Patents

Literature

110results about How to "Increased depth of cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

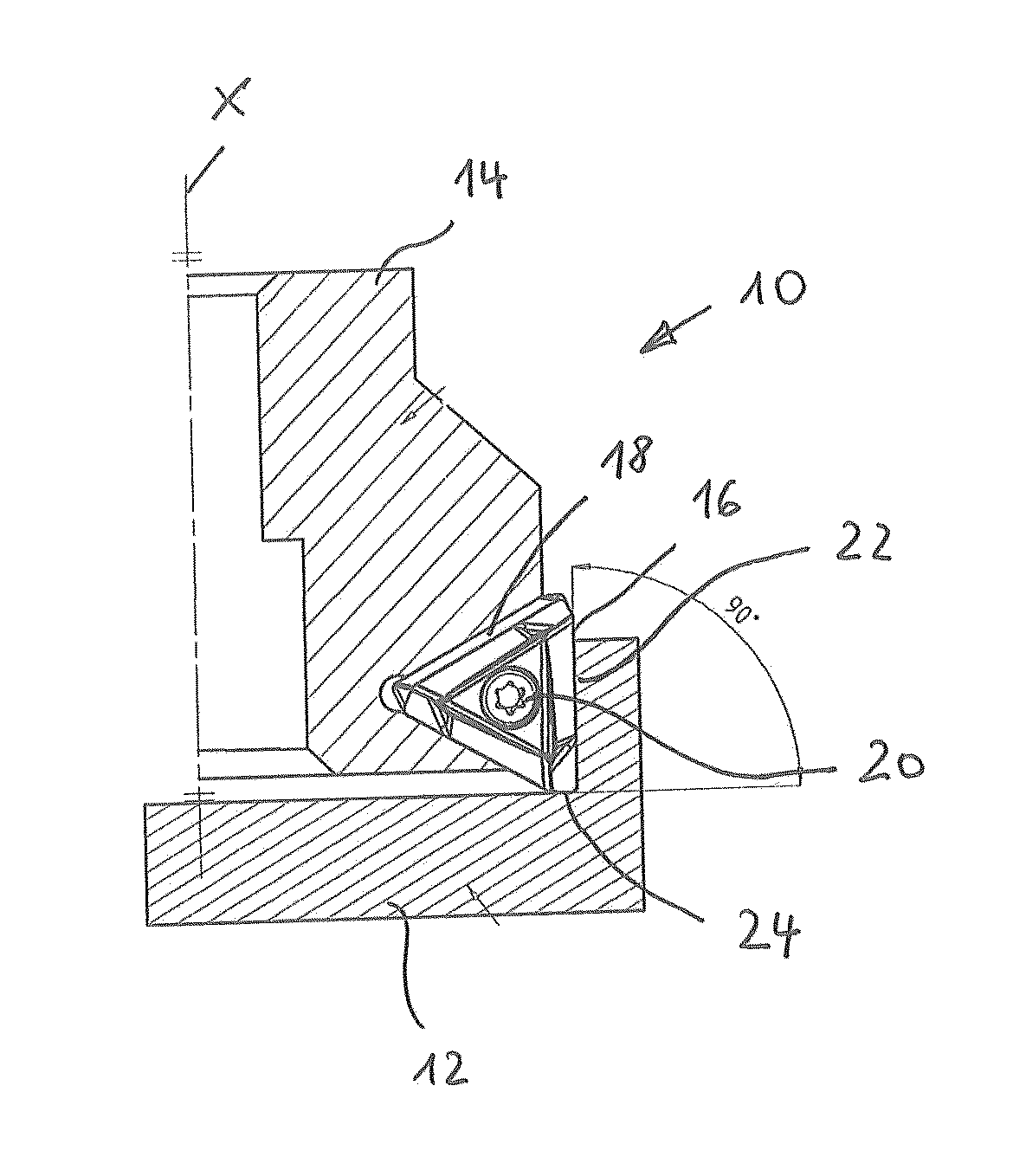

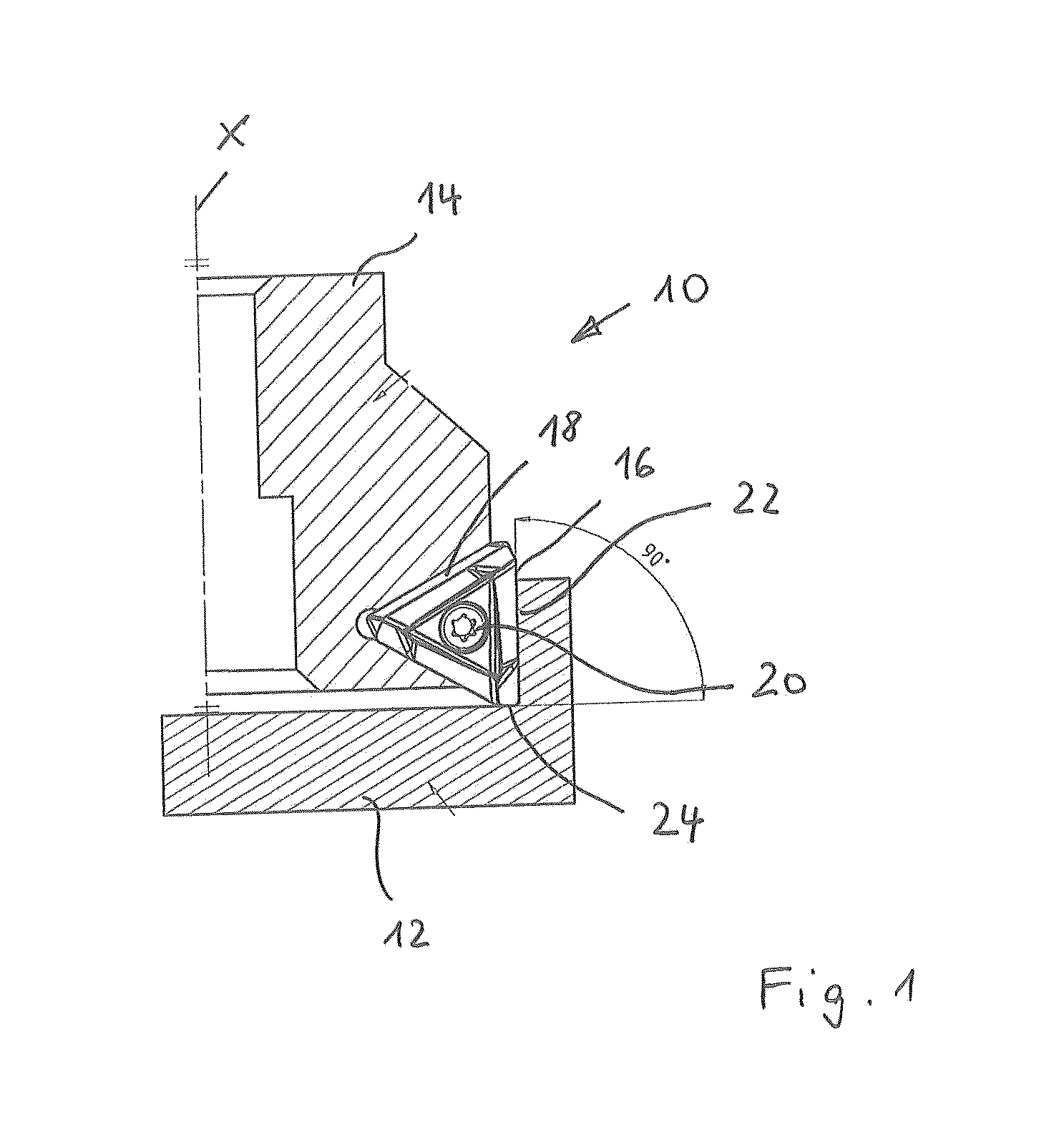

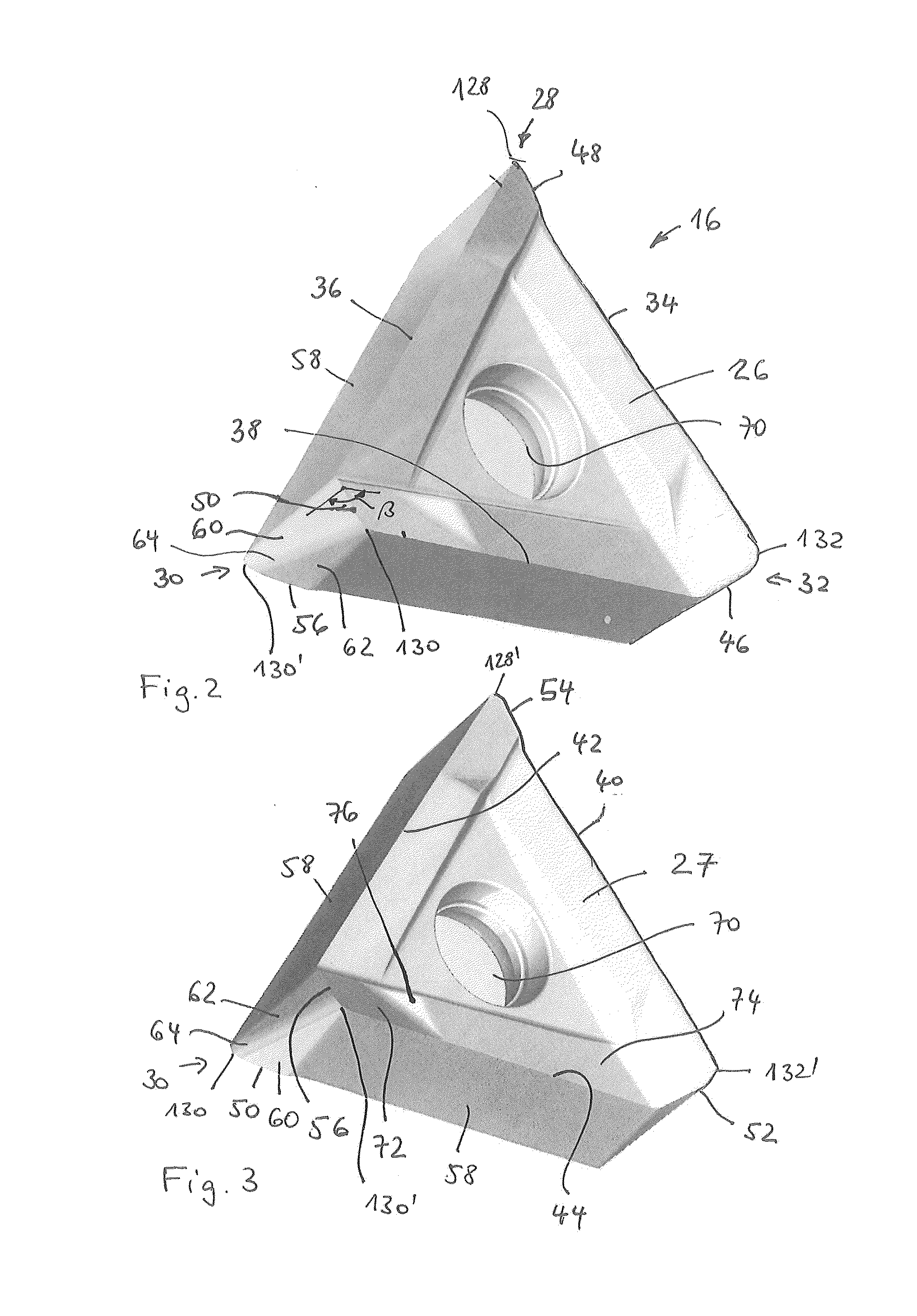

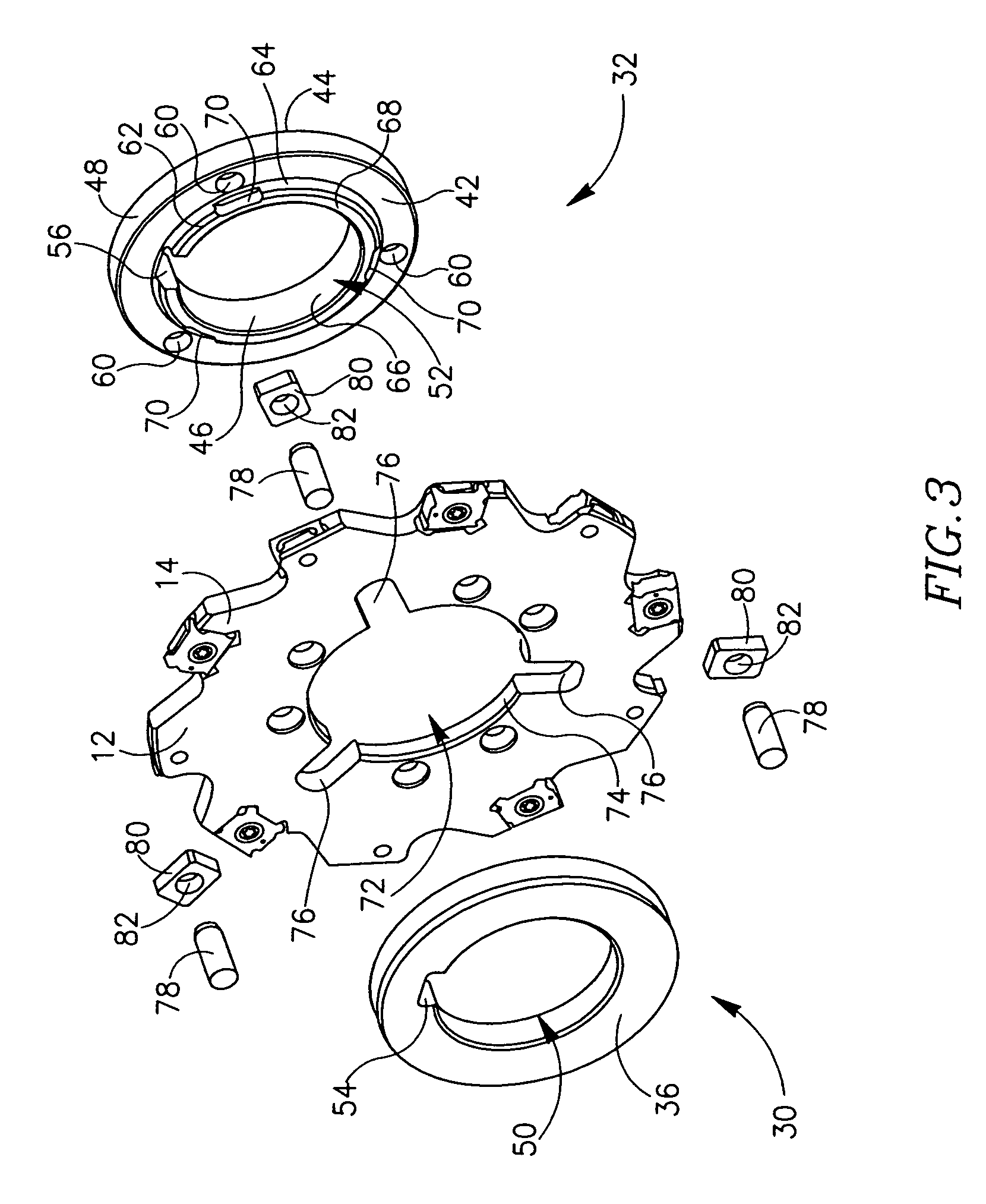

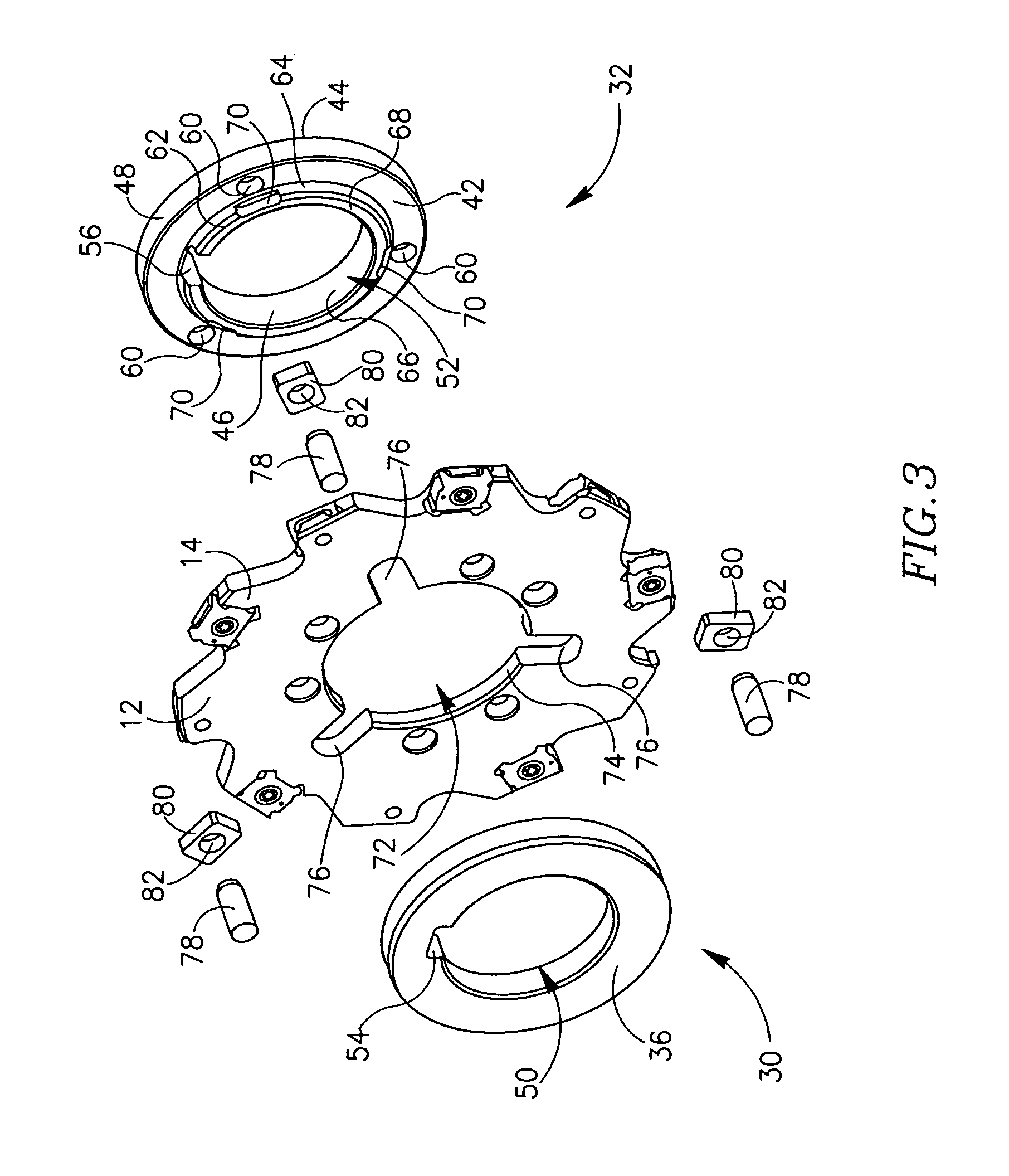

Triangle insert with multiple cutting edges and milling cutter therefor

ActiveUS20130004251A1Increase tool lifeSimplify producibilityMilling cuttersTurning toolsKnife bladesMilling cutter

An indexable insert (16) having a triangular shape with a top surface and a bottom surface (26), as well as a circumferential surface which connects said surfaces, has cutting edges around the corners (28-32). At least in the region of its edges on the top and bottom surface (26), the indexable insert (16) is identical such that all six cutting edges can be used for the same rotational cutting direction. The secondary cutting edges (46, 48, 50) adjoin two main cutting edges (34, 36, 38) and extend at different angles with respect to the same. Over and above this, a surface corner milling cutter with a corresponding indexable insert (16) is described.

Owner:KENNAMETAL INC

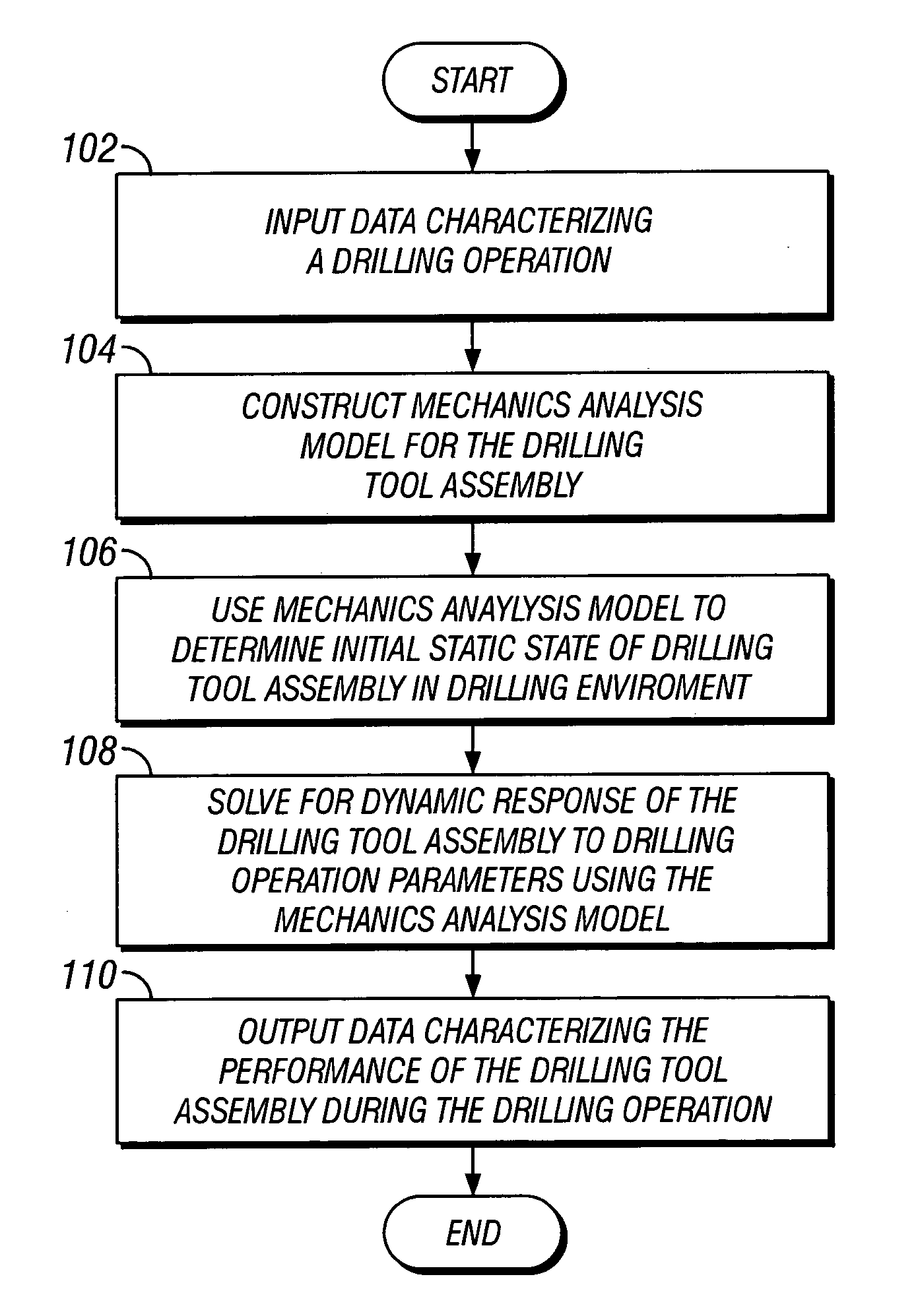

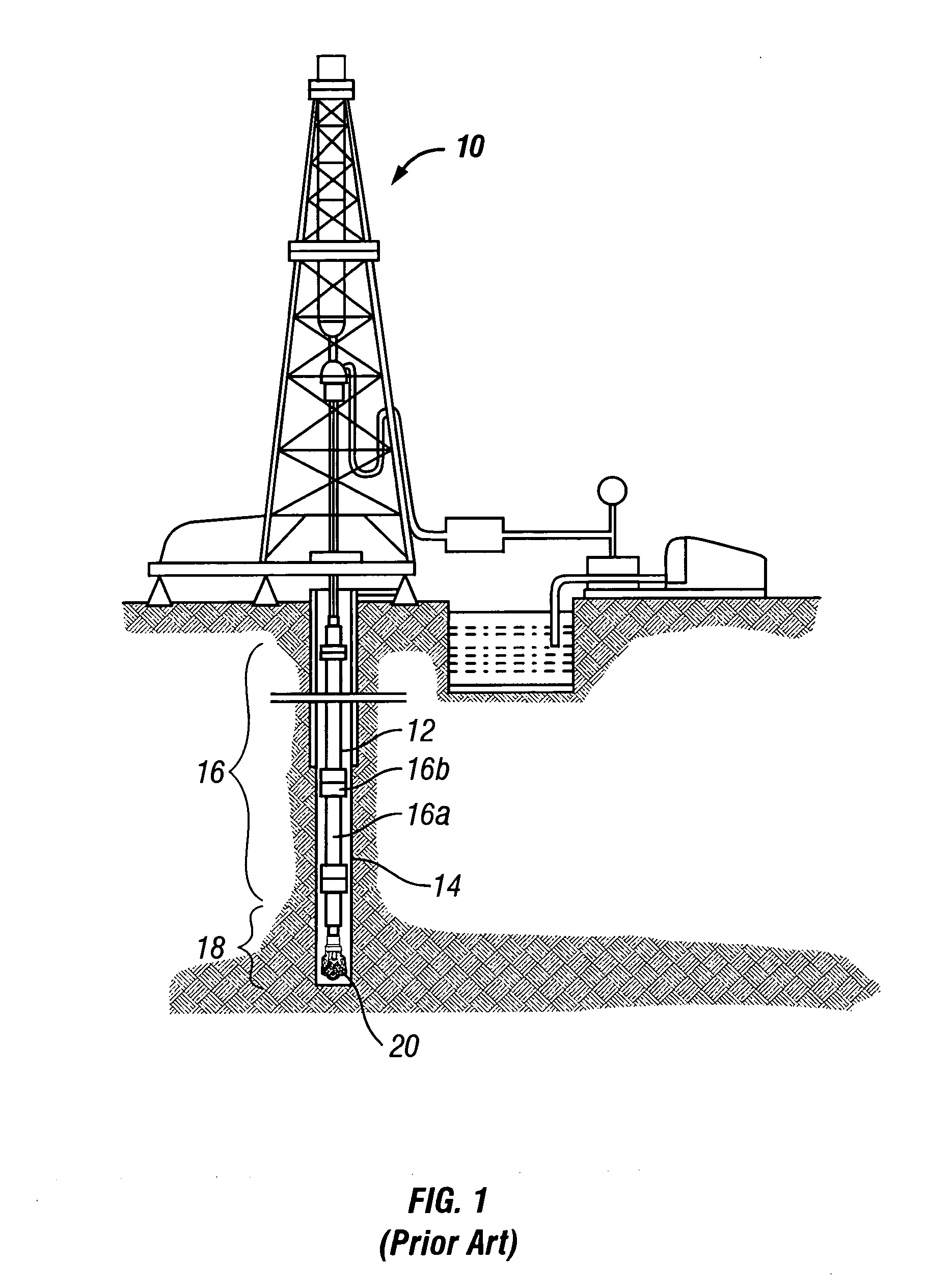

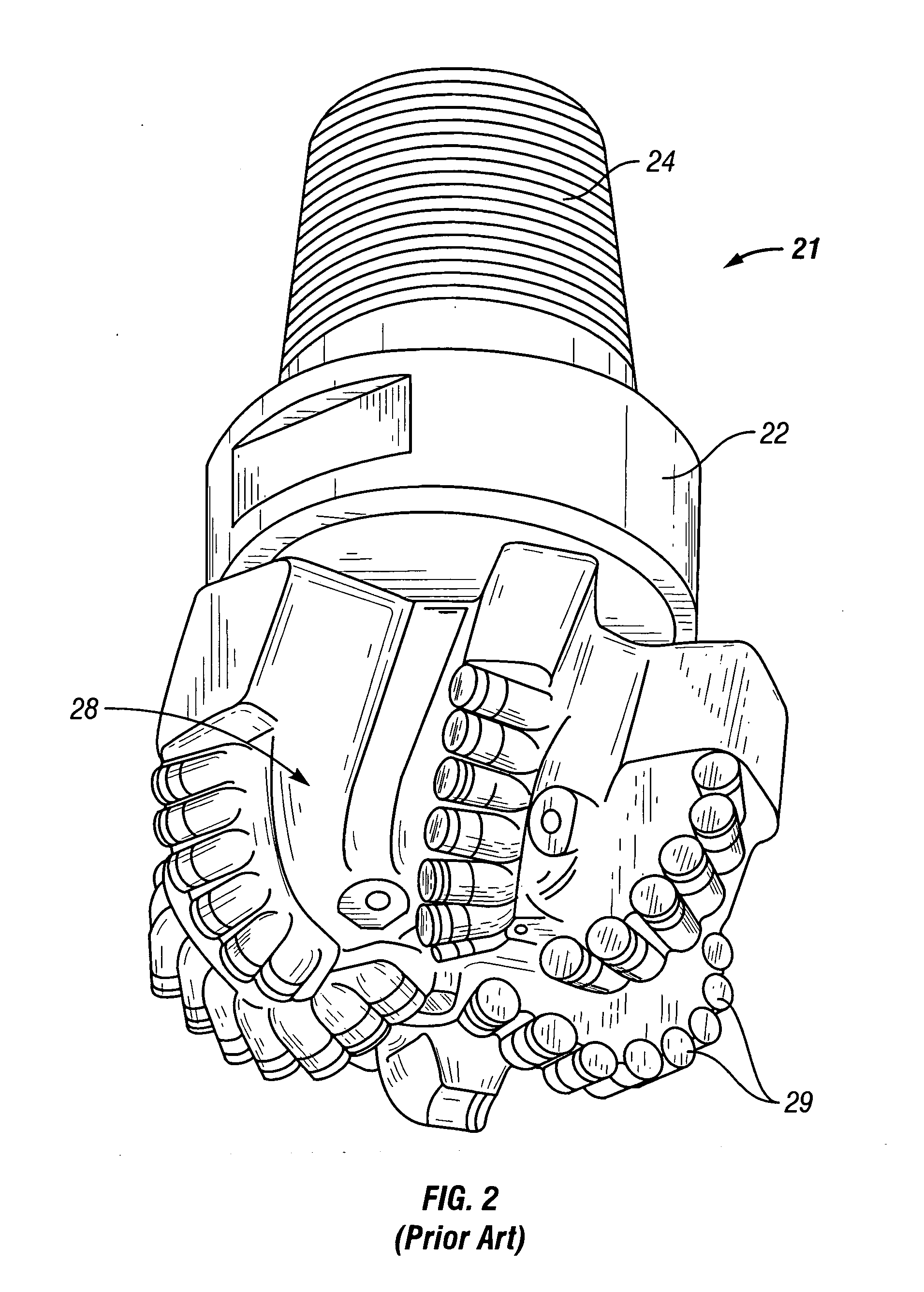

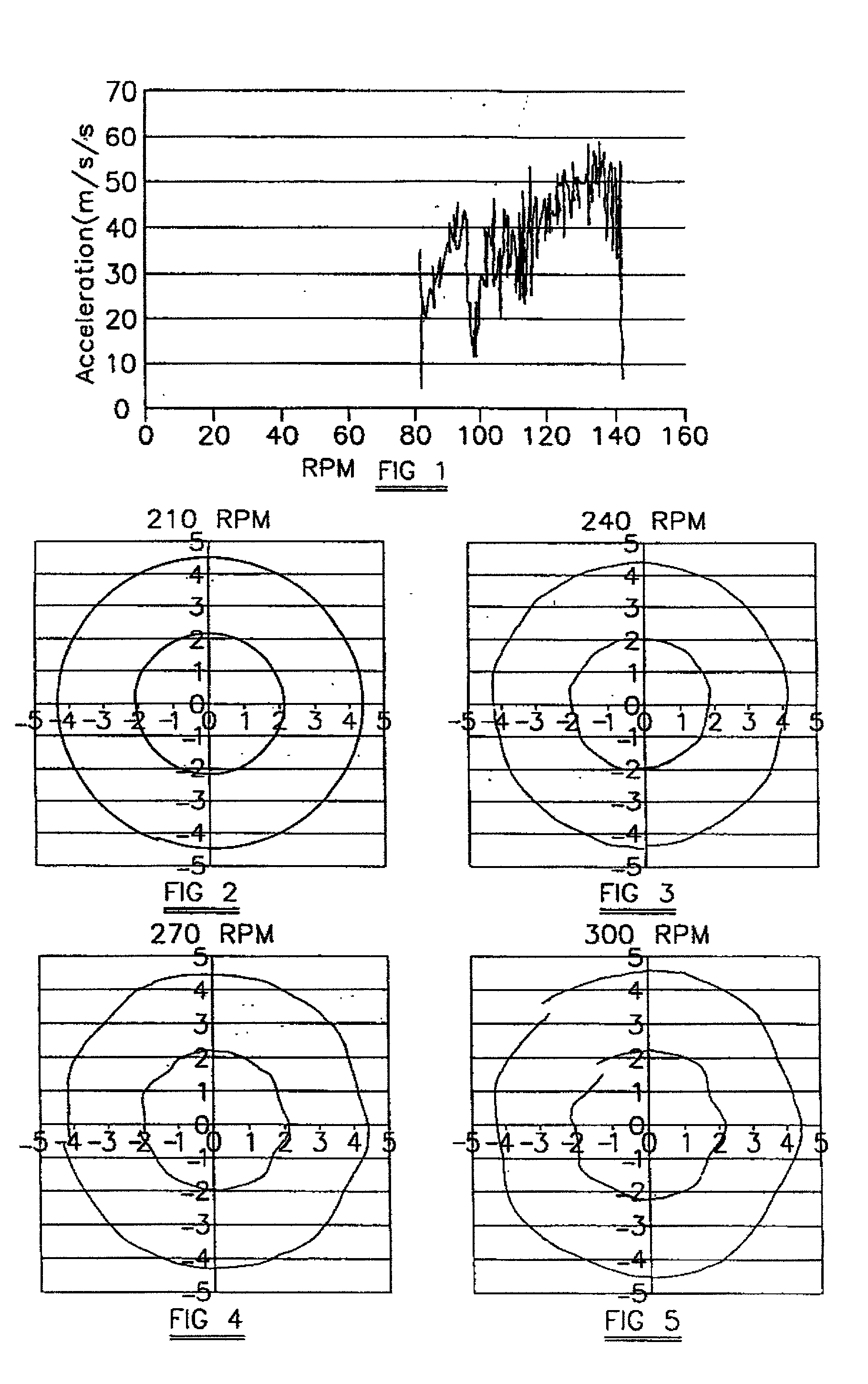

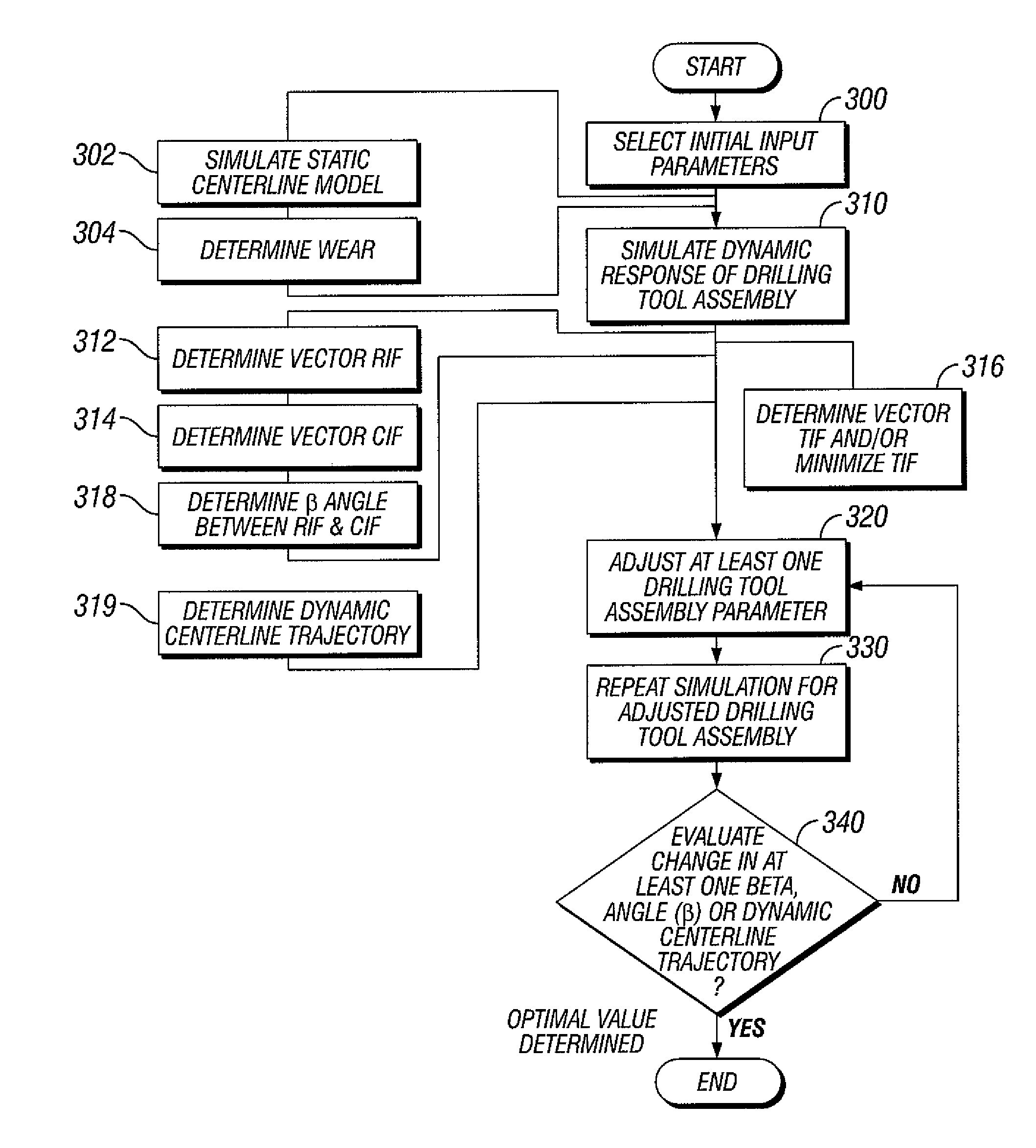

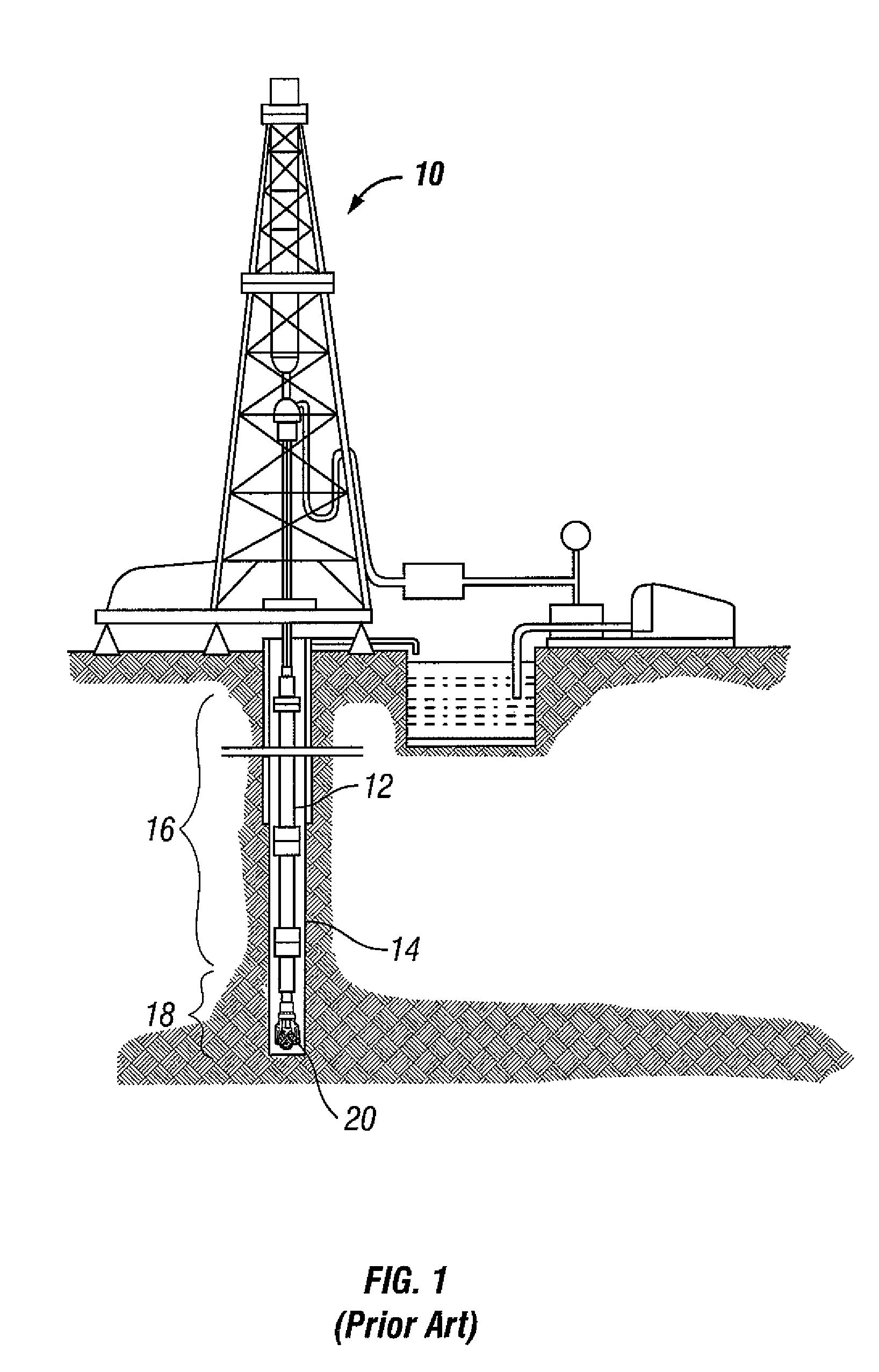

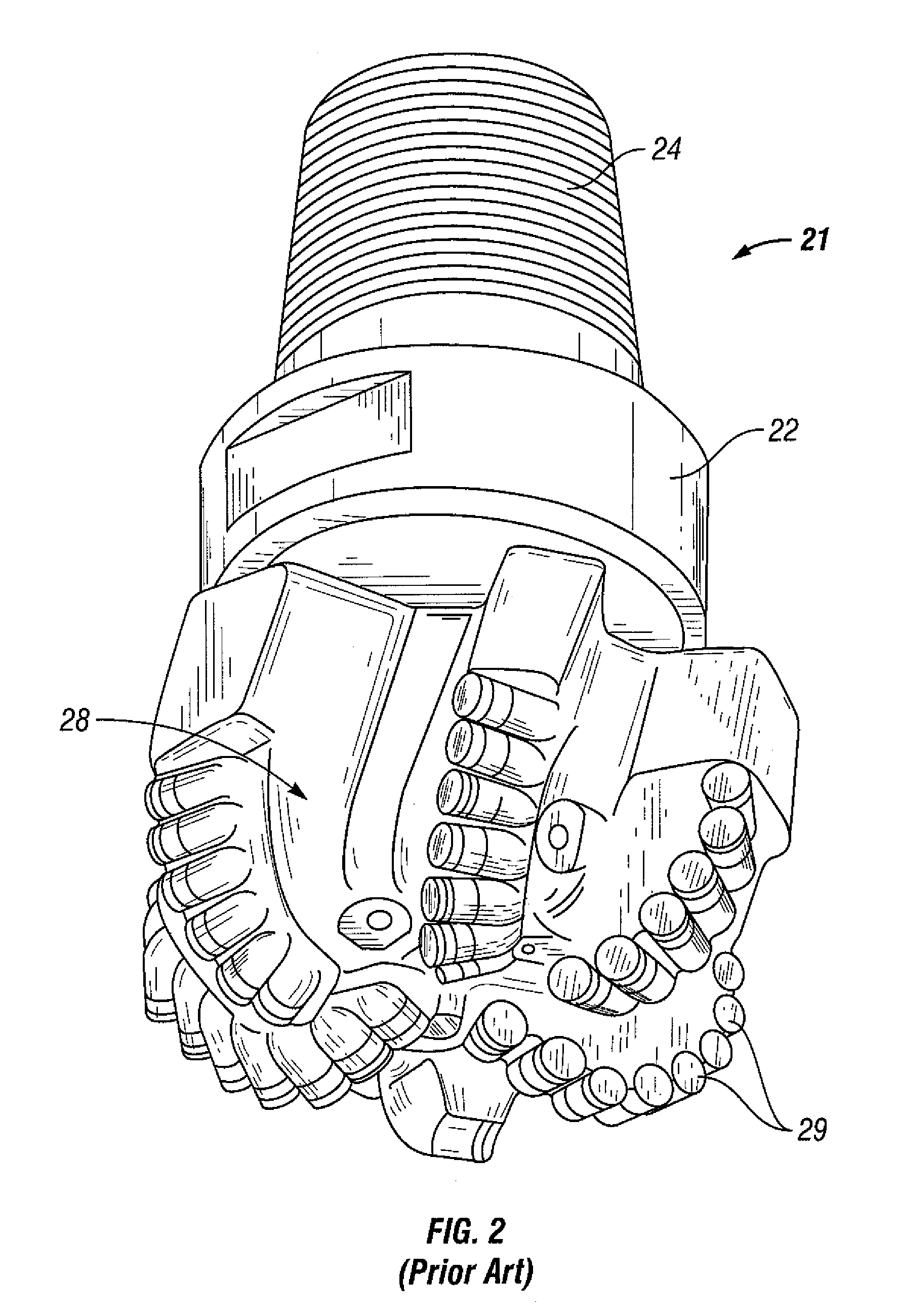

PDC drill bit with cutter design optimized with dynamic centerline analysis and having dynamic center line trajectory

InactiveUS20060167668A1Improve accuracyWeakening rangeDrill bitsDesign optimisation/simulationGraphicsDesign methods

A method for designing a fixed cutter drill bit includes simulating the fixed cutter drill bit drilling in an earth formation, determining a dynamic centerline trajectory of the drill bit, and adjusting at least one design parameter based upon the graphical display of at least the dynamic centerline trajectory. To improve performance, the method can include graphically displaying the dynamic centerline trajectory and / or repeating the simulating, determining, displaying and adjusting to change a simulated performance of the fixed cutter drill bit. A drill bit design may be selected and a drill bit may be made according to the design resulting from the method of designing.

Owner:SMITH INT INC

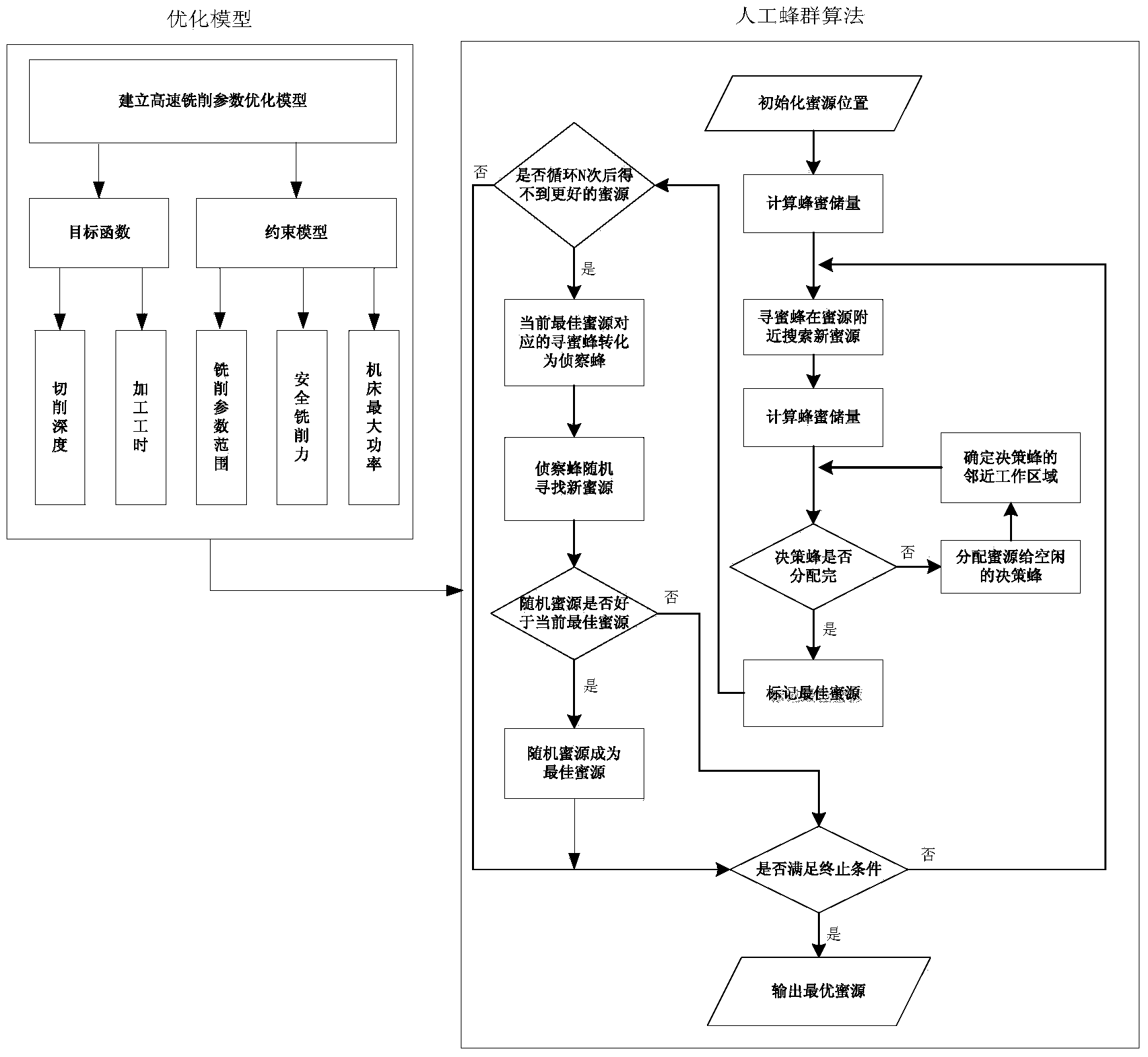

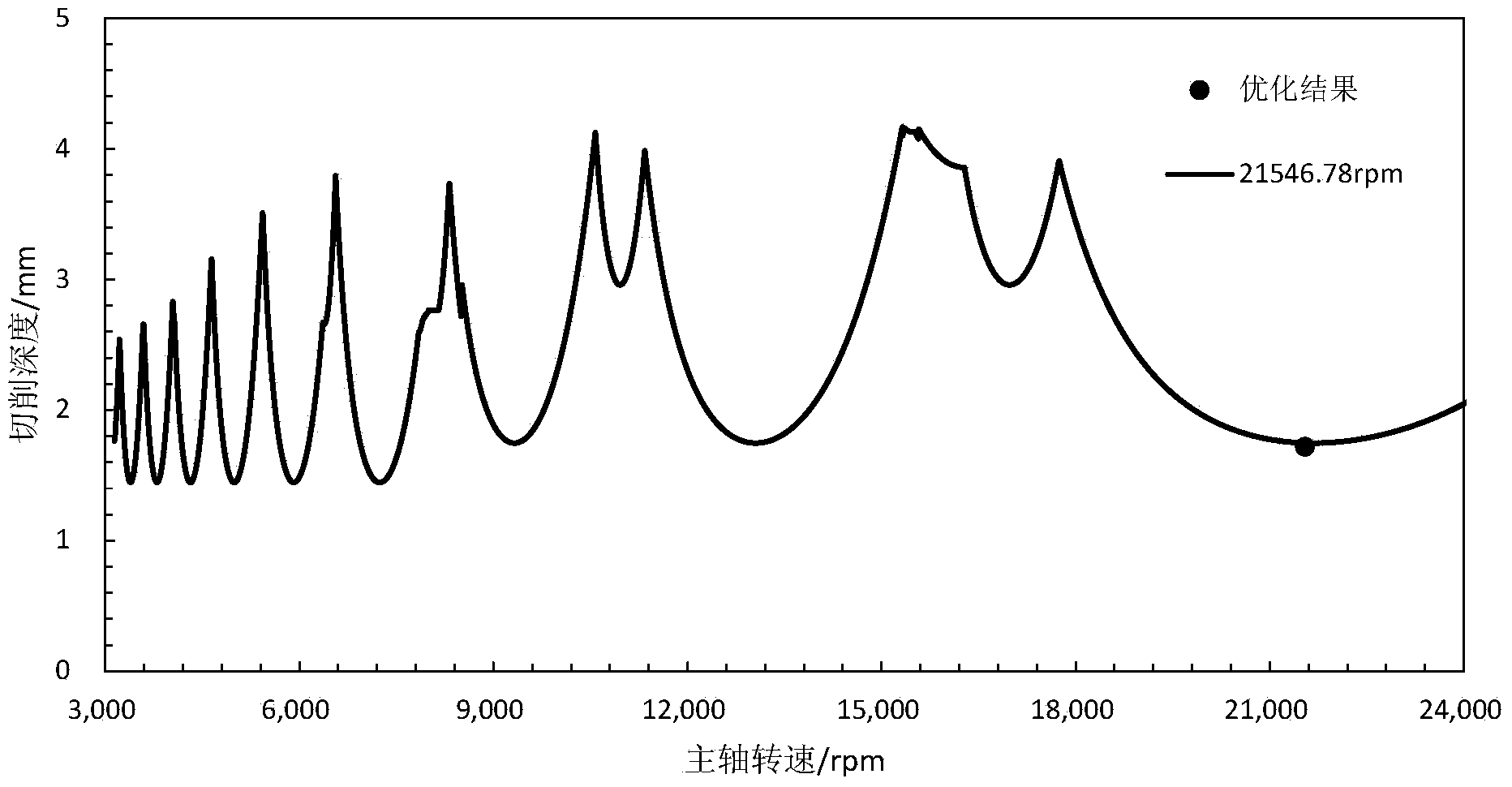

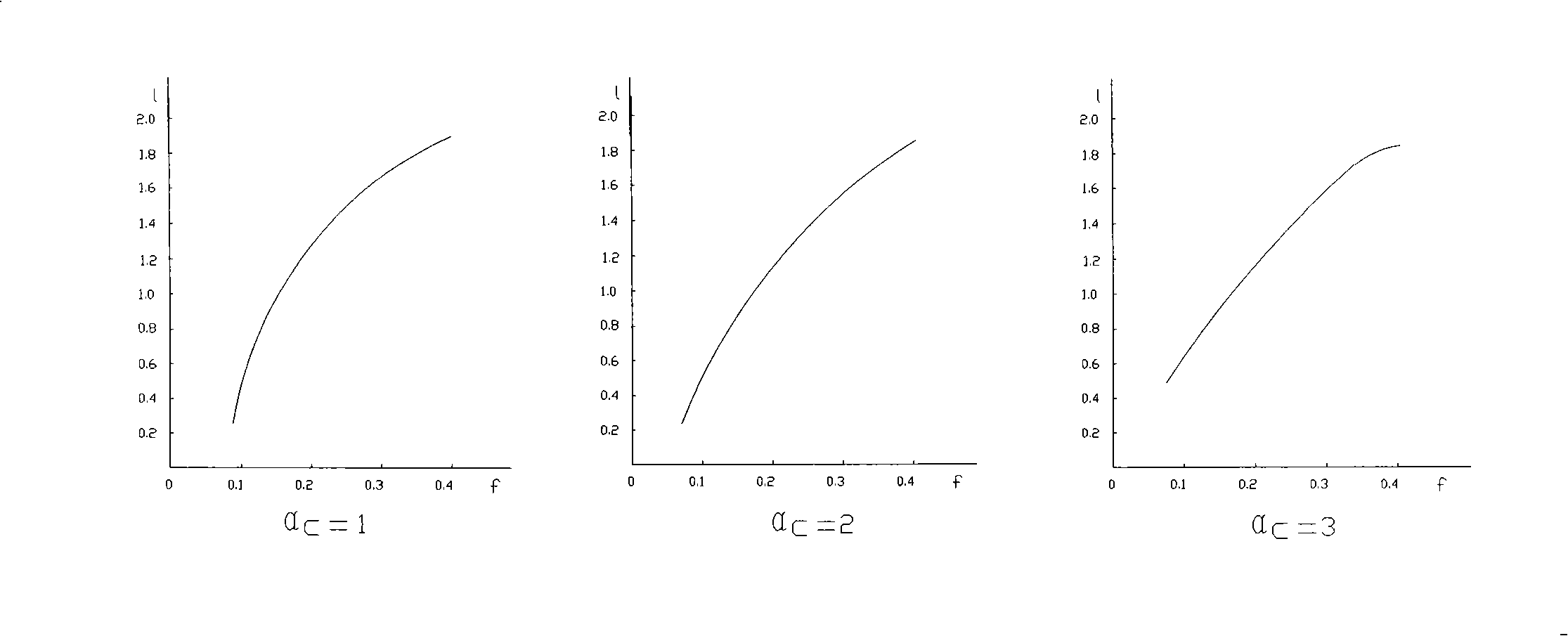

Milling process parameter optimization method

ActiveCN104076733AExcellent milling process parametersImprove productivityNumerical controlProduction rateProcess engineering

The invention provides a milling process parameter optimization method and belongs to the field of cutting machining processes. The coupling effect of a machining device dynamic behavior and the high-speed milling process is considered in the method, the maximum milling extreme cutting depth changing with the rotating speed of a machine tool spindle and shortest machining time of single part are regarded as optimization targets, a milling process parameter optimization model based on cutting stability and productivity is established, and optimal milling process parameters of a milling process parameter combining scheme under the condition that a cutting state is stable when the productivity is maximum are calculated. The milling process parameter optimization method can improve the cutting depth to the most extent during milling, decrease feed times, obtains maximum productivity, meanwhile ensures the cutting stability and avoids flutter. In addition, the milling process parameter optimization method can be applied to the high-speed milling process, the defect that the interactive effect of the machining device dynamic behavior and the milling process parameters is not considered in the high-speed milling process at present is overcome, and optimal high-speed milling process parameters can be obtained.

Owner:TONGJI UNIV

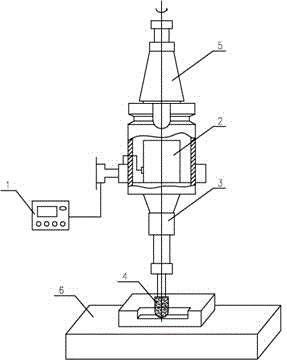

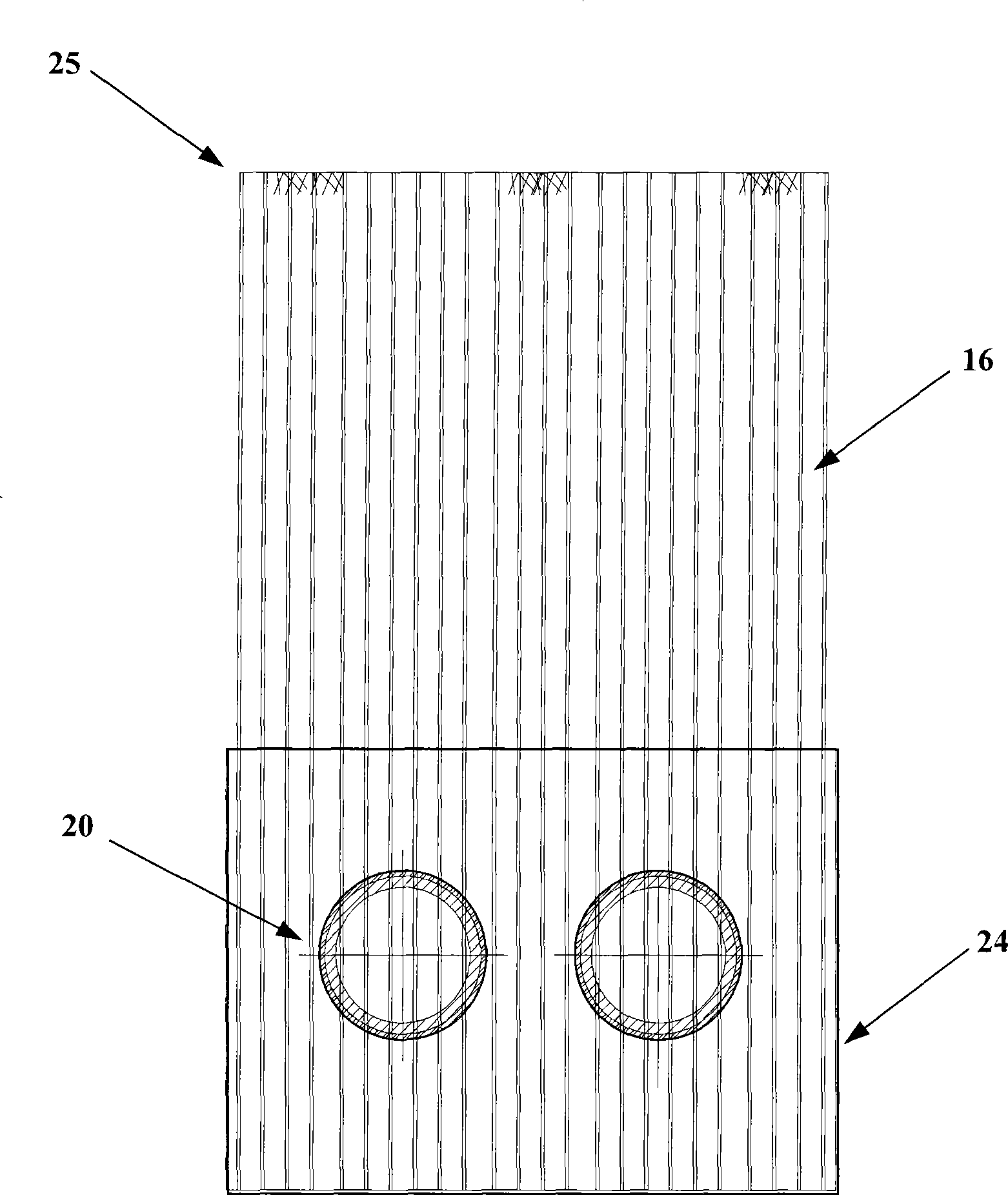

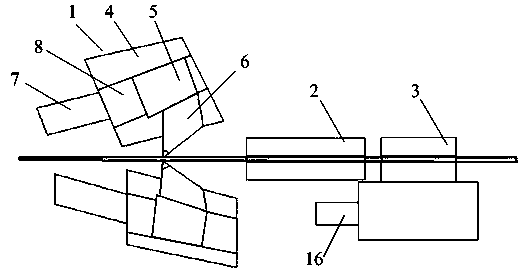

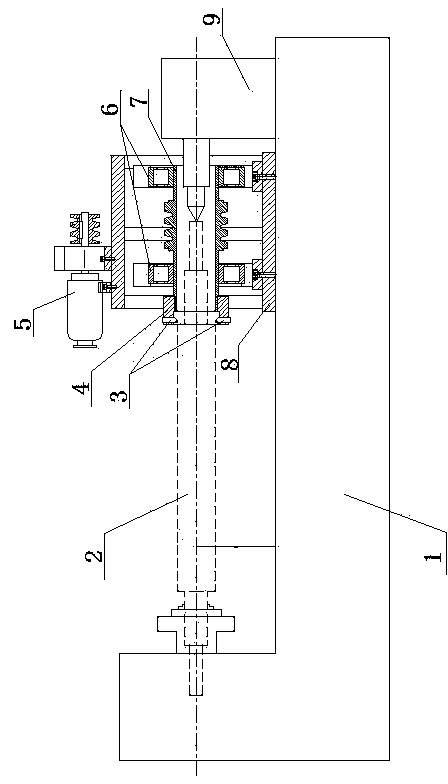

Carbon fiber composite rotary ultrasonic milling and grinding device and method

InactiveCN104647147AGuaranteed machining accuracyImprove surface qualityUltrasonic machiningGrinding

The invention discloses a carbon fiber composite rotary ultrasonic milling and grinding device and a carbon fiber composite rotary ultrasonic milling and grinding method. The carbon fiber composite rotary ultrasonic milling and grinding device comprises an ultrasonic generator, an ultrasonic transducer, an amplitude transformation pole, a tool, a tool handle and a machine tool body. The carbon fiber composite rotary ultrasonic milling and grinding method is achieved by using ultrasound to assist in milling and grinding so as to process non-ablating carbon / carbon composite materials. According to the carbon fiber composite rotary ultrasonic milling and grinding device and the carbon fiber composite rotary ultrasonic milling and grinding method, frequency of an ultrasonic power source used in the carbon fiber composite rotary ultrasonic milling and grinding method is consistent with inherent frequency of the amplitude transformation pole, and therefore the effect that vibration applied onto the amplitude transformation pole can cause resonance of the amplitude transformation pole is guaranteed; ultrasonic milling and grinding is adopted, and therefore surface quality of a carbon fiber composite work piece is obviously improved, and roughness of the carbon fiber composite work piece is reduced by about 16%-36%; ultrasonic machining is adopted, and therefore stress in the feed direction of a grinding head is reduced by about 44%, and stress in the downward pressing direction of the grinding head is reduced by about 46%; ultrasonic processing temperature rise is reduced by 29% from comparison between ultrasonic milling and grinding temperature and traditional milling and grinding cutting temperature of a carbon fiber composite.

Owner:DALIAN KANGSAIPU TECH DEV

Glomerocryst cubic boron nitride composite sheet and preparation method for same

ActiveCN103158287AExtended service lifeIncreased depth of cutMetal layered productsCemented carbideMetal binding

The invention discloses a glomerocryst cubic boron nitride composite sheet and a preparation method for the same. The glomerocryst cubic boron nitride composite sheet comprises a hard alloy matrix and a glomerocryst cubic boron nitride layer, wherein the glomerocryst cubic boron nitride layer is prepared from the raw materials in the following parts by weight: 70-85 parts of cubic boron nitride micro-powder, 10-15 parts of metallic bond, and 5-10 parts of ceramic additive. The method is performed according to the following steps of: A, uniformly mixing; and B, filling the mixture and the hard alloy matrix in a molybdenum cup provided with a salt tube shielding layer for isolating, heating, and synthesising. Compared with the prior art, the glomerocryst cubic boron nitride composite sheet and the preparation method for the same disclosed by the invention have the beneficial effects that the service life of the composite sheet is prolonged, unsoldering phenomenon is avoided, and cutting efficiency is good.

Owner:ZHENGZHOU BERLT HARD MATERIALS

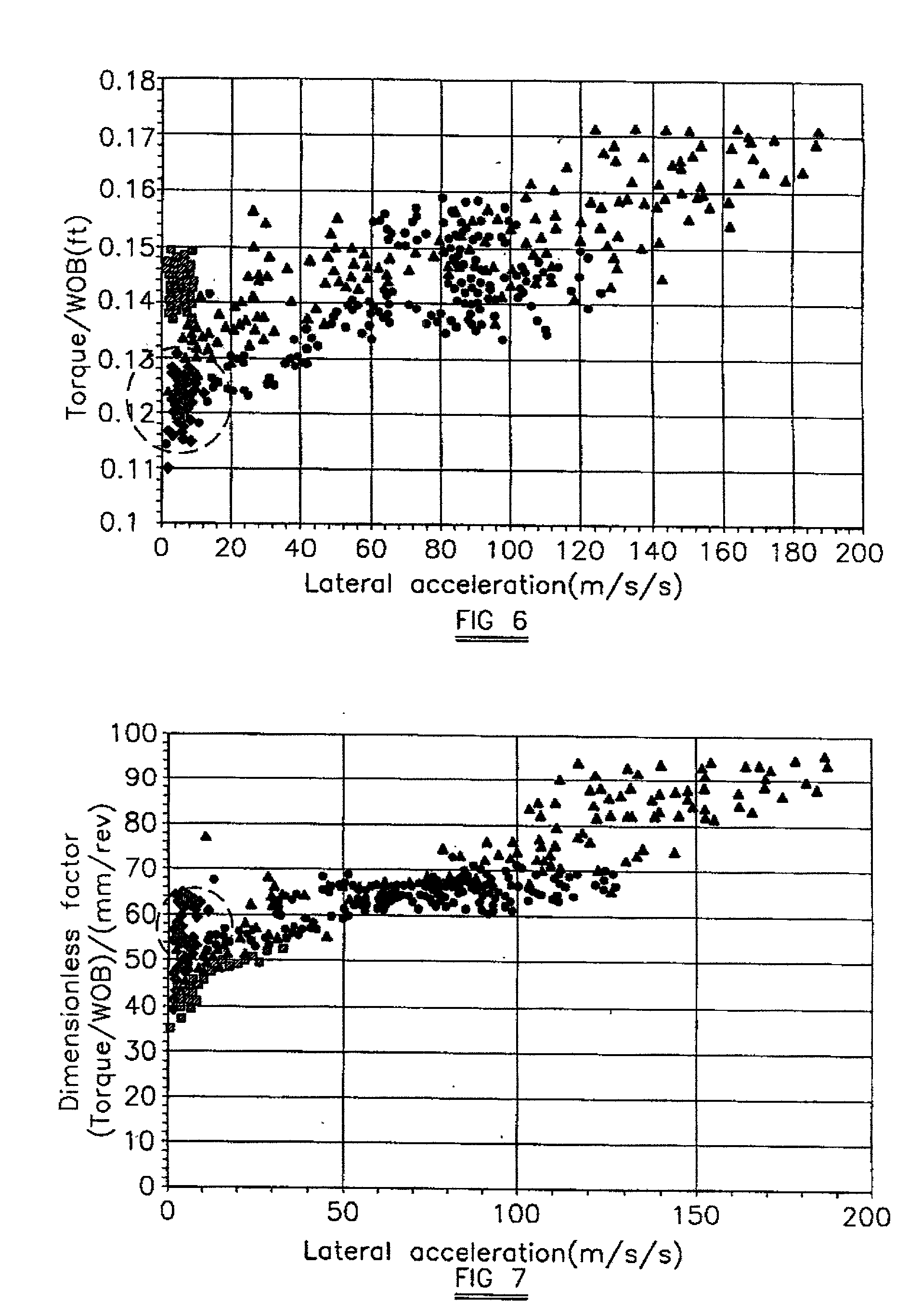

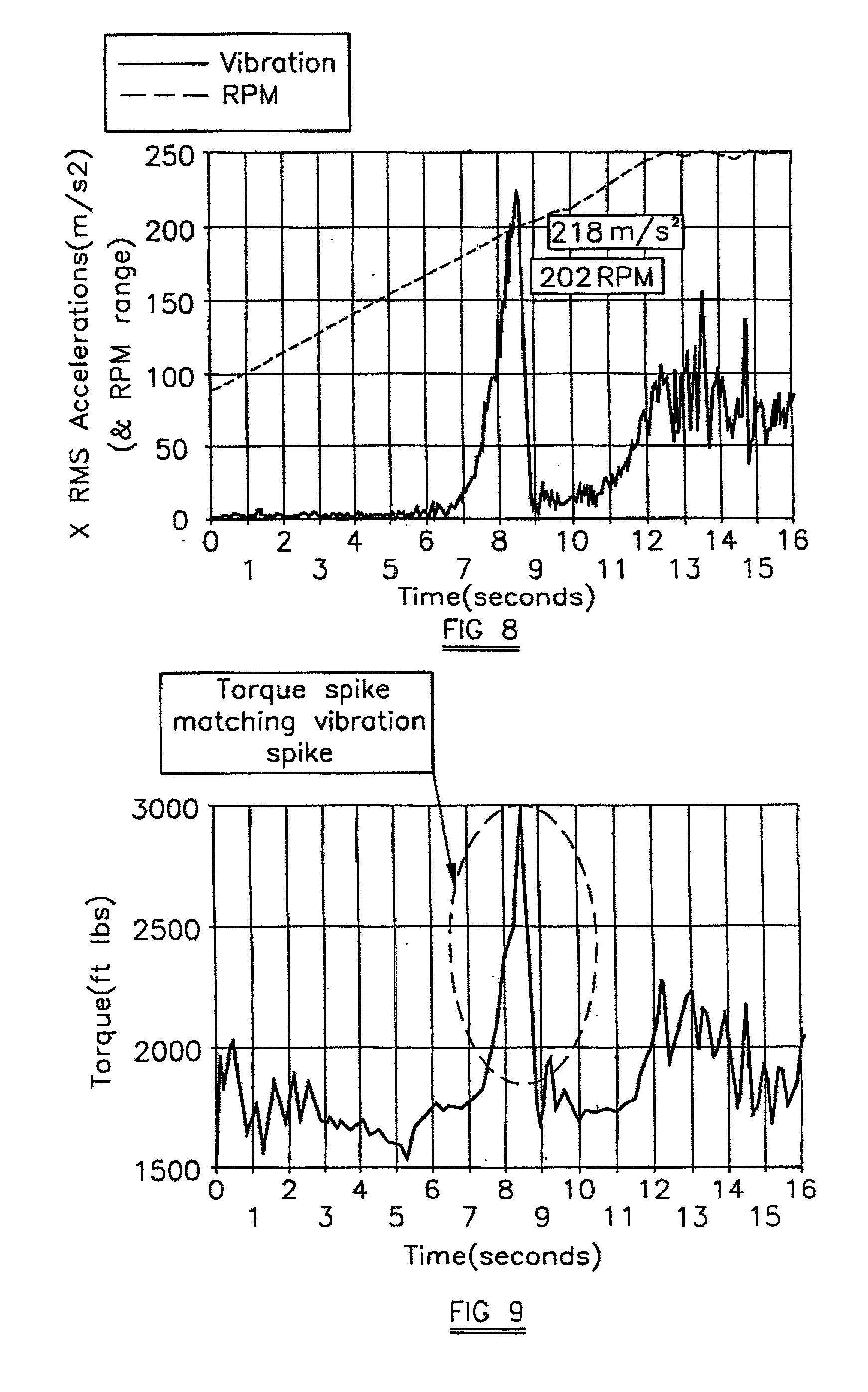

Rotary drag-type drill bits and methods of designing such bits

InactiveUS20010020551A1Trend downIncreased depth of cutDrill bitsDrilling machines and methodsDrill bitControl theory

The invention provides a rotary drag-type drill bit in which the relationship of torque to rotary bit speed is such that torque generally increases with bit speed. Such a bit has a reduced tendency to exhibit the phenomenon known as "stick-slip" while drilling, when compared with bits having a different torque / speed characteristic, as a result of the positive damping effect of the torque / speed relationship. One method of designing such a drill bit comprises ascertaining the torque / rotary bit speed relationship, or other correlated relationships, for a number of different drill bit designs and then selecting from those designs a design having the desired type of relationship. Examples of drill bit structures specifically designed to achieve the desired torque / speed relationship are also disclosed.

Owner:CAMCO INT

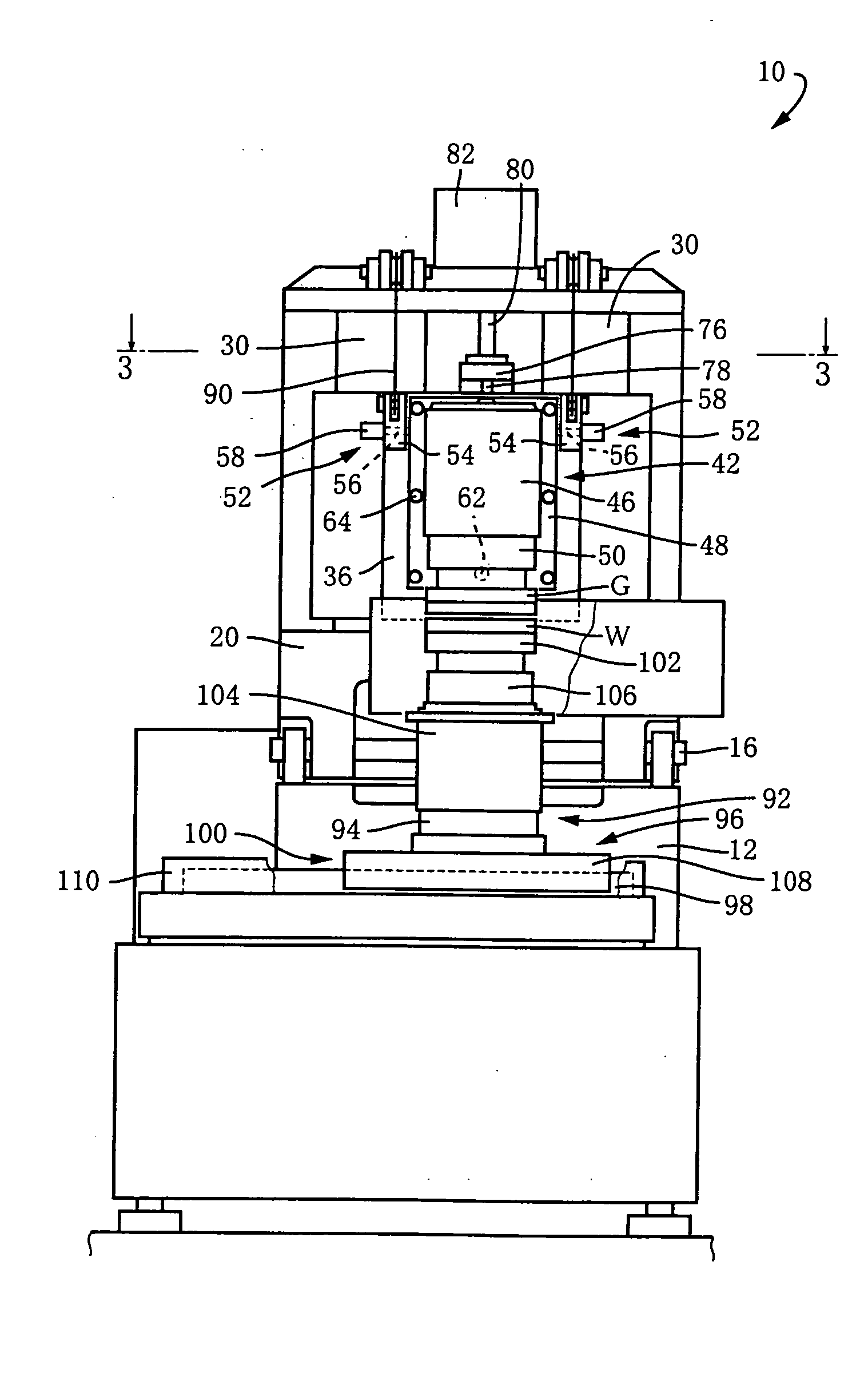

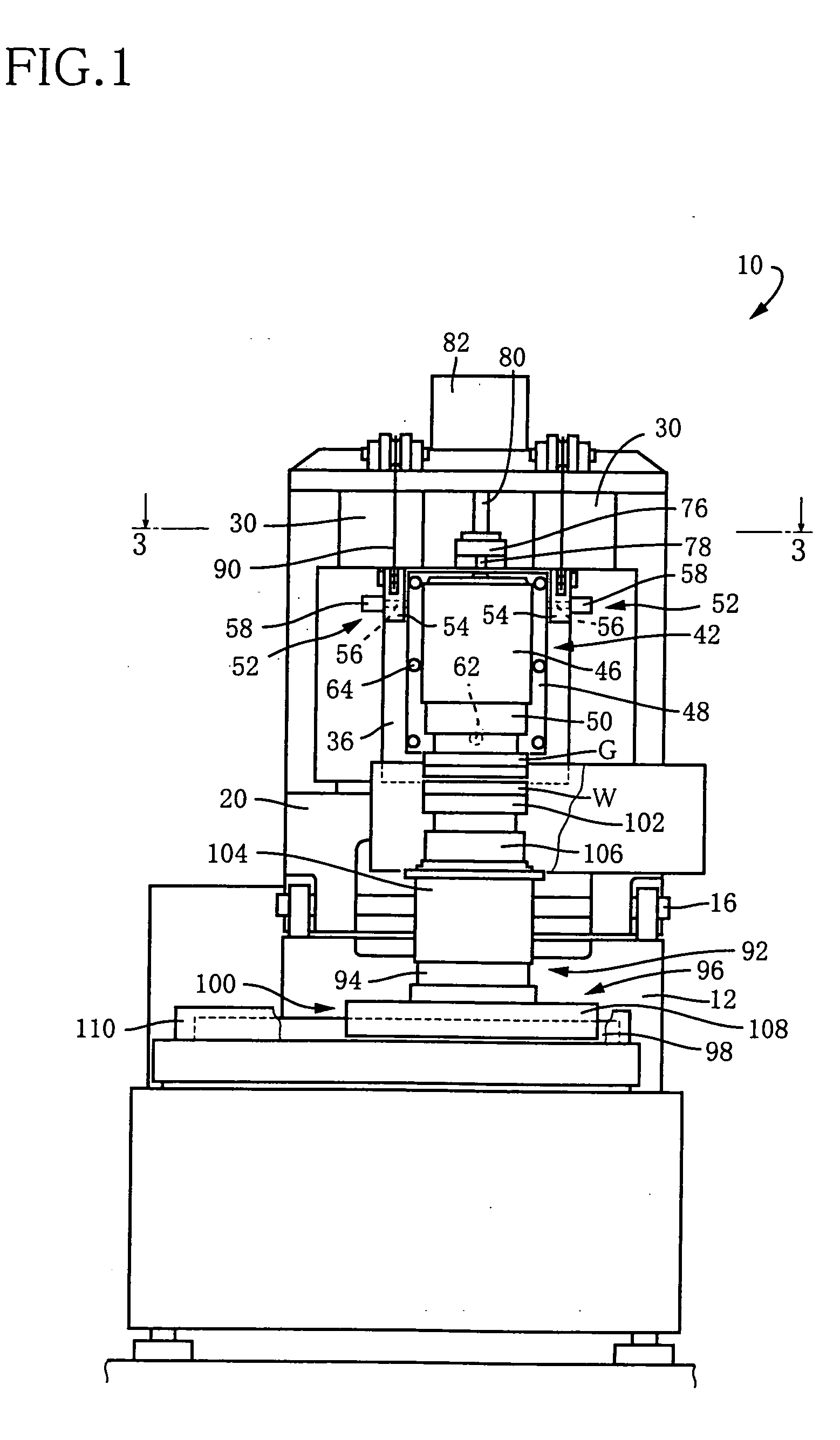

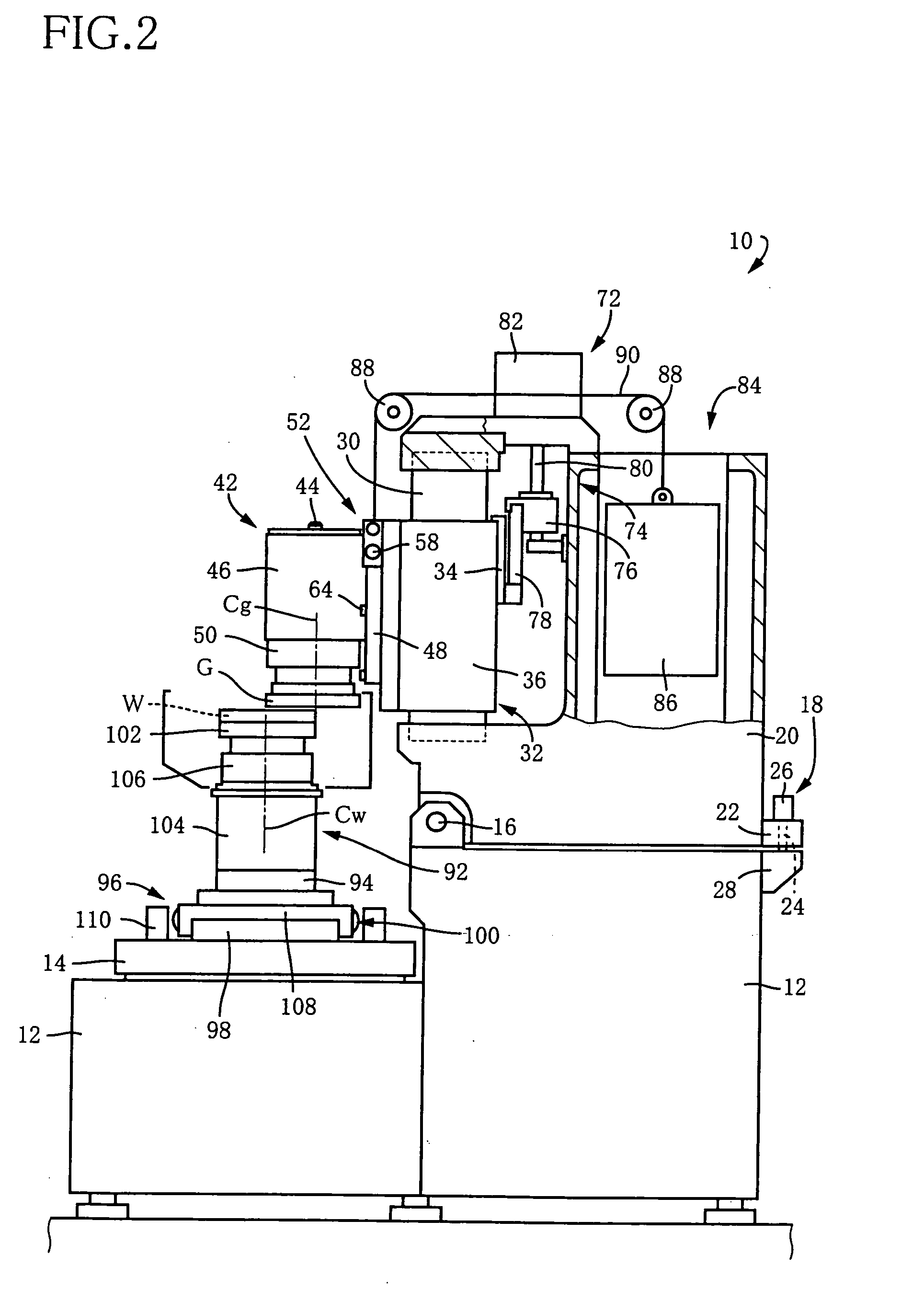

Grinding process and apparatus with arrangement for grinding with constant grinding load

ActiveUS20060073765A1Quality improvementImprove efficiencyPolishing machinesRevolution surface grinding machinesConstant forceGrinding process

A process of grinding a surface of a workpiece, by a grinding tool rotated about its axis. The process includes a grinding step of grinding the workpiece surface, by pressing at least one of the grinding tool and the workpiece against the other of the grinding tool and the workpiece, such that a constant force is exerted on the other of the grinding tool and the workpiece by the at least one of the grinding tool and the workpiece. Also disclosed is a grinding apparatus including: a moving device operable to move at least one of the grinding tool and the workpiece relative to the other of the grinding tool and the workpiece, at least in an infeed direction that increases a depth of cut of the grinding tool into the workpiece; and a controller which controls the moving device, such that the at least one of the grinding tool and the workpiece is pressed against the other of the grinding tool and the workpiece, with a constant force.

Owner:NORITAKE CO LTD

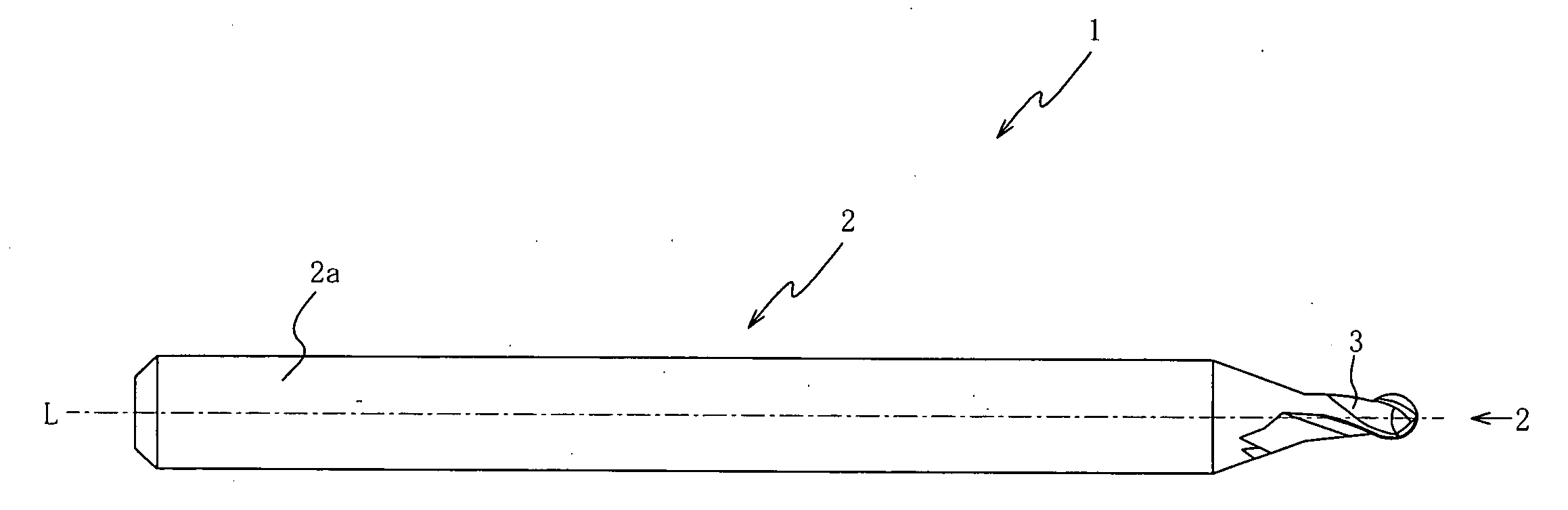

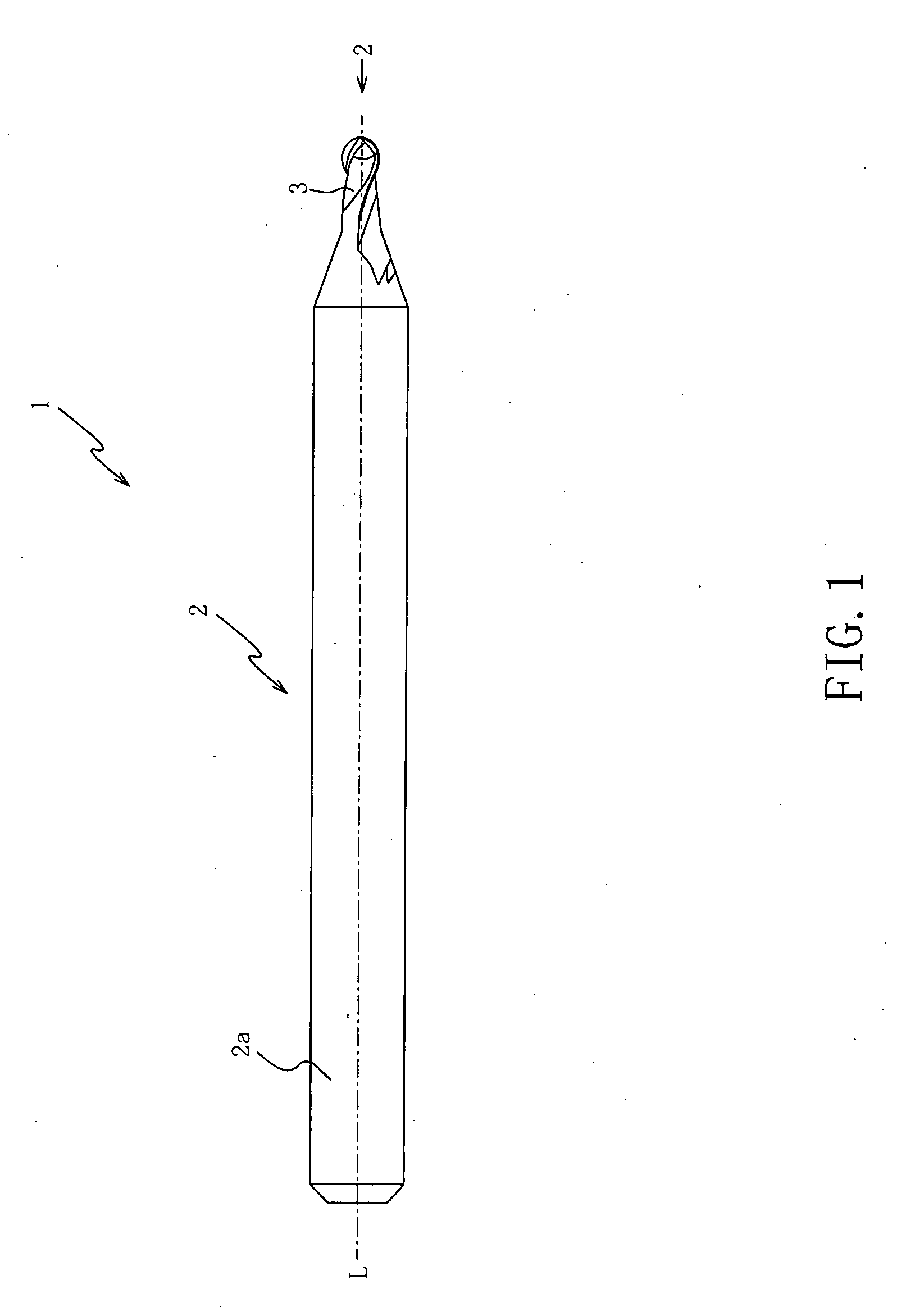

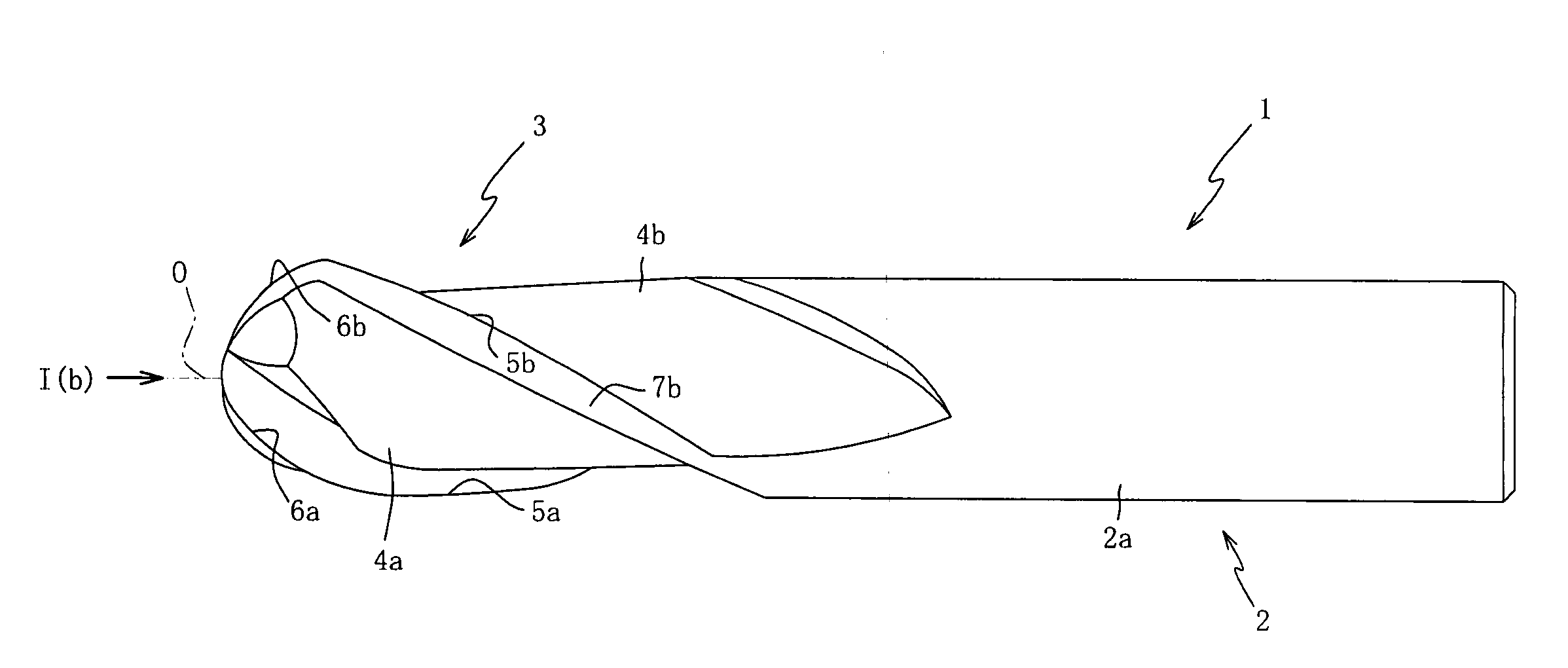

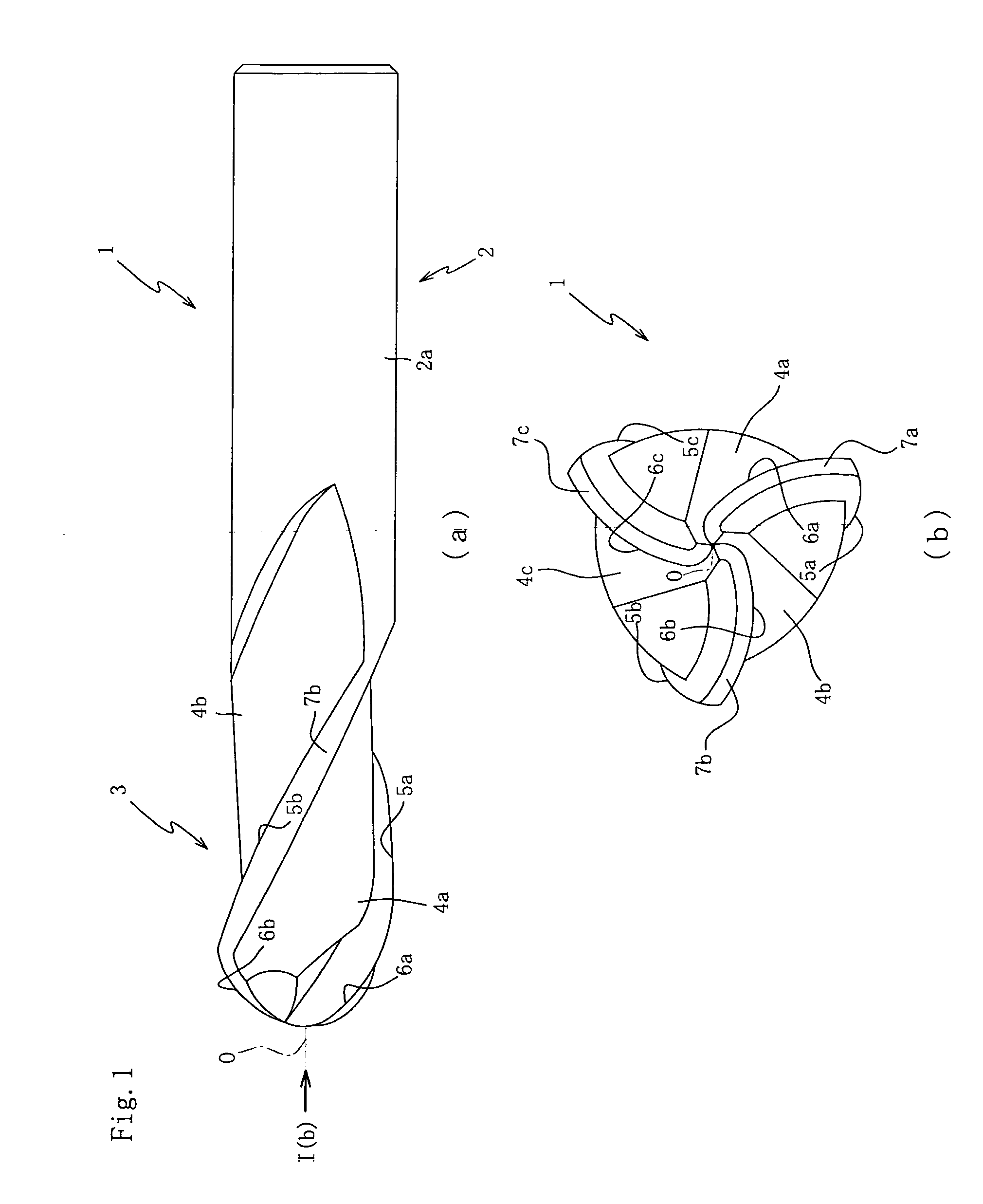

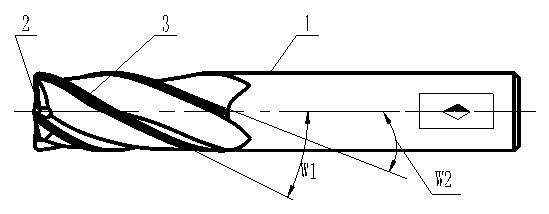

Ball endmill

InactiveUS20070172321A1Increase speedLarge depth of cutMilling cuttersWorkpiecesEngineeringSpherical shaped

A ball endmill includes a cylindrical tool body that is to be rotated about its axis, ball-nosed end cutting edges located in an axially distal end portion of the tool body and describing a semi-spherical-shaped locus during rotation of the tool body, and spiral gashes located in the axially distal end portion of the tool body and defining rake faces of the respective ball-nosed end cutting edges. The tool body is made, at least at its part providing each ball-nosed end cutting edge, of a hard sintered body. Each ball-nosed end cutting edge is inclined with respect to the axis by a helix angle in a range from about 10° to about 30°. The tool body has, in its distal end, a non-gashed central area in which the spiral gashes do not exist. A ratio of a size of the non-gashed central area to a ball nose radius is in a range from about 0.03 to about 0.1.

Owner:OSG +1

Protective cutting construction method for tunnel segment

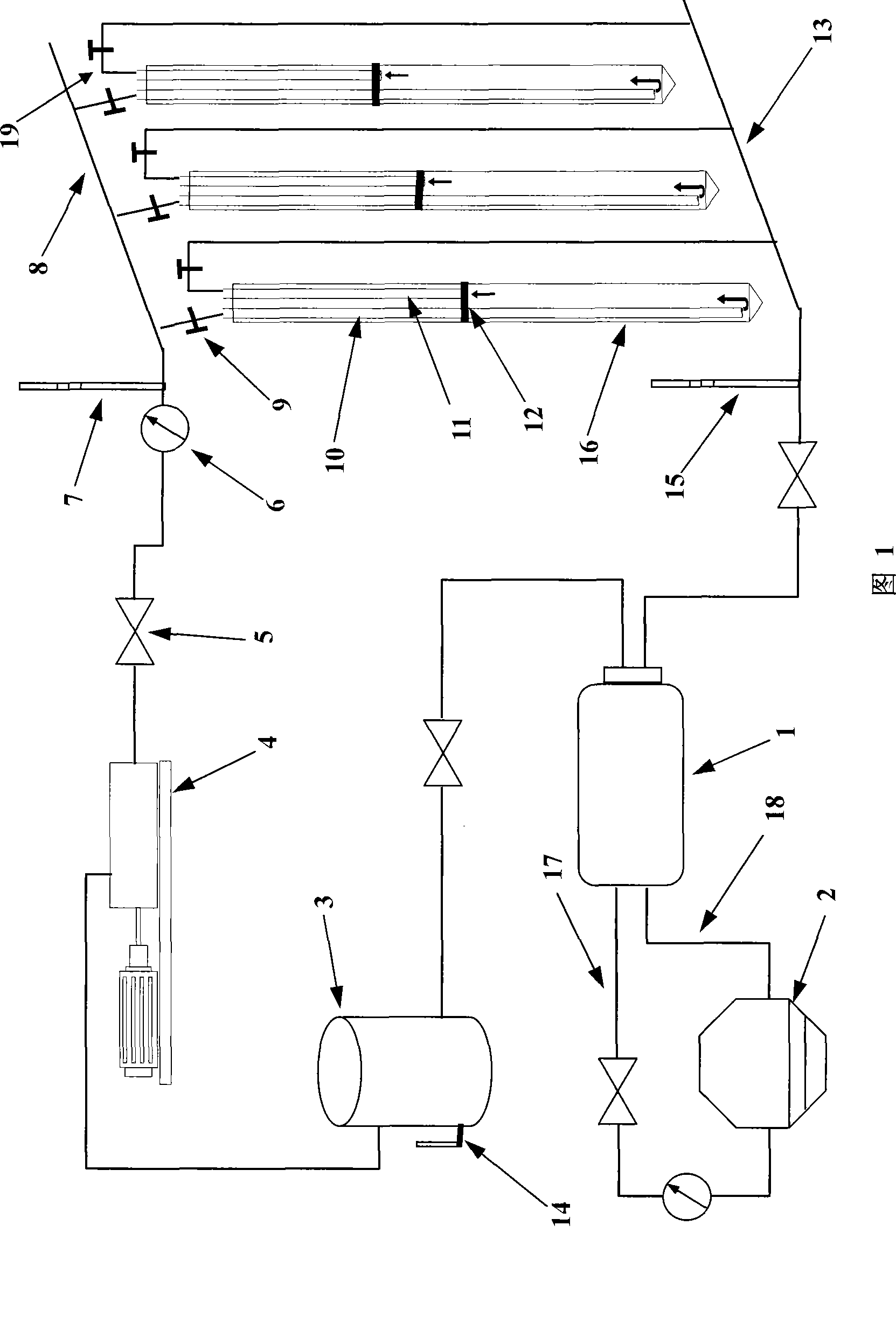

InactiveCN101418567ASolving Cut Cleanup ProblemsHighlight substantiveIce productionCompression machines with non-reversible cycleSaline waterWater cycling

The invention relates to a construction method for protectively cutting a tunneltron piece, which belongs to the field of building engineering. The technical problem to be solved by the construction method is to overcome the defect that adjacent tunneltron pieces are damaged when a general construction method is used for cutting the tunneltron piece. The construction method adopts the technical proposal that: firstly, a filling hole is drilled on the upper part of a tunnel of a region to be frozen, and the frozen region tunnel is filled; secondly, a certain number of drill holes are drilled in the frozen region, and freezing pipes are arranged inside the holes; thirdly, low-temperature brine is conveyed through the freezing pipes for heat exchange, and a frozen cylinder is formed after the temperature is reduced; fourthly, the frozen cylinder is continuously widened to form a frozen wall along with continuation of the freezing effect; and fifthly, a hot brine circulating hole is constructed on the side of the frozen wall, the freezing range is controlled to be expanded to a cutting area, and special equipment is adopted for cutting the tunneltron piece in the cutting area. The construction method has low influence on the adjacent tunneltron pieces when cutting the tunneltron piece, and can be widely used for engineering construction such as cleaning of deep underground barriers, modification and construction of the prior tunnel under special operating conditions, and so on.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

PDC drill bit with cutter design optimized with dynamic centerline analysis having an angular separation in imbalance forces of 180 degrees for maximum time

InactiveUS7831419B2Improve accuracyWeakening rangeDrill bitsDesign optimisation/simulationBeta angleEngineering

A method for designing a fixed cutter drill bit, includes simulating the fixed cutter drill bit drilling in an earth formation, determining radial and circumferential components of imbalance forces on the drill bit and a Beta angle between the radial and circumferential components of the imbalance forces during a period of simulated drilling, and adjusting a value of at least one design parameter for the fixed cutter drill bit at least based upon the Beta angle. To facilitate drill bit design, the Beta angel can be displayed to a drill bit designer. To improve performance, the method can include repeating the simulating, determining, and adjusting to change a simulated performance of the fixed cutter drill bit. A drill bit may be made according to the design resulting from the method.

Owner:SMITH INT INC

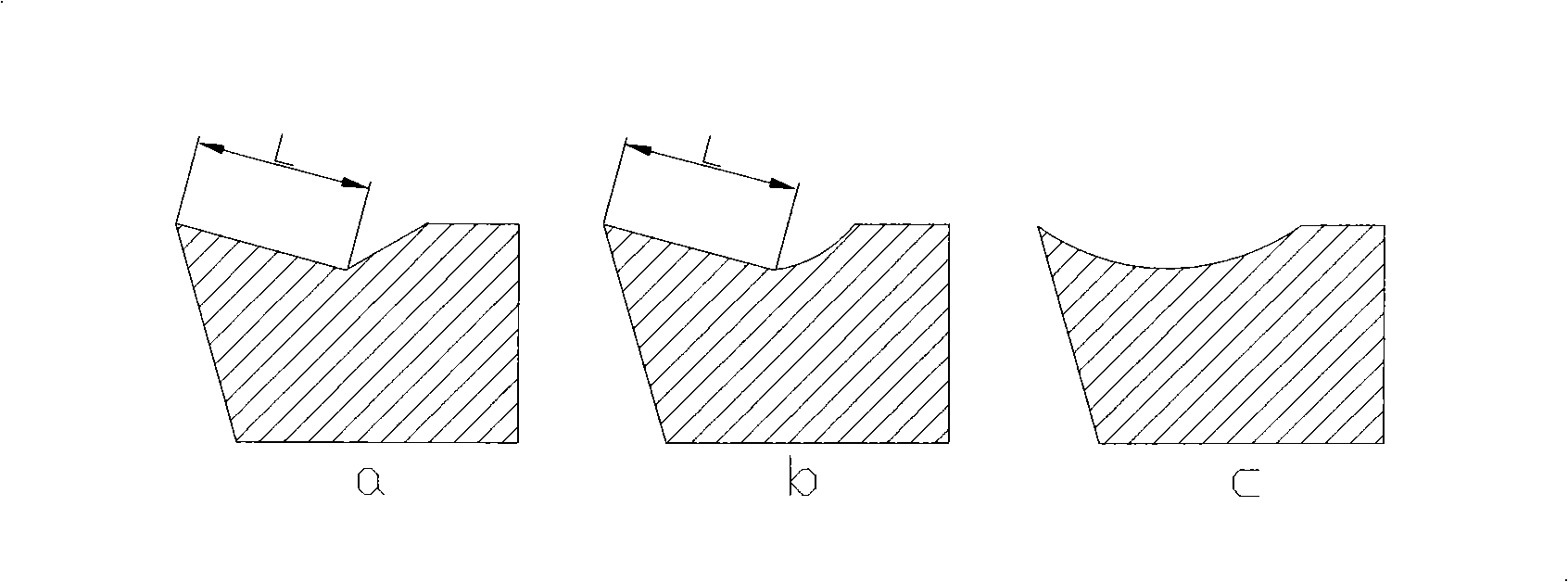

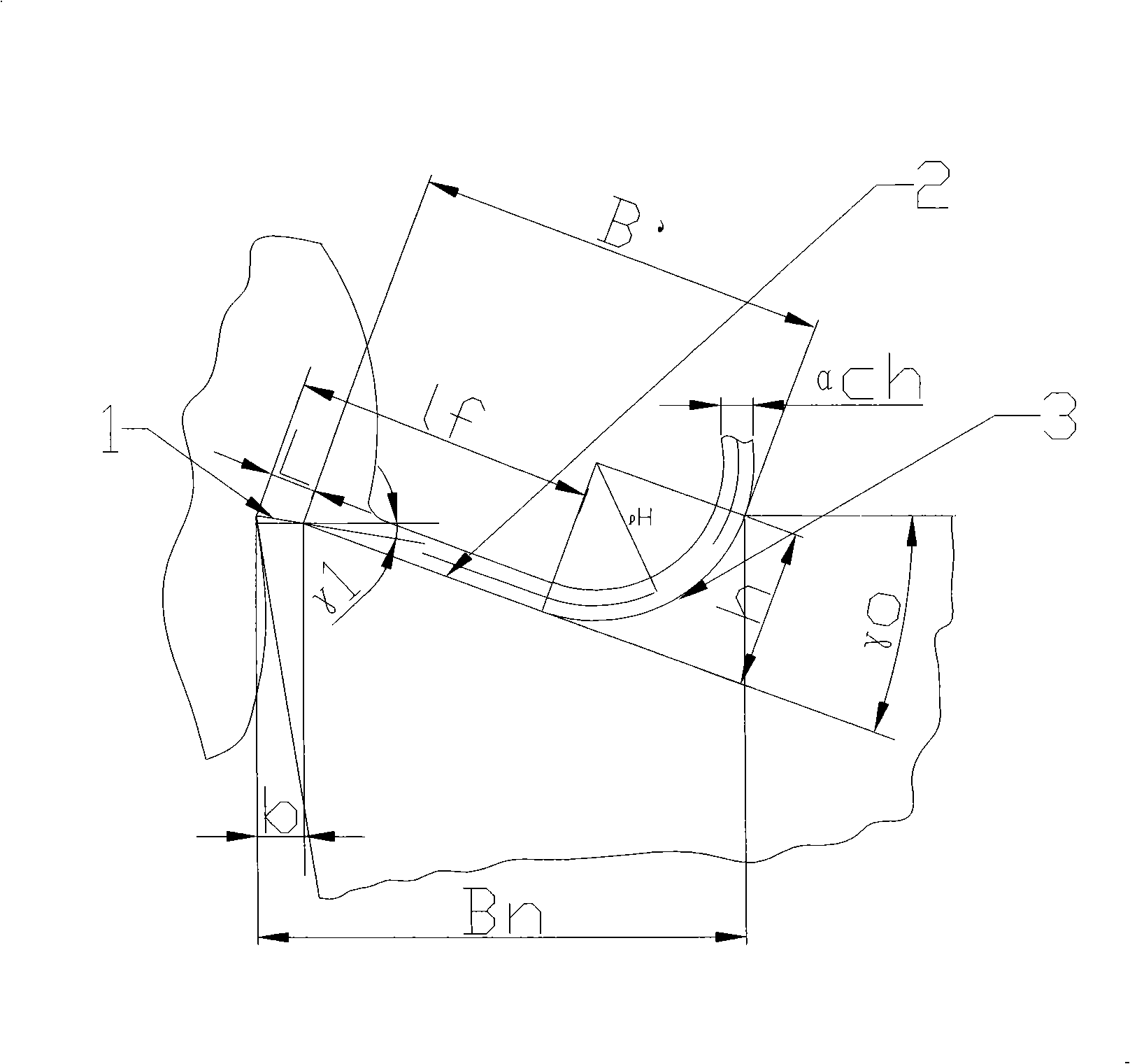

Knife tool chip breaker

InactiveCN101323027ASmooth entryLarge amount of deformationTurning toolsRake angleAutomatic processing

The invention discloses a tool chip breaker, solving the problems of difficult chip breaking caused by great material plasticity and elasticity in the process of automatic processing and thin-cutting. The key of the invention is that a section of major first face and a first front angle are added in the cutting edge of a linear arc-shaped chip breaker, and the back of the major first face is a major second face; according to the parameters of cutting thickness, the major first face and the major second face, the corresponding curvature radius of an arc chip reeling slot is calculated. The tool chip breaker has the advantages that: as a section of the linear major first face is added in the cutting edge, the curvature radius of the arc chip reeling slot is reasonable, the chip deformation is increased, the effect of chip reeling and breaking is improved; the angle of the cutting edge is increased, the strength of the cutting edge is strengthened and the cutting depth is deepened; the new structure ensures that the chip goes into the chip reeling slot more smoothly.

Owner:DALIAN UNIVERSITY

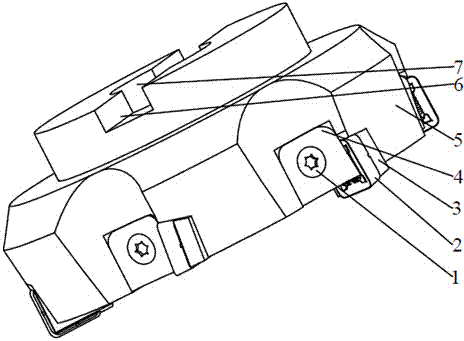

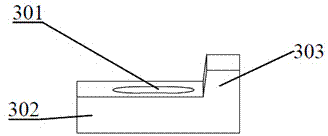

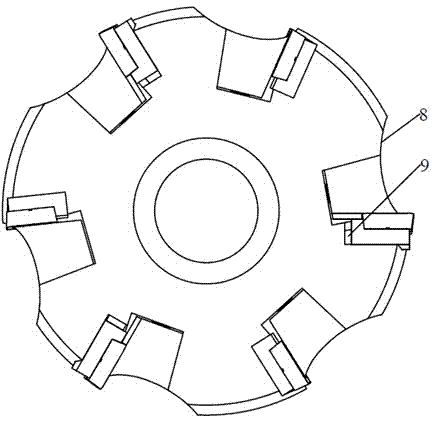

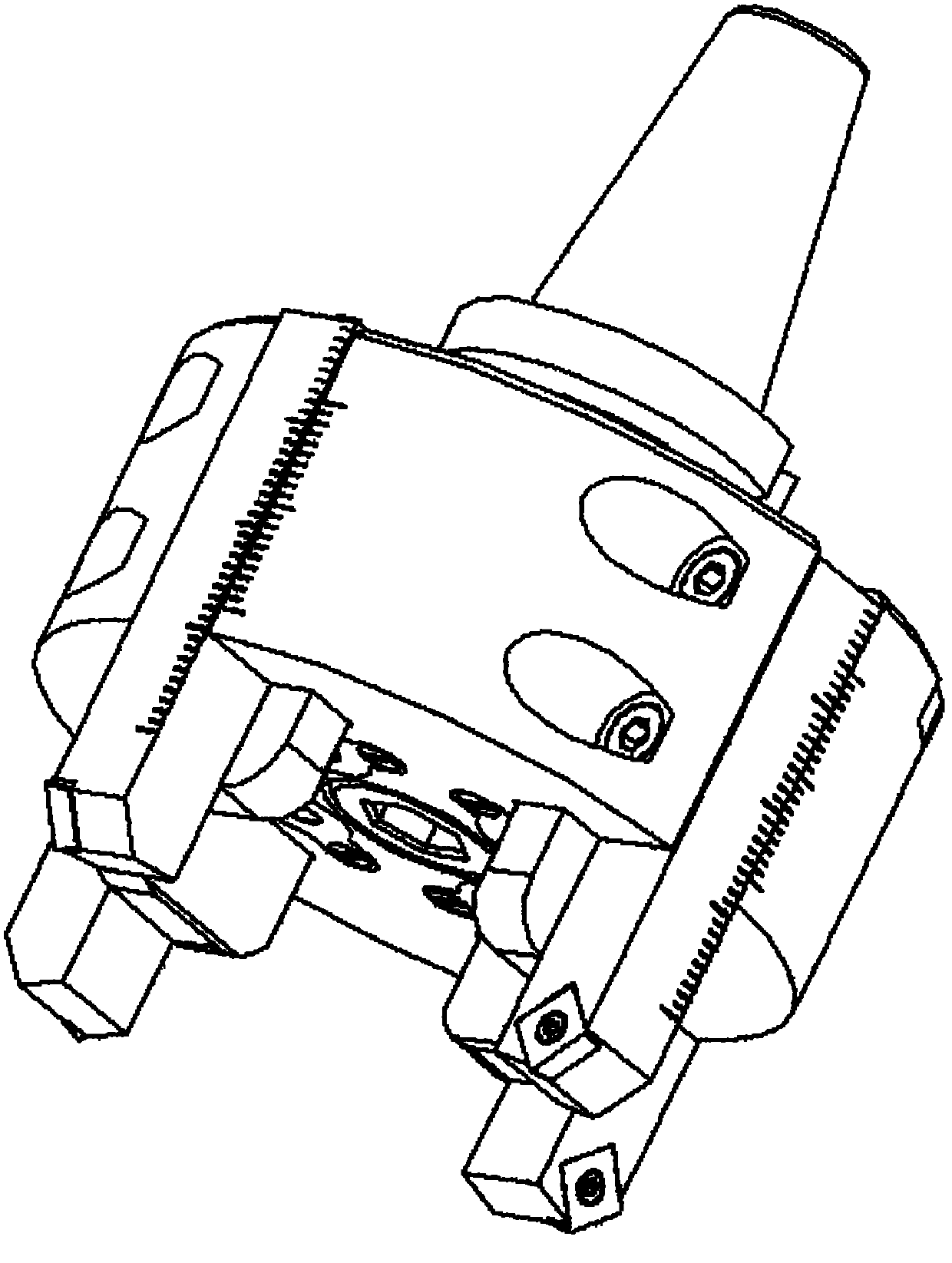

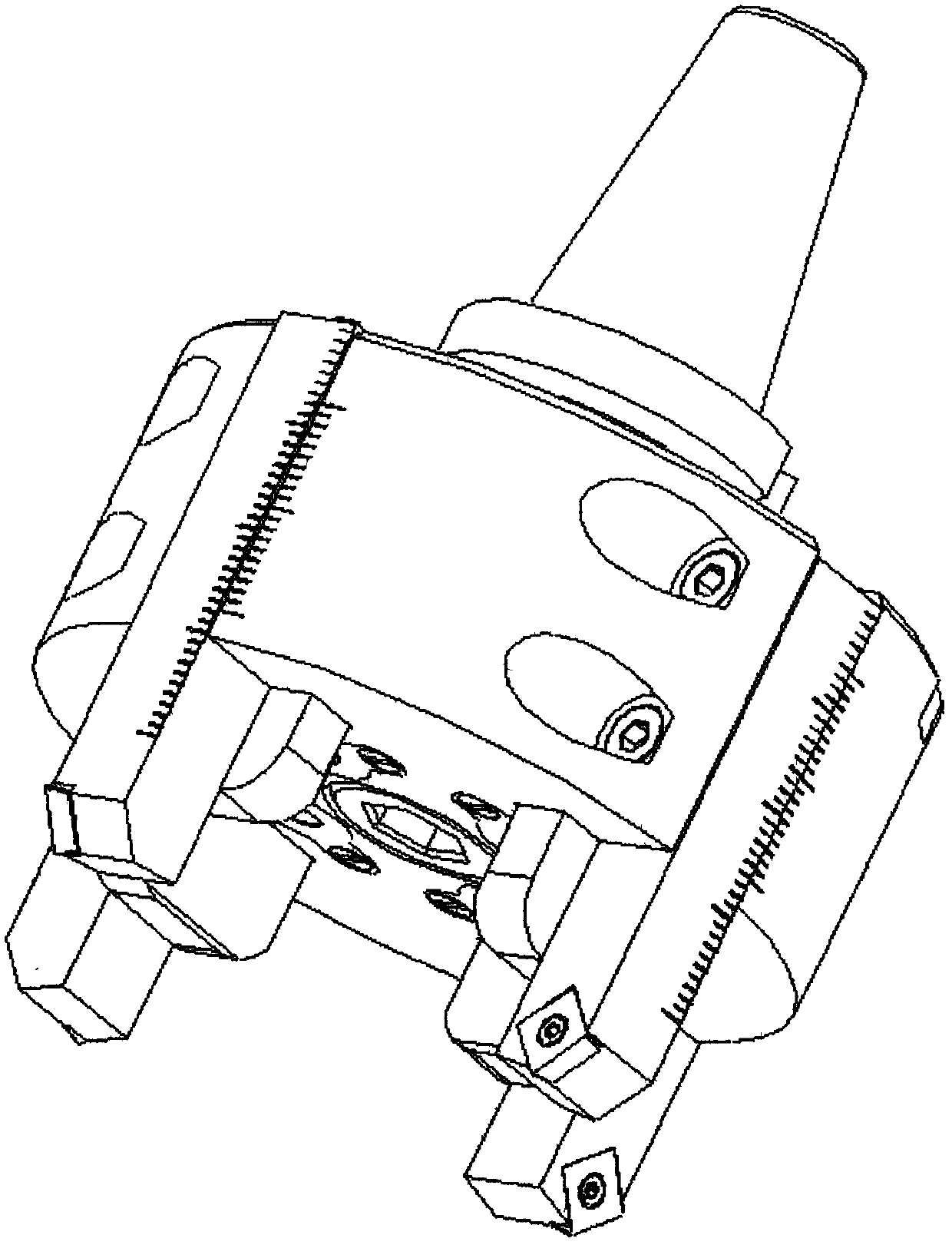

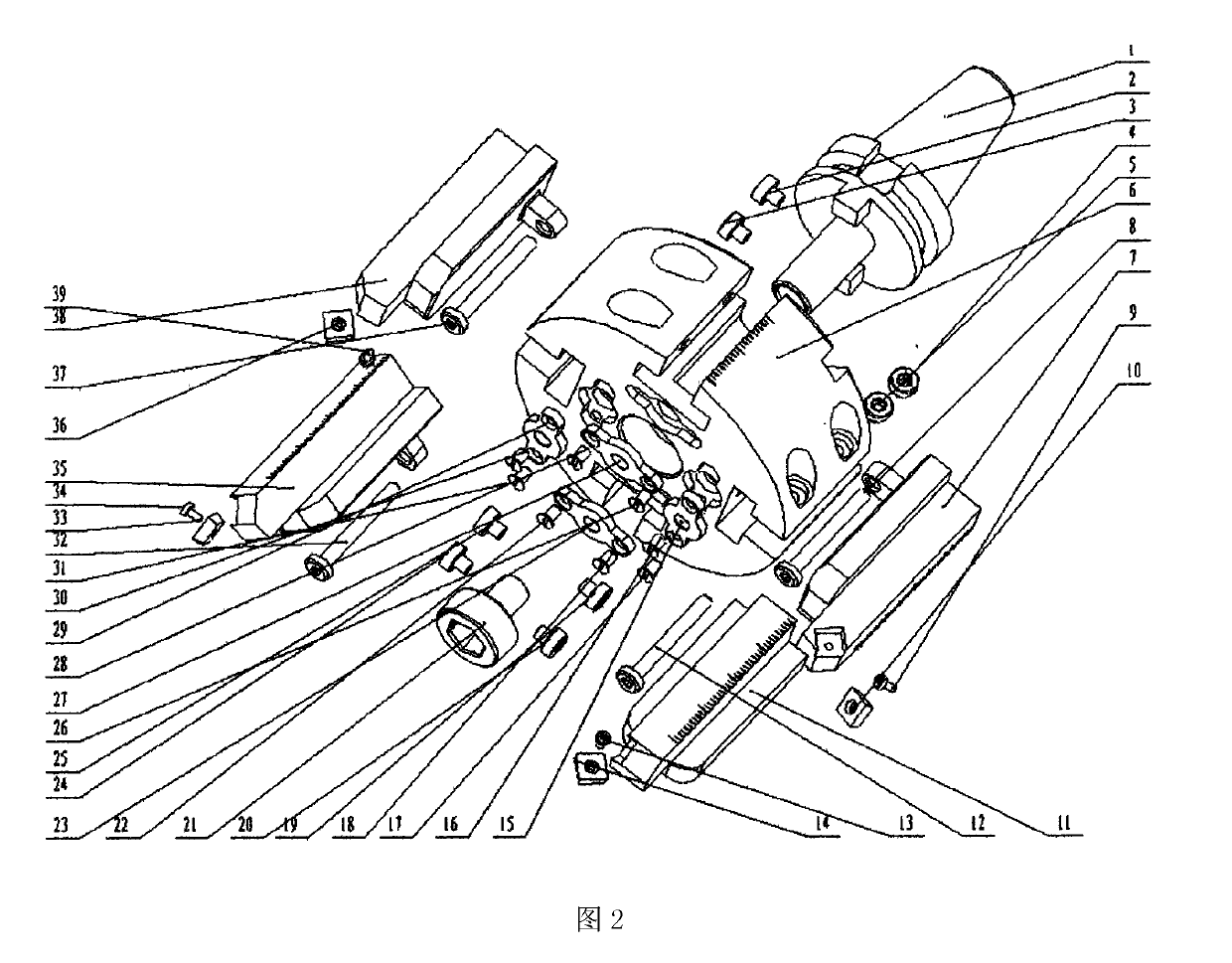

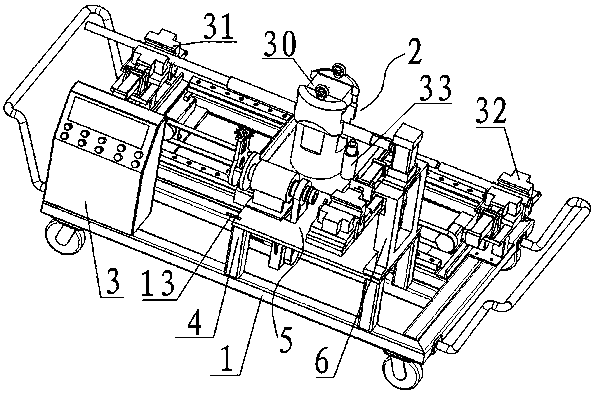

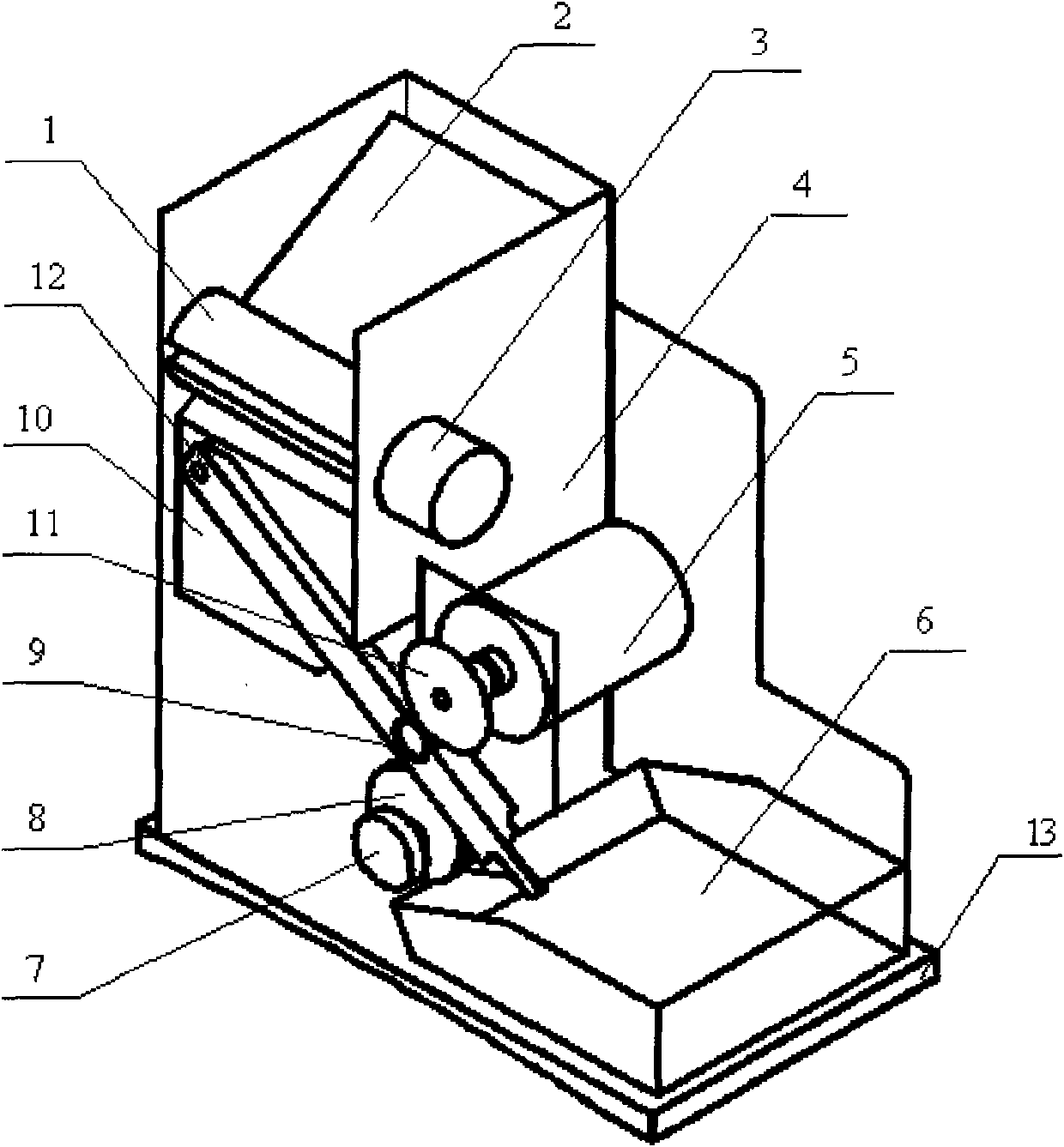

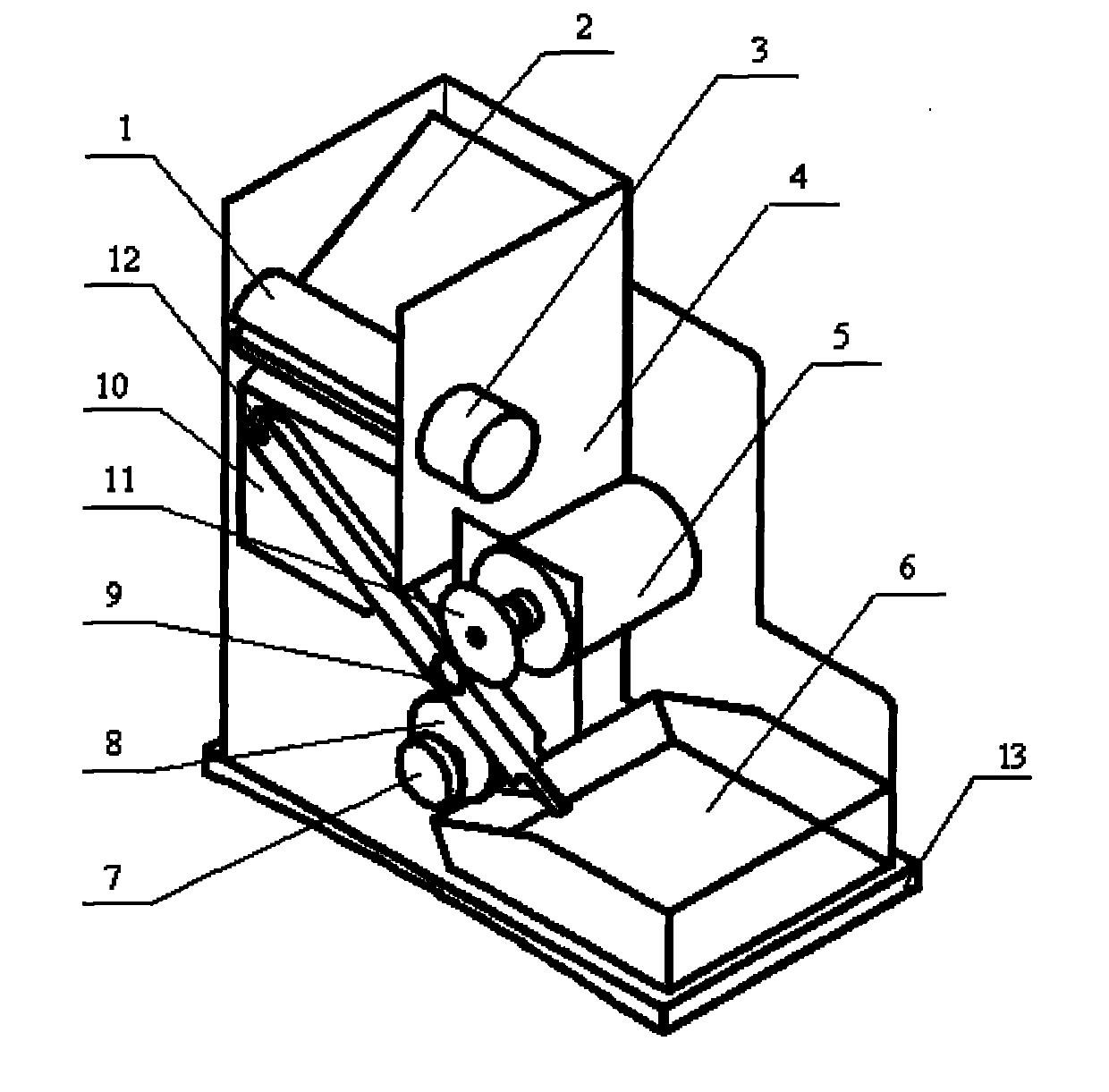

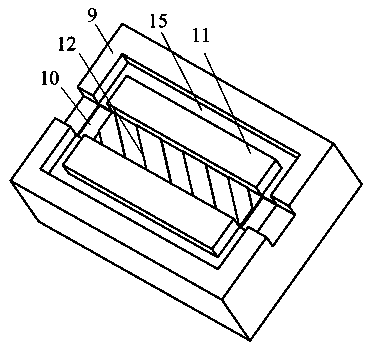

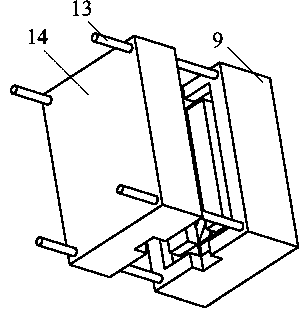

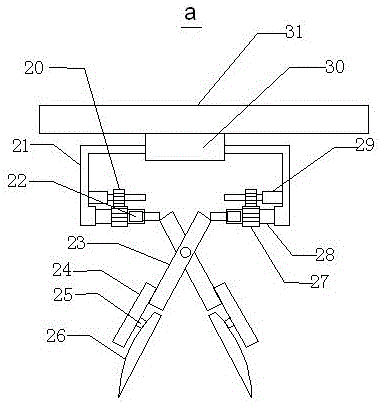

Radially-adjustable heavy-duty cutting layer milling cutter

InactiveCN104841994ARaise the natural frequencyChange milling forceTransportation and packagingMilling cuttersMilling cutterEngineering

The invention discloses a radially-adjustable heavy-duty cutting layer milling cutter applicable to the field of heavy-type milling processing, and aims to solve the problems that during heavy-duty milling water chamber end enclosing, surfaces of workblanks are uneven, multi-defective and poor in machinability; cutting blades are prone to being damaged by impacts during rough machining or hogging machining; during milling, cutting depth changes frequently, which results in that not all cutter teeth are involved in cutting, utilization rate of the milling cutter is low, the cutting layer milling cutter of a fixed radial stepped structure is short in service life, machining efficiency is influenced and the like. Cutter teeth of the cutting layer milling cutter are designed in a stepped distribution, by means of increasing cutting depth, metal removal rate is increased, and machining efficiency is improved; by the aid of a radial adjusting mechanism, the cutting blades in an upper layer are enabled to move radially, a proper overhang amount can be selected, and strength of the cutting blades is enhanced. A radially-adjustable cutter pad is positioned by a pad block, auxiliary time including cutter amounting time, cutter adjusting time and the like is saved; up-warp chip holding grooves are formed in a cutter body in design, the depths of the positions, close to the cutting blades, of the chip holding grooves are far larger than that of the positions, distant from the cutting blades, of the chip holding grooves, up-warp slopes are formed in the chip holding grooves, and when cutting chips flow in the chip holding grooves, the chips can be separated from the cutter body quickly, friction between the chips and the cutter body is reduced, and service life of the cutter body is prolonged.

Owner:HARBIN UNIV OF SCI & TECH

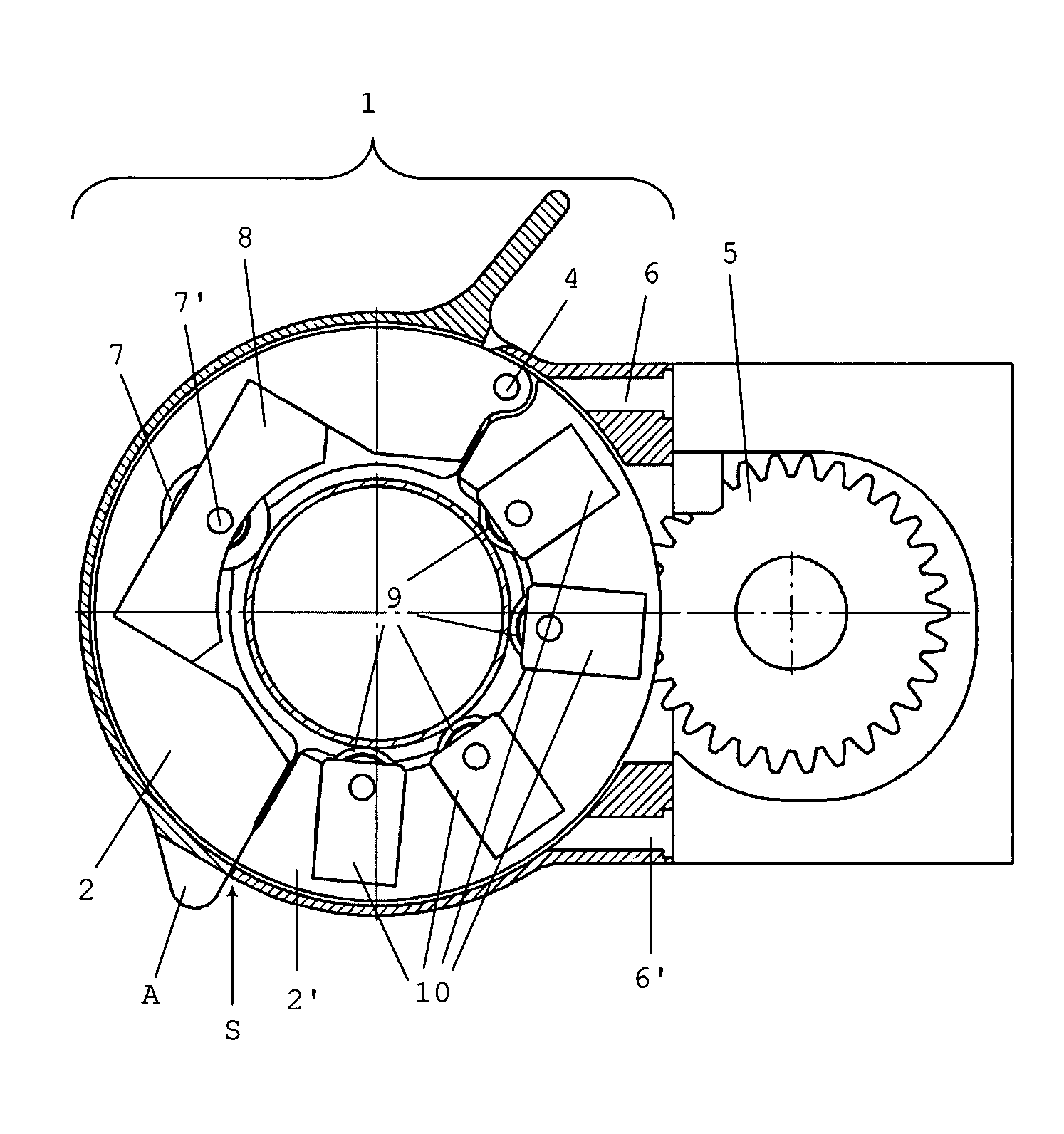

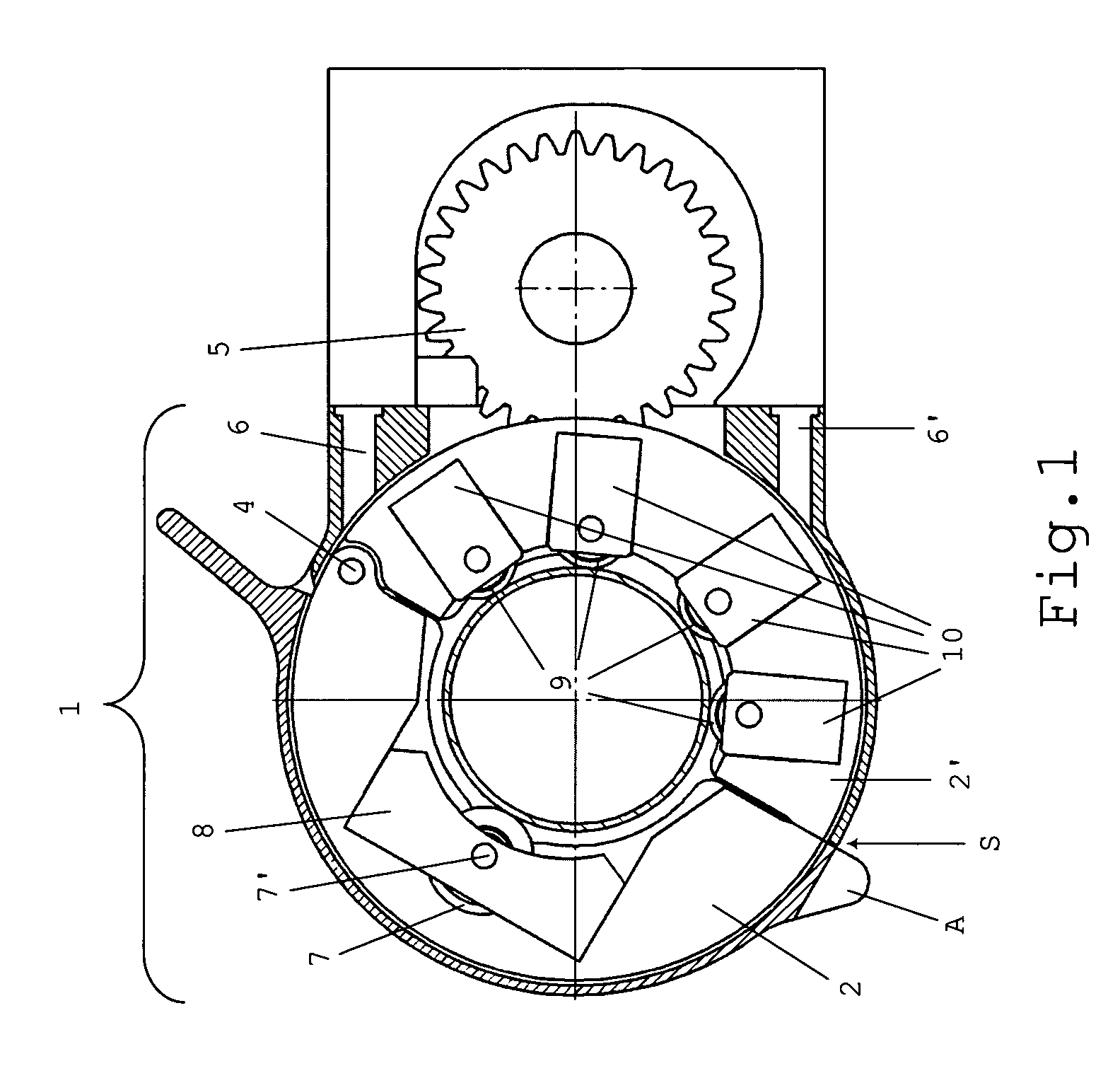

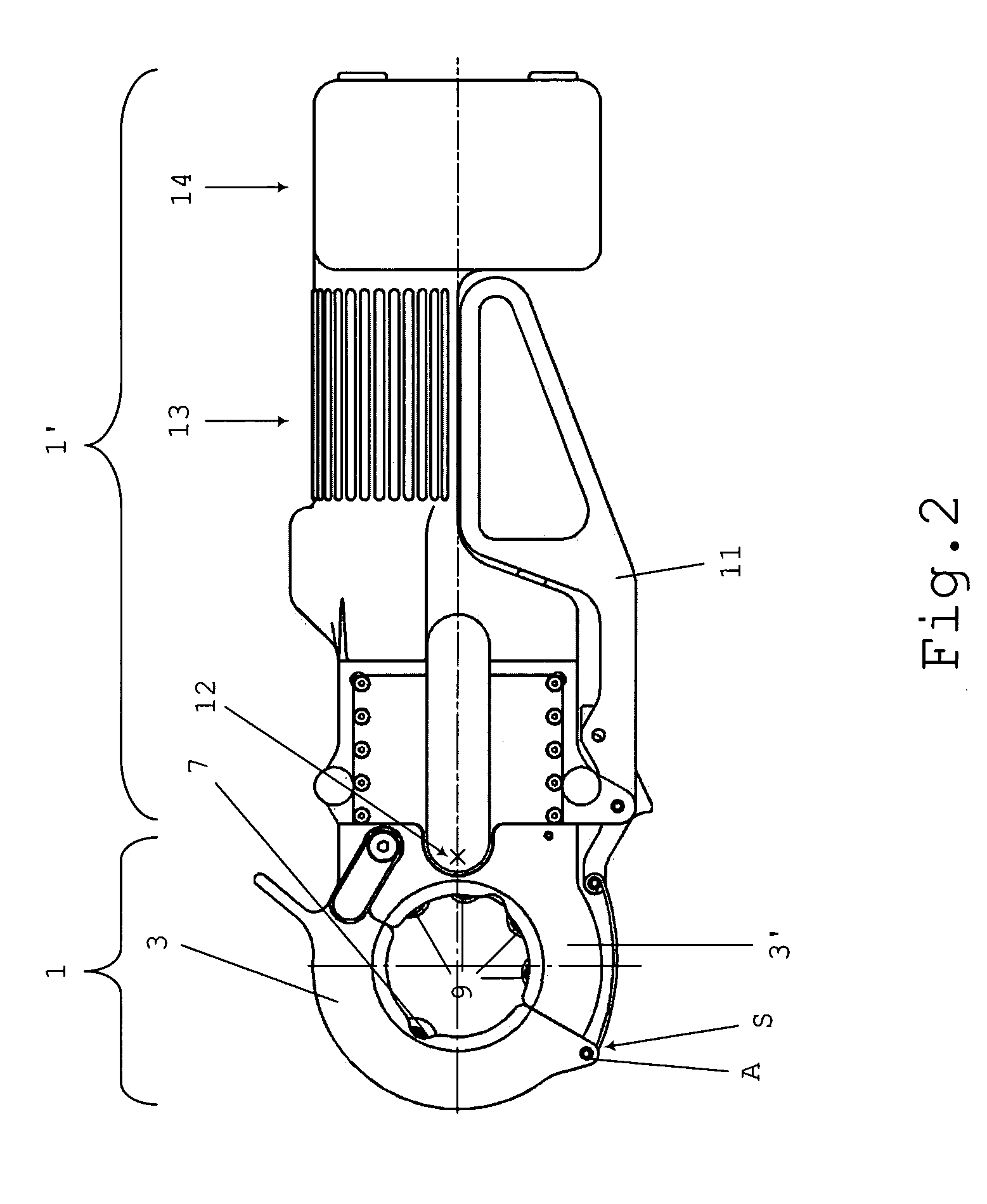

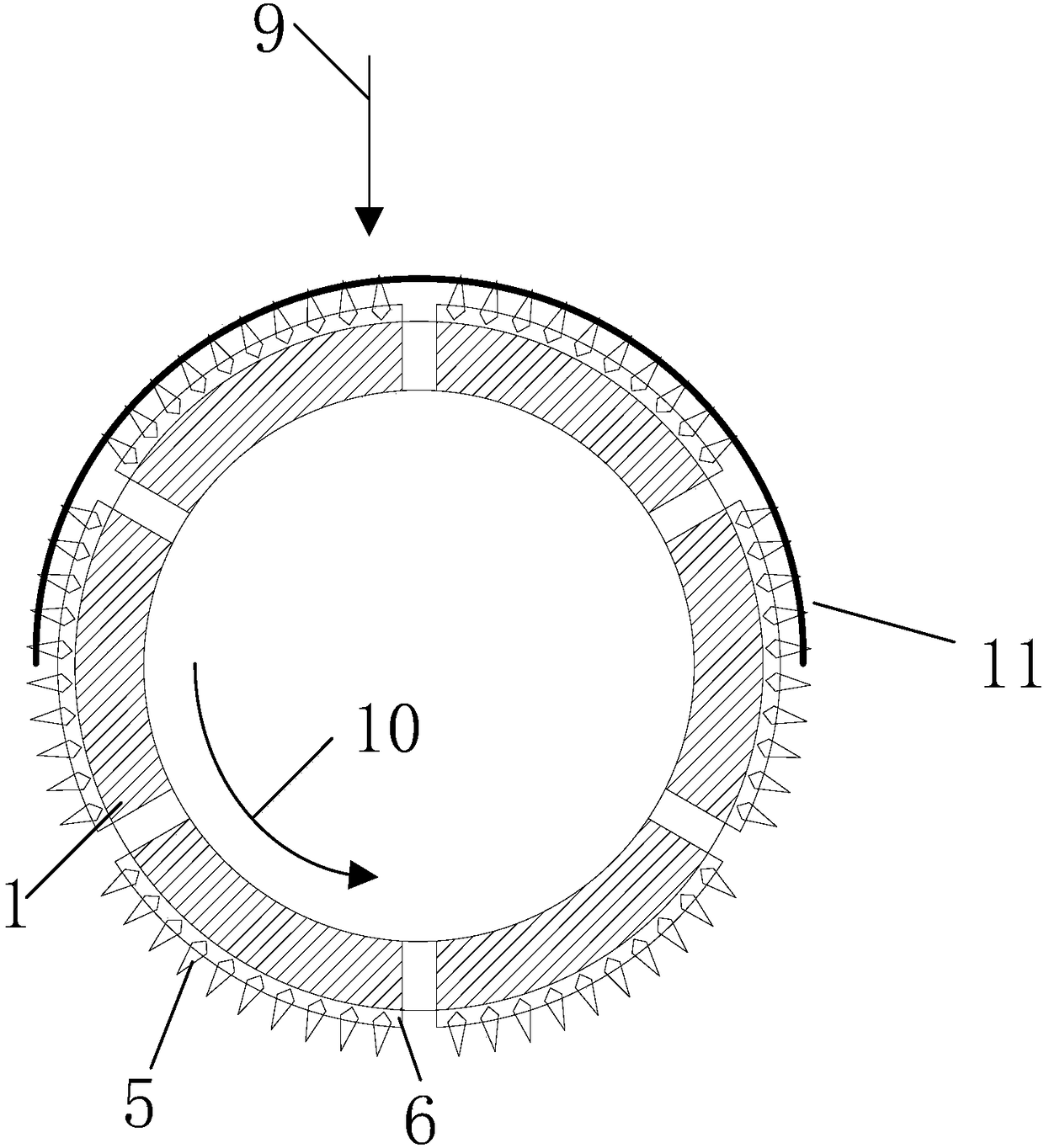

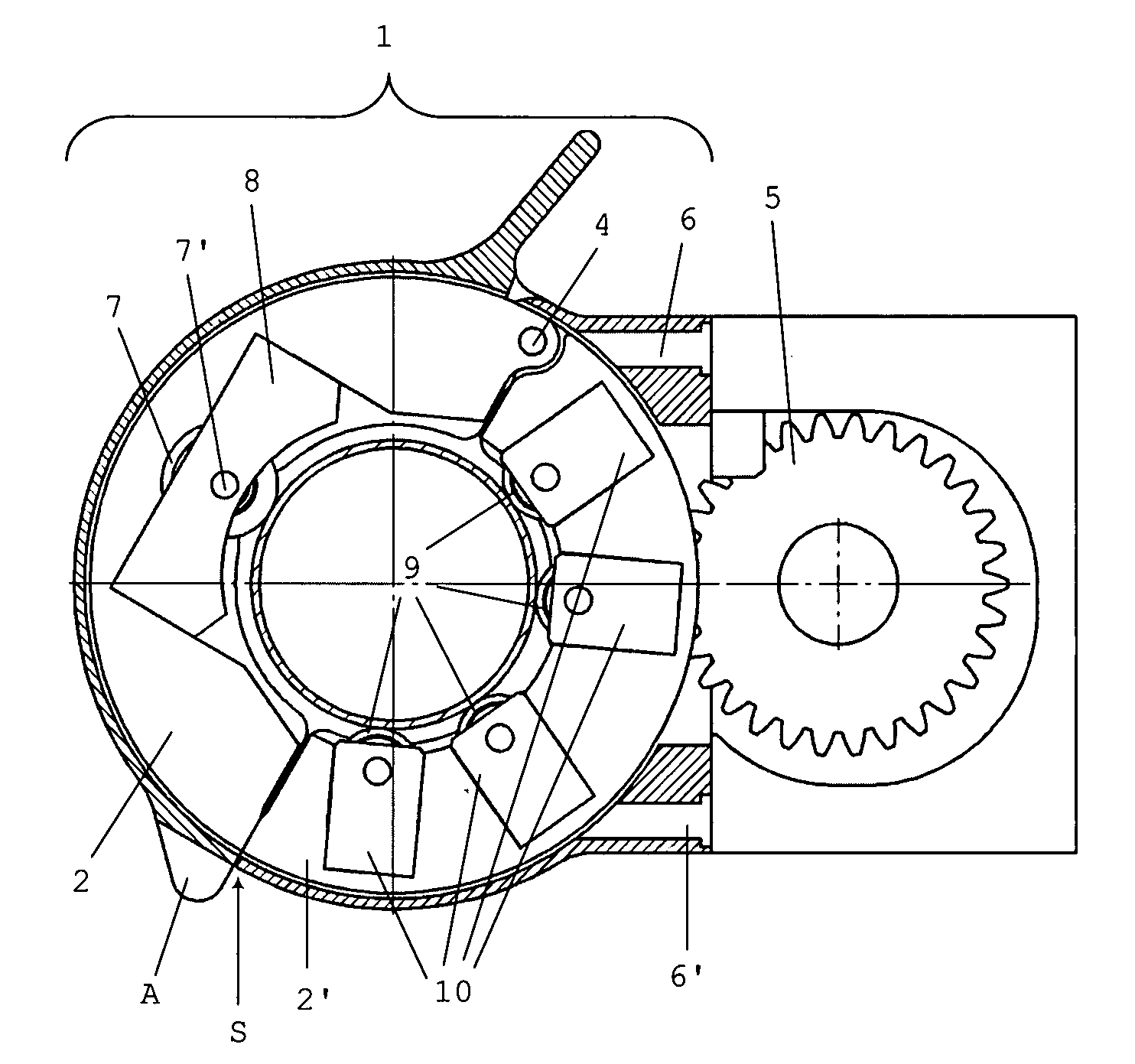

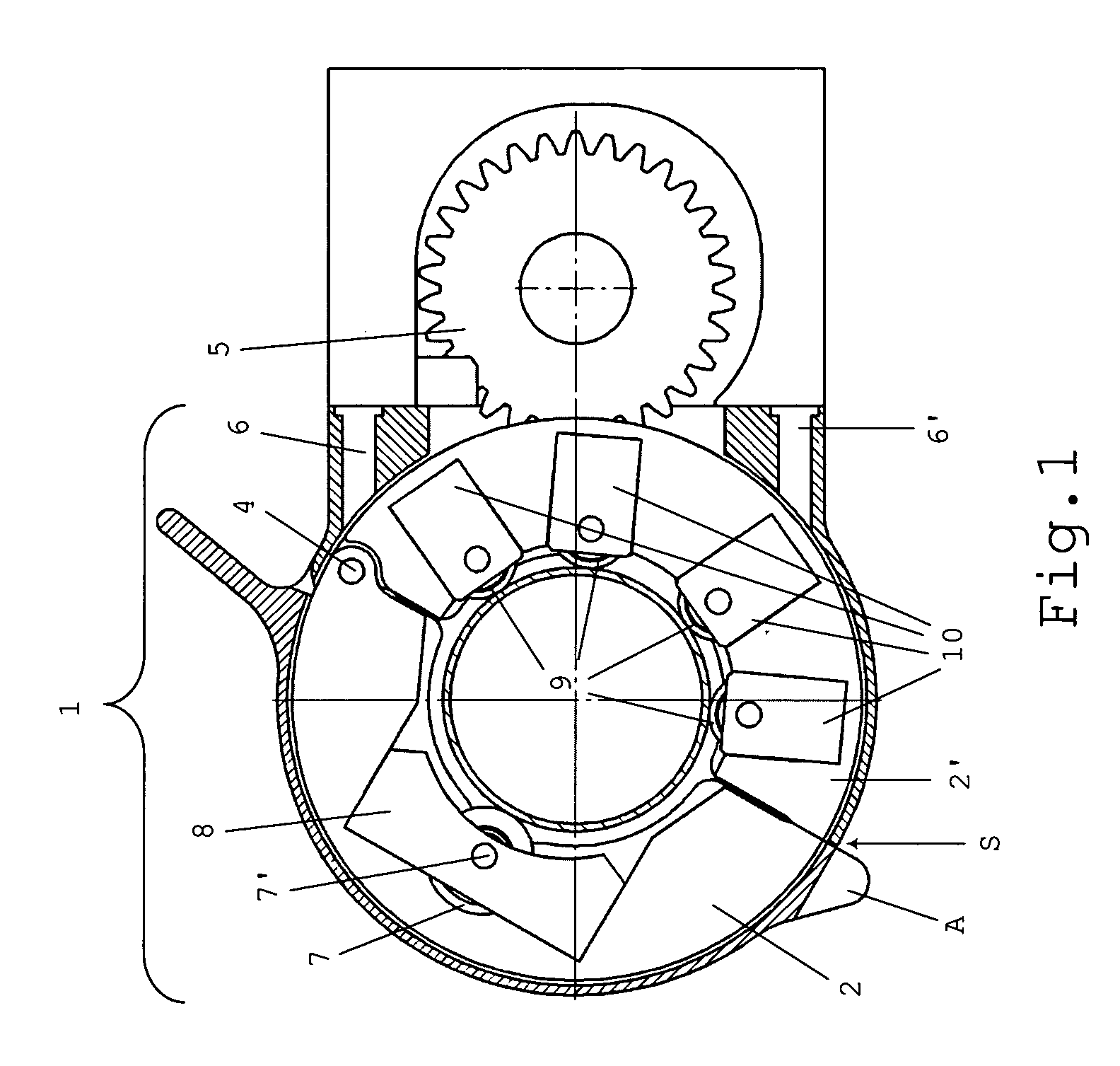

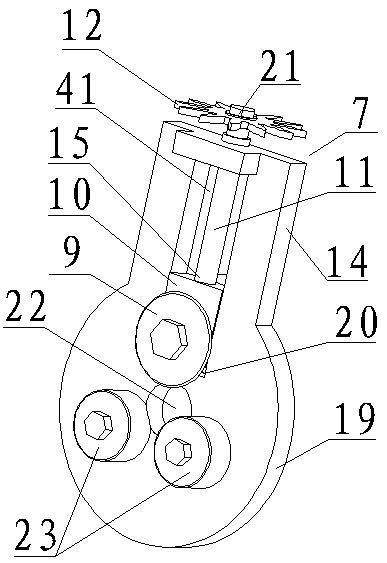

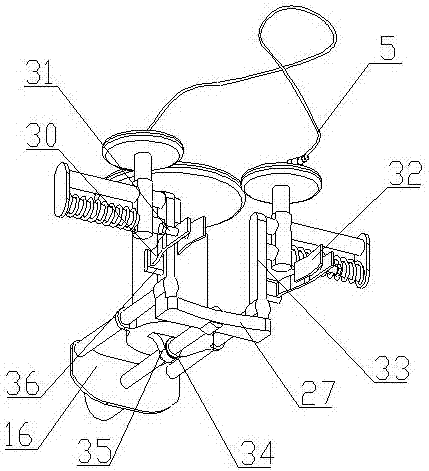

Pipe cutter

InactiveUS8033024B2Improve cut qualityIncreased depth of cutTube shearing machinesMetal working apparatusEngineeringCutting force

A pipe cutter according to the invention has an inner head part which, in the working position, rotates about a pipe which is clamped in the inner head part and is to be processed. Integrated in the inner head part are a spring-mounted cutting wheel head (8) having a cutting wheel (7) for cutting the pipe and a plurality of support rollers (9) in spring-mounted receptacles (10). The arrangement and formation of cutting wheel (7) and support rollers (9) is such that the clamped pipe is at right angles to the cutting wheel (7), and a right-angled cut is thus achieved. Moreover, a defined feed cutting force can be set by the spring mounting of cutting wheel head (8) and support roller receptacles. During cutting, the pressure on the pipe decreases with increasing cutting depth, and the pipe can thus be cut cleanly and without burrs.

Owner:CEKA ELEKTROWERKZEUGE

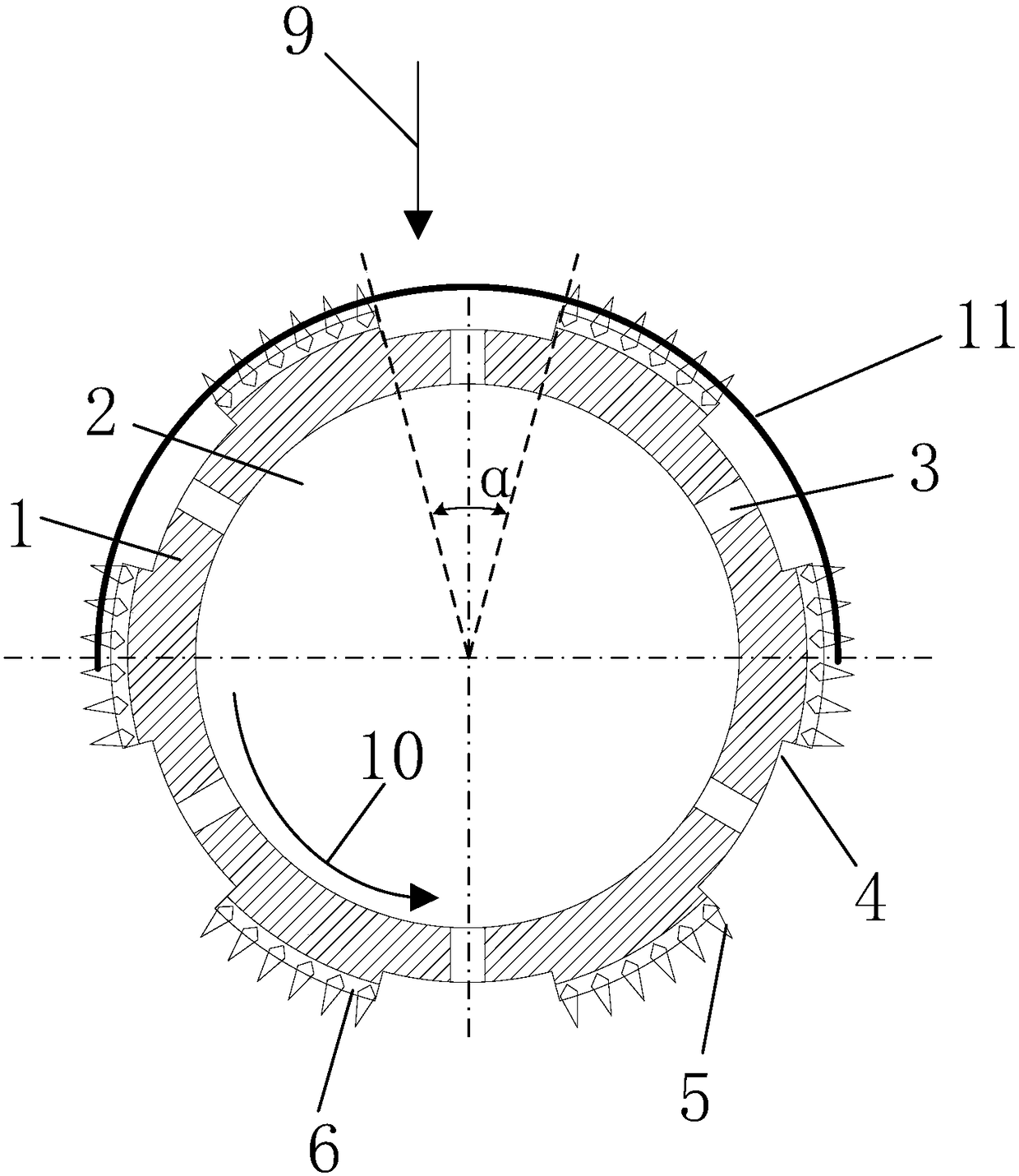

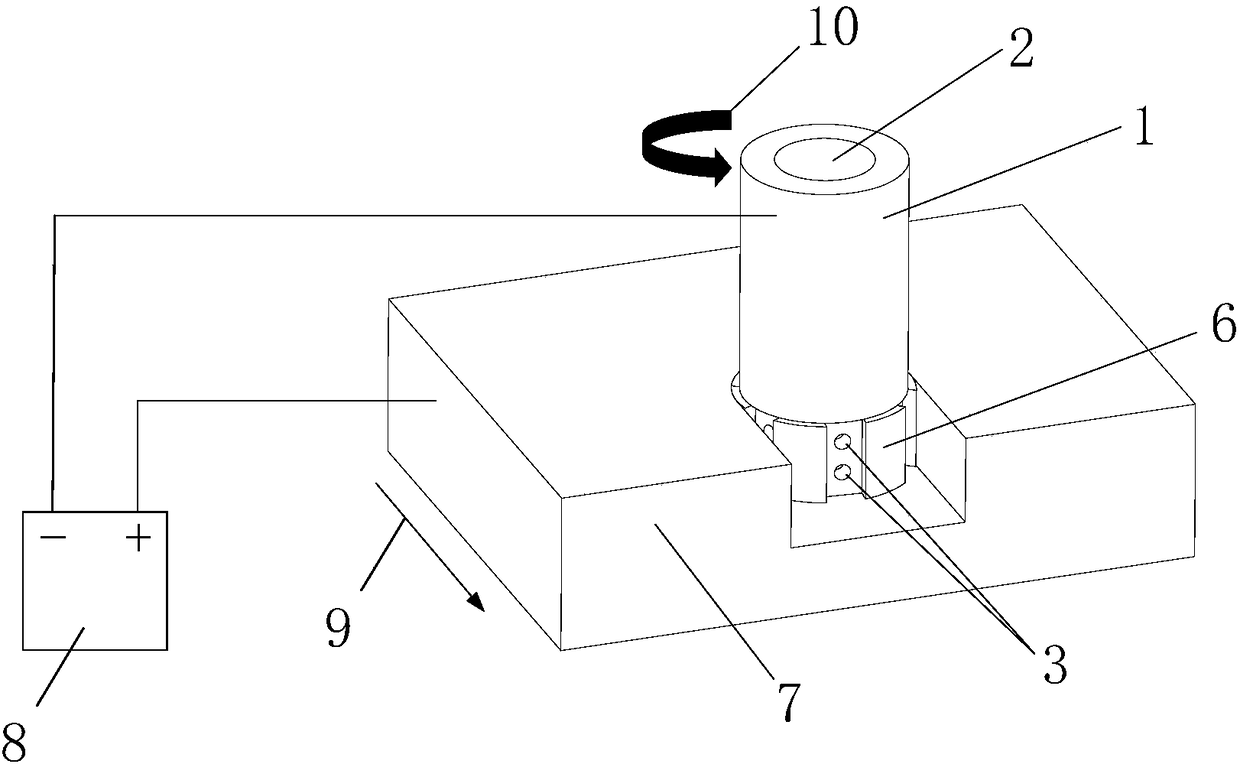

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

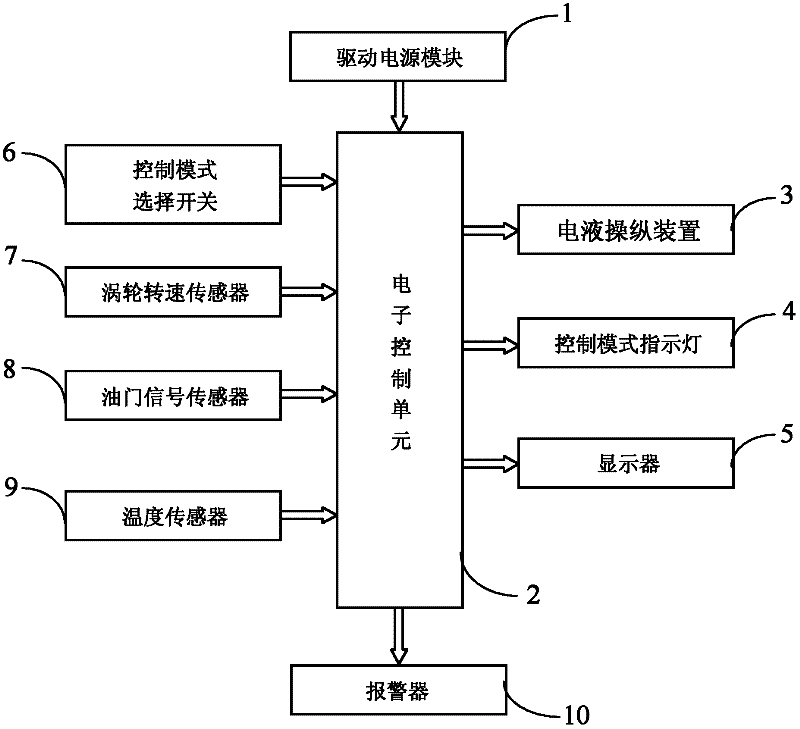

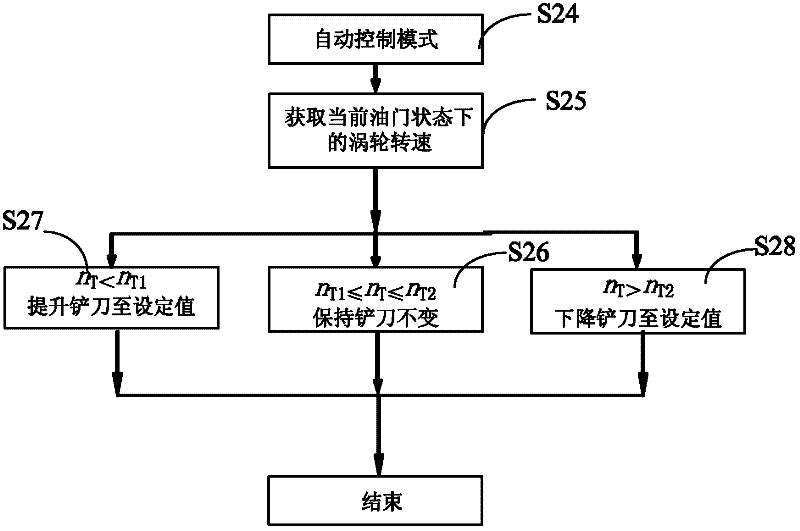

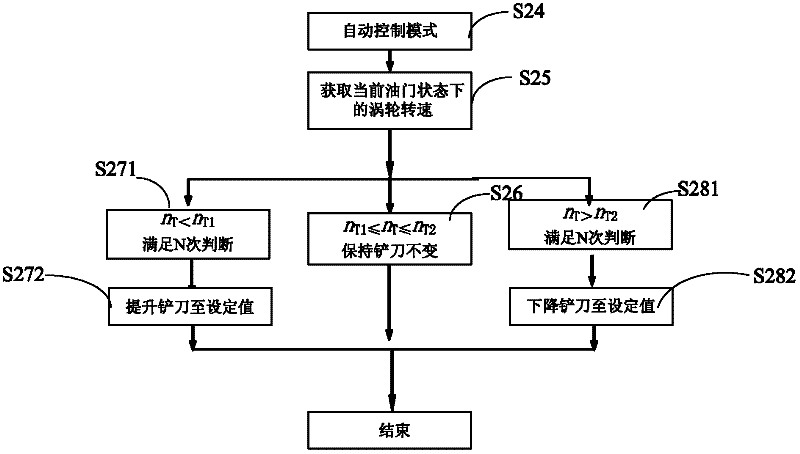

Automatic control system and automatic control method for scraper knife of hydraulic bulldozer

ActiveCN102330442AIncreased depth of cutSoil cut depth reducedMechanical machines/dredgersAutomatic controlControl system

The invention discloses an automatic control method for a scraper knife of a hydraulic bulldozer. The automatic control method comprises the steps of acquiring the rotating speed of a turbine under the current accelerator state, and keeping the scraper knife at the current position when the rotating speed of the turbine is within a first preset range under the accelerator state; descending the scraper knife and increasing the soil cutting depth when the rotating speed of the turbine is higher than the maximum rotating speed of the turbine in the first preset range, and stopping the descendingaction of the scraper knife until the rotating speed of the turbine is reduced within the first preset range; and ascending the scraper knife and reducing the soil cutting depth when the rotating speed of the turbine is lower than the maximum rotating speed of the turbine in the first preset range, and stopping the ascending action of the scraper knife until the rotating speed of the turbine is reduced within the first preset range. The invention can realize the automatic control on ascending and descending of the scraper knife by taking the relationship between the rotating speed of the turbine and the first preset range as judgment basis for whether the scraper knife is ascended or descended, thus improving the production efficiency and operation quality of the traditional bulldozer, and lightening the labor intensity of a driver.

Owner:SHANTUI CONSTR MASCH CO LTD

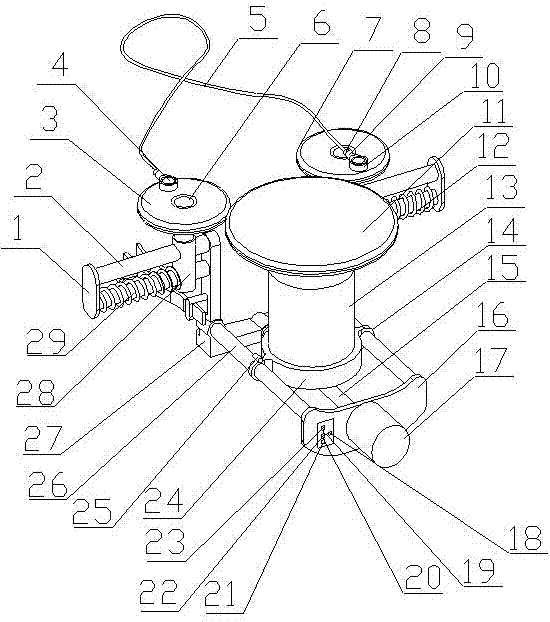

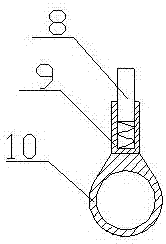

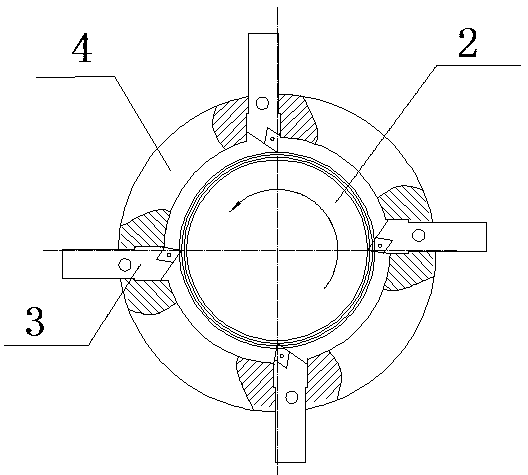

Pipe cutter

InactiveUS20060260133A1Improve cut qualityIncreased depth of cutTube shearing machinesMetal working apparatusEngineeringCutting force

A pipe cutter according to the invention has an inner head part which, in the working position, rotates about a pipe which is clamped in the inner head part and is to be processed. Integrated in the inner head part are a spring-mounted cutting wheel head (8) having a cutting wheel (7) for cutting the pipe and a plurality of support rollers (9) in spring-mounted receptacles (10). The arrangement and formation of cutting wheel (7) and support rollers (9) is such that the clamped pipe is at right angles to the cutting wheel (7), and a right-angled cut is thus achieved. Moreover, a defined feed cutting force can be set by the spring mounting of cutting wheel head (8) and support roller receptacles. During cutting, the pressure on the pipe decreases with increasing cutting depth, and the pipe can thus be cut cleanly and without burrs.

Owner:CEKA ELEKTROWERKZEUGE

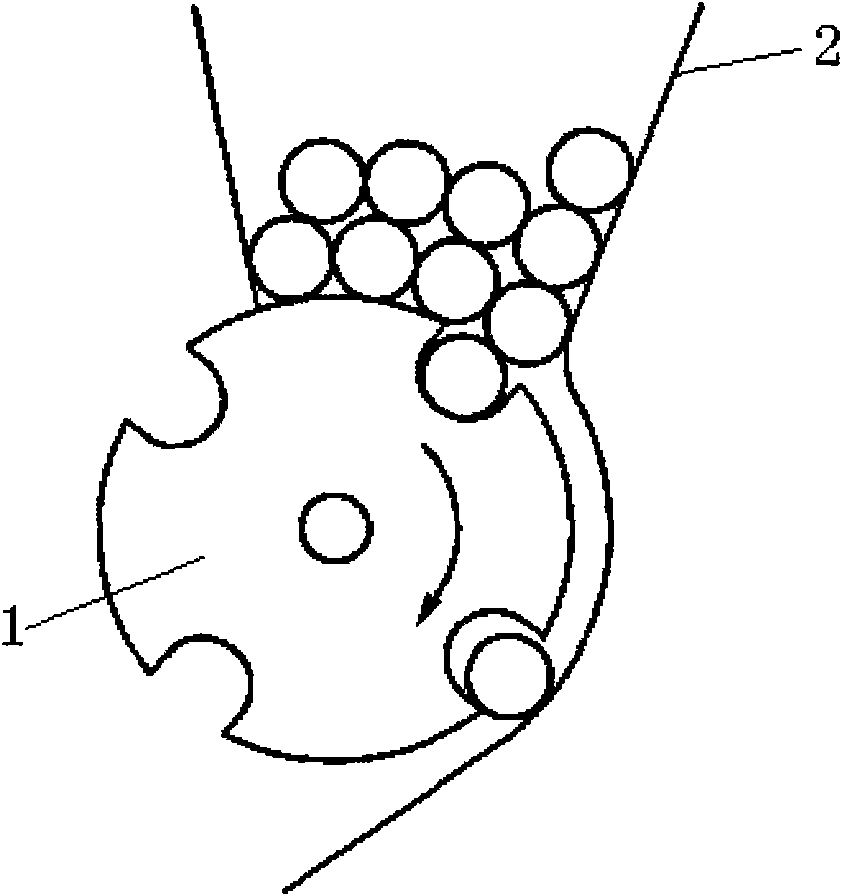

Stepped chip breaking disk milling cutter

The invention relates to a milling cutter used on milling and boring machine tool equipment, in particular to a stepped chip breaking disk milling cutter. A cutter disk is respectively provided with four T-shaped grooves equipped with four cutter bars in a sliding way; the cutter bars are provided with thread holes and are connected with adjusting bolts through the cutter disk, and the adjusting bolts are screwed by a hexagonal wrench so that the cutter bar can be driven to move along the axis of the cutter disk; a specific position of the cutter rod relative to the cutter disk can be obtained conveniently through scales engraved on the cutter during the installation of the cutter bars, the four cutter bars are divided into two groups, a plane can be conveniently milled in two layers at the same time through adjusting the adjusting bolts; and the cutting layer thickness can be adjusted so as to realize the chip breaking cutting; when the milling cutter is in use, the milling force and milling power can be reduced, the cutting layer thickness of once cutting is increased, the cutting efficiency is improved, and the milling cutter is convenient to operate and has strong practicality.

Owner:庞勇

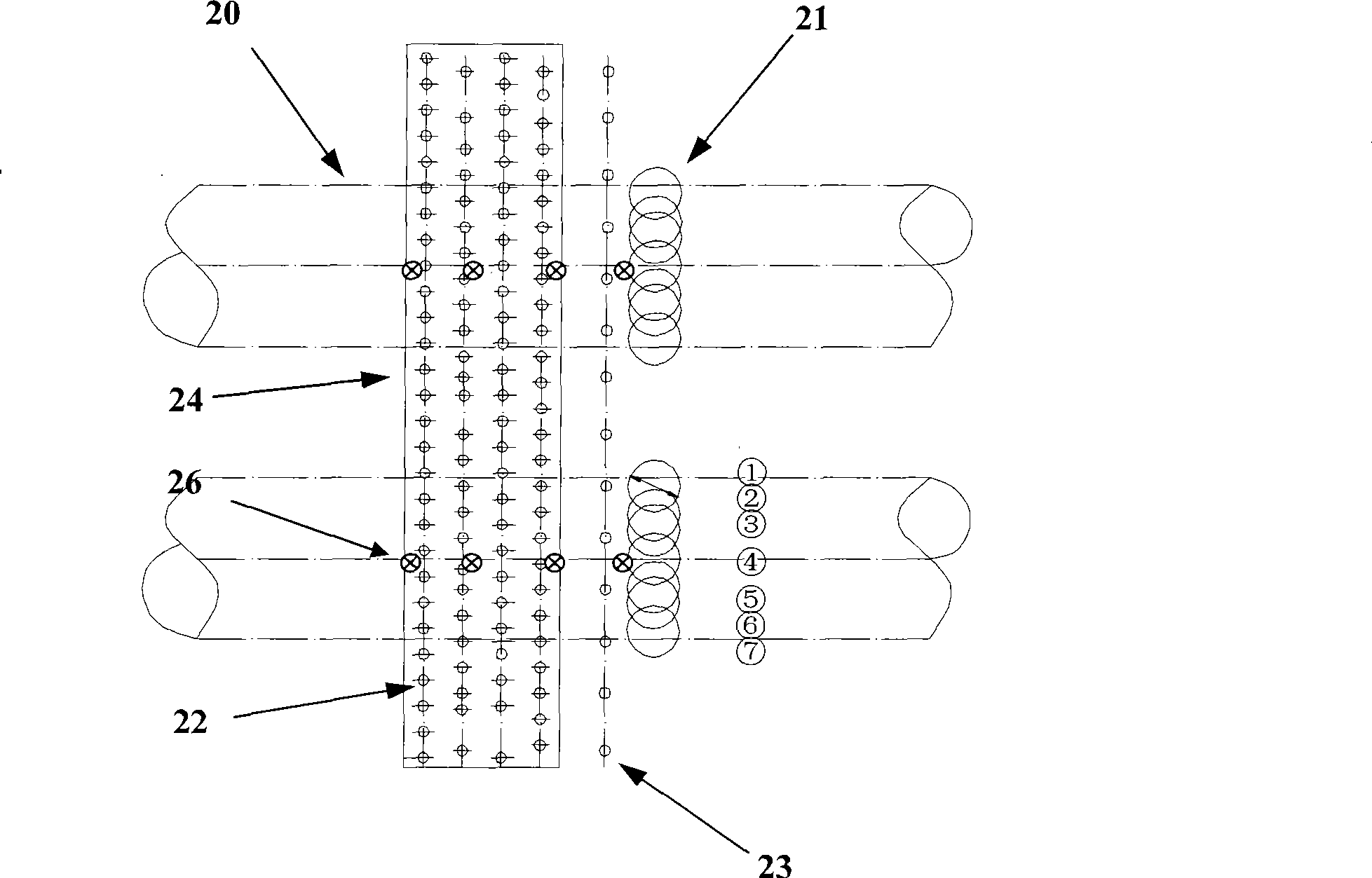

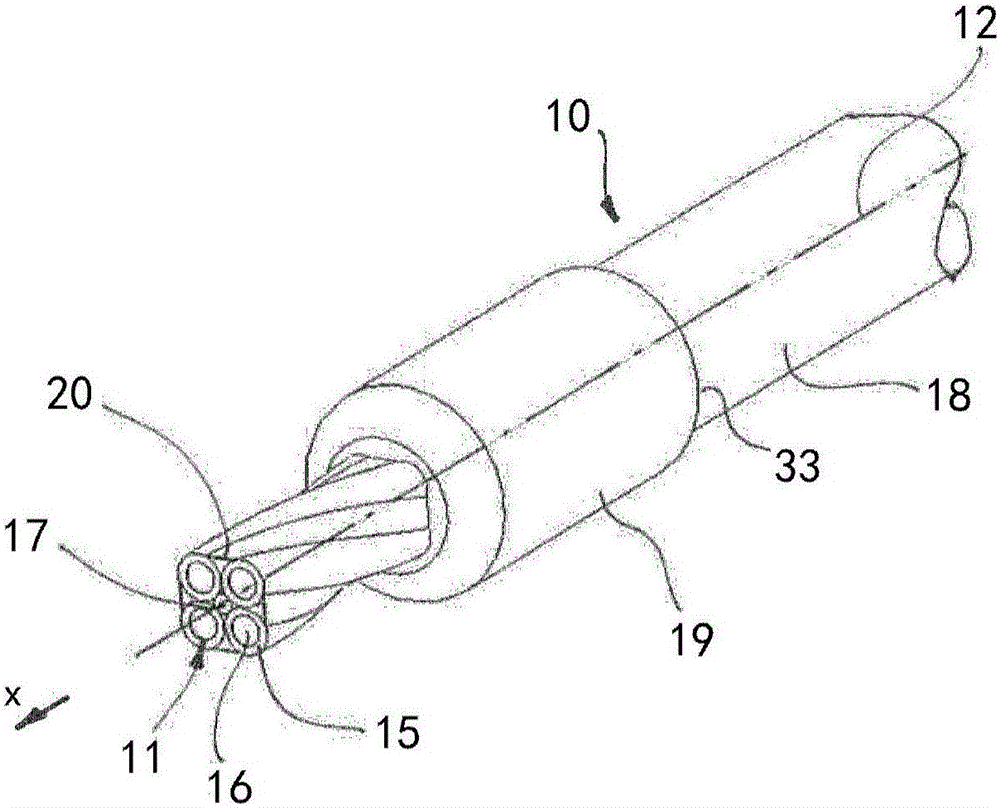

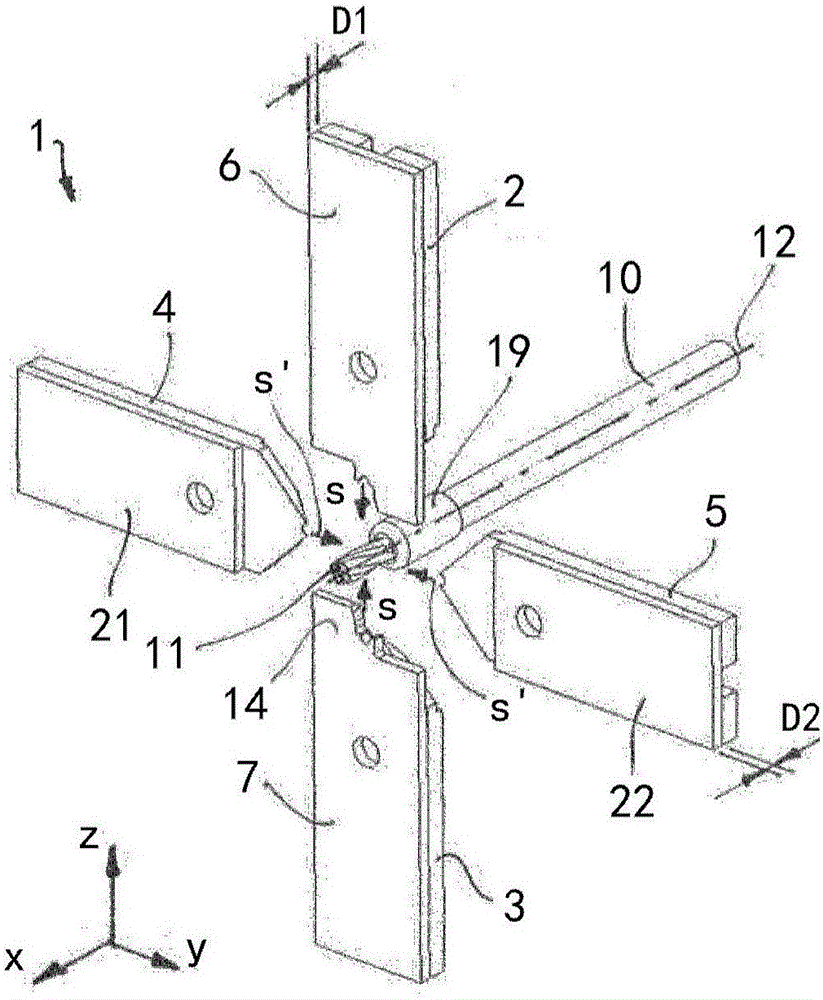

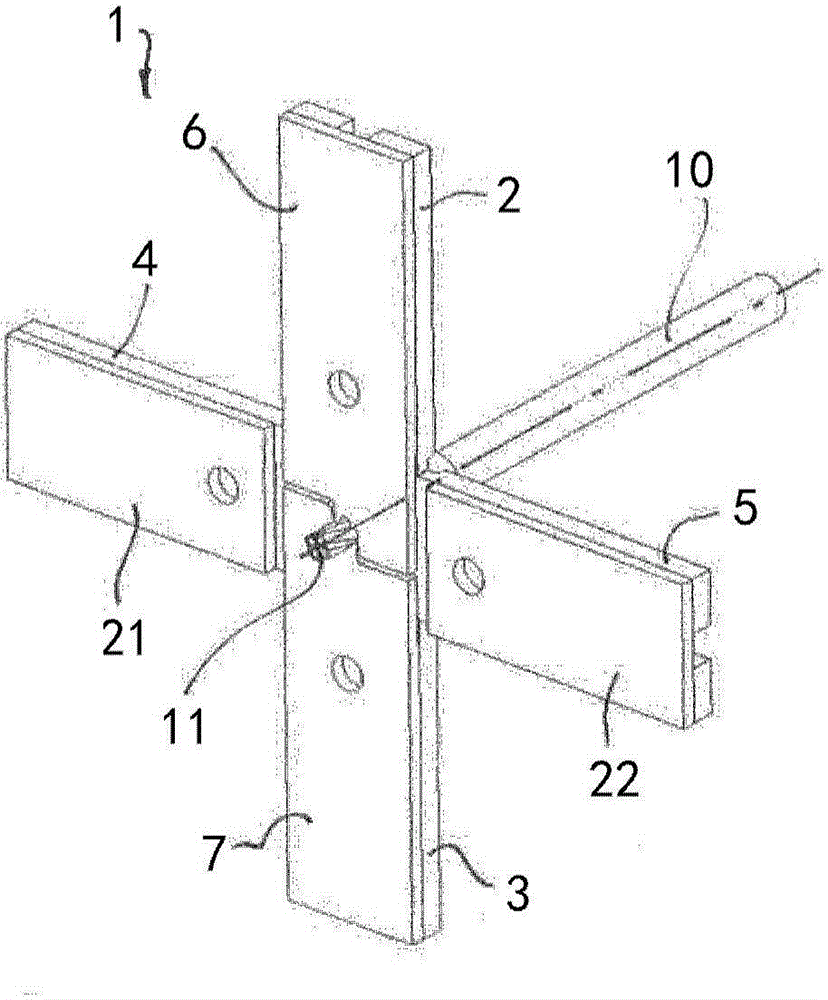

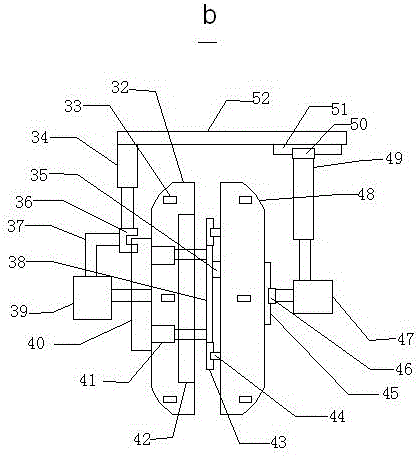

Cable processing apparatus and method for removing a screening film from a screened multi-core round cable

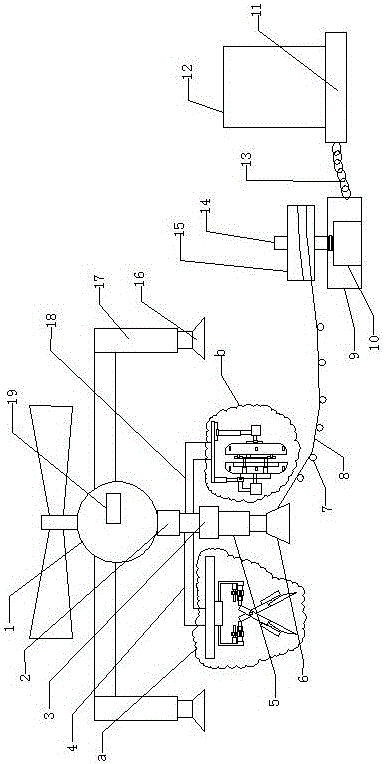

ActiveCN106099620AIncreased depth of cutImprove automationLine/current collector detailsVehicle connectorsEngineeringAbutment

The invention provides a cable processing apparatus for removing a shield film (20) from a shielded four-core round cable (10). The cable processing apparatus has four cutting tools capable of moving radially toward a round cable (2, 3, 4, 5) for cutting a mask film (20). Here, the cutter (2, 3, 4, 5) is distributed to the core (11) of the circular cable (10). The cutting edges (23, 24, 25, 26) of the cutters (2, 3, 4, 5) are respectively recessed. The cutter (2, 3, 4, 5) is provided with guiding elements (6, 7, 8, 9); the guiding element has guide segments (27, 28); the core (11) wrapped by the shielding film is accommodated in the boot segment. The knives (2, 3, 4, 5) protrude with respect to the guide elements (6, 7, 8, 9) in the area of the guide segments (27, 28) with the amount of interference (t). The guide segments (27, 28) have a cylindrical recessed shape and form a recessed abutment against the core (11).

Owner:科迈士瑞士股份有限公司

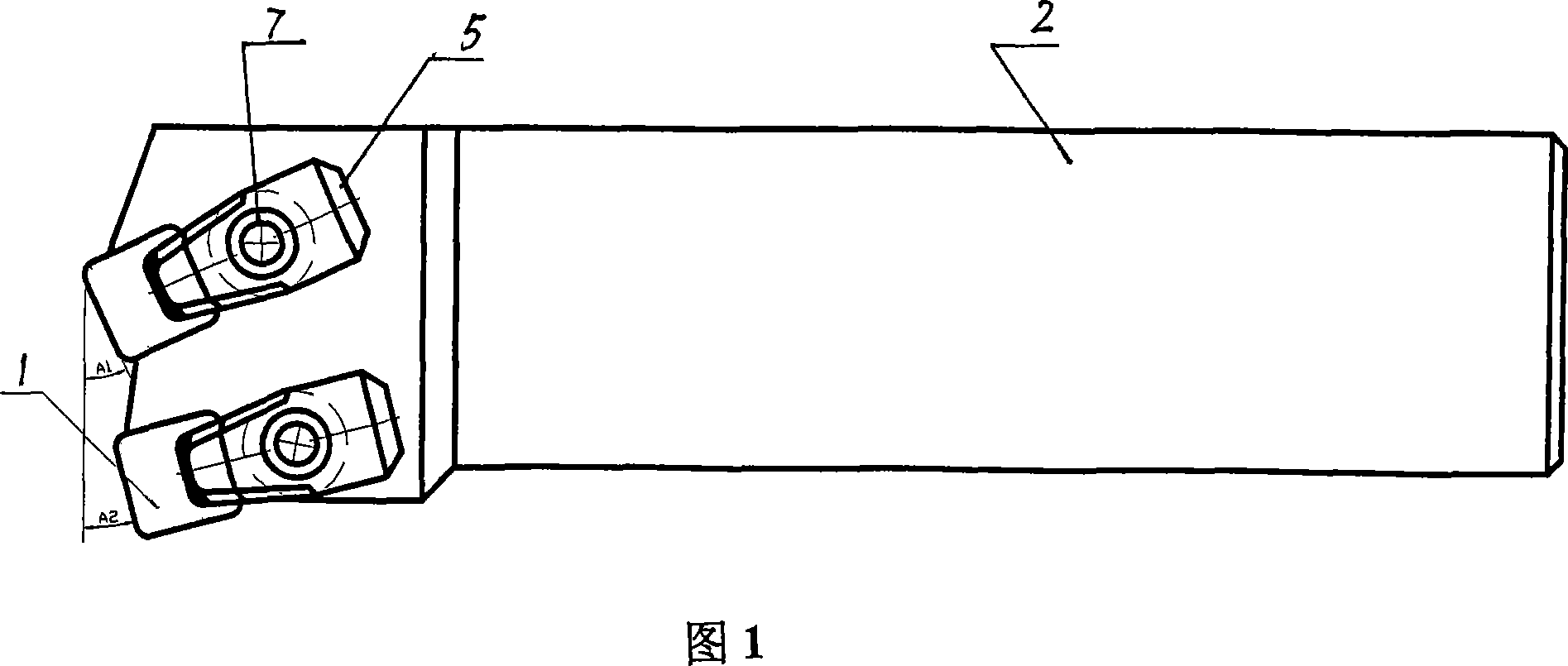

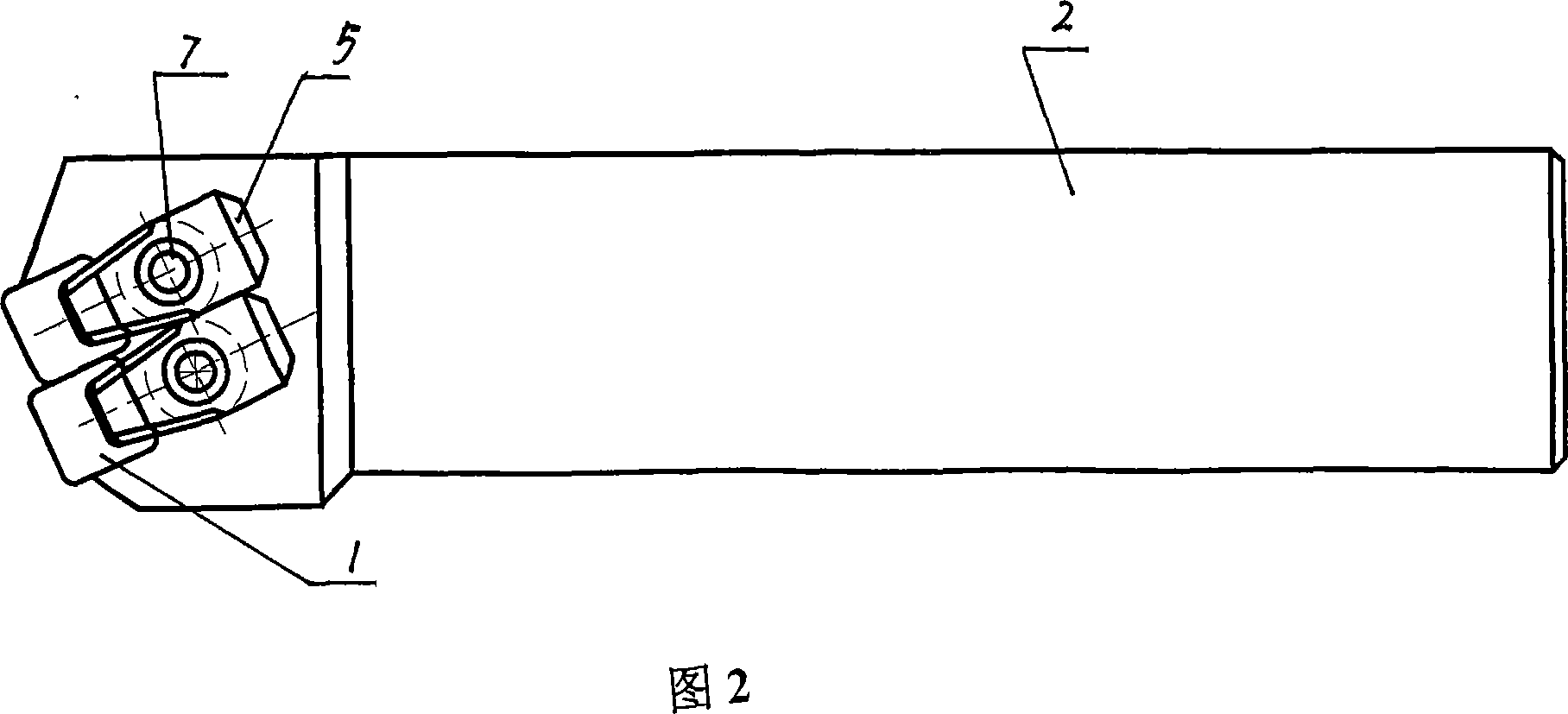

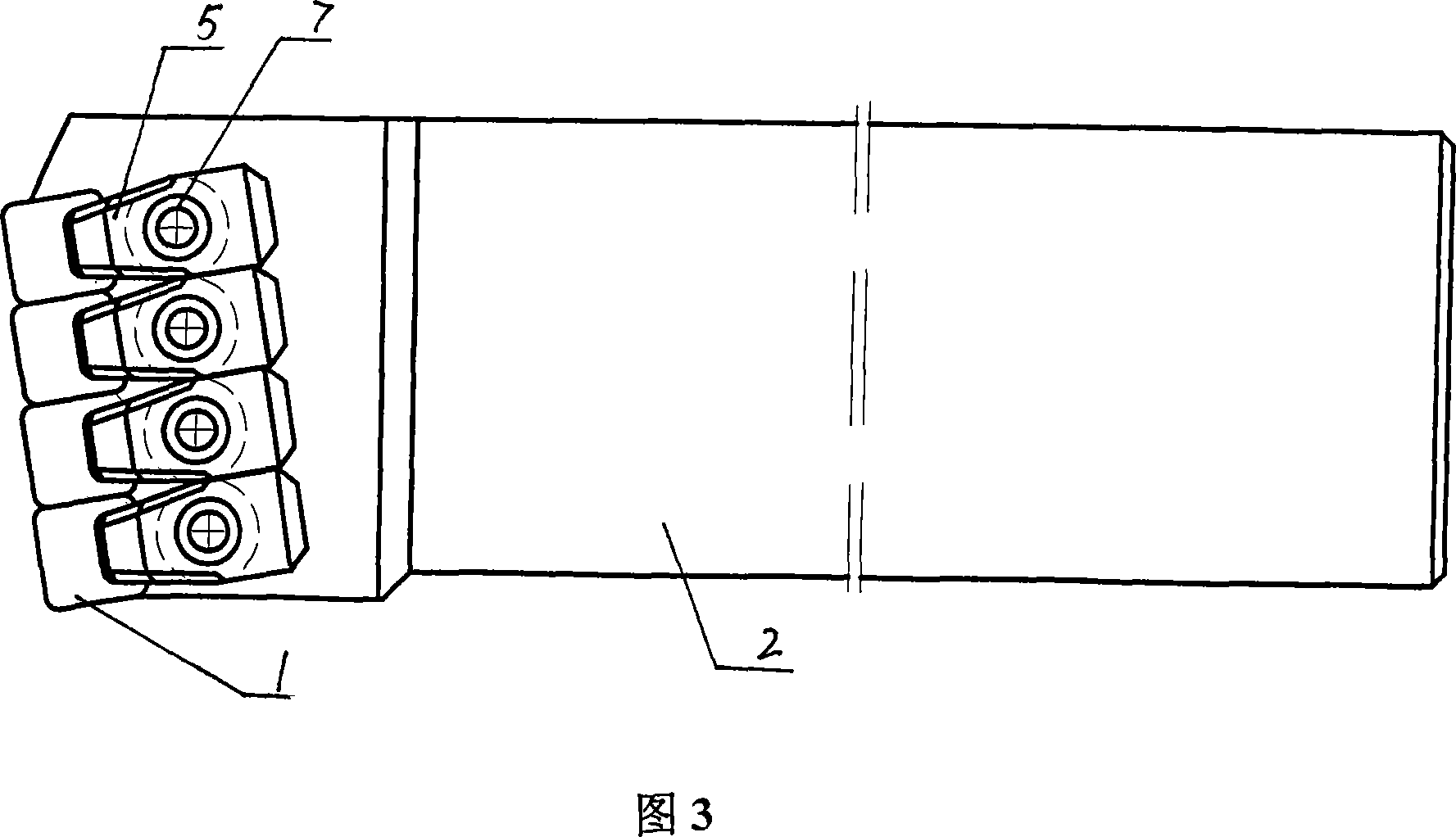

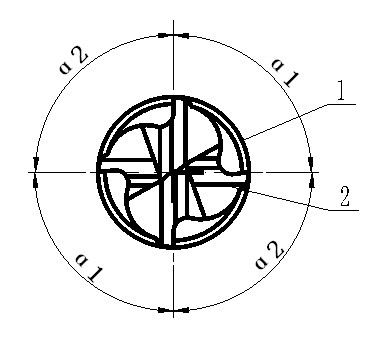

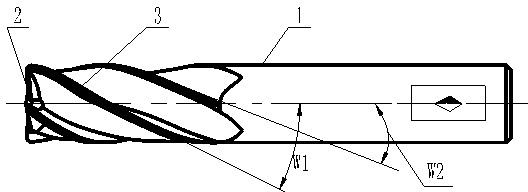

Multi-edge composite cutting tools

InactiveCN101077533AIncreased depth of cutIncrease the amount of cuttingTurning toolsBoron nitrideAlloy

The combined cutting tool with several cutting edges includes one cutter bar, and several cutting blade mounting mechanisms with separately mounted blades in the same or different entering angles. On the one hand, the combined cutting tool with several cutting edges can cut with its multiple cutting edges in doubled cutting depth, increased feed and doubled cutting efficiency. On the other hand, the present invention has flexible machining form, convenient operation, changeable number of cutting edges and adjustable entering angles. In addition, the cutting blades may be made of different materials, cubic boron nitride, diamond, hard alloy, etc. selected based on the machining requirement, machining cost and other factors.

Owner:上海美恩精密工具有限公司

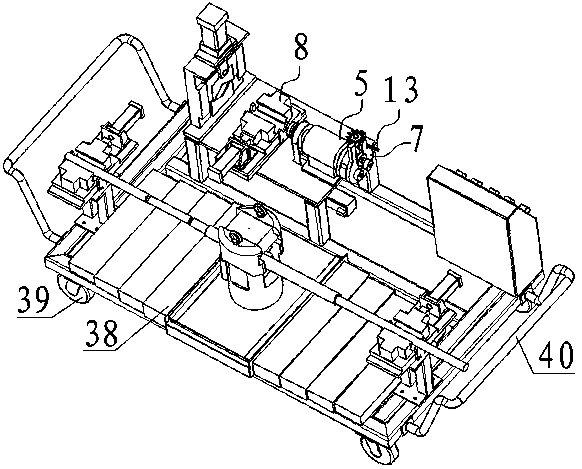

Guide ground wire automatic crimping machine

PendingCN107681407AImprove stabilityQuality improvementConnection formation by deformationElectronic waste recyclingGround contactEngineering

The invention discloses a guide ground wire automatic crimping machine. The machine comprises a crimping platform, a crimping apparatus located on the crimping platform and a wire-stripping apparatusarranged on a left side frame of the crimping apparatus. The wire-stripping apparatus comprises a power mechanism, a wire-stripping mechanism and a first guide ground wire clamping mechanism. The power mechanism is connected to the wire-stripping mechanism in a transmission connection mode through a transmission mechanism. The wire-stripping mechanism comprises a cutting knife component used for wire stripping and a support component used for supporting the cutting knife component. The cutting knife component comprises a wire-stripping blade which can carry out circular motion around a guide ground wire and can carry out radial movement. The first guide ground wire clamping mechanism is used for clamping the guide ground wire. In the invention, a wire cutting apparatus, the wire-strippingapparatus and the crimping apparatus are integrated on one crimping platform, which is convenient for crimping of the guide ground wire, safety is high, operation is simple and work efficiency is increased; the wire cutting apparatus is used to cut the wire and the wire-stripping apparatus is used to carry out wire stripping; and processing precision is high and labor intensity is reduced.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

Device for longitudinally cutting cigarettes

The invention discloses a device for longitudinally cutting cigarettes, which consists of a machine body, a cigarette-sampling device, a longitudinally cutting device, a longitudinally-cutting depth adjusting device, a tobacco shred collecting box and the like. The device has the advantages of realizing fast separation of cigarette tobacco shred from cigarette paper and filter tip, ensuring the quality of the cigarette tobacco shred, avoiding a large amount of manual labor and reducing the influence of personal factor on the quality rank of the tobacco shred, along with reasonable structural design and convenient use. The machine can be operated continuously so as to enhance the separation efficiency of the cigarette tobacco shred, save time for the tobacco shred detection in a laboratoryand obtain consistent high praise from users.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Cutting machine and cutting method thereof

InactiveCN103801767AIncomplete cutting defectsIncreased depth of cutEngineeringMechanical engineering

The invention discloses a cutting machine and a cutting method thereof. The cutting machine comprises a cutting mechanism, a clamping mechanism used for clamping an article to be cut and a feeding mechanism used for conveying the article to be cut to the appropriate position. The cutting mechanism comprises not less than a set of blade holders arranged on the two sides of the article to be cut. Each blade holder is provided with a sliding base which can slide front and back under the limitation of the corresponding blade holder. Each sliding base is provided with a cutting blade, and a certain included angle is formed between the sliding track of each sliding base and the article to be cut. According to the cutting machine, in the cutting process, the cutting blades evenly increase the cutting depth while cutting the article, the defect of incomplete cutting caused by metal deformation or abrasion of the cutting blades in the cutting technology cannot happen, and the cutting machine can cut various materials and is wide in adaptability range.

Owner:胡虎

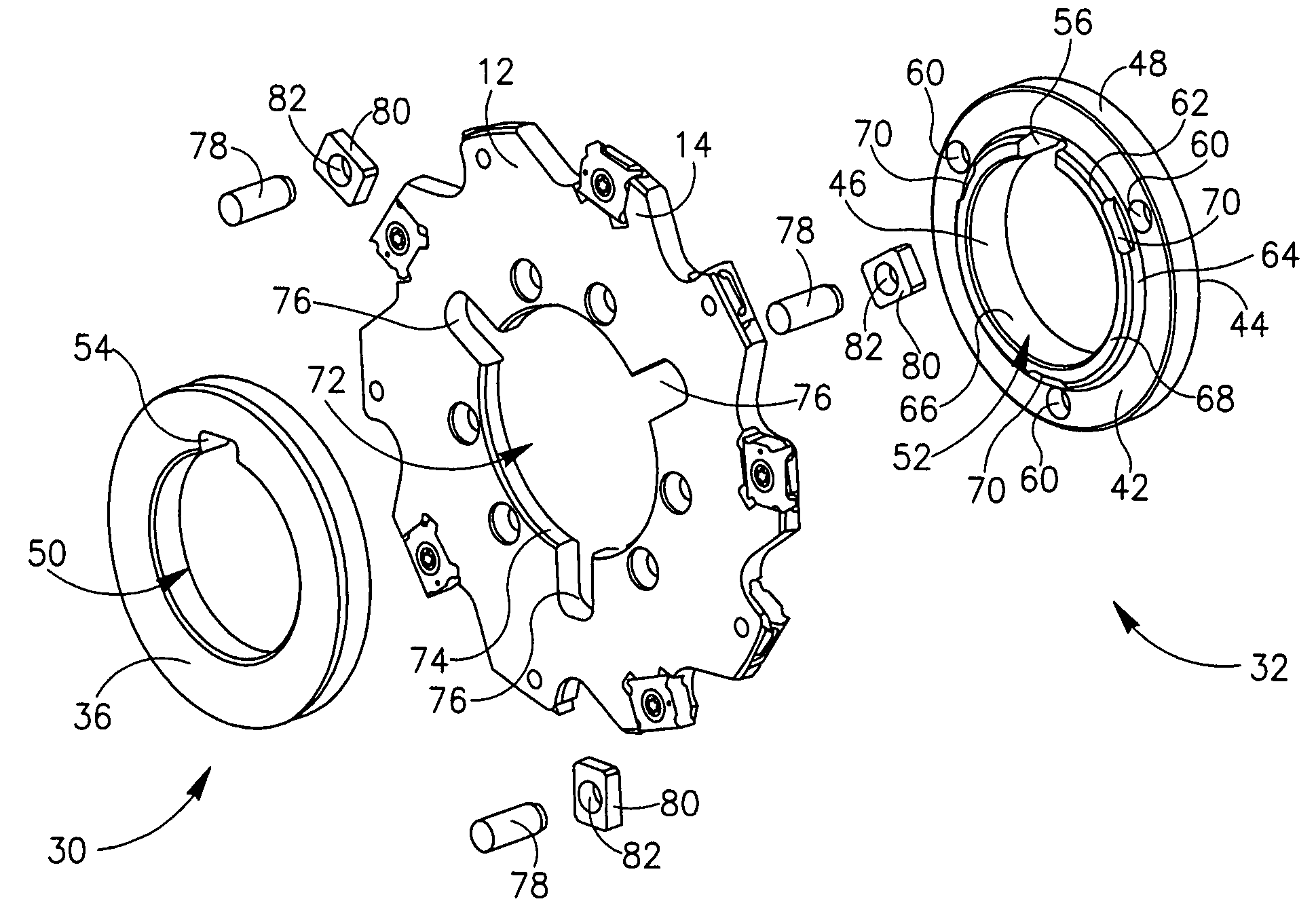

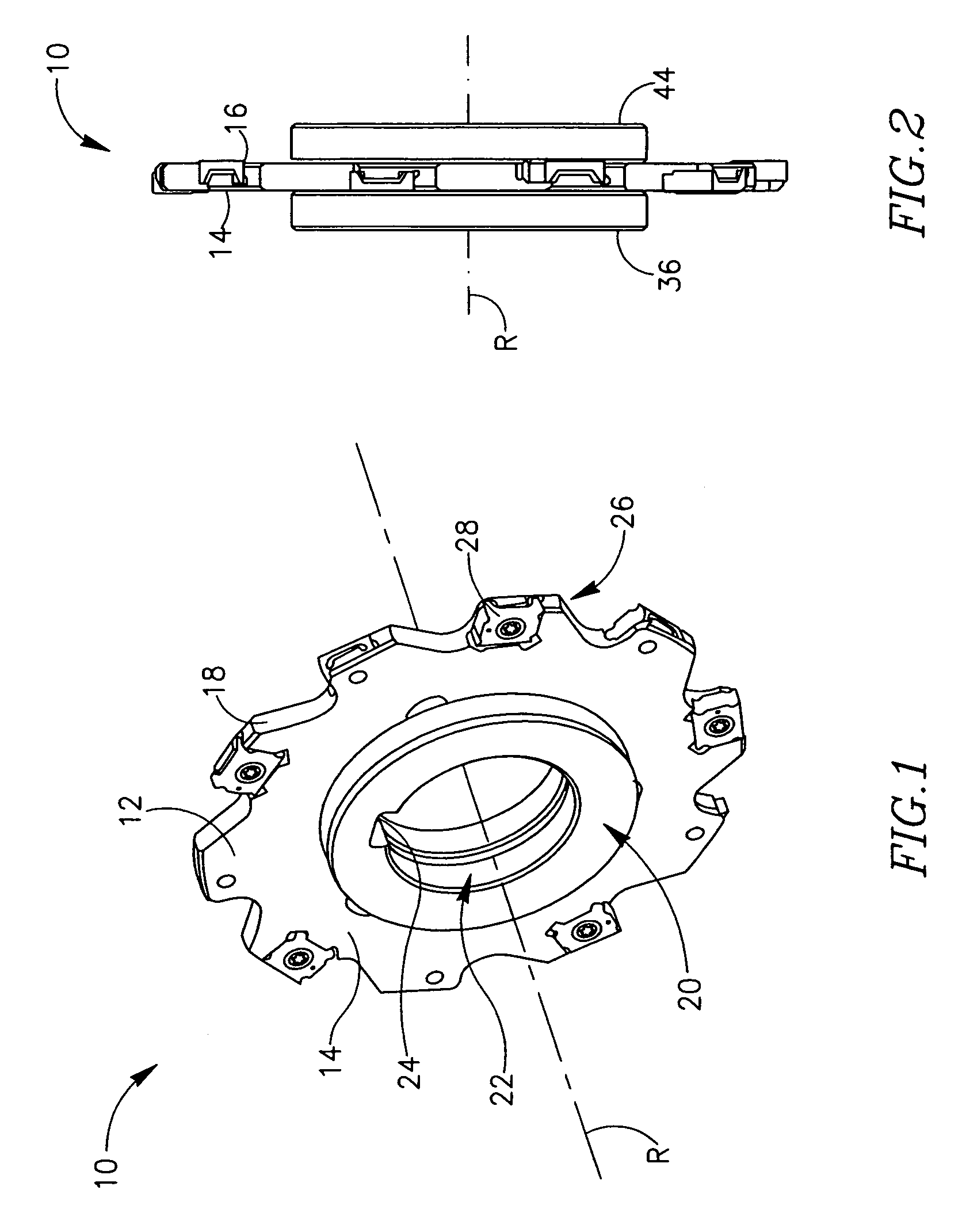

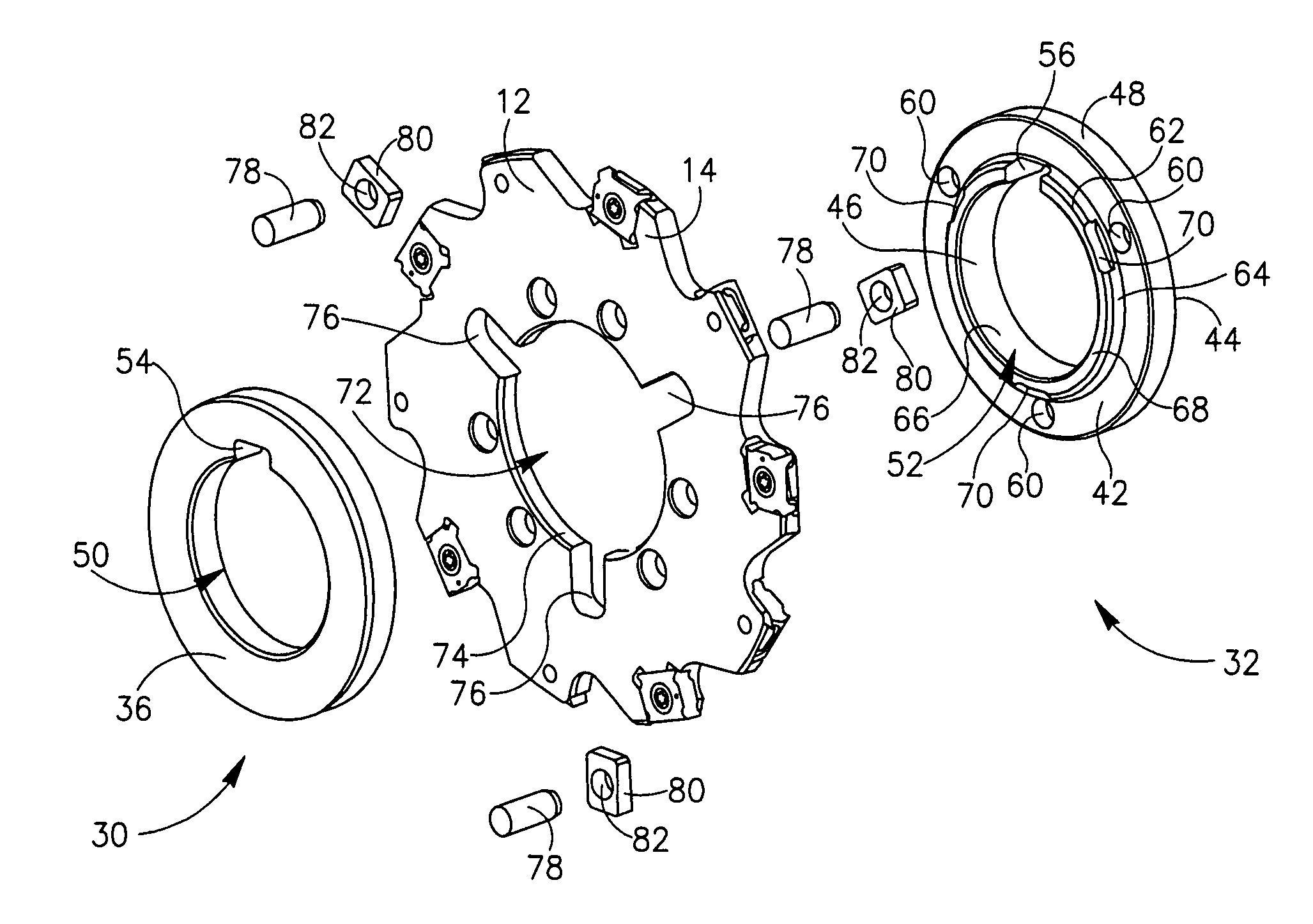

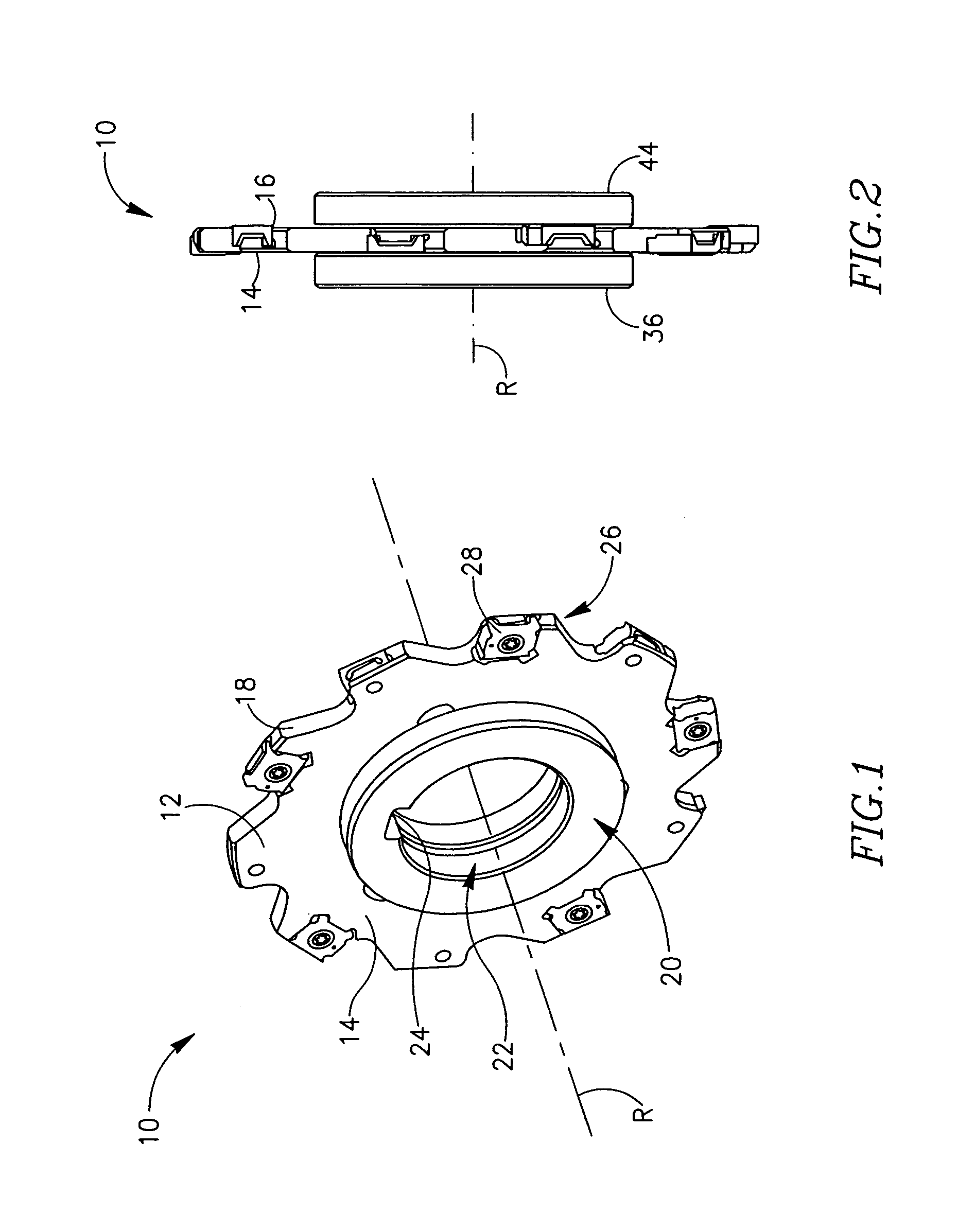

Milling cutter

ActiveUS7112013B2Increased depth of cutEffective wayMilling cuttersMetal sawing toolsMilling cutterEngineering

A milling cutter with a disk like cutter body having radially directed slots and a central aperture. An exchangeable hub comprises two adapter members located on either side of the cutter body. One of the adapter members has a raised portion located in the central aperture. The adapter members are secured to the cutter body by means of pins which are located in blind holes in the adapter members and which pass through engagement members positioned in the slots.

Owner:ISCAR LTD

Livestock breeding ox horn cutting device

InactiveCN107877581ANeat cutting surfaceImprove cutting effectMetal working apparatusTaming and training devicesEngineeringScrew thread

The invention provides a livestock breeding ox horn cutting device and discloses a device for cutting an ox horn through gradual tensioning and reciprocating movement of a rope saw. The livestock breeding ox horn cutting device is characterized in that the middle of a supporting plate and the middle of a fixing plate are connected through a threaded shaft; two sliding bars are symmetrically arranged on the two sides of the threaded shaft; the two ends of the sliding bars are connected with the supporting plate and the fixing plate correspondingly; a moving chassis is arranged between the two sliding bars; a transmission block is arranged in the middle of the bottom end of the moving chassis; a threaded sleeve is arranged on the threaded shaft in a sleeving mode and connected with the transmission block; the two sides of the moving chassis are connected with the two sliding bars through sliding rings correspondingly; a fixed motor is arranged on one side of the fixing plate, and a motorshaft is connected with one end of the threaded shaft; and by adopting the device, the ox horn cutting effect can be effectively improved, and injuries to an ox can be reduced in the ox horn cuttingprocess.

Owner:南京白下高新技术产业园区投资发展有限责任公司

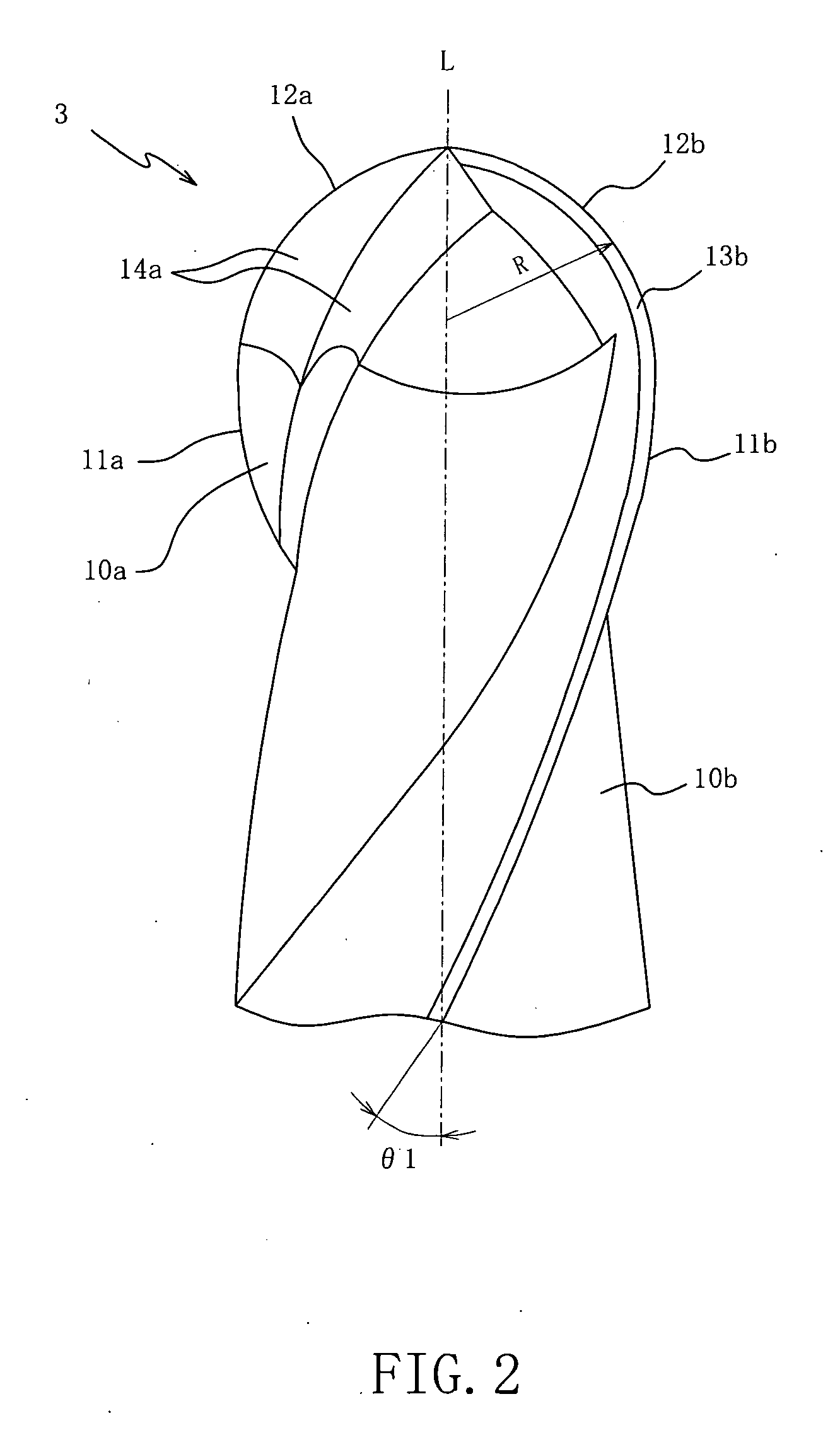

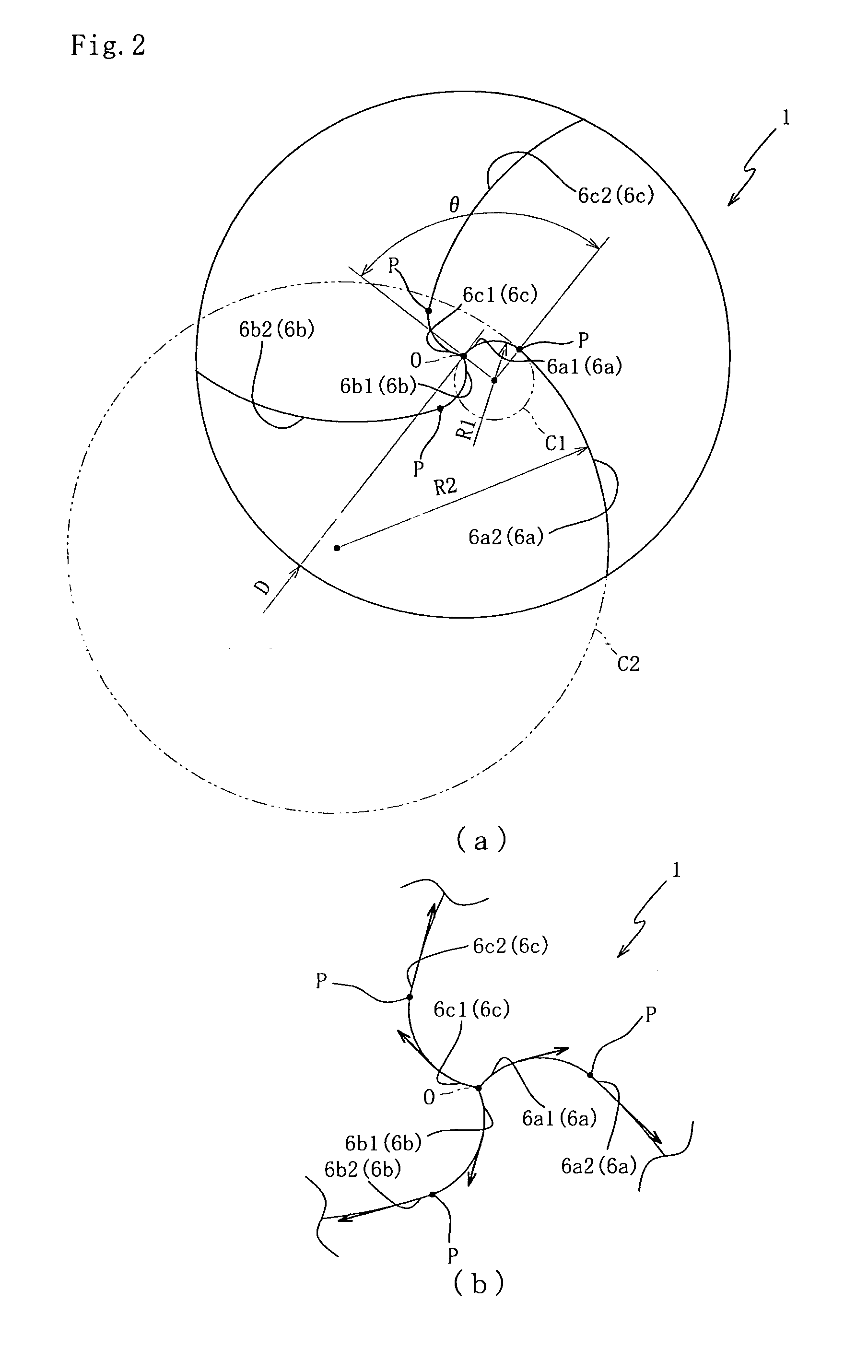

Ball endmill

ActiveUS20070081868A1Avoid vibrationEasily causedMilling cuttersShaping cuttersEngineeringMechanical engineering

A ball endmill having (a) a cylindrical tool body and (b) ball-nosed end cutting edges each of which includes (b-1) a first portion provided by a radially inner portion of each ball-nosed end cutting edge, and (b-2) a second portion provided by a radially outer portion of each ball-nosed end cutting edge. The first portion is defined by a circular arc which is convex in a direction of rotation of the tool body and which has a first radius of curvature as measured in a distal end view perpendicular to the axis. A ratio of the first radius of curvature to an outside diameter of the cylindrical body is not smaller than 0.025 and not larger than 0.10. The second portion is defined by a circular arc which is convex in the direction of the rotation of the tool body and which has a second radius of curvature as measured in the distal end view. The second radius of curvature is larger than the first radius of curvature.

Owner:OSG

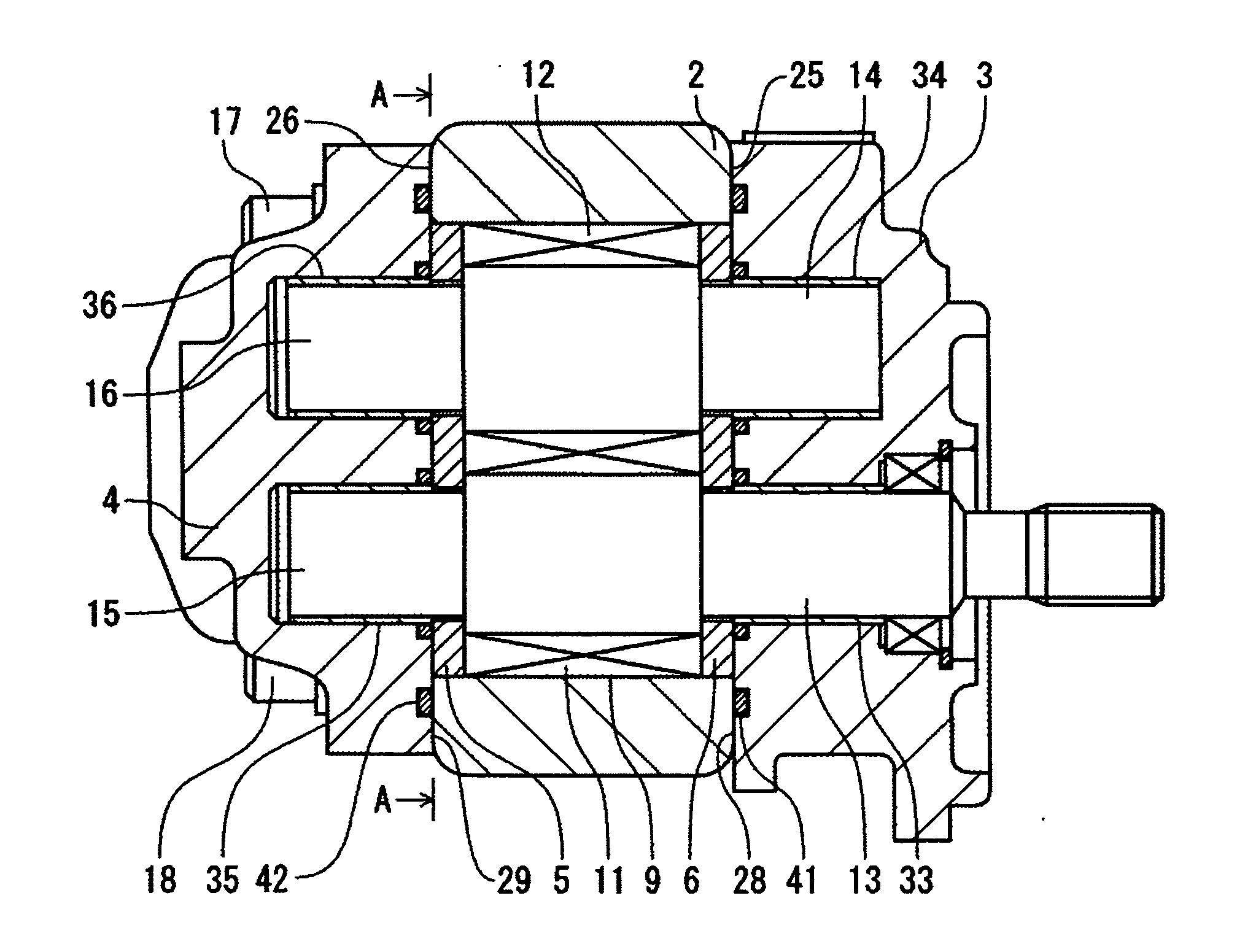

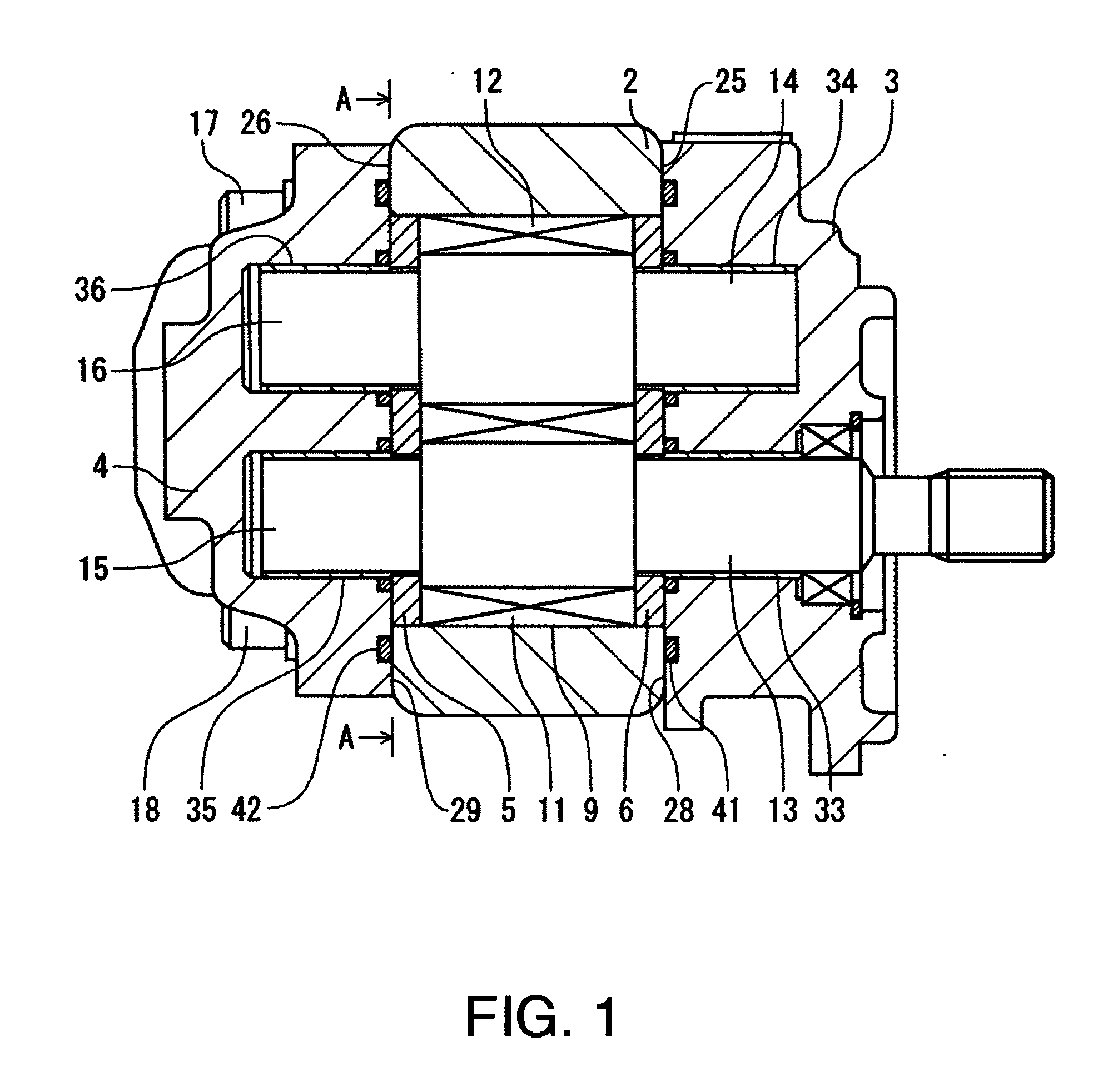

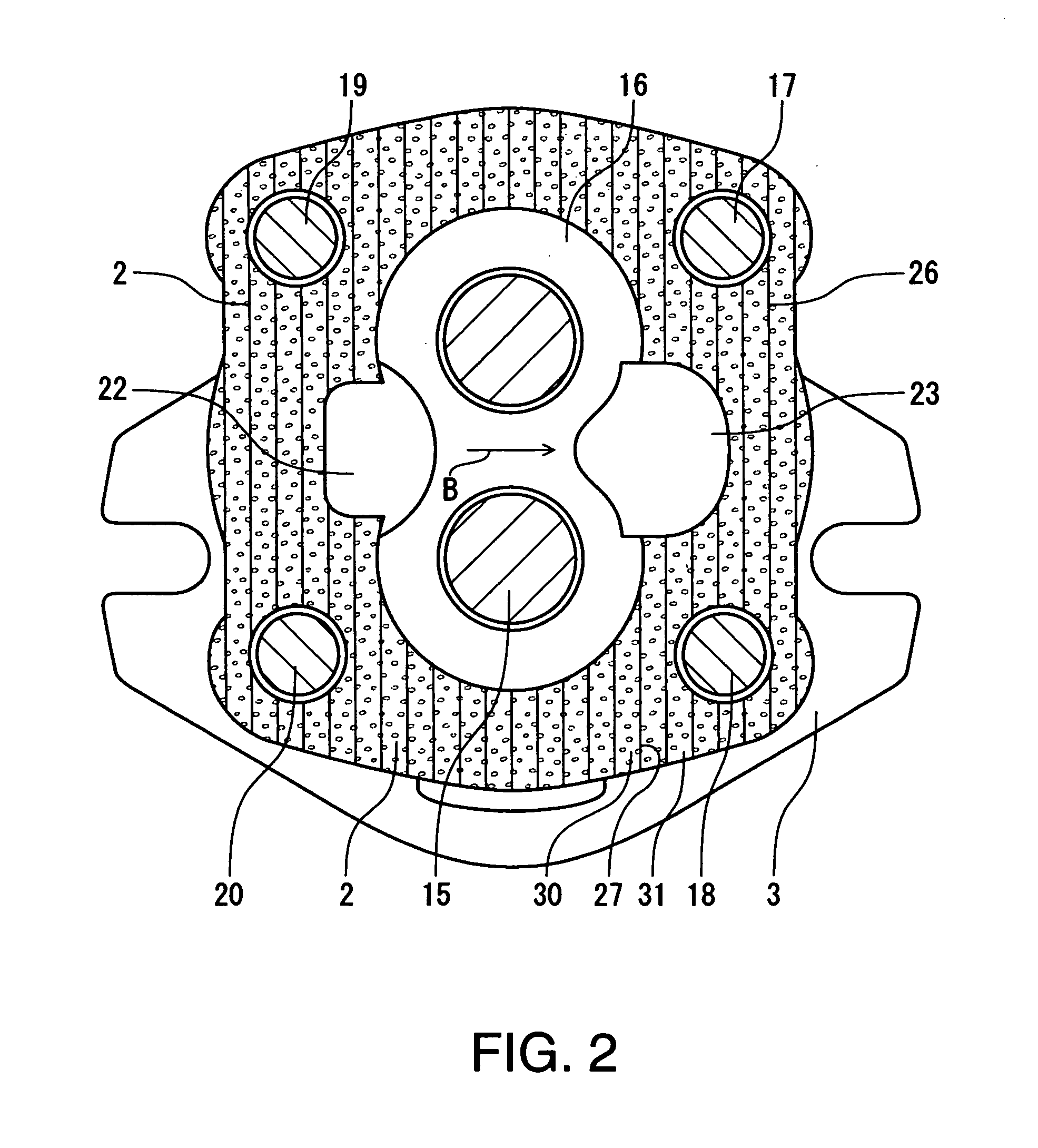

Gear pump

InactiveUS20100202913A1Increase friction forceFluid pressure can be preventedOscillating piston enginesEngine of counter-engagement typeGear pumpGear wheel

A gear pump (1) that discharges a fluid by rotating while a pair of gears (11, 12) are intermeshed includes a body (2) into which the respective gears (11, 12) are incorporated, a housing (3, 4) that contacts the body (2), a number of particles (30) that are interposed between an end surface (25, 26) of the body (2) and an end surface (28, 29) of the housing (3, 4), which contact each other, to prevent positional deviation between the body (2) and the housing (3, 4), and a fastening member (17 to 20) that fastens the housing (3, 4) to the body (2).

Owner:KYB CORP

Milling cutter

ActiveUS20060120813A1Increased depth of cutEffective wayMilling cuttersMetal sawing toolsMilling cutterEngineering

A milling cutter with a disk like cutter body having radially directed slots and a central aperture. An exchangeable hub comprises two adapter members located on either side of the cutter body. One of the adapter members has a raised portion located in the central aperture. The adapter members are secured to the cutter body by means of pins which are located in blind holes in the adapter members and which pass through engagement members positioned in the slots.

Owner:ISCAR LTD

Lathe for fast cutting outer diameters of smooth rolls

The invention provides a lathe for fast cutting outer diameters of smooth rolls. The lathe comprises a lathe body, wherein a cutter box is installed on a middle tray of the lathe body, a hollow rotary shaft coaxially arranged with a rotary axis of a workpiece is installed in the cutter box through a bearing, a vortex cutter head opposite to the workpiece in rotation direction is arranged at the front end of the hollow rotary shaft, and the rotation speed of the vortex cutter head is 3-5 times that of the workpiece; four cutter grooves are evenly formed in the peripheral direction of the vortex cutter head, turning tools are installed in the cutter grooves, and the turning tools are sequentially arranged in a staggered mode in the feeding direction. According to the lathe, the turning tools are arranged on the vortex cutter head according to standards, the vortex cutter head and the workpiece are driven to rotate oppositely through independent power systems, and therefore the cutting speed is improved substantially under the condition that the rotation speed of the lathe is unchanged; besides, the four turning tools can increase the cutting depth, the cutting amount allocated to each turning tool is reduced obviously, therefore, the feeding amount and the cutting speed of the lathe can be improved, the production efficiency can be substantially improved, and the service life of the tools can be prolonged.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

Alga removing device

ActiveCN105887785AExpand the scope of absorptionExpand the cutting rangeWater cleaningEngineeringLinear motor

An alga removing device comprises an unmanned aerial vehicle, a bearing, a first motor, a first support, a fourth air cylinder, a dust collector, floating balls, a rope, a floating plate, a second motor, a floating table, a waste storage tank, a chain, a roll shaft, a coiling block, bottom discs, lifting landing legs, a second support, a controller, second gears, a supporting frame, a first air cylinder, rotating rods, a second linear motor, second movable blocks, blades, first gears, rotating shafts, a third motor, a first movable block, a first linear motor, a first cutter, heating pieces, a second air cylinder, a third movable block, a second sliding block, a frame, a third linear motor, a fourth motor, a second sliding rail, electric push rods, a groove, a first sliding rail, first sliding blocks, a fifth sliding rail, a fifth sliding block, a fifth motor, a second cutter, a third air cylinder, a third sliding block, a third sliding rail and a supporting plate. The lifting landing legs are arranged on the left side and the right side of the unmanned aerial vehicle. The bottom discs are arranged below the lifting landing legs. The alga removing device has the beneficial effect of being capable of automatically removing algae.

Owner:平邑经济开发区投资发展有限公司

Method for improving working stability of end mill and high-stability end mill

InactiveCN102642047ADecentralizationAvoid cutting force vibrationMilling cuttersManufacturing engineeringHelix angle

The invention discloses a method for improving the working stability of an end mill and a high-stability end mill; the number of the teeth of the end mill is manufactured into an even number, so that the end edges of the teeth are unequally distributed on the same circumstance even if the angles of the end edge of each tooth and the end edges of the teeth on both adjacent sides are different, and meanwhile, the spiral angles of a spiral groove of the circumferential edge of each tooth and the spiral grooves of teeth on both adjacent sides are unequal; and consequently, the working stability of the end mill can be improved. The invention not only has the advantages of good working stability, high working efficiency and good processing quality, but also has the advantages of simple structure, easiness in production and long service life.

Owner:XINAN TOOLS GUIZHOU PROV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com