Aeration device based on turbulent microbubbles

An aeration device and micro-bubble technology, applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem that aerobic microorganisms cannot play the role of oxidation and decomposition, limit the treatment capacity of aeration technology, Abnormalities in the aeration tank system and other problems, to achieve the effect of improving gas dissolution efficiency and aeration effect, high gas-water mixing efficiency, and reducing aeration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

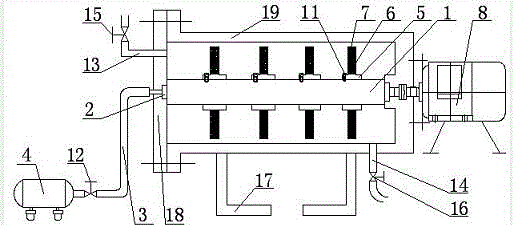

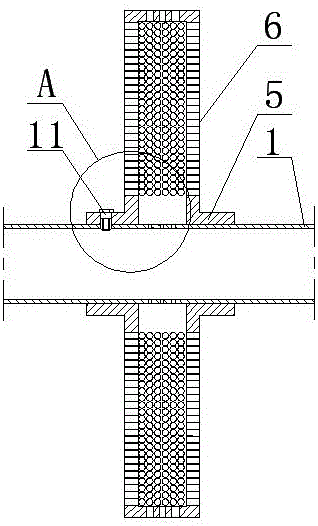

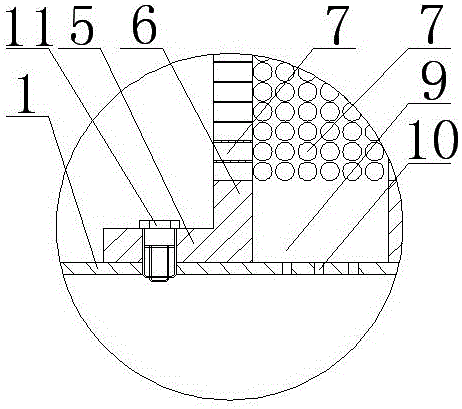

[0023] Such as Figures 1 to 5 As shown, the aeration device based on turbulent microbubbles includes a rotating shaft. The rotating shaft is a hollow shaft with both ends closed. The left end of the rotating shaft is connected to an air intake pipe through a movable adapter. When rotating, the intake pipe remains stationary, and an air compressor is connected to the end of the intake pipe, and the gas compressed in the air compressor can enter the hollow area of the rotating shaft through the intake pipe, and the position of the air intake pipe close to the air compressor is set There is an air intake control valve, which can control the air intake pressure. The air intake pipe communicates with the hollow area inside the rotating shaft. The rotating shaft is fixed with blades through sleeves. Here, four sleeves are arranged at equal intervals on the rotating shaft. And four blades are evenly arranged on the circumferential surface of each sleeve, where the sleeve and the b...

Embodiment 2

[0026] On the basis of Example 1, such as Figures 1 to 5 As shown, it also includes a container body, the container body includes a sealing plate and a cylinder, and the sealing plate is detachably installed at the end of the cylinder, so that the shaft and blades can be easily disassembled and repaired or damaged One end of the rotating shaft is rotatably installed on the sealing plate, and the other end of the rotating shaft is rotatably installed on the end of the cylinder, which is equivalent to rotatably installing the rotating shaft inside the container body. It is located inside the container body, and the container body is provided with a water inlet pipe and an outlet pipe. An air intake control valve is provided, and a one-way valve is provided on the water inlet pipe, which can prevent the liquid in the container from flowing back. A support is provided at the bottom of the container.

[0027] When in use, start the air compressor and adjust the air intake contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com