Pretreatment technology of high-salinity wastewater

A high-salt wastewater pretreatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of water hardness and silicate cannot be removed, and improve Pretreatment effect, saving chemicals, and reducing the effect of influent turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

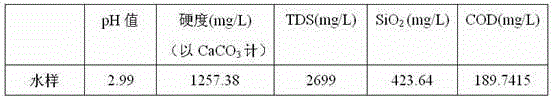

Embodiment 1

[0047] A high-salt wastewater pretreatment process, first remove the hardness of the sewage, and then add drugs to remove SiO 2 , and finally flocculated and precipitated.

[0048] The specific operation steps are:

[0049] 1) First, let the sewage enter the chemical reaction tank, add soda ash and soda lime to the water, and stir with a high-speed mixer to make the chemical react with the raw water quickly and remove the hardness in the water;

[0050] 2) Then enter the coagulation dosing tank, add magnesium and coagulant, stir with a high-speed mixer, the SiO in the sewage 2 React with magnesium agent and precipitate out to form precipitable flocs;

[0051] 3) After entering the flocculation sedimentation-concentration tank system, the alum flowers and water are separated, and the sludge deposited at the bottom of the tank is accelerated and concentrated by the thickening agitator equipped with a mud scraper system, and part of the sludge is continuously circulated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com