Treatment method for waste of positive electrode material of lithium battery

A technology of cathode material and treatment method, which is applied in the field of waste battery material recycling, can solve the problem of lithium not being recycled, and achieve low production cost, simplified metal ion separation process, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

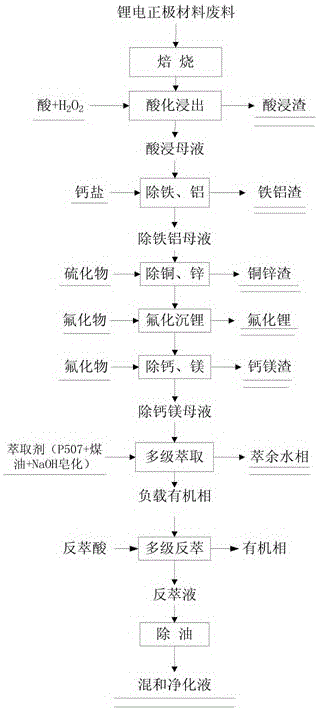

Method used

Image

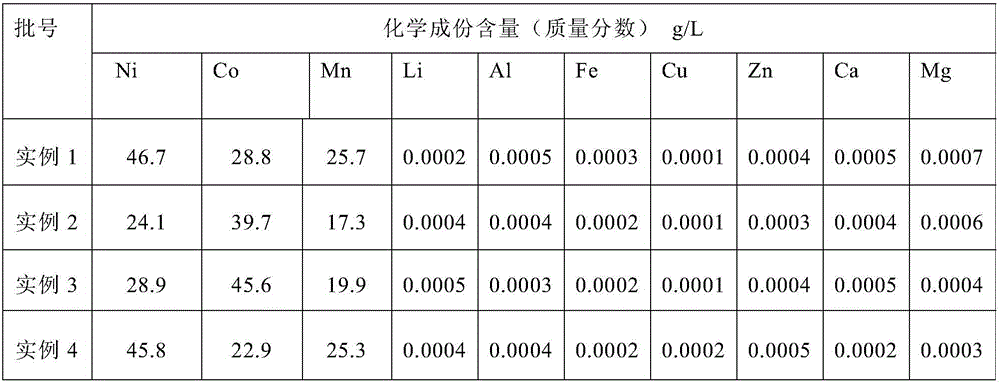

Examples

Embodiment 1

[0061] A Roasting: Roast the lithium battery anode material waste at 300°C for 4 hours;

[0062] B Acidizing leaching: Add 400kg of water to 100kg of roasted waste to adjust the slurry, then add 140kg of 98% (wt%) sulfuric acid to the slurry, and after the temperature is cooled to 40°C, slowly add 32kg of 50% sulfuric acid to the slurry (wt%) hydrogen peroxide, stirred and leached for 2h at 40°C, press-filtered to obtain 550L leached mother liquor, the composition of the leached mother liquor was as shown in Table 1 after determination:

[0063] Table 1 Chemical composition of leaching mother liquor

[0064] element Ni co mn Li Al Fe Cu Zn Ca Mg Contentg / L 49.5 29.8 27.8 11.2 2.3 1.7 1.0 1.0 1.3 1.2

[0065] C. Remove iron and aluminum: Add calcium carbonate to the leaching mother liquor obtained in step B to adjust the pH of the solution to 4.5, and obtain the iron and aluminum mother liquor through pressure filtration. The mea...

Embodiment 2

[0073] A Roasting: Roast the lithium battery anode material waste at 500°C for 1 hour;

[0074] B Acidizing leaching: Add 200kg of water to 100kg of roasted waste to adjust the slurry, then add 440kg of 31% (wt%) hydrochloric acid to the slurry, and then slowly add 32kg of 50% hydrochloric acid to the slurry after the temperature is cooled to 60°C (wt%) hydrogen peroxide, stirred and leached for 2h at 60°C, and press-filtered to obtain 700L leached mother liquor. The composition of the leached mother liquor was as shown in Table 2 after determination:

[0075] Table 2 Chemical composition of leachate

[0076] element Ni co mn Li Al Fe Cu Zn Ca Mg Contentg / L 25.2 41.1 18.4 8.8 0.8 0.7 0.5 0.8 0.8 0.5

[0077] C. Remove iron and aluminum: add calcium carbonate to the leaching mother liquor obtained in step B to adjust the pH of the solution to 5.0, and obtain the iron and aluminum mother liquor through pressure filtration. The mea...

Embodiment 3

[0085] A Roasting: Roast the lithium battery cathode material waste at 400°C for 3 hours;

[0086] B Acidizing leaching: Add 300kg of water to 100kg of roasted waste to adjust the slurry, then add 273.8kg of 65% (wt%) nitric acid to the slurry, and after the temperature is cooled to 50°C, slowly add 82.4kg of 50 % (wt%) hydrogen peroxide, stirred and leached for 2h at 50°C, press-filtered to obtain 600L leached mother liquor, and the ingredients of the leached mother liquor were determined in Table 3:

[0087] Table 3 Chemical composition of leachate

[0088] element Ni co mn Li Al Fe Cu Zn Ca Mg Contentg / L 30.5 47.6 21.3 9.3 0.9 0.6 1.5 1.2 1.3 0.8

[0089] C. remove iron and aluminum: the pH that adds calcium hydroxide to the leaching mother liquor that obtains in the step B and regulates solution is 6.0, obtains iron and aluminum mother liquor through pressure filtration, and Fe content is 0.0002g / L in the measured mother liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com