Method for catalytic wet oxidation of industrial sludge

A technology for catalyzing wet oxidation and industrial sludge, applied in the field of resources and environment, can solve the problems of complex composition of industrial sludge, and achieve the effects of reducing technical difficulty and environmental risks, reducing the solid content and volume of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

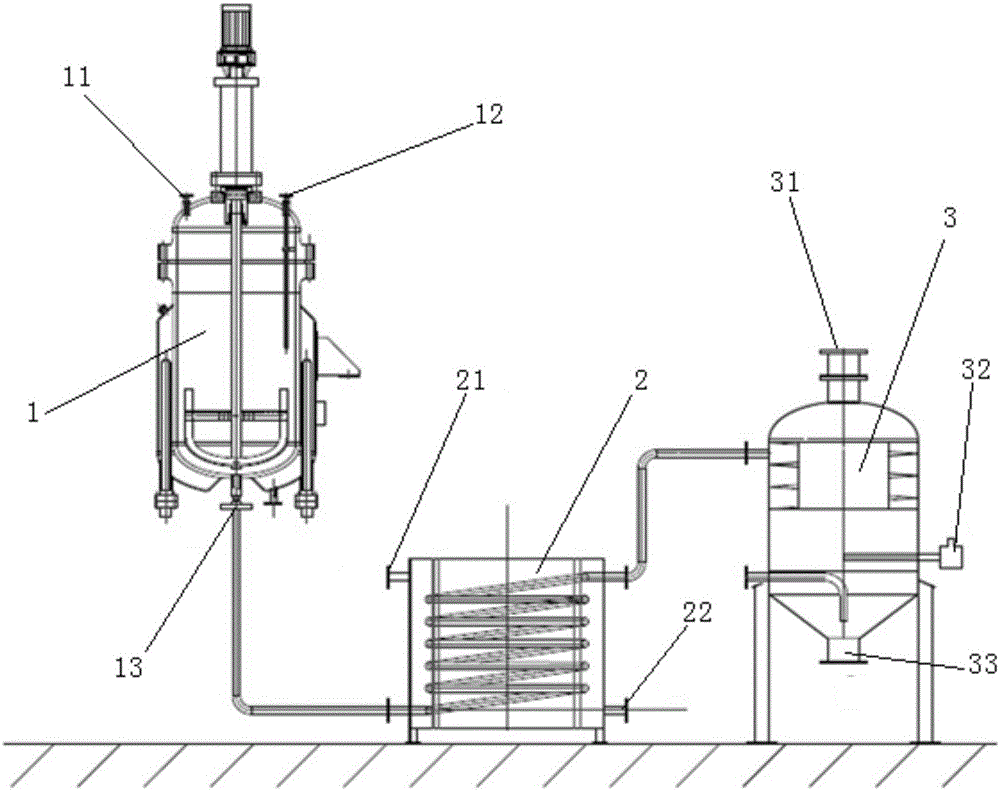

[0031] A method for catalytic wet oxidation treatment of pharmaceutical sludge produced by a pharmaceutical factory, combined with such figure 1 The shown processing device comprises the following steps:

[0032] (1) Pharmaceutical sludge and powdery activated carbon are mixed evenly, and are added in the reactor 1 from reactor mud inlet 11, wherein the moisture content of pharmaceutical sludge is 97%, VSS: SS is 81%, the powdery activated carbon Add-on amount is 5g / L; Pass into oxygen then from reactor oxygen inlet 12, make the oxygen pressure in reactor 1 be 0.6MPa, start reactor 1, make the temperature in the kettle be 220 ℃, pressure be 4.2MPa, make pharmaceutical Sludge was subjected to wet oxidation treatment, and the treatment was stopped after 30 minutes. After wet oxidation, the sludge SS removal rate reached 67%, and the VSS removal rate reached 84%.

[0033] (2) Discharge the treated pharmaceutical sludge from the reactor mud outlet 13 at the bottom of the reactor ...

Embodiment 2

[0037] Using the same device, pharmaceutical sludge raw material and treatment process as in Example 1, only the catalyst selection and treatment conditions have been changed, and the changes are as follows:

[0038] (1) Using Fe 3+ Ions are used as catalysts, and the dosage is 0.05mol / L;

[0039] (2) The conditions of the wet oxidation treatment adopted are as follows: the temperature is 200° C., the pressure is 4.0 MPa, the reaction time is 30 min, and the initial pressure of aeration of oxygen is 0.8 MPa.

[0040]Finally, after wet oxidation, the sludge SS removal rate reached 70%, and the VSS removal rate reached 88%. After plate and frame filtration, the moisture content of the sludge is 58%, and the sludge volume is less than 85%.

Embodiment 3

[0042] Using the same device, pharmaceutical sludge raw material and treatment process as in Example 1, only the catalyst selection and treatment conditions have been changed, and the changes are as follows:

[0043] (1) Using Zn 2+ Ions are used as catalysts, and the dosage is 0.05mol / L;

[0044] (2) The conditions of the wet oxidation treatment adopted are: the temperature is 200° C., the pressure is 4.5 MPa, the reaction time is 60 min, and the initial pressure of oxygen filling is 1.0 MPa.

[0045] Finally, after wet oxidation, the sludge SS removal rate reached 66%, and the VSS removal rate reached 82%. After plate and frame filtration, the moisture content of the sludge is 60%, and the sludge volume is less than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com