Livestock breeding ox horn cutting device

A cutting device and technology of horns, applied in the field of animal husbandry, can solve problems such as head muscle and nerve injuries, high physical exertion of personnel, and horns hurting people, and achieve the effects of reducing damage, improving cutting efficiency, and improving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

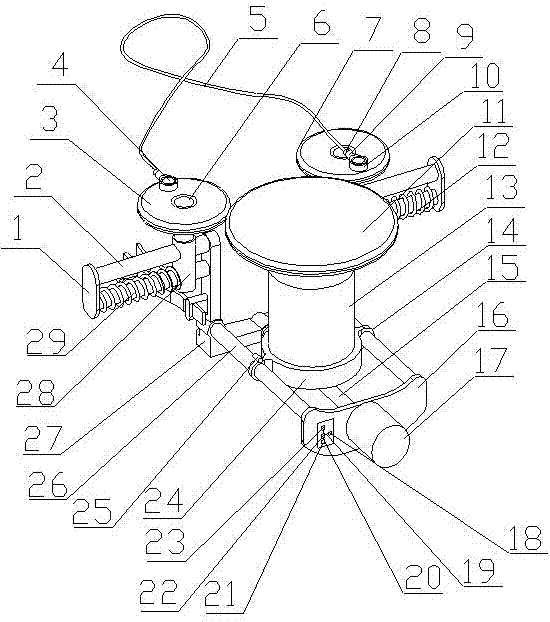

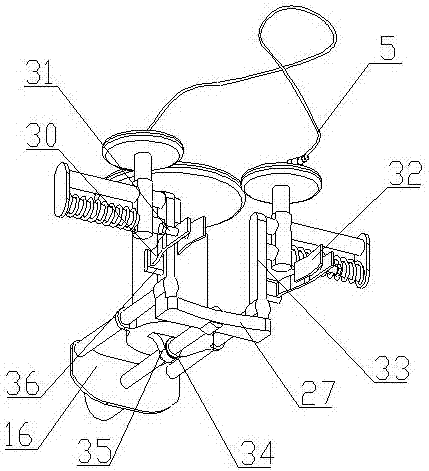

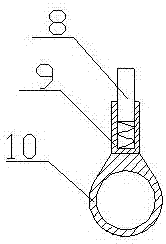

[0029] A cattle horn cutting device for livestock breeding in the present invention is realized in this way. When in use, when cutting cattle horns, firstly adjust the two clamping plates (32) through two adjustment rods, so that the two clamping plates (32) are respectively Clamp on both sides of the horn root, and wrap the wire saw in a circle at the cutting position above the solid part of the horn root, the drive motor (13) works, and drives the drive disc (11) to rotate, and the drive disc (11) is driven by friction Drive the two driven discs (3) to rotate, and the two driven discs (3) rotate in the same direction. During the rotation process, the two driven discs (3) drive the wire saw to move back and forth, and then the wire saw cuts the horns , at the same time, the fixed motor (17) rotates, and drives the threaded shaft (15) to rotate, and then the threaded shaft (15) drives the threaded sleeve (34) to move on the threaded shaft (15), and the threaded sleeve (34) pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com