Patents

Literature

31results about How to "Resistant to shock loads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

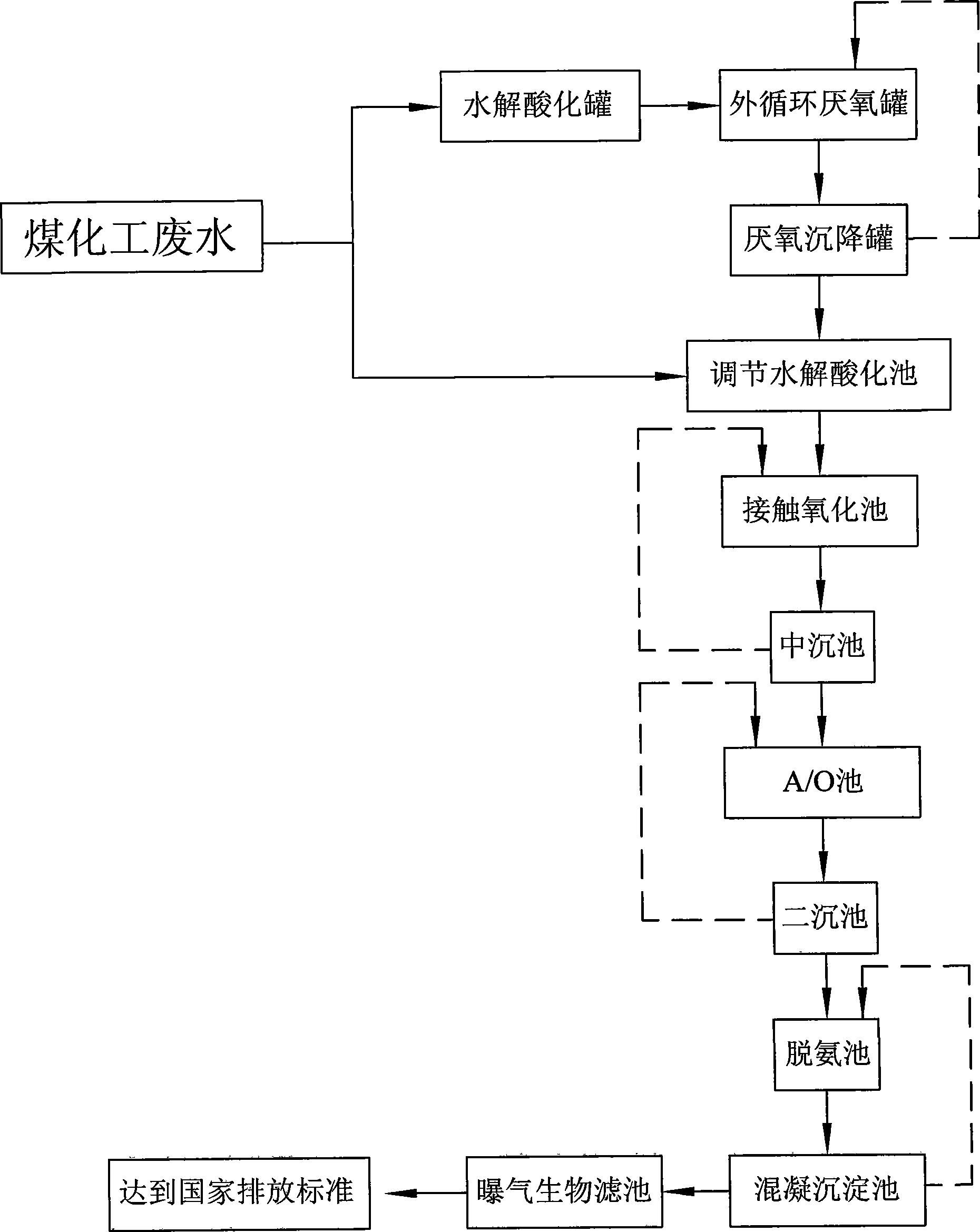

Coal chemical industry wastewater treating method

InactiveCN101503267AEasy to handleImprove the water effectWater contaminantsTreatment with aerobic and anaerobic processesOperational costsBiological filter

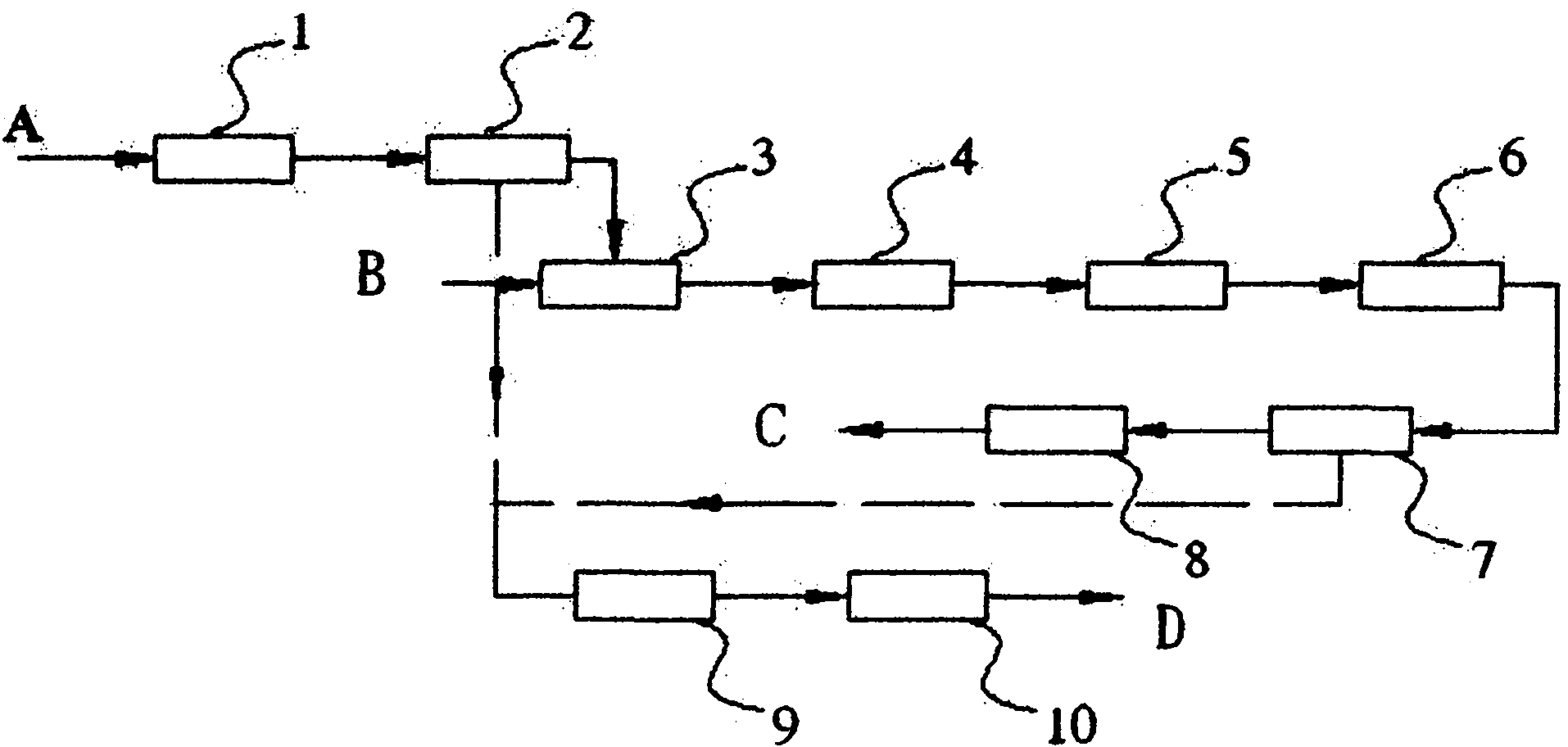

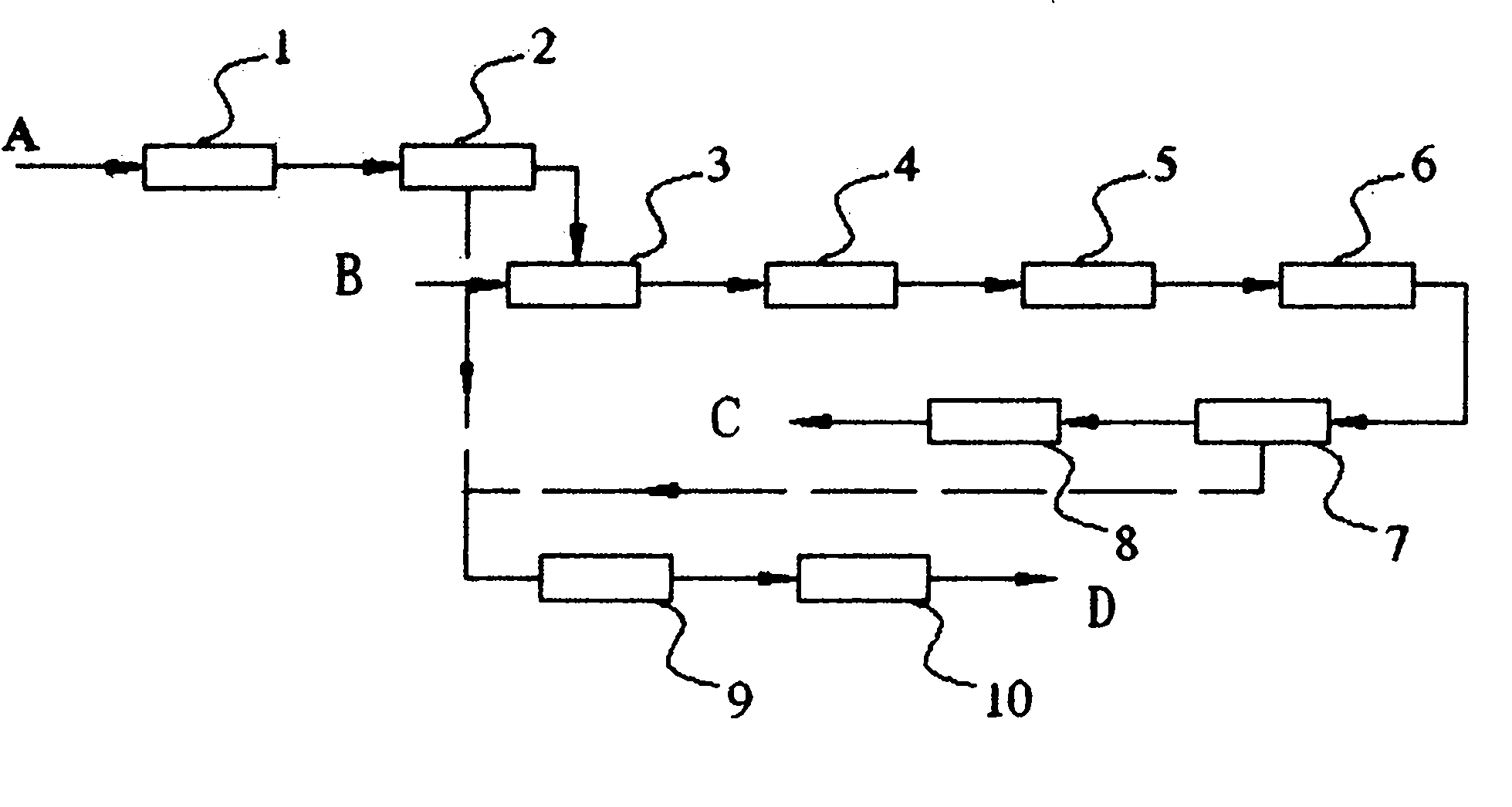

The invention relates to a coal chemical wastewater treatment method, in particular to a chemical wastewater treatment method. The invention aims to solve the problems of the chemical wastewater treatment method such as bad outlet water quality and high operational cost. The method comprises the following steps: pretreating coal chemical wastewater to be treated; then carrying out hydrolytic acidification treatment, external circulating anaerobic treatment, anaerobic sedimentation treatment, adjusting hydrolytic acidification treatment, contact oxidation treatment, sedimentation treatment, A / O treatment, sedimentation treatment, deamination treatment, coagulating sedimentation treatment and aeration biological filter tank treatment, wherein the temperature in an external circulating anaerobic tank is controlled within the scope of 32 to 35 DEG C; the hydraulic detention time is 24 to 36 h; the sludge concentration is controlled between 50 and 100 g / L; the volume load is 5 to 10 kg COD / m.d ; and the pH value is controlled between 7.0 and 7.5. The invention has the advantages of flexible operation, impact load resistance, low operating cost and good treatment effect; after the coal chemical wastewater is treated by the treatment method, the outlet water quality completely can achieve the wastewater comprehensive discharge standard regulated by the State.

Owner:HARBIN INST OF TECH

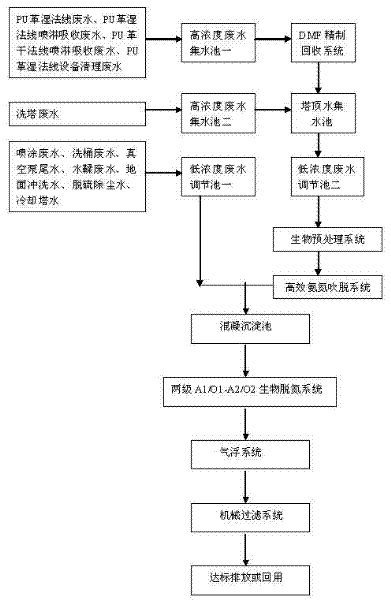

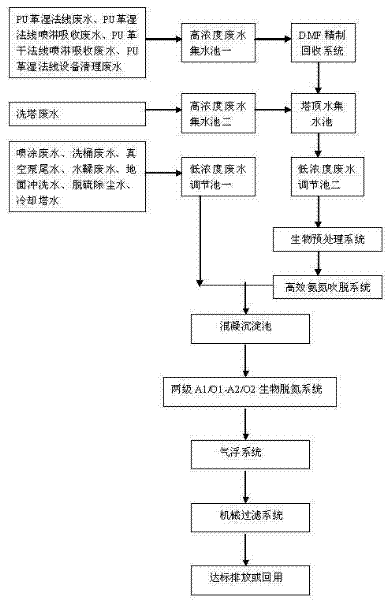

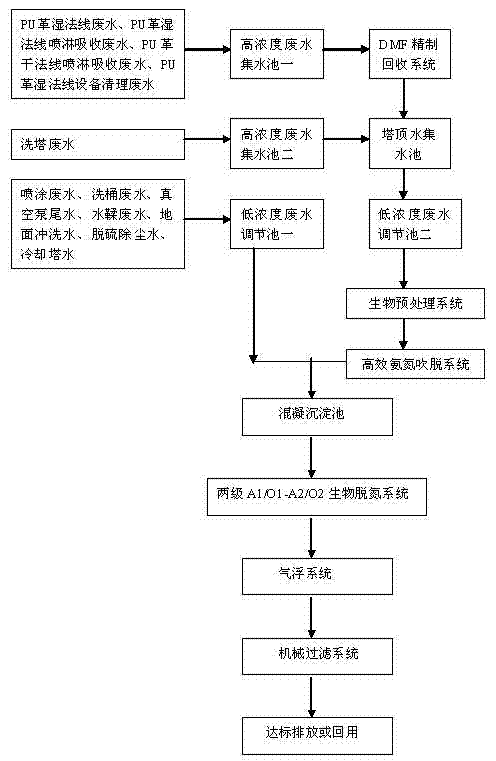

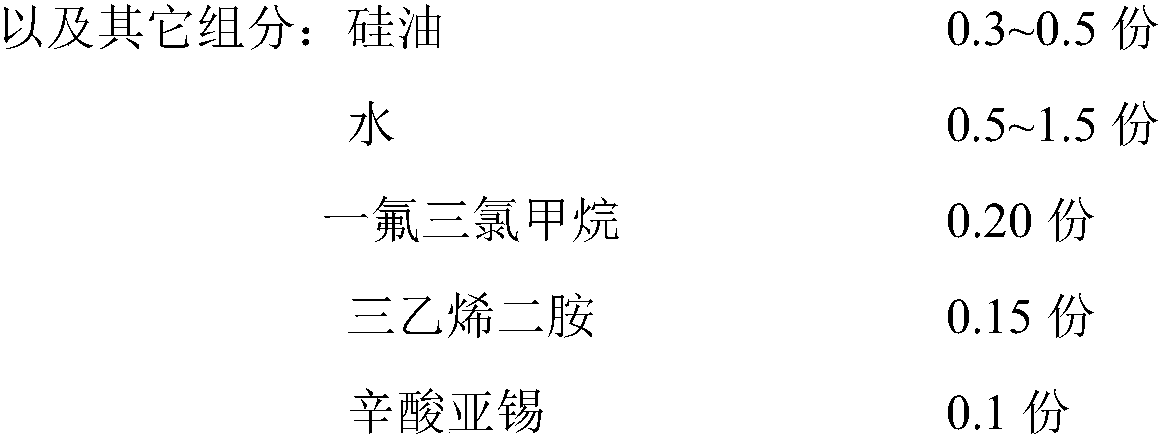

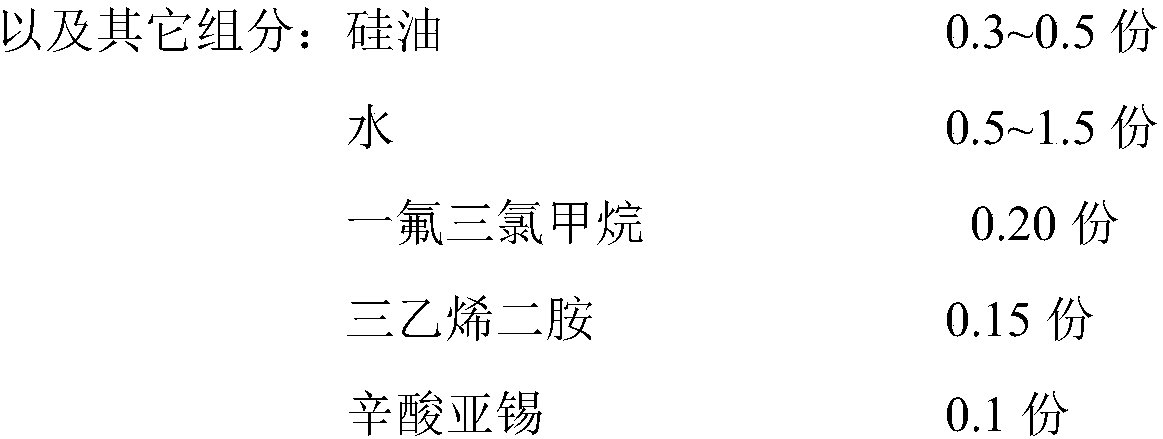

A kind of pu leather wastewater treatment method

ActiveCN102295391ATo achieve the purpose of resource utilizationLow running costMultistage water/sewage treatmentAmmoniacal nitrogenChemical oxygen demand

The invention discloses a PU (Poly Urethane)-leather wastewater-processing method, which comprises the following steps of: step 1, carrying out classified processing for wastewater in PU-leather production; step 2, carrying out biological preprocessing; step 3, carrying out high-efficiency ammonia-nitrogen blowing processing; step 4, carrying out coagulating-sedimentation processing; step 5, carrying out two-stage A1 / O1-A2 / O2 biological-denitrification processing; step 6, carrying out air-flotation processing; and step 7, carrying out mechanical-filtration processing. Through the PU-leather wastewater-processing method, COD (Chemical Oxygen Demand) and ammonia nitrogen in the wastewater can be removed, the wastewater being processed is ensured to be discharged after reaching standards, the problems of impacts of the high-concentration wastewater to a wastewater-processing system and the influence of biological-denitrifying capability reduction caused by the increase of ammonia-nitrogen concentration after the anaerobic hydrolysis of DMF (Dimethyl Formamide) in the wastewater are solved, the operating expenses are reduced, the wastewater processed can be used for production, and a good economic benefit is generated.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

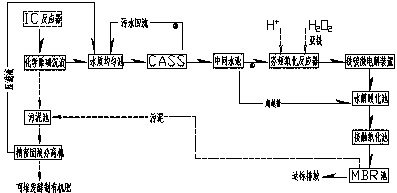

Kitchen wastewater treatment method

InactiveCN103739173AInhibition of bloomsInhibition of reproductionMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention discloses a kitchen wastewater treatment method which comprises the following steps: 1, chemical phosphorus removal is performed on kitchen wastewater flowing out from an IC (internal circulation) reactor; 2, after passing through a water quality equalization tank, the wastewater enters a CASS (Cyclic Activated Sludge System) to react, so that soluble substrates, organisms, phosphorus and an synchronous nitrification and denitrification effect are removed; 3, after the wastewater flows into an intermediate water tank to be subjected to volume regulation, the wastewater enters a Fenton oxidation reactor and an iron-carbon micro-electrolysis device so as to improve biodegradability of the wastewater; 4, after passing through the Fenton oxidation reactor and the iron-carbon micro-electrolysis device, the wastewater directly enters a hydrolysis acidification pool from the intermediate water tank, suspended matter and iron ions are removed and sludge is separated, hydrolyzed and acidified; 5, the wastewater is subjected to aerated oxidation to remove COD (Chemical Oxygen Demand) content; 6, the wastewater enters an MBR (Meane Biological Reactor) pool and hardly degradable substances are degraded, so that the drained wastewater reaches the take-over standard of a sewage treatment plant; 7, after the sludge discharged from a chemical phosphorus removal pool and the MBR pool is processed by a precision solid-liquid separator, solids are prepared into an organic fertilizer and filter-pressing liquid enters the water quality equalization tank.

Owner:HUNAN HAISHANG ENVIRONMENTAL PROTECTION INVESTMENT CO LTD

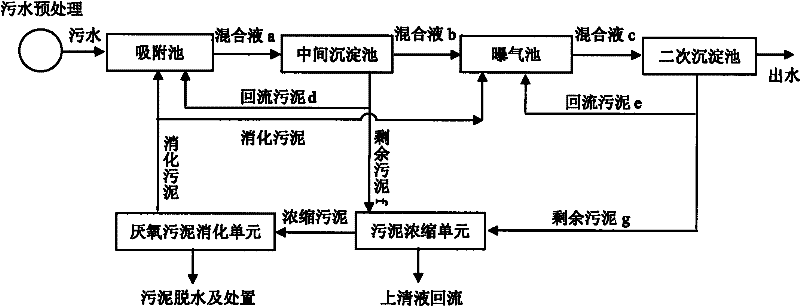

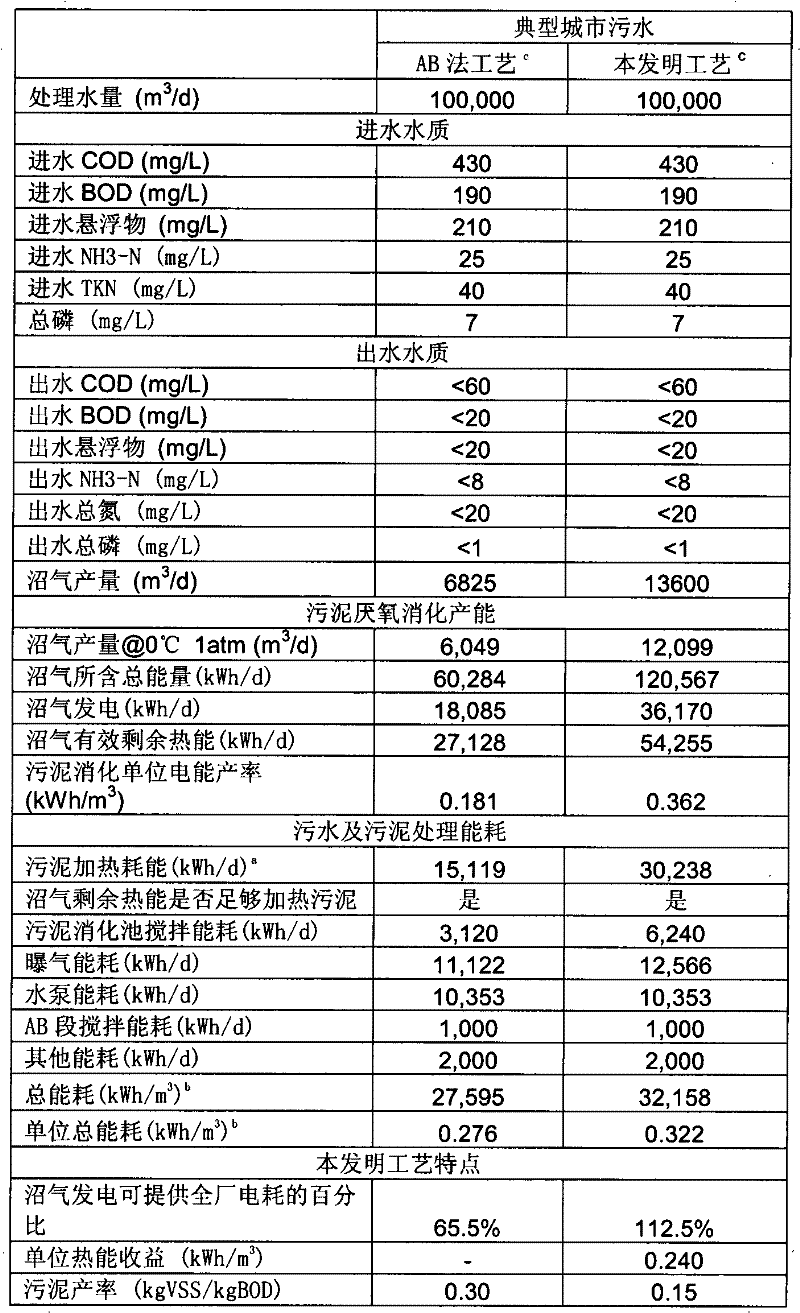

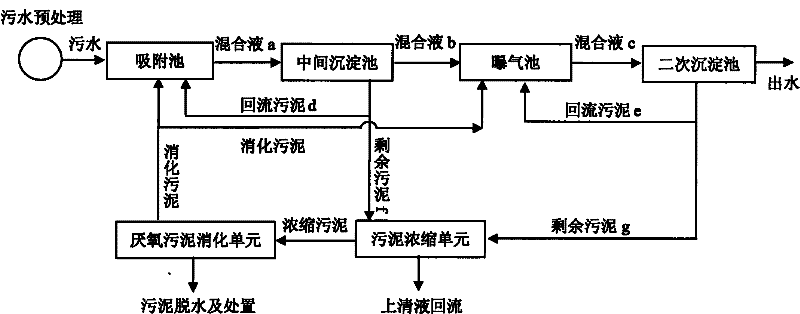

Zero-energy-consumption enhanced AB (adsorption-biodegradation) treatment method for urban sewage

ActiveCN102225825AResistant to shock loadsGuaranteed uptimeSludge treatment by de-watering/drying/thickeningWaste based fuelDigestion TreatmentAnaerobic sludge

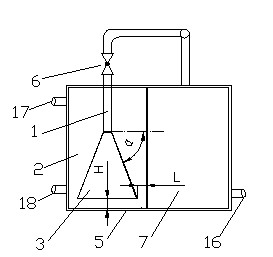

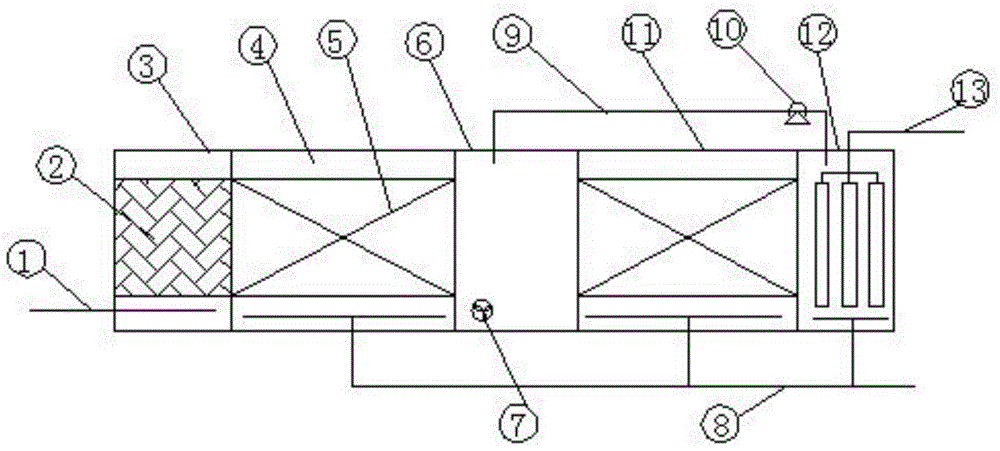

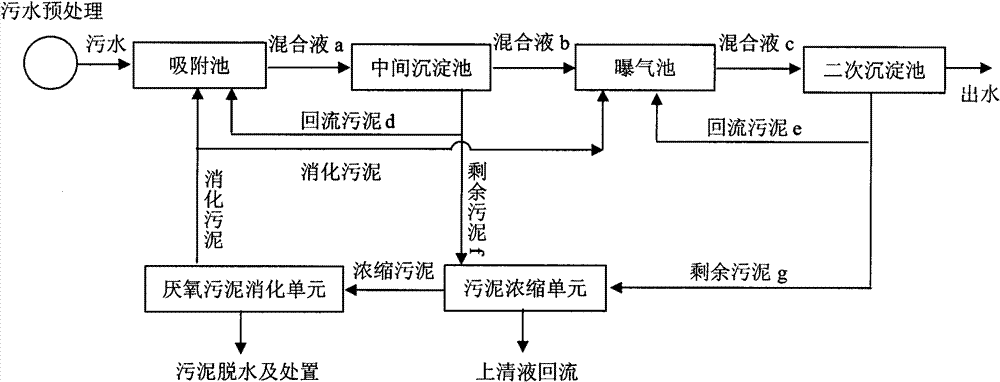

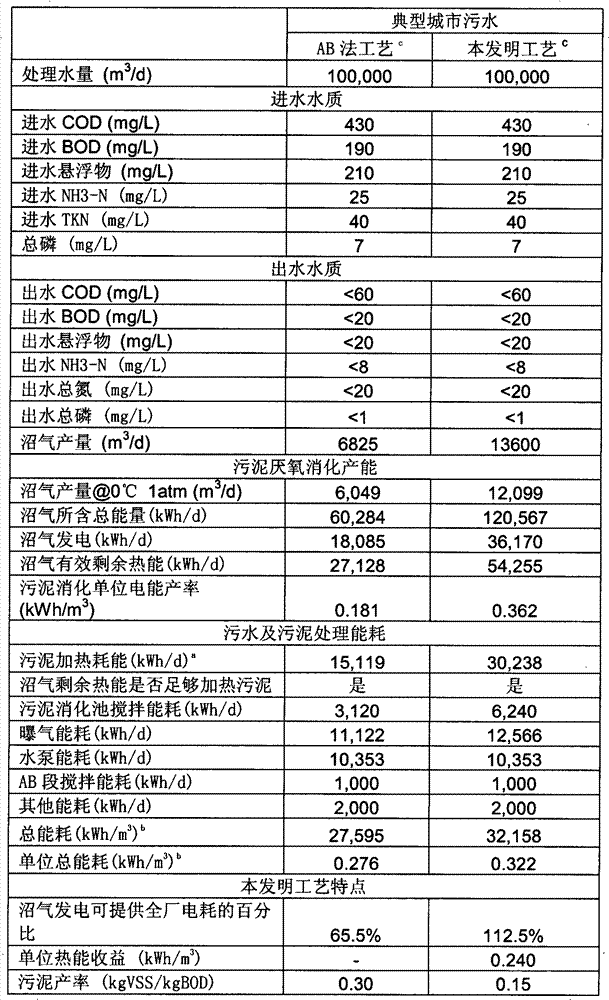

The invention provides a resource treatment method of urban sewage and relates to a sewage treatment technology. The invention discloses a zero-energy-consumption enhanced AB (adsorption-biodegradation) treatment method for urban sewage, which includes the following steps of: simultaneously introducing pretreated urban sewage and digested sludge returned from an anaerobic sludge digestion unit into an adsorption tank for biochemical adsorption reaction; introducing the effluent of the adsorption tank into an intermediate settling tank for sludge-water separation and introducing clarified sewage into an aeration tank; carrying out organic matter biodegradation, nitrification and other biochemical reactions on the sewage and sludge in the aeration tank; introducing the effluent mixed liquidof the aeration tank into a secondary settling tank for sludge-water separation; concentrating the excess sludge discharged from the intermediate settling tank and secondary settling tank sludge and discharging to the anaerobic sludge digestion unit for digestion treatment; and digesting the sludge in the anaerobic sludge digestion unit under an anaerobic condition, returning part of the digestedsludge to the adsorption tank or the aeration tank and dewatering the other part of the digested sludge for sludge treatment.

Owner:深圳市君脉膜科技有限公司

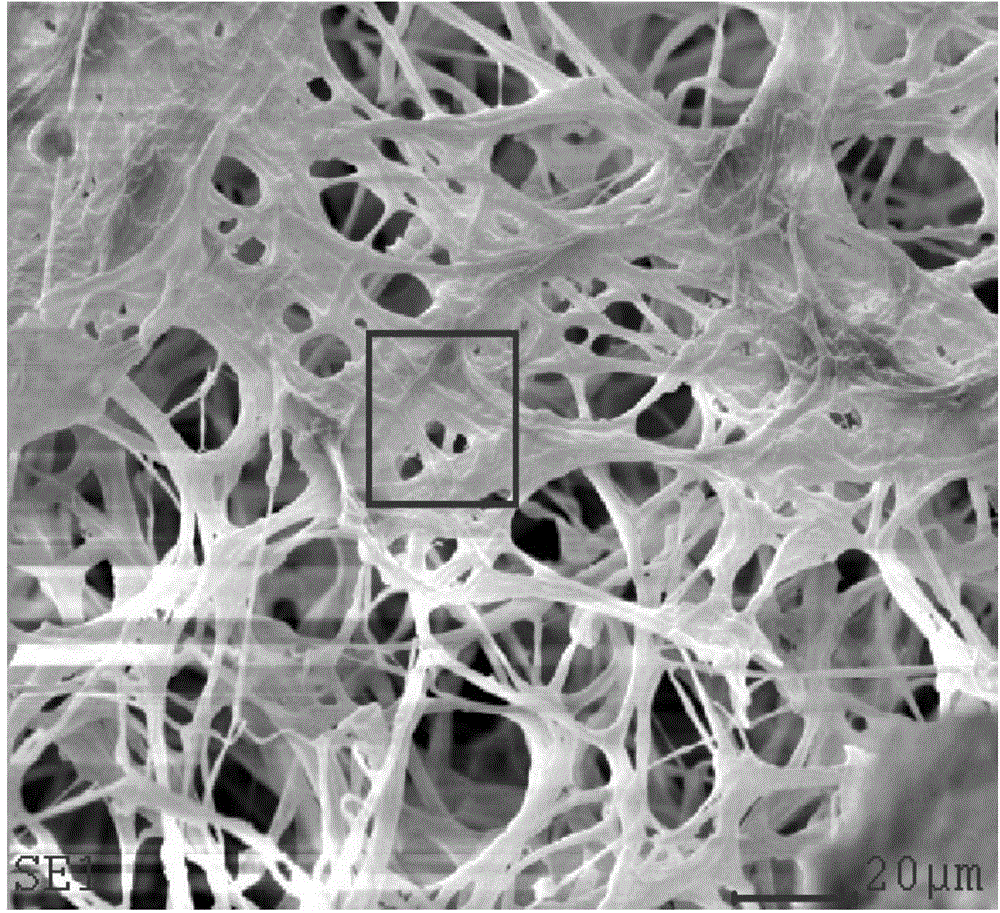

Compound microbial preparation as well as preparation method and application thereof

InactiveCN104313008AToxicAnti-bacteriaWater contaminantsOn/in organic carrierBiotechnologyPhanerochaete

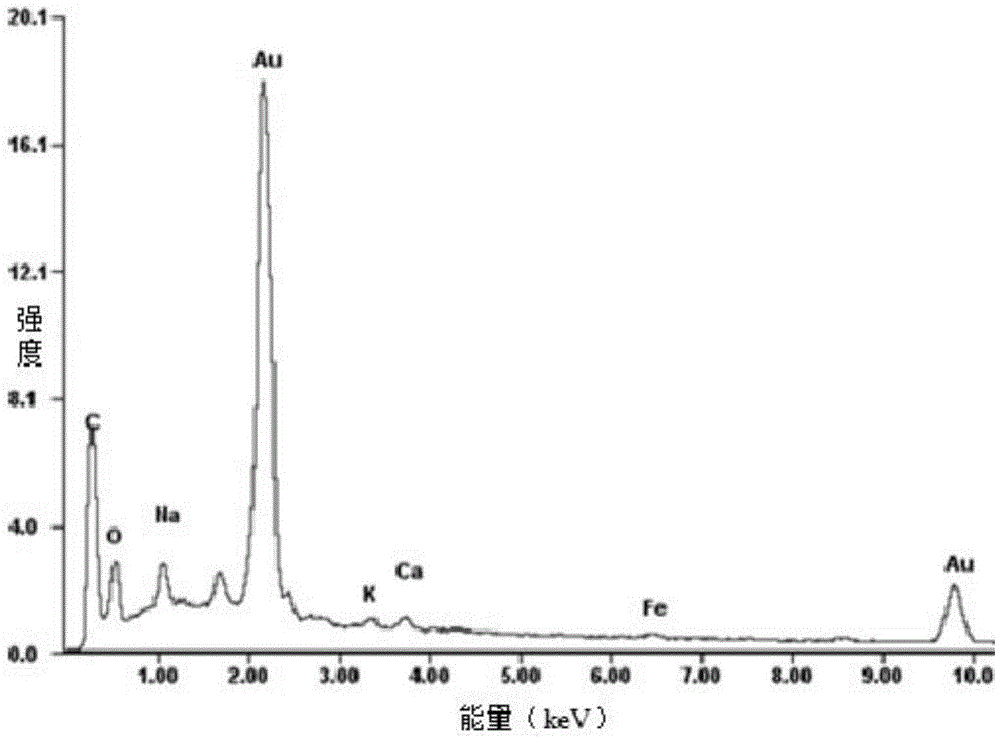

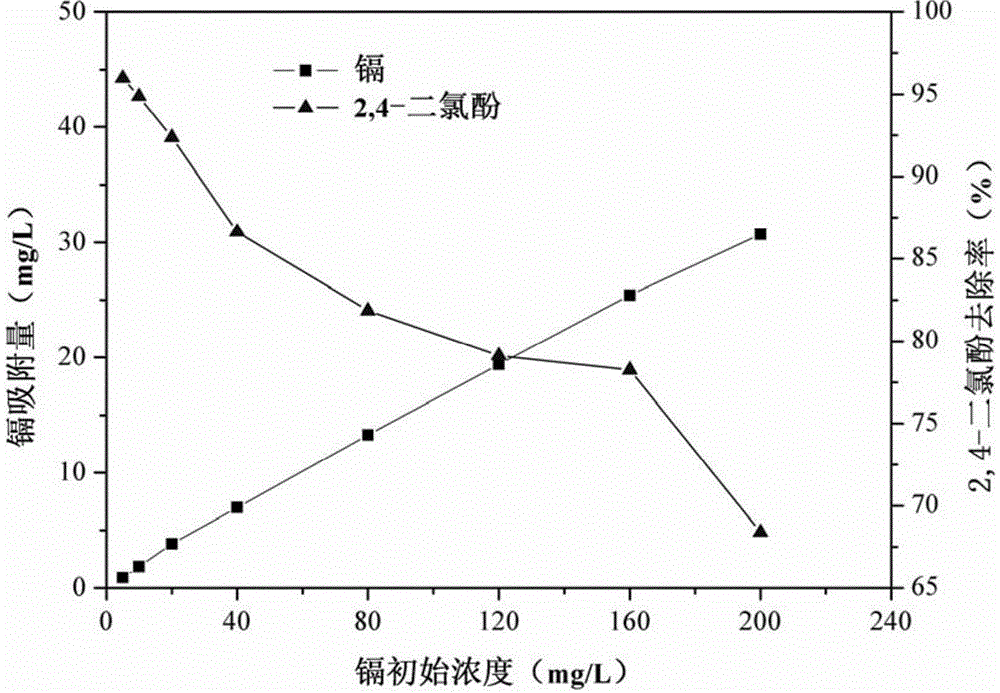

The invention discloses a compound microbial preparation as well as a preparation method and application thereof. The preparation comprises phanerochaete chrysosporium balls, polyvinyl alcohol, silicon dioxide, activated carbon, sodium alginate and zeolite powder, which form the compound microbial preparation through crosslinking by a solution with sodium dihydrogen phosphate. The preparation method comprises the steps of preparing a gel liquid with the polyvinyl alcohol, sodium alginate, silicon dioxide and zeolite powder, mixing with a phanerochaete chrysosporium spore suspension with the activated carbon, then gradually dripping into the solution with the sodium dihydrogen phosphate so as to prepare embedded balls, and cultivating by a Kirk inorganic culture solution so as to prepare the compound microbial preparation. The compound microbial preparation has many gaps, high adsorption efficiency and good selectivity, the adsorbent has strong stability, the preparation method has the advantages of simple operation, low cost, affordability and so on, and the compound microbial preparation can be used for eliminating cadmium and 2, 4-dichlorophen in waste water.

Owner:HUNAN UNIV

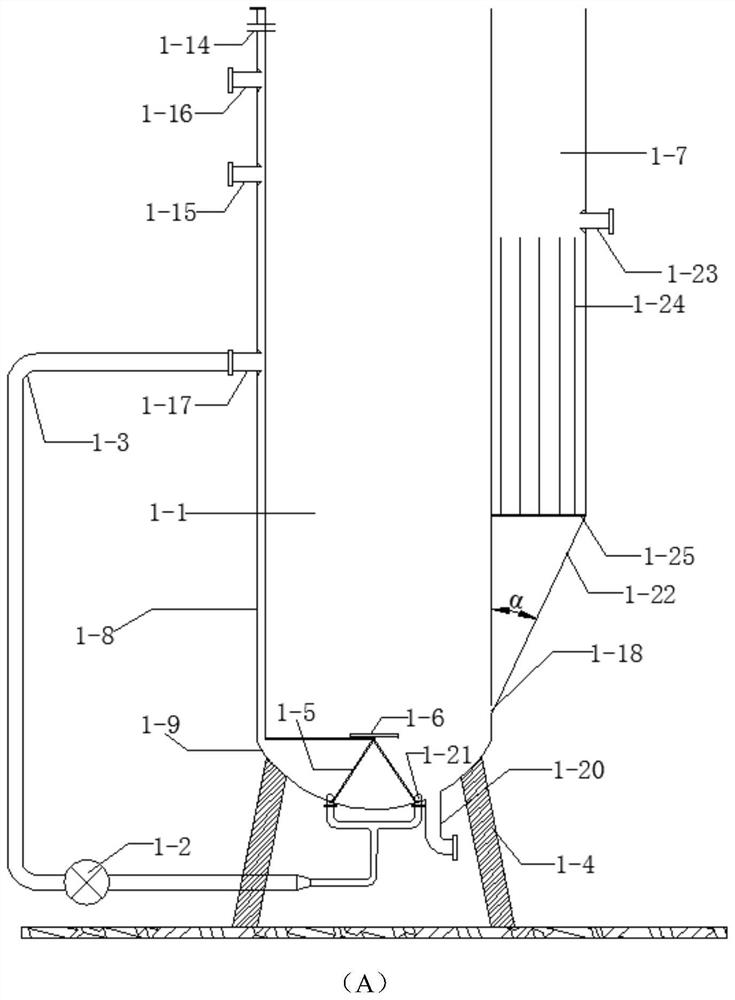

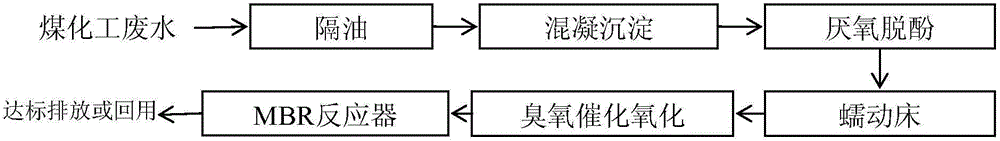

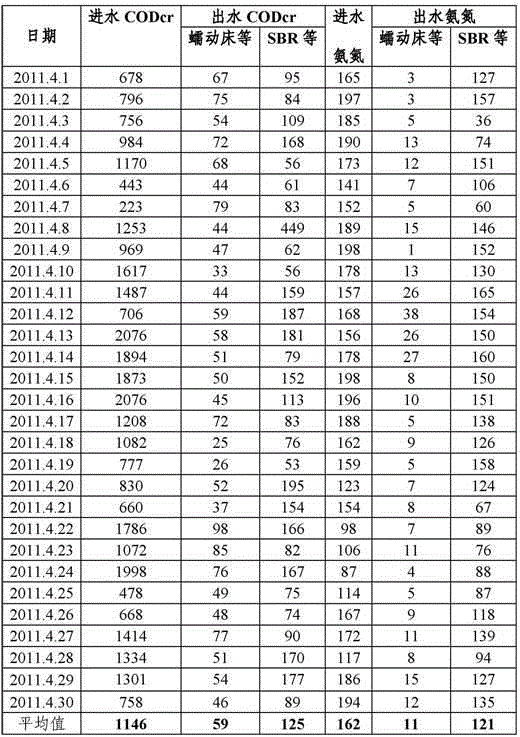

Treatment method of coal chemical waste water

ActiveCN104310712AGood removal effectEasy to handleMultistage water/sewage treatmentBiological water/sewage treatmentChemical oxygen demandTotal nitrogen

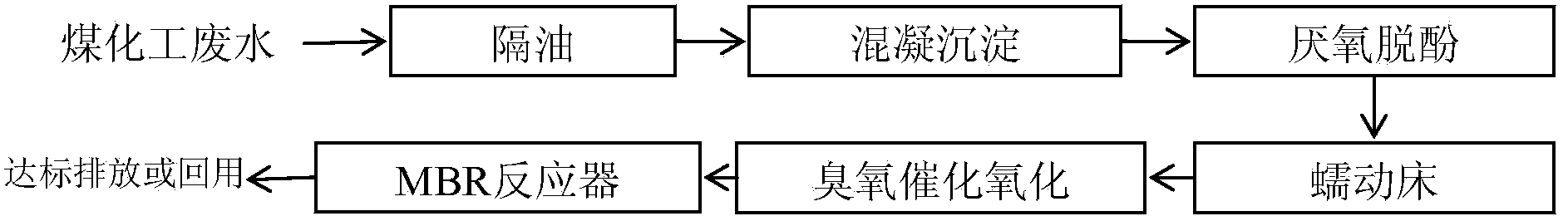

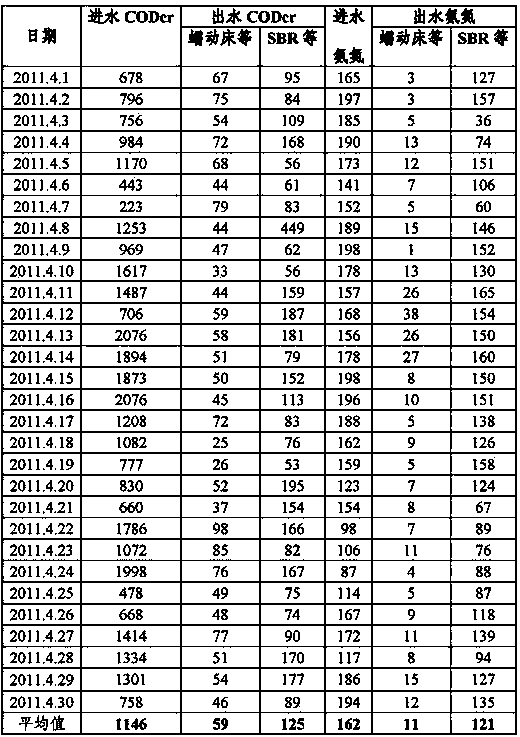

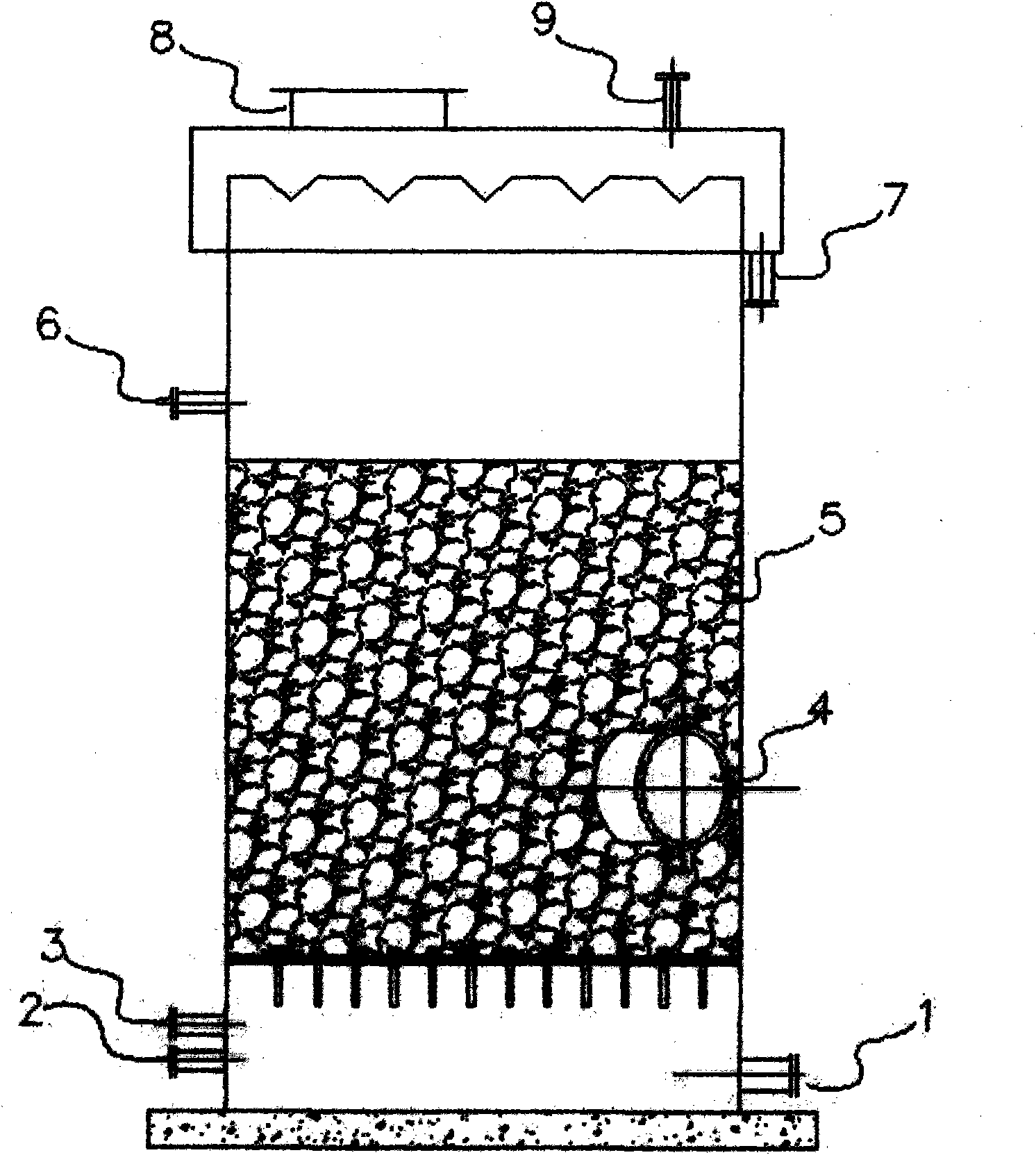

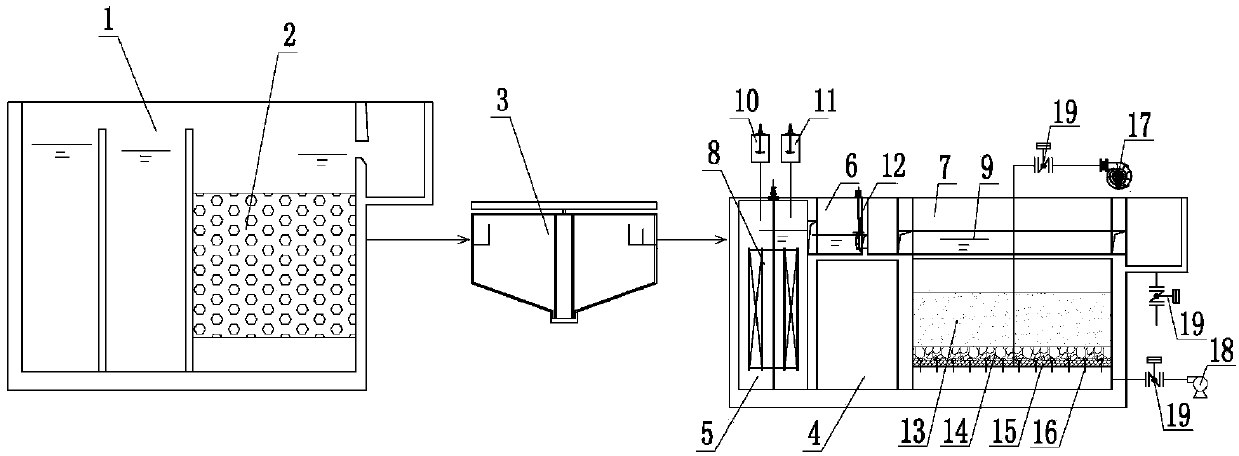

The invention relates to a treatment method of coal chemical waste water. The method comprises the following steps: oil separation, coagulating sedimentation, anaerobic dephenolization, a peristalsis bed, catalytic ozonation, an MBR (Membrane Bio-Reactor) and a clean water reservoir. The coal chemical waste water is treated through the combination of anaerobic dephenolization, the peristalsis bed, catalytic ozonation, the MBR and the like, and the first-grade emission standard of Integrated Wastewater Discharge Standard GB8978-1996 can be met. The purposes of simultaneously removing ammonia nitrogen and total nitrogen while removing COD (Chemical Oxygen Demand) in the peristalsis bed are achieved through fixing an aerobic denitrification microorganism ZHB35 in a biocarrier of the peristalsis bed, moreover, the removal of total phosphorous can be promoted. The treatment method has strong practicability, is suitable for new construction, upgrading and reconstruction engineering of waste water plants, can effectively reduce capital investment and running cost, and has the advantages of impact load resistance, simplicity in management, stable running, great treatment effect and the like.

Owner:BEIJING GEOENVIRON ENG & TECH

Method of all self-oxygen ammonia nitrogen removal by particle sludge

InactiveCN101928068AReduce system space and engineering costReduce operational difficulty and operating costsTreatment with aerobic and anaerobic processesChemistryCarbon source

The invention relates to the technical field of ammonia nitrogen removal in waste water treatment, in particular to a method of all self-oxygen ammonia nitrogen removal by particle sludge. The method comprises the following steps: loading inoculated active sludge into an upflow anaerobic sludge bed reactor; pumping ammonia nitrogen waste water which does not contain organic carbon source out of the bottom of the reactor; causing the waste water to flow out of the upper part of the reactor after flowing through the sludge bed; meanwhile, adopting air aeration; after cultivating for 40-105 days, obtaining favourable all self-oxygen ammonia nitrogen particle sludge; and converting ammonia nitrogen parts into nitrogen gas, and effectively removing the nitrogen gas. The nitrogen removal particle sludge obtained by the method of the invention has good performance, can improve the volume load and operation stability of the reactor, does not need additional carbon resource, is suitable for processing waste water with high ammonia nitrogen ration and low carbon nitrogen ratio and inorganic waste water containing nitrogen.

Owner:DONGGUAN UNIV OF TECH

Culture method of aerobic denitrification particle sludge

InactiveCN101928067AHigh volume loadImprove removal efficiencyTreatment with aerobic and anaerobic processesActivated sludgeNitrite

The invention relates to the technical field of a culture method of particle sludge in a biological treatment technology of waste water, in particular to a culture method of aerobic denitrification particle sludge. The method comprises the following steps: putting inoculated activated sludge into an upflow-type aerobic sludge bed reactor; pumping in waste water containing nitrite and nitrate and organic matters from the bottom of the reactor; ensuring that the waste water flows out of the upper part of the reactor after passing through the reactor; and meanwhile, adopting air aeration, obtaining favourable aerobic denitrification particle sludge after the materials are cultured for 35-120 days. The aerobic denitrification particle sludge obtained by the method has good performance, and the volume loading, the removal efficiency and the operation stability of the reactor can be improved.

Owner:DONGGUAN UNIV OF TECH

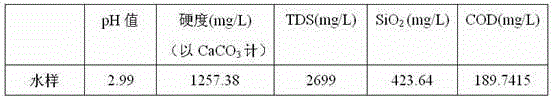

Pretreatment technology of high-salinity wastewater

InactiveCN104556475AResistant to shock loadsFull chemical reactionWater contaminantsWater softeningChemical reactionSludge

The invention discloses a pretreatment technology of high-salinity wastewater. The technology comprises the following steps: feeding sewage into a chemical reaction pond, feeding sodium carbonate and soda lime to water according to the sewage quality characteristics, and rapidly reacting with raw material, crystallizing and separating out kinds of scale forming matters in water, and removing the hardness in water; feeding the sewage to a coagulation dosing pool, feeding a magnesia mixture to the sewage which is subjected to hardness treatment in the step 1, reacting with SiO2 and the magnesia mixture in the sewage, participating and separating out; destabilizing colloid under the action of a coagulant and forming a precipitable flocculent body; feeding the sewage to a flocculent precipitation-concentration pond system, separating alumen ustum from water, accelerating concentration of the sludge participating at the bottom of the pond by virtue of a concentration stirrer with a mud scraper system; and continuously circulating partial sludge into a flocculation basin, simultaneously extracting the residual sludge at regular periods, and feeding to a sludge treatment system. The technology disclosed by the invention has the advantages of full chemical reaction, low residual hardness, good flocculent precipitation effect and impact load resistance and the like; and agents are saved.

Owner:BEIJING SCINOR WATER TECH CO LTD

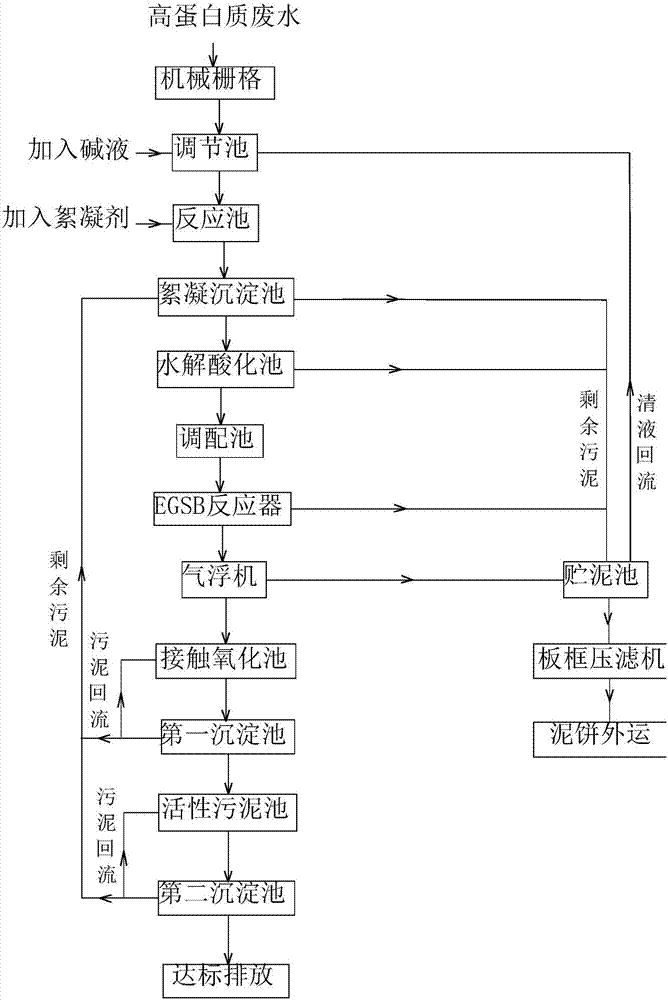

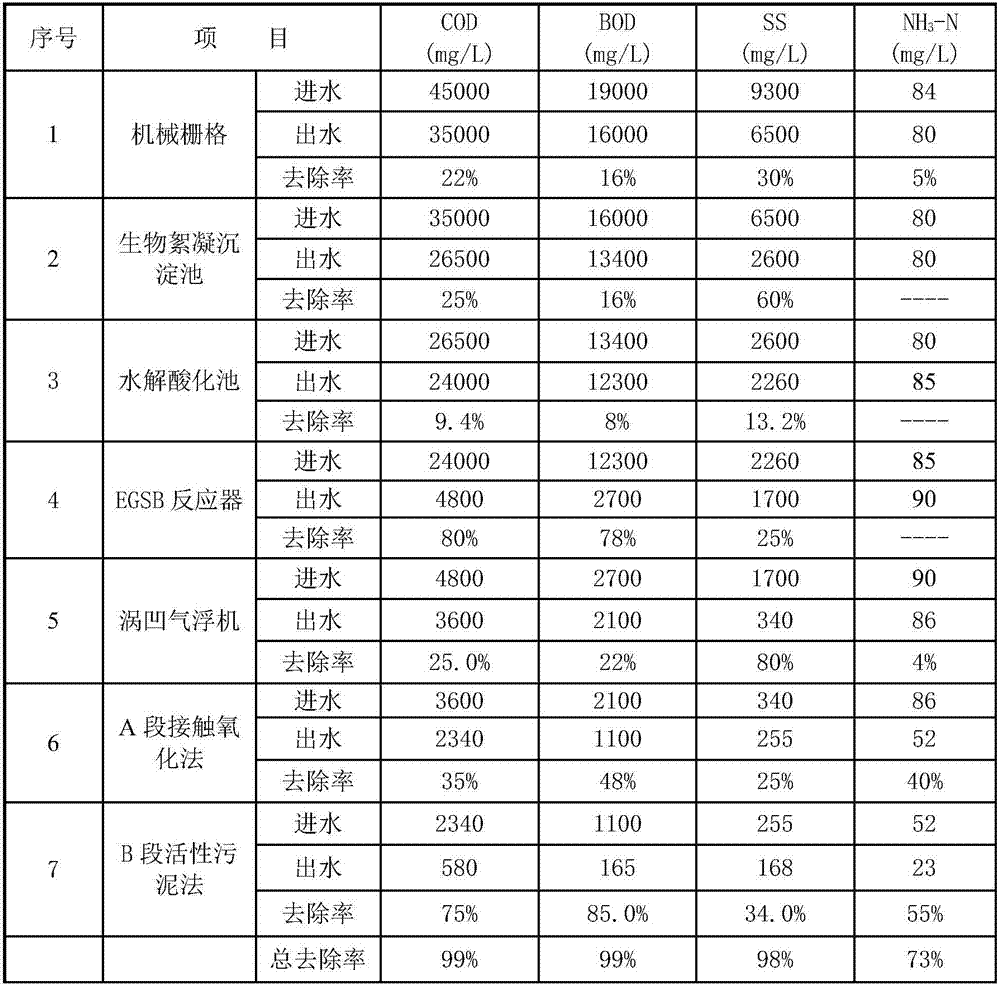

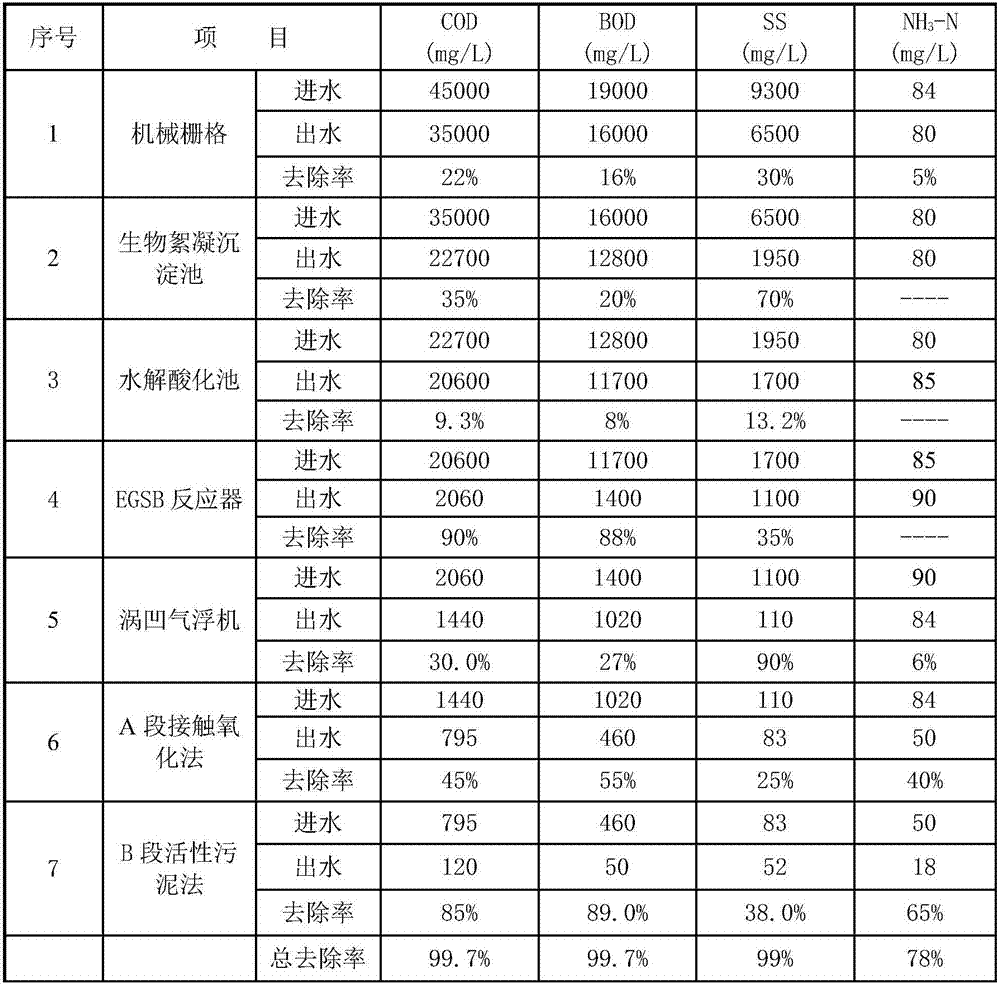

High-protein wastewater treatment process

InactiveCN107500476ALow running costEasy to handleTreatment involving filtrationTreatment with anaerobic digestion processesFlocculationTreatment effect

The invention belongs to the technical field of wastewater treatment and provides a high-protein wastewater treatment process. The high-protein wastewater treatment process adopts a mechanical grid, a regulating pond, a reaction pond, a flocculation settling pond, a hydrolysis acidification pond, a mixing pond, an EGSB reactor, an air-floated machine, a contact oxidation pond, a first settling pond, an active silt pond and a second settling pond. By means of the technical solution, the problems of poor high-protein wastewater treatment effect and high operation cost of a wastewater treatment process in the prior art are solved.

Owner:河北德龙环境工程股份有限公司

Recombinant decorative material production waste water treatment process

InactiveCN101885561AResistant to shock loadsGuaranteed uptimeMultistage water/sewage treatmentSmall footprintOxygen

The invention discloses a recombinant decorative material production waste water treatment process, which comprises the following steps in turn: pre-treating bleaching water and dyeing water, introducing the pretreated bleaching and dyeing water into an iron carbon tower, performing the coagulating sedimentation and mixing the bleaching and dyeing water with panel cleaning water; delivering the mixed waste water into a hydrolysis acidification tank by using a lifting pump to perform anaerobic treatment; delivering the effluent of the hydrolysis acidification tank to a secondary contact oxidization tank for aerobic treatment; delivering the effluent of the aerobic tank into a secondary sedimentation tank for sedimentation, concentrating sludge and returning part of effluent to the hydrolysis acidification tank; and introducing the effluent of the secondary sedimentation tank to a floataion tank to perform further decoloration and discharging the waste water reaching discharging standards. The invention also comprises the iron carbon tower designed according to process requirements. The iron carbon tower is formed by a round steel tank body, the top part of the tank body is sealed and is provided with a feed inlet and an exhaust hole, waste water enters the tank body from a water inlet, and the waste water is discharged from a water outlet after complete reaction. The process has the advantages of low treatment cost, good decoloration effect, small floor area, small single investment, stable operation and the like. The process was successfully used by a recombinant decorative material manufacturer in Jiangsu province and passed the local environmental protection inspection and acceptance.

Owner:深圳嘉汉林业科技有限公司

Biochemical pool MBBR process and denitrification deep-bed filter tank coupled nitrogen and phosphorus removal system and method thereof

PendingCN109650652APrecise Dosing Control MeasuresResistant to shock loadsWater contaminantsTreatment involving filtrationFlocculationControl valves

The invention relates to a biochemical pool MBBR process and denitrification deep-bed filter tank coupled nitrogen and phosphorus removal system and a method thereof. The system comprises a biochemical pool and a secondary sedimentation tank. The biochemical pool is divided into at least two chambers. In the chamber close to the outlet are arranged several suspended fillers. The denitrification deep-bed filter tank is located downstream the secondary sedimentation tank. The denitrification deep-bed filter tank comprises a flocculation basin, inside which a stirring mechanism is arranged and the top of which is provided with a carbon source dosing mechanism and a flocculating agent dosing mechanism. A water inlet main canal is connected downstream, and an intake gate is arranged in the water inlet main canal. A filter grid is arranged downstream. An intake canal is connected under the filter grid. A filter tank is arranged under the intake canal. Inside the filter tank, a filter layer,a supporting layer, a filter board and a filter head disposed on the filter board are successively arranged from top to bottom. The denitrification deep-bed filter tank also comprises a backwashing fan and a backwashing water pump. The outlet of the backwashing fan extends through a pipeline to the supporting layer, and the outlet of the backwashing water pump extends through a pipeline into the filter tank below the filter board. The pipelines are all provided with a control valve. The system of the invention can perform denitrification and physical interception to remove phosphorus.

Owner:浙江中昌水处理科技有限公司

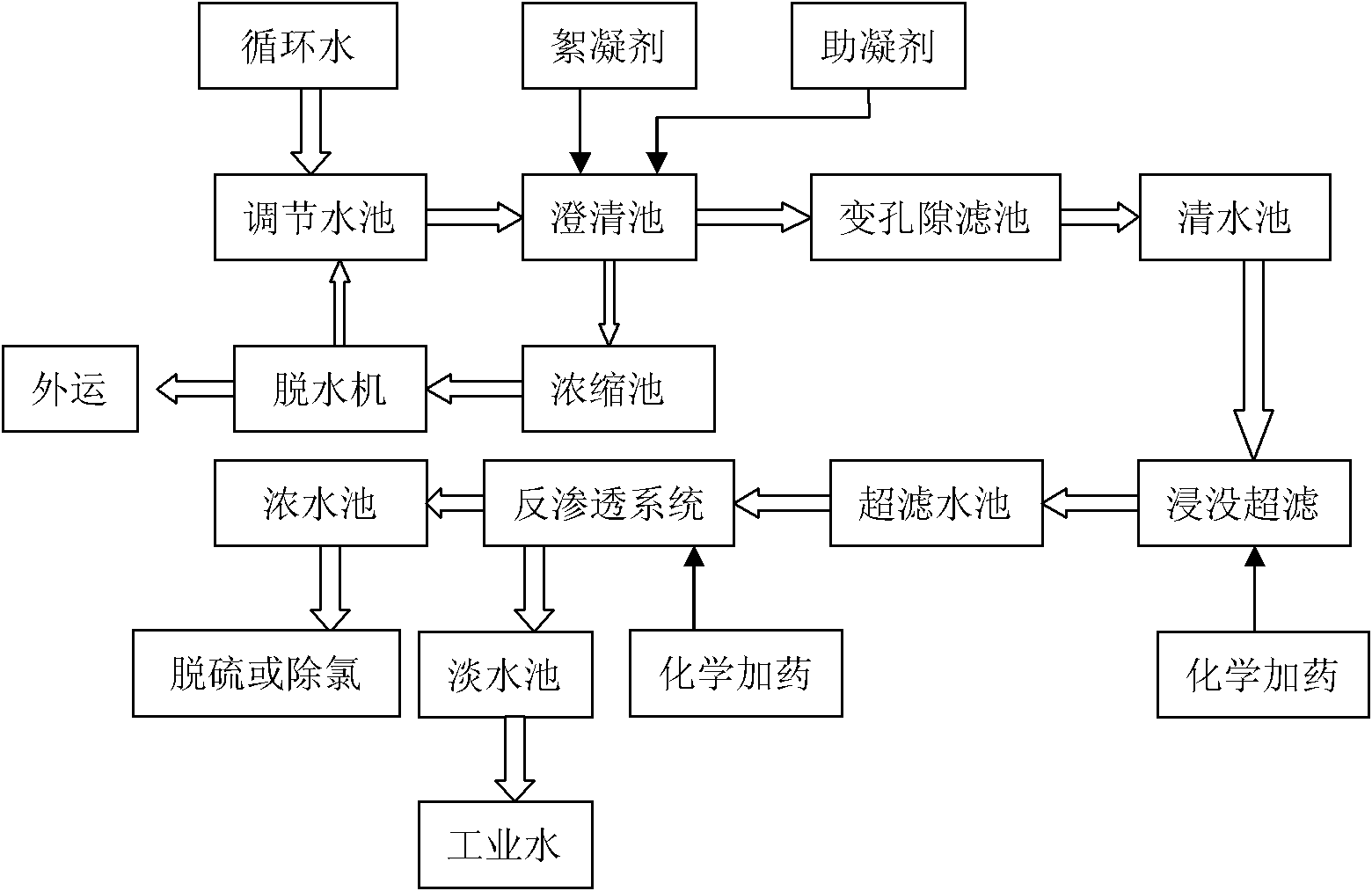

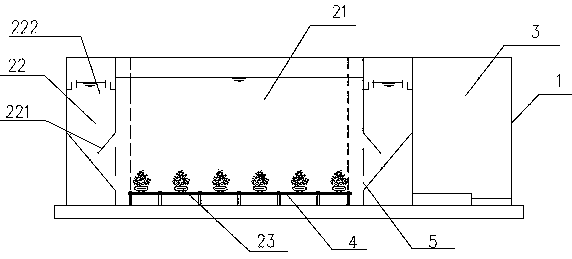

Recycling treatment process and apparatus system of power plant circulating water

InactiveCN102464412AGuaranteed uptimeEasy to installMultistage water/sewage treatmentLoad resistanceWater source

The invention discloses a recycling treatment process and a recycling treatment apparatus system of power plant circulating water. According to the invention, power plant circulating water is sequentially subject to mechanical accelerated clarification, variable void filtration, submerged ultrafiltration and reverse osmosis membrane treatments. Clear water obtained after the treatments is adopted as an industrial water source for the power plant. Compared to existing technologies, mechanical accelerated clarification, variable void filtration, submerged ultrafiltration and reverse osmosis membrane treatment technologies and an apparatus system employing the technologies are adopted. The technology and the system are advantaged in impact load resistance, low operation pressure, simple and feasible technical operation and maintenance, convenient pipeline installation, and the like. With the method and the system, recycling of power plant circulating water can be promoted. The technology and the system satisfy a development trend of energy saving and consumption reducing. With the technology and the system, recycling of water resource is effectively promoted.

Owner:董金奎

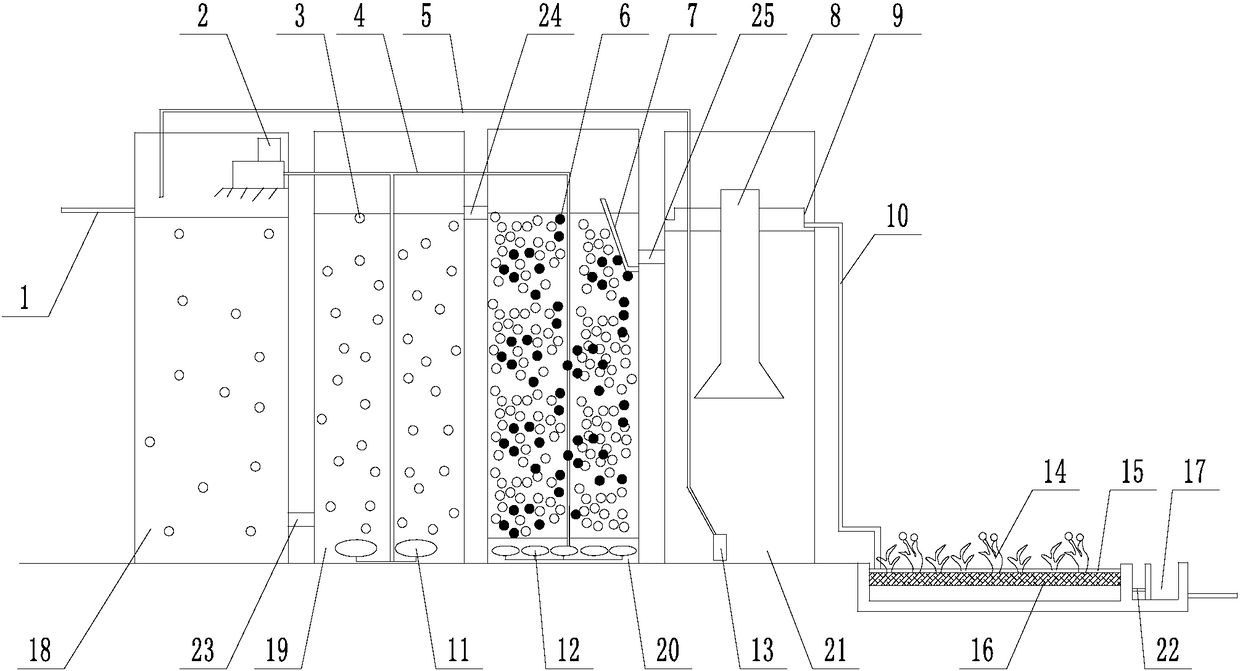

MSBBR wastewater treatment system and wastewater treatment process applying system

InactiveCN108751610APremium removalIncrease concentrationWater treatment parameter controlWater/sewage treatment by irradiationWater treatment systemSludge

The invention discloses an MSBBR wastewater treatment system. The MSBBR wastewater treatment system comprises a pond body outer wall, a reaction zone and an equipment zone, wherein the reaction zone comprises a biological reaction zone and a settling zone; the biological reaction zone is arranged at the middle part of the pond body; the settling zone is arranged at the periphery of the biologicalreaction zone; the biological reaction zone is connected with the settling zone through a draining fine seam; an aeration device and a sludge collecting pipeline are arranged at the bottom of the biological reaction zone. Besides, the invention also discloses a wastewater treatment process applying the MSBBR wastewater treatment system. The MSBBR wastewater treatment system disclosed by the invention has the advantages of stable system / technology, high-quality effluent, few constructs, land conservation, low investment cost, low energy consumption, low operation cost and the like.

Owner:四川美源环能科技有限责任公司

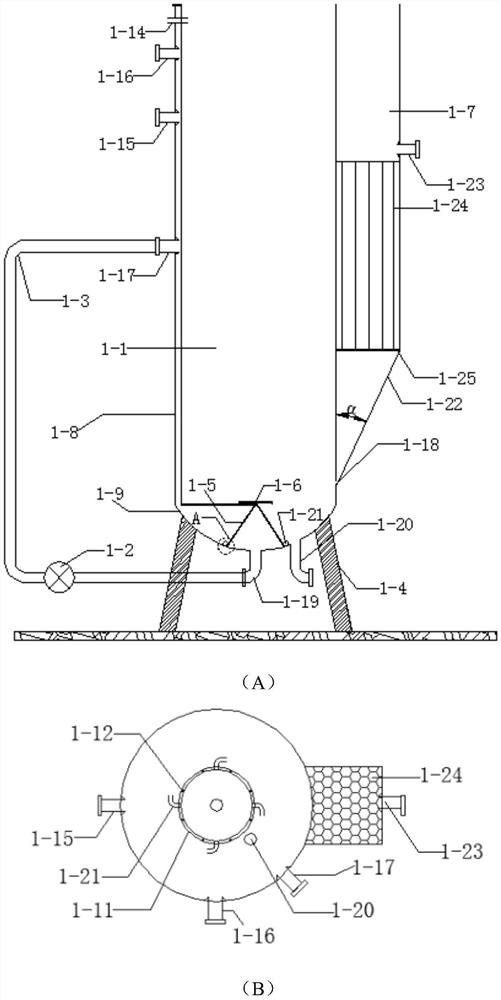

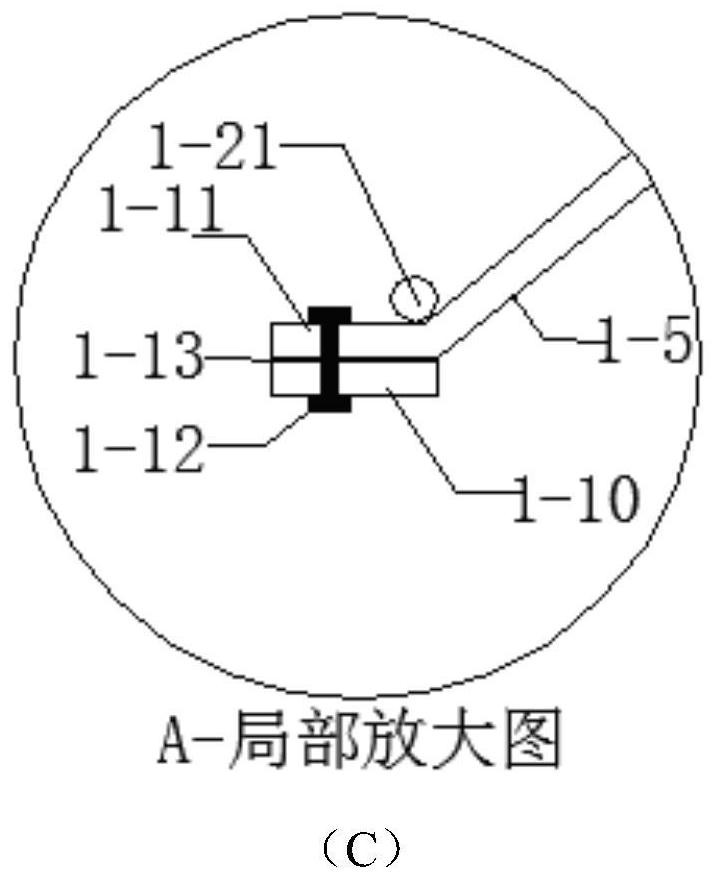

Deep-bed multiplication MBBR reactor for rural sewage treatment

InactiveCN108328879ASmall footprintShort startup timeBiological treatment apparatusMultistage water/sewage treatmentStart timeSludge

The invention discloses a deep-bed multiplication MBBR reactor for rural sewage treatment. The deep-bed multiplication MBBR reactor comprises an anaerobic tank, an anoxic tank, an MBBR tank, a secondary sedimentation tank and a micro-ecology filter bed and is characterized in that the anaerobic tank is connected with a water inlet pipe, the anaerobic tank is communicated with the anoxic tank through a pipeline I, the anoxic tank is communicated with the MBBR tank through a pipeline II, the MBBR tank is communicated with the secondary sedimentation tank through a pipeline III, the secondary sedimentation tank is communicated with the micro-ecology filter bed through a secondary sedimentation tank water outlet pipe, and plants are planted on the micro-ecology filter bed; sewage enters the water inlet pipe, flows into the anaerobic tank, is sequentially treated by the anaerobic tank, the anoxic tank, the MBBR tank and the secondary sedimentation tank and then enters the micro-ecology filter bed. The deep-bed multiplication MBBR reactor has the advantages that an aerobic zone is small in floor space, and civil engineering investment is saved; under conditions that same filler is addedand pollution load is identical, the MBBR tank about accounts for 70% of the capacity of a conventional aerobic tank; meanwhile, the MBBR tank is short in starting time, low in operation energy consumption, resistant to impact load, prolonged in sludge age, free of sludge bulking and resistant to toxic compounds.

Owner:ANHUI JINDALAI ENVIRONMENT ENG CO LTD

Integrated toxic degradation-resistant wastewater treatment device and treatment method

ActiveCN111908722AEnsure swirlReduce processing energy consumptionWater treatment compoundsMultistage water/sewage treatmentEnvironmental chemistryOxidation response

The invention discloses an integrated toxic degradation-resistant wastewater treatment device and treatment method. The device comprises an adjusting tank, a first-stage reactor, a second-stage reactor, a third-stage reactor, a coagulative precipitation tank and a biochemical reaction tank which are sequentially connected in series, and further comprises an aeration blower, wherein the first-stagereactor and the third-stage reactor are advanced oxidation reactors, the second-stage reactor is a Fenton reactor, the coagulative precipitation tank comprises 2-4 stages, each stage of coagulative precipitation tank is formed by connecting a coagulative reaction tank, a primary precipitation tank and a secondary precipitation tank in series, and the biochemical reaction tank is formed by connecting an anoxic tank, an aerobic tank, a precipitation tank and a clean water tank in series. According to the wastewater treatment method provided by the invention, a toxic degradation-resistant wastewater treatment device is combined with reasonable process parameters, a Fenton-like reaction and a Fenton reaction are effectively coupled and cooperate with each other, and proper coagulating sedimentation and biochemical reaction processes are matched, so that the wastewater treatment effect can be enhanced, the wastewater treatment efficiency is improved, and the wastewater treatment cost is reduced.

Owner:SICHUAN UNIV

PU (Poly Urethane)-leather wastewater-processing method

ActiveCN102295391BTo achieve the purpose of resource utilizationLow running costMultistage water/sewage treatmentAmmoniacal nitrogenChemical oxygen demand

The invention discloses a PU (Poly Urethane)-leather wastewater-processing method, which comprises the following steps of: step 1, carrying out classified processing for wastewater in PU-leather production; step 2, carrying out biological preprocessing; step 3, carrying out high-efficiency ammonia-nitrogen blowing processing; step 4, carrying out coagulating-sedimentation processing; step 5, carrying out two-stage A1 / O1-A2 / O2 biological-denitrification processing; step 6, carrying out air-flotation processing; and step 7, carrying out mechanical-filtration processing. Through the PU-leather wastewater-processing method, COD (Chemical Oxygen Demand) and ammonia nitrogen in the wastewater can be removed, the wastewater being processed is ensured to be discharged after reaching standards, the problems of impacts of the high-concentration wastewater to a wastewater-processing system and the influence of biological-denitrifying capability reduction caused by the increase of ammonia-nitrogen concentration after the anaerobic hydrolysis of DMF (Dimethyl Formamide) in the wastewater are solved, the operating expenses are reduced, the wastewater processed can be used for production, and a good economic benefit is generated.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

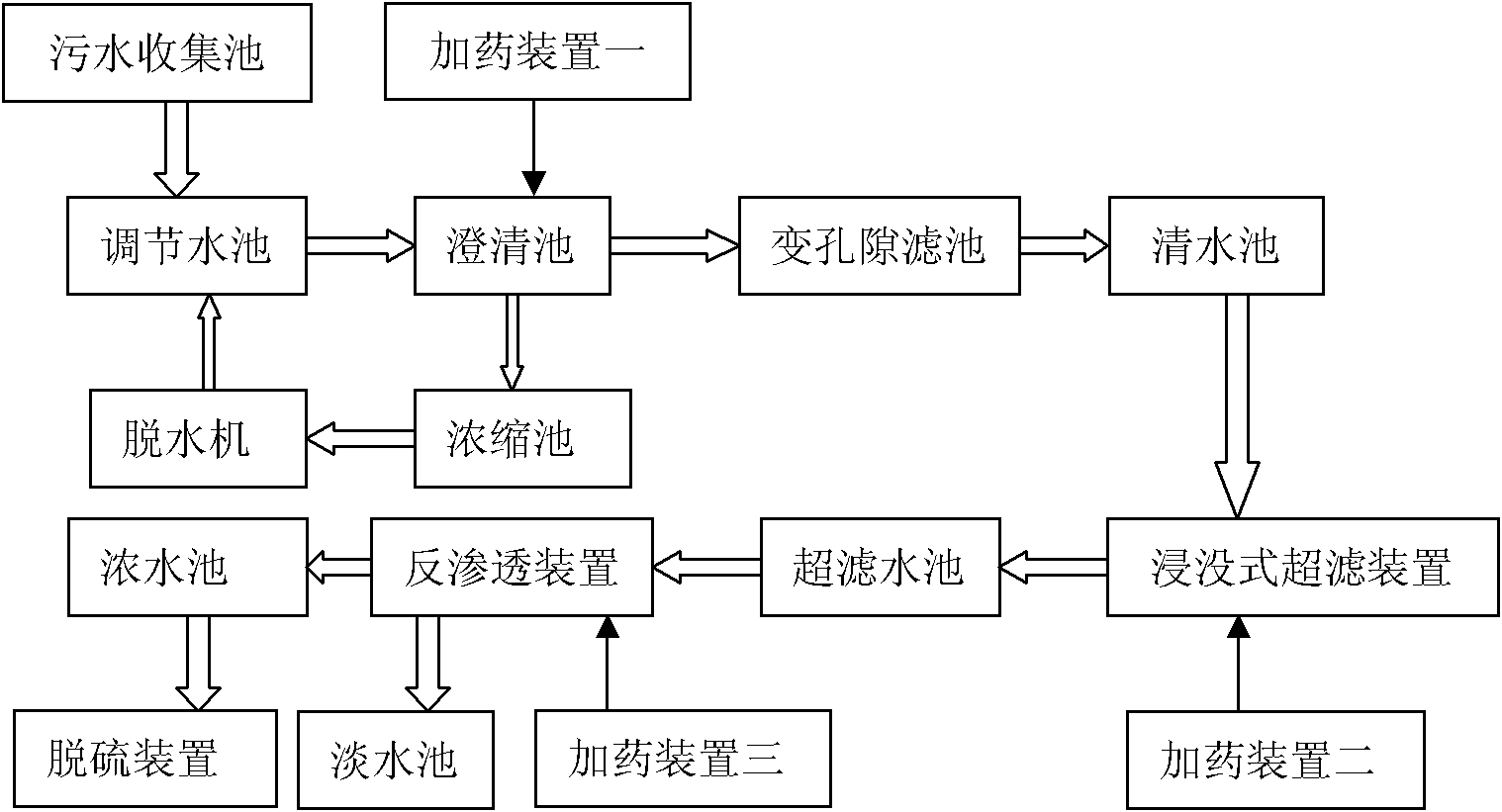

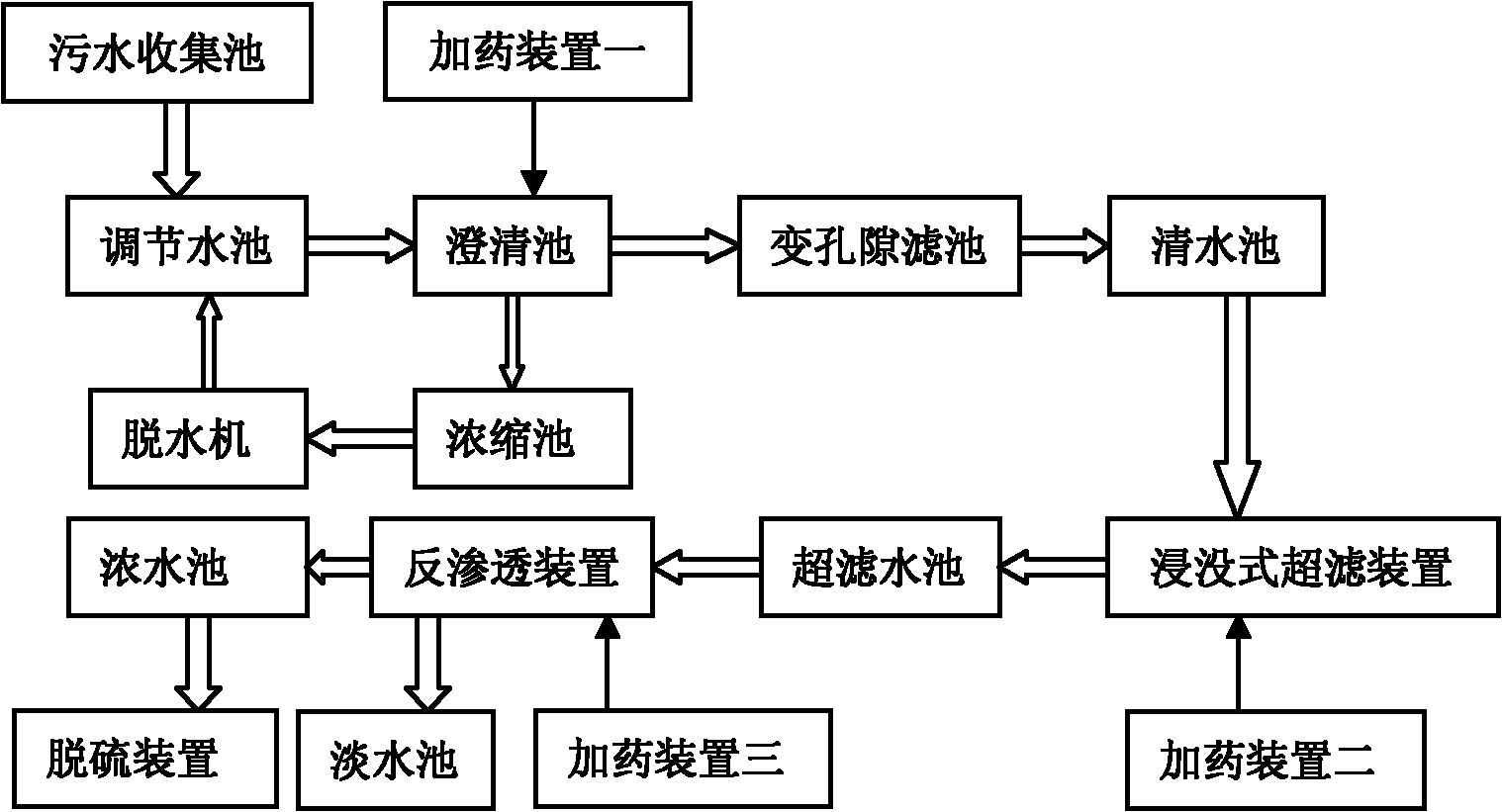

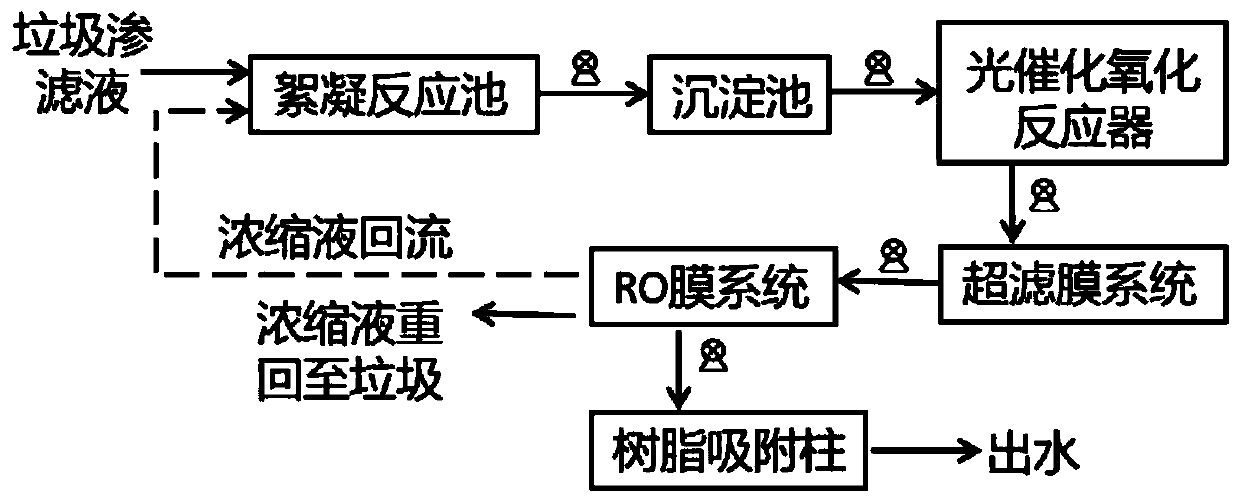

Landfill leachate treatment system and landfill leachate treatment method

InactiveCN110316886ASmall footprintEasy to moveWater/sewage treatment by irradiationWater treatment compoundsWater dischargeAbsorption column

The invention relates to a landfill leachate treatment system and a landfill leachate treatment method. The landfill leachate treatment system comprises a tank, a flocculation reaction pond, a settling pond, a photo-catalytic oxidation reactor, an ultrafiltration membrane filter, an RO membrane filter and a resin adsorption column are successively communicated and arranged inside the tank and areadjacently connected through centrifugal pumps, the RO membrane filter is provided with a concentrated water outlet and a plain water outlet, the concentrated water outlet is communicated with the flocculation reaction pond so as to enable concentrated water to flow back, and the plain water outlet is communicated with the resin absorption column so as to enable plain water to be absorbed and purified by the resin absorption column and be discharged after reaching standard. The landfill leachate treatment system has the advantages that a plurality of treating units are assembled in the tank totreat landfill leachate in a concentrated manner, and the landfill leachate treatment system small in occupied area and high in movability can be moved among various waste transfer stations conveniently and flexibly; the treating units can be flexibly assembled according to water quality variation of the landfill leachate, a water discharging volume of the membrane filter can be adjusted, and thelandfill leachate treatment system is adjustable in operation time, high in anti-load capacity and high in seasonal applicability.

Owner:HUBEI BAIQING ENVIRONMENTAL PROTECTION TECHCO

Method for treating organic chemical wastewater

ActiveCN108083553AIncrease concentrationEasy to removeTreatment using aerobic processesWater treatment compoundsWastewaterRefractory

The invention provides a method for treating organic chemical wastewater. The method comprises the steps of S1, adjusting pH of wastewater to 6-8; S2, subjecting the wastewater treated in step S1 to contact with a polyurethane bioactive carrier to carry out first reaction; S3, subjecting the wastewater treated in step S2 to contact with an immobilized microbial carrier to carry out second reaction; S4, subjecting the wastewater treated in step S3 to contact with a heterogeneous Fenton catalyst and an oxidant to carry out third reaction. A microbial immobilization technique is used herein, thusincreasing microbial content in unit volume and increasing bioreaction speed; the heterogeneous catalytic oxidation is carried out to further catalytically and oxidatively degrade refractory organicsunable to be treated in the microbial immobilization phase, so that system effluent meets the emission standard.

Owner:兰州大学白银产业技术研究院 +1

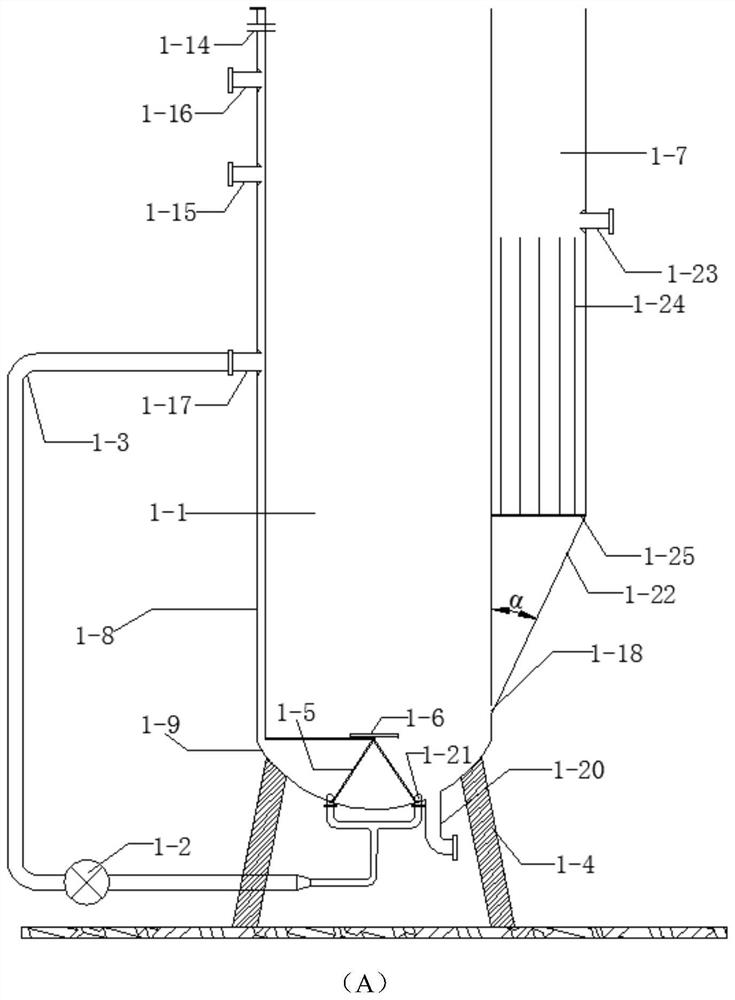

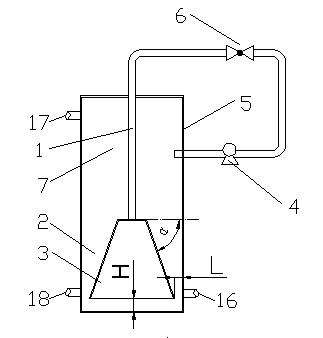

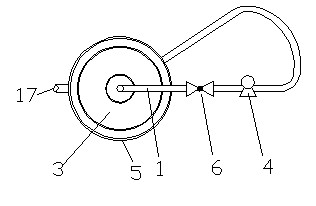

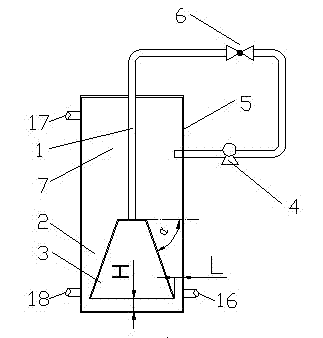

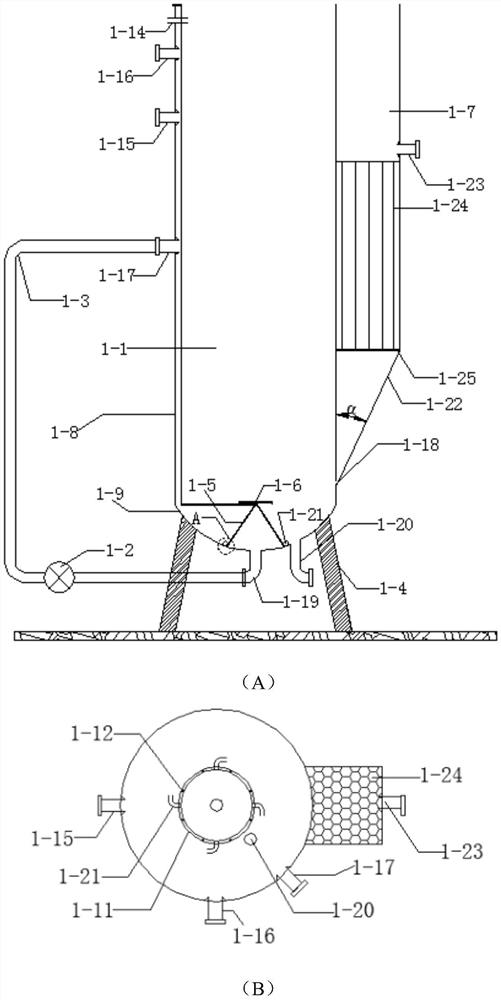

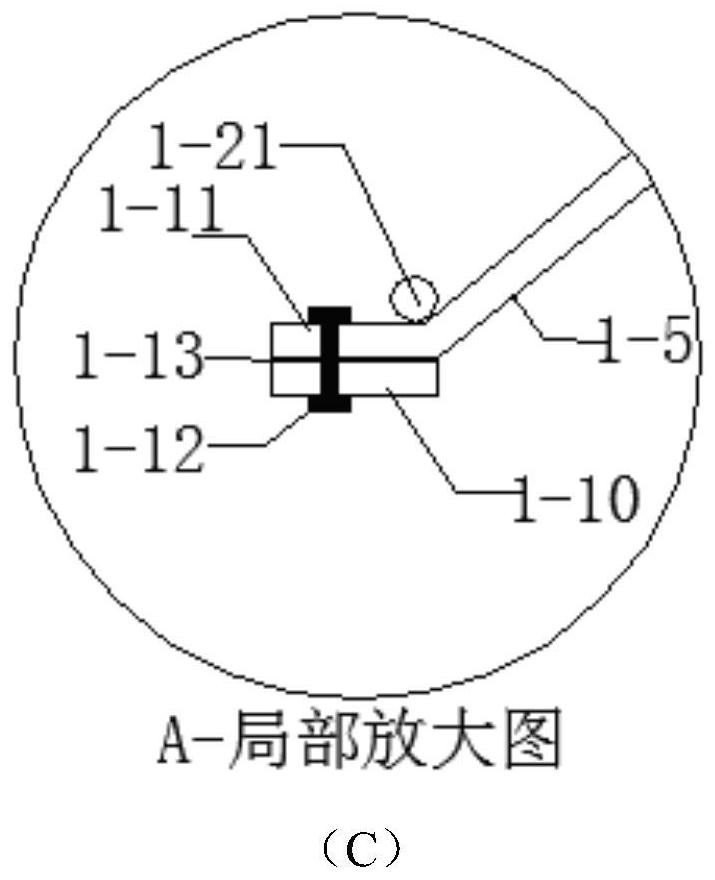

Integrated precipitating and mud collection backflow device

InactiveCN102491469AResistant to shock loadsStrong mixing functionWater/sewage treatment by flocculation/precipitationSludgeWastewater

The invention discloses an integrated precipitating and mud collection backflow device, which comprises a reactor, wherein a reaction zone and a precipitating zone are arranged in the reactor, a funnel with a big opening downwards is arranged in the precipitating zone, gaps are respectively arranged between the lateral side of the funnel and the inner wall and between the bottom end of the funneland the inner wall, the top end of the funnel is connected with a water collection pipe, and the water collection pipe is communicated with the reaction zone after being connected with a pump. The integrated precipitating and mud collection backflow device enables waste water to be sufficiently contacted with mud, organics in waste water to be well degraded, short streams and channeling not to beapt to appear and processing efficiency to be improved.

Owner:ZHENGZHOU UNIV

A biochemical treatment method and device for landfill leachate

ActiveCN104118970BEfficient removalReduce CODMultistage water/sewage treatmentMedicineReverse osmosis

The invention relates to a biochemical treatment method and device for landfill leachate. The method specifically includes: firstly, the pretreated landfill leachate is put into an anaerobic biological filter for treatment, and then undergoes first-level facultative biochemical treatment, anoxic reaction After nitrification treatment and secondary aerobic biochemical treatment, the water is finally discharged through the ceramic membrane module for the subsequent advanced treatment process. The present invention has a good treatment effect, adopts anaerobic-facultative oxygen-anoxic-aerobic microbial environment to form different microbial flora, effectively improves the effect of biochemical treatment of landfill leachate, and reduces the pressure of subsequent advanced treatment. It reduces the investment and operating costs of the overall process; at the same time, it can be combined with adsorption process or reverse osmosis technology to ensure the discharge of landfill leachate up to the standard.

Owner:北京博力扬环保科技有限公司

Zero-energy-consumption enhanced AB (adsorption-biodegradation) treatment method for urban sewage

ActiveCN102225825BResistant to shock loadsGuaranteed uptimeSludge treatment by de-watering/drying/thickeningWaste based fuelDigestion TreatmentAnaerobic sludge

Owner:深圳市君脉膜科技有限公司

Processing method of ammonia-containing tannery wastewater

InactiveCN104628213ALarge residueSubstantially use surplus low residueMultistage water/sewage treatmentHigh concentrationChemical separation

The invention discloses a processing method of ammonia-containing tannery wastewater. The processing method comprises following steps: (1) the ammonia-containing tannery wastewater is mixed with an organic reducing agent at a certain ratio, and is heated to 180 DEG C, and the temperature is maintained for 3 to 4h; (2) an obtained mixture is mixed with ferrous sulfate heptahydrate; and an obtained mixed material is subjected to reaction; (3) the processed wastewater is delivered into a biofilm culturing biological combined stuffing-containing anaerobic pond, and after a certain period of time is delivered into a coagulative precipitation tank for precipitation; (4) a low-pressure deacidifying deaminizing tower is used for steam stripping; (5) a high-pressure deaminizing tower is used for further treatment; and (6) pH value of an obtained product is increased to be larger than 7, the product is delivered into an air stripping tower using a water pump, ammonia nitrogen obtained via air stripping is recycled, and pH value of the product is adjusted to 7 to 8. According to the processing method, valuable middle medium pressure steam can be replaced by excess low-pressure steam in a large degree; used devices are universal chemical separation devices; the processing method is mature and reliable; high concentration wastewater can be recycled; waste is changed into valuables; and recycling is realized.

Owner:QINGDAO BOYANDA IND TECH RES INST GENERAL PARTNERSHIP

A method for treating organic chemical wastewater

ActiveCN108083553BIncrease concentrationEasy to removeTreatment using aerobic processesWater treatment compoundsMicroorganismPtru catalyst

The invention provides a method for treating organic waste water, comprising step S1, adjusting the pH value of the waste water to 6-8; step S2, contacting the waste water treated in step S1 with a polyurethane bioactive carrier to perform the first reaction; step S3, contacting the wastewater treated in step S2 with an immobilized microbial carrier to perform a second reaction; step S4, contacting the wastewater treated in step S3 with a heterogeneous Fenton catalyst and an oxidant to perform a third reaction. This method first adopts the immobilization technology of microorganisms to increase the microbial content per unit volume and speed up the biological reaction speed. Finally, heterogeneous catalytic oxidation is used to further catalyze and oxidize the refractory organic matter that cannot be processed in the immobilization stage of microorganisms, making the system The effluent meets the discharge standard.

Owner:兰州大学白银产业技术研究院 +1

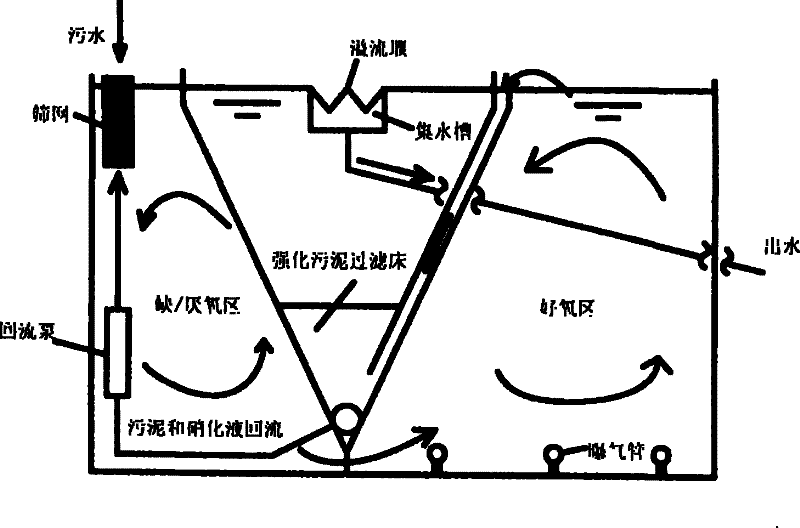

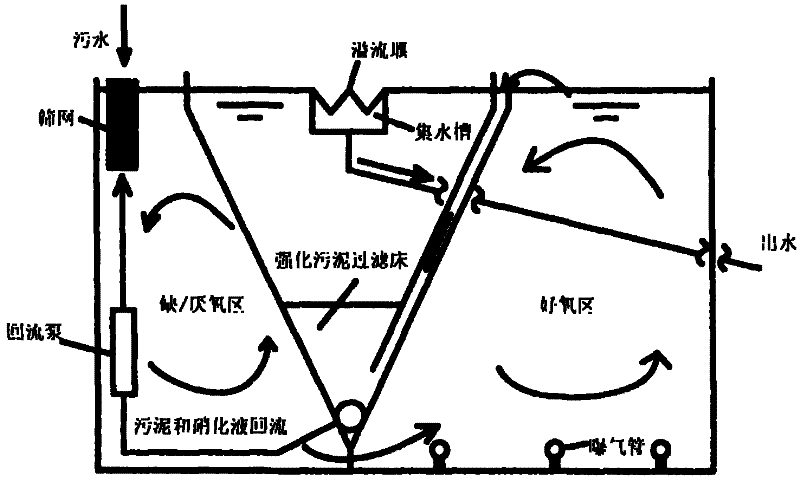

Integral sewage disposal process for strengthening sludge filtrating technology

InactiveCN101289263BHigh volume loadLess investment in infrastructureTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeFiltration

Owner:HARBIN INST OF TECH

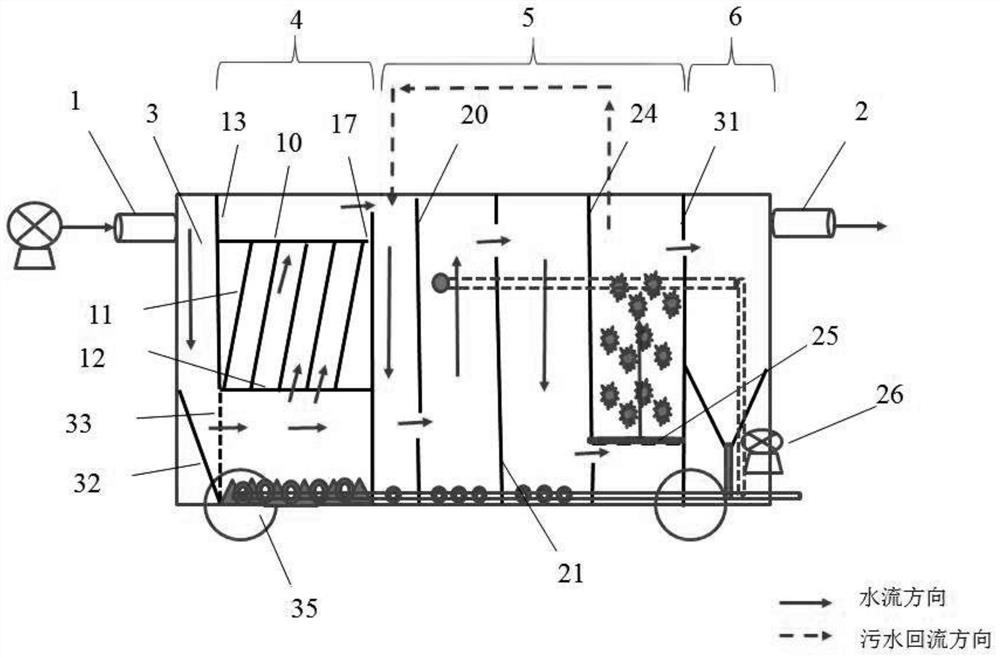

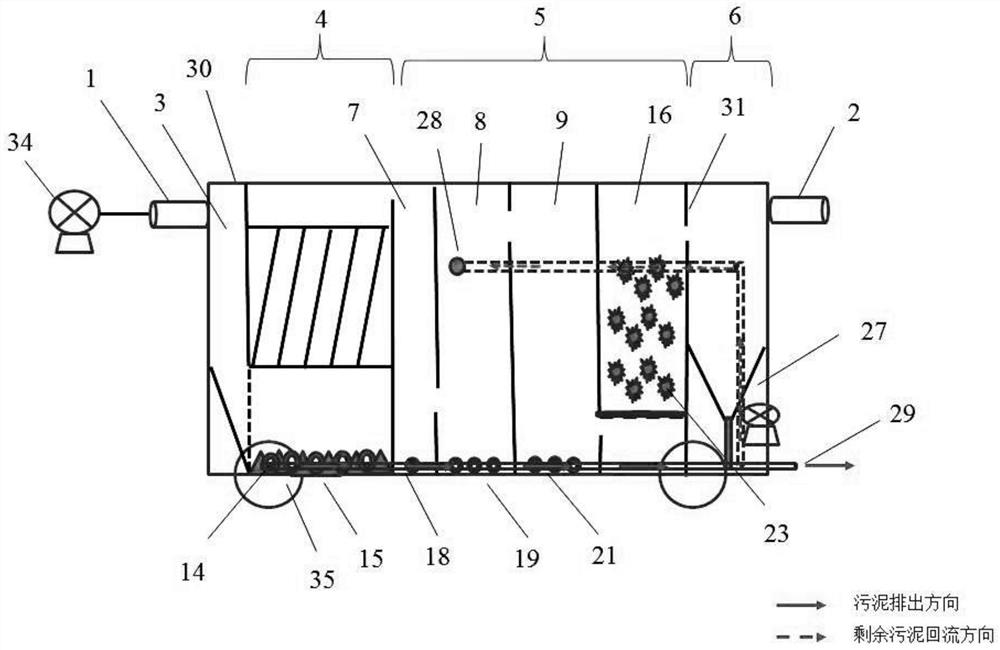

Aquaculture wastewater integrated treatment device and use method thereof

PendingCN114524576ALess investmentReduce power consumptionWater contaminantsWaste water treatment from animal husbandryRecirculating aquaculture systemWater district

The invention relates to an aquaculture wastewater integrated treatment device which comprises an outer box and an inner treatment box, the left end and the right end of the outer box are provided with a water inlet and a water outlet respectively, and the inner treatment box is arranged in the outer box; the internal treatment box sequentially comprises a water distribution area, a primary settling area, a biochemical reaction area and a secondary settling area from left to right. The device is an integrated device capable of efficiently and rapidly degrading aquaculture pollution and low in cost, the aquaculture wastewater integrated treatment device can continuously run for a long time, is high in operability, impact load resistance and maneuverability and high in treatment efficiency, and effectively solves the problems in use of an industrial circulating aquaculture system.

Owner:南京市水产科学研究所 +1

Rapid starting method of shortcut nitrification and denitrification in A/O (Anoxic/Oxic) process

ActiveCN103496788BReduce the difficulty of startingGuaranteed uptimeTreatment with aerobic and anaerobic processesNitrogen removalStart time

The invention discloses a rapid starting method of shortcut nitrification and denitrification in an A / O (Anoxic / Oxic) process. The rapid starting method comprises the following steps of: (1) placing a suspended filler in an oxic tank; (2) respectively placing inoculated sludge in an anoxic tank and the oxic tank; (3) enabling wastewater to sequentially flow through the anoxic tank and the oxic tank in a continuous operation manner, wherein the ammonia nitrogen concentration of the wastewater is 25-60mg / L, the ratio of carbon to nitrogen is 2-8, and the proportion of nitrite in the oxic tank reaches above 70%, and the yielding water nitrogen removal efficiency is stabilized at 80%-90%, thus completing the starting process of the shortcut nitrification and denitrification. The rapid starting method has the advantages that the starting time of the shortcut nitrification and denitrification in the A / O process is short, the accumulation rate of the nitrite in the oxic tank reaches above 70%, the nitrogen removal efficiency of the whole process can reach above 90%, and the long-term stable operation of a reactor can be ensured.

Owner:浙江欧托电气有限公司

Integrated precipitating and mud collection backflow device

InactiveCN102491469BResistant to shock loadsStrong mixing functionWater/sewage treatment by flocculation/precipitationSludgeProcess efficiency

The invention discloses an integrated precipitating and mud collection backflow device, which comprises a reactor, wherein a reaction zone and a precipitating zone are arranged in the reactor, a funnel with a big opening downwards is arranged in the precipitating zone, gaps are respectively arranged between the lateral side of the funnel and the inner wall and between the bottom end of the funneland the inner wall, the top end of the funnel is connected with a water collection pipe, and the water collection pipe is communicated with the reaction zone after being connected with a pump. The integrated precipitating and mud collection backflow device enables waste water to be sufficiently contacted with mud, organics in waste water to be well degraded, short streams and channeling not to beapt to appear and processing efficiency to be improved.

Owner:ZHENGZHOU UNIV

Integrated toxic and refractory wastewater treatment device and treatment method

ActiveCN111908722BEnsure swirlReduce processing energy consumptionSludge treatmentTreatment with aerobic and anaerobic processesAir blowerWastewater disposal

The invention discloses an integrated toxic and refractory wastewater treatment device and a treatment method. The device includes a series-connected adjustment tank, a first-stage reactor, a second-stage reactor, a third-stage reactor, a coagulation sedimentation tank, a biochemical reaction Pool, also includes aeration blower. Both the first-stage reactor and the third-stage reactor are advanced oxidation reactors, the second-stage reactor is a Fenton reactor, and the coagulation and sedimentation tanks include 2 to 4 stages, and the coagulation and sedimentation tanks at all levels are composed of coagulation reaction The biochemical reaction pool is composed of anoxic pool, aerobic pool, sedimentation pool and clear water pool. The wastewater treatment method provided by the invention combines the toxic and refractory wastewater treatment device with reasonable process parameters, effectively coupling the Fenton-like reaction and the Fenton reaction, the two cooperate with each other, and at the same time match the appropriate coagulation sedimentation and biochemical The reaction process can strengthen the wastewater treatment effect, improve the efficiency of wastewater treatment and reduce the cost of wastewater treatment.

Owner:SICHUAN UNIV

A kind of treatment method of coal chemical industry wastewater

ActiveCN104310712BGood removal effectEasy to handleMultistage water/sewage treatmentBiological water/sewage treatmentAmmoniacal nitrogenMicroorganism

The invention relates to a treatment method for coal chemical industry wastewater. The method comprises the following steps: oil separation-coagulation sedimentation-anaerobic dephenolization-peristaltic bed-ozone catalytic oxidation-MBR-clear water tank. The present invention treats coal chemical wastewater by coupling anaerobic dephenolization with peristaltic bed, ozone catalytic oxidation, MBR, etc., and can reach the first-level discharge standard of "Comprehensive Sewage Discharge Standard" GB8978-1996; and through the peristaltic bed The aerobic denitrification microorganism ZHB35 is immobilized inside the biological carrier to realize the removal of ammonia nitrogen and total nitrogen while removing COD in the peristaltic bed pool, and can also promote the removal of total phosphorus. The invention has strong practicability, is suitable for newly-built waste water plants and upgrading and renovation projects, can effectively save infrastructure investment and operating costs, and has the advantages of impact load resistance, simple management, stable operation, and good treatment effect.

Owner:BEIJING GEOENVIRON ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com