Patents

Literature

91results about How to "Achieve the purpose of cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

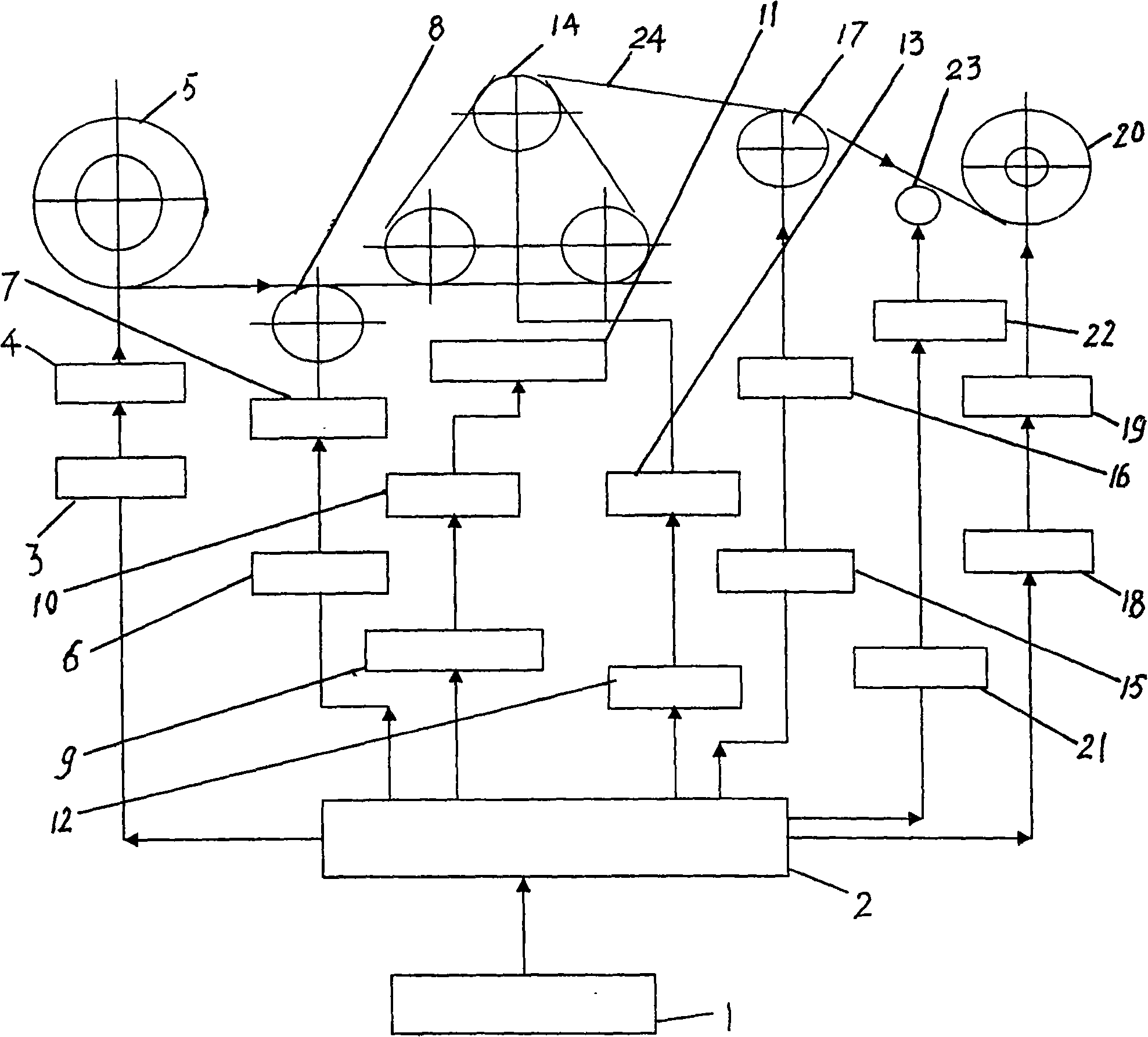

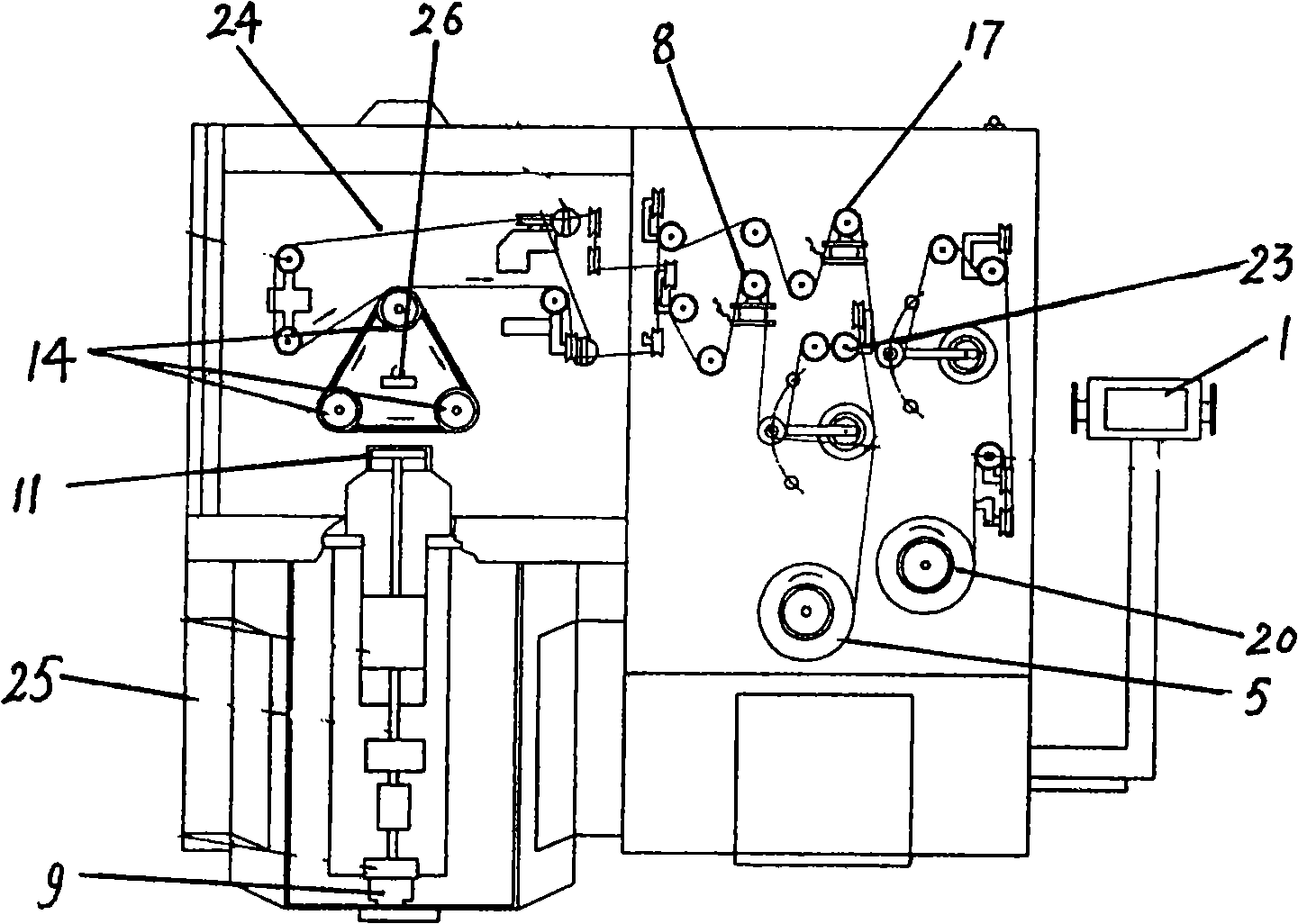

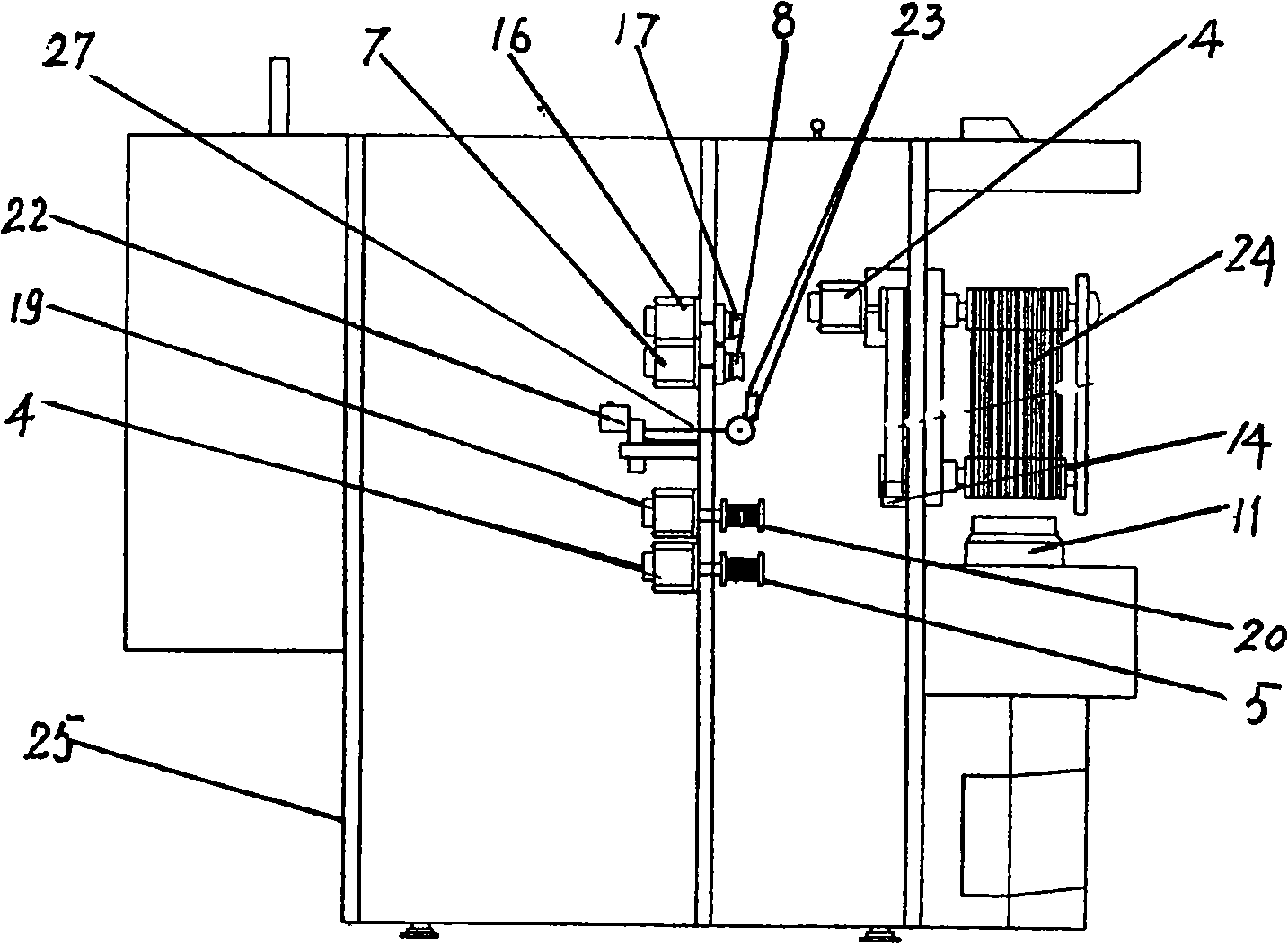

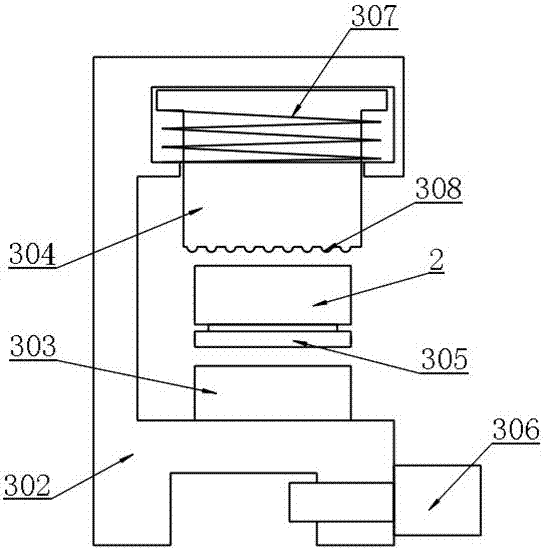

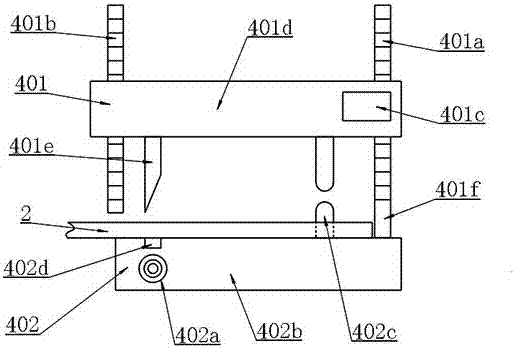

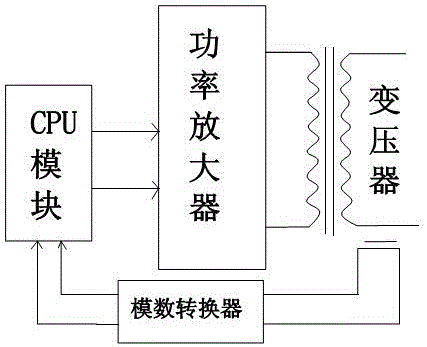

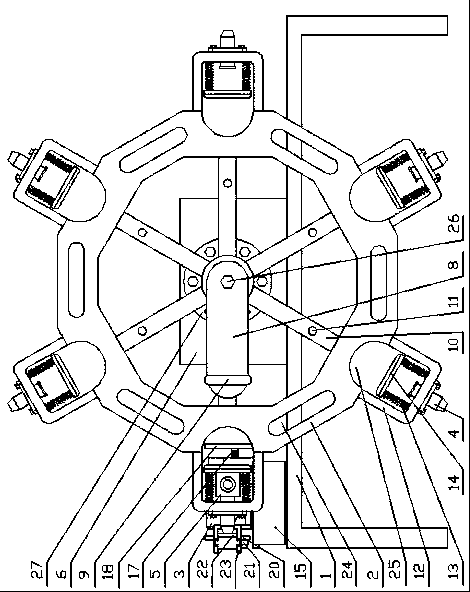

Microcomputer control multiline cutting machine

InactiveCN101301734AConstant tensionAchieve the purpose of being cutGrinding machinesFine working devicesAudio power amplifierWire wheel

The invention provides a micro-computer control multi-wire cutting machine, comprising a frame, a worktable, a metal wire, and a grinding lubricant supply mechanism; the control part of the micro-computer control multi-wire cutting machine adopts the programming of a main substrate to control a CPU module; the parameters of the CPU module are set by a touch display; furthermore, a servo amplifier is controlled by optical fibres; the servo amplifier controls a servo motor; a frame is internally provided with at least six servo amplifiers and six servo motors which respectively control the lifting of the worktable; the micro-computer control multi-wire cutting machine also comprises three rotation rollers, a wiring wheel, a wiring tensioning sensor, a stranding wheel, and a stranding tensioning sensor; the grinding lubricant supply mechanism leads out an emery liquid injection pipe; the outlet of the emery liquid injection pipe is in the middle of an isosceles triangle which is presented by three rotation rollers; the metal wire extends from wiring wheel passing through the wiring tensioning sensor and winding parallel hundreds of rounds on three rotation rollers to form a cut surface, the main substrate programming controls the CPU module so as to control the rotation / direction of the servo motors, thus leading the rotation rollers, stranding wheel and wiring wheel to reciprocate to rotate. The micro-computer multi-wire cutting machine has high cutting precision and working efficiency.

Owner:乐清市新晶电子器件有限公司 +1

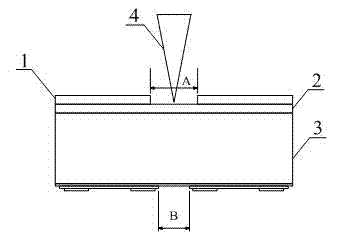

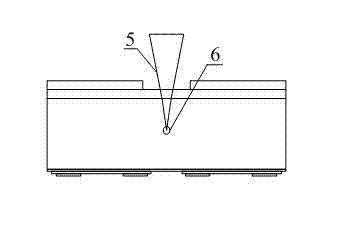

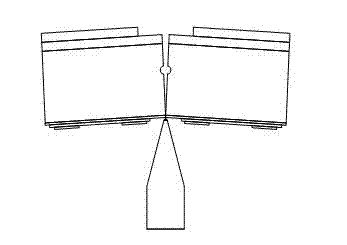

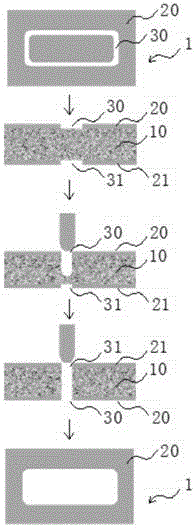

Laser machining method for matching with light-emitting diode (LED) inner cutting process

InactiveCN102500933AAchieve the purpose of cuttingAdjustable widthLaser beam welding apparatusLaser processingWafer

The invention relates to a laser machining method for matching with a light-emitting diode (LED) inner cutting process. According to the laser machining method, metal reflecting films or distributed Bragg reflecting films or double-layer reflecting films which consist of the metal reflecting films and the distributed Bragg reflecting films are distributed on the reverse side of a wafer; laser is focused to the reflecting films, and laser beams and the wafer make relative motion, so that the single-layer reflecting films or one layer or two layers of double-layer reflecting films are removed by gasifying to form a groove; a central line of the groove aligns with that of a cutting way on the front of the wafer; and in the inner cutting process, inner cutting laser is focused inside the wafer by the groove to form an internal crack area and form a linear array along the cutting direction, and pressure is exerted on the cutting way on the front of the wafer, so that the wafer is cracked along the set cutting direction. The method is matched with the inner cutting process to cut the LED wafer, so the method has the characteristics of high speed, high accuracy, small damage to the surface of sapphire and the like.

Owner:SUZHOU DELPHI LASER

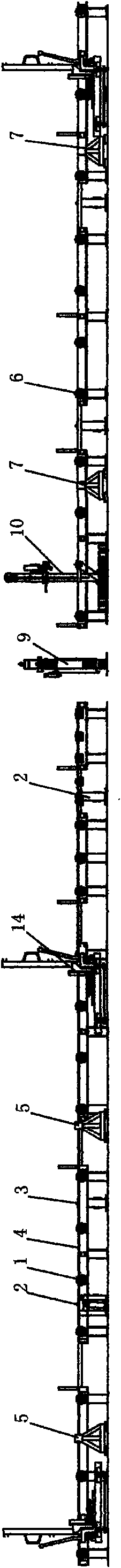

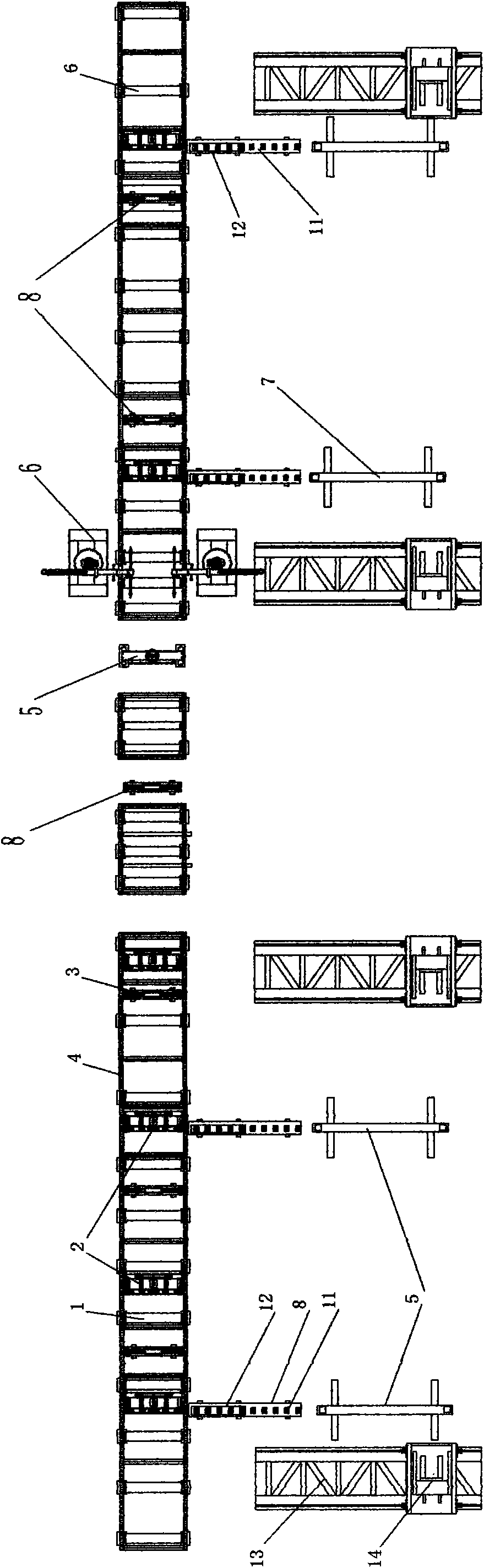

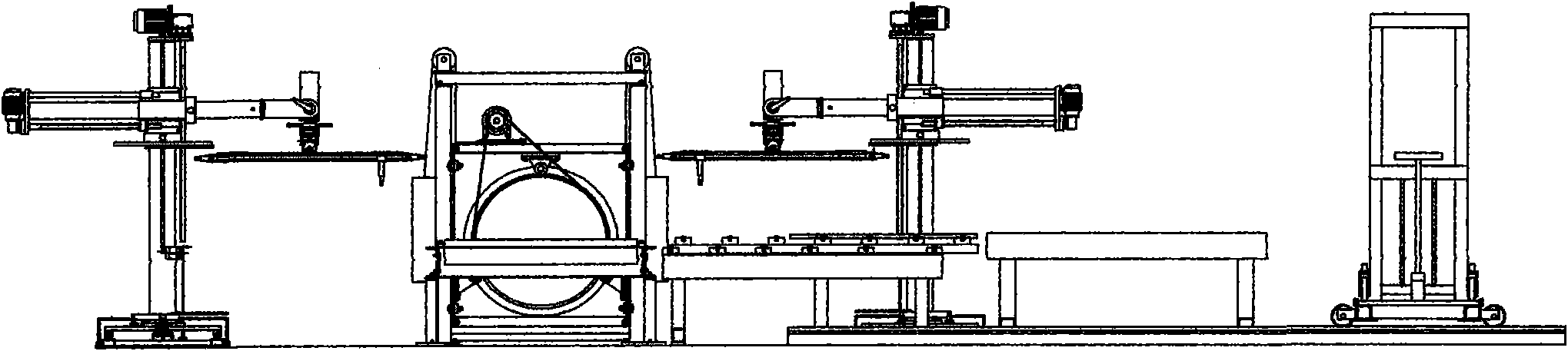

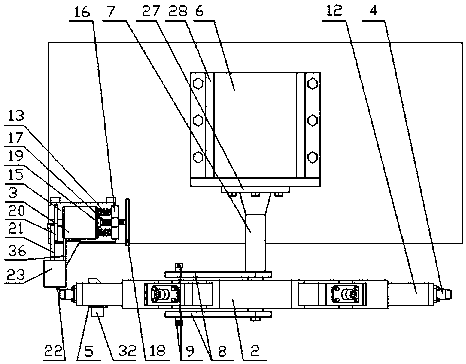

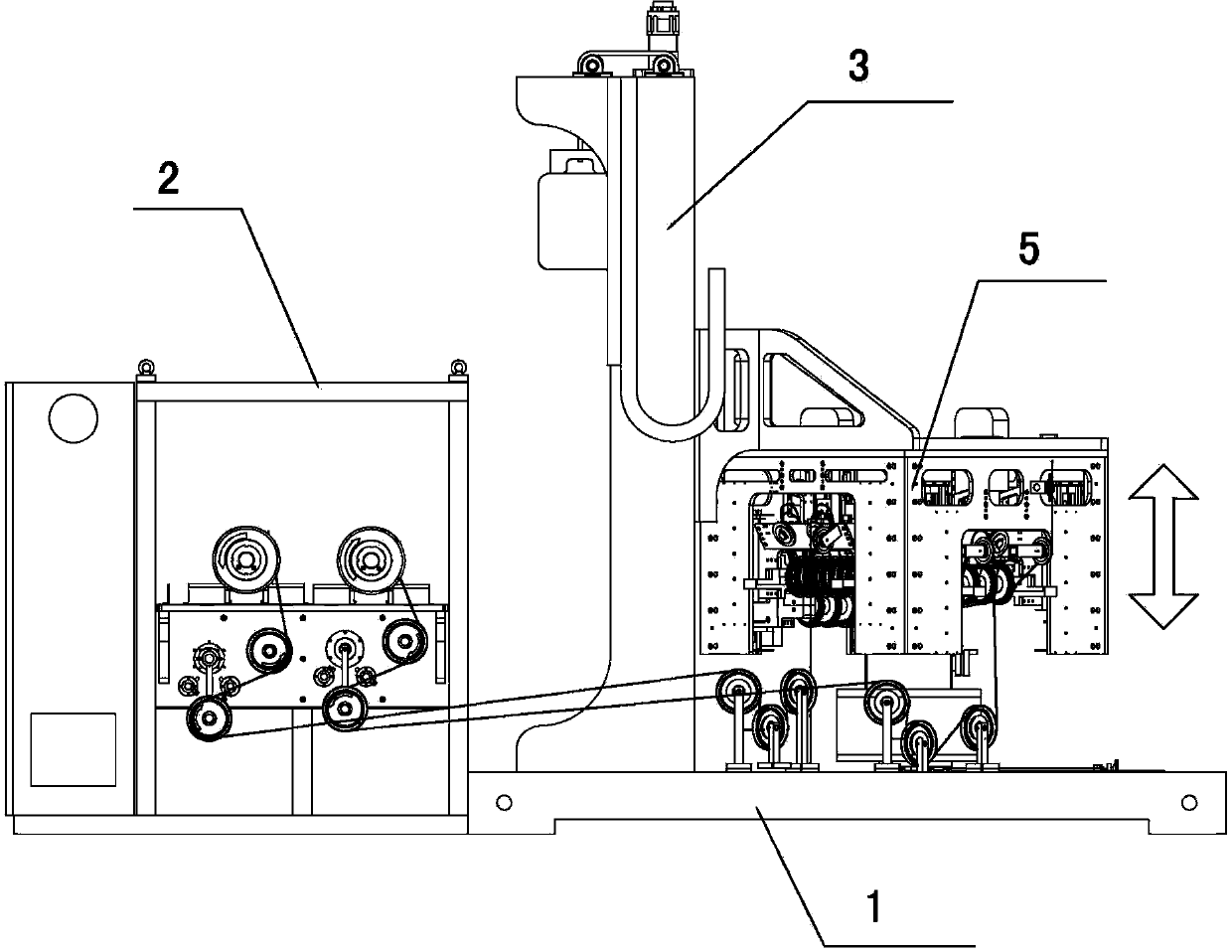

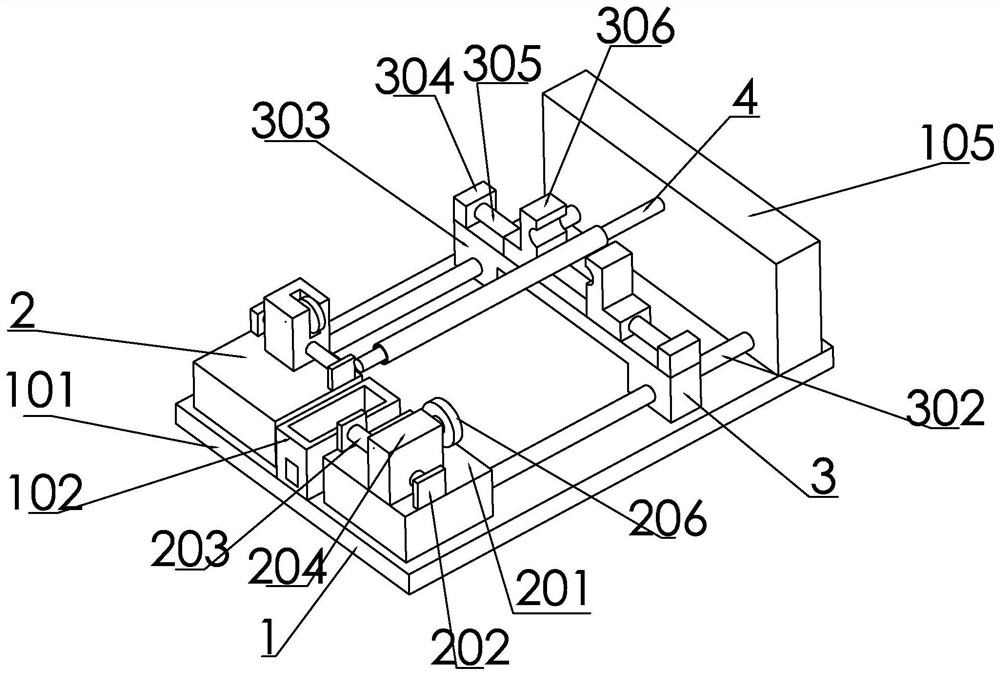

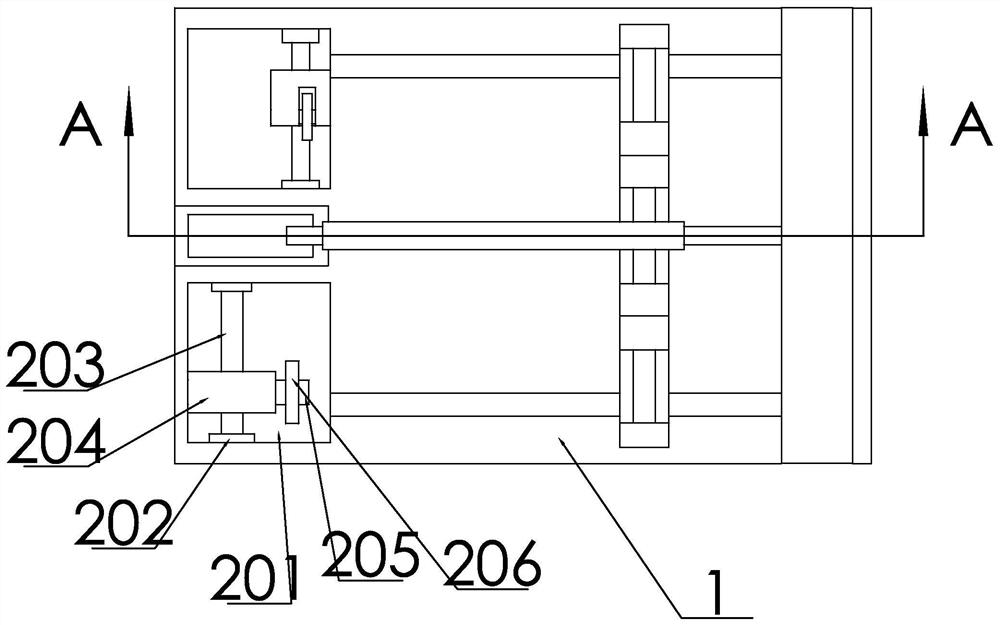

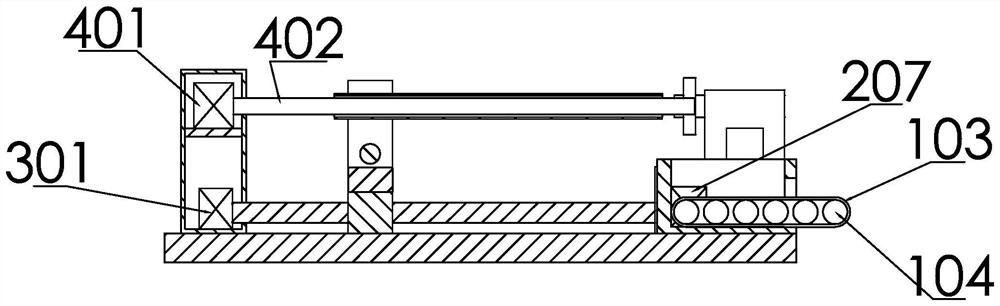

Steel pipe and section steel blanking production line

InactiveCN102284766ASimple loading and unloadingPrecise cuttingGas flame welding apparatusSteel platesSteel tube

The invention relates to a steel pipe and section steel blanking production line. The production line includes a feed line, a discharge line, and a steel pipe and section steel processing device; the feed line includes a feed roller table, a hydraulic lifting roller table, and a steel pipe hydraulic pressure Lifting roller table, a steel scale is arranged on the feeding frame of the feeding roller table, a positioning block is provided at the zero point of the steel scale, and at least one set of feeding lines is provided on one side of the feeding roller table, and the feeding line It includes a sliding feeding device, a raw material conveying device and a raw material storage device; the discharge line is provided with a discharge roller table, a hydraulic lifting roller table and a steel pipe hydraulic lifting roller table, and one side of the discharge roller table is provided with at least one A group of blanking lines, the blanking line includes a sliding discharge device, a processed part delivery device and a processed part storage device The present invention is provided with a steel ruler on the material delivery frame, and a positioning block is arranged at the zero point of the steel ruler, and the cut material Standing on the zero point, the steel ruler on the transport rack can quickly determine the size of the material to be cut, accurate, fast, and error-free; the hydraulic lifting roller table of the steel pipe can be raised when cutting the steel pipe, and the steel pipe can rotate to achieve the purpose of cutting; The invented production line can cut both steel pipe and H steel, with simple, fast loading and unloading, and accurate cutting.

Owner:QINGDAO EAST STEEL TOWER

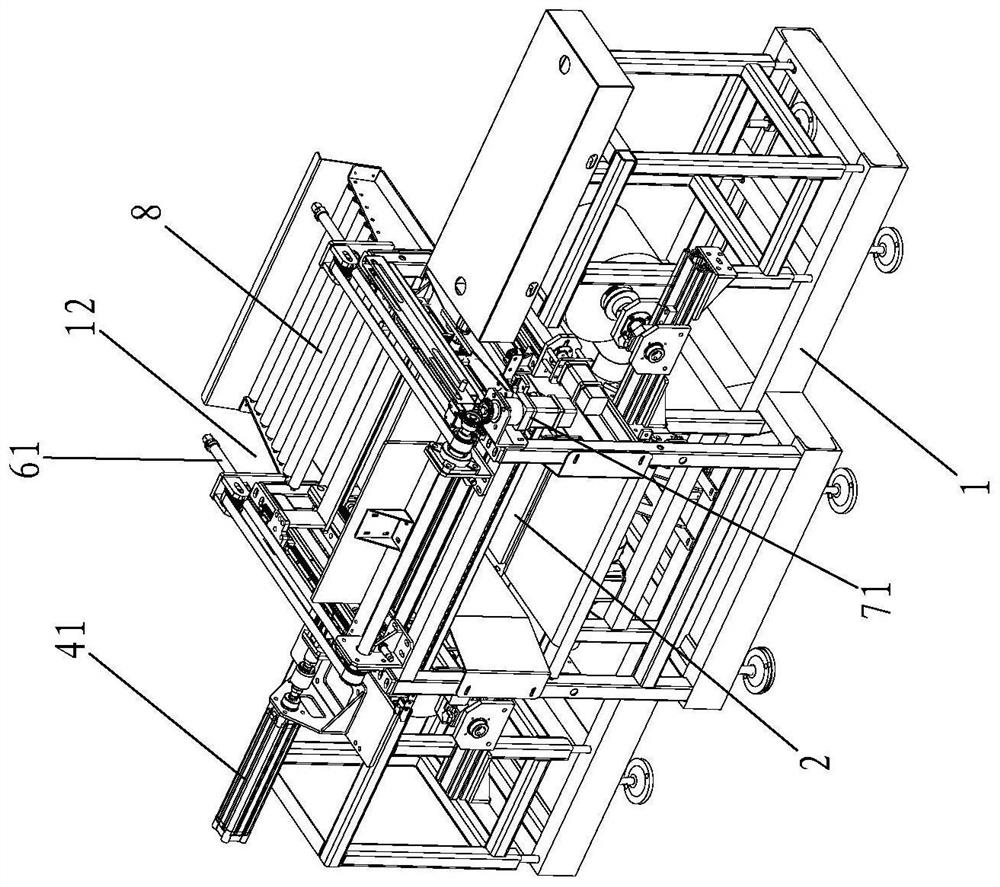

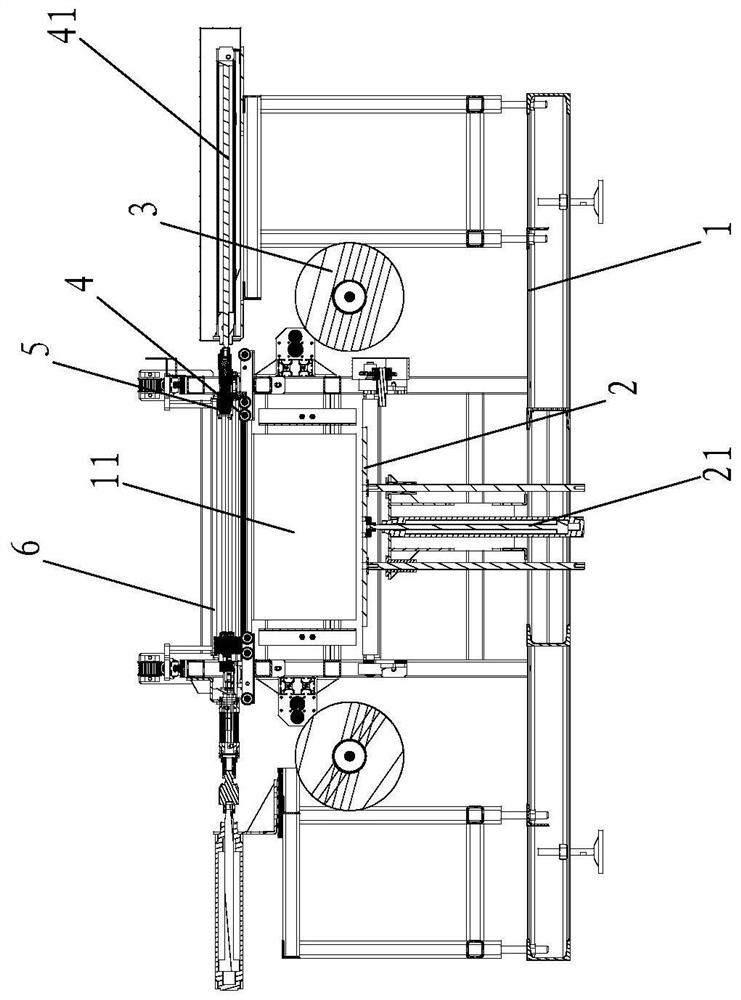

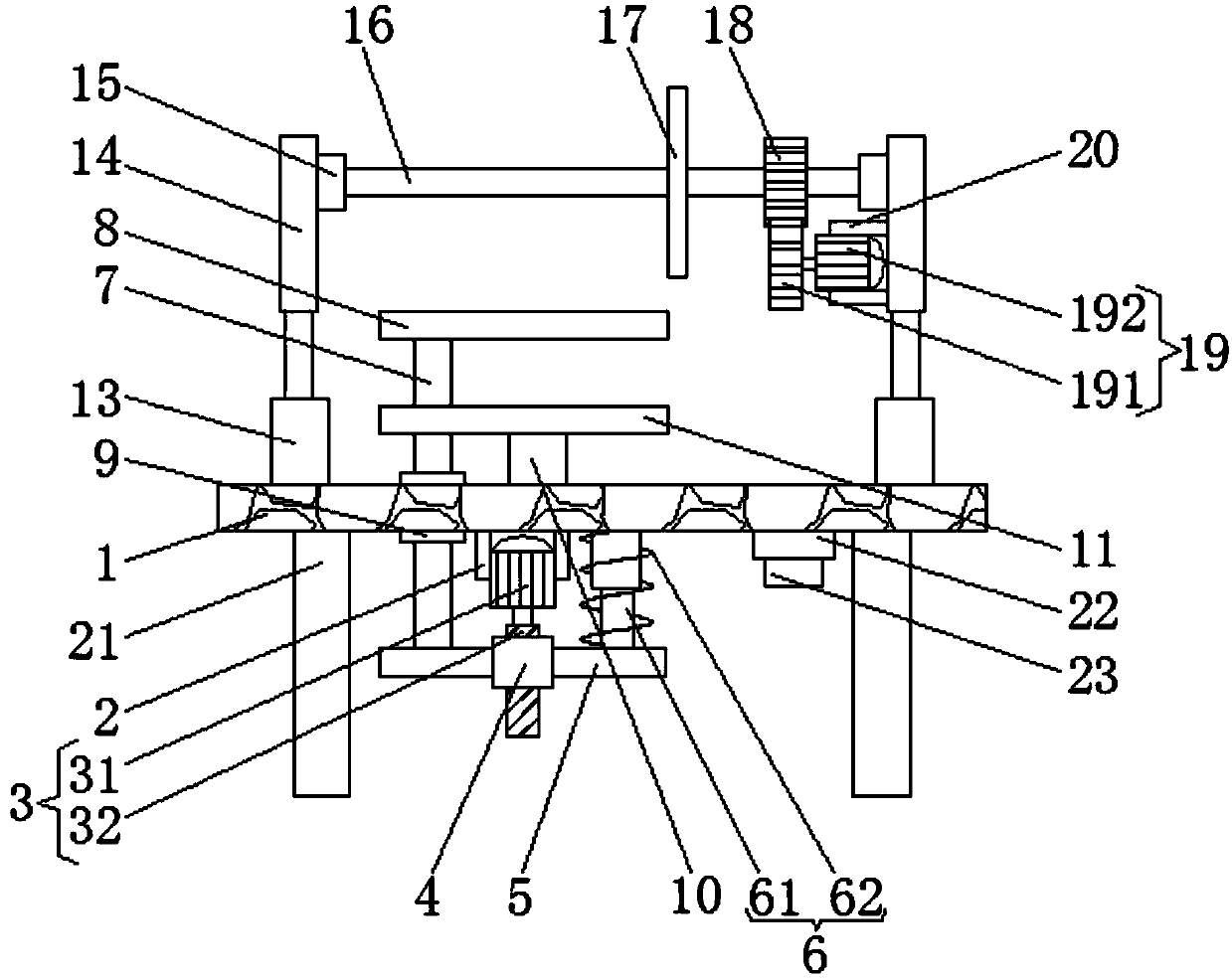

Automatic packaging device

ActiveCN108528782AAchieve slipRealize automatic upward movementWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to the technical field of packaging, in particular to an automatic packaging device which comprises a mounting rack; the mounting rack is provided with a positioning working component, a cover turning mechanism, a box sealing mechanism, a cutter component and a conveying mechanism used for conveying a packaging box onto the positioning working component and comprises a groundbracket, a vertical bracket perpendicular to the ground bracket and a hanging bracket which is arranged at the top end of the vertical bracket and perpendicular to the vertical bracket; the positioning working component comprises a workbench arranged above the conveying mechanism; telescopic cylinders used for enabling the workbench to be capable of realizing lifting are arranged on the two sidesof the workbench respectively and are fixedly installed on the ground bracket; and the upper surface of the workbench is also provided with a bearing air bag. The automatic packaging device solves the problem that equipment for packaging the packaging box is not suitable for packaging the packaging boxes in different types and sizes in the prior art.

Owner:宁波隆锐机械制造有限公司

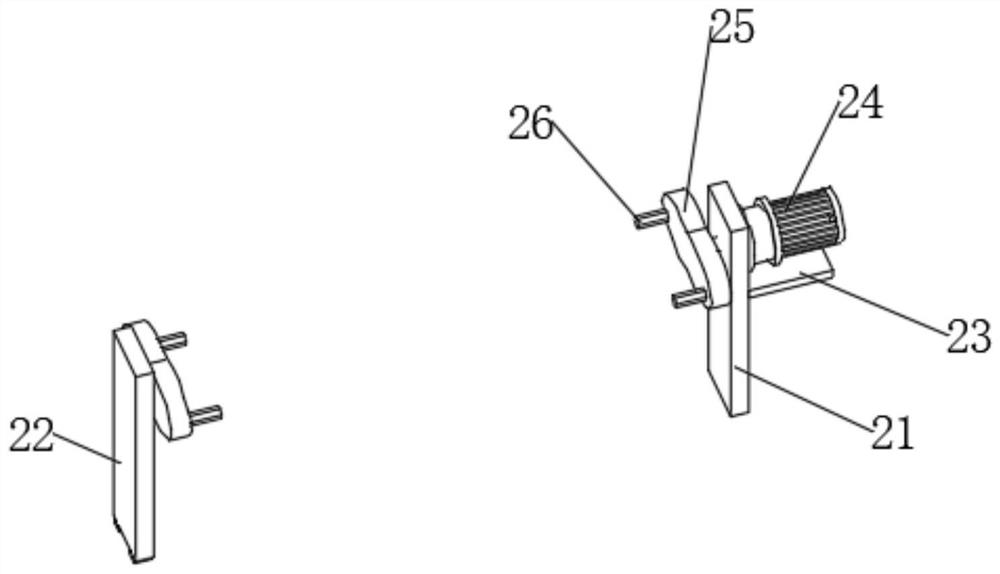

Livestock breeding ox horn cutting device

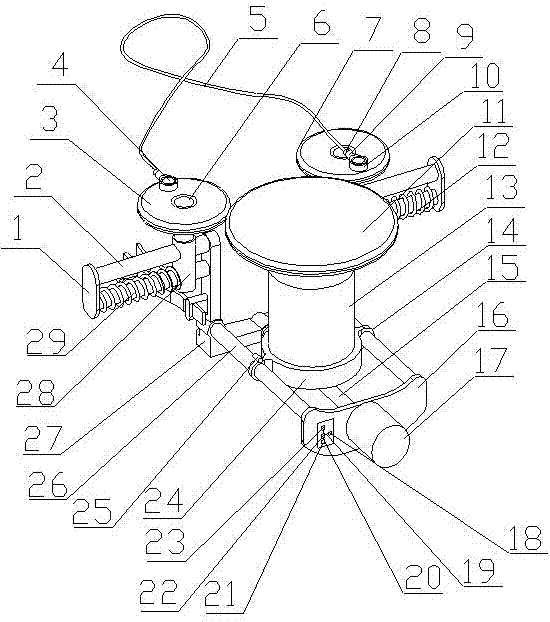

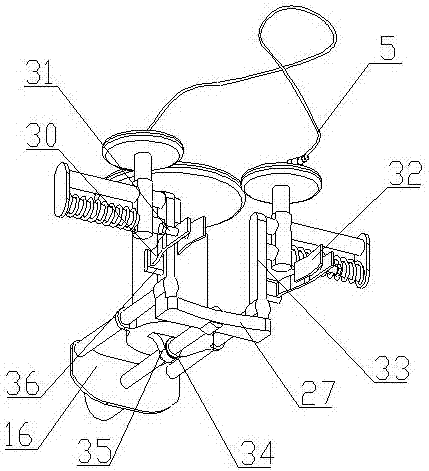

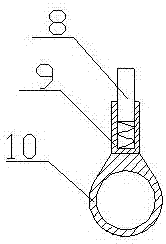

InactiveCN107877581ANeat cutting surfaceImprove cutting effectMetal working apparatusTaming and training devicesEngineeringScrew thread

The invention provides a livestock breeding ox horn cutting device and discloses a device for cutting an ox horn through gradual tensioning and reciprocating movement of a rope saw. The livestock breeding ox horn cutting device is characterized in that the middle of a supporting plate and the middle of a fixing plate are connected through a threaded shaft; two sliding bars are symmetrically arranged on the two sides of the threaded shaft; the two ends of the sliding bars are connected with the supporting plate and the fixing plate correspondingly; a moving chassis is arranged between the two sliding bars; a transmission block is arranged in the middle of the bottom end of the moving chassis; a threaded sleeve is arranged on the threaded shaft in a sleeving mode and connected with the transmission block; the two sides of the moving chassis are connected with the two sliding bars through sliding rings correspondingly; a fixed motor is arranged on one side of the fixing plate, and a motorshaft is connected with one end of the threaded shaft; and by adopting the device, the ox horn cutting effect can be effectively improved, and injuries to an ox can be reduced in the ox horn cuttingprocess.

Owner:南京白下高新技术产业园区投资发展有限责任公司

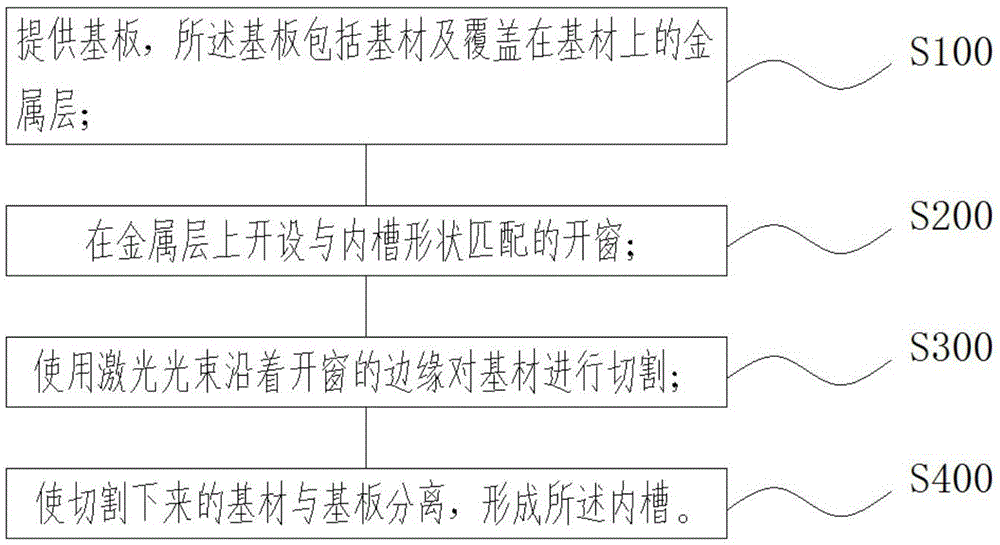

Circuit board inner groove machining method

InactiveCN105578771AElimination of fillet processing restrictionsAchieve the purpose of cuttingPrinted circuit manufactureLaser cuttingEngineering

The invention discloses a circuit board inner groove machining method. The circuit board inner groove machining method comprises the following steps of providing a substrate, wherein the substrate comprises a base material and a metal layer covering the base material; forming an open window matched with the shape of the inner groove in the metal layer; cutting the base material by a laser beam along the edge of the open window; and enabling the cut base material to be separated from the base plate to form the inner groove. According to the circuit board inner groove machining method, the base material is continuously burnt and etched by a thermal effect of laser so as to fulfill the purpose of cutting; the metal layer is relatively low in laser absorption efficiency and relatively high in melting point, and the required destroy energy is relatively high, so that the metal layer is hard to machine by laser; therefore, the open window is formed in the metal layer before performing laser cutting, so that laser only acts on the base material; the laser beam cuts the base material along the edge of the open window, and point machining is converted into continuous processing, so that the circular bead machining limitation for an ultra-small circular bead inner groove is eliminated; and meanwhile, the machining efficiency and the machining precision are effectively improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

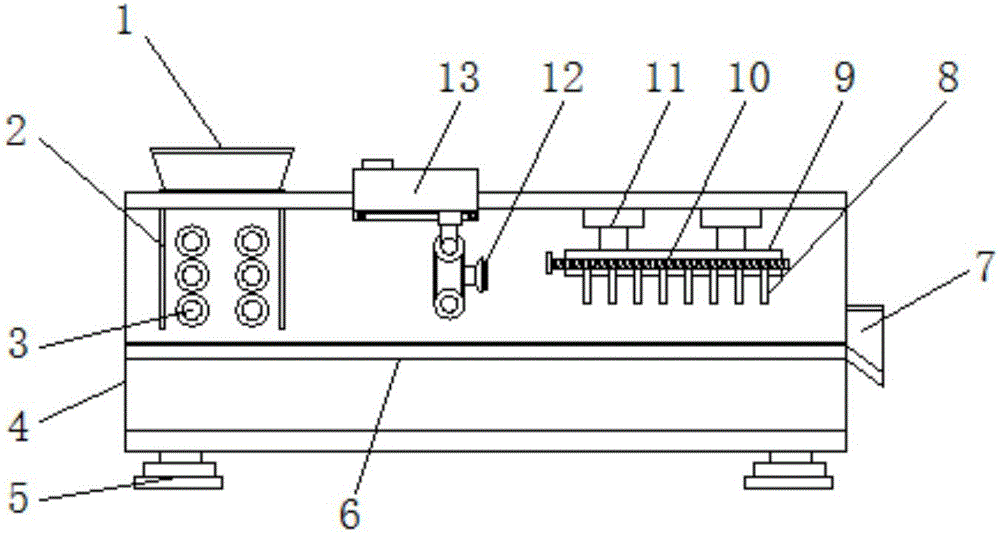

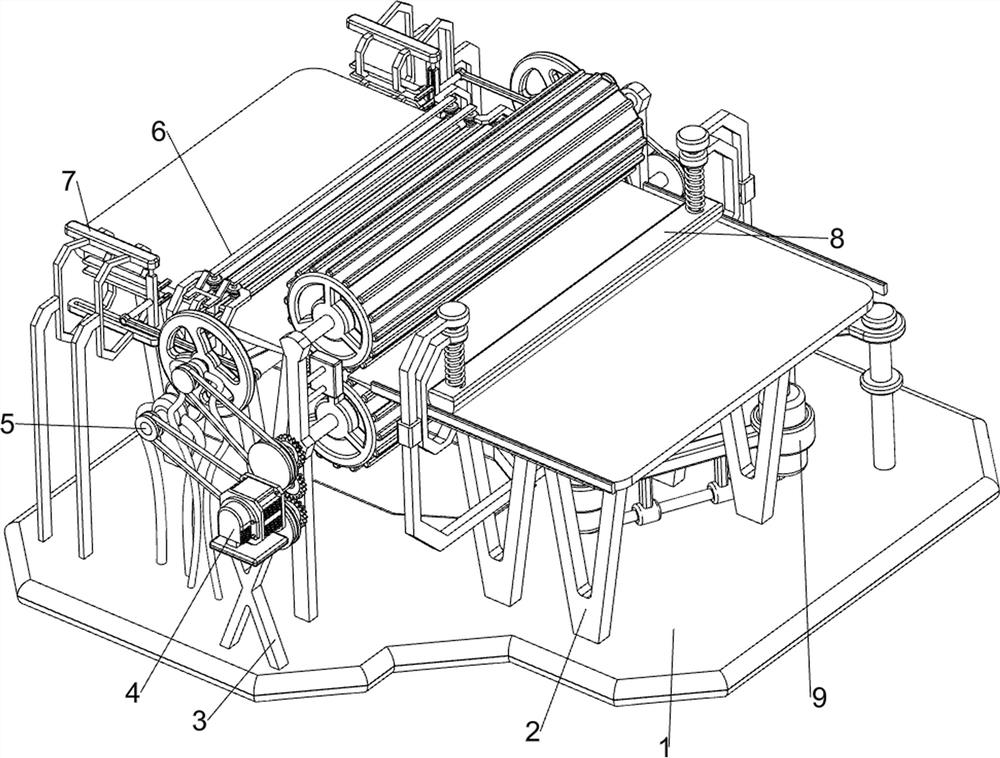

Protective rubber strip cutting machine with high efficiency

ActiveCN107030744AAchieve the purpose of cuttingSimple structureMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of rubber cutting and processing equipment, and particularly relates to a protective rubber strip cutting machine with high efficiency. The cutting machine comprises a main body of the cutting machine; the cutting machine also comprises a conveying unit arranged on the main body of the cutting machine and used for conveying rubber strips; a cutting unit arranged at one side of the conveying unit and used for cutting the rubber strips and discharging materials cut in the form of downward cutting and toggling rotation; a discharge protection unit arranged at one side of the cutting unit; and a cut-off protection unit arranged on the discharge protection unit, connected to the cutting unit electrically, and used for communicating with and cutting off the cutting unit circuit. In the invention, the purpose of cutting the rubber strips is achieved through installing the conveying unit, the cutting unit, the discharge protection unit and the cut-off protection unit on the main body of the cutting machine. The cutting machine provided by the invention has the advantages of good cutting effect and obvious protection effect.

Owner:ANHUI HANCAI SEALING ELEMENT

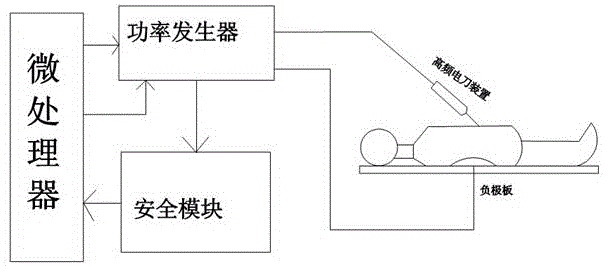

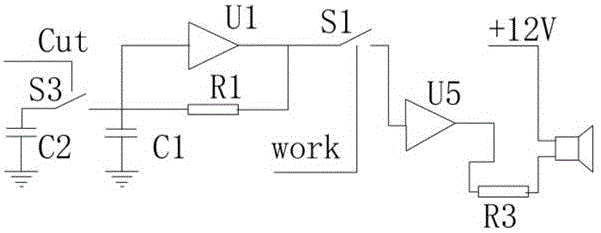

Novel high-frequency electrotomy therapeutic apparatus

InactiveCN105769333AAchieve the purpose of cuttingSurgical instruments for heatingInterface circuitsVariable frequency control

The invention discloses a novel high-frequency electrotomy therapeutic apparatus. The therapeutic apparatus comprises a microprocessor with a built-in control circuit, a power generator, a high-frequency electrotome device, a negative plate, a power supply module and a plurality of interface circuit ends connected with external equipment, wherein the power generator is connected between the microprocessor and the high-frequency electrotome; the high-frequency electrotome device comprises an ultrasonic device and a variable frequency inverter; a power transmitter is also connected with the safety module; and the safety module comprises an automatic detection output frequency module. By adopting the scheme, the high-frequency electrotomy therapeutic apparatus can achieve the cutting aim, and has relatively high safety and low cost.

Owner:SHENZHEN BANGVO TECH

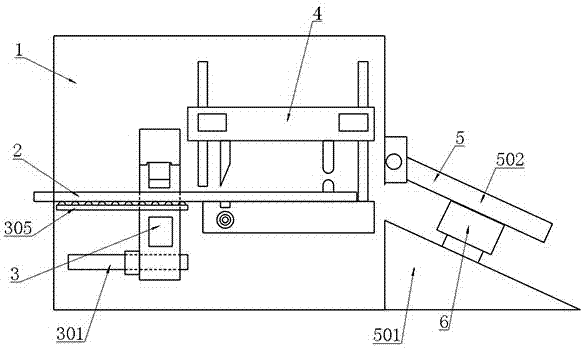

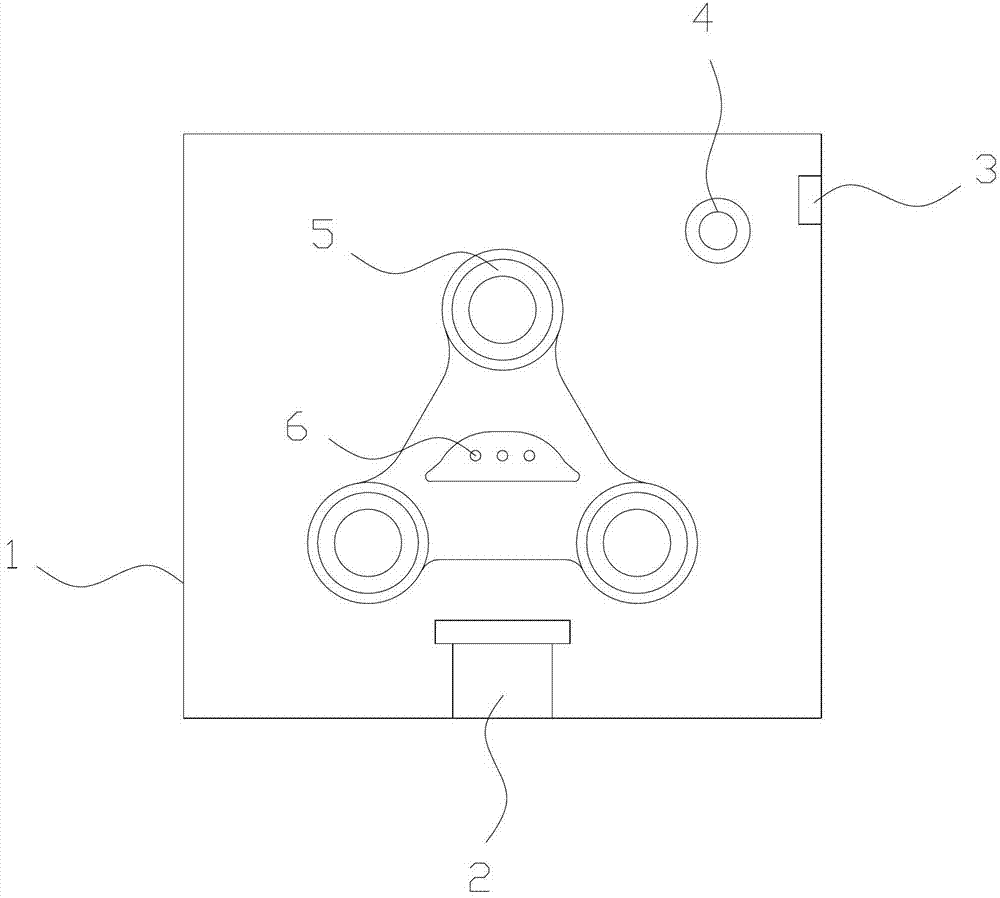

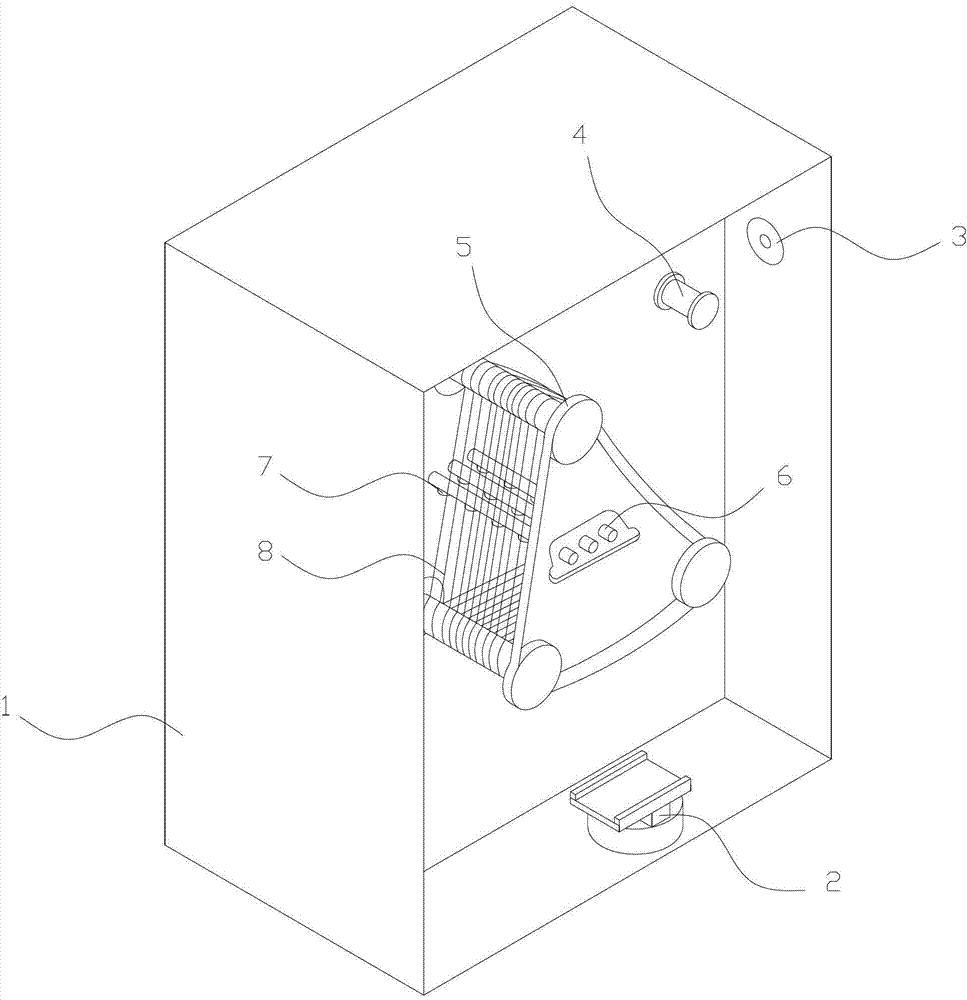

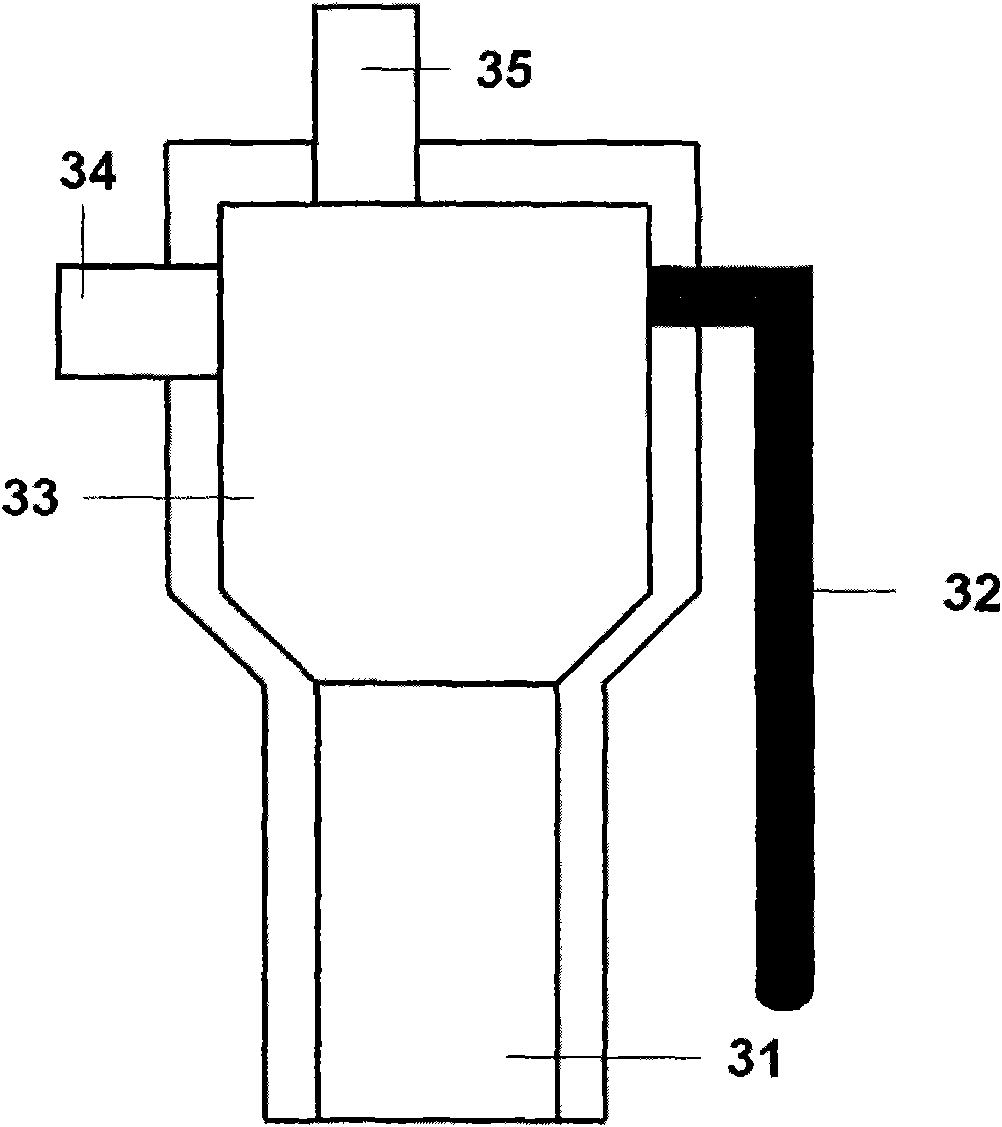

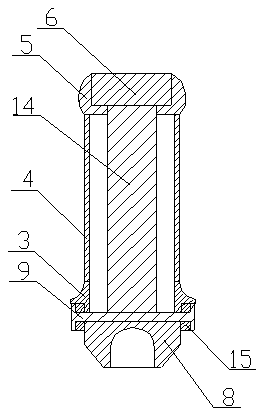

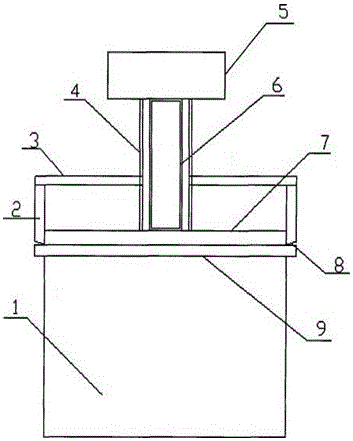

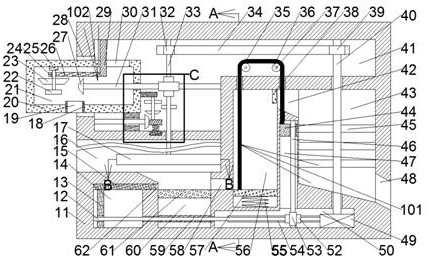

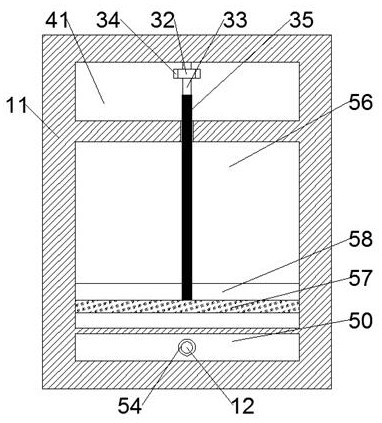

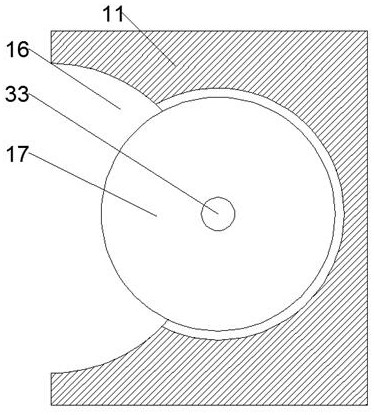

Crystal cutting machine

InactiveCN102773930ASimple structureReasonable designFine working devicesComing outChinese characters

The invention relates to a crystal cutting machine, and belongs to the field of crystal cutting equipment. A main body of the crystal cutting machine is a box body, and the crystal cutting machine is characterized in that a feeding mechanism moving up and down is arranged on the bottom surface of the box body, a paying-off port is formed on the side surface of the box body, and a cutting mechanism and a steel wire transitional roller are arranged on the front surface of the box body; the cutting mechanism comprises roll shafts which are designed in a shape of a Chinese character:pin:, and three sand conveying pipes; steel wires wrap on the roll shafts; and the sand conveying pipes are arranged among the roll shafts, and a sand nozzle is arranged on each sand conveying pipe. The crystal cutting machine is simple in structure and reasonable in design; the steel wires come out of a wire outlet and then are transited to the roll shafts through the transitional roller; when the roll shafts rotate, the steel wires are wrapped on the roll shafts circle by circle; and during the cutting, a material plate to which crystals are adhered is fixed on the feeding mechanism, and when the roll shafts rotate, the feeding mechanism moves upwards, the sand nozzles spray out mortar which falls on the steel wires which reciprocate at a high speed, and the steel wires together with the mortar attached to the steel wires are used for grinding the crystals, so that the aim of the cutting is fulfilled, and the cutting efficiency is high.

Owner:铜陵市琨鹏光电科技有限公司

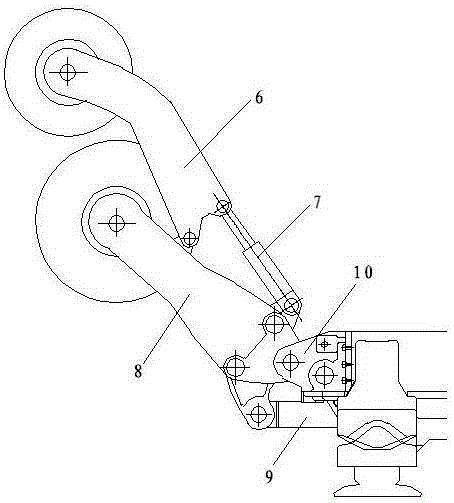

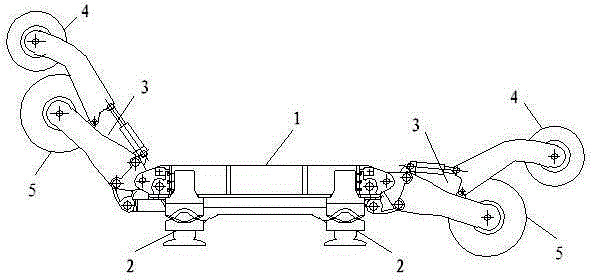

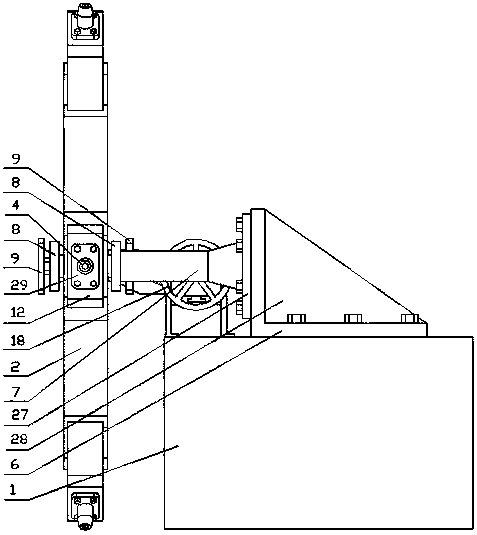

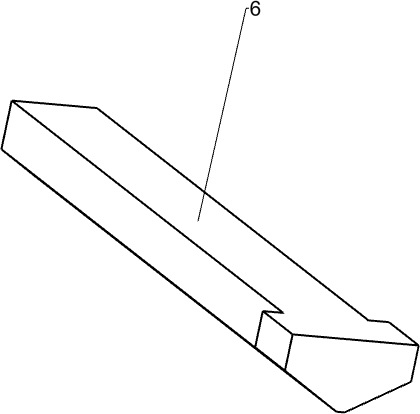

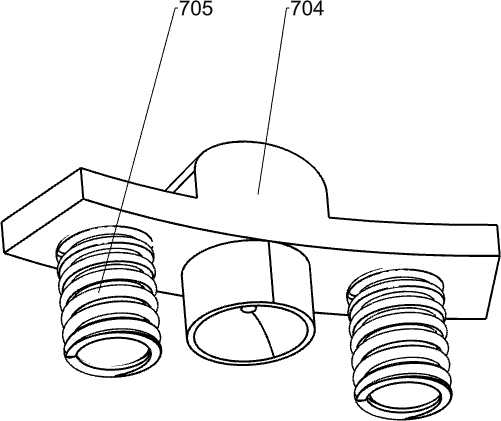

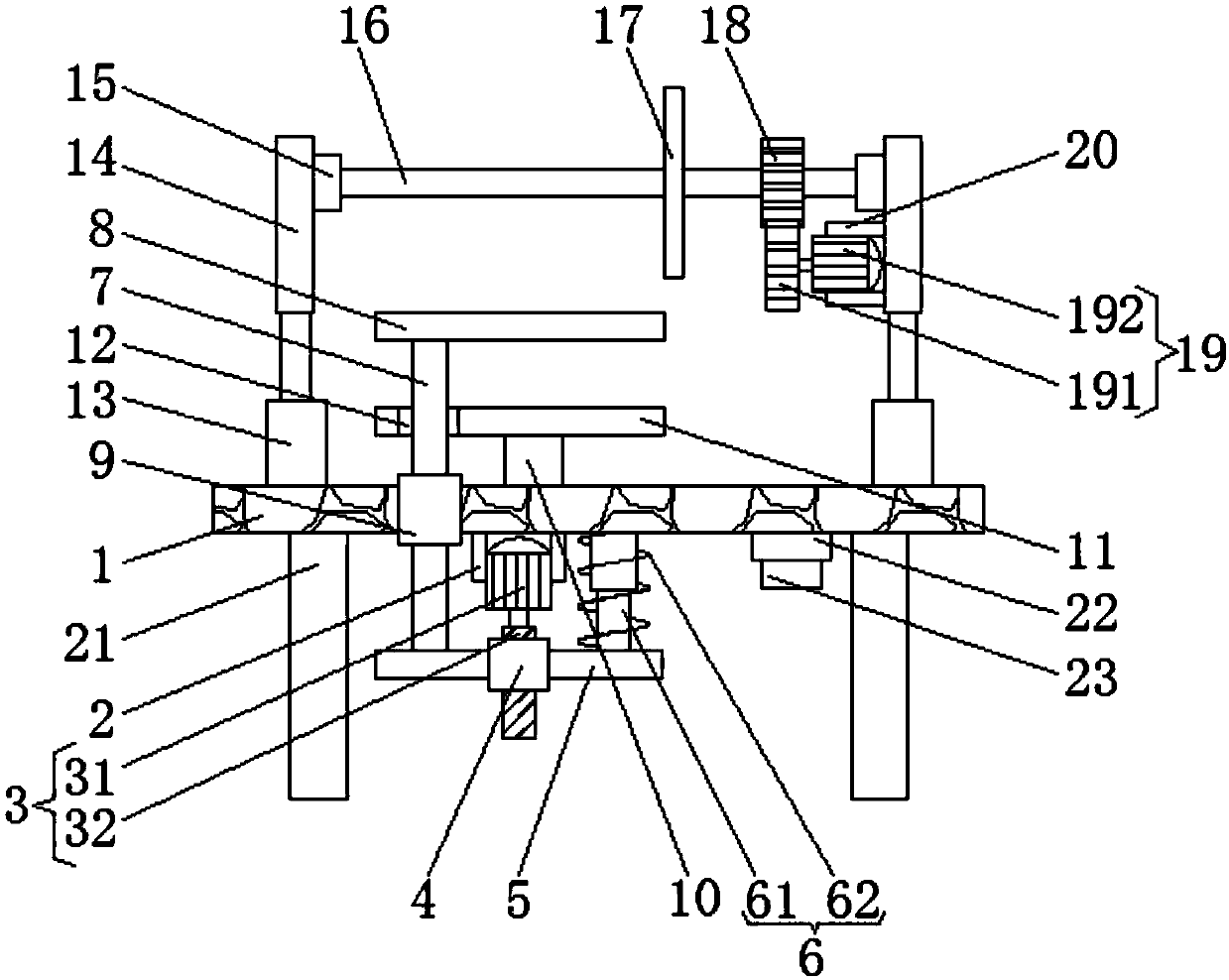

Small roller combined type coal mining machine with large mining height

InactiveCN105201499AWide range of height adjustmentSmall structureCutting machinesAgricultural engineeringCoal mining

The invention relates to a small roller combined type coal mining machine with a large mining height. The small roller combined type coal mining machine comprises a machine body overall structure, a walking mechanism, combined height adjustment devices and coal cutting rollers, wherein the walking mechanism is arranged on the lower side of the machine body overall structure; the combined height adjustment devices are symmetrically mounted on two side surfaces of the machine body overall structure; each combined height adjustment device comprises an upper height adjustment rocker, an upper height adjustment oil cylinder, a lower height adjustment rocker and a lower height adjustment oil cylinder; the upper height adjustment rocker of each combined height adjustment device is hinged to the upper side surface of the corresponding lower height adjustment rocker through a pin shaft; each lower height adjustment rocker is hinged to a hinge ear on the corresponding side surface of the machine body through a pin shaft; the tail end of each upper height adjustment rocker and the tail end of the corresponding lower height adjustment rocker are rotationally connected with the corresponding coal cutting rollers respectively. According to the small roller combined type coal mining machine with the large mining height, swinging cutting is realized through combination of the combined height adjustment rocker devices and the small-diameter rollers, the height adjustment range of the rollers is increased, and the coal mining machine has a large mining height and is suitable for mining thick coal seams and ultra-thick coal seams.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cutting method of special alloy cast iron

ActiveCN102019509AAchieve the purpose of cuttingMeet the needs of specific working conditionsArc welding apparatusMetal working apparatusShielded metal arc weldingAlloy

The invention relates to a cutting method of special alloy cast iron. The cutting method is characterized by comprising the following steps of: welding low-carbon steel weld metal with the width of between 15 and 20 millimeters at a position needing to be cut on the inner surface of a special alloy iron casting by using manual arc welding; performing flame cutting on the weld metal and the special alloy iron casting which is connected with the weld metal and has the fusion depth of between 3 and 5 millimeters by using oxygen-acetylene; welding low-carbon steel weld metal with the width of between 15 and 20 millimeters on the surface of the special alloy iron casting which is exposed out of a cutting position by using manual arc welding; performing flame cutting on the weld metal and the special alloy iron casting which is connected with the weld metal and has the fusion depth of between 3 and 5 millimeters by using oxygen-acetylene; and repeating the steps until a required cutting size is achieved. The cutting method has the characteristics of saving capital and meeting the requirements of a specific working state.

Owner:ANSTEEL GRP MINING CO LTD

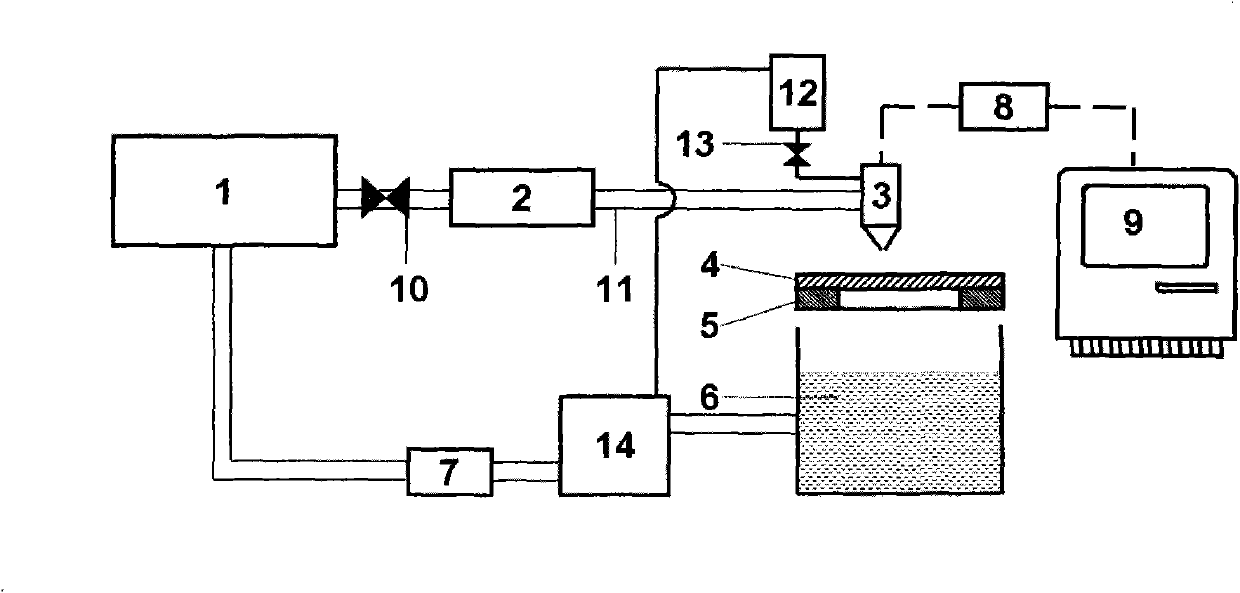

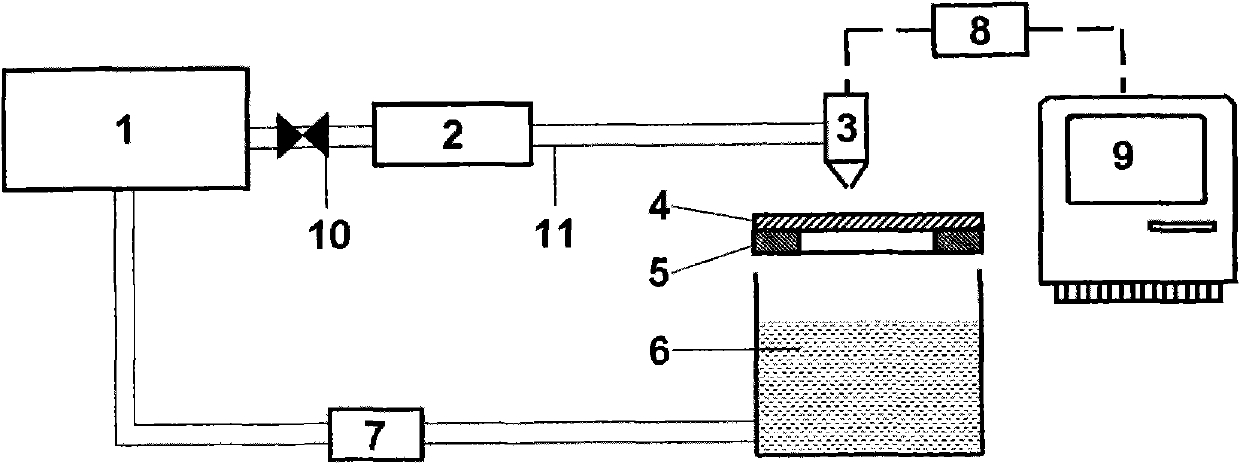

Liquid metal knife cutting system

ActiveCN102554798AAchieve the purpose of cuttingWon't happenAbrasive blasting machinesNumerical controlSpray nozzle

A liquid metal knife cutting system comprises a cutting device, wherein the cutting device comprises a cutting nozzle and a rectification cavity communicated with the upper end of the cutting nozzle. An inlet pipe communicated with the pressure pump outlet through a hose is installed on the lateral wall of the rectification cavity, a miniature camera is installed on an observation hole on the lateral wall of the rectification cavity, and the pressure pump inlet is communicated with the liquid metal storage tank outlet. A workbench is arranged below the cutting nozzle, a recycle container is arranged below the workbench, a connection pipeline at the lower portion of the recycle container is communicated with the storage tank bottom, and a recycle pump is installed on the pipeline of the recycle container. A numerical control table comprises a processor and a data base, wherein the processor is used for calculating relevant cutting parameters in cutting, and the data base is used for recording the cutting parameters corresponding to cutting materials and cutting results. The cutting nozzle of the cutting device is coaxial with a motor shaft, and a motor receives operation commands given out by the numerical control table and controls a cutting path of the cutting nozzle of the cutting device according to the commands to complete cutting of a workpiece to be cut. The cutting system is high in cutting accuracy, stable, low in noise, energy-saving and environment-friendly.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

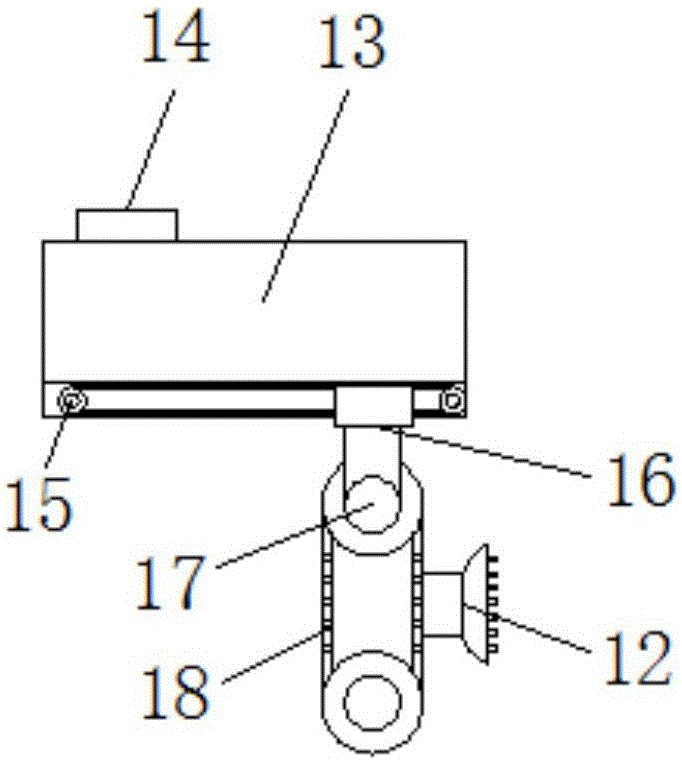

Multi-bit rapid switching and discharging device for food processing

ActiveCN107912485AQuick disassembly workFlexible rotationDough shaping and cutting apparatusFood shapingEngineeringIngested food

The invention discloses a multi-bit rapid switching and discharging device for food processing, which comprises an installing frame, a rotary framework, a cutting motor, a discharging head and a transfer joint; the middle of the upper part of the installing frame is detachably connected with a right angle plate frame, and the right angle plate frame is detachably connected with the fixing shaft; the rotary framework is rotationally fit with the fixing shaft; two positioning cross frames are mounted on the fixing shaft, and extruding frames are evenly distributed on the outer edge of the rotaryframework; the extruding frames are connected with a splint through a group of tension spring, and the cutting motor is matched with an eccentric wheel; the eccentric wheel is connected with a pushing cutter through a link rod, the push cutter is glidingly fit with a chute cutter rest installed on one side of the cutting motor. The multi-bit rapid switching and discharging device for food processing can rapidly replace discharging heads to reach the purpose of processing different shapes of foods; the multi-bit rapid switching and discharging device is simple in operation, low in manufacturing cost, convenient to repair, and avoids the problem of single food processing shape in the traditional processing work.

Owner:崔斯特创新技术(深圳)有限公司

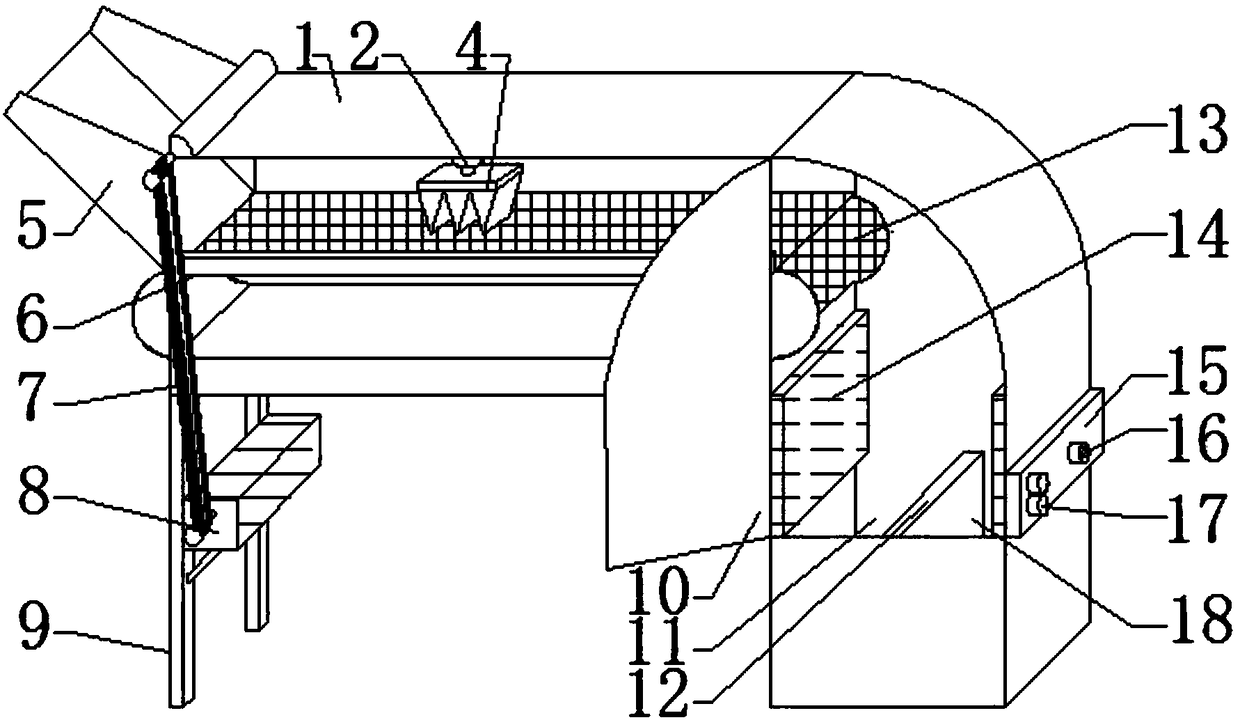

Food production equipment for automatically cutting chestnuts

InactiveCN111990664AAchieve the purpose of cuttingKeep it flat and niceHuskingHullingProcess engineeringIndustrial engineering

The invention relates to equipment for cutting chestnuts, in particular to food production equipment for automatically cutting chestnuts. The purpose is to provide the food production equipment, whichis efficient, and is capable of guaranteeing the safety of workers to a certain degree, reducing the time cost, reducing fatigue of the workers and guaranteeing the neatness of cuts, for automatically cutting the chestnuts. The food production equipment for automatically cutting the chestnuts comprises a second support, a cushion block and a servo motor, wherein the second support is connected with one side of the top side of a first support; the cushion block is connected with the side, close to the second support, of the top side of the first support; and the servo motor is connected with the side, close to the second support, of the bottom side of the first support. According to the food production equipment for automatically cutting the chestnuts, through cooperation of a boss, a sliding block, an electric saw and a follower, the purpose of cutting the chestnuts is achieved, the neatness and the aesthetics of cuts of the chestnuts are guaranteed, the efficiency is improved, and anautomatic operation process is conducted.

Owner:封朝生

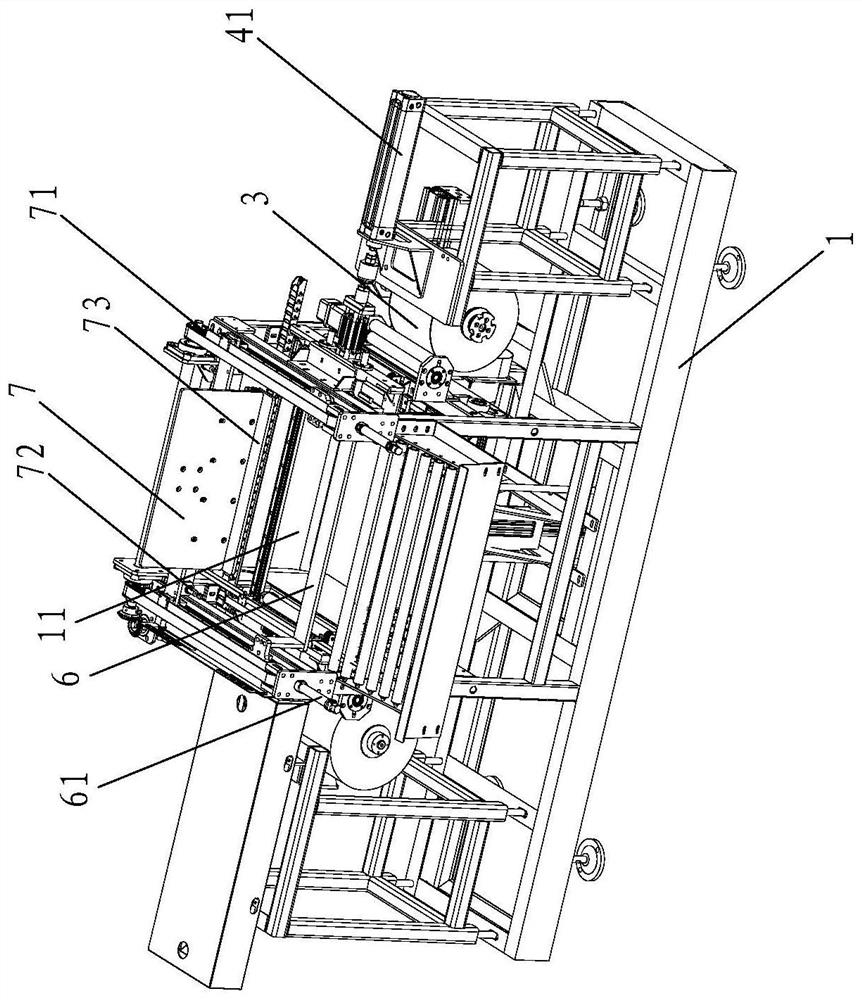

Cigarette carton wrapping, sealing and cutting device and cigarette carton wrapping, sealing and cutting process

PendingCN113044269ANot easy to scatterSimple processWrapping material feeding apparatusWrappingCartonStructural engineering

The invention relates to the field of cigarette carton packaging, in particular to a cigarette carton wrapping, sealing and cutting device which comprises a rack, a lifting channel, a lifting platform and a lifting driving mechanism, unwinding mechanisms are arranged on the rack, a guide mechanism is arranged on the rack, wrapping films of the two unwinding mechanisms are connected with each other after winding around the guide mechanism, a guide driving mechanism is arranged on the rack, the rack is provided with a sealing and cutting mechanism used for sewing and cutting off the wrapping films, the rack is provided with a sealing and cutting driving mechanism used for driving the sealing and cutting mechanism to stretch into the lifting channel so that the sealing and cutting mechanism can get close to the lifting channel, a bearing plate used for supporting cigarette cartons is arranged on the rack and located above the sealing and cutting mechanism and located on one side or two sides of the lifting channel, and the rack is provided with a bearing driving mechanism used for driving the bearing plate to stretch into the lifting channel so as to achieve cigarette carton bearing. The technical problems that a sealing device with a sleeve film is high in cost and low in working efficiency are solved. The invention further provides a cigarette carton wrapping, sealing and cutting process.

Owner:福建科盛智能物流装备有限公司

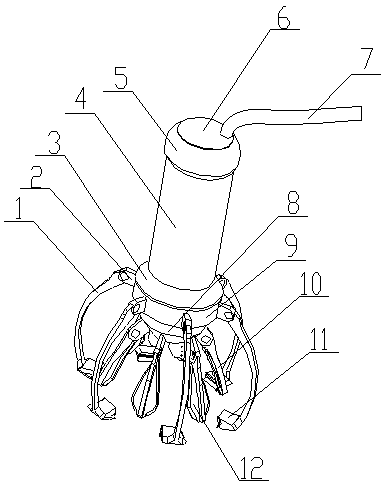

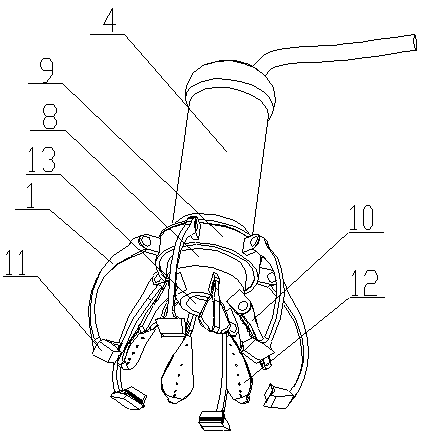

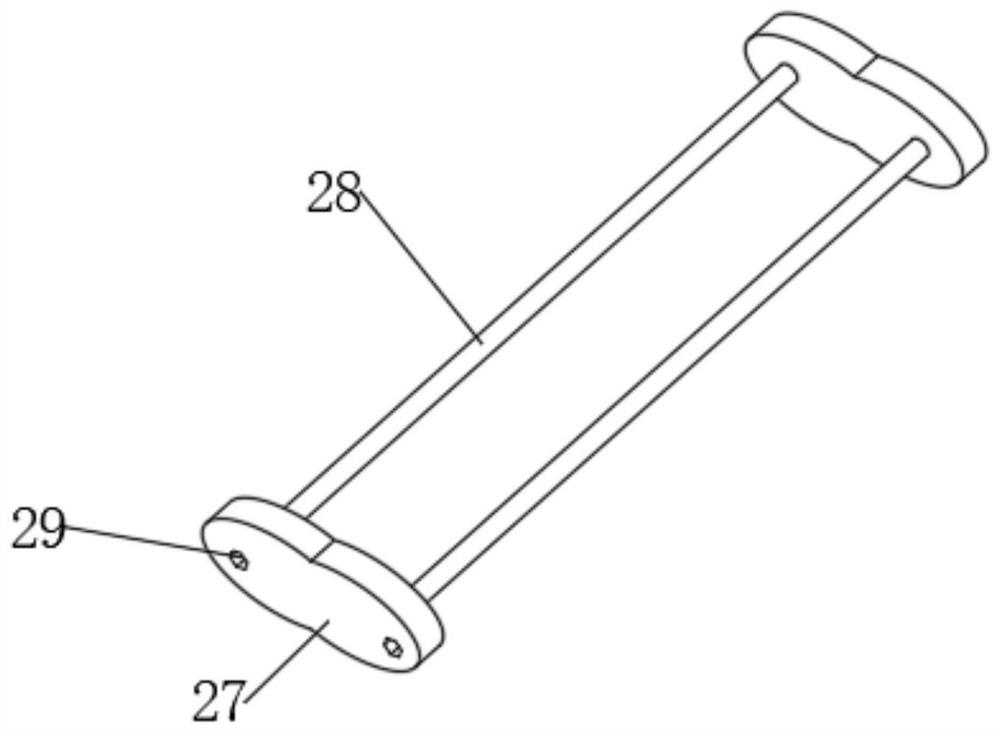

Coconut end cap cutting device for food processing

ActiveCN107736625AAvoid pollutionAchieve the purpose of cuttingHuskingHullingFixed bearingBiochemical engineering

The invention provides a coconut end cap cutting device for food processing and discloses a device for fixing a coconut through multiple clamping plates and then cutting a coconut end cap through rotation of multiple girdling knives. The coconut end cap cutting device for food processing is characterized in that a limiting sleeve is arranged at one end of a handheld cylinder, a protective table isarranged at the other end of the handheld cylinder, a rotating block is arranged in the limiting sleeve, one end of a rotating rod is arranged on the rotating block, one end of a driving rod is arranged in the handheld cylinder and is connected with the middle of the rotating block, the other end of the driving rod penetrates through the handheld cylinder to be connected with the middle of a rotating plate, the rotating plate is of a round plate-like structure, a fixing table is arranged on the rotating plate through a fixing bearing, a buffer cavity is formed in the middle of the fixing table, multiple fixing lugs are arranged on the outer side of the rotating plate at equal intervals, one end of a cutting knife connecting rod is hinged to the corresponding fixing lug on the rotating plate through a hinge pin, the cutting knife connecting rods are of arc-shaped structures, the girdling knives are arranged at the other end of each cutting knife connecting rod, cutting blades are arranged on the girdling knives and face the inner sides of the cutting knife connecting rods, and compressing plates are arranged on the girdling knives.

Owner:徐州中知知识产权服务有限公司

Compact food slicer

InactiveCN107520899ATight fleshAchieve the purpose of cuttingMetal working apparatusMechanical engineeringMicrotome

The invention discloses a compact food slicing machine, which comprises a machine body, a material inlet is arranged on one side of the top of the body, and a feeding pipe is arranged below the inner side of the material inlet, and the inner side of the feeding pipe is symmetrical. Three pressure rollers are provided, a water tank is provided on the other side of the feed pipe, and two rollers are symmetrically provided below the water tank. In the present invention, the compact food slicing machine firstly has a pressure roller directly below the feeding port, and the pressing roller can press the meat falling from the feeding port, so that the meat quality is compact, When the meat falls on the conveyor belt, the conveyor belt will transfer it to the bottom of the blade, and the automatic telescopic control of the XTL100 electric telescopic rod will control the blade to move up and down vertically, so that the purpose of cutting the meat can be achieved, because this is the quality of the meat It is relatively compact, and it is easier to cut. After the slicing is completed, turn on the nozzle to make the nozzle spray water mist, so that the blade can be cleaned.

Owner:CHENGDU LINGGAN YUANSU TECH CO LTD

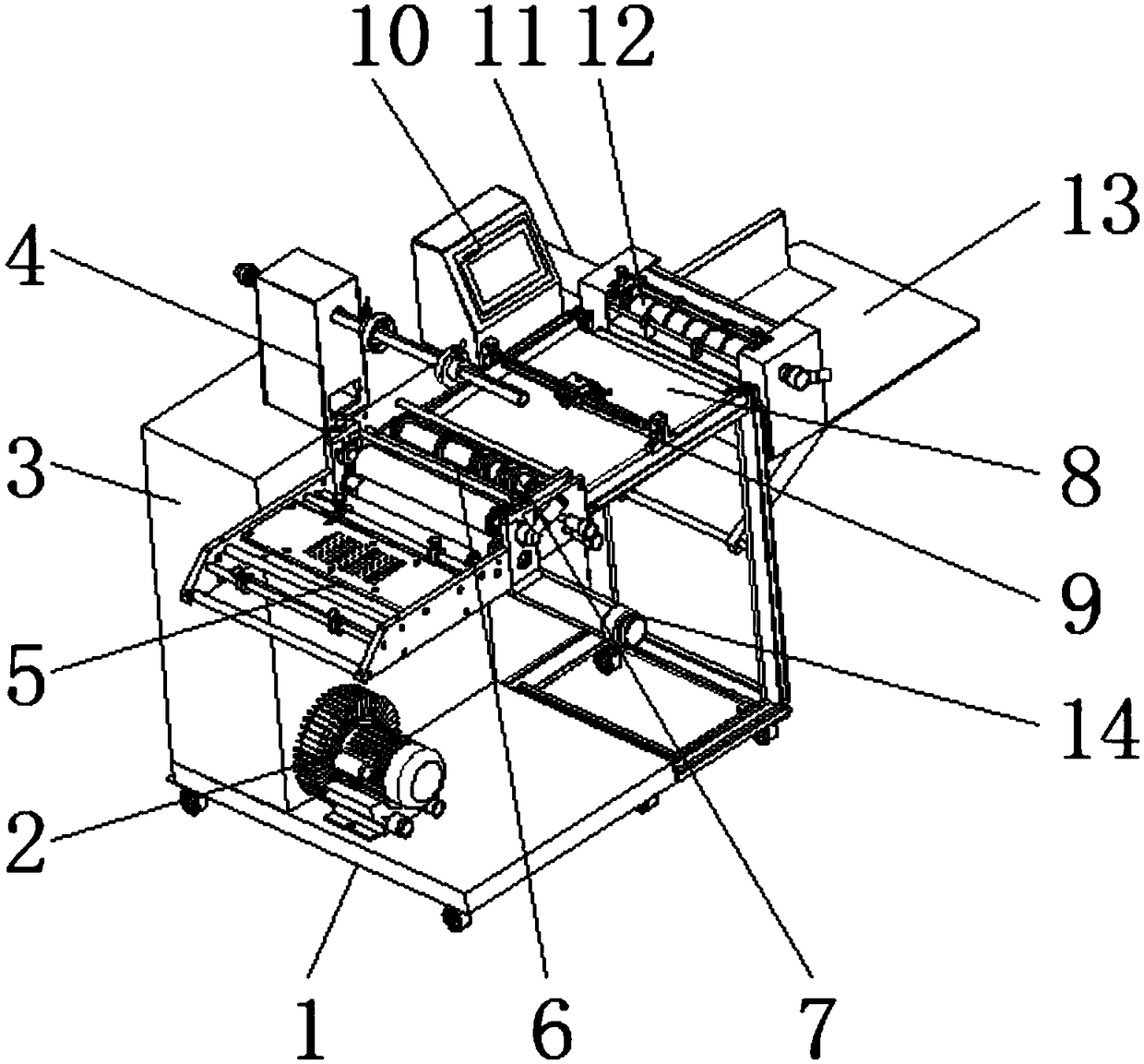

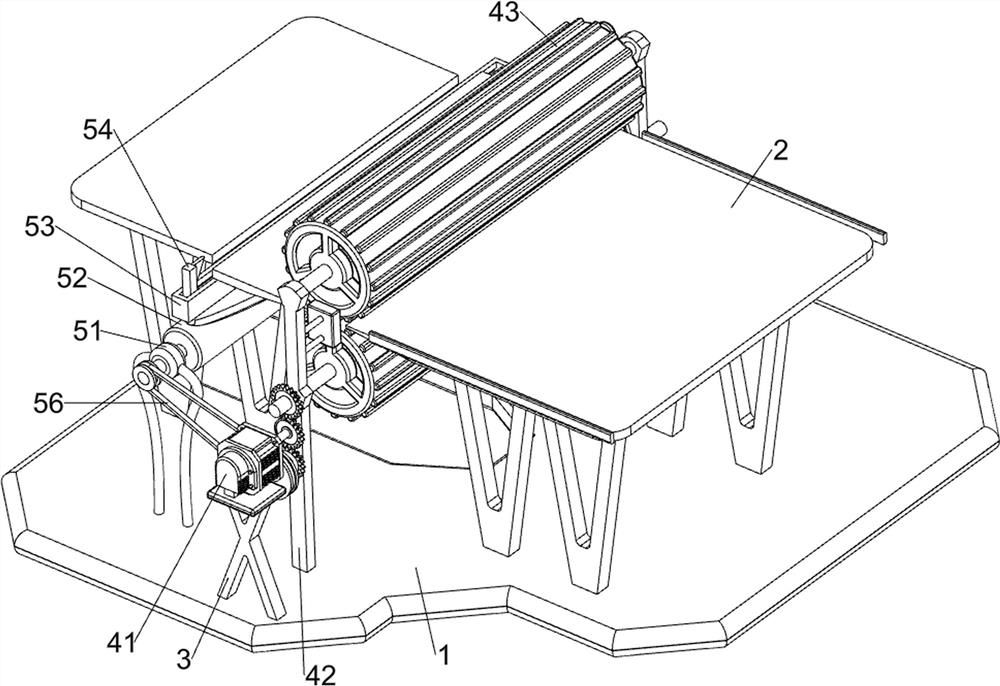

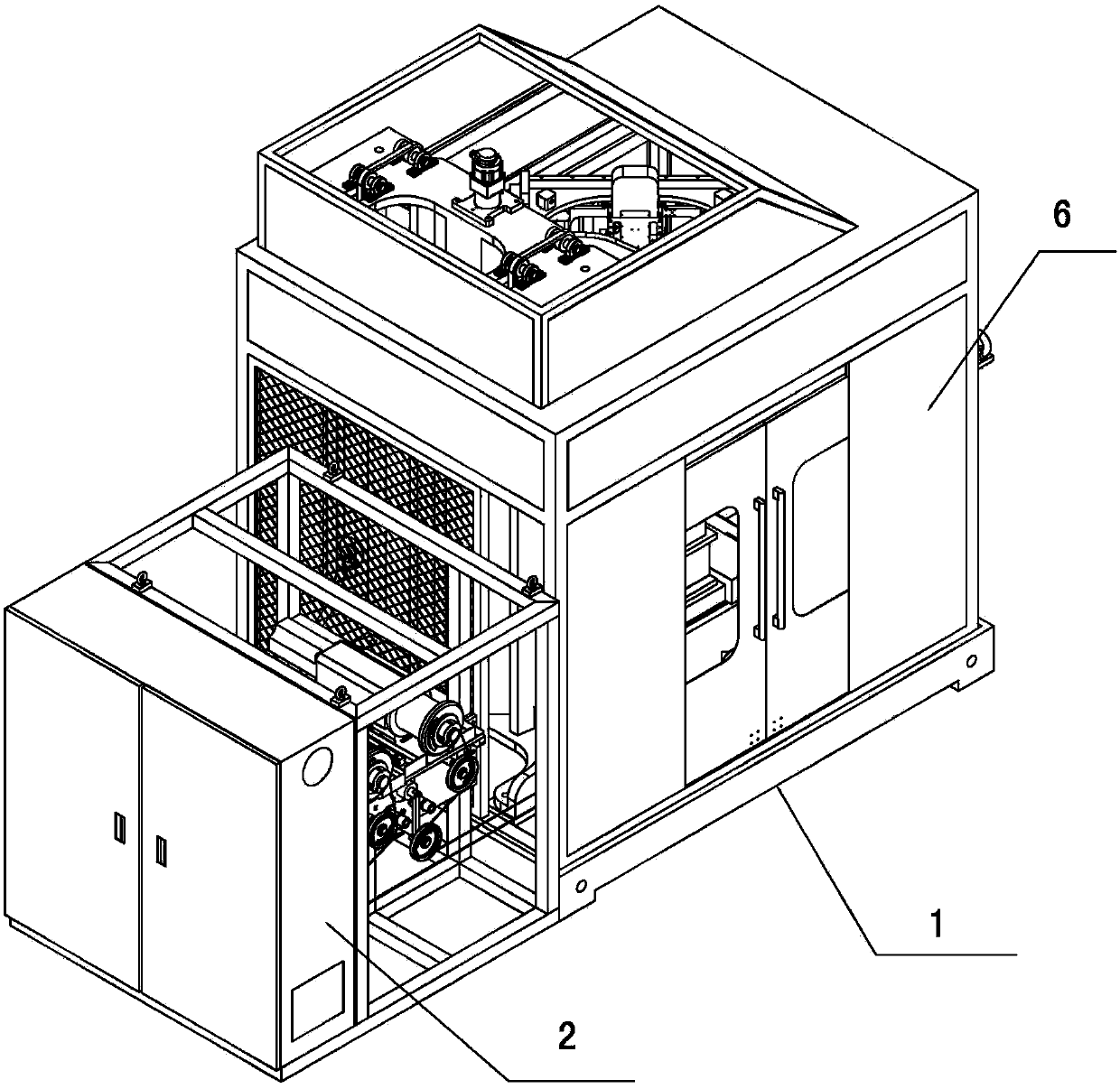

Waste collecting-slitting-paper cutting machine

PendingCN108247701AImprove work efficiencyReduce shaking effectMetal working apparatusPaper recyclingHydraulic cylinderPulp and paper industry

The invention discloses a waste collecting-slitting-paper cutting machine. The waste collecting-slitting-paper cutting machine comprises a base, a motor, fixing blocks and a connection rod; a fan is fixedly installed on the base; an electric box is fixed to the left side of the fan; a waste collecting box is arranged on the electric box, and the left side of the lower portion of the waste collecting box is provided with a storage table; a finished product winding shaft is installed below the bottom of a finished product storage table; slide blocks are externally provided with slide grooves, and a slitting shaft is connected with the middles of the slide grooves; the lower portion of a slide rod is connected with a push plate through a hydraulic cylinder, and a quality inspection table is arranged below the push plate; and a paper cutting shaft is fixedly installed at the bottom of the connection rod. The waste collecting-slitting-paper cutting machine is provided with a cutting machine, a splitting machine and the quality inspection table, thus, the steps of splitting, cutting and quality inspection in the whole label production process are successively connected, the whole label production work is a continuous process, the efficiency of the whole label production work is greatly improved, and the time wasted in different procedure processes is decreased.

Owner:东莞市山瑞机械设备有限公司

Intelligent waste steel impurity sorting device and method

InactiveCN108188142ASimple structureIntelligent sorting is simpleSolid waste disposalMagnetic separationEngineeringImpurity

The invention discloses an intelligent waste steel impurity sorting device which comprises an outer shell. An inlet slide way is fixedly installed on the left side of the outer shell, a rotating rod is fixedly installed on the right side of the inlet slide way, a track is movably installed on the rotating rod, the a cutting circular knife is movably installed in the middle of the rotating rod, a telescopic column is fixedly installed on the upper surface inside the outer shell, a transverse cutting knife is fixedly installed below the telescopic column, a conveying belt is fixedly installed below the transverse cutting knife, a baffle is fixedly installed in front of the conveying belt, supporting legs are fixedly installed on the lower bottom face of the outer shell, a motor is fixedly installed on the right side of the middles of the supporting legs, an electromagnetic plate is fixedly installed below the right side of the conveying belt, a machine door is fixedly installed on the left side of the electromagnetic plate, a waste steel bin is fixedly installed below the electromagnetic plate, and a partition plate is fixedly installed on the right side of the waste steel bin. The intelligent waste steel impurity sorting device is simple in structure, convenient to use, practical, stable in structure and capable of achieving the purposes of intelligent sorting and simple workingprocedures for waste steel impurities.

Owner:ANHUI FENGJIE METAL RESOURCES CO LTD

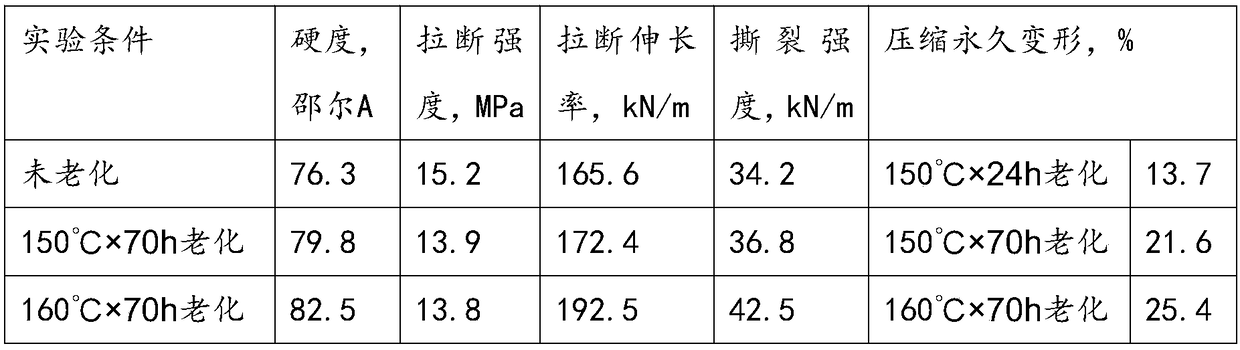

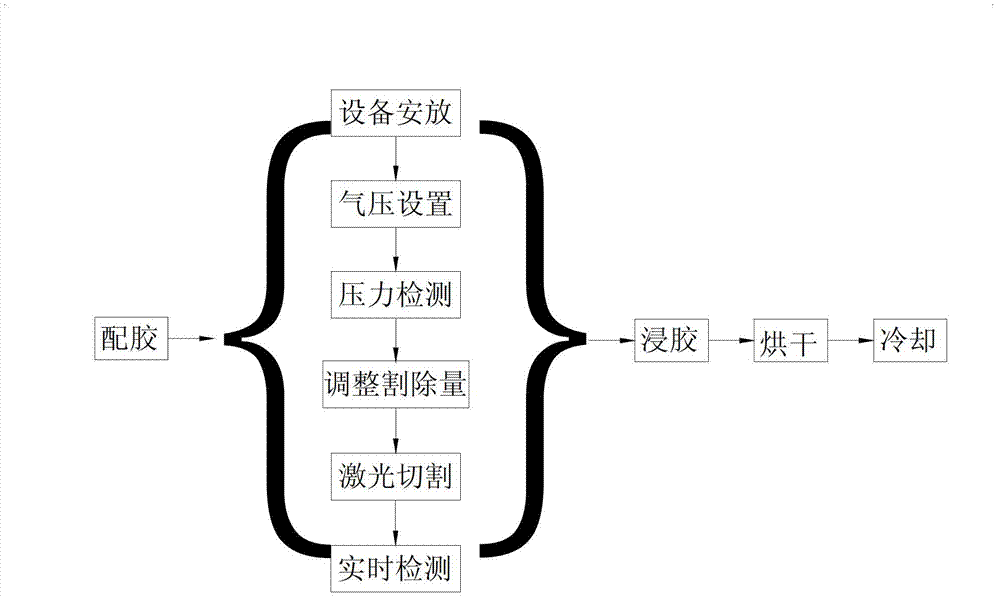

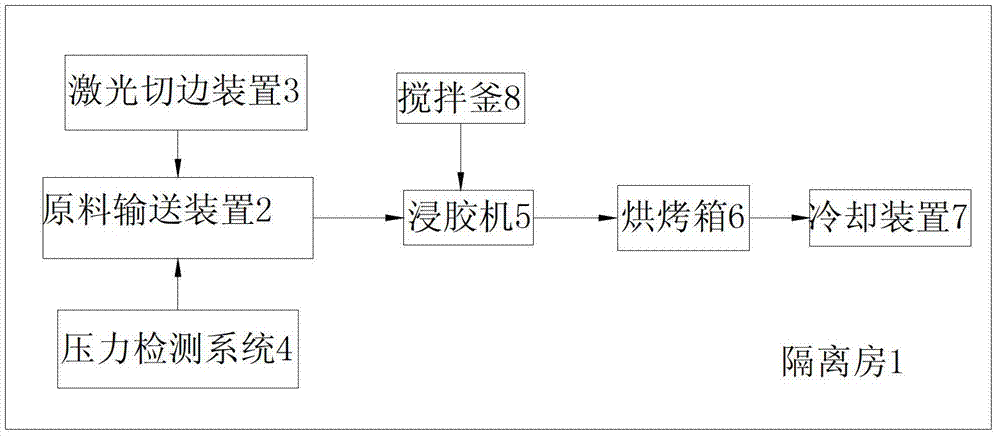

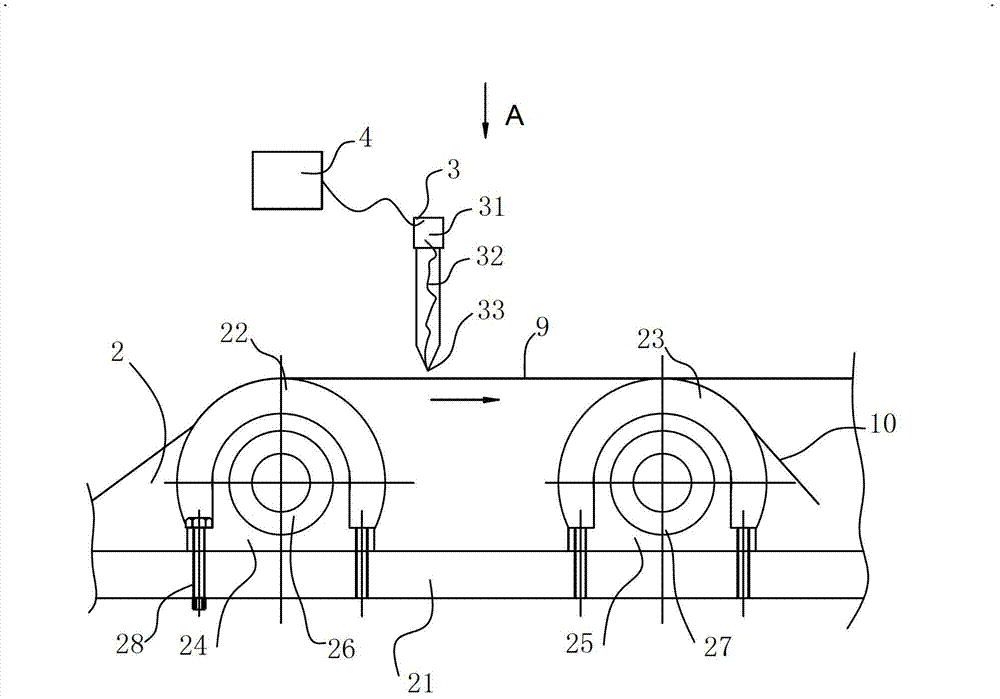

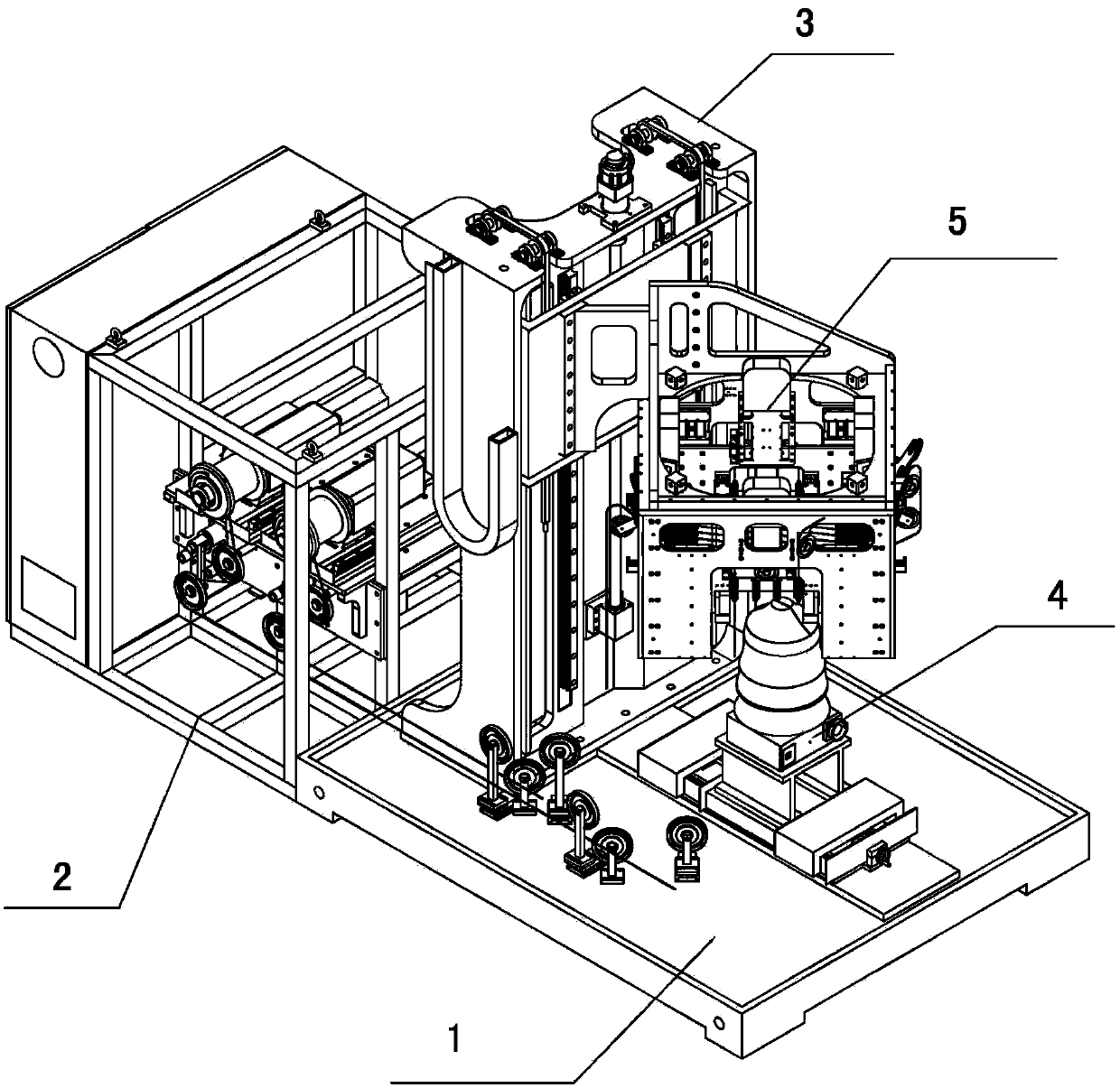

Method and device for producing prepreg

InactiveCN102922864AReduce usageTo achieve the purpose of recyclingLamination ancillary operationsLaminationColloidEngineering

The invention discloses a method for producing a prepreg. The method is specifically that undesirable edges are cut by adopting laser before material coating colloid is reinforced. By using the laser to cut the undesirable edges before the material coating colloid is reinforced, cut edges are not dipped into the colloid and can be recovered by material producing factories to be re-manufactured, the recycling purpose is achieved, and the using amount of the colloid is reduced. According to statistics and compared with traditional cutting method, 200,000 yuan of cost can be saved every year by adopting the method performing cutting while performing gum dipping, no dust cannot be produced in the cutting process of materials, the environment is protected and prevented from being polluted, and simultaneously good health of operating workers is also ensured.

Owner:GUANGDONG SHENGYI SCI TECH

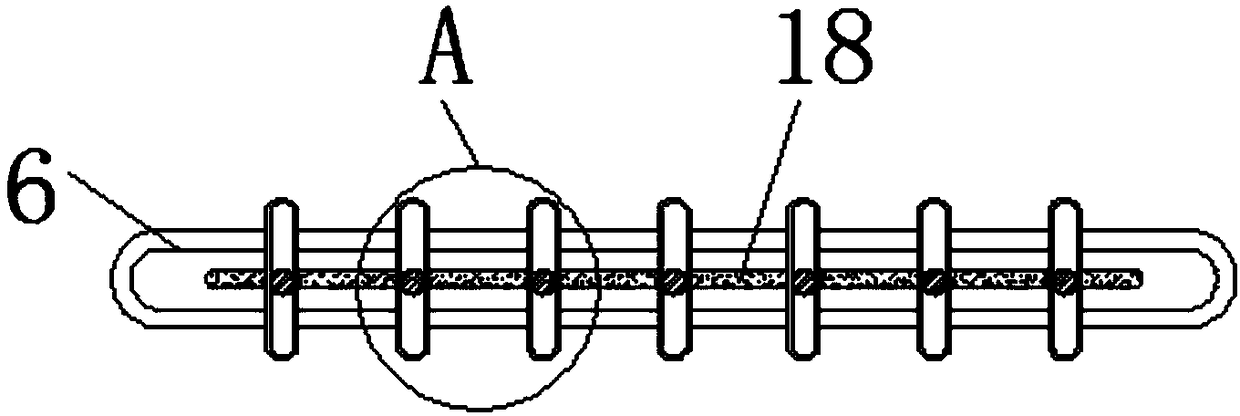

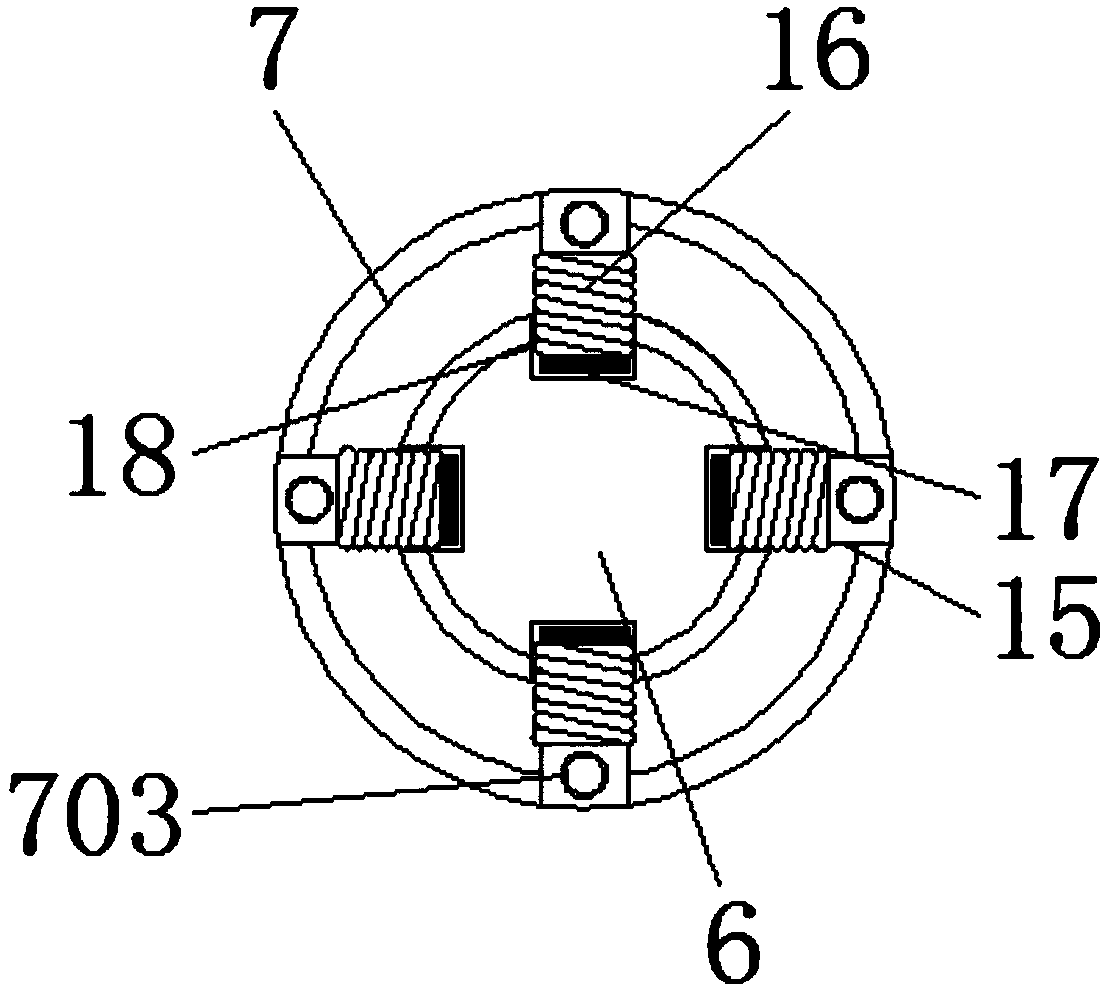

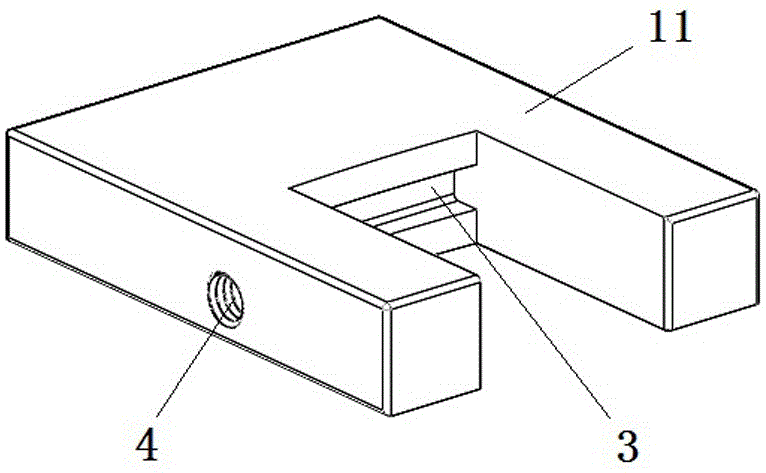

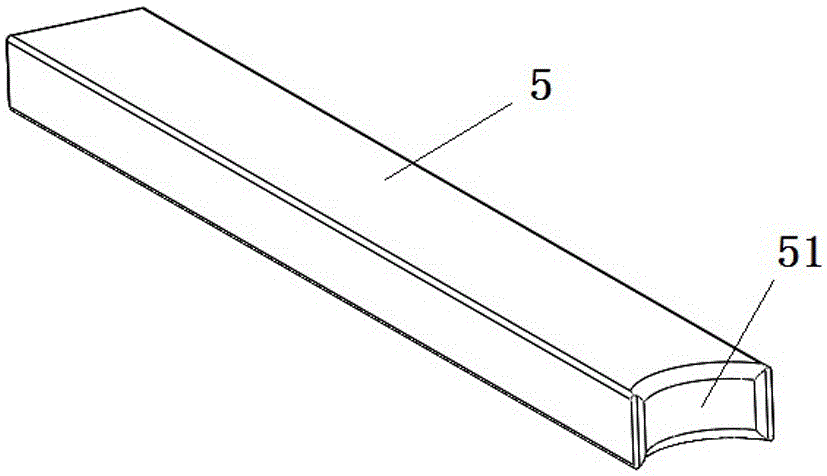

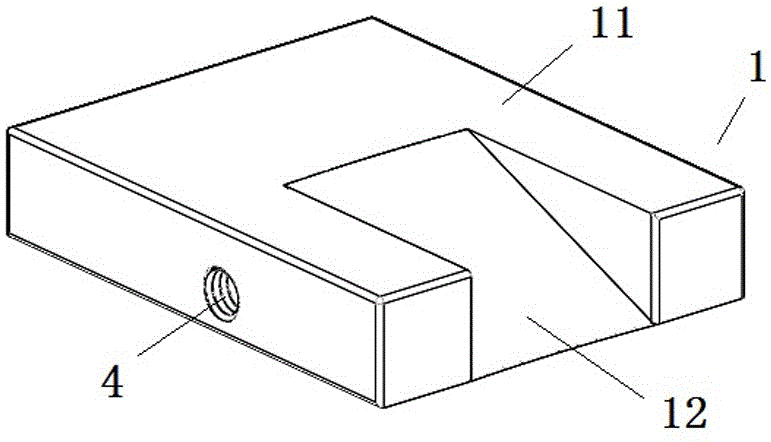

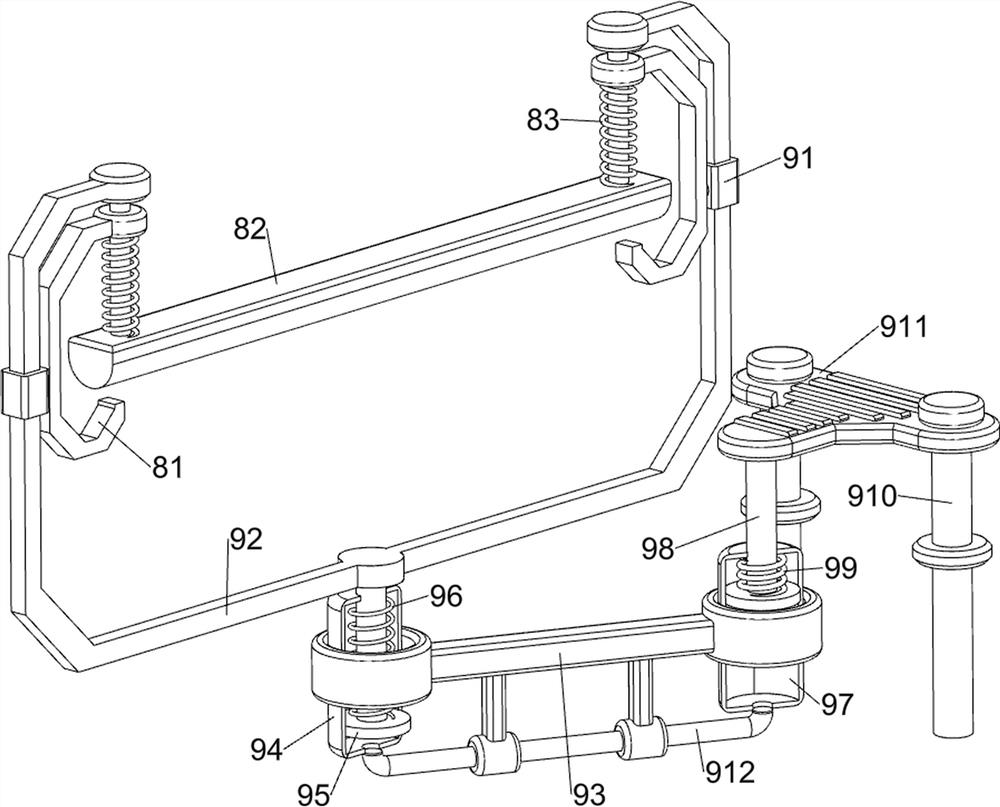

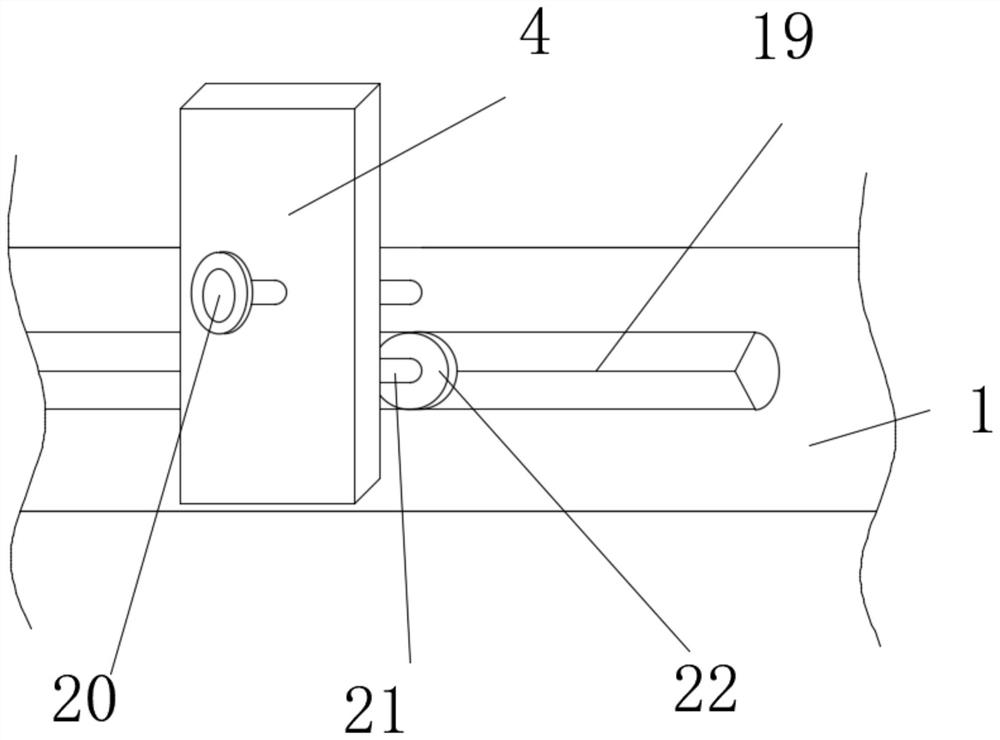

Pipe body uniform shear combination tool and working method thereof

InactiveCN106808012AExtend your lifeImprove shear efficiencyTube shearing machinesShearing toolsShear stressEngineering

The invention relates to a combined cutter for uniform shearing of a pipe body, comprising an upper shearing knife that can move up and down and a fixed lower shearing knife, the upper shearing knife includes an upper knife body and an upper blade, and the lower shearing knife The cutting knife includes a lower knife body and a lower knife edge, and both the upper knife edge and the lower knife edge have arc-shaped knife edges; the invention also relates to a working method for uniformly cutting a pipe body with a combined knife. In the tube body shearing combination tool of the present invention, the arc-shaped edge of the upper blade and the arc-shaped edge of the lower blade work together to make the shearing force more uniform, and it is easy to complete the cutting. The heat generated during the cutting process is small, the wear of the upper blade and the lower blade is small, and the phenomenon of chipping is avoided or reduced. Therefore, the structure design of the present invention is simple and reasonable, the cutting quality and cutting efficiency are high, the tool life is long, and the production cost is low. application prospects.

Owner:FUZHOU UNIV

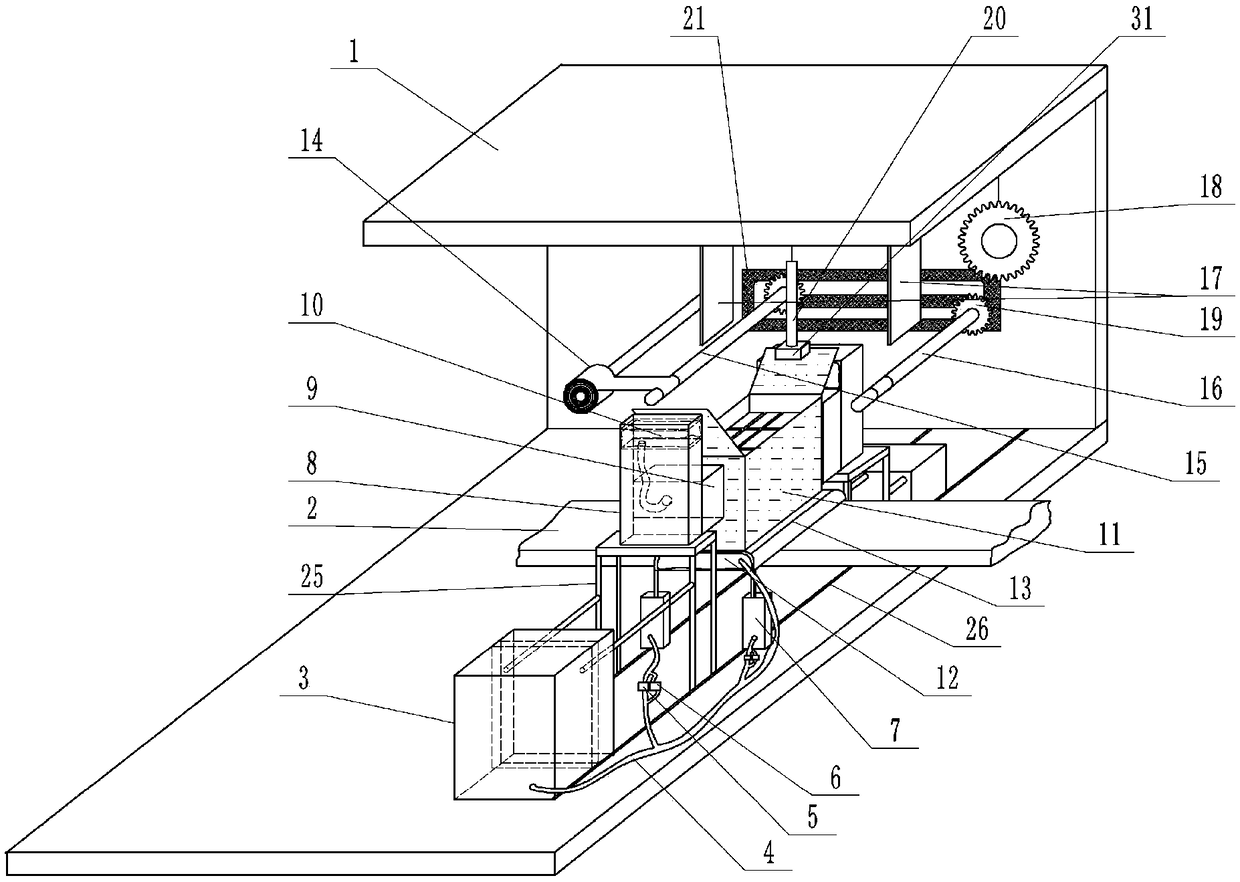

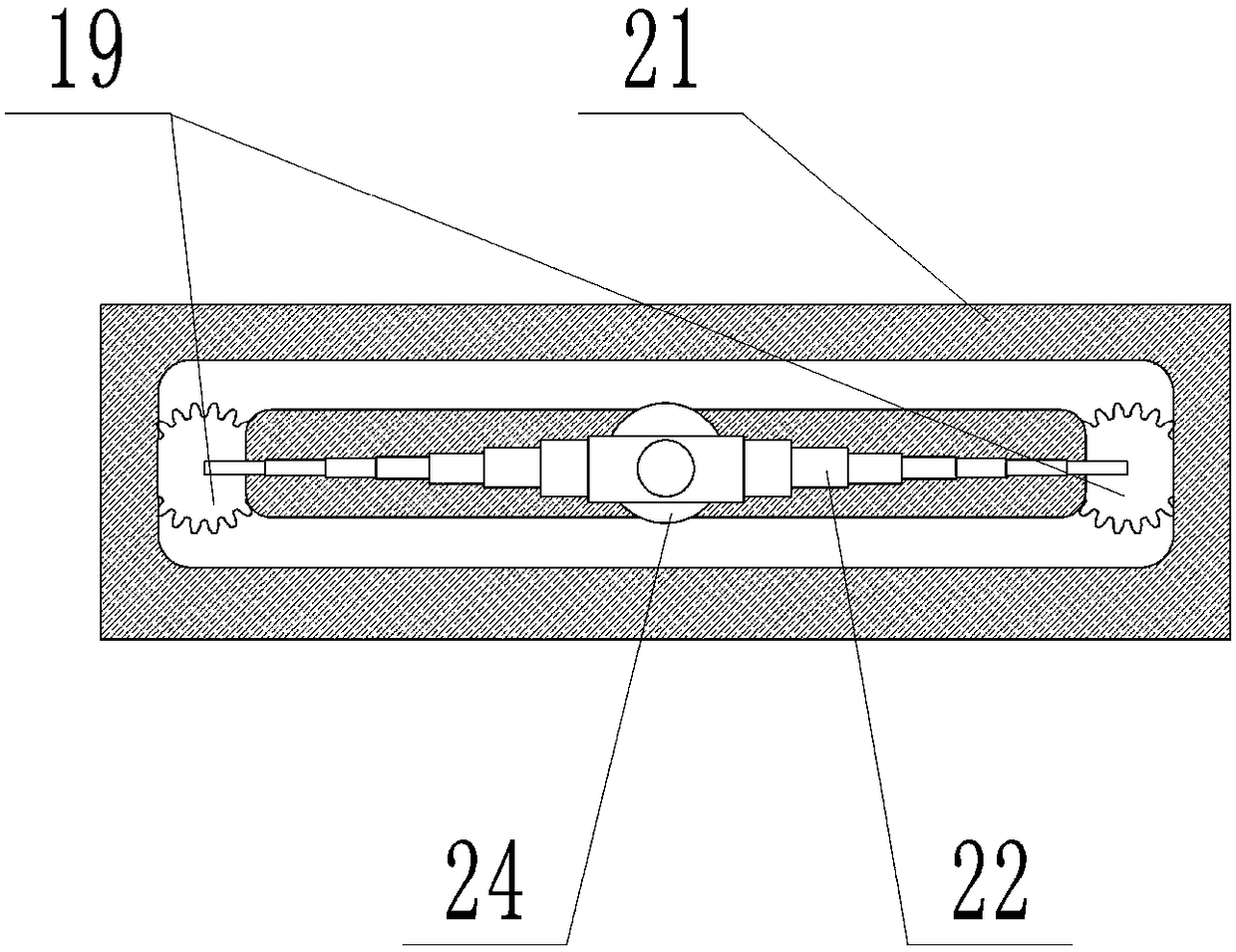

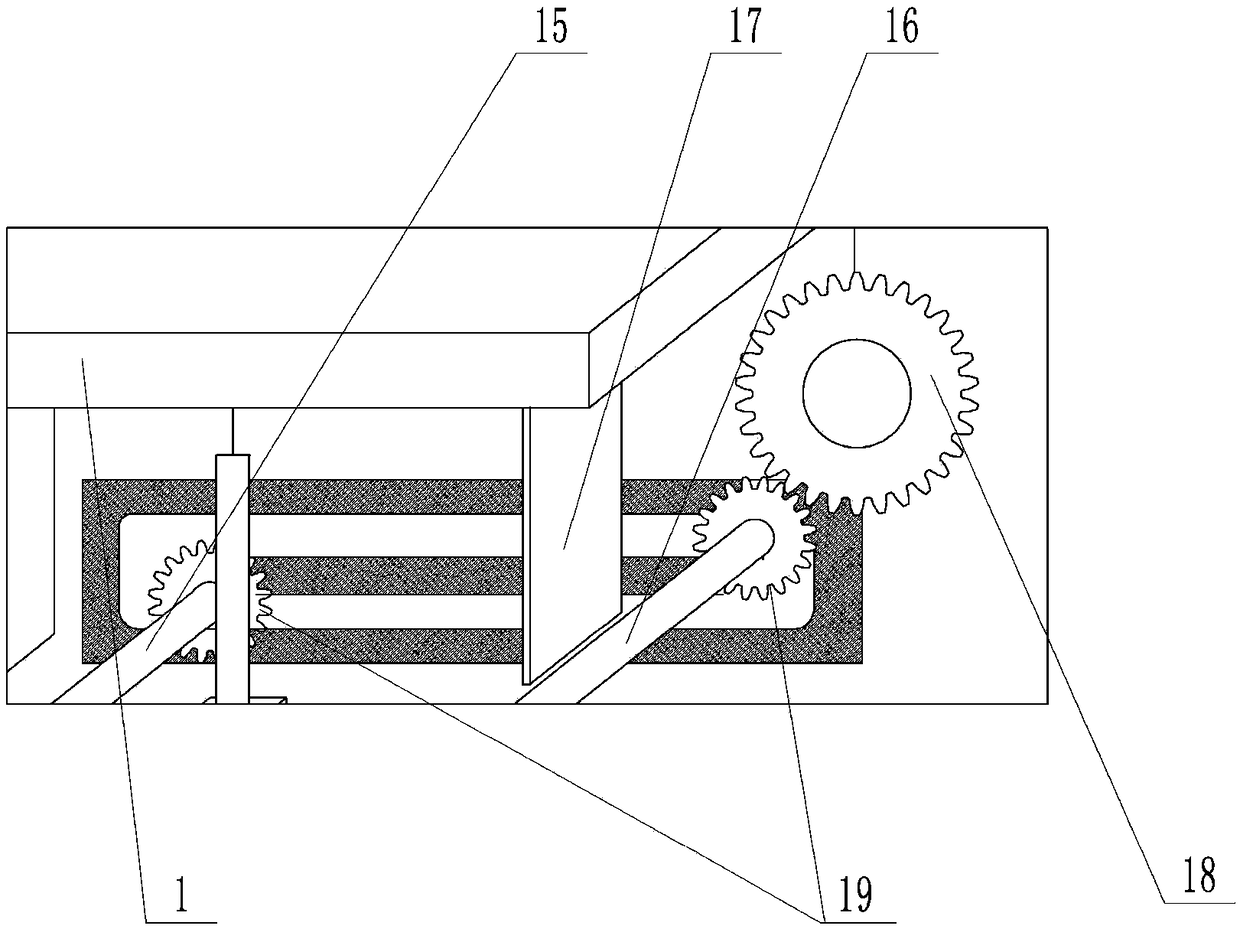

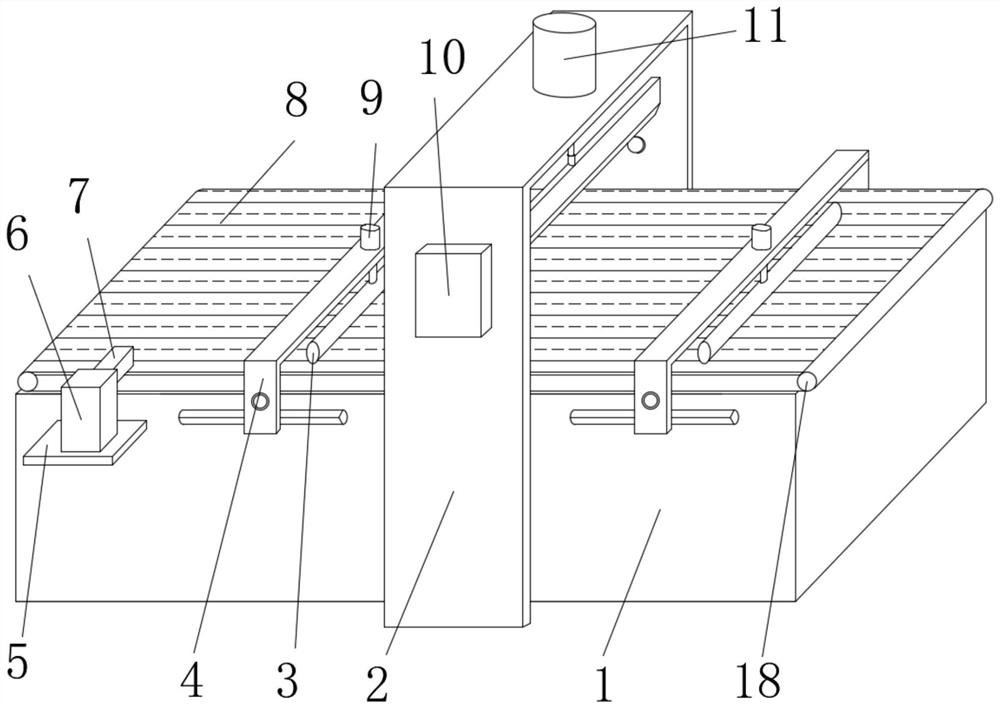

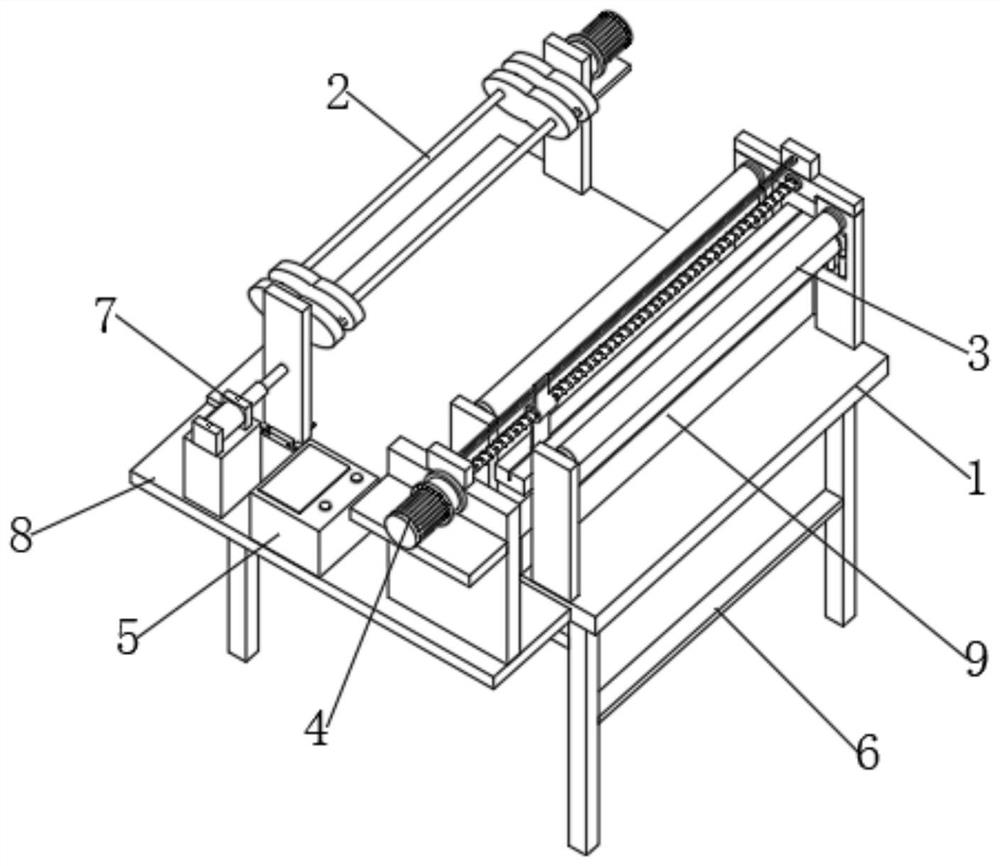

Cutting equipment for cloth bag production

ActiveCN112809793AAchieve automated deliveryRealize the purpose of automatic feedingBag making operationsPaper-makingGear wheelWorkbench

The invention relates to cutting equipment, and especially relates to cutting equipment for cloth bag production. The invention aims at providing the cutting equipment for cloth bag production, enabling a cloth notch to be smooth, realizing automatic cloth conveying, and reducing potential safety hazards. The cutting equipment for cloth bag production comprises a base, workbenches, a support, a transmission mechanism and a cutting mechanism, wherein the two workbenches are connected to the top side of the base; the support is connected to the top side of the base; the transmission mechanism is connected to the top side of the support; and the cutting mechanism is connected to the top side of the base. According to the invention, through cooperation of a servo motor, a conveying cylinder, a tooth-missing gear and a first belt conveying assembly, automatic cloth conveying is achieved, and the purpose of automatic loading is realized.

Owner:南京中隐客归网络科技有限公司

Cutting device for knitwear production

PendingCN112779758AEasy to cutEasy to useSevering textilesMetal working apparatusPortal frameIndustrial engineering

The invention discloses a cutting device for knitwear production. The cutting device comprises a main body; a first portal frame is arranged at the position, close to the middle, of the right side of the main body; a control panel is installed at the position, close to the upper side, of the front end of the first portal frame; a storage plate is fixedly connected to the position, located on the left side, of the front end of the main body; a fan is arranged at the upper end of the storage plate; an air pipe is connected to the position, close to the upper end, of the rear side of the fan; a conveying belt is arranged at the upper end of the main body; two sets of second portal frames are arranged at the position, close to the left side, of the front end of the main body; another set of second portal frames are located on the right side of the first portal frame; first air cylinders are connected to the centers of the upper ends of the two sets of second portal frames; and a second air cylinder is arranged at the position, close to the center, of the upper end of the first portal frame. When the cutting device for knitwear production is used, knitwear with different thicknesses can be cut, so that the time and labor are saved, and the cutting device is more convenient and quicker to use.

Owner:海宁市佰润贸易有限公司

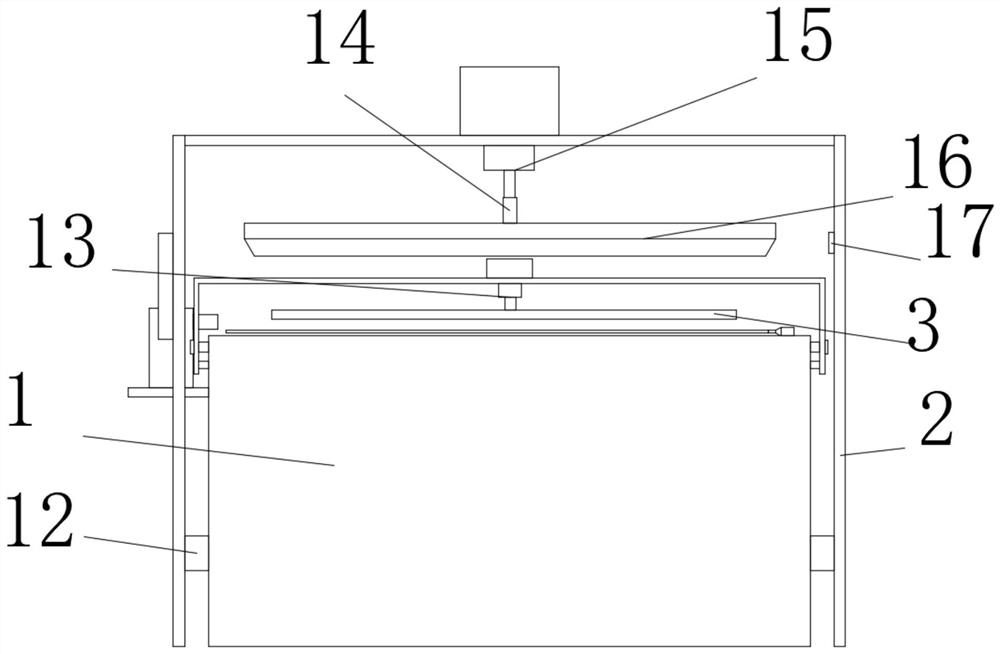

Glass cutting device for glass production

InactiveCN106082621AImprove work efficiencySmooth cutting surfaceGlass severing apparatusGlass productionEngineeringGlass production

The invention relates to a glass cutting device for glass production. The glass cutting device comprises an operation platform for glass plate loading, a pressure flat plate located above the glass plate, a lifting mechanism which is located above the glass plate and is connected to a pressure column, and a cutting lifting shaft connected to the lifting mechanism. The cutting lifting shaft is provided with a support. The support is provided with a cutting column for cutting the glass plate outside the operation platform. The glass cutting device has high work efficiency and good effects.

Owner:合肥协耀玻璃制品有限公司

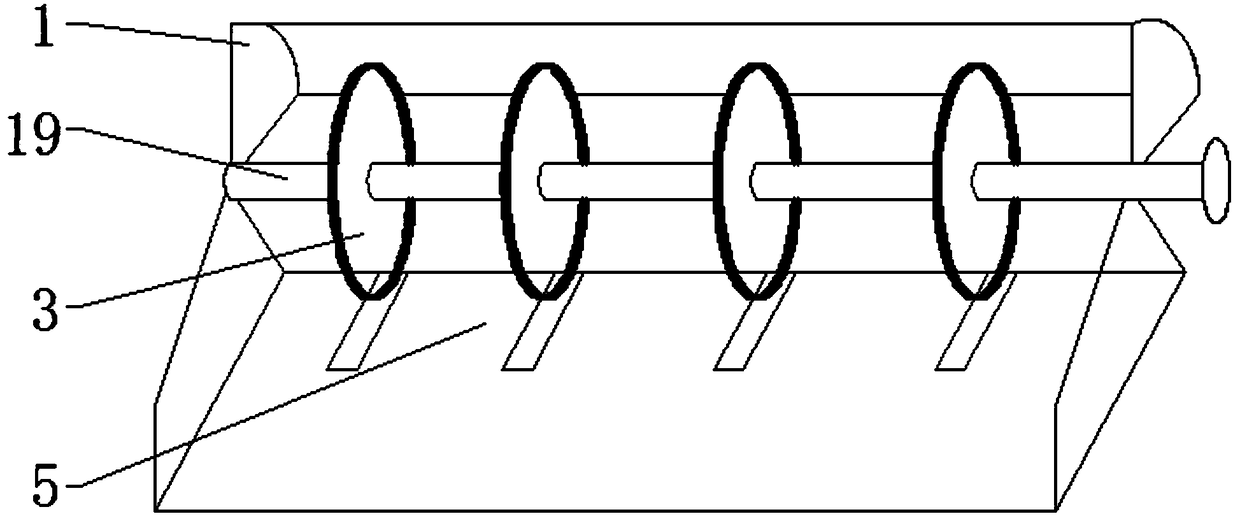

Swing type sapphire cutting machine

InactiveCN104191535AAchieve the purpose of cuttingReduce resistanceFine working devicesEngineeringConductor Coil

The invention discloses a swing type sapphire cutting machine which comprises a main framework, a pay-off and take-up mechanism, a lifting mechanism, a base and a head. The pay-off and take-up mechanism and the lifting mechanism are respectively fixedly mounted on the main framework, the head is mounted on the lifting mechanism and can move up and down on the lifting mechanism, the base is fixedly mounted on the main framework and is correspondingly arranged below the head, the head comprises a first winding set, a second winding set, a third winding set and a fourth winding set, and the lifting mechanism is arranged on the winding sets and drives the winding sets to ascend and descend, so that diamond wires are in point contact with sapphire instead of line contact, and the sapphire can be smoothly cut. The swing type sapphire cutting machine has the advantages that the swing type sapphire cutting machine is provided with the swing type head, the diamond wires are in point contact with the sapphire instead of surface contact in sapphire cutting procedures, accordingly, resistance can be reduced in the cutting procedures, and the purpose of cutting the sapphire can be achieved.

Owner:高本龙

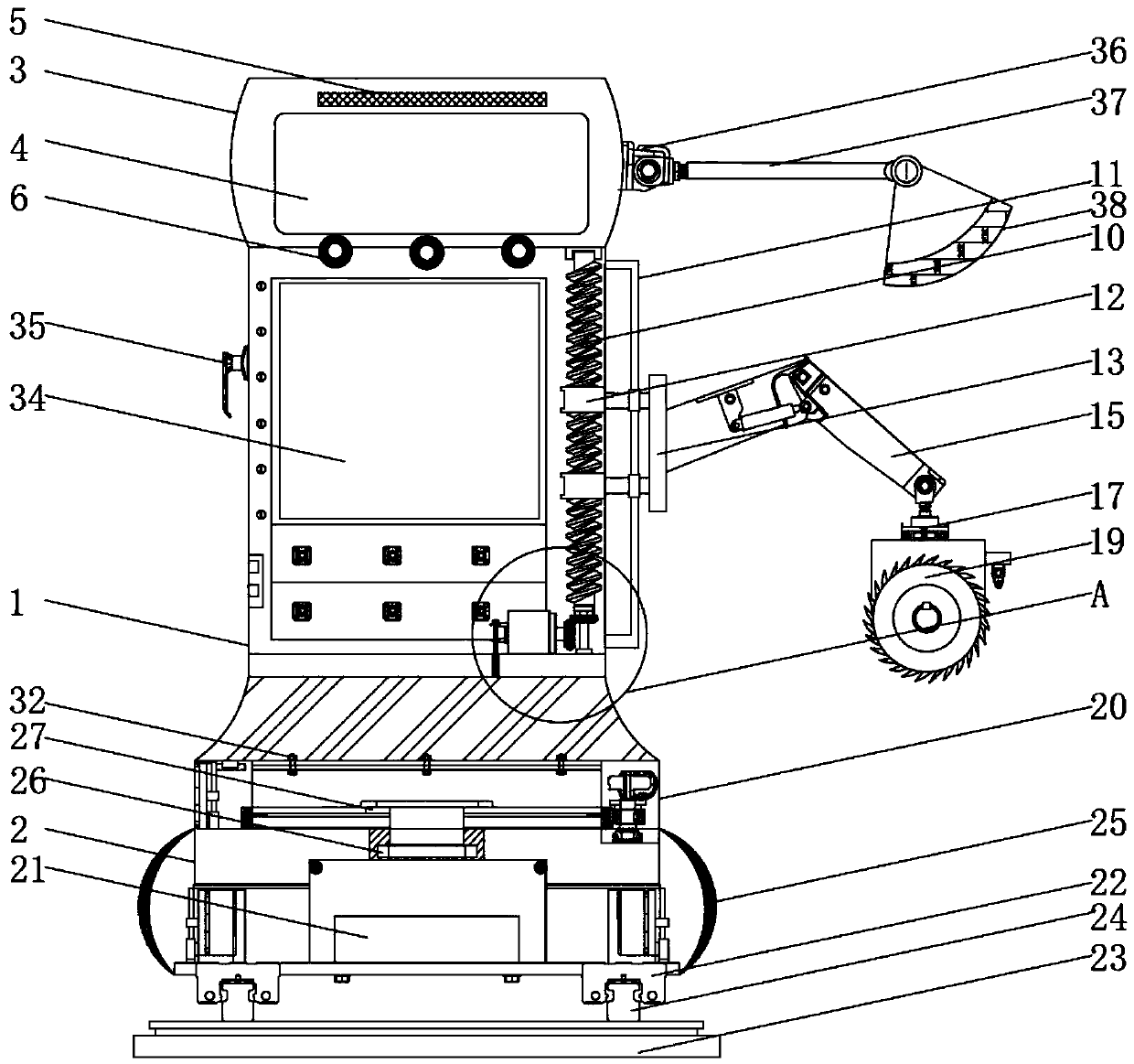

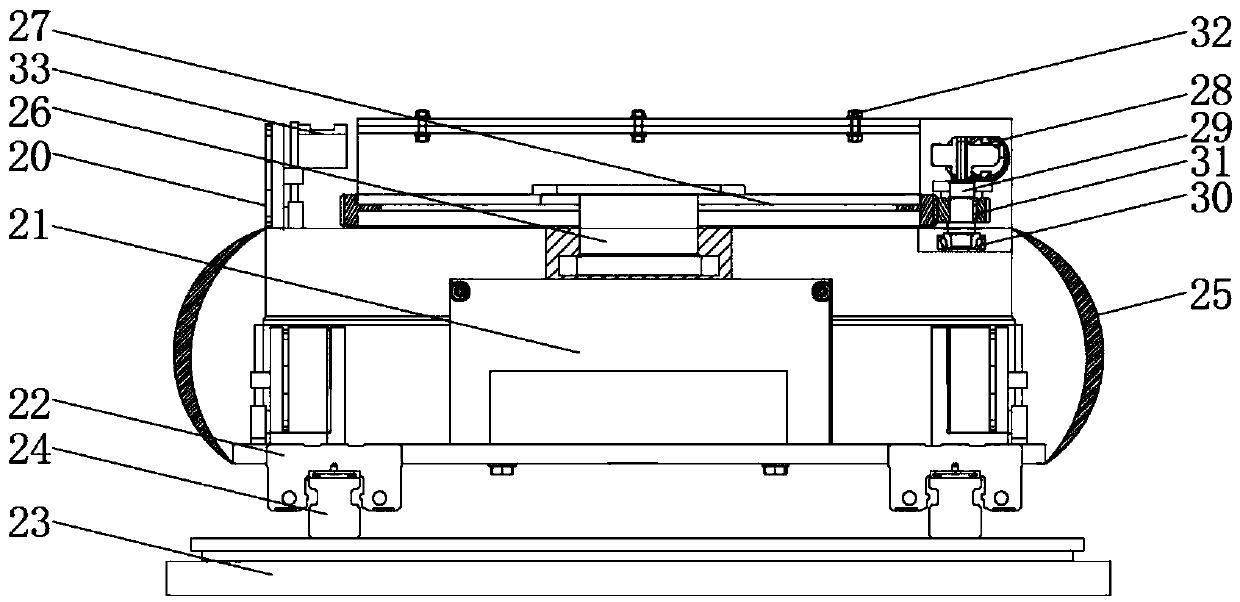

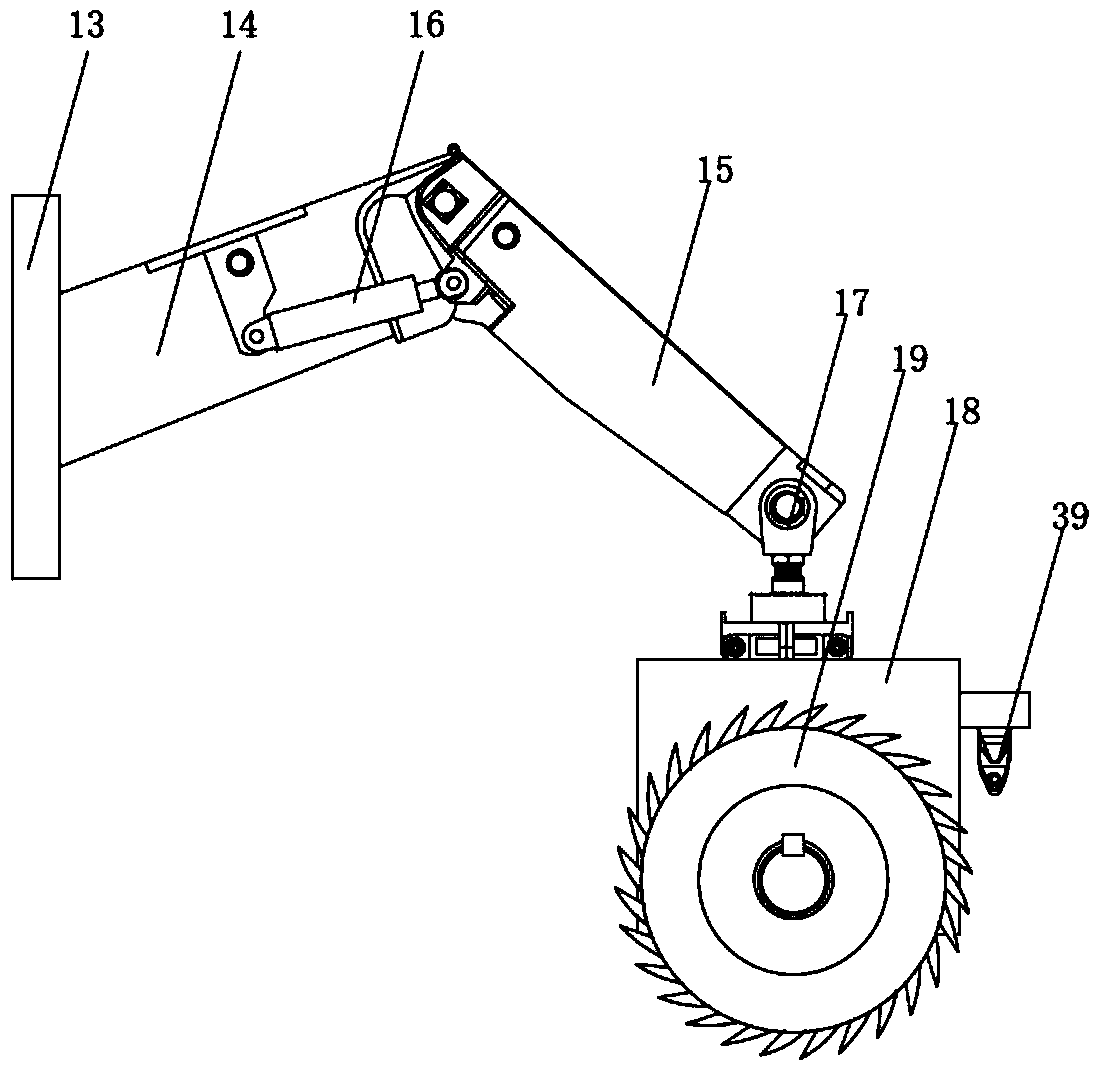

Intelligent wood cutting robot

InactiveCN109623959AAchieve the purpose of cuttingReduce riskProfiling/shaping machinesManipulatorTablet computerControl system

The invention discloses an intelligent wood cutting robot, and relates to the technical field of intelligent robots. The robot comprises a robot body, the robot body comprises a robot truck and a robot base, wherein a rotating module is arranged between the robot truck and the robot base, a robot control module is arranged at the top of the robot truck, a control system is arranged inside the robot control module, a control tablet computer is arranged on the outer side of the robot control module, the bottom of the inner wall of the robot truck is fixedly connected with a lifting motor, an output shaft of the lifting motor is provided with a bevel gear I, and a bevel gear II is connected with the upper part of the bevel gear I in a meshing mode. According to the intelligent wood cutting robot, the purpose of cutting wood is achieved, safety protection for workers can be realized, the risk of work can be reduced, the height of mechanical arms for cutting and the angle between the mechanical arms for cutting can be freely adjusted, so that the overall angle adjustment and movement can be facilitated.

Owner:李聪聪

Harvester capable of effectively separating and crushing weeds

InactiveCN112616426AAvoid mixingAchieve the purpose of cuttingMowersAgricultural engineeringMechanical engineering

The invention discloses a harvester capable of effectively separating and crushing weeds. The harvester comprises a harvesting carrier, a cutting cavity with a leftward opening is formed in the harvesting carrier, a transmission cavity is formed at the upper end wall of the cutting cavity in a communicating manner, and a sliding cavity is formed in the left end wall of the transmission cavity and communicates with the outside. The harvester is mainly applied to the process that green grass on a lawn is harvested to be used for feeding back soil, in the harvesting process, a powerful wind wheel is triggered by an adsorption mechanism to rotate, then the weeds in green grass piles are strongly adsorbed by the powerful wind wheel to enter an adsorption cavity to be placed, and then the weeds are prevented from being mixed into the green grass; and meanwhile, the purpose of cutting the green grass is achieved through rotation of a cutting tool, the green grass can fall down from a high position through a pulling mechanism to be thoroughly cut and crushed by a crushing tool and is finally discharged through a discharging cavity, the effect of feeding back soil is achieved, and then the soil is more fertile.

Owner:成都市新都区灰范商贸有限公司

Circuit board cutting device with good fixing effect

InactiveCN109877893ASmooth rotationCompact structurePrinted circuit manufactureMetal working apparatusEngineeringElectrical and Electronics engineering

The invention discloses a circuit board cutting device with a good fixing effect. The circuit board cutting device with the good fixing effect comprises a bottom board; the lower surface of the bottomboard is fixedly connected with two first fixing rods; the opposite faces of the two first fixing rods are fixedly connected with the left side face and the right side face of a first drive device separately; the surface of the first drive device is in threaded connection with a threaded cap; the threaded cap is clamped on the upper surface of a movable board; the upper surface of the movable board is fixedly connected with the lower surface of the bottom board through a telescopic device; and the telescopic device is located on the right side of the first drive device. According to the circuit board cutting device with the good fixing effect, through mutual cooperation of a first motor, a threaded column, the threaded cap, the movable board, a telescopic rod, a spring, a slide rod, an extrusion board, a carrier board, a rotary shaft, a first gear, a second gear, a second motor and a cutting piece, the purpose of fixing circuit boards and cutting the circuit boards is achieved, and errors caused by movement of the circuit boards during movement are avoided.

Owner:江门市新会区高航信息咨询有限公司

Winding device with cutting structure for chemical fiber braid

PendingCN112678592AQuick installationQuick releaseSevering textilesWebs handlingFiberHydraulic cylinder

The invention discloses a winding device with a cutting structure for a chemical fiber braid. The winding device comprises a table plate, a supporting frame, a winding mechanism, two sets of pressing mechanisms, a cutting assembly, a supporting mechanism, a mounting plate, a pushing mechanism, and a control box, wherein the supporting frame is fixedly arranged at the lower end of the table plate, the winding mechanism is fixedly arranged on the front portion of the upper end of the table plate, the two sets of pressing mechanisms are fixedly arranged on the rear portion of the upper end of the table plate, the cutting assembly is arranged above the two sets of pressing mechanisms, the supporting mechanism is arranged between the two sets of pressing mechanisms, the mounting plate is fixedly arranged at the left end of the table plate, the pushing mechanism and the control box are fixedly arranged at the upper end of the mounting plate, the pushing mechanism is composed of a base and a second hydraulic cylinder fixedly arranged at the upper end of the base, and the winding mechanism is composed of a driving mechanism and a winding assembly. According to the winding device with the cutting structure for the chemical fiber braid, the winding assembly is conveniently and rapidly mounted and dismounted, the winding assembly is conveniently replaced, operation is easy, convenient and fast, automatic cutting can be carried out without the help of external cutting equipment, and the winding device has wide application prospects and is suitable for popularization.

Owner:吴江保利化纺有限公司

Metal ring machining system

InactiveCN113714911AAchieve the purpose of cuttingAvoid burrs and other phenomenaEdge grinding machinesRevolution surface grinding machinesMachining systemWorkbench

The invention belongs to the technical field of cutting machining equipment, and particularly relates to a metal ring machining system. The system comprises a workbench, a feeding grinding component used for grinding the outer circumferential face of a metal ring is arranged on the workbench, and a clamping component is arranged on the workbench. An internal grinding part used for grinding the inner circumferential face of the metal ring is further arranged on the workbench, the functions of automatically cutting the metal ring and grinding the inner face and the outer face can be achieved, the cutting flatness of the metal ring is guaranteed, and the follow-up machining difficulty is reduced.

Owner:杭州富阳锋拓机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com