Mixer for gas engine and exhaust gas recirculation (EGR) mixer

A gas engine and mixer technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems that the mixing uniformity of recirculated exhaust gas and fresh air can no longer meet the requirements of engine stable operation, and the intake pipeline is short. , to achieve good market application value, low overall cost, and high gas utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

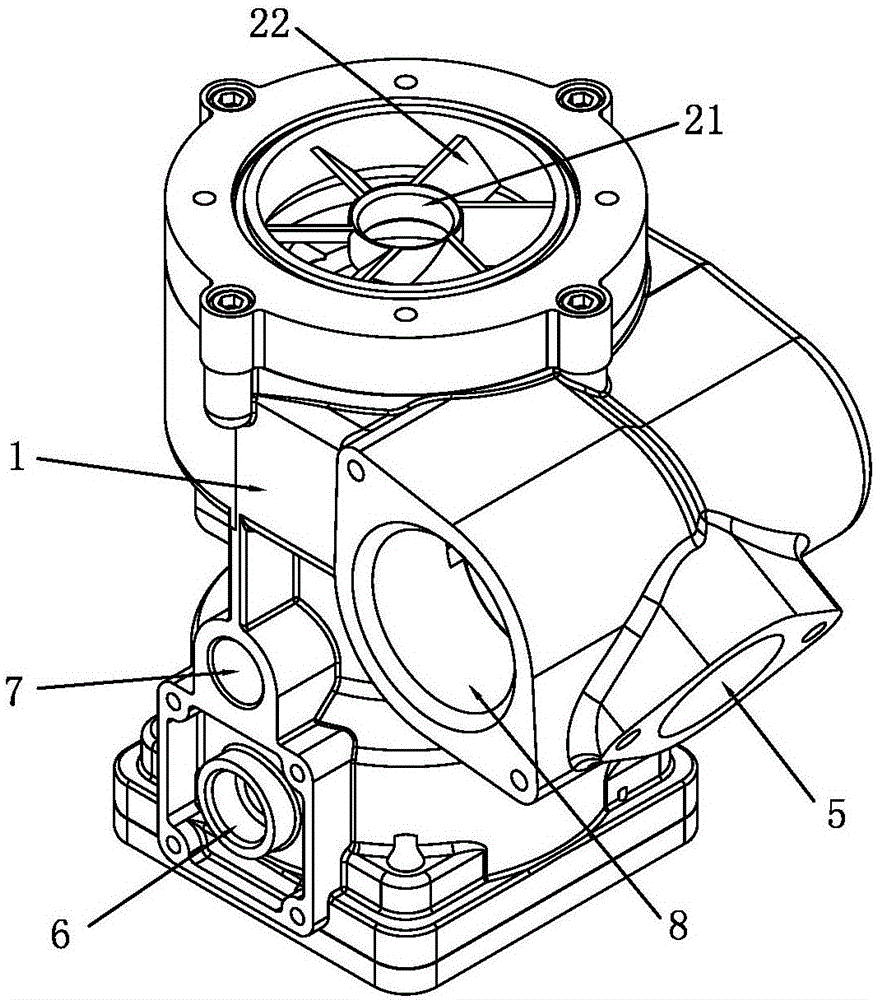

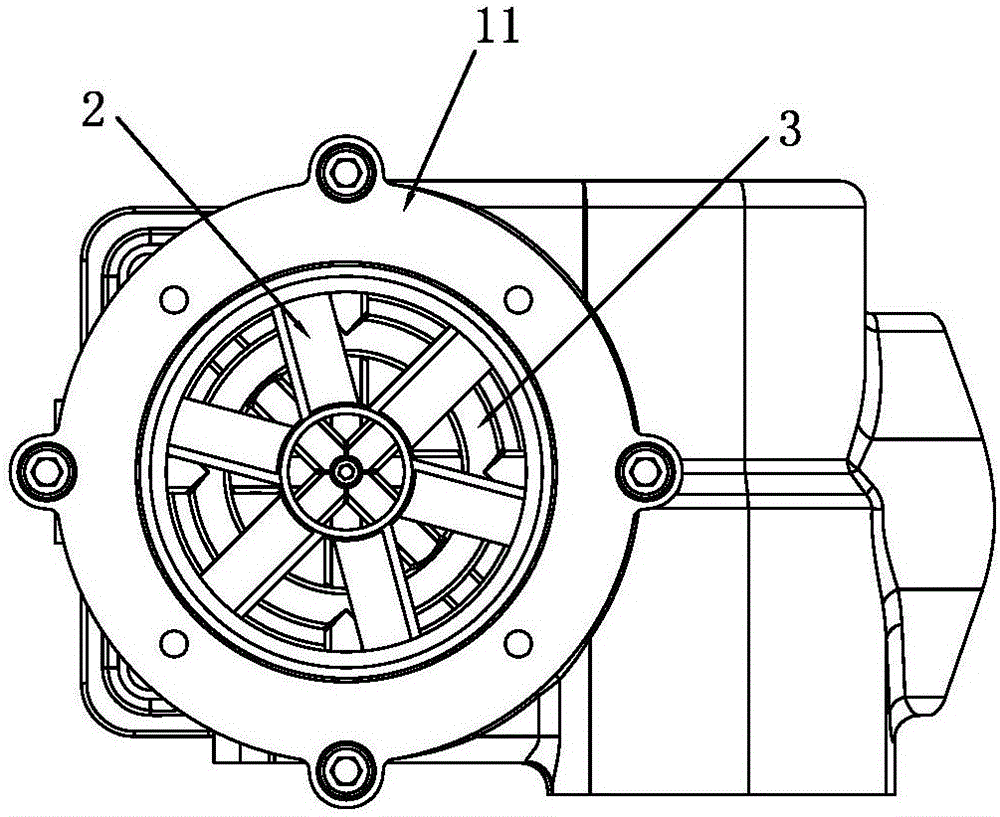

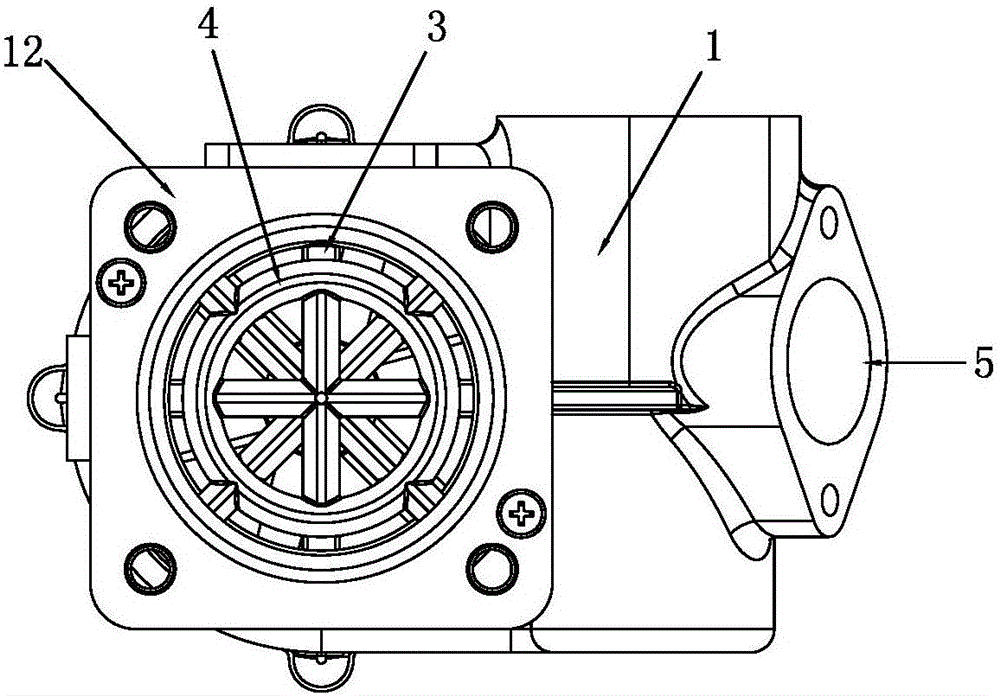

[0030] Such as figure 1 with Figure 5 As shown, a gas engine mixer provided by this embodiment includes a mixer body 1 that penetrates up and down. The upper end of the mixer body 1 is an air inlet, and the lower end is an air outlet. There is a turbulent body 2, a gas core 4 is provided at the gas outlet, an EGR core 3 is provided between the turbulent body 2 and the gas core 4, and the mixer body 1 is provided with an exhaust gas inlet 5 and a gas inlet 6 , the EGR core 3 communicates with the exhaust gas inlet 5, and the EGR core is used to inject the exhaust gas connected to the exhaust gas inlet into the mixer body. The gas wick 4 communicates with the gas inlet 6, and the gas wick is used for injecting the gas connected to the gas inlet into the mixer body. The EGR core 3 and the gas core 4 have the same structure, and the following will further describe the EGR core 3 and the gas core 4 by taking the gas core as an example.

[0031] Such as Figure 5 with Image 6...

Embodiment 2

[0056] Such as Figure 8 with Figure 9 As shown, another gas engine mixer provided in this embodiment differs from the gas engine mixer in Embodiment 1 only in that the gas core 4 is arranged at the air inlet of the mixer body 1, The turbulent body 2 is arranged at the gas outlet of the mixer body 1 , and the EGR core 3 is arranged between the gas core 4 and the turbulent body 2 . The EGR core 3 communicates with the exhaust gas inlet 5, the gas core 4 communicates with the gas inlet 6, and the positions of the exhaust gas inlet 5 and the gas inlet 6 are adjusted according to the positions of the EGR core 3 and the gas core 4 Make adaptive changes.

Embodiment 3

[0058] Such as Figure 10 with Figure 11 As shown, an EGR mixer provided in this embodiment includes a mixer body 1, an EGR core 3 and a turbulent body 2 are arranged in the mixer body 1 along the flow direction of the air, and an exhaust gas is arranged on the mixer body 1. The intake port 5 and the exhaust gas intake port 5 communicate with the EGR core 3 .

[0059] The EGR core 3 in this embodiment has the same structure as the gas core in Embodiment 1, including a guide ring, a guide column arranged in the guide ring, and a guide ring arranged between the guide ring and the inner wall of the mixer. Ventilation column, diversion column, guide ring and ventilation column are all provided with spray holes; the diversion column intersects at the center of the guide ring and divides the guide ring into four uniform parts, and the ventilation column divides the guide ring And the space between the mixer body is divided into four uniform parts. The cross-sections of the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com