Patents

Literature

1290results about How to "Reduce processing energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

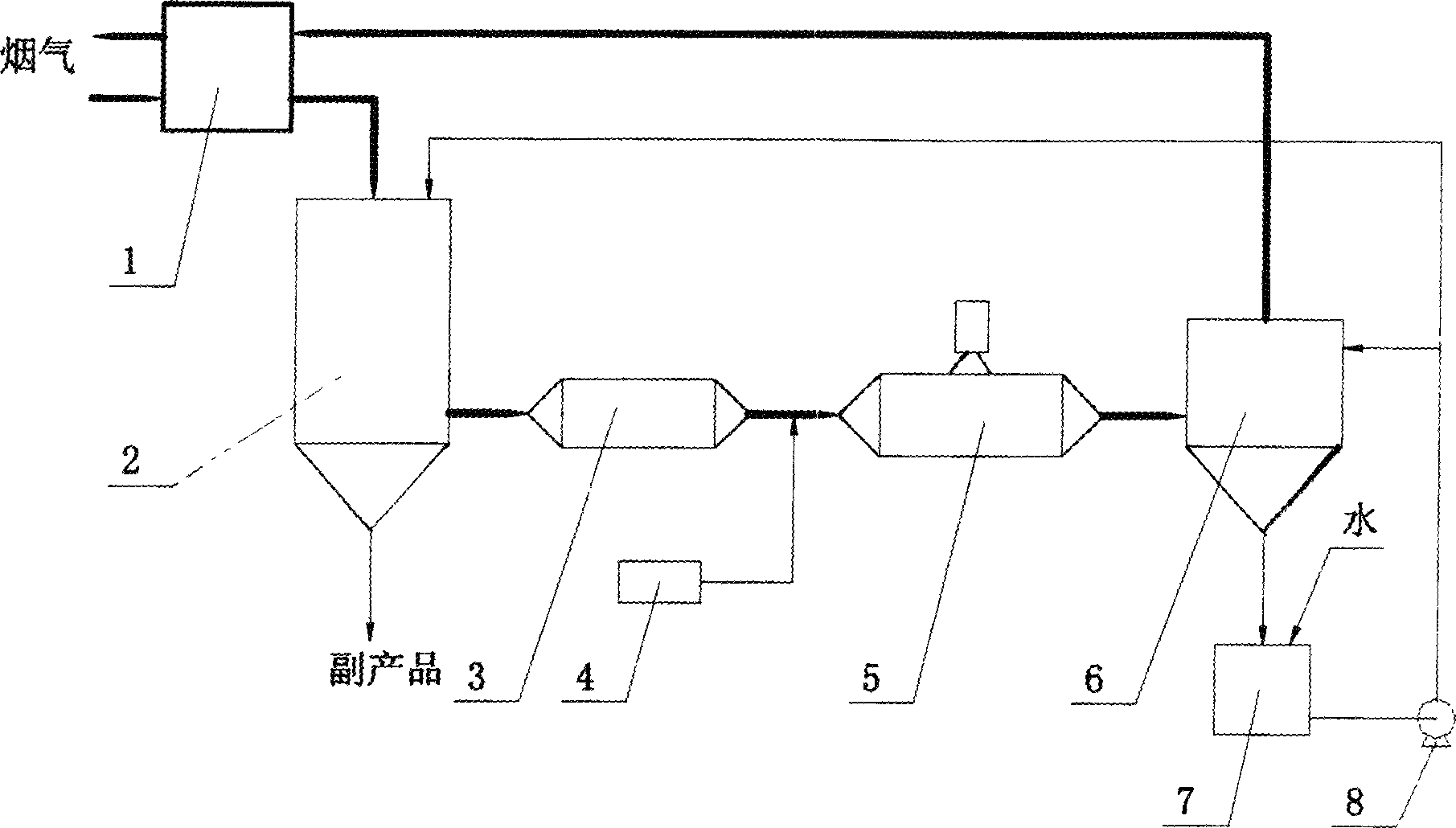

Method of sintering low temperature waste heat circulation and discharged waste gas reduction and device thereof

InactiveCN101893384AReduce process energy consumptionConducive to environmental protectionWaste heat treatmentFluePollutant

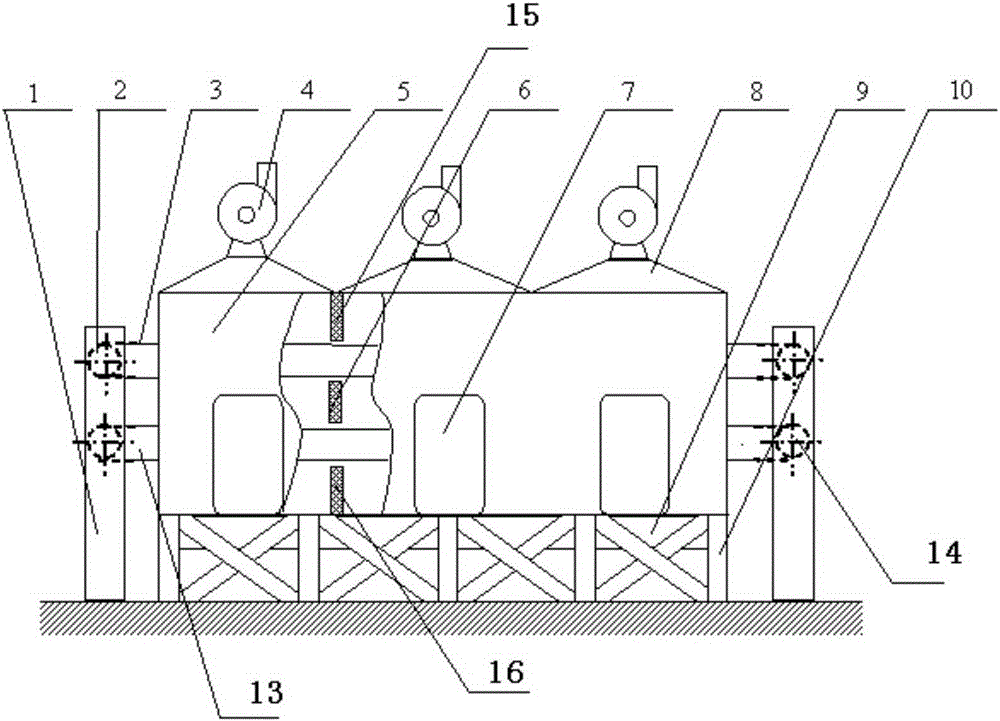

The invention discloses a method of sintering low temperature waste heat circulation and discharged waste gas reduction and a device thereof. The method comprises the following steps: drawing out flue gas having a high temperature in an air bellow on the rear part of the main-flue of a sintering machine; dedusting; mixing the flue gas with hot waste gas extracted from a sintering cool machine into a mixer to form the mixed hot waste gas; and transmitting the mixed hot waste gas on the surface of the material layer of the sintering machine for circular sintering. The device comprises a high temperature flue gas circulation pipeline of the sintering machine connected with a high temperature flue of the sintering machine, a hot waste gas circulation pipeline of a sintering cool machine connected with the sintering cool machine and a total circulation pipeline connected with a sintering machine fan cover. By using the invention, the waste gas discharging total amount and the pollutants discharging amount produced in a sintering process can be greatly reduced, the low temperature waste heat in the flue gas can be recycled and energy consumption of the sintering process can be saved, thus, the method of the invention has significant energy saving and emission reduction value.

Owner:BAOSHAN IRON & STEEL CO LTD

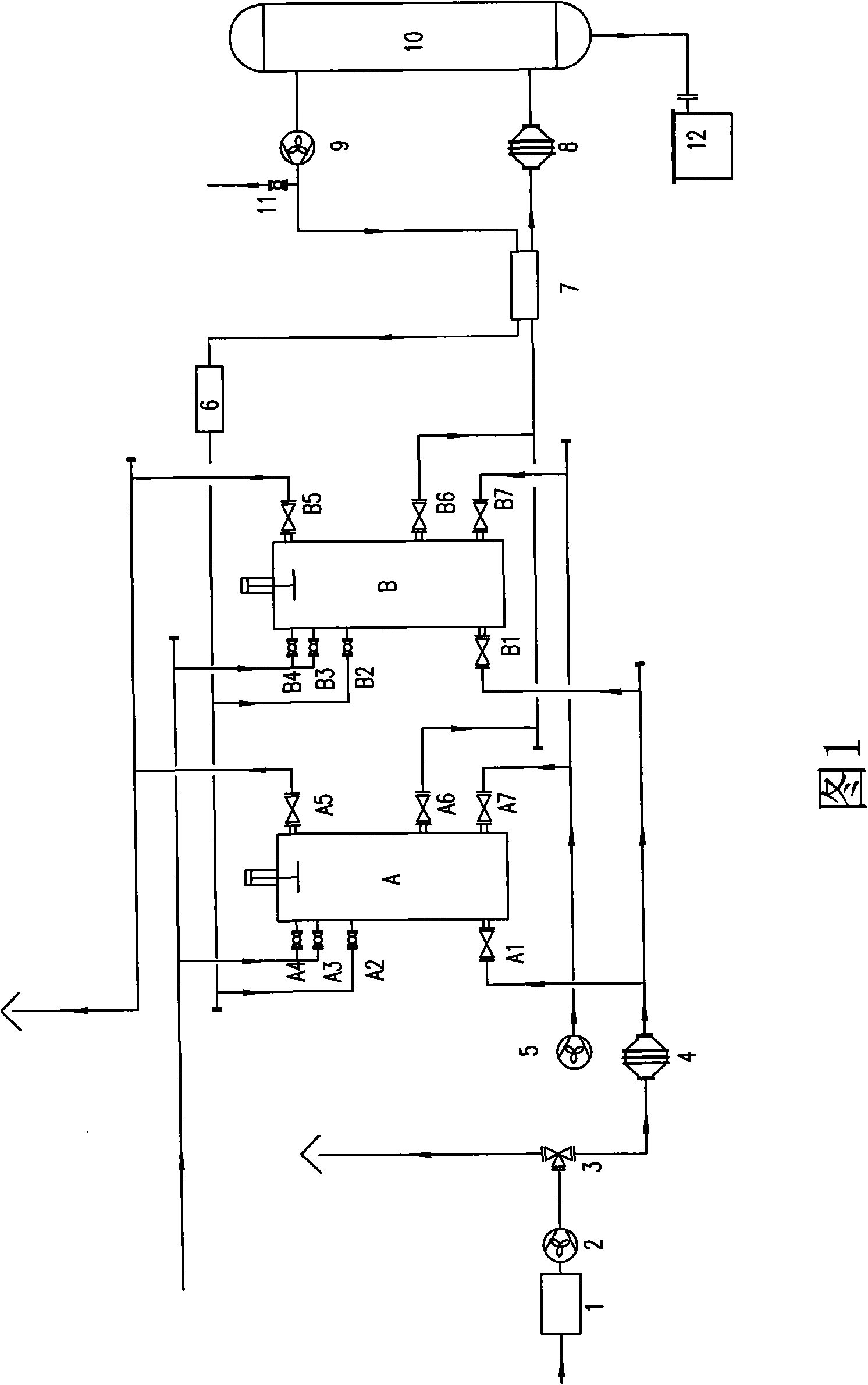

Active carbon fiber organic gas recovery method and system using nitrogen as desorption medium

InactiveCN101288820AReduce water contentAchieving zero emissionsDispersed particle separationCombustible gas purificationSolubilityFiber

The invention relates to a method for recovering active carbon fibre organic waste gas by taking nitrogen as desorption medium, belonging to the field of environmental protection. The method for recovering active carbon fibre organic waste gas by taking nitrogen as desorption medium takes the active carbon fibre as a fixed bed adsorber of the adsorbent, adopts thermal nitrogen desorption and can recover and reuse the organic waste gas and nitrogen at the same time. The method of the invention adopts the thermal nitrogen adsorption, generates no secondary contaminant, realizes that the exhaust reaches the standard of the environmental protection, leads the adsorption layer to keep dry at the same time, improves the utilization ratio of the active carbon fibre and prolongs the service life of the active carbon fibre. As vapour is not used for desorption, the equipment has no corrosion problem, thus greatly reducing the manufacture cost of the equipment. The method of the invention has extremely good recovery effects on solvent with large water solubility and easy hydrolysis performance and organic waste gas with high boiling point, has low water content in the recovered products, high quality of the solvent and reduces the running cost.

Owner:中节能天辰(北京)环保科技有限公司

Non-oriented electrical steel produced by sheet continuous casting and rolling and method thereof

The invention relates to non-oriented electrical steel produced by sheet continuous casting and rolling and a method thereof. The steel contains the following components by in percentage of by weight: 0.0031%-0.01% of C, 1.0-1.7% of Si, 1.0-2.4% of Si+2Al, at mostnot less than 0.5% of Al, 0.5-1.5% of Mn, not less thanat most 0.10% of P, not less thanat most 0.008% of S, not less thanat most 0.005% of N, not less thanat most 0.008% of Ti, and not less thanat most 0.010% of Ca, wherein Si+2Al is 1.0-2.4%. The method comprises the following steps of: smelting and treating by in vacuum; continuously casting, and controlling the thickness of a casting blank to be thickness within 50-90mm; soaking, controlling the temperature of the casting blank to be 850-950 DEG C before entering the furnace; finish rolling; coiling at the temperature of 690-780 DEG C; prickling; cold rolling; decarburizing, and controlling at the temperature to of 800-920 DEG C; and coating or not coating as required by users. The invention has no need of additionally arranging equipment and the normalizing and secondary cold rolling of hot rolled plates, the magnetism of the steel plate is good, and the corrugated defect is not found in test.

Owner:武汉钢铁有限公司

Environmental-friendly dust-free calcium-zinc composite heat stabilizer for PVC processing

ActiveCN101602863AAchieve individual synthesisAvoid it happening againCarboxylic acid salt preparationThermal stabilityZinc

The invention relates to an environmental-friendly dust-free calcium-zinc composite heat stabilizer for PVC processing, which comprises the following components: 20 to 80 percent of metallic soap of main stabilizer, 10 to 60 percent of auxiliary stabilizer and 5 to 30 percent of lubricant. The invention also provides a preparation method of the heat stabilizer. The environmental-friendly dust-free calcium-zinc composite heat stabilizer has the advantages of meeting the requirements for environmental protection, along with excellent thermal stability, low cost of production and use, high efficiency and innocuity.

Owner:九江天盛塑料助剂有限公司

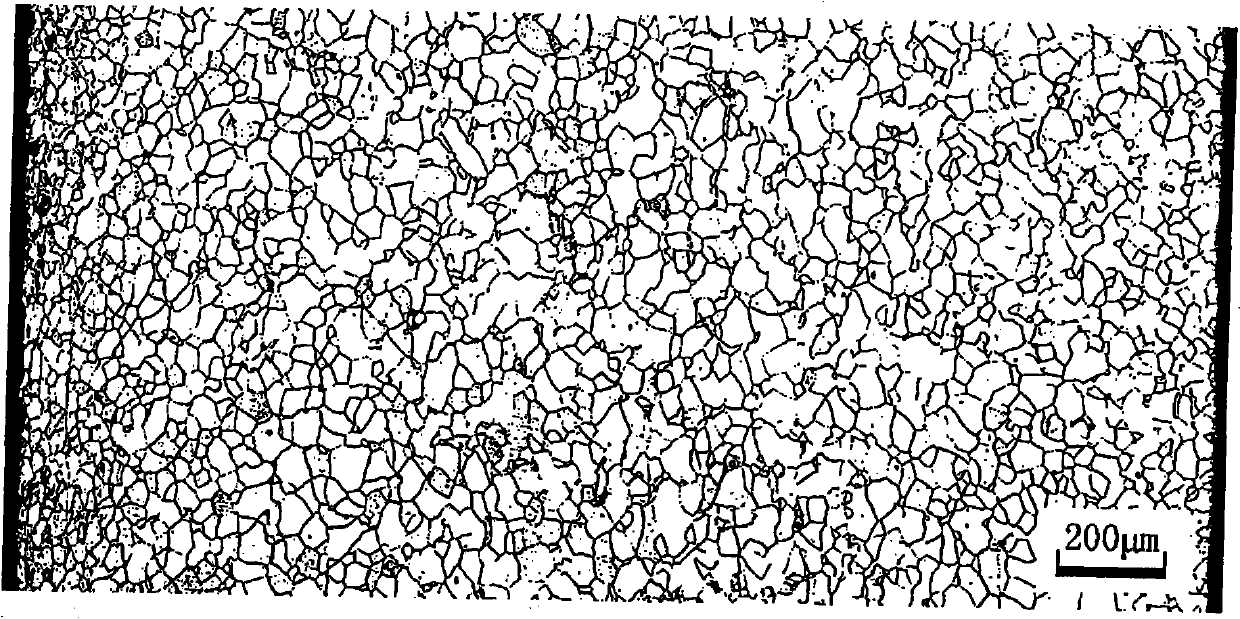

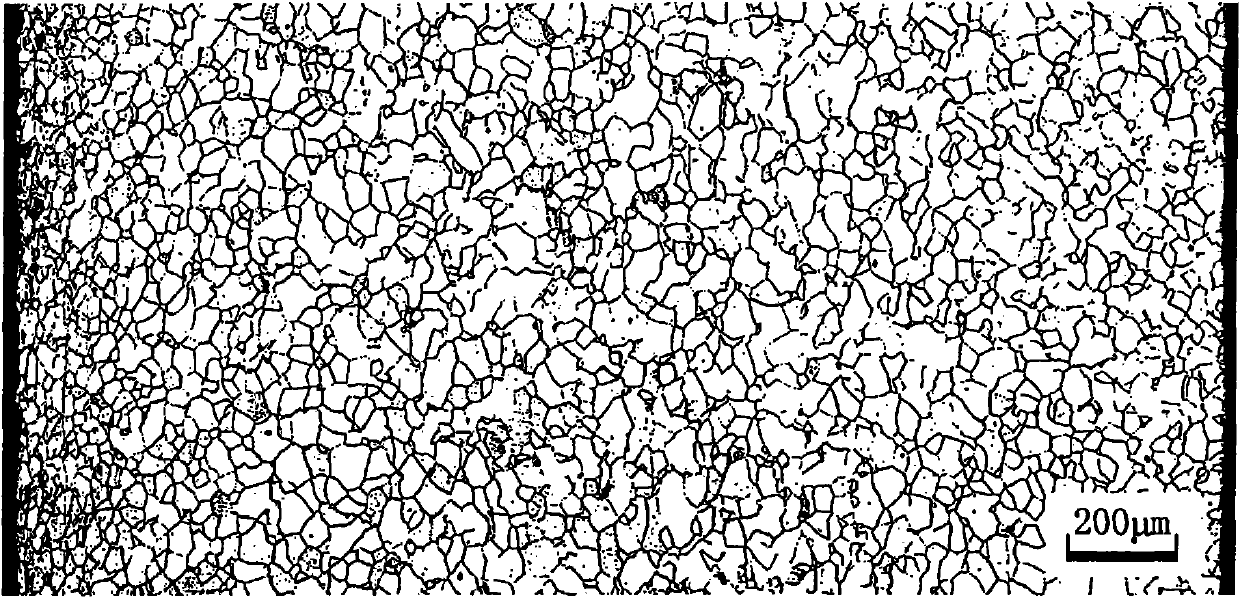

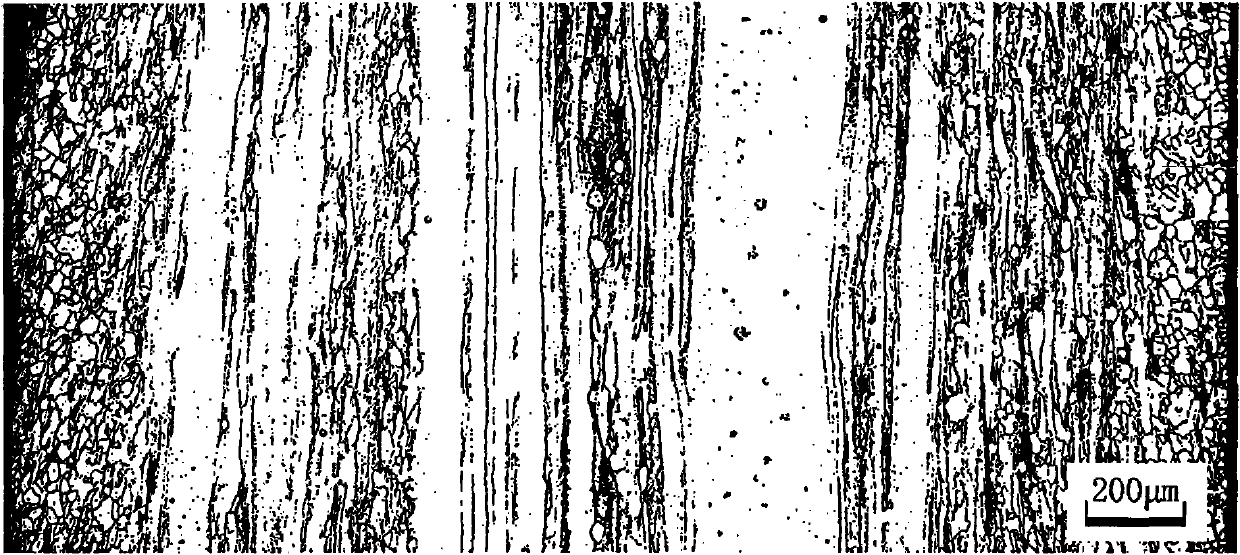

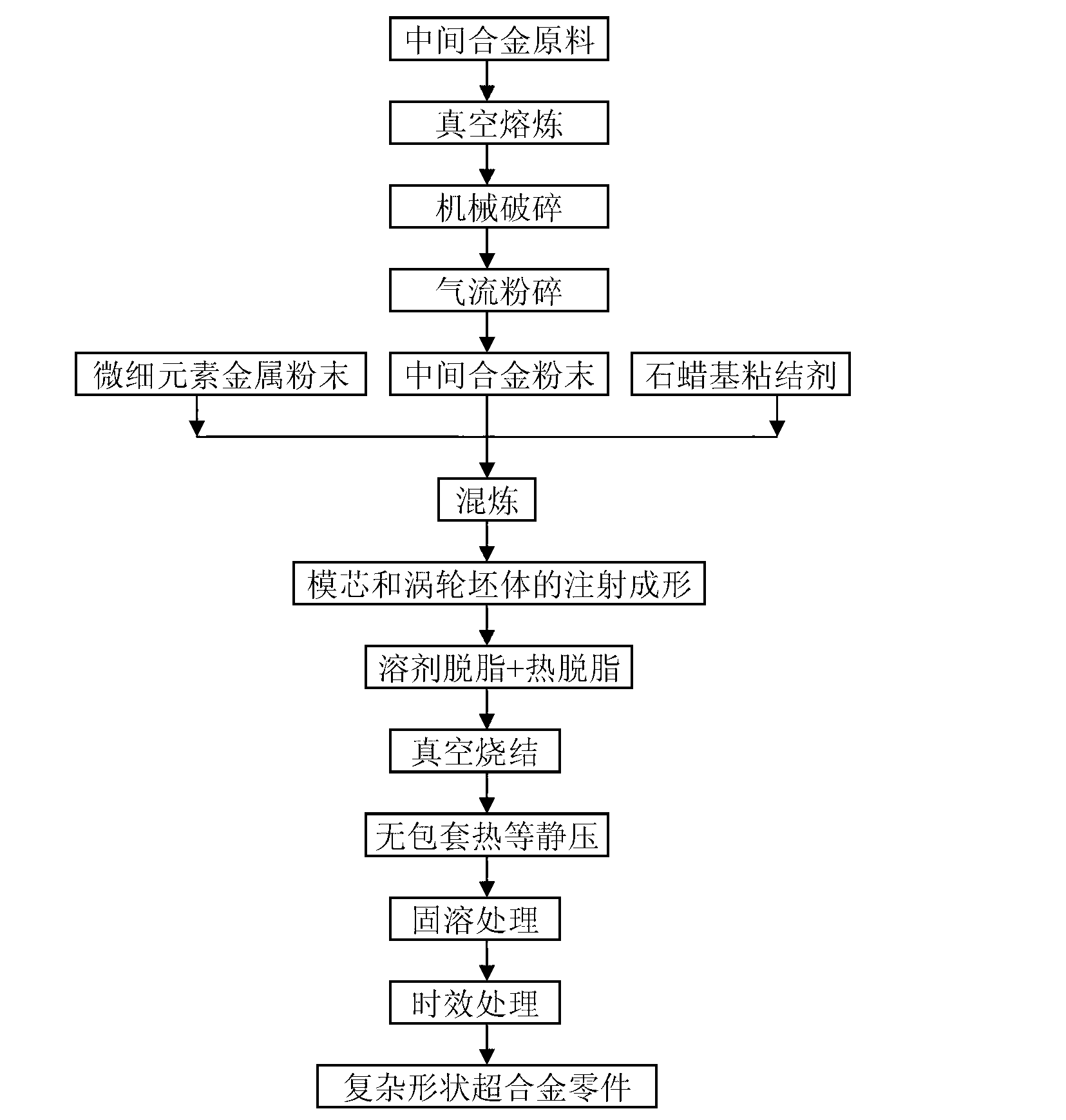

Method for preparing powder super-alloy by near net shape

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

Cooling and drying synchronizing method for rotary hearth furnace

ActiveCN105349773ASimple structureEasy to processRotary drum furnacesComposite materialHeating system

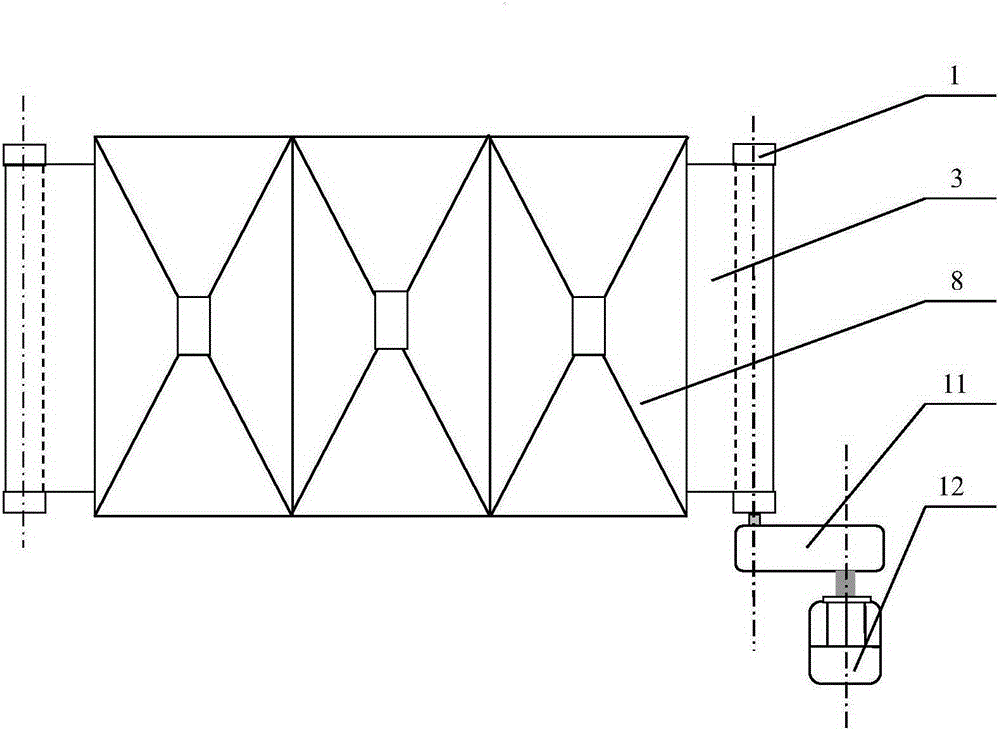

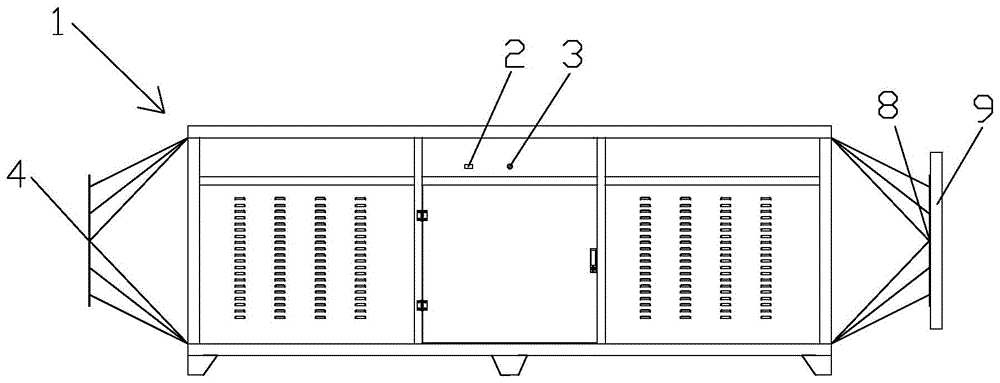

The invention relates to a cooling and drying synchronizing method for a rotary hearth furnace. The method specifically includes the following steps that firstly, red pellets of the rotary hearth furnace uniformly fall on a lower-layer chain plate at a feeding end A2 through a first guiding chute, and meanwhile green pellets of the rotary hearth furnace uniformly fall on an upper-layer chain plate at a feeding end B1 through a first distributor; secondly, it is guaranteed that the rotation direction of the upper-layer chain plate and the rotation direction of the lower-layer chain plate are opposite by adjusting the rotating speed of both the upper-layer chain plate and lower-layer chain plate; thirdly, cold air ascends and penetrates through the red pellets on the lower-layer chain plate so as to cool the red pellets, and meanwhile the temperature of the cold air increases, so that the cold air is changed into pre-heated air; fourthly, the pre-heated air continues to ascend and penetrates through the green pellets on the upper-layer chain plate so as to dry and pre-heat the green pellets, and meanwhile the temperature of the pre-heated air decreases, so that the pre-heated air is changed into hot air containing certain heat; and finally, the hot air is pumped out, enters a dust falling room, then enters a dust removing room from the dust falling room and is transferred into an air pre-heating system in the rotary hearth furnace through the dust removing room for use.

Owner:SHANDONG IRON & STEEL CO LTD

Method for extracting chromium and vanadium from vanadium slag at low temperature and normal pressure

ActiveCN105400967ALow reaction temperatureReduce reaction energy consumptionSlagReaction temperature

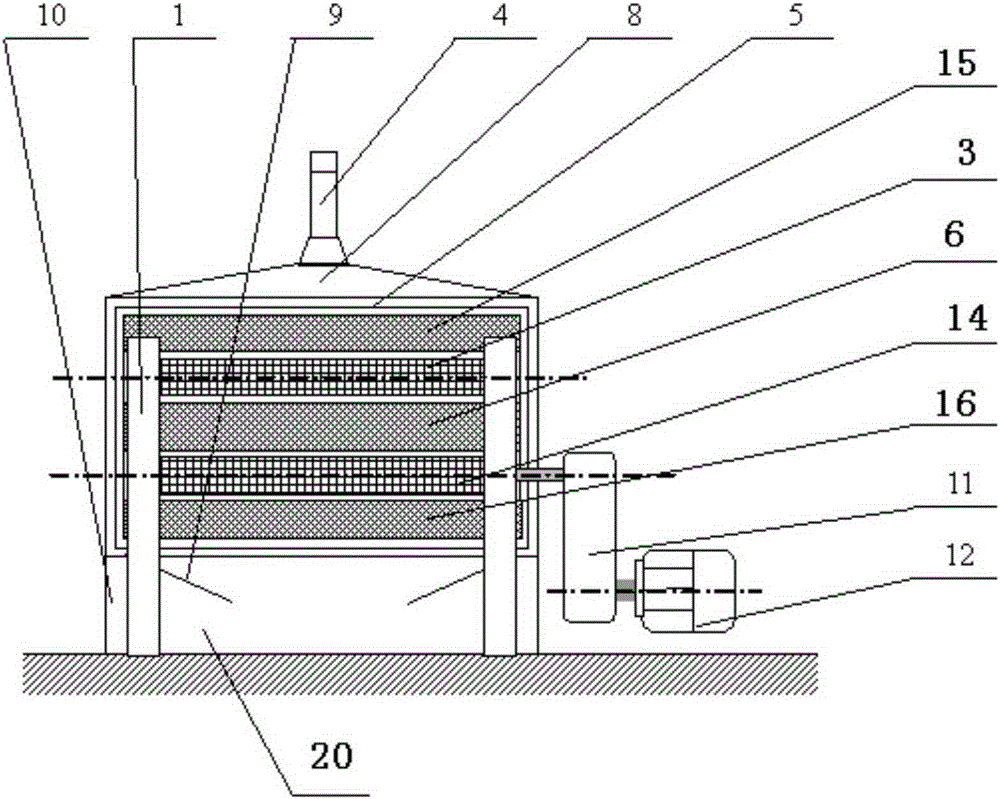

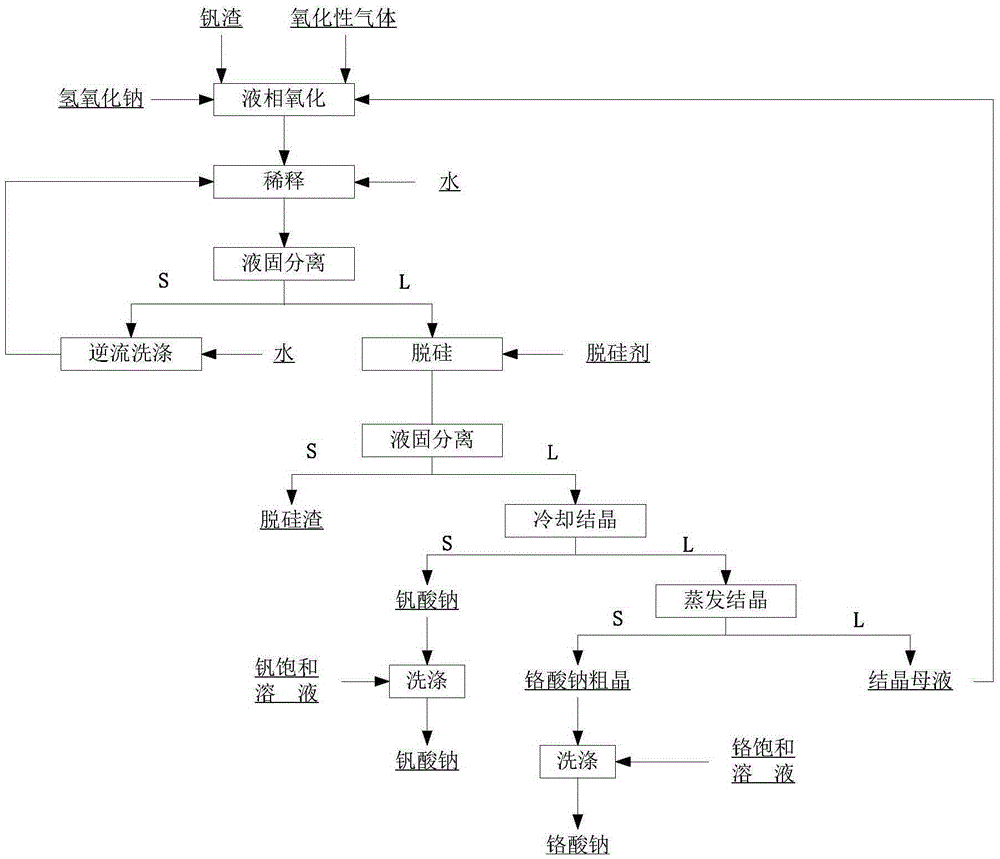

The invention relates to the field of vanadium slag hydrometallurgy and vanadium chemical engineering, in particular to a method for extracting chromium and vanadium from vanadium slag at a low temperature and the normal pressure. The method comprises the following steps that firstly, burdening, wherein the vanadium slag and a NaOH solution are mixed to form reaction slurry; secondly, reaction, oxide gas is led into the reaction slurry through a micro-hole arrangement device to carry out normal-pressure oxidative leaching, and after the reaction, solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4, water soluble impurity components and iron-rich tailings is obtained; thirdly, solid-liquid separation; fourthly, impurity removing; fifthly, sodium vanadate crystallization; and sixthly, sodium chromate crystallization. According to the method, chromium and vanadium efficient common extraction can be achieved, the extraction efficiency of both chromium and vanadium can be higher than 85%, more importantly, after the micro-hole gas distribution manner is adopted, the oxygen solubility can be obviously improved, the reaction temperature and alkali concentration are obviously reduced compared with those of an existing vanadium extraction method, the operation safety is greatly improved, and reaction energy consumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

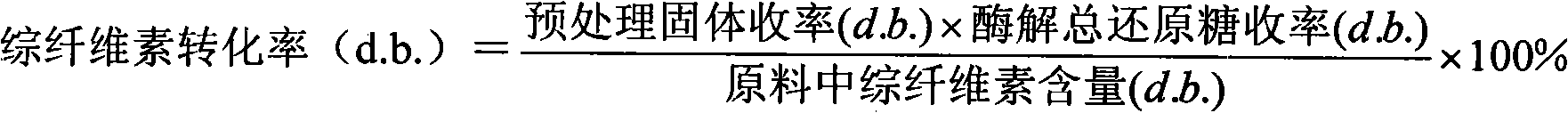

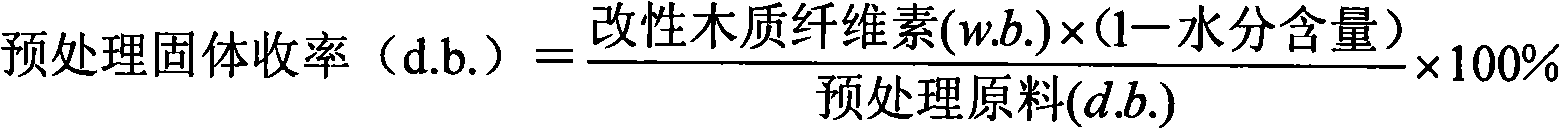

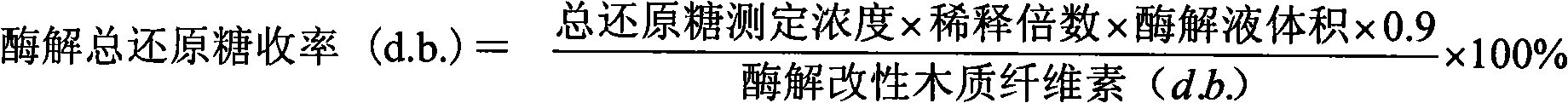

Pre-treatment method for highly-effective saccharification of lignocellulose

InactiveCN101255479AReduce the cost of trainingImprove securitySugar derivativesSugar derivatives preparationCelluloseLiquid glucose

The invention discloses a pretreatment method for effectively saccharifying lignocellulose, particularly discloses a pretreatment method of lignocellulose with room-temperature light-concentration lye, characterized in the method comprises the steps of coarse grinding, lye wetmilling, alkali recovery and enzymolysizing. The ground lignocellulose is mixed with univalent metal lye having a concentration of 0.1% to 3%, solid and liquid are separated under room temperature after wet grinding, wherein the liquid is used for recovering univalent metal lye, and the solid, namely the modified lignocellulose, is used for further enzymolysizing for preparing liquid glucose. According to the invention, lignocellulose is used as the raw material, room temperature condition without external heating can be selected, low-concentration lye is pretreated, the lye can be effectively recovered, the enzymolysis efficiency is improved, the glucose yield is increased, the cost is lowered, the economical efficiency is enhanced, and drawbacks of high energy consumption, low glucose recovery rate, and high equipment requirements in current lignocellulose pretreatment method are made up.

Owner:NANJING TECH UNIV

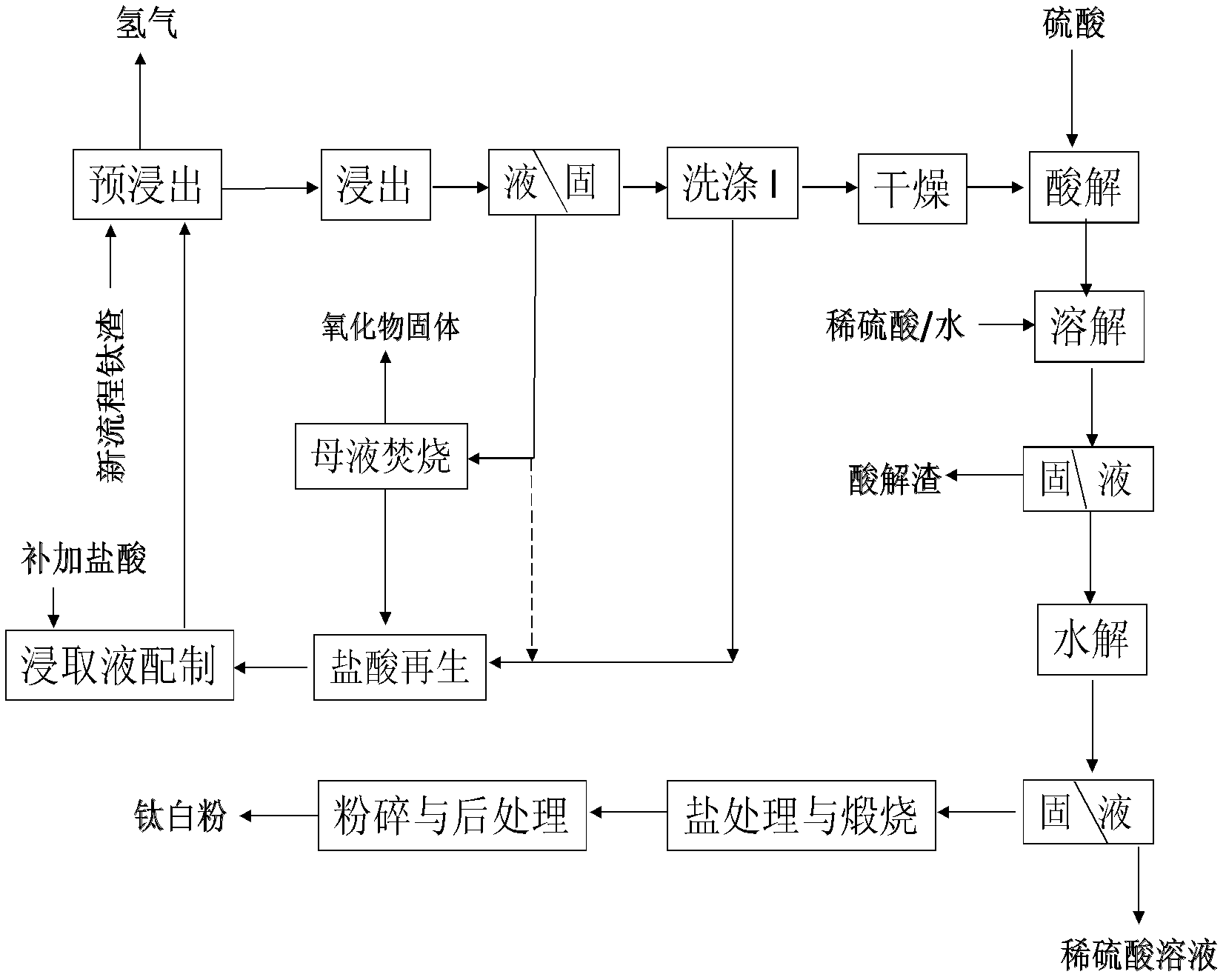

Method for preparing titanium pigment by using titanium residues obtained by directly reducing titanium-iron oxide

InactiveCN102627321AEfficient removalLow impurity contentTitanium dioxideProcess efficiency improvementBrown iron oxideScrap

The invention provides a method for preparing a titanium pigment by adopting a novel direct reduction flow. A novel raw material is provided for the production of a titanium pigment with a sulfuric acid process, and a process flow is provided for downstream utilization of a direct reduction product of vanadium titano-magnetite simultaneously. A novel hydrochloric acid pretreatment process with a novel direct reduction flow for titanium residues is adopted, so that dyeing elements such as aluminum, calcium, magnesium, iron, chromium, vanadium and the like in the titanium residues in the novel process are removed effectively, pretreated titanium-rich hydrochloric acid leaching residues are directly applied to production of a titanium pigment with a sulfuric acid process, the conventional refrigeration iron removing and concentration purifying processes are not required, special aluminum, chromium and vanadium processes are not required, ferrous sulfate is not produced, and ammonia alum waste as well as chromium, vanadium and ferrous sulfide residues which are difficult to treat are not produced. Moreover, the used hydrochloric acid and sulfuric acid are completely recycled in an enclosed loop, and a diluted waste acid liquid is not produced.

Owner:沙立林 +1

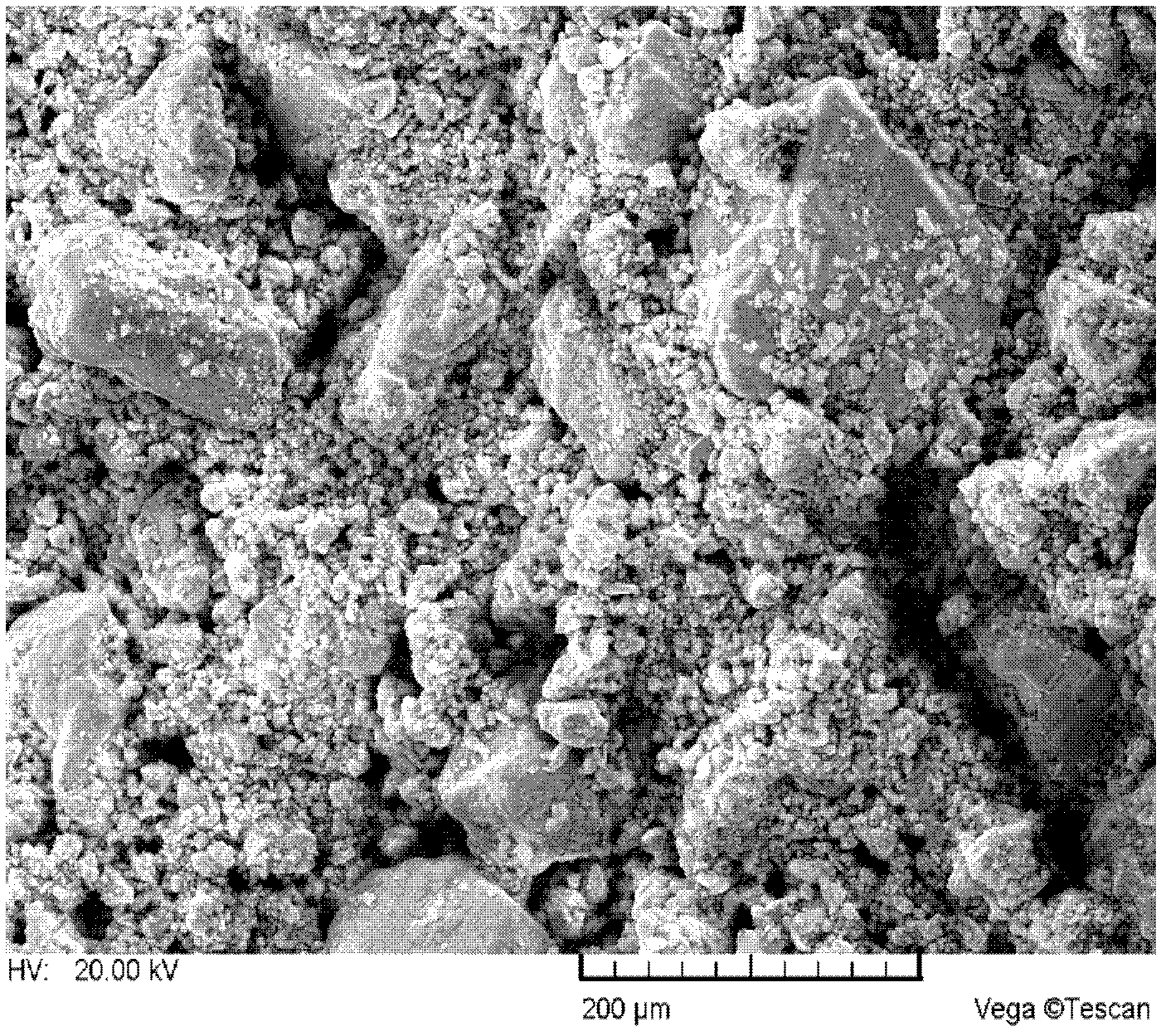

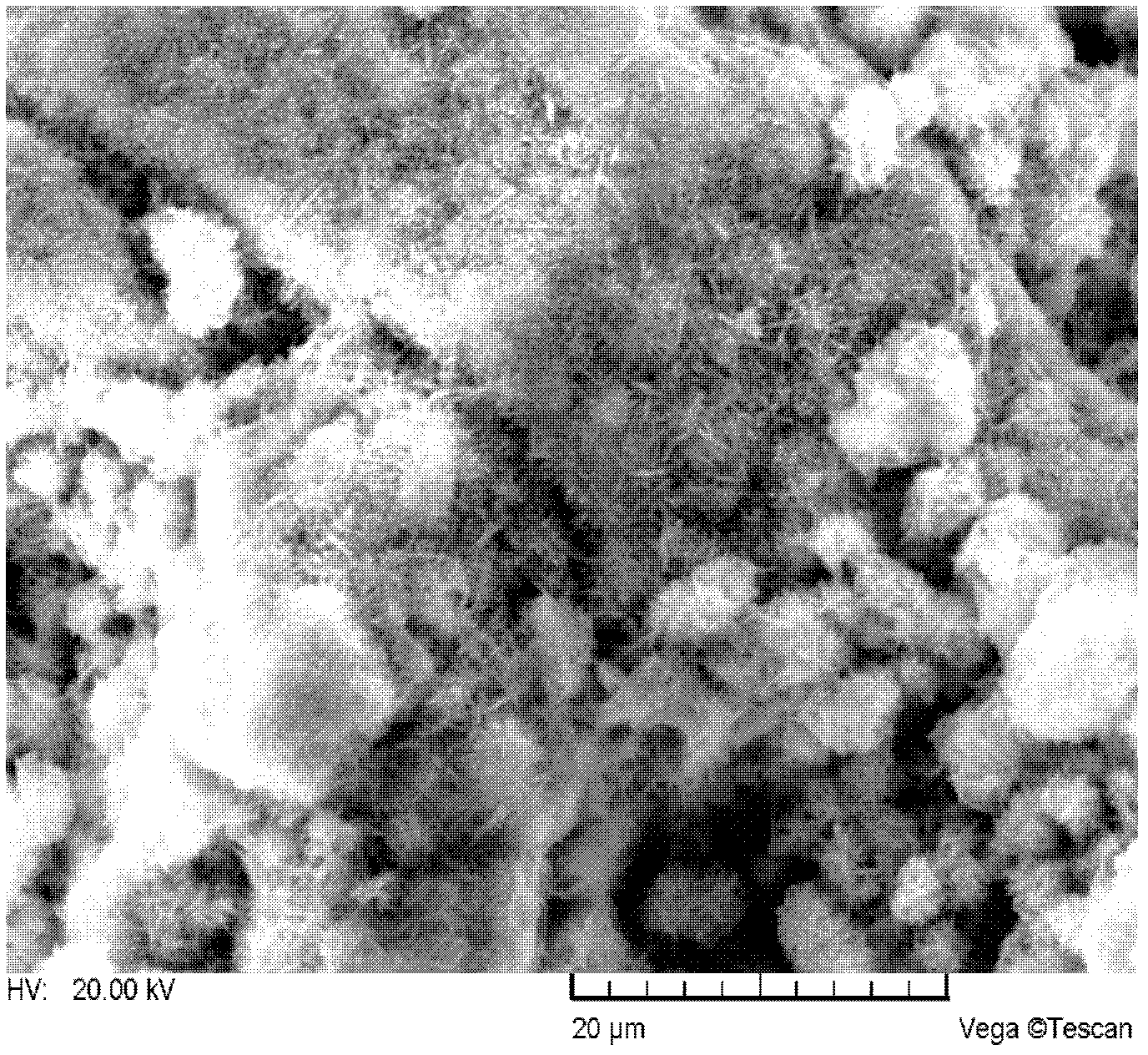

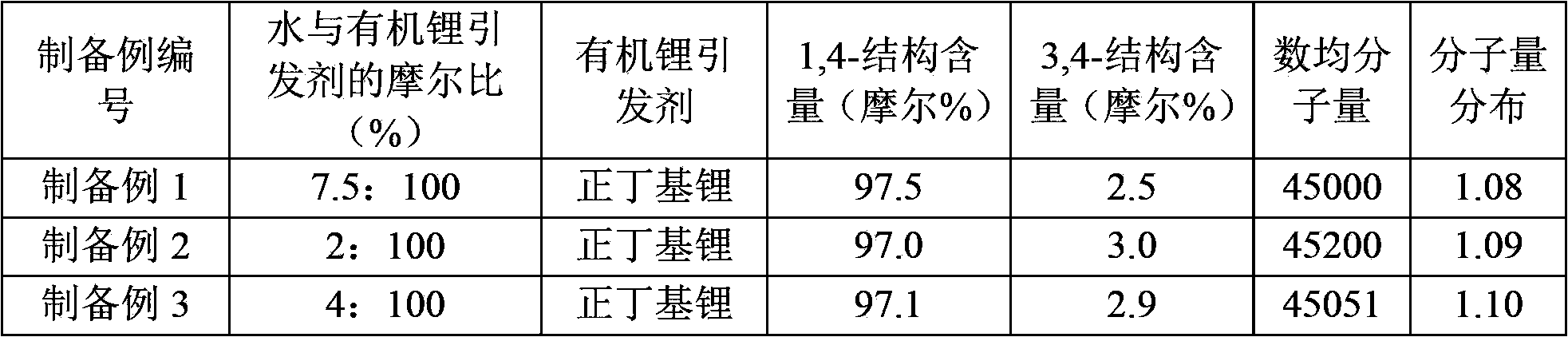

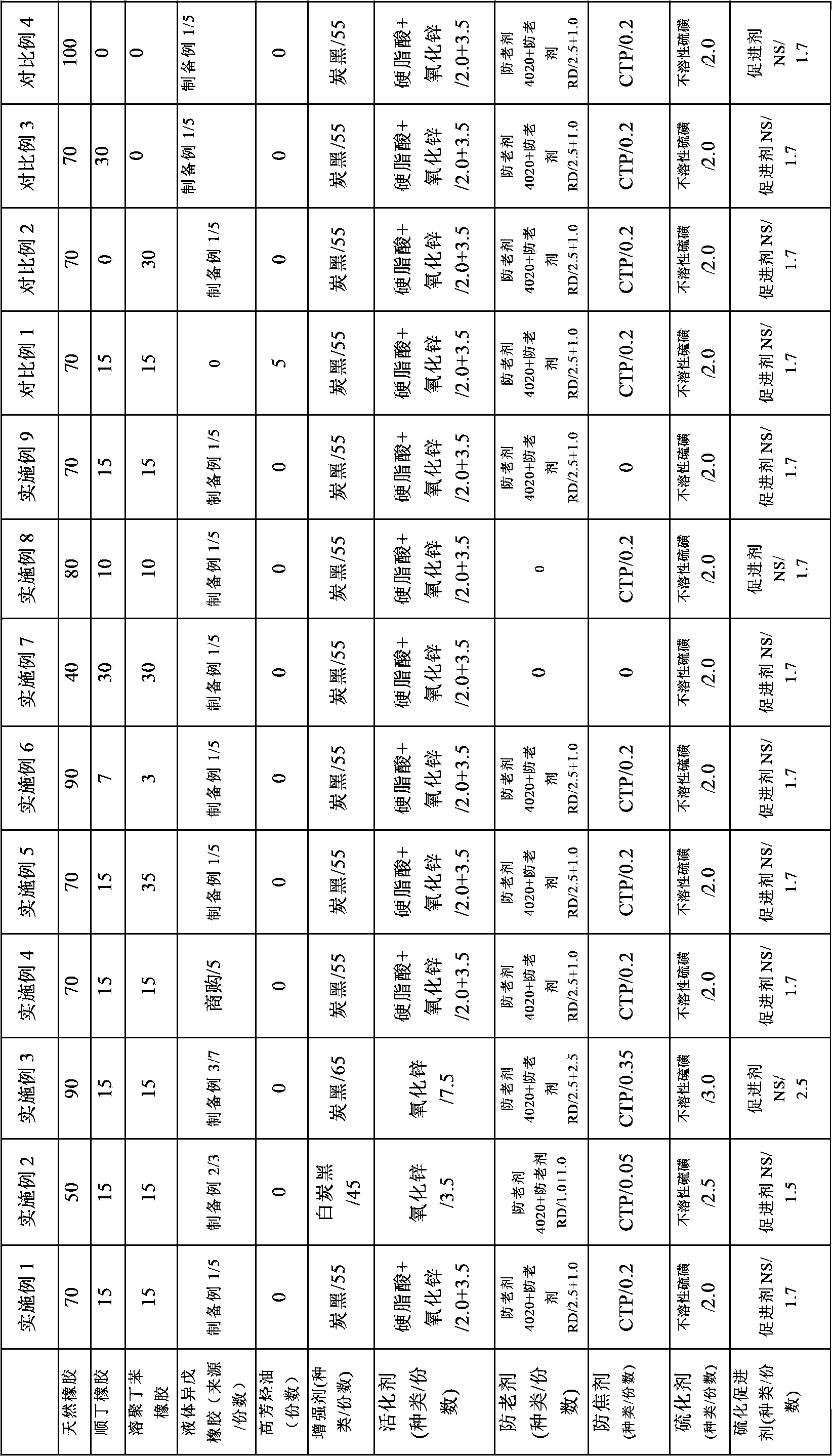

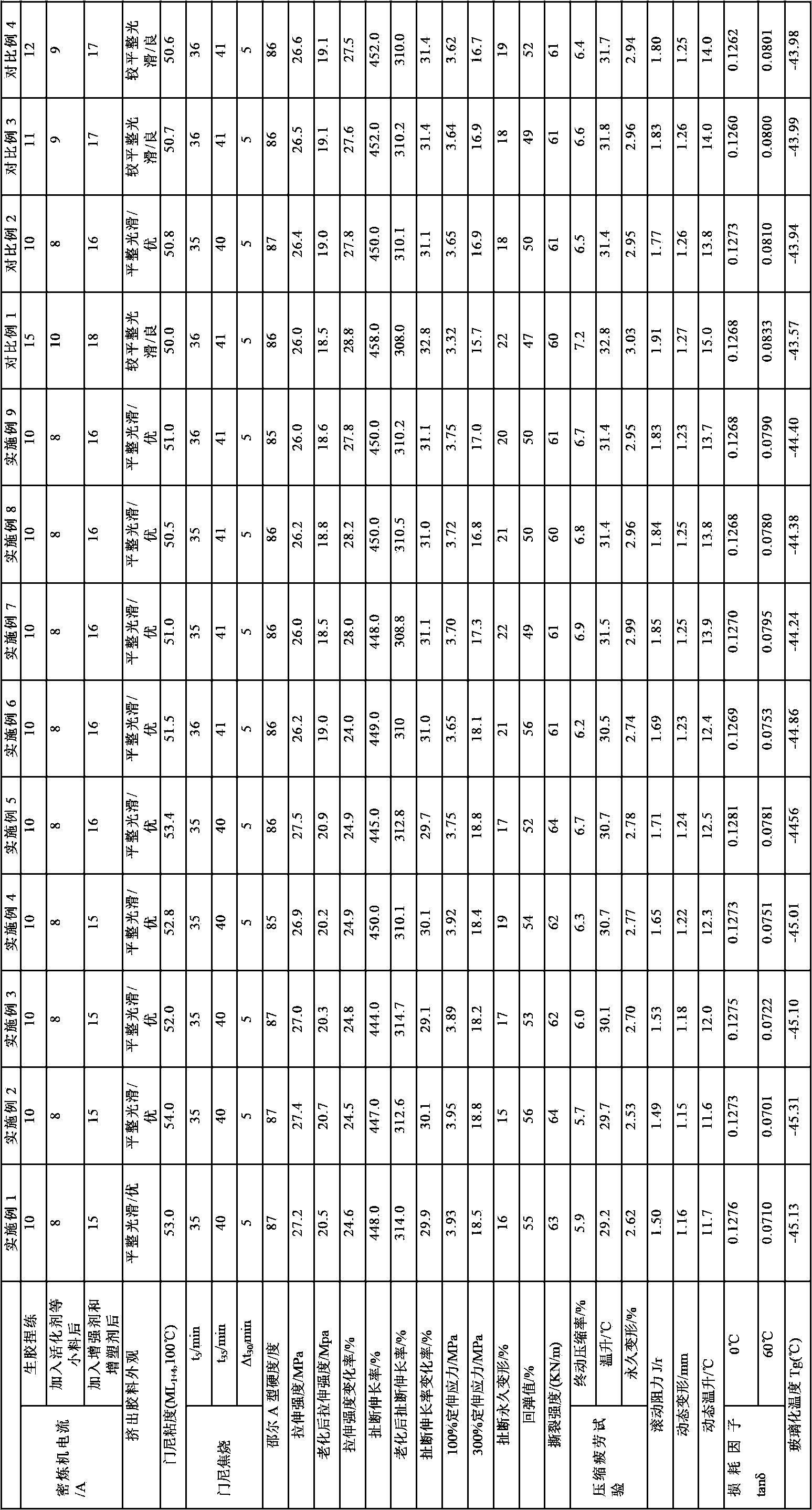

Rubber composition, tyre tread rubber and preparation method thereof

ActiveCN103788422AImprove securityEnsure safetySpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention relates to a rubber composition. The composition comprises a main body rubber, a vulcanizing agent, a vulcanization accelerator, an activator and a reinforcing agent. The composition also comprises liquid isoprene rubber. The main body rubber comprises natural rubber, butadiene rubber and solution polymerized styrene-butadiene rubber. The invention also discloses tyre tread rubber and a preparation method thereof. The tyre tread rubber provided by the invention is low in processing energy consumption, good in surface quality of extruding and calendaring rubber materials, good in physical and mechanical properties and ageing resistant property, and relatively small in compression set and heat generation, and can improve durability of the tyre and prolong the service life of the tyre. The tyre tread rubber provided by the invention has good wet skid resistance and low rolling resistance, can guarantee security of the tyre in a driving process and is benefit for energy conservation of the tyre.

Owner:CHINA PETROLEUM & CHEM CORP +1

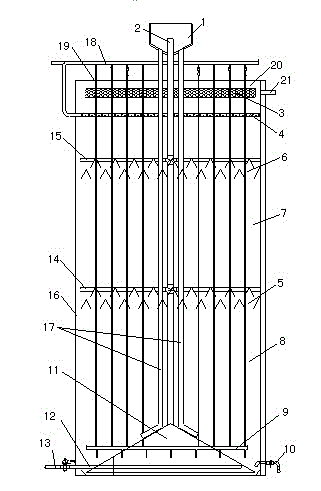

Three-stage circulation aerobic reactor

ActiveCN103332784AStart fastGrow fastSustainable biological treatmentBiological water/sewage treatmentLoad resistanceThree stage

The invention discloses a three-stage circulation aerobic reactor, which comprises a pond body, wherein the inside of the pond body is partitioned into a conical sewage expansion area, an aerobic reaction area, an anaerobic reaction area and a sediment filtering layer from bottom to top in sequence; the upper part of the aerobic reaction area is provided with a primary gas-solid-liquid separation area; the upper part of the anaerobic reaction area is provided with a secondary gas-solid-liquid separation area; three-phase separators are respectively arranged in the primary gas-solid-liquid separation area and the secondary gas-solid-liquid separation area; a water outlet weir is arranged above the sediment filtering layer; a water outlet pipe is arranged on the water outlet weir; the top of the pond body is provided with a double-stage circular reflowing system; the double-stage circular reflowing system comprises an air-lift pipe, a gas-liquid separating tank and a lower layer reflowing pipe; an upper layer reflowing pipe is arranged between the secondary gas-liquid separation area and the sediment filtering layer; and the upper layer reflowing pipe is connected with an aeration air inlet pipe arranged above the pond body. The reactor is provided with a three-stage circular reflowing system, and has the characteristics of rapid start of flocculent sludge, high impact load resistance, low requirement on the PH value of inflow water, high particle sludge increasing speed, low energy consumption, high treating efficiency and stable water yielding quality.

Owner:山东许中华环保科技有限公司

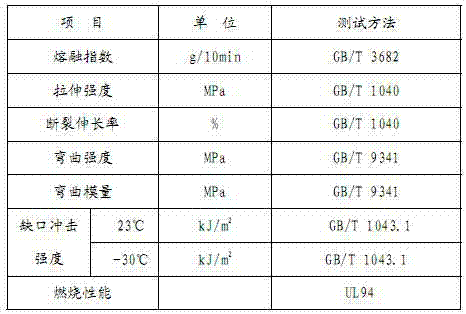

High-fluidity environmental protection halogen-free flame-retardant HIPS composite material and its preparation method

The invention belongs to the technical field of macromolecular compound combination and relates to a high-fluidity environmental protection halogen-free flame-retardant HIPS composite material, which is composed of the following components of: by weight, 29-50 parts of high impact polystyrene (HIPS), 15-35 parts of polyphenylene oxide (PPO), 3-12 parts of a flexibilizer, 5-20 parts of a phosphorus flame retardant, 1-7 parts of a flame-retardant synergistic agent, 0.2-1.0 part of a heat stabilizer, 0.2-0.8 part of an antioxidant and 0.5-1.2 parts of a processing aid. The invention also discloses a preparation method of the HIPS composite material. The composite material provided by the invention is a halogen-free flame retardation HIPS / PPO alloy with high fluidity and excellent mechanical properties.

Owner:深圳市比克新材科技有限公司

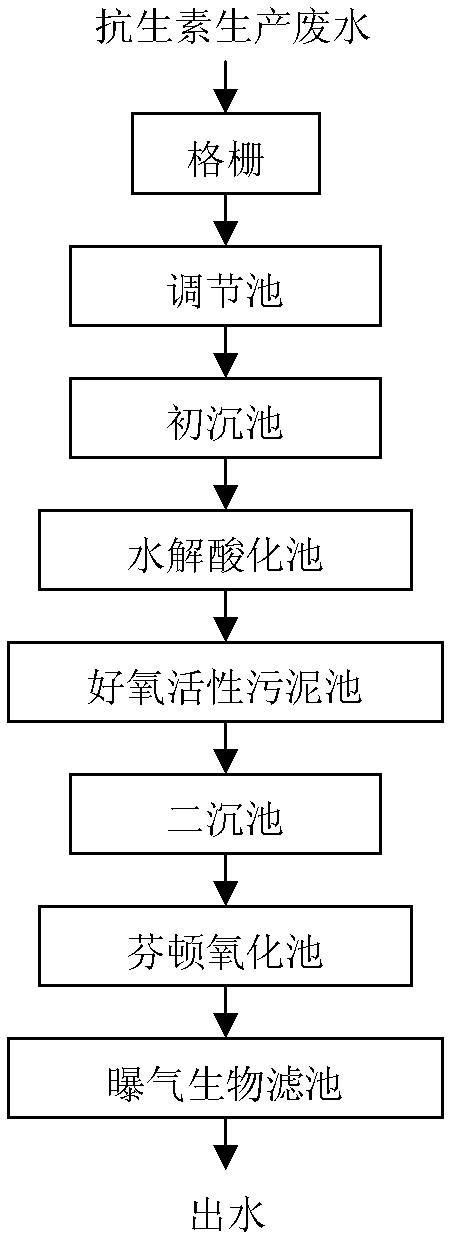

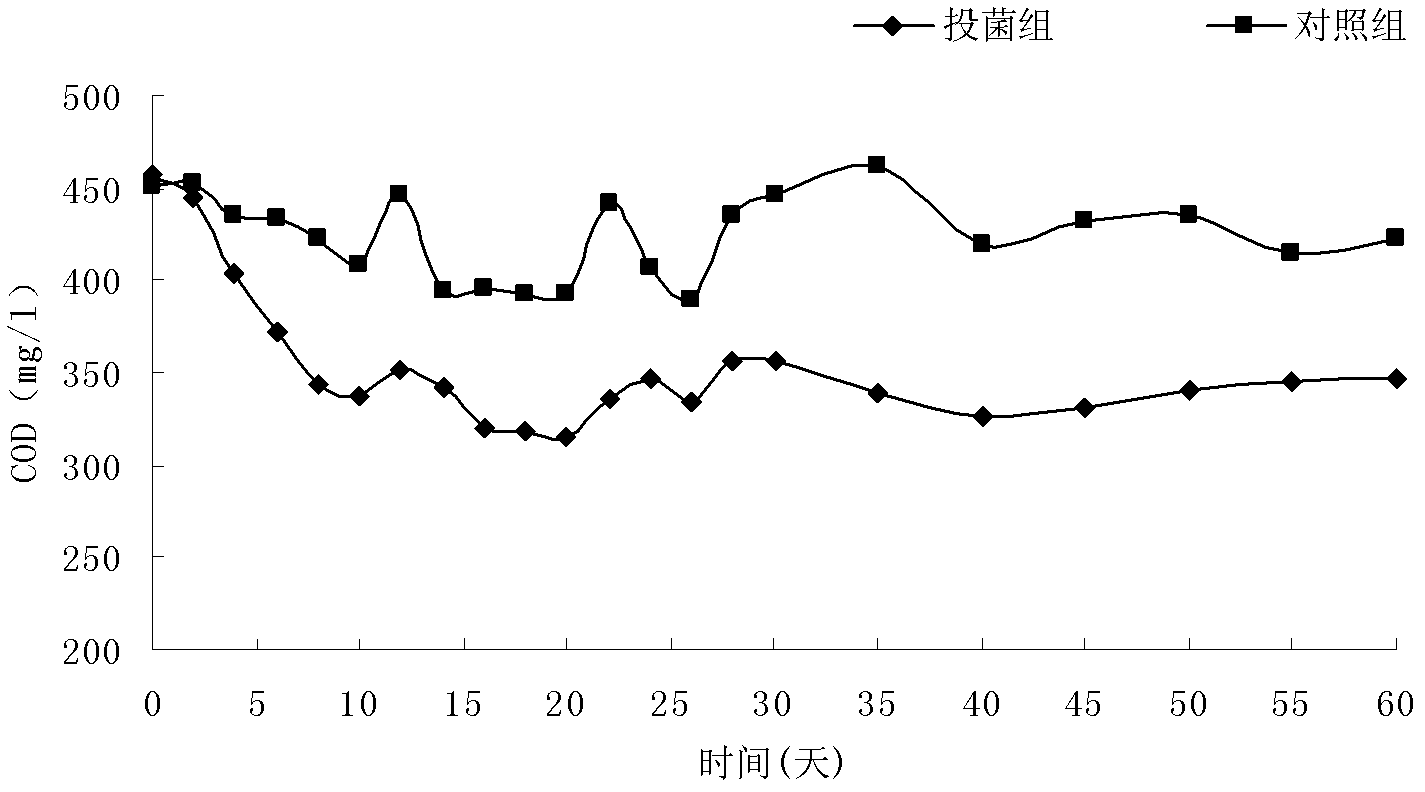

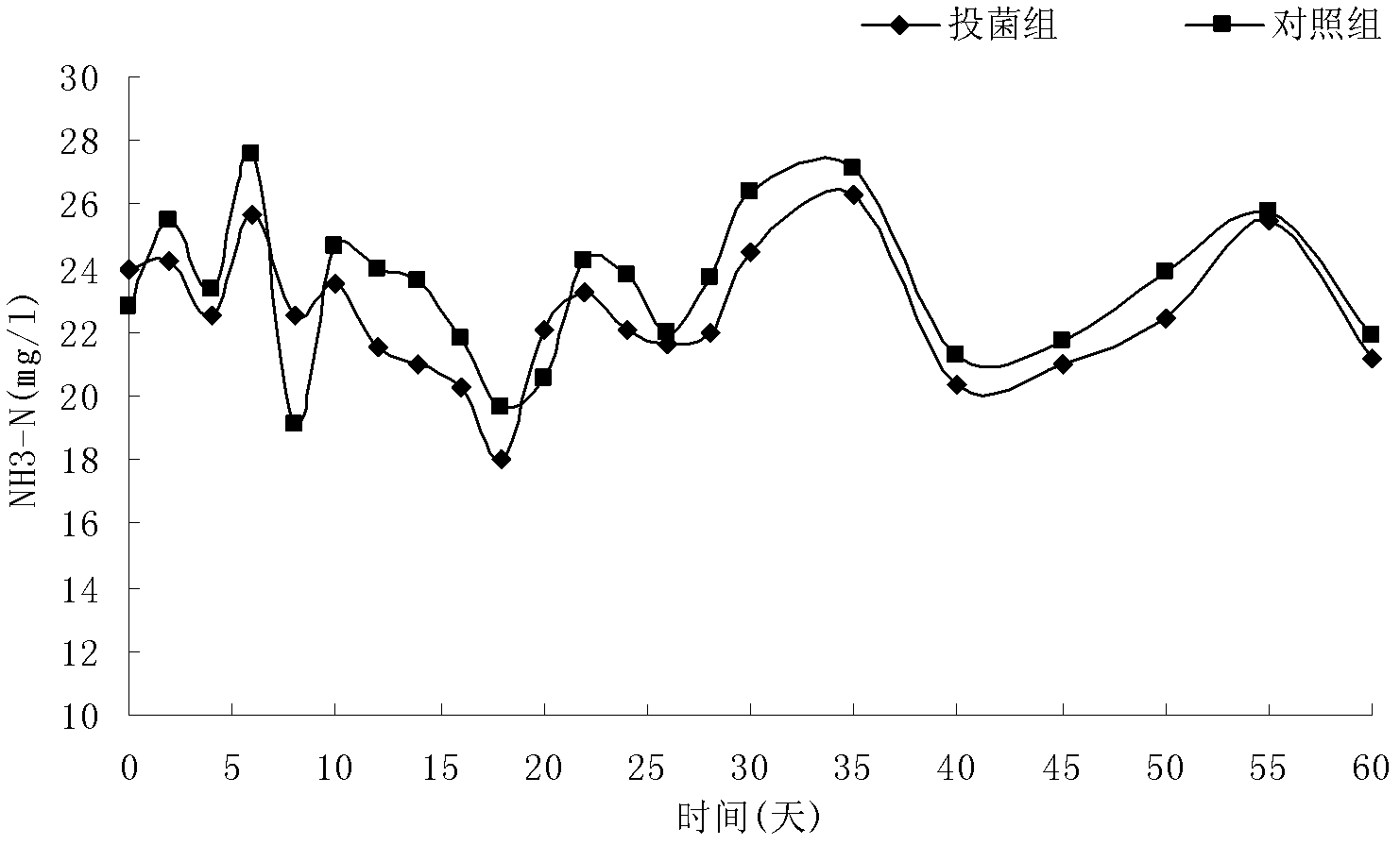

Method for treating antibiotic wastewater

ActiveCN102583903AStrong ability to apply poisonSmall volumeMultistage water/sewage treatmentBioaugmentationChemistry

The invention discloses a method for treating antibiotic wastewater and belongs to the field of wastewater treatment. The treatment method comprises the following steps: pre-treatment, hydrolysis and acidification, bioaugmentation-based first-stage treatment, Fenton oxidation and biological advanced treatment. The method is applied to treat wastewater from antibiotic production, works with high efficiency, ensures that the effluent quality is safe and stable and meets the requirements listed in the water quality standard GB / T18920-2002, and can achieve the purposes of beneficial cycle of water resources and green production in enterprises.

Owner:SHANDONG NEWTIME PHARMA

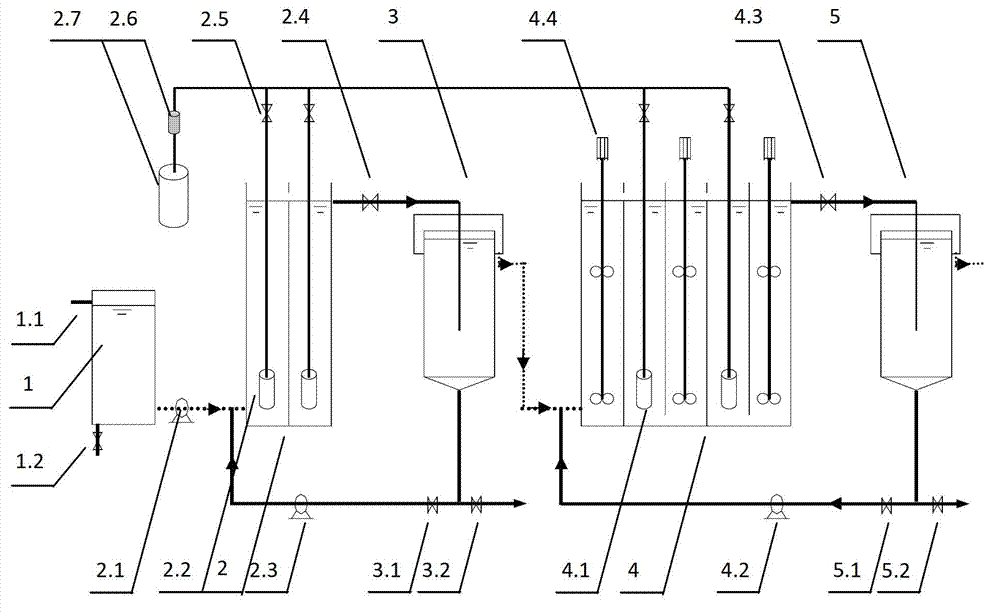

Continuous flow urban sewage partial nitrification and anaerobic ammonia oxidation denitrification method

ActiveCN103086568AHigh recovery rateImprove realized recovery rateMultistage water/sewage treatmentActivated sludgeNitrate nitrogen

The invention discloses a continuous flow urban sewage partial nitrification and anaerobic ammonia oxidation denitrification method and belongs to the field of sewage. The method comprises the following steps of: allowing urban sewage to enter a biological adsorption reactor, adsorbing organic matters in water to activated sludge through the adsorption action of the activated sludge, and carrying out denitrification and anaerobic ammonia oxidation in an anoxic area of a partial nitrification anaerobic ammonia oxidation reactor to remove residual organic matters in water and nitrate nitrogen in return sludge; carrying out the partial nitrification in an aerobic area, and carrying out the anaerobic ammonia oxidation action in the anoxic area; repeating the actions in the aerobic area and the anoxic area; and finally, fulfilling the aim of removing nitrogen from the sludge.

Owner:上海立源生态工程有限公司

Method for removing aldehydes in epoxypropane reaction mixture

The invention relates to a method for removing aldehydes in an epoxypropane reaction mixture. The method comprises carrying out primary aldehyde removal on an epoxypropane reaction mixture through an aldehyde-free resin tank so that aldehyde content is reduced and epoxypropane product purity is guaranteed, orderly removing water and unreacted propylene, feeding the materials containing epoxypropane and methanol into an epoxypropane refining tower, carrying out extraction on methanol in the middle section of the tower through desalinized water containing ethanolamine or hydrazine hydrate, simultaneously removing residual aldehyde in the epoxypropane product, separating the separated aqueous solution through a methanol tower, feeding the aqueous solution into a membrane separation device, further removing residual aldehydes and impurities, returning the methanol as circulation methanol at a penetration side to a reaction system and returning aldehyde-containing methanol at a retentate side to a collection tank. The method utilizes less devices, reduces a disposable investment, does not need hydrogen in a separation and recovery process, does not increase a safety risk, is safe and reliable in use and reduces later waste water treatment energy consumption.

Owner:JIANGSU YIDA CHEM

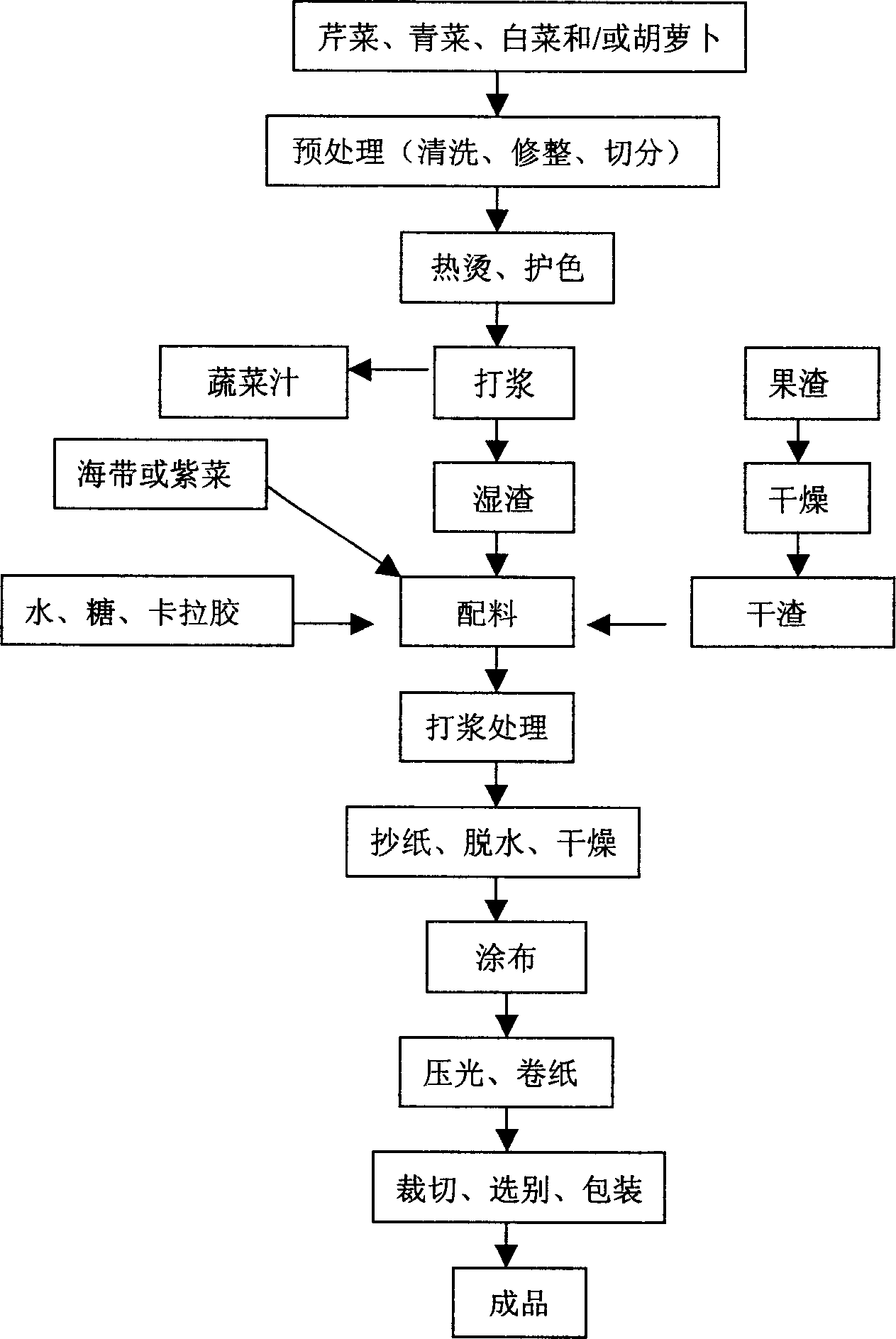

Preparation methodof edible package paper

The invention relates to an edibility packaging paper preparing method. It uses fruit processing tailings that apple and orange pomace, fresh vegetable that celery, cabbage, carrot etc as raw material, hydrophilic property high molecular material that polysaccharide, protein, antioxidant etc as auxiliary materials. The preparing method includes the following steps: preprocessing, blanching, color protecting, pulping, forming agent and protective agent adding, paper copying, dehydrating, drying, coating, burnish, coil paper, cutting, sizing, and packaging. The product can be used not only as fallow food to eat directly, but also as foods packing paper.

Owner:JIANGNAN UNIV

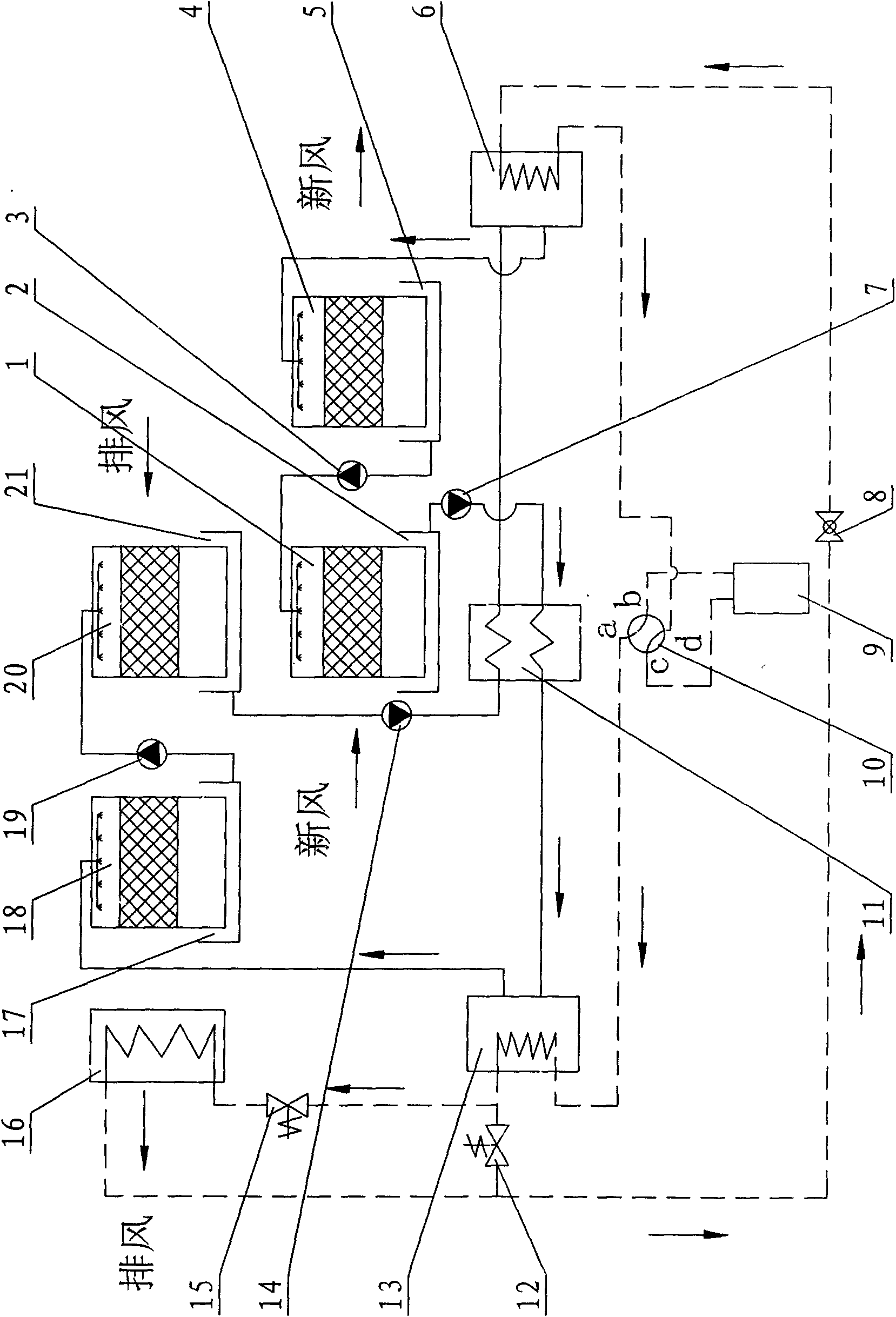

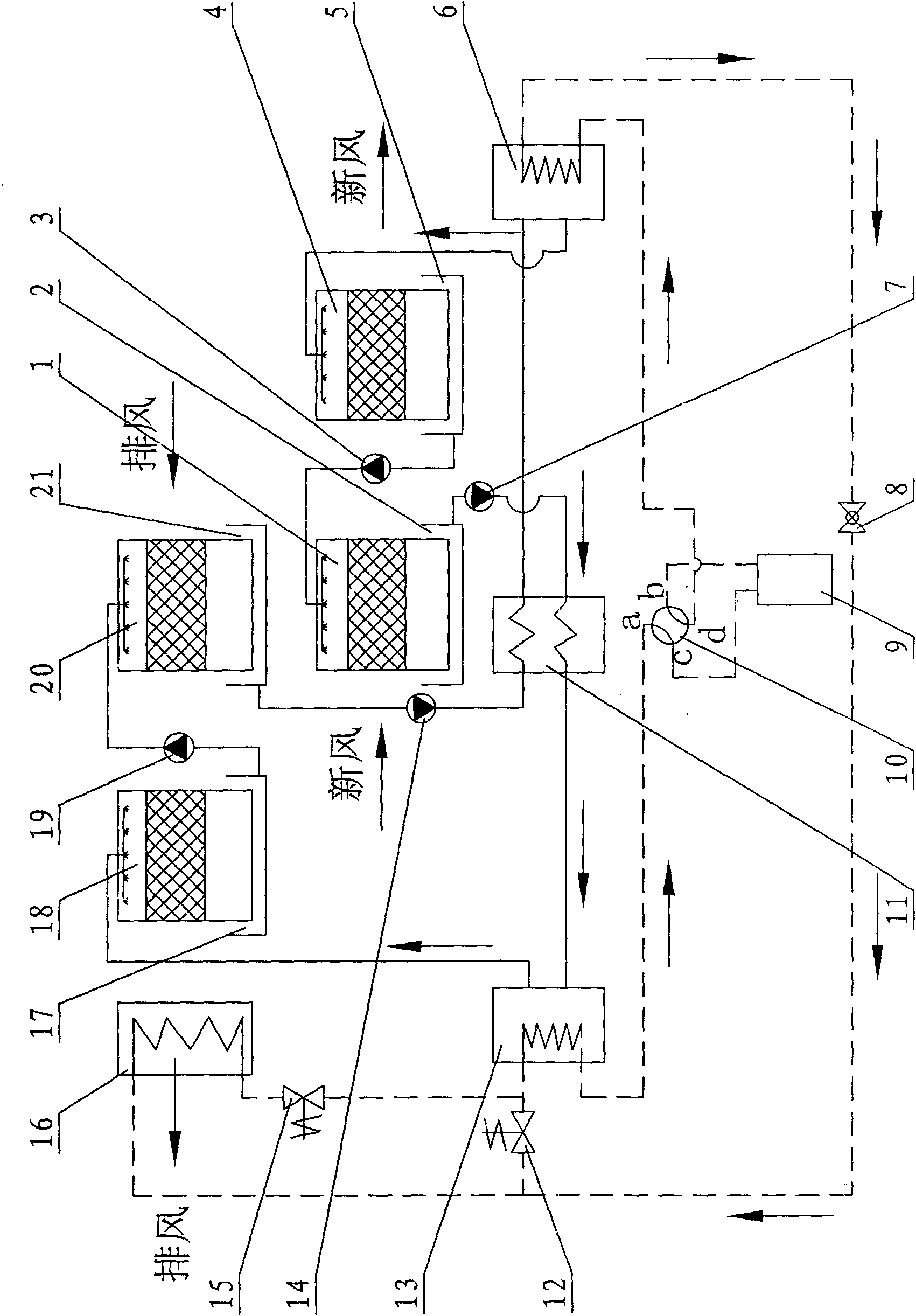

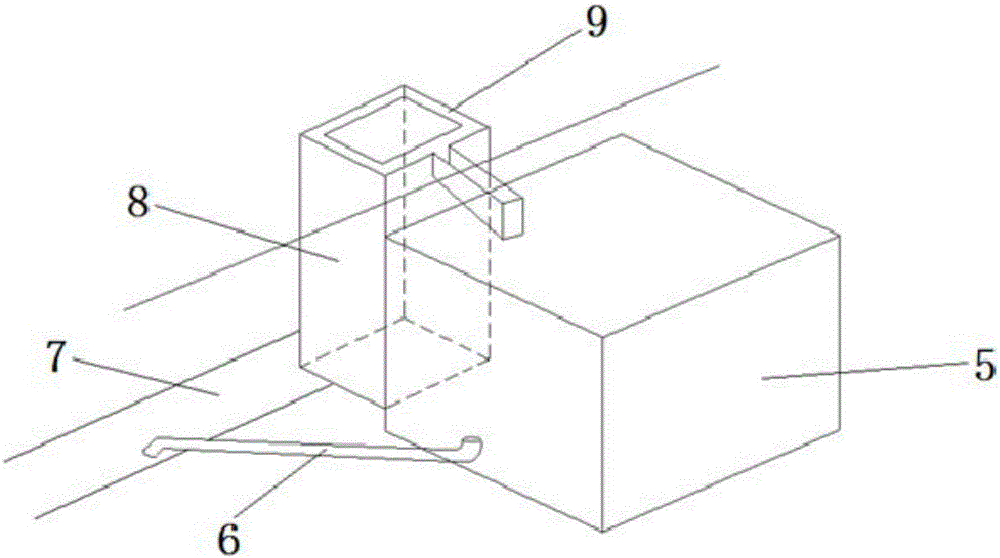

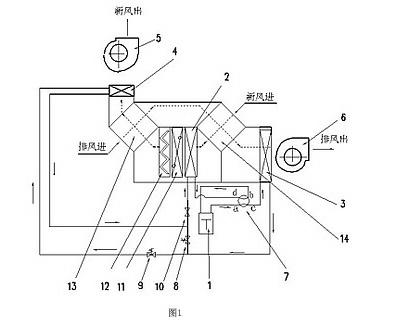

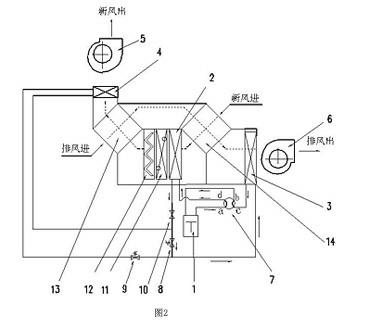

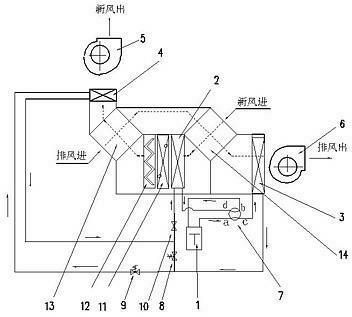

Heat pump coupling contraflow type liquid-desiccant central ventilation system and control method thereof

InactiveCN101876469AReduce processing energy consumptionImprove qualityEnergy recovery in ventilation and heatingHeat recovery systemsLower gradeLow graded

A heat pump coupling contraflow type liquid-desiccant central ventilation system and control method thereof comprise a heat pump system and a liquid-desiccant and fresh air regeneration processing system, wherein the heat pump system comprises a compressor, a four-way directional control valve, a condenser, an evaporator and a throttle member; the liquid-desiccant and fresh air regeneration processing system comprises a fresh air processing module, a liquid regeneration module, a heat exchanger and a liquid pump; both the fresh air processing module and the liquid regeneration module are serially connected with the pipes by the two liquid heat exchangers through a liquid pool. The fresh air processing module is arranged in an indoor air inlet; the liquid regeneration module is arranged in an indoor air outlet to recycle the energy of the indoor exhaust wind. The invention adopts liquid-desiccant to process the fresh air of the air conditioner and removes the dust and the bacteria in the air through spraying the liquid so as to purify the air. The system can recycle the energy of the indoor exhaust wind, which reduces the energy for processing the fresh air; the heat pump is used for providing energy for the liquid to make use of the low-grade heat source.

Owner:广东浩特普尔空调有限公司

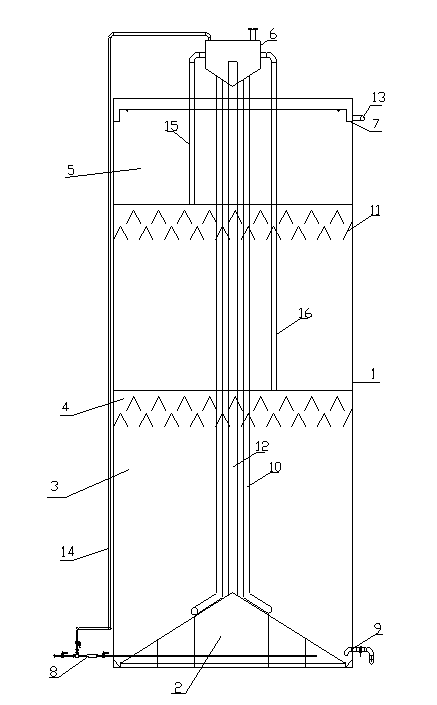

Double-circulation anaerobic reactor

ActiveCN103011402AGrow fastPool heightWaste based fuelTreatment with anaerobic digestion processesLoad resistanceWater quality

The invention provides a double-circulation anaerobic reactor. The double-circulation anaerobic reactor comprises a cell body, wherein the cell body is sequentially divided into a cone-shaped sludge bulking region, a main reaction region, a secondary reaction region and a sediment region from bottom to top, a first-stage gas-solid-liquid separation region is arranged at the upper part of the main reaction region, a second gas-solid-liquid separation region is arranged at the upper part of the secondary reaction region, an effluent weir is arranged above the sediment region, a first-stage sewage gas pipe is connected between an air-water separation tank and the first-stage gas-solid-liquid separation region, a second-stage sewage gas pipe is connected between the air-water separation tank and the second-stage gas-solid-liquid separation region, a sewage gas circulating pipe is connected between the air-water separation tank and a water distribution pipe, the water distribution pipe is arranged at the bottom of the cell body, and a sludge discharging pipe is further arranged at the bottom of the cell body. The double-circulation anaerobic reactor has the advantages that the cell body has low height, the double-circulation anaerobic reactor can be started quickly by flocculent sludge with high shock load resistance, the requirement on a PH value of inflow water is low, granule sludge increases quickly, the processing energy consumption is low, the processing efficiency is high, the effluent quality is stable, and the double-circulation anaerobic reactor is simple to operate and convenience to run.

Owner:山东许中华环保科技有限公司

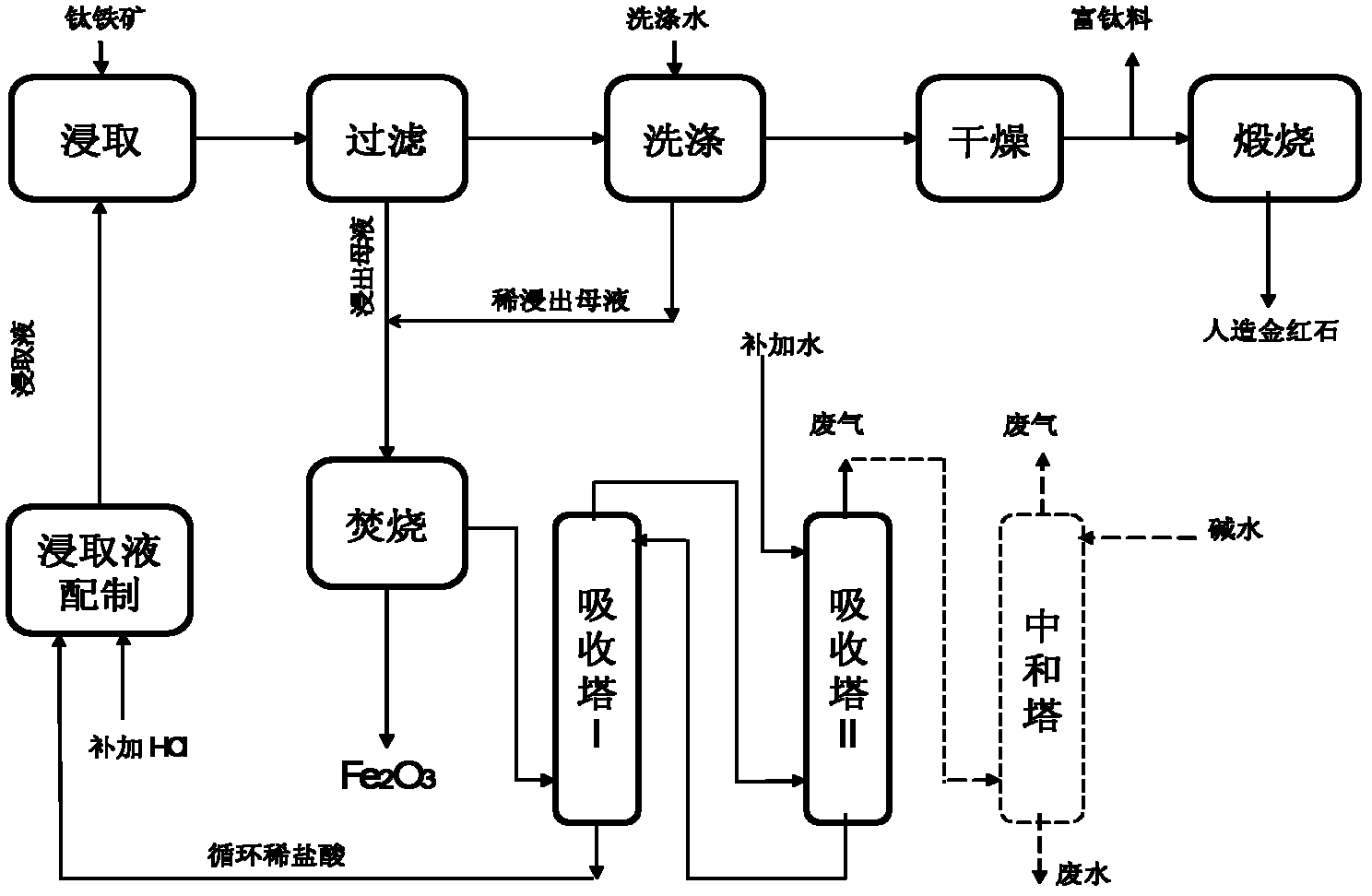

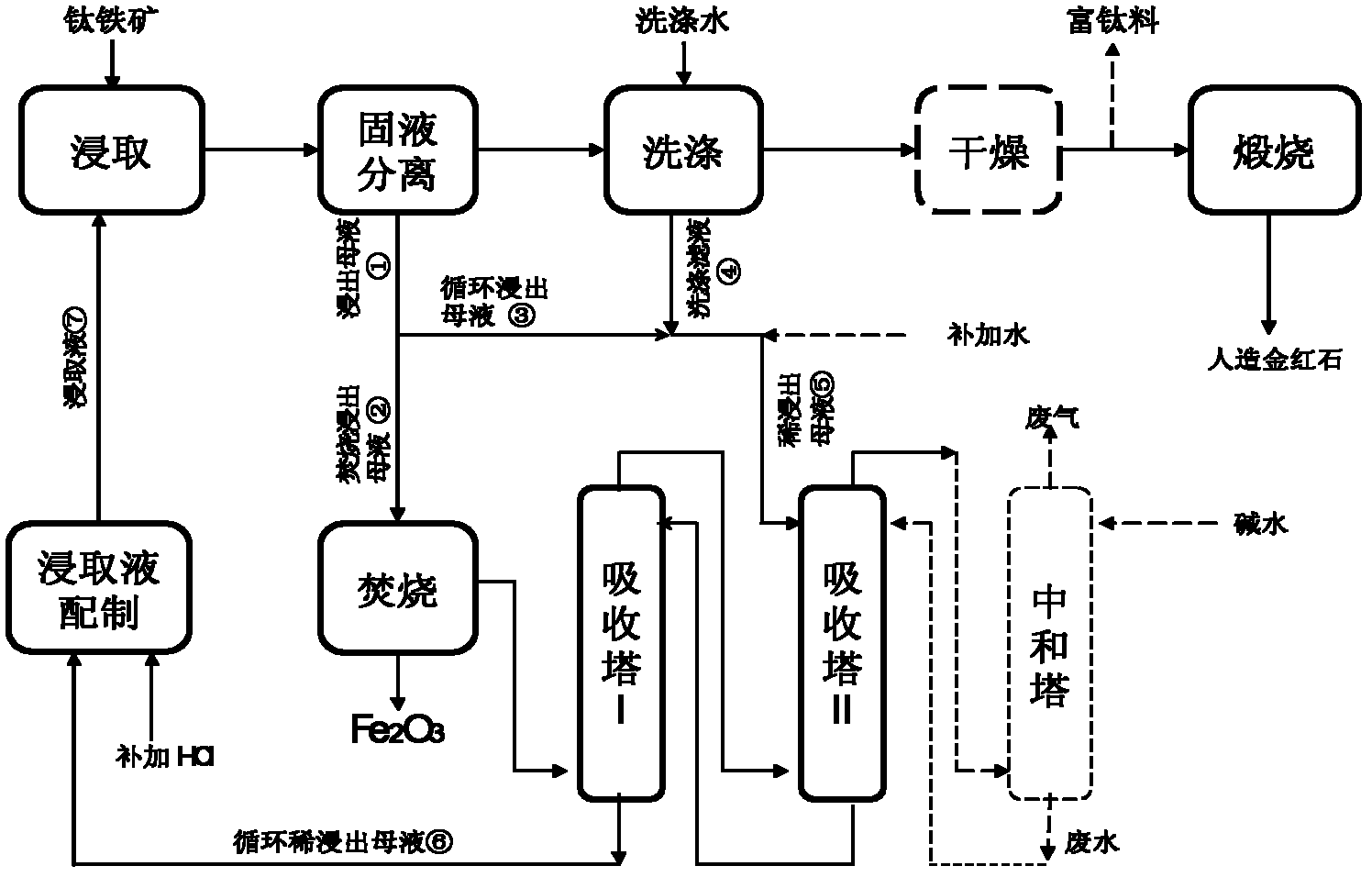

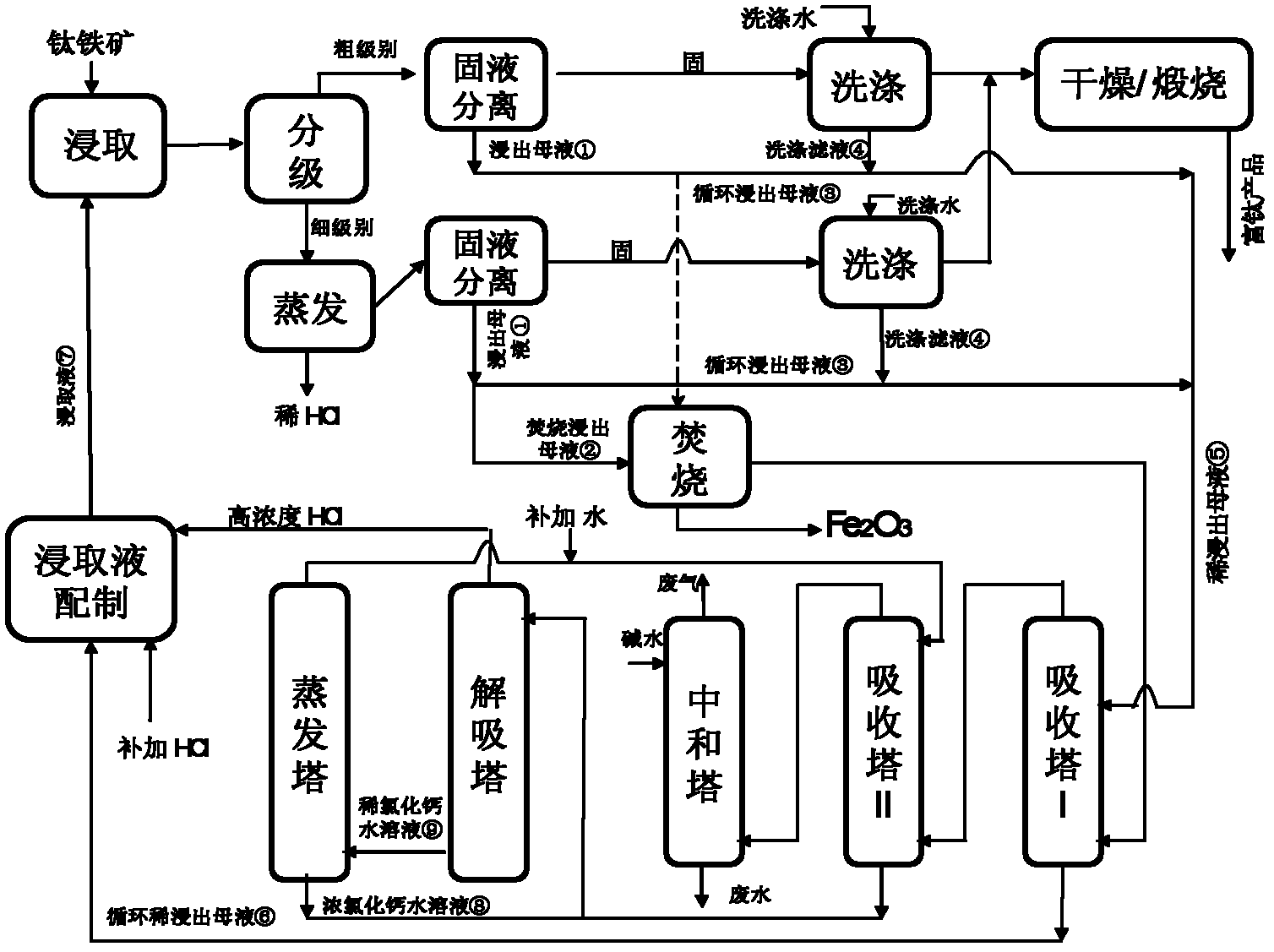

Method for treating hydrochloric acid leachate of ferrotitanium materials

InactiveCN102352437AReduce incinerationReduce processing energy consumptionPregnant leach solutionMaterial balance

The invention provides a method for treating hydrochloric acid leachate of ferrotitanium materials. The method comprises the following steps of: dividing and burning leached mother liquid which is obtained by leaching the ferrotitanium materials by using hydrochloric acid leaching liquid; recovering hydrogen chloride obtained by burning for regeneration and cyclic utilization of the leaching liquid. By the method provided by the invention, the leachate is divided according to material balance of the leach elements (mainly comprising iron) of the hydrochloric acid leachate; and one part of theleachate after division is burned and the other part of the leachate is directly or indirectly absorbed by the hydrochloric acid to return to the leaching procedure, so that completely closed circuitcirculation is formed. By the method provided by the invention, the defect of overlarge energy consumption in the burning procedure after the ferrotitanium materials are leached by the conventional hydrochloric acid can be overcome and the burning quantity of the leached mother liquid can be reduced by 40 to 55 percent, so that the energy consumption of the whole process can be reduced by 35 to 45 percent. The method has a good industrial application prospect.

Owner:沙立林 +1

Method for preparing thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization

The invention discloses a method for preparing a plastic / rubber thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization. The method comprises the followings steps: (1) mixing plastic, rubber and a vulcanization system at a certain proportion, and putting the mixture into an extruder or an injection molding machine to mix, fuse and plasticize the polymer into a fusant; (2) controlling gas to be in a supercritical state by a supercritical fluid conveying system and injecting the gas into a cylinder of the extruder or the injection molding machine; (3) mixing the injected supercritical fluid with the polymer fusant and the vulcanization system; (4) causing a chemical reaction of the plastic, the rubber and the vulcanization system, which is promoted by the supercritical fluid; and (5) releasing the supercritical fluid from the polymer fusant at the pressure which is lower than a critical value, converting the supercritical fluid into gas to be discharged by a vacuum pump. The supercritical fluid assisted plastic / rubber dynamic vulcanization can promote dispersion and size decrease of the rubber phase in the plastic, and effectively reduce processing energy consumption for extrusion or injection shaping.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing environment-friendly honeycomb ceramic heat accumulator by use of waste slag

InactiveCN103992099AImprove microstructureSolve the problem of high brittlenessBreaking strengthProcess equipment

The invention discloses a method for preparing an environment-friendly honeycomb ceramic heat accumulator by use of waste slag. On the basis of introducing a great quantity of waste slag and optimizing the traditional process, the new sintering method and technology are applied to the traditional ceramic product, the dry-process equipment is adopted, and one-time formation and two-time laser short-time sintering are realized. The environment-friendly honeycomb ceramic heat accumulator provided by the invention is produced in a clean and pollution-free manner, and the product has the production advantages of high strength, good thermal shock resistance, low processing energy consumption, short production period and cleanness and no pollution. The breaking strength of the honeycomb ceramic heat accumulator is 35-42MPa, the true density is 2.2-2.4g / cm<3>, the water absorption is 0.2-0.9%, the operating temperature is 1,000-1,250 DEG C, and the requirements for the performance of a heat accumulation material in a regenerative thermal oxidizer (RTO) device can be met.

Owner:SHAANXI UNIV OF SCI & TECH

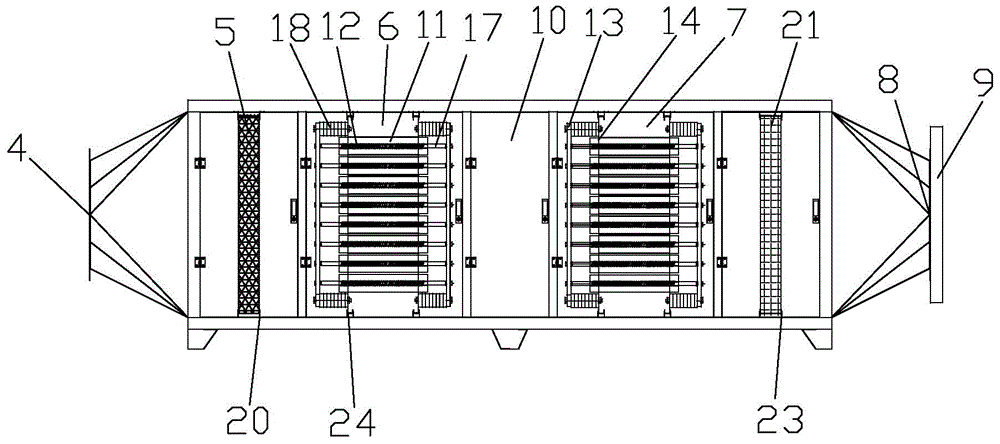

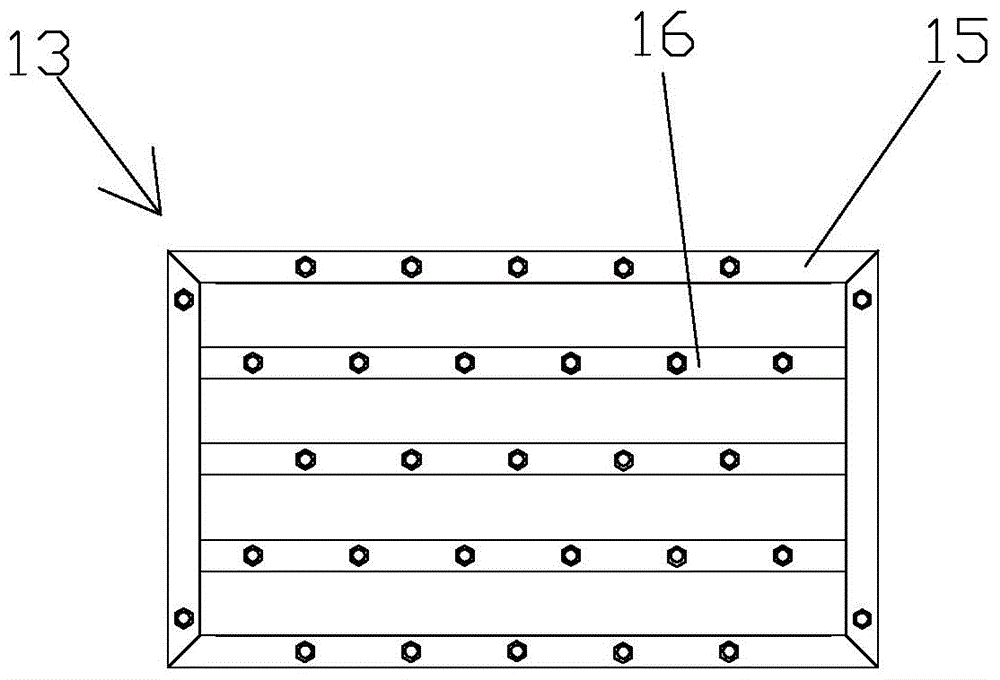

Low-temperature plasma waste gas purifying method

InactiveCN104084009AAvoid secondary pollutionEliminate gaseous pollutantsDispersed particle separationSteel tubeChemical bond

The invention relates to a low-temperature plasma waste gas purifying method. Waste gas enters a box body via an air inlet; the waste gas entering the box body is firstly required to be subjected to pretreatment of a high-temperature gas-liquid filtering net; the waste gas subjected to pretreatment enters a processing chamber; molecules in the waste gas can be decomposed in extremely short time due to low-temperature plasma in the processing chamber; the waste gas passing through the processing chamber enters a gas remixing chamber; concentration of the waste gas is uniform due to the gas remixing chamber so as to prepare for the entering of the waste gas in a second processing chamber; the waste gas passing through the gas remixing chamber enters the second processing chamber to be further decomposed. Compared with the prior art, the method has the advantages that under the acceleration effect of an electric field to the processing chambers, high-energy electrons are generated in stainless steel tubes, when the average energy of the electrons exceeds the molecule chemical bond energy of a target management object, the molecule bond cracks so as to achieve the aim of eliminating gaseous pollutants; by multi-stage processing, pollutant molecules can be easily decomposed efficiently; the processing energy consumption is low; the secondary pollution is prevented.

Owner:ZHEJIANG HUIER COATING ENVIRONMENTAL PROTECTION EQUIP

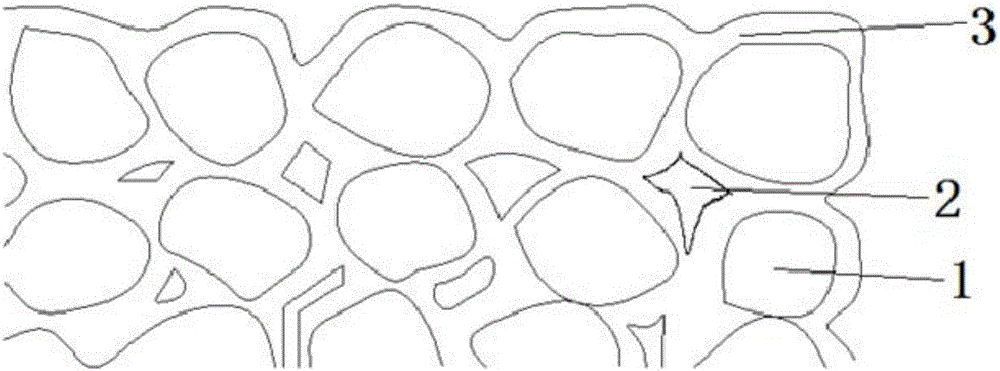

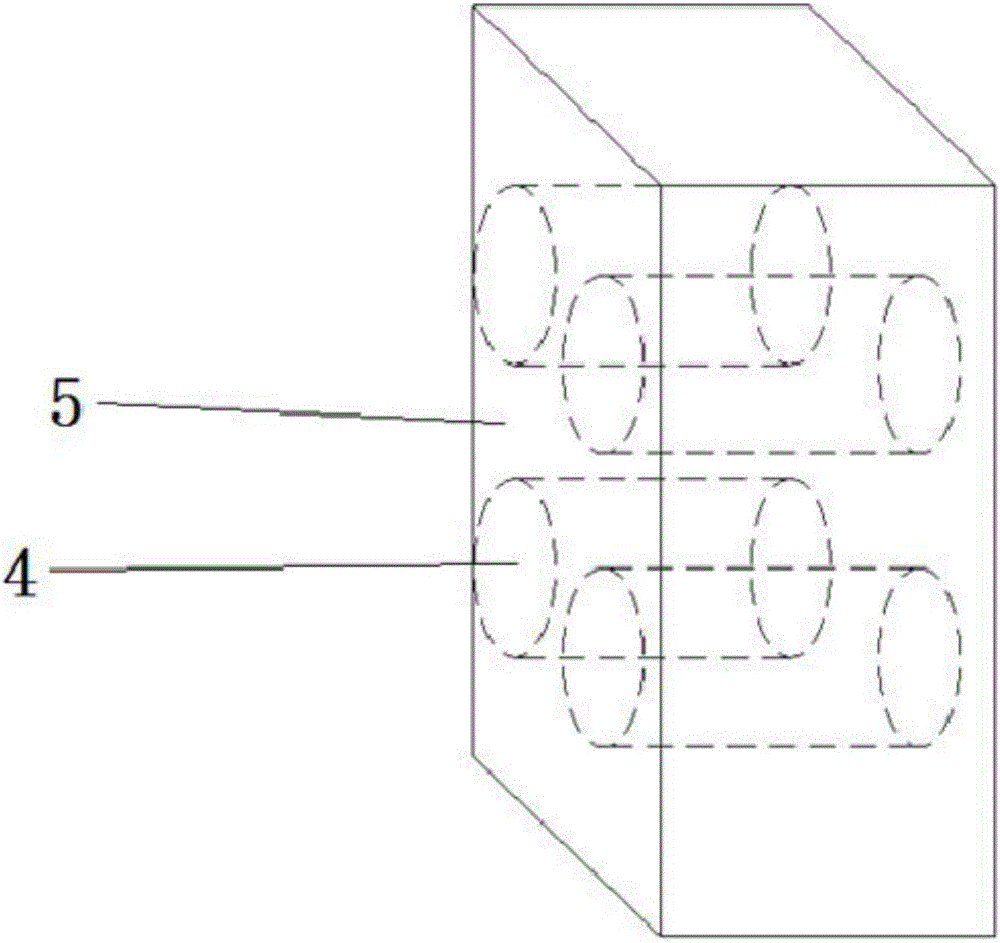

Pervious material as well as preparation method and application thereof

InactiveCN105924201AHigh compressive strengthImprove flexural strengthCeramicwareBreaking strengthPorosity

The invention provides a pervious material as well as a preparation method and an application thereof. The pervious material is mainly prepared from a coarse aggregate, an adhesive material, a water purification functional material, and water. As being influenced by a natural shape of the coarse aggregate, the interior of the pervious material is provided with multiple gaps with a high porosity, the gaps can allow a water body to pass through, and the water body can be filtered by virtue of the water purification functional material. The pervious material provided by the invention has high compression strength and breaking strength, has functions of storage regulating permeation and storage regulating purification at the same time, and can be used for constructing various underground spaces for purifying and storing dispersed rainwater by virtue of a simple way of building blocks. The preparation method of the pervious material provided by the invention is simple in process and low in cost, and is suitable for large-scale production. The pervious material provided by the invention has the functions of storage regulating permeation and storage regulating purification at the same time, can be used for constructing various underground water purification devices and underground reservoirs, and can also be used for constructing debris flow protection slopes.

Owner:海绵城市道路材料(深圳)有限公司

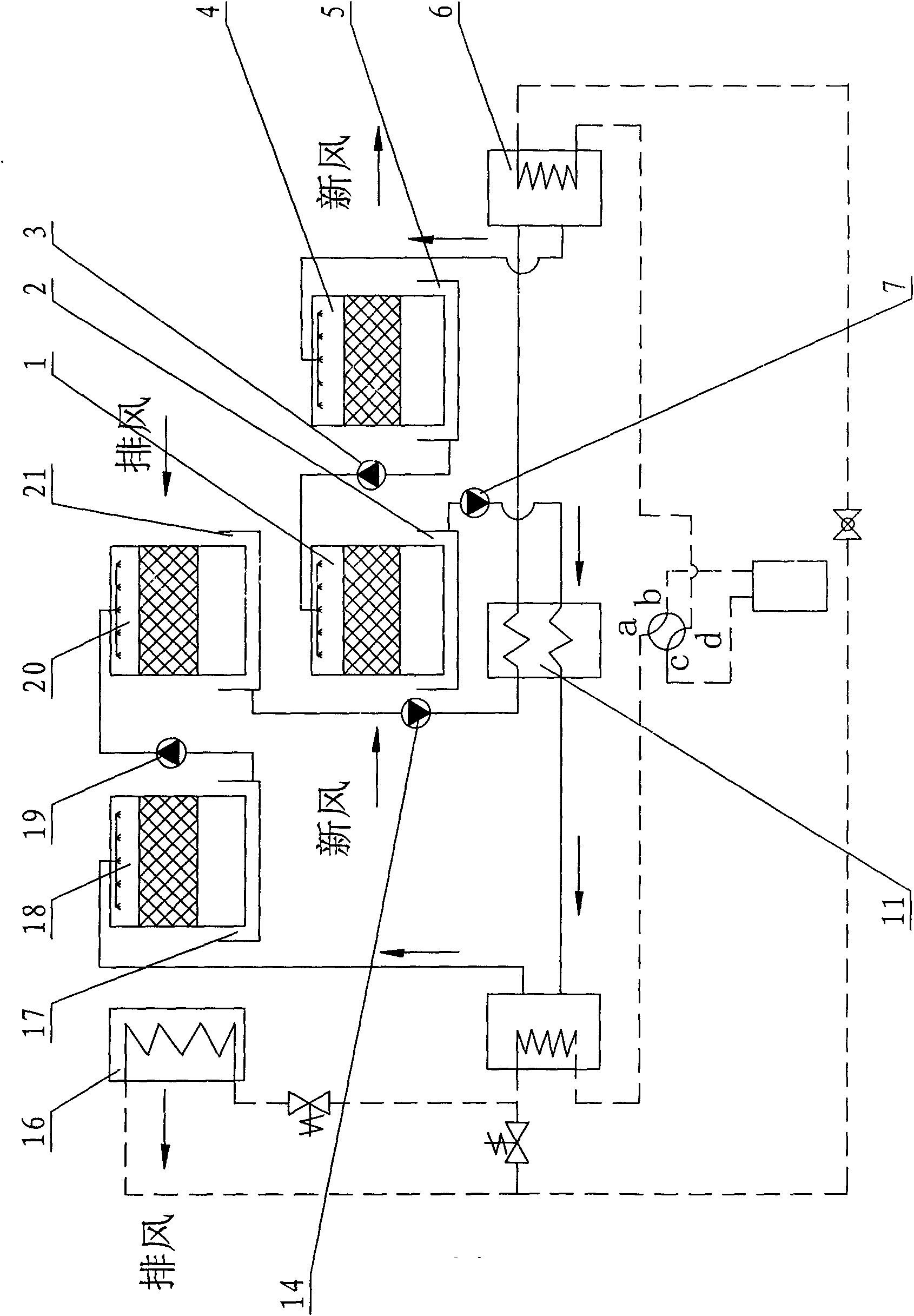

Ice-storage cold-heat pump coupled multi-stage total-heat recovery fresh air processor

InactiveCN102589073AReduce processing energy consumptionImprove qualityEnergy recovery in ventilation and heatingHeat recovery systemsFresh airEngineering

The invention discloses an ice-storage cold-heat pump coupled multi-stage total-heat recovery fresh air processor, belonging to the energy source utilization technology and the air adjusting field. The processor consists of an air exhaust part, a fresh air processing part, a total-heat recoverer and a heat pump system. The heat pump system comprises a compressor, a condenser, a condensation heat recoverer, an evaporator and an expansion valve. The indoor low-temperature low-humidity exhaust air is used for exhausting the condensation heat quantity of a refrigerating system in summer; and the indoor high-temperature high-humidity exhaust air is used for exhausting the evaporation cold quantity of the refrigerating system in winter. The total-heat recoverer performs multi-stage total-heat recovery of fresh air and exhaust air so as to improve the heat recovery efficiency. The heat pump system provides necessary cold quantity and heat quantity to a fresh air processing system. The ice-storage cold provides the low-temperature frozen water to completely dehumidify the fresh air so as to achieve lower moisture content.

Owner:吕智

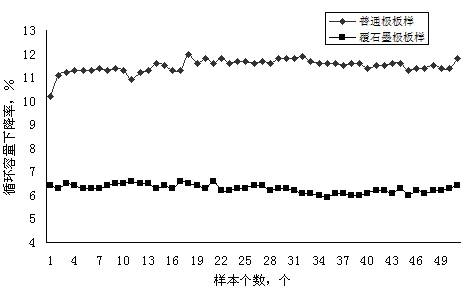

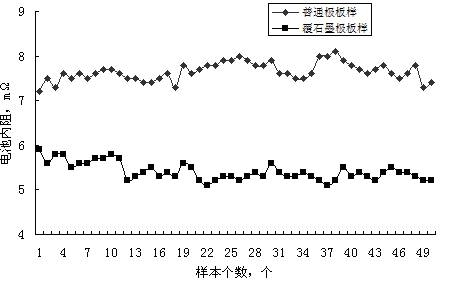

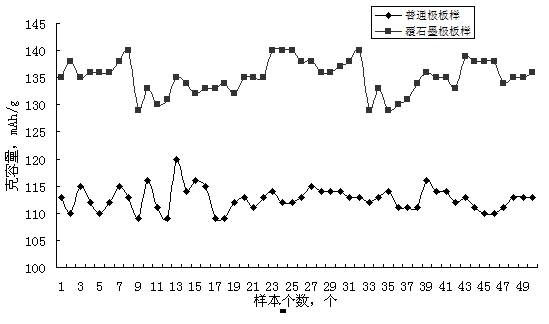

Electrode current collector material of lithium ion battery and preparation method thereof

InactiveCN101958418AGuaranteed electrical conductivityGood chemical propertiesElectrode carriers/collectorsCarbon layerInternal resistance

The invention provides an electrode current collector material of a lithium ion battery and a method for preparing the material. The method comprises the following steps of: coating a carbon layer on the surface of a copper foil or an aluminum foil, wherein the thickness of the coated carbon layer is 0.003-0.015mm; and depositing the carbon layer on the surface of the copper foil or the aluminum foil by utilizing a physical vapor deposition method, and then carrying out thermal treatment. While ensuring the conductive property of the material as a current collector, the material improves the chemical property of easy oxidization of the foil in the working process of the battery, enhances the corrosion resisting property of the foil, and can effectively prevent a metal dendritic crystal produced by the lithium ion battery in the working process due to reaction, increase the safety performance of the battery, reduce the internal resistance of the battery and effectively prolong the service life of the battery. The process has the advantages of low temperature, less distortion and damage on the material, low energy consumption, less pollution and lower cost.

Owner:CHANGDE LYRUN MATERIAL

Plasma process for purifying coal-burning boiler smoke gas

InactiveCN1628892AMentioned sync rateEffective absorptionDispersed particle separationParticulatesHazardous substance

This invention relates to coal-burning boiler smoke new process and device by use of corona discharge and electron beam plasm compound technique, which comprises the following steps: the boiler smoke goes through static dust cleaner and exchanges heat with gag to gas converter; then it goes into frog drying tower for wetting and lowering temperature; then it enters the corona discharge chamber to make oxidation to generate acid substance; the product is mixed with smoke and ammonia injected by liquid ammonia tar and then enters the electronic speeder to generate electronic beam reaction; the generated ammonia sulfate and ammonium nitrate mixed particles are collected in the solution groove.

Owner:BEIJING STATE GRID POWER TECH

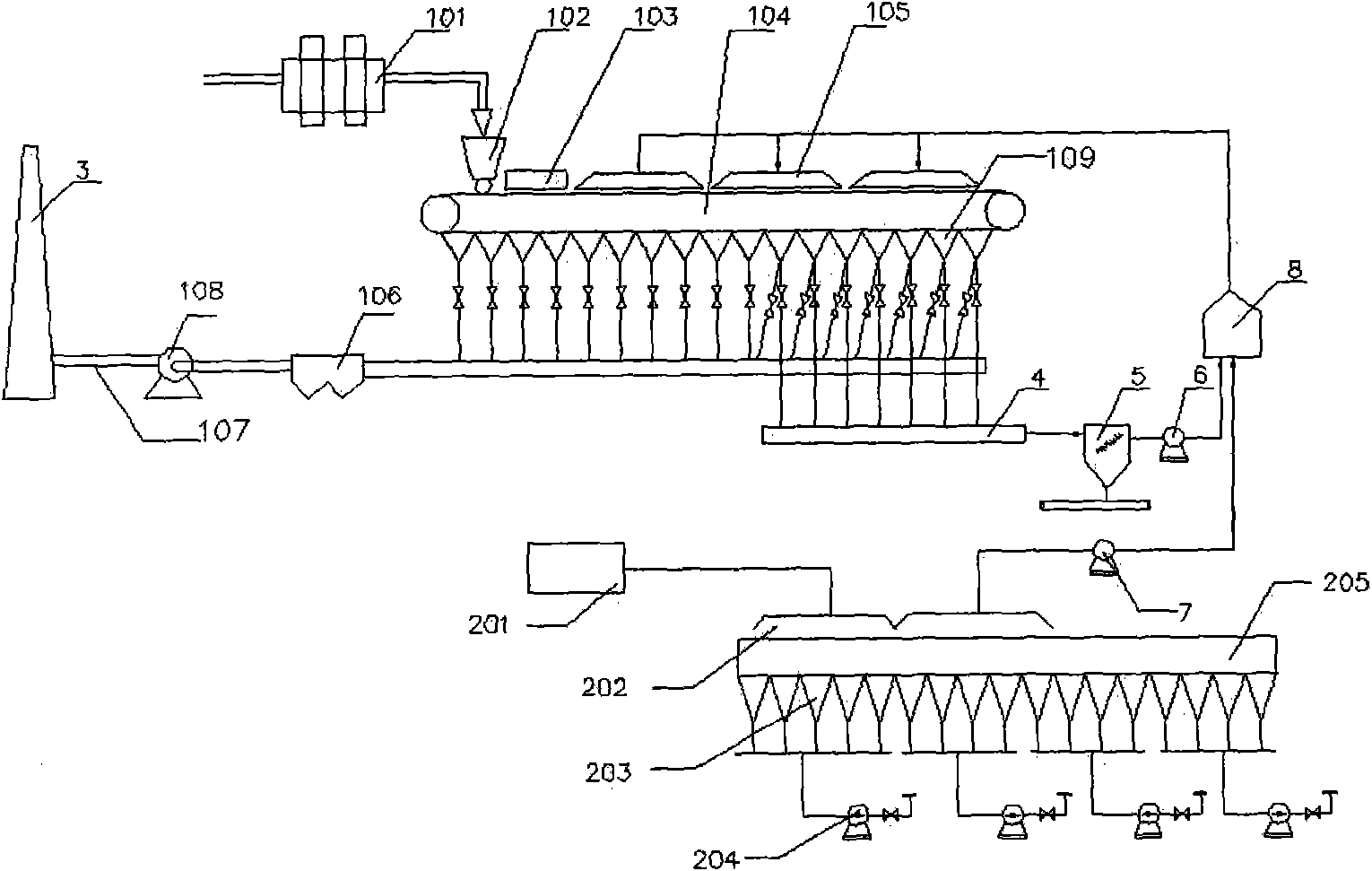

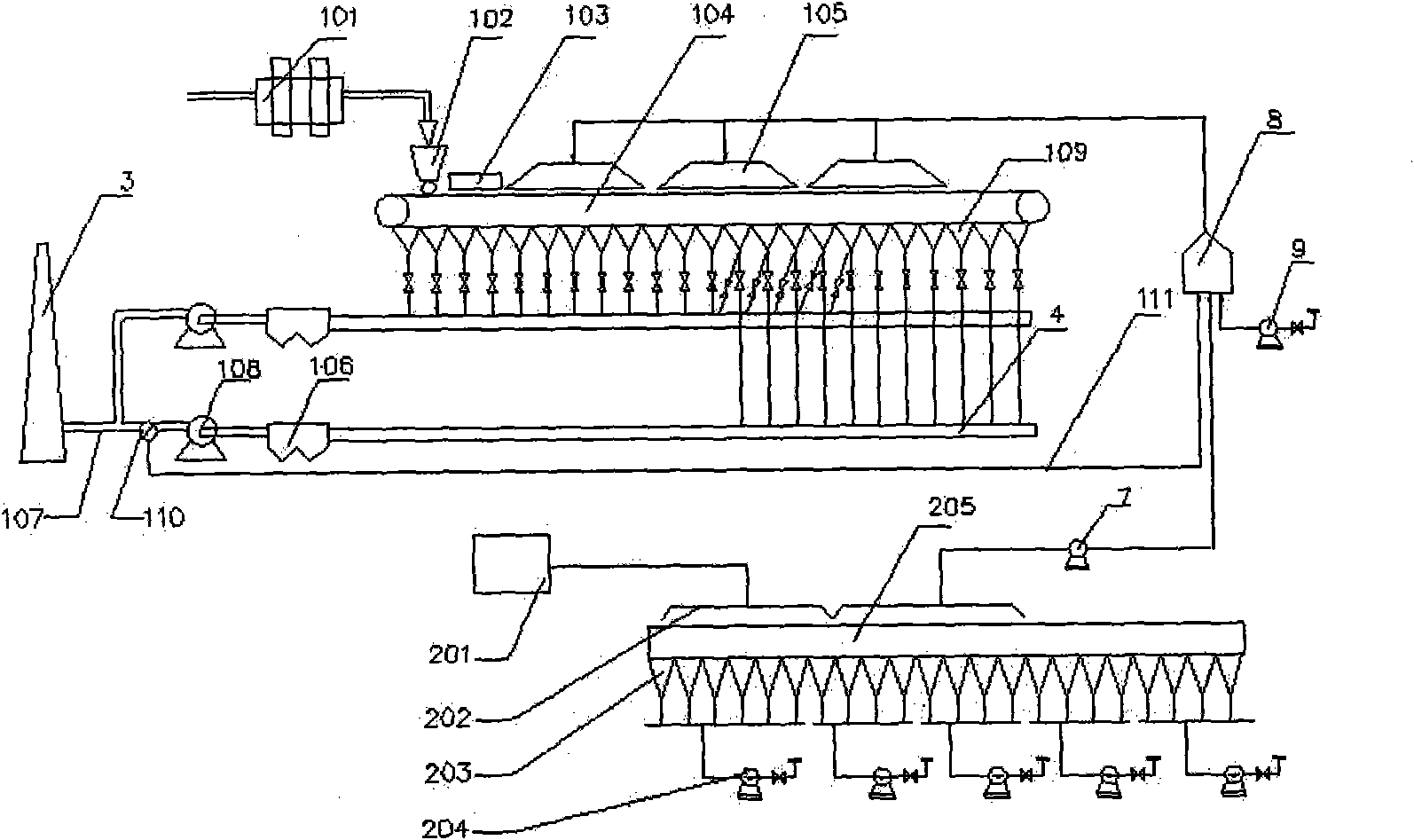

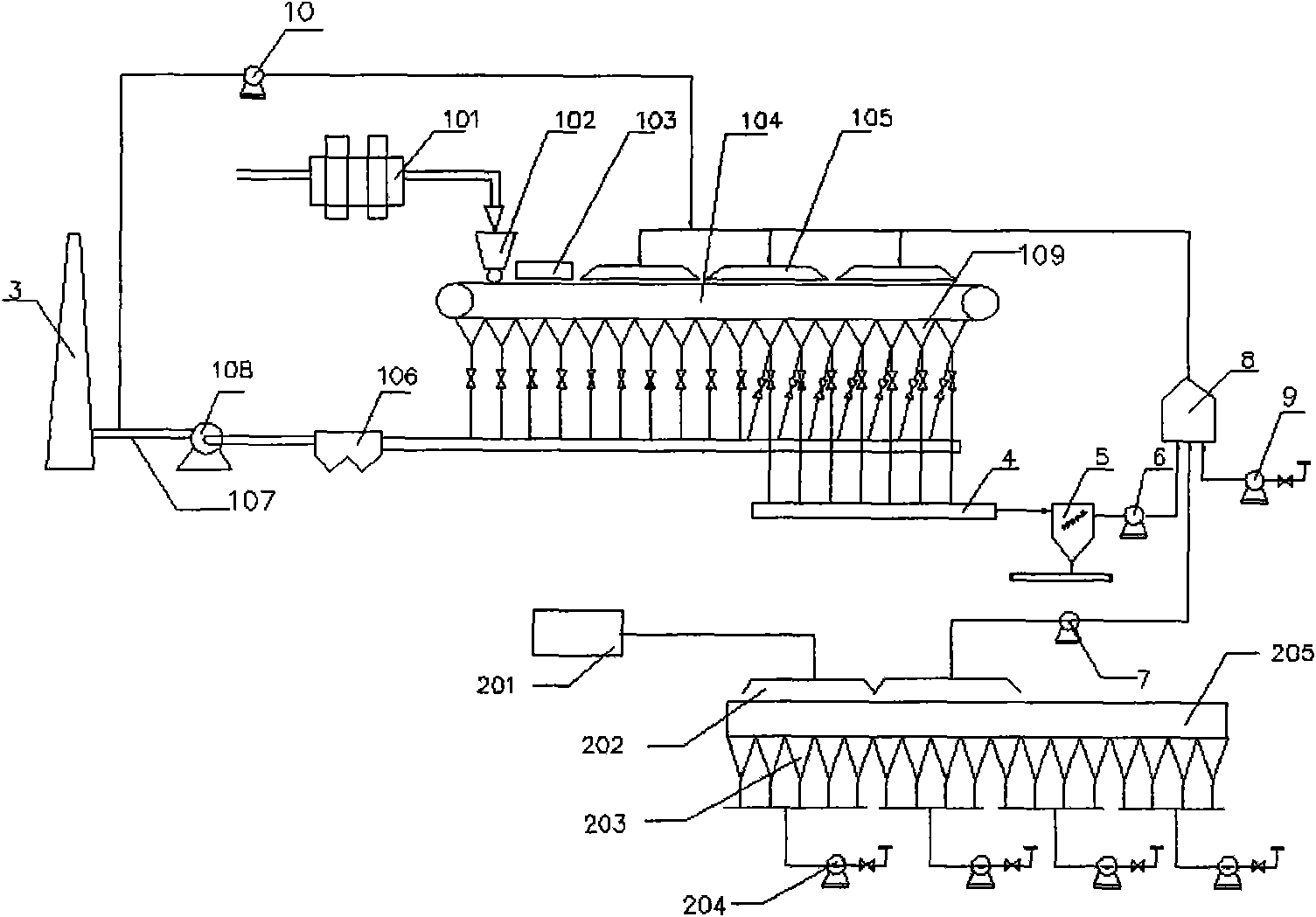

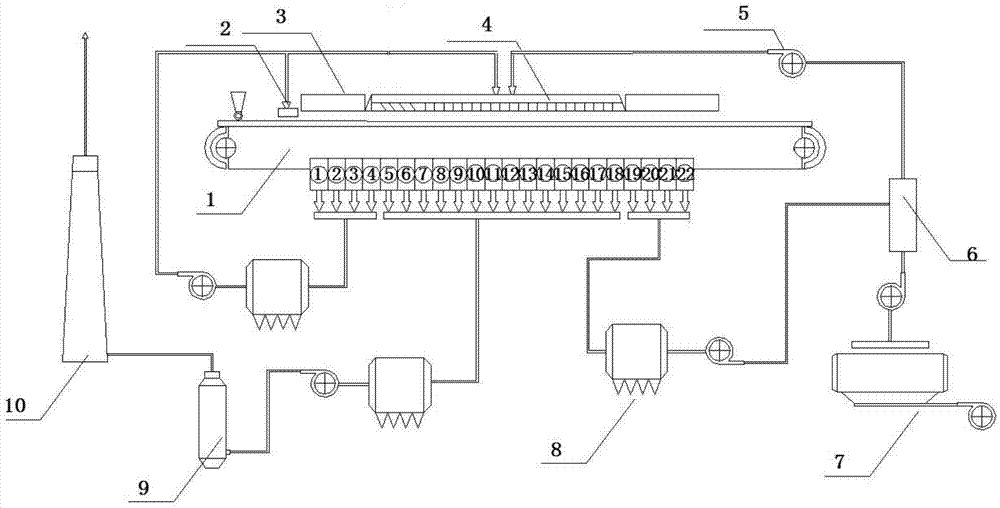

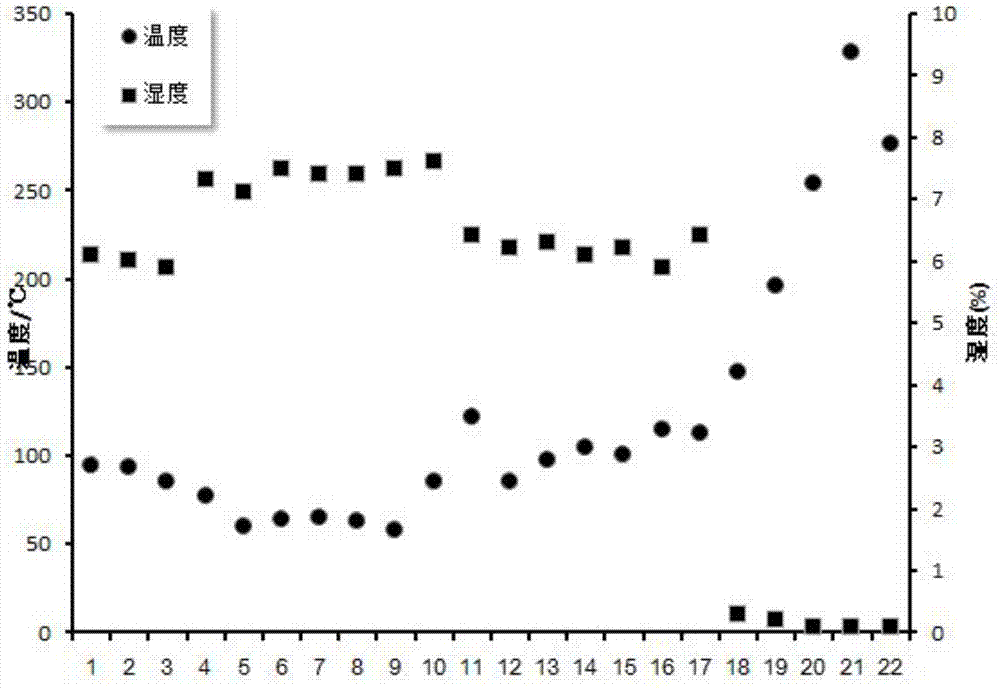

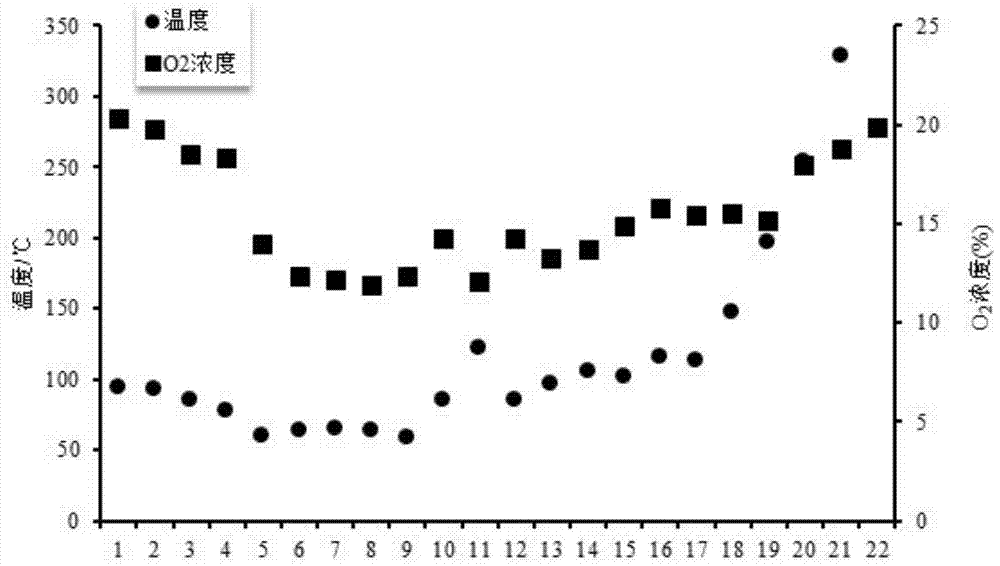

Sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system

ActiveCN104748567ARealize emission reduction controlEmission reductionGas treatmentDispersed particle separationHigh humidityHigh energy

The invention provides a sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system. According to the process, sintering flue gas is divided into low-temperature high-oxygen low-humidity section sintering flue gas, medium-temperature low-oxygen high-humidity section sintering flue gas and high-temperature high-oxygen low-humidity section sintering flue gas according to the emission characteristics of flue gas temperature and oxygen concentration and humidity. The low-temperature high-oxygen low-humidity section sintering flue gas is subjected to dust removal and then is led into a sintering machine for hot air sintering and hot air ignition. The medium-temperature low-oxygen high-humidity section sintering flue gas is subjected to dust removal and desulfurization treatment. The high-temperature high-oxygen low-humidity section sintering flue gas is mixed with cooling machine waste gas and then is led into the sintering machine for hot air sintering. The sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system can conduct staged utilization on flue gas waste heat, recover low-temperature sensible heat in flue gas, enable carbon monoxide left in the sintering flue gas to be secondarily combusted and reduce the energy consumption in the sintering process on the premise that the quality and yield of sintered ores are ensured. Cyclic flue gas utilization is achieved, the pollutant emission quantity of unit sintering ores and total emission quantity of the sintering flue gas are reduced, and the sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system have very high energy-saving emission-reduction value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

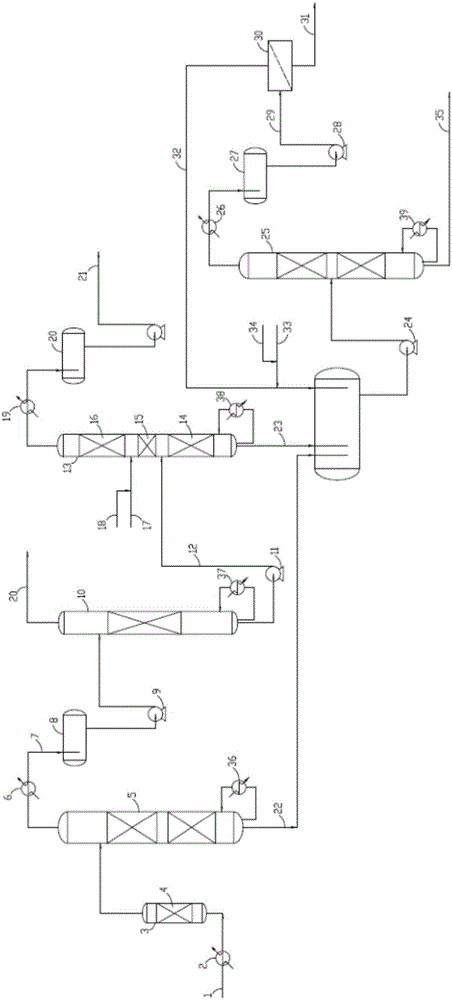

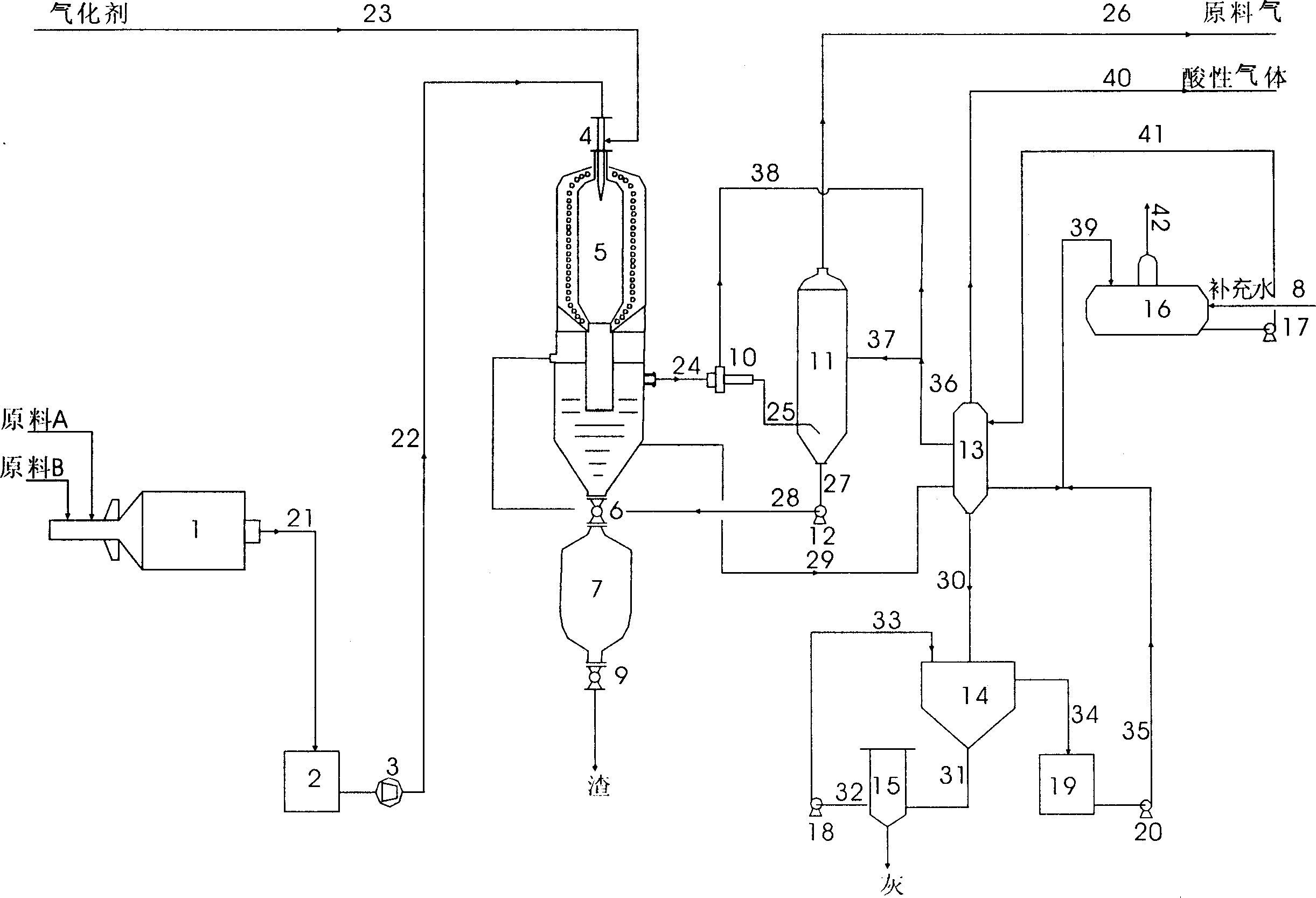

Pressurized gasifying process of polynary slurry

ActiveCN1637118AWide variety of sourcesFulfil requirementsChemical industryCombustible gas purificationThermal energyHydrogen

The pressurized gasifying process of polynary slurry includes five steps of preparing polynary slurry, pressurizing to gasify, purifying coarse gas, exhausting cinder and processing grey water. Specifically, the slurry prepared with one or several kinds of carbon and hydrogen containing material through grinding is made to produce intense oxidation with gasifying agent in gasifying furnace, so as to produce coarse gas with CO and H2 as main components; the coarse gas is thrice washed to produce required material gas; the cinder is chilled before exhaust; and the wash produced grey water is processed through concentration, precipitation and filtering to eliminate its ash component before being returned to the system for reuse while its heat is recovered. The said technological process has wide material adaptability, high gasification index, low investment in apparatus and other advantages.

Owner:XIAN ORIGIN CHEM TECH

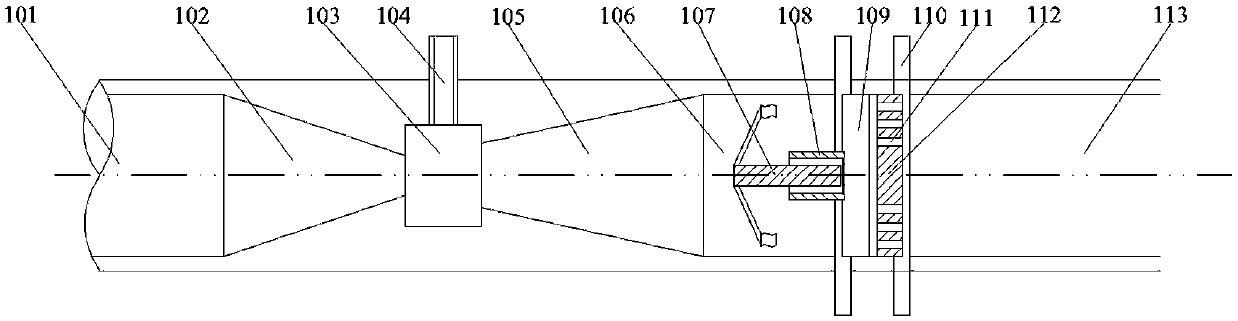

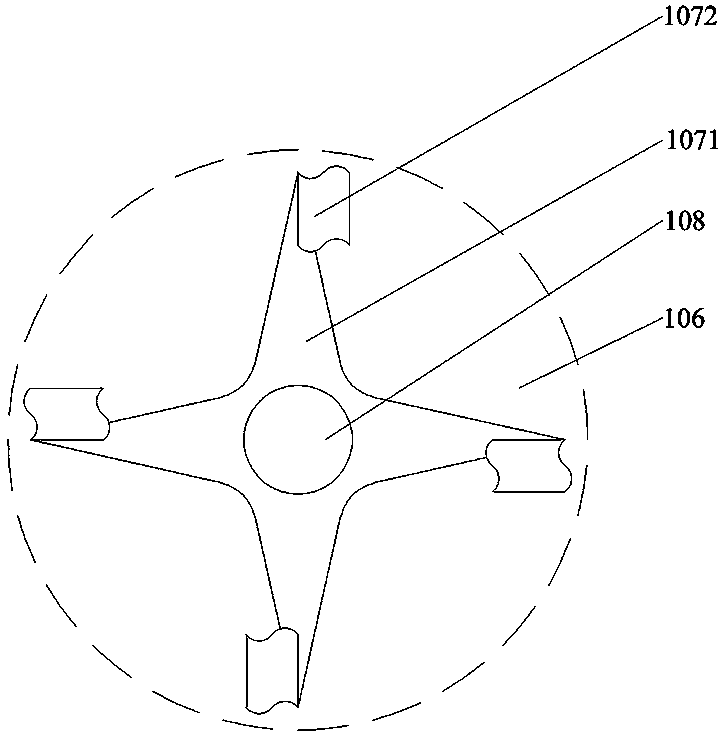

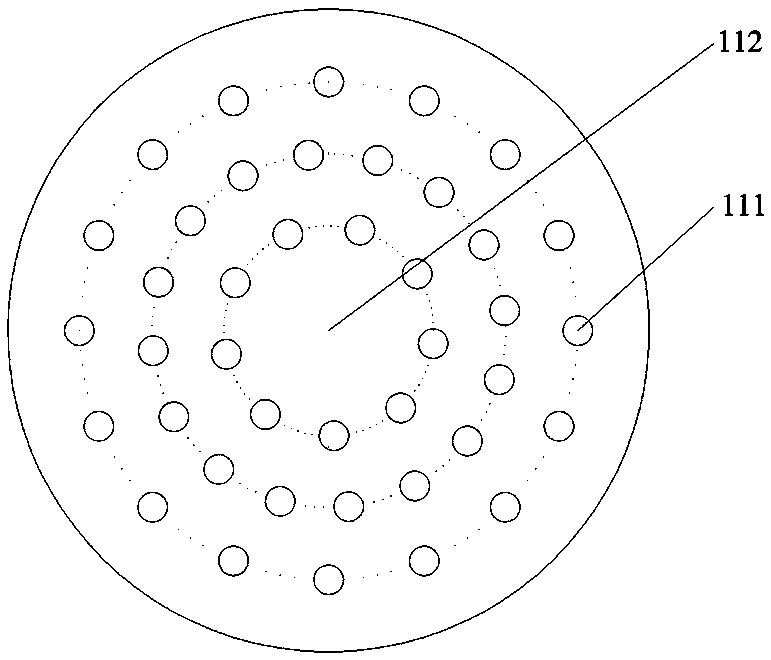

Hydrodynamic cavitation reactor

ActiveCN105502626AImprove developmentEnhanced CrashWater treatment compoundsWater/sewage treatment by oxidationVena contracta diameterReaction front

The invention discloses a hydrodynamic cavitation reactor. The hydrodynamic cavitation reactor comprises a reaction front section, a reactor middle section and a reactor rear section, wherein a negative pressure bin, a fluid jet contraction cavity, a fluid jet expansion cavity and an oxidant inlet are arranged in the reactor front section, the fluid jet contraction cavity and the fluid jet expansion cavity are located at two ends of the negative pressure bin, and the oxidant inlet is formed in the upper part of the negative pressure bin; a swirler rotating in the axial direction of the reactor is arranged in a swirling cavity in the reactor middle section; an orifice plate with small holes formed in the surface is arranged in the reactor rear section and is perpendicular to the axial direction of the reactor. The hydrodynamic cavitation reactor generates instant high temperature and high pressure through three-level cavitation effects of first-level jetting, second-level swirling and third-level current limiting to directly degrade organic matters, harmless degradation of conventional organic pollutants difficult to degrade is realized, and the hydrodynamic cavitation reactor can be applied to wastewater treatment in any occasions.

Owner:ZHONGBEI UNIV

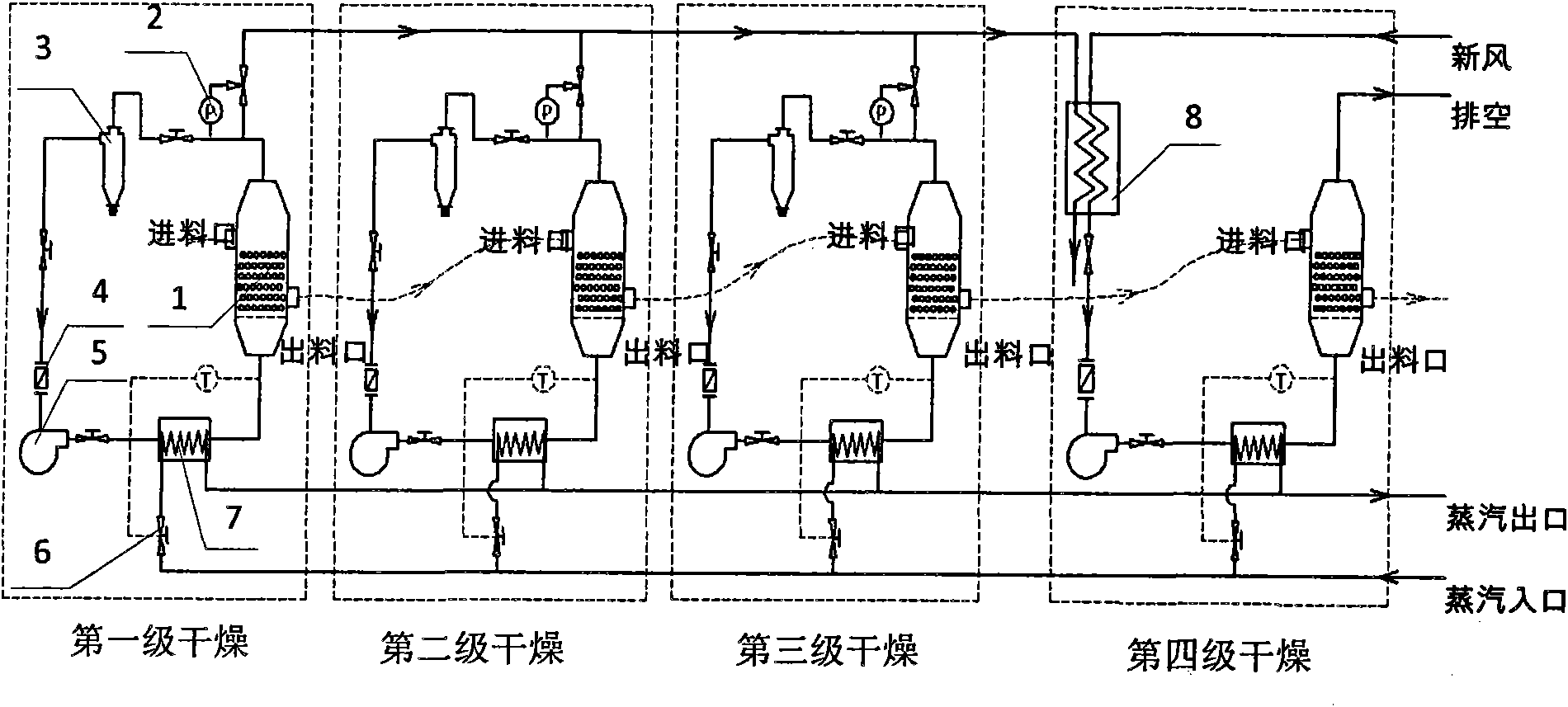

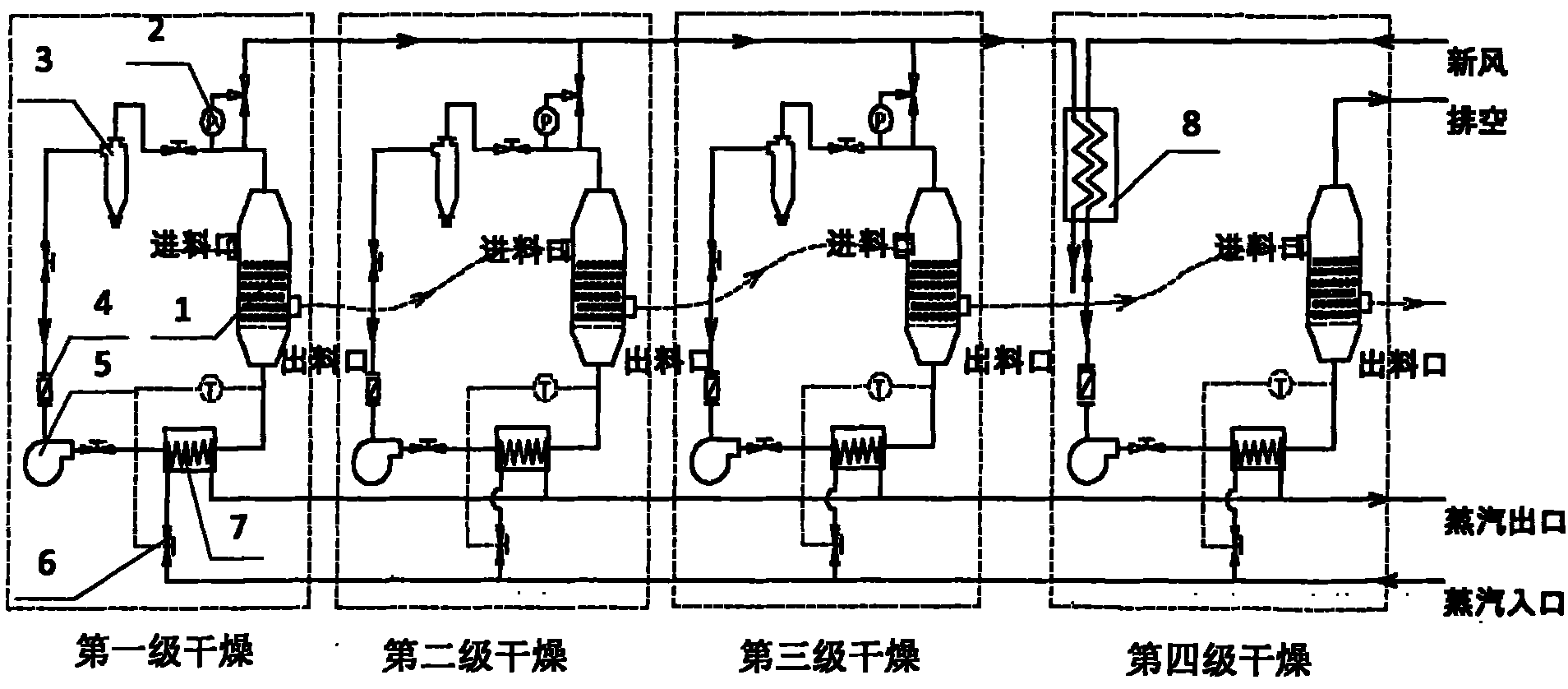

Novel silica gel energy-saving drying device and process thereof

ActiveCN101788221AImprove drying qualityImprove qualityDrying solid materials with heatDrying gas arrangementsThree stageProcess engineering

The invention discloses a novel energy-saving silica gel drying device and a process thereof, which can dry silica gel rapidly and efficiently with the drying thermal efficiency improved to 50 percent from 35 percent of the prior art. The device comprises at least one superheated steam drying unit and at least one hot air drying unit. A required material can be obtained through speed-raising drying and constant-speed drying of the superheated steam drying unit and drying of the hot air drying unit. The process is a superheated steam-hot air combined multi-stage silica gel drying process, the first three stages adopt superheated steam drying, the first-stage steam drying is mainly a speed-raising drying stage, the second stage and the third stage are respectively a stage of constant-speed drying at the corresponding temperature, wherein the silica gel drying speed is high, no breakage or cracking can be easily caused, good properties of the porous structure can be maintained, the drying quality is high, and the fourth-stage hot air drying can maintain a relatively high drying speed. The superheated steam-hot air combined multi-stage silica gel drying process has the advantages of good quality of the dried silica gel and high speed, and the closed drying circulation system has significant effect on energy conservation and emission reduction.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com