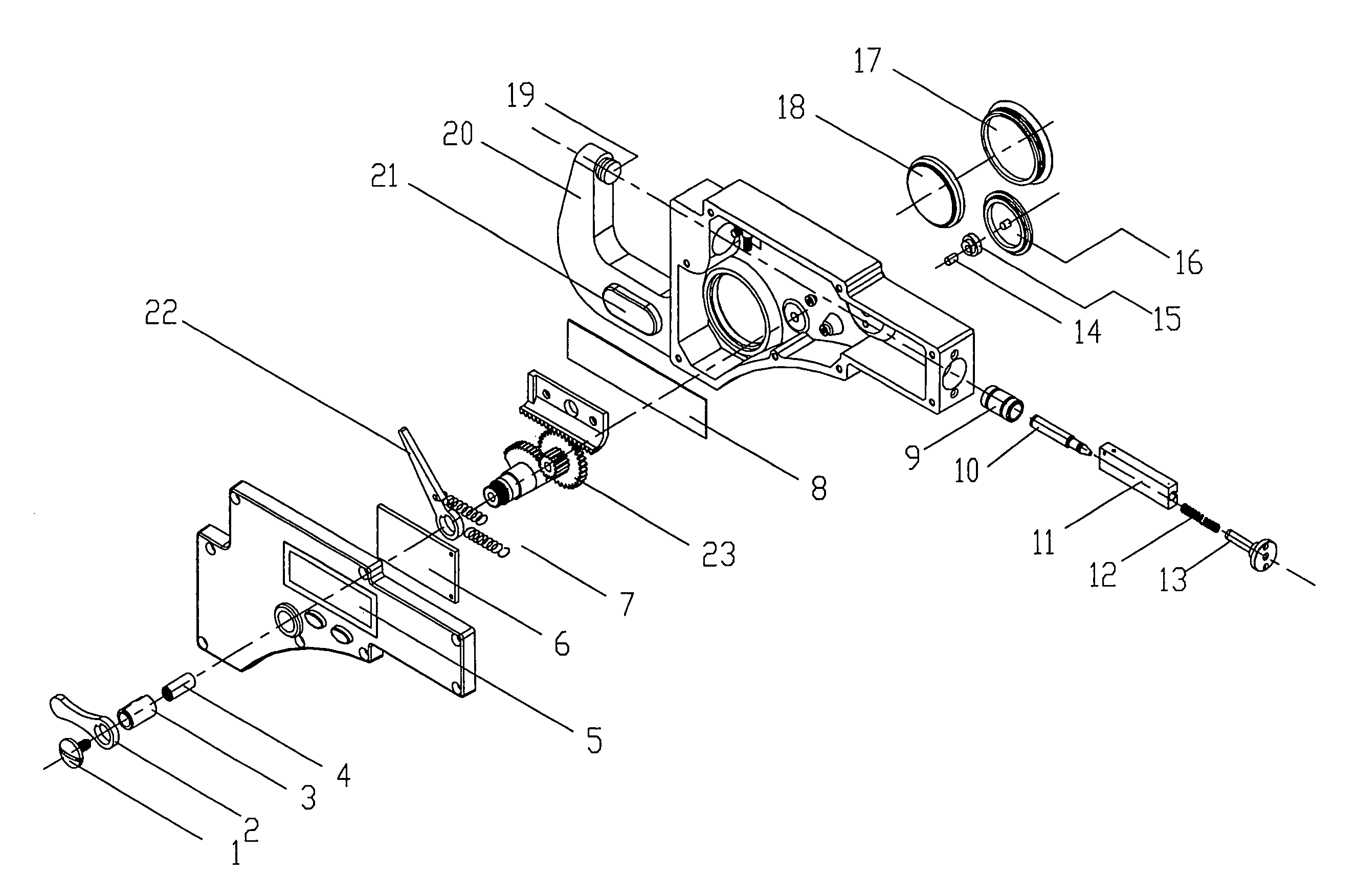

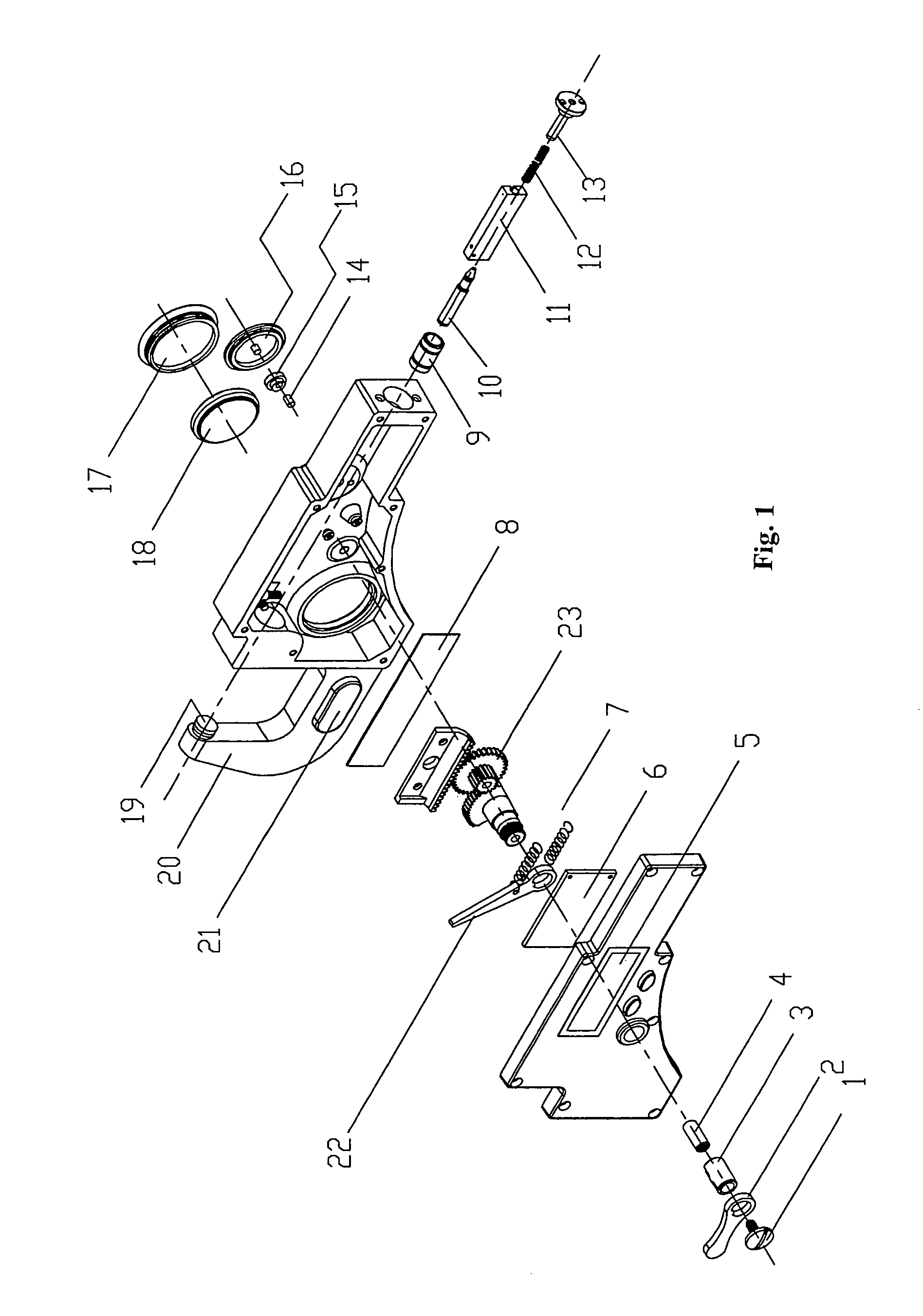

High-speed measuring electronic digital outside micrometer

ActiveUS8091251B1Without loss of accuracyFaster and precise travelMicrometersMechanical measuring arrangementsLinear motionMicrometer

A high-speed measuring electronic digital outside micrometer allowing a user to make measurements quickly and effectively compared to conventional electronic outside micrometers with rotary thread spindles, which have limited measuring speed. This high-speed measuring electronic digital outside micrometer features: a linear motion digital sensor, a linear scale digital sensor, a linear motion digital sensor base, a digital display unit, an electronic processing unit, a micrometer body, a linear spindle, a linear spindle movement unit, a spindle control unit, a micrometer anvil, and retractable springs. In a stationary position, the measuring surface of the micrometer anvil and the linear spindle are in contact to the other. By operating the spindle control unit, it will create distance between the micrometer anvil and the linear spindle measuring surface. This distance is a measurable distance of the micrometer. By set free of the spindle control unit, the retractable springs will re-set the micrometer to its stationary position.

Owner:ZHANG YANCHEN +1

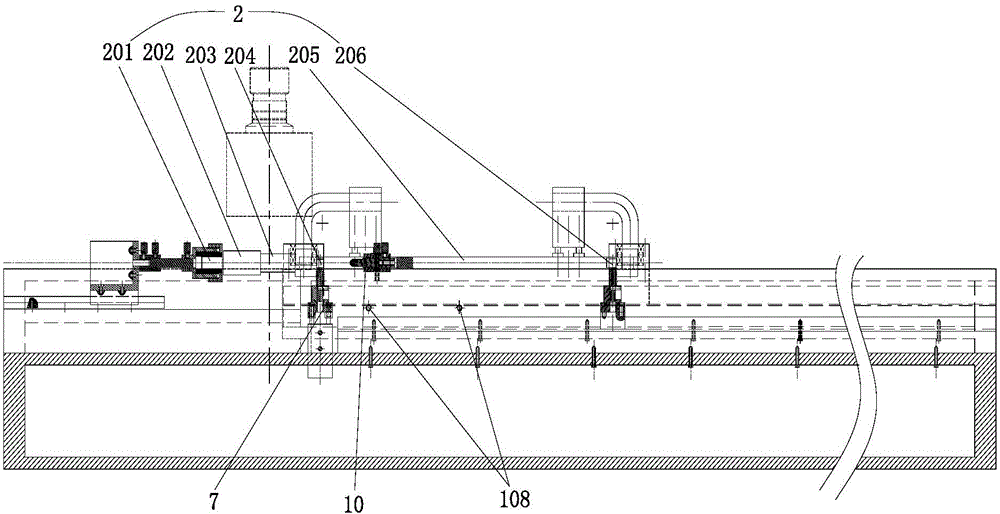

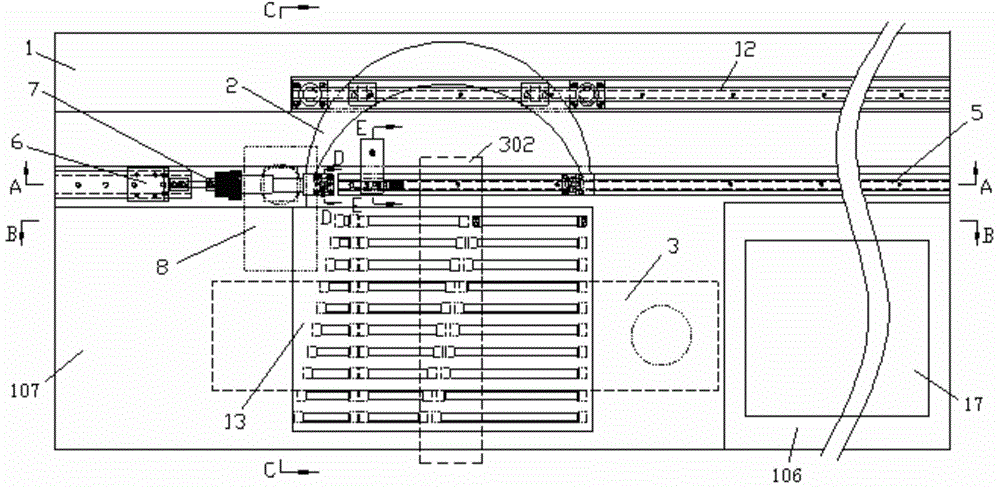

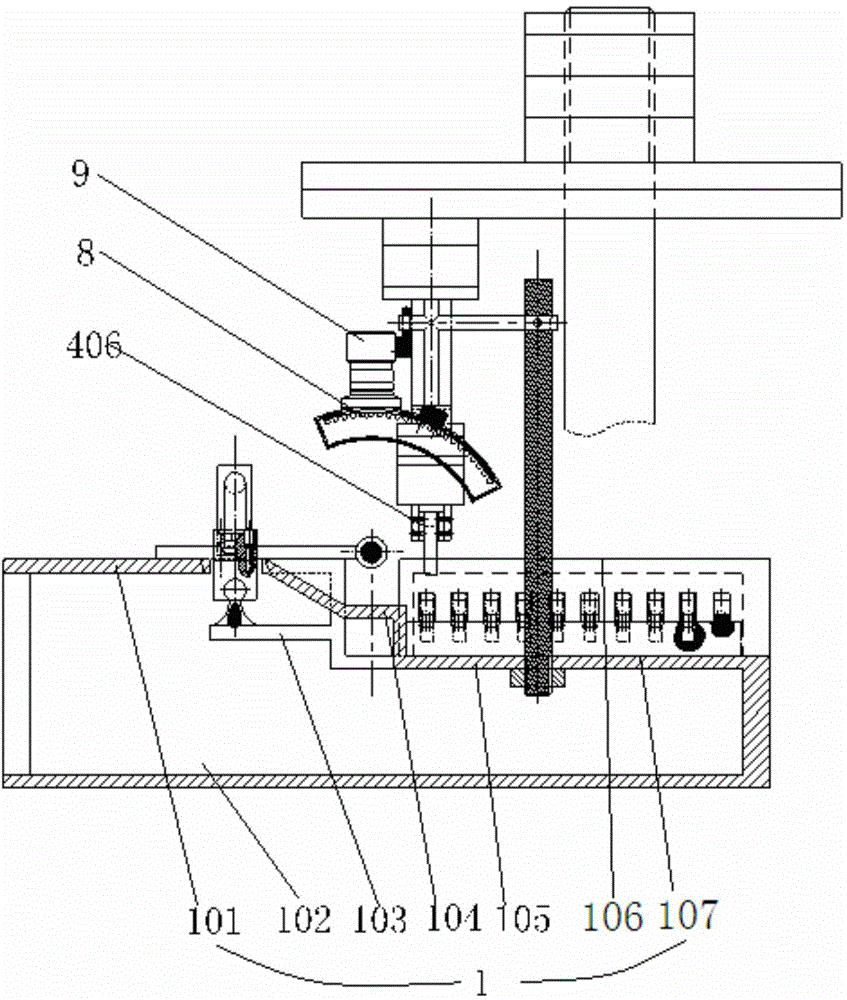

Micrometer verification system

The invention relates to a micrometer verification system which comprises a micrometer verification device, an automatic microdrum rotating device, a machine vision device, a three-dimensional operating table and a block gauge clamping device. The micrometer verification device comprises a step-shaped micrometer verification table, a micrometer fixing clamp capable of sliding transversely is arranged on a high step, and a micrometer verification position locating mechanism used for supporting and locating a micrometer lead screw detecting head and a fixed detecting head is arranged on a low step of the micrometer verification table. The automatic microdrum rotating device is arranged on the micrometer verification table, and used for automatically rotating a microdrum of a micrometer. The machine vision device is erected on the micrometer verification table. The three-dimensional operating table is arranged on the micrometer verification table. The block gauge clamping device is arranged on the three-dimensional operating table, and used for clamping a block gauge on a block gauge box, and the block gauge box is arranged below the three-dimensional operating table. The problem that existing micrometer verification is low in efficiency and large in work strength is solved, and the accuracy and verification precision of a micrometer verification result are improved.

Owner:王煜

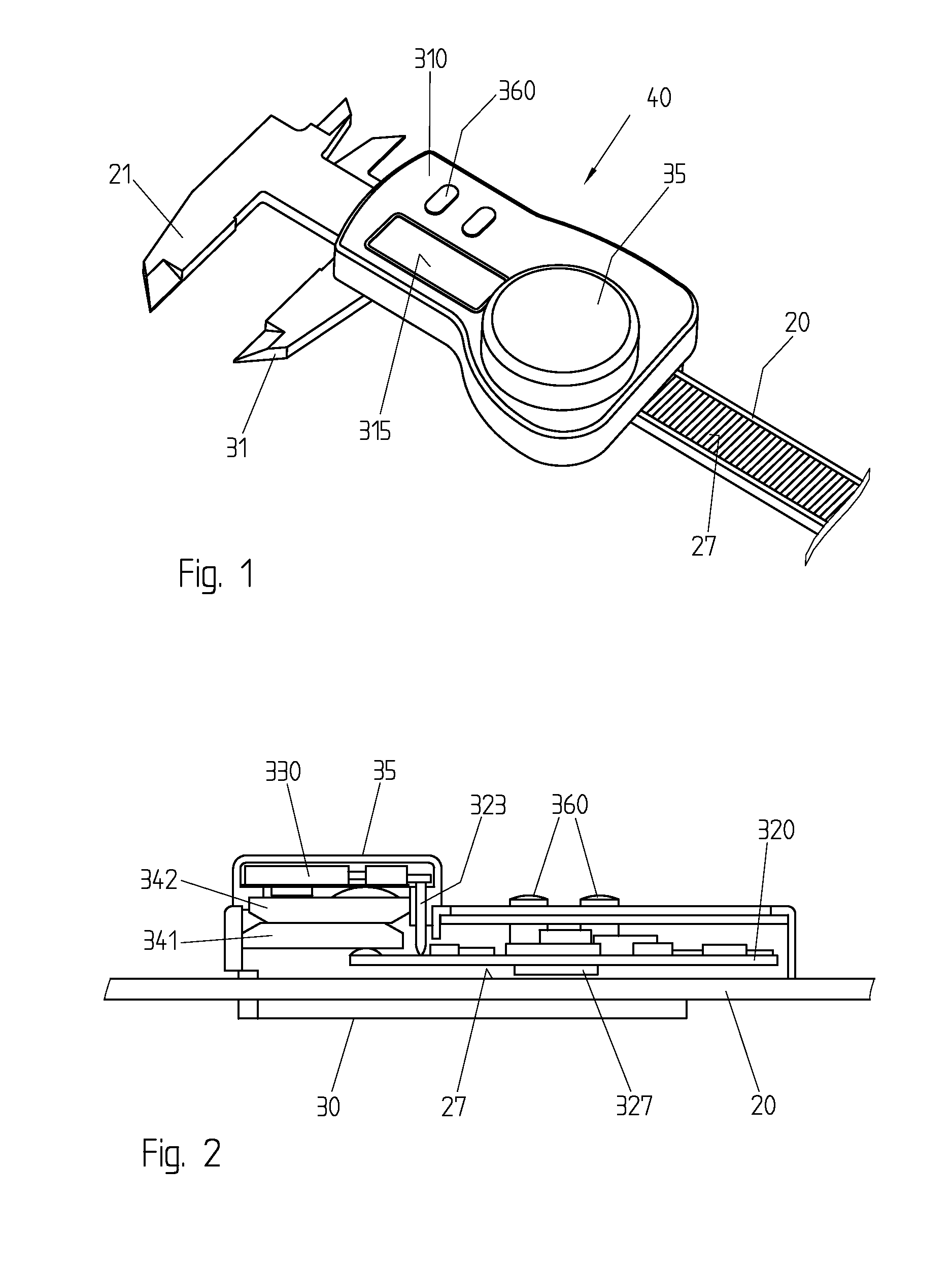

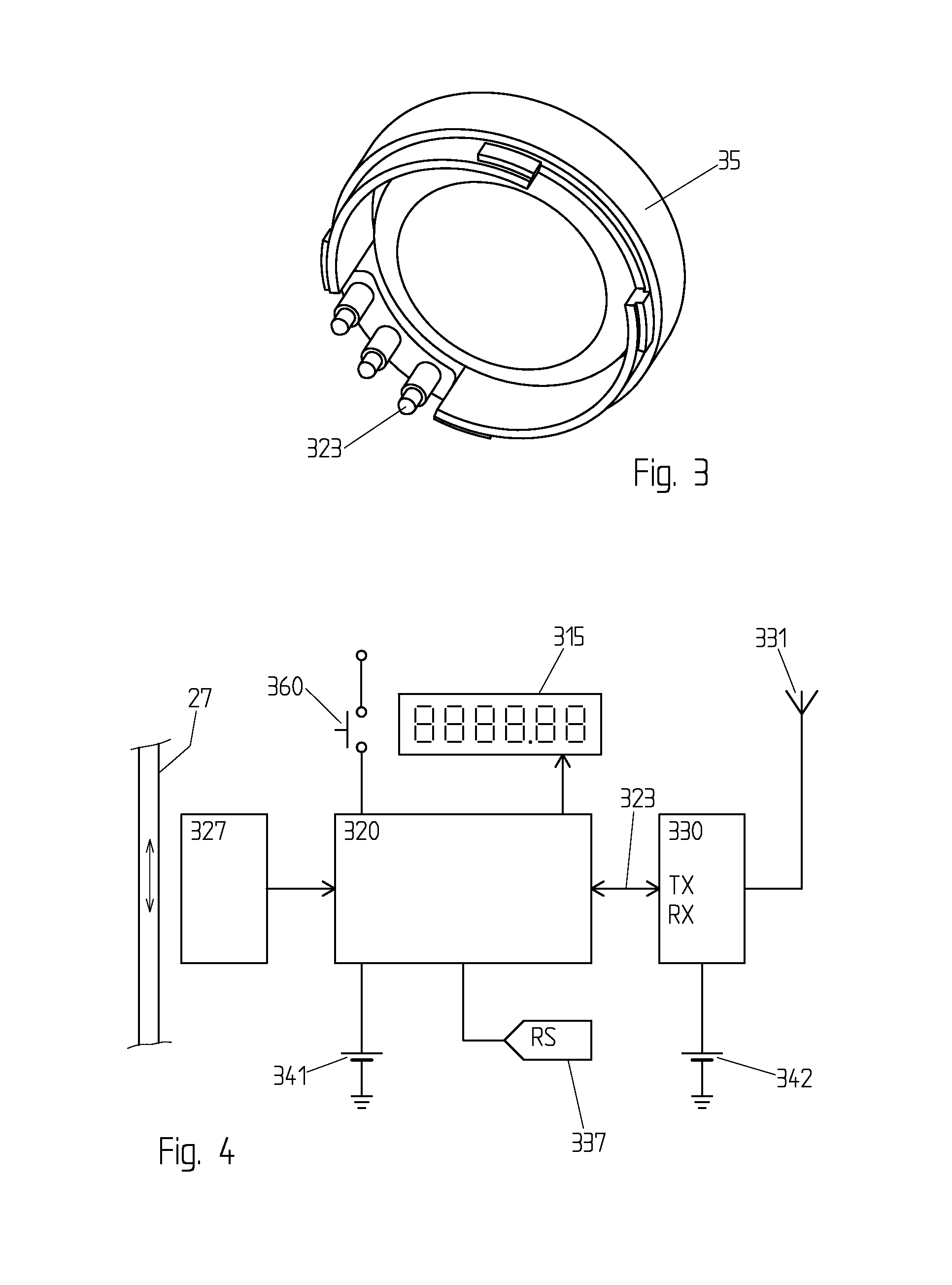

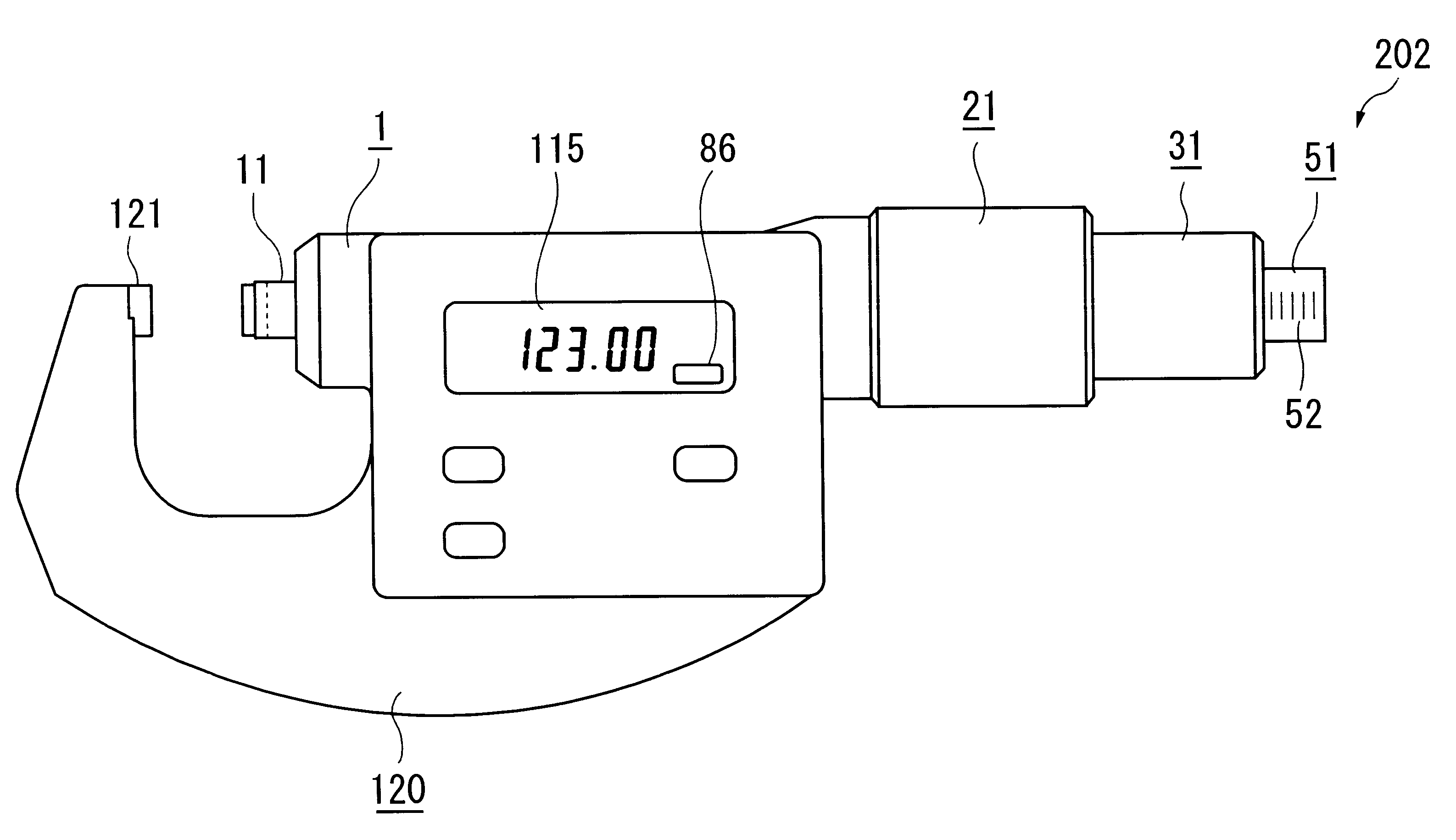

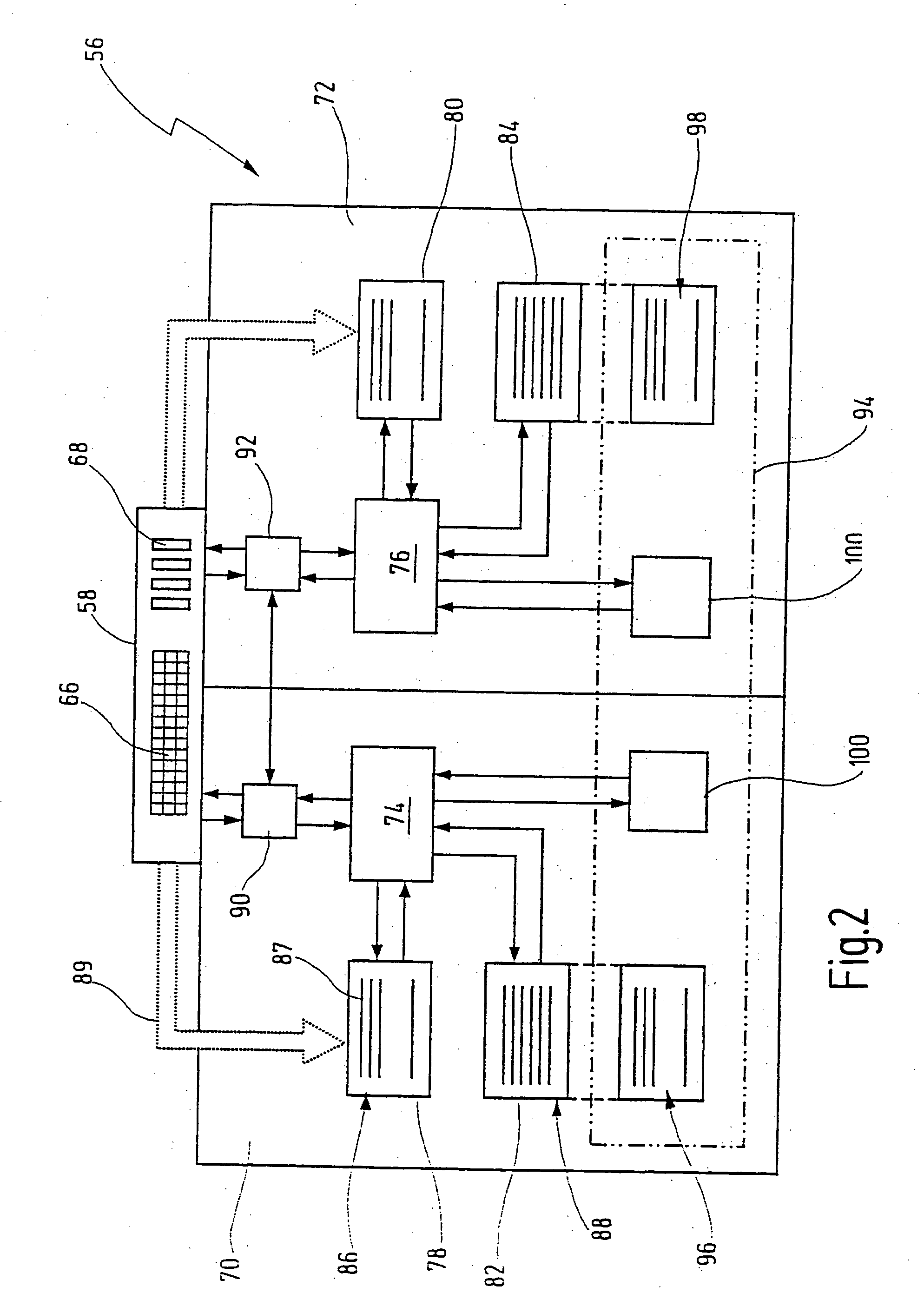

Instrument for measuring dimensions equipped with an interface and corresponding interface

ActiveUS20120203504A1Raise the possibilityGood user interfaceMicrometersTransmission systemsCommunication interfaceMeasuring instrument

Electronic measuring instrument equipped with a removable intelligent processing and radio communication interface. The interface allows managing additional features such as bidirectional communication of commands and measurement data with printers, computers or other external devices, as well as the transmission of instructions or measurement programs to the instrument. The radio interface may be connected with several measuring instruments such as callipers, micrometers, comparators or height gauges. It is integrated into the lid of the battery compartment of the instrument, so that it can be installed and removed easily and without impairing the seal. The cover also includes an extra battery for the processing and radio transmission interface.

Owner:TESA SE

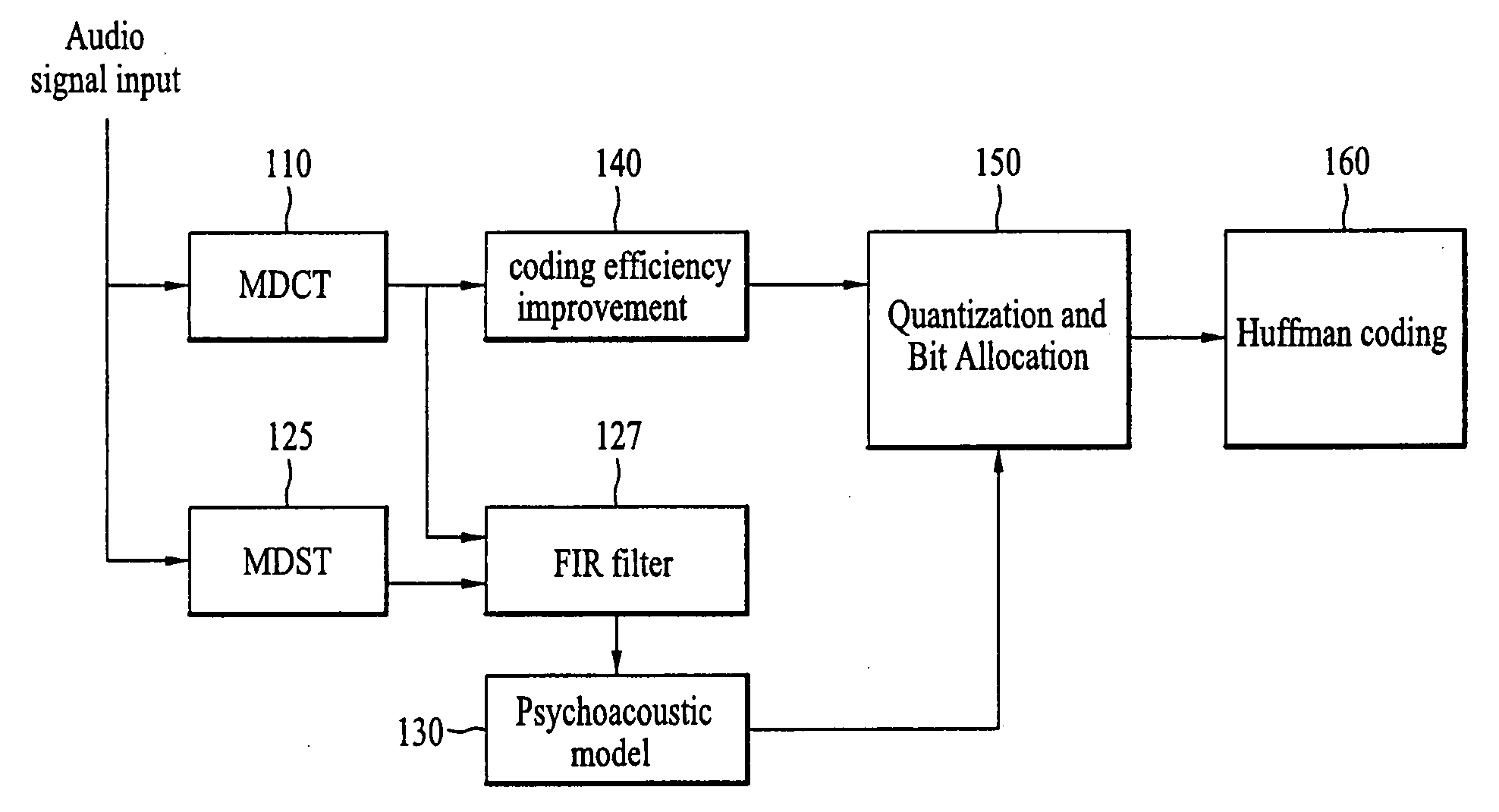

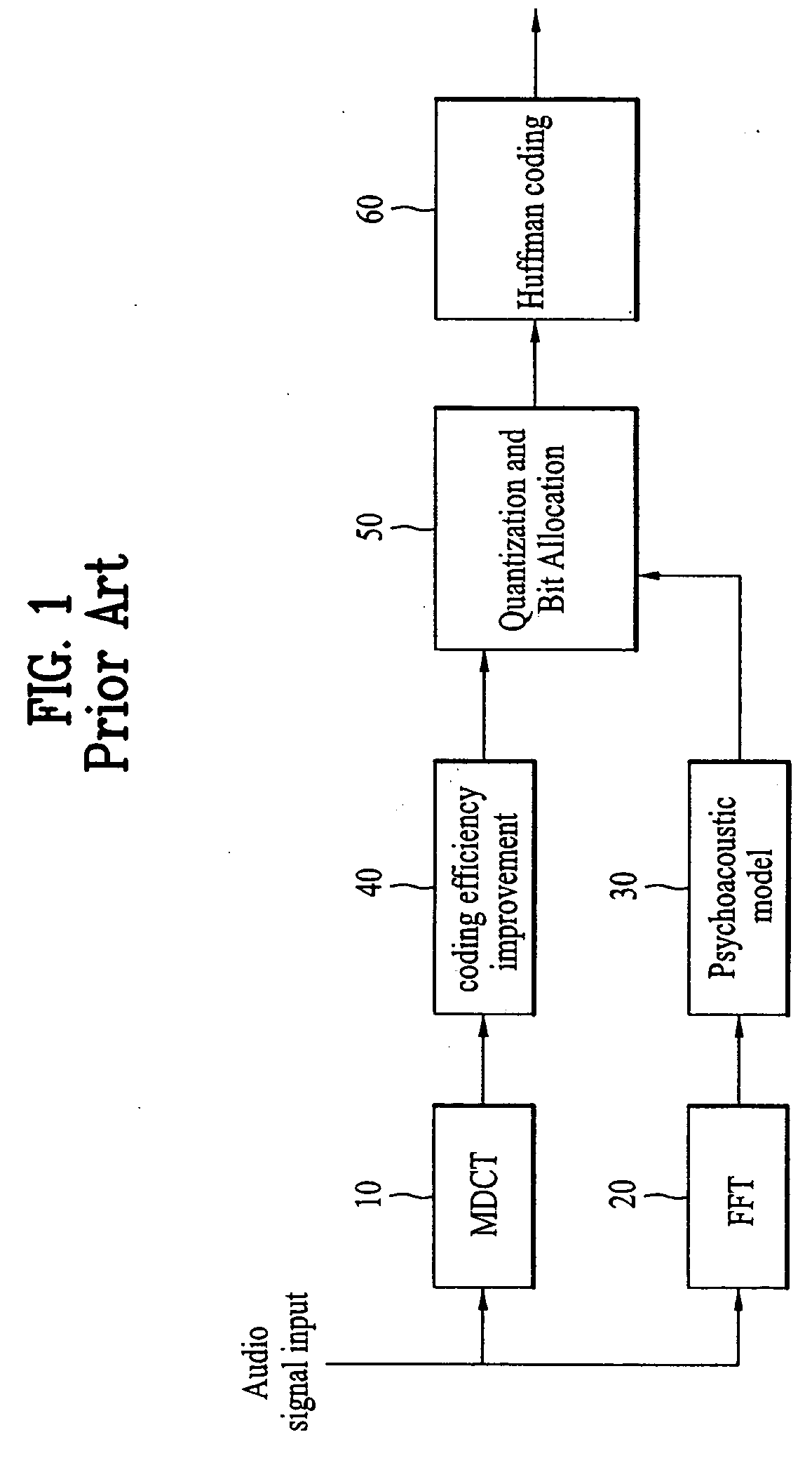

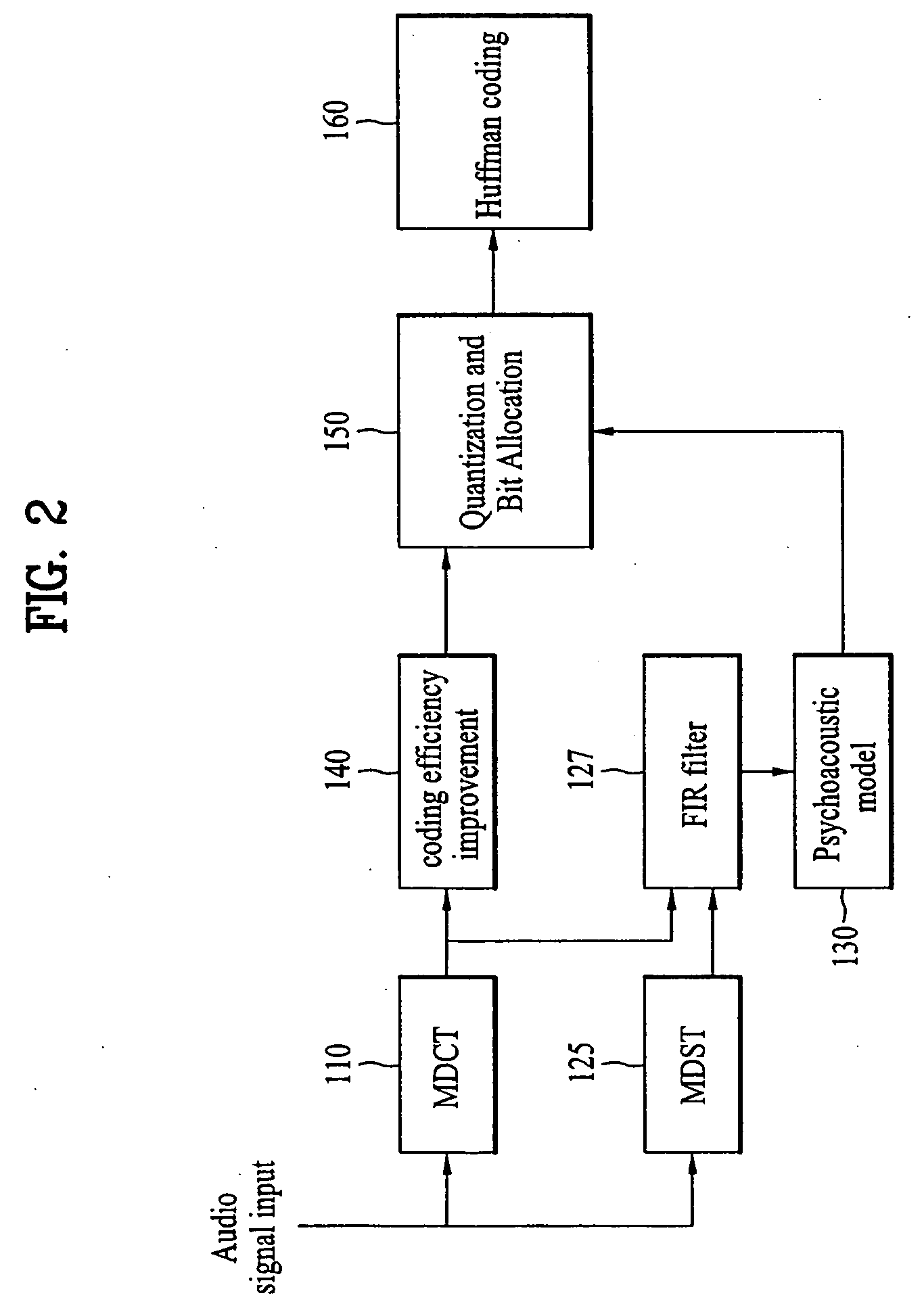

Method and apparatus for coding audio signal

InactiveUS20060253276A1Reduce calculationImprove efficiencyMicrometersSpeech analysisAudio frequencyAudio signal

An audio coding method and apparatus capable of improving efficiency of a MPEG-4 AAC (Moving Picture Expert Group-4 Advanced Audio Coding) process are disclosed. The audio coding method and apparatus reduce the number of calculations of an audio coding algorithm to improve efficiency of an audio coding process. Specifically, the audio coding method and apparatus reduce the number of calculations required for a Psychoacoustic model process of the MPEG-4 AAC algorithm capable of coding an audio signal.

Owner:LG ELECTRONICS INC +1

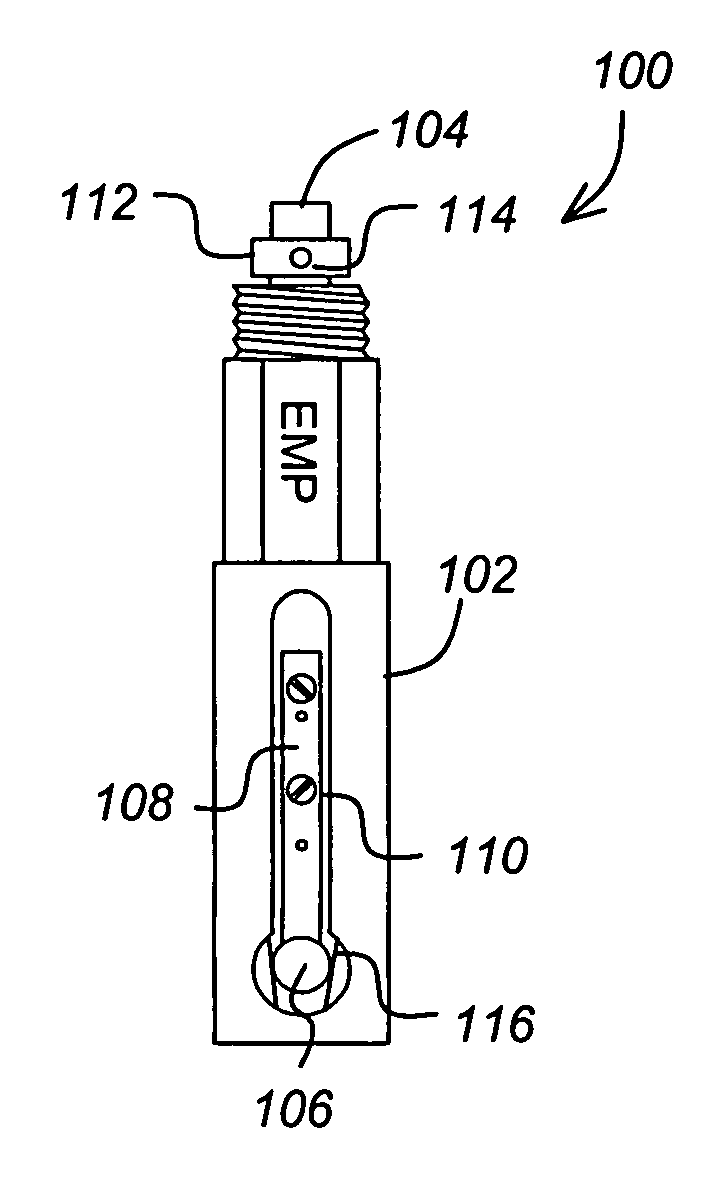

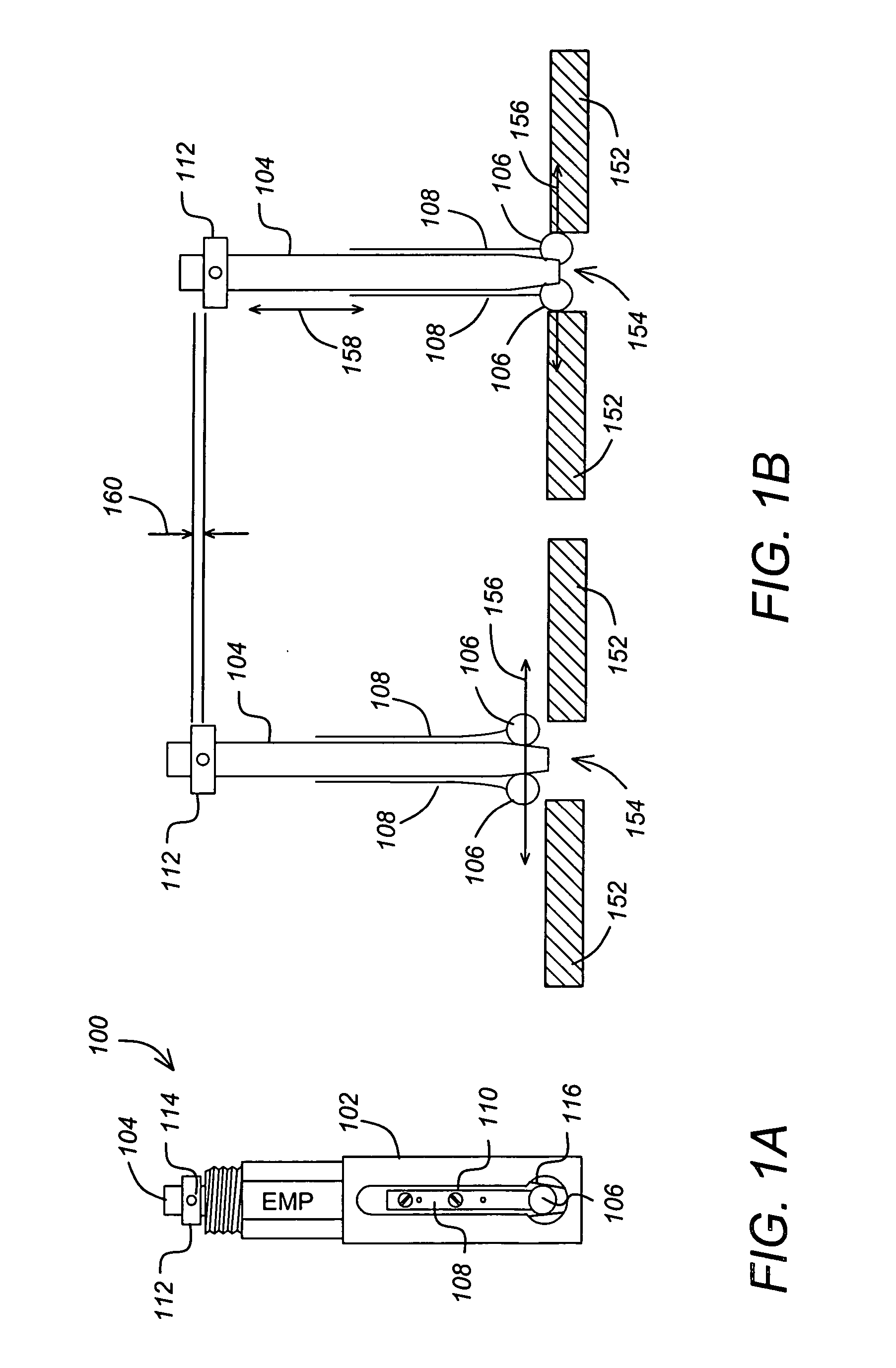

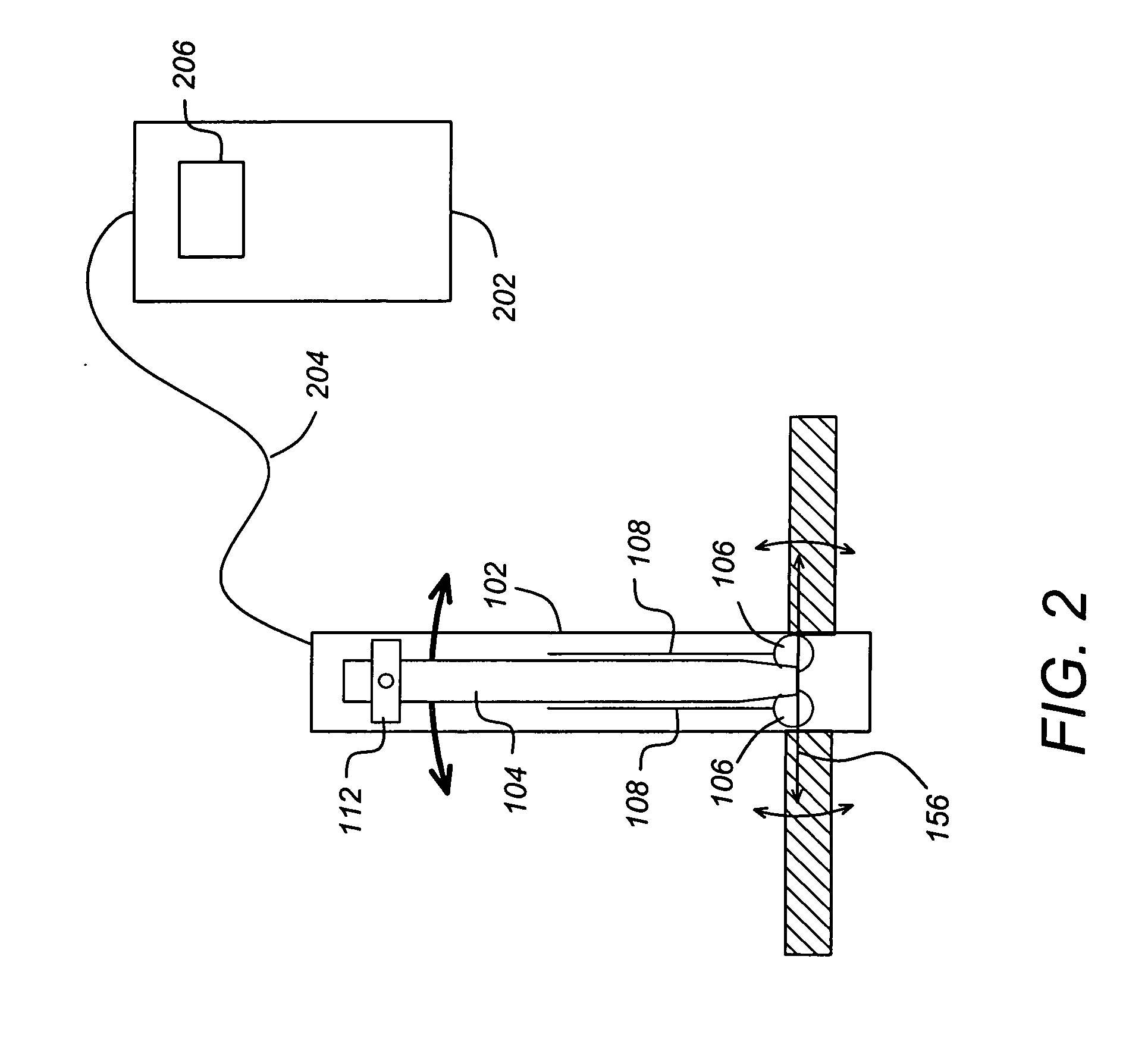

Method and apparatus for hole diameter profile measurement

ActiveUS20070051003A1Reduces operator-induced measurement variationReduce measurement biasPlug gaugesMicrometersData acquisitionMeasured depth

A method and apparatus for measuring the bore diameter of a hole as a function of hole depth is disclosed. In one embodiment, the apparatus comprises a diametric probe, for generating first measured bore diameter data along a diametric probe sensitive axis; a foot, for positioning the diametric probe sensitive axis in a plane parallel to the hole; a linear distance probe, coupled to the diametric probe, for generating first measured depth data describing the depth of the diametric probe sensitive axis within the hole; and a data acquisition system, for recording first measured bore diameter data from the diametric probe and first measured depth data from the linear distance probe of an insertion of the diametric probe into the hole.

Owner:THE BOEING CO

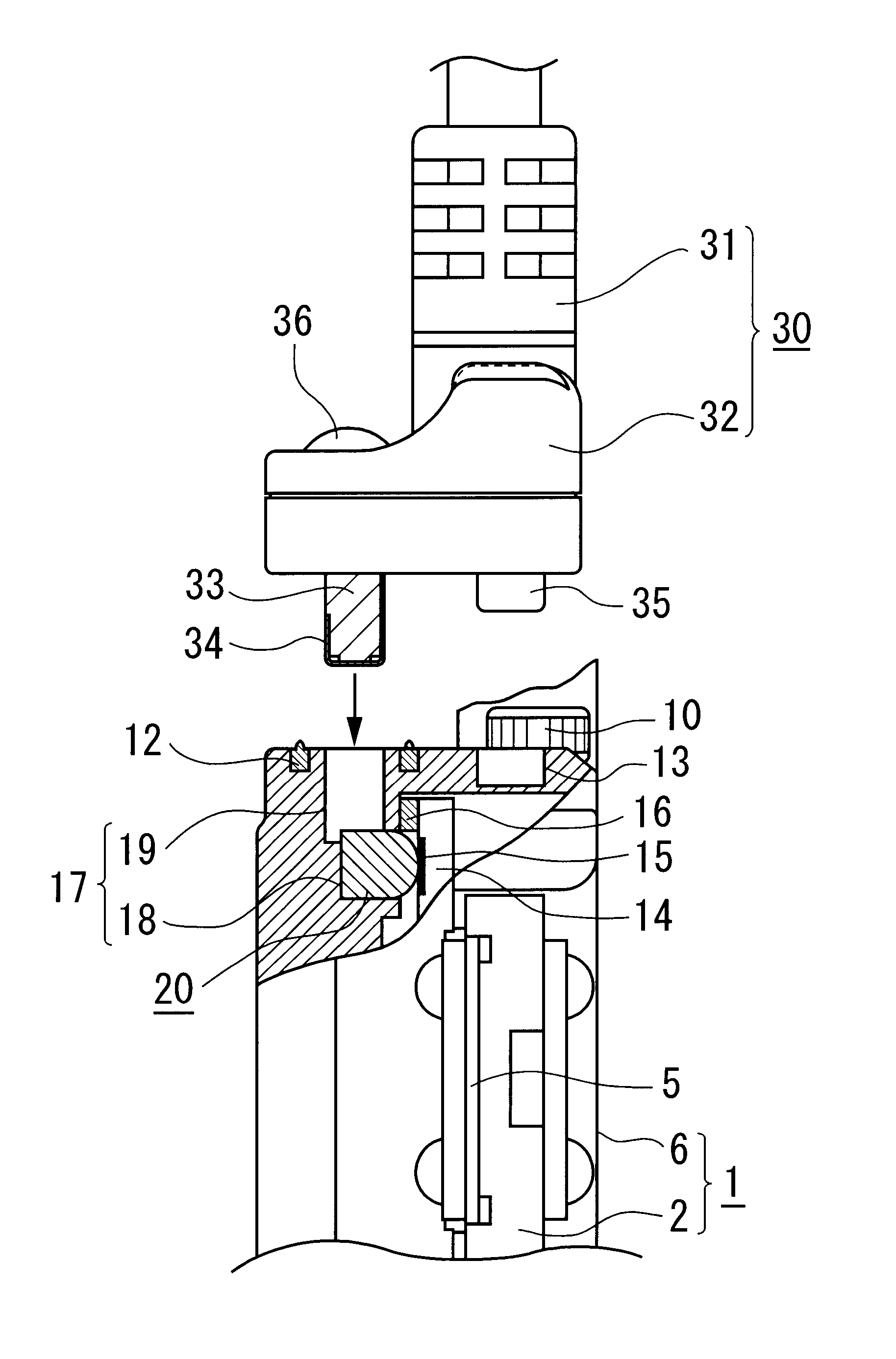

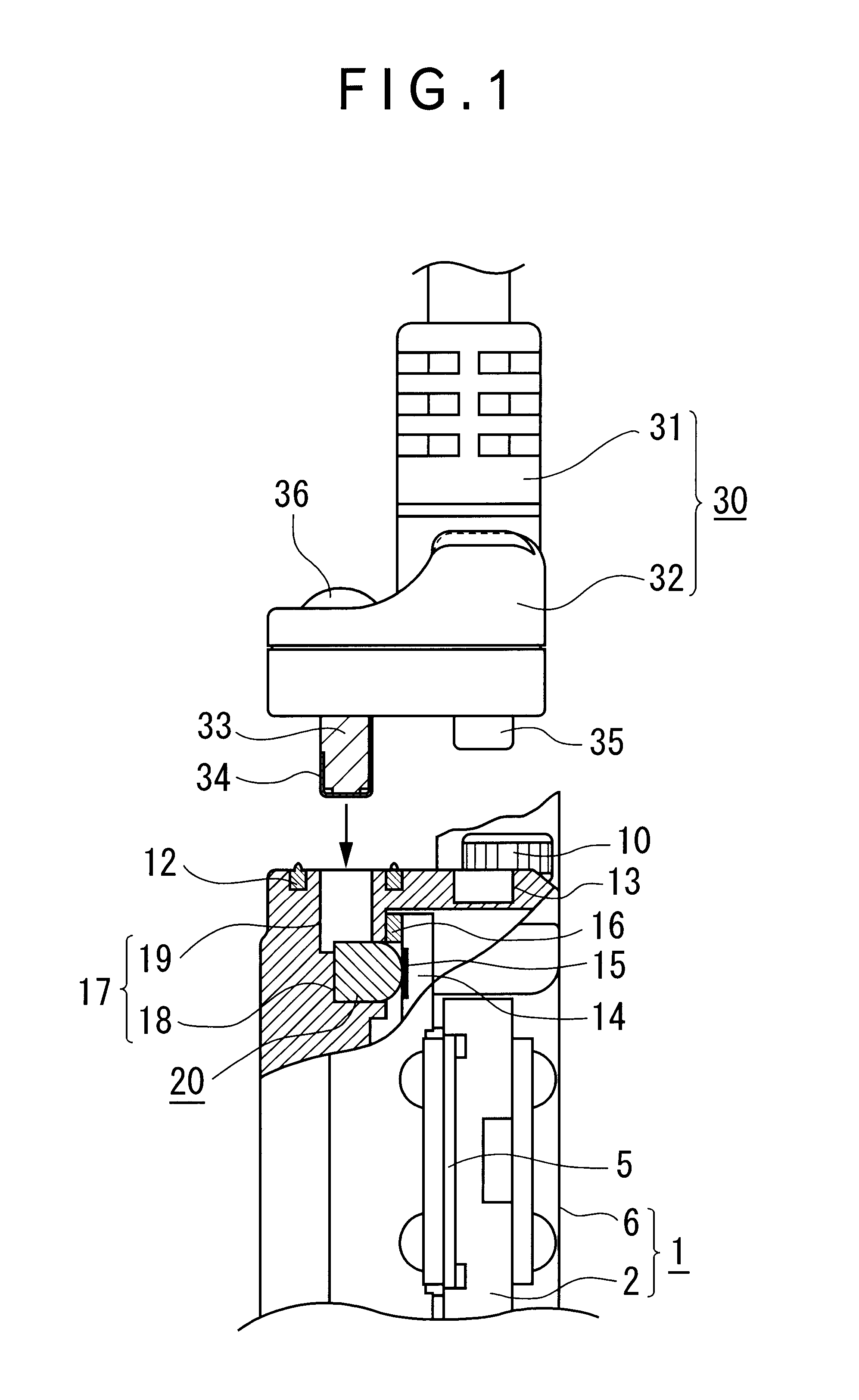

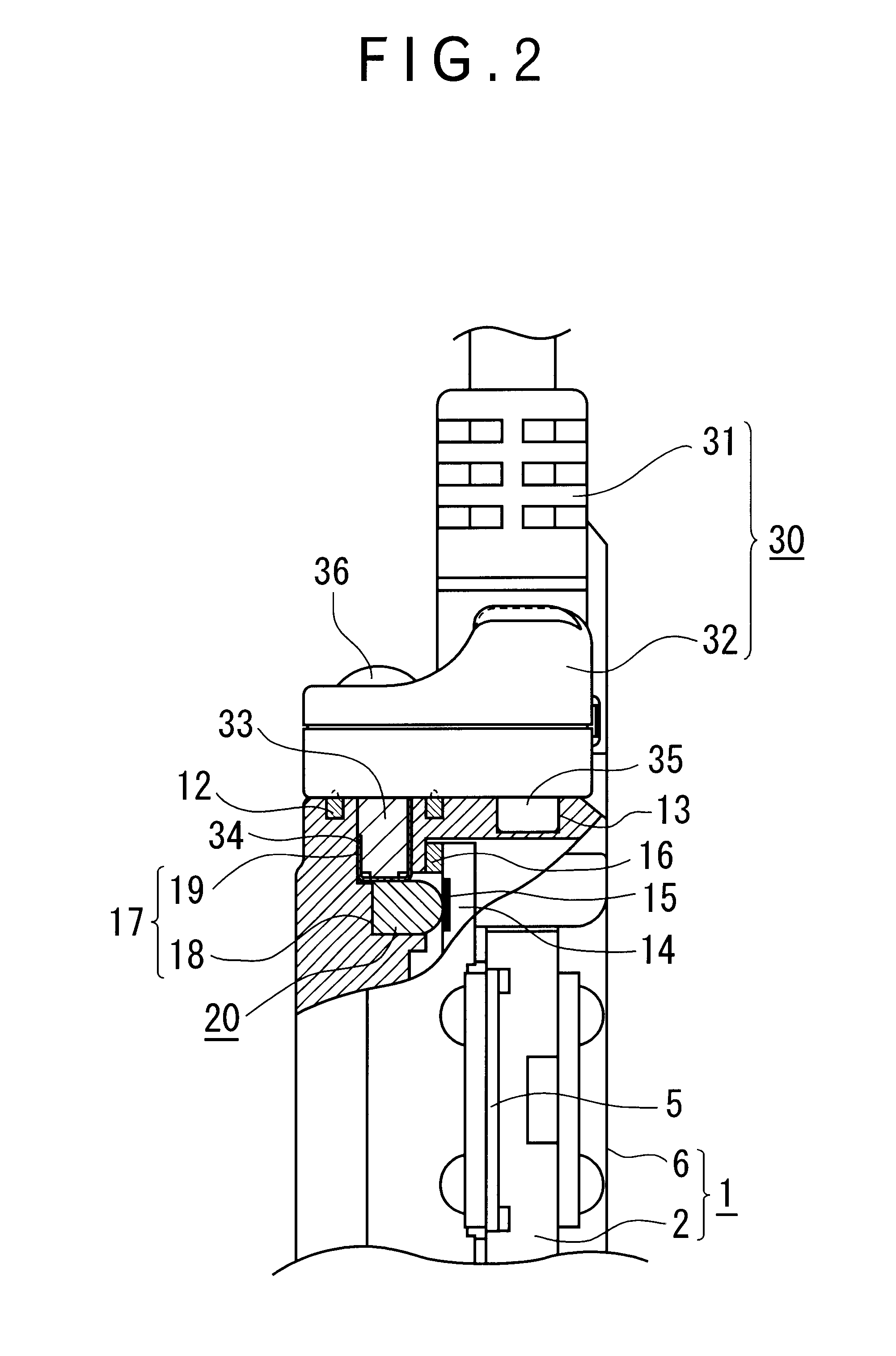

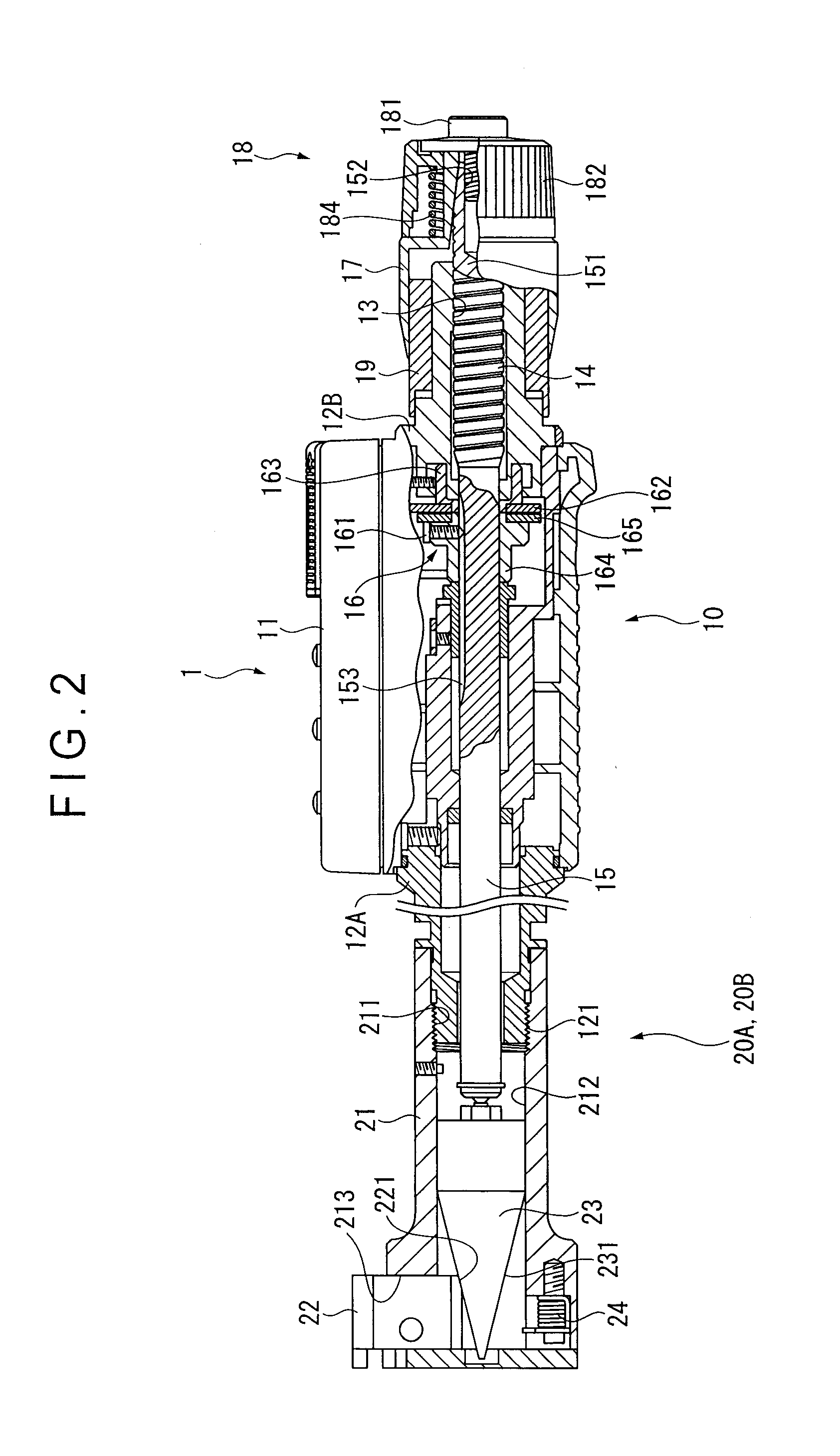

Output-attached measuring instrument

An output-attached measuring instrument has: a measuring instrument body (1) having a circuit board (14) for processing a measurement signal from a sensor as a measurement data, an output electrode (15) for outputting the measurement data, and a connector hole (17) in communication with the output electrode and opening to an outer surface; and a connection cable (30) having a connector (32) capable of attaching to and detaching from the connector hole on an end thereof for transmitting the measurement data obtained by the measuring instrument body to an external device, the connector having a projection (33) capable of being plugged to and unplugged from the connector hole and a connector terminal (34) exposed on a surface thereof, where an elastic connector (20) having am electro-conductive portion for electrically connecting the connector terminal and the output electrode is accommodated in a space of the connector hole of the measuring instrument body and the elastic connector shuts the connector hole when the projection is unplugged from the connector hole and electrically connects the connector terminal and the output electrode through the electro-conductive portion when the projection is plugged into the connector hole.

Owner:MITUTOYO CORP

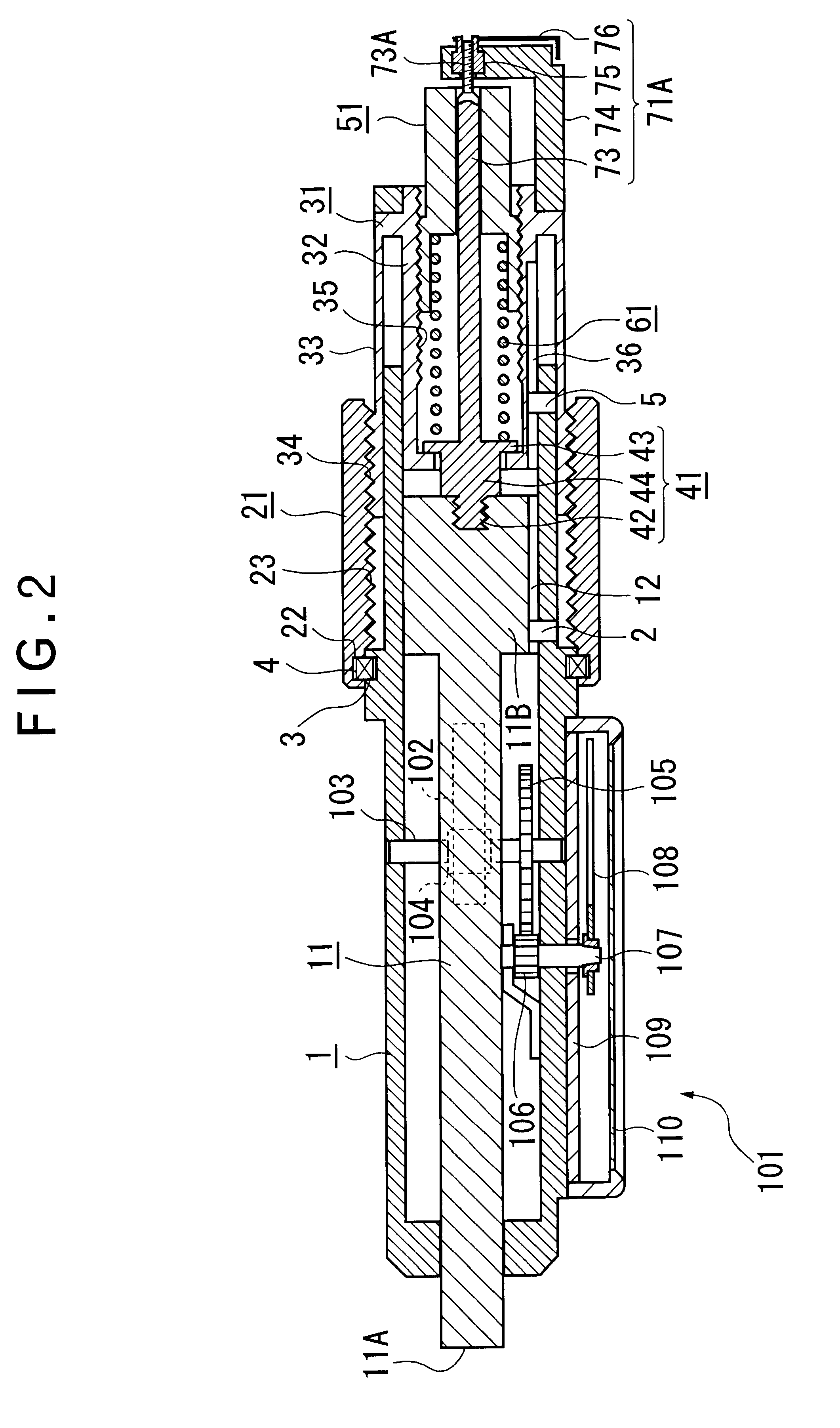

Measuring instruments

InactiveUS6553685B2Convenient ArrangementAvoid volatilityMicrometersMechanical measuring arrangementsMeasuring instrumentMechanical engineering

A measuring instrument includes a spindle (11) provided to a body (1), a sleeve (31) movable in the same direction as the spindle and stoppable at a desired position, a connector (41) for connecting the sleeve and the spindle and allowing relative movement of the sleeve and the spindle in the moving direction thereof by a predetermined stroke; a pressure spring (61) accommodated in the sleeve for biasing the spindle in a direction for the spindle to abut to the workpiece through the connector, and a biasing force indicator (71) for indicating the pressure spring.

Owner:MITUTOYO CORP

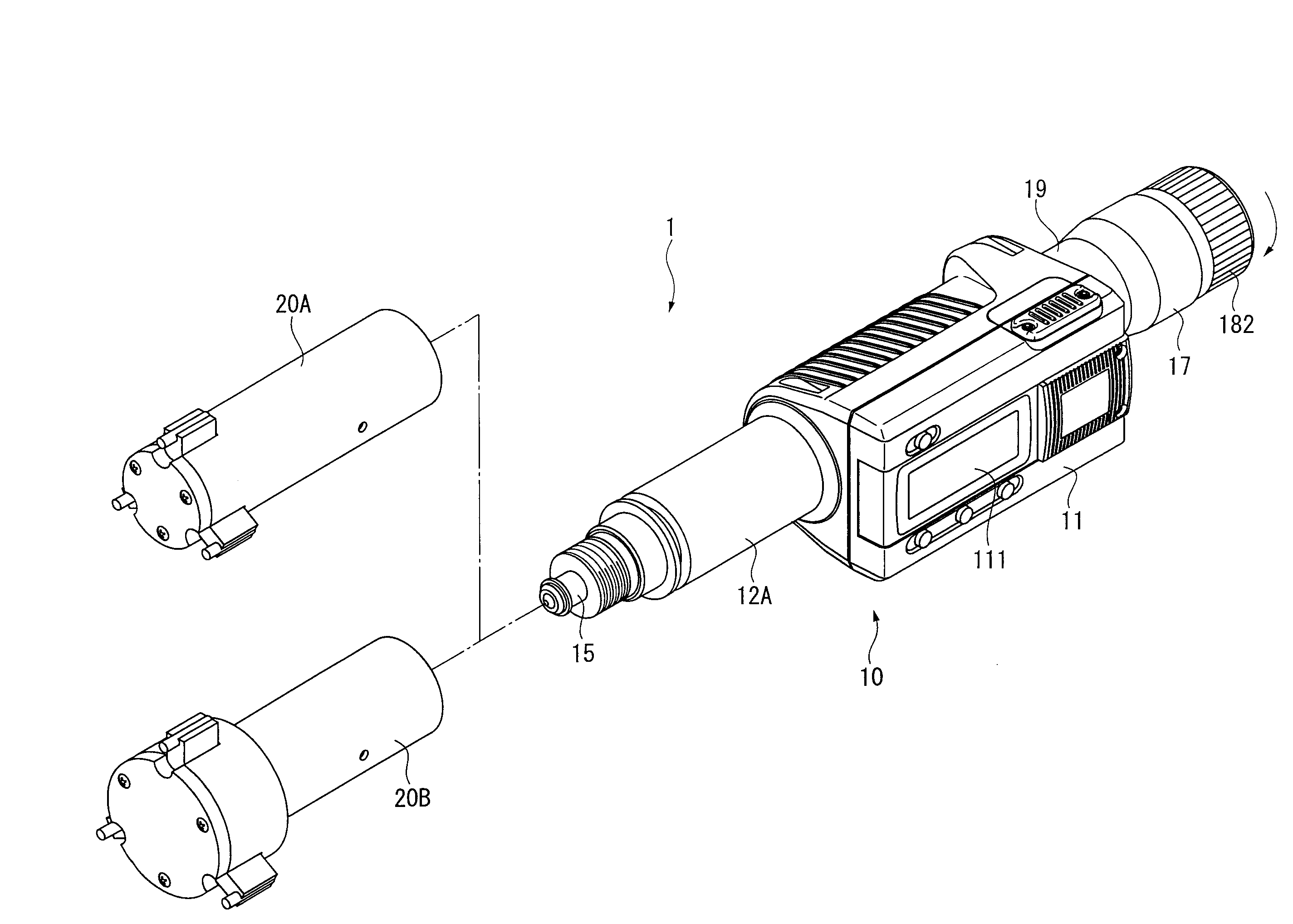

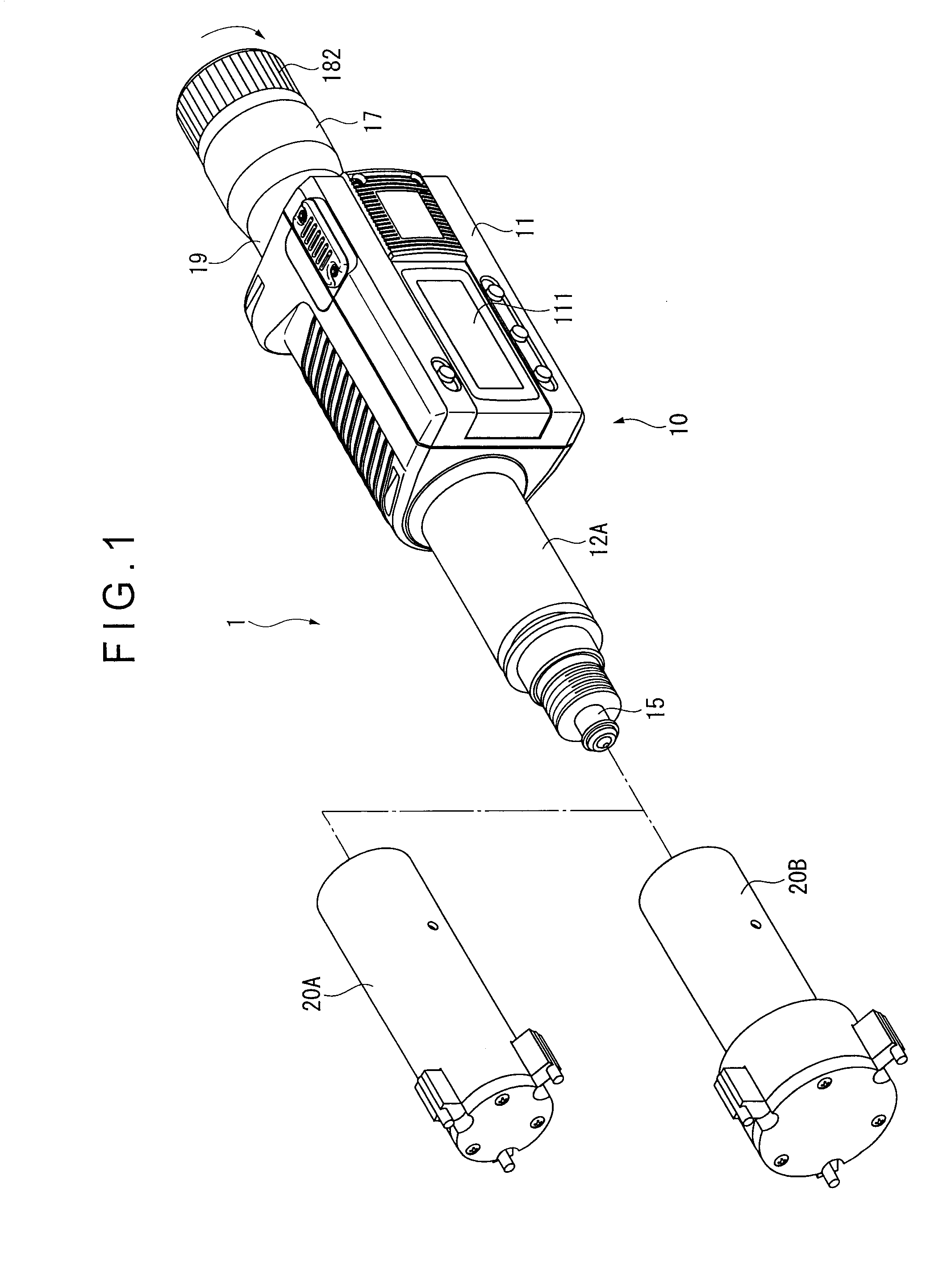

Inside diameter measuring tool

ActiveUS20100005676A1Increased durabilityEasy to operateMicrometersMechanical diameter measurementsScrew threadEngineering

An inside diameter measuring tool includes: a main body; an axially moving spindle having a male screw to be screwed to the main body; a plurality of contact pieces provided on the main body, the measuring pieces moving in a direction substantially orthogonal to the axial direction of the spindle; and a conical member interposed between the contact pieces and the spindle, the conical member advancing and retracting the contact pieces in the direction substantially orthogonal to the axial direction of the spindle. The lead of the male screw of the spindle is 1.0 mm or more and the cone angle of the conical member is less than 53 degrees. Preferably, the lead of the male screw is 2.0 mm and the cone angle of the conical member is approximately 28 degrees.

Owner:MITUTOYO CORP

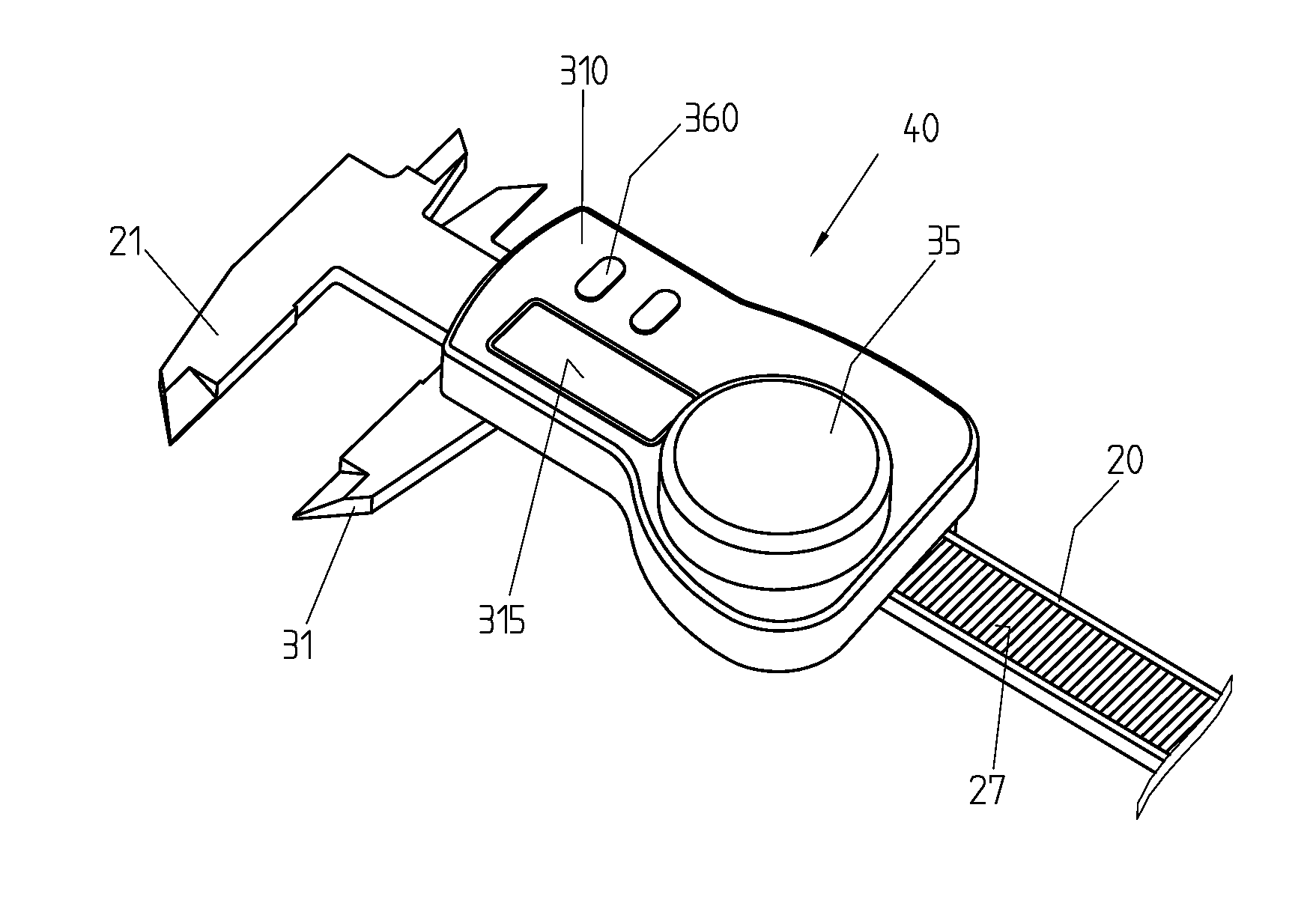

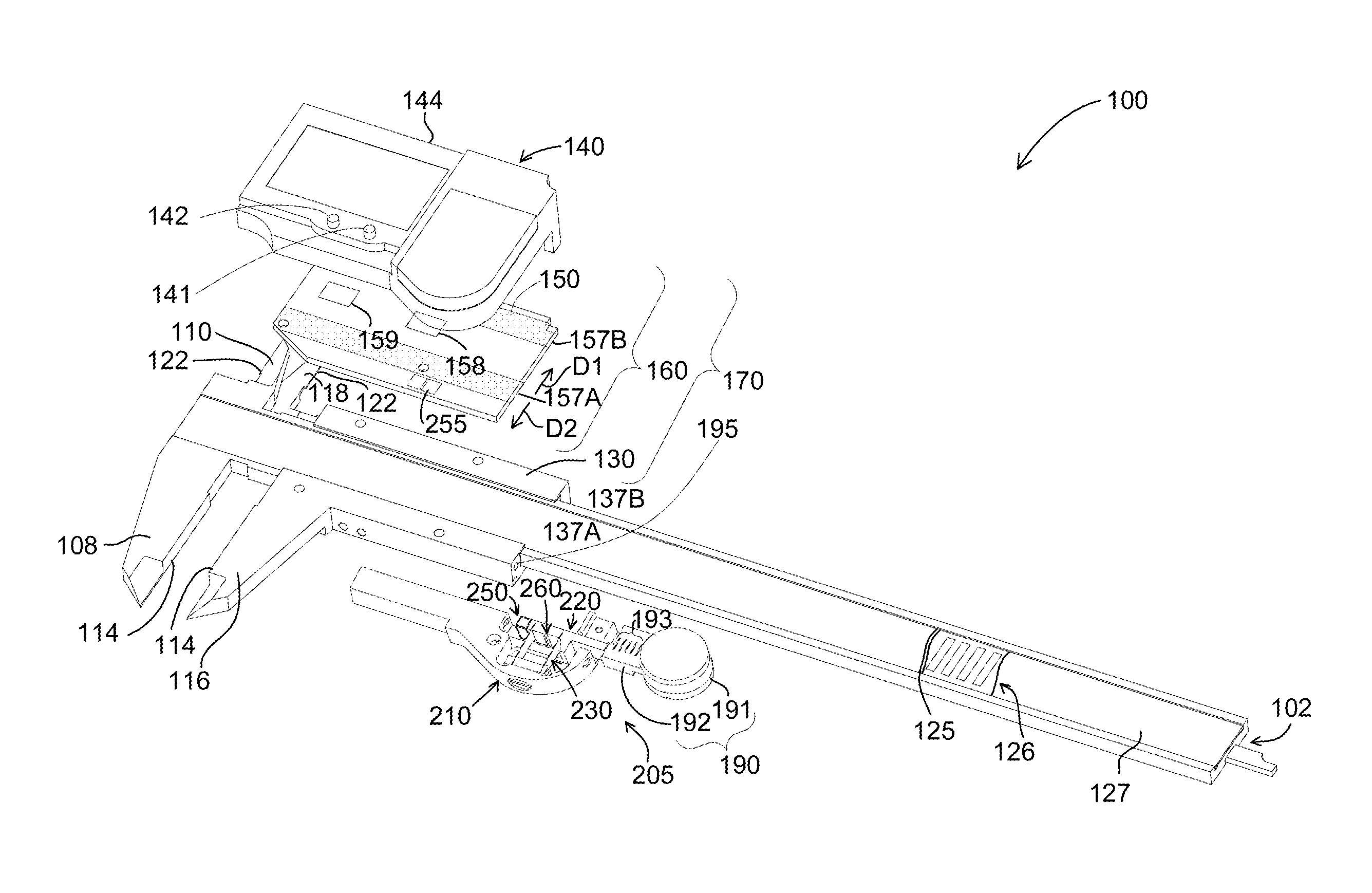

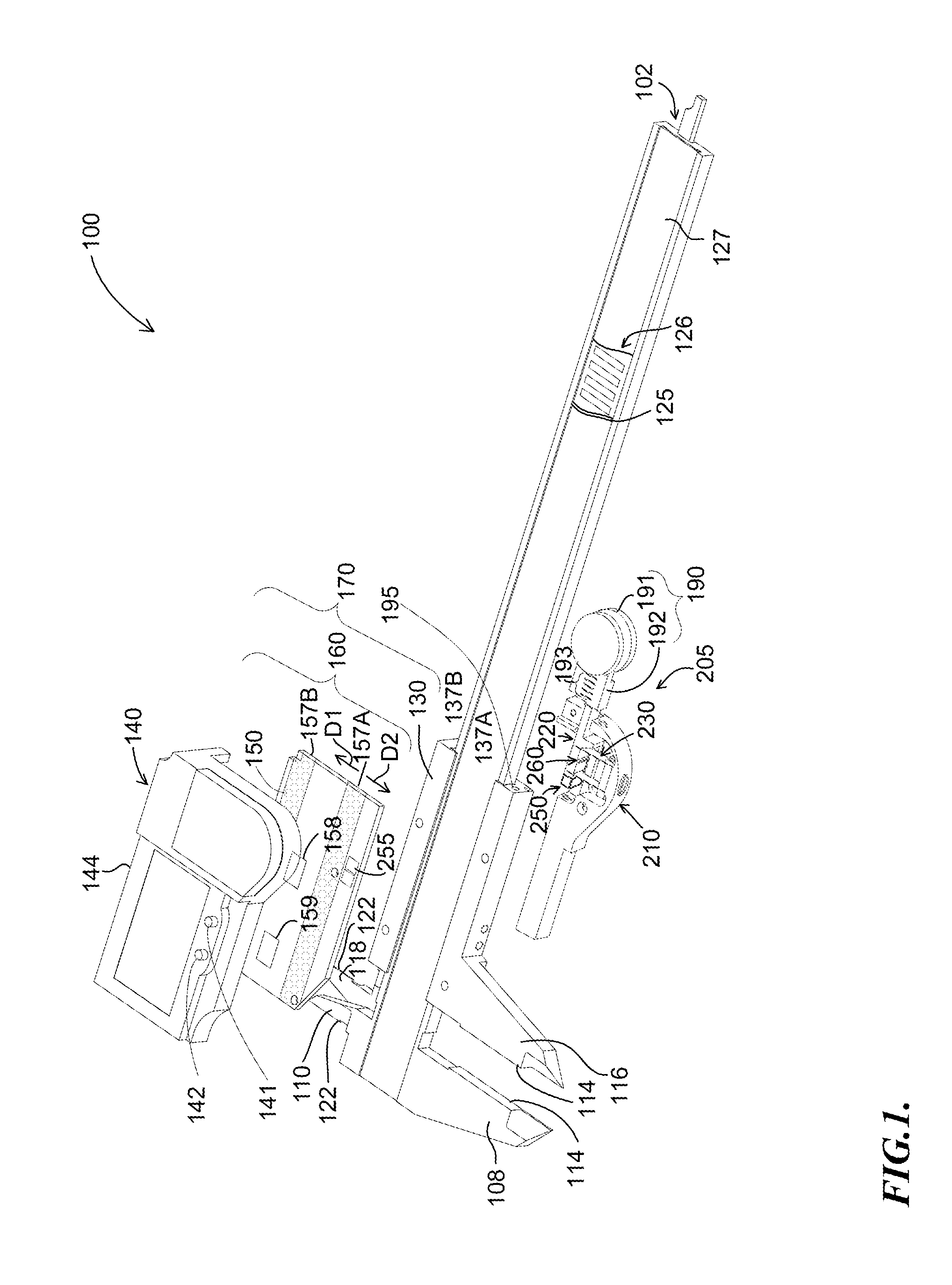

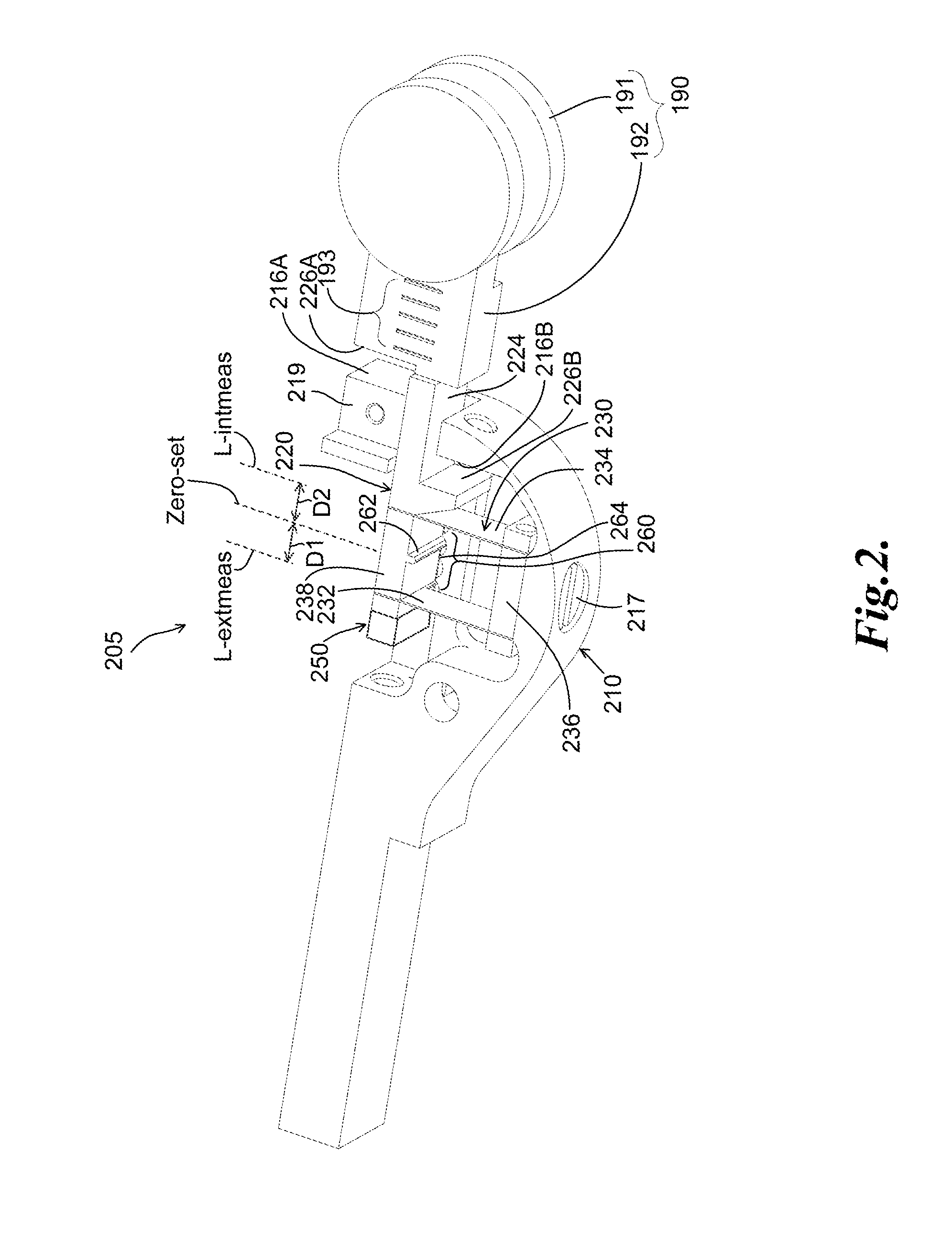

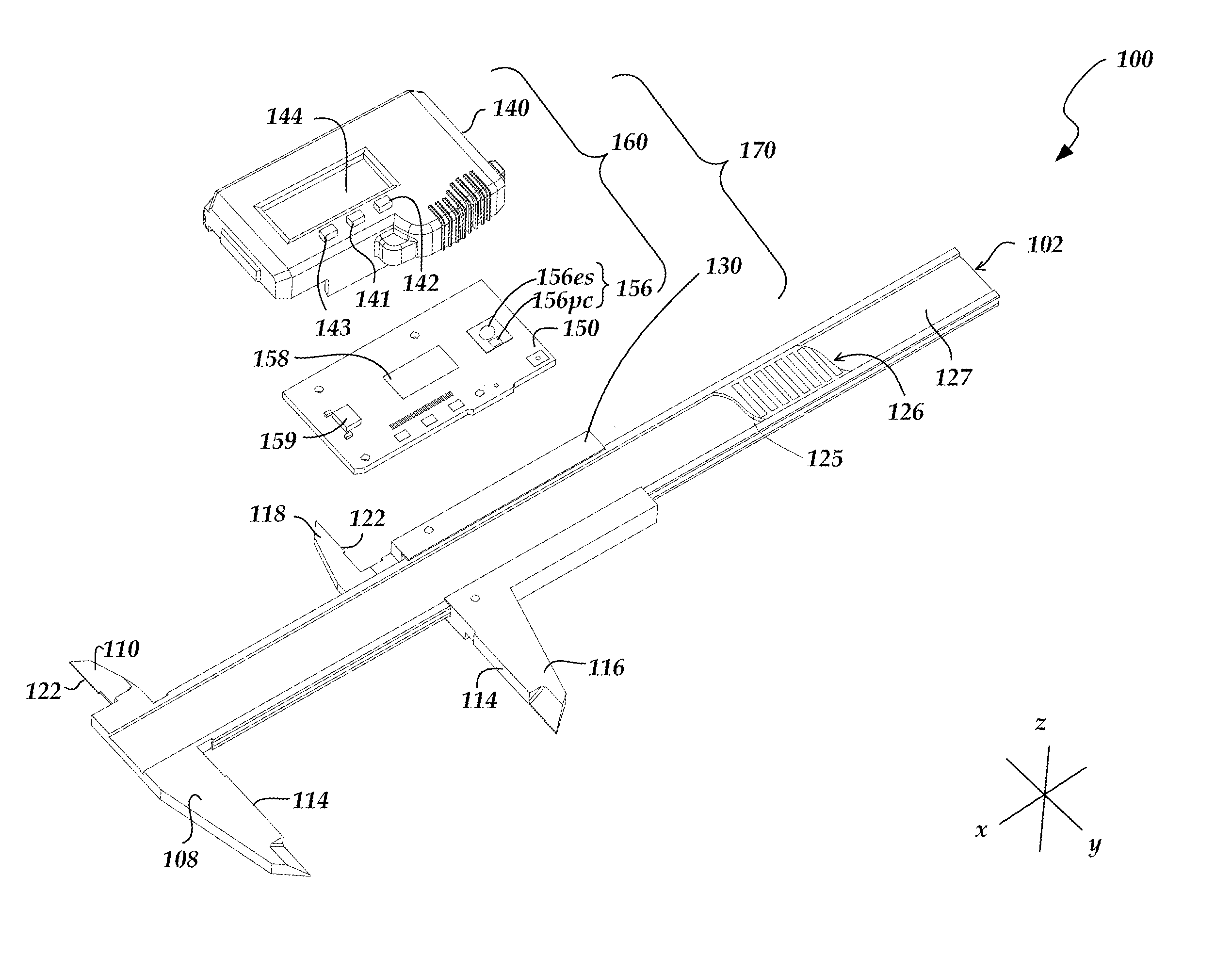

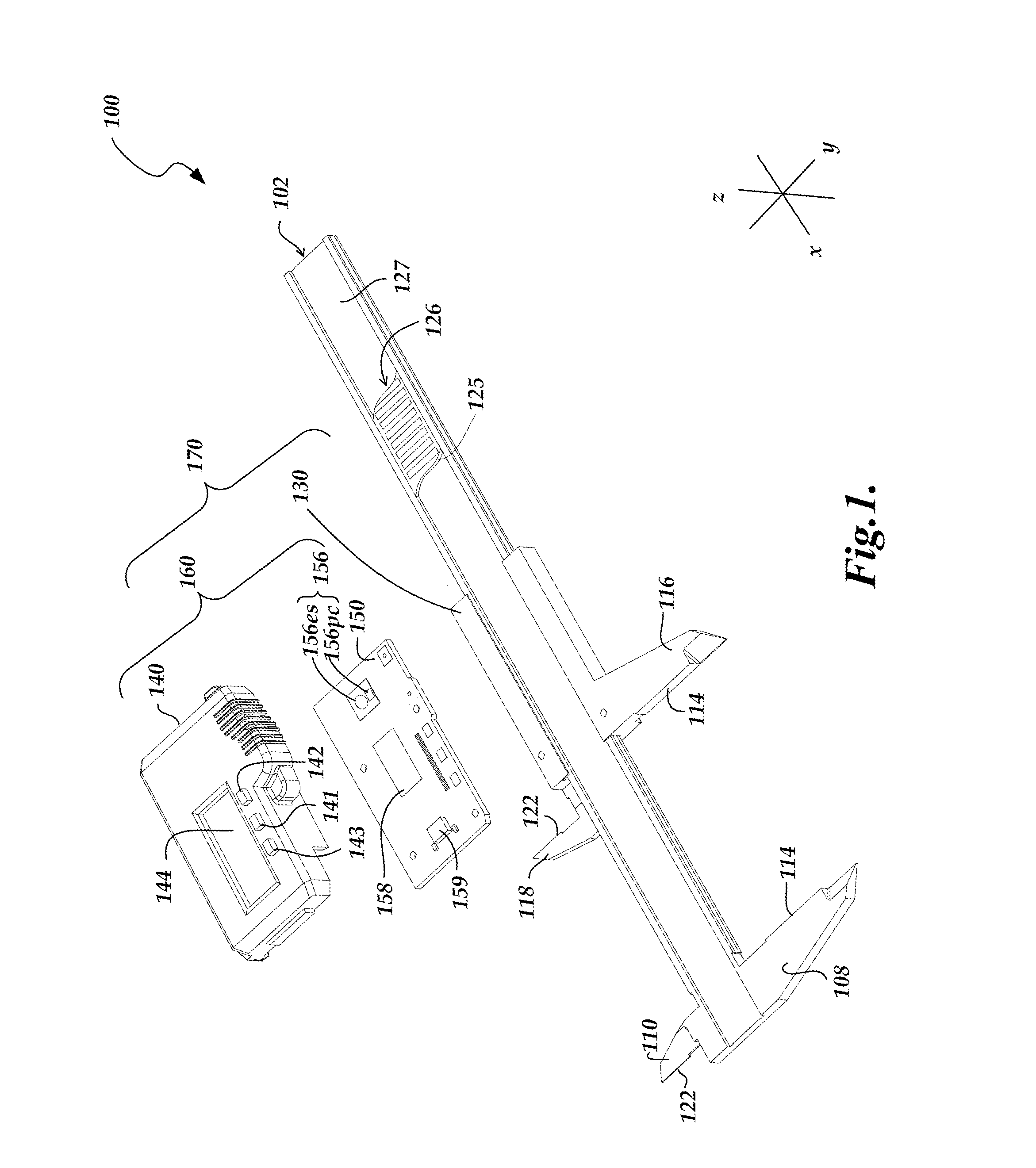

Flexible mount for coupling force actuator to caliper jaw

ActiveUS20150276366A1Reduced parts countLower assembly costsWalking sticksMicrometersCalipersActuator

A flexible mount is provided for coupling a force actuator to a caliper jaw. The flexible mount includes a first mounting portion for being coupled to the caliper jaw, a second mounting portion for being coupled to the force actuator, and a flexible element (e.g., a parallel flexure) coupled between the first and second mounting portions. When a force is applied to the force actuator (e.g., by a user pushing on a thumbwheel) along the measuring axis direction, the flexible element flexes to generate a measuring force that is applied to the caliper jaw. The use of the flexible mount results in more control and a better feel for a user when attempting to exert control to provide a desired amount of force during a measuring process. The flexible mount may also utilize a fastening configuration that is compatible with existing mounting features on existing caliper jaws.

Owner:MITUTOYO CORP

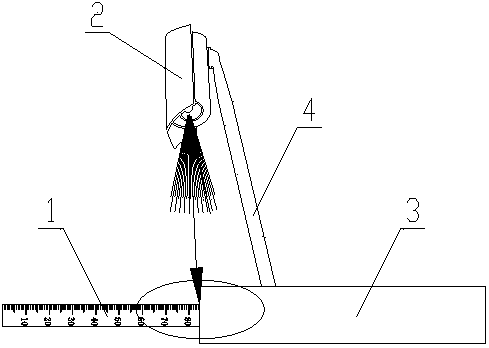

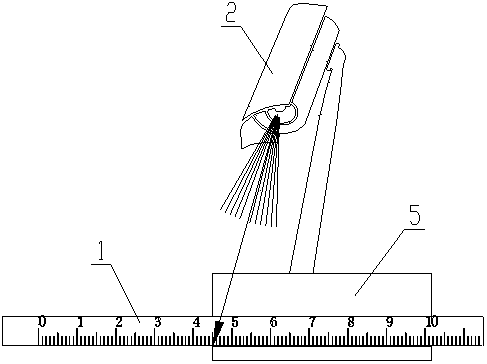

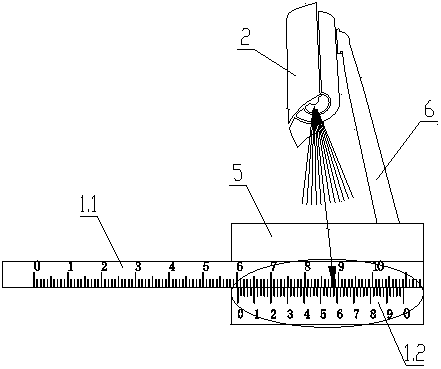

Video measuring tool based on camera

InactiveCN104315936AAvoid influences such as temperature driftImprove reliabilityTelevision system detailsMicrometersComputer graphics (images)Engineering

The invention discloses a video measuring tool based on a camera. The video measuring tool comprises a measuring tool body and the camera (2), wherein the camera (2) is used for shooting scale marks on a graduated scale body (1) to obtain a scale mark image, and the measuring tool body can be an extension scale, a sliding scale, a micrometer caliper and a universal angle meter. By the adoption of the video measuring tool, scale values can be shown accurately in a visualized mode through the scale mark image, reading of the scale values is achieved by shooting the scale mark image with the camera, errors caused by failures of electronic elements are eliminated, influences of temperature drift of the electronic elements can be avoided fundamentally, influences of failures of a temperature compensation circuit can be avoided, it is physical scale marks that are shot by the camera, neither the scale marks nor the camera can be affected by temperature drift, scale reading results are high in reliability, maintenance is easy, and cost is low. For special engineering projects, remote network monitoring of multiple tools to be measured can be achieved, monitoring efficiency is improved, and monitoring workload and cost are reduced.

Owner:SICHUAN JINMA TECH

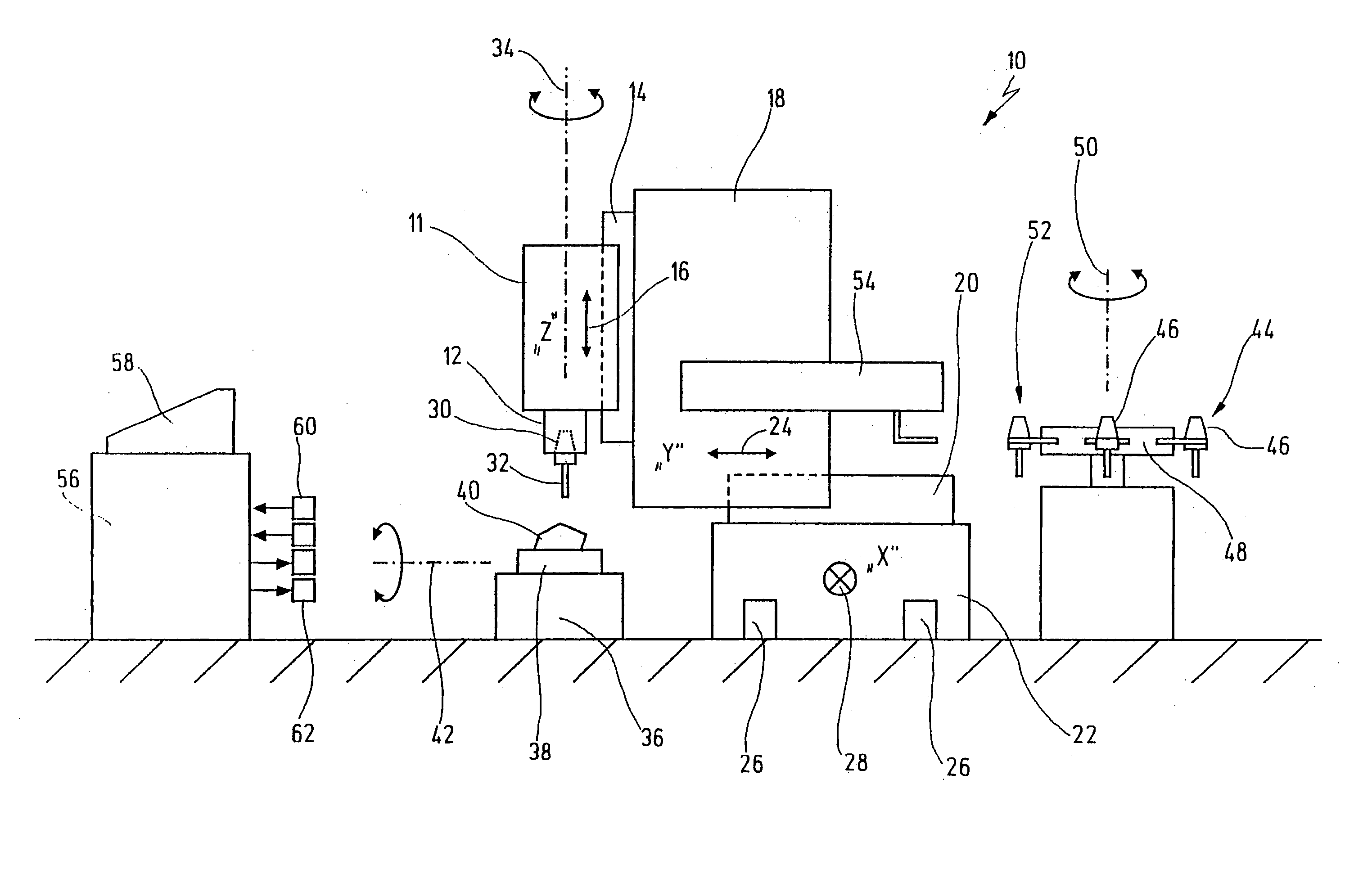

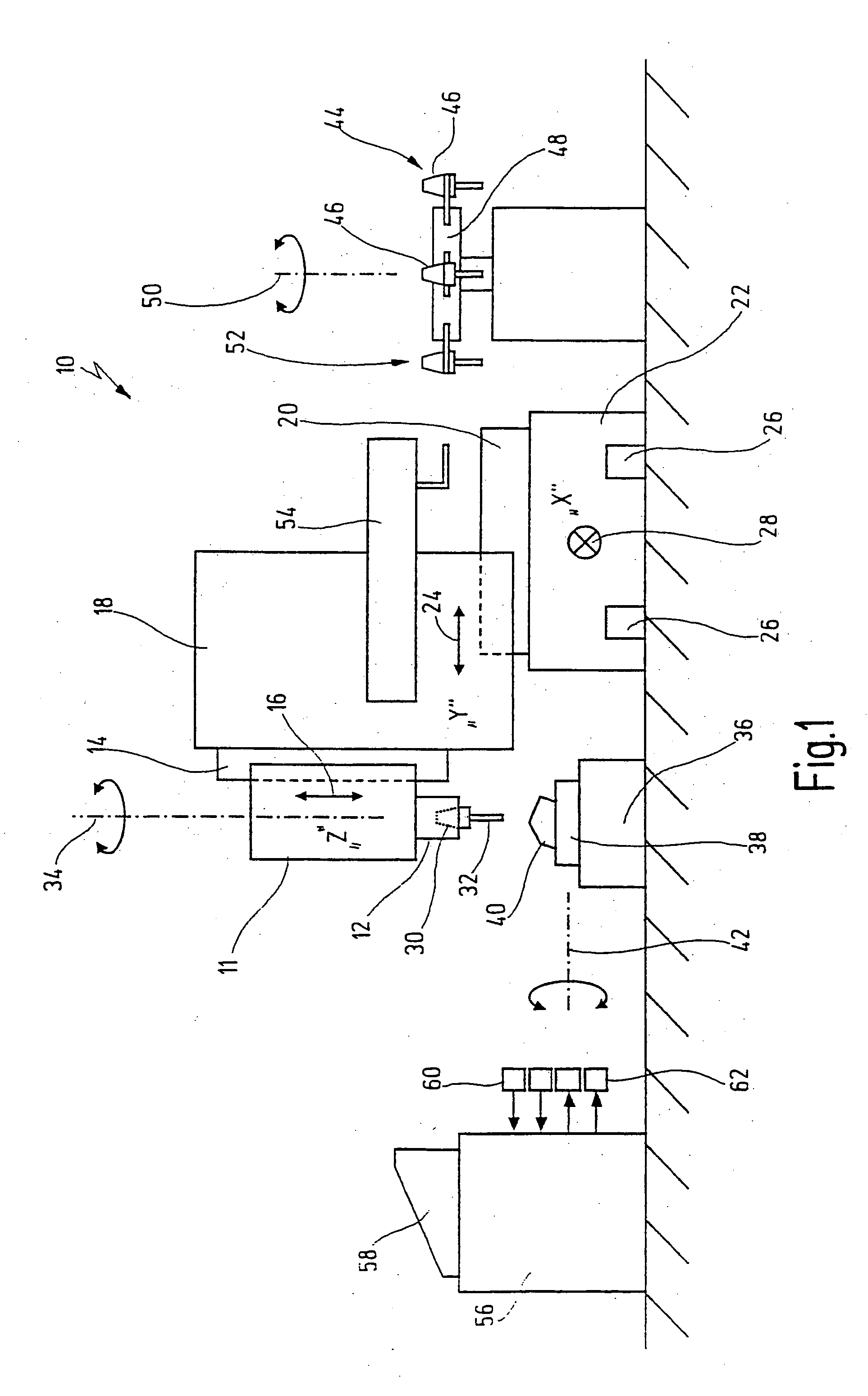

Machine tool and method for operating a machine tool

ActiveUS20050209730A1Reduce downtimeHigh product yieldLathesTool changing apparatusRelative motionMachine tool

A machine tool comprises a tool carrier moveable relative to a workpiece to be machined. A controller controls the relative movement of the tool carrier and the workpiece by means of a control program. If an unplanned event occurs during the operational movement of the machine, the relative movement of the tool and the workpiece is stopped, and a restart from a starting position is carried out later. The starting position is in this case approached along a trajectory, and the trajectory is determined automatically as a function of the machining operation in which the unplanned event occurred.

Owner:STAMA MASCHFAB GMBH

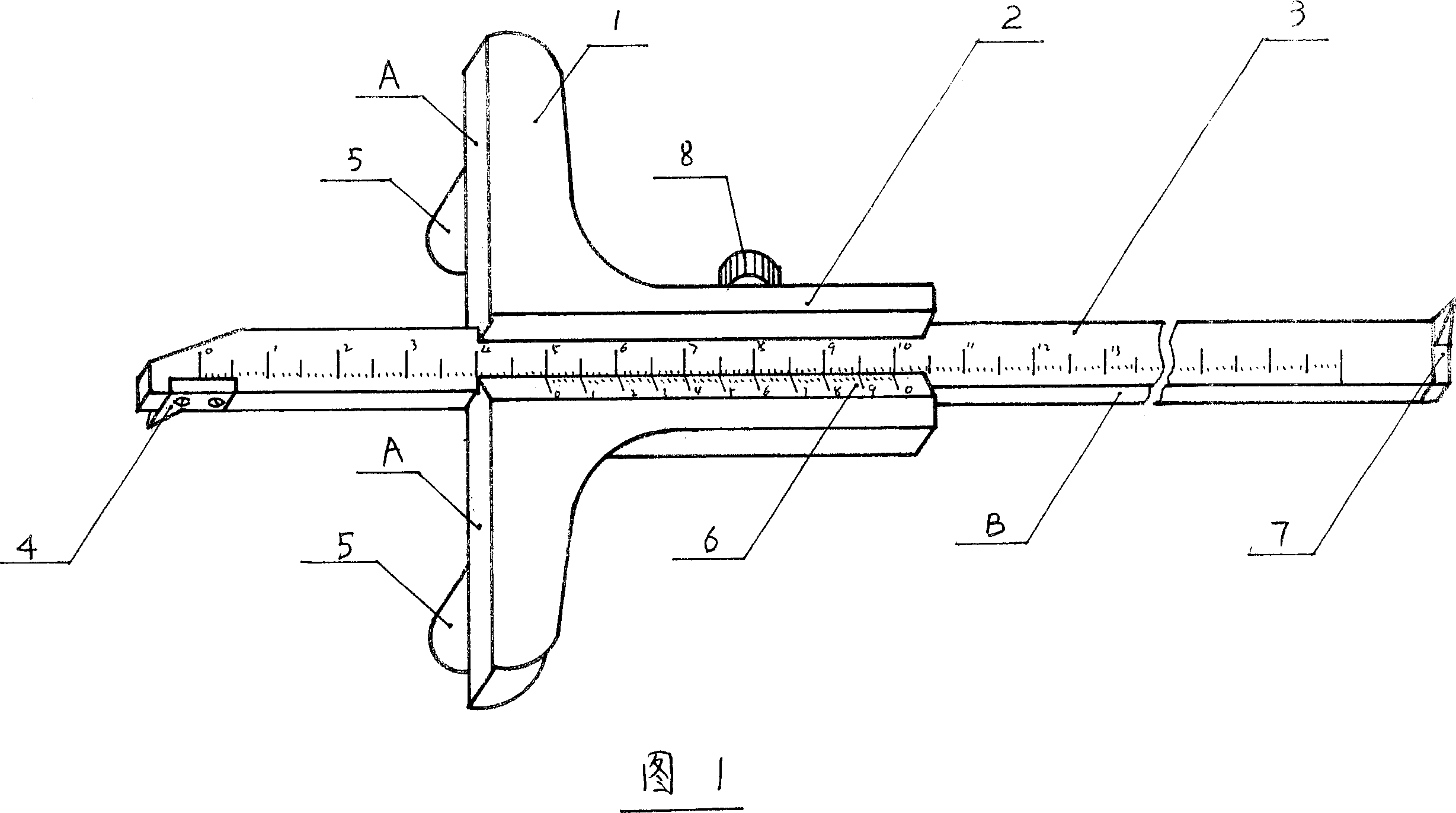

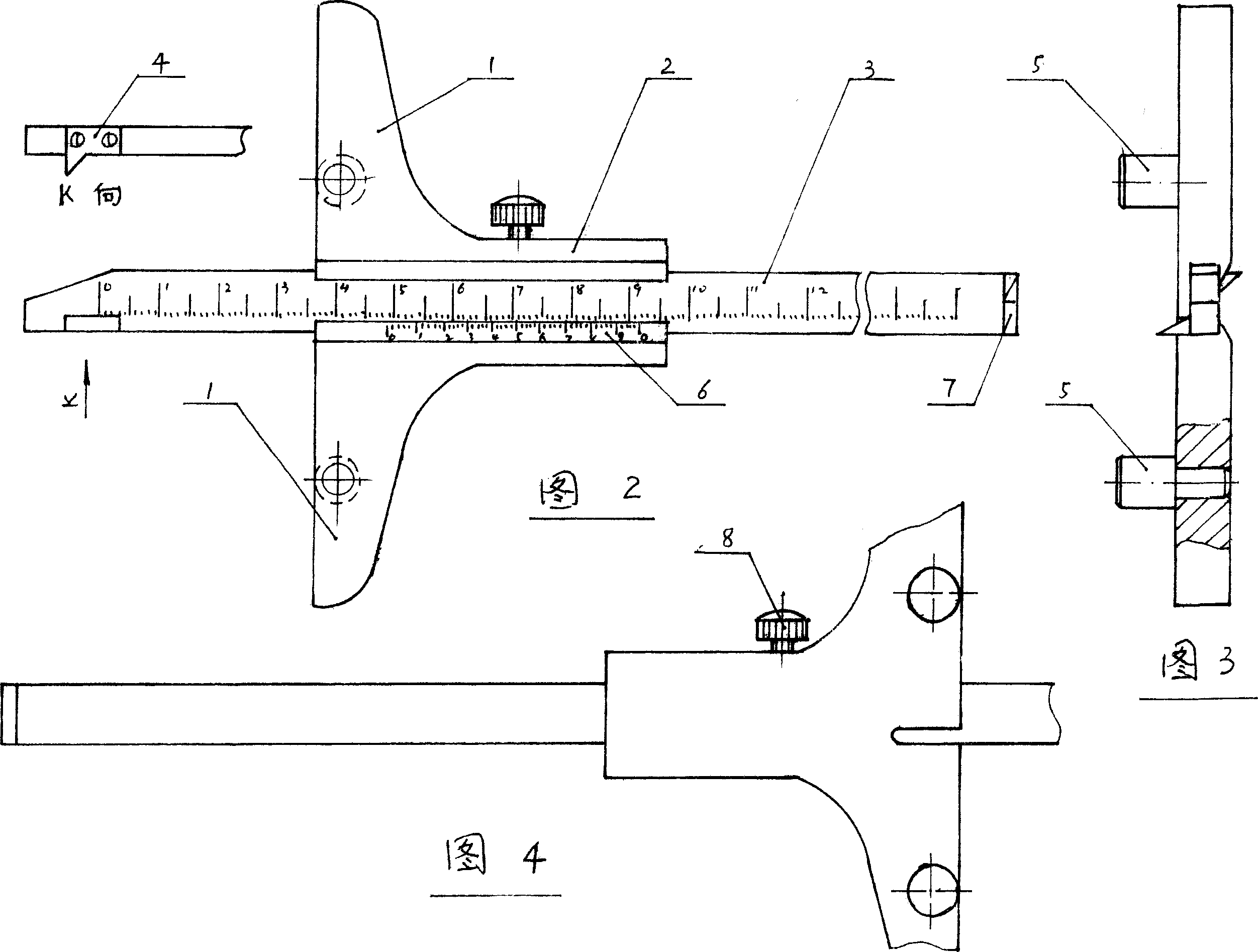

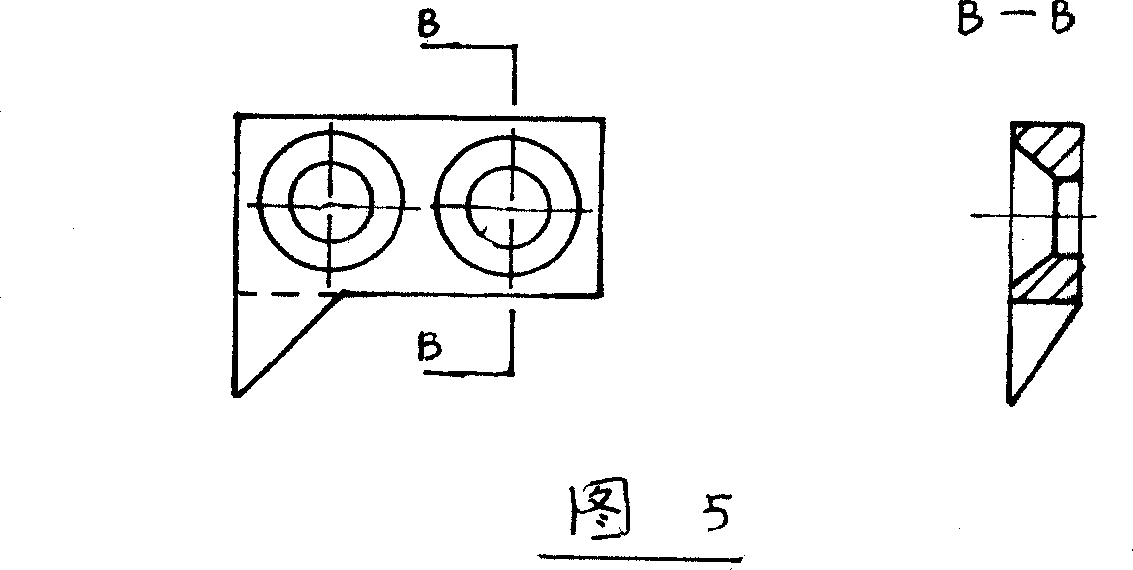

Multifunction depth vernier

The invention relates to a multi-function depth vernier gage. Based on the existing depth vernier gage, it enlarged the circle arc angle which connects the taping buck (2) and the card foot (1) side, and added two column localization foots (5) on the card foot (1) and located the plate shape scriber (4) on the front straight side (B) of the host ruler (3), the end lateral section of the host ruler (3) was loaded with a standby plate shape scriber (7), the back of the taping buck(2) near the card foot (1) side is equipped with a long gap, the plate shape scriber (4) can enter it following the host ruler(3), the host ruler (3) front end surface can be even with the card surface (A), and align the zero position, the main ruler (3) side (B)is vertical and divides equally of the central segment of the two column localization foots (5), moreover, the two column localization foots (5) outer annulus spool thread with card surface (A) in identical plane. The invention is used for the machine-finishing profession worker to survey the work piece depth, pull similar to pass cover, the stuffy lid, the bearing seat and so on (in particular large diameter) work piece end surface screw (hitch) the hole distribution round line as well as delimits the axis and the hole center core labor (quantity), its structure is simple, easy to operate.

Owner:朱光锥

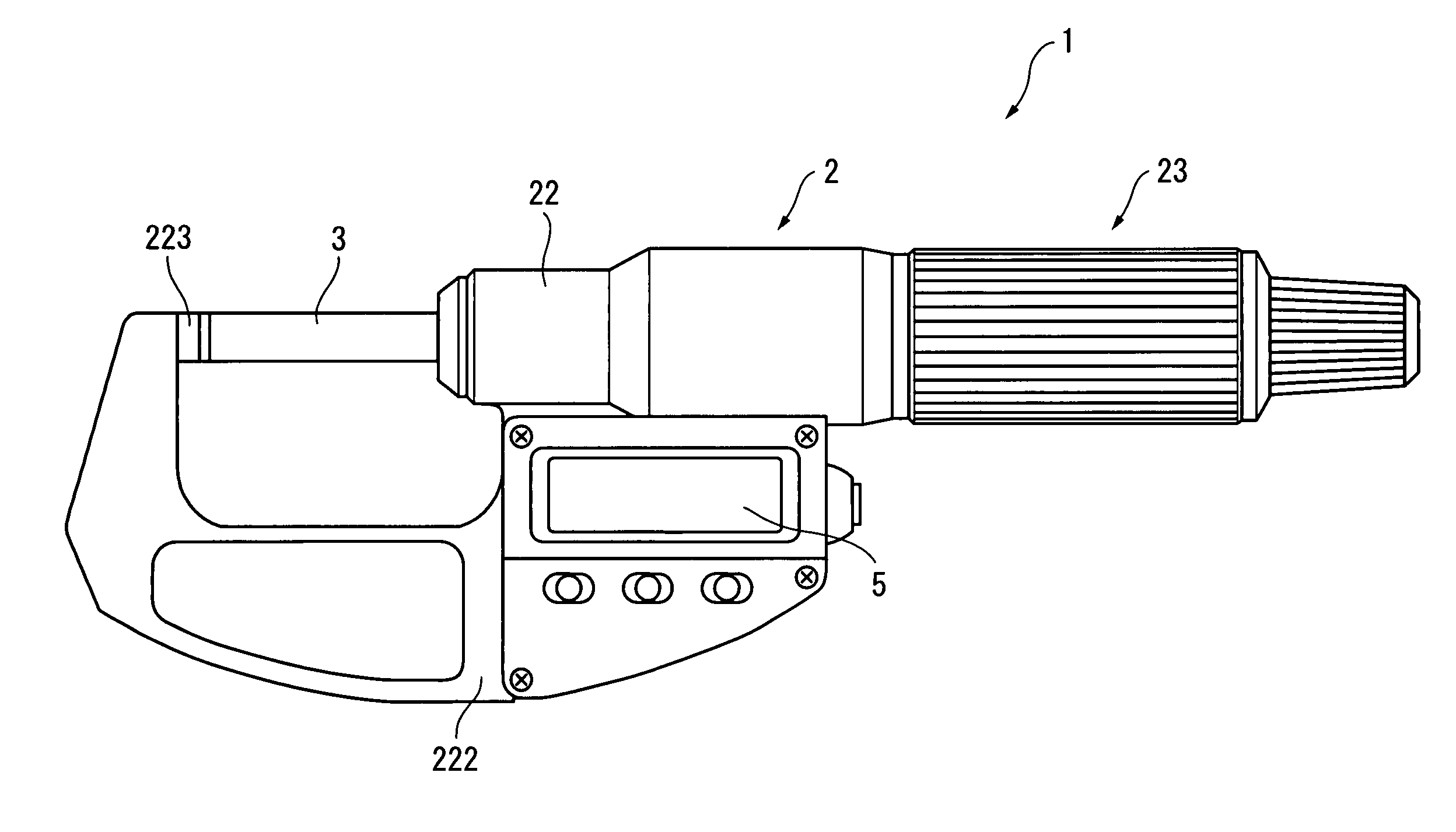

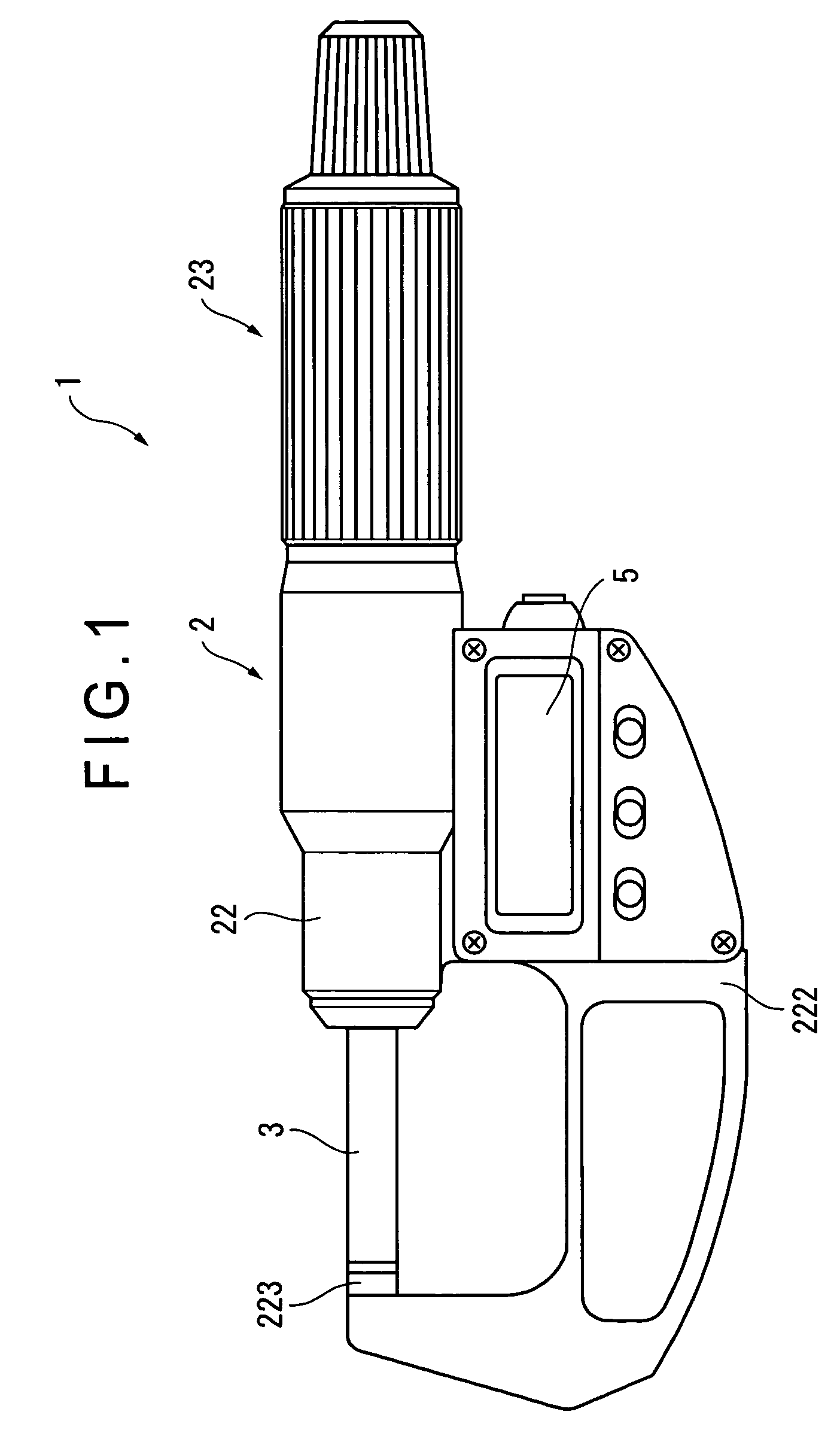

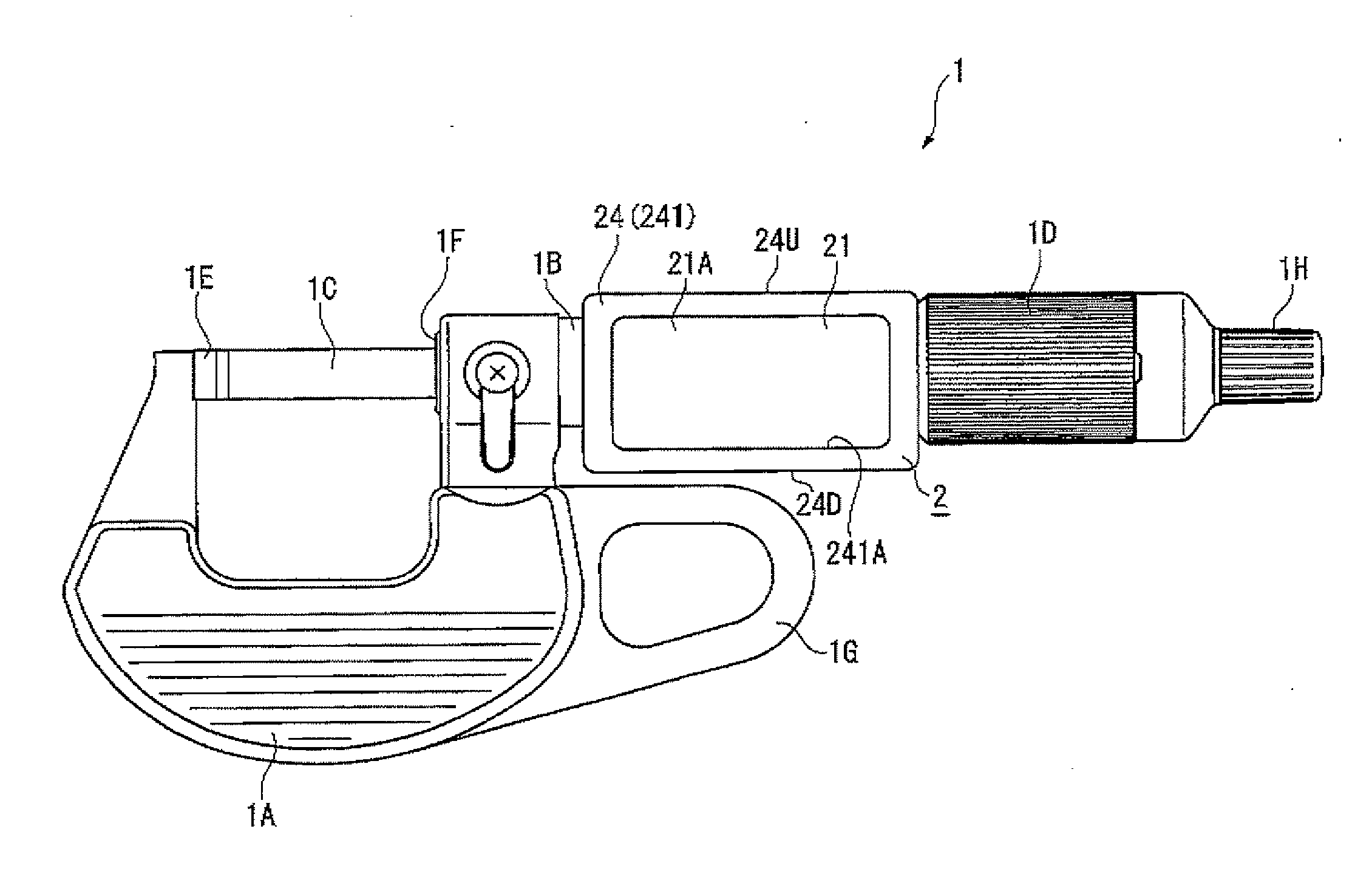

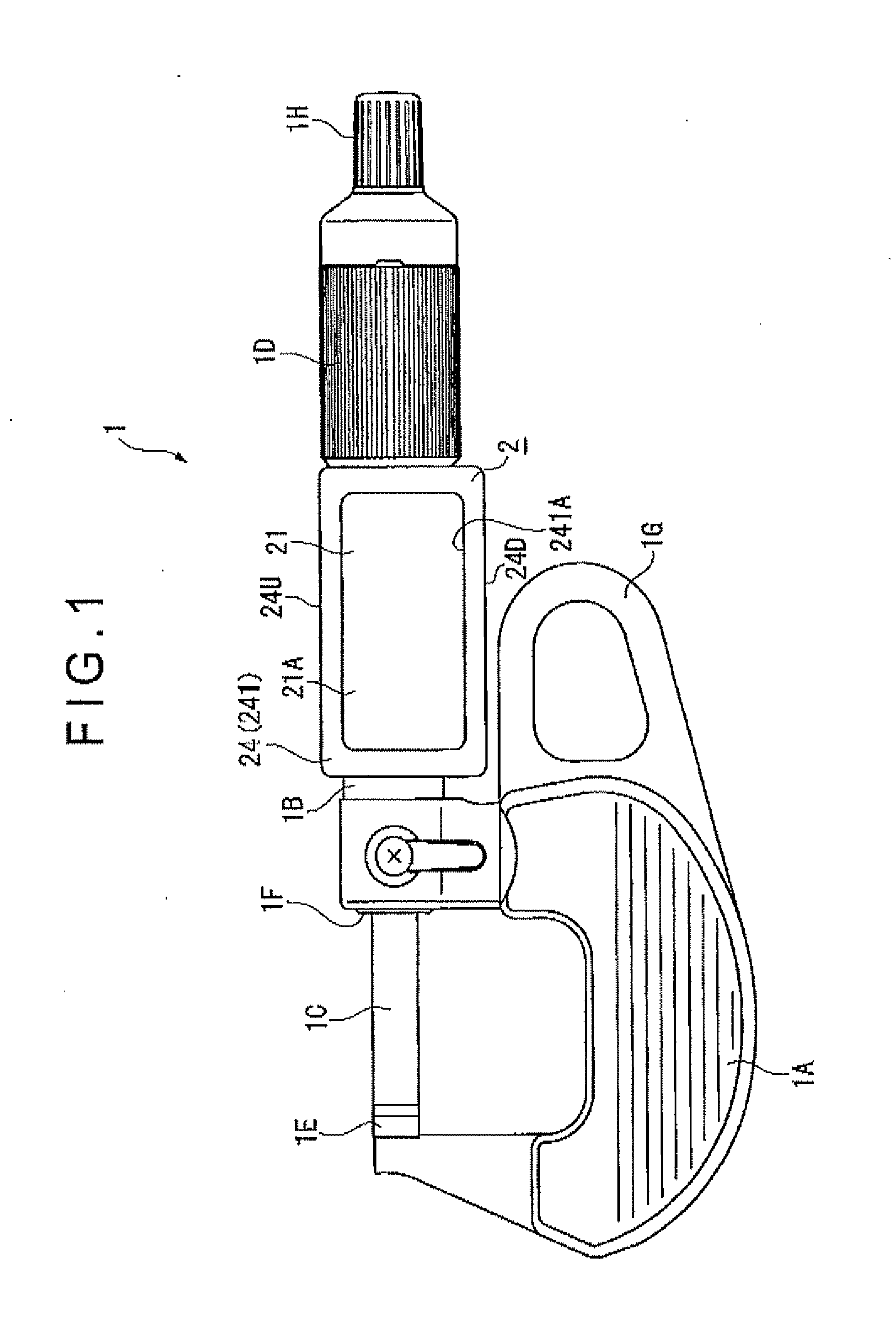

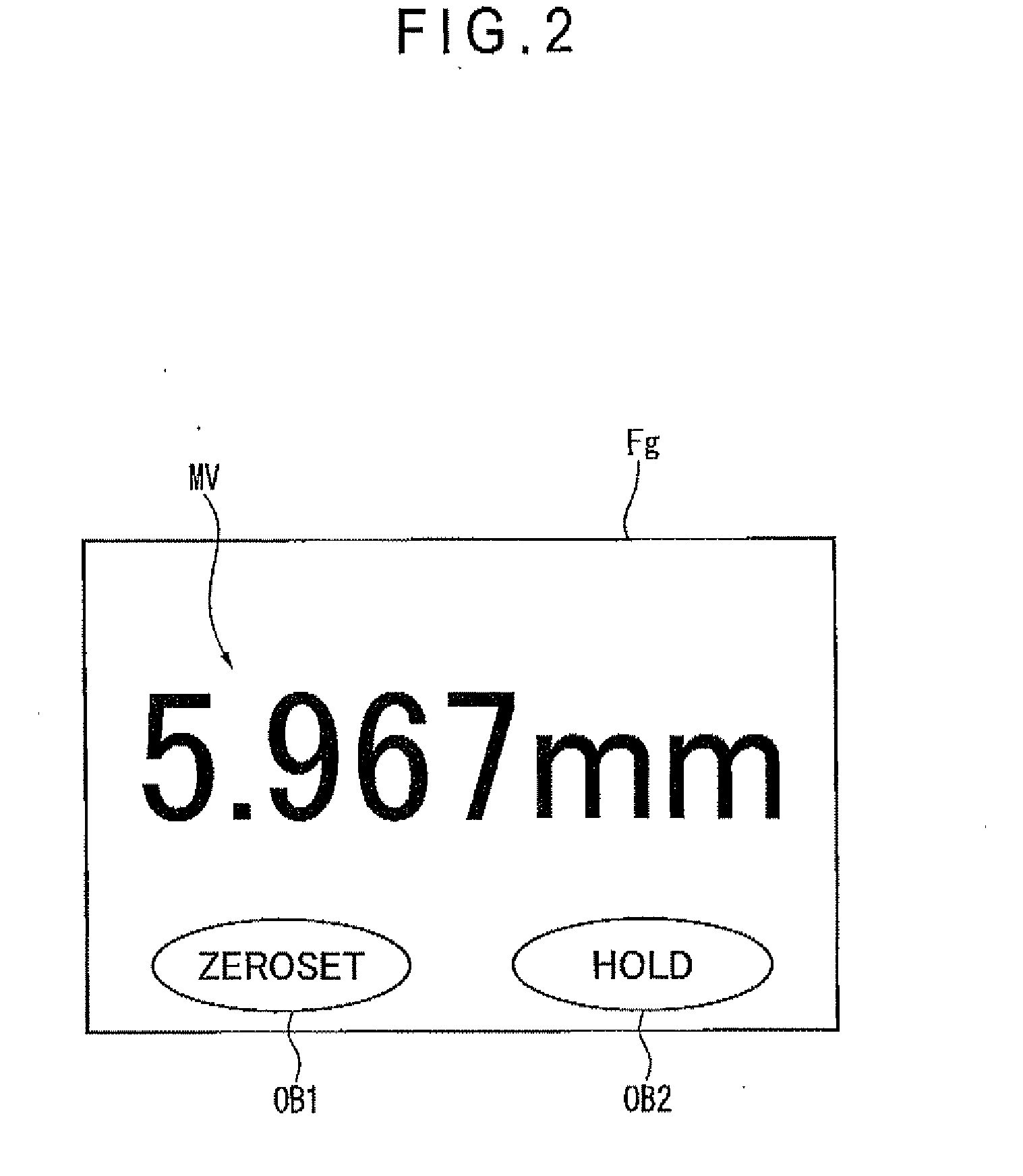

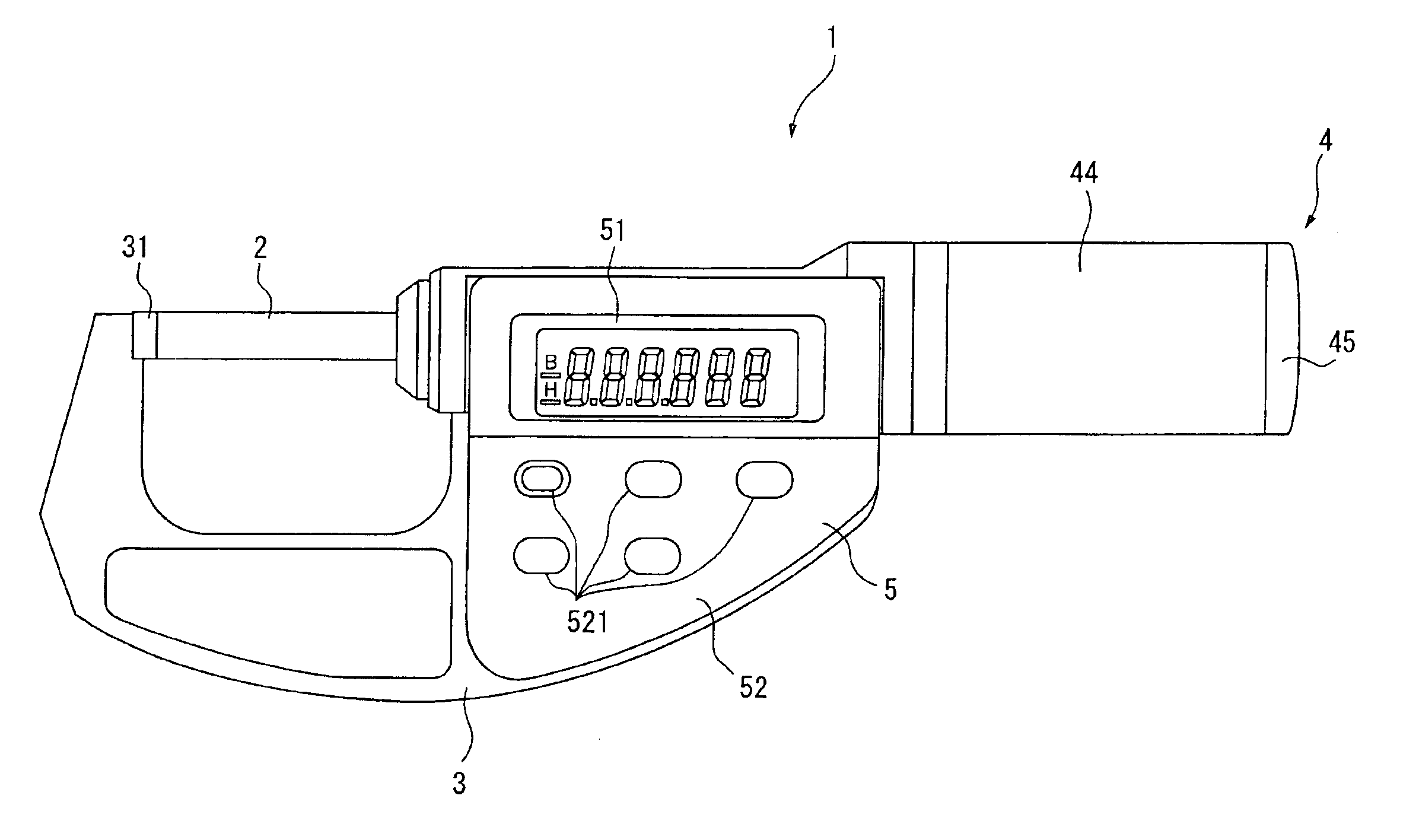

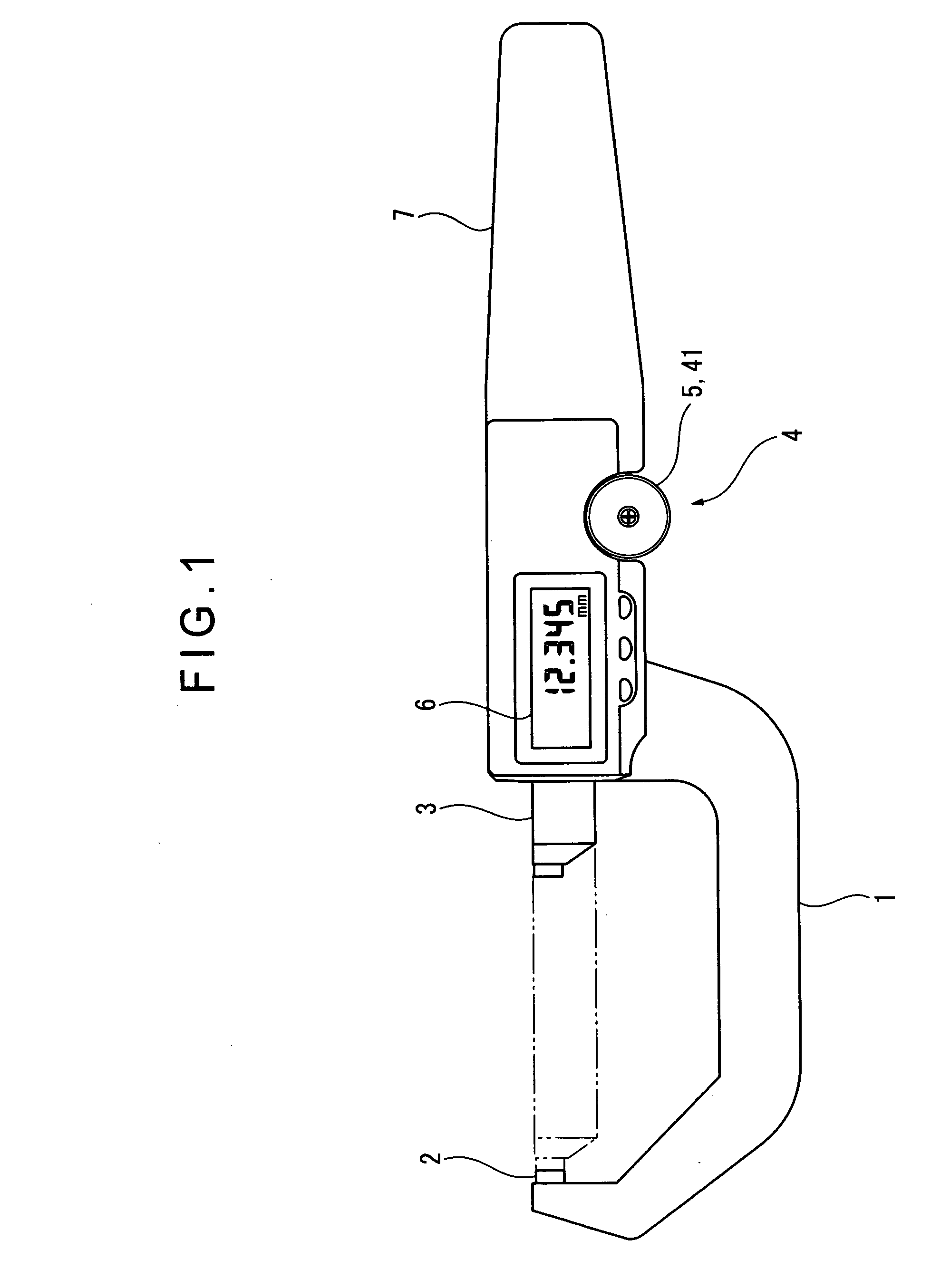

micrometer

ActiveUS20130091720A1Accurate measurementAvoid thermal expansionMicrometersMechanical measuring arrangementsMicrometerDisplay device

A micrometer includes: a displacement detector that detects a displacement of a spindle; a display device that is rotatably attached to a fixed sleeve; and a control device that controls the display device. The display device includes: an image display section that displays an image including a measurement value based on the displacement detected by the displacement detector; a surface member that faces the image display section and has a touch surface; a position sensor that detects a position pressed on the touch surface; and a support member that supports the image display section, the surface member and the position sensor while the touch surface is exposed to an outside, the support member being rotatably attached to the fixed sleeve.

Owner:MITUTOYO CORP

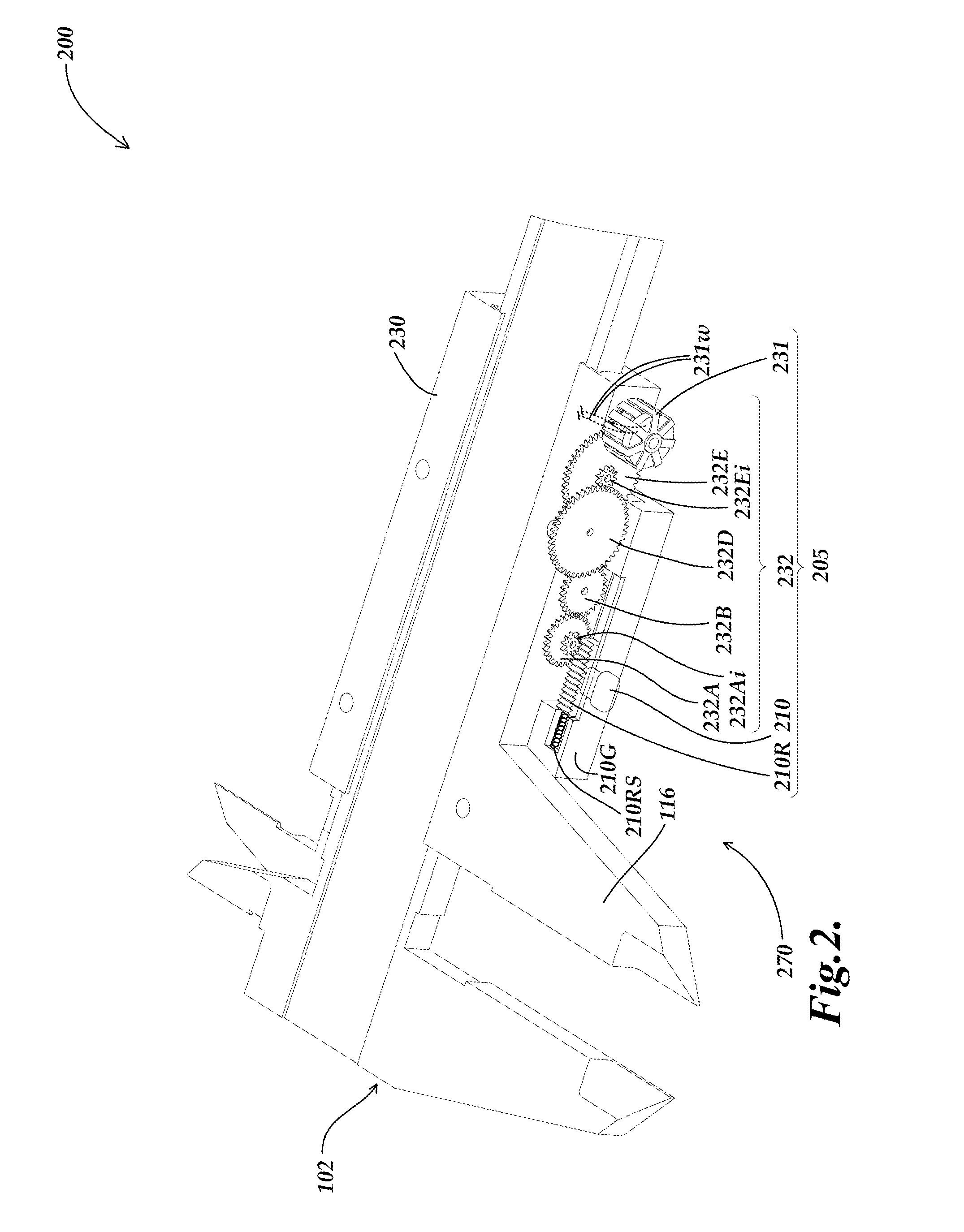

Electronic Caliper Configured to Generate Power for Measurement Operations

An electronic caliper generates power for measurement operations. The caliper comprises a scale member, a slider, a signal processing portion configured to measure a displacement between the scale member and slider, a power generating arrangement attached to the slider comprising a gear assembly configured to rotate in response to a force provided through a power generating handle to the gear assembly by a user moving the power generating handle relative to the gear assembly, and a power generator coupled to the gear assembly and configured to rotate in response to force provided by the rotating gear assembly and provide power to the signal processing portion. The power generating arrangement generates power as the user moves the power generating handle, and the power generating arrangement contributes a motion resistance force component of at most 20N as the user moves the power generating handle with a maximum manual acceleration.

Owner:MITUTOYO CORP

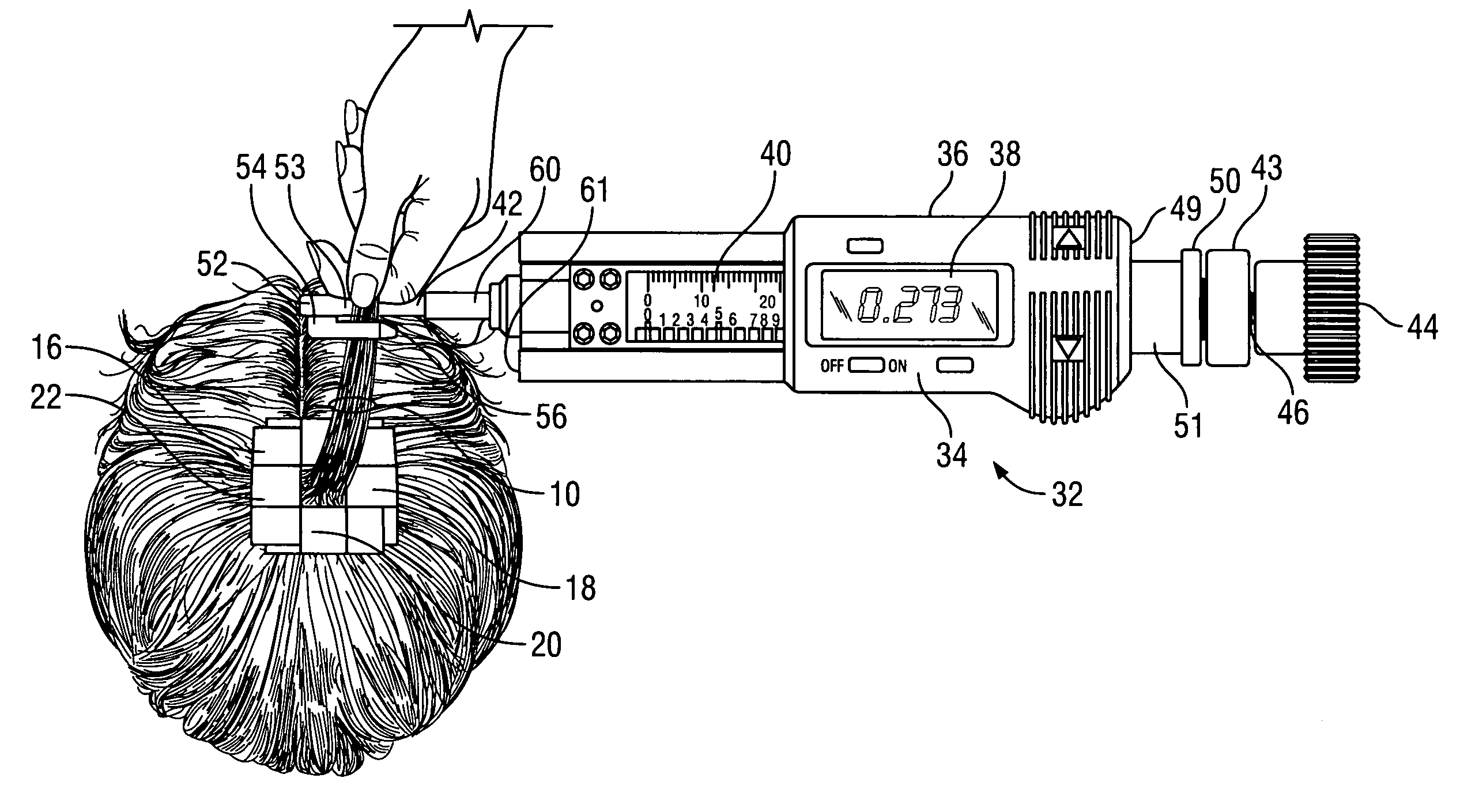

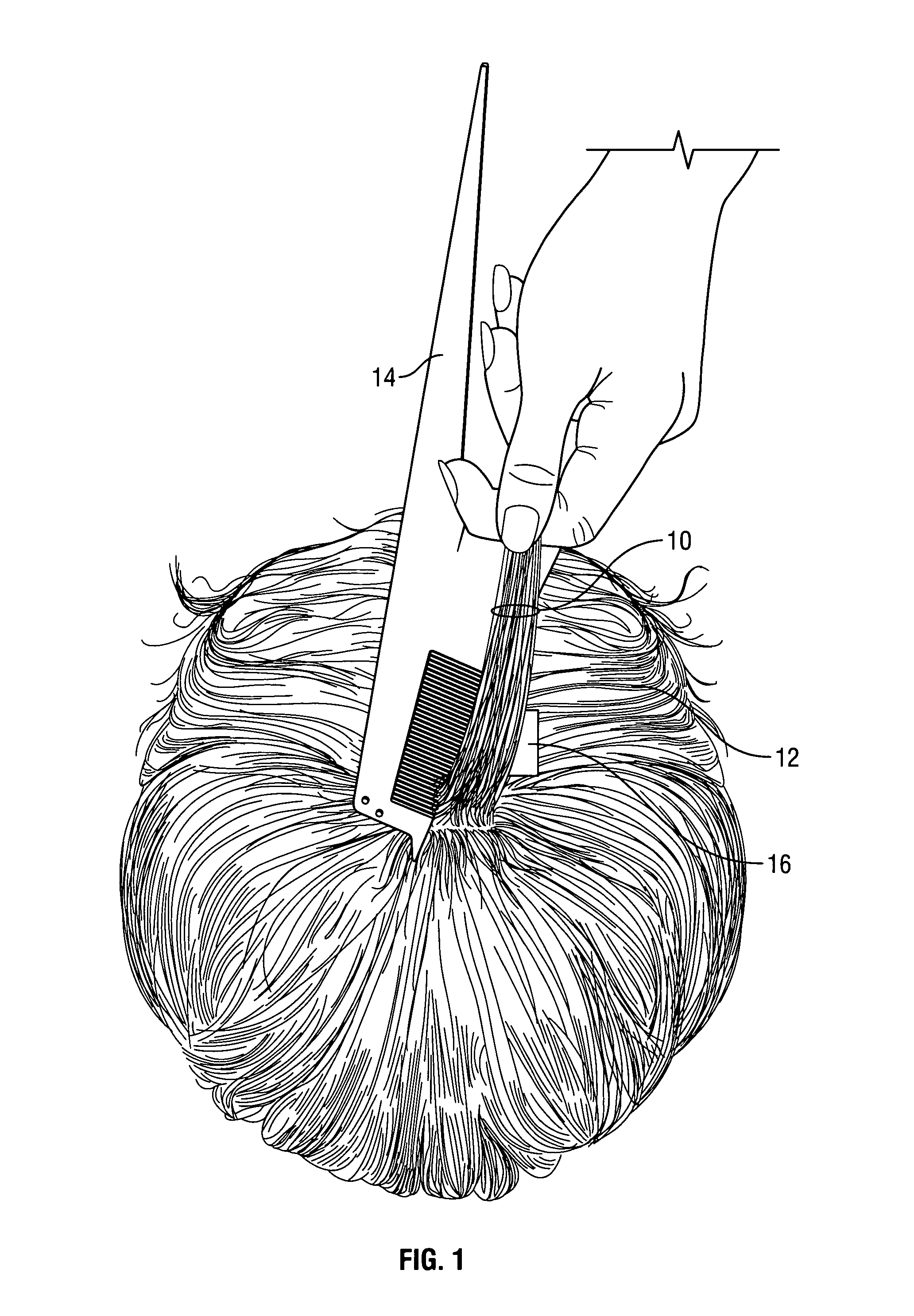

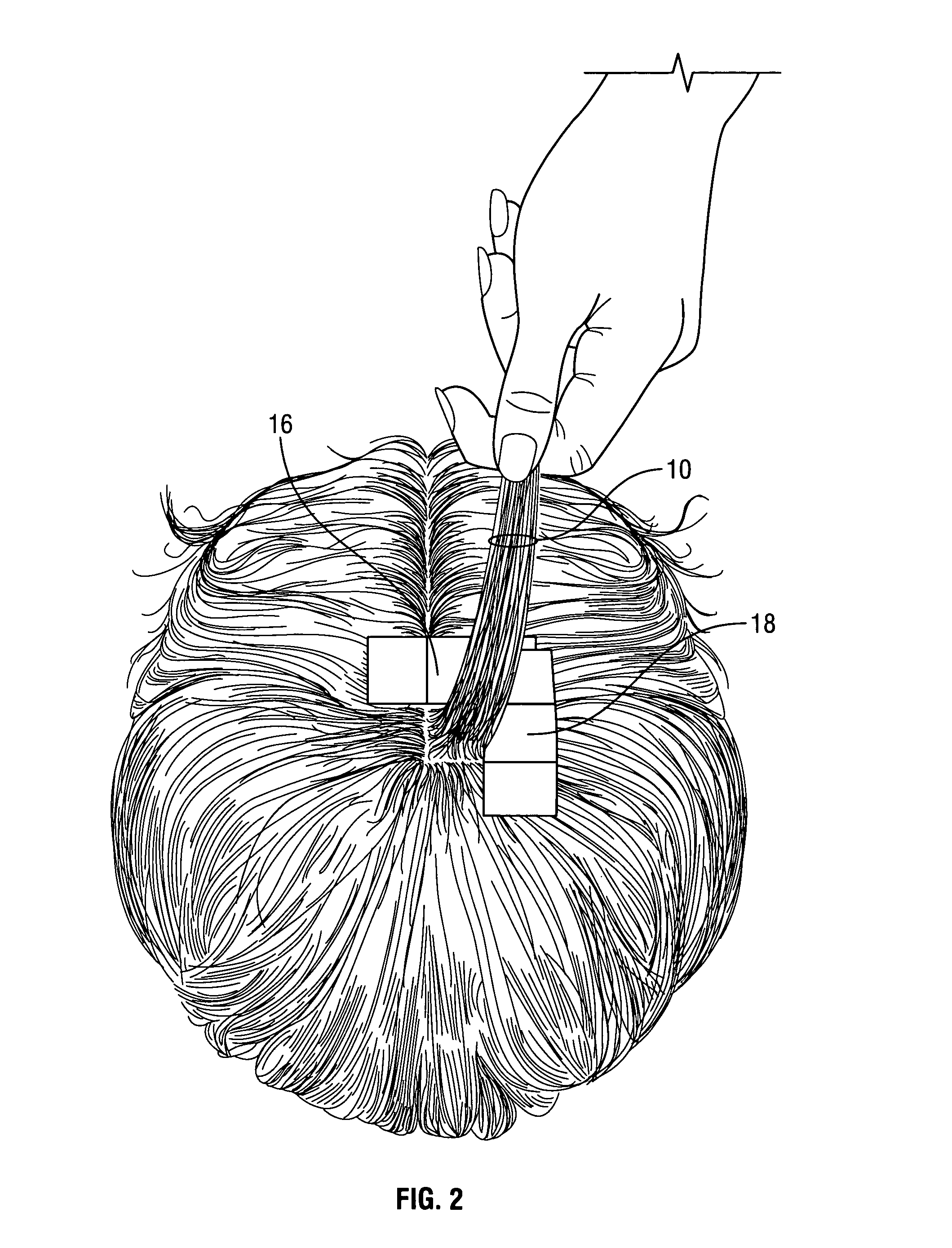

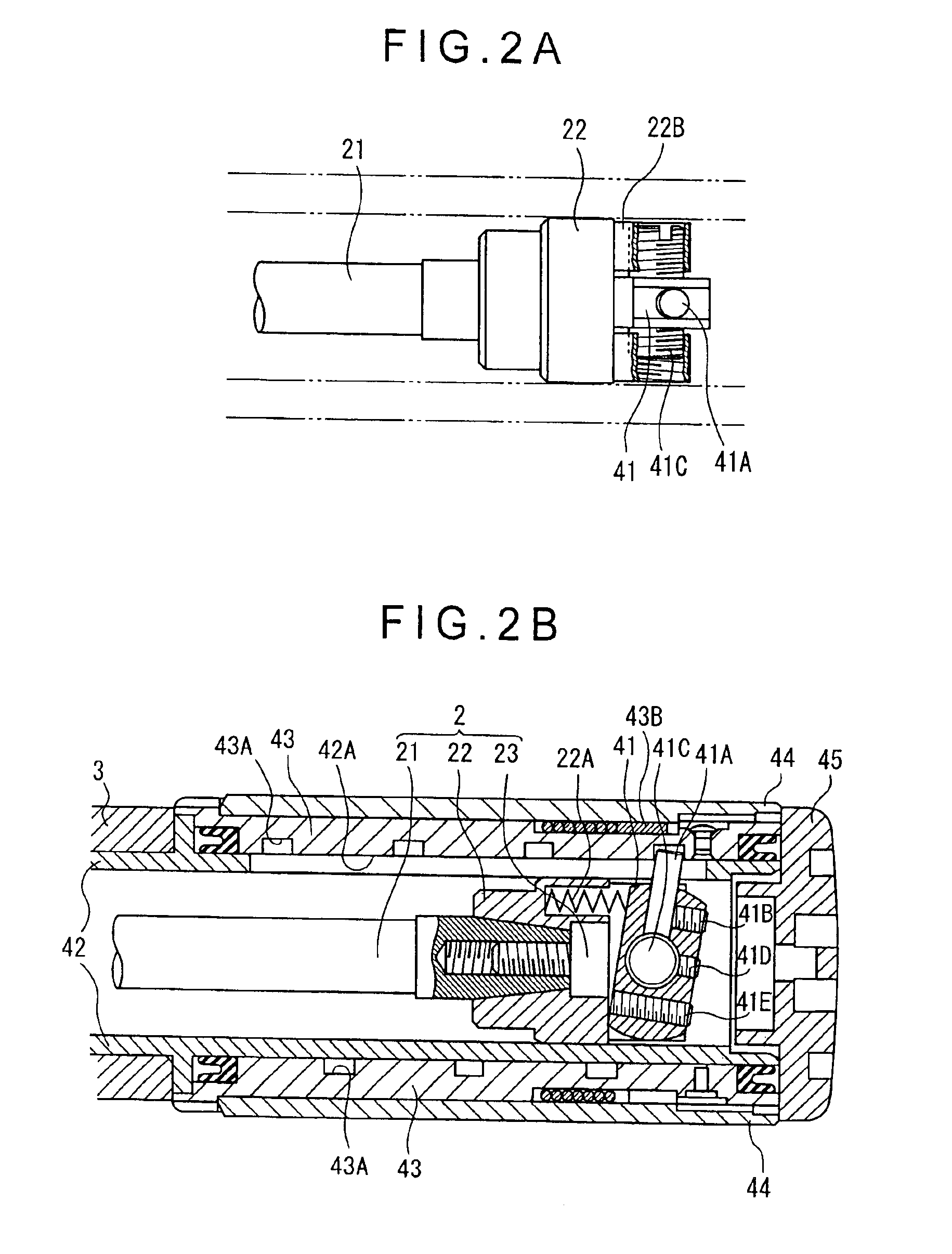

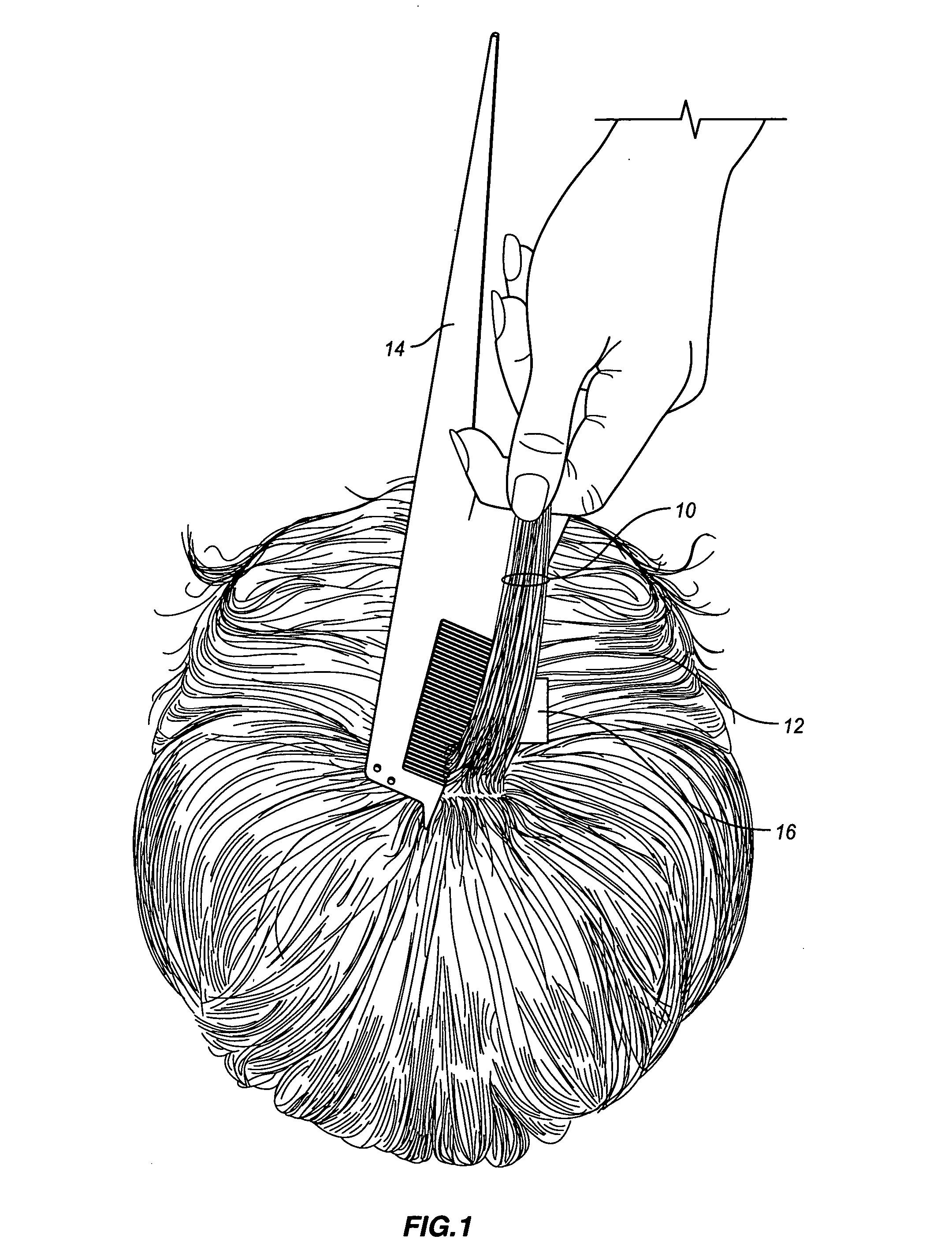

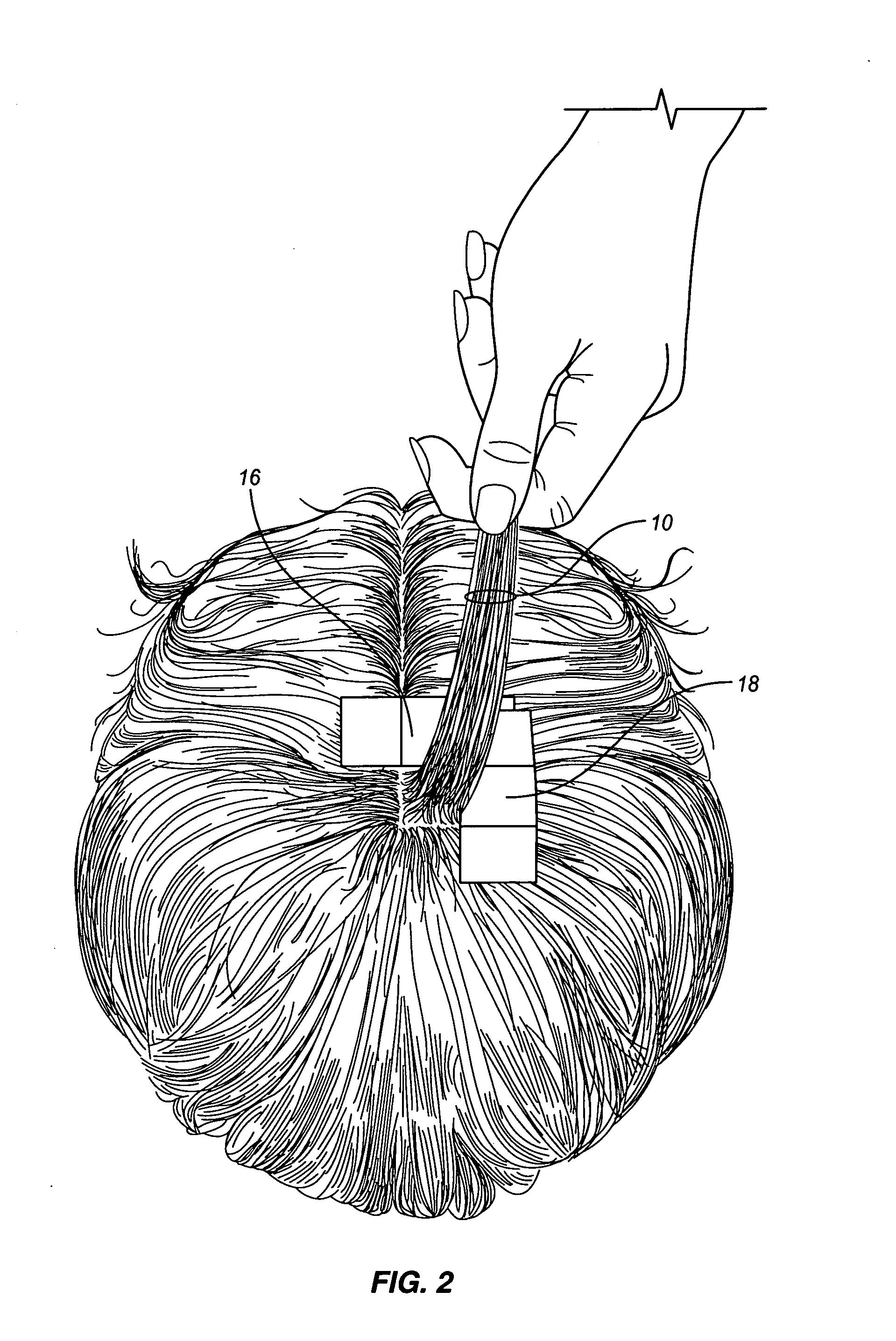

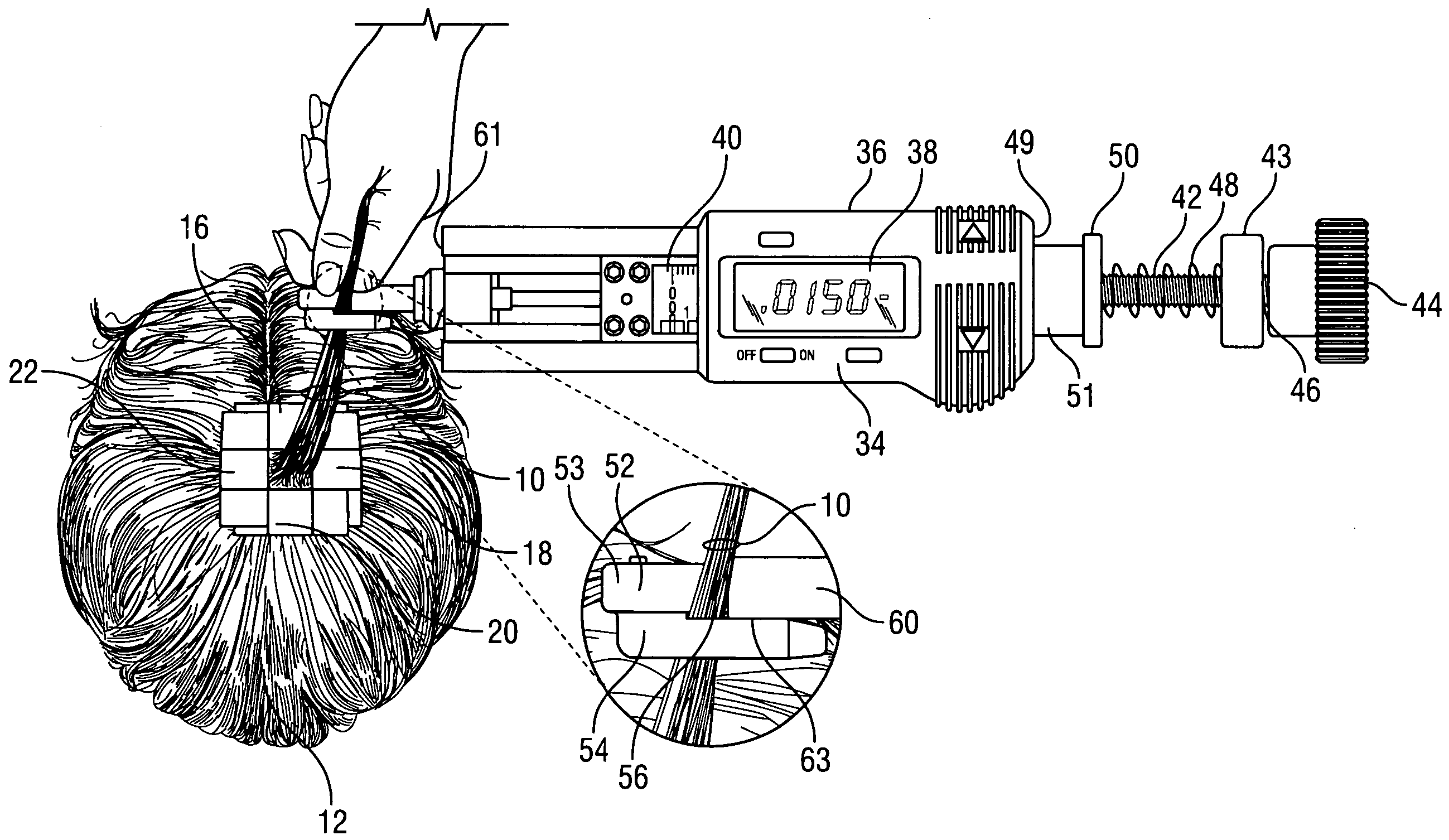

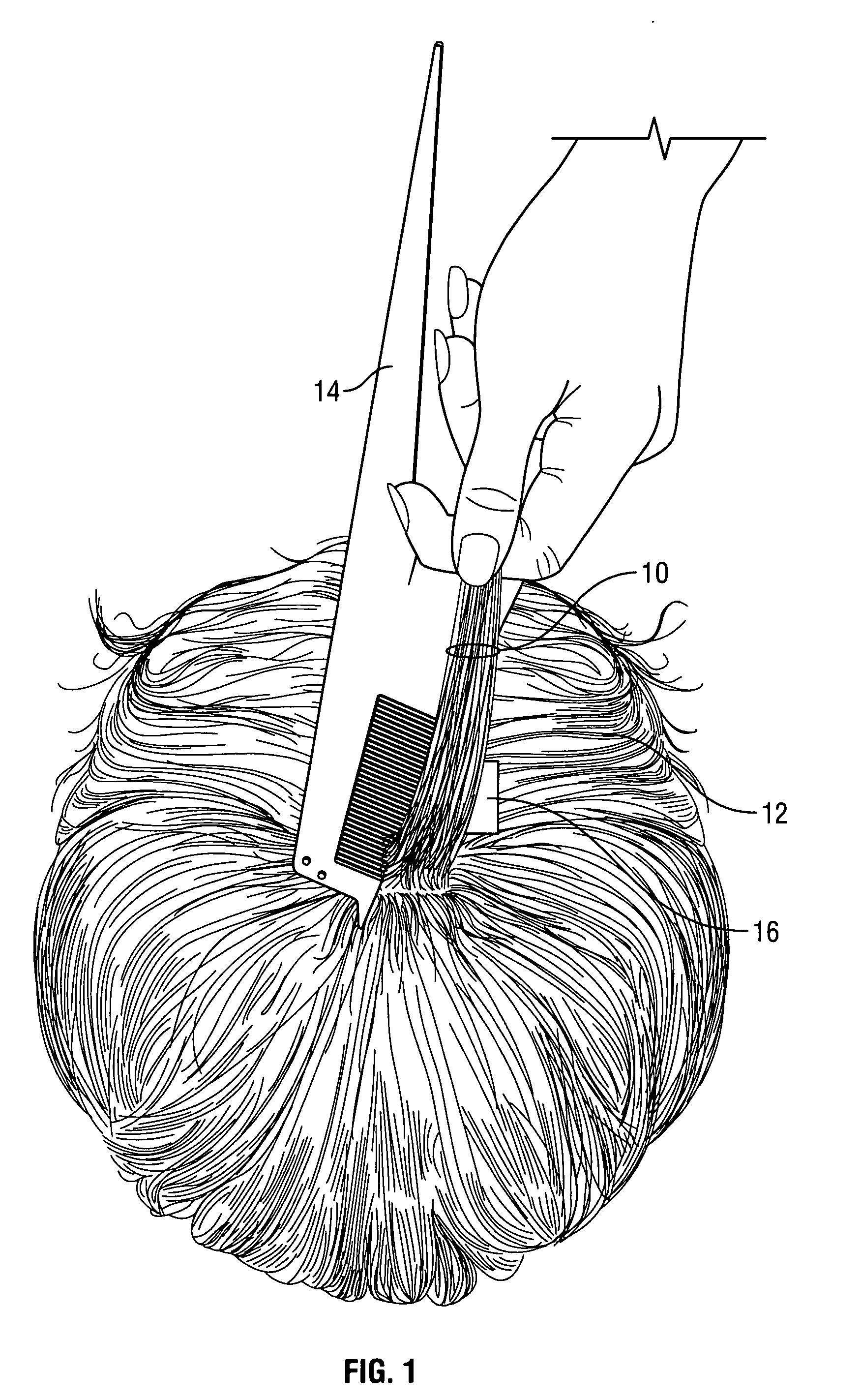

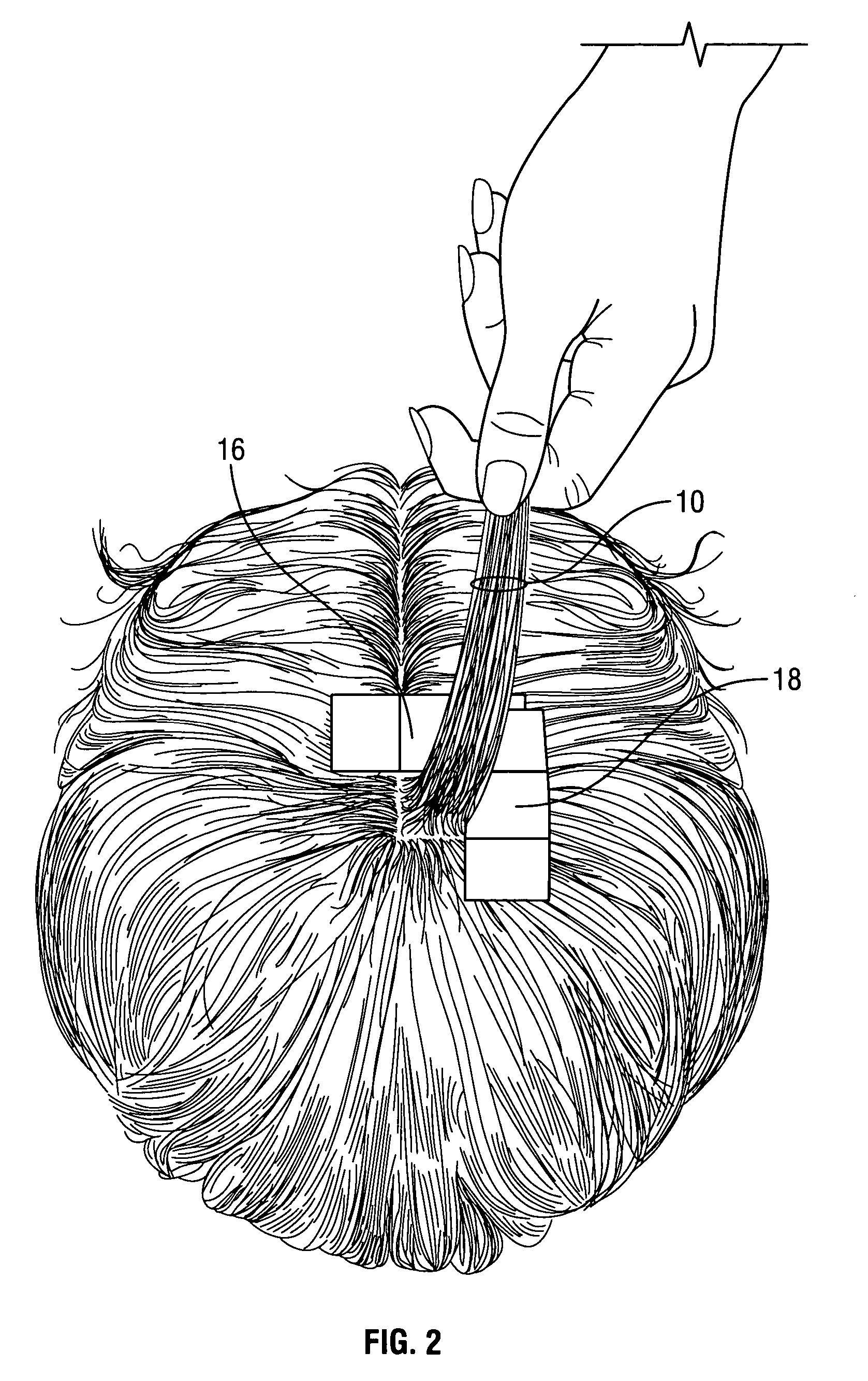

Method and device for measuring fluctuations in the cross-sectional area of hair in a pre-determined scalp area

ActiveUS6993851B2Easy to implementFluctuation of measurementMicrometersSlide gaugesEngineeringHair streams

The method for isolating an area of hair-bearing skin and measuring a combined cross section of hair in the area comprising the steps of: preparing a pre-measured site on the scalp; isolating a standardized bundle of uncut hair at the site; compressing the bundle of hair with a measurable load while simultaneously measuring the height of the bundle of hair with a piston and cylinder device.One embodiment of the device comprises a body having a slot for receiving a bundle of hair, an anvil positioned adjacent said slot, and a mechanism for causing relative movement between the body having the slot and the anvil thereby to compress a bundle of uncut hair received in the slot against the anvil.

Owner:BERNARD COHEN TECH LLC

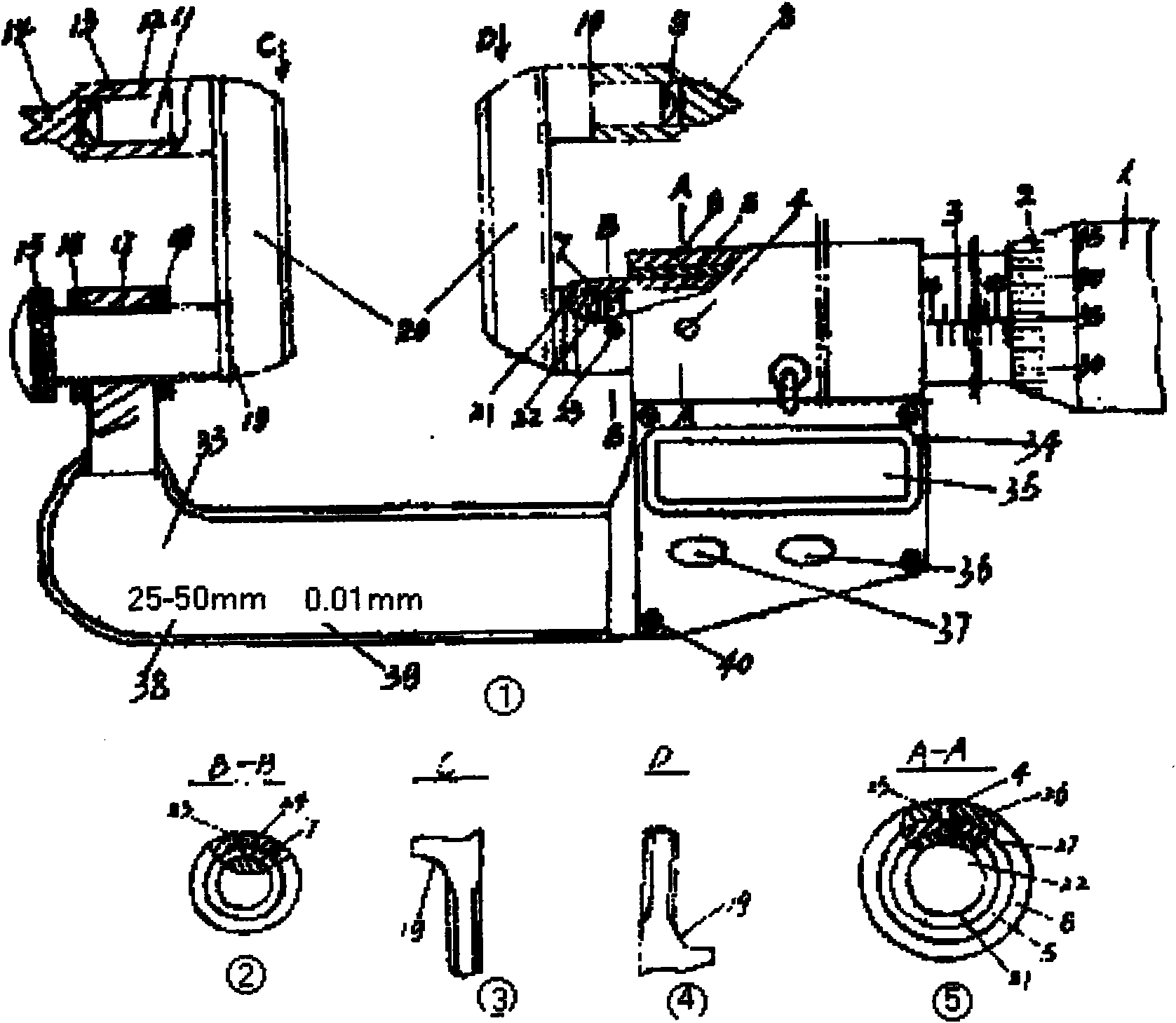

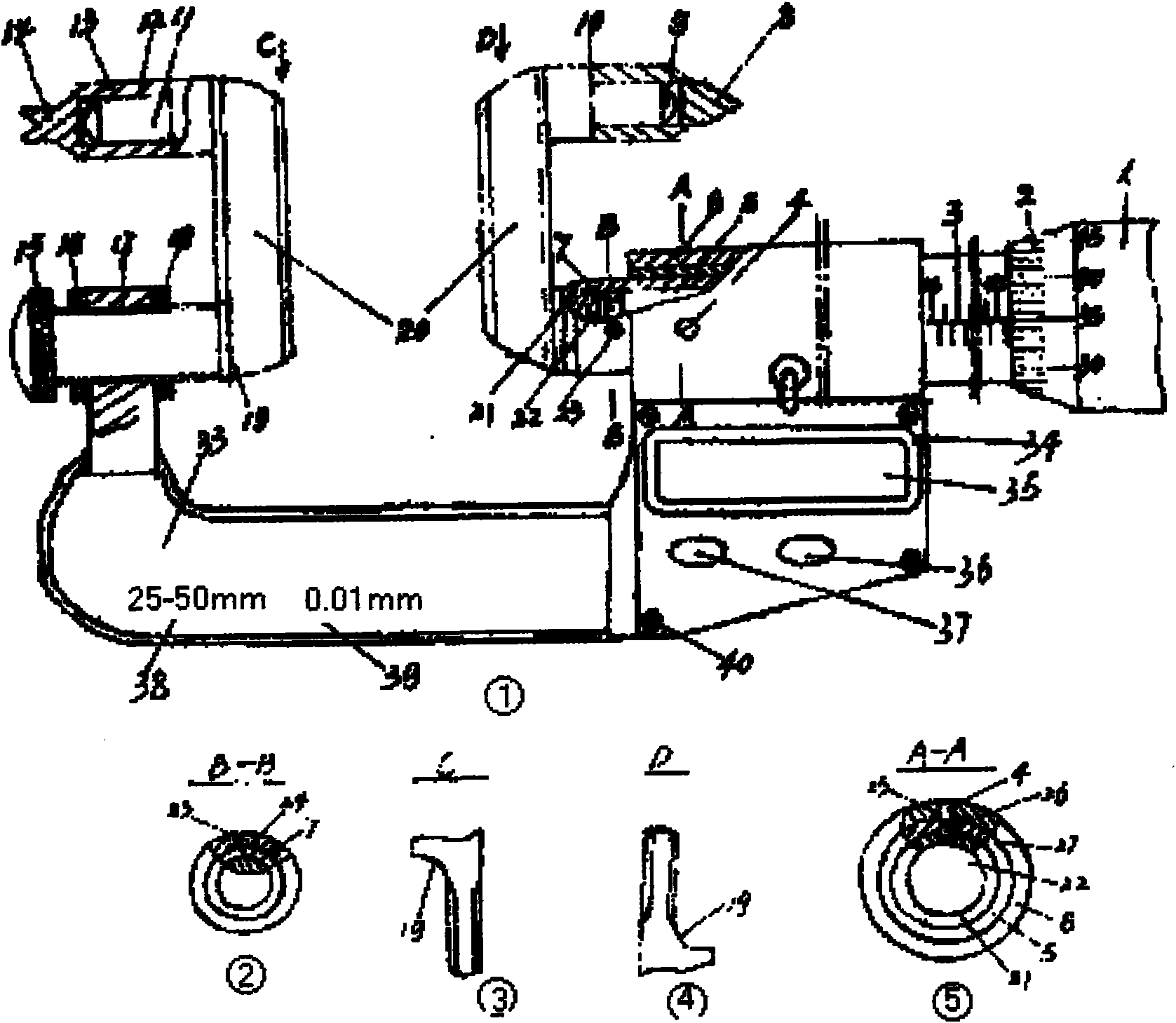

Multipurpose digital display internal micrometer

InactiveCN102109307AEasy to measureQuick measurementMicrometersMechanical diameter measurementsSize measurementMicrometer

The invention discloses a multipurpose digital display internal micrometer. The multipurpose digital display internal micrometer comprises elbow measuring frames (20) which can be assembled with replaceable measuring heads and various types of replaceable measuring heads (8 and 14); the elbow measuring frame on the left side can be adjusted through nuts (16 and 18); the elbow measuring frame on the right side can synchronously move backward and forward along with a micrometric screw (22) of the multipurpose internal micrometer; and the size of an object to be measured is displayed through a digital display device. The multipurpose digital display internal micrometer is particularly more convenient and faster in the aspects of size measurement and read of internal diameters, internal threads and internal channels.

Owner:SUZHOU CUIZHI NEW TECH DEV

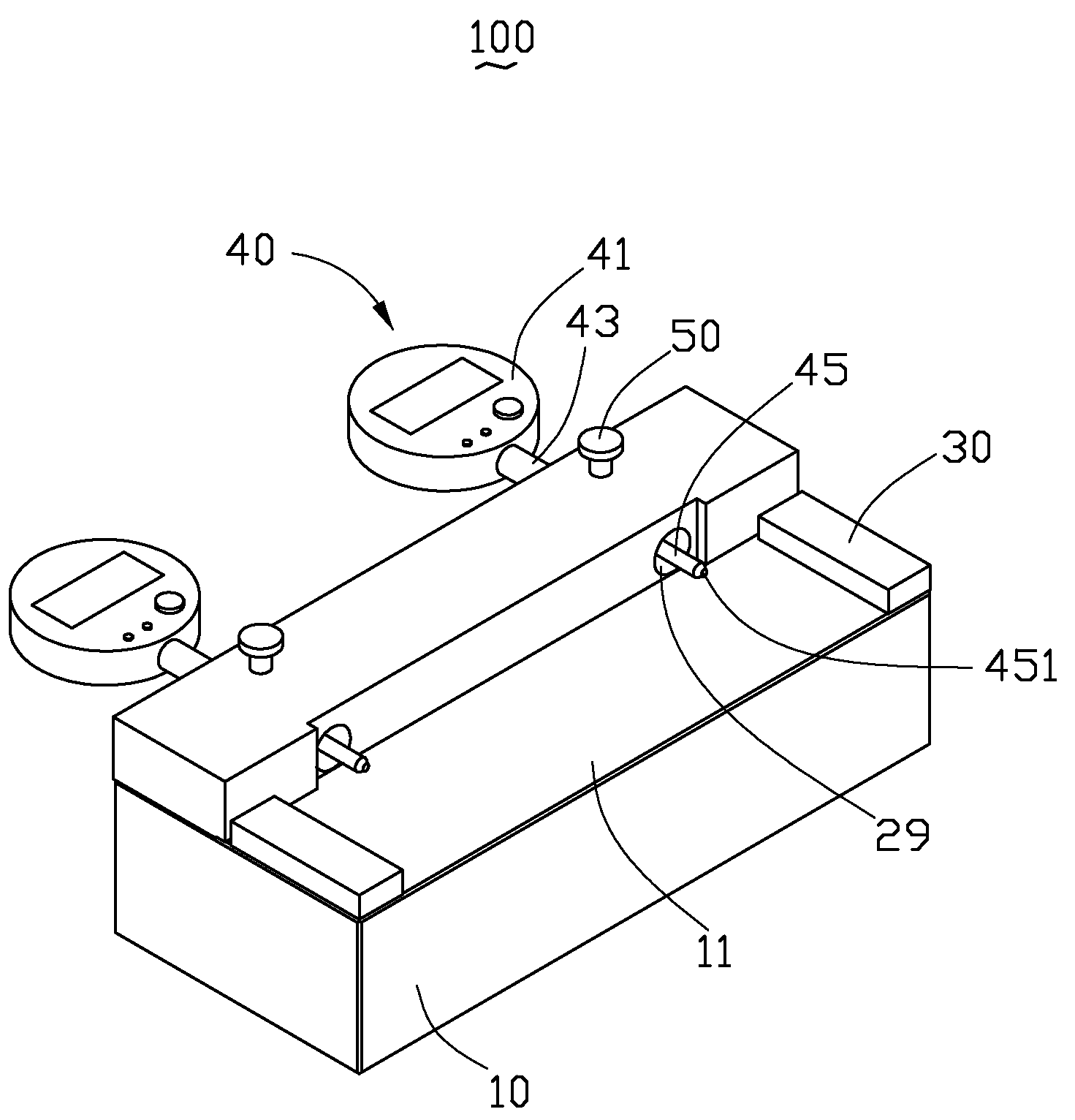

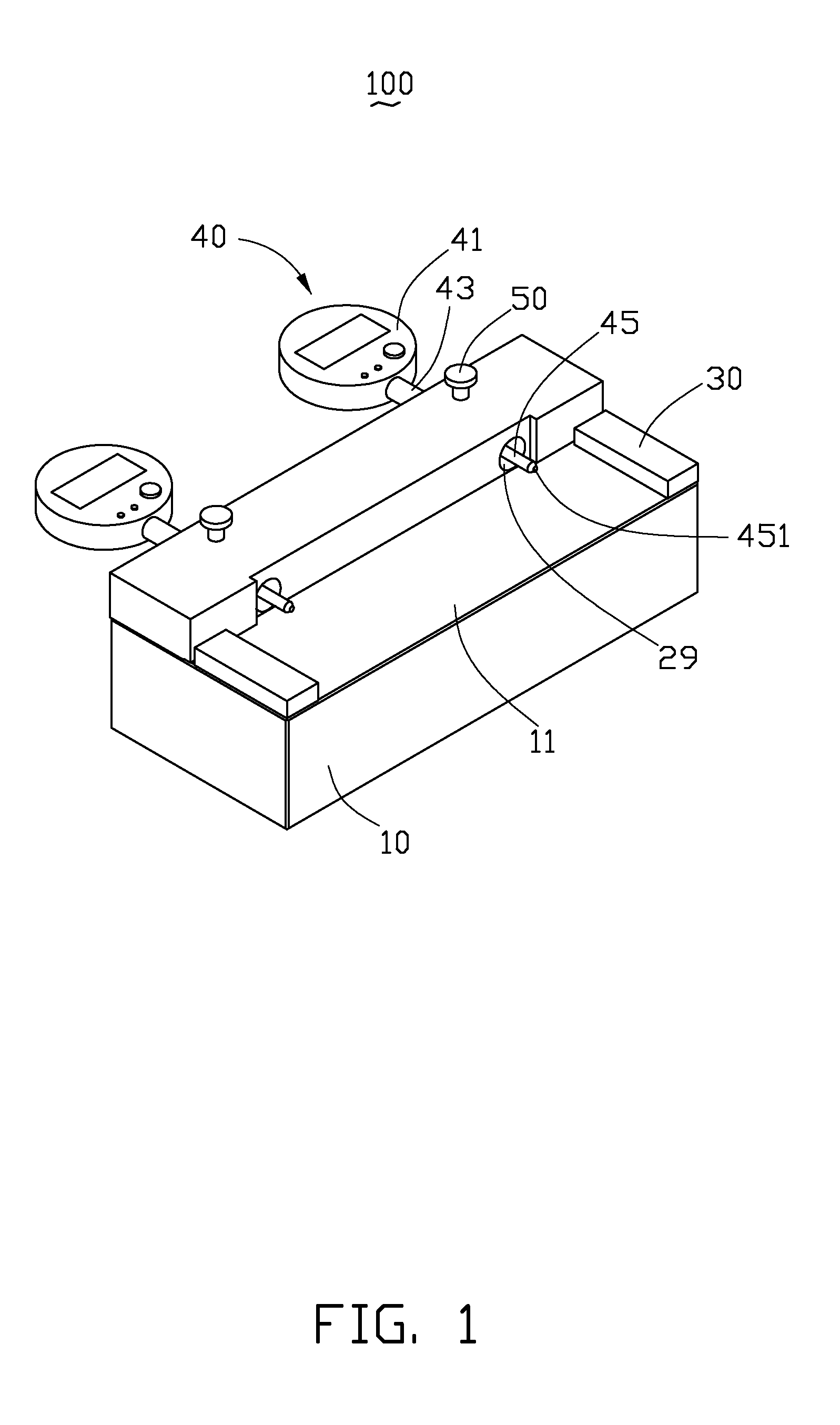

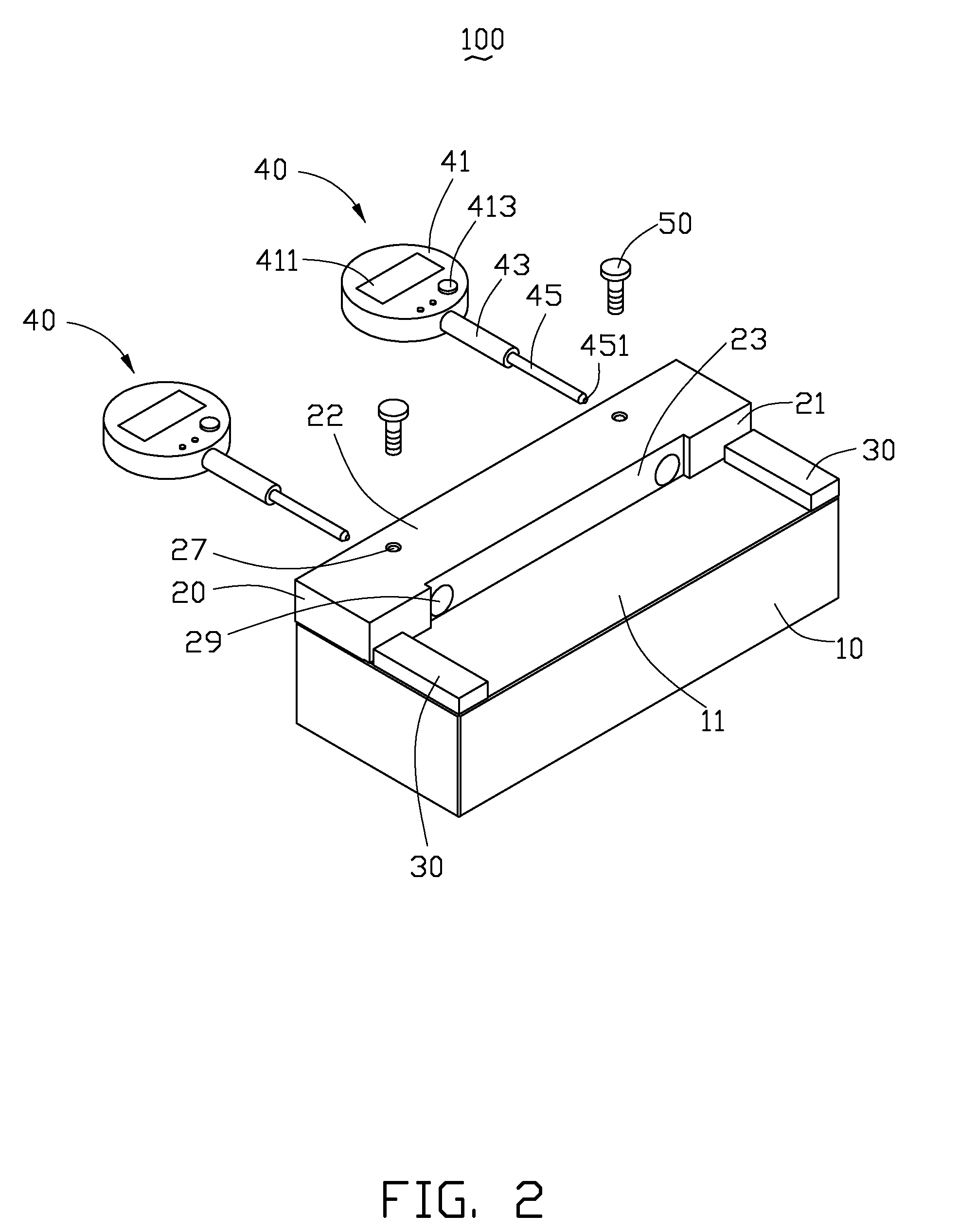

Measurement apparatus

A measurement apparatus for measuring a distance between a base surface and an upper surface of a stepped structure of a workpiece. The measurement apparatus includes a supporting member having an upper surface for supporting the workpiece, a holding member fixed on the top surface, and a micrometer. The holding member includes a reference platform and a depression formed on the reference platform and facing the upper surface. The micrometer is fixed to the holding member and includes an extendable measuring shaft with a contacting portion extending out of the reference platform. The distance is measured by pushing the workpiece into the depression until the base surface make contact with the reference platform.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

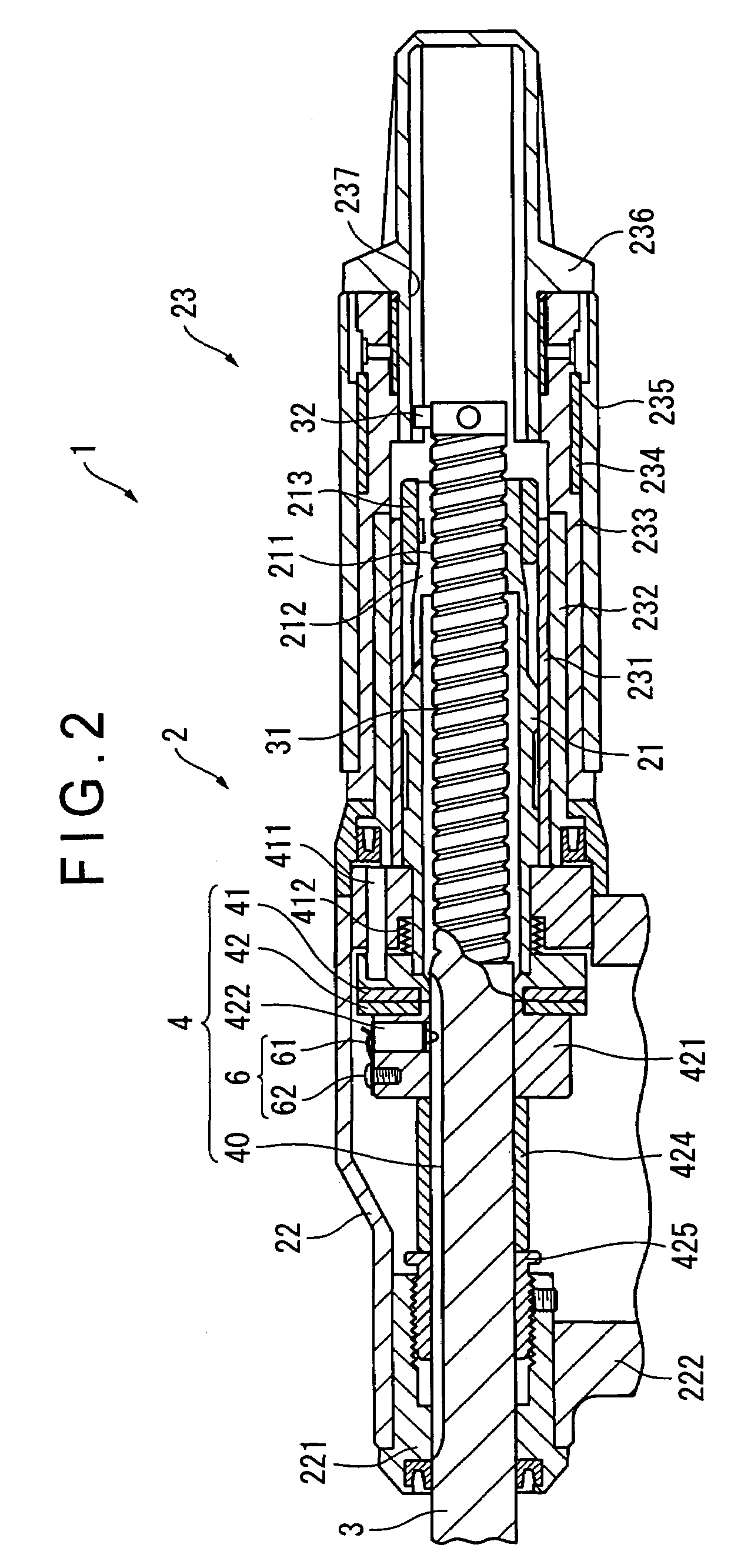

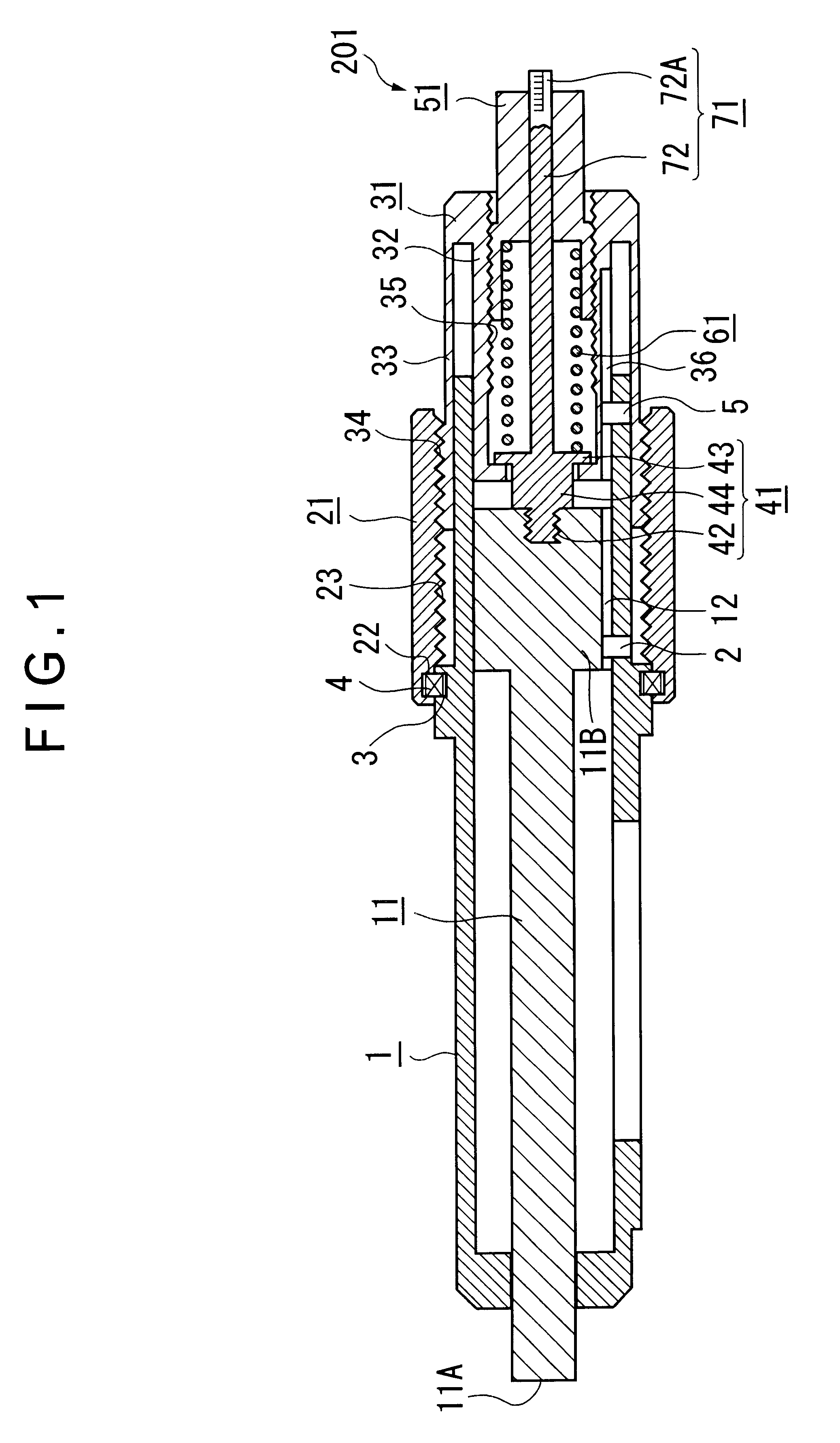

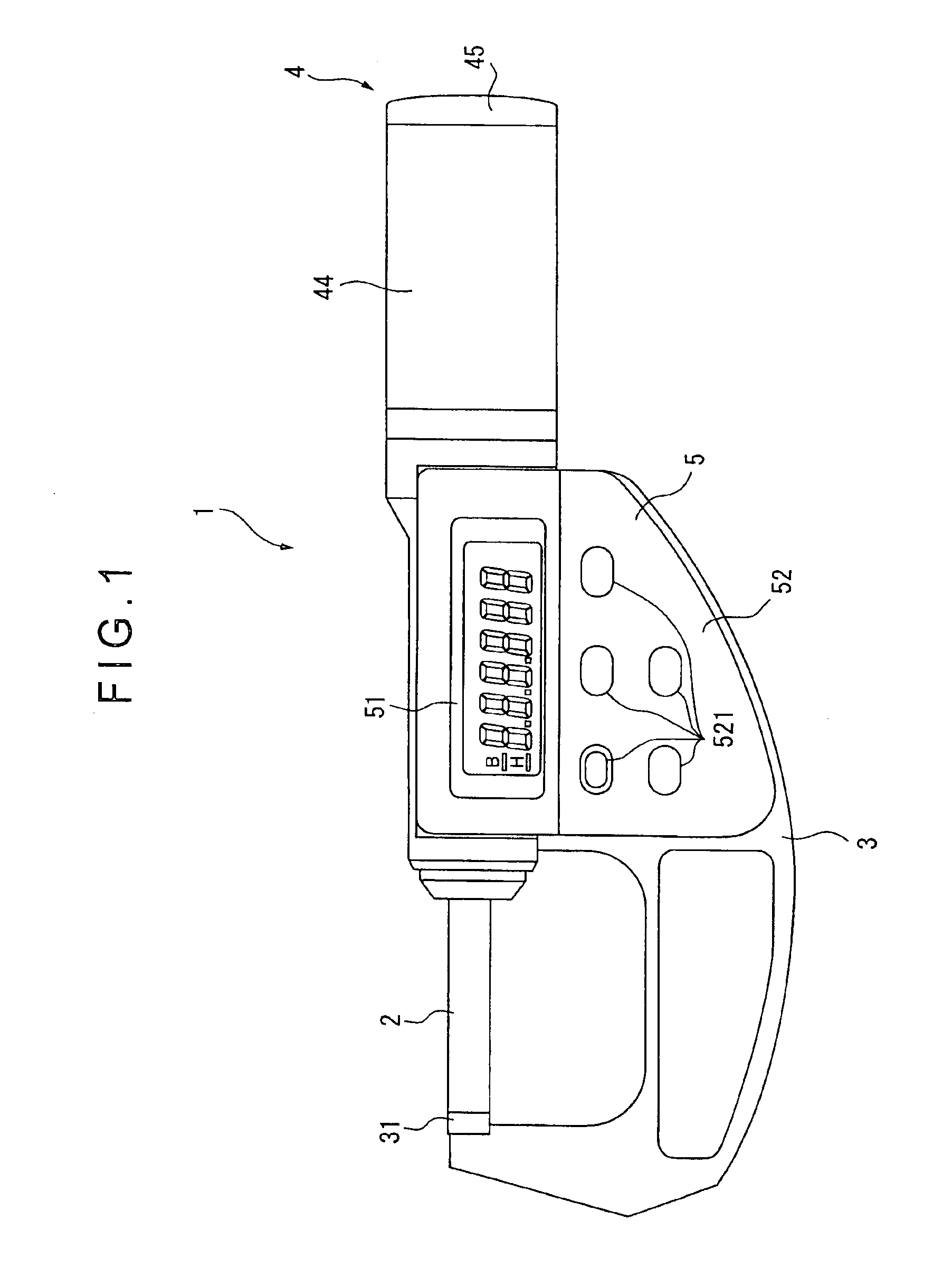

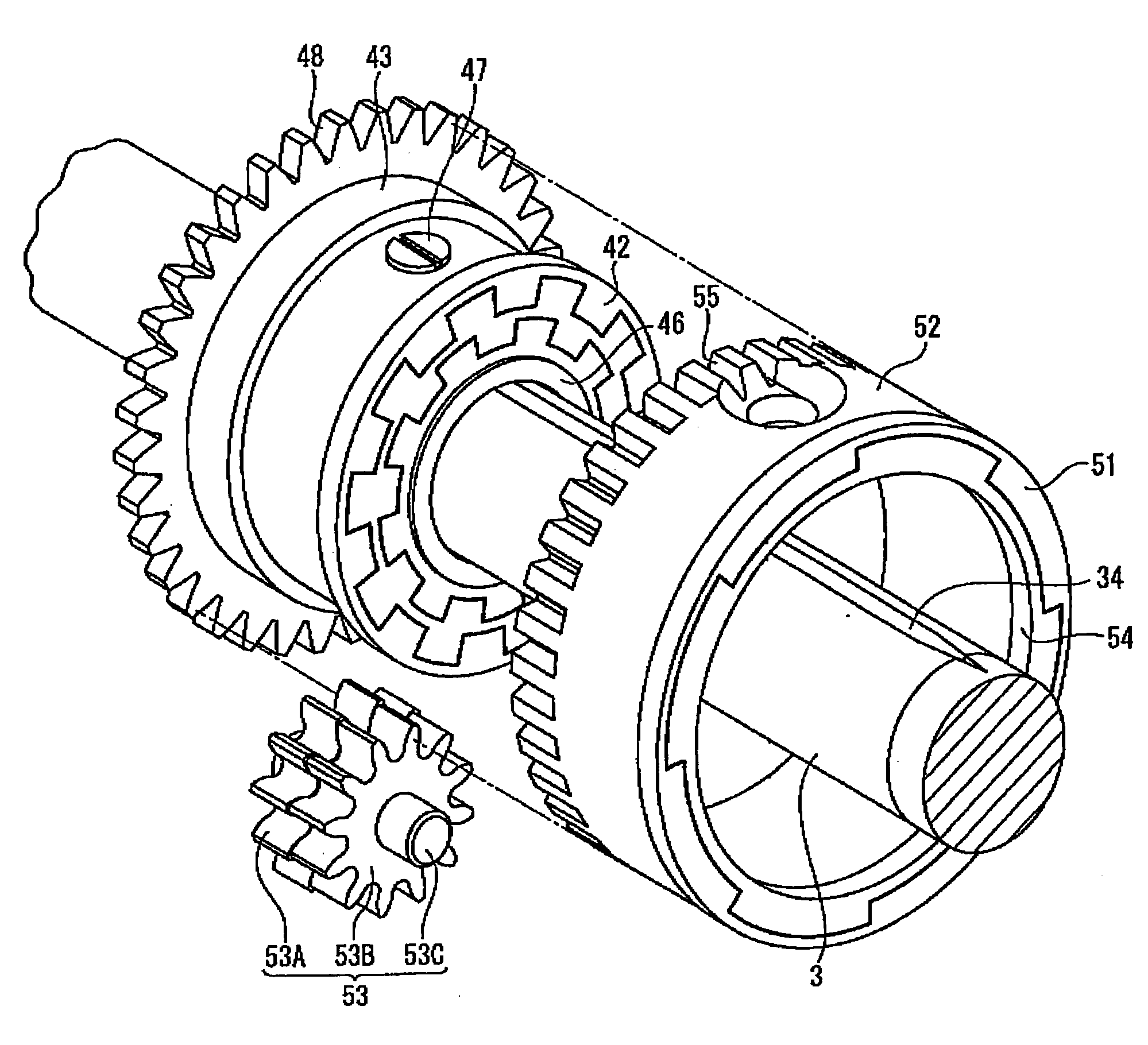

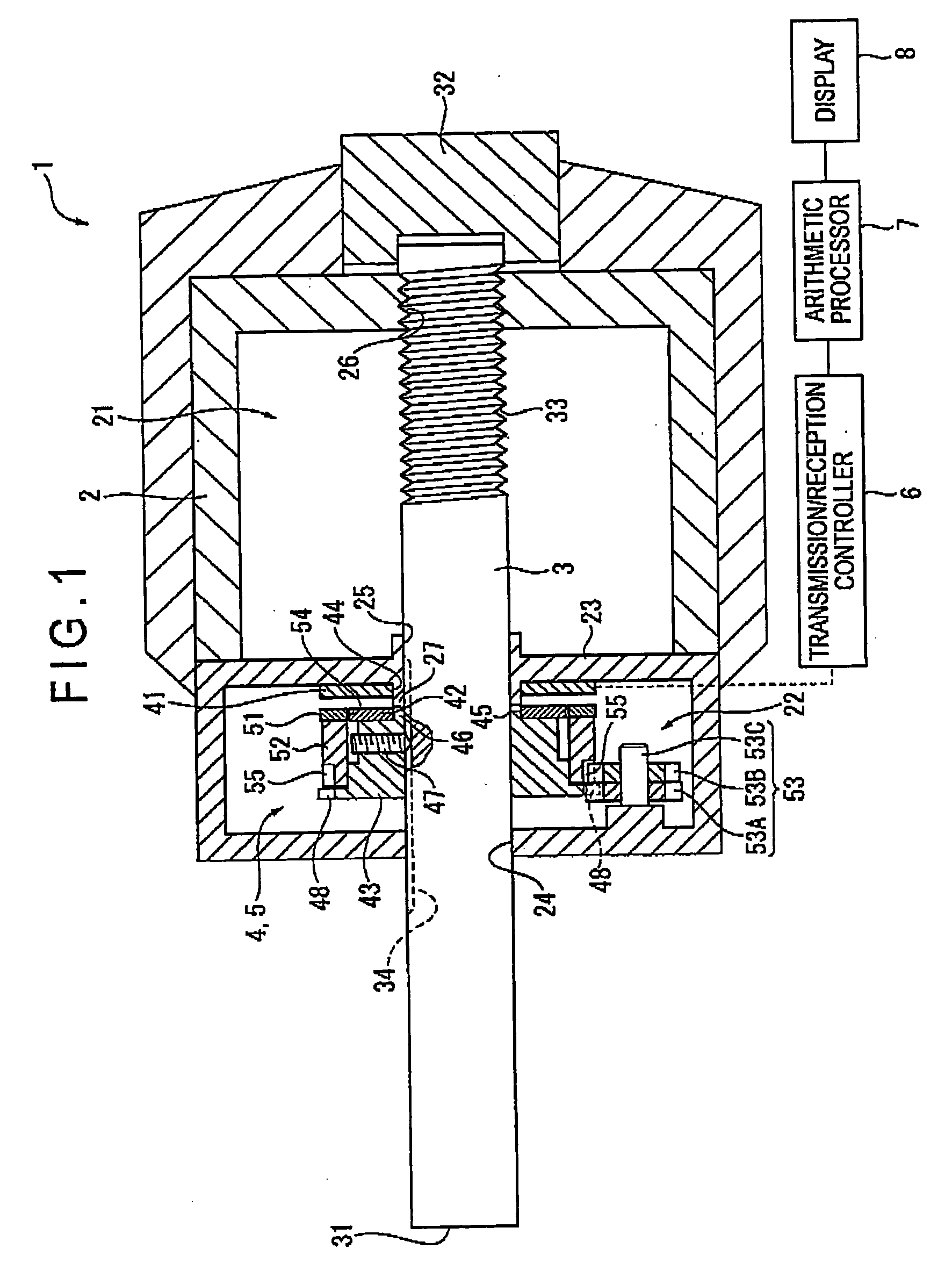

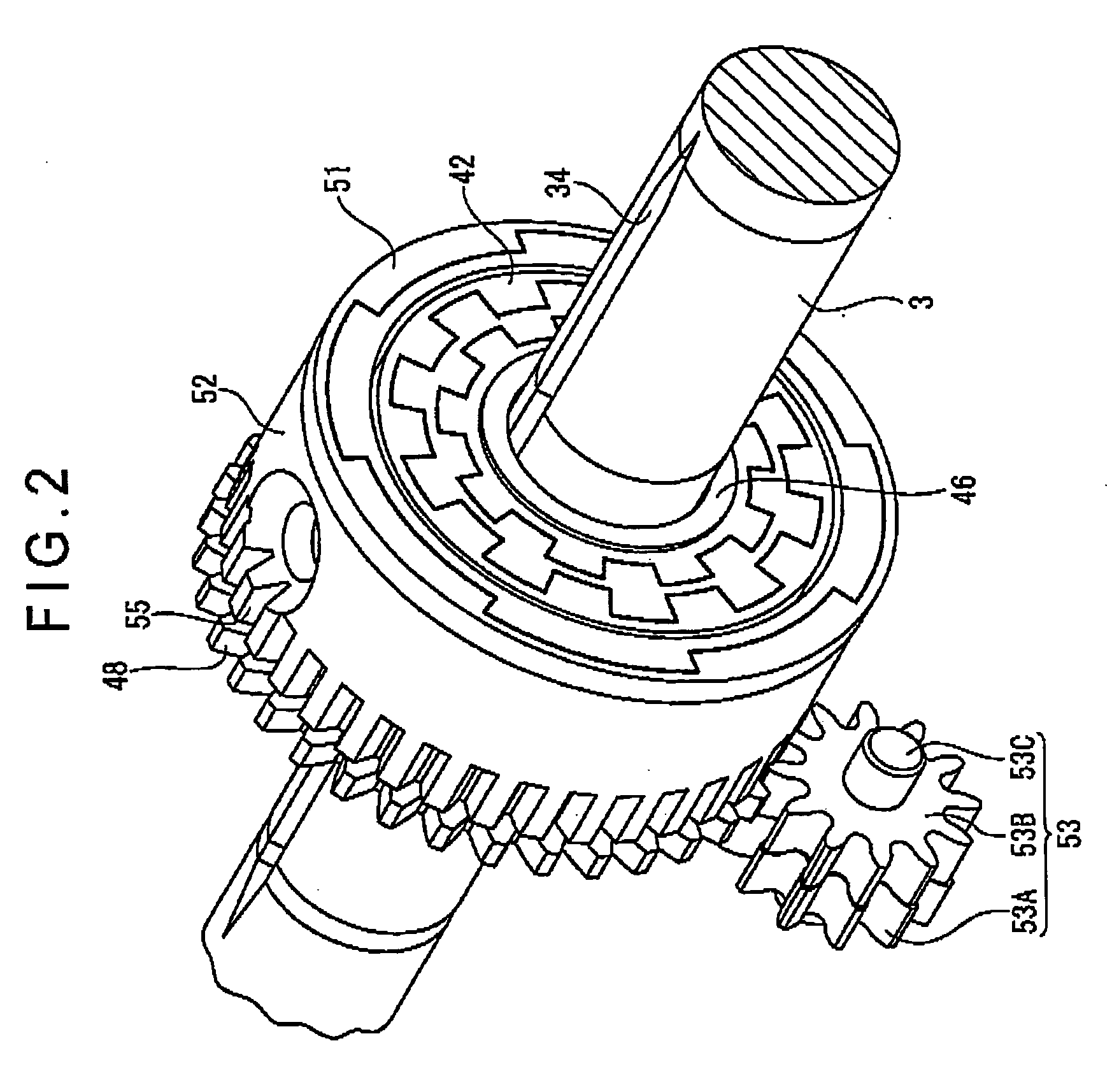

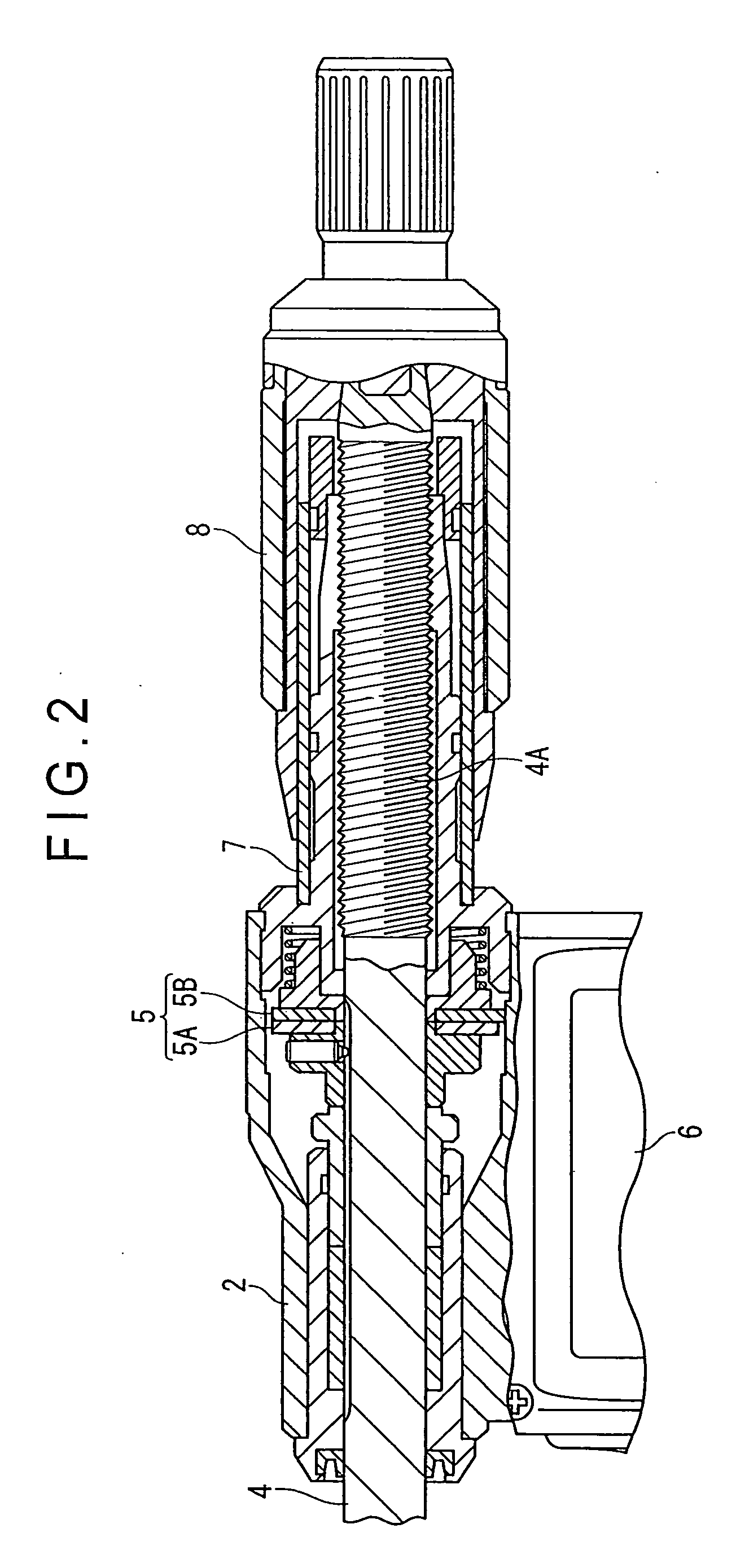

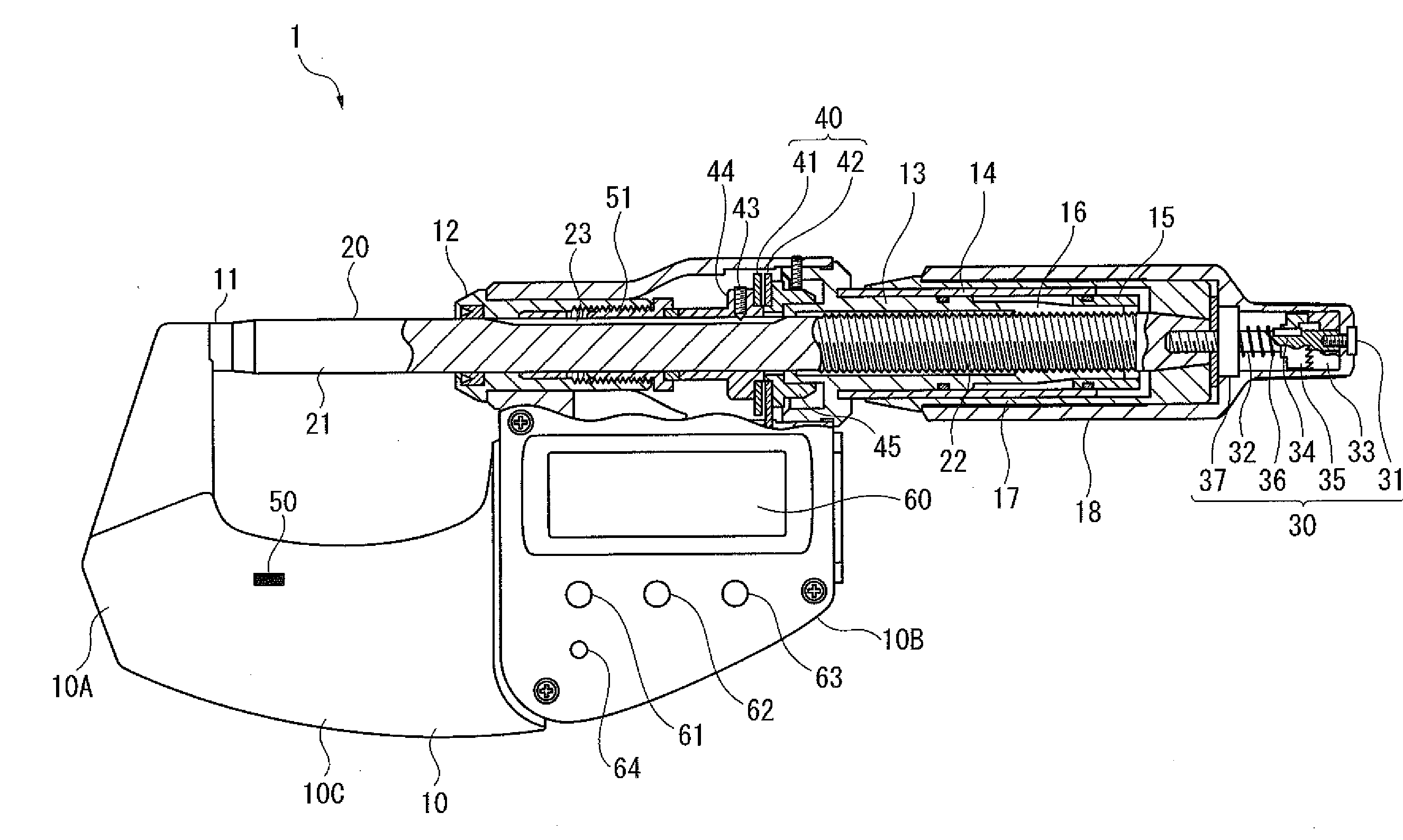

Rotary movement converting mechanism and measuring instrument

ActiveUS6915591B2Avoid displacementMicrometersMechanical measuring arrangementsLinear motionMeasuring instrument

A rotary movement converting mechanism for converting a rotary movement of a rotary body (43) into a linear movement of a movable body (2) has a support body (42) fixed to a body frame (3) and provided with a slit (42A) along an axial direction of the rotary body (43), a spiral groove (43A) formed on the inner circumference of the rotary body (43), and a top member (41) provided on the movable body (2). The top member (41) has an engaging member (41 A) inserted through the slit (42A) and having a tip end engaged with the spiral groove (43A), and a stop member (41C) for stopping the linear movement of the movable body (2) when a load is applied on the linear movement of the movable body (2). Accordingly, when a load is applied on the linear movement of the movable body (2), the linear movement is stopped and the minute displacement of the movable body (2) is restrained, thereby enhancing the stability of a measuring instrument in measuring a workpiece.

Owner:MITUTOYO CORP

Method, device and cartridge for measuring fluctuations in the cross-sectional area of hair in a pre-determined scalp area

ActiveUS20050229418A1Easy to implementFluctuation of measurementMicrometersSlide gaugesVolumetric Mass DensityScalp

A flexible measuring tape is extended from a predetermined location on a face a predetermined distance to a location on a scalp. A 2 cm by 2 cm square bundle of hair about that location is isolated. The bundle of isolated hair is captured in a slit in a two-part cartridge, one part being slidable in the other part about a changeable length slit 1 mm wide. The cartridge is placed in an “L” shaped end of a plunger extending from a first end of a body of a measuring device. The plunger is drawn into the body of the device to compress the hair in the changeable length slit as the two parts of the cartridge are pushed together between an end of the “L” and the first end of the body. A spring is provided on the plunger between a second end of the body of the device and an inner end of a knob at an outer end of the plunger. The spring applies the same load regardless of the bundle's size and urges the “L” shaped end toward the body to compress the bundle of hair and the amount of compressed hair is read off of a gauge as DDI, Density-Diameter Index, which represents the cross-sectional area of the compressed bundle of hair. After the measurement is made, the smaller part is pulled part way out of the larger part of the cartridge so the cartridge easily can be pulled off of the bundle of hair and discarded.

Owner:BERNARD COHEN TECH LLC

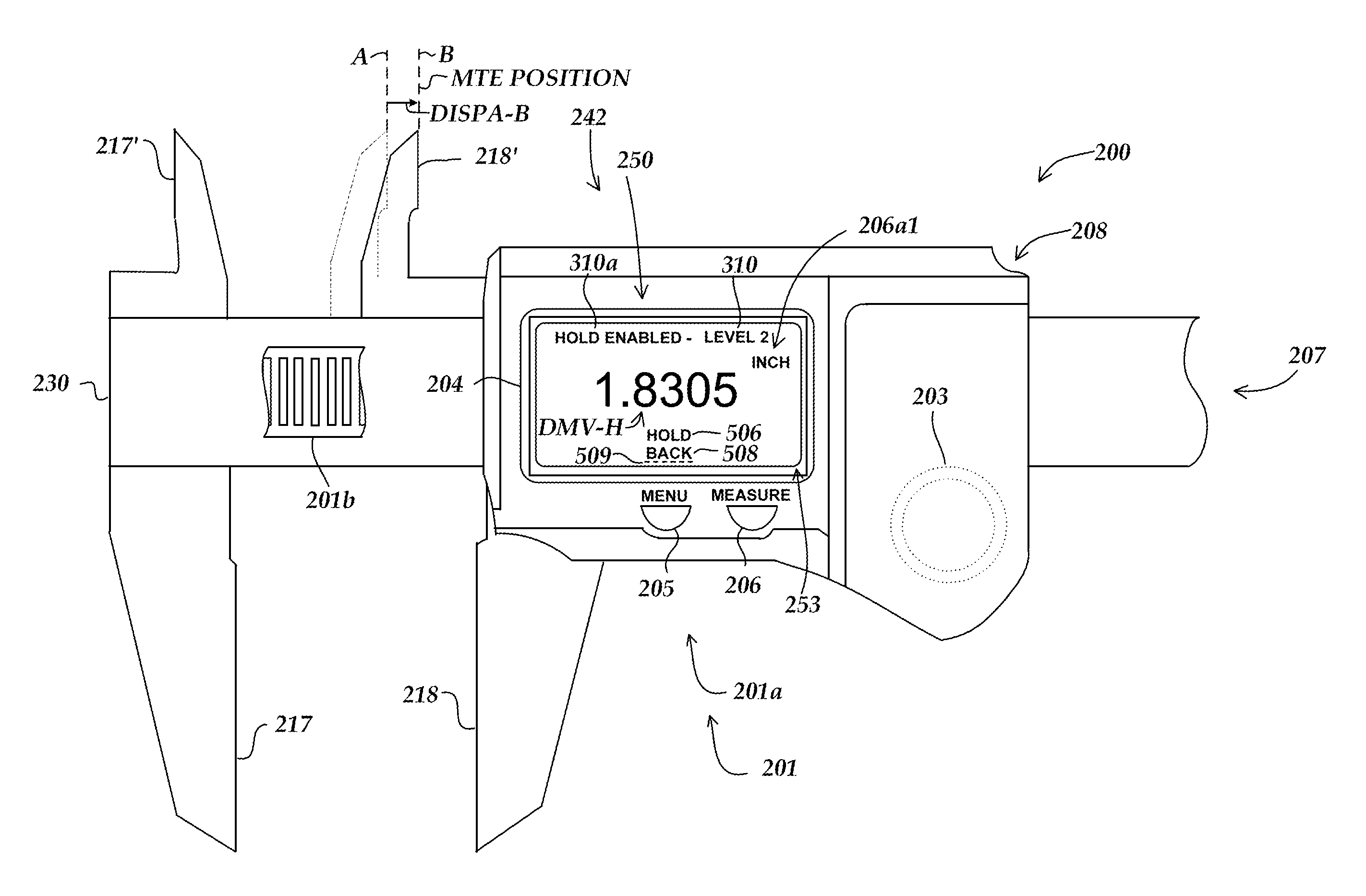

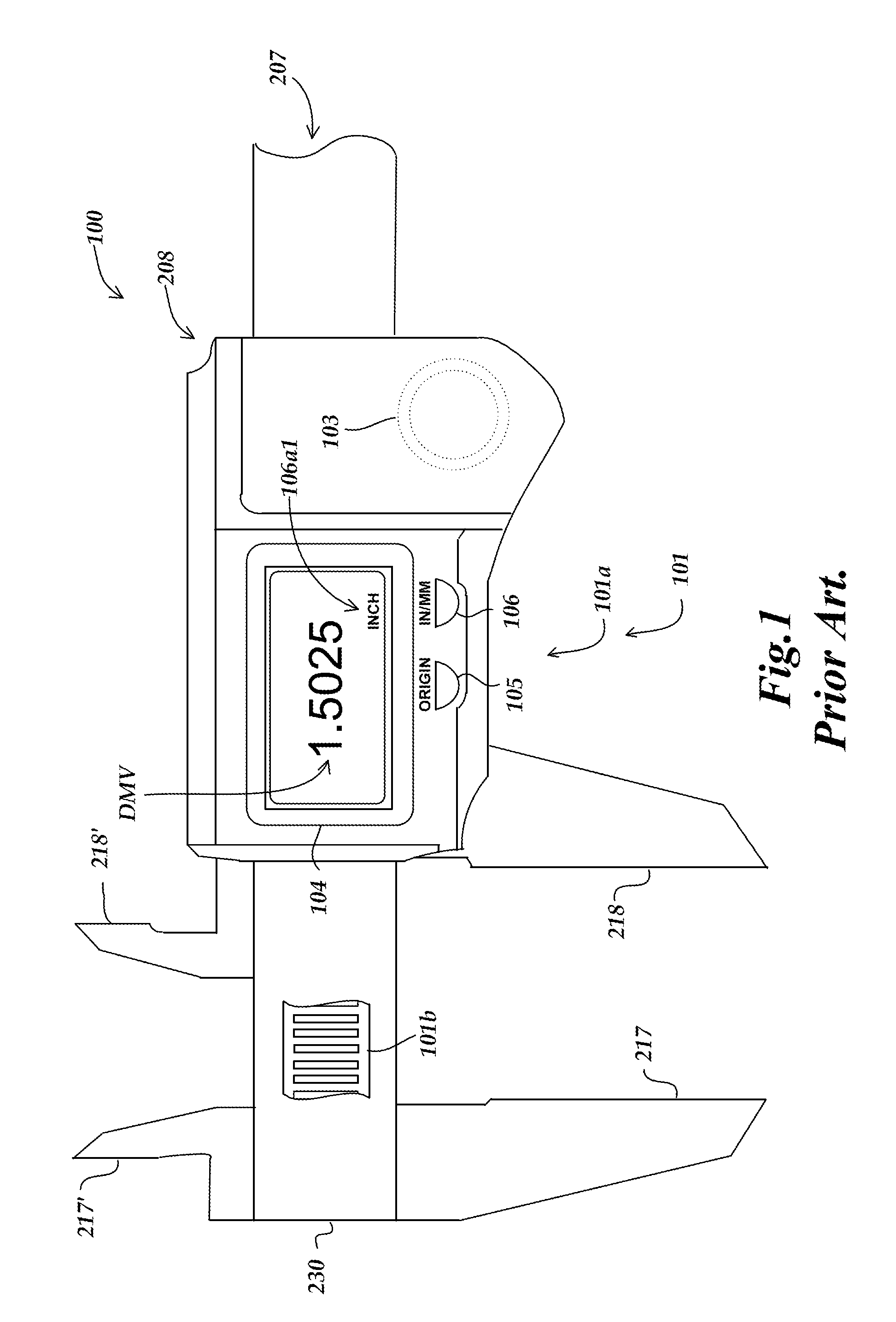

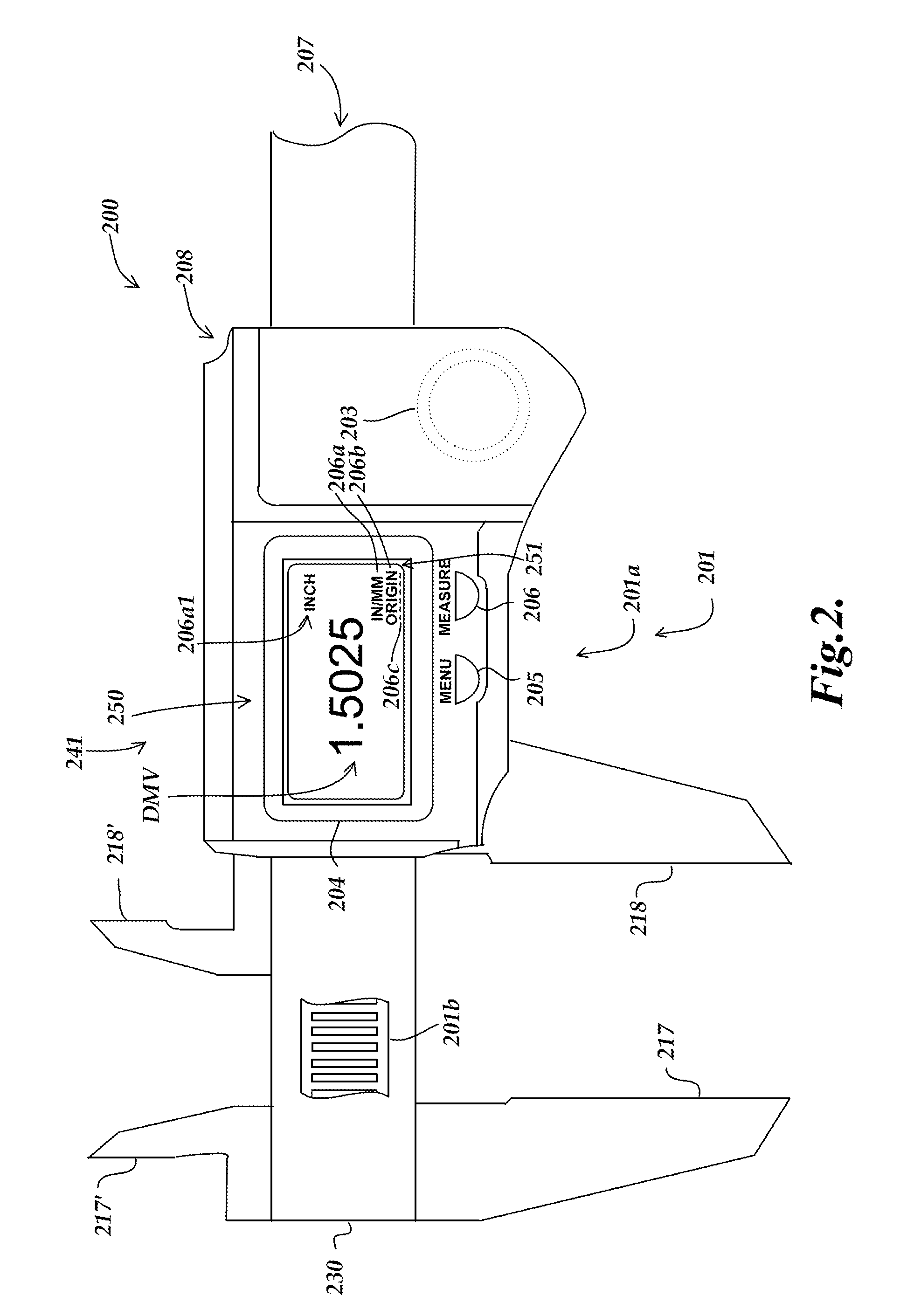

Handheld measuring device comprising a user interface responsive to changes in a displacement sensed by a displacement sensor

A measuring device is provided including a user interface responsive to changes in a displacement sensed by a displacement sensor. The measuring device (e.g., a handheld caliper or micrometer) includes a displacement sensor, a display, a signal processing and control portion, and a user interface. The displacement sensor includes a readhead and a scale displaceable relative to one another along a measuring axis under the manual control of a user, with the display being connected to the readhead. In a first user interface mode, displacement measurement values are displayed and are responsive to changes in the displacement of the displacement sensor. In a second user interface mode, operation control elements are displayed in the user interface and an operation control element action visible in the user interface (e.g., movement of a selection indicator) is responsive to changes in the displacement of the displacement sensor.

Owner:MITUTOYO CORP

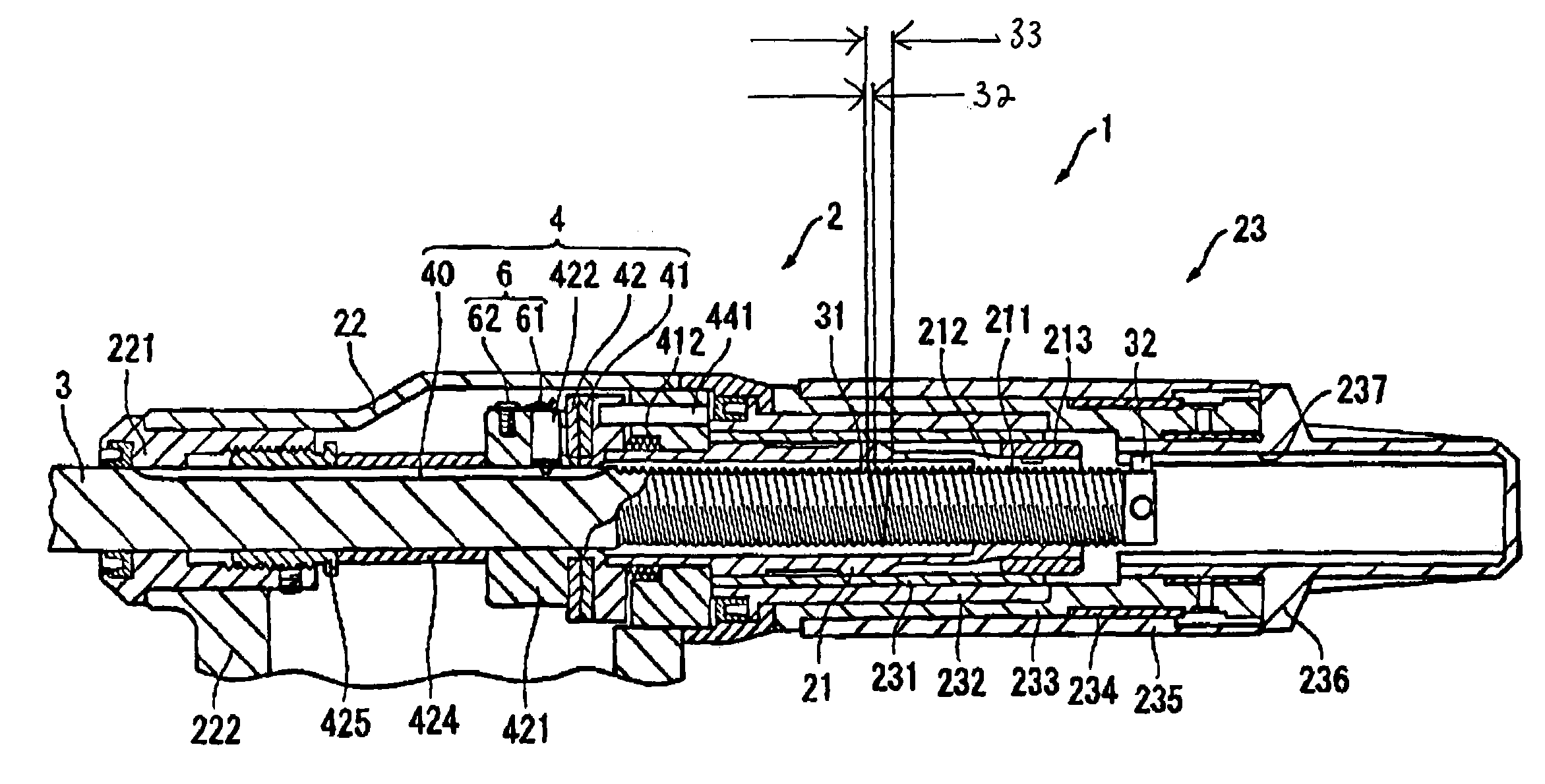

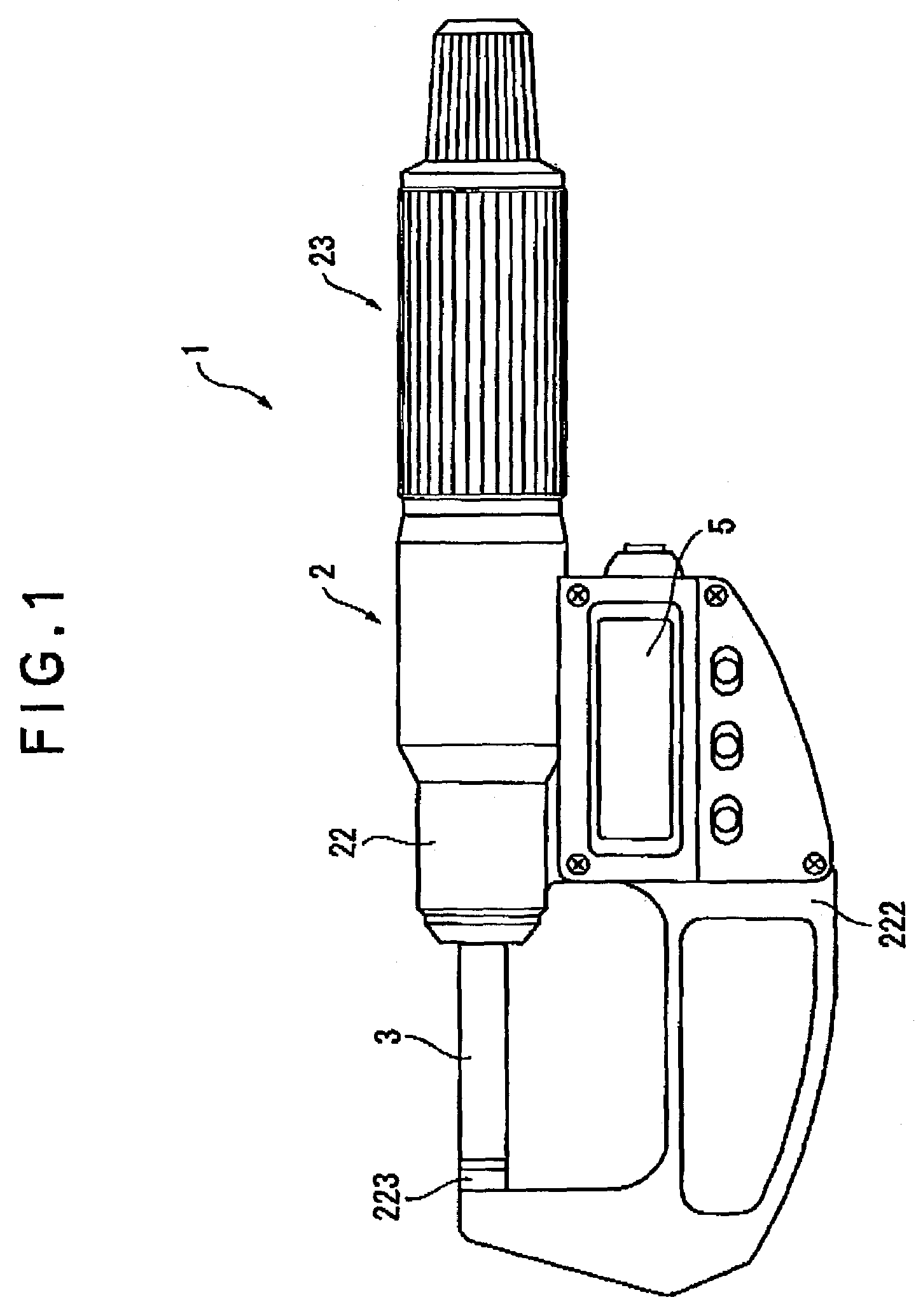

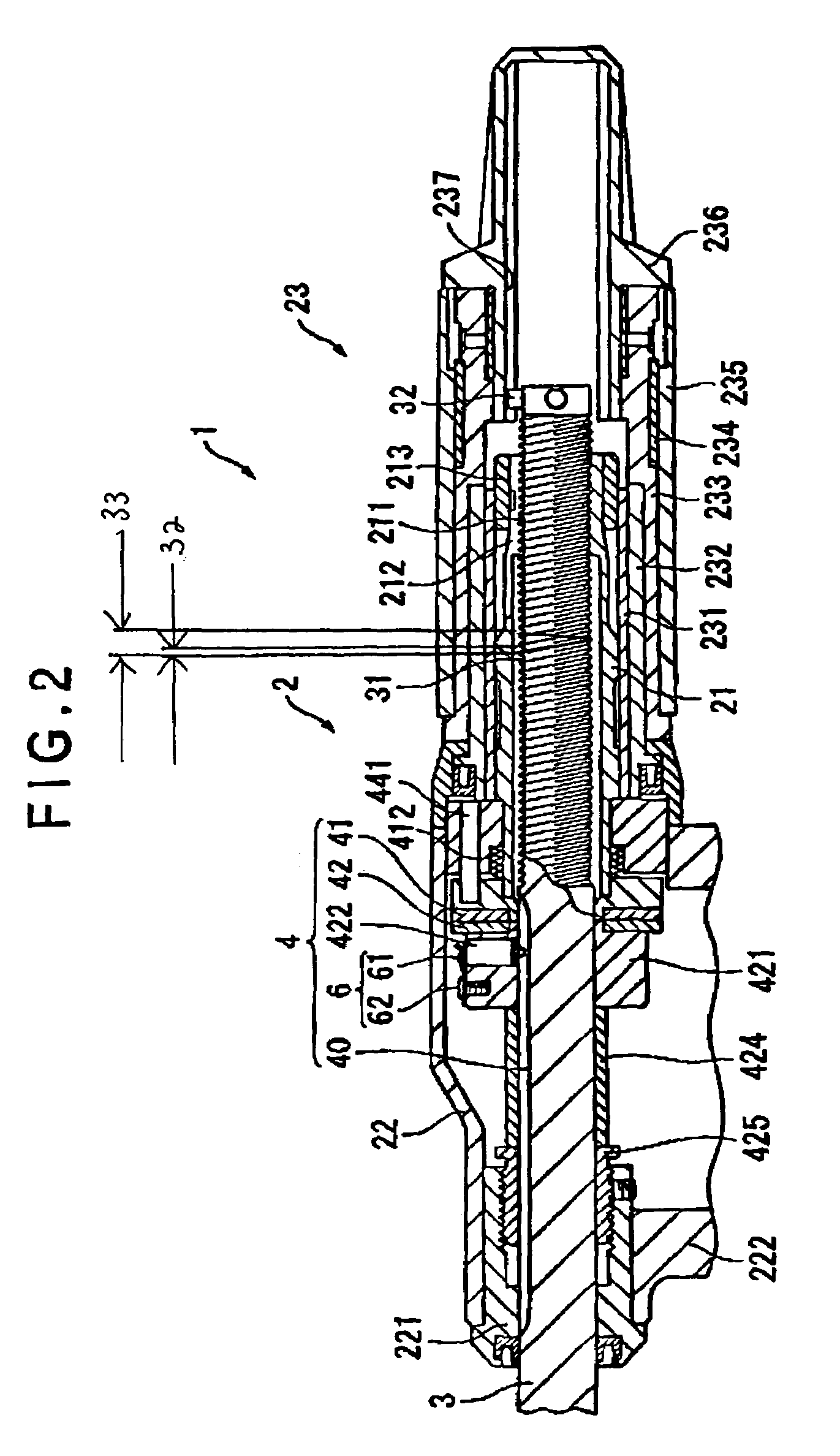

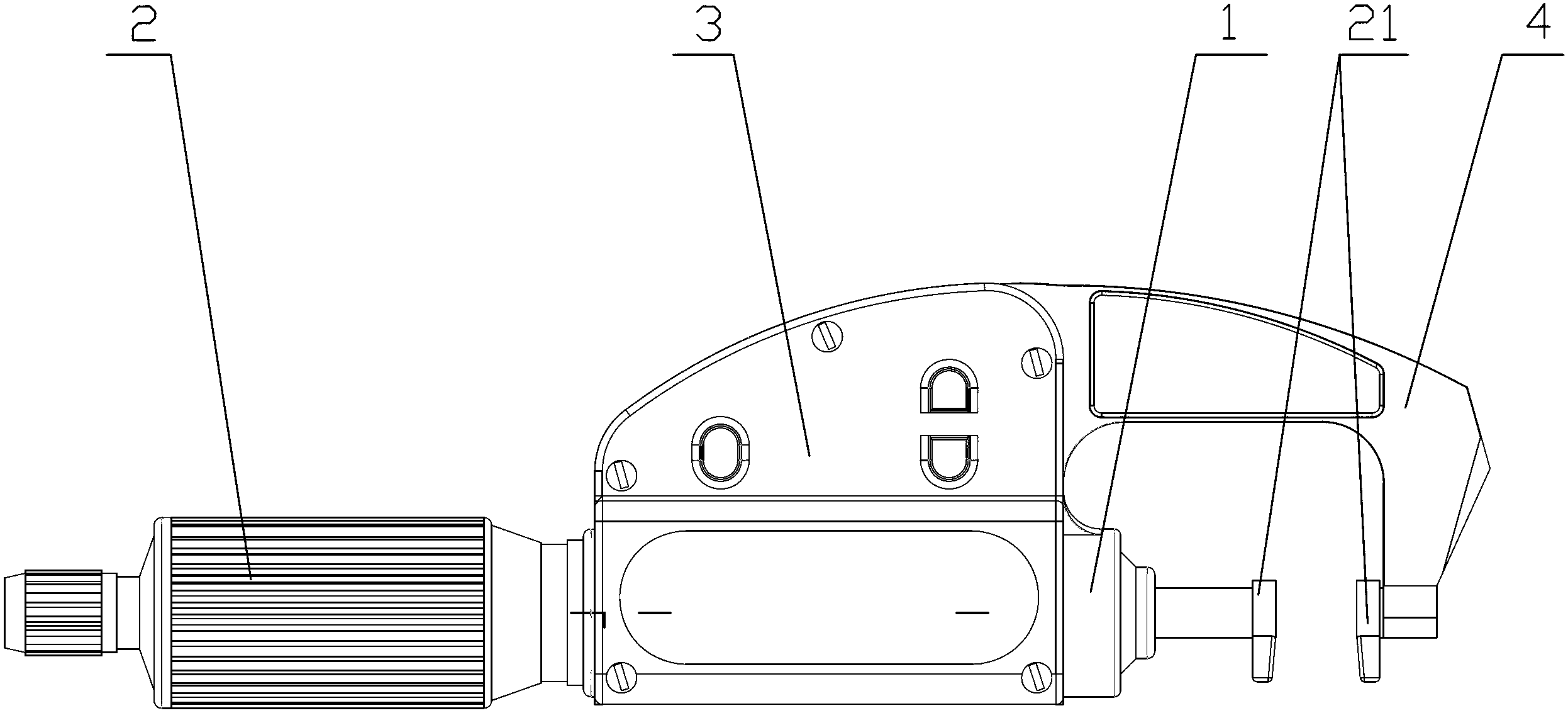

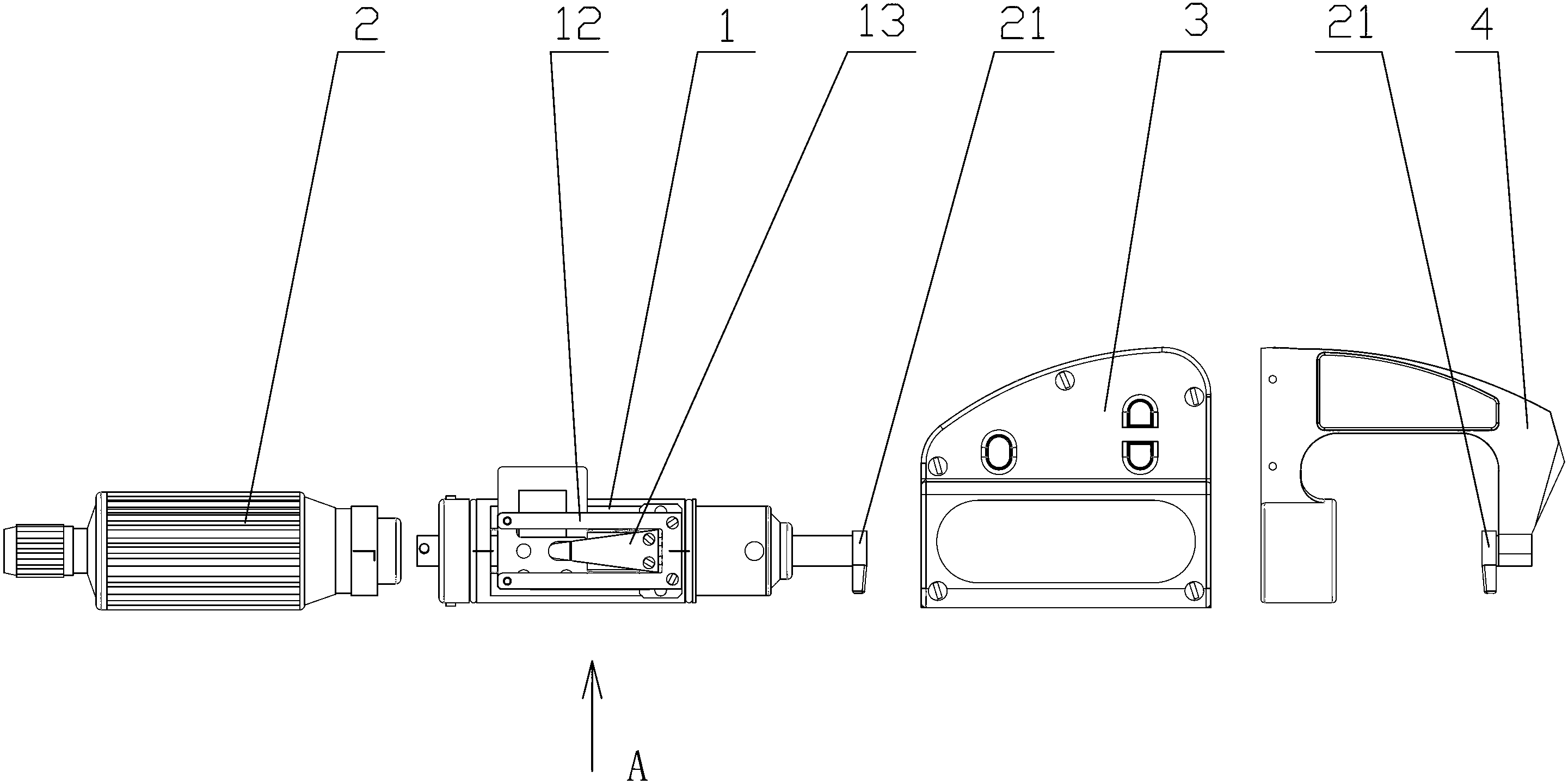

Measuring device using multi-start threaded spindle

InactiveUS7013576B2Improve accuracyMicrometersMechanical measuring arrangementsAxial displacementOperability

Provided is a measuring device 1 for measuring the size of an object comprising a body 2, and a spindle 3 which is screwed into the body 2 and axially advances and retracts by screwing with respect to the body 2, the measurement being based on the axial displacement of the spindle 3 effected by the revolution of the spindle, wherein the spindle is screwed into the body 2 via a multiple-start thread 31. Therefore, it is possible to displace the spindle 3 at a high speed, which improves the operability of the measuring device.

Owner:MITUTOYO CORP

Absolute position measuring apparatus

ActiveUS20090031578A1Easy to manufactureEasily downsizedMicrometersMechanical measuring arrangementsMeasurement deviceEngineering

An absolute position measuring apparatus includes a first rotary encoder that detects a rotation of a spindle as a phase signal which varies in a first cycle and a second rotary encoder that detects the rotation of the spindle as another phase signal which varies in a second cycle. A rotation of a first rotor of the first rotary encoder is transmitted to a second rotor via a relay gear that is meshed with a first gear provided on an outer circumference of a first rotary cylinder and a second gear provided on an outer circumference of a second rotary cylinder. Thus, an absolute position of the spindle is calculated on the basis of two phase signals that are different in cycle. Further, it is not necessary to provide a conventionally-known spiral key groove so that the apparatus can be easily downsized. Manufacturing costs can be also reduced.

Owner:MITUTOYO CORP

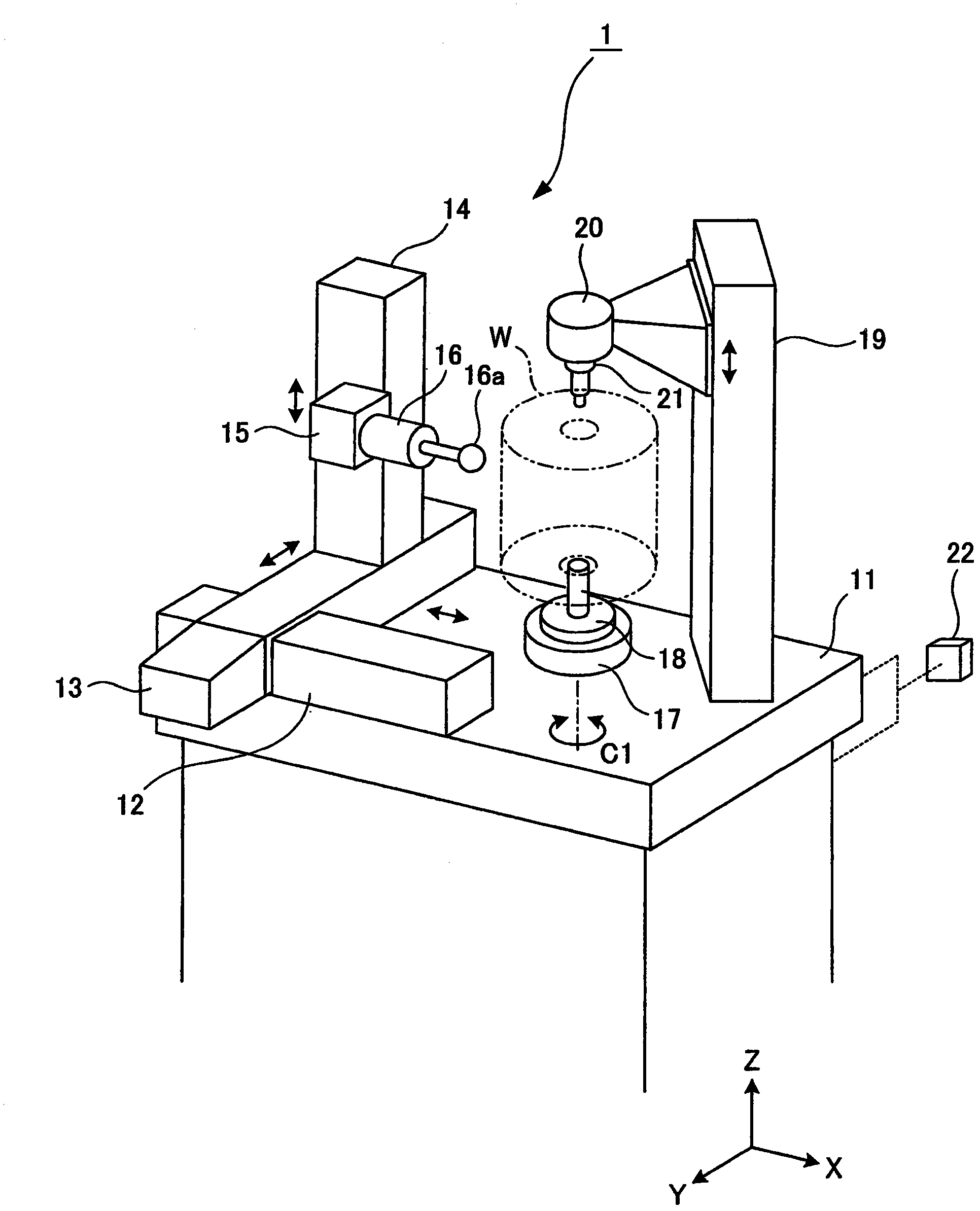

Method of measuring gear

InactiveCN102216725AReduce travelSmall sizeMicrometersMechanical counters/curvatures measurementsAngular degreesEngineering

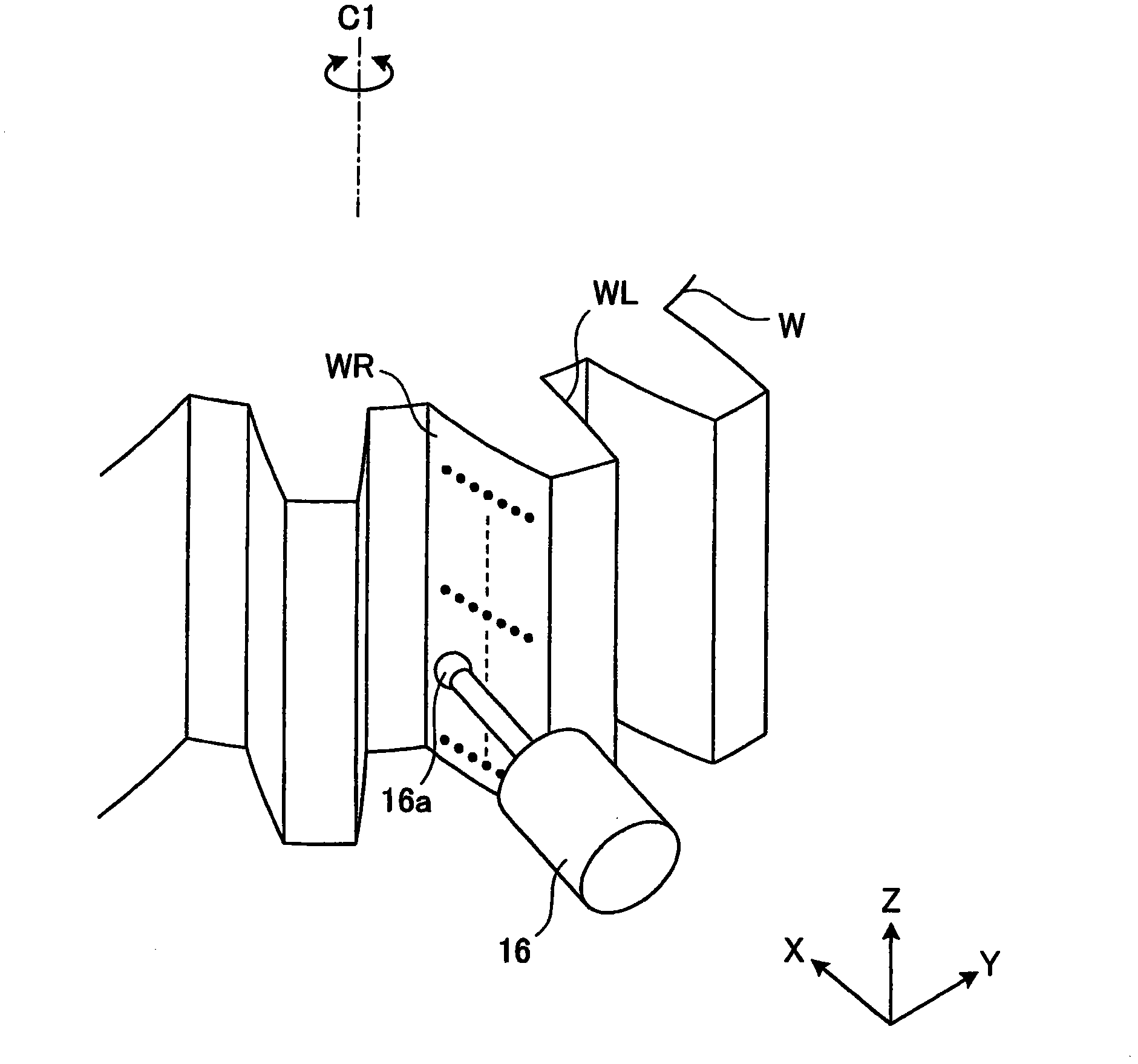

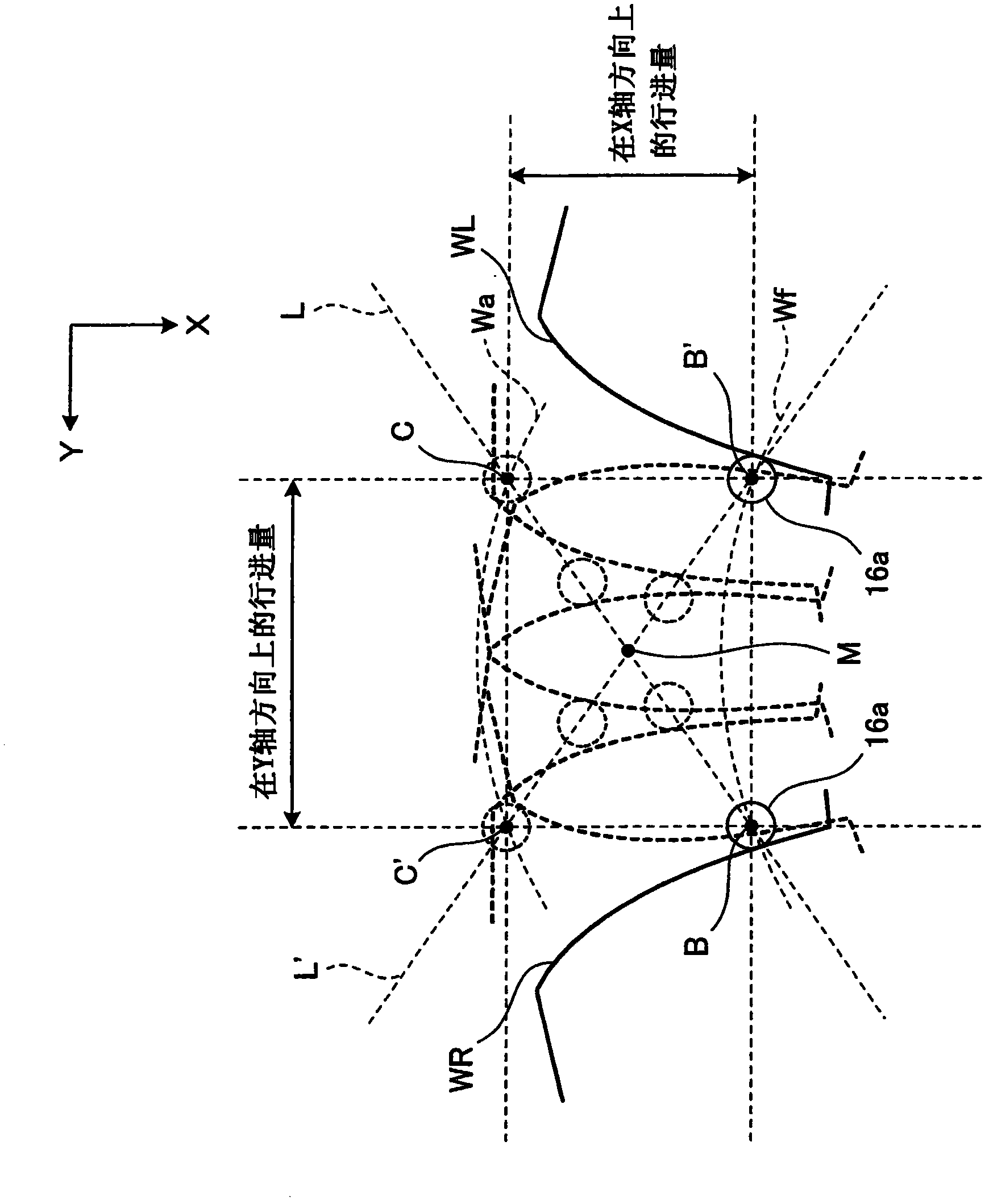

Provided is a method of measuring a gear wherein the movement range of a stylus is reduced during a measurement by reducing the distance of movement of the stylus in order to downsize a machine. A method for measuring the profile of a gear by performing a synchronizing control on the movement of a stylus and the rotation of a work, and by moving the stylus linearly in a state where the stylus is kept in contact with the right tooth flank or left tooth flank according to the rotation of the work, wherein a tangent touching a contact point which is located after rotation of a predetermined rotation angle a in one direction from a contact point on the base circle of the work, and a tangent touching a contact point which is located after rotation of a predetermined rotation angle a in the opposite direction from a contact point on the base circle of the work are set, the stylus is moved along a tangent when the right tooth flank is measured and moved along another tangent when the left tooth flank is measured, and the intersection of two tangents is set at the middle point between the measurement start position and the measurement end position.

Owner:MITSUBISHI HEAVY IND LTD

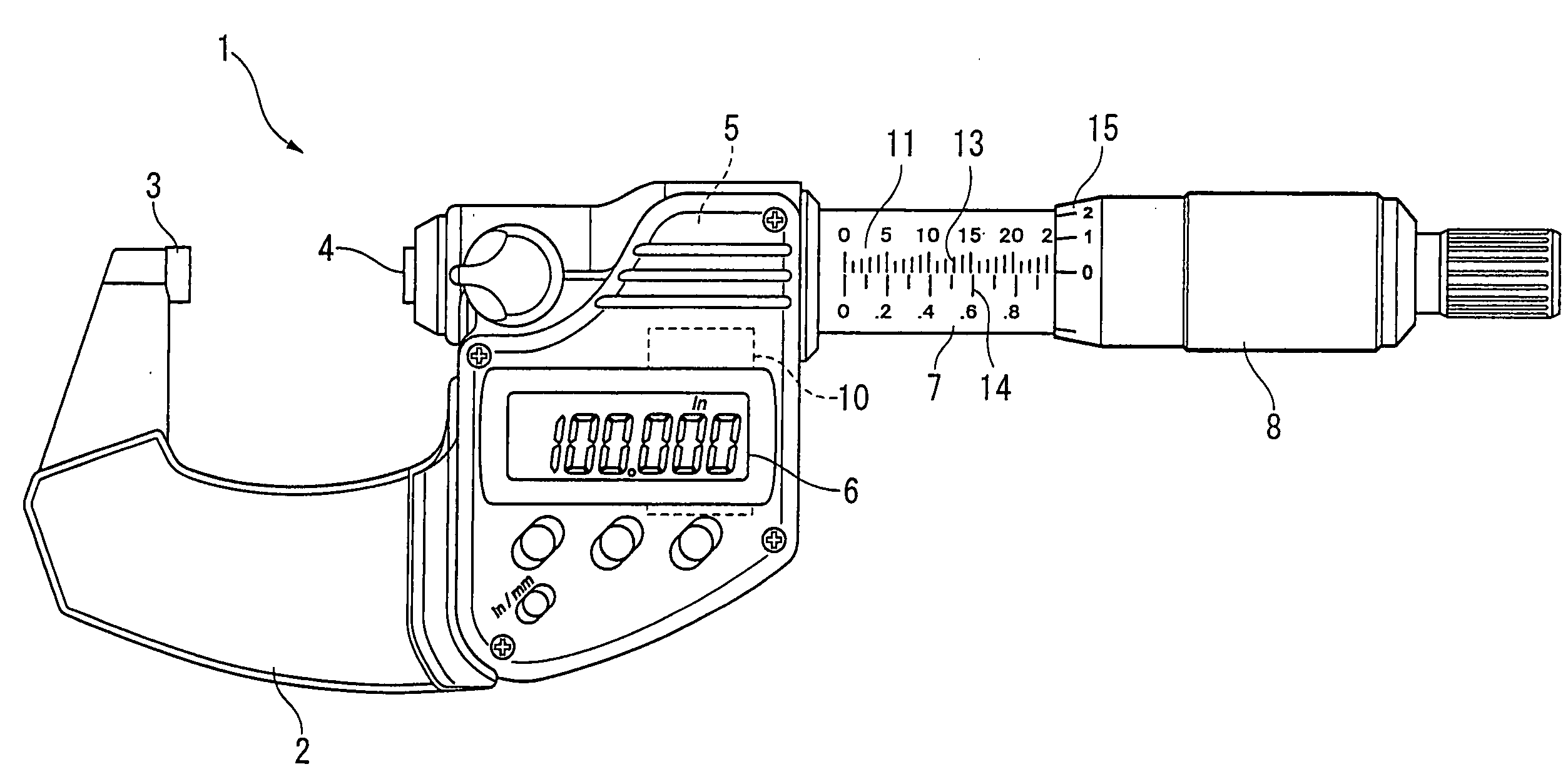

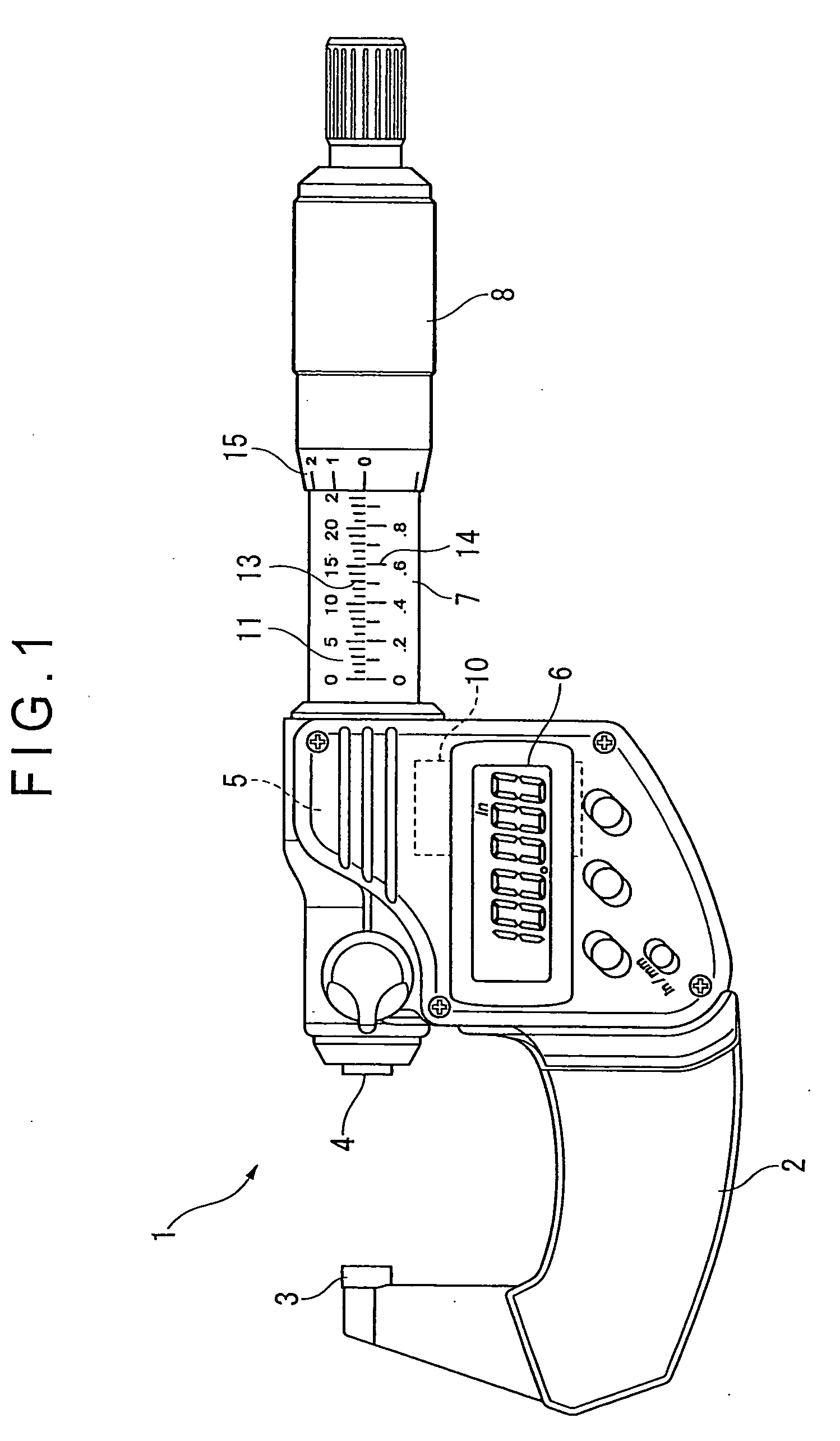

Digital displacement measuring instrument

ActiveUS20090282689A1Low production costEasy to operateMicrometersMechanical measuring arrangementsMeasuring instrumentEngineering

A digital displacement measuring instrument detects a displacement of a spindle by an encoder and then displays the displacement on a digital display unit. With an imaginary base line centered along an axial direction of an outer circumference of a sleeve, a millimeter graduation for displaying the displacement of the spindle in millimeters is provided on one side, and the inch graduation for displaying the displacement of the spindle is provided on the other side.

Owner:MITUTOYO CORP

Method and device for measuring fluctuations in the cross-sectional area of hair in a pre-determined scalp area

The method for isolating an area of hair-bearing skin and measuring a combined cross section of hair in the area comprising the steps of: preparing a pre-measured site on the scalp; isolating a standardized bundle of uncut hair at the site; compressing the bundle of hair with a measurable load while simultaneously measuring the height of the bundle of hair with a piston and cylinder device. One embodiment of the device comprises a body having a slot for receiving a bundle of hair, an anvil positioned adjacent said slot, and a mechanism for causing relative movement between the body having the slot and the anvil thereby to compress a bundle of uncut hair received in the slot against the anvil.

Owner:BERNARD COHEN TECH LLC

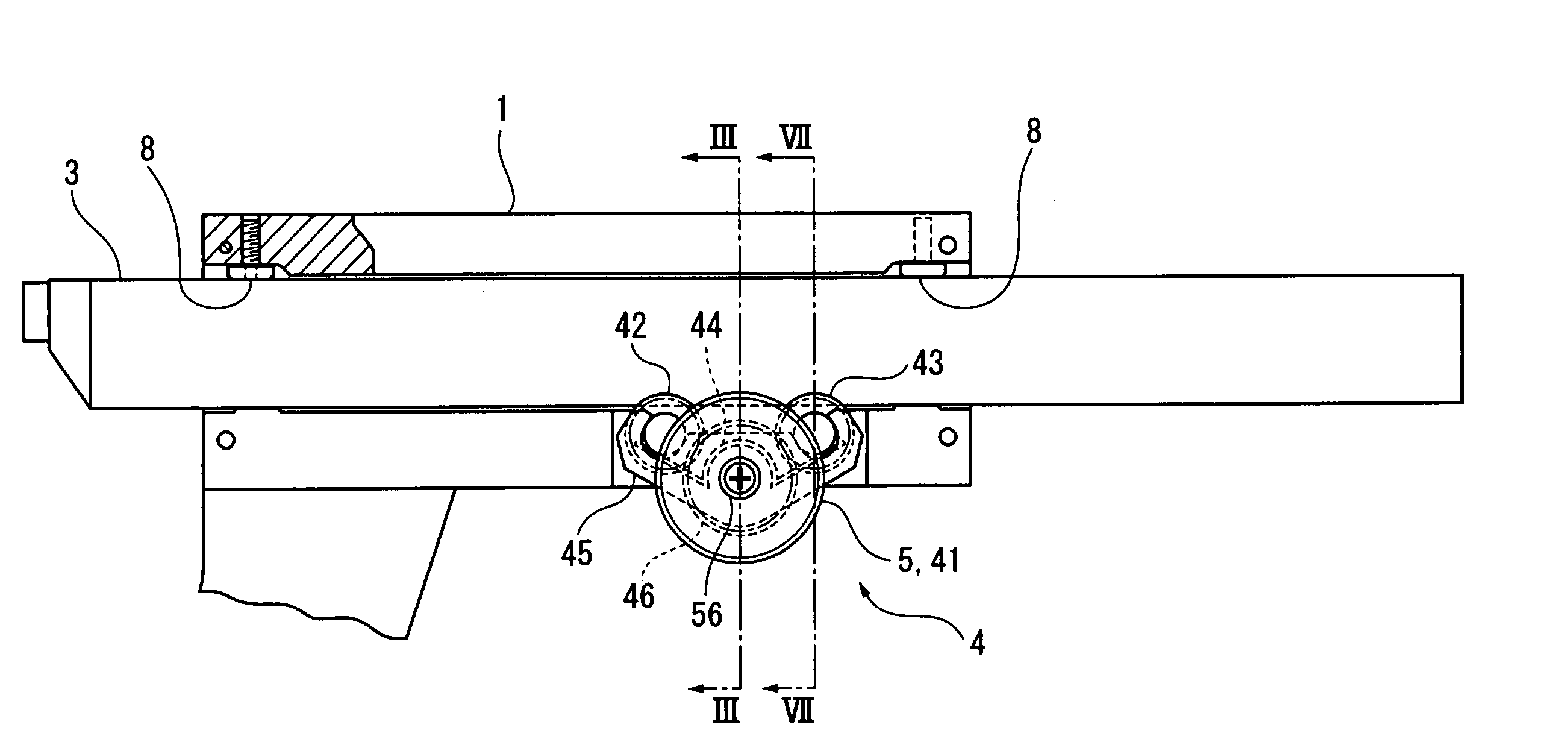

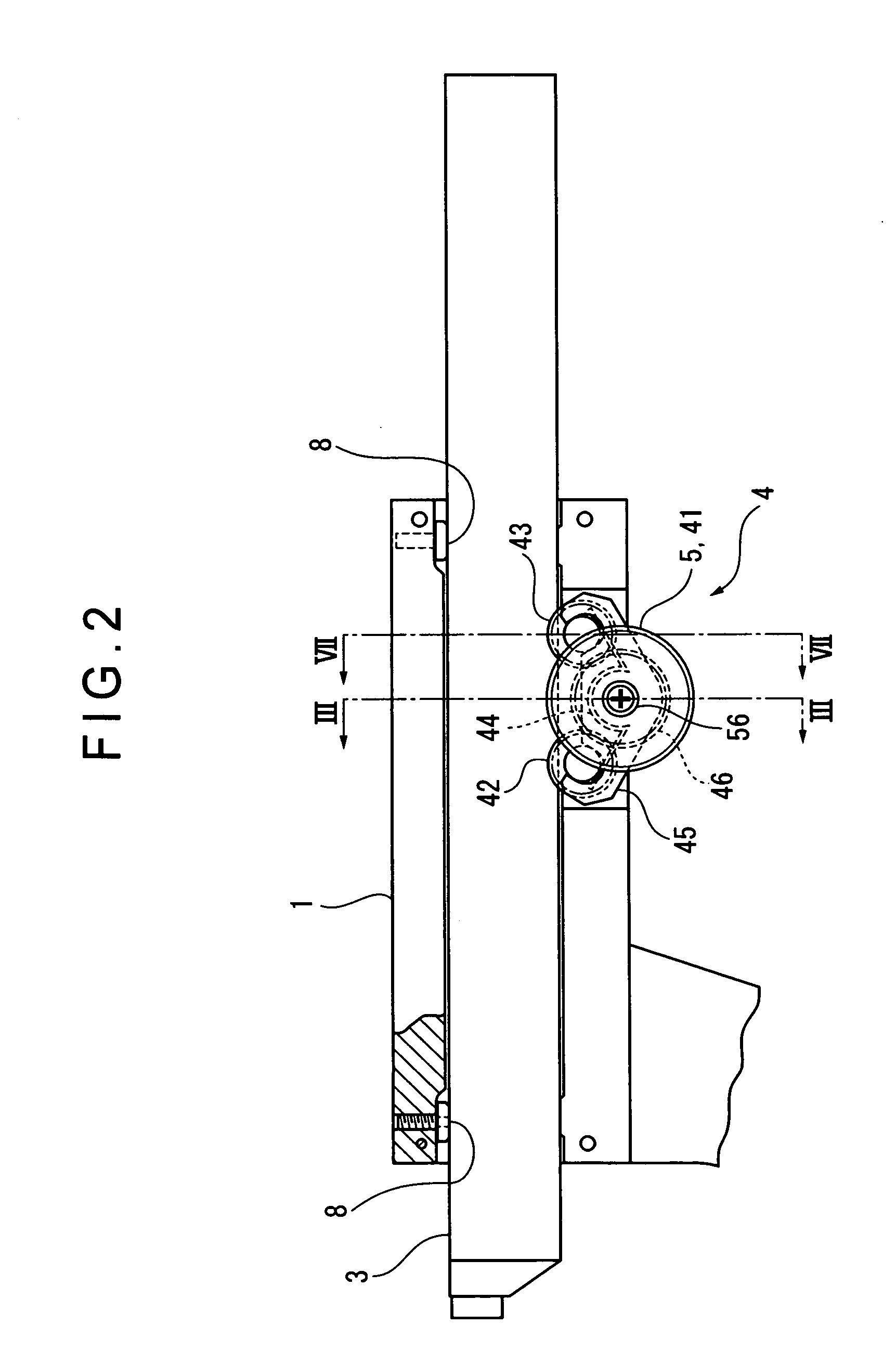

Measuring tool

ActiveUS20070068027A1Smooth movementEasy to operateMicrometersMechanical measuring arrangementsEngineeringTransmitter

A measuring tool has a slider (3) supported to a body frame (1) and a feeding mechanism (4) for moving the slider in axial direction. The feeding mechanism includes: an outer roller (41) rotatably supported to the body frame (1); a forward feed roller (42) disposed between the outer roller (41) and the slider (3) at a position closer to a forward side of the slider (3) relative to the outer roller (41); a reverse feed roller (43) disposed at a position on a reverse side; a roller holder (45) supporting these feed rollers to allow them to move along the circumference around the axis of the outer roller; a first leaf spring (44) that biases these feed rollers toward the slider side; and a power transmitter (46) connecting the outer roller (41) to these feed rollers to transmit the rotation of the outer roller to the feed rollers.

Owner:MITUTOYO CORP

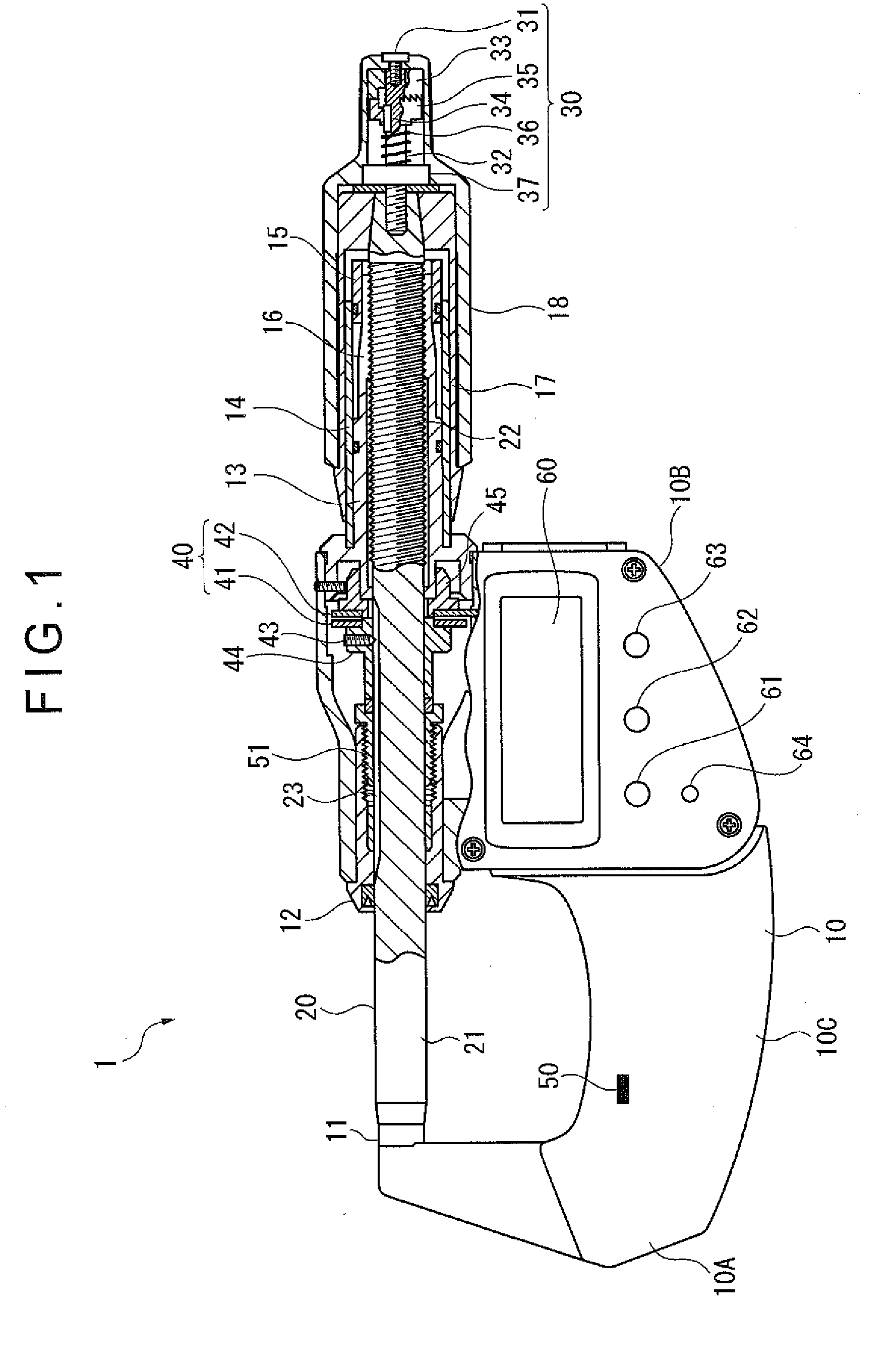

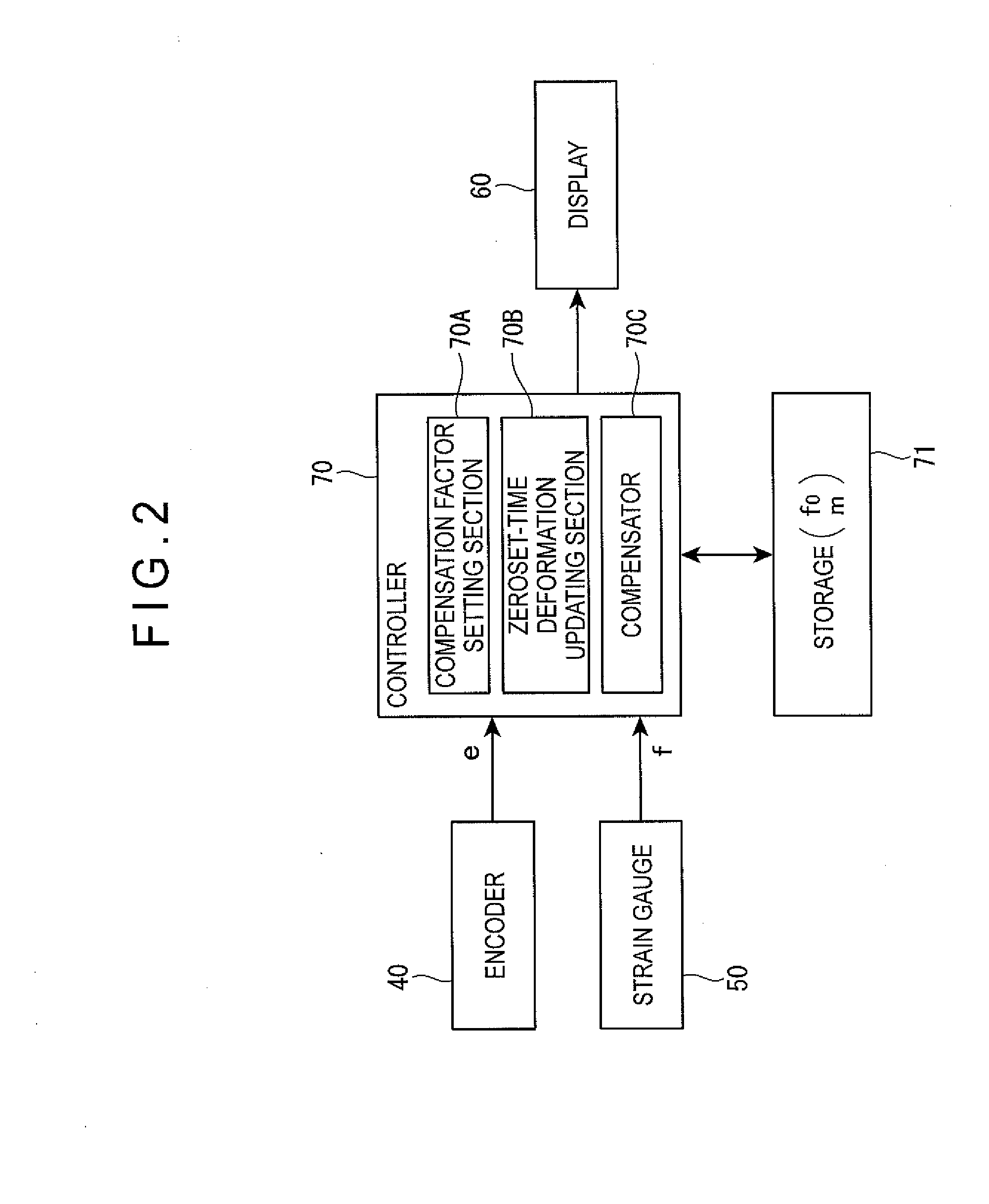

Micrometer

ActiveUS20130276319A1Good repeatabilityReduce measurement errorMicrometersMechanical measuring arrangementsMicrometerDisplay device

A micrometer includes: a frame; an anvil; a spindle; an encoder; a display; a strain gauge that detects a deformation of the frame; a storage that stores a change amount of the detection value (a displacement of the spindle detected by the encoder) per a unit deformation detected by the strain gauge, as a compensation factor; and a compensator that compensates the detection value based on a difference between a zeroset-time deformation that is detected by the strain gauge when a command for zeroset is given and a measurement-time deformation that is detected by the strain gauge in measurement, and based on the compensation factor stored in the storage.

Owner:MITUTOYO CORP

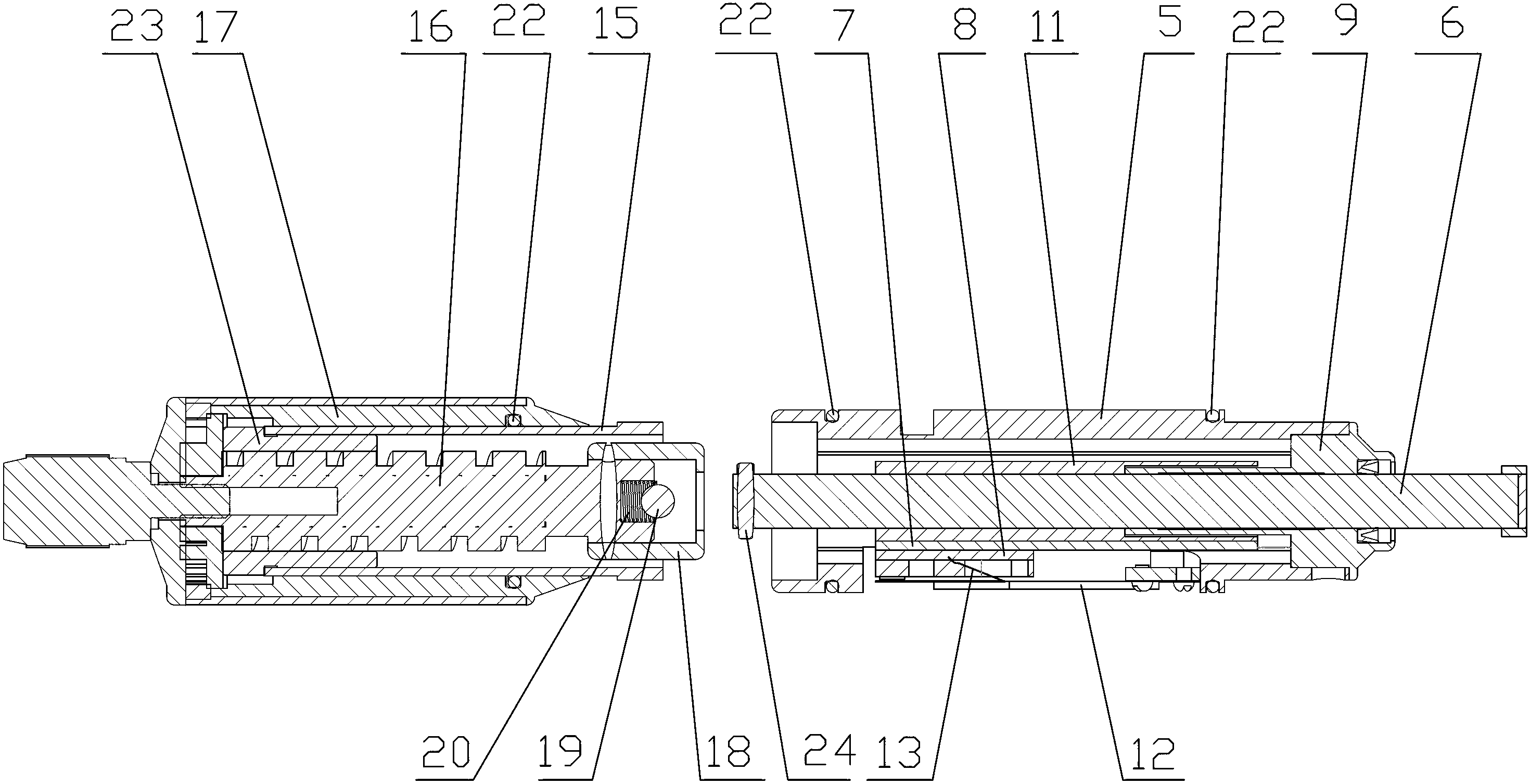

High-protection direct-acting digital display micrometer

ActiveCN102853727AFull scale error correctionGuaranteed measurement accuracyMicrometersMicrometerSteel ball

The invention discloses a high-protection direct-acting digital display micrometer, which comprises a measuring head, a propelling assembly, a display screen and a U-shaped arch, a tube body of a measuring bush is embedded into the display screen, the front section of the measuring bush is embedded into the U-shaped arch, a measuring rod is arranged inside the measuring bush, the front section of the measuring rod is in sliding fit with a positioning sleeve on the front end of the measuring bush, and the rear section of the measuring rod is supported on an adjusting screw which is vertically arranged on the rear section of the measuring bush in a sliding way through two linked guide pillars on two sides of the measuring rod; a main grid is arranged on a main grid seat, and an auxiliary grid is in floating fit with the main grid through a suspension stretching spring leaf which is installed on the tube body of the measuring bush; an electric appliance null-setting mechanism is arranged between the measuring rod and the positioning sleeve; and a large-pitch lead screw of the propelling assembly is in floating connection with the measuring rod through a steel ball. The measuring rod structure and the electric appliance null-setting mechanism in precise positioning on the front end and auxiliary positioning on the rear end are adopted to be matched with a floating auxiliary grid component, so that the movement and measurement precision of a sensor can be guaranteed; and moreover, the structure is simple, easiness in assembling is realized, and the cost is low.

Owner:钟胜 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com