Nanometer water purifying material for organic removal, its preparation method and uses

A nanometer and water purification technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of low efficiency, fine particles, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

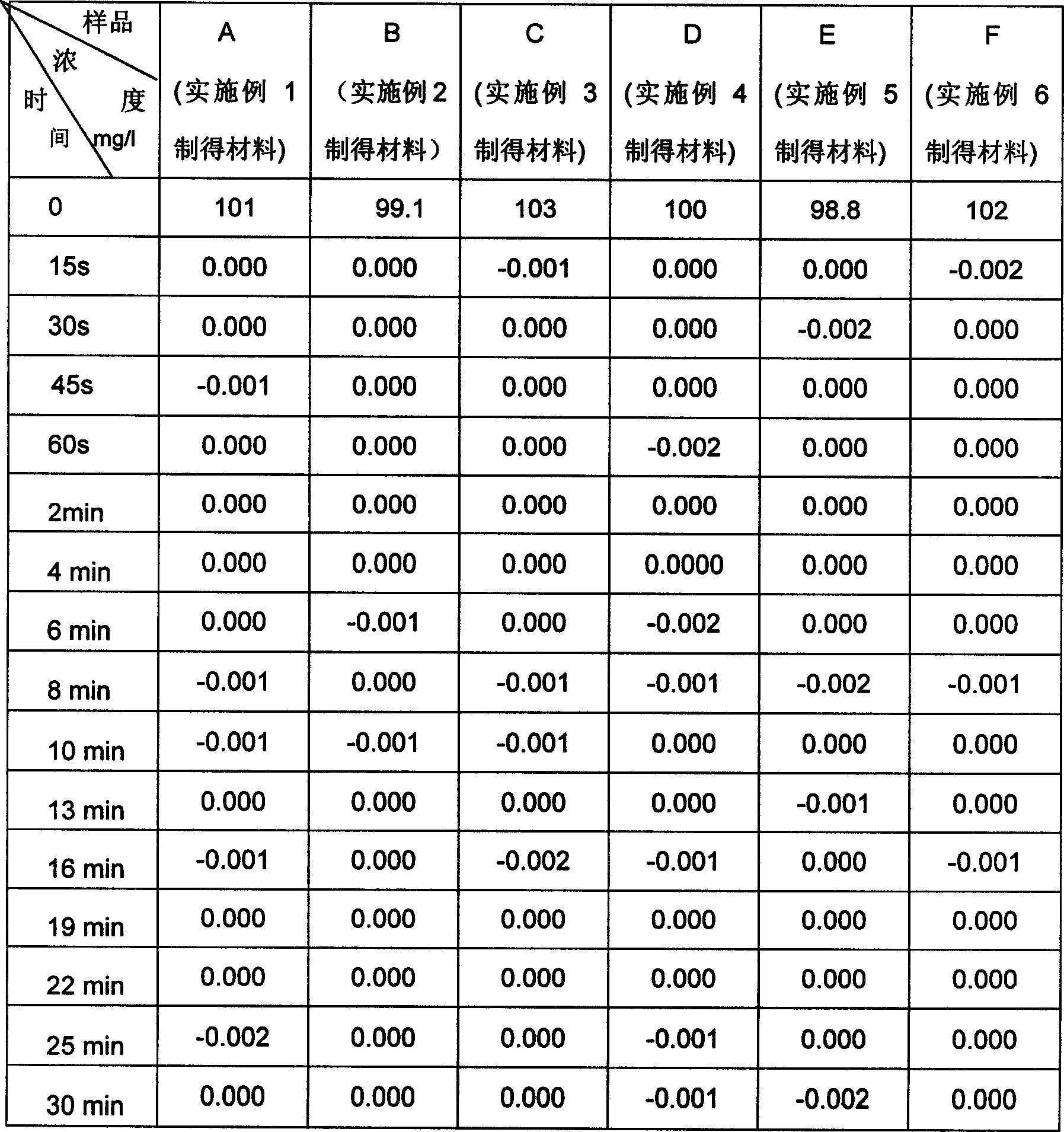

Embodiment 1

[0039] Mix 16g of C-- glass fiber in 250ml of distilled water, add 85ml of 8g / l sodium salicylate, then heat the mixture to 45°C, add 10.5g of aluminum powder (particle size: 15nm), and place Ultrasonic oscillation at 50°C for 38min in an ultrasonic tank, then add 10ml of 18g / l tetrahexyl orthosilicate alcohol solution to the mixture, continue ultrasonic oscillation for 65min, then take it out and cool it at room temperature; put 7.5g microcrystalline cellulose in 250ml Soak and homogenize in distilled water for 1.5 hours, then add 50ml of 1.0g / l polyvinyl alcohol solution and mix evenly; filter the two mixtures prepared above, and dry the filter material in a drying oven at 95°C for 2 hours. Promptly obtain 55.8g nano water purification material of the present invention, it is composed of: the oxidation-hydroxide phase of aluminum: 54.4%, glass fiber: 28.7%, cellulose: 13.4%, wherein the particle diameter of oxidation-aluminum hydroxide is 20 Nano, specific surface area 736 s...

Embodiment 2

[0041]Soak 8g of activated carbon fiber in 250ml of distilled water, homogenize for 65min, add 30ml of 4.5g / l polyvinyl alcohol solution and mix evenly; take 12g of D--glass fiber and mix evenly in 250ml of distilled water, add 3.5g / l of molybdenum phosphoric acid 20ml, then heated to 90°C, added 8.5% aluminum powder (particle size: 20nm), then placed in an ultrasonic tank and ultrasonically oscillated at 95°C for 2.5h, then added 22ml of 15g / l tetrahexyl orthosilicate alcohol solution to the mixture Continue to ultrasonically oscillate for 45 minutes, then take it out, and cool it at room temperature; filter the two mixtures prepared above, and dry the filter material in a drying oven at a temperature of 180° C. for 5 hours to obtain 47.9 g of the nanometer water purification filter of the present invention. The material is composed of: aluminum oxide-hydroxide phase: 51.3%, glass fiber: 25.1%, activated carbon fiber: 16.7%, wherein the particle size of oxide-hydroxide aluminu...

Embodiment 3

[0043] Soak 5.5g of polyethylene in 100ml of ethanol, homogenize for 45min, add 20ml of 4g / l polyvinyl alcohol solution and mix evenly; take 7.0g of E-glass fiber and mix evenly in 350ml of distilled water, add 40ml of 6g / l boric acid, Then heat to 45°C, add 3.5g of aluminum powder (particle size: 15nm), then place in an ultrasonic tank and vibrate ultrasonically at 50°C for 2.5h, then add 25ml of 19g / l tetrahexyl orthosilicate alcohol solution to the mixture to continue Ultrasonic vibration for 55 minutes, take it out, and cool it at room temperature; filter the two mixed solutions prepared above, and dry the filter material in a drying oven at a temperature of 120° C. for 4.5 hours to obtain 24.3 g of the nanometer water purification material of the present invention. Its composition is: aluminum oxide-hydroxide phase: 41.6%, glass fiber: 28.8%, polyethylene: 22.6%, wherein the particle diameter of aluminum oxide-hydroxide is 20 nanometers, and the specific surface area is 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com