Patents

Literature

649 results about "Outer annulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

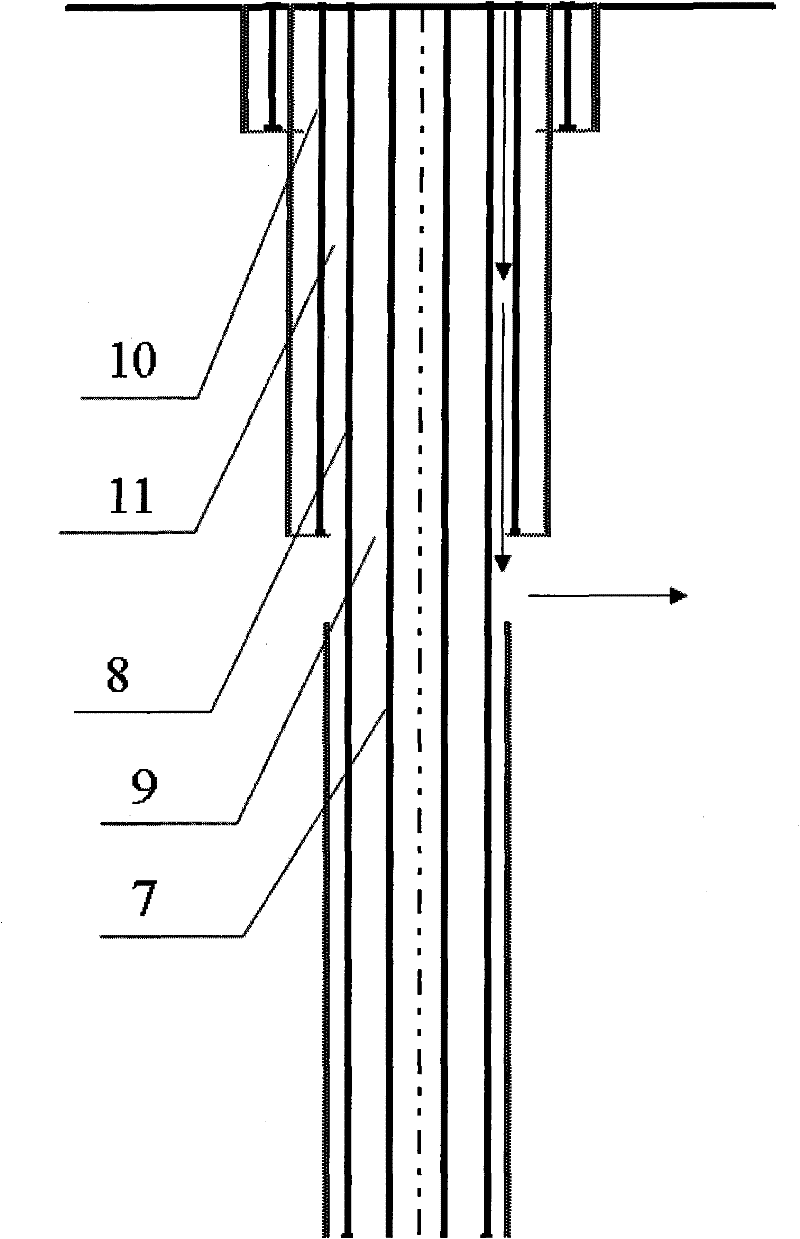

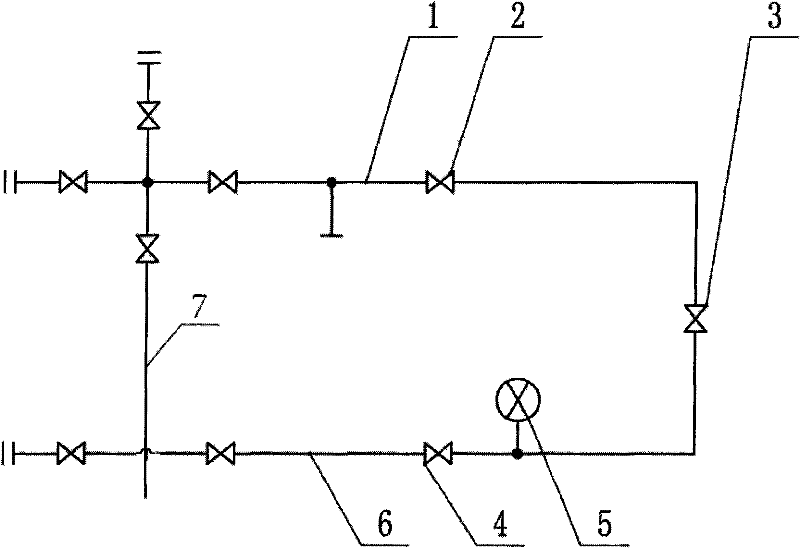

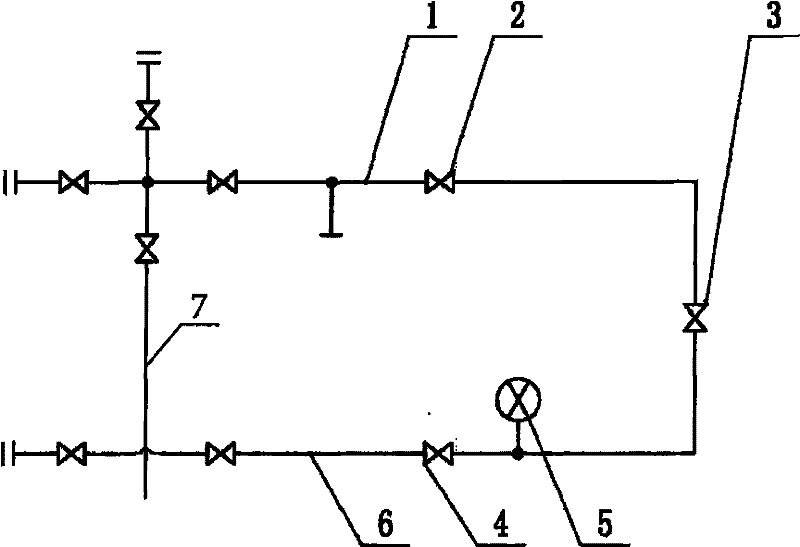

Rock debris annulus reinjection device and control method thereof

The invention discloses a rock debris annulus reinjection system. A water injection well is taken as a reinjection well, an inner annulus (9) is formed between a water injection pipeline (7) in the middle and a 9-5 / 8' sleeve (8), and an outer annulus (11) is formed between the 9-5 / 8' sleeve (8) and a 13-3 / 8' sleeve (10). The system is characterized in that: a water injection pipeline isolating valve (2), a pressure control valve (3), an inner annulus isolating valve (4) and an inner annulus pressure meter (5) are arranged between an extension pipe (1) of the water injection pipeline (7) and an outlet pipeline (6) of the inner annulus (9). The system is used for the rock debris reinjection operation technology of offshore oilfield drilling; and when rock debris is reinjected into the outer annulus between the 13-3 / 8' sleeve and the 9-5 / 8' sleeve, the allowable outlet pressure of the pressure control valve is adjusted, and the inner annulus is pressurized, so that rock debris reinjection slurry cannot flow into the inner annulus, the space of the inner annulus is protected, and the completeness of the water injection well is protected.

Owner:JEREH ENERGY SERVICES

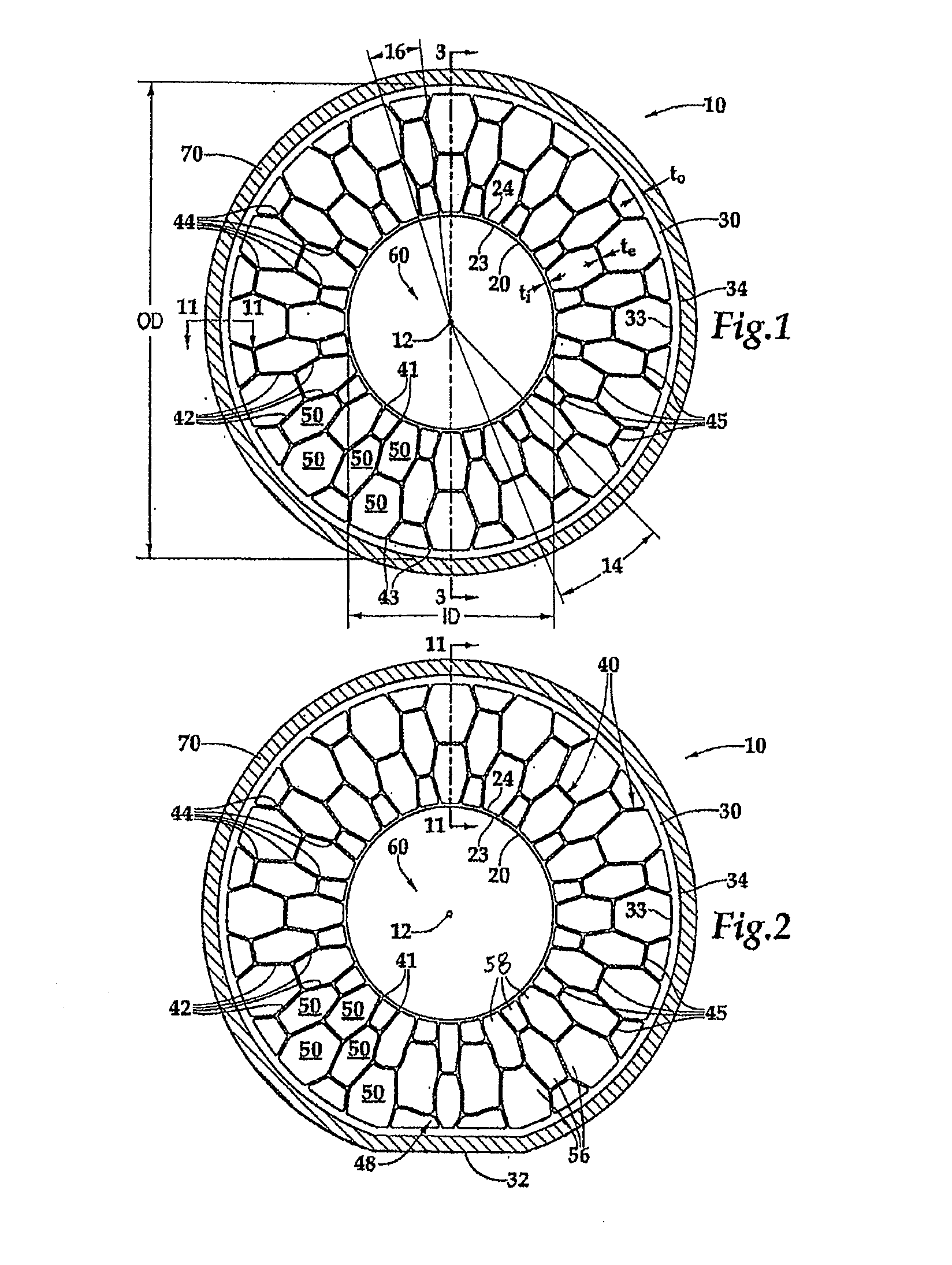

Tension-based non-pneumatic tire

ActiveUS20110079335A1Facilitate bucklingAdd benefitNon-inflatable tyresTyre tread bands/patternsEngineeringMechanical engineering

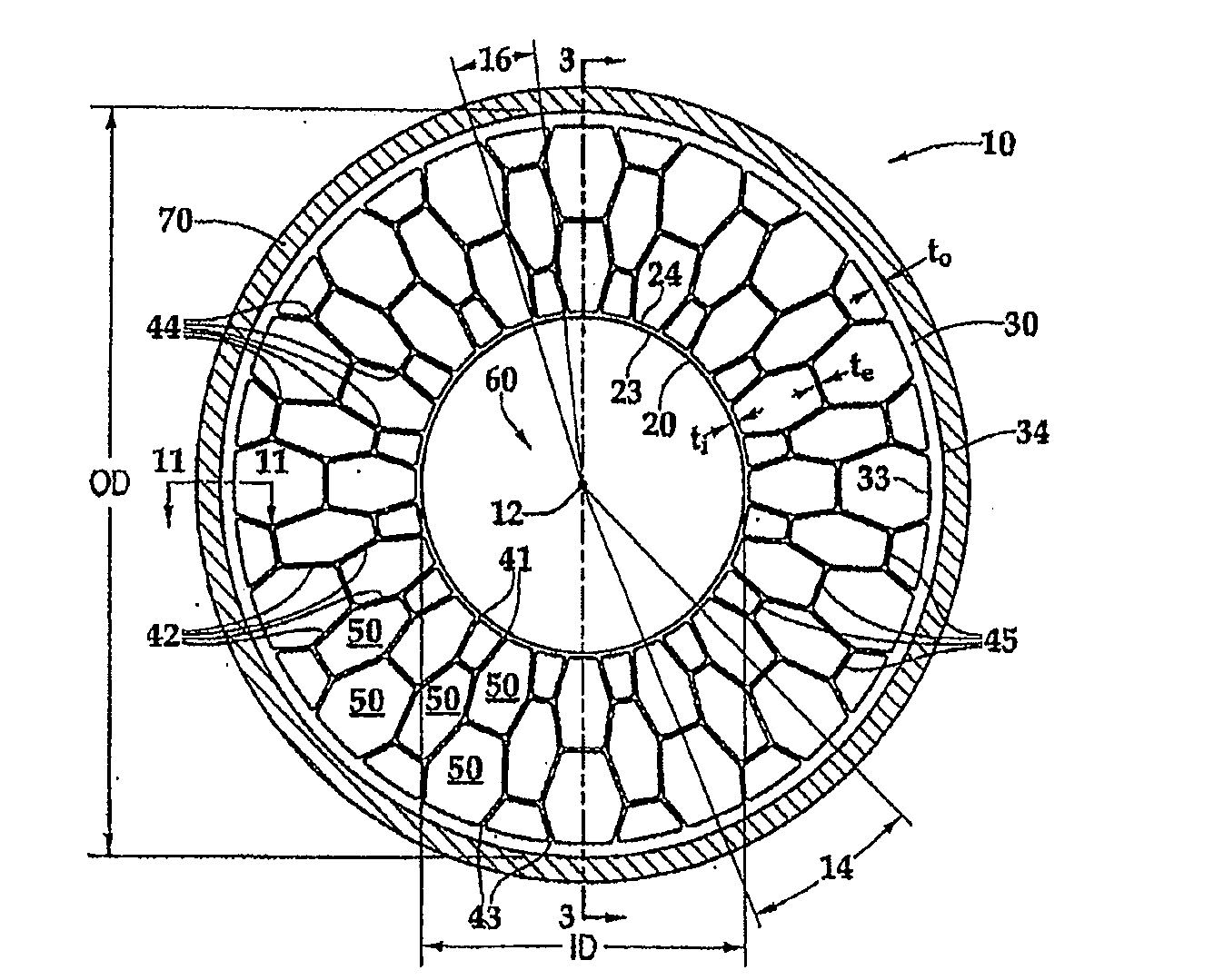

A non-pneumatic tire for supporting a load by working in tension comprising a generally annular inner ring, a generally annular outer ring, and an interconnected web having a plurality of web elements and comprising a plurality of generally polygonal openings. Web elements are sized, curved, oriented, and comprised of varying thicknesses of material which facilitates buckling when subjected to a compressive load. By buckling, those elements in a deformed portion of the tire between a wheel and a footprint region where the tire contacts a surface can assume a significantly reduced portion of the load, if any. This causes web elements in other portions of the interconnected web to operate in tension to support the load.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

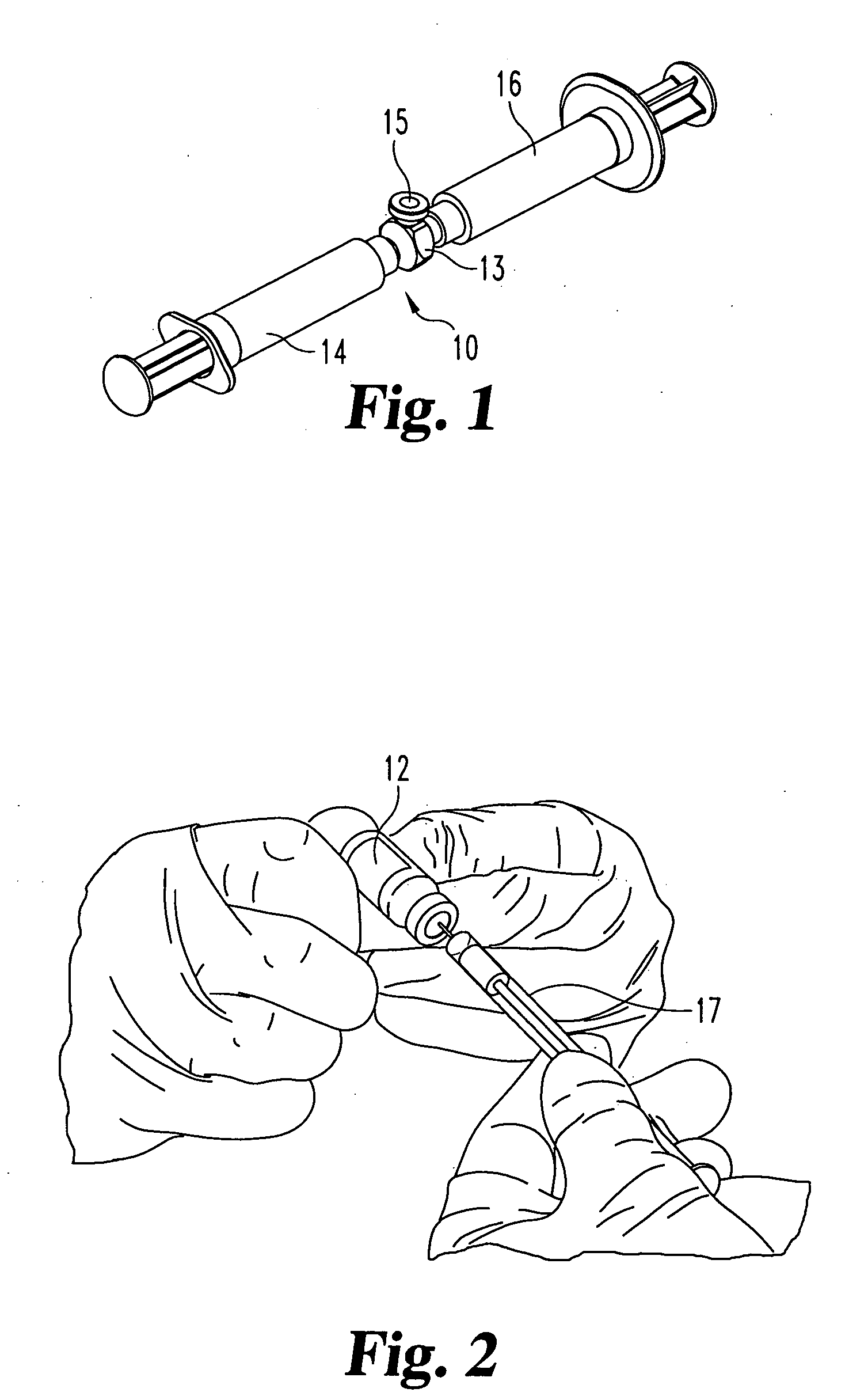

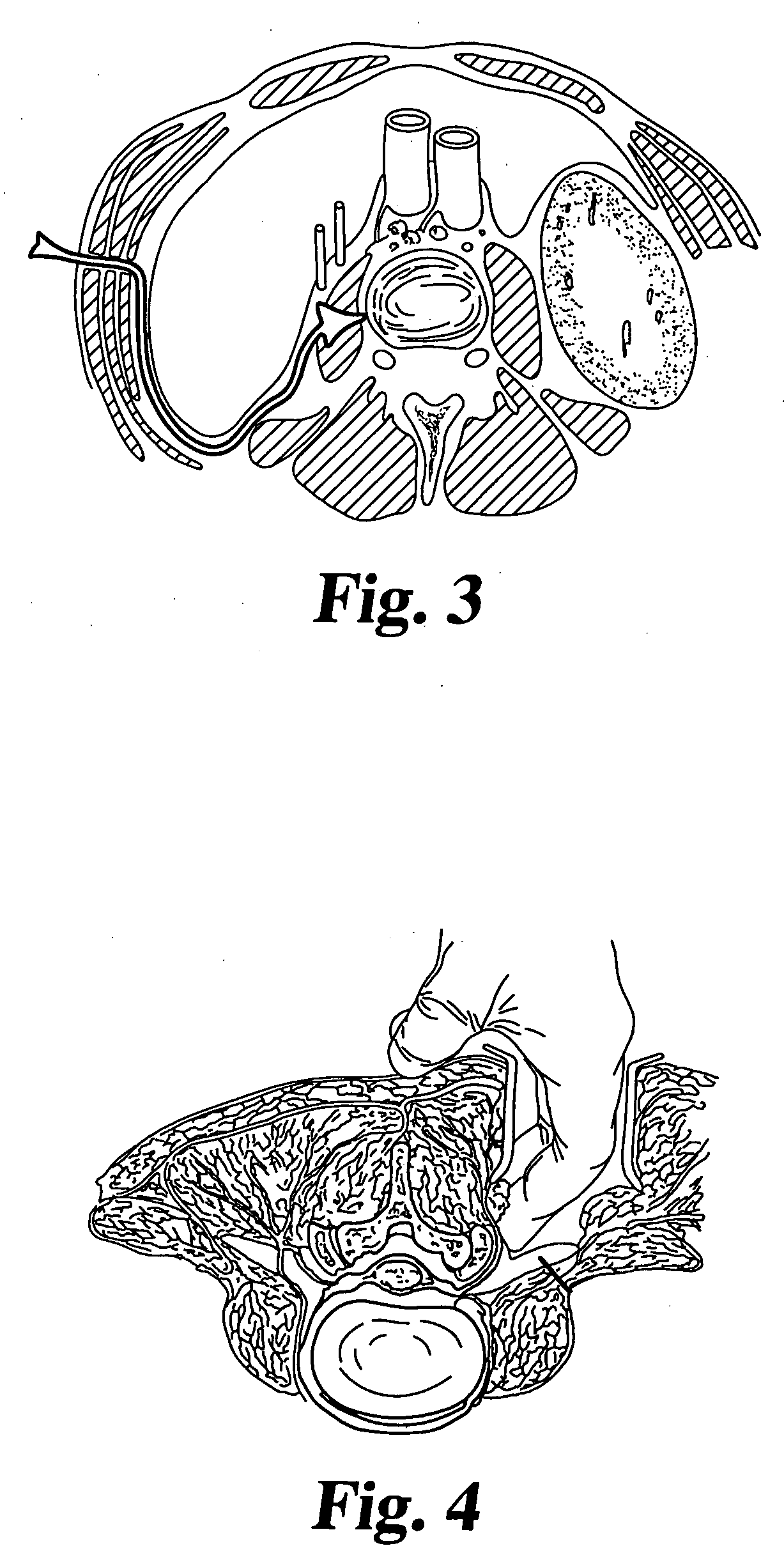

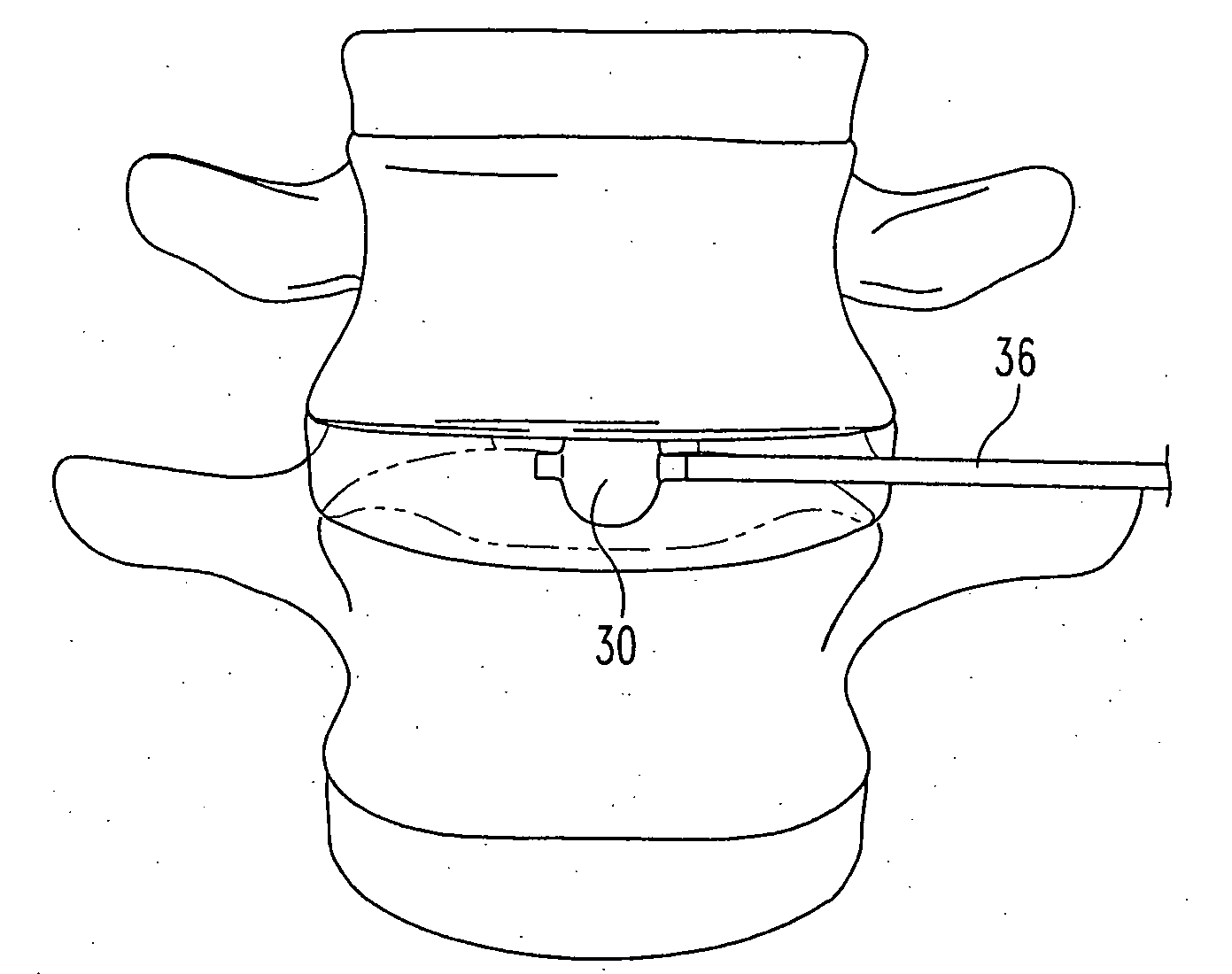

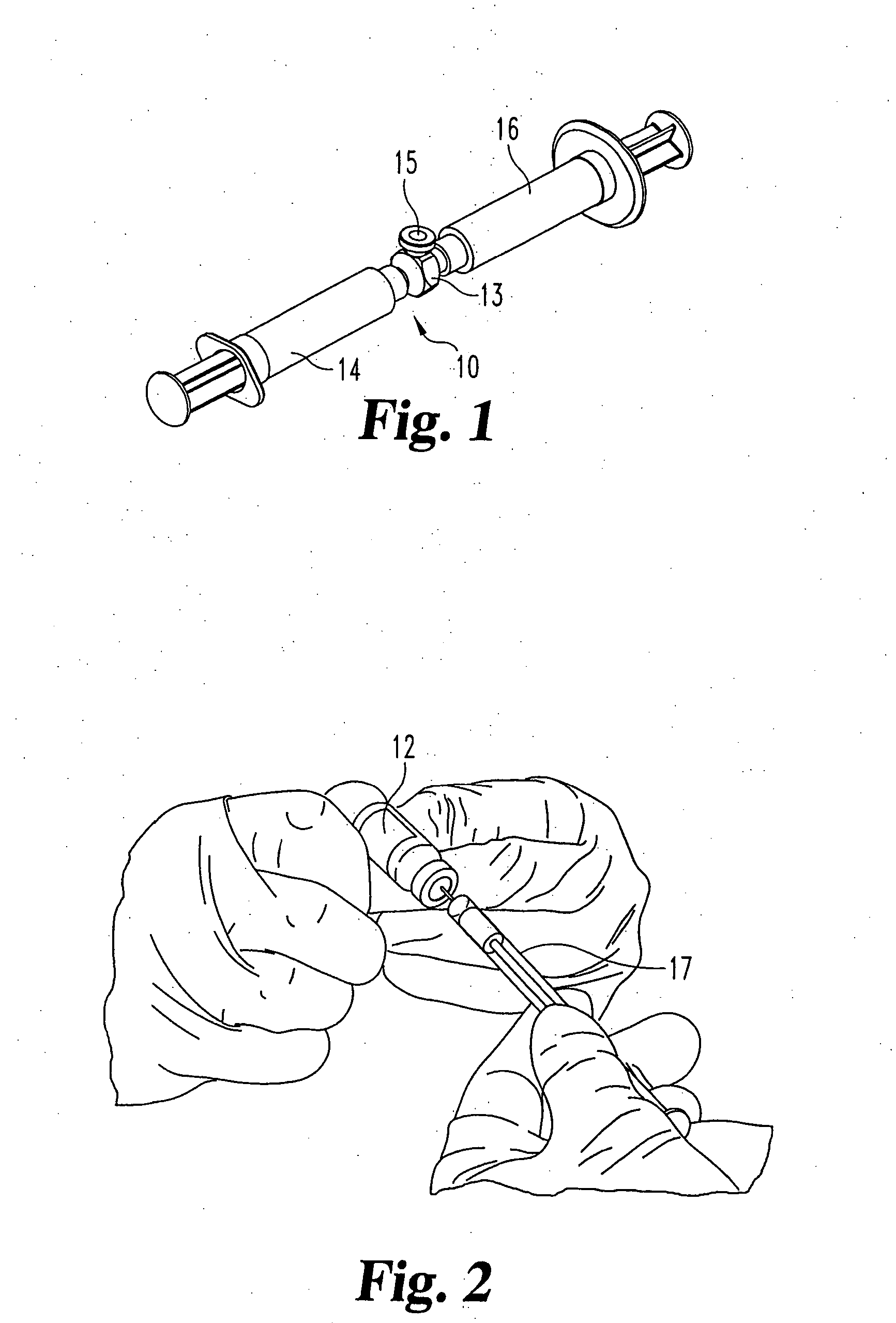

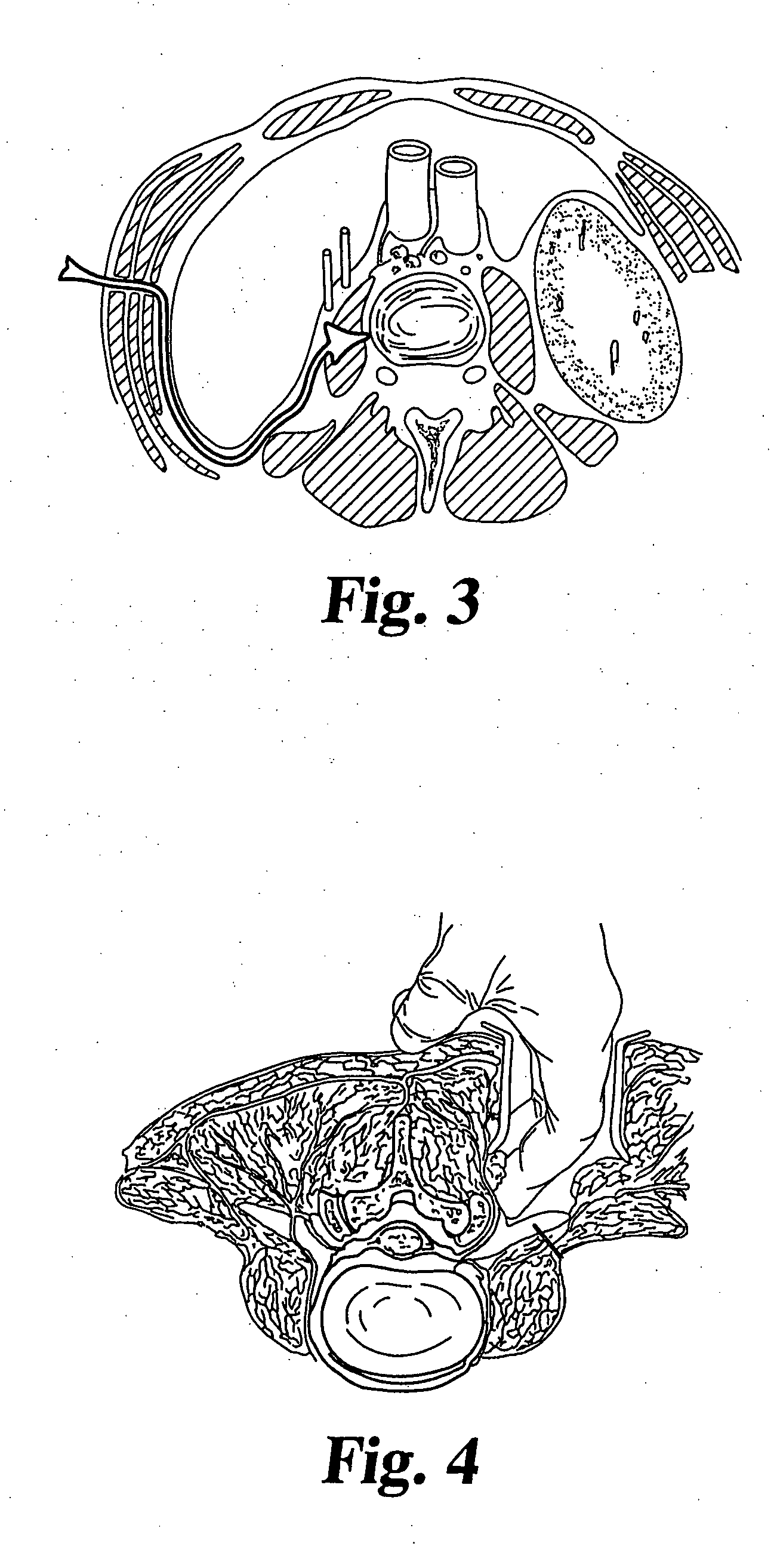

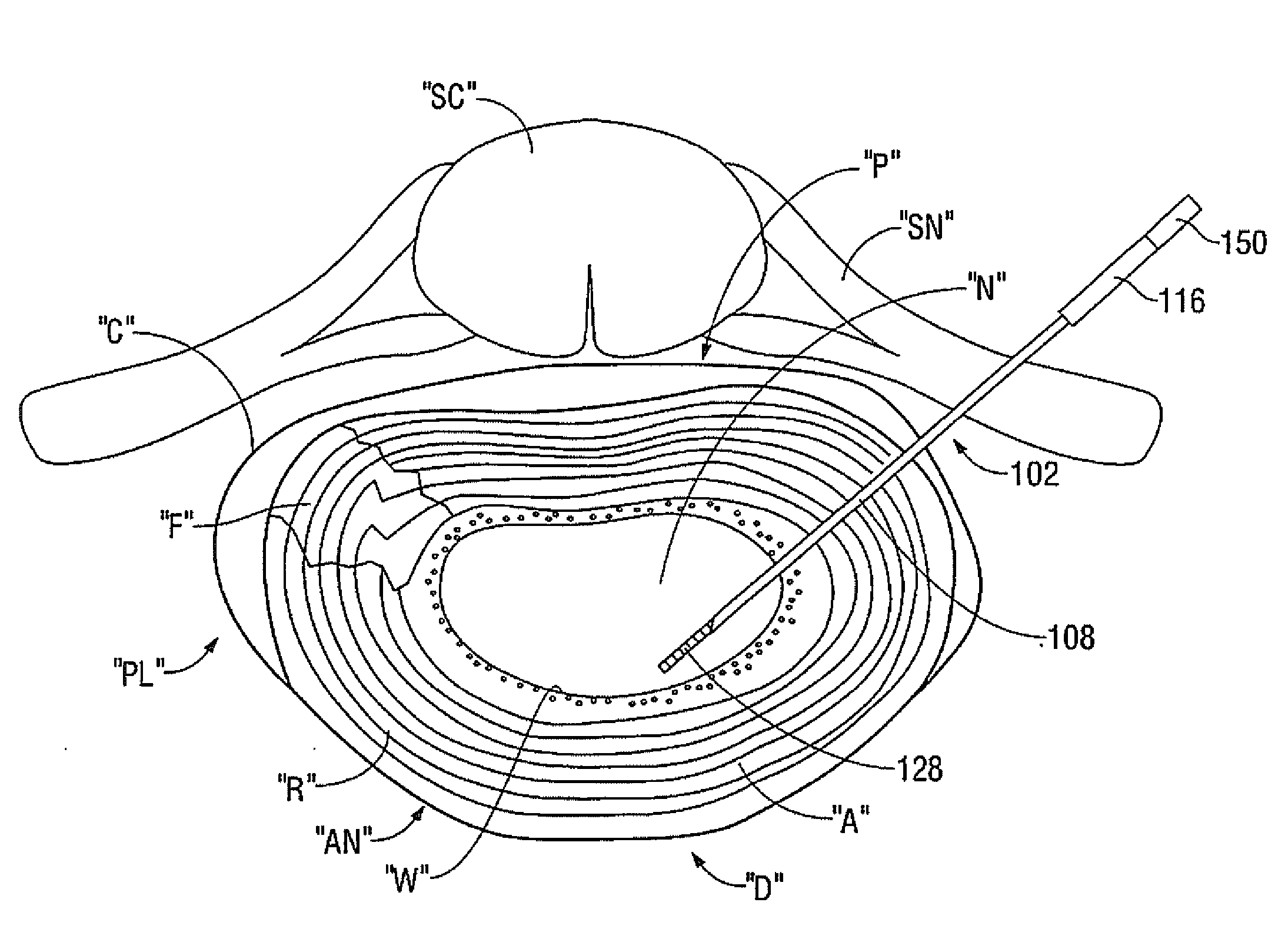

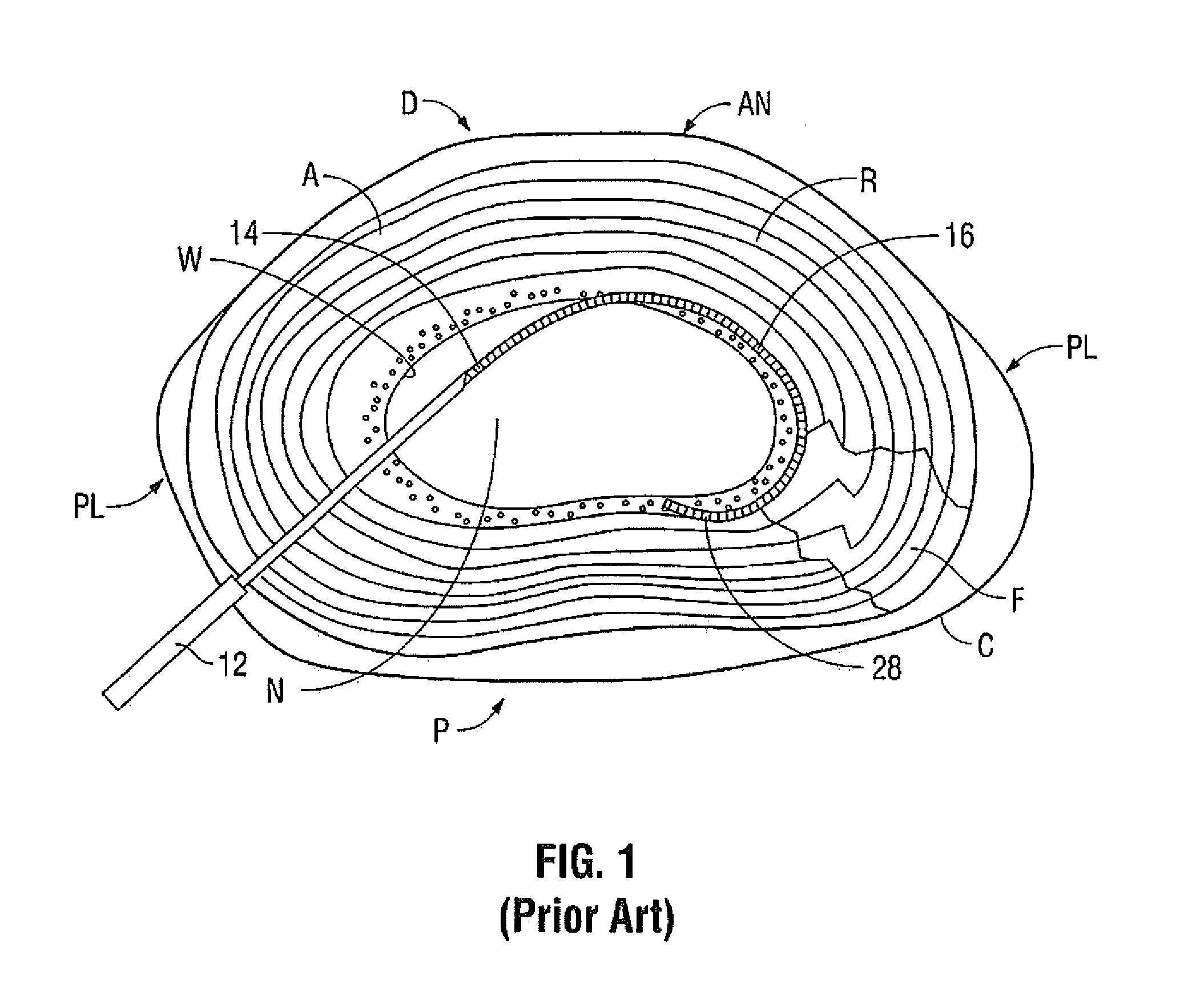

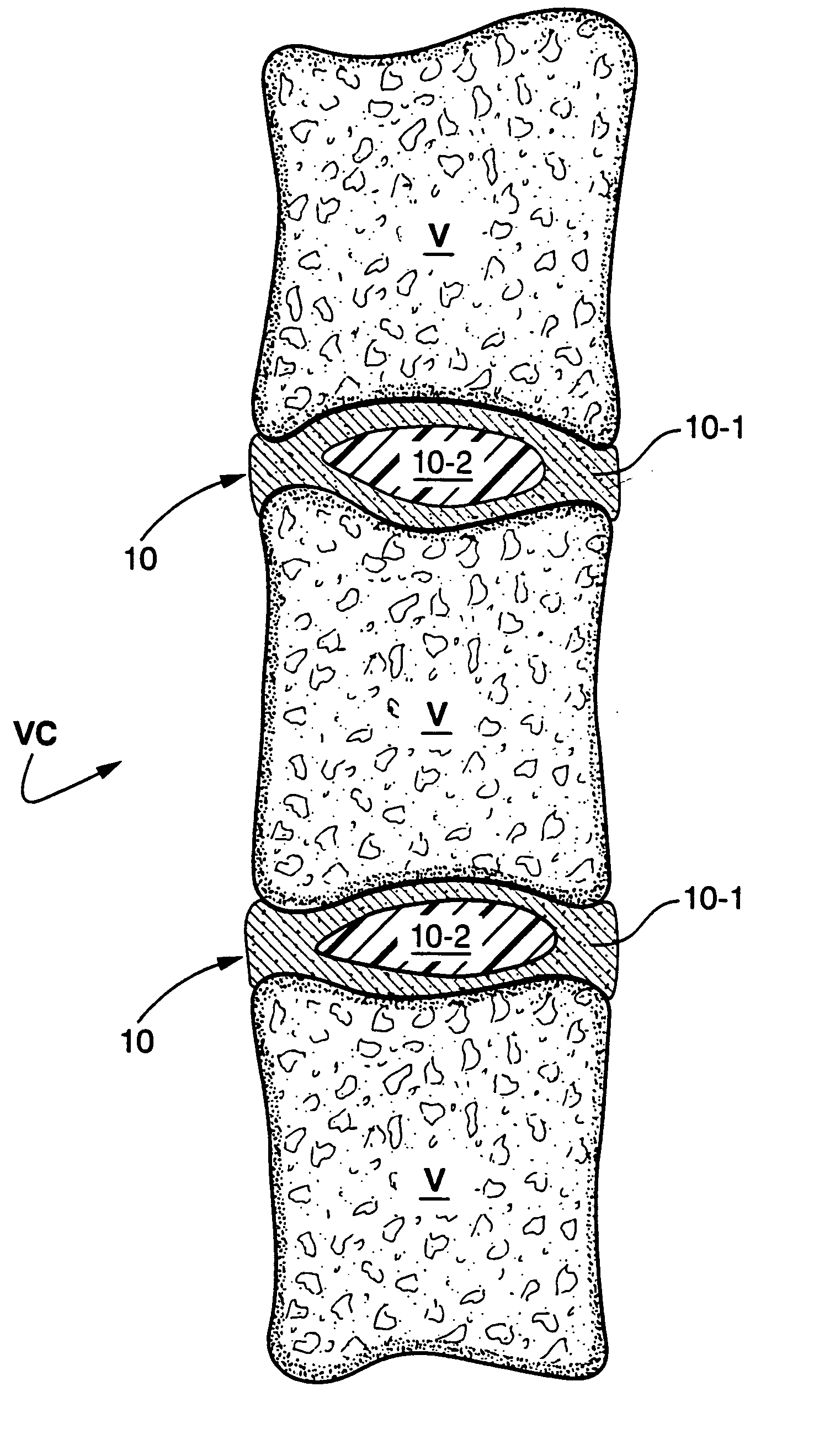

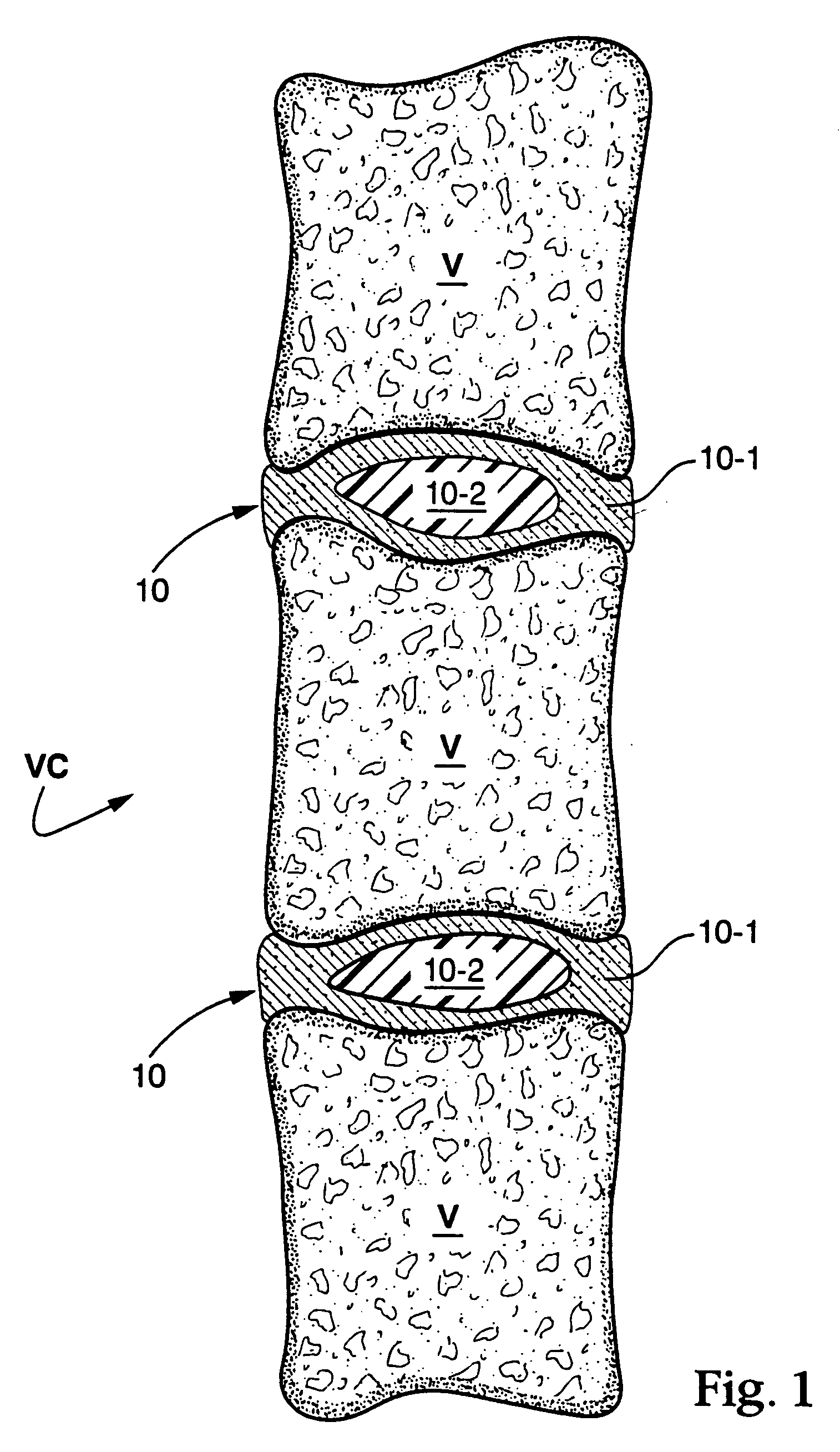

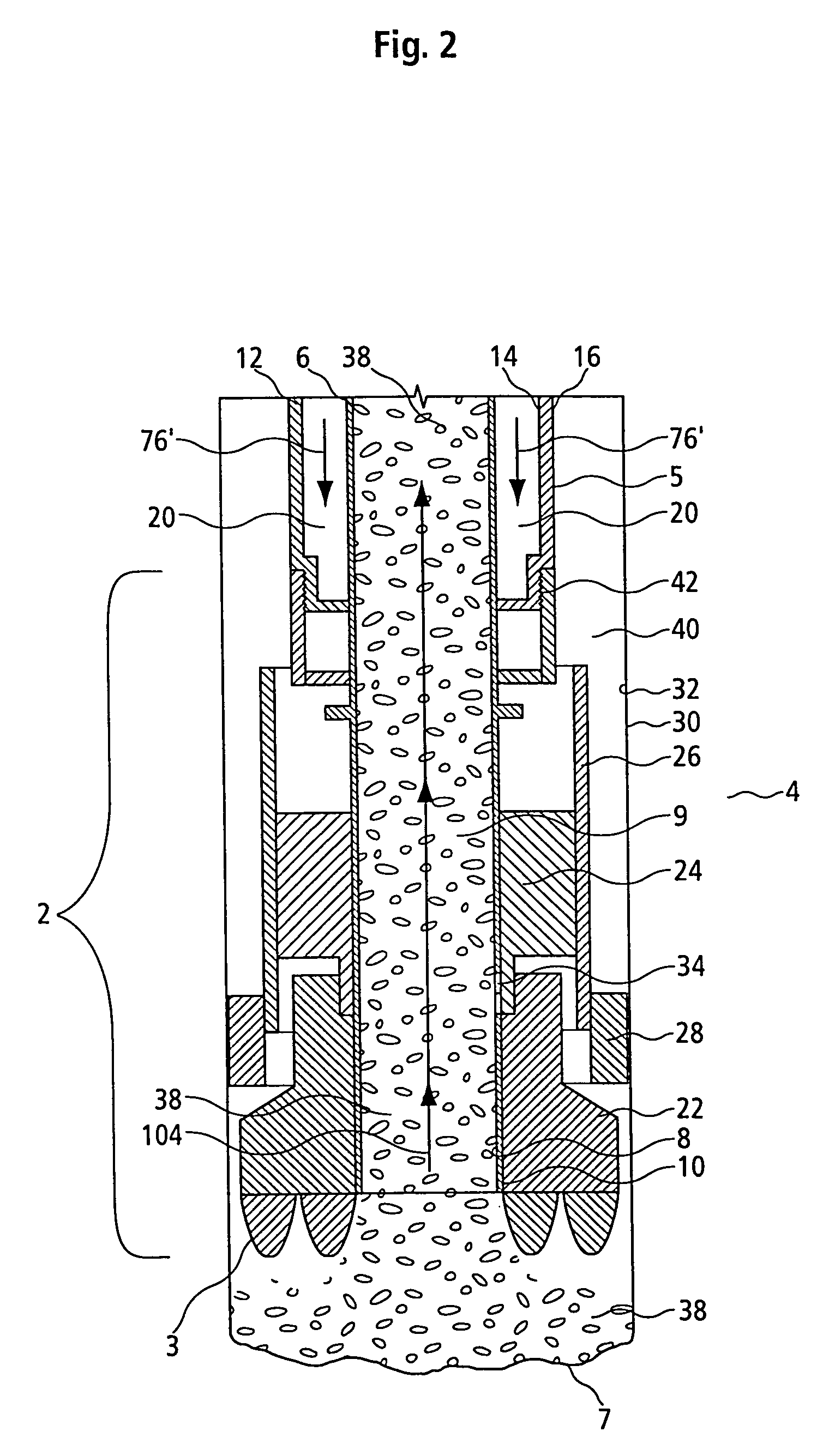

Methods for injecting a curable biomaterial into an intervertebral space

A method for treating a diseased or damaged spinal disc having an inner nucleus pulposus and an outer annulus is provided comprises the steps of: providing access to the nucleus pulposus through the annulus; removing at least a portion of the nucleus pulposus to create an intradiscal space; determining the integrity of the annulus; and then sealably introducing under pressure a curable biomaterial through the annulus access directly into the intradiscal space. The step of determining the integrity of the annulus may be accomplished by introducing into the disc a fluid solution under a first pressure. The curable biomaterial may subsequently be introduced through the annulus directly into said intradiscal space at a second pressure that is increased or decreased from the first pressure as a function of the viscosity of the biomaterial relative to the fluid solution. In certain embodiments, a distraction force is applied to the disc space.

Owner:SPINEWAVE

Methods for treating defects and injuries of an intervertebral disc

A method for treating a herniated spinal disc between opposing vertebral bodies having a damaged outer annulus and an inner nucleus pulposus comprises the steps of: providing access to the nucleus pulposus through the annulus; removing at least a portion of the nucleus pulposus to create an intradiscal space; applying a first distraction force on the opposing vertebral bodies from within the intradiscal space; applying a second distraction force on the opposing vertebral bodies externally of the intradiscal space; and introducing a curable biomaterial through the annulus access directly into the intradiscal space. The first distraction force is applied within the disc space to distract the anterior aspect of the intradiscal space, while the second distraction force is applied exterior to the disc to act on the posterior aspect of the vertebral bodies. The first distraction force is applied prior to the application of the second distraction force and then removed. The second distraction force is maintained during the introduction of the biomaterial into the intradiscal space.

Owner:SPINEWAVE

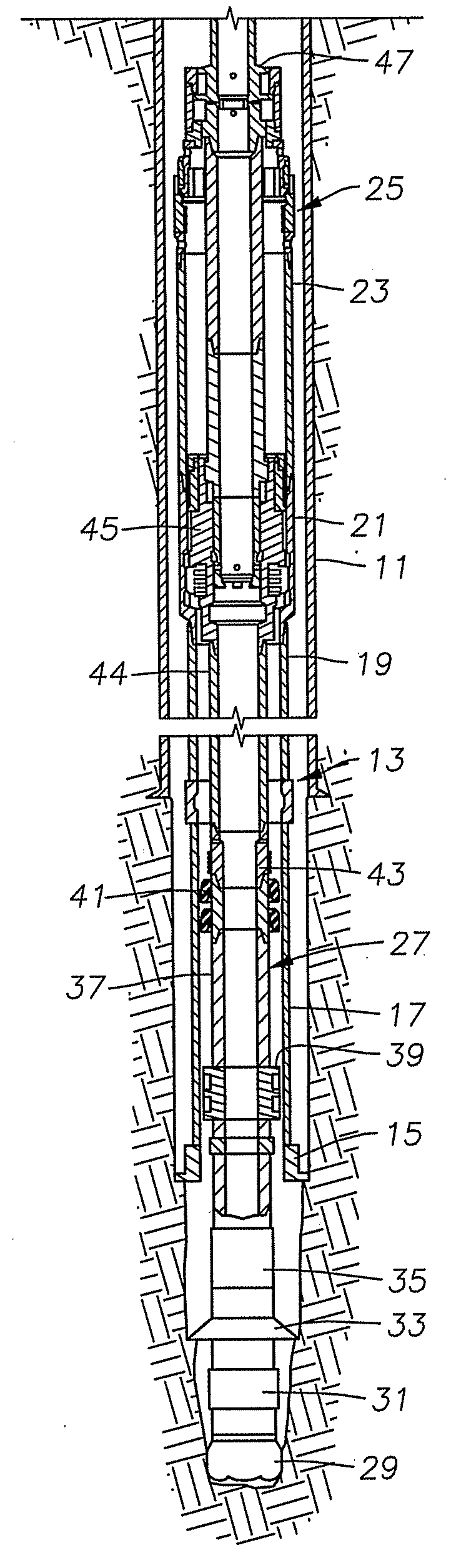

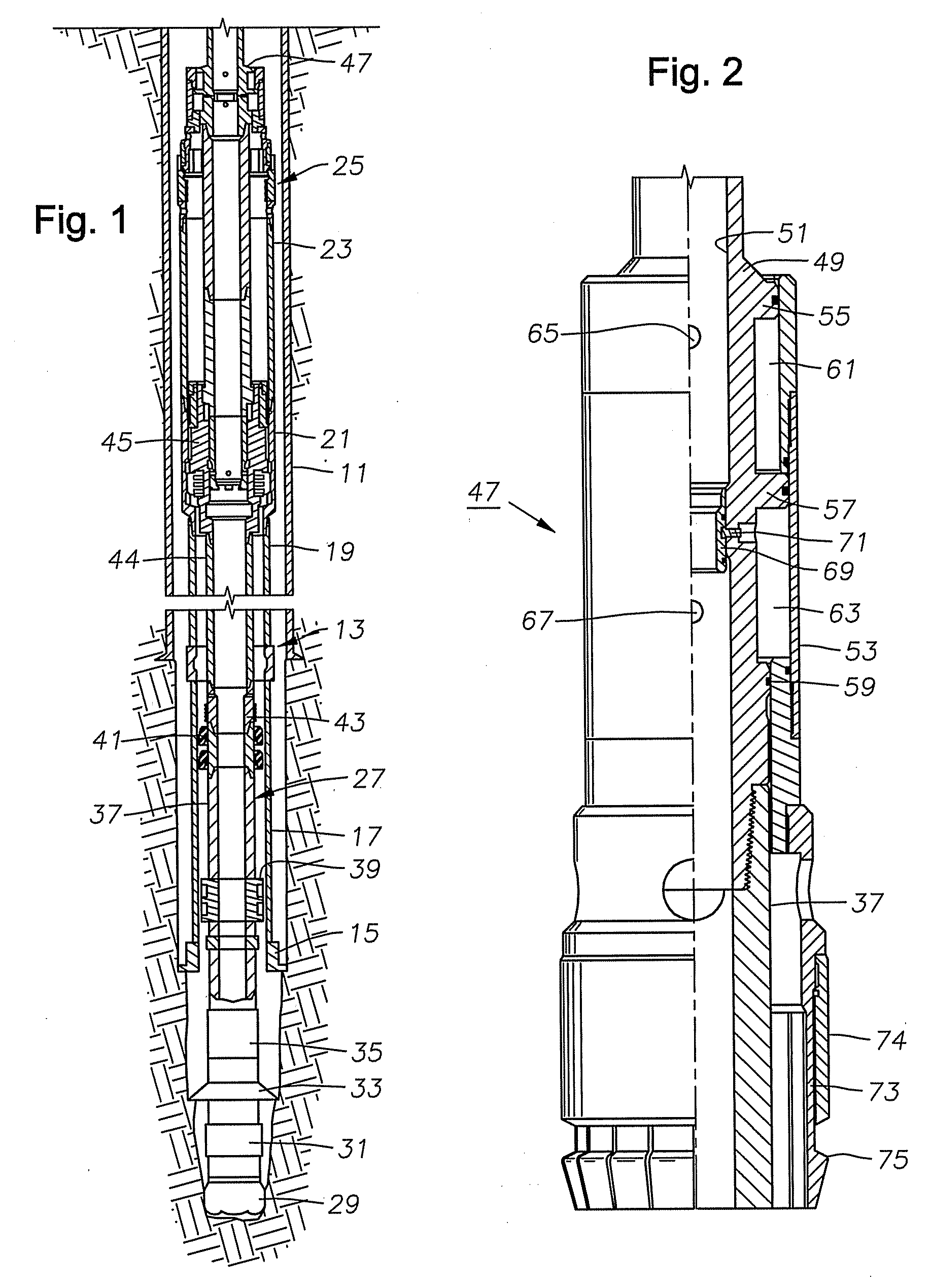

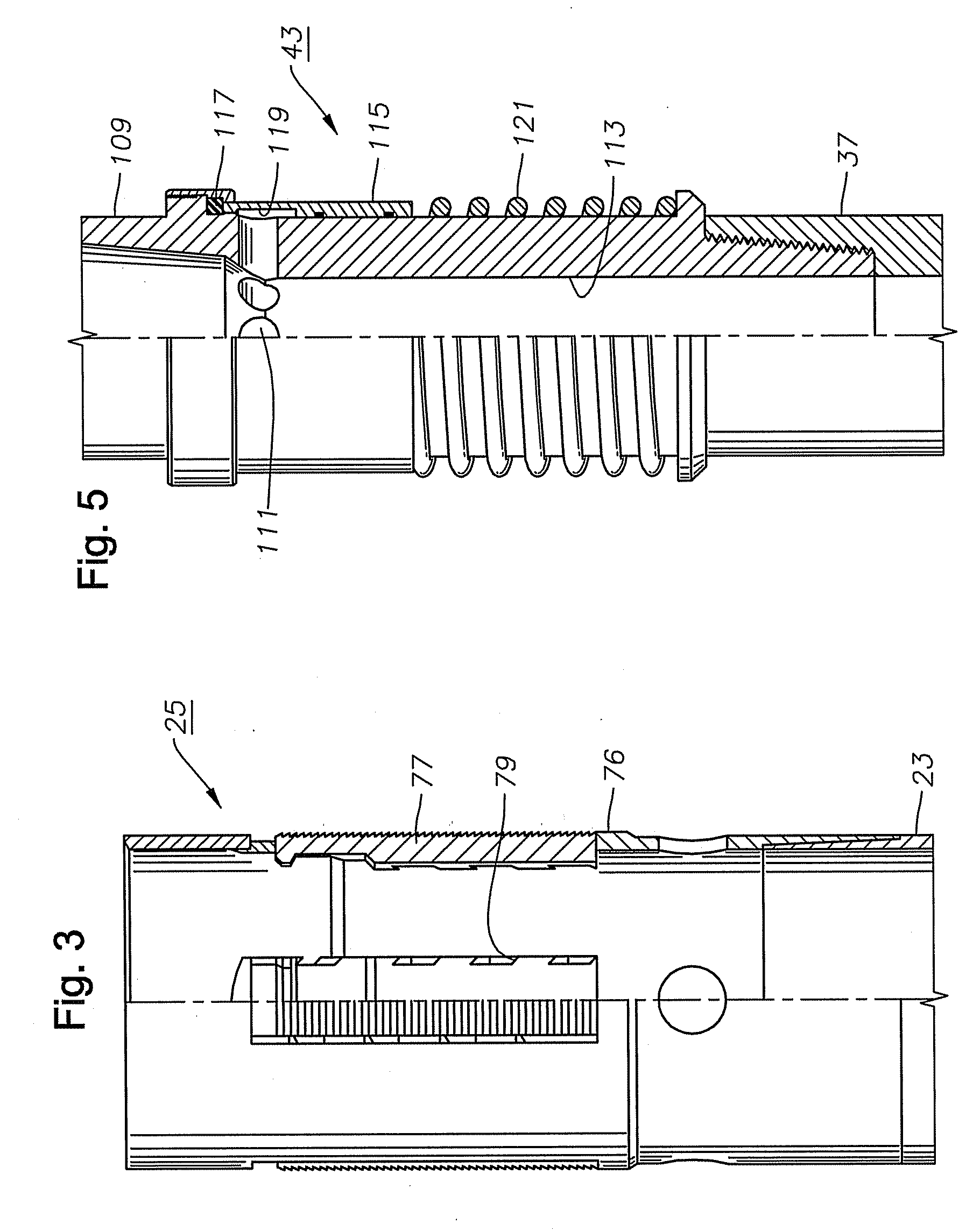

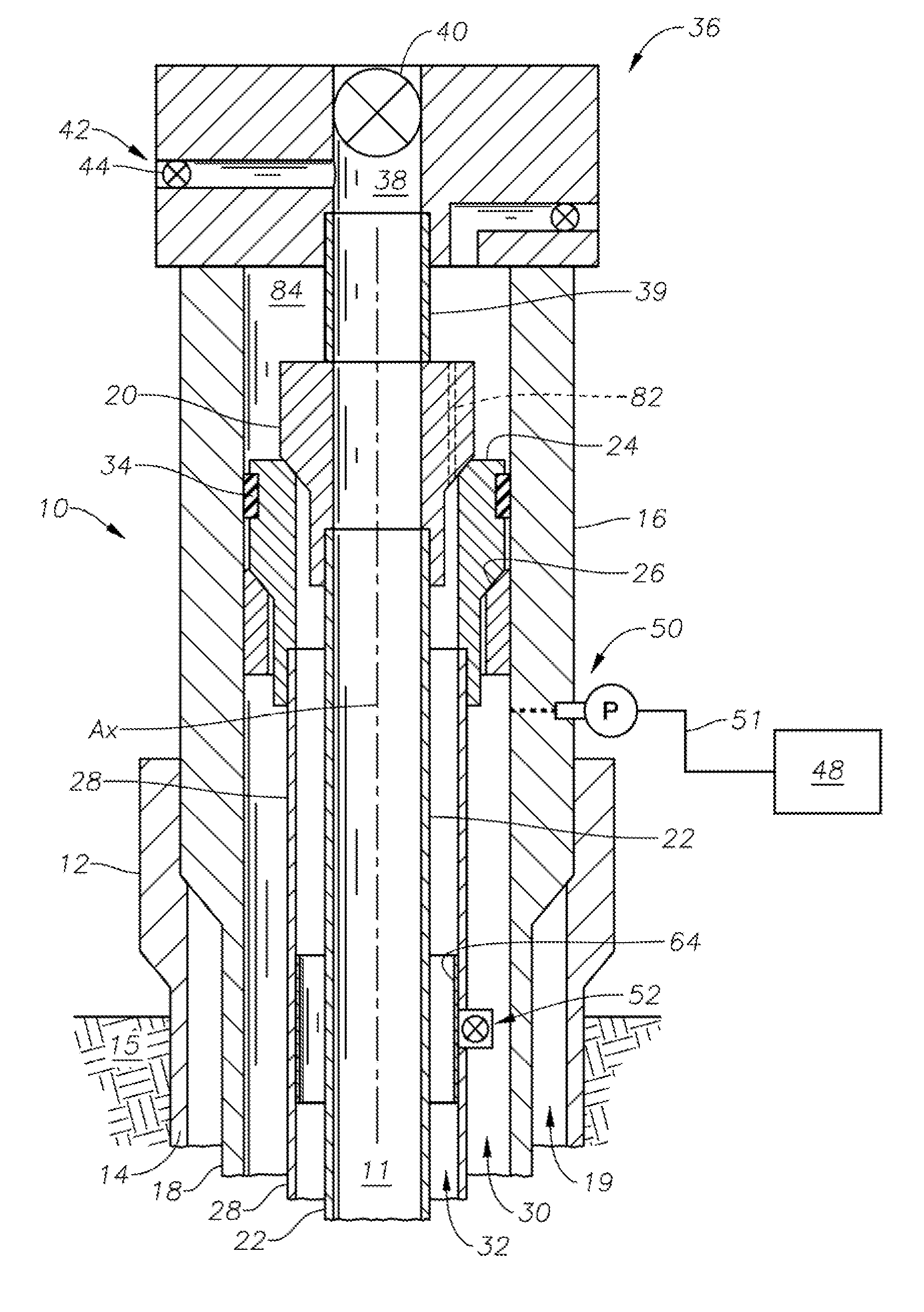

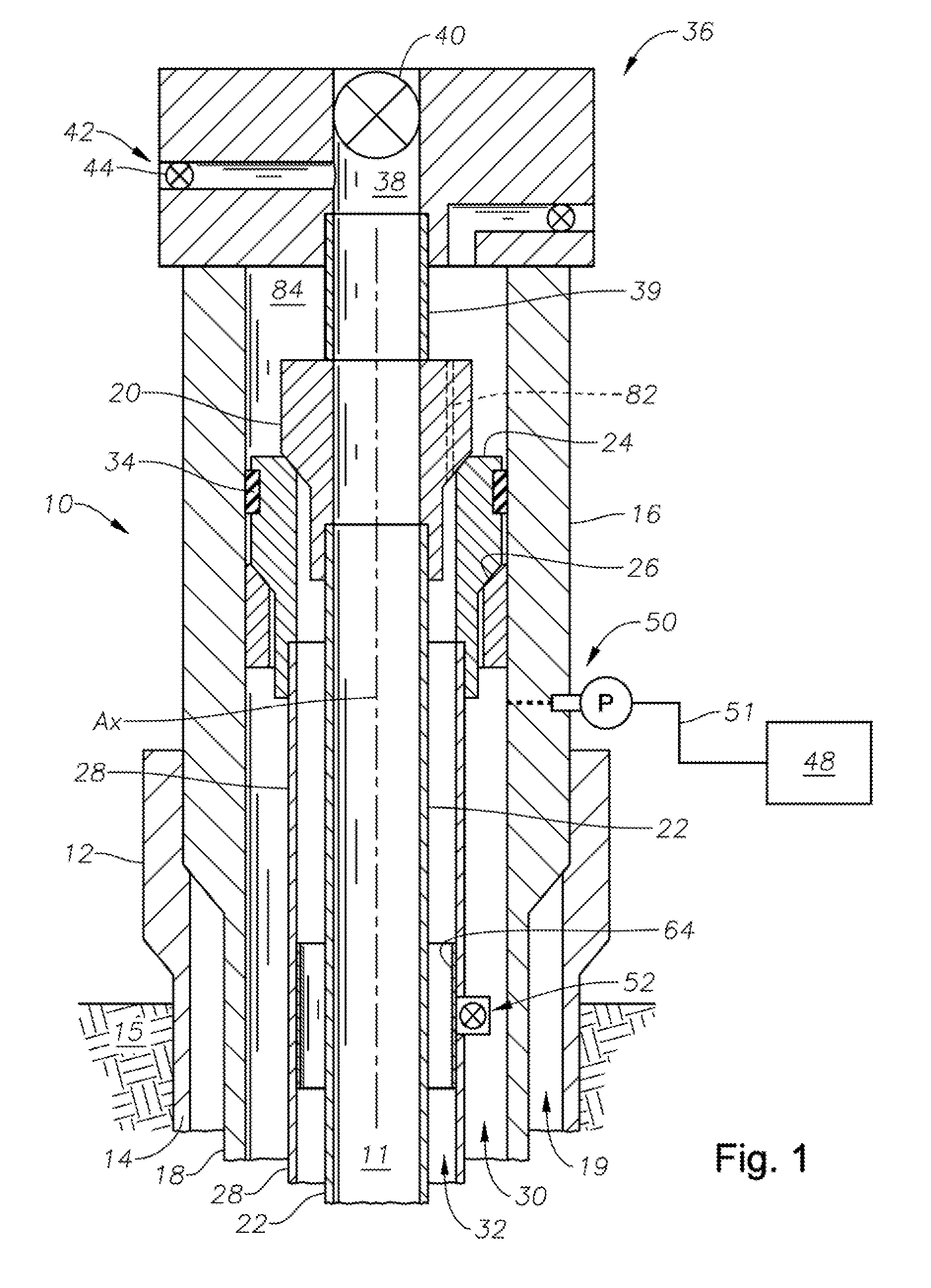

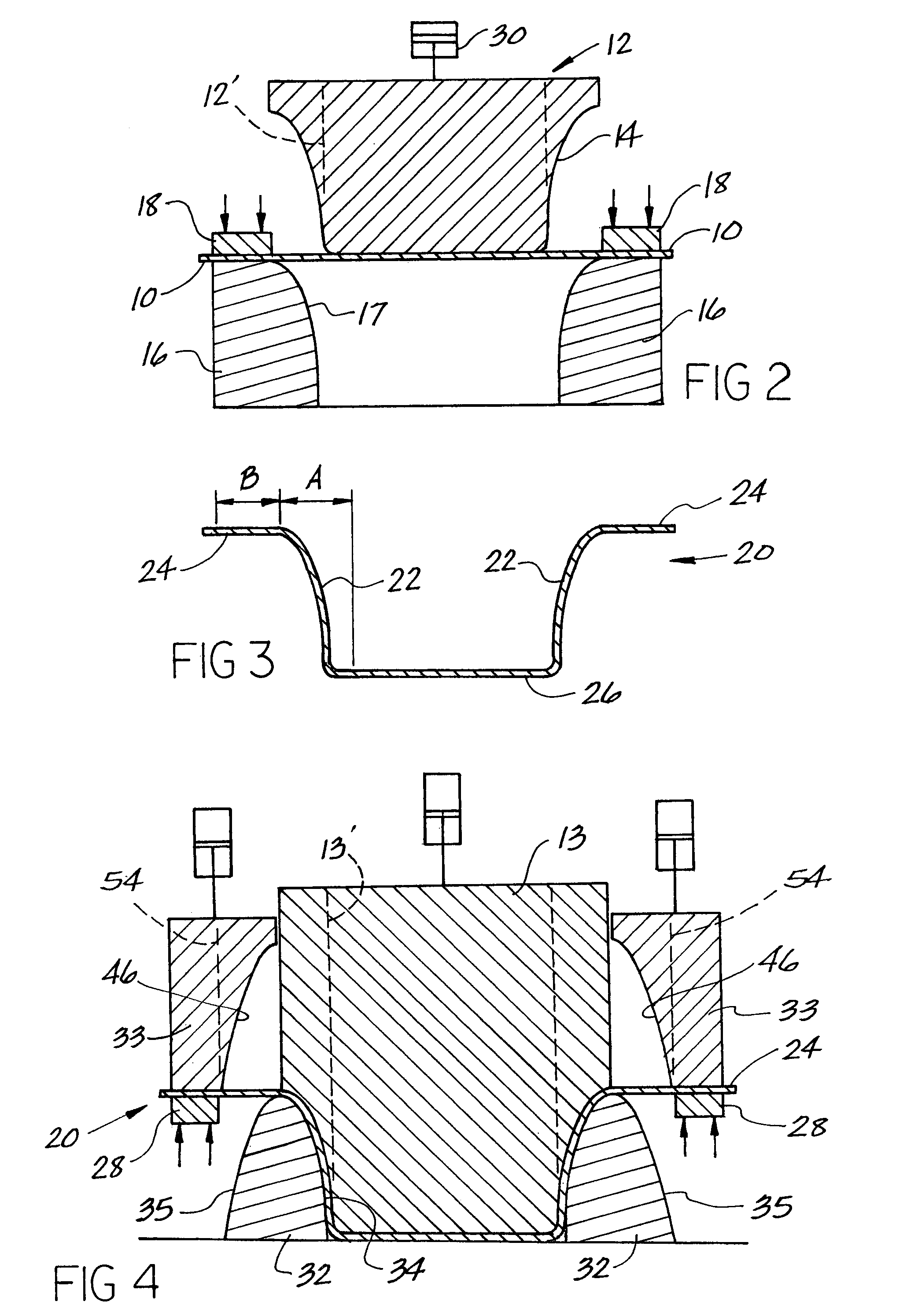

Liner Drilling and Cementing System Utilizing a Concentric Inner String

A method of drilling a well and installing a liner includes assembling concentric inner and outer strings of tubulars. A drill bit is located at the lower end of the inner string and a liner with a liner hanger makes up part of the outer string. The inner and outer strings may be rotated in unison to drill the well. At a selected depth, the operator sets the liner hanger and retrieves the inner string. The operator lowers a packer and a cement retainer on a string of conduit. The packer engages the liner hanger and the cement retainer is conveyed to the lower end of the liner. The cement retainer prevents cement in the outer annulus from flowing back up the string of conduit. The operator manipulates the conduit to set the packer.

Owner:SCHLUMBERGER TECH CORP

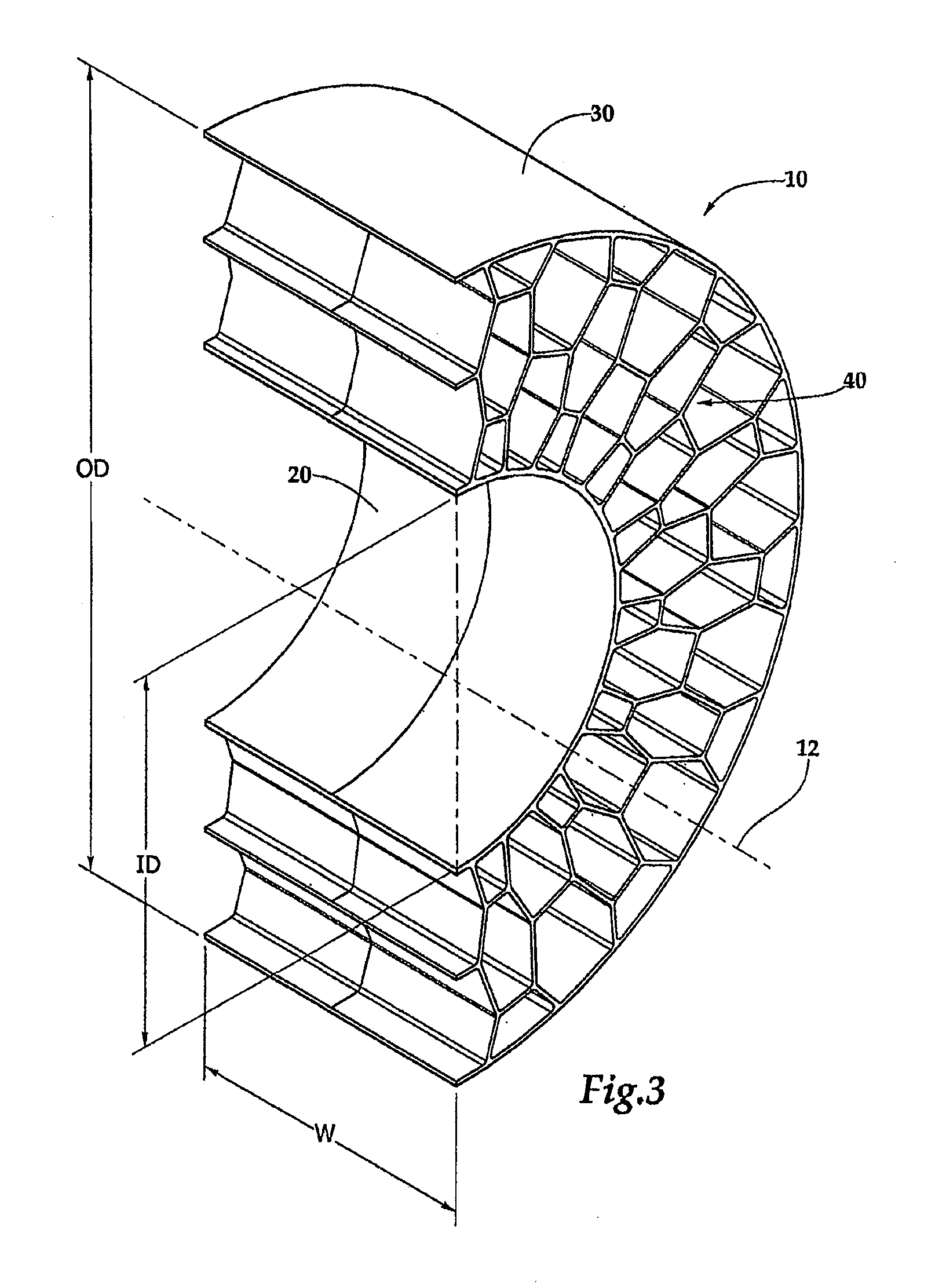

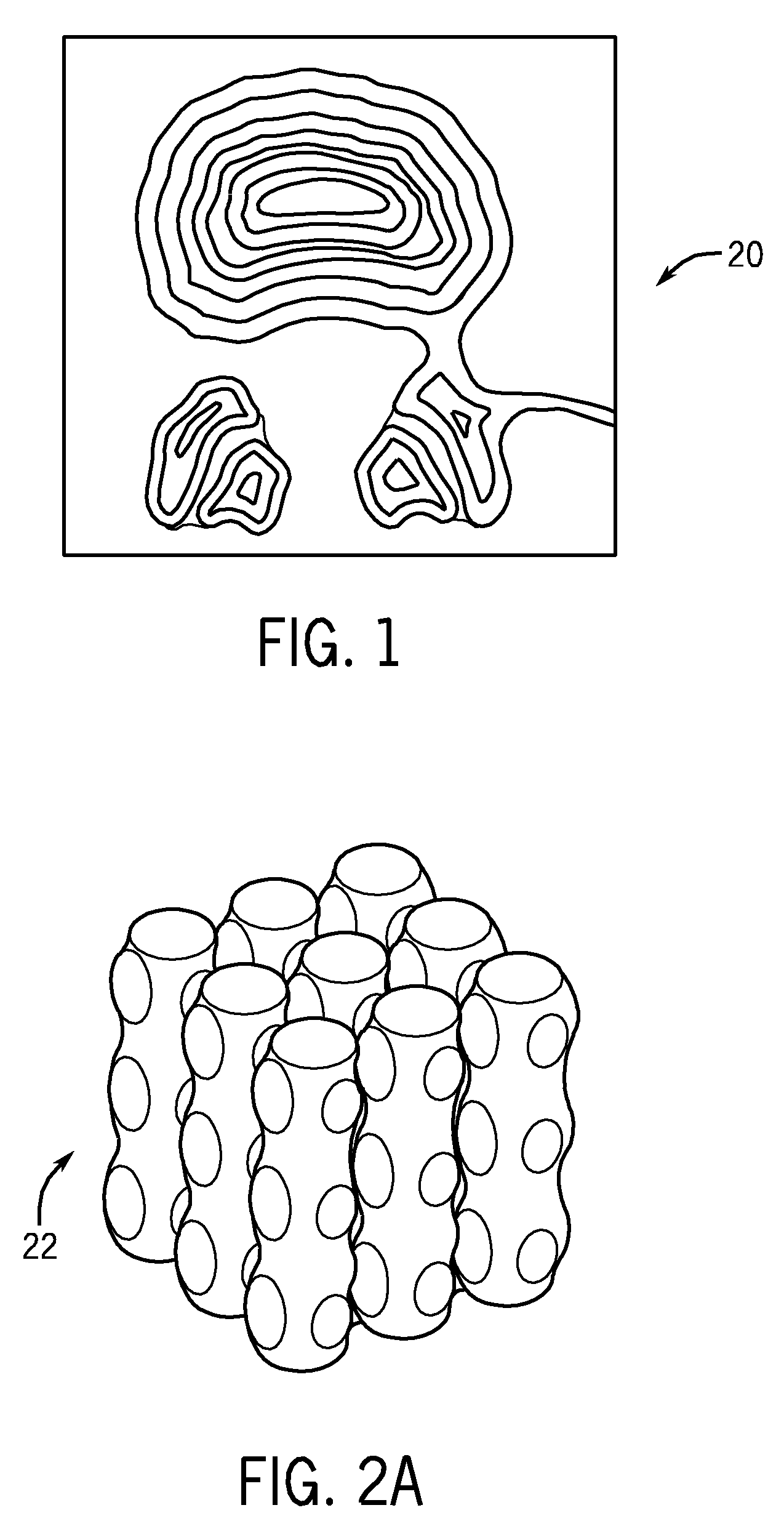

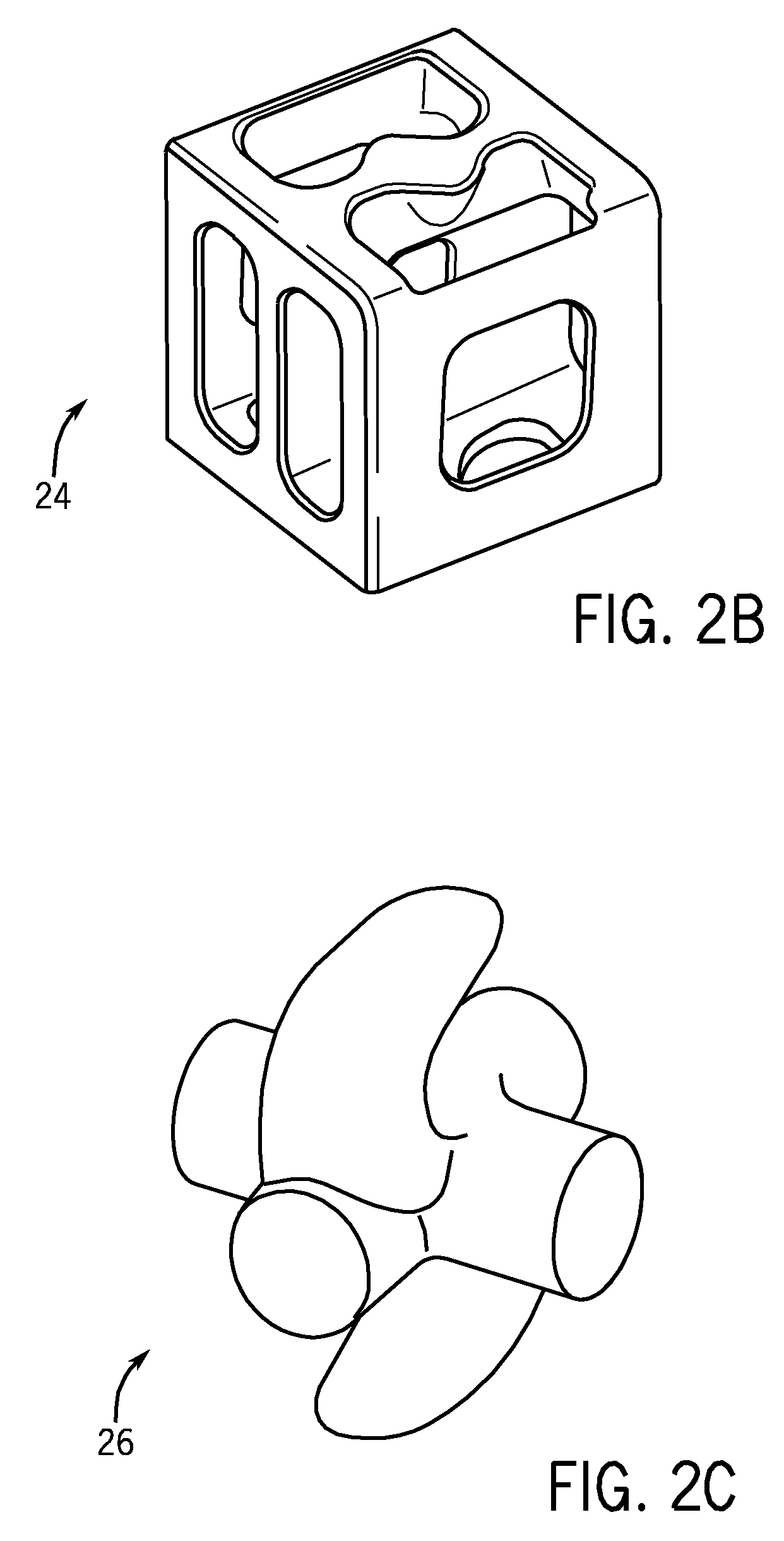

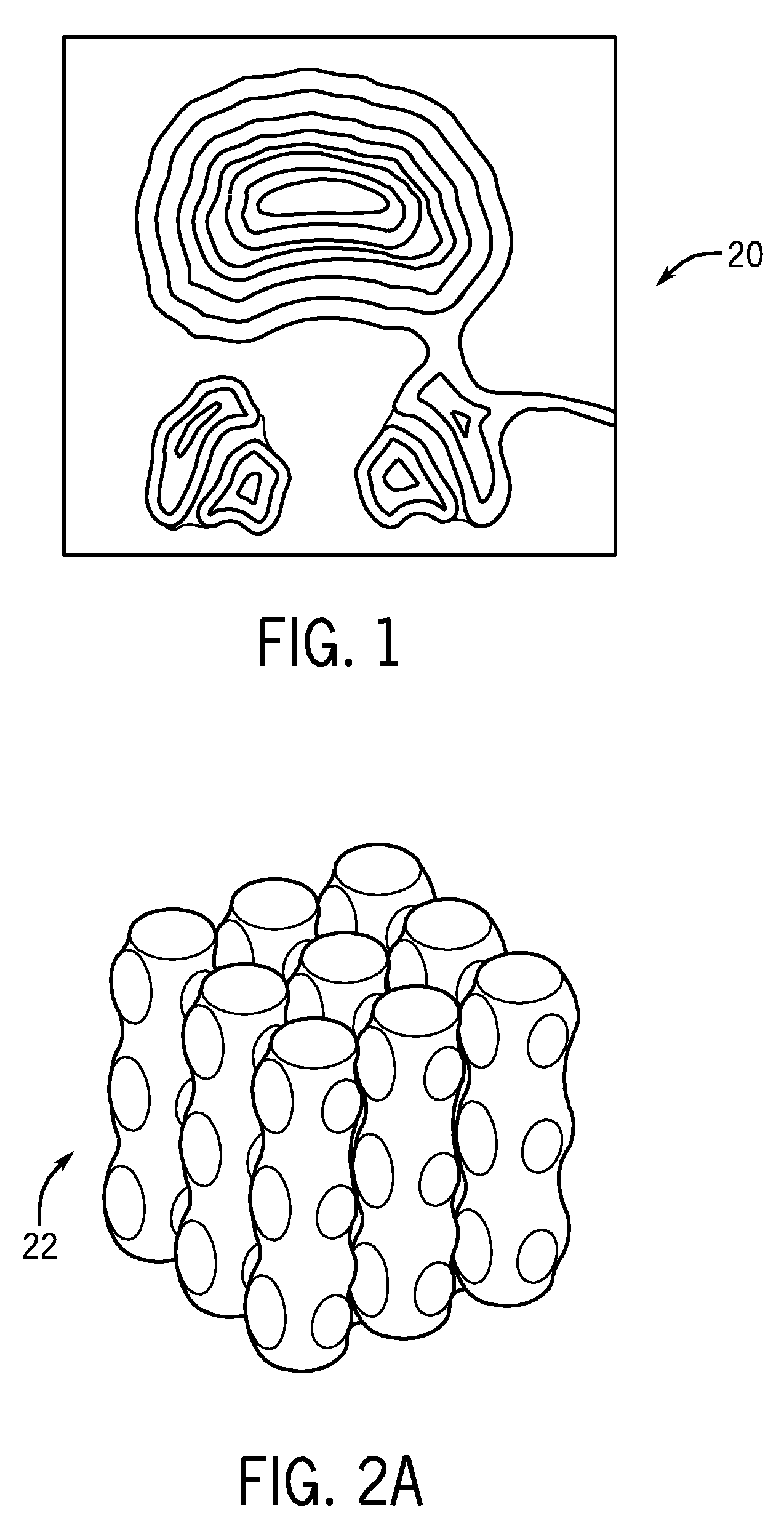

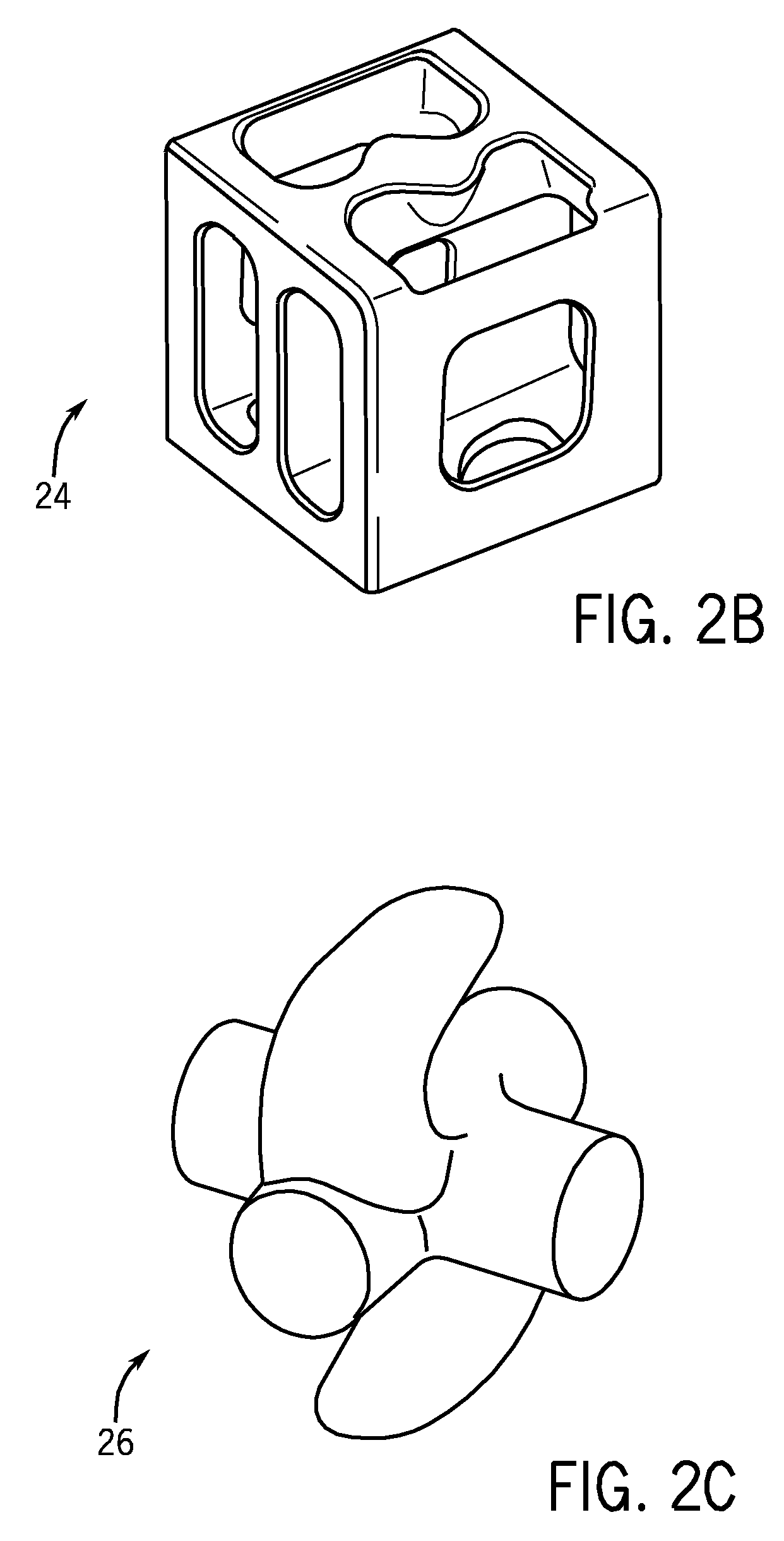

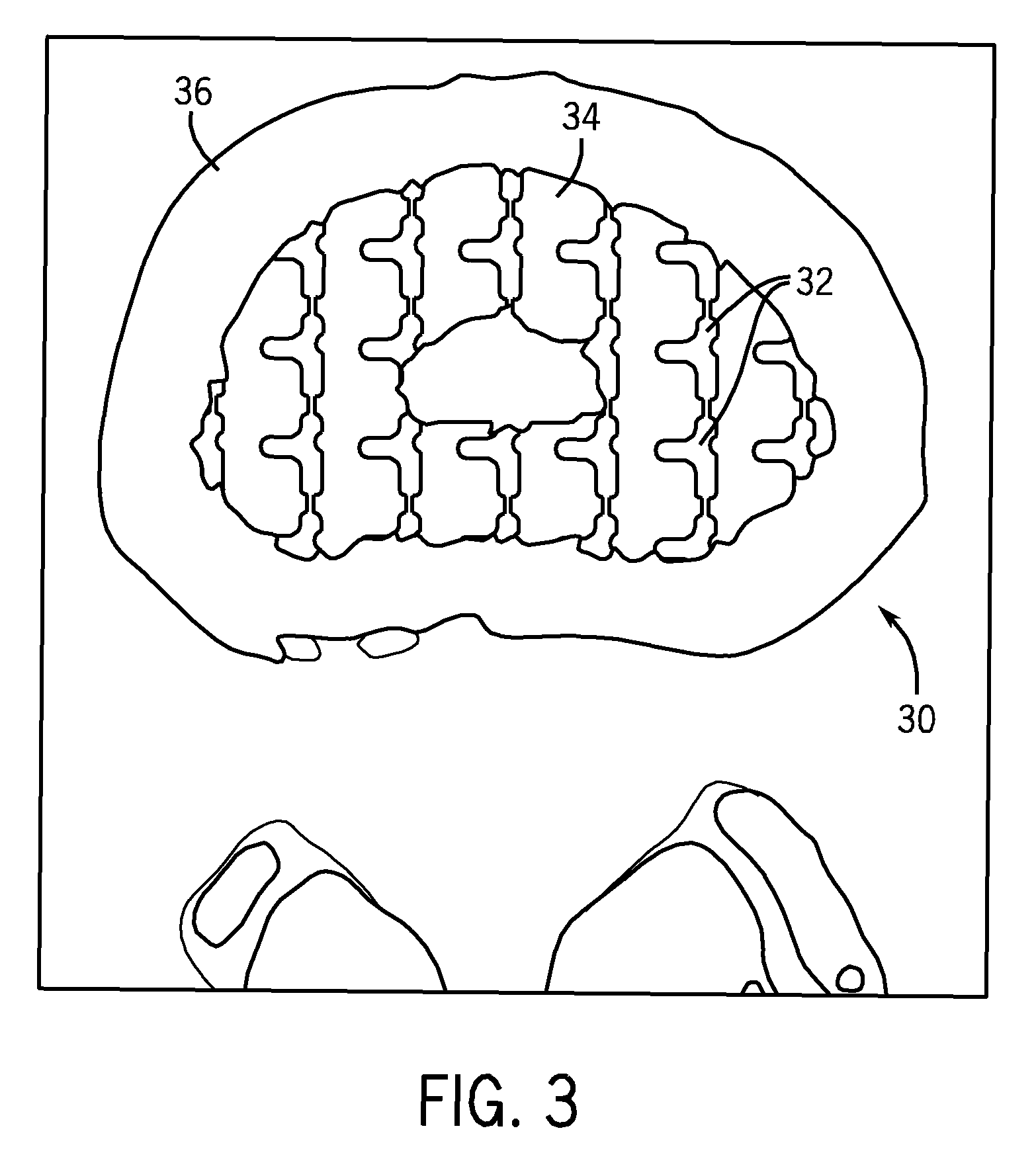

Engineered Scaffolds for Intervertebral Disc Repair and Regeneration and for Articulating Joint Repair and Regeneration

ActiveUS20080195211A1Eliminate needDesired effective mechanicalAdditive manufacturing apparatusBone implantProperty distributionMR - Magnetic resonance

Methods for the engineering and preparation of intervertebral disc repair scaffolds and articulating joint repair scaffolds are disclosed. The methodology utilizes either magnetic resonance images or combined magnetic resonance and computed tomography images as a template for creating either the intervertebral scaffold or the joint repair scaffold (e.g., osteochondral scaffold) with fixation to the underlying bone. The disc scaffold design may include an outer annulus that may contain desired structures and a central nucleus pulposus region that could either contain a designed microstructure or a contained hydrogel. The osteochondral scaffold may include a bone compartment interface with a cartilage compartment. The bone compartment may interface with a cutout portion of the bone through fixation components. Different microstructure designs may be created for the bone and cartilage compartment to represent desired mechanical and mass transport properties. The scaffolds are designed with a microstructure that controls elastic and permeability property distribution within the scaffold.

Owner:RGT UNIV OF MICHIGAN +1

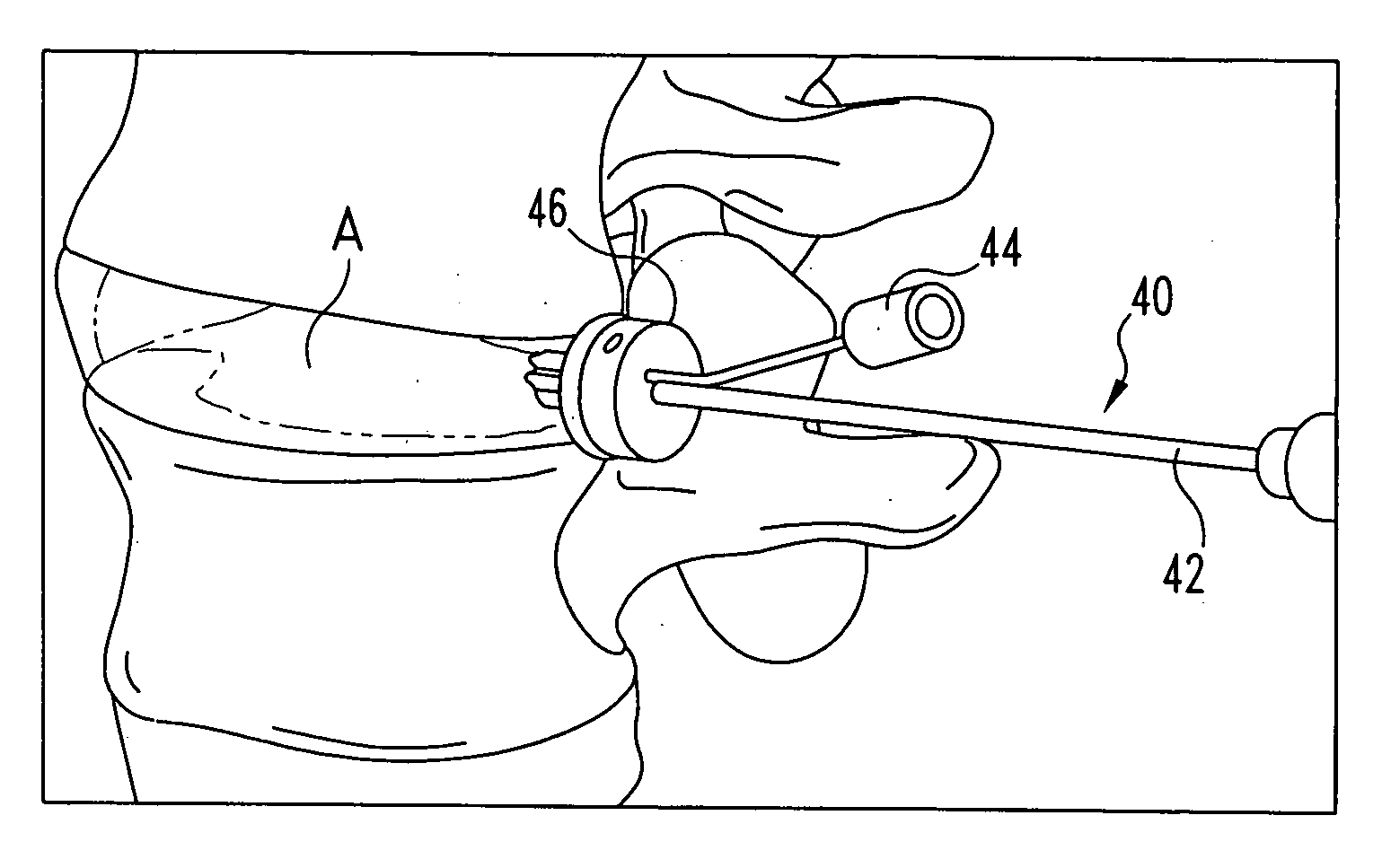

Method for Treatment of an Intervertebral Disc

InactiveUS20100145424A1Relief the painHelp positioningElectrotherapyBone implantElectromagnetic fieldIntervertebral disk

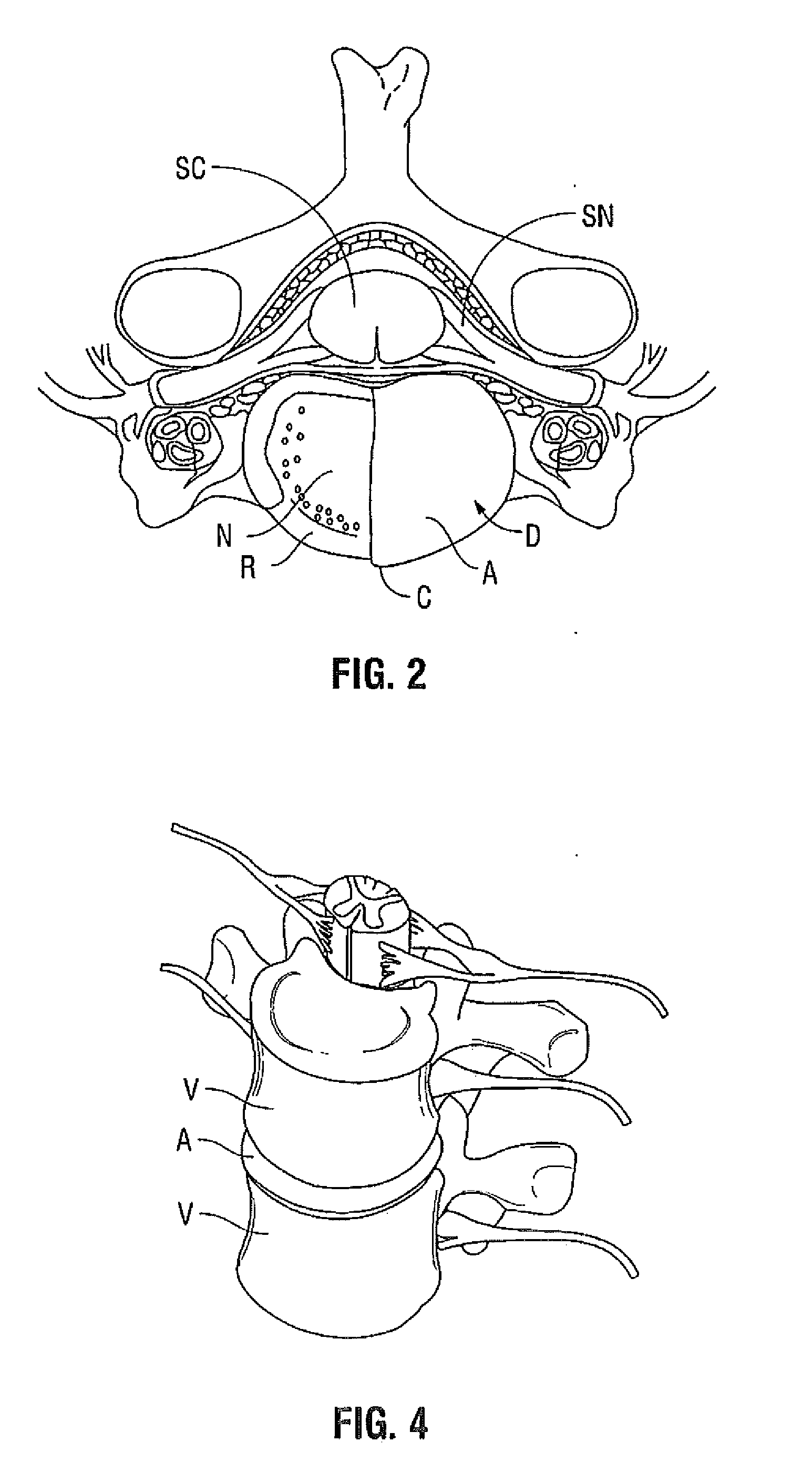

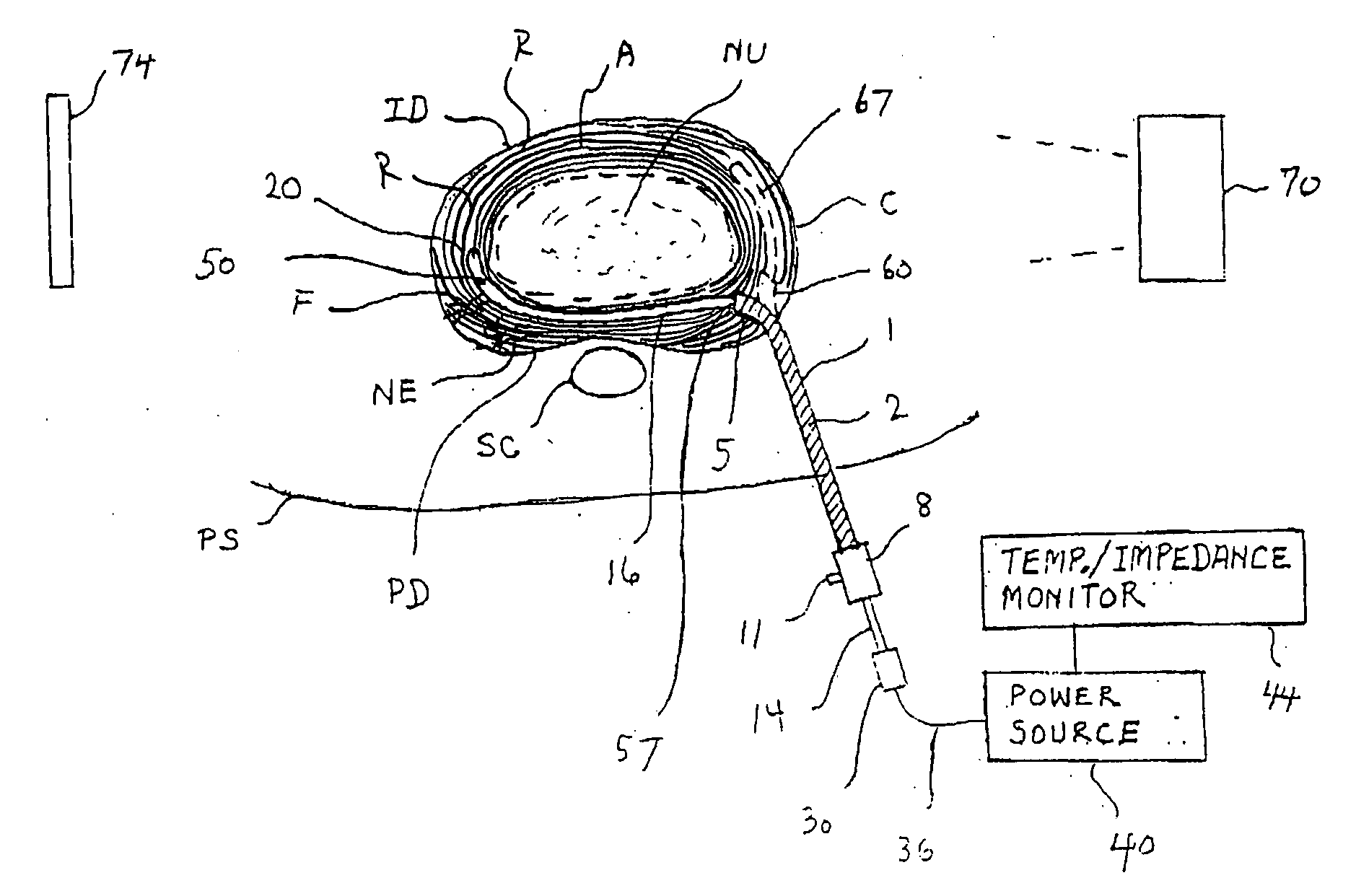

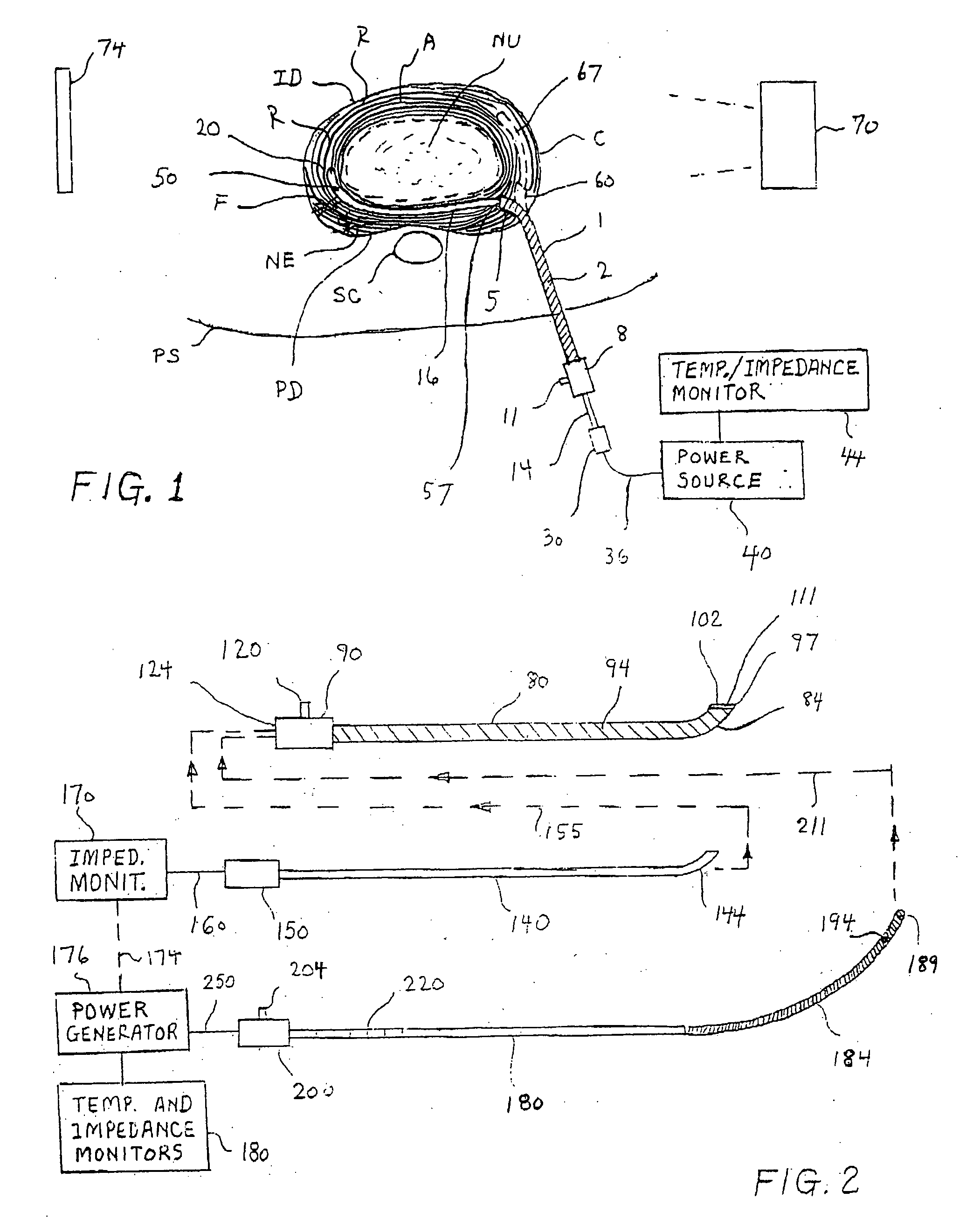

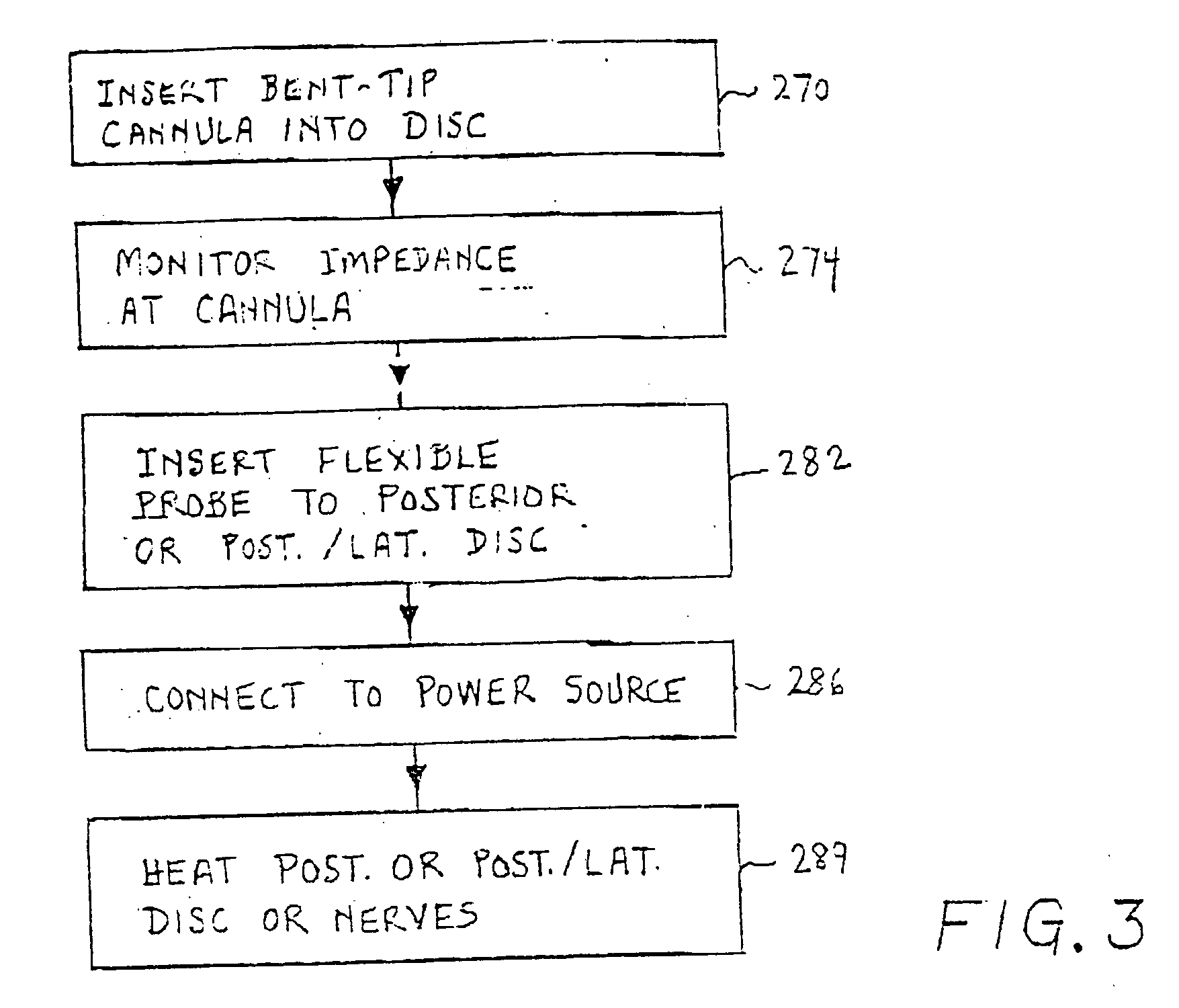

The present disclosure is directed to methods for relieving pain associated with an intervertebral disc having a disc nucleus pulposus and an outer annulus fibrosus surrounding the nucleus pulposus. The method includes the steps of providing an elongated thermal or electromagnetic probe member having a flexible guidable region adjacent the distal end thereof; introducing the flexible guidable region of the probe into the annulus fibrosus of the intervertebral disc or nucleons pulpous; and supplying thermal or electromagnetic energy, from an energy source, to heat or induce an electromagnetic field adjacent to the annulus fibrosus sufficient to produce a thermal or electromagnetic effect on the intervertebral disc. The flexible guidable region of the probe may be introduced at a location which is in relative close proximity to the region of intervertebral disc to be thermally or electromagnetically treated.

Owner:COVIDIEN AG

Apparatus for thermal treatment of an intervertebral disc

InactiveUS20040015218A1Surgical instruments for heatingTherapeutic coolingThermal energyThermal probe

An apparatus and method for treating an intervertebral disc having an inner nucleus pulpous and an outer annulus fibrous includes a thermal probe defining proximal and distal ends and having a guidable region adjacent the distal end thereof. The guidable region is characterized by having sufficient rigidity to advance within the annulus fibrous of the intervertebral disc in response to an axial force exerted on the proximal end of the thermal probe while having sufficient flexibility to substantially follow and conform to an azimuthal course defined by the natural striata of the annulus fibrous. The thermal probe is adapted for connection to a thermal energy source to provide thermal energy to the annulus fibrous to alleviate pain associated with the intervertebral disc.

Owner:JTC TRUSTEES +1

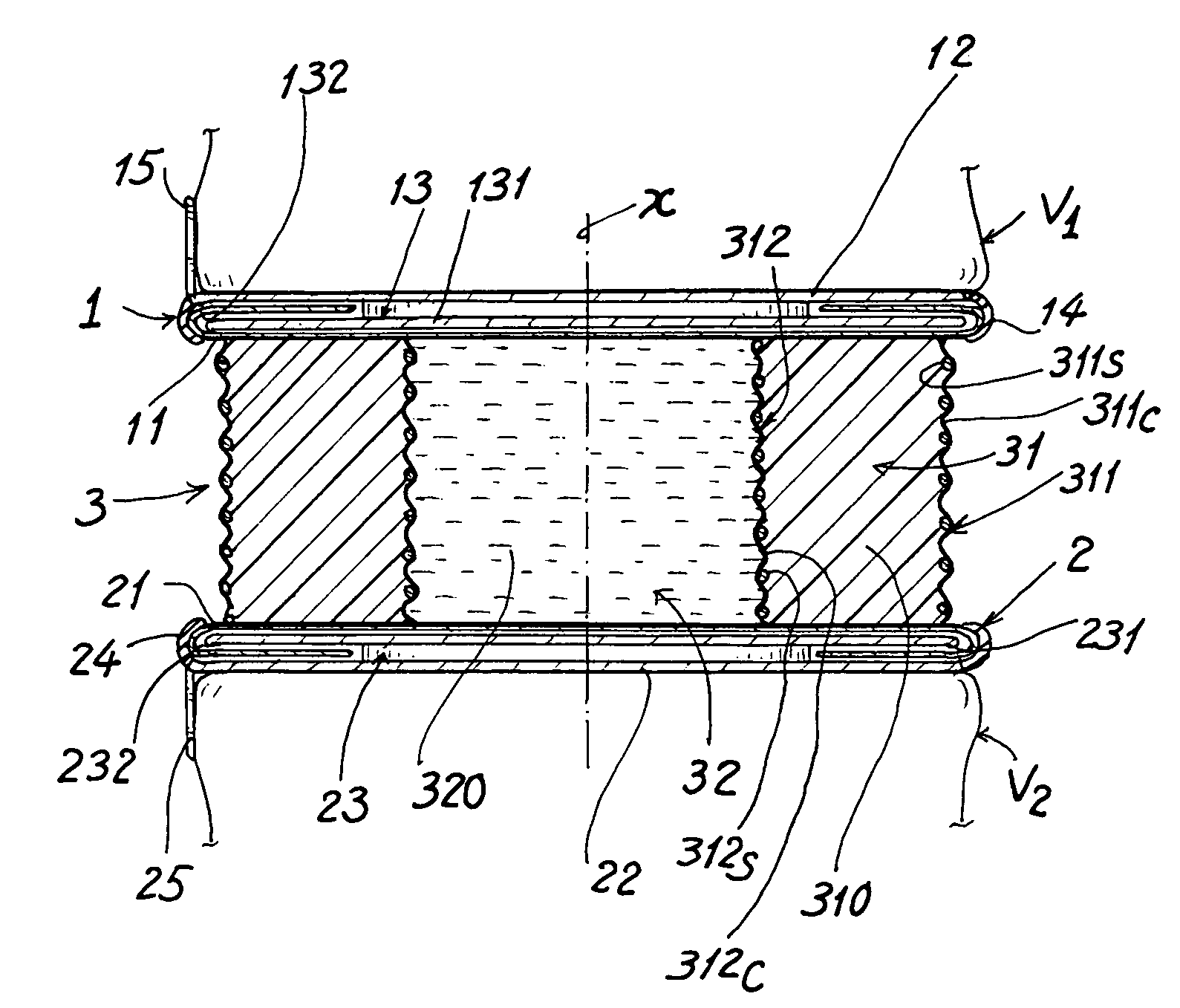

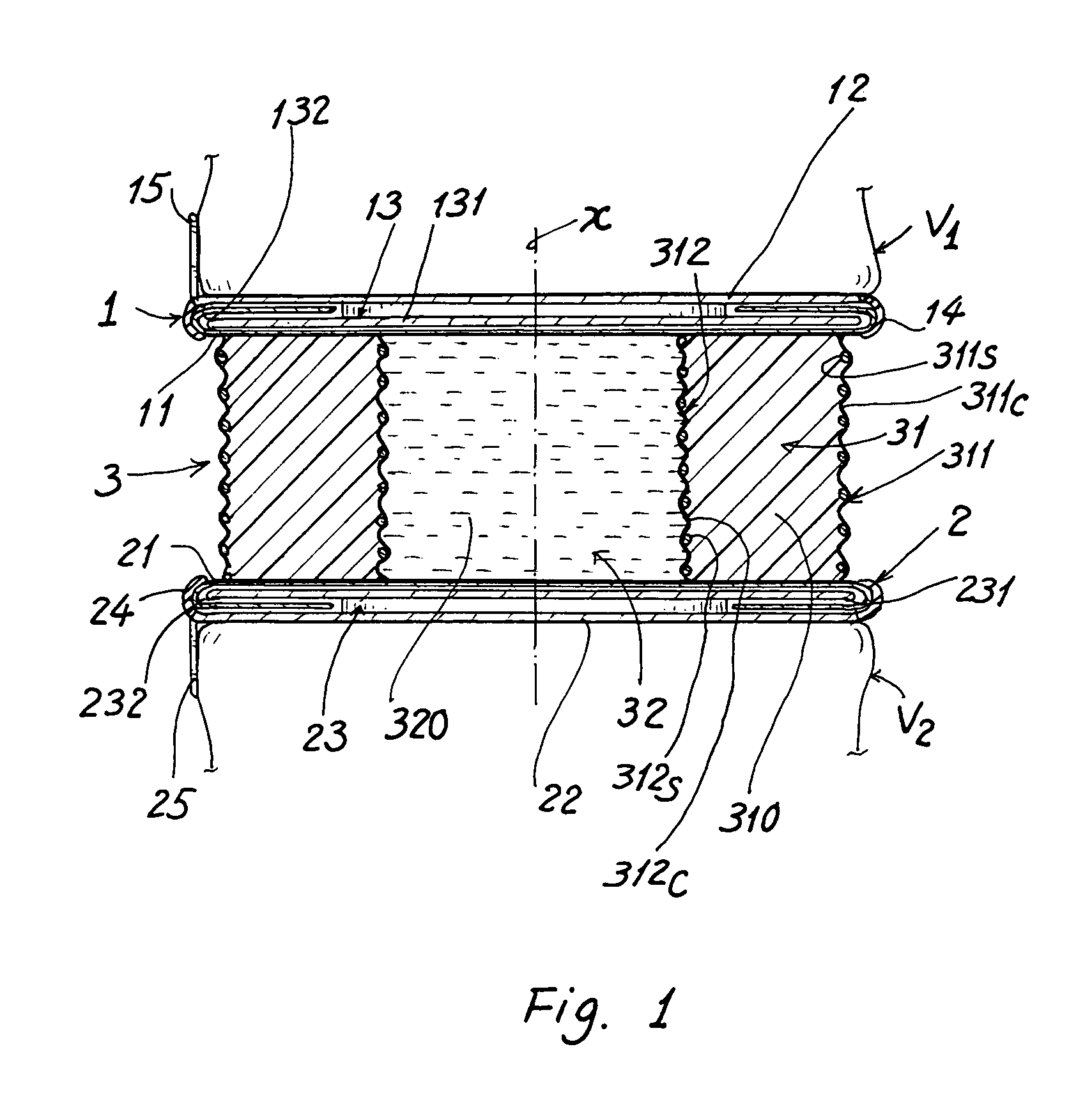

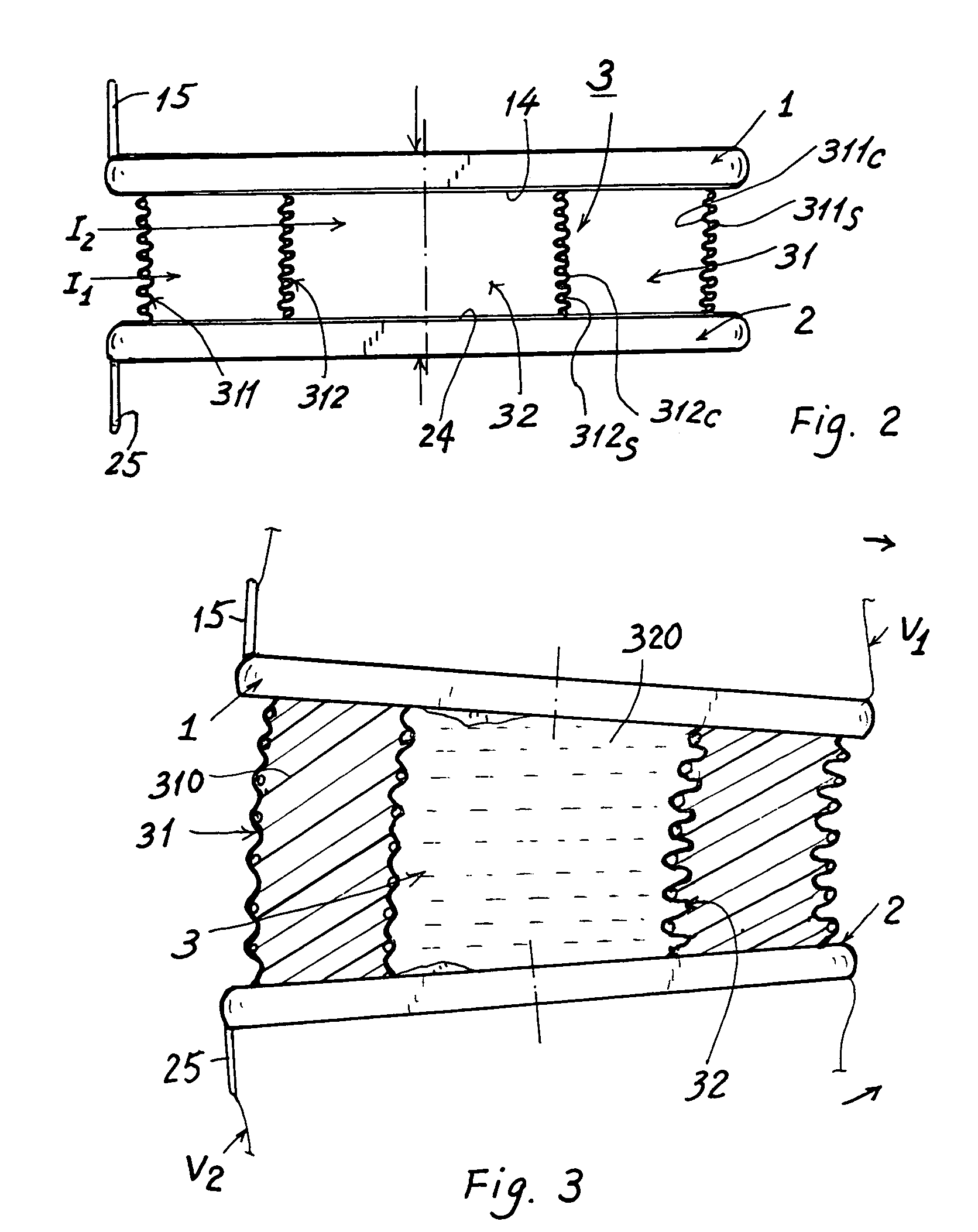

Artificial intervertebral disc flexibly oriented by spring-reinforced bellows

InactiveUS6984246B2Nice flexibilitySupporting strengthJoint implantsSpinal implantsCoil springEngineering

An artificial intervertebral disc includes: an upper retaining member secured to an upper vertebra; a lower retaining member secured to a lower vertebra adjacent to the upper vertebra; and a nucleus member flexibly resiliently formed between the upper and the lower retaining members having at least an outer and an inner bellows each reinforced and integrally formed with a helical spring to define an outer annulus between the outer and inner bellows and a core formed within the inner bellows.

Owner:SHI TAIN YEW

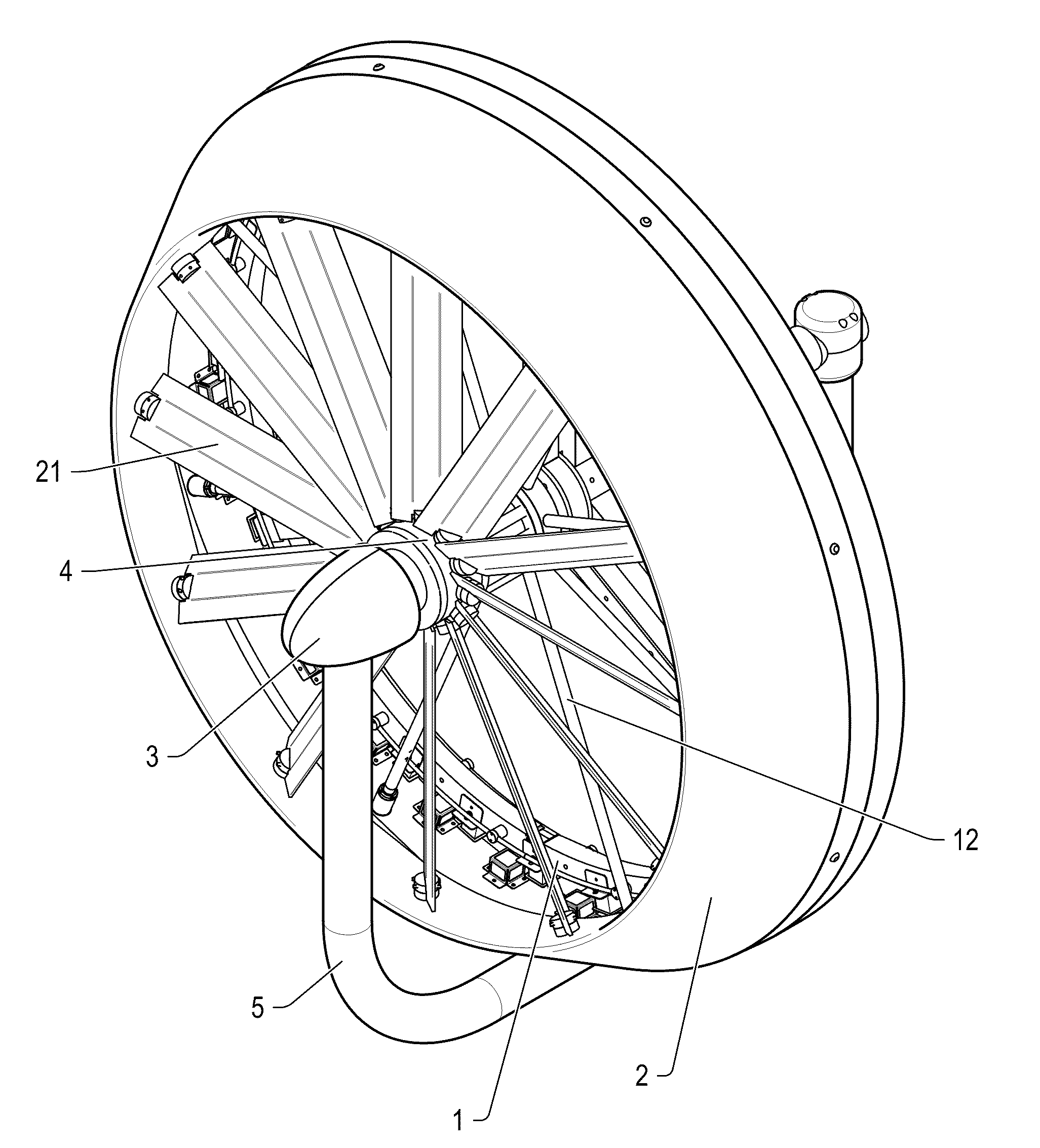

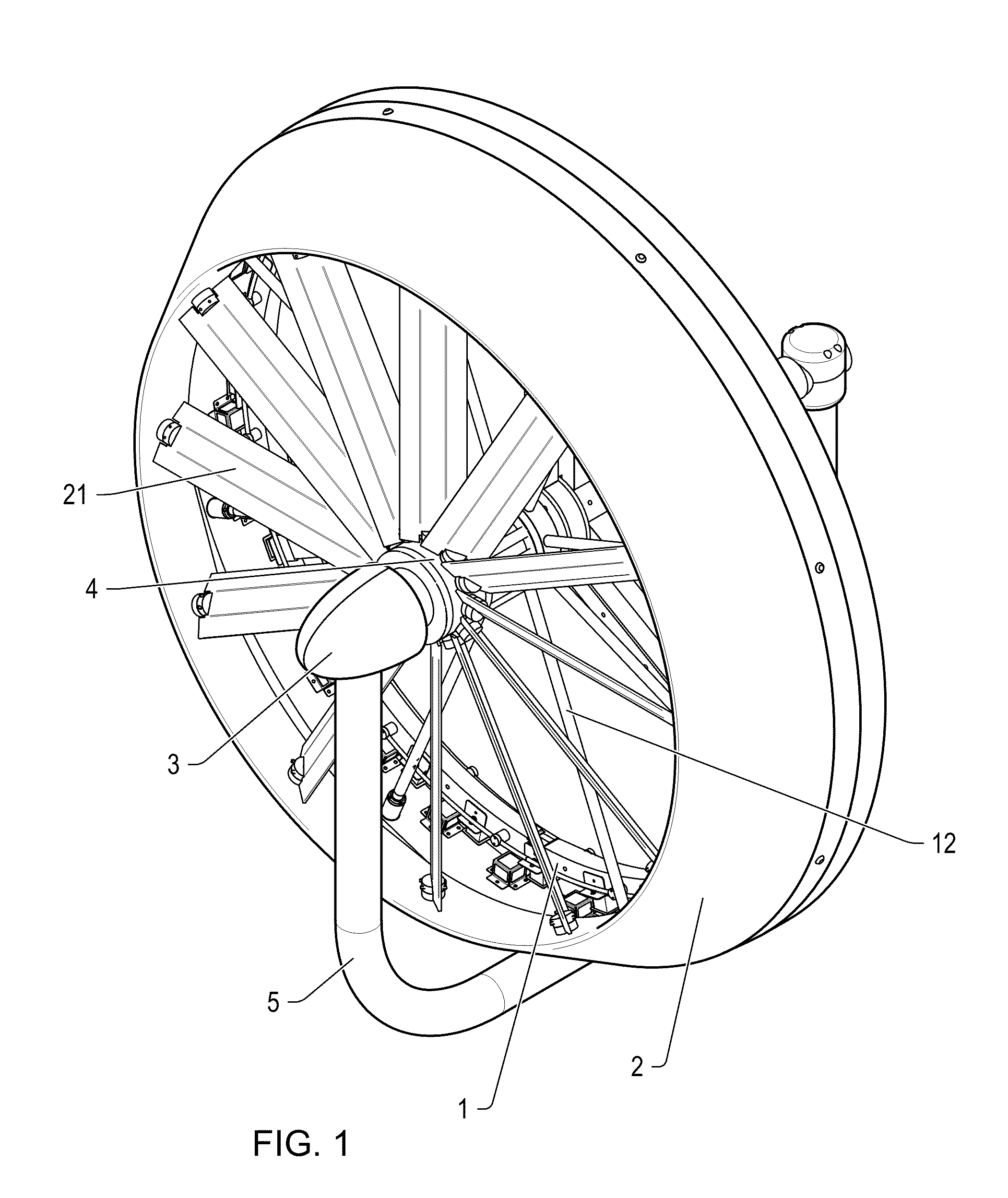

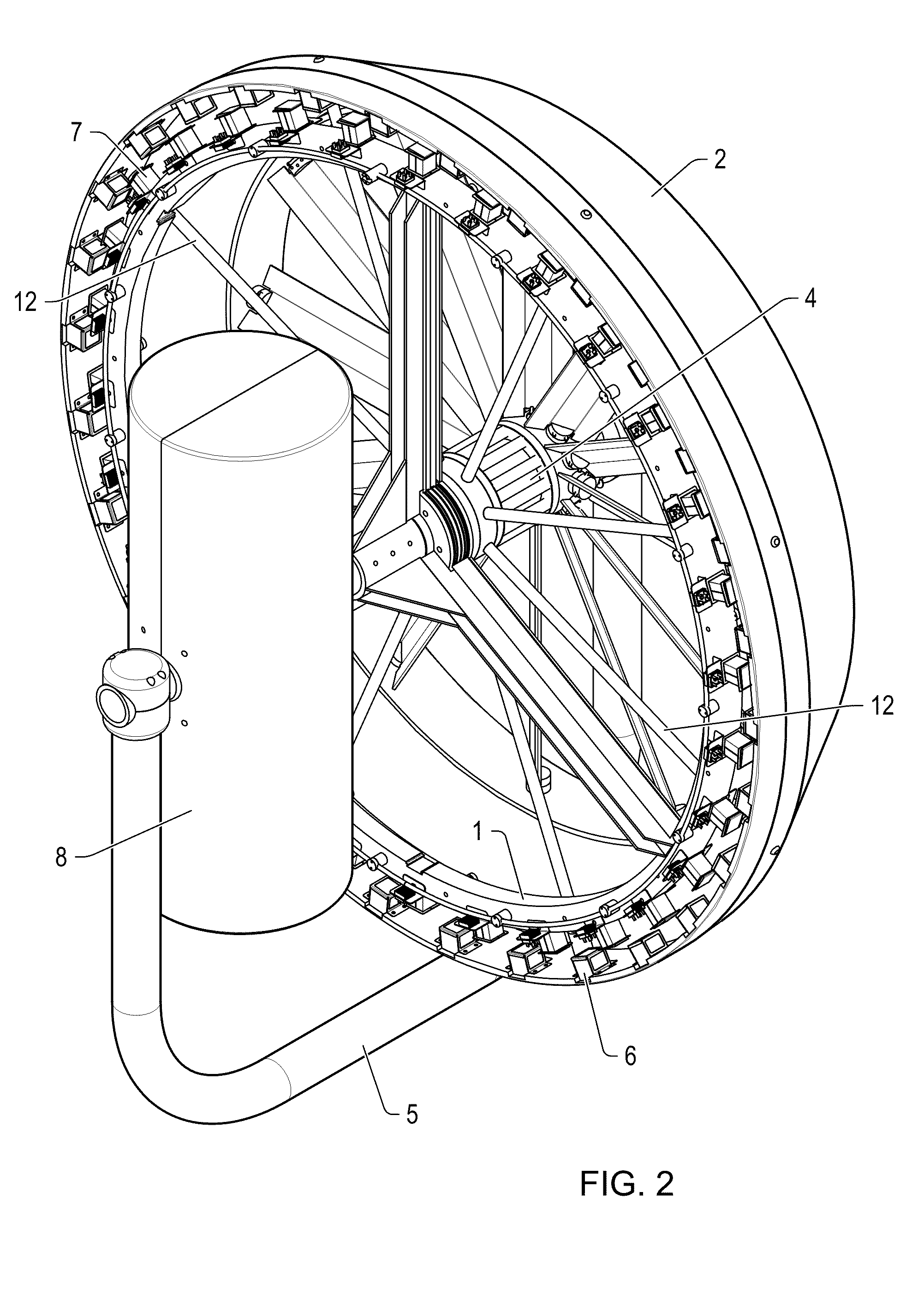

Direct Current Brushless Machine and Wind Turbine System

InactiveUS20100148515A1Improve efficiencyHigh relative moving magnetPump componentsReaction enginesElectrical conductorPressure difference

A direct current brushless electric machine is described that comprises a sequence of permanent magnets where the N and S magnetic poles being alternately arranged adjacent to each other, each exerting a magnetic field; phase coils are composed of a group of conductors, each conductor being laid essentially in parallel with each other, each coil being displaced by a full range of a single magnetic pole of the permanent magnet, such that each phase coil is alternately disposed adjacent to each other; and magnetic field or every other coil is in the same orientation to form an armature positioned opposite to the permanent magnet movable with respect to the armature with a predetermined amount of air gap provided between the phase coils and the permanent magnets. The electric machine operates as a generator when the power is flowing from a prime mover, such as the turbine blade extracting energy from the wind or water. The electric machine operates as a motor when the current is applied to the coils in a sequence to move the rotor when the turbine blades move the wind or water.Also described is an aerodynamic system comprising inner and outer annulus disposed driving fans, with a pressure differential flow enhancing aerodynamic housing, able to concentrate and make laminar rough and turbulent intake air molecule flows, creating a smooth rotationally organized downstream vortex field, with maximum power extraction from building structure directed velocity flow enhancements.

Owner:GEDDRY MARY +1

Engineered scaffolds for intervertebral disc repair and regeneration and for articulating joint repair and regeneration

ActiveUS8275594B2Eliminate needDesired effective mechanical and mass transport propertyAdditive manufacturing apparatusBone implantProperty distributionMass transport

Owner:RGT UNIV OF MICHIGAN +1

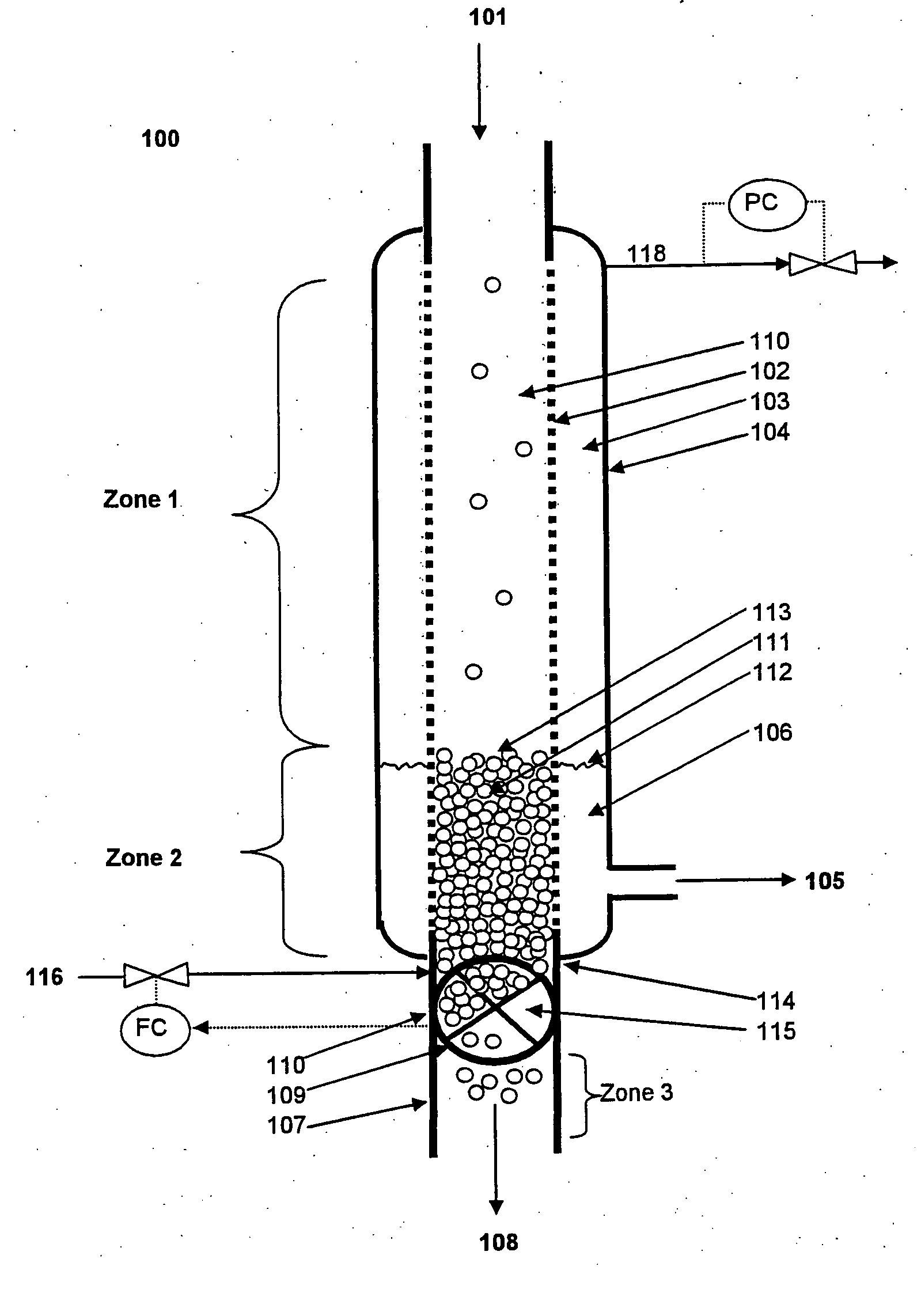

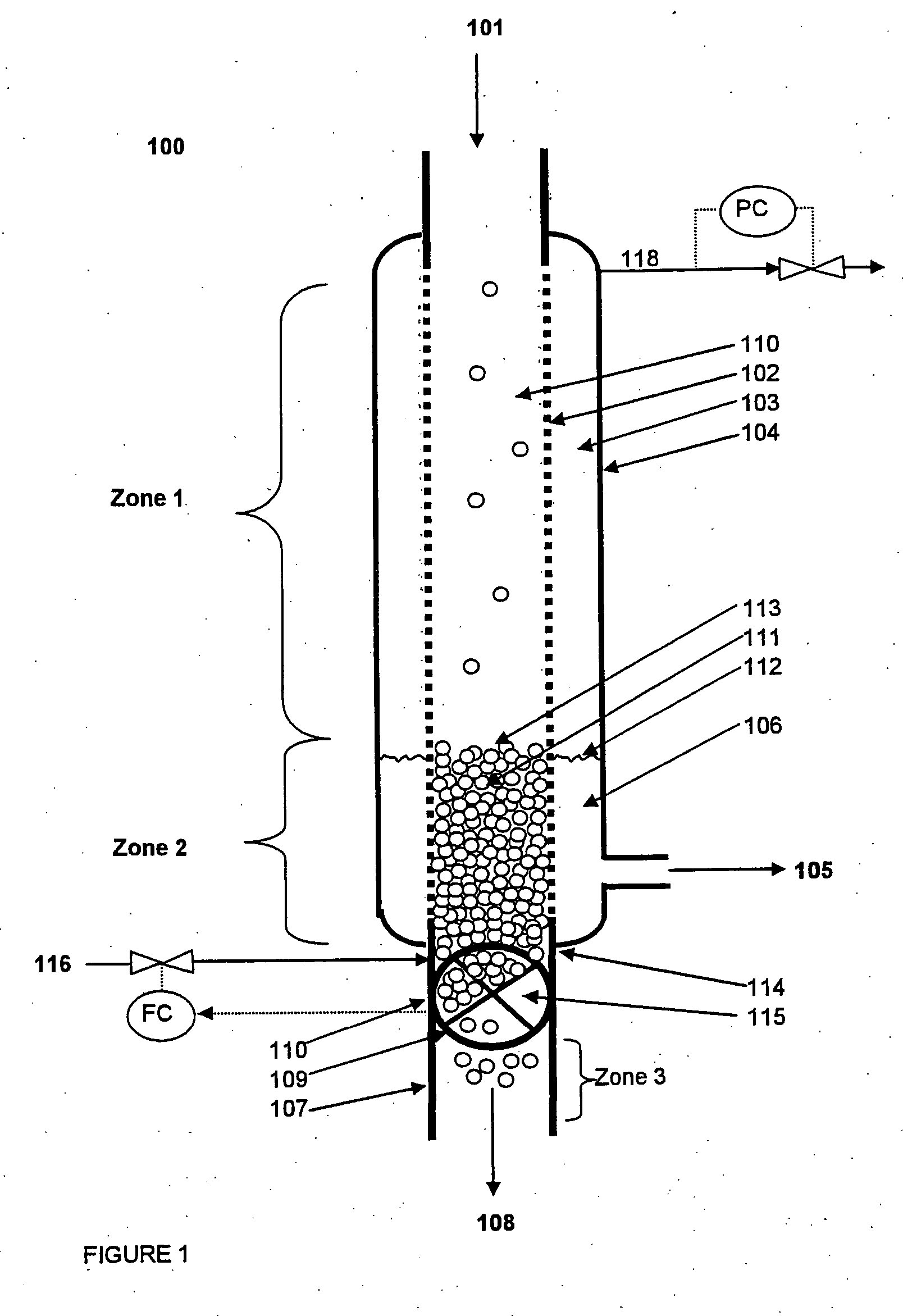

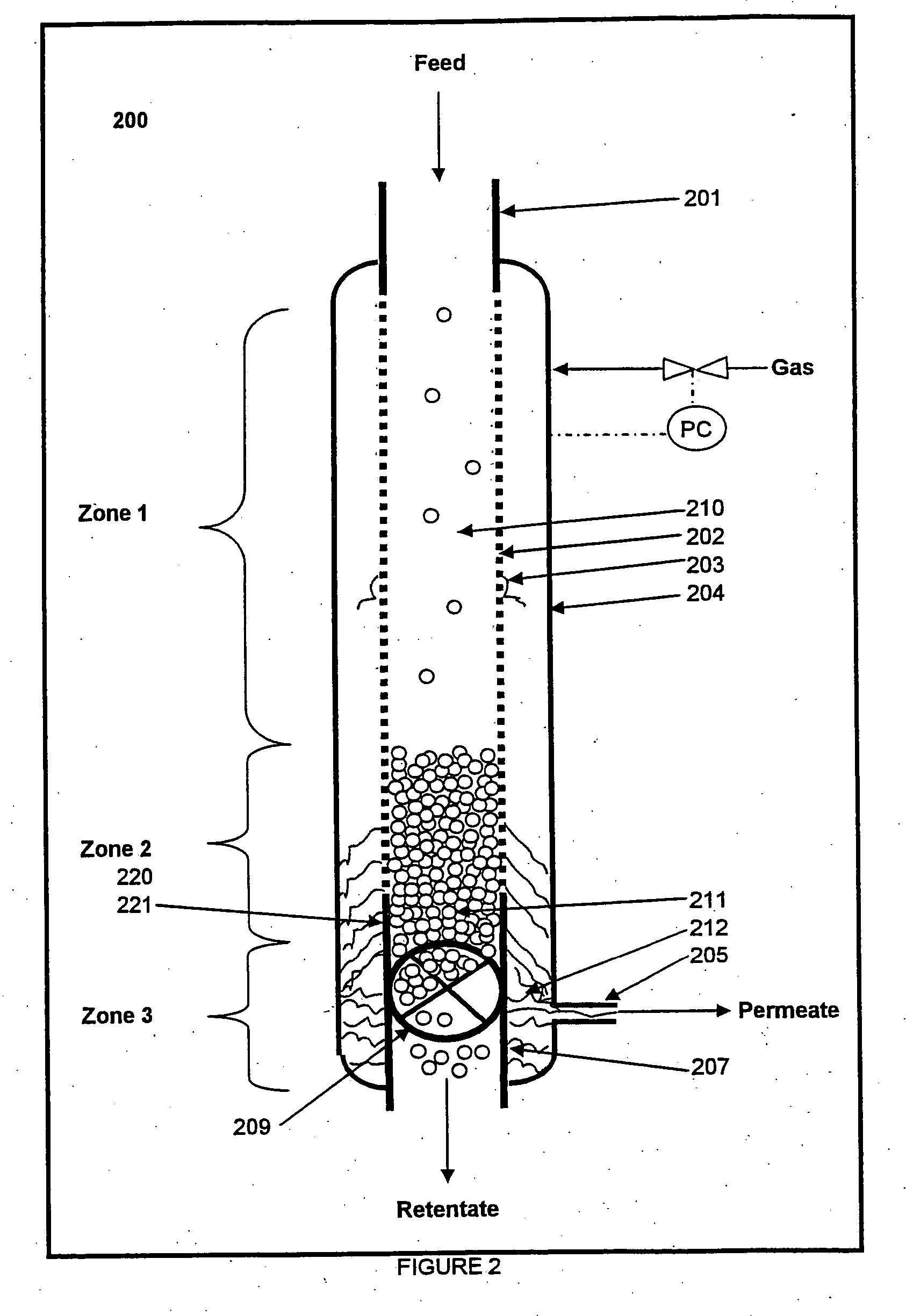

Crystallized pellet/liquid separator

ActiveUS20070062872A1Keep the pressureLow solidsWater/sewage treatment by centrifugal separationUltrafiltrationLiquid temperatureReverse osmosis

A process and apparatus which reduces the fines in a liquid discharge stream and / or increases the dryness of a solids discharge stream while under a pressure equal to or greater than the vapor pressure of the liquid. There is provided a process for separating particles such as polyethylene terephthalate or polyethylene naphthalate from a liquid in a slurry comprising: a. feeding a slurry comprising solid particles and a liquid into a within a separation zone maintained at a pressure equal to or greater than the vapor pressure of the liquid; b. contacting the slurry in the separation zone with a porous filter, optionally a microfilter, nanofilter, reverse osmosis filter, or ultrafilter, and separating liquid from the particles, wherein the liquid flows through the filter into an outer annulus defined as a space between the wall of the separation device and the filter, and said porous filter optionally having a terminal point beyond which the separated liquid does not pass from the outer annulus back through the filter; c. accumulating no liquid in the outer annulus or accumulating liquid in the outer annulus at a level below or in front of the terminal point, and continuously discharging the separated liquid from the outer annulus through a liquid outlet; d. decoupling the particles from the separation zone through the solids outlet to a low pressure below the vapor pressure of the liquid at the liquid temperature within the separation zone while maintaining a pressure on the particles prior to decoupling at or above the vapor pressure of the liquid within the separation zone.

Owner:ALPEK POLYESTER SA DE CV

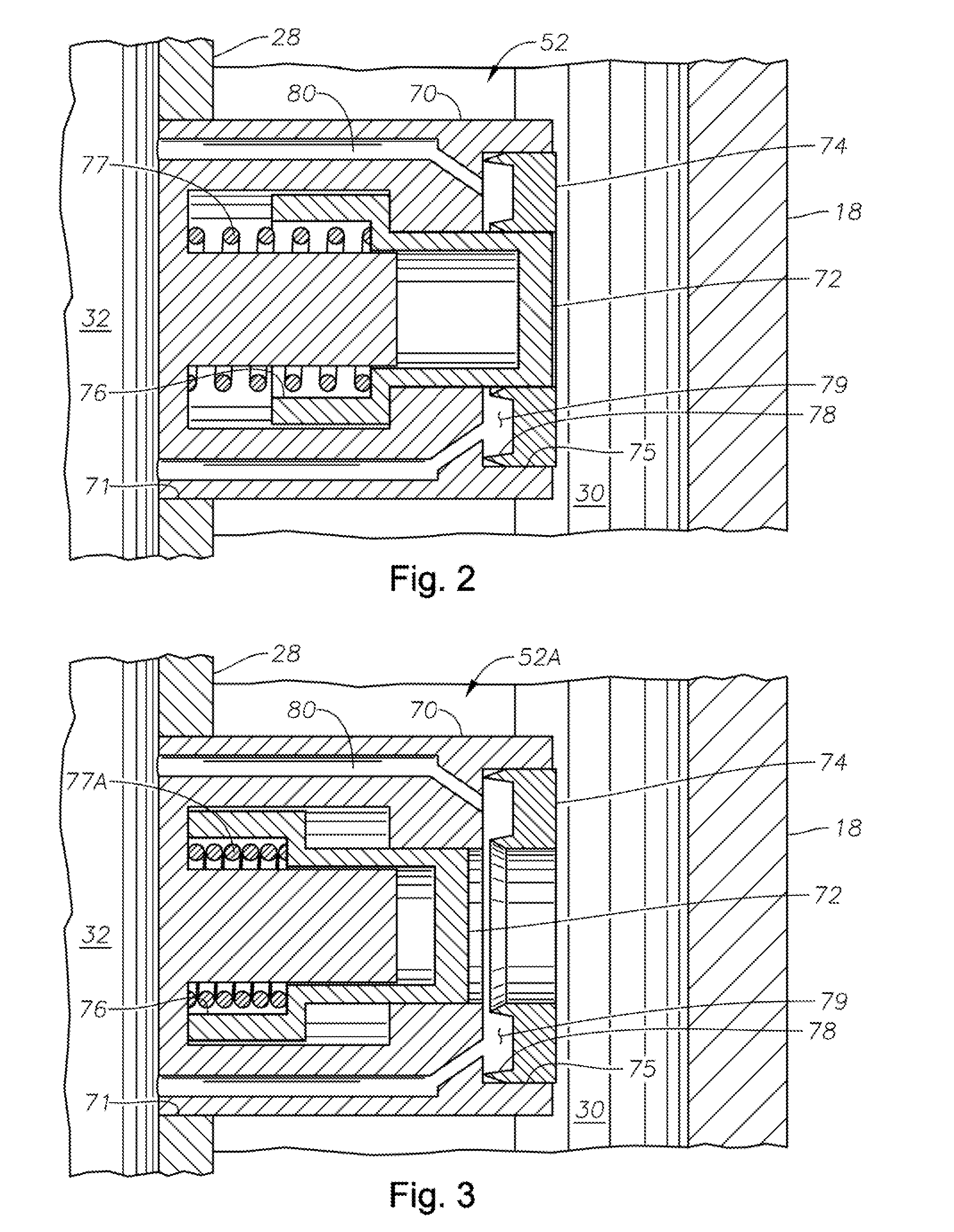

Non-intrusive pressure measurement device for subsea well casing annuli

InactiveUS6513596B2Preserve integrityMaximize safetySurveyConstructionsEngineeringIntelligent sensor

A well data monitoring system which enables annulus pressure and other well parameters to be monitored in the outer annuli of the well casing program without adding any pressure containing penetrations to the well system. This non-intrusive approach to monitoring pressure and other well parameters in the annuli preserves the pressure integrity of the well and maximizes the safety of the well. In the preferred embodiment an intelligent sensor interrogation system which can be located externally or internally of the pressure containing housing of the wellhead is capable of interrogating and receiving data signals from intelligent well data sensors which are exposed to well parameters within the various annuli of the well and wellhead program.

Owner:FMC TECH INC

Non-intrusive pressure measurement device for subsea well casing annuli

InactiveUS20010027865A1Preserve integrityMaximize safetySurveyConstructionsEngineeringIntelligent sensor

A well data monitoring system which enables annulus pressure and other well parameters to be monitored in the outer annuli of the well casing program without adding any pressure containing penetrations to the well system. This non-intrusive approach to monitoring pressure and other well parameters in the annuli preserves the pressure integrity of the well and maximizes the safety of the well. In the preferred embodiment an intelligent sensor interrogation system which can be located externally or internally of the pressure containing housing of the wellhead is capable of interrogating and receiving data signals from intelligent well data sensors which are exposed to well parameters within the various annuli of the well and wellhead program.

Owner:FMC TECH INC

In situ bioprosthetic filler and methods, particularly for the in situ formation of vertebral disc bioprosthetics

InactiveUS20050102030A1Dissipate impact energyDissipate energyBone implantSpinal implantsCross-linkFiber

Bioprosthetic devices include an exterior biological tissue member which at least partly defines a cavity, and a proteinaceous biopolymer which fills the cavity, and intercalates and is chemically bound (fixed) to the tissue of the surrounding biological tissue member. In preferred forms. the bioprosthetic device is a bioprosthetic vertebral disc having a fibrillar outer annulus which surrounds and defines an interior cavity and is formed by removal of at least a substantial portion of the natural gelatinous core therefrom. The cavity defined by the fibrillar outer annulus may then be filled with a flowable proteinaceous biopolymer. Preferably, the proteinaceous biopolymer is a liquid mixture comprised of human or animal-derived protein material and a di- or polyaldehyde, which are allowed to react in situ to form a cross-linked biopolymer within the cavity. The liquid mixture may be formed in advance of being introduced into the cavity, or may be formed simultaneously during introduction into the cavity.

Owner:CRYOLIFE

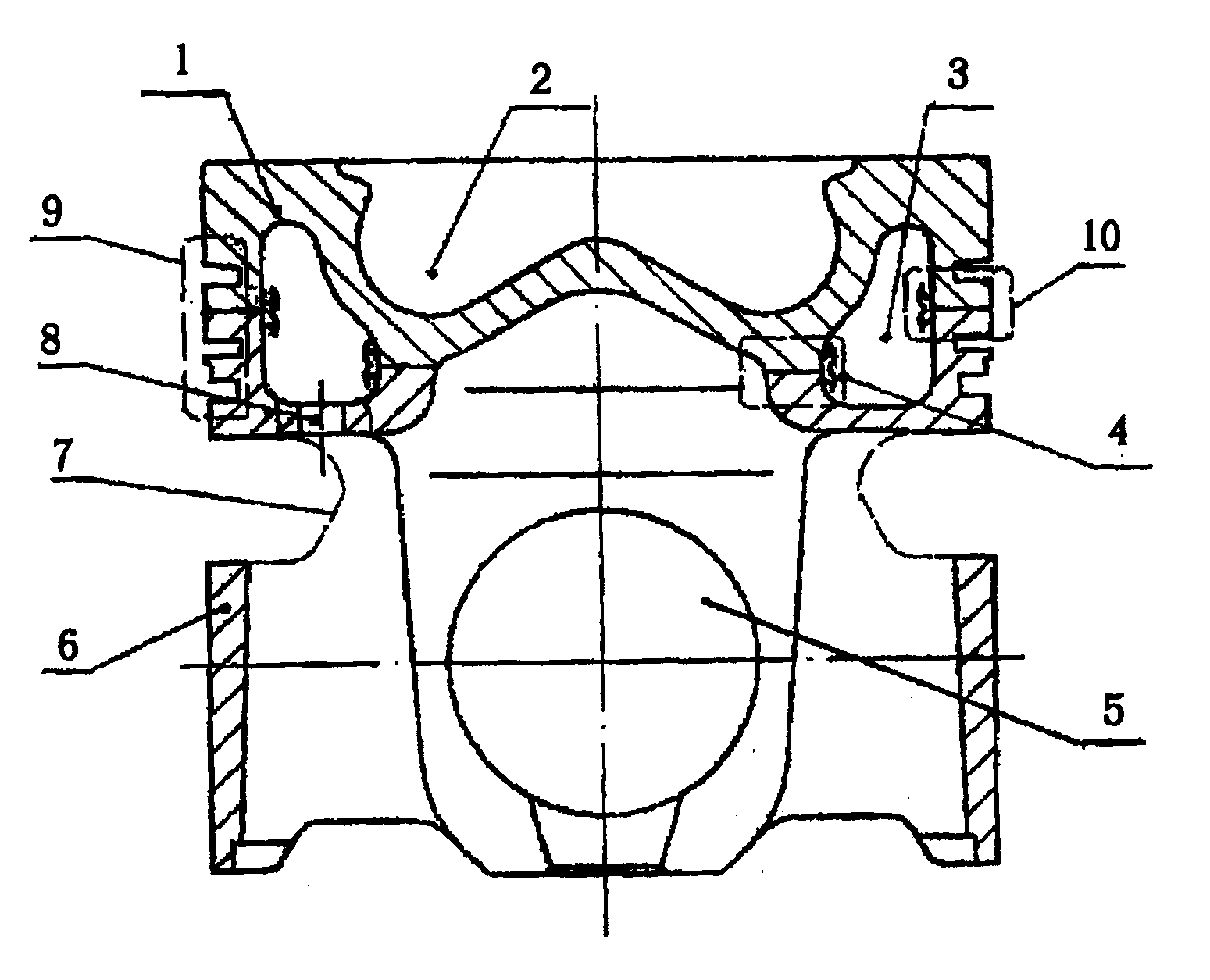

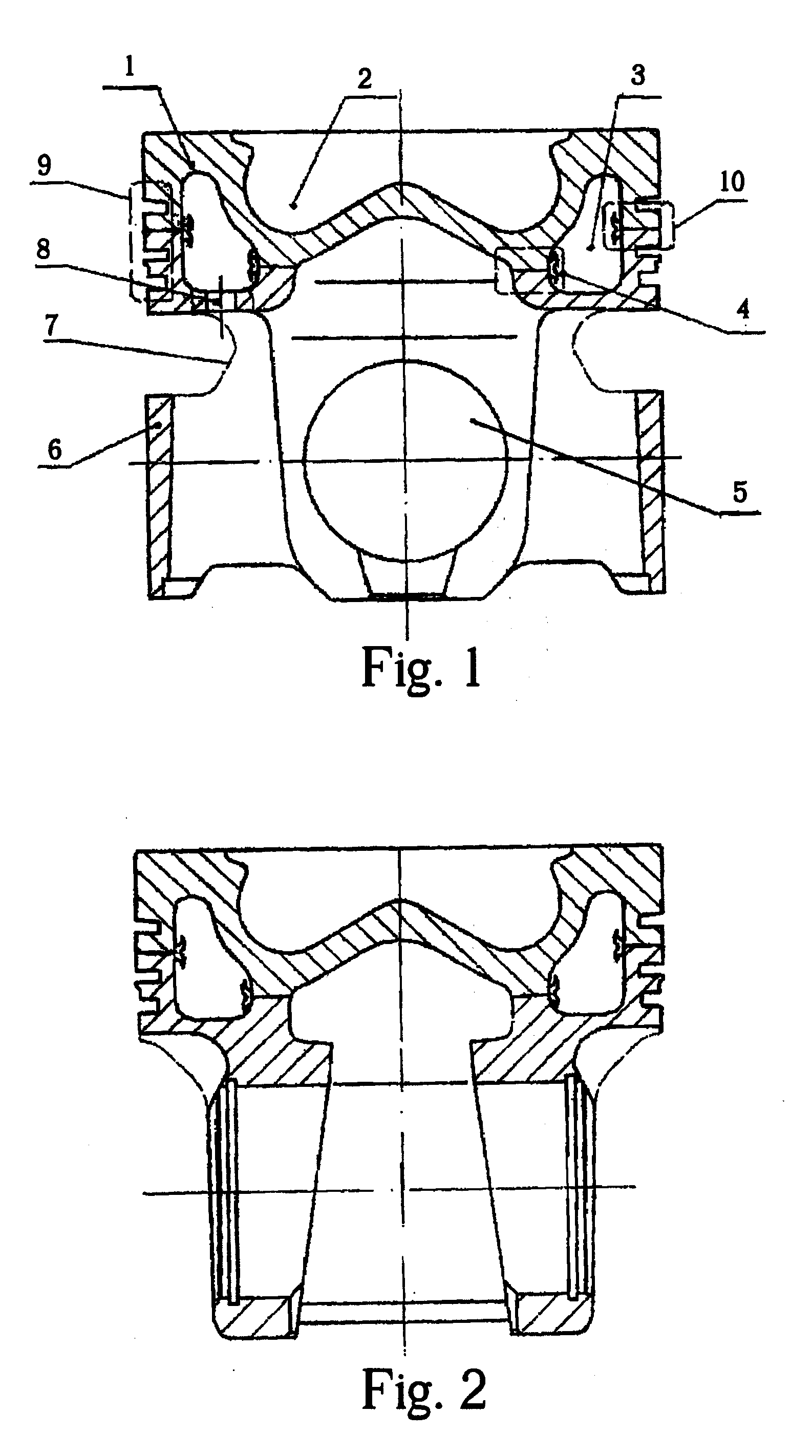

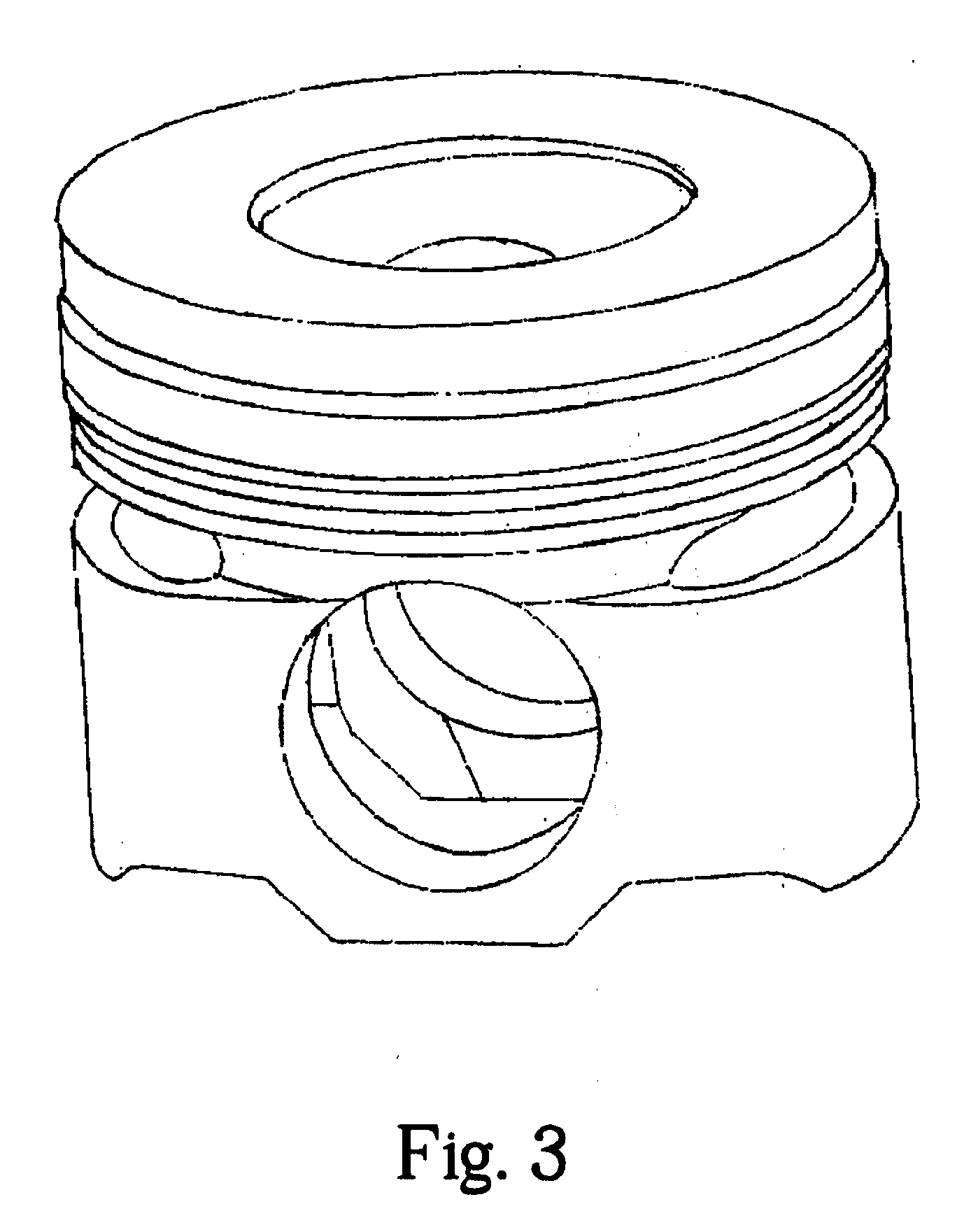

Welding Forged Steel Single Piece Piston and Its Manufacturing Methods

InactiveUS20070079775A1Simple manufacturing processImprove structural strengthAir coolingMachines/enginesFriction weldingCombustion chamber

The present invention has provided a welding forged steel single piece piston and its manufacturing methods. A semi-finished head and a semi-finished skirt are forged respectively; the semi-finished head and semi-finished skirt are heat-treated respectively; rough machining is carried out respectively to the semi-finished head and the semi-finished skirt, and a face of weld between the two adjacent ring grooves is higher than the one under the combustion chamber; the head and the skirt are welded together through friction welding; an annular groove, a combustion chamber, a ring groove, a pinhole, an outer annulus and oil inlet / outlet holes are manufactured respectively; and the surface of the piston is phosphorized and graphitized. Compared with one-piece forged piston, it has better processing technology, because the head and skirt are forged respectively and then welded together. Over-all structural rigidity of the piston has been increased, and distortion of the ring groove in high temperature is slight because the cooling oil recess is sealed through welding. As the annular groove is located on the upper part of skirt, the weight of body of the piston is lowered and this kind of structure can accelerate engine oil returning on, decrease the clearance between the piston and the cylinder and reduce the engine oil consumption.

Owner:SHANDONG BINZHOU BOHAI PISTON

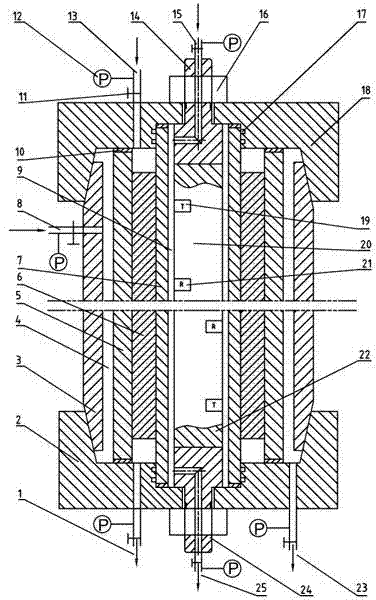

Device and method for evaluating influence of pressure change on completeness of cement sheath

The invention provides a device and a method for real simulation of underground environments, completeness maintaining of experiment equipment, and accurate and omnibearing evaluation of completeness of a cement sheath. The device mainly comprises an upper end cap, a lower end cap, an outer pipe, a middle pipe, the cement sheath, a sleeve pipe, a long source distance sector cement bond logging instrument (SBT (segmented bond tool)) and a high-temperature and high-pressure kettle. The method comprises the following steps of utilizing the high-temperature and high-pressure kettle to simulate the stratum temperature pressure of the curing and forming of the cement sheath; loading and unloading an inner annulus and an outer annulus, so as to simulate the actions of change of well shaft pressure and stratum pressure on the cement sheath under the actual working condition; utilizing a transmitting probe and a receiving probe of the SBT to continuously transmit and receive acoustic wave signals, and performing the omnibearing and high-resolution compensation type attenuation rate measurement, so as to obtain the bonding qualities of a first interface and a second interface of the cement sheath of the well cementing cement sheath under the actual stratum environment, and the amounts, sizes and bearings of cracks and channeling in the cement sheath. The device and the method have the advantage that the underground environment can be really simulated in the omnibearing way, so as to accurately and efficiently evaluate the completeness of the well cementing cement sheath, provide the new method and basis for indoor cement slurry evaluation systems and sites to take the targeted measures, and improve the well cementing quality.

Owner:SOUTHWEST PETROLEUM UNIV

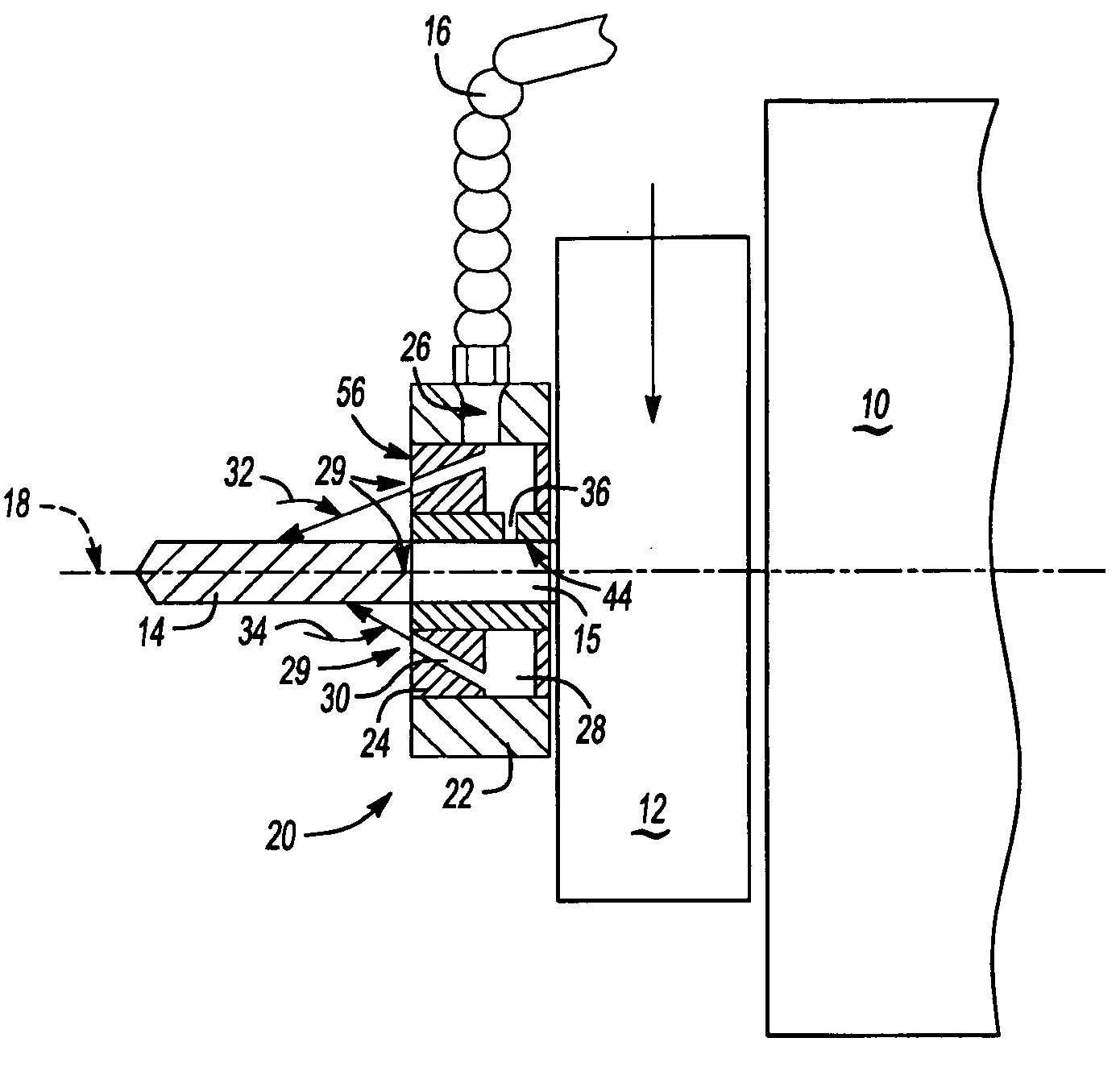

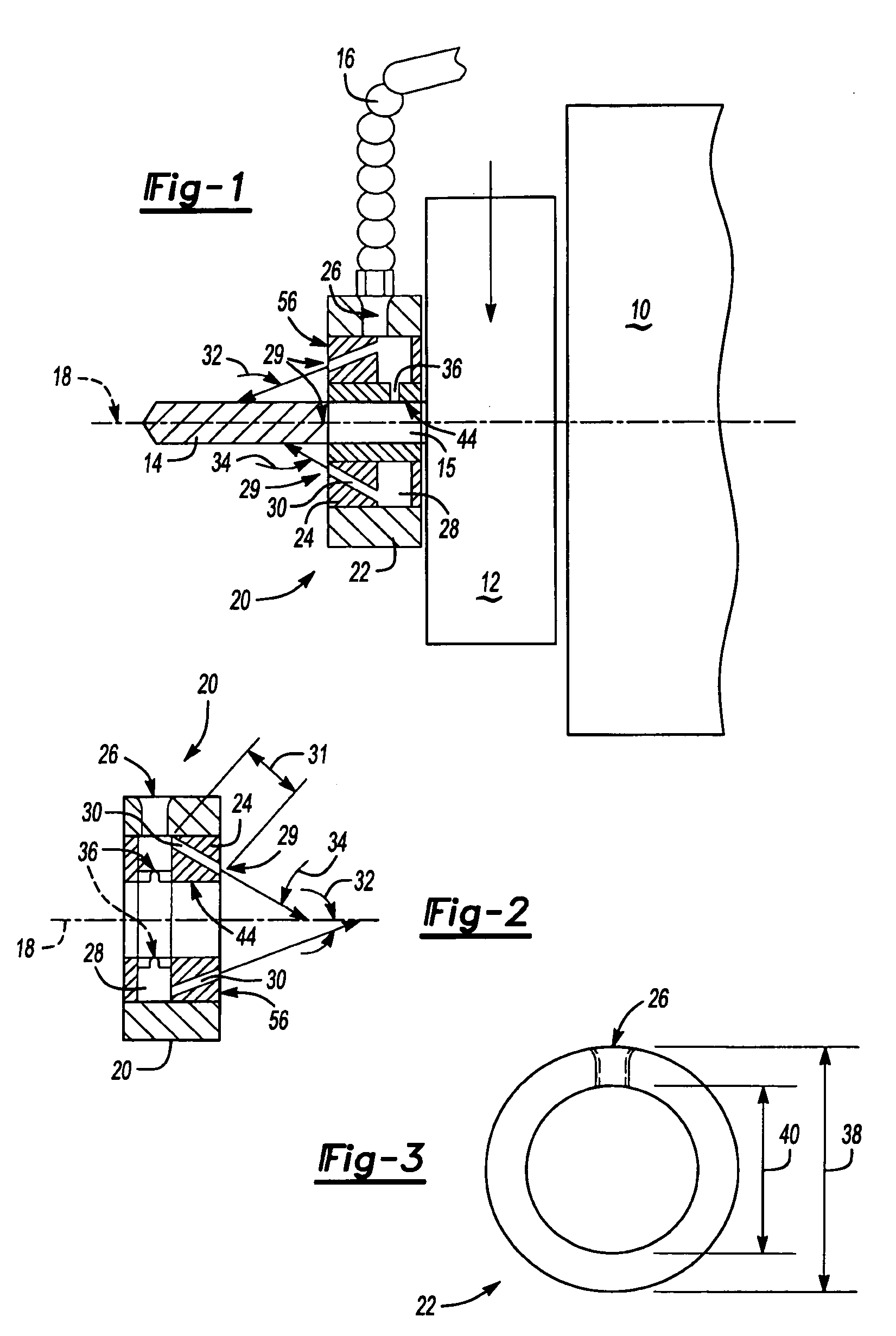

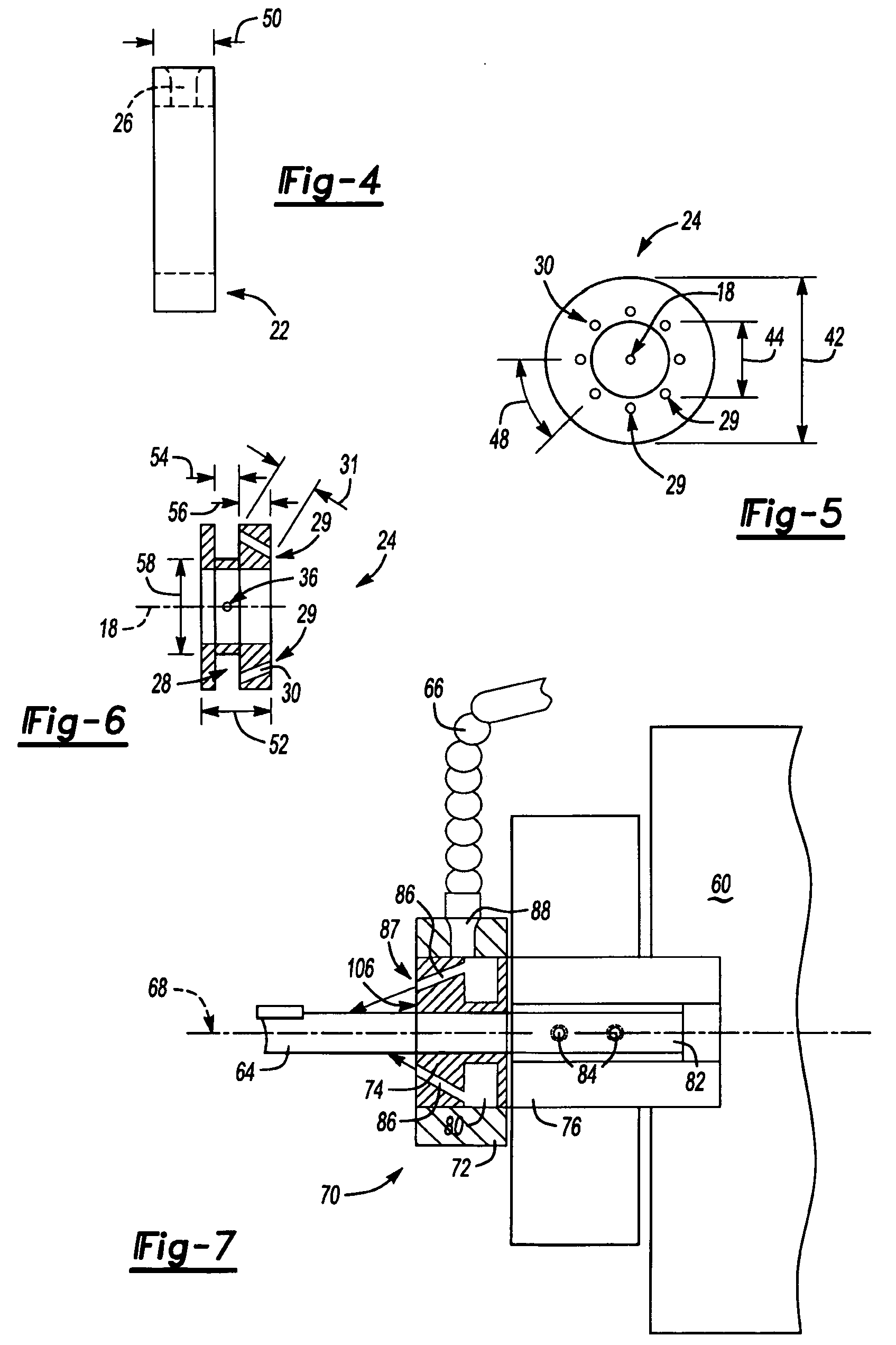

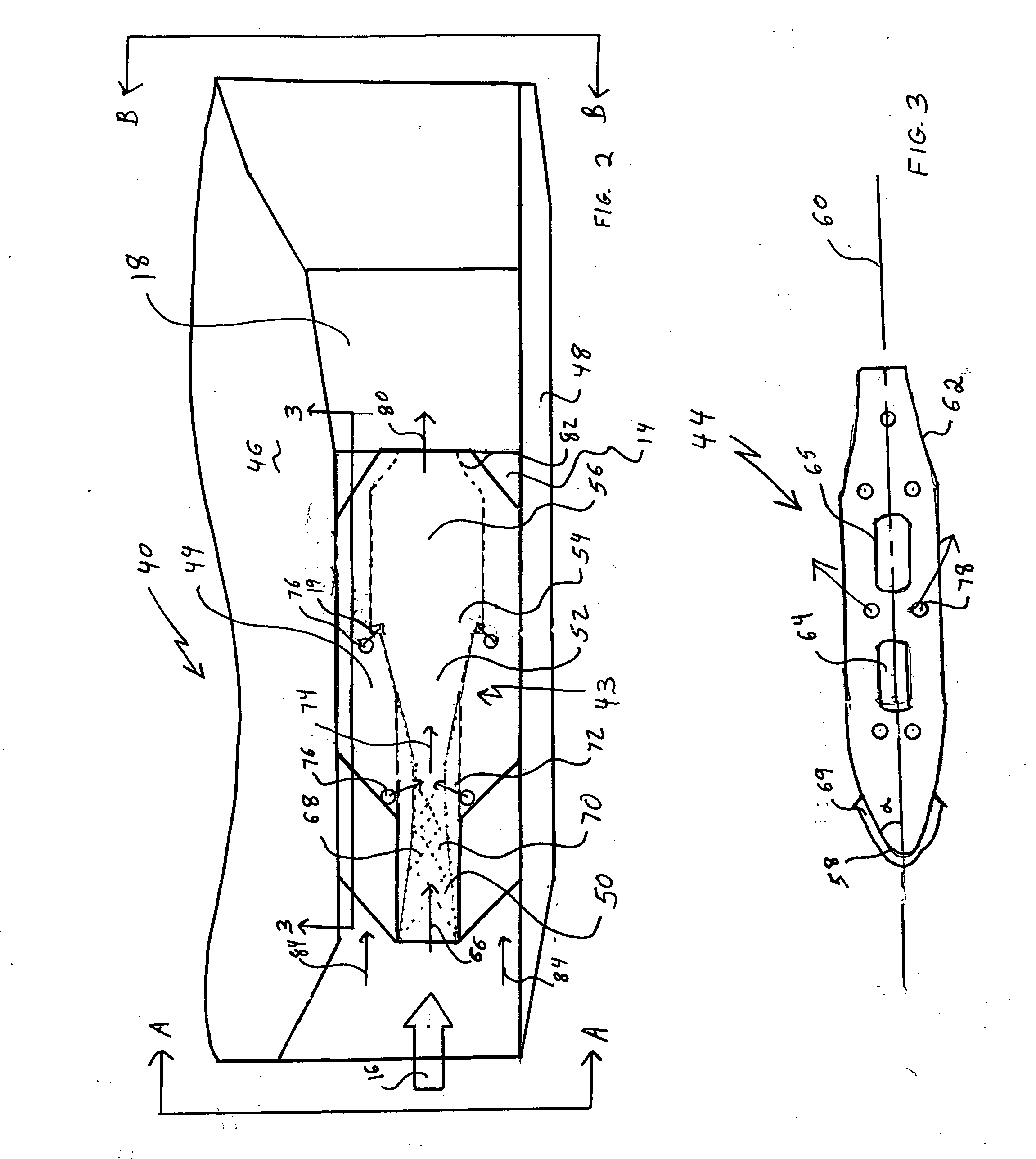

Tool coolant application and direction assembly

InactiveUS20050169718A1Easy to installSleeve/socket jointsTransportation and packagingCooling fluidPhysics

A coolant assembly for supplying coolant fluid to a tool includes an outer ring defining an inlet and an insert pressed within the outer ring including an annular channel. The annular channel is in communication with the inlet defined by the outer ring and includes a plurality of passages disposed to direct fluid along an axis of a tool. At least two of the passages are disposed at different angles relative to the axis of the tool to direct coolant along the entire length of the tool in order to provide a uniform and consistent stream of coolant and uniform and consistent temperature of the tool.

Owner:ADVANCED NT

Surface treated aluminum nitride baffle

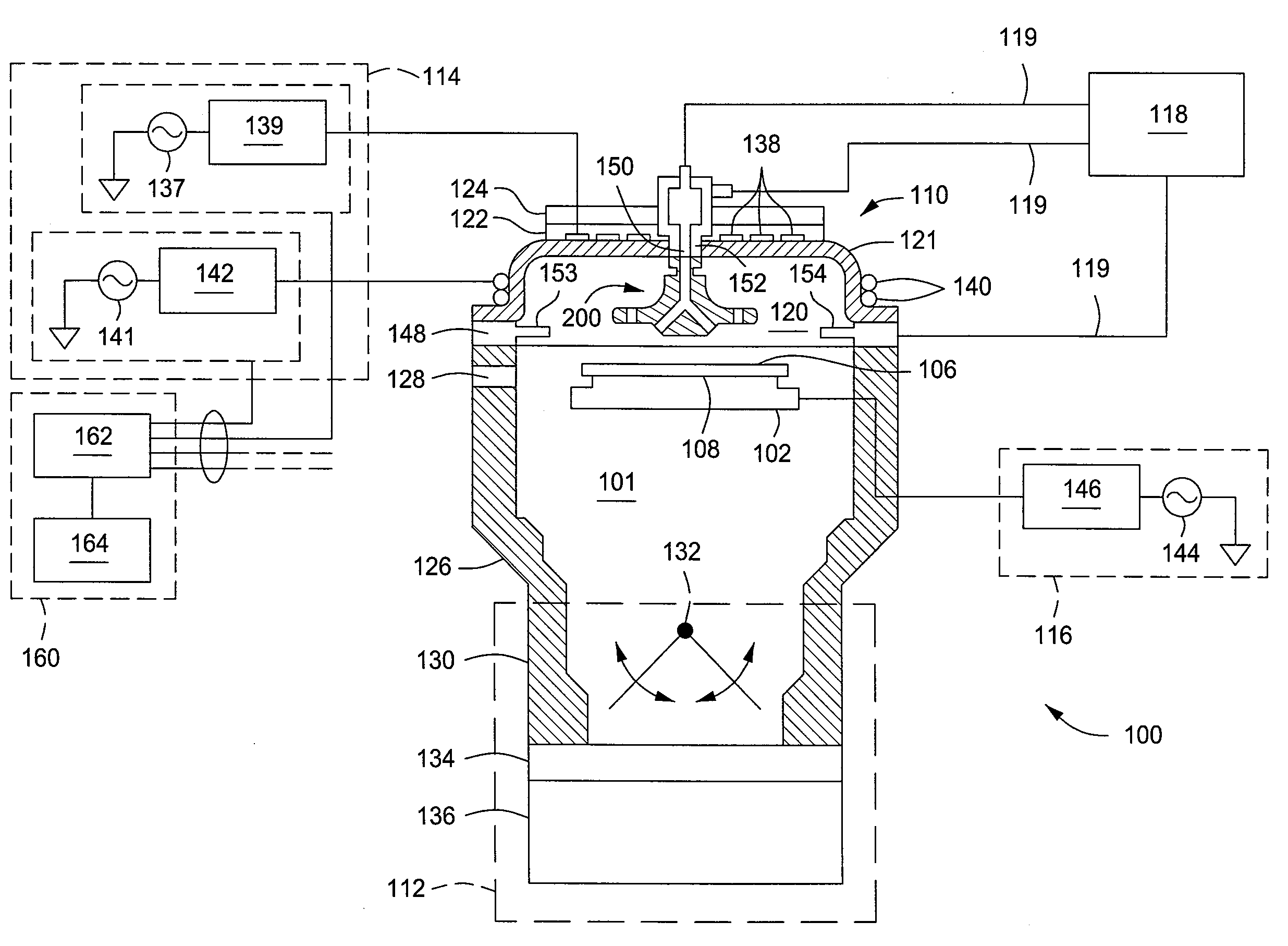

ActiveUS20100048028A1Eliminating and reducing excess metal oxideElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogenNitride

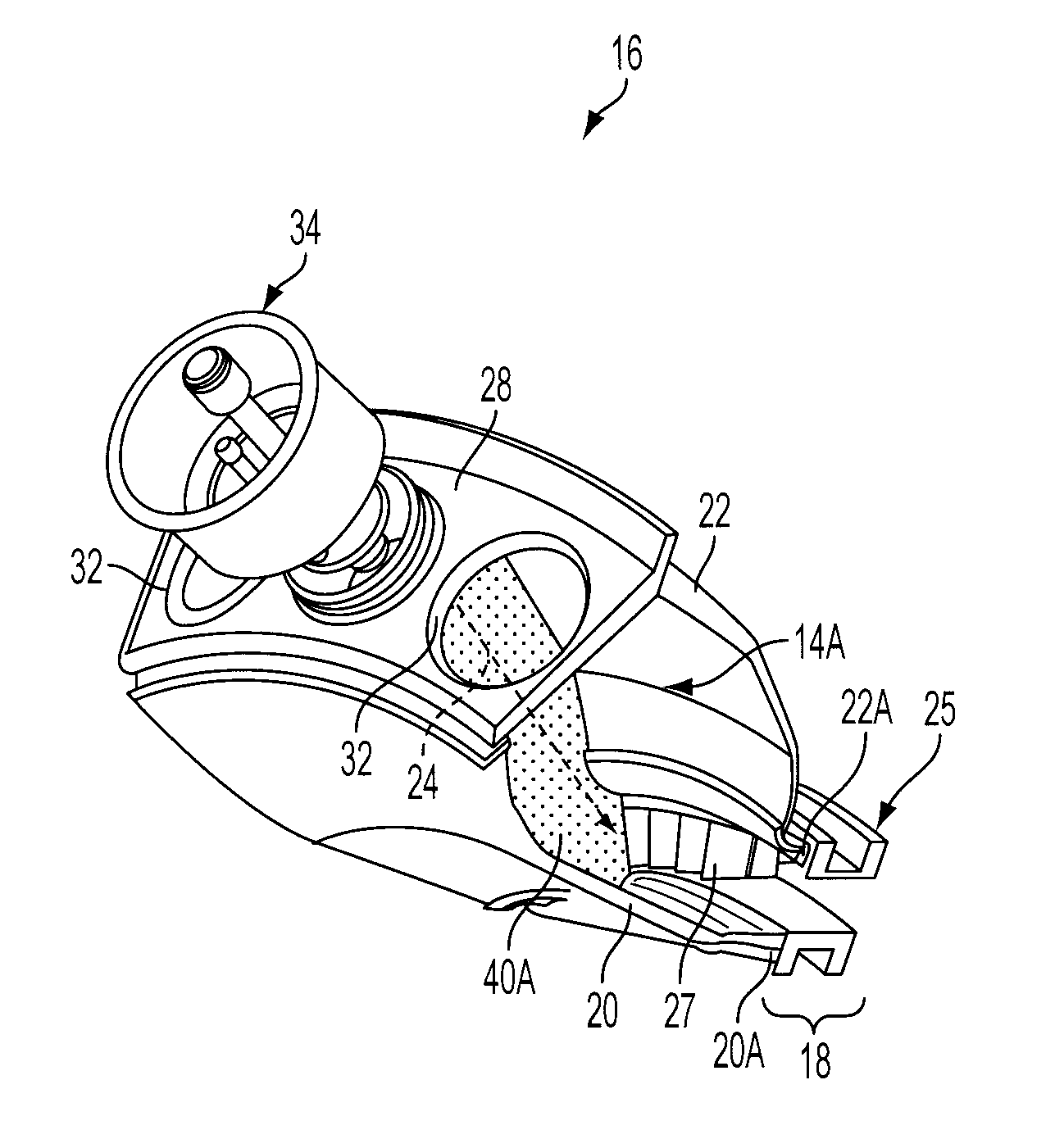

Methods and apparatus relating to aluminum nitride baffles are provided herein. In some embodiments, a baffle for use in semiconductor process chambers may include a body comprising aluminum nitride and a metal oxide binding agent, wherein a ratio of aluminum nitride to metal oxide on a surface of the body is greater than or equal to the ratio within the body. In some embodiments, the body may have a center stem and an outer annulus coupled to and extending radially outwards from a lower portion of the center stem. In some embodiments, a method of fabricating a baffle may include sintering aluminum, nitrogen, and a metal oxide binding agent to form a body of the baffle, the body having excess metal oxide binding agent disposed on a surface thereof; and removing a bulk of the excess metal oxide binding agent from a surface of the body.

Owner:APPLIED MATERIALS INC

Casing Annulus Management

InactiveUS20110114333A1Avoid flowFluid removalWell/borehole valve arrangementsEngineeringPressure difference

A wellbore tubular set concentrically between an inner an and outer annulus has a pressure relief valve that opens when pressure in the outer annulus exceeds pressure in the inner annulus by an amount that can damage the tubular. The relief valve closes and reseats when the pressure differential is reduced to below the damaging threshold. The relief valve can include a spring for reseating the valve. A pressure gauge can be included within the outer annulus for monitoring whether or not the relief valve is operating properly.

Owner:VETCO GRAY

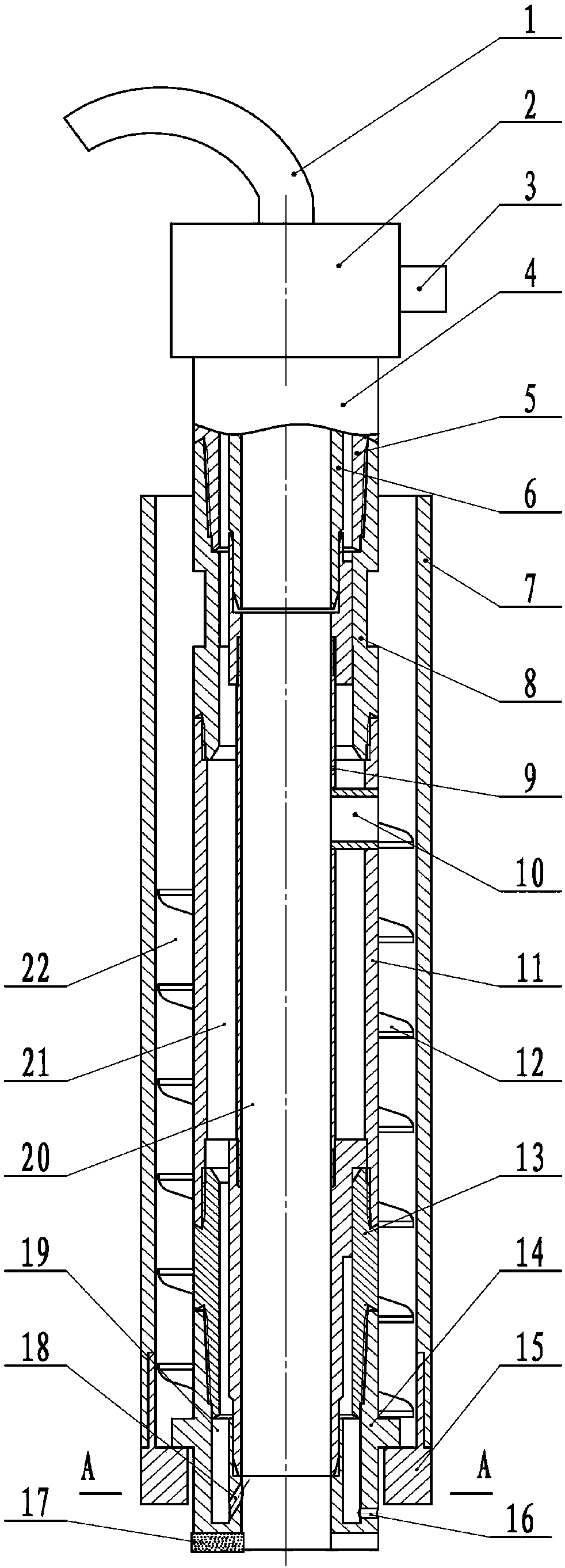

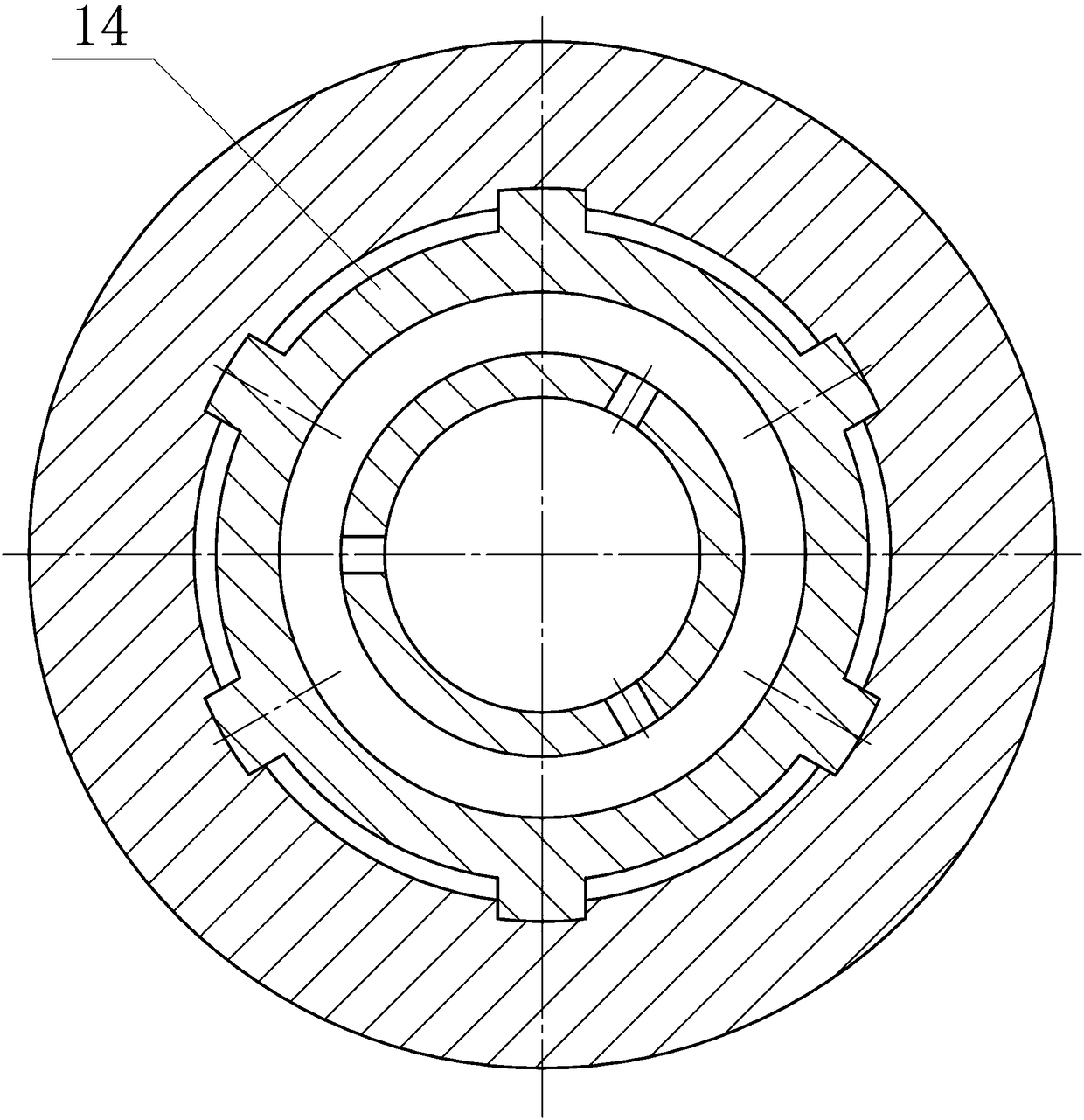

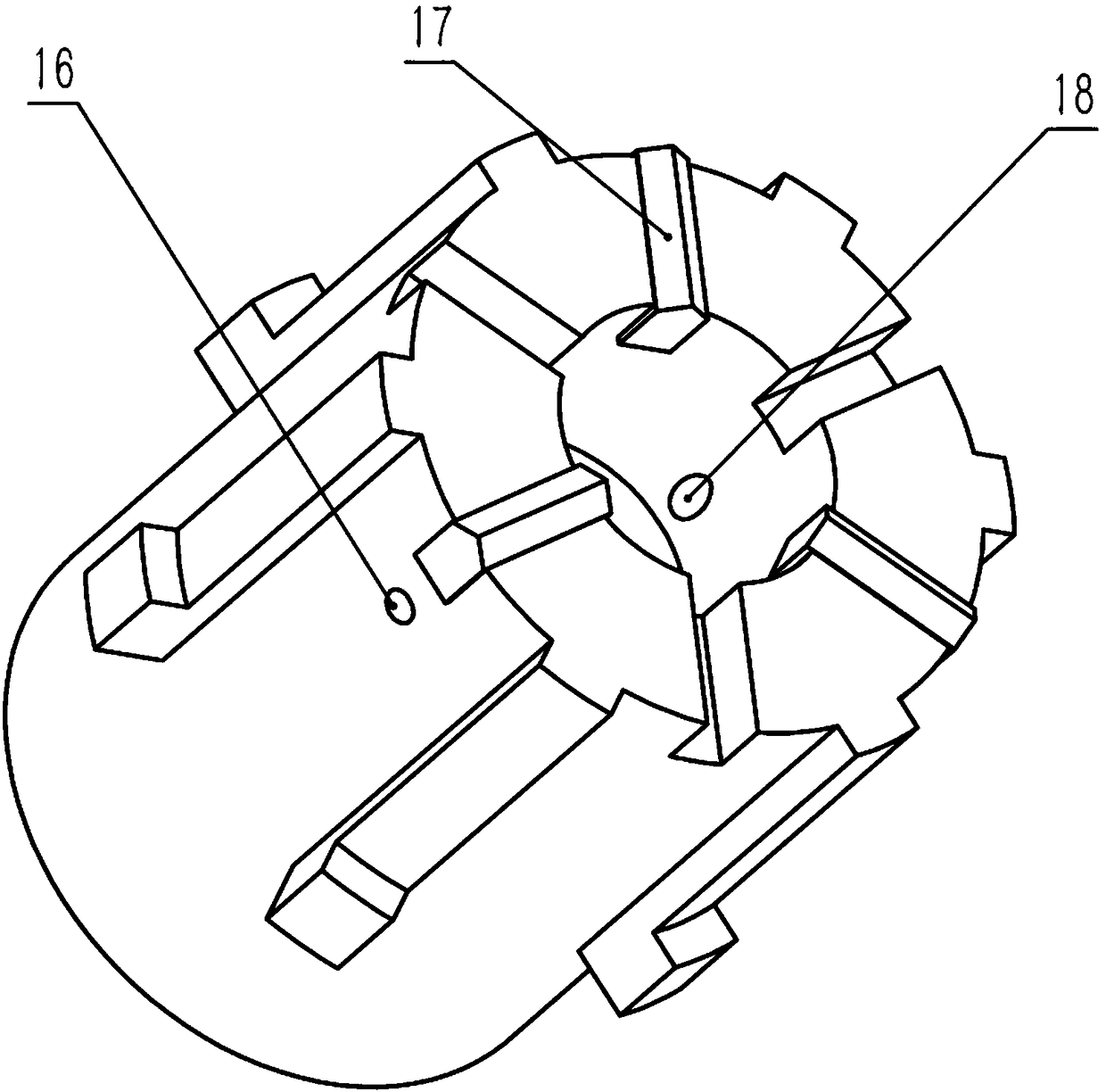

Loose-soft rock soil stratum reverse circulation casing-following drilling tool and drilling process

PendingCN108086930AImprove migration efficiencyImprove connection strengthDrilling rodsConstructionsAugerHelical blade

The invention discloses a loose-soft rock soil stratum reverse circulation casing-following drilling tool and a drilling process. The drilling tool is of a coaxial three-passage structure and comprises a double-wall drilling stem, an auger stem, a drilling bit, a casing and a casing shoe, a central hole of an inner tube of the double-wall drilling stem and a central hole of an inner tube of the auger stem form a slag discharging passage, an annular gap between the inner tube of the auger stem and an outer tube of the auger stem forms an air incoming passage, and an annular gap between the outer tube of the auger stem and the casing forms an outer ring passage; compressed air enters the drilling bit through the air incoming passage and then is diverted and used for assisting a cutting bladeto break a stratum and realize reverse circulation deslagging. Drillings suspended in the outer ring passage go up along spiral blades, enters a deslagging passage through a deslagging window and then returns to the ground surface. Reverse circulation deslagging through a fluid medium and deslagging assisted by the spiral blades are adopted in the process of drilling, so that casing-following drilling is realized to protect hole walls, the problems of bit burying and difficulty in deslagging and hole forming in the process of loose-soft rock soil drilling can be solved, and integration of drilling, collapse preventing, dedusting and wall protecting is realized.

Owner:JILIN UNIV

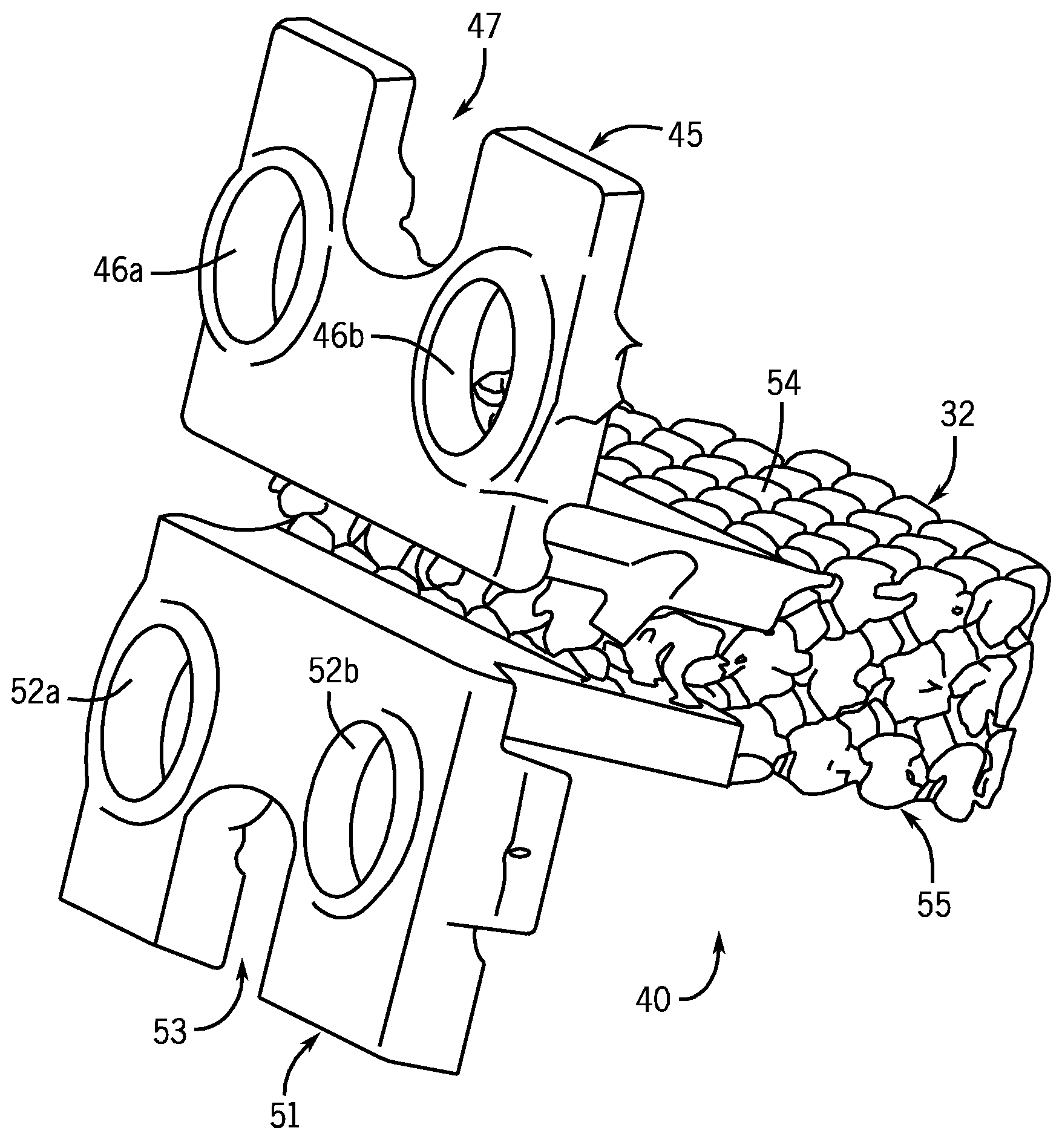

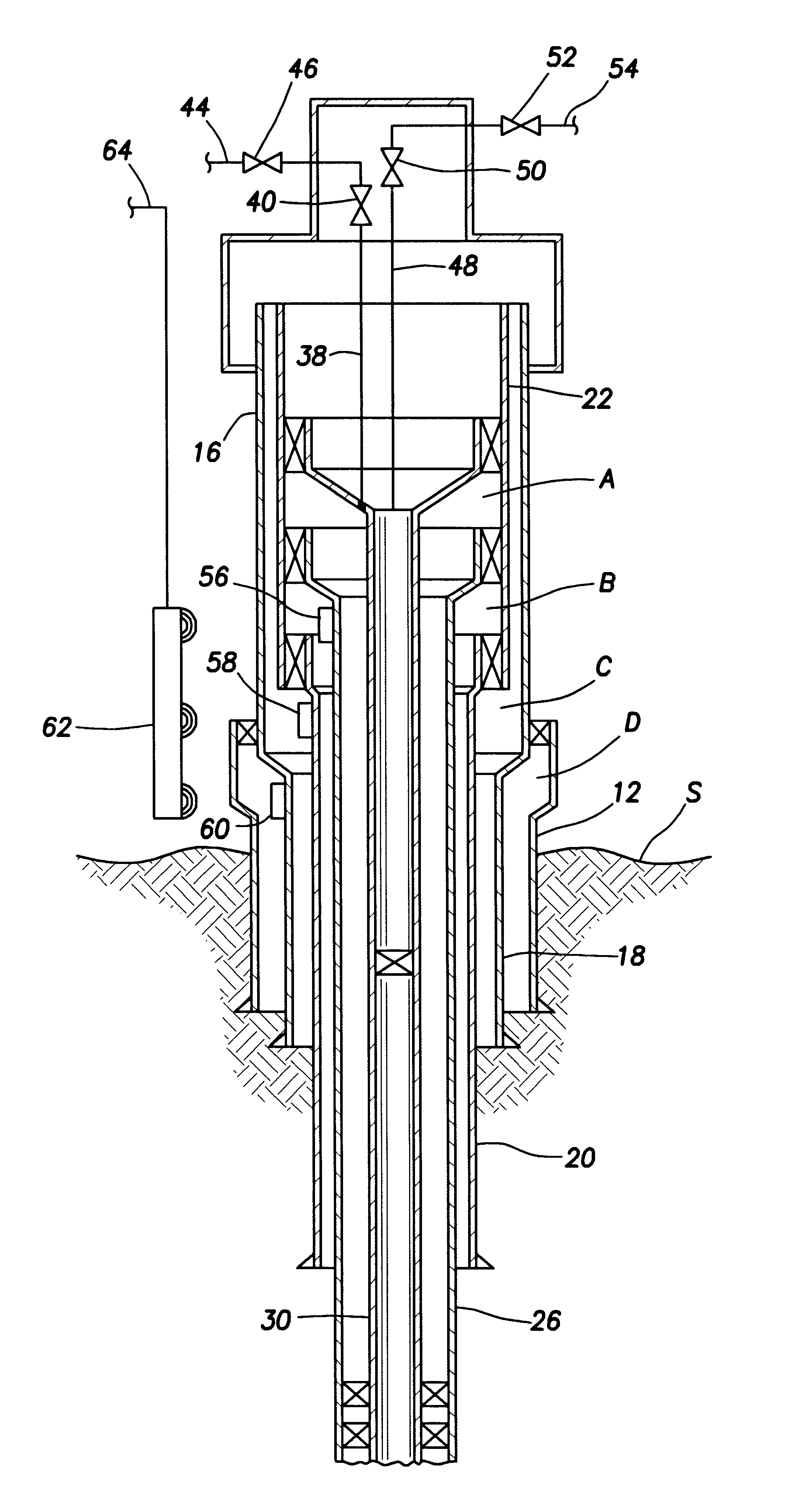

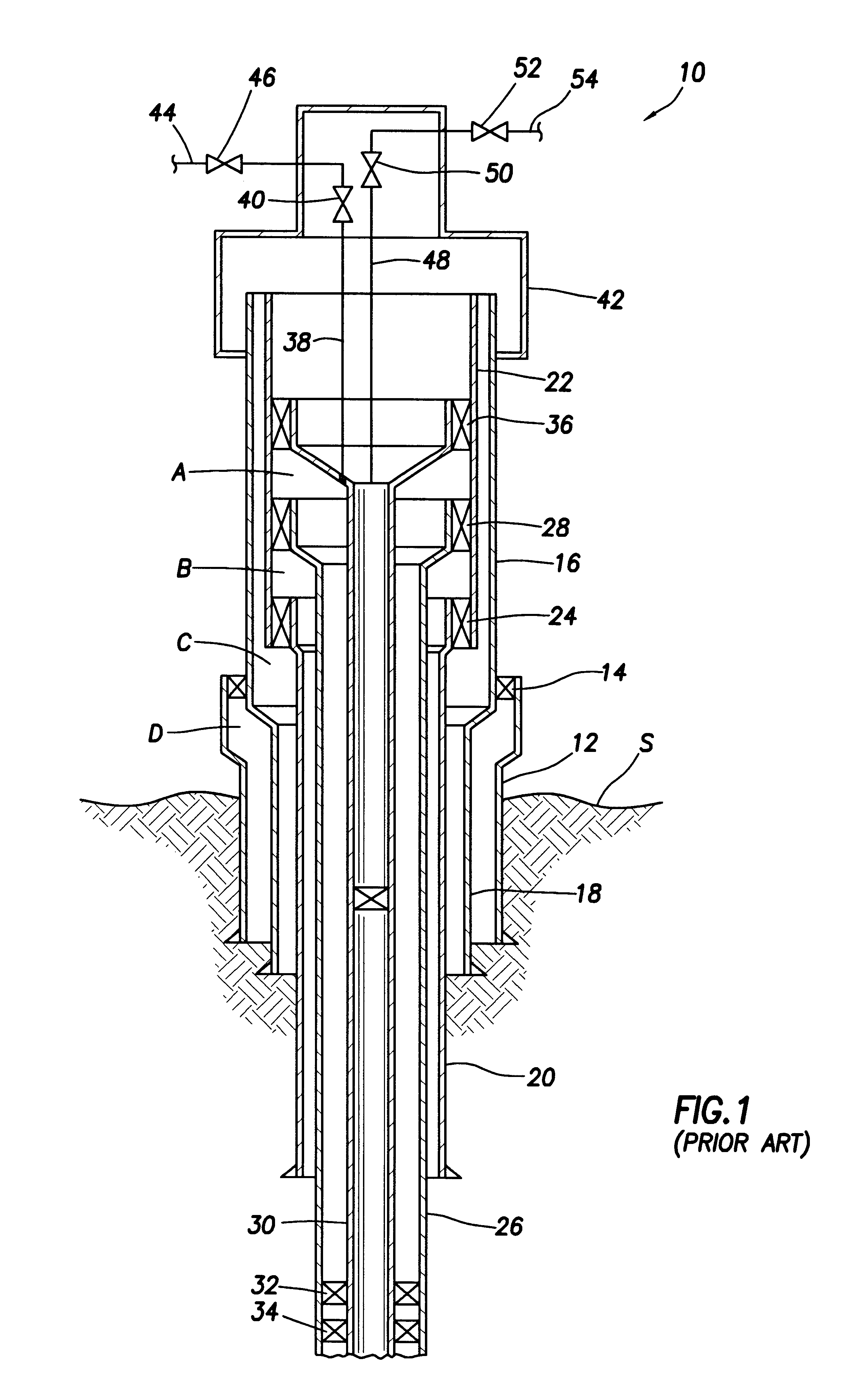

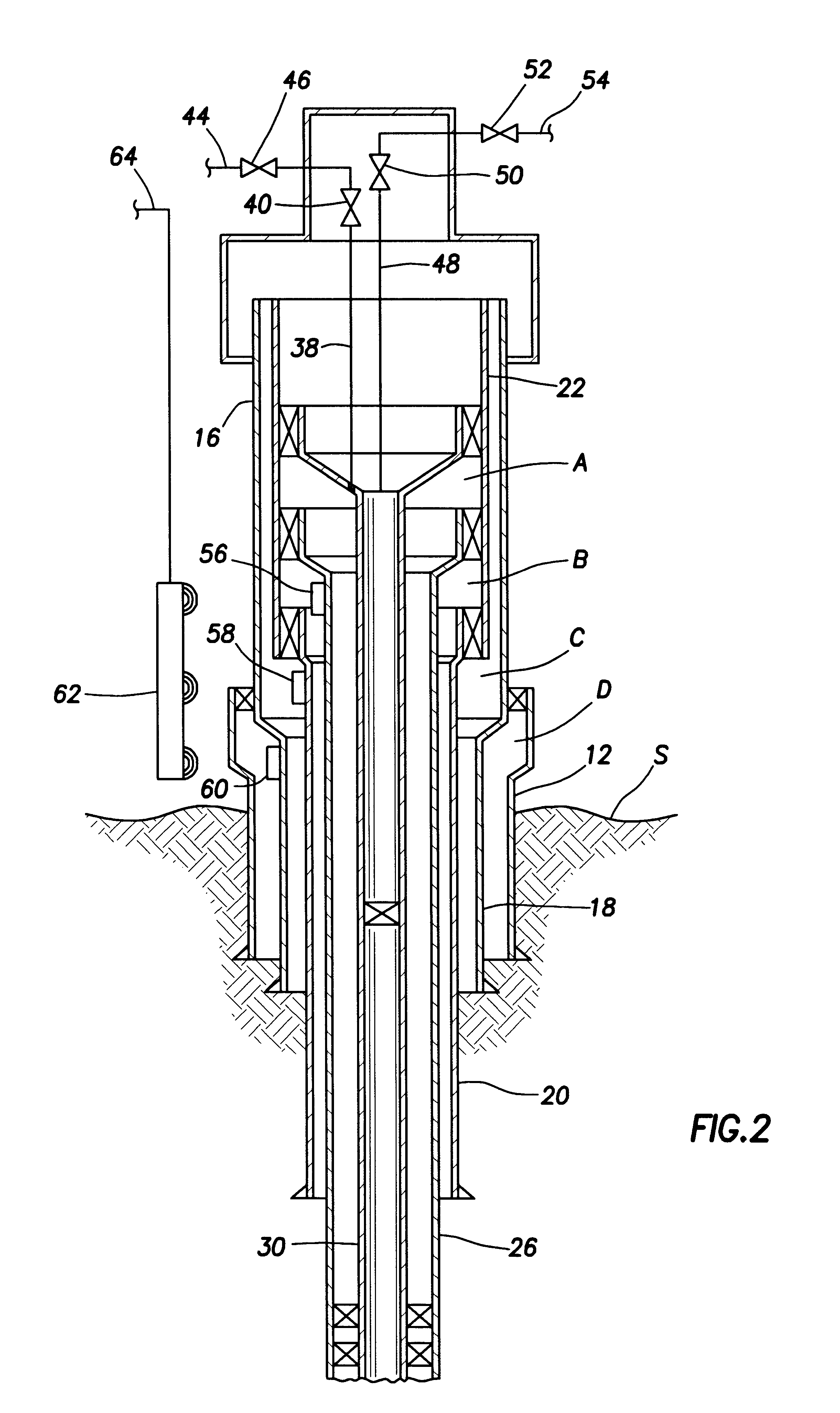

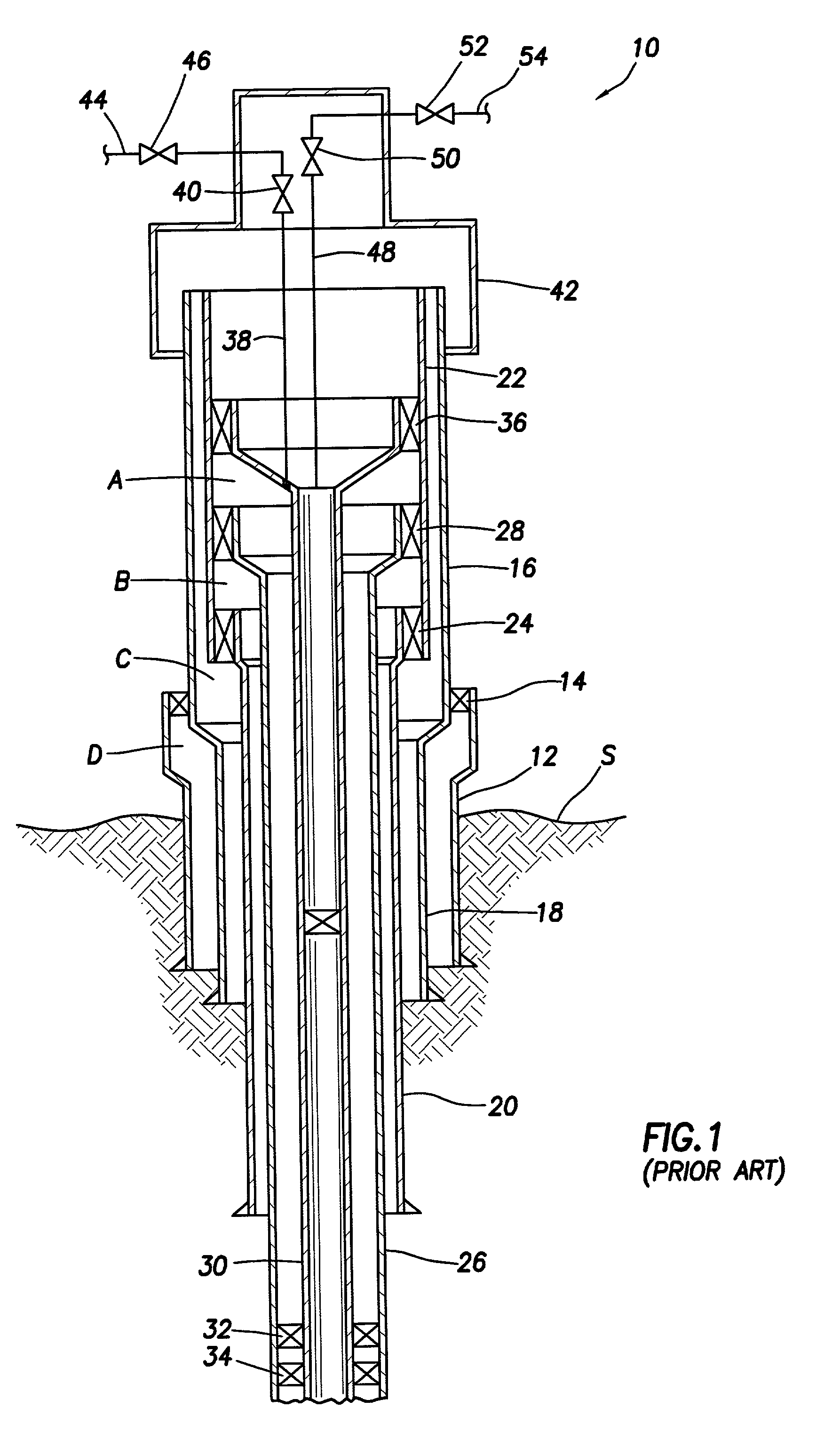

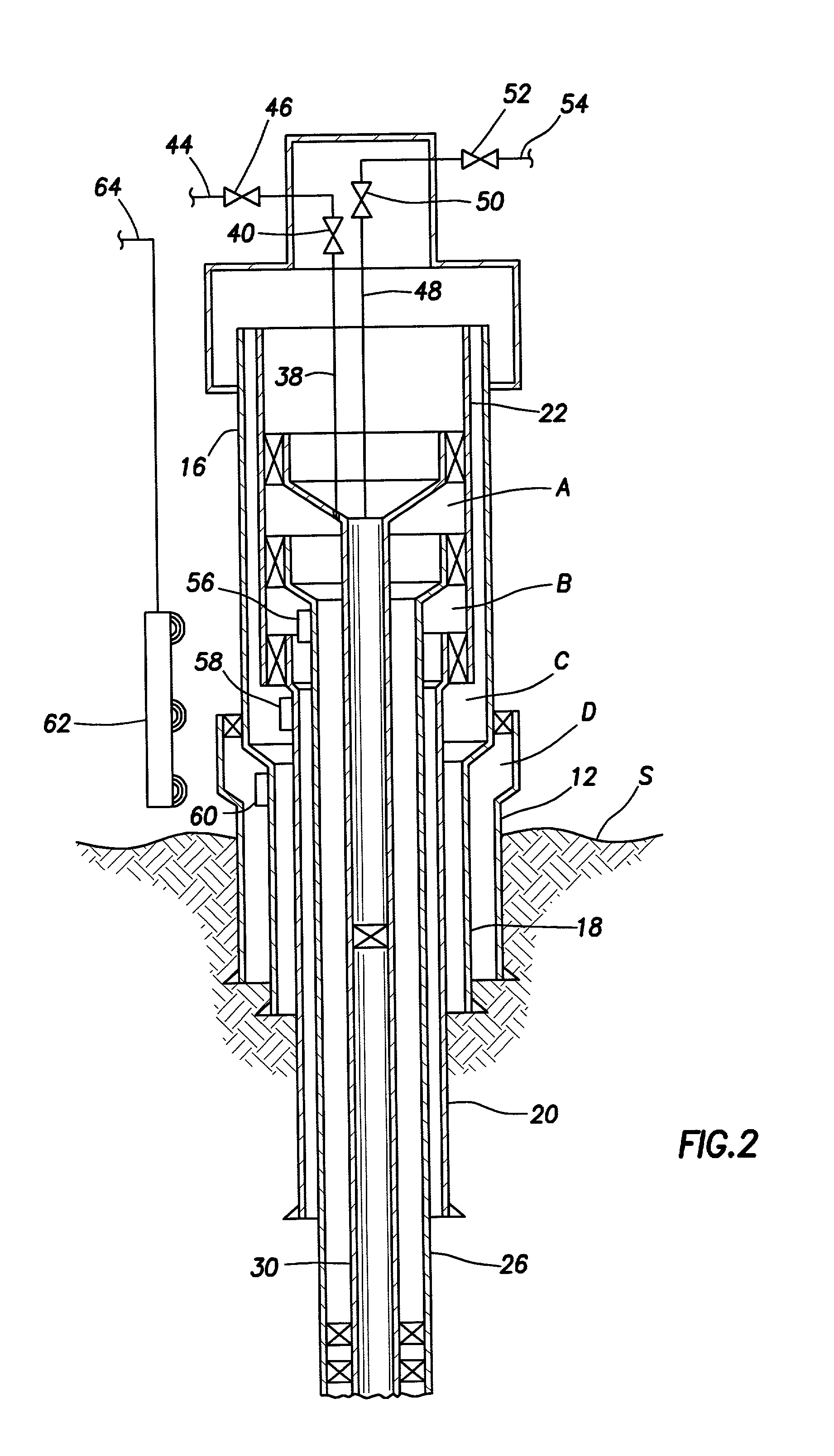

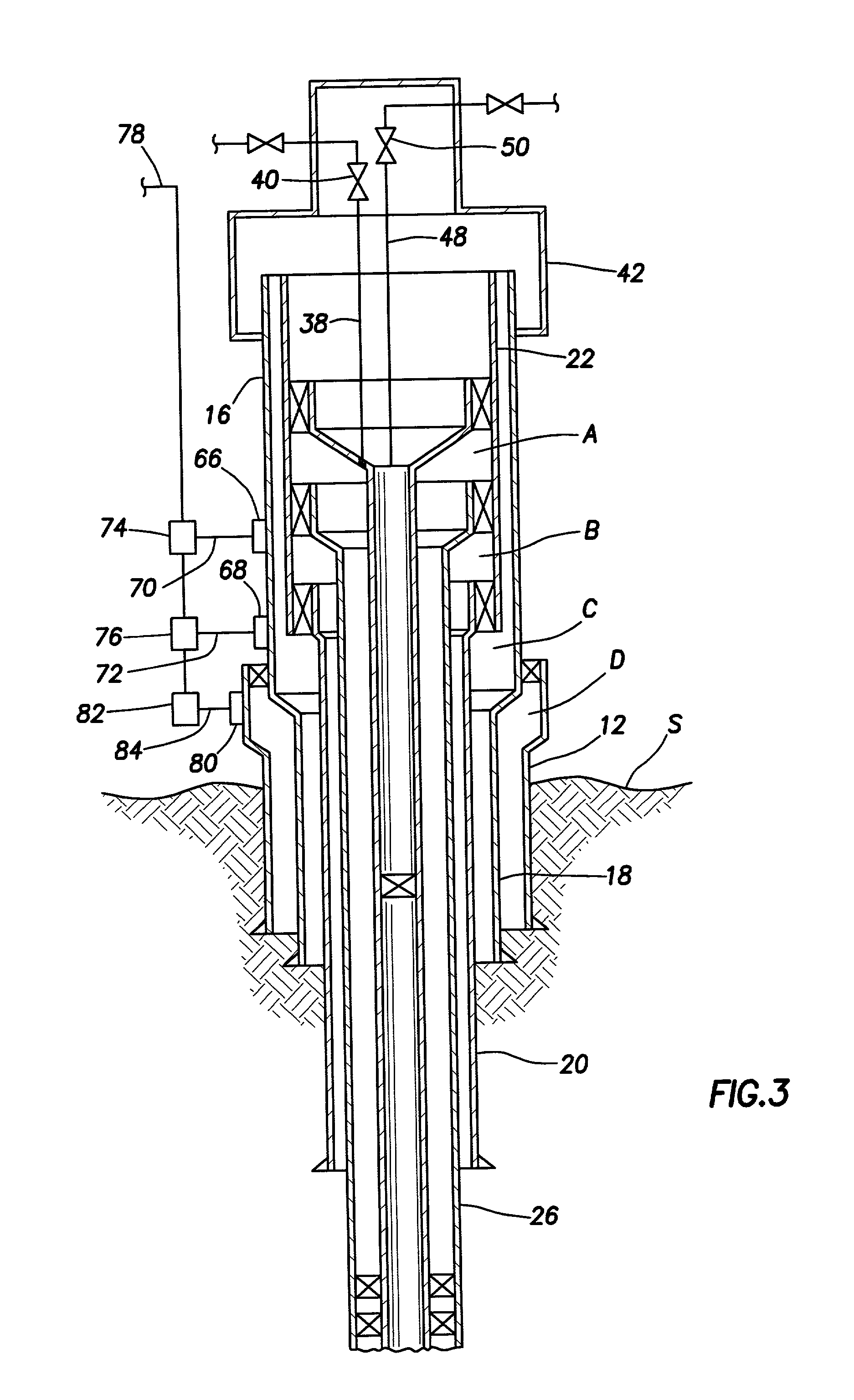

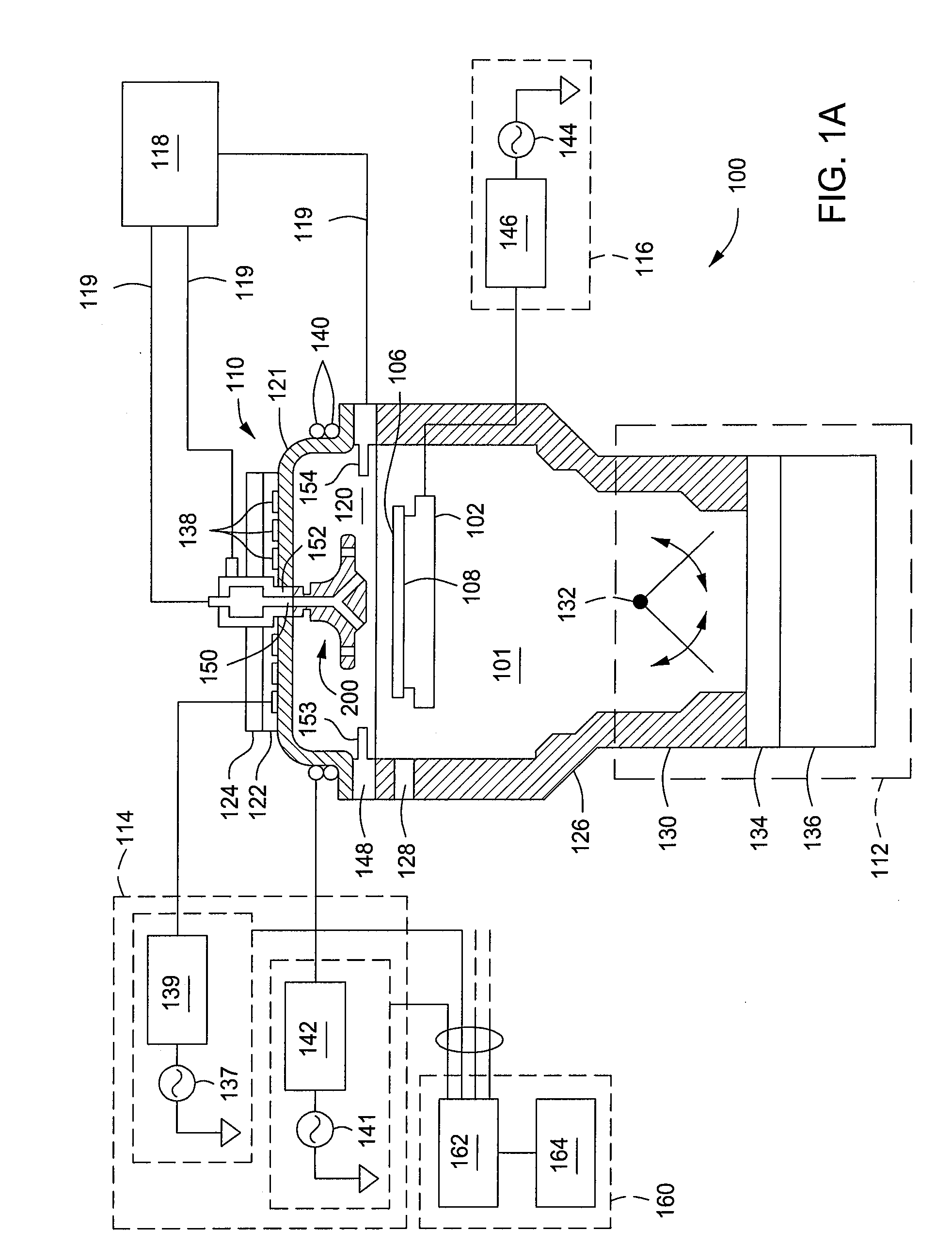

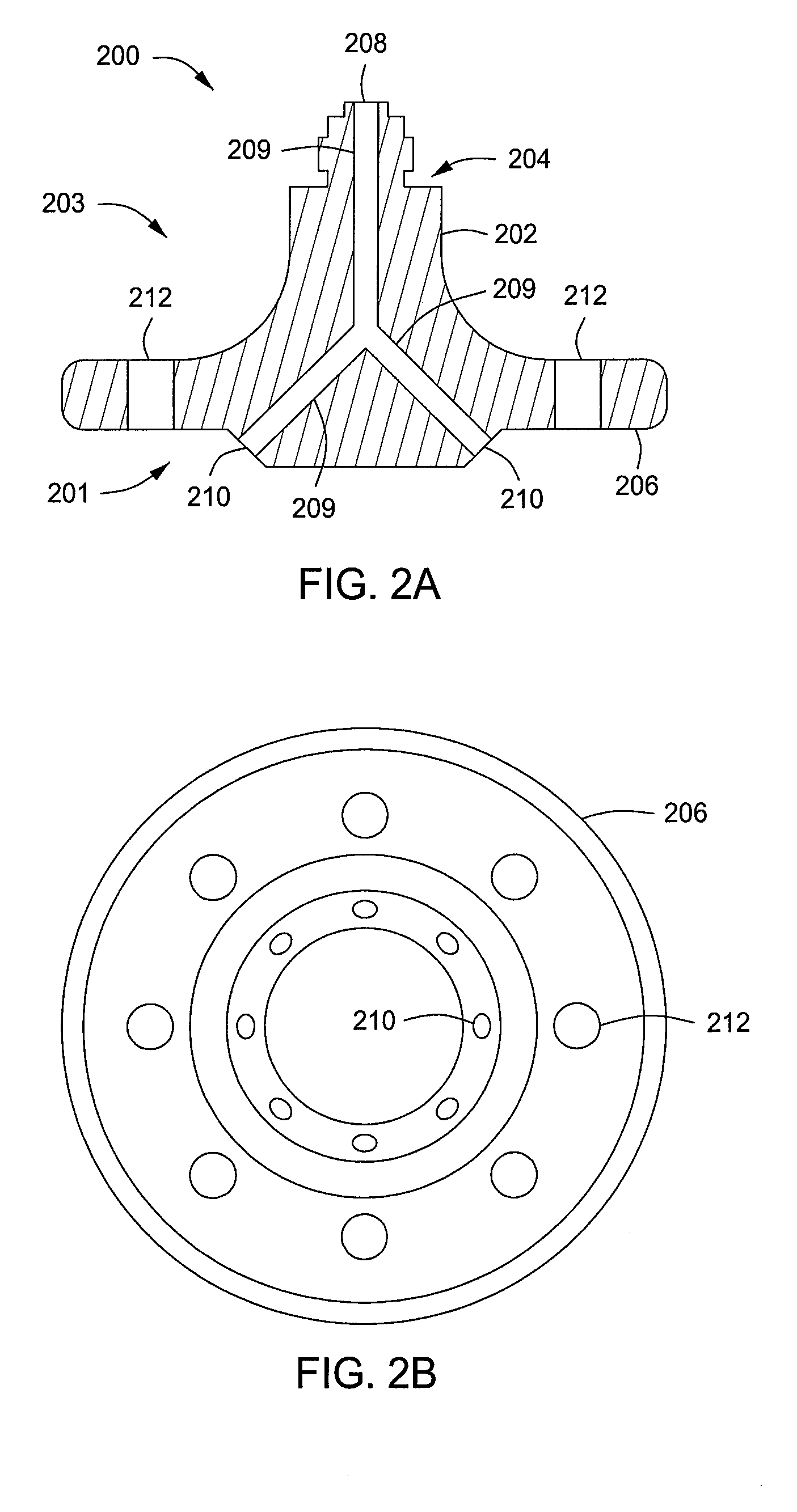

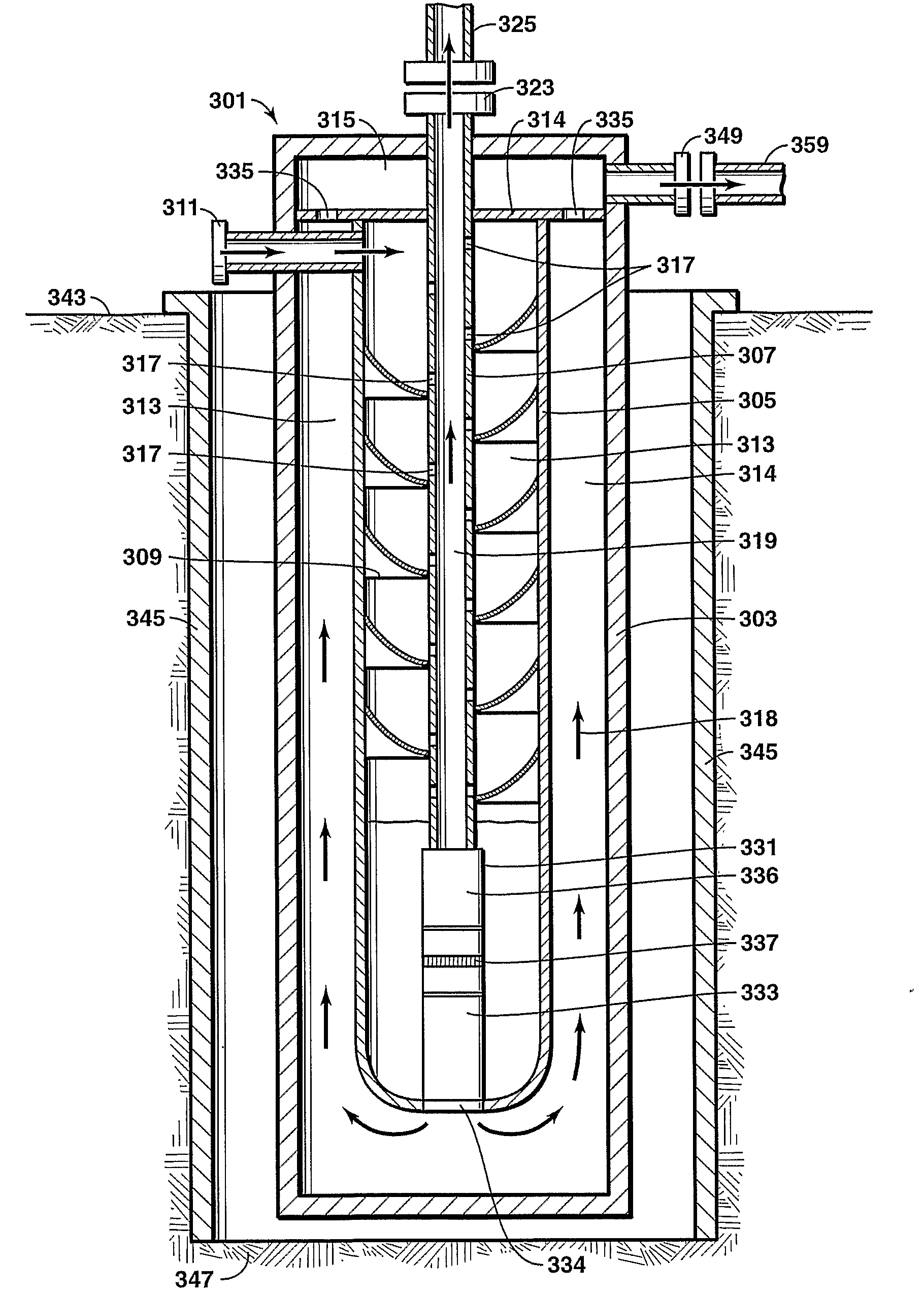

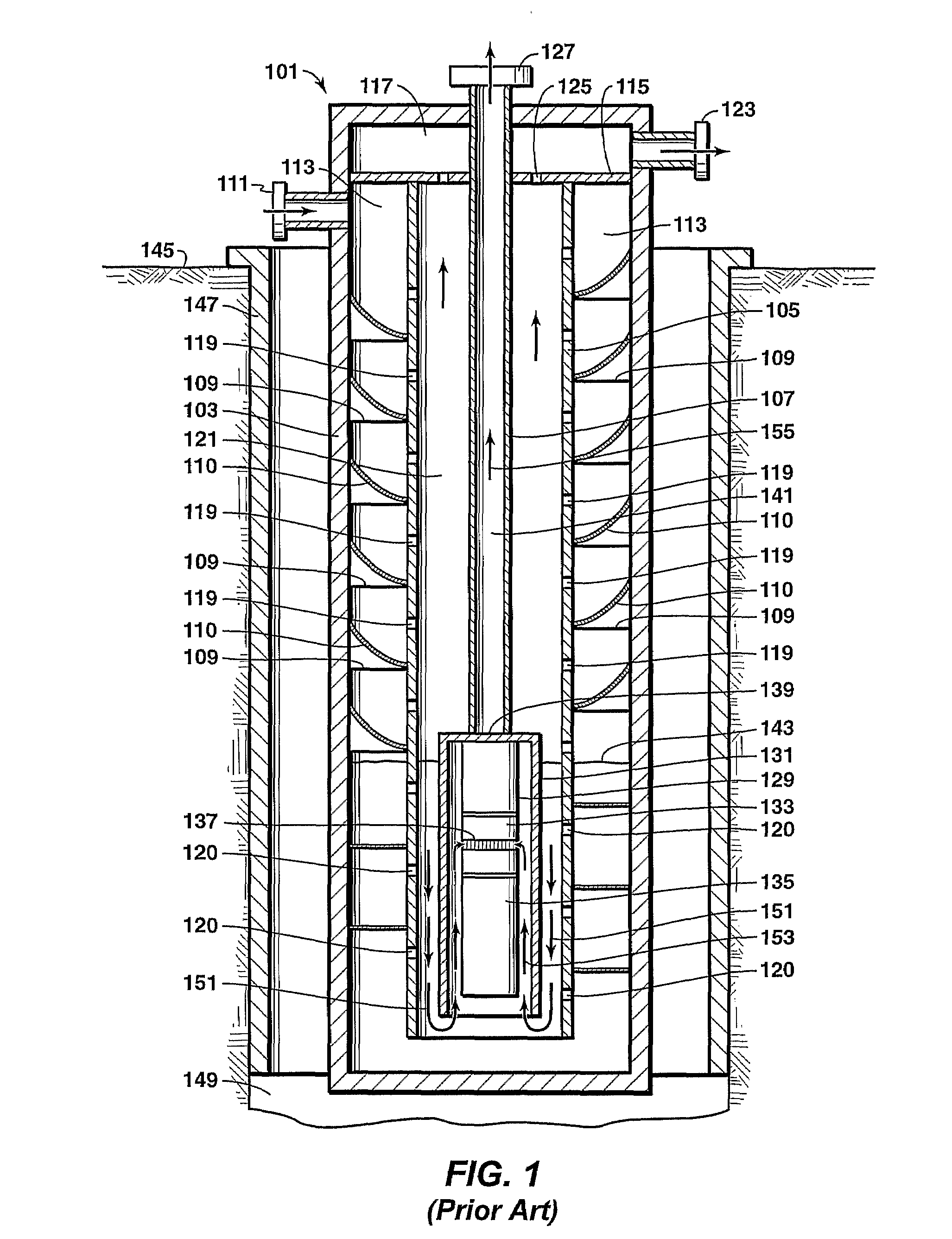

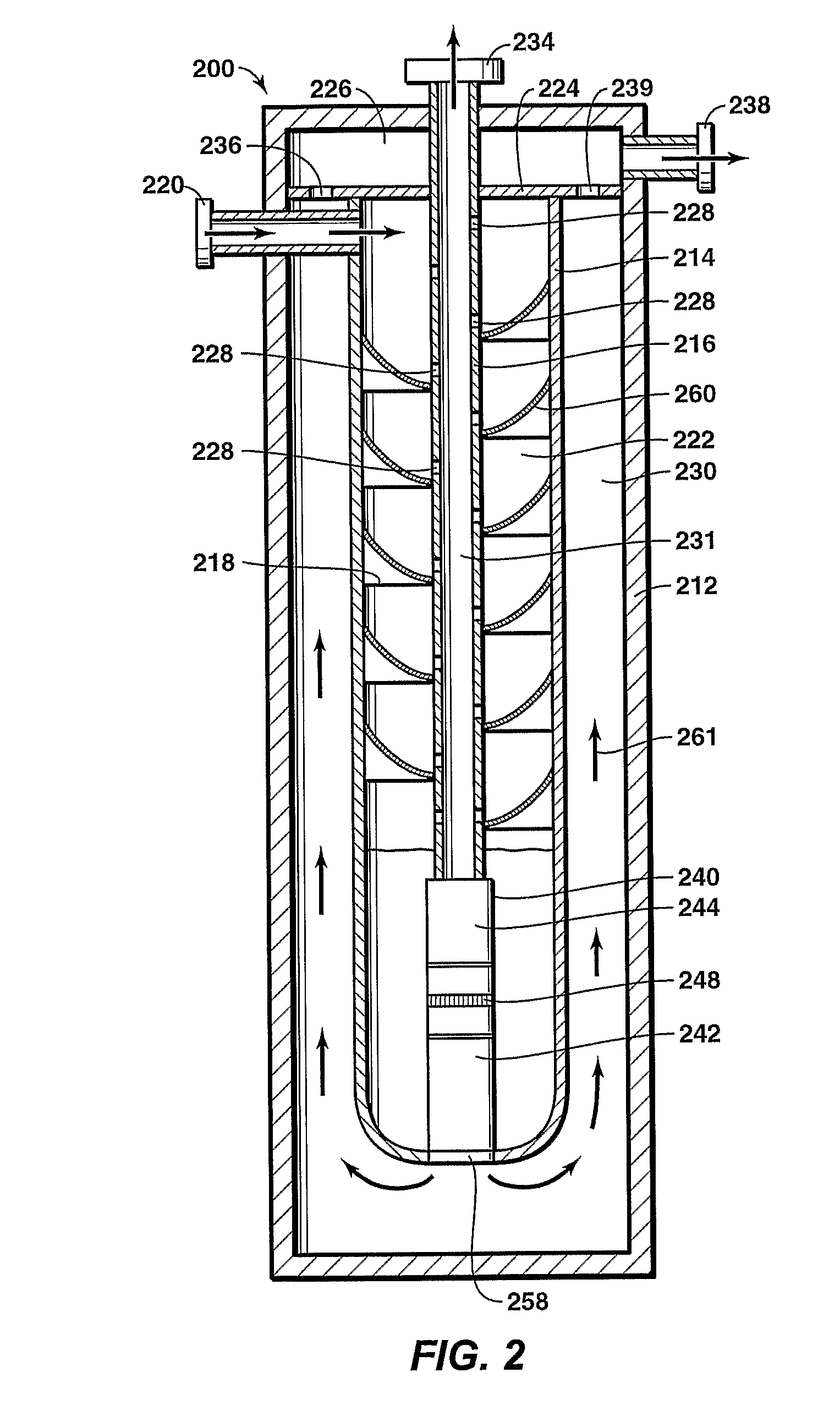

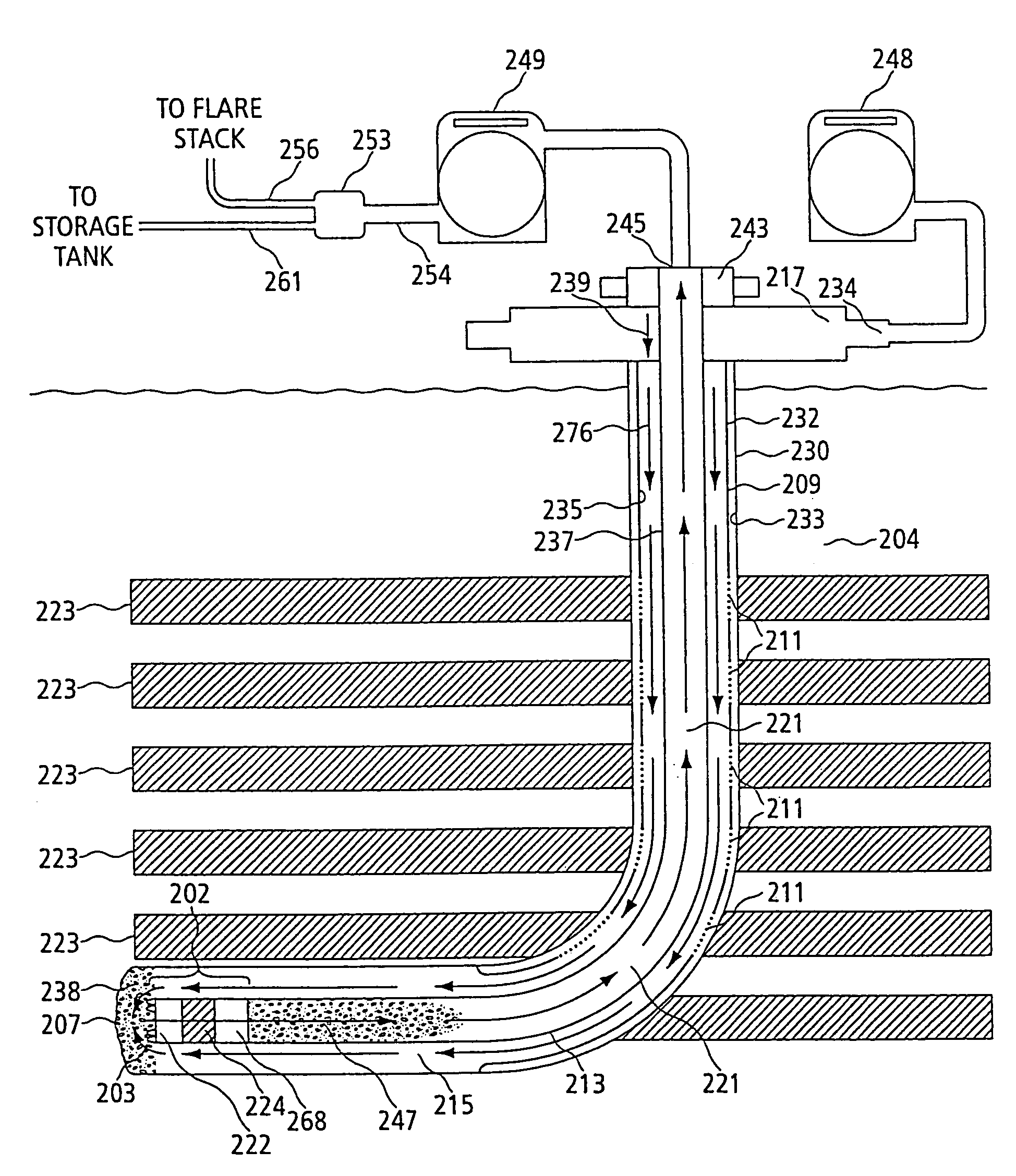

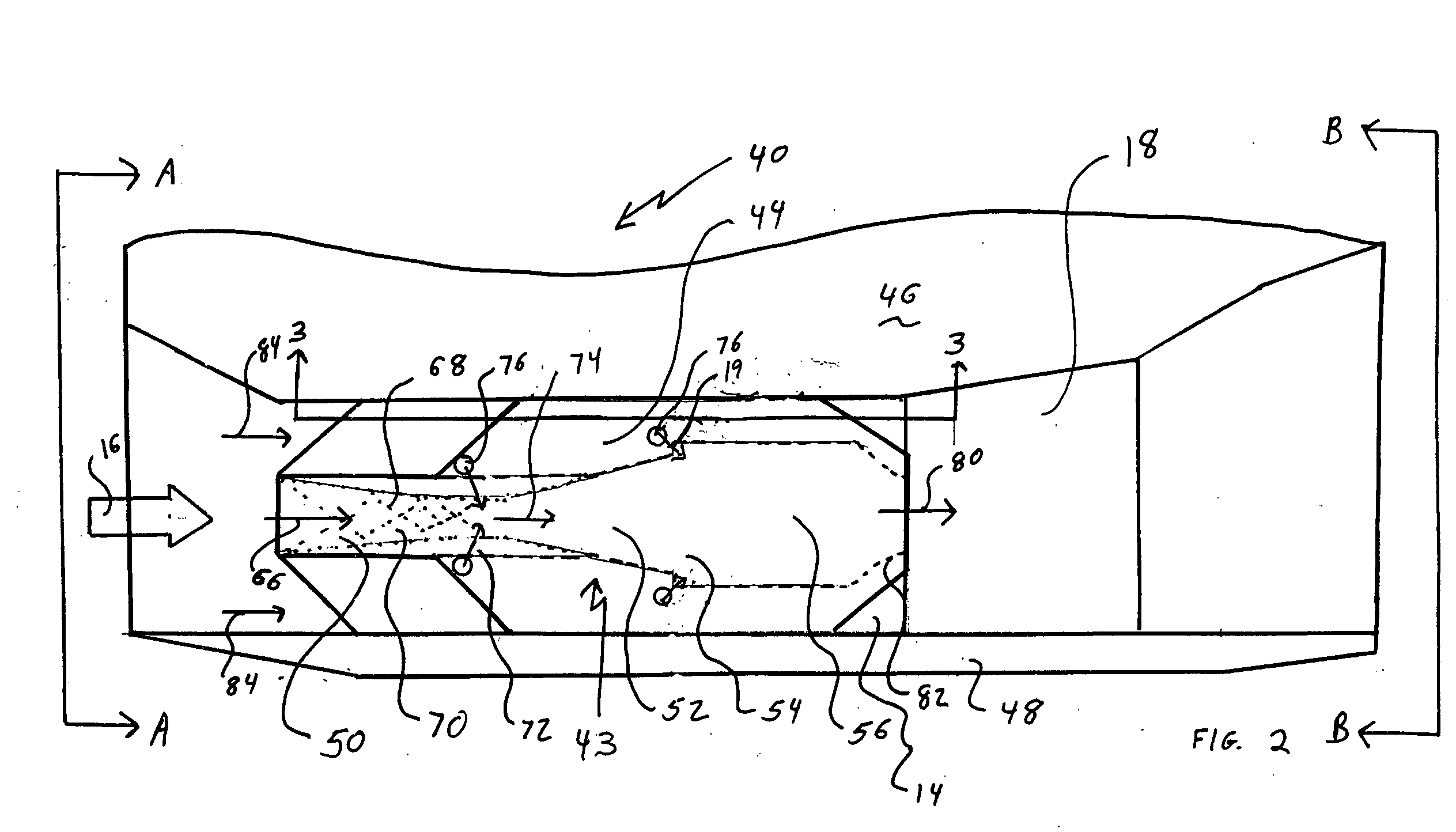

Vertical Annular Separation and Pumping System With Outer Annulus Liquid Discharge Arrangement

A system for producing hydrocarbon fluids from a subsea formation comprises at least one producing well (1) penetrating the formation (2) for producing hydrocarbon fluids. At least one dummy well (7) is hydraulically connected to the at least one producing well (1) for routing the hydrocarbon fluids from the producing well to the dummy well. At least one pump (8) is disposed in the at least one dummy well. The pump takes suction flow from the dummy well (7) and boosts the flow energy of the discharge flow of hydrocarbon fluids.

Owner:EXXONMOBIL UPSTREAM RES CO

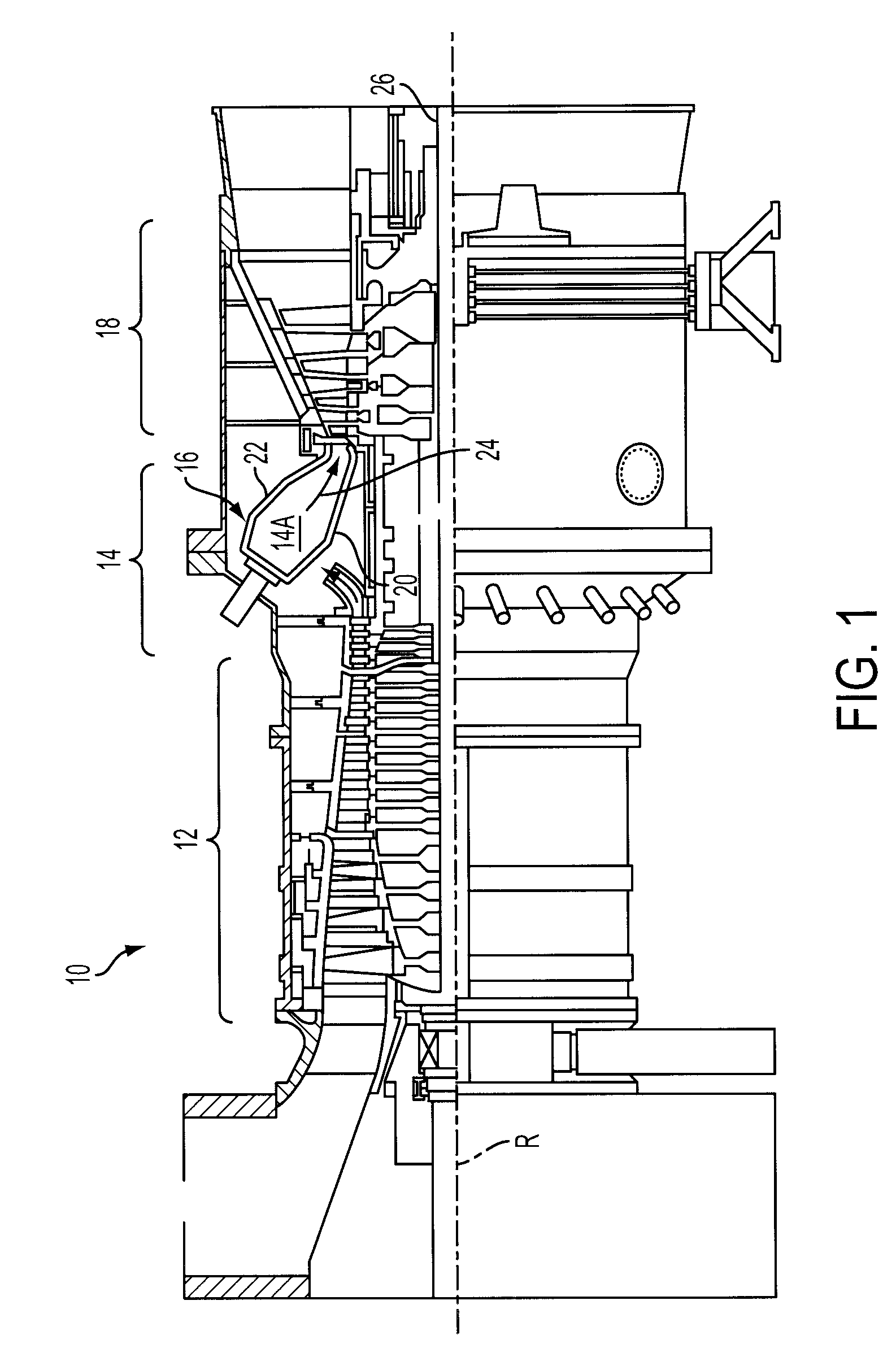

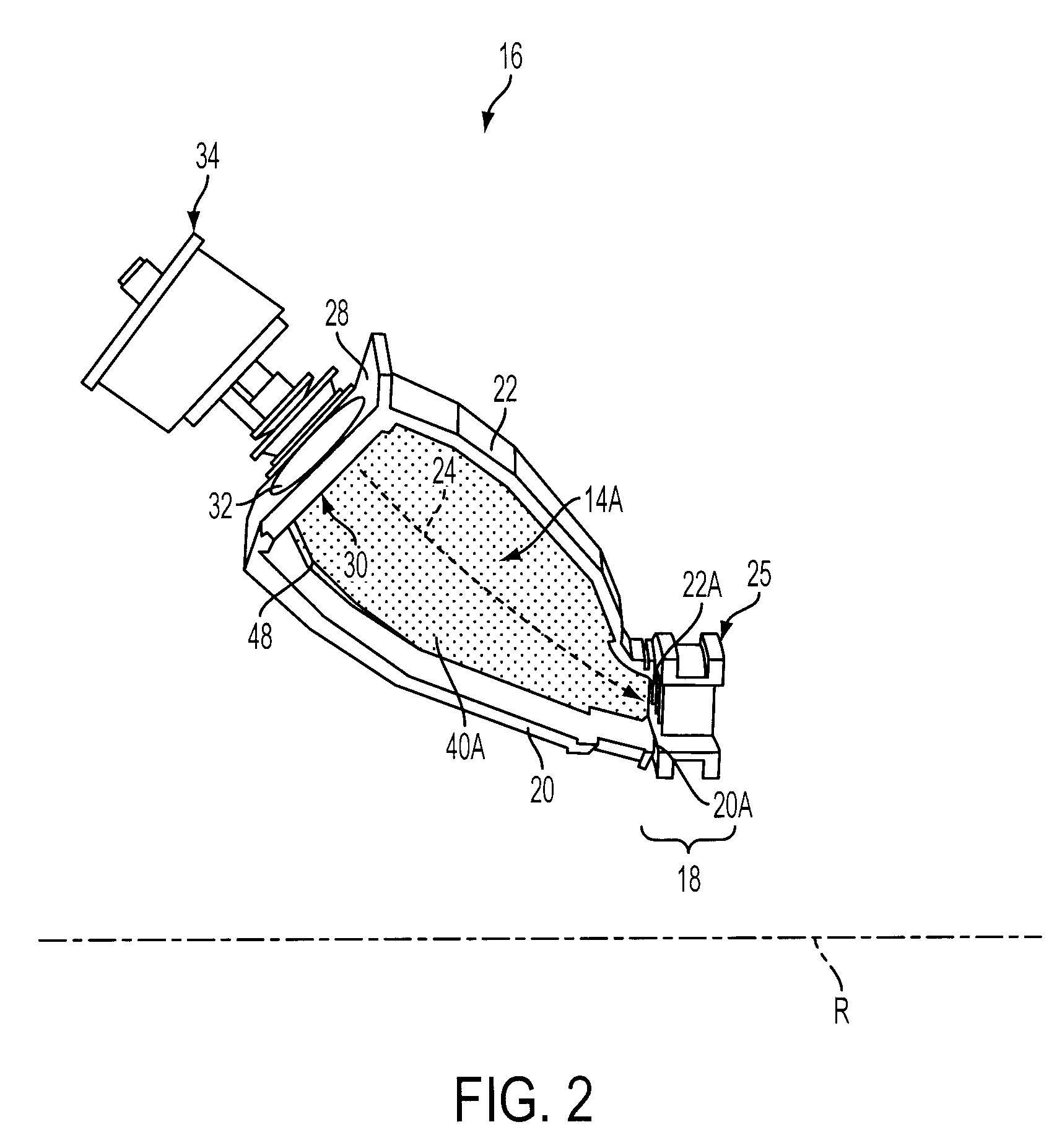

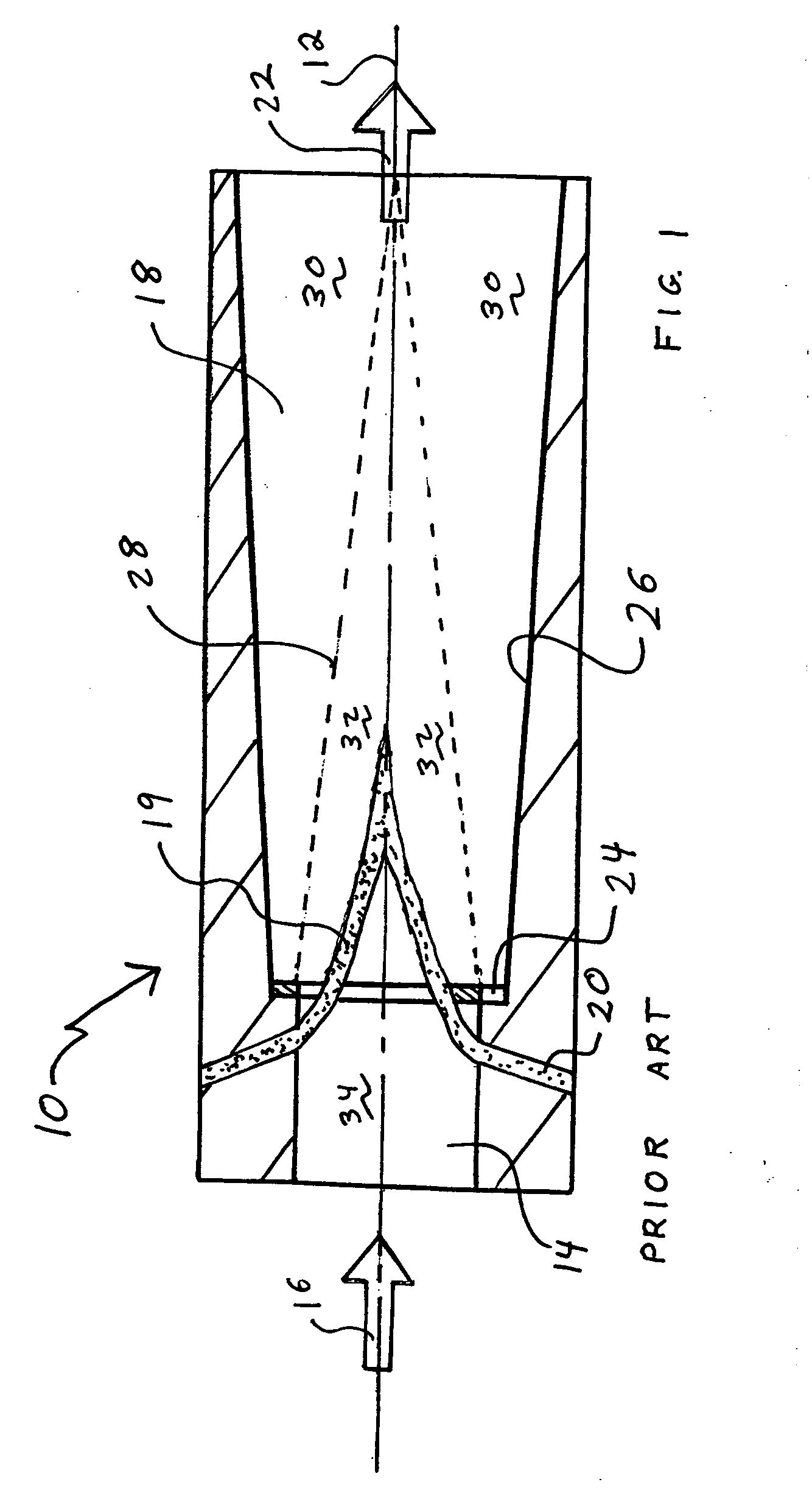

Segmented annular combustor

Owner:SIEMENS ENERGY INC

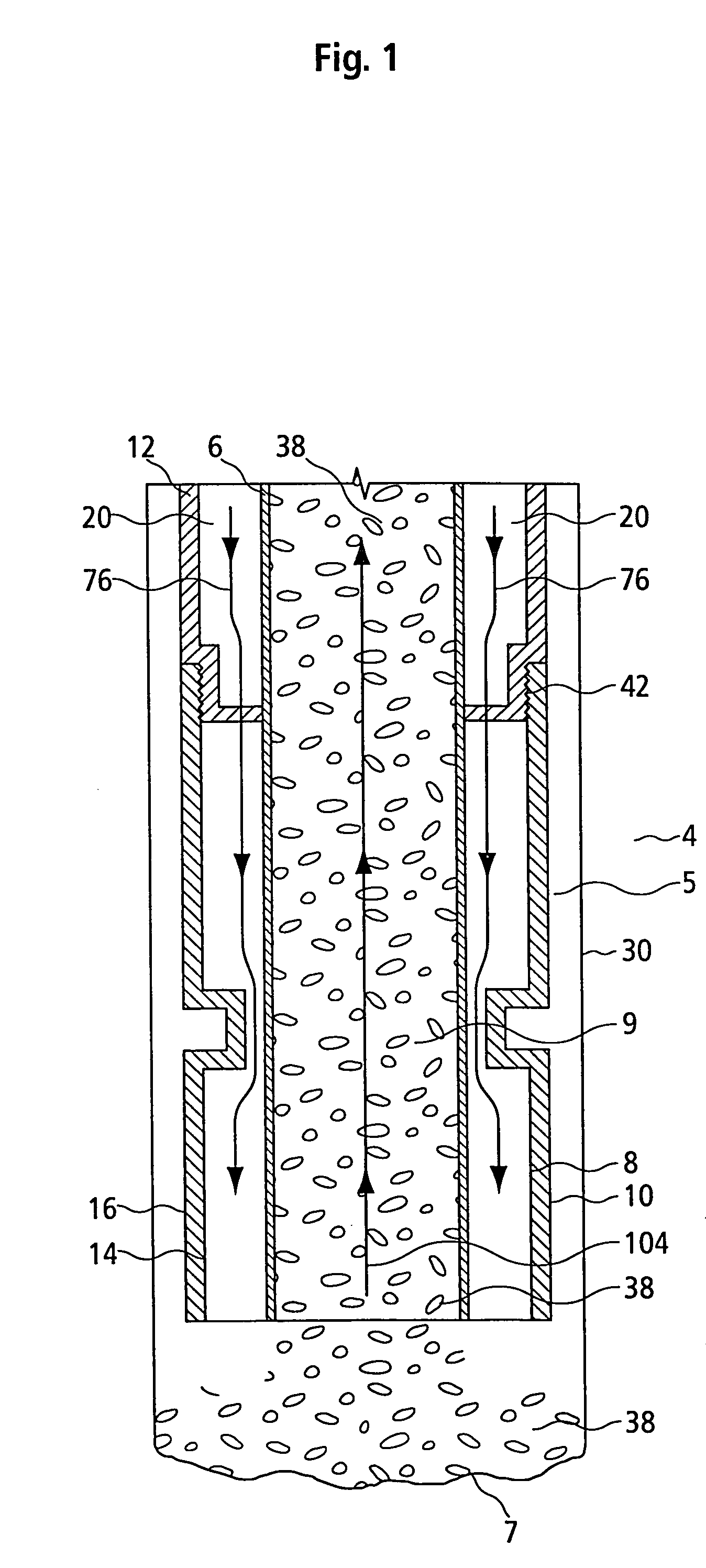

Reverse circulation clean out system for low pressure gas wells

ActiveUS7090018B2Avoid damageEasy to produceDrilling rodsConstructionsEngineeringMechanical engineering

The present invention provides an apparatus and a method for removing undesirable material from a well bore in a hydrocarbon formation with minimum damage to the formation. The apparatus comprises a concentric tubing string, said concentric tubing string further comprising an inner tube means having an inner annulus therethrough and an outer tube means forming an outer annulus between said outer tube means and said inner tube means, means for introducing into said well bore a pressurized clean out medium through one of the said inner annulus and outer annulus, and means for removing said material and clean out medium through the other of the said inner annulus and said outer annulus to the surface of said well bore. In a preferred embodiment, the introducing means comprises a discharge compressor or mud pump and the removing means comprises a suctioning compressor.

Owner:PRESSSOL

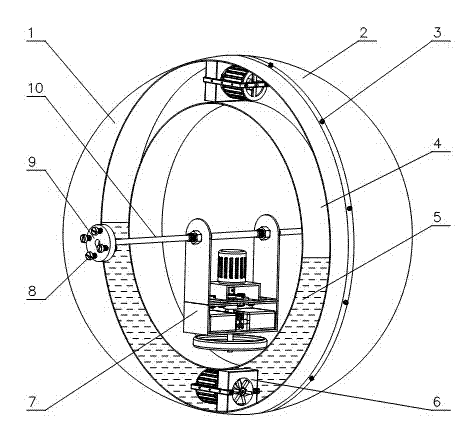

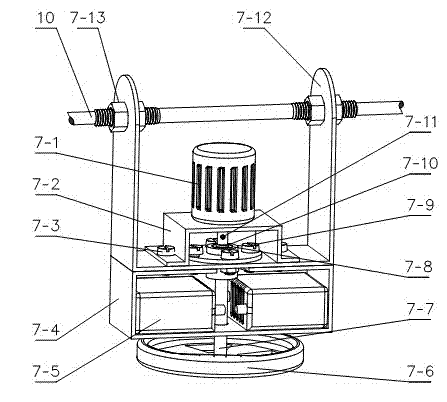

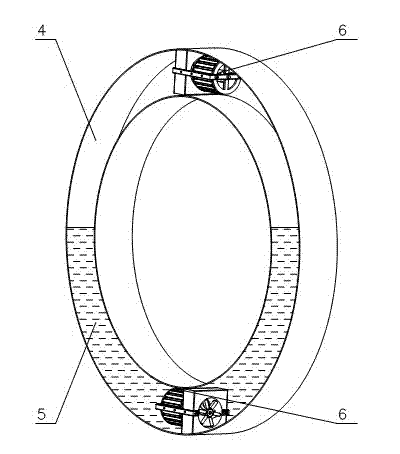

Fluid driving spherical robot

The invention belongs to the field of electromechanical technique, and relates to a spherical moving robot, and in particular relates to a fluid driving spherical robot which comprises a spherical shell, an annular seal container, axial flow devices, an inner driving rotating mechanism and a main shaft. The fluid driving spherical robot is characterized in that the spherical shell consists of two hemispherical shells including a left hemispherical shell and a right hemispherical shell; the annular seal container is positioned in the spherical surface; the outer annular surface of the container is concentric with the spherical surface of the spherical shell; the container is filled with fluid; the volume of the fluid is half of the volume of the container; two axial flow devices are symmetrically installed in the annular seal container; the axial flow devices drive a liquid to flow in the annular seal container, thus the mass center of the spherical robot is changed, thus the spherical robot can move forwards and backwards; the inner driving rotating mechanism positioned in the spherical shell mainly comprises an inner driving bracket, a motor, a motor support, a flywheel shaft, a flywheel, an electricity supply power supply and a controller; the main shaft is fixedly connected with the inner driving bracket through the motor support; the fly wheel is installed on the inner driving bracket through a bearing; the motor shaft is connected with the fly wheel through a coupling; and the motor drives the lower part of the motor to rotate together with the flywheel shaft vertical to the main shaft and the fly wheel, and the spherical robot takes a turn under the driving of the fluid on the basis of an angular momentum conservation principle.

Owner:TAISHAN UNIV

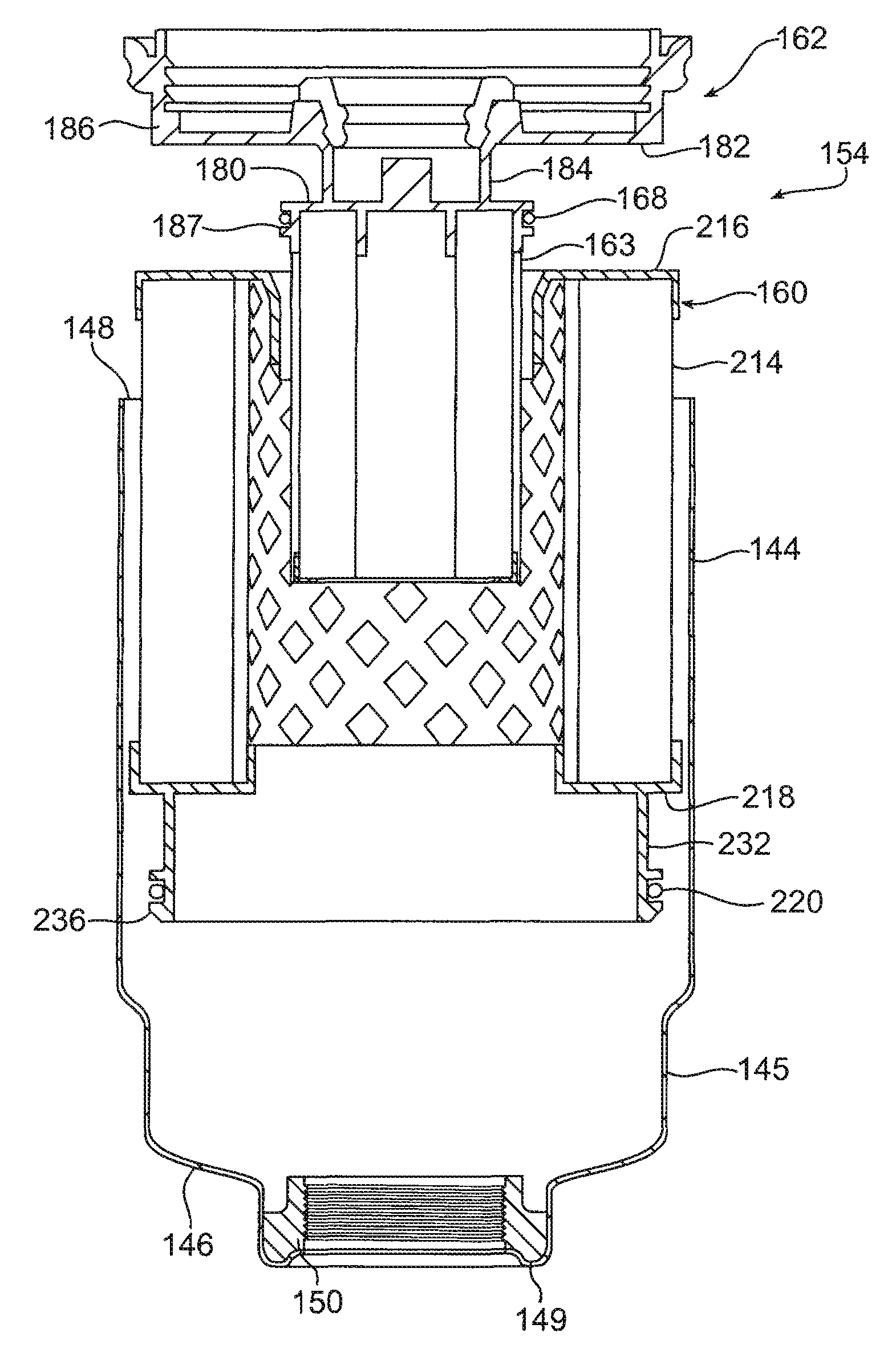

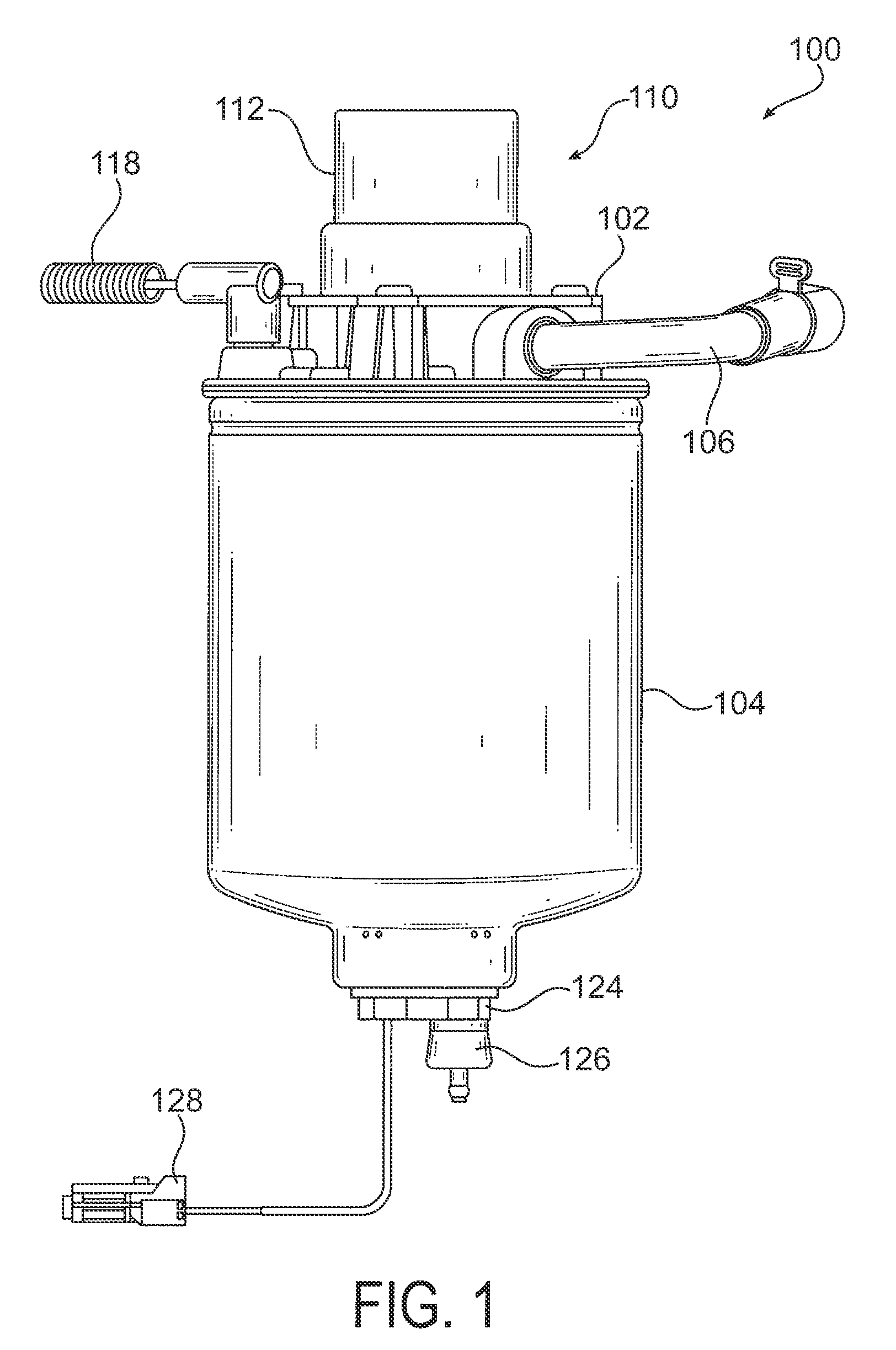

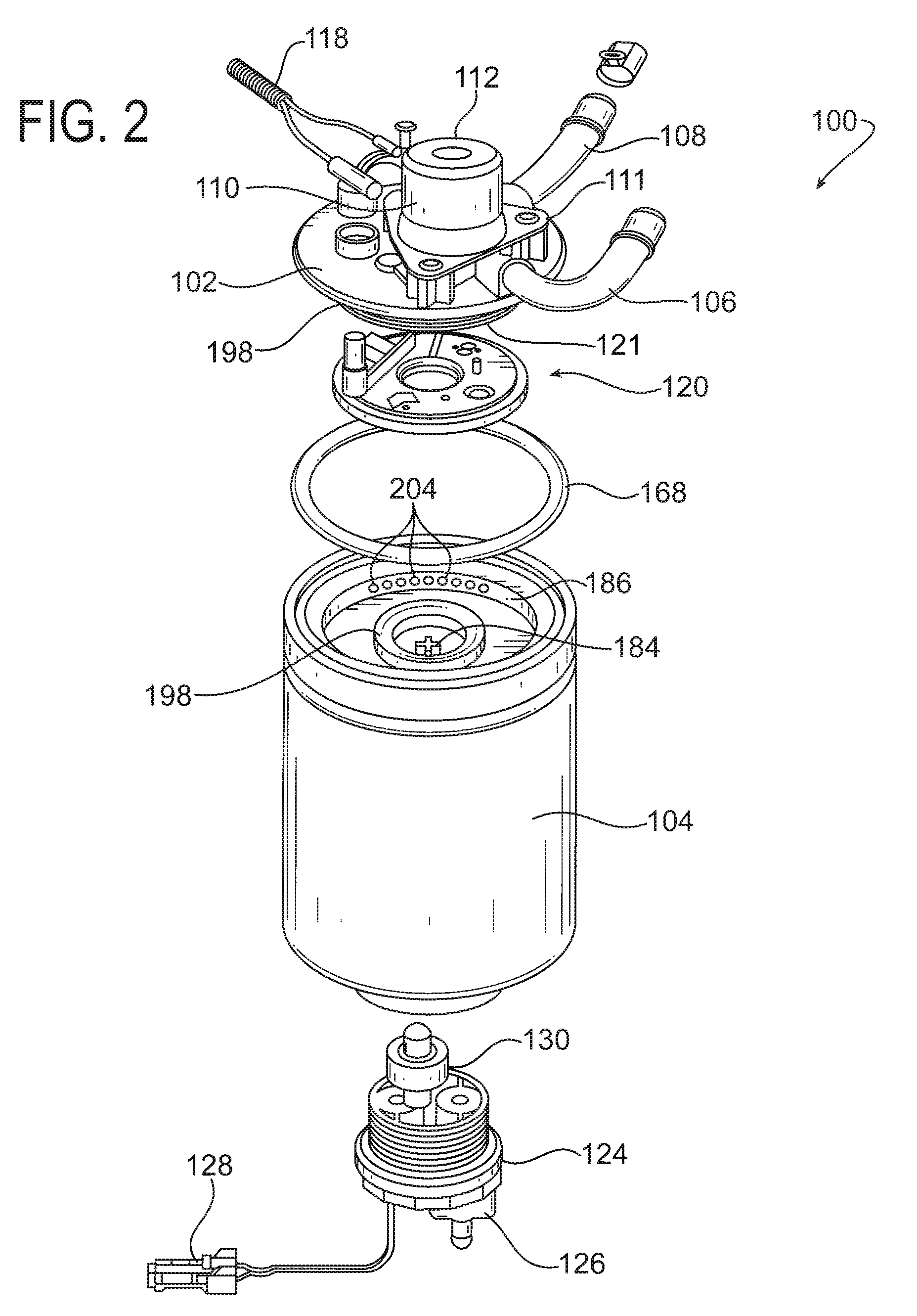

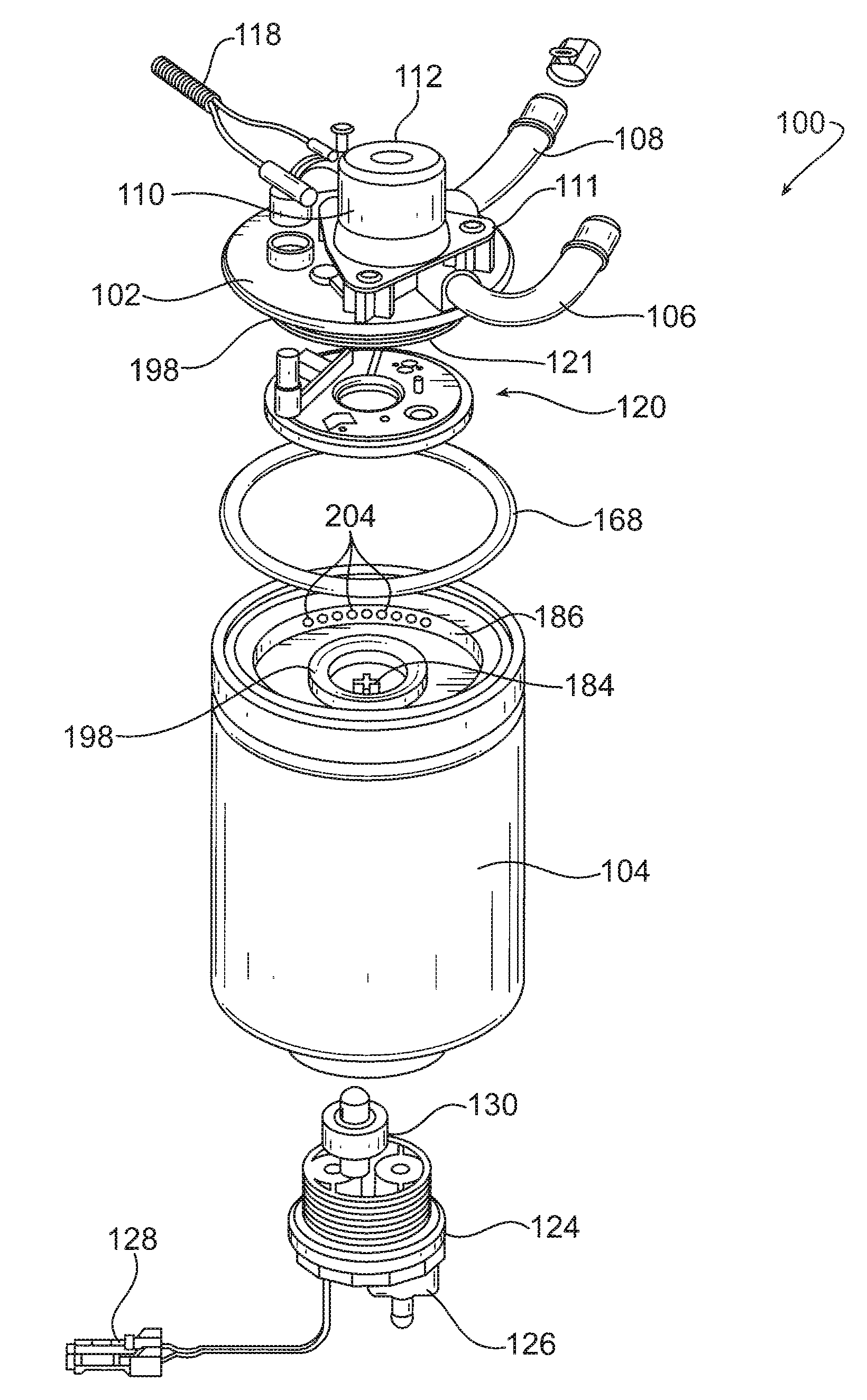

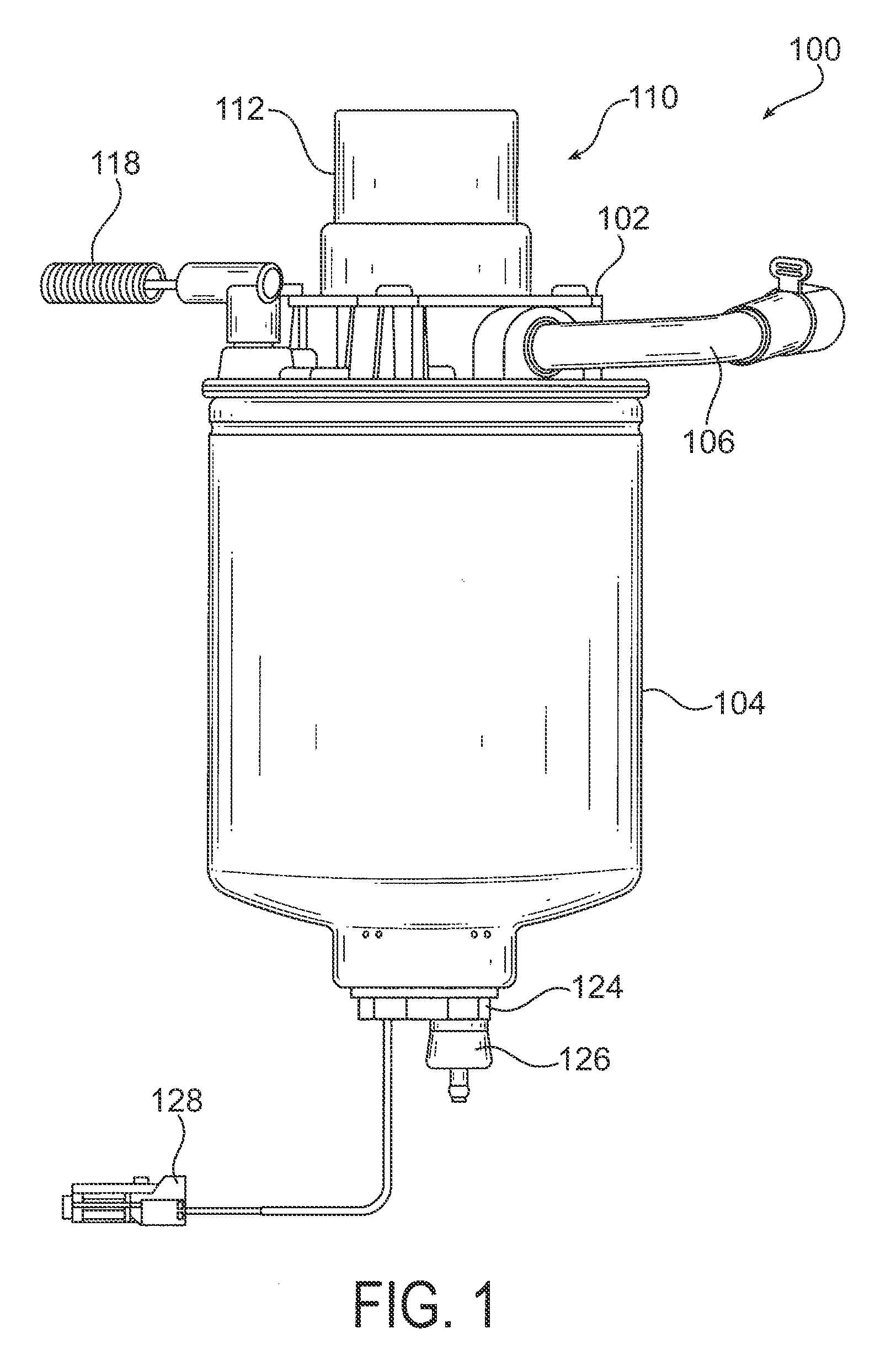

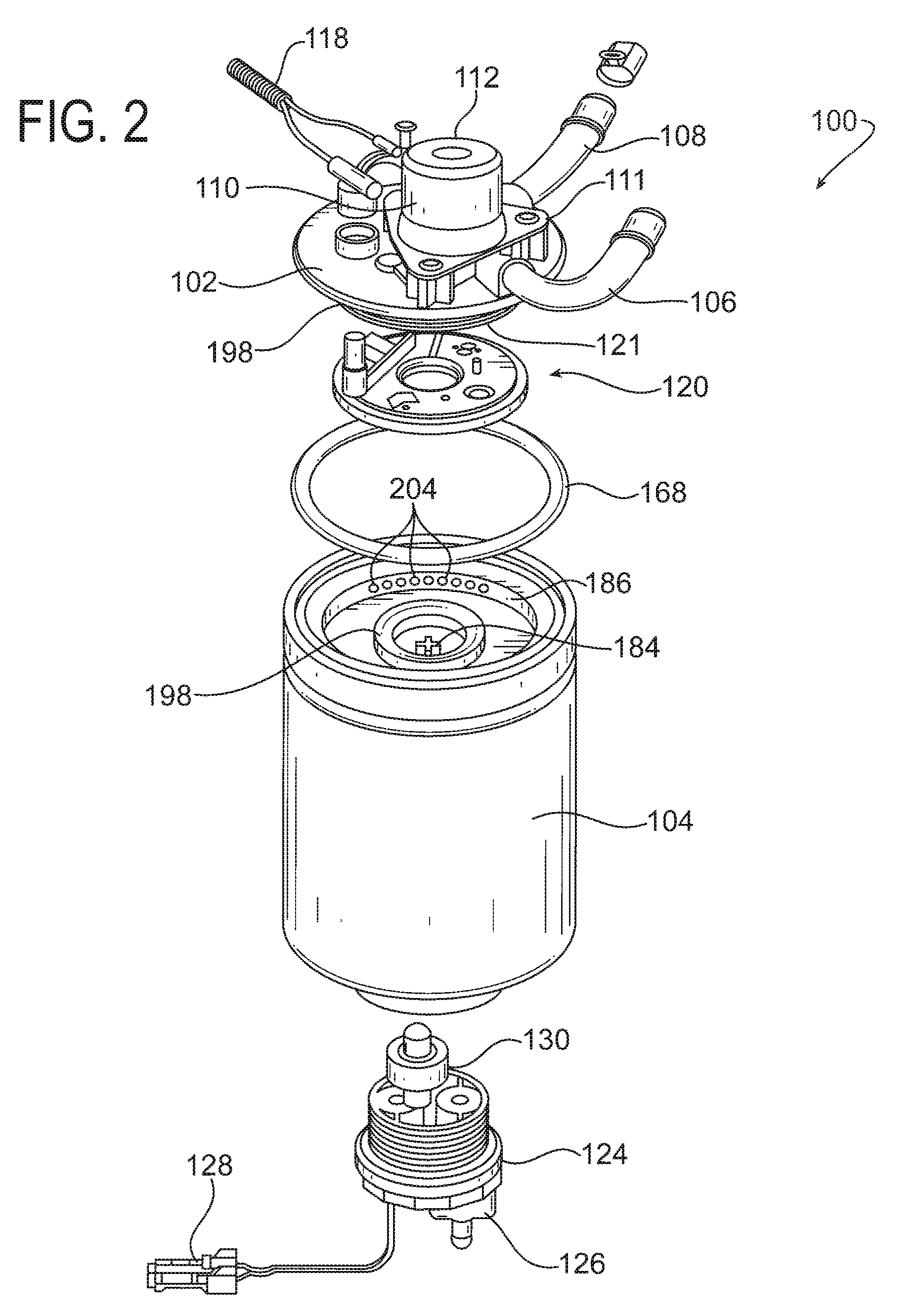

Coalescing element

ActiveUS8034240B2Simple and straightforward to manufactureSimple and straightforward to and assembleSeparation devicesSedimentation separationFilter mediaScrew thread

Owner:PARKER INTANGIBLES LLC

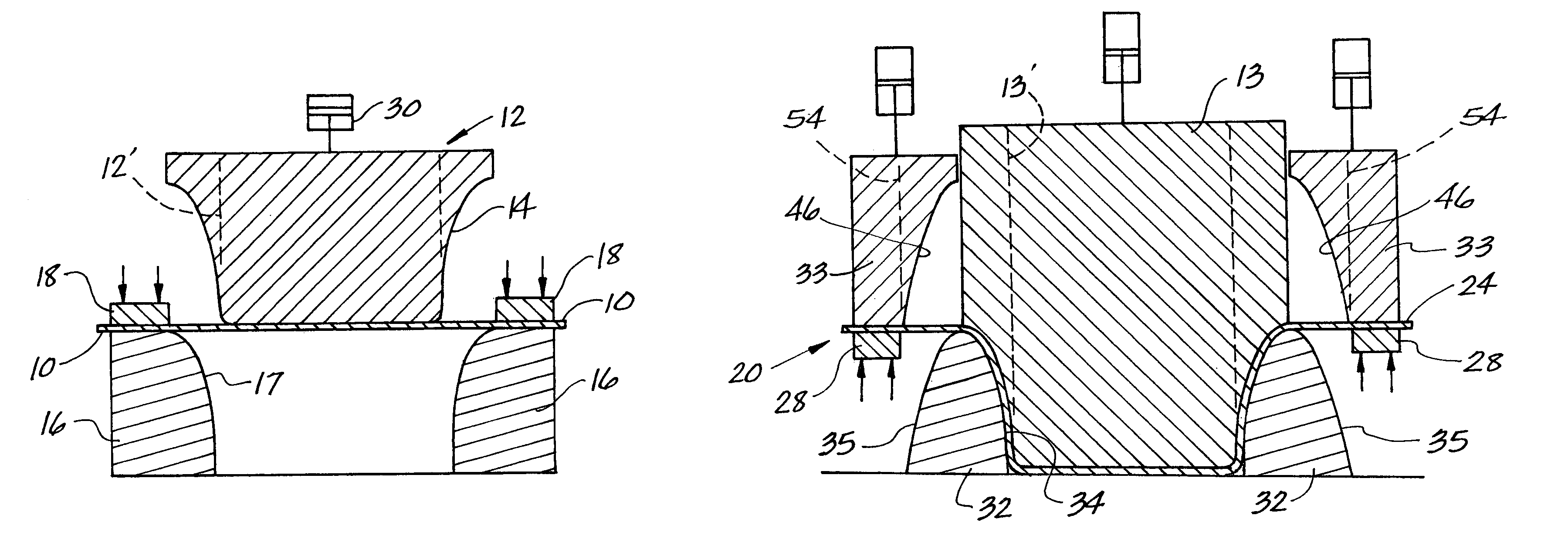

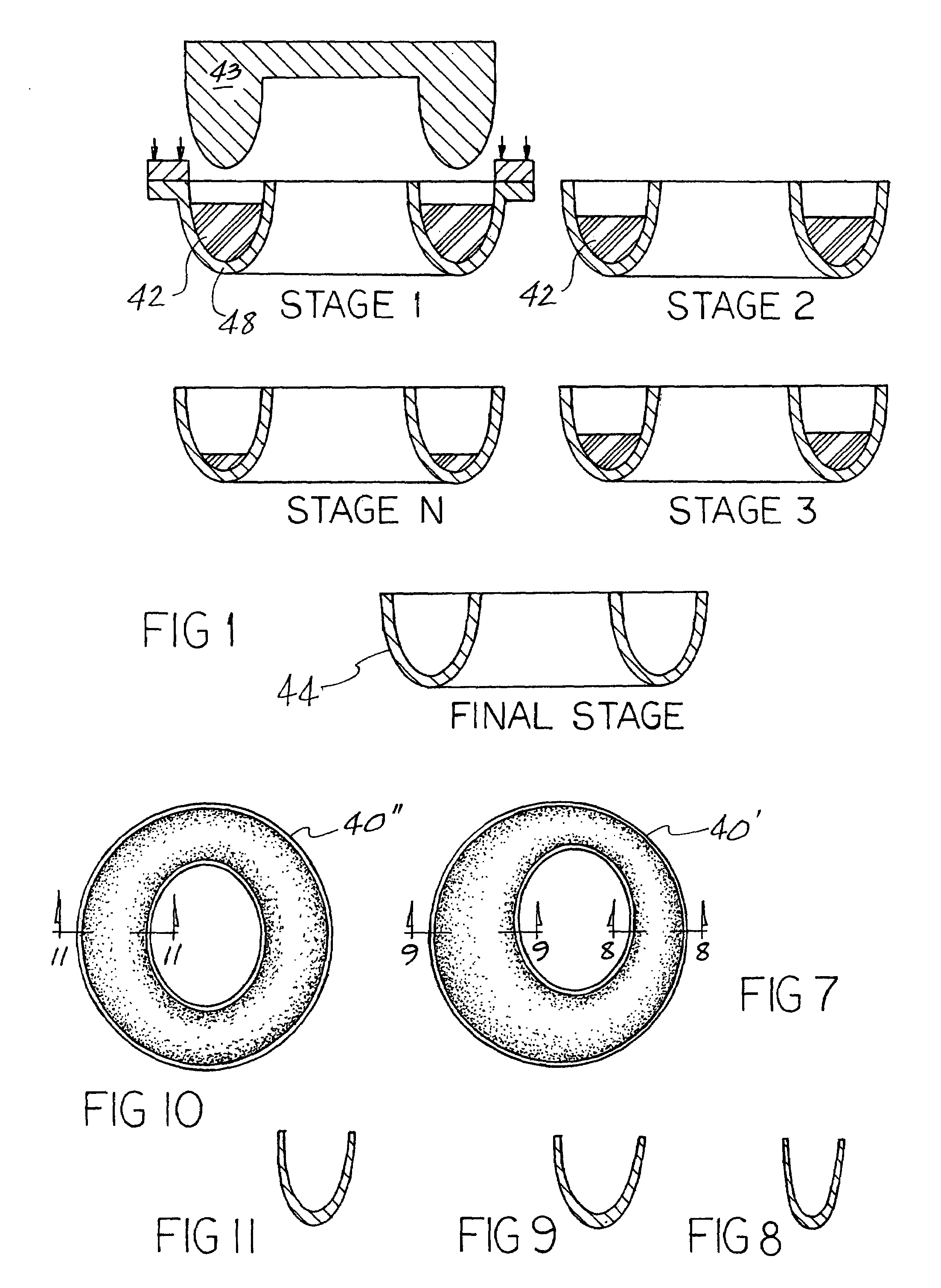

Nacelle nose cap forming method and apparatus

A method and apparatus for draw forming a flat sheet blank into a 3-dimensional-nacelle nose cap for an aircraft engine in two stages; the blank having an outer annular portion and an inner annular portion. Draw forming the inner annular portion into a shape of an arcuate circular inner wall and then draw forming the outer annular portion into an arcuate outer wall adjacent the inner wall with the combination of walls being U-shaped in cross section.

Owner:TEXTRON INNOVATIONS

Core burning for scramjet engines

InactiveUS20080092519A1Reducing combustor heat loadReduces combustor heat loadCosmonautic vehiclesCosmonautic propulsion system apparatusRamjetCombustion chamber

A pilot for a scramjet provides a flame front whose arrival at the wall of the scramjet combustor is delayed thereby reducing combustor heat load. By combining in-stream injection of fuel with an interior pilot and a lean (fuel-poor) outer annulus, the bulk of combustion is confined to the scramjet combustor center. This concept, referred to as “core-burning,” further reduces combustor heat load. One such pilot is for a two dimensional scramjet effective to propel a vehicle. This pilot includes a plurality of spaced apart struts separated by ducts and a strut pilot contained within each strut. A second such pilot is for an axisymmetric scramjet engine has, in sequence and in fluid communication, an air intake, an open bore scramjet isolator and a scramjet combustor. This centerbody pilot pod includes a pilot isolator disposed between the air intake and a pilot diffuser, the pilot diffuser disposed between the pilot isolator and a pilot with the pilot disposed between the pilot diffuser and a pilot combustor. The pilot pod is in axis symmetry around a central axis of the scramjet isolator and supported by a plurality of struts extending from an inner wall of the open bore to an outer surface of the centerbody pilot pod.

Owner:AEROJET ROCKETDYNE INC

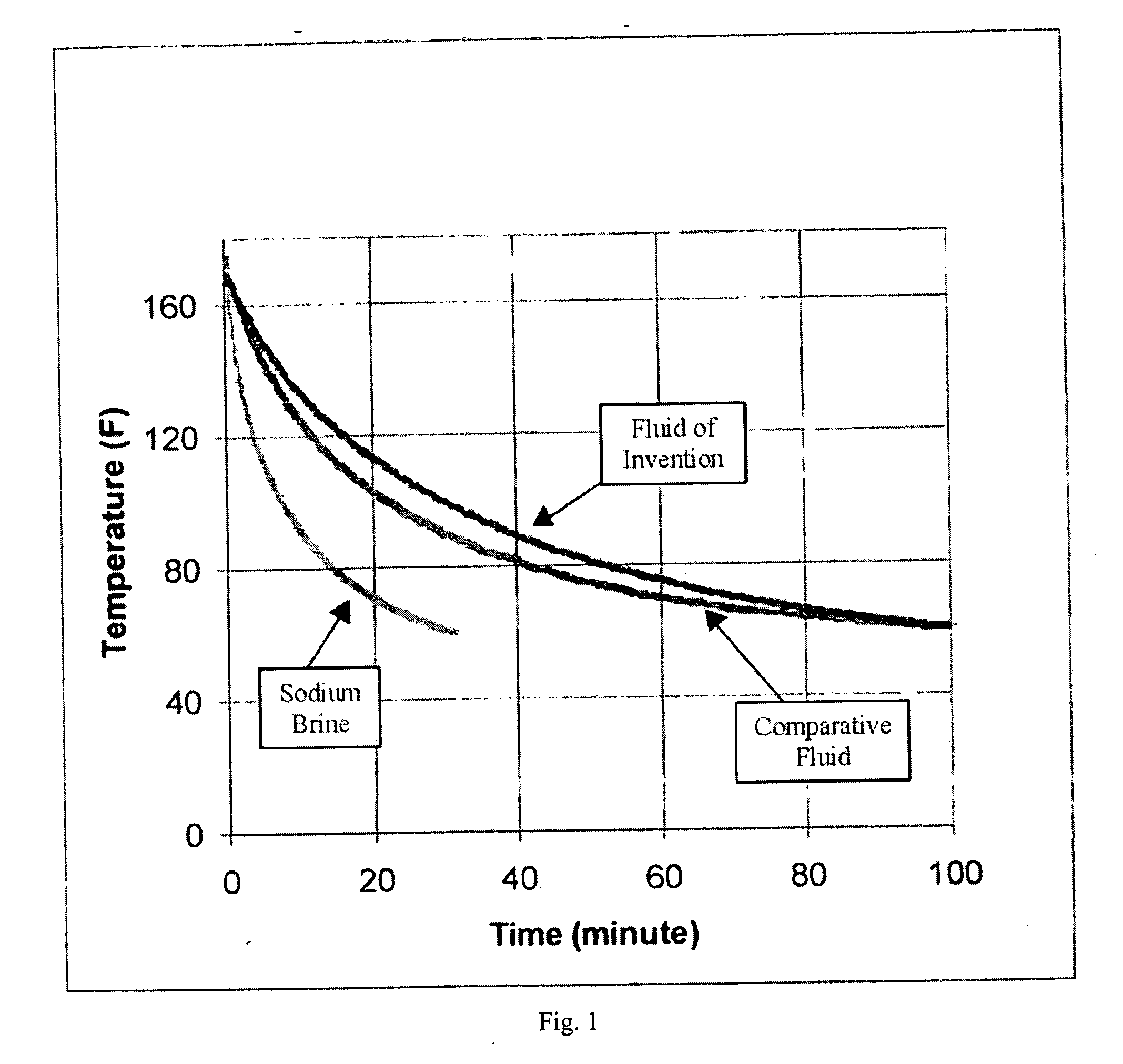

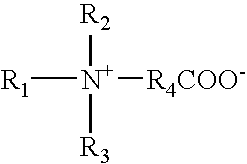

Methods and compositions for thermal insulation

ActiveUS20060131536A1Reduce convection flow velocityLow viscosityThermal insulationInsulationThermal insulationChemistry

Unwanted heat loss from production tubing or uncontrolled heat transfer to outer annuli is inhibited by introduction into the annuli a thermal insulating packer fluid or a riser fluid containing a zwitterionic surfactant, an alcohol and a brine. The viscosity of the composition is sufficient to reduce the convection flow velocity within the annulus. The invention has particular applicability with high density brines.

Owner:BAKER HUGHES INC

Coalescing element

ActiveUS20100219117A1Simple and straightforward to manufactureSimple and straightforward to and assembleSeparation devicesWater/sewage treatmentFilter mediaEngineering

A filter element includes a cylindrical housing enclosing a ring-shaped filter media assembly. The media assembly includes inner and outer media rings, moveably supported relative to one another, to remove particulate matter and water from a fluid stream. The outer ring surrounds the inner ring and is sealed by a first seal to the housing. An end cap assembly at the upper end of the element includes an annular end cap piece attached to an upper end of the inner ring, a flat plate, and a threaded flange portion bounding the periphery of the plate. A second seal is provided between the upper end cap of the inner ring, and an upper end cap of the outer ring. The housing is secured to the media assembly by forming an open end of the housing around the flange portion.

Owner:PARKER INTANGIBLES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com