Pebble impurity removal equipment for bridge guardrail pouring

A technology for small stones and guardrails, which is applied in the field of small stones removal equipment, and can solve problems affecting the quality of concrete bridge guardrails and reducing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

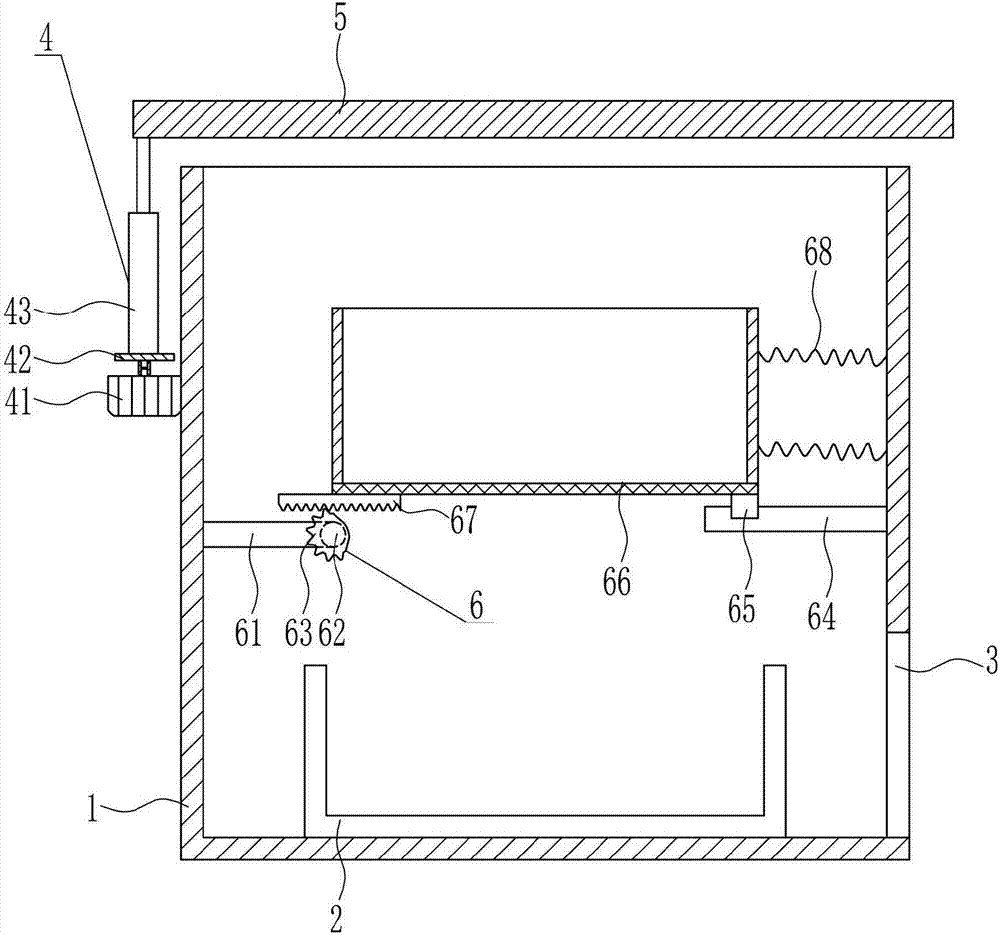

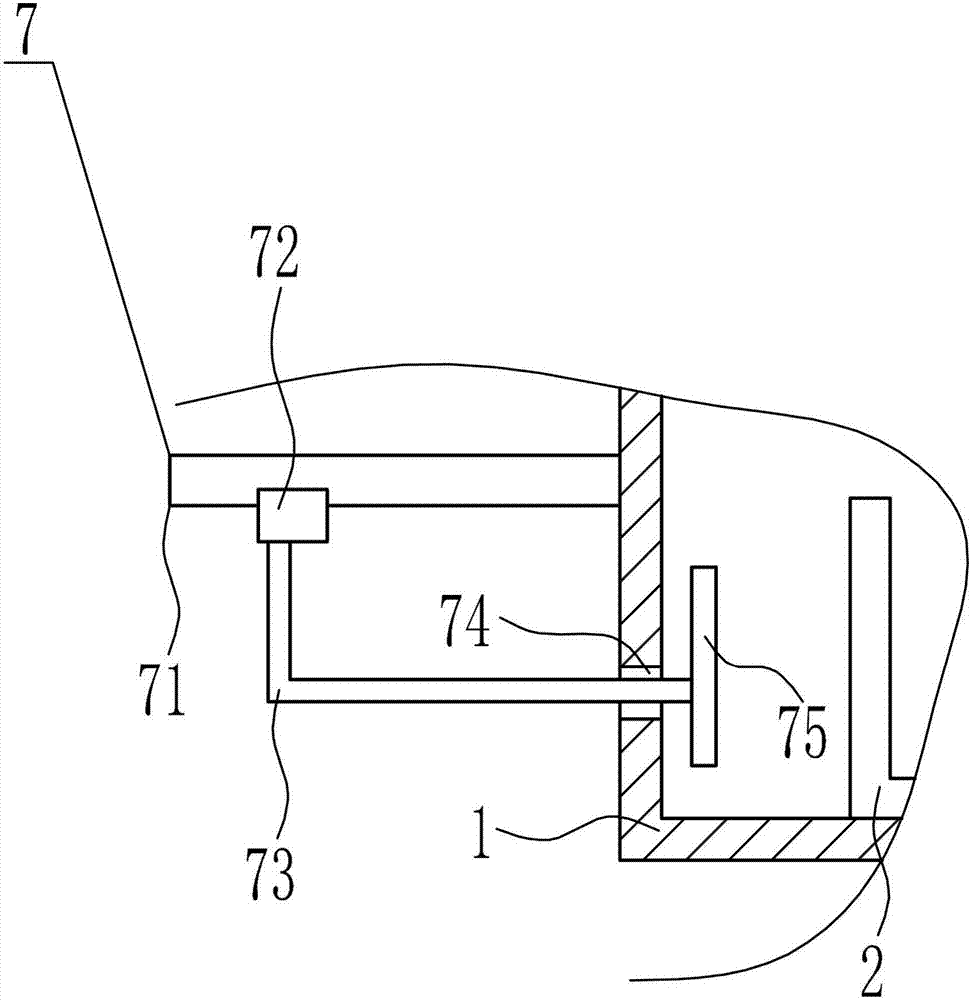

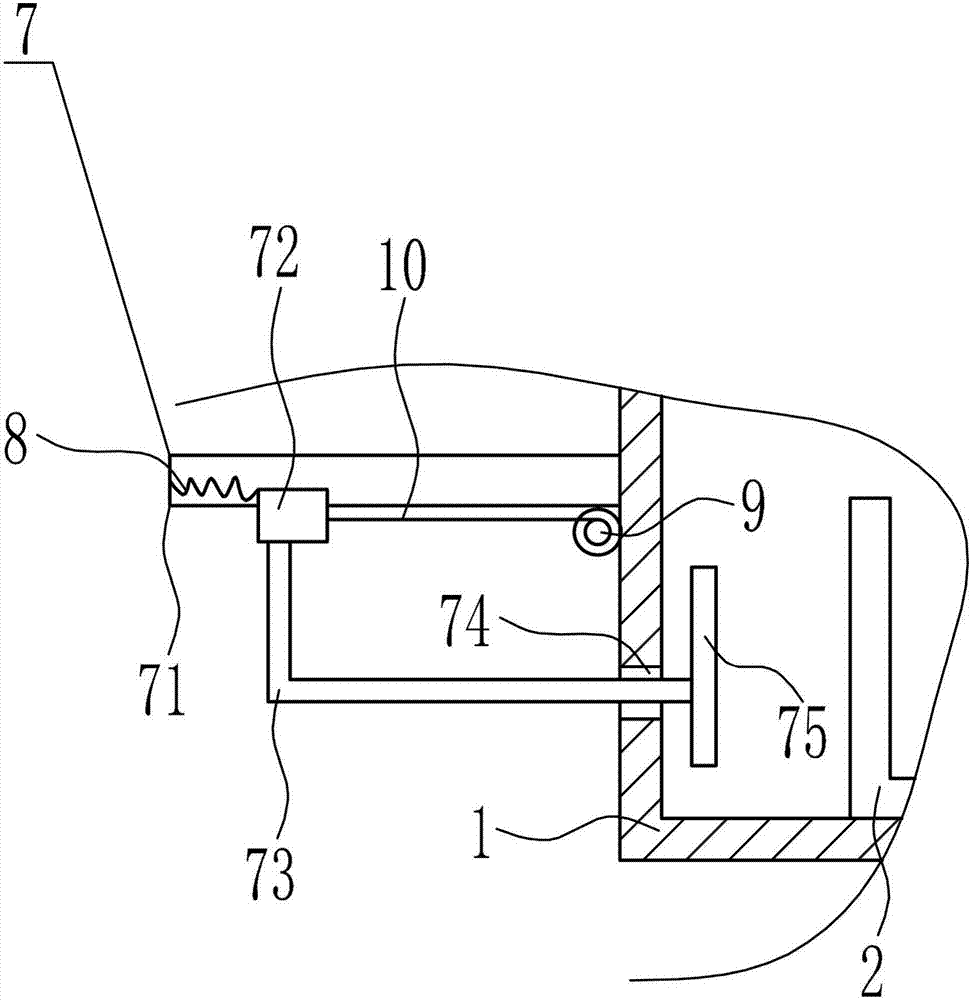

[0026] A kind of small stone impurity removal equipment for bridge guardrail pouring, such as Figure 1-3 As shown in the figure, it includes a box body 1, a collection frame 2, an automatic opening and closing mechanism 4, a cover plate 5 and an impurity removal device 6. The box body 1 is arranged openly, and the inner bottom of the box body 1 is provided with a collection frame 2. The box body 1 The lower part of the right side is vertically opened with an opening 3, the upper part of the left side of the box body 1 is provided with an automatic opening and closing mechanism 4, the automatic opening and closing mechanism 4 is connected with a cover plate 5, the cover plate 5 cooperates with the box body 1, and the box body 1 An impurity removal device 6 is arranged in the middle of the inner part.

Embodiment 2

[0028] A kind of small stone impurity removal equipment for bridge guardrail pouring, such as Figure 1-3 As shown in the figure, it includes a box body 1, a collection frame 2, an automatic opening and closing mechanism 4, a cover plate 5 and an impurity removal device 6. The box body 1 is arranged openly, and the inner bottom of the box body 1 is provided with a collection frame 2. The box body 1 The lower part of the right side is vertically opened with an opening 3, the upper part of the left side of the box body 1 is provided with an automatic opening and closing mechanism 4, the automatic opening and closing mechanism 4 is connected with a cover plate 5, the cover plate 5 cooperates with the box body 1, and the box body 1 An impurity removal device 6 is arranged in the middle of the inner part.

[0029] The automatic opening and closing mechanism 4 includes a first motor 41, a horizontal plate 42 and a cylinder 43. The upper part of the outer left side surface of the box...

Embodiment 3

[0031] A kind of small stone impurity removal equipment for bridge guardrail pouring, such as Figure 1-3 As shown in the figure, it includes a box body 1, a collection frame 2, an automatic opening and closing mechanism 4, a cover plate 5 and an impurity removal device 6. The box body 1 is arranged openly, and the inner bottom of the box body 1 is provided with a collection frame 2. The box body 1 The lower part of the right side is vertically opened with an opening 3, the upper part of the left side of the box body 1 is provided with an automatic opening and closing mechanism 4, the automatic opening and closing mechanism 4 is connected with a cover plate 5, the cover plate 5 cooperates with the box body 1, and the box body 1 An impurity removal device 6 is arranged in the middle of the inner part.

[0032] The automatic opening and closing mechanism 4 includes a first motor 41, a horizontal plate 42 and a cylinder 43. The upper part of the outer left side surface of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com