Patents

Literature

123 results about "Antibiotic production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The large-scale production of an antibiotic depends on a fermentation process. During fermentation, large amounts of the antibiotic-producing organism are grown. During fermentation, the organisms produce the antibiotic material, which can then be isolated for use as a drug.

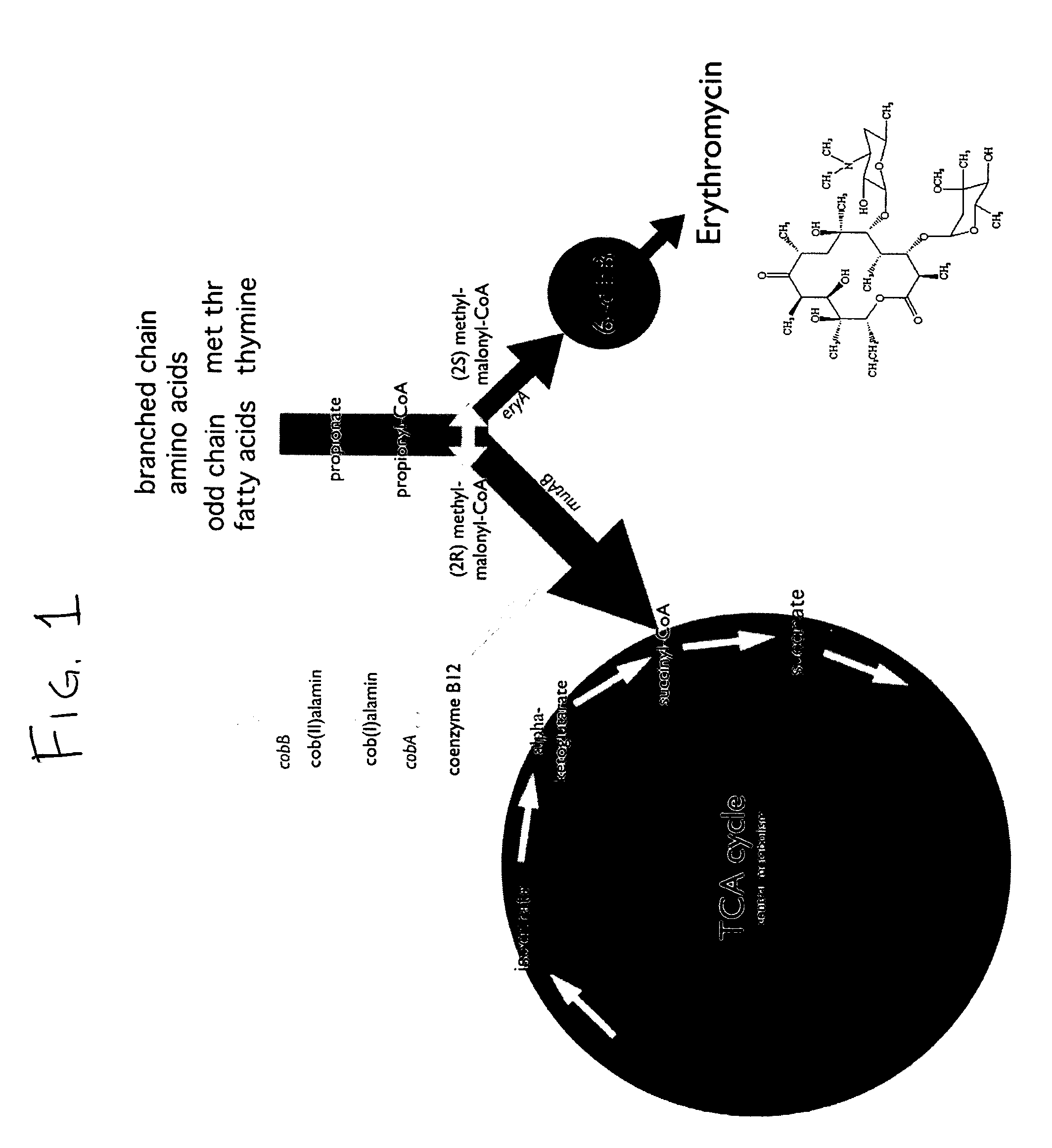

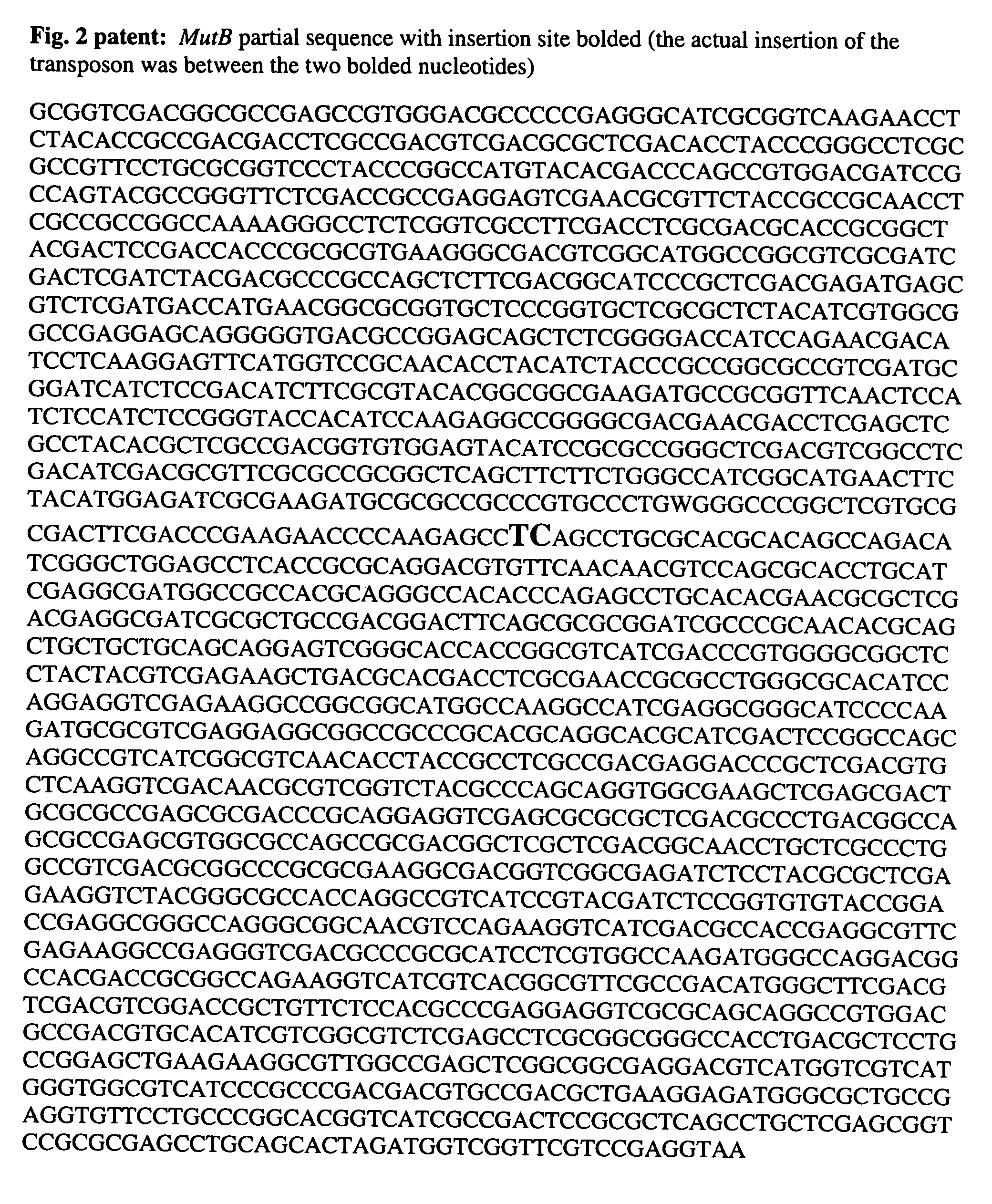

Methods of increasing production of secondary metabolites by manipulating metabolic pathways that include methylmalonyl-coa

A process of increasing the cellular production of secondary metabolites, such as antibiotics, is provided. The process is particularly useful for increasing antibiotic production by bacterial cells, especially erythromycin. The process includes the step of increasing the activity of methylmalonyl-CoA mutase.

Owner:FERMALOGIC

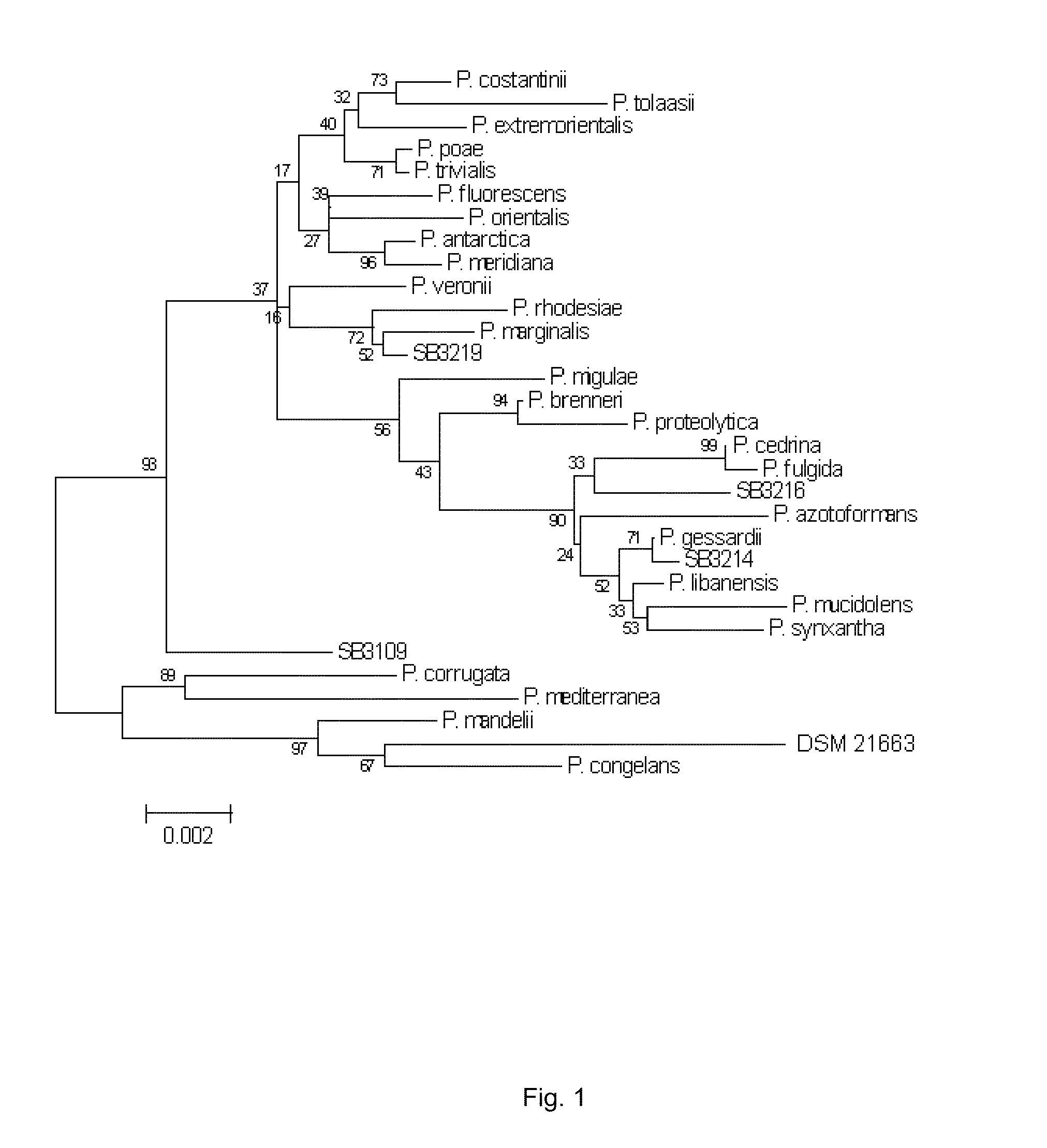

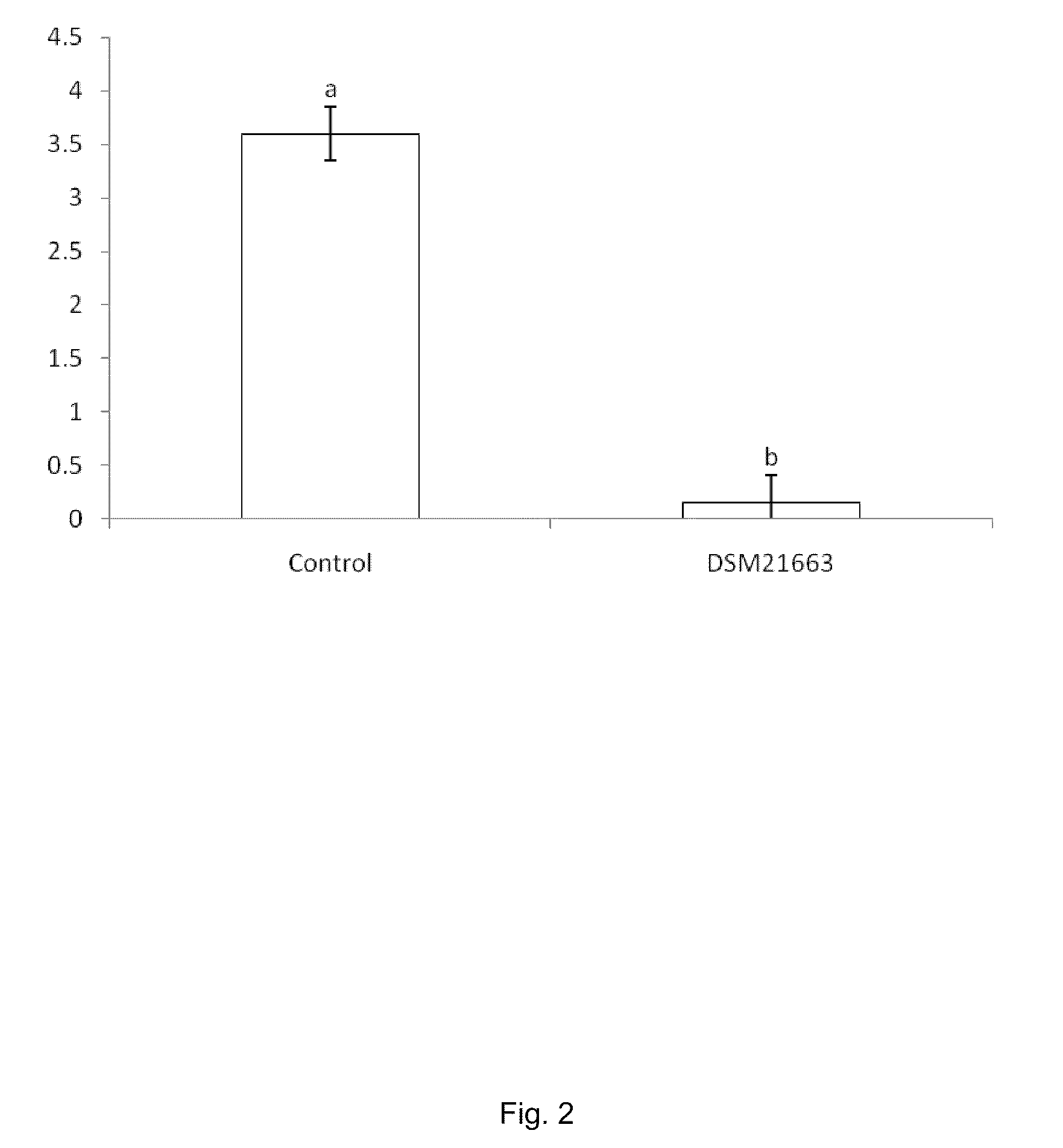

Pseudomonas Bacterium

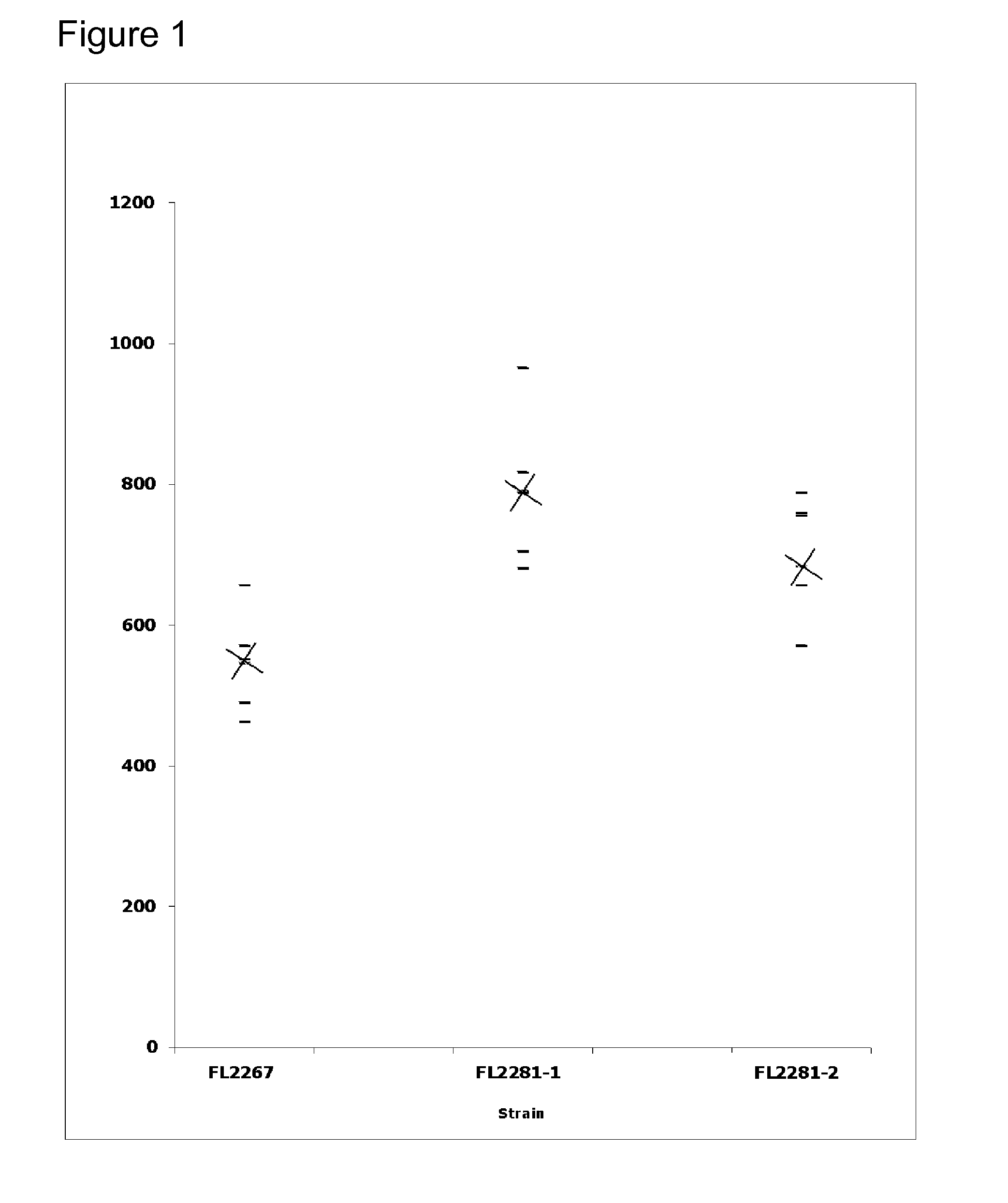

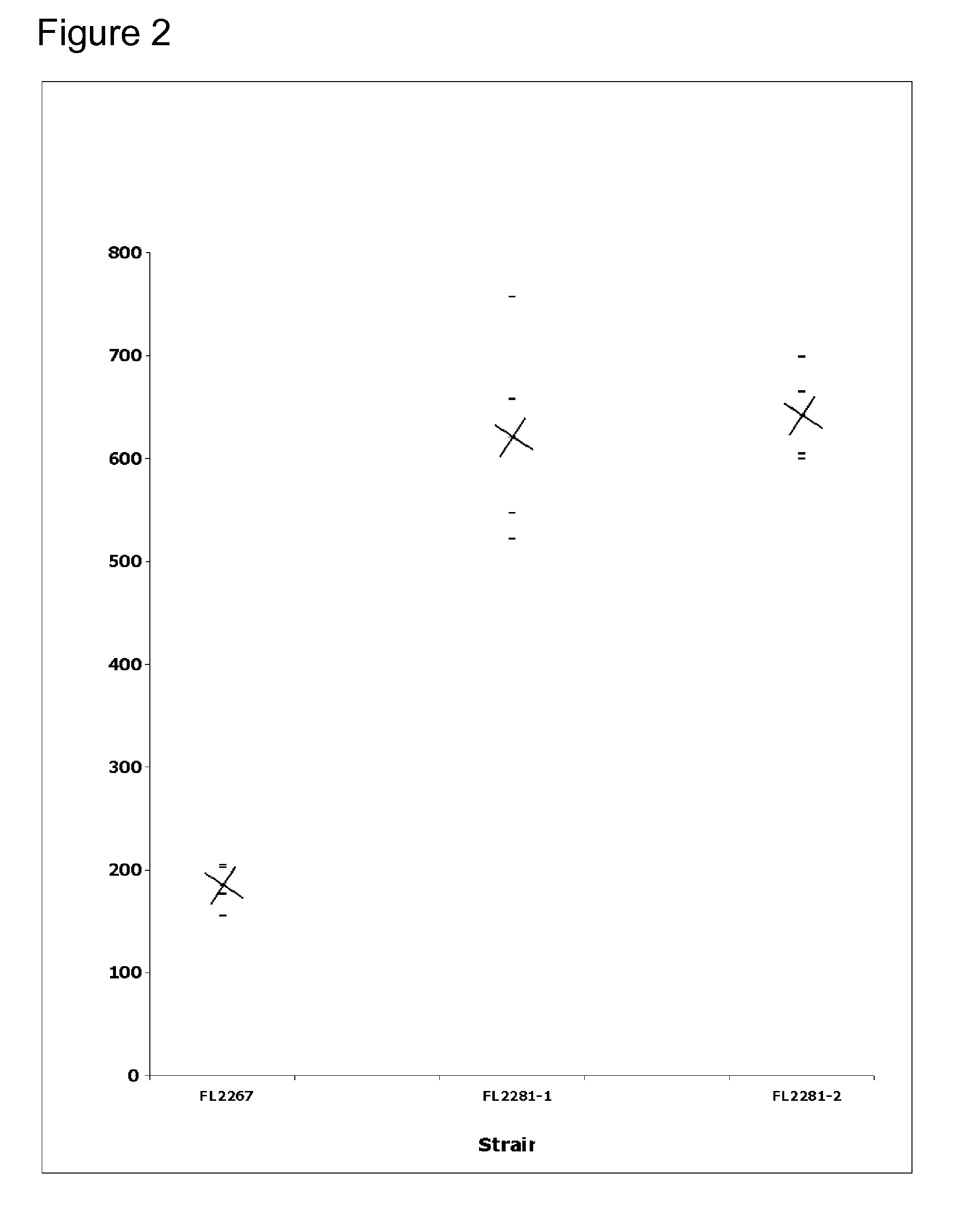

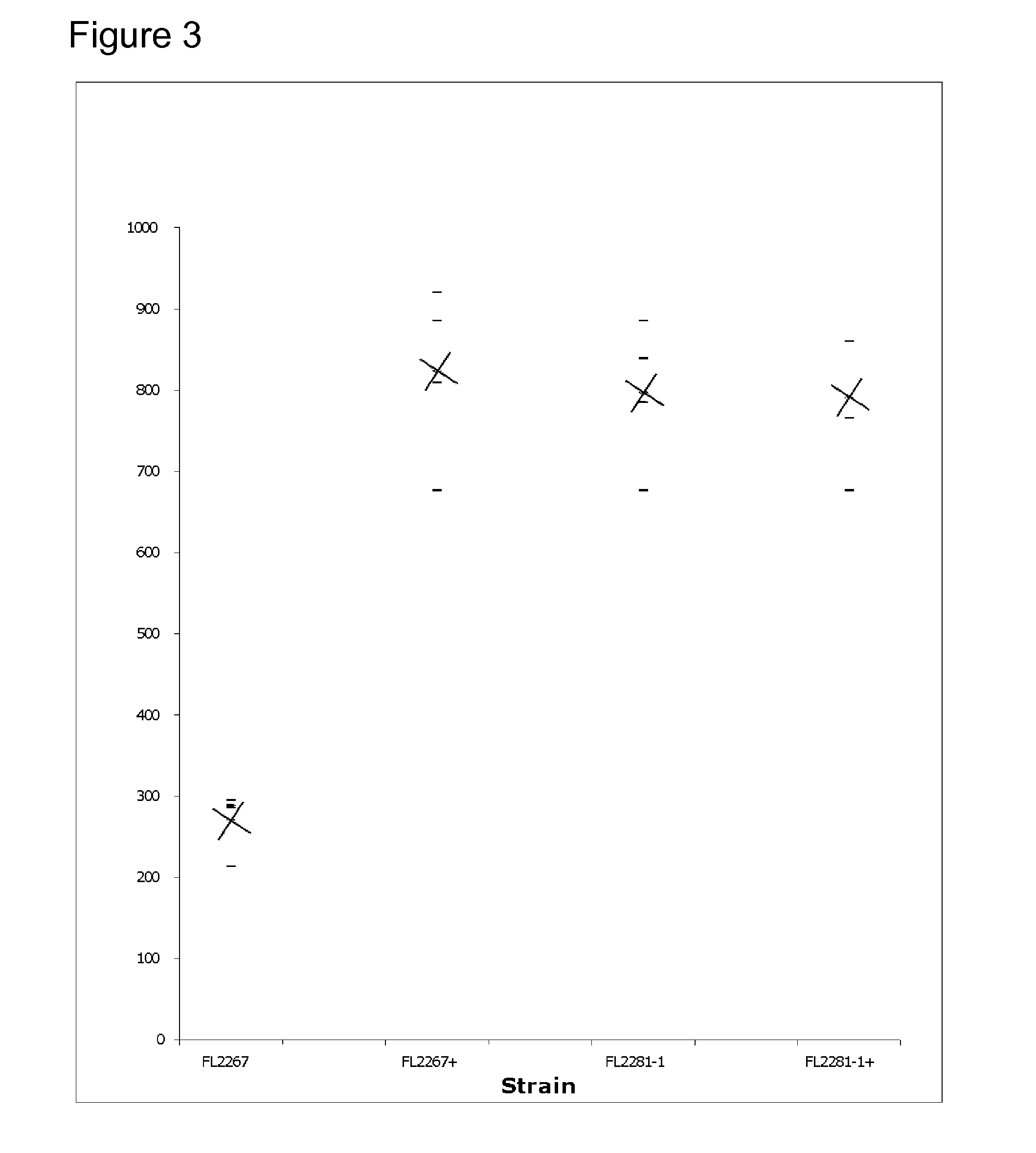

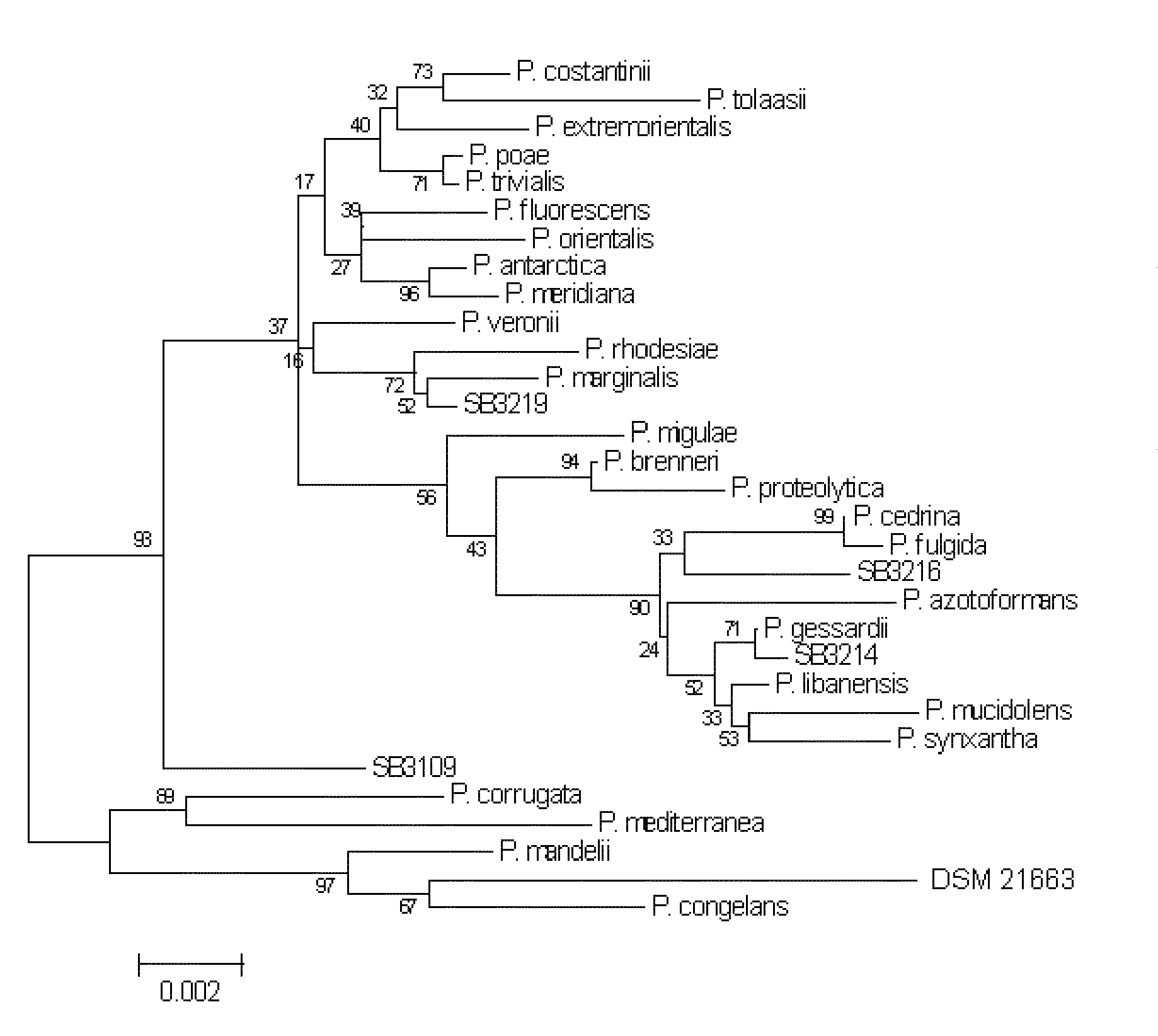

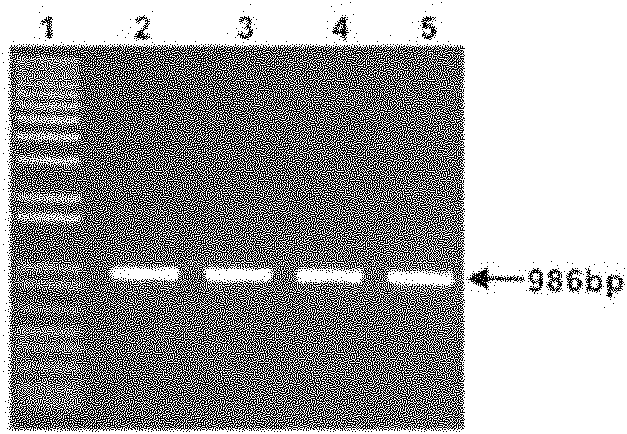

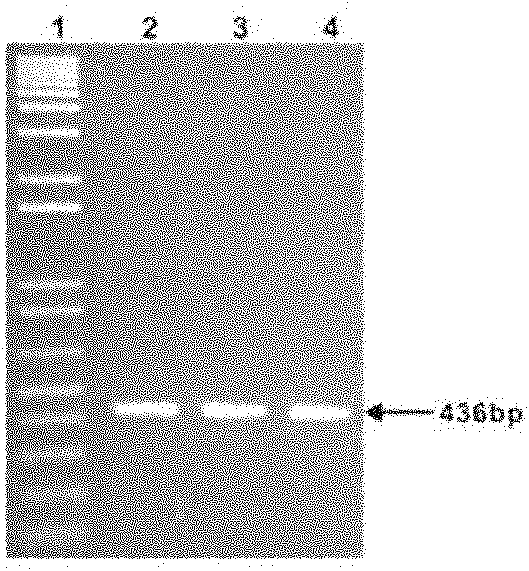

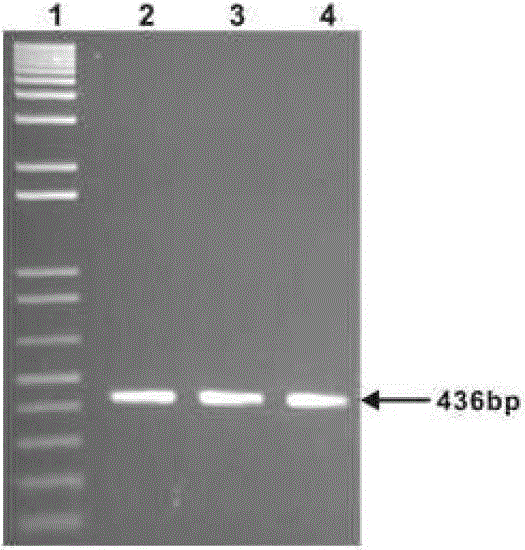

According to the present invention a new isolate of a Pseudomonas spp, DSM 21663, has been shown to possess unique properties. This Pseudomonas is a plant growth-promoting rhizobacterium (PGPR). Among its modes of action involved in plant growth-promotion are anti-biotic production (2,4-diacetylphloroglucinol, (DAPG); pyrrolnitrin, PRN and others), indole-3-acetic acid (IAA) production and phosphate solubilization, and production of unique volatiles. The strain is fluorescent, oxidase-positive, and has the ability to suppress soil-borne root and foliar pathogens of both fungal and bacterial origin.

Owner:NOVOZYMES AS

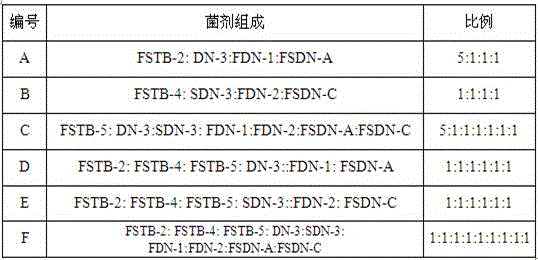

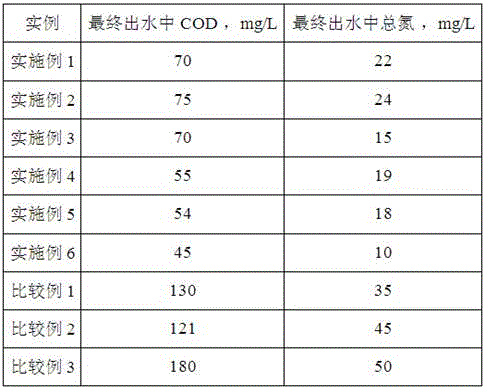

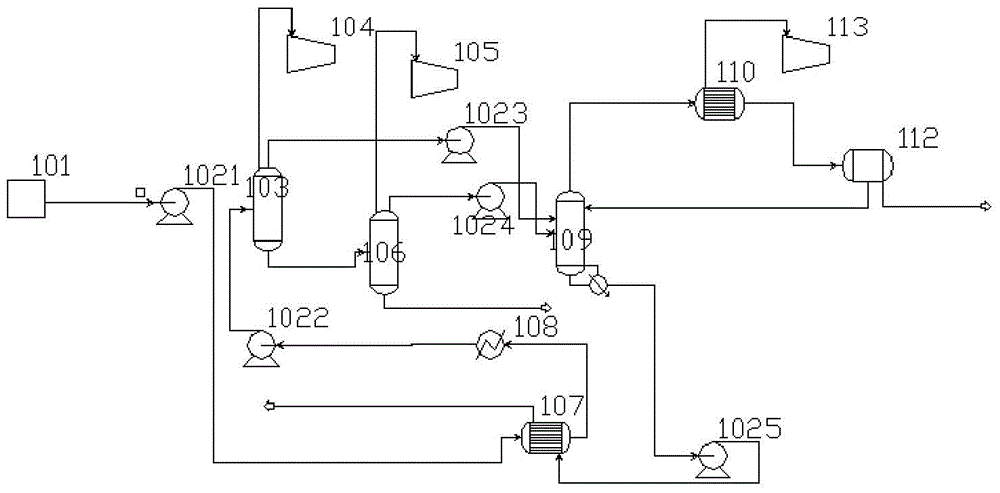

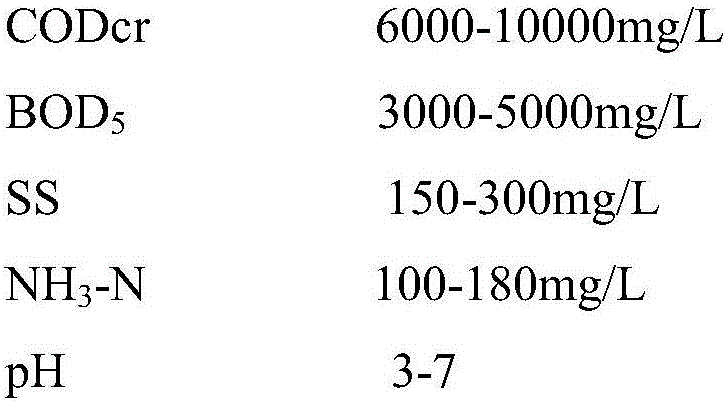

Method for treating waste water of antibiotic production

ActiveCN106746159AEfficient removalImprove processing efficiencyWater/sewage treatment by centrifugal separationTreatment using aerobic processesWastewaterTotal nitrogen

The invention relates to a method for treating waste water of antibiotic production. The method comprises the following steps: (1) removing suspended materials from the waste water by adopting air flotation treatment; (2) treating the waste water by a high-grade oxidation technology to improve the biodegradability; (3) performing coagulating sedimentation on oxidation effluent and filtering to remove the generated precipitate; (4) performing anaerobic biochemical treatment on filtering effluent; (5) performing aerobic biochemical treatment on anaerobic effluent and adding salt-resistant COD-removing denitrifying microbial inoculums. According to the method, an air flotation-coagulating sedimentation-high-grade oxidation-anaerobic biochemical-aerobic biochemical combined treatment process is adopted, and the specific COD-removing denitrifying microbial inoculums are added in an aerobic unit, so the antibiotic in the waste water can be tolerated, the COD and the total nitrogen in the waste water can be removed efficiently, and the method has the characteristics of simple process, high treatment efficiency, low treatment cost and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antibiotic pharmaceutical wastewater processing method and device

ActiveCN103183403AAchieve continuous separationTo achieve resourceSemi-permeable membranesDispersed particle separationAntibiotic YMembrane reactor

The invention discloses an antibiotic pharmaceutical wastewater processing method and an antibiotic pharmaceutical wastewater processing device, and belongs to a wastewater processing technology. According to the invention, a porous filtering membrane is specifically arranged between an anion-exchange membrane and a cation-exchange membrane of an electrodialyzer membrane reactor, such that electrodialysis is intrinsically coupled with a membrane filtering process. Macromolecular substances such as mycelia, proteins, and colloidal are retained with a sieving effect of the porous filtering membrane, such that ion-exchange membrane surface pollution is reduced. Also, under an effect of a direct current electric field, with a selective permeability of the ion-exchange membranes upon charged ions, separation and concentration of anions and cations, and charged antibiotic ions are realized. With an adopted external direct current electric field, a specific solute can be effectively prevented from forming membrane pollution on the surface of the porous filtering membrane, such that the processing process can be safely and stably operated. With the method and the device, antibiotic wastewater processing system investment and operation cost can be greatly reduced; and salt ions and residual antibiotics can be highly efficiently recovered from pharmaceutical wastewater. The method and the device have important application values in antibiotic production and wastewater processing.

Owner:天津大远科技有限公司

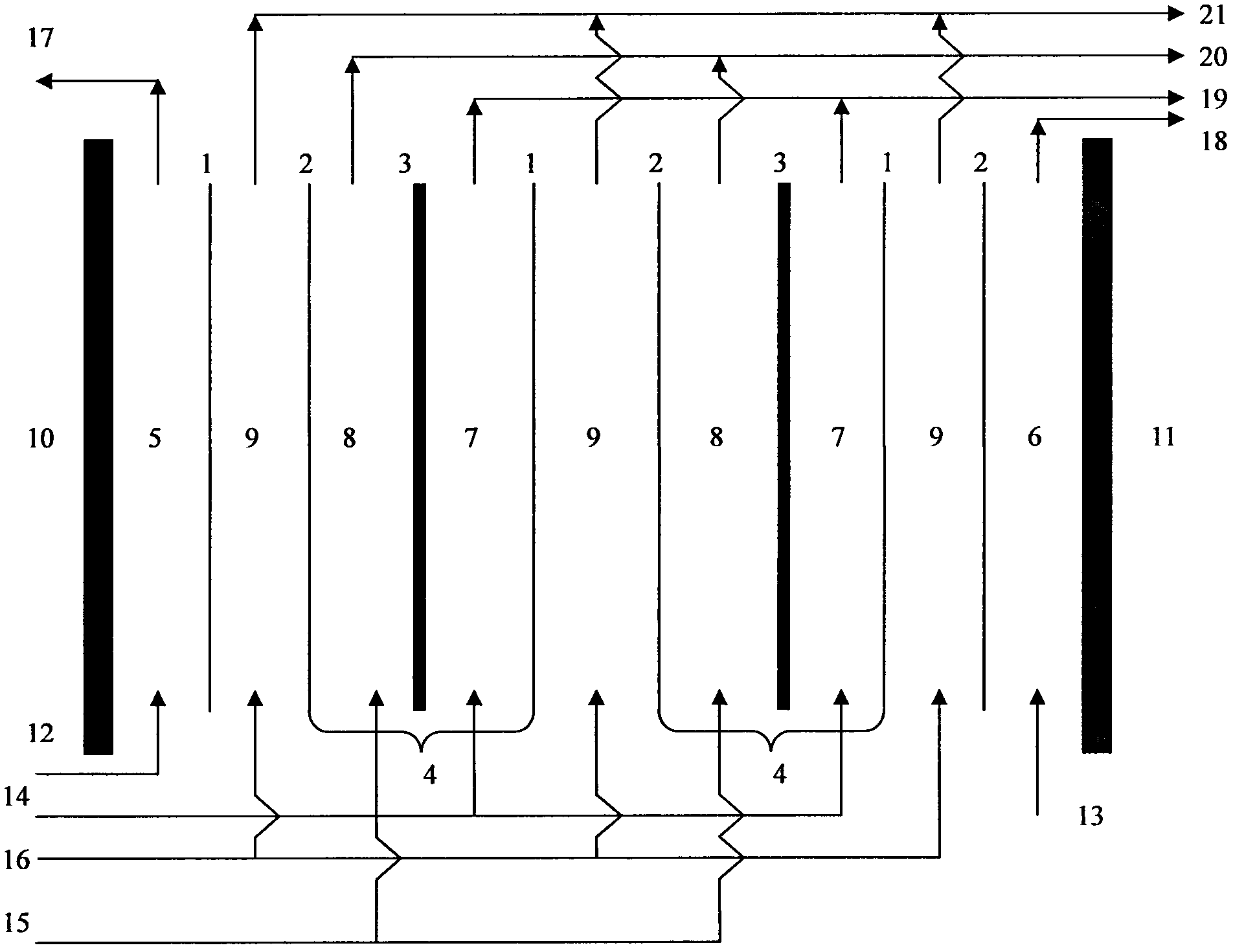

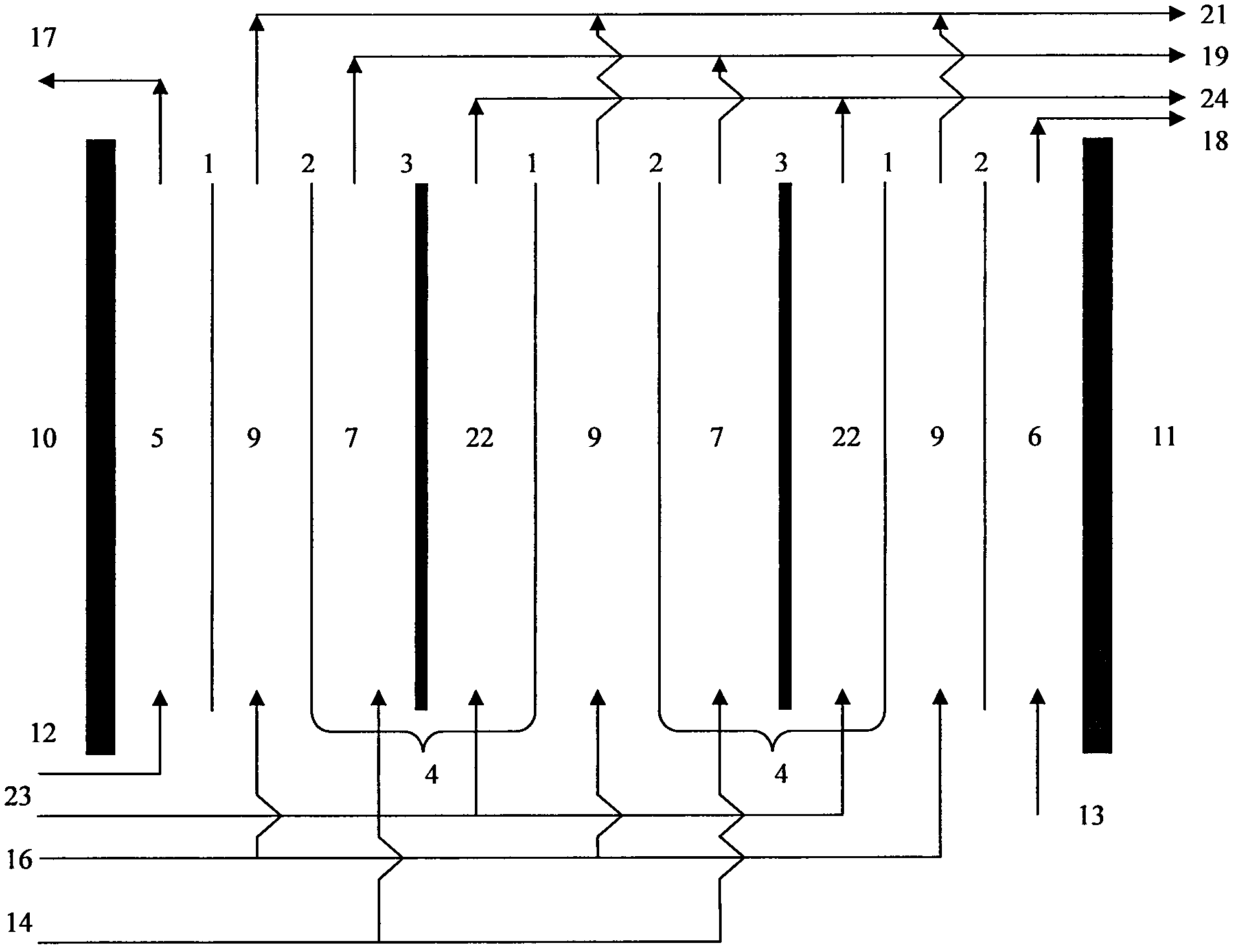

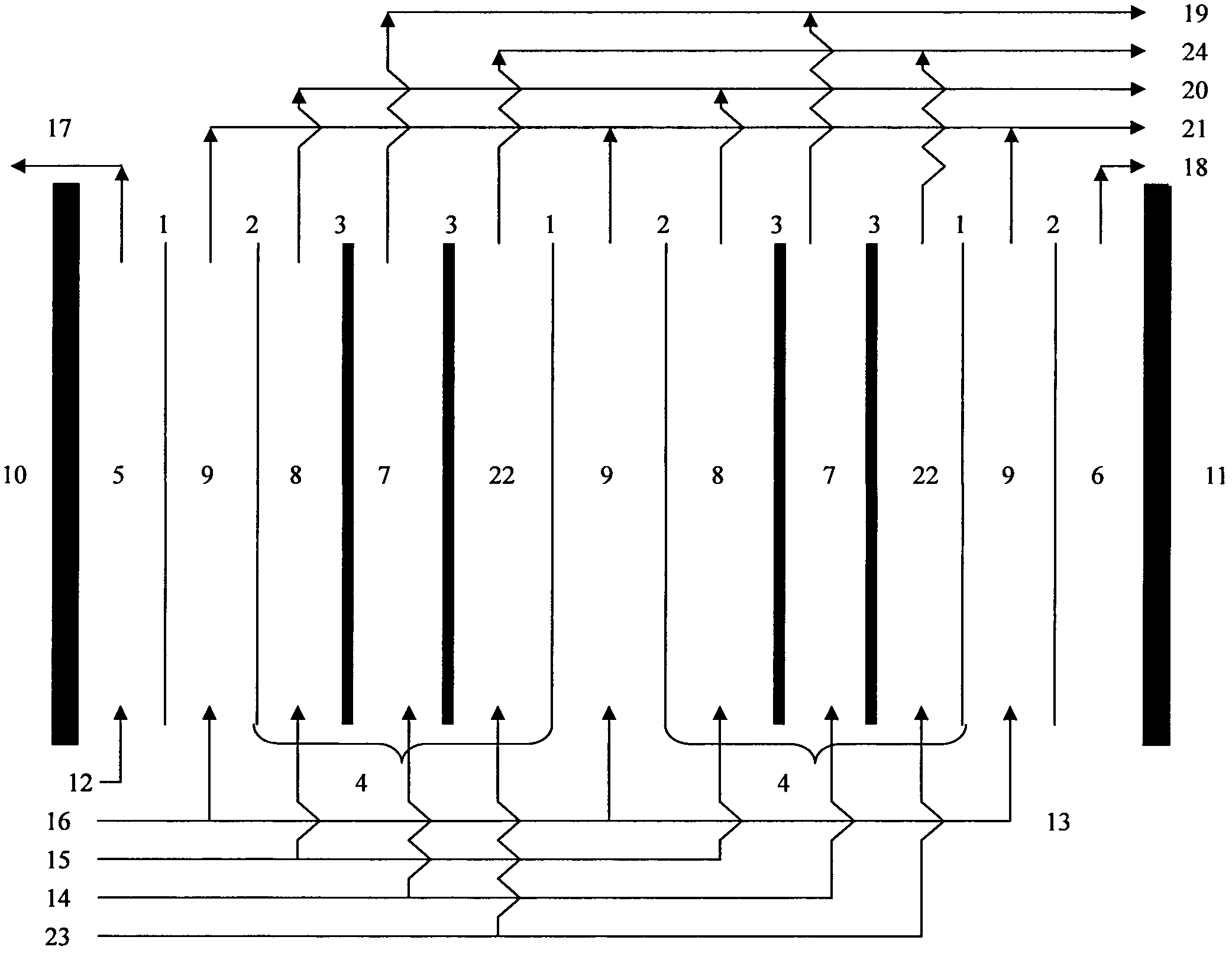

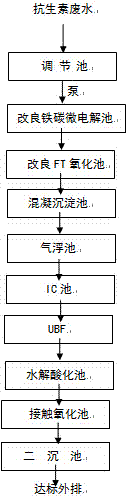

Treatment method of antibiotic production wastewater

ActiveCN104843934APromote degradationReduce water concentrationMultistage water/sewage treatmentElectrolysisWater quality

The invention discloses a treatment method of antibiotic production wastewater. The innovation point is as follows: through an adjusting tank, antibiotic successively enters an iron-carbon micro-electrolysis tank, an FT oxidation tank, a coagulative precipitation tank, an air floatation tank, a treating tank equipped with an anaerobic internal circulation reactor, an upflow sludge blanket filtering basin, a hydrolysis acidification pool, a contact aeration basin and a secondary sedimentation tank so as to undergo recovery processing. According to the treatment method of antibiotic production wastewater, improved iron-carbon micro-electrolysis and improved coal / natural gas indirect liquefaction FT oxidation technologies are adopted for pretreatment, so as to destroy and degrade hardly-degraded and toxic organic pollutants in wastewater. Thus, toxicity is destroyed and water concentration is reduced while biodegradable performance of pollutants in wastewater is improved. Favorable conditions are created for follow-up biochemical treatments, and treatment efficiency and effluent quality standard are raised.

Owner:NANTONG DAHENG ENVIRONMENTAL ENG CO LTD

Lipopeptide-producing bacillus pumilus and application thereof

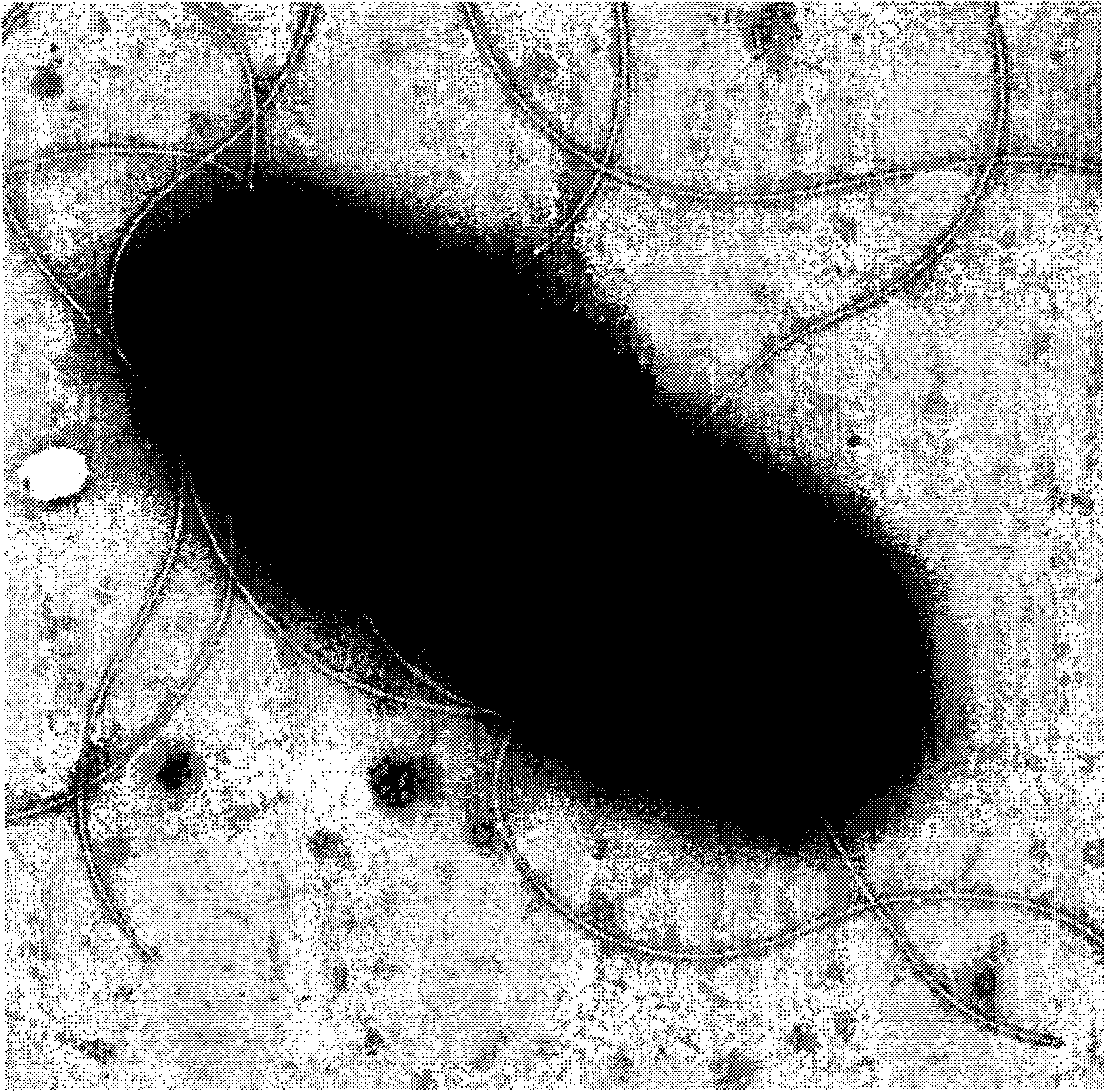

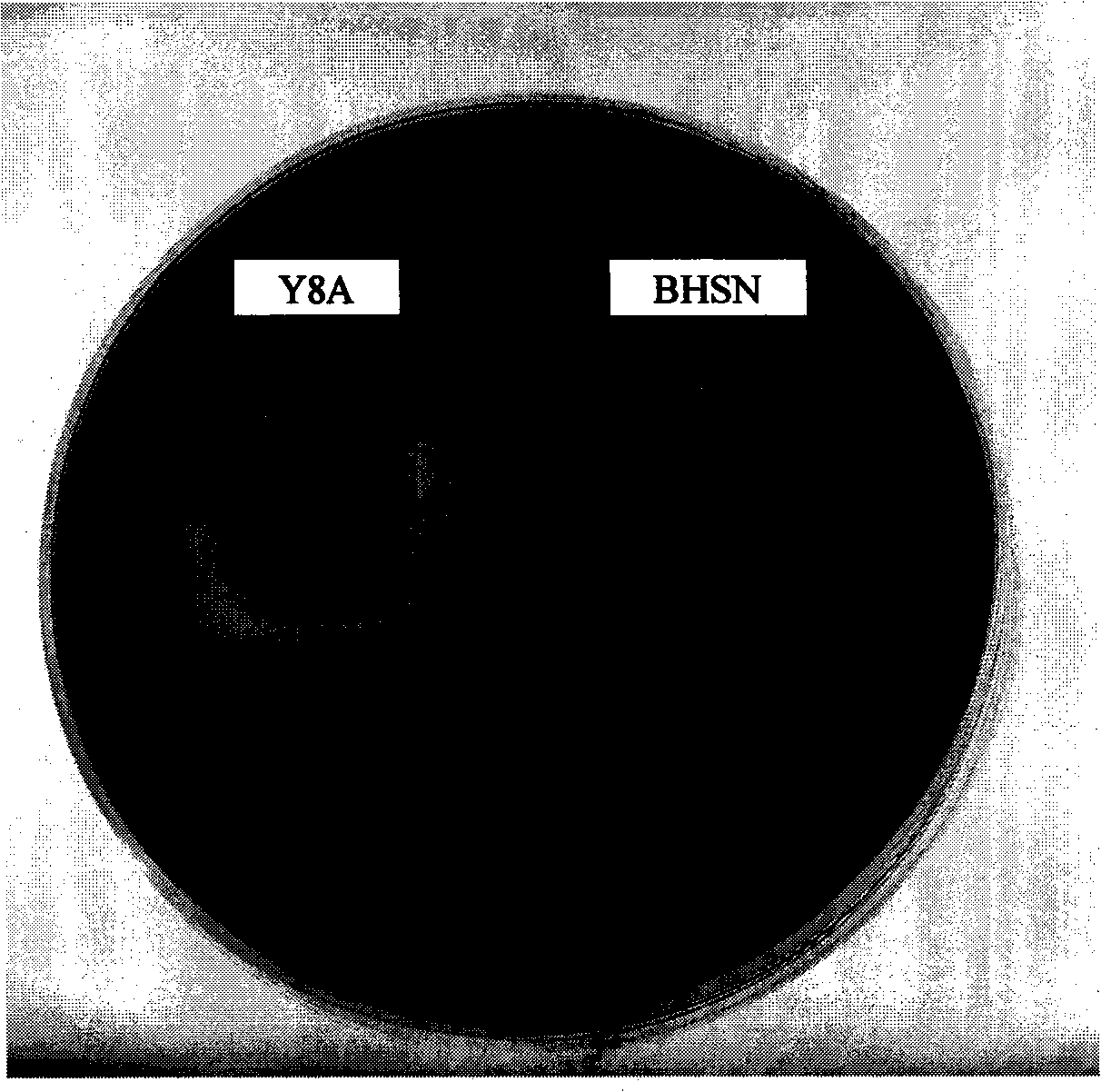

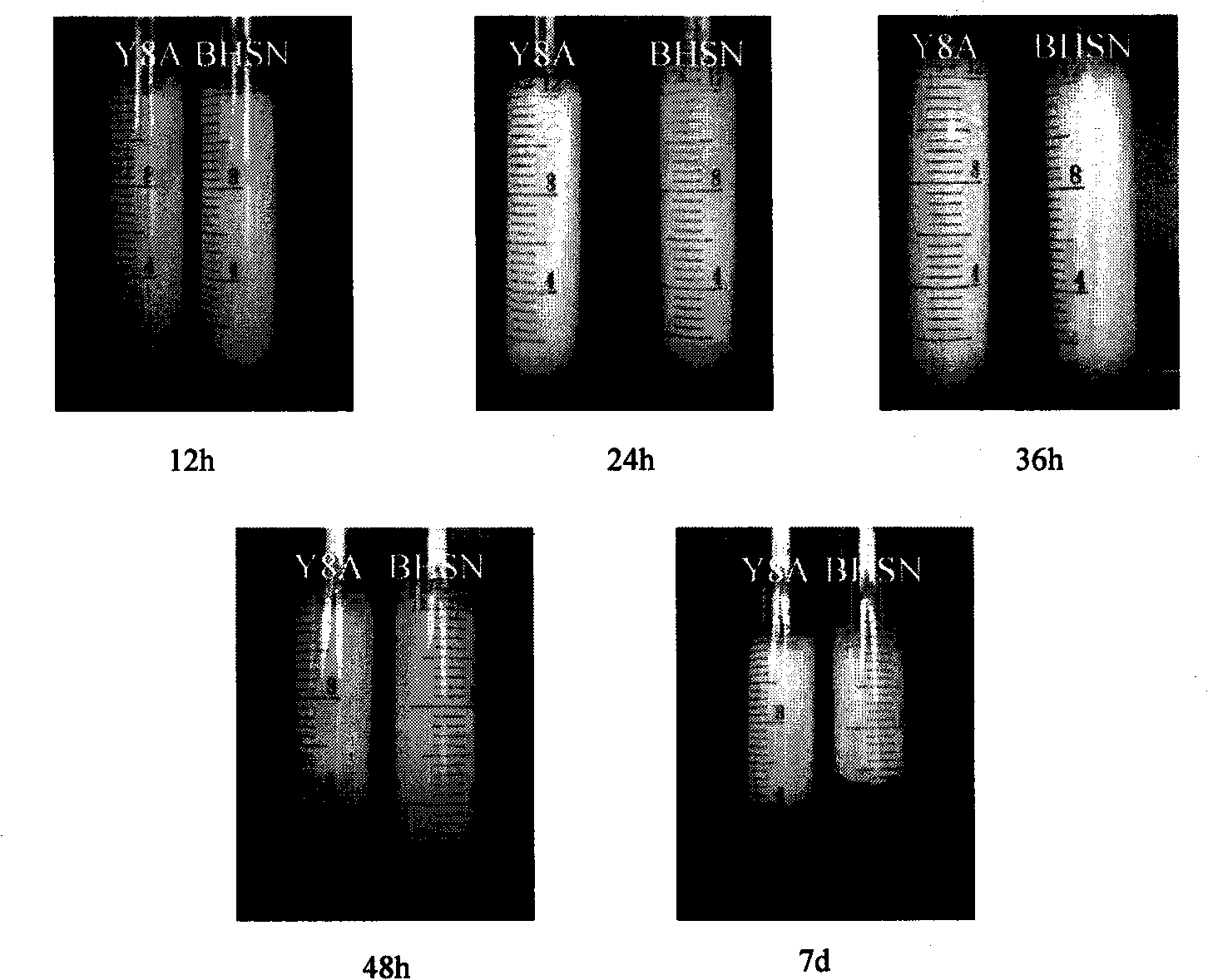

ActiveCN101560483AThe fermentation process is simpleEasy to operateBacteriaWater contaminantsAntibiotic YBacterial strain

The invention discloses a lipopeptide-producing bacillus pumilus, and classification thereof is named to be Bacillus pumilus Y8A which is preserved by China Center for Type Culture Collection (CCTCC) in Wuhan University with the preservation number of CCTCCM 209108. The invention also discloses an application of the lipopeptide-producing bacillus pumilus in promoting the micro-biological degradation process of petroleum and / or cyhalothrin pesticide. Bacterial strain Y8A of the invention can produce lipopeptide biosurfactant with high efficiency and stability, thereby effectively promoting the micro-biological degradation process of petroleum and / or cyhalothrin pesticide degrading bacteria. Bacterial strain Y8A with the function of efficiently producing lipopeptide is expected to work as a new-generation bacteria and cosolvent for antibiotic production and, is widely used in agriculture, medicine, cosmetic and food industries, and can be used for restoration of pollutant environment together with other organic pollution degrading microbes. The bacterial strain is resistant to a plurality of antibiotics with easy fermentation course and convenient operation.

Owner:NANJING AGRICULTURAL UNIVERSITY

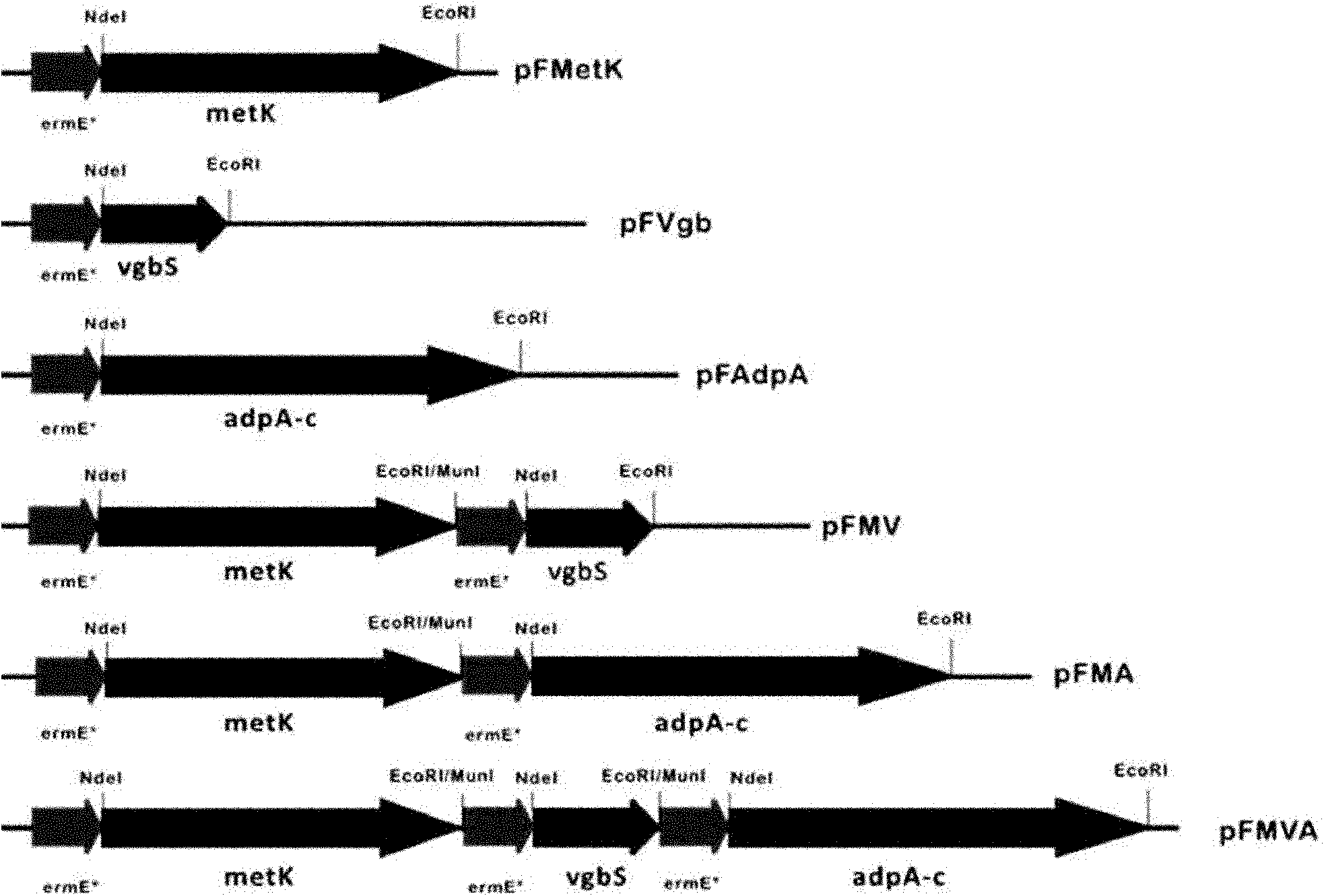

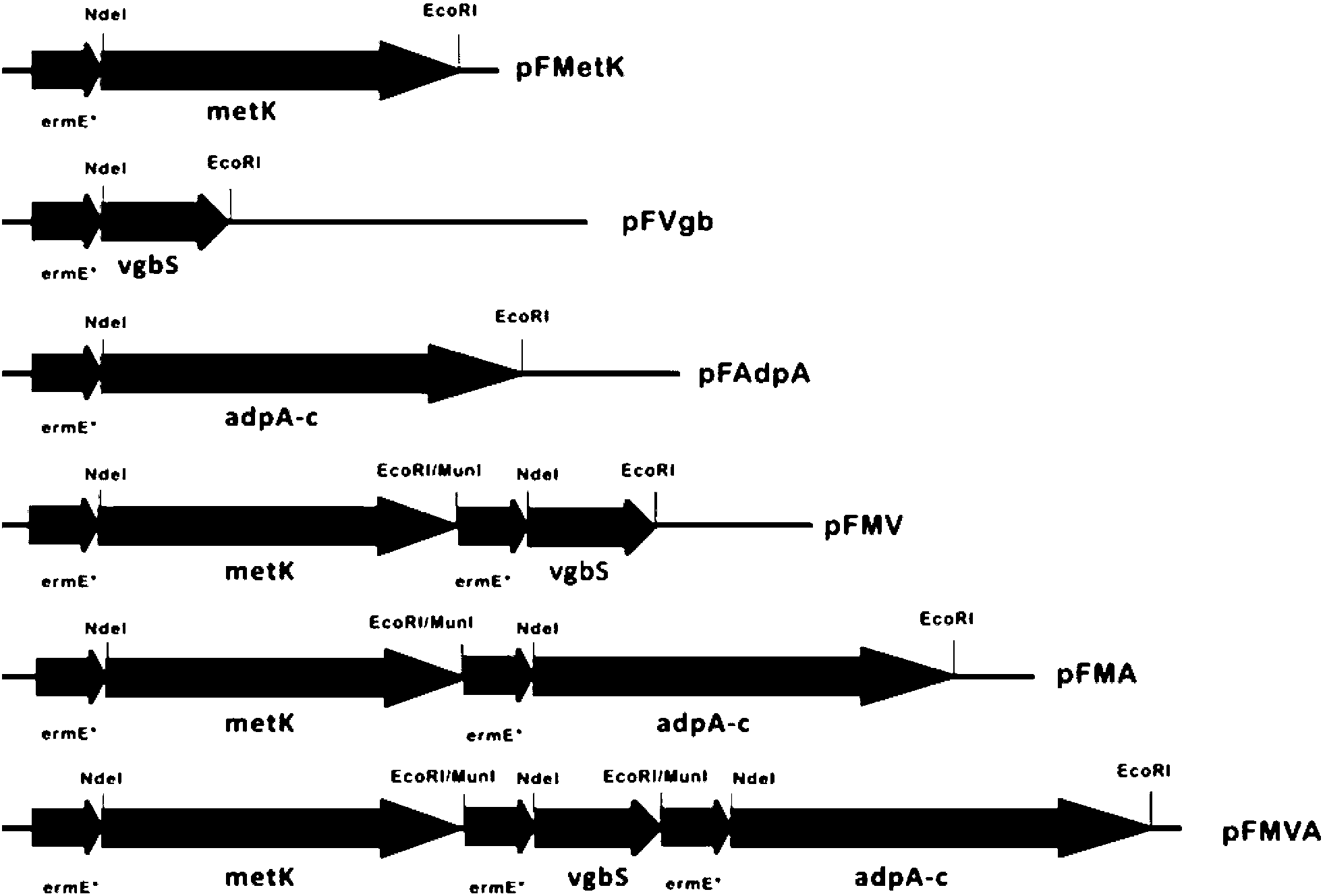

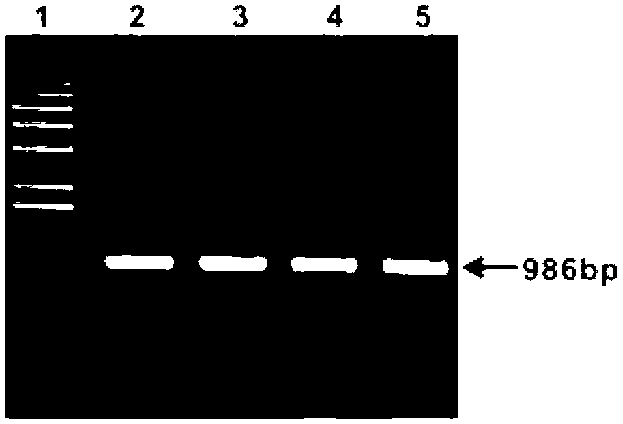

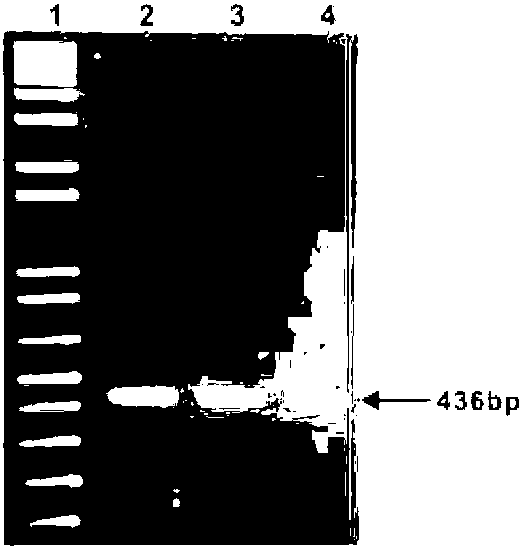

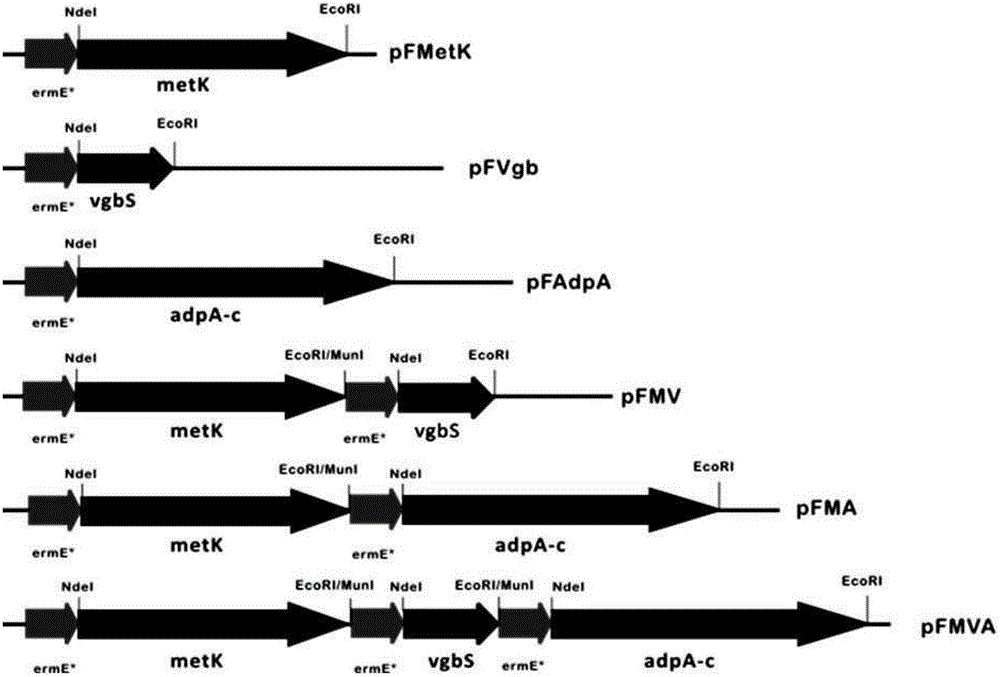

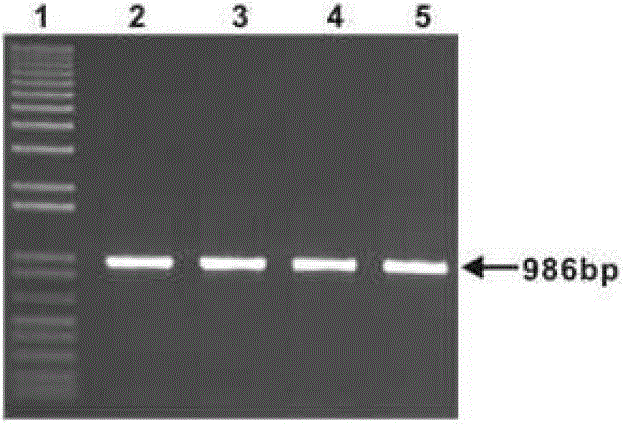

Method for improving yield of Streptomyces antibiotics and plasmid thereof

The invention discloses a method for improving the yield of Streptomyces antibiotics, and belongs to the technical field of biomedicine. The yield is improved by constructing corresponding integrative expression plasmids, namely pFMetK, pFVgb, pFAdpA, pFMV, pFMA and pFMVA of a metK gene and / or a vgbs gene and / or an adpA-c gene, and transferring the integrative expression plasmids to Streptomyces ZYJ-6. In the method, exogenous genes such as regulator genes, precursor synthesis genes and the like are simultaneously introduced into an antibiotic producing strain so as to improve the yield of the antibiotics.

Owner:SHANGHAI JIAO TONG UNIV

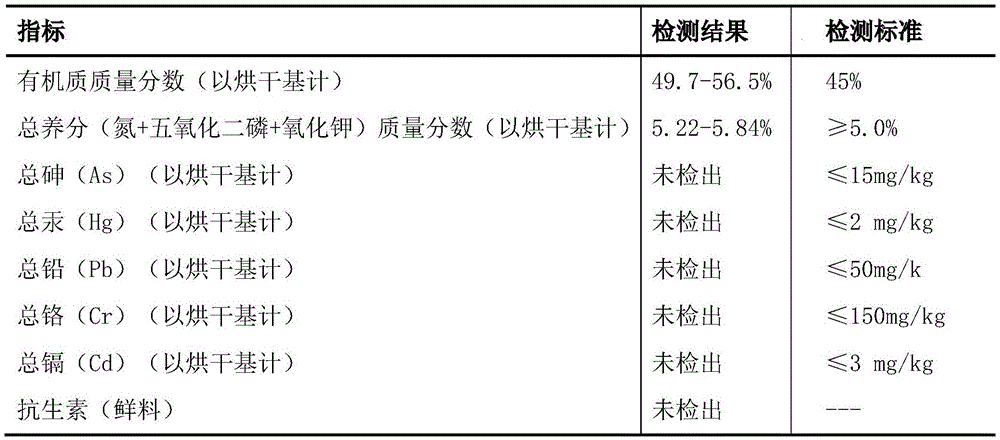

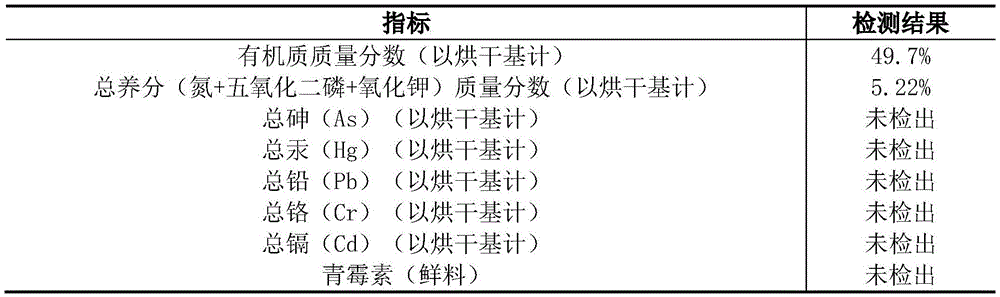

Resourceful treatment method for antibiotics mushroom dregs

InactiveCN105642652AAdapt to resource processingReasonable process combinationSolid waste disposalBiotechnologyPenicillin

The invention provides a resourceful treatment method for antibiotics mushroom dregs, wherein mushroom dregs produced during production of antibiotics such as penicillin, erythrocin and cephalosporin are treated by the steps of intensified hydrolysis, mushroom dregs blending, two-phase anaerobic digestion, deep dehydration, resource utilization and the like. Aiming at the practical problems of a large quantity of antibiotics mushroom dregs and great treatment difficulty, the antibiotics mushroom dregs are subjected to harmless and resourceful treatment, thus providing basis for difficulties urgent to be solved of pharmaceutical enterprises.

Owner:THE FIRST AFFILIATED HOSPITAL OF XINXIANG MEDICAL UNIV

Method for increasing titer of bacitracin in fermentation liquid by using oxygen carrier

InactiveCN102899375AIncrease dosageImprove solubilityMicroorganism based processesFermentationOxygenTiter

The invention relates to a method for increasing titer of bacitracin in fermentation liquid by using oxygen carrier. A certain amount of oxygen carrier is added into a fermentation medium to improve the oxygen dissolution condition and greatly increase titer of bacitracin fermentation liquid, without changing other fermentation conditions. The method has simple process; the oxygen carrier in the production process can be recycled, so as to reduce production cost; therefore, the method has an important guiding significance for antibiotic production.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Daptomycin extraction method

ActiveCN105481950AReduce healthy stressLittle side effectsPeptide preparation methodsFiltrationGradient elution

The invention relates to the technical field of antibiotic production, in particular to a daptomycin extraction method. The method includes the following steps of firstly, filtering daptomycin fermentation liquor through a ceramic film; secondly, making filtered liquor pass through large-pore adsorption resin so that eluant can be collected; thirdly, mixing NM-Q anion exchange resin with the obtained eluant, and collecting eluant; fourthly, making the eluant obtained in the third step pass through a reverse phase silica gel MNsil-C18 column, conducting gradient elution on the column through an ammonium acetate ethanol solution, and collecting eluant; fifthly, concentrating the daptomycin eluant obtained in the fourth step, adding calcium acetate and isopropyl alcohol, and conducting standing, crystallization, suction filtration and drying to obtain daptomycin crystallization powder. The method has the advantages that the virulent acetonitrile solution is not used as the eluant, pressure on the environment and health of production personnel is reduced, the use of acid-base regulator is reduced, and the production cost is reduced.

Owner:LIVZON GROUP FUZHOU FUXING PHARMACEUTICAL CO LTD

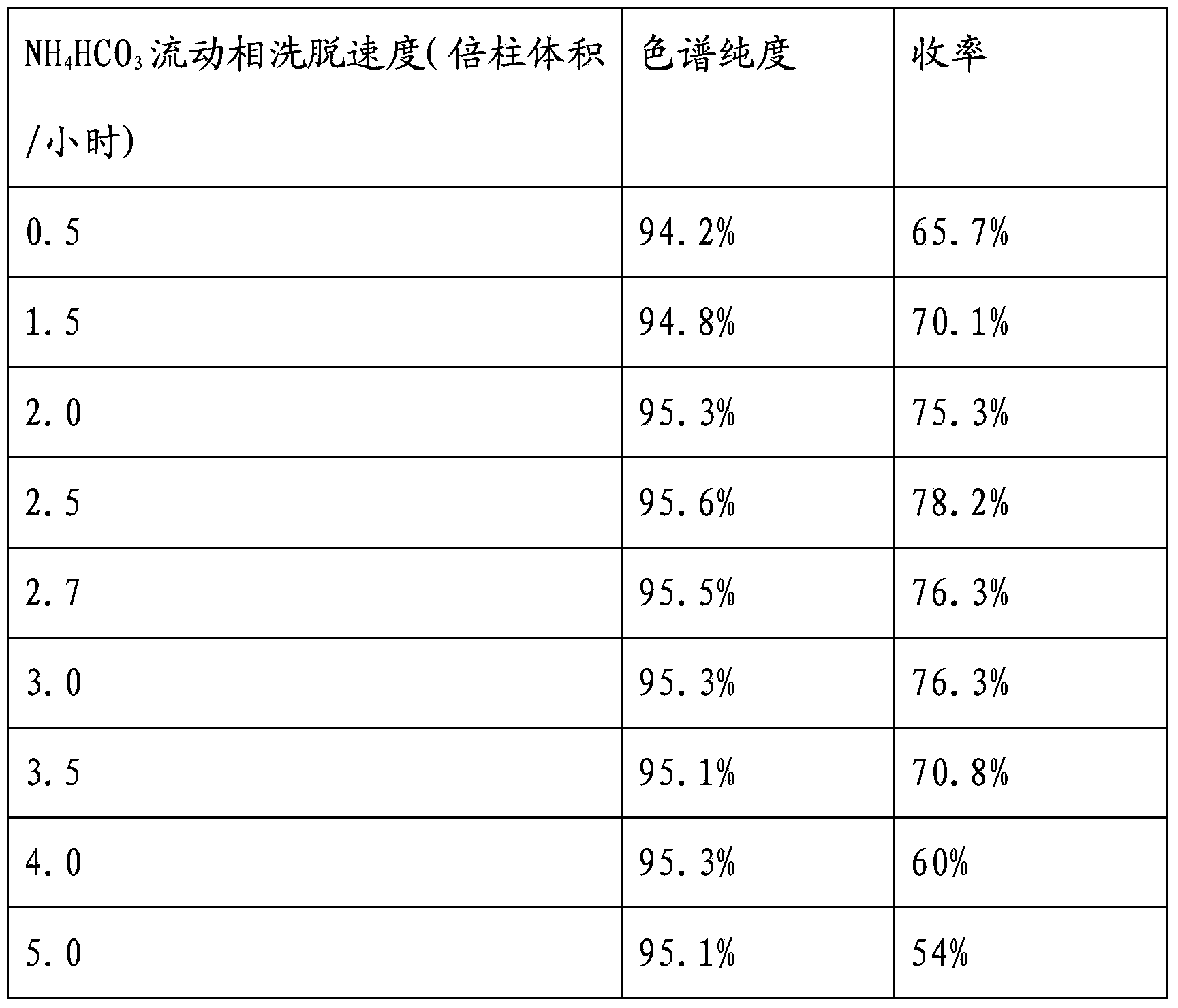

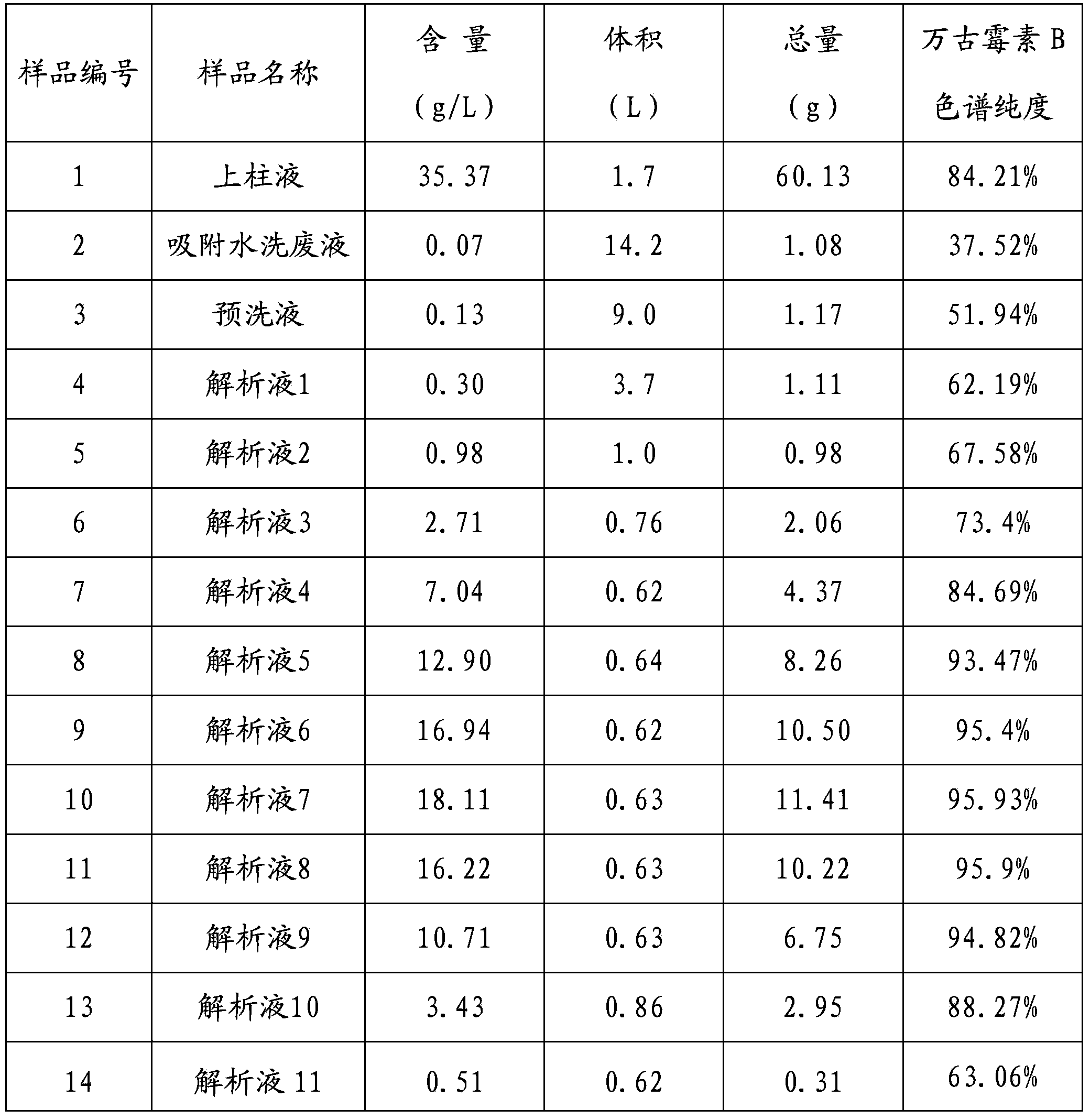

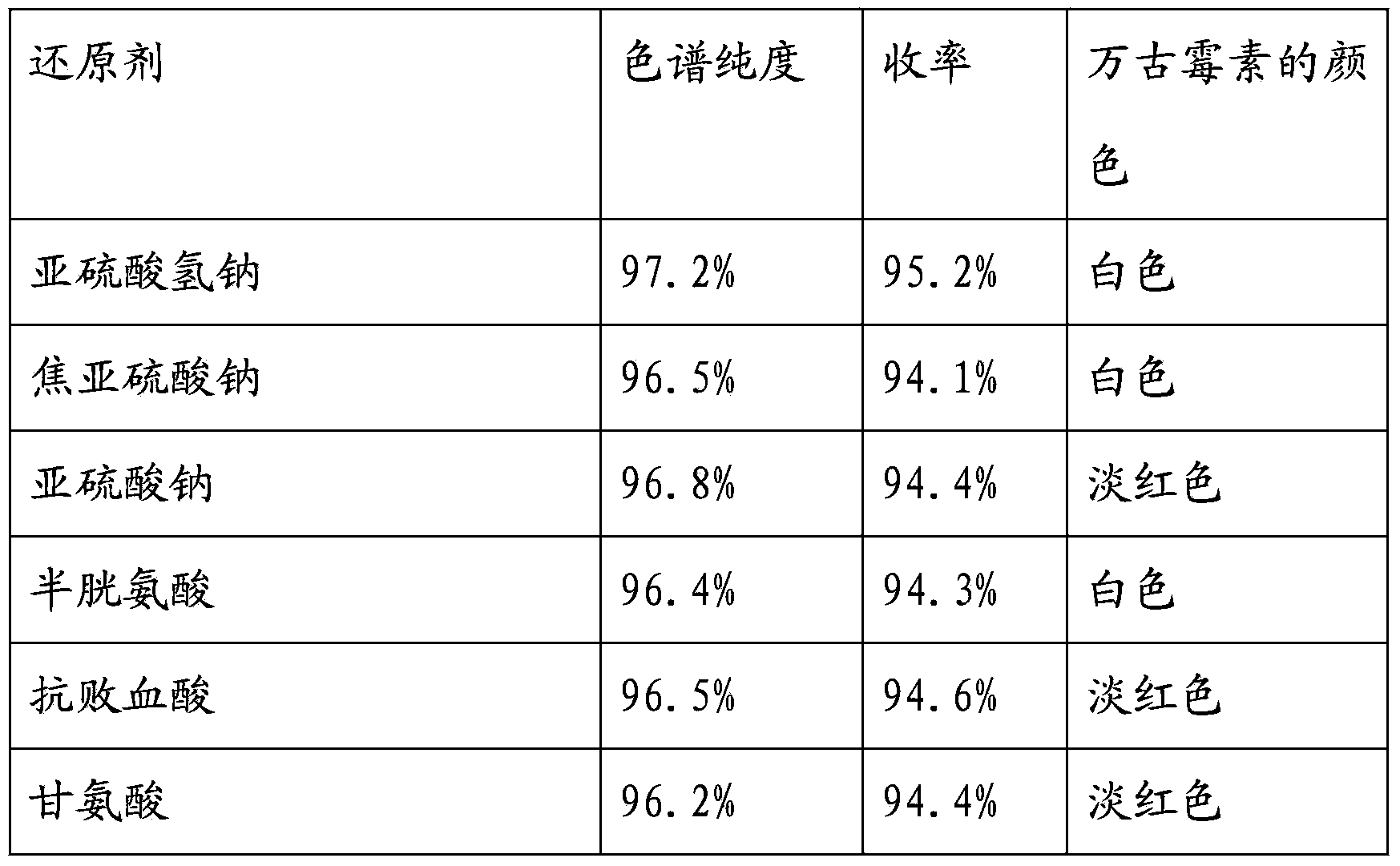

Preparation method of vancomycin with high purity

ActiveCN103408639ASmall granularityLow swelling ratePeptide preparation methodsChromatography liquidVancomycin

The invention belongs to the field of antibiotic preparation technologies, and more specifically relates to a preparation method of vancomycin with high purity. The preparation method comprises following steps: a destaining solution of vancomycin is subjected to column chromatography in a chromatography media, wherein the chromatography media is UniPMM50CAR, the NH4HCO3 mass concentration of a mobile phase of column chromatography is 0.2 to 0.7%; when absorbance rises to 40 at a detection wavelength of 280nm, chromatography liquids are collected segment by segment, the pH value of the chromatography liquids is adjusted to 3.0 to 3.5, the chromatography liquids are preserved under 4 DEG C, and the collected chromatography liquids are mixed. Bubbles in the chromatographic column caused by degradation of carbonate are not likely to generate by using the preparation method. The preparation method is capable of increasing stage number and separation efficiency. The appearance of the obtained vancomycin is improved significantly, purity is as high as 99%, and the vancomycin can be taken orally or by injection.

Owner:LIVZON GROUP FUZHOU FUXING PHARMACEUTICAL CO LTD

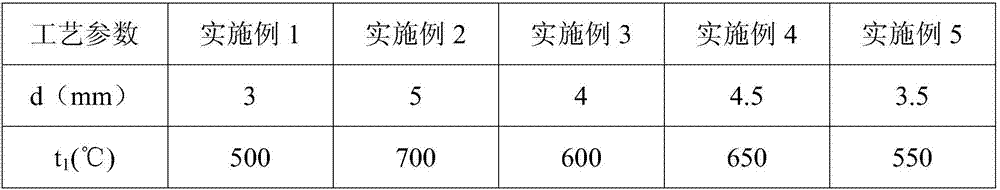

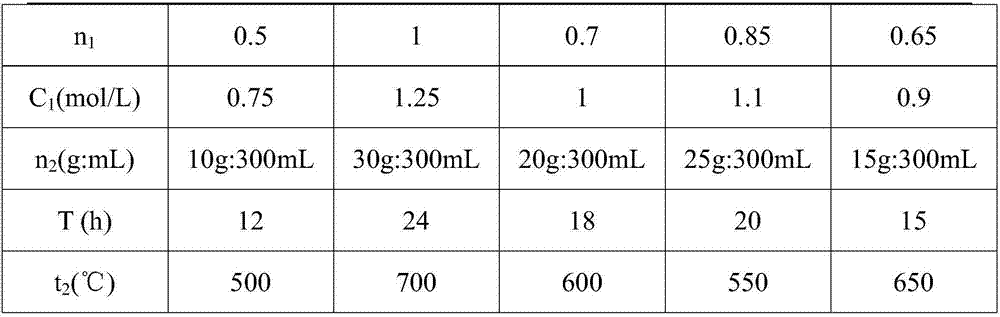

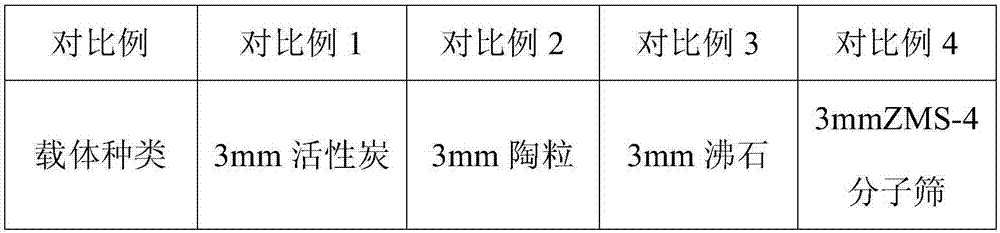

Catalyst for catalytic oxidation of ozone, and preparation method and application thereof

InactiveCN106964349ASimple preparation processLow costHeterogenous catalyst chemical elementsCatalyst activation/preparationNitrateCatalytic oxidation

The invention discloses a preparation method for a catalyst used for catalytic oxidation of ozone. The preparation method comprises the following steps: a, cleaning gamma-Al2O3 with a diameter of 3 to 5 mm by using deionized water and then carrying out drying and high-temperature roasting so as to obtain pretreated gamma-Al2O3; b, soaking the pretreated gamma-Al2O3 in a NaOH solution for 3 to 6 h, carrying out filtering, then taking the soaked gamma-Al2O3 out, washing the soaked gamma-Al2O3 with distilled water until the pH value of the soaked gamma-Al2O3 does not change, then carrying out drying in a drying oven with a temperature of 100 to 120 DEG C, and then soaking the dried gamma-Al2O3 in a mixed solution of ferric nitrate and copper nitrate so as to obtain a catalyst precursor, wherein the concentration of the mixed solution of ferric nitrate and copper nitrate is 0.75 to 1.25 mol / L; and c, drying the catalyst precursor and carrying out high-temperature roasting so as to obtain the catalyst used for catalytic oxidation of ozone. The preparation method is simple in process, low in cost and easy for realization of large-scale industrial production. The catalyst for catalytic oxidation of ozone prepared by using the preparation method is applicable to treatment of antibiotic production wastewater.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Treating agent for lincomycin hydrochloride production waste water and its preparation method and usage method

InactiveCN1865175AEasy to useSimple and fast operationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSolventEnergy conservation

This invention relates to a waste water treatment agent for treating the waste water during the jiemycin hydrochloride production and the preparation method and process of using thereof. This treatment agent is made of formaldehyde, dicyandiamide, catalyst, cationic starch, water and assisting solvent raw material. The COD of the waste water can be decreased below 300mg / L after treated by this treatment agent and can meet the national standard of discharging. It overcomes the disadvantage that the total discharging pollutant does not decrease by diluting the high-concentrated jiemycin organic waste water in the current manufacturing enterprise. Besides, this treatment agent is easy soluble and dispersing in waste water, thus has a high usage efficiency and good economical benefits. In the meantime, the mass amount marsh gas and organic deposition substances produced during the treatment process can be used as fuel and farm manure respectively, which can obtain a good effect of comprehensive utilization, energy saving and cost decreasing.

Owner:南阳市鹿城生化研究所

Process method for recycling butanol-butyl acetate from antibiotic production wastewater

ActiveCN104151136AIncrease relative volatilityLow quality scoreOrganic compound preparationWater contaminantsButyl acetatePhase splitting

The invention relates to a process method for recycling butanol-butyl acetate from antibiotic production wastewater. The process method comprises the following steps: preheating wastewater of which the content of butanol-butyl acetate is 1-5 percentage by mass by using a tower bottom of a rectifying tower; further heating to 80-85 DEG C by using a heat exchanger, feeding into a flash column; feeding distillate from the top of the flash column into the rectifying tower; and separating the distillate. As a tubular type heat exchanger on the top of the rectifying tower is connected with a pressure reducer so that the shell pass of the rectifying tower and the tubular type heat exchanger is maintained to be less than 35kPa. The steam on the top of the tower is condensed and fed into a phase splitting tank, the light phase is fed into a tank to be detected, the heavy phase flows back, and the tower bottoms are cooled to 30-35 DEG C and discharged. By adopting the process method, the recycling rates of butanol and butyl acetate are greatly increased; by comprehensive utilization of pressure-reduced distillation and heat, the energy consumption can be reduced and remarkable practicability and economical efficiency are achieved.

Owner:HEBEI UNIV OF TECH

Method recovering butylacetate in antibiotic production process

InactiveCN1534012APrevent protein denaturationAvoid formingOrganic compound preparationChemical industryButyl acetateAntibiotic Y

A process for recovering the butyl acetate generated during production of antibiotics includes resin adsorption of the solution containing the butyl acetate, water washing, analyzing the saturated resin by saturated steam, condensing the analyzed liquid, laying asid, and phase separation. Its advantages are high recovery rate, less energy consumption and low cost.

Owner:NORTH CHINA PHARMA COMPANY

Method for improving yield of streptomycete antibiotic and plasmid thereof

InactiveCN102703495AHigh purityIncrease productionBacteriaMicroorganism based processesAntibiotic YRegulator gene

The invention discloses a method for improving yield of streptomycete antibiotic, belonging to the biomedical technical filed. The method comprises the steps of constructing integrated expression plasmids pEMetK, pEVgb, pFAdpA, pFMV, pFMA and pFMVA corresponding to metK gene and / or vgbS gene and / or adpA-c gene; transferring the integrated expression plasmids to streptomycete ZYJ-6, so that the yield improvement is realized. According to the method, foreign genes such as regulator gene, precursor synthetic gene and the like are introduced to the antibiotic production strain so as to increase antibiotic yield.

Owner:SHANGHAI JIAO TONG UNIV

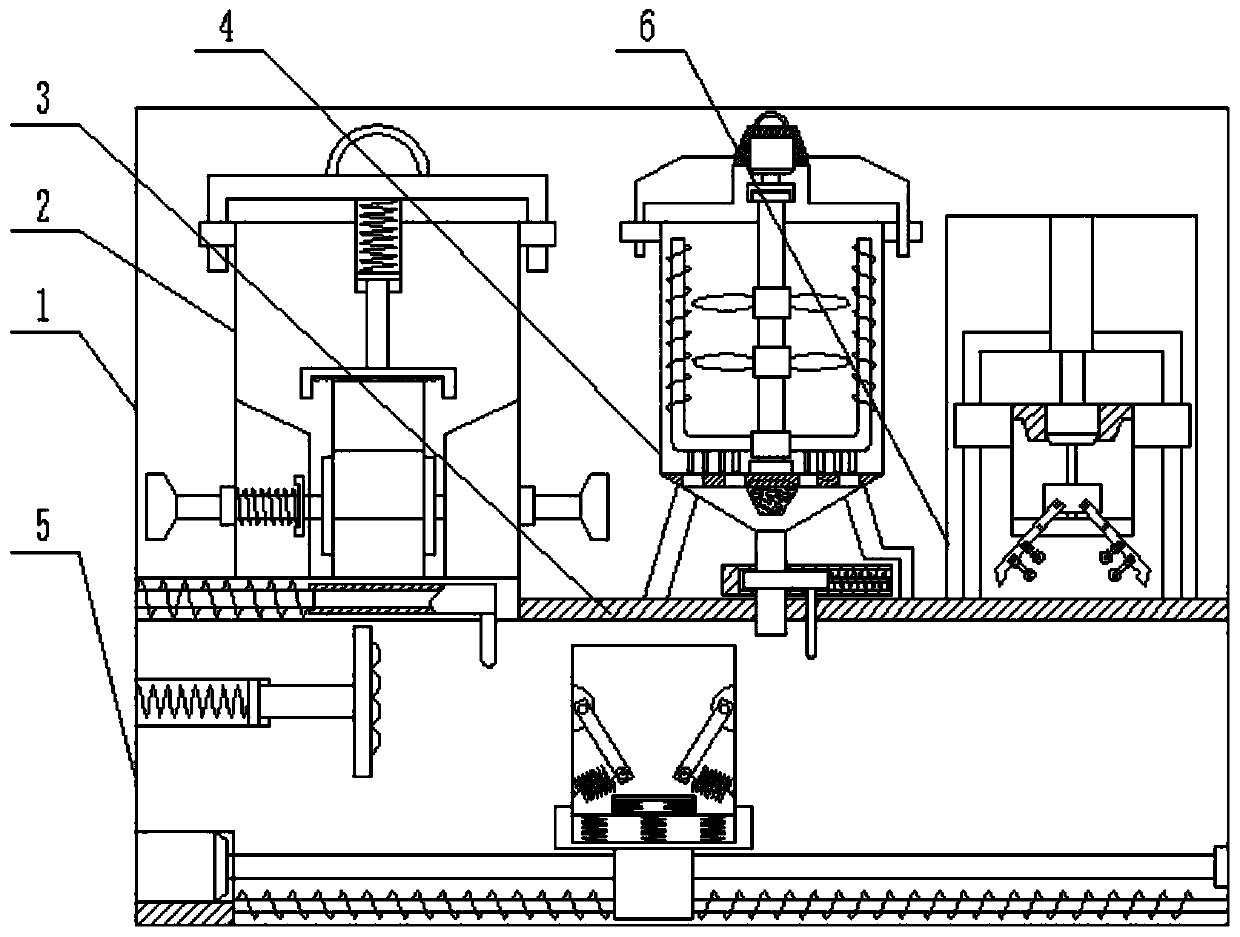

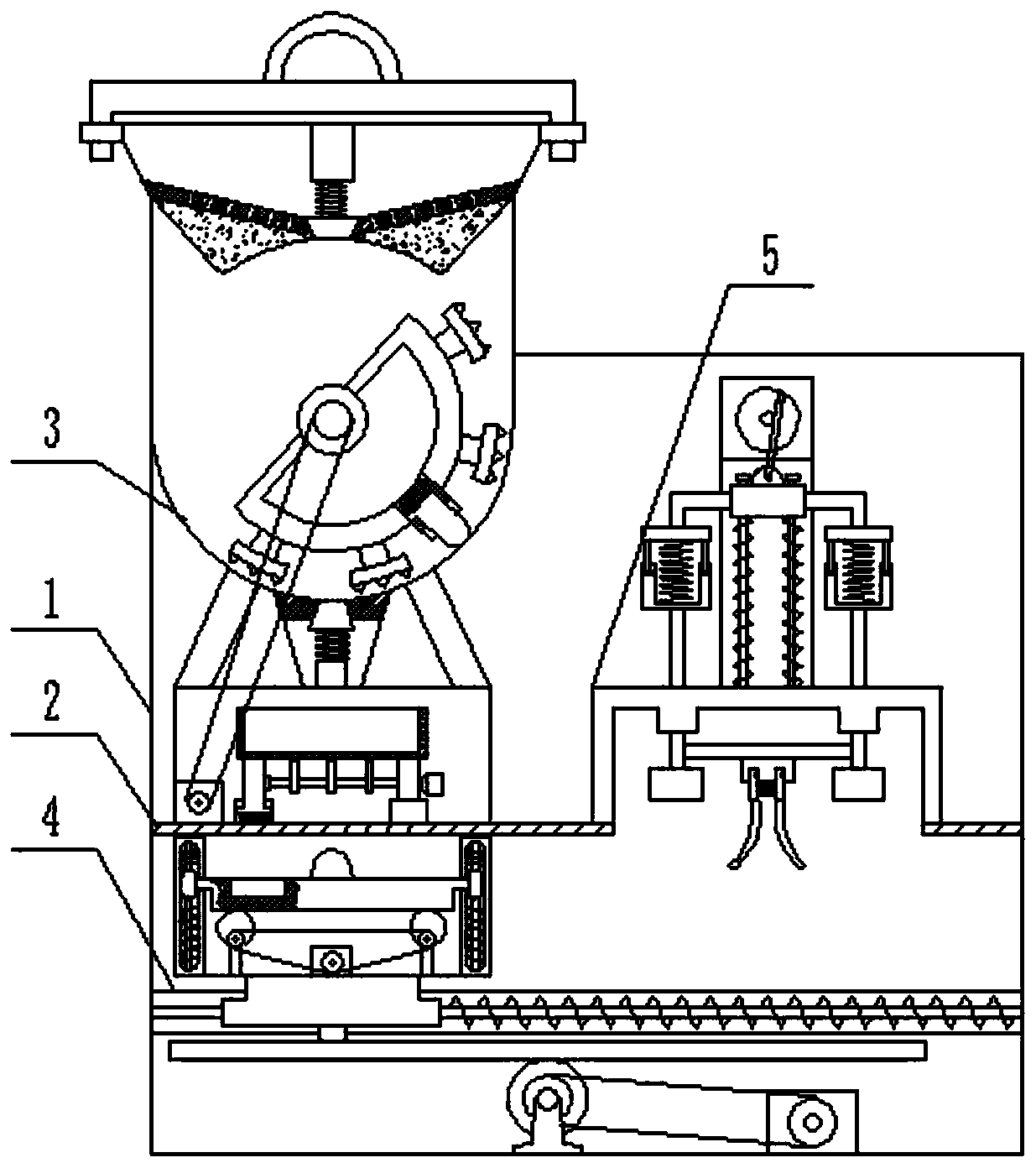

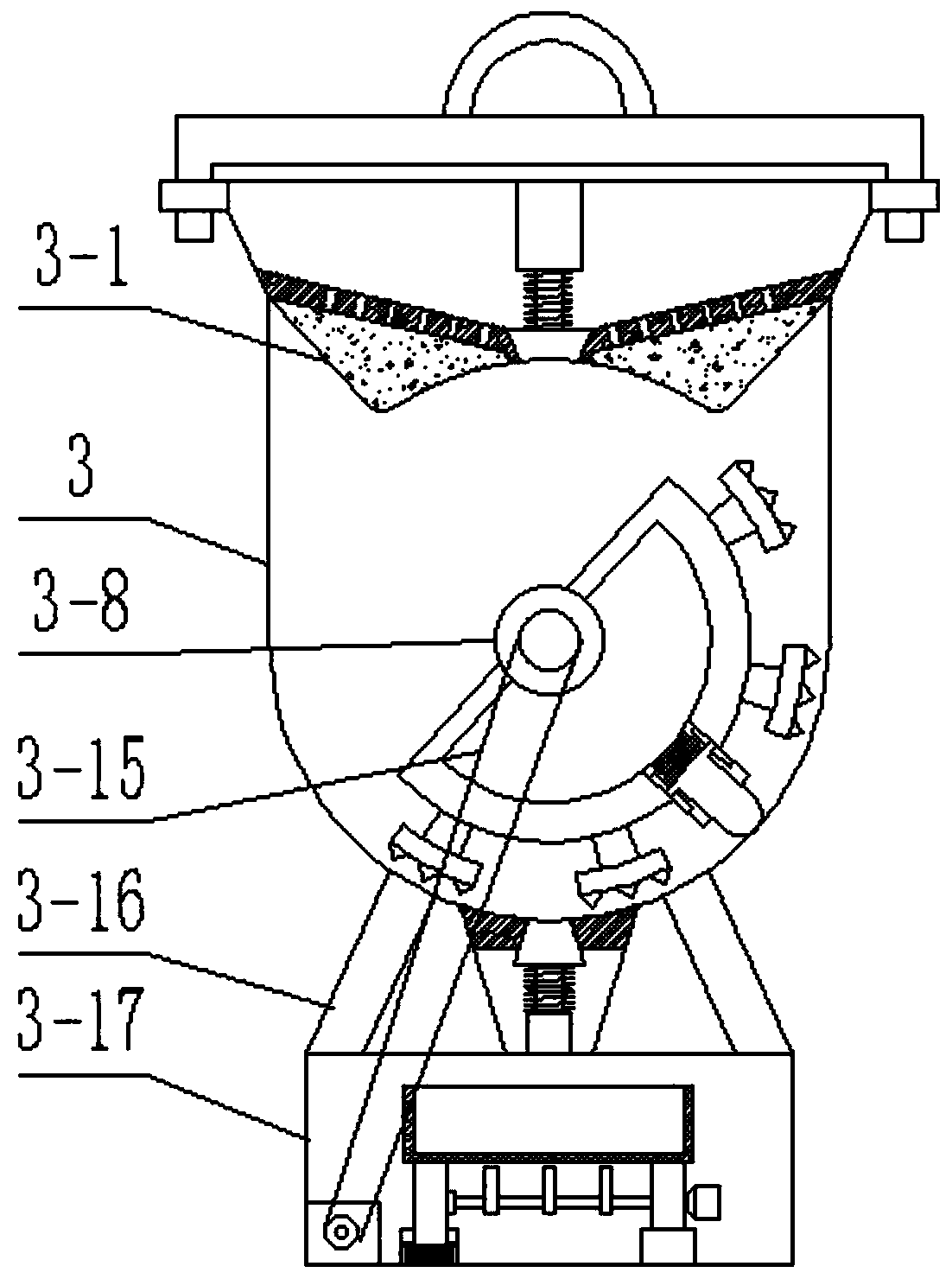

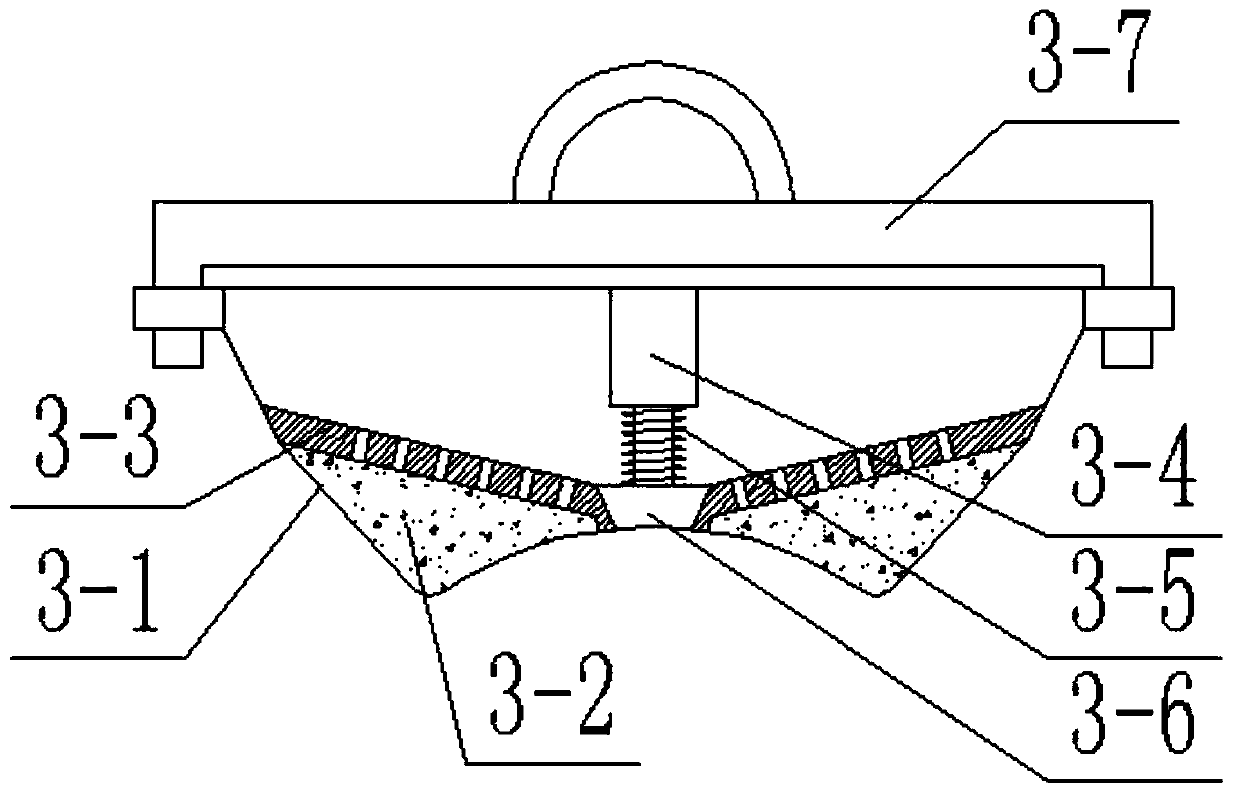

Intelligent antibiotics discharging and filling device

ActiveCN110203471ASolve drying problemsSolve the hazardRotary stirring mixersSolid materialAntibiotic YEngineering

The invention relates to an antibiotics related device, in particular to an intelligent antibiotics discharging and filling device. The device comprises a shell, a can storage box, a partition plate,a material storage box, a moving box and a sorting box. The device can be used for solving the problems that antibiotics needs to be mixed and then packaged and formed during production and manufacturing, and raw materials needs to be guaranteed to be dry during processing and filling, can further be used for solving the problem that existing antibiotics is manually mixed and then packaged duringproduction, manufacturing and filling, and the raw materials can be polluted due to the fact that operators can be directly contacted with the antibiotics raw materials during manual operation, and can further be used for solving the problems that the raw materials cannot be guaranteed to be dry, and the operators are directly exposed to and contact with the antibiotics raw materials for a long time, so that the harm to bodies can be caused.

Owner:王天宇

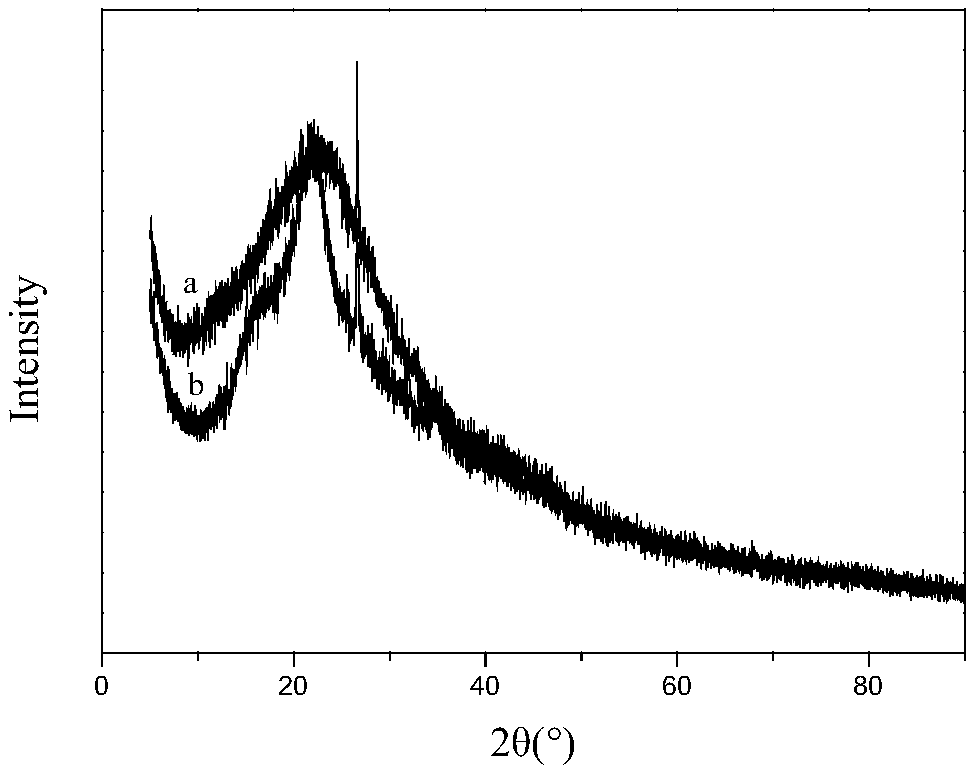

Furfural-residue-based biochar and application thereof

InactiveCN108745291AWide variety of sourcesLow priceOther chemical processesWaste water treatment from animal husbandryHigh rateCarbonization

The invention relates to furfural-residue-based biochar, obtained by mixing furfural residue with a dehydrating agent and then performing a carbonization reaction on the mixture. In a preferred technical scheme, concentrated sulfuric acid and soluble sulfate are taken as the composite dehydrating agent, and furfural residue is converted into biochar, which is used for adsorbing antibiotics. The test shows that the surface of the biochar is rich in oxygen-containing functional groups such as carboxyl groups and hydroxyl groups, the highest rates of removing tetracycline and oxytetracycline at initial concentration of 200 mg / l are 98.0% and 95.5% respectively, and the maximal adsorption capacities are 162 mg / g and 335 mg / g respectively. The furfural-residue-based biochar can be applied to wastewater treatment in antibiotic production plants, hospitals and livestock farms.

Owner:宁夏然尔特工业产业研究院(有限公司)

Process of increasing cellular production of biologically active compounds

InactiveUS20060234958A1Increase productionInhibitory activityBiocideBacteriaCompound (substance)Organic chemistry

A process of increasing the cellular production of biologically active compounds is provided. The process is particularly useful for increasing antibiotic production by bacterial cells. The process includes the step of inhibiting the activity of methylmalonyl-CoA mutase.

Owner:FERMALOGIC

Method for improving erythromycin fermentation titer and promoting erythromycin A synthesis

ActiveCN102757991AIncrease contentReduce manufacturing costMicroorganism based processesFermentationBetaineStreptomyces

The invention relates to a method for improving erythromycin fermentation titer and promoting erythromycin A synthesis. The method comprises the steps of: during the fermentation tank fermentation culture process of producing erythromycin utilizing streptomyces erythreus as seeds through fermentation, adopting an erythromycin fermentation basic formula which contains betaine, edible oil and trace elements, controlling the corresponding biomass concentration, ventilation ratio, fermentation tank pressure, fermentation temperature, stirring rate and pH and the edible oil concentration in a fermentation liquor to produce erythromycin through fermentation, and adding a Tween-20 surfactant during the fermentation process. According to the invention, through creating an environment which is contributed to the antibiotics production of streptomyces erythreus, the streptomyces erythreus metabolism is developed towards the direction which is benefit to erythromycin synthesis, finally, the erythromycin fermentation cost is lowered, and the erythromycin fermentation titer and the erythromycin A synthesis are improved.

Owner:宁夏泰瑞制药股份有限公司

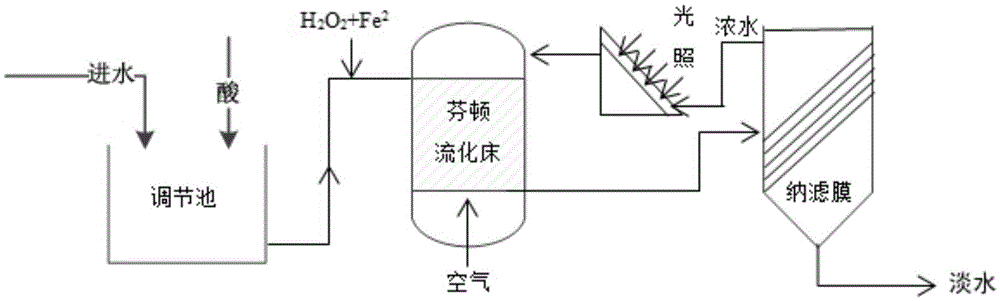

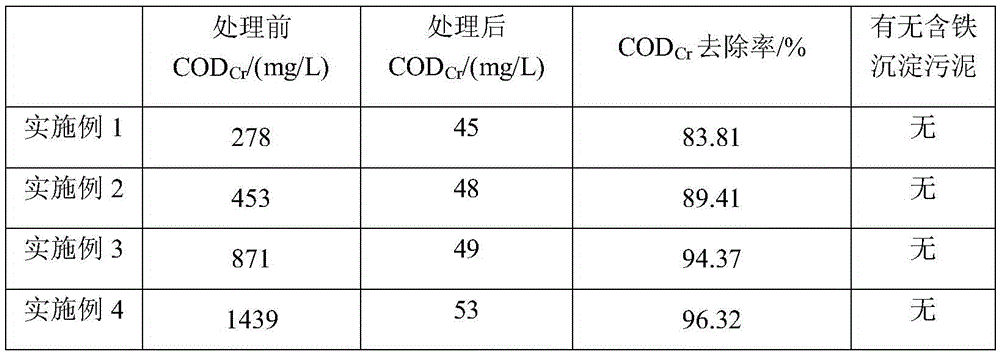

Treatment method of antibiotic production wastewater

ActiveCN105645639AReduce usagePrevent the occurrenceWater treatment compoundsMultistage water/sewage treatmentPhotocatalytic reactionSludge

The embodiment of the invention discloses a treatment method of antibiotic production wastewater. The method includes the steps of conveying antibiotic production wastewater to a Fenton oxidation device to be subjected to Fenton oxidation after the pH of antibiotic production wastewater is regulated to be acidic, conveying wastewater subjected to Fenton oxidation to a membrane separation reactor to be subjected to membrane separation, conveying concentrated water obtained through membrane separation to a photocatalysis reactor, conducting photocatalysis reduction reaction so that Fe3+ in concentrate water can be reduced into Fe2+, discharging or recycling fresh water obtained through membrane separation, conveying concentrated water obtained after the photocatalysis reduction reaction to the Fenton oxidation device, and continuing to process antibiotic production wastewater. Ferrite is added only at the start stage, only pH value regulation and hydrogen peroxide addition are conducted in the later period, and therefore generation of sludge containing iron precipitate is eradicated. Sludge containing iron precipitate does not need to be additionally processed, the processing cost can be reduced, ferrite needs to be added only at the start stage, the use amount of ferrite can be quite small, and the processing cost is further reduced.

Owner:POTEN ENVIRONMENT GRP +1

Method for improving yield of streptomyces antibiotics and plasmids thereof

InactiveCN102719388AHigh purityIncrease productionBacteriaMicroorganism based processesStreptomycesAntibiotic Y

The invention discloses a method for improving yield of streptomyces antibiotics in the technical field of bio-medicine. The method comprises the following steps of: constructing corresponding integrated expression plasmids pFMetK, pFVgb, pFAdpA, pFMV, pFMA and pFMVA of metK genes and / or vgbS genes and / or adpA-C genes, and transferring the integrated expression plasmids to streptomyces ZYJ-6 so as to improve the yield. Exogenous genes such as regulatory genes and precursor synthesis genes are simultaneously introduced into antibiotic producing strains to increase the yield of the antibiotics.

Owner:SHANGHAI JIAO TONG UNIV

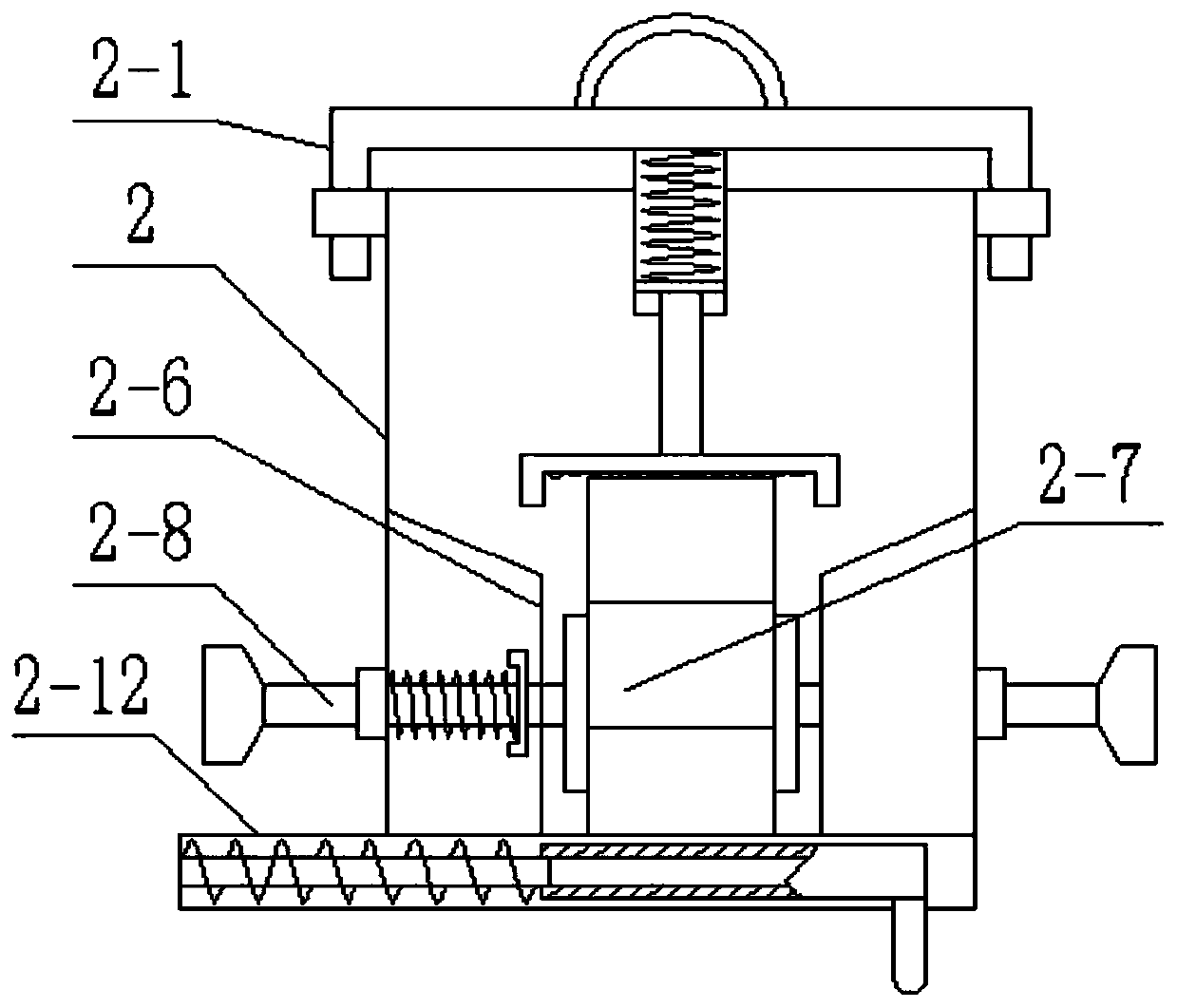

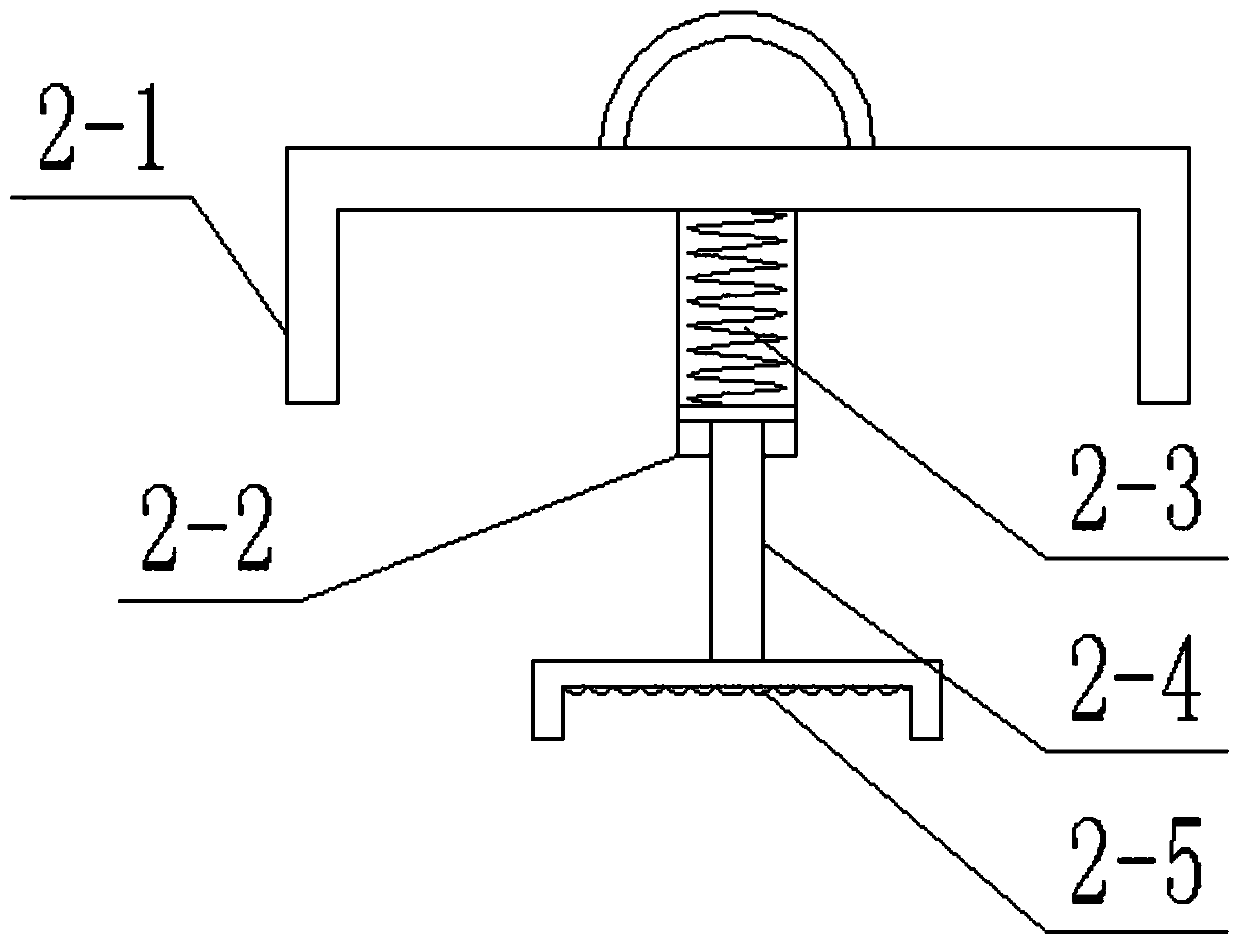

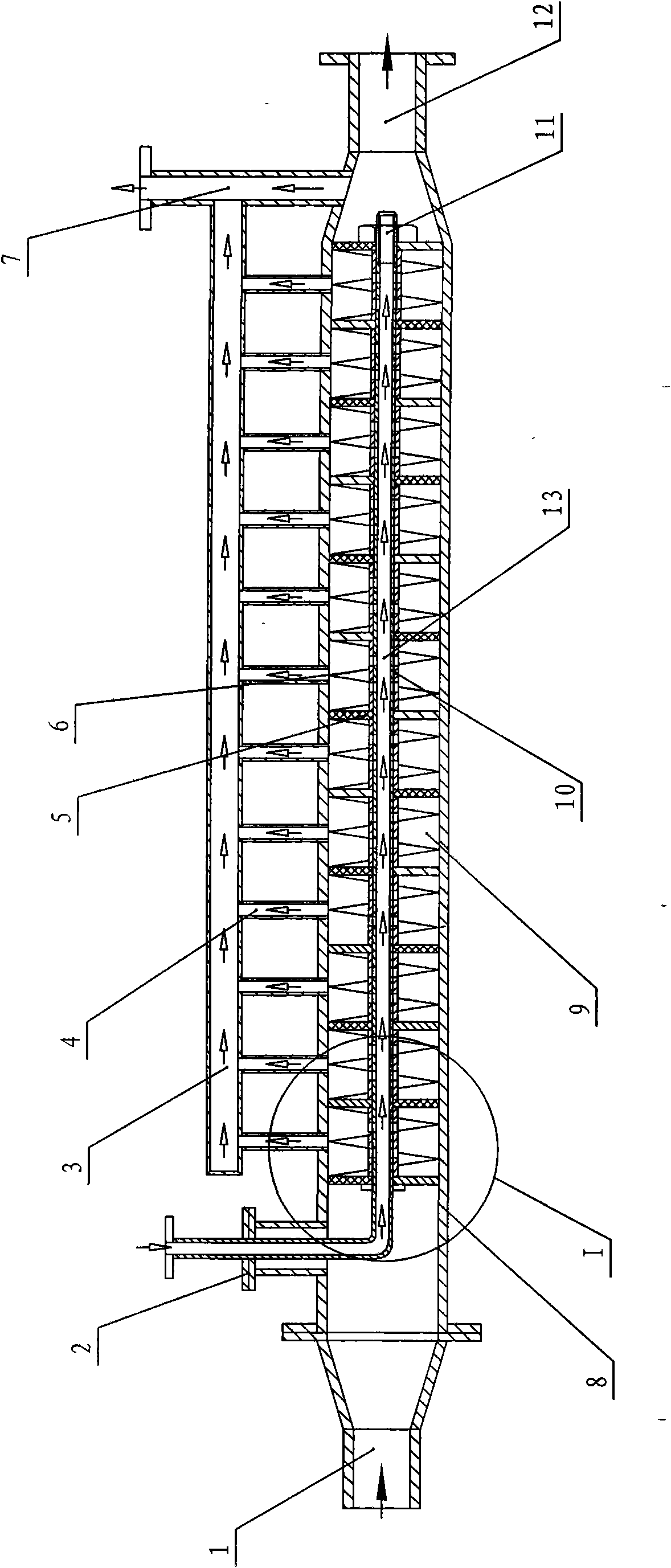

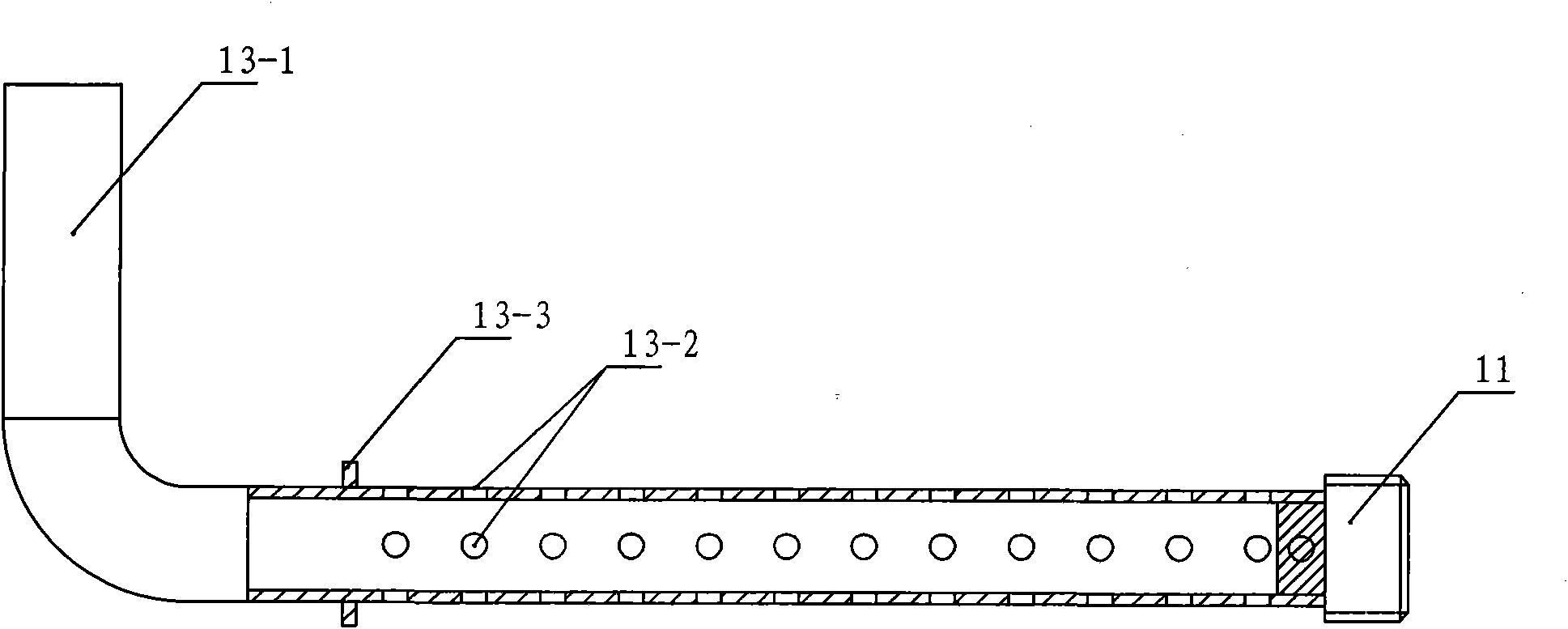

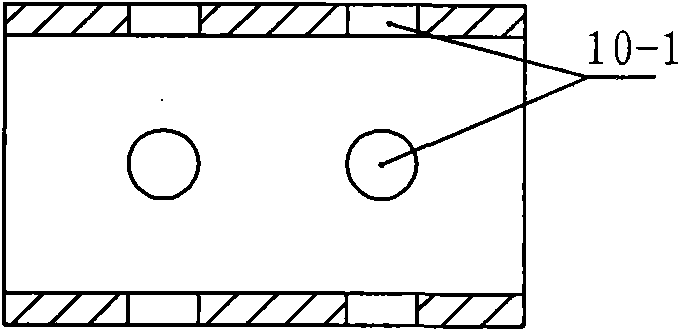

Extraction multi-chamber mixer used in antibiotic production

ActiveCN101890253AImprove split blendingIncrease turbulence velocityFlow mixersLiquid solutions solvent extractionEngineeringMixing chamber

The invention relates to an extraction multi-chamber mixer used in antibiotic production. The mixer of the invention comprises a cylindrical shell, wherein the two ends of the cylindrical shell are provided with a charge tube and a discharge tube; a certain number of dummy plates are arranged in the shell to divide the interior of the shell into multiple mixing chambers; half of the dummy plates are entities, and the other half of the dummy plates are sieve plates distributed with through holes; the adjacent mixing chambers are communicated through the sieve plates; a central tube is arranged at the middle part of the dummy plates in a penetrating mode, and the length of the central tube is matched with that of the cylindrical shell; one end of the central tube, which is close to the discharge tube, is enclosed; the other end of the central tube, which is close to the charge tube, penetrates out from the cylindrical shell through a bent tube; all the parts of the central tube, which are in the mixing chambers, are provided with air hole; and the upper part of each mixing chamber is provided with an exhaust tube. The mixer has high mixing efficiency and can fully mix materials and improve extracting speed and effect.

Owner:濮阳泓天威药业有限公司

Antibiotic tablet mixing and forming device

InactiveCN110154437APrevent drynessSolve the hazardRotary stirring mixersTransportation and packagingBiochemical engineeringAntibiotic Y

The invention relates to an antibiotic related device, in particular to an antibiotic tablet mixing and forming device which comprises a shell, a partition plate, a mixing box, a forming control box and a stamping box. By adopting the antibiotic tablet mixing and forming device, the problems that mixing and then split charging forming are needed during production and preparation of antibiotics; drying of raw materials needs to be ensured during processing; manual mixing, split charging and then forming are adopted, and the raw materials of the antibiotics are directly contacted due to manual operation to cause pollution of the raw materials during production and preparation of the antibiotics; drying of the raw materials cannot be ensured; and harms can also be caused to a body of an operator as the operator is directly exposed to and contacts the raw materials of the antibiotics for a long time can be solved.

Owner:普瑞赛森(山东)生物医学科技有限公司

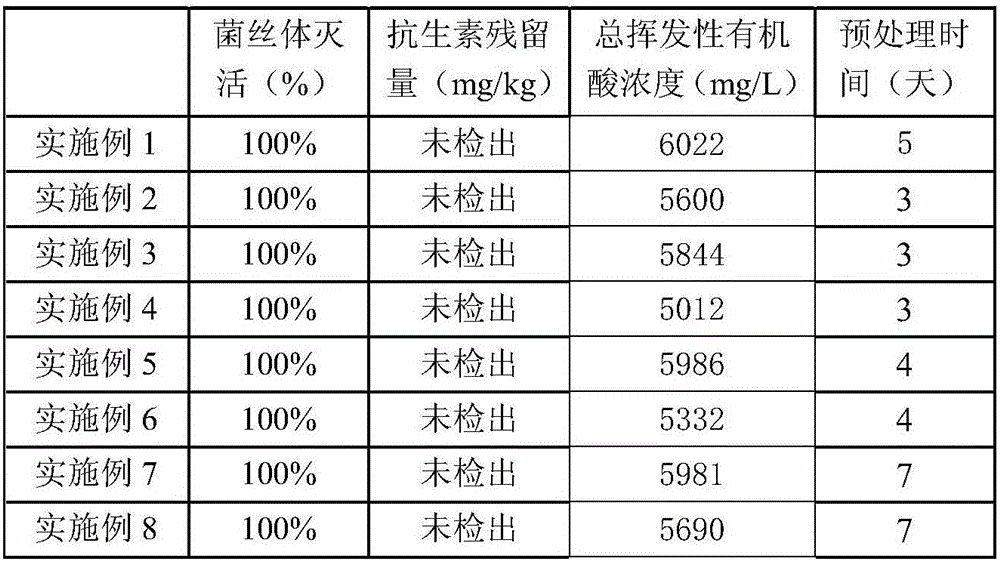

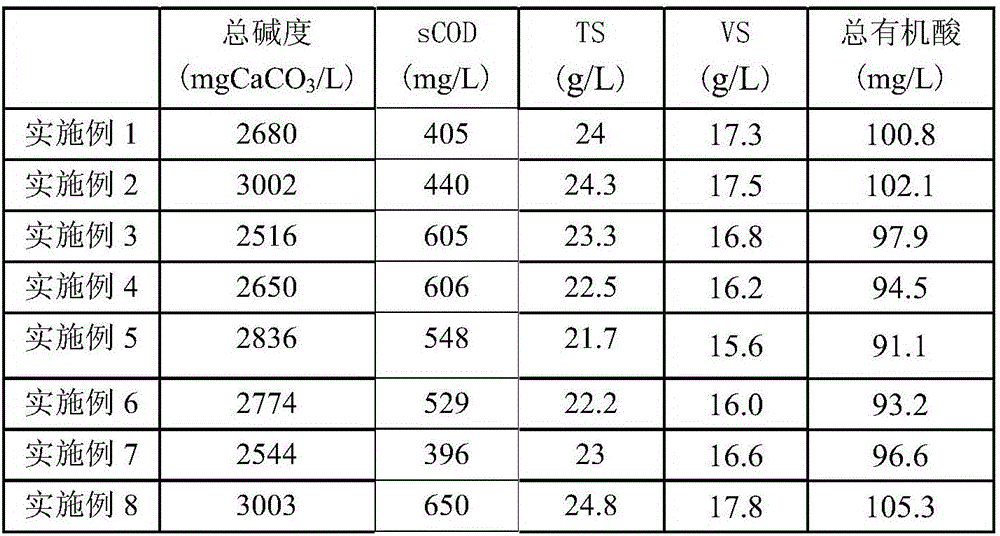

Pretreatment method of ferment antibiotic fungi residues

ActiveCN106480104AImprove metabolic activityAccelerated hydrolysis and acidificationWaste based fuelFermentationHigh concentrationMicroorganism

The invention discloses a pretreatment method of ferment antibiotic fungi residues. The pretreatment method comprises ultrahigh temperature reinforced acidogenic fermentation treatment of the ferment antibiotic fungi residues. Thermophilic hydrolysis acid-forming bacteria are used for performing high temperature anaerobic digestion treatment on the ferment antibiotic fungi residues, so that the fungi residues are hydrolyzed and acidified, antibiotic producing bacteria in the fungi residues are inactivated, and retained antibiotics are degraded. The fungi residues pretreated through the method can be directly subjected to subsequent biochemical treatment after being subjected to antibiotic removal. According to the method disclosed by the invention, the antibiotic producing bacteria can be completely killed, the antibiotics in the fungi residues can be removed, inhibition of high-concentration antibiotics to microorganisms is reduced, the difficulty in treatment of the fungi residues based on the subsequent biochemical method is reduced, generation of drug-resistant fungi and drug-resistant genes in the subsequent biochemical treatment is reduced, the harmless treatment efficiency of the antibiotic fungi residues is improved, and environmental protection is facilitated.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

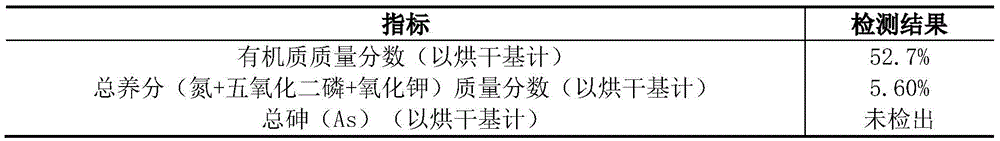

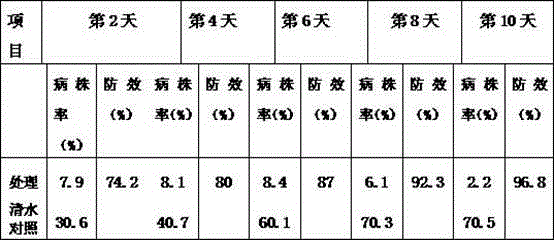

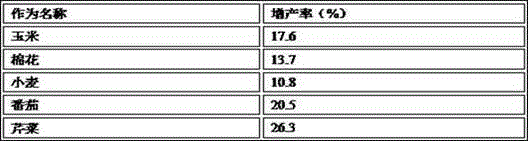

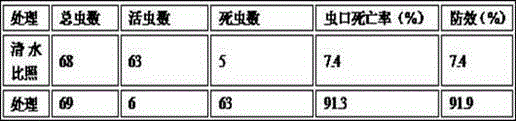

Medium-trace element environmental protection fertilizer with characteristics of plant disease and insect pest resistance and high stress resistance

InactiveCN105347905AIncrease productionImprove qualityFertilising methodsFertilizer mixturesInsect pestPlant disease

The present invention relates to a medium-trace element environmental protection fertilizer with characteristics of plant disease and insect pest resistance and high stress resistance, particularly to a green environmental protection fertilizer comprising a mixture of azadirachtin, matrine, brassinolide and the like and a medium-trace element fertilizer mixture, wherein the fertilizer has effects of effective bacterial killing, prevention and control of the ground and underground plant diseases and insect pests, further has characteristics of no toxic-side effect, no drug residue and no drug resistance, and is the optimal pollution-free product production additive replacing antibiotics, wherein the mixture of azadirachtin, matrine and brassinolide is derived from the natural plant extract. According to the present invention, after using the medium-trace element environmental protection fertilizer, the growth of crops, vegetables and other economic crops is good, the medium-high toxicity chemical pesticide consumption is significantly reduced, the plant diseases and the insect pests are significantly reduced, the farmer pesticide investment is significantly reduced, the yield and the quality of crops are substantially improved, the farmer labor is substantially reduced, the labor activeness is improved, the production efficiency and the benefits of farmers are substantially improved, the food safety is effectively protected, and the purposes of country benefiting and people benefiting are achieved.

Owner:朱崇靖

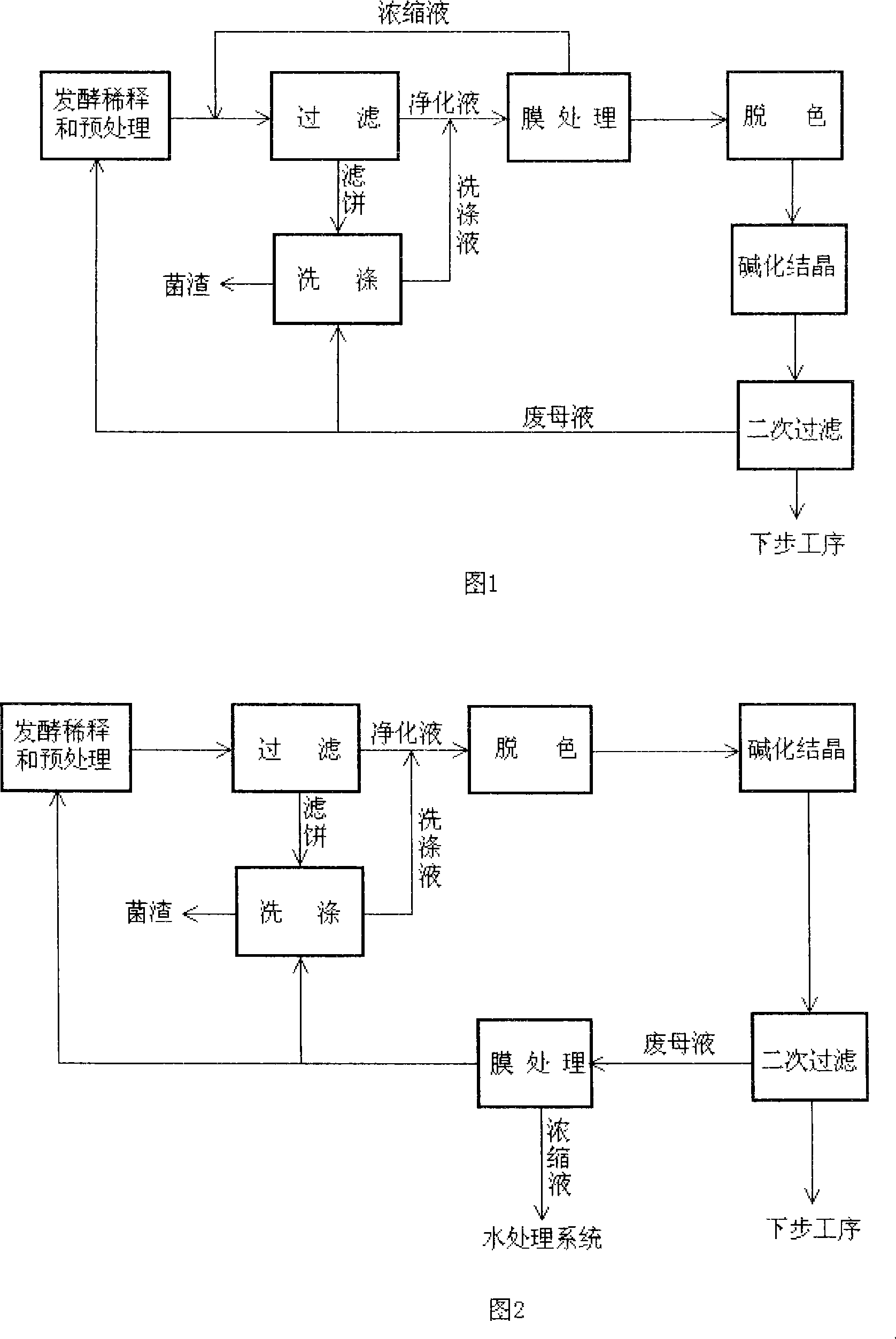

Antibiotic clean production method

InactiveCN101139307AGuaranteed purityGuaranteed reuseSugar derivativesWater/sewage treatment bu osmosis/dialysisPenicillinFiltration

The present invention discloses method of the antibiotic clean production, aiming to solve the problem of the treatment of the wastewater in the antibiotic production process with the existing biosynthesis. The method comprises the dilution of the ferment solution and the pretreatment, the filtration, the bleaching, the alkalization and crystallization, and the secondary filtration step. The present invention is characterized in that the process is added with the membrane processing step. The invention has two operational ways: one way is that the membrane processing step is arranged between the filtration and the bleaching, which means that the purified solution is done with the membrane processing; the other way is that the membrane processing step is arranged after the secondary filtration step, which means that the waste mother solution is done with the membrane processing. The use of the method has the following effects: the saving of the clean water resource, the reduction of the wastewater discharge, the improvement of the recycling rate of the product, the repeated use of the chemical additives, the reduction of the investment and running cost of the corporate environmental treatment, the usefulness to the long-term, continuous and stable development of the relative industry and so on. The method is suitable for the transformation of the antibiotic clean production such as the tetracycline, penicillin, aminoglycoside, macrolide and other antibiotics.

Owner:承德市环境科学研究院

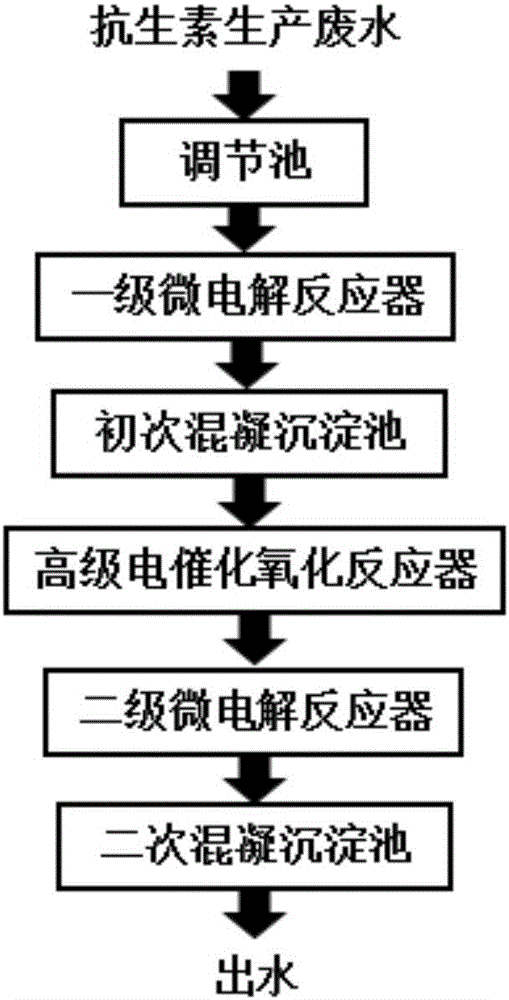

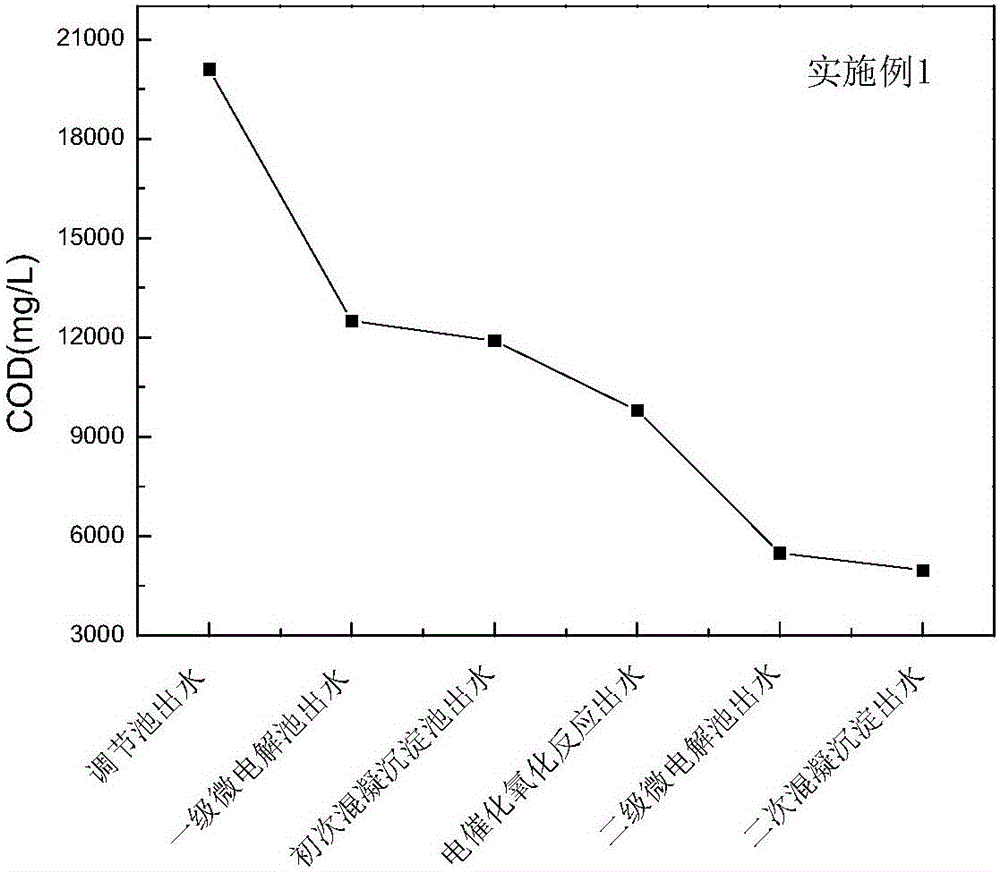

Pretreatment method of antibiotic production waste water

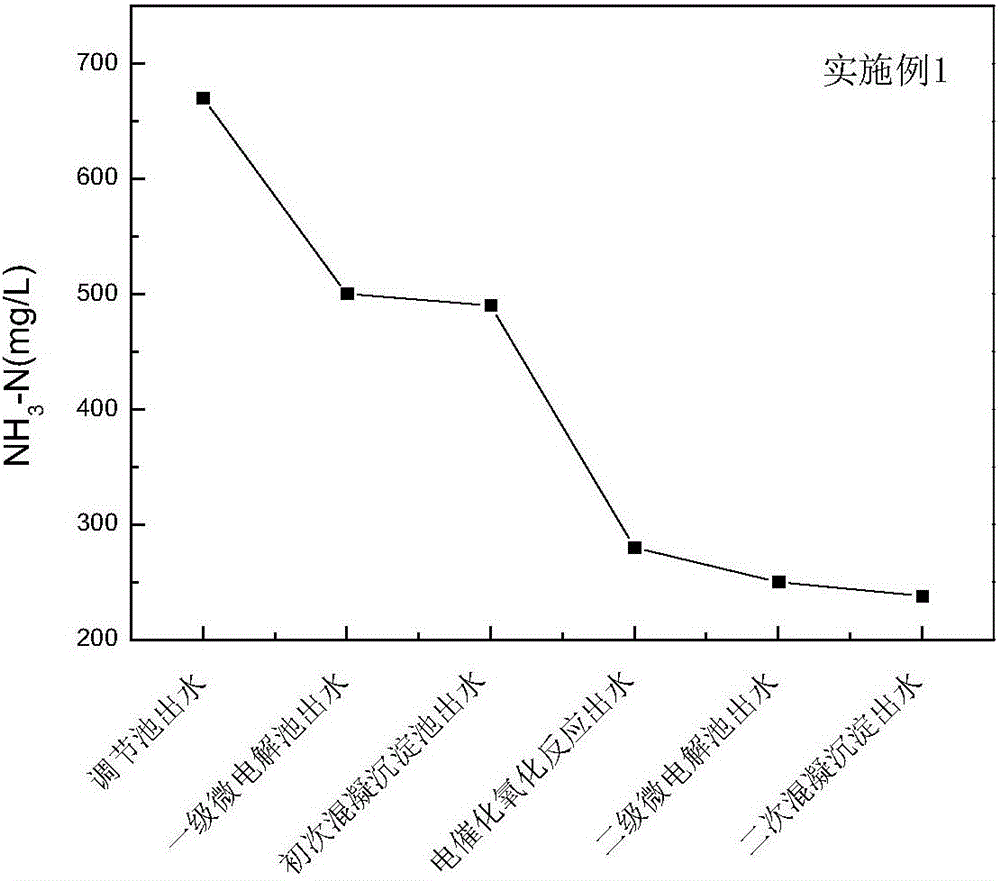

ActiveCN106587445AReduce chromaReduce the pressure of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by neutralisationPretreatment methodElectrolysis

The invention provides a pretreatment method of antibiotic production waste water. The method is characterized in that the method comprises the following steps: (1) first level micro-electrolysis; (2) primary coagulating sedimentation; (3) advanced electrocatalytic oxidation; (4) second level micro-electrolysis; (5) secondary coagulating sedimentation. The method mainly aims at deficiency in the prior waste water pretreatment method in the antibiotic production process, and has the advantages of high treatment efficiency and low treatment cost; COD and chromaticity of antibiotic production waste water treated by the process reach the standard.

Owner:SHENYANG POLYTECHNIC UNIV +1

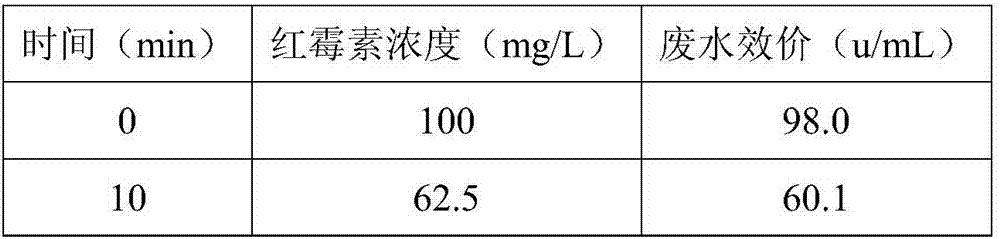

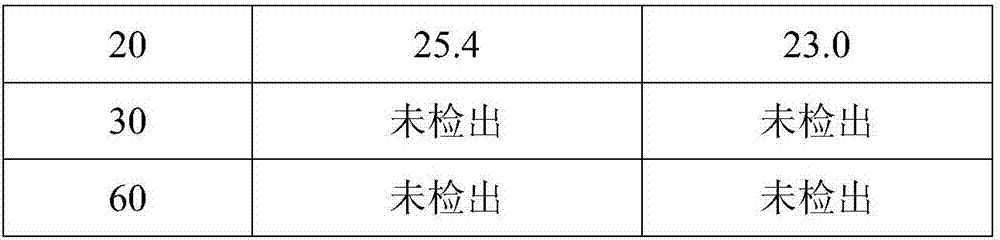

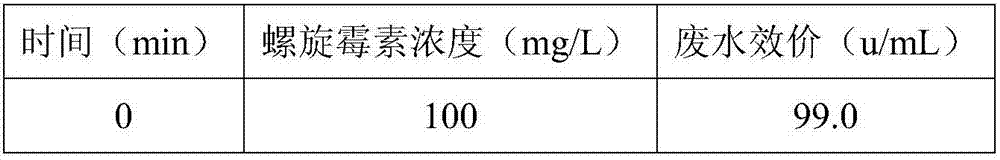

Method for pretreating wastewater obtained from antibiotic production

ActiveCN106986434ALower titerEffective destructionWater treatment parameter controlWater contaminantsHigh concentrationMicroorganism

The invention discloses a method for pretreating wastewater obtained from antibiotic production. The method comprises the following steps: adding a solid base to wastewater obtained from antibiotic production, and hydrolyzing the residual antibiotics in the wastewater obtained from antibiotic production under the action of the solid base. The method provided by the invention has high antibiotic degradation efficiency and low antibiotic residue, and the biological toxicity of the wastewater obtained from antibiotic production is significantly reduced. The antibiotic wastewater pretreated by the method provided by the invention can be directly subjected to the subsequent biochemical treatment. The method provided by the invention can completely remove the antibiotics in the antibiotic wastewater, reduce the inhibition of the high concentration antibiotics to microorganisms, reduce the difficulty of the subsequent biochemical treatment of the antibiotic wastewater, and reduce the production of drug-resistant bacteria and drug-resistant genes in the subsequent biochemical treatment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

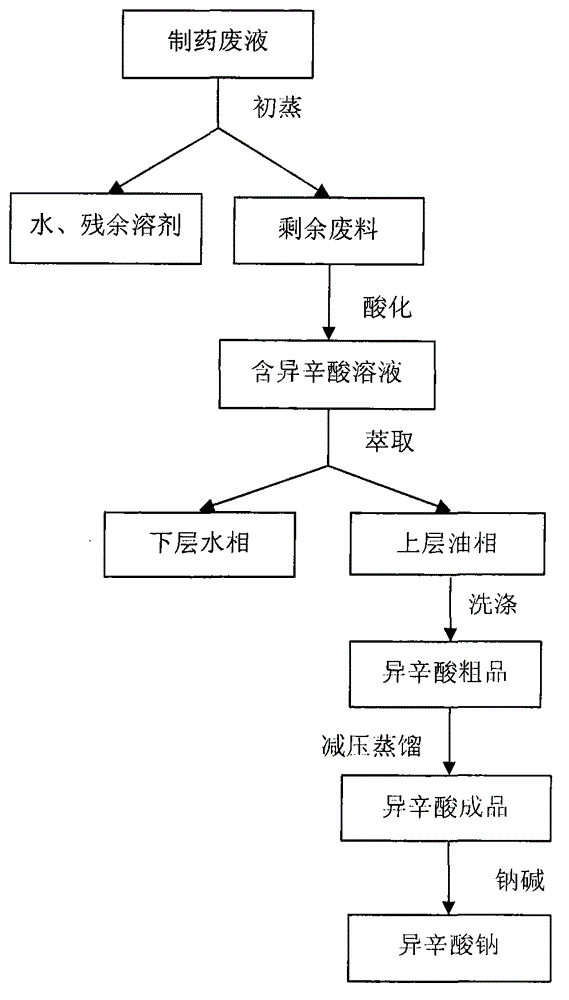

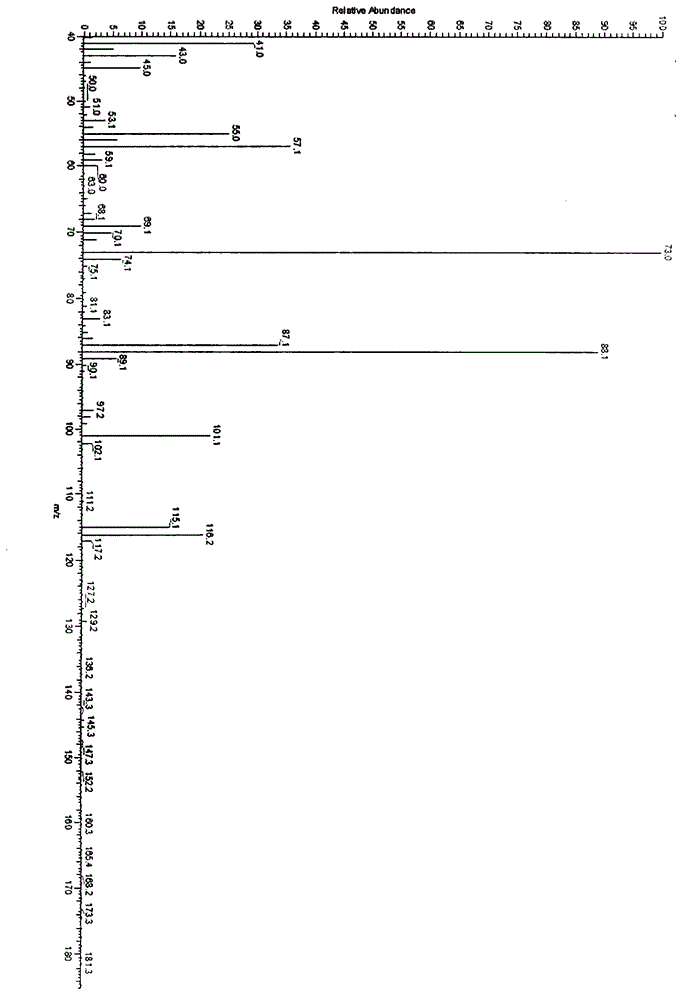

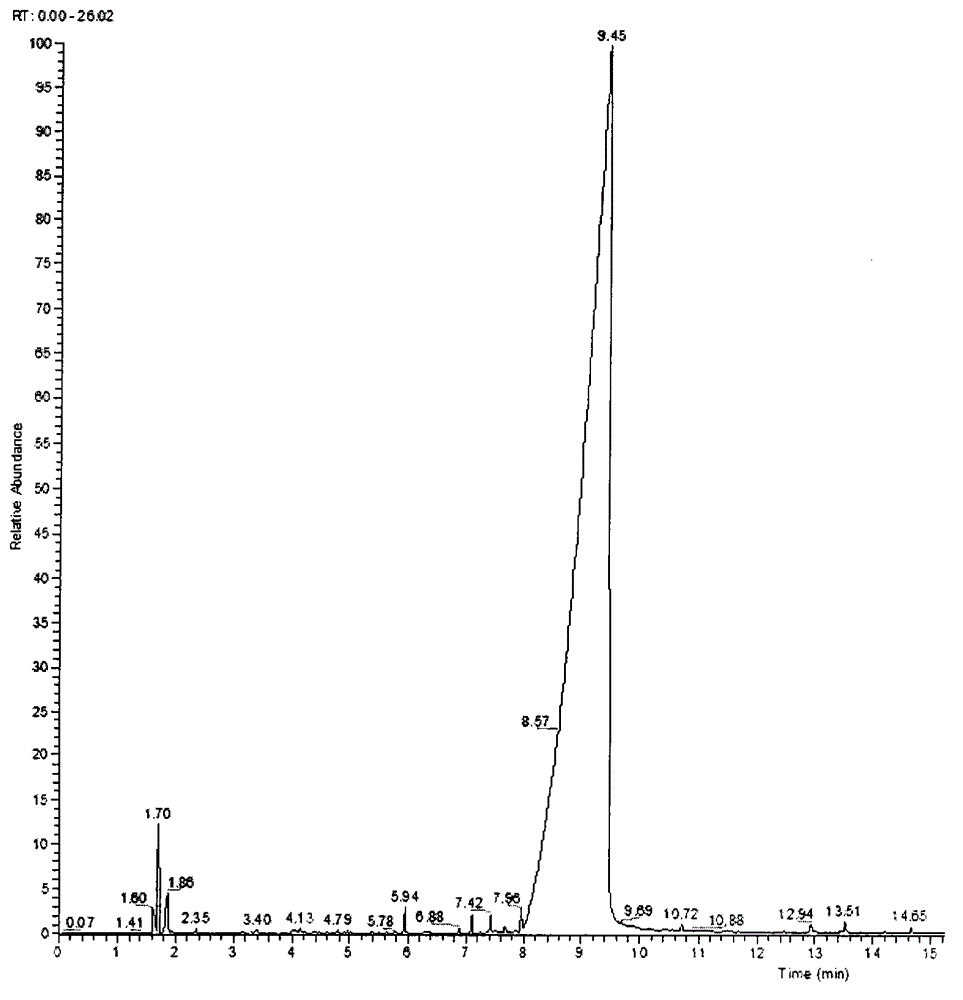

Process for recovering sodium isooctoate from pharmaceutical waste liquor

InactiveCN104672079ALow costEasy to operatePreparation from carboxylic acid saltsOrganic compound preparationDistillationOil phase

The invention discloses a process for recovering isooctanoic acid from pharmaceutical waste liquor and transforming isooctanoic acid into sodium isooctoate. The process comprises the following steps of: removing water and residual organic solvents which are contained in the waste liquor through preliminary distillation, then adding acid for acidification to transform isooctoate contained in a waste material into isooctanoic acid, adding an extracting agent to split the phase of the acidified waste material, and repeatedly washing an oil phase rich in the isooctanoic acid by using distilled water to obtain a crude isooctanoic acid product; then carrying out reduced pressure distillation to obtain a finished isooctanoic acid product; finally reacting the obtained finished isooctanoic acid product with sodium alkali to generate sodium isooctoate. The process disclosed by the invention can be used for effectively recovering isooctanoic acid contained in antibiotic production waste liquor, namely ampicillin sodium, amoxicillin sodium, cephalosporin sodium salt and the like which are obtained through a solvent crystallization method, and transforming isooctanoic acid into salt-forming agent sodium isooctoate capable of being recycled.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com