Patents

Literature

96results about How to "High cutting precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

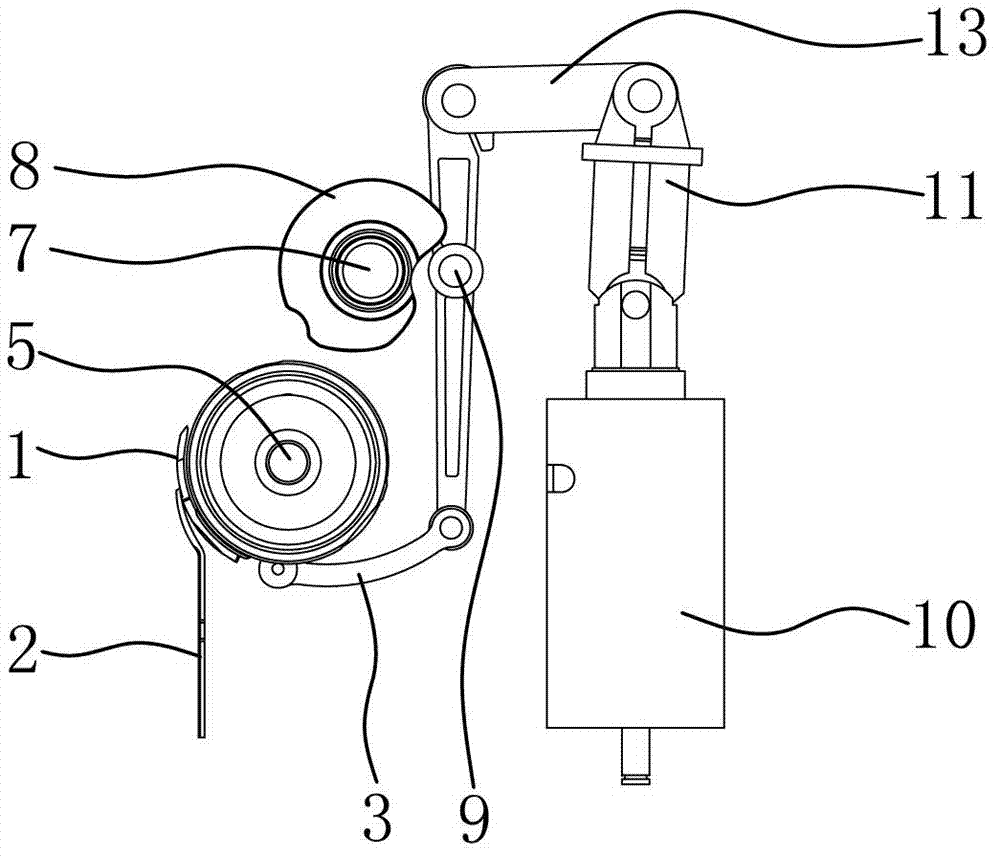

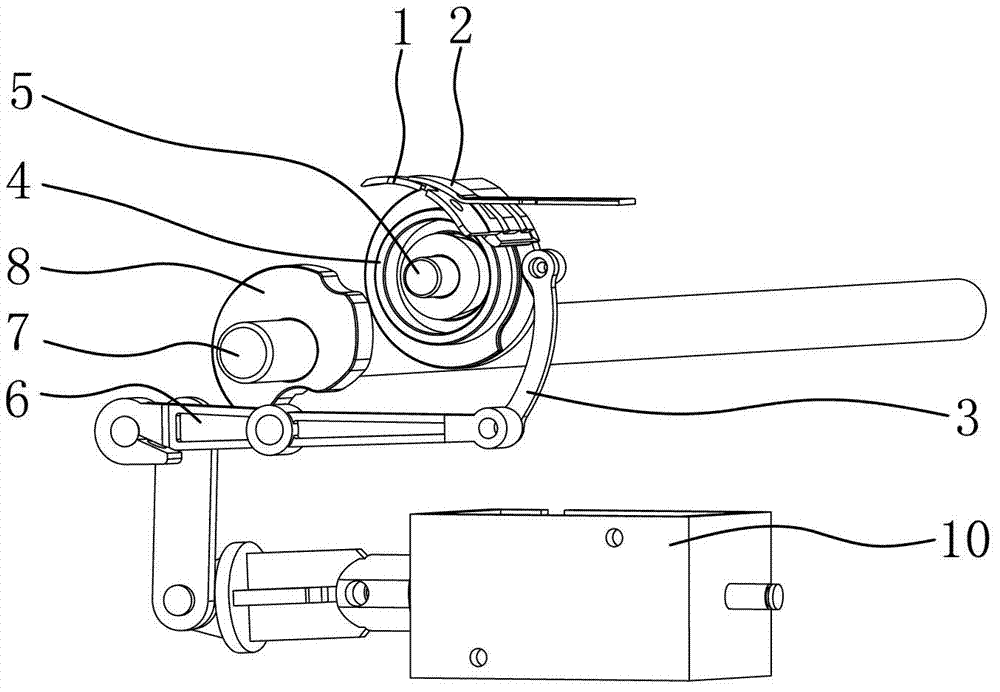

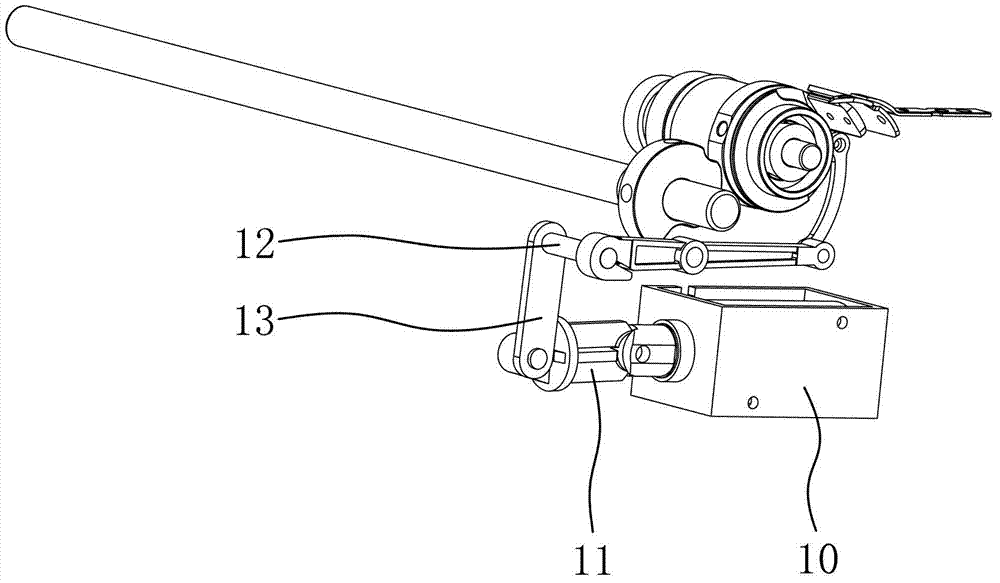

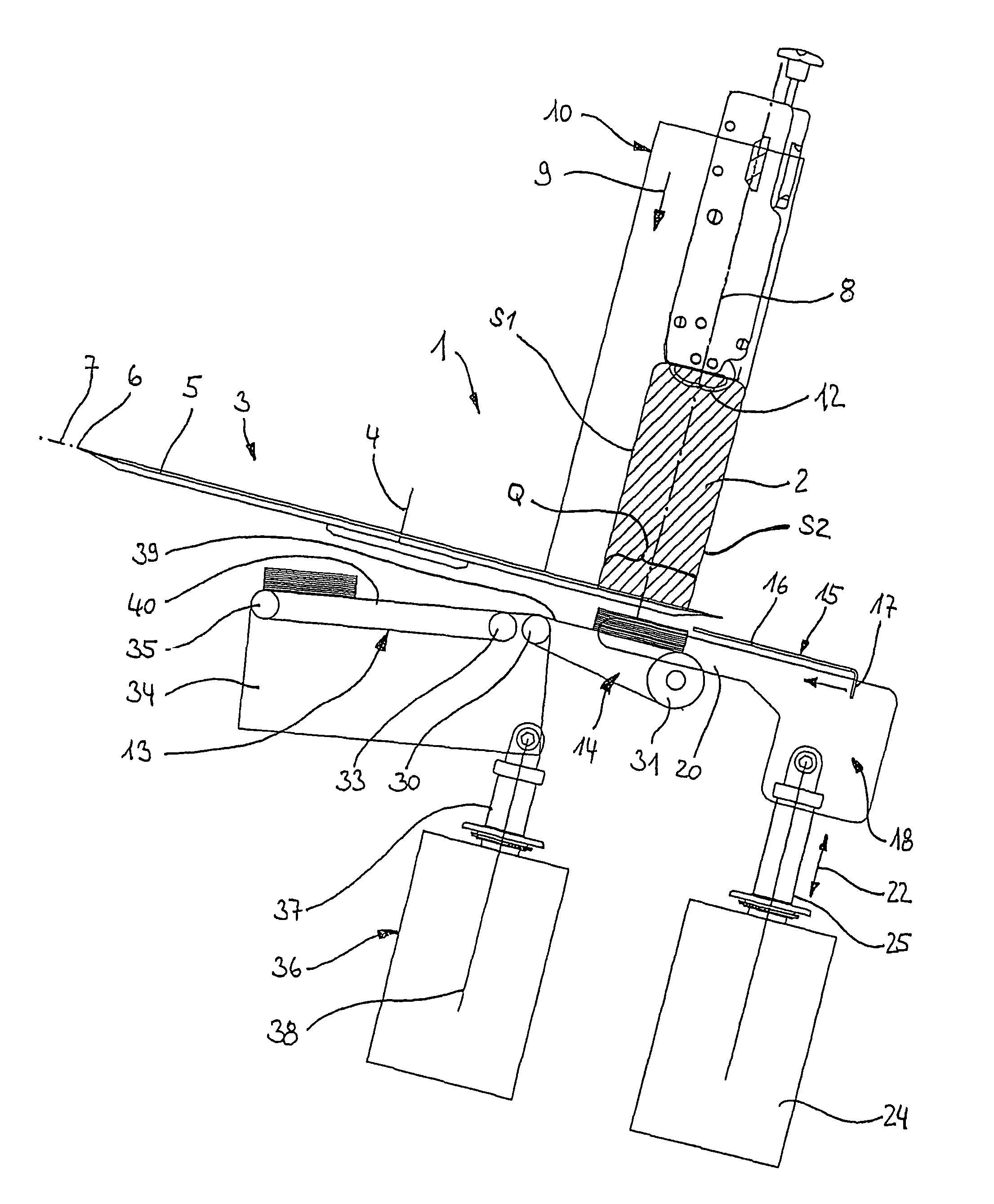

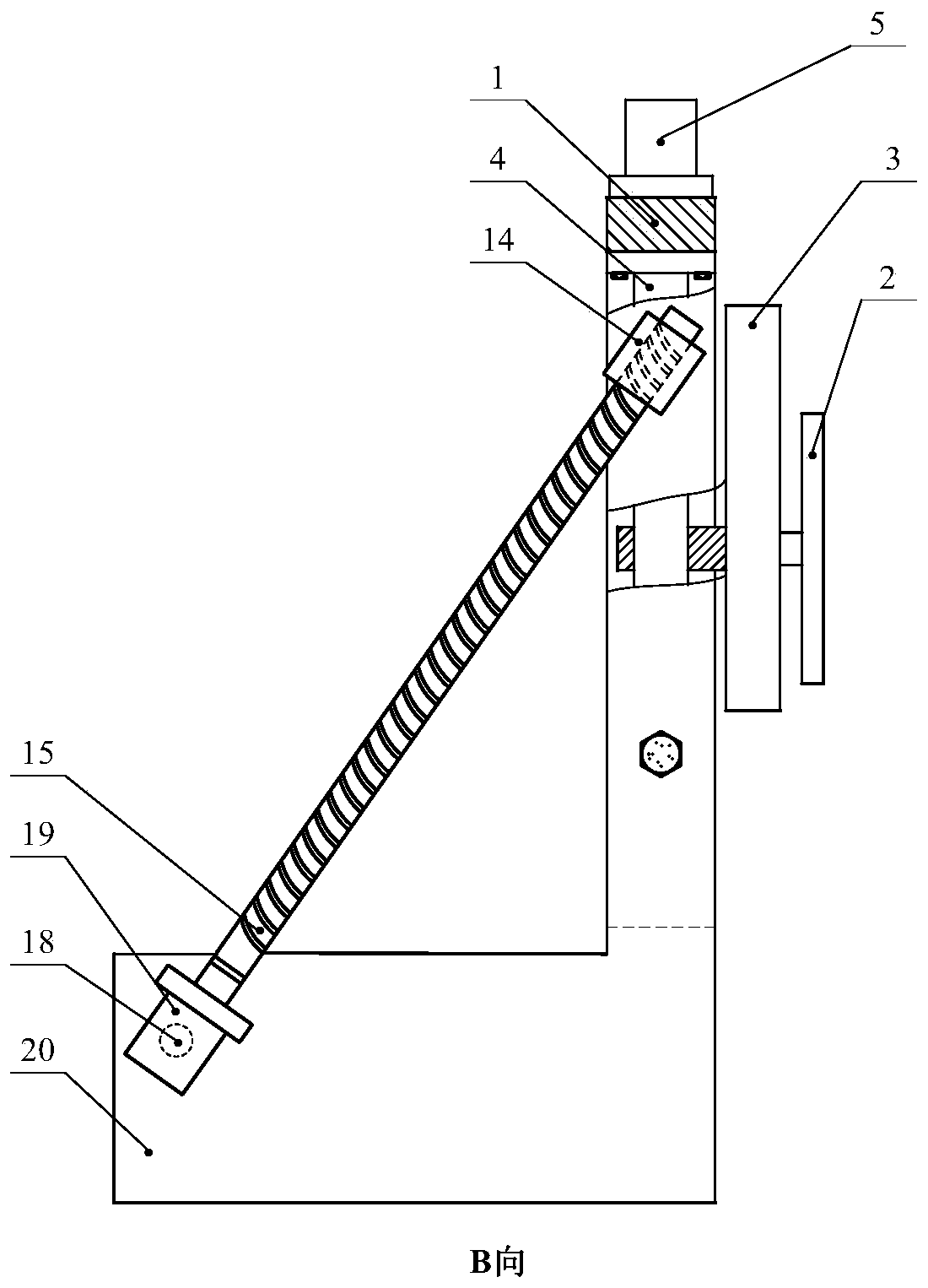

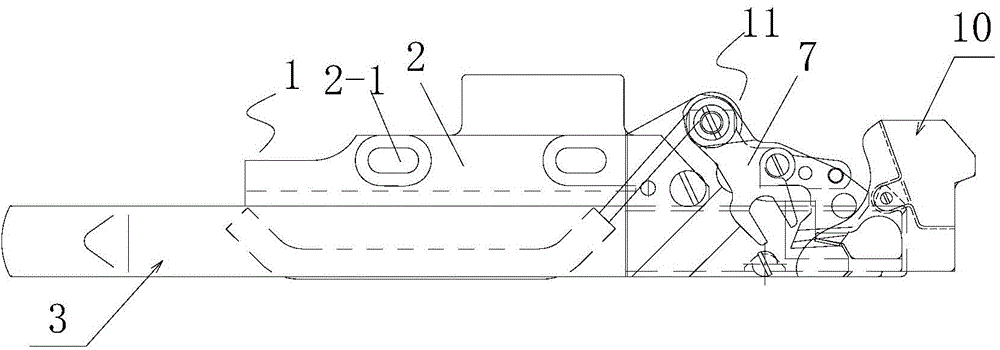

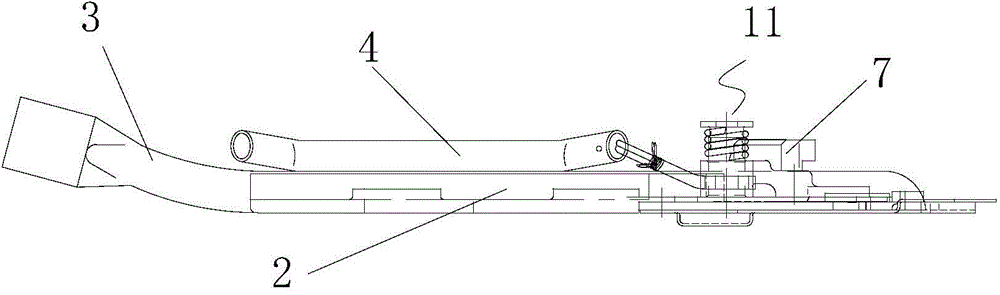

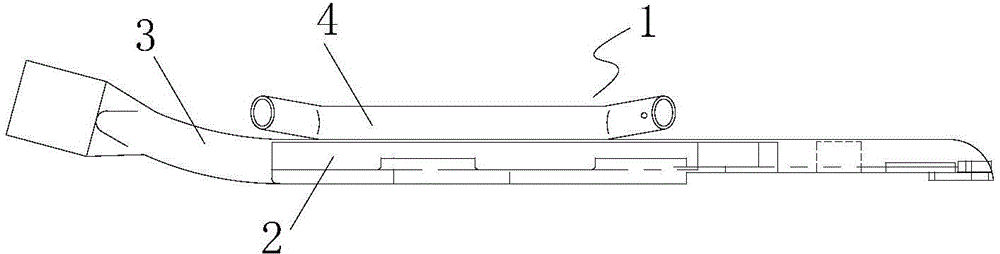

Automatic cutting device of sewing machine

InactiveCN102877230AAvoid hitting pinsGuaranteed stable workNeedle severing devicesEngineeringKnife holder

The invention provides an automatic cutting device of a sewing machine and belongs to the technical field of sewing machines. The device can solve the problems of discontinuous operation, affected production efficiency and the like caused by the needle-bumping phenomenon in the prior art. The device comprises a moving knife, a fixing knife, a connecting rod and a cutting electromagnet, which cooperate with each other to cut threads, wherein the fixing knife is fixed on a base of the sewing machine, the moving knife and one end of the connecting rod are fixed on a cutting knife holder, the cutting knife holder is sleeved on a lower shaft, the other end of the connecting rod is hinged with one end of a transmission rod, and the other end of the transmission rod is connected with a moving iron of the cutting electromagnet; and a feed lifting rock shaft is provided with a cutting cam, the cutting cam is positioned on the side of the transmission rod, and the transmission rod is fixedly provided with a cylindrical pin which is matched with the cutting cam to drive the transmission rod to move. The device provided by the invention has the advantages of high cutting accuracy, convenience in operation, simple structure and the like.

Owner:JACK SEWING MASCH CO LTD

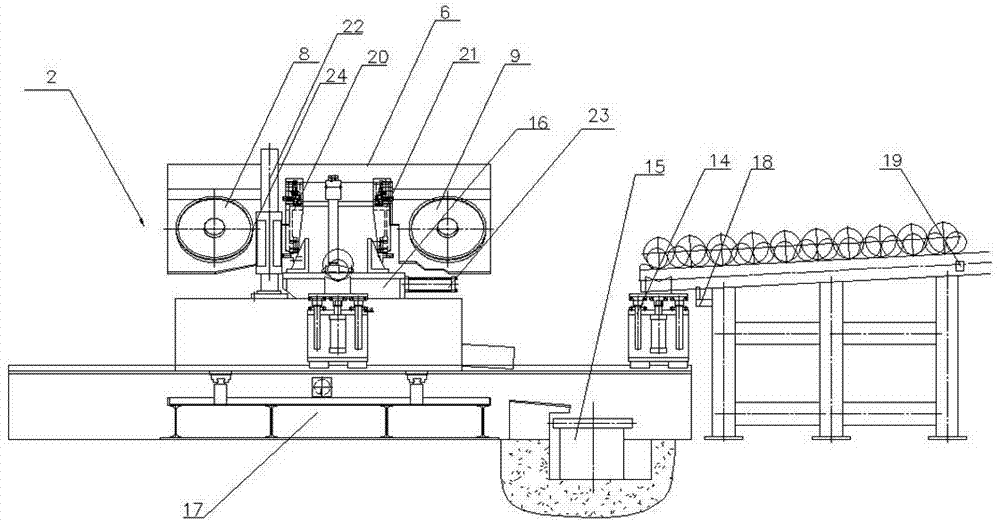

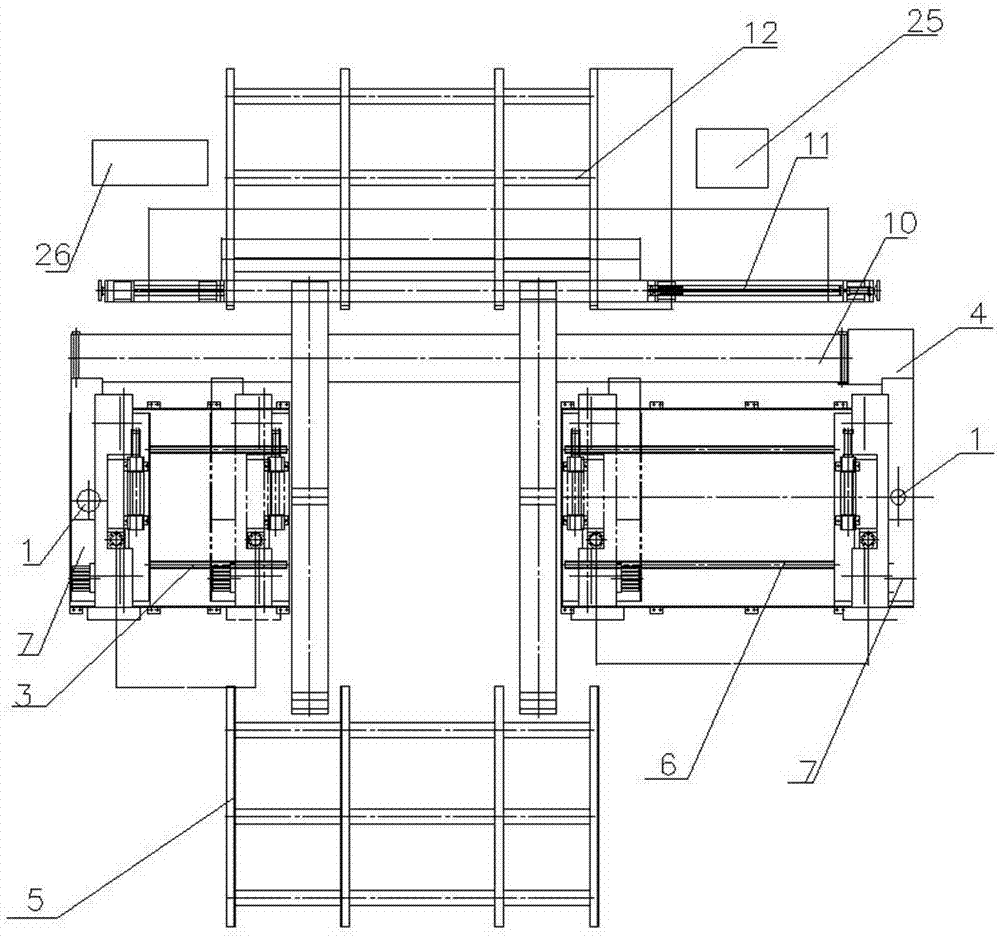

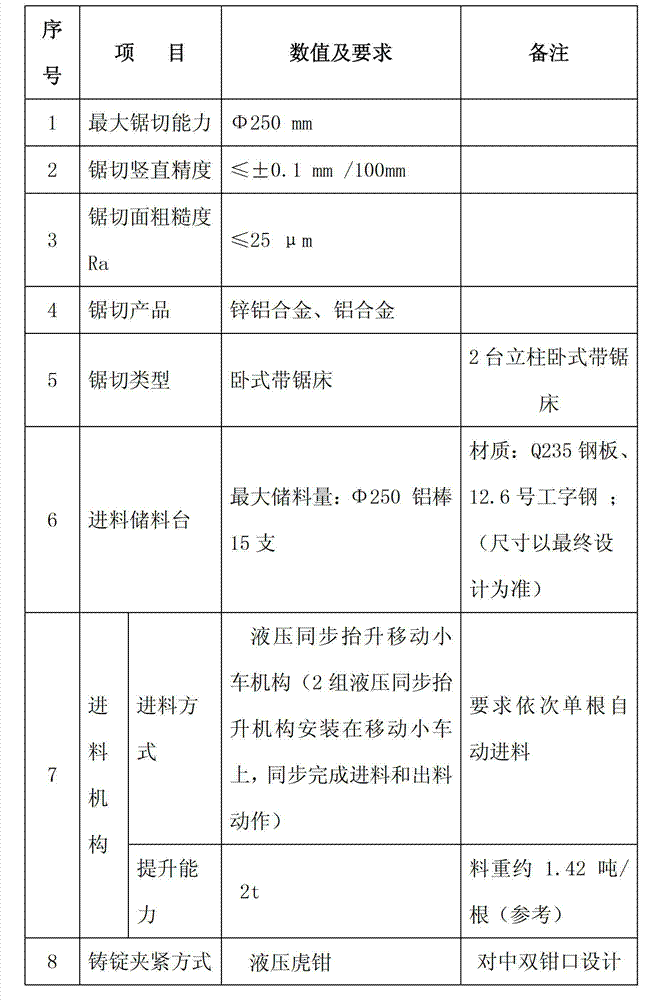

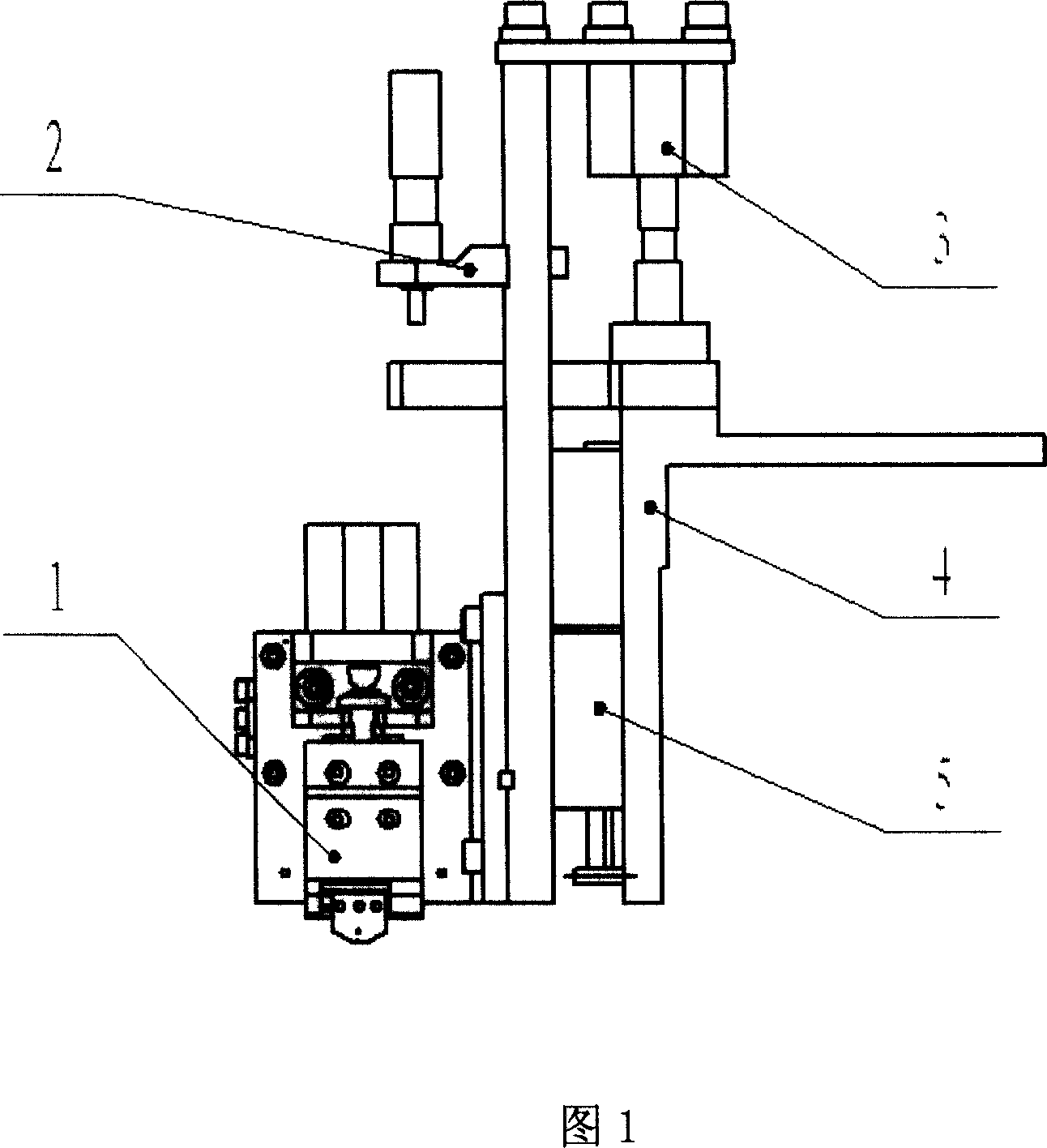

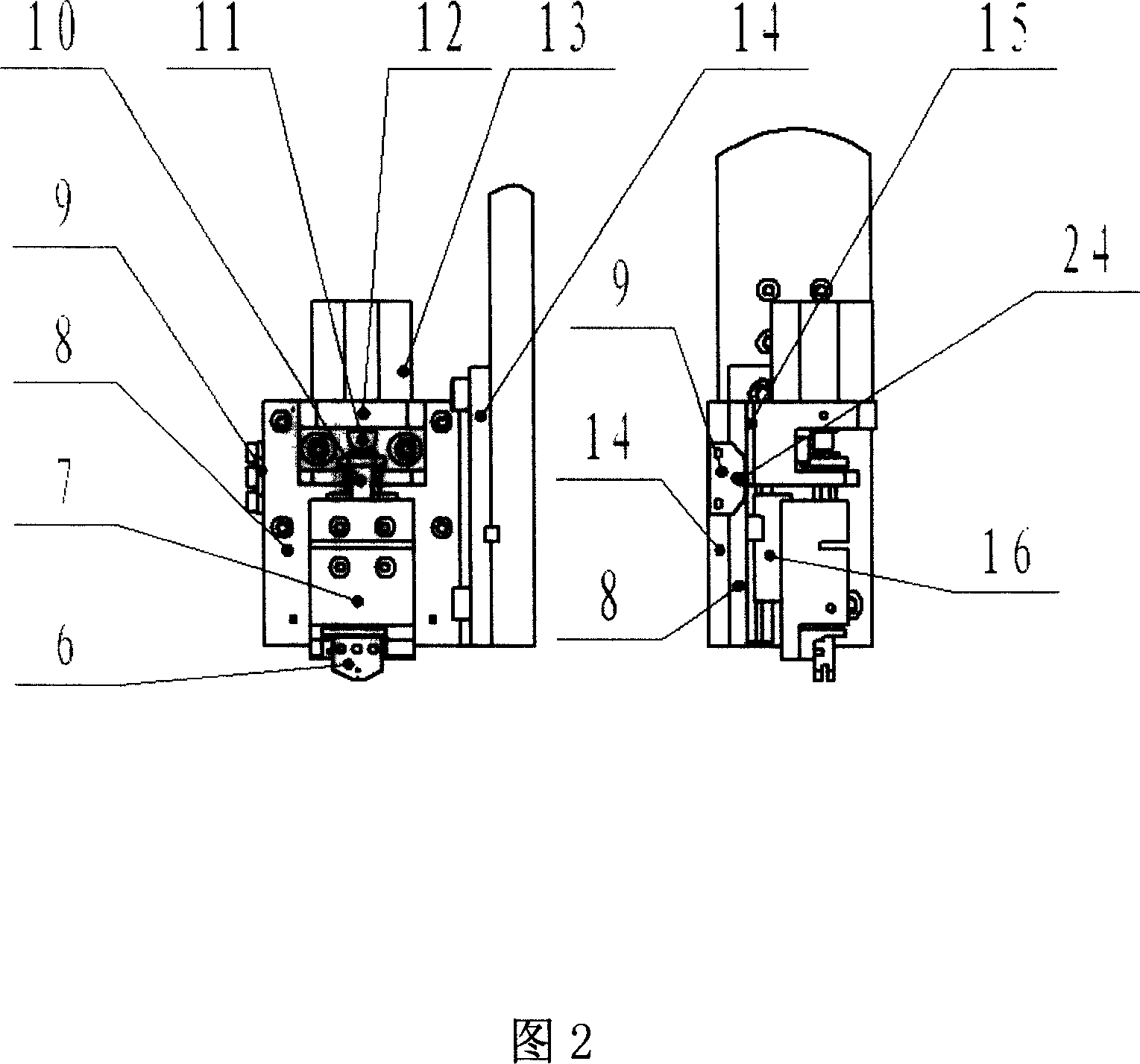

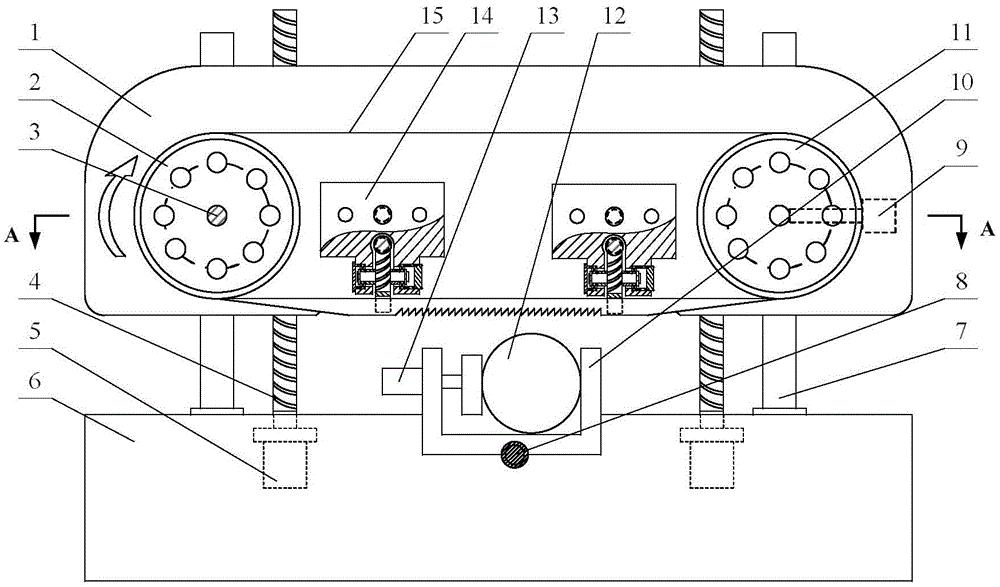

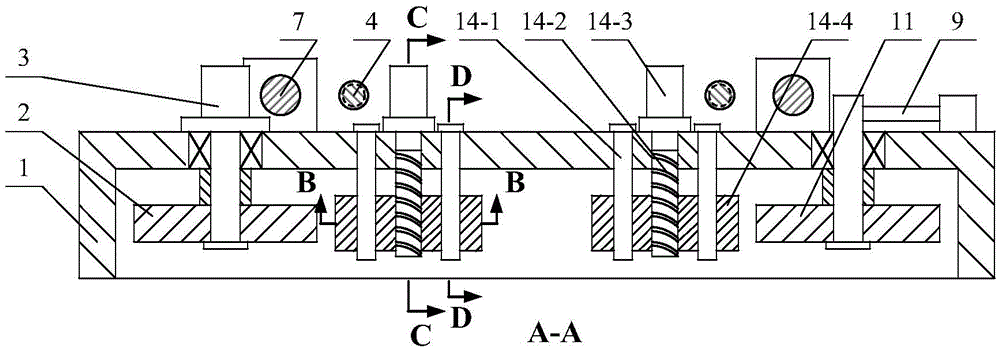

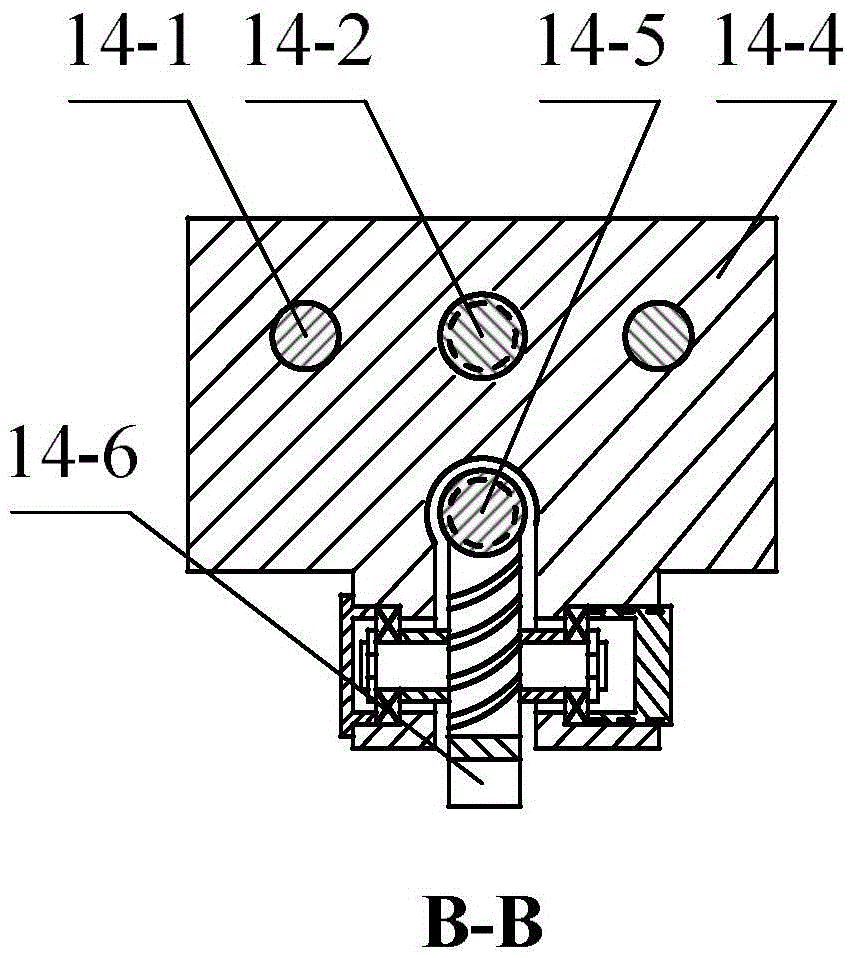

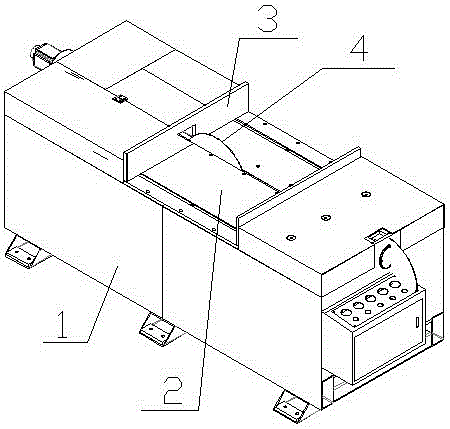

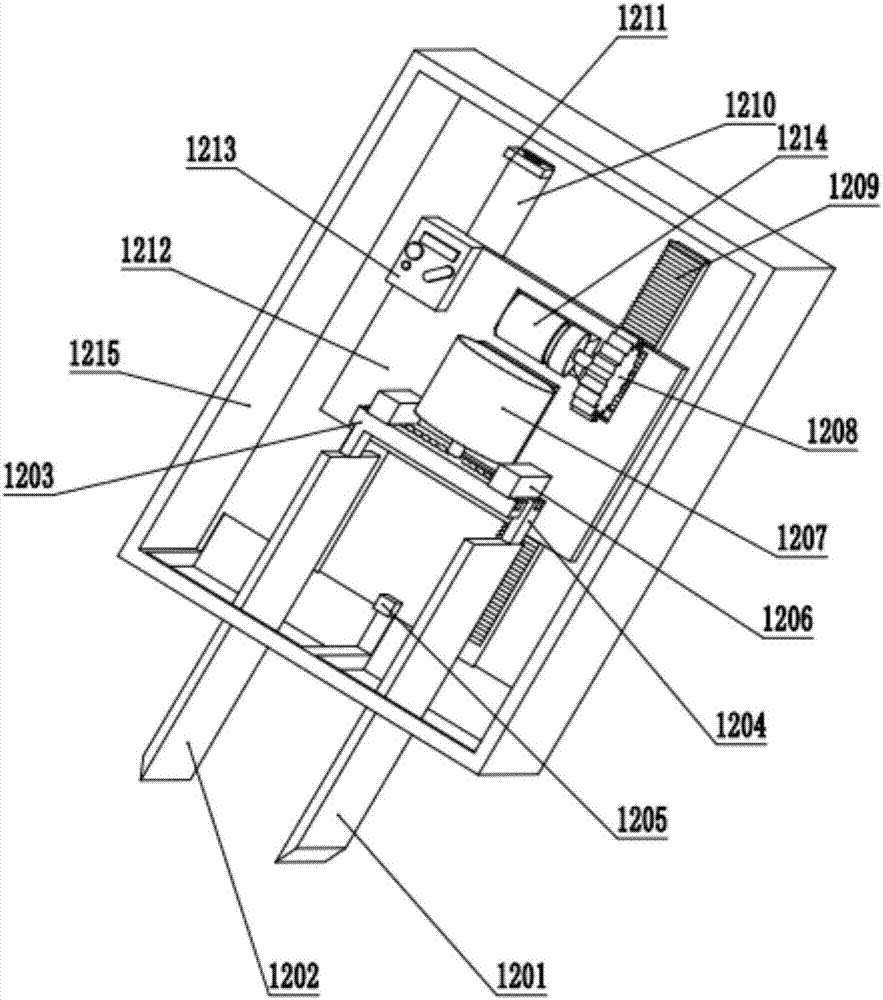

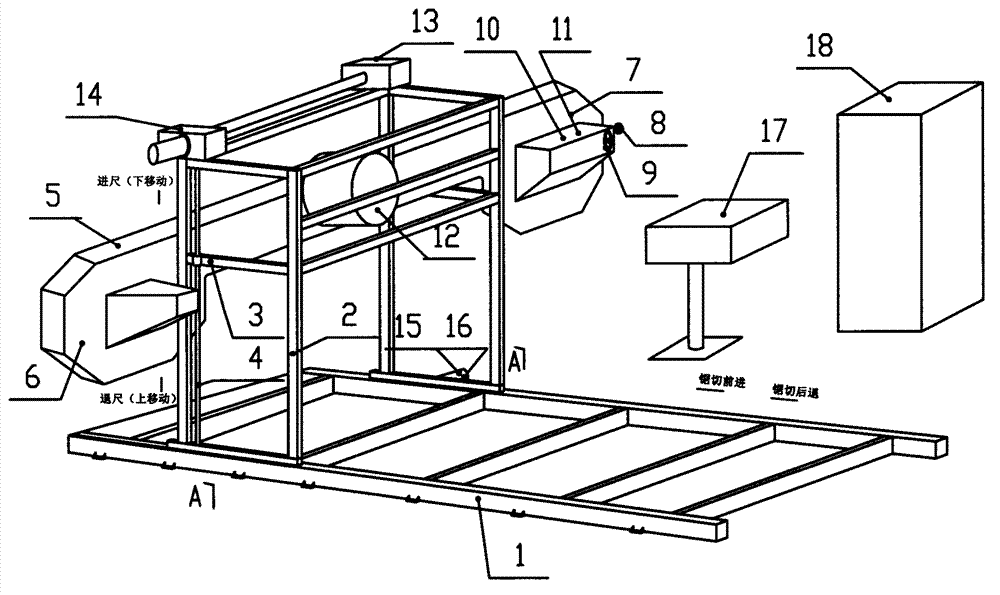

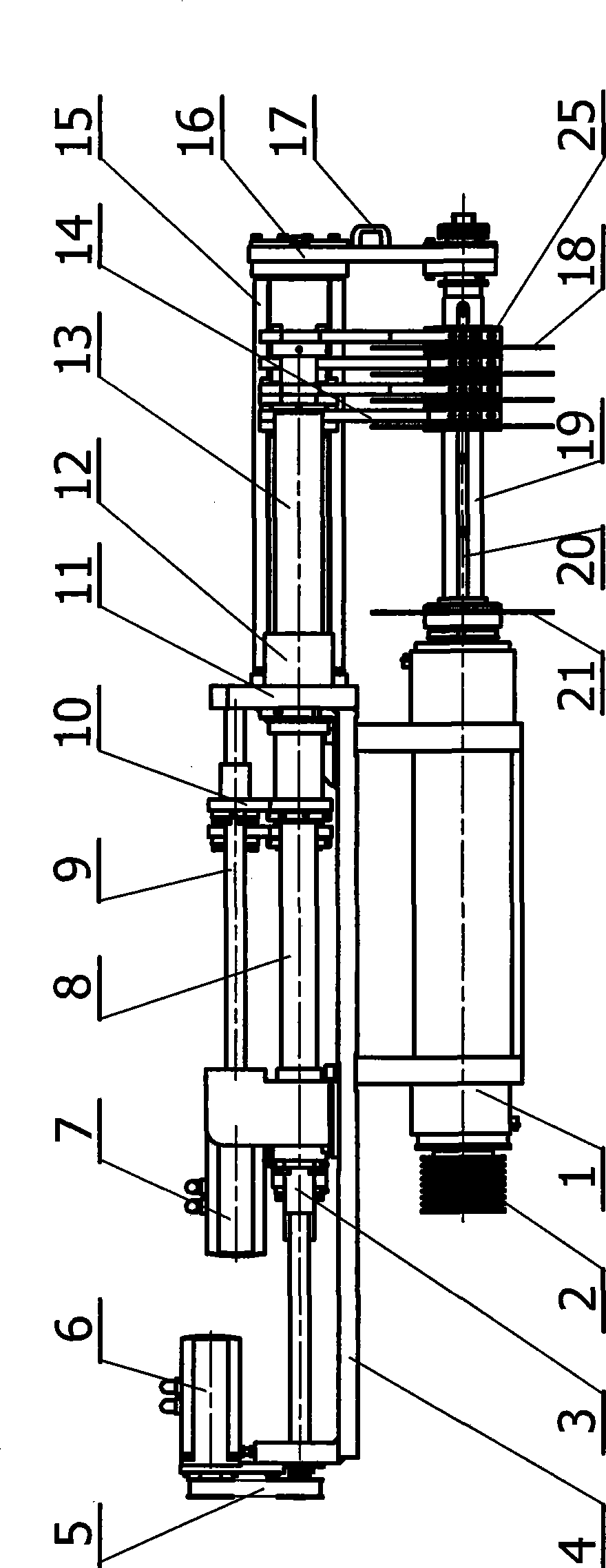

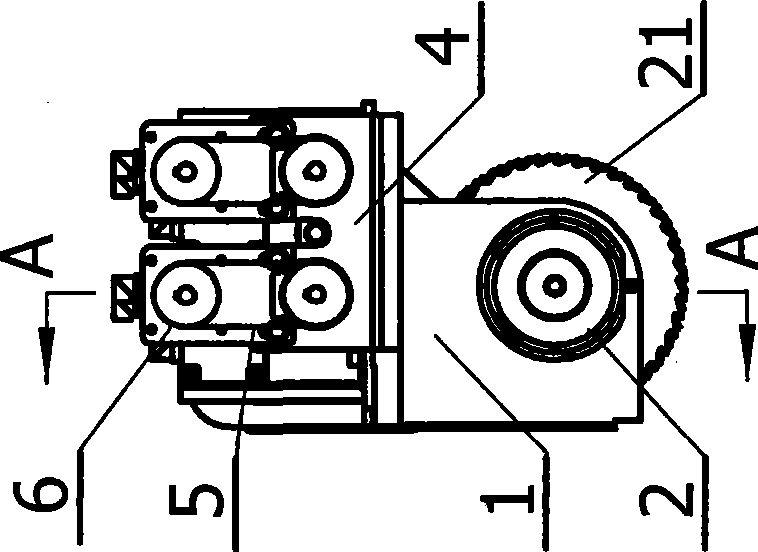

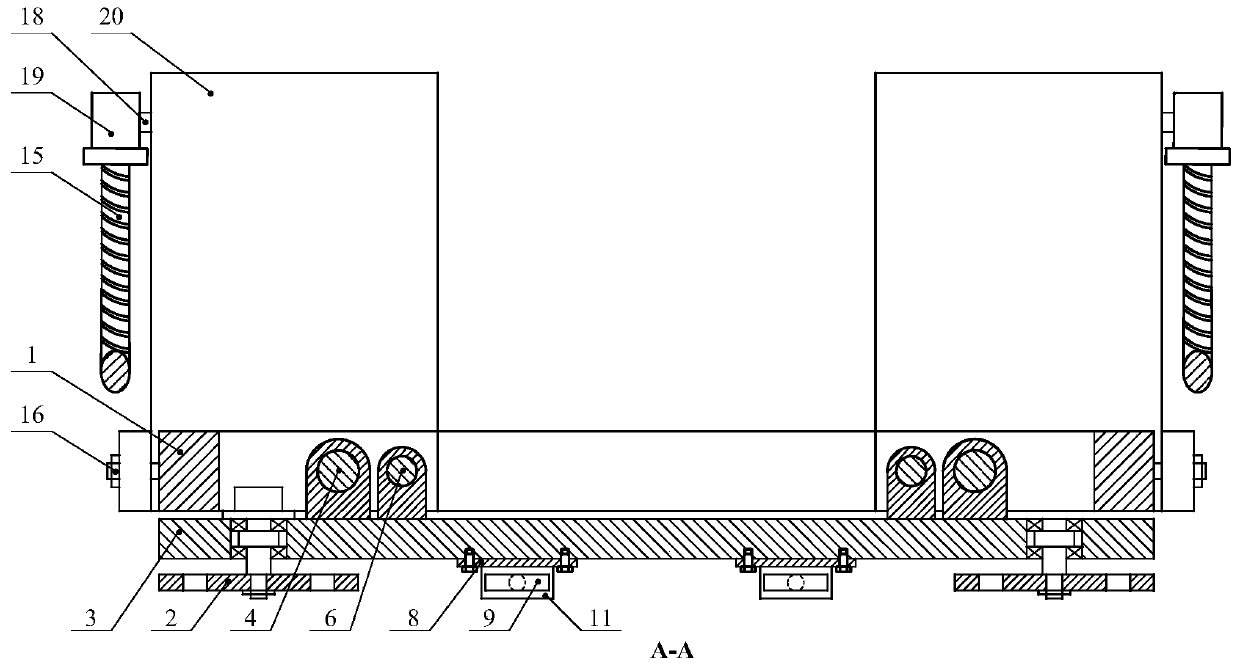

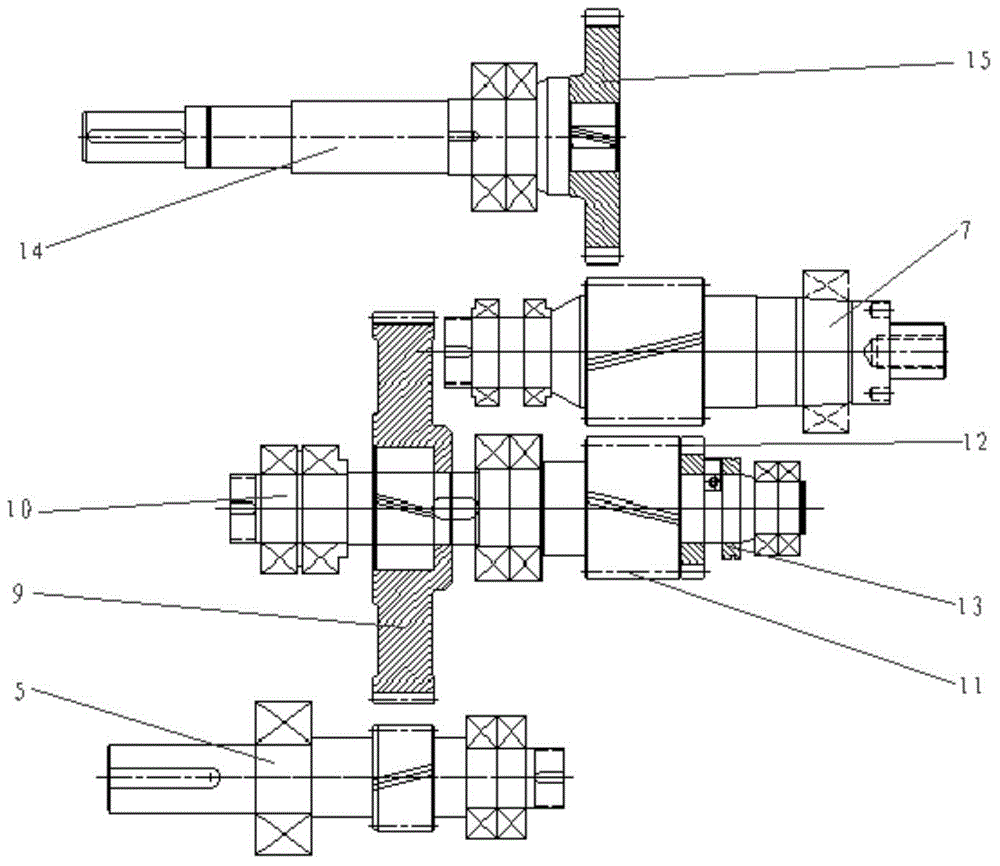

Aluminum bar saw cutting unit

ActiveCN103028780AQuick sortingGuaranteed secondary scratchesMetal sawing devicesAutomatic control devicesStructural engineeringDrive motor

The invention relates to machining equipment, in particular to an aluminum bar saw cutting unit, which comprises a sawing machine host, a feeding mechanism, a discharging mechanism, a waste collection device, a hydraulic system and an electric control system connected with one another, wherein the sawing machine host comprises two mutually symmetric sawing machines, and a clamping device and a sizing device at one end of the sawing machines; each sawing machine comprises a pedestal, a saw carrier on the pedestal, a transmission system, a saw belt tensioning mechanism, a saw carrier feeding system, a saw belt left guide arm and a saw belt right guide arm; the transmission system comprises a driving saw wheel, a driven saw wheel, a transmission belt and a driving motor; the feeding mechanism comprises a feed and storage rack, a cast ingot leveling mechanism and a feeding and discharging lift moving trolley; the discharging mechanism comprises a feeding and discharging lift moving trolley and a discharge and storage rack; and the hydraulic system is connected with a saw belt tensioning hydraulic device, a saw cutting feed hydraulic device and a trolley lift hydraulic device. According to the aluminum bar saw cutting unit, the production efficiency and the saw cutting accuracy of the machine tool are greatly improved.

Owner:ZHE JIANG CHENLONG SAWING MACHINE CO LTD

Cutter head components mechanism for lining and cutting

InactiveCN101011824ASolve the technical problem of low cutting precisionSolve the technical problem of low cutting accuracyGlass severing apparatusOther workshop equipmentEngineeringMechanical engineering

The invention relates to the tool bit mechanism for cutting lines, which comprises the cutting mechanism, limit mechanism, up and down moving mechanism, fixed reference, guide component, with the track of the said guide component setting on the fixed reference, guiding component sliding up and down along the guide track, limit plate fixed on the top of the reference, micro bit on the top of the left of the limit plate, joint plate connected with the right of the limit plate, alighting cylinder fixed on the cylinder installation plate, with the alighting shaft jointing with the joint plate, adjusting fixing plate under the lower left of the said installation plate with active cutting bit on it. It is simple and reasonable in structure, extensive in application, convenient in installation, highly precise in cutting.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

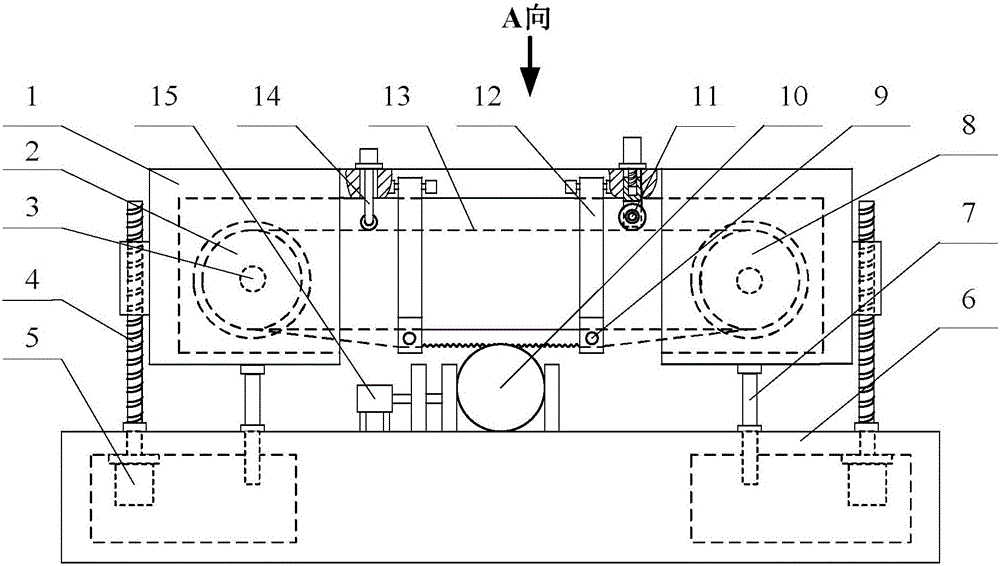

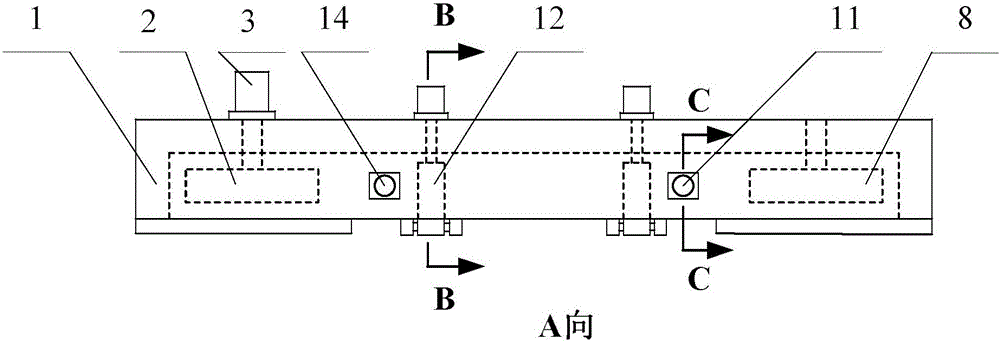

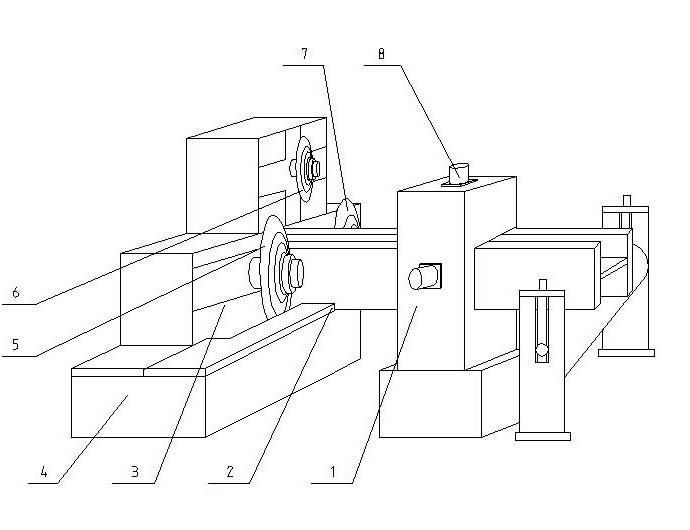

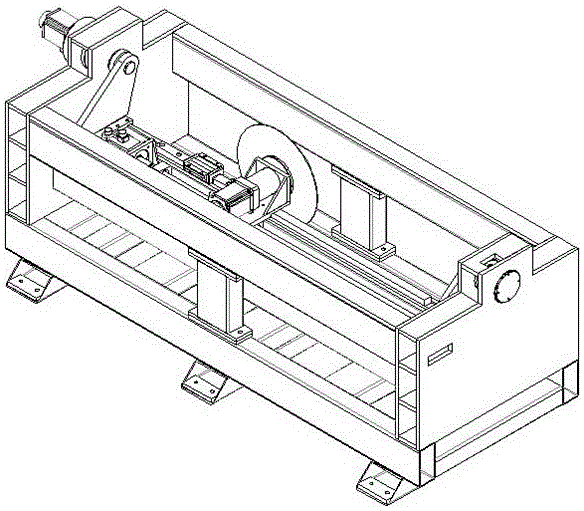

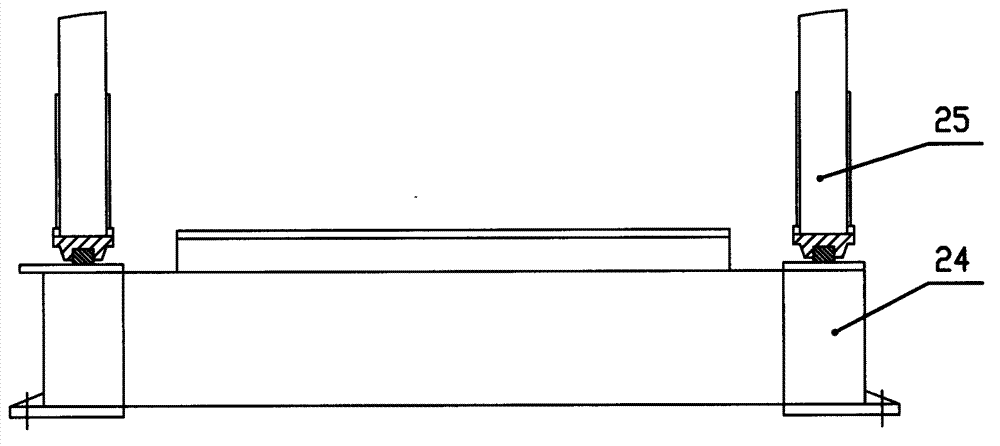

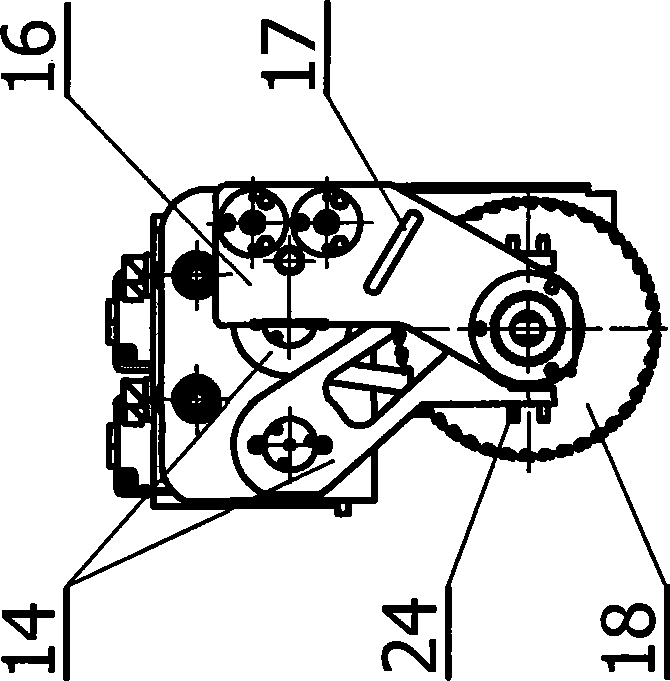

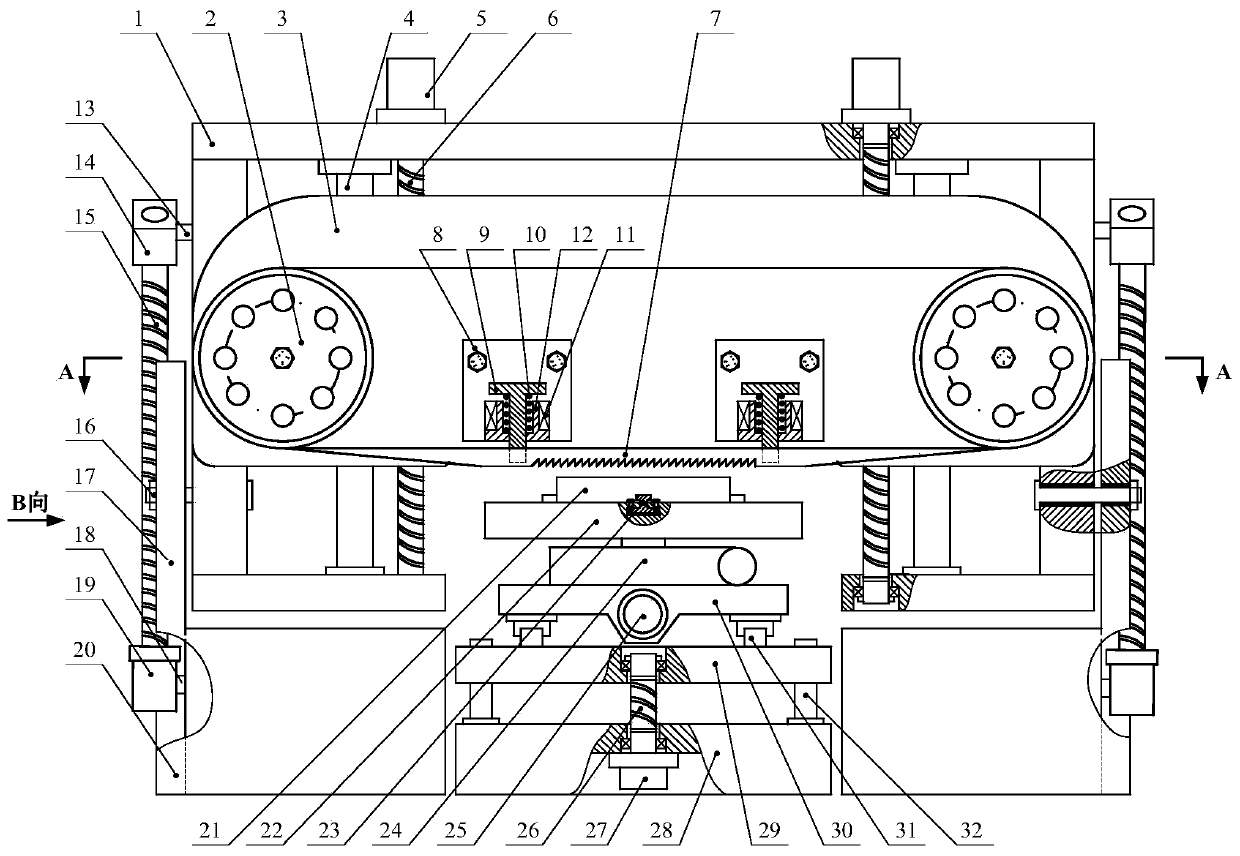

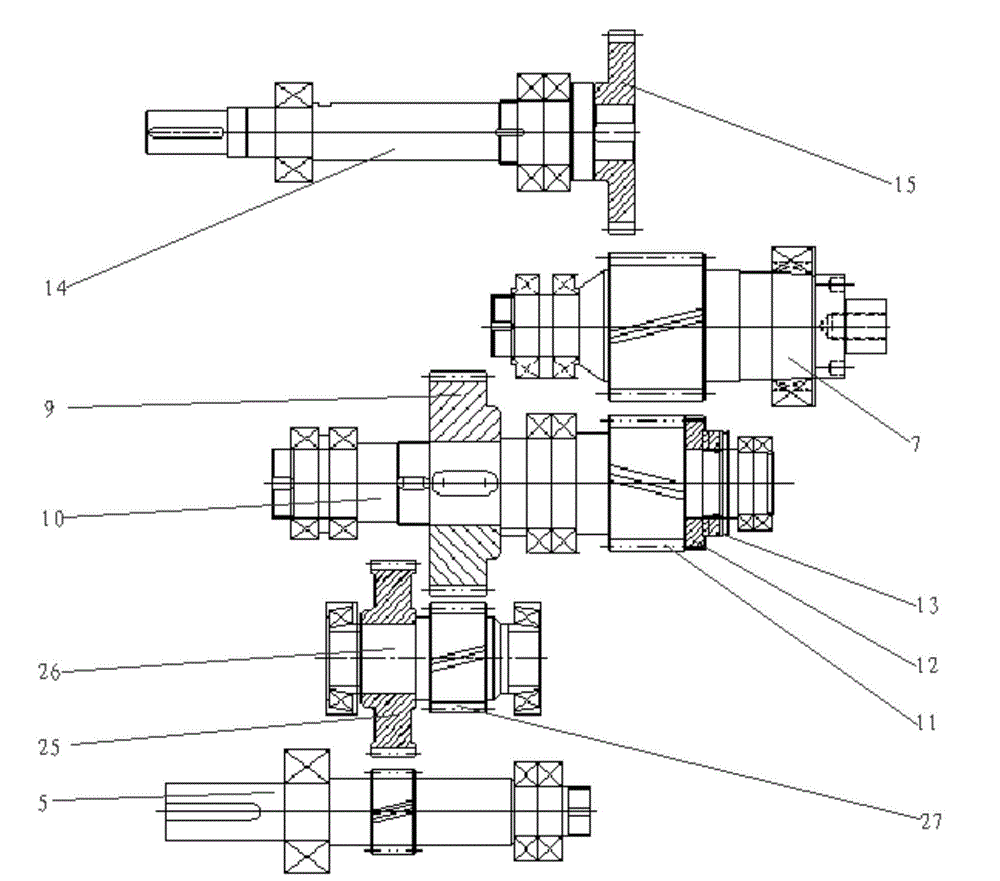

Numerical control band sawing machine with correction devices

ActiveCN105643011ASolve the problem of reduced sawing accuracyHigh cutting precisionMetal sawing devicesNumerical controlMotor drive

The invention discloses a numerical control band sawing machine with correction devices. An existing band sawing machine has the problem that in the saw cutting process, because of sawing band deflection and deformation, the workpiece saw cutting precision is reduced. By means of a clamping mechanism of the numerical control band sawing machine, a workpiece is clamped on a working table; a driving sawing band wheel and a driven sawing band wheel are installed on a saw frame; a sawing band is connected with the driving sawing band wheel and the driven sawing band wheel and is tensioned by a tensioning mechanism; a main movement servo motor drives the driving sawing band wheel; a feeding servo motor drives a feeding mechanism so that the saw frame can be driven to move up and down for feeding; and the two sawing band guide and correction devices are installed in the saw frame. By means of a lead screw and nut transmission mechanism driven by a servo motor, micro displacement is achieved; and by means of a worm and gear speed reducer driven by the servo motor, micro swinging is achieved. By means of two transmission mechanisms, two-freedom-degree linkage of rotation and horizontal movement is achieved for guide blocks, the problem that in the saw cutting process of the existing band sawing machine, because of sawing band deflection and deformation, the workpiece saw cutting precision is reduced is solved, and the saw cutting precision is greatly improved.

Owner:HANGZHOU DIANZI UNIV

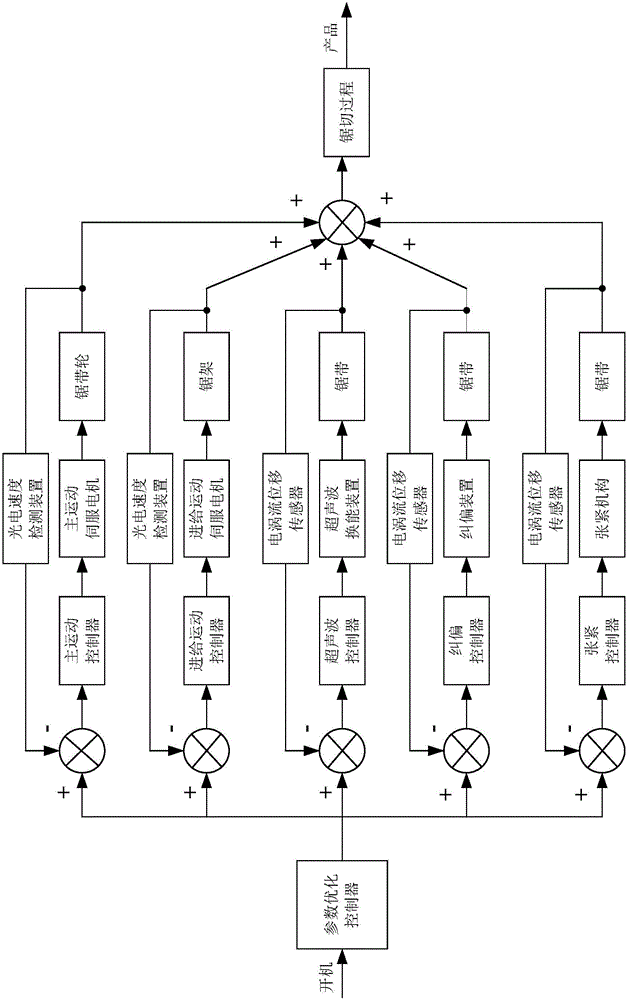

Numerical control band sawing machine with vibration attenuation and deviation rectification control device

ActiveCN105665822ASolve the problem of obvious decline in sawing qualityEliminate vibrationMetal sawing devicesNumerical controlVibration attenuation

The invention discloses a numerical control band sawing machine with a vibration attenuation and deviation rectification control device. An existing band sawing machine tool has the problems that a saw band vibrates, deviates and deforms, and consequently the workpiece saw cutting quality is lowered. A clamping mechanism clamps a workpiece to a workbench of a machine body. A saw band is tightened through a tightening mechanism. A main movement servo motor drives a drive saw band wheel. A feeding servo motor drives a feeding mechanism so as to drive a saw frame. Two deviation rectification devices are provided with eddy current displacement sensors for detecting displacement of the two ends of the saw cutting part of the saw band and inputting the detection result into a control module for calculating the vibration value and the saw cutting error of the saw band. The tightening mechanism, the deviation rectification devices and a vibration attenuation device are all controlled by the control module. By the adoption of the numerical control band sawing machine with the vibration attenuation and deviation rectification control device, according to the detection result of saw band vibration, the vibration attenuation device and the tightening mechanism are jointly controlled, and vibration is eliminated; and according to the detection result of the saw band movement error, automatic adjustment is achieved through the deviation rectification devices, so that the saw cutting accuracy and surface quality are improved greatly.

Owner:HANGZHOU DIANZI UNIV

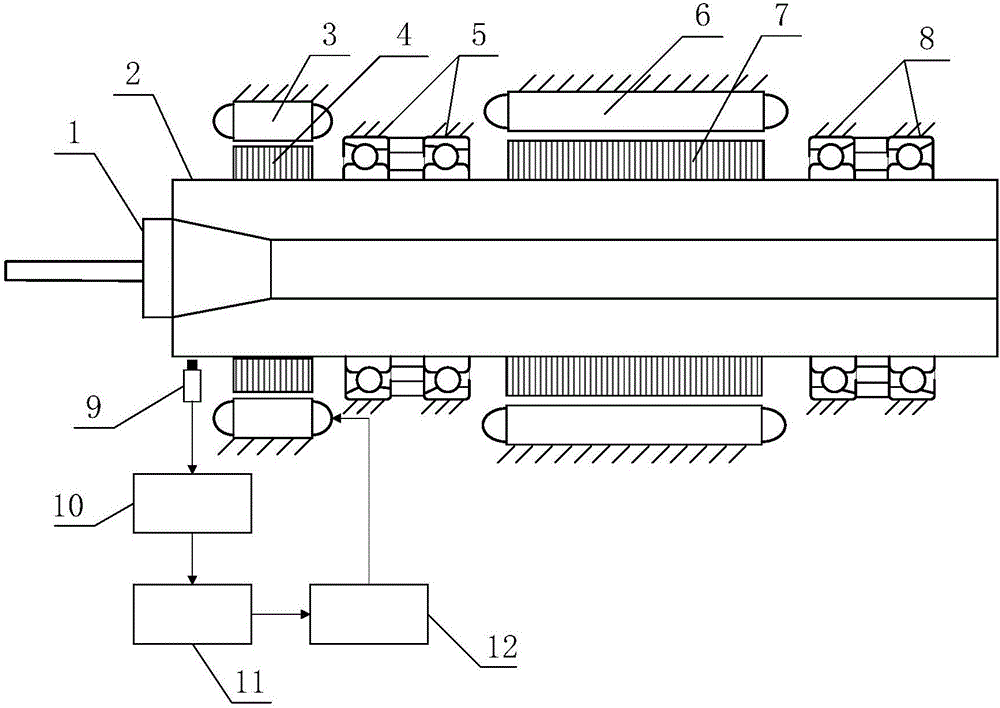

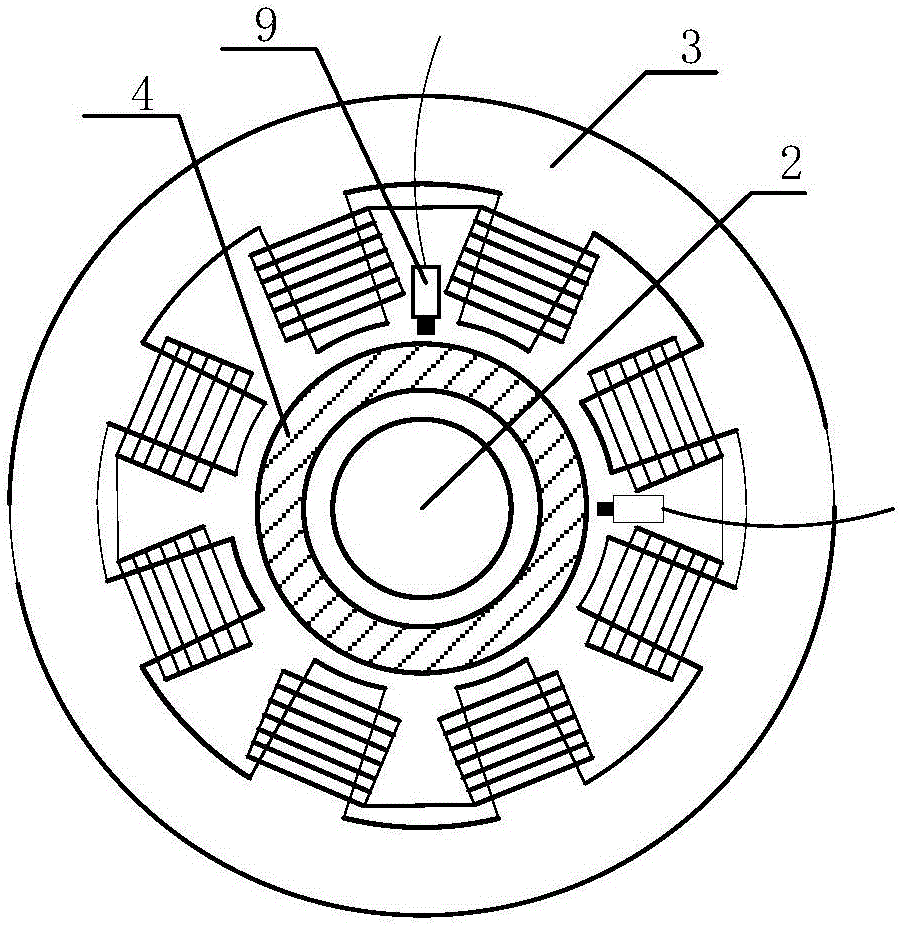

Online active type cutting chatter restraining system and method for intelligent milling motorized spindle

ActiveCN106392753ARealize intelligenceIncrease the critical speedMaintainance and safety accessoriesAxial displacementMagnetic bearing

The invention provides an online active type cutting chatter restraining system and method for an intelligent milling motorized spindle. The online active type cutting chatter restraining system for the intelligent milling motorized spindle comprises a sensing portion, a controller and a chatter restraining adjustment and control device, wherein the sensing portion, the controller and the chatter restraining adjustment and control device are sequentially connected. The sensing portion comprises a non-contact type eddy current displacement sensor and a signal collector, wherein the non-contact type eddy current displacement sensor is installed at the front end of the spindle and used for measuring the axial displacement of the spindle, and the signal collector is used for collecting displacement signals of the non-contact type eddy current displacement sensor and converting the displacement signals to acceleration signals. The controller is used for outputting voltage control signals to the chatter restraining adjustment and control device according to the acceleration signals output by the signal collector. The chatter restraining adjustment and control device comprises a power amplifier and an active type electromagnetic bearing. The active type electromagnetic bearing comprises a rotor core and a stator core, wherein the rotor core is installed at the front end of the spindle, and a copper coil is wound around the stator core. The power amplifier is used for converting the received voltage signals into current control signals. The output end of the power amplifier is connected with the copper coil. The online active type cutting chatter restraining method for the intelligent milling motorized spindle comprises the steps of identifying and restraining chatter in the machining process.

Owner:XI AN JIAOTONG UNIV

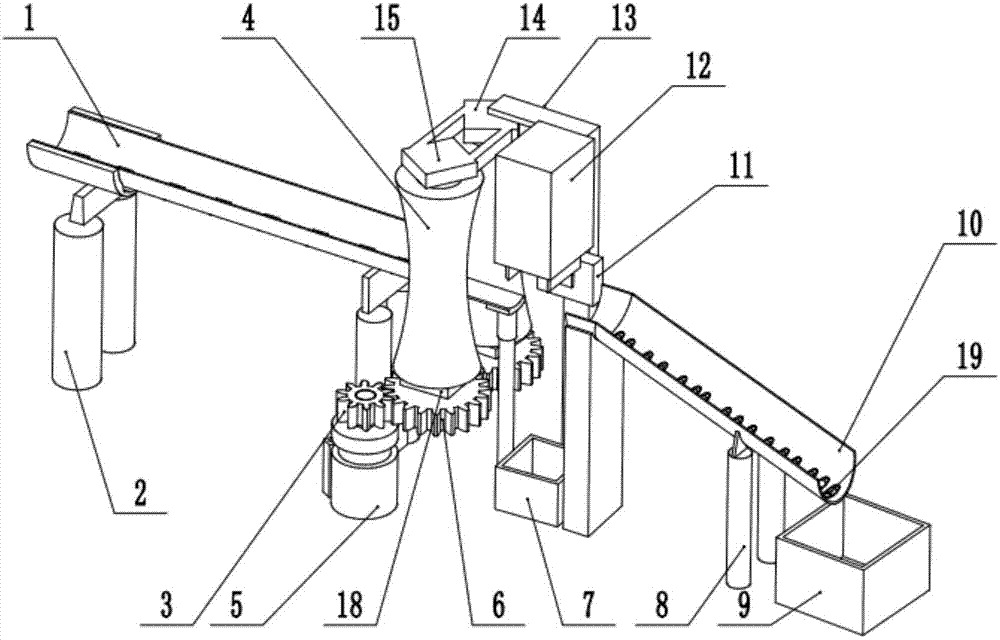

Three-segment profiled H-shaped steel rapid saw cutting device and method

InactiveCN102658397ASimple structureEasy to operateMetal sawing devicesMetal sawing toolsCircular sawEngineering

The invention discloses a three-segment profiled H-shaped steel rapid saw cutting device, which comprises a sawing machine provided with a circular saw web, wherein a loading workbench is arranged at the bottom of the sawing machine; a roller path is formed on the loading workbench; a horizontal saw web for cutting an H-shaped steel web plate and vertical saw webs for cutting an H-shaped steel flange are arranged on the sawing machine; the vertical saw webs are arranged on both sides of H-shaped steel respectively; the horizontal saw web is arranged between the two vertical saw webs and above the H-shaped steel; and the three blades are arranged on the same plane. The saw cutting device provided by the invention has the advantages of simple structure, convenience for operating, low manufacturing cost and high saw cutting precision; and a method for performing rapid saw cutting on the H-shaped steel by using the device is simple, the conventional discontinuous saw cutting is replaced by three-segment continuous cutting, the cutting difficulty is lowered, and the saw cutting stability is improved.

Owner:TANGSHAN METALLURGICAL SAW BLADE

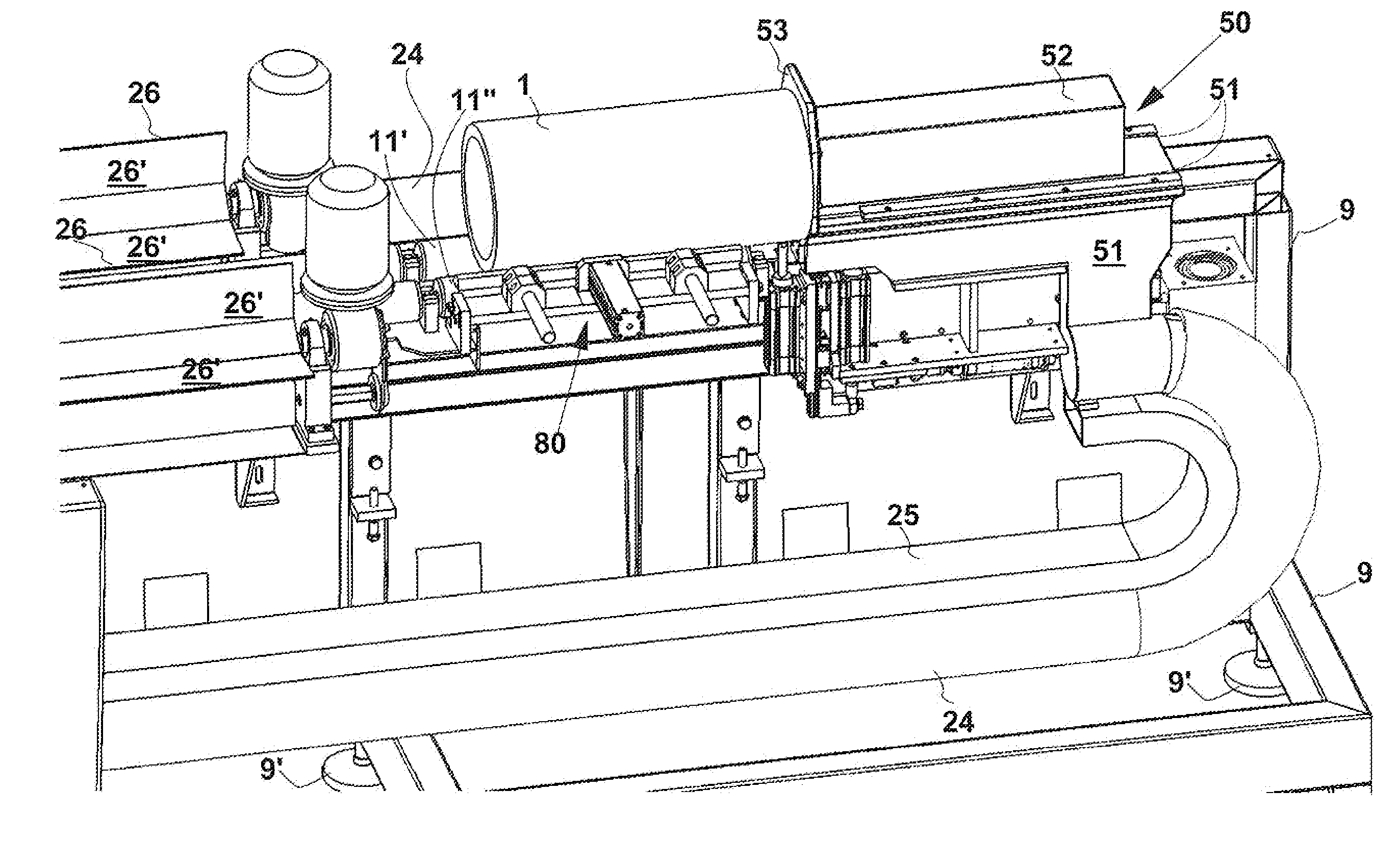

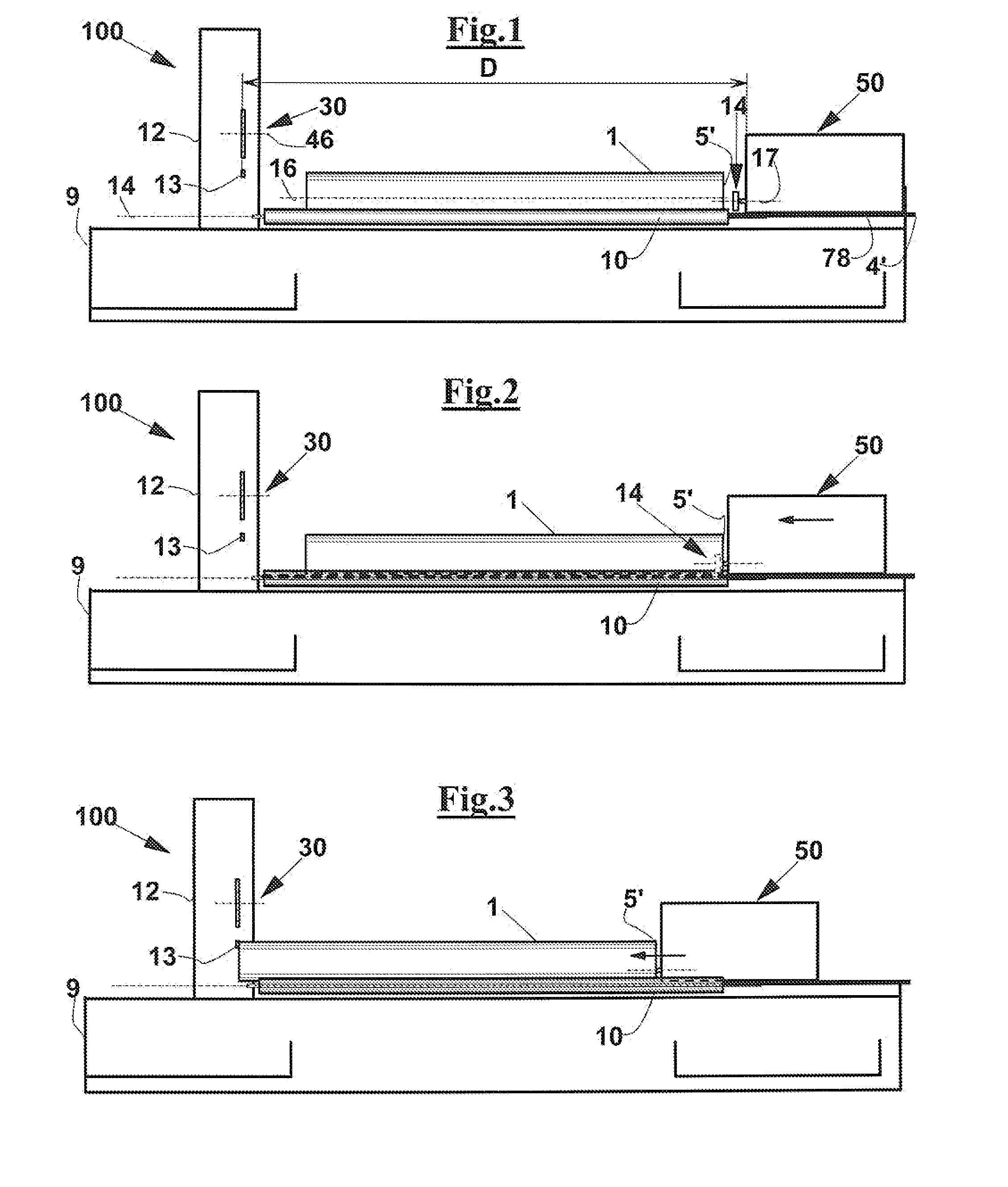

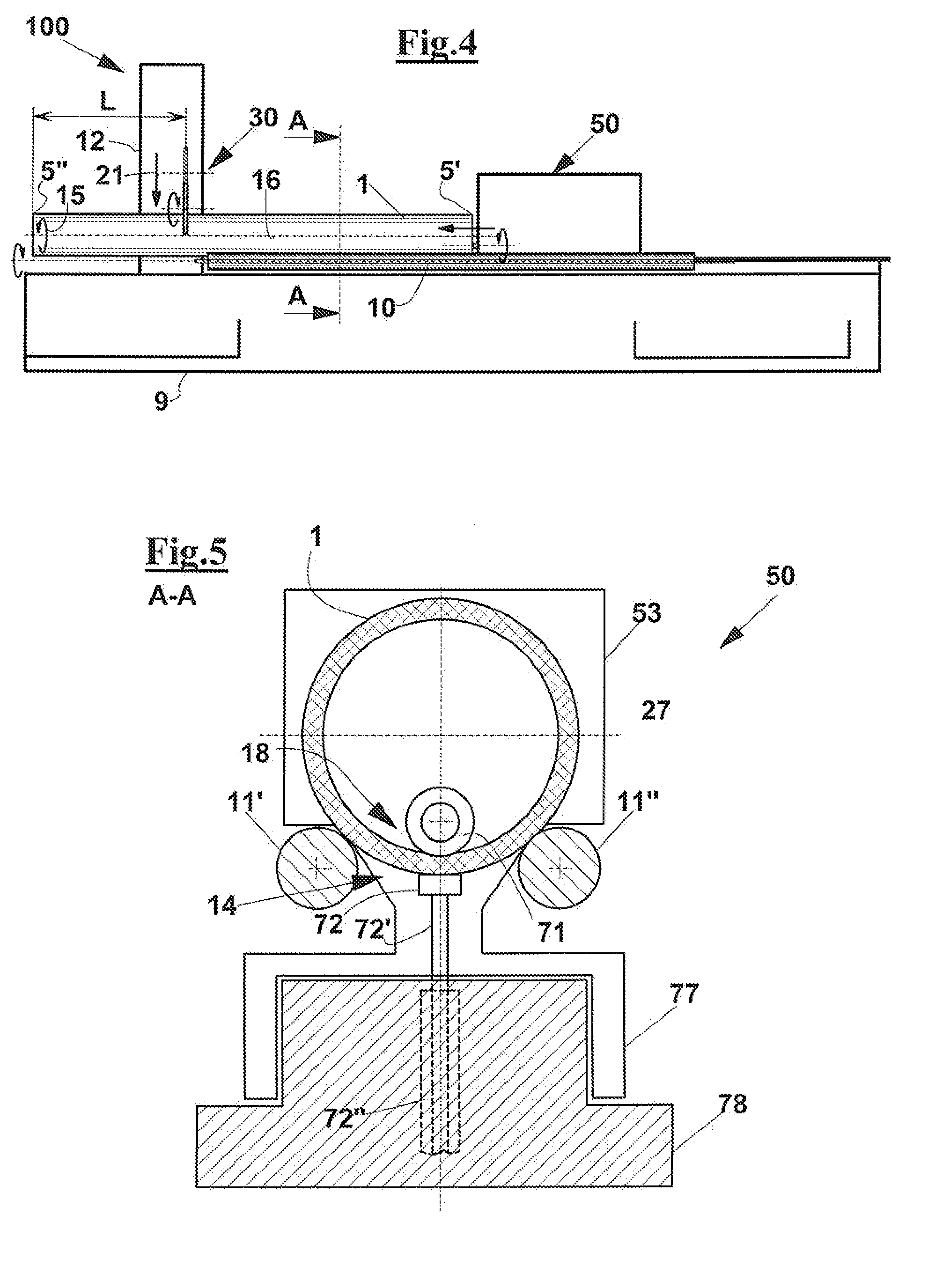

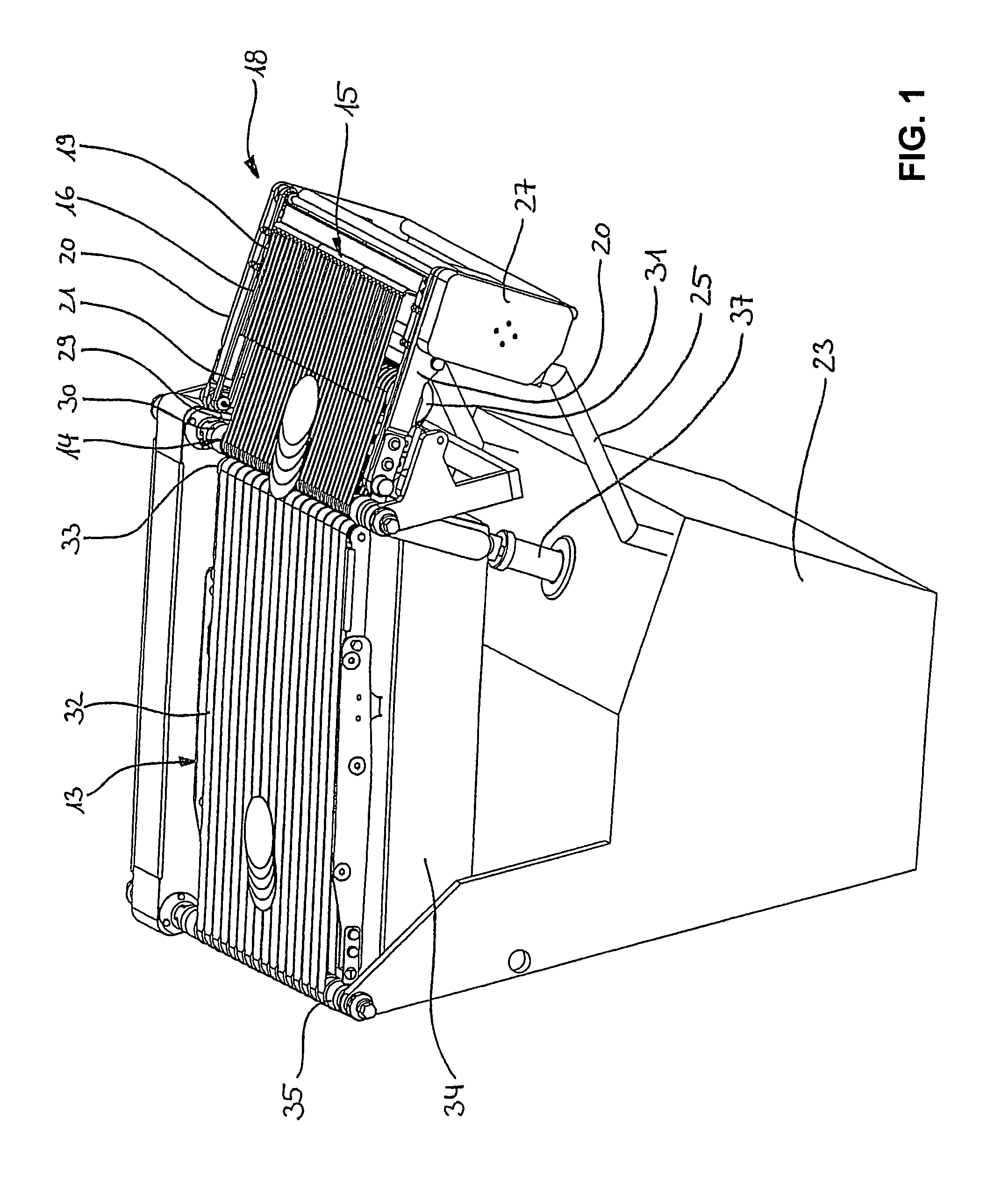

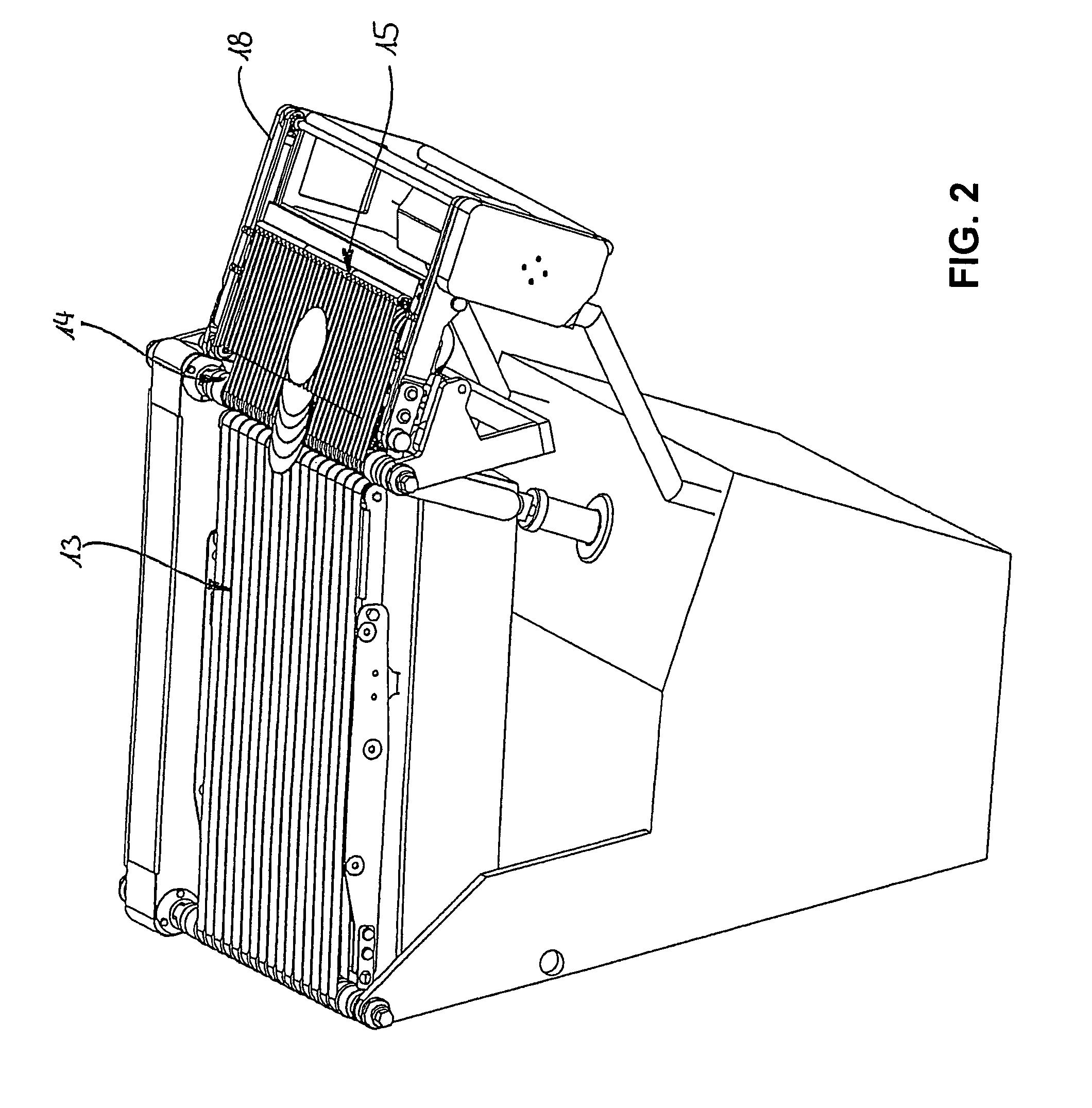

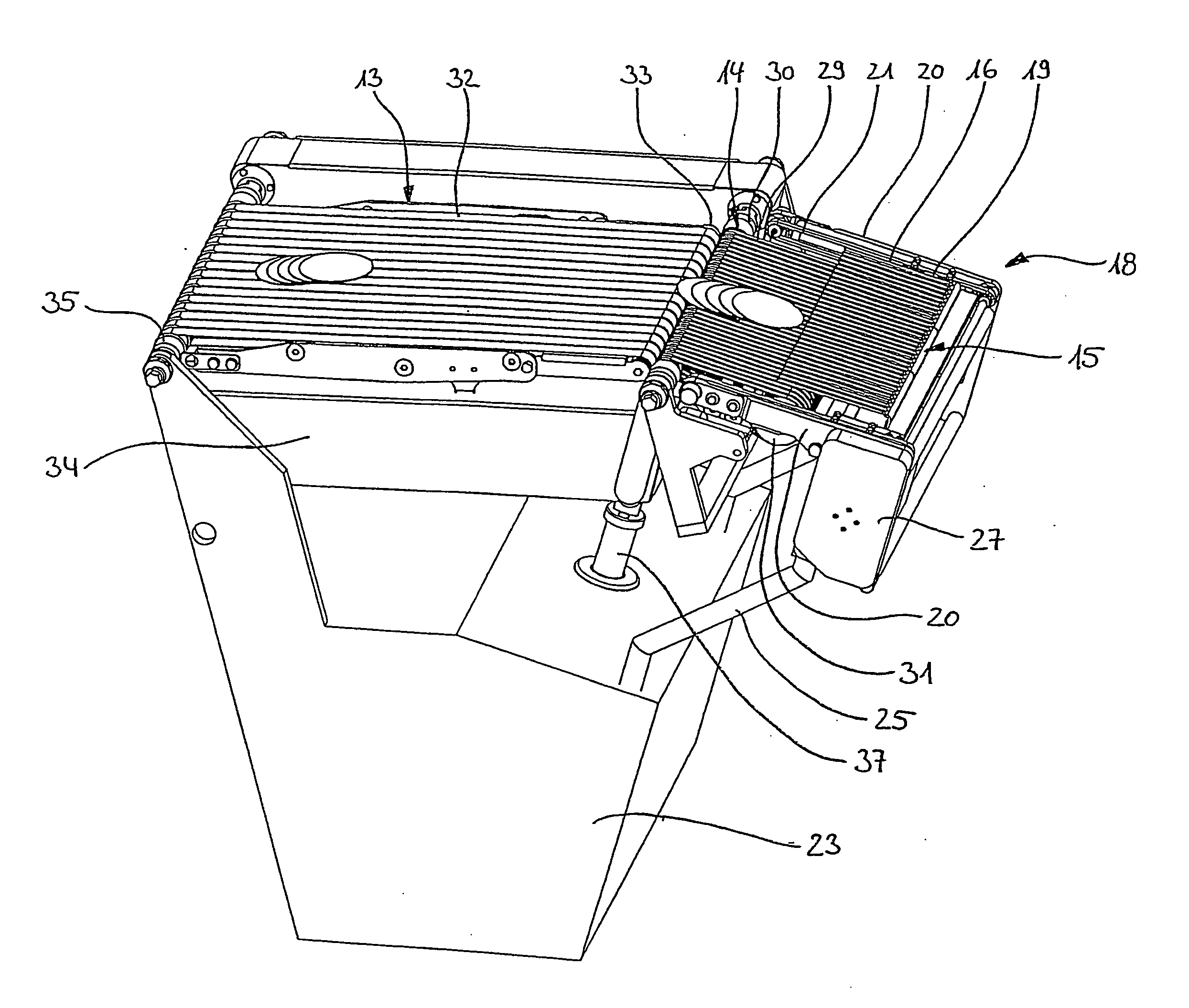

Apparatus for transversally sawing a tubular body

ActiveUS20140174266A1High cutting precisionImprove accuracyTurning machine accessoriesMetal working apparatusEngineeringTranslatory motion

Owner:GA VO MECCANICA SNC

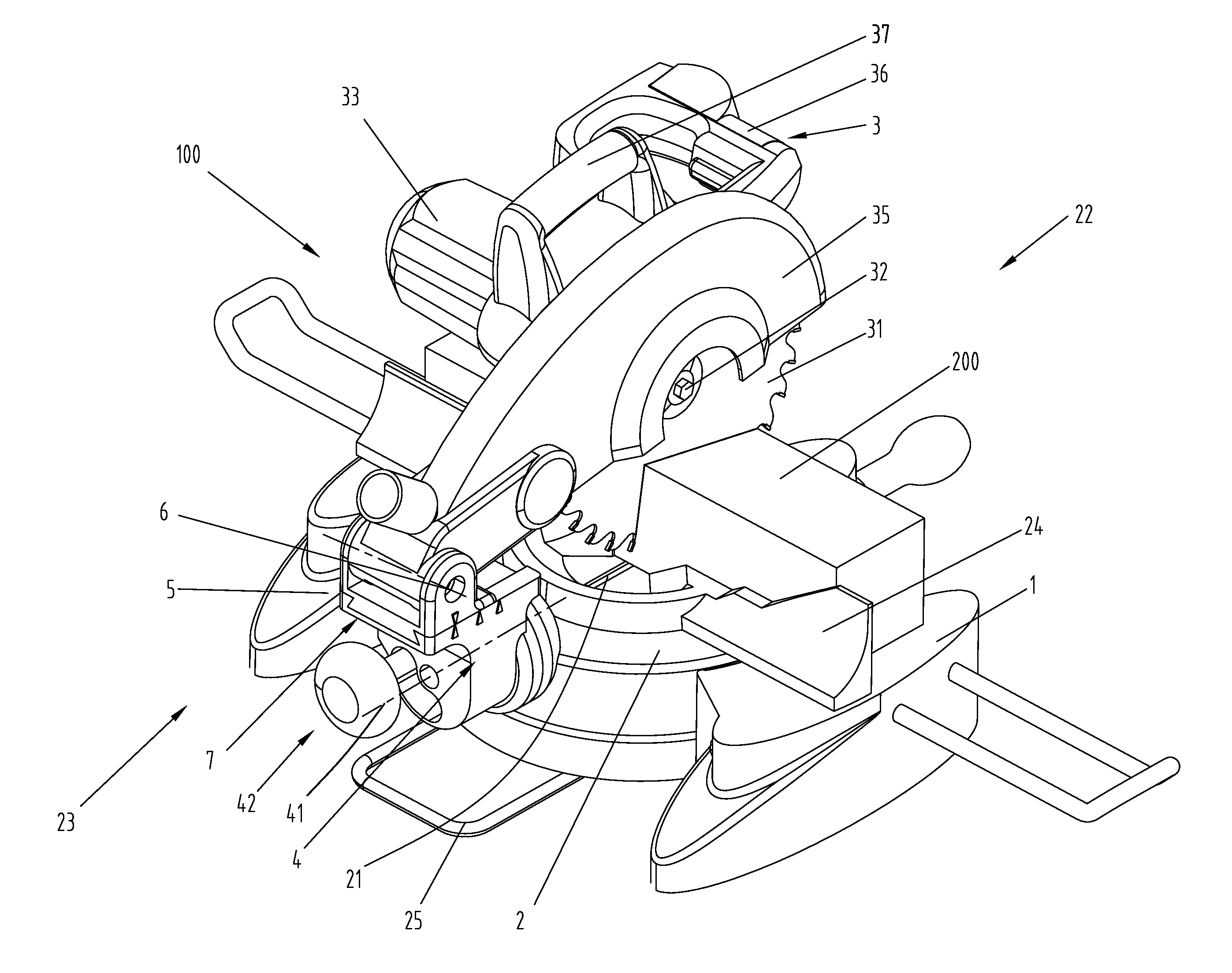

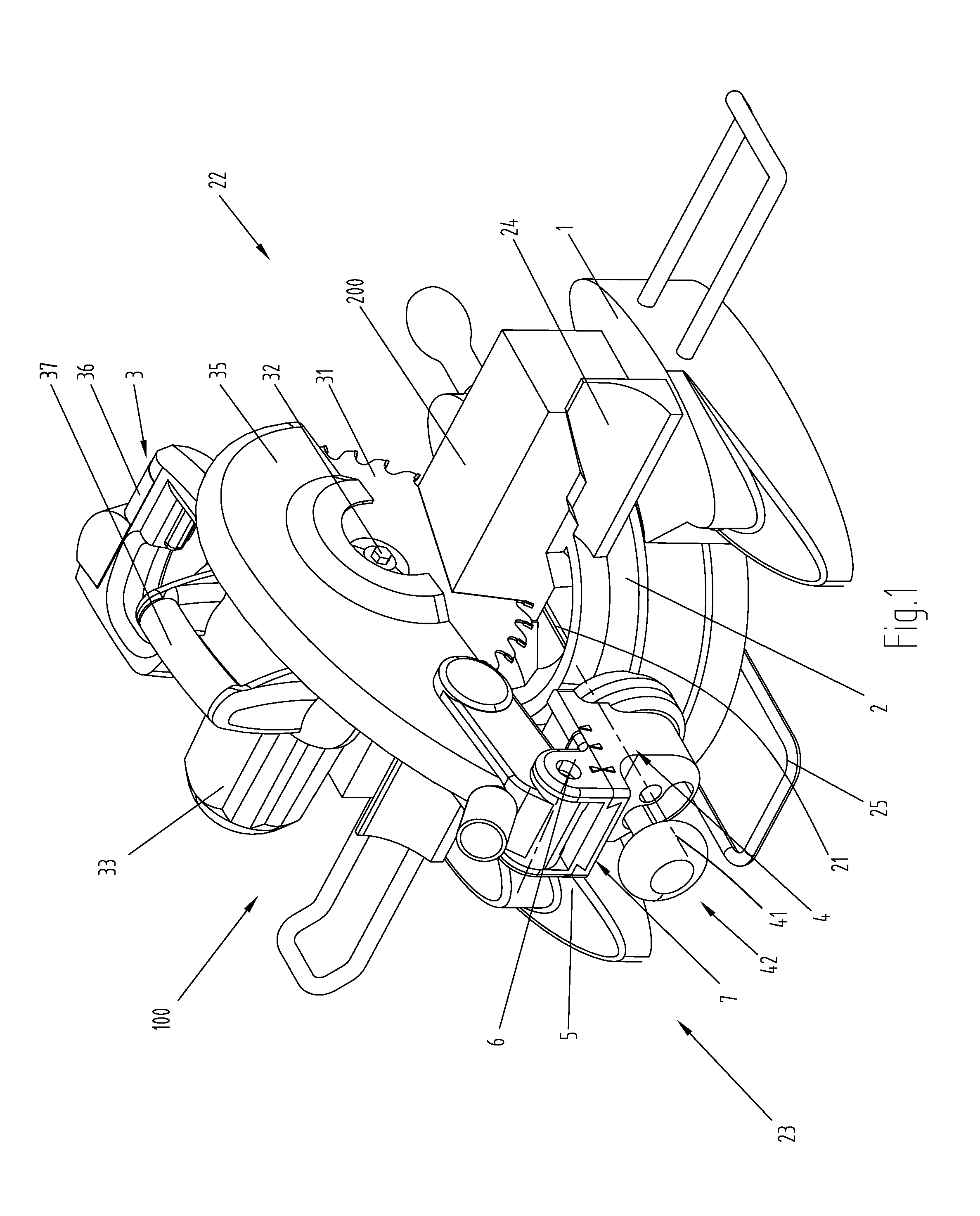

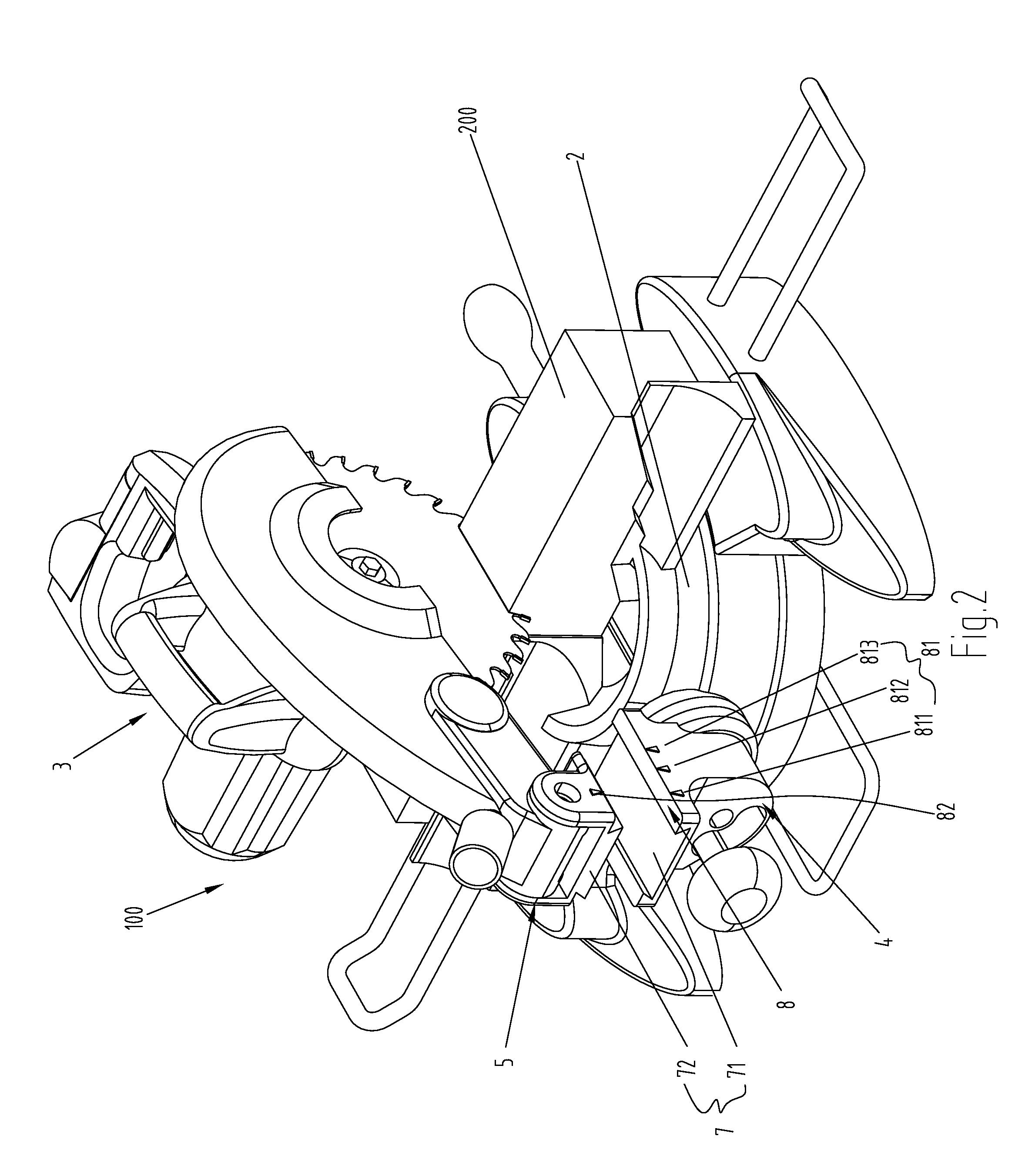

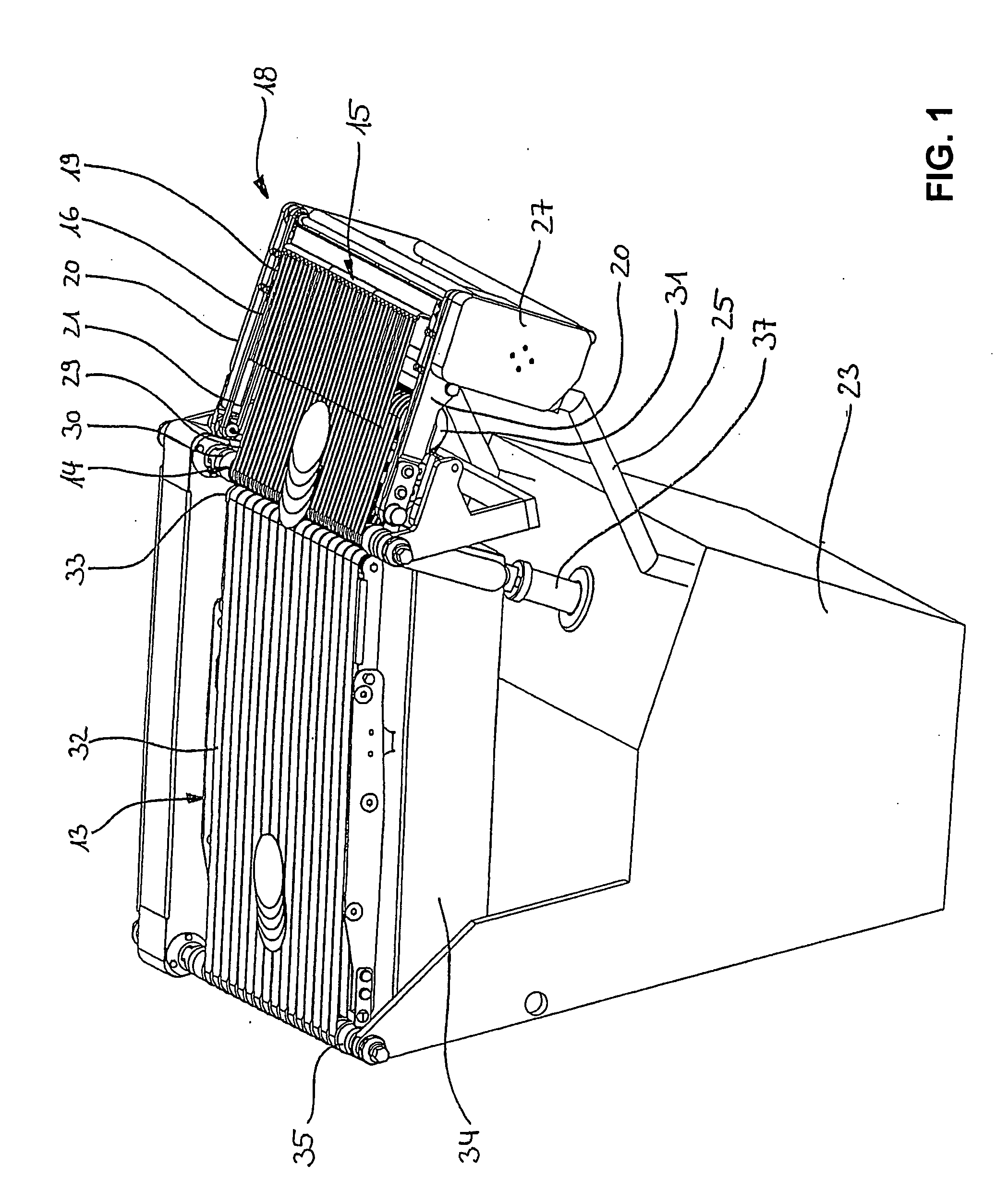

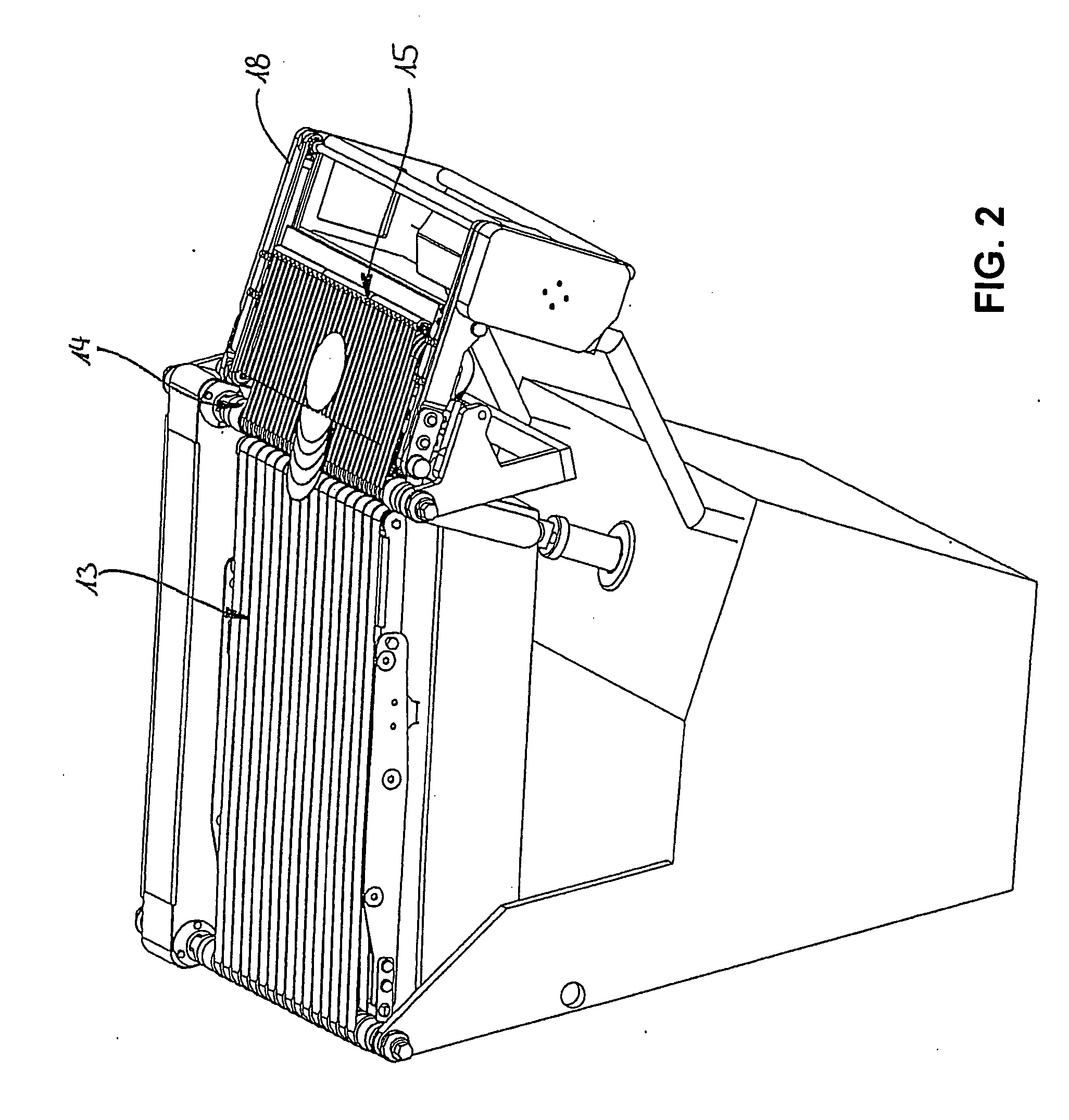

Miter saw

InactiveUS20110179925A1Easy to fixImprove cutting effectMetal sawing devicesGuide fencesMechanical engineeringEngineering

A miter saw comprises a worktable; a first support member attached to the worktable; a second support member attached to the first support member; a saw unit pivotally connected to the second support member via a pivot; and a matching mechanism disposed between the first support member and the second support member, the matching mechanism is operated to cause the second support member to move with respect to the first support member, and the second support member is moved to reach a plurality of predetermined working positions to perform cutting operation. Thus, the cutting capacity of the miter saw is improved for the miter saw being able to cut workpieces with more specifications.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Multifunctional discharging sawing machine sawing device

InactiveCN106735541AHigh cutting precisionImprove consistencyMetal sawing devicesMechanical engineeringEngineering

The invention discloses a multifunctional discharging sawing machine sawing device which comprises a saw mechanism, a feeding mechanism and an angle adjustment mechanism; the sawing mechanism is installed on the feeding mechanism, the feeding mechanism is installed on the angle adjustment mechanism and comprises a feeding frame, the feeding frame is provided with a ballscrew, the ballscrew is provided with a nut seat, and the sawing mechanism is fixed to the nut seat. By means of the multifunctional discharging sawing machine sawing device, multiple steel profiles can be cut in multiple angles, straight-opening sawing and inclined-opening sawing can be performed on the same profile, in the cutting process, the angles are converted automatically and completed completely automatically, sawing precision is high, consistency is good, and product quality is improved.

Owner:JINAN HUAXIN AUTOMATION ENG

Sugarcane dissection device

The invention discloses a sugarcane dissection device and belongs to the field of food processing machineries. In specific, a roller is adopted for feeding, a photoelectric sensor is utilized to measure the length of a nodal bud, and a cutter automatically adjusts the spaces to cut off a sugarcane to reasonably cut the sugarcane into sections; and a photoelectronic device has a plurality of modes and can precisely cut the sugarcane with different colors and different states into sections after being mounted with a light-projector and an optical receiver with different colors. The sugarcane dissection device has the advantages of high efficiency and precision and low noise during working. According to the sugarcane sectioned by the sugarcane dissection device, the nodal bud and pulp are separated and placed separately, the pulp is not damaged due to extrusion, is attractive in appearance, excellent in taste and convenient to eat and utilize, and the nodal bud can be conveniently planted.

Owner:威海神舟信息技术研究院有限公司

Numerical-control band saw machine for sawing American cork wood

ActiveCN102962870AShort dynamic response timeEasy and flexible clampingBand sawsNumerical controlDrive wheel

The invention relates to a numerical-control band saw machine for sawing American cork wood, and the numerical-control band saw machine comprises a saw machine, a saw frame, a vehicle body, a linear guideway pair, a ball screw, a variable frequency motor, a servo motor, an air pump, a numerical control operating desk, an electric control cabinet and the like; the sawing part of the saw machine comprises a band saw driving wheel, a band saw driven wheel, a tensioning mechanism, a tray, a housing and the like; the tension of a cutter is adjusted by virtue of an adjusting handwheel, the exposed teeth of the cutter are adjusted by a saw blade exposed tooth adjusting handwheel; the wood is clamped by a pneumatic device, the clamping force is adjusted by a regulation valve, the clamping force is realized by an operation handle, 01 gear is a wood clamping gear, N is a neutral gear, and 02 gear is a wood loosening gear; the linear guideway pair and the variable frequency motor are adopted for a walking part, the sawing precision is stable and reliable, the servo motor is adopted for a sawing part, the ball screw is lifted, an imported special cutter is adopted, and the numerical-control band saw machine is steady in operation, small in sawing kerf and high in yield.

Owner:江苏东巨机械科技有限公司

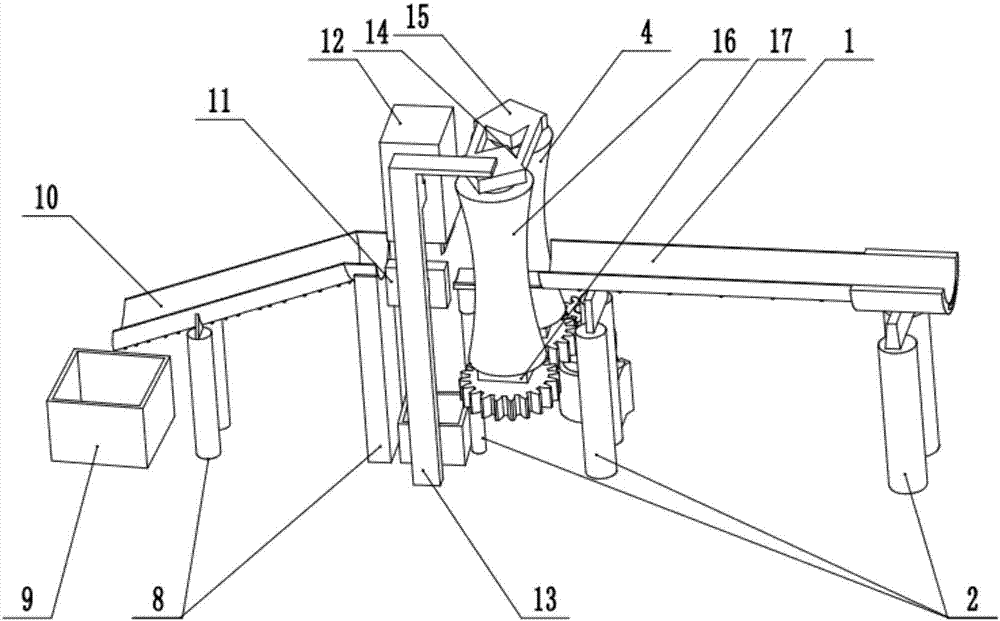

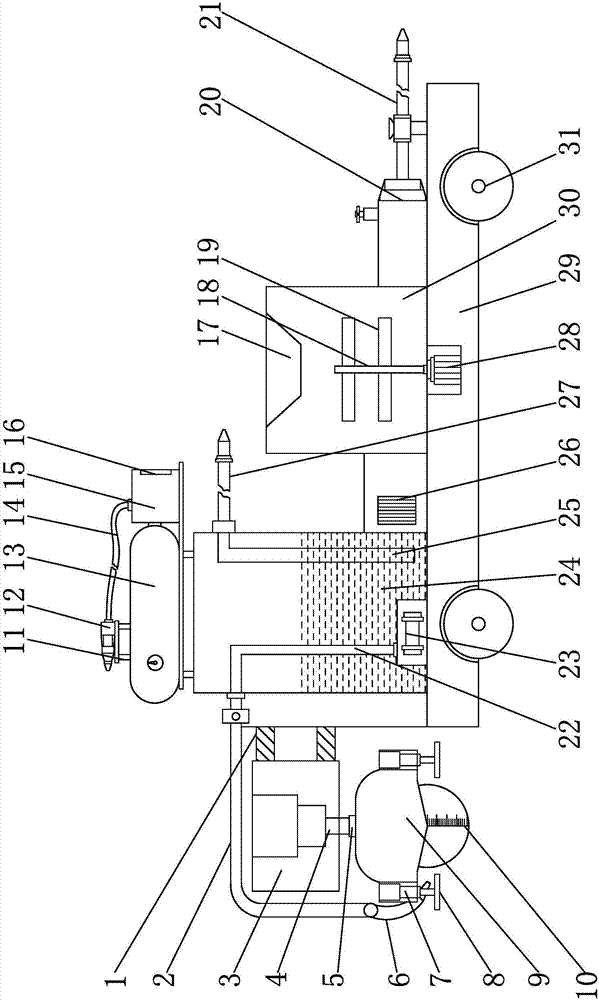

Joint cutting and filling integrated machine for road building

InactiveCN107090765AImprove work efficiencySmall footprintRoads maintainenceEngineeringMechanical engineering

The invention discloses a joint cutting and filling integrated machine for road building. The joint cutting and filling integrated machine comprises a cutting blade, a water tank, a bearing base plate and a mixing burdening tank. Four corners at the bottom end of the bearing base plate are each provided with a roller, the water tank is installed at one end of the top of the bearing base plate, and the mixing burdening tank is installed at the other end of the top of the bearing base plate; a pressurization device is installed between the mixing burdening tank and the water tank, a connecting frame is installed on the bearing base plate of the side, away from the pressurization device, of the water tank, and a fixing block is installed at the top end of the side, away from the water tank, of the connecting frame; and a booster pump is installed on the bearing base plate of the side, away from the pressurization device, of the mixing burdening tank, and a jetting gun is installed on the side, away from the mixing burdening tank, of the booster pump. The joint cutting and filling integrated machine for road building can achieve the road joint cutting and filling integrated automatic operating function and has the advantages that joint cutting and filling do not need labor, joint cutting precision is high, joint cutting quality is high, road quality is good, and working efficiency is high.

Owner:福建省龙祥建设集团有限公司

Cutting system for numerical control cutting machine

InactiveCN102699435AReal-time monitoring and adjustment of tensionMonitor and adjust tensionMetal sawing devicesNumerical controlPull force

The invention discloses a cutting system for a numerical control cutting machine. The cutting system for the numerical control cutting machine comprises a machine cover, saw belt wheels, a saw belt and saw belt clamping mechanisms; a driving saw belt wheel and a driven saw belt wheel are respectively mounted at both ends on the front surface of the machine cover; driving motors are mounted on the driving saw belt wheel and the driven saw belt wheel for driving the driving saw belt wheel to rotate; the saw belt is mounted on the driving saw belt wheel and the driven saw belt wheel; the saw belt clamping mechanisms are further arranged on the machine cover; the saw belt clamping mechanisms are located between the driving saw belt wheel and the driven saw belt wheel; the saw belt passes through the saw belt clamping mechanisms; a saw belt tensioning mechanism and a tension sensor are further mounted on the machine cover; a saw belt axle of the driven saw belt wheel and the saw belt tensioning mechanism are fixed; and the tension sensor is arranged between the saw belt axle and the saw belt tensioning mechanism. With the adoption of the manner, the cutting system for the numerical control cutting machine can be used for monitoring and adjusting tension stressed by the saw belt in real time, can carry out stepless speed regulation on the motors, and randomly controls the cutting linear speed of the saw belt, so that the service life of the saw belt and the sawing precision can be greatly improved.

Owner:苏州赛特尔集团机械有限公司

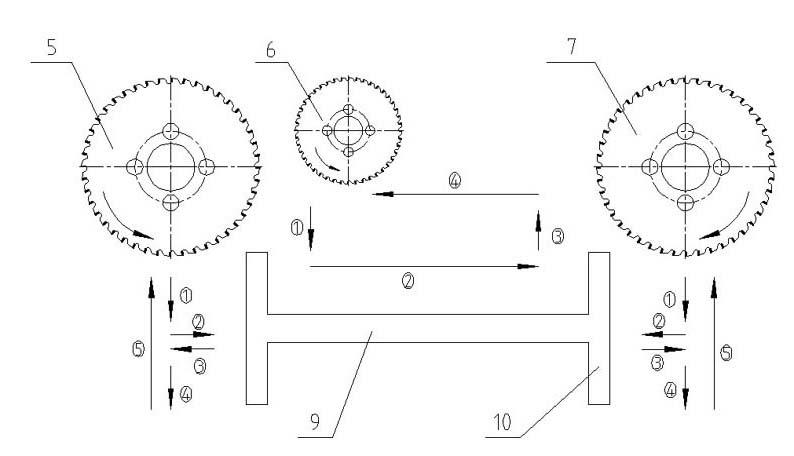

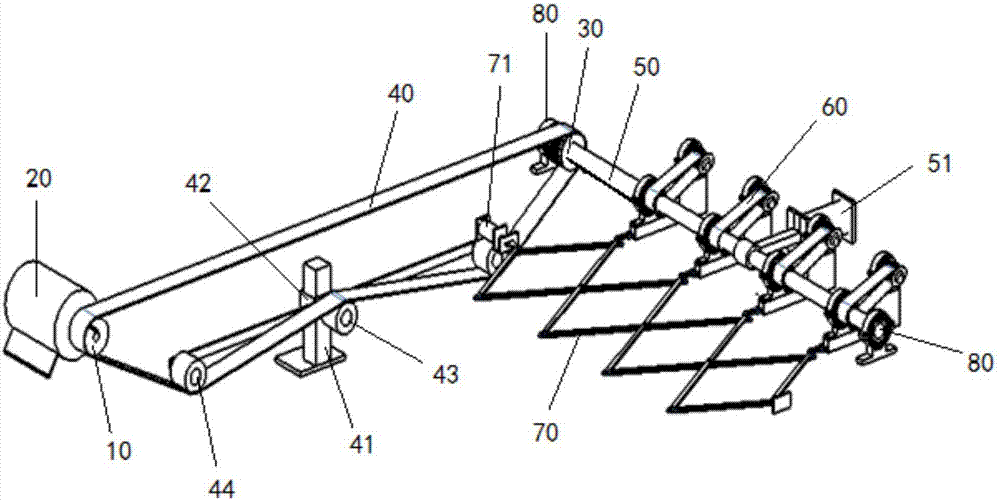

Medium-density fiberboard sawing method and sawing device

PendingCN107053346AReduce the impactReduce energy consumptionCircular sawsDrive shaftMedium density fiberboard

The invention discloses a medium-density fiberboard sawing method and a sawing device. The sawing device comprises a driving pulley, an electromotor which is connected with the driving pulley and drives the driving pulley to rotate and a conveying belt for connecting the driving pulley to a driven pulley and driving the driven pulley to rotate through the driving pulley, wherein the driven pulley is connected with a transmission shaft through key connection; the transmission shaft is connected with a plurality of sawing mechanisms through key connection; the bottoms of the sawing mechanisms are connected with a scissor mechanism through threads; a first cylinder is connected with the transmission shaft through a guide rod and drives the transmission shaft through the guide rod so as to realize longitudinal movement; and a second cylinder is connected with the scissor mechanism through a guide rod and drives the scissor mechanism through the guide rod so as to realize transverse movement. The separation of the electromotor from the sawing mechanisms is realized, the energy consumption of the sawing device is reduced, and the sawing precision of the sawing mechanisms is also greatly improved; and at the same time, the problem that the sawing device stops for manually adjusting the clearances of sawing blades when different dimensions of plates are cut is thoroughly solved, and the production efficiency of the sawing device is greatly increased.

Owner:WUHAN UNIV OF SCI & TECH

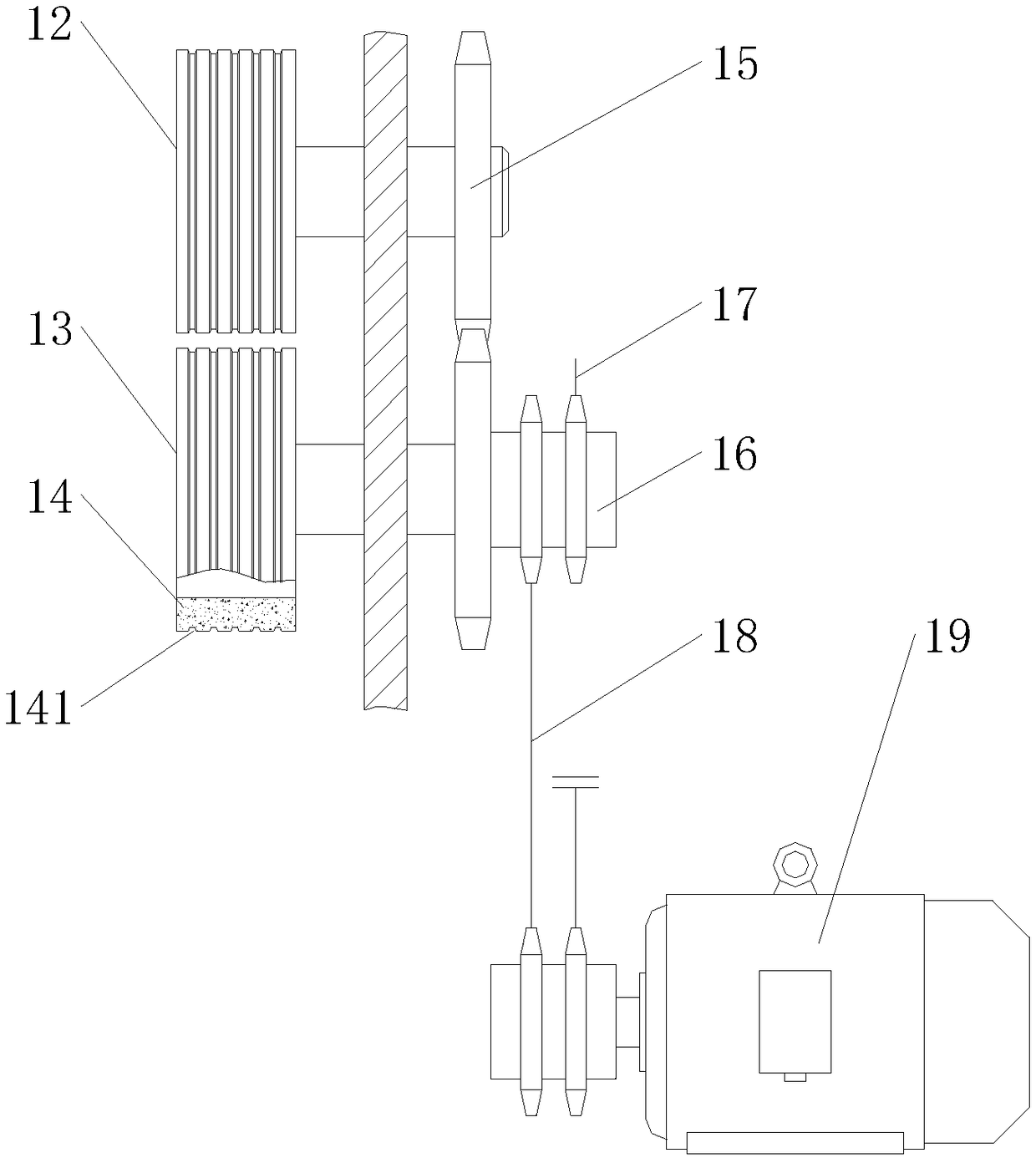

High-performance bamboo cane wiredrawing machine

InactiveCN108437118AHigh cutting precisionRealize dual driveCane mechanical workingBark-zones/chip/dust/waste removalAgricultural engineering

The invention discloses a high-performance bamboo cane wiredrawing machine which comprises a machine box. A wiredrawing device is arranged on one side of the machine box, a falling plate is arranged below the wiredrawing device, the end of the falling plate is provided with a collection groove, a rotary protection cover is arranged on the outer side of the wiredrawing device, the lower end of theprotection cover is provide with an inclined plate, the wiredrawing device comprises a bamboo cane inlet, a first rotating wheel set, a first positioning plate set, a cane cutting knife set, a secondpositioning plate set and a second rotating wheel set which are sequentially arranged on the side wall of the machine box in the horizontal direction, and the bottom of the collection groove located below the cane cutting knife set is provided with a dust suction pipe. The high-performance bamboo cane wiredrawing machine has the advantages of being high in working stability, low in production costand capable of removing dust conveniently.

Owner:ZHEJIANG LIANGYUE BOARD IND CO LTD

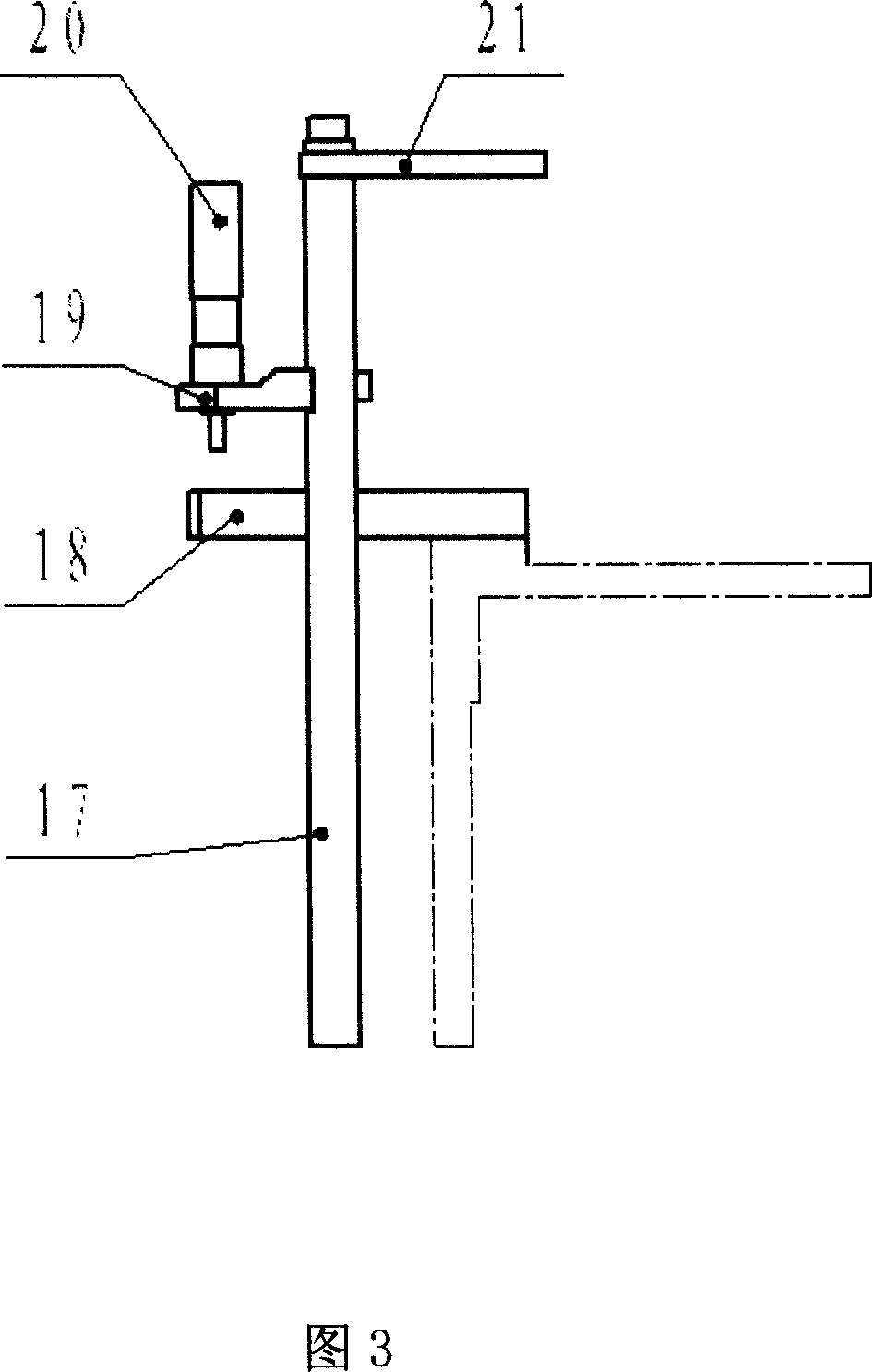

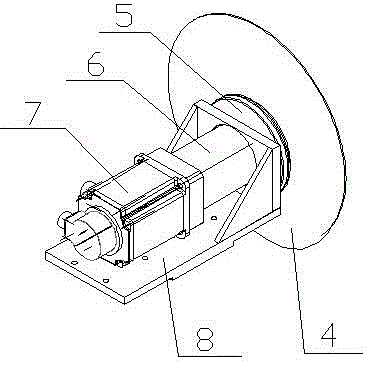

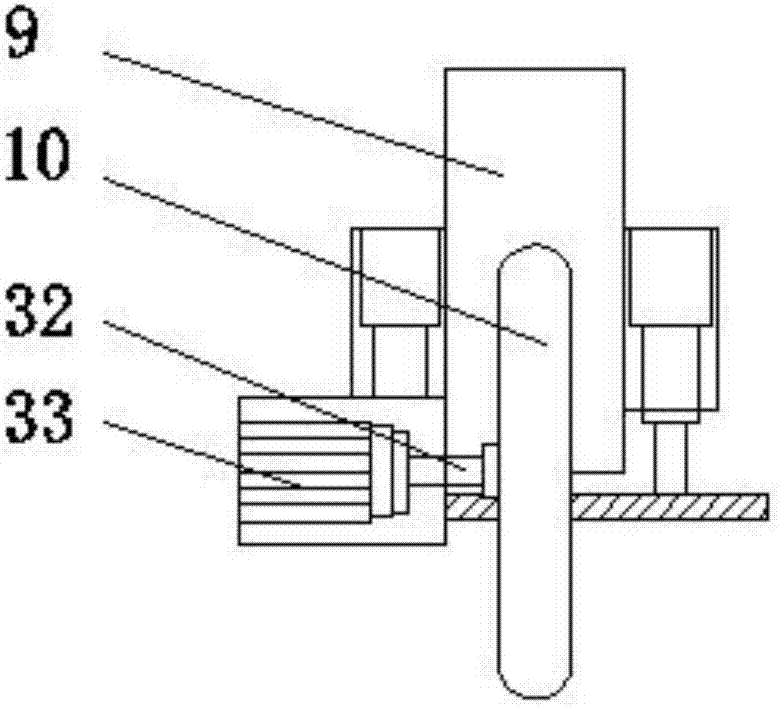

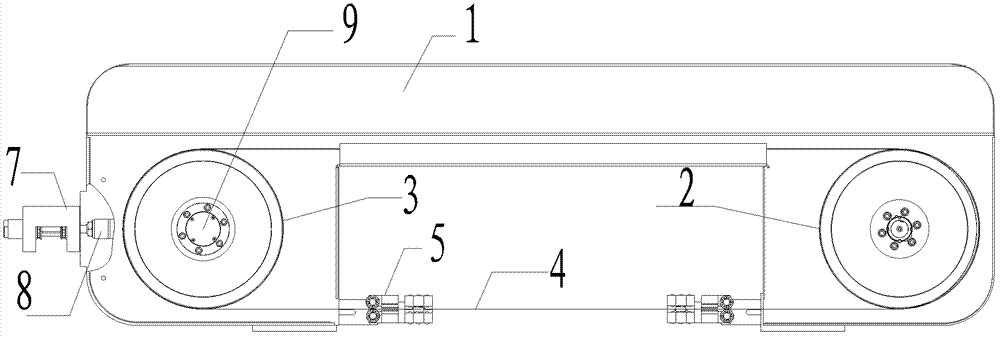

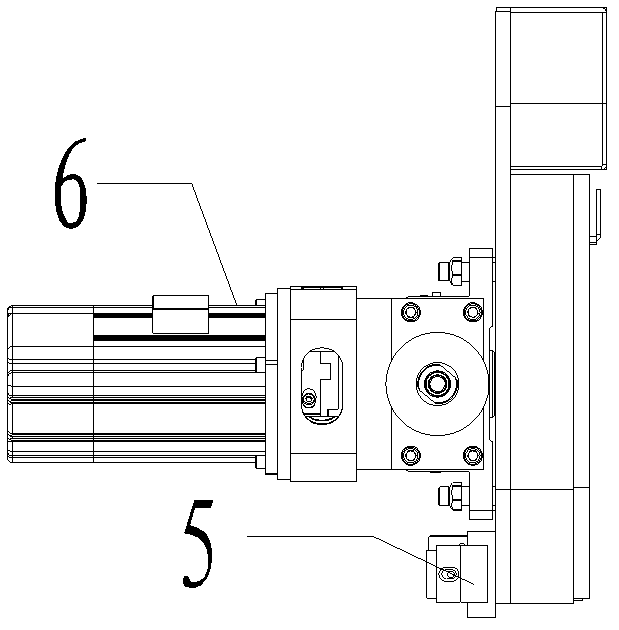

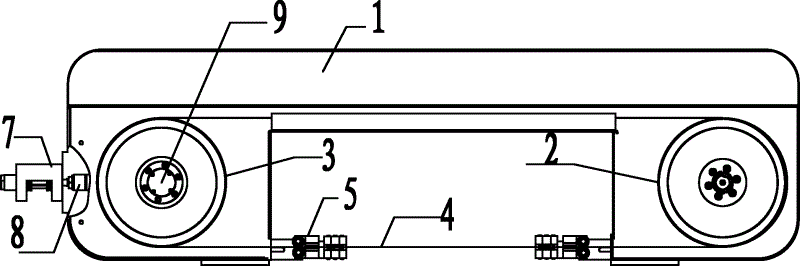

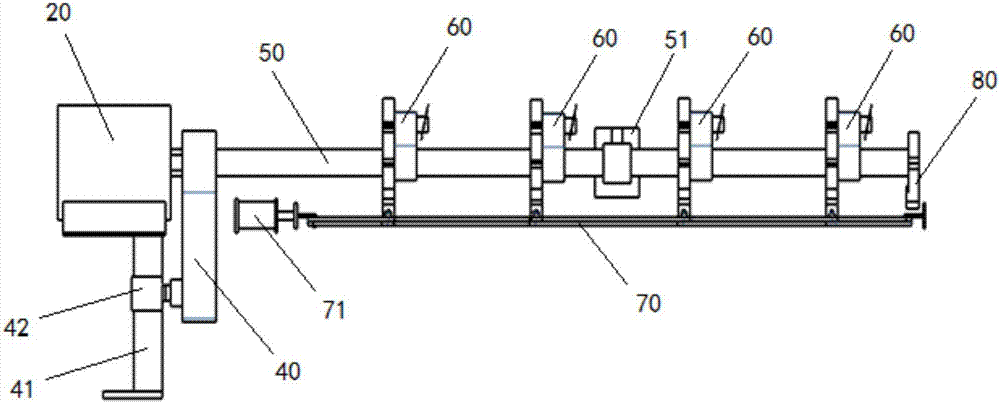

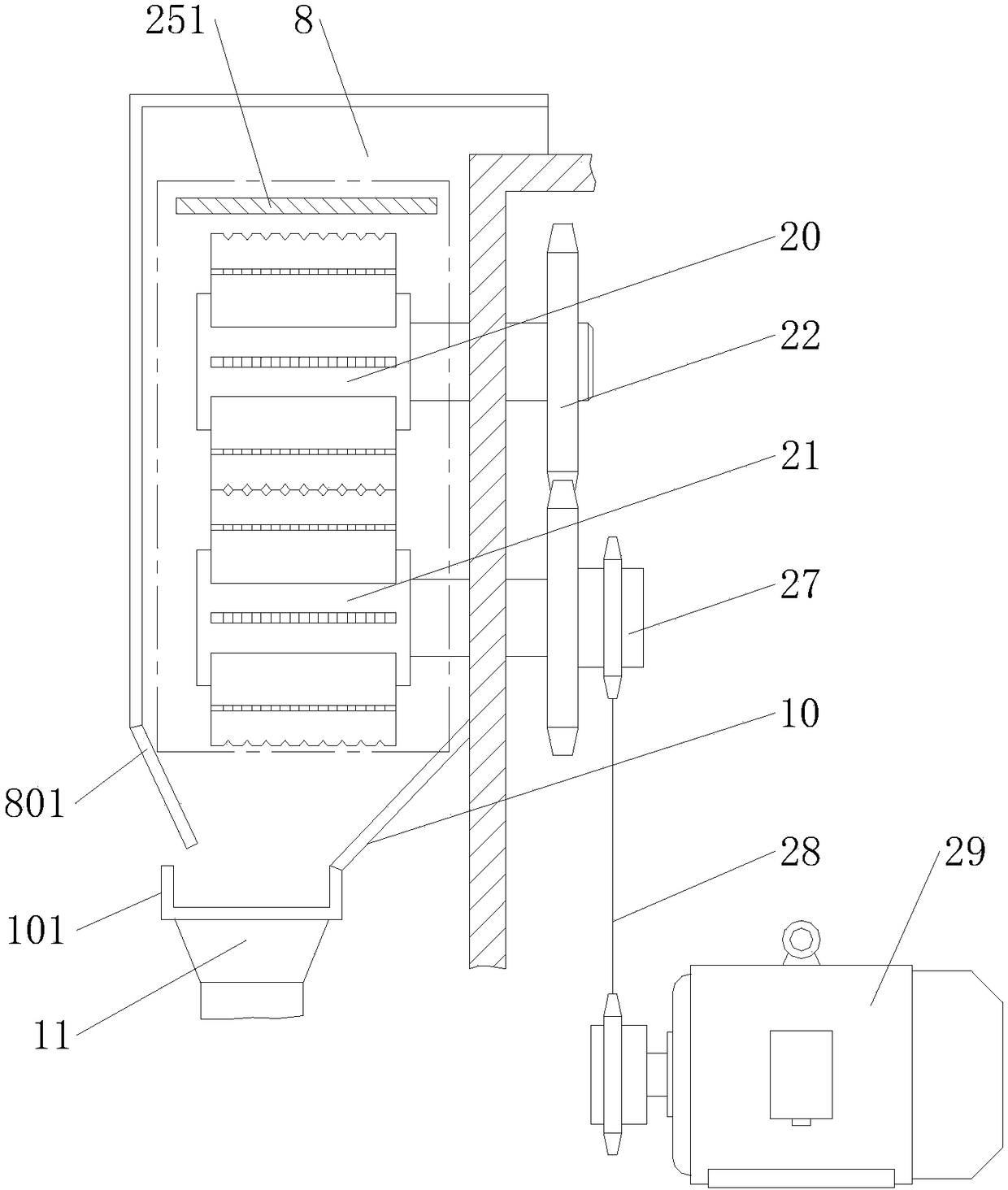

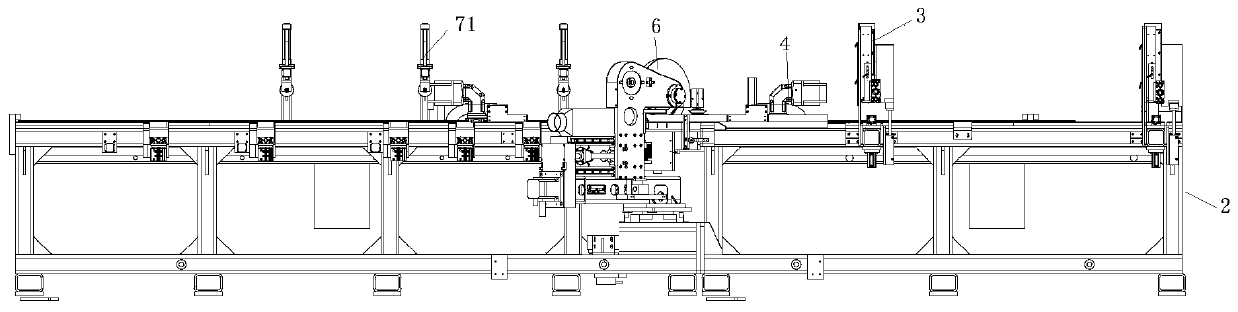

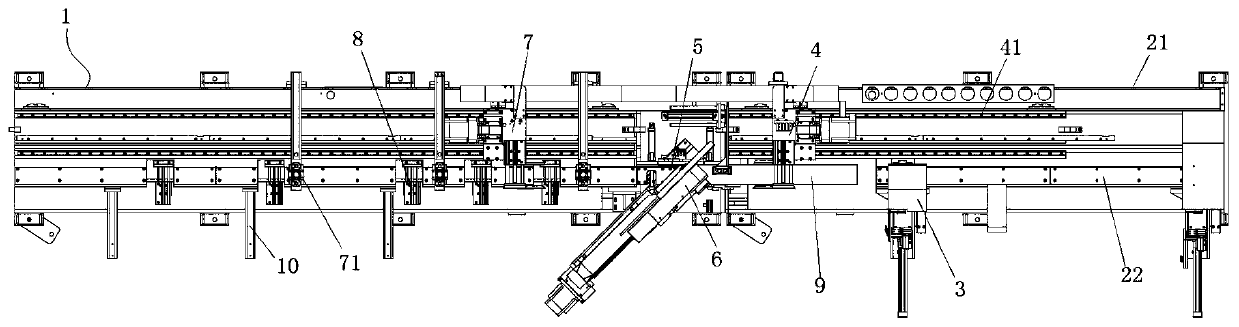

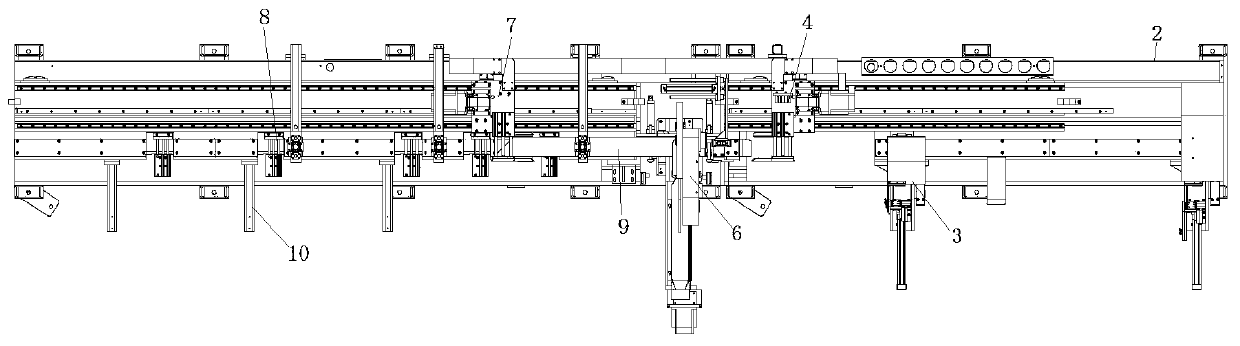

Automatic sizing device of aluminum bar sawing machine

InactiveCN104959875AQuick size adjustmentHigh cutting precisionMetal sawing accessoriesMeasurement/indication equipmentsEngineeringReducer

The invention relates to an automatic sizing device of an aluminum bar sawing machine. The automatic sizing device comprises a conveying track, sizing marks, a rack, an adjusting screw rod, a polish rod, an air cylinder and a sizing baffle. The automatic sizing device is characterized in that the sizing marks are arranged on the upper portions of the two sides of the conveying track respectively, and the rack is arranged on the side portion of the conveying track; the adjusting screw rod and the polish rod are installed on the upper portion of the rack in a transverse running through mode; a coder is installed at one end of the adjusting screw rod, and a driven chain wheel is installed at the other end of the adjusting screw rod; the driven chain wheel is connected with a driving chain wheel arranged on a speed reducer through a chain; the speed reducer is connected with a stepping motor; the polish rod and the adjusting screw rod are connected with a sizing device support with a cavity in a sleeved mode; the air cylinder is arranged inside the sizing device support, and the sizing baffle is connected with the bottom end of the air cylinder. According to the automatic sizing device of the aluminum bar sawing machine, sizing adjustment can be quickly carried out, the sawing precision is improved, manual sizing is avoided, labor force is reduced, the labor intensity is lowered, and potential safety hazards are avoided.

Owner:甘肃广银铝业有限公司

Method for cutting a food standard into slices

InactiveUS8893599B2Improve performanceHigh cutting precisionMetal working apparatusEngineeringMechanical engineering

A method for cutting a food strand into slices, including the steps of feeding the food strand forward to a cutting device including a rotating blade, successively cutting off slices, placing the cut off slices onto an intermediary storage device moveable transversal to the feed direction and in feed direction in order to form a portion, wherein a stacked or fish scaled slice arrangement with a total of n slices is generated and n is a natural number≧3, transferring a non-finished portion including m slices, wherein m is a natural number and m<n, in its entirety from the intermediary storage device to a conveying device, wherein the slices are extracted through the conveying device, wherein the transferred portion after being transferred to the conveying device is completed by cutting off and adding at least one additional slice and is subsequently extracted.

Owner:REIFENHAEUSER UWE

Method for cutting a food standard into slices

InactiveUS20130061729A1Improve cutting performanceLow design complexityMetal working apparatusEngineeringMechanical engineering

A method for cutting a food strand into slices, including the steps of feeding the food strand forward to a cutting device including a rotating blade, successively cutting off slices, placing the cut off slices onto an intermediary storage device moveable transversal to the feed direction and in feed direction in order to form a portion, wherein a stacked or fish scaled slice arrangement with a total of n slices is generated and n is a natural number≧3, transferring a non-finished portion including m slices, wherein m is a natural number and m<n, in its entirety from the intermediary storage device to a conveying device, wherein the slices are extracted through the conveying device, wherein the transferred portion after being transferred to the conveying device is completed by cutting off and adding at least one additional slice and is subsequently extracted.

Owner:REIFENHAEUSER UWE

Automatic filmcutting and laminating device and filmcutting and laminating integrated packing method

PendingCN109733669ALow costEasy to operateWrapping material feeding apparatusProduction lineIntegrated operations

The invention relates to an automatic filmcutting and laminating device and a filmcutting and laminating integrated packing method. A flat pressing profiling cutting die is adopted, the integrated operation of film laminating and film cutting can be realized as long as a corresponding film cutting and laminating profiling die and a profiling cutting tool are prepared, the device integrates film sending and waste film recycling, and film cutting operation is synchronously completed while film laminating is conducted. Cutting tool designing does not disturb a product, thus product appearance andsurface condition can be well protected, the automatic film cutting and laminating device and the film cutting and laminating integrated packing method are suitable for protection film packing of products with complex surfaces, irregular shapes and structures, polyhedron products and products with curved surface, the applicability of the products and fields is wide due to the fact that the compression direction and the compression angle can be adjusted according to requirements, meanwhile, packing of the different products can use the same base tabledue to the replaceabilityof the film cutting and laminating profiling die and the profiling cutting tool of the device, adaptability and compatibility are good, and the automatic film cutting and laminating device and the film cutting and laminating integrated packing method can be used for automatic assembly line packing operation of different product lines.

Owner:武汉抱冰工业发展有限公司 +1

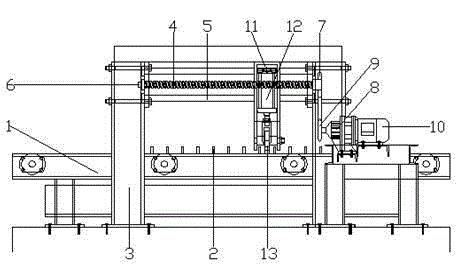

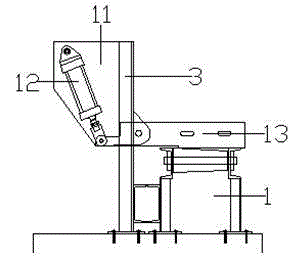

Decorative moulding sawing machine

PendingCN110014483AReduce labor intensityImprove work efficiencyFeeding devicesGripping devicesMechanical engineeringEngineering

The invention relates to a decorative moulding sawing machine. The decorative moulding sawing machine comprises a rack, a sawing workbench assembly, a rotatable sawing assembly and a rear clamping device. The rack is provided with a table board. The sawing workbench assembly and a front clamping device are connected to be arranged on the rack, and the sawing workbench assembly is used for clampingand locating decorative mouldings. The rotatable sawing assembly is arranged on the rack in a manner of corresponding to the sawing workbench assembly and is used for sawing the decorative mouldings.The rear clamping device is connected with the sawing workbench assembly to be arranged on the rack and is used for locating and conveying the decorative mouldings. When the front clamping device conveys the decorative mouldings onto the sawing workbench assembly, the decorative mouldings are clamped and located by the sawing workbench assembly, and one ends of the decorative mouldings are sawn by the rotatable sawing assembly. When the rear clamping device locates the decorative mouldings, the decorative mouldings are clamped and located by the sawing workbench assembly. According to the decorative moulding sawing machine, manual operation is replaced, the labor intensity of workers is reduced, and the work efficiency is improved through cooperation of the front clamping device and the rear clamping device.

Owner:NANTONG YUETONG CNC EQUIP CO LTD

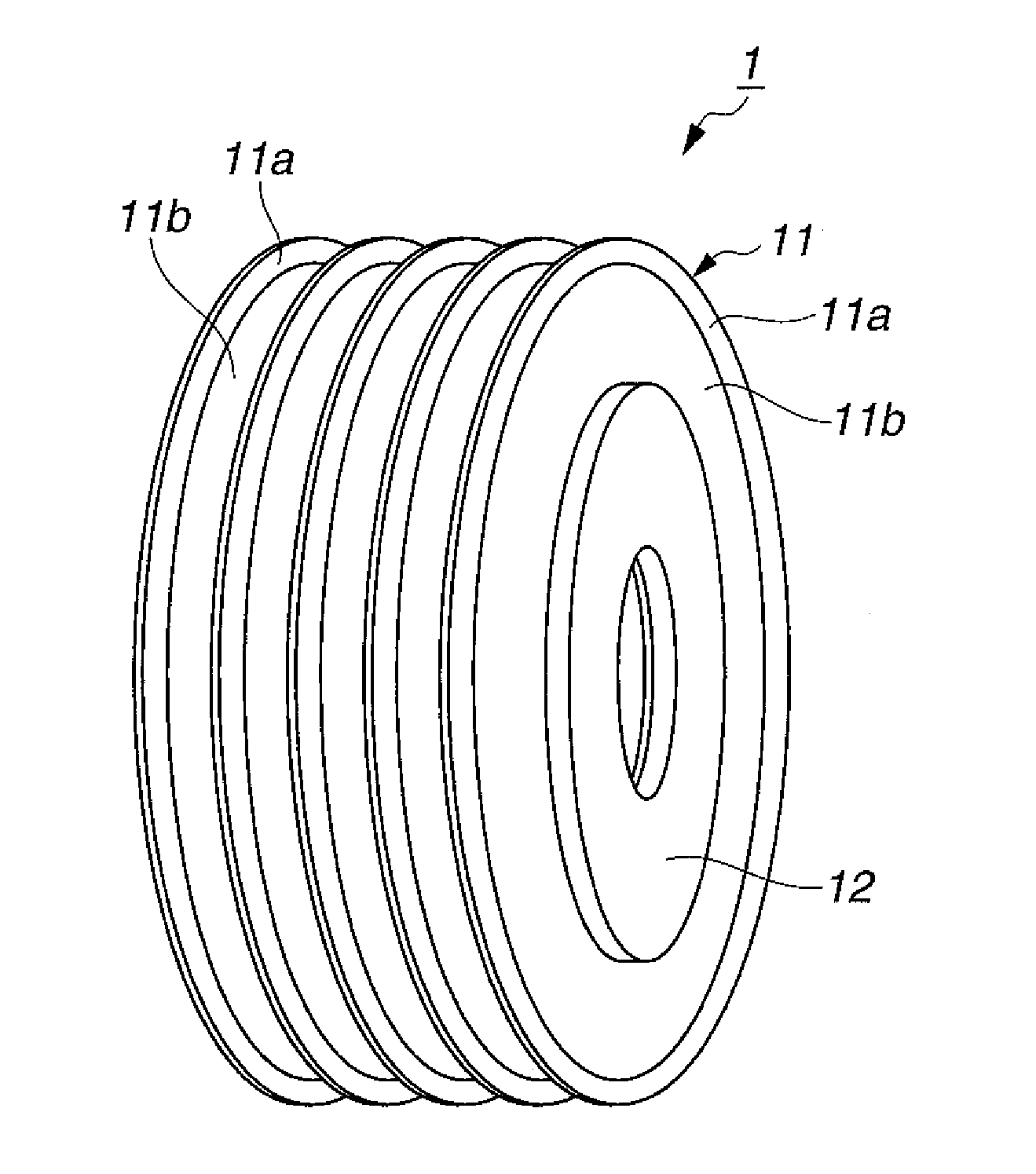

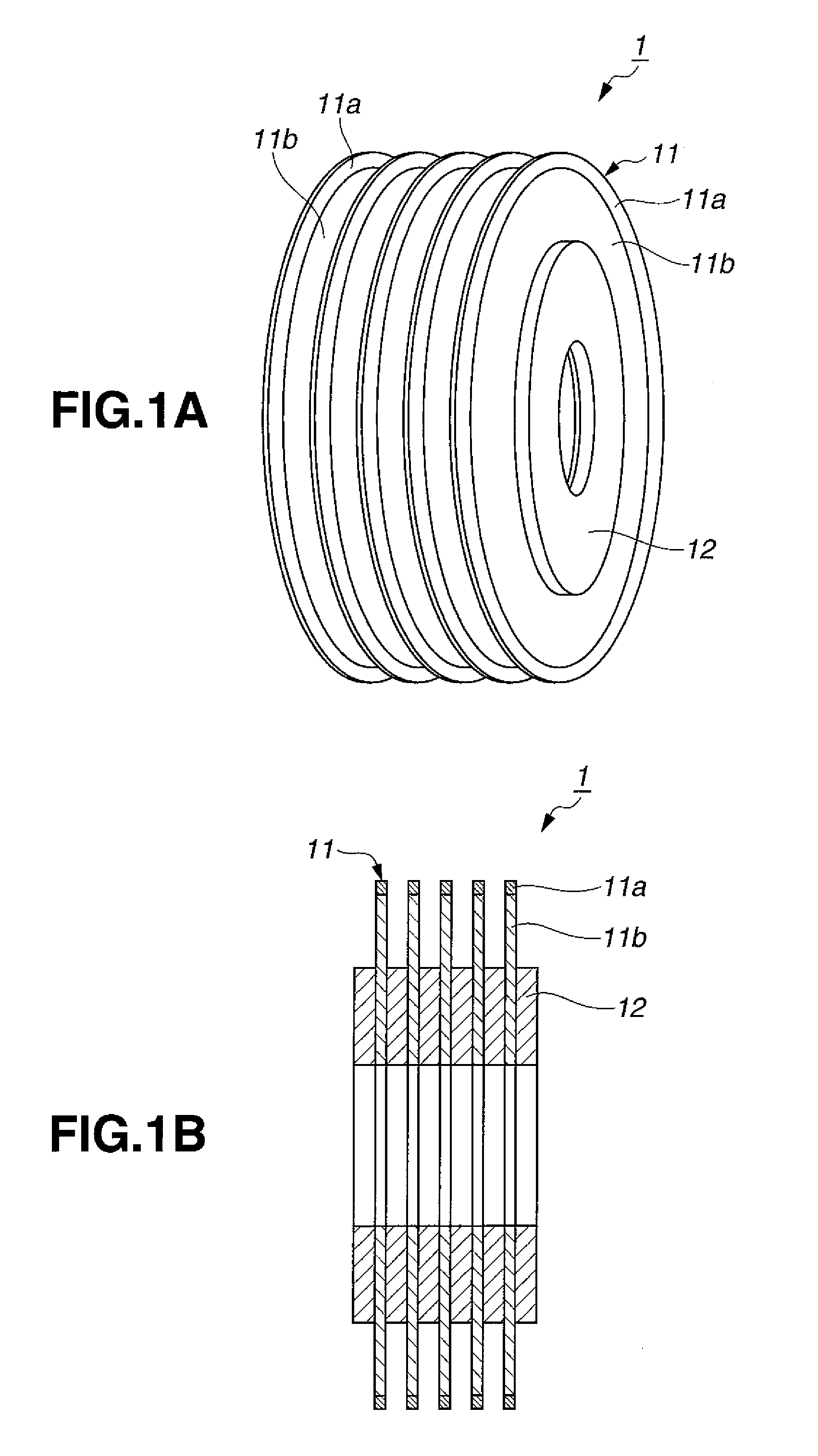

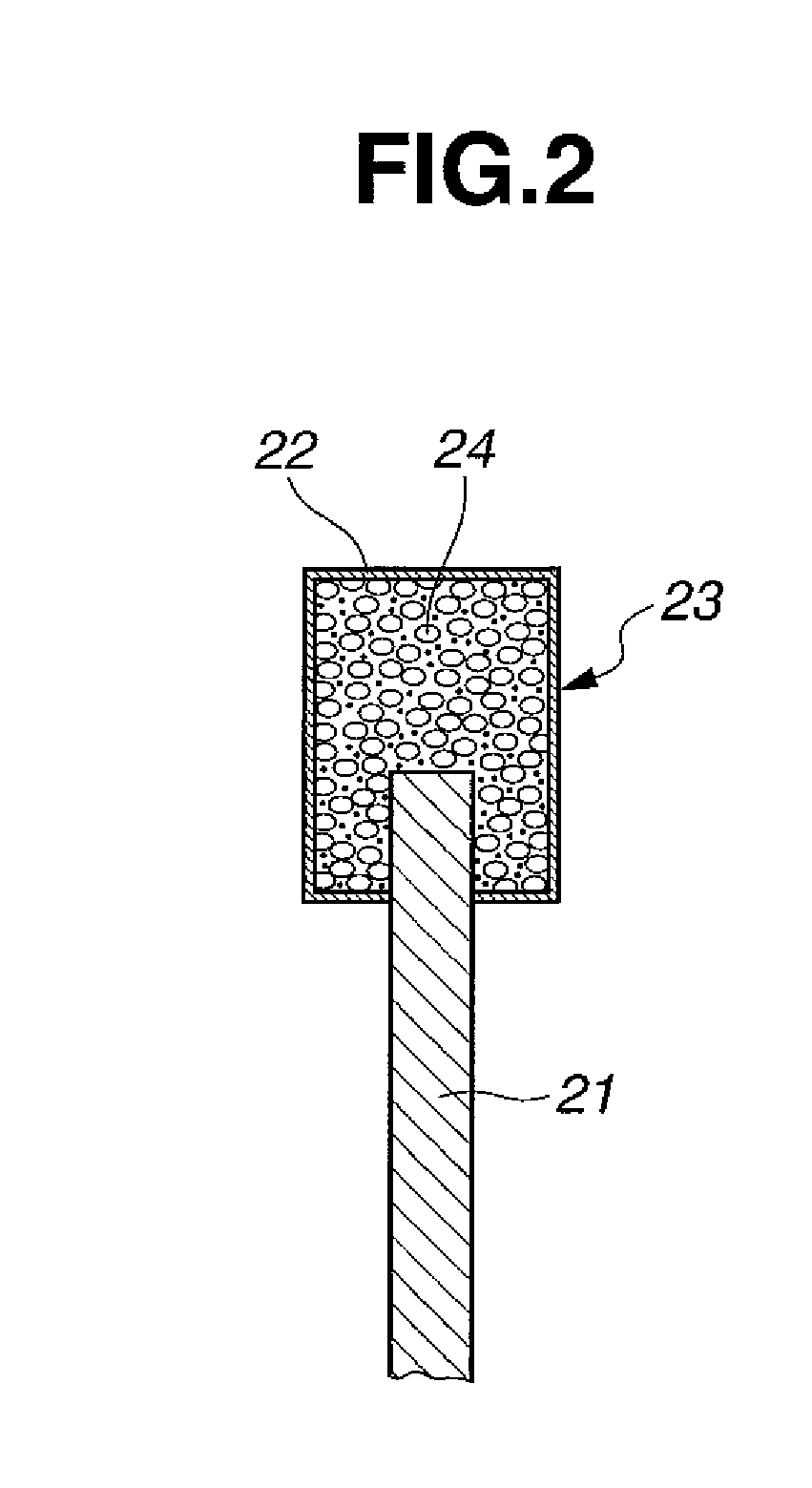

Saw blade and method for multiple sawing of rare earth magnet

InactiveUS20130137343A1Reduce resistanceHigh cutting precisionRevolution surface grinding machinesBonded abrasive wheelsEngineeringRare-earth magnet

A multiple blade assembly comprising a plurality of spaced apart saw blades mounted on a rotating shaft is used for sawing a rare earth magnet block into multiple pieces by rotating the plurality of saw blades. The saw blade comprises a core in the form of a thin doughnut disk and a peripheral cutting part on an outer peripheral rim of the core. The cutting part is made of a composition comprising an abrasive, a resin binder, and a lubricant.

Owner:SHIN ETSU CHEM IND CO LTD

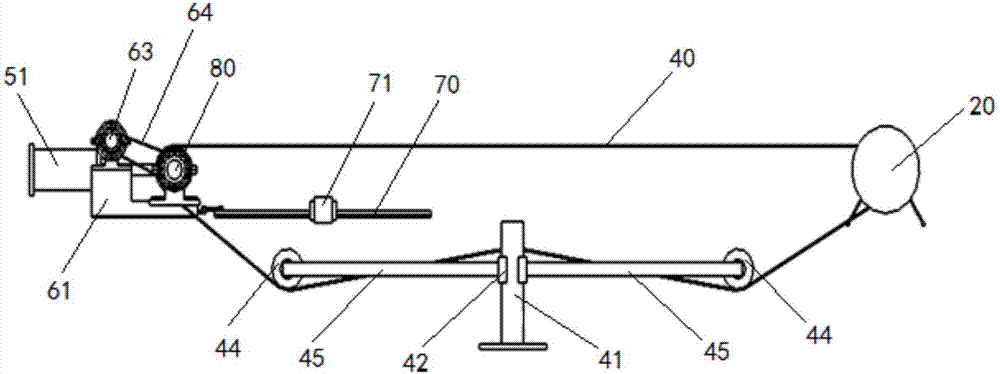

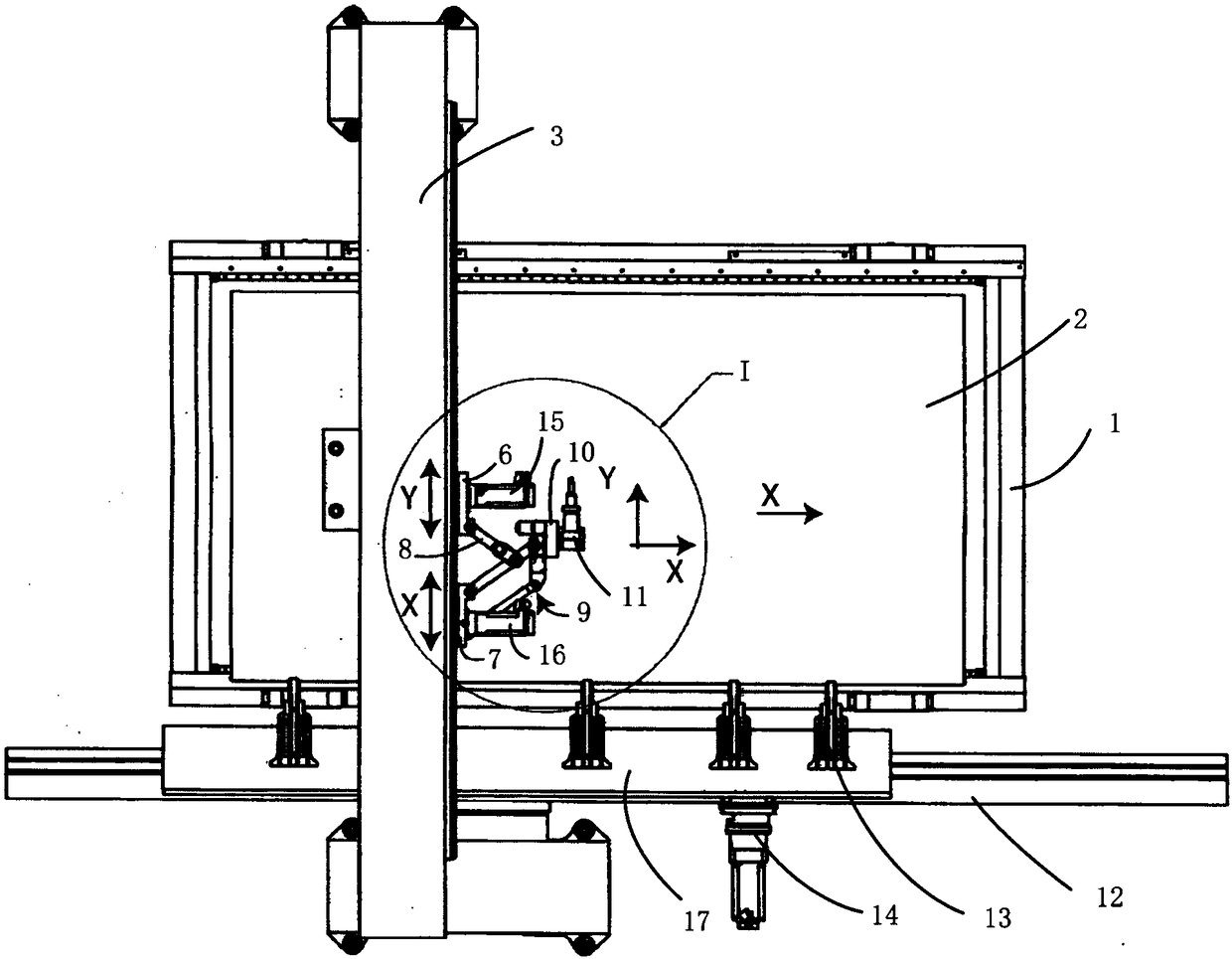

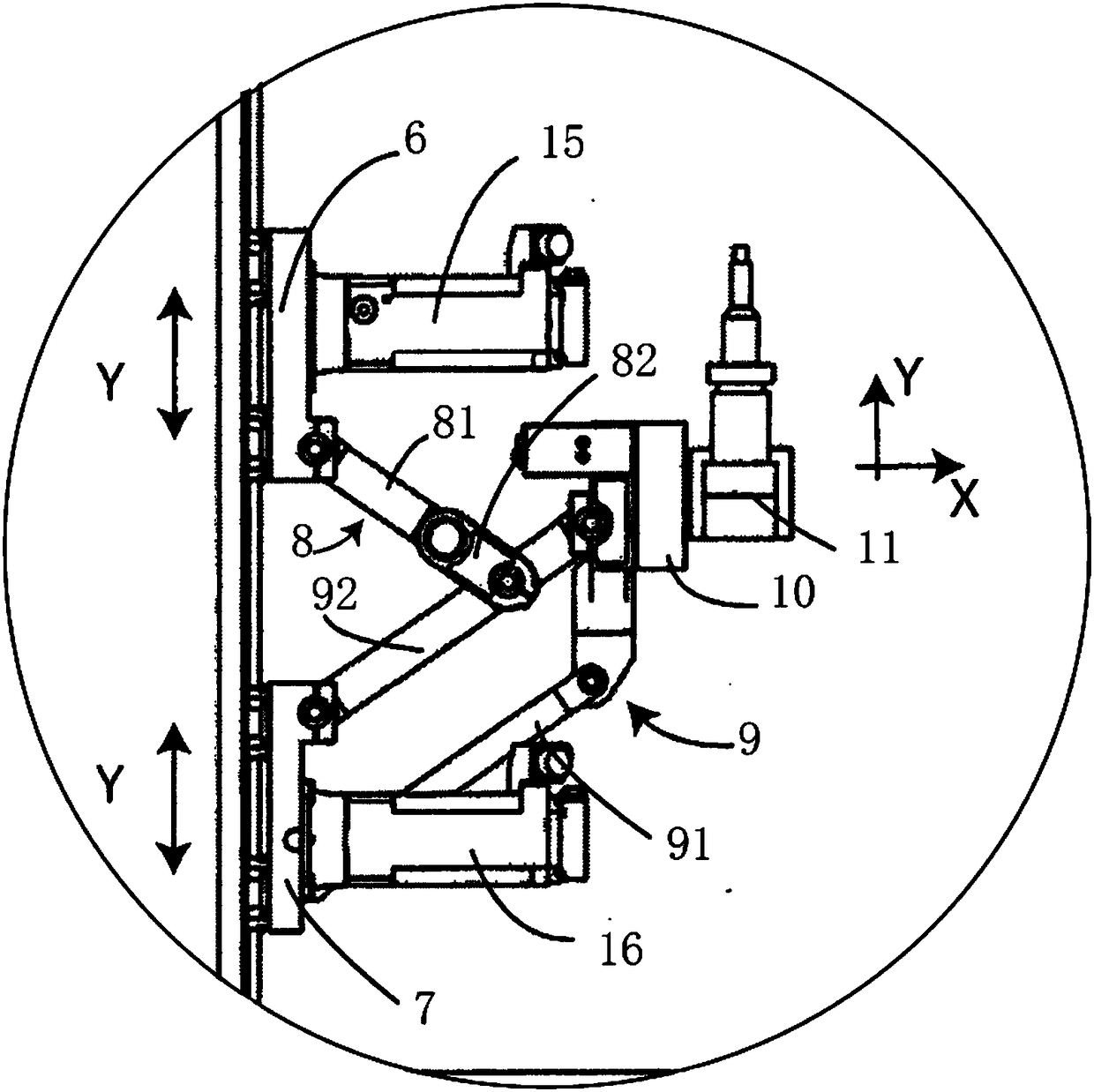

Laser cutting machine of board or strip

PendingCN108406136AGood for controlling inertiaHigh cutting precisionWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingPortal frame

The invention discloses a laser cutting machine of a board or a strip. The laser cutting machine of the board or the strip comprises a working table surface, a laser head and a portal frame crossing the upper part of the work table surface, and the board or the strip can be pulled to move horizontally and vertically on the working table surface. The portal frame is slidably and horizontally provided with a first sliding block and a second sliding block in the transverse direction, the laser head is installed on an installation seat and is arranged downwards, and a first connecting rod mechanism is connected between a first sliding seat and the installation seat in a hinged mode. A second connecting rod mechanism is connected between a second sliding seat and the installation seat or between the second sliding seat and the first connecting rod mechanism, and the first sliding block and the second sliding block are separately driven by a first transverse power device and a second transverse power device to move independently, so that the laser head can move in the transverse direction or in the longitudinal direction or in the resultant movement direction of the first sliding block and the second sliding block. The laser cutting machine of the board or the strip can reduce inertia and improves cutting accuracy.

Owner:金凯达(佛山)智能装备有限公司

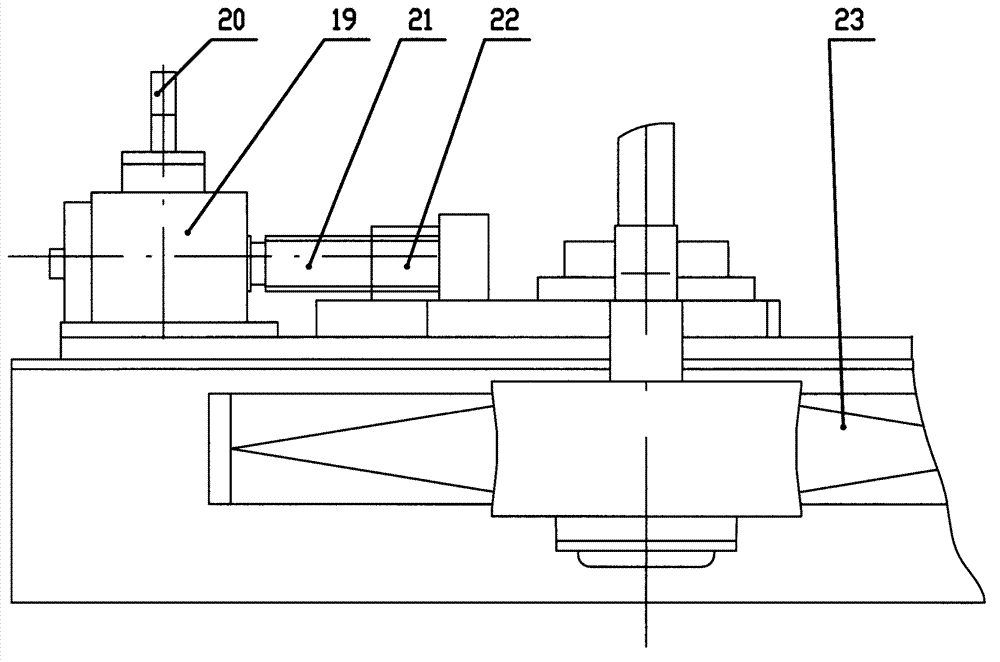

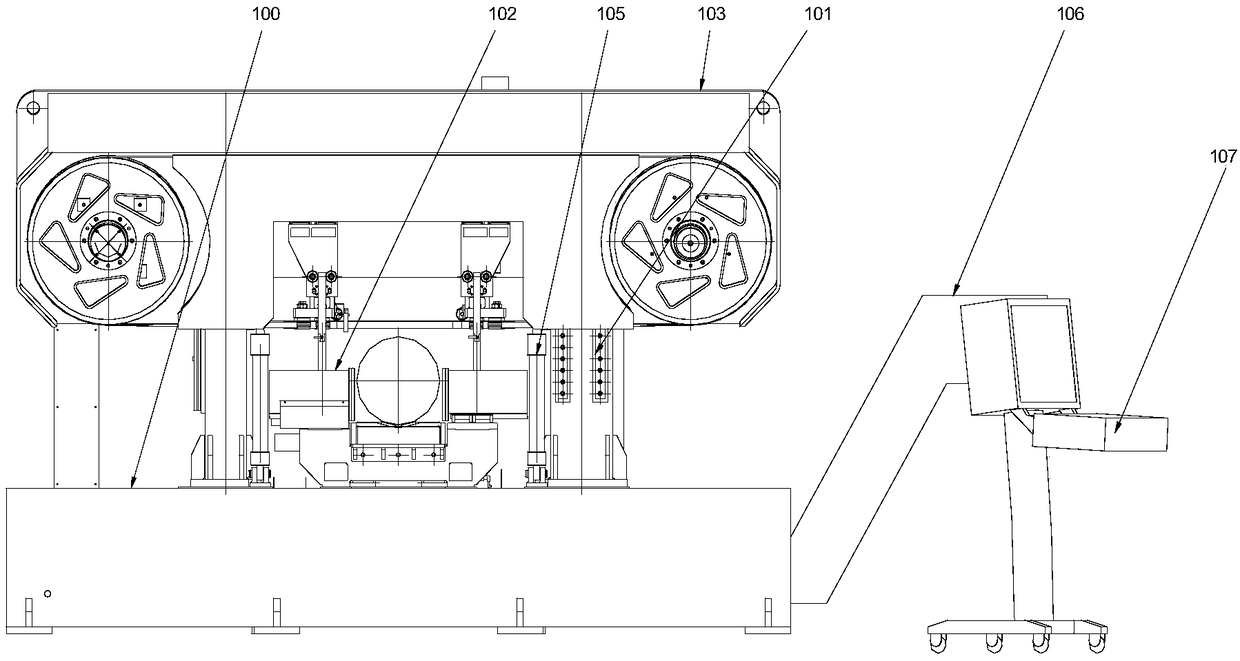

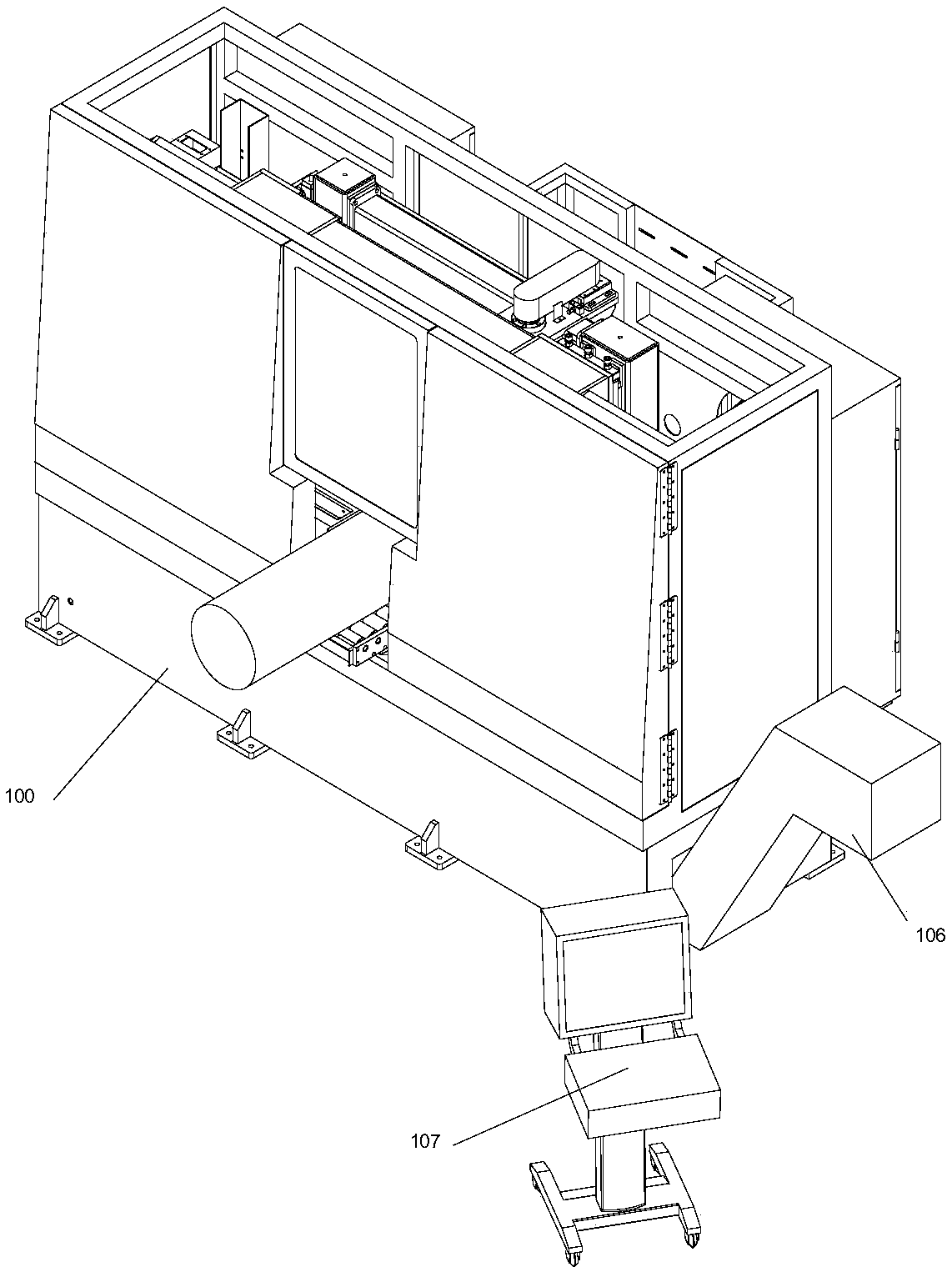

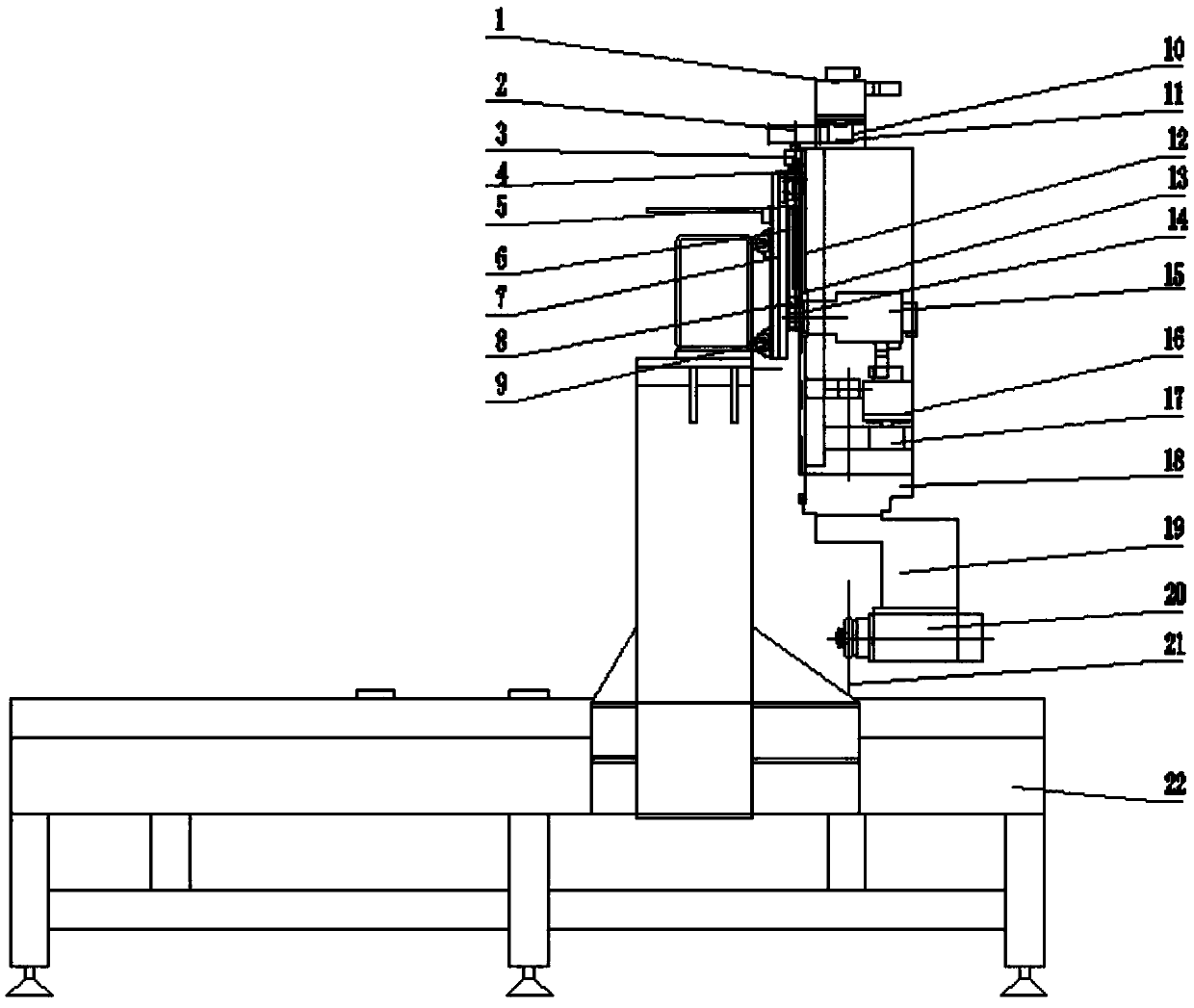

Ultrahigh-speed horizontal band sawing machine

PendingCN108526593AChange mechanical stateEliminate Directional Rotational MomentMetal sawing devicesUltra high speedMotor drive

The invention discloses an ultrahigh-speed horizontal band sawing machine. The ultrahigh-speed horizontal band sawing machine comprises a base, a vertical column, a machine table and a sawing frame and further comprises a servo driving system and a sawing frame lifting balance system. The servo driving system comprises a servo motor, a decelerator and a ball lead screw. The decelerator is mountedon the vertical column, the ball lead screw is connected with the sawing frame, and the servo motor drives the sawing frame to rise and fall by driving the ball lead screw to rotate. The sawing framelifting balance system is used for reducing the axial linear load of the servo motor and provided with symmetrically arranged oil cylinders, a hose and an energy storage device. The lower ends of theoil cylinders are fixed to the base, the upper ends of the oil cylinders are connected with the sawing frame, and the energy storage device is connected with the two oil cylinders through the hose. The sawing frame is inclined forwards relative to the vertical column to be arranged. According to the ultrahigh-speed horizontal band sawing machine, the design that the rear inclination angle of a traditional sawing frame is 35 degrees is changed, the design that the front inclination angle is 12 degrees is adopted, thus the overall gravity center of the sawing frame and the motion axis are basically overlapped, the mechanical state of lifting motion of the sawing frame in the sawing process is changed, moment of rotation in the Y-axis direction of the sawing frame is eliminated, friction resistance between a sliding sleeve and the vertical column during lifting motion of the sawing frame is reduced, and the service life of the machine is prolonged.

Owner:昆山汉田机械工业有限公司

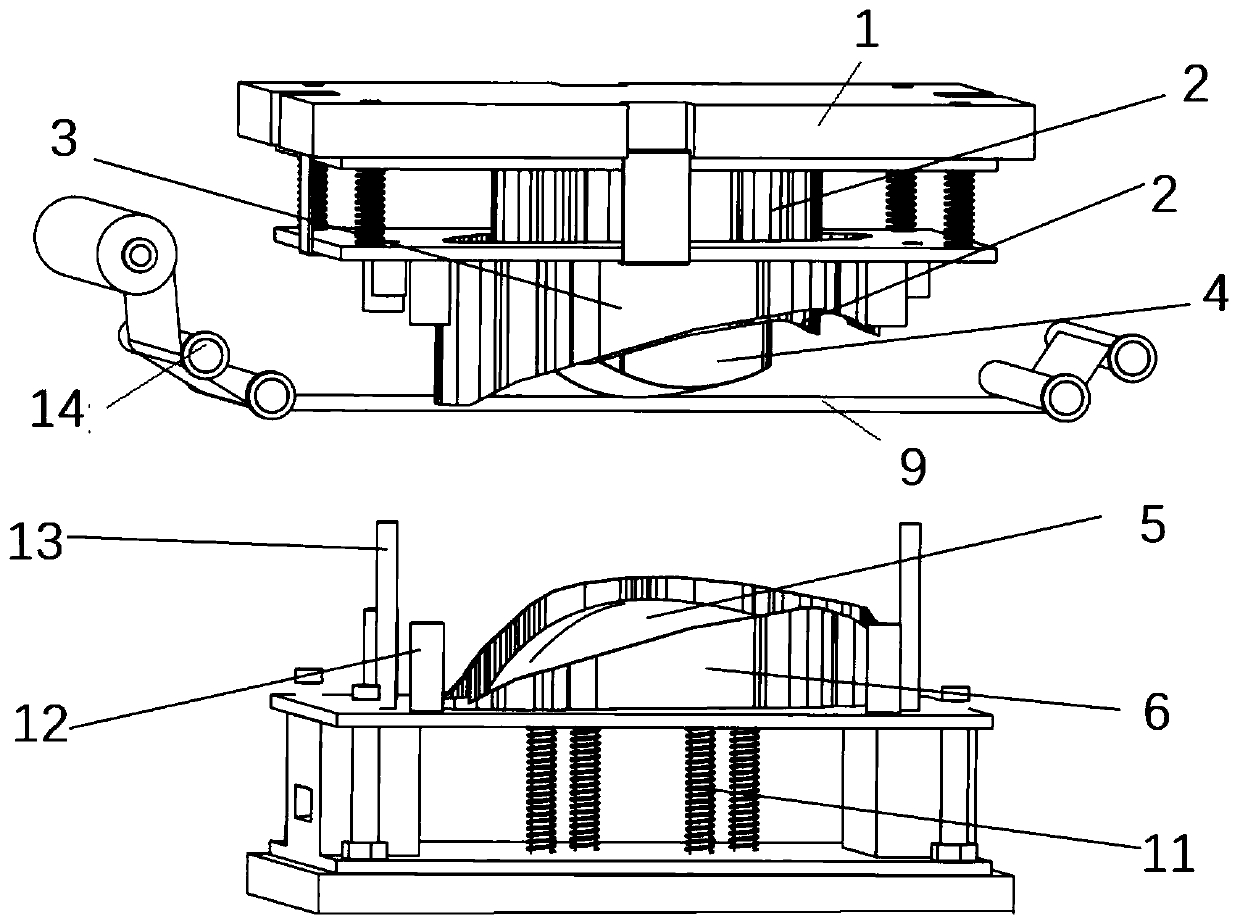

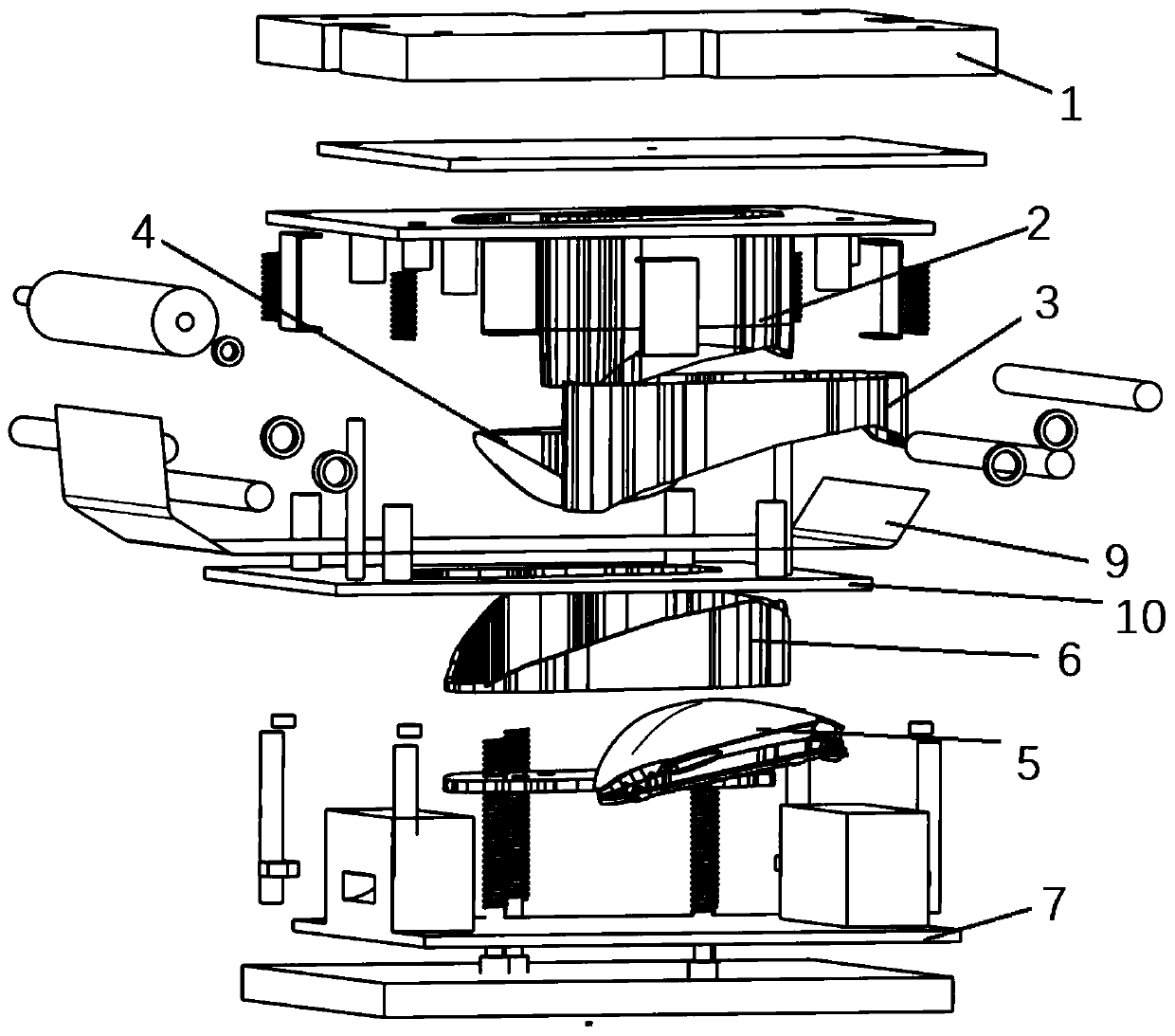

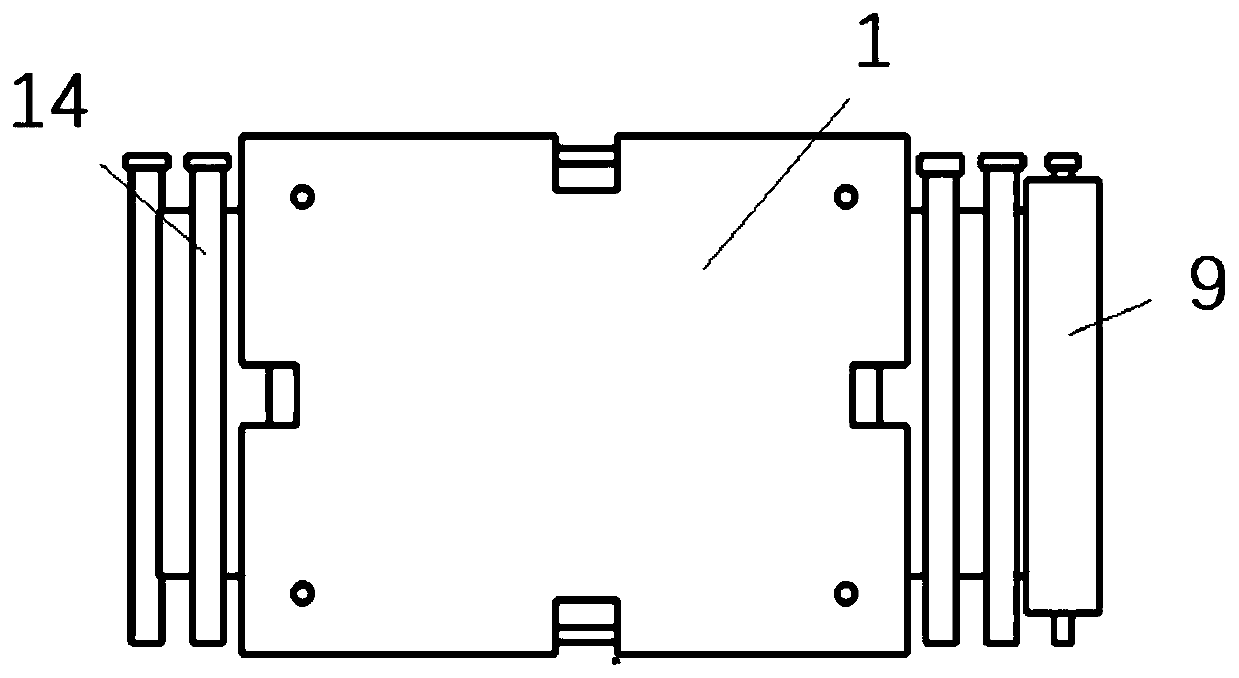

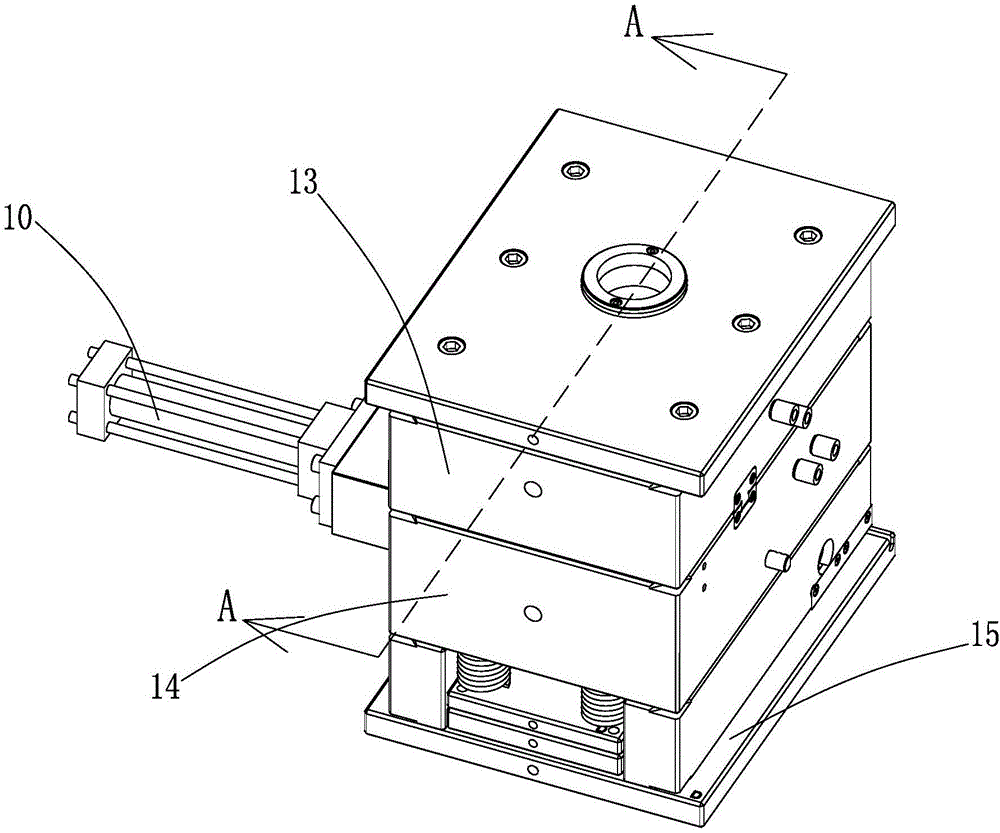

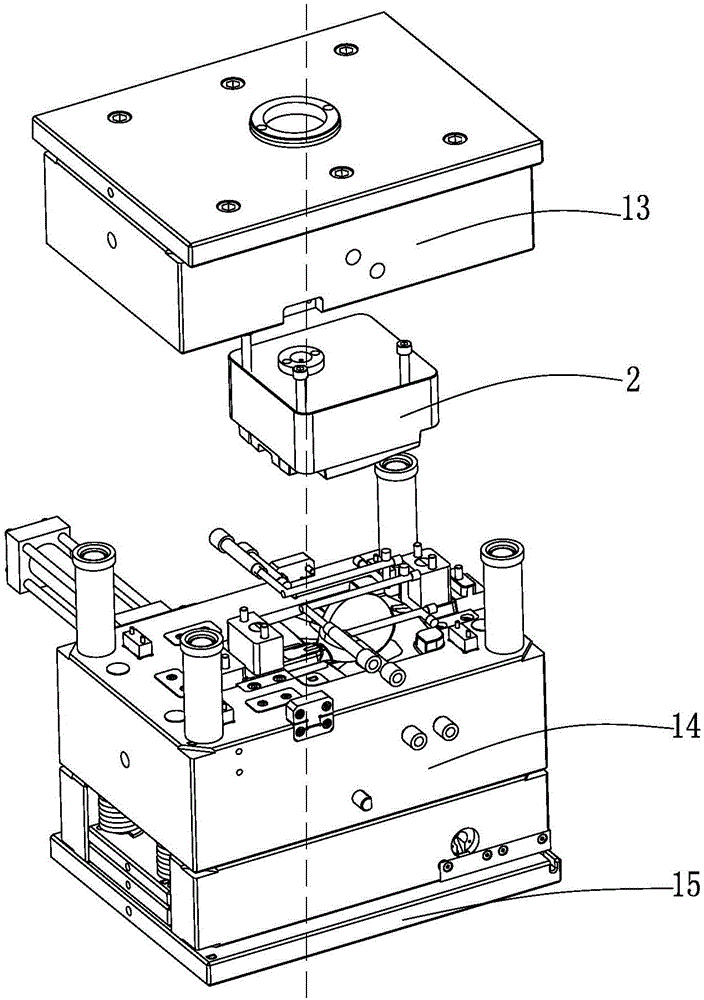

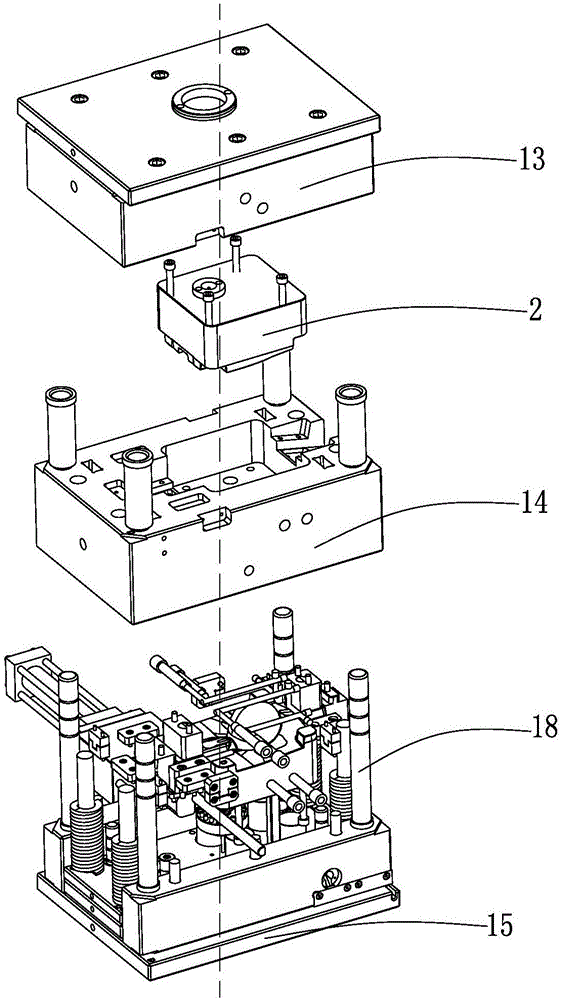

In-mould cutter pressure-retreating-resistant water gap automatic cutting device

The embodiment of the invention provides an in-mould cutter pressure-retreating-resistant water gap automatic cutting device. The device comprises a male mould core and a female mould core matched with the male mould core in a covering mode. The male mould core and the female mould core are matched and cover each other to form a mould cavity used for product forming, the male mould core is provided with a water gap communicated with the mould cavity, a cutter and a driving locking device are arranged on the side, communicated with the mould cavity, of the water gap, the cutter can extend into the mould cavity to cut the water gap, and the driving locking device drives the cutter to reciprocate and locks the cutter during injection molding to prevent the cutter from retreating under influence of injection molding pressure. The driving locking device locks moving of the cutter and achieves automatic cutting of the cutter, the automation degree is high, the problem that the cutter retreats under the influence of injection molding pressure is effectively prevented, product appearance is guaranteed, and production efficiency is improved.

Owner:中山市登盈精密注塑有限公司

Mandrel structure of circular saw machine for preferably cutting timber in longitudinal direction

The present invention discloses a saw shaft structure of optimized longitudinal cutting circular sawing machine, which comprises a saw shaft and a saw shaft base that is used for supporting the saw shaft. The saw shaft is at least sleeved with a sawblade sliding sleeve which can move along the axial direction and rotate along with the saw shaft. The sawblade sliding sleeve is at least fixedly installed with a movable circular saw blade which is movably connected with a circular saw blade shifting fork. The circular saw blade shifting fork is connected with a screw pair. The saw shaft is at least fixedly installed with a fixed circular saw blade and is at least fixedly installed with a saw shaft driving key. The shaft hole of sawblade sliding sleeve is at least internally provided with a driving key groove that is corresponding with the saw shaft driving key. The saw shaft structure can realize the axial sliding adjustment to the circular saw blade conveniently and flexibly. Longitudinally material cutting can be executed according to an optimal cutting plan. The saw shaft structure also has higher material yielding rate and production efficiency, and is widely used in various multi-blade circular sawing machine.

Owner:JIANGSU JIANGJIA MACHINERY

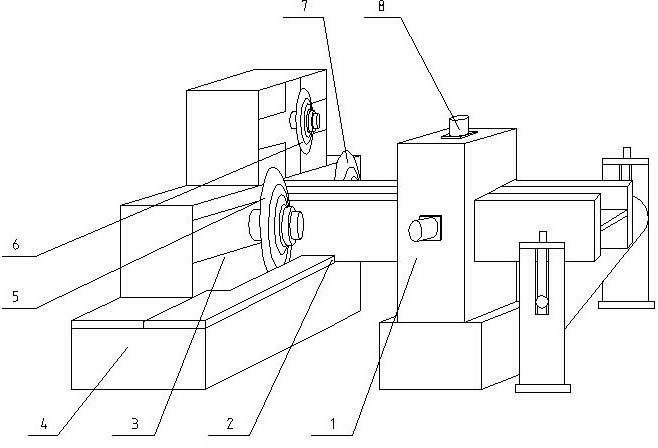

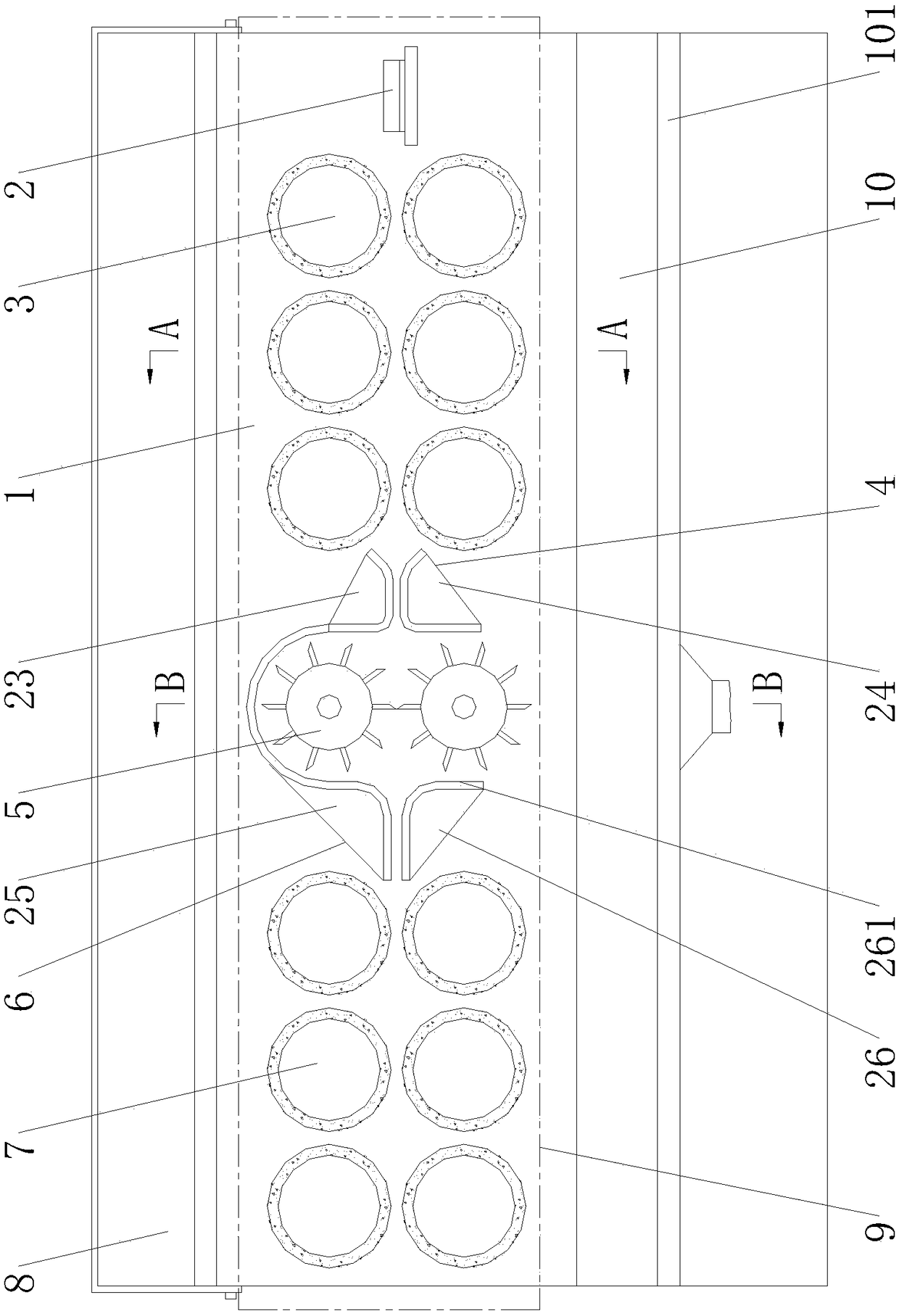

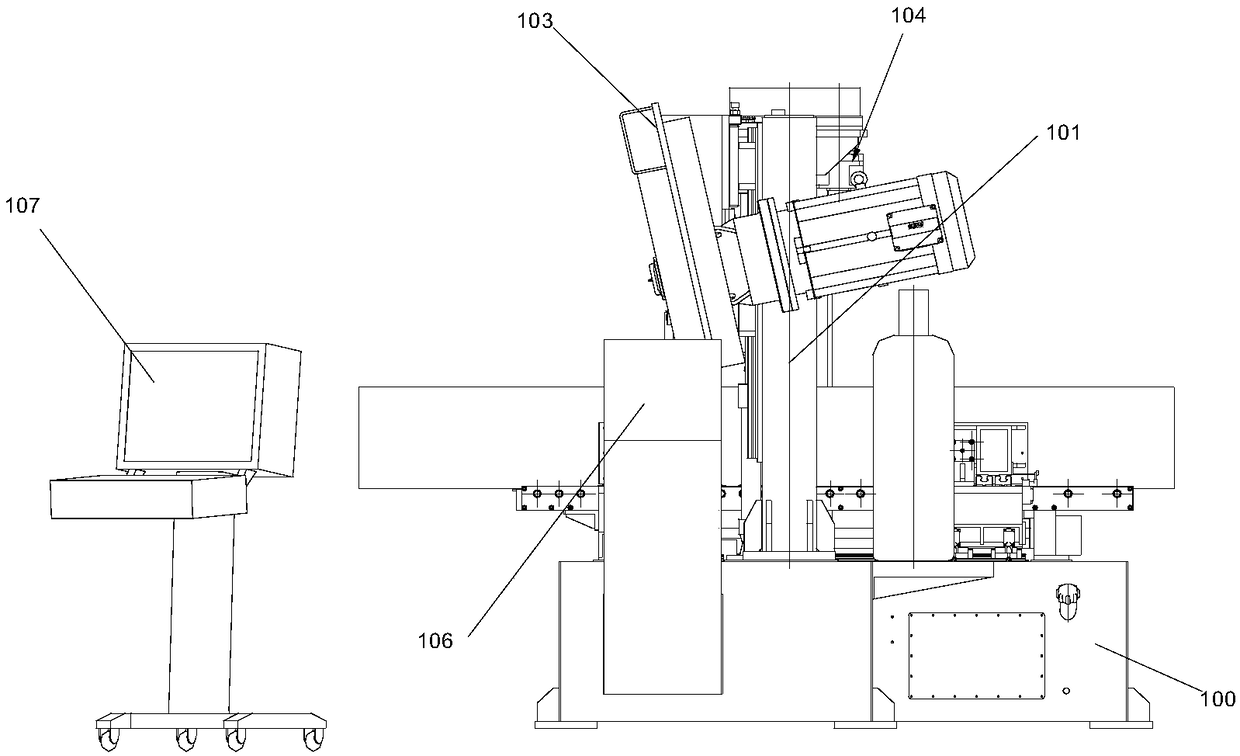

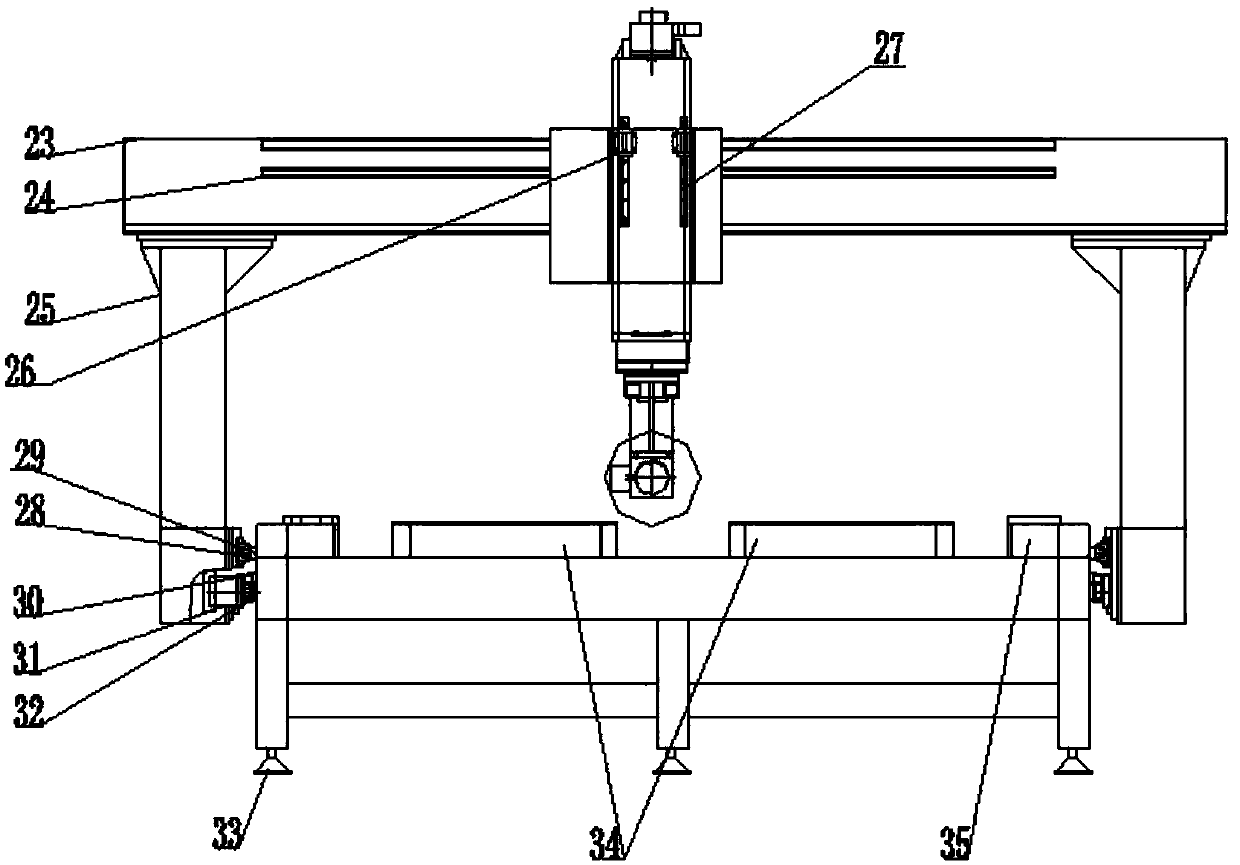

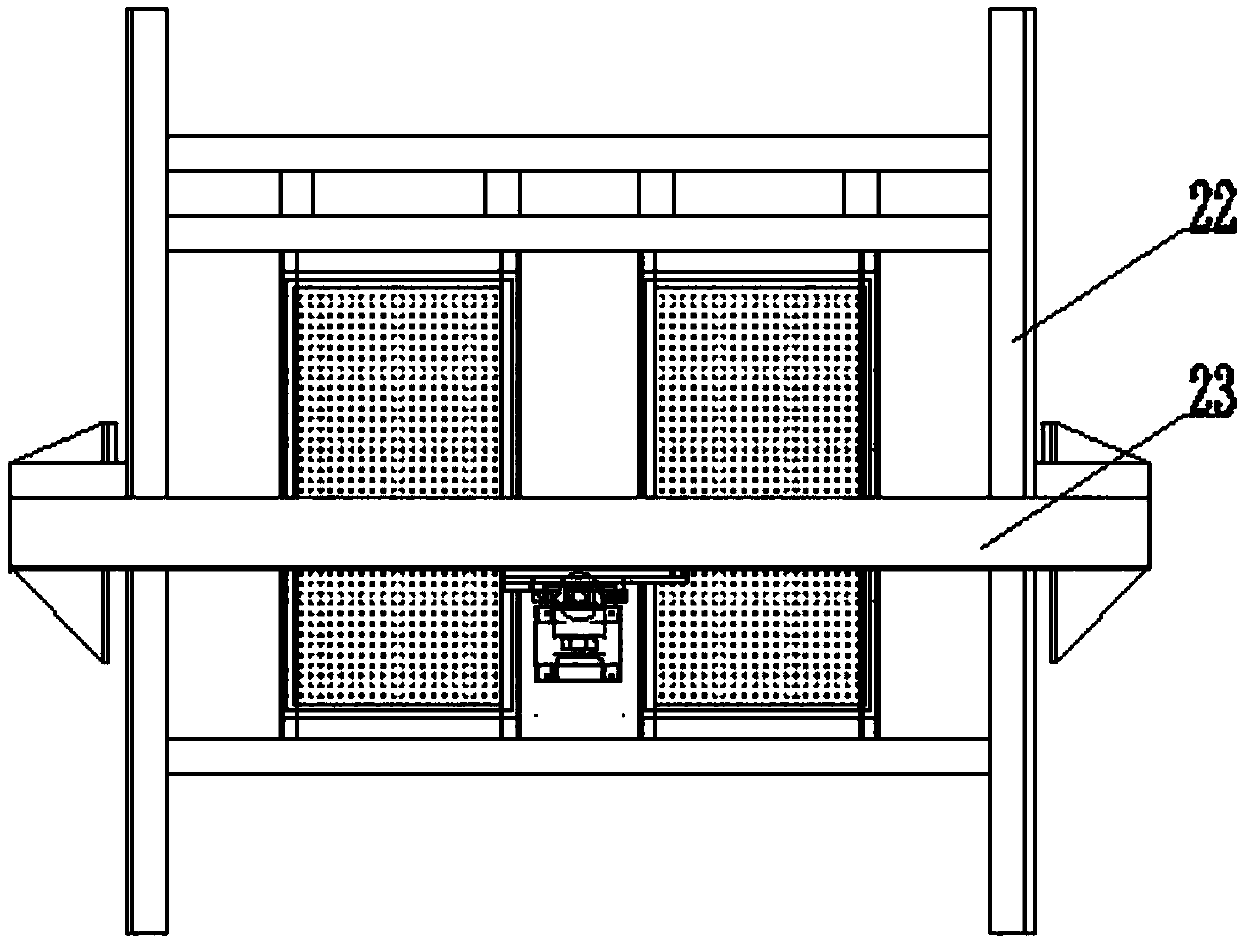

Large aerospace shell sawing equipment and sawing method thereof

ActiveCN109954940AImprove the range of sawing adaptationAutomatically adjust the tilt angleMetal sawing devicesMetal sawing accessoriesFeed driveEngineering

The invention discloses large aerospace shell sawing equipment and a sawing method thereof. The sawing angles for large aerospace shells are not simplex, so that a multiple-angle sawing function of asawing machine is needed. The large aerospace shell sawing equipment comprises a gantry, band saw wheels, a sawing frame, a saw band, a base, a workbench, guide chip-breaking assemblies, feeding driving assemblies, cutting direction adjusting driving assemblies, a two-axis workbench driving mechanism and a pulsation generating assembly. Each guide chip-breaking assembly comprises an oscillating guide bottom plate, an oscillating guide block, an oscillating spring, an oscillating coil and a hollow iron core, wherein the oscillating coil is wound on the hollow iron core, a suction block is arranged at the top end of the oscillating guide block, the oscillating guide block and the hollow iron core form a sliding pair, and the oscillating guide block is sleeved with the oscillating spring. Thepulsation generating assembly comprises a worm speed reducer and a pulsation generating motor. According to the large aerospace shell sawing equipment and the sawing method thereof, automatic adjusting devices enabling the sawing frame to be inclinable are designed, and the inclination angle of the sawing frame can be adjusted automatically according to sawing requirements.

Owner:HANGZHOU DIANZI UNIV

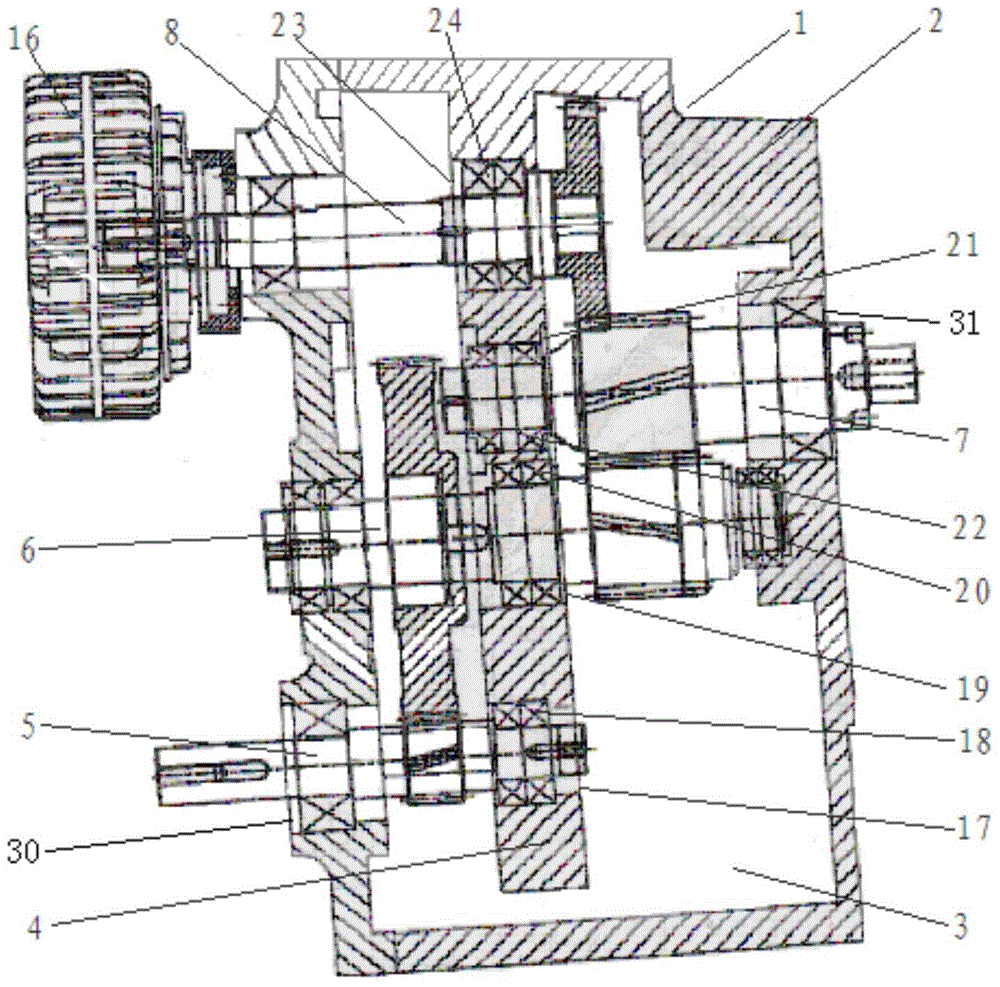

Sawing gearbox

InactiveCN103603945ALower requirementIncrease forceMetal sawing devicesDriving apparatusGear wheelEngineering

The invention relates to a sawing gearbox. The sawing gearbox comprises a box body, wherein a working cavity is arranged inside the box body, an input hole used for fixing an input gear shaft is formed in the left end face of the box body, an output hole used for fixing an output gear shaft is formed in the right end face of the box body, the input gear shaft is arranged on the lower portion of the box body, a speed reducer is arranged above the input gear shaft, the output gear shaft is arranged above the speed reducer, and a brake device is arranged above the output gear shaft. The sawing gearbox has the advantages that the sawing accuracy is improved, cost is reduced greatly, the sawing gearbox is applicable to heavy cutting due to the adoption of a spiral gear transmission structure, the accuracy is stable, and the sawing gearbox is reliable, durable, high in overload bearing capacity, low in energy consumption, small in vibration and low in noise.

Owner:东莞市晋诚机械有限公司

Side suction thread shearing device of industrial sewing machine

InactiveCN104790131AHigh cutting precisionSimple and fast operationNeedle severing devicesEngineeringIndustrial sewing machine

The invention relates to a side suction thread shearing device of an industrial sewing machine. The side suction thread shearing device is characterized by comprising a side suction device body, a supporting plate, a thread residue suction pipe, an oil suction pipe, a movable cutter, a fixed cutter, a control lever, a triangular fixed block and a semicircular fixed block, wherein the oil suction pipe and the thread residue suction pipe are fixedly connected to form a whole structure; the whole side suction device body is formed by fixedly connecting the thread residue suction pipe, the oil suction pipe and the supporting plate; the fixed cutter is fixedly connected with the supporting plate; a movable cutter connection rod mechanism is formed by fixedly connecting the movable cutter and the control lever; the control lever is in sliding connection with a shaft sleeve; and the shaft sleeve is connected with a bracket. Compared with the prior art, the side suction thread shearing device has the advantages of high thread shearing precision, simplicity and convenience for operation, simple structure and the like. By virtue of the device, the problems that the working is not continuous due to a firing pin phenomenon and the production efficiency is influenced and the like are avoided.

Owner:天津市中马骏腾精密机械制造有限公司

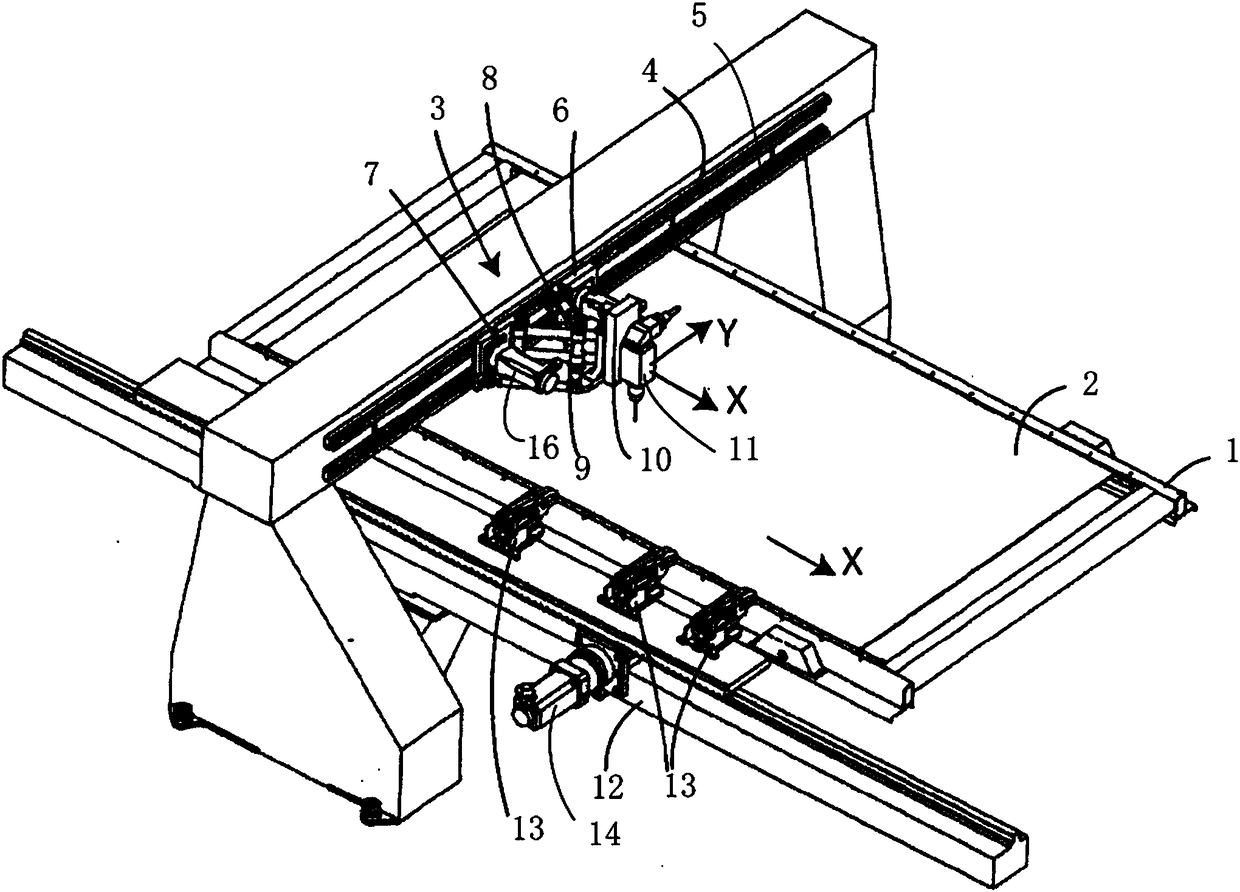

Full-automatic saw blade cutting type numerical control processing equipment

PendingCN109530794AHigh cutting precisionImprove processing efficiencyMetal sawing devicesNumerical controlEngineering

The invention discloses full-automatic saw blade cutting type numerical control processing equipment. The full-automatic saw blade cutting type numerical control processing equipment comprises a lathebody, a transverse beam arranged above the lathe body, a main shaft mounted on the transverse beam and a saw blade arranged at the end part of the main shaft, wherein lateral stand columns are symmetrically arranged at two sides of the lathe body; two ends of the transverse beam are fixedly connected with the lateral stand columns; the transverse beam is provided with an X-axis servo motor for driving the main shaft to move along the X-axis direction; each lateral stand column is provided with a Y-axis servo motor for driving the lateral stand column to move along the Y-axis direction; the transverse beam is provided with a Z-axis servo motor for driving the main shaft to move along the Z-axis direction; the transverse beam is provided with a C-axis servo motor for driving the main shaftto rotate along the C-axis direction; the X-axis direction, the Y-axis direction and the Z-axis direction are mutually vertical; the C-axis direction is parallel to the upper surface of the lathe body; and the Z-axis direction is vertical to the C-axis direction. The full-automatic saw blade cutting type numerical control processing equipment disclosed by the invention can be used for carrying out360-degree cutting at any angle; and the cutting efficiency is ensured and the cutting precision also can be greatly improved.

Owner:苏州艾派克斯数控机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com