Patents

Literature

877results about "Wood working safety devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

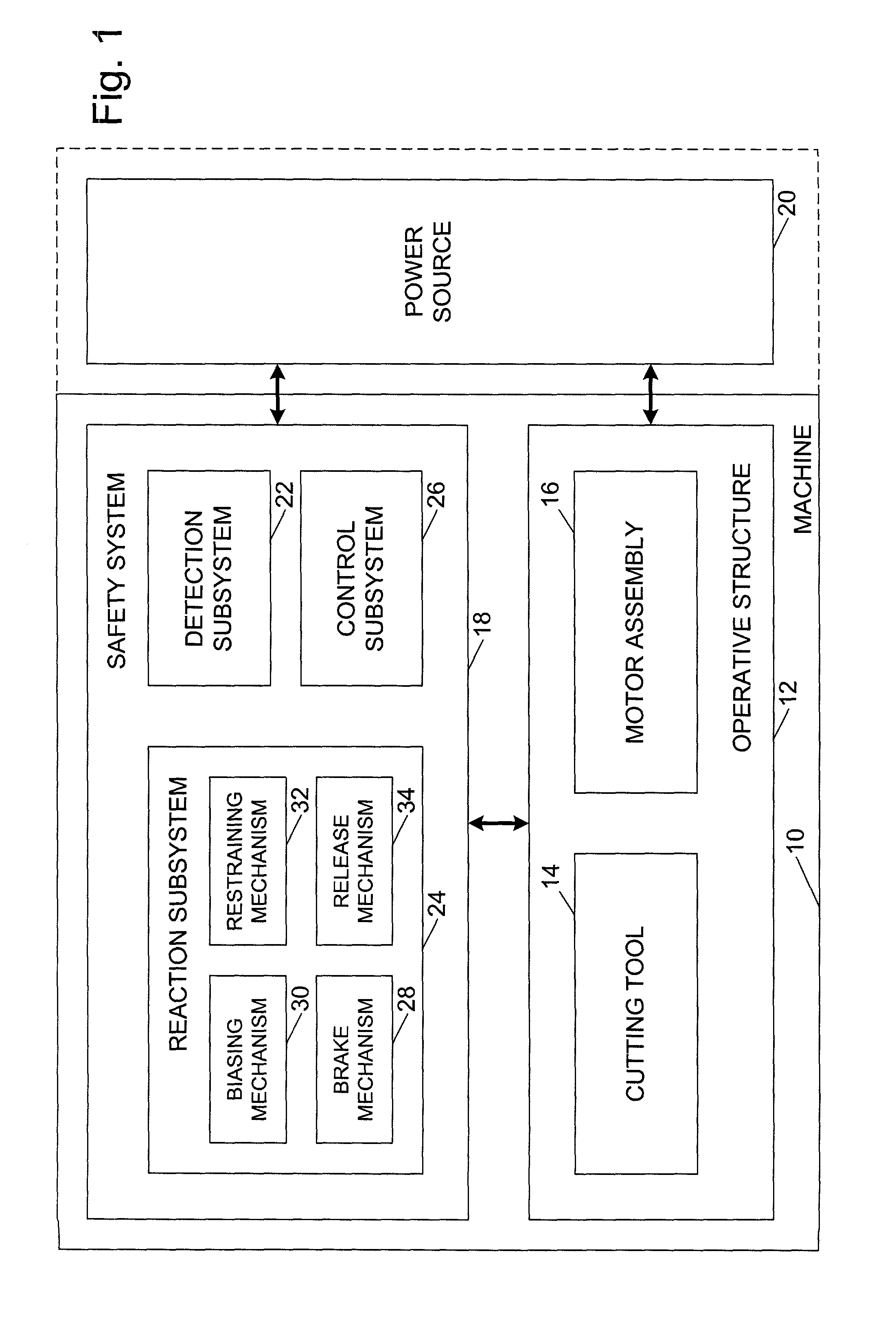

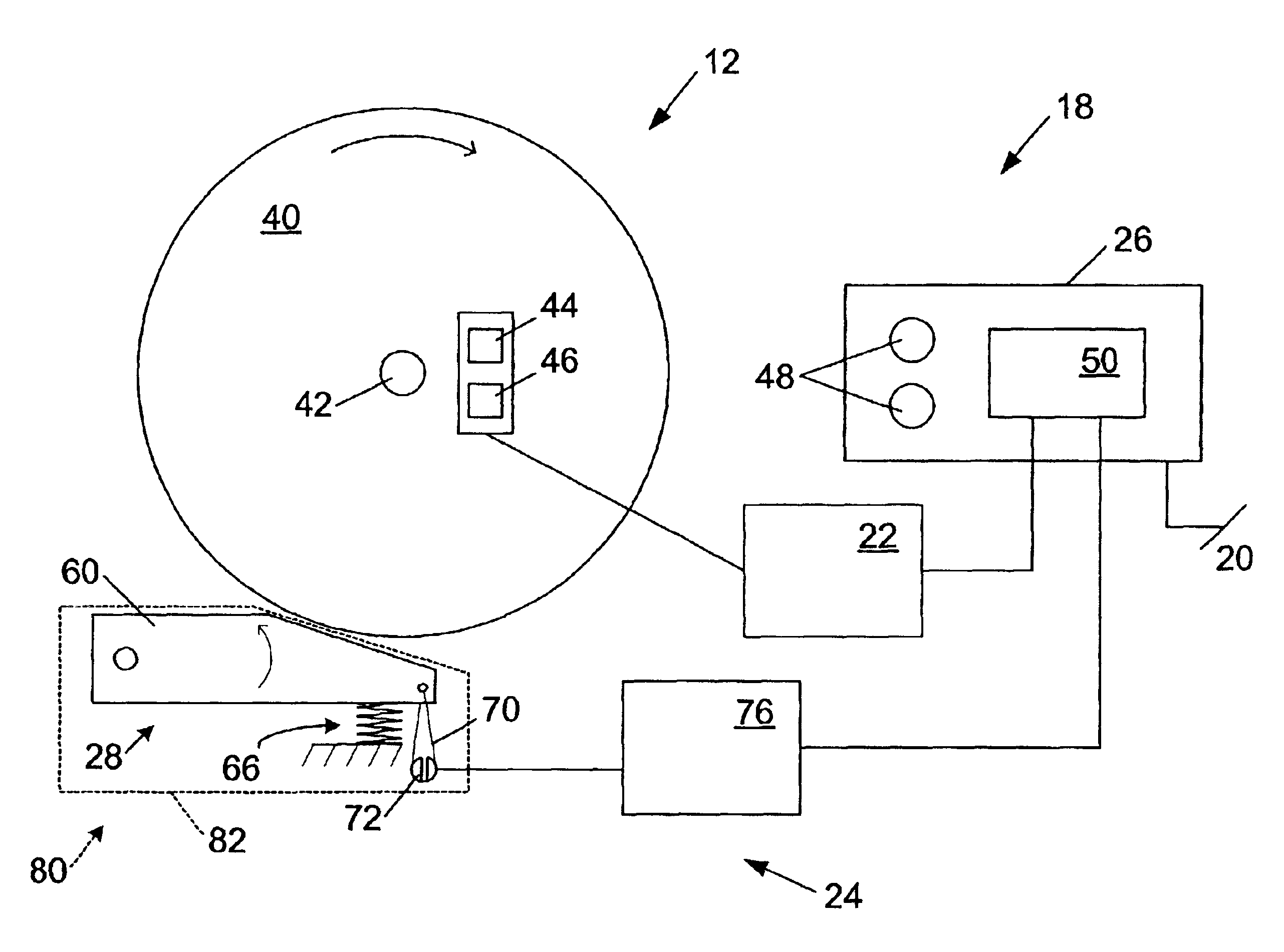

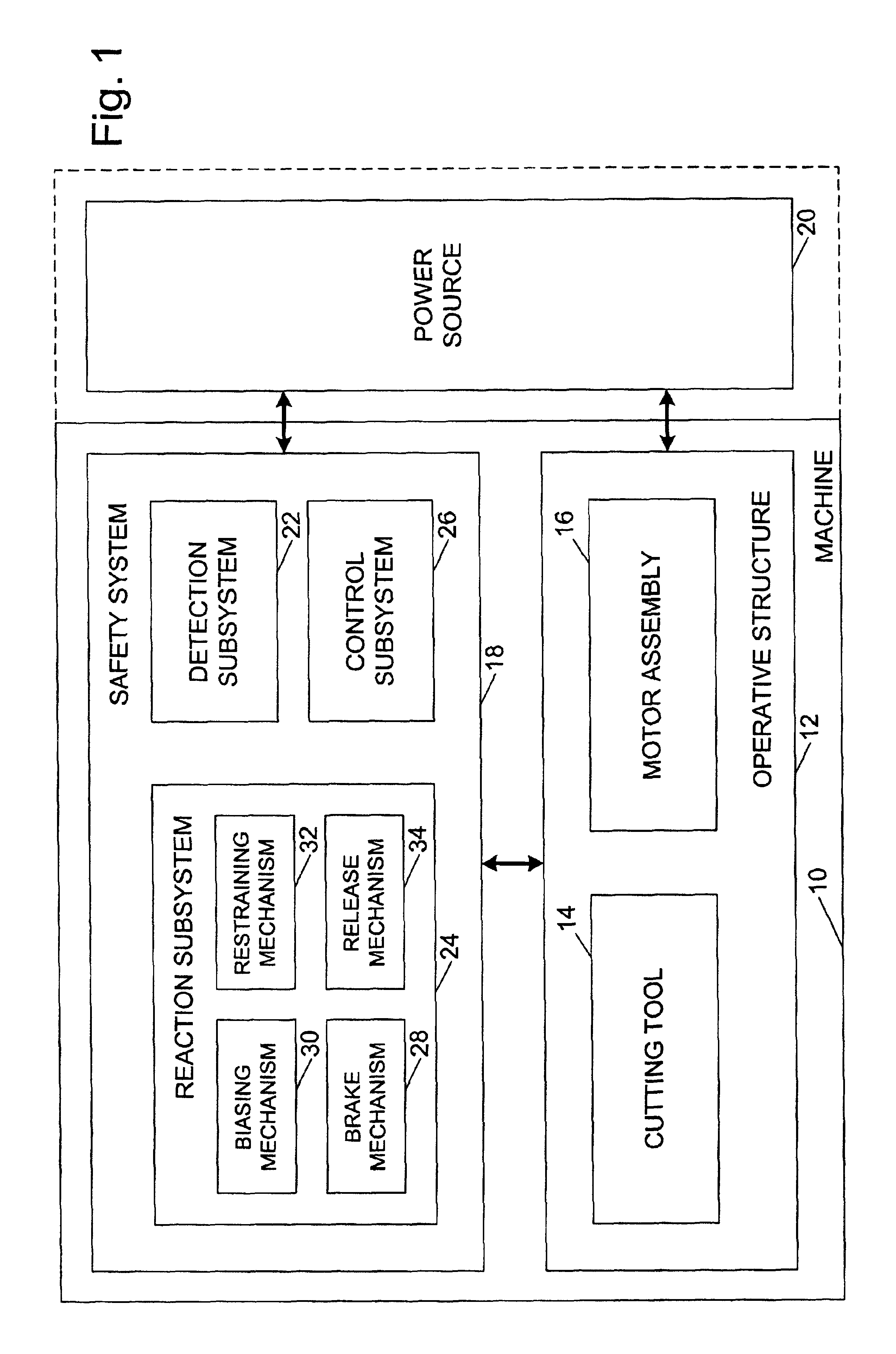

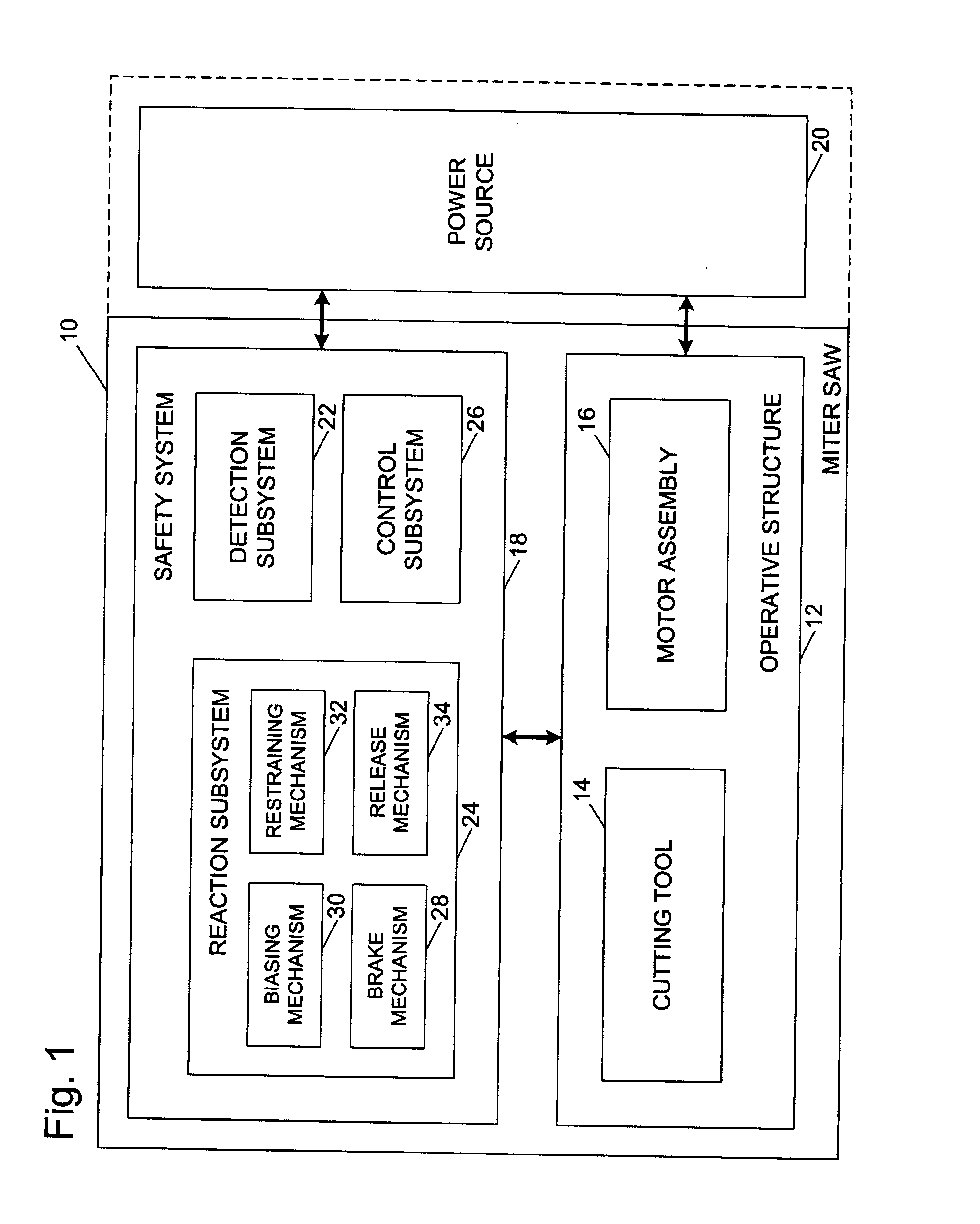

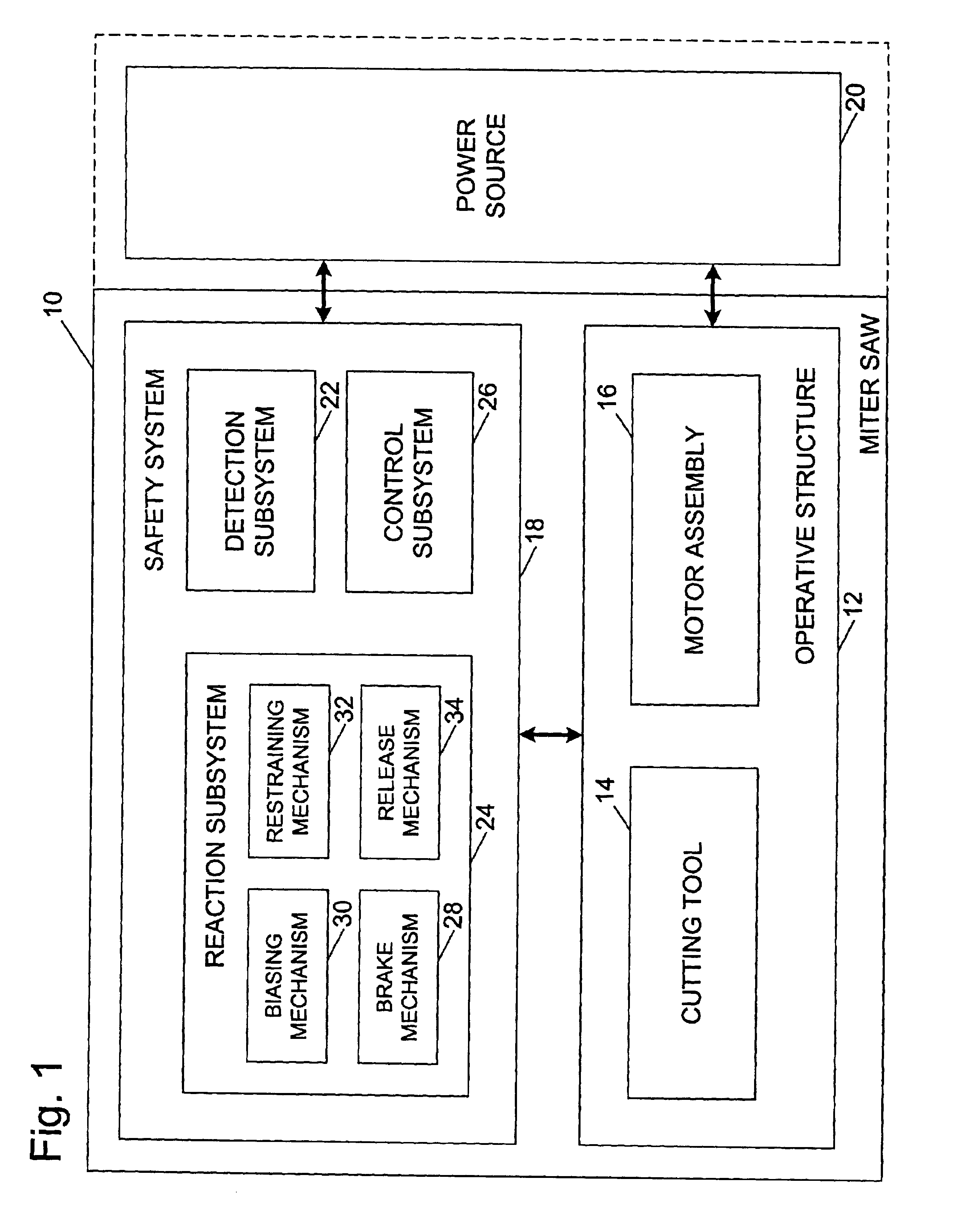

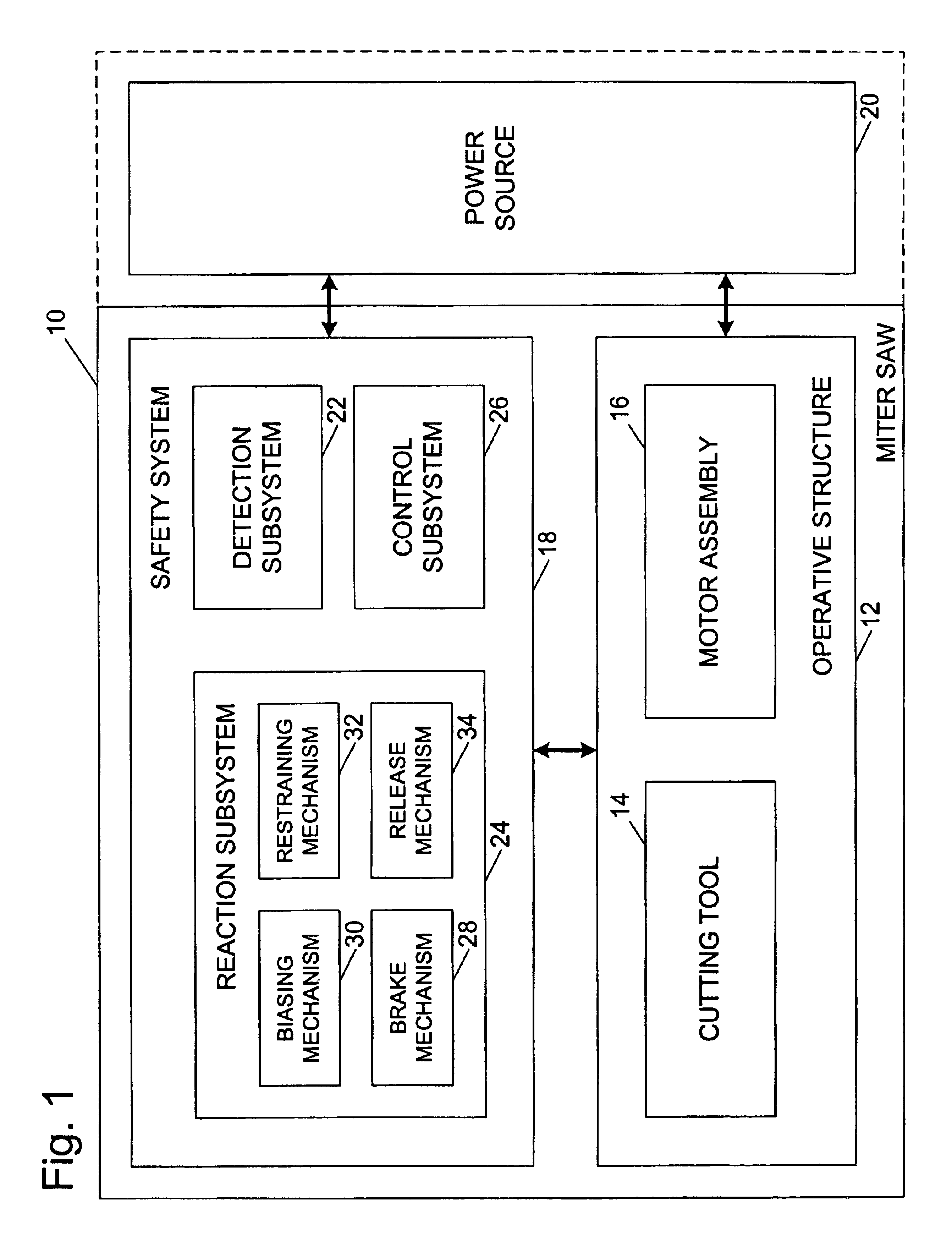

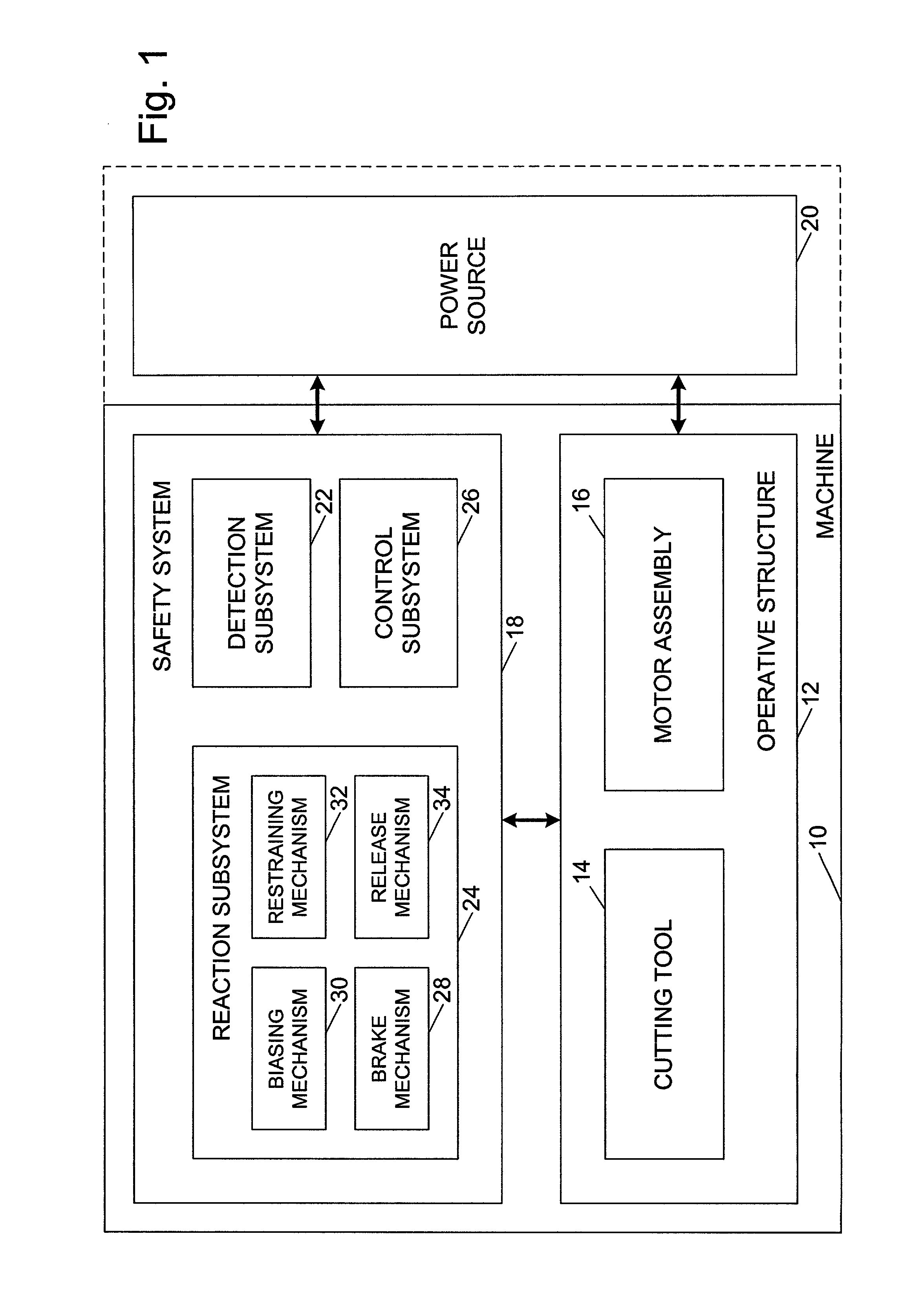

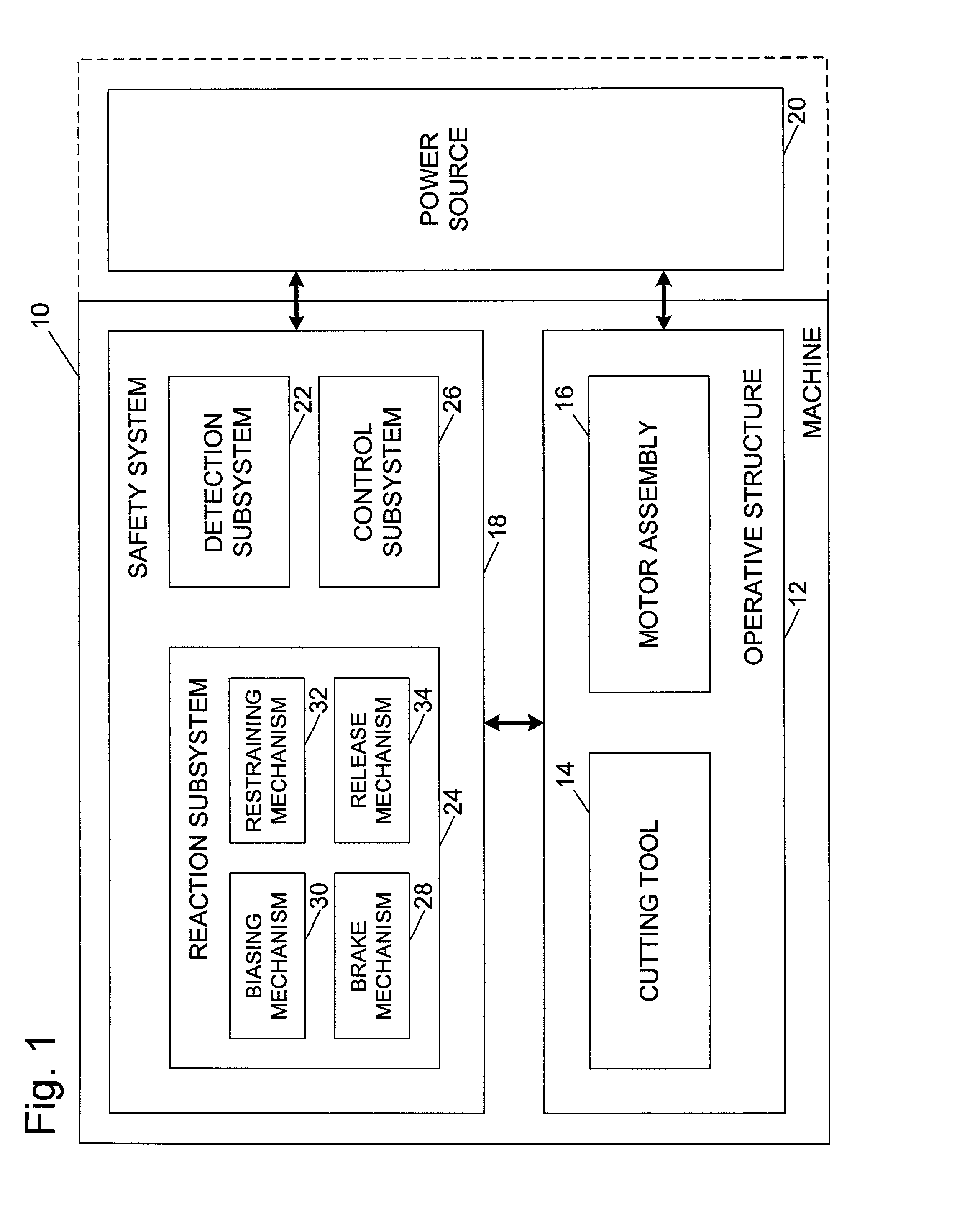

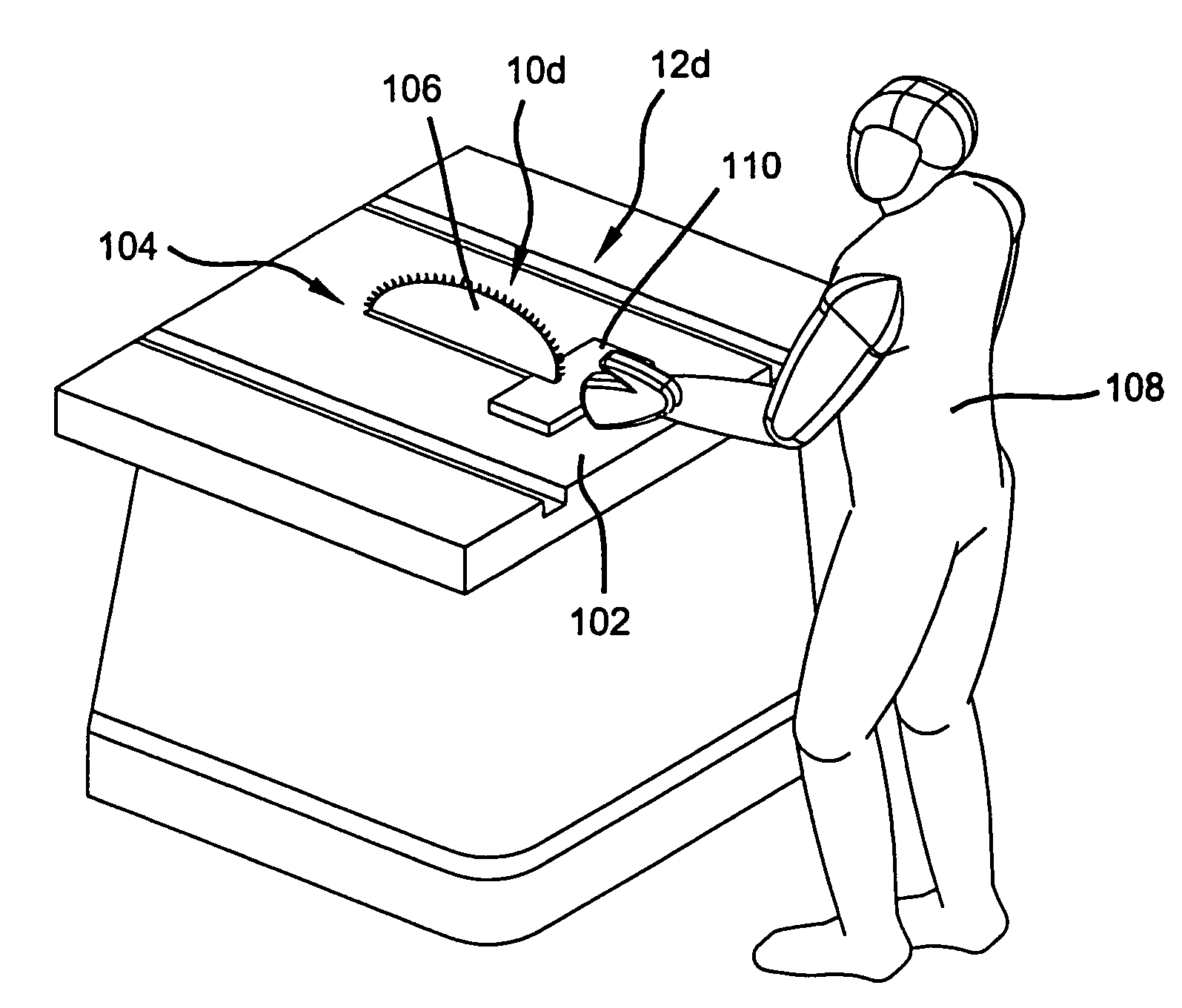

Safety systems for power equipment

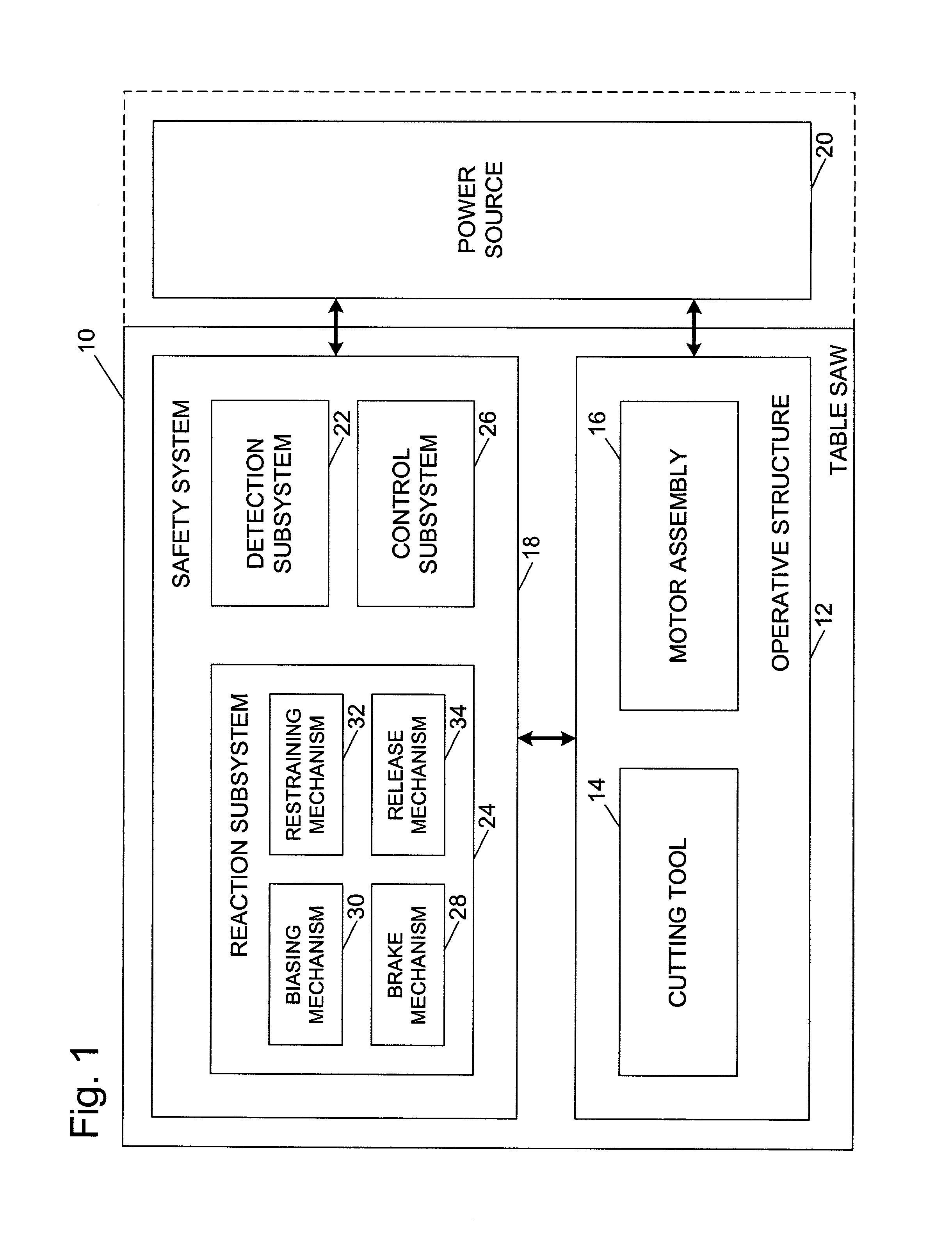

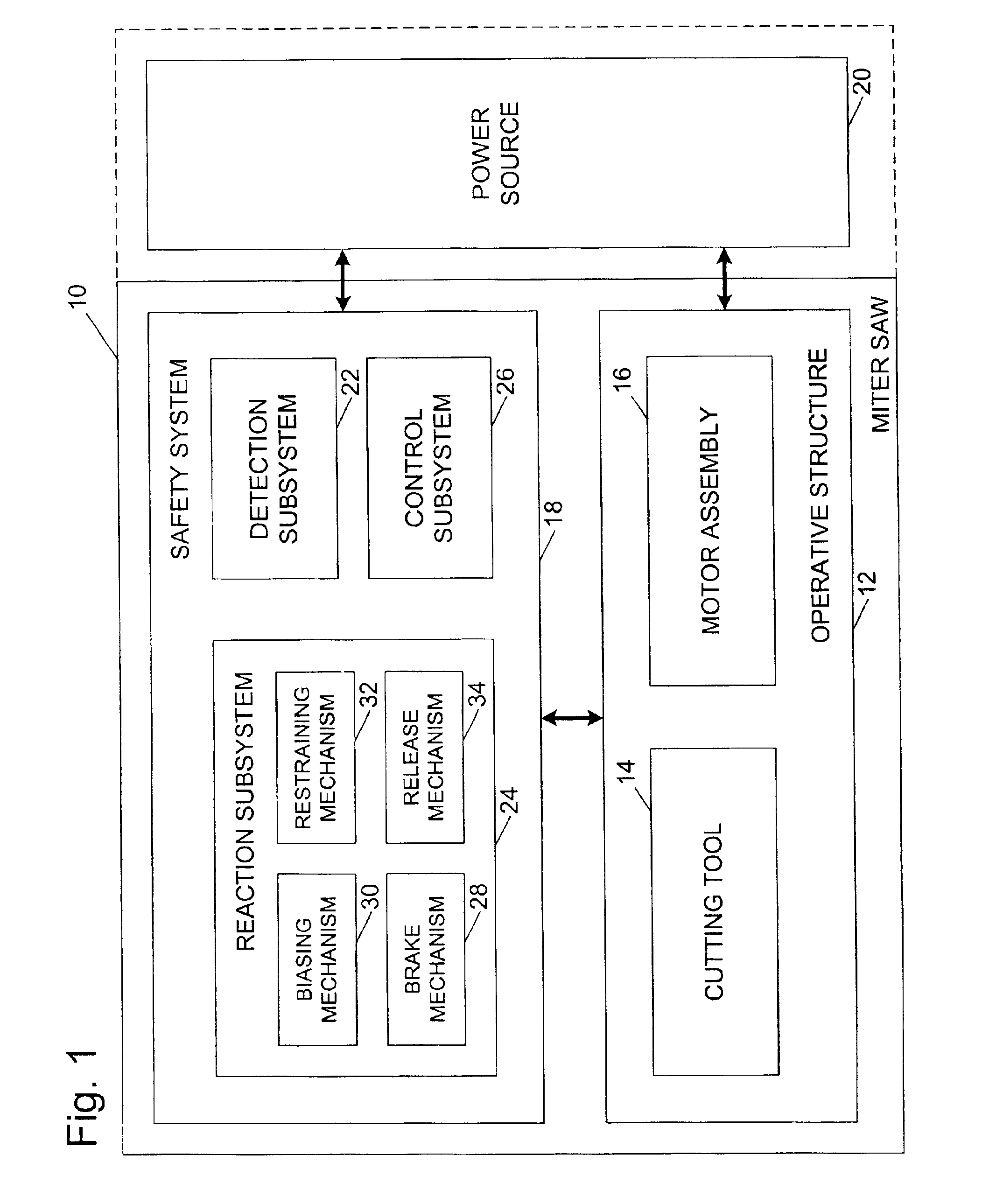

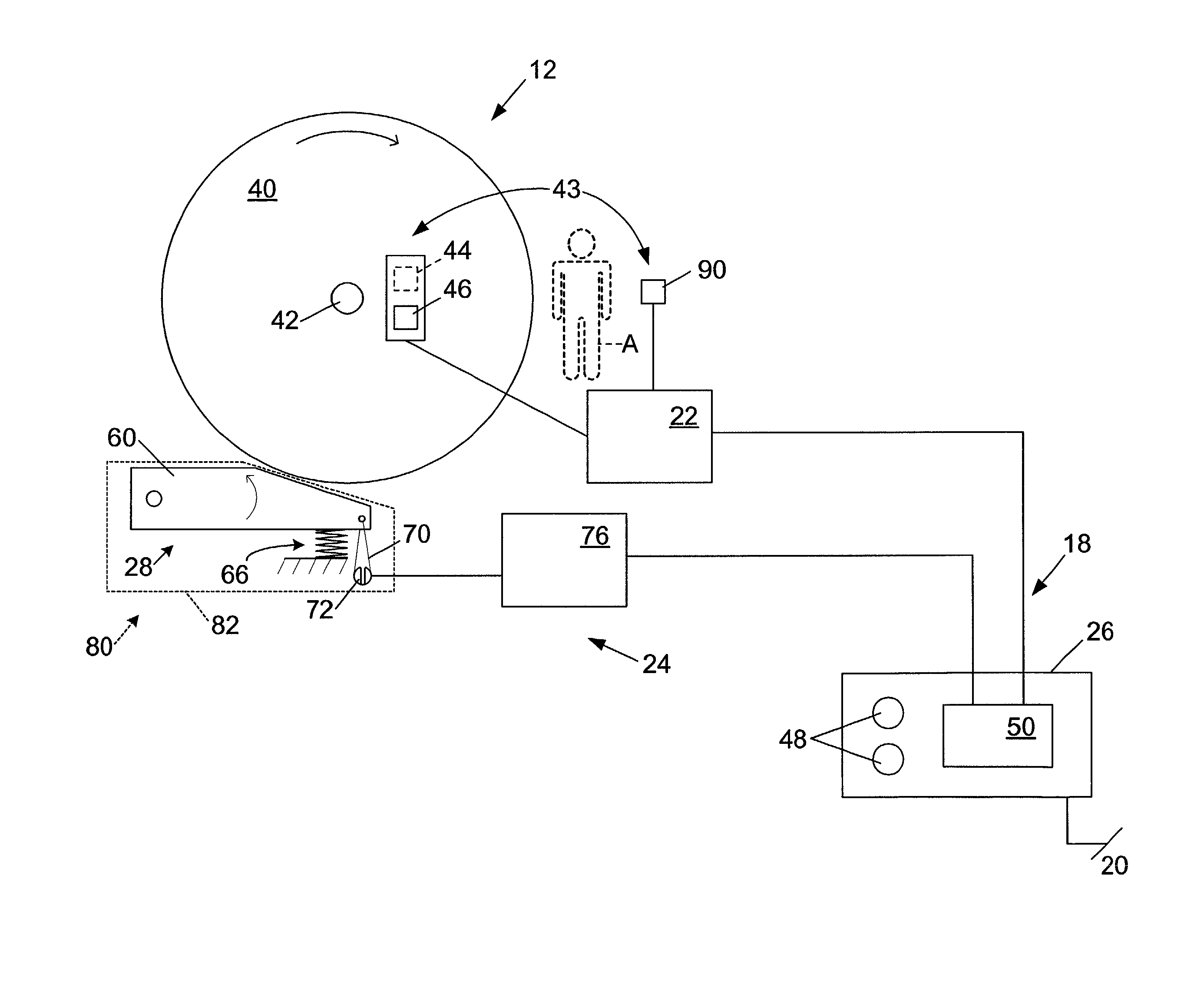

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

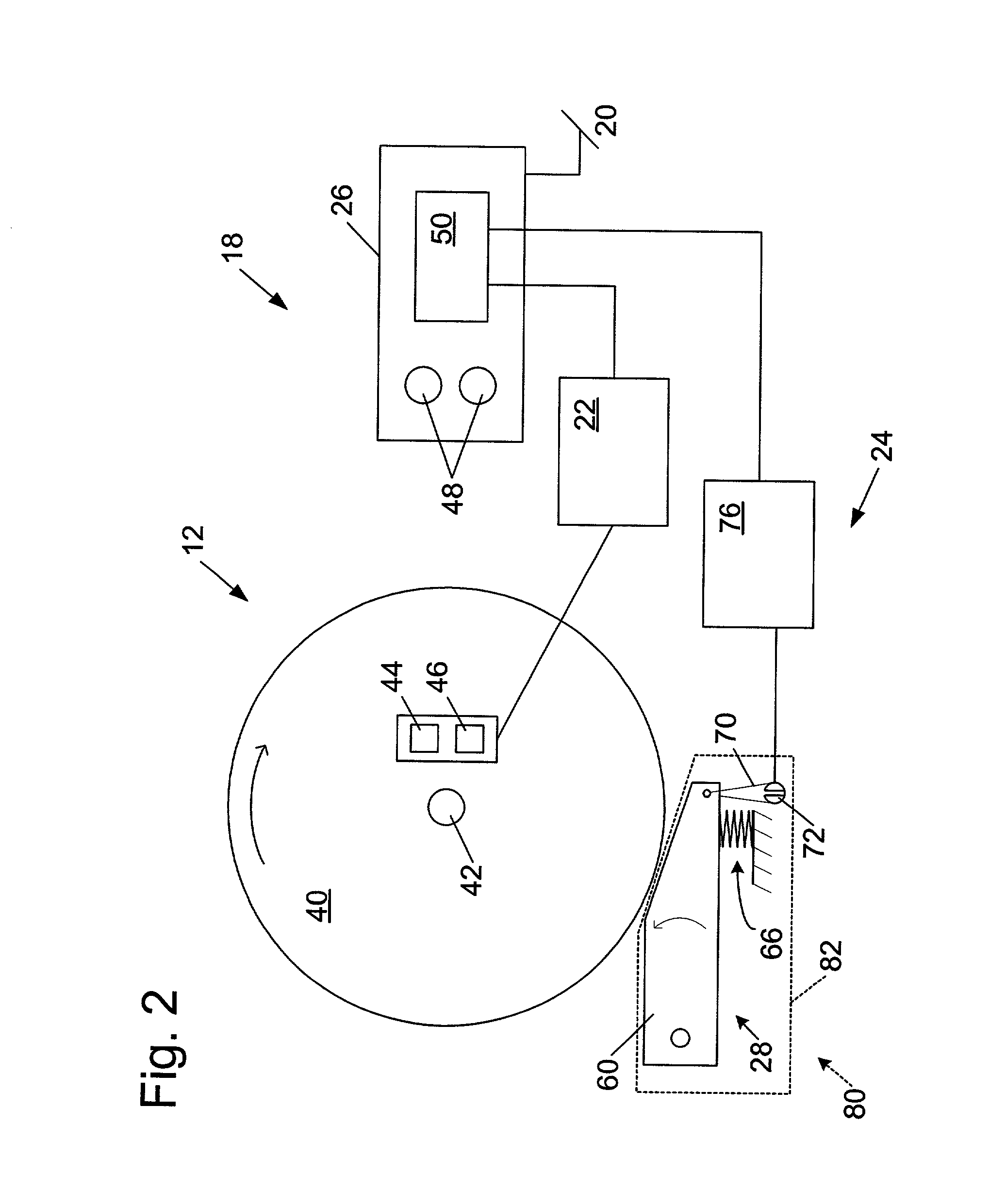

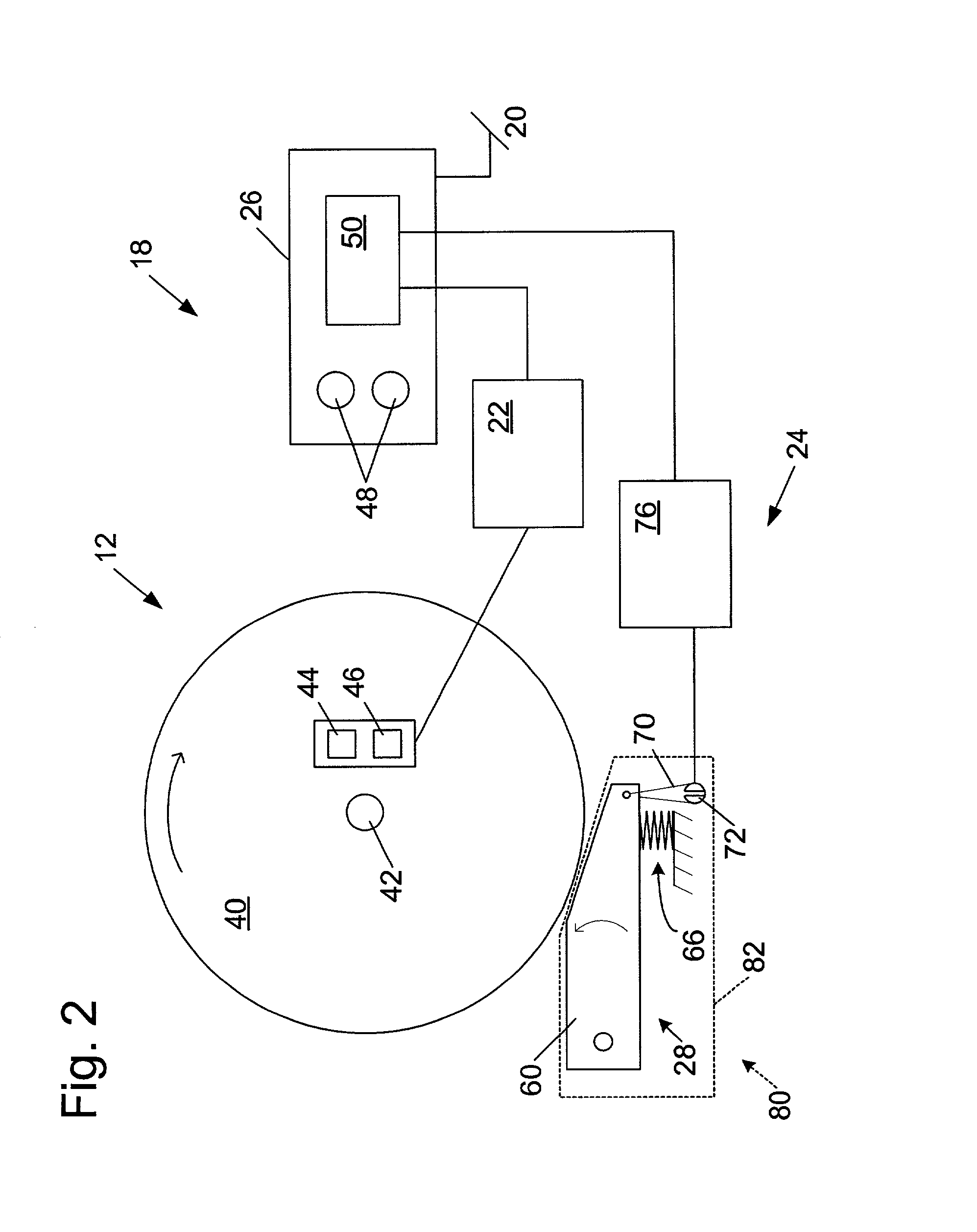

Safety detection and protection system for power tools

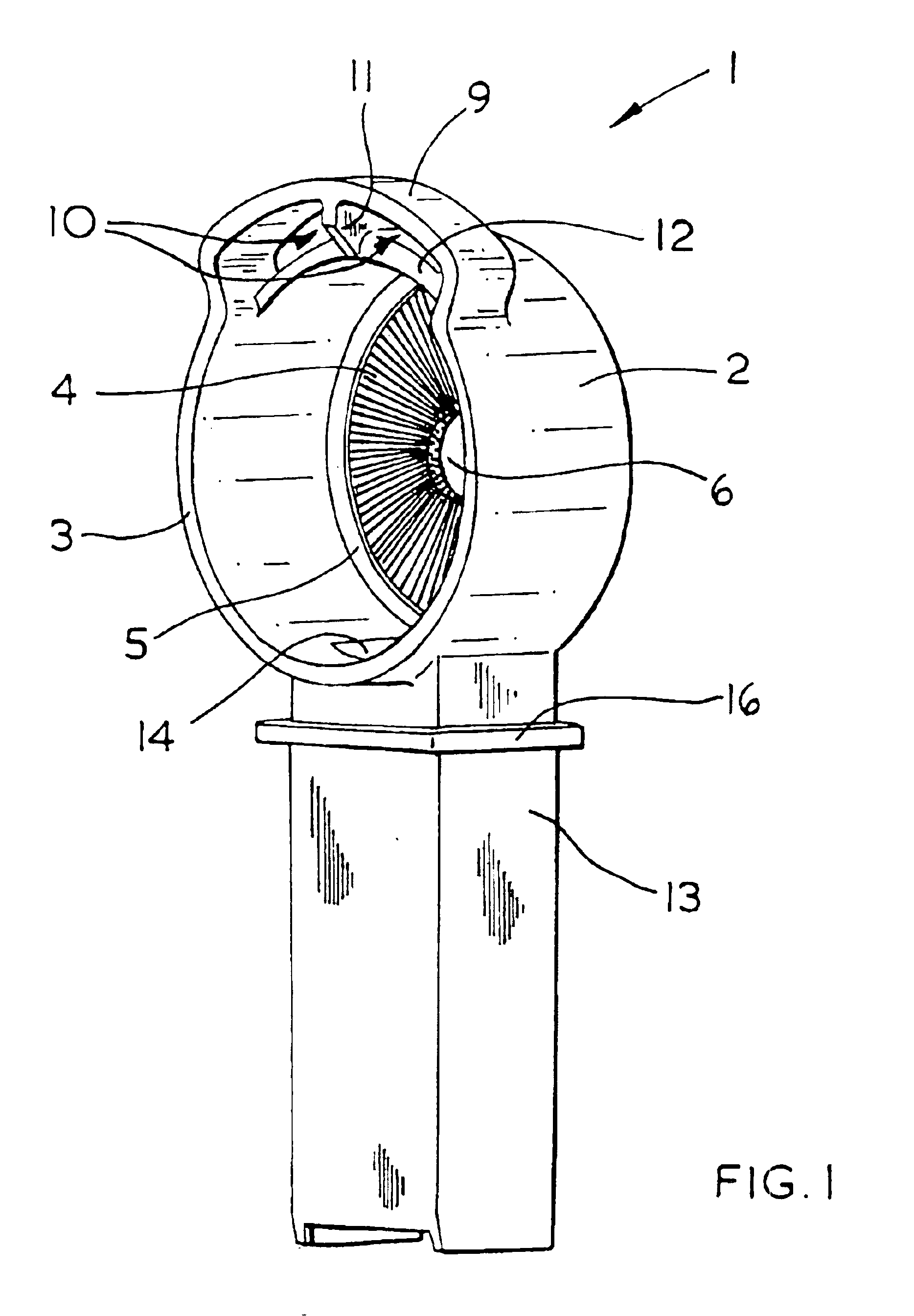

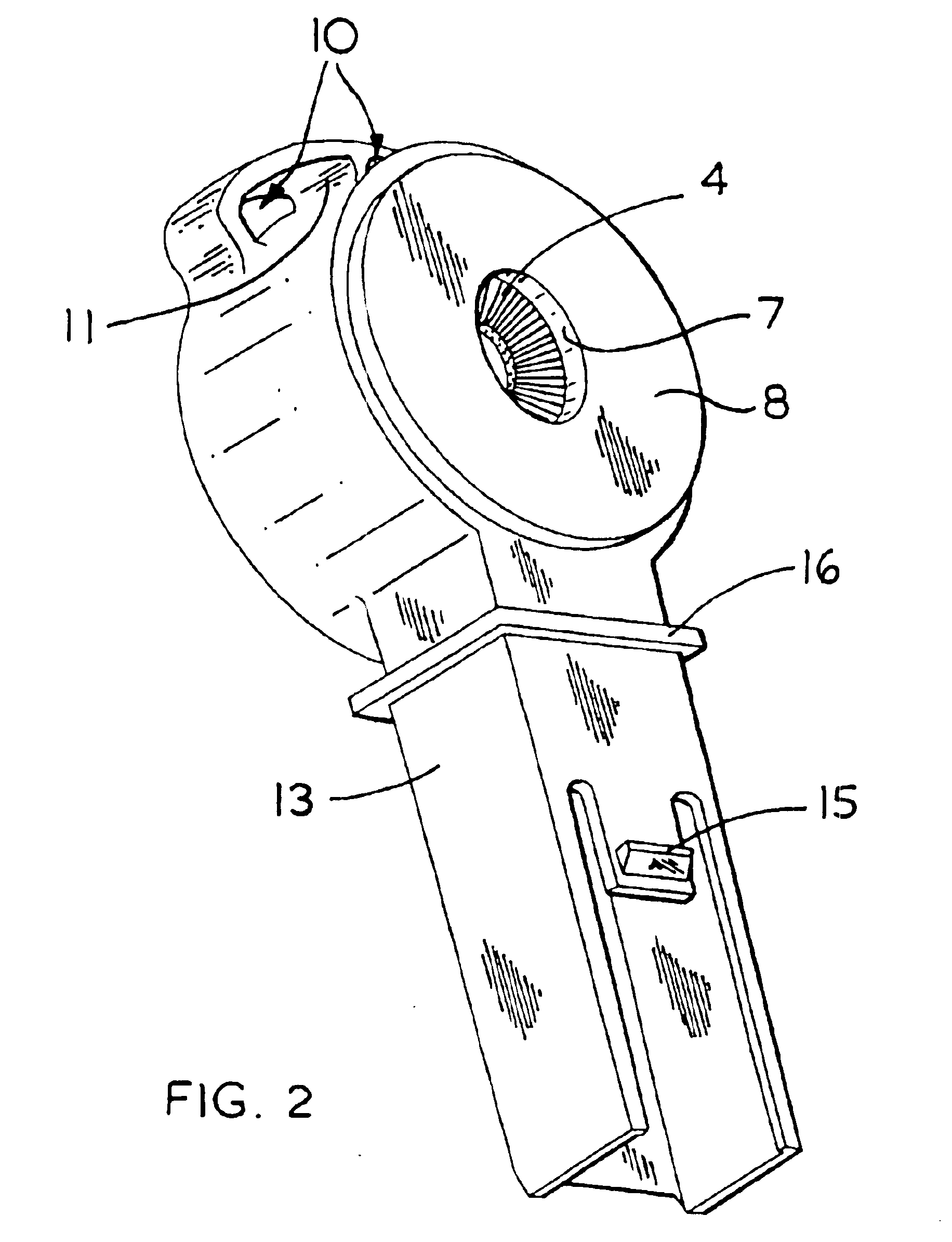

InactiveUS6922153B2Quick stopRule out the possibilityDC motor speed/torque controlEmergency protective circuit arrangementsPower toolProtection system

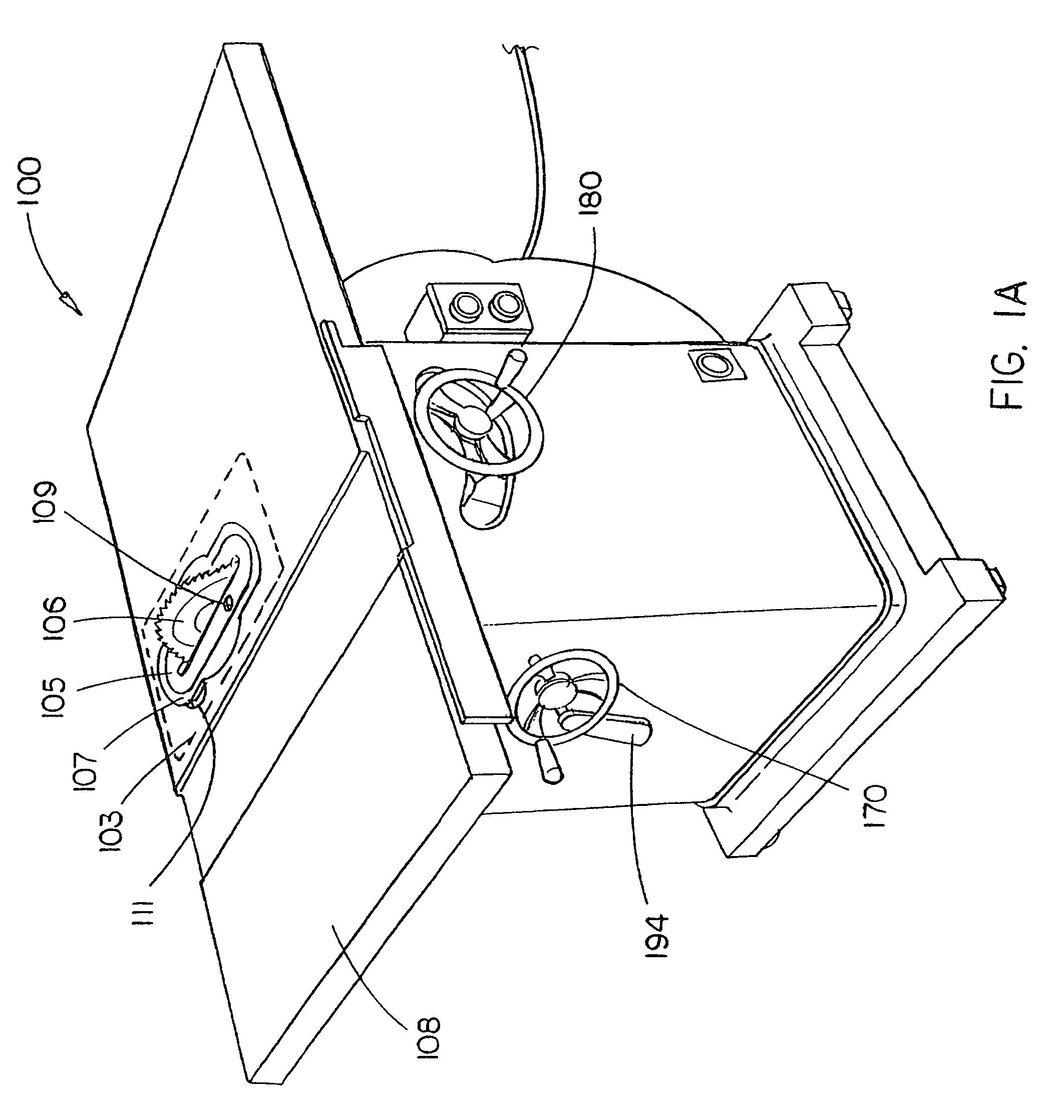

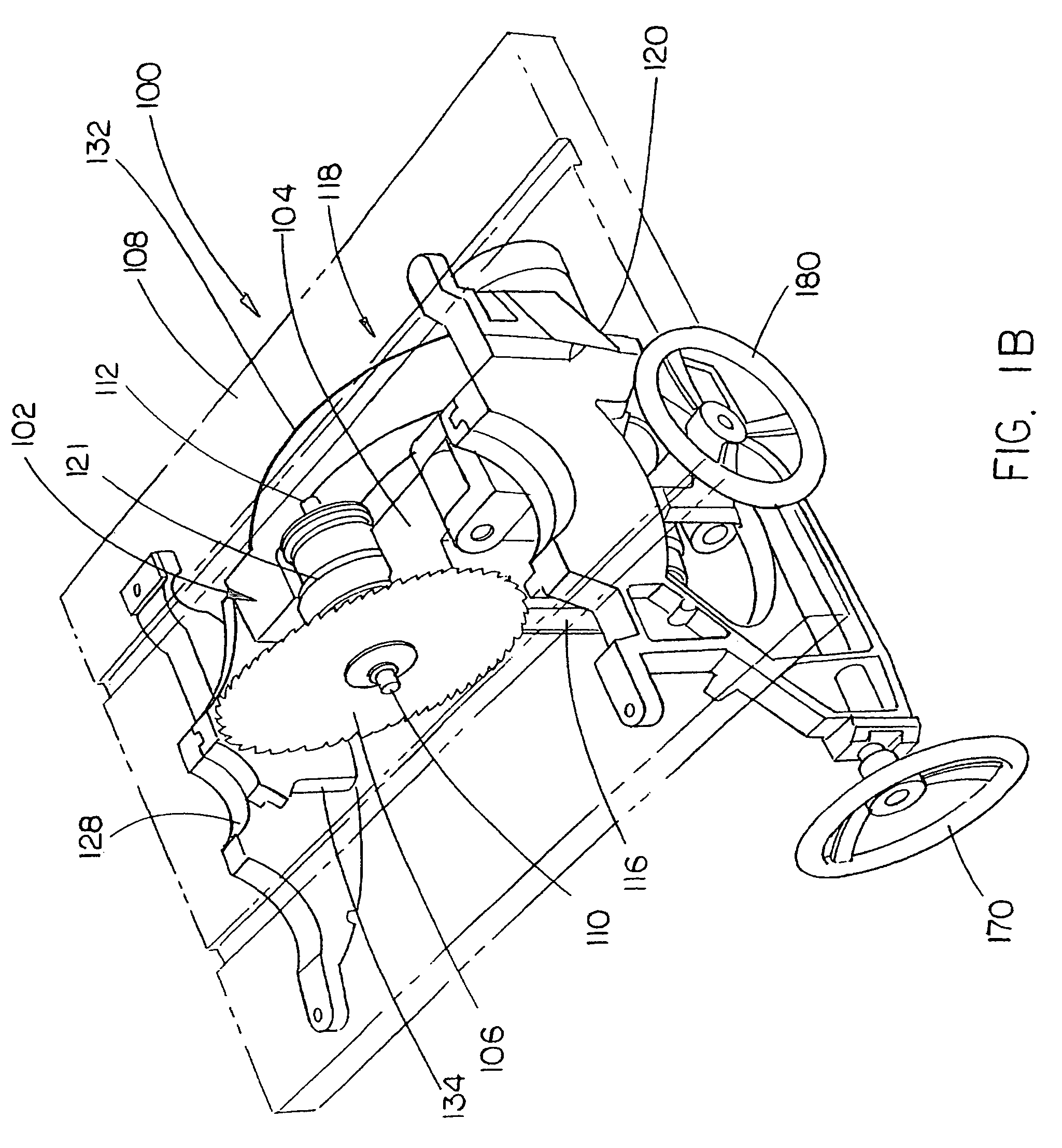

A detection system for detecting a dangerous condition for an operator using a power tool of the type which has an exposed blade relative to a work surface and a protection system for minimizing, if not eliminating the possibility of a user being injured by contacting the blade. In one preferred embodiment of the present invention, a proximity detection system is capable of detecting the presence of a user near the blade of a table saw and a protection system that can either retract the blade below the work surface of the table saw or terminate the drive torque to the blade which can result in rapid stopping of the saw blade by a work piece that is being cut.

Owner:CREDO TECH CORP +1

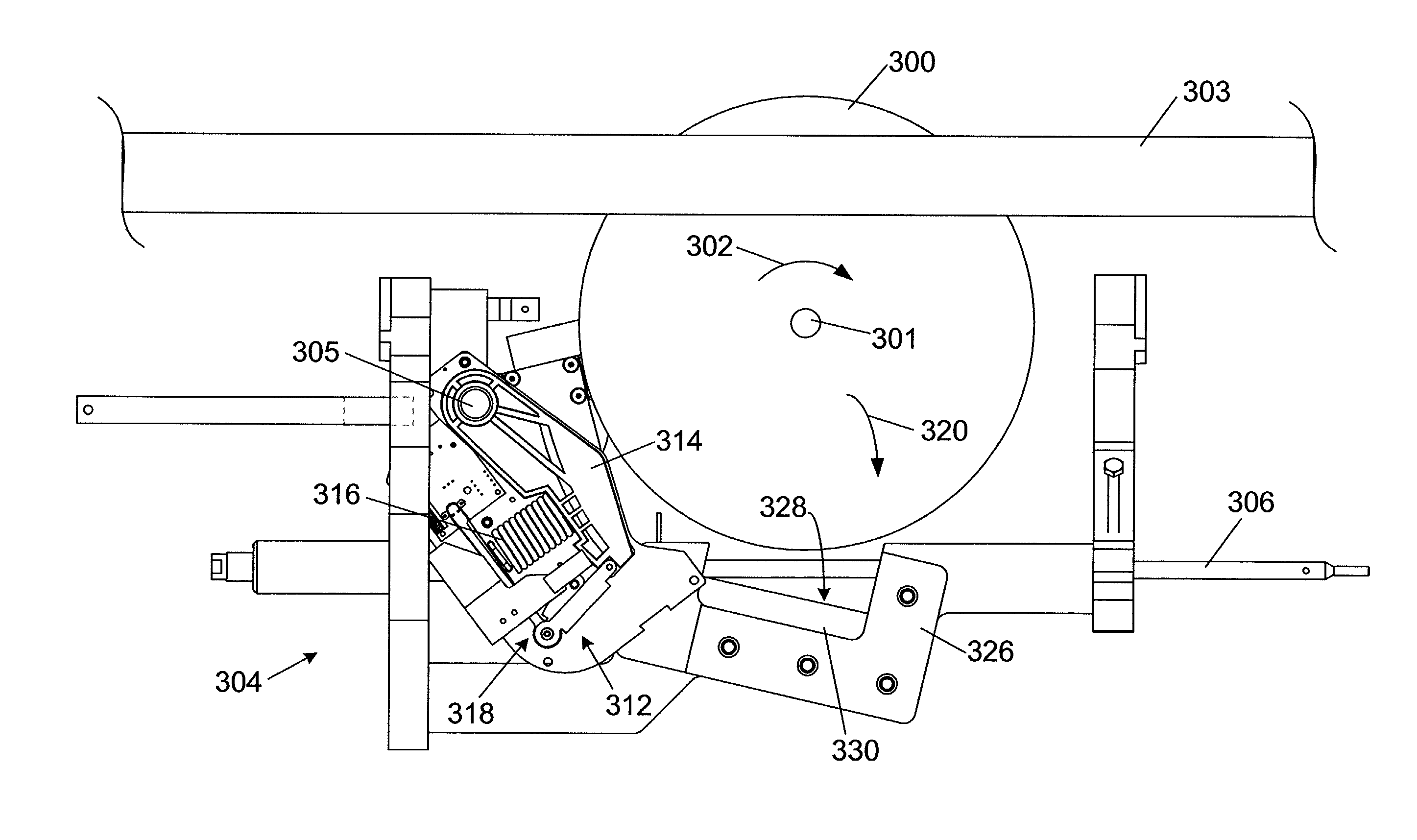

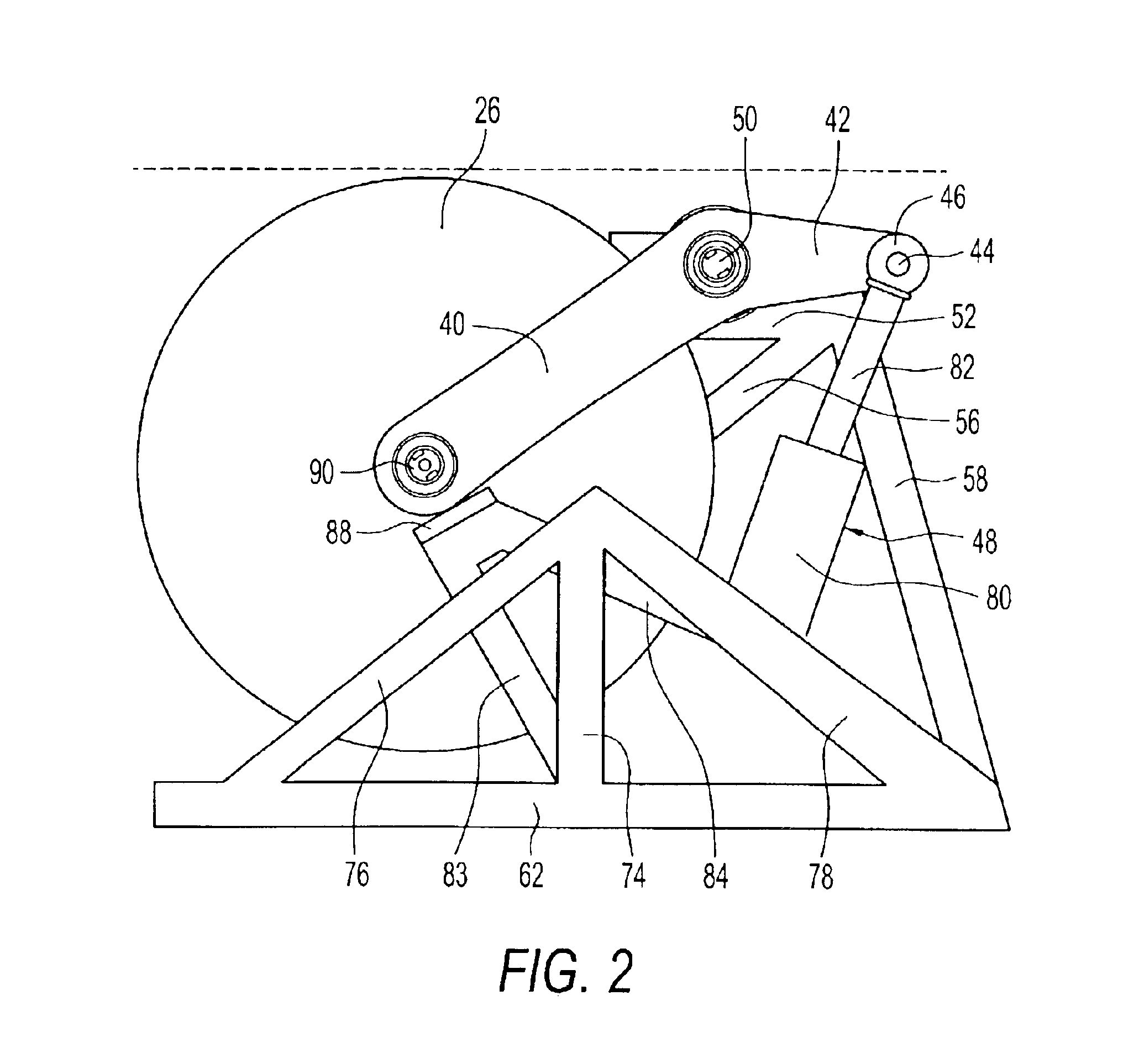

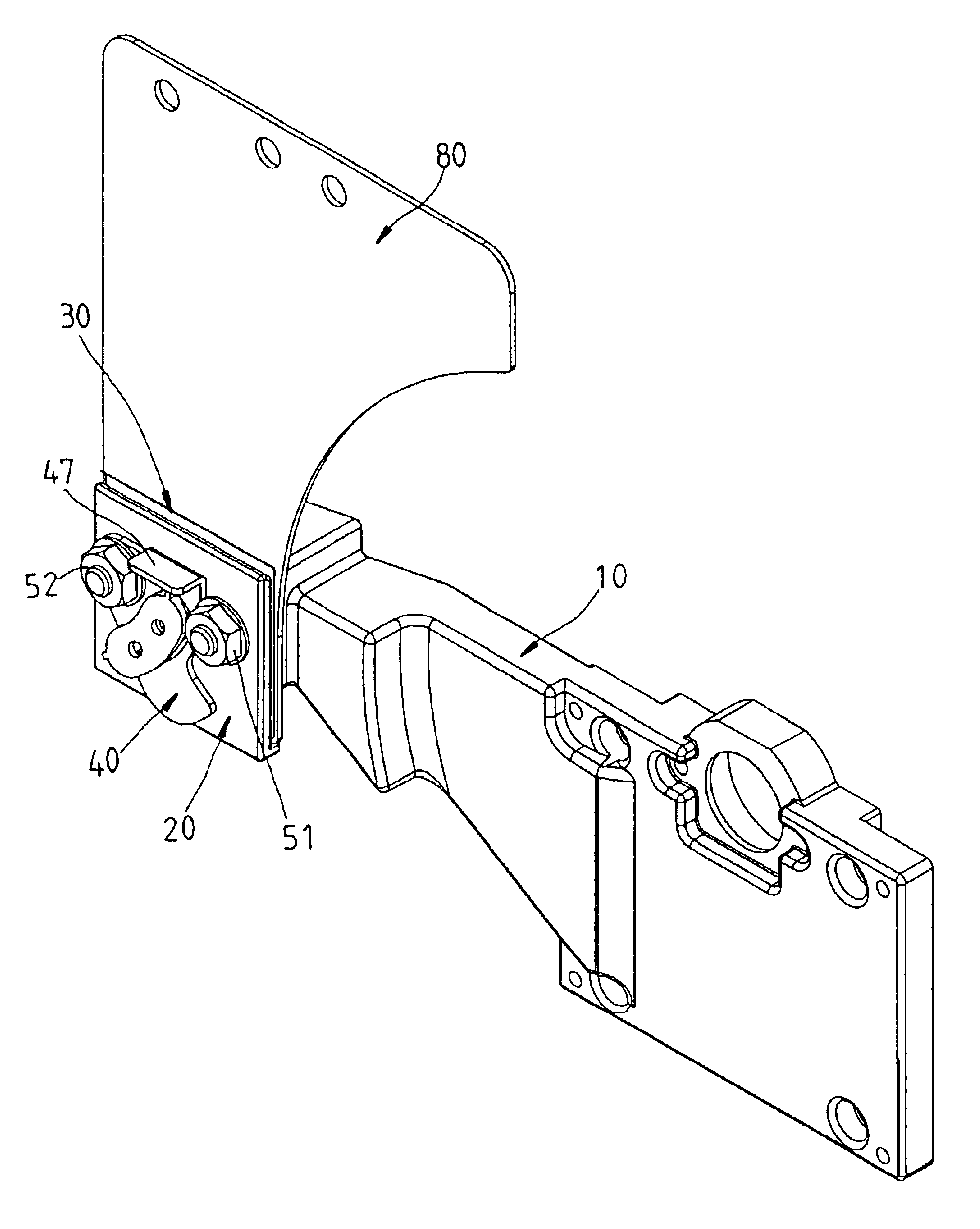

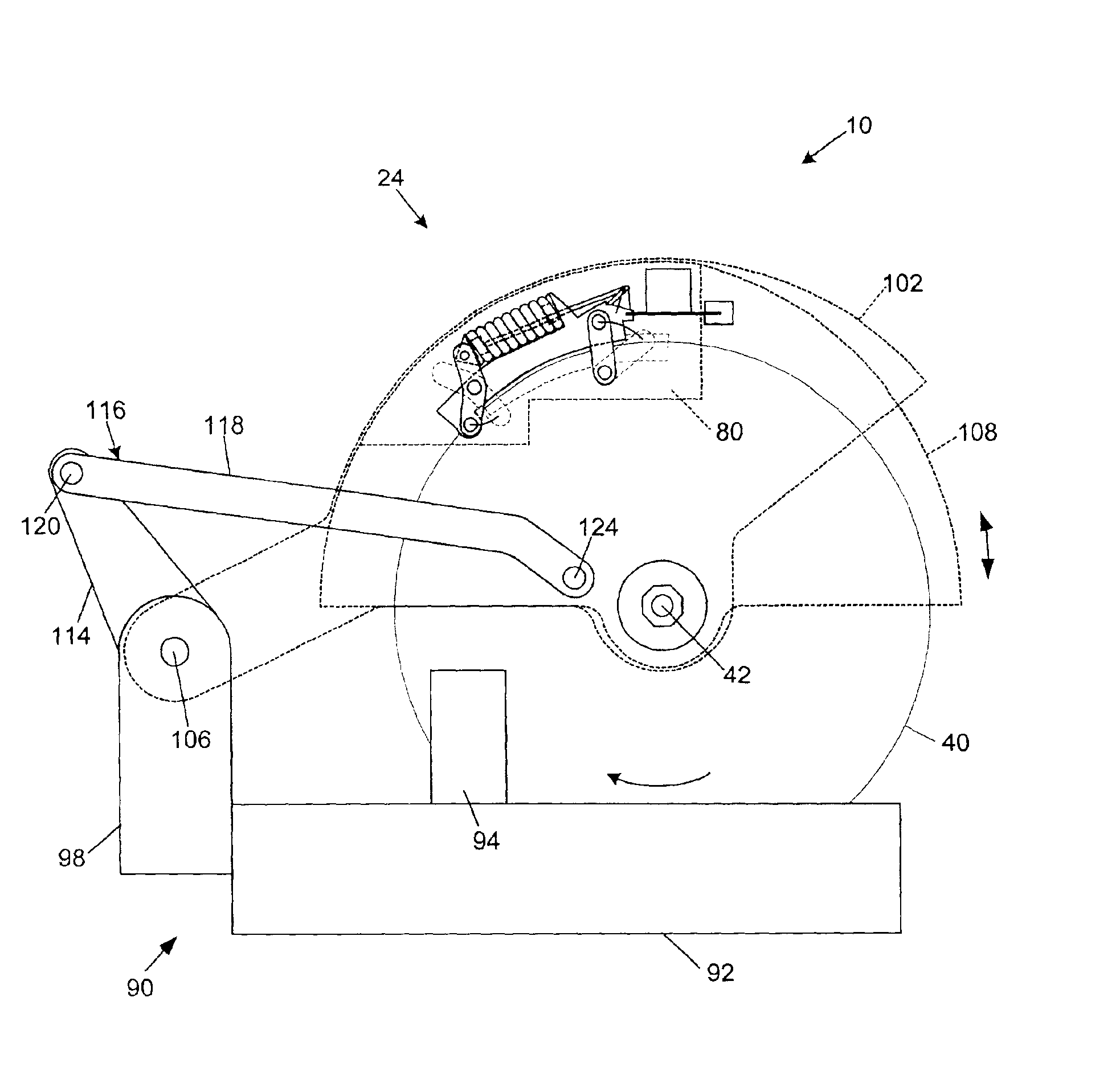

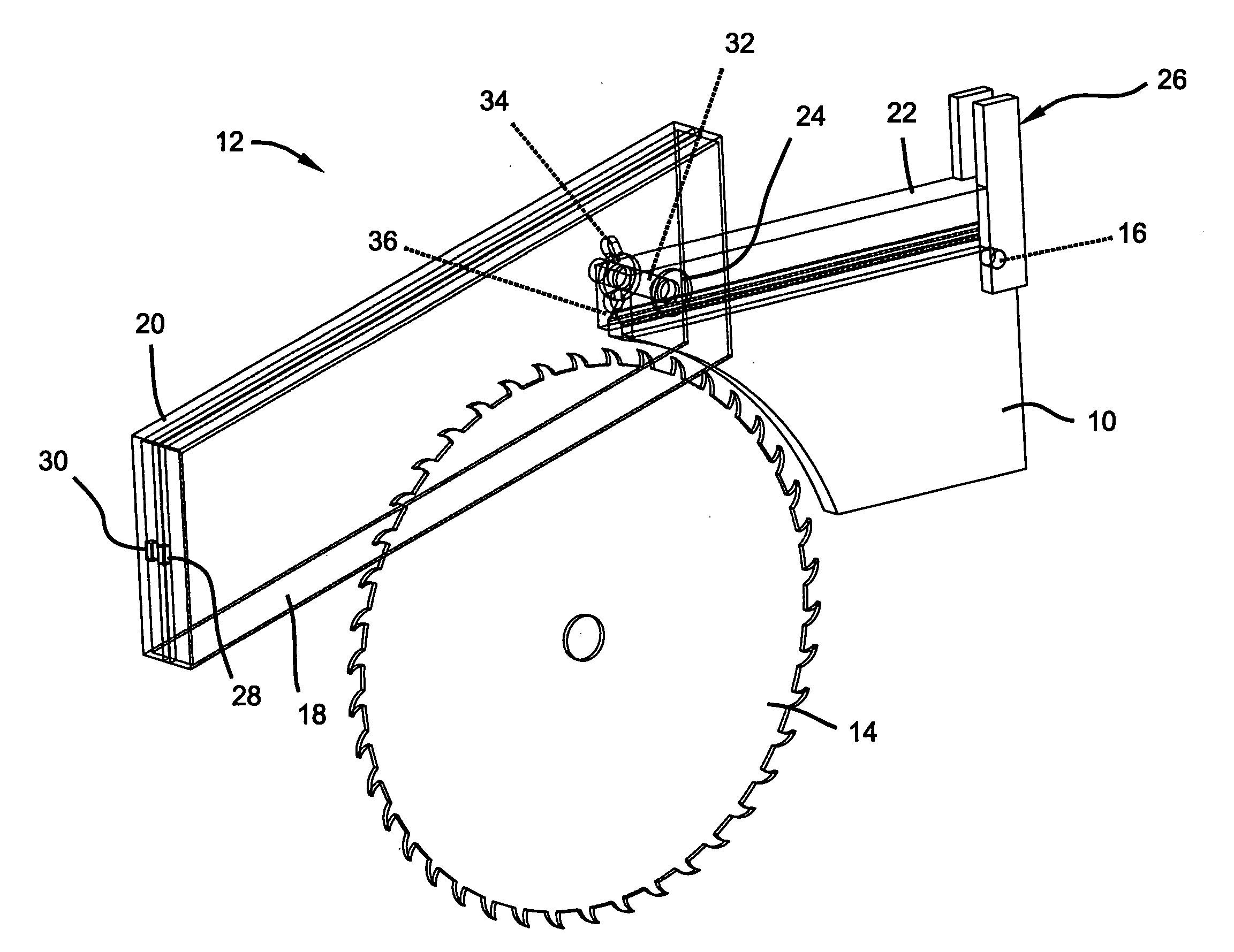

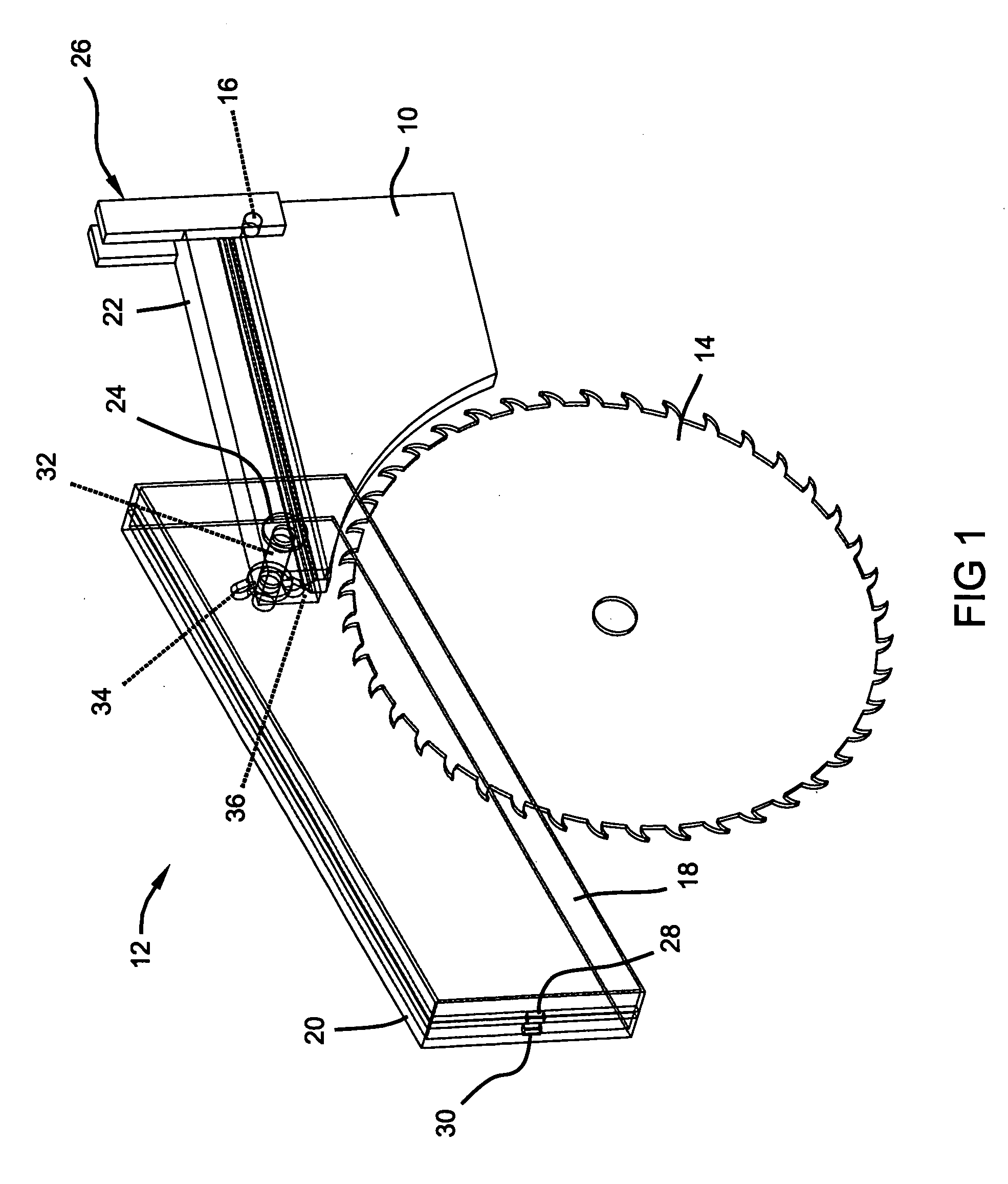

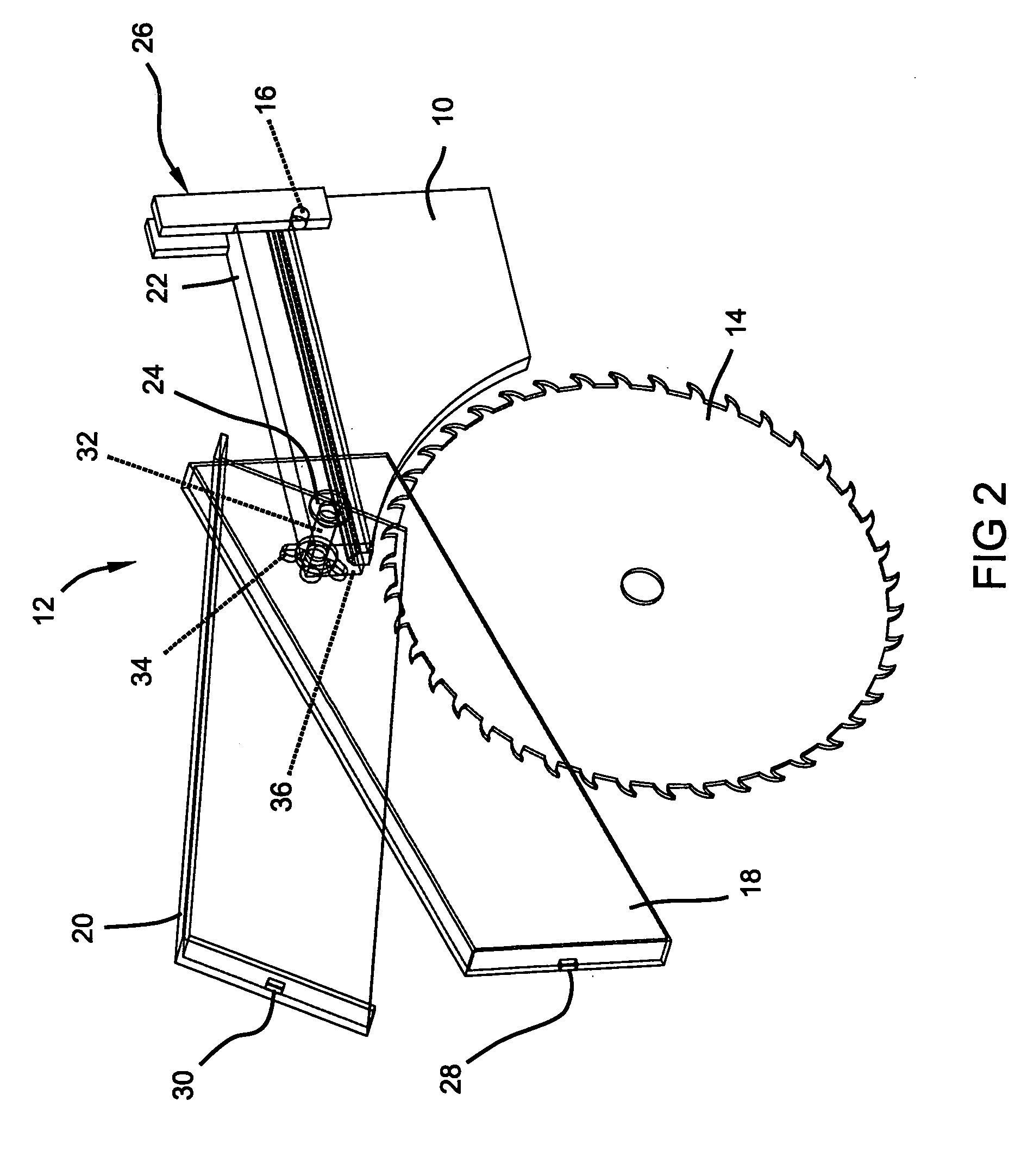

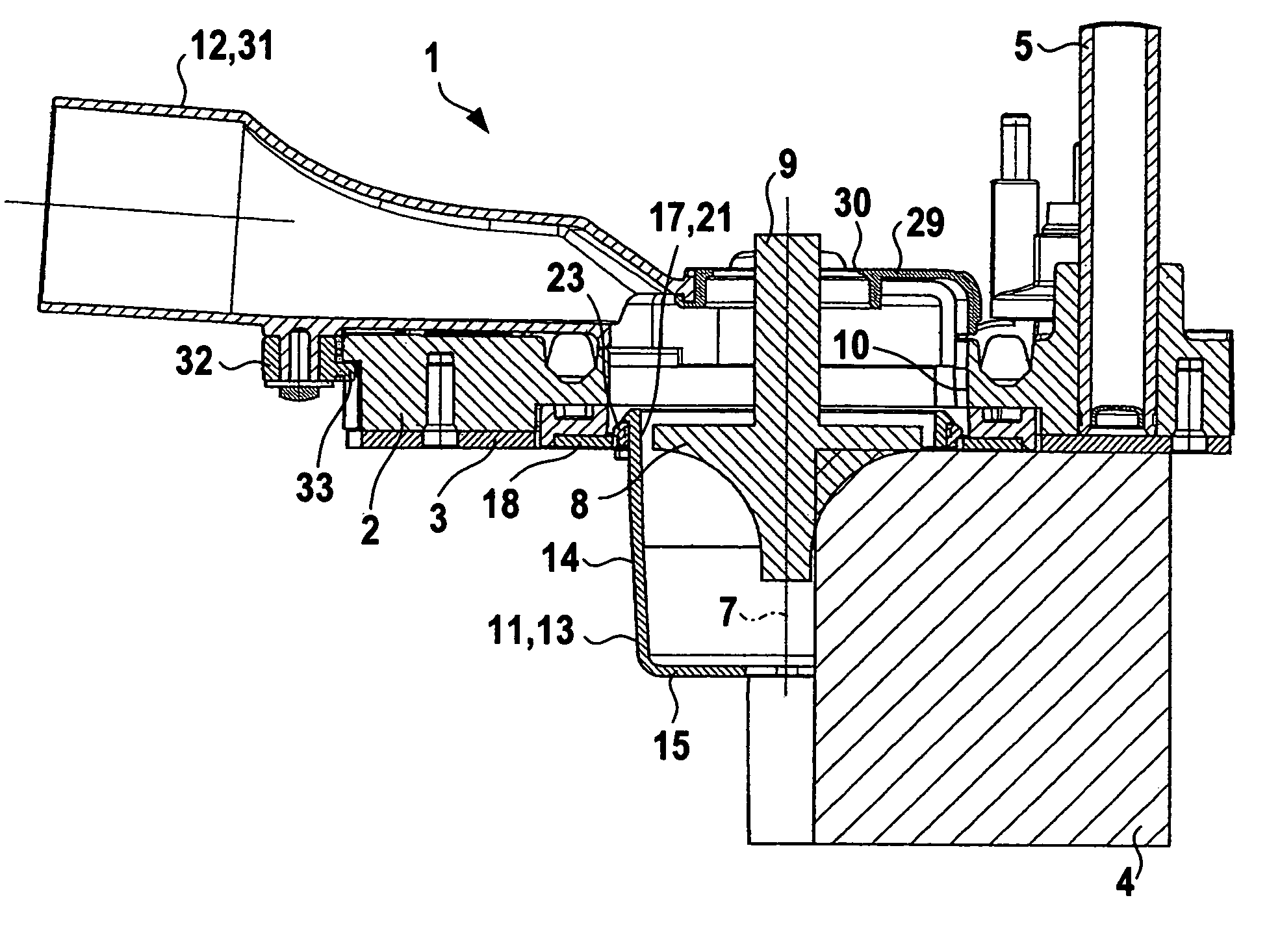

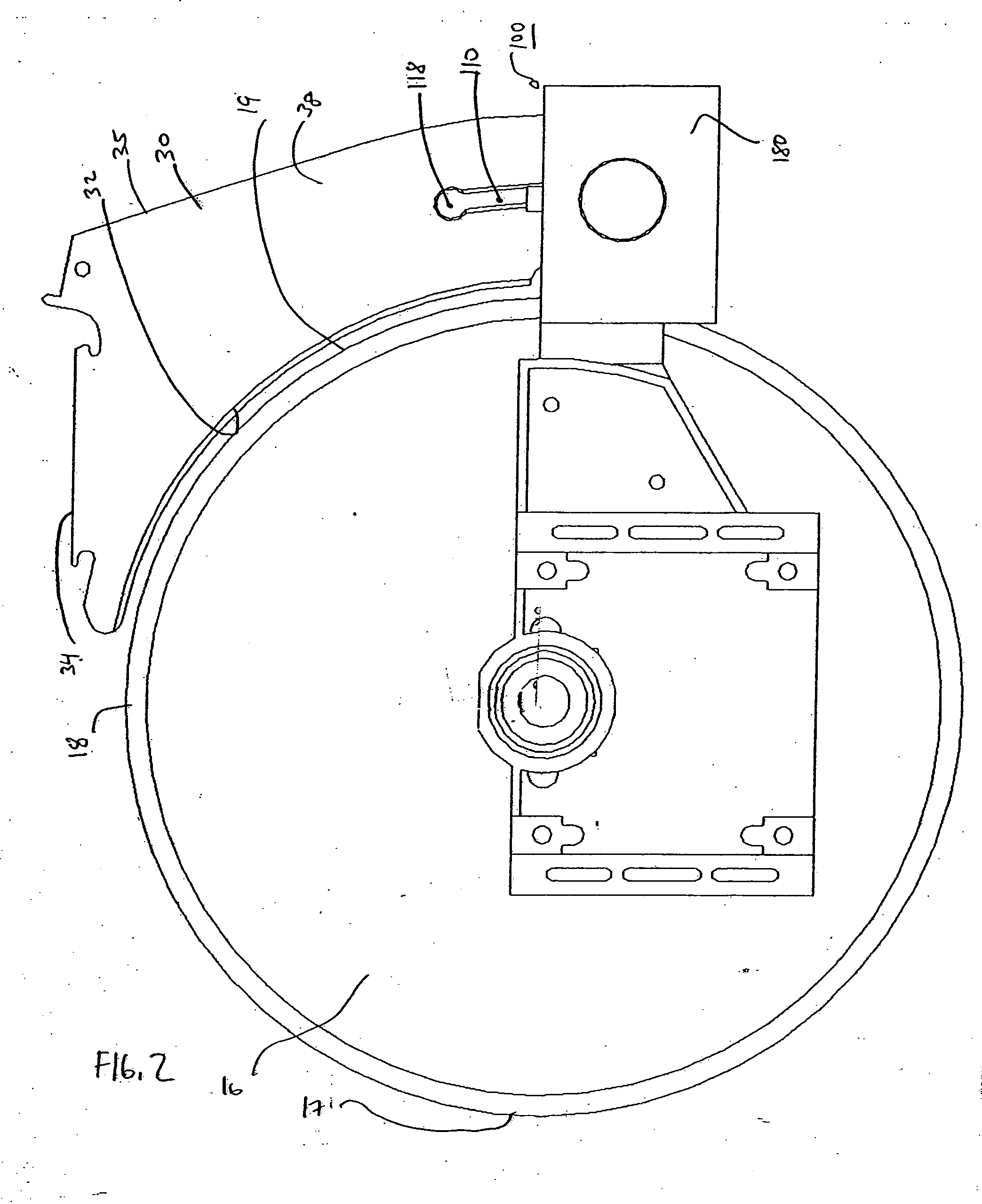

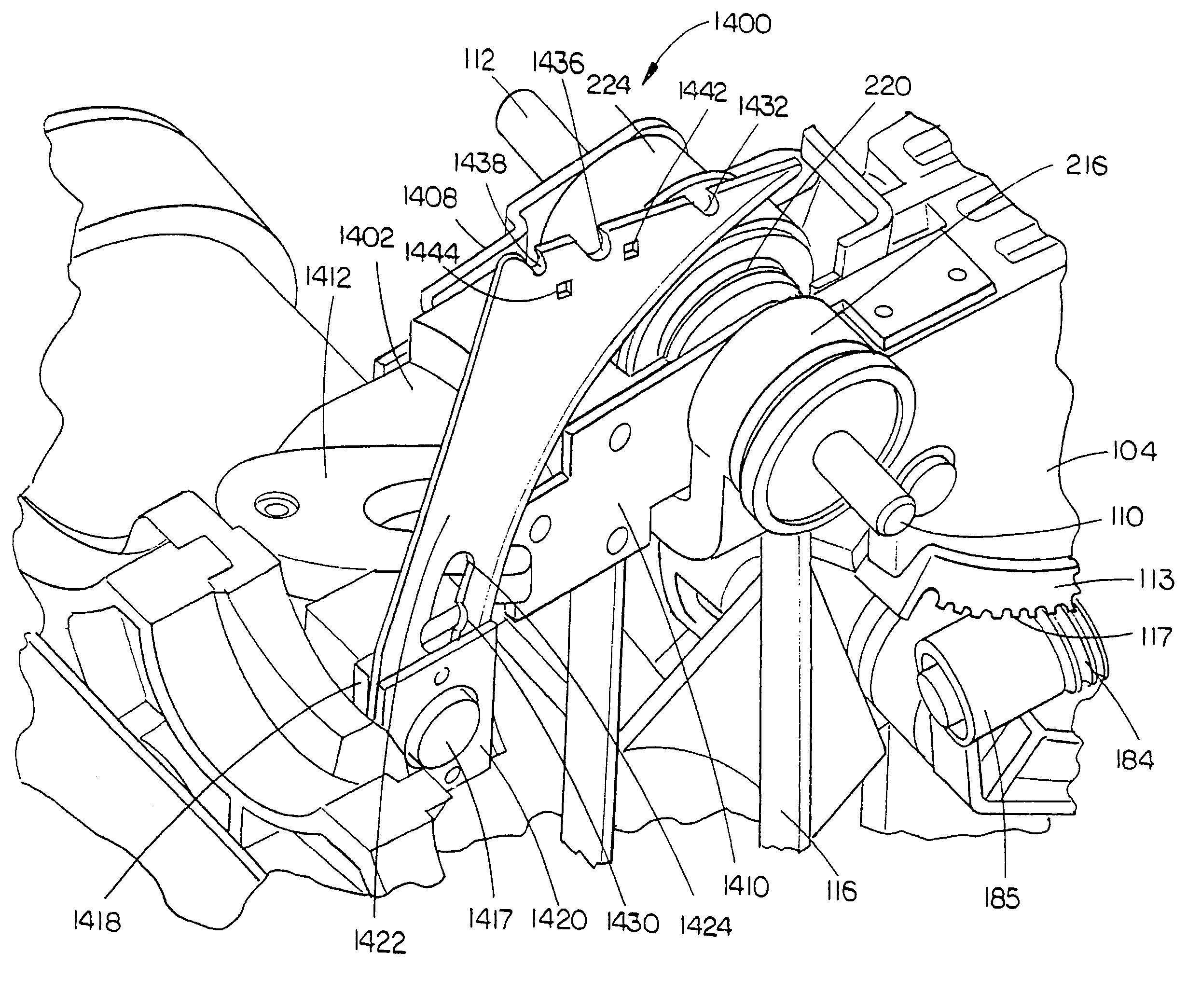

Brake positioning system

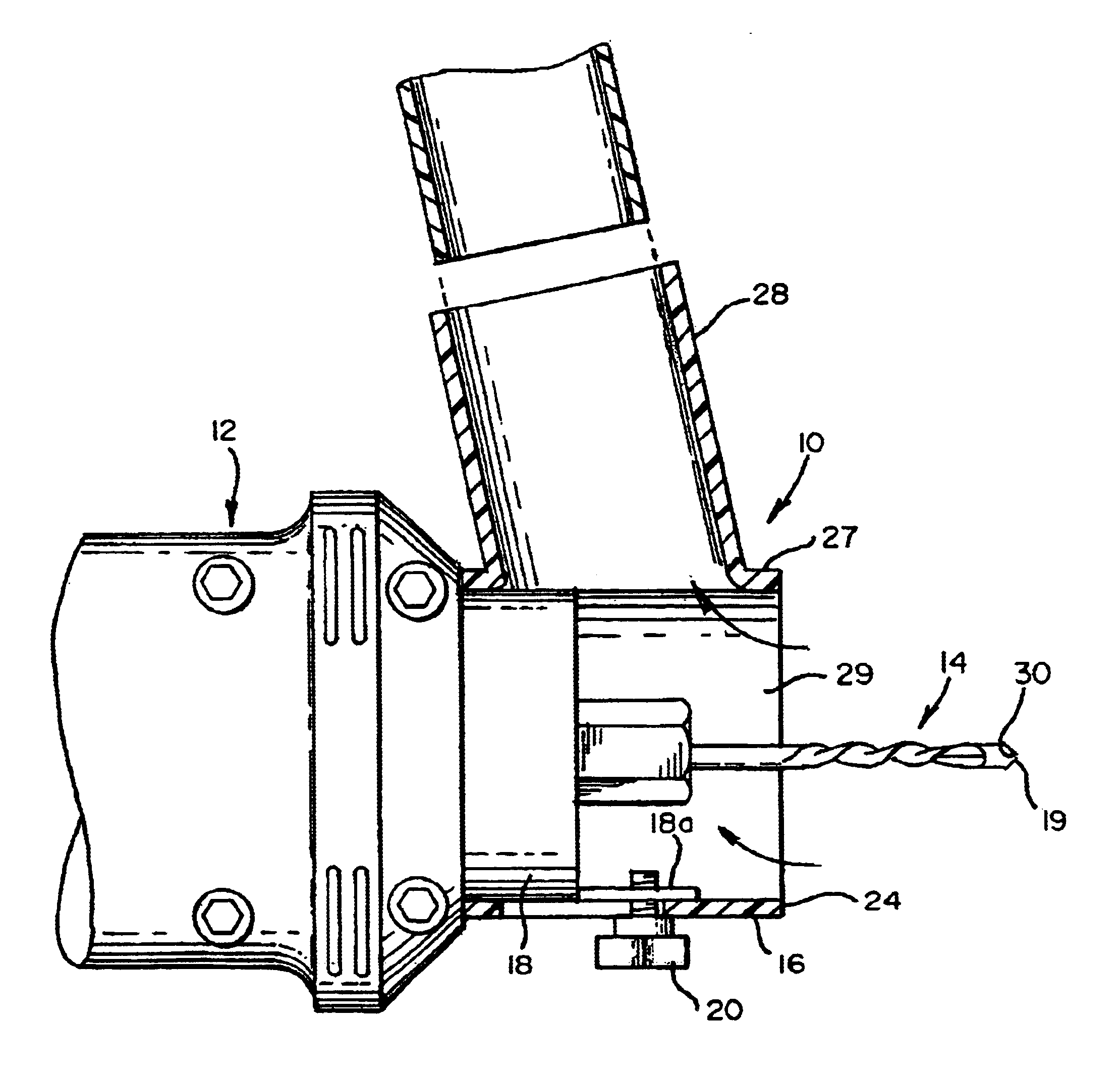

InactiveUS6857345B2Multi-purpose machinesEngineering safety devicesEngineeringMechanical engineering

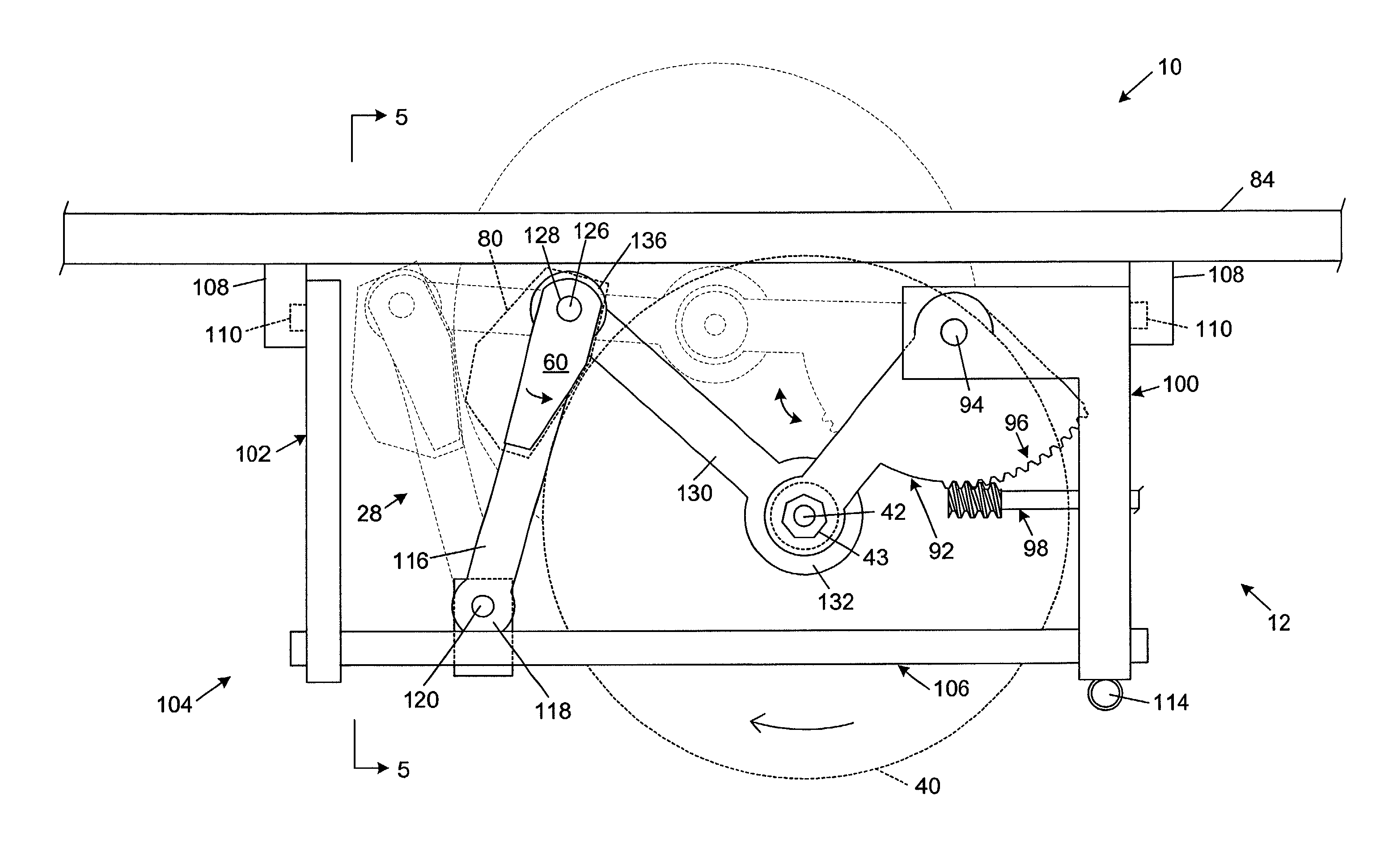

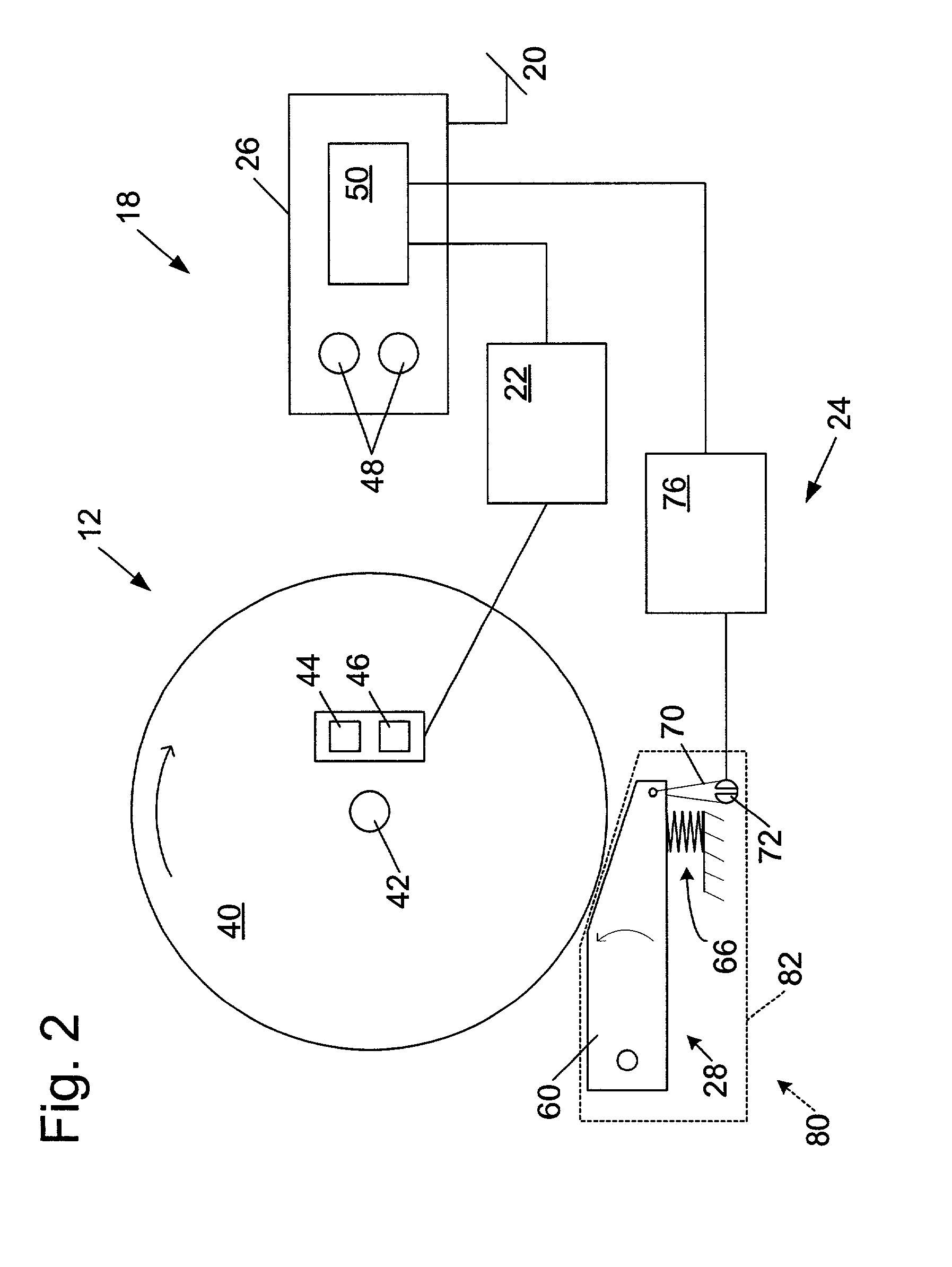

A saw is disclosed having a detection system adapted to detect a dangerous condition between a person and a saw blade, and a brake adapted to stop the saw blade in response to detection of the dangerous condition. The saw further includes a brake positioning system that allows the brake to be positioned in at least two different operable positions to accommodate at least two different blade diameters. The saw may include a system to detect brake-to-blade spacing.

Owner:SAWSTOP HLDG LLC

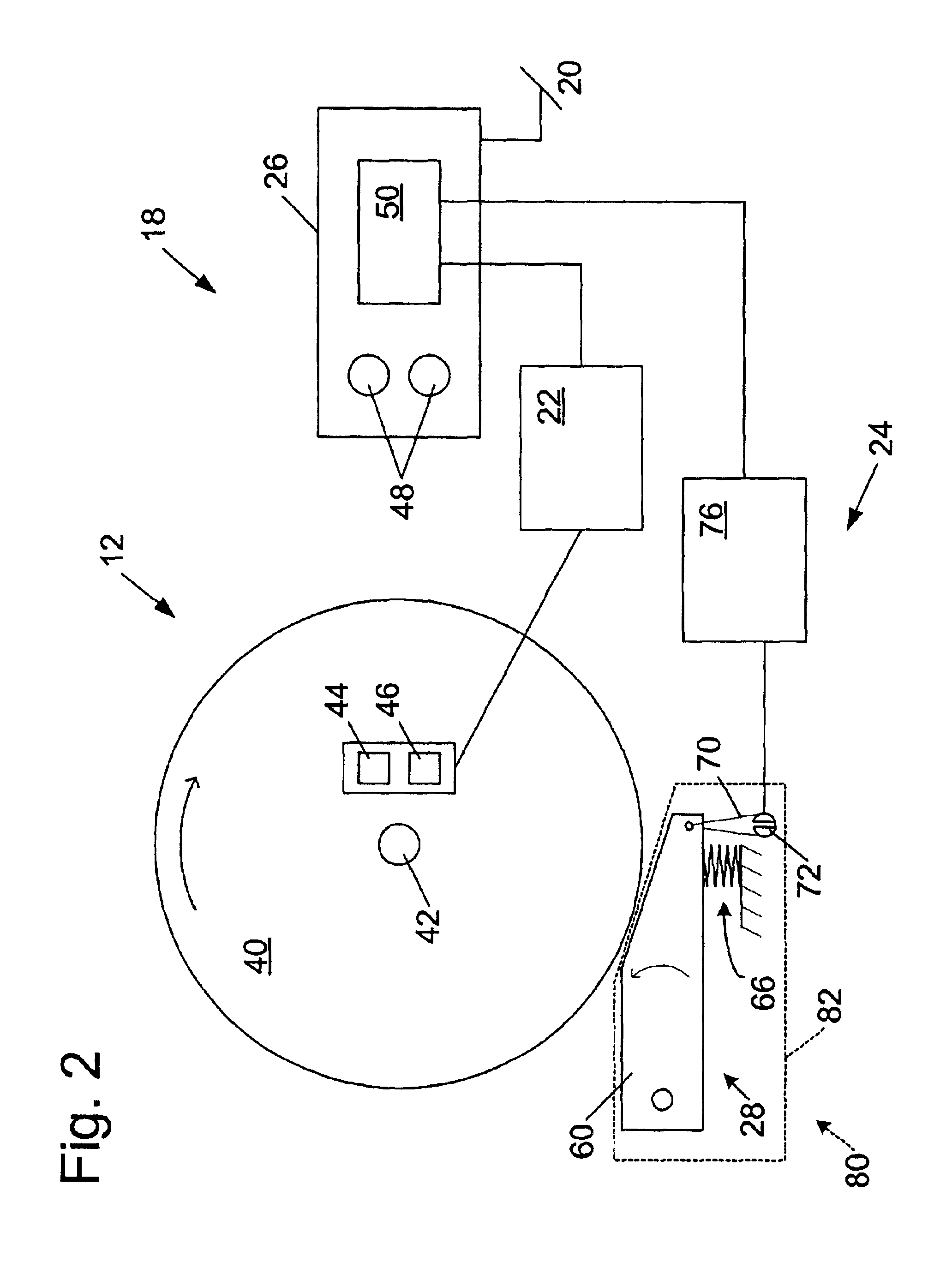

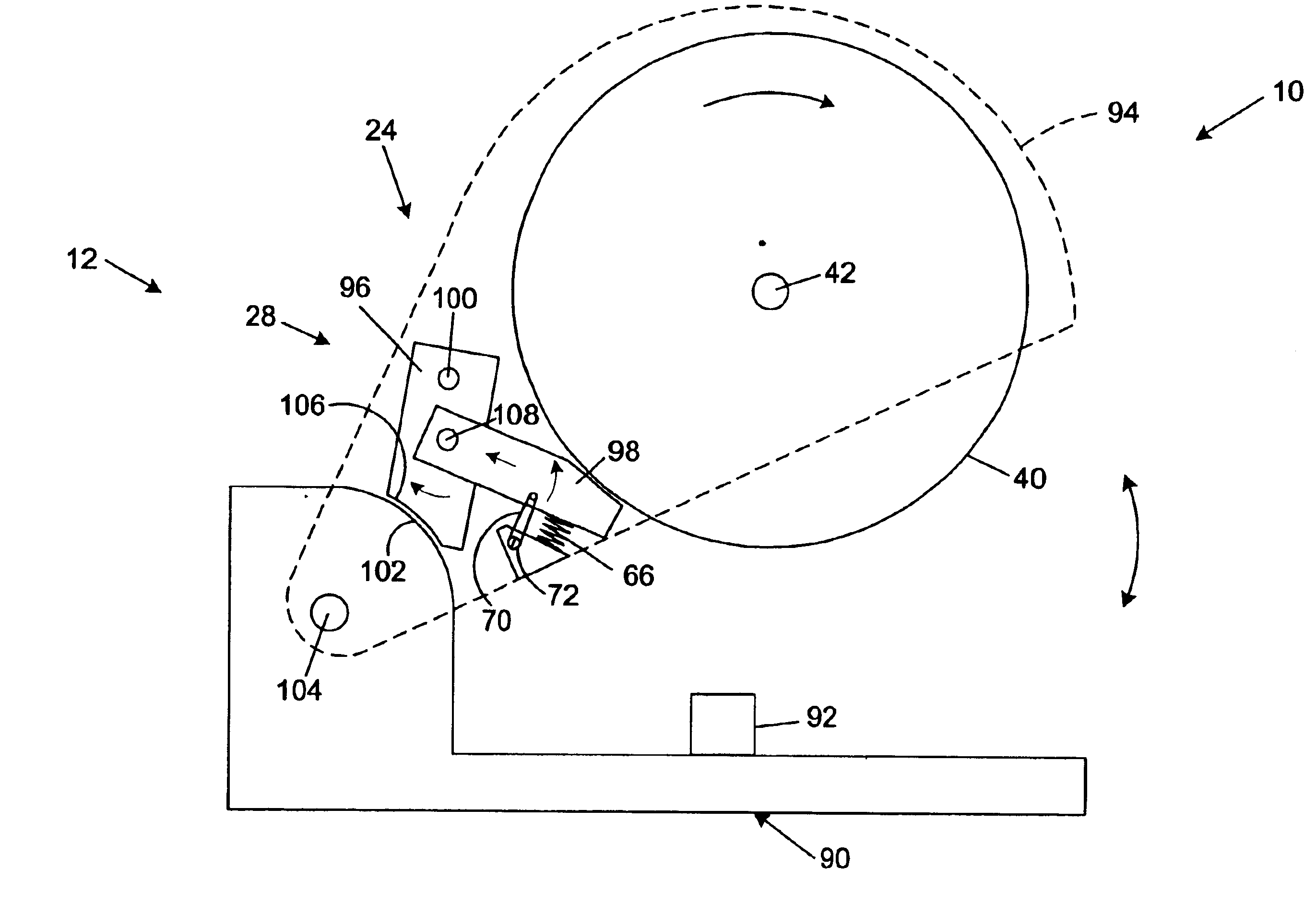

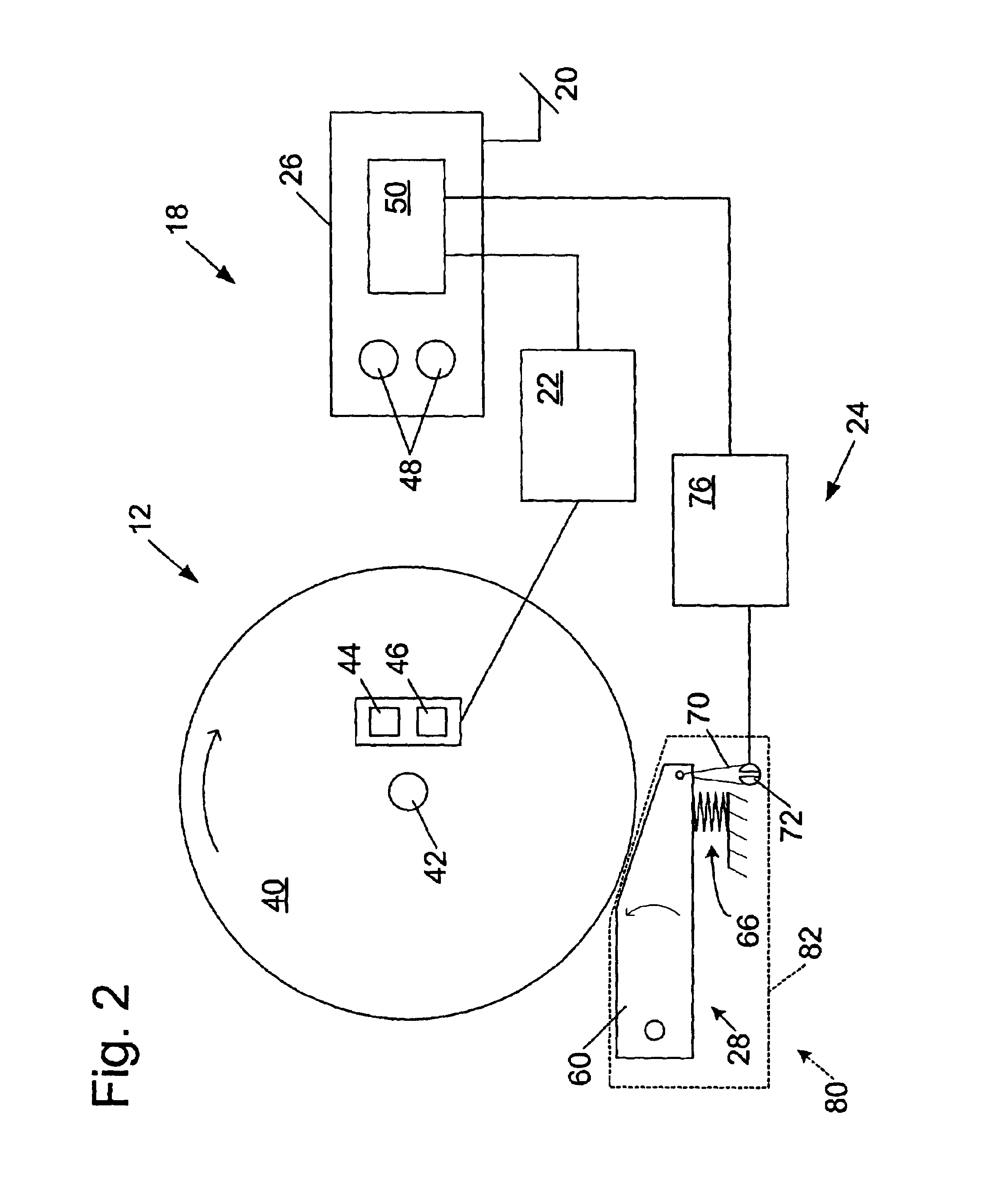

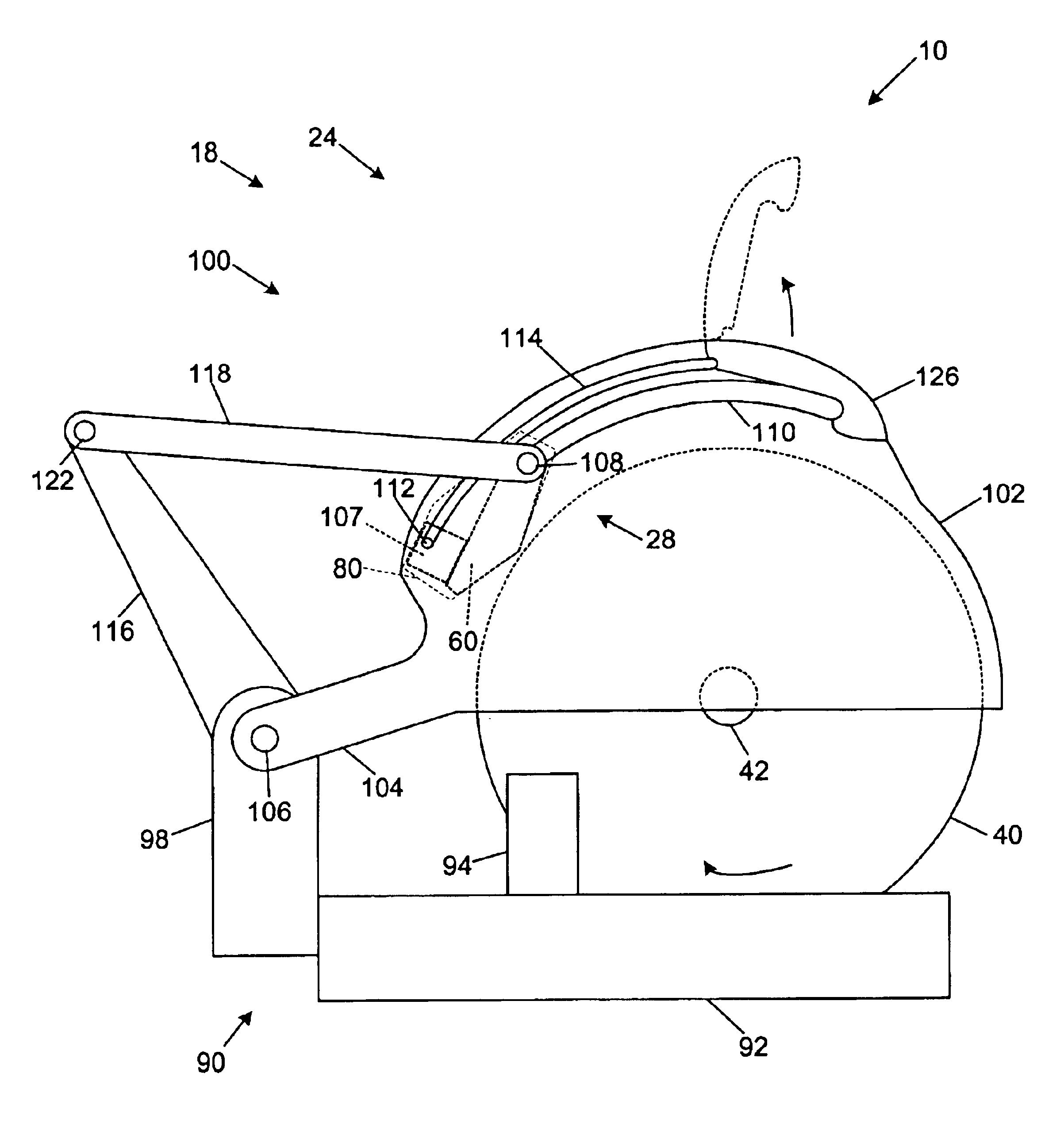

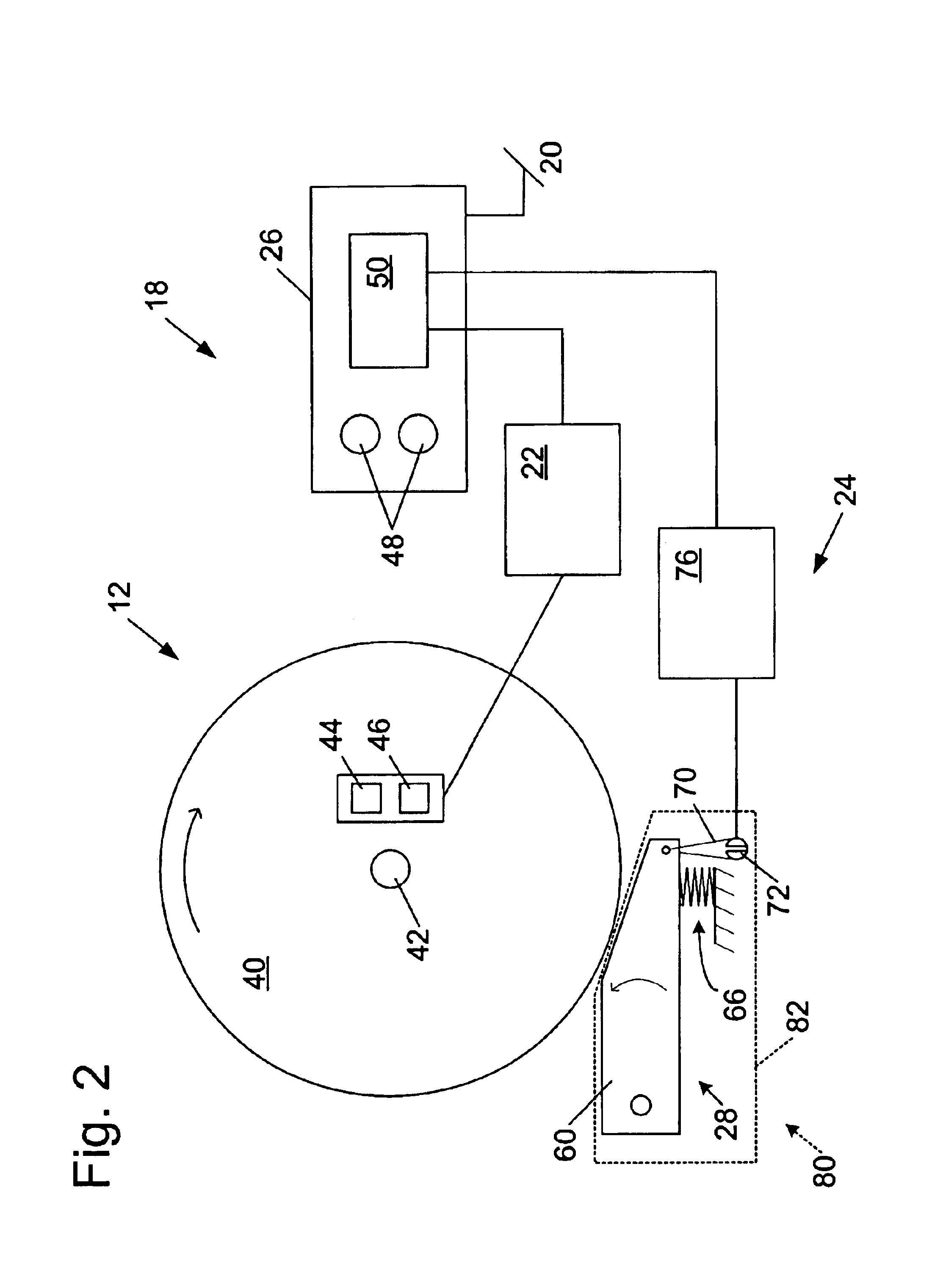

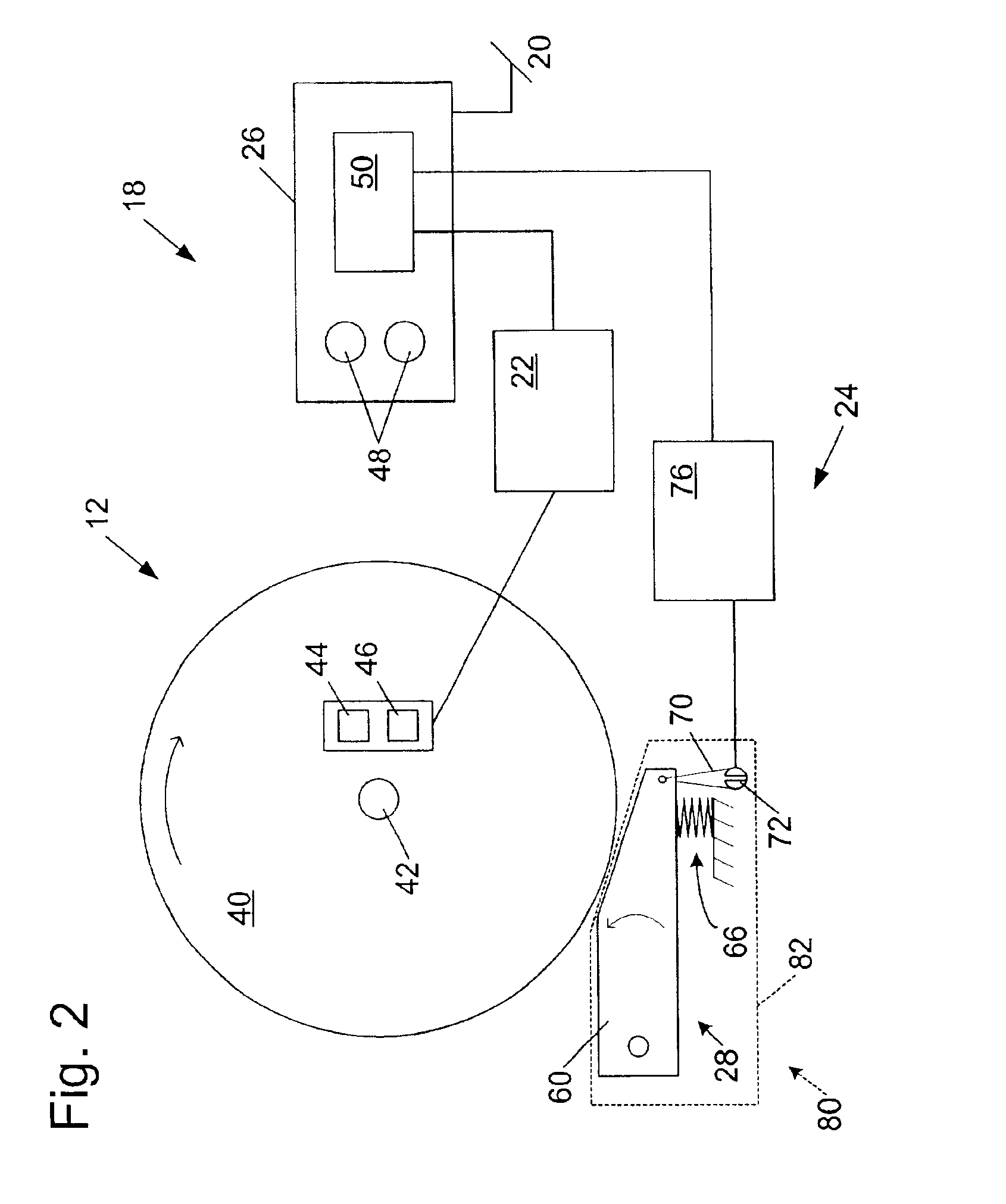

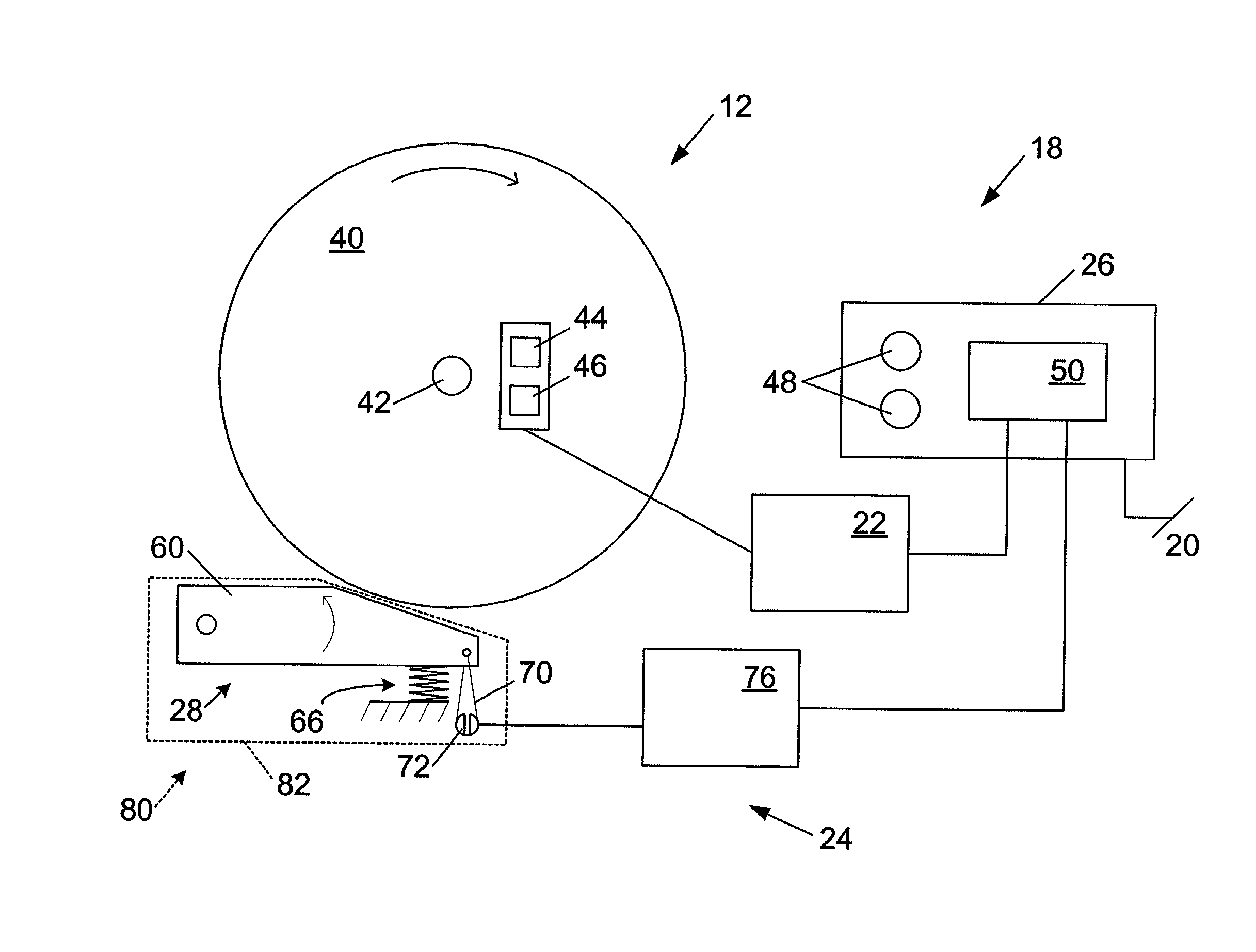

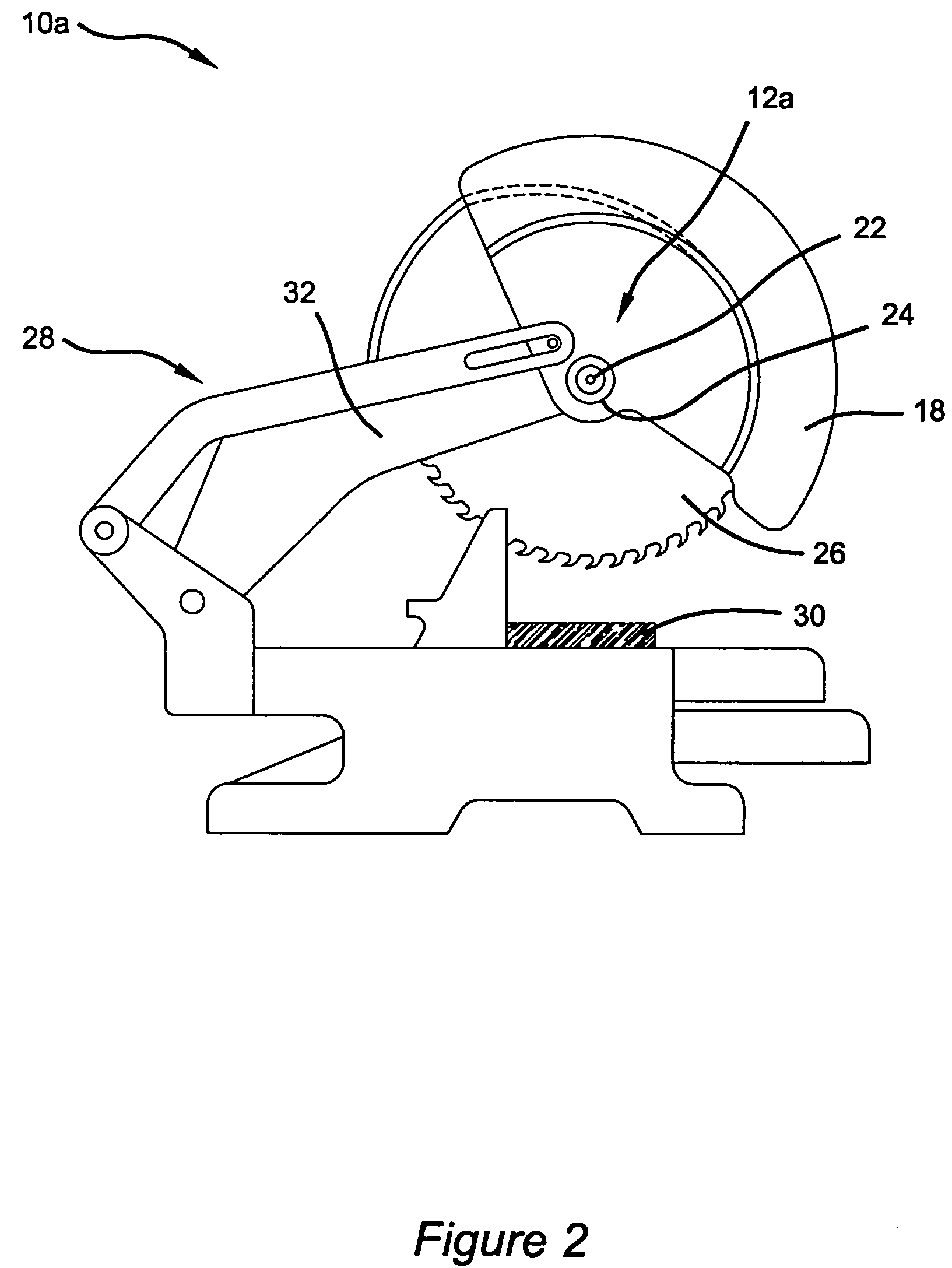

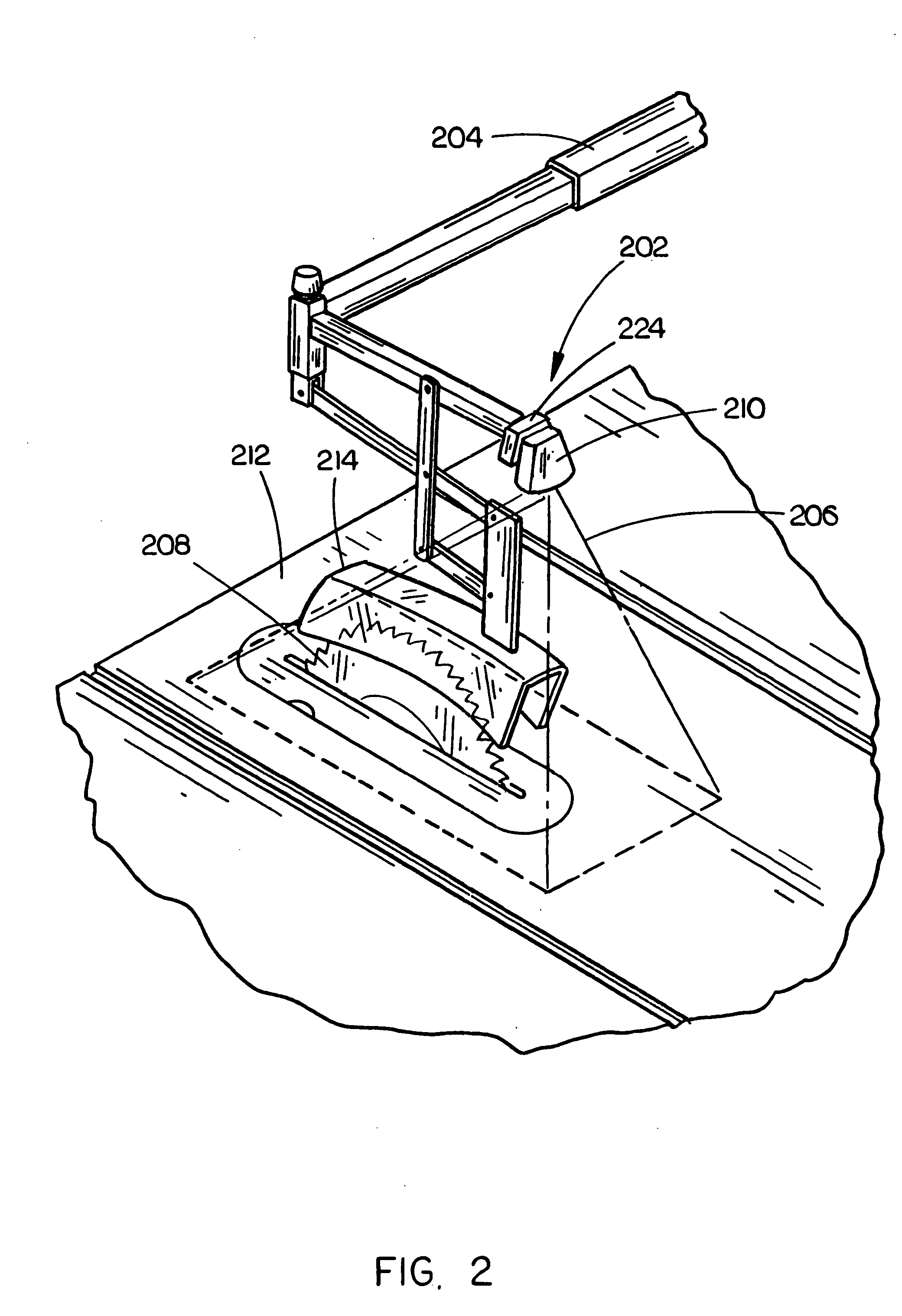

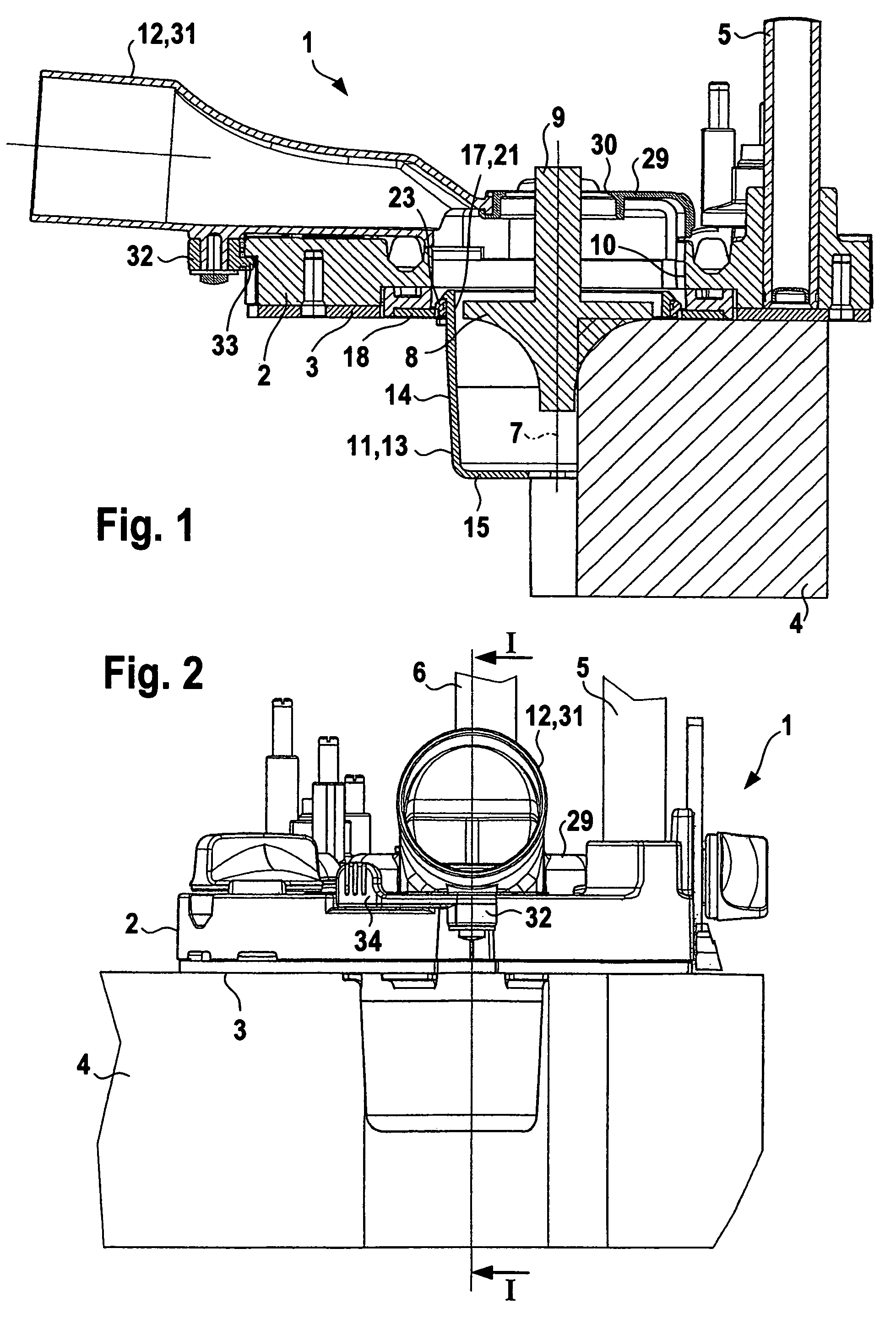

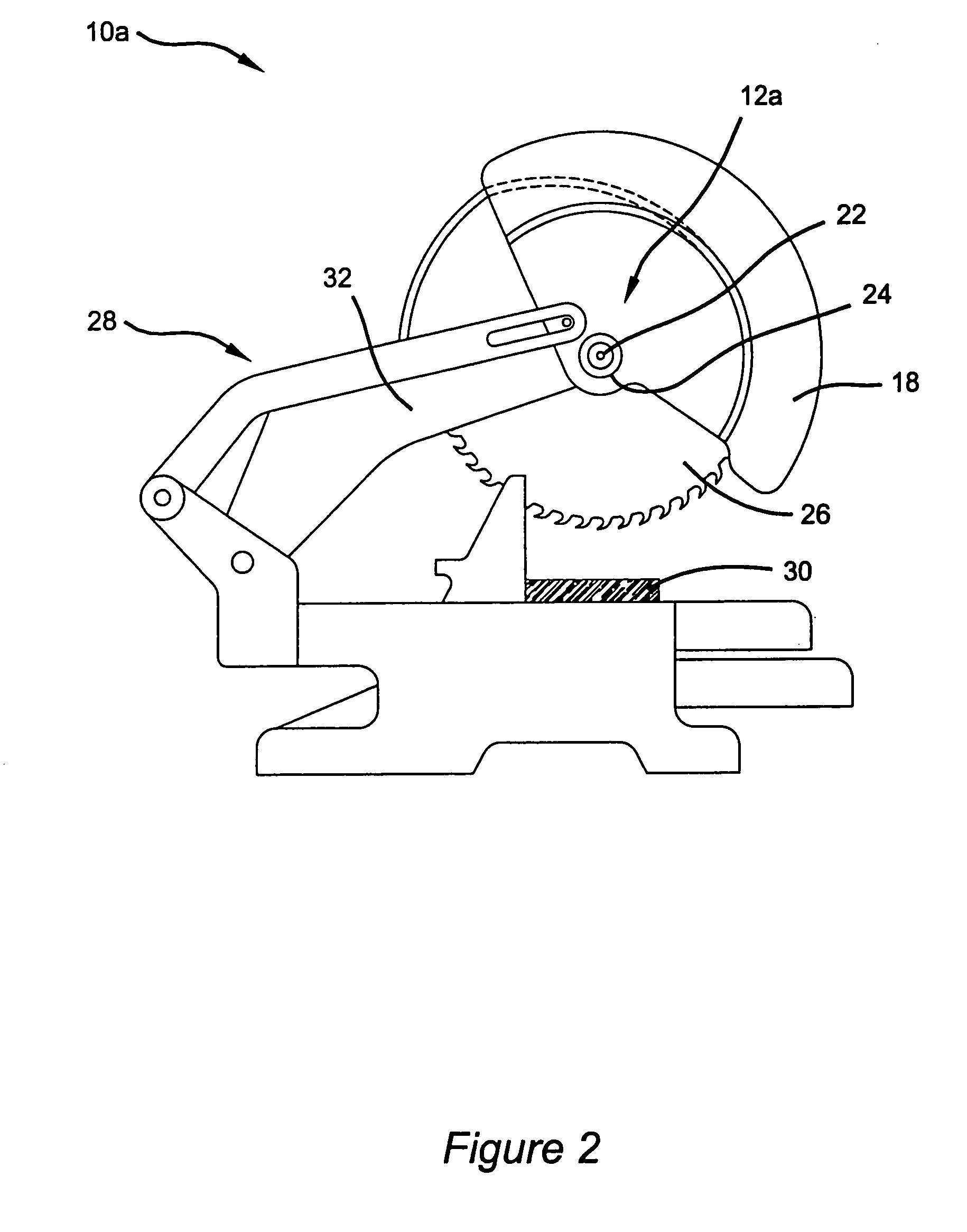

Miter saw with improved safety system

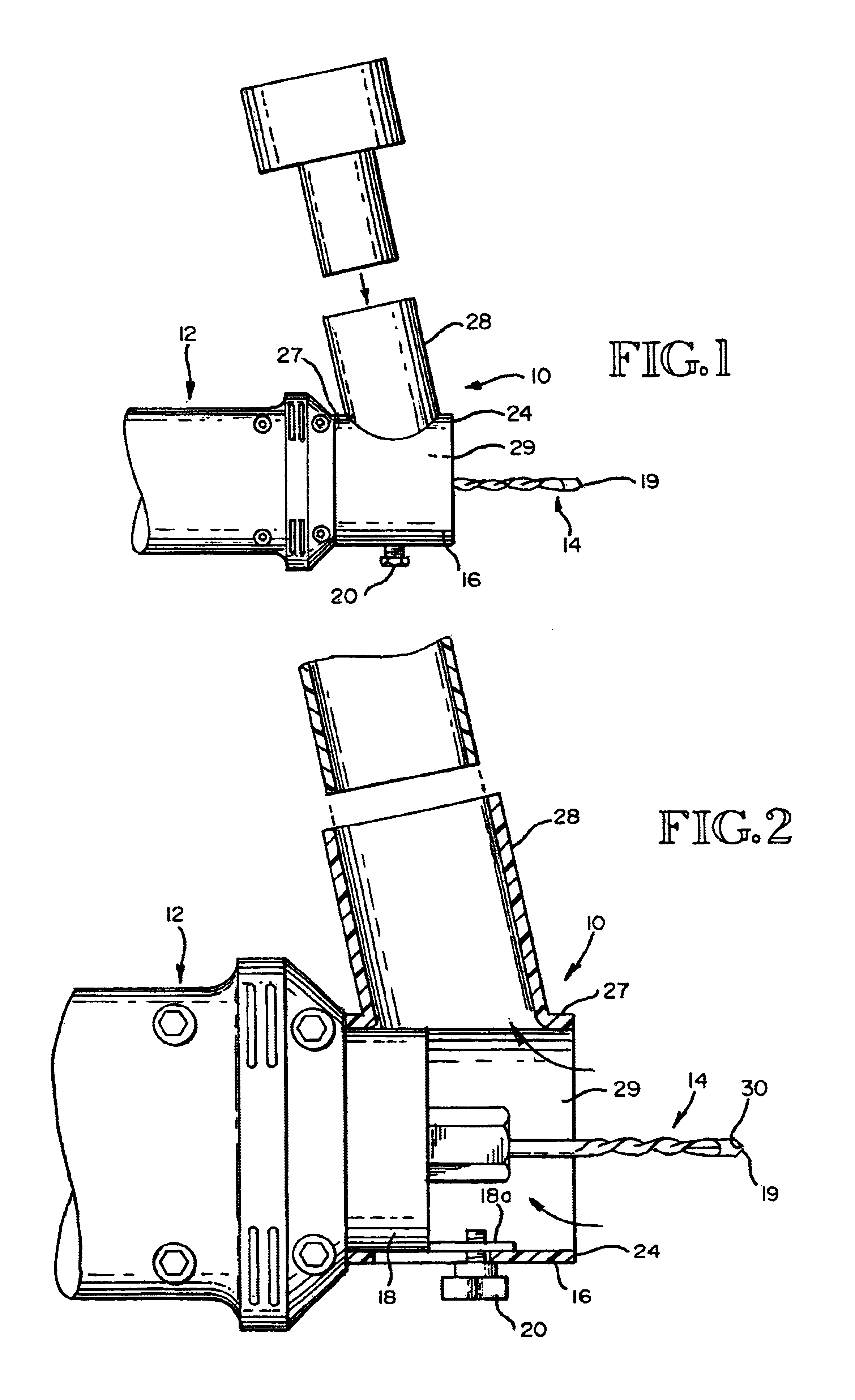

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

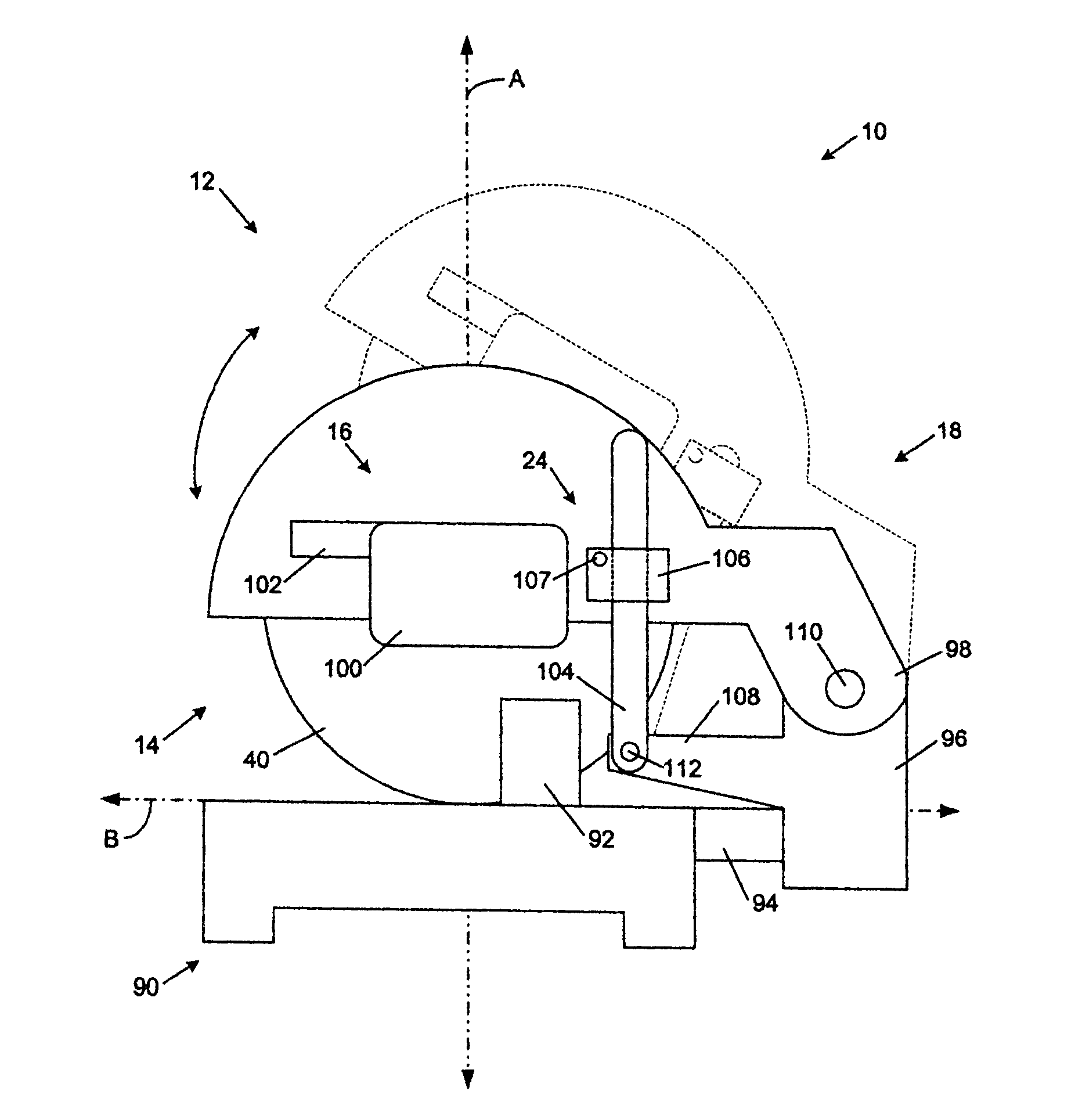

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

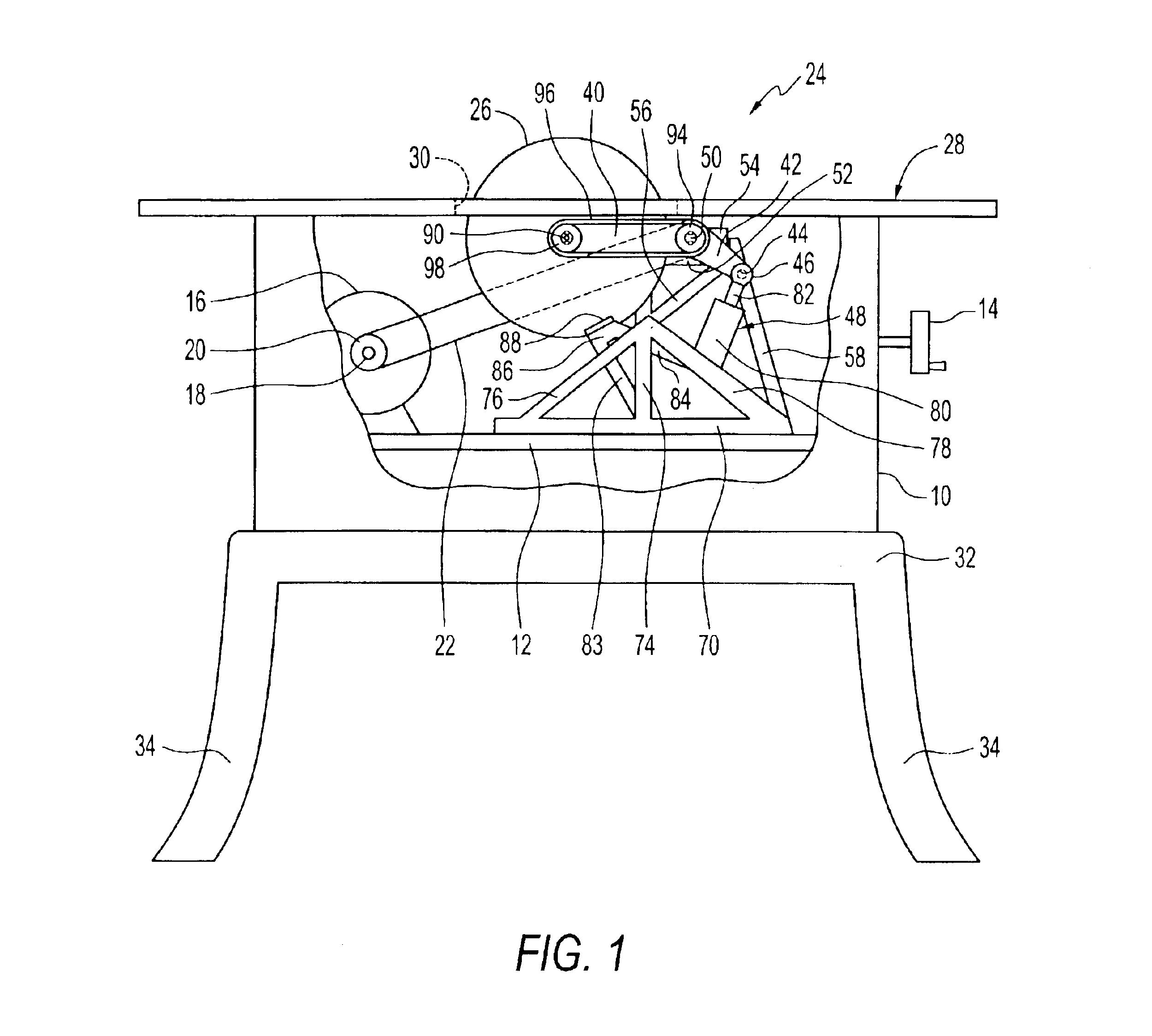

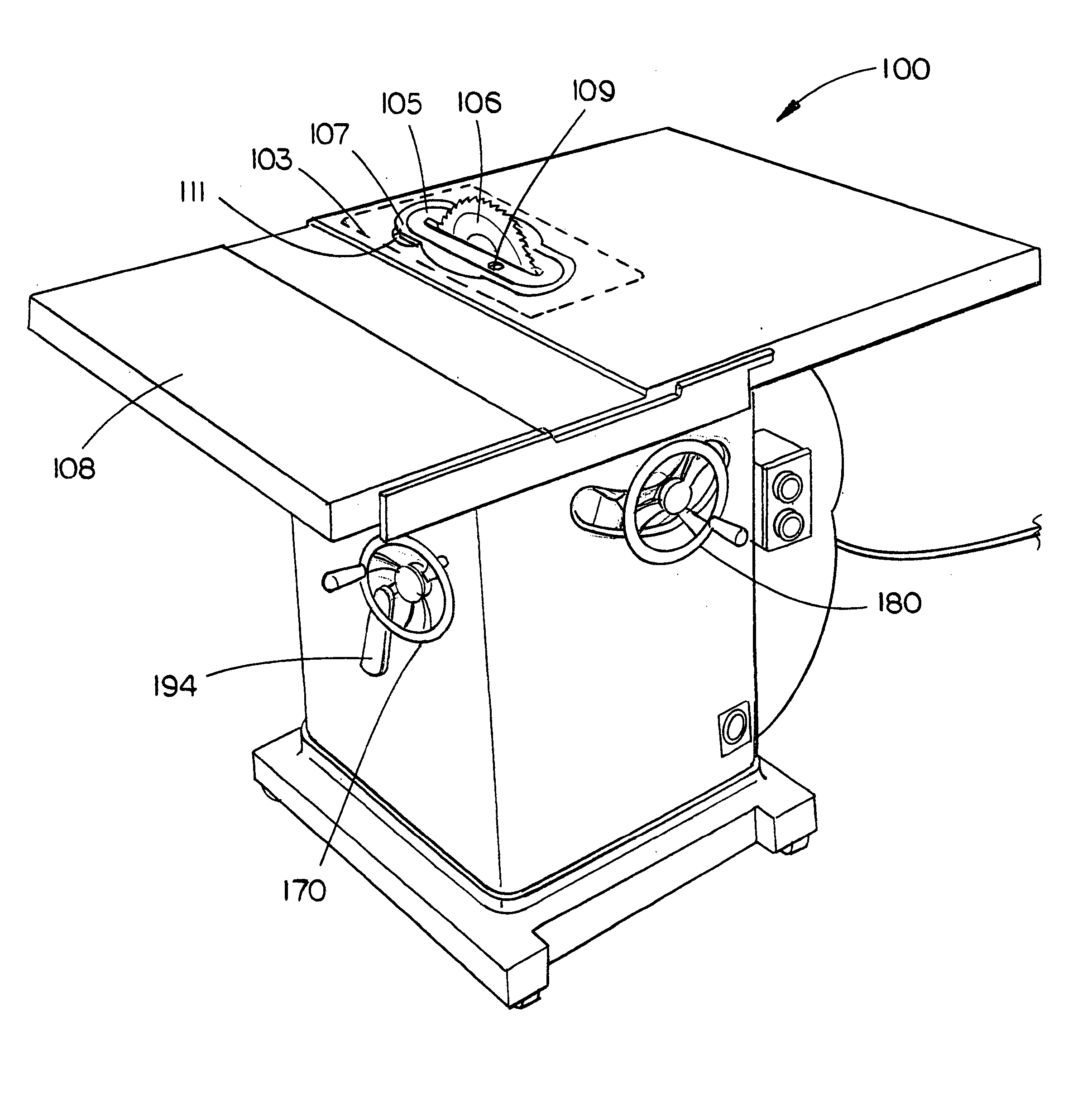

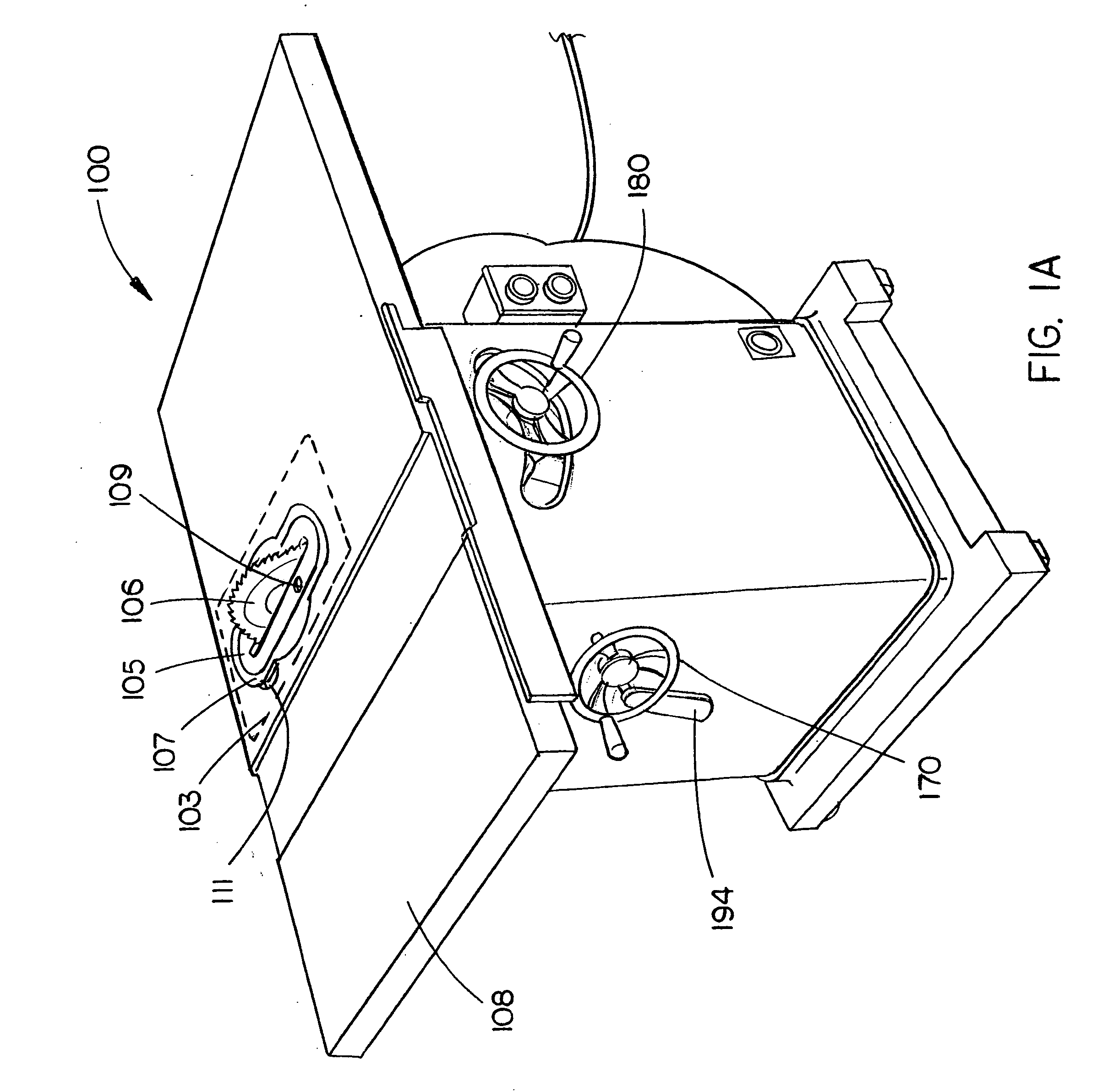

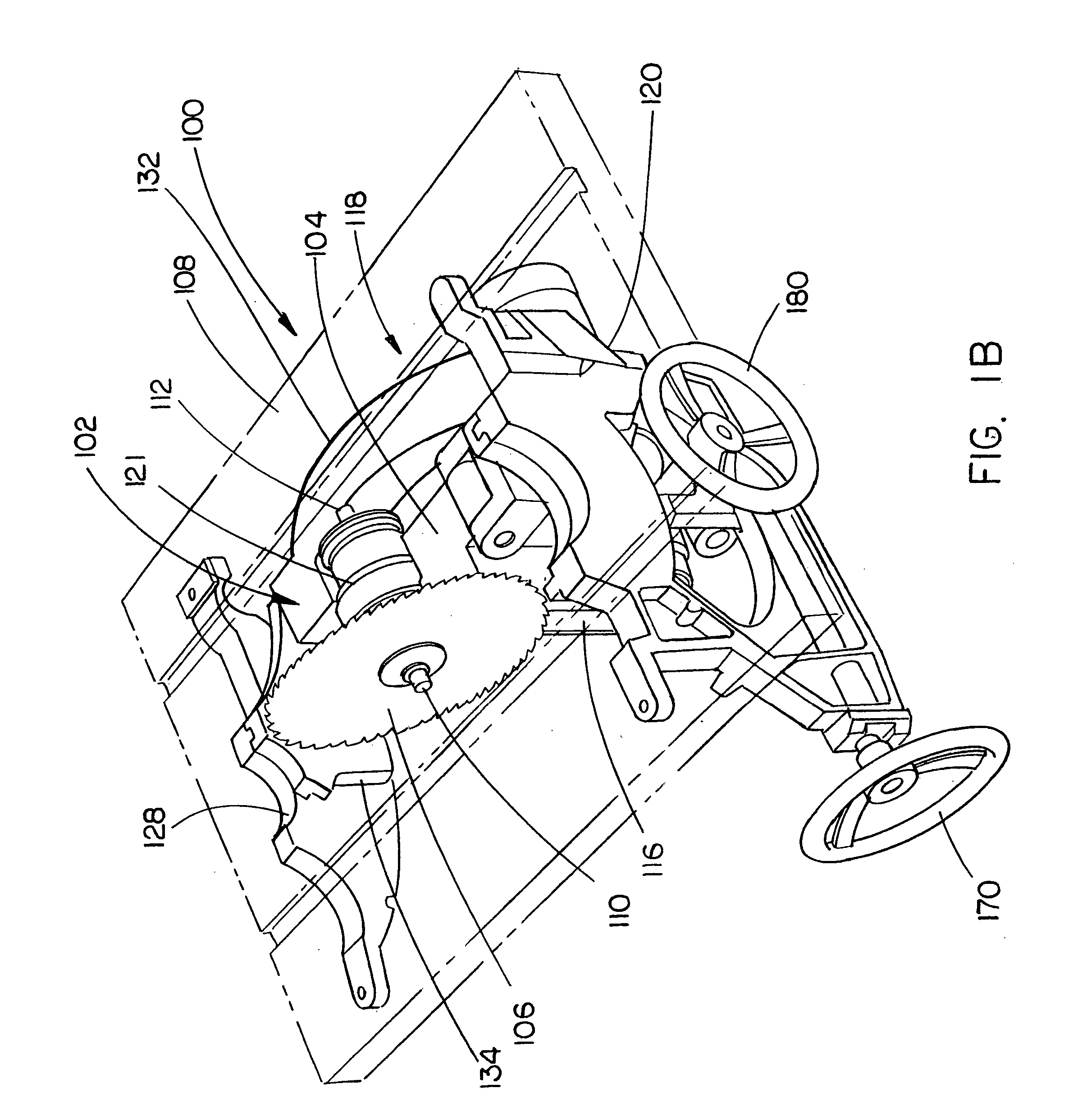

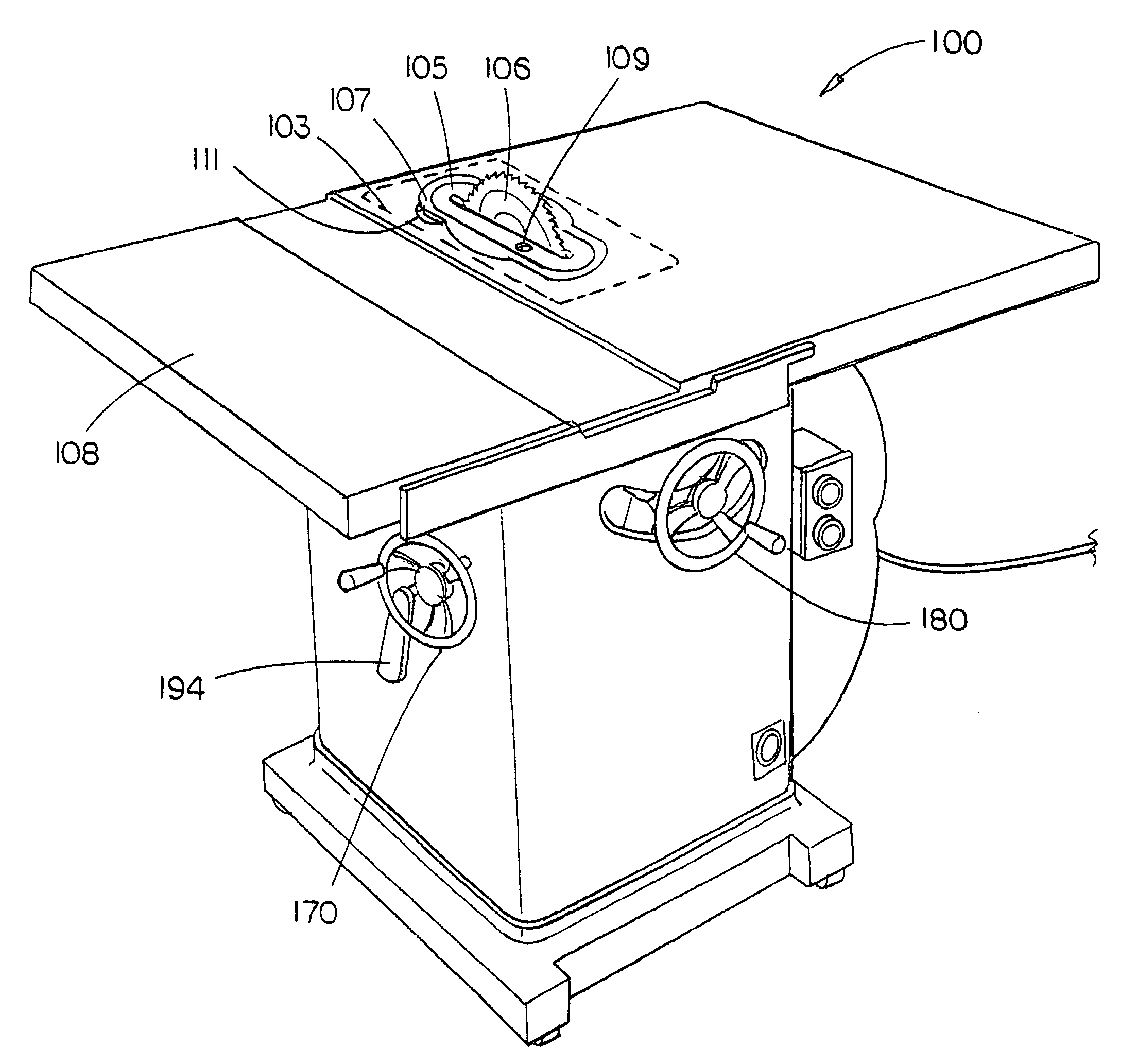

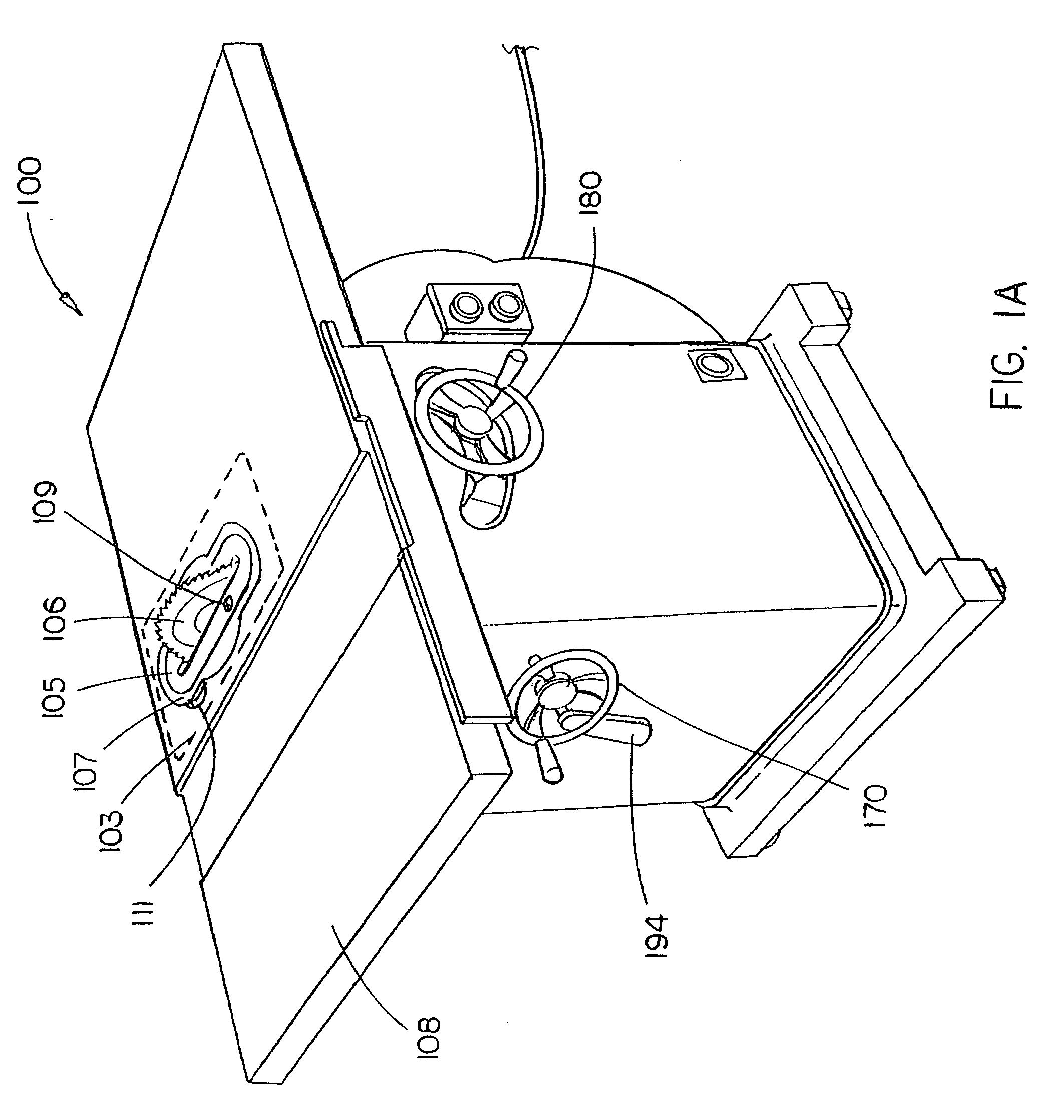

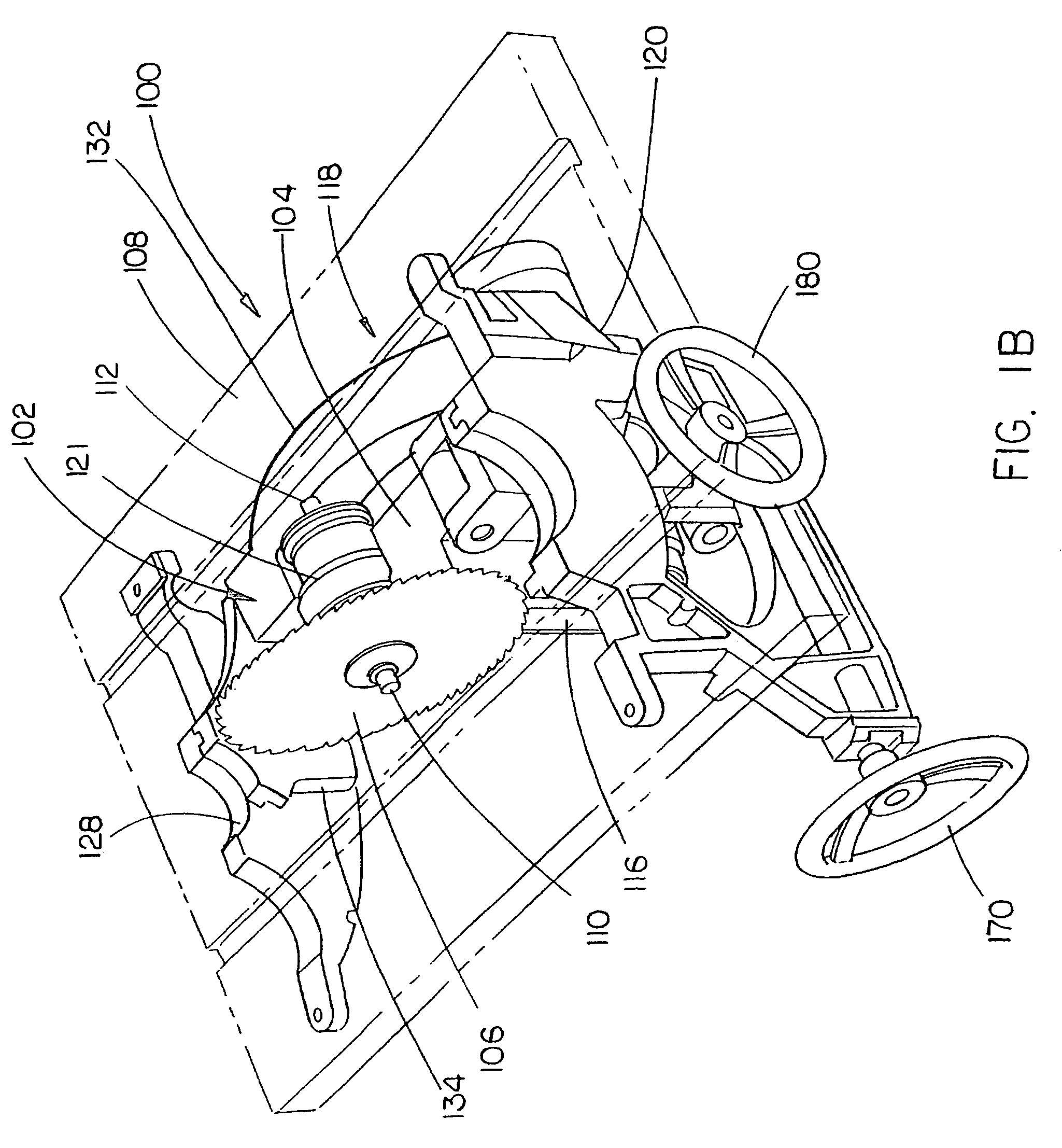

Table saw with improved safety system

InactiveUS6994004B2Metal sawing devicesMetal sawing accessoriesMechanical engineeringPositioning system

A table saw having a brake mechanism configured to engage and stop a blade is disclosed. The table saw includes a brake positioning system configured to adjust the position of the brake mechanism to maintain the brake mechanism in an operative position relative to the blade as the blade is raised and lowered.

Owner:SAWSTOP HLDG LLC

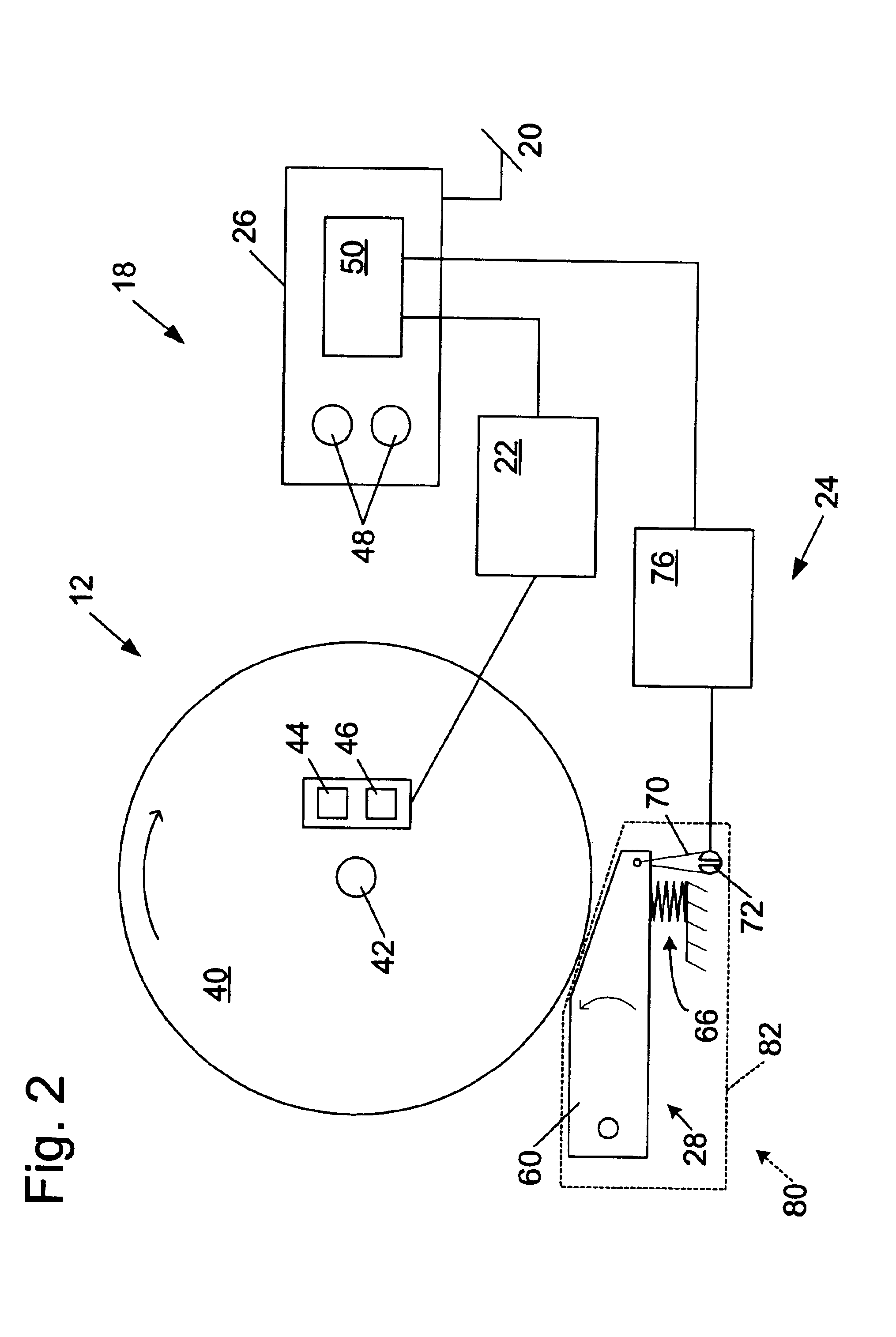

Miter saw with improved safety system

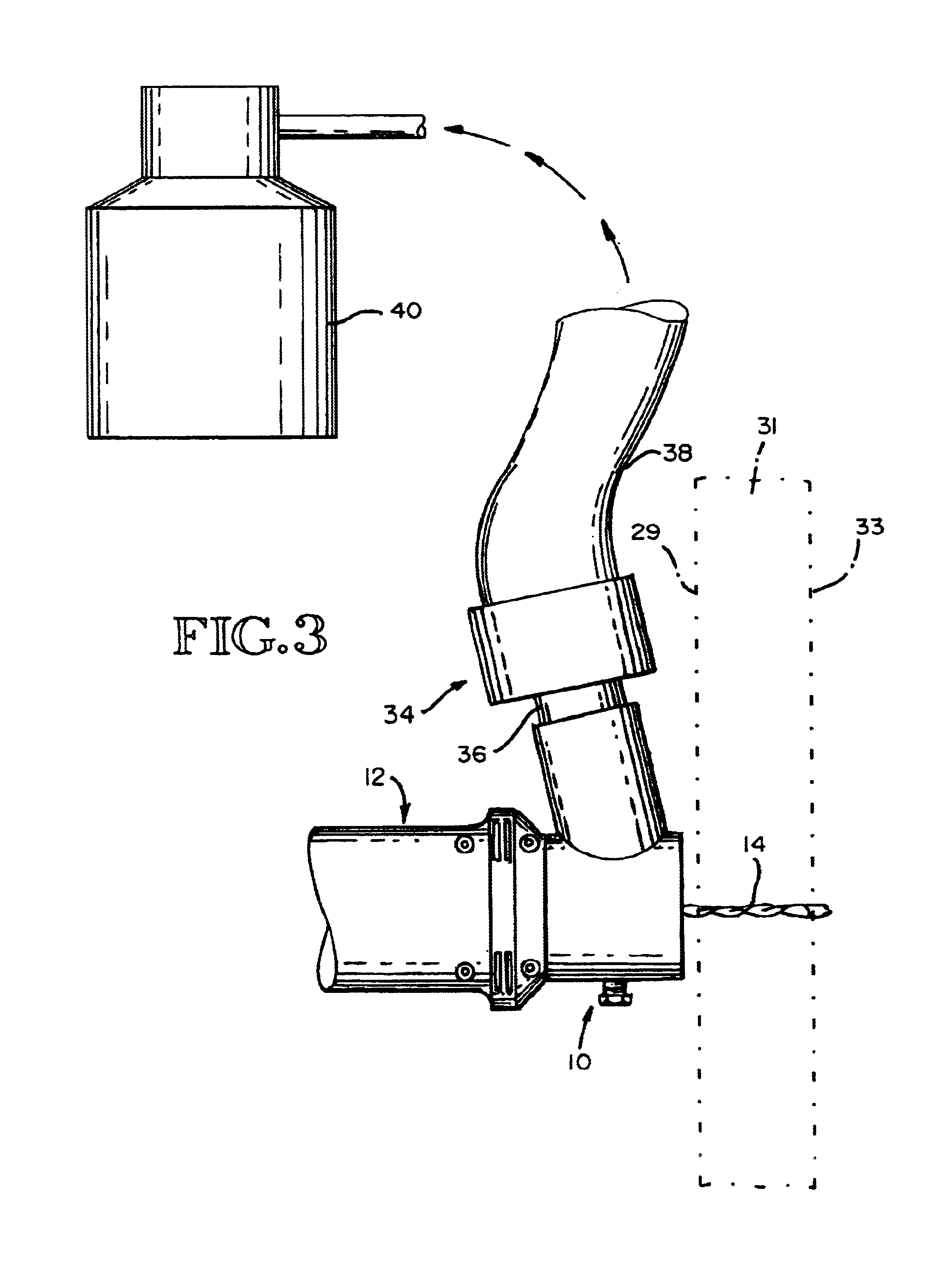

InactiveUS6880440B2Limit and even prevent injuryImprove the security systemEmergency protective circuit arrangementsEngineering safety devicesEngineeringMechanical engineering

A miter saw having a base and an arm that pivots toward the base is disclosed. A blade is supported by the arm, and is designed to cut workpieces resting on the base when the arm and blade pivot downward. The saw includes a detection system configured to detect one or more dangerous conditions between a person and the blade, such as when a person accidentally touches the spinning blade, and the saw includes a reaction system to stop the downward movement of the blade and arm when the dangerous condition is detected.

Owner:SAWSTOP HLDG LLC

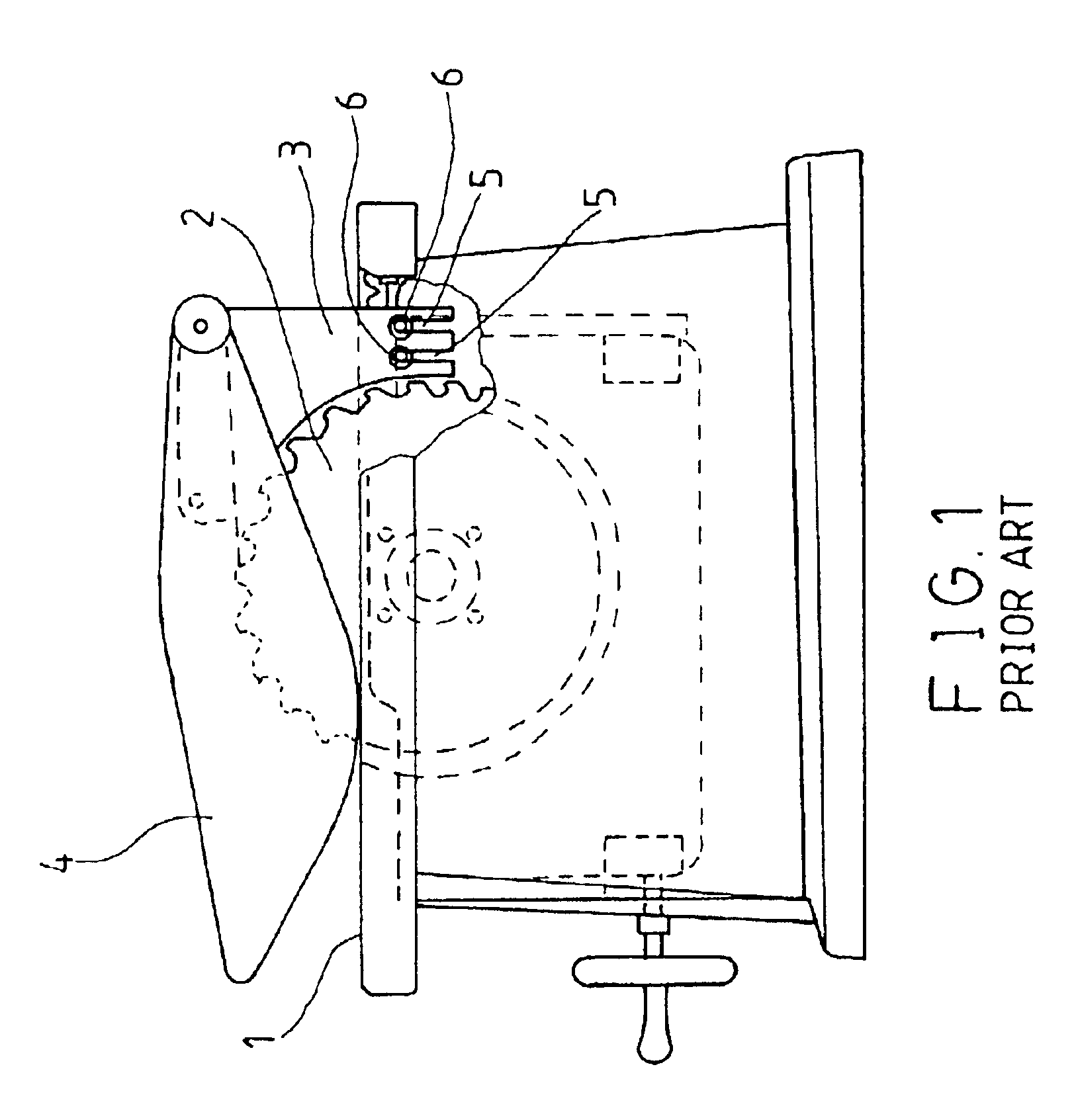

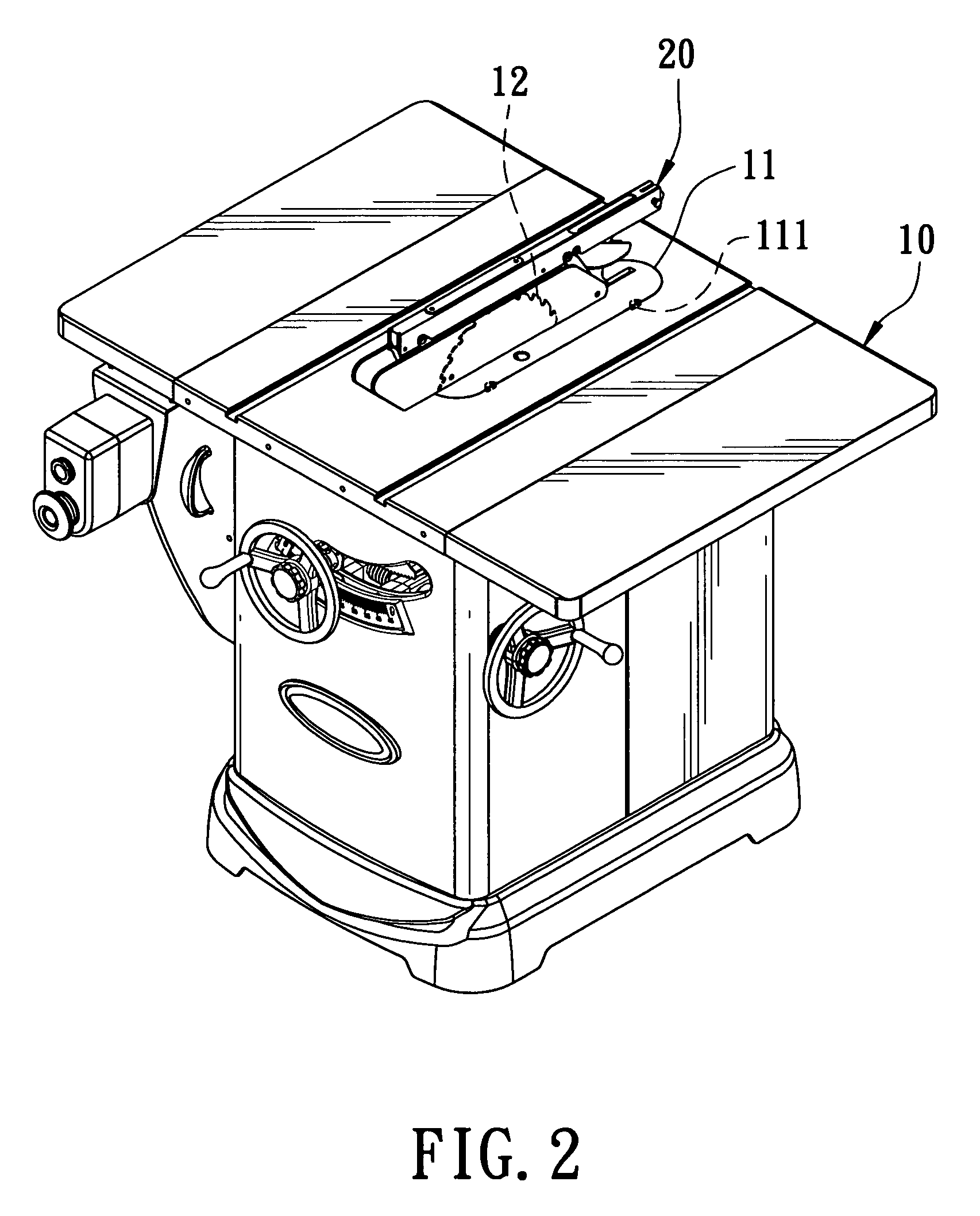

Quick-detachable blade guard mounting structure

Owner:DURQ MACHINERY

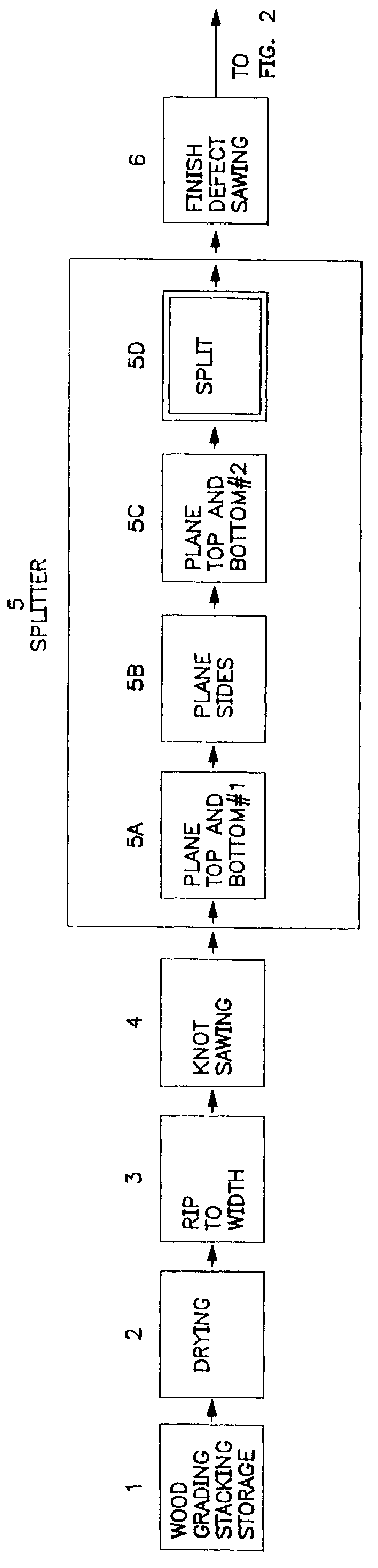

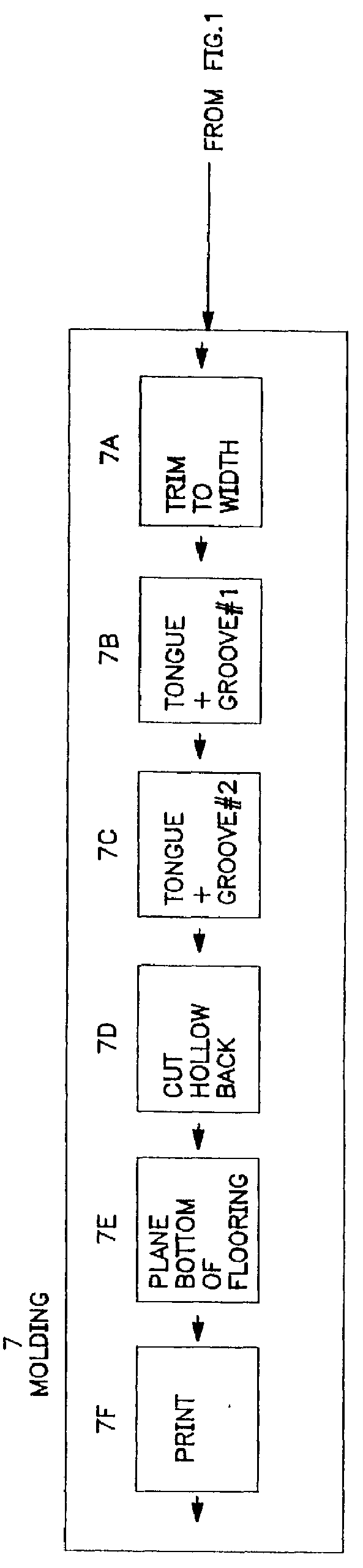

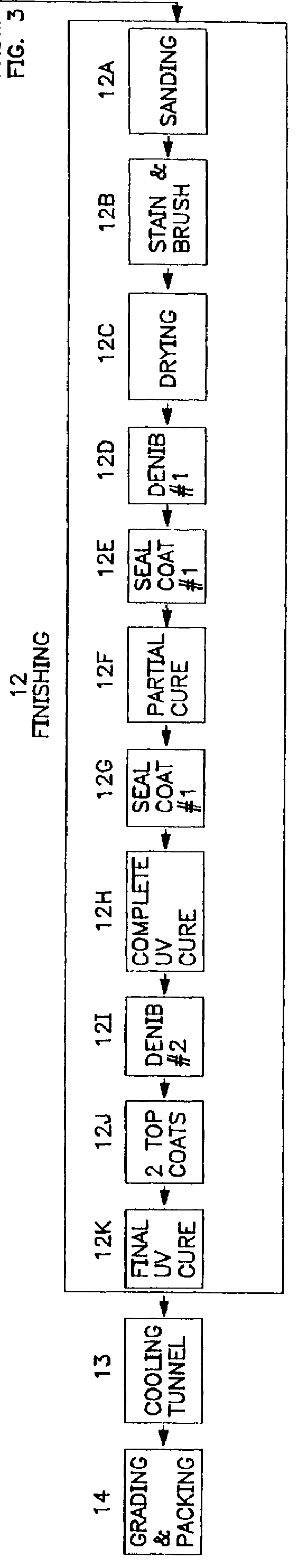

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

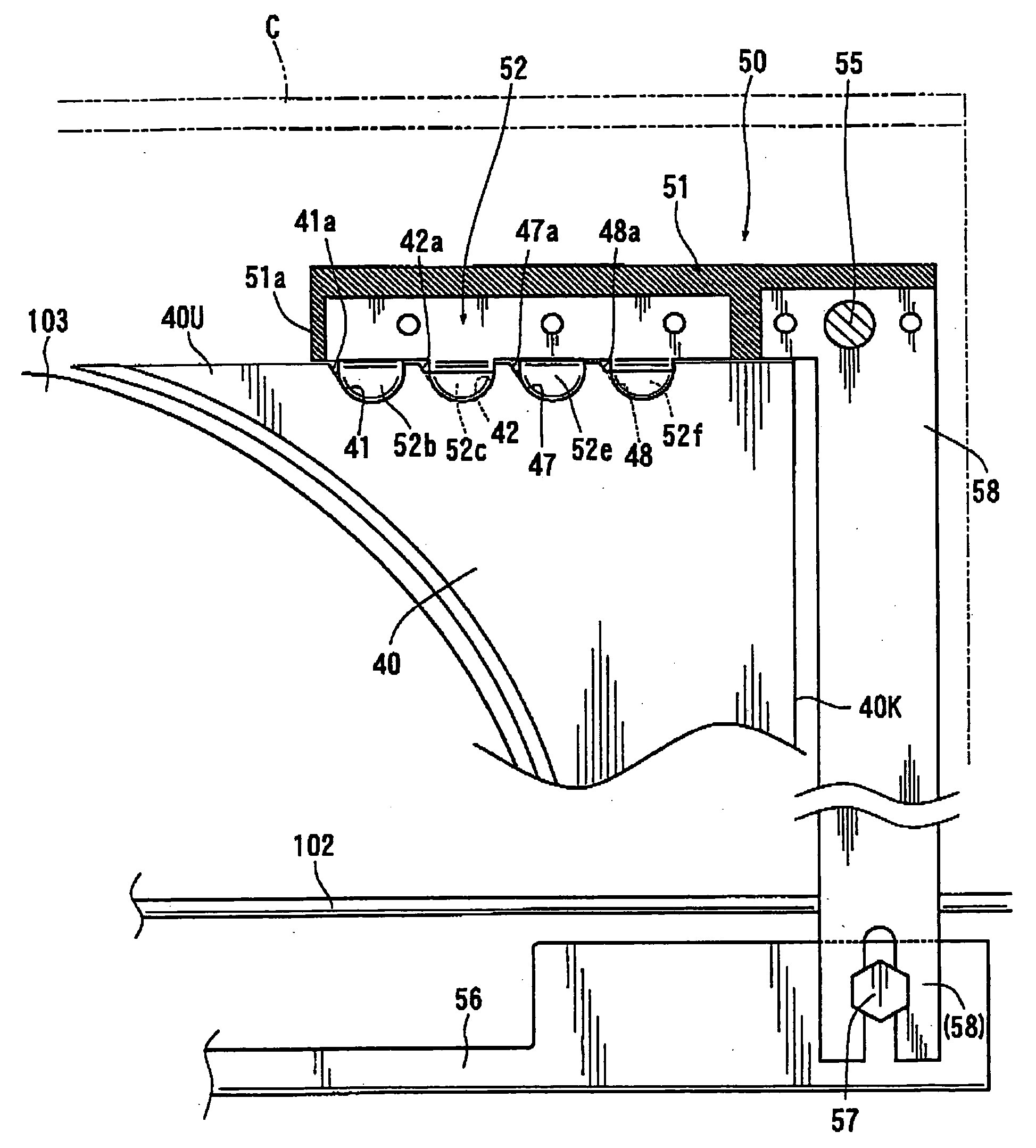

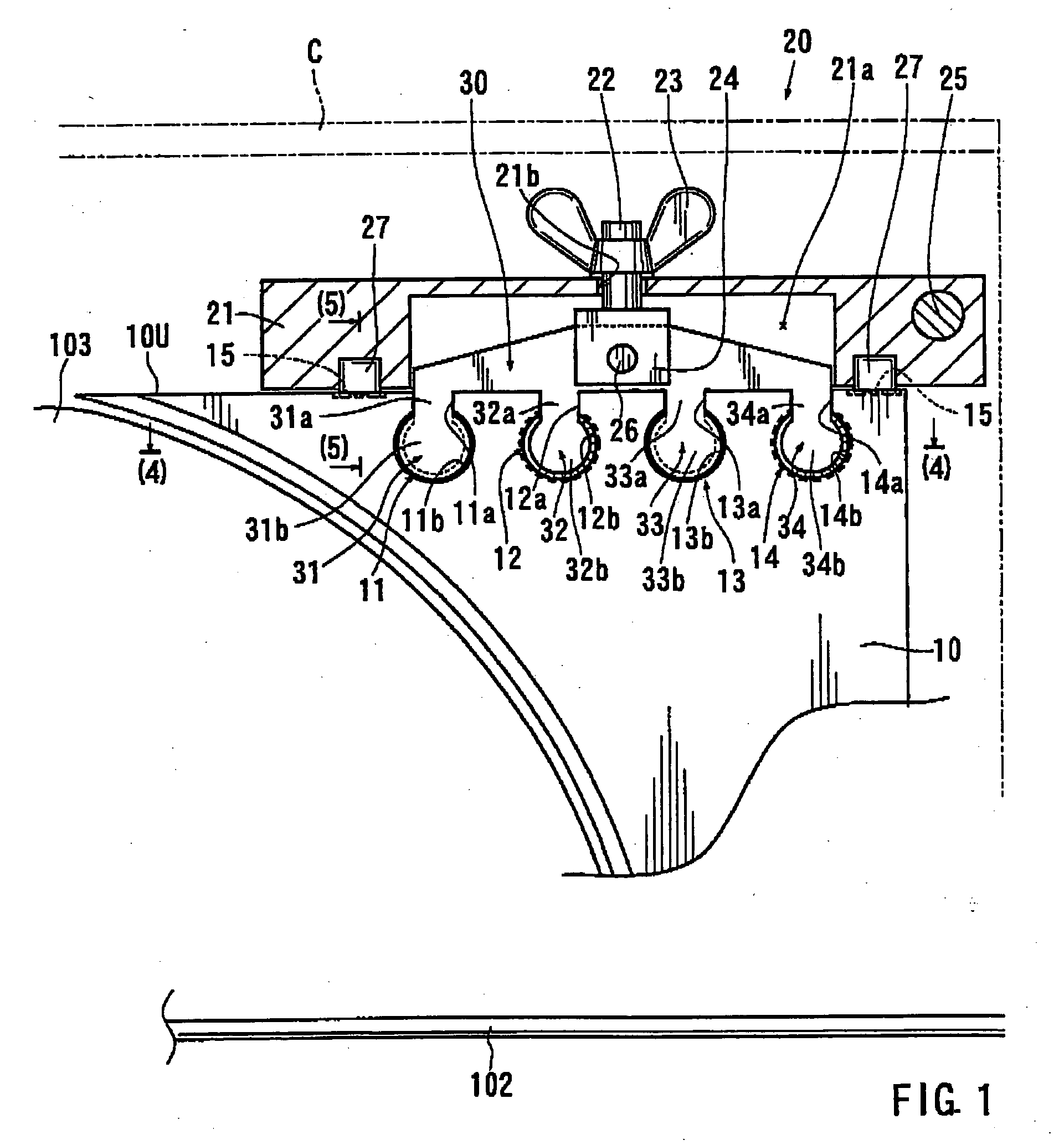

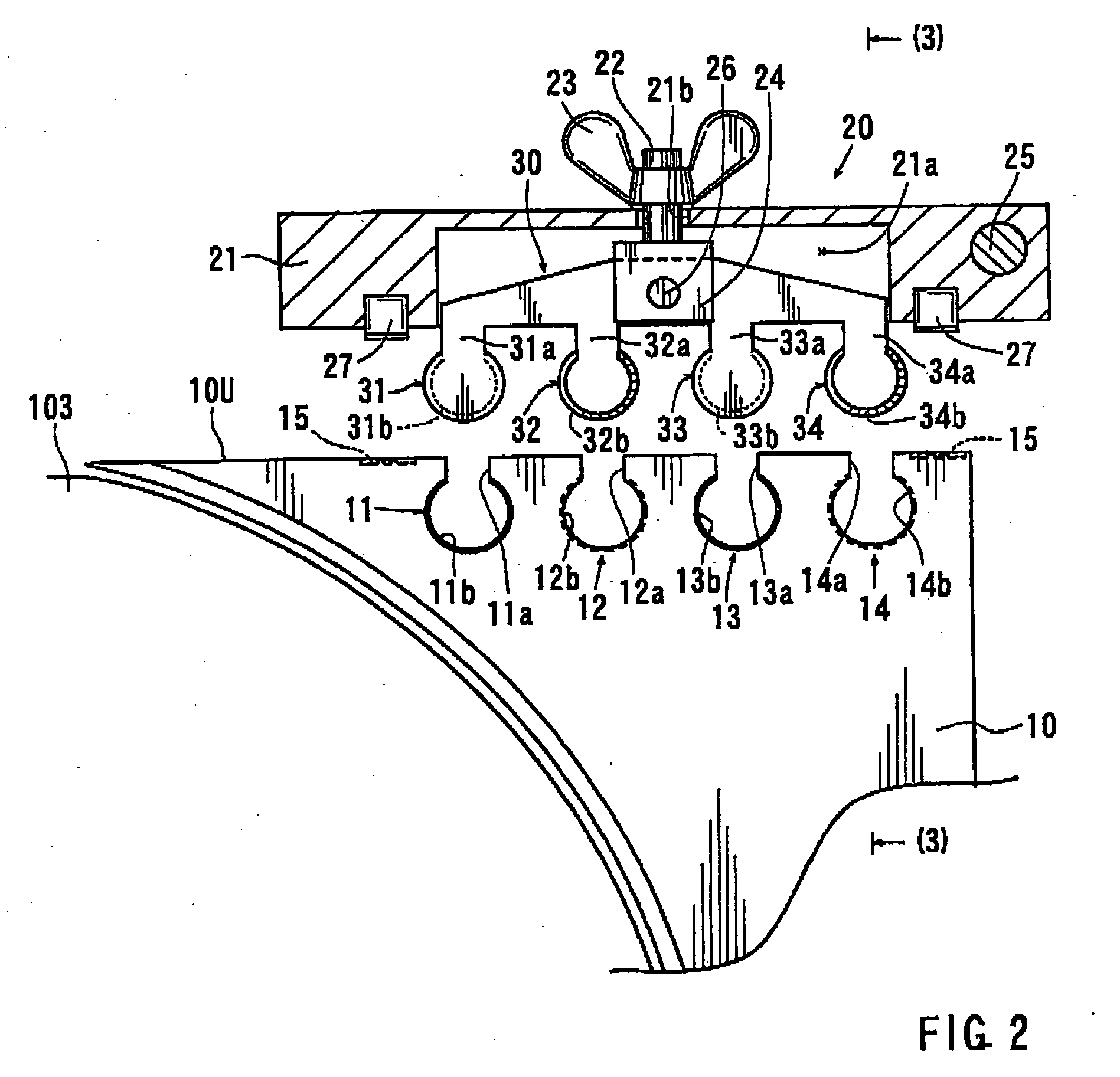

Miter saw with improved safety system

InactiveUS6945148B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMechanically actuated brakesEngineeringMechanical engineering

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6877410B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMetal sawing devicesMechanical engineeringReaction system

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

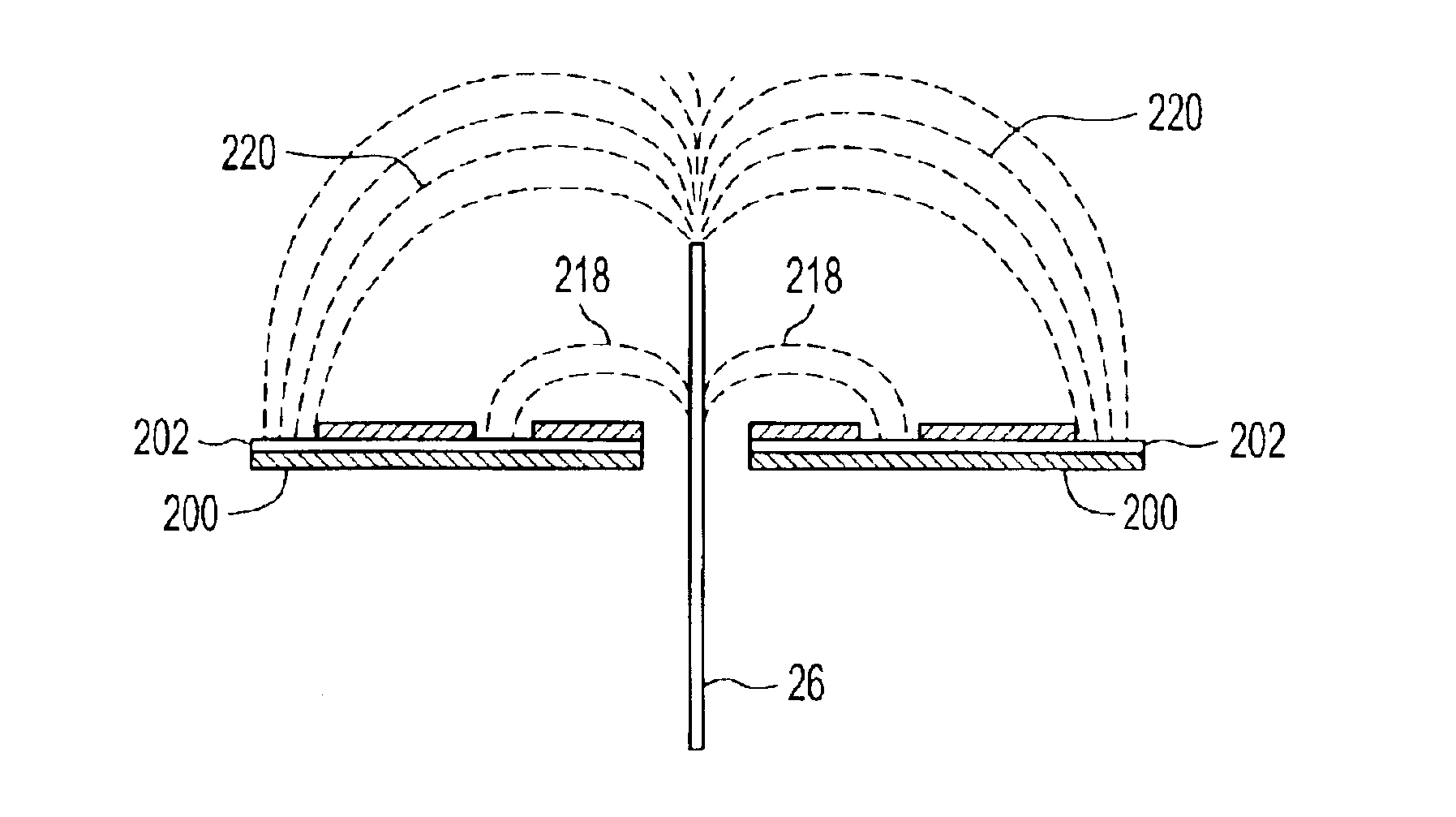

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

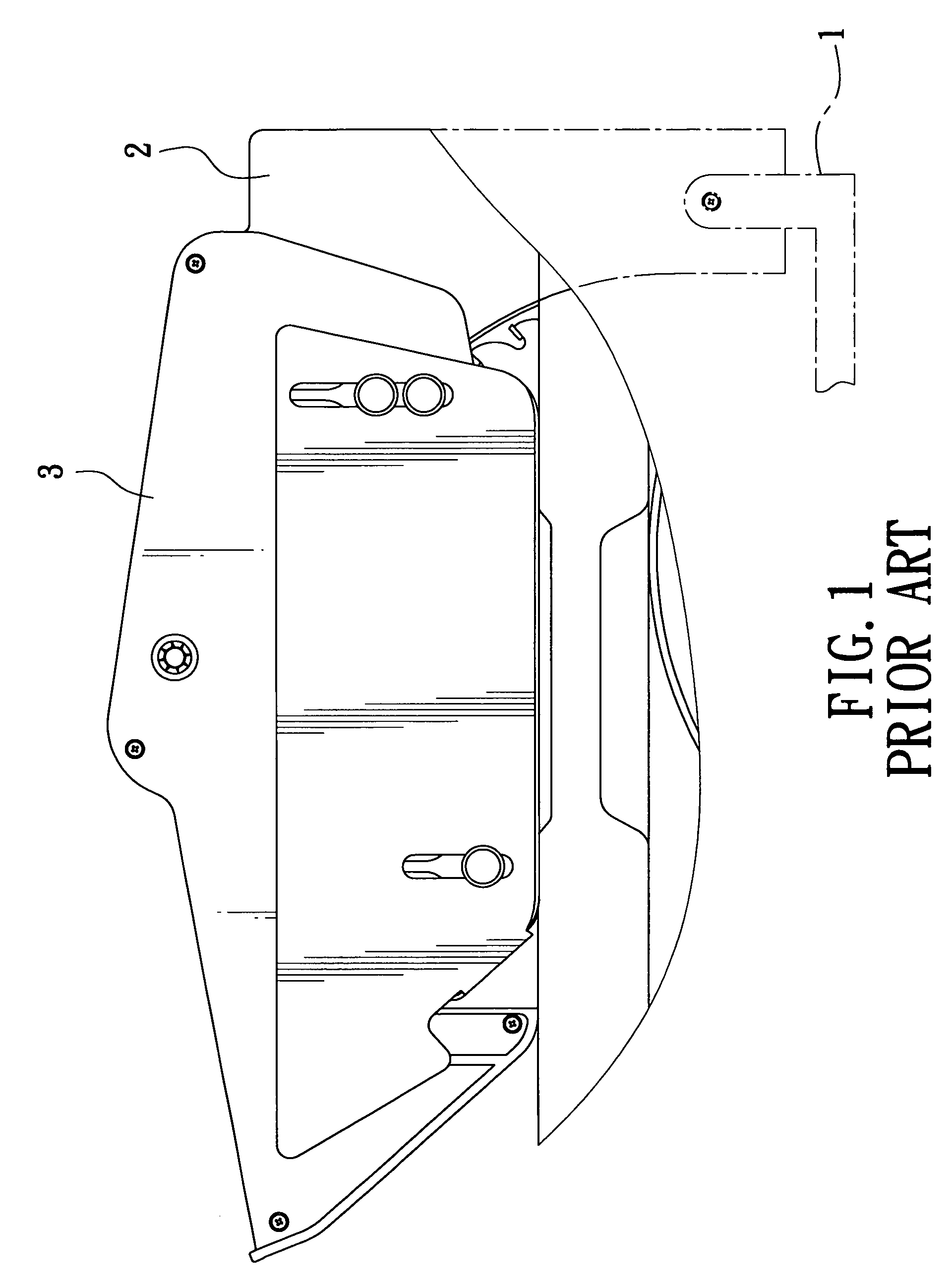

Mountings for riving knives of table saws

ActiveUS20050211034A1Easy to implementEasy to operateMetal sawing devicesGuide fencesSingle plateEngineering

A device for mounting a cover of a cutting blade to a riving knife may have an engaging member for releasably engaging at least a part of the riving knife from both sides, in a direction of thickness of the riving knife. The engaging member is manually operable without any additional tools. A device for mounting a riving knife to a table saw may include a manually operable lock member and a biasing member. The biasing member is arranged and constructed to normally bias the lock member towards a lock position. The riving knife may be divided into a first knife portion and a second knife portion. A positioning device may position the first knife portion and the second knife portion substantially within a single plate.

Owner:MAKITA CORP

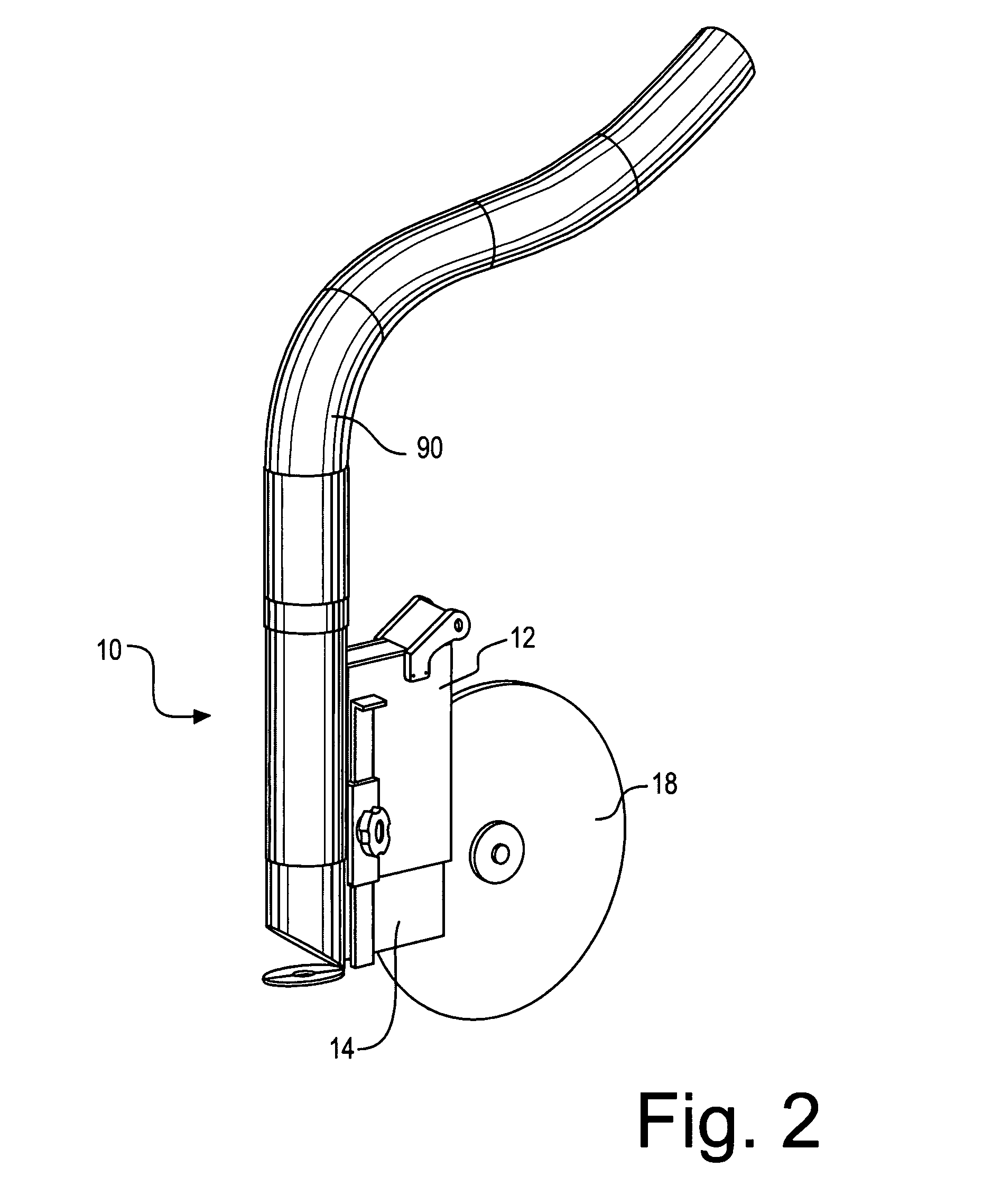

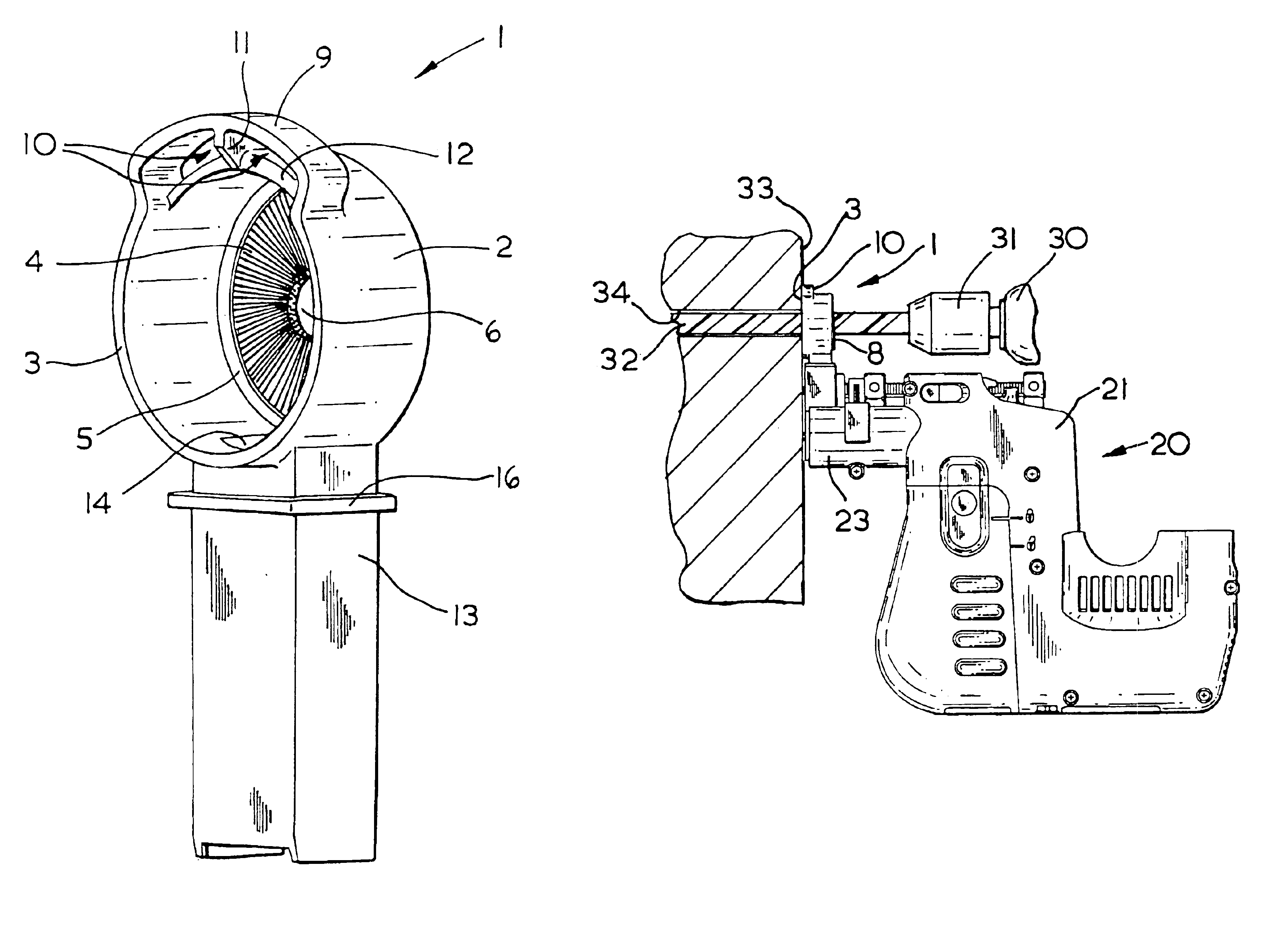

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

Optical proximity device for power tools

The present invention is directed to a power tool including a working element for performing a task. A light source is arranged to project a beam of light adjacent the working element. A detector, such as an electro-optic type detector, is communicatively coupled to the power tool such that the detector is capable of detecting the presence of a human body part in the beam of light. If a body part is detected, the detector may communicate to stop operation of the working element.

Owner:BLACK & DECKER INC

Quickly detachable protective cover unit of a table sawing machine

InactiveUS7210386B1Rapid positioningLess timeMetal sawing devicesGuide fencesEngineeringMechanical engineering

The quickly-detachable protective cover unit of a table sawing machine includes a protective cover, a non-return plate, a protective plate, a combining plate and an extending plate. The extending plate positioned at one side of the saw blade of a table sawing machine has its inner end fixed with a quickly-detachable handle unit for positioning the combining plate thereon. The protective plate is inserted through the saw blade and the combining plate, positioned on the table-sawing machine. The non-return plate and the protective cover are respectively provided with a quickly detachable device to fit in the positioning hole of the combining plate. The components of the quickly detachable protective cover unit are combined by quickly detachable mechanism so they can be disassembled or assembled quickly, needing no tool for carrying out disassembling work.

Owner:KINGSAND MACHINERY

Table saw guard

A table saw guard assembly for guarding a blade on a table saw is provided. The table saw guard assembly includes a support structure and a hood assembly including at least one of a front curtain, first side curtain, second side curtain and top curtain, wherein each of said curtains are independently moveable and / or removable from the hood assembly. Furthermore, a table saw guard assembly is provided including a quick release mechanism for connecting the hood assembly to the support structure.

Owner:BLACK & DECKER INC

Dual bevel table saw

InactiveUS20040118261A1Efficient use ofMaximizing functional capabilityMetal sawing devicesGuide fencesEngineeringMechanical engineering

A dual bevel table saw provides a table saw enabled with a dual sided arbor assembly and a bi-directional bevel assembly. The dual sided arbor assembly coupled with the bevel assembly further provides for the positioning of a motor and a saw blade to allow for the full range of angular adjustment to be enabled without having to sacrifice any of the cutting features of the saw blade such as depth of cut. The dual bevel table saw may further include a companion saw assembly to provide increased functionality provided by the dual bevel table saw.

Owner:BLACK & DECKER INC

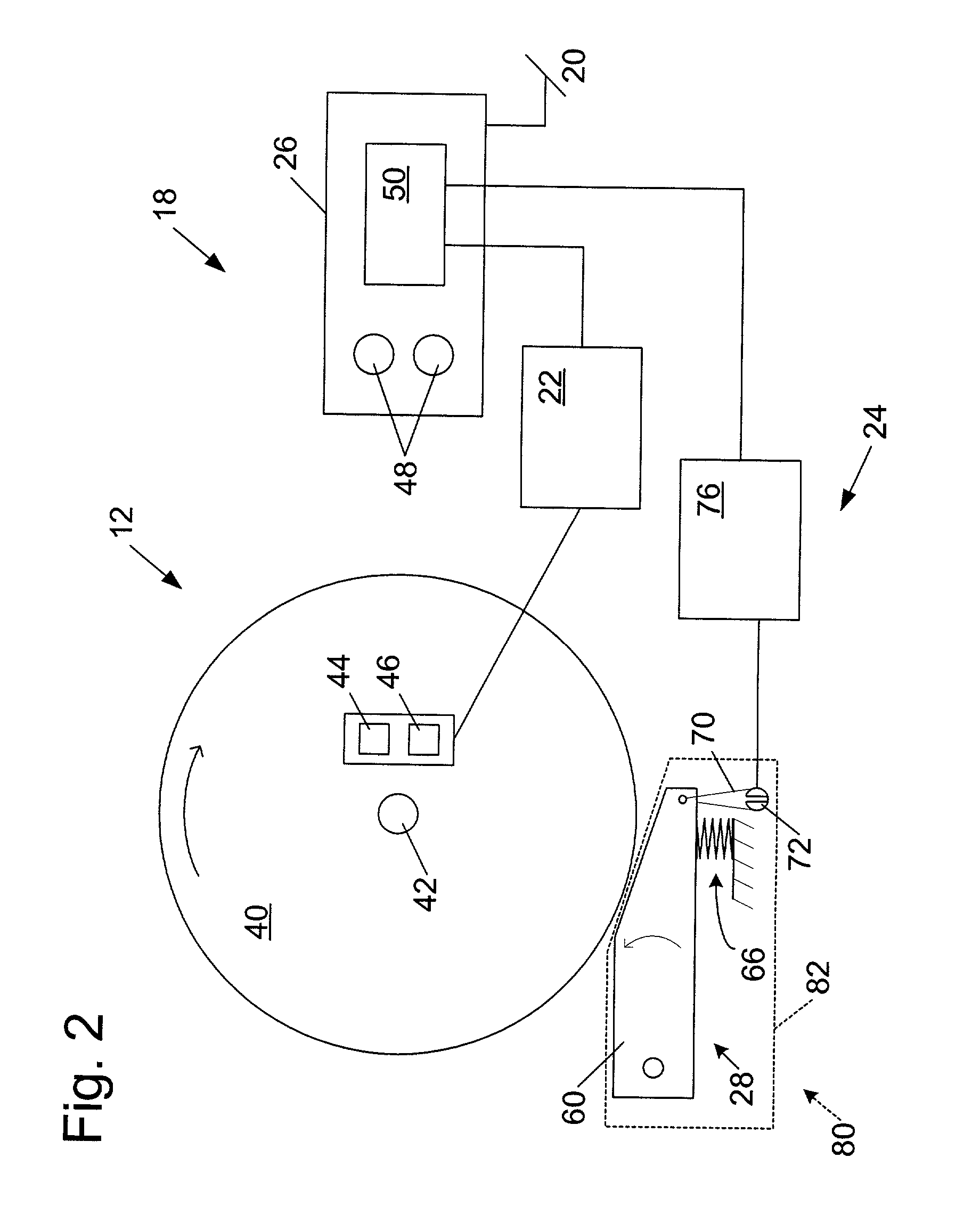

Contact detection system for power equipment

InactiveUS7377199B2Risk minimizationReduce riskMetal sawing devicesMetal sawing accessoriesPower equipmentEngineering

A woodworking machine having one or more dangerous portions of the machine is disclosed. The machine also includes a safety system configured to detect accidental contact between a person and at least one of the dangerous portions by electrically coupling a signal to the person's body, and detecting if the signal becomes coupled to the dangerous portion.

Owner:SAWSTOP HLDG LLC

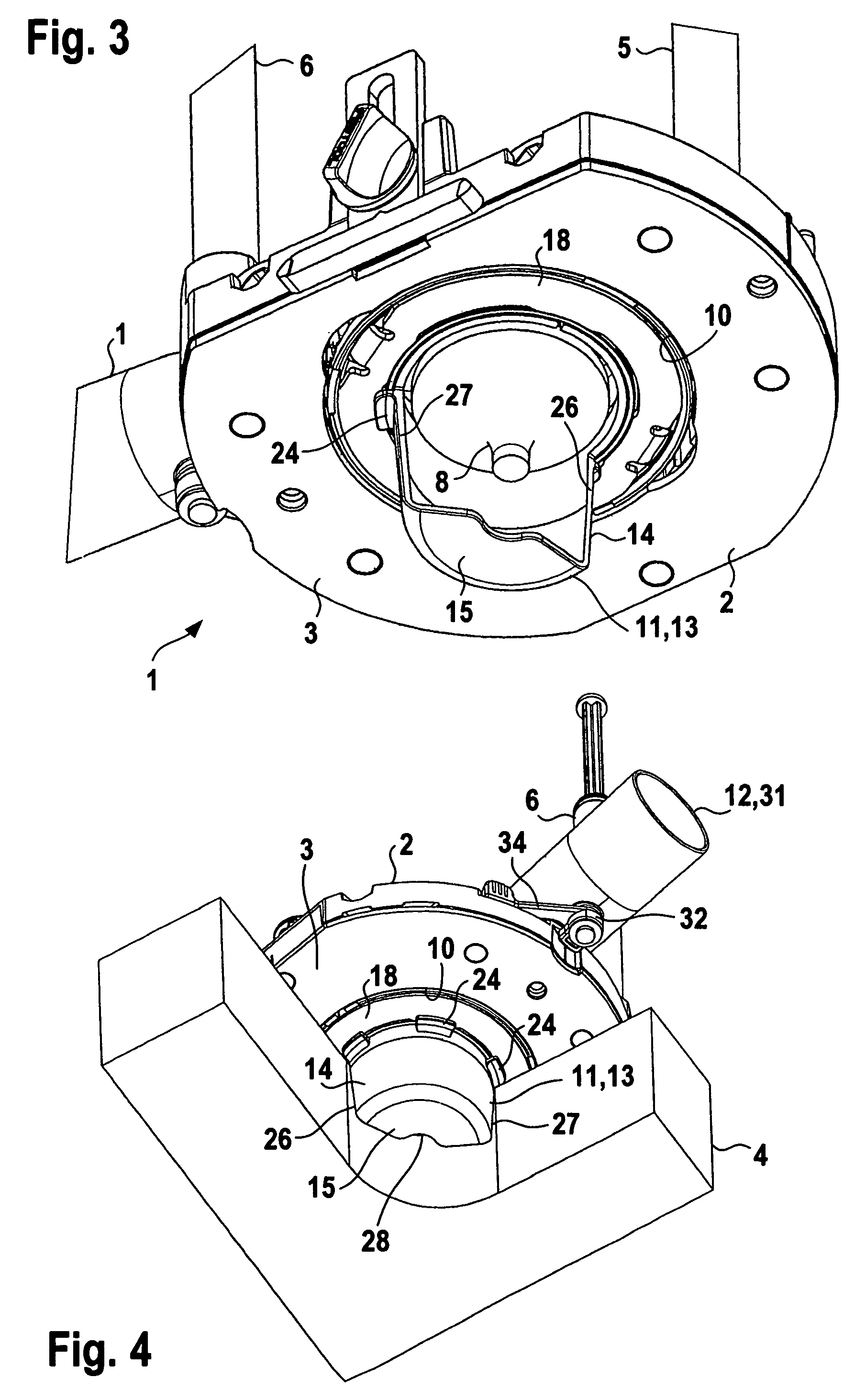

Dust extractor device for a router

ActiveUS7290967B2Maximum effectivenessSpace minimizationMulti-purpose machinesProfiling/shaping machinesEngineeringFoot boards

A dust extractor device of a router has rotatable dust trap part able to be connected with a foot plate of the router and arranged to the side of the routing tool underneath the foot plate, such dust trap part being open toward the routing tool. The foot plate has an access opening for the routing tool. The dust trap part is constituted by an extractor hood with a hood casing at least essentially centered on the axis of rotation and a hood floor. The hood casing and the hood floor extend in the peripheral direction through an angle equal to or less than 180°. The extractor hood is open at its top side and opens into the access opening. The top end region of the extractor hood is rotatably supported on a holder, which is detachably secured to the foot plate and in the position of use extends around the access opening. The top side of the access opening is provided with a covering means, which is detachably attached to the foot plate and covers the access opening, such covering means having in it an access opening for the routing tool. The connection means is, in the position of use, in open connection with the access opening.

Owner:FESTOOL GMBH

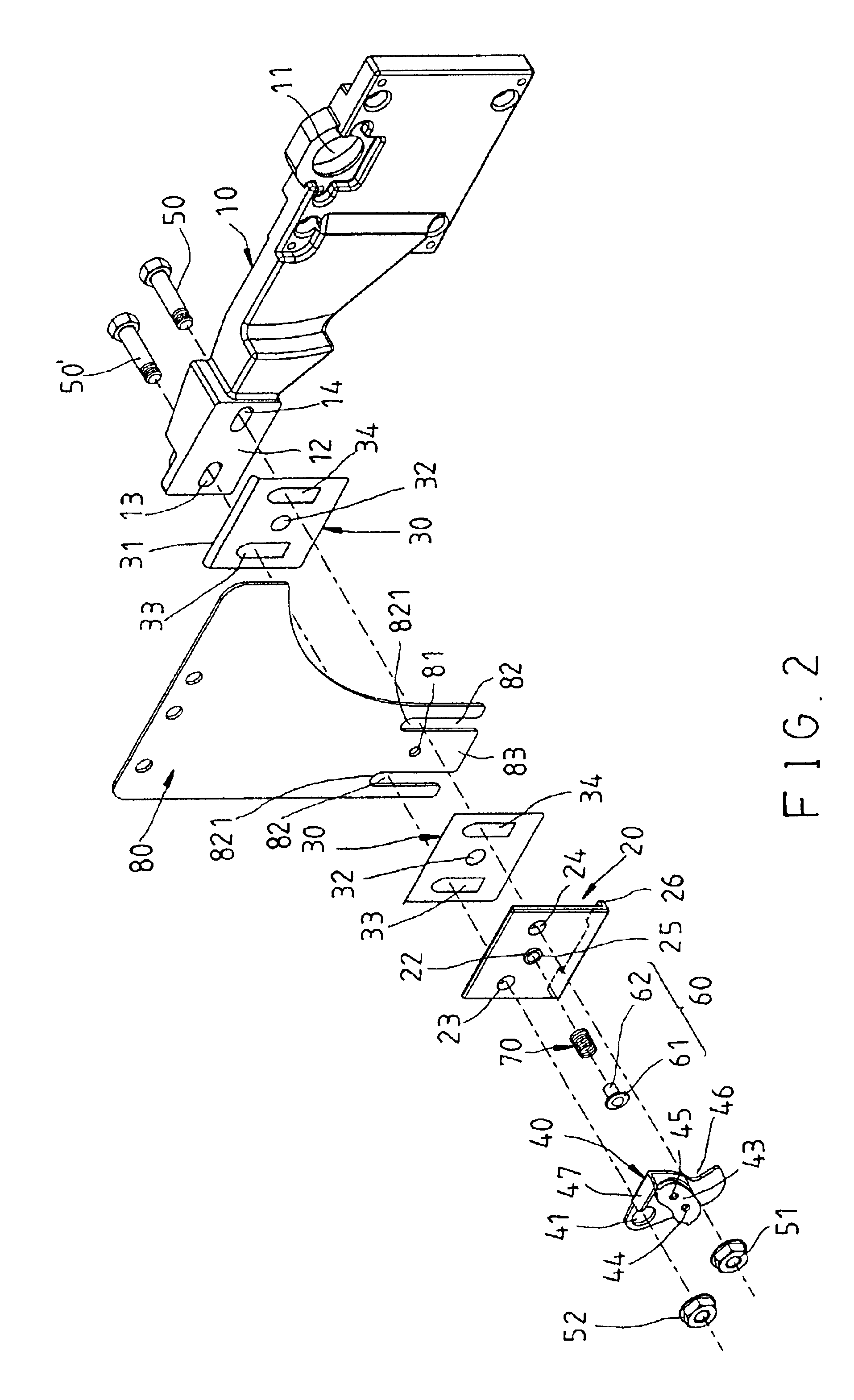

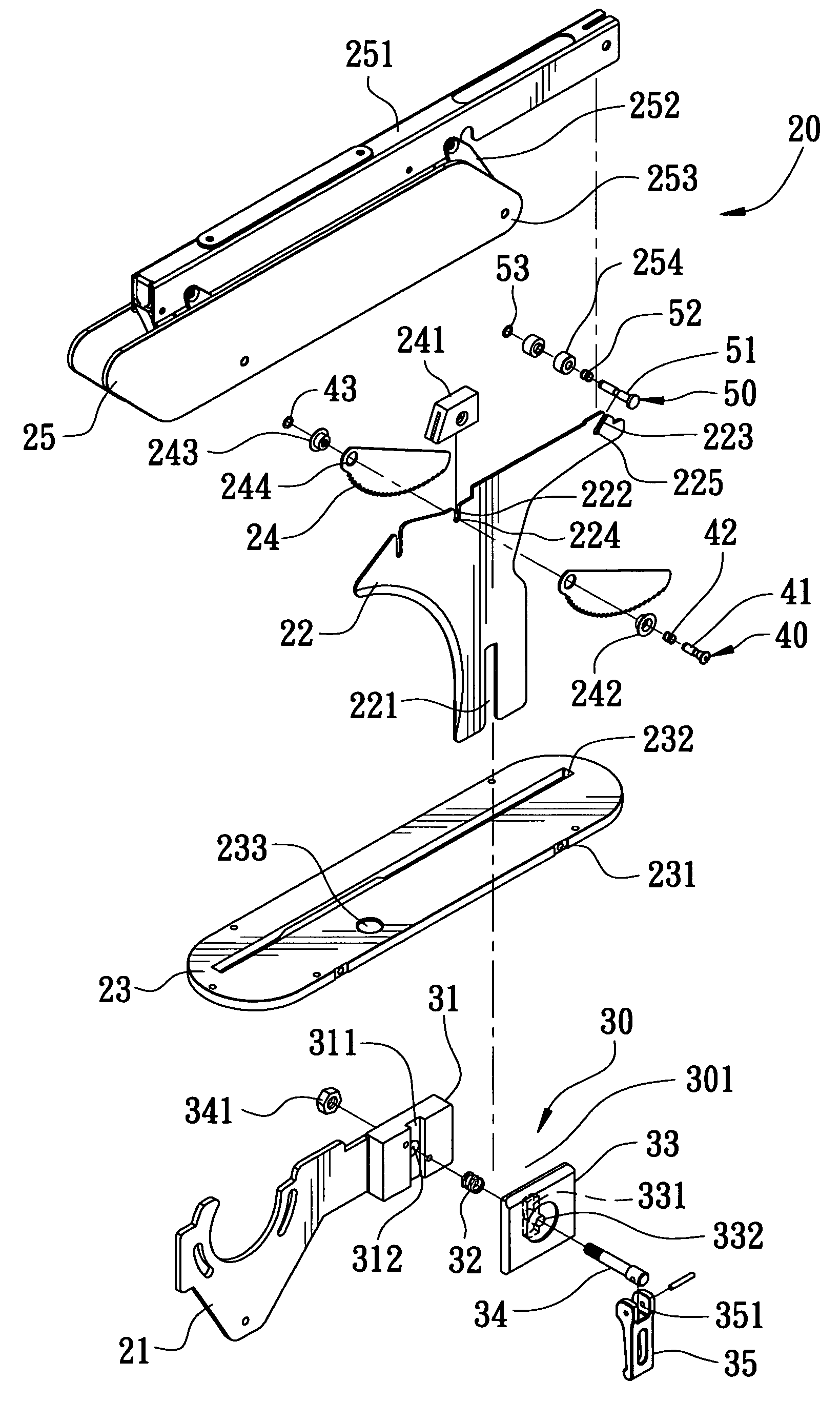

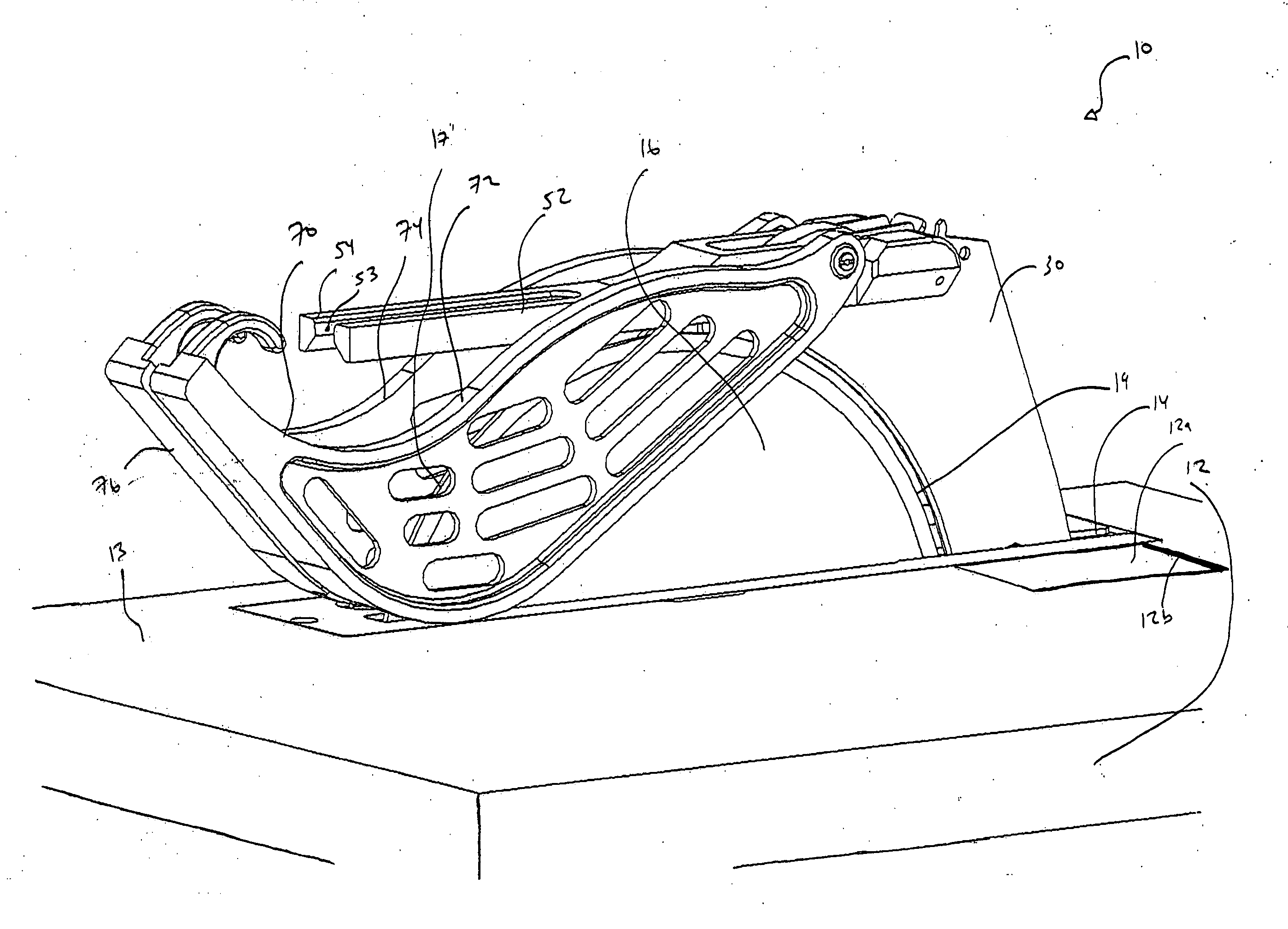

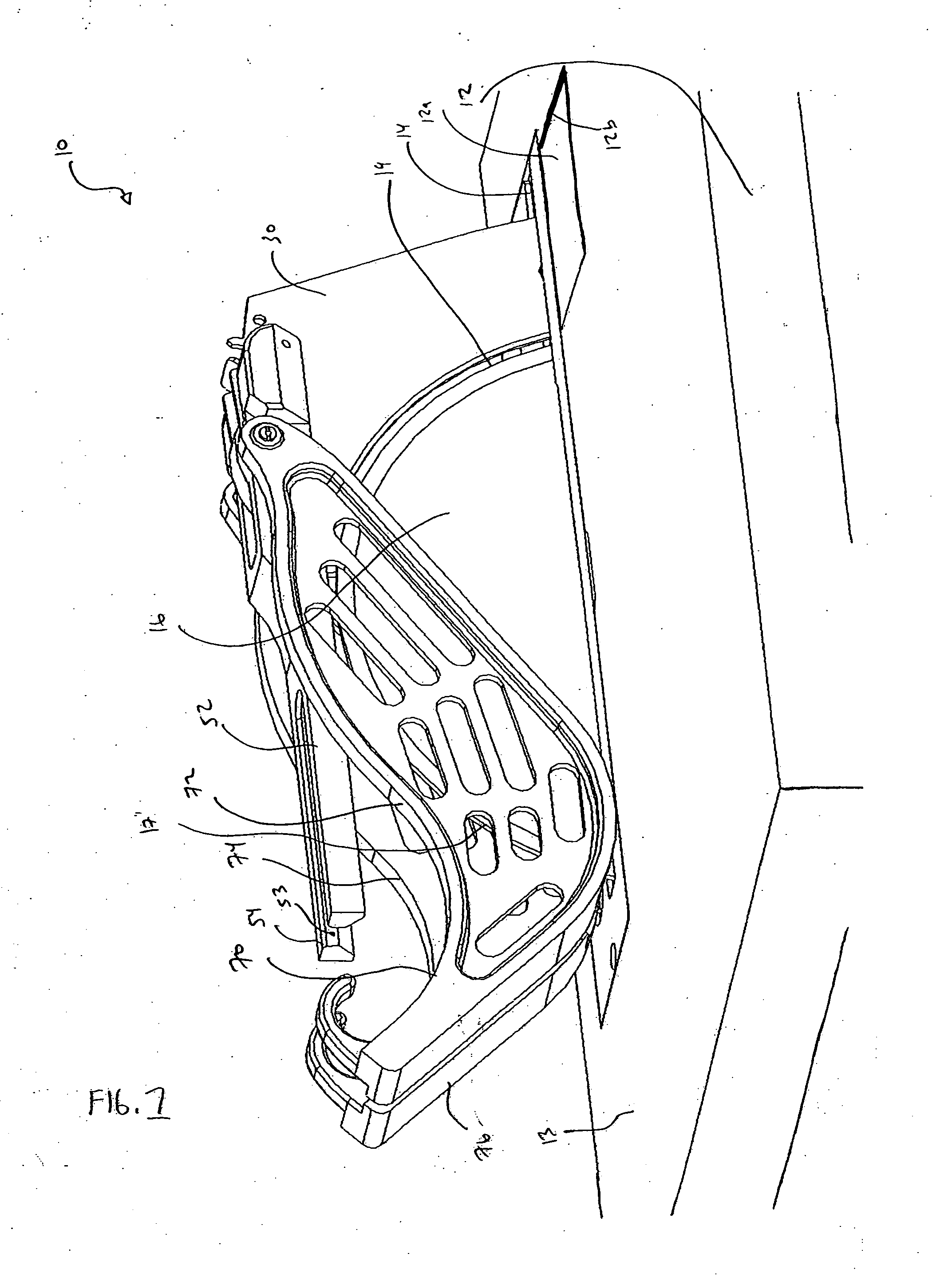

Riving knife assembly for a dual bevel table saw

ActiveUS20050188806A1Efficient use ofFunction maximizationMetal sawing devicesGuide fencesMechanical engineering

An embodiment of the present invention is directed to a riving knife assembly for a dual bevel table saw, comprising: a first armature configured for coupling with a beveling member; a second armature adjustably and rotatably coupled with the first armature; a first mounting member coupled with the second armature; a first riving bracket coupled with the second armature and configured for adjustably coupling with a bearing retaining nut of a dual arbor assembly; a second riving bracket coupled with the first mounting member and configured for adjustably coupling with the inside of a first bore of a first height bracket; a quick release handle disposed upon the first mounting member; an eccentric shaft coupled with the quick release handle; a locking pin having a locking pin body, a second mounting member, a head member coupled with a sheathing member, and a spring loaded assembly, the locking pin operationally coupled with the eccentric shaft; and, a riving knife configured with an engagement assembly for engaging with the locking pin; wherein the spring loaded assembly enables the head member and a circular engagement member disposed on the locking pin body proximal to the head member of the locking pin to be set in a locked position and a release position relative to the second mounting member, the sheathing member and the riving knife; wherein the locked and release positions are established by manipulation of the quick release handle.

Owner:BLACK & DECKER INC

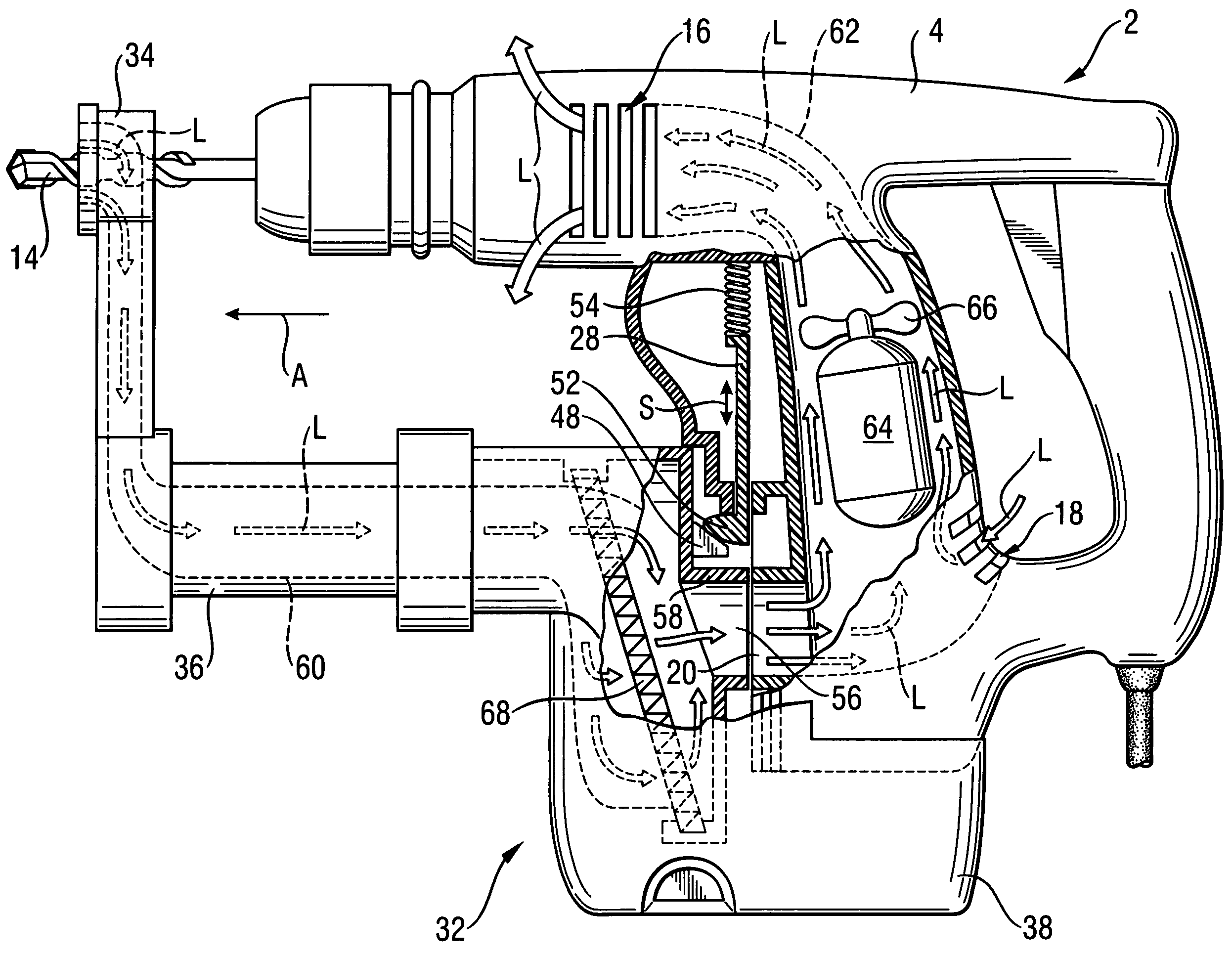

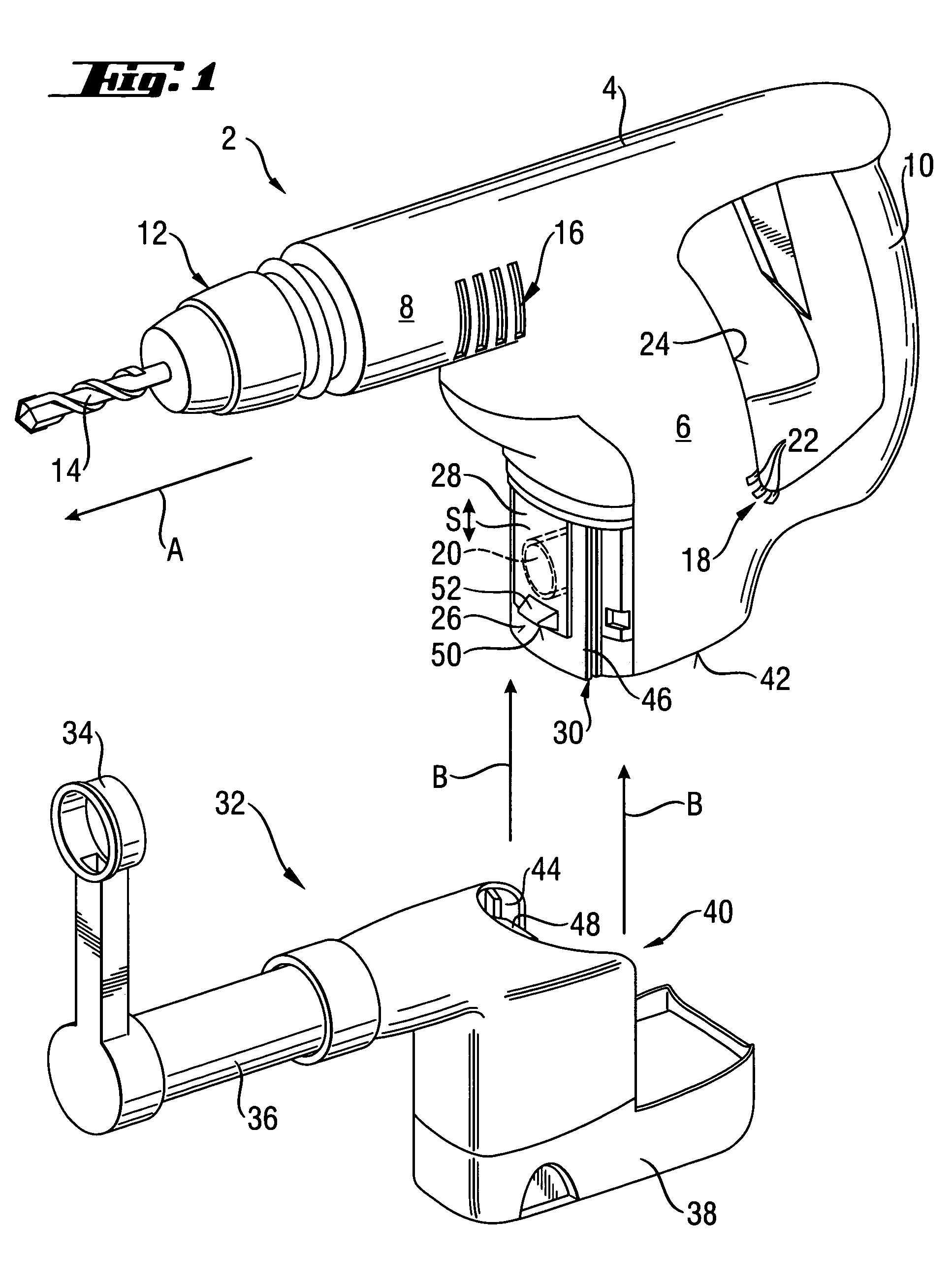

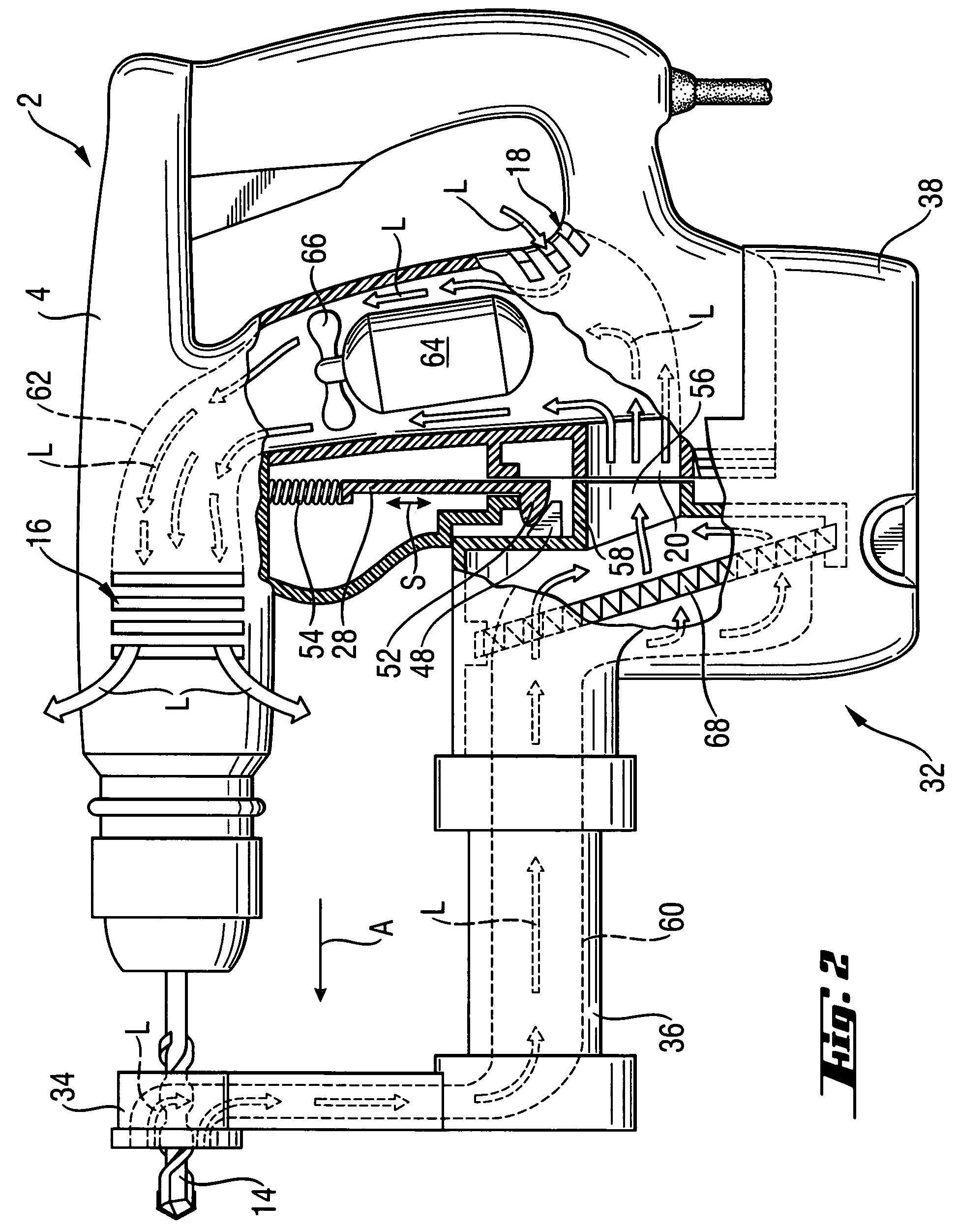

Hand-held power tool with a dust suction module

InactiveUS7354226B2Cost-effectiveAccurate guidanceThread cutting feeding devicesDrilling rodsSeparated stateHand held

A hand-held power tool (2) connectable with a dust suction module (32) includes a motor (64) and an air flow generator (66) which for cooling the motor (64) is located, together with the motor (64), in air flow path (62) between an air inlet and an air outlet (16) both formed in the tool housing, (4, 6), with an air inlet having a side opening (18) and a connection opening (20) connectable with the suction path (60) of the dust suction module (32) and the dust suction module (32) having a suction conduit (58) for connecting the suction path (60) with the air flow path (62) and adjoining the connection opening (20) in a connected condition of the dust suction module (32) with the power tool, and with the power tool (2) further having a closing member provided on the connection opening (20), operable by the dust suction module (32), and having, in an attached position of the dust section module (32), an open position, and having a closed position in the detached condition of the dust suction module (32).

Owner:HILTI AG

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

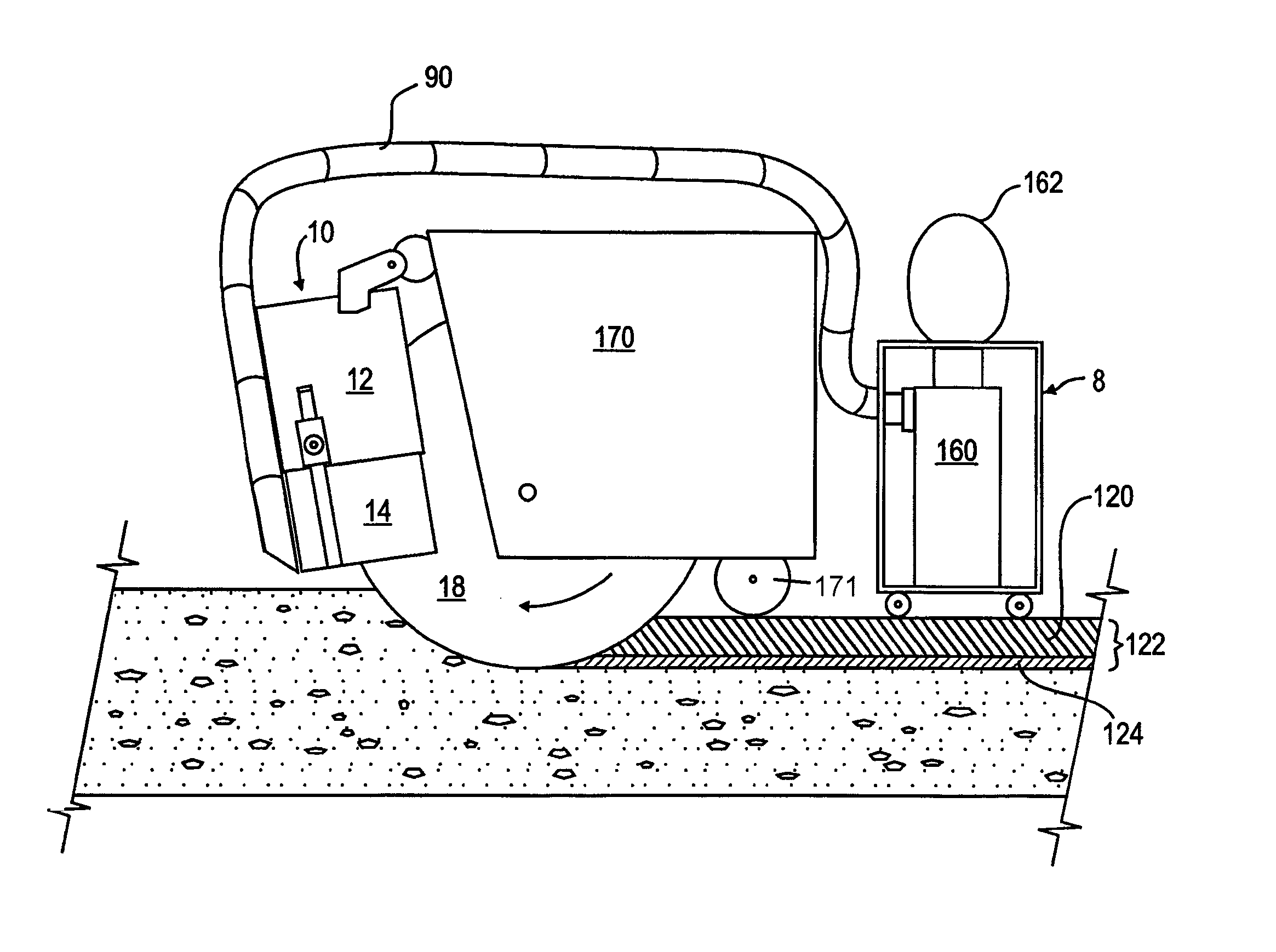

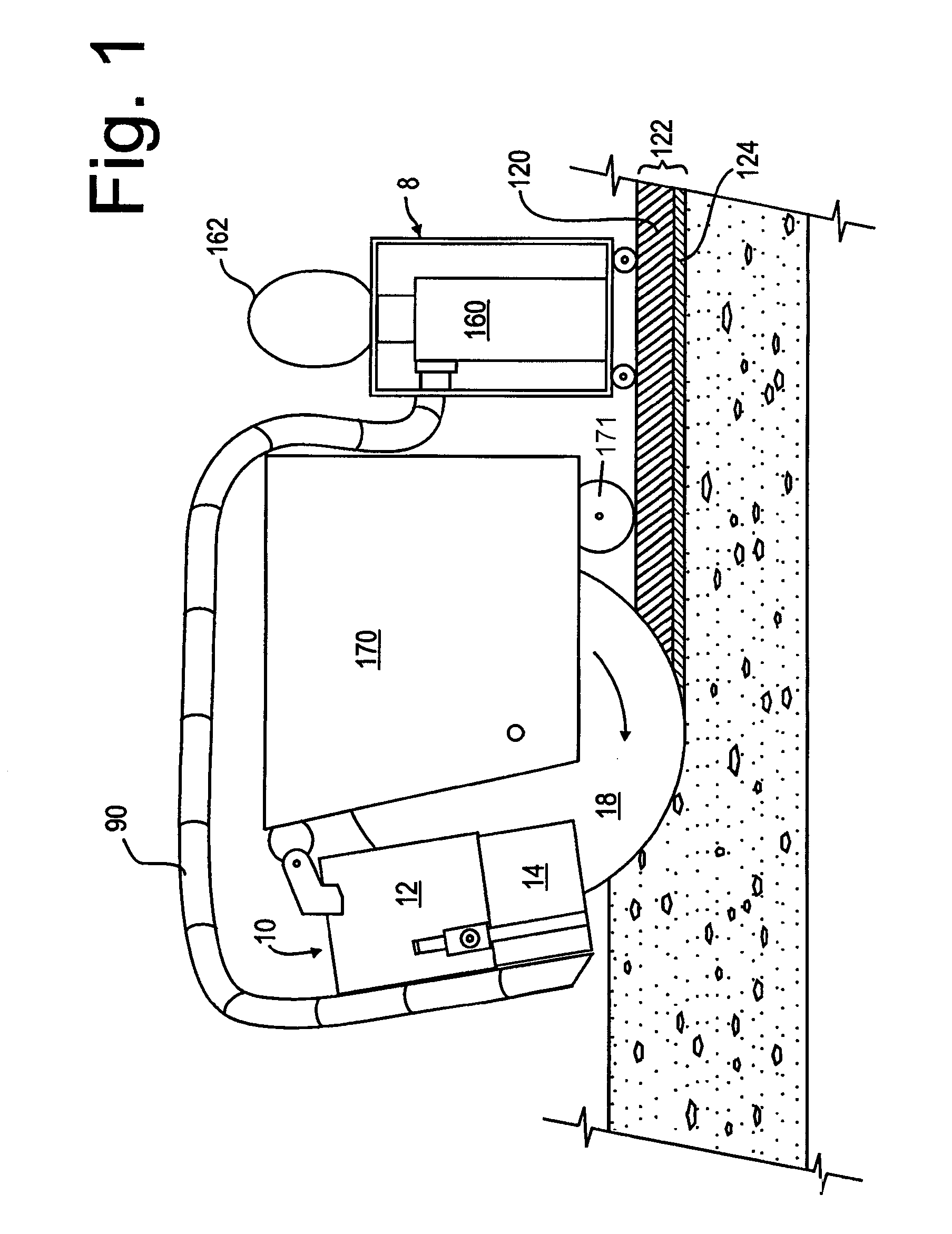

Slab saw with dust collector and method of dry-cutting pavement

A dust collector is provided for use with a SLAB saw, especially suited for dry-cutting a channel within pavement or similar exterior surface. The collector includes telescoping upper and lower housings, an open front and lower base to receive a portion of a circular saw into the interior of the housing, and an exhaust outlet, for attaching to a vacuum duct, so as to exhaust dust-laden air from the interior of the housing. The housing includes a pivot mount, pivotally mounting the unit to a slab saw. Also provided is a system, including the dust collector with a circular saw and optionally a vacuum source and dust filter unit or units. Also provided is a method for dry-cutting a trench or channel within pavement or similar hard outside surface, which is particularly suitable for laying of cable such as fiber optic cable. The method may include the step of cutting through the pavement into the underlying hard-packed substrate.

Owner:TERASPAN NETWORKS

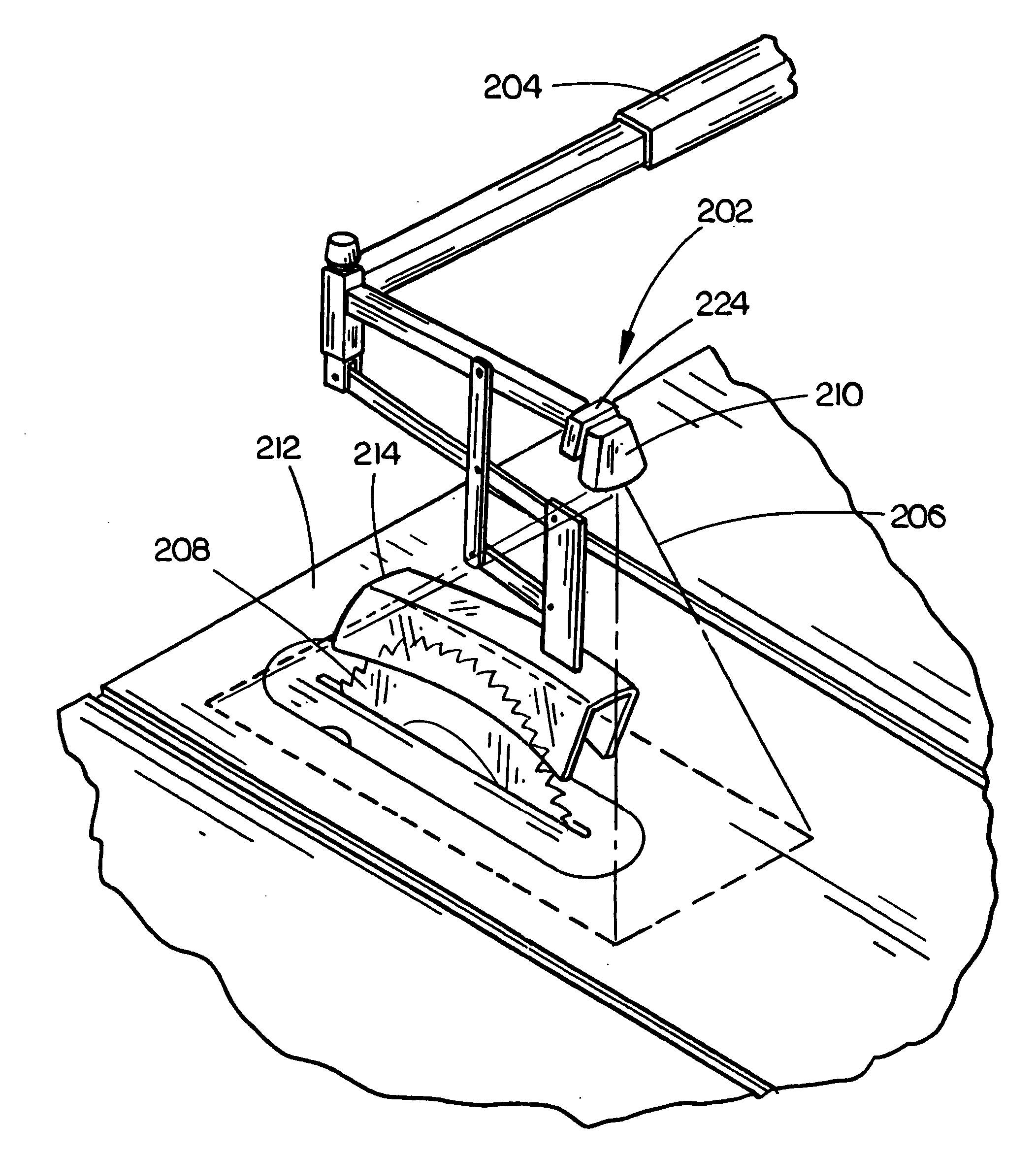

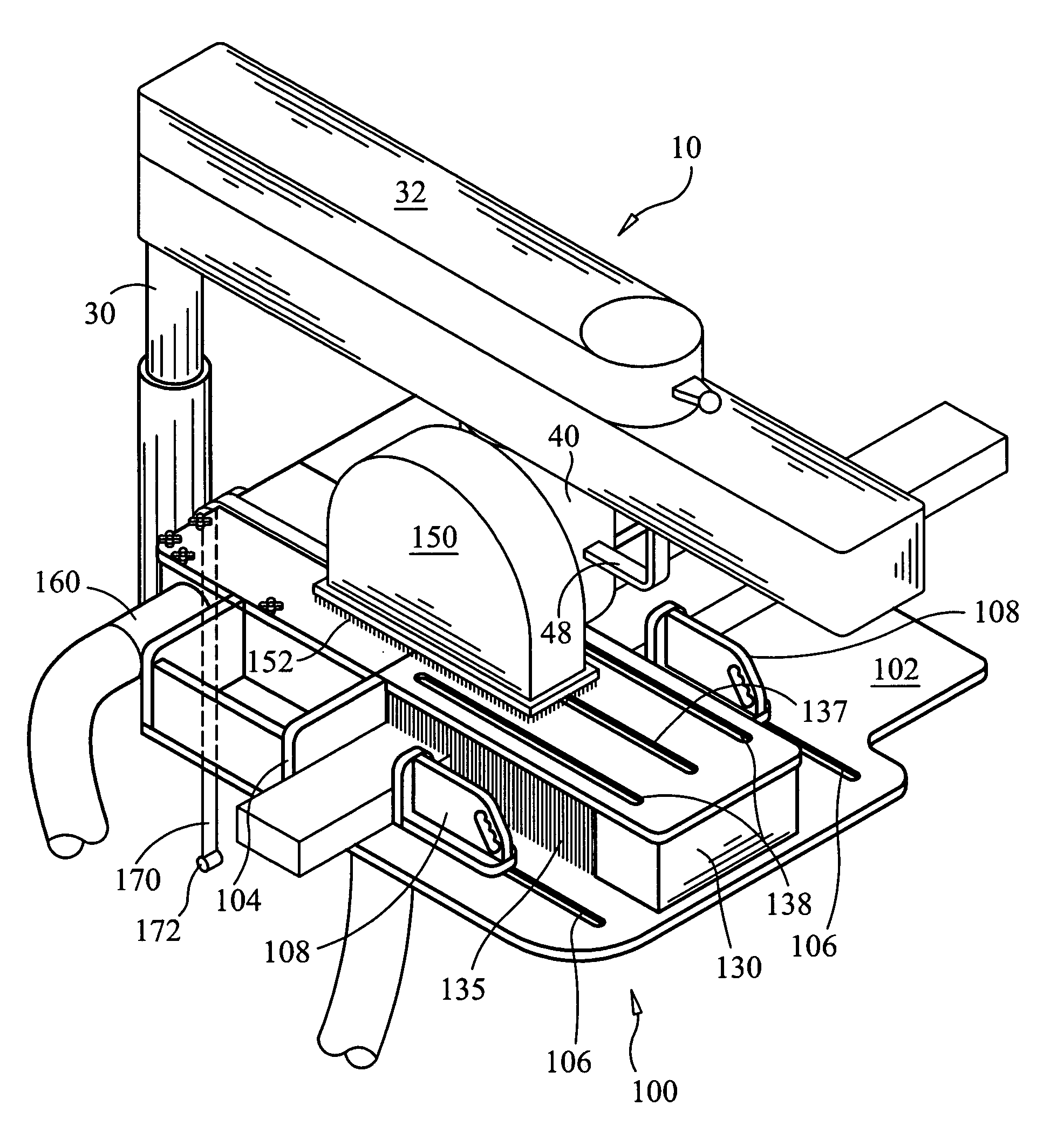

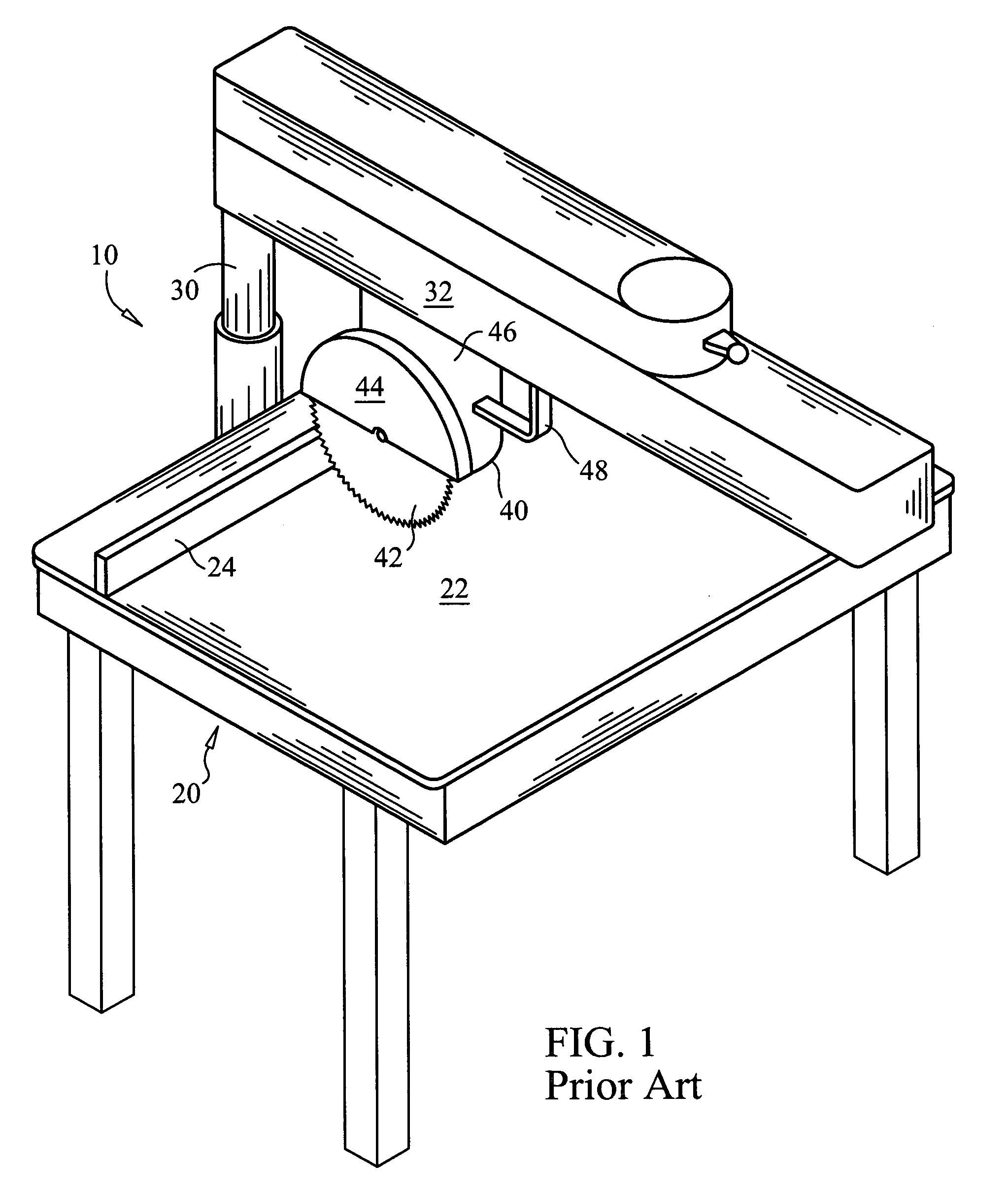

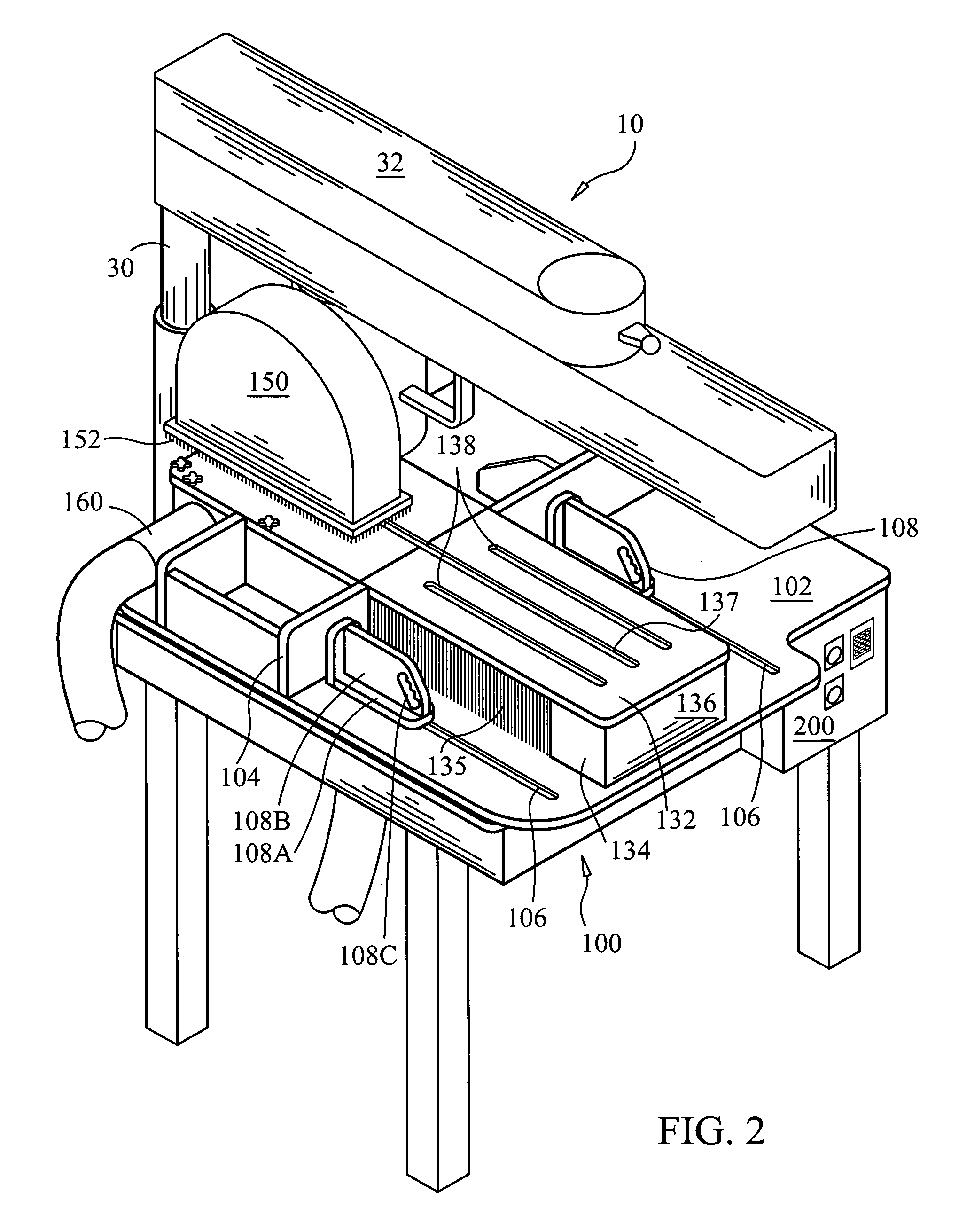

Radial arm saw safety top

InactiveUS7044039B2Overcome disadvantagesMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

A radial arm saw is adapted with a safety top configured with cutting box enclosure that contains and collects substantially all of the sawdust generated during use. A dust collection system is in fluid communication with the cutting box for removing the sawdust contained therein. Spring biased push blocks function to hold the work piece in place during the sawing process while maintaining the user's hands safely away from the saw blade. A laser alignment device projects a beam within the cutting box along the cutting plane. A control panel is provided to allow use by authorized users upon entry of an authorization code.

Owner:POWELL MICHAEL S

Dust collector attachment for a spiral power tool

The dust attachment which is used with a spiral saw power tool includes a first attachment portion which at a rear end has a substantially dust-tight fit with a mounting head portion of the tool. The other (forward) end extends beyond a forward edge of the mounting head portion, but such that the spiral saw bit extends beyond the forward edge of the attachment portion by a distance which is slightly greater than that of the thickness of the workpiece. An attaching member such as a screw secures the dust attachment portion to the tool. An dust exit tube extends from a side surface of the attachment portion and communicates with the interior of the attachment portion. The dust exit tube extends at an angle away from the attachment portion toward the rear end thereof.

Owner:WEISS STEPHEN F

Dust extraction shroud for a power tool

A dust extraction shroud for a drill, which surrounds a drill bit and which lies adjacent the work surface, comprises a body portion defining a first inlet adapted to engage the work surface and to surround the location at which said bit penetrates the surface. The shroud body further defines a first outlet connected to a source of suction and a third inlet for allowing the bit to pass through said body portion. A first sealing means is arranged in said third inlet for surrounding said bit and resisting the flow of air. Wherein said body portion includes at least one protruding portion defining a second inlet between said protruding portion and an adjacent part of said body, and on a side of said protruding portion remote from the first inlet. The second inlet admits air to enter said body portion and travel to the first outlet.

Owner:BLACK & DECKER INC

Riving knife clamp for a table saw

A table saw comprising a table including an aperture to receive a portion of a rotatable saw blade extending from below the table and a riving knife extending through the aperture from below the table. The riving knife includes a slot that receives a first pin and the riving knife includes a plurality of recesses. A cam that operatively engages the first pin and is rotatable to cause linear motion of the first pin with respect to the slot such that when the cam is in a first position the riving knife may be retained in a selected position and when the cam is in a second position the riving knife may be movable to another selected position, wherein the rotation of the cam additionally causes movement of a second pin that may be received within one of the plurality of recesses.

Owner:EASTWAY FAIR OF TRIDENT CHAMBERS

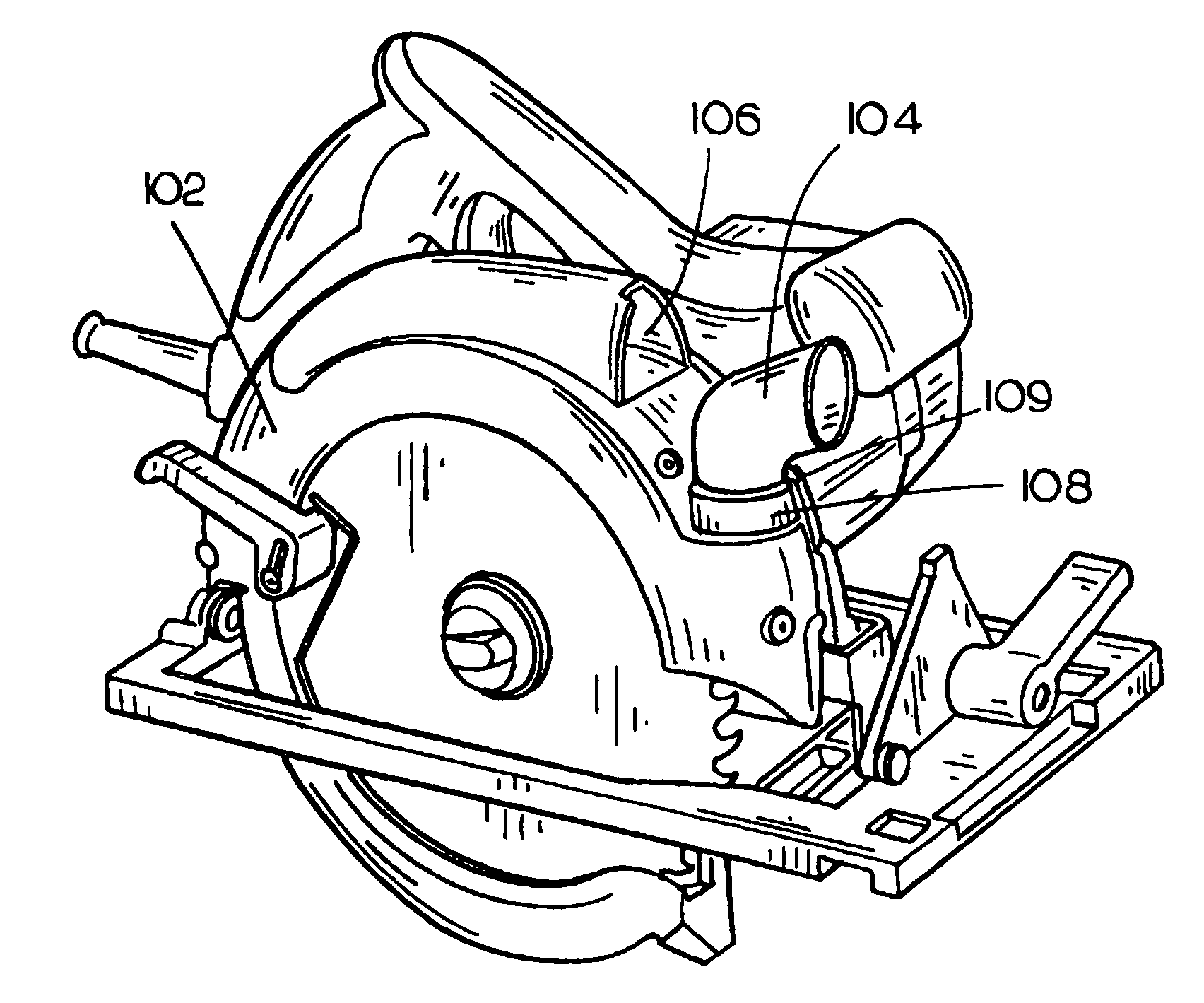

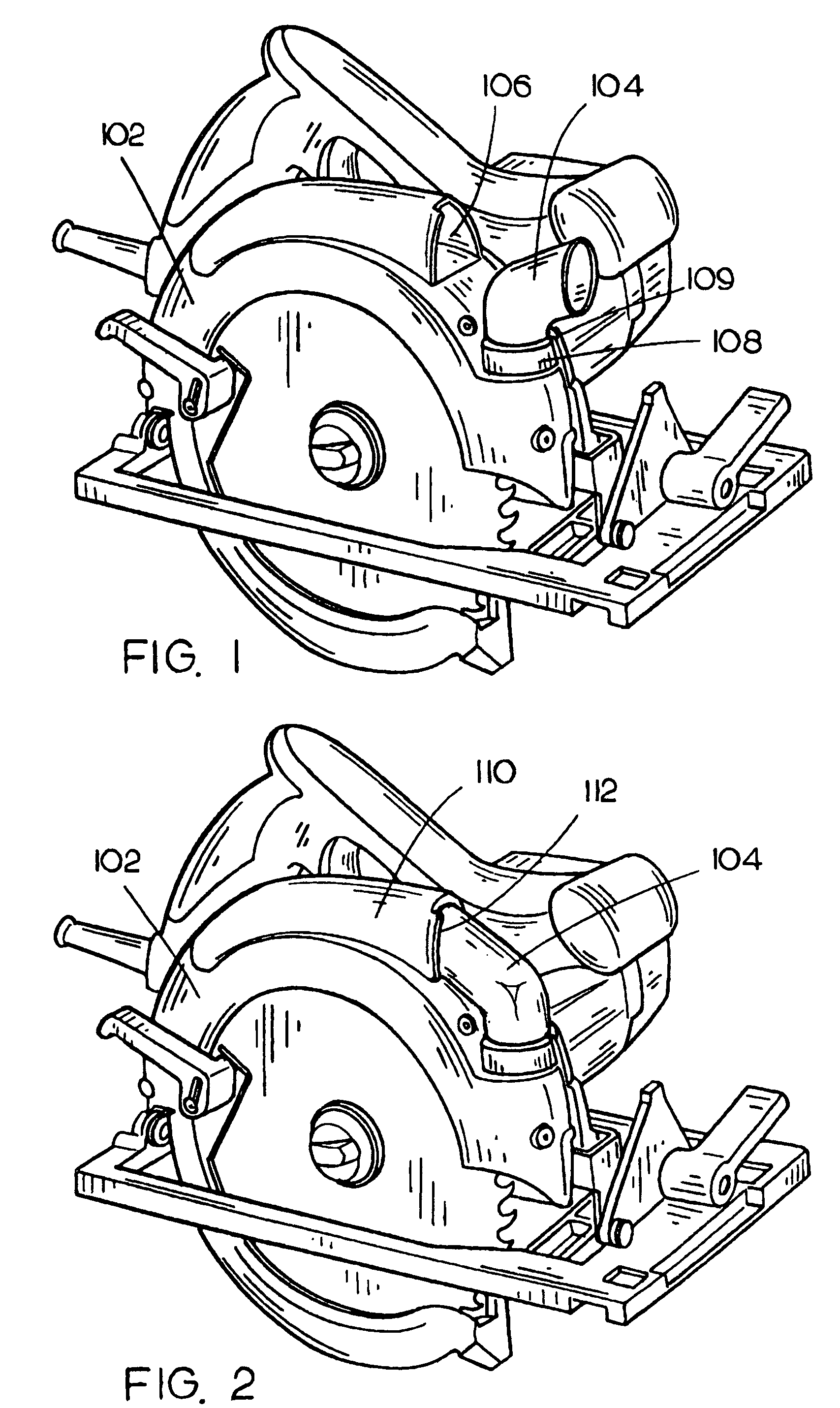

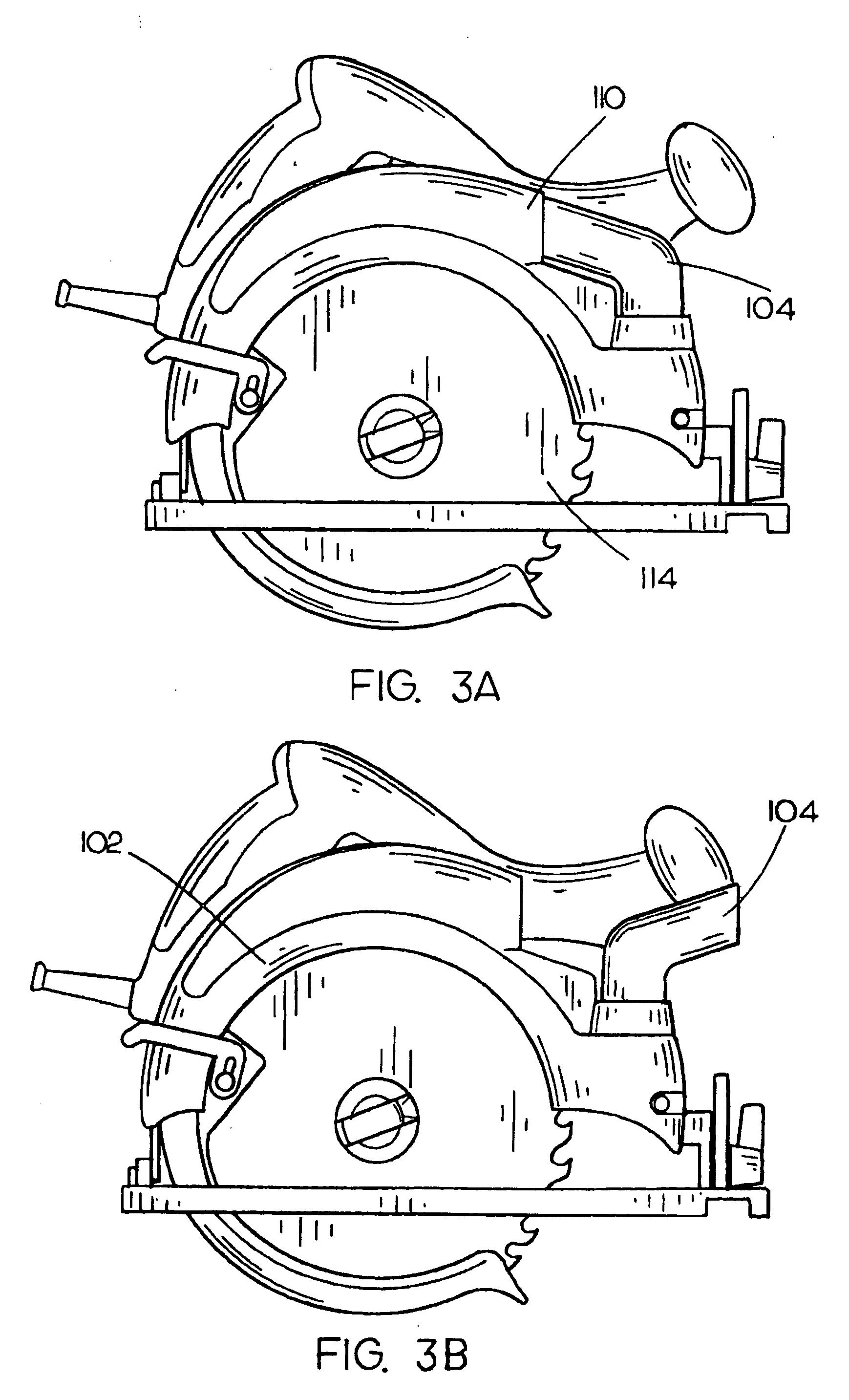

Variable dust chute for circular saws

The present invention is directed to a hand-held circular saw with an integrated dust collection system. Such saw may include an upper blade guard for protecting the user from a saw blade, the upper blade guard configured with a front region and a back region, the front region including a hollow channel to control the pathway of dust and debris and a dust collection system incorporated within the front region of the upper blade guard allowing dust and debris to be directed away from the user.

Owner:BLACK & DECKER INC

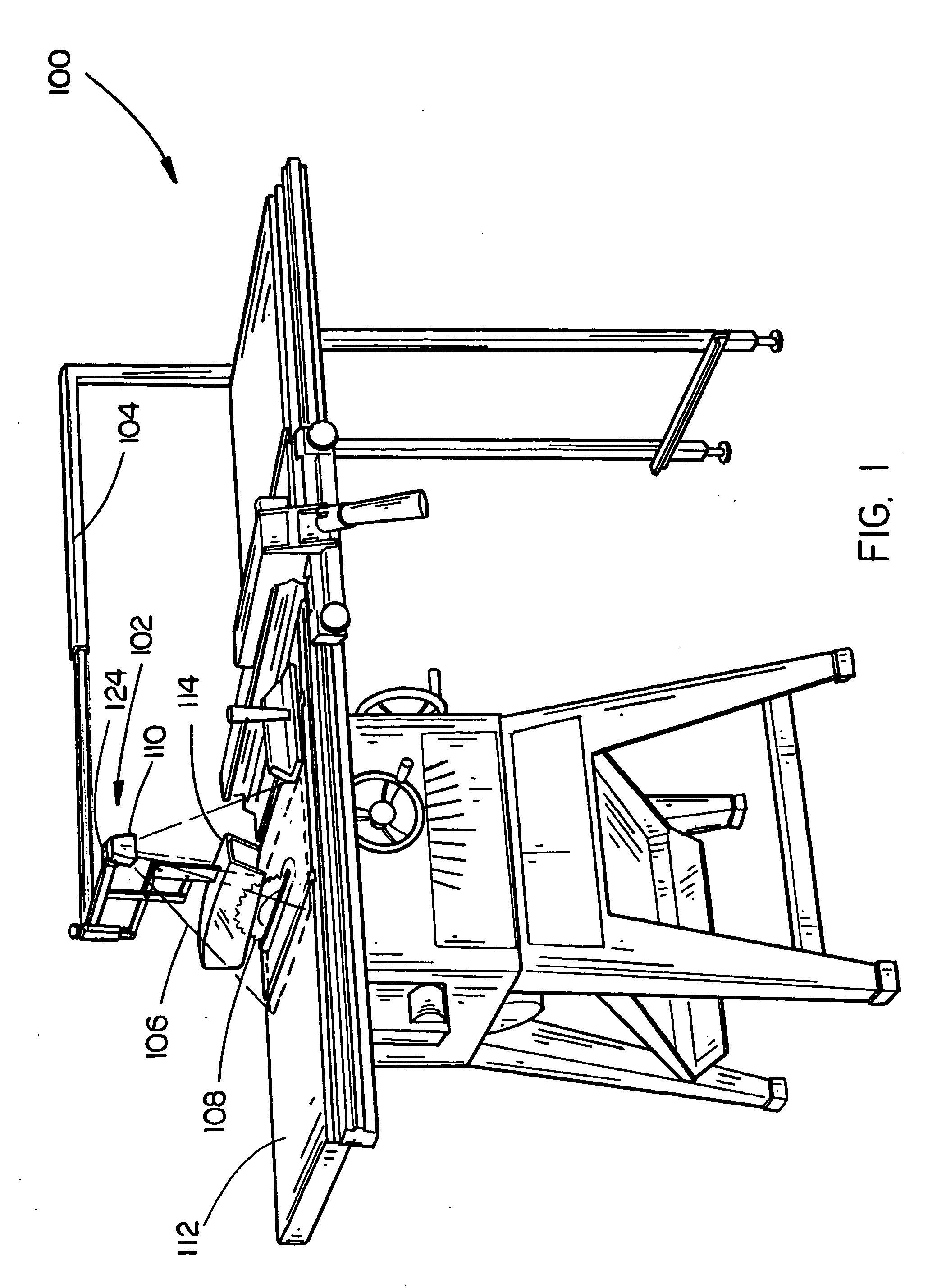

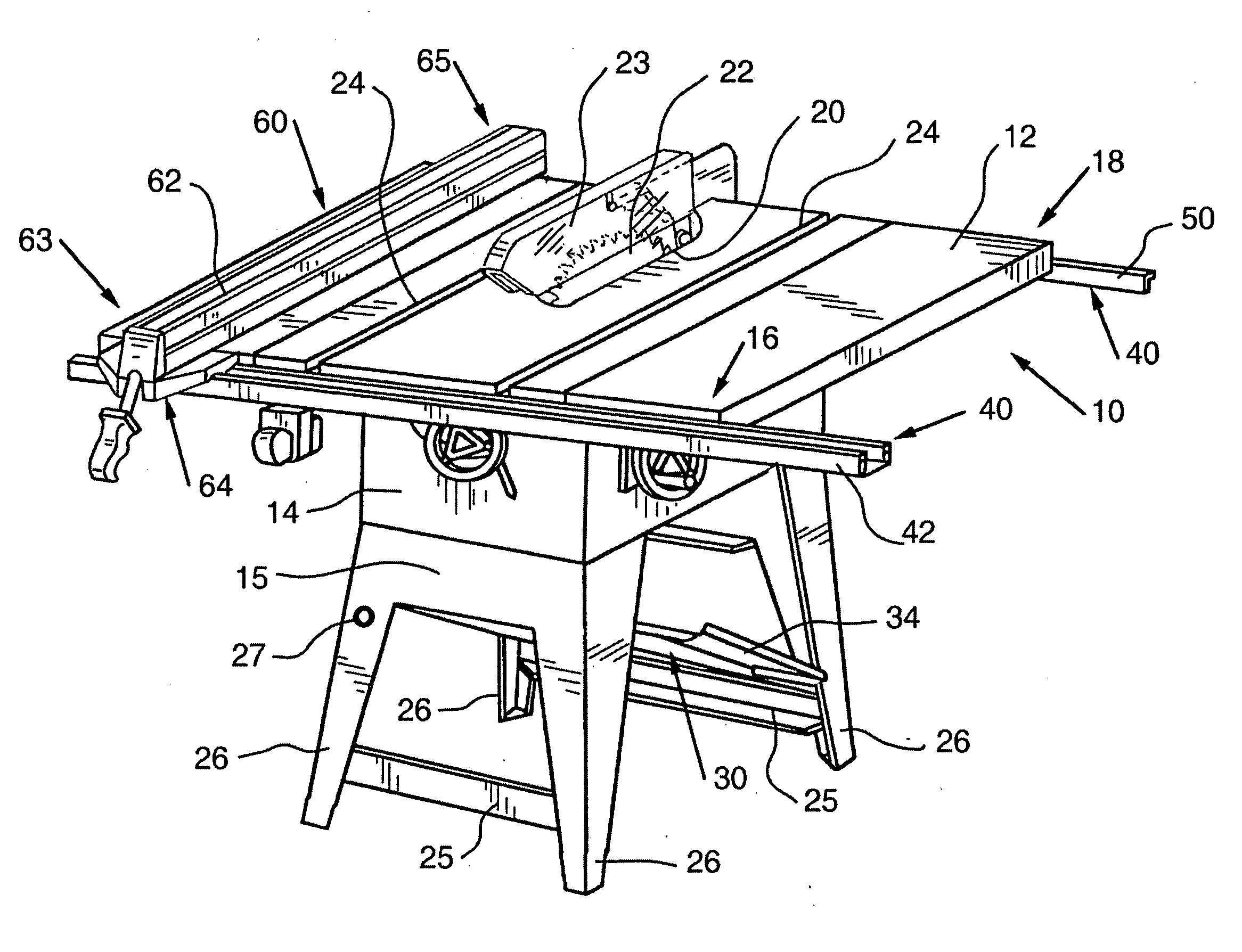

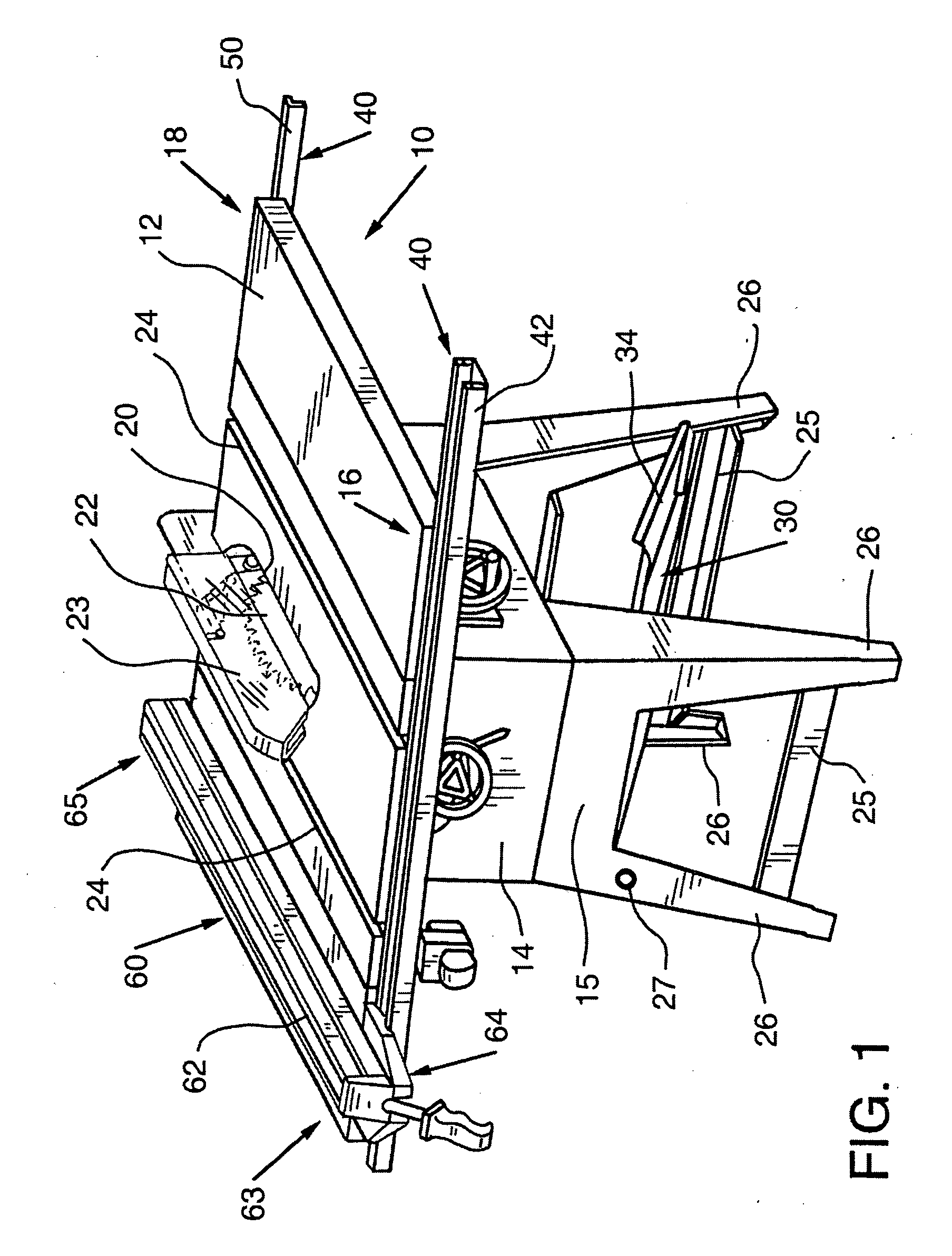

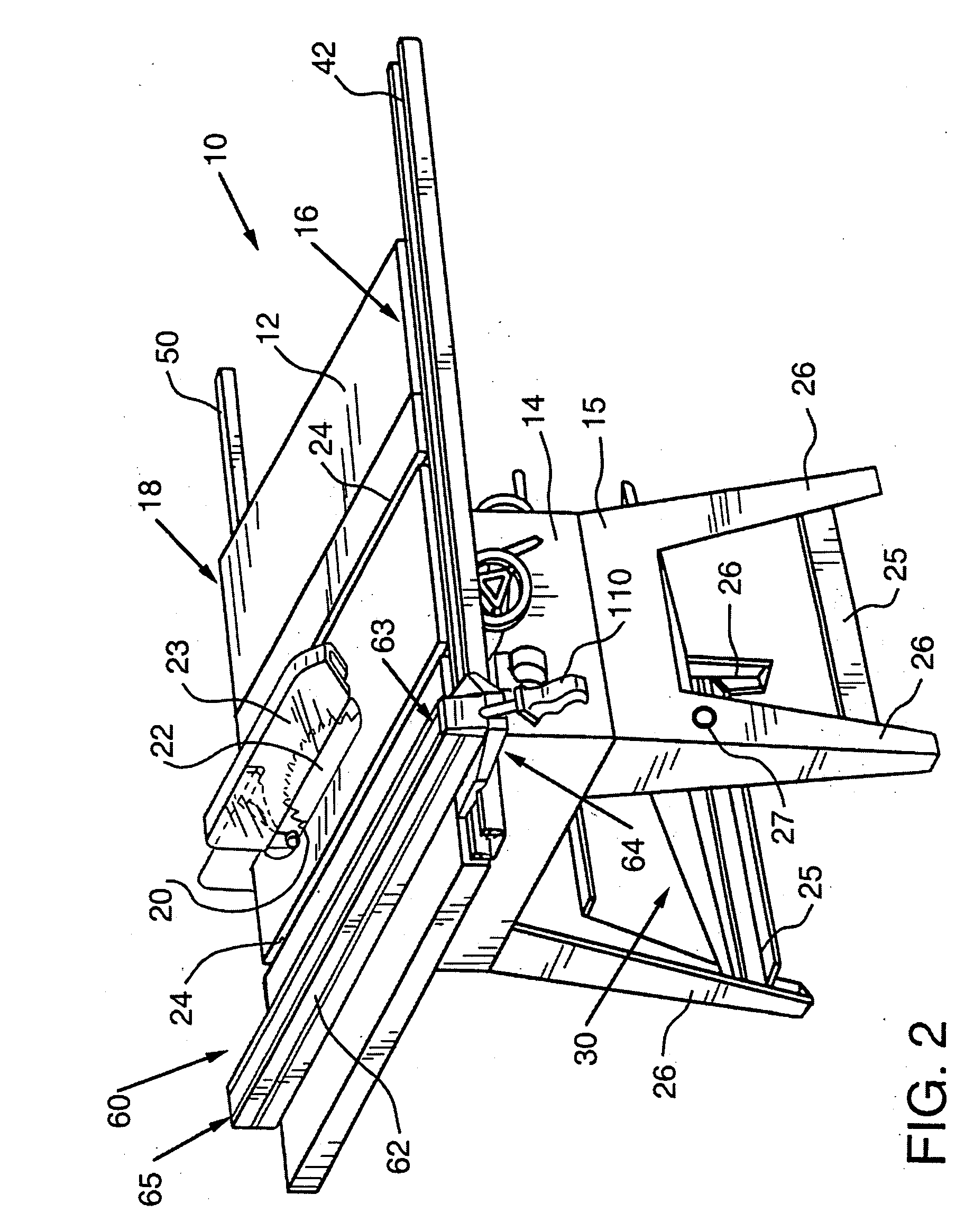

Sawing apparatus and saw fence system

InactiveUS20050087049A1Consistent supportEasy to adjustMetal sawing devicesMetal sawing accessoriesCollection systemEngineering

A sawing apparatus and a saw fence. The saw apparatus may include a work surface. The saw may include a rail system disposed along the edges of the work surface, for the attachment of accessories thereto. The saw may be provided with workpiece guide adapted to be attached to the rail system for guiding workpieces during the operation of the saw. The workpiece guide may also be provided with an infeed extension that rides on the rail system and is capable of supporting workpieces during the operation of the saw. The infeed extension may be adjustable relative to the work surface of the saw. The saw may further be provided with a debris collection system for the collection of debris produced by the cutting operations of the saw.

Owner:DELTA INT MACHINERY

Riving knife assembly for a dual bevel table saw

ActiveUS7137327B2Efficient use ofFunction maximizationMetal sawing devicesGuide fencesEngineeringRivet

An embodiment of the present invention is directed to a riving knife assembly for a dual bevel table saw, comprising: a first armature configured for coupling with a beveling member; a second armature adjustably and rotatably coupled with the first armature; a first mounting member coupled with the second armature; a first riving bracket coupled with the second armature and configured for adjustably coupling with a bearing retaining nut of a dual arbor assembly; a second riving bracket coupled with the first mounting member and configured for adjustably coupling with the inside of a first bore of a first height bracket; a quick release handle disposed upon the first mounting member; an eccentric shaft coupled with the quick release handle; and a riving knife configured with an engaging assembly for engaging with a locking pin or a guard assembly or a kickback finger system.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com