Pressurized gasifying process of polynary slurry

A technology of pressurized gasification and multi-slurry, which is used in granular/powder fuel gasification, chemical industry, combustible gas purification, etc., can solve the problems of large investment in equipment and less investment in production equipment, and achieve low process energy consumption , good for the environment and low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

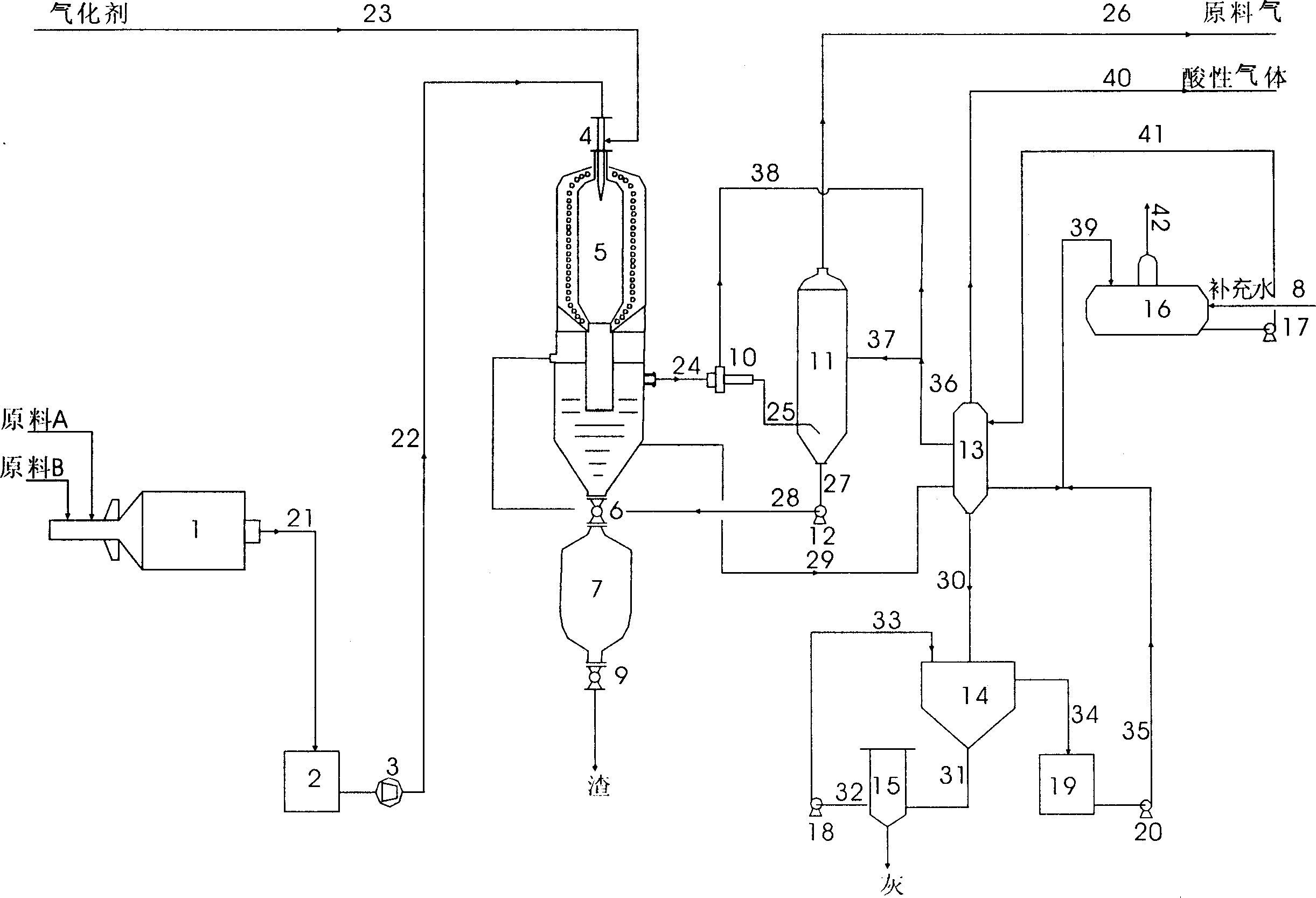

[0013] as attached figure 1 As shown, the present invention includes five parts of multi-component slurry preparation, pressurized gasification, crude gas purification, ash discharge and ash water treatment, that is, one or several hydrocarbon-containing substances are used to prepare the output through one co-grinding Slurry, in the semi-water-cooled wall gasifier 5, the slurry and the gasification agent undergo a severe partial oxidation reaction to generate CO and H 2 The main crude gas, after the crude gas is washed and purified three times, the raw material gas produced meets the requirements for use, and the ash produced by the gasification of the raw material is directly discharged from the ash discharge system at the bottom of the furnace after being quenched; the ash produced by washing is successively passed through Concentration, precipitation and filtration are used to remove the ash carried by it. The by-product steam can recover the heat energy of the gray water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com