Silt and sewage treatment method

A sewage treatment method, mud and sand technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of long drying time, long sedimentation time, sludge High water content and other problems, to achieve high water purification efficiency and good water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

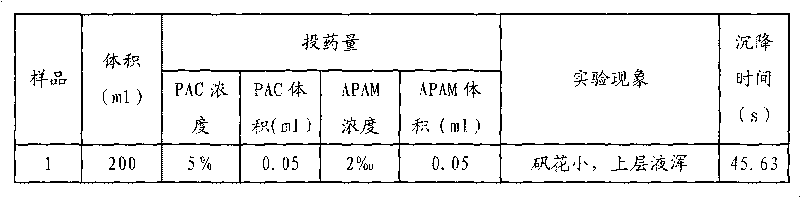

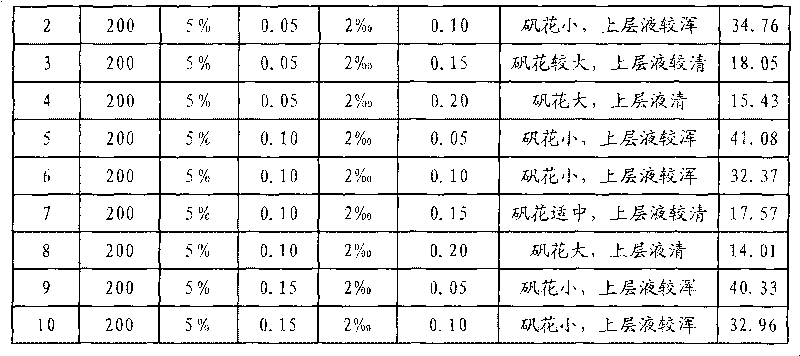

Examples

Embodiment 1

[0042] A mud sand sewage treatment method, the sewage is produced by washing crushed stones in a quarry, which contains a large amount of mud sand with a solid content of about 4%. In this embodiment, the sewage discharged from the production line is directly treated, and the sewage flows through the coarse sand separation device, the fine sand separation device, the primary flocculant adding device, and the secondary flocculant adding device. The above devices treat the sewage in sequence.

[0043] Firstly, sand separation is performed on the above-mentioned sewage, and the above-mentioned sand separation step includes a primary separation step and a secondary separation step. The primary separation step uses spiral centrifugation to separate the coarse sand in the sewage, and the secondary separation uses a cyclone group and a high-frequency vibration device to separate the fine sand in the sewage.

[0044] Preparation of anionic polyacrylamide solution: add water to a cont...

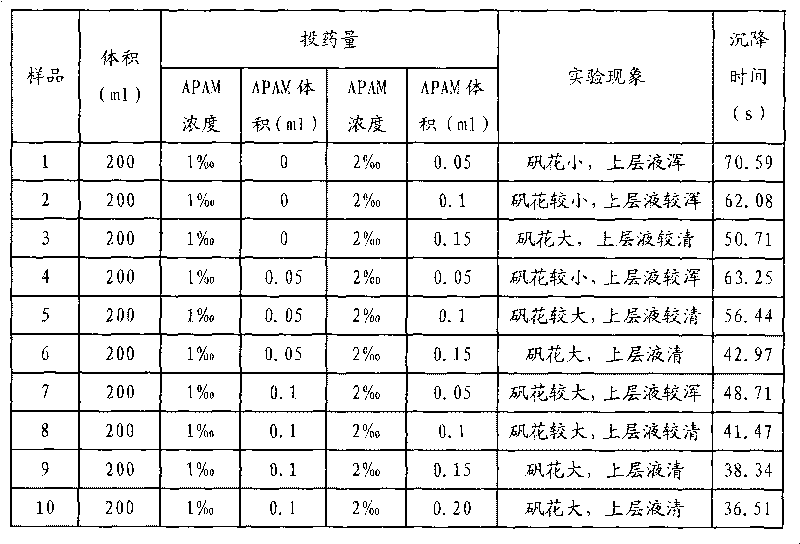

Embodiment 2

[0049] A mud sand sewage treatment method, the sewage is produced by washing crushed stones in a quarry, which contains a large amount of mud sand with a solid content of about 5%. In this embodiment, the sewage discharged from the production line is directly treated, and the sewage flows through the coarse sand separation device, the fine sand separation device, the primary flocculant adding device, and the secondary flocculant adding device. The above devices treat the sewage in sequence.

[0050] Firstly, sand separation is performed on the above-mentioned sewage, and the above-mentioned sand separation step includes a primary separation step and a secondary separation step. The primary separation step uses spiral centrifugation to separate the coarse sand in the sewage, and the secondary separation uses a cyclone group and a high-frequency vibration device to separate the fine sand in the sewage.

[0051] Preparation of anionic polyacrylamide solution: add water to the co...

Embodiment 3

[0056] A mud sand sewage treatment method, the sewage is produced by washing crushed stones in a quarry, which contains a large amount of mud sand with a solid content of about 4.5%. In this embodiment, the sewage discharged from the production line is directly treated, and the sewage flows through the coarse sand separation device, the fine sand separation device, the primary flocculant adding device, and the secondary flocculant adding device. The above devices treat the sewage in sequence.

[0057] Firstly, sand separation is performed on the above-mentioned sewage, and the above-mentioned sand separation step includes a primary separation step and a secondary separation step. The primary separation step uses spiral centrifugation to separate the coarse sand in the sewage, and the secondary separation uses a cyclone group and a high-frequency vibration device to separate the fine sand in the sewage.

[0058] Preparation of anionic polyacrylamide solution: add water to a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com