Integrated toxic and refractory wastewater treatment device and treatment method

A kind of waste water treatment, refractory technology, applied in special compound water treatment, natural water treatment, multi-stage water treatment and other directions, can solve the problems of environmental damage, high equipment cost, large area, etc. The effect of reducing equipment costs and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

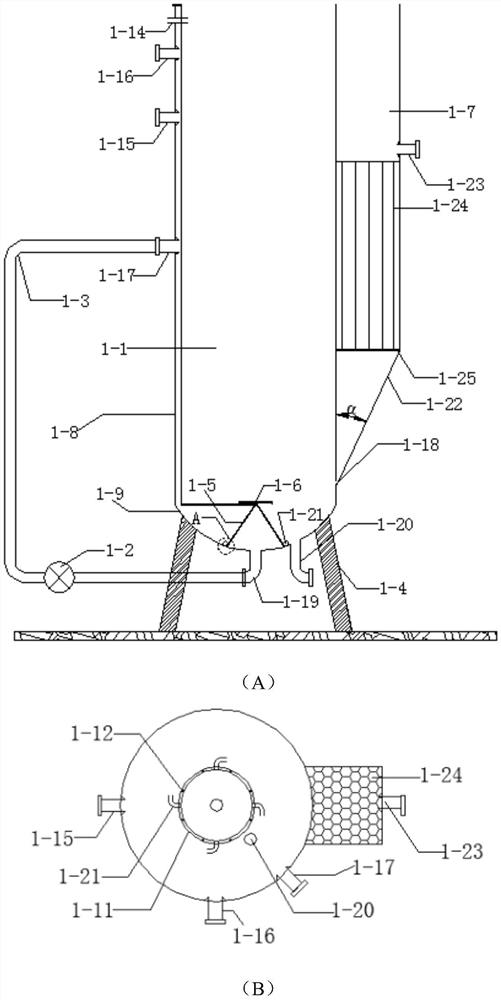

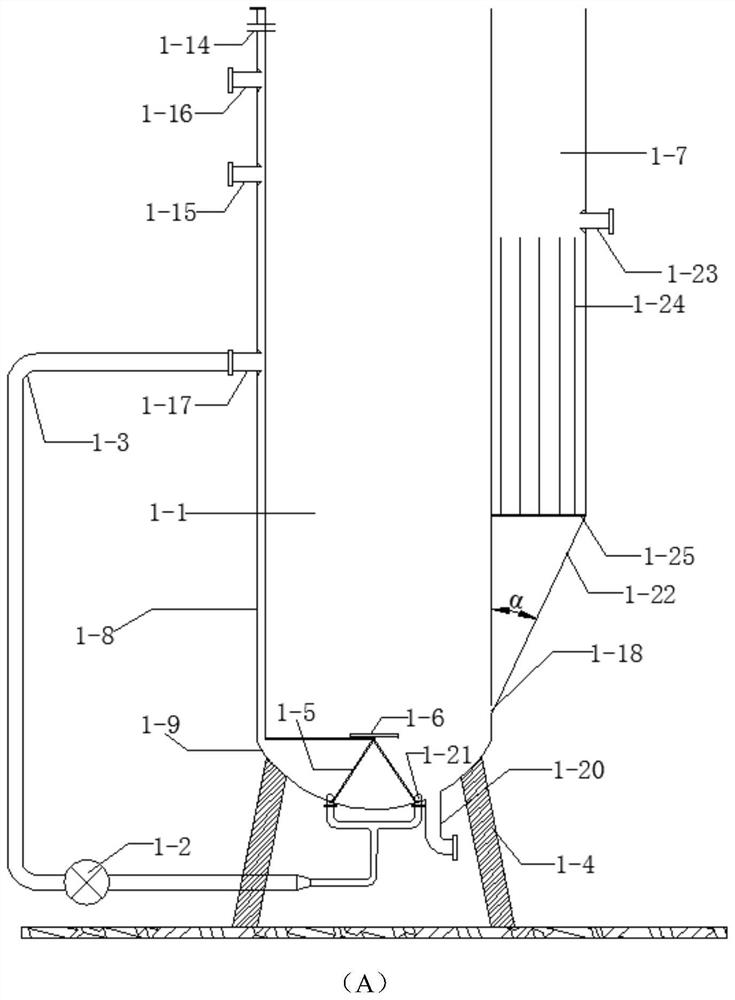

[0056] Example 1: Advanced Oxidation Reactor Structure

[0057] In this example, the structural schematic diagram of the advanced oxidation reactor is as follows figure 1 As shown, it includes the first reaction tank 1-1, the first return pump 1-2, the first return pipe 1-3, the first support 1-4, the first conical baffle 1-5, and the aeration disc 1-6 1. Settling tank 1-7, vertical flow pipe 1-24 is arranged in the settling tank.

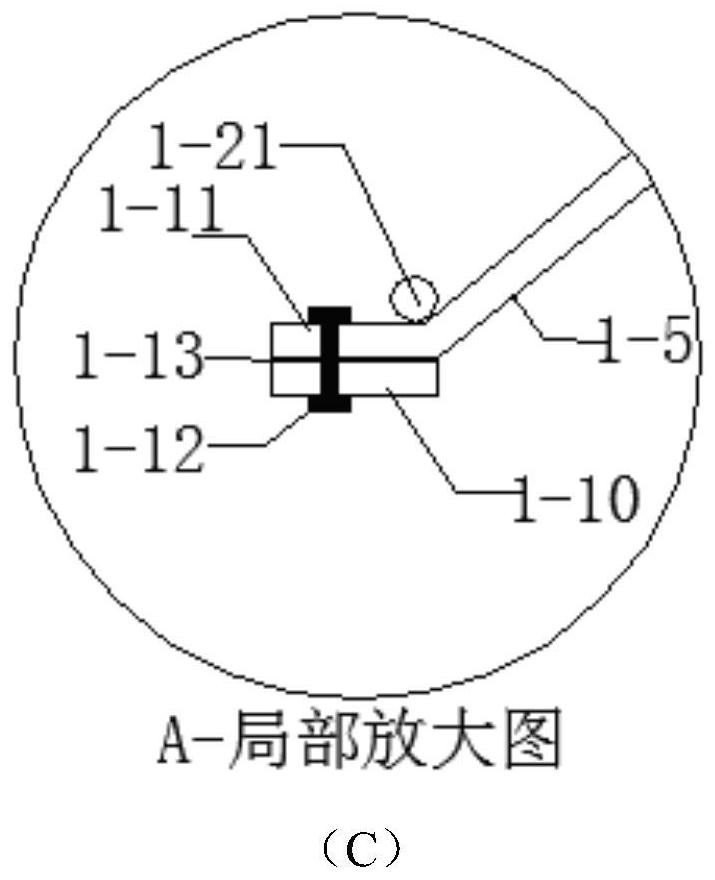

[0058] The first reaction tank 1-1 is made up of the first cylinder 1-8 and the first spherical cap 1-9, and the height of the first spherical cap 1-9 is less than the radius of the first cylinder 1-8, and the first cylinder 1 The inner diameter of -8 is equal to the inner diameter of the opening end of the first spherical cap 1-9, one end of the first cylinder 1-8 is connected with the opening end of the first spherical cap 1-9, and the bottom of the first spherical cap 1-9 is provided with There is a lower flange 1-10; the first conical baffle ...

Embodiment 2

[0062] Example 2: Advanced Oxidation Reactor Structure

[0063] In this embodiment, the structure of the advanced oxidation reactor is basically the same as that of the advanced oxidation reactor in Example 1, except that the cone angle of the first conical baffles 1-5 is 60°, and the first conical baffles The ratio of the height of the plate 1-5 to the height of the first reaction tank 1-1 is 1:8, and three evenly distributed first 90° elbows are horizontally arranged at the same height position of the first conical baffle plate 1-5 1-21, the angle between the sedimentation tank bottom 1-22 and the vertical plane is 30°, the opening height of the first water outlet is 50mm, and the nominal diameter of the vertical flow pipe 1-24 is 10mm.

Embodiment 3

[0064] Example 3: Advanced Oxidation Reactor Structure

[0065] In this example, the structure of the advanced oxidation reactor is as follows figure 2 As shown, the structure of the advanced oxidation reactor in Example 1 is basically the same, the difference is that: the first 90 ° elbow 1-21 adopts another arrangement, in the same way as the first spherical cap 1-9 Four first 90° elbows 1-24 evenly arranged horizontally on the height position connect the inside and outside of the first spherical crown 1-9, and each first 90° elbow 1-21 is located on the first conical baffle The end surface of the outer wall of 1-5 is close to the outer wall of the first conical baffle 1-5, one end of the first return pipe 1-3 is connected to the first return water outlet 1-17, and the other end is connected to the first spherical cap 1 through a branch pipe Each first 90° elbow 1-21 on -9 is connected; the first cone baffle 1-5 is not connected in a detachable manner, but is directly fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com