Patents

Literature

4904results about How to "Guaranteed purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

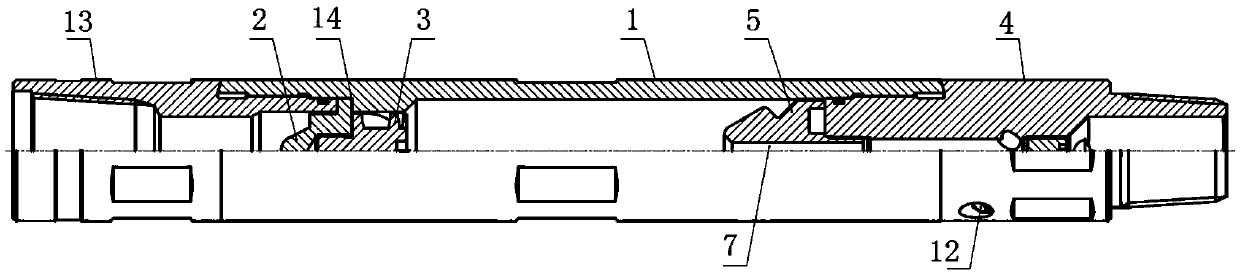

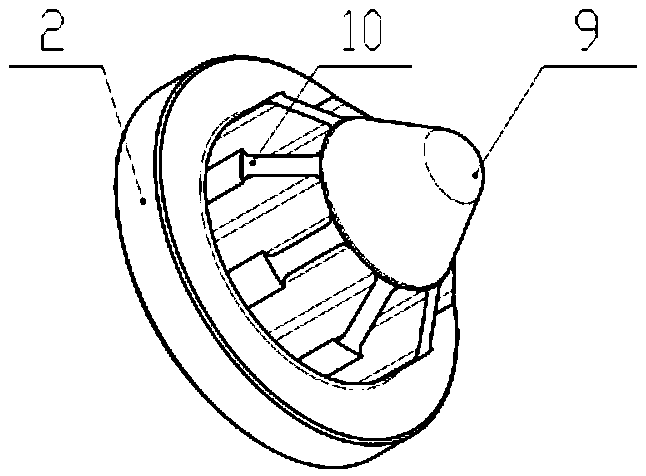

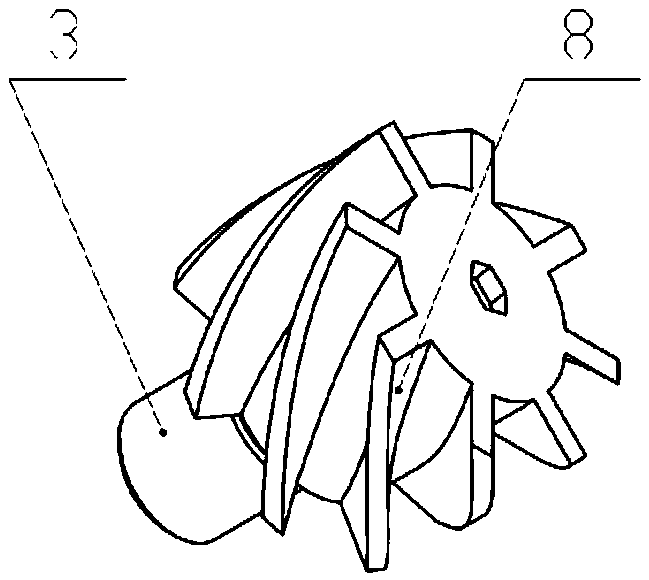

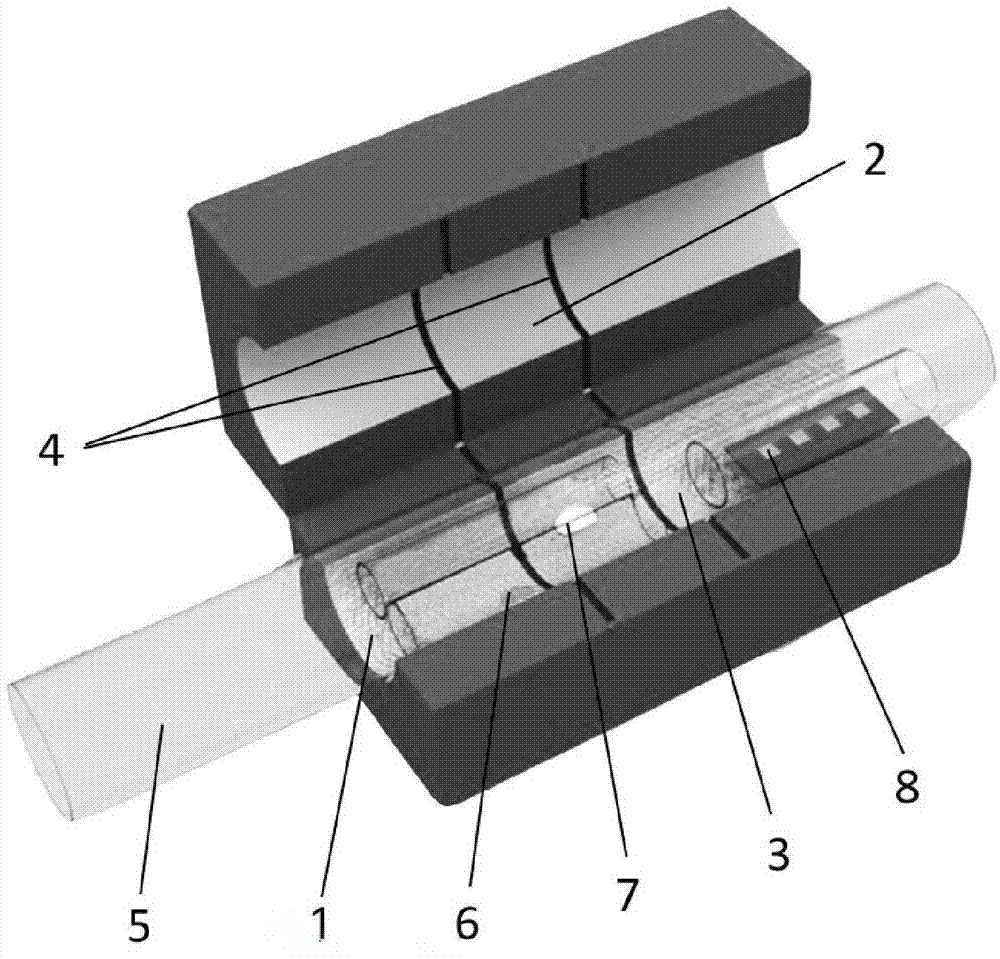

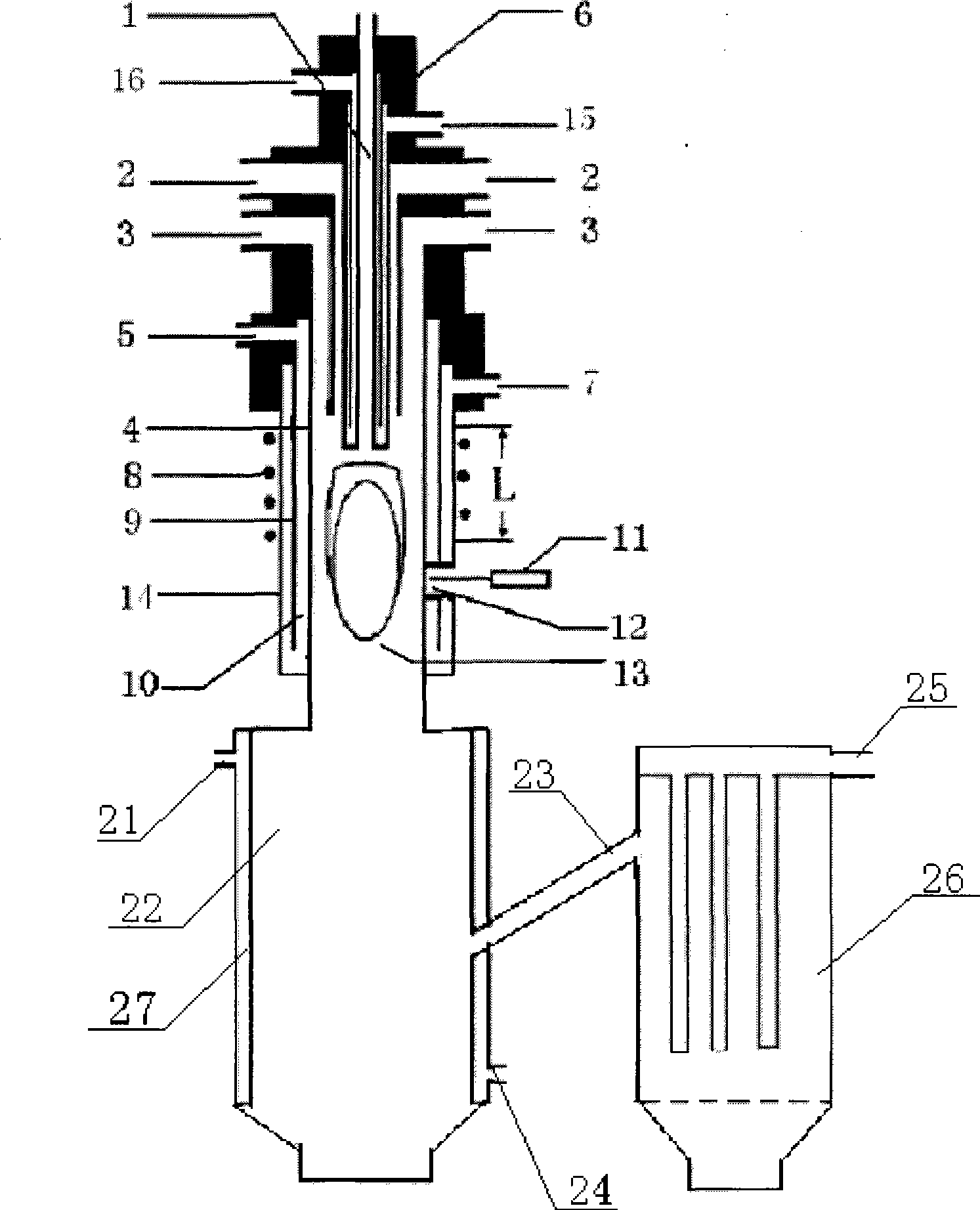

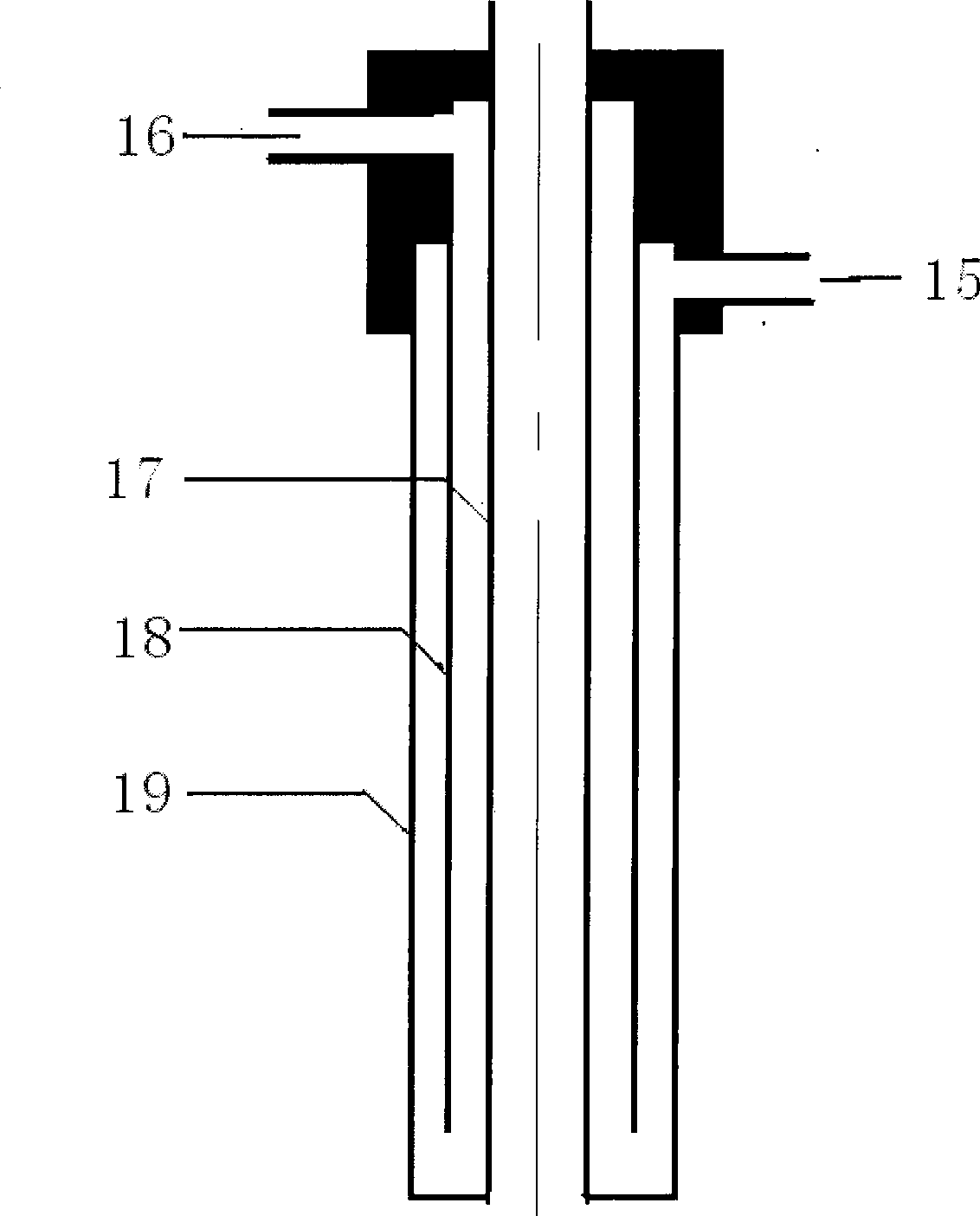

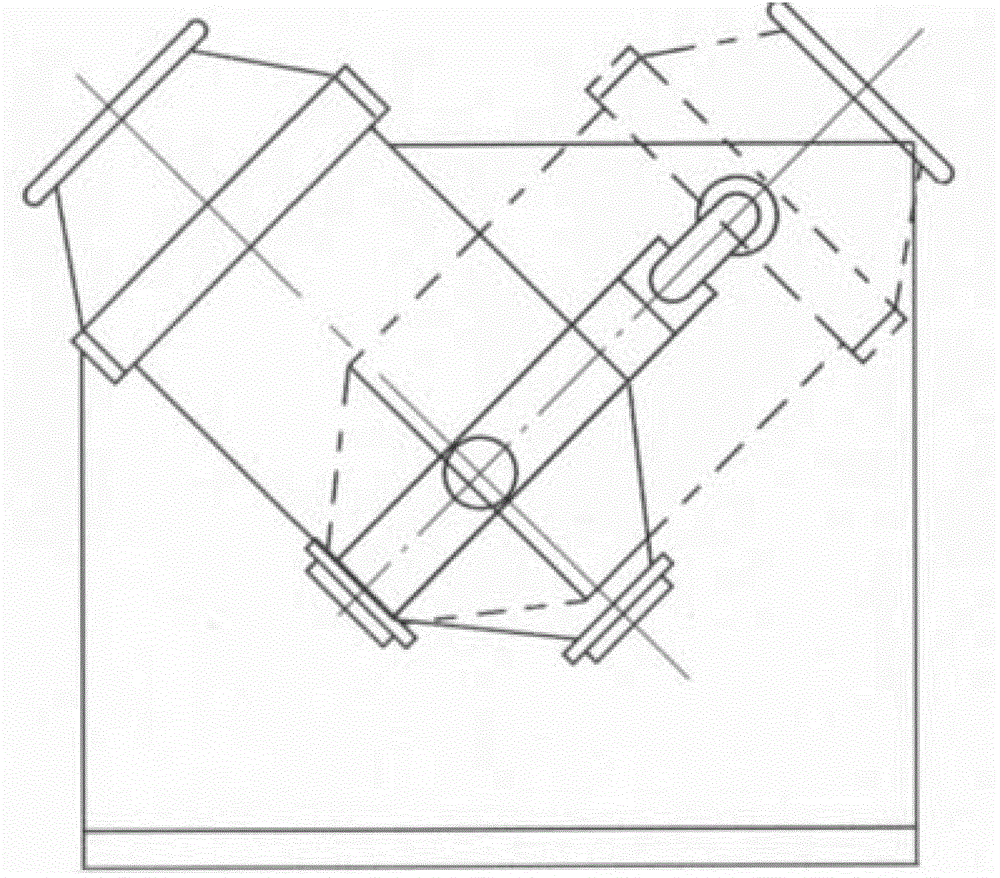

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

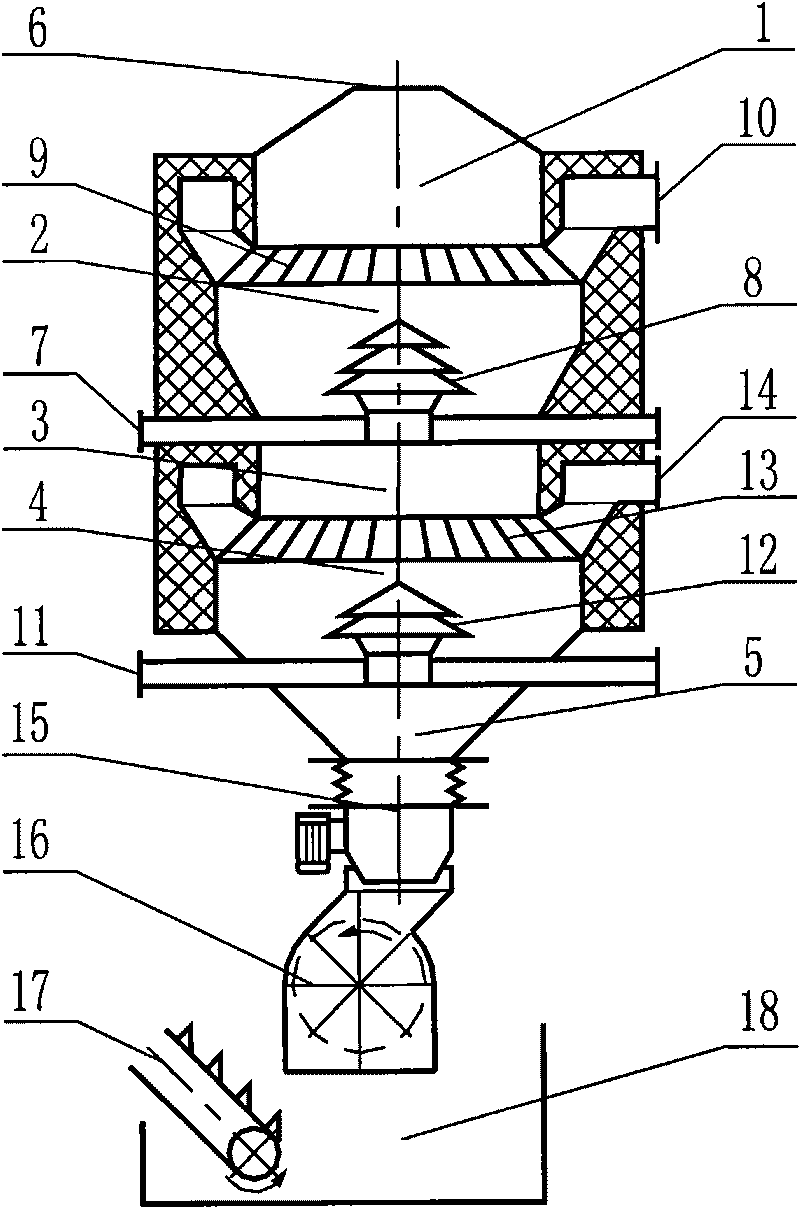

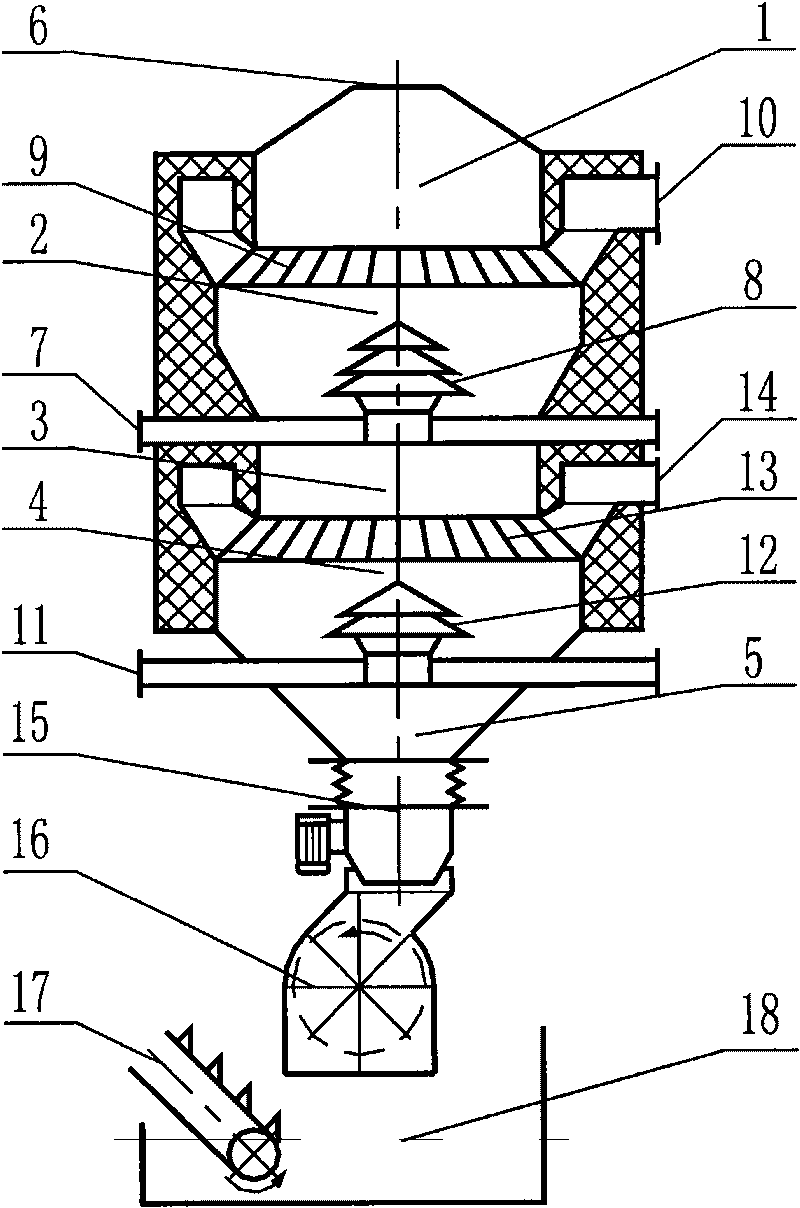

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

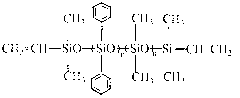

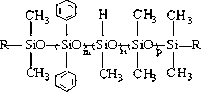

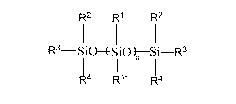

Silicon rubber with high refractive index and high transparency for optical encapsulation and preparation method thereof

ActiveCN103122149AHigh refractive indexImprove mechanical propertiesSemiconductor devicesHydrogenPolymer science

The invention relates to silicon rubber with high refractive index and high transparency for optical encapsulation and a preparation method thereof. The silicon rubber is prepared from a phenyl vinyl polysiloxane component A, a silicon resin component B containing phenyl vinyl, a phenyl component C containing hydrogen polyoxyalkylene, a platinum catalyst component D, a catalytic inhibitor component E, a modified polysiloxane component F, and a water remover component G in a mixing manner. The silicon rubber not only has over 1.50 of refractive index, but also is good in transparency, excellent in adhesion, and stable in performance, can resist heat and ultraviolet radiation for a long period of time, can meet various requirements of LED (light-emitting diode) encapsulation, and is an ideal encapsulation material of the LED. The silicon rubber can be packaged into a bi-component product; the product has good storage stability; and high transparency is still kept after the product is stored for over 6 months.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

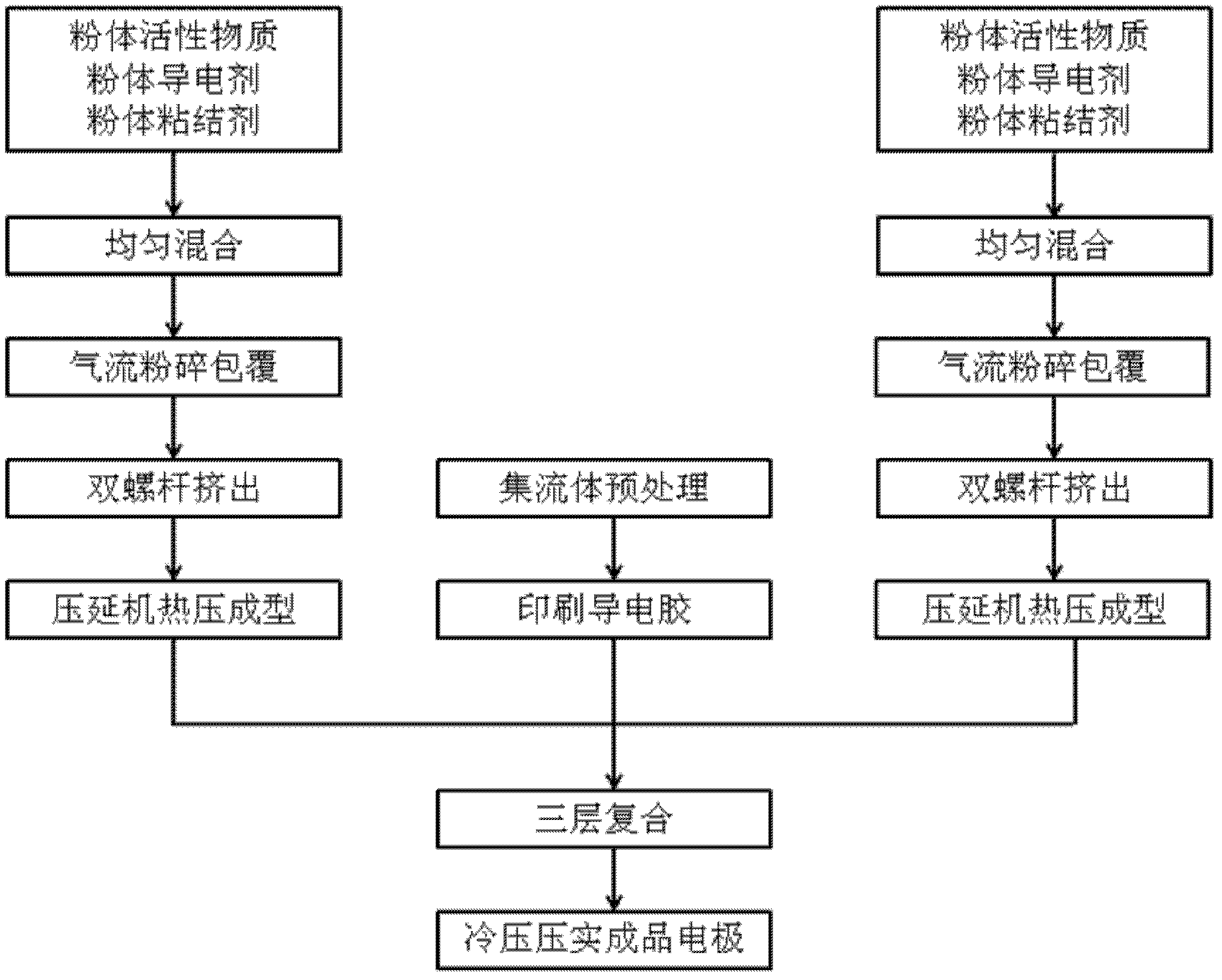

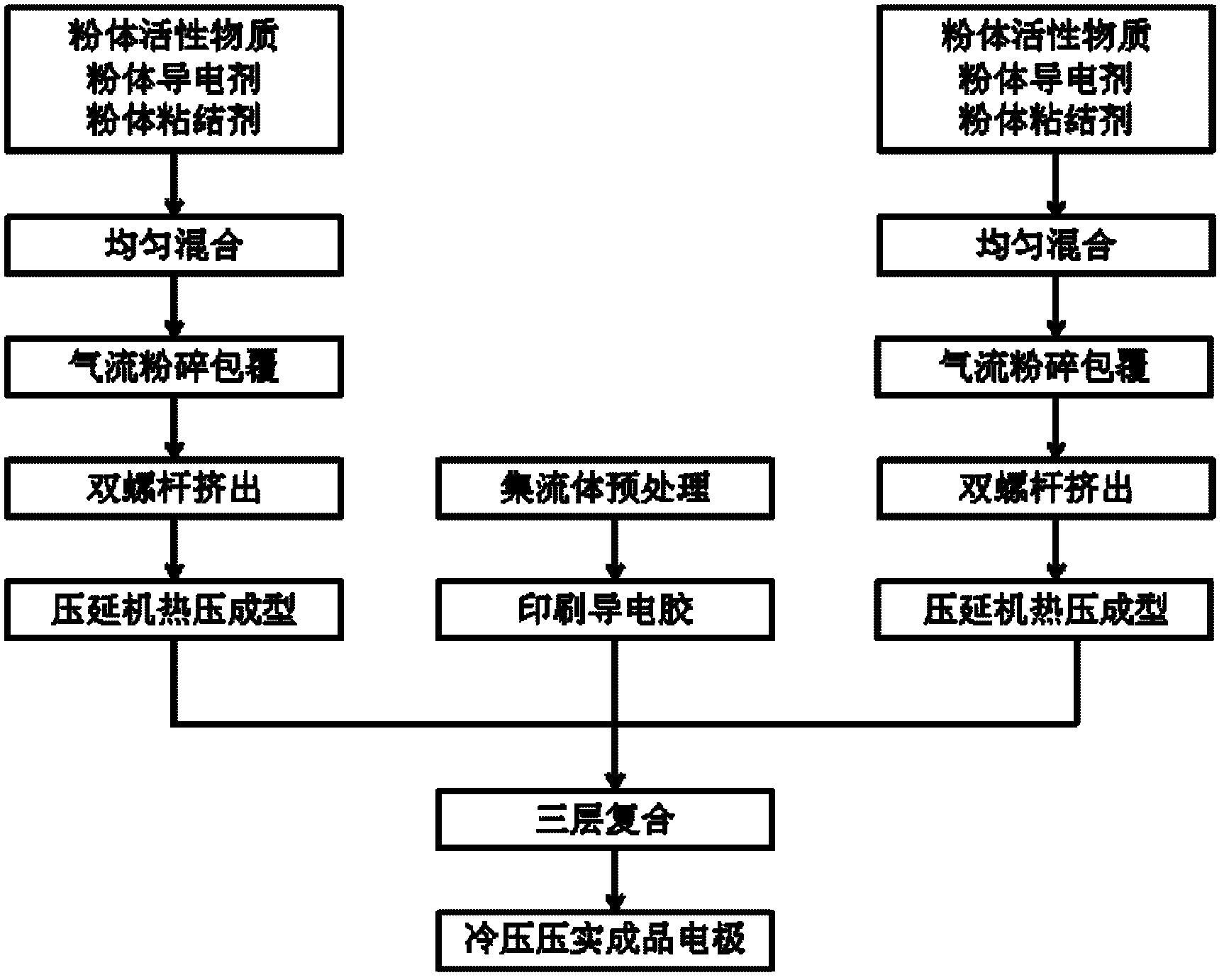

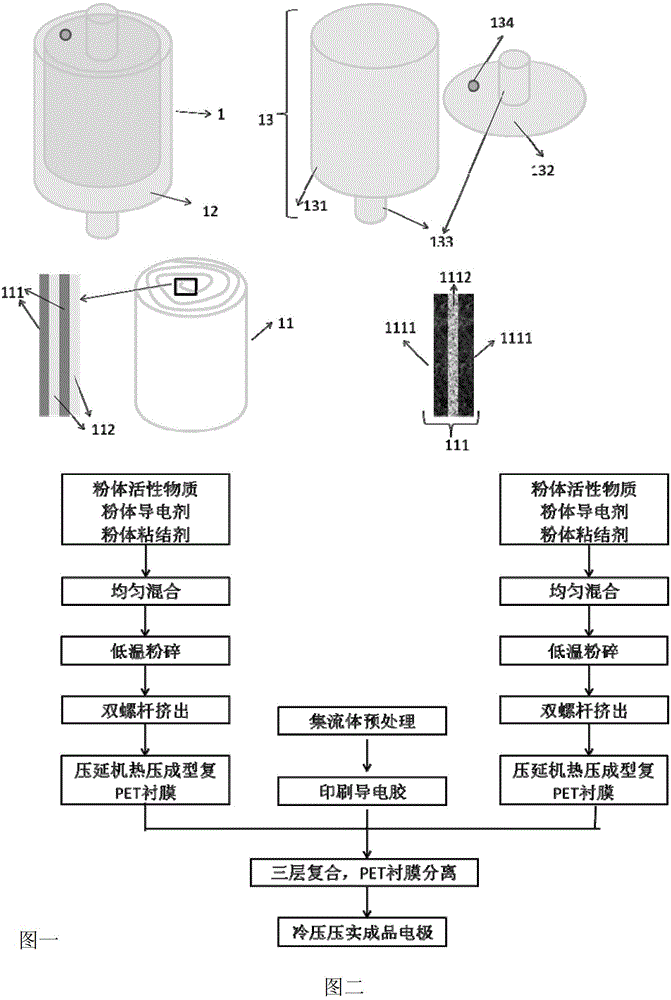

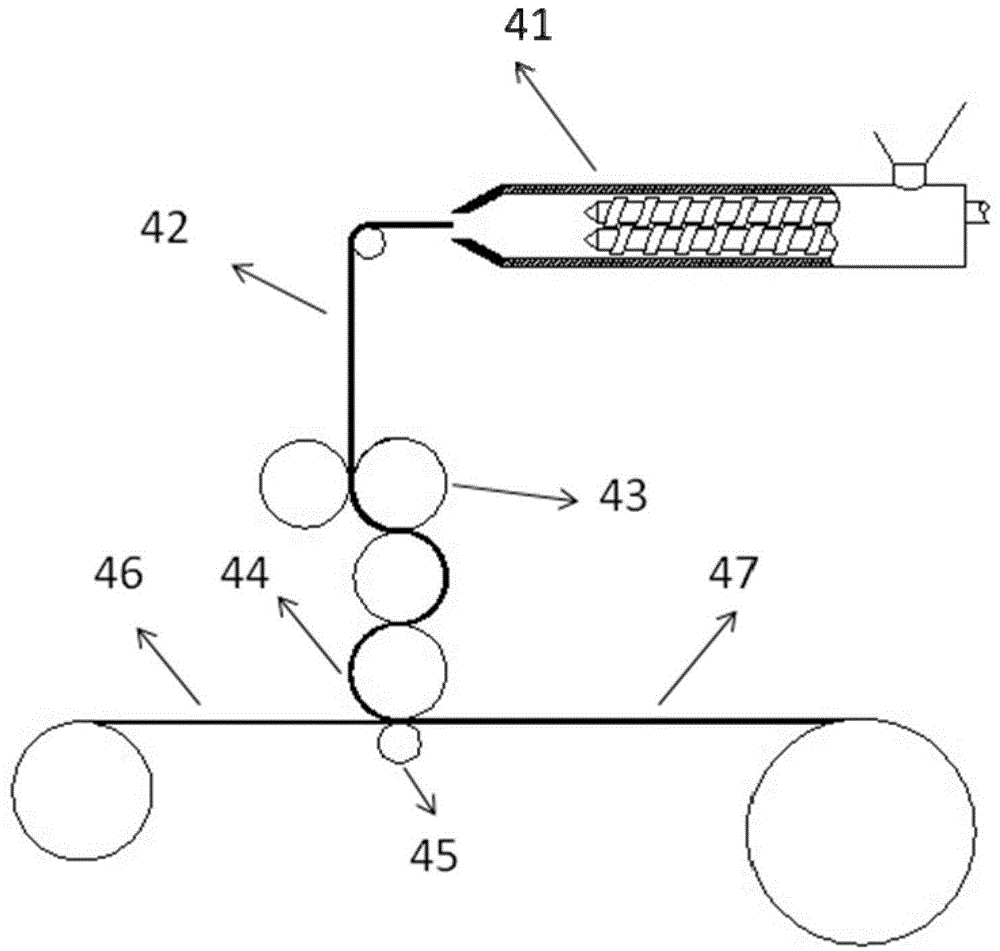

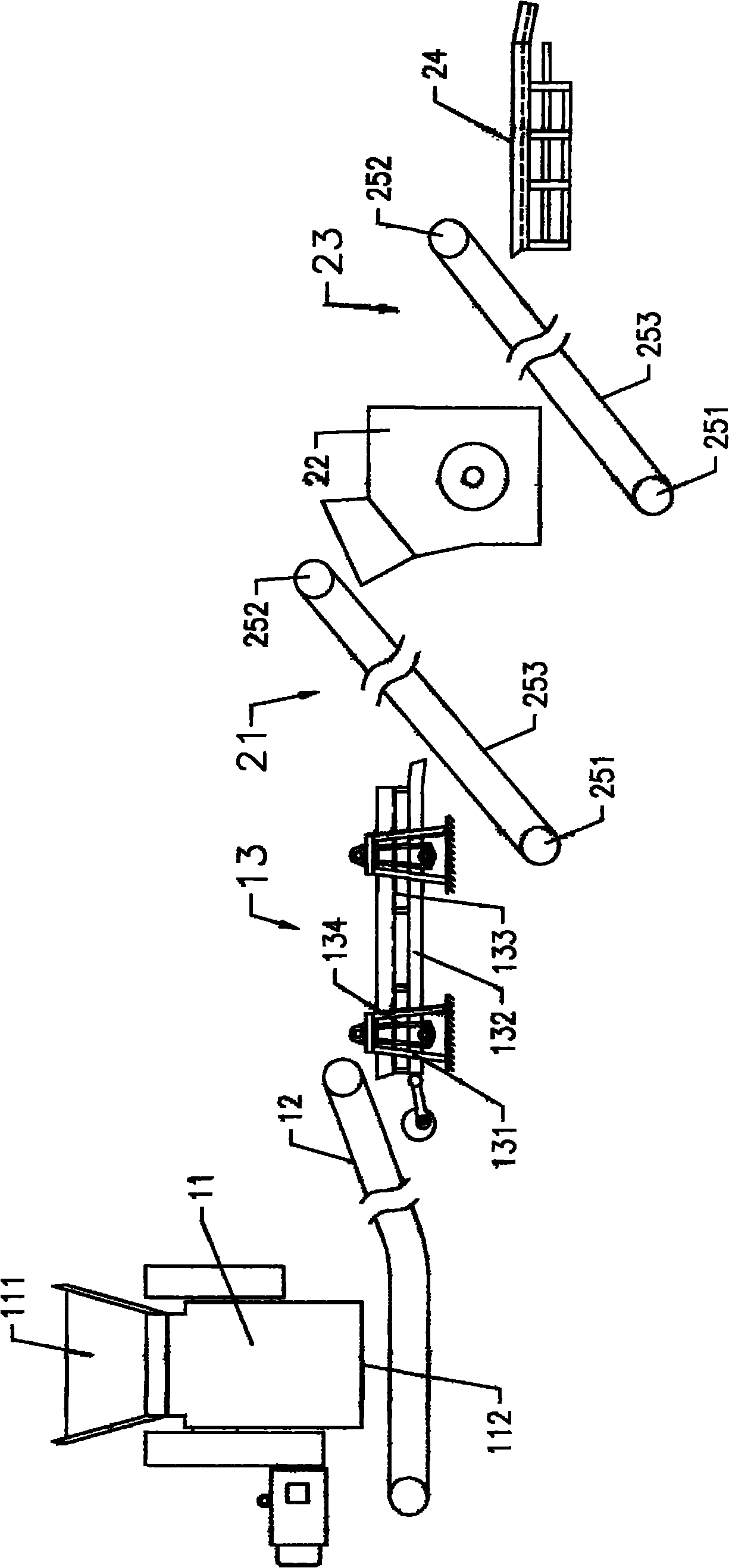

Powder-based electrode forming method

ActiveCN102629681AWell mixedImprove the mixing effectElectrode manufacturing processesHybrid capacitor electrodesAdhesiveCrusher

The invention relates to a powder-based electrode forming method, which comprises the following steps of: uniformly mixing a powder active substance, a powder conductive agent and a powder adhesive through a three-dimensional powder mixer or a zero-gravity powder mixer; crushing through a low-temperature crusher; performing fibrous extrusion forming through a double-screw extruder or an internal mixer / open mill and then achieving target thickness through hot pressing of a calender; and finally performing three-layer compounding with a current collector of a printing conductive adhesive to form an electrode and performing cold rolling to improve the compaction density. According to the powder-based electrode forming method, a method of assisting machining by using a solvent is abandoned, so that the purity of an electrode material is guaranteed to the greatest extent, no energy waste of a drying process or restriction to the time of the drying process exists in a production process, the cost is reduced, the energy loss is reduced, and the working speed is increased.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

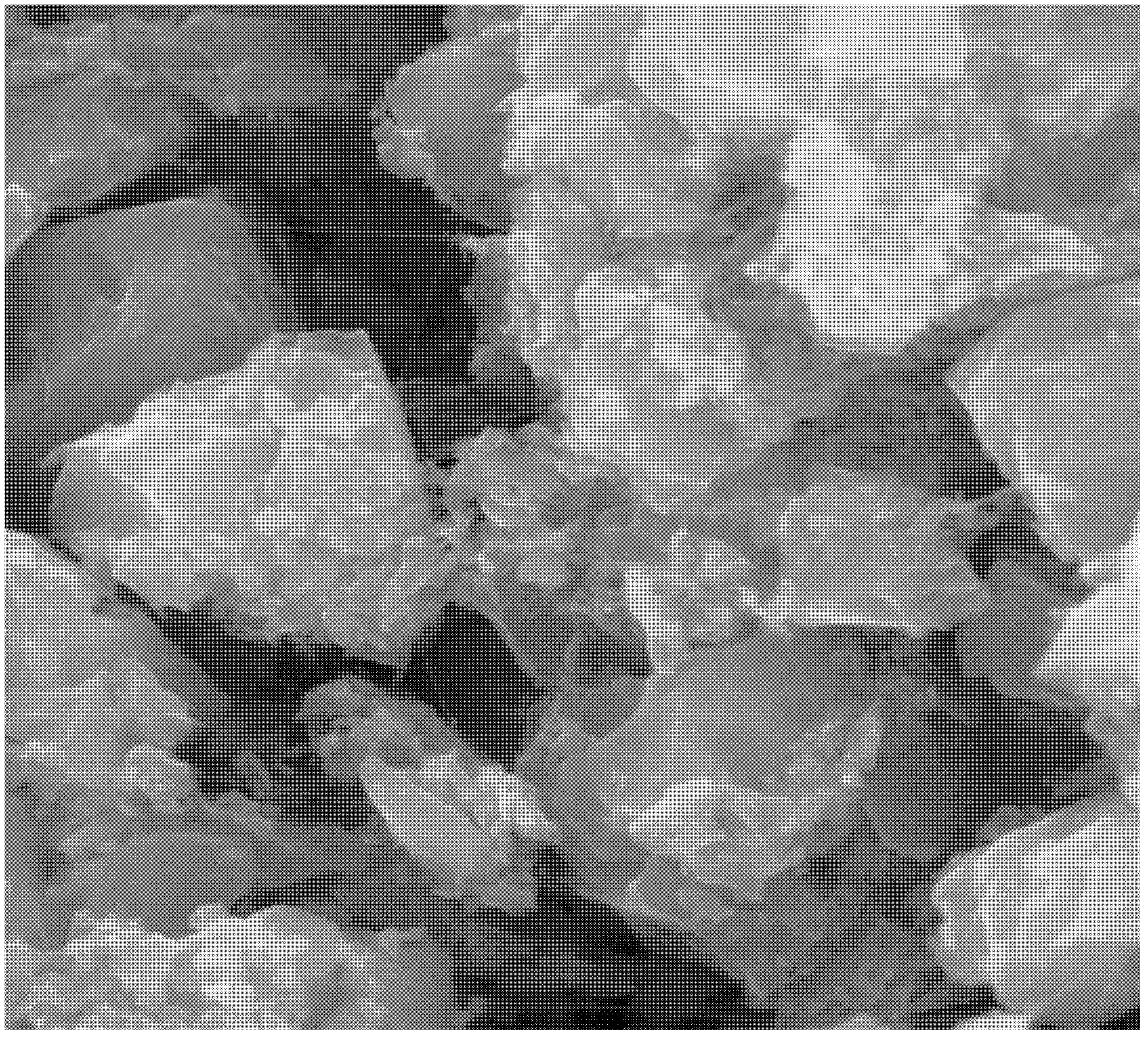

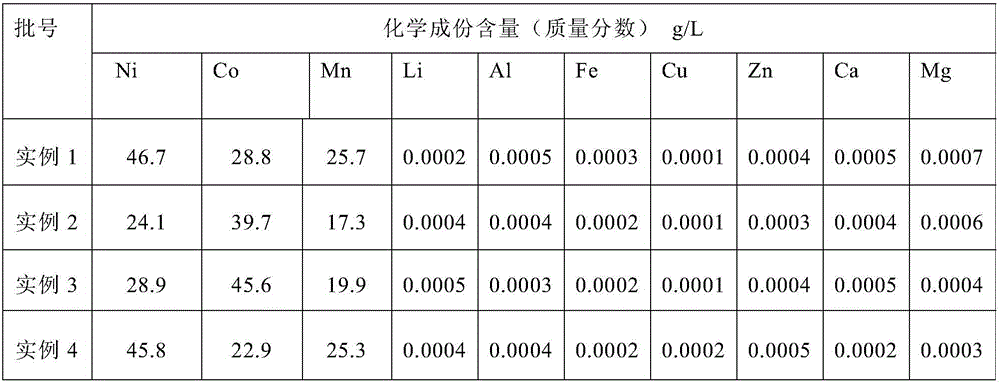

Method for preparing anode material lithium nickle cobalt manganic acid of lithium ion battery

InactiveCN101510603AConducive to neutralizing the balanceGood effectElectrode manufacturing processesNickel compoundsLithium hydroxideNew energy

The invention relates to a preparation method of Ni-Co lithium manganate which is a cathode material for a lithium ion battery, which pertains to the field of new energy material and preparative technique. The preparation method comprises the following steps: 1. a sulfate mixture solution of nickel, cobalt and manganese is prepared in accordance with a certain concentration; 2. the mixture solution, NH3 water and a sodium hydroxide solution are continuously injected into a reactor and stirred, and a spherical or quasi-spherical multiple hydroxide A of Ni, Co and Mn is obtained after the filtration, washing and drying are conducted over the mixture; 3. the dry multiple hydroxide A of Ni, Co and Mn is presintered to obtain a spherical multiple oxide B of Ni, Co and Mn; and 4. after being added with a right quantity of alcohol, the product B is evenly mixed with lithium hydroxide and the mixture is sintered, smashed and screened to obtain a spherical LizNixCoyMnxO2 cathode material C for the lithium ion battery. With the preparation method, the particle size and distribution of the product A and product B are easy to control and the spherical Ni-Co lithium manganate C with stable quality, high density, high capacity and high discharge plateau is obtained; therefore, the preparation method is applicable to stabilizing industrial production.

Owner:JILIN JIEN NICKEL IND

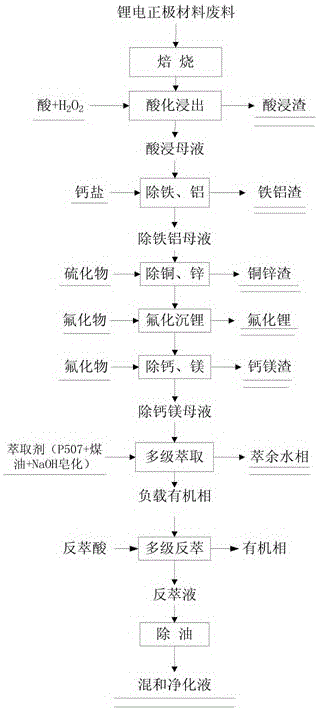

Treatment method for waste of positive electrode material of lithium battery

InactiveCN106505272AHigh recovery rateGuaranteed purityWaste accumulators reclaimingProcess efficiency improvementPhysical chemistryManganese

The invention discloses a treatment method for waste of a positive electrode material of a lithium battery. The method comprises the steps of (A) roasting; (B) acidifying and leaching; (C) iron and aluminum removal; (D) copper and zinc removal; (E) fluorinating lithium deposition; (F) calcium and magnesium removal; (G) multi-stage extraction; and (H) oil removal. According to the treatment method for the waste of the positive electrode material of the lithium battery, multiple valuable metals of lithium, cobalt, manganese, nickel and the like contained in the positive electrode material of the lithium battery can be comprehensively recovered; the treatment method has the advantages that the metal recovery rate is high, the obtained lithium product is good in quality and the treatment method is friendly to environment, low in production cost and suitable for industrial production.

Owner:GANFENG LITHIUM CO LTD

Method for preparing metal chalcogenide film

ActiveCN103194729AControl thicknessSmall sizeChemical vapor deposition coatingDeposition temperatureSulfur

The invention discloses a method for preparing a metal chalcogenide film. The method is used for growing the metal chalcogenide film on a substrate with the vapor deposition process by using a chalcogen source and a metal element source and comprises the following steps of: providing three temperature zones, wherein the temperature of the three temperature zones can be controlled independently, and the chalcogen source, the metal element source and the substrate are put in the three temperature zones respectively; controlling the three temperature zones, evaporating the chalcogen source to generate the chalcogen source steam, evaporating the metal element source to generate the metal element source steam, and heating the substrate to the predetermined deposition temperature; providing a carrier gas, and enabling the carrier gas to flow through the three temperature zones in sequence to deliver the metal element source steam to the substrate to deposit and grow so as to form the metal chalcogenide film. The method disclosed by the invention is simple, dispenses with the original complex step of introducing a nucleation site and effectively ensures the purity and the surface cleanness of a sample. The metal chalcogenide film prepared by adopting the method has high quality.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

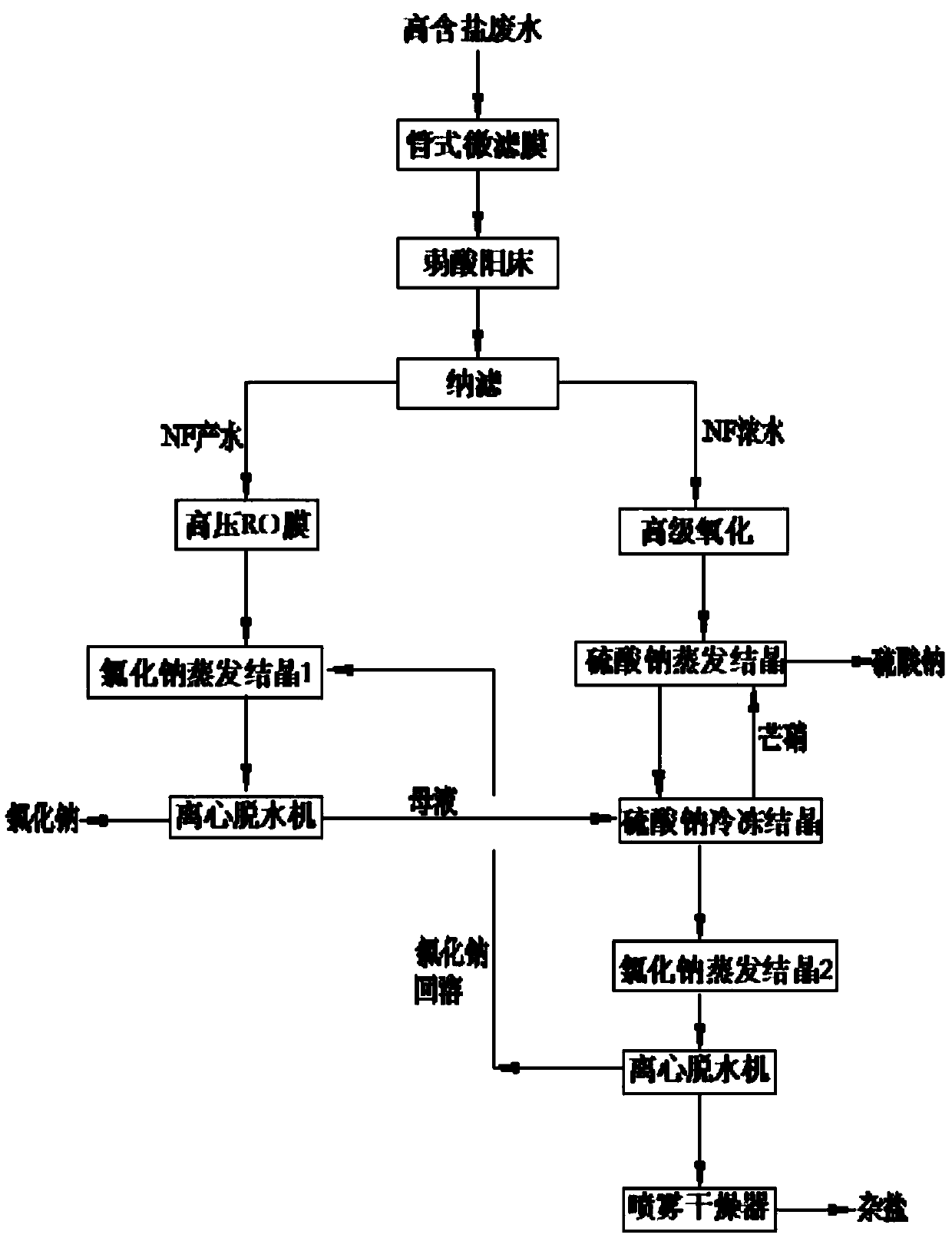

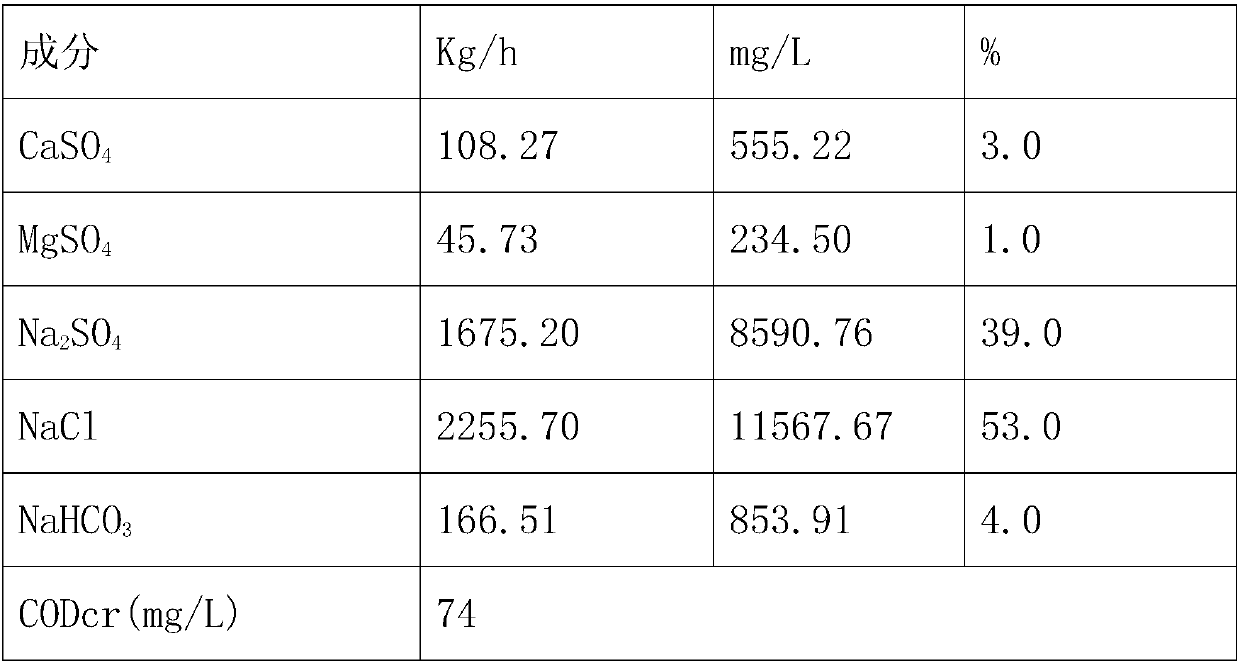

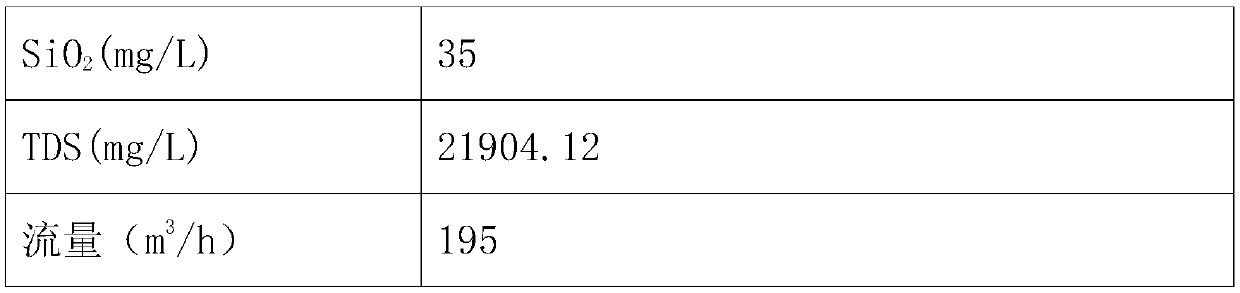

Resource technology and system for separating salt from high-salinity wastewater

InactiveCN107619144ASolve the problem of pipe blockageReduce energy consumptionMultistage water/sewage treatmentAlkali metal chloridesMirabiliteProduced water

The invention discloses a zero-drainage technology for recycling crystallizing salt from high-salinity wastewater and a treatment system thereof. The treatment system comprises a tubular microfiltration system, a weak acid resin hardness removal system, a nanofiltration membrane salt separating system, a nanofiltration concentrated water oxidizing system, a nanofiltration concentrated water sodiumsulfate evaporating and crystallizing system, a sodium sulfate freezing and crystallizing system and the like. The zero-drainage technology has the advantages that the pretreated wastewater is subject to nanofiltration primary salt separating, the salt component in the produced water is mainly sodium chloride, the sodium chloride with purity no lower than 98.5% is obtained by membrane concentration, evaporating and crystallizing, and the sodium sulfate with purity 99.1% or more is produced by MVR (mechanical vapor recompression) crystallizing after concentrated water oxidizing; a mother liquid after evaporating and crystallizing of sodium sulfate and a mother liquid after nanofiltration evaporating and crystallizing are mixed and frozen, so as to obtain mirabilite, and the mirabilite is converted into anhydrous sodium sulfate after sodium sulfate evaporating and crystallizing; at the premises of ensuring quality, the whole recycling rate of salt reaches 90% or above; finally, a smallamount of mother liquid is sprayed, dried and cured, and the zero-drainage effect of wastewater is realized.

Owner:侯新春 +1

Globular titanium micro-powder or ultra-micro powder preparation device and method

The invention belongs to a process for preparing and processing powder material by taking plasma as a heat source, in particular to a process and an apparatus of metal titanium powder material for powder metallurgy, plasma spray, injection forming, gel injection molding and the like. The invention has the advantages that: the adoption of the high temperature spheroidization and rapid condensation special spheroidization technique can improve the sphericity and purity of titanium powder, and both a reactor and the titanium powder spheroidization process are cooled with circulating water, thereby ensuring the sealing performance of equipment, also reducing the use of inert gases, effectively reducing costs, improving the production efficiency and guaranteeing the purity of spherical titanium powder.

Owner:SOUTHWESTERN INST OF PHYSICS

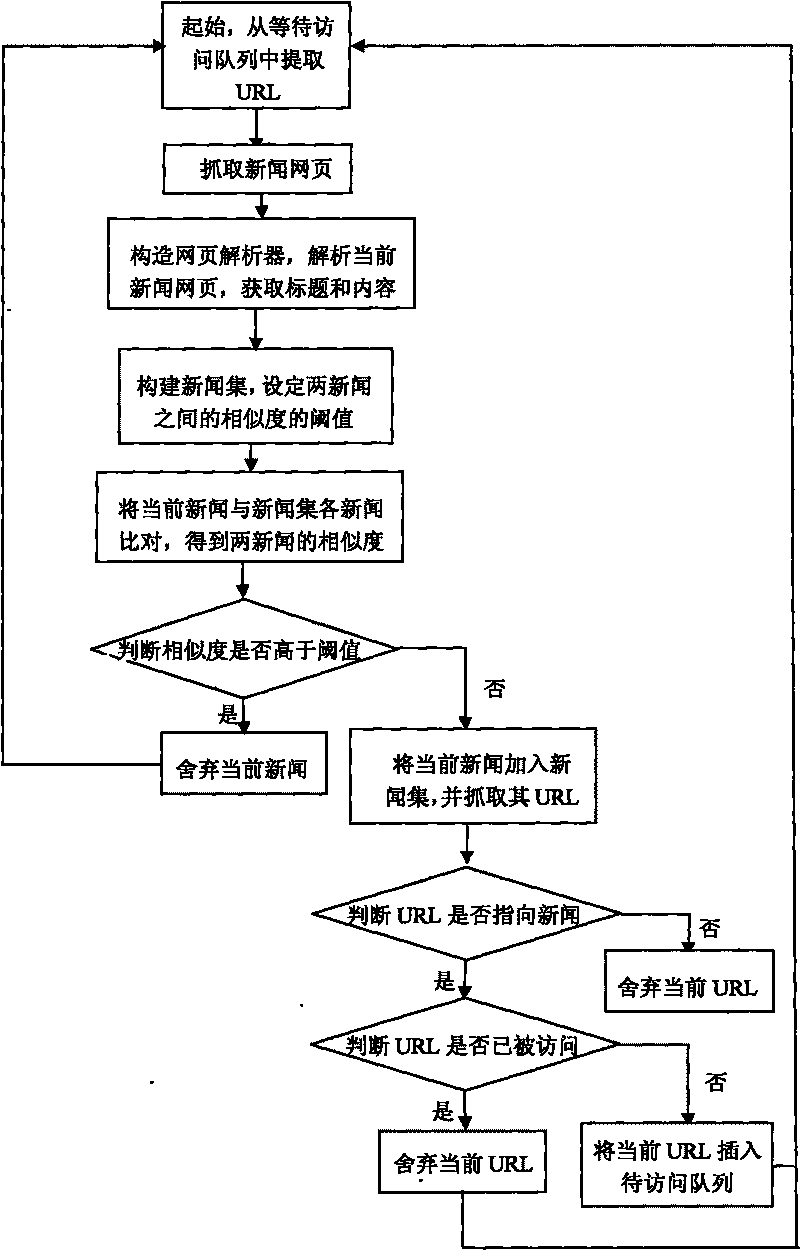

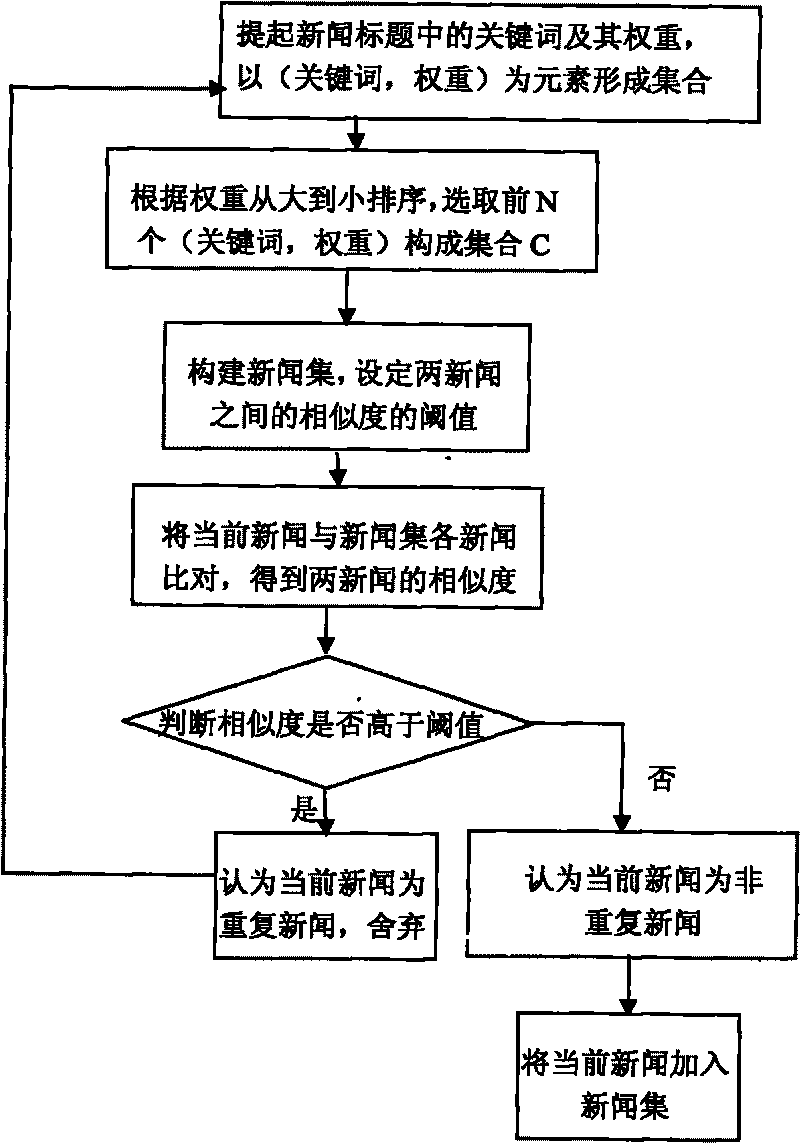

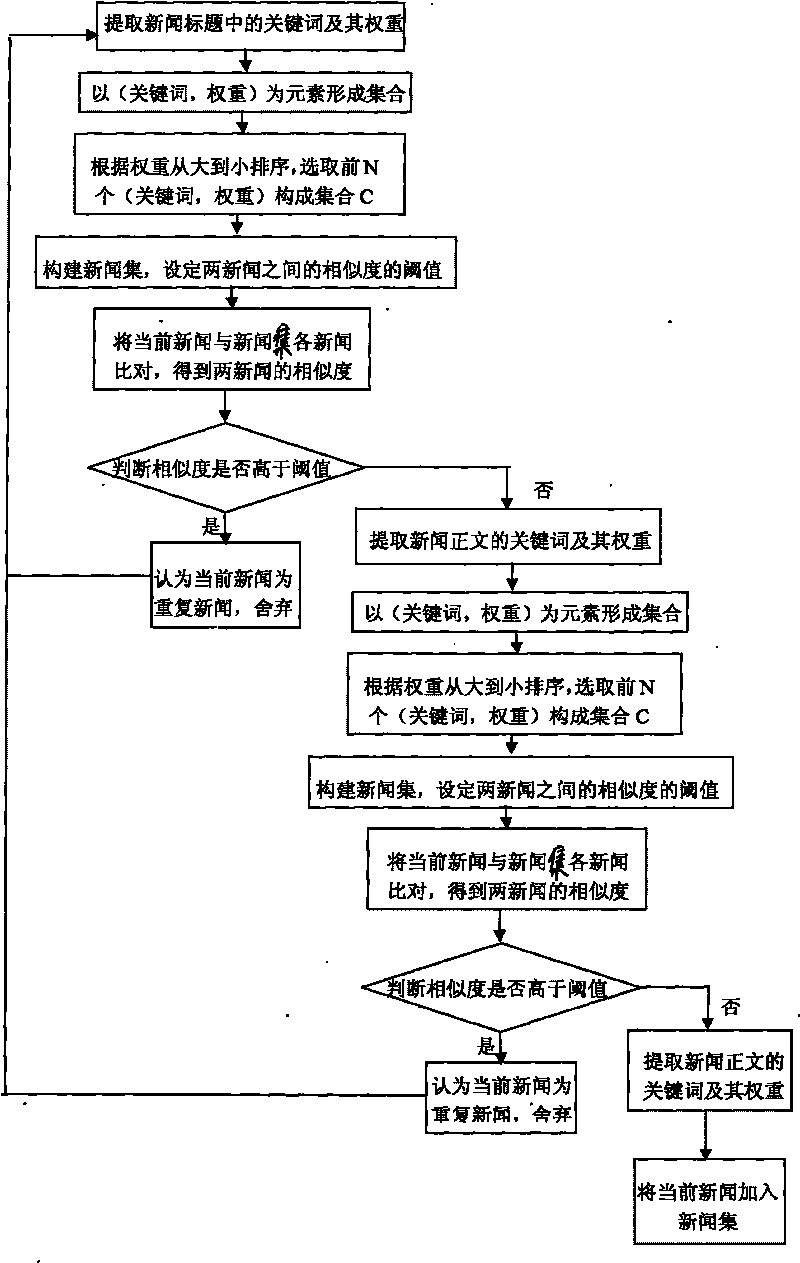

Method for constructing webpage crawler based on repeated removal of news

ActiveCN101694658AAvoid downloadingReduce consumptionSpecial data processing applicationsUniform resource locatorWeb page

The invention relates to a method for constructing a webpage crawler based on the repeated removal of news, which comprises the following steps: constructing an analyzer for analyzing news webpages; constructing a news set; setting a threshold value of the similarity among the webpages; comparing the currently grabbed news webpage with the news set and judging whether the similarity is higher than the threshold value or not; if the similarity is lower than the threshold value, adding the current webpage into the news set; if the similarity is higher than the threshold value, discarding the news and grabbing the next webpage; grabbing a URL of the current webpage and judging whether the URL points at the news webpage or not, if so, judging whether the URL is accessed or not; otherwise, discarding; if the URL is accessed, discarding the URL; if the URL is not accessed, storing the URL into a queue to be accessed; sequentially extracting the URL from the queue to be accessed to access; and repeatedly executing the steps. The invention has the advantages of high algorithm efficiency, less resource waste and convenient data maintenance and prevents from grabbing the webpage with repeated content.

Owner:ZHEJIANG UNIV

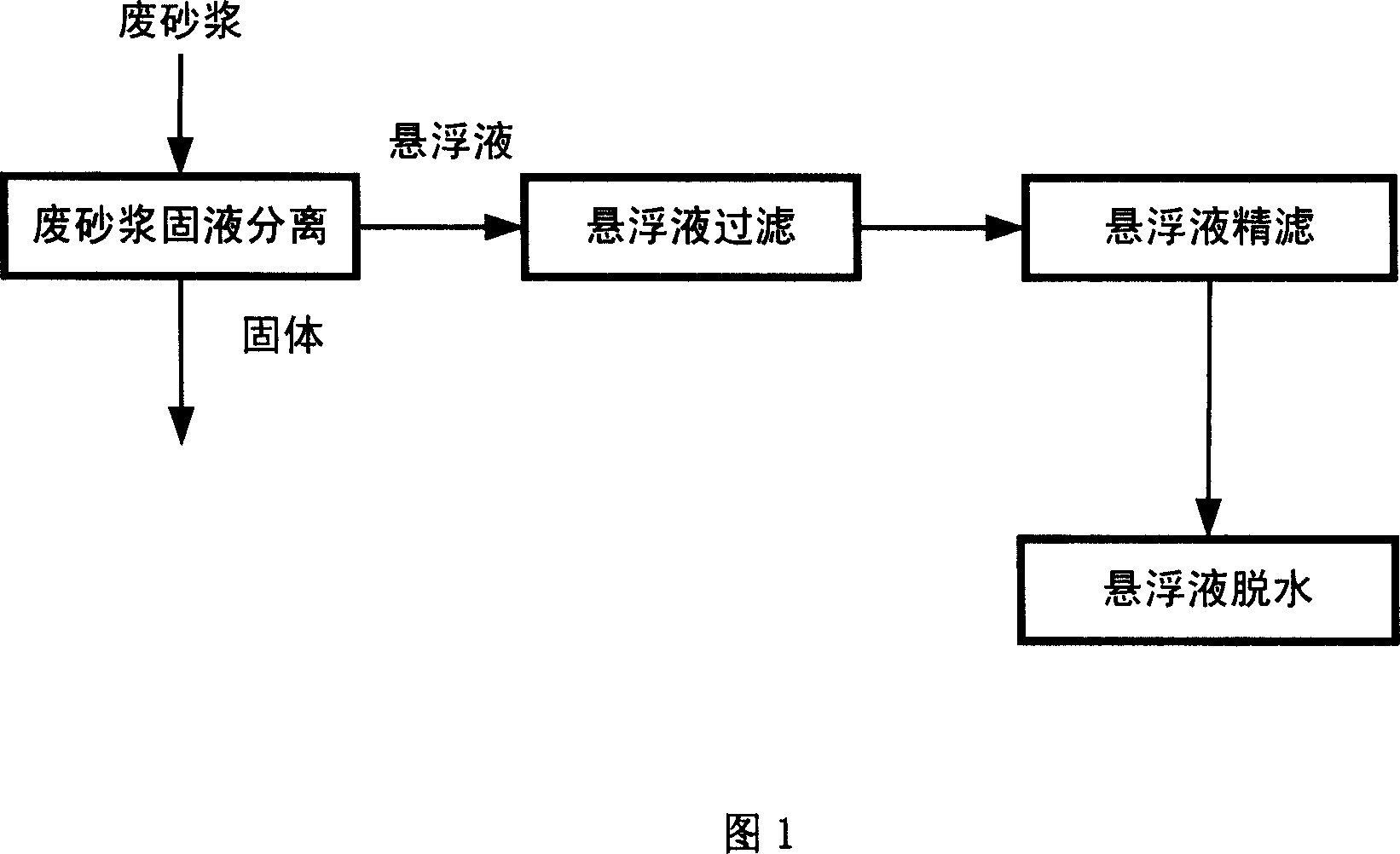

Method of recycling cutting suspension

InactiveCN101032806AGuaranteed purityAvoid adverse effects from re-useAbrasive machine appurtenancesRecovery methodPolyethylene glycol

The waste cutting suspension recovering process features that the waste linear cutting sand pulp from silicon chip processing is multiple stage treated through the steps of solid-liquid separation, initial filtering of the suspension, final filtering of the suspension, and concentrating and drying of the suspension. The process has recovered polyethylene glycol-base or oil-base suspension possess performance the same as or near that of new material and capacity of being reused. The present invention raises material using efficiency, lowers silicon chip producing cost and avoids environmental pollution caused by exhausting waste linear cutting sand pulp.

Owner:PRECISION RECYCLING TECH CO LTD

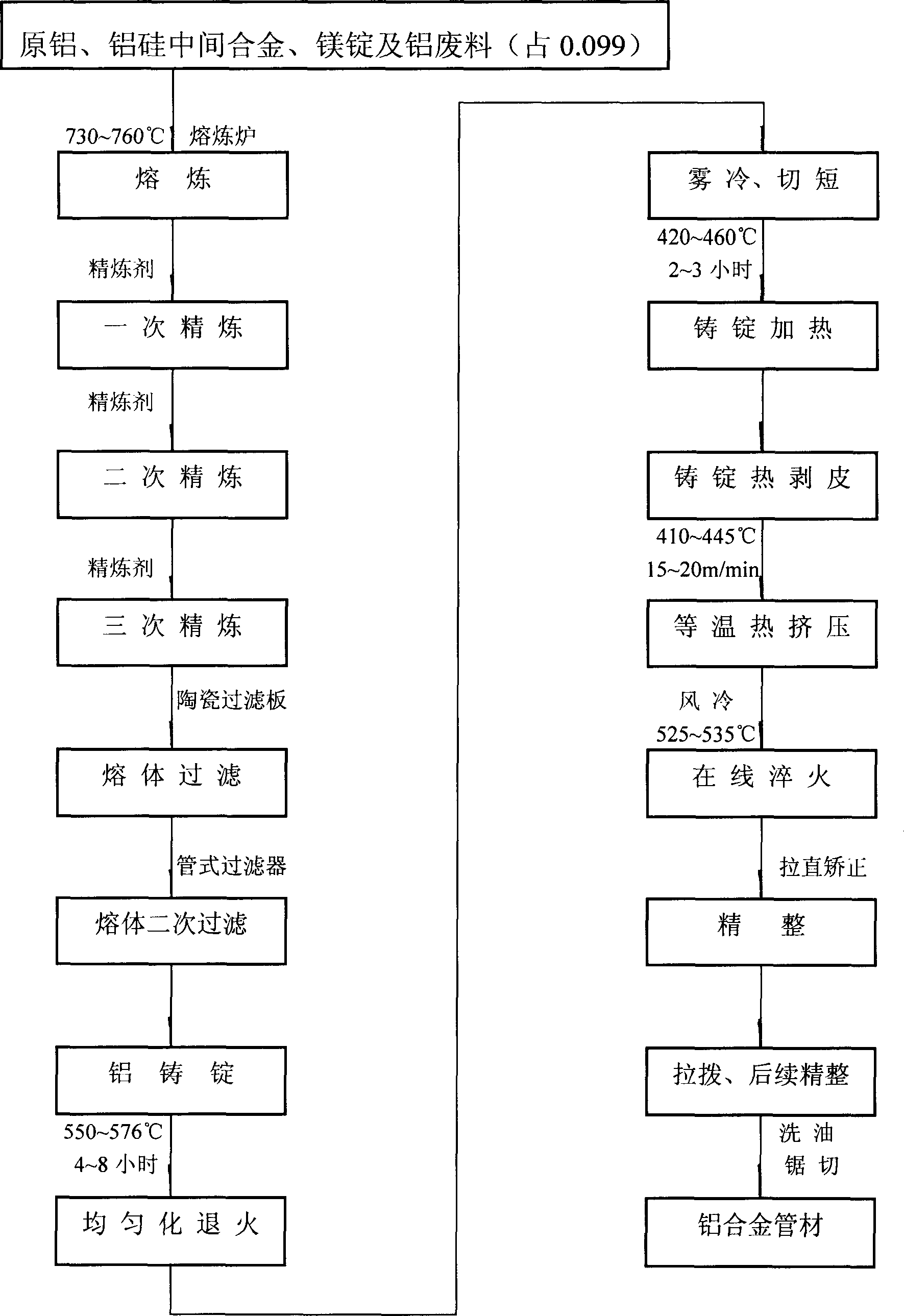

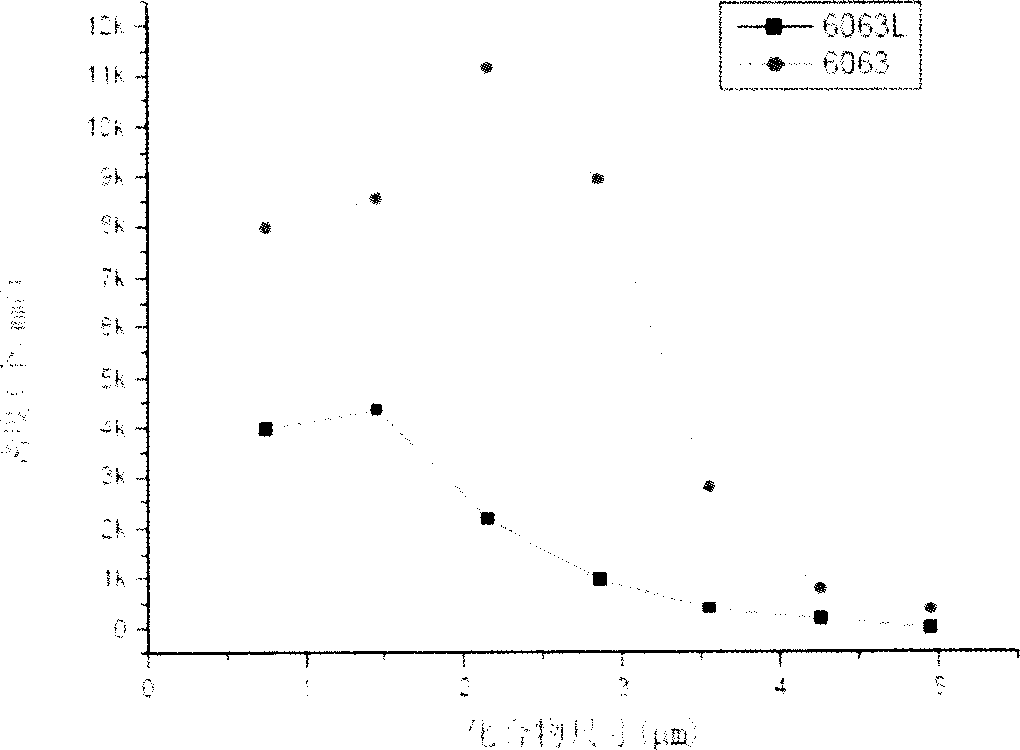

Aluminum alloy pipe for high purity and high precision light sensitive drum base material and producing method

The present invention is a kind of aluminum alloy pipe for making photosensitive drum and belongs to the field of non-ferrous metal pipe manufacture. The aluminum alloy pipe is made of material comprising Si 0.20-0.23 weight portion, Mg 0.45-0.50 weight portion, Fe 0.01-0.15 weight portion, impurity elements S and P 0.00-0.01 weight portion and Al 99.34-99.11 weight portions. It is produced through smelting, refining, in-situ fining, in-situ deairing, filtering, casting to form ingot, annealing, heating ingot to peel, extruding breakdown, quenching, finishing, drawing, post-finishing and other steps. The aluminum alloy pipe has low impurity content, and is suitable for manufacturing high purity and high precision photosensitive drum and similar products.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

High performance super capacitor and manufacturing process thereof

ActiveCN102723211AWell mixedImprove the mixing effectElectrolytic capacitorsBiochemical engineeringSupercapacitor

The invention relates to a high performance super capacitor and a manufacturing process thereof. The super capacitor comprises an electrode core, an electrolyte and a shell. The manufacturing process comprises steps that: tabs and leading-out terminals of the prepared electrode core positive and negative poles are welded; the electrode core with the well-welded leading-out terminals is encased in the shell; the shell with the electrode core encased is put in a vacuum drying furnace for vacuum drying; and finally a vacuum liquid filling sealing test is carried out. In an aspect of the electrode manufacturing method, the manufacturing process of the invention abandons a method which uses a solvent for assisted processing, thus to the greatest degree, the purity of the electrode material is ensured. In addition, during the production process, the manufacturing process of the invention has no drying energy waste and drying time constraint, and therefore reduces cost, reduces energy loss, and improves working speed. The manufacturing process of the invention further adopts an advanced assembly process to avoid problems such as secondary pollution and processing consistency in the traditional assembly technology, and greatly improves the stability of the super capacitor.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

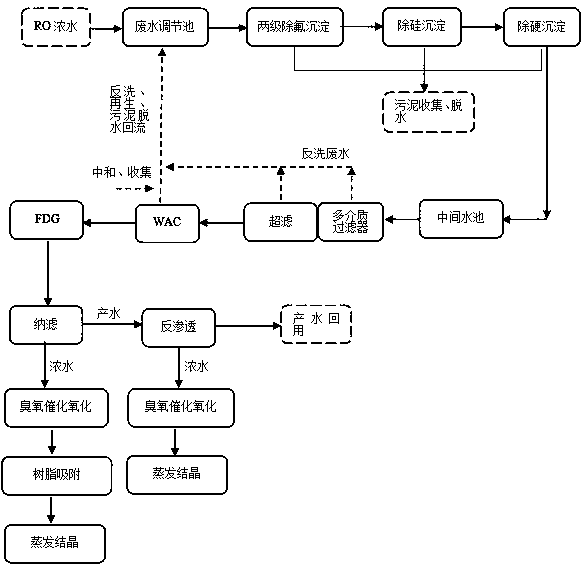

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

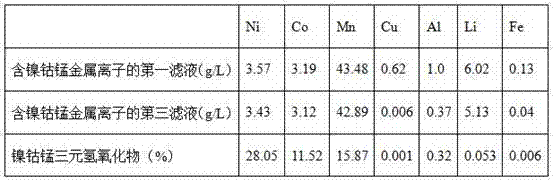

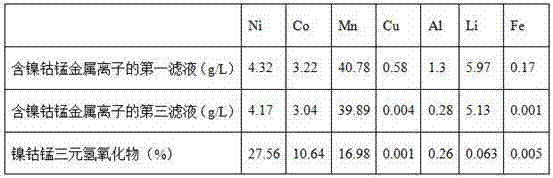

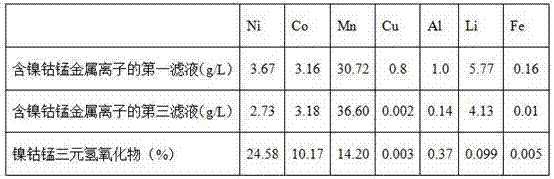

Method for preparing ternary hydroxide from nickel cobalt manganese recycled from waste lithium ion batteries through liquid phase method

ActiveCN107117661ALabor savingEasy to industrializeWaste accumulators reclaimingNickel oxides/hydroxidesManganeseSlurry

The invention discloses a method for preparing ternary hydroxide from nickel, cobalt and manganese in waste lithium ion batteries recovered by a liquid phase method, belonging to the technical field of metallurgical recovery of valuable metals, and solves the increasingly prominent problem of recycling waste lithium ion batteries. question. The invention uses waste lithium ion batteries as raw materials, and the main production steps include: dismantling and crushing, pulping, leaching, copper removal by extraction, iron and aluminum removal by precipitation, and preparation of nickel-cobalt-manganese ternary hydroxide. In the invention, the whole battery is crushed and then processed, no harmful gas is generated in the whole process of recovery and preparation, and green recovery is realized from the root. Raw material requirements, the entire production process is more convenient to operate, and the product is more pure, suitable for industrialization.

Owner:JINCHUAN GROUP LIMITED

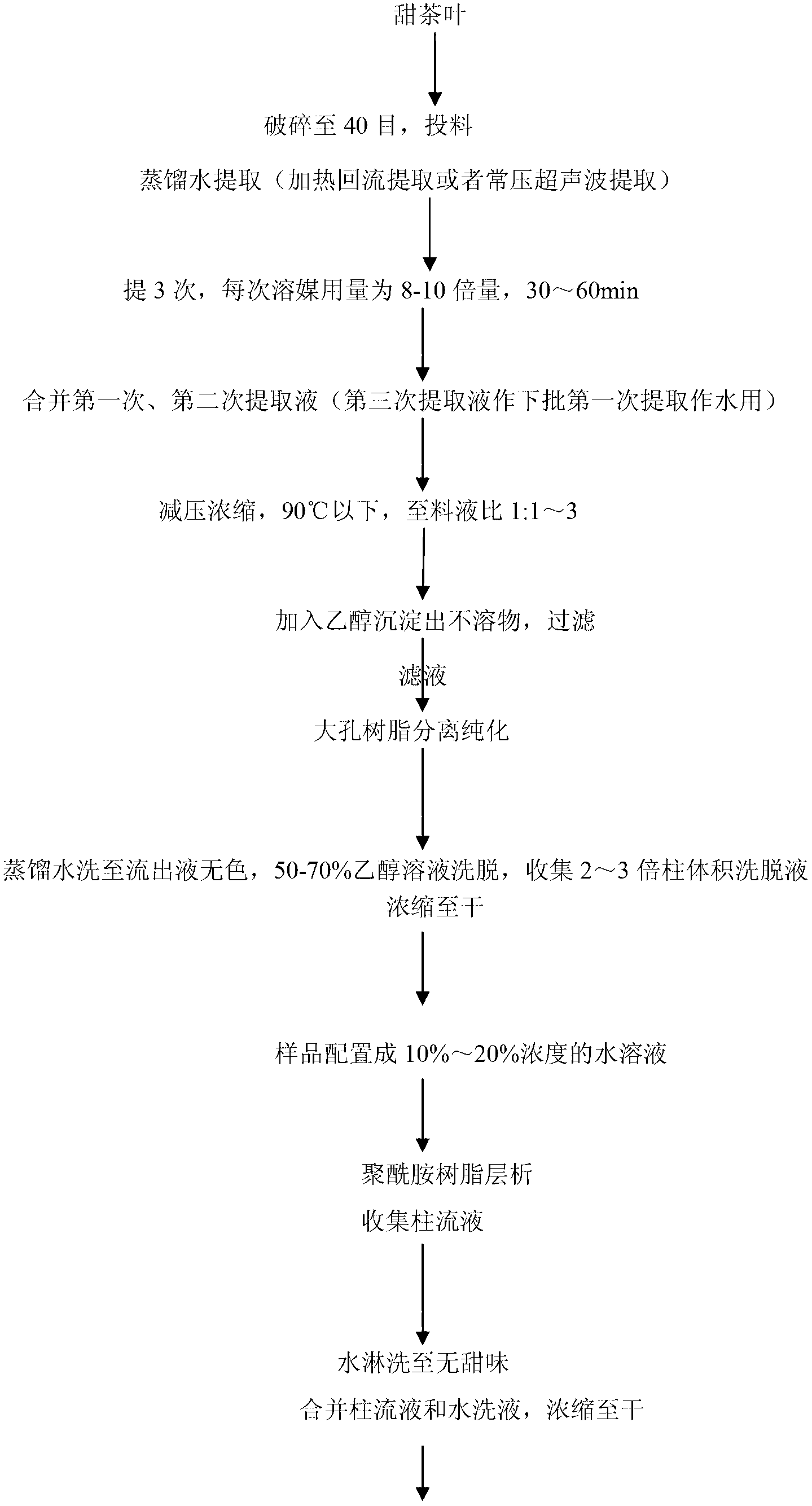

Production method for extracting sweet tea glucoside from sweet tea leaves

ActiveCN102838644AAvoid dependenceReduce manufacturing costSugar derivativesSugar derivatives preparationAlcoholSolvent

The invention provides a production method for extracting sweet tea glucoside from sweet tea leaves. The method comprises the following process flows of: smashing a sweet tea crude drug; extracting a solvent; concentrating; precipitating with alcohol; purifying with macroporous resin; concentrating; carrying out chromatography with polyamide resin; concentrating; crystallizing and recrystallizing; drying; and obtaining a finished product. By using the method, a high-quality sweet tea glucoside product can be produced, and the method also has the advantages of reducing the material loss, shortening the production period, improving the product yield and reducing the production cost and is suitable for the industrial production; the purity of the sweet tea glucoside produced by utilizing the method is higher than 98 percent, so that the product purity is high, and the component is single; the color of the sweet tea glucoside is white and good; and meanwhile, the technical difficulty of industrially producing a high-content and high-quality sweet tea glucoside extractive is overcome, so that large-scale production is smoothly produced.

Owner:HUNAN NUSTREETCARAX

Device and method for cooling coke

InactiveCN101705101AQuality improvementIncrease productionCoke quenchingCombustible gas productionWater vaporEngineering

The invention discloses a device and a method for cooling coke. The device consists of a prestorage section, a vapor cooling section, a transitional section, a physically cooling section and a discharge section, wherein the upper prestorage section and the vapor cooling section are communicated by a vaporization gas collection channel; the middle transitional section and the physically cooling section are communicated by high-temperature coolant collection channel; a rotary discharge valve of the discharge second is immersed in liquid-sealed coke quenching tank; and a coke conveying device is arranged in the liquid-sealed coke quenching tank or a belt conveyor is arranged at the outlet of the discharge valve to convey the coke to the outside. The method for cooling the coke by vapor and coke oven gases comprises: introducing the vapor into the vapor cooling section; performing vaporization and generating synthesis gases; and introducing the coke oven gases into the physically cooling section to allow the coke oven gases to absorb the sensible heat of the coke and perform physical heat exchange with the coke. The device and the method have the advantages of reducing circulating gas volume, recovering the sensible heat of high-temperature coke, generating water gas and fully utilizing resources.

Owner:TAIYUAN UNIV OF TECH

Disk shearing blade and method for manufacturing the same

ActiveCN101177765AImprove wear resistanceHigh strengthShearing machinesFurnace typesHigh intensityWear resistance

A disc scissors blade and its manufacturing method, the composition weight percentage of the material of the disc scissors blade is: C: 0.40-0.70%, Si: 0.50-1.2%, Mn: 0.20-0.50%, Ni: 1.00-1.50% %, Cr: 4.00-6.00%, Mo: 0.50-2.00%, V: 0.30-1.50%, Nb: 0.10-0.80%, P≤0.02%, S≤0.02%. The method introduces an electroslag remelting process into a common manufacturing method of disc shears, and increases the temperature of quenching and tempering heat treatment and final heat treatment. The disc scissors have good wear resistance and deformation resistance, and are suitable for slitting or trimming hot-rolled high-strength thick steel plates. In addition, the disc shear blade of the present invention also has a good use effect on disc shears in other similar working conditions, and can also be applied to disc shears for stripping or edge trimming of cold-rolled strip steel, and also has a promotional effect on non-ferrous metal disc shears. value and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Ru agate glaze and processing method and application thereof

The invention discloses a Ru agate glaze, which contains the following components by weight parts: 6 to 26 parts of agate, 40 to 65 parts of feldspar, 10 to 23 parts of calcite, 13 to 28 parts of black limestone, 3 to 8 parts of limonite, 2 to 4 parts of talcum and 5 to 10 parts of chestnut ash. The invention also discloses a processing method for the Ru agate glaze and the application of the Ru agate glaze on Ru porcelains, and also discloses a Ru porcelain. The basic tones of the glaze of the Ru porcelain fired with the Ru agate glaze are green and blue, and therefore the glaze can present the deep colors of azure, cyan and bluish white as well as the bright, transparent colors of pea green, light green and light greenish blue; the texture of the porcelain body is fine and dense, the porcelainizing degree is high, the water absorption does not exceed 1.2 percent, and the sound is silvery when the product is knocked; the thermostability is good, and defects, such as through cracks and leakage, do not exist.

Owner:郭秀贞

Novel production method for glutamic acid

ActiveCN102703537AReduce lossesLess waste waterOrganic compound preparationMicroorganism based processesHigh concentrationFluidized bed drying

The invention discloses a novel production method for glutamic acid, belonging to the technical field of the production of amino acid. The novel production method for the glutamic acid comprises the following steps of: removing thalli and insolubles by means of high-speed disc separation; evaporating and concentrating separated glutamic acid material liquid through a multi-effect plate type evaporator at low temperature, wherein the generated secondary steam condensed water is used for fermentation ingredients of the glutamic acid; performing continuous isoelectric extraction on the glutamic acid in the evaporated glutamic acid concentrated solution; absorbing the glutamic acid by making supernatant fluid pass through ion exchange columns; performing isoelectric reextraction on the analyzed glutamic acid; inputting high-concentration wastewater into a fertilizer workshop for producing fertilizer; squeezing heavy phase (mycoprotein) through a plate frame, and granulating; and drying through a fluid bed, and thus producing high-protein feed. The novel production method for the glutamic acid has the advantages of low unit consumption of liquid ammonia and sulfuric acid, high extraction yield of the glutamic acid, less ion exchange investment and the like; and meanwhile, the purity of the extracted glutamic acid is high, sodium glutamate can be produced without crystalloblast, resources are fully used in the whole process, the aims of energy conservation and consumption reduction are achieved, and the novel production method for the glutamic acid has a wide application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

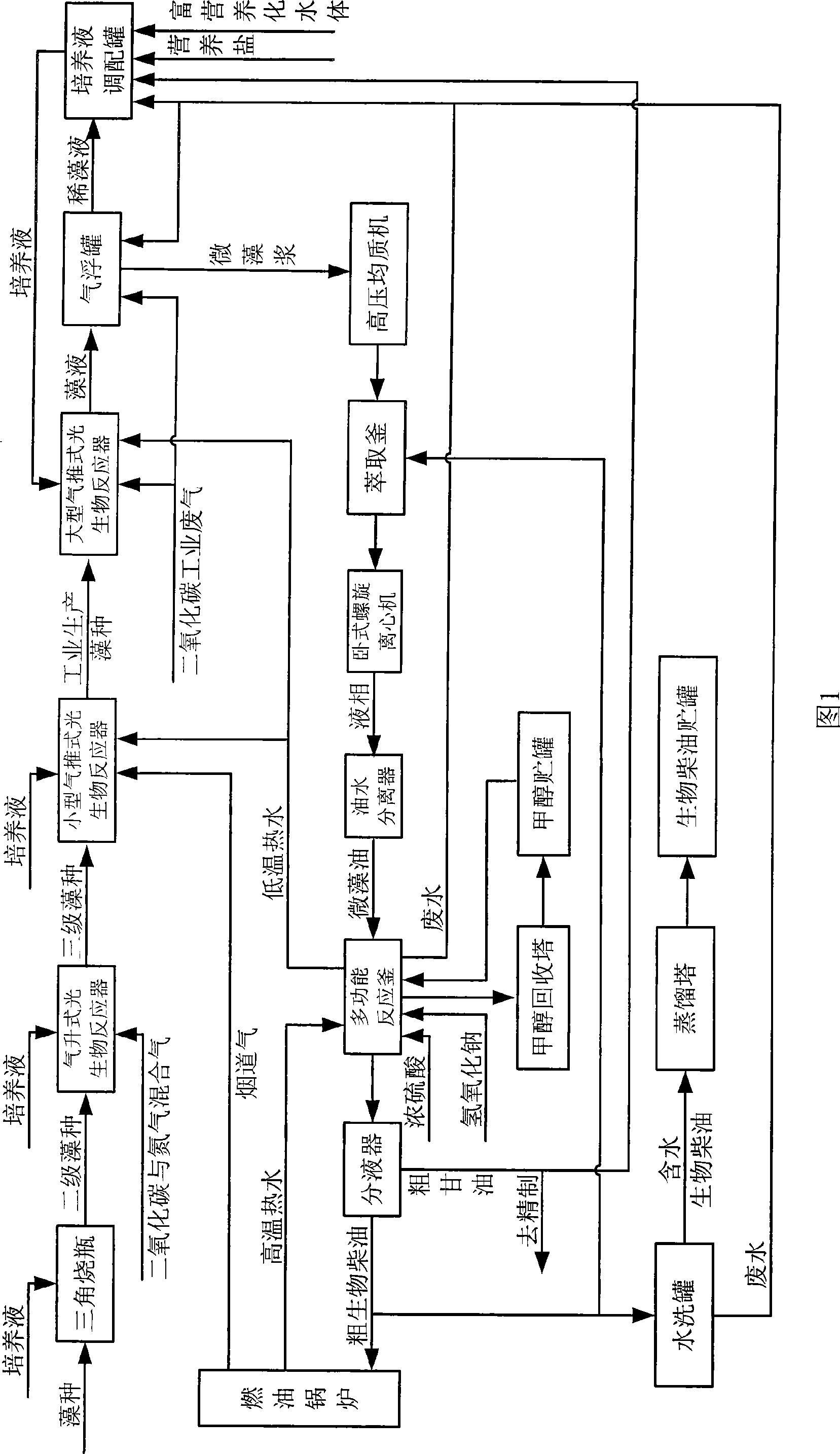

Process for preparing fine algae cultivation coupling biological diesel oil refining

The invention relates to the fields of microalgae culturing project, biodiesel refining and environment protection, in particular to a production method for refining the biodiesel through microalgae culturing and coupling. In the method, carbon dioxide industrial waste water and eutrophicated surface water or industrial waste water is used as main material to extensively culture the microalgae containing oil, and microalgae oil is used as the material to refine the biodiesel and simultaneously realize the drainage reducing of carbon dioxide, the control of polluted water and the cleaning production of biodiesel. The method is characterized in that the waste gas of carbon dioxide and the eutrophicated water are firstly used to culture and collect the microalgae; and then extraction, pre-processing and interchange esterification reaction of microalgae is carried out. In the invention, the two processing of culturing the microalgae and refining the biodiesel are coupled together; the ''three wastes'' and waste heat generated during the reefing process of the biodiesel and the unsalable outgrowth of crude glycerine are used as the materials and the heat source for culturing the microalgae; therefore, not only the production cost is reduced, but also the discharge of the ''three wastes'' is eliminated.

Owner:王彤

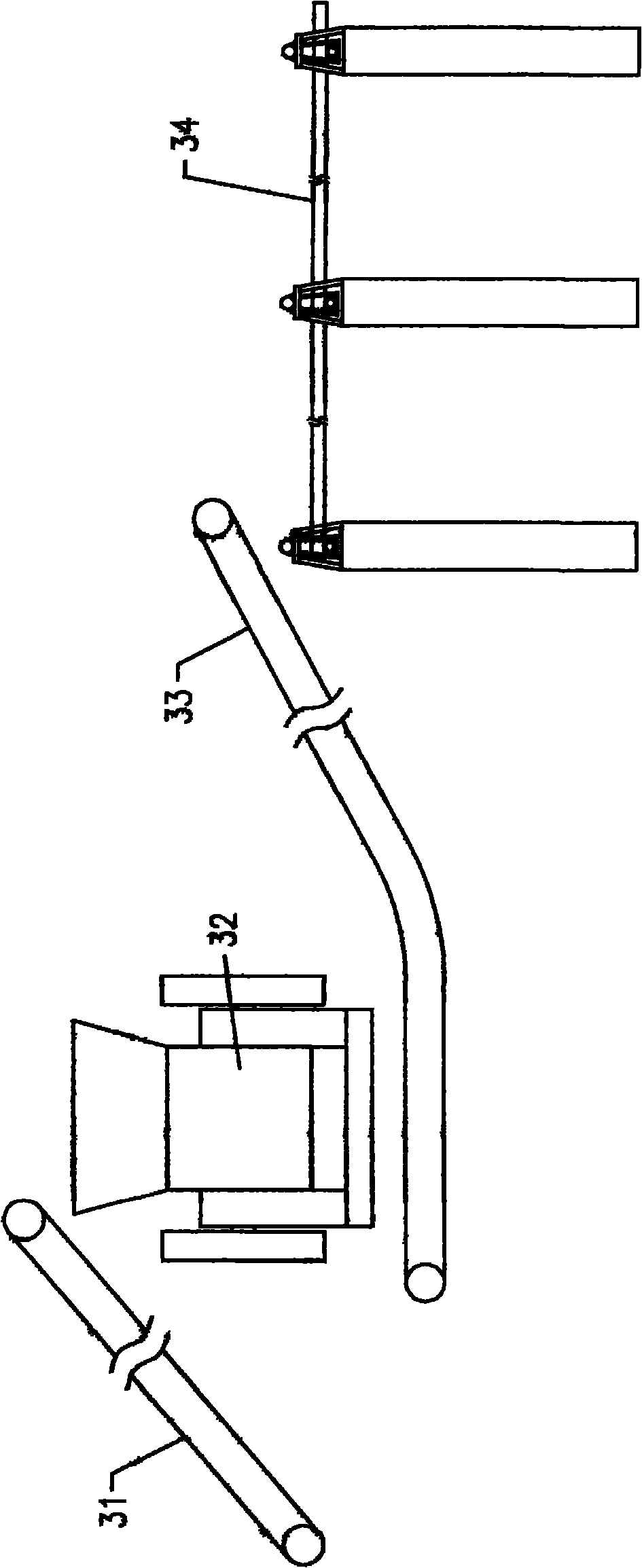

Technique for producing ultra high-strength terylene industry filament yarn

InactiveCN101144195AGuaranteed purityGuaranteed viscosity uniformityArtificial filament heat treatmentMelt spinning methodsSetting timeFilament yarn

The present invention discloses a production process for an ultra high tenacity polyester industrial filament. The production process adopts a one-step method of spinning and stretching, and the method comprises the solid state tackifying, the melt spinning, the high temperature stretching, the heat setting, and the winding forming. The present invention adopts the innovative five-pair hot roll stretching heat setting process, compared with the traditional four-pair hot roll stretching heat setting, the the present invention adopts two-stage heat stretching, the processing method of the two-stage heat setting effectively reduces the stretching speed of fiber, and prolongs the heat setting time of the fiber, so that the fiber has an even stable orientation structure while the physical performance of products is ensured, the spinning condition is optimized. The ultra high tenacity polyester industrial filament prepared by utilizing the method of the present invention has the advantages that the intensity is high, the stretching and the dry heat shrinkage are reasonable, the heat resistant performance is good, and the impact resistant performance and the fatigue resistant performance are good.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

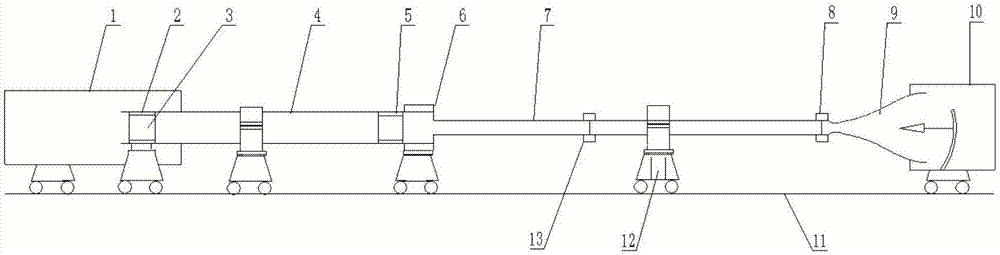

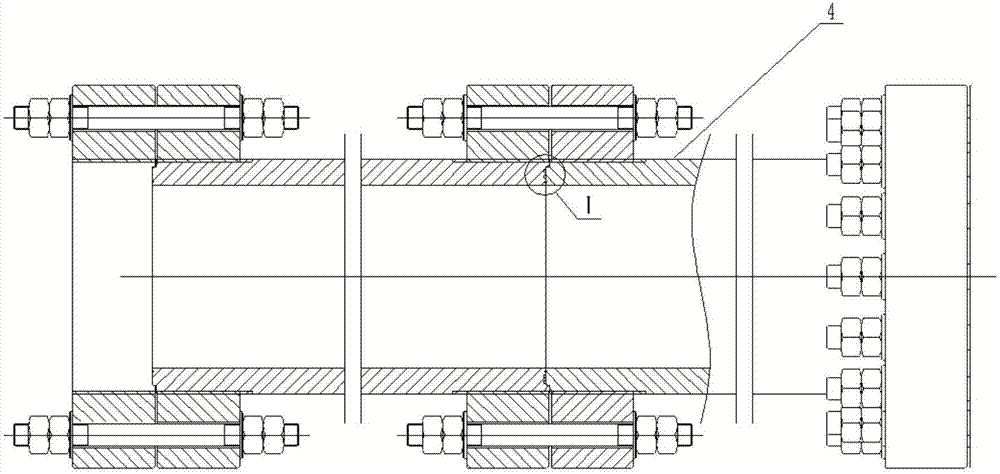

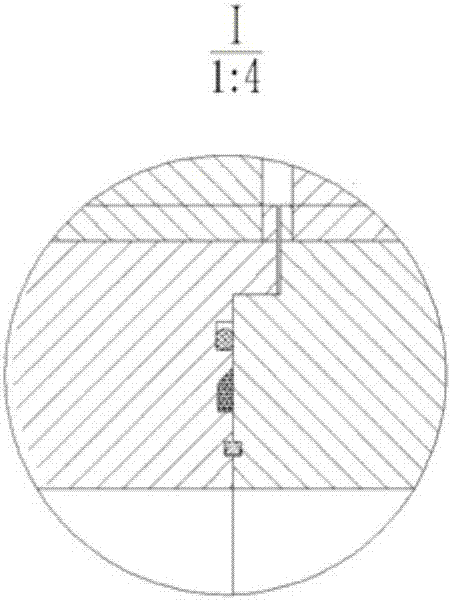

2-m-Maglitude free-piston-driven high-enthalpy shock tunnel

A 2-m-maglitude free-piston-driven high-enthalpy shock tunnel comprises a high-pressure gas storage chamber, a piston launching mechanism, a piston, a compression tube, a piston stop mechanism, a maincapsule mechanism, a shock wave tube, a small capsule mechanism, a spray tube, a test segment, a track and a support system. The high-pressure gas storage chamber is arranged at the upstream of the piston launching mechanism and stores high-pressure air. After being launched through the piston launching mechanism, the piston may move to the downstream of the compression tube at increased speed; when the piston arrives at the tail end of the compression tube, most energy is transmitted to helium-argon mixed light gas, and high-temperature high-pressure gas is generated; at this moment, a membrane of the main capsule mechanism breaks, incoming shock wave is generated and passes through the shove wave tube until its tail end, the shoe wave may be reflected, and high-temperature high-pressuregas is generated to cause breakage of a membrane of the small capsule mechanism. The high-temperature high-pressure test gas passes through the spray pipe to the test segment, and free stream conditions required are acquired.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

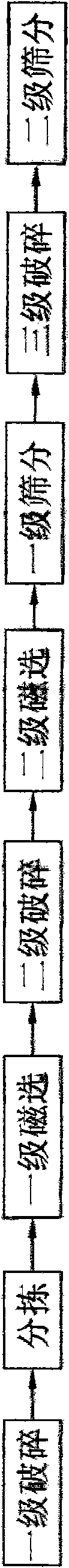

Construction waste comprehensive treatment method

InactiveCN102009059AReduce pollutionLow costConstruction waste recoverySolid waste disposalForeign matterSocial benefits

The invention discloses a construction waste comprehensive treatment method which comprises the following steps: primary crushing, sorting, primary magnetic separation, secondary crushing, secondary magnetic separation, primary screening, tertiary crushing and tertiary screening. The construction waste comprehensive treatment method can be used for thoroughly sorting foreign matters in the construction waste, thereby enhancing the quality of the regenerative aggregate. The invention has the advantages of reasonable procedure arrangement, low labor consumption and high efficiency, and is simple to operate. When being used for treating construction waste, the method has the social benefits of saving land resources and reducing environmental pollution.

Owner:潍坊大于环保建材有限公司

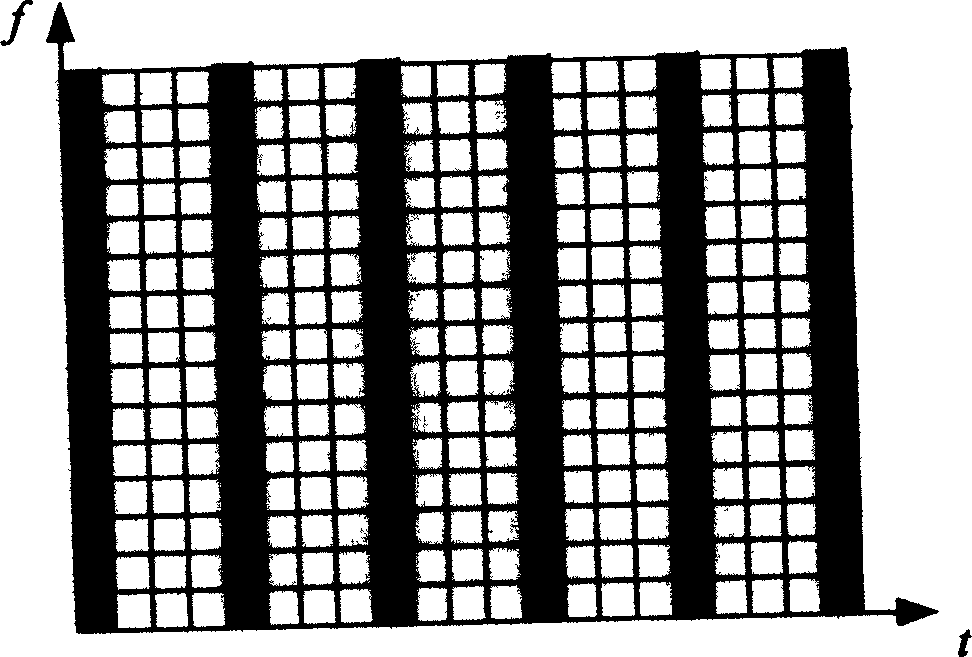

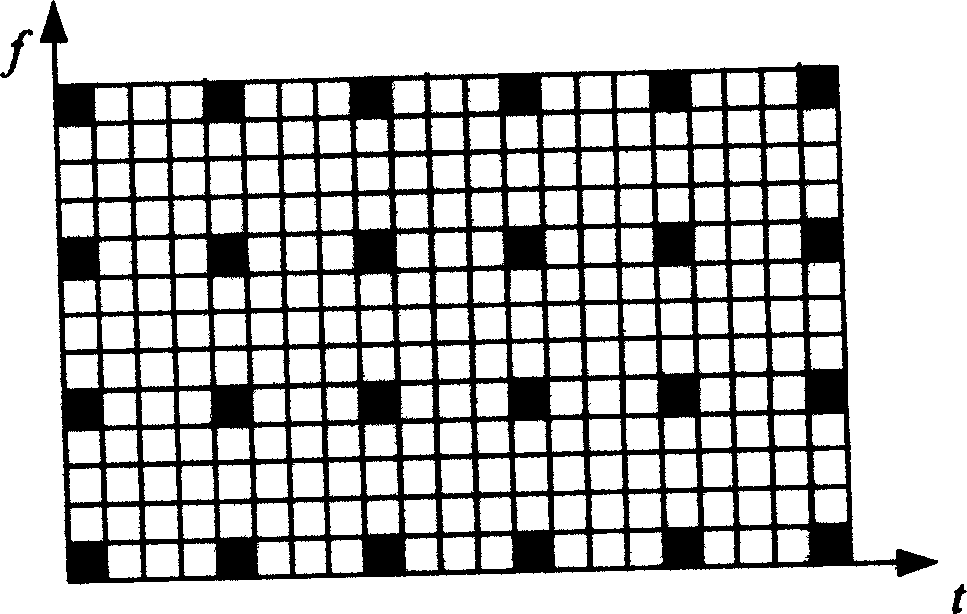

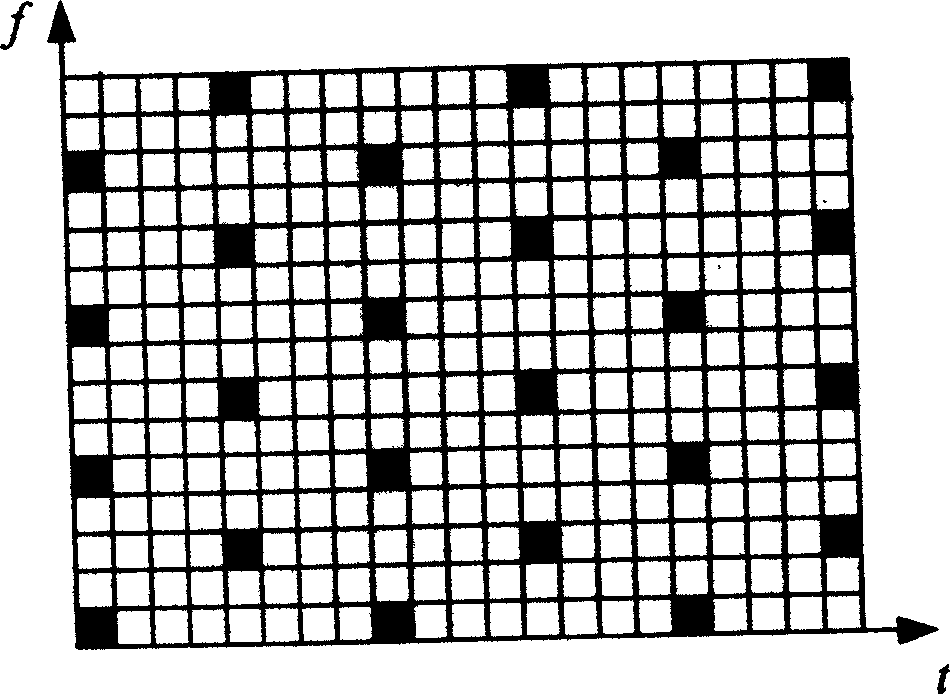

Guiding plan based on time frequency synchronous training sequence

InactiveCN1553621AAccurate Fading CompensationEasy to passTransmitter/receiver shaping networksSignal channelsData signalEngineering

This invention discloses a guiding project based on time and frequency's synchronized training sequence. It uses the good period correlated characteristic and constant amplitude of CAZAC sequence to serve the CAZAC sequence as the known measuring sequence, and cramps out a part of sequence from CAZAC sequence to serve as guiding signal. Amplifies properly the guiding signal's power, and inserts the digital signal into the relevant place of the guiding signal and sets to zero. The measuring sequence can either be used to synchronize the time and frequency, also can be used to the channel estimation. The invention can make more precise channel estimation, higher data demodulation performance to make the system tracing the fading of the channel more precisely and duly.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

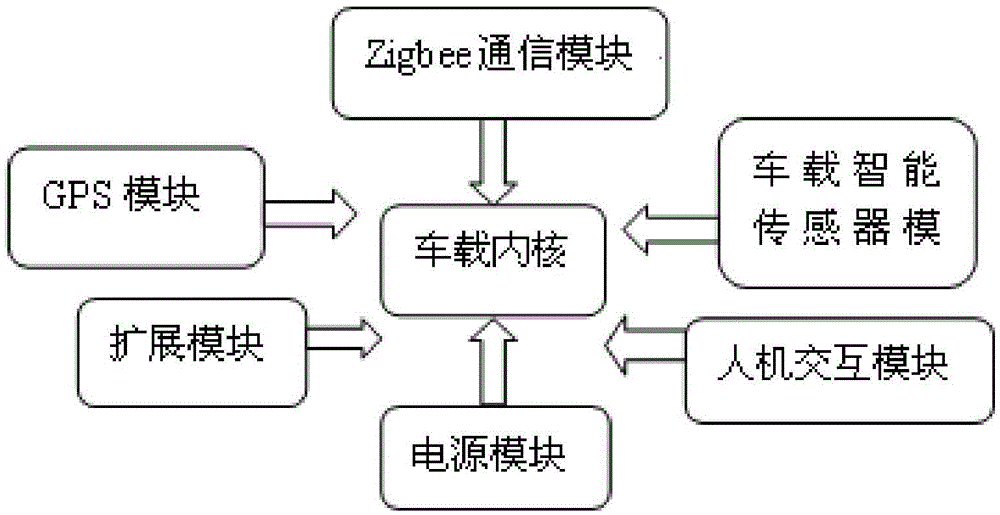

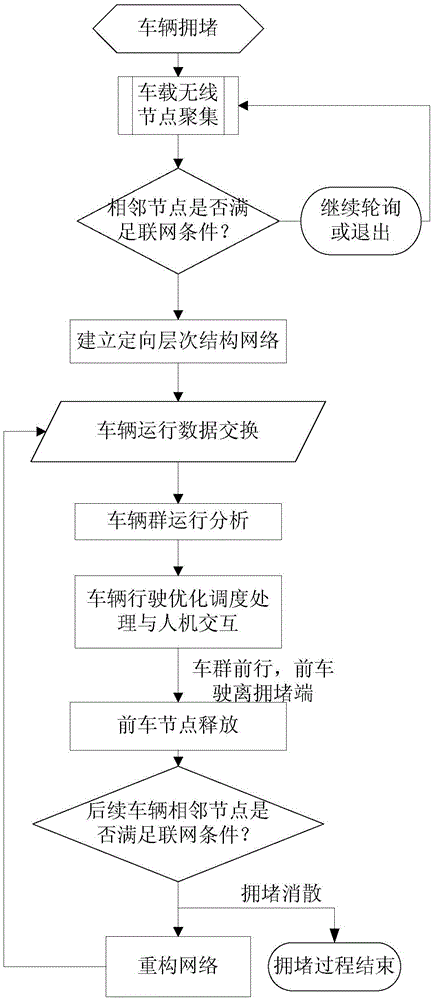

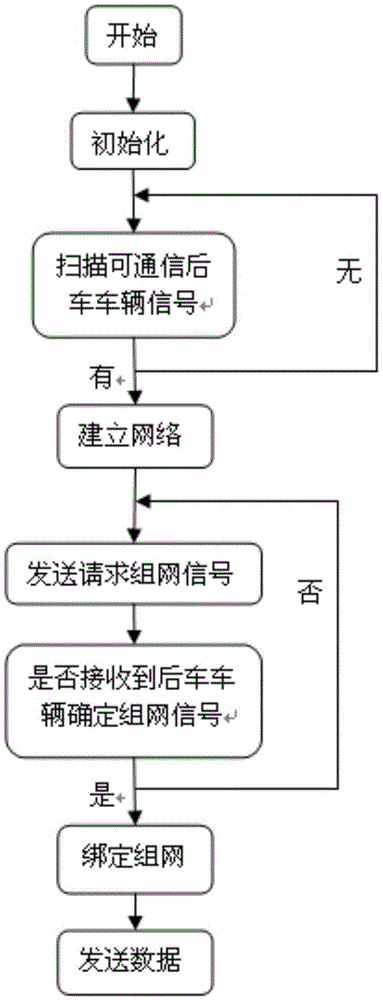

Intelligent traffic flow congestion dispersal method through vehicle group autonomous cooperative scheduling

ActiveCN105631793AGuaranteed purityAvoid serious traffic jamsData processing applicationsRoad vehicles traffic controlMobile vehicleDriver/operator

The invention provides an intelligent traffic flow congestion dispersal method through vehicle group autonomous cooperative scheduling. An intelligent vehicle-mounted terminal and a wireless communication module are integrated, a cooperative scheduling algorithm optimization index and vehicle driving parameter acquisition and processing process is built according to a vehicle following model in the case of traffic flow congestion, the optimization index reflects the vehicle group passing efficiency, the intelligent vehicle-mounted terminal and an adjacent vehicle build a wireless communication network, a guiding instruction is generated according to the cooperative scheduling algorithm and the protocol, a vehicle queuing position and estimated passing time are provided for a driver through a man-computer interface, and the driver is guided to select a proper speed and a proper direction. The method of the invention has the advantages of low cost, high terminal integration, simple mounting, high sensitivity, quick response speed and the like, and is applicable to various motor vehicles, such as freight cars, buses and cars, which run in traffic dense areas such as urban areas and freeways.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of high-purity cannabidiol

ActiveCN108083989AImprove solubilityGuaranteed purityOrganic chemistryHydroxy compound active ingredientsChemical industryPolyamide

The invention belongs to the field of pharmaceutical and chemical industry, and specifically relates to a preparation method of high-purity cannabidiol. The preparation method is characterized by comprising the following steps: taking leaves of cannabis sativa and the plant top occupying one fifth of the whole plant as extraction parts, performing purification by using macroporous absorbent pillarchromatography and polyamide pillar chromatography joint technology, and performing crystallization refining by using a mixed solvent system, thereby maximally improving the yield in the premise of guaranteeing the acquisition of a high-purity product. According to the method provided by the invention, the CBD purity of the obtained product is high, the yield is high, the process is simple, and the industrialization is easy to realized.

Owner:山东析木津健康科技有限公司

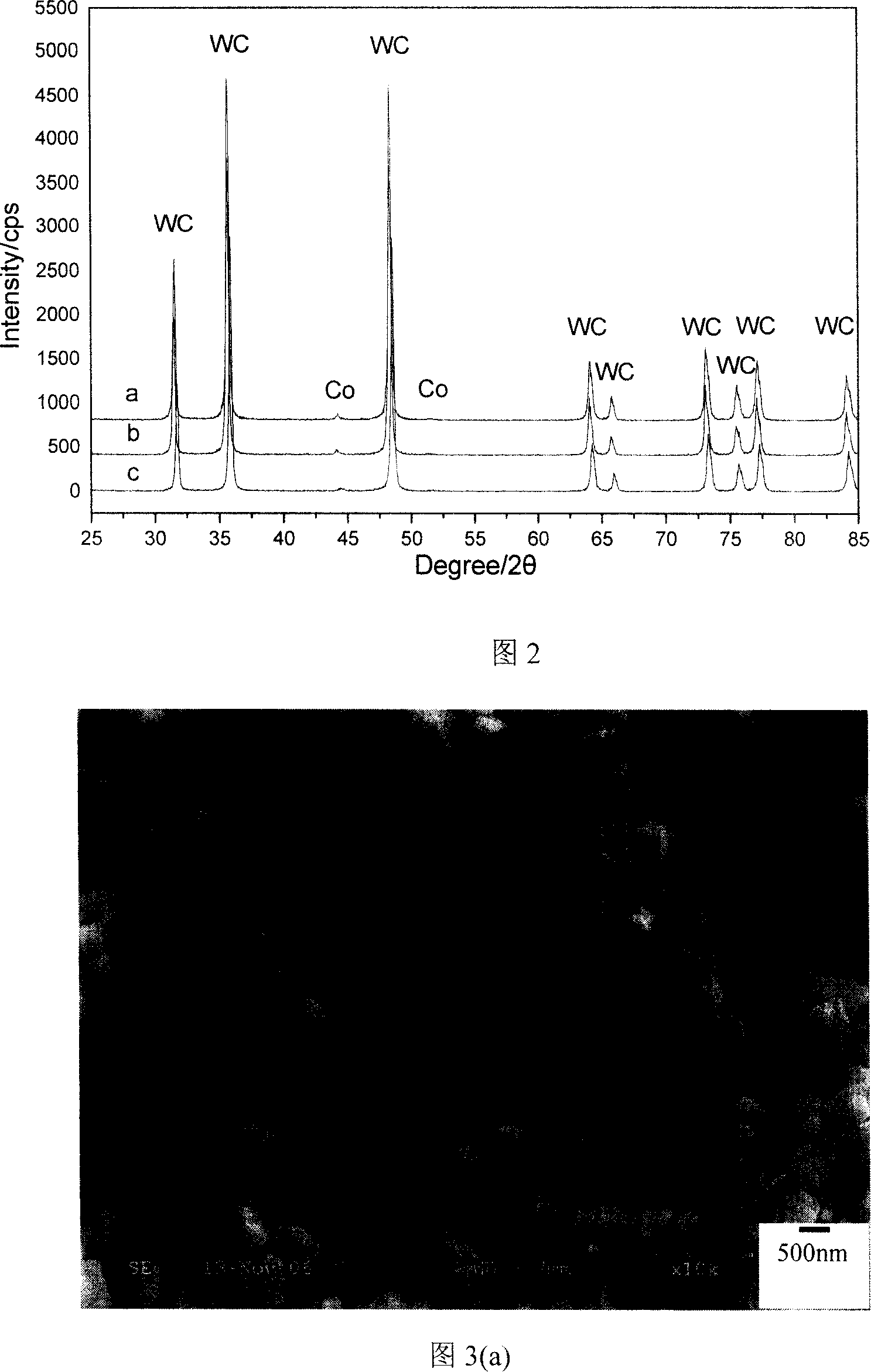

Simple fast preparing process of superfine WC-Co composite powder

The simple fast preparation process of superfine WC-Co composite powder belongs to the field of nanometer powder preparing technology. The preparation process includes the following steps: mixing WO2.9, Co3O4 and carbon black material in the required Co content; ball milling the mixture in a ball milling into superfine powder and cold pressing; heating in a vacuum furnace at vacuum condition to produce redox and carbonizing reaction at heating rate of 15-30 deg.c / min, reaction temperature 1050-1150 deg.c for 3-4 hr. The present invention has simple preparation path and short technological process, and obtains WC-Co composite powder of average particle size smaller than 400 nm.

Owner:BEIJING UNIV OF TECH

Technical for manufacturing jewelry by using hard gold

InactiveCN101810387AHigh hardnessIncrease elasticityJewelleryElectroforming processesManufacturing technologyEngineering

The invention provides a process for manufacturing jewelry by using hard gold. The technique mainly comprises the following steps of: 1, molding; 2, opening a jelly mould; 3, injecting wax; 4, trimming the wax; 5, applying silver oil; 6, manufacturing a raw blank; 7, removing the wax; 8, removing silver; 9, welding; 10, modifying the mould; 11, picking stones and embedding stones; 12, treating the surface; and 13, carving by laser. The method ensures that the molecular structure of gold changes by utilizing hard gold jewelry manufacturing technology and applying the metal reinforcing technology in aerospace science and technology to jewelry manufacture and adjusting temperature, pH value, current, pulse power supply, additive and other technical parameters of electrotyping solution in an electrotyping process, thereby effectively improving the hardness and the elasticity of the gold. On the premise of ensuring the purity of the gold, the hardness of the gold is 4 times that of the traditional gold, so that the technique requirements of the fashion jewelry design are met. The gold jewelry and art decorations manufactured by the method cannot be easily scratched or deform, so that the artistic quality of the jewelry and decorations can be greatly improved.

Owner:惠州市博艺黄金珠宝有限公司

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

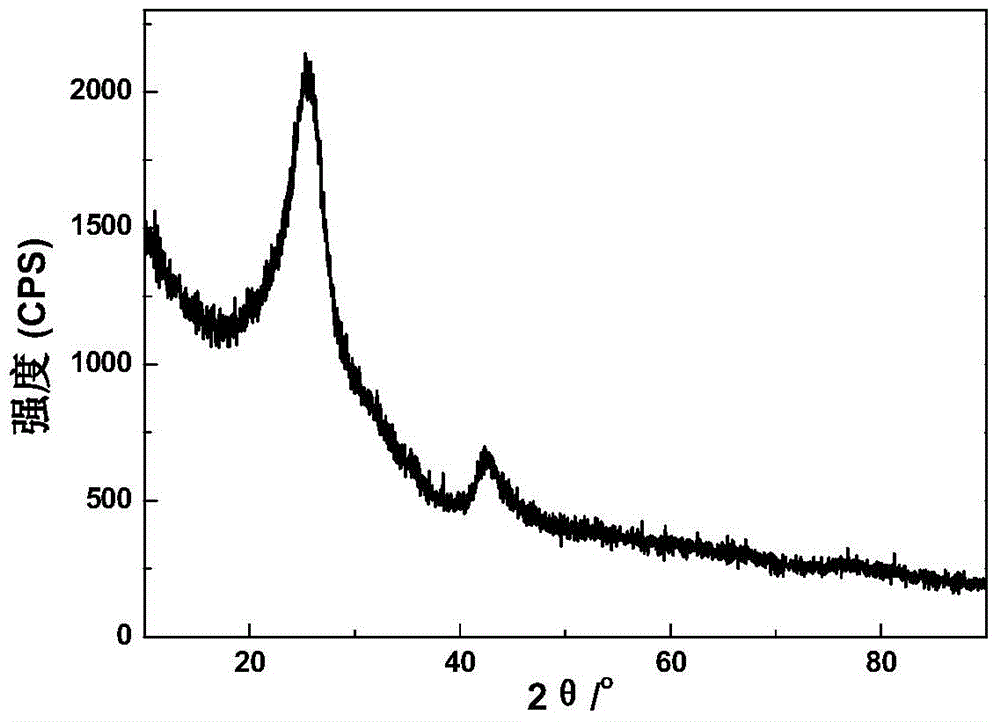

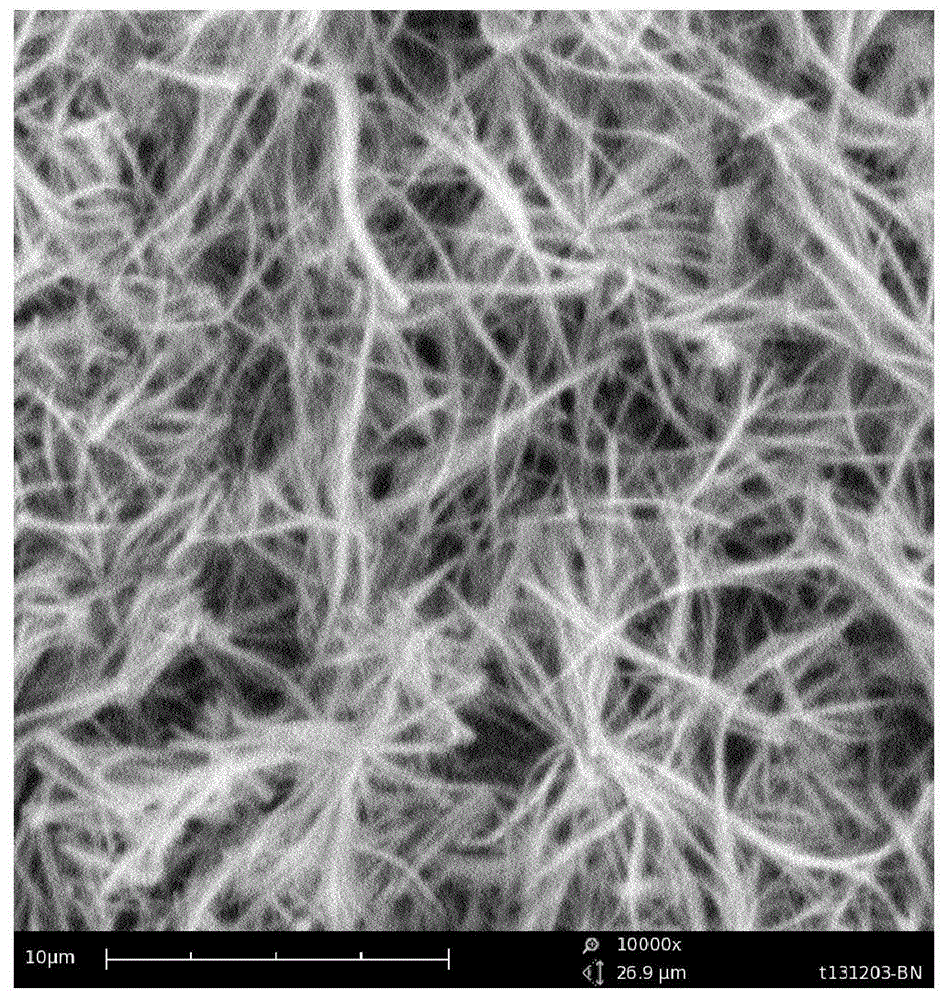

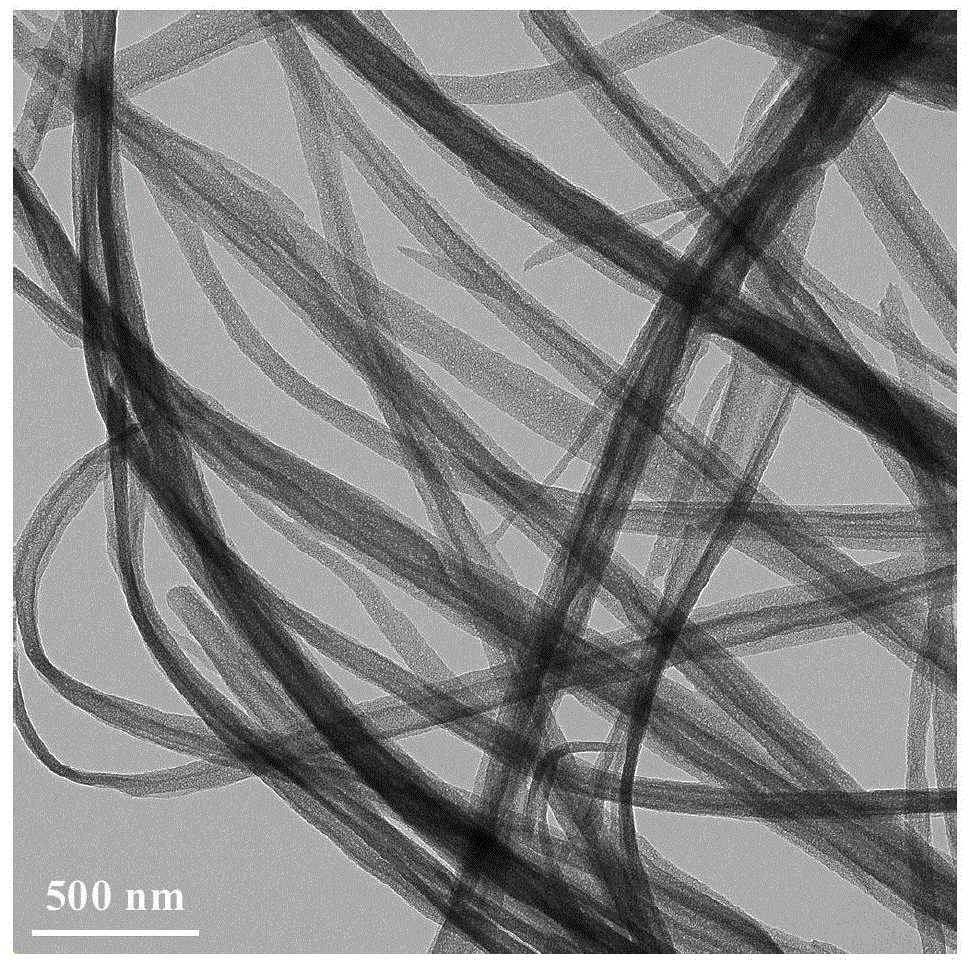

Preparation method of porous boron nitride nanofibers

ActiveCN104528671AUniform shapeDiffraction peaks are clearMaterial nanotechnologyNitrogen compoundsFiberSynthesis methods

The invention relates to a preparation method of porous boron nitride nanofibers. The preparation method mainly utilizes a three-step synthesis method, namely (1) synthesizing melamine diboronic acid precursor powder from boric acid and melamine in a hydrothermal manner; (2) rapidly freezing and cooling a hot water solution of a melamine diboronic acid precursor with liquid nitrogen by virtue of a freeze-drying method, then drying, and synthesizing melamine diboronic acid nanofibers; and (3) carrying out high-temperature thermal cracking on the melamine diboronic acid nanofibers in protective atmosphere, so as to obtain the porous boron nitride nanofibers. According to the preparation method, molecular crystals of melamine diboronic acid are rapidly separated and nucleated by virtue of a freeze drying technique, so that the growth of the crystals is avoided; the diameters of the prepared porous boron nitride nanofibers reach a nanometer scale, and the porous boron nitride nanofibers are high in purity, uniform in shape, high in slenderness ratio and large in specific surface area.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com