Patents

Literature

942results about How to "For precise cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pointer instrument reading identification method

InactiveCN107609557AImprove anti-interference abilityPrevent inversionImage analysisCharacter and pattern recognitionCentroidLinear fitting

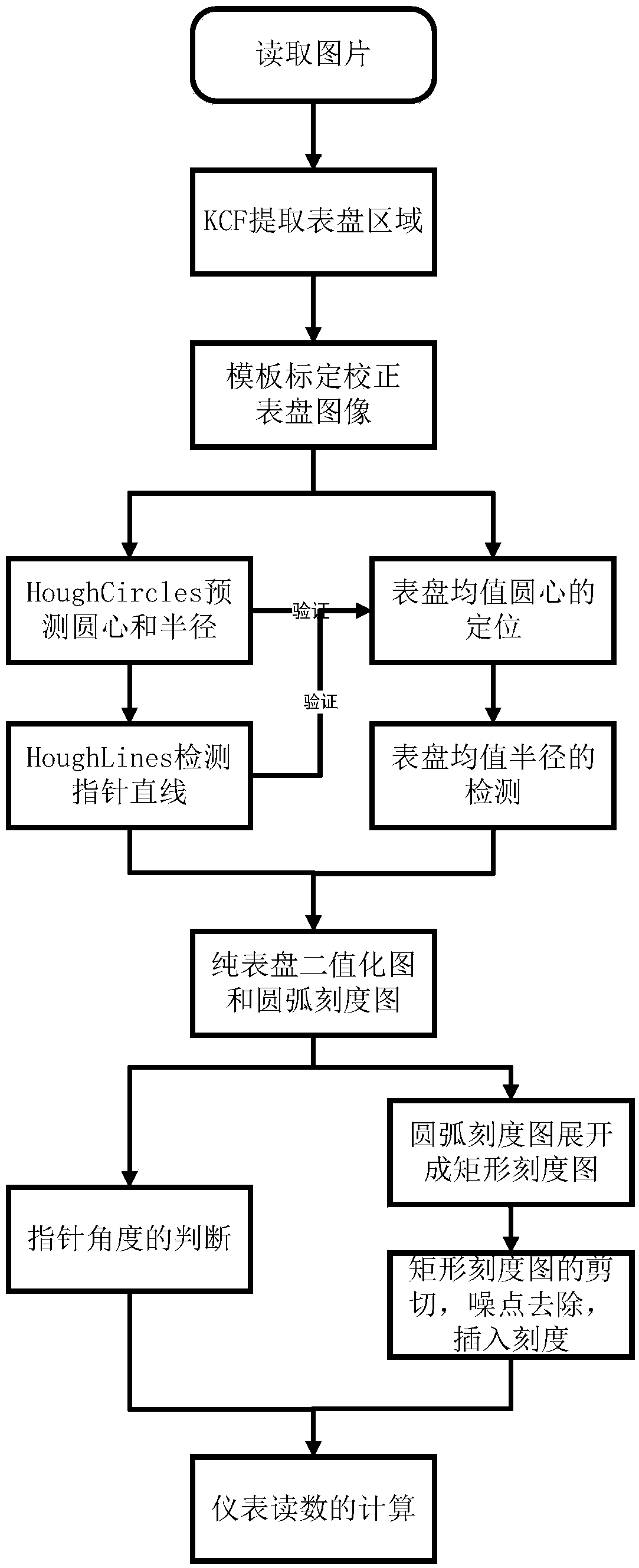

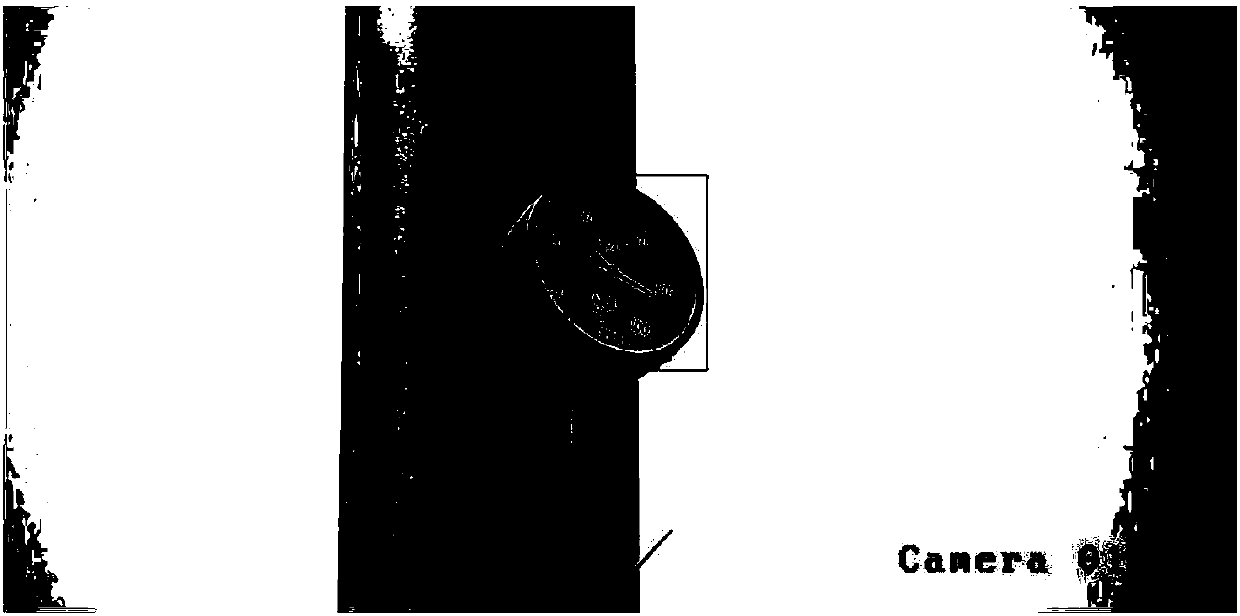

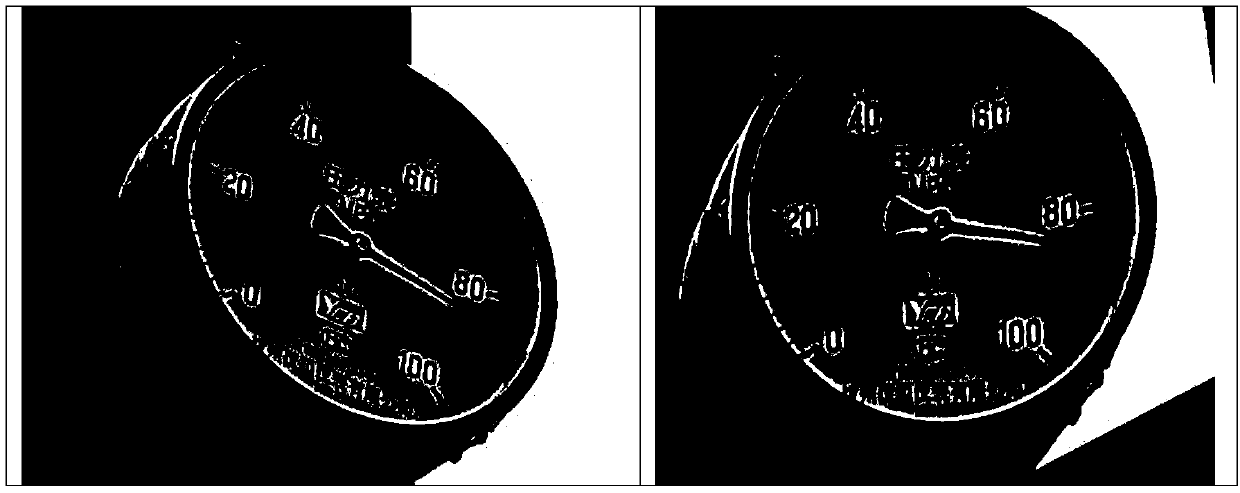

The invention discloses a pointer instrument reading identification method. The method comprises the steps of extracting a dial plate, removing interference, and correcting the dial plate by using affine transformation; performing circle detection and straight line detection on the dial plate to obtain predicted circle center and pointer angle; based on features of a scale connected domain on thedial plate, screening out the scale connected domain, performing linear fitting on the scale connected domain, calculating an intersection point of every two fitting straight lines, and performing screening verification on a to-be-selected circle center by utilizing the predicted circle center and pointer angle to obtain the circle center of the dial plate, wherein a distance from the centroid ofthe scale connected domain to the circle center on the dial plate is the radius of the dial plate; and according to information such as the circle center of the dial plate, the radius of the dial plate, the straight lines of a pointer, extracting an arc scale bar of the dial plate, expanding the arc scale bar in a rectangular shape, then according to horizontal coordinate distribution of scale onthe rectangular scale bar, performing minimum and maximum scale detection, noisy point removal and scale insertion, and finally in combination with the pointer angle, calculating reading of the dial plate. The method is high in universality and high in timeliness; and the reading has relatively high accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

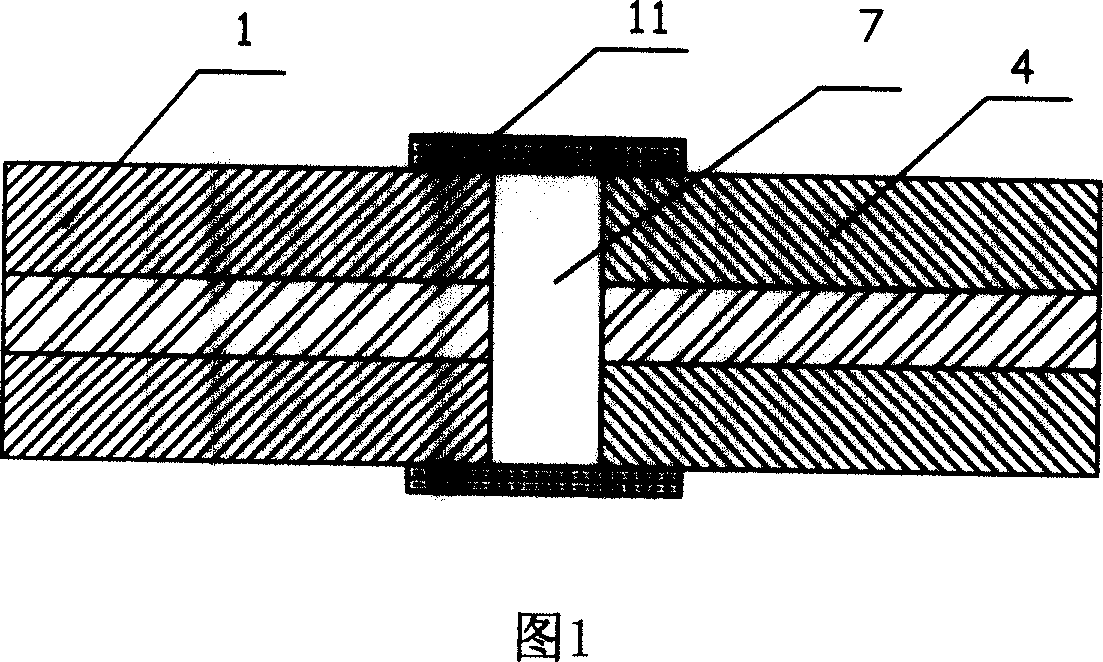

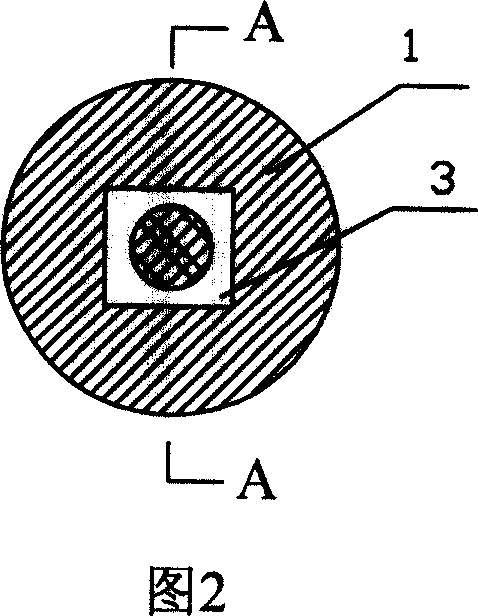

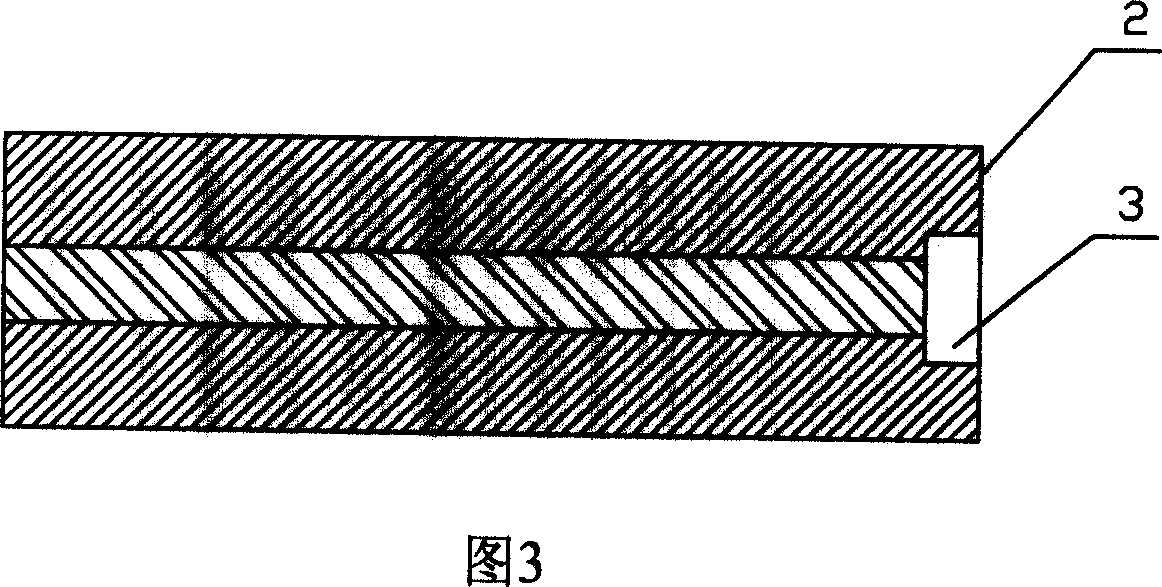

Optical fiber Fabry-Perot sensor and manufacture method therefore

InactiveCN101034007AGood mechanical stabilityMechanical stability High temperature resistanceFluid pressure measurement by electric/magnetic elementsForce measurementPhysicsSingle-mode optical fiber

This invention relates to a good mechanical stability, high temperature resistant and good optical property optical fiber sensor, includes optical fiber and by-met optical fiber. optical fiber or / and by- met fiber optic end face have micro-flutes, and via butt joint together; The described micro-flute forms a FP cavity which has plain optical reflection surface. The invention adoptive laser machining craft can apply to every kind of optical fiber; be able to cutting optical fiber precisely, and are prone to execute different kinds of range's pressure sensor; optical property of the sensor is very fine; both the two stage optical fiber can be common single mode optical fiber, they are completely compatible; The contrast ratio of sensor's reflecting stripe can reach 10 dB upwards.

Owner:冉曾令

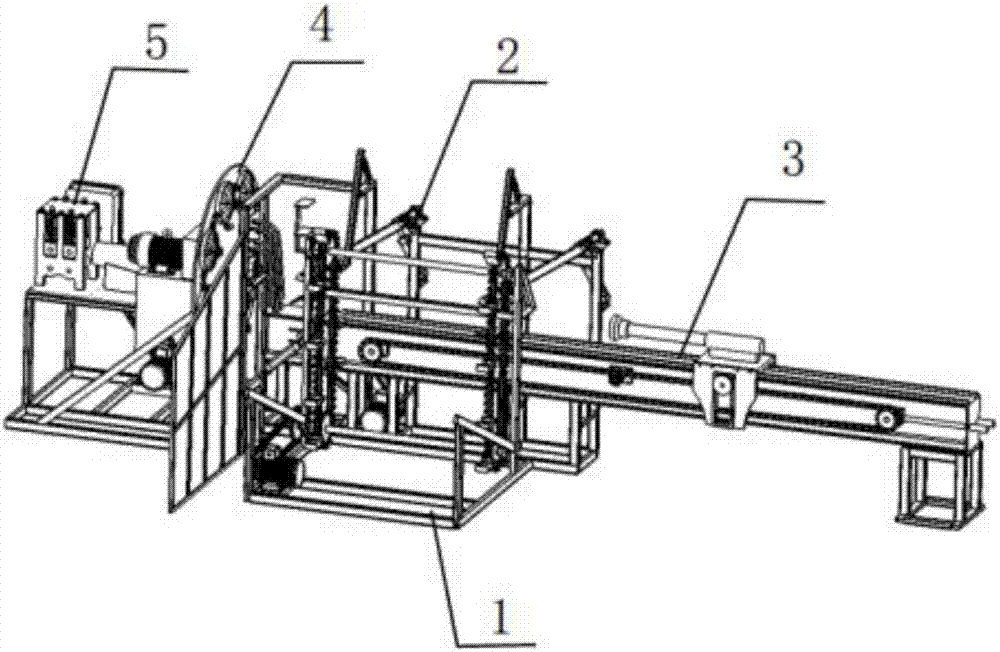

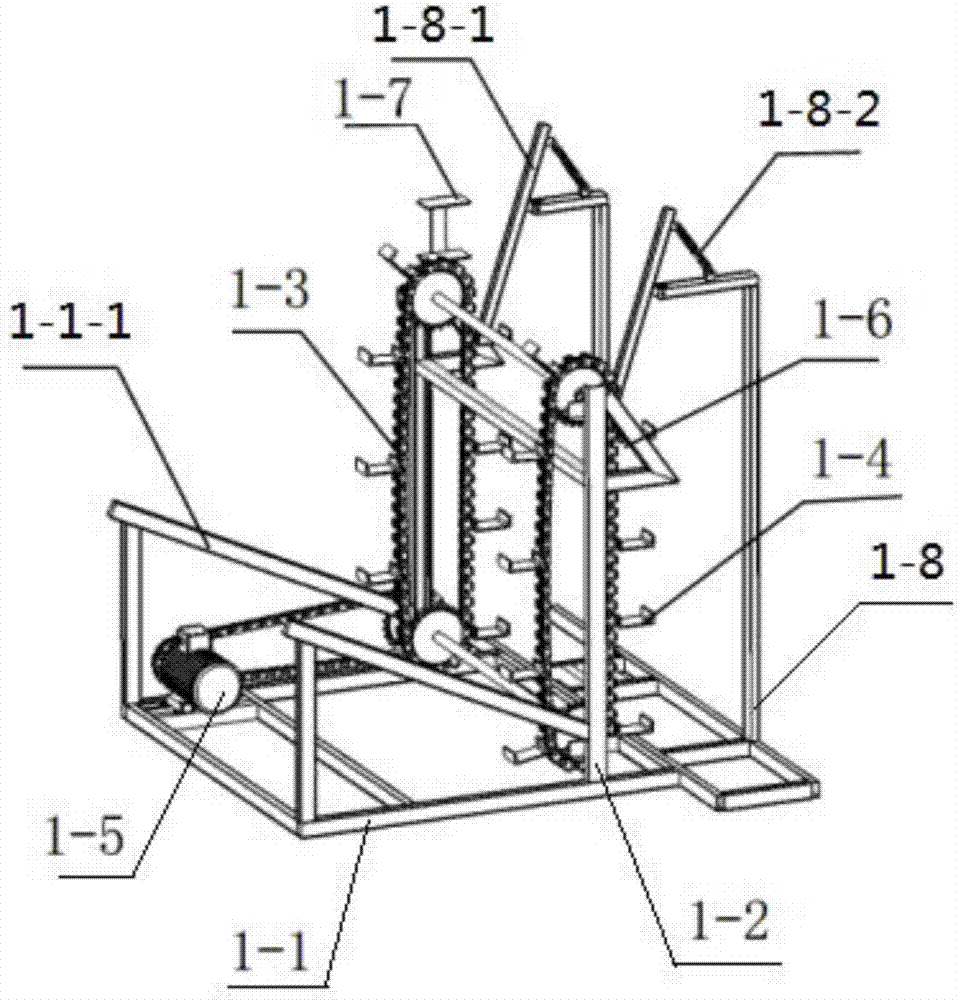

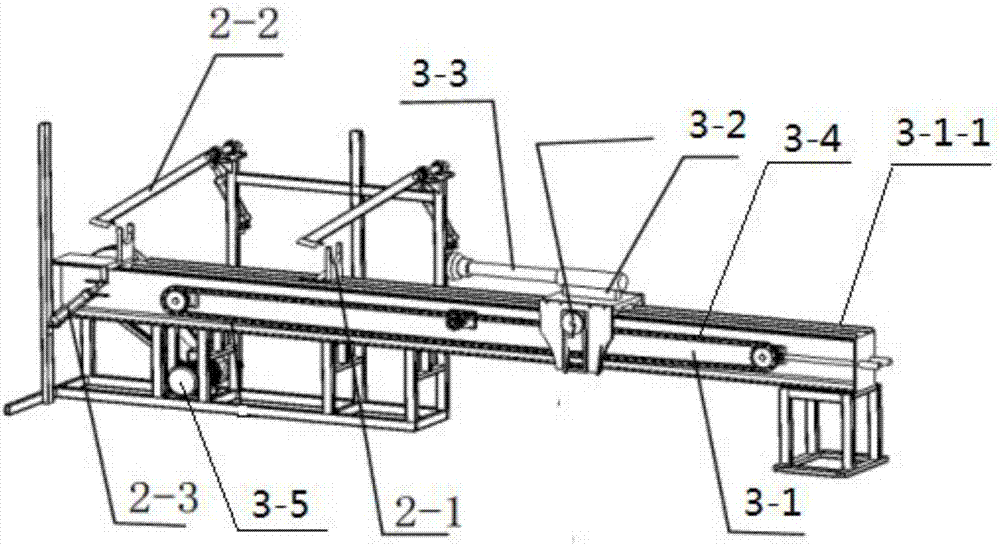

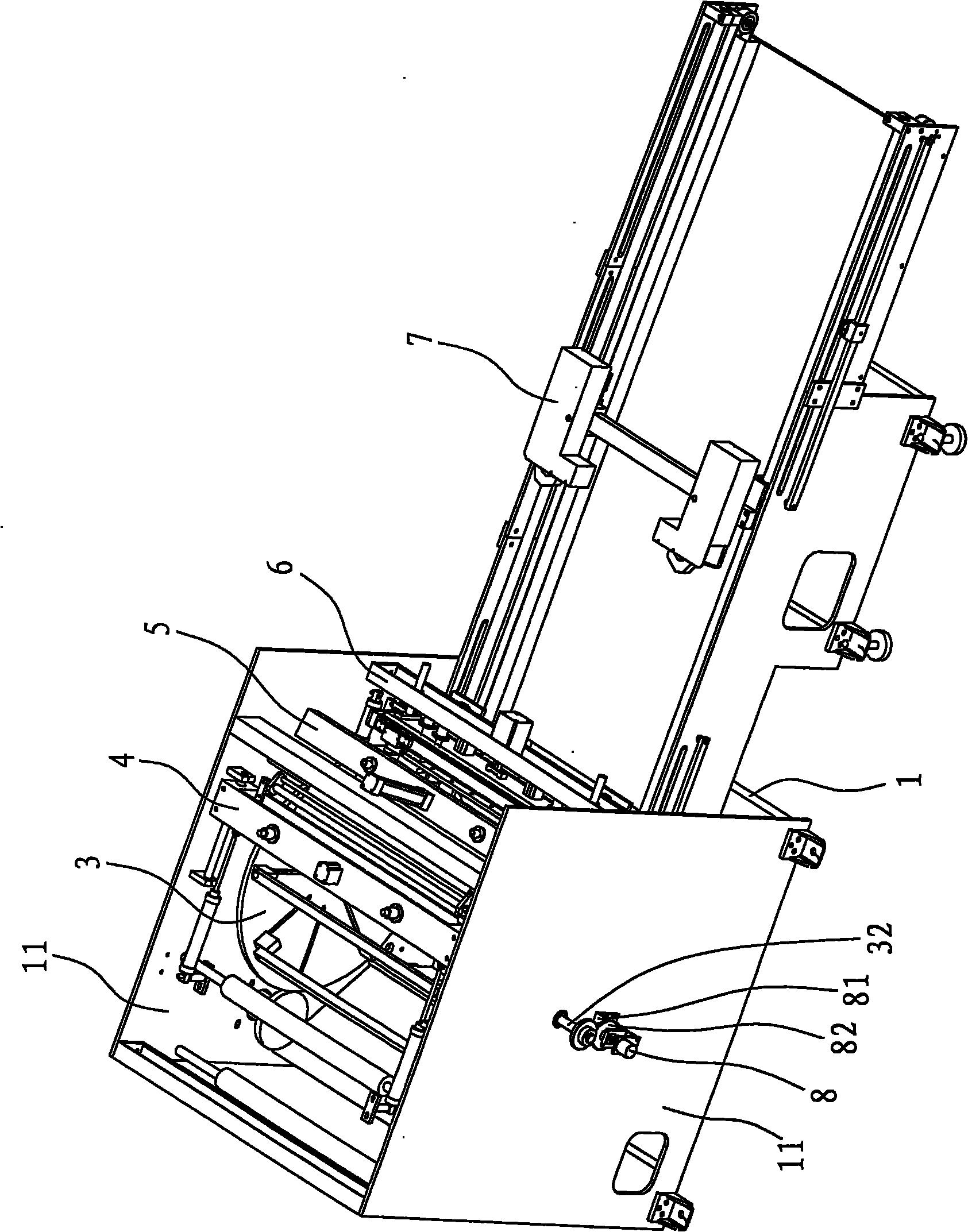

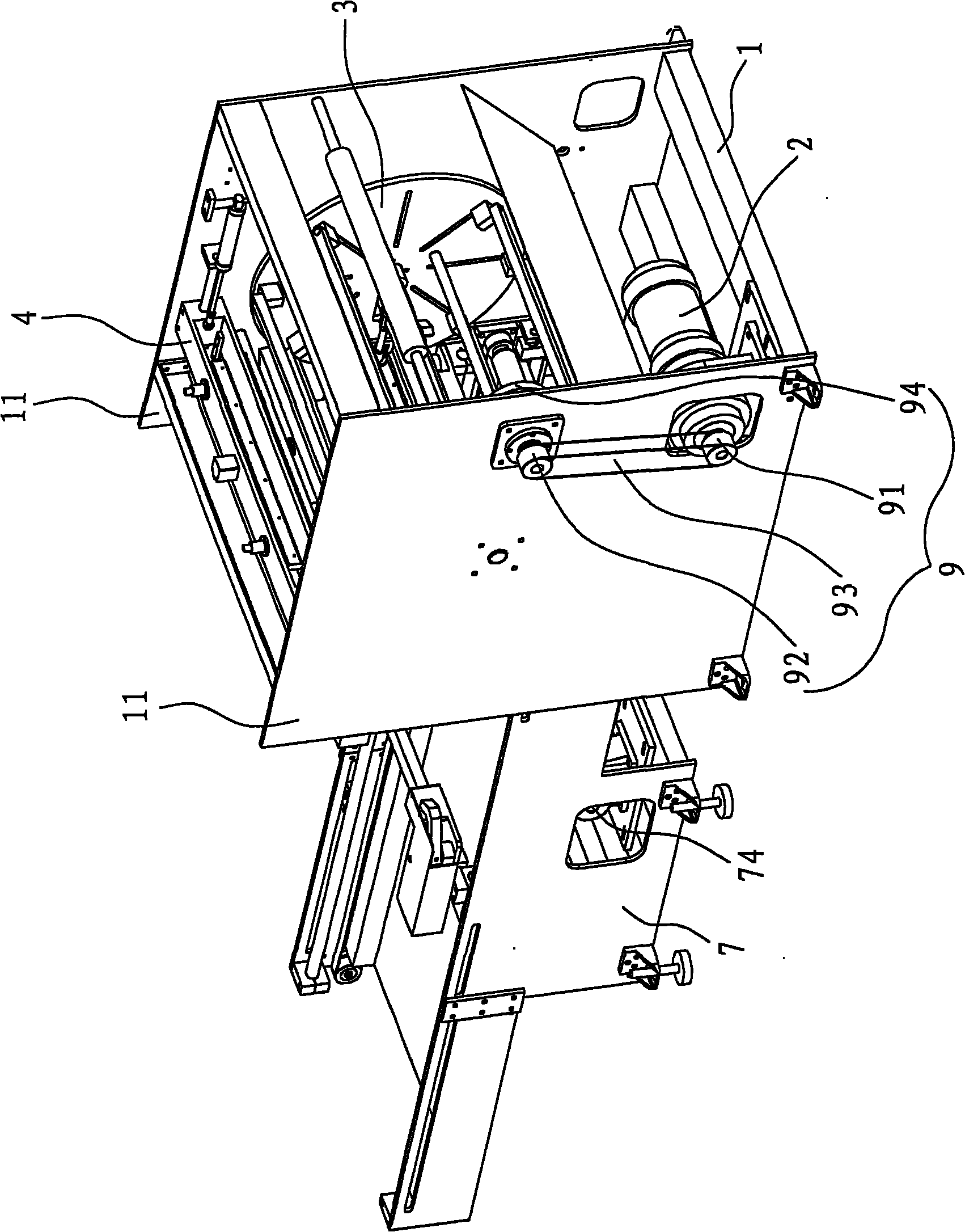

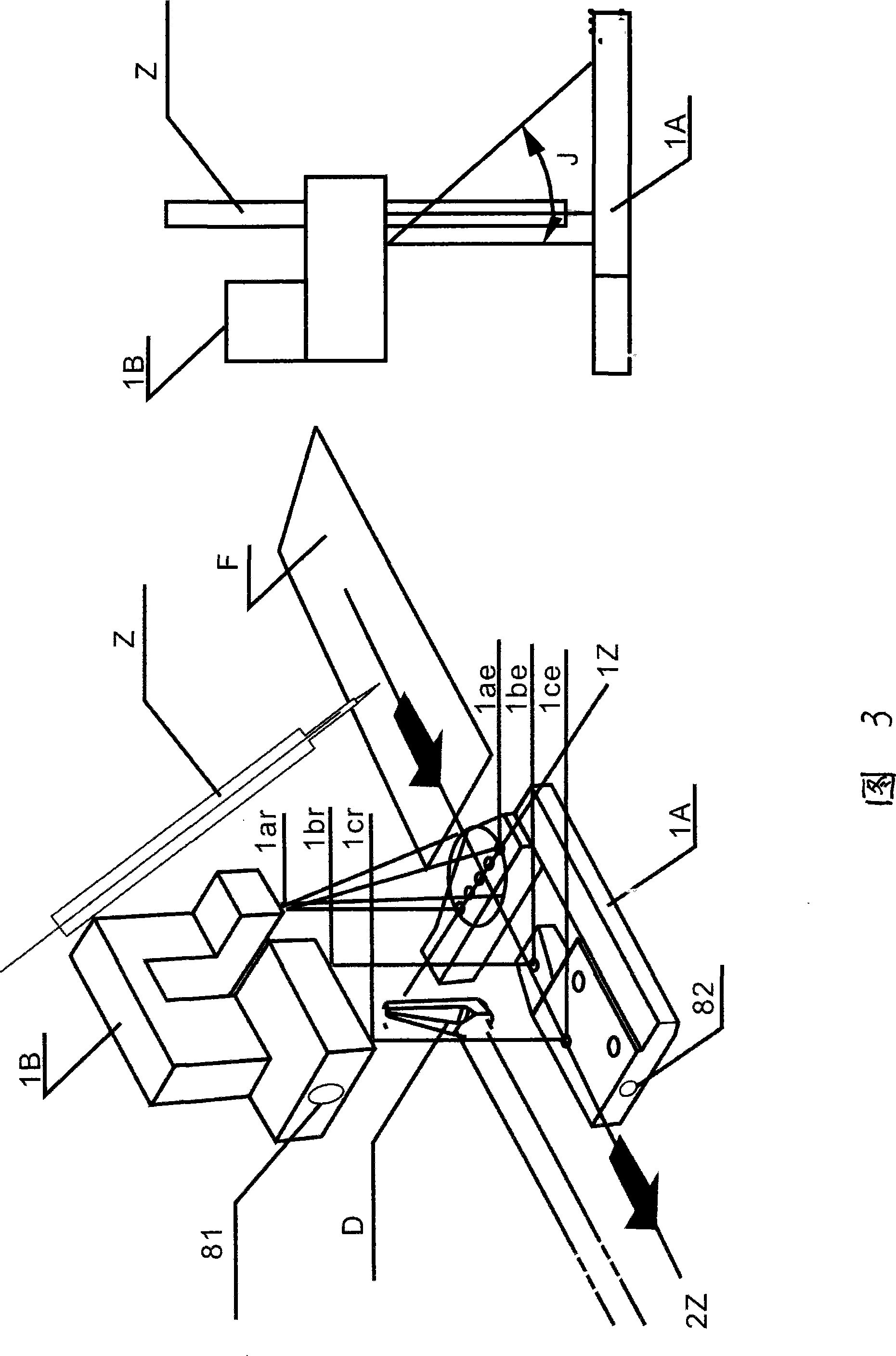

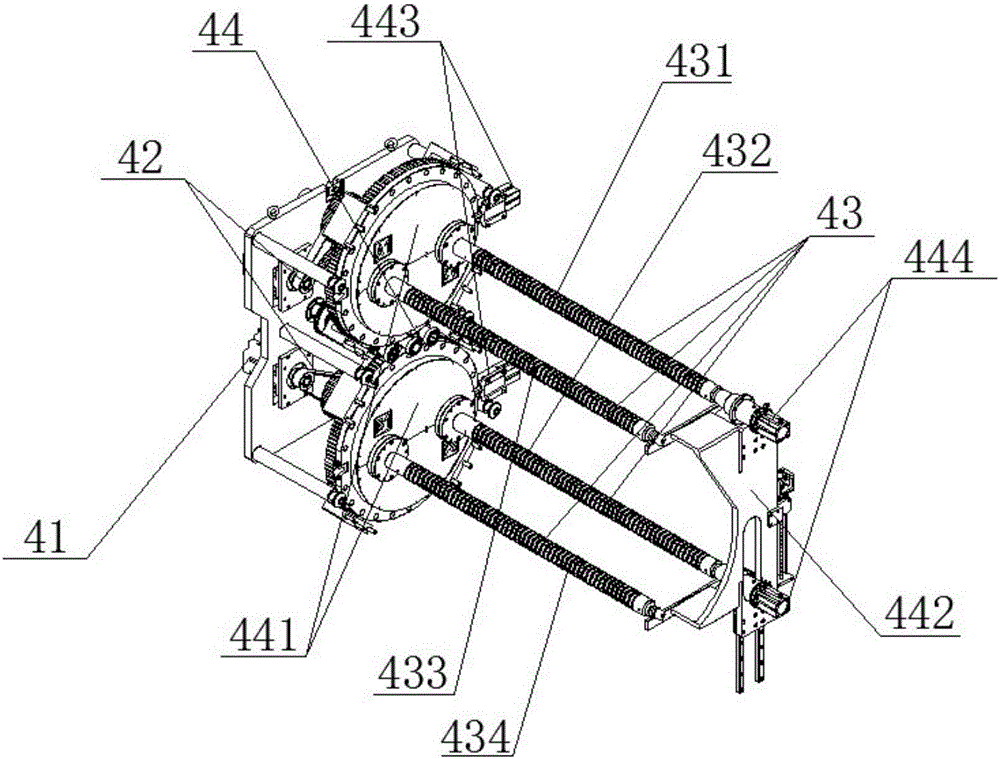

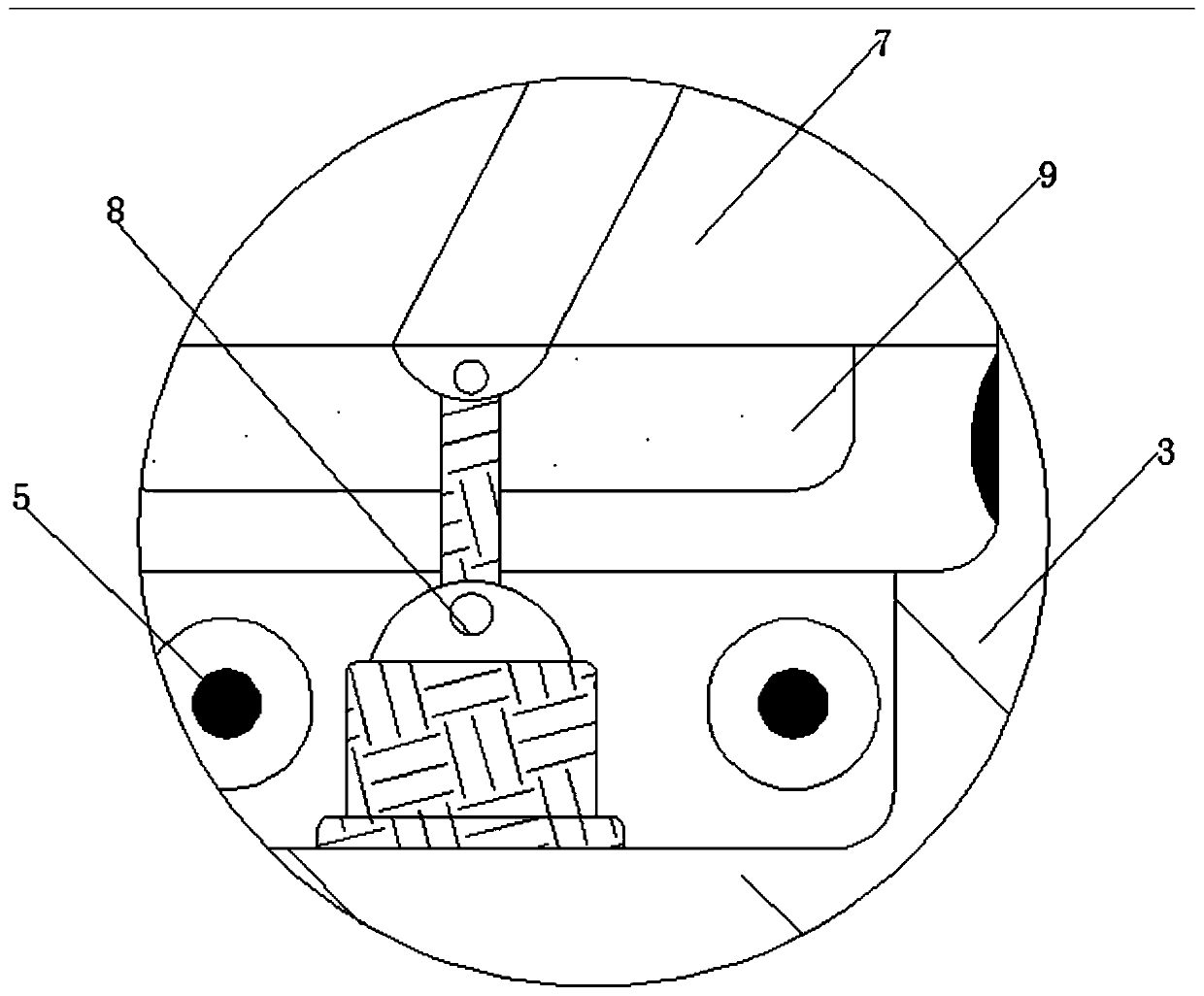

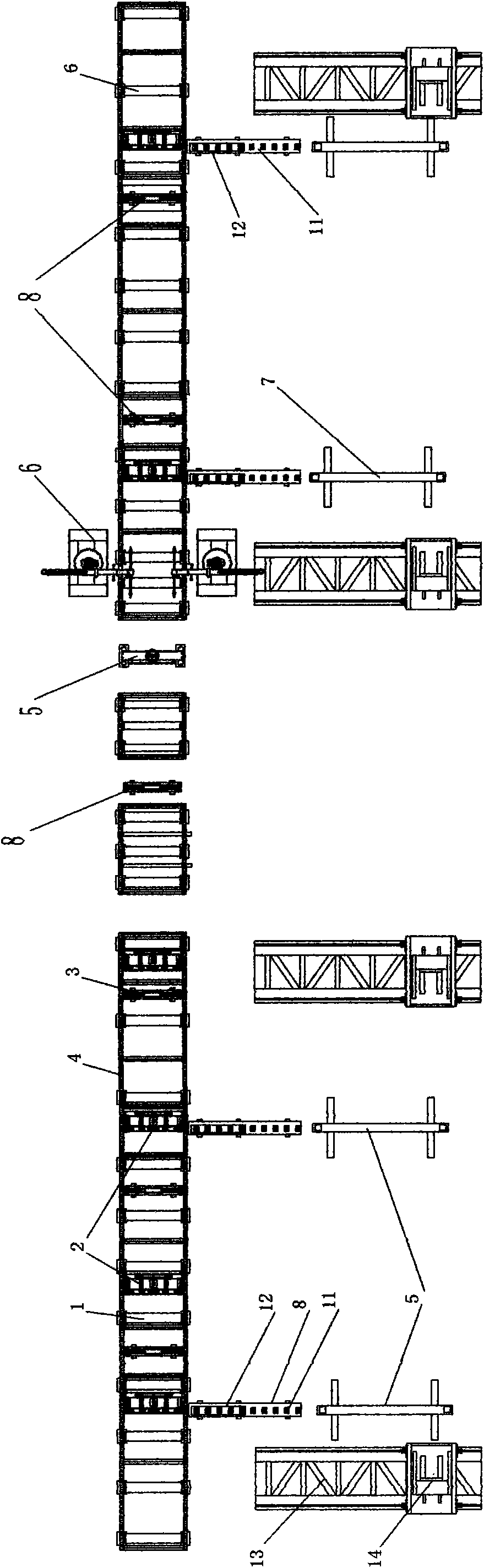

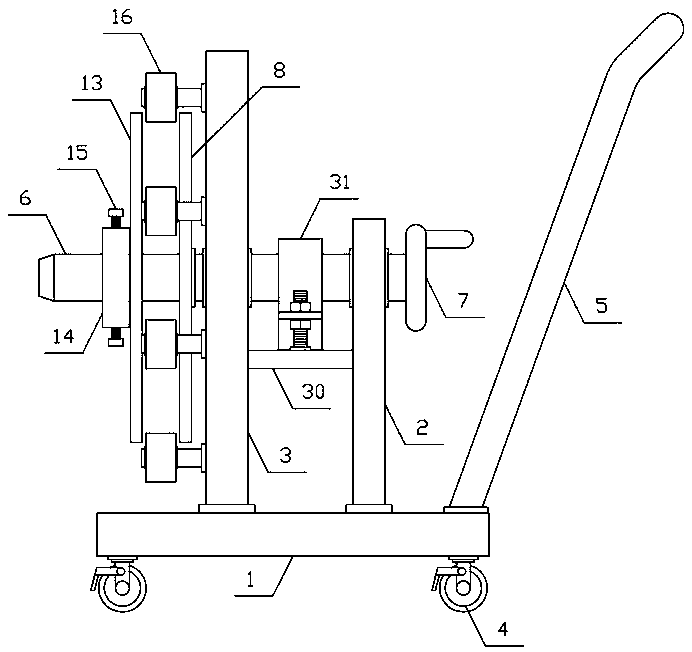

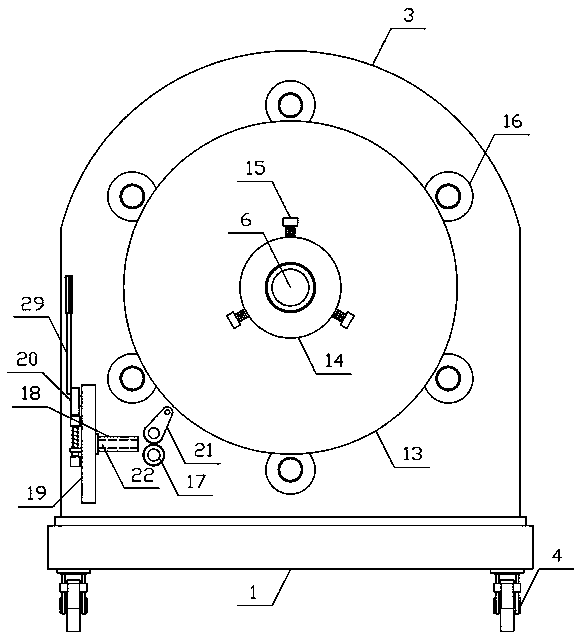

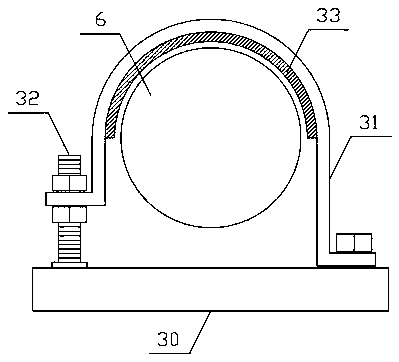

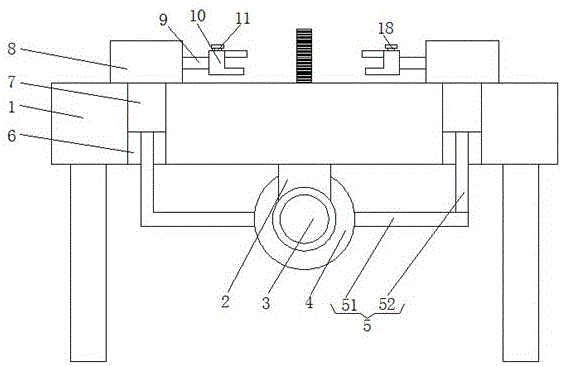

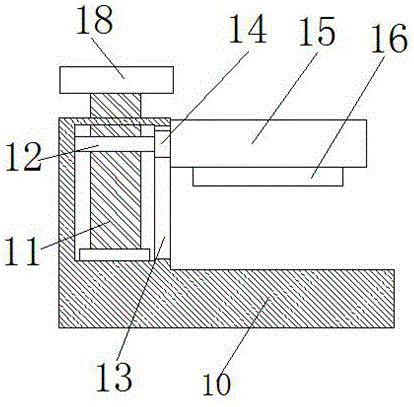

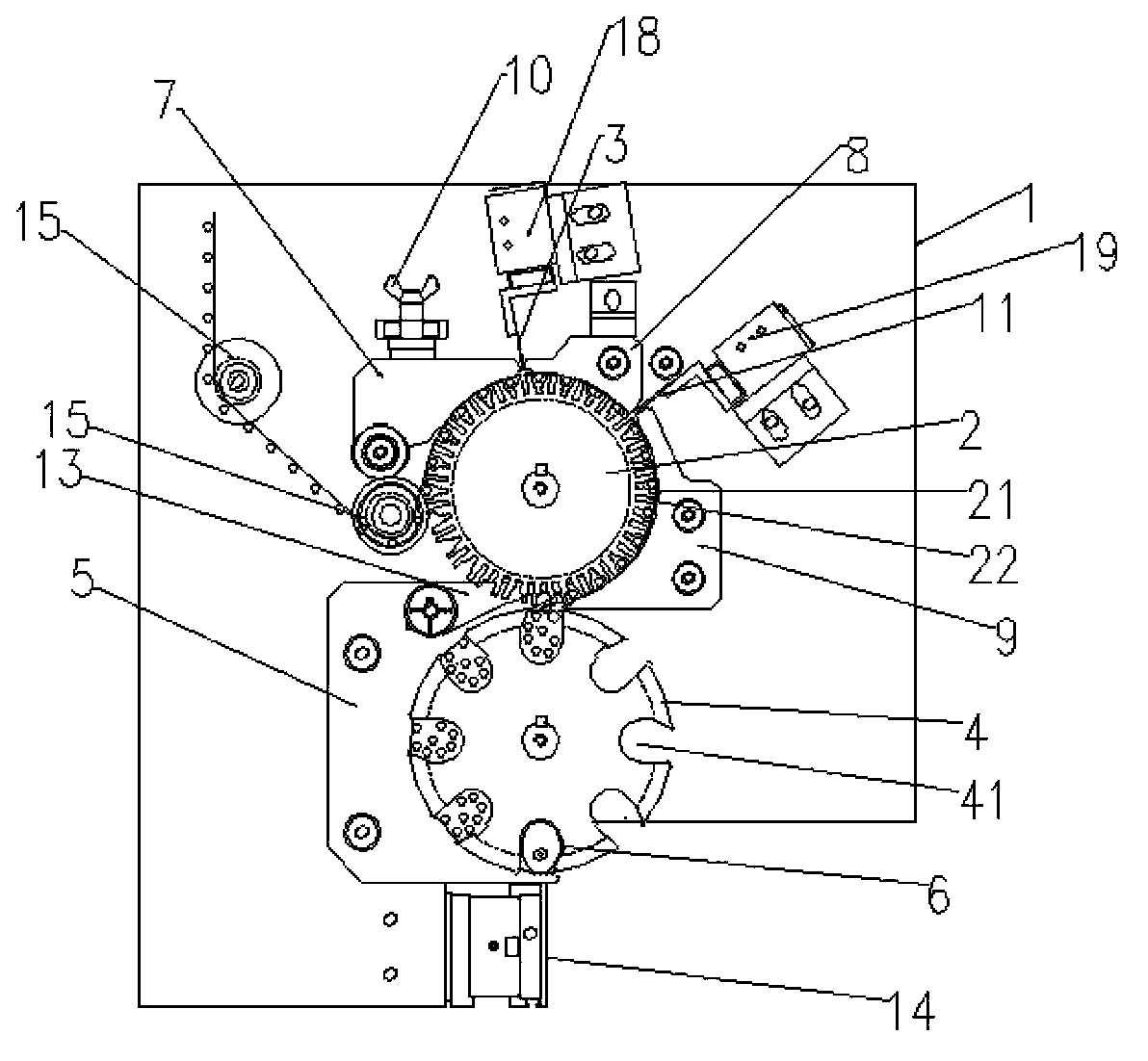

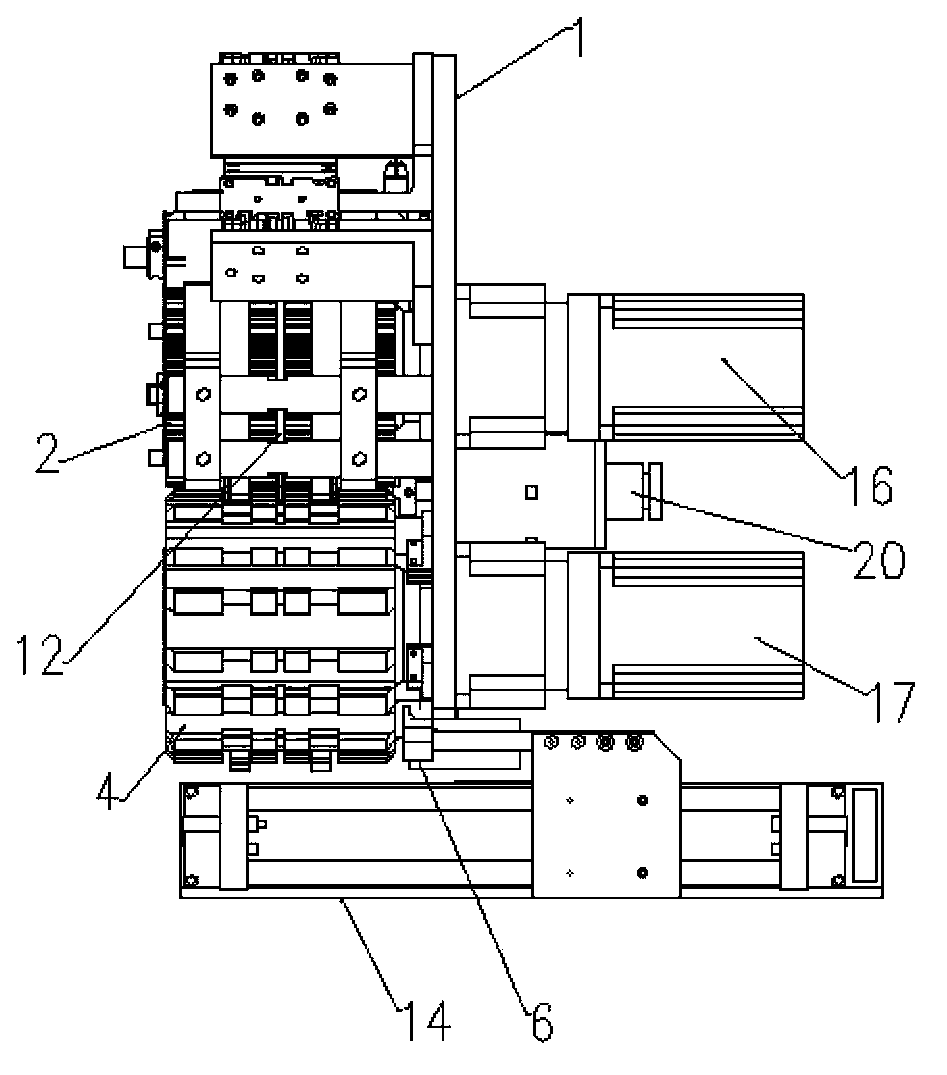

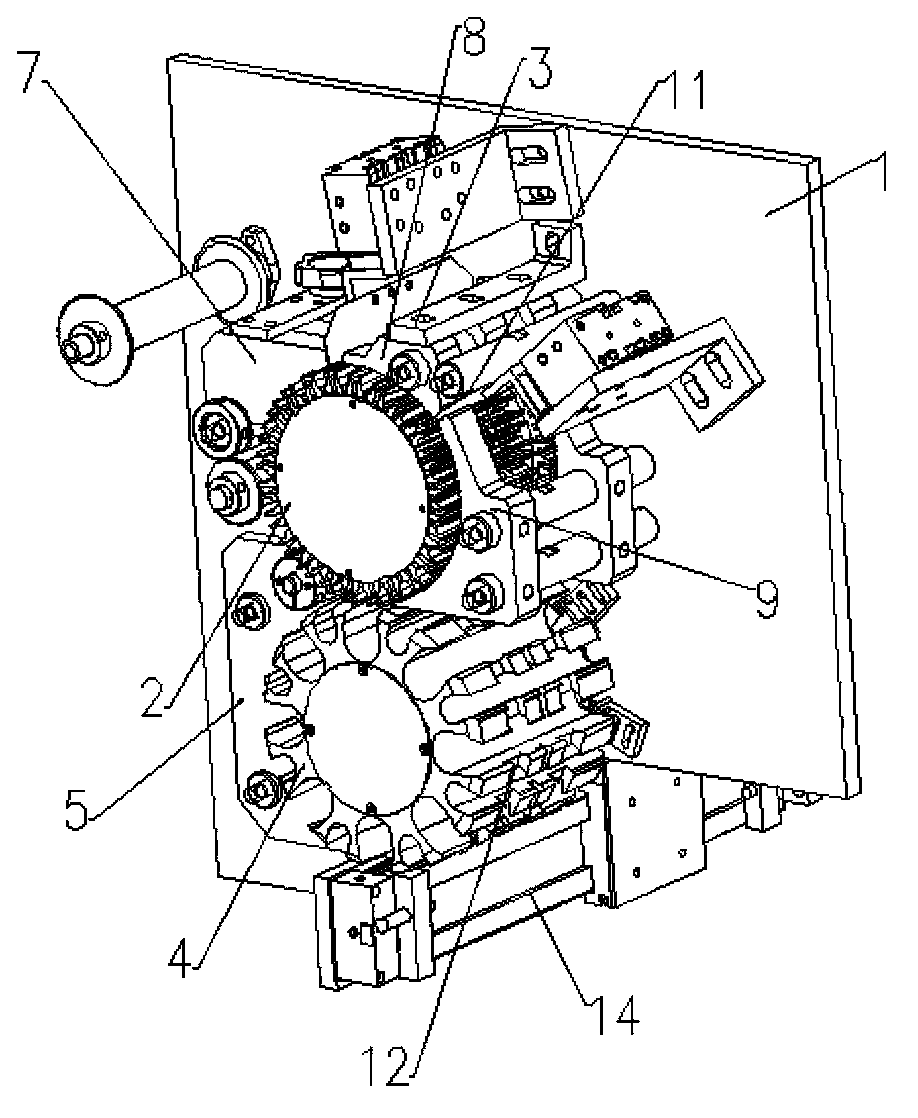

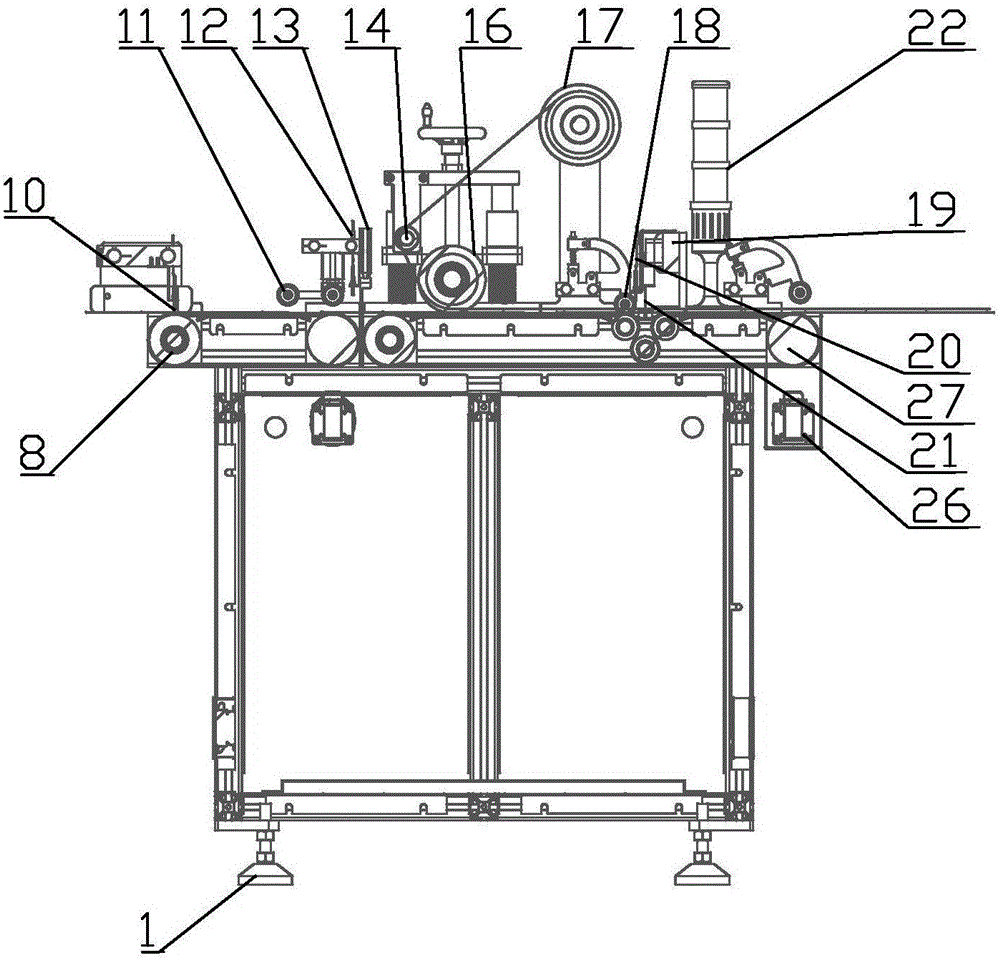

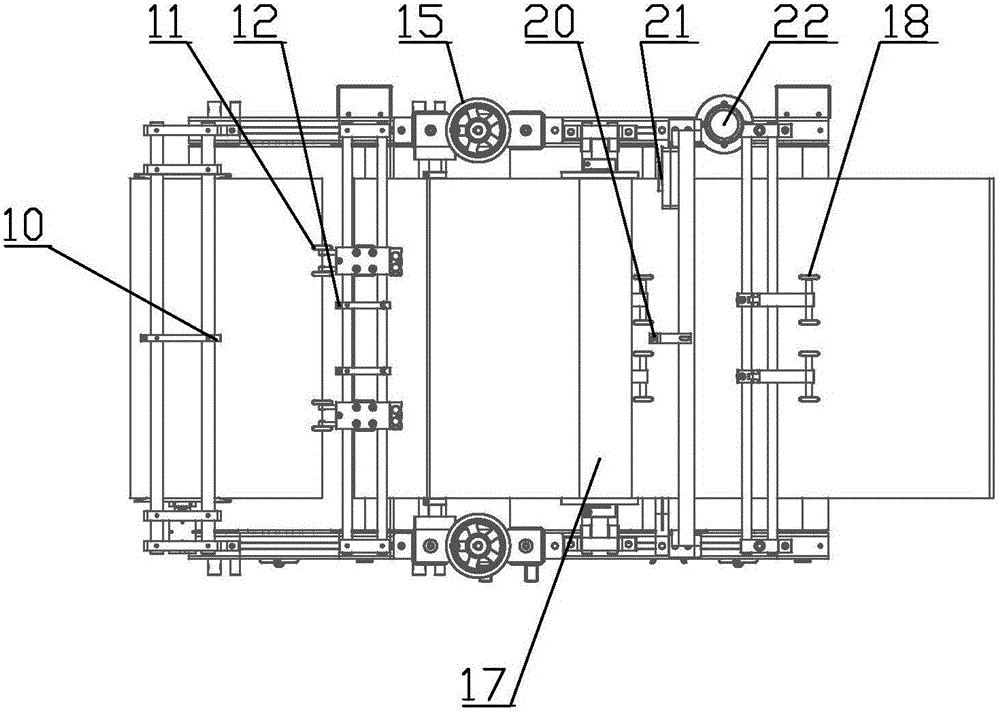

Automatic bamboo breaking machine

ActiveCN107150393APrecise deliveryAccurate control of coordinated operationWood splittingBio-packagingControl systemControl engineering

The invention relates to an automatic bamboo breaking machine. The automatic bamboo breaking machine comprises a feeding device, a clamping and positioning device, a bamboo breaking pushing disk device, a tool rotating disk device, an output device and a control system. The feeding device and the clamping and positioning device are located on the two sides of one end of the bamboo breaking pushing disk device. The tool rotating disk device is located on the front part of the end, close to the feeding device and the clamping and positioning device, of the bamboo breaking pushing disk device, and the output device is located on the tail part of the tool rotating disk device. The control system controls the feeding device, the clamping and positioning device, the bamboo breaking pushing disk device, the tool rotating disk device and the output device to run in a cooperative manner. The automatic bamboo breaking machine has the beneficial effects that the bamboo breaking machine can accurately control cooperative running of the devices, a bamboo tube is conveyed and positioned reliably, the bamboo tube can be accurately cut into bamboo canes, the finally cut bamboo canes can be conveyed out, the automation degree is relatively high, and the production efficiency is improved.

Owner:GUANGXI NORMAL UNIV

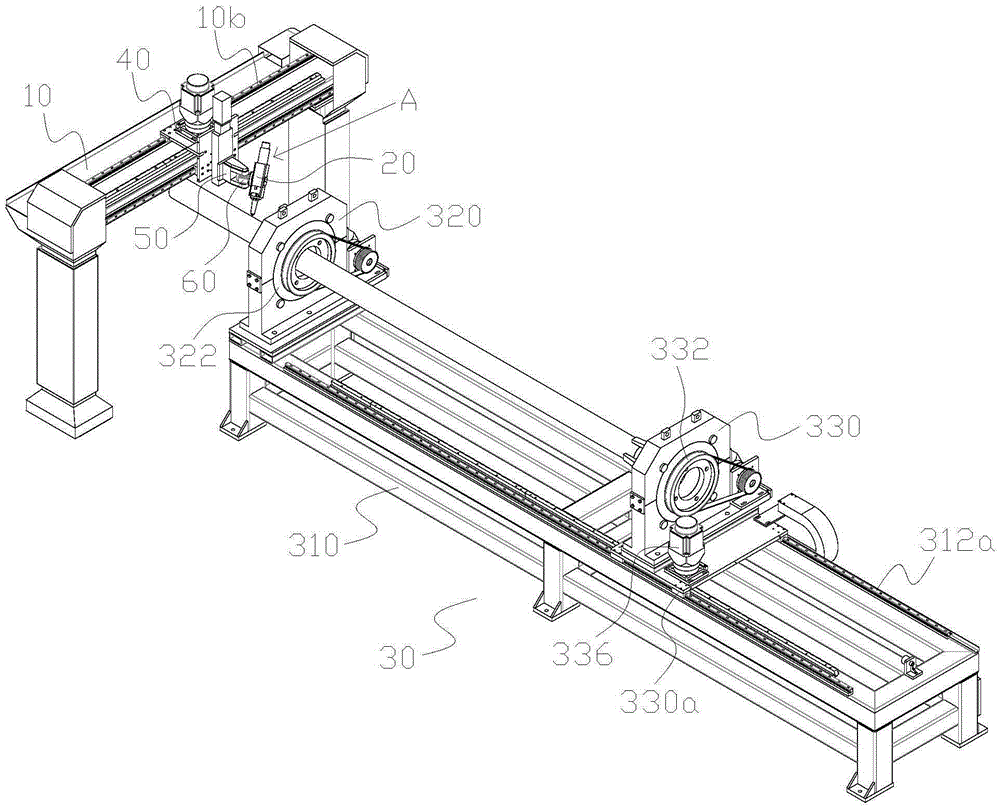

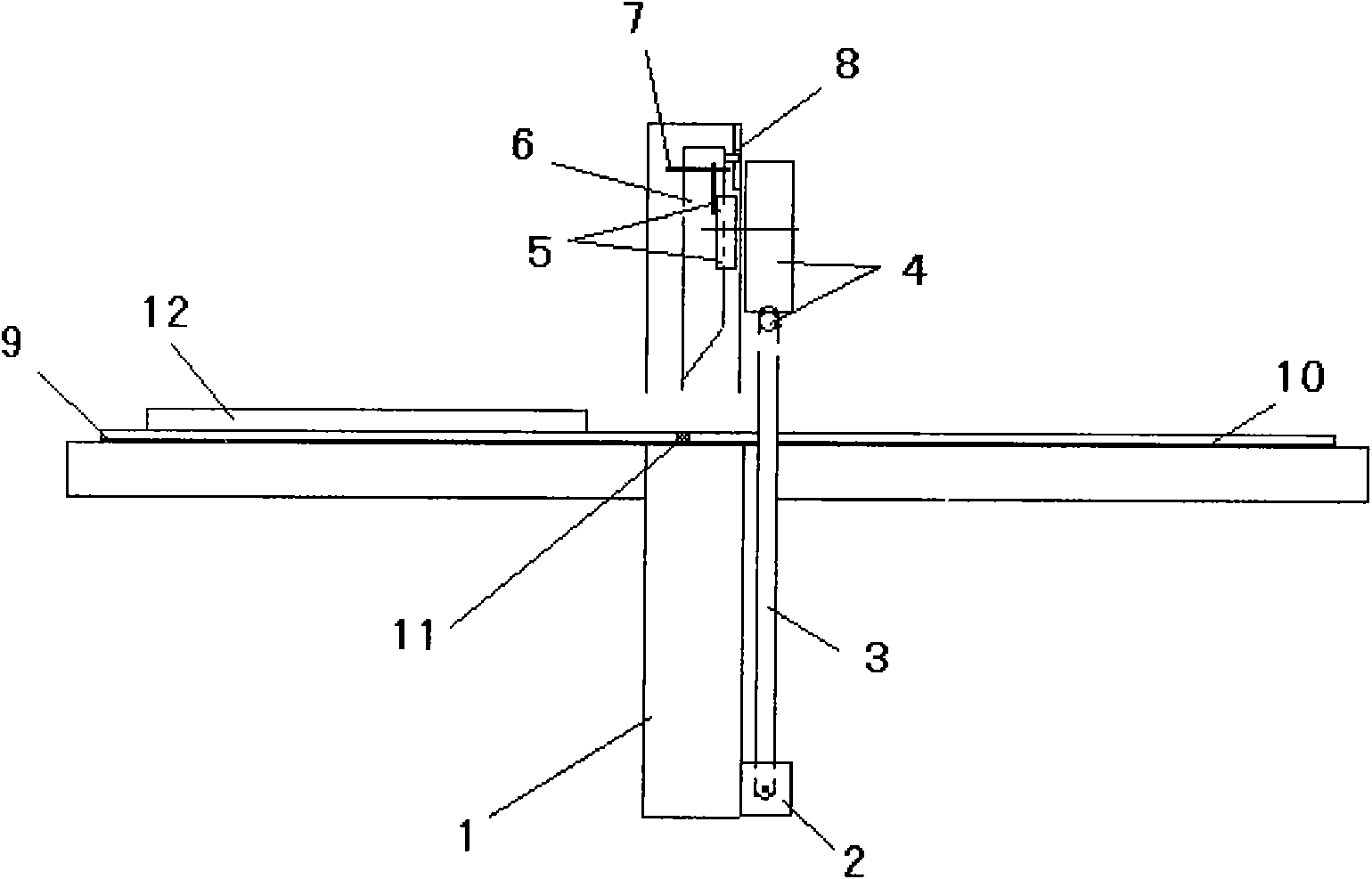

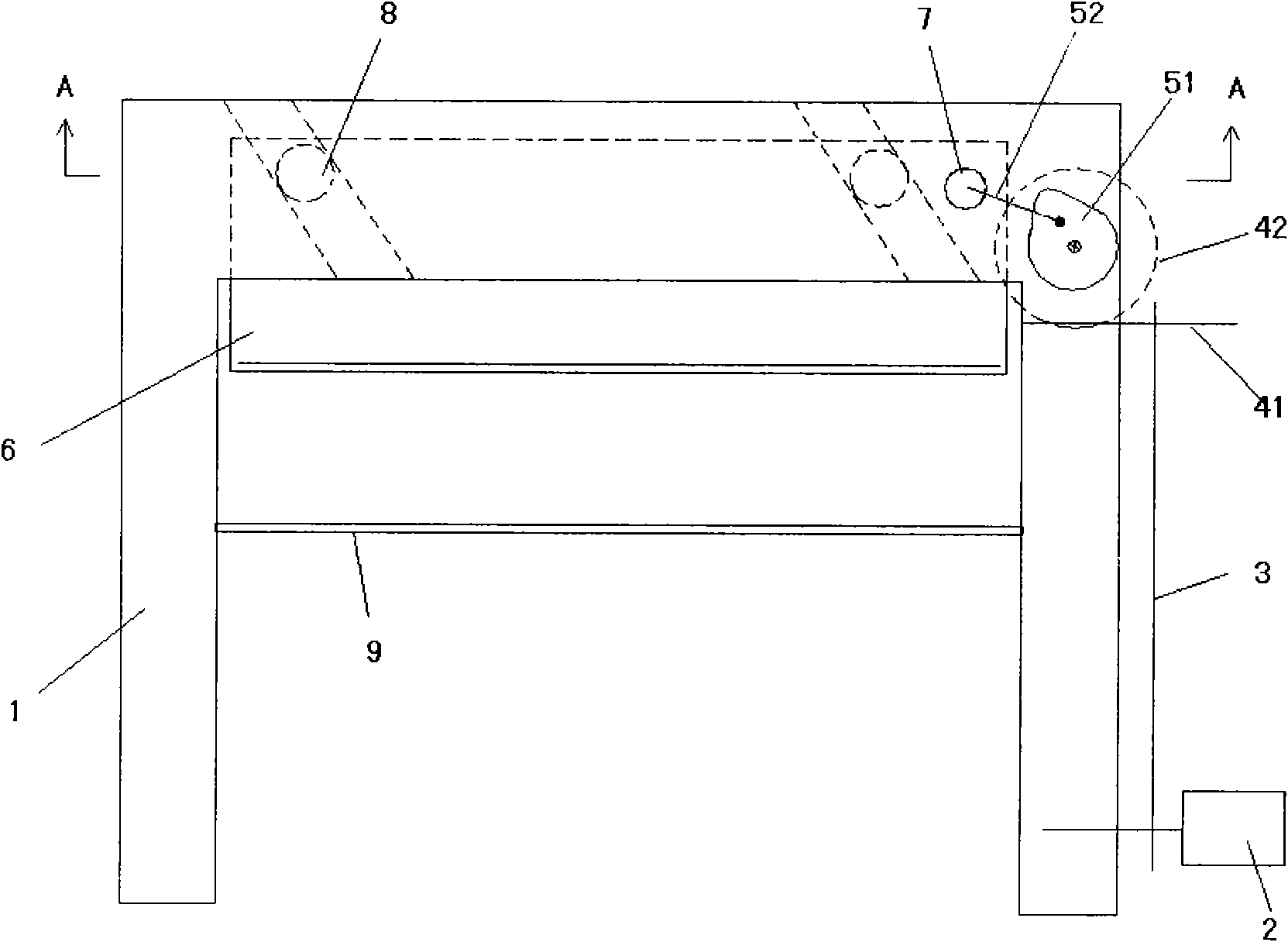

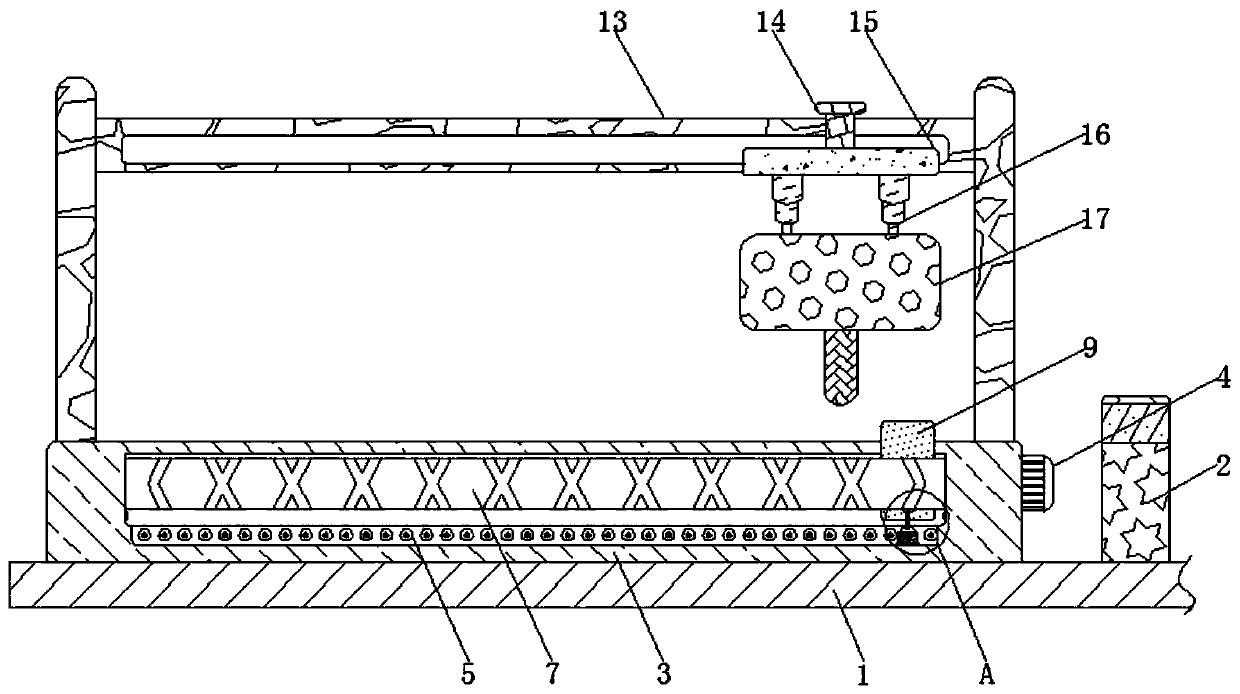

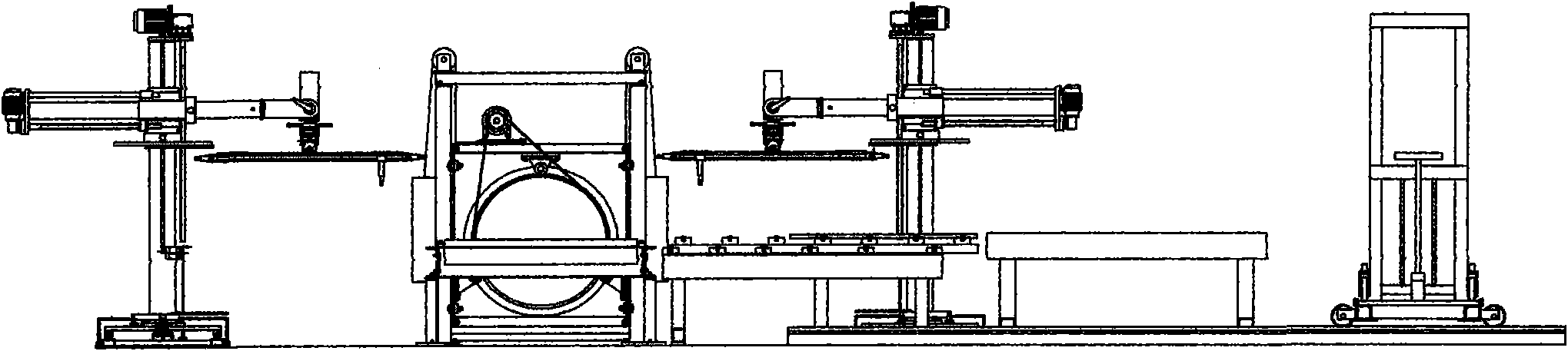

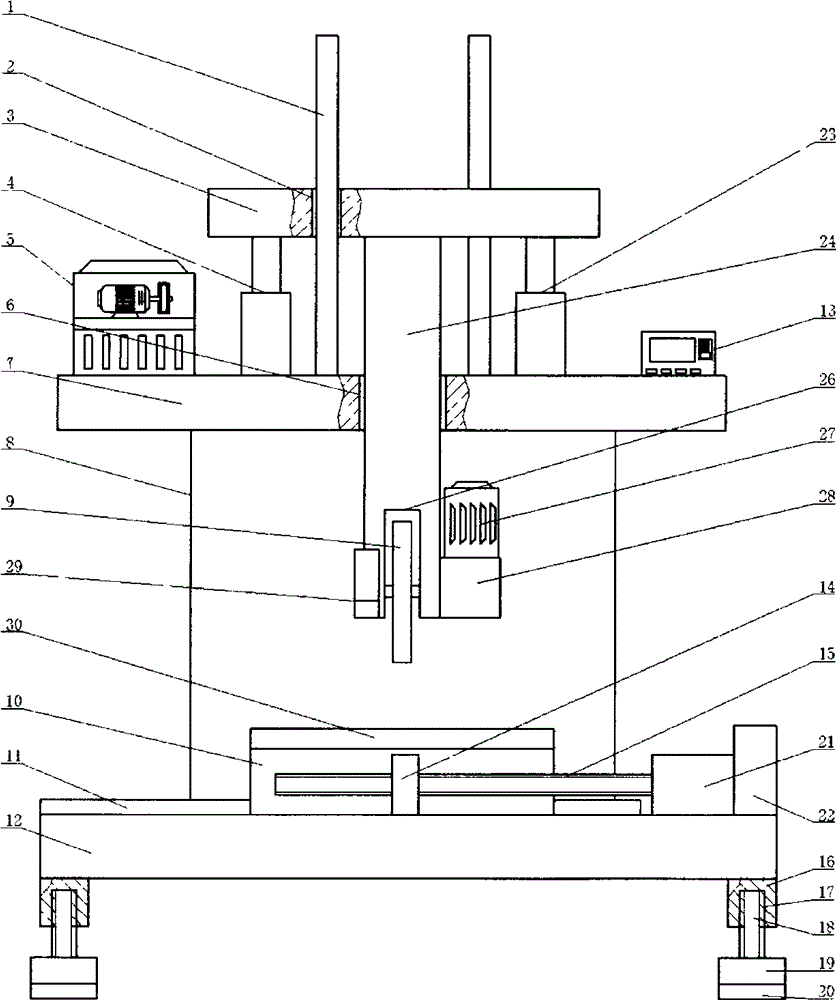

Laser pipe cutting machine and pipe cutting method thereof

InactiveCN105397306AFor precise cuttingAchieve multi-angle effectMetal working apparatusLaser beam welding apparatusVertical planeProgrammable logic controller

The invention discloses a laser pipe cutting machine and a pipe cutting method thereof. The laser pipe cutting machine comprises a portal frame, a laser cutting head, a fixing device and a PLC (programmable logic controller), wherein a first driving frame capable of moving on the horizontal X axis along the portal frame is arranged on the portal frame; a second driving frame capable of moving on the vertical Z axis along the first driving frame is arranged on the first driving frame; a rotating frame capable of horizontally rotating on the horizontal plane around the second driving frame is arranged on the second driving frame; and the laser cutting head is mounted on the rotating frame, and can vertically rotate on the vertical plane around the rotating frame. The laser pipe cutting machine can be used for rotationally cutting pipes from different angles, so that the pipes are cut precisely, the pipe abutting is smooth, and the abutting quality is high. According to the pipe cutting method of the laser pipe cutting machine, the pipes are cut precisely.

Owner:GUANGZHOU TONRY LASER EQUIP CO LTD

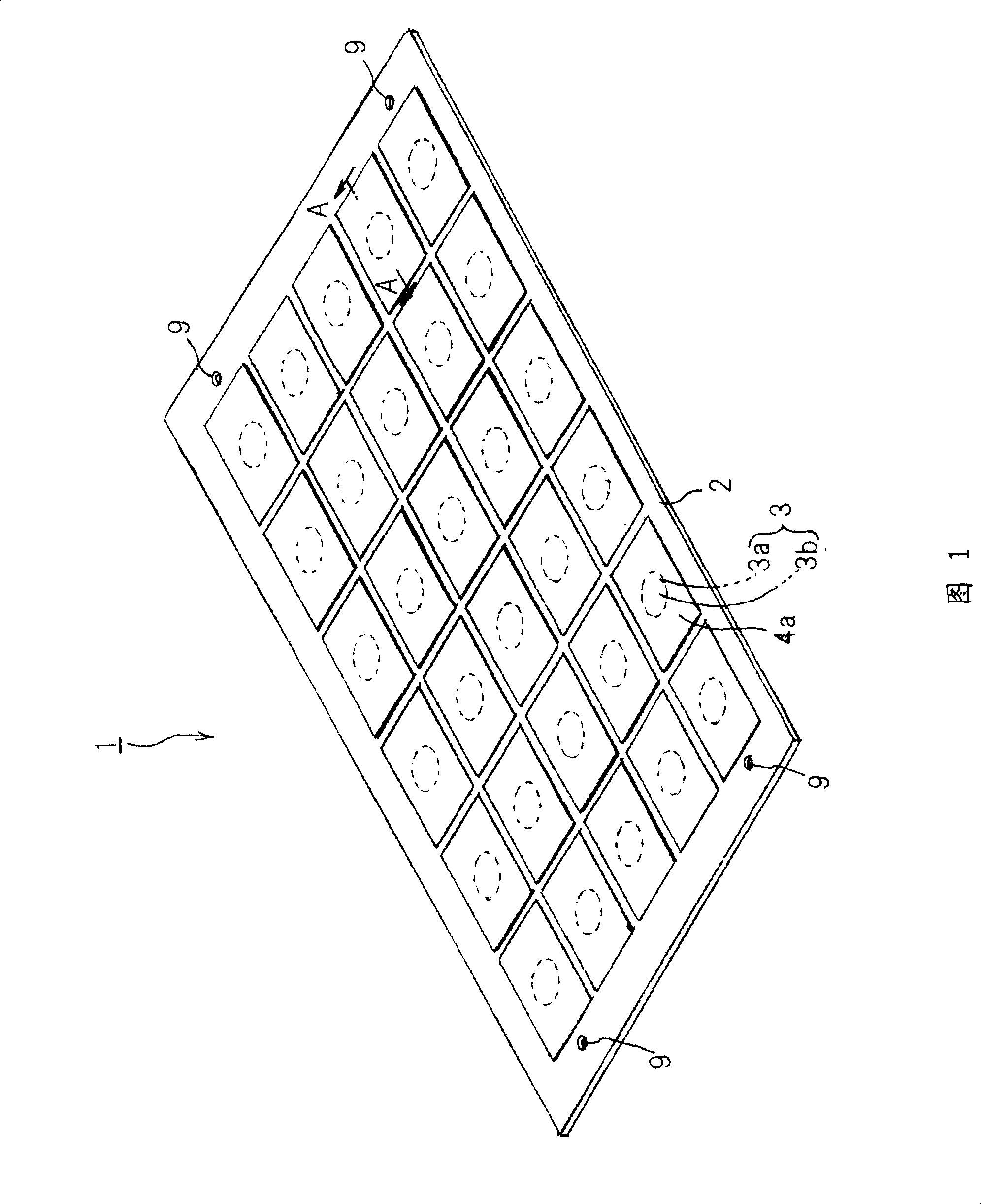

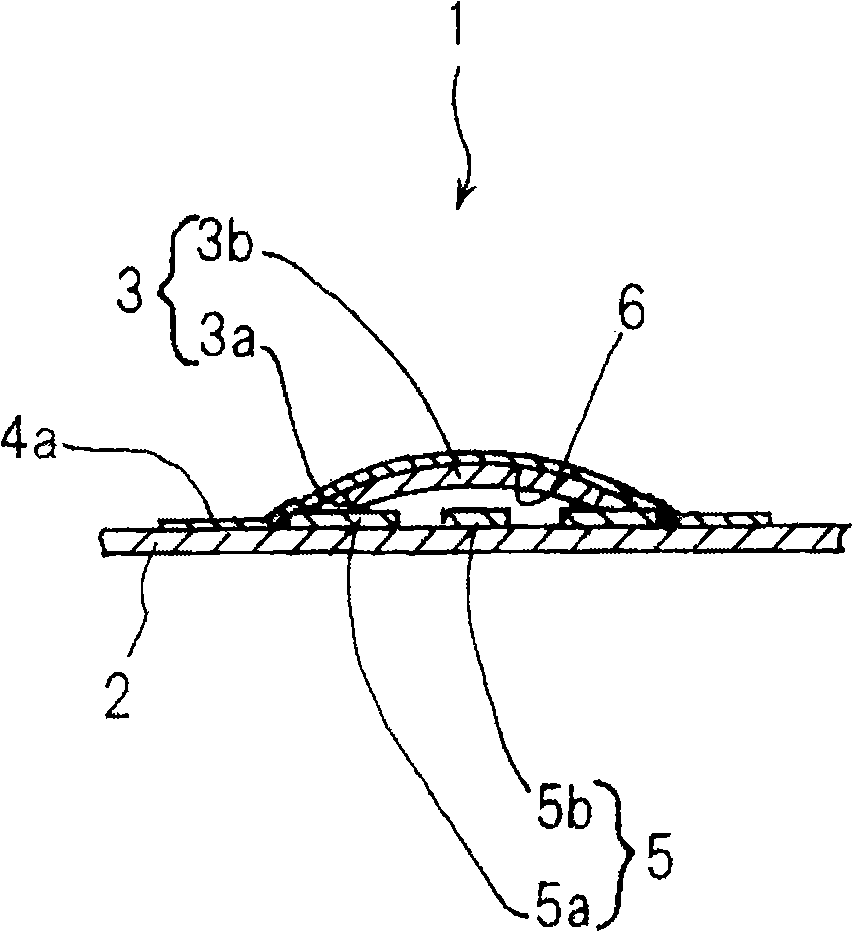

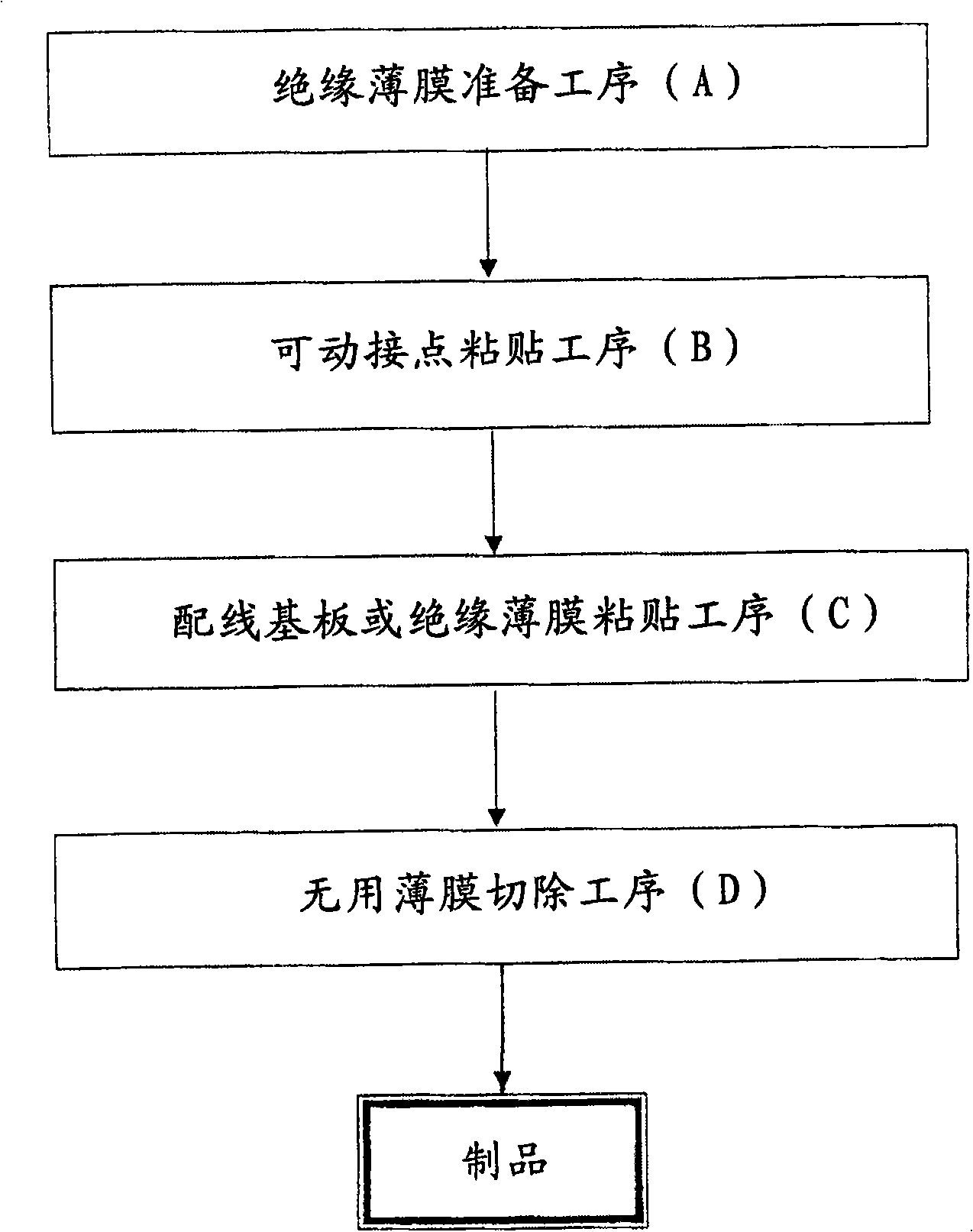

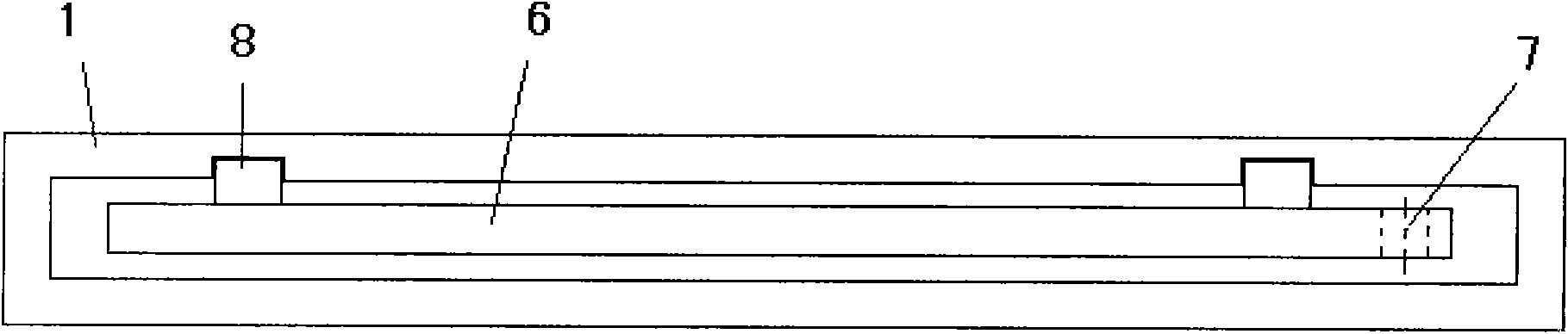

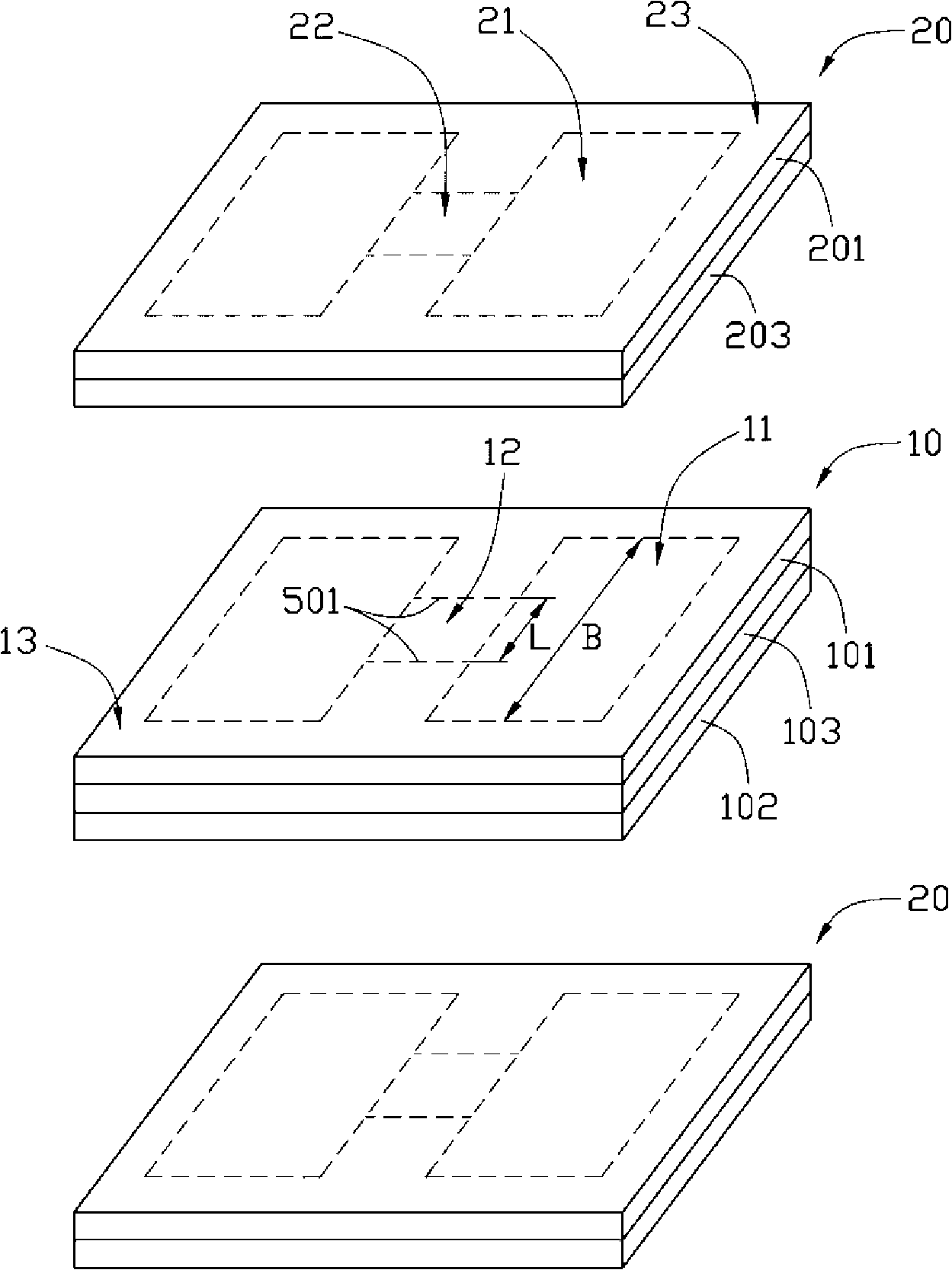

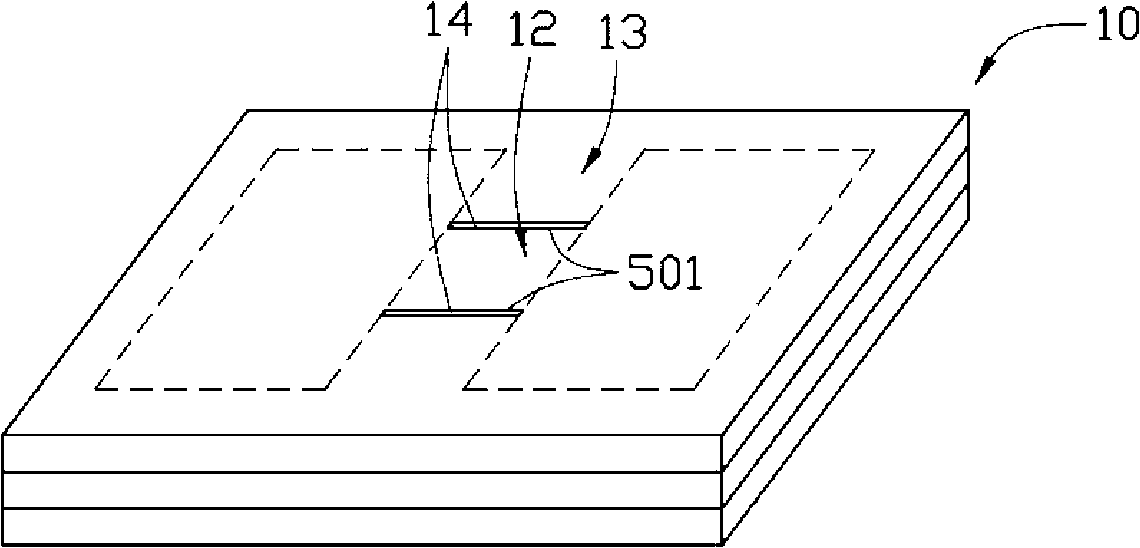

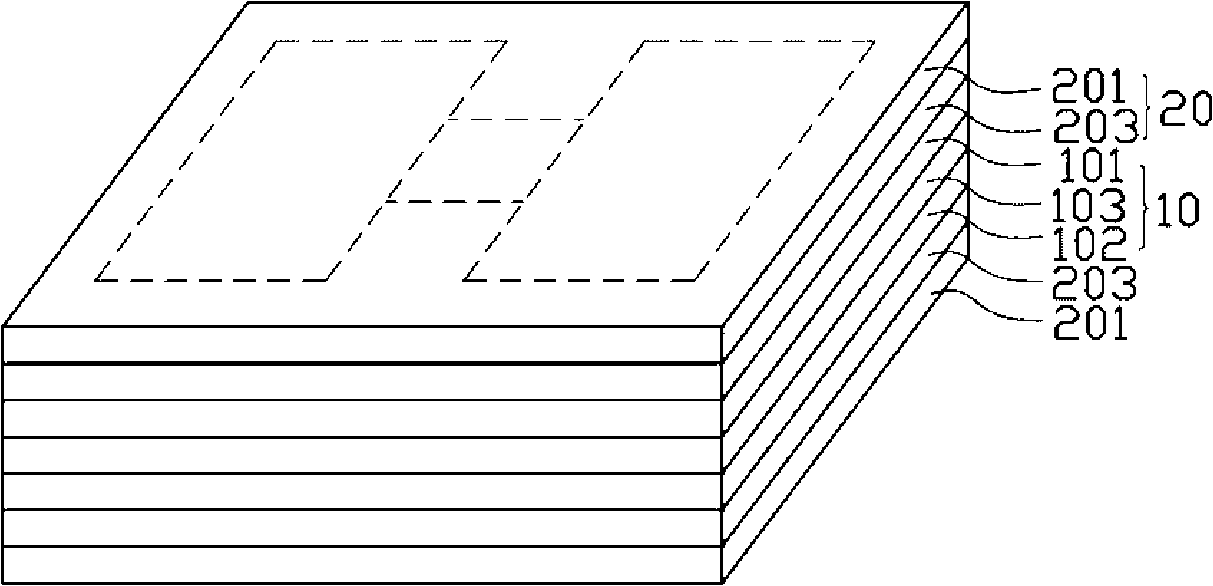

Method of manufacturing panel switch and panel switch

ActiveCN101335147AReduce manufacturing costShorten the manufacturing periodElectric switchesMovable contactsMan-hourEngineering

The invention provides a method for manufacturing a panel switch with reduced man hour, improved operability and lowered cost. The panel switch and a method of manufacturing the same are provided. The panel switch includes insulating films and a base layer having a stationary contact. Each insulating film includes an adhesive layer, and an apex portion of a moving contact adhered to the adhesive layer. The insulating films are aligned and adhered on top of each other and the adhered insulating films are aligned and adhered to the base layer such that the locations of the moving contacts of the respective insulating films align with the stationary contact of the base layer. The method includes applying an adhesive layer to an insulating film; adhering a moving contact onto the adhesive layer; aligning the moving contact with a stationary contact of a base member and adhering the insulating film to the base member; and cutting and removing an excess portion from the insulating film with a laser.

Owner:MITSUMI ELECTRIC CO LTD

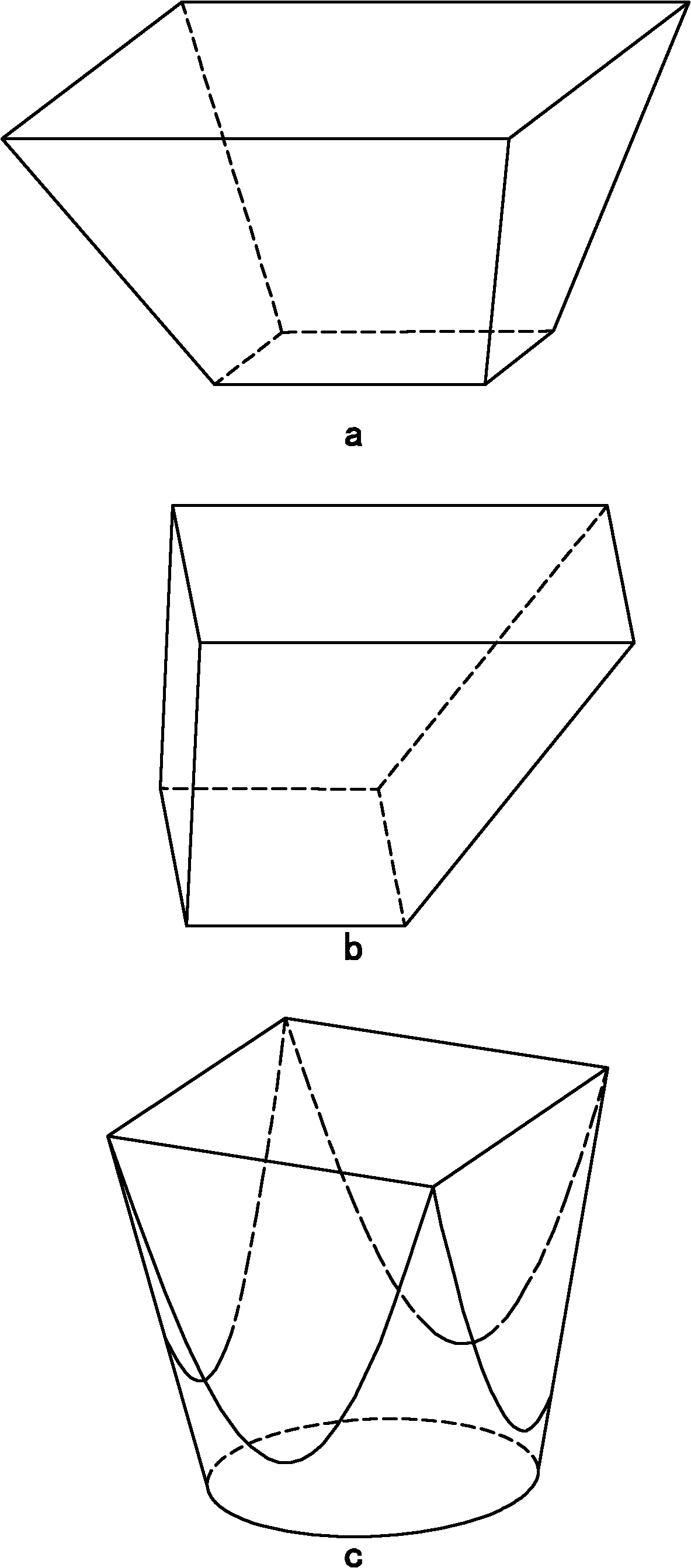

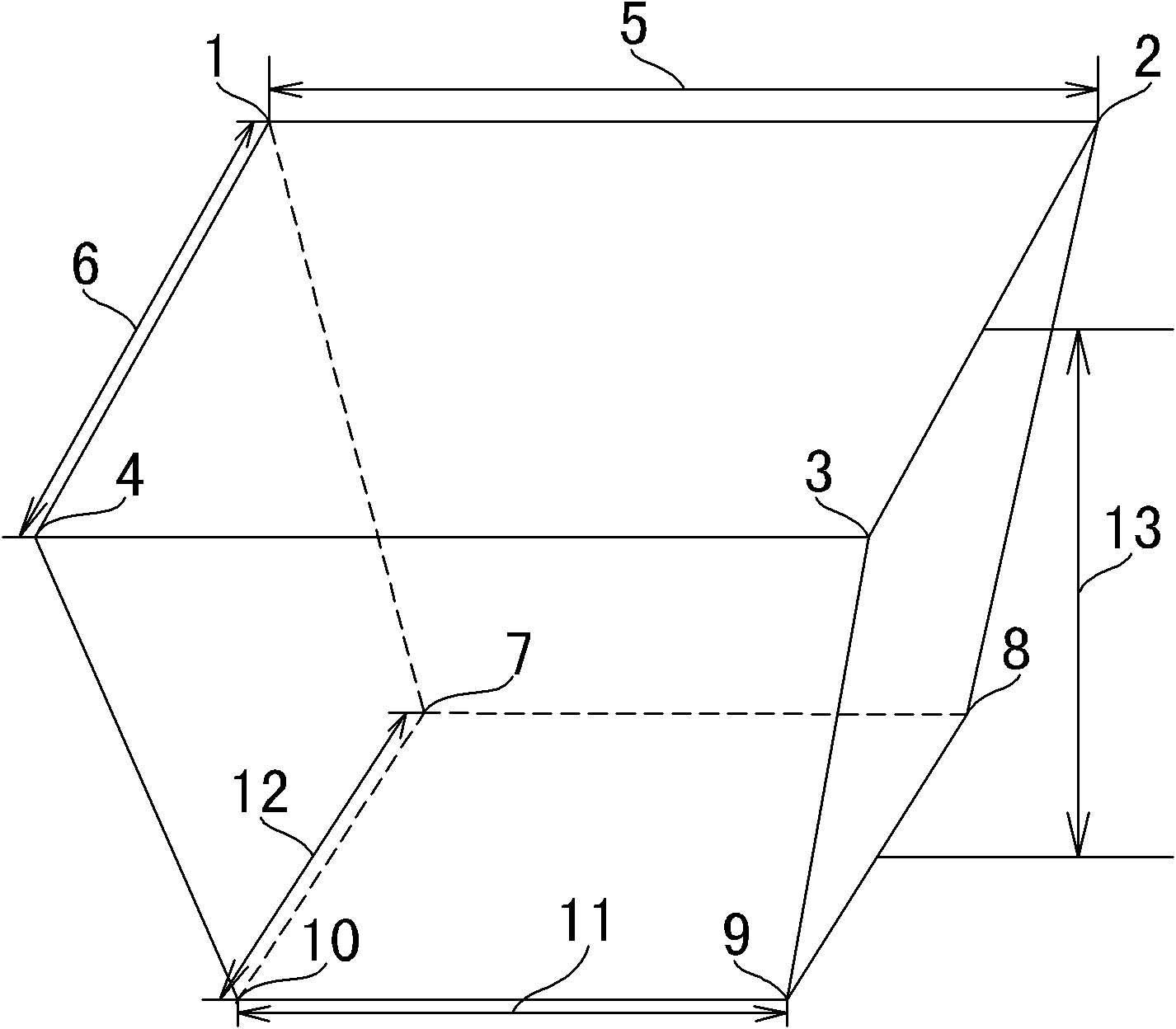

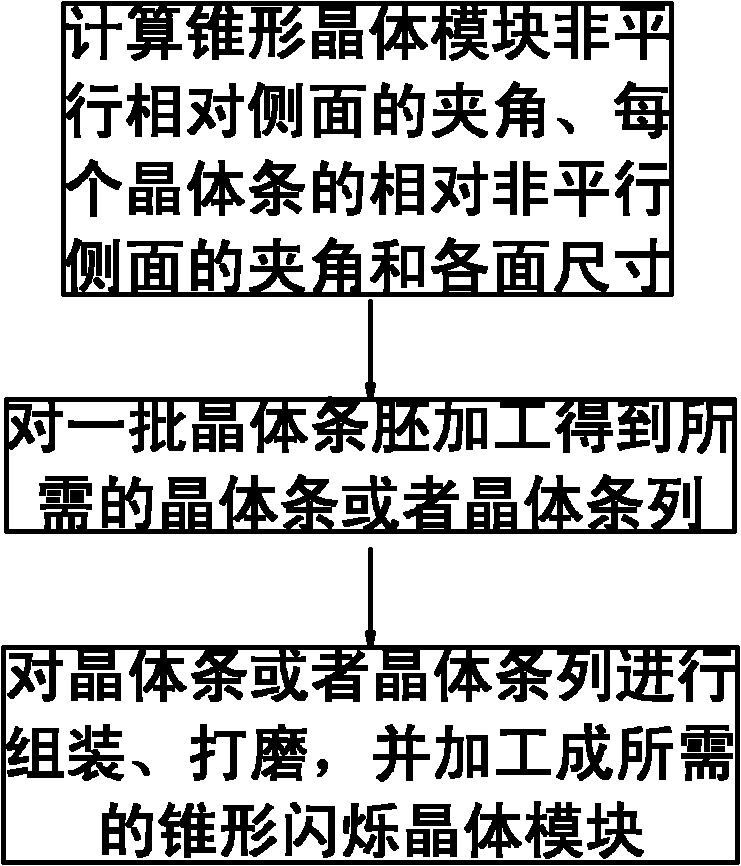

Conical scintillation crystal module and processing method thereof

ActiveCN102129082AHigh sensitivityReduce the problem of missing collectionX/gamma/cosmic radiation measurmentImaging qualityImage resolution

The invention discloses a conical scintillation crystal module and a processing method thereof. The stereo shape of the appearance of the scintillation crystal module is of a conical table, the top surface of the conical table is mutually parallel to the bottom surface, the top surface is rectangular, and the area of the top surface is greater than that of the bottom surface. The scintillation crystal module is formed by splicing and bonding m*n crystal strips. The processing method comprises the following steps of: calculating the size of each crystal strip according to the size of the conical scintillation crystal module and the array number of the crystal strips, assembling and polishing the crystal strips obtained by processing a batch of crystal strip blanks, and processing the crystal strips into the conical scintillation crystal module as required. By designing the conical scintillation crystal module directly coupled with a photoelectric conversion device, the advantages of improving the sensitivity of a medical imaging system, reducing the problems on data acquisition deletion and improving the imaging quality of the system can be achieved under the condition that the energy resolution and the time resolution of the system are not affected.

Owner:NANJING RAYCAN INFORMATION TECH

Cutting device of phloem fiber

The invention relates to a cutting device of phloem fiber, which is characterized in that the cutting device comprises a reverse U-shaped machine frame, one side of the machine frame is provided with a motor, the motor drives a group of worm and gear mechanisms through a transmission mechanism, worm wheels in the worm and gear mechanisms are coaxially connected with a crank disc of a crank connecting rod mechanism, a connecting rod is eccentricly connected on the crank disc, the other end of the connecting rod is connected with a cutter, the cutter spans between two vertical beams of the machine frame and is movably supported on the cross beam of the machine frame, the cutter is provided with a guide block and a guide groove in inclined movement correspondingly to the cross beams of the machine frame, both sides of the machine frame under the cutter are respectively provided with a material inlet support plate and a material outlet support plate, a cutter falling groove right aligned with the cutter is connected between the material inlet support plate and the material outlet support plate, and a hard pad block is arranged in the cutter falling groove. When the device provided by the invention is used for cutting the phloem fiber, the time and the labor can be saved, the cutting length required by the technology can be realized, the manual operation error can be reduced, and the production efficiency is high.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

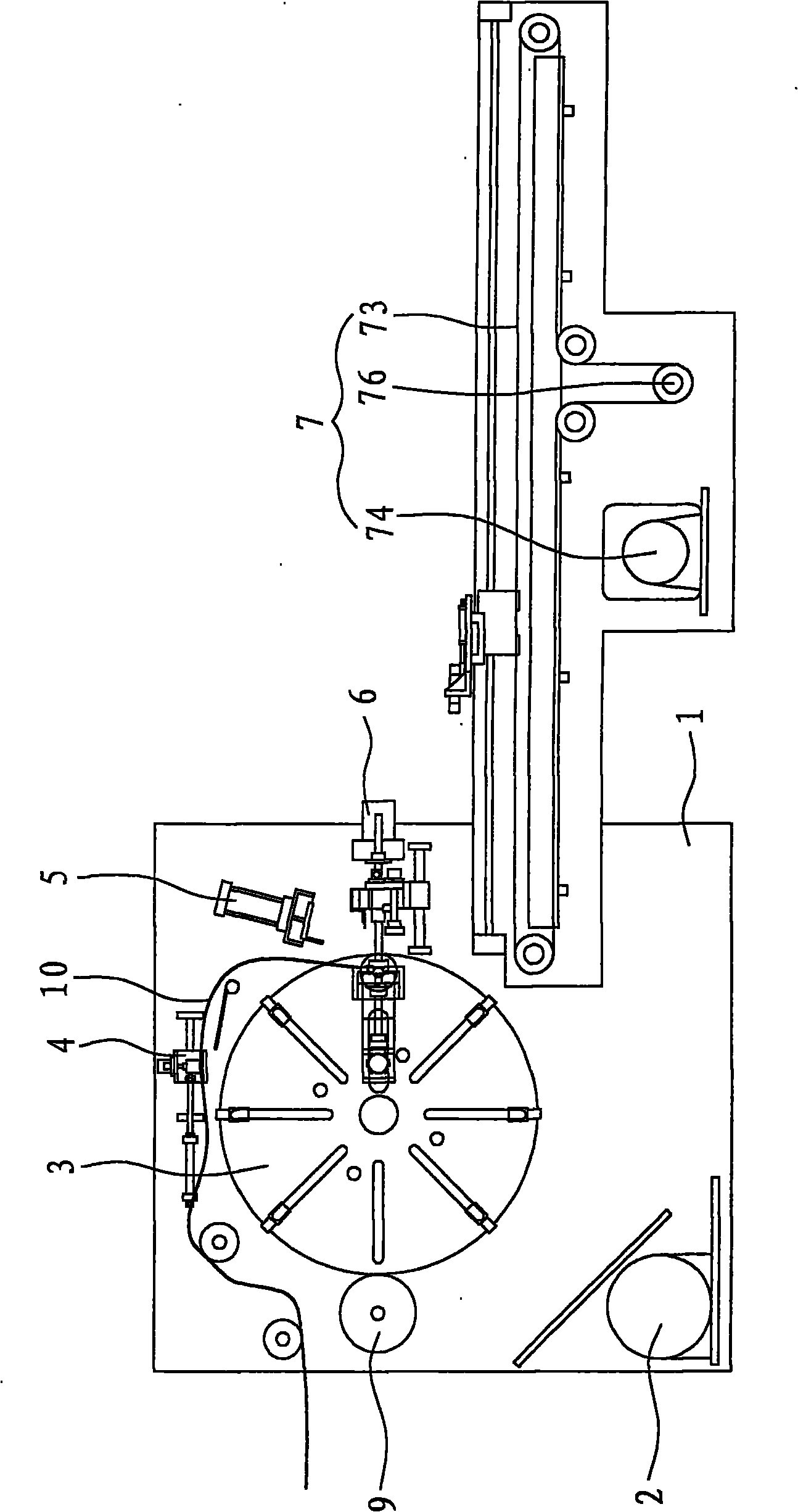

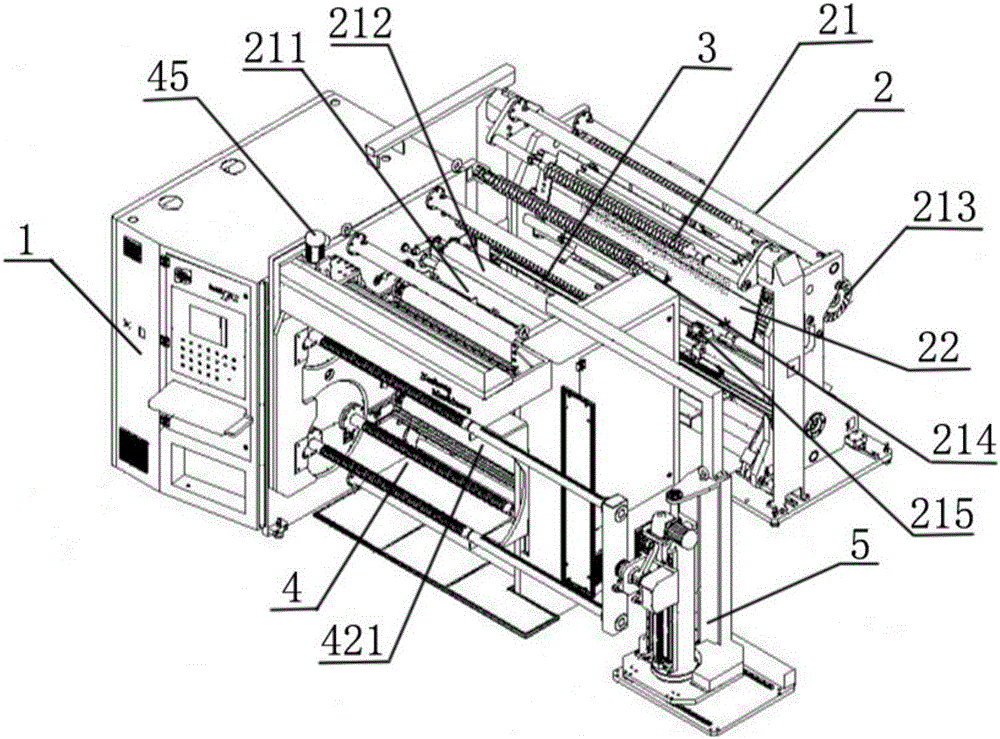

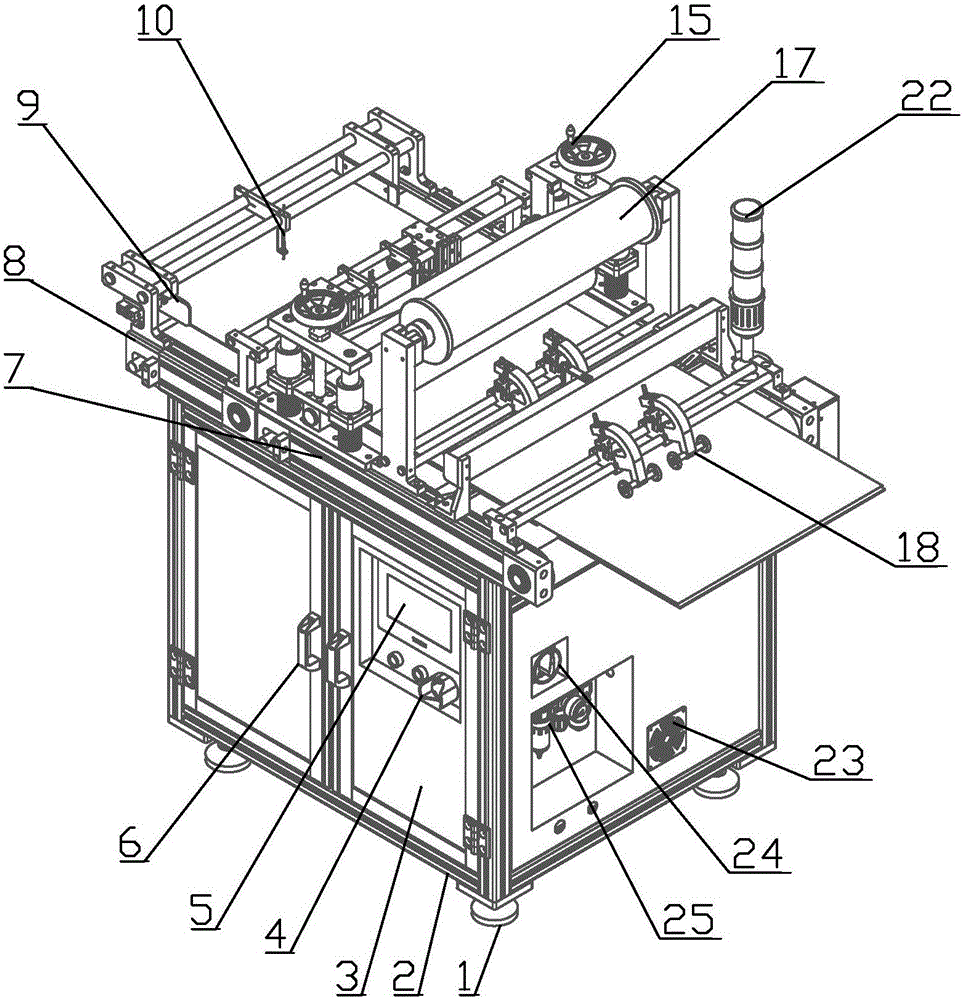

Film cutting machine

InactiveCN102152327AFor precise cuttingHigh precisionMetal working apparatusWebs handlingConductor CoilKnife blades

The invention discloses a film cutting machine which mainly comprises a motor, a rack, a winding device, a feed device, a guide device, a wafering device, a discharge device, and a detecting device, wherein the winding device can be rotatably mounted on the rack; the feed device is mounted on the rack; the guide device is mounted on the rack and is arranged at the output end of the feed device; the wafering device is mounted on the rack and is arranged below the guide device; the discharge device is mounted at one side of the rack; and the detecting device is mounted at the outer wall of a side plate of the rack. As one end of a rotating shaft of the film cutting machine stretches out of the outer wall of a machine bench and the stretching end of the film cutting machine is provided with a group of gears; one side of a driven gear is provided with the detecting device; the detecting device can detect an angle of a turntable through detecting an angle of a gear coaxial with the turntable; therefore, when the turntable rotates to a proper angle, a cutting plate of a chucking device is just vertical to a blade, so that a film is accurately cut. Therefore, the film cutting machine has high winding and cutting accuracy.

Owner:厦门亚太创新机器有限公司

All-in-one machine with numerical control ink-jet drawing and laser cutting

ActiveCN102350874ADischarge in timeDissipate heat in timePrintingLaser beam welding apparatusElectricityNumerical control

The invention discloses an all-in-one machine with numerical control ink-jet drawing and laser cutting. The machine comprises a bracket, a rectangular working platform supported on the bracket, a power distribution box, a control circuit board and a main control board connected with the control circuit board, wherein the left edge and the right edge of the working platform are respectively provided with a longitudinal guide rail; a cross beam capable of moving on the longitudinal guide rail in a reciprocating manner is erected between the longitudinal guide rails; the cross beam is provided with a transverse trolley track which is provided with a trolley; the trolley is provided with an ink-jet device and a condensing lens of a laser cutting device; and the ink-jet device and the laser cutting device are respectively and electrically connected with the control circuit board. The all-in-one machine has the advantages that an ink-jet mode and a laser cutting mode are simultaneously applied in a cutting machine; since cut materials can not be contacted in both the ink-jet mode and the laser cutting mode, all the materials needing to be cut can be cut accurately, the high temperature and the wastes generated by cutting can be discharged in time, a laser tube can be dissipated in time, and the all-in-one machine provides multiple data output modes.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

Front and rear automatic shear line device of overedger sewing products

InactiveCN101446006AAccuratePrecise positioning in placeNeedle severing devicesSewing-machine control devicesYarnState of art

The invention discloses a front and rear automatic shear line device of overedger sewing products, which consists of a transmission-type synchronous scanning opto-electronic group, a blowing device, an enabling signal sensor, a front cut dust collecting device, a stepping sensor, an electromagnetic or pneumatic shear knife rest (an executing mechanism) and an electrical control box. A full-automatic shear line device which is provided with a front blade and a rear blade of the sewing products that are controlled by photoelectric detection; on the premise of no human intervention, the shear process of freely setting yarn at the front end and the rear end of the sewing products can be completed. As the device is not needed to be stopped for trimming, the sheared thrum is absorbed cleanly at the same time. As the device is not needed to be stopped for trimming, and the sheared thrum is absorbed cleanly at the same time, the working efficiency of the single device is increased by over 30% compared with the prior art; the efficiency and the reliability are high.

Owner:王国秋 +1

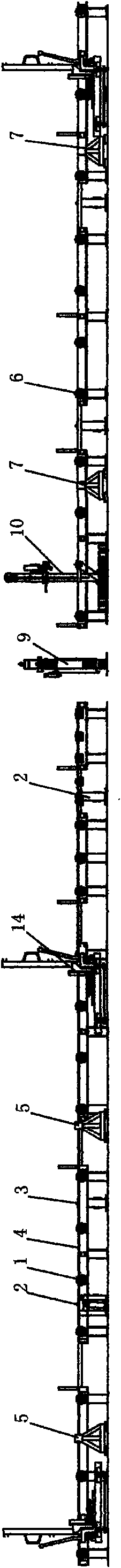

Thin film dividing and cutting machine with rolling shafts overturnable

ActiveCN106241473AAvoid wastingIncrease productivityArticle deliveryWebs handlingEngineeringMechanical engineering

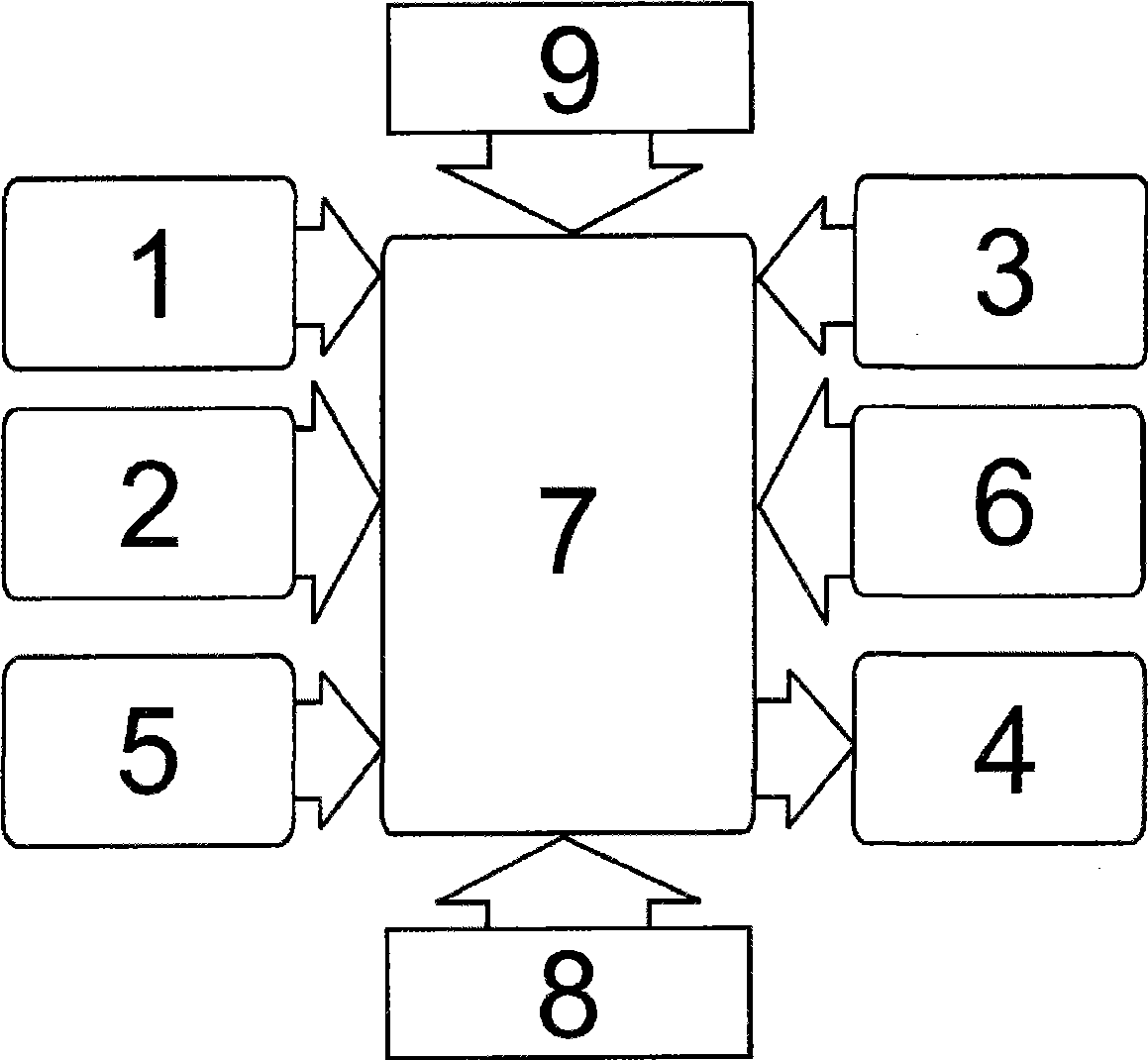

The invention relates to the field of dividing and cutting machines and discloses a thin film dividing and cutting machine with rolling shafts overturnable. The thin film dividing and cutting machine comprises a PLC control mechanism, an unrolling mechanism, a dividing and cutting mechanism, a rolling mechanism and a discharging mechanism. The PLC control mechanism is connected with the unrolling mechanism, the dividing and cutting mechanism, the rolling mechanism and the discharging mechanism. The unrolling mechanism comprises an unrolling motor, an unrolling transmission mechanism and a material receiving platform. The unrolling transmission mechanism comprises a main traction roller, a traction pressing roller, an unrolling brake, a guide roller and a deviation-rectifying controller. The rolling mechanism comprises a rolling motor, rolling transmission mechanisms, a rolling shaft overturning mechanism and the two or more rolling shafts. The rolling shaft overturning mechanism comprises rolling shaft overturning plates, a rolling shaft supporting plate, overturning plate air cylinders and rolling shaft air cylinders, wherein the overturning plate air cylinders are used for driving the rolling shaft overturning plates to be overturned and located, and the rolling shaft air cylinders are used for locating the rolling shafts. One end of each rolling shaft is connected with the corresponding rolling shaft overturning plate, and the other end of each rolling shaft is connected with the rolling shaft supporting plate. The thin film dividing and cutting machine has the beneficial effects that rolling efficiency is high; rolling is conducted neatly; and time and labor are saved in the discharging process.

Owner:江阴市科盛机械有限公司

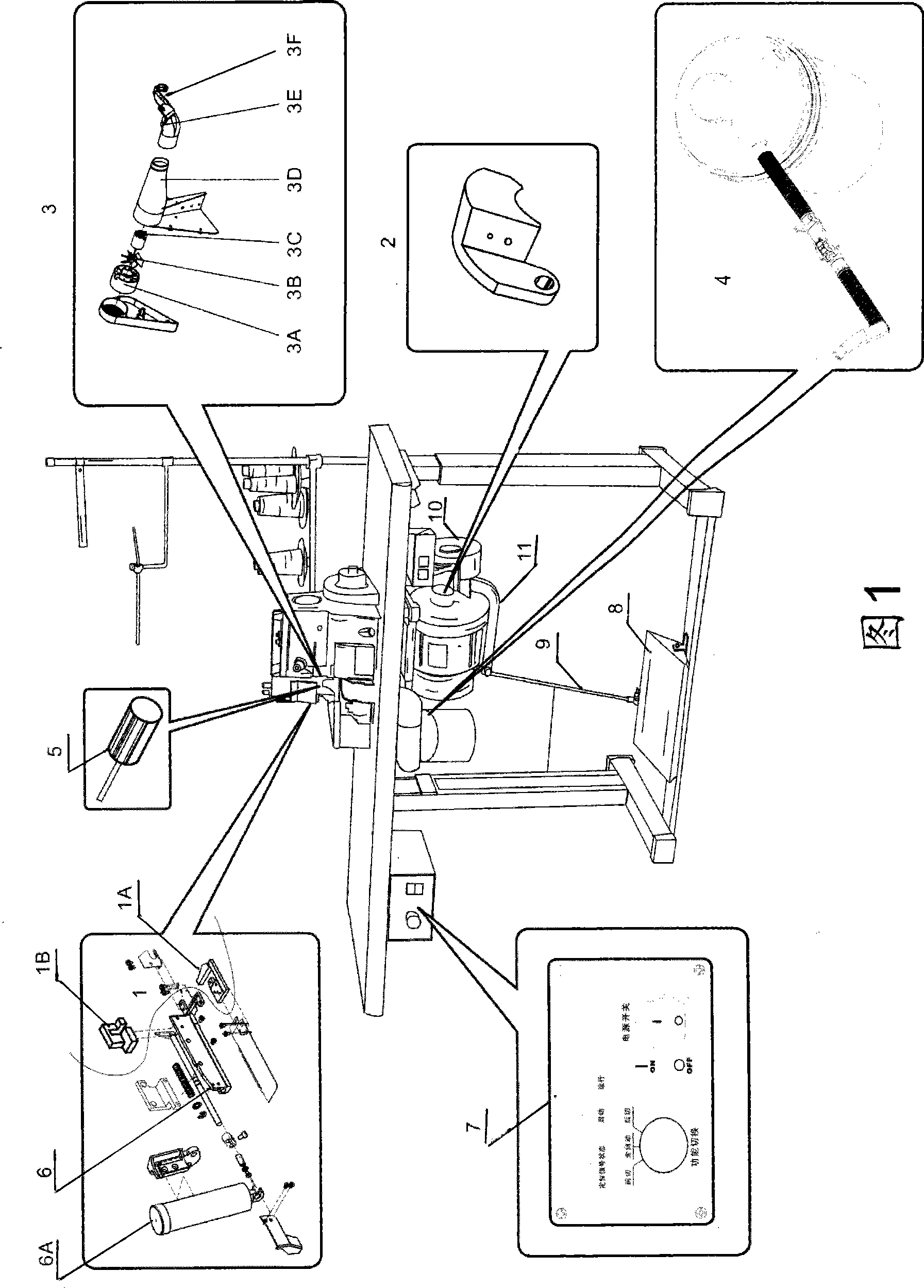

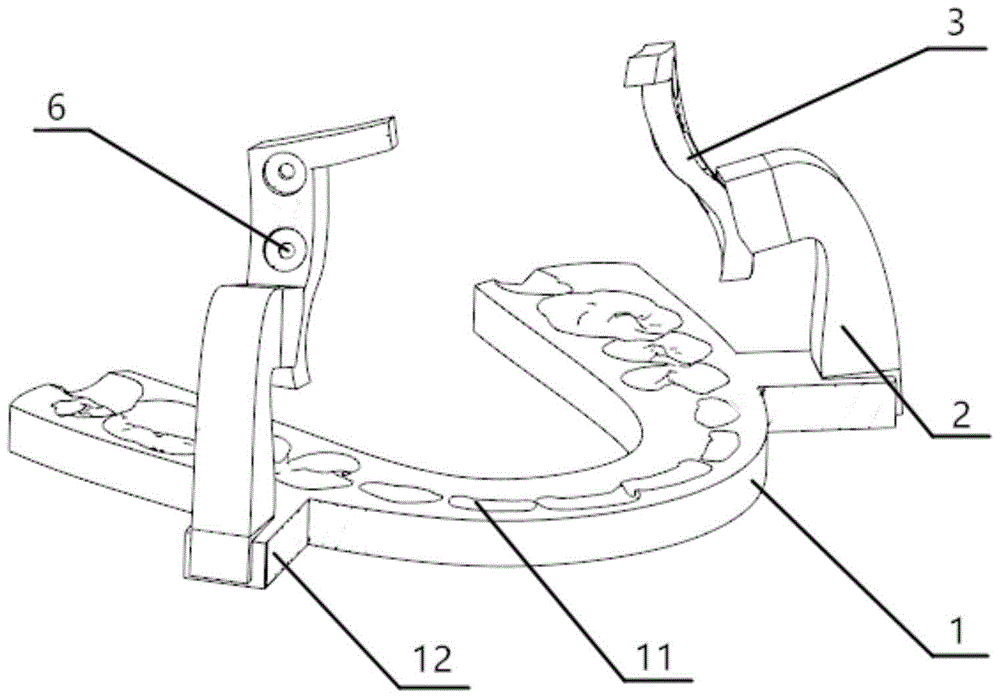

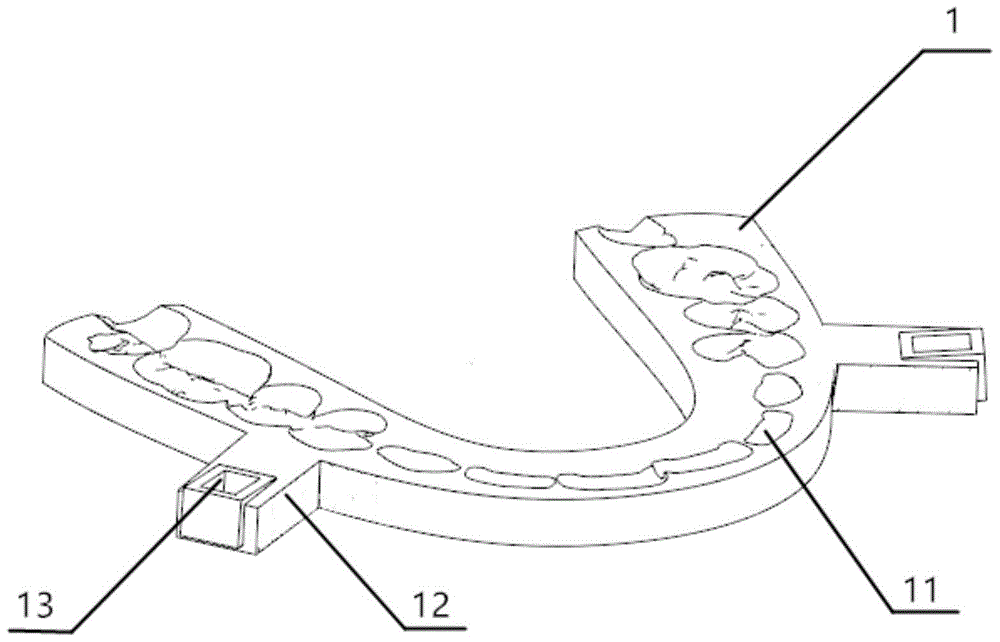

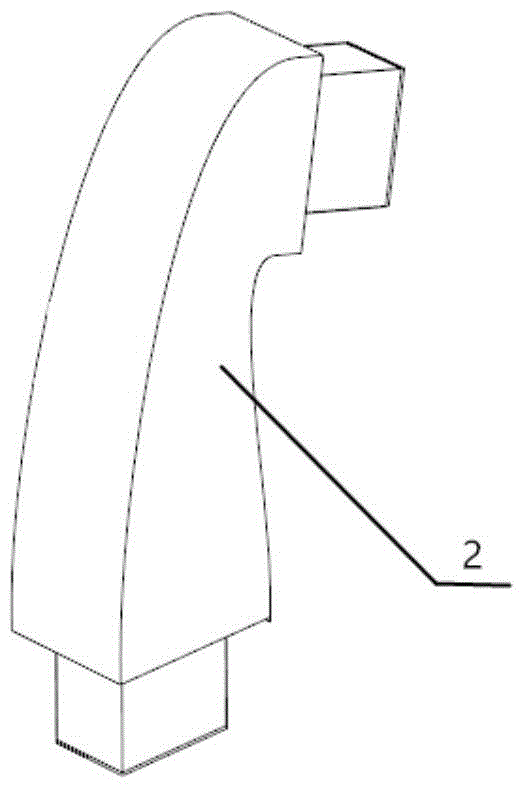

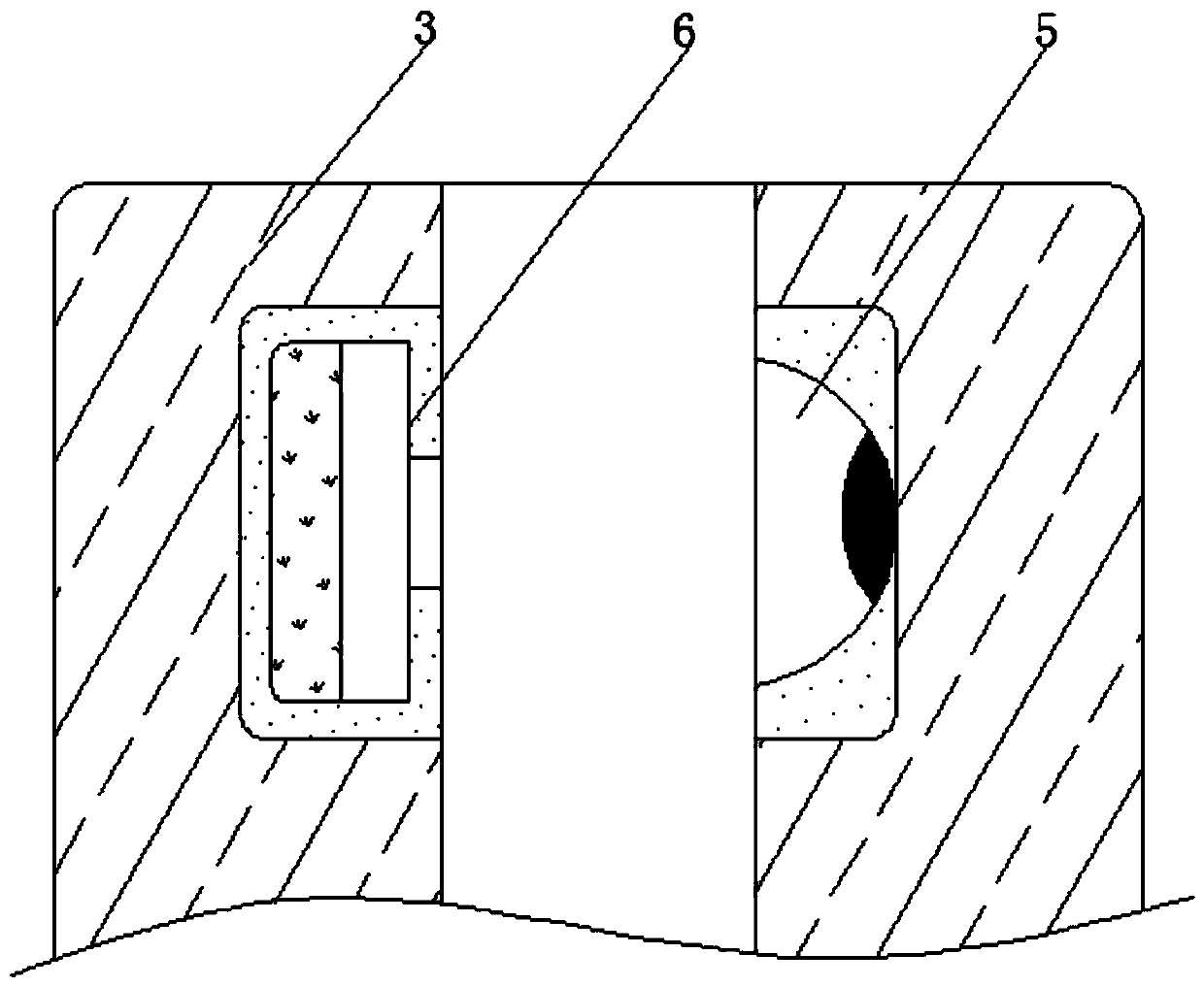

A subapical osteotomy locating guide plate and a manufacture method therefor

ActiveCN105686886AAvoid damageProlong surgery timeInstruments for stereotaxic surgeryMaxillary OsteotomyIntermaxillary bones

The invention provides a subapical osteotomy locating guide plate and a manufacture method therefor. The subapical osteotomy locating guide plate belongs to assisting medical instruments. The subapical osteotomy locating guide plate comprises a locating occlusion plate (1), connecting rods (2) and maxillary osteotomy line guide plates (3). The locating occlusion plate (1) is provided with an initial tooth print (11) and is connected with the maxillary osteotomy line guide plates (3) via the connecting rods (2). Each maxillary osteotomy line guide plate (3) is provided with two screw holes (6). The maxillary osteotomy line guide plates (3) are provided with non-circular insertion grooves b (31). One end of each connecting rod (2) matches the corresponding insertion groove b (31). The subapical osteotomy locating plate solves the problem that no intermaxillary bone locating guide device is available in subapical osteotomy. When the subapical osteotomy locating guide plate is applied to assist doctors with surgeries, the current most common complication of subapical osteotomy can be prevented.

Owner:SICHUAN UNIV

Method for preparing soft hard combined board

ActiveCN101494956AHigh forming precisionGood molding effectPrinted circuit assemblingPrinted circuit aspectsMetallurgyWaste material

The invention provides a method for manufacturing soft-hard combined plate, which comprises the following steps: providing at least one soft substrate and at least one hard substrate, where both the soft substrate and the hard substrate comprise a first region for forming, a second region for forming and a waste material region; cutting the boundary between the second region for forming and the waste material region on the soft substrate by a first tool; matching the soft substrate and the hard substrate, and pressing the soft substrate and the hard substrate; removing the second region for forming of the hard substrate; cutting the boundary between the first region for forming and the waste material region by a second tool to cause the waste material region to fall off, thereby obtaining the soft-hard combined plate. The soft-hard combined plate manufacturing method with the above technical solution achieves better forming effect and higher forming precision.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Steel pipe cutting device for stainless steel doors and windows

InactiveCN111570902AFor precise cuttingEasy to operateMeasurement/indication equipmentsFeeding apparatusElectric machineSS - Stainless steel

The invention relates to the technical field of stainless steel doors and windows, and discloses a steel pipe cutting device for stainless steel doors and windows. The device comprises a bottom plate,wherein the outside of the bottom plate is fixedly connected with a support frame, the outside of the bottom plate is fixedly connected with a base, the outside of the base is movably connected witha motor, the inside of the base is movably connected with lamp beads, the inside of the base is movably connected with photosensitive components, the inside of the base is movably connected with a screw rod, and the outside of the screw rod is movably connected with a connecting rod. Under the interaction of the bottom plate, support frame, base, motor, lamp beads, photosensitive components, screwrods, connecting rods and sliders, the operator can input the length data of the stainless steel to be cut into a control center, so that the moving distance of the slider of transporting the steel pipe can be controlled by the characteristics of the photoresistor. Thereby, steel pipes with different length requirements are cut. The operation can cut steel pipes more accurately and save time andeffort.

Owner:广西富迎门窗有限责任公司

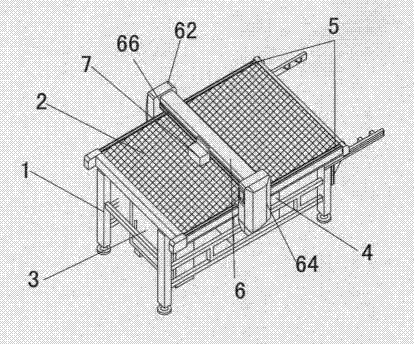

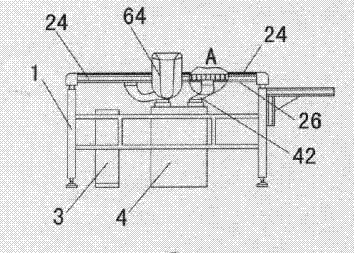

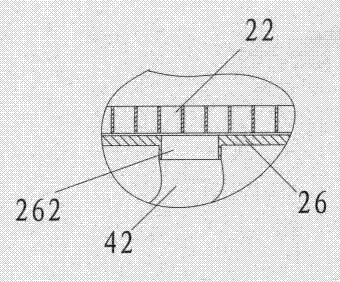

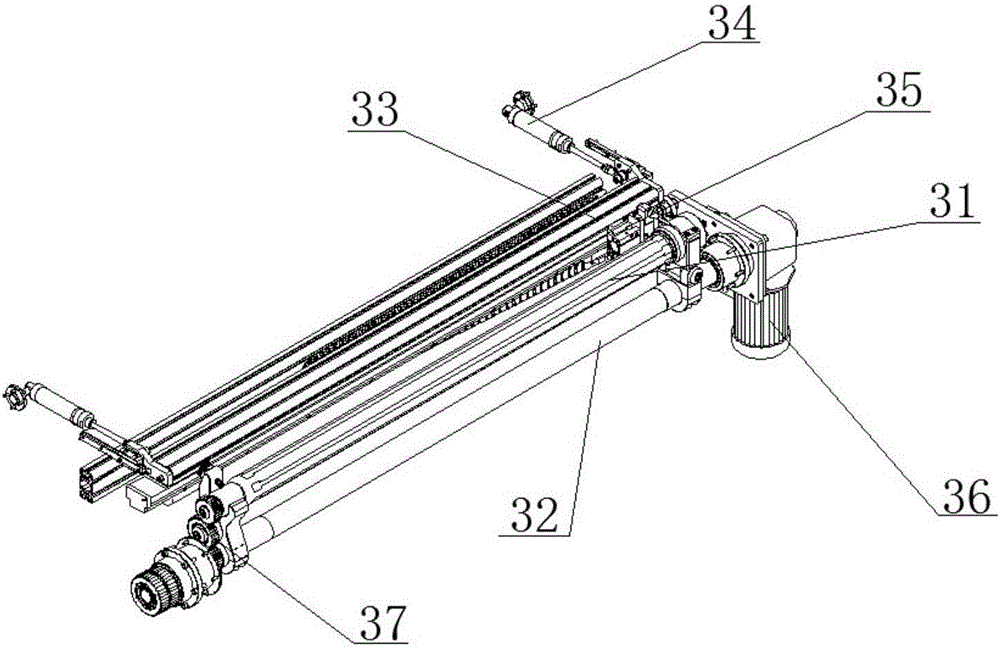

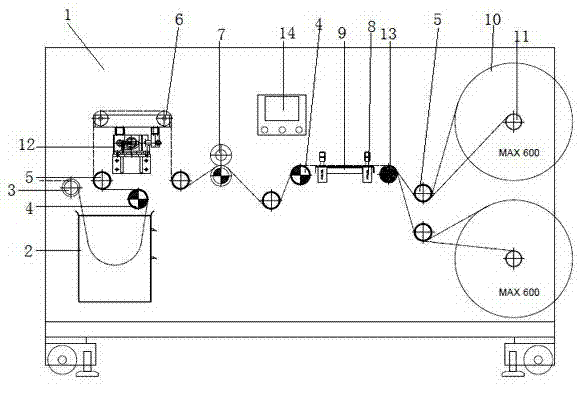

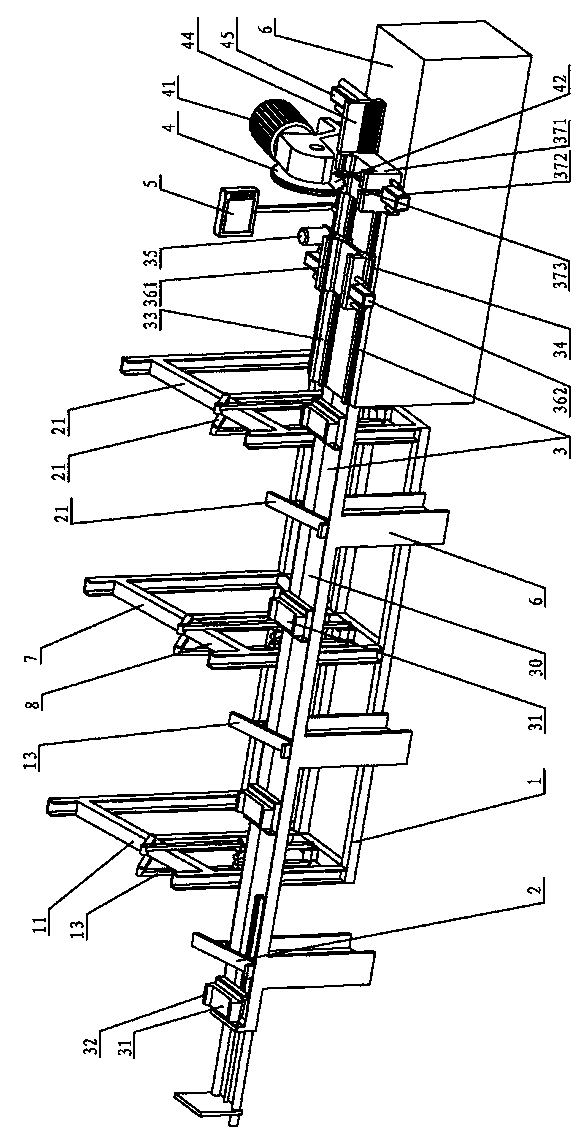

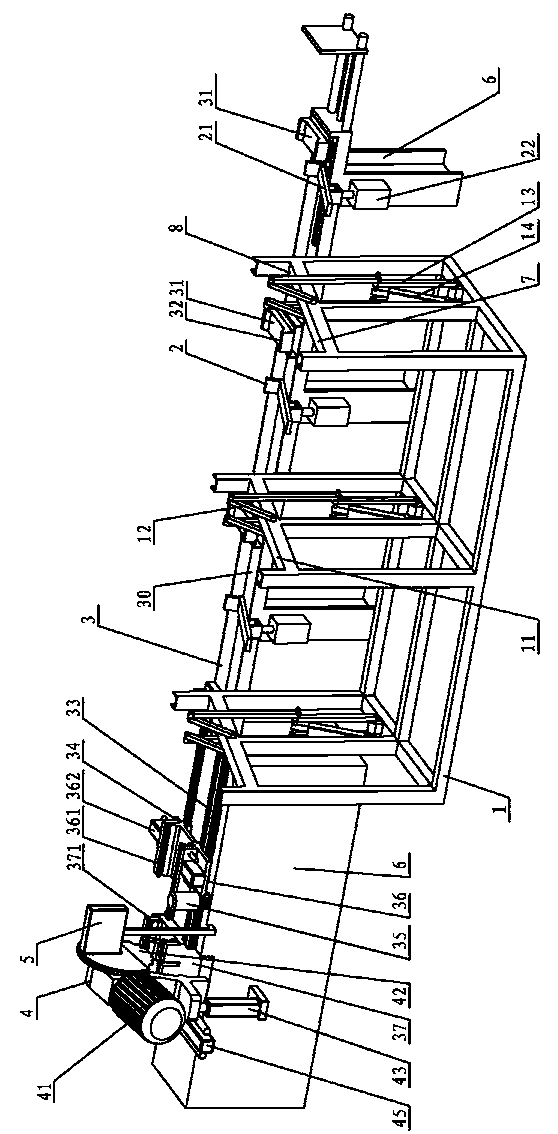

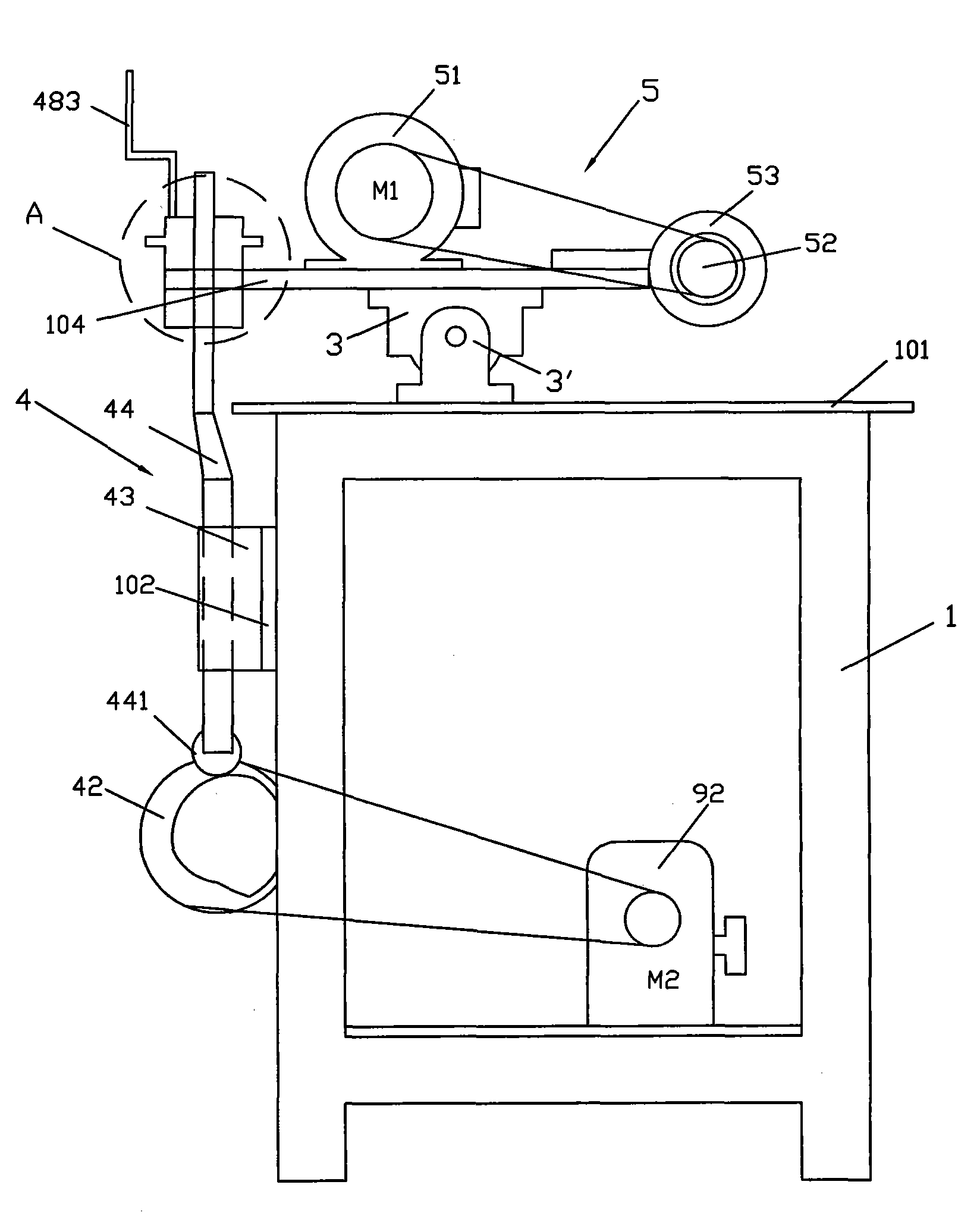

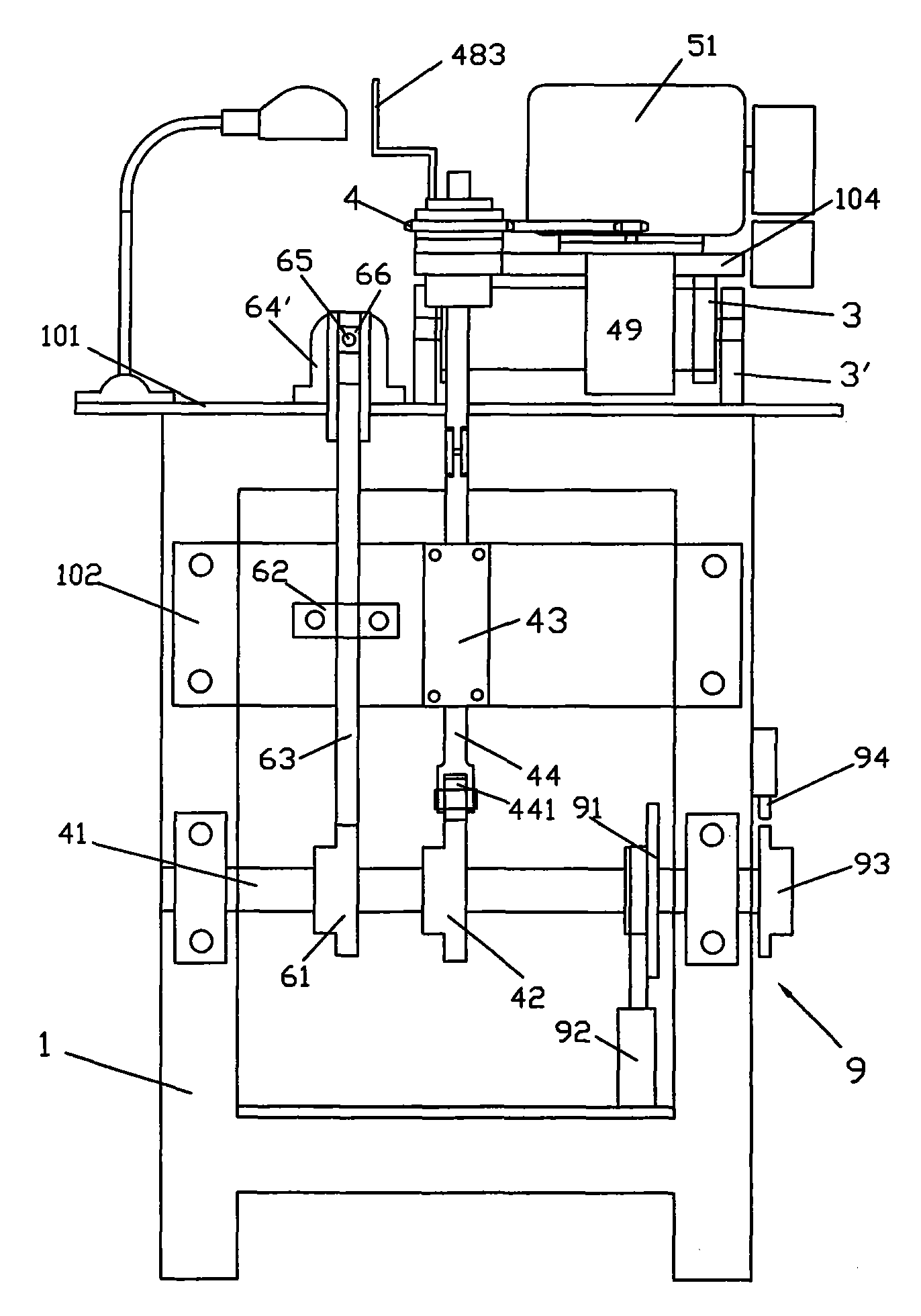

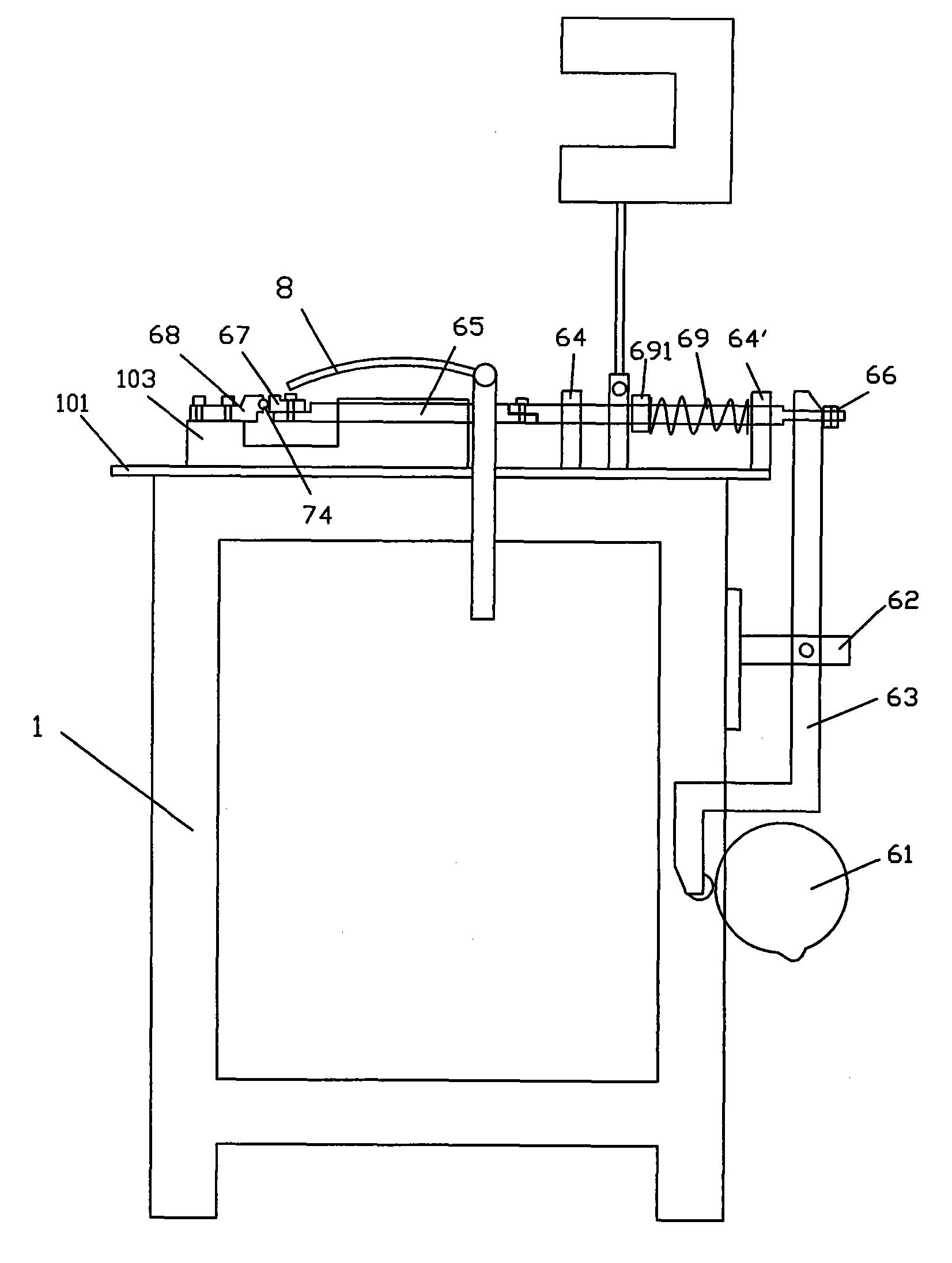

Automatic splitting machine

InactiveCN103693495AFor precise cuttingCompact structureArticle deliveryWebs handlingProgrammable logic controllerEngineering

The invention discloses an automatic splitting machine, which comprises a body, a programmable logic controller (PLC), and a roll release shaft, a material storage box, a flattening mechanism, a splitting mechanism, a receiving mechanism and a rolling mechanism which are fixedly connected with the body, controlled by the PLC and sequentially arranged in the feeding direction, and also comprises a plurality of driving rollers and tension shafts. The automatic splitting machine has the advantages that the automatic splitting machine is compact in integral structure, small in floor area, high in speed and efficiency, accurate in splitting, easy to operate and stable in work, material putting deviation is corrected by a deviation rectifying mechanism, the tension is well controlled and timely adjusted through the tension shafts and a tension detector in the working process, and the splitting quality is guaranteed; moreover, the negative pressure material storage box can effectively prevent a material from being deformed or damaged in the material storage box due to gravity action.

Owner:珠海嘉威自动化科技有限公司

Steel pipe and section steel blanking production line

InactiveCN102284766ASimple loading and unloadingPrecise cuttingGas flame welding apparatusSteel platesSteel tube

The invention relates to a steel pipe and section steel blanking production line. The production line includes a feed line, a discharge line, and a steel pipe and section steel processing device; the feed line includes a feed roller table, a hydraulic lifting roller table, and a steel pipe hydraulic pressure Lifting roller table, a steel scale is arranged on the feeding frame of the feeding roller table, a positioning block is provided at the zero point of the steel scale, and at least one set of feeding lines is provided on one side of the feeding roller table, and the feeding line It includes a sliding feeding device, a raw material conveying device and a raw material storage device; the discharge line is provided with a discharge roller table, a hydraulic lifting roller table and a steel pipe hydraulic lifting roller table, and one side of the discharge roller table is provided with at least one A group of blanking lines, the blanking line includes a sliding discharge device, a processed part delivery device and a processed part storage device The present invention is provided with a steel ruler on the material delivery frame, and a positioning block is arranged at the zero point of the steel ruler, and the cut material Standing on the zero point, the steel ruler on the transport rack can quickly determine the size of the material to be cut, accurate, fast, and error-free; the hydraulic lifting roller table of the steel pipe can be raised when cutting the steel pipe, and the steel pipe can rotate to achieve the purpose of cutting; The invented production line can cut both steel pipe and H steel, with simple, fast loading and unloading, and accurate cutting.

Owner:QINGDAO EAST STEEL TOWER

Automatic pipe cutter

ActiveCN103252529AHigh degree of automationSimple structureMetal-working feeding devicesTube shearing machinesAutomationPiston rod

The invention relates to an automatic pipe cutter which is used for cutting pipes and comprises a machine frame. The machine frame is provided with a material storing device, a material taking device, a material pushing device, a cutting device and a control device. The material storing device comprises a material storing frame, and the material pushing device is placed on one side of the material storing frame. The material pushing device comprises a conveying platform, a clamping component which is used for clamping the pipes and a material pushing drive which is used for driving the clamping component. The material taking device is placed between the material storing device and the material pushing device and comprises a material taking plate and a cylinder B which is placed below the material taking device, wherein the material taking device is connected between the material storing frame and the conveying platform, one end of the material taking plate stretches into the edge of the material storing frame, the other end of the material taking plate stretches to the conveying platform, and a piston rod of the cylinder B is connected with the material taking plate. The cutting device is arranged at the end of the machine frame, the material pushing device is placed between the conveying platform and the cutting device. The automatic pipe cutter is high in automation degree, and achieves complete automation in the processes of material taking, material pushing and cutting.

Owner:JINHUA YAHU TOOLS

Packing steel belt unwinding and cutting device

ActiveCN105364158APrevent proliferationEasy to moveShearing machinesShearing toolsRubber materialCam

The invention discloses a packing steel belt unwinding and cutting device and belongs to the field of packaging machines and equipment. The packing steel belt unwinding and cutting device comprises a horizontal movement base, a rotary supporting frame, an unwinding support and a discharging and cutting mechanism. A rotary shaft is horizontally and rotatably connected to the middle of the unwinding support. A braking mechanism is arranged on the outer side of the portion, between the unwinding support and the rotary supporting frame, of the rotary shaft. A material supporting baffle is vertically and fixedly arranged on the portion, at one side of the unwinding support, of the rotary shaft. A limiting baffle is vertically arranged on the portion, at one side of the material supporting baffle, of the rotary shaft. A limiting sleeve is arranged at the outer end of the rotary shaft. The discharging and cutting mechanism comprises a rubber material guiding roller, a discharging plate, a cutting supporting frame and a cutting cam. The discharging plate is horizontally arranged at one side of the cutting supporting frame. An upper cutting knife and a lower cutting knife are arranged on the portions, at the upper side and the lower side of a discharge outlet, of the cutting supporting frame respectively. The packing steel belt unwinding and cutting device is simple in structure and convenient to use; a packing steel belt can be rapidly and efficiently unwound and cut stably and accurately, the working efficiency of workers is improved, and the use requirements are met.

Owner:ZHEJIANG HUASHUN METAL MATERIAL CO LTD

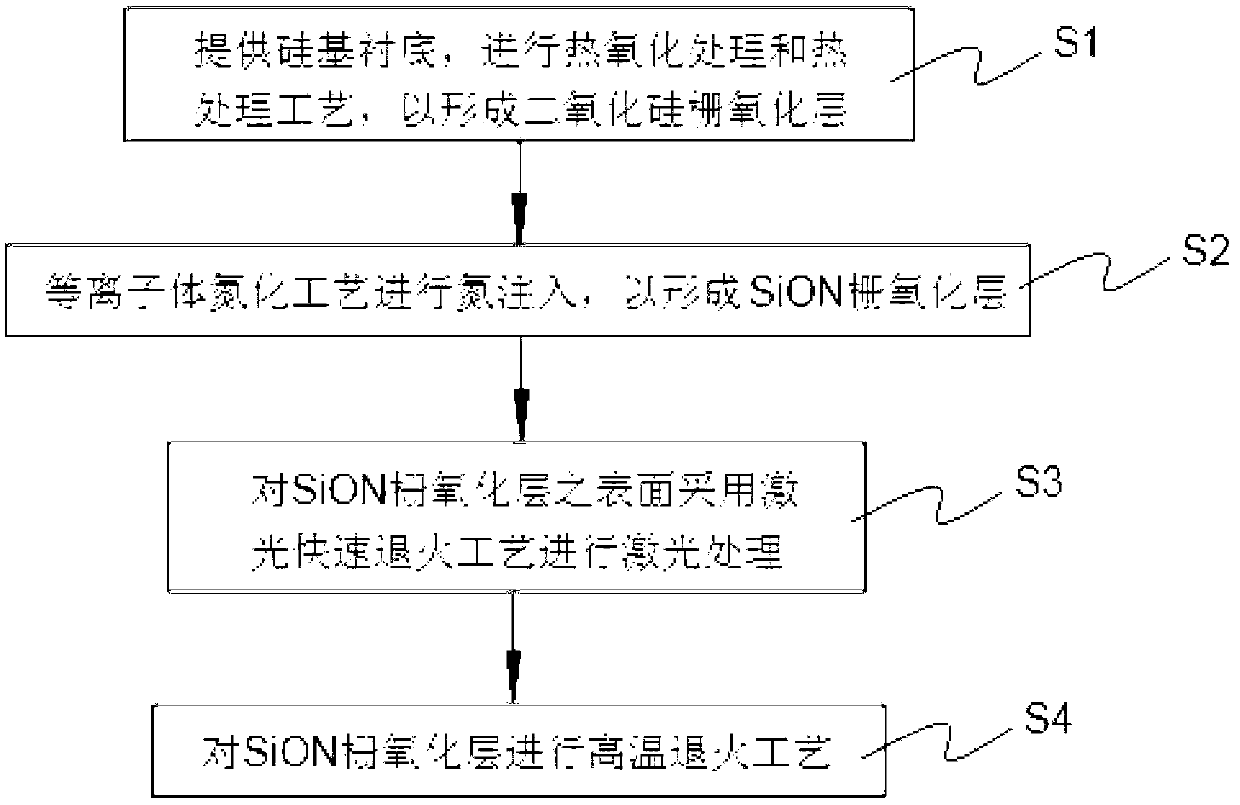

Preparation method of gate oxide

InactiveCN103346077AHigh and stable nitrogen contentPrevent volatilizationSemiconductor/solid-state device manufacturingSemiconductor devicesPlasma nitridationGate oxide

A preparation method of gate oxide includes the steps of providing a silicon substrate, conducting thermal oxidation treatment, implementing a technology for heating processing to form silicon dioxide gate oxide, conducting nitrogen injection on the silicon dioxide gate oxide by using a plasma nitriding technology to form SiON gate oxide, conducting laser treatment on the surface of the SiON gate oxide by using a laser rapid annealing technology, and conducting high temperature annealing on the SiON gate oxide with the surface being treated in a laser mode. According to the preparation method of the gate oxide, before high temperature annealing is conducted on the SiON gate oxide, the laser rapid annealing technology is introduced for conducting the laser treatment on the surface of the SiON gate oxide, an intrinsic oxide layer is removed, the bad influence of organic matter absorption on nitrogen doping is prevented, moreover, the formed non-crystallizing surface can prevent surface nitrogen atoms from volatilizing, and meanwhile the nitrogen atoms can be stopped from diffusing towards an SiO2 / Si interface. Therefore, high and stable nitrogen content can be guaranteed, accurate clipping of the dielectric coefficient of SiON gate media is achieved, and the electrical properties of devices can be effectively improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

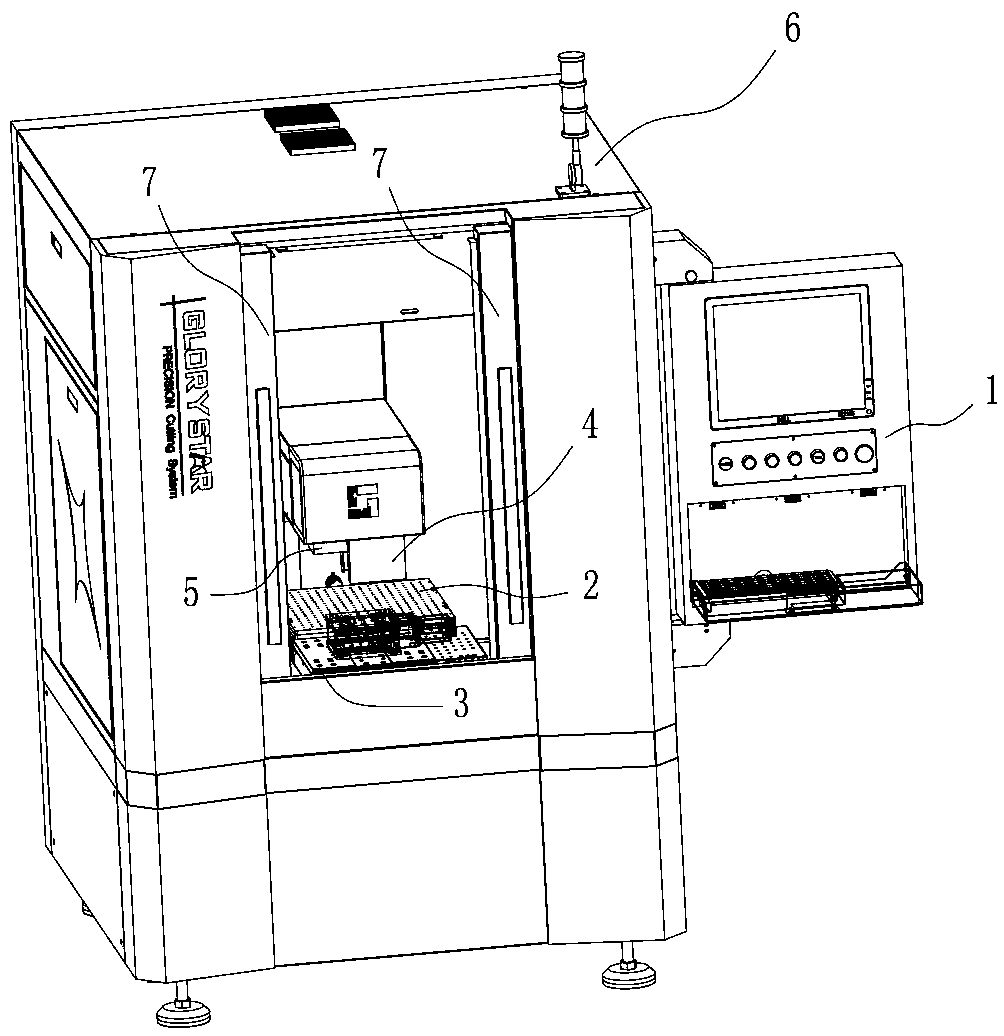

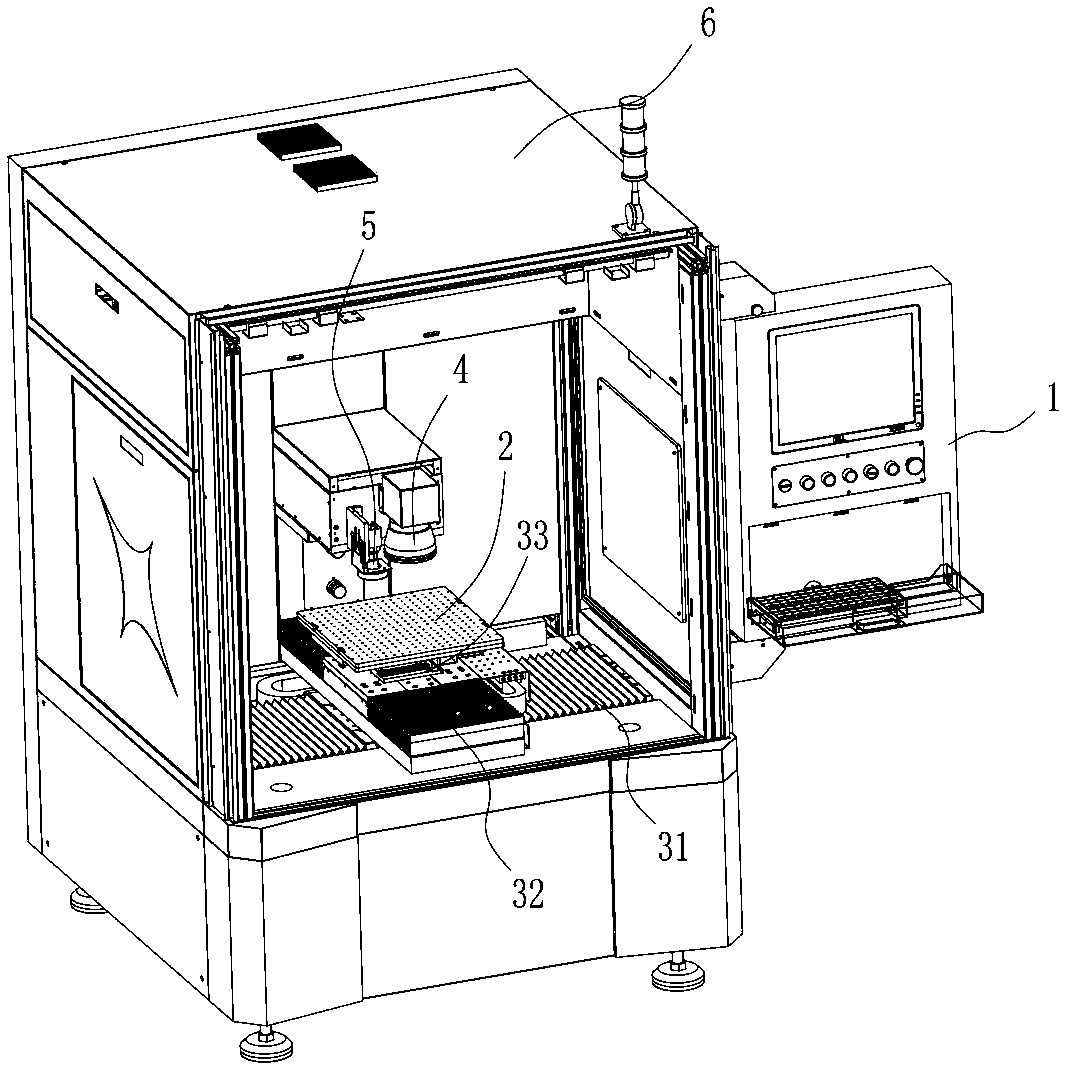

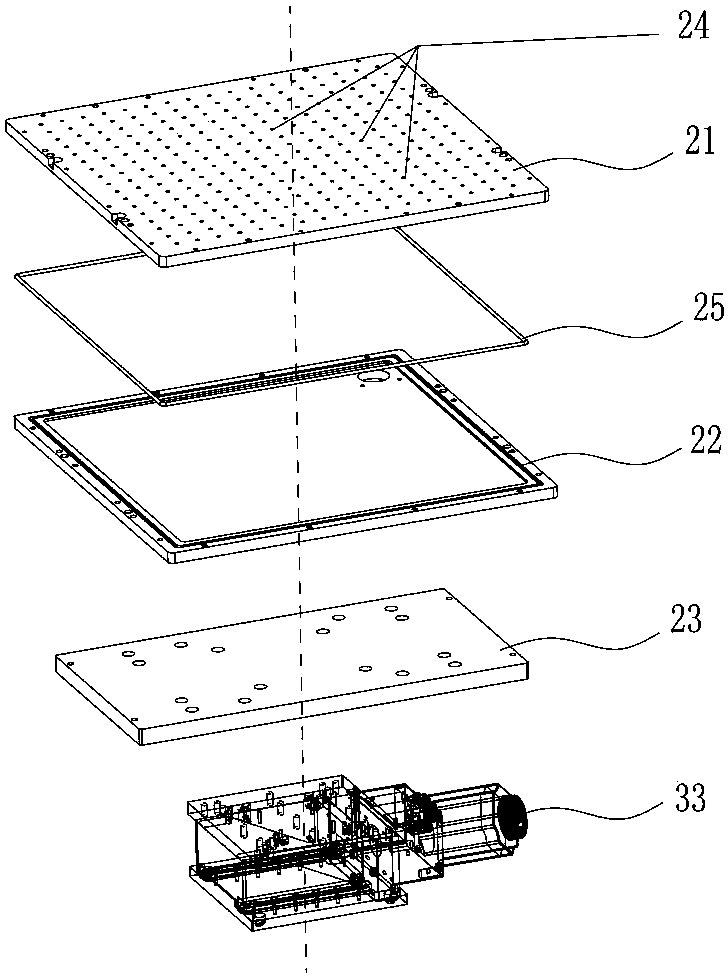

Precise laser cutting machine for thin flexible board and cutting method

PendingCN107755905ACutting stabilityFor precise cuttingLaser beam welding apparatusControl systemLaser cutting

The invention discloses a precise laser cutting machine for a thin flexible board and a cutting method. The precise laser cutting machine comprises a control system, a vacuum absorbing positioning platform, an XYZ-axis transmission system, a laser cutting system and a CCD positioning system, wherein the vacuum absorbing positioning platform, the XYZ-axis transmission system, the laser cutting system and the CCD positioning system are electrically connected to the control system; the laser cutting system is used for performing laser cutting on the thin flexible board; the CCD positioning systemis used for shooting images of a plurality of position points of the thin flexible board and transmitting to the control system; the control system is used for comparing the images of the position points of the thin flexible board with the image of a standard position point and then determining the error value; the XYZ-axis transmission system is controlled through the control system to compensate the error value during laser cutting. With the adoption of the machine, the distance from a laser cutting device to a product can be adjusted; the product can be absorbed and fixed through vacuum; the positioning error can be determined by CCD positioning; and moreover, the positioning error value can be compensated in X, Y and Z directions.

Owner:DONGGUAN GLORYSTAR LASER TECH

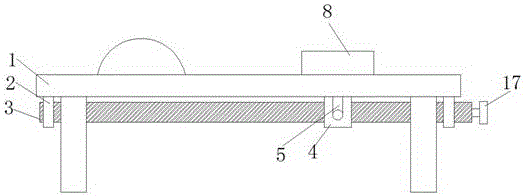

Plank cutting machine cutting plank accurately

InactiveCN107175728AThere will be no tilting of the cut surfaceFor precise cuttingProfiling/shaping machinesEngineeringScrew thread

The invention discloses a plank cutting machine cutting a plank accurately. The plank cutting machine comprises a cutting machine body. A bearing is fixedly mounted at the bottom of a holding plate of the cutting machine body. A threaded rod is arranged on the lower portion of the holding plate of the cutting machine body. The inner wall of the bearing is fixedly connected with the outer surface of the threaded rod. A nut is in threaded connection with the outer surface of the threaded rod. The outer surface of the nut is fixedly connected with one end of a connecting rod. A sliding groove is formed in a top plate of the cutting machine body. A sliding block is slidably mounted in the sliding groove. By arranging the threaded rod, the nut and the connecting rod, when the threaded rod rotates, the nut is driven to move and drives the sliding block to move through the connecting rod when moves, thus a movable block is driven to move and drives the plank fixed to a fixing block to move when moves, and then the plank is cut; and due to the limitation of the sliding groove, the plank is cut more accurately, and the situation of inclined cut faces is avoided.

Owner:赵咪咪

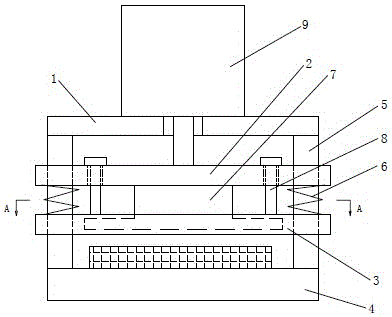

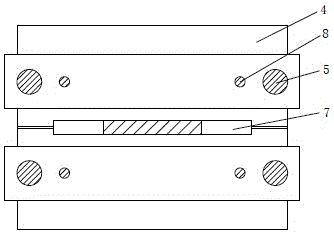

Sponge pressing cutting mechanism

InactiveCN105128049AAvoid deformationAvoid wastingMetal working apparatusEngineeringMechanical engineering

The invention discloses a sponge pressing cutting mechanism and belongs to the field of sponge cutting equipment. The sponge pressing cutting mechanism comprises a fixed frame. A cutter fixing plate, a pressing plate and a table top for placing sponge are arranged on the fixed frame from top to bottom. The table top is provided with four guide pillars penetrating the cutter fixing plate and the pressing plate, and the guide pillars between the cutter fixing plate and the pressing plate are sleeved with springs. The cutter fixing plate is provided with a cutter, and the pressing plate is provided with an opening for the cutter to pass. A limiting screw penetrates the cutter fixing plate, the threaded end of the limiting screw extends out of the cutter fixing plate and is fixedly connected with the pressing plate, the fixed frame is provided with an oil cylinder, and a piston rod of the oil cylinder is connected with the cutter fixing plate. The cutter performs cutting stably downwards while the goal of fixed pressing is achieved, sponge deformation is limited to a certain limit, the cutting is accurate, the rate of finished products is improved, and the raw material waste is avoided.

Owner:CHENGDU DUOLIDUO NEW MATERIAL

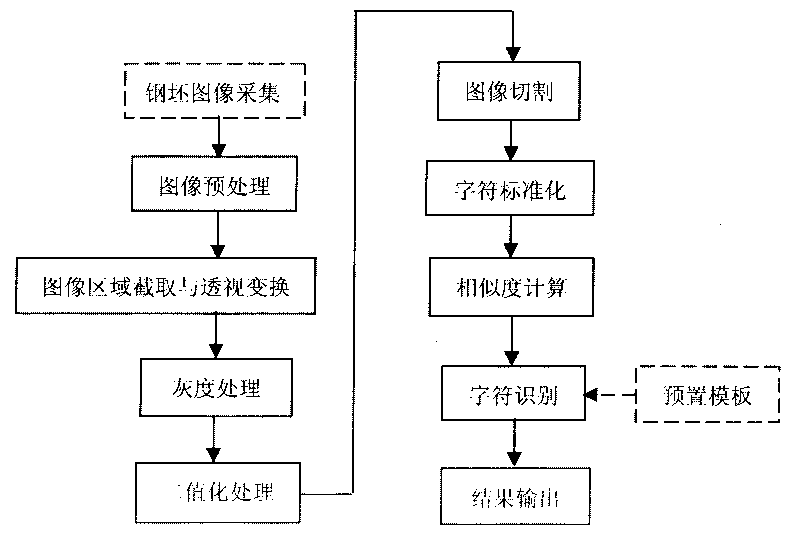

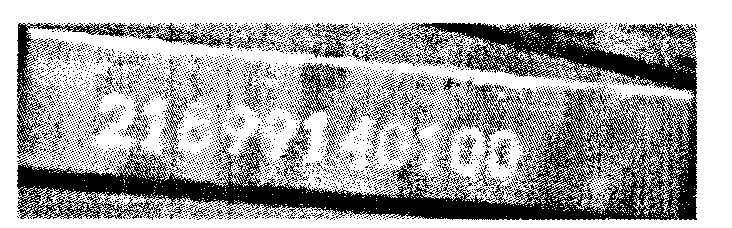

Method for automatically identifying number of steel billet

InactiveCN101739556AFor precise cuttingEfficient cuttingCharacter and pattern recognitionDegree of similarityComputer science

The invention discloses a method for automatically identifying the number of a steel billet in the technical field of character identification, which comprises the following steps: (1) preprocessing an image; (2) intercepting the area of the number of the steel billet and carrying out perspective collineation; (3) performing gray scale processing on the image; (4) processing by binarization; (5) cutting a numerical symbol; (6) standardizing a character; (7) calculating the degree of similarity and identifying the character; and (8) judging whether the number of the steel billet is mistaken or not. The invention can realize the overall process of the automatic identification and control of the number of the steel billet in an on-line way and has the following obvious technical advantages: (1) the cutting of the character is accurate and effective, and the cutting error rate is smaller than 0.1%; and (2) the identification of the character is accurate and quick, the identifying precision ratio reaches 100%, and the operation period of the identification of the number of the entire steel billet does not exceed 100ms.

Owner:SHANGHAI JIAO TONG UNIV

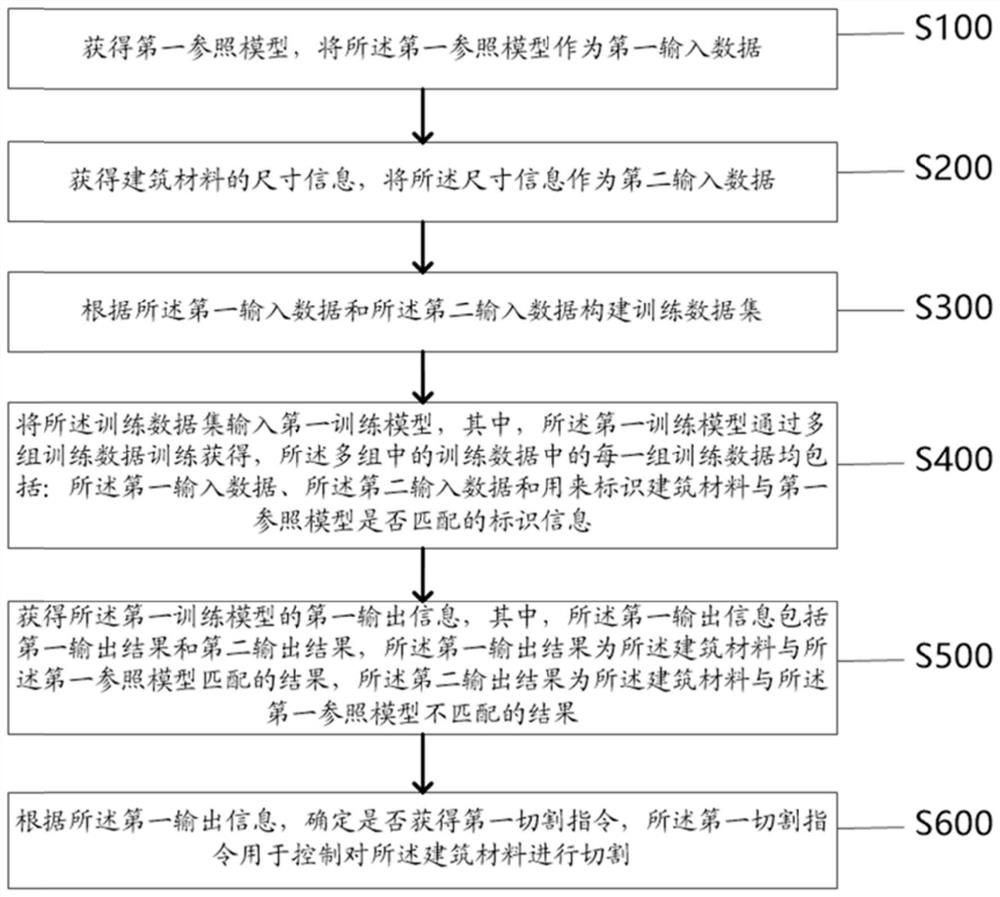

Energy-saving and environment-friendly building construction method and device

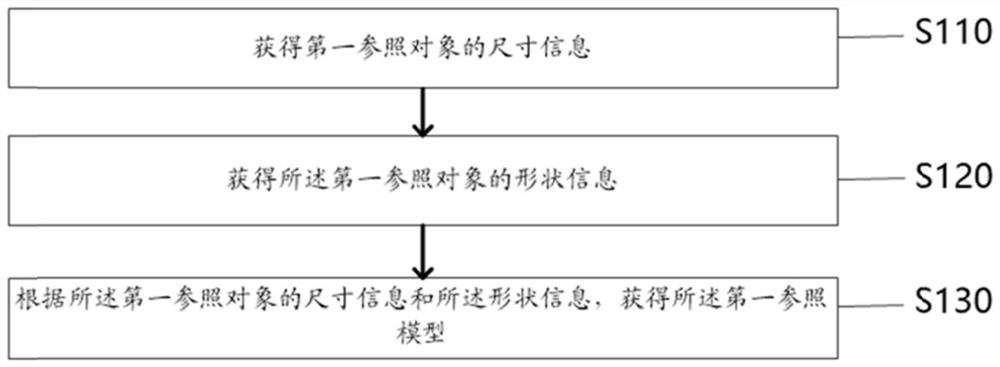

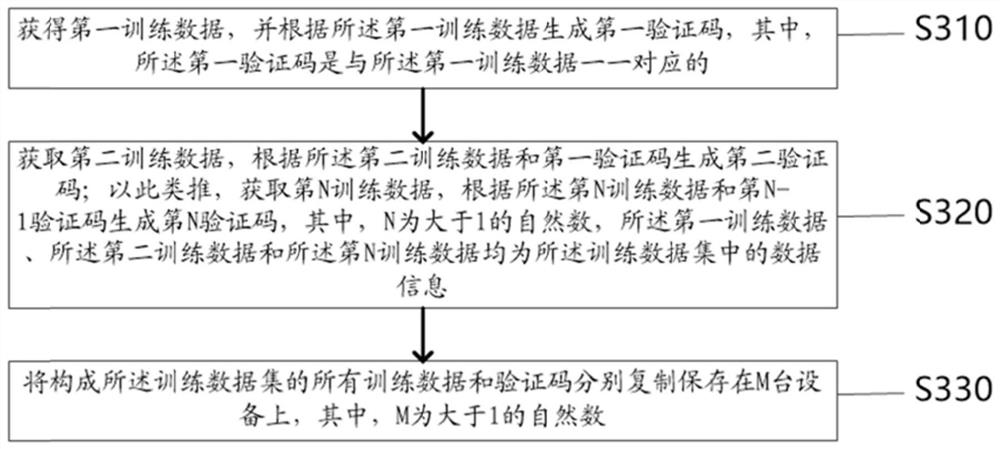

ActiveCN111951128AFor precise cuttingSave materialData processing applicationsCharacter and pattern recognitionReference modelData set

The invention discloses an energy-saving and environment-friendly building construction method. The method comprises the following steps: obtaining a first reference model, and taking the first reference model as first input data; obtaining building material size information, and taking the size information as second input data; constructing a training data set according to the first input data and the second input data; inputting the training data set into a first training model; obtaining first output information of the first training model, the first output information comprising a first output result and a second output result, the first output result being a result of matching the building material with the first reference model, and the second output result being a result of matchingthe building material with the second reference model; wherein the second output result is a result that the building material is not matched with the first reference model; according to the first output information, determining whether a first cutting instruction is obtained or not, and using the first cutting instruction to control the cutting of the building material. The technical effects ofaccurately cutting building materials, saving the building materials and protecting the environment are achieved.

Owner:IANGSU COLLEGE OF ENG & TECH

Slitting and feeding device for row straw

The invention discloses a slitting and feeding device for a row straw. A pineapple head and a collector are rotatably positioned on a rack; the outer side of the circumference of the pineapple head is provided with a plurality of straw containing slots and cutter slots at an interval; the outer side of the circumference of the collector is provided with a plurality of straw collection slots; the opening of the straw containing slot between the feeding end and the discharging end of the pineapple head can be covered by a material blocking device; a first cutter can extend into the cutter slot of the pineapple head to cut off the row straw; the cut-off row straws on the discharging side of the pineapple head can be sent into the straw collection slots of the collector by a material guide device; a push rod is positioned on the rack; the straws in the straw collection slots of the collector can be pushed out of the straw collection slots by the push rod; the pineapple head, the collector, the first cutter and the push rod are respectively driven by a first driving device, a second driving device, a third driving device and a fourth driving device to move; the first driving device, the second driving device, the third driving device and the fourth driving device are controlled by a controller to act. According to the slitting and feeding device for the row straw, which is disclosed by the invention, the straw can be fully-automatically slit and conveyed, manpower is saved, slitting can be accurately carried out, and the packaging quality is guaranteed.

Owner:KUSN FASTEC MACHINERY

Cutting machine

InactiveCN101585163AAvoid frequent and unevenFor precise cuttingGrinding machinesElectric machinerySprocket

The invention provides a cutter, which includes a frame, a workstation equipped thereon, a fixed panel equipped on the back side, a material clamping base equipped on the workstation; a upper and a lower support connected in a pivoted connection, wherein, the lower support is fixed above the workstation; the upper panel is connected above the support saddle; a upper panel connected to the upper support, a variable-depth adjustment mechanism, a cutting device, a feeding mechanism and a controlling mechanism. During processing, the material rod is installed on the material clamping base foot firstly, and is hanged with heavy in the slideway, one end of the material rod is installed in the clamping foot. Abrasion wheel pieces are installed according to standards and nuts are fastened. The cutting electric motor is started to drive the abrasion wheel pieces to rotate, and then the main electric motor is started for cutting. The main electric motor drives the speed-changing box, and then the speed-changing box drives the driving shaft to rotate by the sprocket chain. When the abrasion wheel piece cuts and returns, the movable clamping foot looses and the material rod protrudes, and then the movable clamping foot clamps again for cutting.

Owner:PINGHU HAITE ALLOY

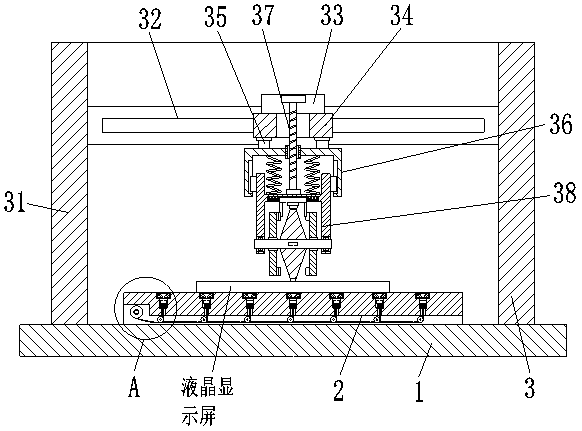

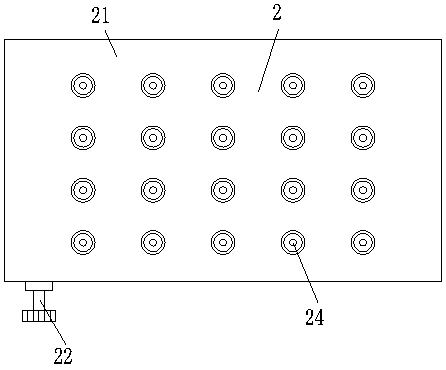

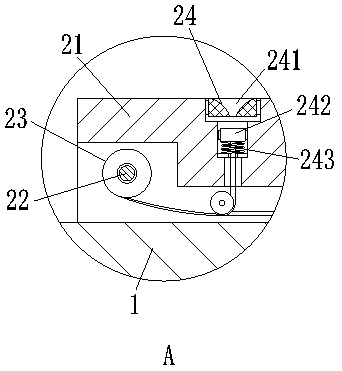

Mobile phone liquid crystal display screen cutting device

ActiveCN110789006AEffective support and fixationAvoid displacementWorking accessoriesStone-like material working toolsLiquid-crystal displayEngineering

The invention relates to a mobile phone liquid crystal display screen cutting device. The mobile phone liquid crystal display screen cutting device comprises a bottom plate, a bearing frame and a cutting device. The bearing frame is installed in the middle of the upper end of the bottom plate. The cutting device is arranged above the bearing frame and installed on the bottom plate. The mobile phone liquid crystal display screen cutting device can solve the problems that: in the prior art, when a liquid crystal display screen is cut, the pressure adjusting effect between a cutting knife wheel and the liquid crystal display screen is poor, adjustment is inconvenient, the phenomenon that the liquid crystal display screen is broken easily due to the fact that the pressure is too large during cutting is caused, and waste of the liquid crystal display screen is caused easily; and in addition, when the equipment in the prior art cuts the liquid crystal display screen, glass fragments adheringto the surface of the cutting knife wheel cannot be cleaned usually, the phenomenon that the glass fragments are broken easily in the cutting process is caused, the regularity of notches is affected,and subsequent use of the liquid crystal display screen is affected.

Owner:深圳市弗塔信息技术有限公司

Intelligent aluminum cutting device

InactiveCN104439503ACompact structureLow manufacturing costMetal sawing devicesMetal sawing accessoriesAluminiumEngineering

An intelligent aluminum cutting device comprises a base, wherein a slide rail is arranged on the upper portion of the base, a sliding plate is arranged on the upper portion of the slide rail and can slide on the slide rail, a protection plate is arranged on the upper portion of the sliding plate, a nut is arranged on one side of the sliding plate, a motor frame is arranged at one end of one side of the base, a stepping motor is arranged on the motor frame, a threaded rod is arranged on an output shaft of the stepping motor and matched with the nut, and a support is installed on one side of the middle of the base. By means of the intelligent aluminum cutting device, the positions of cut aluminum parts can be adjusted in the aluminum part cutting process. The stepping motor can drive the sliding plate to freely slide on the slide rail through the cooperation of a lead screw and the nut, and therefore the positions of the aluminum parts can be adjusted when the aluminum parts are cut through the intelligent aluminum cutting device, and the aluminum parts can be accurately cut through the intelligent aluminum cutting device.

Owner:CHANGSHU YULI MACHINERY

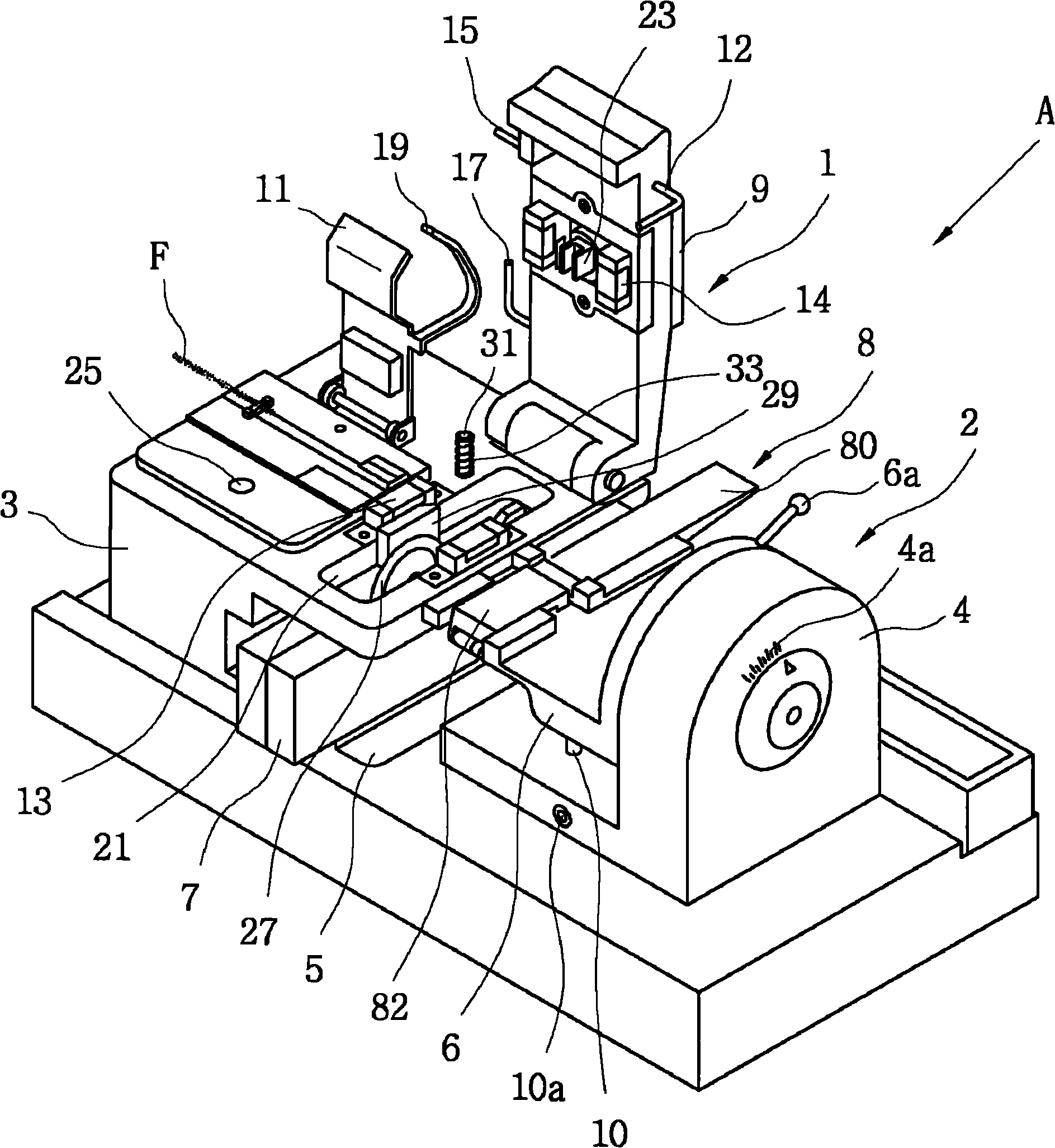

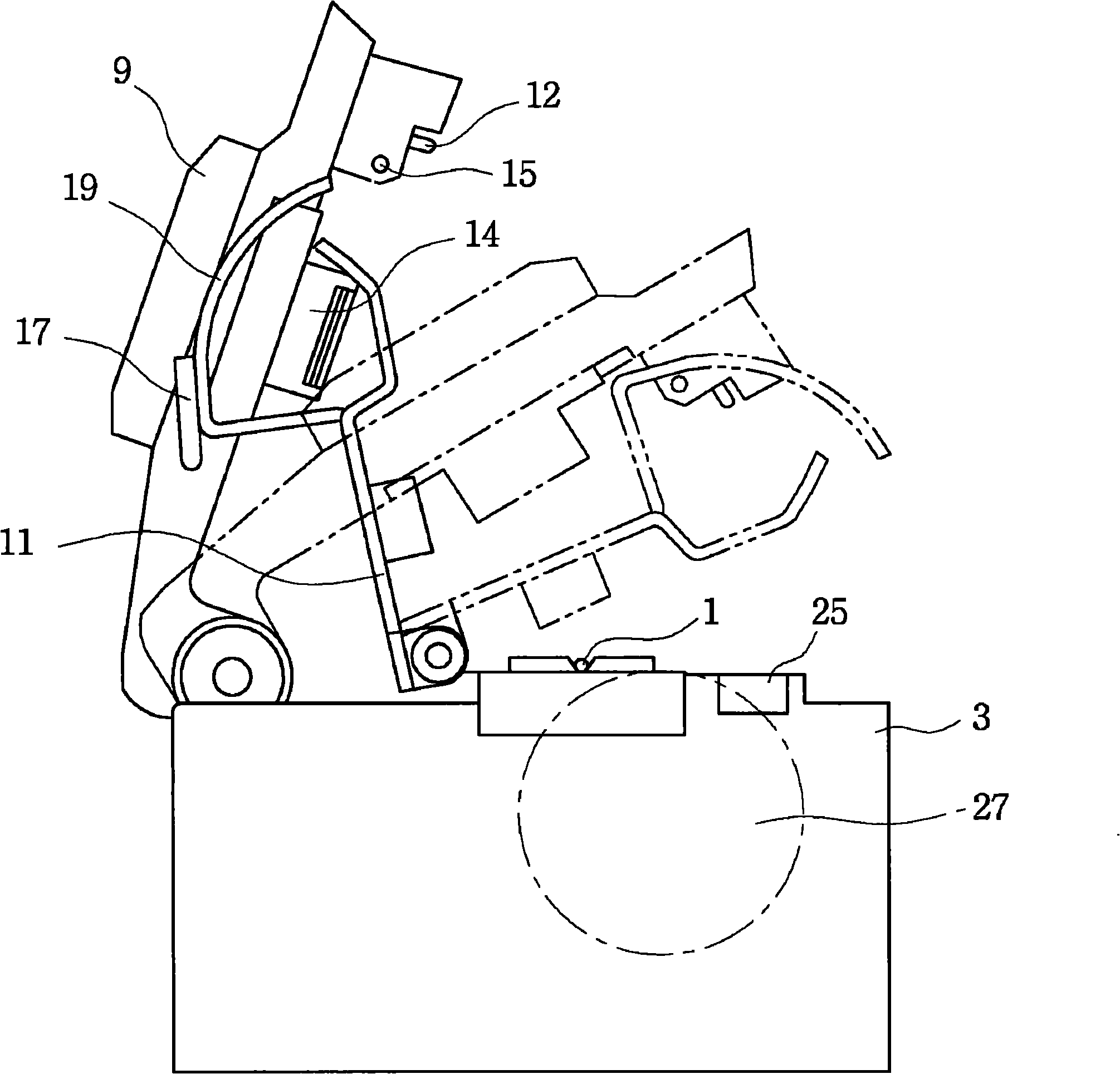

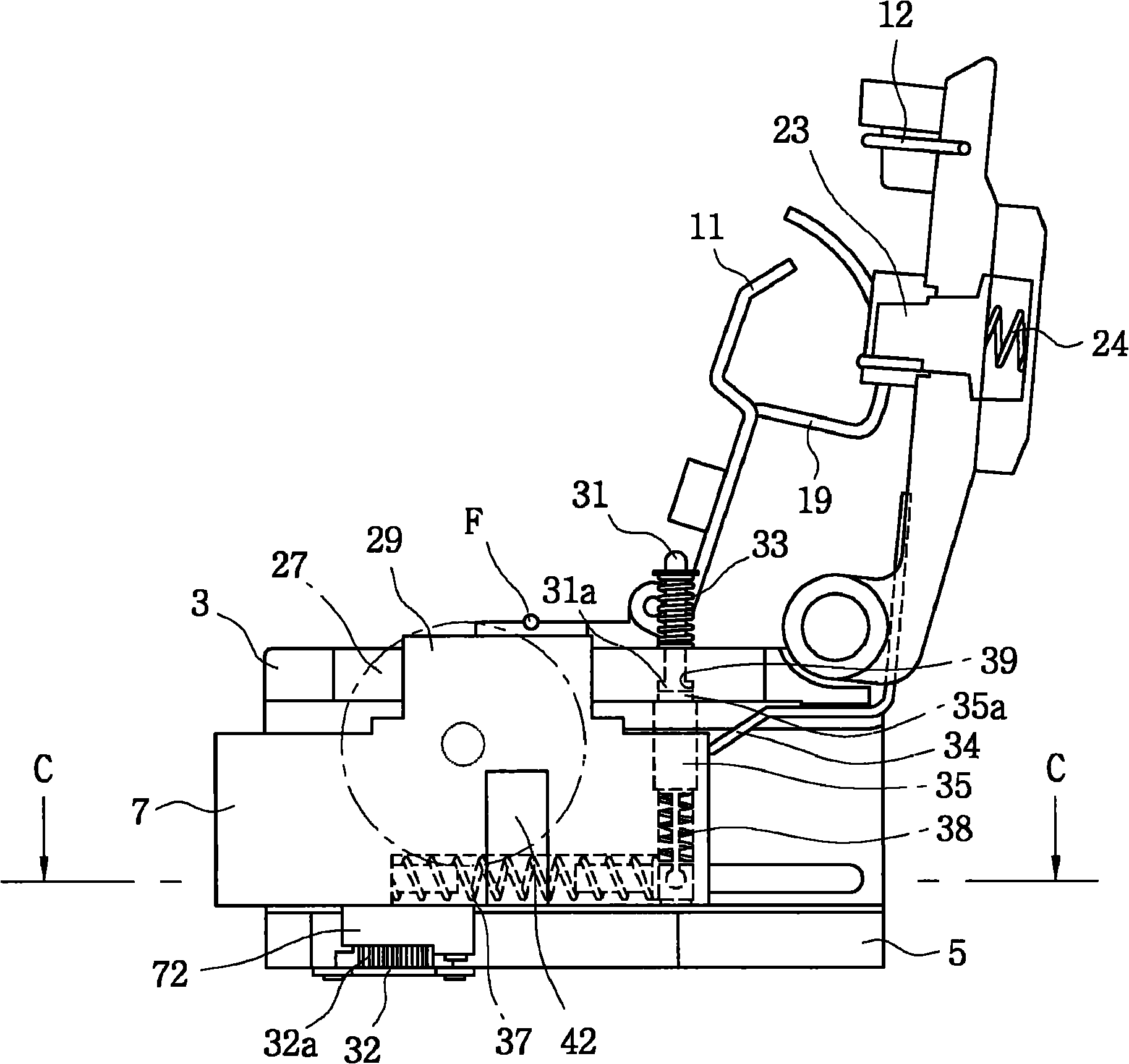

Optical fiber cleaver

InactiveCN102152325AReliable clampingPrecisely Cut SectionsGlass making apparatusCoupling light guidesEngineeringOptical fiber cable

An optical fiber cleaver is disclosed. The optical fiber cleaver of the invention moves a slide block (7) by the elastic force of an elastic member, and scores the optical fiber by a blade (27) in the slide block (7). The optical fiber cleaver comprises a damper (32) which is used for buffering the moving speed of slide block (7) under elastic force of the elastic member to cause the moving speed of the slide block (7) to approach a constant speed.

Owner:ILSIN TECH CO LTD

Sheet film laminating machine

PendingCN105922709AHigh positioning accuracyIncrease production capacityLaminationLamination apparatusSheet filmChassis

The invention discloses a sheet film laminating machine. The sheet film laminating machine comprises a bottom frame, a touch screen, a conveying belt, a guide mechanism, a feeding sensor, pressing wheels, sensors, a material blocking mechanism, a laminating rubber roller, a discharging drum, automatic pressing wheels, a shearing sensor, a shearing blade and a servo motor. An electric cabinet is installed inside the bottom frame, the conveying belt is arranged on the upper portion of the bottom frame, the servo motor is arranged on the rear part of the bottom frame, and the guide mechanism, a warping preventing mechanism, a discharging mechanism, the laminating rubber roller, the front pressing wheel set, a shearing mechanism and the automatic pressing wheels are arranged across the upper portion of the conveying belt and connected with a front frame and a rear frame of the bottom frame in a screwed mode. The feeding sensor is arranged on the guide mechanism, and the warping preventing mechanism and the pressing wheels are arranged in front of the discharging mechanism. According to the sheet film laminating machine, the sensors are used for detecting the positions of plates and the film laminating length, starting and ending of film laminating are automatically judged, the shearing blade automatically judges the position of a gap, the film laminating position precision is high, the dimension among the film-laminated plates is stable, the length of incoming materials is not distinguished, and automatic arranging and automatic shearing are achieved.

Owner:KUNSHAN HENGXU AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com