Patents

Literature

201results about How to "Low solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

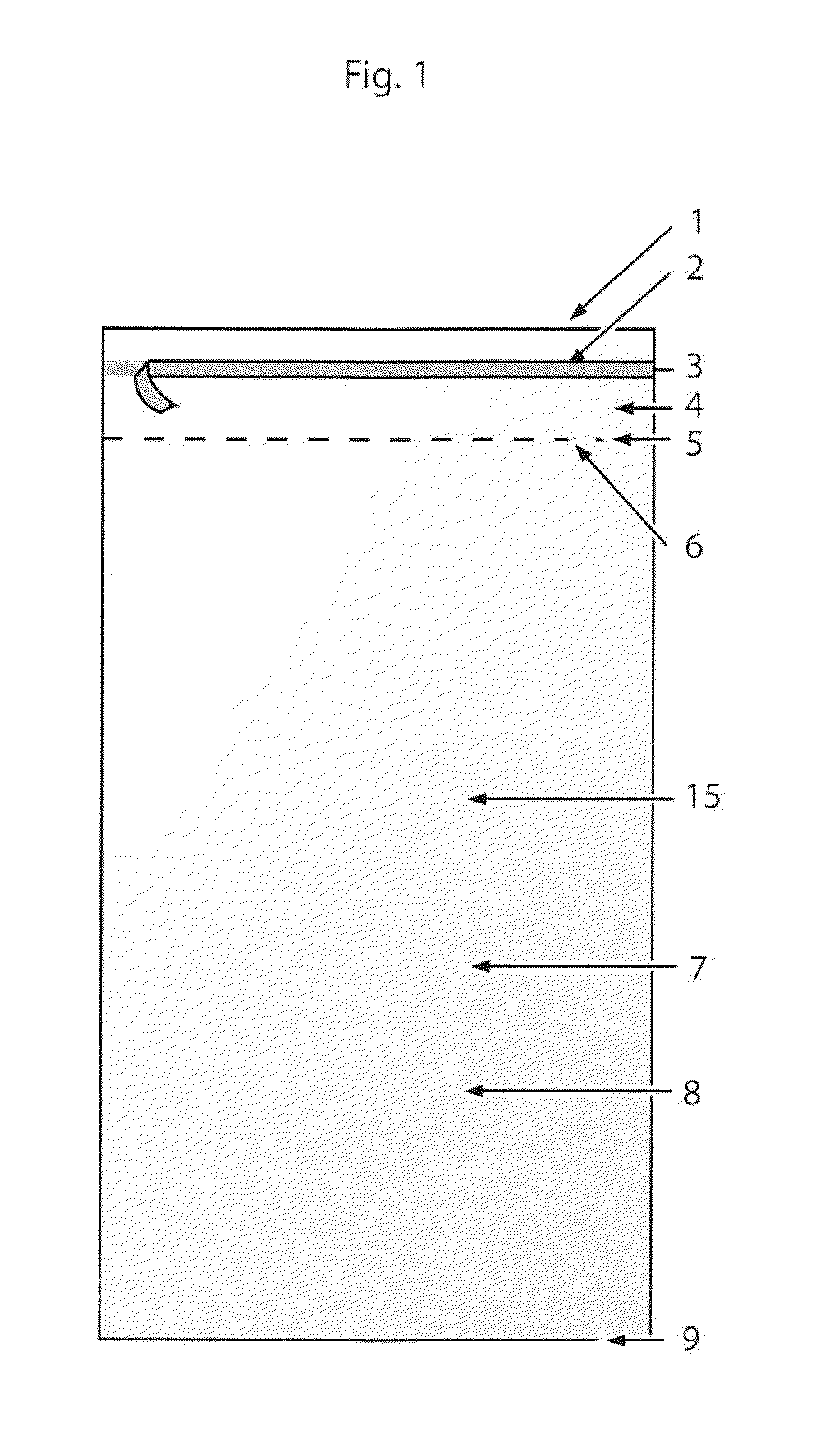

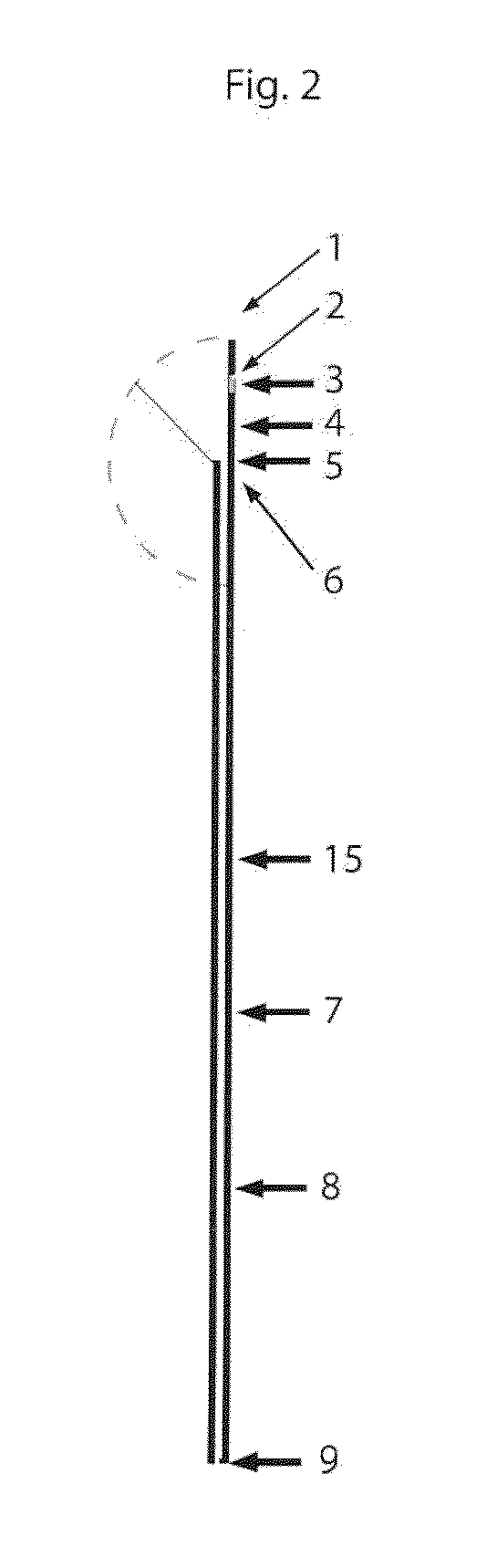

Crystallized pellet/liquid separator

ActiveUS20070062872A1Keep the pressureLow solidsWater/sewage treatment by centrifugal separationUltrafiltrationLiquid temperatureReverse osmosis

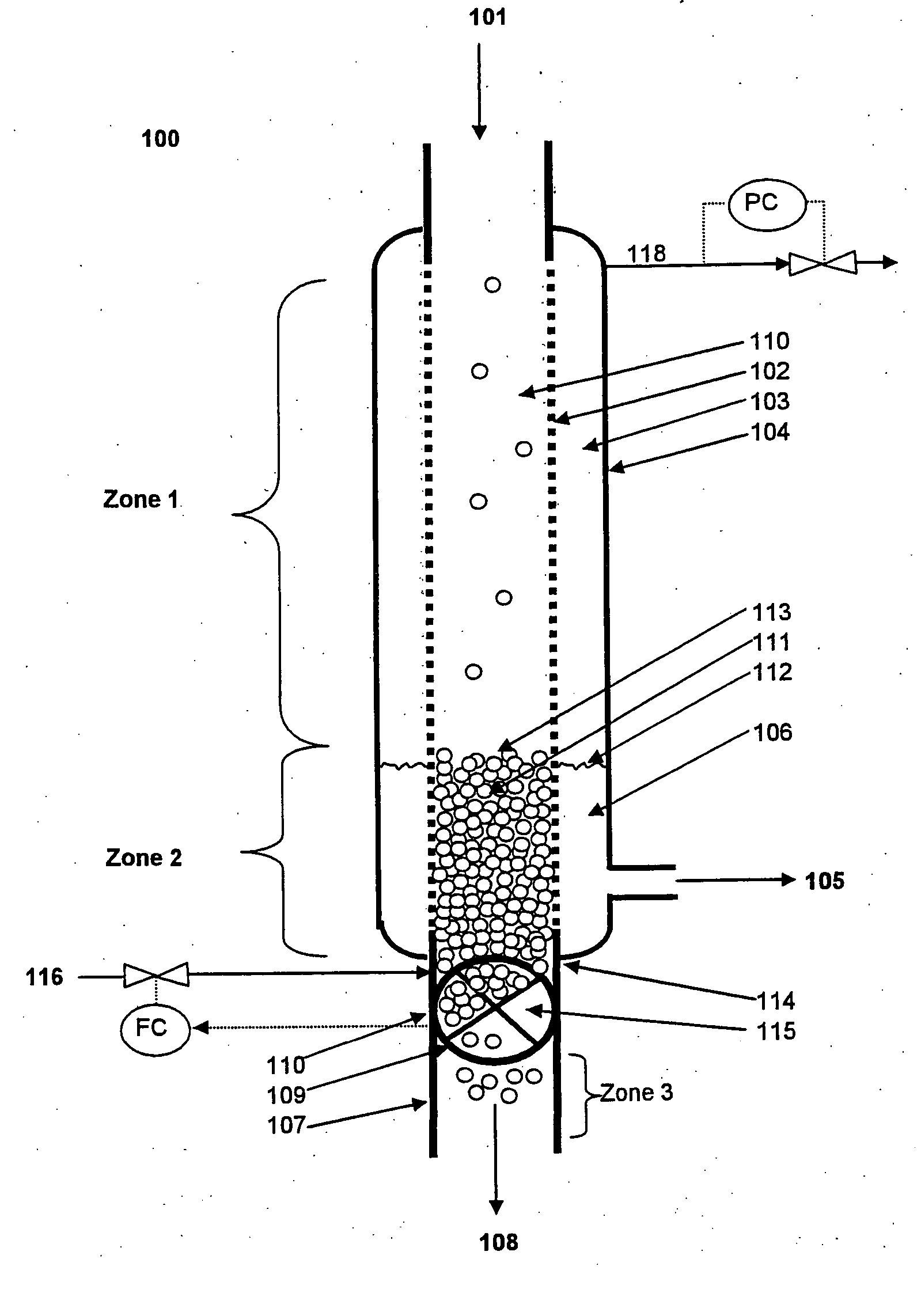

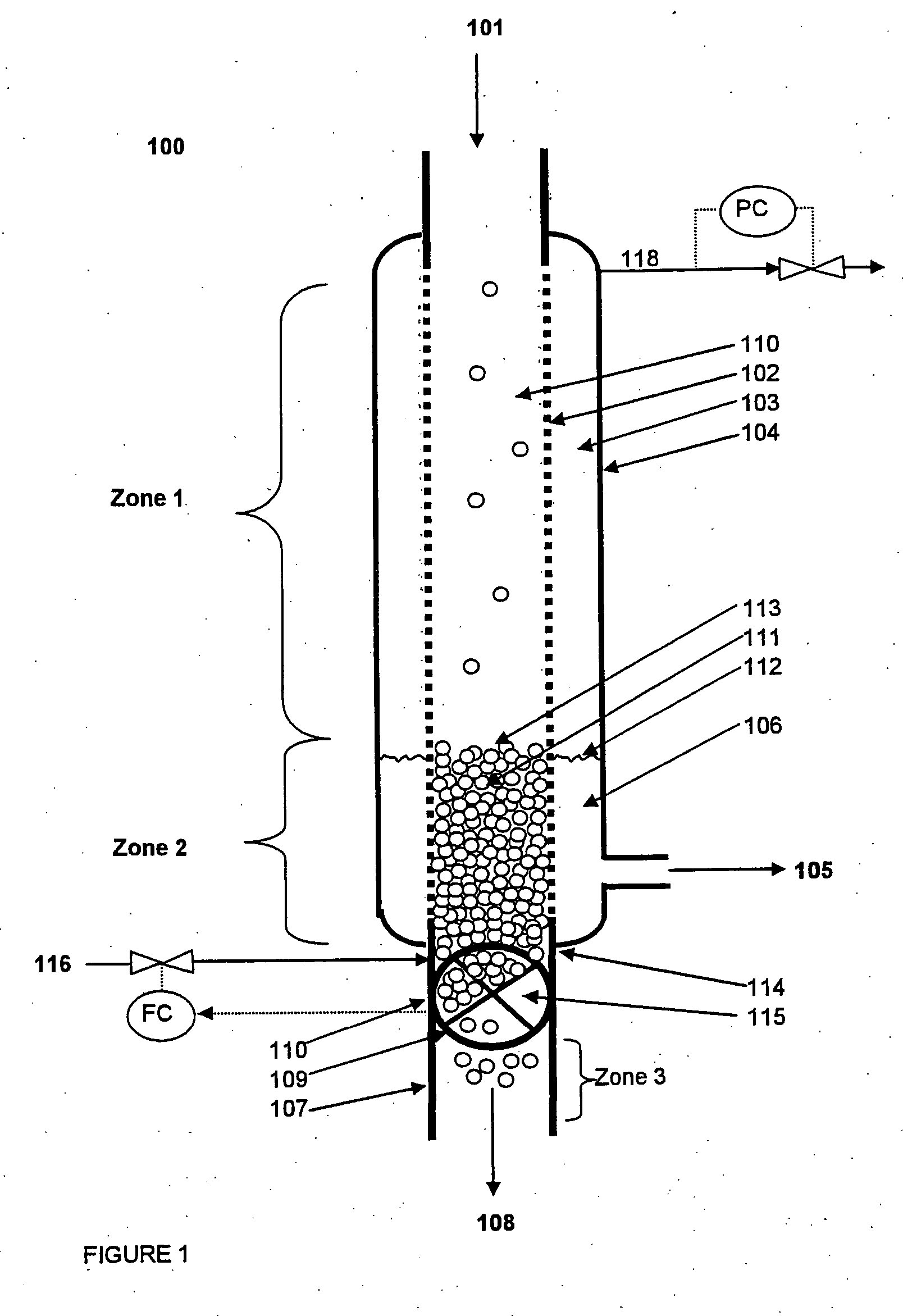

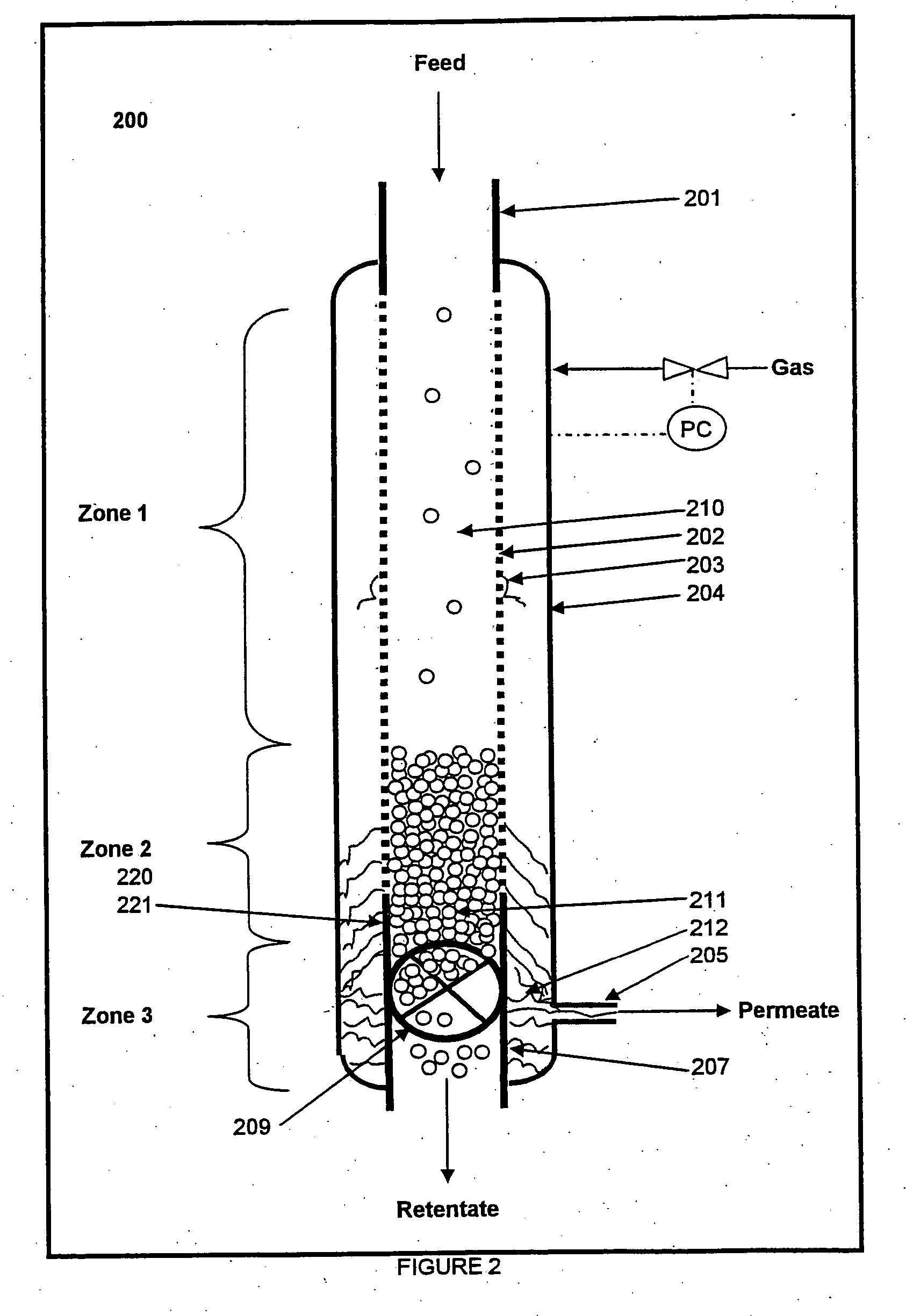

A process and apparatus which reduces the fines in a liquid discharge stream and / or increases the dryness of a solids discharge stream while under a pressure equal to or greater than the vapor pressure of the liquid. There is provided a process for separating particles such as polyethylene terephthalate or polyethylene naphthalate from a liquid in a slurry comprising: a. feeding a slurry comprising solid particles and a liquid into a within a separation zone maintained at a pressure equal to or greater than the vapor pressure of the liquid; b. contacting the slurry in the separation zone with a porous filter, optionally a microfilter, nanofilter, reverse osmosis filter, or ultrafilter, and separating liquid from the particles, wherein the liquid flows through the filter into an outer annulus defined as a space between the wall of the separation device and the filter, and said porous filter optionally having a terminal point beyond which the separated liquid does not pass from the outer annulus back through the filter; c. accumulating no liquid in the outer annulus or accumulating liquid in the outer annulus at a level below or in front of the terminal point, and continuously discharging the separated liquid from the outer annulus through a liquid outlet; d. decoupling the particles from the separation zone through the solids outlet to a low pressure below the vapor pressure of the liquid at the liquid temperature within the separation zone while maintaining a pressure on the particles prior to decoupling at or above the vapor pressure of the liquid within the separation zone.

Owner:ALPEK POLYESTER SA DE CV

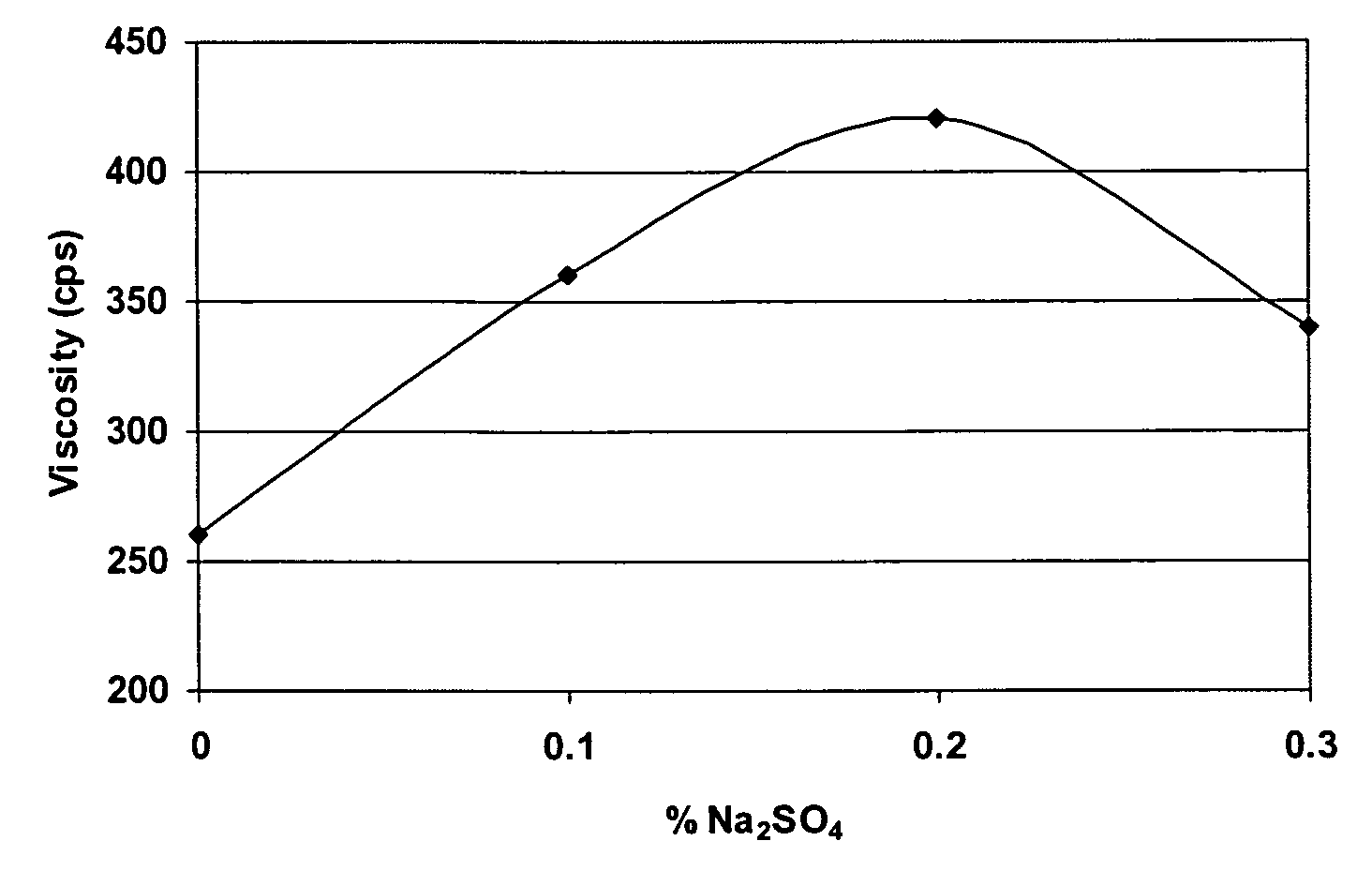

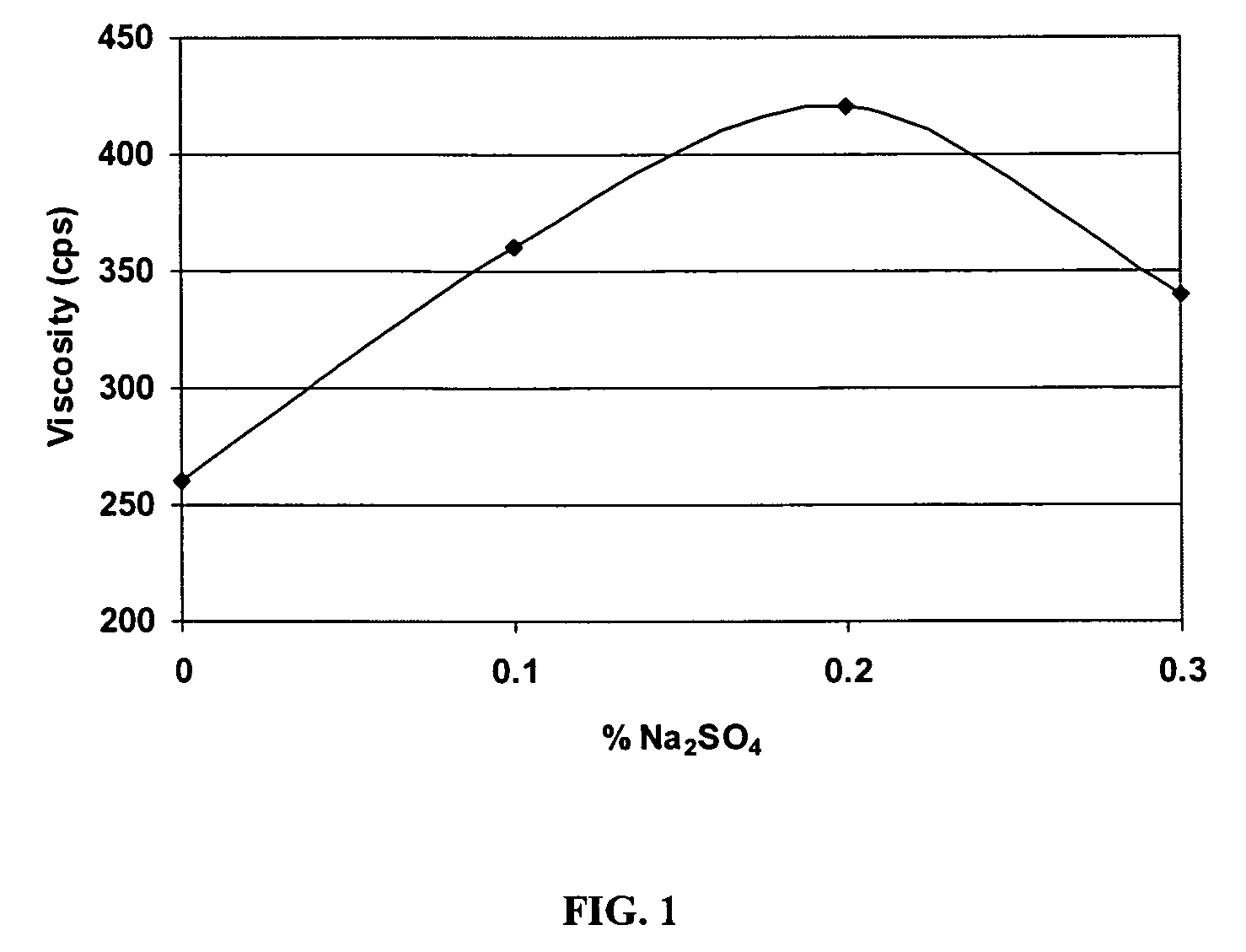

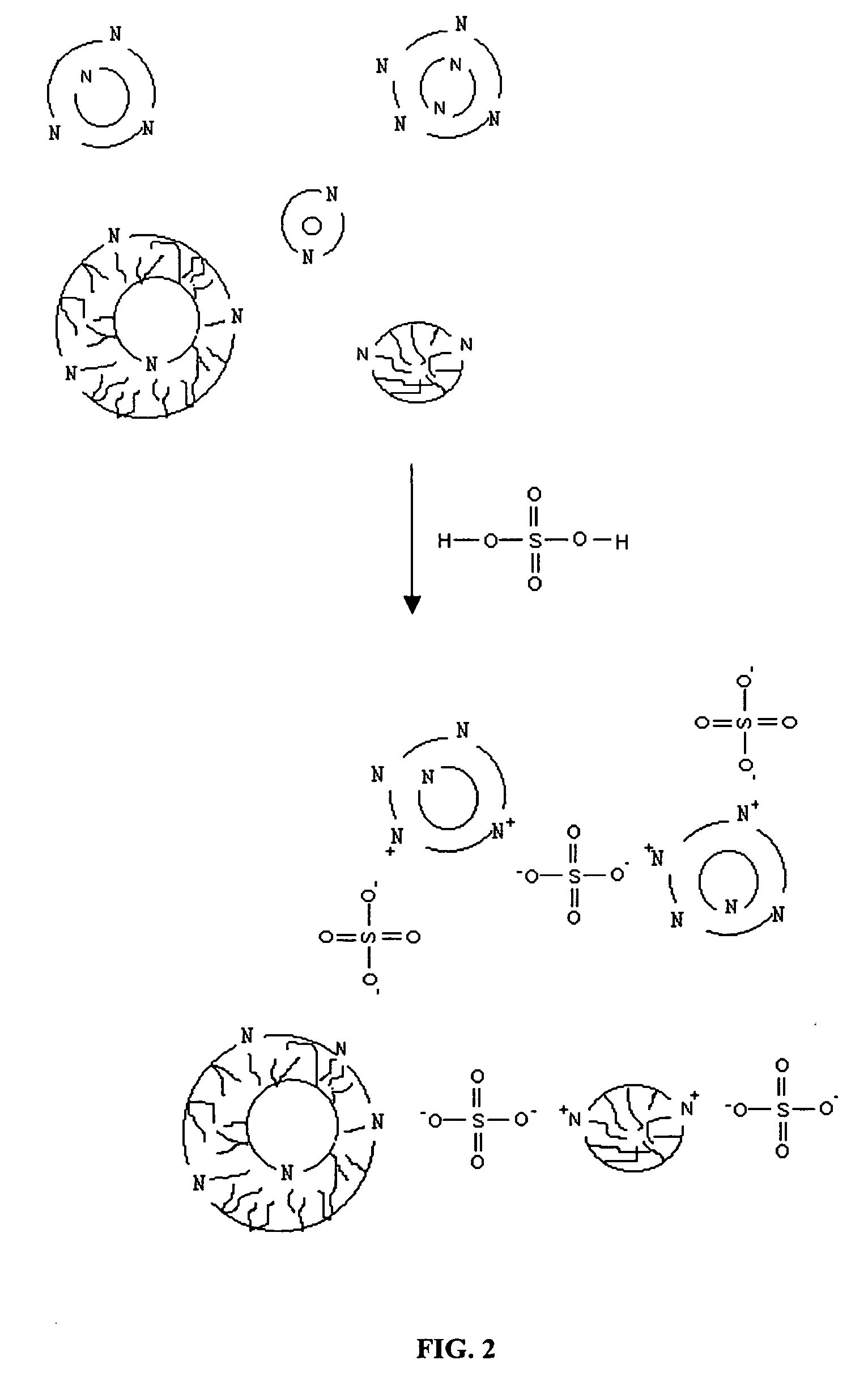

Low solids, high viscosity fabric softener compositions and process for making the same

InactiveUS20060264352A1Improve propertiesImprove stabilityCationic surface-active compoundsDetergent mixture composition preparationViscosityOrganic chemistry

Disclosed are low solids and high viscosity fabric softener compositions and processes for preparing them. The composition contains from about 0.05% to about 10% by weight of a rheology modifying fabric softening active comprising at least one long chain amine of the present technology, a derivative thereof, or a mixture thereof, and from about 0% to 10% by weight of an additional fabric softening active dispersed in water.

Owner:STEPAN COMPANY

Method of dewatering grain stillage solids

ActiveUS20050079270A1Improve throughputShorten the timeBy-product recoveryFood processingAcryditeSodium methacrylate

A method of dewatering corn stillage solids comprising adding to the solids an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

Method of dewatering grain stillage solids

ActiveUS7566469B2Improve dehydration effectSmall apertureBy-product recoveryFood processingSodium methacrylateSodium salt

A method of dewatering corn stillage solids comprising adding to the solids an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

High-thermal-conductivity polymer conductive ink and production process thereof

The invention discloses high-thermal-conductivity polymer conductive ink. The high-thermal-conductivity polymer conductive ink comprises the following components in percentage: 20-80% of conductive functional unit, 1-30% of resin, 1-30% of solvent and 1-20% of additive, wherein the conductive functional unit comprises a conductive polymer and functional unit particles, wherein the conductive polymer content accounts for 60-99% of mass of the conductive functional unit and the content of functional unit particles account for 1-40% of mass of the conductive functional unit. According to the high-thermal-conductivity polymer conductive ink disclosed by the invention, the content of the conductive ink solid particles is reduced, the dispersion stability of the conductive ink is improved, and the universal process is imparted; and meanwhile, the functional unit particles act as both a conductive unit and a thermal conductive unit and thus both the high conductivity and high thermal conductivity are imparted.

Owner:李娟 +1

Phenol-formaldehyde resin having low concentration of tetradimer

InactiveUS20080064284A1Improve stabilityLimited shelf lifeSynthetic resin layered productsAldehyde/ketone condensation polymer adhesivesGlass fiberFiber

A phenol-formaldehyde resin, having a low concentration of tetradimer, making the resin suitable for preparing a binder composition for making non-woven fiber products, such as fiberglass insulation, prepared by reacting phenol and formaldehyde in the presence of a sulfite source.

Owner:GEORGIA PACIFIC CHEM LLC

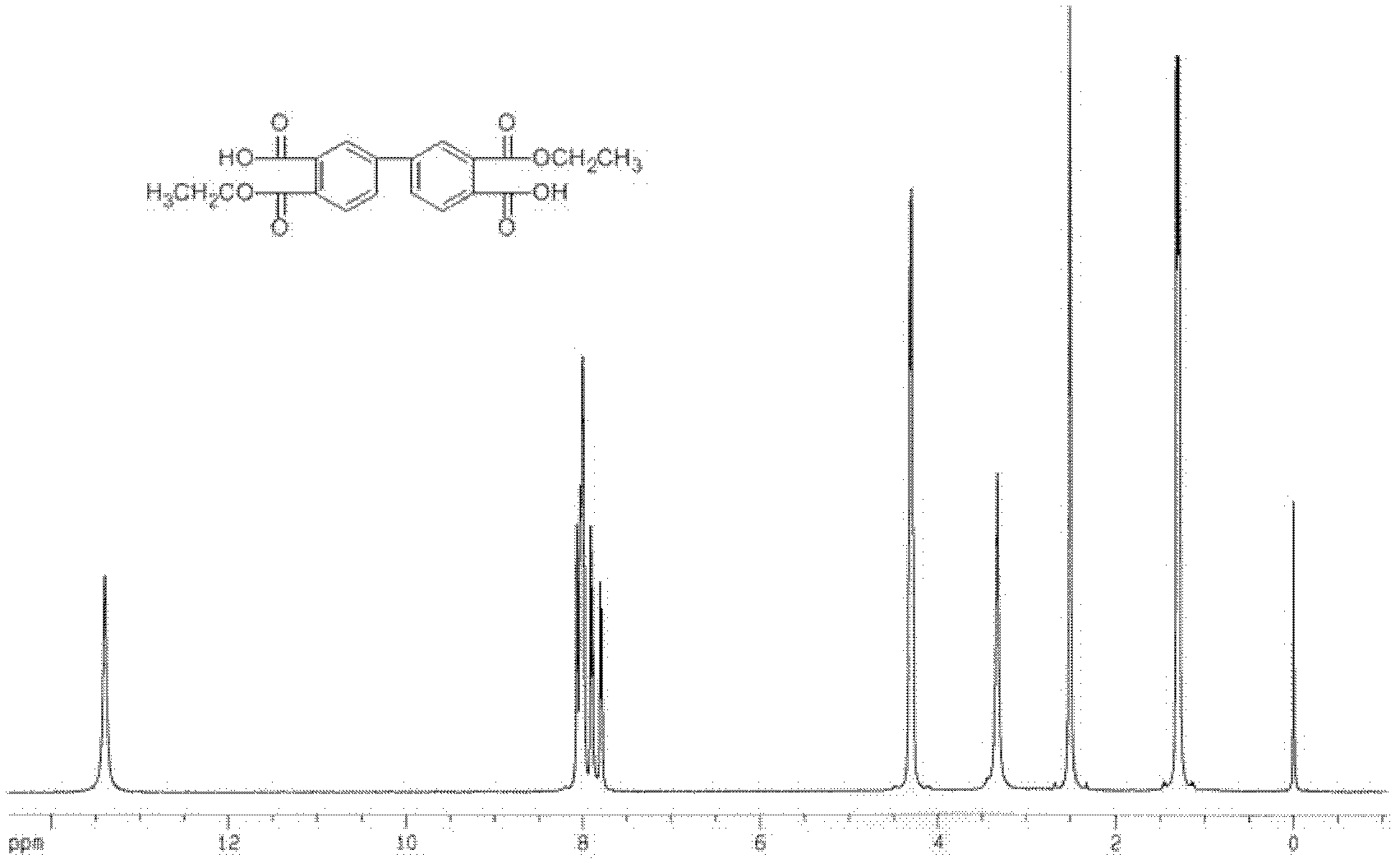

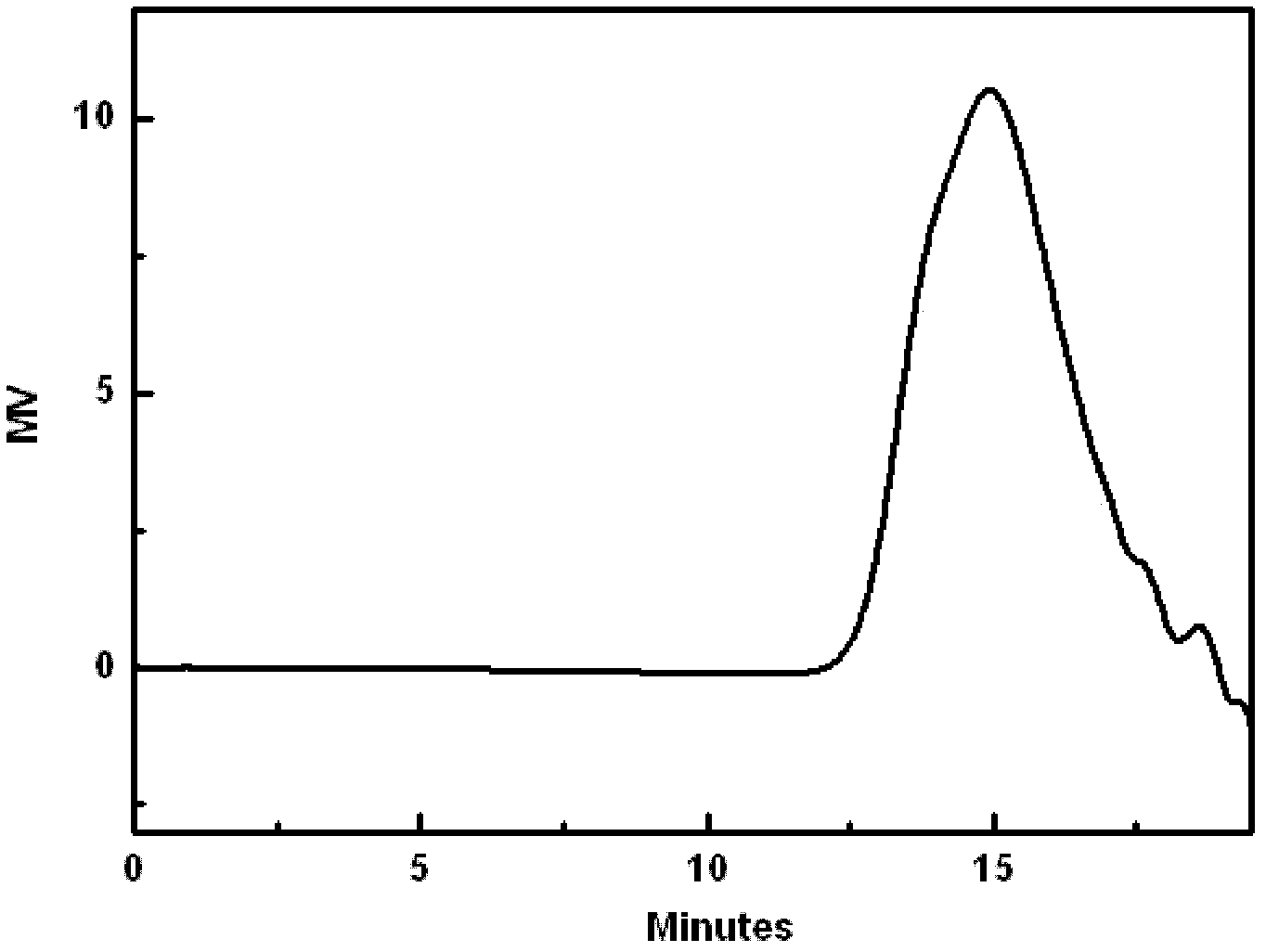

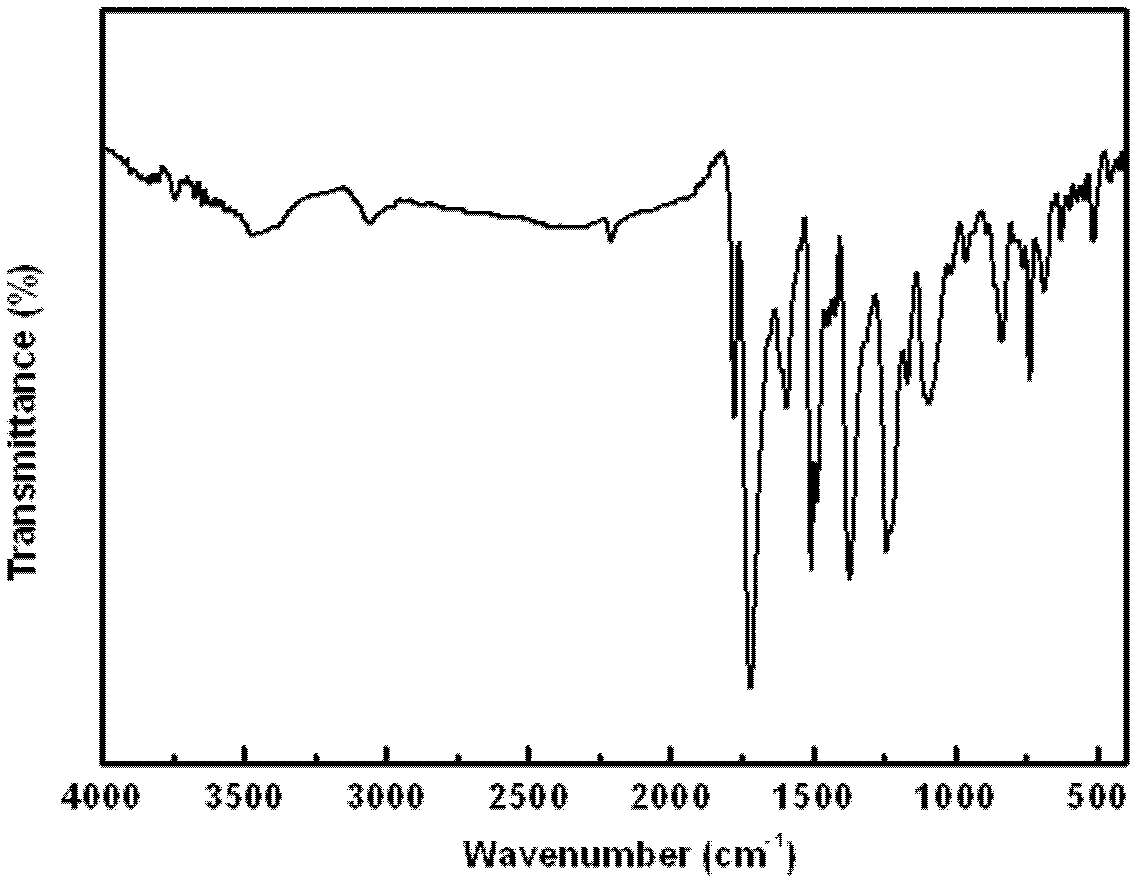

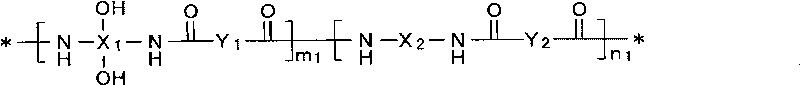

Polyimide resin as well as preparation method and application thereof

The invention discloses polyimide resin with low melt viscosity and high toughness as well as a preparation method of a composite material of the polyimide resin. The resin is high in solid content, low in solution viscosity and is easy to steep carbon fibers to prepare a high-quality carbon fiber prepreg (a belt or cloth); a melt resin formed by heating and melting the resin has the characteristics of low melt viscosity and wide melting temperature; a resin condensate formed by heating and solidifying is high in toughness and high in Tg (glass-transition temperature). The resin is suitable for steeping reinforced fibers to prepare prepregs, and a carbon fiber reinforced composite material prepared by the autoclave and the hot hubbing forming process is excellent in impact-resistant toughness, comprehensive mechanical property and high-temperature resistant performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

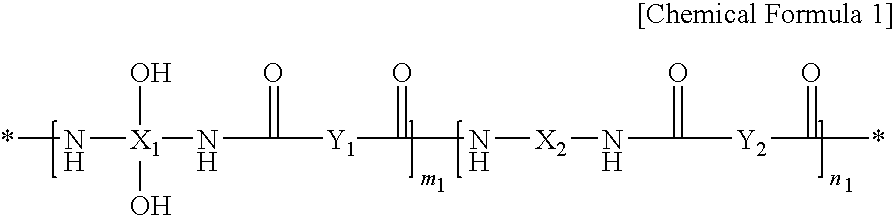

Positive type photosensitive resin composition

ActiveCN101727006AHigh resolutionExcellent pattern formationRadiation applicationsPhotomechanical apparatusSilane compoundsPolymer science

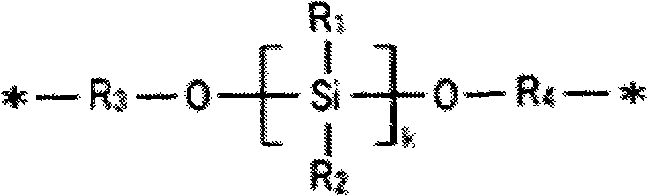

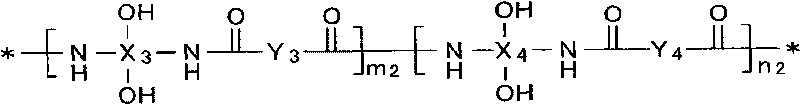

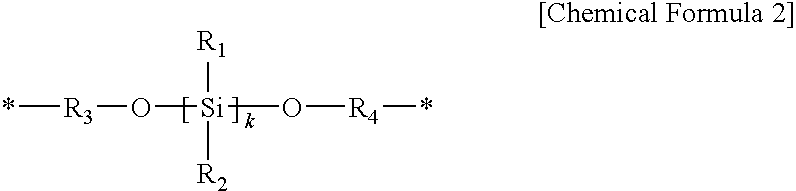

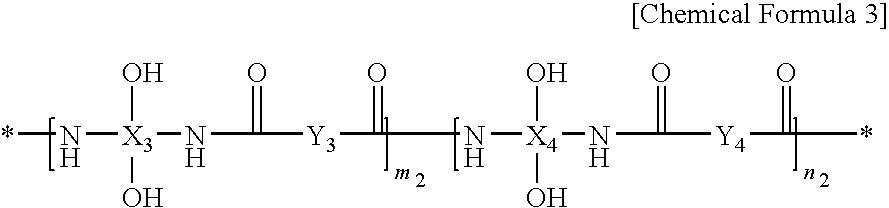

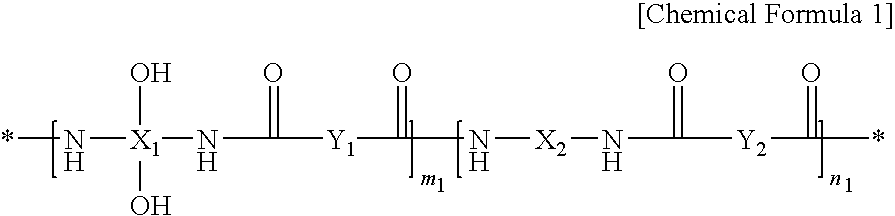

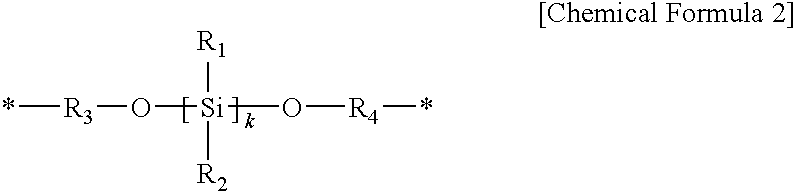

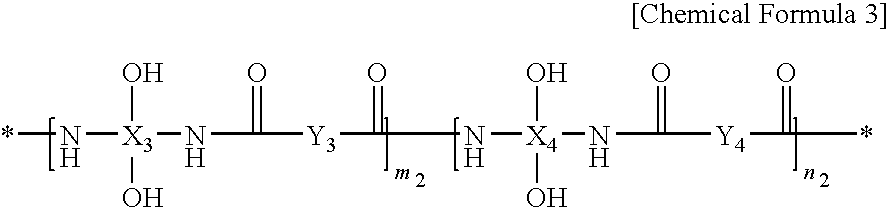

Disclosed is a positive photosensitive resin composition that includes (A) a first polybenzoxazole precursor that includes: a repeating unit of Chemical Formula 1 and a thermally polymerizable functional group at least one terminal end; (B) a second polybenzoxazole precursor that includes a repeating unit of Chemical Formula 3; (C) a photosensitive diazoquinone compound; (D) a silane compound; and (E) a solvent.

Owner:CHEIL IND INC

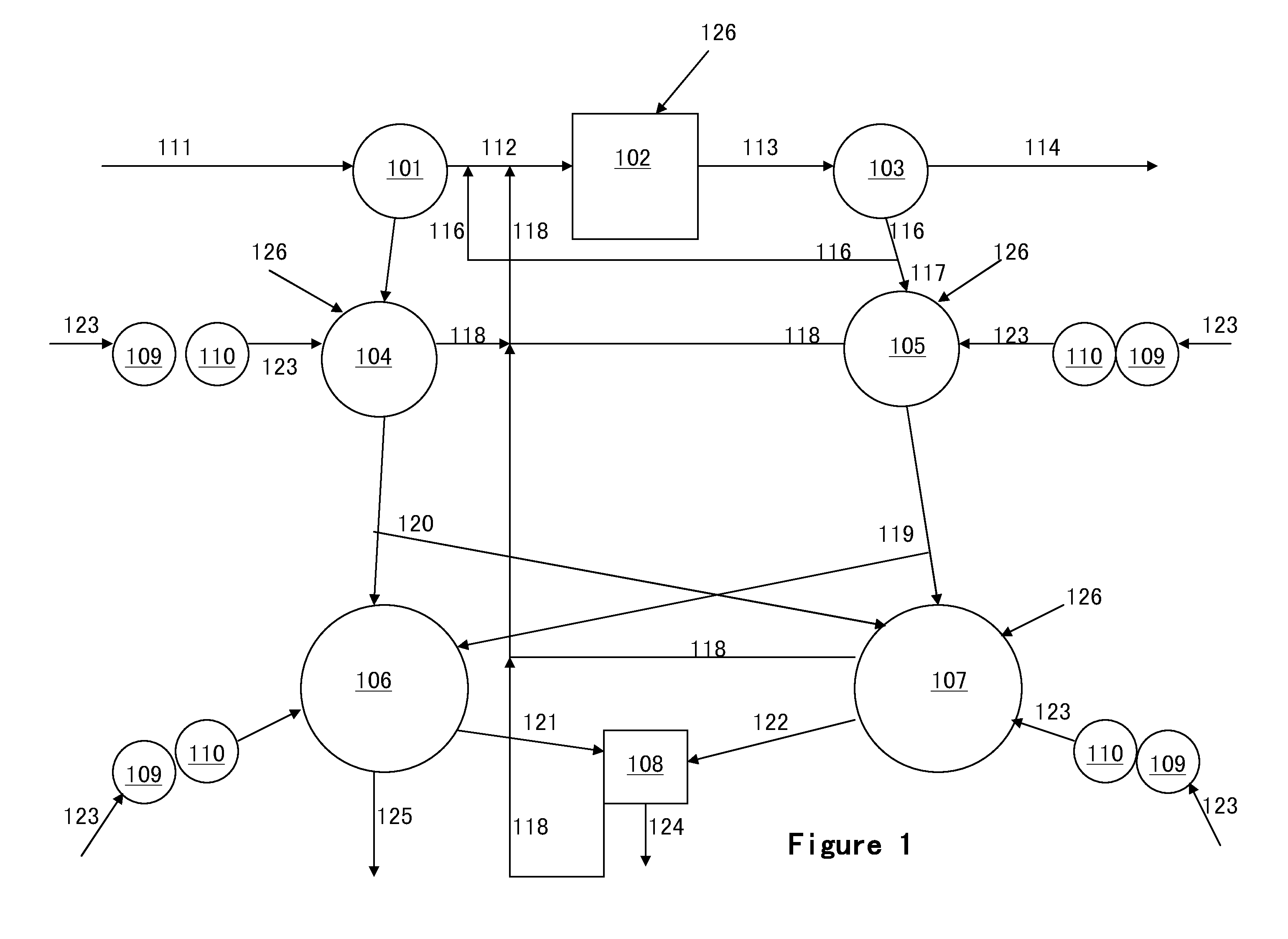

Process and system for recovery of asphaltene by-product in paraffinic froth treatment operations

ActiveUS20100096297A1Improved quality and cleanlinessIncrease heightWorking-up pitch/asphalt/bitumen by selective extractionTreatment with plural serial refining stagesParaffin waxThree stage

A process for treating bitumen froth with paraffinic solvent is provided which uses three stages of separation. Froth and a first solvent are directed to a first stage at a solvent / bitumen ratio for precipitating few or substantially no asphaltenes. A first stage underflow is directed to a second stage and a first stage overflow is directed to a third stage. A second stage underflow is directed to waste tailings and the second stage overflow joins the first stage overflow. A third stage underflow is recovered as an asphaltene by-product and a third stage overflow is recovered as a diluted bitumen product. At least a second solvent is added to one or both of the second or third stages for controlling a fraction of asphaltenes in the third stage underflow. Asphaltene loss to waste tailings is minimized and asphaltenes are now recovered as asphaltene by-product.

Owner:CANADIAN NATURAL RESOURCES

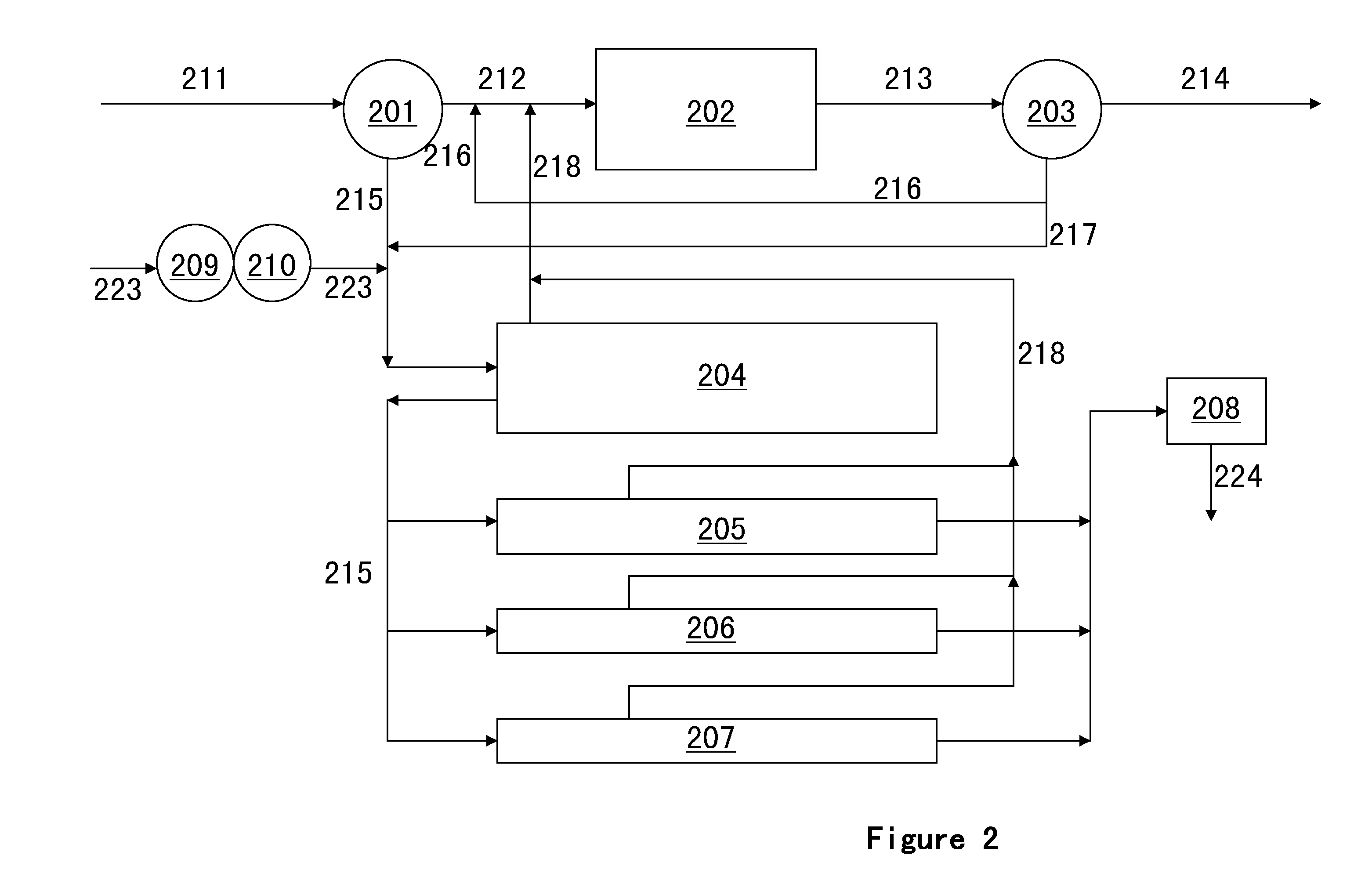

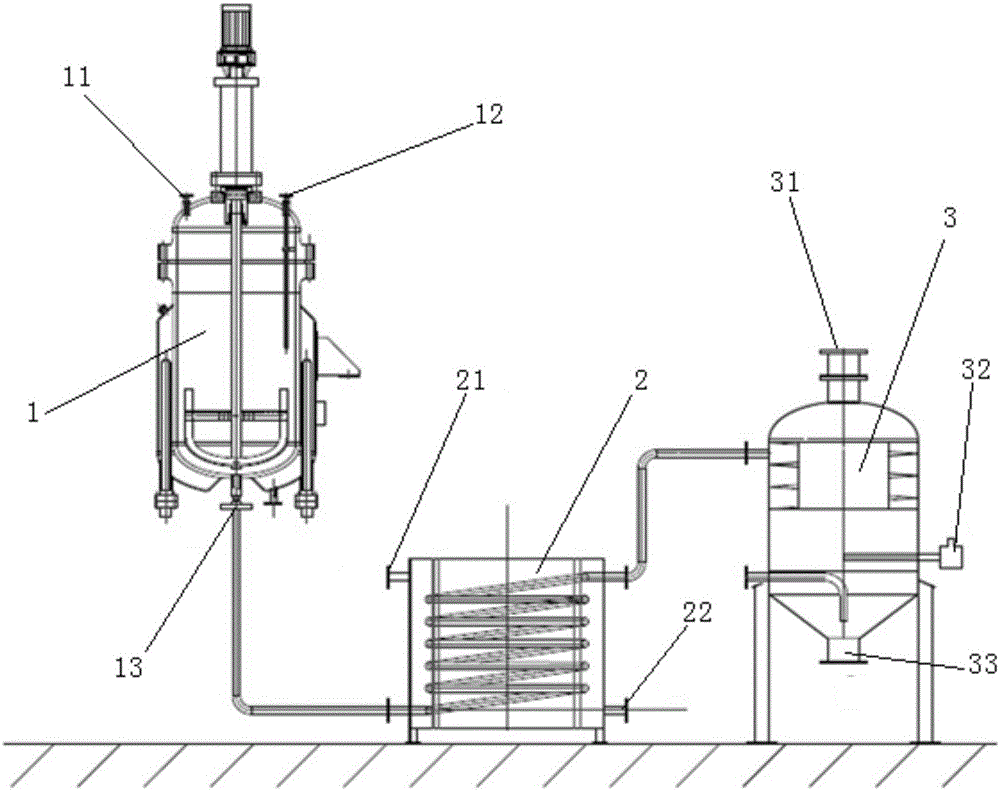

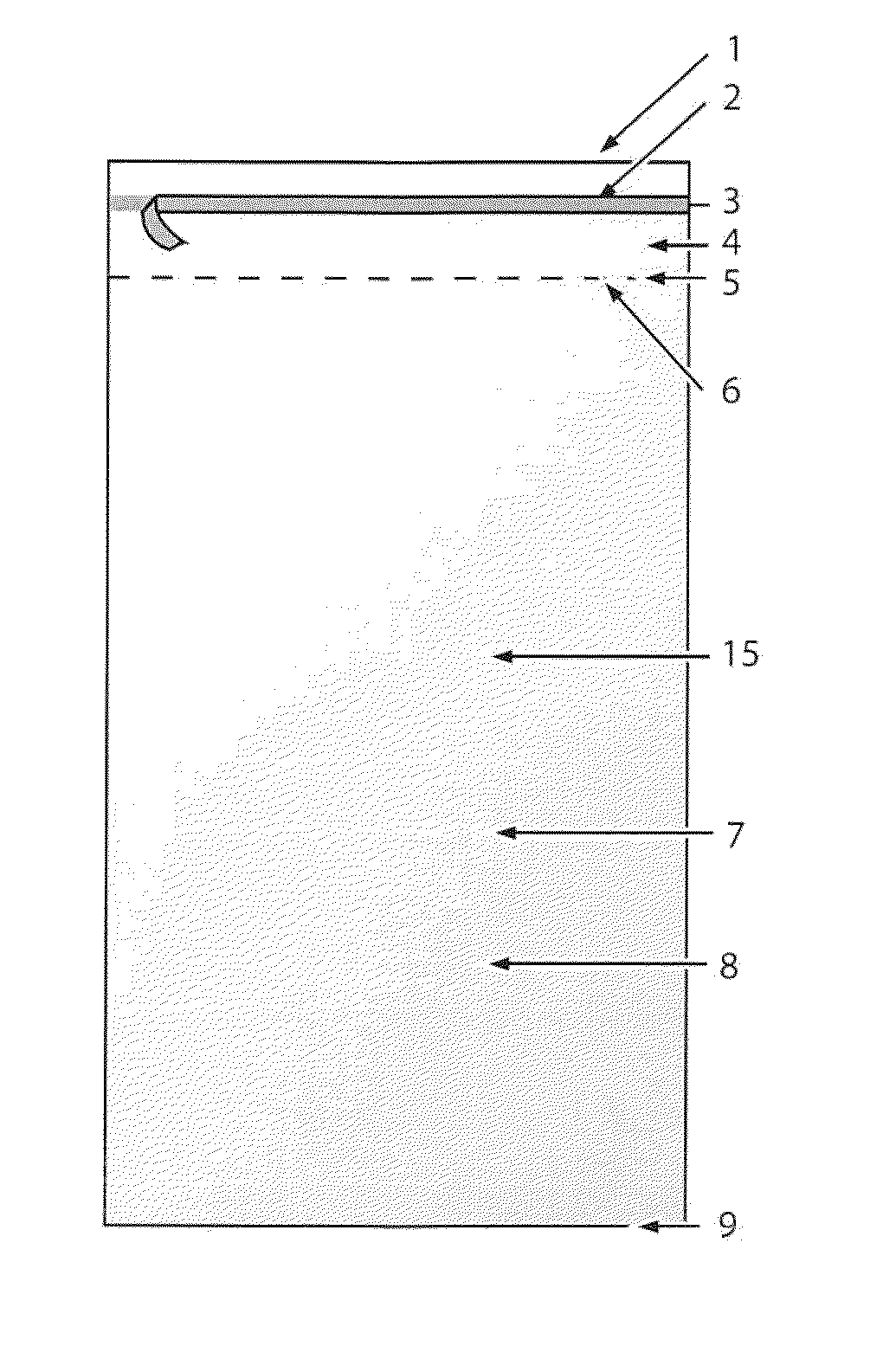

Vacuum rotary dryer

InactiveUS6052917AReduce pressureLow solidsDrying solid materials without heatRotary drum furnacesProcess engineeringAtmospheric pressure

PCT No. PCT / JP97 / 04543 Sec. 371 Date Aug. 10, 1998 Sec. 102(e) Date Aug. 10, 1998 PCT Filed Dec. 10, 1997 PCT Pub. No. WO98 / 26244 PCT Pub. Date Jun. 18, 1998A vacuum rotary dryer capable of charging solids into a rotary drum and discharging the solids from the rotary drum without any manual operation contacting solids with the hands is provided. A rotary drum (23) is mounted thereon with a gas flow pipe (46) and a solids feed and discharge pipe (56). The solids feed and discharge pipe (56) is connected to a feed source of the solids and a pressure reducing unit (53) reduces a pressure in the rotary drum through the gas flow pipe (46), to thereby feed solids to be dried to the rotary drum (23). After drying of solids in the drum, the solids feed and discharge pipe (56) is connected to a solids suction and transport structure and the gas flow pipe (46) is rendered open to an atmospheric pressure. A swing section (56b) of the solids feed and discharge pipe (56) is pivotally moved, to thereby be intruded into solids while keeping the rotary drum (23) inclined, resulting in solids being removed through a distal end of the swing section by suction. Finally, the distal end of the swing section (56b) is rendered opposite to a lowermost portion of the rotary drum to remove substantially all solids in the rotary drum therefrom.

Owner:MATSUMOTO KIKAI SEISAKUSHO

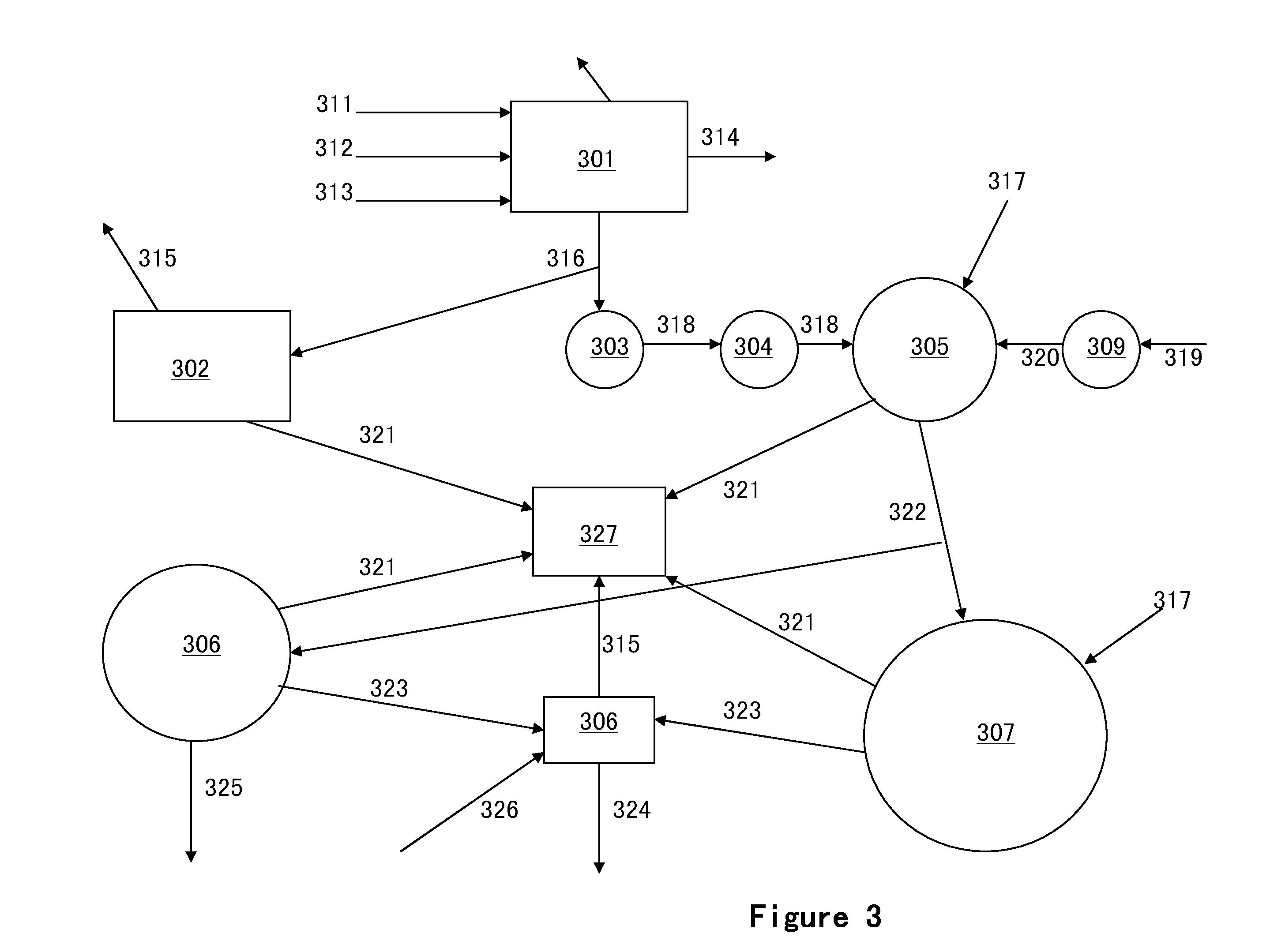

Methods for Treatment of Waste Activated Sludge

InactiveUS20110272350A1Reduce sludge disposal costsCost for disposalSludge treatment by de-watering/drying/thickeningSludge processingBiological bodyActivated sludge

A process for treating waste primary or activated sludge solids that have been removed to a digester phase of the activated sludge process through the use of powdered natural lignocellulosic materials (PNLM) and / or powdered kenaf core (PKC). These materials help this process by: (a) thickening of primary and / or waste activated sludge through adsorption, attached growth and achieving closer proximity of organisms by stimulating reduction of their associated ECP substance; (b) enhancing endogenous reduction of primary and / or waste activated sludge by thickening (see above) and improving the ratio of available carbon to available nitrogen by delivering a continuing gradual release of sugar from degrading PNLM and / or PKC; (c) enhancing the speed of endogenous reduction of primary and / or waste activated sludge—through higher efficiencies (same processes as above); and (d) improving dewatering characteristics of wasted primary and / or wasted activated sludge solids (through reduction and breakdown of ECP materials and higher densification of solids).

Owner:SKILLICORN PAUL +1

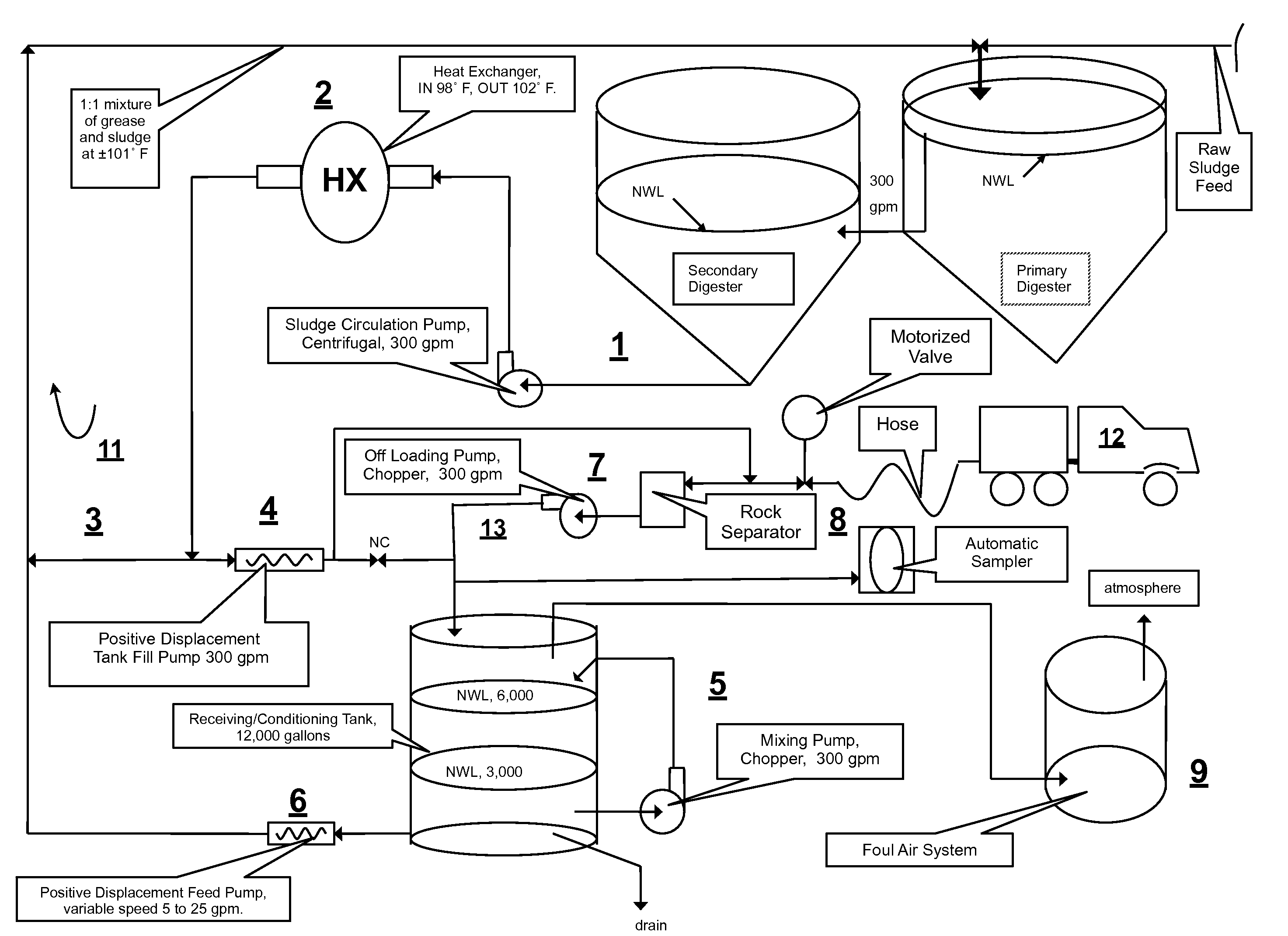

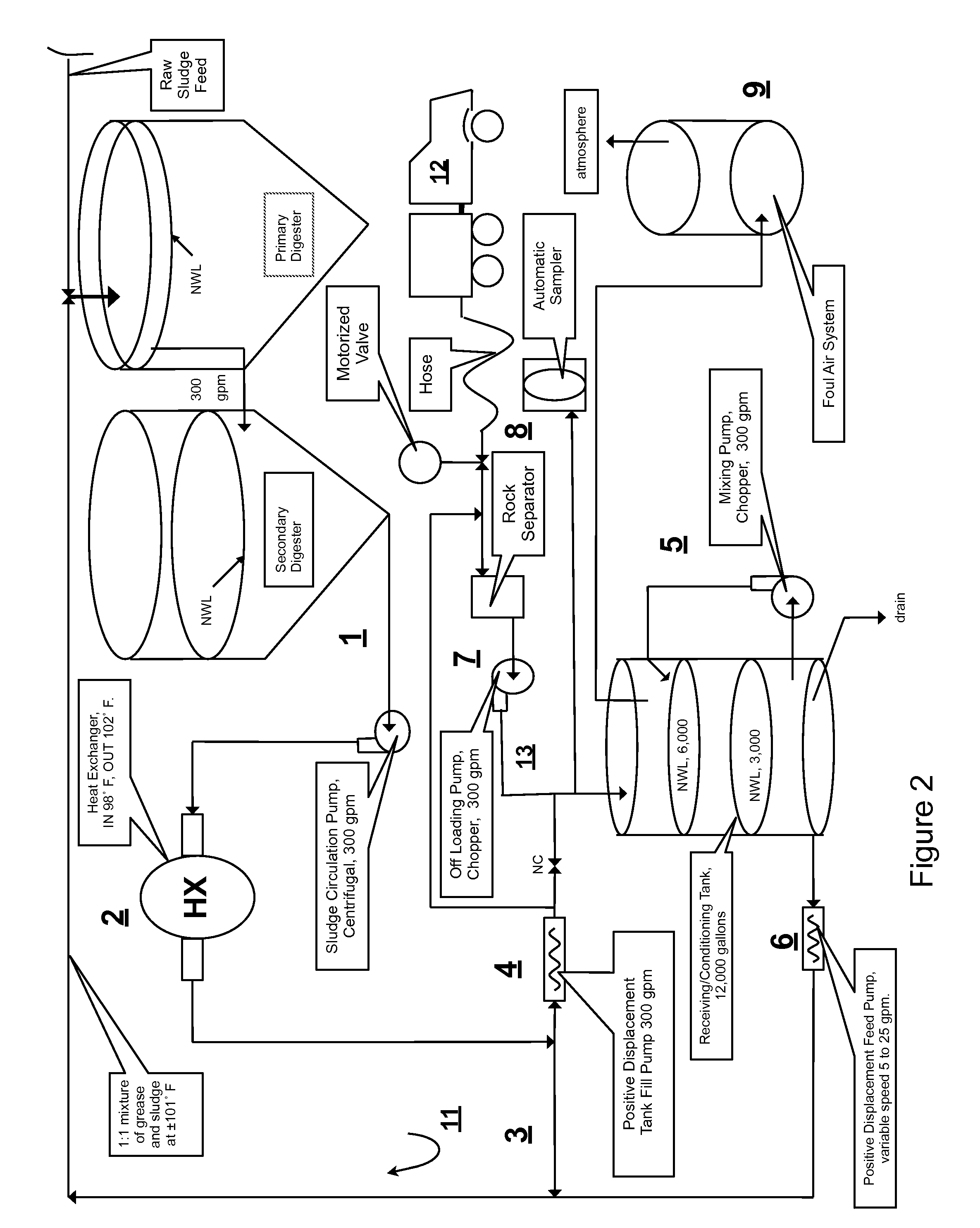

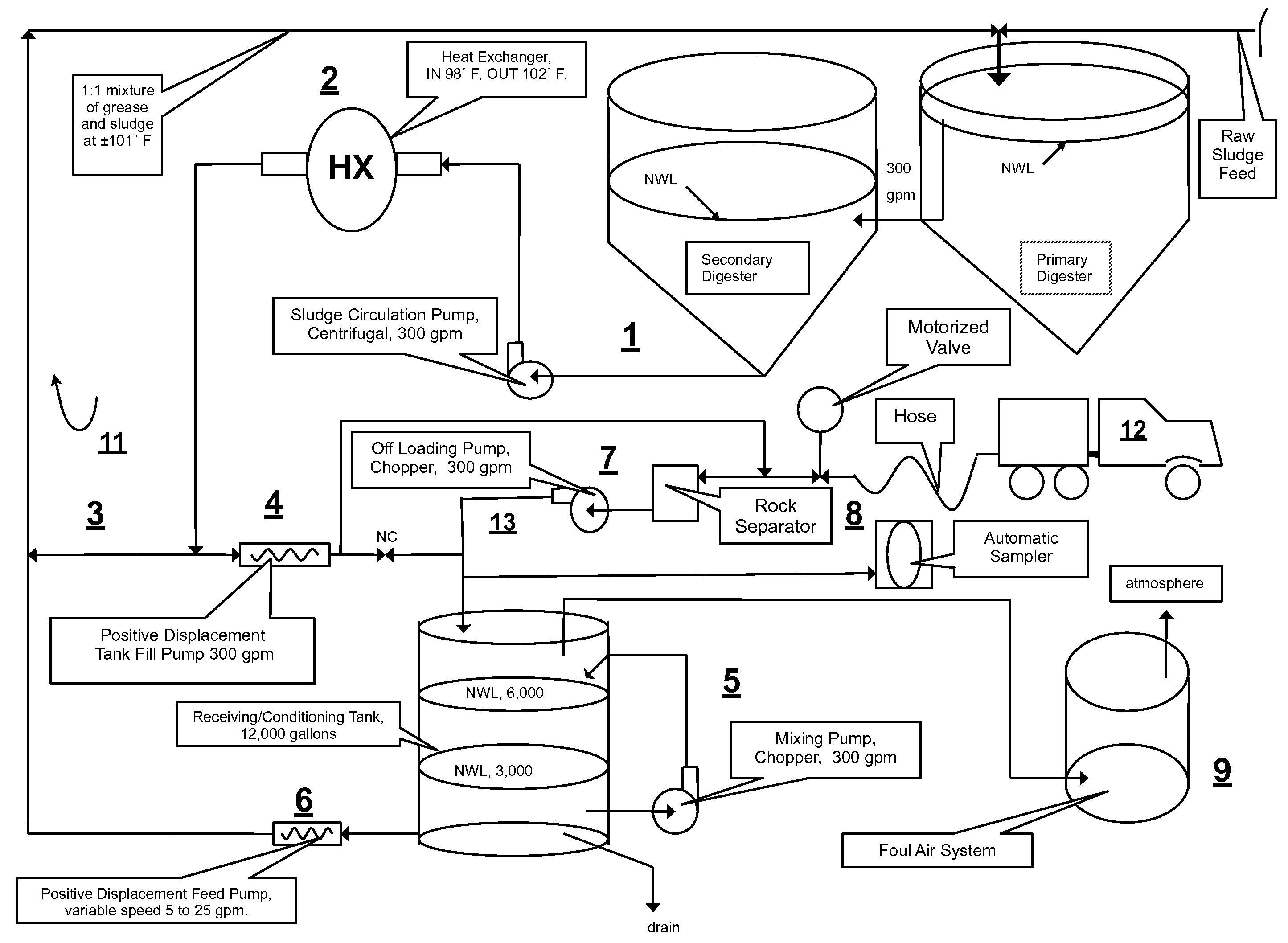

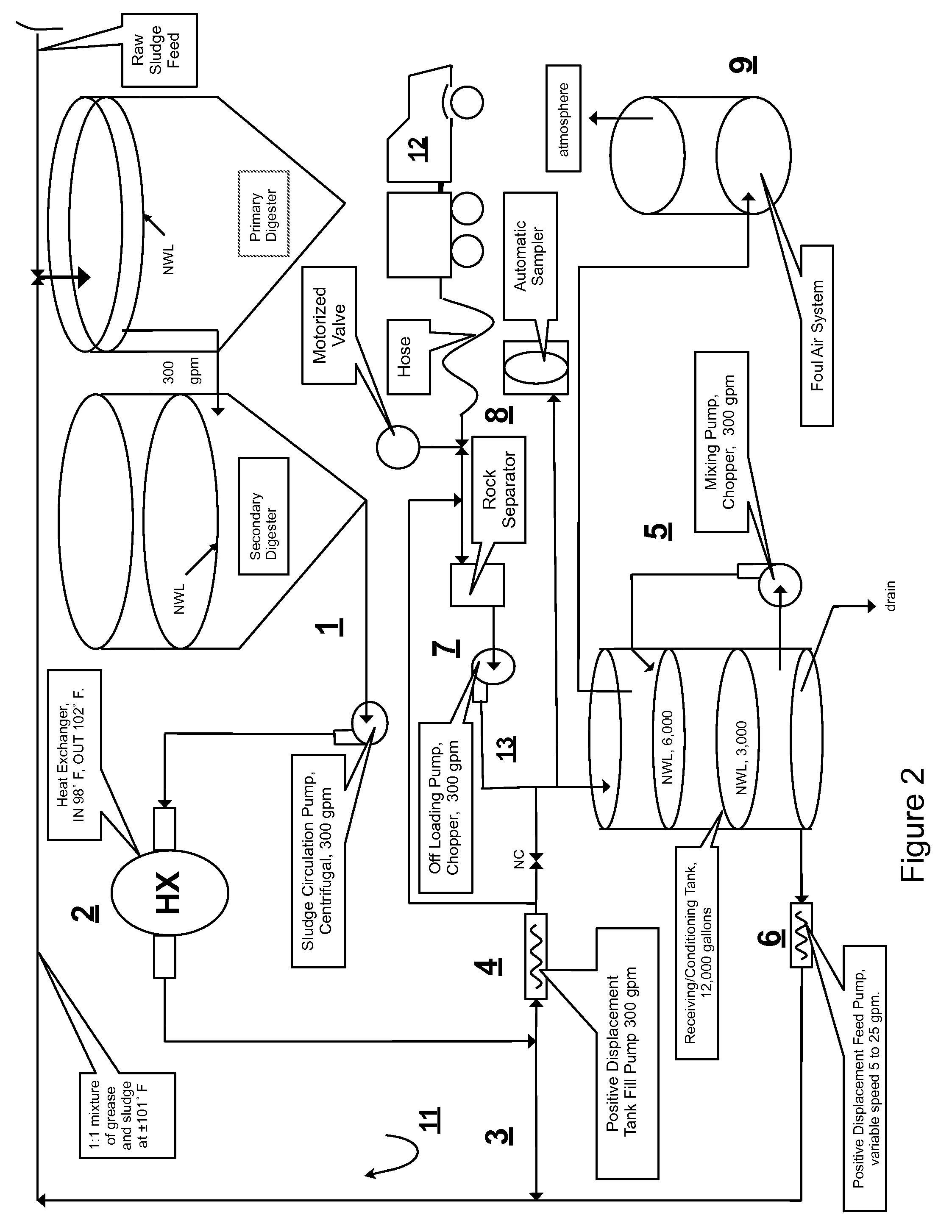

Integrated cogeneration wastewater sewage and waste polar fats/ oils/ greases/waxes (FOG) waste treatment method and facility

InactiveUS20080203014A1Rule out the possibilityLow solidsBioreactor/fermenter combinationsGeneral water supply conservationOil and greaseVolatile fatty acids

Integrated sewage or digestible wastes, and fats, oils, greases and waxes (FOG) waste treatment methods, systems and facilities include a slipstream loop incorporating circulation pumps, hot water heat exchangers and conventional anaerobic digesters for continuously circulating actively digesting sludge at a rate to preclude solid settlement accumulation as a warm flowable slurry source. The warmed actively digesting sludge is pumped from the slipstream loop through a rock trap into a delivery / input loop both for aiding transport or delivery of FOG waste to, and for partially filing a closed receiving / conditioning holding tank, where the warmed actively digesting sludge softens and liquefies the FOG wastes offloaded into the holding tank for further treatment at a desired treatment temperature range (whether psychrophilic, mesophilic, or thermophilic). The contents of the closed receiving / conditioning holding tank are continuously mixed by a bottom-top recirculation chopper pump to pre-treat the FOG wastes, liquefying and decreasing solids particle size allowing acidogens in the actively digesting sludge to pre-digest such wastes producing volatile fatty acids, some biogas and a highly bioreactive, flowable feedstock slurry. The produced highly bioreactive, flowable feedstock slurry can then injected back into the actively digesting sludge slipstream loop at a controlled rate where the resultant mixture then is introduced, together with raw sewage or other digestible wastes, into input or head ends of waste treatment systems having anaerobic digesters for digestion of solids and steady-state methane production. Advantages of the integrated system relate to a partial digestion of the FOG in the reaction / holding tank generating volatile fatty acids that suppress expression of methane producing methagens in the holding tank, increased steady-state methane production and significantly reduced solids volume of treated digestible wastes (sewage) and FOG wastes.

Owner:MAGNER JOSEPH A +1

Positive photosensitive resin composition

ActiveUS8198002B2High resolutionHigh sensitivityRadiation applicationsPhotomechanical apparatusSilane compoundsChemical compound

Disclosed is a positive photosensitive resin composition that includes (A) a first polybenzoxazole precursor that includes: a repeating unit of Chemical Formula 1 and a thermally polymerizable functional group at at least one terminal end; (B) a second polybenzoxazole precursor that includes a repeating unit of Chemical Formula 3; (C) a photosensitive diazoquinone compound; (D) a silane compound; and (E) a solvent.

Owner:CHEIL IND INC

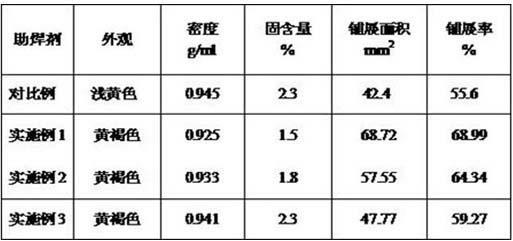

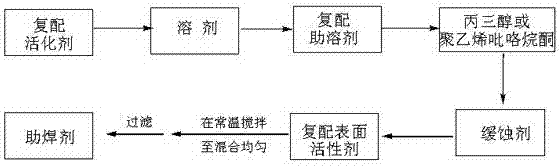

Lead-free environmentally friendly soldering flux and preparation method thereof

InactiveCN101972906AReduce manufacturing costIncrease productivityWelding/cutting media/materialsSoldering mediaSolventRosin

The invention relates to a lead-free environmentally friendly soldering flux and a preparation method thereof. The method comprises the following steps of: mixing synthetic organic acid, an activating agent and a mixed alcohol solvent at normal temperature according to a component formula; pouring an obtained mixture into a stainless steel container, and then adding modified rosin particles; stirring materials in the container until the rosins are all dissolved, and then stopping stirring; and standing still, filtering and hermetically packaging to obtain a soldering flux product. The lead-free environmentally friendly soldering flux is a no-clean soldering flux with low solid content, less rosin and no halide, has the characteristics of quick dry, bright and firm welding spot, uniform spreading, full structure, no corrosivity, excellent solderability, good soldering wetting, stable property, and the like, conforms to the property requirements of various electrical appliances and is suitable for soldering computers and peripheral equipment or high-precision multilayer board electronic assemblies. When in use, the soldering flux product has the advantages of low smoke, no pollution to working environment, no influence on the human health, no pollution to tracks and clamps of a tinning furnace, higher insulating impedance, good environment friendly performance and stronger market competitiveness.

Owner:DANFENG RONGYI ELECTRONICS

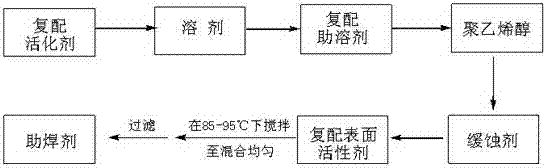

Rosin-based flux for ZnSn-based lead free solder and preparation method thereof

InactiveCN102581522ALow solidsHigh insulation resistanceWelding/cutting media/materialsSoldering mediaRosinSoldering

Rosin-based flux for a ZnSn-based lead free solder comprises rosin, an organic acidity activator, a corrosion inhibitor, a surfactant and an organic solvent. According to the invention, the solder can be additionally provided in injection, spraying or atomization method, the addition amount is easy to accurately control, the disadvantage that the prior soldering flux is hard to brush is overcome, no paste agent, stabilizing agent or thixotropic agent or other substances containing high solid content are included, the solid content of the solder is low, the wetting power to ZnSn-based solder is strong, the residue after welding is little, a metal oxide-film can be effectively removed, the expansion rate is not less than 75%, the effects of film forming and base material protection are possessed, and the preparation method is simple and practicable.

Owner:HENAN UNIV OF SCI & TECH

Method for catalytic wet oxidation of industrial sludge

InactiveCN105776794ALow solidsAchieve reductionSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeOrganic content

The invention relates to a method for catalytic wet oxidation of industrial sludge. The method includes the steps of (1), uniformly mixing industrial sludge raw materials with a catalyst, delivering the mixture into a reaction kettle, and feeding oxygen into the reaction kettle so as to subject the industrial sludge to wet oxidation; (2), delivering the industrial sludge subjected to wet oxidation into a cooler to cool, and delivering the cooled industrial sludge into a three-phase separator so as to obtain solid sludge at the bottom of the three-phase separator; (3), subjecting the solid sludge to dehydration treatment. Compared with the prior art, the method for catalytic wet oxidation of the industrial sludge has the advantages that the industrial sludge is reduced remarkably, refractory organics are removed to kill harmful pathogenic bacteria, treated sludge organic content is low to facilitate subsequent treatment, a liquid phase obtained after solid waste separation returns to an industrial wastewater treatment system to supplement a carbon source, and wet oxidation conditions can be lowered remarkably by the catalyst, so that energy consumption is reduced.

Owner:SHANGHAI HUANGU INVESTMENT MANAGEMENT CO LTD

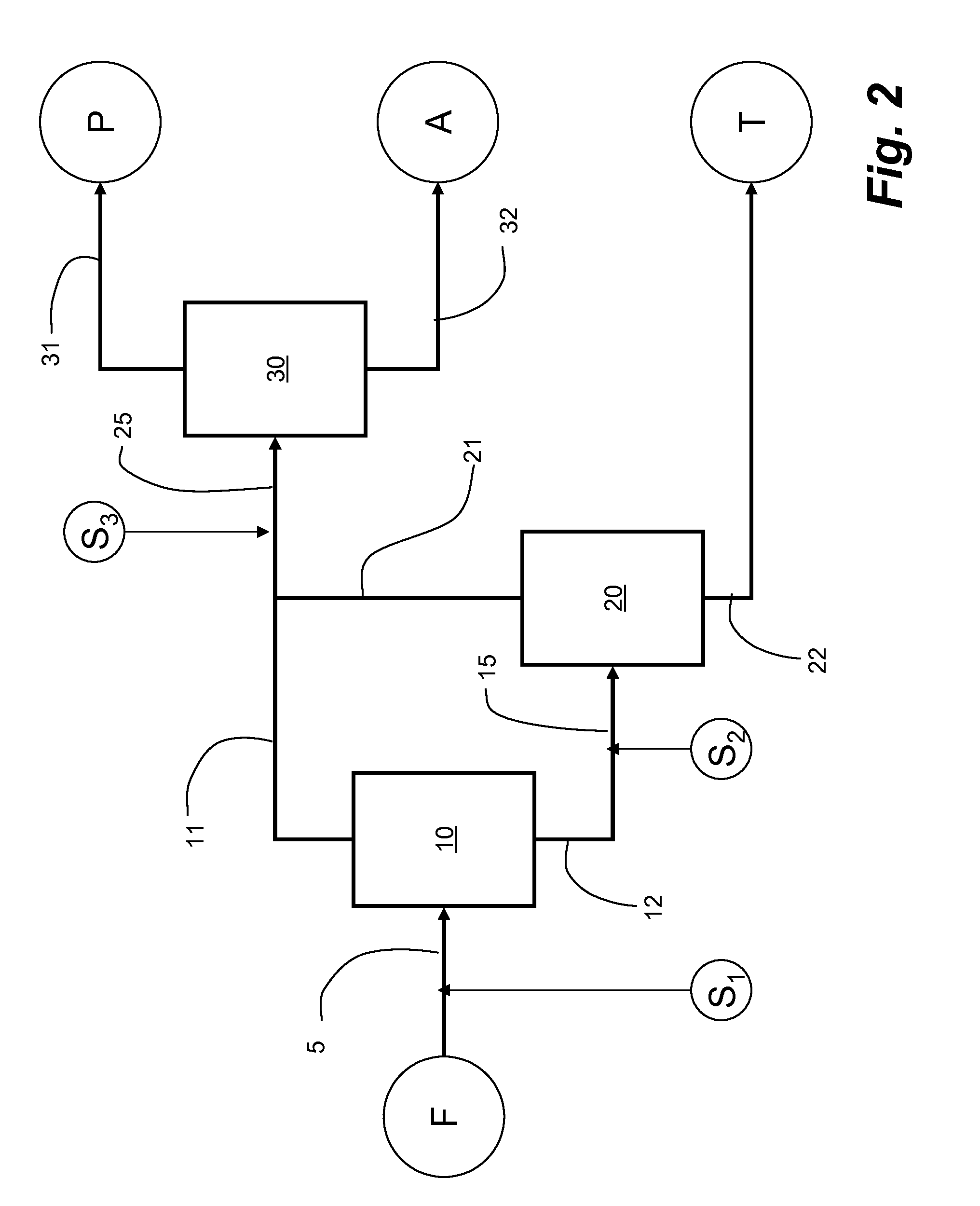

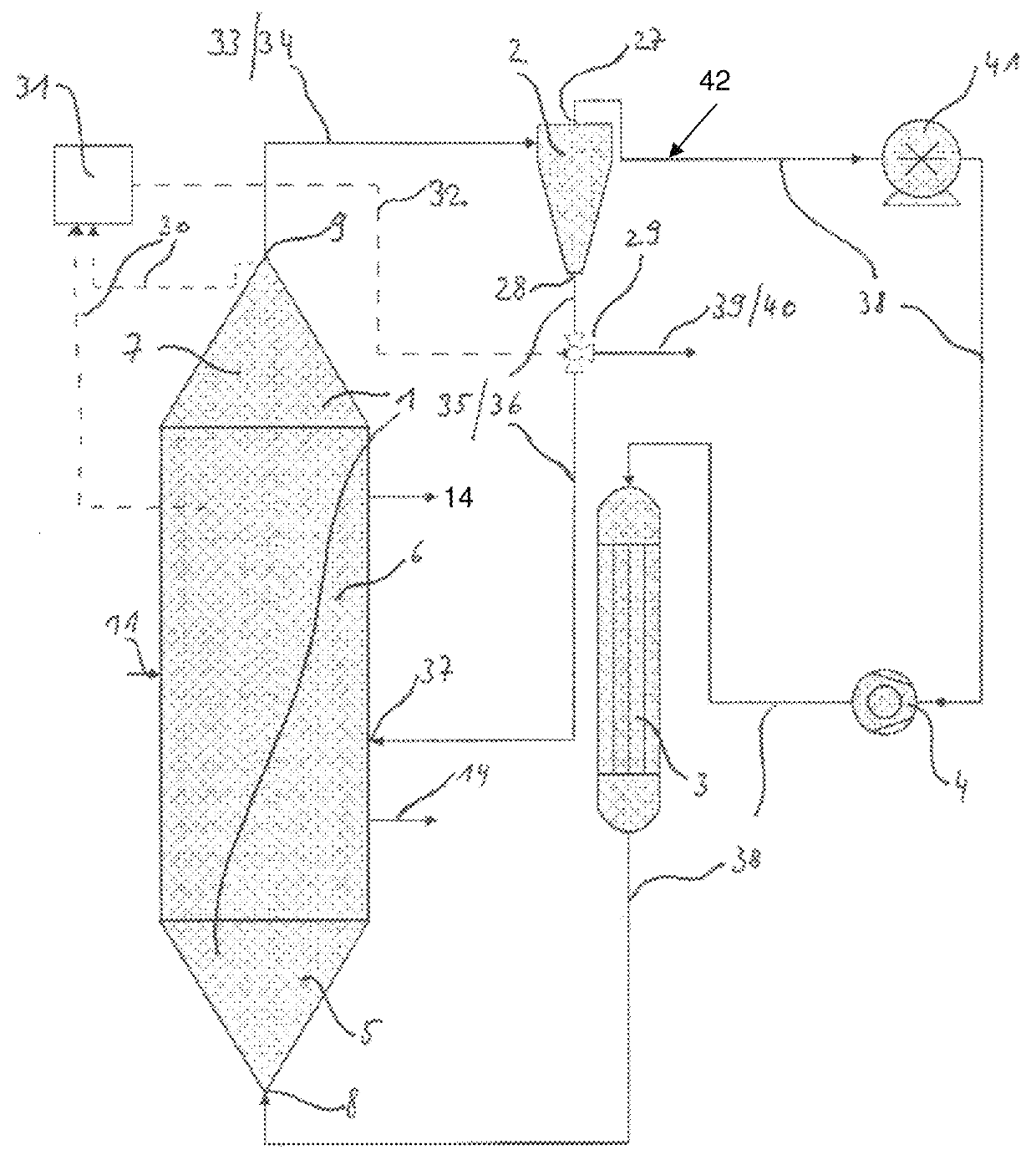

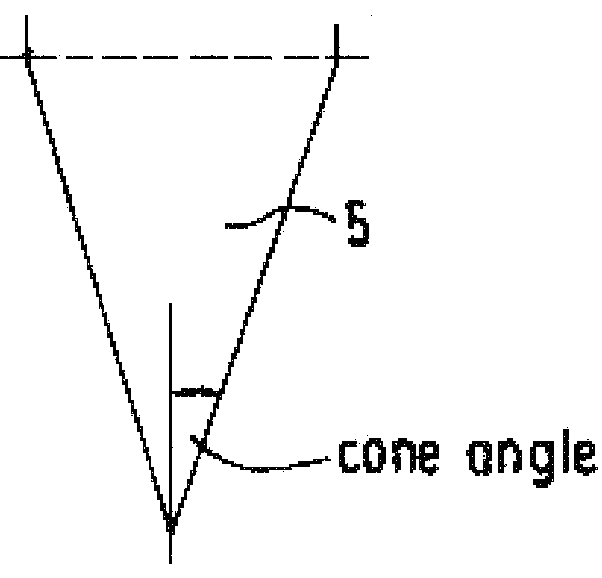

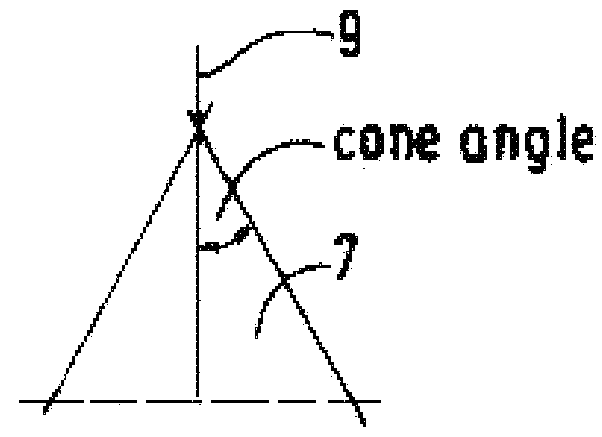

Reactor assembly and method for polymerization of olefins

ActiveUS9382359B2Great degree of separationLow amountChemical/physical/physico-chemical stationary reactorsFluidized bedOlefin polymerization

Reactor assembly for the production of polymers including a fluidized bed reactor and method for operating the reactor assembly.

Owner:BOREALIS AG

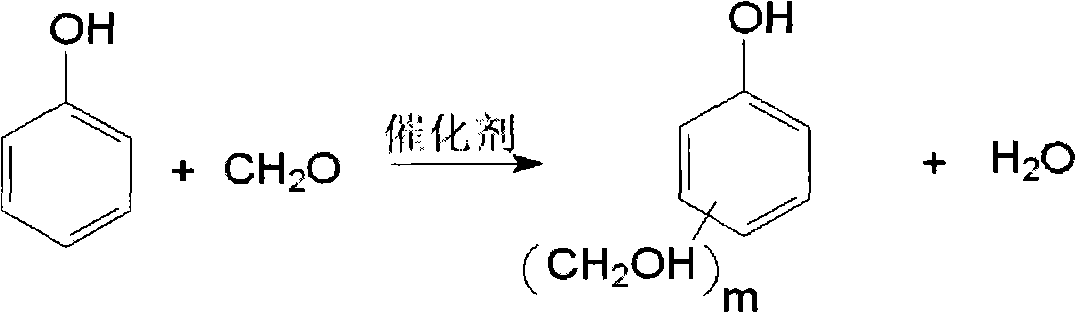

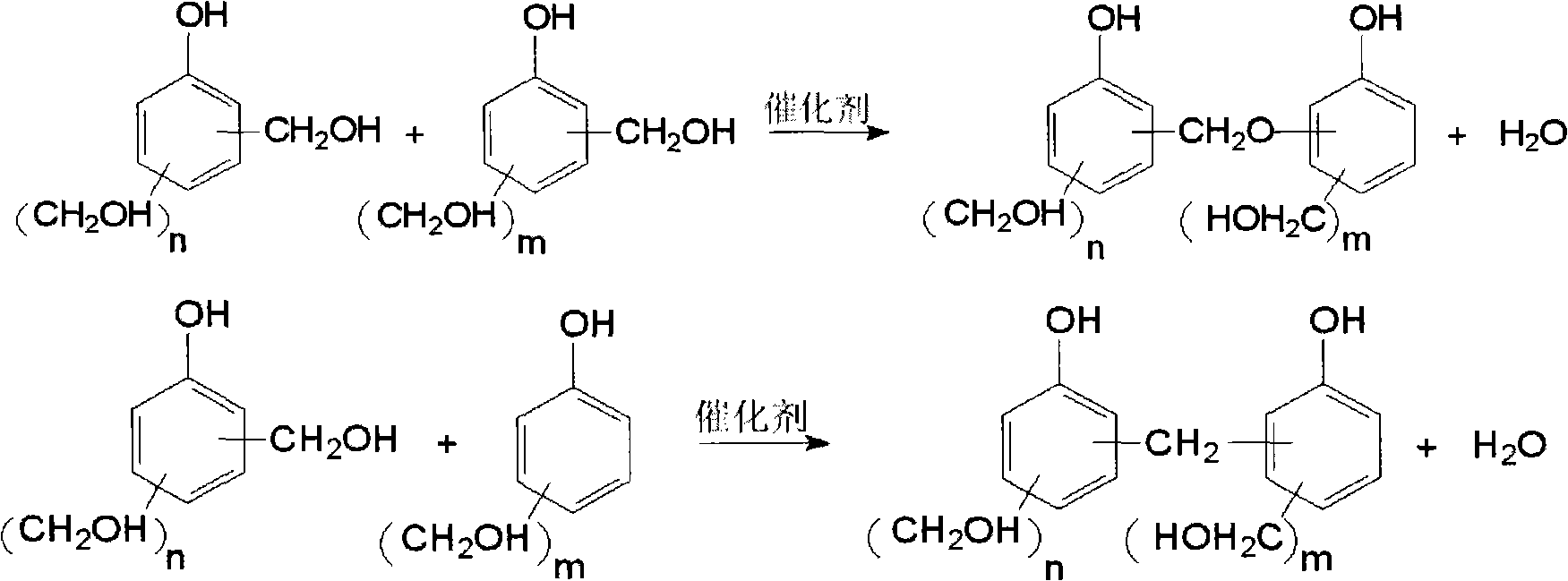

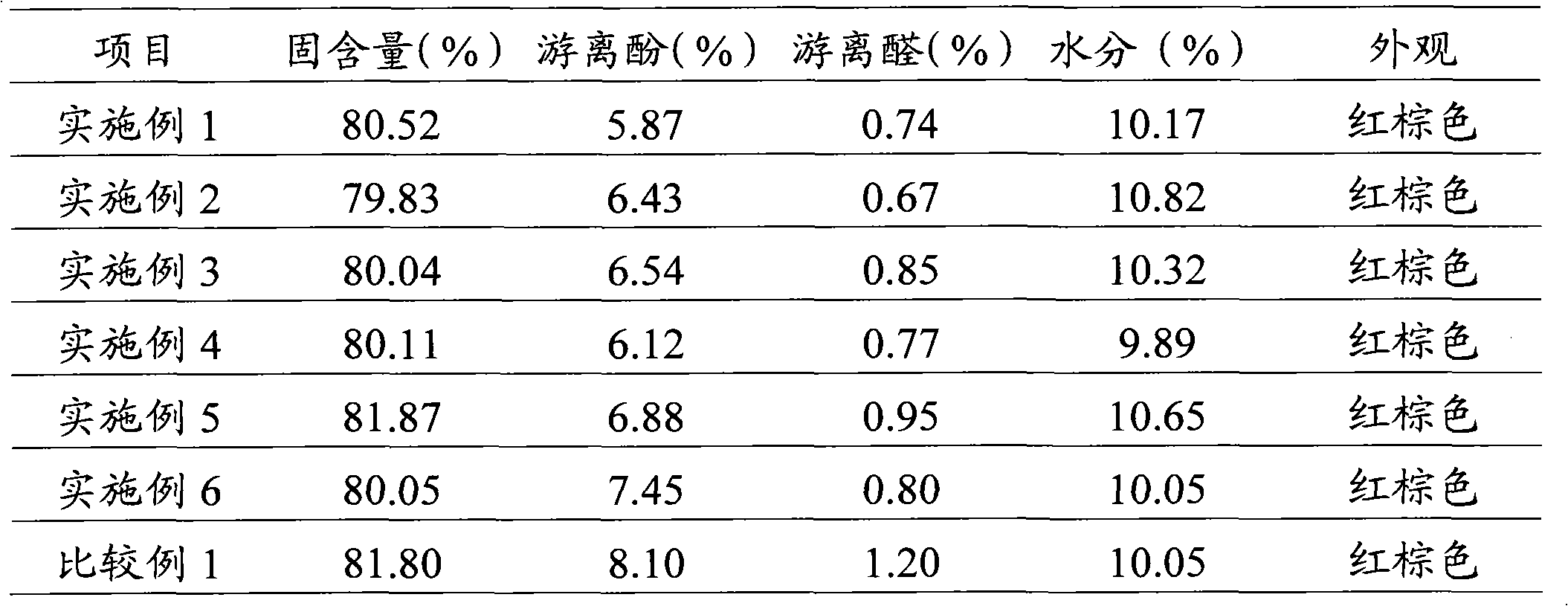

Preparation method for phenolic resin

The invention provides a preparation method for phenolic resin, which comprises the following steps: carrying out reaction on phenol, formaldehyde and organic compound containing amino and organic phosphorus compound under the condition of a basic catalyst to obtain the phenolic resin, wherein the organic phosphorus compound contains phosphorous and oxygen double bond, phosphorous and oxygen bond or hydroxyl. In the invention, the organic compound containing amino and the organic phosphorus compound are taken as modifiers to modify the phenolic resin; and nitrogenous groups and phosphoric groups are directly introduced in the structure of the phenolic resin and have the synergism inflaming retarding function so as to obtain the phenolic resin with excellent fire resistance. At the same time, the organic compound containing amino and the organic phosphorus compound enable the hydroxy content of the phenolic resin to be reduced and enable the hygroscopicity resistance of the phenolic resin to be improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

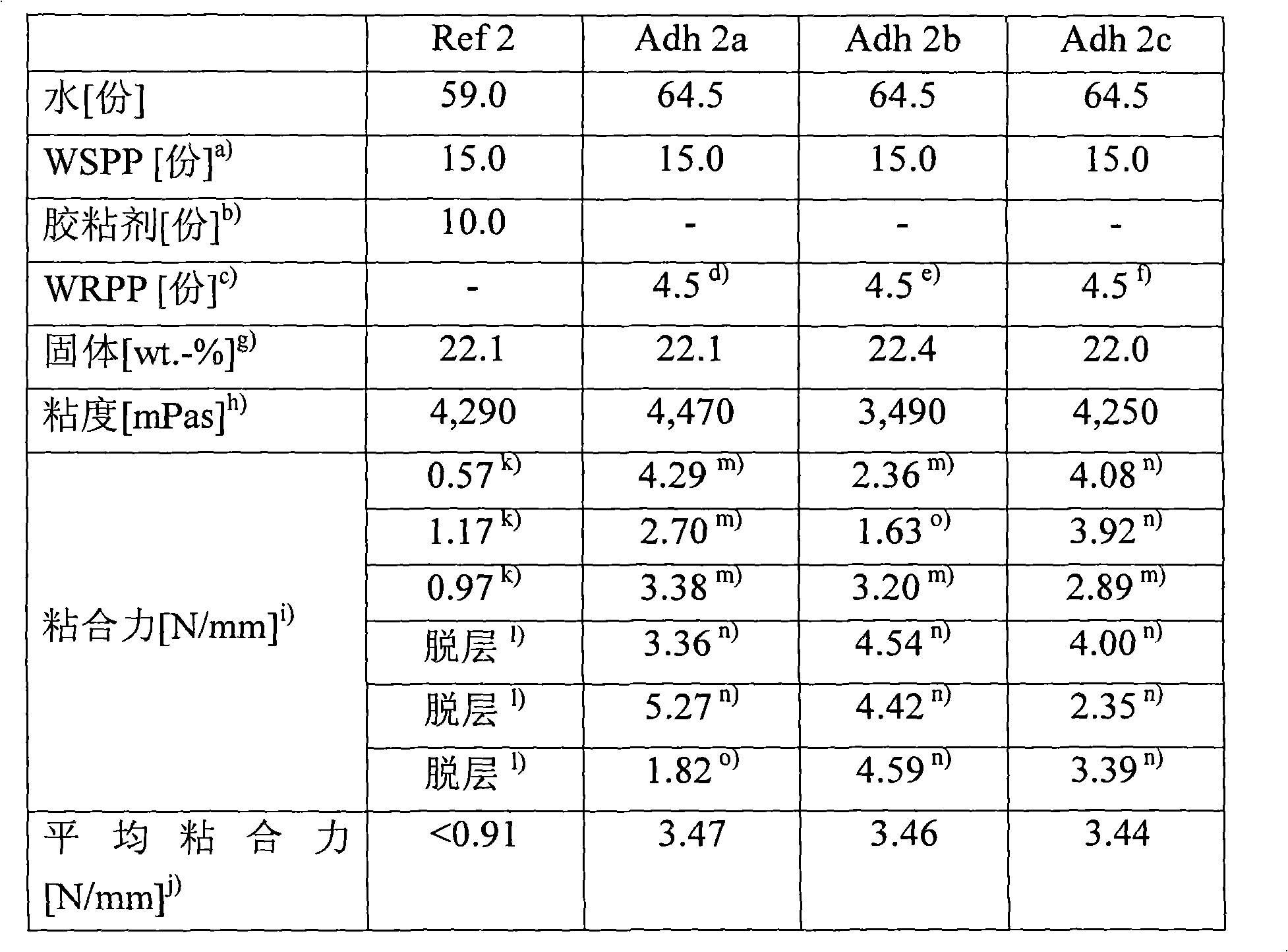

Novel water-based adhesives for industrial applications

InactiveCN101263184AHigh speedImprove curing speedProtein adhesivesStarch adhesivesWater basedCardboard

The invention relates to water-based adhesives for industrial applications obtained by mixing water-redispersible polymer powder and water-soluble polymer powder with water, wherein the weight ratio of the water-redispersible polymer powder to the water- soluble polymer powder is from about 0.001 : 1 to 100 : 1 and the water-based adhesive has a set speed of less than 300 sec, when measured with a 36 [mu]m thick layer at 23 DEG C and 50% relative humidity and 385 [mu]m thick carton boards with a weight of 275 3 g / m<2> and Cobb values on one side of 43 g / min / m<2> and 27 g / min / m<2> on the other side, has a solids content of about 7.5 to 70 wt.-% and a Brookfield viscosity at 23 DEG C at 20 rpm, measured according to the ASTM D1084 standard, of about 500 to 10'0OO mPas. The water-based industrial adhesive has the capability to bond a low surface tension substrate to a cellulosic substrate, in particular with a weight-ratio of water-redispersible polymer powder to water-soluble polymer powder from about 0.5 : 1 to 100 : 1 , thus can replace conventional aqueous adhesives based on synthetic polymer dispersions. The benefits of the invention are manifold such as faster set speeds and increased machine speeds, logistical advantages due to handling powders instead of liquids, leading to e.g. prolonged shelf life, no water transportation and being an environmentally friendly, low VOC containing adhesive.

Owner:HENKEL KGAA

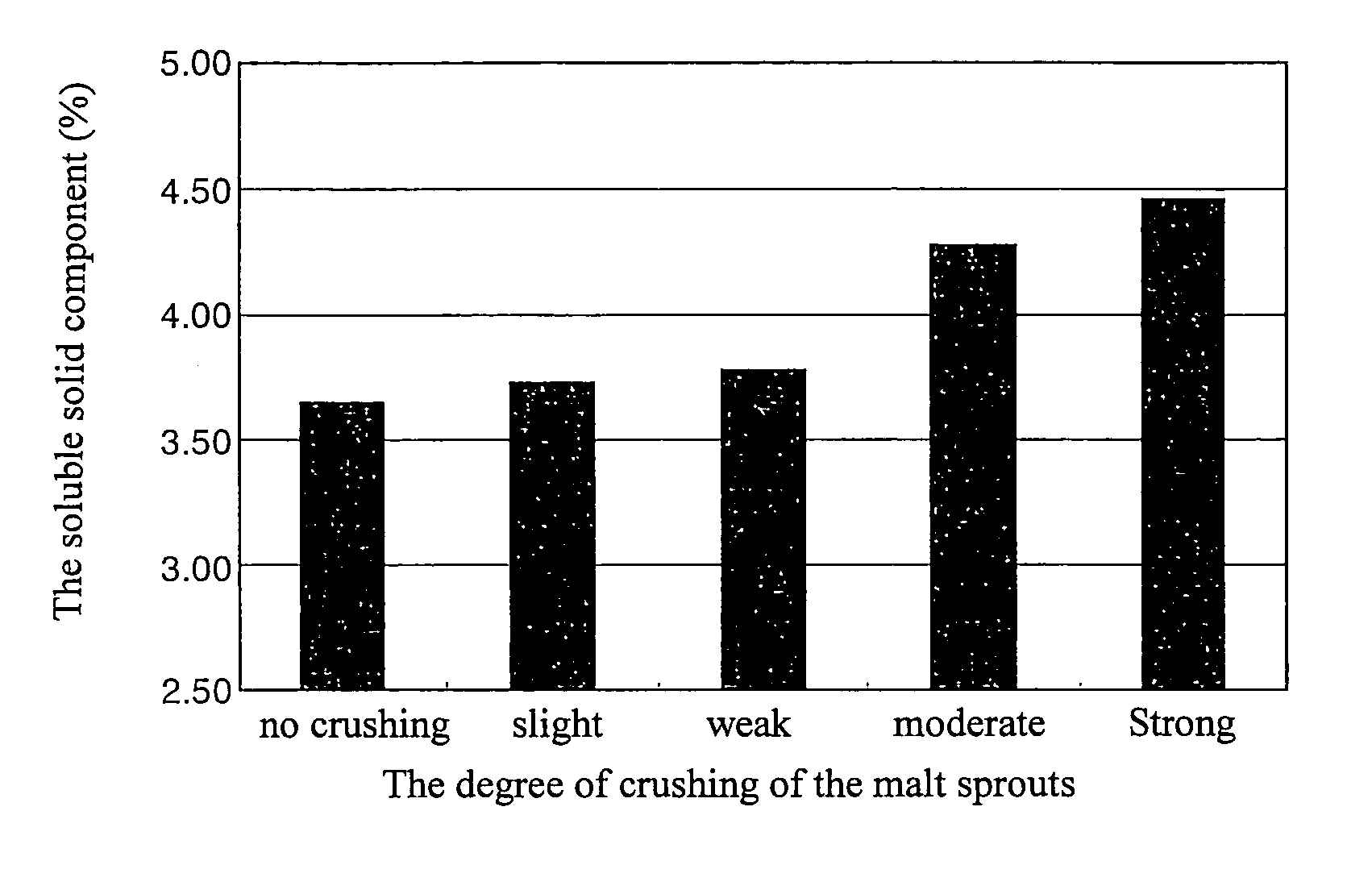

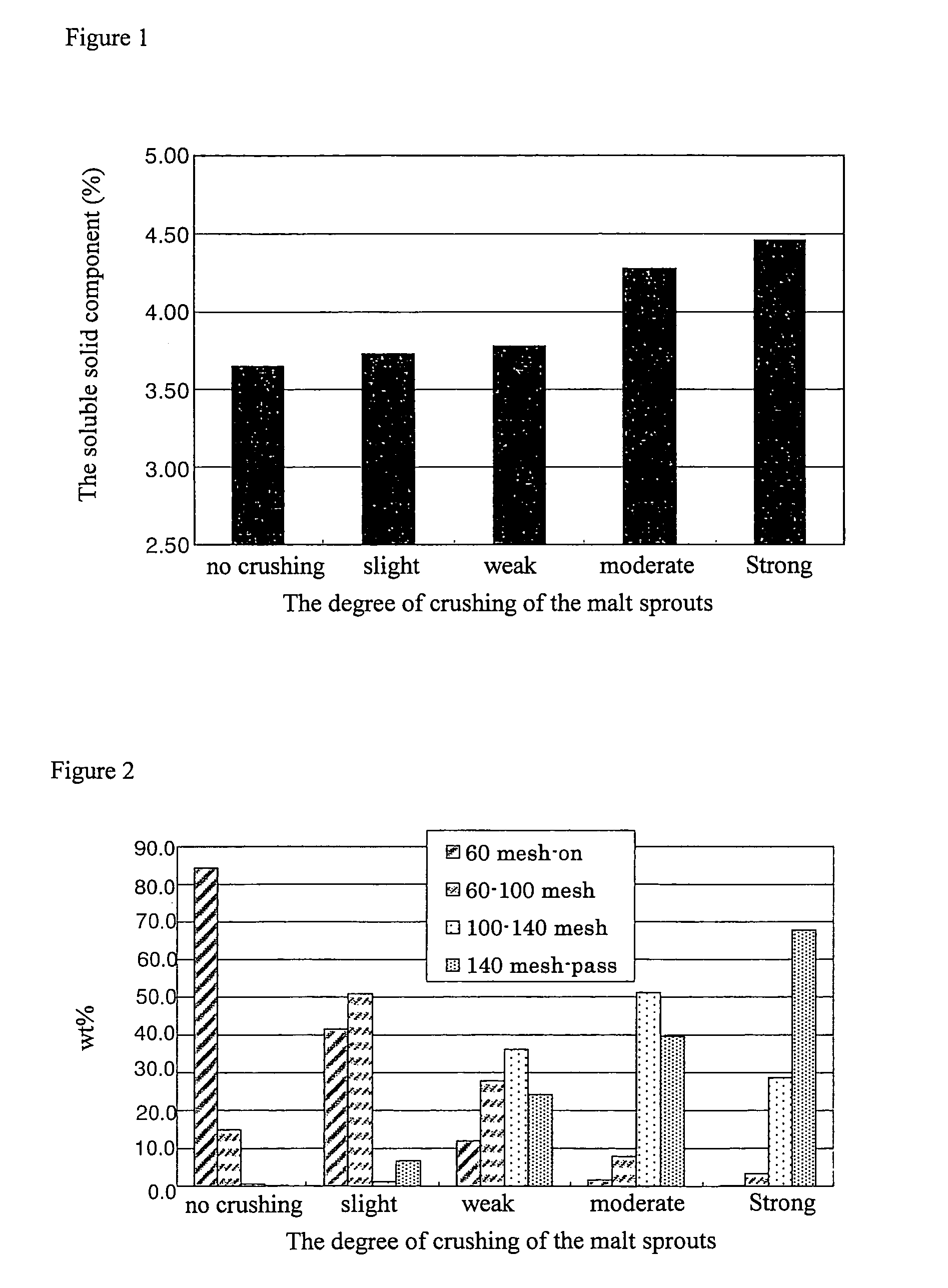

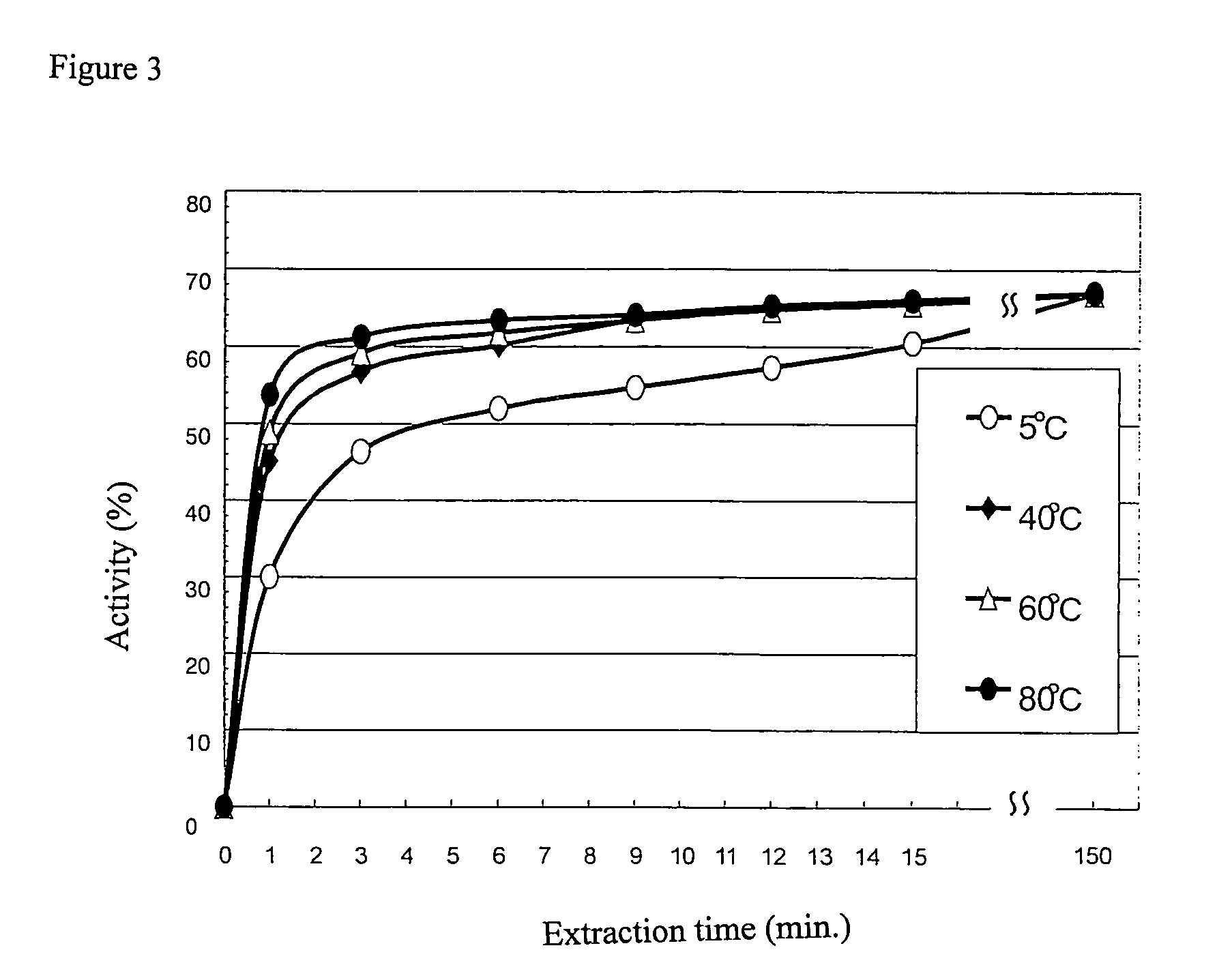

Process for producing food and beverage products from malt sprouts

Owner:SUNTORY HLDG LTD

Positive Photosensitive Resin Composition

ActiveUS20100099043A1High resolutionHigh sensitivityRadiation applicationsPhotomechanical apparatusSilane compoundsChemical compound

Disclosed is a positive photosensitive resin composition that includes (A) a first polybenzoxazole precursor that includes: a repeating unit of Chemical Formula 1 and a thermally polymerizable functional group at least one terminal end; (B) a second polybenzoxazole precursor that includes a repeating unit of Chemical Formula 3; (C) a photosensitive diazoquinone compound; (D) a silane compound; and (E) a solvent.

Owner:CHEIL IND INC

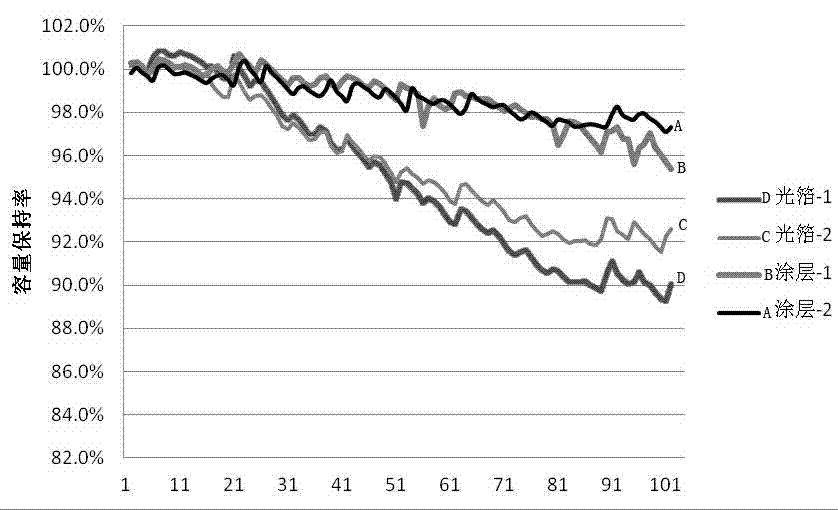

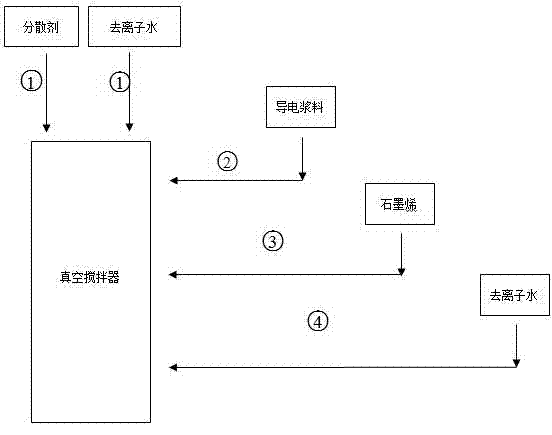

Method for preparing high-conductivity slurry from doped graphene

ActiveCN103500812AReduce thicknessGood dispersion processing performanceElectrode manufacturing processesSecondary cellsDoped grapheneInternal resistance

The invention discloses a method for preparing high-conductivity slurry from doped graphene, relates to the field of preparation methods of high-conductivity slurry and overcomes the technical defect of poor conductivity of the traditional mature conductive slurry. The method comprises the following steps: (1) weighing conductive slurry, graphene, a dispersing agent and deionized water according to the mass ratio of 100: (5-15): (3-5):700; (2) mixing the dispersing agent and 1 / 2 of deionized water, and stirring for 1h under a vacuumized condition; (3) adding the conductive slurry, and stirring for 30min under the vacuumized condition; (4) adding the graphene, and stirring for 2h under the vacuumized condition; and (5) adding the residual deionized water, stirring for 30min under the vacuumized condition, measuring the viscosity and solid content of the prepared slurry, and controlling the viscosity to be 100-500mpa.s and controlling the solid content to be 3-8%. The mature conductive slurry is diluted, and most of the original conductive agents are replaced with a small part of doped high-conductivity graphene, so that the preparation process of the slurry is simplified, and the slurry is high in conductivity, small in internal resistance, uniform in particle size distribution, easy to coat, low in cost and high in cost performance.

Owner:深圳好电科技有限公司

Low-VOC (volatile organic compound) non-cleaning flux comprising complex surfactant and method for preparing same

InactiveCN102699576AReduce dosageLow solidsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceActive agent

The invention discloses a low-VOC (volatile organic compound) non-cleaning flux comprising a complex surfactant and a method for preparing the flux. The flux can be coated on the welding surface of printed circuit boards in a spraying and dip way, is applicable to the lead-free welding process and mainly comprises deionized water, a complex activating agent, a complex surfactant, a complex co-solvent, a film-forming agent and a corrosion inhibitor. The flux contains less than 4.5% of VOC and less than 2.5% of solid, is environmentally friendly, free from cleaning, nonflammable and not easy to burn, has high insulation resistance and is convenient to store and transport. The process for preparing the flux is simple and suitable for the preparation of a large amount of flux and the industrial production, and the raw materials for preparing the flux are easy to obtain and low in cost.

Owner:GUANGDONG UNIV OF TECH

S.a.c. degradable bags for discreet disposal of used or soiled personal care products

InactiveUS20110229059A1Convenient easy dispensingReadily and consistently availableFlexible coversWrappersPurchasingPersonal Care Product

A packaging system for the disposal of any manner of used or soiled personal care products includes a package member configured for the receipt of the used personal care products therein. The unique packaging disposal system member is comprised of a biodegradable, degradable, opaque, sealable, generally a soft-side bag like structure which is part of common element consisting of multiple packaging systems which are connected together or to a common element. The package member includes an opaque external surface having a desired nondescript aesthetic configuration or appearance for the purpose of discreet disposal of used or soiled personal care products. The aesthetic configuration of the said invention may include any manner of print, color, etc., for the purpose of disposal instructions, warnings or purchasing indicia. In other words, one viewing the package from the outside is not given obvious, noticeable indication that the package contains used or soiled personal care products nor are the items contained therein visible through the packaging system member.

Owner:GOLDEN GROUP INT

Water-base halogen-free no-clean scaling powder used for lead-free solder

InactiveCN103042319AHalogen freeLow solidsWelding/cutting media/materialsSoldering mediaWater basedSolvent

The invention discloses a water-base halogen-free no-clean scaling powder used for lead-free solder. The water-base halogen-free no-clean scaling powder used for lead-free solder comprises, by weight, organic acid activating agent 2.0%-8.0%, alkyl alcohol amine 0.5-1.0%, cosolvent 8-25%, surface active agent 0.1-1.0%, corrosion inhibitor 0.2-0.8%, film-forming agent 2.0-5.0%, antibacterial agent 0.05-0.25%, and the balance deionized water. The scaling powder is long in term of protection, free of rosin and halogen, low in solid content and good in wettability, no residual is left after welding, requires not cleaning, is full and bright in welding points, and has no corrosion in copper mirror test; and surface insulation resistance of a substrate is larger than 108 Omega, and the substrate is low in cost, good in reliability and suitable for electronic material lead-free solder.

Owner:郴州金箭焊料有限公司

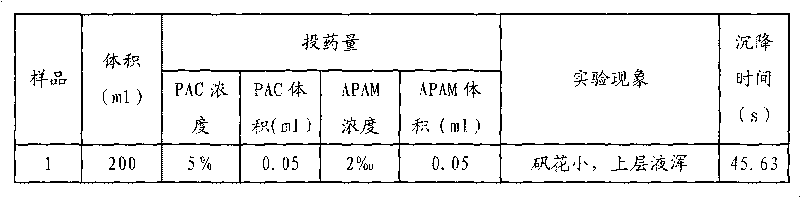

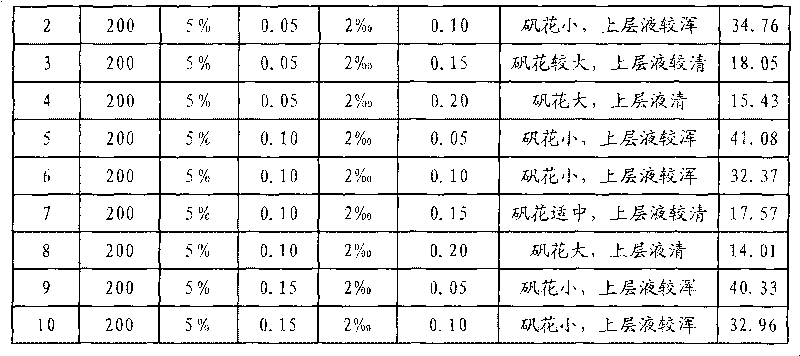

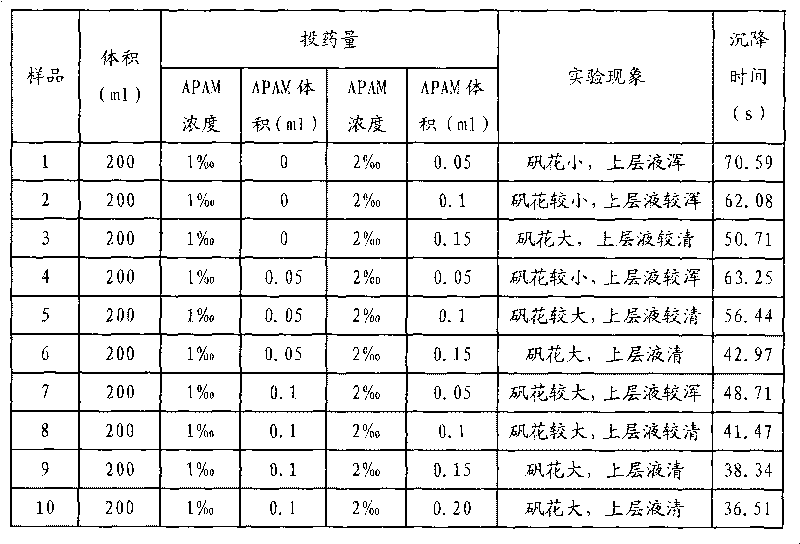

Silt and sewage treatment method

InactiveCN101708907AImprove water purification efficiencyGood water purification effectSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentChemistryPolyacrylamide

The invention relates to a silt and sewage treatment method, and belongs to the technical field of mine sewage treatment. The method comprises the following steps: (1) performing silt separation, namely performing primary separation on the silt and the sewage, and separating sand out; (2) performing sedimentation treatment, namely adding 0.2 to 0.4 mass percent solution of anionic polyacrylamide into the sewage, then adding 0.1 to 0.3 mass percent solution of anionic polyacrylamide into the sewage after sediment is generated, and separating the sediment out; and (3) performing sediment filter pressing, namely filter-pressing the sediment separated out by the step (2). The method of the invention effectively solves the mine sewage treatment problem, and separates three useful substances out comprising coarse sand, fine sand and sludge so as to increase the creation income of the enterprise.

Owner:湖州鹿山坞矿业有限公司

Integrated cogeneration wastewater sewage and waste polar fats/ oils/ greases/waxes (FOG) waste treatment method and facility

InactiveUS7485230B2Low solidsHigh energyBioreactor/fermenter combinationsGeneral water supply conservationVolatile fatty acidsCogeneration

A system and method integrating treatment of waste, polar Fats / Oils / Greases (FOG) with conventional anaerobic wastewater treatment facilities for biologically fueling digestion of solids in, and steady state production of methane from treated wastewater streams that includes a slipstream loop circulating warmed, actively digesting sludge from the base to the head of the anaerobic wastewater treatment facility, a conditioning tank with input screened by a rock trap, actively digesting sludge pumped from the slipstream loop into the tank via the rock trap, before and after FOG wastes are pumped from a hauler tank via a hose connecting to the rock trap into the conditioning tank and mixed with actively digesting sludge in the tank to produce a feedstock slurry rich in volatile fatty acids for injection at a metered rate back into the actively digesting sludge slipstream loop for introduction at the head of the anaerobic wastewater treatment facility.

Owner:MAGNER JOSEPH A +1

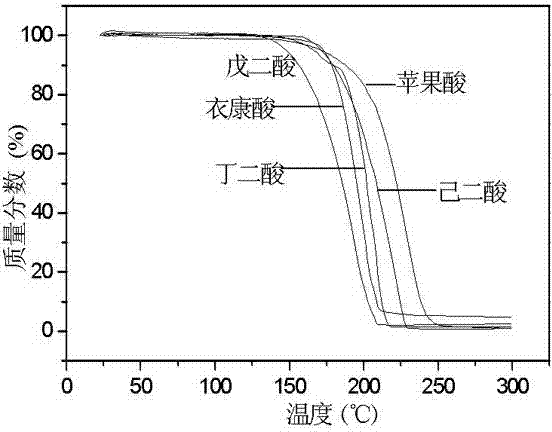

Water-based halogen-free resin-free antimicrobial no-clean soldering flux

InactiveCN103785974ALow solidsImprove wettabilityWelding/cutting media/materialsSoldering mediaChemistrySurface-active agents

The invention discloses a water-based halogen-free resin-free antimicrobial no-clean soldering flux. The soldering flux comprises, by weight, 9-25 parts of activating agents, 1-5 parts of surface active agents, 1-5 parts of film-forming agents, 0.01-0.08 part of corrosion inhibitor, 0.1-1 part of antioxidant, 0.5-1 part of antibacterial agent, 0.1-0.5 part of organic solvent and the balance deionized water. The activating agents comprise at least two kinds of DL-malic acid, succinic acid, glutaric acid, adipic acid, phthalic acid, citric acid and lactic acid; the surface active agents comprise at least one of fatty acid methyl ester ethoxylate or isomerism tridecane alcohol ethoxylate, the corrosion inhibitor comprises at least one of benzotriazole (BTA) and triethylamine, and the antibacterial agent is chitosan. Through the mode, the water-based halogen-free resin-free antimicrobial no-clean soldering flux has the advantages of being free of resin and halogen, low in solid content, good in wettability, low in cost and good in stability.

Owner:SUZHOU LOTTE CHEM TECH

Vacuum pressure impregnating and glue-applying technique

InactiveCN101497205ALow solidsHigh bonding strengthWood treatment detailsWood veneer joiningWood veneerVacuum pressure

The invention provides a vacuum pressure impregnation sizing process, and relates to a process for producing plywood for container bottom plates, in particular to a vacuum impregnation sizing process for wood veneers, bamboo mats, bamboo curtains or bamboo chips. The process comprises drying treatment, resin adhesive preparation, sizing and secondary drying. The process for sizing has the advantages of reducing the production cost, ensuring uniform adhesive-absorbing amount and guaranteeing the gluing strength of the plywood for container bottom plates.

Owner:云南永利发林业有限公司

Luminescent lanthanide complex, and articles and inks containing the luminescent complex

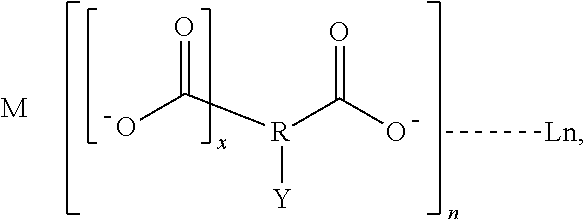

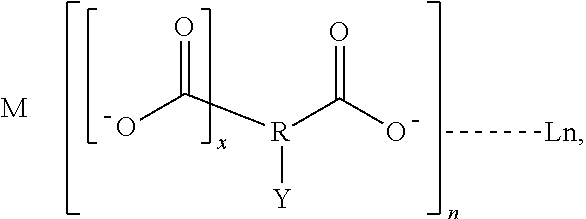

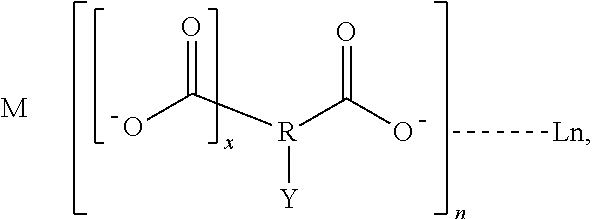

Luminescent lanthanide complex and inks containing the complex as well as its method of production and article including the complex, wherein the complex includes the formula:wherein M is chosen from the alkali cations Li+, Na+, K+, Rb+ and Cs+ and mixtures thereof and is present to neutralize charge of the complex;wherein Ln is chosen from the trivalent rare-earth cations of Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, and Yb and mixtures thereof;wherein R is a C5 to C6 heteroaryl:wherein Y is an optionally substituted C3-C8 heterocycloalkyl moiety linked to R by an N atom;wherein n is an integer of 3 or 5; andwherein x is an integer of 0 or 1.

Owner:SICPA HLDG SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com