Steel pipe and section steel blanking production line

A production line and steel pipe technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of low work efficiency and complicated operation, and achieve the effect of simple loading and unloading and precise cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

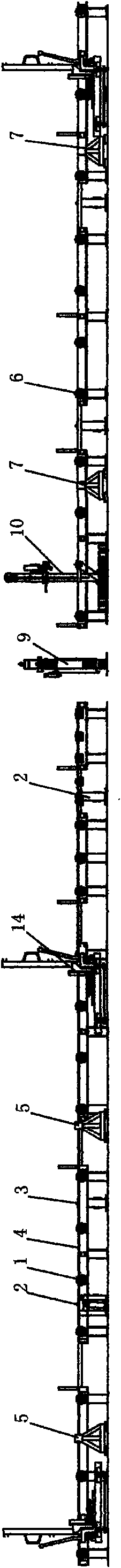

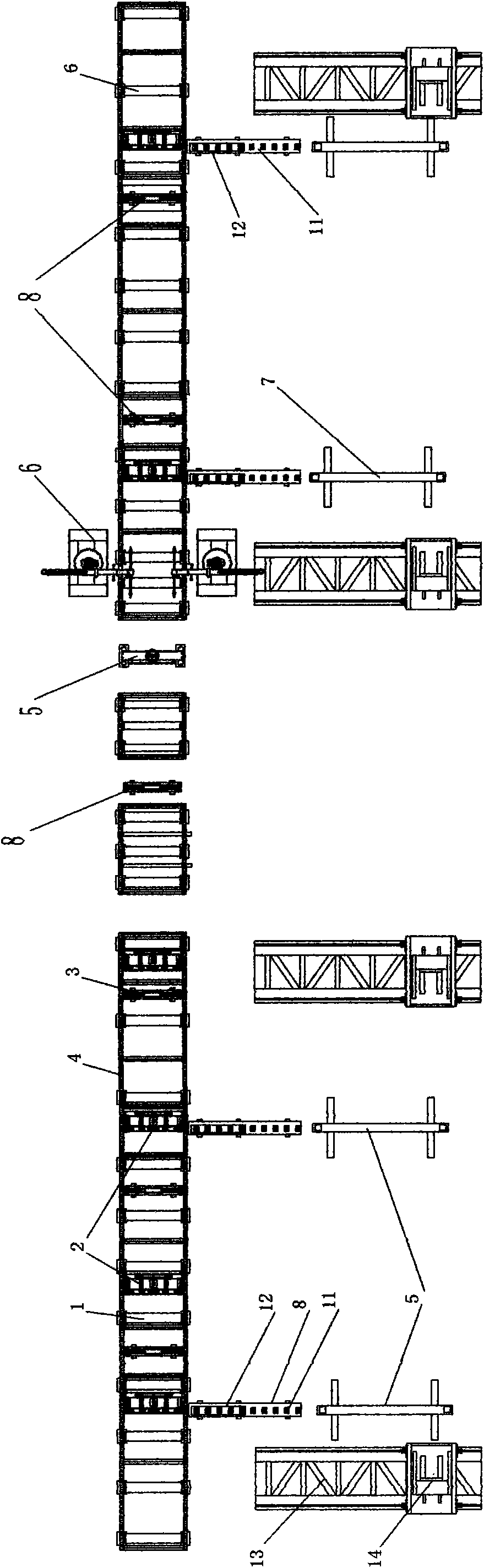

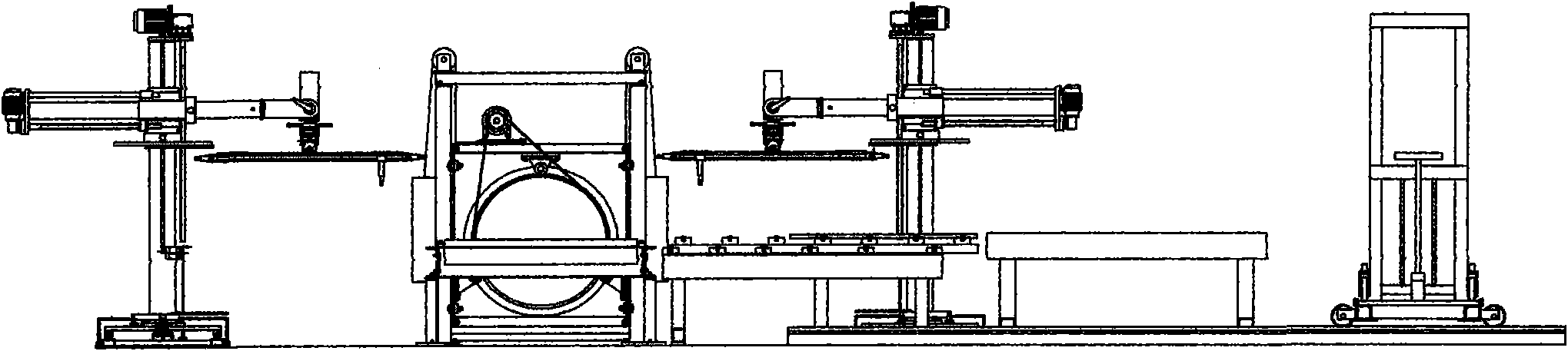

[0026] A steel pipe and section steel blanking production line, the production line includes a feed line, a discharge line, and steel pipe and section steel processing devices 9, 10; the feed line includes a feed roller table 1, a hydraulic lifting roller table 2 and Steel pipe hydraulic lifting roller table 3, a steel scale is provided on the feeding rack 4 of the feeding roller table 1, a positioning block is provided at the zero point of the steel ruler, and at least one set of feeding lines is provided on one side of the feeding roller table 1, The feeding line includes a sliding feeding device, a raw material conveying device and a raw material storage device 5; the discharging line is provided with a discharging roller table 6, a hydraulic lifting roller table 2 and a steel pipe hydraulic lifting roller table 3, One side of the material roller table 6 is provided with at least one set of unloading lines, and the unloading line includes a sliding discharge device, a workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com