Low-temperature plasma waste gas purifying method

A low-temperature plasma and waste gas purification technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as high cost and secondary pollution, and achieve the effect of avoiding secondary pollution and eliminating gaseous pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

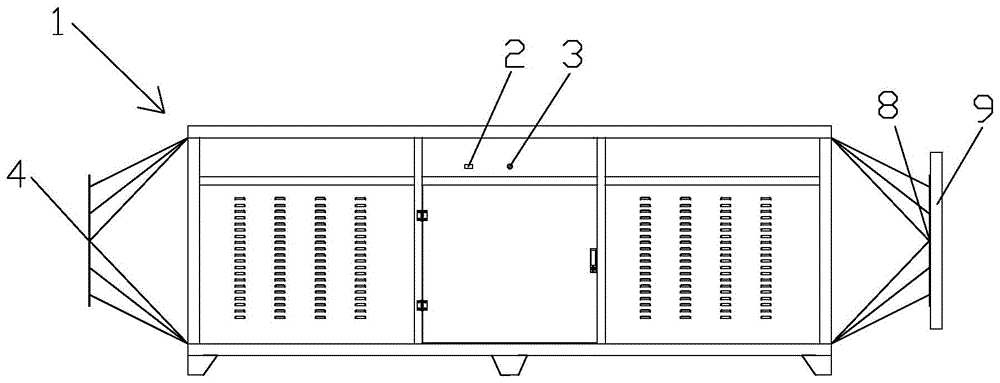

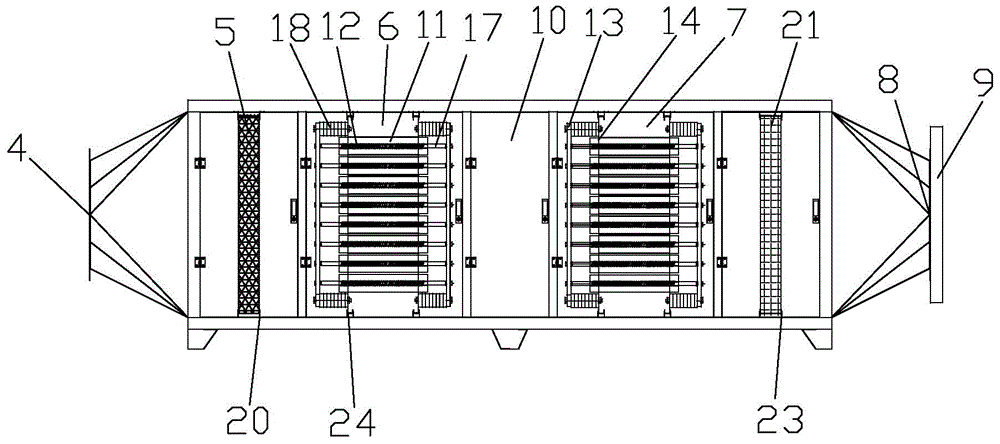

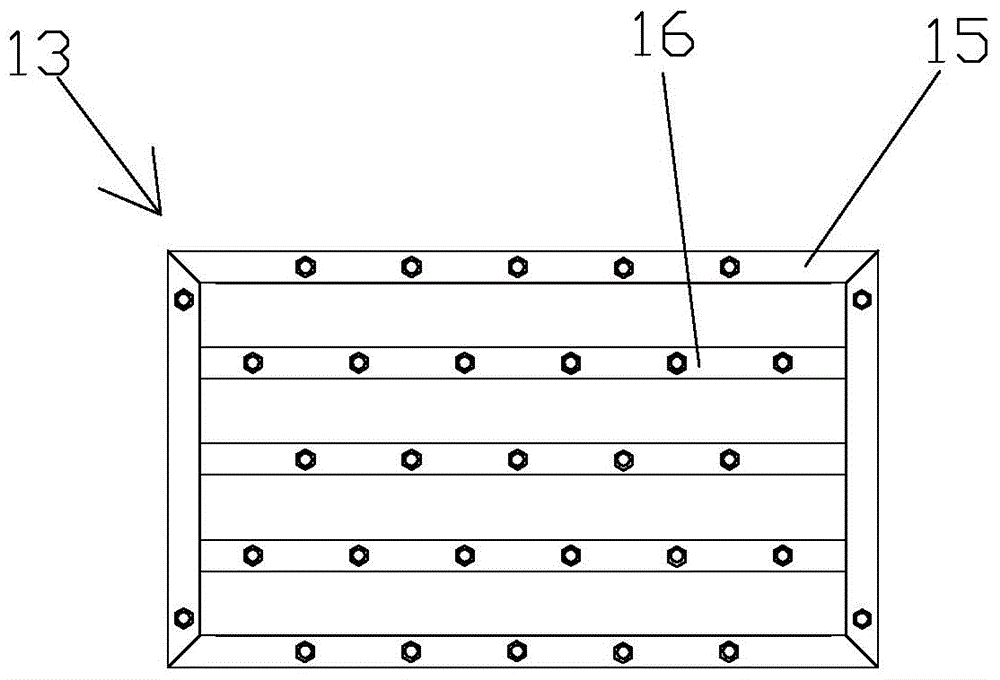

[0022] Embodiment: a kind of low temperature plasma exhaust gas purification method, such as Figure 1-2 As shown in the figure, it includes a box body 1, a controller 2 and a display 3 fixedly arranged on the box body 1, and an air inlet 4, a gas-liquid filter screen 5, and a primary treatment chamber 6 are arranged in the box body 1 from left to right. , secondary processing chamber 7 and air outlet 8, an exhaust fan 9 is provided at the air outlet 8, and a gas remixing chamber 10 is provided between the primary processing chamber 6 and the secondary processing chamber 7; A plurality of stainless steel pipes 11 parallel to each other are arranged in the secondary processing chamber 7, and a mace 12 full of sharp teeth is pierced in each stainless steel pipe 11. The stainless steel pipe 11 and the mace 12 are along the The mace 12 is not in contact with the inner wall of the stainless steel pipe 11, and the two are respectively connected to the positive and negative electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com