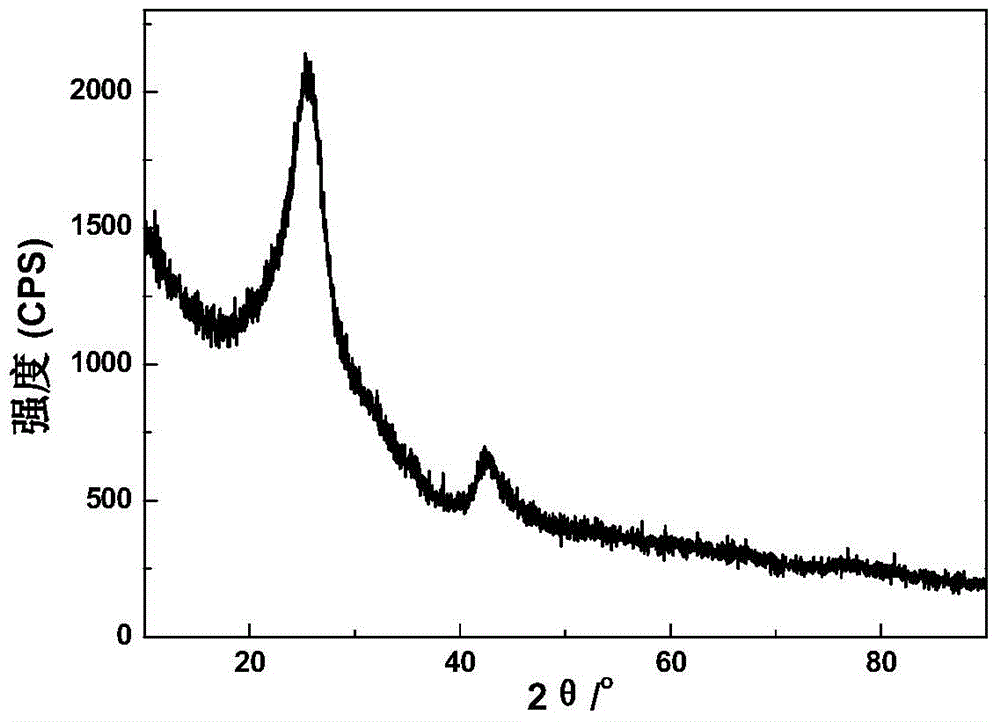

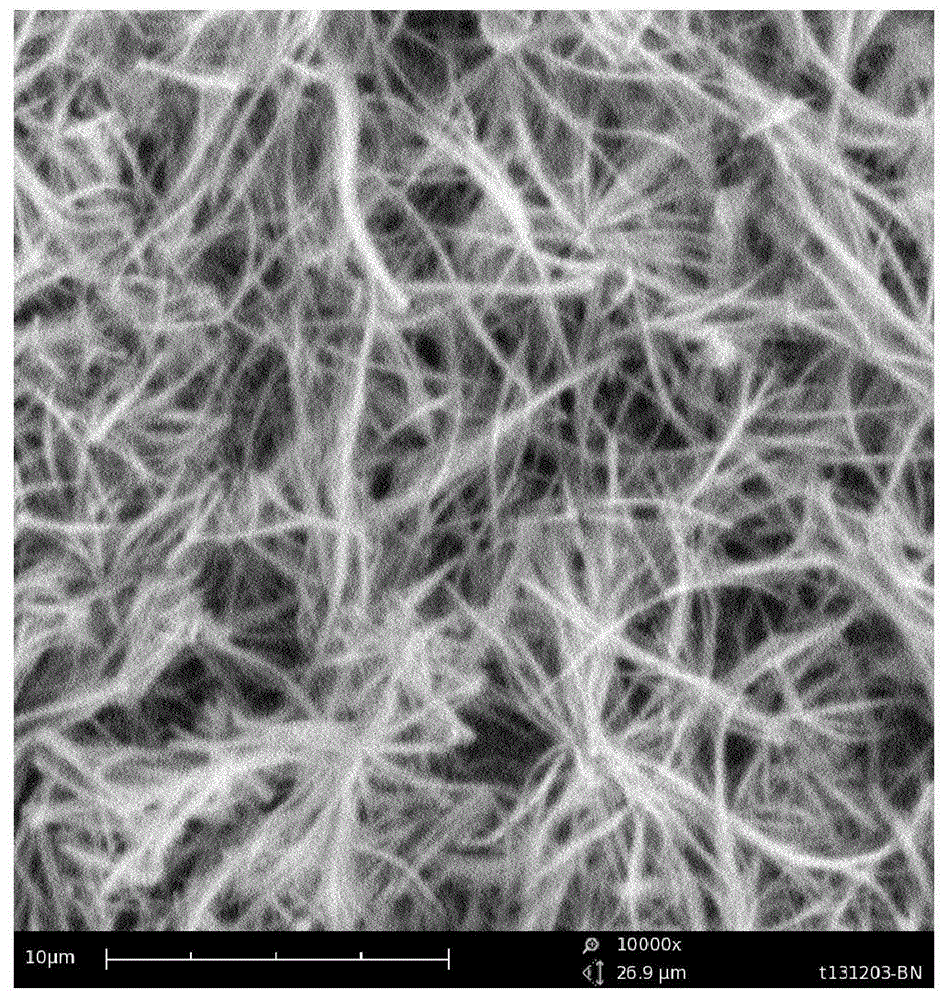

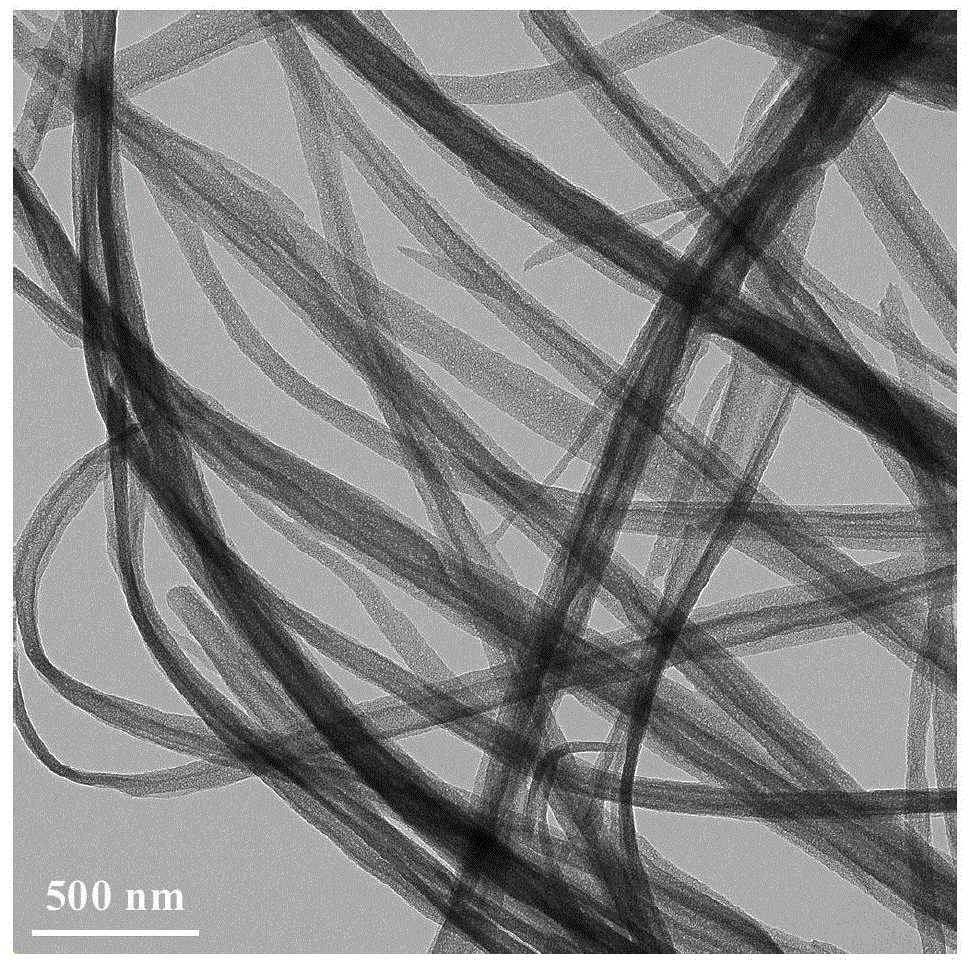

Preparation method of porous boron nitride nanofibers

A technology of nanofibers and boron nitride, which is applied in the direction of chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of inability to obtain nanofibers, high cost, low yield, etc., achieve non-toxic methods, reduce energy consumption and Production cost, effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Dissolve melamine and boric acid in water to obtain a mixed solution of melamine-boric acid-water, the concentration of which is to contain 0.012 grams of melamine and 0.018 grams of boric acid per milliliter of water, then stir for 2 hours and add to a reactor with a reflux device , preheat to 85°C to dissolve and keep it warm for 5 hours; then cool the solution to 25°C at a rate of 1°C per minute, and a white precipitate precipitates, keep the temperature for 8 hours, and filter to obtain a solid precipitate;

[0030] (2) Put the precipitate obtained in step (1) into a 95° C. drying oven and keep it warm for 8 hours to obtain a white solid;

[0031] (3) Add the white solid obtained in step (2) into water, wherein, add 0.006 g of white solid per milliliter of water, then preheat to 85° C. to dissolve it and keep it warm for 2 hours;

[0032](4) Add the solution prepared in step (3) into a spray kettle, spray it into a container equipped with liquid nitrogen, and th...

Embodiment 2、 example 3

[0036] Change the concentration of melamine in step (1) in Example 1 into 0.005 gram and 0.05 gram melamine in every milliliter of water respectively. Other operations are the same as in Example 1, and the product obtained is the same as in Example 1.

Embodiment 4、 example 5

[0038] The concentration of step (1) boric acid in embodiment 1 is changed to contain 0.005 gram, 0.5 gram boric acid respectively in every milliliter of water, and other each operation is all identical with embodiment 1, and the product that obtains is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com