Patents

Literature

817results about How to "Good effect of removing impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method for waste of positive electrode material of lithium battery

InactiveCN106505272AHigh recovery rateGuaranteed purityWaste accumulators reclaimingProcess efficiency improvementPhysical chemistryManganese

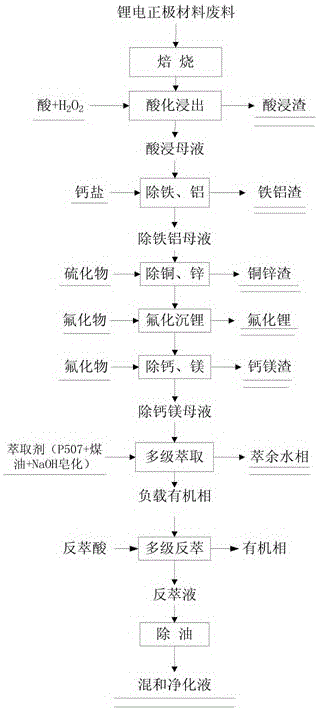

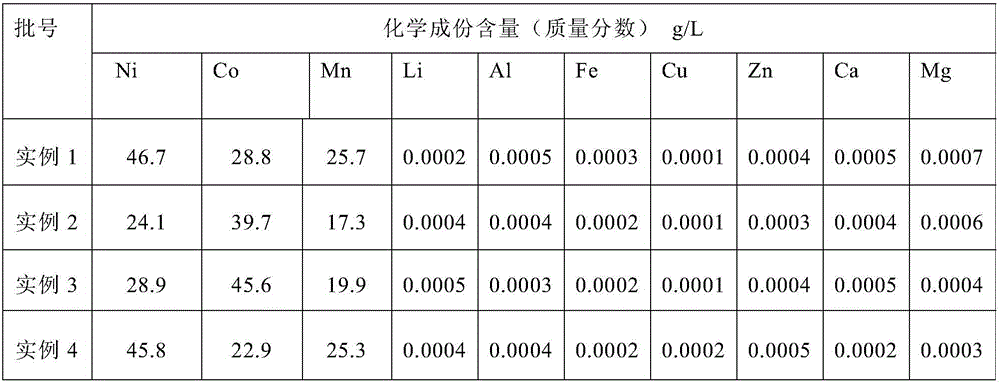

The invention discloses a treatment method for waste of a positive electrode material of a lithium battery. The method comprises the steps of (A) roasting; (B) acidifying and leaching; (C) iron and aluminum removal; (D) copper and zinc removal; (E) fluorinating lithium deposition; (F) calcium and magnesium removal; (G) multi-stage extraction; and (H) oil removal. According to the treatment method for the waste of the positive electrode material of the lithium battery, multiple valuable metals of lithium, cobalt, manganese, nickel and the like contained in the positive electrode material of the lithium battery can be comprehensively recovered; the treatment method has the advantages that the metal recovery rate is high, the obtained lithium product is good in quality and the treatment method is friendly to environment, low in production cost and suitable for industrial production.

Owner:GANFENG LITHIUM CO LTD

Extraction and separation method of cannabidiol

ActiveCN108314608AGood removal effectRemove completelyOrganic chemistryOrganic compound preparationSolubilityOrganic solvent

The invention discloses an extraction and separation method of cannabidiol. According to the method disclosed by the invention, the water solubility of the cannabidiol is enhanced through adopting analkaline solution and the cannabidiol is extracted and enriched by utilizing an organic solvent; then the cannabidiol is purified and enriched through a polyamide resin column, neutral aluminum oxideand a bonded silica gel column; then the cannabidiol is crystallized to obtain high-purity cannabidiol. The method disclosed by the invention is easy to operate, strong in practicability and suitablefor industrial popularization and application.

Owner:FIRST AFFILIATED HOSPITAL OF KUNMING MEDICAL UNIV +1

Refining agent for aluminium and aluminium alloy melting

InactiveCN102312104AReduce dosageGood effect of removing impuritiesProcess efficiency improvementSlagHydrogen content

The invention provides a refining agent for melting processing of aluminium and aluminium alloy, and the refining agent comprises the following six components of KCl, NaCl, CaF2, Na2SiF6, Na3AlF6, C2Cl6. When the refining agent of the invention is used for melting of aluminium and aluminium alloy, the degassing and impurity-removing effect is better; the hydrogen content in aluminium alloy melt is lower; the burning loss of the metal can be reduced effectively; meanwhile the refining agent has certain heating effect, so the hot slag recovery is more convenient and the recovery rate is higher.

Owner:ALNAN ALUMINIUM CO LTD

Dispersive air brick and preparation method thereof

The present invention relates to a dispersive air brick and a preparation method thereof. According to the technical scheme of the invention, 50 to 80 wt% of plate-shaped corundum is adopted as an aggregate. 12 to 32 wt% of aluminum oxide fine powders, 5 to 10 wt% of alumina micro powders and 3 to 8 wt% of a binding agent are adopted as matrix materials. According to the method, firstly, the matrix materials are uniformly mixed, and then the matrix materials and the aggregate are put into a mixer. 0.1 to 0.3 wt% of a water reducing agent and 4 to 6 wt% of water, counted relative to the sum of the aggregate and the matrix materials, are additionally added. The obtained mixture is stirred for 3 to 5 minutes, and then is cast and molded. After an obtained product is standing at the room temperature for 20 to 30 hours, the obtained product is dried for 22 to 26 hours at the temperature of 90 to 120 DEG C. then the obtained product is thermally insulated for 3 to 6 hours at the temperature of 1450 to 1650 DEG C. In this way, the dispersive air brick can be obtained. The plate-shaped corundum is in the form of equal-diameter particles, and the particle sizes of the equal-diameter particles are 2 to 5 mm. The method has the advantages of simple process, low labor intensity, high production efficiency, no pollution to the environment, and low cost. The prepared dispersive air brick is good in air permeability, strong in impurity-removing capability, excellent in thermal shock stability and good in penetration resistance performance.

Owner:江苏锦耐新材料科技有限公司

Process for refining high-purity bismuth from bismuth-containing material generated from anode mud recovery

ActiveCN101886174AReduction of Bismuth Content RequirementsExpand sourcePhotography auxillary processesProcess efficiency improvementTemperature controlBismuth

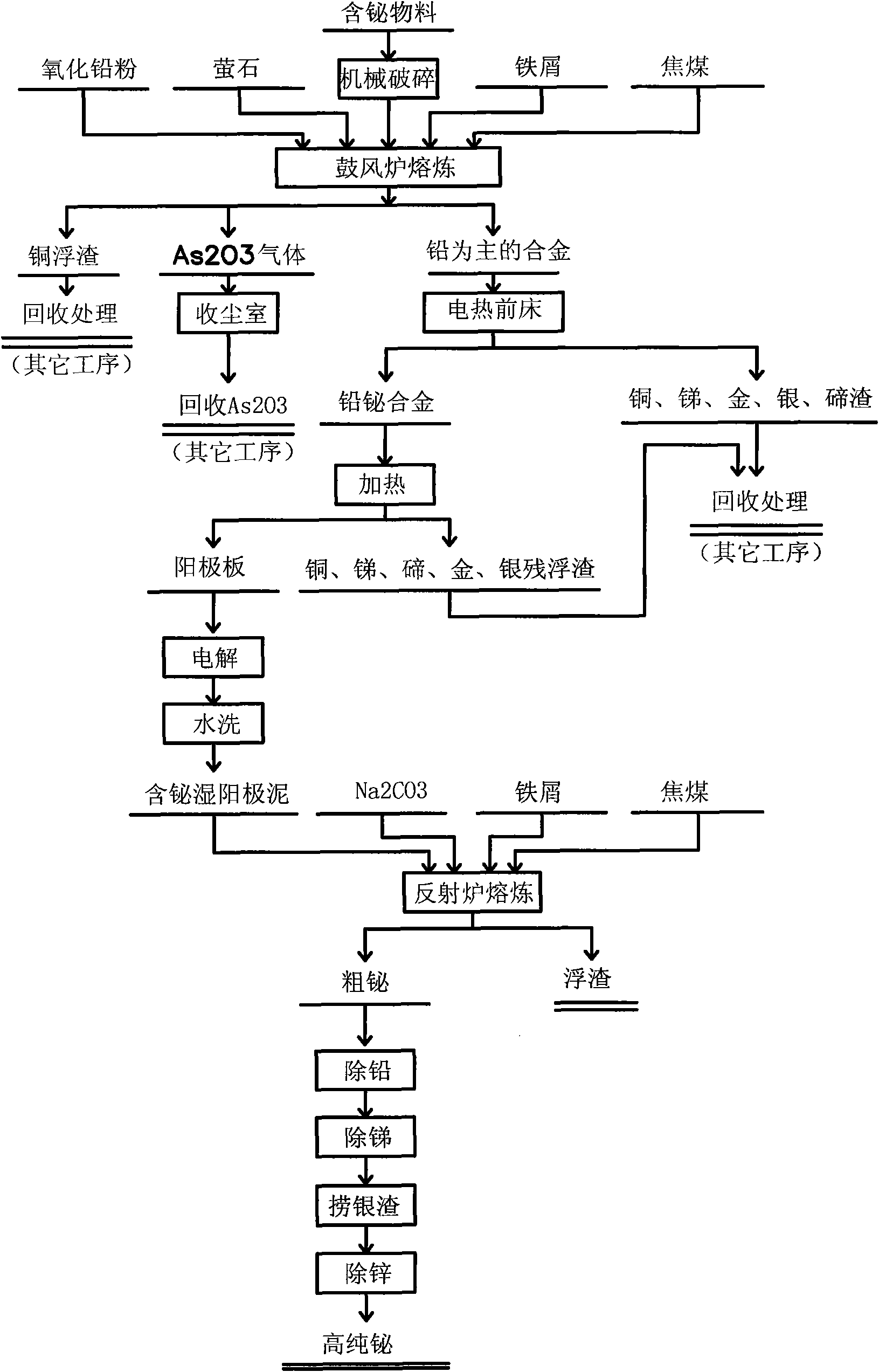

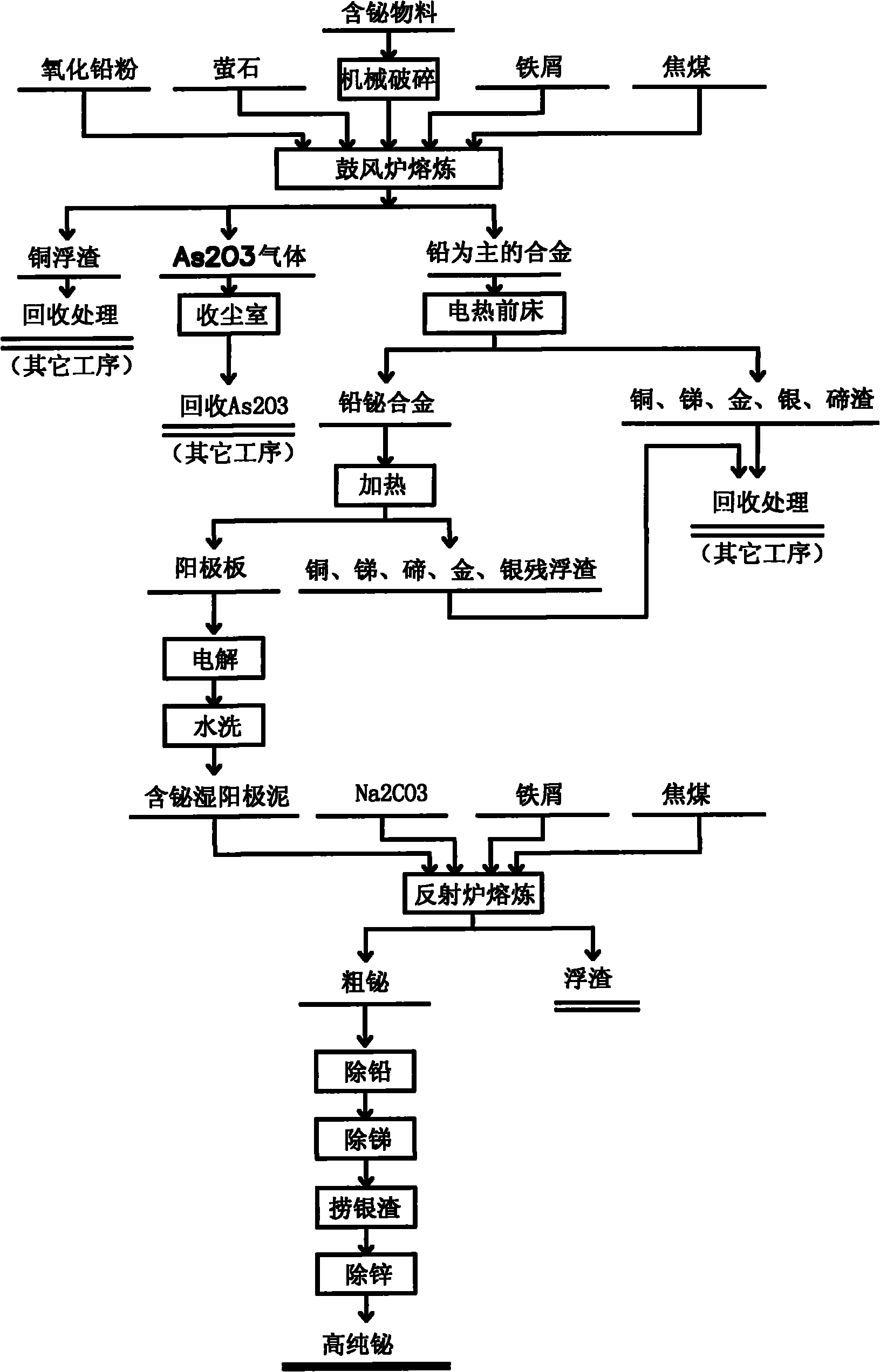

The invention relates to a process for refining high-purity bismuth from bismuth-containing materials generated from anode mud recovery, belonging to the technical field of processes of recovering smelting bismuth by combining a wet process and a pyrogenic process of non-ferrous metal. The process comprises the following steps of: firstly increasing the content of bismuth contained in the bismuth-containing materials to obtain crude bismuth by adopting an enrichment process; and then further refining and purifying the crude bismuth into the high-purity bismuth by adopting a selective accurate temperature-control smelting method according to different melting points of compounds between bismuth metal and impurity-containing metal. Compared with the prior art, the invention reduces the requirements for the content of the bismuth contained in raw materials and can realize the economic and high-efficiency recovery of the bismuth metal, refine the high-purity bismuth and reduce the environmental pollution.

Owner:郴州雄风环保科技有限公司

Preparation method of highly pure quartz sands

The invention discloses a preparation method of highly pure quartz sands. The method comprises the following steps: 1, roughing: cleaning a raw material, and crushing the cleaned raw material; 2, carrying out calcining and water quenching: calcining the crushed raw material, taking out particles, and quenching the particles in an ice-water mixture; 3, carrying out electric separation and magnetic separation: milling the quenched particles, carrying out electric separation and magnetic separation twice, and carrying out pulse magnetic field treatment; 4, pickling: immersing a material obtained in step 3 in a hydrochloric acid solution, filtering the immersed material, dialyzing the obtained first filtrate to recover hydrochloric acid, preparing a first mixed acid by using the recovered hydrochloric acid and a sulfuric acid solution, immersing quartz sands in the first mixed acid, filtering the immersed quartz sands, dialyzing the obtained second filtrate to obtain recovered mixed acid, preparing a second mixed acid by using the recovered mixed acid and a nitric acid solution, immersing the quartz sands in the second mixed acid, adding the immersed quartz sands to a sodium carbonate solution, and flushing the quartz ands; 5, floating the flushed quartz sands; and 6, drying the floated quartz sands. The preparation method allows highly pure quartz sands with the SiO2 content to be not lower than 99.995% to be produced, and takes a greatly lower acid amount than traditional methods.

Owner:江苏凯达石英股份有限公司

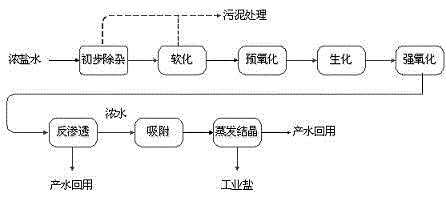

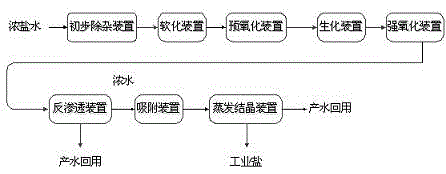

Method and device for realizing zero emission of strong brine

ActiveCN105541017ATake advantage ofEase of useGeneral water supply conservationWater treatment compoundsLoad resistanceEvaporation

The invention provides a method and a device for realizing zero emission of strong brine, overcoming the defects that the existing strong brine treatment technology is high in crystallized impurity salt treatment cost and severe in harm. The impurity removal, softening, pre-oxidation, biochemical and strong oxidation techniques are used for purifying the strong brine, the strong brine after being treated is pre-concentrated by adopting a reverse osmosis way, the reverse osmosis concentrated water is further purified by adopting an adsorption method, and finally the evaporation and quality-divided crystallization technology is used for separating the water to obtain industrial salt. By adopting the method and device, the zero emission of the strong brine is realized, the emission of dangerous waste is reduced, and the recycling is realized. Meanwhile, the general process is mature, the design is reasonable, the impact load resistance is relatively high, the chemical source is convenient, and the cost is low.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Method for producing oxygen-free copper rod from secondary copper

ActiveCN103114208ALow costReduce physical workloadProcess efficiency improvementMetal rolling arrangementsNatural gasMetal impurities

The invention discloses a method for producing an oxygen-free copper rod from secondary copper, which comprises the following steps of: (A) feeding the secondary copper into a furnace, and heating for melting; (B) refining to remove metal impurities; (C) reducing with natural gas to obtain pure copper; (D) adding rare earth and a complex deoxidizer and then outputting copper; and (E) casting, and performing continuous casting and rolling to obtain an oxygen-free copper rod. Compared with a traditional up-draw process, the method disclosed by the invention can adopt the easily available secondary copper as a raw material for production and can process a great quantity of secondary copper once, and overcomes the shortcomings of high production cost and low production efficiency of the up-draw process adopting secondary copper as raw material; natural gas reduction replaces poling, thereby being more environment-friendly and ensuring lower cost; and moreover, the labor capacity is small, and the defect of bad working condition in poling is overcome.

Owner:绵阳铜鑫铜业有限公司

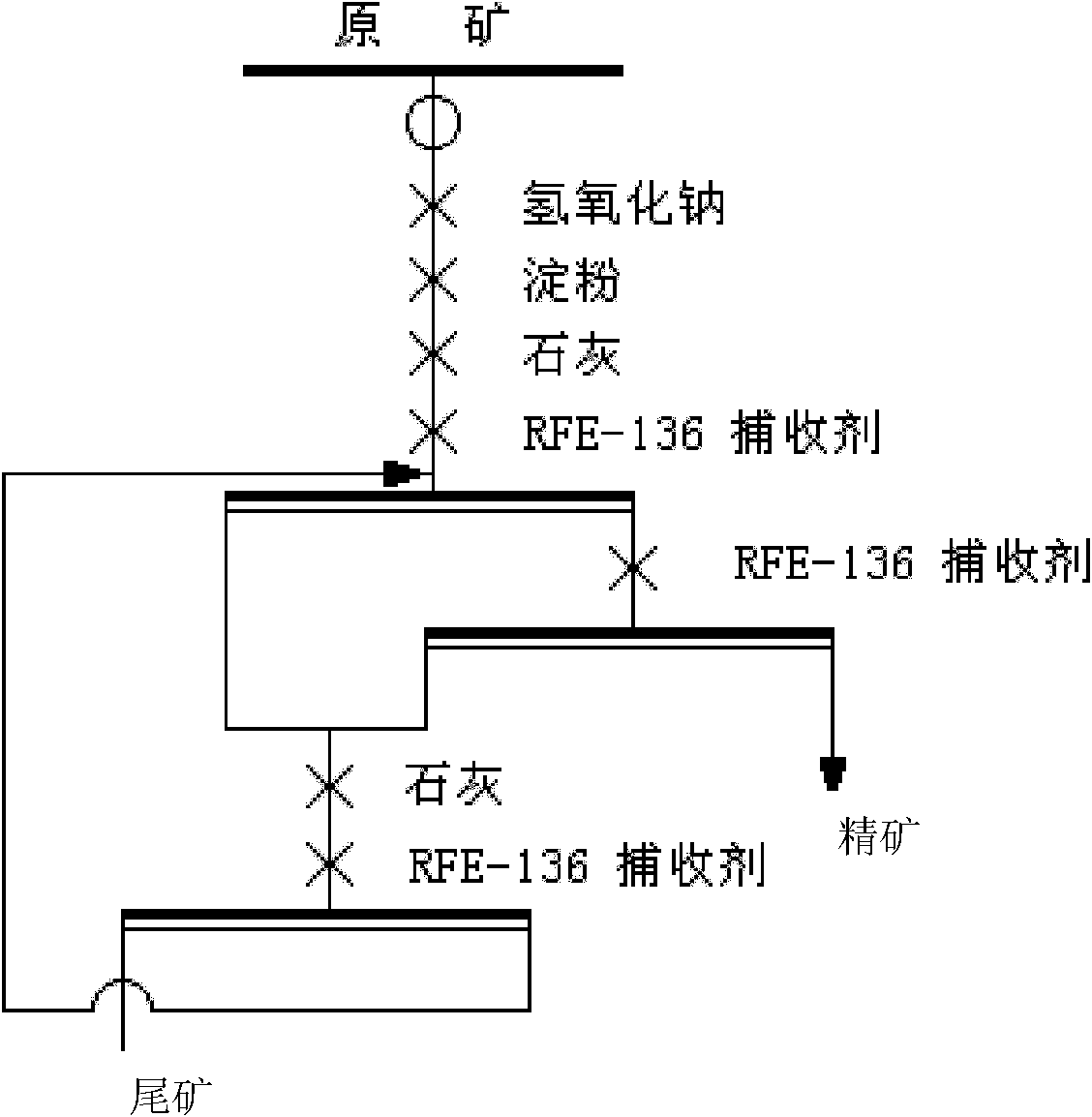

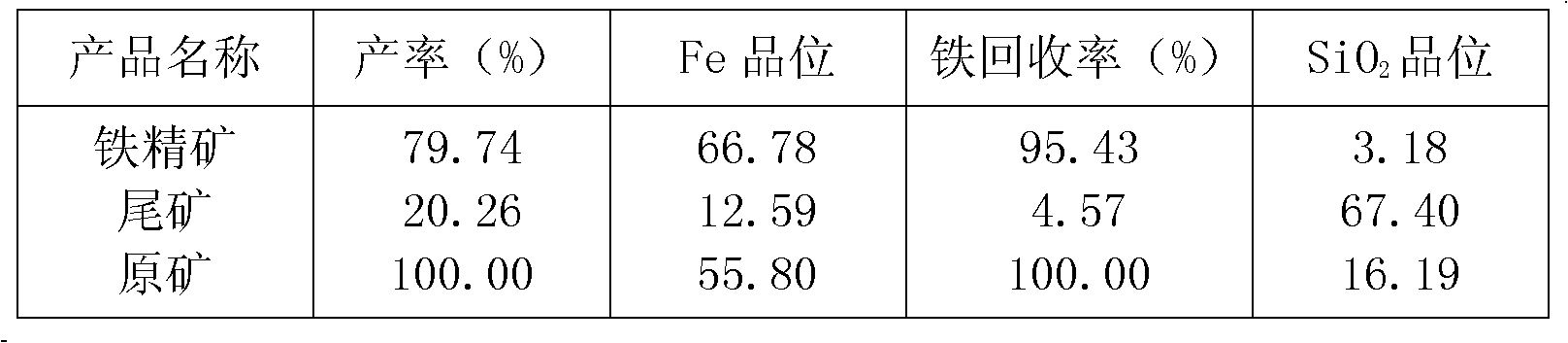

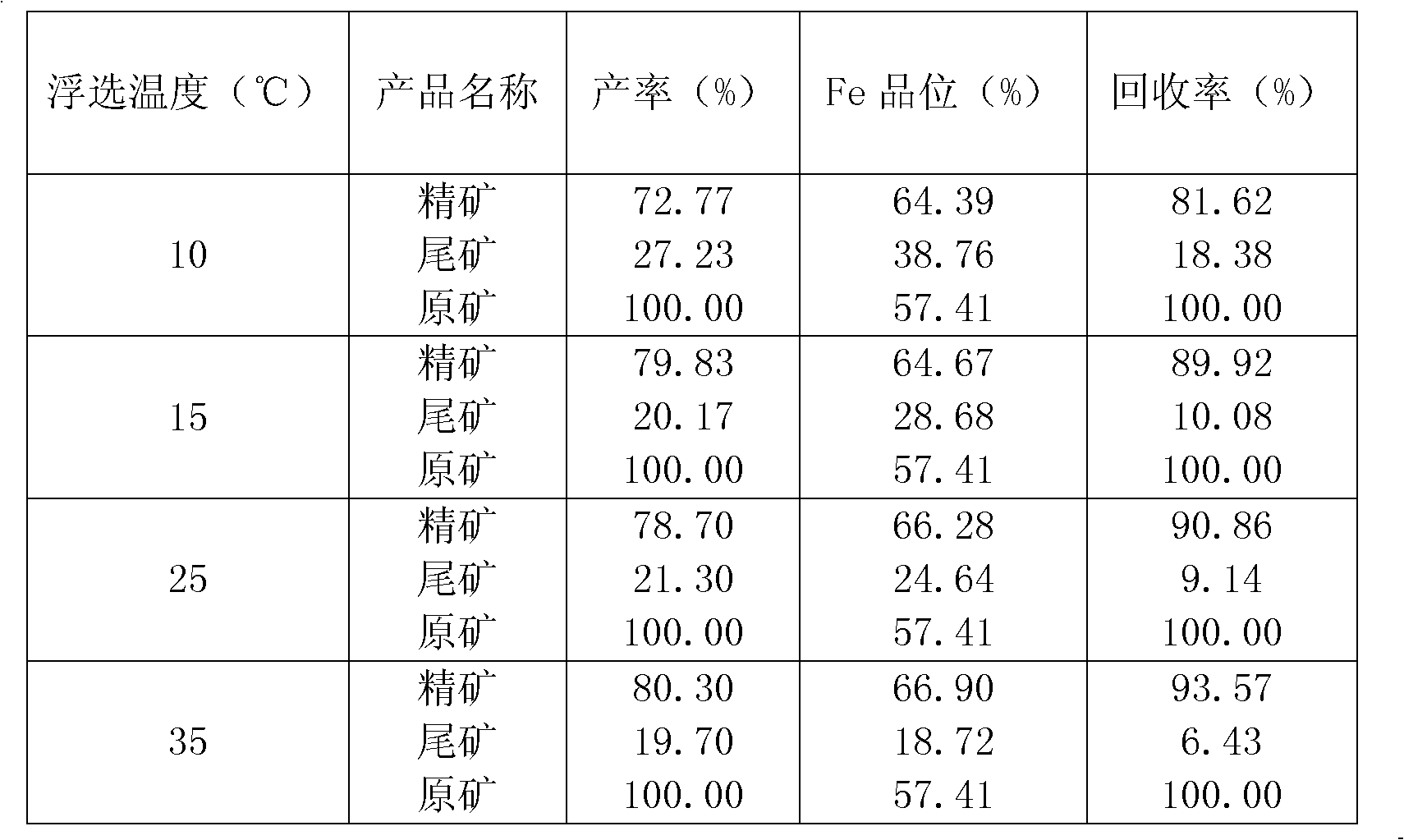

Iron ore flotation anion/cation collector and preparation method thereof

The invention relates to an iron ore concentrating flotation drug and a preparation method thereof and in particular discloses an iron ore flotation anion / cation collector. In the invention, a main agent for preparing an anion collector comprises fatty acid and a derivative thereof, and a main agent for preparing a cation collector comprises organic amine and / or a quaternary ammonium salt; and auxiliary agents of the two collectors also comprise an organosilicon compound, chloralkane, fatty alcohol, an emulsifier and water, wherein the auxiliary agent of the anion collector also comprises hydrocarbon oil. The preparation method of the collectors comprises the following steps of: synthesizing the main agents through organic reactions; weighing other components according to certain weight parts; mixing according to a certain sequence; and uniformly stirring to prepare micro-emulsion homogeneous phase viscous liquid. The collectors have the advantages of strong collecting capacity, high anti-argillization capacity, low production cost, hard water resistance, stable property, small drug dosage, good selectivity, environmental protection, safety, low temperature adaptability, and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing icariin

InactiveCN101812100AGood effect of removing impuritiesHigh puritySugar derivativesSugar derivatives preparationAlcoholMacroporous resin

The invention relates to a method for preparing icariin, which comprises the following process steps: ethanol extraction, concentration, low-alcohol macroporous resin enrichment, polyamide separation and purification, and recrystalization. When the method is used for producing the icariin, the process is simple, the product yield is high, and the product purity is high. The process is also suitable for producing icariin of different content levels; and the product prepared by the process meets food and medical requirements.

Owner:苏州宝泽堂医药科技有限公司

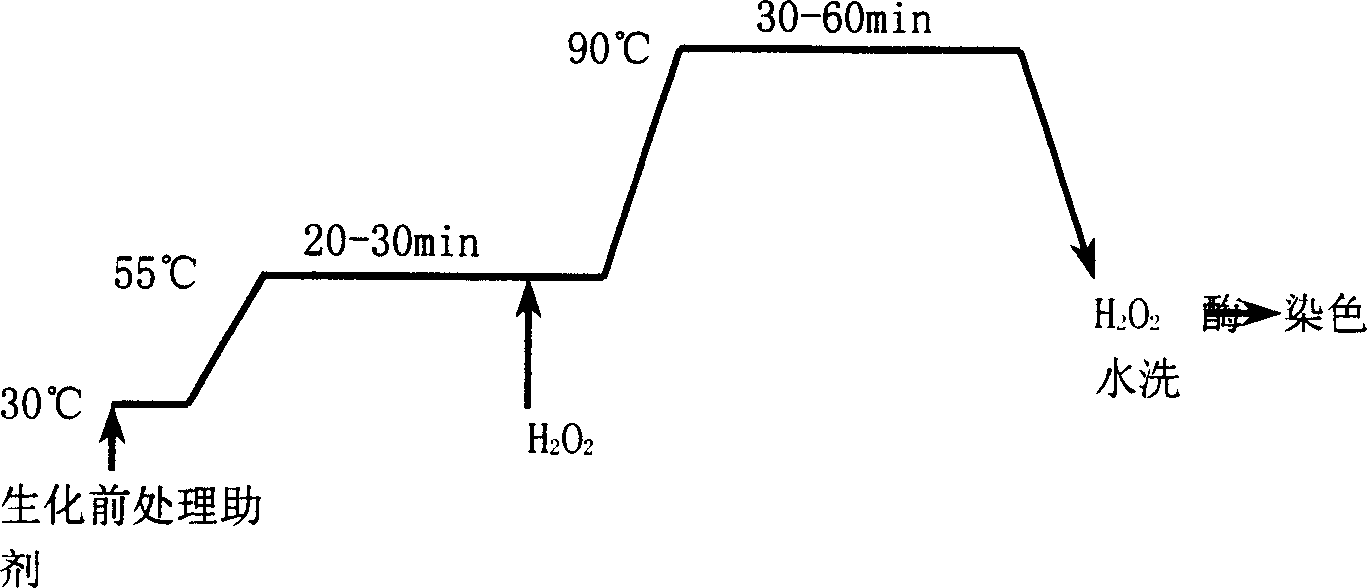

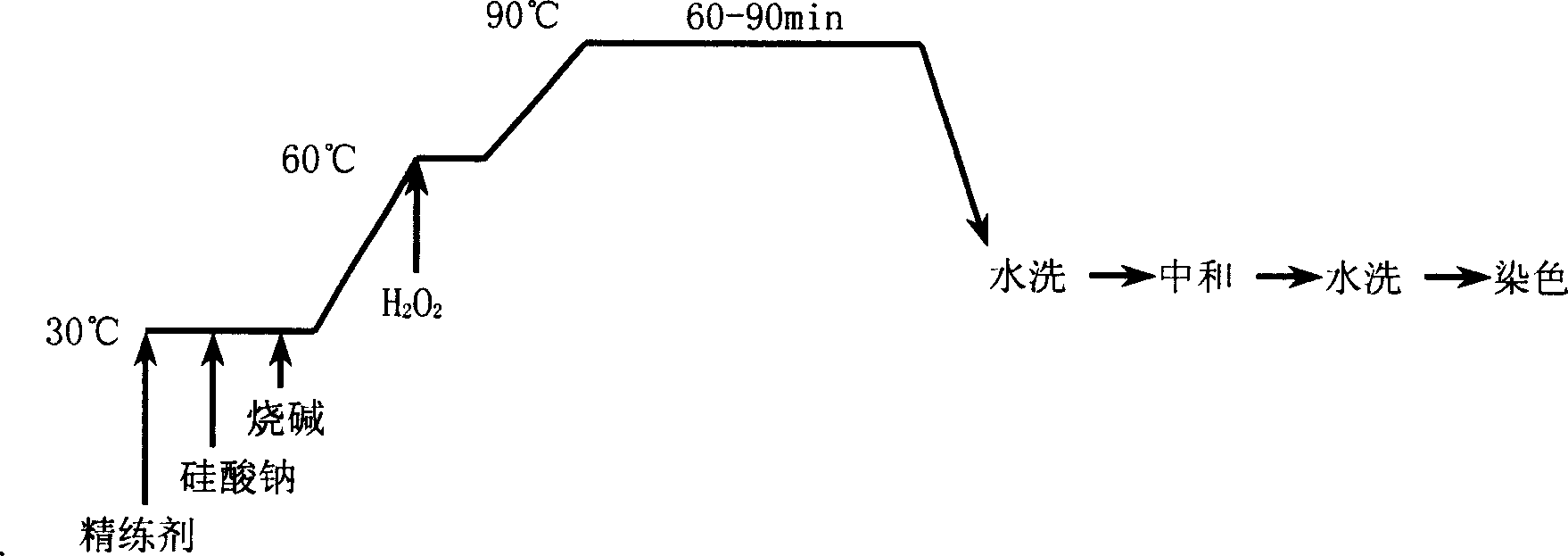

Cellulose fibre, textile assistant for union biochemical pretreatment, perparing method and use

The invention relates to the method to use special biology enzyme (pectic enzyme, fibrin enzyme, lipase, albumen enzyme, lacquer enzyme, xylan enzyme, polysaccharide enzyme, and catalase) and environment-friendly effective surfactant to produce aid fitting the biochemical pretreatment of fibrin fiber, and its fabric, and its processing technology. The aid for short flow of zoology pretreatment made of a host of biology enzyme and environment-friendly surfactant can fit the short flow of zoology pretreatment of fibrin fiber and its fabric. The invention advances the quality of the production. At the same tie, it reduces pollution to the environment, and it achieves the process of pretreatment of fibrin fiber and its fabric with the interreaction with biology enzyme and surfactant. Moreover, thep rocess does little harm to the fiber and it has an effective removement of residue. Additionally, it is friendly to the environment.

Owner:DONGHUA UNIV +1

Solution preparation method of electrolytic manganese metal

InactiveCN103451423AReduce manufacturing costLow impurity contentPhotography auxillary processesElectrolysisFiltration

The invention relates to a solution preparation method of electrolytic manganese metal, and relates to improvement of a preparation process of an electrolytic stock solution in a process of producing manganese metal through a wet method. The method is characterized in that the preparation process comprises the following steps: (1) adding returned anode liquor to manganese ore raw material mineral powder, and adding sulfuric acid for leaching reaction; (2) carrying out primary pressure filtration on leaching reaction slurry, carrying out solid-liquid separation to obtain leaching filter liquor; (3) neutralizing the separated leaching filter liquor, and then oxidizing to remove iron; (4) regulating the PH value, and then sulfurizing to remove heavy metal; (5) carrying out secondary pressure filtration; (6) standing for separating; (7) carrying out third-time pressure filtration to complete a solution preparation process. The method disclosed by the invention can be used for effectively reducing the impurity content of liquid, reducing the consumption of a sulfurizing agent SDD (Sodium Dimethyl Dithiocarbamate) and reducing the production cost of electrolytic manganese, is obvious in impurity removing effect, and can be used for reducing the sulfur content of a product, enhancing the quality of the product and achieving the effect of removing the heavy metal through sulfurization.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

Refining agent for smelting aluminum alloy

The invention relates to a refining agent for smelting an aluminum alloy. The refining agent is characterized by comprising the following components by mass percent: 35% to 45% of NaCl, 25% to 35% of KNO3, 3% to 8% of CaF2, 6% to 10% of Na2SiF6, 7% to 12% of Na3AlF6, 5% to 10% of graphite and 0.5% to 1.5% of rare earth. The refining agent has the characteristics of good refining effect, strong degassing capacity and the like, and cannot generate noxious gas during a production process.

Owner:COSCO W M J ALUMINUM DEV CO LTD

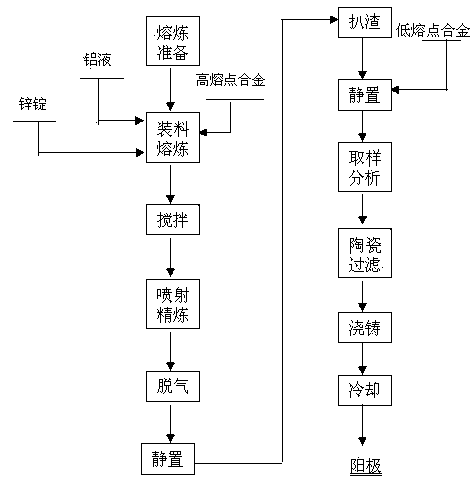

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

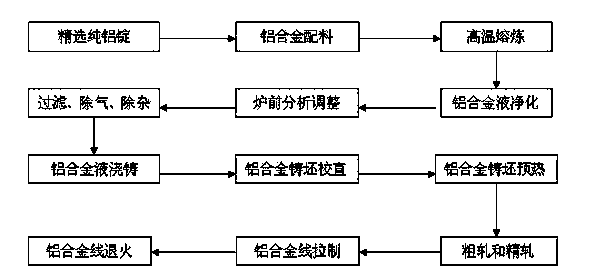

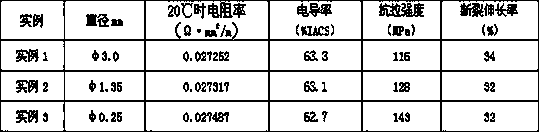

Energy-saving high-elongation soft aluminum alloy wire and preparation method thereof

InactiveCN104032191AUniform compositionGuaranteed mass productionMetal/alloy conductorsImpurityEnergy analysis

The invention relates to an energy-saving high-elongation soft aluminum alloy wire and a preparation method thereof. The aluminum alloy wire is mainly composed of the following components in percentage by weight: 0.05-0.40% of Cu, 0.10-0.40% of Zr, 0.25-1.00% of Fe, 0.01-0.22% of Mg, 0.001-0.15% of Si, 0.05-0.15% of Y, 0.05-0.10% of Sc, and the balance of Al and other inevitable impurity elements. The amount of each element in the other inevitable impurity elements does not exceed 0.03%, and the total amount of all the other inevitable impurity elements does not exceed 0.15%. The aluminum alloy wire has the advantages of favorable creep resistance, high elongation percentage, favorable bending property and the like, is easy for machine-shaping, and can ensure the stability of the electrical connection.

Owner:JIANGSU CHANGFENG CABLE

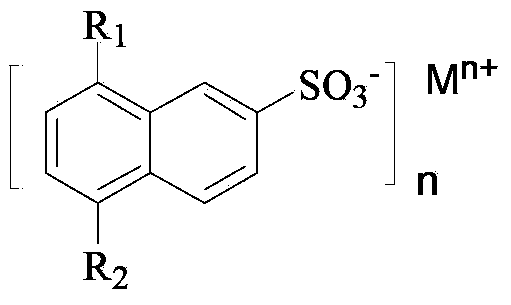

Synergic extraction agent and method for selectively extracting nickel in acidic nickeliferous solution through synergic extraction agent

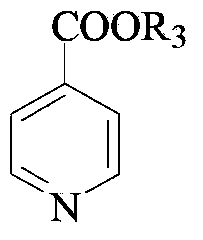

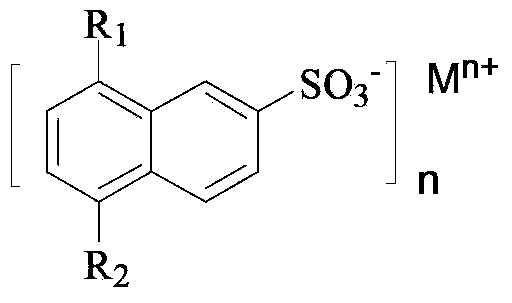

The invention discloses a synergic solvent extraction and a method for selectively extracting nickel in an acidic nickeliferous solution through the synergic extraction agent. The synergic solvent extraction is the compound of naphthalene sulfonic acid or naphthalenesulfonate and pyridine carboxylic ester; the method comprises the following steps: adopting the synergic solvent extraction to selectively extract nickel ions from the acidic nickeliferous solution, adopting mineral acid to conduct back extraction on loaded organic phase to obtain highly purified nickeliferous solution to realize effective separation of nickel ions with impurity ions of iron ions, aluminium ions, manganese ions, magnesium ions, calcium ions, chromium ions and the like. Through adoption of the method, the recovery ratio of the nickel ions is high, the effect on separating the nickel ions from impurities is good, the process is short, and industrialization is easy to realize.

Owner:CENT SOUTH UNIV +1

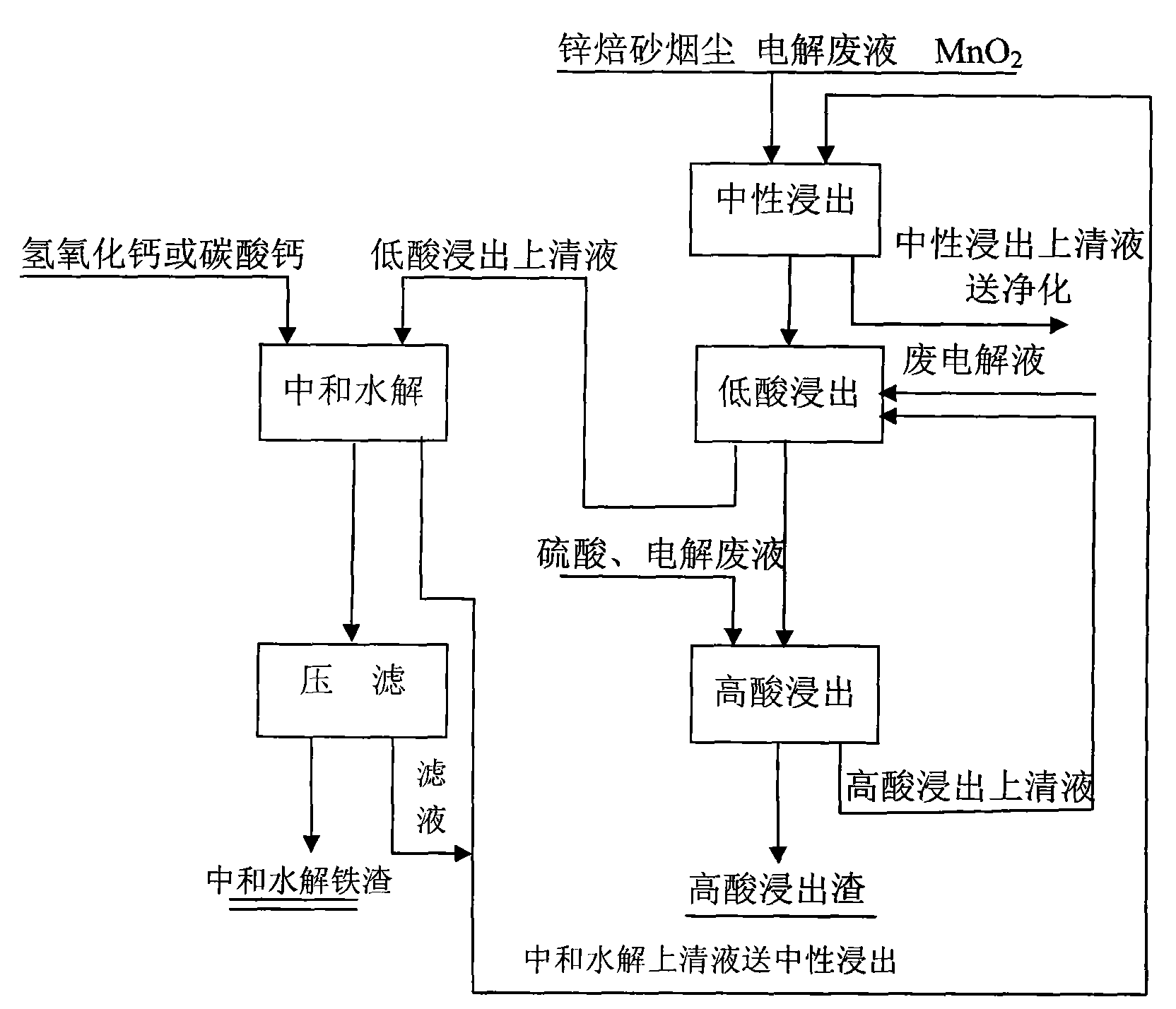

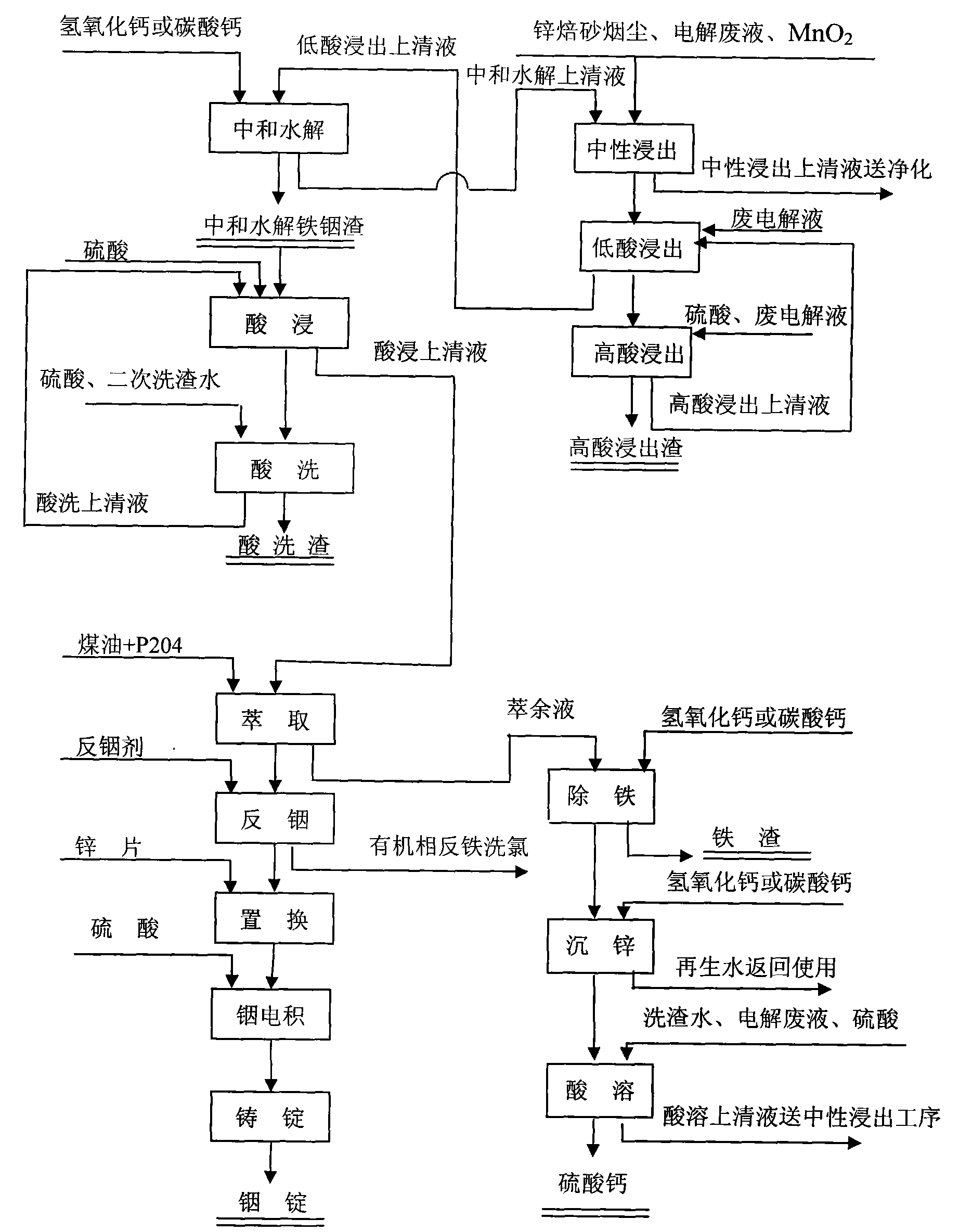

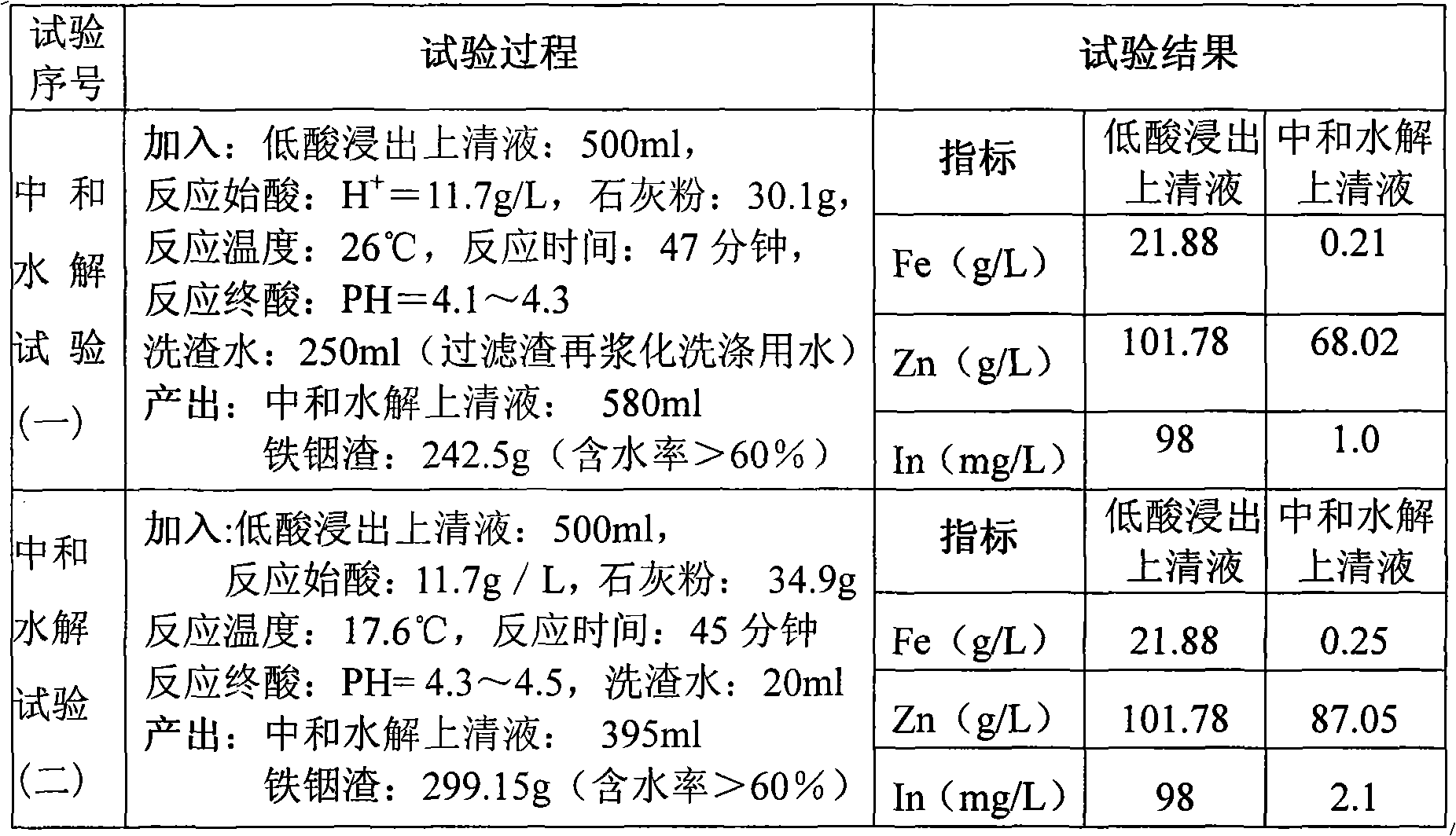

Zinc smelting process by neutralization and hydrolysis iron removal method

InactiveCN101629246AReduce processShort processProcess efficiency improvementCalcium hydroxideIndium

The invention relates to a nonferrous metal smelting technology, in particular to a zinc smelting process by a neutralization and hydrolysis iron removal method for smelting zinc and indium from zinc roasting-sand smoke dust. The zinc smelting process comprises the following working procedures: A. leaching a working section comprising a neutral leaching working procedure, a weak acid leaching working procedure and a strong acid leaching working procedure: delivering the supernatant obtained after neutral leaching to the purifying and the electrodeposit working procedure for extracting zinc; and B. a neutralization and hydrolysis working procedure: delivering the supernatant obtained after weak acid leaching to the neutralization and hydrolysis working procedure, adding in calcium hydroxide or calcium carbonate for neutralizing hydrolysis for iron removal, and returning the supernatant obtained after neutralization and hydrolysis to the neutral leaching working procedure, wherein the iron residues obtained after neutralization and hydrolysis are piled when no indium is included, and when the iron residues obtained after neutralization and hydrolysis are iron residues including indium, the iron residues are delivered to the pickling working procedure, and the supernatant obtained after pickling is delivered to a traditional centrifugal-extraction indium-extracting system for indium extraction. The invention shortens the process flow of the zinc metallurgy (including indium extracting), invents a method for removing iron at normal temperature and comprehensively recycling the zinc and indium without coal consumption at normal temperature, achieves the purposes of saving energy, reducing consumption, reducing the zinc and indium production cost and having good impurity cleaning effect and also provides a process flow simply following the traditional process.

Owner:杨志杰

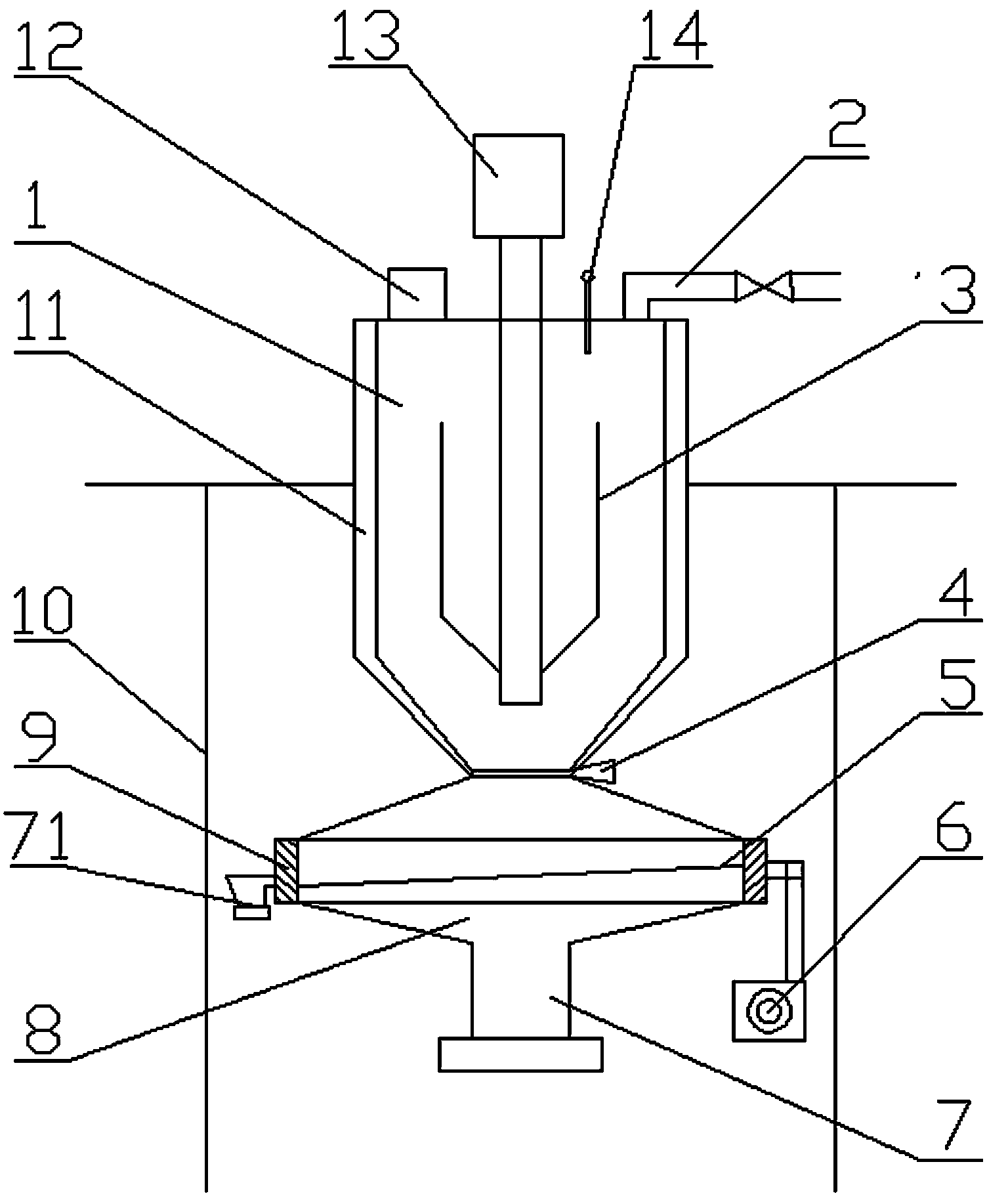

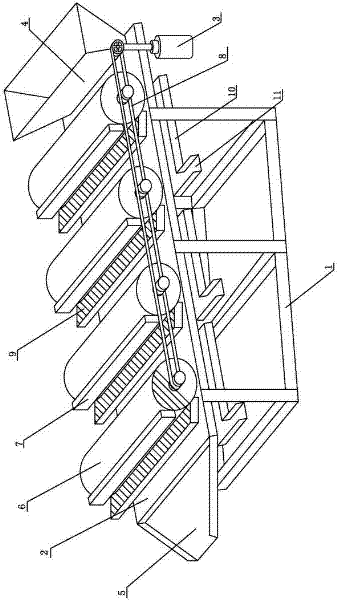

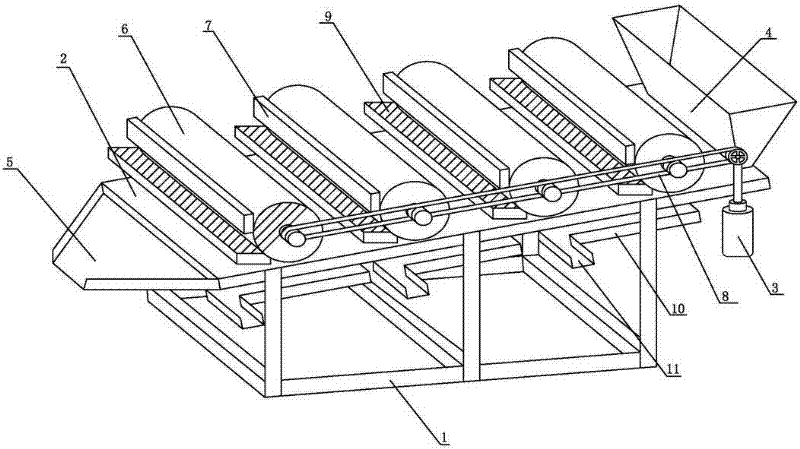

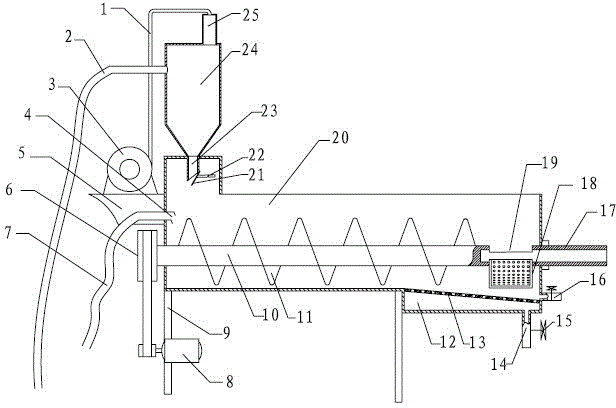

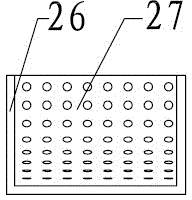

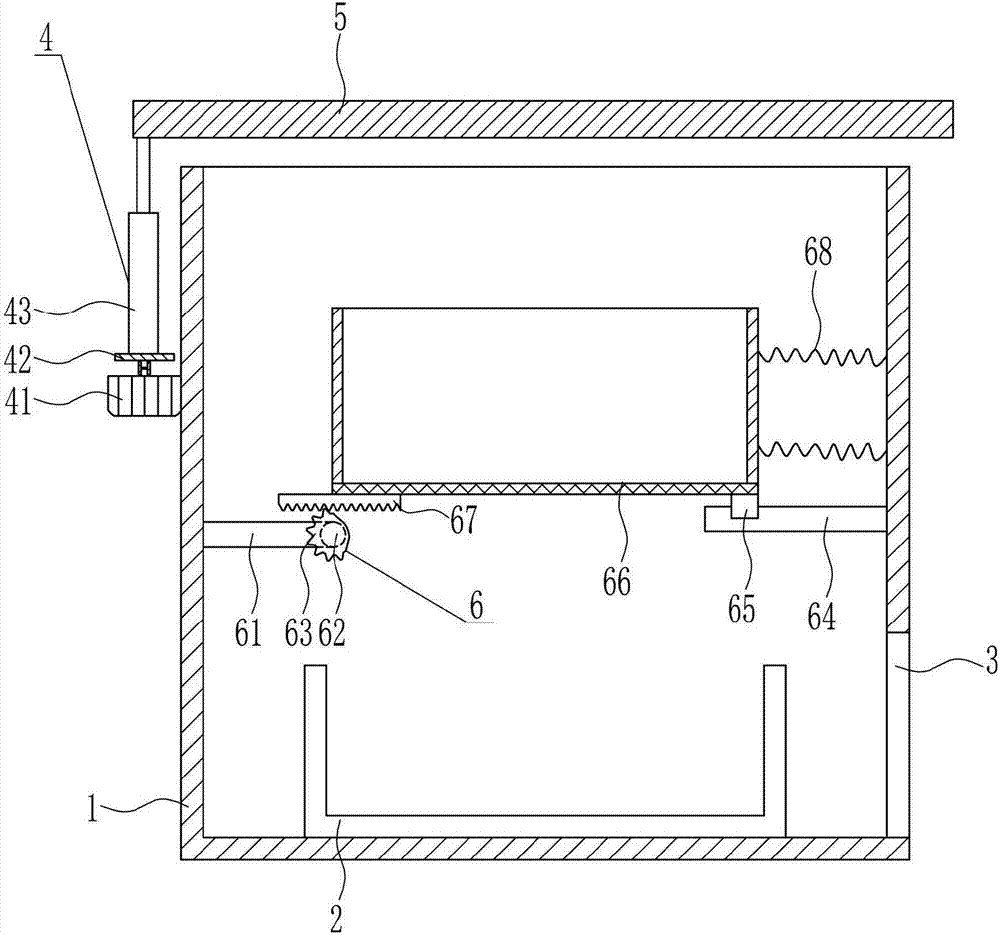

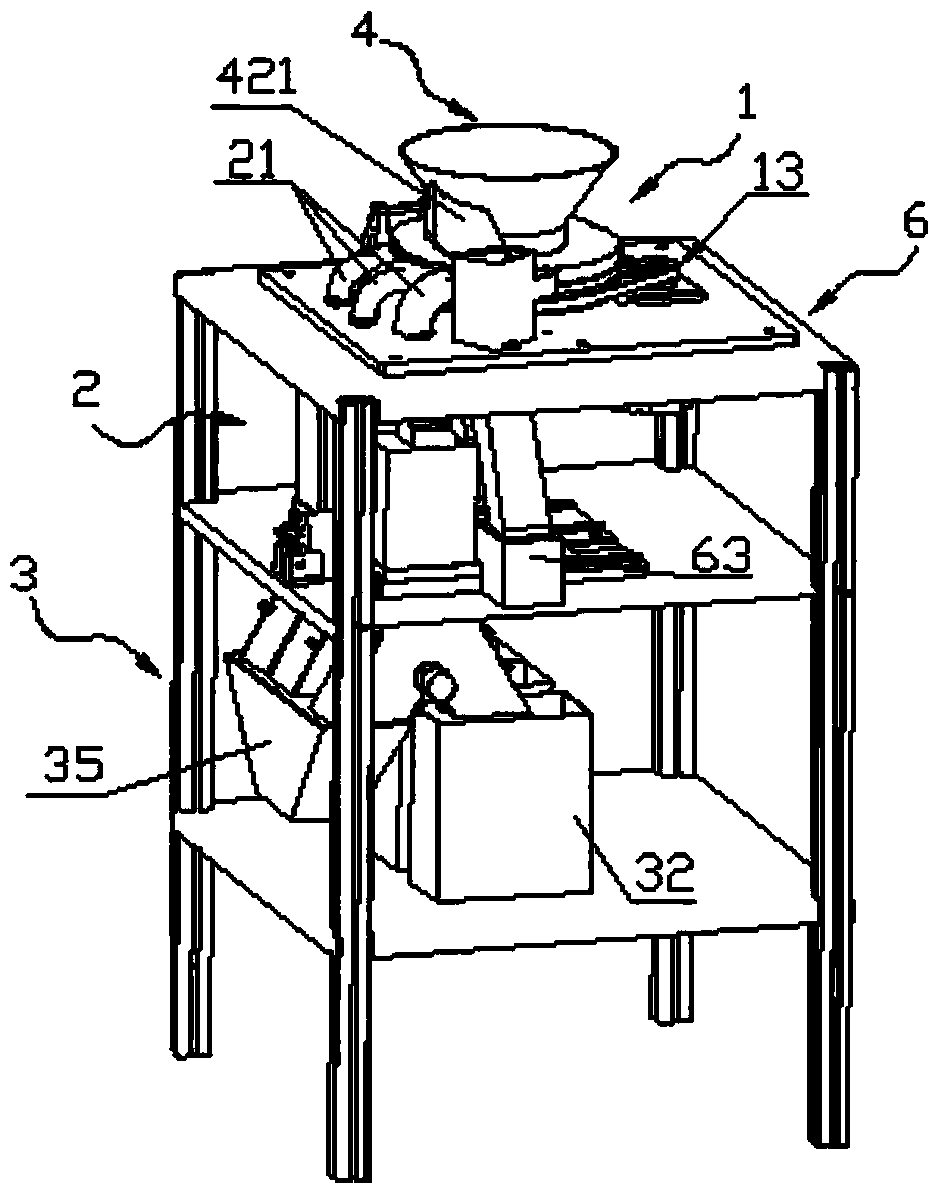

Feeding device

InactiveCN103822446AKeep dryGood effect of removing impuritiesSievingScreeningControl valvesLower face

The invention provides a feeding device which comprises a support, a drying device and a screening device. The drying device is fixed on the support, and the drying device is movably connected with the screening device through a material control valve. The drying device comprises a tube body, a stirring shaft connected with a speed reducing motor and a heating cavity, the stirring shaft extends into the tube body and is fixedly provided with a stirring paddle, the heating cavity is arranged outside the tube body in a sleeved mode, and an upper cover of the tube body is provided with a feeder nose, a humidometer and a liquid outlet. The screening device comprises a screening cavity, an oblique screening mesh, a vibration motor, a material flowing opening and an impurity outlet. The screening mesh is fixed on the screening cavity through a spring and is connected with the vibration motor. The material flowing opening is formed in the bottom of the screening cavity, and the impurity outlet is in parallel contact with the lower face of the screening mesh. The feeding device has the advantages of being capable of supplying particle materials to a lower level device under a sealing environment, being good in drying and impurity removing effect, shortening the production cycle, and improving the production efficiency.

Owner:MINGSHENG CHEM MACHINERY NANTONG

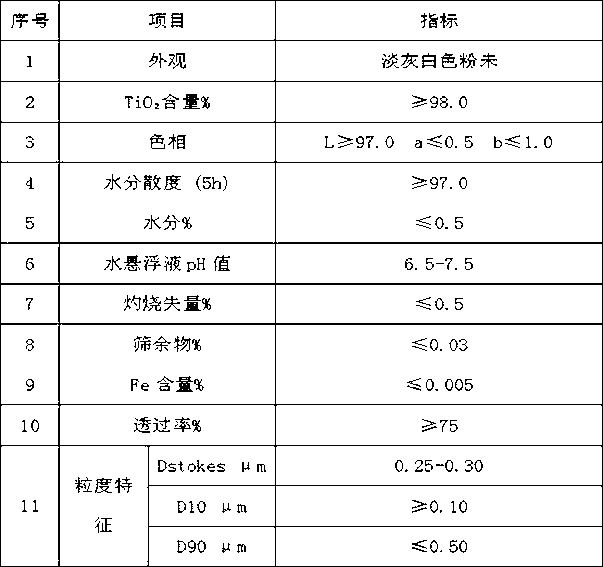

Method for preparing titanium dioxide for delustering chemical fibers

The invention belongs to the field of fine chemical engineering, and particularly relates to a method for preparing titanium dioxide for delustering chemical fibers. The method comprises the following technological flows: slurry making, iron-removal filtering, wet grinding, diluting, iron-removal filtering, grading, surface treatment, washing settling, atomized drying, grinding and packaging. The method provided by the invention has the advantageous effects as follows: 1, the prepared products have controllable particle sizes and stable dispersity; 2, the impurity removal effect is good; 3, the removal effect of soluble slats is good; and 4, the product quality is guaranteed.

Owner:JIAXING GAOSHENG NEW MATERIAL TECH

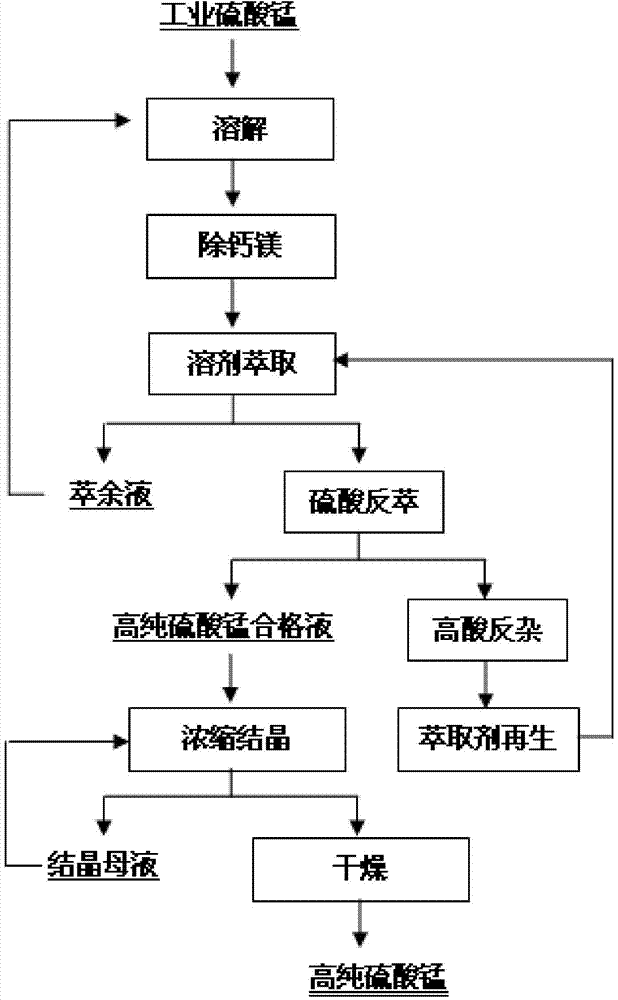

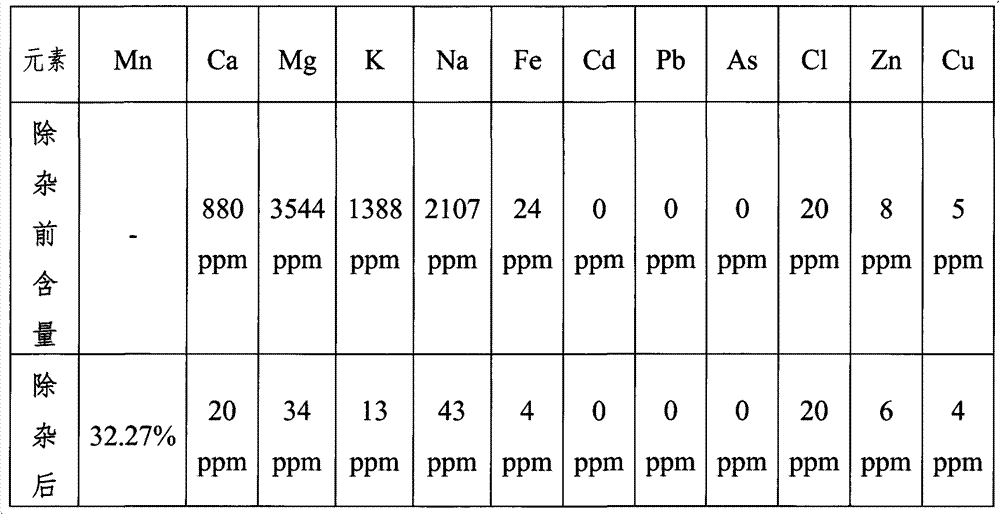

Method for preparing high-purity manganese sulfate with industrial manganese sulfate as raw material

The invention discloses a method for preparing high-purity manganese sulfate with industrial manganese sulfate as a raw material. The method is characterized in that the method in combination of chemical impurity removal and extraction impurity removal is carried out to remove calcium, magnesium, potassium, sodium, zinc, iron, halogen and other anions and cations from industrial manganese sulfate. The prepared high-purity manganese sulfate is high in purity and few in impurities; the method has the advantages of being simple in chemical impurity removal, less in villiaumite consumption, high in extraction impurity removal performance, capable of separating a plurality of anions and cations, free of alkali for organic regeneration, low in cost, etc.

Owner:HUNAN BRUNP RECYCLING TECH +1

Pretreatment method for deacidification and impurity removal of acid leaching liquid of vanadium extracted from stone coal

The invention relates to a pretreatment method for deacidification and impurity removal of acid leaching liquid of vanadium extracted from stone coal. Ion exchange resin and carbon materials are used for being prepared into a composite electrode plate which is placed in a capacitive deionization assembly, a direct-current power source is powered on, the acid leaching liquid of vanadium extracted from stone coal is subjected to pretreatment of deacidification and impurity removal, the treated composite electrode plate is in short connection or reverse connection, and the desorption process is performed. The method is little in energy consumption, the pretreatment efficiency is improved, loss of precipitated and mixed V in the solid and liquid separating process is reduced, and therefore the using amount of chemical agents is small, the V loss rate is low, and the impurity removal effect is obvious. The pretreatment method further has the advantages that the technology is flexible, and the method can be used for pretreatment of deacidification and impurity removal of acid leaching liquid of vanadium extracted from stone coal and can also be used for treatment of other high-acid multi-impurity leaching liquid.

Owner:WUHAN UNIV OF TECH

Tea Static Cleaner

ActiveCN102294303ASimple structureReasonable designElectrostatic separationEngineering plasticMechanical engineering

The invention discloses an impurity-removing device, in particular to a tea static impurity-removing device which removes impurities from tea with static, comprising a rack, a delivery sheet arranged on the rack, a motor arranged at one end of the rack, and a feeding hole and a discharging hole arranged at the two ends of the delivery sheet, characterized in that: the upward side of the delivery sheet is provided with a felt strip and a horizontal engineering plastic roller, the felt strip frictionally contacts with the horizontal engineering plastic roller, and the motor is connected with the engineering plastic roller through a driving belt to drive the engineering plastic roller to roll. The tea static impurity-removing device has the advantages of simple structure and reasonable design, can effectively remove a plurality of impurities mixed in tea with static generated by the friction between the felt strip and the horizontal engineering plastic roller with good impurity-removing effect. According to the invention, the impurity-removing process can be complete at a time, so that the work efficiency is effectively improved, and the production cost is saved.

Owner:YUNNAN PROV AGRI MACHINERY INST

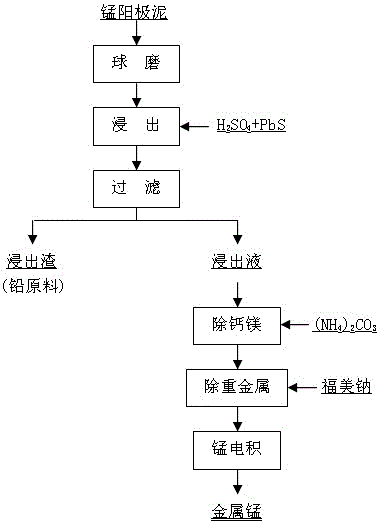

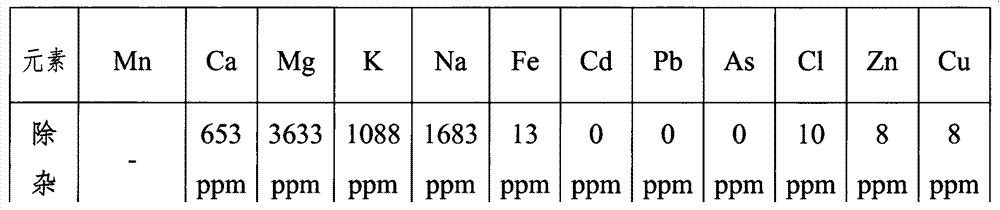

Method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime

ActiveCN106544511AWide variety of sourcesLow costPhotography auxillary processesProcess efficiency improvementLead smeltingElectrolysis

The invention provides a method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime. The method comprises the steps that firstly, the manganese anode slime, lead sulfide concentrate and ball milling liquid are mixed and subjected to wet-type ball milling; secondly, leaching of valuable metals such as manganese and selenium is conducted, leachate is reserved, and leached residues serve as lead smelting raw materials for recycling lead and silver; thirdly, a calcium-magnesium removing agent is added for impurity removing; and fourthly, a neutralizer, namely, ammonium hydroxide, and ammonium sulfate are added, a cleaning agent, namely, sodium dimethyl dithiocarbamate is dropwise added, and after stewing is conducted, activated carbon is added for adsorption, filter pressing is conducted, an electrolyzing additive is dropwise added into filtrate, and electrolytic manganese metal is prepared through electrolyzation. The method is small in investment, simple in technology, low in cost and capable of effectively increasing the comprehensive recovery rate.

Owner:ZHUZHOU SMELTER GRP

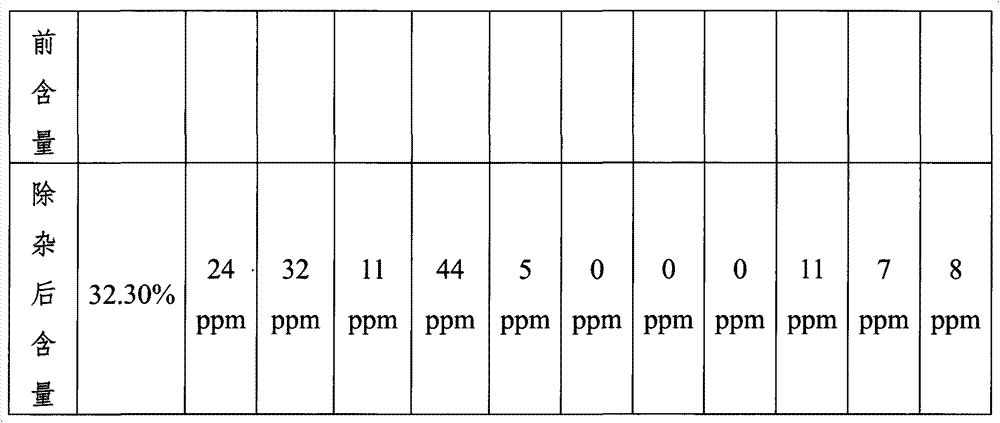

Method for reducing contents of calcium ions, magnesium ions, potassium ions and sodium ions in manganese sulfate

The invention discloses a method for reducing contents of calcium ions, magnesium ions, potassium ions and sodium ions in manganese sulfate. F<-1> in FeF3 can be used for precipitating the calcium ions and the magnesium ions in a solution, Fe<3+> can generate sulfate together with the potassium ions and the sodium ions so as to be precipitated, and Fe(OH)3 formed by hydrolyzing the superfluous Fe<3+> has a remarkable flocculation effect, so that the FeF3 is used as a novel manganese sulfate impurity removal agent; and the calcium ions, the magnesium ions, the potassium ions and the sodium ions are successively precipitated through adjusting the pH value, thus the calcium ions, the magnesium ions, the potassium ions and the sodium ions difficultly separated in common manganese sulfate are separated at one step, and the obtained product can meet the requirement of high-purity manganese sulfate for producing battery-grade or electronic-grade manganese-based raw materials on the contents of the calcium ions, the magnesium ions, the potassium ions and the sodium ions. The method has the advantages of fewer impurity removal agent adding times, simple process, low cost, remarkable impurity removal effect, high purity and obtained manganese sulfate yield and the like, and is easy to produce on large scale.

Owner:湘潭电化科技股份有限公司

Quartz sand purifying technology

The invention provides a quartz sand purifying technology, and belongs to the field of preparation process of quartz sand. The quartz sand purifying technology provided by the invention comprises the steps of crushing, scrubbing, desliming, flotation, acid leaching and microbiological leaching, and optimizing treatment is performed on all steps. The technology is simple, and excellent in purification effect, and the high-quality refined quartz sand of which the content of SiO2 is equal to or greater than 99.9%, the content of Fe2O3 is less than or equal to 0.006%, the content of Al2O3 is less than or equal to 0.05% and the content of TiO2 is less than or equal to 0.02%.

Owner:成都兴能新材料股份有限公司

Impurity removal cleaning machine for sesame

InactiveCN104643270AIngenious and reasonable designSimple processGas current separationFood treatmentSedimentSesamum orientale

The present invention relates to equipment for removing impurities in sesame and cleaning the sesame, in particular to an impurity removal cleaning machine for the sesame. The impurity removal cleaning machine is provided with a cleaning groove, a sesame storage bin is installed above the front end of the cleaning groove, an impurity removal bucket is installed at the top of the sesame storage bin, the lower portion of the sesame storage bin is in an inverted-cone shape, a discharging tube is arranged at the bottom of the sesame storage bin, and a movable cover plate is installed on a discharging port of the discharging tube. A rotary shaft is arranged in the cleaning groove, an auger is arranged on the rotary shaft, a filter net I is installed at the bottom of the rear end of the cleaning groove, and a mud sediment groove is formed below the filter net I. A mud discharging tube is arranged at the bottom of the mud sediment groove, the tail end of the rotary shaft is a hollow blind tube with an outer open end, an opening is formed in the side wall of the hollow blind tube, a sesame scooping hopper is installed on the opening and provided with a circular-arc-shaped filter net II, baffles are arranged at the two ends of the filter net II, and a sand discharging tube is installed on the lower portion of the rear end of the cleaning groove. Cleaning and impurity removing of the sesame are finished in the same equipment in a one-off mode and performed at the same time, the multiple operation processes of cleaning, sand and stone removing, impurity removing and the like are omitted, working efficiency is high, and cleaning and impurity removing effects are good.

Owner:山东省十里香芝麻制品股份有限公司

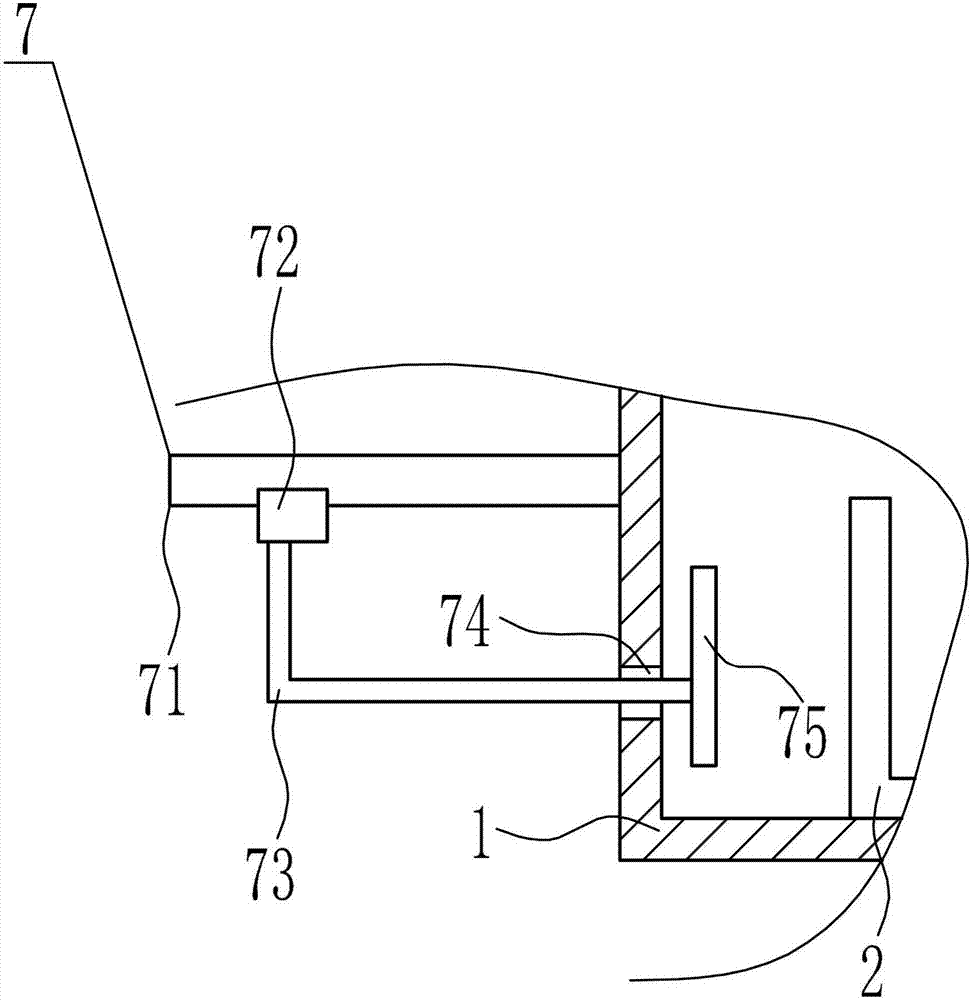

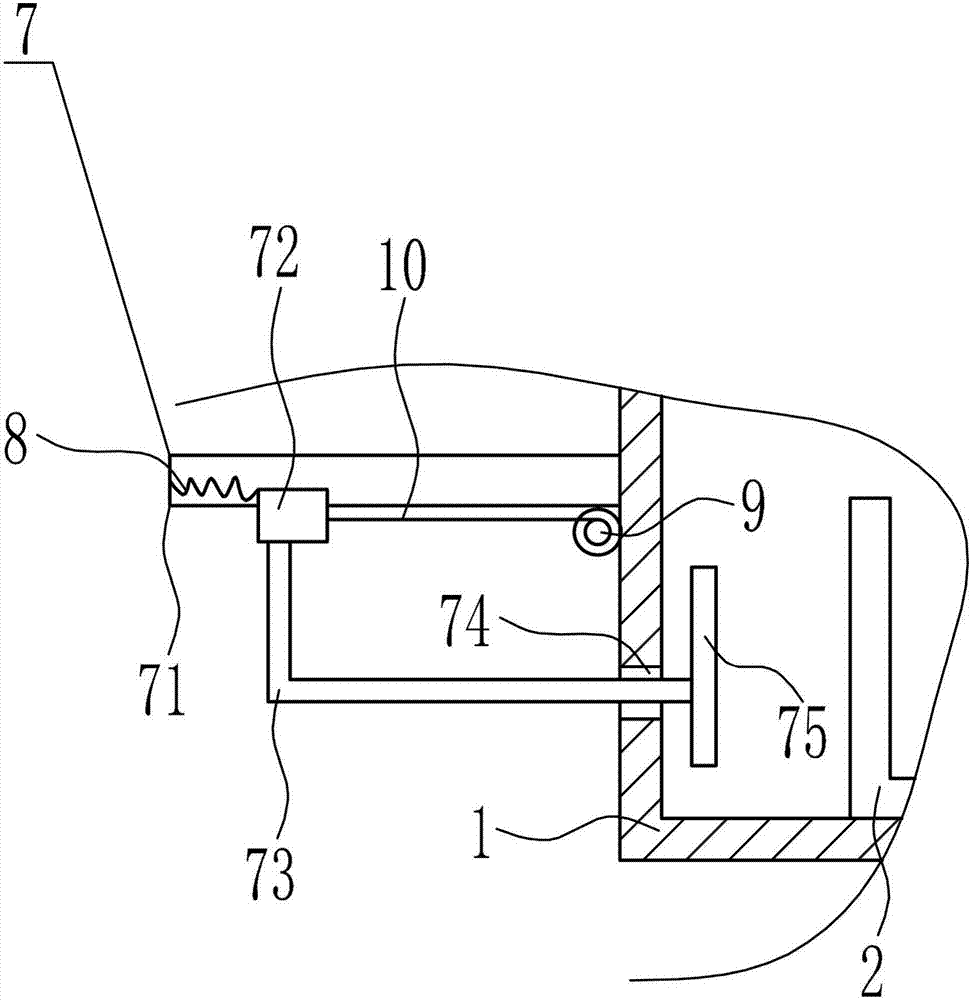

Pebble impurity removal equipment for bridge guardrail pouring

The invention belongs to the technical field of bridge guardrail pouring, and particularly relates to pebble impurity removal equipment for bridge guardrail pouring. According to the technical purposes, the pebble impurity removal equipment for bridge guardrail pouring is easy to operate, convenient to use, good in impurity removal effect and not prone to polluting the environment, and dust is not prone to flying in the impurity removal process. To achieve the above technical purposes, the pebble impurity removal equipment for bridge guardrail pouring is provided and comprises a box and the like. The box is arranged in an opening manner. A collecting frame is arranged at the bottom in the box. An opening is formed in the lower portion of the right side face of the box in the vertical direction. An automatic opening and closing mechanism is arranged at the upper portion of the left side face of the box and connected with a cover plate. The cover plate is matched with the box, and an impurity removal device is arranged at the middle portion in the box. The pebble impurity removal equipment achieves the effects that operation is simple, using is convenient, the impurity removal effect is good, dust is not prone to flying in the impurity removal process, and the environment is not prone to being polluted.

Owner:张宏飞

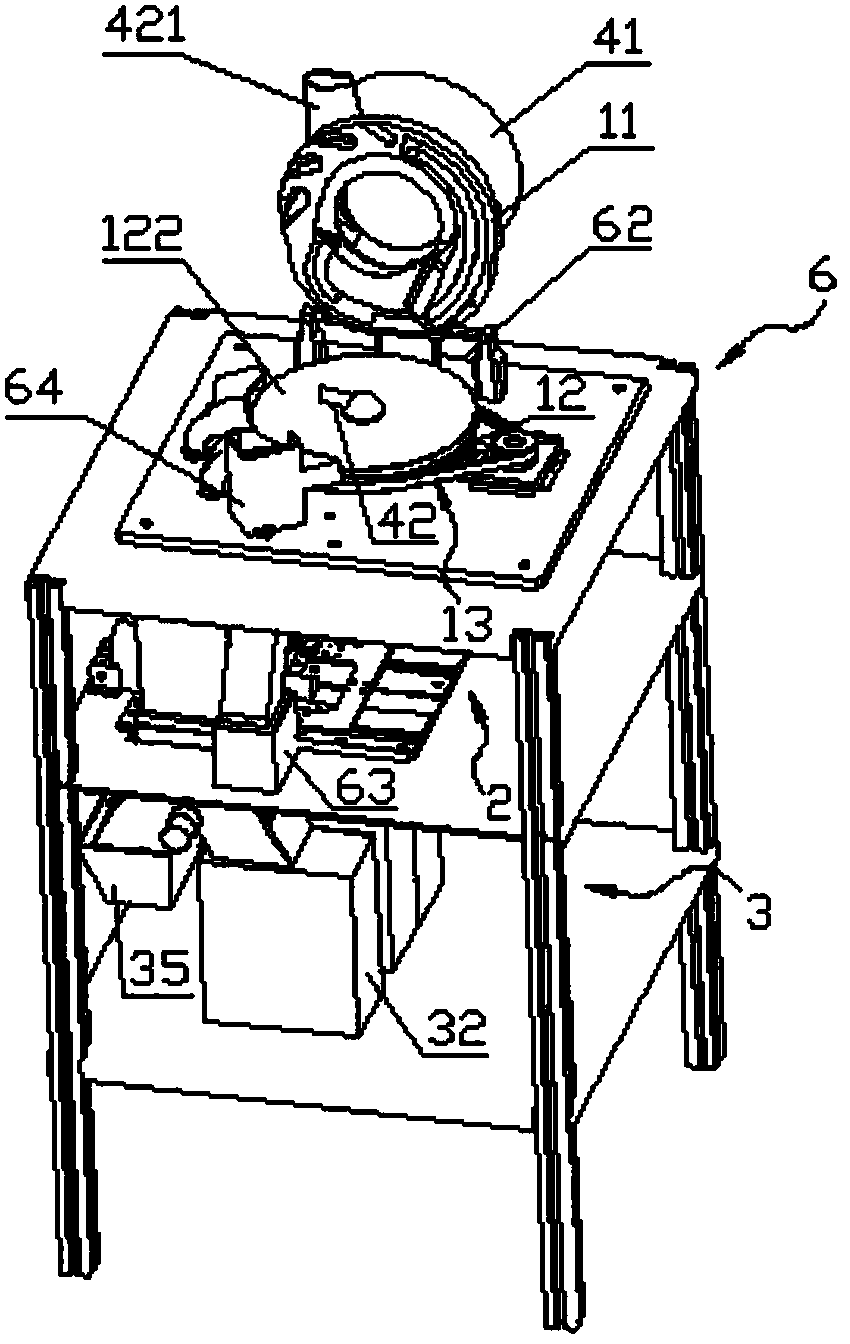

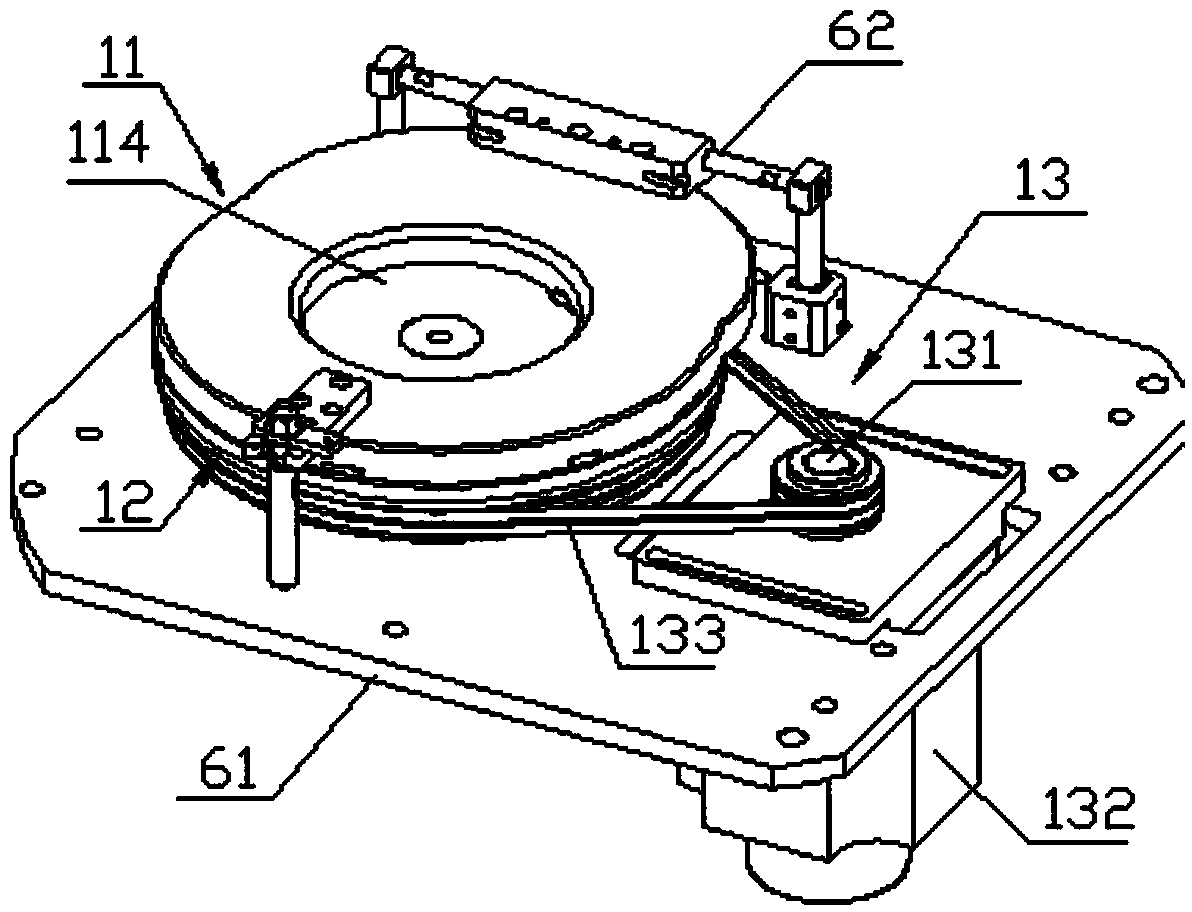

Coin sorting machine

The invention relates to a coin sorting machine. The coin sorting machine comprises a sorting device (1), a temporary storage device (2) and a storage device (3) which are arranged in sequence on a frame (6) from top to bottom, wherein the sorting device (1) is used for sorting coins of different currency values; the temporary storage device (2) is for sorted coins of each face value to wait for confirmation of the currency values; the storage device (3) is used for storing each coin of a confirmed currency value; the sorting device (1) comprises a sorting disk (11), an elastic rotating disk (2) arranged on the lower side of the sorting disk (11), and a transmission mechanism (13) for driving the elastic rotating disk (12) to rotate relative to the sorting disk (11); the sorting device (1) is used for storing coins of different currency values through rotation of the elastic rotating disk (12) relative to the sorting disk (11) and a corresponding notch and a coin outlet in the sorting disk; the sorted coins enter the temporary storage device (1) to wait for confirmation by each customer in order to be returned and stored. By adopting the coin sorting machine, possible contradiction generated by the difference between a value estimated by the customer and a value counted in a bank can be greatly reduced.

Owner:江苏科思机电工程有限公司

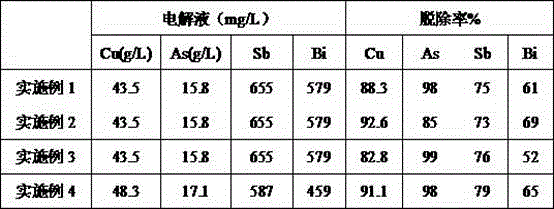

Method for cleaning copper electrolyte to remove impurities

InactiveCN106086936ASimple structureReduce the amount of copperPhotography auxillary processesElectrolysis componentsElectrolysisCopper

The present invention discloses a method for cleaning copper electrolyte to remove impurities; first, bismuth salt is used as a chemical precipitator to remove arsenic, antimony and bismuth in the electrode by co-precipitation, and solid-liquid separation is carried out; second, the obtained solid precipitate is subjected to precipitator alkali-soaking regeneration by using sodium hydroxide; third, the obtained impurity-removed liquid is subjected to segmental electrodeposition copper removal by using insoluble lead as an anode and stainless as a cathode, and a post-copper removal liquid is returned to an electrolytic system. The method has the advantages of low investment, good process simplicity, good operational convenience, good impurity removal effect and zero pollution, efficient and low-cost removal of the impurities such as arsenic, antimony and bismuth in open circuit electrolyte is achieved, and copper recycling and electrolytic waste liquid purification and reuse are achieved.

Owner:紫金铜业有限公司

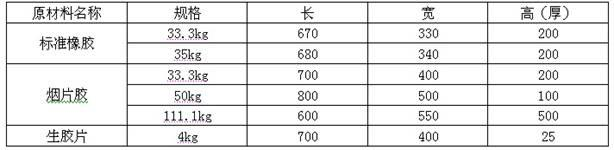

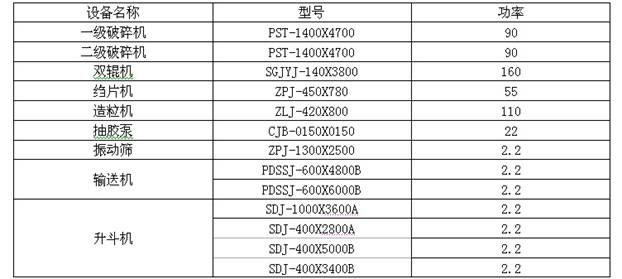

Process for processing rubber

The invention relates to the field of chemical industry, in particular to a process for processing natural rubber. The process comprises procedures of crushing, creping, granulating, baking, weighing and packaging; the process is characterized by using a twin-roll machine for prewashing and extruding after crushing; during the granulating process, a vibration screen is added for separating water and glue from purities; the granulating procedure is repeated for 3 times; and the creping procedure is repeated for 10 times. According to the processing process of the invention, a selection range of raw materials can be widened; according to the process, the hazardous substances such as impurities and ashes and the like of the rubber can be removed; the rubber can obtain excellent consistence, and can satisfy requirements of producing high-quality products such as radial ply tires; and the similar imported materials can be replaced, so that the current situation of importing the similar rubber can be changed.

Owner:KUNMING GAOSHEN CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com