Patents

Literature

220 results about "Woodworking machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Woodworking machine is a wood machine that is intended to process wood. These machines are usually powered by electric motors and are used extensively in woodworking.

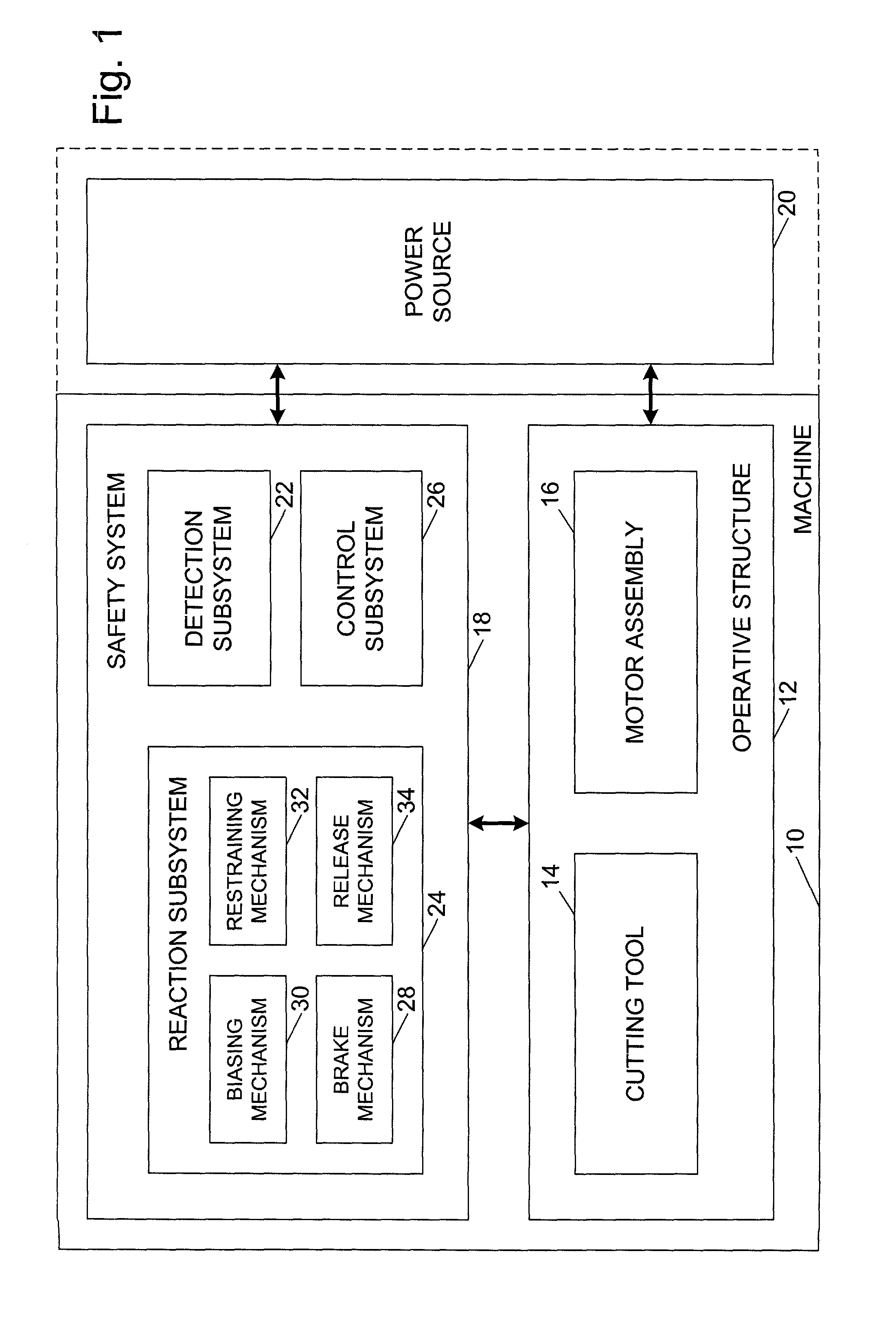

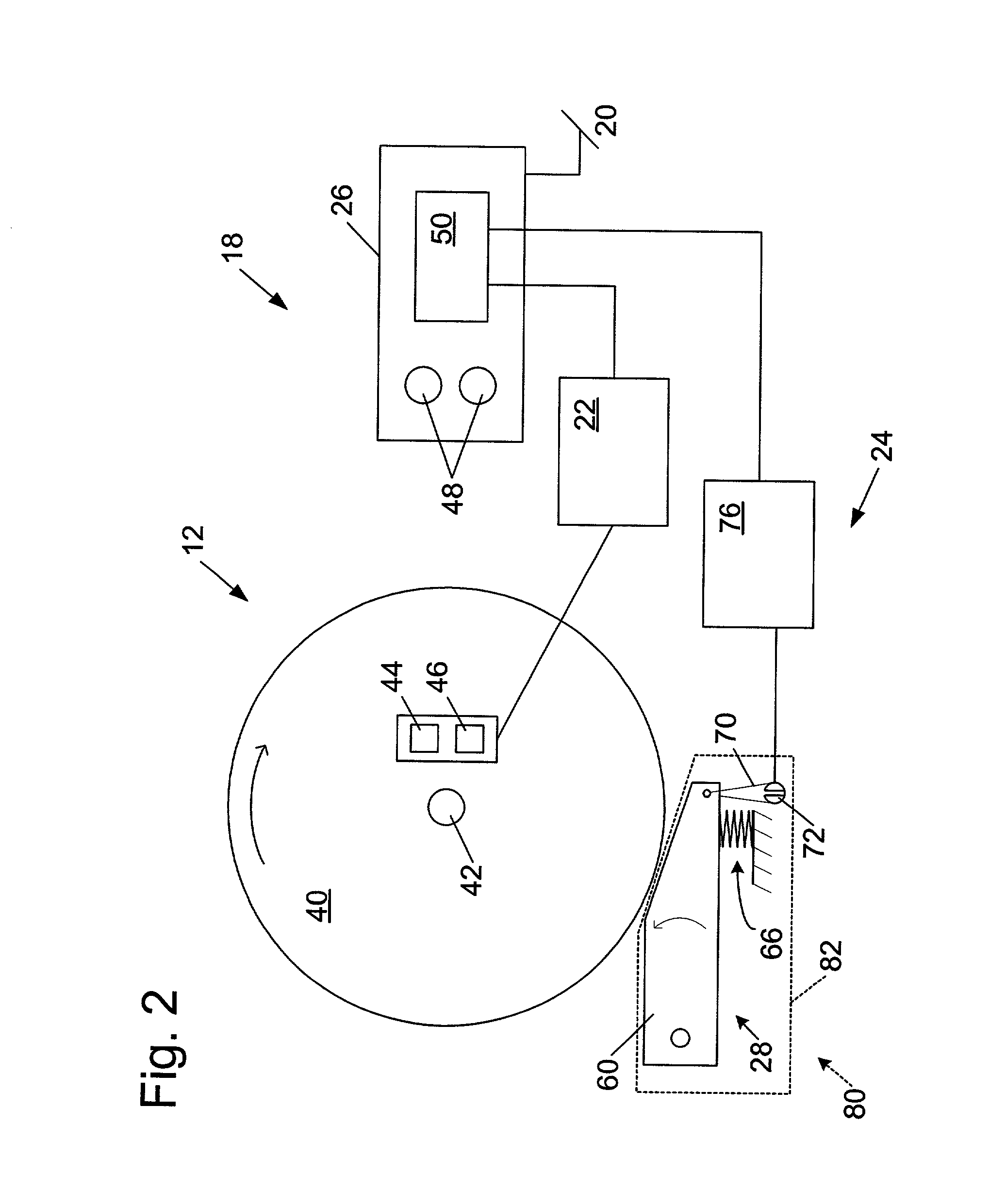

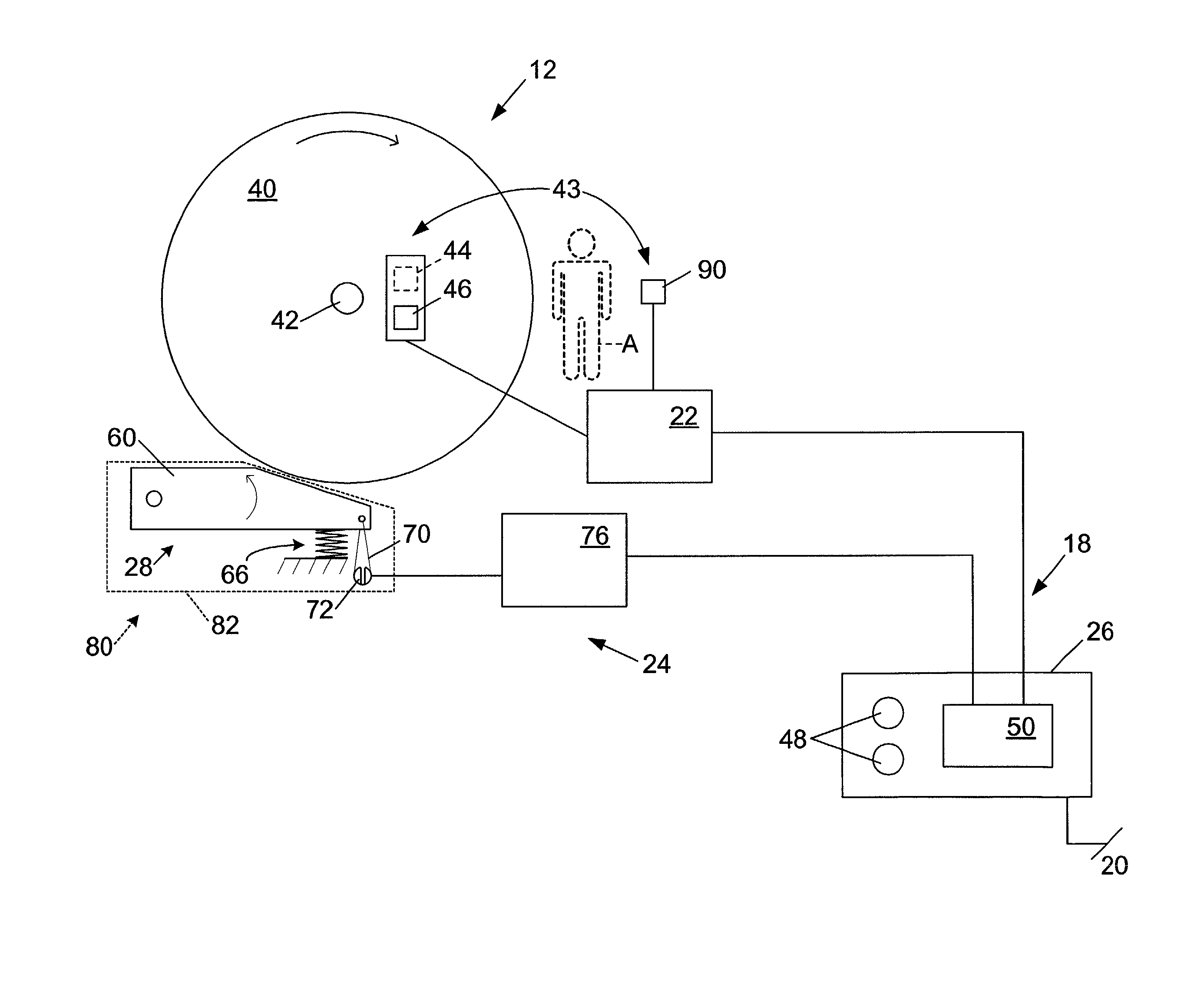

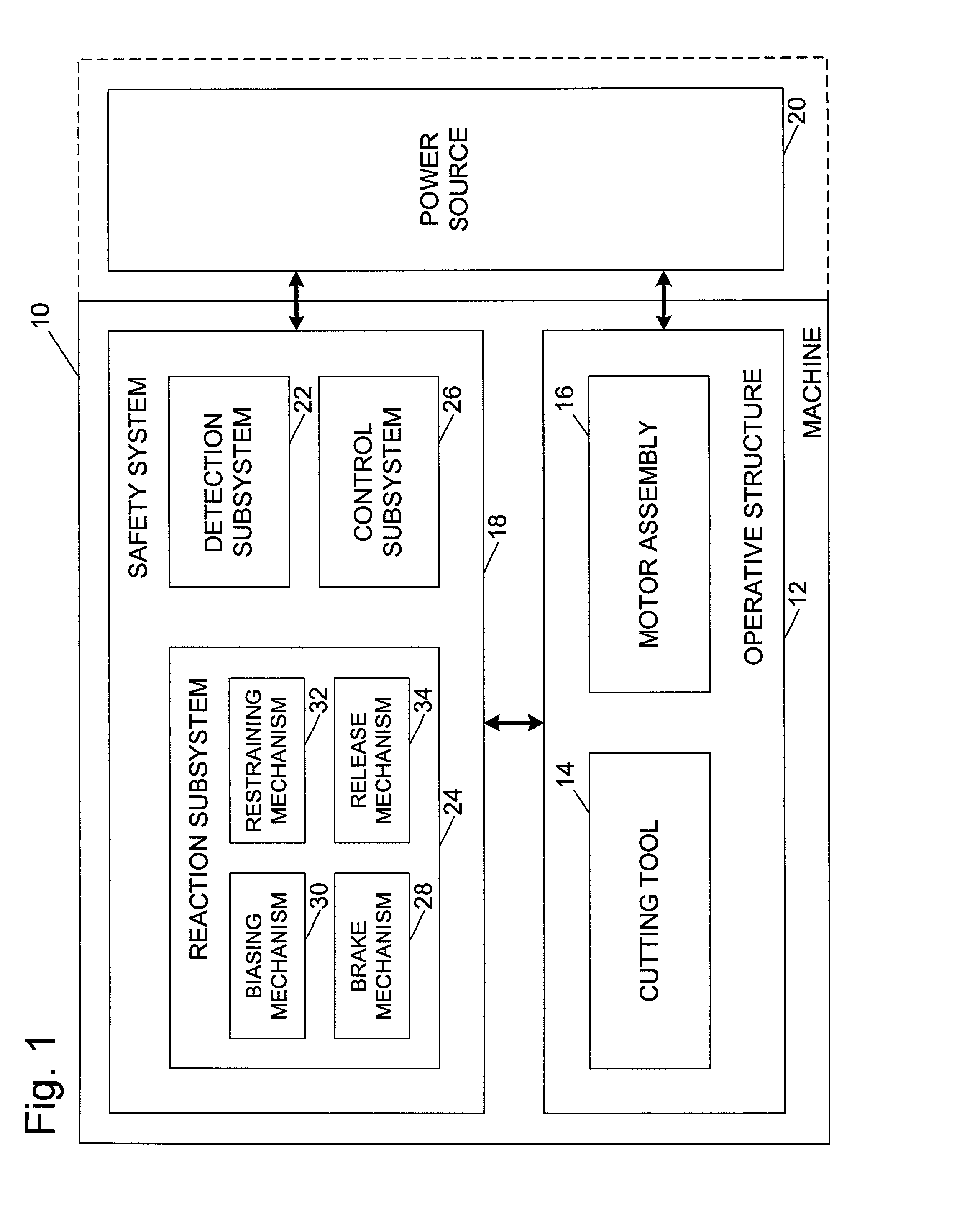

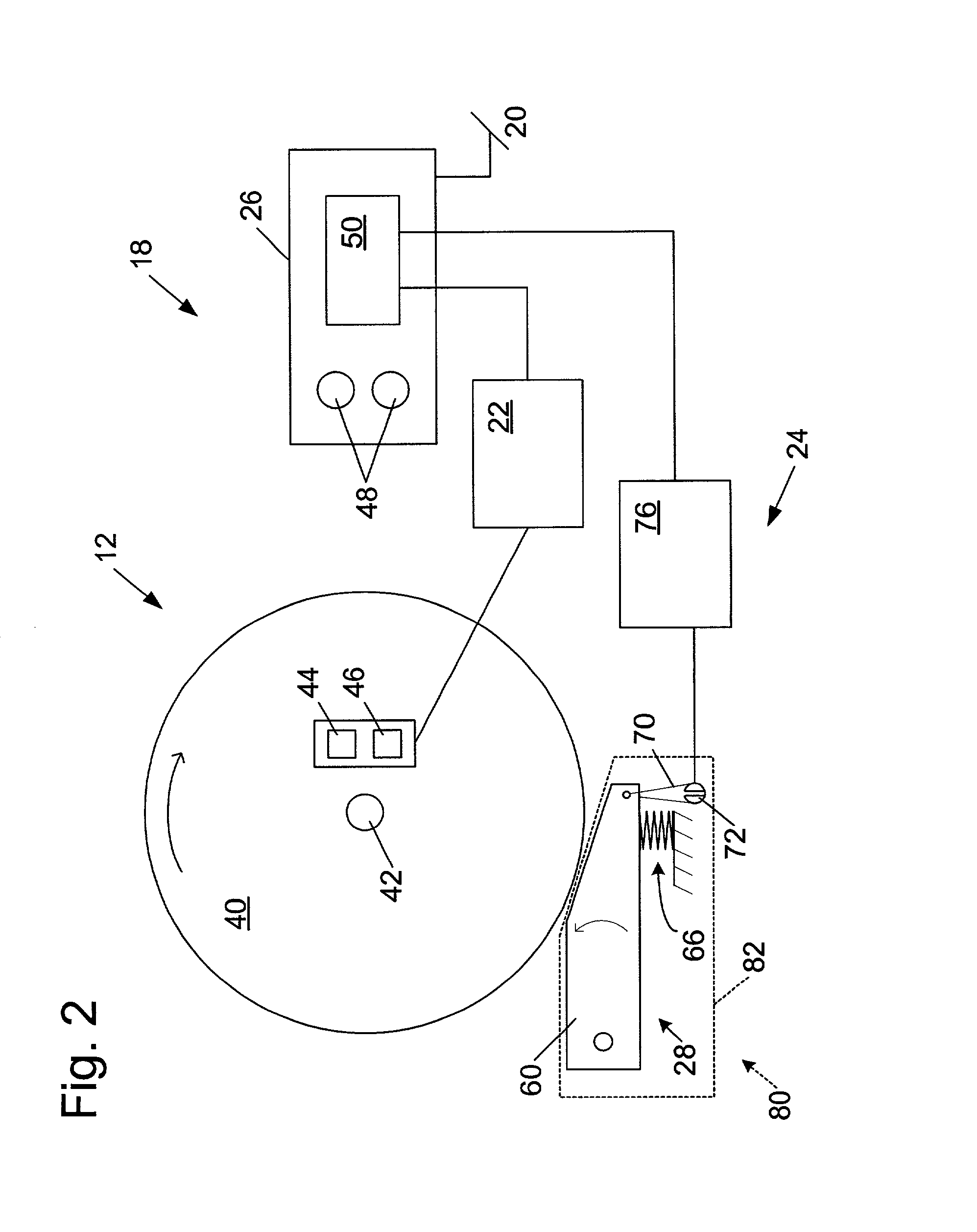

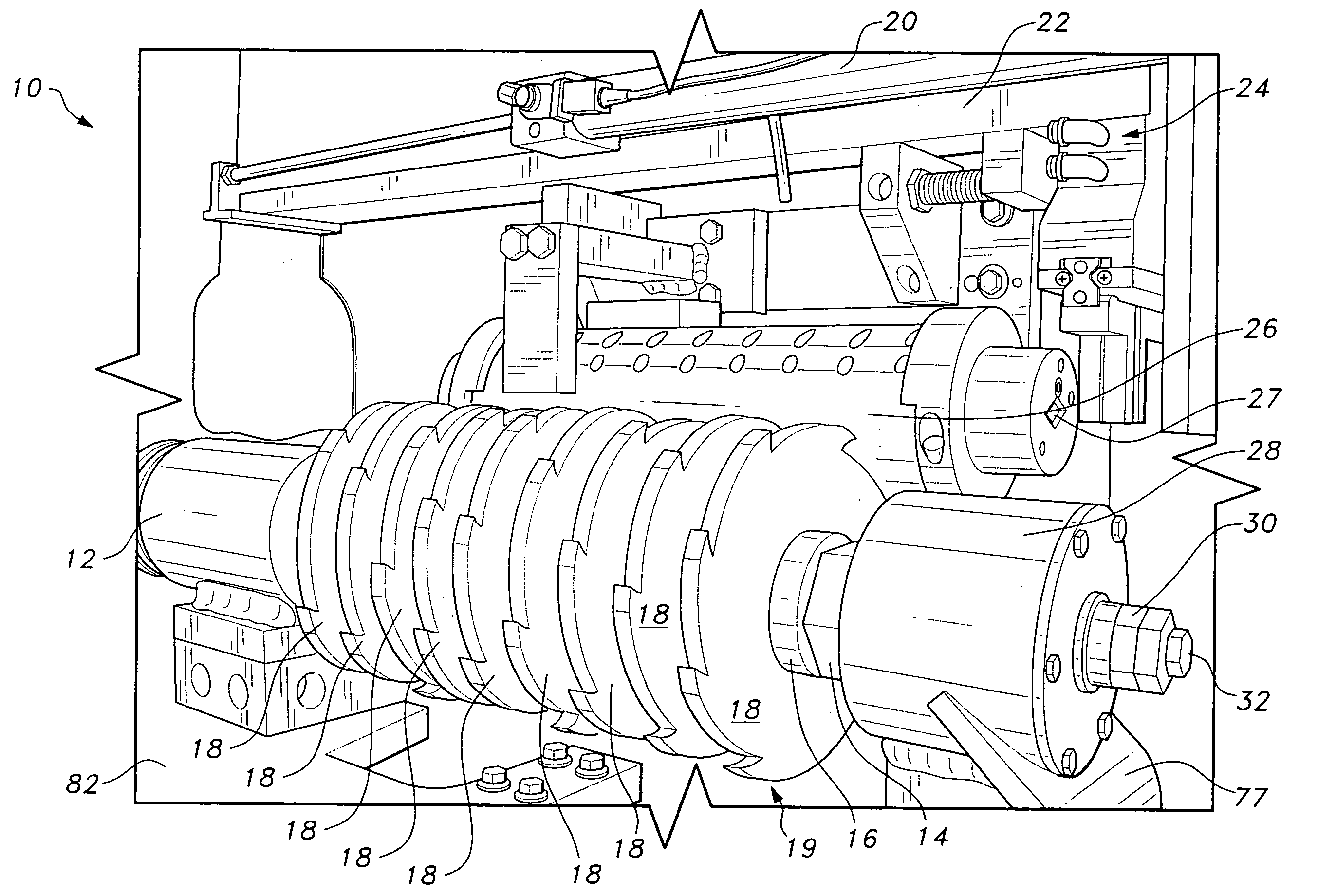

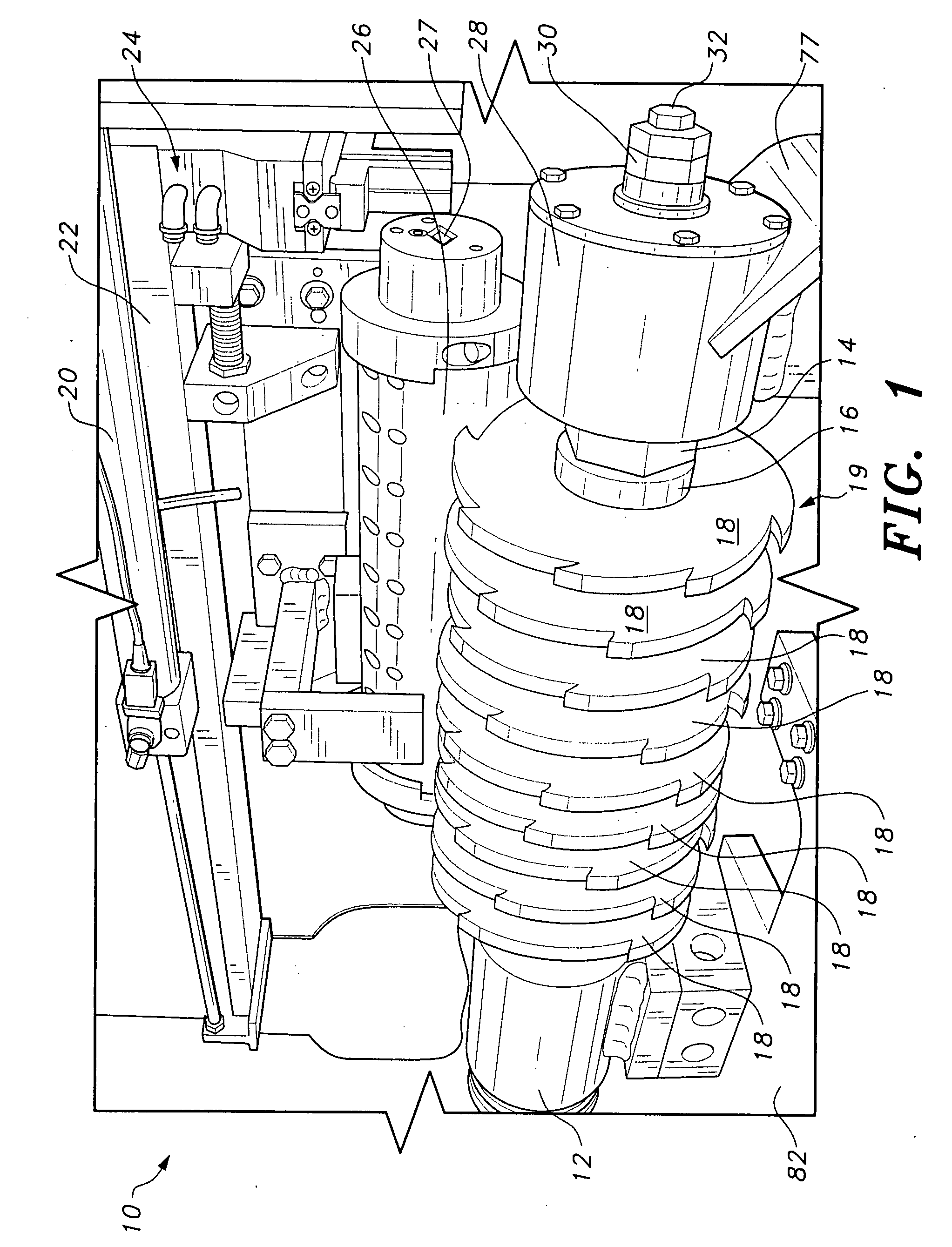

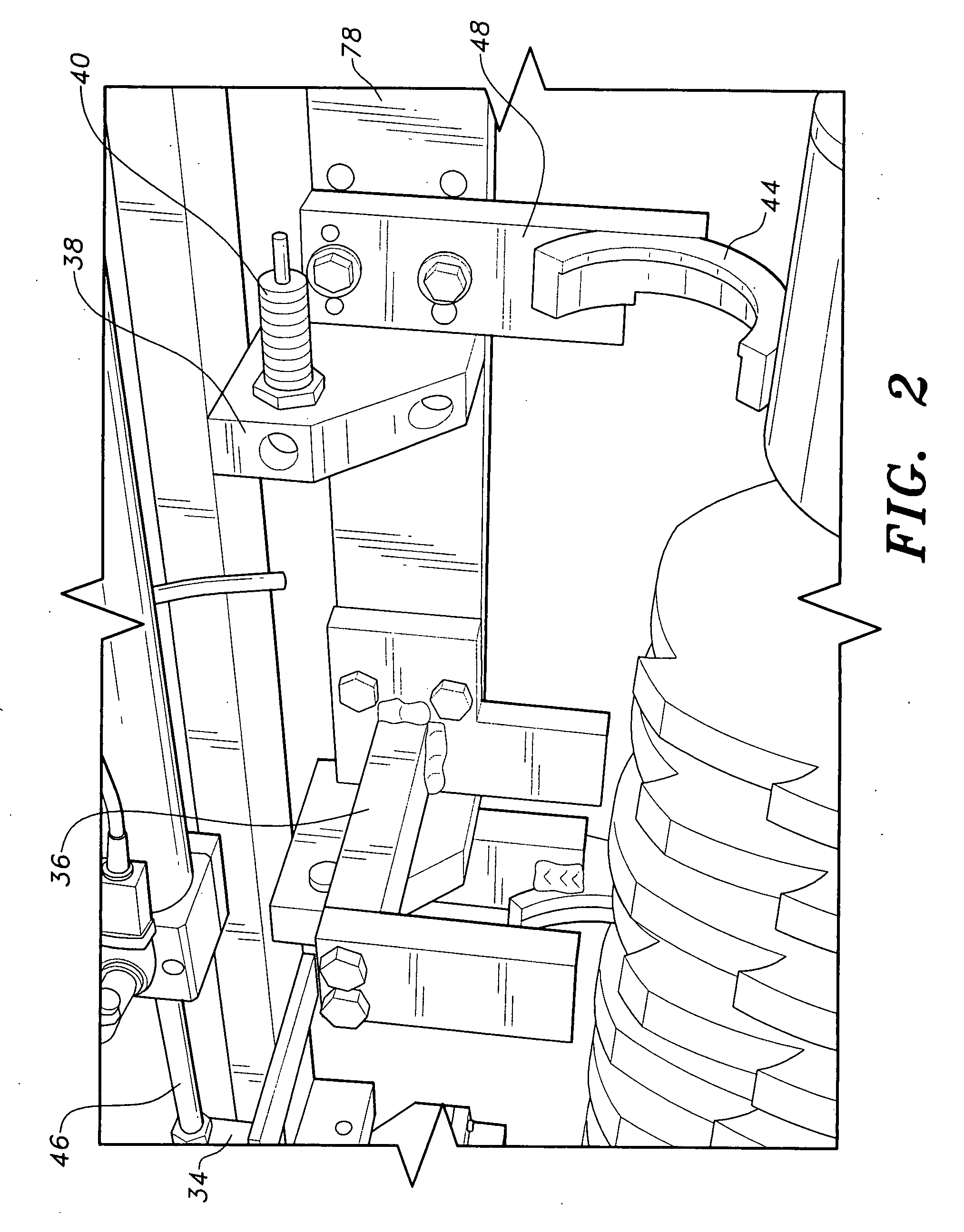

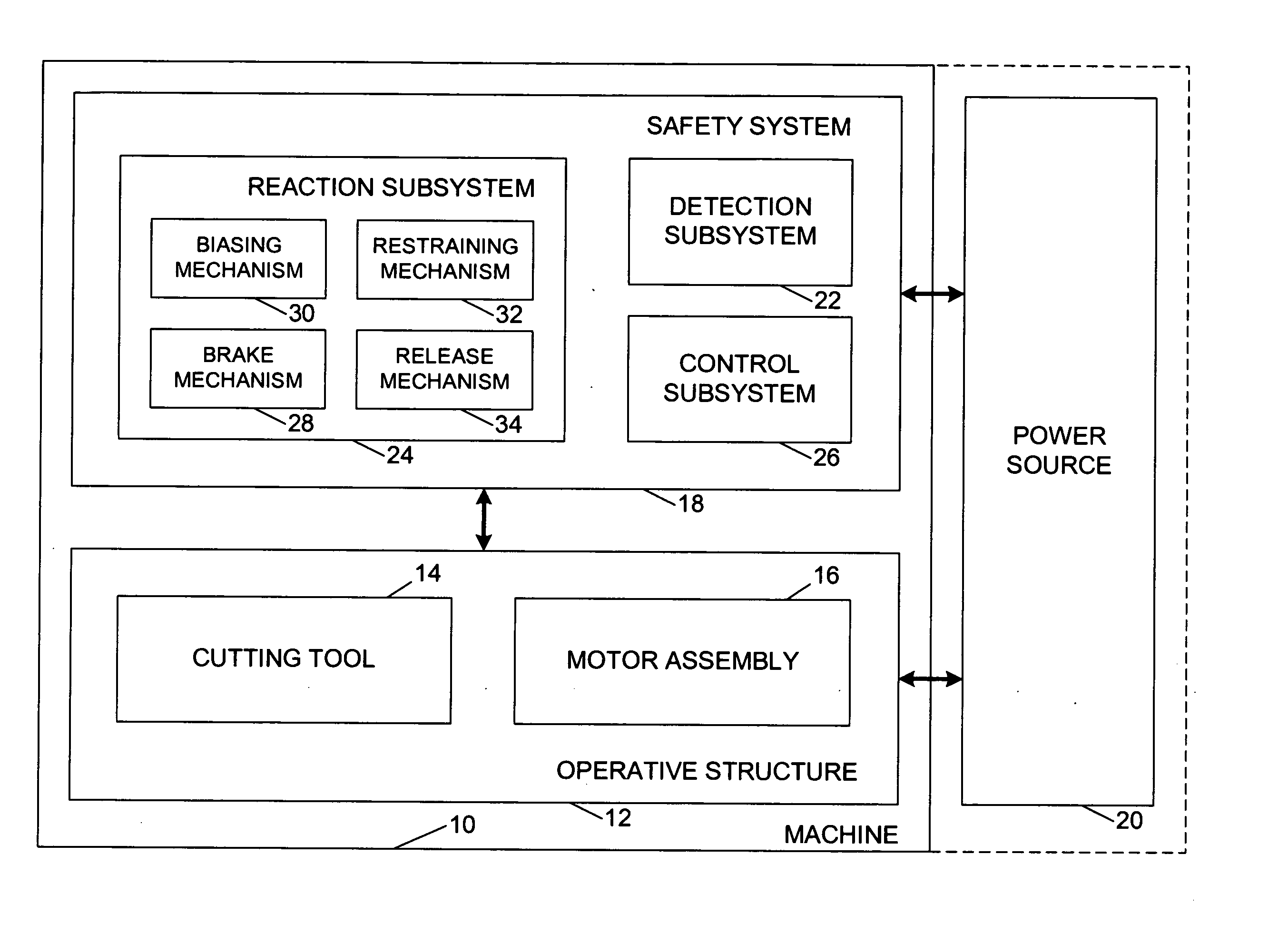

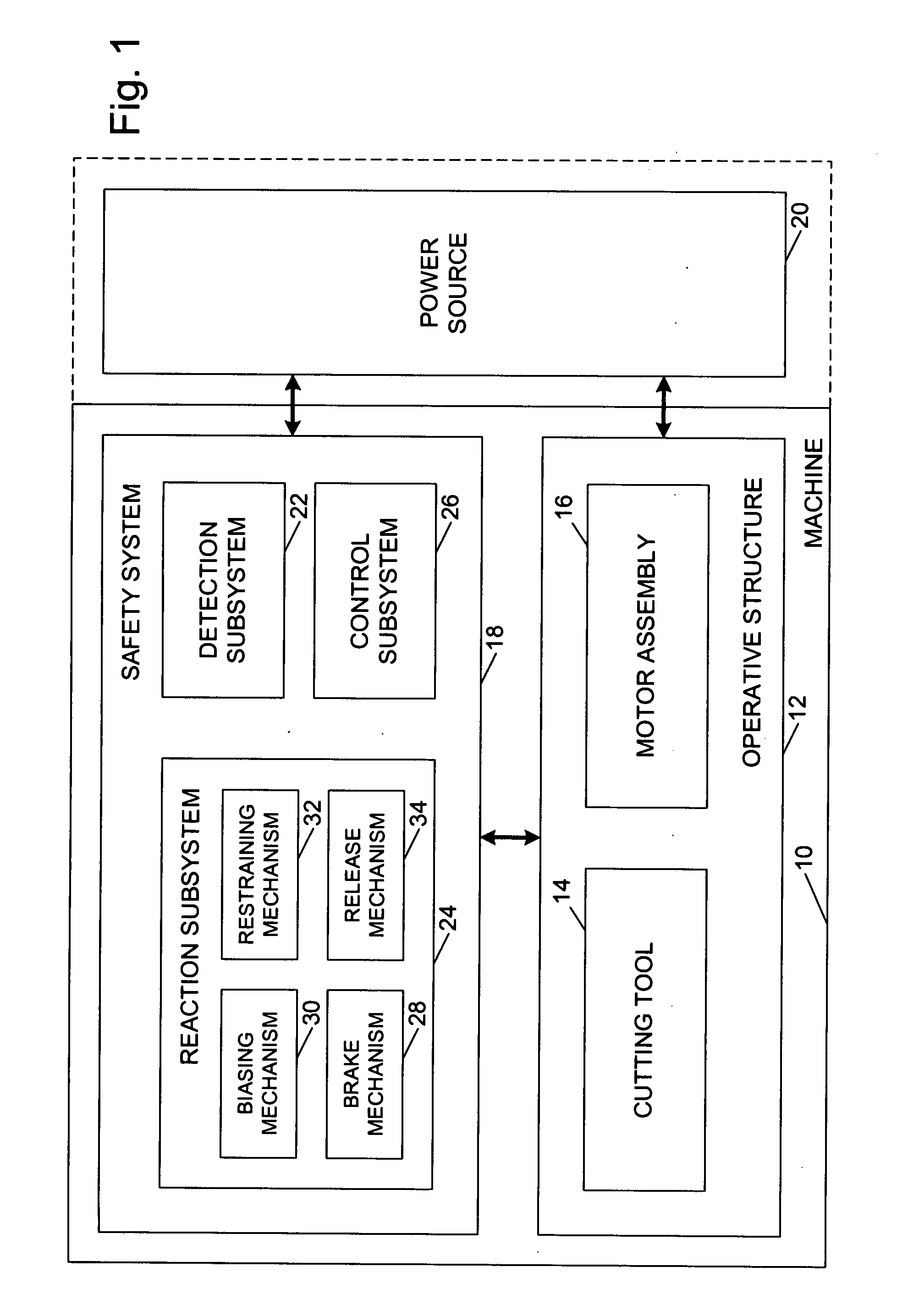

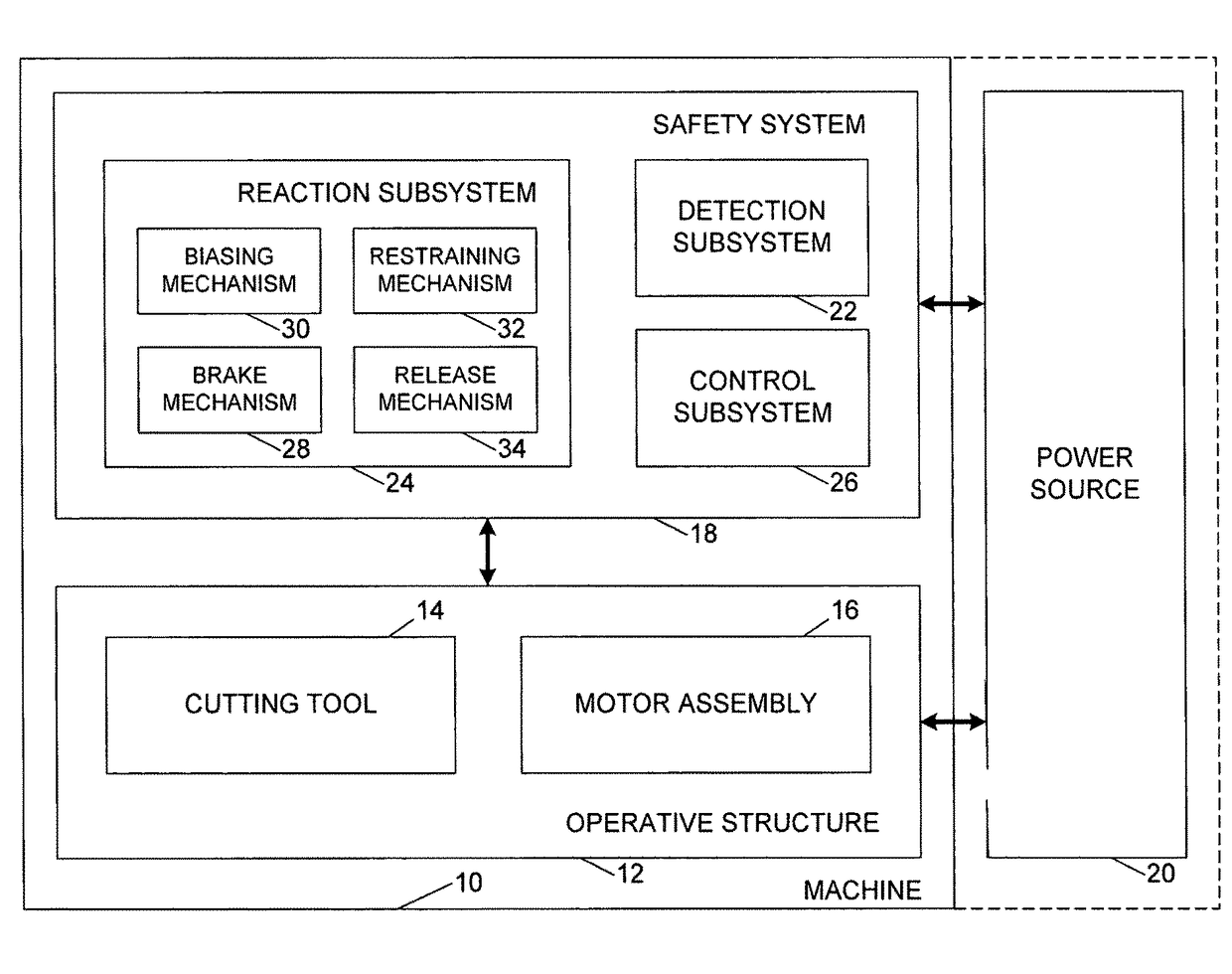

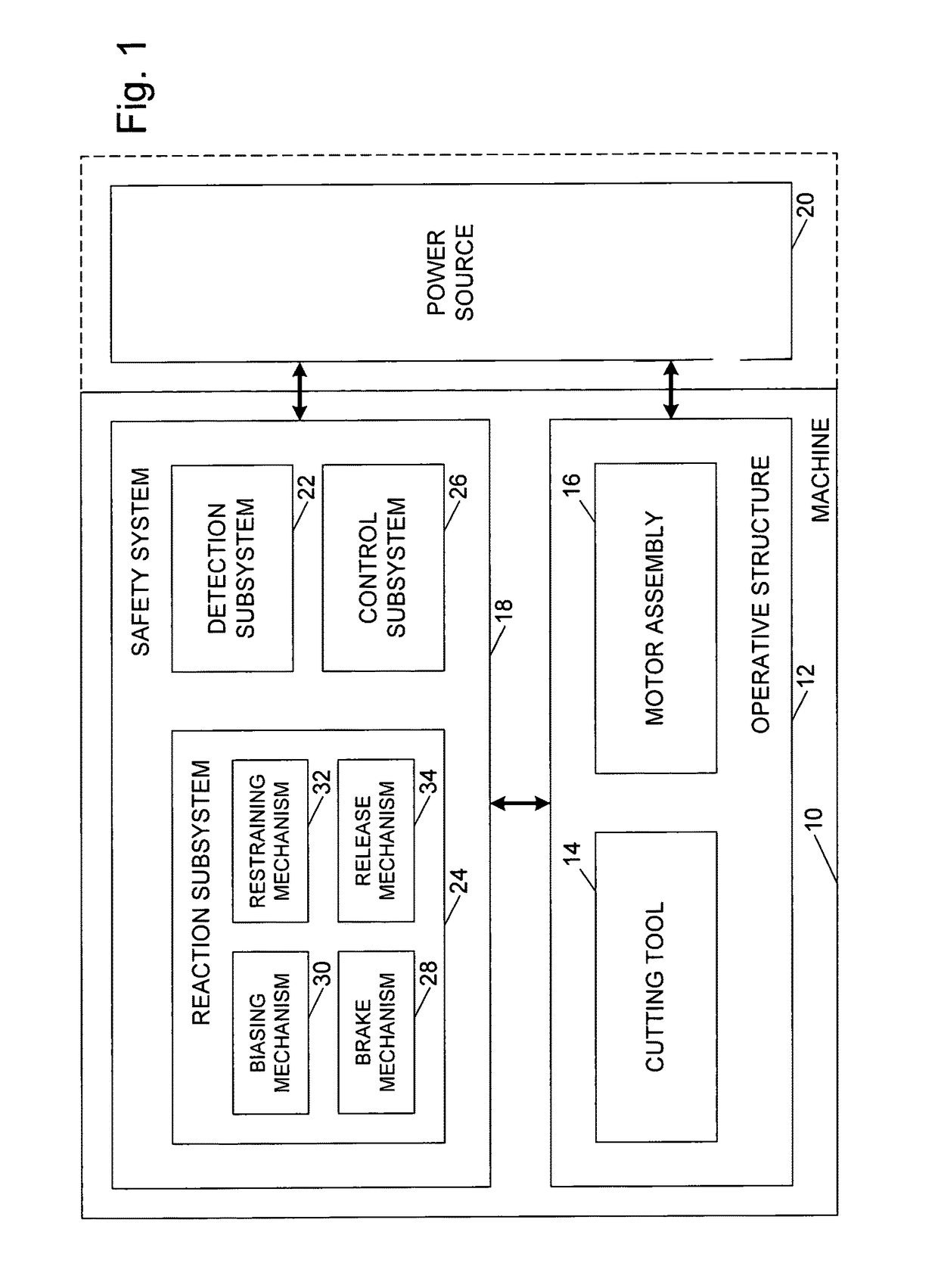

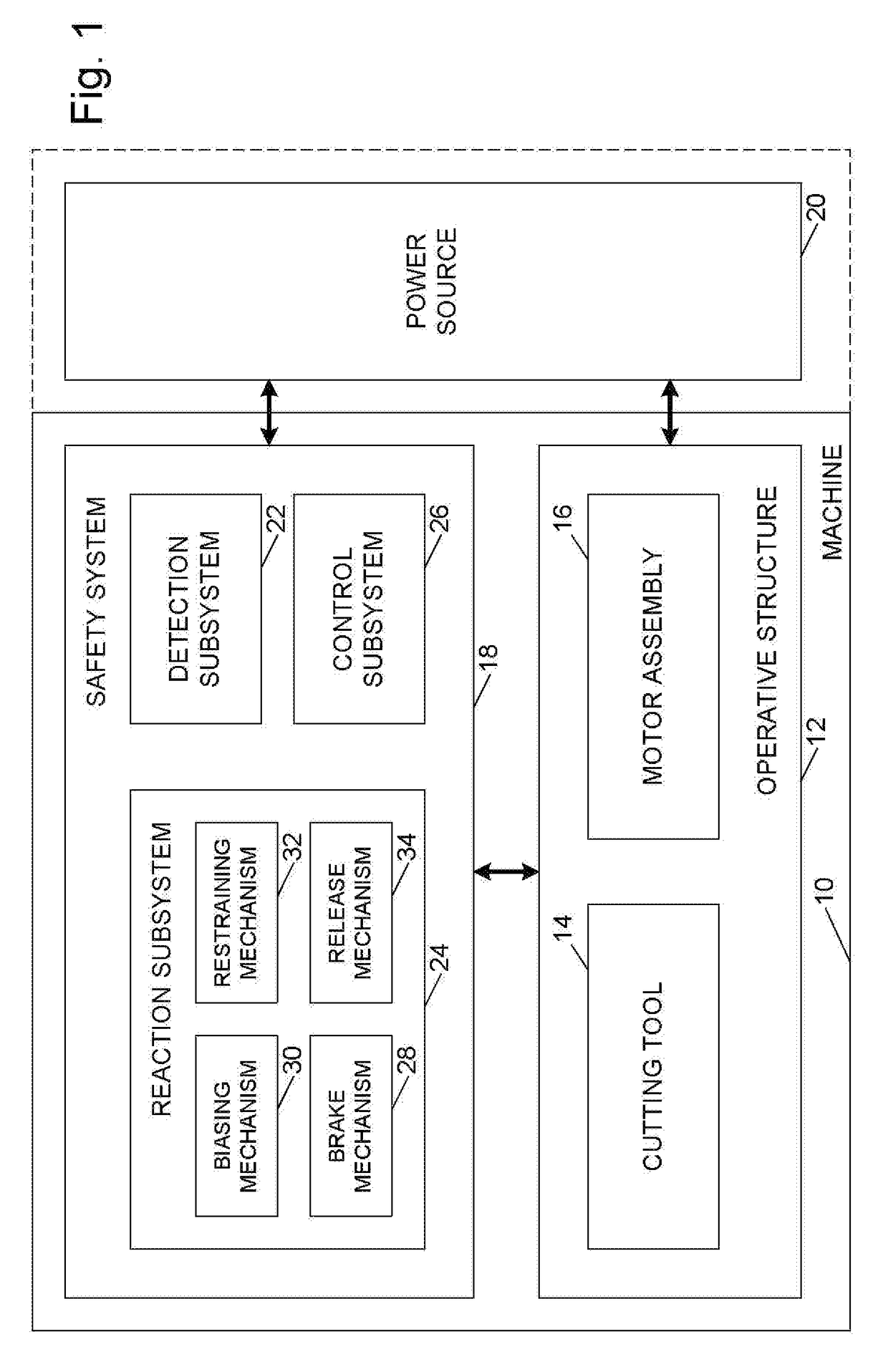

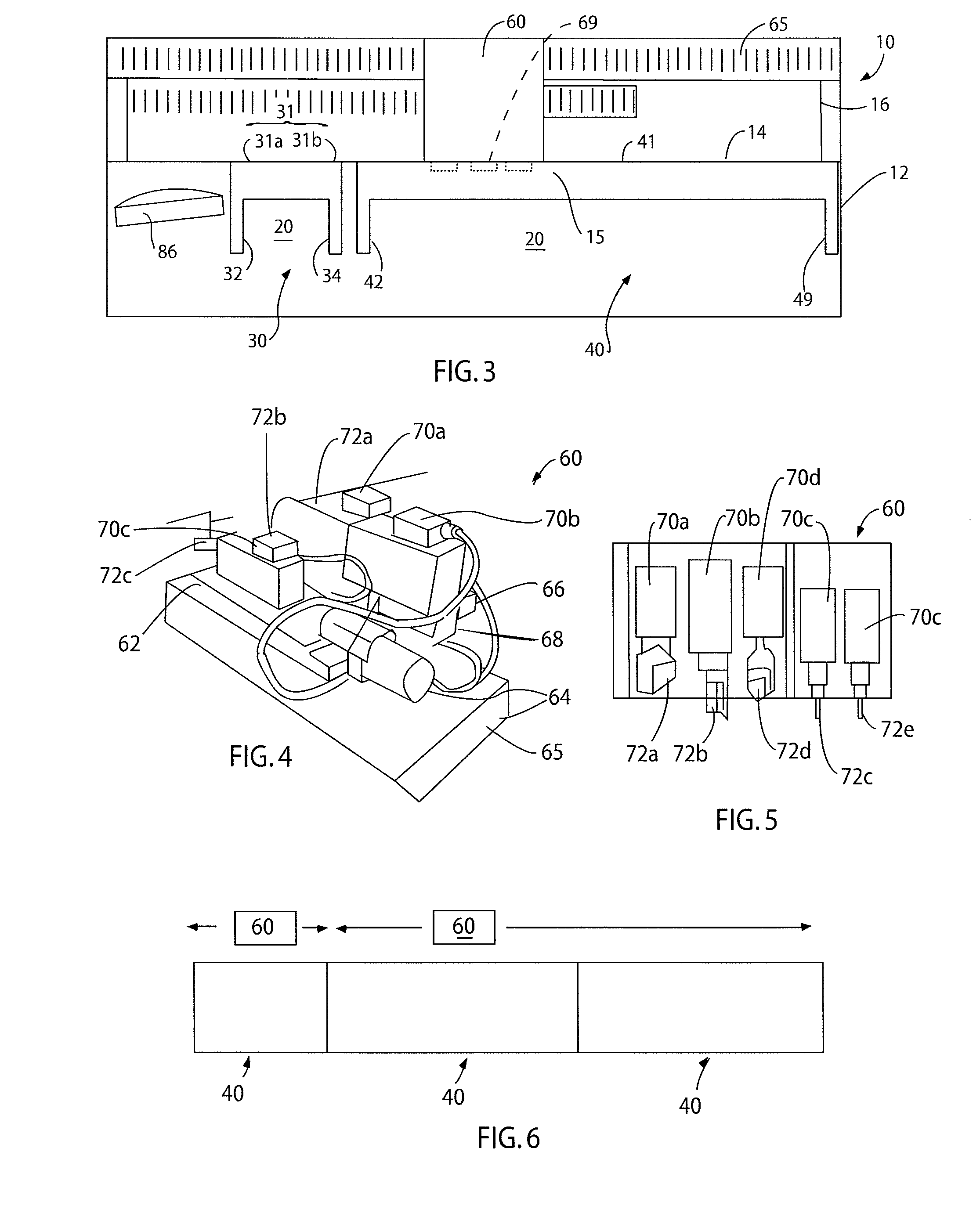

Safety systems for power equipment

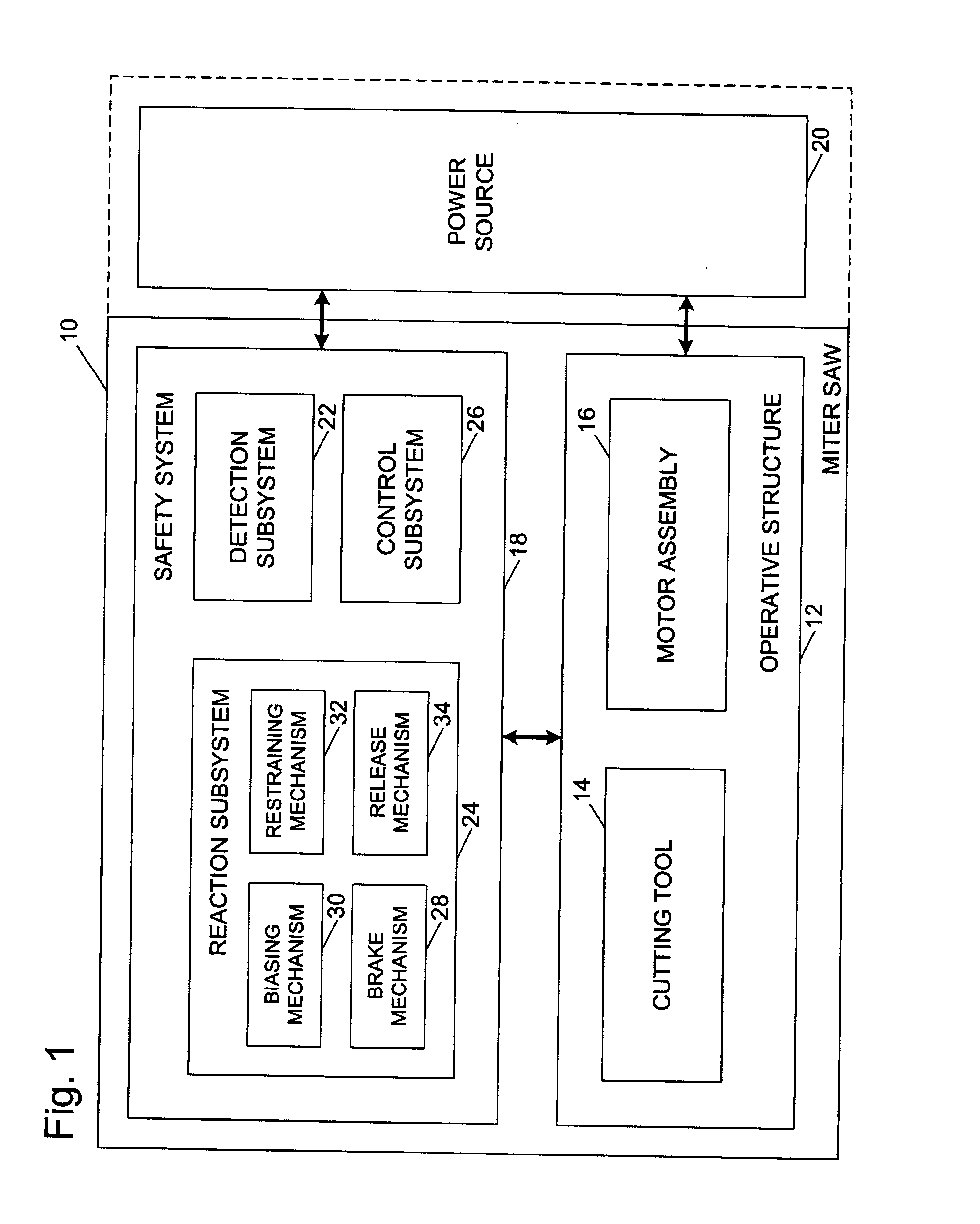

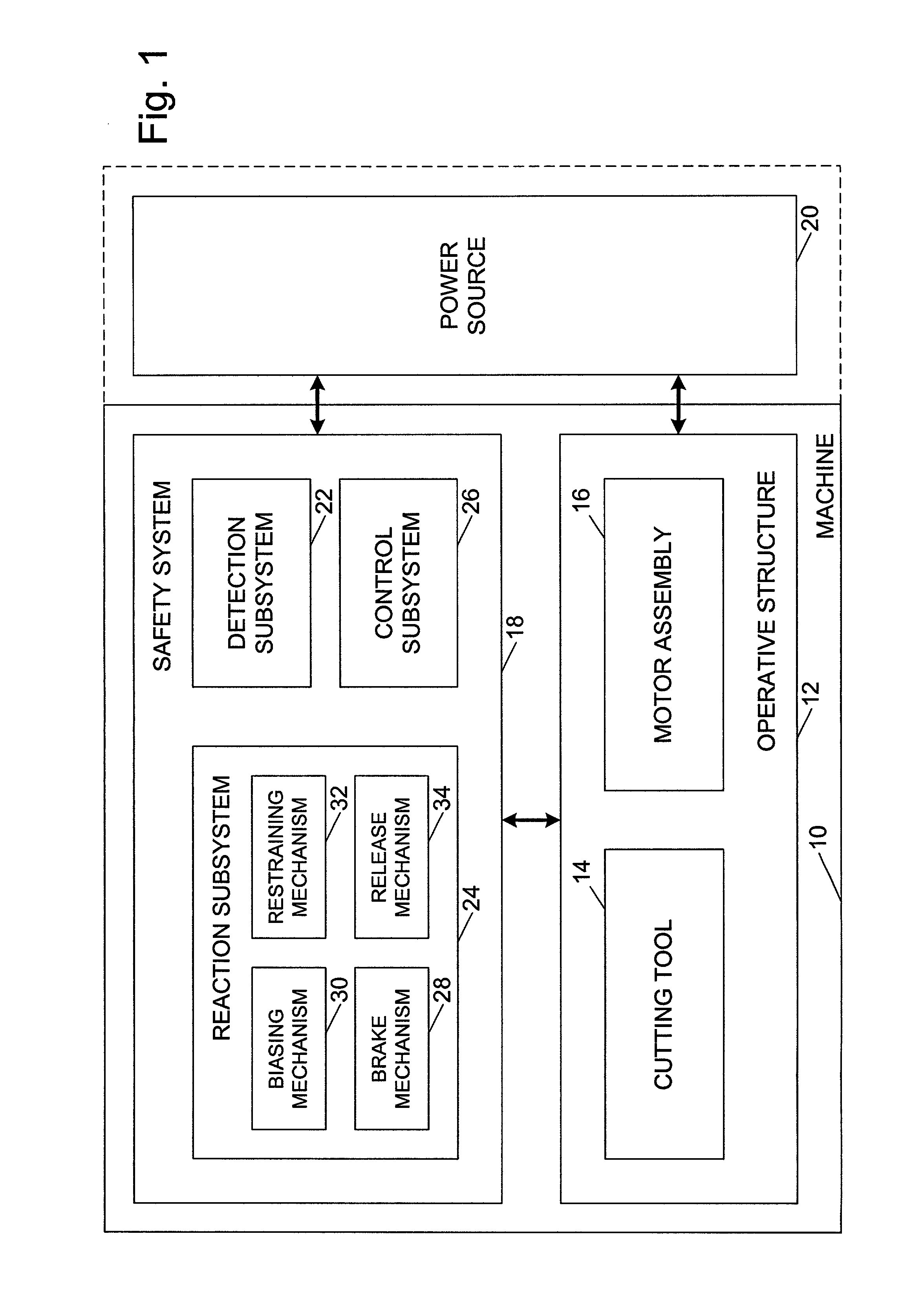

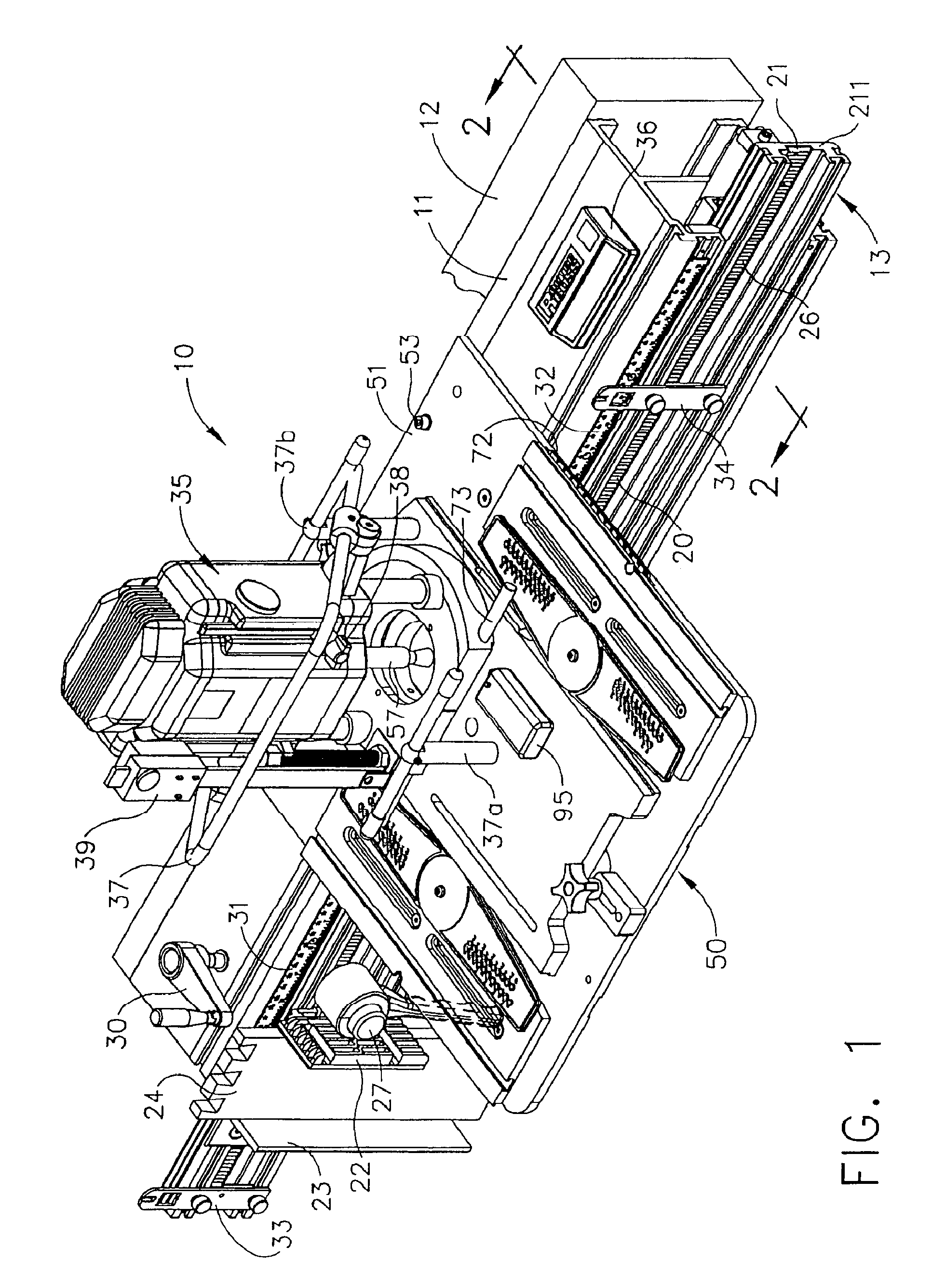

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

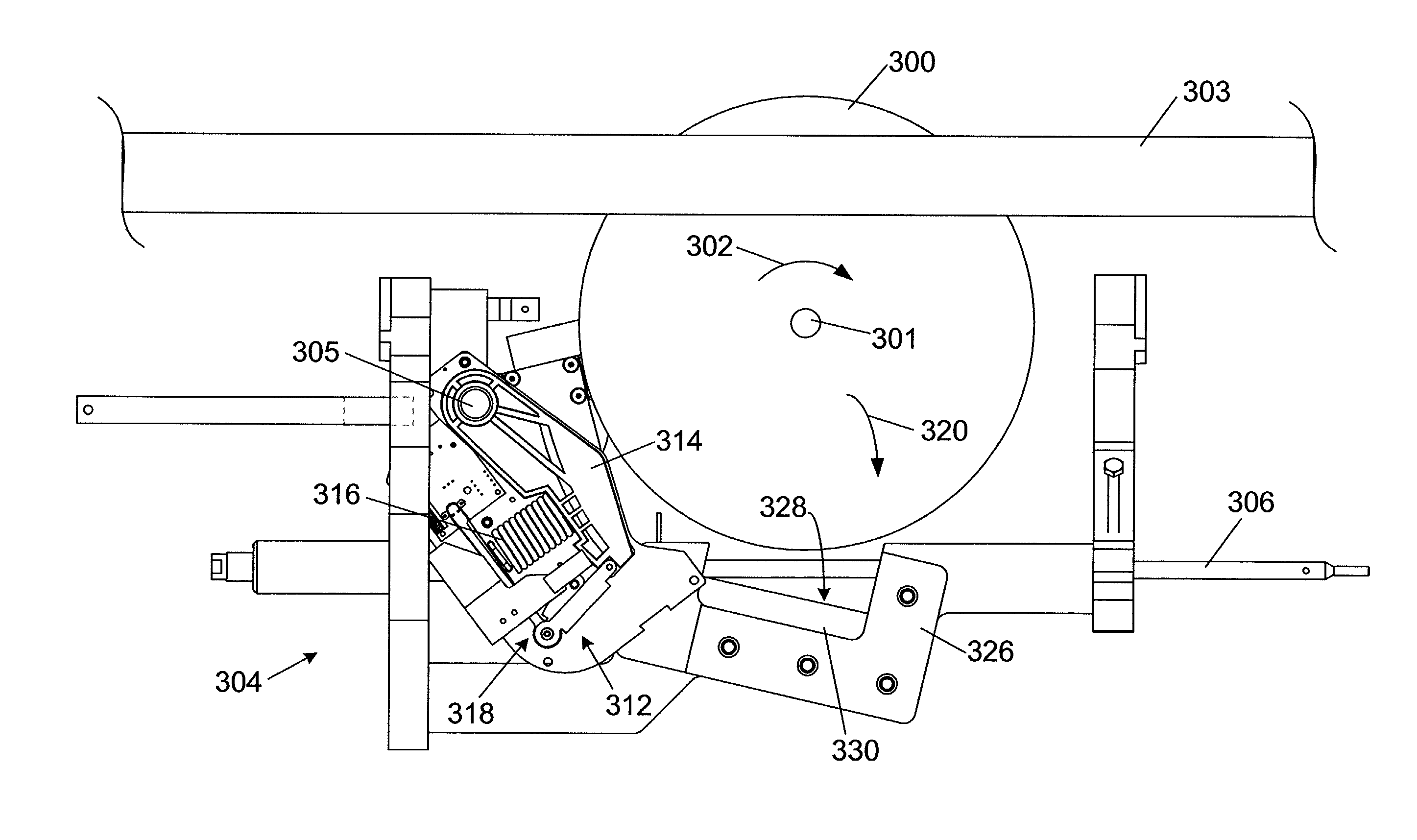

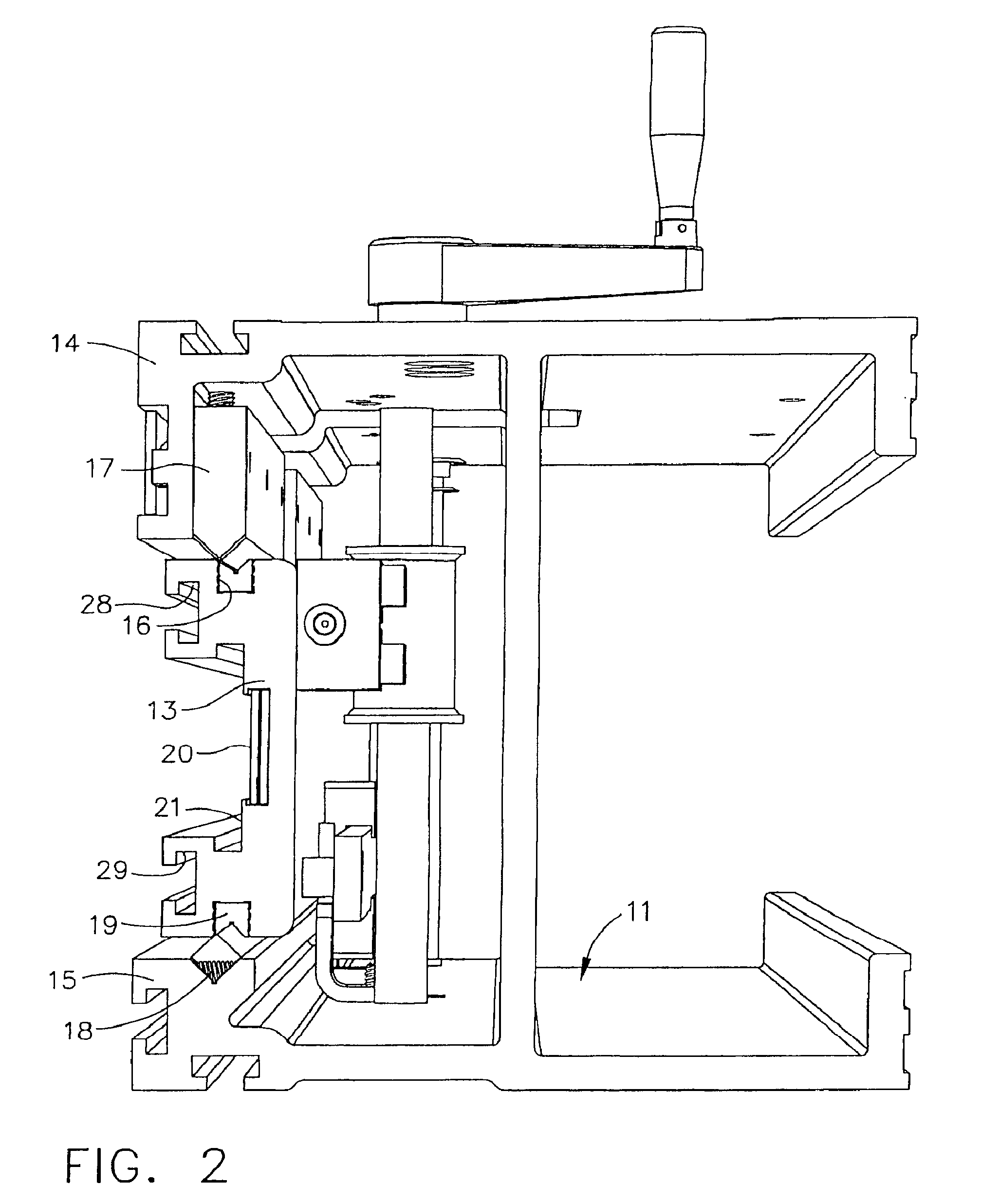

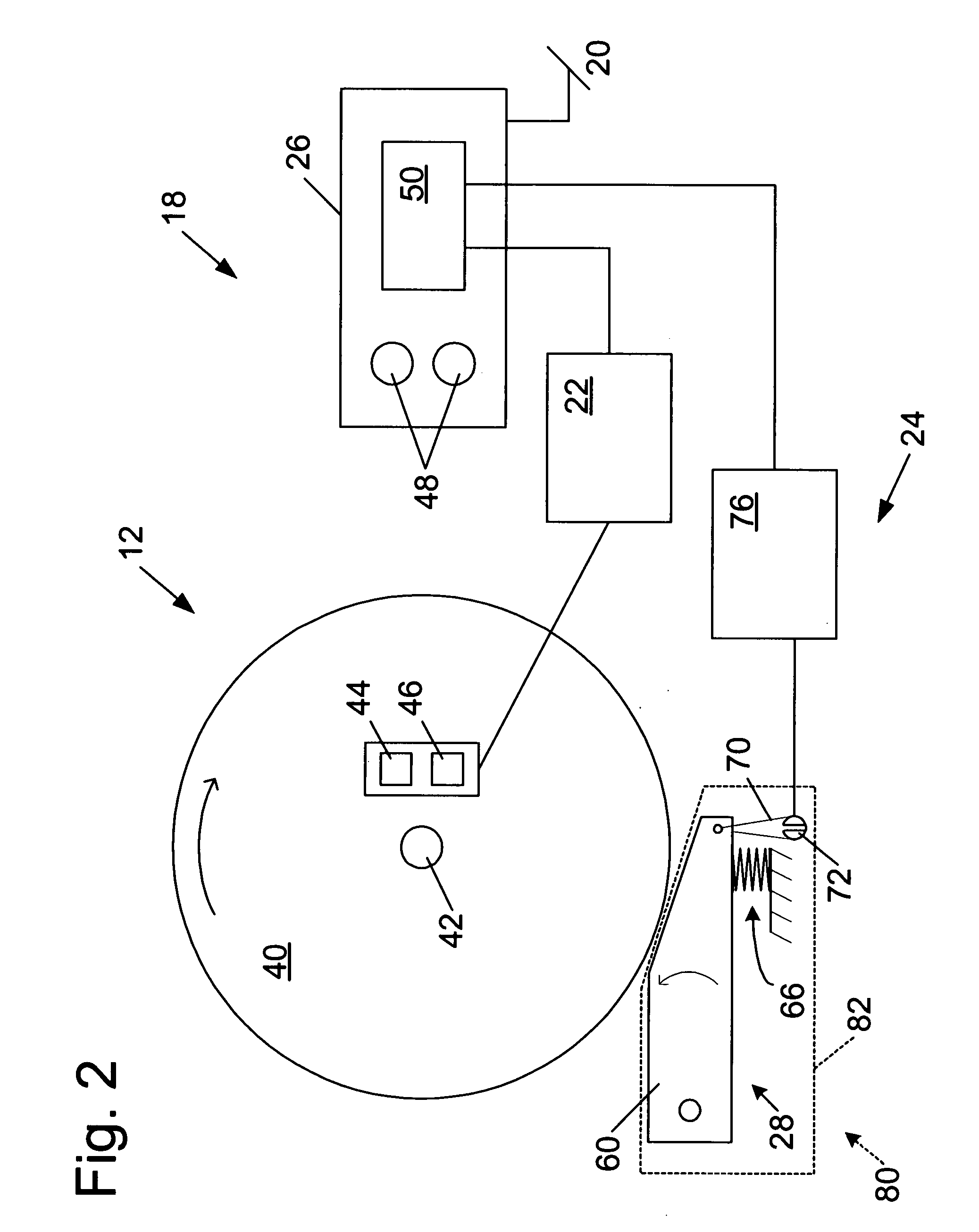

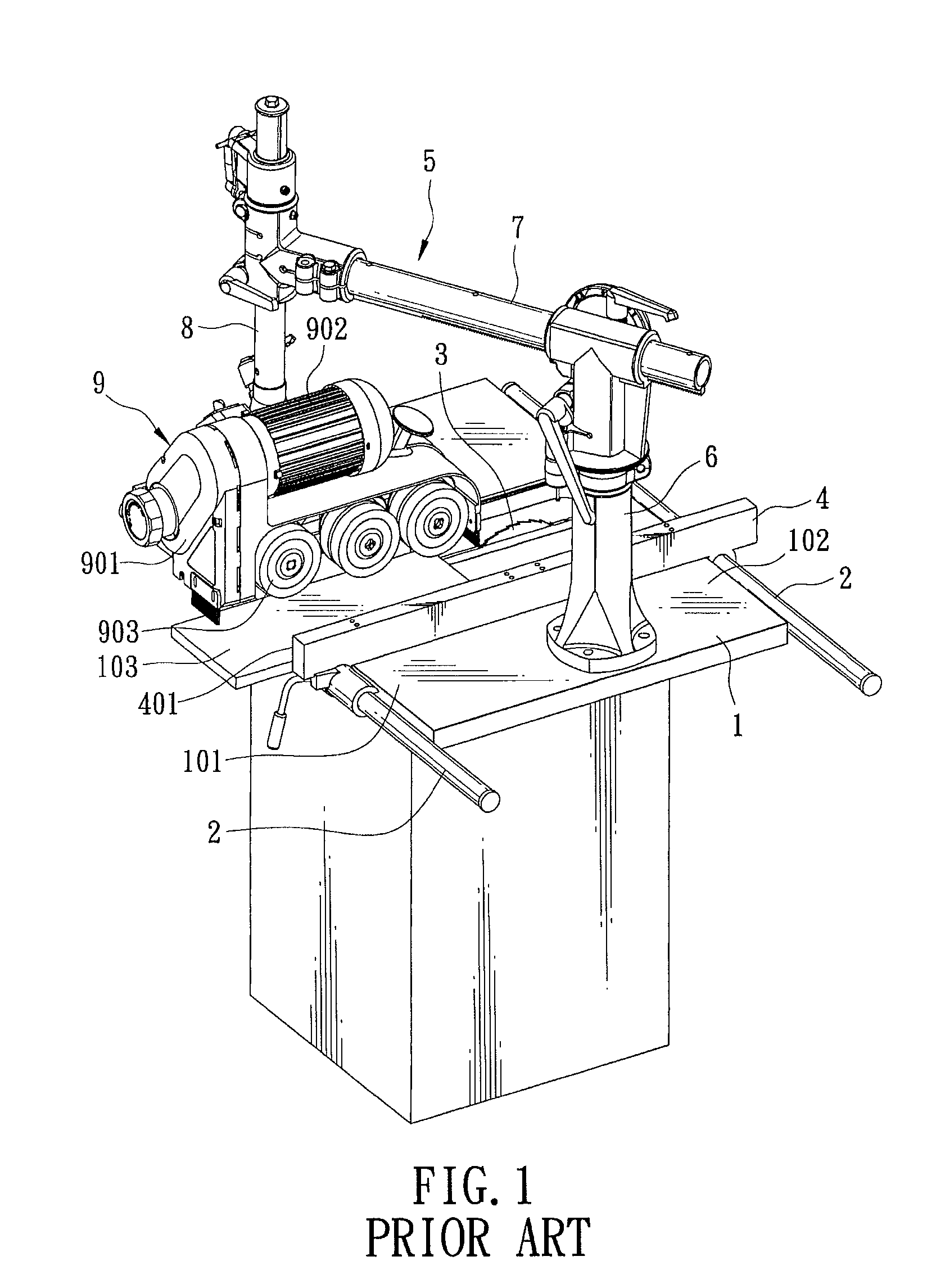

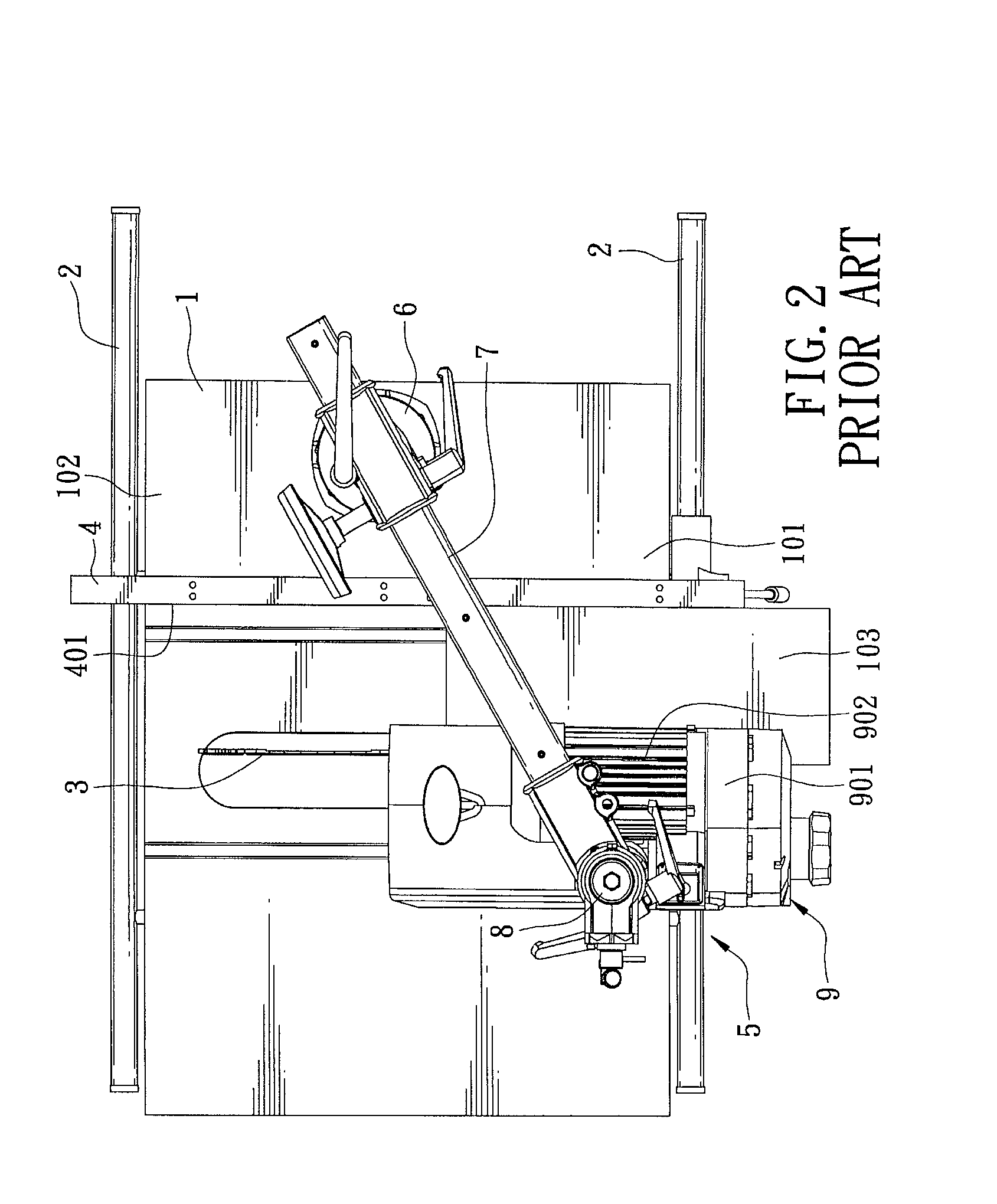

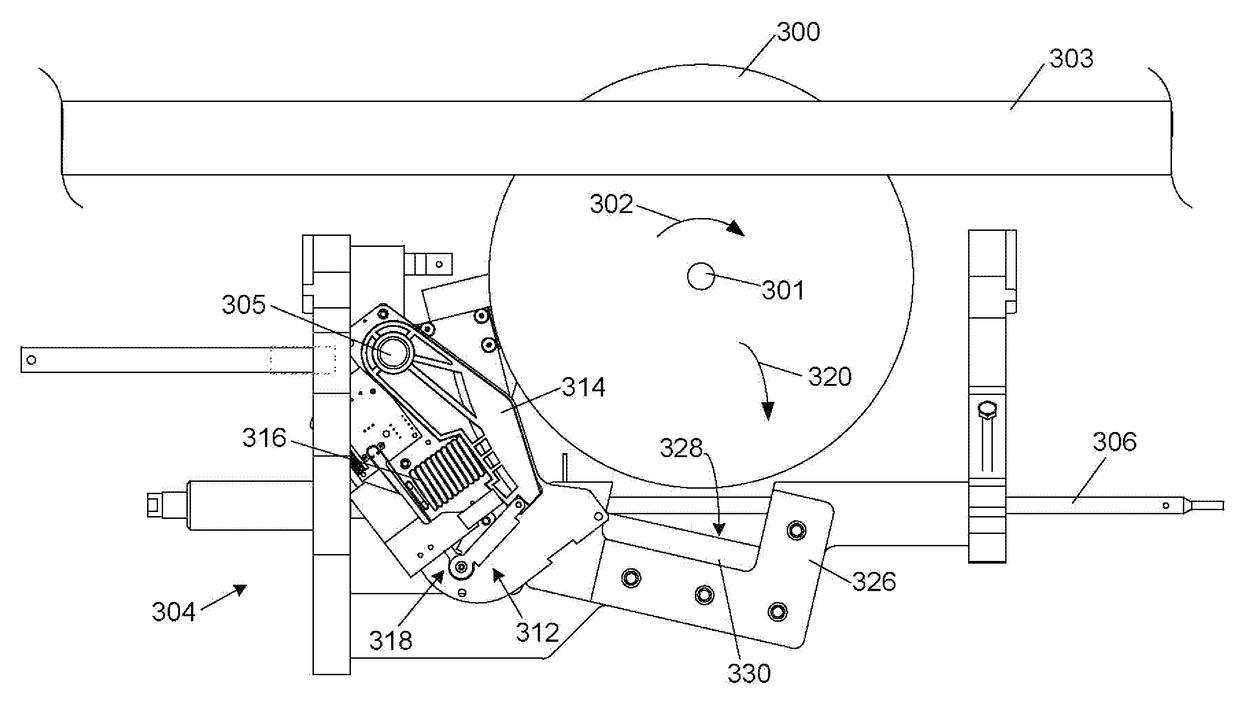

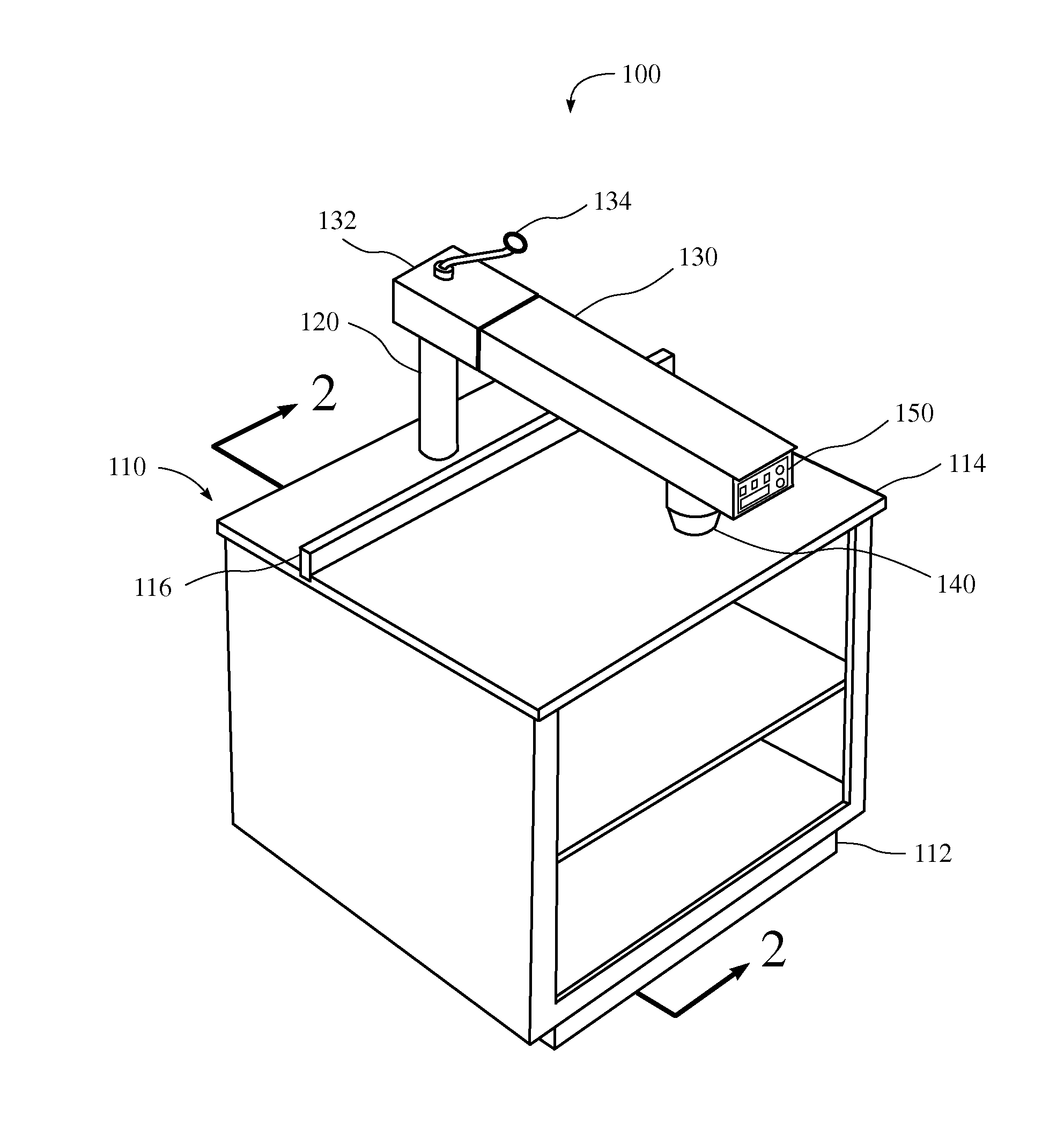

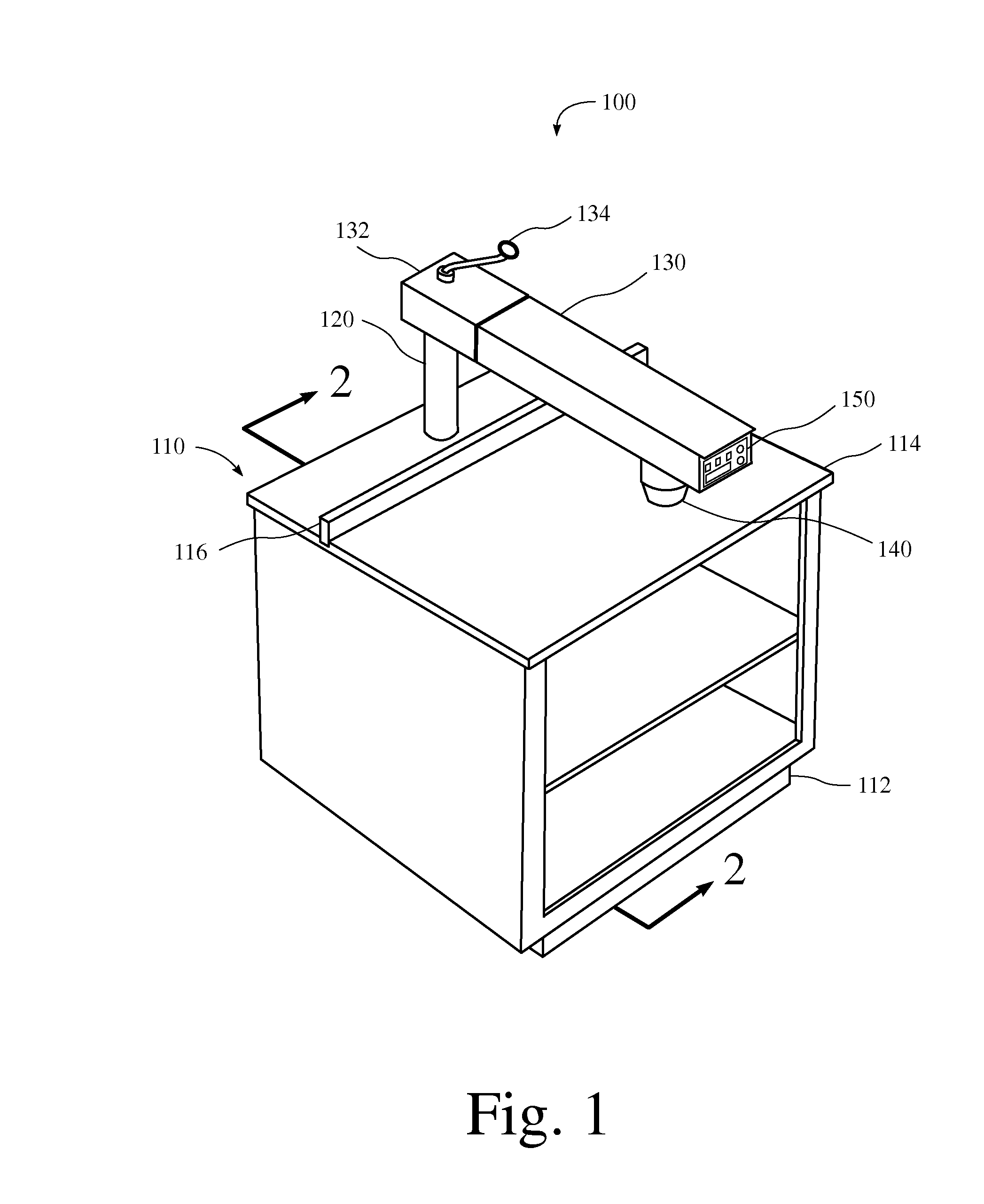

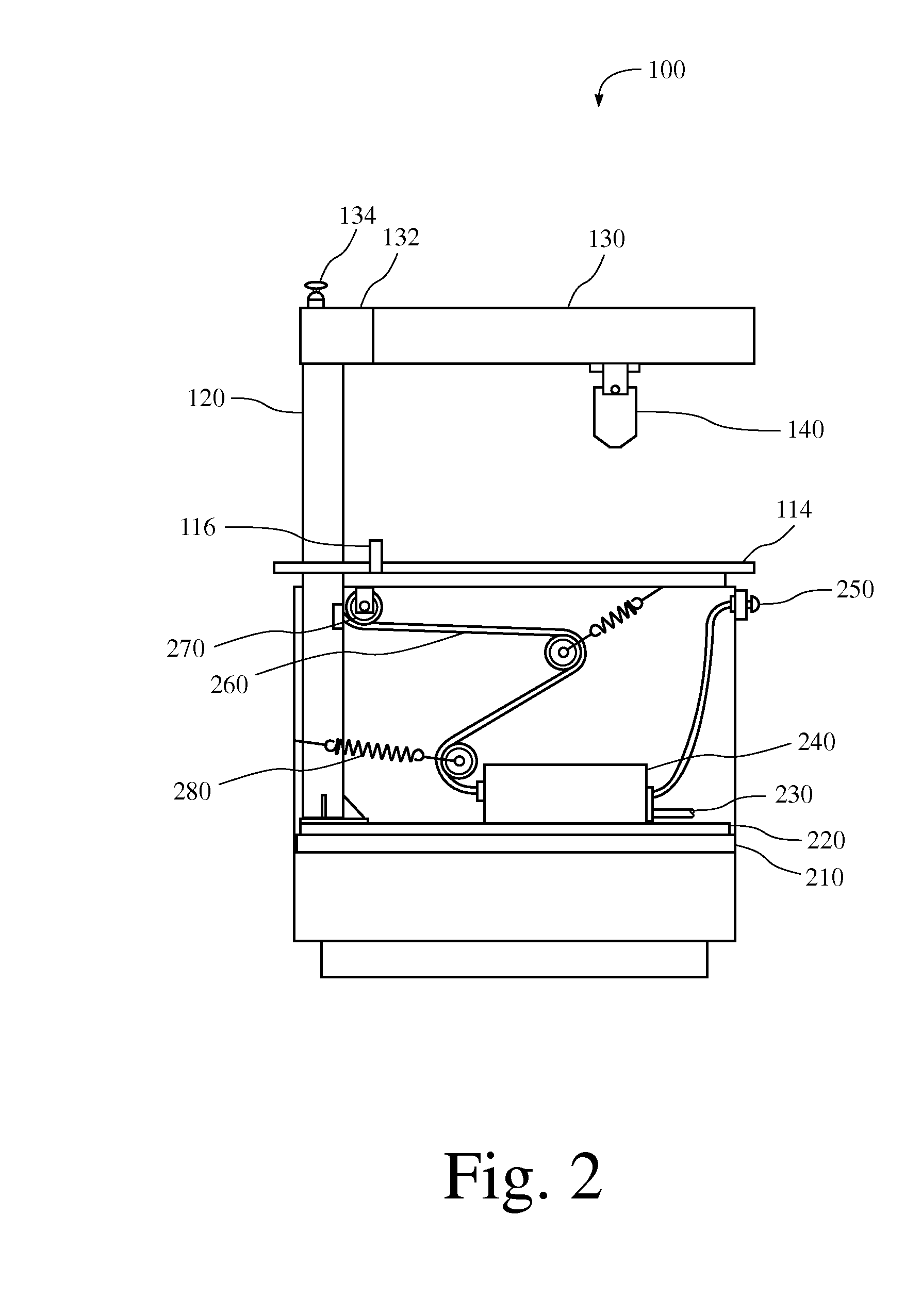

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

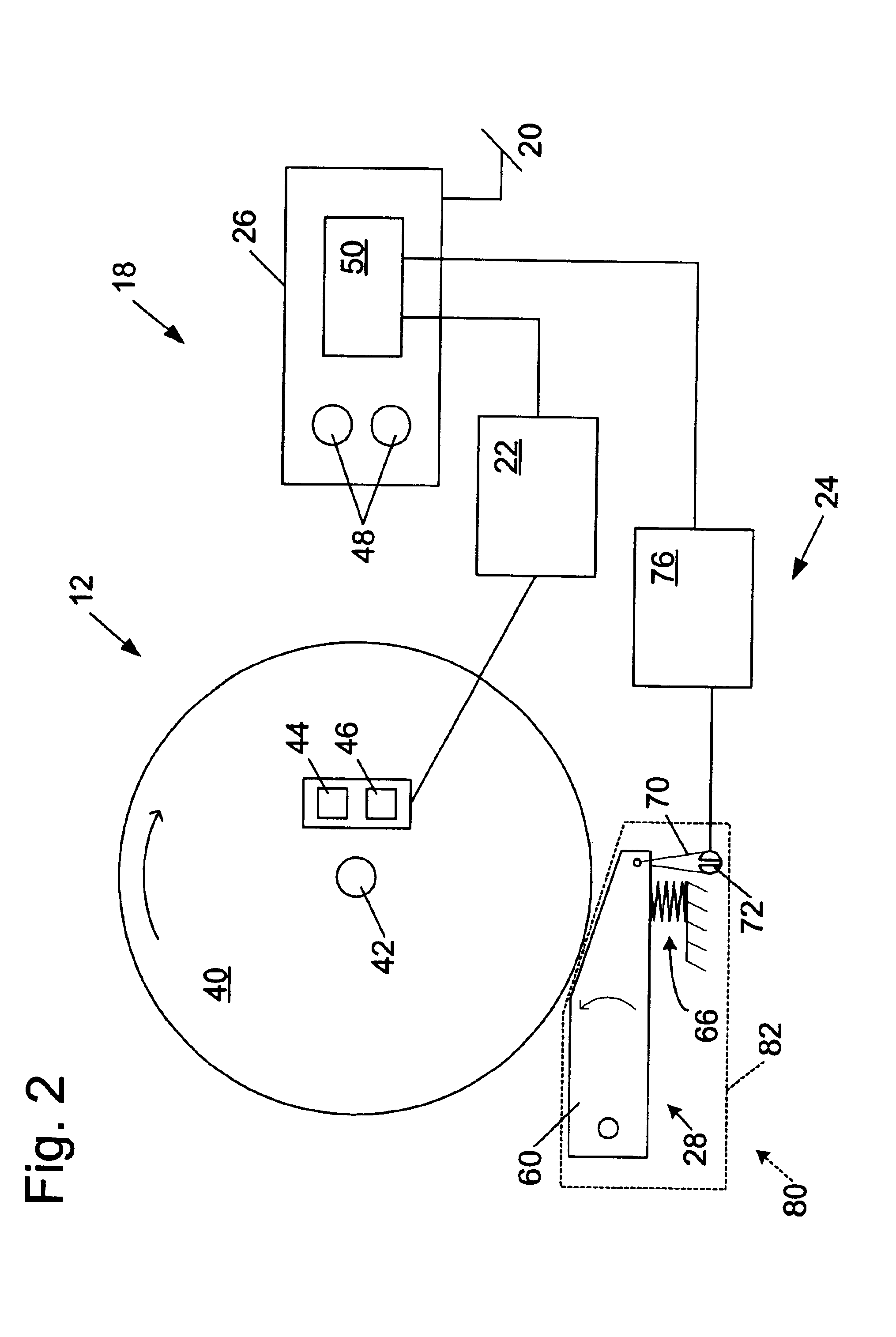

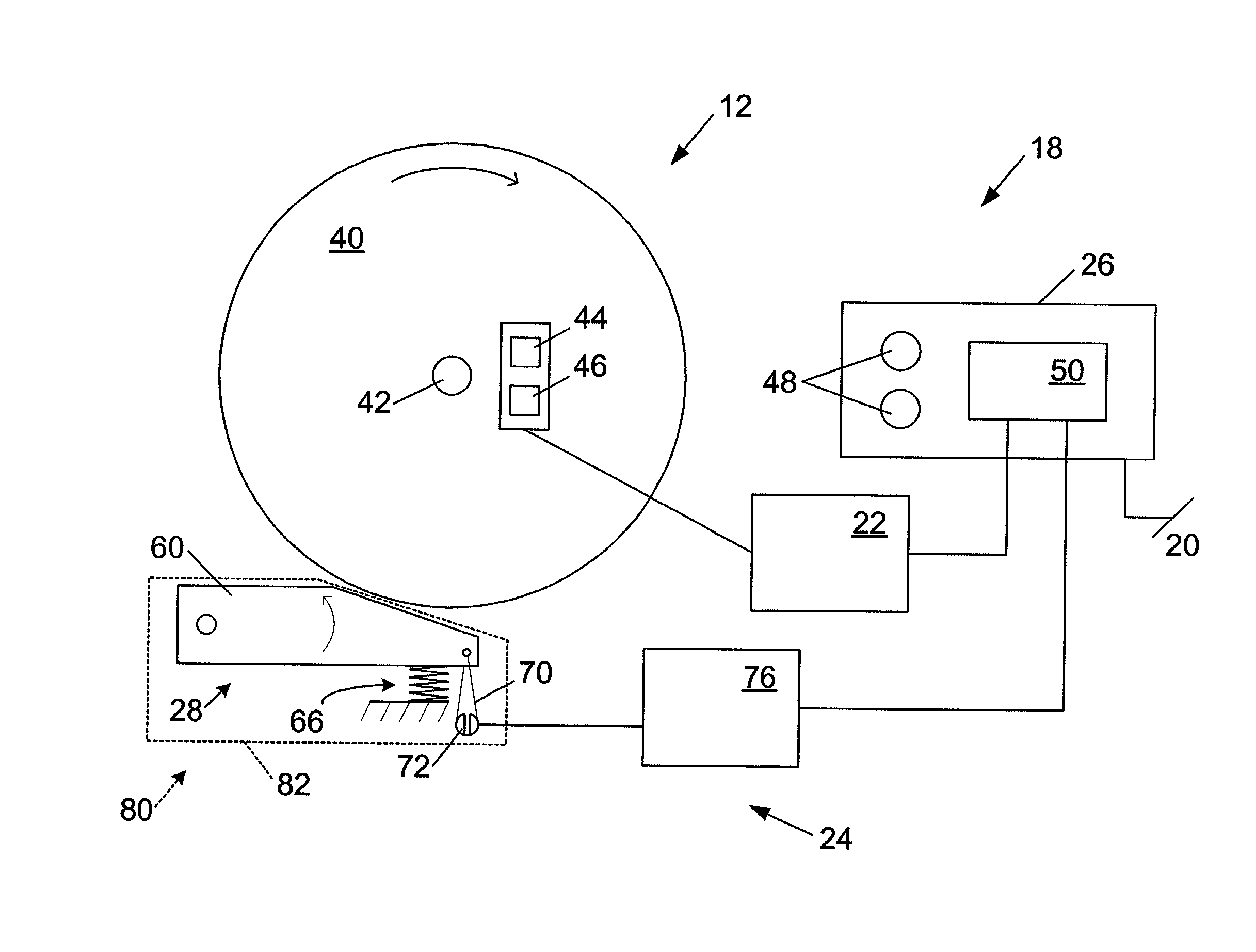

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

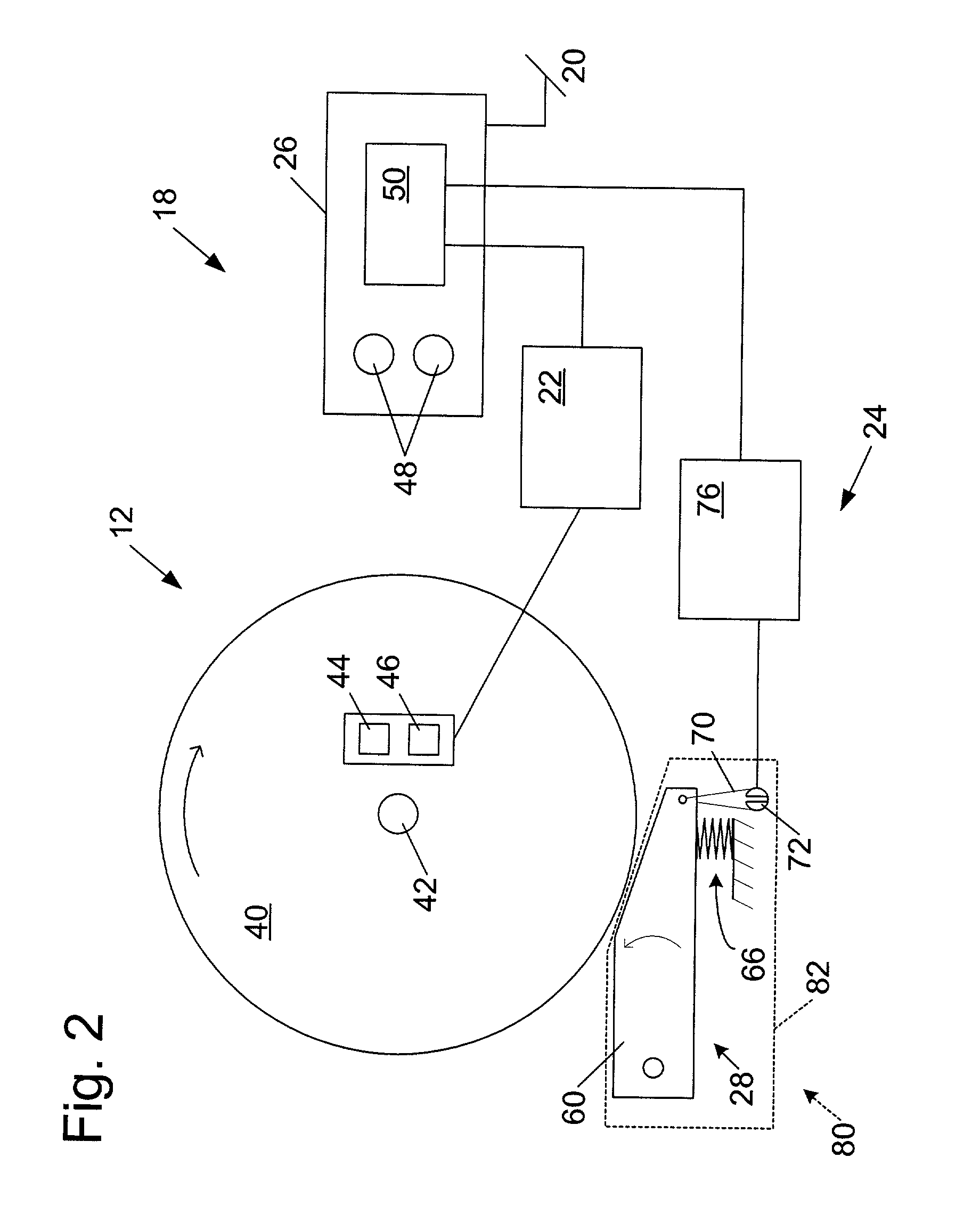

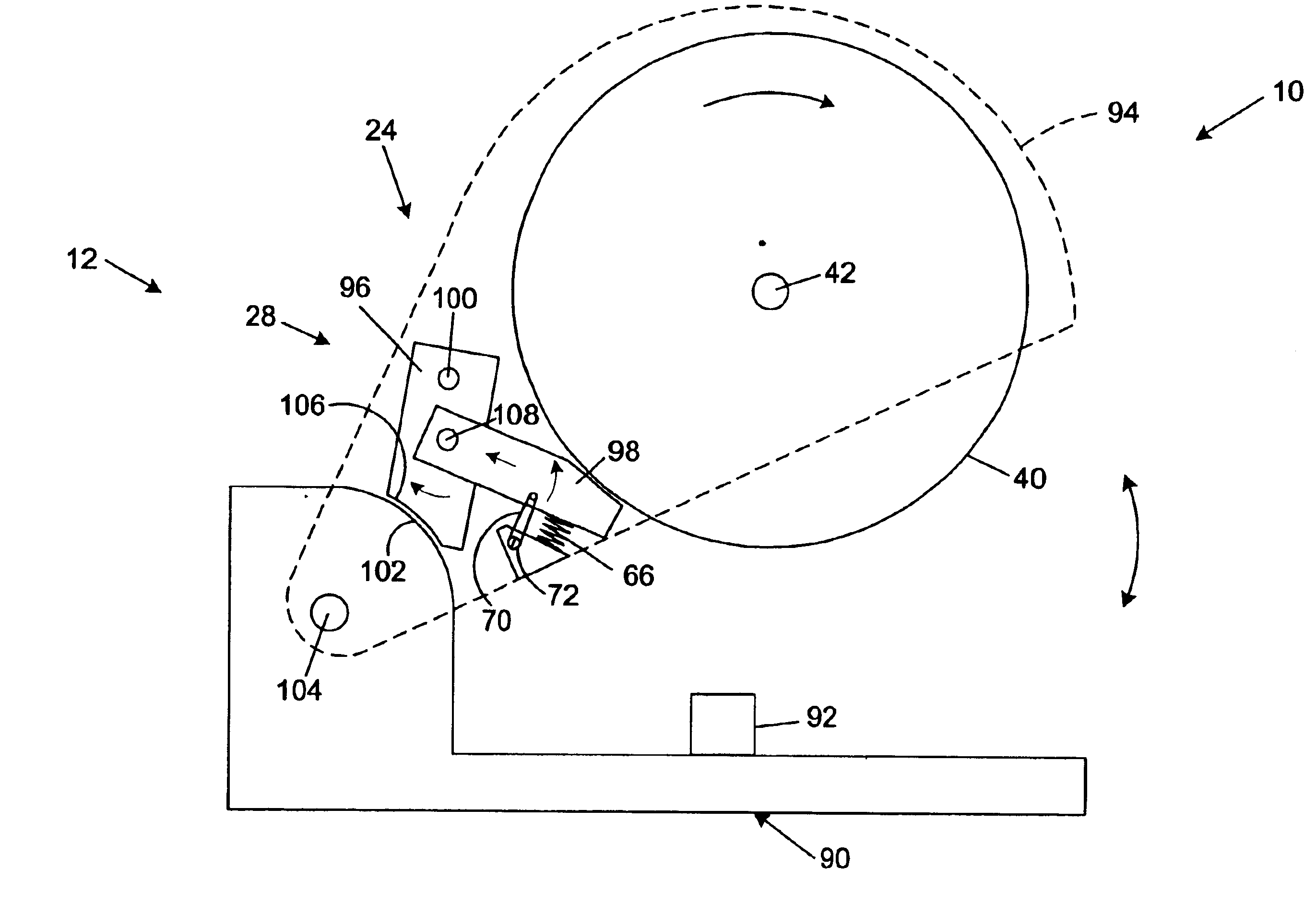

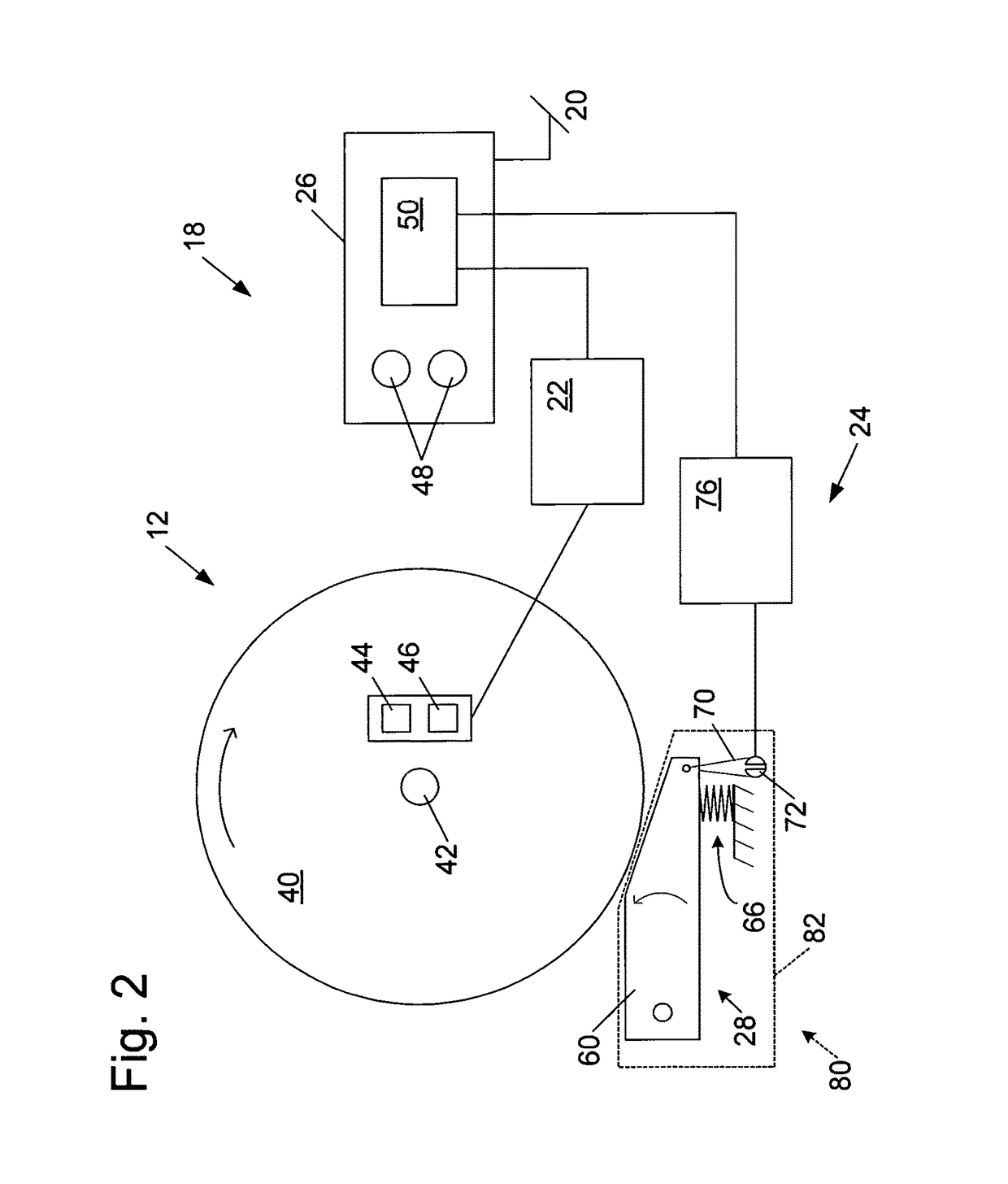

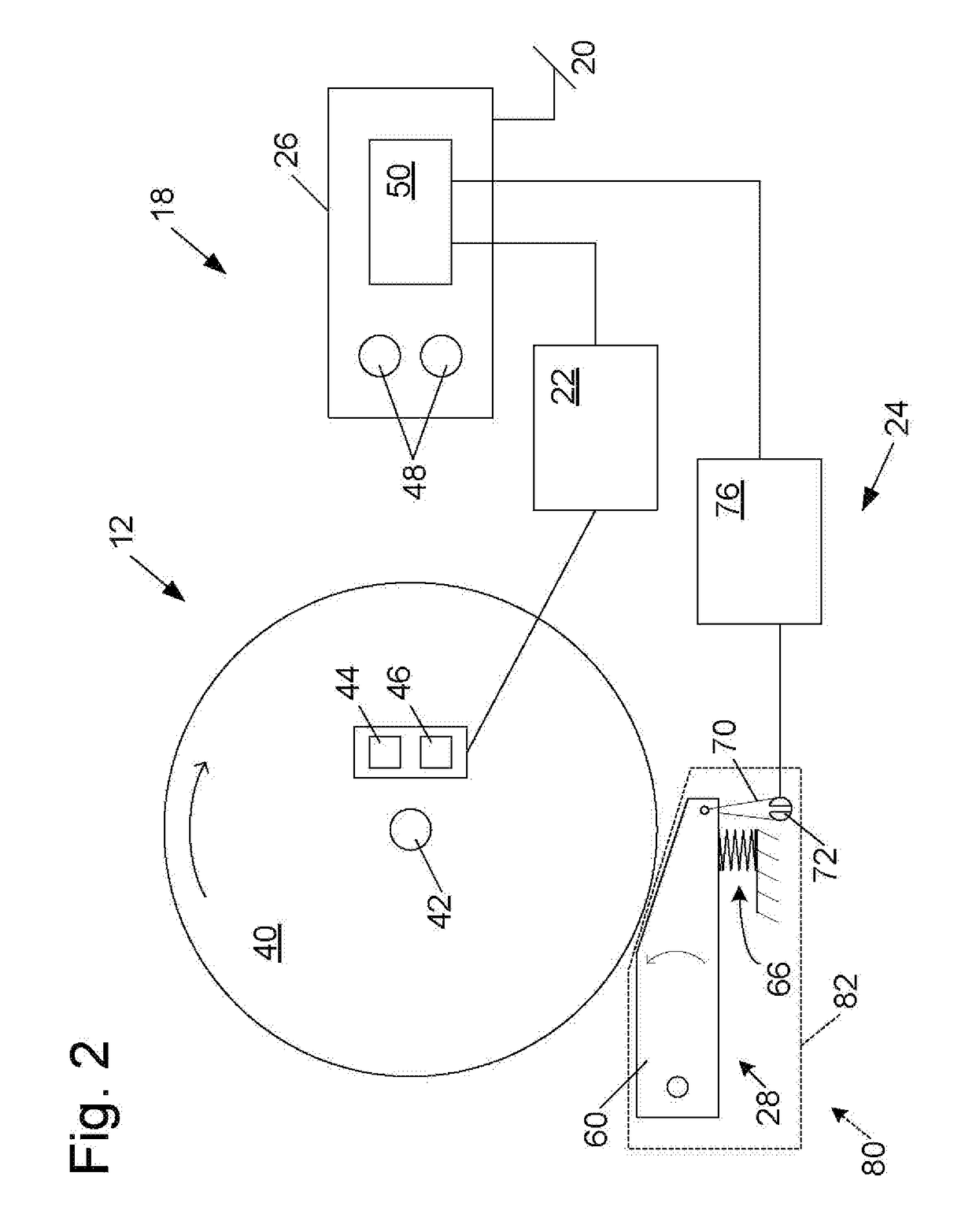

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

Contact detection system for power equipment

InactiveUS7377199B2Risk minimizationReduce riskMetal sawing devicesMetal sawing accessoriesPower equipmentEngineering

A woodworking machine having one or more dangerous portions of the machine is disclosed. The machine also includes a safety system configured to detect accidental contact between a person and at least one of the dangerous portions by electrically coupling a signal to the person's body, and detecting if the signal becomes coupled to the dangerous portion.

Owner:SAWSTOP HLDG LLC

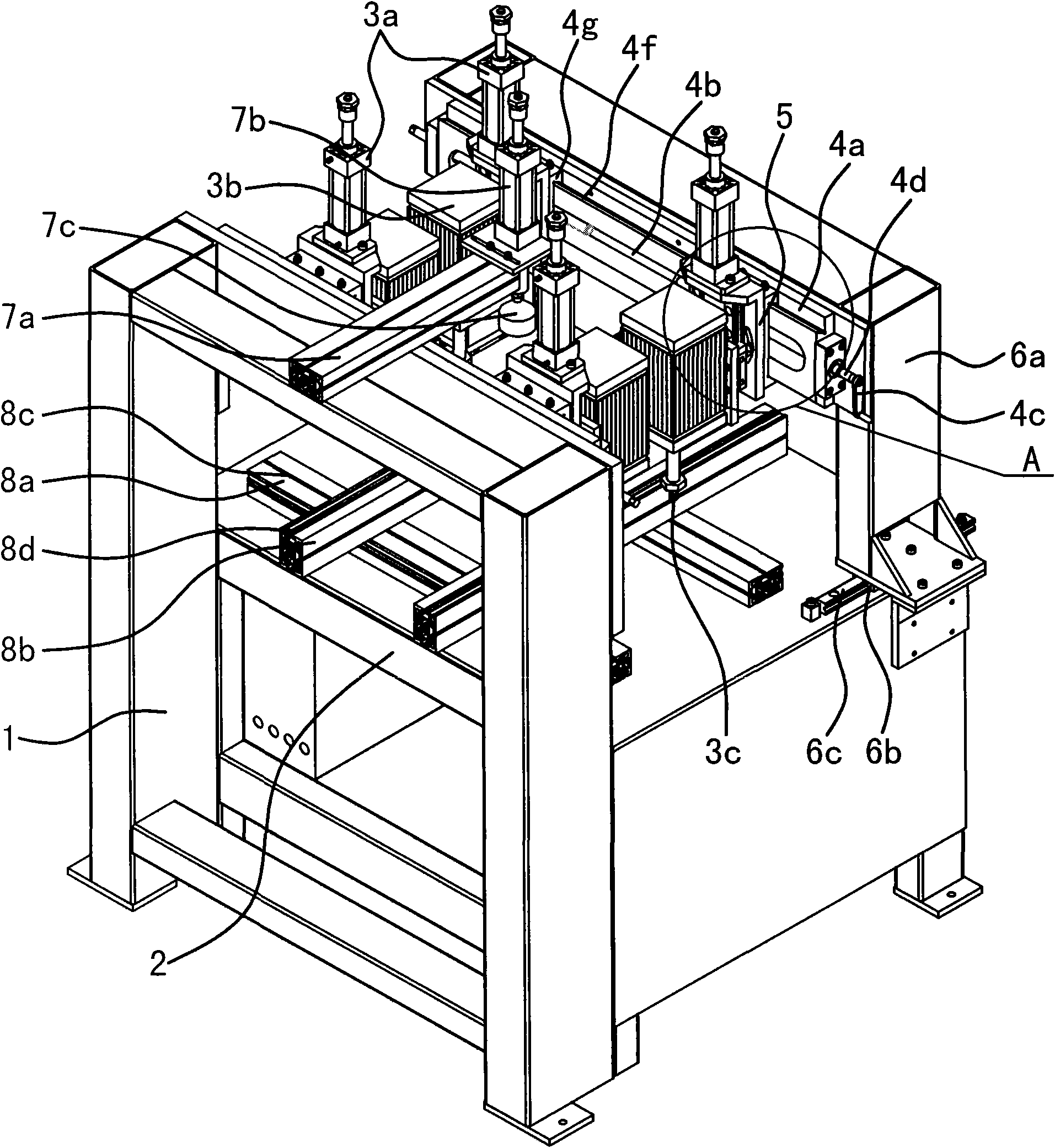

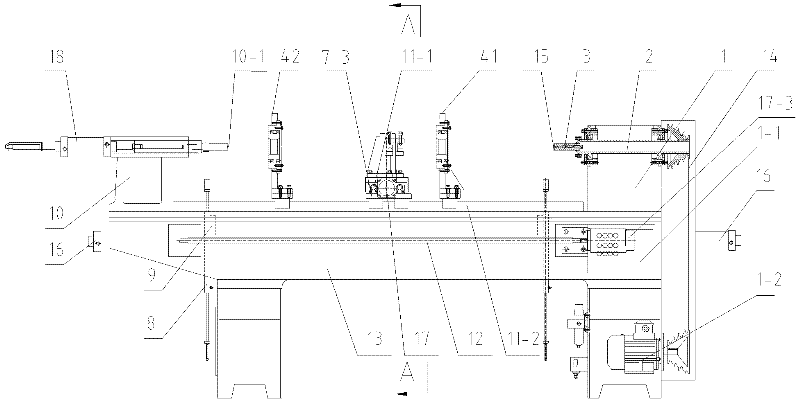

Automatic woodworking machine

InactiveCN103481335AImprove machining accuracyHigh degree of automationMulti-purpose machinesWoodworking machineServomotor

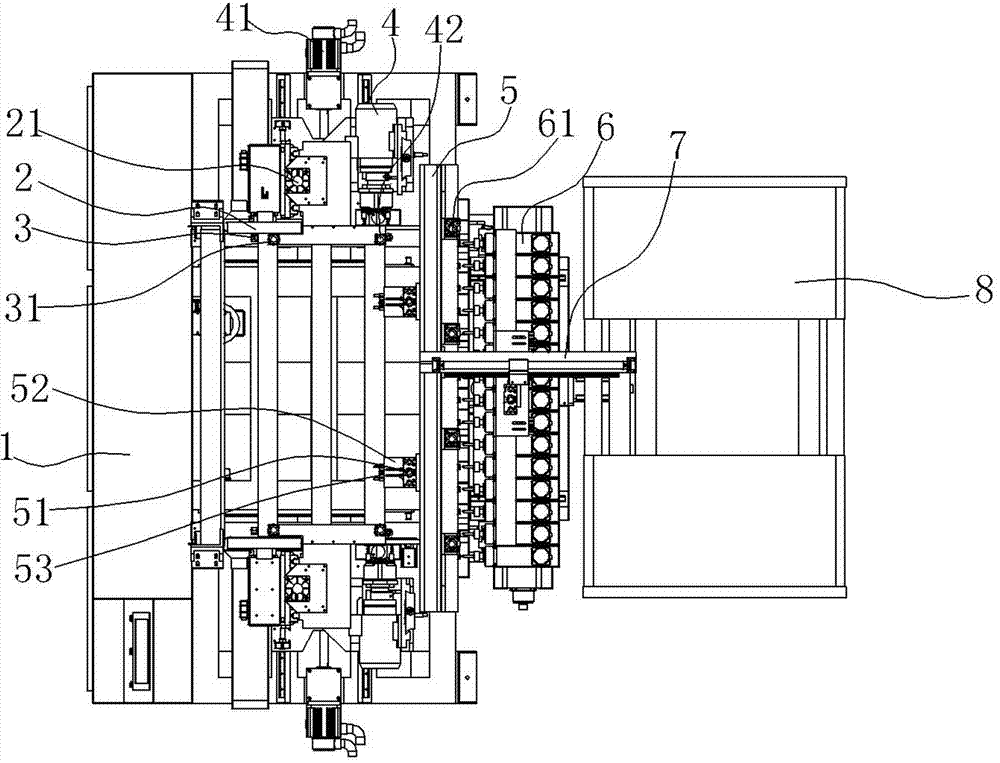

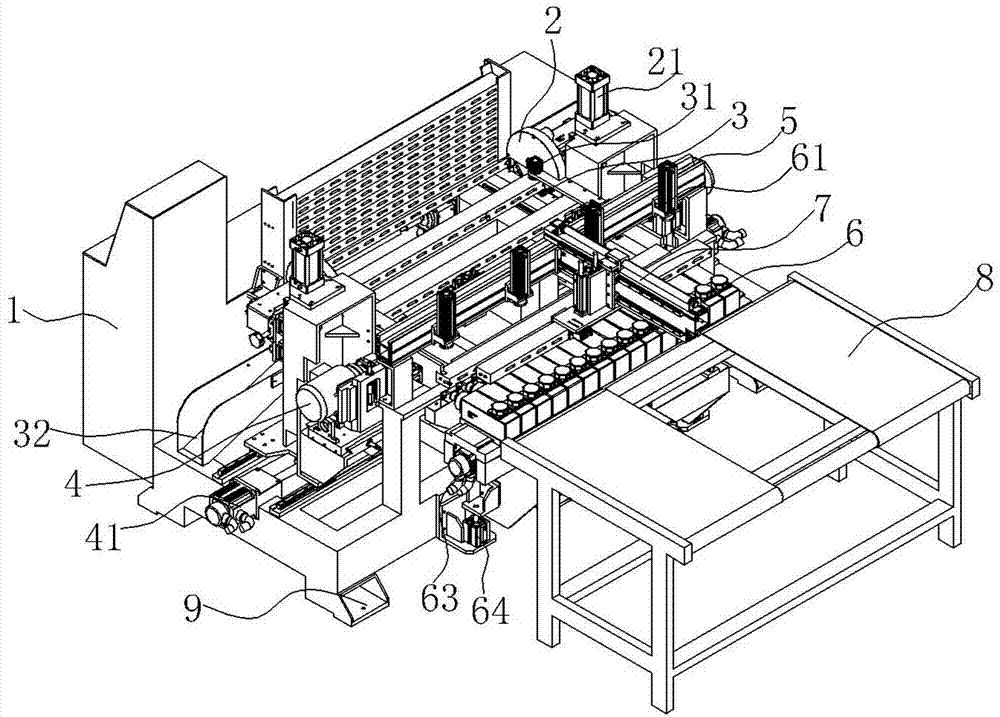

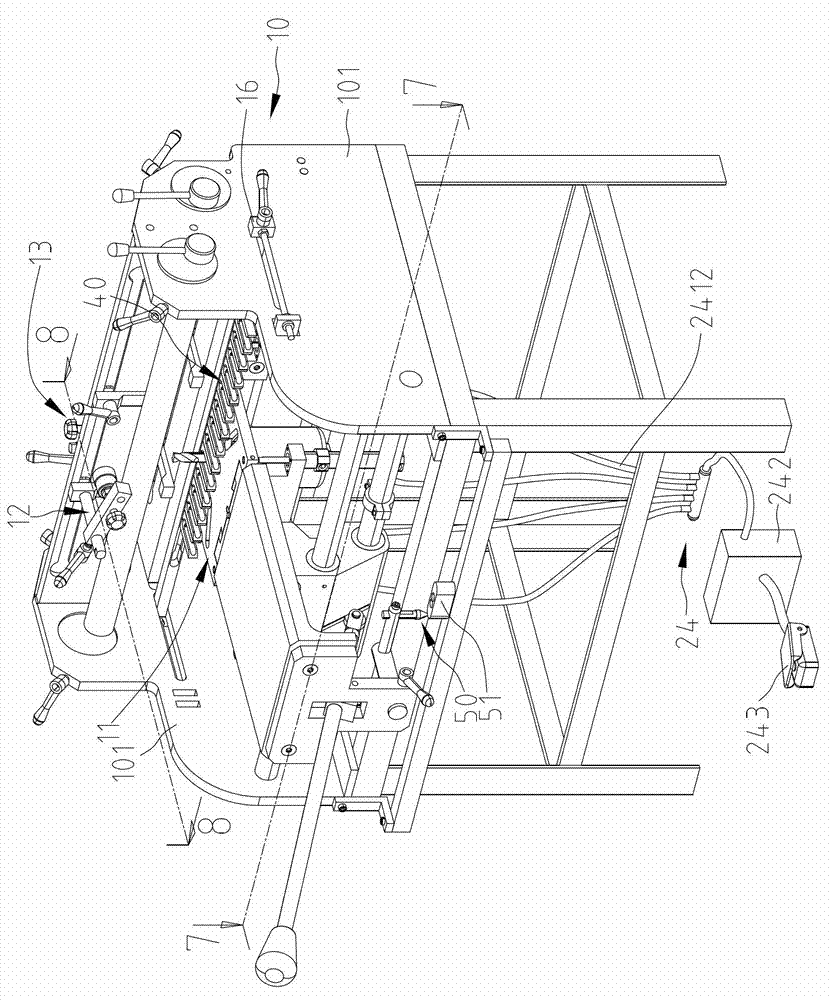

The invention provides an automatic woodworking machine, belongs to the technical field of woodworking machines, and solves the problems that a conventional woodworking machine is not high in processing efficiency and relatively low in product precision. The automatic woodworking machine comprises a machine frame, wherein a workpiece conveying mechanism is arranged on the machine frame; a feed hopper is arranged at the front end of the conveying mechanism; a cutting mechanism, a drilling mechanism and a groove milling mechanism are also arranged on the machine frame; the cutting mechanism comprises power heads respectively arranged at two ends of the machine frame, saw blades arranged on the output shafts of the power heads and lifting air cylinders for driving the saw blades to move up and down. According to the invention, a PLC system is adopted to control a servomotor, the cylinders, the power heads and other electric appliance mechanisms to act together, so that flush cutting, end-part drilling, side-surface groove milling and the like of sheet metal can be realized through one-time positioning, and the machining precision is high; end products can be grabbed and placed on a conveying line through an automatic reclaiming mechanism after the processing is finished, so that the degree of automation and the processing efficiency are high.

Owner:TAIZHOU EVOK MASCH CO LTD

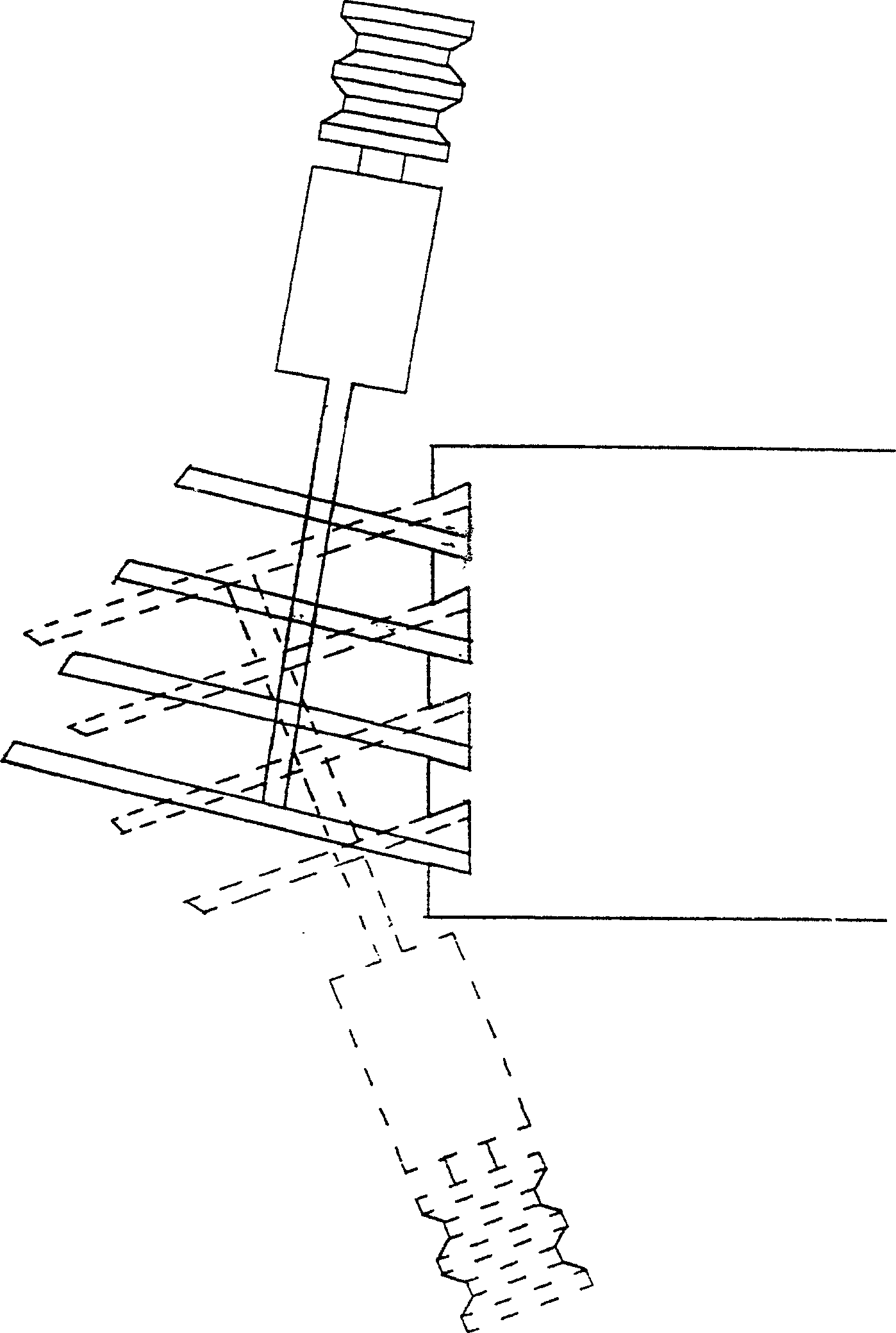

Wood Working Machine

InactiveUS20090188584A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWoodworking machineLaser source

A wood working machine is described that includes a mounting plate assembly for supporting a cutting tool, the mounting plate assembly including a base plate, first and second spaced apart intermediate plates on the base plate, and first and second guide plate elements pivotally supported on respective first and second intermediate plates, and a cutting tool support plate slidably disposed between the first and second guide plate elements, the guide plate elements including means defined therein for positioning each of the guide plate elements at selected angular intervals with respect to the respective first and second intermediate plates, whereby the cutting tool support plate is slidably movable on the base plate between the guide plate elements at a prescribed angle. The mounting plate assembly may include laser sources providing crossed laser beams for accurately positioning the tool bit of the cutting tool near a work piece, and light sources for illuminating the tool bit. A digital sensor may be included for precise positioning of the work piece held beneath the base plate on a movable carrier.

Owner:STEPP LEWIS E

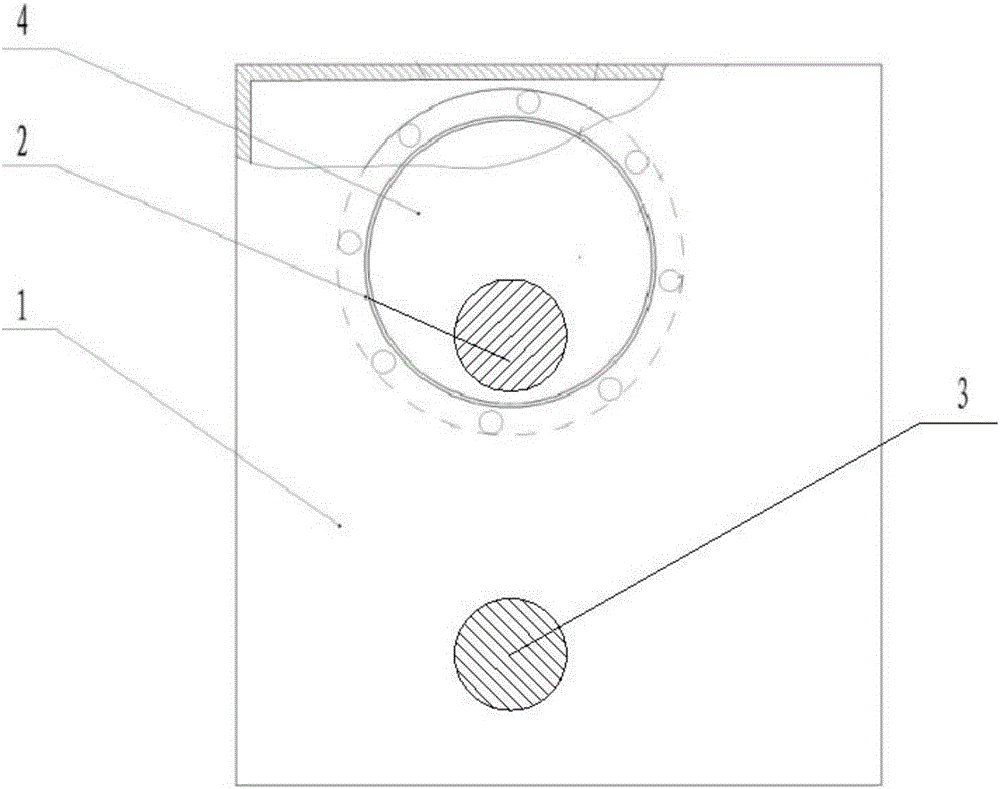

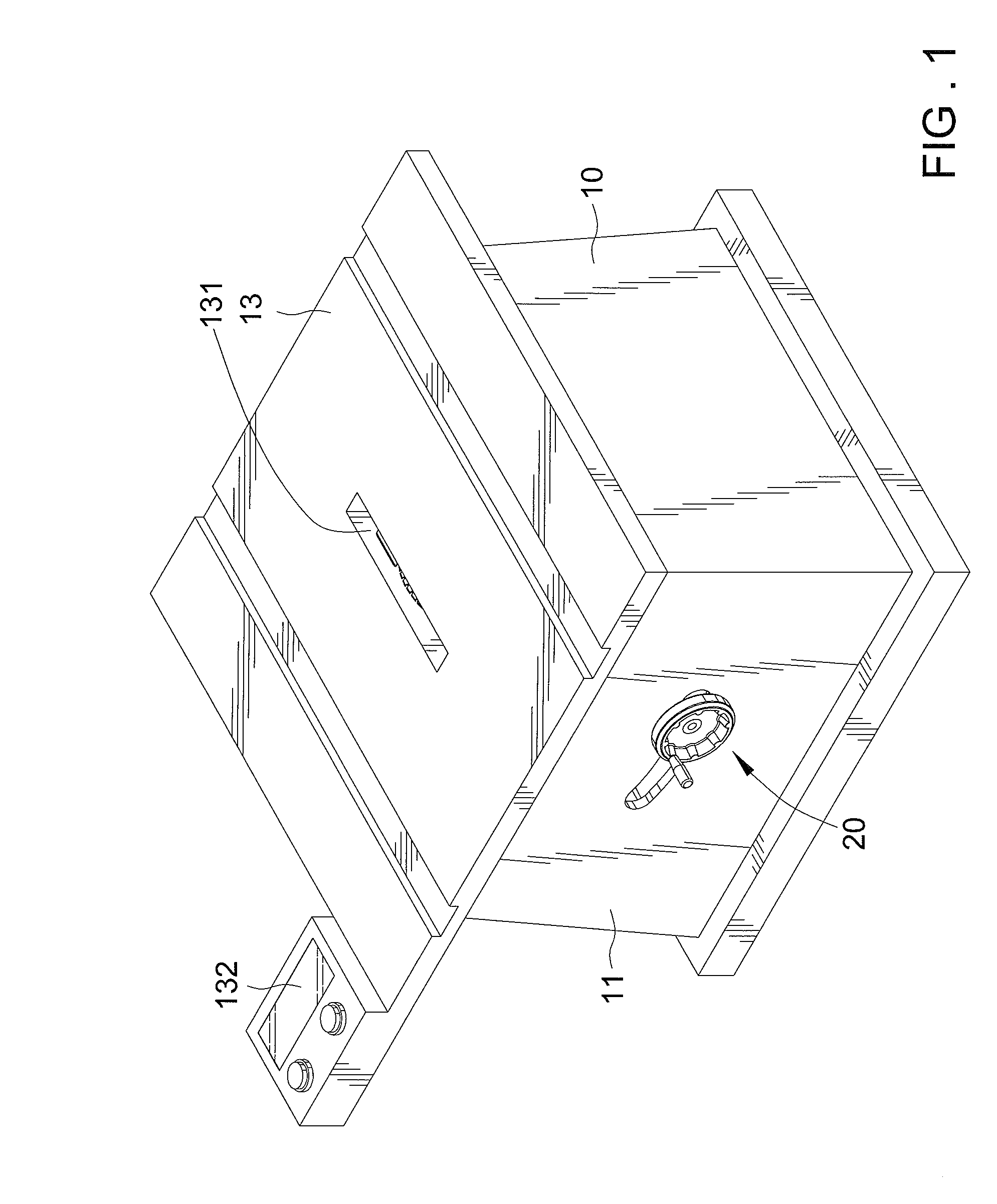

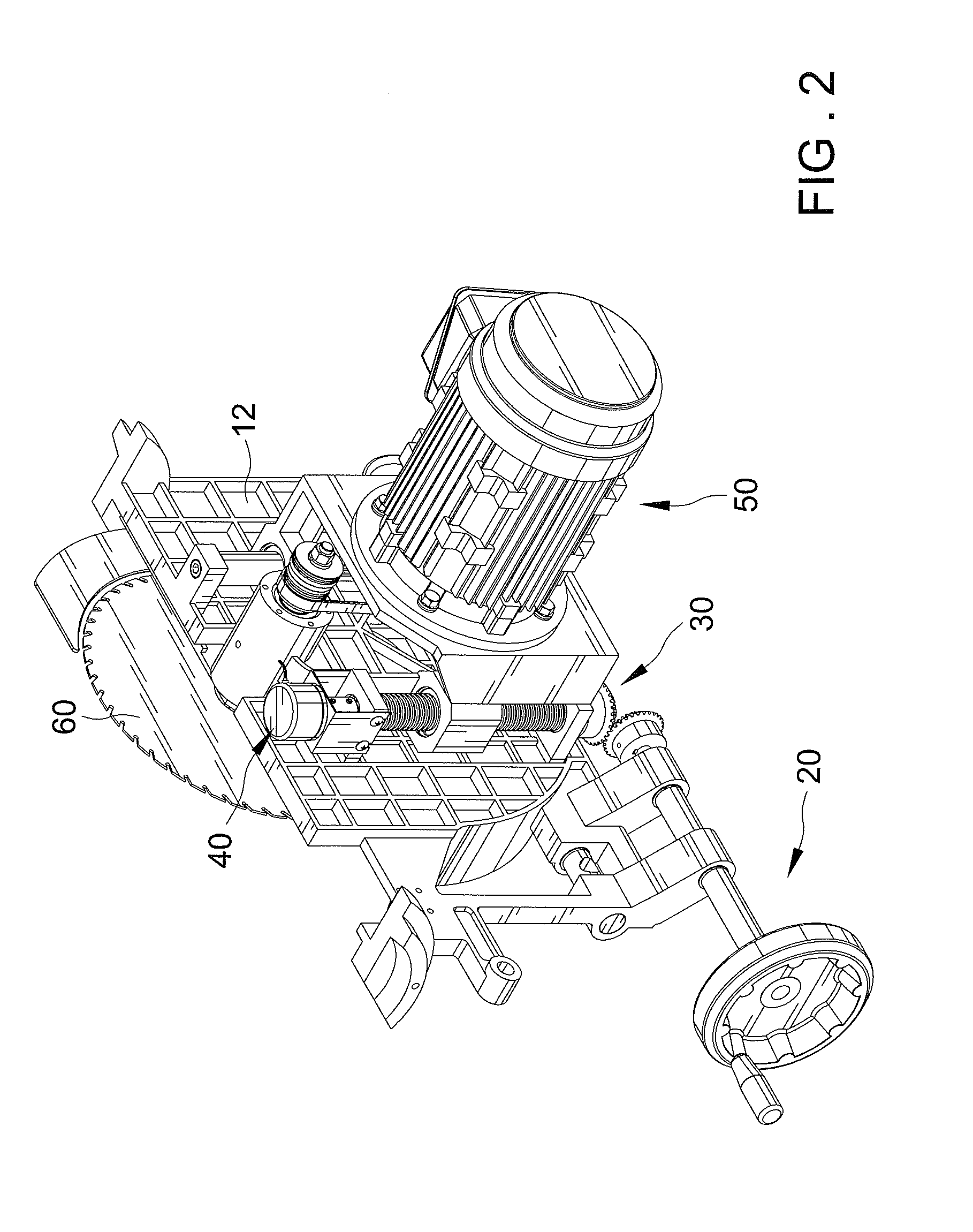

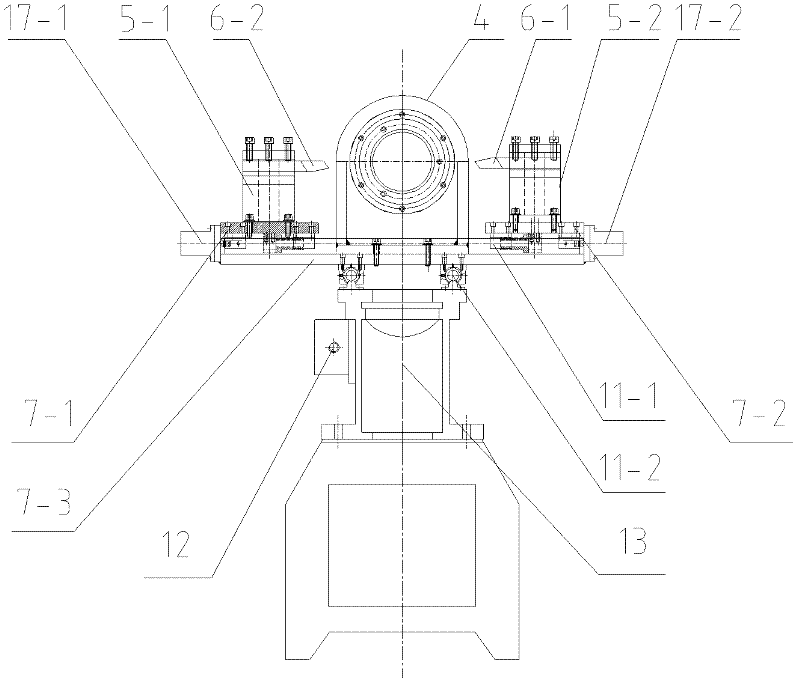

Positioning device for adjusting saw blade shafts of multi-saw-blade woodworking machine

InactiveCN106313186AImprove efficiencyImproving the Efficiency of Adjusting the Saw Shaft of a Multi-Blade Woodworking MachineCircular sawsEngineeringWoodworking machine

The invention relates to a positioning device for adjusting saw blade shafts of a multi-saw-blade woodworking machine. The positioning device comprises an eccentric wheel mechanism arranged on a box body of the multi-saw-blade woodworking machine. The first saw blade shaft and the second saw blade shaft are vertically and oppositely arranged on the box body. The portions, corresponding to the front mounting shaft hole position and the rear mounting shaft hole position of the first saw blade shaft, on the box body are correspondingly provided with assembling circular holes with the same diameter and tolerance. The two assembling circular holes are correspondingly provided with eccentric wheels matched with the assembling circular holes. A mounting hole for mounting the first saw blade shaft is formed in the eccentric shaft position of each eccentric wheel. The assembling circular holes of the eccentric wheels are internally in a rotatable transition fit. A clamping hole is formed in the outer side of the first saw blade shaft. The side, corresponding to the clamping hole, of the outer side of the box body is provided with a positioning device body for positioning the first saw blade shaft when the saw blade shafts of the multi-saw-blade woodworking machine are adjusted. The positioning device has the beneficial effects that the efficiency of adjusting the saw blade shafts of the multi-saw-blade woodworking machine can be improved, and the time and labor are saved.

Owner:ZIYUAN COUNTY DUOLISHI WOODWORKING MACHINERY

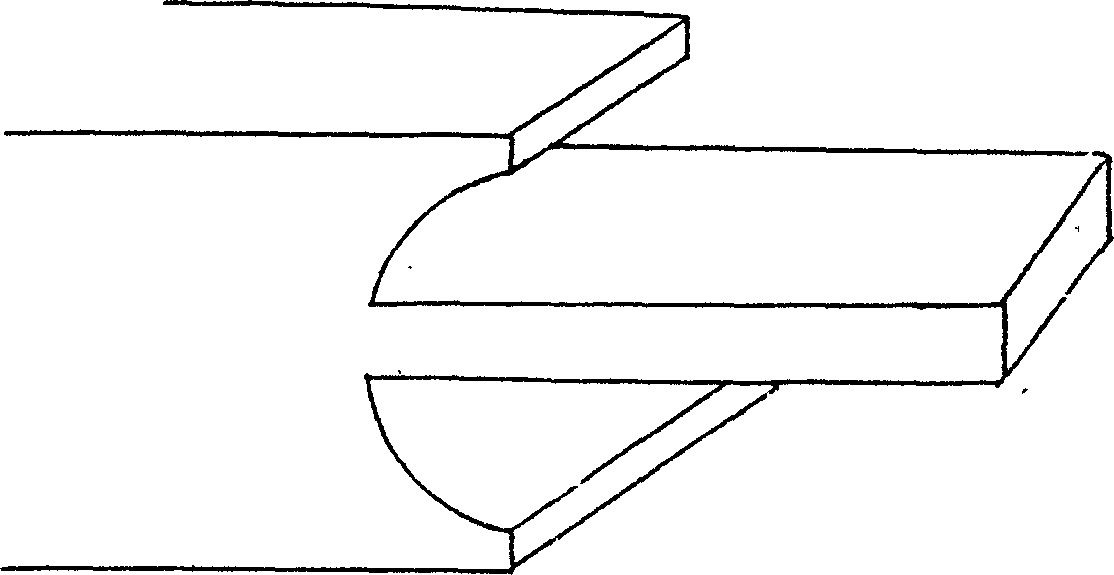

Woodworking machine for shaping molding

The woodworking machine for shaping molding has a hollow cylindrical cartridge with end caps having openings defined therein adapted for inserting a blank strip of molding through the cartridge. Robotic grippers advance the molding strip through the cartridge in indexed increments. A cutter assembly is mounted on a movable table, the cutter assembly having a plurality of spaced apart cutters. An electronic control system, preferably including a programmable logic controller, causes the grippers to grip the blank molding, insert the blank through the cartridge, actuate the cutter assembly and move the table so that the cutters simultaneously cut a plurality of notches in the molding, retract the cutter assembly, advance the molding the indexed distance, and automatically repeat the cycle, ejecting the strip when notches have been formed in the entire length of the molding. The machine may be used to form dental molding.

Owner:BURKHOLDER LEON R

Woodworking Machine with Sensing Device

Owner:META INT

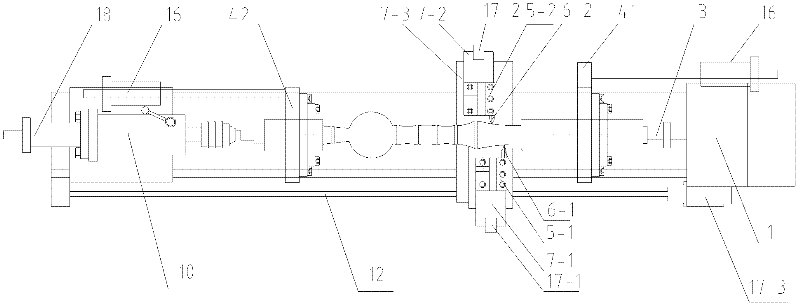

Seat drilling machine

InactiveCN101570029AFreely adjust the travel distanceImprove work efficiencyStationary drilling machinesBatch processingEngineering

The invention provides a seat drilling machine, and belongs to the field of a woodworking machine tool. The seat drilling machine solves the technical problems of multiple clamping and positioning, complicated operation, low dimension precision of holes, low working efficiency, difficult batch processing and the like existing in the existing drilling technique. The seat drilling machine comprises a machine tool rack and a workstation; wherein, the workstation is fixed on the machine tool rack to place working pieces. The seat drilling machine is characterized in that a drilling equipment is arranged above the workstation, and comprises a driving air cylinder which is vertically arranged; a piston rod of the driving air cylinder is fixedly connected with a motor which is vertically arranged; an output shaft of the motor is connected with a drill bit; a transversal adjusting mechanism enabling the driving air cylinder to horizontally and transversally move is arranged between the driving air cylinder and the workstation. The seat drilling machine can drill a plurality of holes by clamping once, the dimension precision is high, and the working efficiency is high.

Owner:TAIZHOU EVOK MASCH CO LTD

Detection system for power equipment

InactiveUS20070199622A1Engineering safety devicesMitre joint working devicesEngineeringPower equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

Woodworking machine for shaping molding

The woodworking machine for shaping molding has a hollow cylindrical cartridge with end caps having openings defined therein adapted for inserting a blank strip of molding through the cartridge. Robotic grippers advance the molding strip through the cartridge in indexed increments. A cutter assembly is mounted on a movable table, the cutter assembly having a plurality of spaced apart cutters. An electronic control system, preferably including a programmable logic controller, causes the grippers to grip the blank molding, insert the blank through the cartridge, actuate the cutter assembly and move the table so that the cutters simultaneously cut a plurality of notches in the molding, retract the cutter assembly, advance the molding the indexed distance, and automatically repeat the cycle, ejecting the strip when notches have been formed in the entire length of the molding. The machine may be used to form dental molding.

Owner:BURKHOLDER LEON R

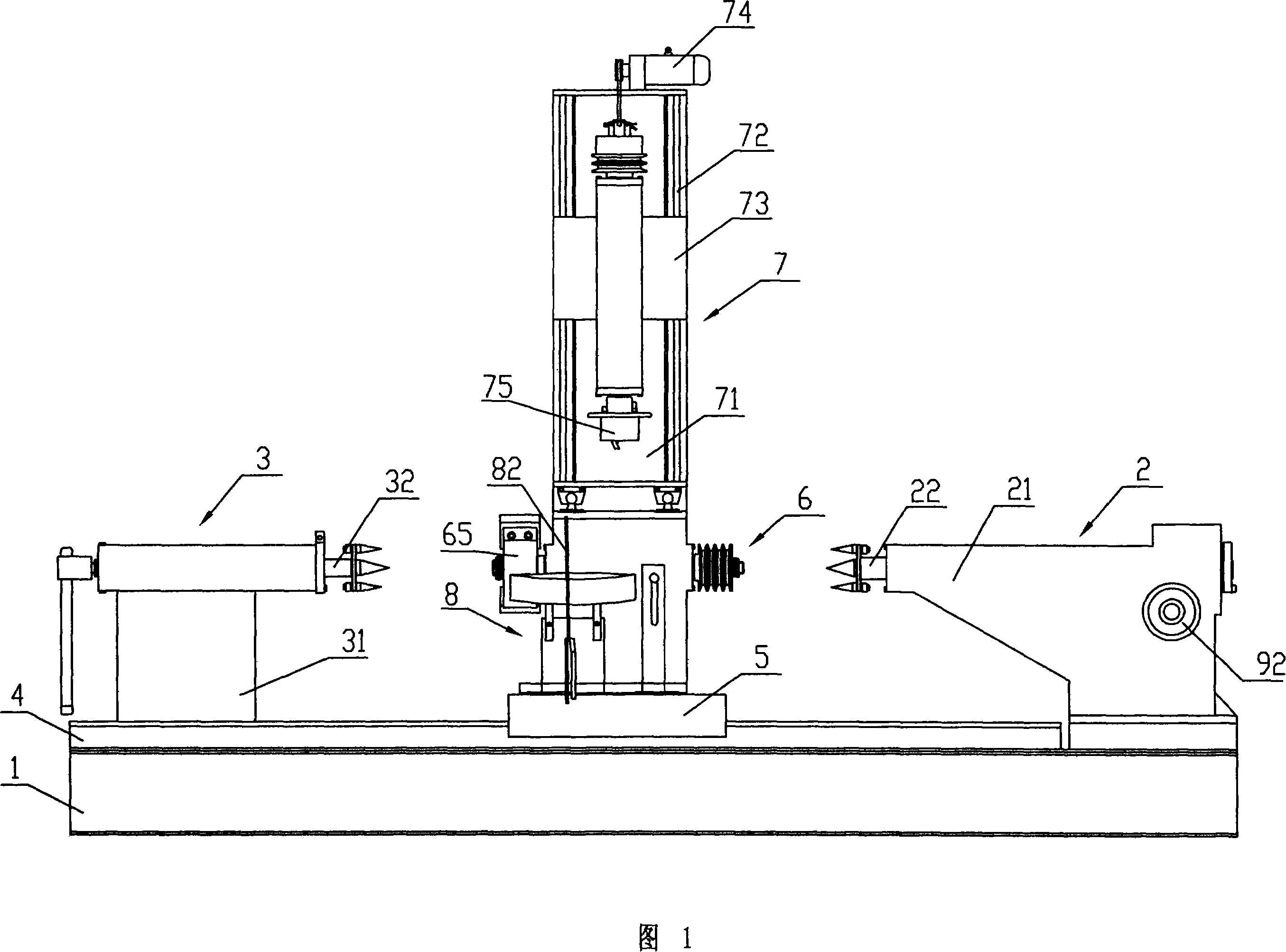

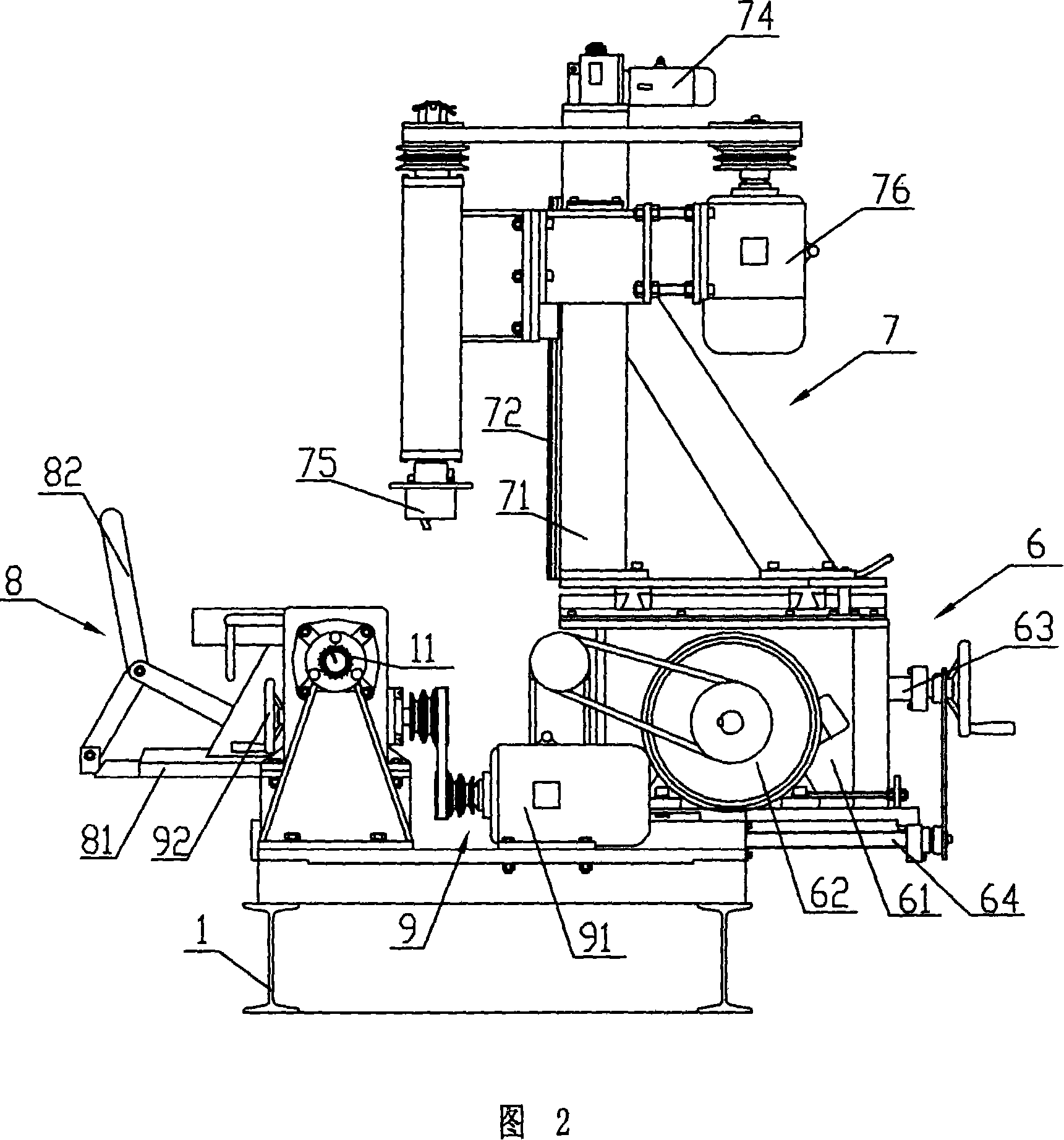

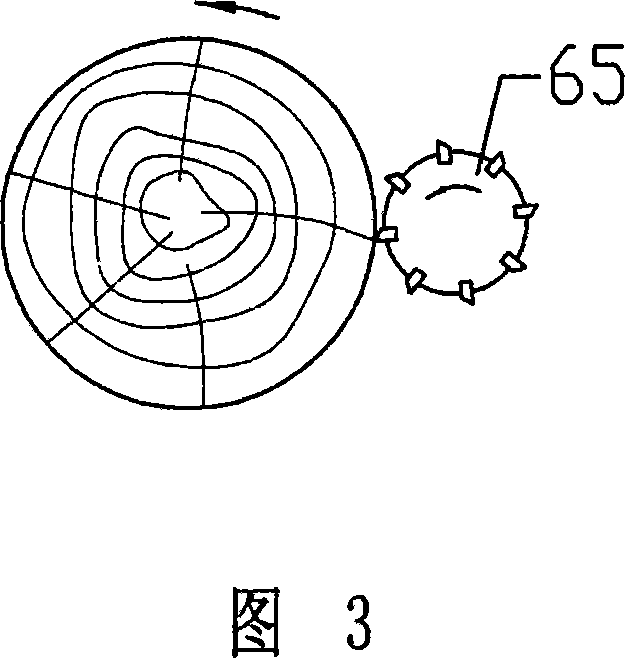

Carpentry machine tool used for log processing

InactiveCN101058196AImprove processing efficiencyEasy to stackProfiling/shaping machinesWood-turning machinesCircular discEngineering

The invention relates to a woodworking tool machine for original wood processing that comprises the vertical track base with both ends sticking the original wood and driving its motor tail base and support tail base, sliding base between them and being able to move along the vertical track, horizontal milling and cutting device for the original wood with vertical milling device installed on the horizontal milling base. The woodworking machine is not only able to process original wood with high efficiency, but also be able to vertical concave slot, horizontal concave slot and vertical sawing seam processing on the wood. It is multifunctional, with convenience for wood transportation, usage and storage.

Owner:杜明干

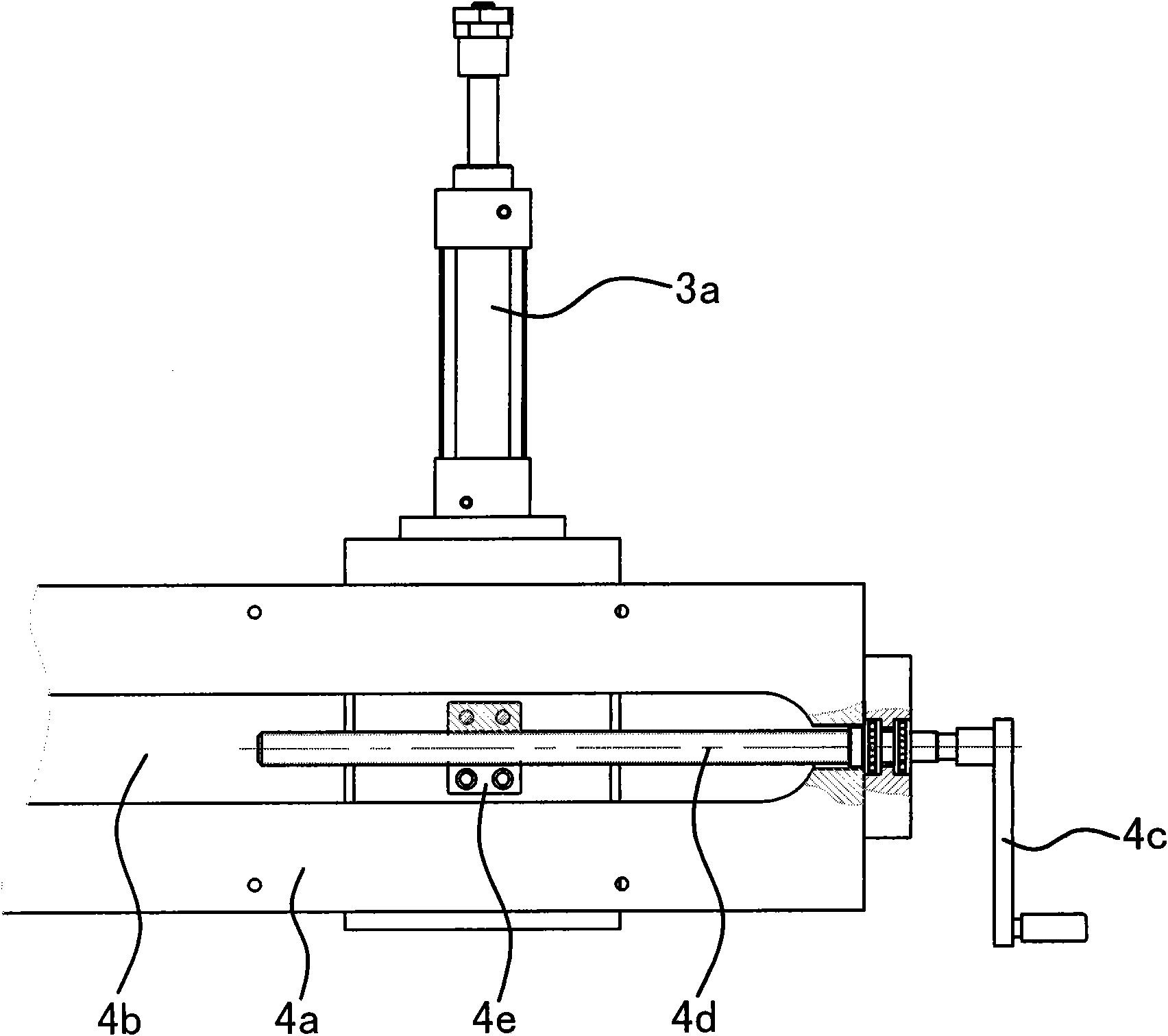

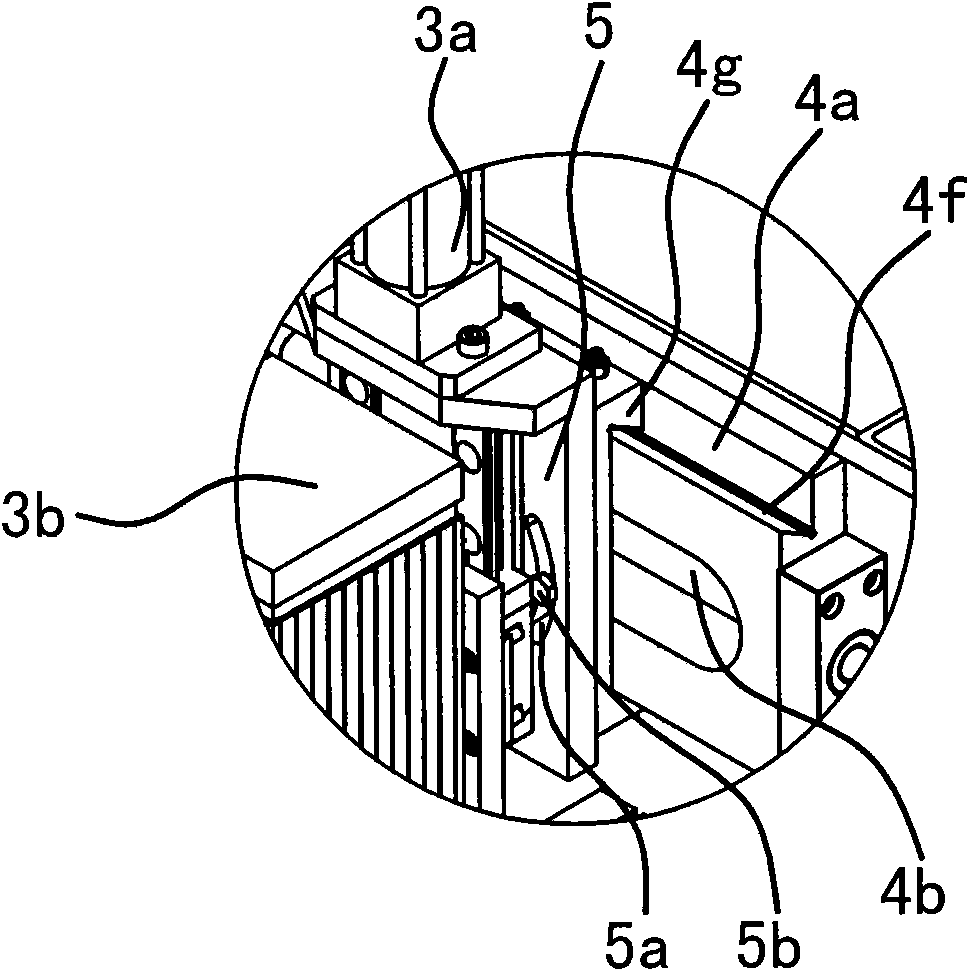

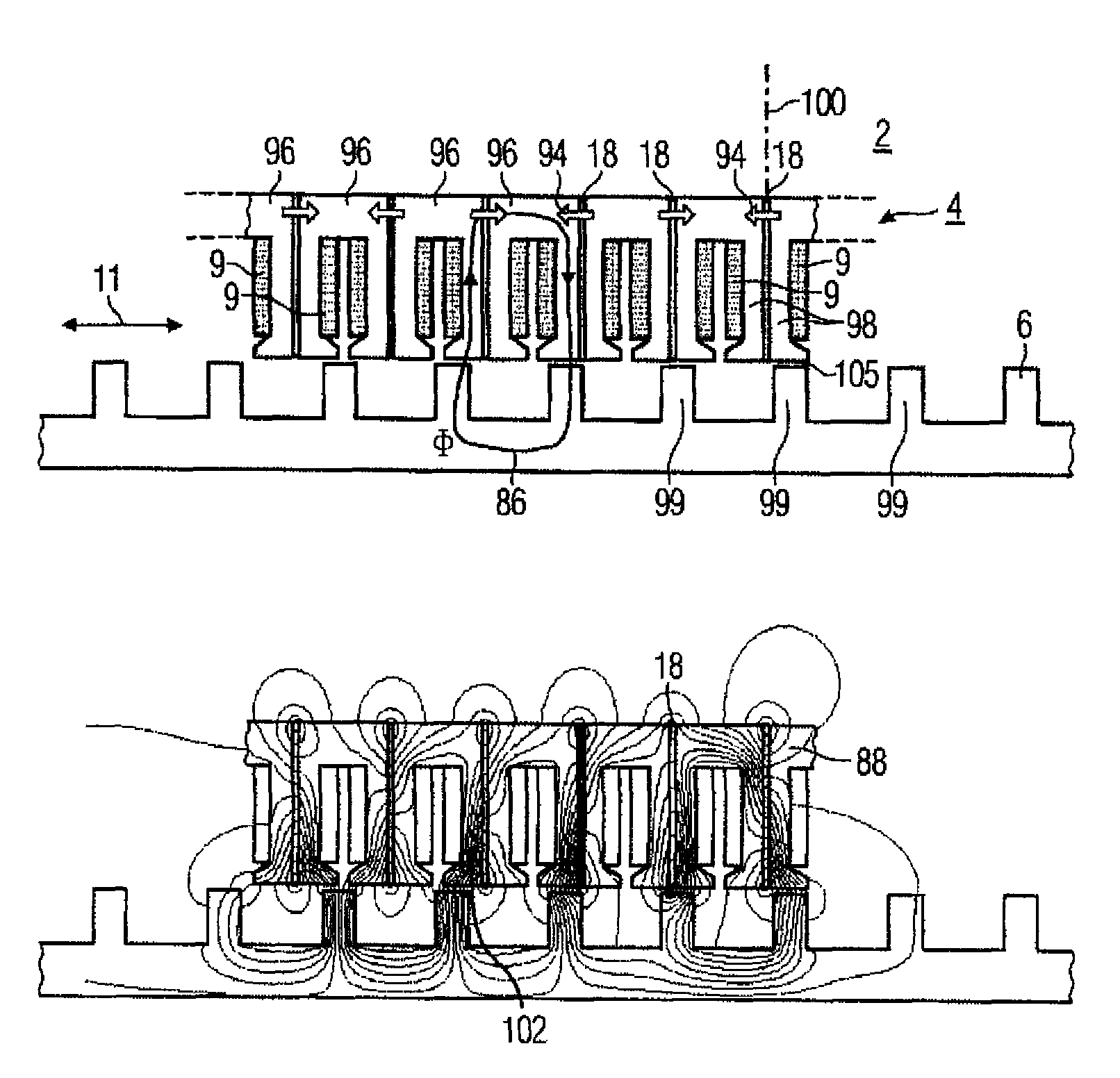

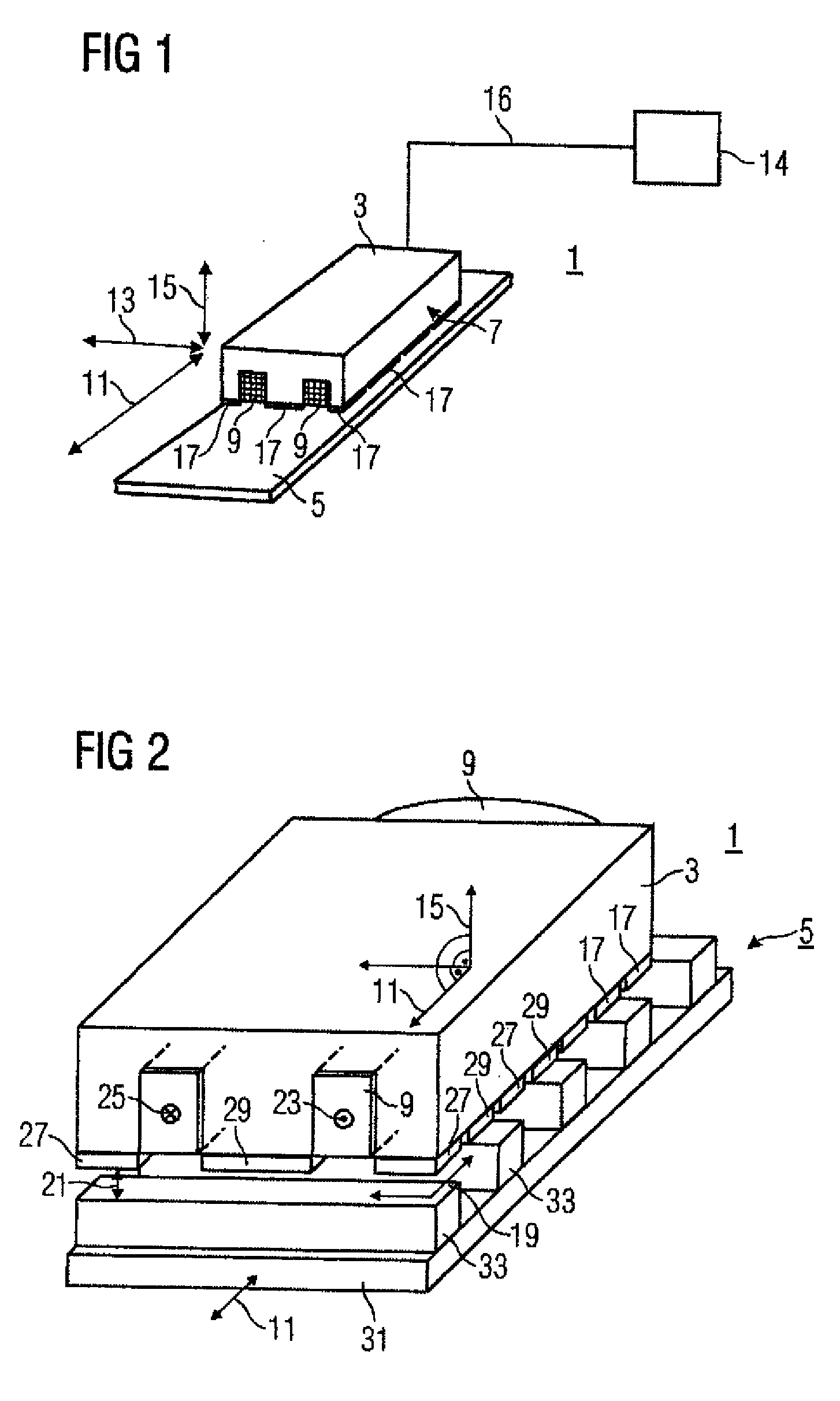

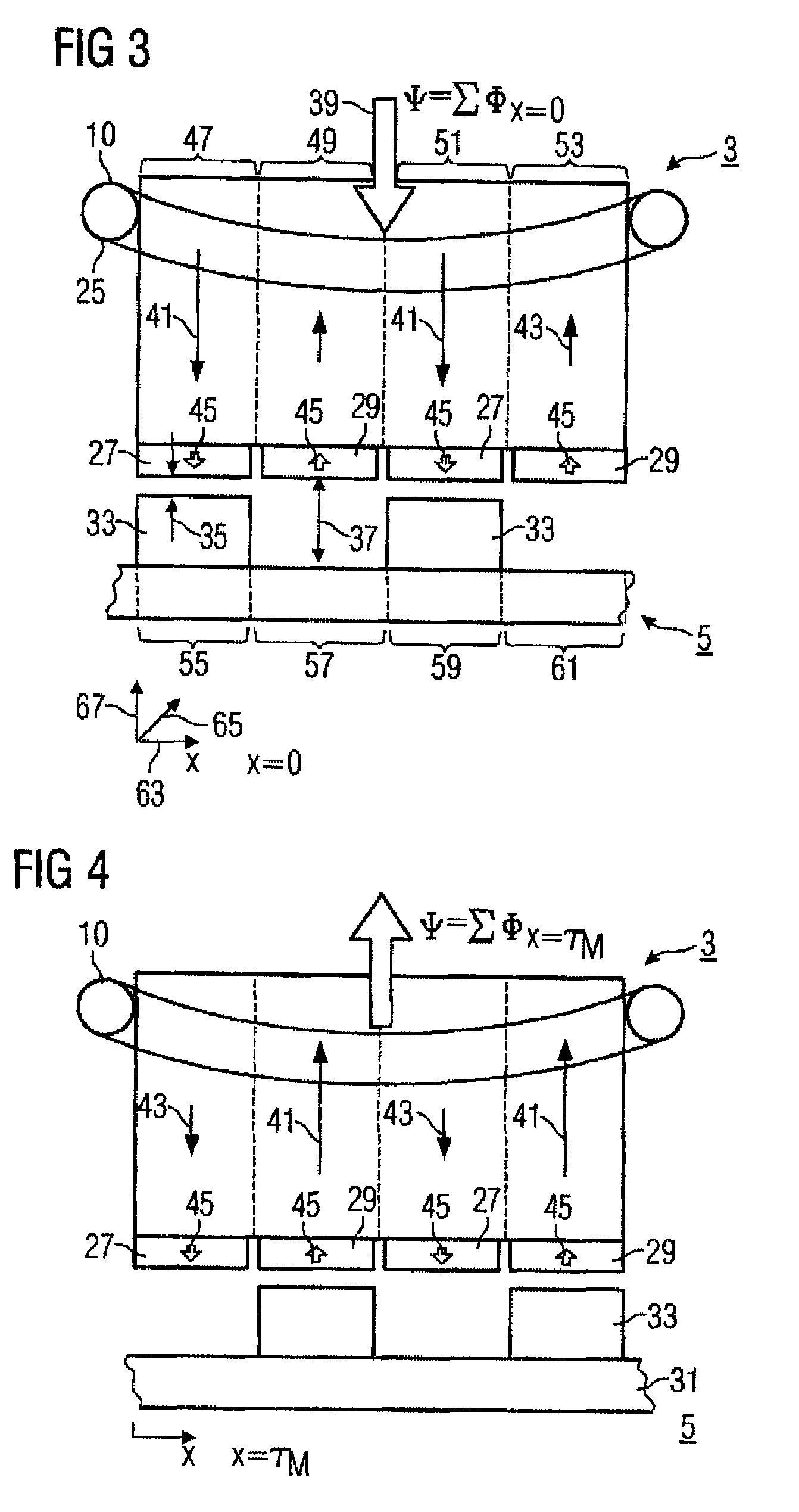

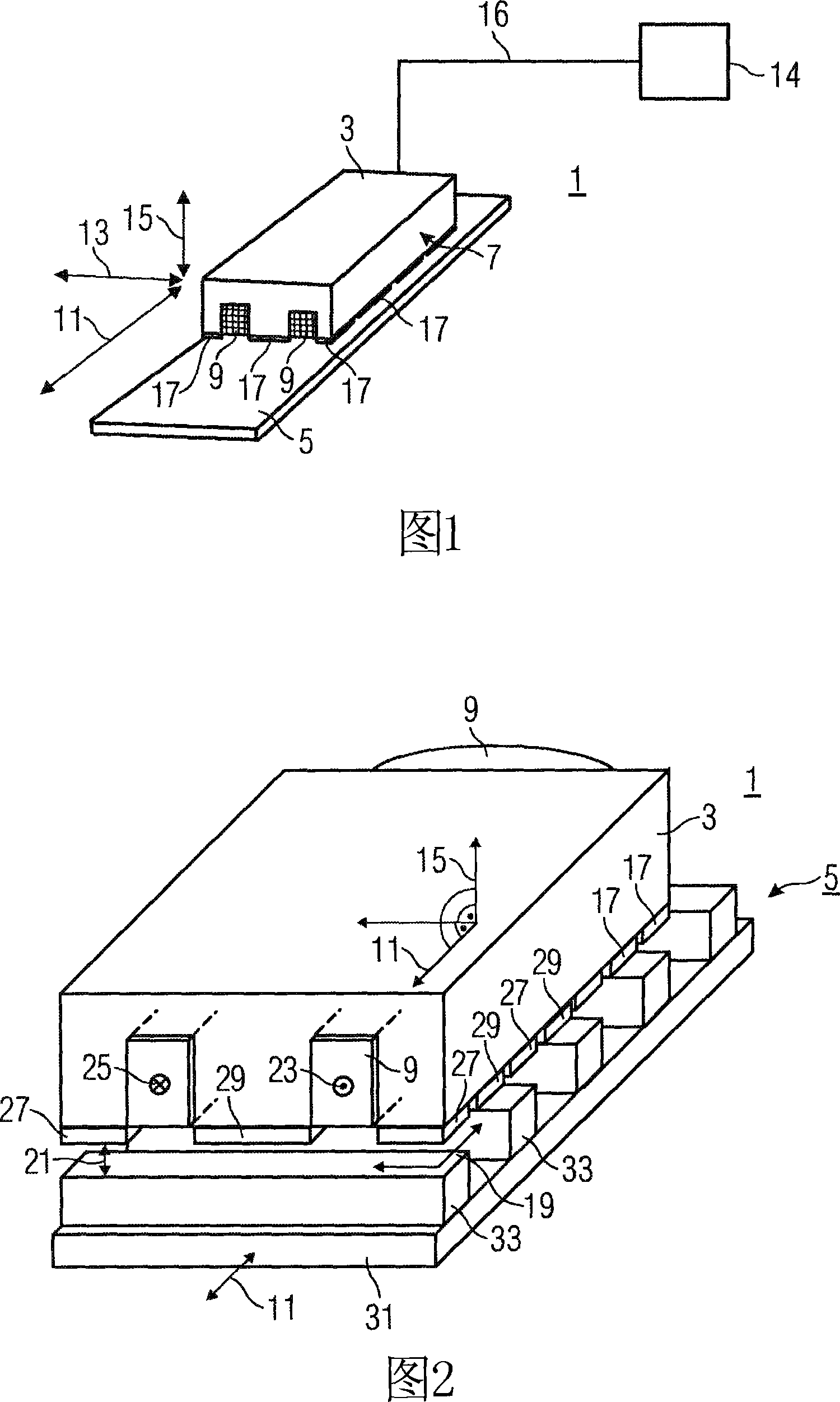

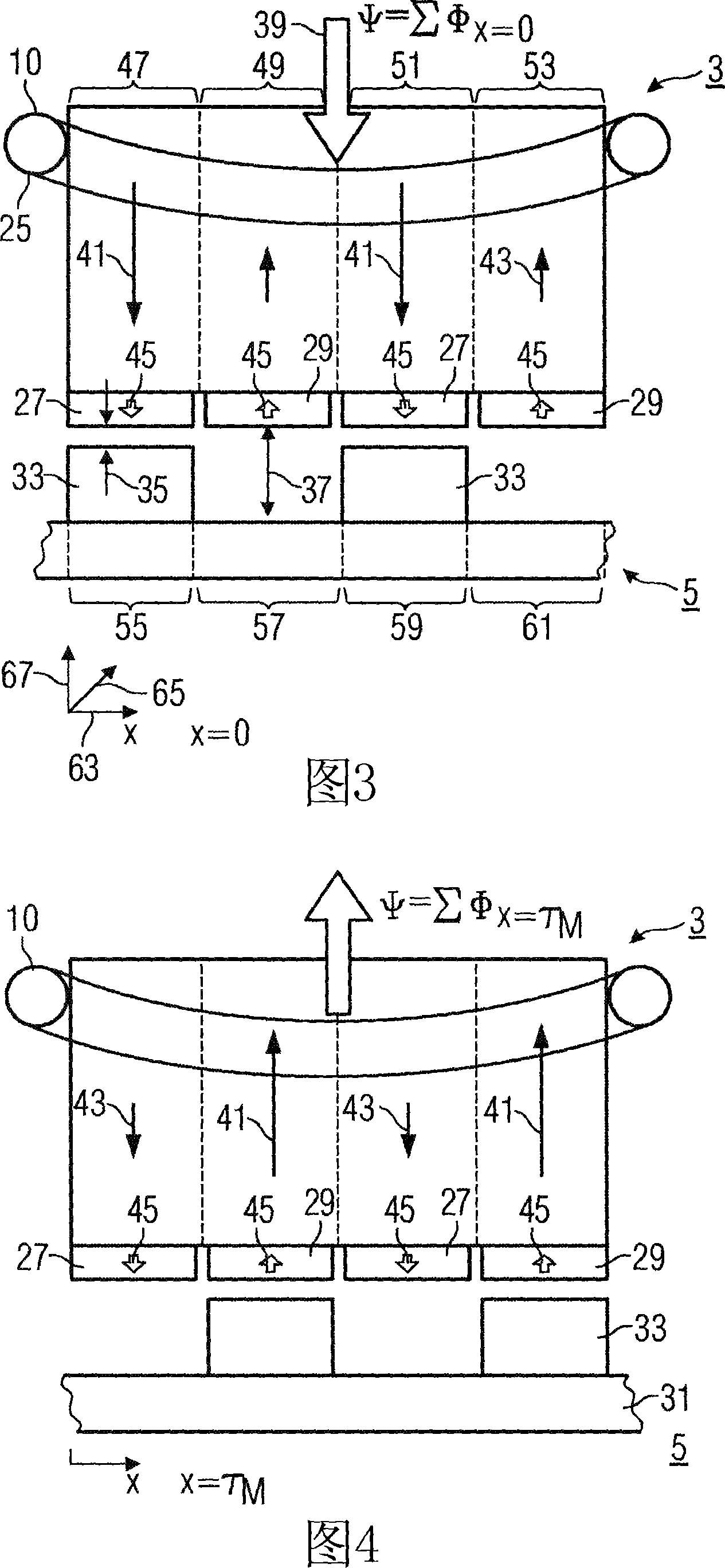

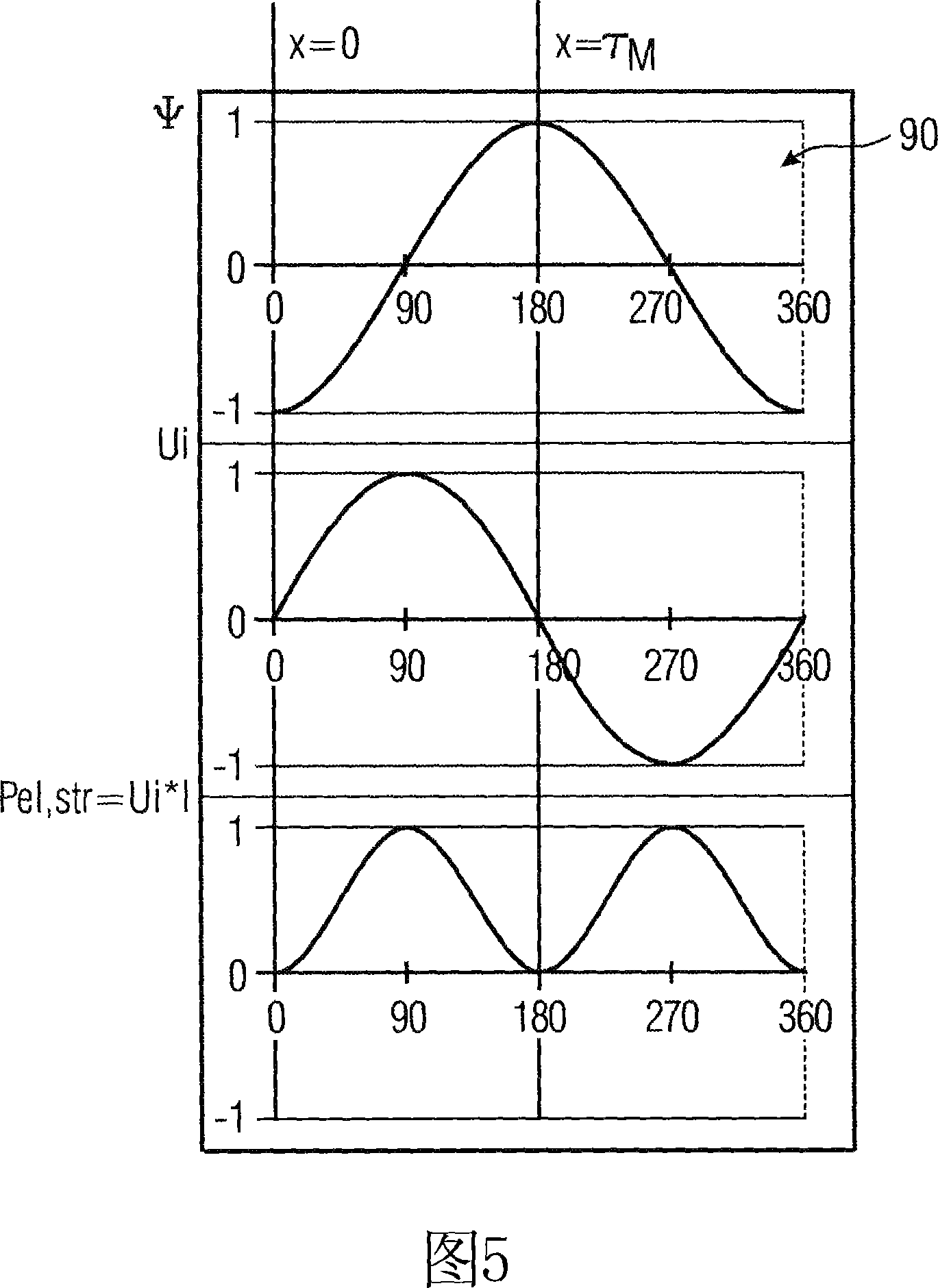

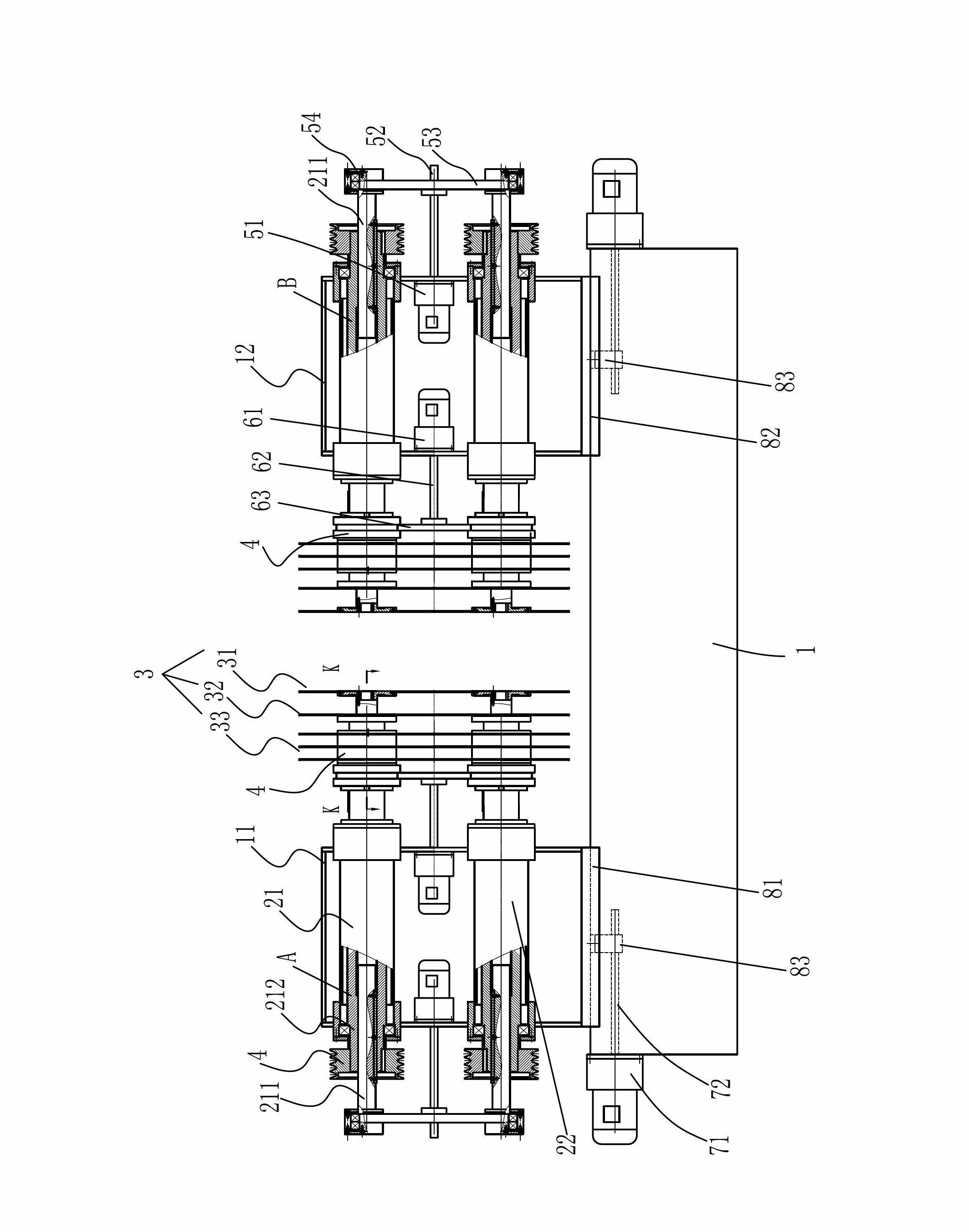

Woodworking machine with linear direct drive

InactiveUS7859142B2Good precisionDetect directlyMetal sawing devicesSynchronous generatorsMagnetic sourceWoodworking machine

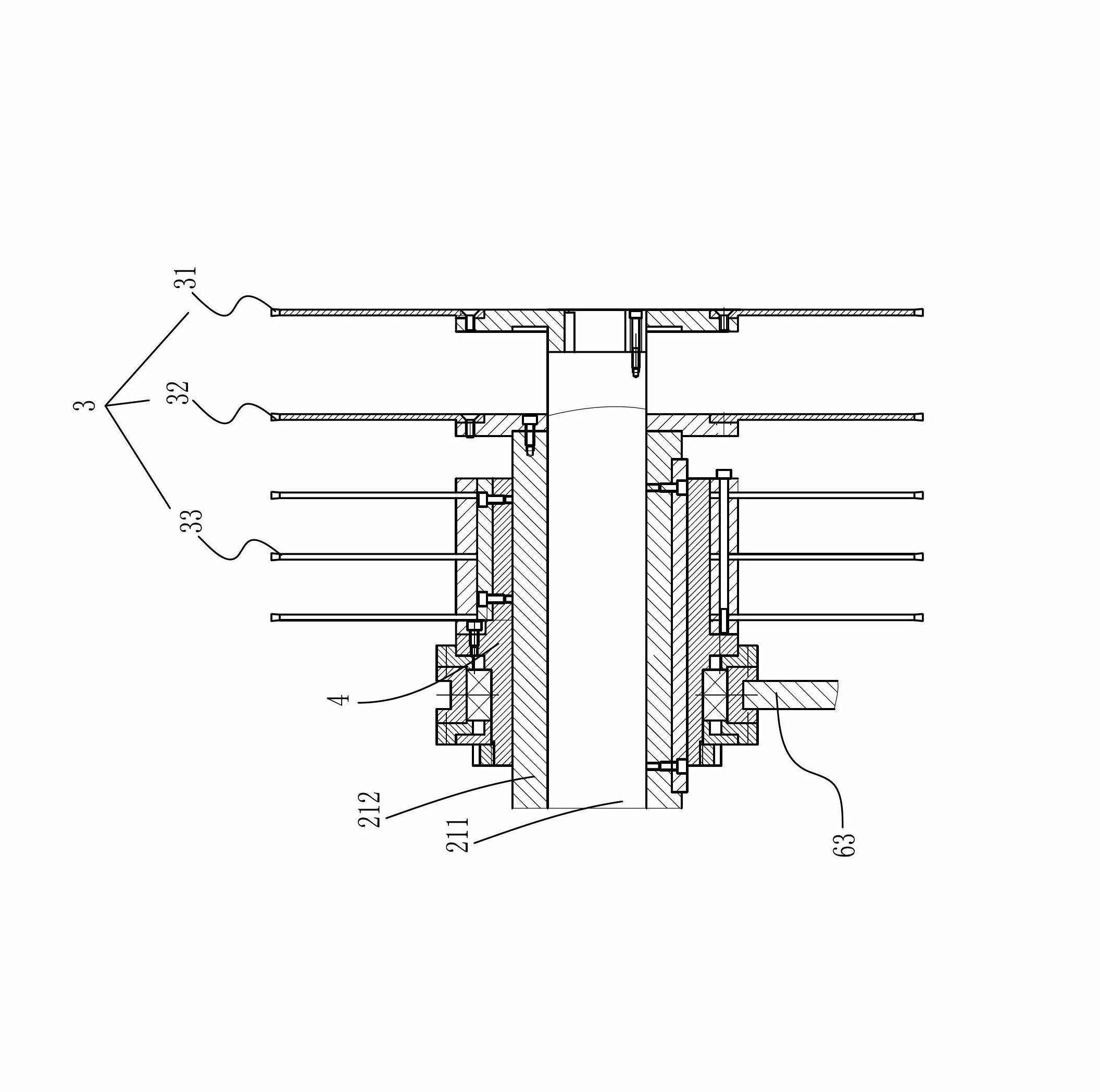

The aim of the invention is to provide a robust, simple woodworking machine. To achieve this, the invention provides a machine comprising at least one linear direct drive, which contains a primary part (3, 3a, 3b, 4, 4a, 4b) with a first element (9, 10, 12, 14) for generating a first magnetic field and at least one additional element (17, 18, 20, 27, 28, 29, 30) for generating an additional magnetic field. The first element (9) for generating the first magnetic field is positioned, in particular, in such a way in relation to the additional element (17, 18, 20, 27, 28, 29, 30) for generating the additional magnetic field that the first magnetic field overlaps the additional magnetic field. The machine also comprises a secondary part (5, 6, 6a, 6b), which comprises magnetic return elements and is devoid of magnetic sources. According to the invention, the primary part (3, 3a, 3b, 4, 4a, 4b) and / or the secondary part (5, 6, 6a, 6b) is or are suitable for guiding or placing at least one workpiece and / or for guiding and / or placing at least one tool for machining the workpiece.

Owner:SIEMENS AG

a woodworking machine

InactiveCN102259355AEasy to processGuaranteed balance and stabilityWood-turning machinesElectric machineryEngineering

The invention relates to a woodworking machine tool, which belongs to the field of woodworking machinery and equipment, and comprises an interconnected headstock, a spindle, a chuck, a tool holder, a tool holder, a turning tool, a sliding plate, a feeding cylinder, a feeding rack, a tailstock, and a bed Body, guide rail, lead screw, stepping motor, wherein, the number of said tool holders is more than two, which are respectively arranged on the sliding plate; on the sliding plate; the number of the turning tool is the same as the number of the tool holder, the turning tool is arranged in a direction perpendicular to the axis of the lathe, and the tip of the turning tool is along the axis of the lathe The parallel directions are misaligned with each other. Compared with the prior art, the present invention has a novel structure and simple operation, effectively overcomes the defects of single knife and single knife holder for wood production and processing, greatly improves the processing efficiency, increases the smoothness of the finished product, and correspondingly reduces the economic cost. The invention is suitable for popularization and application in wood processing related fields.

Owner:陆卫斌

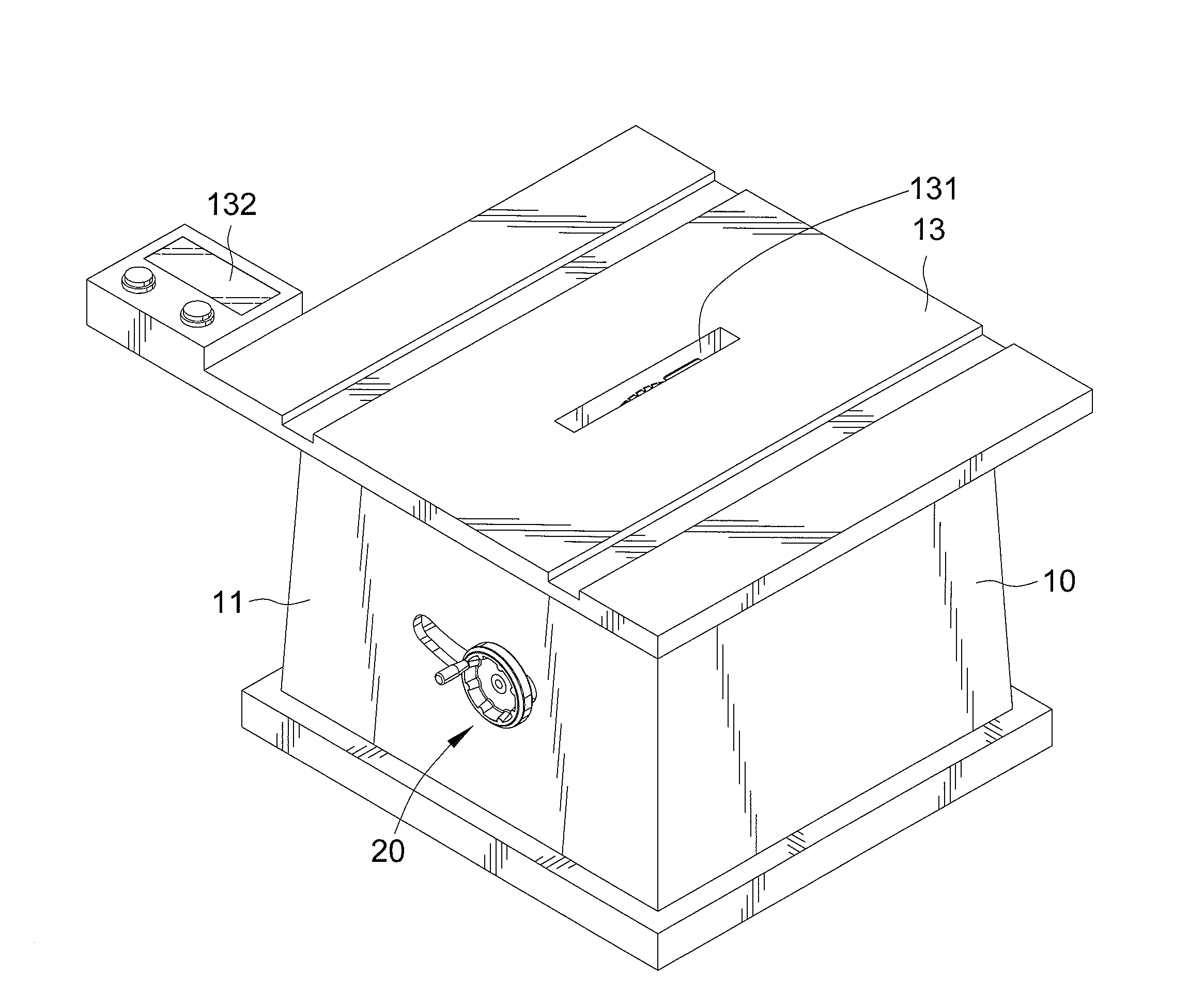

Woodworking sawing machine

ActiveCN103358360AQuick cutImprove cutting efficiencyPortable power driven sawsBark-zones/chip/dust/waste removalIndustrial AccidentEngineering

The invention provides a woodworking sawing machine, and belongs to the technical field of woodworking machines. The technical problems that industrial accidents can occur easily when an existing woodworking sawing machine is operated, and thus personal safety is seriously affected are solved. The woodworking sawing machine comprises a machine frame, an electric saw and a workbench which is fixed on the machine frame. The electric saw comprises a driving motor and a saw blade which is fixed on an output shaft of the driving motor. The workbench is provided with a bar-shaped channel which allows the saw blade to pass through, and the driving motor is placed below the workbench and can slide in the direction of the channel. The upper end of the saw blade passes through the channel and is placed above the workbench. A driving structure which can drive the driving motor to move is arranged between the driving motor and the machine frame. The woodworking sawing machine has the advantages of being capable of reducing the contacting probability of the saw blade and workers and improving the safety.

Owner:颜夏根

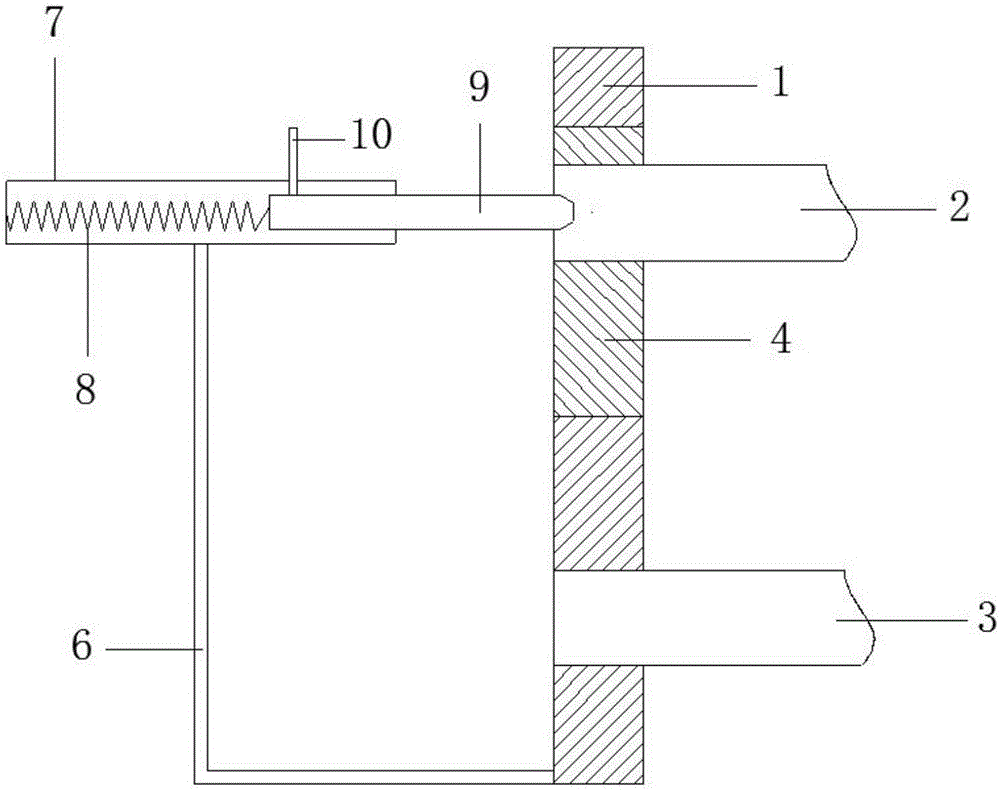

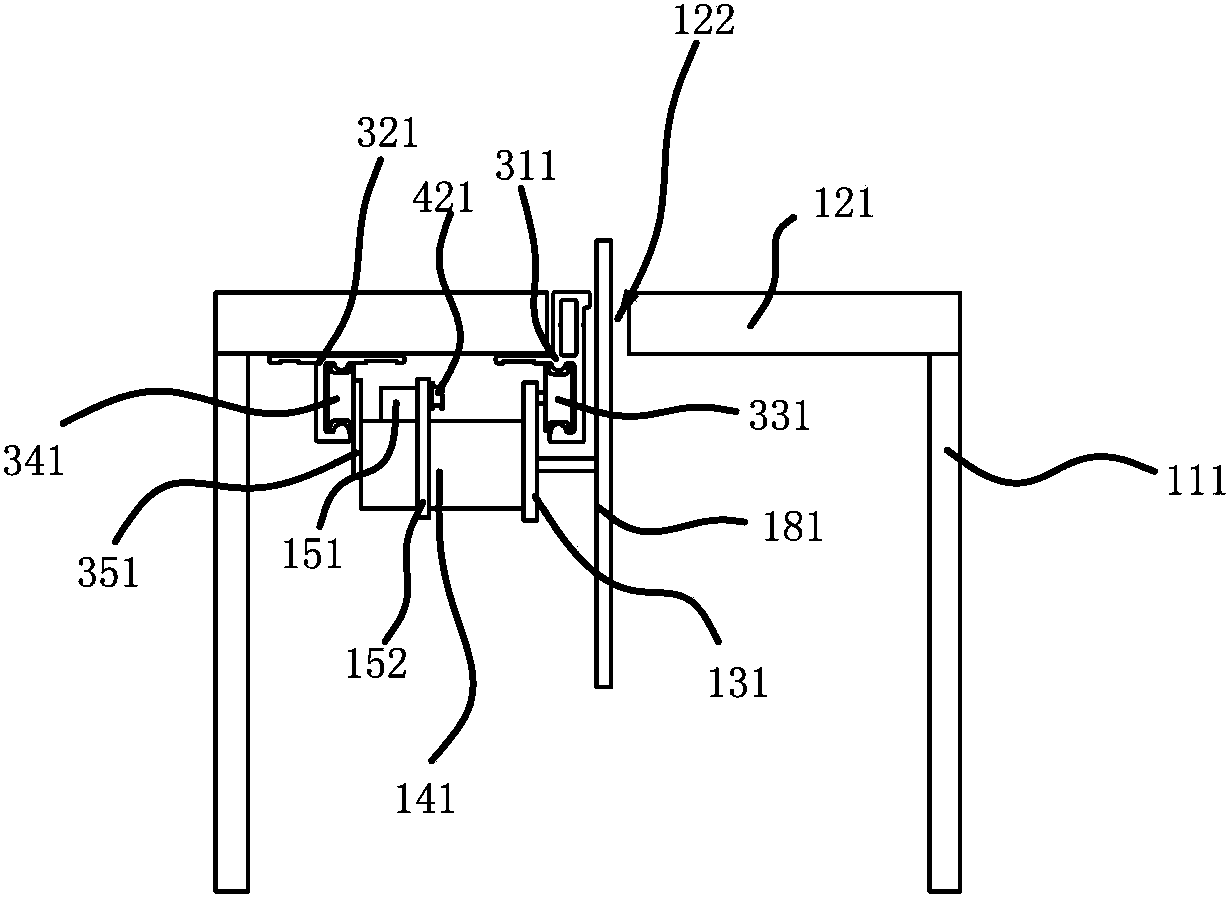

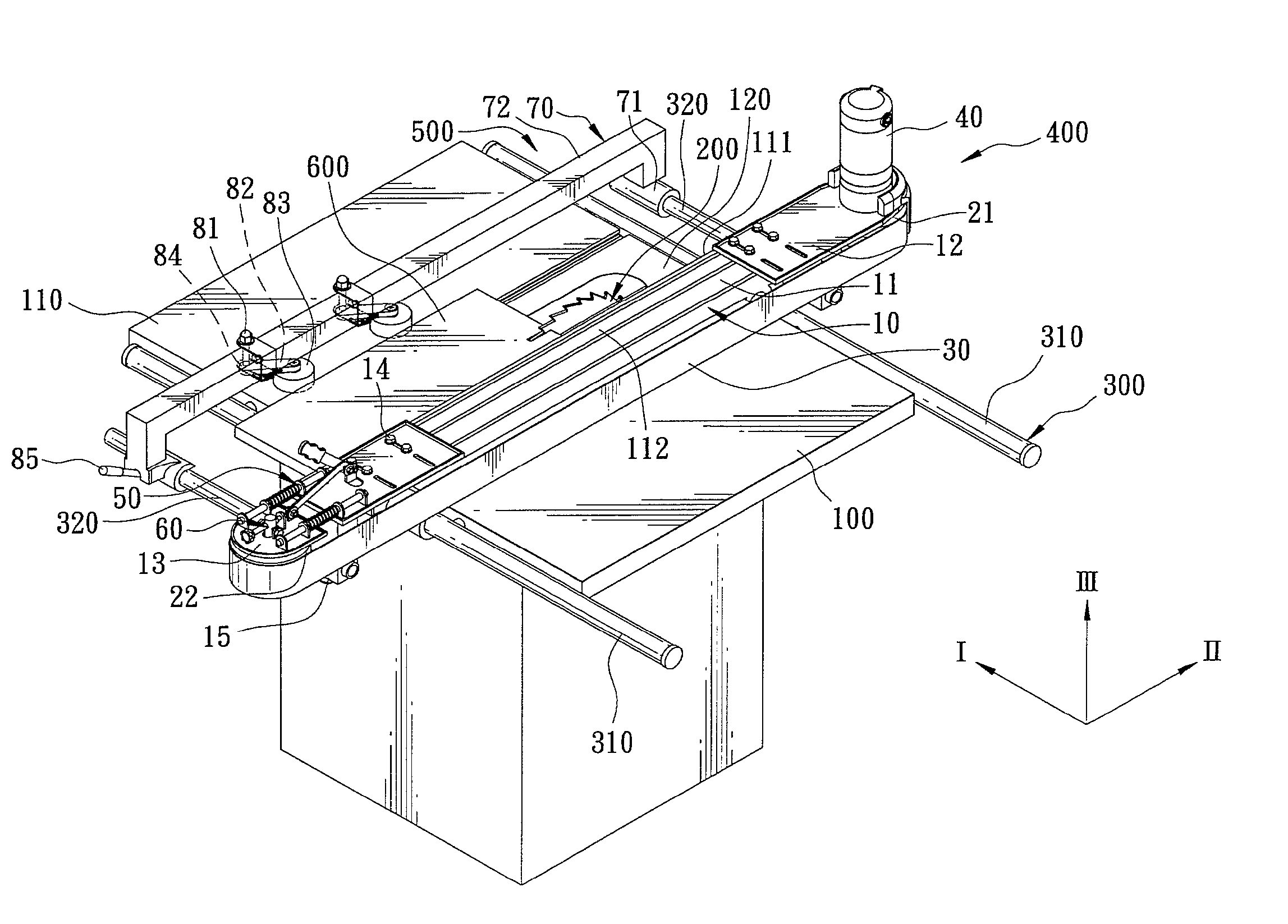

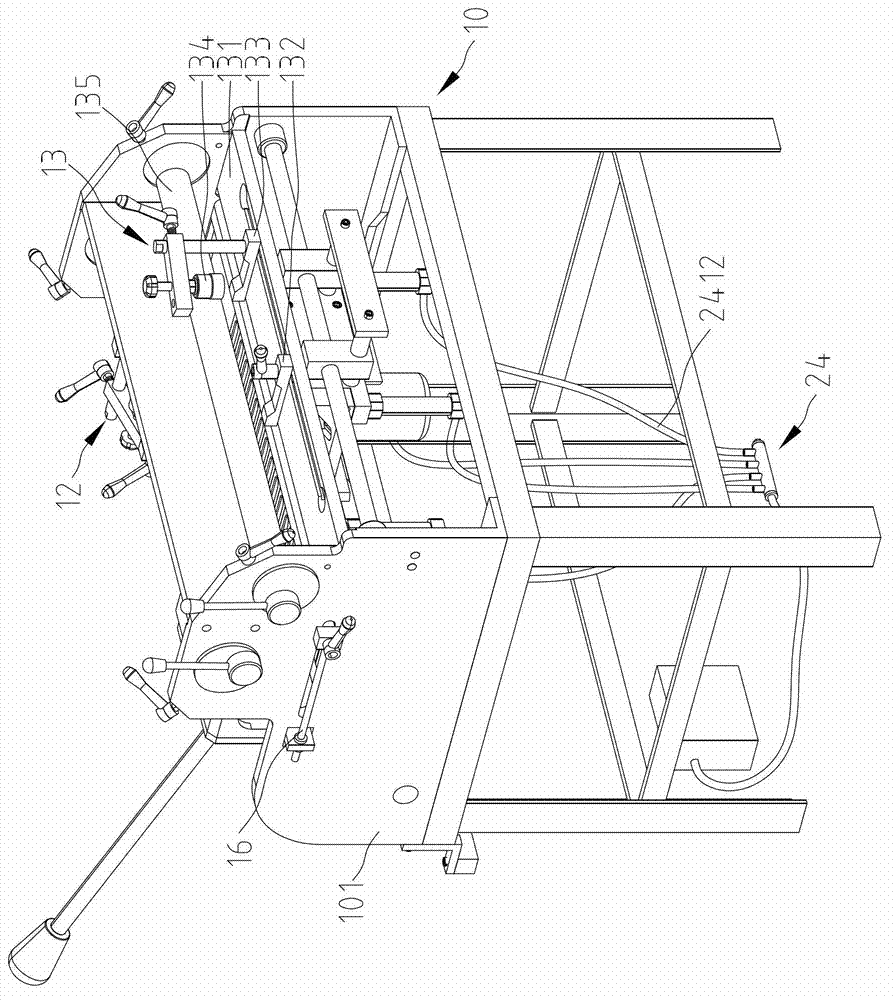

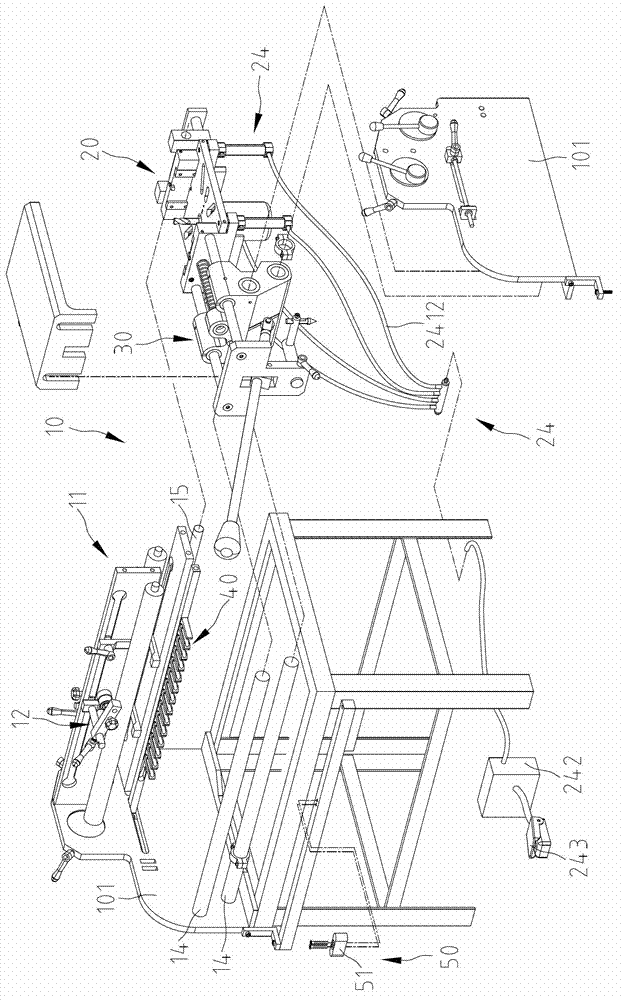

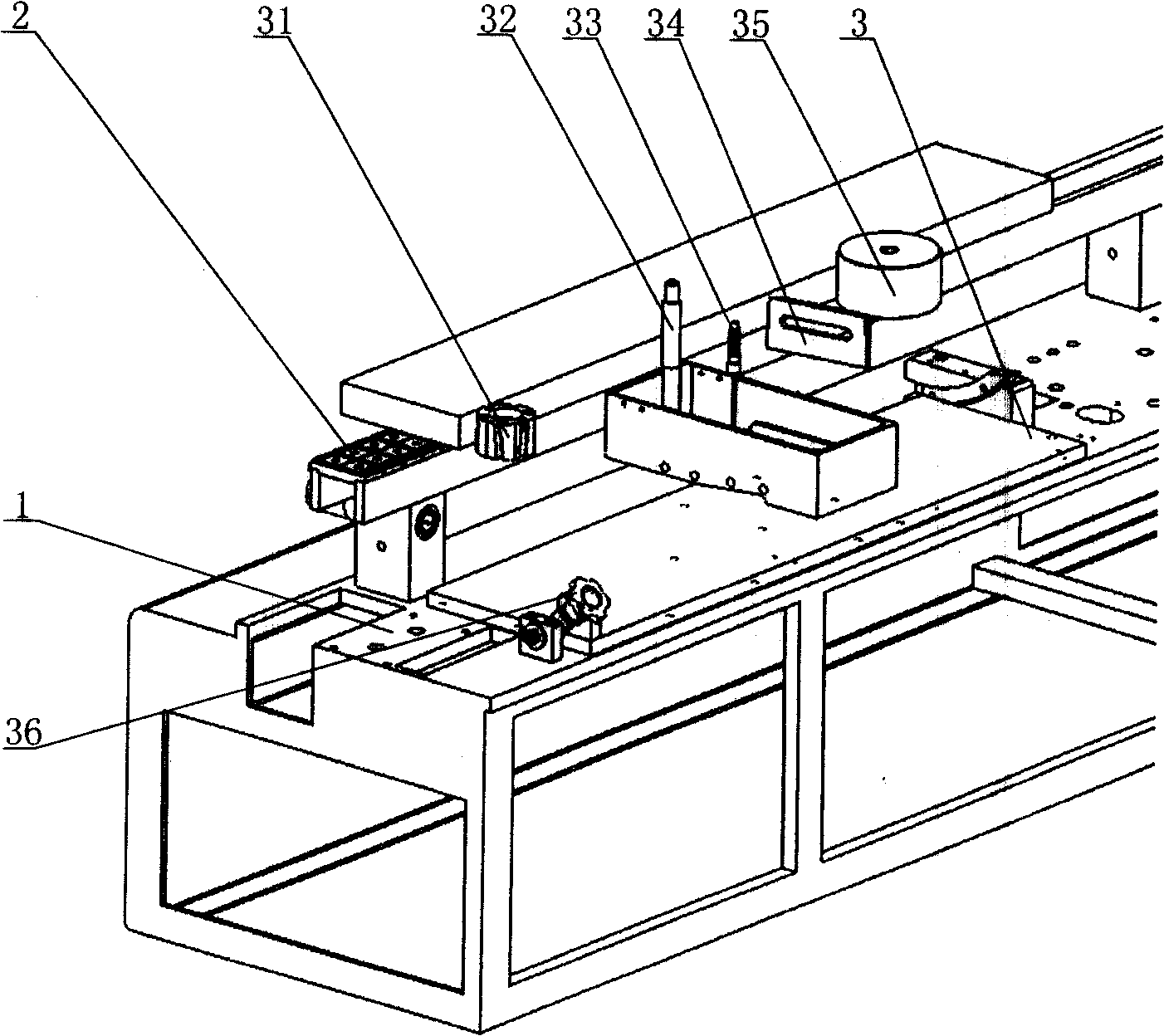

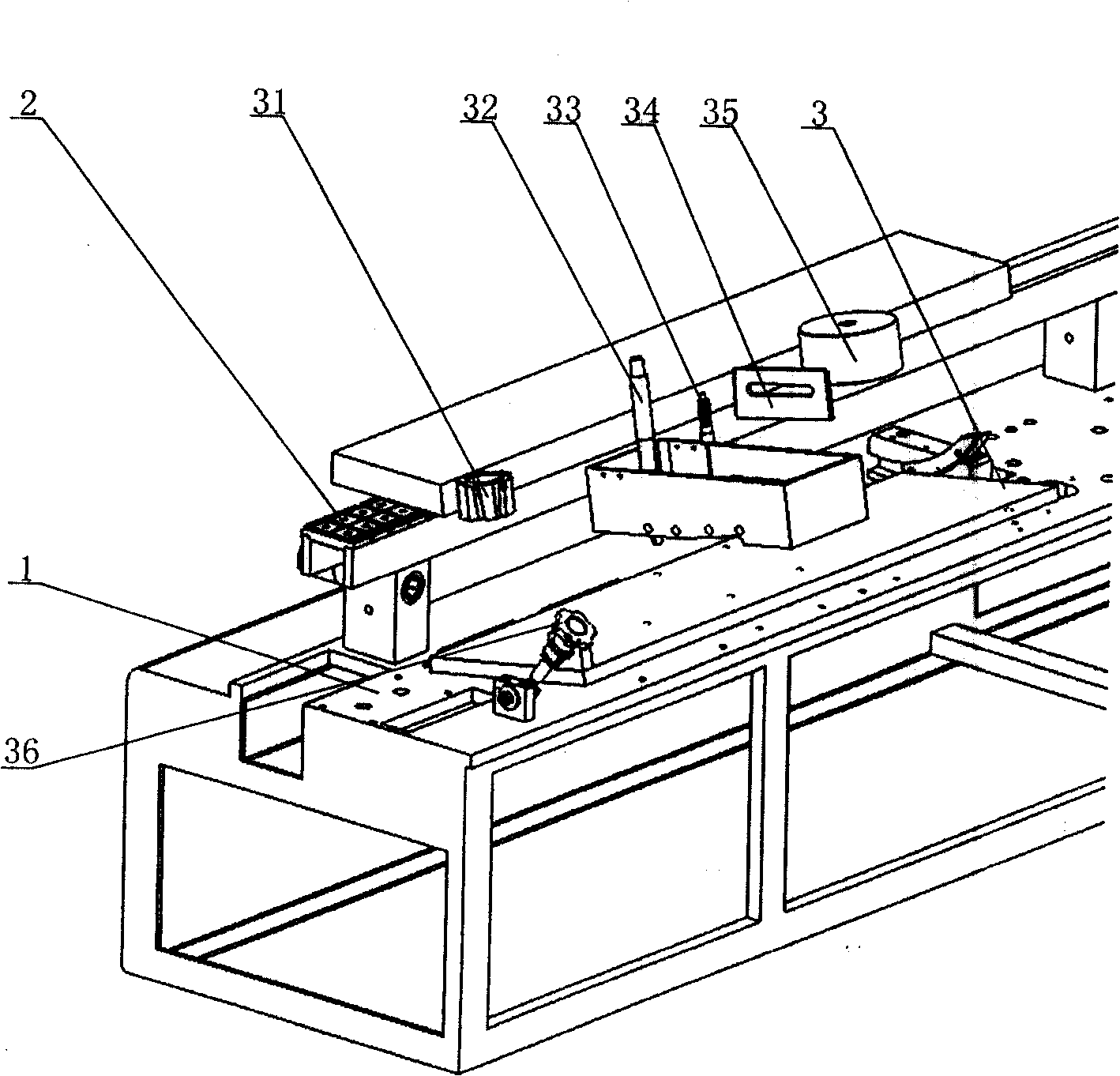

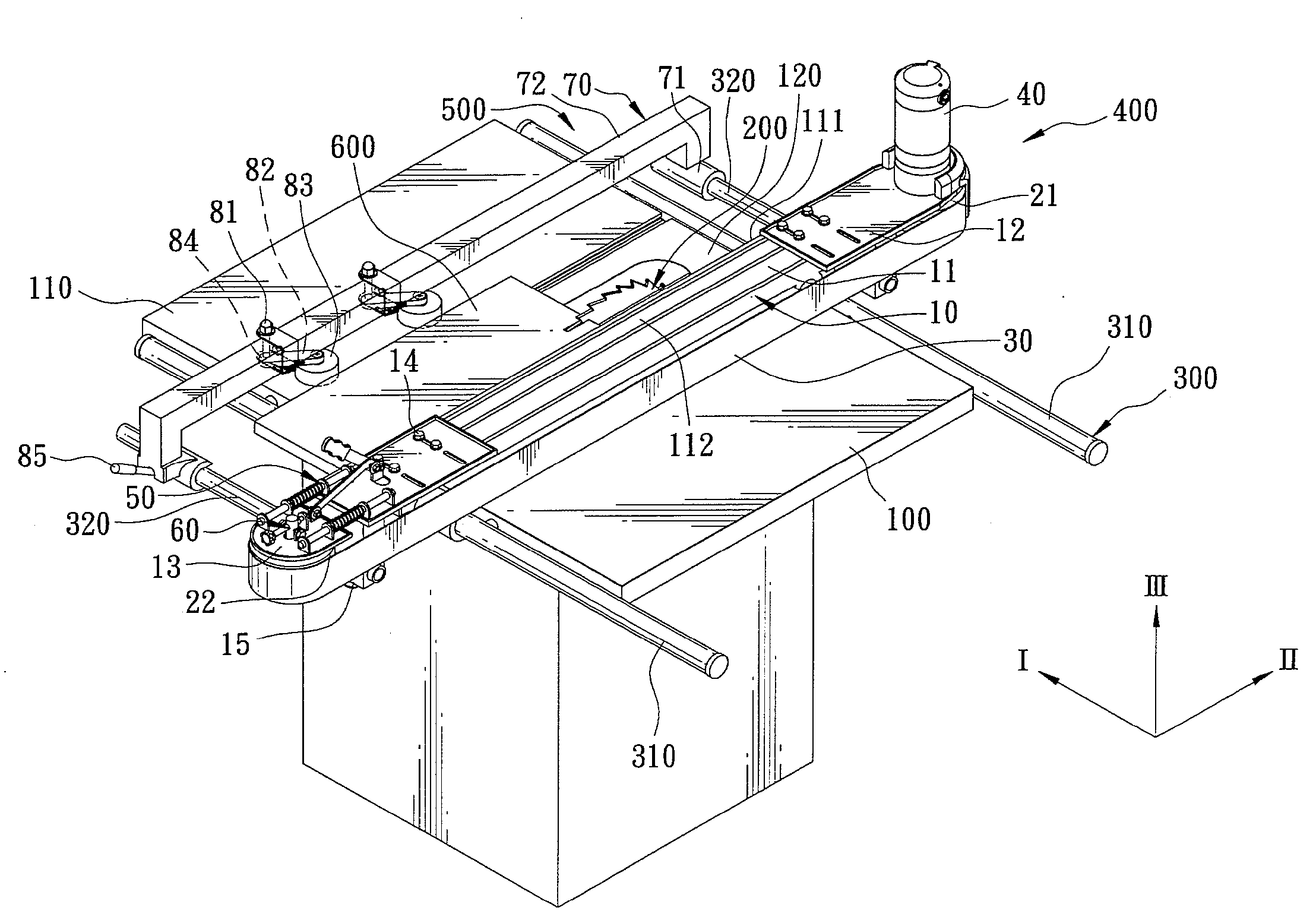

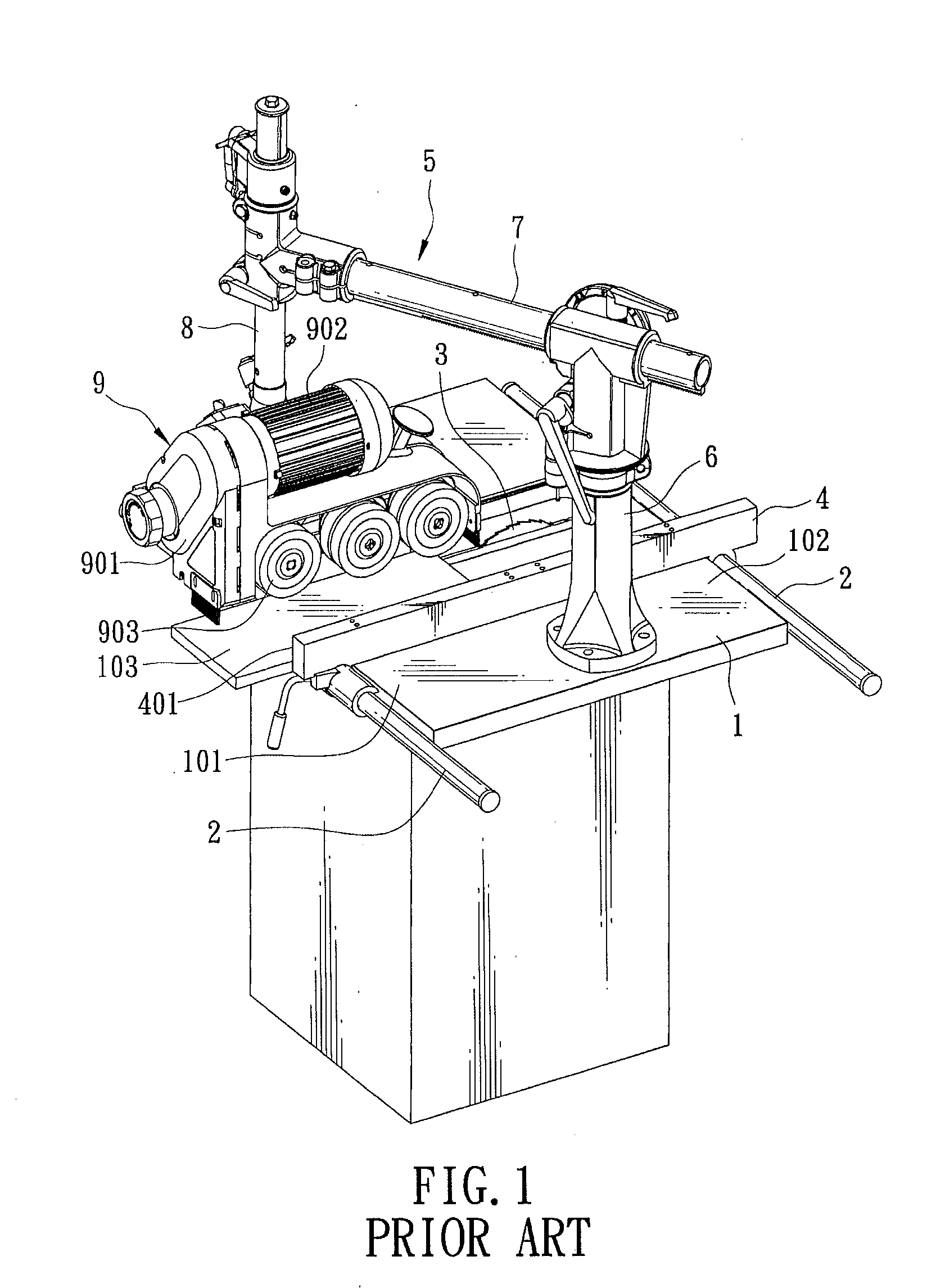

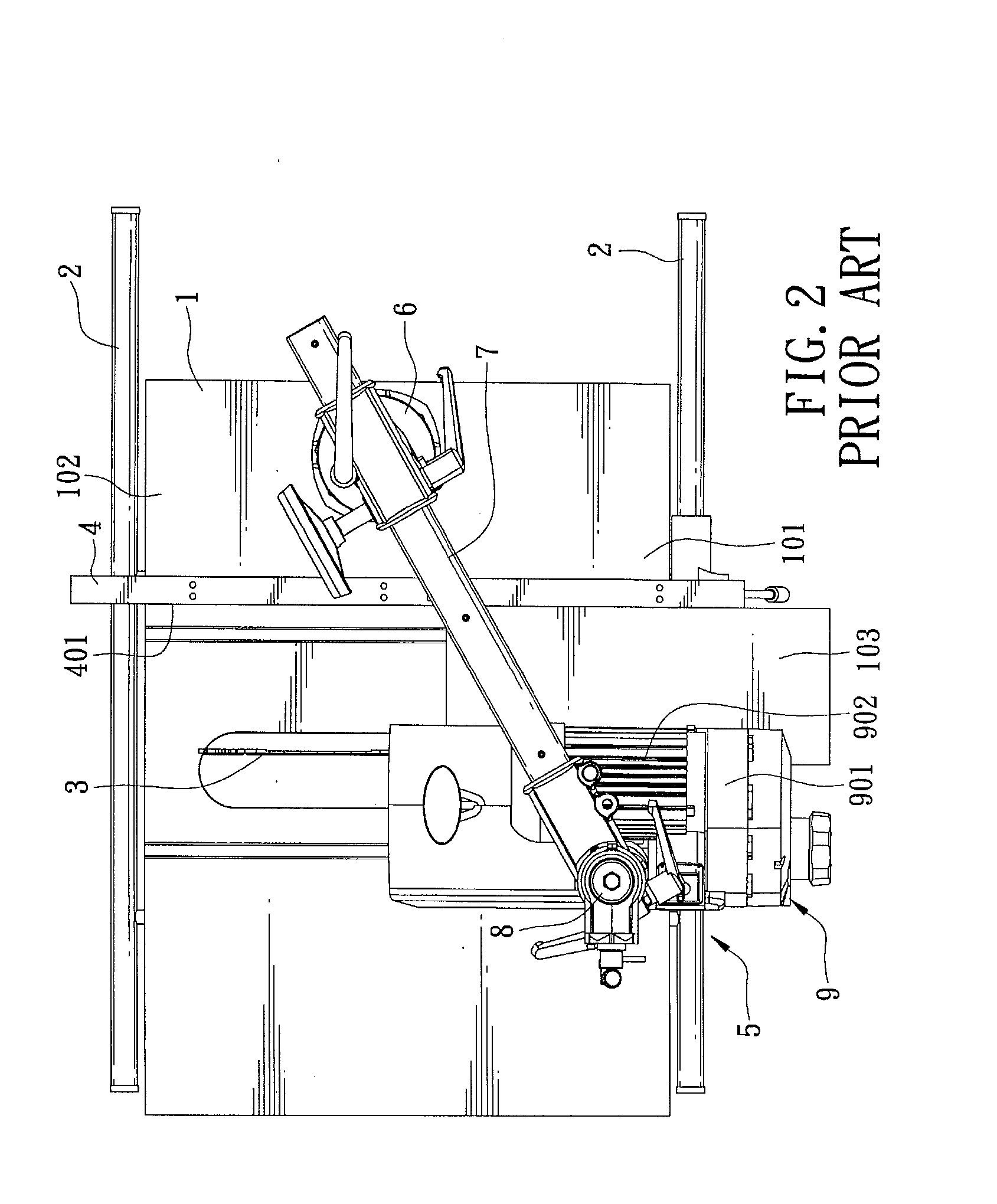

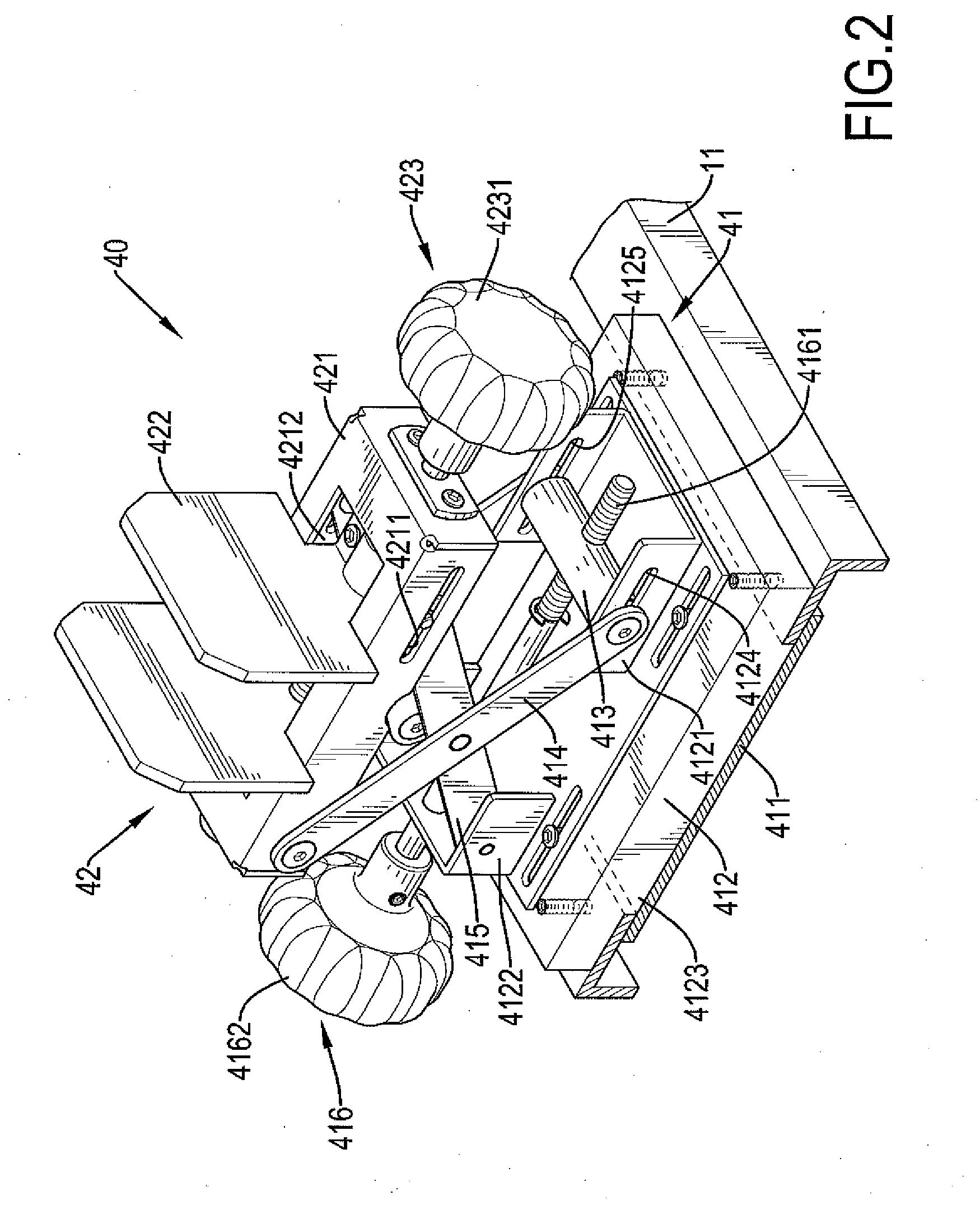

Feeding mechanism for a woodworking machine

InactiveUS7730914B2Overcome disadvantagesWood feeding arangementsFeeding devicesEngineeringWoodworking machine

A feeding mechanism is adapted for use with a woodworking machine. The feeding mechanism includes a rail unit adapted to be disposed on two sides of a worktable, a feeding unit, and a press roller unit. The feeding unit includes a slidable body adapted to extend across the worktable and disposed slidably on the rail unit, two spaced apart rollers disposed on the slidable body, a belt component trained on the rollers, and a driving component for driving the rollers to rotate along with the belt component. The press roller unit is adapted to extend slidably across the worktable and includes a slidable seat disposed slidably on the rail unit, a press roller connected pivotally to the slidable seat, and a resilient component adapted for biasing the press roller to press the workpiece against the feeding unit.

Owner:LIN CHIN CHI

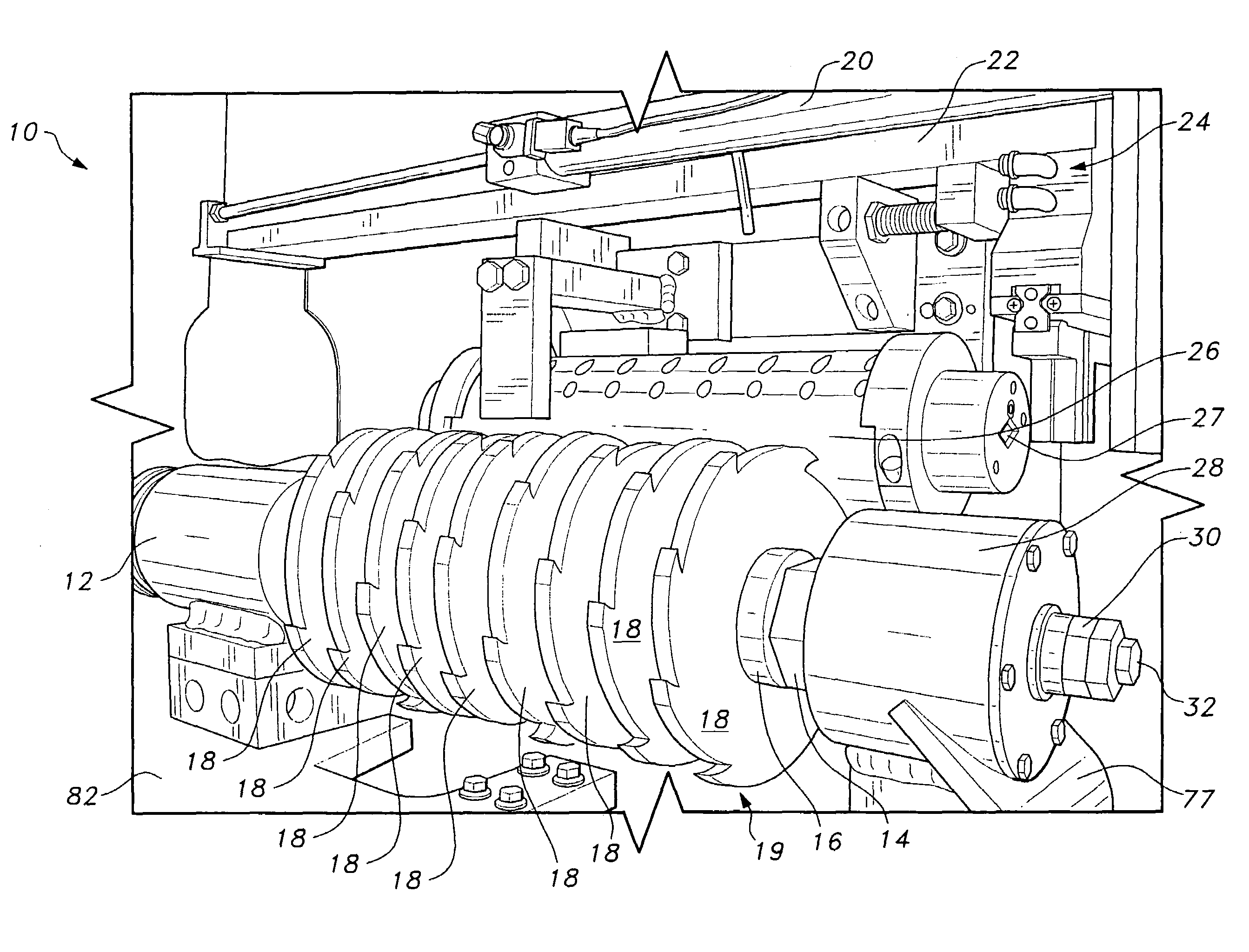

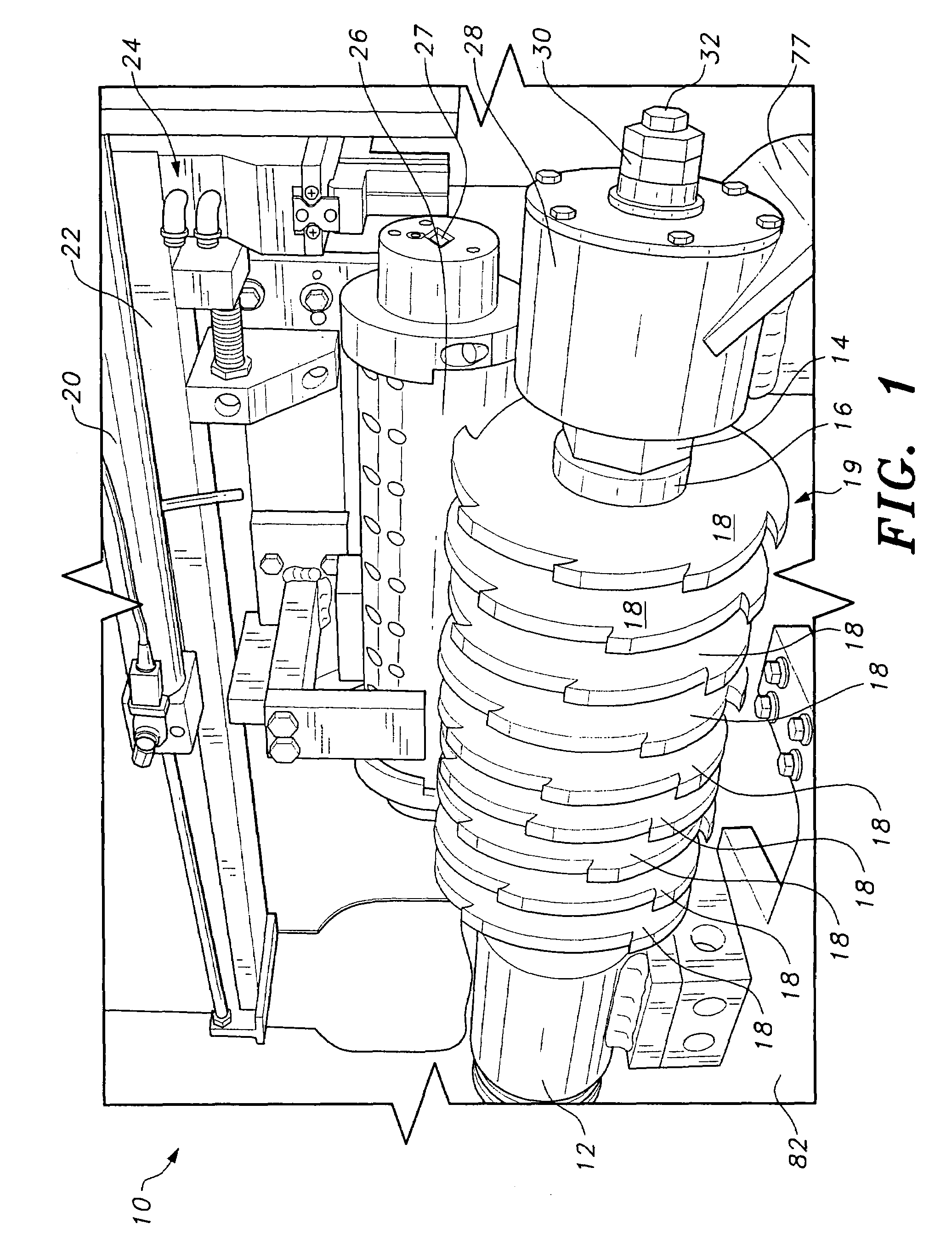

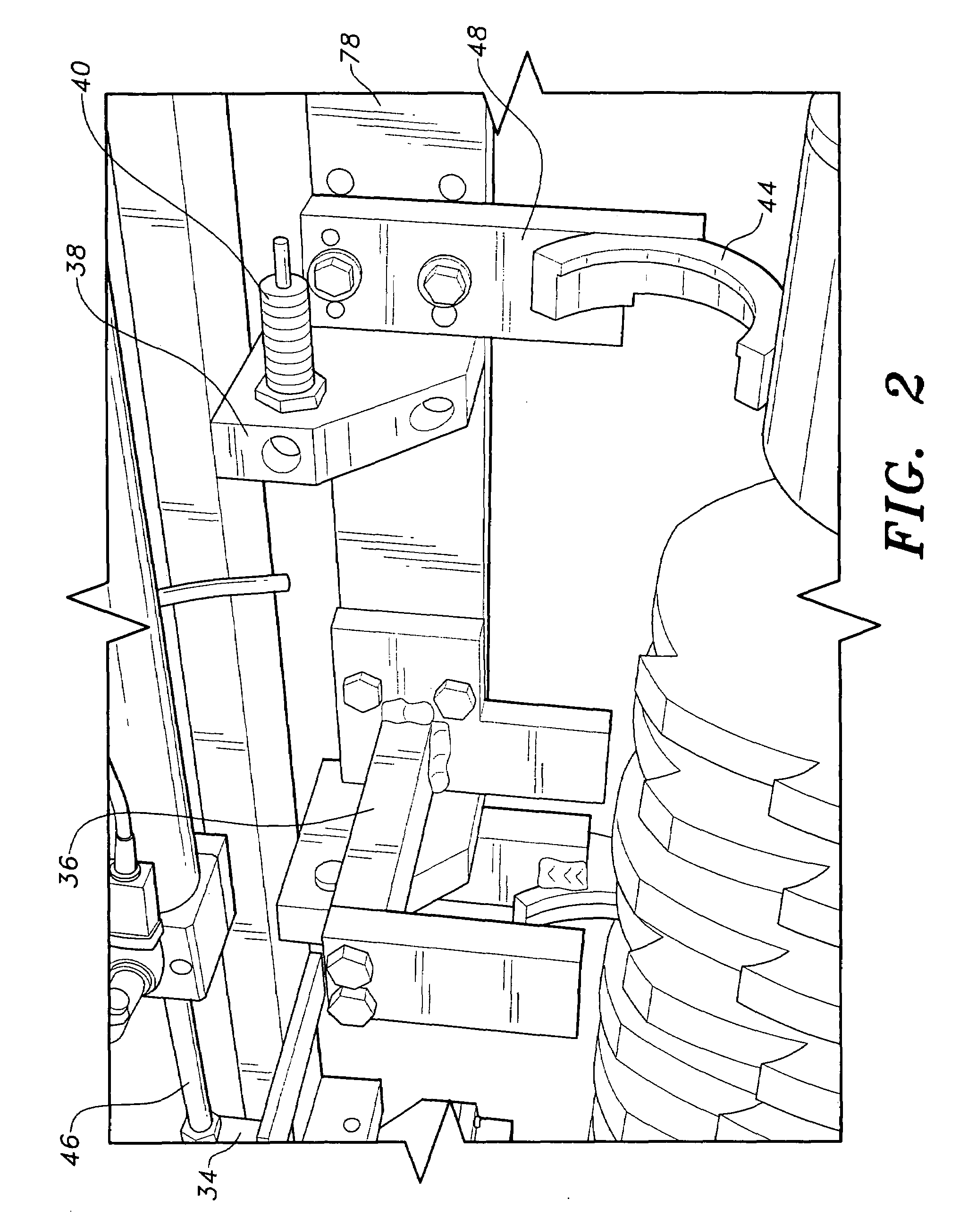

Safety systems for power equipment

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

Woodworking machine comprising a linear direct drive

The aim of the invention is to provide a robust, simple woodworking machine. To achieve this, the invention provides a machine comprising at least one linear direct drive, which contains a primary part (3, 3a, 3b, 4, 4a, 4b) with a first element (9, 10, 12, 14) for generating a first magnetic field and at least one additional element (17, 18, 20, 27, 28, 29, 30) for generating an additional magnetic field. The first element (9) for generating the first magnetic field is positioned, in particular, in such a way in relation to the additional element (17, 18, 20, 27, 28, 29, 30) for generating the additional magnetic field that the first magnetic field overlaps the additional magnetic field. The machine also comprises a secondary part (5, 6, 6a, 6b), which comprises magnetic return elements and is devoid of magnetic sources. According to the invention, the primary part (3, 3a, 3b, 4, 4a, 4b) and / or the secondary part (5, 6, 6a, 6b) is or are suitable for guiding or placing at least one workpiece and / or for guiding and / or placing at least one tool for machining the workpiece.

Owner:SIEMENS AG

Safety systems for power equipment

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem. The machine may also include a bypass or override mode where in an injury mitigation system is disabled for certain cuts.

Owner:SAWSTOP HLDG LLC

Laser Woodworking Machine

InactiveUS20120037274A1Reasonable space requirementImprove the security environmentWooden sticks manufactureMulti-purpose machinesEngineeringLaser cutting

Owner:HENDERSON CHARLES L

Guide device of woodworking machine

ActiveCN102886801ATo achieve the purpose of milling tenon and grooveTongue/grooves making apparatusEngineeringWoodworking machine

The invention discloses a guide device of a woodworking machine, which comprises a machine table, a working table, a traction moving device and a guide device, wherein the machine table is provided with a placing part and at least one first transverse sliding rod, and the placing part is used for placing a work piece; the working table comprises a lifting platform, a first substrate and a second substrate, the lifting platform is arranged between the first substrate and the second substrate, the lifting platform, the first substrate and the second substrate can slide transversely and longitudinally in relative to the machine table, the lifting platform can lift in relative to the machine table, and a cutter is arranged on the lifting platform to mill the work piece; and the traction moving device transversely slides on the first sliding rod, is combined on the working table and can drive the working table to slide transversely and longitudinally in relative to the machine table, and the guide device is used for milling tenon grooves with different distances and sizes according to requirements.

Owner:杨瑞炤

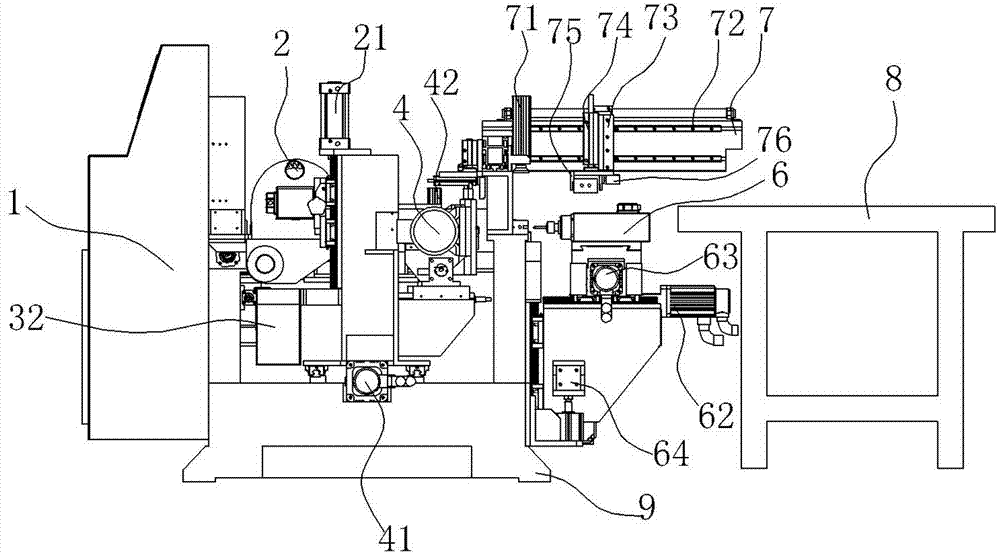

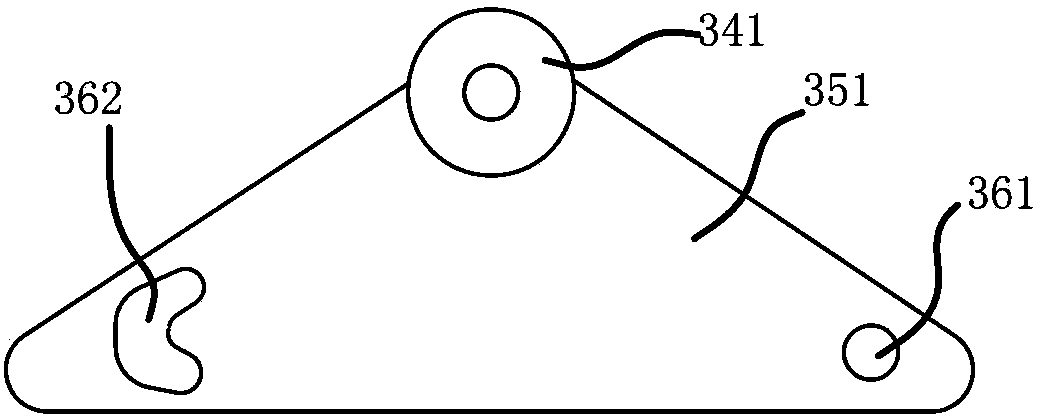

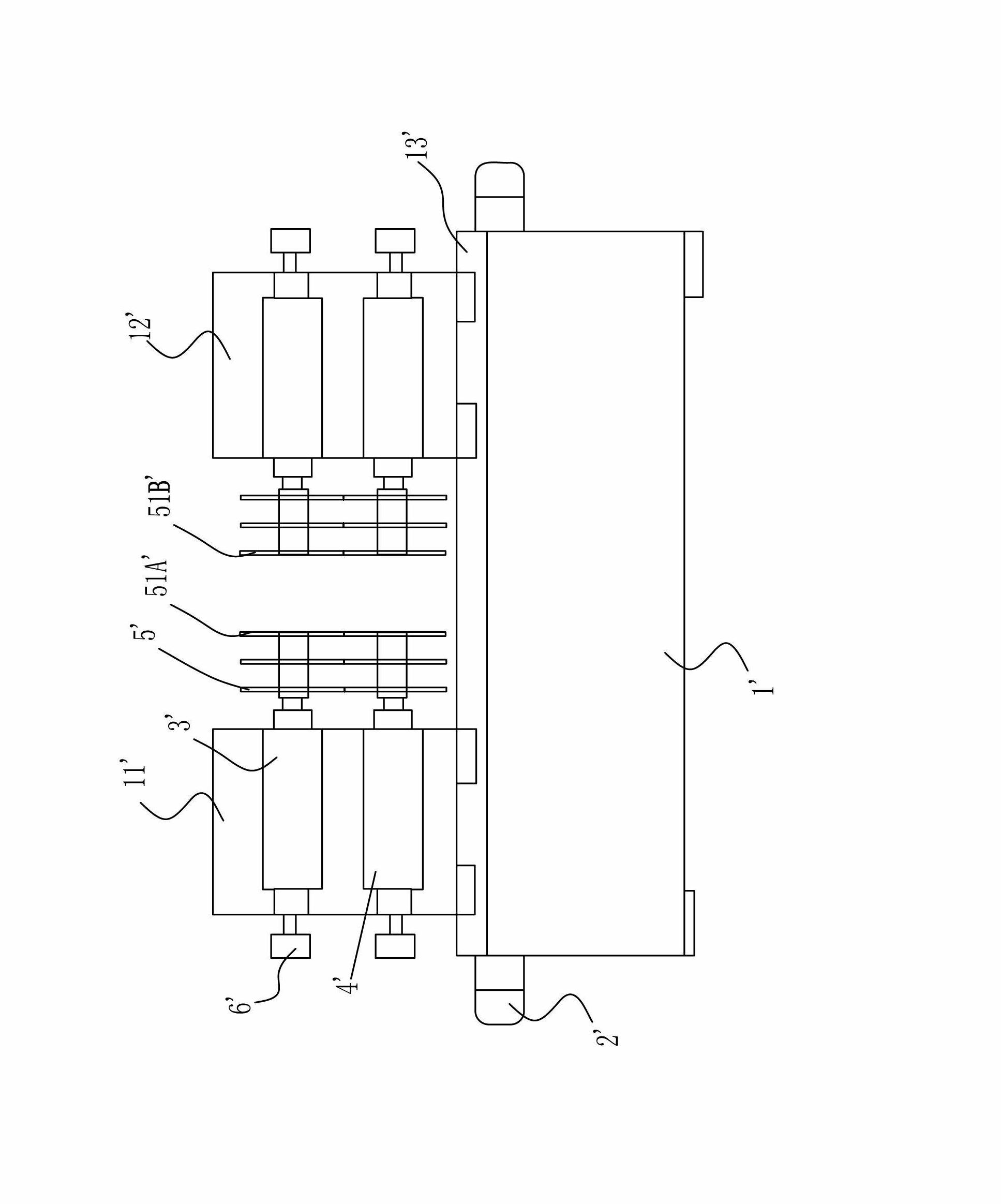

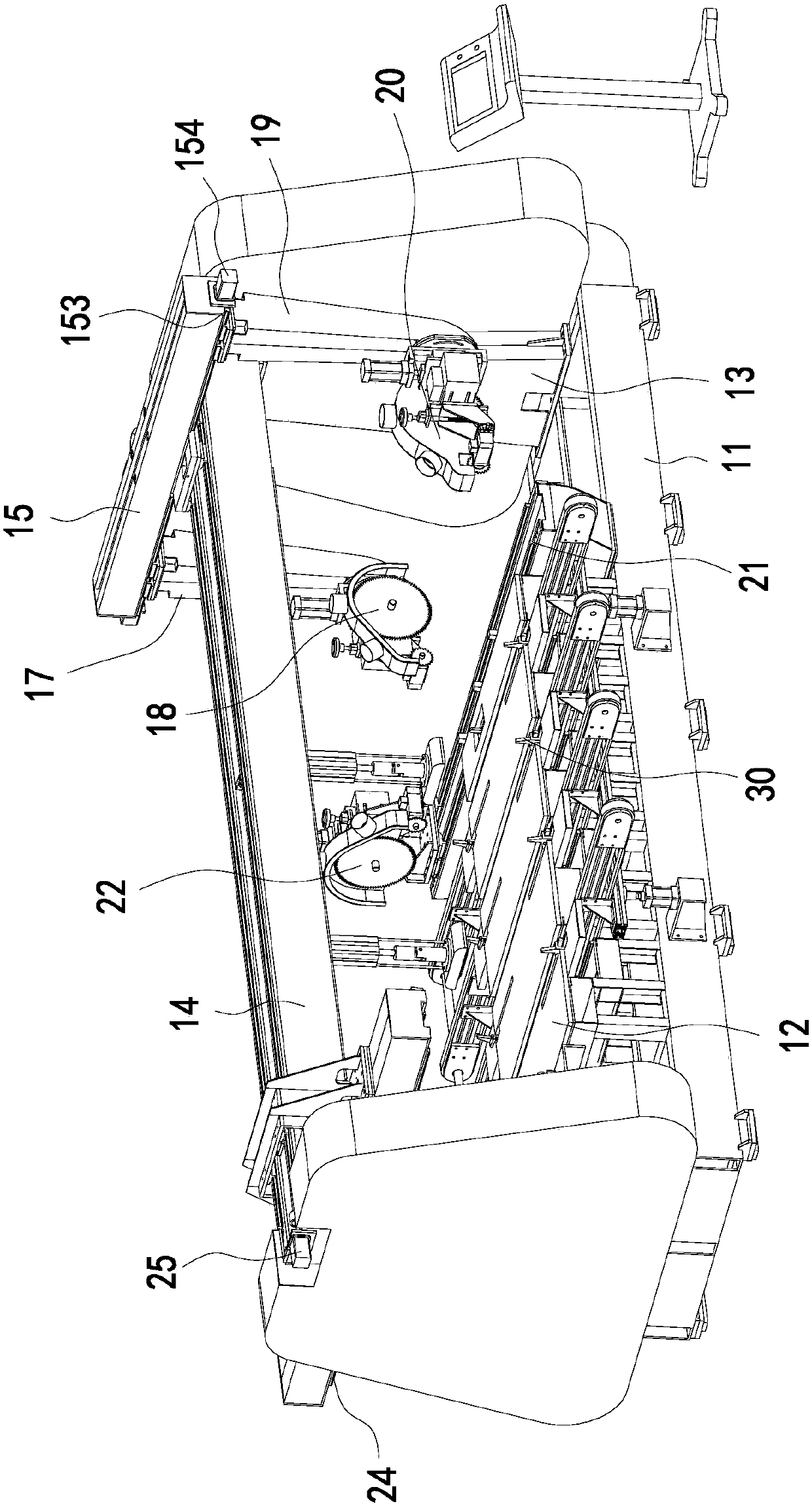

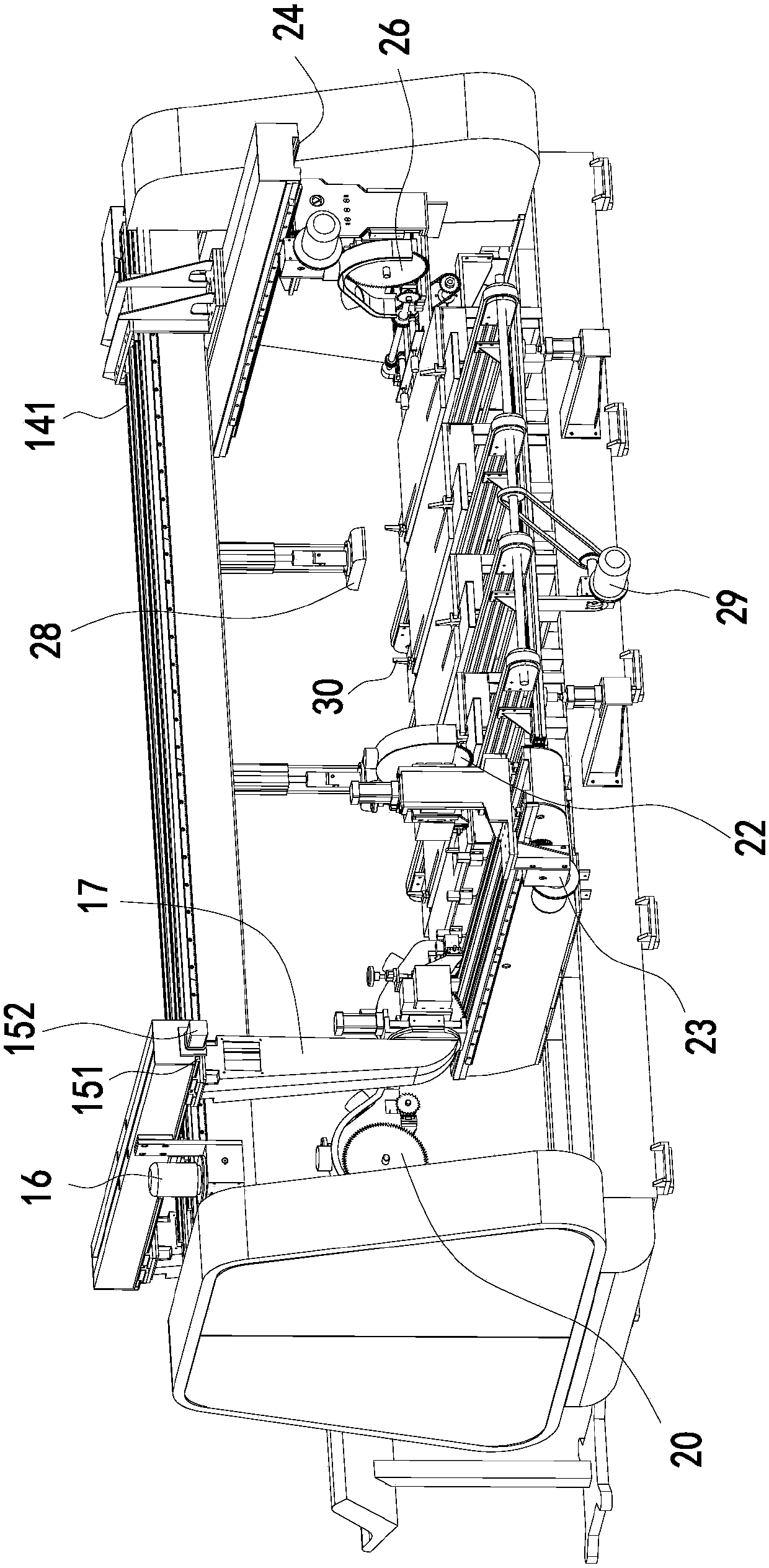

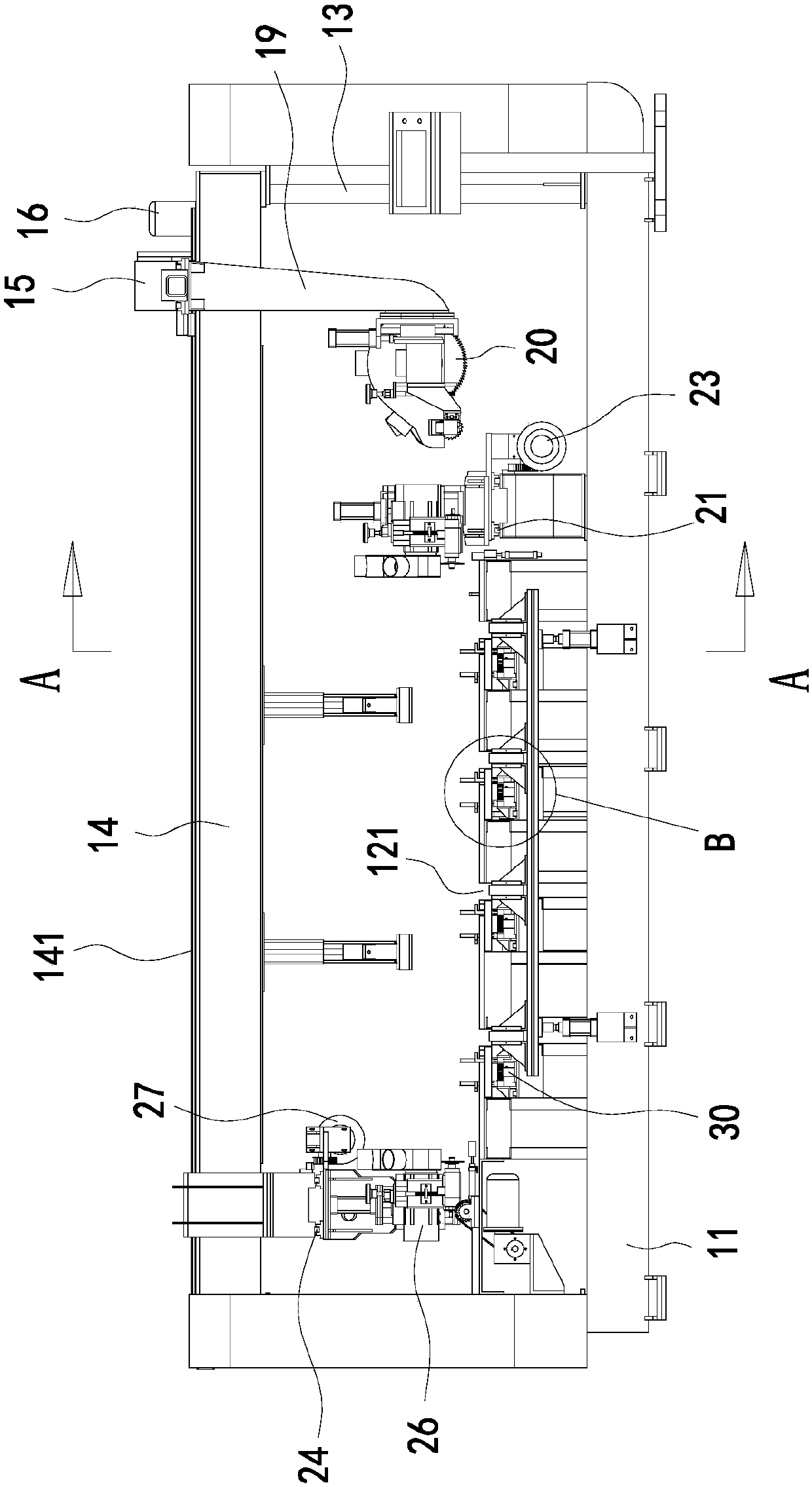

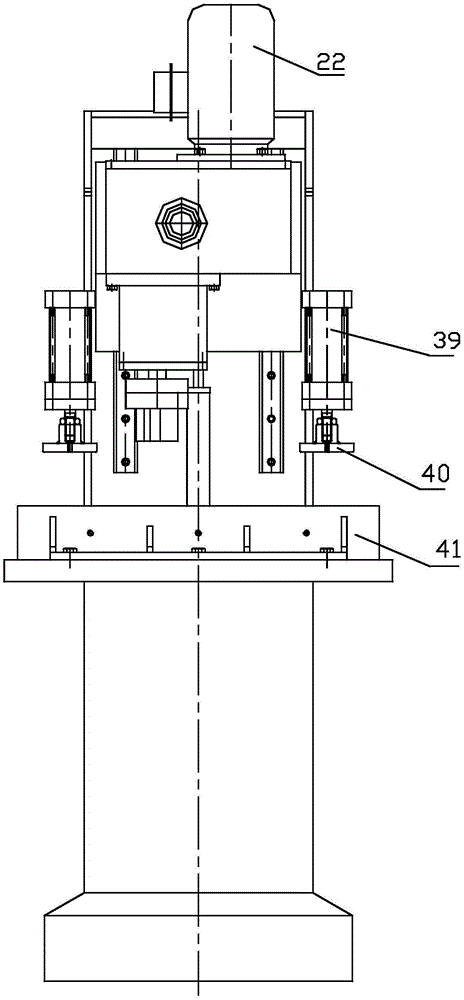

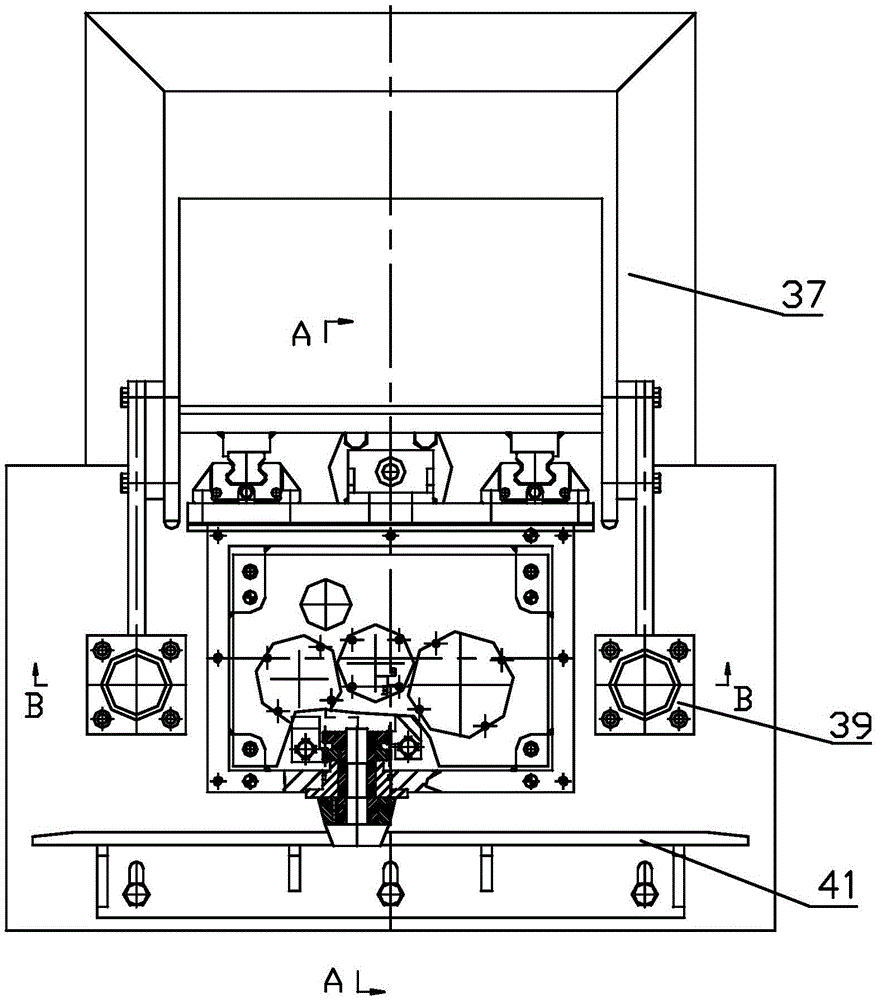

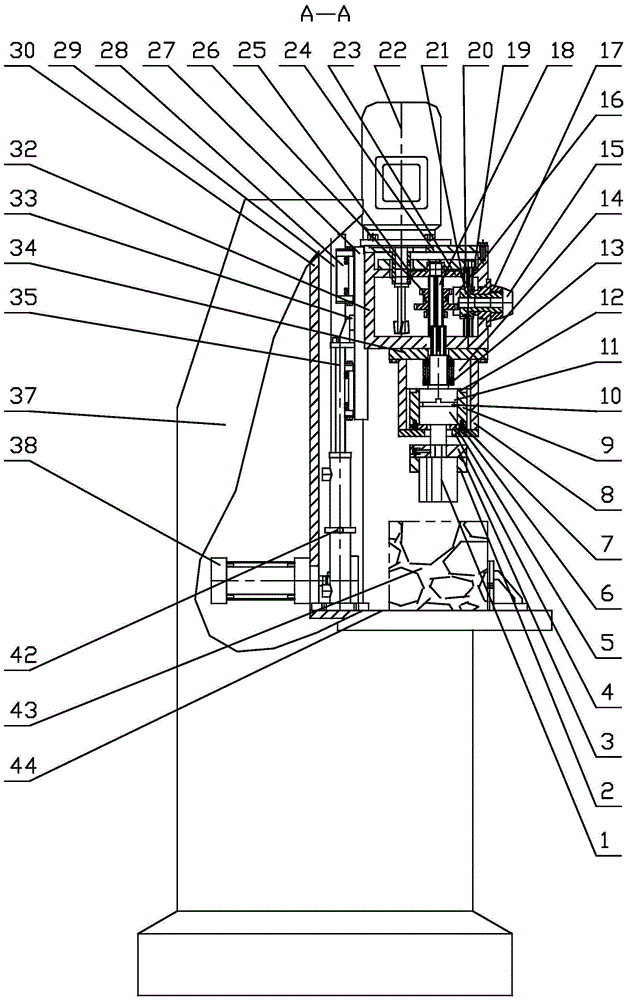

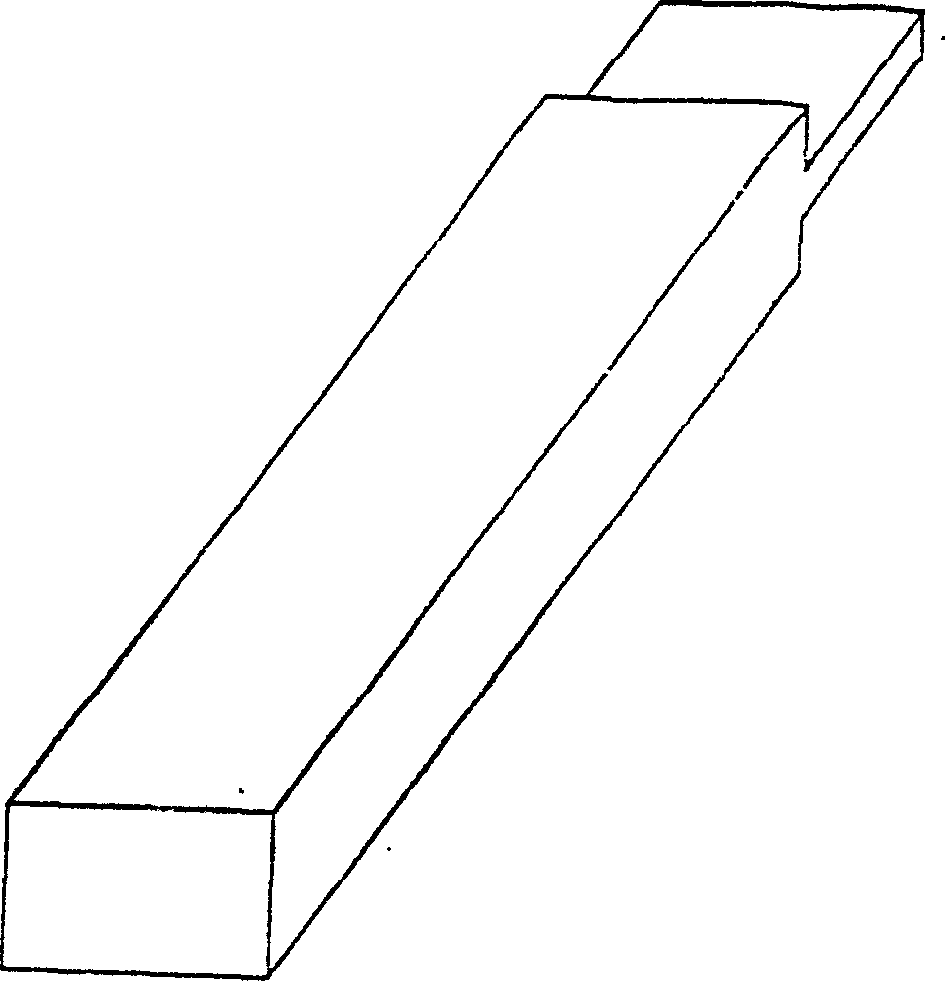

Full-automatic bilateral upper and lower shaft multi-blade woodworking sawing machine

The invention relates to a woodworking machine, and provides a full-automatic bilateral upper and lower shaft multi-blade woodworking sawing machine which is reasonable in structural design and high in sawing accuracy. The distance between saw blades is adjustable and can be relatively adjusted according to the diameter of different raw wood, the use value of the raw wood is high, raw materials are slightly wasted, and boards of various specifications can be processed according to the actual requirement. The machine comprises a machine body, left and right spindle boxes which are respectively arranged on the two longitudinal sides of the machine body and can longitudinally slip along the machine body, and left and right saw shaft assemblies rotatably arranged on the left and right spindle boxes, wherein each of the left and right saw shaft assemblies comprises an upper saw shaft and a lower saw shaft which are respectively arranged at the upper and lower positions of each of the left and right spindle boxes; the same number of saw blade groups are arranged on each independent upper saw shaft and lower saw shaft; each saw blade group comprises a first saw blade, a second saw blade and a combined saw blade; and distance adjusting devices for adjusting the distance between the first saw blade and the second saw blade and the distance between the second saw blade and the combined saw blade are respectively arranged on each upper saw shaft and each lower saw shaft.

Owner:JINJIANG SHENGONG MACHINERY MFG

Tiltable edge treatment woodworking machine tool

InactiveCN101264620AMeet the requirements of edge banding on non-vertical surfacesEasy to operateWood working apparatusDomestic articlesEngineeringWoodworking machine

The invention discloses a tiltable edge sealing woodworking machine, comprising a body and a conveyor table for workpiece, which is characterized in that a tiltable workbench is arranged on the body, the tiltable workbench is provided with an edge milling device, a gelatinizing device, a belt loading device, a belt cutting device and an edge pressing device. By adjusting the corresponding devices according to the angle of edge sealing surface of workpiece to seal the edge of non right angle surface, the woodworking machine has the advantages of convenient operation, high working efficiency and stable machining quality.

Owner:姚永和

Woodworking four-edge cutting machine

InactiveCN107901133AEasy to adjust the positionSimple structureCircular sawsEngineeringWoodworking machine

The invention relates to a woodworking four-edge cutting machine for cutting edges of a plate. The woodworking four-edge cutting machine comprises a lathe body, a working table, a vertical column, a cross beam, a longitudinal beam, a transverse feeding mechanism, a first crane jib, a first longitudinal adjusting mechanism, a first transverse cutting saw, a second crane jib, a second longitudinal adjusting mechanism, a second transverse cutting saw, a first longitudinal guide rail, a first longitudinal cutting saw, a first longitudinal feeding mechanism, a second longitudinal guide rail, a transverse adjusting mechanism, a second longitudinal cutting saw, a second longitudinal feeding mechanism, a compressing mechanism and an automatic feeding mechanism. The first transverse cutting saw andthe second transverse cutting saw are symmetrically distributed along the central line of the cross beam, an automatic centering mechanism is arranged in a longitudinal groove of the working table soas to allow a to-be-machined plate to be symmetrically distributed along the central line of the cross beam. The woodworking four-edge cutting machine is simple and reasonable in structure, and the machining efficiency is high. Because the first transverse cutting saw and the second transverse cutting saw are symmetrically distributed, position adjustment of the plate is facilitated, the machining precision and the production efficiency are improved greatly, and the service life is prolonged.

Owner:罗嘉航

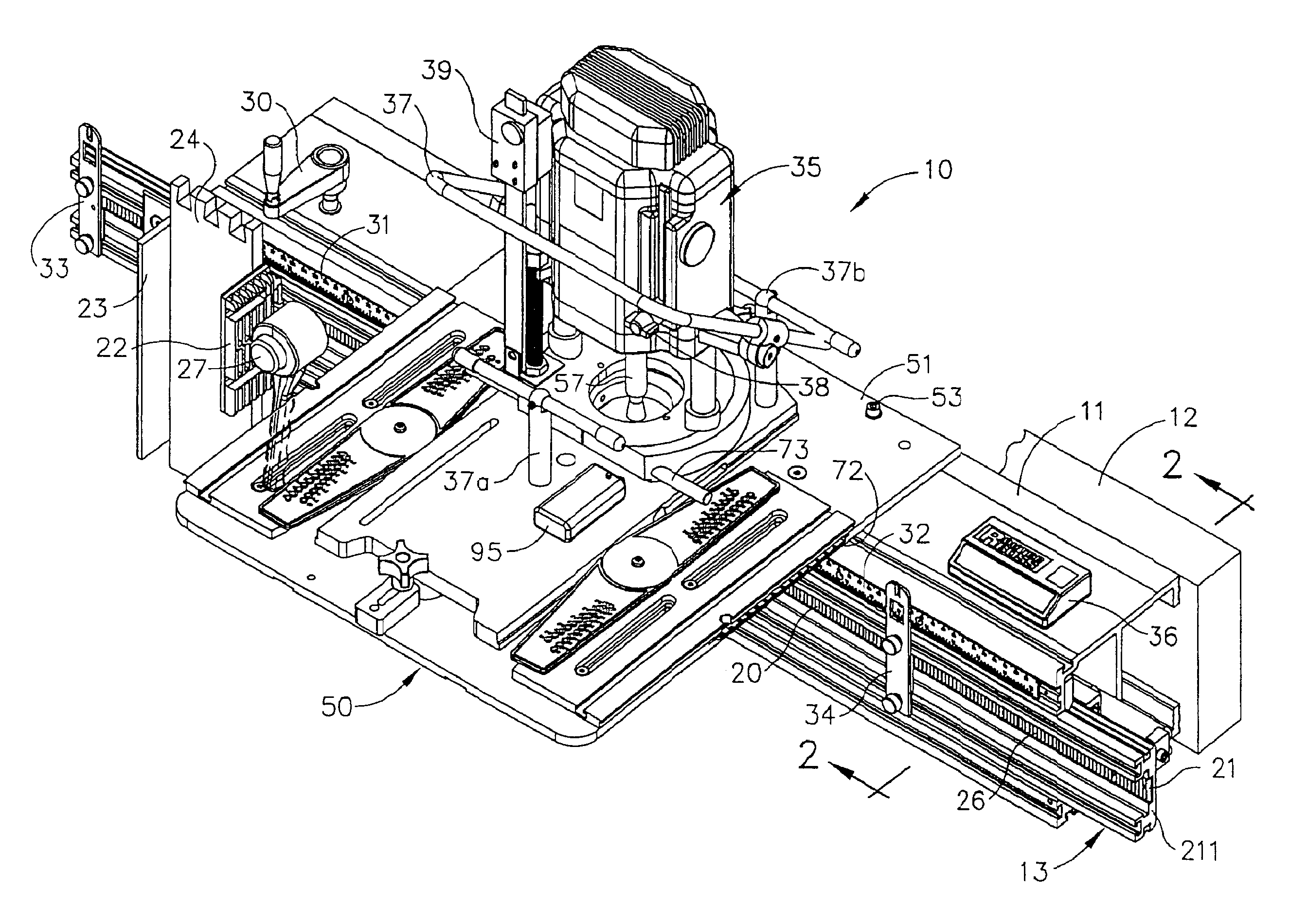

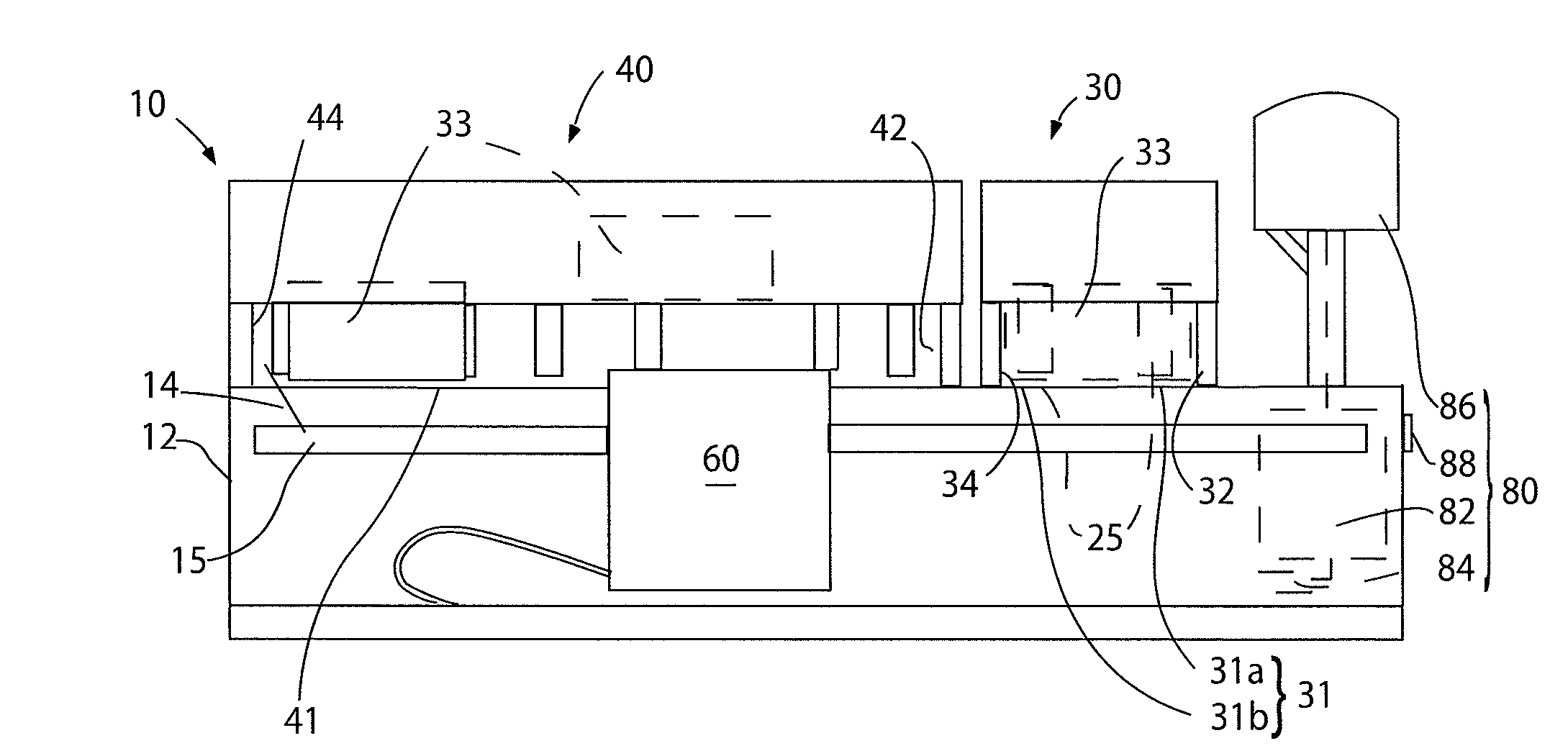

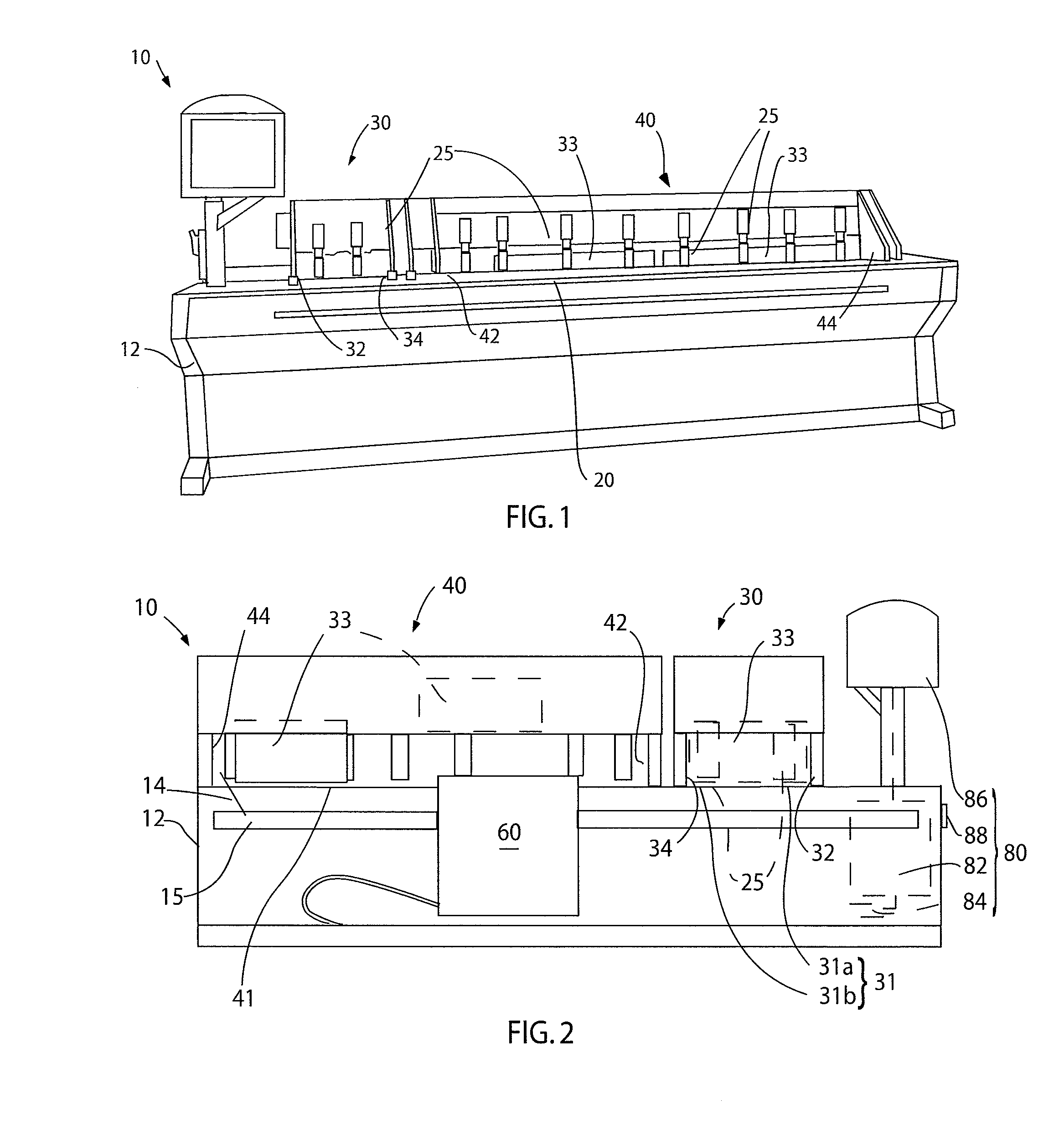

Apparatus and methods for shaping and machining elongate workpieces

InactiveUS20100154934A1Avoid badMinimize visibilityTongue/grooves making apparatusMulti-purpose machinesWoodworking machineVisible surface

The present invention includes methods in which work pieces are machined based upon the appearance of their surfaces. The work piece may be processed in such a way that surfaces with desirable features may be oriented so as to form visible surfaces of a finished part. In addition, the present invention includes woodworking machines that define joint features in and shape surfaces of rough work pieces.

Owner:HATCH JR J MELVON +1

Feeding mechansim for a woodworking machine

InactiveUS20090133779A1Overcome disadvantagesWood feeding arangementsFeeding devicesEngineeringWoodworking machine

A feeding mechanism is adapted for use with a woodworking machine. The feeding mechanism includes a rail unit adapted to be disposed on two sides of a worktable, a feeding unit, and a press roller unit. The feeding unit includes a slidable body adapted to extend across the worktable and disposed slidably on the rail unit, two spaced apart rollers disposed on the slidable body, a belt component trained on the rollers, and a driving component for driving the rollers to rotate along with the belt component. The press roller unit is adapted to extend slidably across the worktable and includes a slidable seat disposed slidably on the rail unit, a press roller connected pivotally to the slidable seat, and a resilient component adapted for biasing the press roller to press the workpiece against the feeding unit.

Owner:LIN CHIN CHI

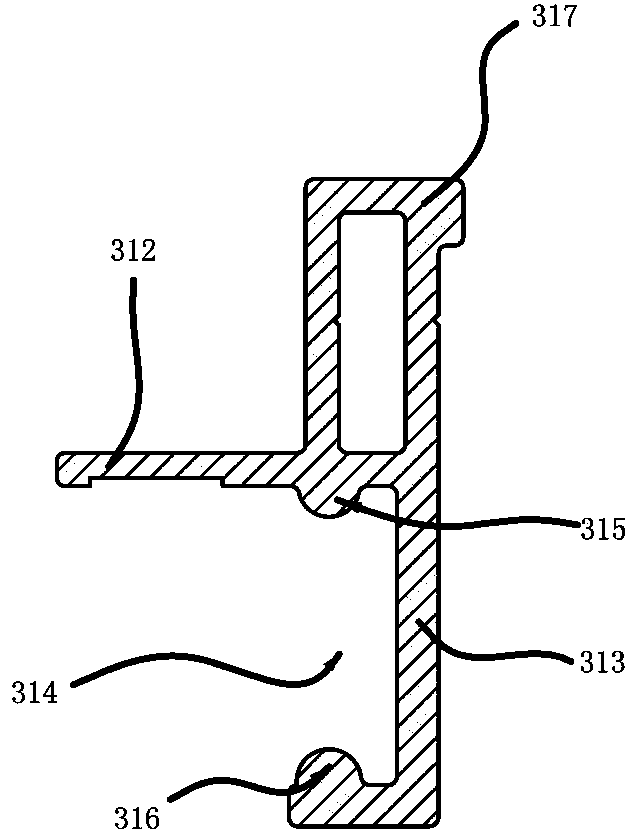

Woodworking square hole drilling machine and three-blade drill bit

ActiveCN105479551AImprove machining accuracyHigh precisionStationary drilling machinesWood turning toolsEngineeringWoodworking machine

The invention relates to the field of woodworking machines, and provides a woodworking square hole drilling machine and a three-blade drill bit. The woodworking square hole drilling machine comprises a lathe bed, a motor, a drive unit and the three-blade drill bit. The drive unit is arranged below the motor and arranged on the lathe bed in a sliding manner in the vertical direction. The drive unit comprises a gearbox and a drill sleeve fixedly arranged below the gearbox. An output shaft of the motor stretches into the gearbox and is meshed with a camshaft through a plurality of gears and a spline shaft. The camshaft penetrates out of the gearbox and stretches into the drill sleeve. A square sleeve is sleeved with the drill sleeve, and a groined guide frame for limiting the movement direction of the square sleeve is fixedly arranged in the drill sleeve. A cam is arranged at the bottom of the camshaft and stretches into the square sleeve. A Reuleaux triangle block is arranged in the square sleeve, and the cam and the Reuleaux triangle block are connected through a cross connector. An output shaft of the Reuleaux triangle block penetrates out of the drill sleeve and is connected with the three-blade drill bit. According to the woodworking square hole drilling machine and the three-blade drill bit, the efficiency for manufacturing a square hole can be improved, labor intensity is lowered, and the precision for machining the square hole is improved.

Owner:YINGKOU XINBAIYUN MACHINERY CO LTD

Multifunctional single side tenon-making machine for carpenter

InactiveCN1803417AReasonable layoutEasy to useWood mortising machinesWood slotting machinesEngineeringMachine tool

The invention discloses a multifunctional carpentry single-sided tenon-making machine, which comprises the following parts: machine body, working bench and clamp device on the machine body board, wherein the end saw, tenon knife rack, level knife shaft and vertical knife shaft are assembled on the front and back of machine body.

Owner:何沛佳

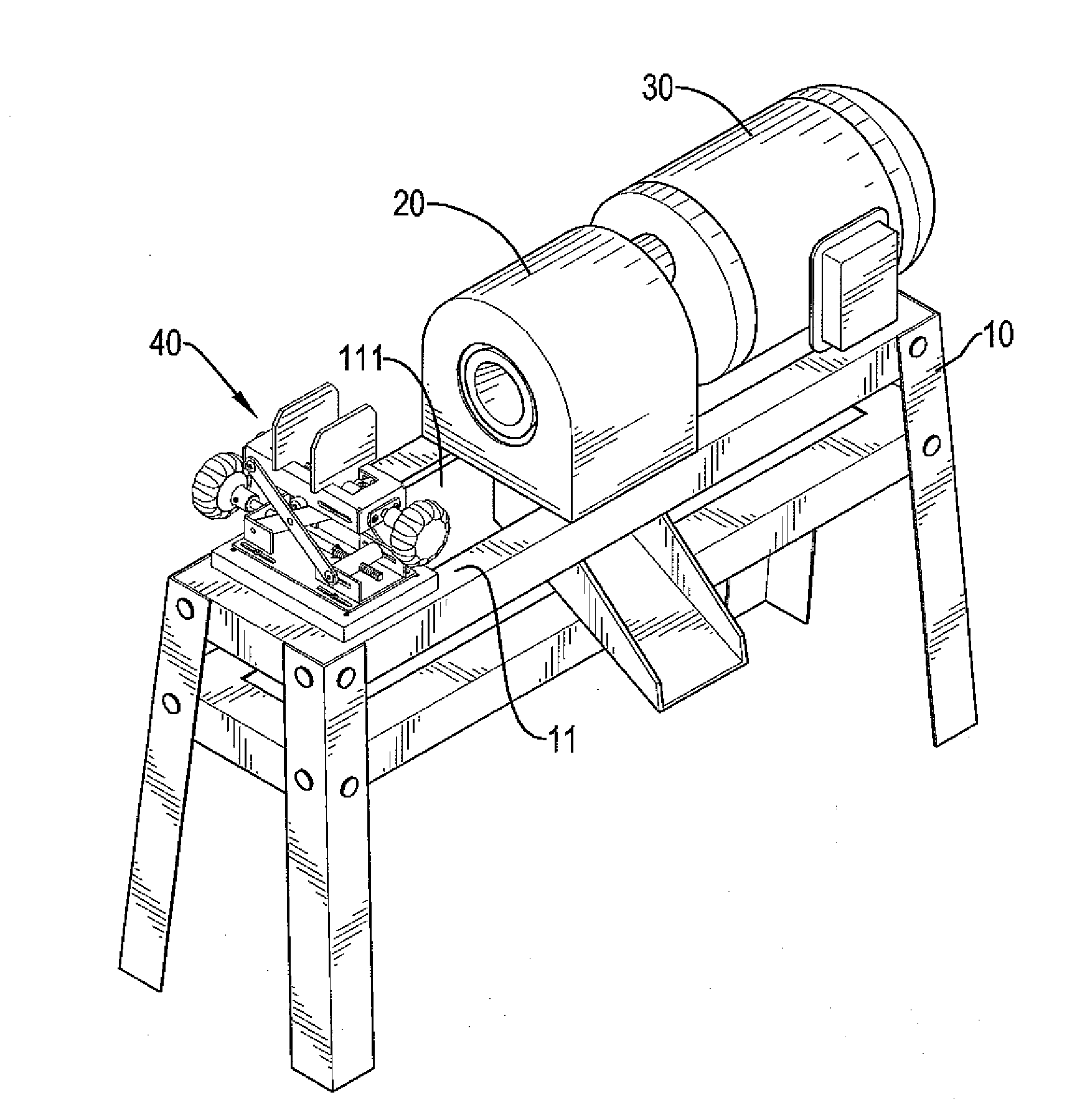

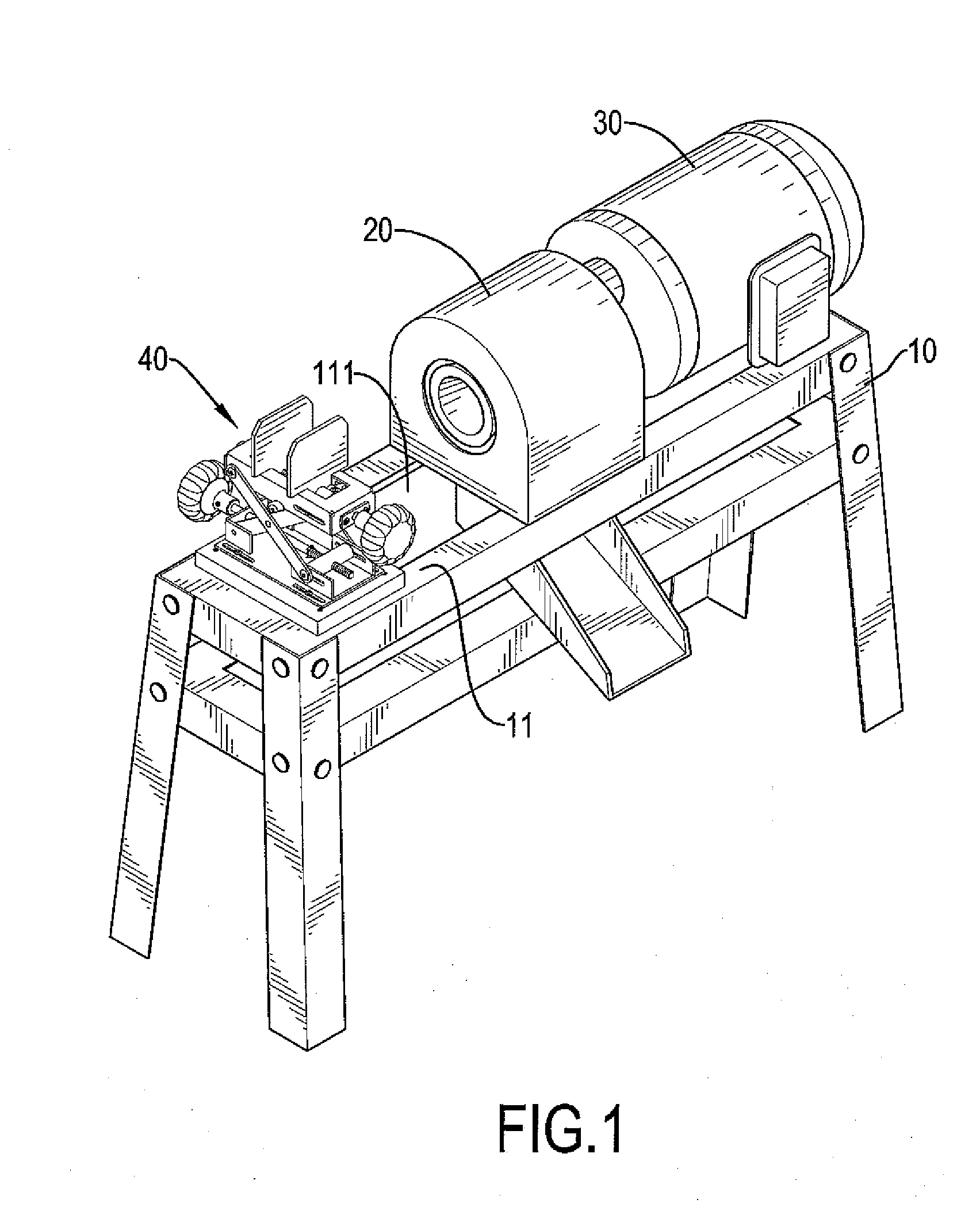

Woodworking Machining Apparatus

InactiveUS20130048149A1Prevent disengagementWood-turning machinesProfiling/shaping machinesEngineeringWoodworking machine

A woodworking machining apparatus includes a bed, a machining assembly, a driving mechanism and a clamping mechanism. The clamping mechanism is mounted on the bed and is movable relative to the machining assembly. The clamping mechanism has a height adjuster and a holding adjuster. The height adjuster includes a height adjusting base, a sliding rod, first connecting rod, a second connecting rod, a height adjusting lever and a stabilizing board for stably lifting the holding adjuster. The holding adjuster includes a holding base, two clamping sheets and a holding lever for keeping a wood workpiece in a middle of the holding adjuster. The wood workpiece is clamped between the clamping sheets and is lifted by the height adjuster. Therefore, an axis of the wood workpiece can be aligned with the machining assembly.

Owner:LIU RONG CHENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com