Coal chemical industry wastewater treating method

A technology for coal chemical wastewater and treatment methods, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor effluent quality and high operating costs, and achieve strong adaptability , low operating cost and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

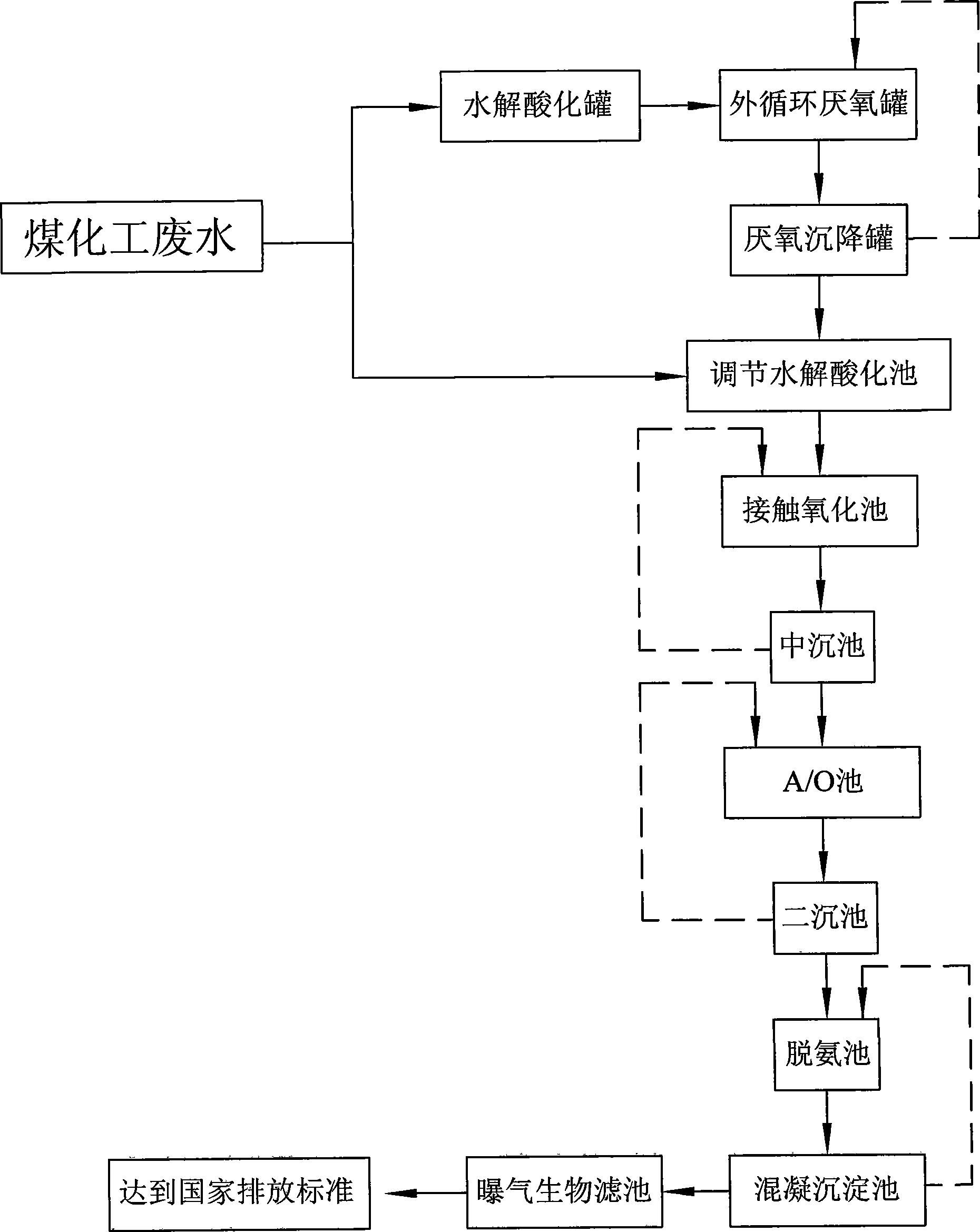

[0019] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of coal chemical industry wastewater treatment method of this embodiment is realized in this way:

[0020] 1. Hydrolysis and acidification treatment: first, the coal chemical wastewater to be treated is pretreated by phenol ammonia extraction, so that the CODcr concentration of the coal chemical wastewater pretreated by phenol ammonia extraction is controlled between 2000mg / L and 4000mg / L, and the total phenol concentration Control between 400mg / L~800mg / L, unit phenol concentration between 150mg / L~250mg / L, NH 3-N concentration is controlled between 100mg / L~250mg / L, petroleum hydrocarbon concentration is controlled between 50mg / L~150mg / L, and then accounts for 30%~50% of the total volume of the pretreated coal chemical wastewater The coal chemical wastewater flows into the hydrolysis acidification tank for hydrolysis acidification treatment. The sludge concentration in the hydrolysis aci...

specific Embodiment approach 2

[0038] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one of this embodiment, the CODcr concentration of the coal chemical industry wastewater after phenol ammonia extraction pretreatment is 3000mg / L, and the total phenol concentration is 600mg / L, unit phenol concentration is 200mg / L, NH 3 -N concentration is 200mg / L, petroleum hydrocarbon concentration is 100mg / L, then the coal chemical industry wastewater accounting for 40% of the total volume of the pretreated coal chemical industry wastewater flows into the hydrolysis acidification tank for hydrolysis acidification treatment, the hydrolysis acidification tank The sludge concentration inside is 1500mg / L, the hydrolytic acidification treatment temperature is 35°C, the hydraulic retention time is 18h, and the volume load is 20kgCOD / m 3 d. The pH value is 6.0. With this treatment process, the COD removal rate is 10%, and the total phenol removal rate is 8%.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step two of this embodiment, the FeCl 2 4H 2 The dosage of O is 4.0mg·L -1 d -1 (where d: means day), the CoCl 2 ·6H 2 The dosage of O is 0.4mg·L -1 d -1 (where d: means day), the NiCl 2 ·6H 2 The dosage of O is 0.8mg·L -1 d -1 (where d: indicates day), the temperature in the external circulation anaerobic tank is 34°C, the hydraulic retention time is 30h, the sludge concentration is 80g / L, and the volume load is 7kgCOD / m 3 d. The pH value is 7.3. With this treatment process, the COD removal rate is 60%, and the total phenol removal rate is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com