Antibiotic clean production method

A technology of clean production and antibiotics, applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of long-term, sustained and stable development, unfavorable promotion and application, and inconformity with energy conservation and emission reduction. To achieve the effect of solving the problem of wastewater treatment, reducing the operation cost and reducing the degree of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

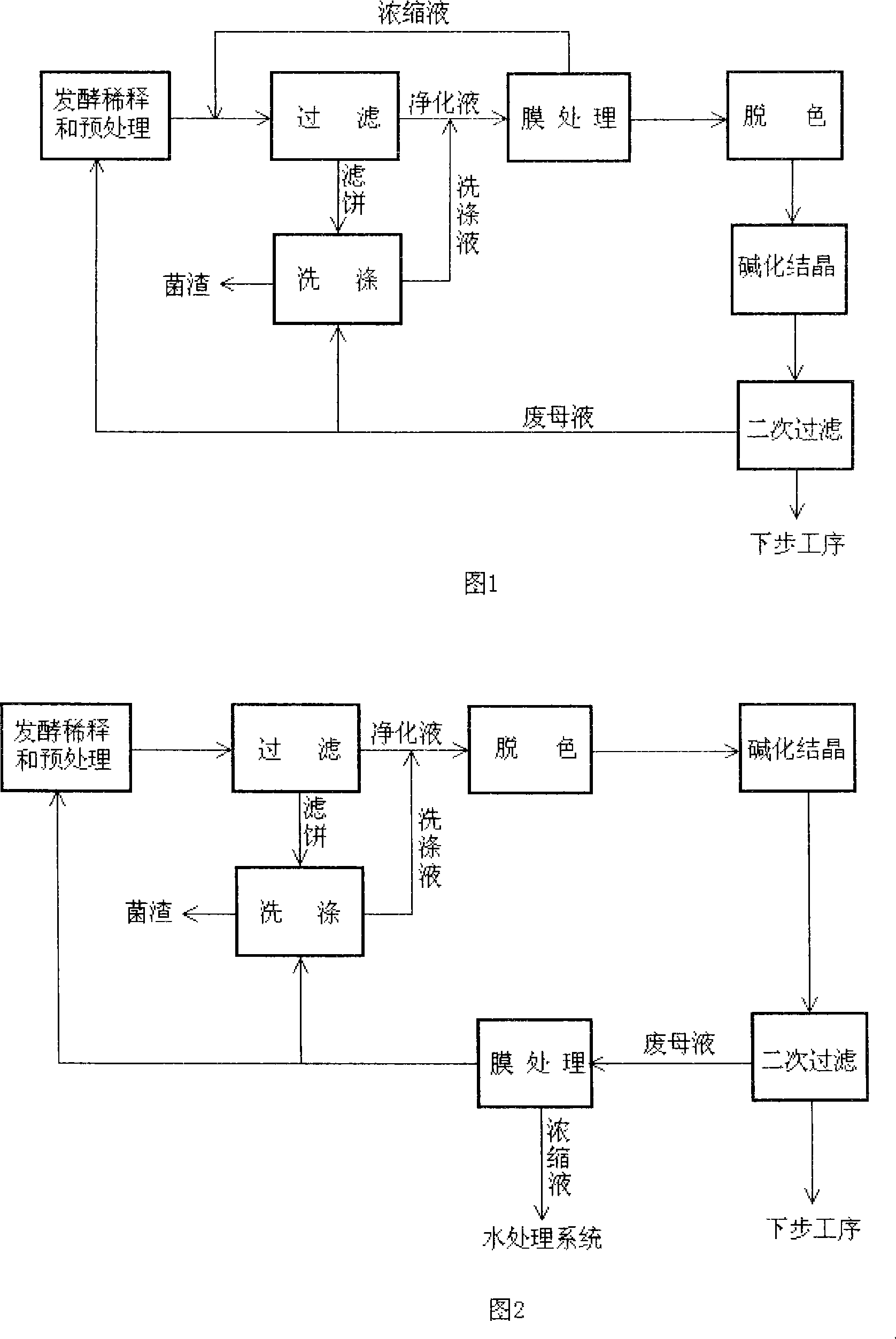

[0014] Taking oxytetracycline clean production as an example below, the present invention will be described in detail in conjunction with the accompanying drawings.

[0015] Oxytetracycline clean production method 1, as shown in Figure 1, the method includes fermentation broth dilution and pretreatment-filtration-decolorization-alkaline crystallization-secondary filtration step, which is characterized in that a membrane is added between the filtration step and the decolorization step The treatment step is to carry out membrane treatment on the purified liquid. After the impurities are removed by the membrane treatment, the concentrated liquid is sent back to the filtration step to continue the filtration treatment. The purified liquid is then subjected to decolorization, alkalization crystallization, secondary filtration, washing, and extraction of wet State oxytetracycline, and then dried into oxytetracycline base finished product. Among them, most of the waste mother liquor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com