Hydrodynamic cavitation reactor

A reactor and post-stage technology, applied in the field of wastewater treatment equipment, can solve the problems of low cavitation effect and less OH, and achieve the effects of low energy consumption, simple operation, and improved treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

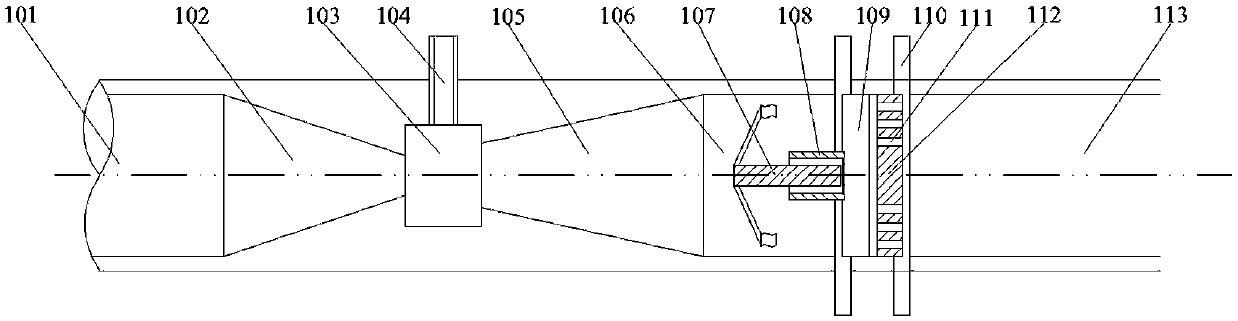

[0027] The specific structure of the hydrodynamic cavitation reactor is as follows: figure 1 As shown, it consists of three parts: the front section of the reactor, the middle section of the reactor and the back section of the reactor, wherein the front section of the reactor and the middle section of the reactor are integrated, and the back section of the reactor is connected to the middle section of the reactor through a flange 110 . A fluid inlet 101 is arranged on the front section of the reactor, and a fluid outlet 113 is arranged on the rear section of the reactor.

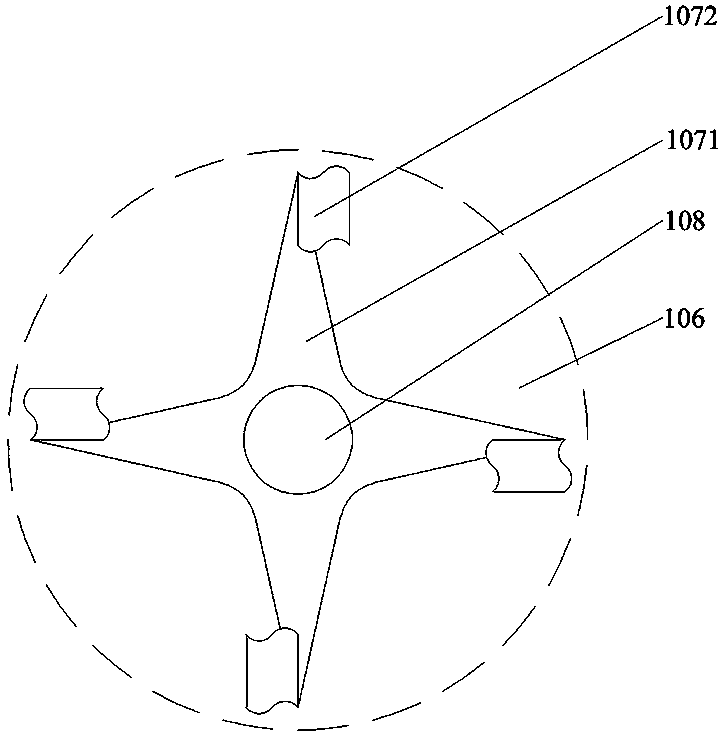

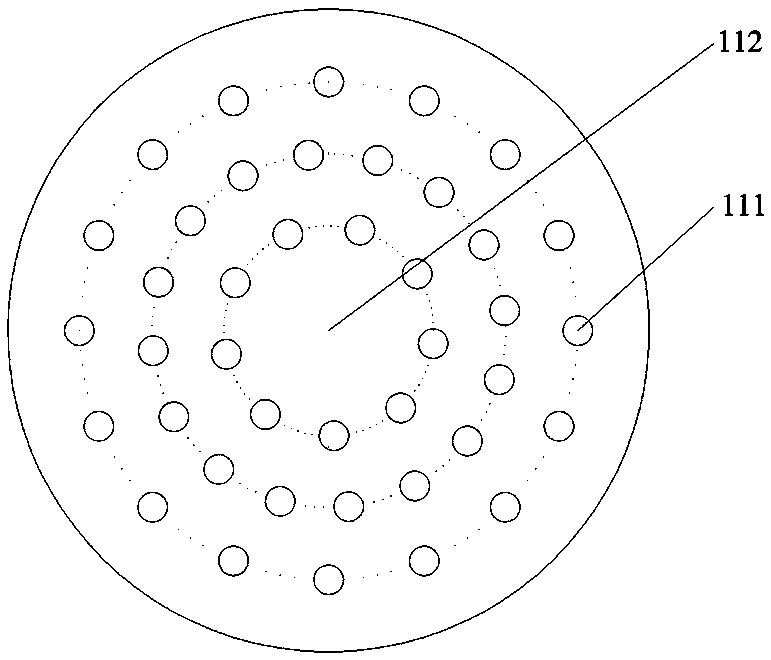

[0028] The front section of the reactor is provided with a fluid jet contraction chamber 102, a negative pressure chamber 103 and a fluid jet expansion chamber 105. The expansion port of the fluid jet contraction chamber 102 is connected to the fluid inlet 101, and the contraction port is connected to the negative pressure chamber 103. The negative pressure chamber The other end of 103 is connected to the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com