Full-automatic bilateral upper and lower shaft multi-blade woodworking sawing machine

A fully automatic, multi-piece technology, applied to wood processing equipment, circular saws, sawing equipment, etc., can solve the problems of not being able to saw the best sawing position of the log, and not being able to adjust the relative adjustment of the size and shape changes, so as to improve the utilization Value, high sawing precision, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

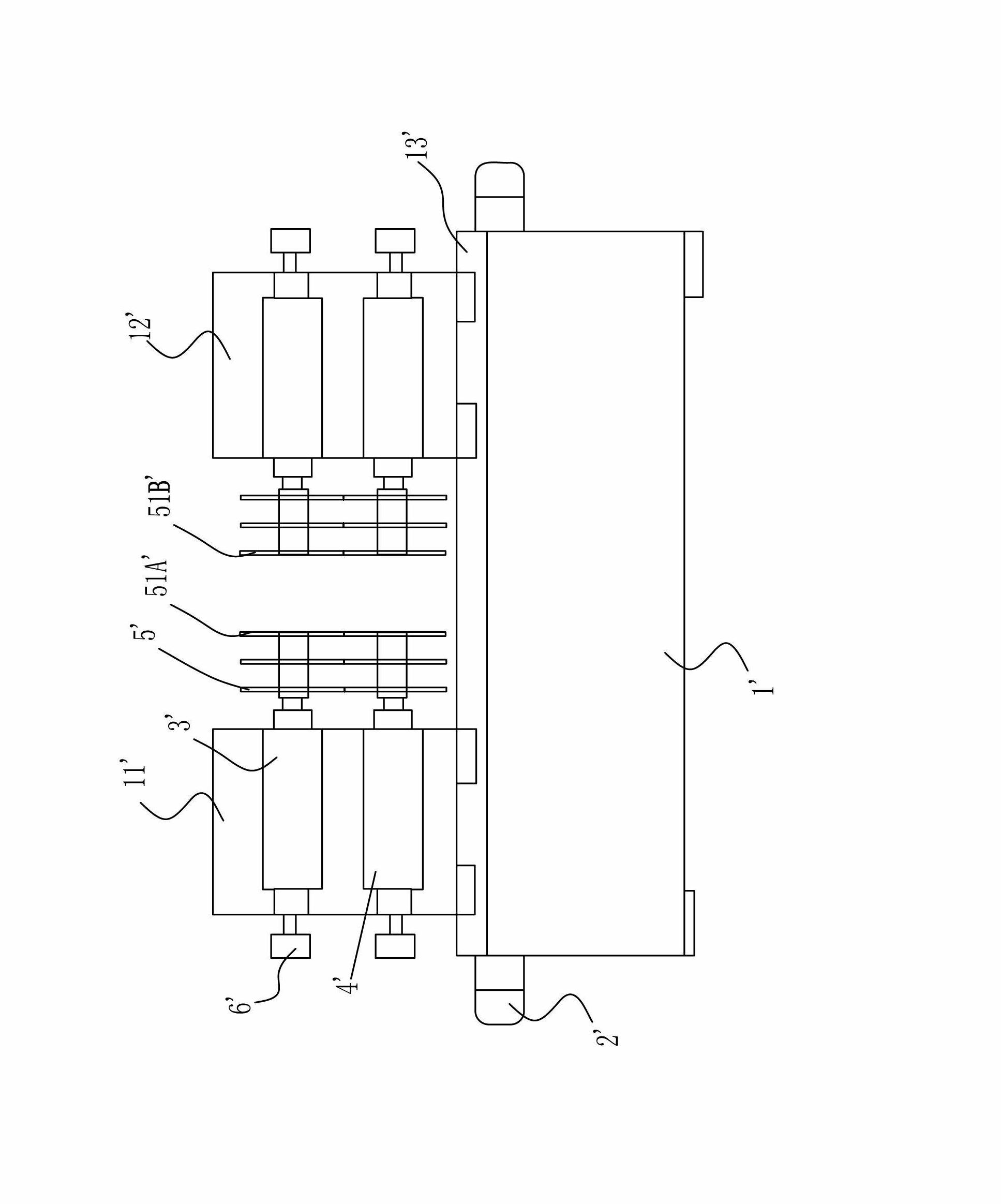

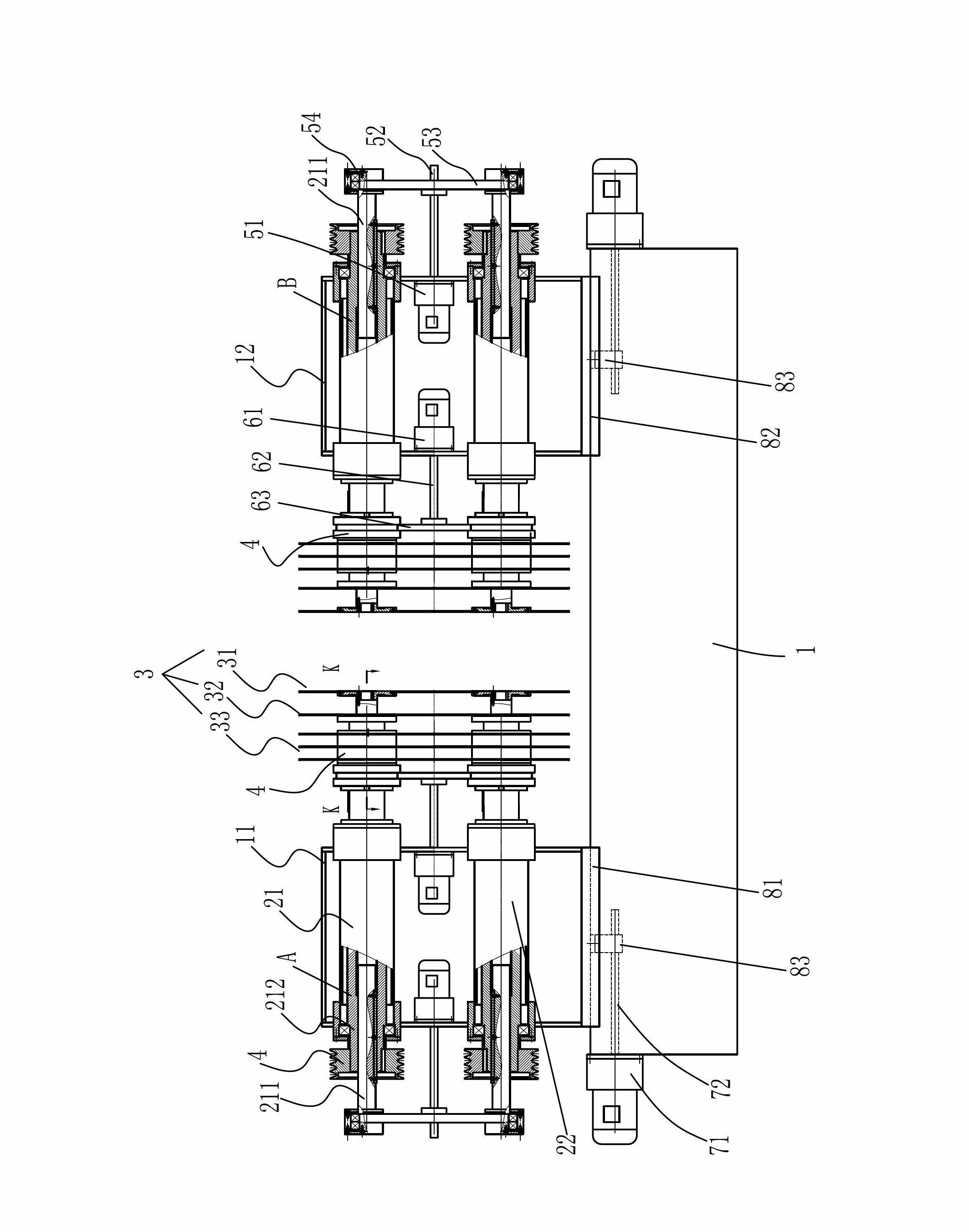

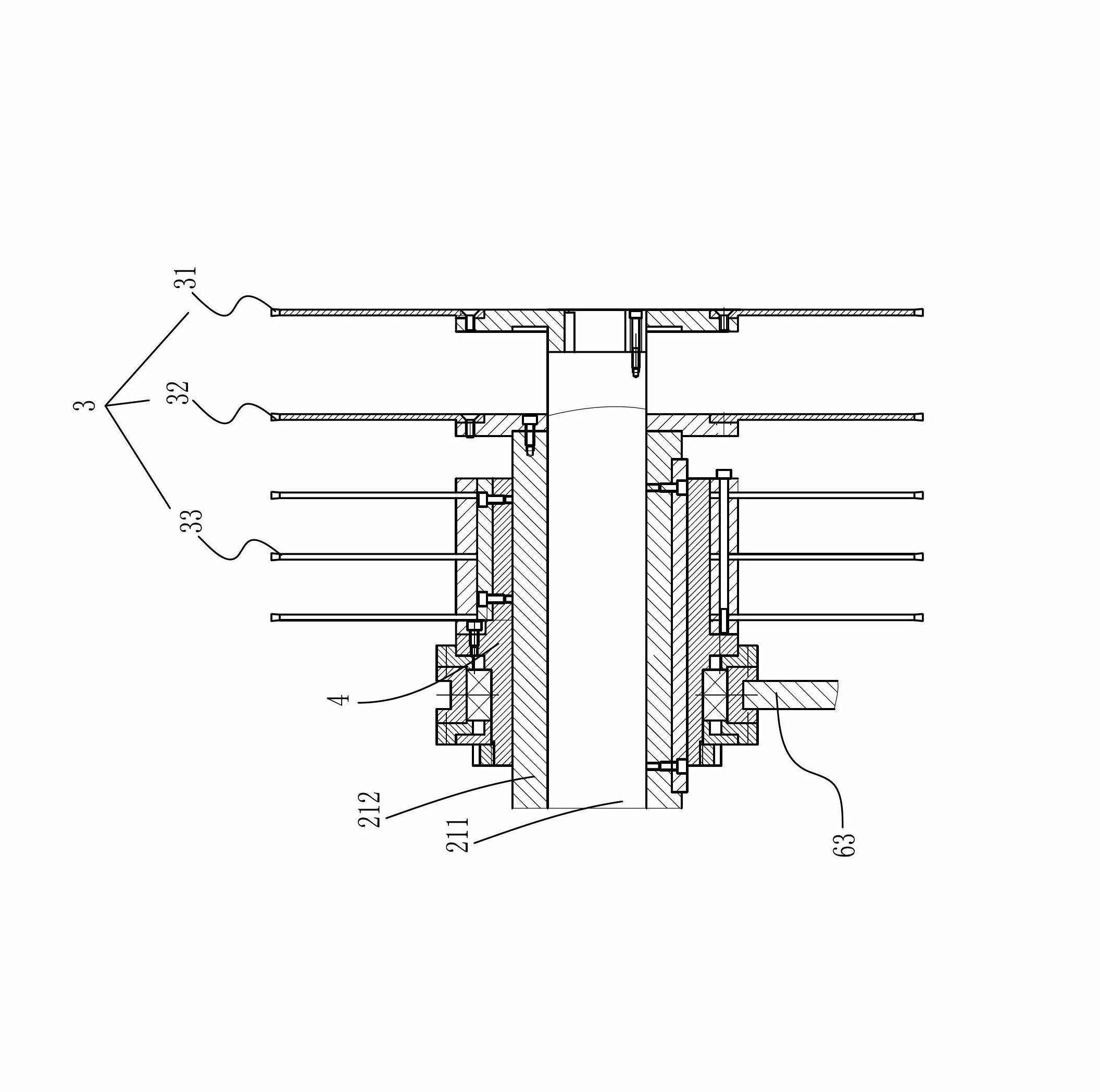

[0020] refer to Figure 2 to Figure 3 , this embodiment discloses a fully automatic two-sided upper and lower axis multi-piece woodworking sawing machine, including a bed 1, a left spindle box 11 respectively arranged on both longitudinal sides of the bed 1 and capable of sliding longitudinally along the dovetail guide rails on both sides of the bed, and The right spindle box 12 and the left saw shaft assembly A and the right saw shaft assembly B rotatably arranged on the left and right spindle boxes, the left and right saw shaft assemblies respectively include the upper saw shaft 21 and the lower saw shaft 22. The upper and lower saw shafts are respectively installed at the upper and lower positions of the left and right headstocks at a certain angle staggered from front to back, each independent upper and lower saw shafts are equipped with the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com