Patents

Literature

2018 results about "Oxidative treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidative Therapy involves treating the body with extra oxygen. Many believe that the use of oxidative therapy is the wave of the future in the treatment of resistant bacteria which have resulted from the overuse of antibiotics in people and animals.

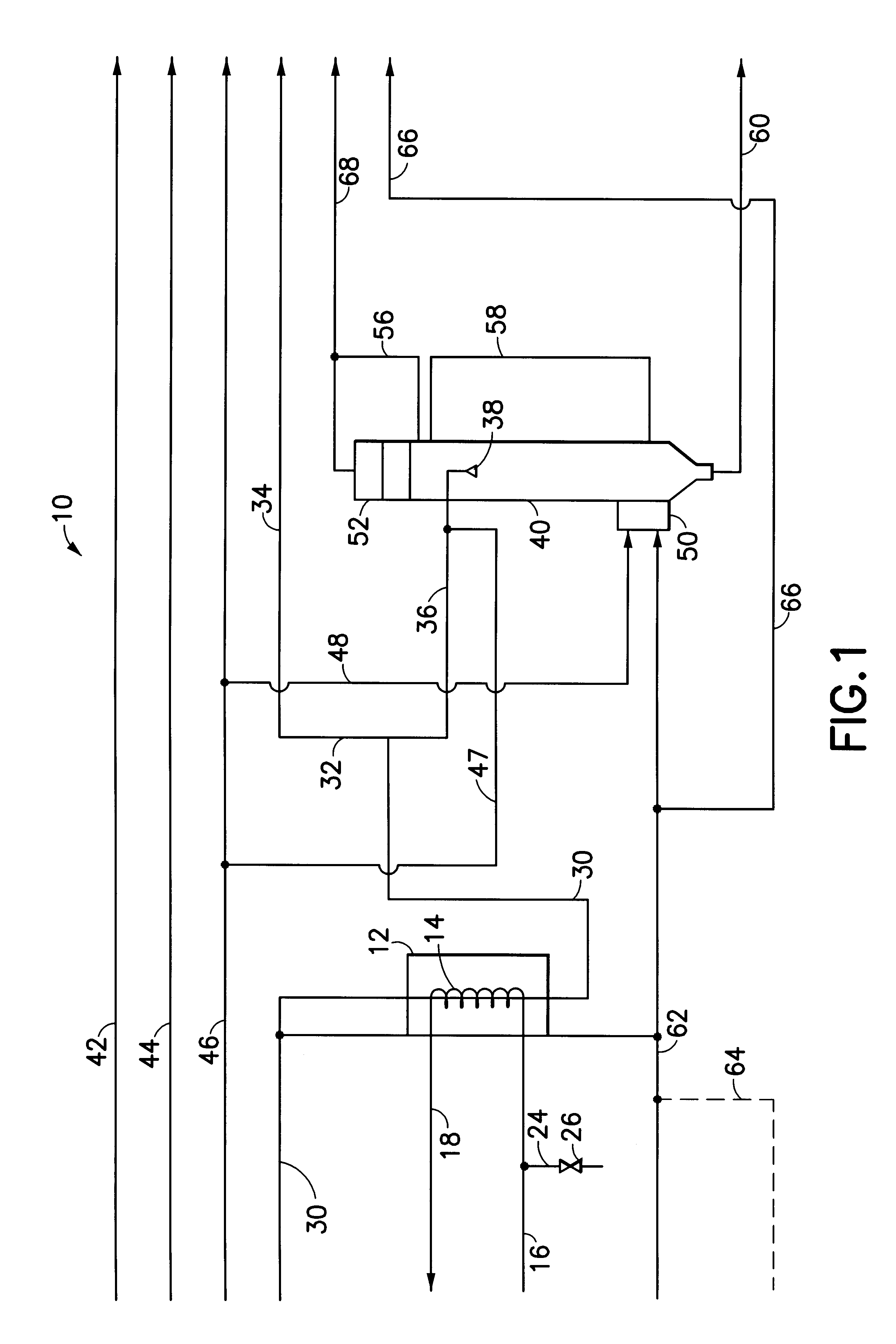

Effluent gas stream treatment system having utility for oxidation treatment of semiconductor manufacturing effluent gases

InactiveUS6322756B1Reduce sensitivityReduces water requiredCombination devicesExhaust apparatusOxygenOxidative treatment

An effluent gas stream treatment system for treatment of gaseous effluents such as waste gases from semiconductor manufacturing operations. The effluent gas stream treatment system comprises an oxidation unit to which an oxygen-containing gas such as ozone may be added, with input of energy (e.g., thermal, radio frequency, electrical, microwave, etc.), to effect oxidation of oxidizable species in the effluent, such as halocompounds (e.g., chlorofluorocarbons, perfluorocarbons), CO, NF3, nitrogen oxides, and sulfur oxides). The effluent gas stream treatment system may include a wet scrubber associated with the oxygen-containing gas source, so that the gas stream is contacted with the oxygen-containing gas during the wet scrubbing operation, to enhance removal of oxidizable species in the gas stream during treatment.

Owner:BHT SERVICES PTE LTD

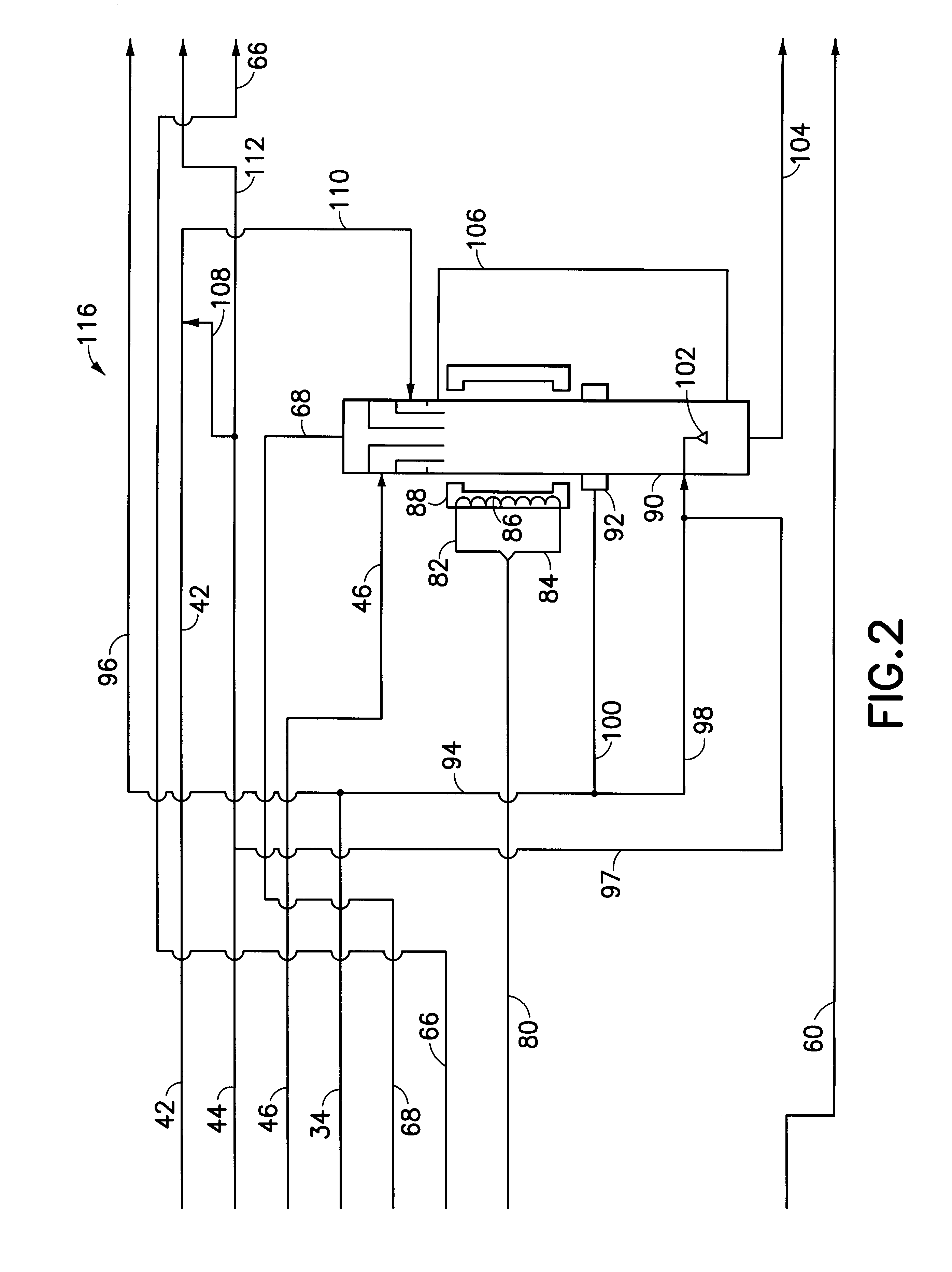

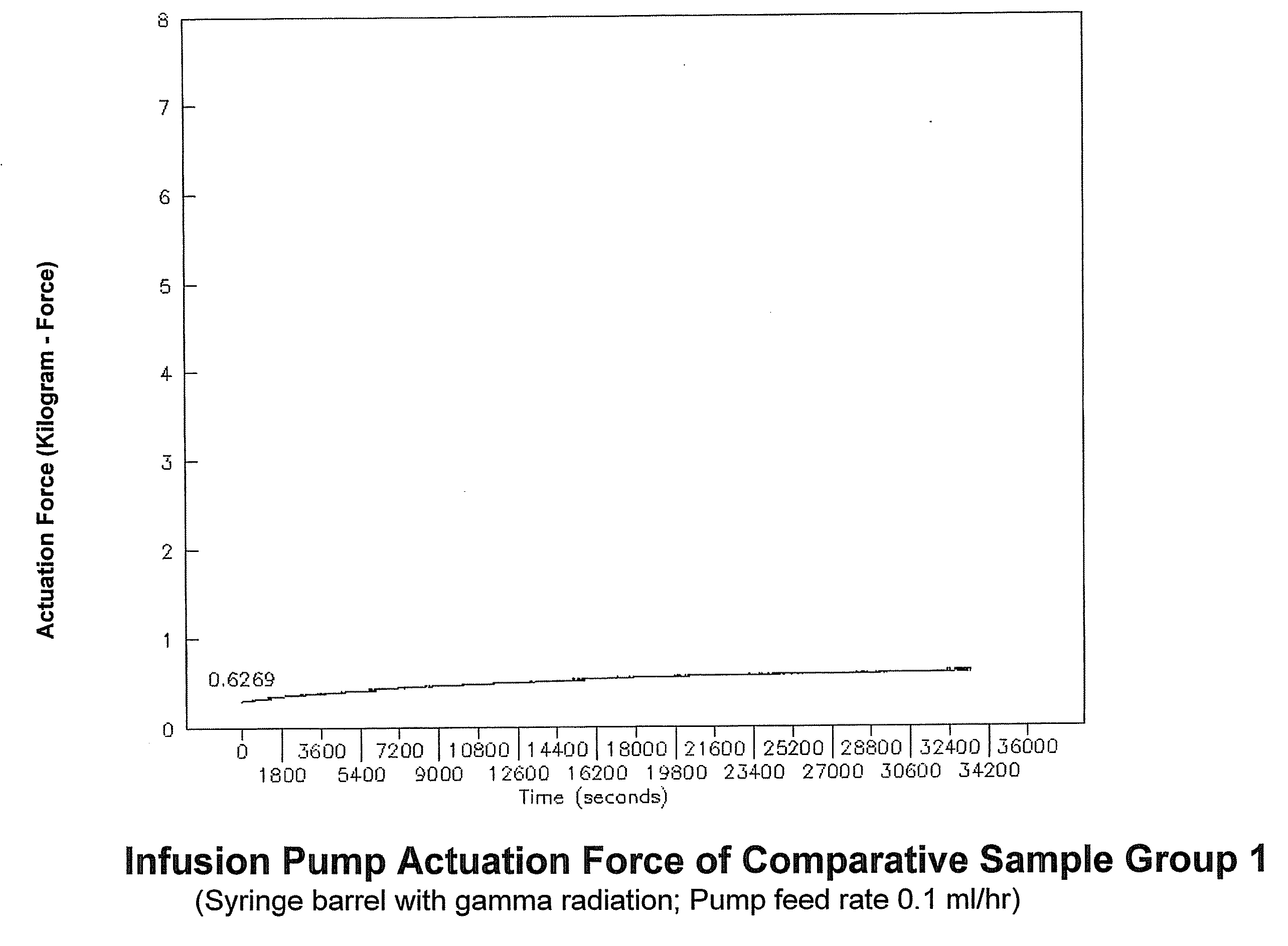

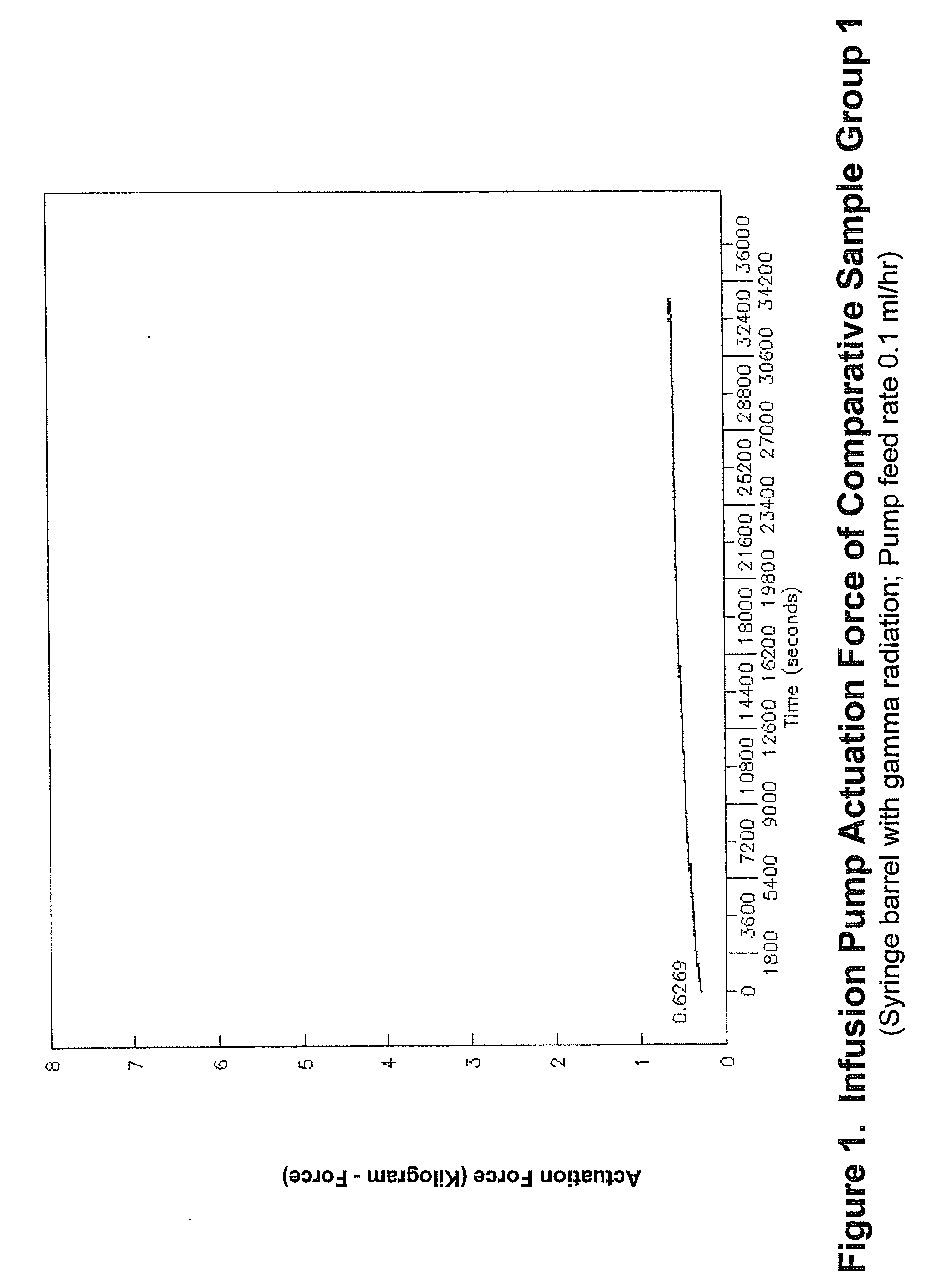

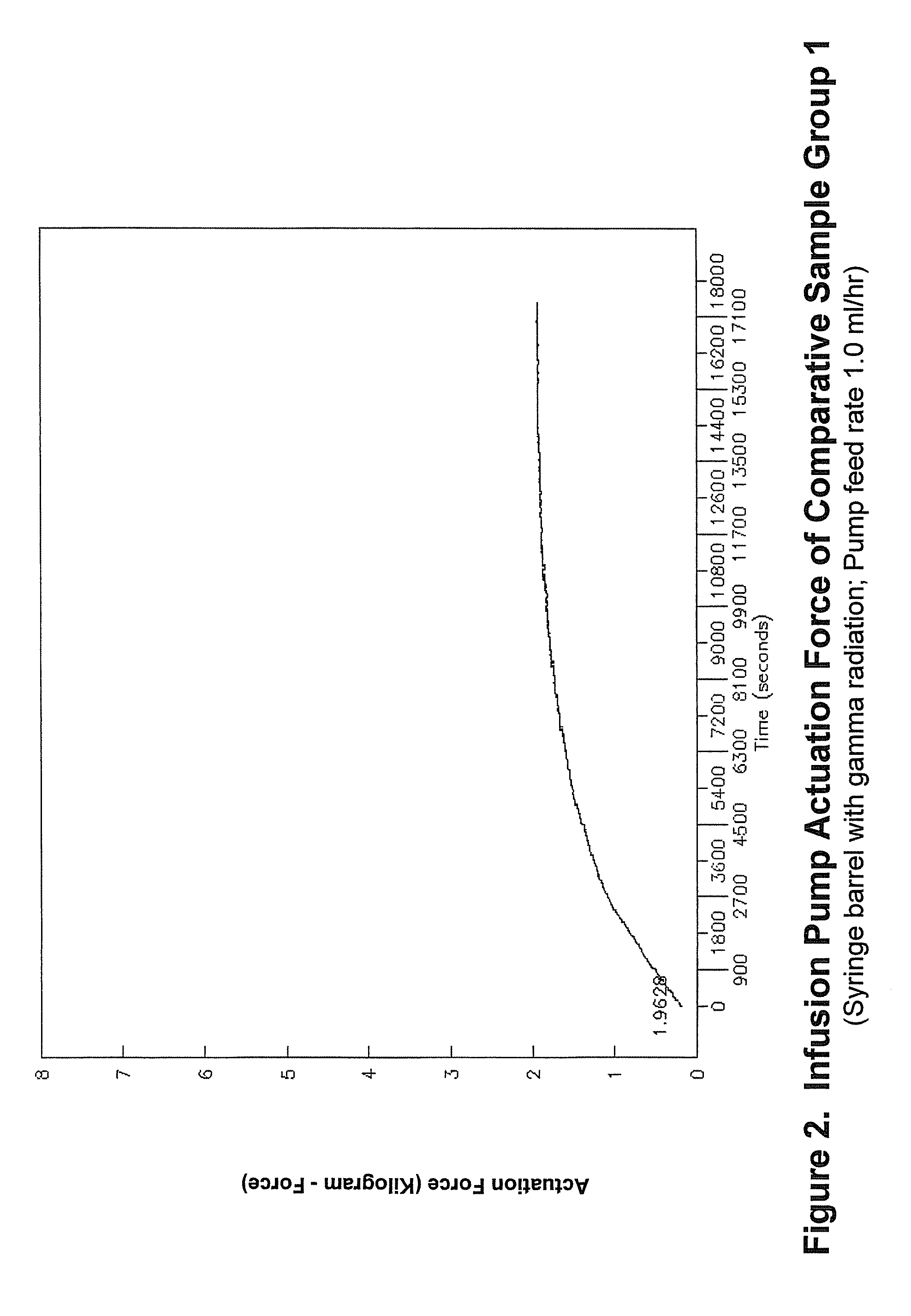

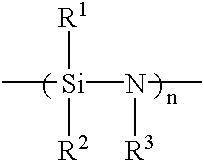

Medical Components Having Coated Surfaces Exhibiting Low Friction and Methods of Reducing Sticktion

This invention relates to components useful for medical articles, such as a syringe assembly, having sliding surface(s) coated with a composition including organopolysiloxane(s), the coating being adhered to the surface(s) of the component by crosslinking induced by oxidative treatment and irradiation with an isotope, electron beam or ultraviolet radiation or heat treatment; medical articles including the same; methods to reduce static and kinetic friction between slidable surfaces; and articles of low friction prepared thereby.

Owner:BECTON DICKINSON & CO

Mixing and dispersion of nanotubes by gas or vapor expansion

InactiveUS6908572B1Coating stabilityImprove mechanical propertiesMaterial nanotechnologyNanoinformaticsTarget surfaceSulfur

Novel methods and compositions for coating target surfaces with non-entangled multi-wall carbon nanotubes are disclosed. In one aspect, the methods and compositions of the invention comprise dispersion of non-entangled multi-wall carbon nanotubes in solvent, and application of the non-entangled multi-wall carbon nanotube / solvent mixture to a surface by spraying. In another aspect, the methods and compositions of the invention comprise dispersion of non-entangled multi-wall carbon nanotubes in solvent, and applying the nanotube / solvent mixture to a suitable matrix by spraying to form a surface coating which is substantially contiguous with the surface of the matrix. The compositions of the invention are substantially free of metal oxides and sulfur, and do not require harsh oxidative treatments.

Owner:UNIV OF KENTUCHY RES FOUND

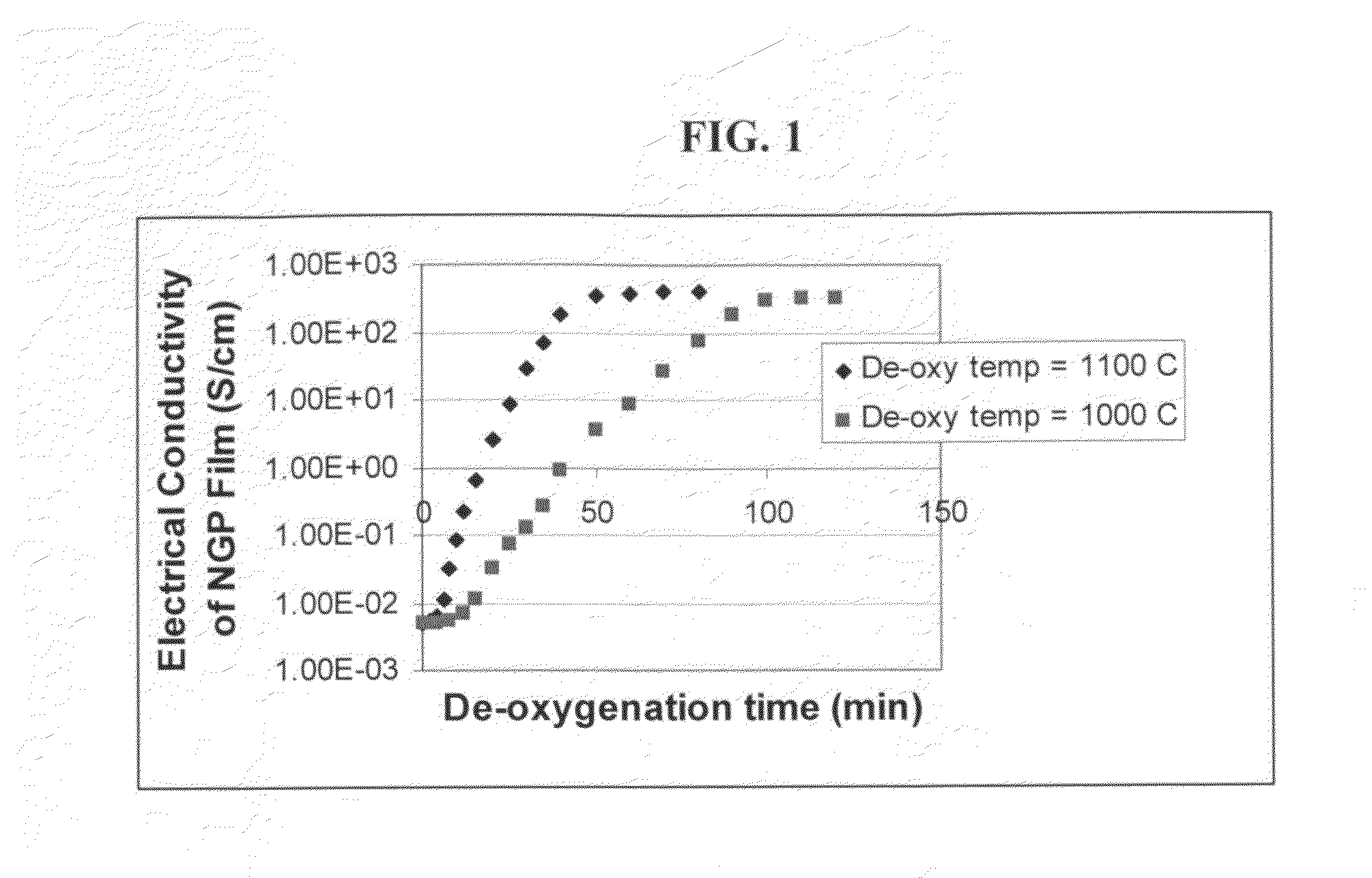

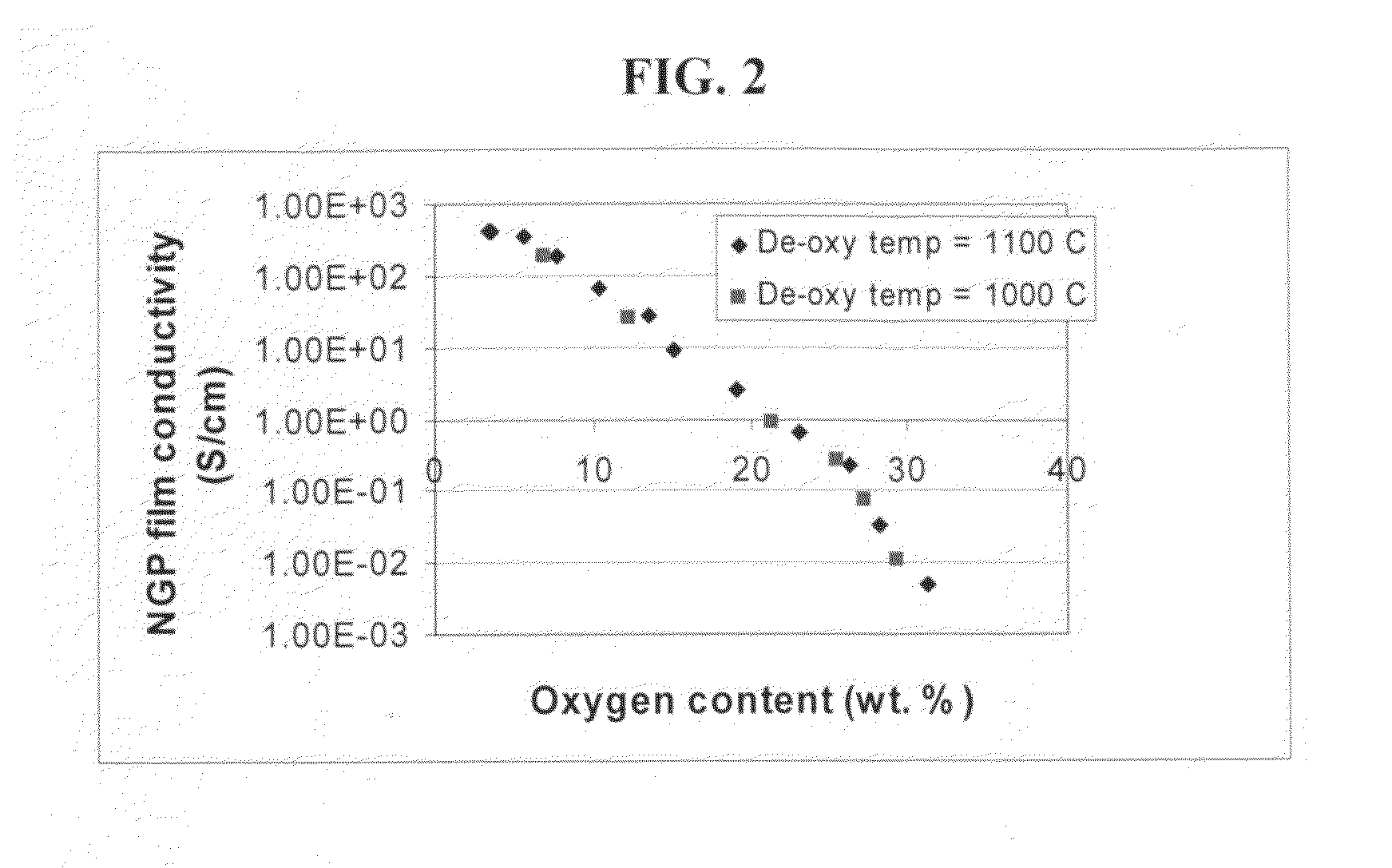

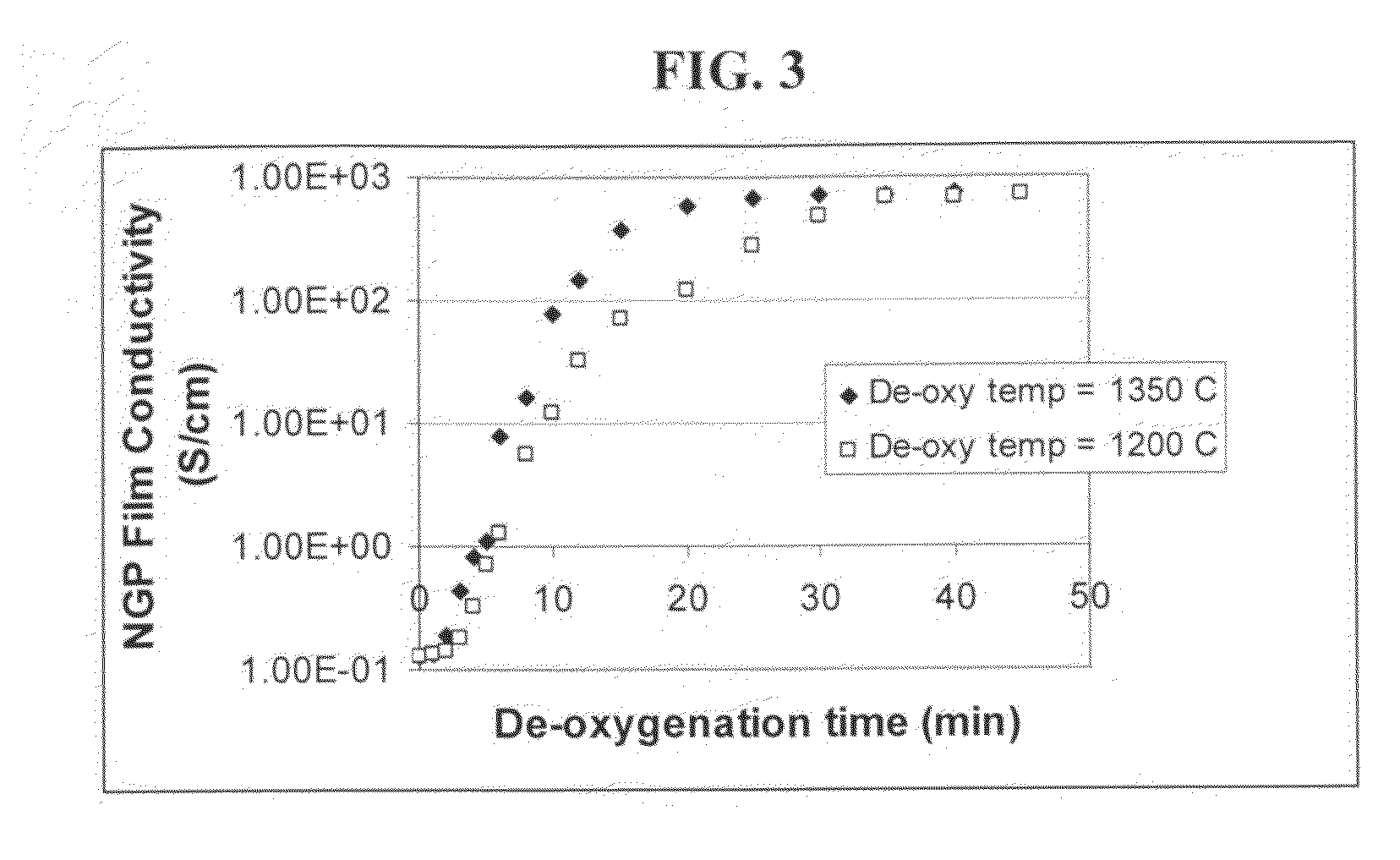

Process for producing dispersible and conductive Nano Graphene Platelets from non-oxidized graphitic materials

ActiveUS20100056819A1Impart dispersibilityImpart solubilityMaterial nanotechnologyPigmenting treatmentDisplay deviceSolar cell

The present invention provides a process for producing nano graphene platelets (NGPs) that are both dispersible and electrically conducting. The process comprises: (a) preparing a pristine NGP material from a graphitic material; and (b) subjecting the pristine NGP material to an oxidation treatment to obtain the dispersible NGP material, wherein the NGP material has an oxygen content no greater than 25% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

Regeneration of plating baths

InactiveUS6391209B1Maximize gasLower Level RequirementsDialysis systemsCell componentsParticulatesFiltration

The present invention provides a system and method for selectively removing organic and inorganic contaminants from plating baths. More particularly, the invented method relates to the use of a source of energy in combination with chemical oxidants, alone or in conjunction with a catalyst to oxidize organic contaminants in the plating bath to a level such that the electroplating bath can be recovered and reused after appropriate chemical adjustment. The oxidative treatment method may be a continuous process or a batch process that is performed in a single pass and the endpoint of the oxidative process detected by a sensor. Residual organics, and chloride ions in the bath are removed from the solution by a chemisorption or physisorption treatment. Inorganic contaminants are removed from the electroplating bath by selective ion exchange resins or electrodialysis, while particulate and suspended colloidal particles are removed by filtration before the treated plating bath is recycled.

Owner:ENTEGRIS INC

Catalyst for treatment of waste water, and method for treatment of waste water using the catalyst

InactiveCN102686521AStabilizationImprove purification effectWater contaminantsCatalyst activation/preparationIridiumWater use

Disclosed are: a catalyst which can exhibit an excellent catalytic activity and excellent durability for a long period in the wet oxidation treatment of waste water; a wet oxidation treatment method for waste water using the catalyst; and a novel method for treating waste water containing a nitrogenated compound, in which a catalyst to be used has a lower catalytic cost, the waste water containing the nitrogenated compound can be treated at high purification performance, and the high purification performance can be maintained. The catalyst for use in the treatment of waste water comprises an oxide of at least one element selected from the group consisting of iron, titanium, silicon, aluminum, zirconium and cerium as a component (A) and at least one element selected from the group consisting of silver, gold, platinum, palladium, rhodium, ruthenium and iridium as a component (B), wherein at least 70 mass% of the component (B) is present in a region positioned within 1000 [mu]m from the outer surface of the component (A) (i.e., the oxide), the component (B) has an average particle diameter of 0.5 to 20 nm, and the solid acid content in the component (A) (i.e., the oxide) is 0.20 mmol / g or more. The waste water treatment method uses a catalyst (a pre-catalyst) which is placed on an upstream side of the direction of the flow of the waste water and can convert the nitrogenated compound contained in the waste water into ammoniacal nitrogen in the presence of an oxidizing agent at a temperature of not lower than 100 DEG C and lower than 370 DEG C under a pressure at which the waste water can remain in a liquid state and a downstream-side catalyst (a post-catalyst) which is placed downstream of the direction of the flow of the waste water and can treat the waste water containing ammoniacal nitrogen.

Owner:NIPPON SHOKUBAI CO LTD

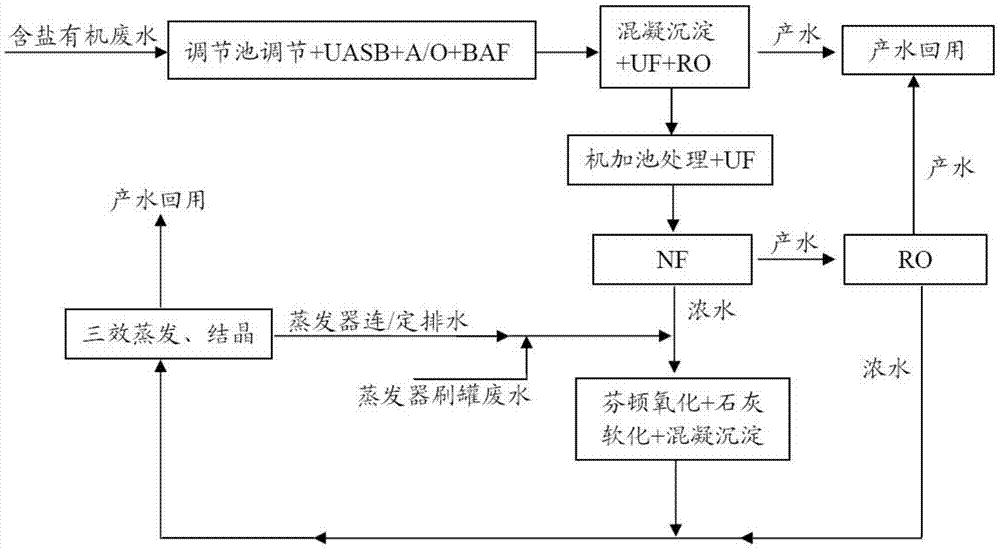

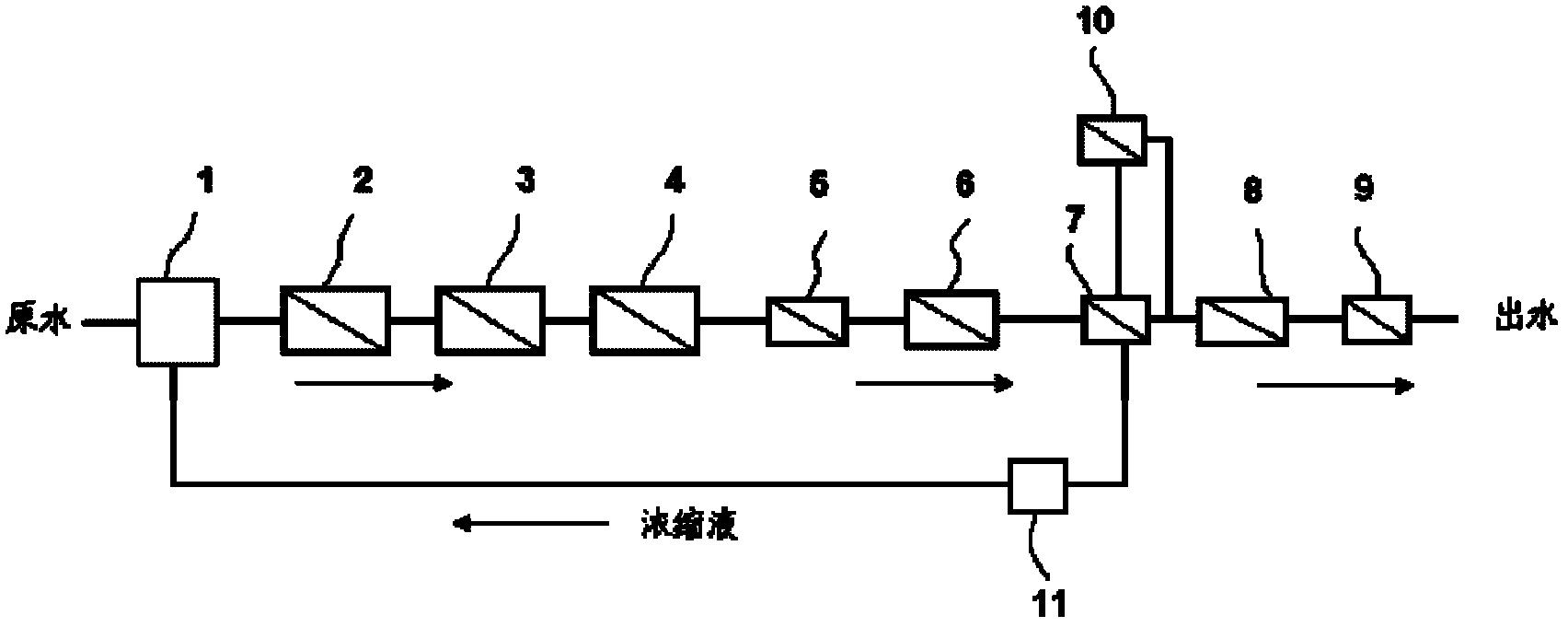

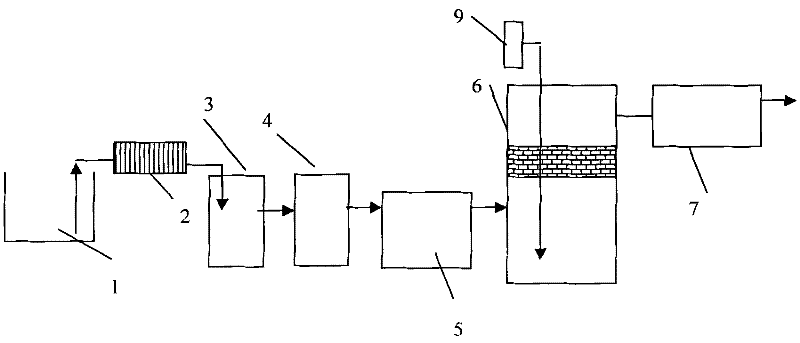

Zero-discharge treatment method of salt-containing organic wastewater

InactiveCN105439395AEasy to handleEfficient reuseTreatment using aerobic processesTreatment involving filtrationEvaporationOrganic matter

The invention provides a zero-discharge treatment method of salt-containing organic wastewater. The method comprises the following steps that biochemical treatment and filtering treatment are performed on wastewater; then, membrane concentration is performed; pure-water-producing high-organic-matter-content membrane concentration concentrated water and optional low-organic-matter-content membrane concentration concentrated water are obtained; the high-organic-matter-content membrane concentration concentrated water is used for high-grade oxidation treatment; high-grade oxidation produced water is used for regulation treatment to obtain high-grade oxidation outlet water; the obtained high-grade oxidation outlet water is subjected to evaporation treatment; or the obtained high-grade oxidation outlet water and the low-organic-matter-content membrane concentration concentrated water are mixed under the condition that the low-organic-matter-content membrane concentration concentrated water exists in the step, and then, the evaporation treatment is carried out; external discharge concentration liquid of an evaporator and / or high-salt-content high-organic-matter-content wastewater discharged during the tank brushing of the evaporator are conveyed back into a high-grade oxidation treatment unit; after the liquid is mixed with the high-organic-matter-content membrane concentration concentrated water, the high-grade oxidation treatment is carried out. The wastewater treatment method is stable and reliable; the long-period and stable operation of an evaporation system can be ensured; the zero discharge of the industrial wastewater is realized.

Owner:DATANG INT CHEM TECH RESINST

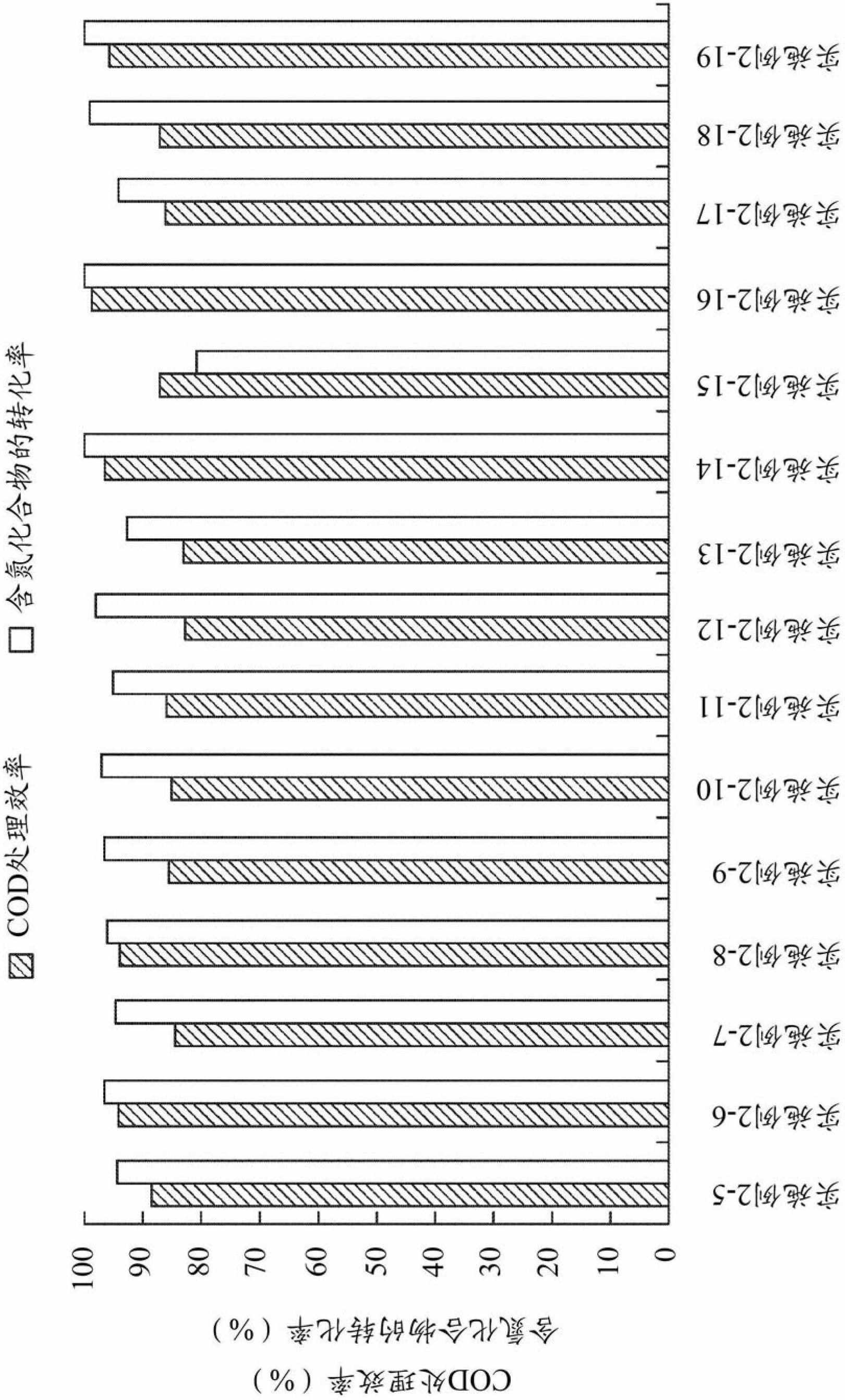

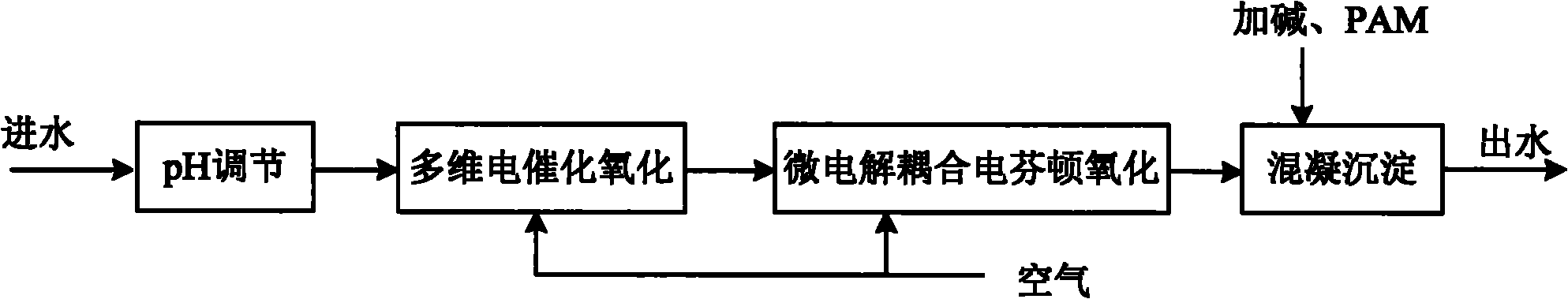

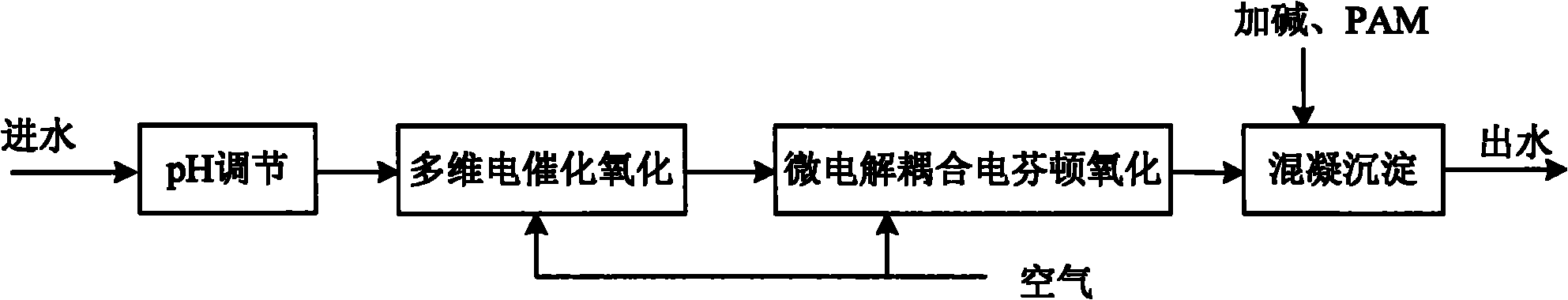

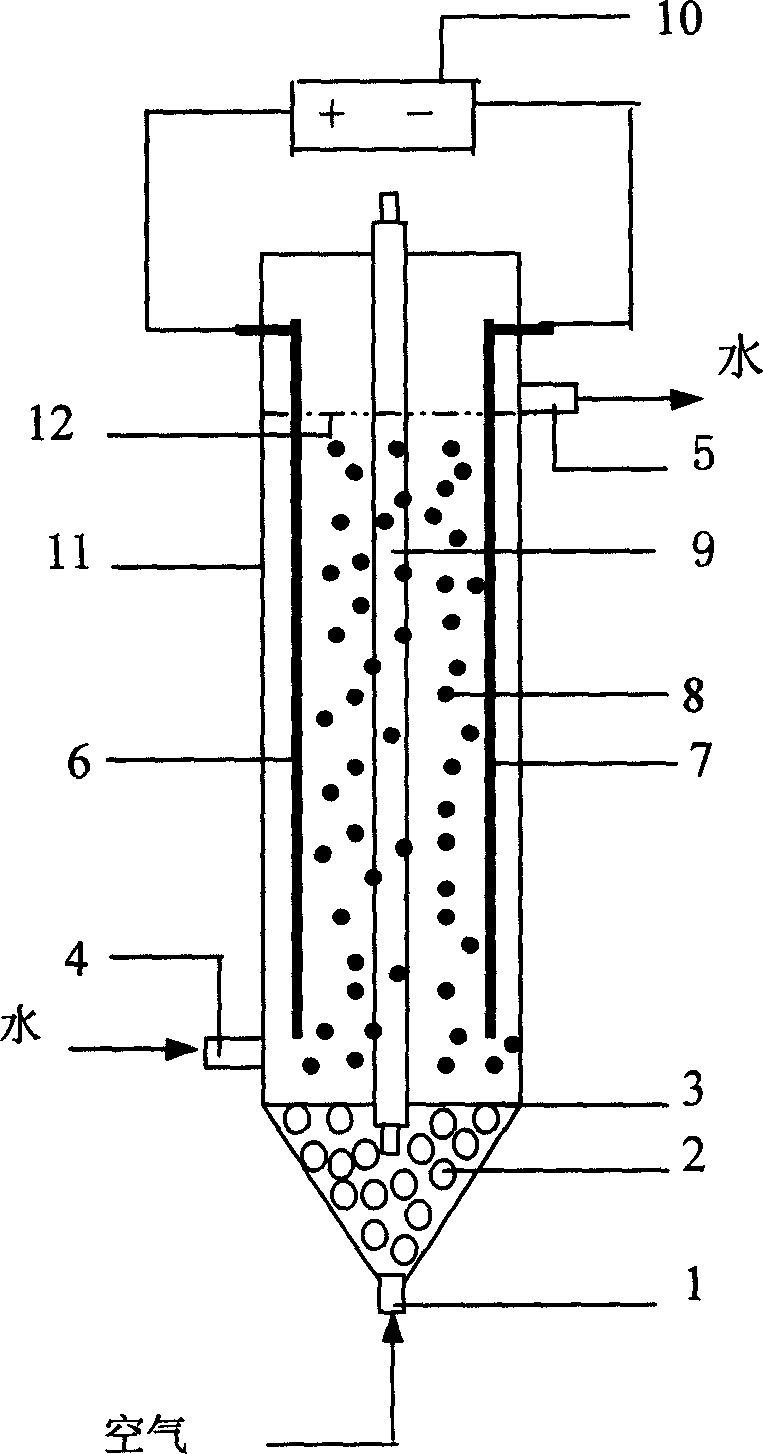

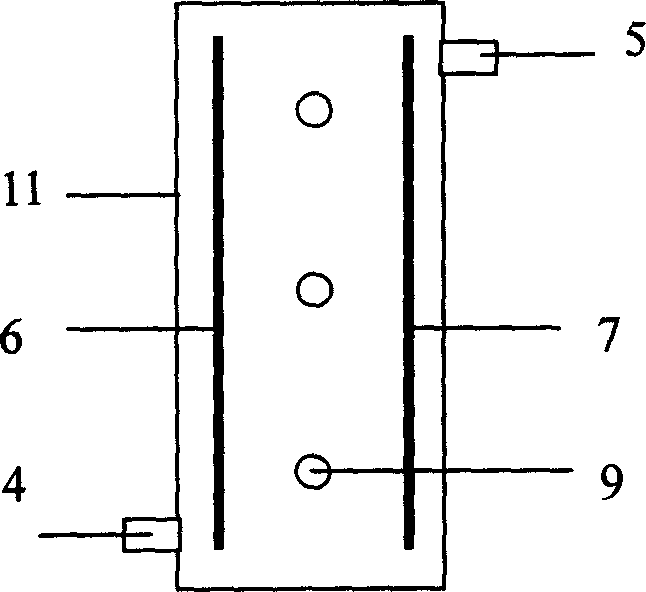

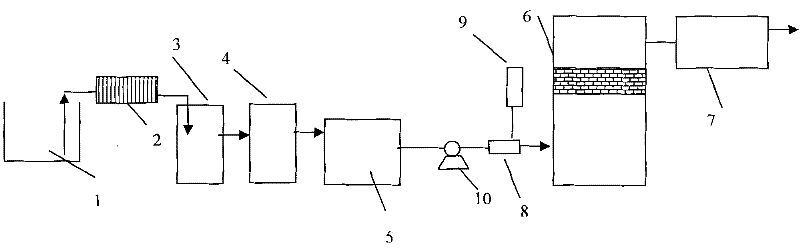

Technology for processing high-concentration organic wastewater in composite electrochemical method

ActiveCN101955280AStrong oxidation abilityIncrease oxidation potentialWater contaminantsMultistage water/sewage treatmentChemical treatmentHigh concentration

The invention relates to a technology for processing high-concentration organic wastewater in a composite electrochemical method, which comprises the main four steps of: pH adjustment, multidimensional electrocatalytic oxidization processing, micro coupling electric fenton reaction oxidation processing and coagulating sedimentation processing. The invention has the technical advantage that the technology has good breaking, chain scission, degradation effects to benzene ring organics, heterocyclic organics, polycyclic organics, macromolecule organics and sustaining organics, which have the most difficulty to degradation. Besides, the technology has no obvious selection to various kinds of high-concentration organic wastewater, has broad-spectrum processing effect, and is an effective measurement for pre-processing to high-concentration organic wastewater having difficulty to degradation. The invention is characterized in that the technology uses second-grade electrochemical processing equipment to realize third-grade advanced oxidation combination processing, effectively utilizes H2O2 and Fe2+ generated by the second-grade electrochemical processing equipment, and makes fenton oxidated and coupled in a micro reactor. During the technological processes, the oxidation capacity is strong to weak, and has reasonable distribution. The pH valve of wastewater does not need repeatedly adjusting. The invention has the obvious characteristics of low electric consumption, little medicine consumption, high processing efficiency, and good controllability.

Owner:南京赛佳环保实业有限公司

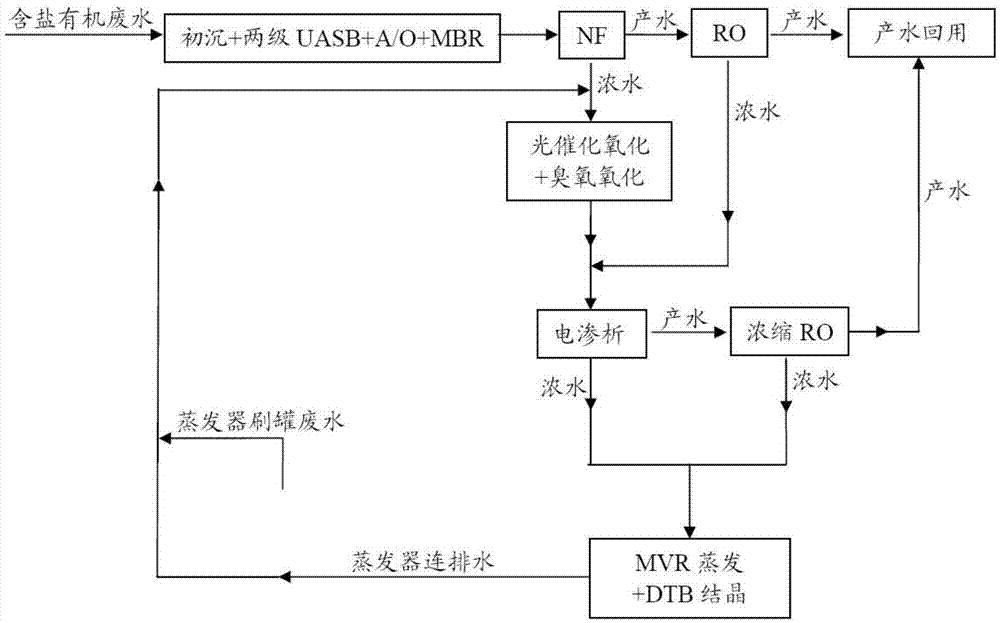

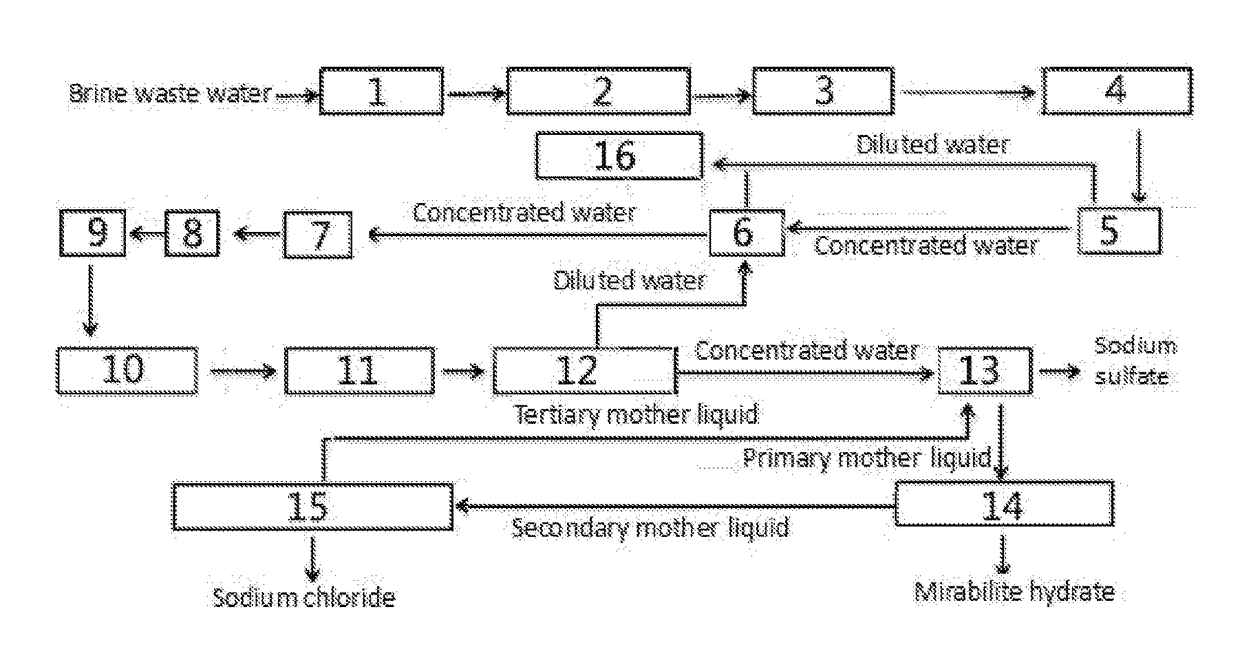

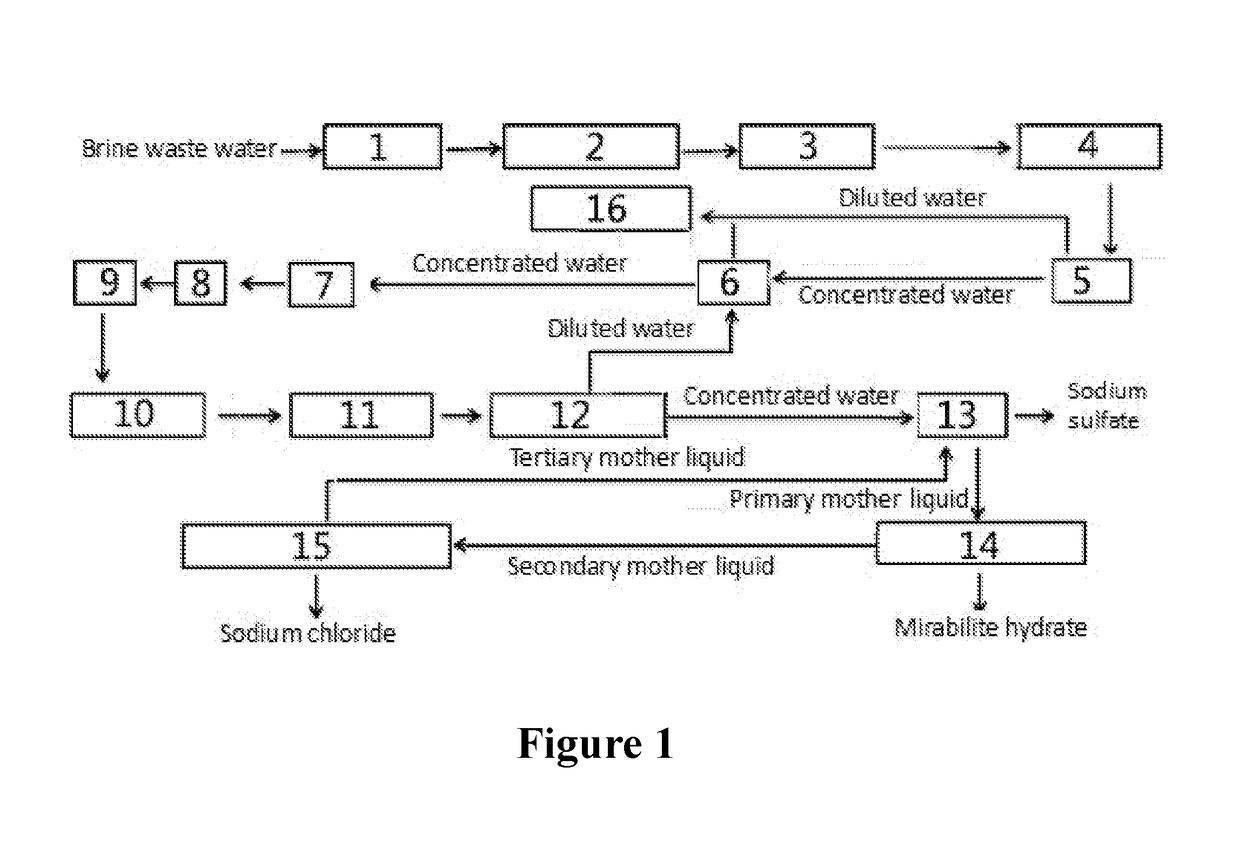

Method and System for Treating Brine Waste Water

ActiveUS20180148350A1Reduce pollutionExtended service lifeScale removal and water softeningSustainable biological treatmentSaline waterWastewater

The present invention relates to a method for zero-release treatment of brine waste water, comprising: (1) pretreatment; (2) reverse osmosis treatment; (3) advanced oxidation treatment; (4) biochemical treatment; (5) electrodialysis concentration; (6) circulating crystallization. Compared with the prior art, the method for zero-release treatment of brine waste water provided in the present invention realizes zero release or near zero release of waste water, improves salt recovery efficiency, can recover high-quality sodium sulfate, mirabilite and sodium chloride, and turns crystalline salts into a resource; the membrane treatment unit can operates stably in the process for a long operation period at a low cost, and the entire process has high economic efficiency.

Owner:CHINA PETROCHEMICAL CORP +1

Process method for treating hardly-biodegradable organic wastewater

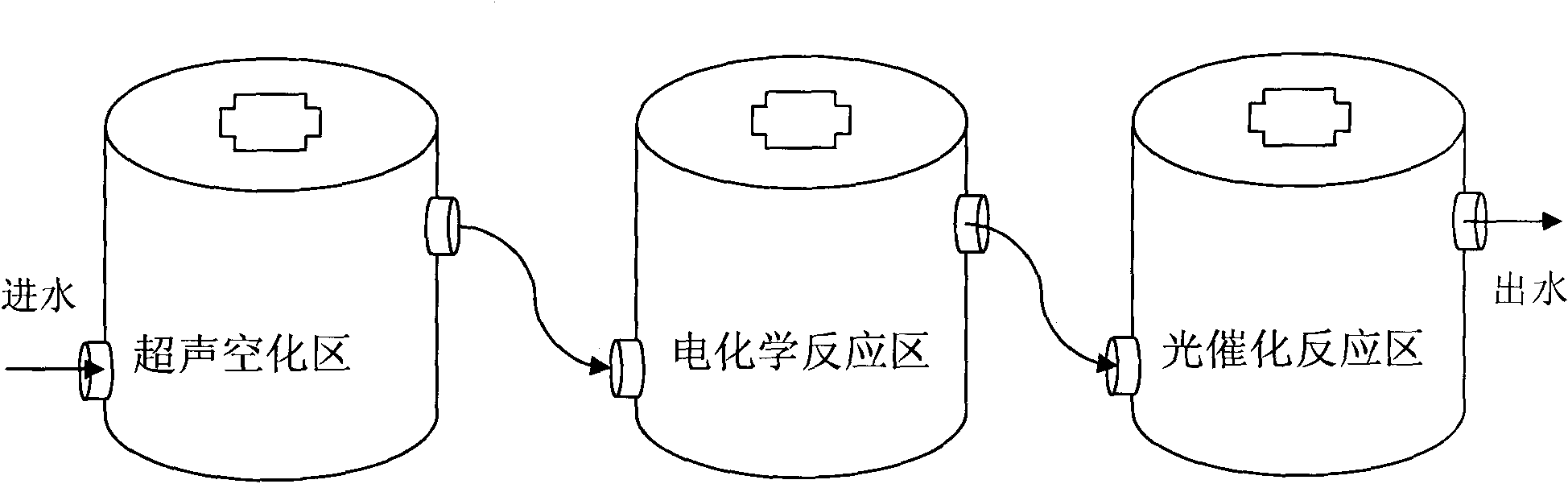

ActiveCN101786756AReduce dosageReduce generationWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsElectrochemical responseUltrasonic cavitation

The invention relates to a process method for treating hardly-biodegradable organic wastewater, and the method comprises the following steps: mainly utilizing the combination of ultraviolet light, electrochemistry, ultrasonic waves and oxidation-reduction chemical reaction for treating the hardly-biodegradable organic wastewater, and treating the wastewater by three reaction units of an ultrasonic cavitation zone, an electrochemical reaction zone and an ultraviolet light catalytic reaction zone, thereby realizing the high-efficient multi-stage deep wastewater oxidation reaction which combines the ultrasonic wastewater treatment method, the ultrasonic light and the collaborative Fenton reagent oxidation wastewater treatment, as well as the electrochemistry and the collaborative Fenton reagent oxidation wastewater treatment, effectively treating a variety of types of hardly-biodegradable organic wastewater and leading the COD removal rate of the wastewater after the treatment to be more than 90%.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Light emitting device

InactiveUS6781148B2Electroluminescent light sourcesSolid-state devicesUltravioletMoisture absorption

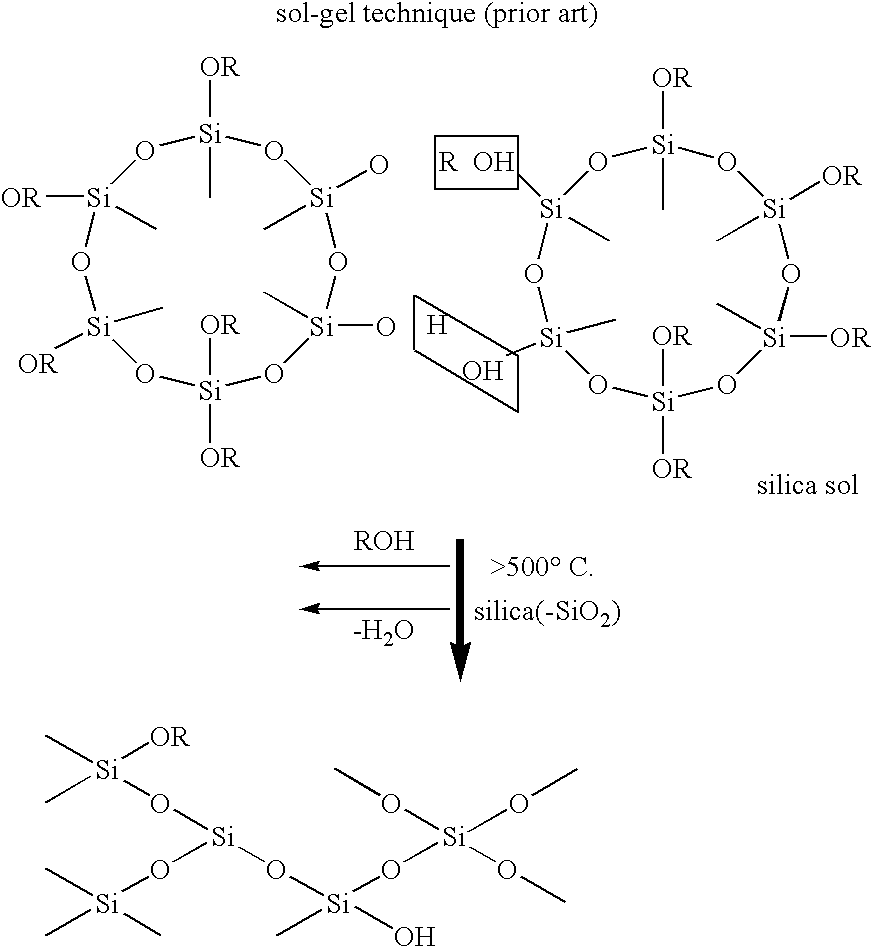

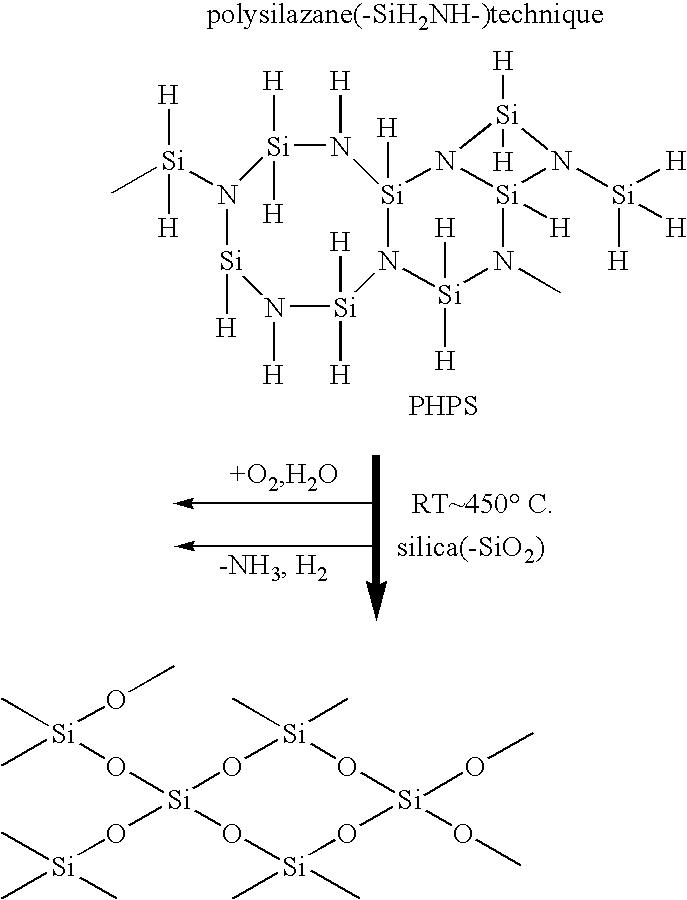

The invention aims to provide a light emitting device comprising a base material or protective member which has improved light transmittance, heat resistance, passivation (gas barrier, oligomer release prevention and minimized outgassing), anti-water or moisture-absorption, stability against chemical degradation, dimensional and shape stability, anti-surface-reflection, electrical insulation, UV degradation resistance, and weather resistance, and is highly productive due to possible film formation under atmospheric pressure, and hence, a light emitting device featuring high reliability, ease of manufacture and low cost. The object is attained by a light emitting device comprising a base material (1) having flexibility, light transparency and heat resistance, a lower electrode (4) having light transmittance, a light emitting layer (4), and an upper electrode (4) formed on the base material, the device further comprising a silica film and / or a siliceous film (3) which is formed on the substrate side as viewed from the light emitting layer (4) or on opposite sides of the substrate by applying polysilazane and subjecting it to oxidative treatment.

Owner:FUTABA CORPORATION

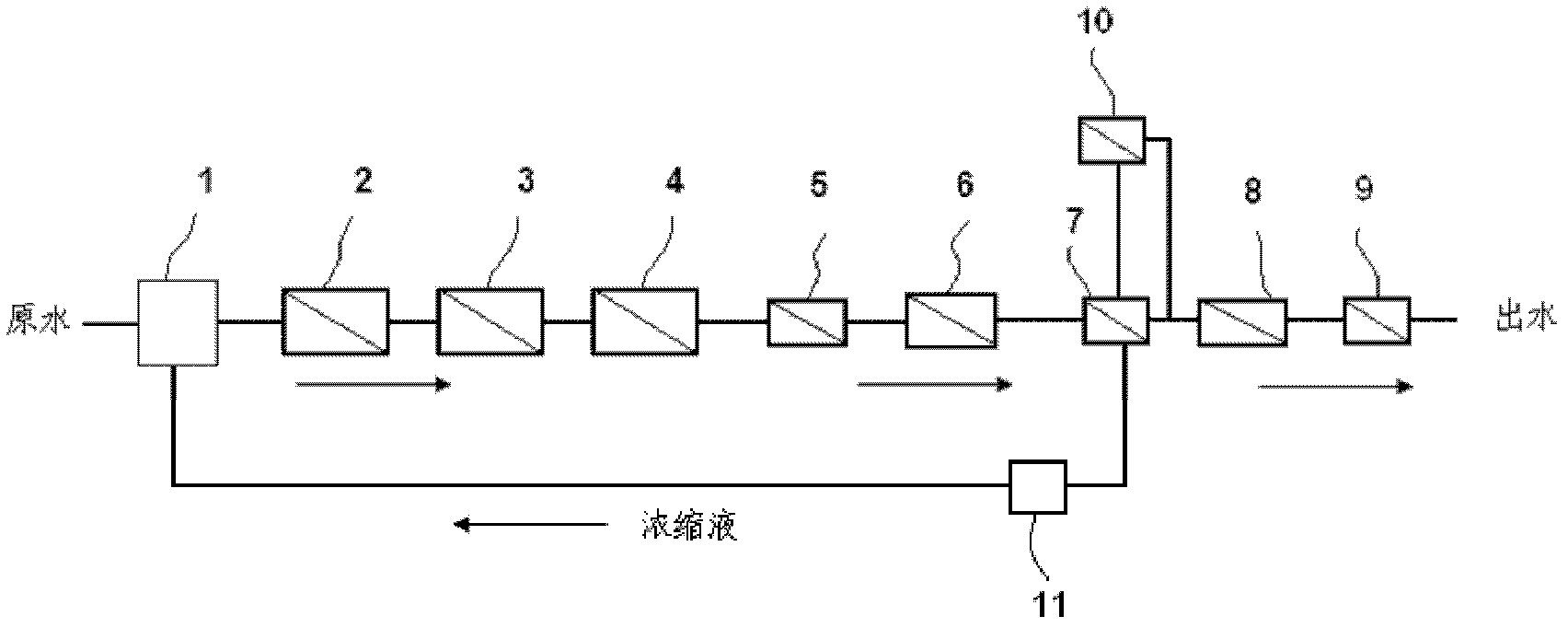

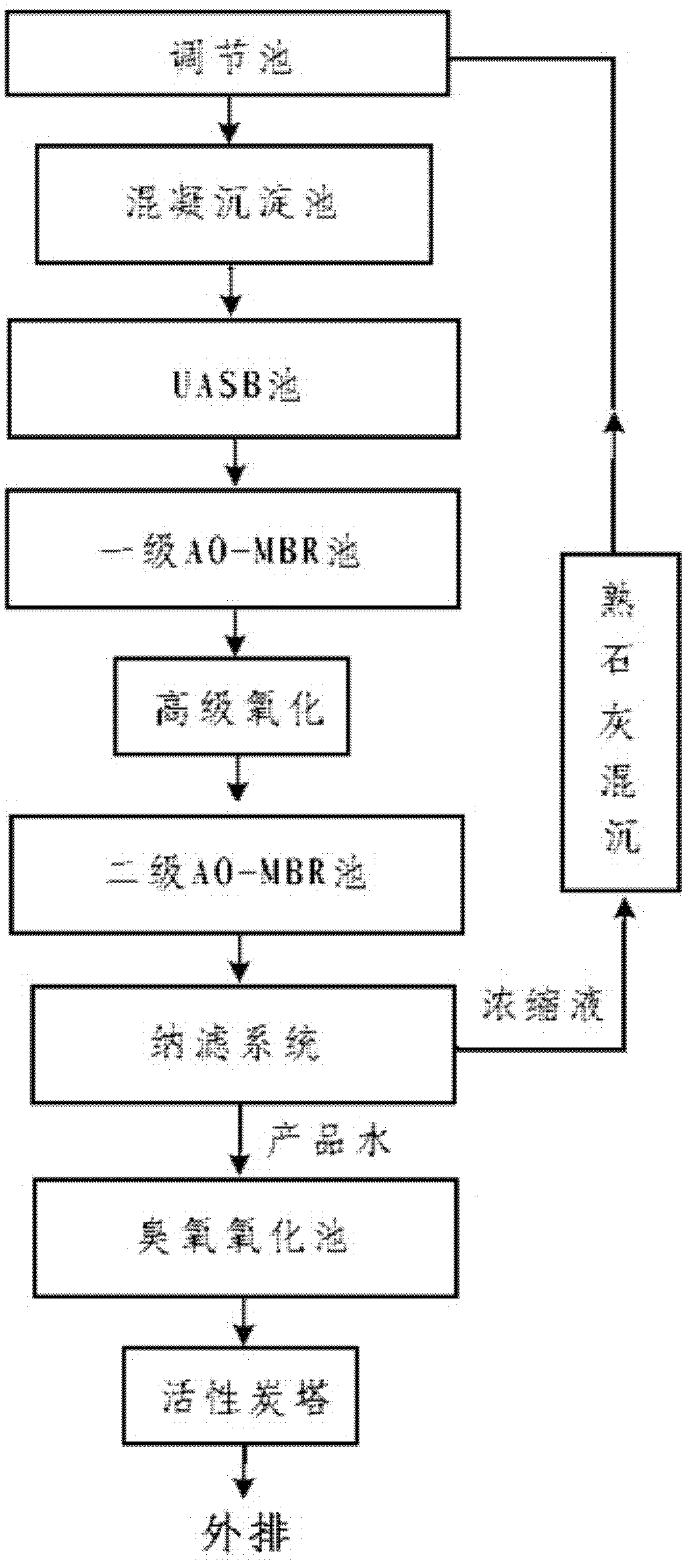

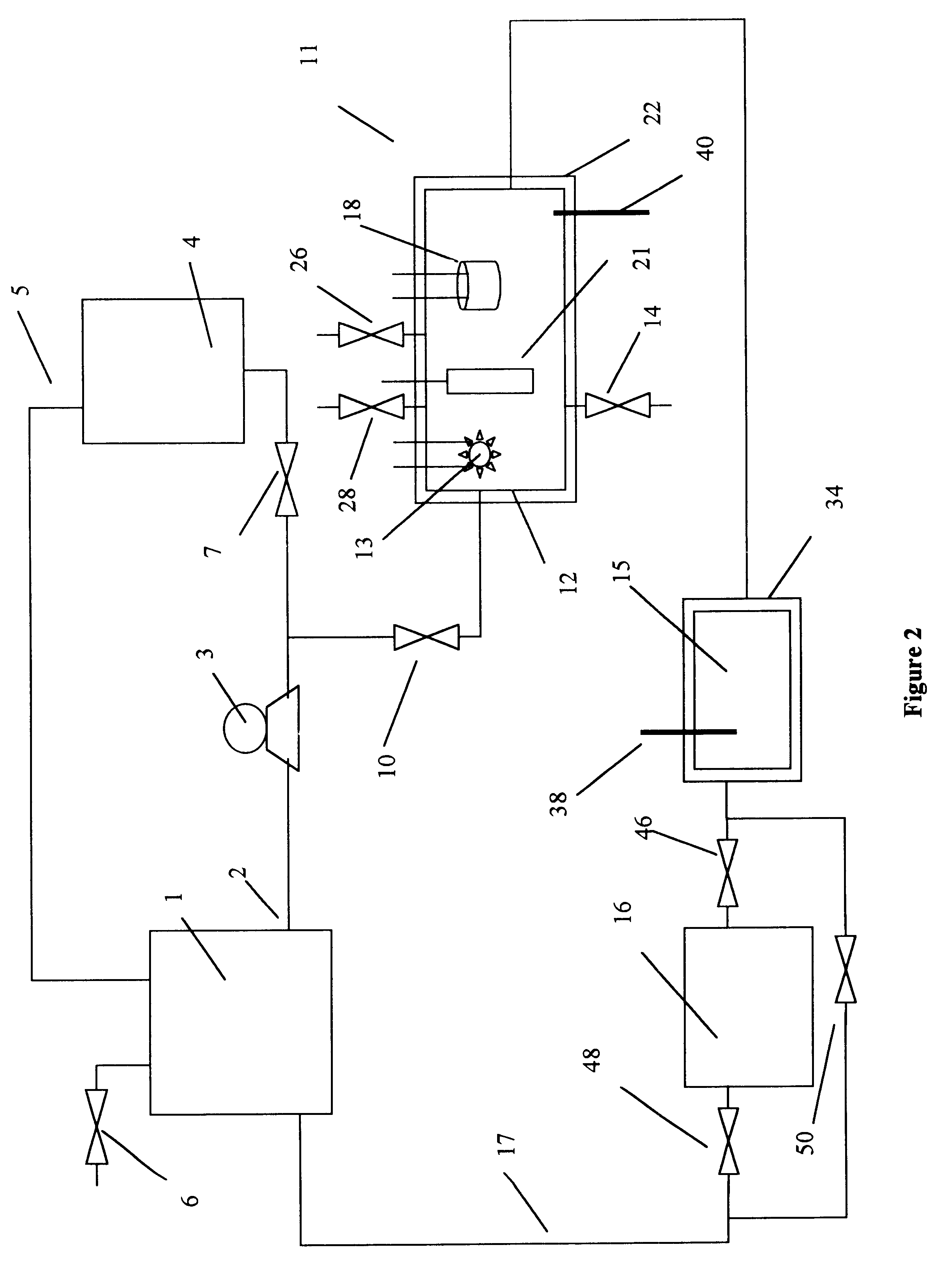

Advanced treatment system and method for high-concentration percolate in comprehensive garbage disposal plant

InactiveCN102503046AEasy to handleRequirements to meet emission concentration limitsMultistage water/sewage treatmentActivated carbon filtrationReverse osmosis

The invention discloses an advanced treatment system and method for high-concentration percolate in a comprehensive garbage disposal plant, belonging to the field of industrial waste water treatment. The system is formed by connecting a regulating tank, a coagulative precipitation tank, an upflow anaerobic sludge bed reaction tank, a primary anoxic and aerobic membrane bioreactor, advanced oxidation treatment equipment, a secondary anoxic and aerobic membrane bioreactor, nanofiltration membrane treatment equipment, an ozone contact tank and an active carbon filtering tower in sequence. According to the system, garbage percolate can be treated comprehensively, different pollutants in garbage percolate are treated in a classified way by combining physical, chemical and biological treatment,advanced treatment of garbage percolate is realized, and classified treatment for removing pollutants such as organic matters, heavy metals, ammonia, nitrogen and the like is performed, so that treated effluent strictly reaches the requirement of water pollution discharge degree limit in the Household Garbage Landfill Pollution Control Standard, the system runs stably for a long time, and treatment cost is lower than that of a secondary disc pipe reverse osmosis membrane process.

Owner:BEIJING YIPU INT WATER AFFAIRS

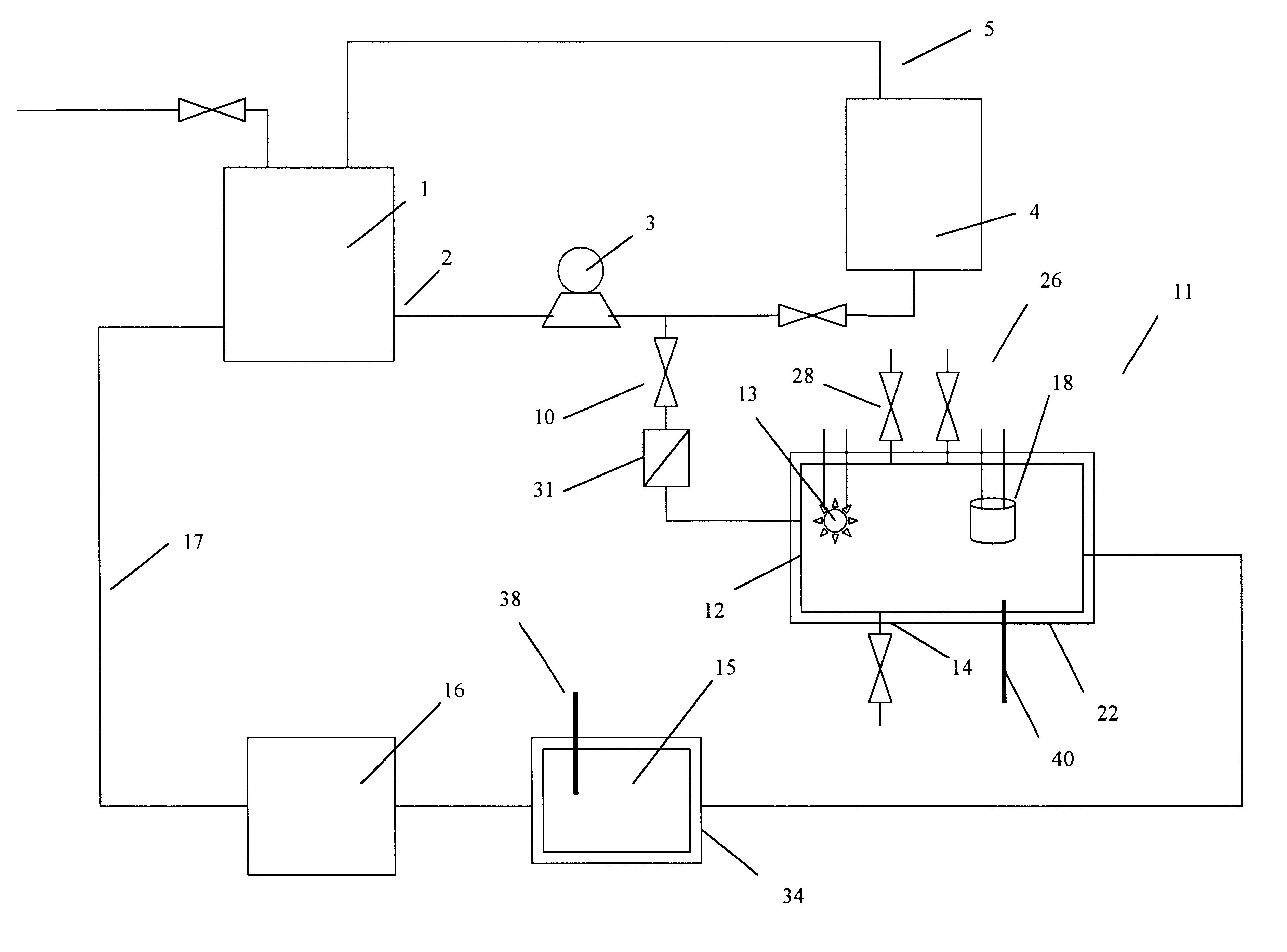

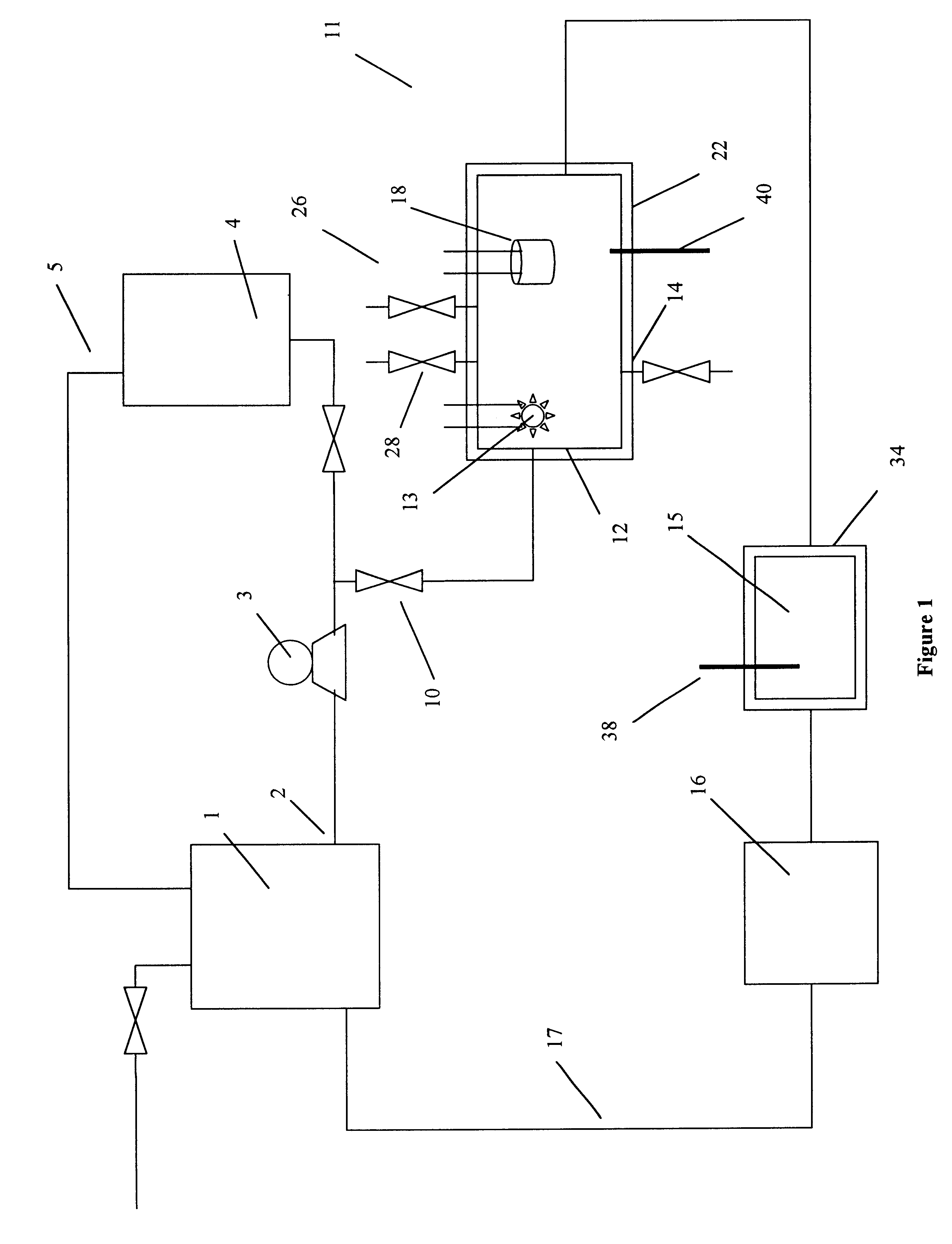

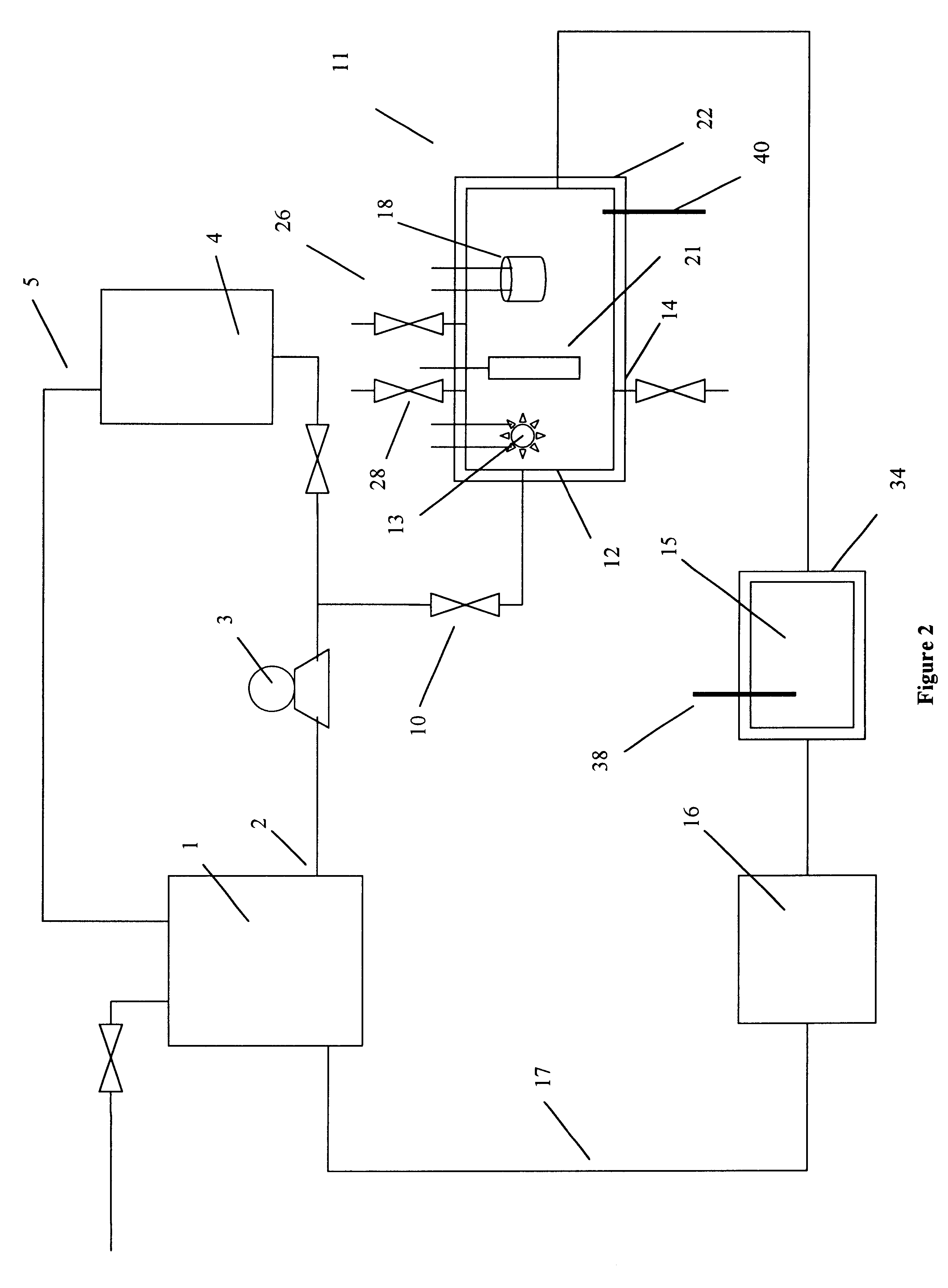

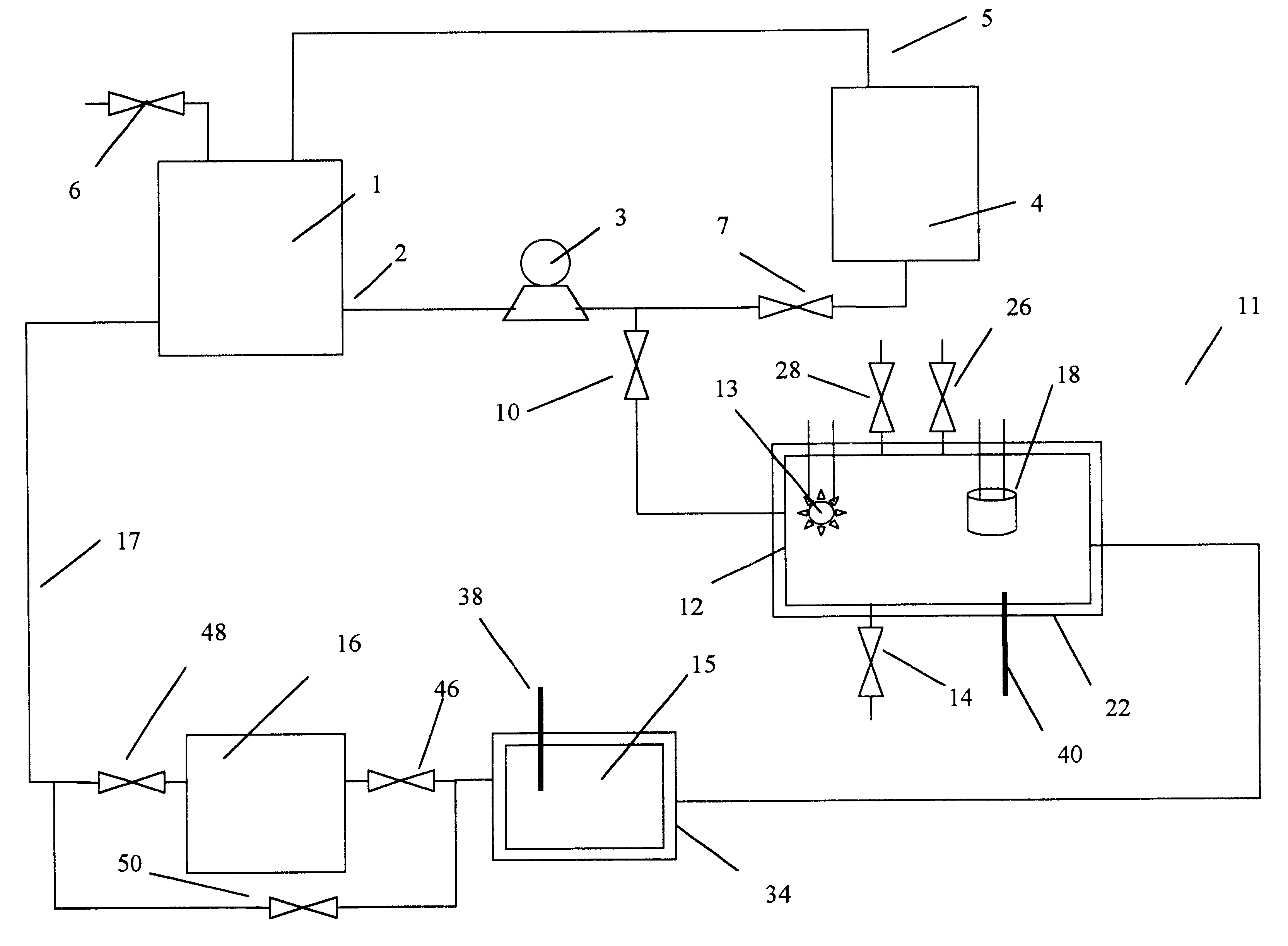

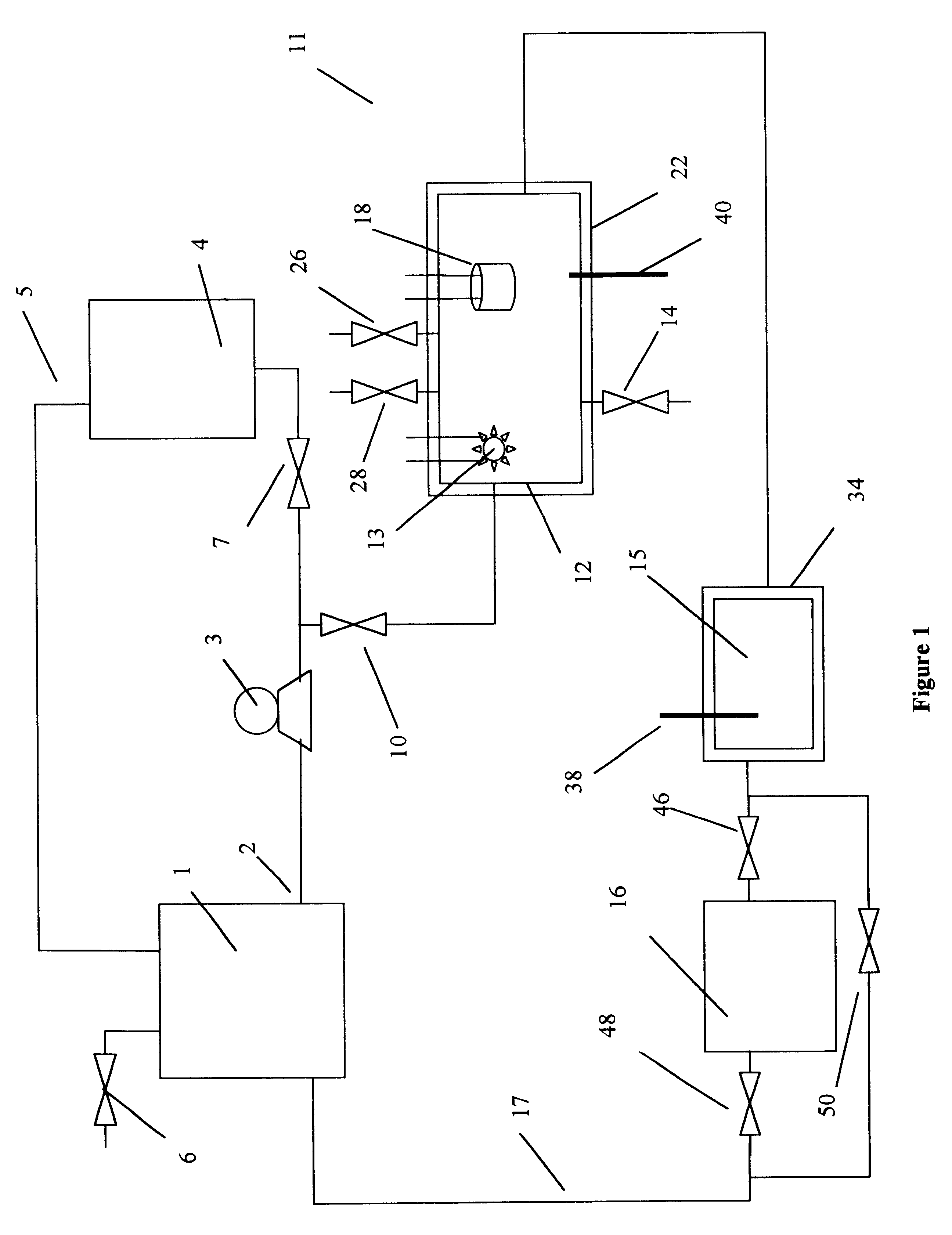

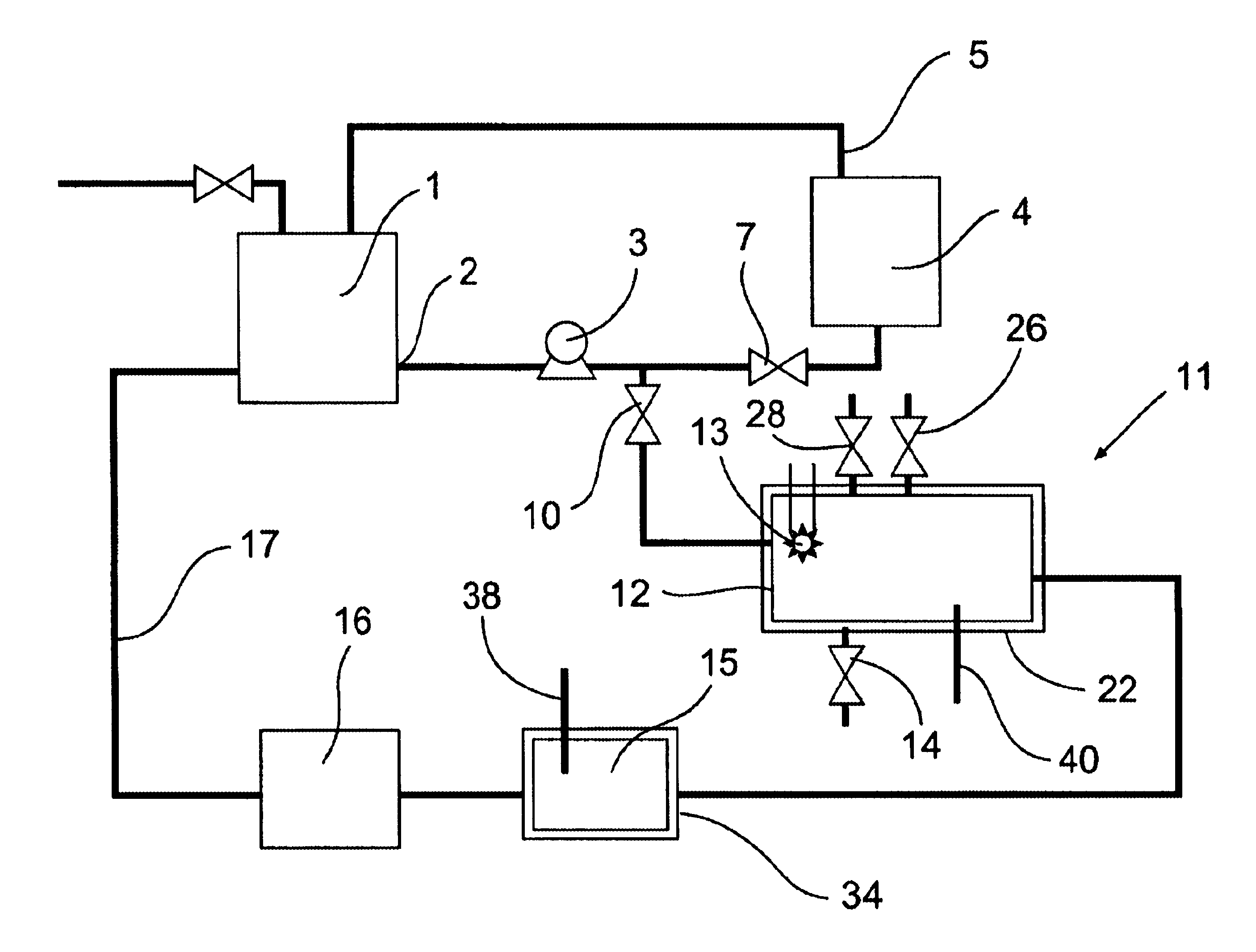

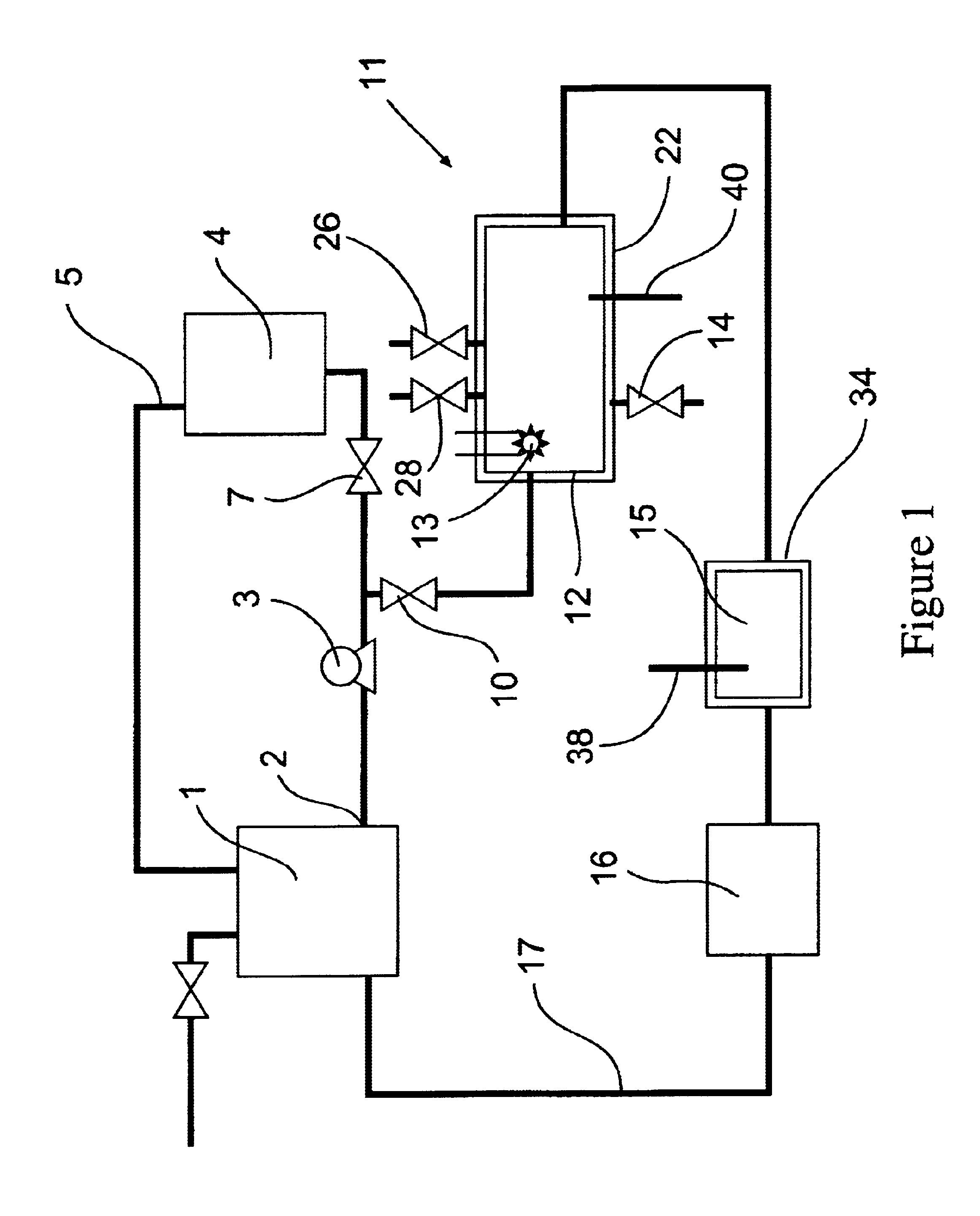

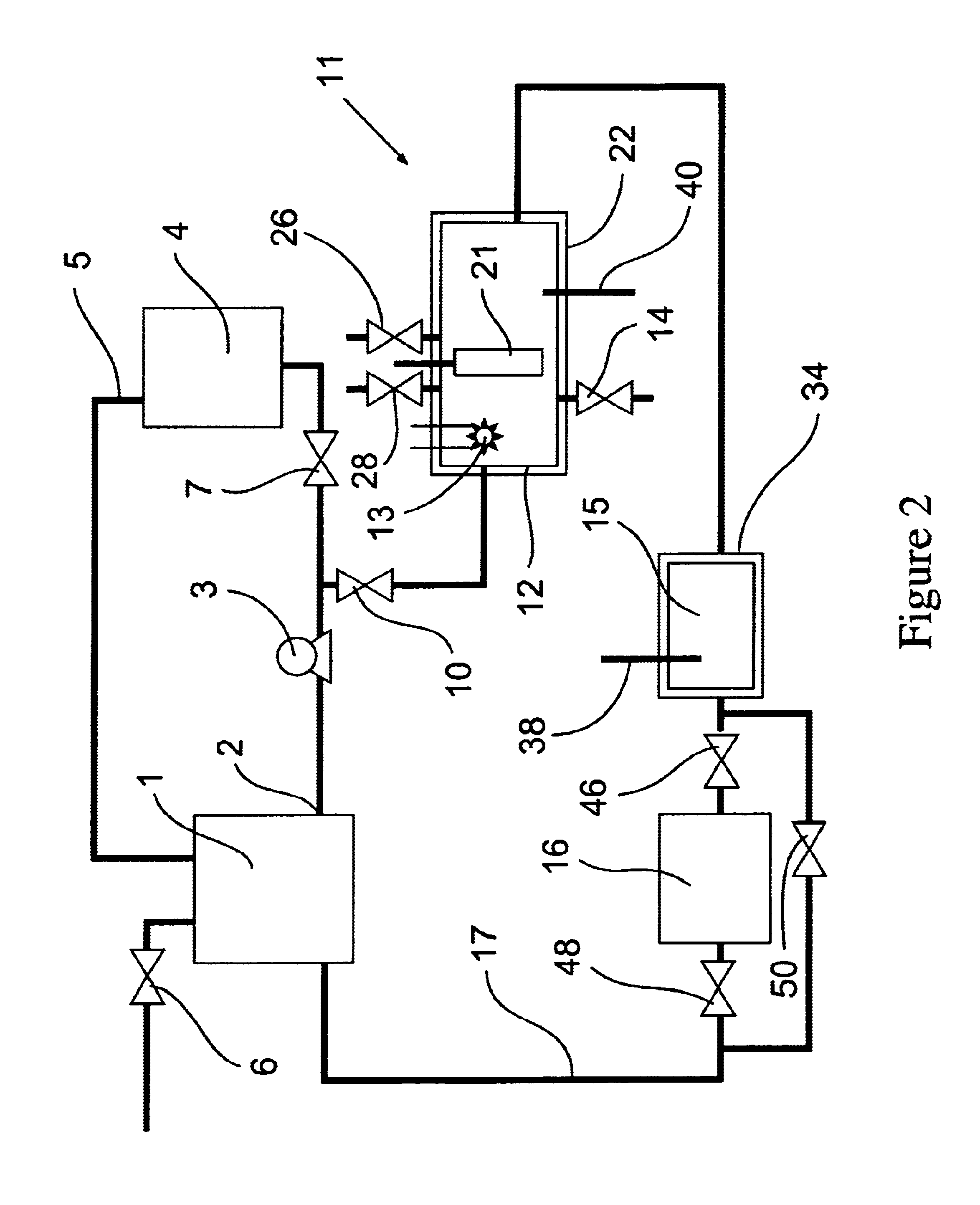

Regeneration of plating baths and system therefore

InactiveUS6596148B1Maximize gasLower Level RequirementsDialysis systemsCell componentsParticulatesFiltration

The present invention provides a system and method for selectively removing one or more organic and also preferably one or more inorganic contaminants from plating baths. More particularly, the invented method relates to the use of a source of energy in combination with chemical oxidants, alone or in conjunction with a catalyst to oxidize organic contaminants in the plating bath to a level such that the electroplating bath can be recovered and reused after appropriate chemical adjustment. The oxidative treatment method may be a continuous process or a batch process that is performed in a single pass and the endpoint of the oxidative process detected by a sensor. Residual organics, if desired, and chloride ions in the bath are removed from the solution by a chemisorption or physisorption treatment. Inorganic contaminants are removed from the electroplating bath by selective ion exchange resins or electrodialysis, while particulate and suspended colloidal particles are removed by filtration before the treated plating bath is recycled.

Owner:ENTEGRIS INC

Treatment method of high-concentration wastewater

InactiveCN103663860AReduce wasteReduce dosageMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention relates to a treatment method of high-concentration wastewater. The treatment method comprises the following steps: (1) pretreatment; (2) flocculent sedimentation treatment; (3) biochemical treatment; (4) membrane biological reaction treatment; (5) adsorption treatment; (6) oxidation treatment; (7) filtration treatment; (8) membrane treatment; (9) disinfection treatment; and (10) evaporative crystallization treatment. The method disclosed by the invention has the advantages that the wastewater with the COD (Chemical Oxygen Demand) concentration up to 96000mg / L can be treated and the COD removing rate is up to 99.98% to ensure that the treated wastewater meets the standards of drinking water and an unexpected technical effect is brought; compared with a dozen or dozens of hours in the prior art, the aerobic reaction time and the anaerobic reaction time are greatly shortened and the treatment efficiency is obviously increased; and the concentrated solution finally generated in the method only accounts for below 2% of water inflow, which is greatly reduced compared with the prior art, so that the waste of water is obviously reduced and the treatment cost is saved.

Owner:曹寅亮

Aluminum strip continuous anodic oxidation automatic production line

InactiveCN101676439AContinuous production saves time and laborAnodisationWinding machineProduction line

Owner:浙江聚力文化发展股份有限公司

Treatment method of waste water containing organic phosphorus

ActiveCN101704606AHigh removal rateEasy to operateWater contaminantsMultistage water/sewage treatmentElectrochemical responseElectrolysis

The invention relates to a treatment method of waste water containing organic phosphorus, comprising the following steps: leading process waste water containing organic phosphorus to pass through a sand filtration tank for removing suspended matter and then adjusting the pH value thereof to 3-4; leading the process waste water to pass through a high-efficient catalytic oxidation apparatus, adding hydrogen peroxide for conducting oxidative degradation of the process waste water; then introducing the process waste water to a catalytic micro-electrolysis device, adding scrap iron and activated carbon and stirring, conducting electrochemical reaction, blasting air into the lower part of the catalytic micro-electrolysis device, and removing hard-degradable organic matter in the process waste water; and introducing the effluent of the catalytic micro-electrolysis device into an oxidation kettle, adding hydrogen peroxide for conducting multistage oxidation treatment, later adding lime, adjusting the pH value of the process waste water to 8-9, then adding flocculant for conducting precipitation, and forming ironic phosphate and calcium phosphate precipitate, thus removing phosphorus in the waste water. Compared with the prior art, the treatment method transforms the organic phosphorus into inorganic phosphorus for removal and has high removal rate of total phosphorus and low running cost, and the formed phosphate can be recycled and reused.

Owner:CAC NANTONG CHEM

Catalyst for wastewater treatment and method for wastewater treatment using said catalyst

ActiveCN101045204AHigh mechanical strengthIncreased durabilitySludge treatmentMetal/metal-oxides/metal-hydroxide catalystsIridiumCerium

The present invention relates to a catalyst for wastewater treatment and a method for wet oxidation treatment of wastewater using the catalyst, in particular, the catalyst of the present invention can suitably be used in wet oxidation treatment of wastewater, under high temperature and high pressure conditions. The present invention provides a catalyst for wastewater treatment containing a catalytic active constituent containing at least one kind of an element selected from the group consisting of manganese, cobalt, nickel, cerium, tungsten, copper, silver, gold, platinum, palladium, rhodium, ruthenium and iridium, or a compound thereof, and a carrier constituent containing at least one kind of an element selected from the group consisting of iron, titanium, silicon, aluminum and zirconium, or a compound thereof, characterized in that solid acid amount of the carrier constituent is equal to or more than 0.20 mmol / g.

Owner:NIPPON SHOKUBAI CO LTD

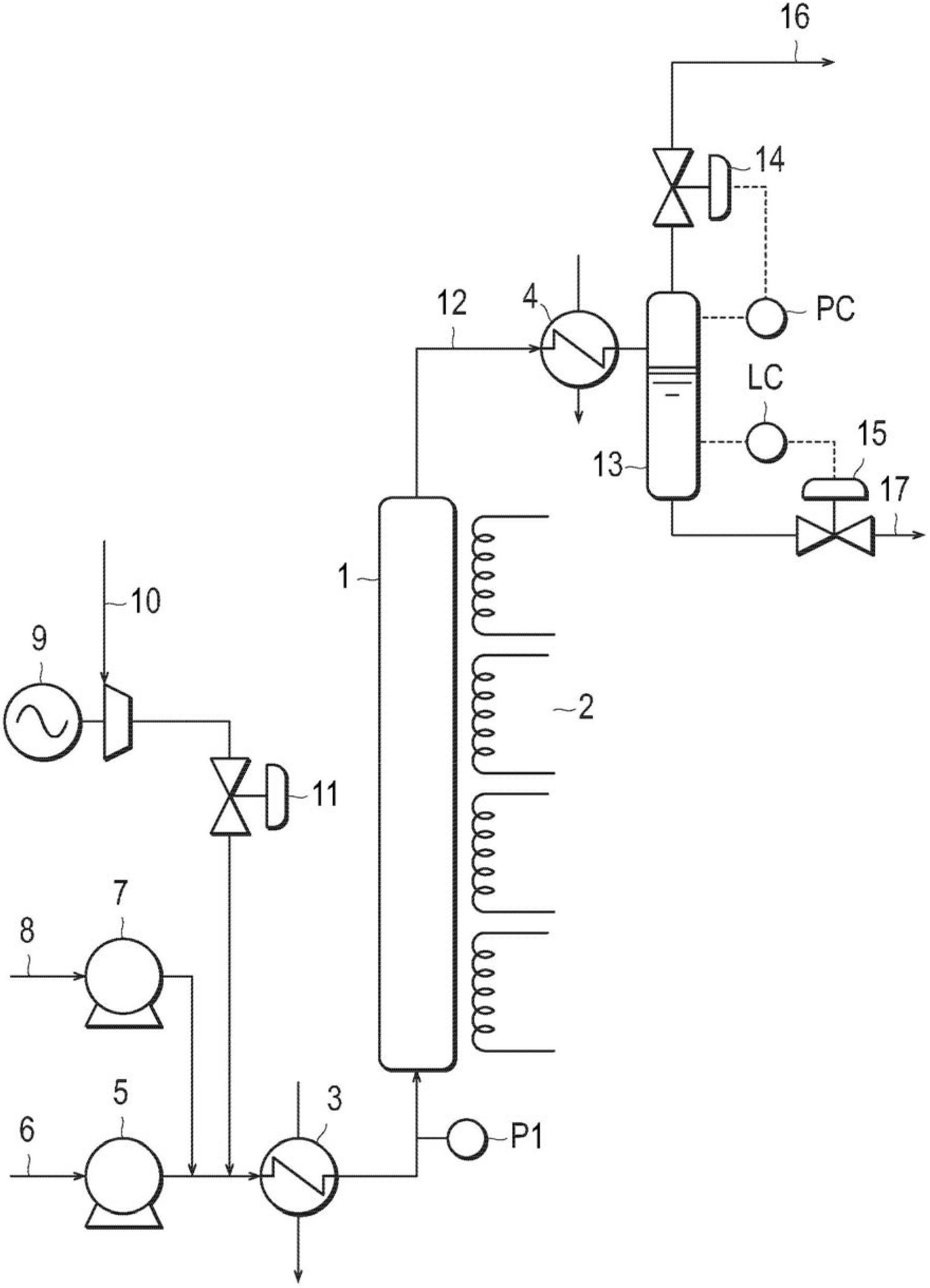

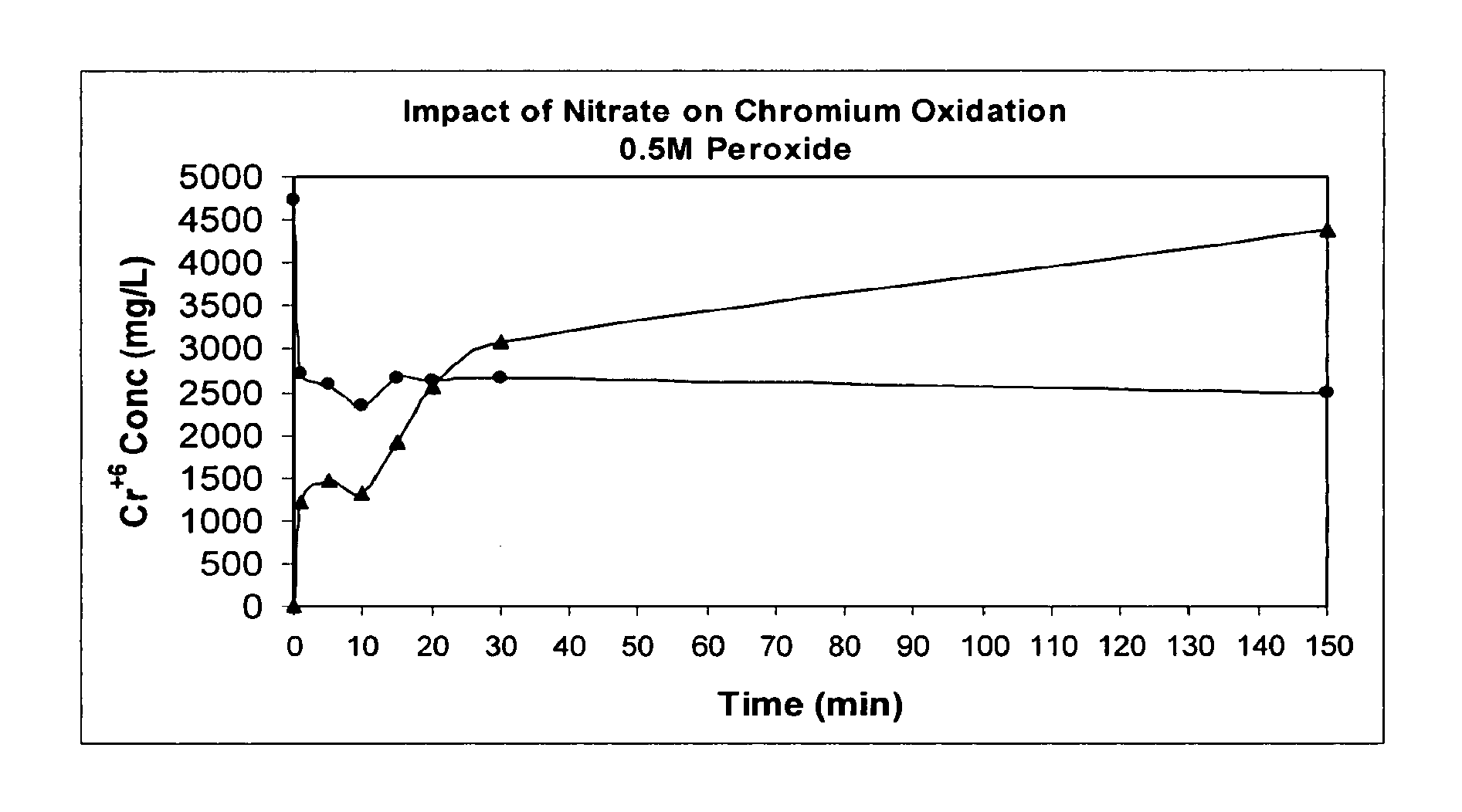

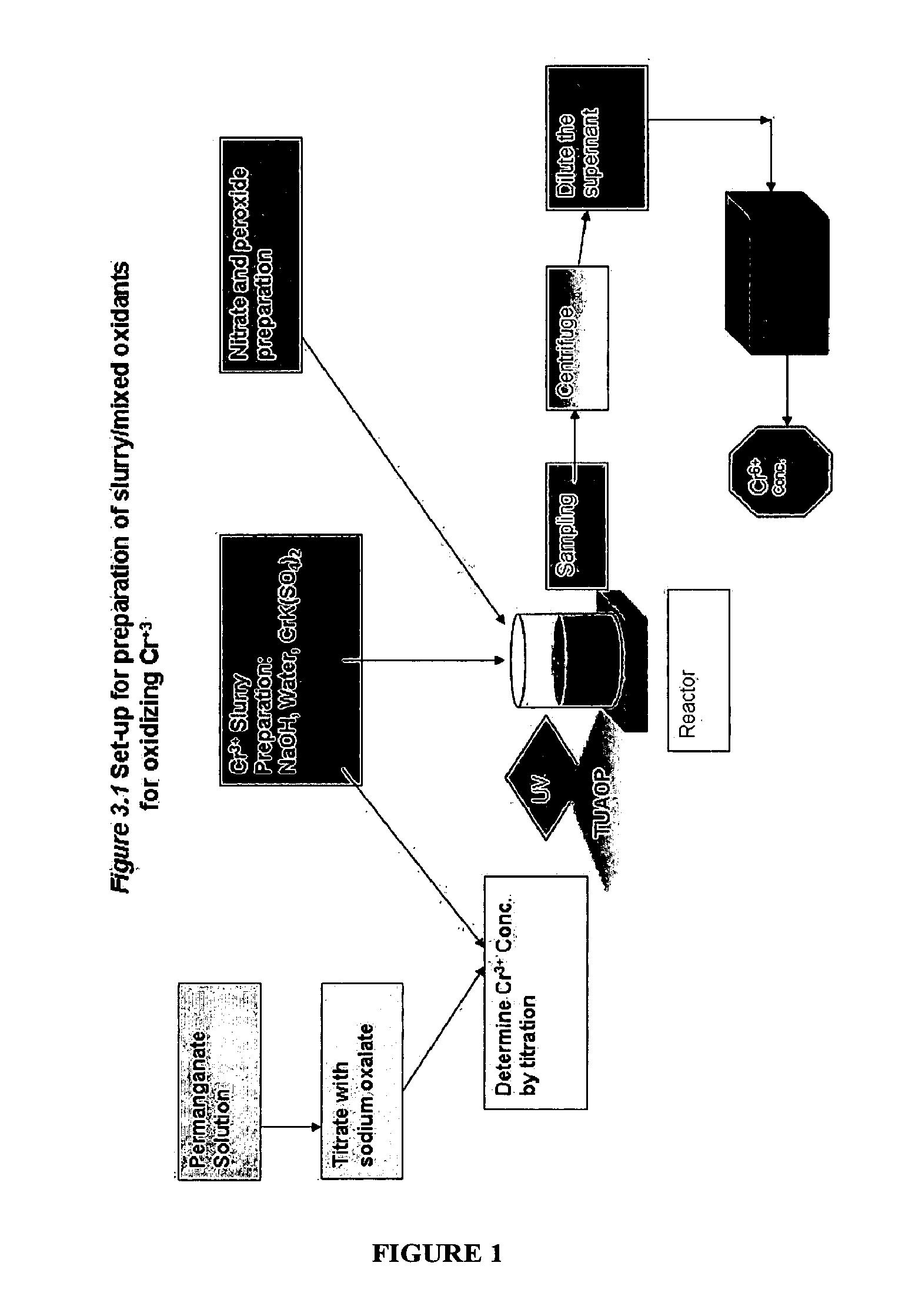

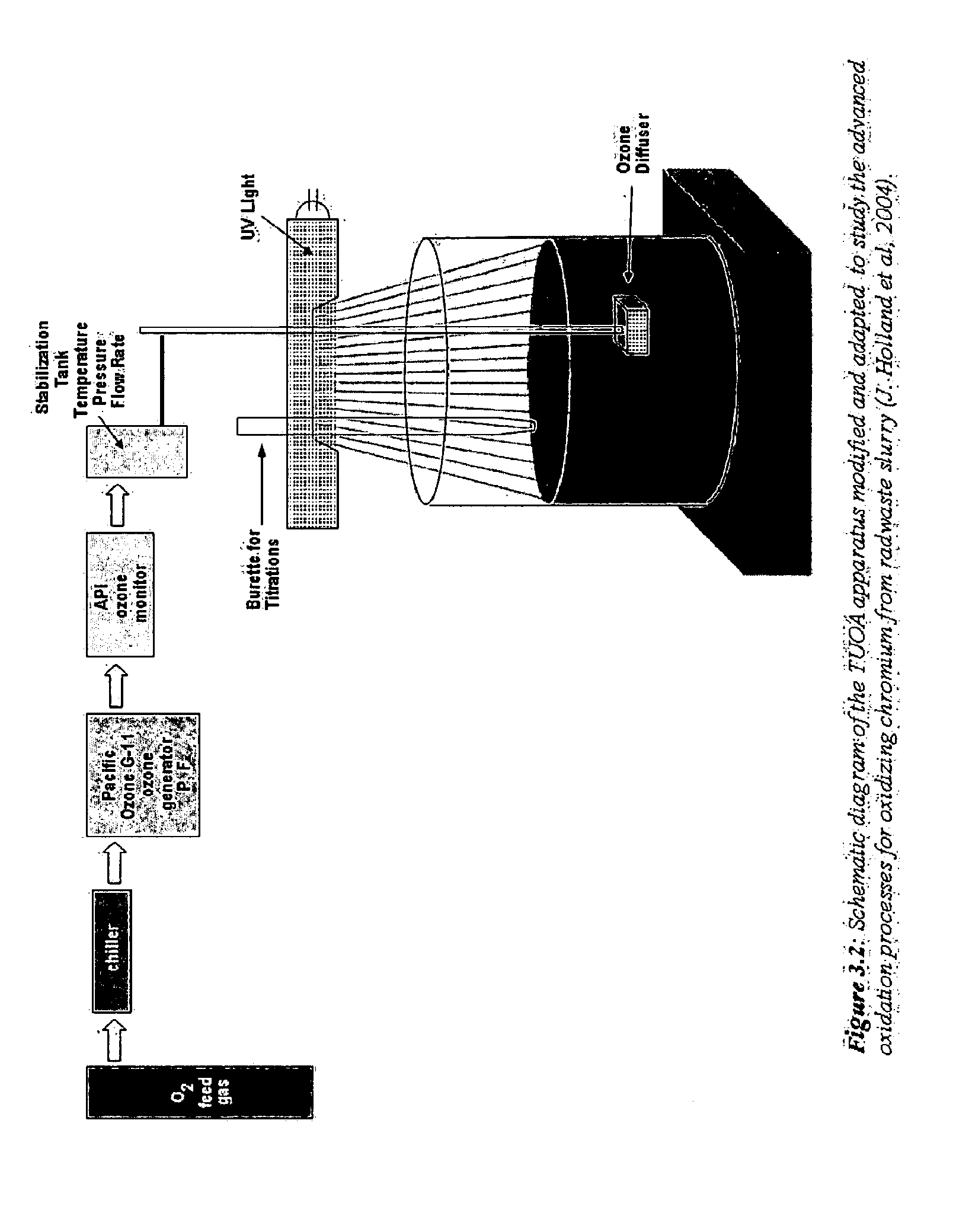

Oxidative Treatment Method

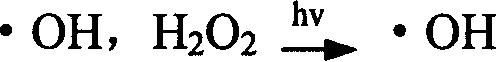

InactiveUS20100320156A1Quickly and efficiently decomposeEffective treatmentWater/sewage treatment by irradiationDecorative surface effectsElectrolysisWaste stream

The present invention provides a method for oxidizing a substance (e.g., in a waste stream, drinking water, a paper pulp slurry, or on a surface), which uses free radicals and reactive species generated from multiple oxidants. The method comprises combining peroxynitrite or peroxynitrous acid and at least one additional oxidizing agent for a period of time sufficient to oxidize the substance of interest. The peroxynitrite or peroxynitrous acid preferably is formed by irradiation of nitrate ion and / or nitric acid (e.g., with UV or gamma rays). The yield of free radicals and reactive species, which are the intermediate species that perform the oxidation may be increased by addition of a catalysts, electromagnetic radiation, sonic waves, and / or electrolysis.

Owner:TULANE EDUCATIONAL FUND

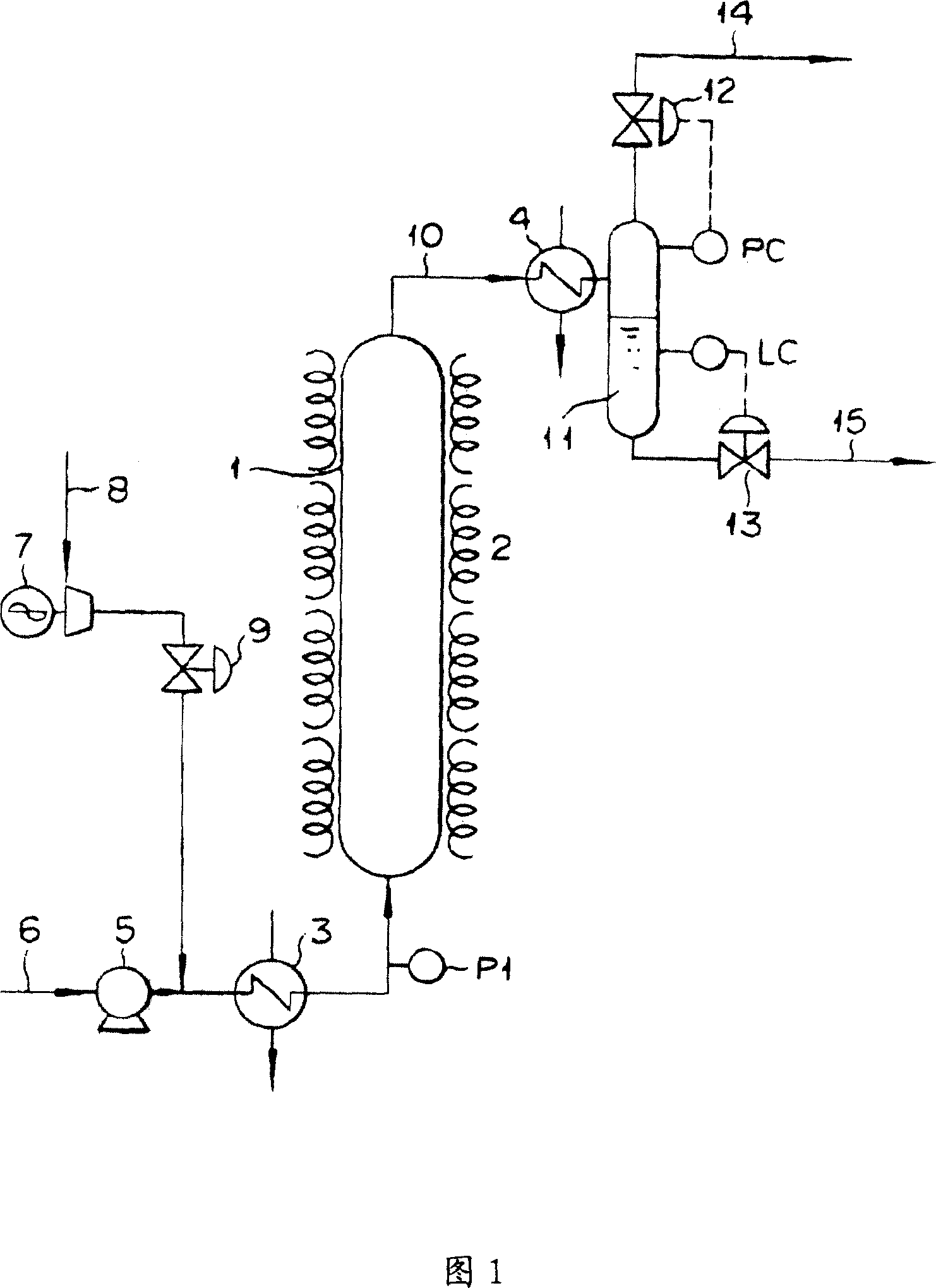

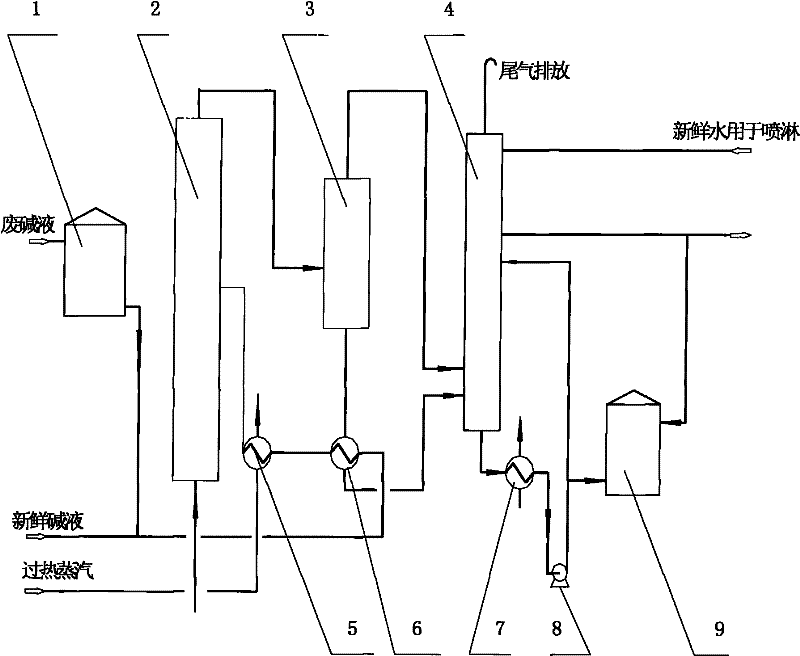

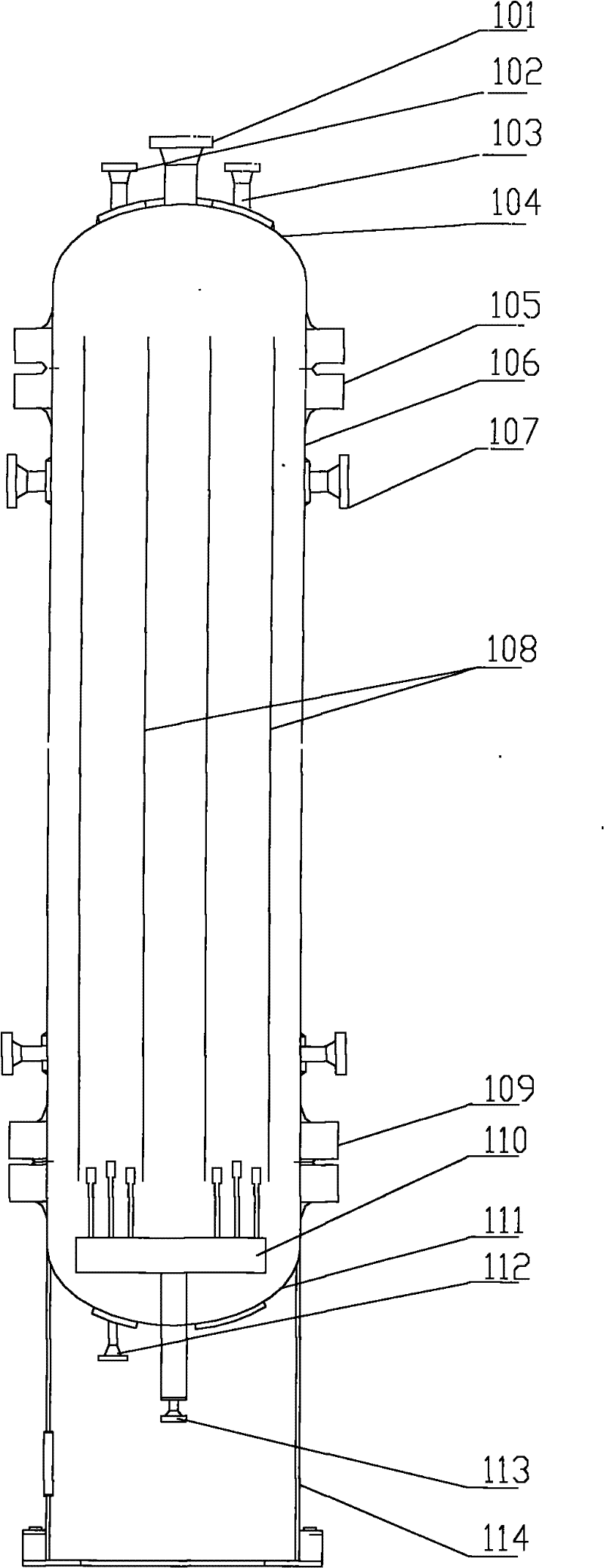

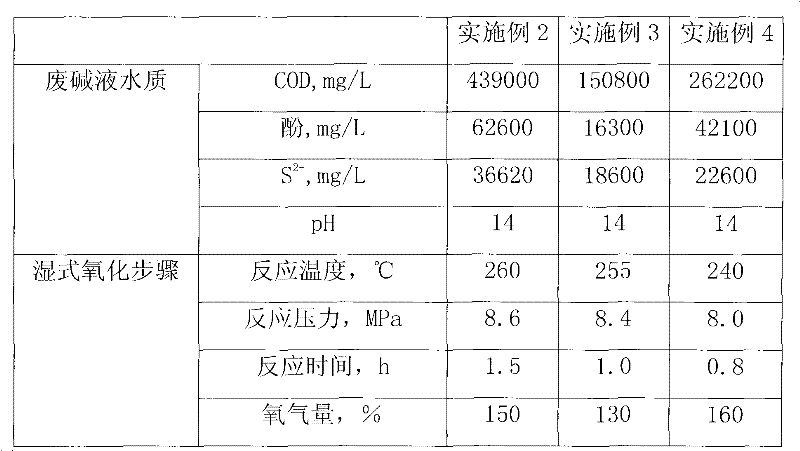

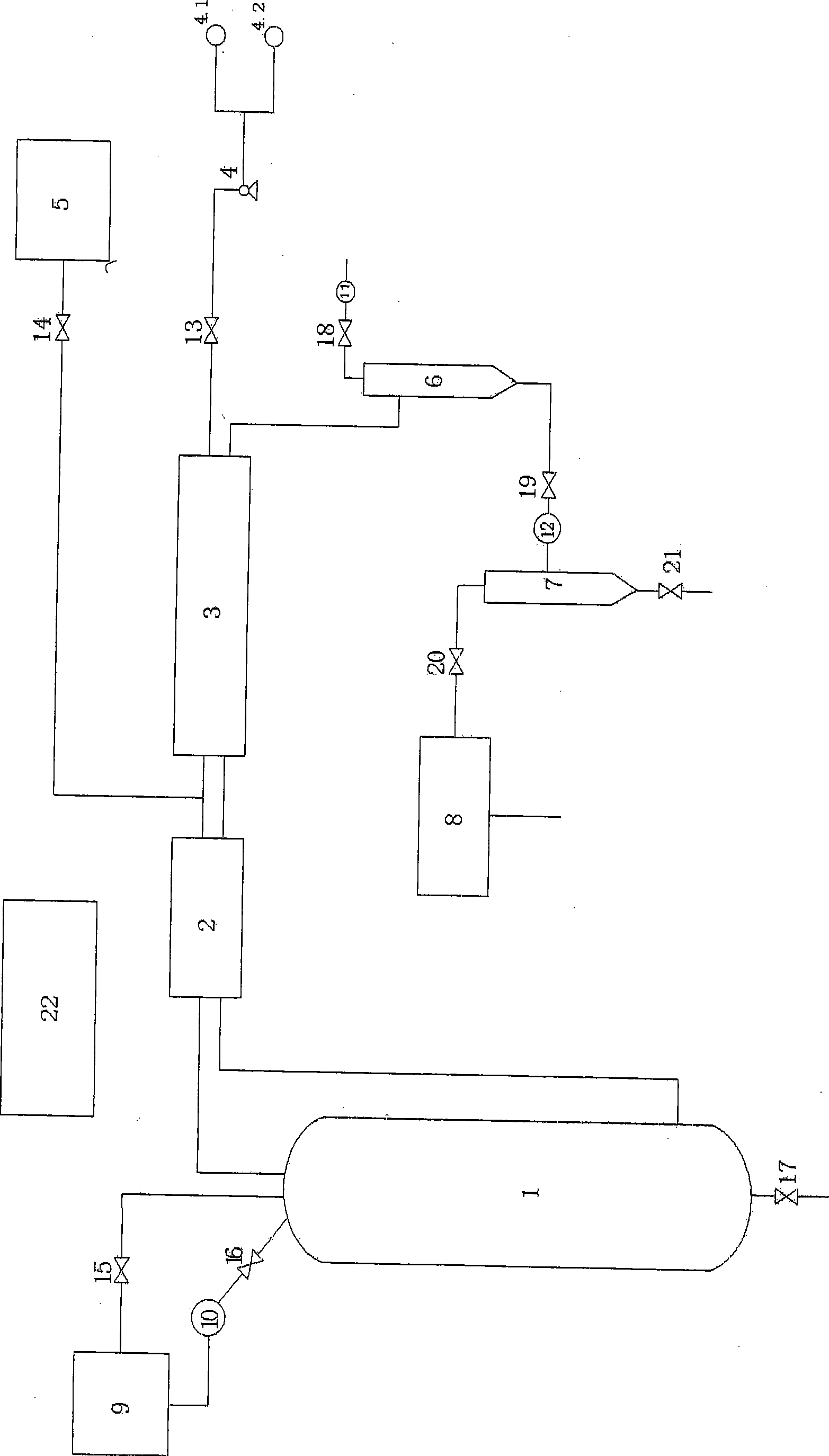

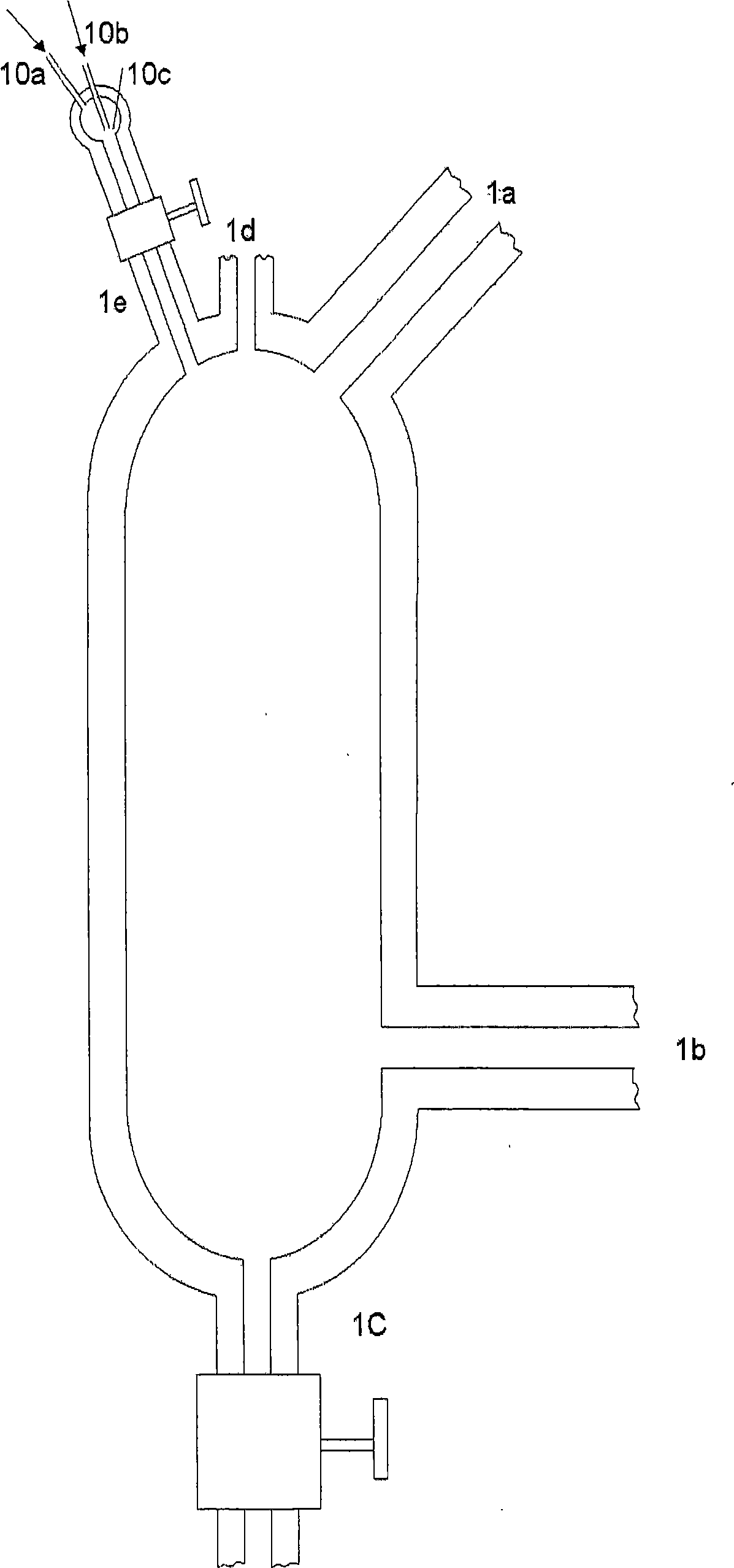

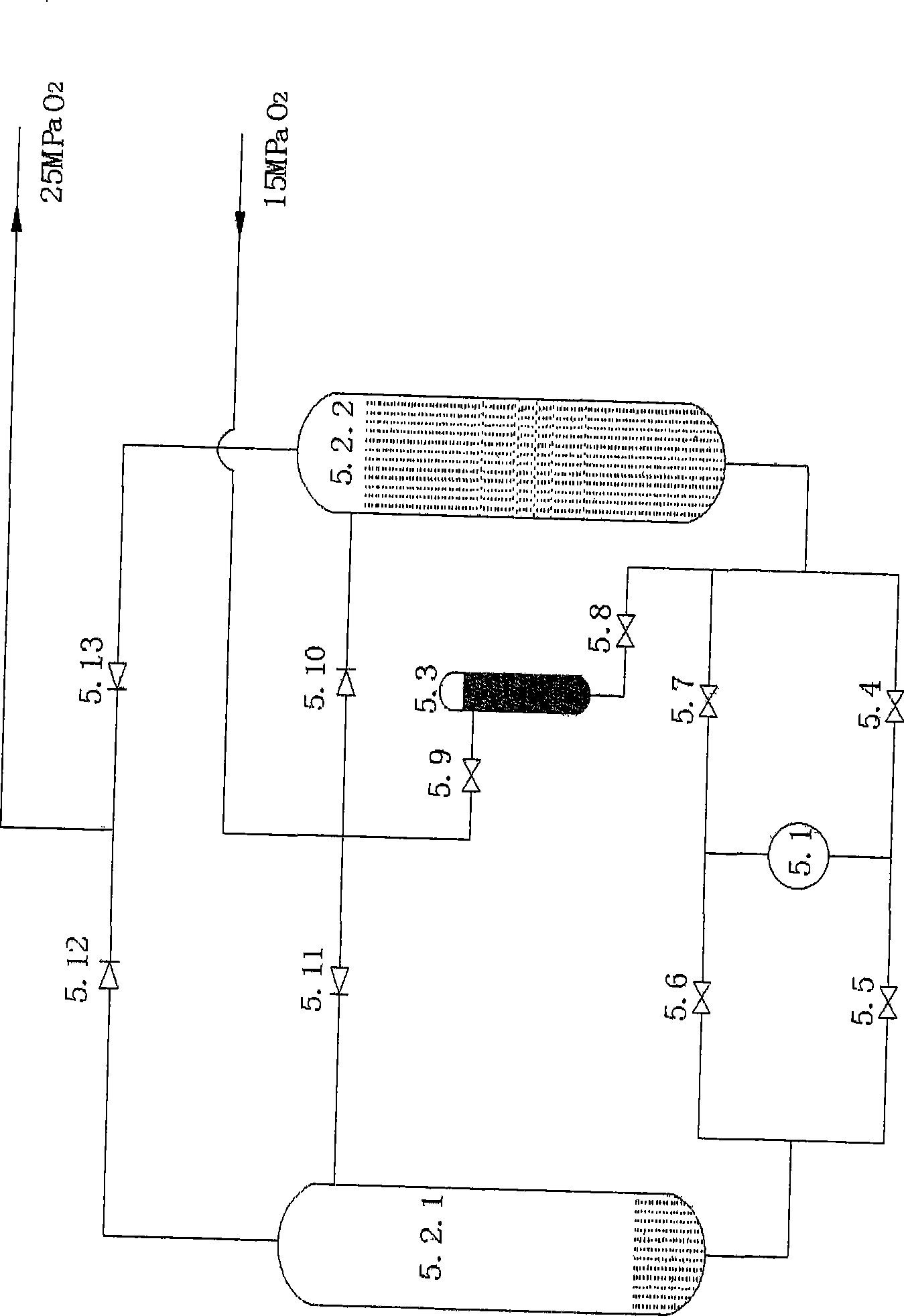

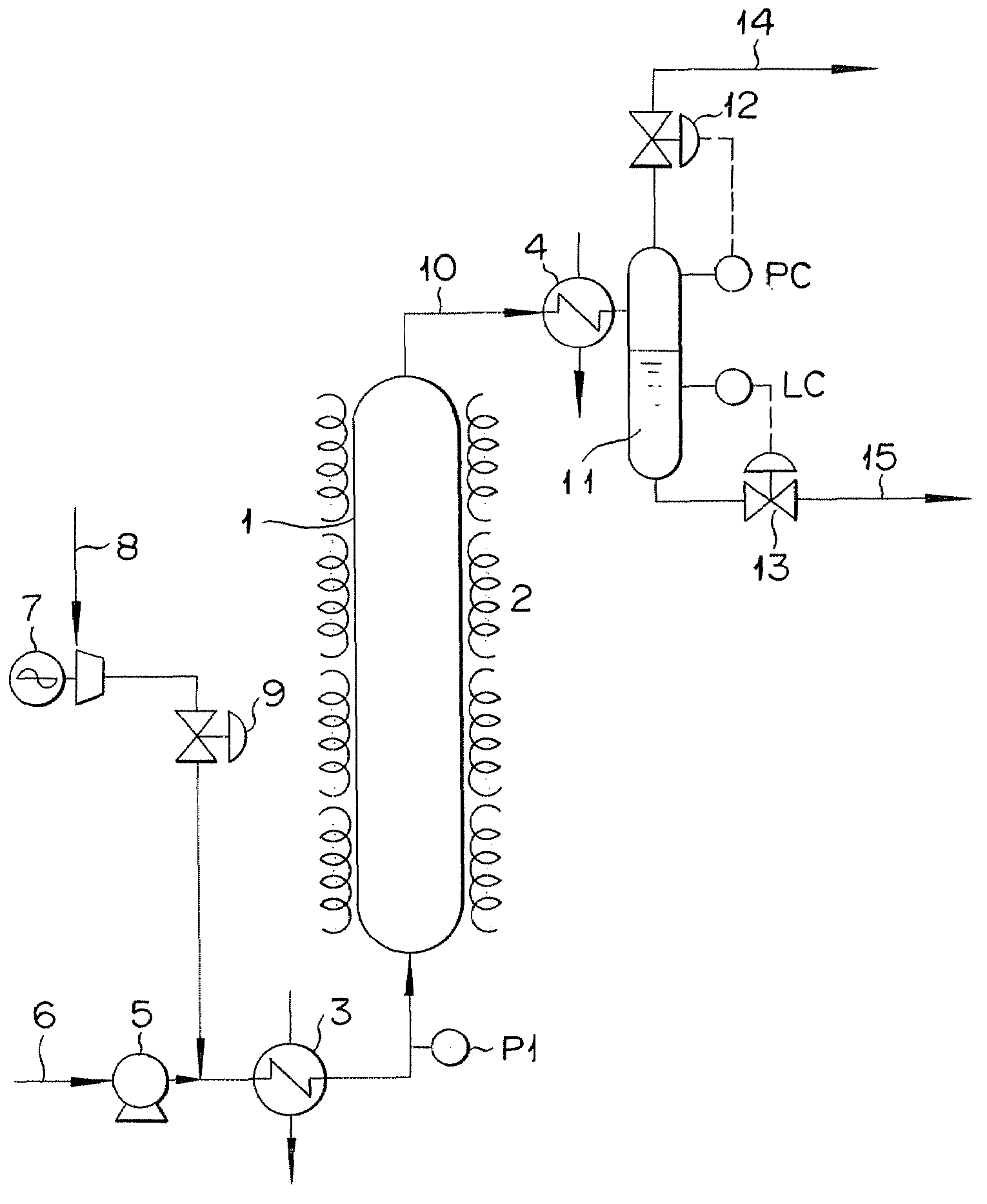

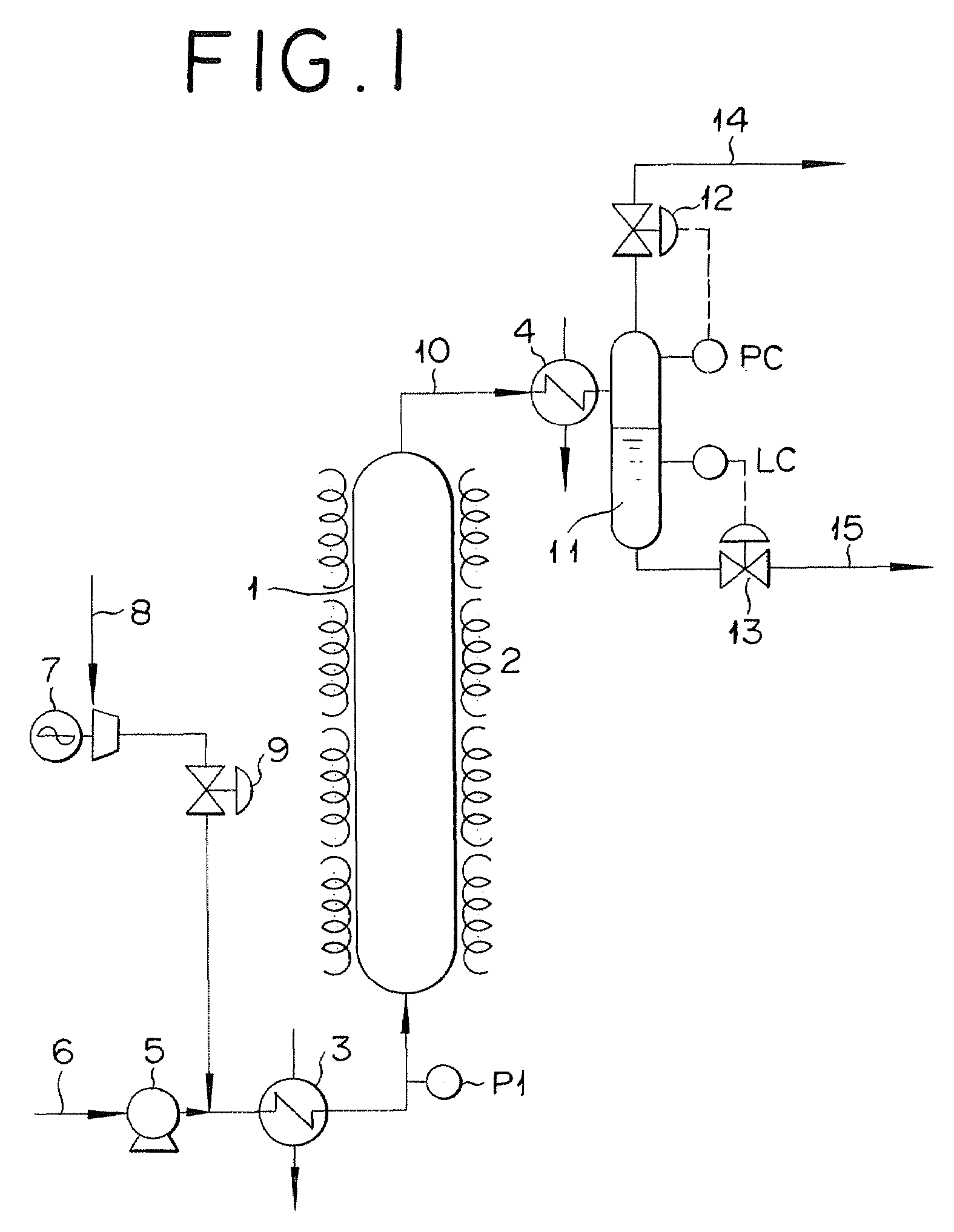

A high-temperature wet oxidation method for treating waste caustic soda

InactiveCN102285729ANo impactNo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh concentrationGas phase

The invention discloses a method for treating waste lye by high-temperature wet oxidation. At 220°C to 260°C and under the pressure of keeping the waste lye in liquid phase, the waste lye is contacted with air exceeding the theoretical oxygen demand, and the waste lye is used The oxygen in the air oxidizes the inorganic sulfide and organic matter in the waste caustic so that the sulfur in it is converted into sulfate, and the organic matter is oxidized and decomposed into water and carbon dioxide; the reacted material discharged from the wet liquid phase oxidation reactor enters the high-pressure gas-liquid separator , The oxidized spent lye after gas-liquid separation and the waste lye feed are exchanged for heat, and the oxidized spent lye after heat exchange and the gas phase separated from gas and liquid enter the cooling and washing tower. Compared with the prior art, the method of the present invention has low energy consumption, the removal rate of S2- can reach 100%, the removal rate of COD can reach 75%-85%, and the waste lye after treatment can be directly discharged into the sewage treatment system, effectively alleviating the The pressure brought by the high concentration of wastewater in sewage treatment plants.

Owner:CHINA PETROLEUM & CHEM CORP +1

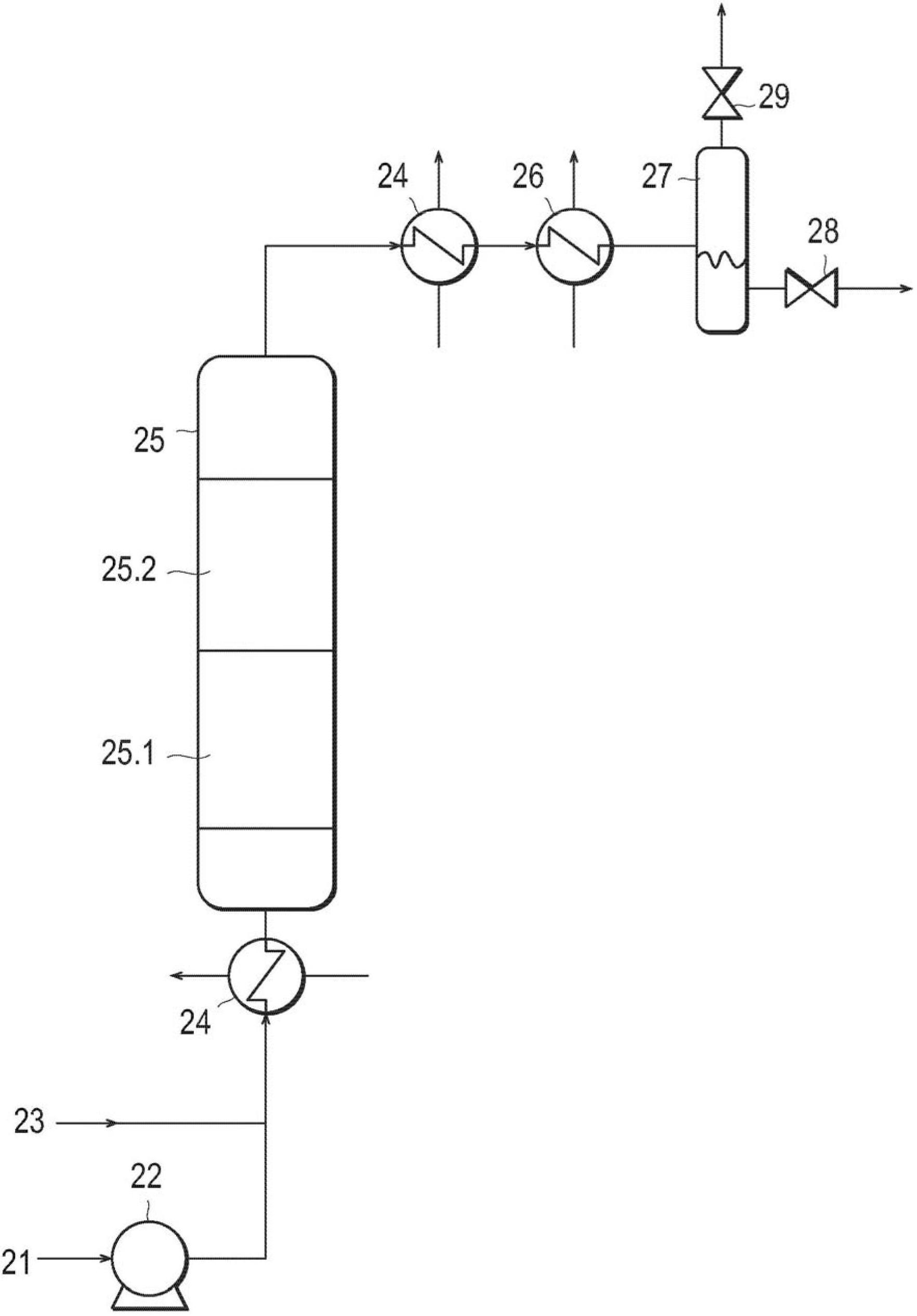

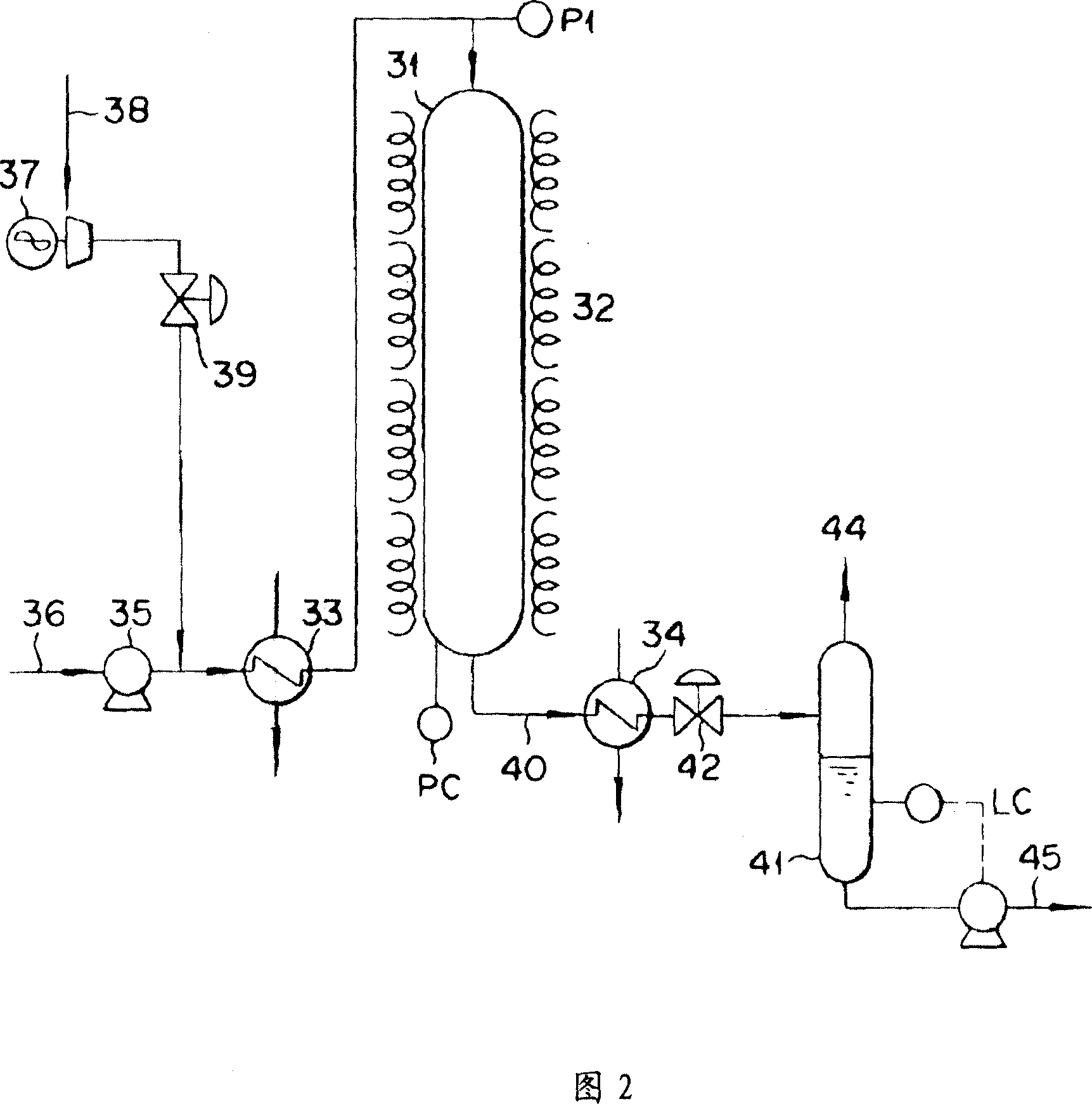

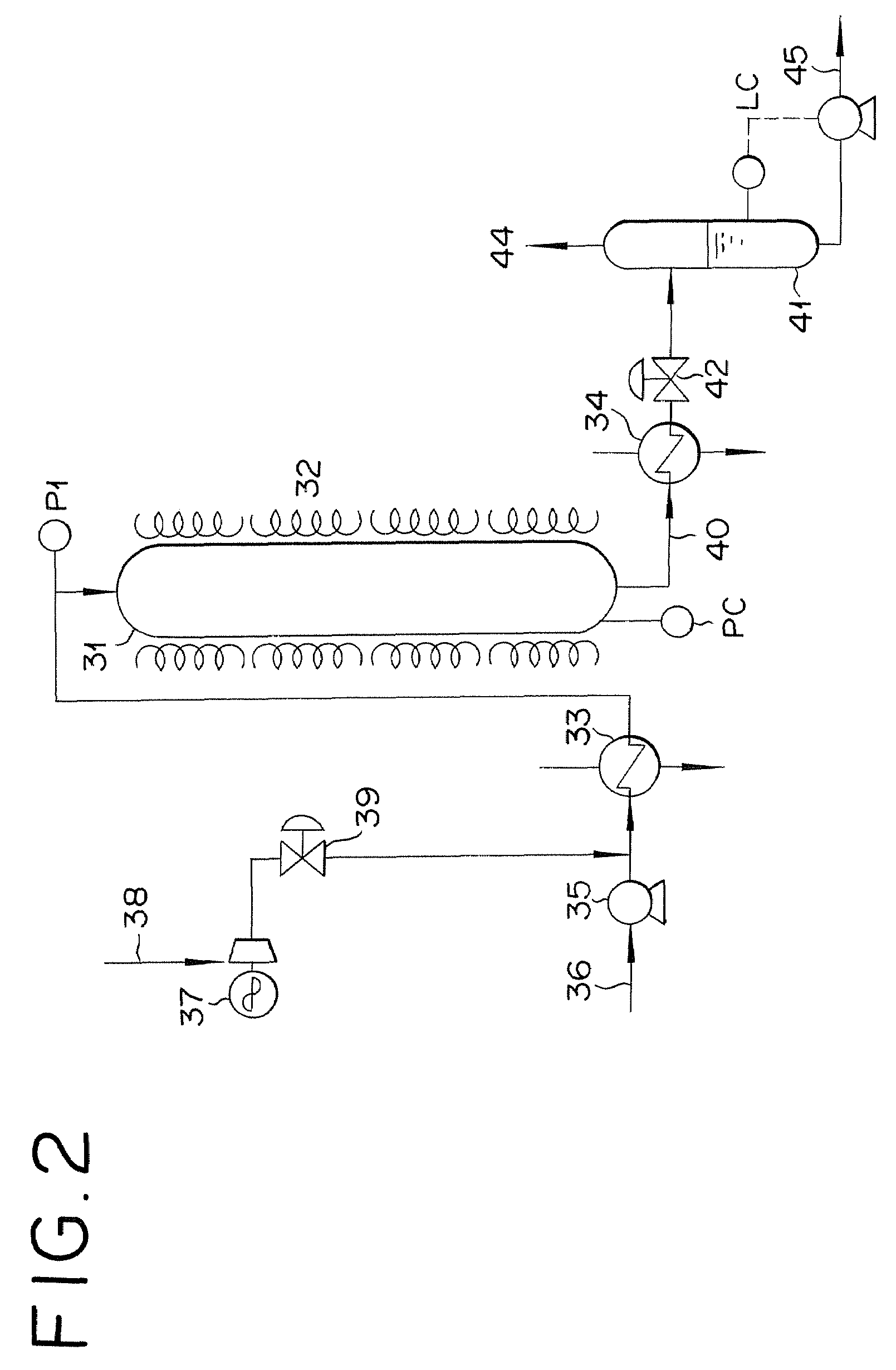

Method and device for oxidizing and treating sewage or sludge containing organic substances by supercritical water

InactiveCN101544419AGuaranteed uptimeReduce construction costsSludge treatment by oxidationByproduct vaporizationCombustionSludge

The invention relates to a method and a device for oxidizing and treating sewage or sludge containing organic substances by supercritical water. The method adopts a combustion reaction furnace, and is characterized in that substance flow of the sewage or the sludge containing the organic substances and oxidant (such as oxygen or hydrogen peroxide and the like) are preheated by a heat exchange device respectively and then enter the combustion reaction furnace, the sewage or the sludge containing the organic substances is oxidized and treated under a supercritical state, the treated substance flow is cooled by the heat exchange device again, then residual gas in the substance flow is separated by adopting a gas-liquid separator, and the lower part of the combustion reaction furnace discharges salt slag through a slag discharging hole and a valve. The method has the advantages of reasonable and practical process, energy conservation and low operation cost.

Owner:楼龙春

Waste water treatment catalyst and preparation method thereof

ActiveCN102049256AIncrease contentEvenly distributedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsManganeseBULK ACTIVE INGREDIENT

The invention relates to a waste water treatment catalyst and a preparation method thereof. The catalyst of the invention takes active carbon as a carrier and one or several of oxides of metals such as copper, iron, manganese, vanadium, zinc and titanium as an active ingredient. The preparation method comprises: firstly, preparing high-temperature active carbon carrier at 350 to 700 DEG C; secondly, immersing the high-temperature active carbon carrier in the immersion liquor containing active metal components or spraying immersion liquor containing active metal components to immerse the high-temperature active carbon carrier so as to load a catalytic active component onto the active carbon carrier quickly; and finally, cooling, washing and drying to obtain the catalyst. The catalyst prepared by the method has the advantages that the content of the active metal components is high, and the active metal components are insusceptible to loss in waste water. The catalyst is mainly used in the catalytic oxidization treatment process of waste water.

Owner:CHINA PETROLEUM & CHEM CORP +1

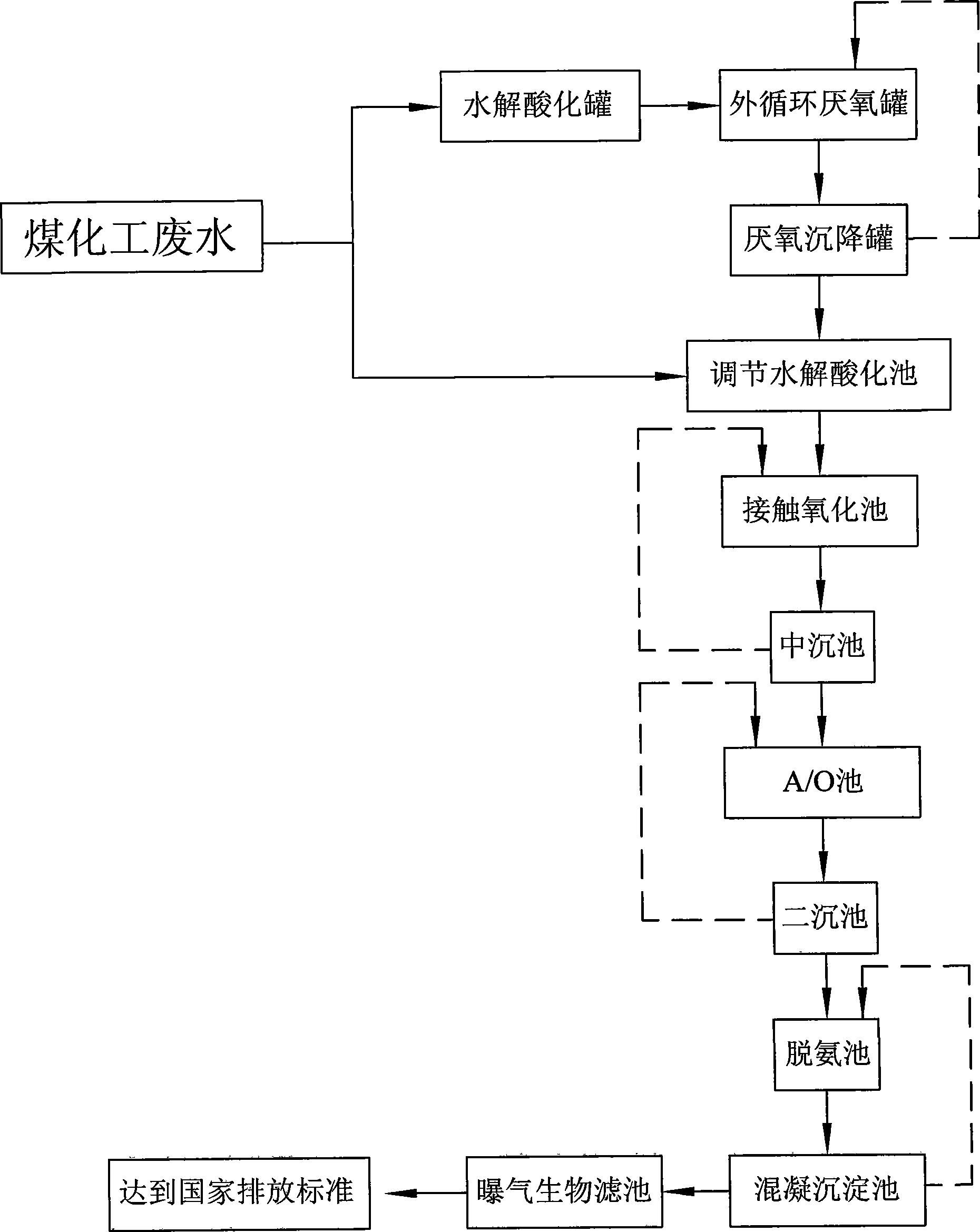

Coal chemical industry wastewater treating method

InactiveCN101503267AEasy to handleImprove the water effectWater contaminantsTreatment with aerobic and anaerobic processesOperational costsBiological filter

The invention relates to a coal chemical wastewater treatment method, in particular to a chemical wastewater treatment method. The invention aims to solve the problems of the chemical wastewater treatment method such as bad outlet water quality and high operational cost. The method comprises the following steps: pretreating coal chemical wastewater to be treated; then carrying out hydrolytic acidification treatment, external circulating anaerobic treatment, anaerobic sedimentation treatment, adjusting hydrolytic acidification treatment, contact oxidation treatment, sedimentation treatment, A / O treatment, sedimentation treatment, deamination treatment, coagulating sedimentation treatment and aeration biological filter tank treatment, wherein the temperature in an external circulating anaerobic tank is controlled within the scope of 32 to 35 DEG C; the hydraulic detention time is 24 to 36 h; the sludge concentration is controlled between 50 and 100 g / L; the volume load is 5 to 10 kg COD / m.d ; and the pH value is controlled between 7.0 and 7.5. The invention has the advantages of flexible operation, impact load resistance, low operating cost and good treatment effect; after the coal chemical wastewater is treated by the treatment method, the outlet water quality completely can achieve the wastewater comprehensive discharge standard regulated by the State.

Owner:HARBIN INST OF TECH

Catalyst for wastewater treatment and method for wastewater treatment using said catalyst

InactiveUS20070210010A1High activityIncreased durabilitySludge treatmentWater/sewage treatment by substance additionIridiumManganese

The present invention relates to a catalyst for wastewater treatment and a method for wet oxidation treatment of wastewater using the catalyst, in particular, the catalyst of the present invention can suitably be used in wet oxidation treatment of wastewater, under high temperature and high pressure conditions. The present invention provides a catalyst for wastewater treatment containing a catalytic active constituent containing at least one kind of an element selected from the group consisting of manganese, cobalt, nickel, cerium, tungsten, copper, silver, gold, platinum, palladium, rhodium, ruthenium and iridium, or a compound thereof, and a carrier constituent containing at least one kind of an element selected from the group consisting of iron, titanium, silicon, aluminum and zirconium, or a compound thereof, characterized in that solid acid amount of the carrier constituent is equal to or more than 0.20 mmol / g.

Owner:NIPPON SHOKUBAI CO LTD

Method of treating the surface of substrates

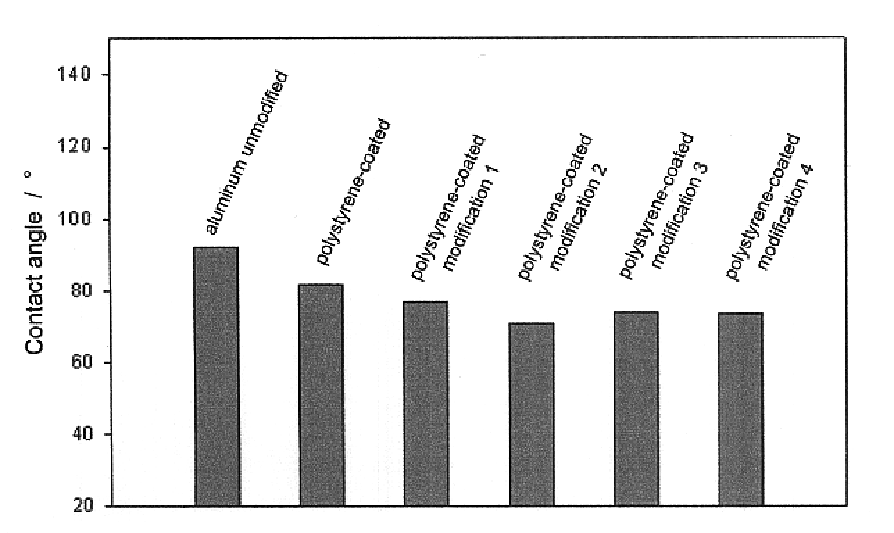

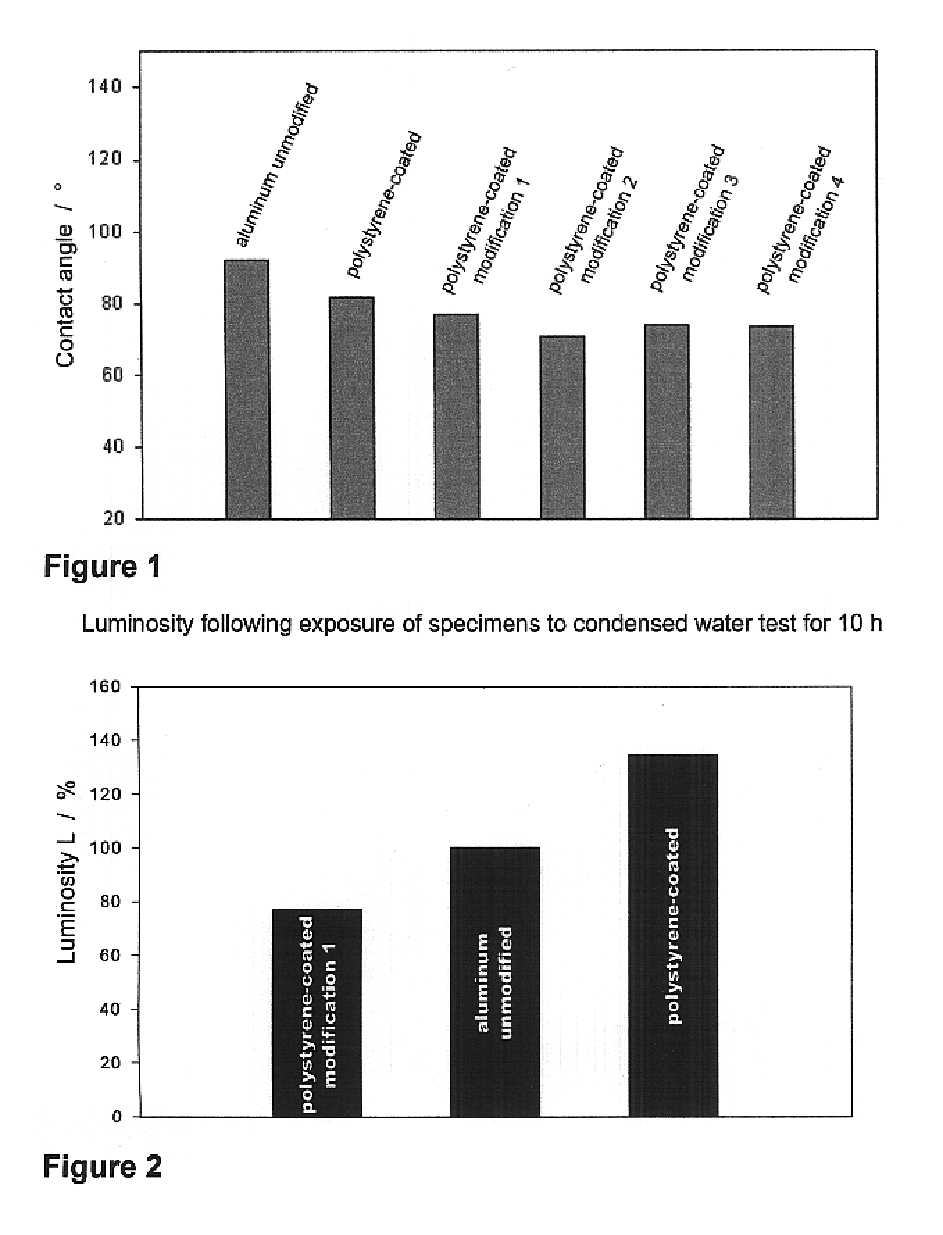

InactiveUS7026051B2Easy to useReduce usagePigmenting treatmentGlass/slag layered productsPolymer solutionOxidative treatment

In order to provide a method by means of which the surface of substrates can be protected from corrosive attack and which, in particular, avoids the necessity for oxidative treatment to form oxide layers on surfaces or for phosphatizing or chromatizing treatment steps and is, in addition, simple to apply, it is proposed that the substrate be brought into contact with a solution of a polymer which exhibits UCST properties and which is caused to be deposited onto the surface of the substrate as a layer by decreasing the temperature of the polymer solution.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

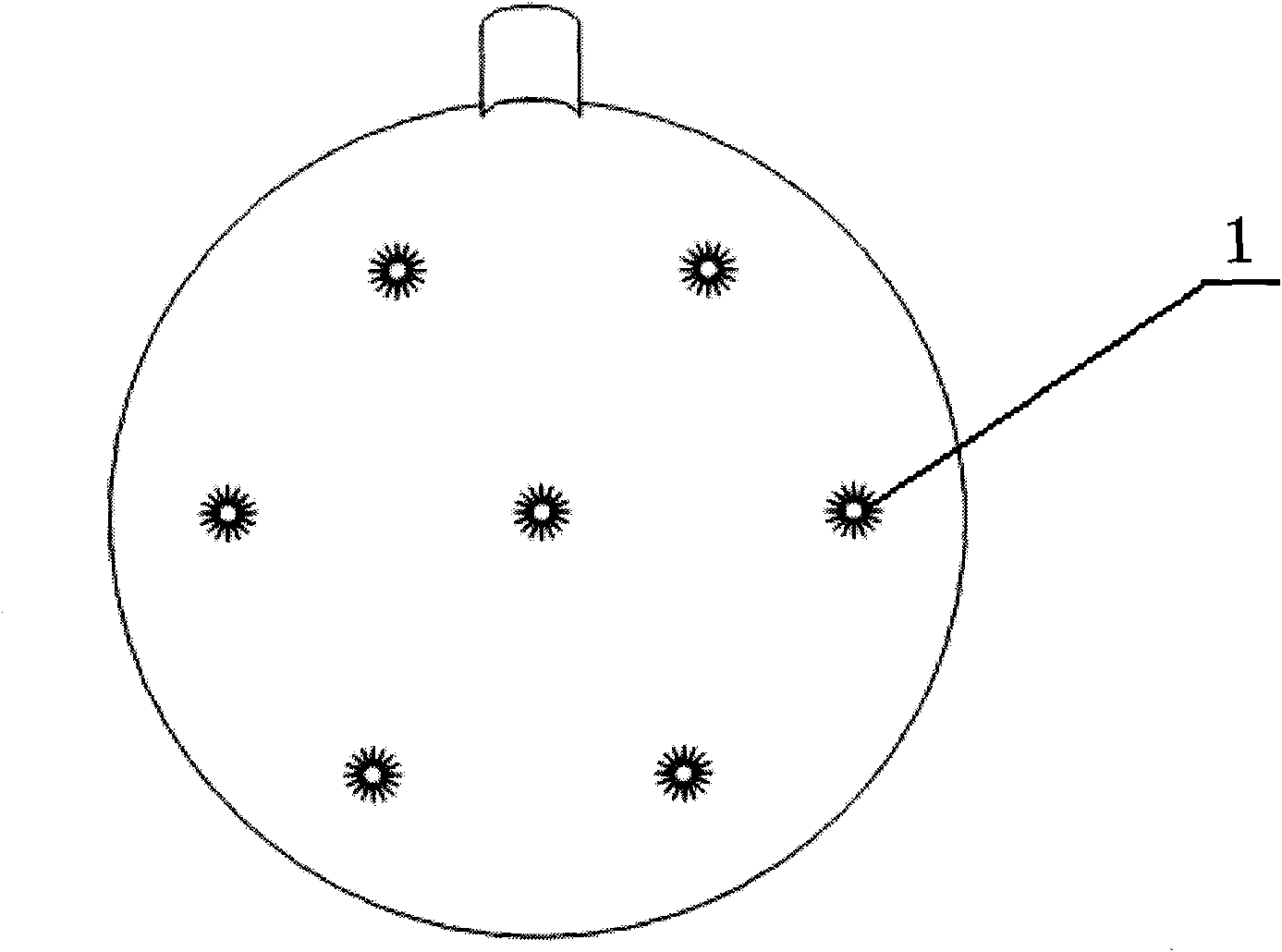

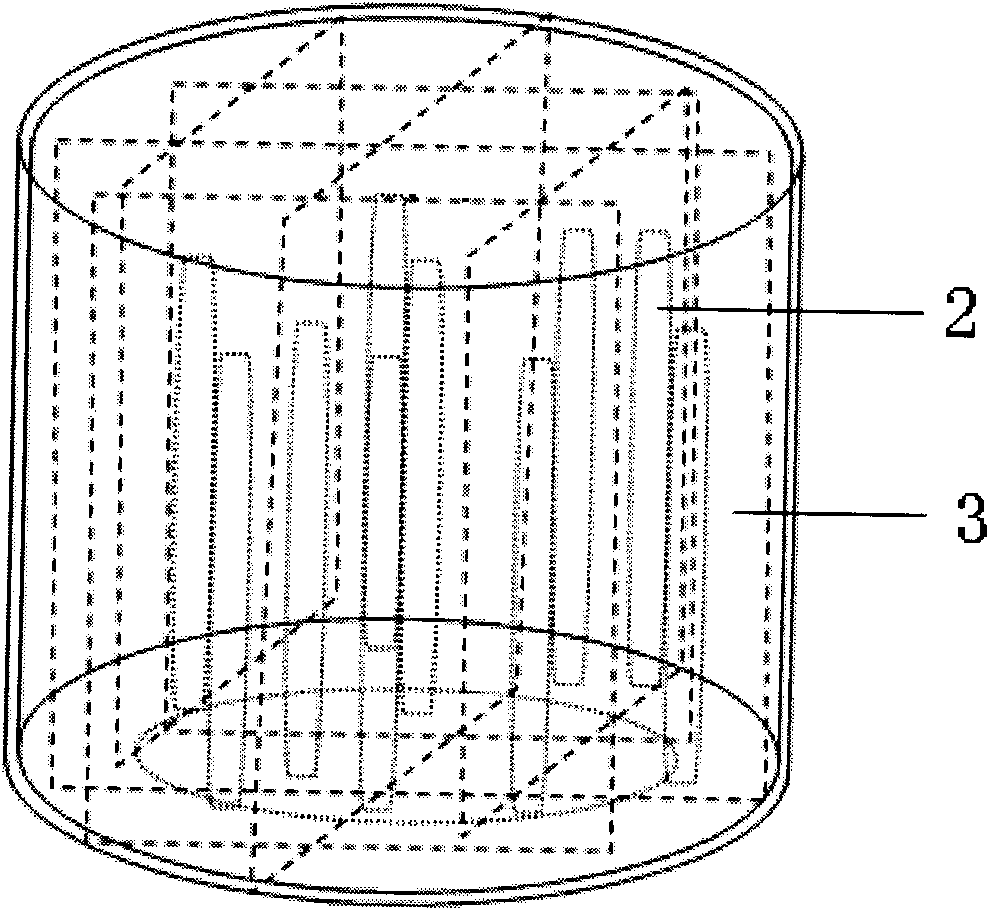

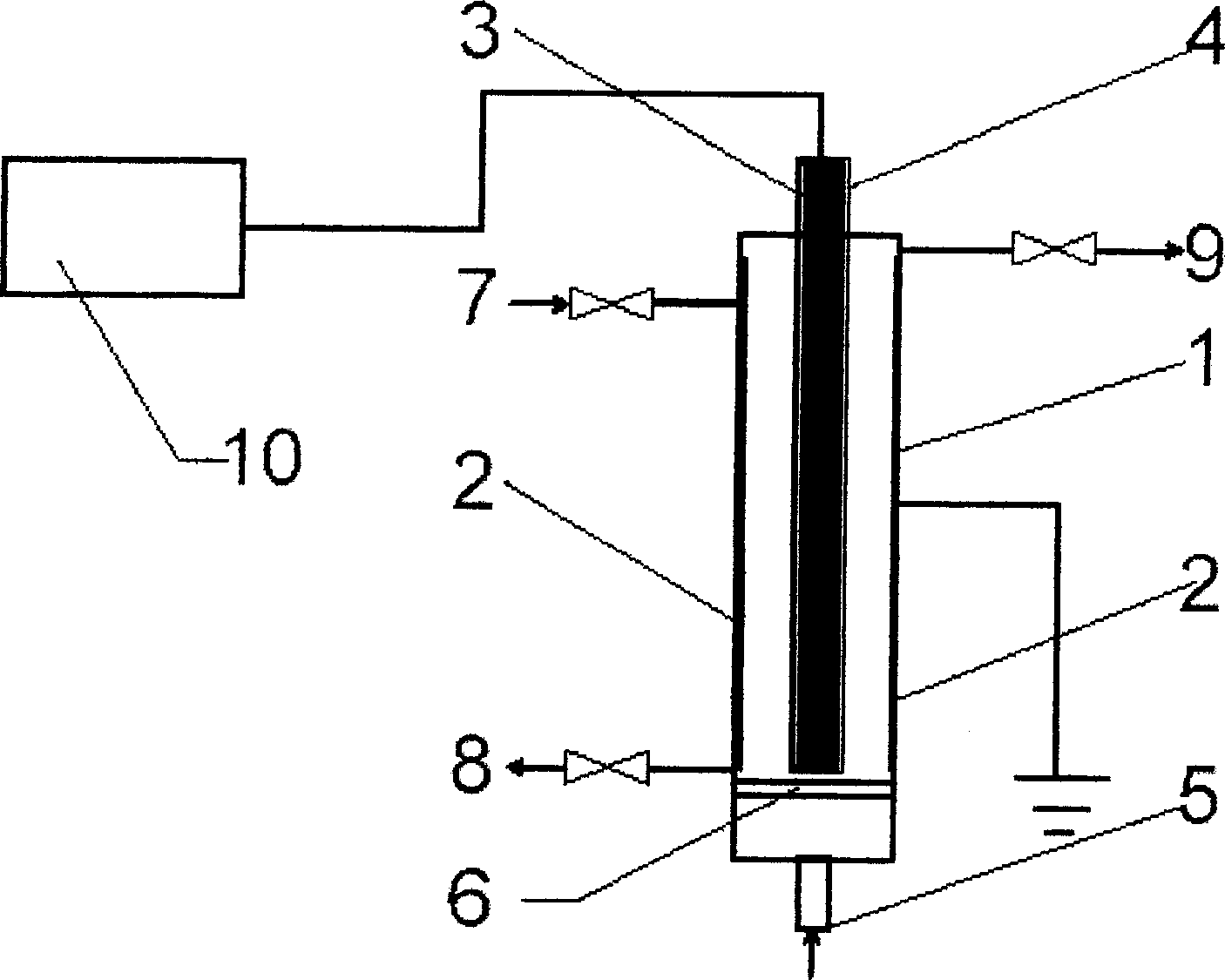

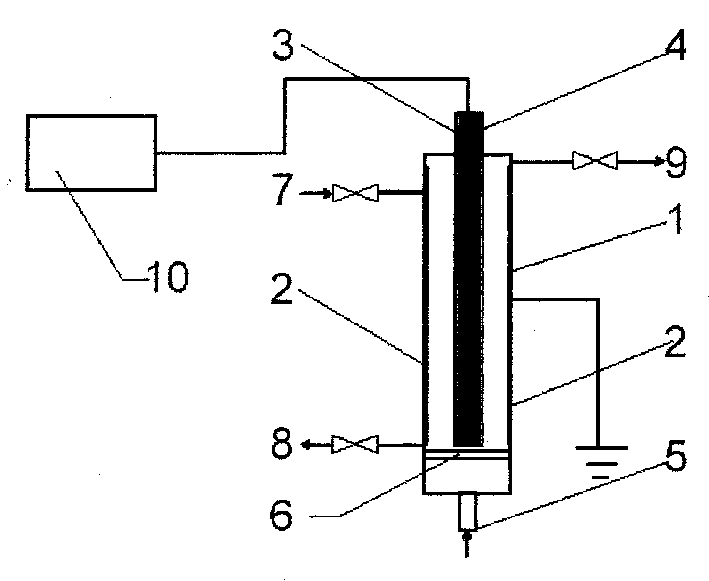

Photoelectrocatalysis and oxidation device for treating organic substance in water

InactiveCN1562795ACompact and reasonable structureMass transfer coordinationPhysical/chemical process catalystsWater/sewage treatment by irradiationUltraviolet lightsVolumetric Mass Density

Fluid-bed photo-electro catalytic organic water processing device consists of titanium-base oxide positive electrode, negative oxygen electrode, TiO2 / C sulfide particle, ultraviolet light source, constant potentiometer DC power source, air distribution board and casing. Not only oxidizing action of positive electrode and reducting action of negative oxygen electrode are used, but also active perssad OH, H2O2, OH- and light, photocatalysis are used, to go deep into bed layer by strong stirring of fluidized particle to increase OH density of the system and to be uniform, TiO2 on surface of fluidized particle produces OH by lighting continuously, and surface of TiO2 particle is renewed continuously.

Owner:TAIYUAN UNIV OF TECH

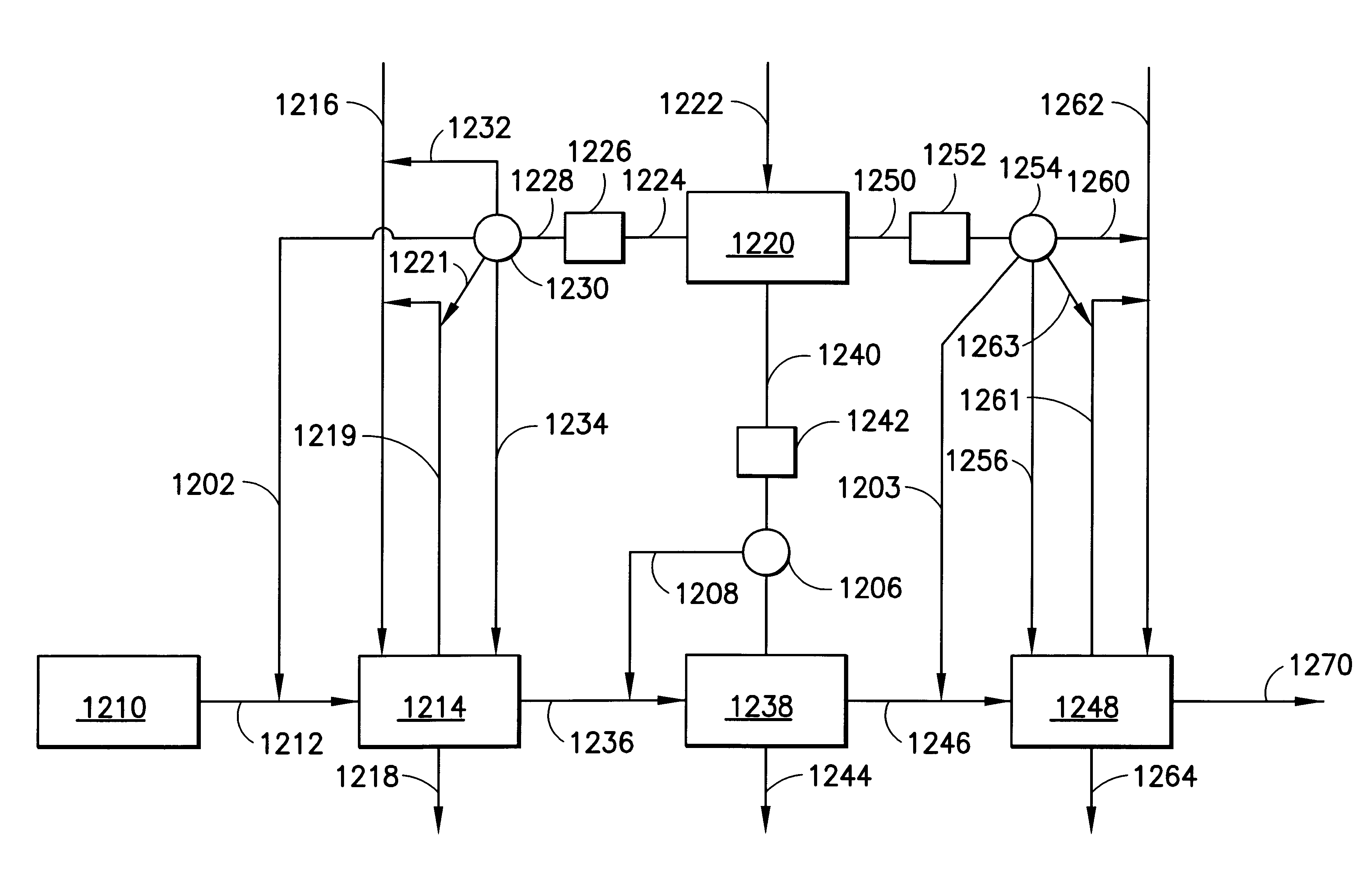

Method and system for regenerating of plating baths

InactiveUS6942779B2Lower Level RequirementsMaximize gasCellsWater/sewage treatment by irradiationParticulatesFiltration

The present invention provides a system and method for selectively removing one or more organic and inorganic and also preferably one or more inorganic contaminants from plating baths. More particularly, the invented method relates to the use of a source of energy in combination with chemical oxidants, alone or in conjunction with a catalyst to oxidize organic contaminants in the plating bath to a level such that the electroplating bath can be recovered and reused after appropriate chemical adjustment. The oxidative treatment method may be a continuous process or a batch process that is performed in a single pass. Residual organics, if desired and chloride ions in the bath are removed from the solution by a chemisorption or physisorption treatment. Inorganic contaminants are removed from the electroplating bath by selective ion exchange resins or electrodialysis, while particulate and suspended colloidal particles are removed by filtration before the treated plating bath is recycled.

Owner:ENTEGRIS INC

Advanced treatment method for fracturing flow-back fluid

ActiveCN102161536AHigh removal rateSimple processMultistage water/sewage treatmentWater/sewage treatment by oxidationLiquid wasteTreatment effect

The invention discloses an advanced treatment method for fracturing flow-back fluid, belongs to the field of water treatment of the development of oil and gas fields, and particularly relates to an advanced treatment method for the fracturing flow-back fluid generated during the operation of the oil and gas fields. The treatment method for the fracturing flow-back fluid, which has high effect and continuous treatment process, is provided to solve the problems that the treatment effect is lower, the continuous treatment cannot be performed, and the cost is higher existing in the prior art. The method comprises the following steps of: pre-oxidizing waste liquor with the pH value of between 8 and 12, adding a coagulant and performing gel breaking treatment and adding a Fenton reagent and treating, and performing secondary coagulation and oxidization treatment. In the method, through homogeneous and heterogeneous catalysis reactions, the treatment cost is reduced, and the removal rate of organic substances is also high; and chemical oxygen demand (COD) of effluent can meet the national sewage discharge standard.

Owner:四川绿源环保技术开发有限公司

Water-treating bipolar pulse discharge process

InactiveCN1440934AImprove production efficiencyEasy to handleWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment using germicide/oligodynamic-processPersistent organic pollutantWastewater

The present invention belongs to the field of low temperature plasma applying technology and is especially a high-grade discharging and low temperature plasma oxidizing water processing method. One in-situ bipolar pulse discharge low temperature plasma water voltage power supply, covering of the discharge electrodes with medium, filling of the gap between the electrodes by air-liquid mixture of fine bubbles and processed water. The present invention has strengthened electric field between the electrodes, protected high-voltage electrodes and long service life, and may be used in sterilizing water, decoloring waste water and catalytically degrading matters hard to degrade biologically and lasting organic pollutant.

Owner:DALIAN UNIV OF TECH

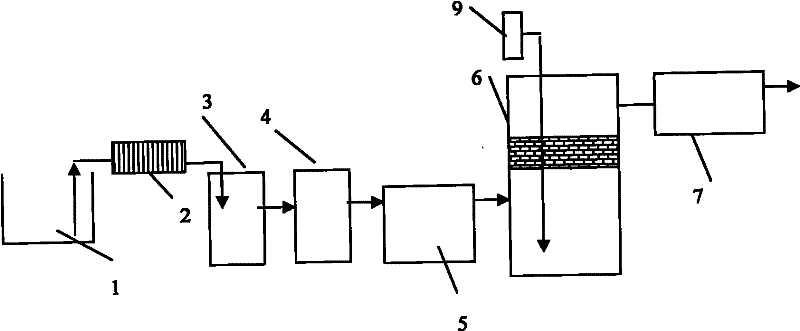

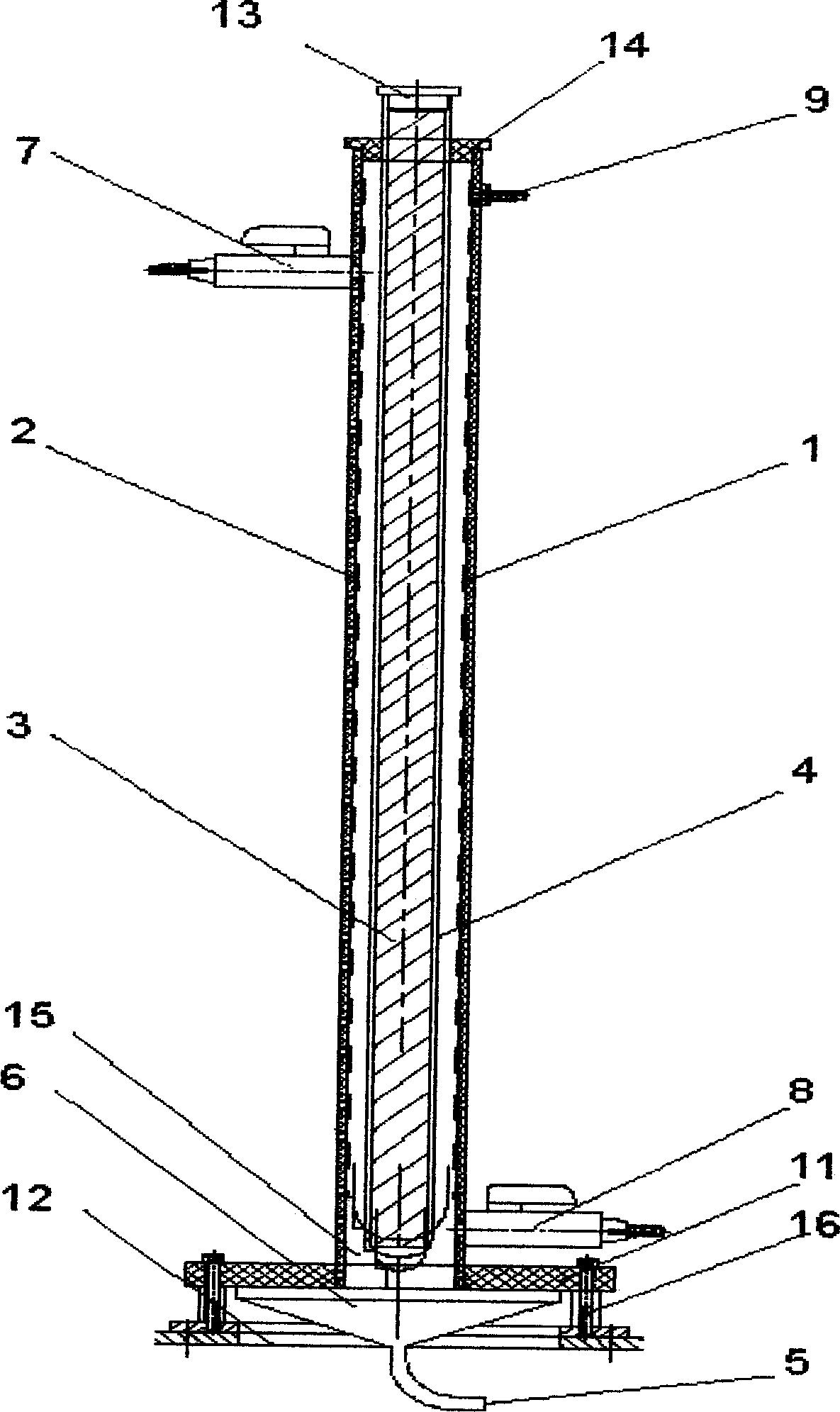

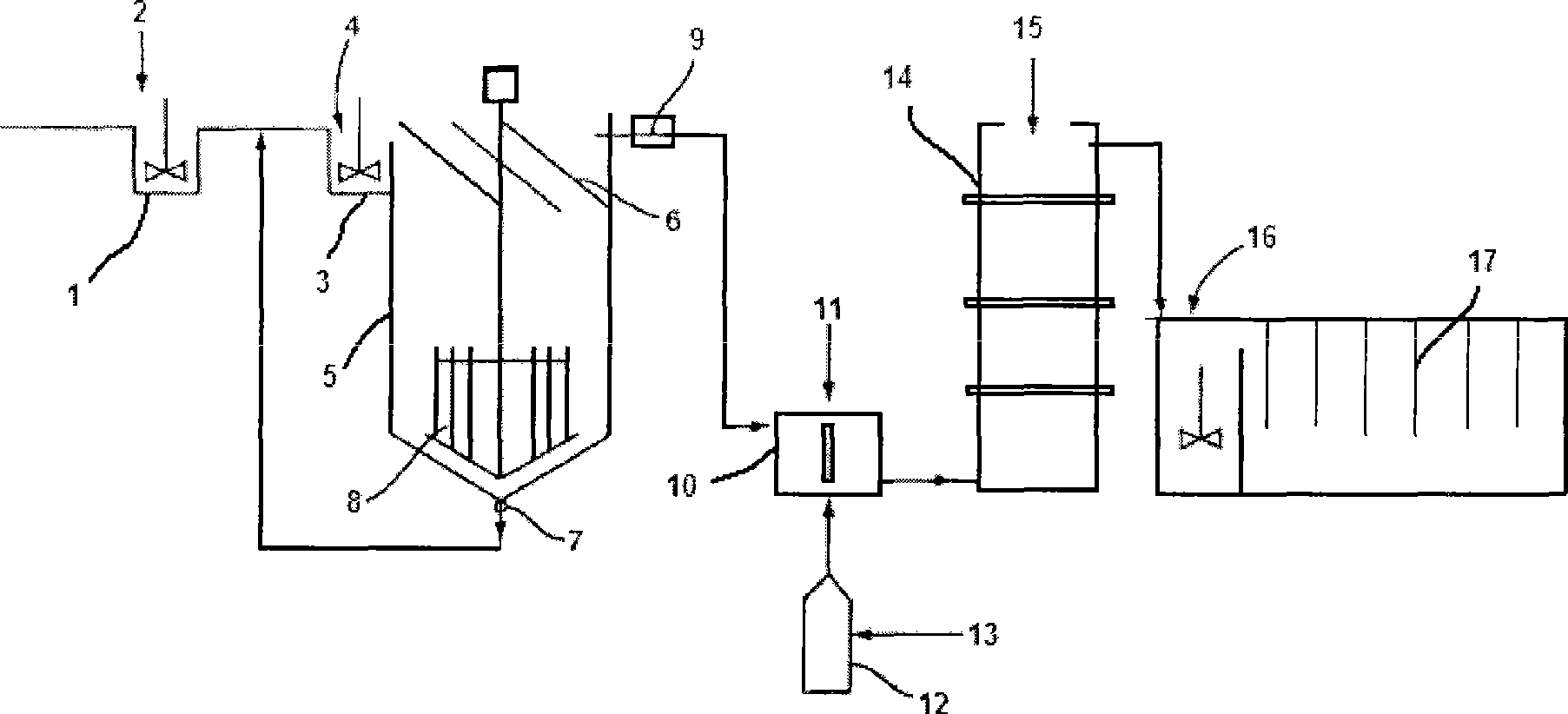

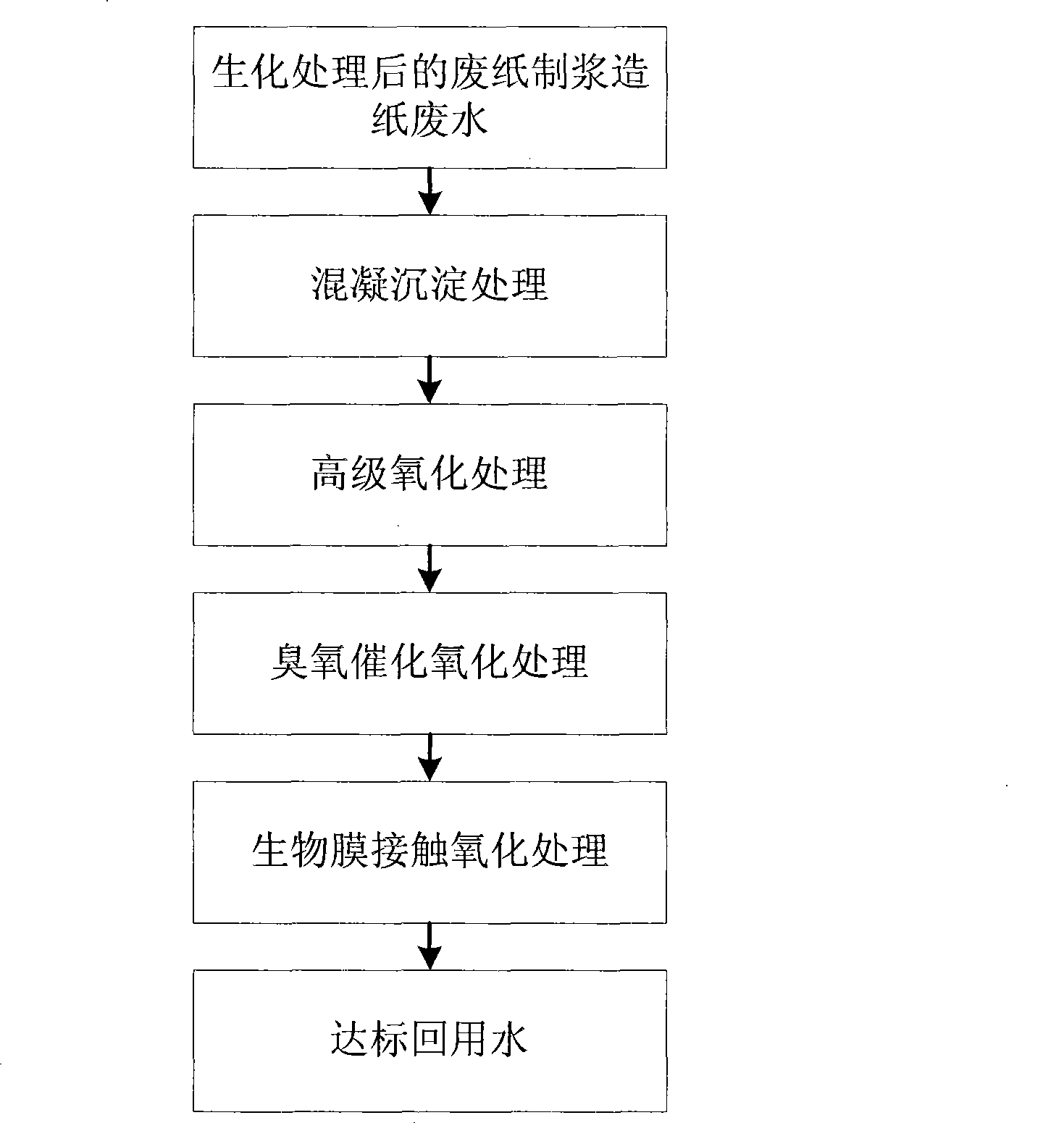

Advanced treatment method and processing system for wastepaper pulping and papermaking waste water

InactiveCN101372382AHigh degree of modernizationEasy to operateMultistage water/sewage treatmentWaste water treatment from plant processingTreatment resultsAfter treatment

The invention discloses a wastewater advanced treatment method of pulping and paper making from waste paper and a treatment system thereof. The system is a wastewater advanced treatment system formed in a way that a pre-coagulation tank, a coagulation reaction tank, a coagulation sedimentation tank, an advanced oxidation treatment device, a catalytic ozonation device and a biomembrane contact oxygenation device are connected in sequence. The system can realize the organic combination of the coagulation sedimentation treatment, the advanced oxidation treatment, catalytic ozonation treatment and biomembrane contact oxygenation treatment. The wastewater treatment of pulping and paper making from waste paper is carried out by the combination of physical, chemical and biological treatments, and can achieve better treatment result on the premise that low operation cost is guaranteed. After treatment, the effluent can not only meet the first class discharge standard, but also meet the requirements of industrial reused water.

Owner:SOUNDGRP CO LTD

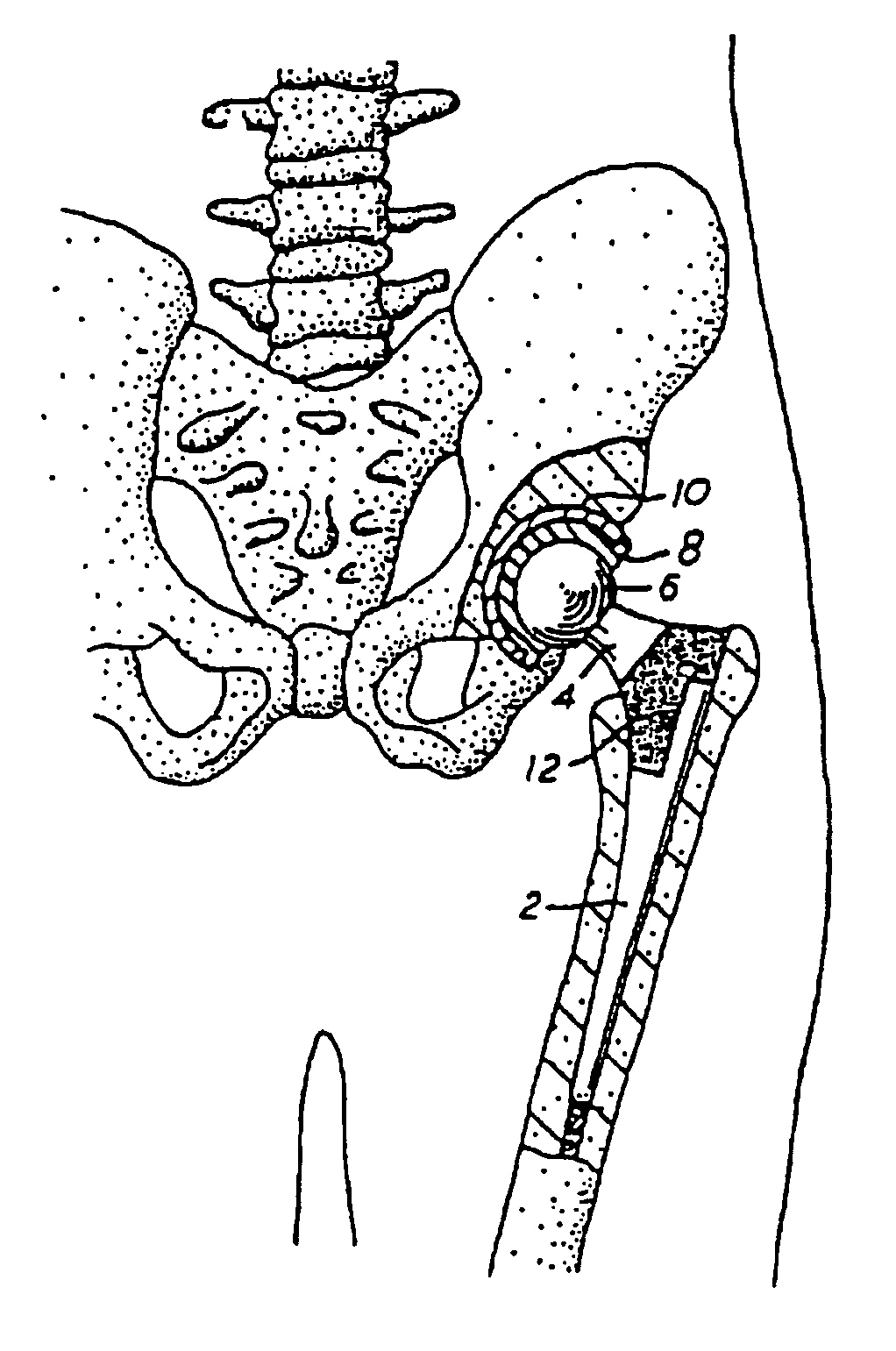

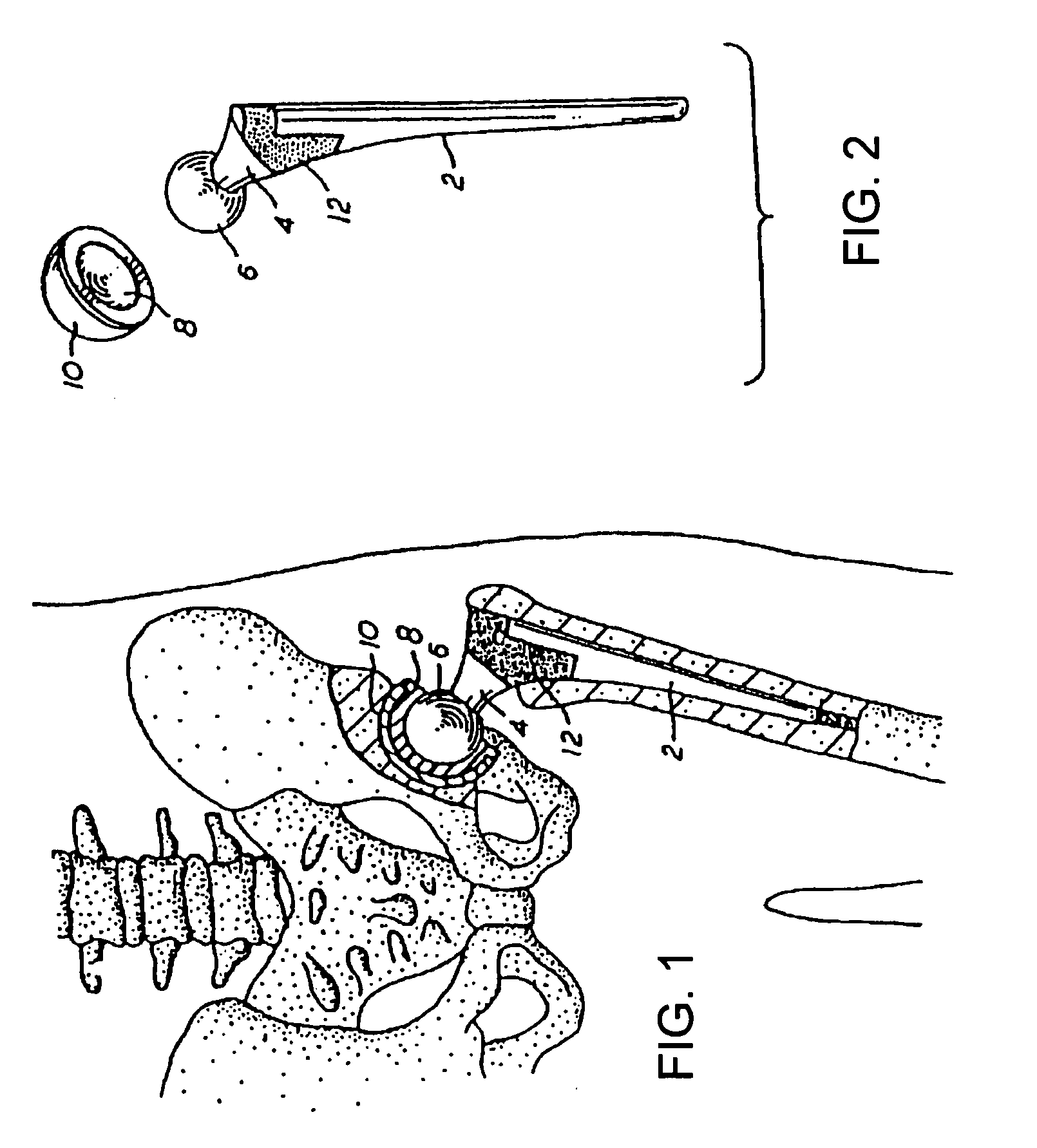

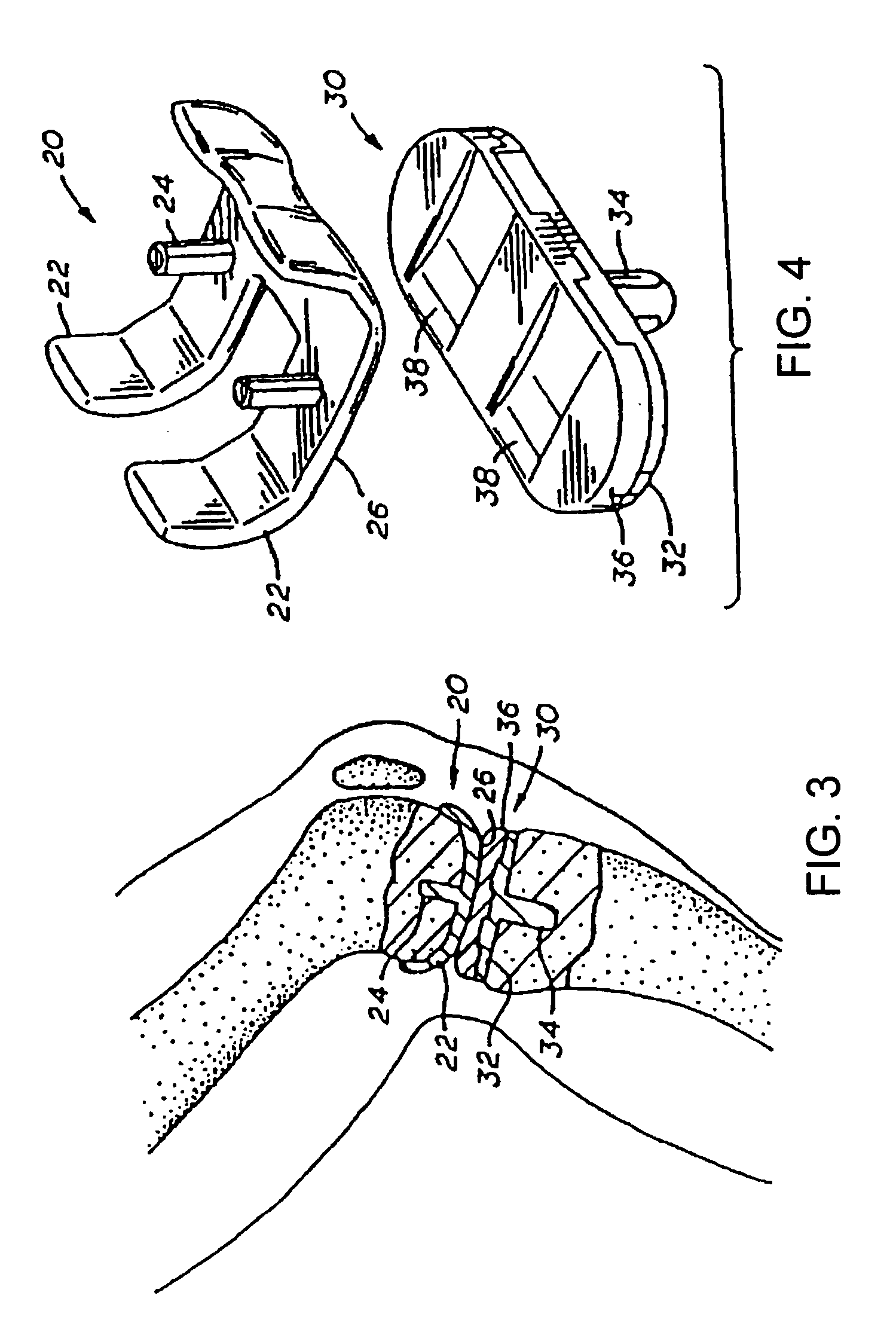

Method of surface oxidizing zirconium and zirconium alloys and resulting product

ActiveUS20060058888A1Bone implantSurface reaction electrolytic coatingWear resistantSurface oxidation

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the oxidative treatment of an amorphous zirconium or zirconium alloy substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com